Page 1

FUJITSU SEMICONDUCTOR

DATA SHEET

DS04-27709-4E

ASSP F or Pow er Supply Applications (Secondary battery)

DC/DC Converter IC

for Charging Li-ion battery

MB3887

DESCRIPTION

■

The MB3887 is a DC/DC converter IC suitable for down-conversion, using pulse-width (PWM) charging and

enabling output voltage to be set to any desired level from one cell to four cells.

These ICs can dynamically control the secondary batter y’s charge current by detecting a voltage drop in an AC

adapter in order to keep its power constant (dynamically-controlled charging) .

The charging method enables quick charging, f or example, with the A C adapter during operation of a notebook PC.

The MB3887 provides a broad power supply voltage range and low standby current as well as high efficiency,

making it ideal for use as a built-in charging device in products such as notebook PC.

This product is covered by US Patent Number 6,147,477.

FEATURES

■

• Detecting a voltage drop in the AC adapter and dynamically controlling the charge current

(Dynamically-controlled charging)

(Continued)

PACKAGE

■

24-pin plastic SSOP

(FPT-24P-M03)

Page 2

MB3887

(Continued)

• Output voltage setting using external resistor : 1 cell to 4 cells

• High efficiency : 96% (VIN = 19 V, Vo = 16.8 V)

• Wide range of operating supply voltages : 8 V to 25 V

• Output voltage setting accuracy : 4.2 V ± 0.74% (T a = −10 °C to +85 °C , per cell)

• Charging current accuracy : ±5%

• Built-in frequency setting capacitor enables frequency setting using external resistor only

• Oscillation frequency range : 100 kHz to 500 kHz

• Built-in current detection amplifier with wide in-phase input voltage range : 0 V to VCC

• In standby mode, leave output voltage setting resistor open to prevent inefficient current loss

• Built-in standby current function : 0 µA (standard)

• Built-in soft-start function independent of loads

• Built-in totem-pole output stage supporting P-channel MOS FET devices

2

Page 3

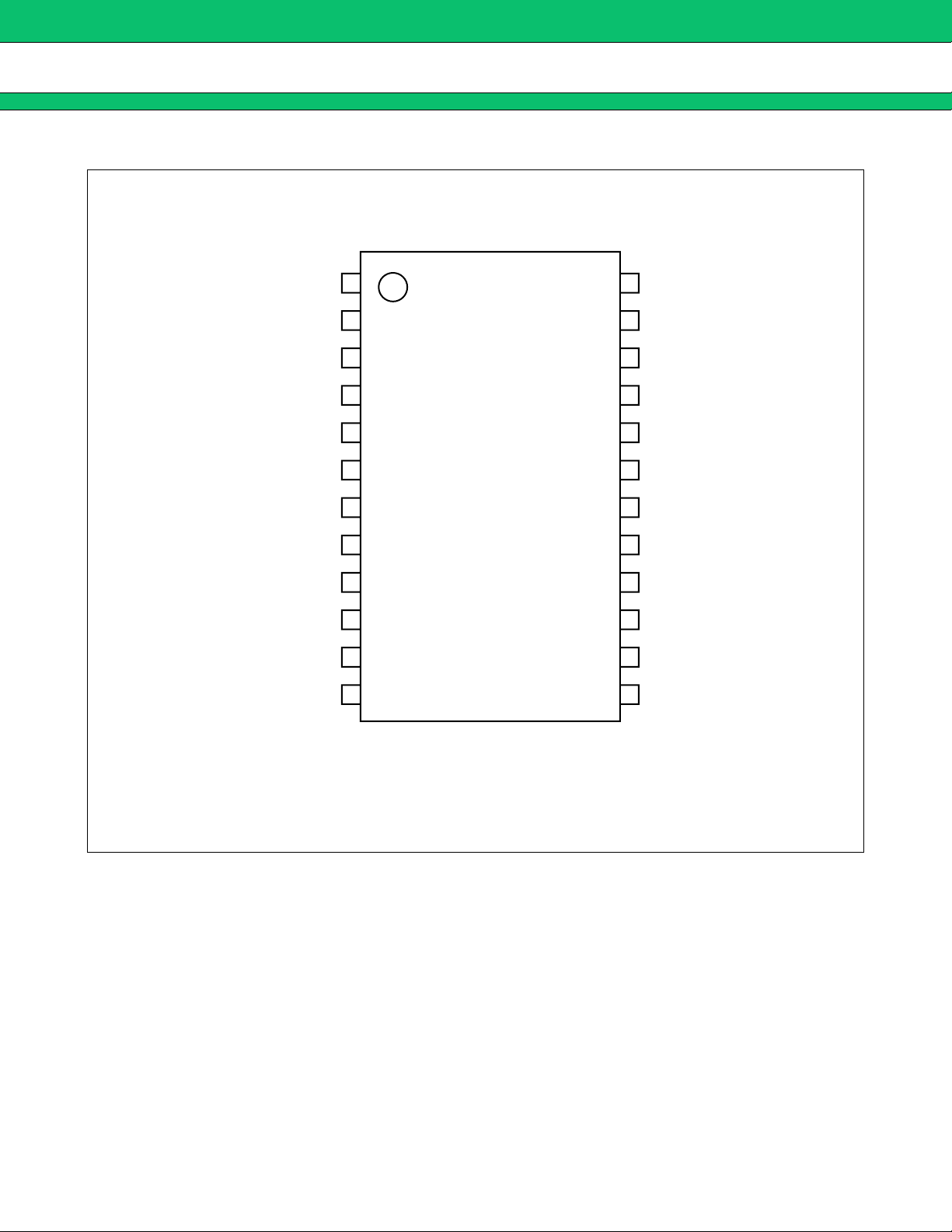

PIN ASSIGNMENT

■

−INC2 :

OUTC2 :

+INE2 :

−INE2 :

FB2 :

VREF :

FB1 :

MB3887

(TOP VIEW)

: +INC2

1

2

3

4

5

6

7

24

: GND

23

: CS

22

: VCC (O)

21

: OUT

20

: VH

19

: VCC

18

−INE1 :

+INE1 :

OUTC1 :

OUTD :

−INC1 :

10

11

12

: RT

8

9

17

16

15

14

13

: −INE3

: FB3

: CTL

: +INC1

(FPT-24P-M03)

3

Page 4

MB3887

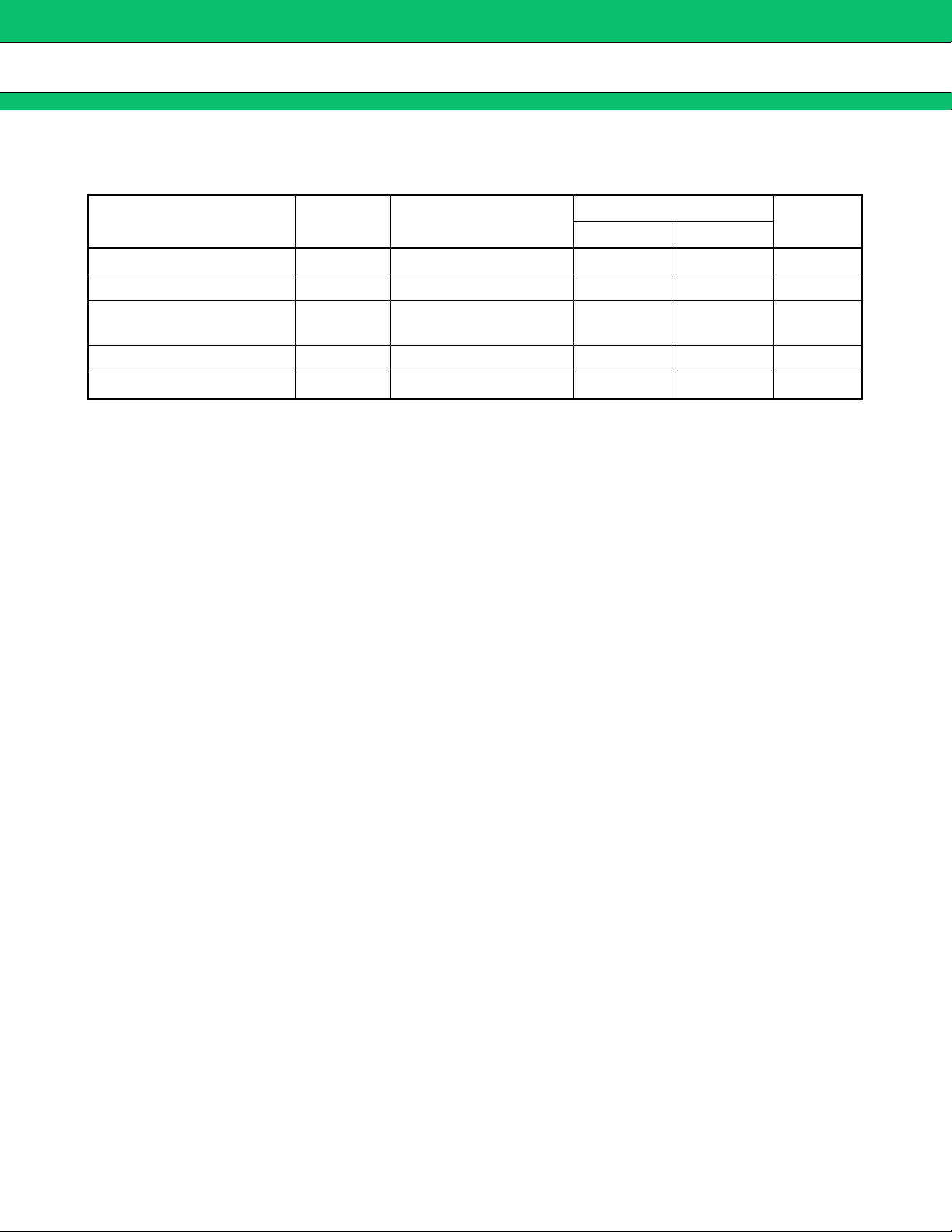

PIN DESCRIPTION

■

Pin No. Symbol I/O Descriptions

1 −INC2 I Current detection amplifier (Current Amp2) input terminal.

2 OUTC2 O Current detection amplifier (Current Amp2) output terminal.

3 +INE2 I Error amplifier (Error Amp2) non-inverted input terminal.

4 −INE2 I Error amplifier (Error Amp2) inverted input terminal.

5 FB2 O Error amplifier (Error Amp2) output terminal.

6 VREF O Reference voltage output terminal.

7 FB1 O Error amplifier (Error Amp1) output terminal.

8 −INE1 I Error amplifier (Error Amp1) inverted input terminal

9 +INE1 I Error amplifier (Error Amp1) non-inverted input terminal.

10 OUTC1 O Current detection amplifier (Current Amp1) output terminal.

With IC in standby mode, this terminal is set to “Hi-Z” to prevent loss

11 OUTD O

of current through output voltage setting resistance.

Set CTL terminal to “H” level to output “L” level.

12 −INC1 I Current detection amplifier (Current Amp1) input terminal.

13 +INC1 I Current detection amplifier (Current Amp1) input terminal.

Power supply control terminal.

14 CTL I

15 FB3 O Error amplifier (Error Amp3) output terminal.

16 −INE3 I Error amplifier (Error Amp3) inverted input terminal.

17 RT ⎯

18 VCC ⎯ Power supply terminal for reference power supply and control circuit.

19 VH O Power supply terminal for FET drive circuit (VH = VCC − 6 V) .

20 OUT O External FET gate drive terminal.

21 VCC (O) ⎯ Output circuit power supply terminal.

22 CS ⎯ Soft-start capacitor connection terminal.

23 GND ⎯ Ground terminal.

24 +INC2 I Current detection amplifier (Current Amp2) input terminal.

Setting the CTL terminal at “L” level places the IC in the standby

mode.

Triangular-wave oscillation frequency setting resistor connection

terminal.

4

Page 5

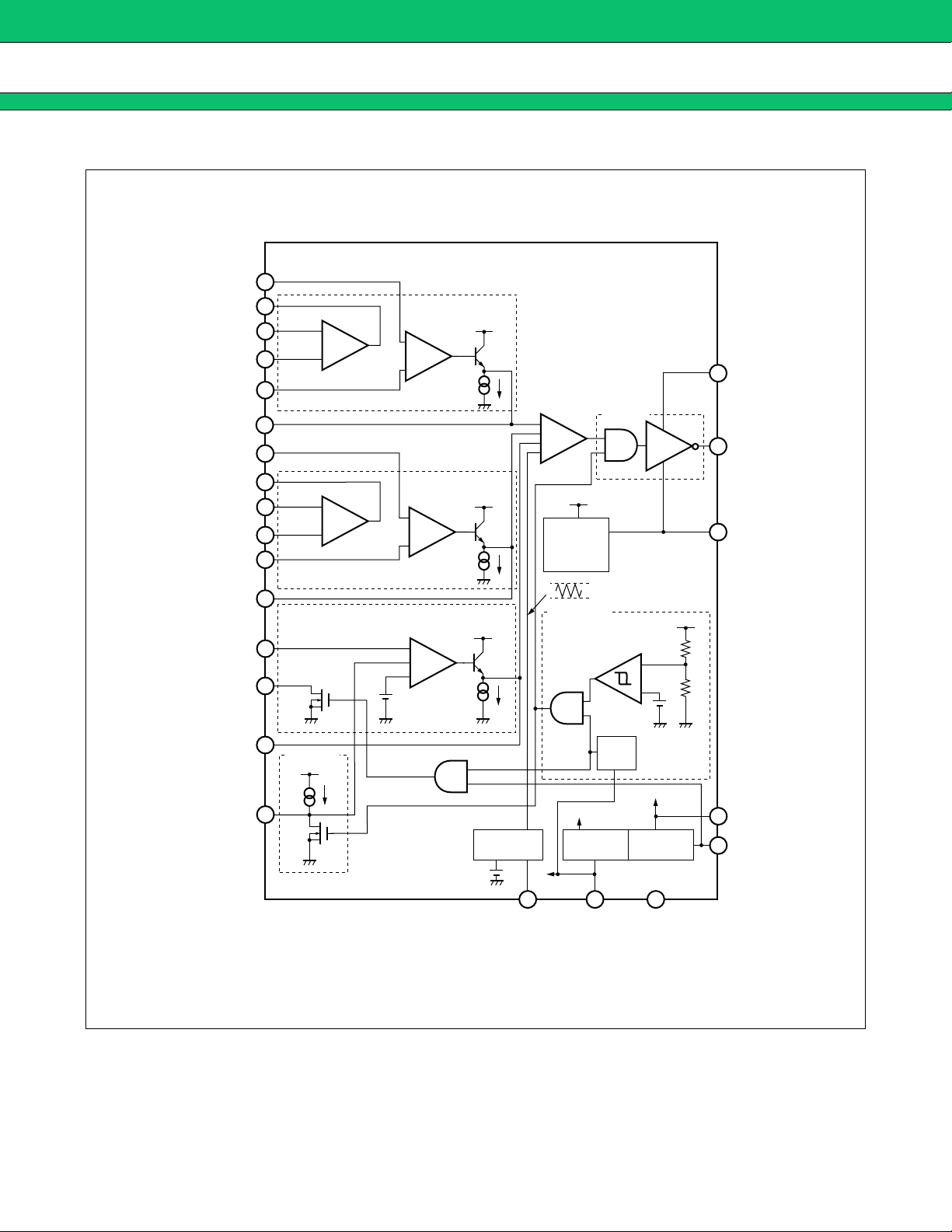

BLOCK DIAGRAM

O

O

)

■

−INE1

UTC1

+INC1

−INC1

+INE1

FB1

−INE2

8

10

<Current Amp1>

13

12

9

7

4

+

× 20

−

<Error Amp1>

VREF

−

+

<PWM Comp.>

+

+

+

−

<OUT>

Drive

MB3887

21

VCC (O

20

OUT

2

UTC2

+INC2

−INC2

+INE2

FB2

−INE3

OUTD

FB3

CS

<Current Amp2>

24

1

3

5

16

11

15

<SOFT>

VREF

22

+

× 20

−

10

µA

<Error Amp2>

VREF

−

+

<Error Amp3>

VREF

−

+

+

4.2 V

45 pF

VCC

Bias

Voltage

<VH>

<UVLO>

(VCC UVLO)

4.2 V

<OSC>

17 6 23

RT

<REF> <CTL>

bias

VREF

2.5 V

1.5 V

0.91 V

(0.77 V)

VREF

UVLO

VREF

5.0 V

(V

CC

215 kΩ

+

35 kΩ

−

VCC

GND

− 6 V)

VCC

19

18

14

VH

VCC

CTL

5

Page 6

MB3887

ABSOLUTE MAXIMUM RATINGS

■

Parameter Symbol Conditions

Unit

Min Max

Rating

Power supply voltage V

Output current I

Peak output current I

Power dissipation P

Storage temperature T

CC

OUT

OUT

STG

VCC, VCC (O) terminal*

⎯⎯60 mA

Duty ≤ 5 %

(t = 1 / f

D

Ta ≤ +25 °C ⎯ 740*

× Duty)

OSC

⎯−55 +125 °C

2

⎯ 28 V

⎯ 700 mA

1

mW

*1 : The package is mounted on the dual-sided epoxy board (10 cm × 10 cm) .

*2 : Refer to “ THE SEQUENCE OF THE START-UP AND OFF OF THE POWER SUPPLY” for details.

WARNING: Semiconductor devices can be permanently damaged by application of stress (voltage, current,

temperature, etc.) in excess of absolute maximum ratings. Do not exceed these ratings.

6

Page 7

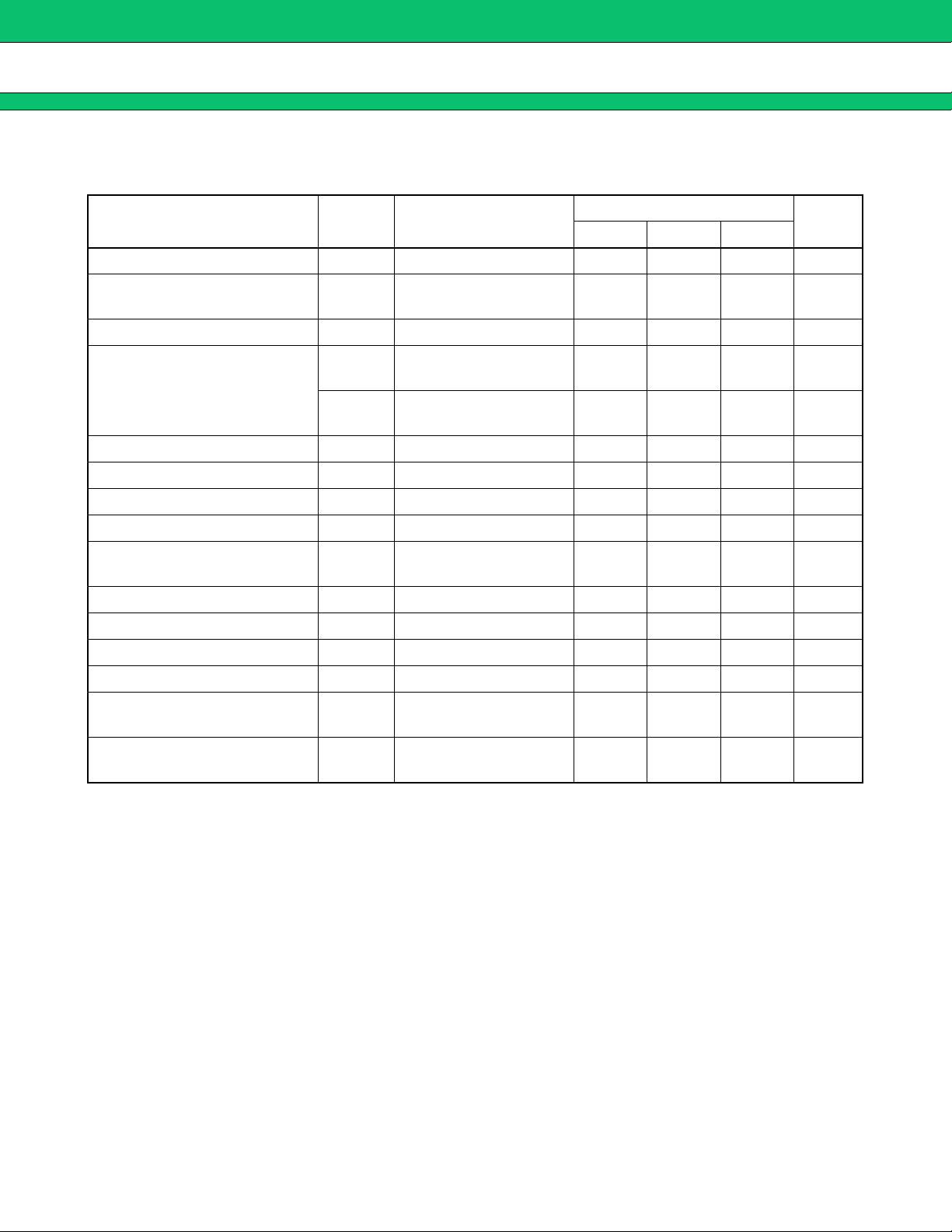

RECOMMENDED OPERATING CONDITIONS

■

MB3887

Parameter Symbol Conditions

Power supply voltage V

Reference voltage output

current

I

VH terminal output current I

V

Input voltage

V

OUTD terminal output voltage V

OUTD terminal output current I

OUTD

CTL terminal input voltage V

Output current I

Peak output current I

Oscillation frequency f

Timing resistor R

Soft-start capacitor C

CC

REF

VH

INE

INC

OUTD

CTL

OUT

OUT

OSC

T

S

Value

Unit

Min Typ Max

VCC, VCC (O) terminal* 8 ⎯ 25 V

⎯

⎯

−INE1 to −INE3, +INE1,

+INE2 terminal

+INC1, +INC2, −INC1,

−INC2 terminal

−1 ⎯ 0mA

0 ⎯ 30 mA

0 ⎯ V

0 ⎯ V

− 1.8 V

CC

CC

⎯ 0 ⎯ 17 V

⎯ 0 ⎯ 2mA

⎯ 0 ⎯ 25 V

⎯−45 ⎯+45 mA

Duty ≤ 5 %

(t = 1 / fosc × Duty)

−600 ⎯+600 mA

⎯ 100 290 500 kHz

⎯ 27 47 130 kΩ

⎯⎯0.022 1.0 µF

V

VH terminal capacitor C

Reference voltage output

capacitor

C

Operating ambient

temperature

VH

REF

Ta ⎯−30 +25 +85 °C

⎯⎯0.1 1.0 µF

⎯⎯0.1 1.0 µF

* : Refer to “ THE SEQUENCE OF THE START-UP AND OFF OF THE POWER SUPPLY” for details.

WARNING: The recommended operating conditions are required in order to ensure the normal operation of the

semiconductor device. All of the device’s electrical characteristics are warranted when the device is

operated within these ranges.

Always use semiconductor devices within their recommended operating condition ranges. Operation

outside these ranges may adversely affect reliability and could result in device failure.

No warranty is made with respect to uses, operating conditions, or combinations not represented on

the data sheet. Users considering application outside the listed conditions are advised to contact their

FUJITSU representatives beforehand.

7

Page 8

MB3887

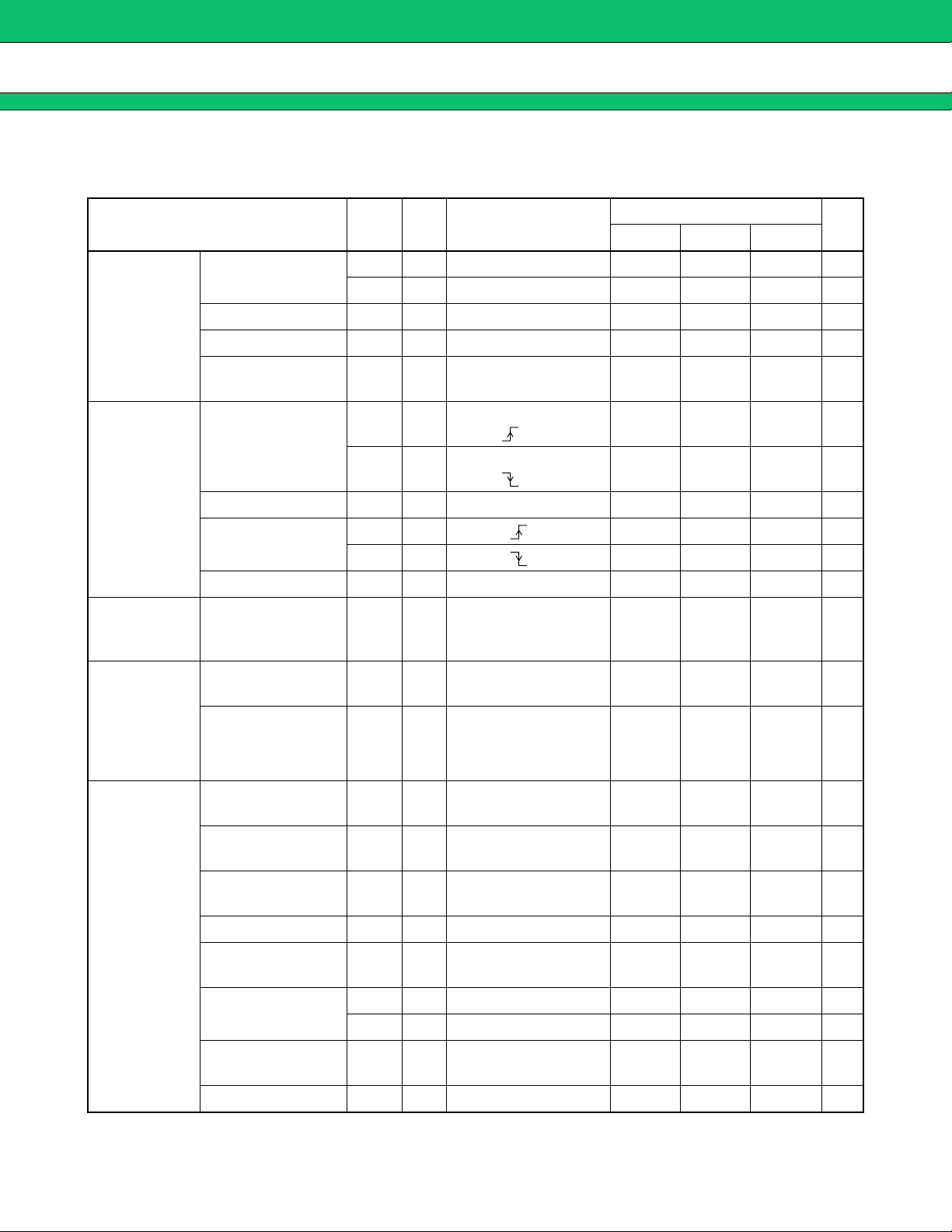

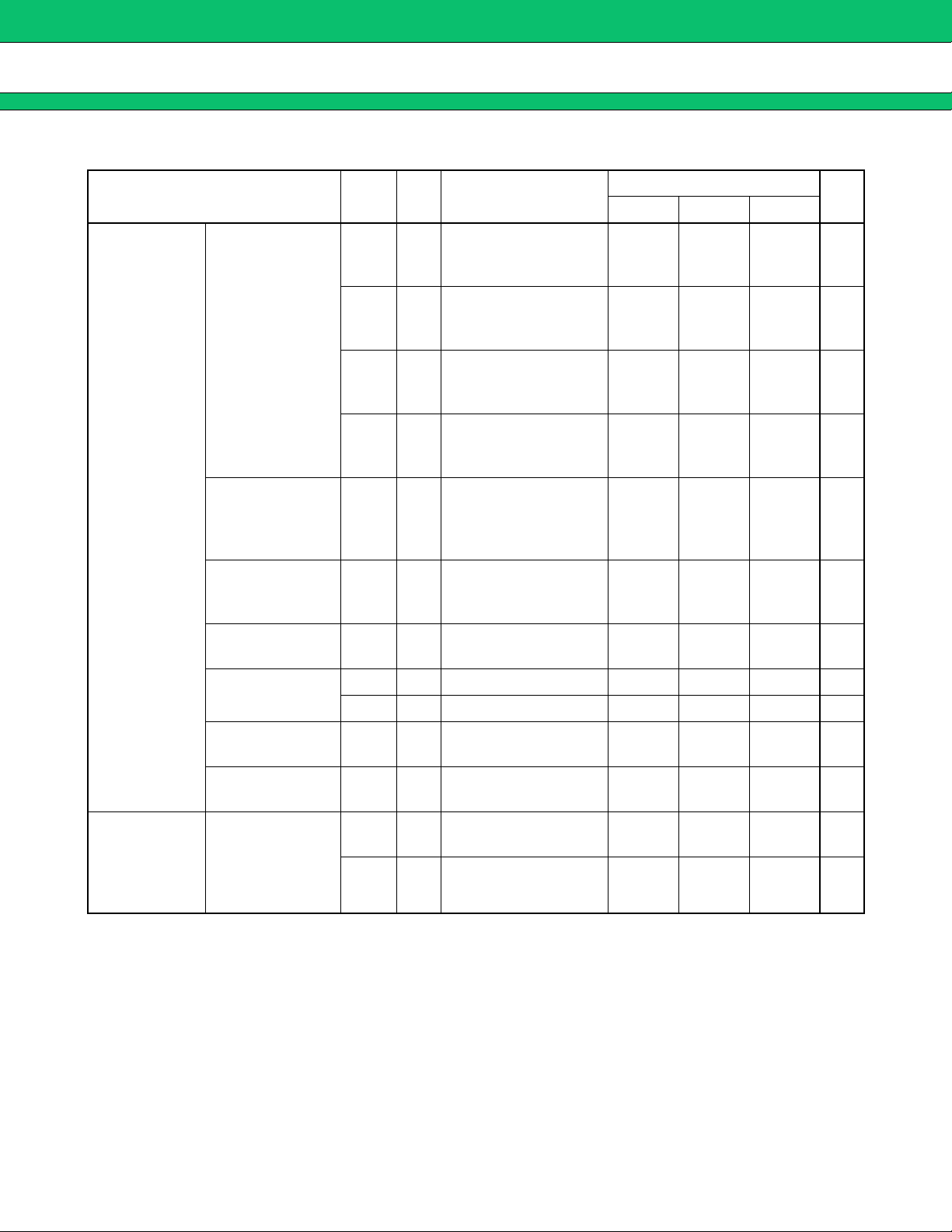

ELECTRICAL CHARACTERISTICS

■

Parameter

Sym-

bol

(Ta = +25 °C, VCC = 19 V, VCC (O) = 19 V, VREF = 0 mA)

Pin

No.

Conditions

Min Typ Max

Value

Unit

1.

Reference

voltage block

[REF]

2.

Under voltage

lockout protection circuit

block

[UVLO]

3.

Soft-start block

[SOFT]

4.

Triangular

waveform oscillator circuit

block

[OSC]

V

REF1

6Ta = +25 °C 4.967 5.000 5.041 V

Output voltage

V

REF2

6Ta = −10 °C to +85 °C 4.95 5.00 5.05 V

Input stability Line 6 VCC = 8 V to 25 V ⎯ 310mV

Load stability Load 6 VREF = 0 mA to −1 mA ⎯ 110mV

Short-circuit output

current

Ios 6 VREF = 1 V −50 −25 −12 mA

V

TLH

VCC = VCC (O) ,

18

VCC =

6.2 6.4 6.6 V

Threshold voltage

V

Hysteresis width V

V

THL

H

TLH

VCC = VCC (O) ,

18

VCC =

5.2 5.4 5.6 V

18 VCC = VCC (O) ⎯ 1.0* ⎯ V

6VREF = 2.6 2.8 3.0 V

Threshold voltage

V

Hysteresis width V

Charge current I

Oscillation

frequency

f

THL

CS

OSC

6VREF = 2.4 2.6 2.8 V

6 ⎯⎯0.2 ⎯ V

H

22 ⎯−14 −10 −6 µA

20 RT = 47 kΩ 260 290 320 kHz

Frequency

temperature

∆f/fdt 20 Ta = −30 °C to +85 °C ⎯ 1* ⎯%

stability

Input offset voltage V

3, 4,

IO

FB1 = FB2 = 2 V ⎯ 15mV

8, 9

Input bias current I

In-phase input

5-1.

Error amplifier

block

[Error Amp1,

Error Amp2]

voltage range

Voltage gain A

Frequency

bandwidth

Output voltage

Output source

current

Output sink current I

* : Standard design value.

8

3, 4,

B

8, 9

3, 4,

V

CM

8, 9

5, 7 DC ⎯ 100* ⎯ dB

V

⎯ −100 −30 ⎯ nA

⎯ 0 ⎯ V

− 1.8 V

CC

BW 5, 7 AV = 0 dB ⎯ 2* ⎯ MHz

V

V

I

SOURCE

5, 7 ⎯ 4.7 4.9 ⎯ V

FBH

5, 7 ⎯⎯20 200 mV

FBL

5, 7 FB1 = FB2 = 2 V ⎯−2 −1mA

5, 7 FB1 = FB2 = 2 V 150 300 ⎯µA

SINK

(Continued)

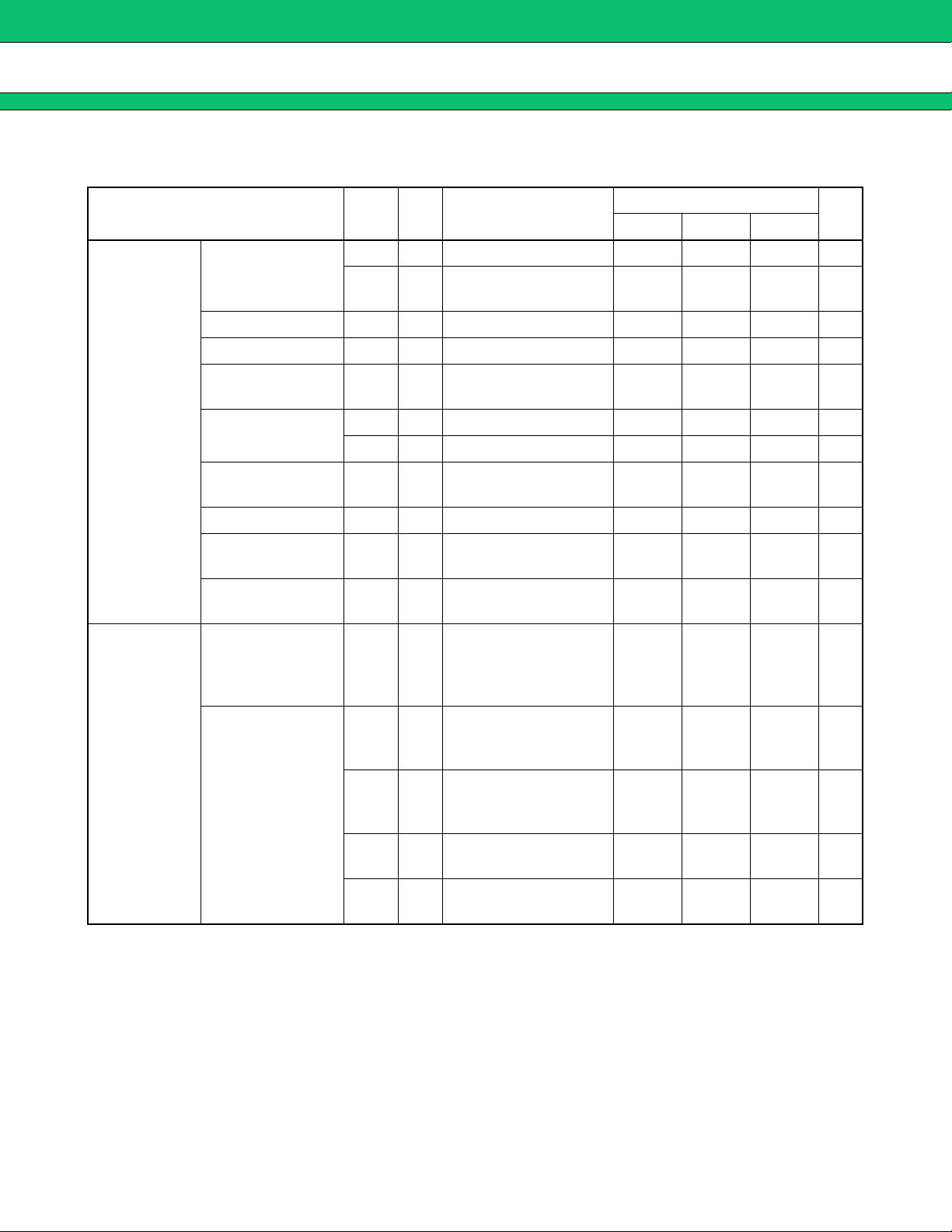

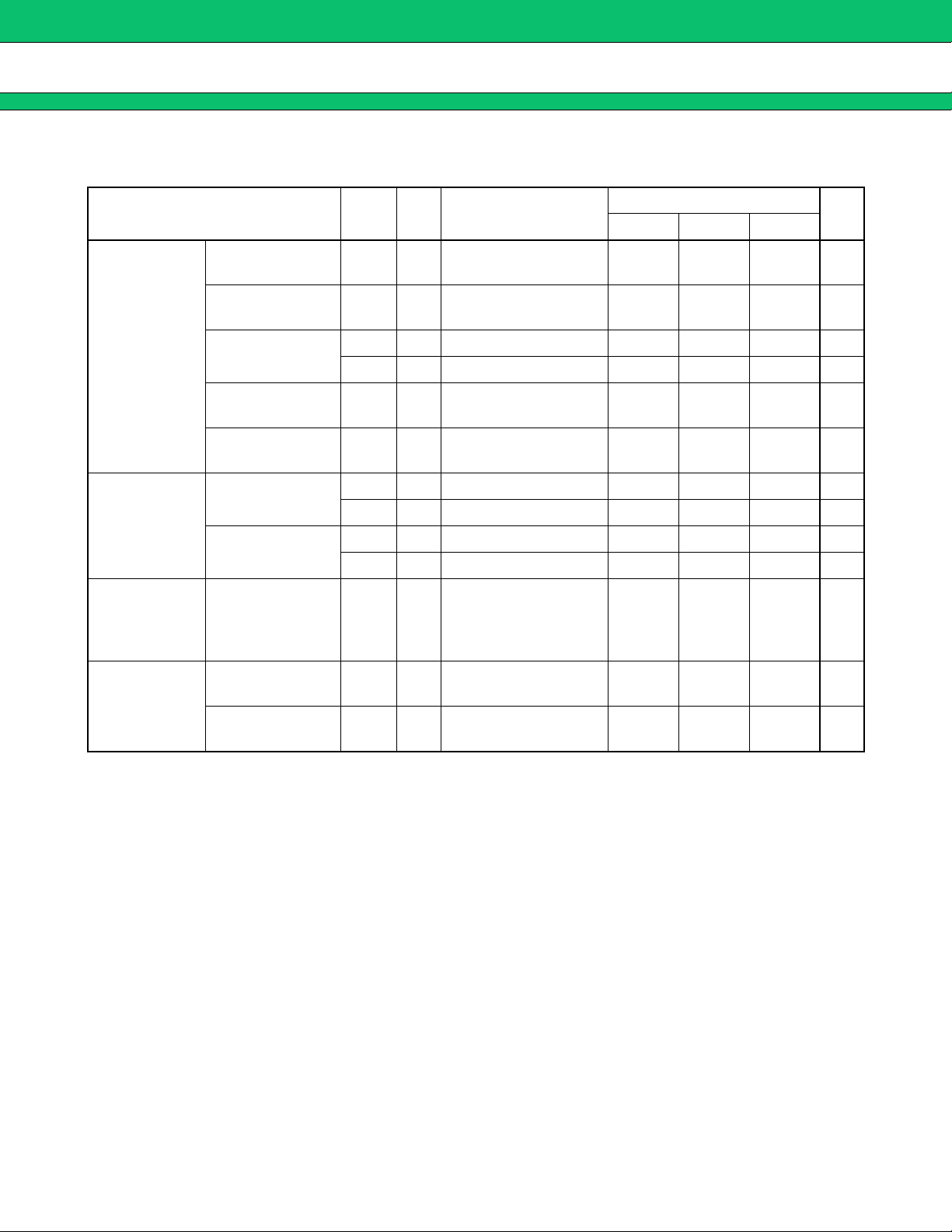

Page 9

Parameter

Sym-

bol

MB3887

(Ta = +25 °C, VCC = 19 V, VCC (O) = 19 V, VREF = 0 mA)

Pin

No.

Conditions

Min Typ Max

Value

Unit

5-2.

Error amplifier

block

[Error Amp3]

6.

Current detection amplifier

block

[Current

Amp1, Current

Amp2]

V

Threshold voltage

V

Input current I

Voltage gain A

Frequency

bandwidth

BW 15 AV = 0 dB ⎯ 2* ⎯ MHz

V

Output voltage

V

Output source

current

I

SOURCE

Output sink current I

OUTD terminal

output leak current

OUTD terminal

output ON resistor

I

R

Input offset voltage V

I

+INCH

I

−INCH

Input current

I

I

TH1

TH2

INE3

V

FBH

FBL

SINK

LEAK

ON

IO

+INCL

−INCL

16 FB3 = 2 V, Ta = +25 °C 4.183 4.200 4.225 V

FB3 = 2 V,

16

Ta = −10 °C to +85 °C

4.169 4.200 4.231 V

16 −INE3 = 0 V −100 −30 ⎯ nA

15 DC ⎯ 100* ⎯ dB

15 ⎯ 4.7 4.9 ⎯ V

15 ⎯⎯20 200 mV

15 FB3 = 2 V ⎯−2 −1mA

15 FB3 = 2 V 150 300 ⎯µA

11 OUTD = 17 V ⎯ 01µA

11 OUTD = 1 mA ⎯ 35 50 Ω

1,

+INC1 = +INC2 =

12,

−INC1 = −INC2 =

13,

3 V to VCC

24

+INC1 = +INC2 =

13,

3 V to VCC,

24

∆V

= −100 mV

IN

−3 ⎯+3mV

⎯ 20 30 µA

+INC1 = +INC2 =

1, 12

3 V to VCC,

⎯ 0.1 0.2 µA

∆Vin = −100 mV

13, 24+INC1 = +INC2 = 0 V,

∆Vin = −100 mV

+INC1 = +INC2 = 0 V,

1, 12

∆Vin = −100 mV

−180 −120 ⎯µA

−195 −130 ⎯µA

* : Standard design value

(Continued)

9

Page 10

MB3887

Parameter

6.

Current

detection

amplifier block

[Current Amp1,

Current Amp2]

Sym-

bol

V

OUTC1

V

OUTC2

Current detection

voltage

V

OUTC3

V

OUTC4

In-phase input

voltage range

V

Voltage gain A

Frequency

bandwidth

BW 2, 10 AV = 0 dB ⎯ 2* ⎯ MHz

V

OUTCH

Output voltage

V

(Ta = +25 °C, VCC = 19 V, VCC (O) = 19 V, VREF = 0 mA)

Pin

No.

Conditions

Min Typ Max

Value

+INC1 = +INC2 =

2, 10

3 V to VCC,

1.9 2.0 2.1 V

∆Vin = −100 mV

+INC1 = +INC2 =

2, 10

3 V to VCC,

0.34 0.40 0.46 V

∆Vin = −20 mV

+INC1 = +INC2 =

2, 10

0 V to 3 V,

1.8 2.0 2.2 V

∆Vin = −100 mV

+INC1 = +INC2 =

2, 10

0 V to 3 V,

0.2 0.4 0.6 V

∆Vin = −20 mV

1,

CM

12,

13,

⎯ 0 ⎯ V

24

+INC1 = +INC2 =

2, 10

V

3 V to VCC,

19 20 21 V/V

∆Vin = −100 mV

2, 10 ⎯ 4.7 4.9 ⎯ V

2, 10 ⎯⎯20 200 mV

OUTCL

CC

Unit

V

7.

PWM

comparator

block

[PWM Comp.]

* : Standard design value

10

Output source

current

Output sink current

Threshold voltage

I

SOURCE

I

SINK

V

TL

TH

V

2, 10 OUTC1 = OUTC2 = 2 V ⎯−2 −1mA

2, 10 OUTC1 = OUTC2 = 2 V 150 300 ⎯µA

5, 7,

Duty cycle = 0 % 1.4 1.5 ⎯ V

15

5, 7,

Duty cycle = 100 %⎯2.5 2.6 V

15

(Continued)

Page 11

(Continued)

Parameter

Sym-

bol

MB3887

(Ta = +25 °C, VCC = 19 V, VCC (O) = 19 V, VREF = 0 mA)

Pin

No.

Conditions

Min Typ Max

Value

Unit

8.

Output block

[OUT]

9.

Control block

[CTL]

10.

Bias voltage

block

[VH]

11.

General

Output source

current

Output sink

current

Output ON

resistor

I

SOURCE

I

SINK

R

OH

R

OL

20

20

20 OUT = −45 mA ⎯ 6.5 9.8 Ω

20 OUT = 45 mA ⎯ 5.0 7.5 Ω

Rise time tr1 20

Fall time tf1 20

14 IC Active mode 2 ⎯ 25 V

ON

V

CTL input voltage

V

I

CTLH

14 IC Standby mode 0 ⎯ 0.8 V

OFF

14 CTL = 5 V ⎯ 100 150 µA

Input current

I

Output voltage V

Standby current I

Power supply cur-

rent

CTLL

CCS

I

14 CTL = 0 V ⎯ 01µA

19

H

18

18

CC

OUT = 13 V, Duty ≤ 5 %

(t = 1 / f

× Duty)

OSC

OUT = 19 V, Duty ≤ 5 %

(t = 1 / f

× Duty)

OSC

OUT = 3300 pF

(Si4435 × 1)

OUT = 3300 pF

(Si4435 × 1)

VCC = VCC (O) =

8 V to 25 V,

VH = 0 to 30 mA

VCC = VCC (O) ,

CTL = 0 V

VCC = VCC (O) ,

CTL = 5 V

⎯−400* ⎯ mA

⎯ 400* ⎯ mA

⎯ 50* ⎯ ns

⎯ 50* ⎯ ns

VCC − 6.5 VCC − 6.0 VCC − 5.5 V

⎯ 010µA

⎯ 812mA

* : Standard design value

11

Page 12

MB3887

6

5

4

3

2

1

0

5

6

5

4

3

2

1

0

5

6

5

4

3

2

1

0

0

5

5

5

5

5

4

4

4

4

0

1

0

TYPICAL CHARACTERISTICS

■

Power supply current vs. Power supply voltage

Ta = +25 °C

(mA)

CC

CTL = 5 V

Power supply current I

0 5 10 15 20 2

Power supply voltage V

CC

(V)

Reference voltage

vs. Reference voltage output current

Ta = +25 °C

(V)

REF

VCC = 19 V

CTL = 5 V

Reference voltage V

0 5 10 15 20 25 3

Reference voltage output current I

REF

(mA)

Reference voltage vs. Power supply voltage

(V)

REF

Ta = +25 °C

CTL = 5 V

VREF = 0 mA

Reference voltage V

0 5 10 15 20 2

Power supply voltage VCC (V)

Reference voltage

vs. Operating ambient temperature

.08

.06

(V)

REF

.04

.02

.00

.98

.96

.94

Reference voltage V

.92

−40 −20 0 20 40 60 80 10

VCC = 19 V

CTL = 5 V

Operating ambient temperature Ta ( °C)

CTL terminal current, Reference voltage

vs. CTL terminal voltage

000

Ta = +25 °C

900

(µA)

CTL

12

CTL terminal current I

VCC = 19 V

800

700

600

500

400

300

200

100

0

0 5 10 15 20 25

CTL terminal voltage V

VREF

ICTL

(V)

CTL

1

9

(V)

8

REF

7

6

5

4

3

2

1

Reference voltage V

0

(Continued)

Page 13

MB3887

1

0

3

3

3

3

3

2

2

2

2

5

3

3

3

3

3

2

2

2

2

2

2

2

2

0

4

2

4

2

4

4

4

4

4

4

4

0

Triangular wave oscillation frequency

vs. Timing resistor

1 M

(Hz)

OSC

00 k

frequency f

Triangular wave oscillation

10 k

10 100 100

Timing resistor RT (kΩ)

Triangular wave oscillation frequency

vs. Operating ambient temperature

20

15

10

05

00

95

(kHz)

90

OSC

85

80

75

70

frequency f

65

Triangular wave oscillation

60

−40 −20 0 20 40 60 80 10

Ta = +25 °C

VCC = 19 V

CTL = 5 V

VCC = 19 V

CTL = 5 V

RT = 47 kΩ

Triangular wave oscillation frequency

vs. Power supply voltage

40

30

20

10

(kHz)

OSC

00

90

80

frequency f

70

Triangular wave oscillation

60

0 5 10 15 20 2

Power supply voltage VCC (V)

Error amplifier threshold voltage

vs. Operating ambient temperature

.25

.24

.23

.22

(V)

.21

TH

.20

.19

.18

voltage V

.17

.16

Error amplifier threshold

.15

−40 −20 0 20 40 60 80 10

Ta = +25 °C

CTL = 5 V

RT = 47 kΩ

VCC = 19 V

CTL = 5 V

Operating ambient temperature Ta ( °C)

Operating ambient temperature Ta ( °C)

(Continued)

13

Page 14

MB3887

T

T

T

Error amplifier gain and phase vs. Frequency

V

Ta = +25 °C

180

90

0

−90

−180

40

A

20

(dB)

V

0

Gain A

−20

−40

1 k 10 k 100 k 1 M 10 M

φ

Frequency f (Hz)

Error amplifier gain and phase vs. Frequency

40

20

(dB)

V

0

Gain A

−20

−40

Ta = +25 °C

V

A

φ

180

90

0

−90

−180

Phase φ (deg)

Phase φ (deg)

IN

IN

10 kΩ

1 µF

10 kΩ

1 µF

VCC = 19 V

4.2 V

240 kΩ

10 kΩ

+

2.4 kΩ

10 kΩ10 kΩ

+

2.4 kΩ

10 kΩ10 kΩ

10 kΩ

8

(4)

9

(3)

4.2 V

16

22

−

+

Error Amp1

(Error Amp2)

VCC = 19 V

240 kΩ

−

+

+

Error Amp3

4.2 V

(5)

15

7

OU

OU

14

1 k 10 k 100 k 1 M 10 M

Frequency f (Hz)

Current detection amplifier gain and phase vs. Frequency

40

20

(dB)

V

0

Gain A

−20

−40

1 k 10 k 100 k 1 M 10 M

A

V

φ

Ta = +25 °C

180

90

0

−90

−180

Phase φ (deg)

Frequency f (Hz)

VCC = 19 V

13

+

(24)

×20

−

12

(1)

Current Amp1

(Current Amp2)

12.55 V12.6 V

10

(2)

OU

(Continued)

Page 15

(Continued)

8

7

6

5

4

3

2

1

7

0

Power dissipation vs. Operating ambient temperature

00

40

00

(mW)

D

00

00

00

00

00

00

Power dissipation P

0

−40 −2002040608010

Operating ambient temperature Ta ( °C)

MB3887

15

Page 16

MB3887

FUNCTIONAL DESCRIPTION

■

1. DC/DC Converter Unit

(1) Reference voltage block (REF)

The reference voltage generator uses the voltage supplied from the VCC terminal (pin 18) to generate a temperature-compensated, stable voltage (5.0 V Typ) used as the reference supply voltage for the IC’s internal

circuitry.

This terminal can also be used to obtain a load current to a maximum of 1mA from the reference voltage VREF

terminal (pin 6) .

(2) Triangular wave oscillator block (OSC)

The triangular wave oscillator builds the capacitor for frequency setting into, and generates the triangular wave

oscillation waveform by connecting the frequency setting resistor with the RT terminal (pin 17) .

The triangular wave is input to the PWM comparator on the IC.

(3) Error amplifier block (Error Amp1)

This amplifier detects the output signal from the current detection amplifier (Current amp1) , compares this to

the +INE1 terminal (pin 9) , and outputs a PWM control signal to be used in controlling the charging current.

In addition, an arbitrary loop gain can be set up by connecting a feedback resistor and capacitor between the

FB1 terminal (pin 7) and -INE1 terminal (pin 8) , providing stable phase compensation to the system.

(4) Error amplifier block (Error Amp2)

This amplifier (Error Amp2) detects voltage drop of the AC adapter and outputs a PWM control signal.

In addition, an arbitrary loop gain can be set by connecting a feedback resistor and capacitor from the FB2

terminal (pin 5) to the −INE2 terminal (pin 4) of the error amplifier, enabling stable phase compensation to the

system.

(5) Error amplifier block (Error Amp3)

This error amplifier (Error Amp3) detects the output voltage from the DC/DC conver ter and outputs the PWM

control signal. External output voltage setting resistors can be connected to the error amplifier inverted input

terminal to set the desired level of output voltage from 1 cell to 4 cells.

In addition, an arbitrary loop gain can be set by connecting a feedback resistor and capacitor from the FB3

terminal (pin 15) to the −INE3 terminal (pin 16) of the error amplifier, enabling stable phase compensation to

the system.

Connecting a soft-start capacitor to the CS terminal (pin 22) prevents rush currents when the IC is turned on.

Using an error amplifier for soft-start detection makes the soft-start time constant, independent of the output load.

(6) Current detection amplifier block (Current Amp1)

The current detection amplifier (Current Amp1) detects a voltage drop which occurs between both ends of the

output sense resistor (R

terminal (pin 12) . Then it outputs the signal amplified by 20 times to the error amplifier (Error Amp1) at the next

stage.

) due to the flow of the charge current, using the +INC1 terminal (pin 13) and −INC1

S

16

Page 17

MB3887

(7) PWM comparator block (PWM Comp.)

The PWM comparator circuit is a voltage-pulse width conver ter for controlling the output duty of the error

amplifiers (Error Amp1 to Error Amp3) depending on their output voltage.

The PWM comparator circuit compares the triangular wave generated by the triangular wave oscillator to the

error amplifier output voltage and turns on the external output transistor during the interval in which the triangular

wave voltage is lower than the error amplifier output voltage.

(8) Output block (OUT)

The output circuit uses a totem-pole configuration capable of driving an external P-channel MOS FET.

The output “L” level sets the output amplitude to 6 V (Typ) using the voltage generated by the bias v oltage b lock

(VH) .

This results in increasing conversion efficiency and suppressing the withstand v oltage of the connected external

transistor in a wide range of input voltages.

(9) Control block (CTL)

Setting the CTL terminal (pin 14) low places the IC in the standby mode. (The supply current is 10 µA at maximum

in the standby mode.)

CTL function table

CTL Power OUTD

L OFF (Standby) Hi-Z

HON (Active) L

(10) Bias voltage block (VH)

The bias voltage circuit outputs V

mode, this circuit outputs the potential equal to VCC.

−6 V (Typ) as the minimum potential of the output circuit. In the standby

CC

2. Protection Functions

Under voltage lockout protection circuit (UVLO)

The transient state or a momentary decrease in supply voltage or internal reference voltage (VREF) , which

occurs when the power supply (VCC) is turned on, may cause malfunctions in the control IC, resulting in

breakdown or degradation of the system.

To prevent such malfunction, the under voltage lockout protection circuit detects a supply voltage or internal

reference voltage drop and fixes the OUT terminal (pin 20) to the “H” level. The system restores voltage supply

when the supply voltage or internal reference voltage reaches the threshold v oltage of the under v oltage lock out

protection circuit.

Protection circuit (UVLO) operation function table

When UVLO is operating (VCC or VREF voltage is lower than UVLO threshold voltage.)

OUTD OUT CS

Hi-Z H L

17

Page 18

MB3887

R

R

3. Soft-Start Function

Soft-start block (SOFT)

Connecting a capacitor to the CS terminal (pin 22) prevents rush currents when the IC is turned on. Using an

error amplifier for soft-start detection makes the soft-start time constant, being independent of the output load

of the DC/DC converter.

SETTING THE CHARGING VOLTAGE

■

The charging voltage (DC/DC output voltage) can be set by connecting external voltage setting resistors (R3,

R4) to the −INE3 terminal (pin 16) . Be sure to select a resistor value that allows you to ignore the on-resistor

(35 Ω, 1mA) of the internal FET connected to the OUTD terminal (pin 11) . In standby mode, the charging

voltage is applied to OUTD termial. Therefore, output v oltage must be adjusted so that v oltage applied to OUTD

terminal is 17 V or less.

Battery charging voltage : V

VO (V) = (R3 + R4) / R4 × 4.2 (V)

O

V

O

B

3

−INE3

16

4

11

OUTD

22

CS

METHOD OF SETTING THE CHARGING CURRENT

■

<Error Amp3>

−

+

+

4.2 V

The charge current (output limit current) value can be set with the voltage at the +INE1 terminal (pin 9) .

If a current exceeding the set v alue attempts to flow, the charge voltage drops according to the set current v alue.

Battery charge current setting voltage : +INE1

+INE1 (V) = 20 × I1 (A) × R

(Ω)

S

METHOD OF SETTING THE TRIANGULAR WAVE OSCILLATION FREQUENCY

■

The triangular wave oscillation frequency can be set b y the timing resistor (RT) connected the RT terminal (pin 17) .

Triangular wave oscillation frequency : f

f

(kHz) := 13630 / RT (kΩ)

OSC

OSC

18

Page 19

MB3887

C

METHOD OF SETTING THE SOFT-START TIME

■

For pre venting rush current upon activation of IC, the IC allows soft-start using the capacitor (Cs) connected to

the CS terminal (pin 22) .

When CTL terminal (pin 14) is placed under “H” level and IC is activated (V

is turned off and the external soft-start capacitor (Cs) connected to the CS terminal is charged at 10 µA.

Error Amp output (FB3 terminal (pin 15) ) is determined by comparison between the lower voltage of the two

non-reverse input terminals (4.2 V and CS terminal voltage) and re v erse input terminal voltage (−INE3 terminal

(pin 16) voltage) . Within the soft-start period (CS terminal voltage < 4.2 V) , FB3 is determined by comparison

between −INE3 terminal voltage and CS terminal voltage, and DC/DC con verter output voltage goes up proportionately with the increase of CS terminal voltage caused by charging on the soft-start capacitor.Soft-start time

is found by the following formula :

Soft-start time : ts (time to output 100 %)

t

(s) := 0.42 × CS (µF)

S

≥ UVLO threshold voltage) , Q2

CC

= 4.9 V

= 4.2 V

= 0 V

Soft-start time: ts

15

FB3

16

−INE3

CS

22

VREF

10 µA 10 µA

CS terminal voltage

Comparison with Error Amp block − INE3

voltage.

Error

Amp3

−

+

+

4.2 V

S

Q2

UVLO

Soft-start circuit

19

Page 20

MB3887

V

V

V

E

E

E

■ AC ADAPTOR VOLTAGE DETECTION

With an external resistor connected to the +INE2 terminal (pin 3) , the IC enters the dynamically-controlled

charging mode to reduce the charge current to keep AC adapter po wer constant when the partial potential point

A of the AC adapter voltage (VCC) becomes lower than the voltage at the −INE2 terminal.

AC adapter detection voltage setting : Vth

Vth (V) = (R1 + R2) / R2 × −INE2

<Error Amp2>

−

+

CC

R1

R2

−INE2

A

+INE2

4

3

■ OPERATION TIMING DIAGRAM

rror Amp2 FB2

rror Amp1 FB1

2.5

rror Amp2 FB3

1.5

OUT

Constant voltage control Constant current control

AC adapter dynamically-

controlled charging

20

Page 21

MB3887

PROCESSING WITHOUT USING THE CURRENT AMP

■

When Current Amp is not used, connect the +INC1 terminal (pin 13) , +INC2 terminal (pin 24) , −INC1 terminal

(pin 12) , and −INC2 terminal (pin 1) to VREF, and then leave OUTC1 terminal (pin 10) and OUTC2 terminal

(pin 2) open.

“Open”

+INC2

1312

24

−INC1 +INC1

−INC2

1

10

OUTC1

2

OUTC2

6

VREF

Connection when Current Amp is not used

21

Page 22

MB3887

PROCESSING WITHOUT USING OF THE ERROR AMP

■

When Error Amp is not used, leave FB1 terminal (pin 7) , FB2 terminal (pin 5) open and connect the −INE1

terminal (pin 8) and −INE2 terminal (pin 4) to GND and connect +INE1 terminal (pin 9) , and +INE2 terminal (pin

3) , to VREF.

23

GND

“Open”

9

+INE1

+INE2

3

8

−INE1

4

−INE2

7

FB1

5

FB2

6

VREF

Connection when Error Amp is not used

22

Page 23

PROCESSING WITHOUT USING OF THE CS TERMINAL

T

■

When soft-start function is not used, leave the CS terminal (pin 22) open.

22

CS

MB3887

“Open”

Connection when soft-start time is not specified

NOTE ON AN EXTERNAL REVERSE-CURRENT PREVENTIVE DIODE

■

• Insert a reverse-current prev entive diode at one of the three locations marked * to pre vent re verse current from

the battery.

• When selecting the rev erse current prev ention diode, be sure to consider the re v erse voltage (V

current (I

) of the diode.

R

VCC(O)

21

OUT

20

VH

19

VIN

*

*

A B

I1

*

Battery

RS

BAT

) and reverse

R

23

Page 24

MB3887

THE SEQUENCE OF THE START-UP AND OFF OF THE POWER SUPPLY

■

Please start up and off the VCC terminal (pin 18) and VCC(O) terminal (pin 21) of the power supply terminal at

the same time. No do occurrence of the bias from the VH terminal (pin 19) , when there is a period of 8 V or

less in the VCC voltage after previously starting up VCC(O). At this time, there is a possibility of leading to

permanent destruction of the device when the voltage of 17 V or more is impressed to the VCC(O) terminal.

Moreover, when earliness VCC falls more than VCC(O) when falling, it is similar.

24

Page 25

APPLICATION EXAMPLE

2

r

■

AC Adapto

MB3887

O

V

B

R1

A

I1

0.033 Ω

Battery

C3

100 µF

VIN = 13.93 V to 25 V

(at 3 cell)

<Error Amp1>

IIN

VIN = 17.65 V to 25 V

(at 4 cell)

VCC (O)

VREF

−

C1

+

C5

0.1 µF

21

<PWM Comp.>

+

22 µF

<OUT>

+++

Q1

OUT

20

Drive

−

L1

22 µH

VCC

VREF

<Error Amp2>

+ +

D1

−

VH

C2

19

CC − 6 V)

(V

Bias

Voltage

+

100 µF

Output voltage (Battery

voltage) is adjustable

VCC

2.5 V

1.5 V

<VH>

<UVLO>

VREF

<Error Amp3>

Note:

Set output voltage so

that voltage applied to

OUTD terminal is 17 V or

less.

35 kΩ

215 kΩ

+

−

0.91 V

(0.77 V)

VREF

UVLO

(VCC UVLO)

+

+

−

4.2 V

VCC

VCC

18

4.2 V

C7

0.1 µF

CTL

14

<REF> <CTL>

<OSC>

VREF

5.0 V

bias

45 pF

17 6 23

GND

VREF

RT

R2

C9

0.1 µF

47 kΩ

R8

<Current Amp1>

8

10

−INE1

OUTC1

100 kΩ

C10

+

× 20

13

−INC1

+INC1

A

R9

10 kΩ

5600 pF

10

VREF

<SOFT>

µA

22

CS

C4

0.022 µF

−

12

B

R12

R14

+INE1

30 kΩ

1 kΩ

9

R13

R15

R16

00 kΩ

FB1

20 kΩ

120 Ω

7

Q2

4

−INE2

C8

10000 pF

SW

2

OUTC2

R7

22 kΩ

R4

−

+

× 20

<Current Amp2>

1

−INC2

R5

330 kΩ

3

+INE2

24

+INC2

82 kΩ

R6

68 kΩ

R10

FB2

30 kΩ

5

R19

100 kΩ

R11

16

11

−INE3

200 kΩ

C6

1500 pF

R17

100 kΩ

R3

330 kΩ

R18

30 kΩ

OUTD

15

FB3

25

Page 26

MB3887

PARTS LIST

■

COMPONENT ITEM SPECIFICATION VENDOR PARTS No.

Q1

Q2

D1 Diode VF = 0.42 V (Max) , IF = 3 A ROHM RB053L-30

P-ch FET

N-ch FET

VDS = −30 V, ID = ±8 A (Max)

VDS = 60 V, ID = 0.115 A

(Max)

VISHAY SILICONIX

VISHAY SILICONIX

Si4435DY

2N7002E

L1 Inductor 22 µH

C1

C2, C3

C4

C5

C6

C7

C8

C9

C10

R1

R2

R3

R4

R5

R6

R7

R8

R9

R10 to R12

R13

R14

R15

R16, R18

R17, R19

OS-CON

Electrolytic Condenser

Ceramics Condenser

Ceramics Condenser

Ceramics Condenser

Ceramics Condenser

Ceramics Condenser

Ceramics Condenser

Ceramics Condenser

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

Resistor

TM

22 µF

100 µF

0.022 µF

0.1 µF

1500 pF

0.1 µF

10000 pF

0.1 µF

5600 pF

0.033 Ω

47 kΩ

330 kΩ

82 kΩ

330 kΩ

68 kΩ

22 kΩ

100 kΩ

10 kΩ

30 kΩ

20 kΩ

1 kΩ

120 Ω

200 kΩ

100 kΩ

3.5 A,

31.6 mΩ

25 V (10 %)

25 V (10 %)

50 V

16 V

10 V

25 V

10 V

16 V

10 V

1.0 %

0.5 %

0.5 %

0.5 %

0.5 %

0.5 %

0.5 %

0.5 %

1.0 %

0.5 %

0.5 %

0.5 %

0.5 %

0.5 %

0.5 %

TDK

SANYO

SANYO

TDK

KYOCERA

MURATA

MURATA

MURATA

KYOCERA

MURATA

SEIDEN TECHNO

KOA

KOA

KOA

KOA

KOA

KOA

KOA

KYOCERA

KOA

KOA

KOA

ssm

KOA

KOA

SLF12565T-

220M3R5

25SL22M

25CV100AX

C1608JB1H223K

CM21W5R104K16

GRM39B152K10

GRM39F104KZ25

GRM39B103K10

CM21W5R104K16

GRM39B562K10

RK73Z1J-0D

RK73G1J-473D

RK73G1J-334D

RK73G1J-823D

RK73G1J-334D

RK73G1J-683D

RK73G1J-223D

RK73G1J-104D

CR21-103-F

RK73G1J-303D

RK73G1J-203D

RK73G1J-102D

RR0816P121D

RK73G1J-204D

RK73G1J-104D

Note : VISHAY SILICONIX : VISHAY Intertechnology, Inc.

ROHM : ROHM CO., LTD.

TDK : TDK Corporation

SANYO : SANYO Electric Co., Ltd.

KYOCERA : Kyocera Corporation

MURATA : Murata Manufacturing Co., Ltd.

SEIDEN TECHNO : SEIDEN TECHNO CO., LTD.

KOA : KOA Corporation

ssm : SUSUMU Co., Ltd.

OS-CON is a trademark of SANYO Electric Co., Ltd.

26

Page 27

REFERENCE DATA

1

0246810121416

1

0

1

0

■

MB3887

Conversion efficiency vs. Charge current

(Constant voltage mode)

100

Ta = +25 °C

98

VIN = 19 V

BATT charge voltage =

96

set at 12.6 V

94

SW = ON

92

Efficiency η (%) =

BATT × IBATT) /

(V

90

(V

IN × IIN) × 100

88

86

84

82

Conversion efficiency η (%)

80

10 m 100 m 1 10

BATT charge current I

BATT

(A)

Conversion efficiency vs. Charge current

(Constant voltage mode)

00

98

96

94

92

90

88

86

84

82

Conversion efficiency η (%)

80

10 m 100 m 1 1

BATT charge current I

Ta = +25 °C

VIN = 19 V

BATT charge voltage =

set at 16.8 V

SW = ON

Efficiency η (%) =

(V

BATT × IBATT) /

(V

IN × IIN) × 100

(A)

BATT

Conversion efficiency vs. Charge current

(Constant current mode)

00

Ta = +25 °C

98

VIN = 19 V

96

BATT charge voltage =

set at 12.6 V

94

SW = ON

92

Efficiency η (%) =

(V

BATT × IBATT) /

90

(V

IN × IIN) × 100

88

86

84

82

Conversion efficiency η (%)

80

BATT charge voltage V

BATT

(V)

Conversion efficiency vs. Charge current

(Constant current mode)

00

98

96

94

92

90

88

86

84

82

Conversion efficiency η (%)

80

0 2 4 6 8 10121416182

BATT charge voltage V

Ta = +25 °C

VIN = 19 V

BATT charge voltage =

set at 16.8 V

SW = ON

Efficiency η (%) =

(V

BATT × IBATT) /

(V

IN × IIN) × 100

(V)

BATT

(Continued)

27

Page 28

MB3887

1

0

1

0

1

1

1

1

1

5

2

1

1

1

1

1

5

Conversion efficiency vs. Charge current

(Constant voltage mode)

00

98

96

94

92

90

88

86

84

82

Conversion efficiency η (%)

80

10 m 100 m 1 1

BATT charge current I

Ta = +25 °C

VIN = 19 V

BATT charge voltage =

set at 16.8 V

SW = ON

Efficiency η (%) =

(V

BATT × IBATT) /

(V

IN × IIN) × 100

(A)

BATT

BATT voltage vs. BATT charge current

(set at 12.6 V)

8

6

4

(V)

2

BATT

0

8

6

4

BATT voltage V

2

0

Dead Battery MODE DCC MODE

01232.51.50.5 4

BATT charge current I

Ta = +25 °C VIN = 19 V

BATT : Electronic load

(Product of KIKUSUI PLZ-150W)

DCC : Dynamically-Controlled

BATT

,

(A)

Conversion efficiency vs. Charge current

(Constant current mode)

00

98

96

94

92

90

88

86

84

82

Conversion efficiency η (%)

80

0 2 4 6 810121416182

BATT charge voltage V

Ta = +25 °C

VIN = 19 V

BATT charge voltage =

set at 16.8 V

SW = ON

Efficiency η (%) =

(V

BATT × IBATT) /

(V

IN × IIN) × 100

(V)

BATT

BATT voltage vs. BATT charge current

(set at 16.8 V)

0

8

6

(V)

4

BATT

2

0

8

6

4

BATT voltage V

2

4.53.5

0

Dead Battery MODE DCC MODE

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5

BATT charge current I

BATT : Electronic load,

(Product of KIKUSUI PLZ-150W)

Ta = +25 °C

VIN = 19 V

DCC : Dynamically-Controlled

(A)

BATT

(Continued)

28

Page 29

MB3887

V

0

)

V

0

)

V

V

0

)

V

0

)

Switching waveform constant voltage mode

(set at 12.6 V)

BATT (mV)

100

−100

V

D (V)

Ta = +25 °C

VIN = 19 V

BATT = 1.5 A

98 mVp-p

0

15

10

5

0

01234567891

VBATT

VD

Switching waveform constant voltage mode

(set at 16.8 V)

15

0

Ta = +25 °C

VIN = 19 V

BATT = 1.5 A

58 mVp-p

VBATT

VD

BATT (mV)

100

−100

D (V)

(µs

Switching waveform constant current mode

(set at 12.6 V, with 10 V)

BATT (mV)

100

−100

V

D (V)

Ta = +25 °C

VIN = 19 V

BATT = 3.0 A

98 mVp-p

VBATT

0

V

15

10

5

0

01234567891

D

Switching waveform constant current mode

(set at 16.8 V, with 10 V)

15

0

Ta = +25 °C

VIN = 19 V

BATT = 3.0 A

96 mVp-p

VBATT

V

D

BATT (mV)

100

−100

V

D (V)

(µs

10

5

0

01234567891

(µs

10

5

0

01234567891

(µs

(Continued)

29

Page 30

MB3887

V

s)

V

s)

V

s)

V

s)

(Continued)

Soft-start operating waveform

constant voltage mode

(set at 12.6 V)

BATT (V)

20

Ta = +25 °C, VIN = 19 V

10

BATT = 12 Ω

0

CS (V)

V

V

CTL (V)

4

2

0

5

0

0 2 4 6 8 101214161820

ts = 10.4 ms

Soft-start operating waveform

constant voltage mode

(set at 16.8 V)

BATT (V)

20

Ta = +25 °C, VIN = 19 V

10

BATT = 12 Ω

0

V

CS (V)

4

2

0

ts = 10.4 ms

VBATT

VCS

VCTL

VBATT

VCS

(m

Discharge operating waveform

constant voltage mode

(set at 12.6 V)

BATT (V)

20

10

0

CS (V)

V

4

2

0

V

CTL (V)

VCTL

5

0

0 2 4 6 8 101214161820

Discharge operating waveform

constant voltage mode

(set at 16.8 V)

BATT (V)

20

10

0

V

CS (V)

4

2

0

VBATT

VCS

Ta = +25 °C

VIN = 19 V

BATT = 12 Ω

(m

VBATT

VCS

V

CTL (V)

5

0

0 2 4 6 8 101214161820

VCTL

(m

CTL (V)

V

VCTL

5

0

02468101214161820

Ta = +25 °C

VIN = 19 V

BATT = 12 Ω

(m

30

Page 31

MB3887

USAGE PRECAUTIONS

■

• Printed circuit board ground lines should be set up with consideration for common impedance.

• Take appropriate static electricity measures.

• Containers for semiconductor materials should hav e anti-static protection or be made of conductive material.

• After mounting, printed circuit boards should be stored and shipped in conductive bags or containers.

• Work platforms, tools, and instruments should be properly grounded.

• Working personnel should be grounded with resistance of 250 kΩ to 1 MΩ between body and ground.

• Do not apply negative voltages.

• The use of negative voltages below −0.3 V may create parasitic transistors on LSI lines, which can cause

malfunction.

ORDERING INFORMATION

■

Part number Package Remarks

MB3887PFV

24-pin plastic SSOP

(FPT-24P-M03)

31

Page 32

MB3887

PACKAGE DIMENSION

■

24-pin plastic SSOP

(FPT-24P-M03)

INDEX

Note 1) *1 : Resin protrusion. (Each side : +0.15 (.006) Max) .

Note 2) *2 : These dimensions do not include resin protrusion.

Note 3) Pins width and pins thickness include plating thickness.

Note 4) Pins width do not include tie bar cutting remainder.

2

5.60±0.10 7.60±0.20

*

(.220±.004) (.299±.008)

Details of "A" part

+0.20

–0.10

1.25

.049

(Mounting height)

+.008

–.004

0.25(.010)

112

0.65(.026)

0.10(.004)

0.10(.004)

0.24

.009

+0.08

–0.07

+.003

–.003

0.13(.005)

M

2003 FUJITSU LIMITED F24018S-c-4-5

Dimensions in mm (inches) .

Note : The values in parentheses are reference values.

"A"

0~8

˚

0.50±0.20

(.020±.008)

0.60±0.15

(.024±.006)

0.10±0.10

(.004±.004)

(Stand off)

32

Page 33

MB3887

FUJITSU LIMITED

All Rights Reserved.

The contents of this document are subject to change without notice.

Customers are advised to consult with FUJITSU sales

representatives before ordering.

The information, such as descriptions of function and application

circuit examples, in this document are presented solely for the

purpose of reference to show examples of operations and uses of

Fujitsu semiconductor device; Fujitsu does not warrant proper

operation of the device with respect to use based on such

information. When you develop equipment incorporating the

device based on such information, you must assume any

responsibility arising out of such use of the information. Fujitsu

assumes no liability for any damages whatsoever arising out of

the use of the information.

Any information in this document, including descriptions of

function and schematic diagrams, shall not be construed as license

of the use or exercise of any intellectual property right, such as

patent right or copyright, or any other right of Fujitsu or any third

party or does Fujitsu warrant non-infringement of any third-party’s

intellectual property right or other right by using such information.

Fujitsu assumes no liability for any infringement of the intellectual

property rights or other rights of third parties which would result

from the use of information contained herein.

The products described in this document are designed, developed

and manufactured as contemplated for general use, including

without limitation, ordinary industrial use, general office use,

personal use, and household use, but are not designed, developed

and manufactured as contemplated (1) for use accompanying fatal

risks or dangers that, unless extremely high safety is secured, could

have a serious effect to the public, and could lead directly to death,

personal injury, severe physical damage or other loss (i.e., nuclear

reaction control in nuclear facility, aircraft flight control, air traffic

control, mass transport control, medical life support system, missile

launch control in weapon system), or (2) for use requiring

extremely high reliability (i.e., submersible repeater and artificial

satellite).

Please note that Fujitsu will not be liable against you and/or any

third party for any claims or damages arising in connection with

above-mentioned uses of the products.

Any semiconductor devices have an inherent chance of failure. You

must protect against injury, damage or loss from such failures by

incorporating safety design measures into your facility and

equipment such as redundancy, fire protection, and prevention of

over-current levels and other abnormal operating conditions.

If any products described in this document represent goods or

technologies subject to certain restrictions on export under the

Foreign Exchange and Foreign Trade Law of Japan, the prior

authorization by Japanese government will be required for export

of those products from Japan.

F0501

© 2005 FUJITSU LIMITED Printed in Japan

Page 34

Loading...

Loading...