Page 1

FUJITSU SEMICONDUCTOR

SUPPORT SYSTEM

F2MC-16 Family EMULATOR

SS01-71045-1E

QFP-100P PROBE HEADER

MB2147-583

OPERATION MANUAL

Page 2

PREFACE

Thank you for purchasing th e QFP -10 0P *1 probe header (MB2147-583) for the F2MC*2 -16 familyemulator.

The QFP-100P probe header is used to connect the F

the F

Fujitsu F

This manual explains the handling of the QFP-100 P probe head er for the F

Before using the MB2147-583, be sure to read this manual.

Consult the Sales representatives or the Support representatives of Fujitsu Limited for mass-produced MCUs and evaluation MCUs.

*1 : The lead pitch of PACKAGE (FPT-100P-M06) is 0.65 mm and the body size is 14 mm × 20

*2 : F

*3 : re ferred to as "em ul ator"

*4 : referred to as "adapter board"

■ Handling and use

The handling and use of this product and no tes regard ing safety are i ncluded in the hard ware manual

of the F

2

2

MC-16L/16LX emulator PGA -299P adapt er boar d (MB214 7-20*4) to a user system. That uses

2

MC *1 -16LX microcontroller MB90940 series (QFP-100P).

MC-16L/16LX emulator (MB2147-01*3)and

2

MC-16 family emulator.

mm. Using the product safely.

2

MC is the abbreviation used for FUJITSU Flexible Microcontroller.

2

MC-16 family emulator.

Follow the instructions in for the use of this product.

2

• F

MC-16L/16LX EMULATOR

MB2147-01 HARDWARE MANUAL

2

• F

MC-16L/16LX EMULATOR PGA-299P ADAPTER BOARD

MB2147-20 HARDWARE MANUAL

■ Caution of the products described in this document

The following precautions apply to the product described in this manual.

The wrong use of a device will give an injury and may cause malfunction on cus-

CAUTION

Cuts

tomers system.

This product has parts with sharp points that are exposed.

Do not touch edge of the product with your bare hands.

When connect the header board to the user system, correctly position the index

Damage

mark (▲) on the NQPACK mounted on the user system with the index mark (▲)

on the header board, otherwise the emulator system and user system might be

damaged.

Damage

When mounting a mass production MCU, correctly position pin 1, otherwise the

mass production MCU and user system might be damag ed.

Page 3

• The contents of this document are subject to change without notice.

Customers are advised to consult with FUJITSU sales representatives before ordering.

• The informati on, such as descriptions of function and application circuit examples, in this document are presented solely for the purpose of reference to show examples of op erations an d uses of FUJITS U semi conducto r devi ce; FUJITSU

does not warrant proper operation of the device with respect to use based on such information. When you develop

equipment incorporating the device based on such information, you must assume any responsibility arising out of such

use of the information. FUJITSU assumes no liab ility for any damages whatsoever arising out of the use of the information.

• Any information in this document, including descriptions of function and schematic diagrams, shall not be construed

as license of the use or exercise of any intellectual property right, such a s pa ten t ri ght or c op yri gh t , or any o the r ri gh t

of FUJITSU or any third party or does FUJITSU warrant non-infringement of any third-party’s intellectual property

right or other right by using such information. FUJITS U assumes no liabil ity for any infringeme nt of the intellectual

property rights or other rights of third parties which would result from the use of information contained herein.

• The products described in this document are designed, developed and manufactured as contemplated for general use,

including without limitation, ordinary industr ial use, genera l office use, personal u se, and household use, b ut are not

designed, developed and manufactured as contemplated (1) for use accompanying fatal risks or dangers that, unless

extremely high safety is secured, could have a serious effect to the public, and could lead directly to death, personal

injury, severe physical damag e or other loss (i.e., nuclear reac tion cont rol in nuclear facility, aircraft flight control, air

traffic control, mass transport control, medical life support system, missile launch control in weapon system), or (2)

for use requiring extremely high reliability (i.e., submersible repeater and artificial satellite).

Please note that FUJITSU will not be liable against you and/or any third party for any claims or damages arising in

connection with above-mentioned uses of the products.

• Any semiconductor devices have an inherent chance of failure. You must protect against injury, damage or loss from

such failures by incorporating safety design measures into y our facility and equ ipment such as redundan cy, fire protection, and prevention of over-current levels and other abnormal operating conditions.

• If any products described in thi s document represen t goods or technol ogies subject to certa in restriction s on export under the Foreign Exchange and Foreign Trade Law of Japan, the prior authorization by Japanese government will be

required for e x por t of th os e pro du c ts fr om J a pan .

©2005 FUJITSU LIMITED Printed in Japan

Page 4

1. Checking the Delivered Product

Before using the QFP-100P probe h eader, confirm that the following components are included in the

box:

• QFP-100P Probe Header

• Screws for securing header board (M2 × 10 mm, 0.4 mm pitch) : 4

• Washer : 4

• NQPACK100RB179

• HQPACK100RB179

• Operation manual (Japanese version) : 1

• Operation manual (English version, this manual) : 1

*1 : Referred to as "header board". Header board is mounted on the YQPACK100RB179 (Tokyo

Eletech Corporation), referred to as “YQPACK”.

*2 : IC socket manufactured by Tokyo Eletech Corporation, referred to as “NQPACK”, and sup-

plied with a special screwdriver and 3 guide pins. A socket offering higher reliability,

NQPACK100RB179-SL (T okyo Eletech Co rporation, so ld separate ly), can be used by making

an IC socket mounting hole on the user system board. For more information, contact Tokyo

Eletech Corporation.

*3 : IC Socket cover manufactured by Tokyo Eletech Corporation, r eferred to as “HQPACK”, with

4 screws for securing HQPACK (M2 × 6 mm, 0.4 mm pitch).

*1

*2

*3

: 1

: 1

: 1

This product is used as an emulator system by combining with an optional emulator and adapter

board.

Consult the Sales Department or the Support Department of Fujitsu Limited for the adapter or the

emulator of this product.

2. Handling Precautions

The header board is precision-manufactured to improve dimensional accuracy and to ens ure reliable

contact. The header is therefore sensitive to mechanical shock. To ensure correct use of the header

in the proper environment, observe the following points regarding its insertion and removal:

• To avoid placi ng stress on the NQPACK mo unted on the user sys tem board during connect ing

the header board.

1

Page 5

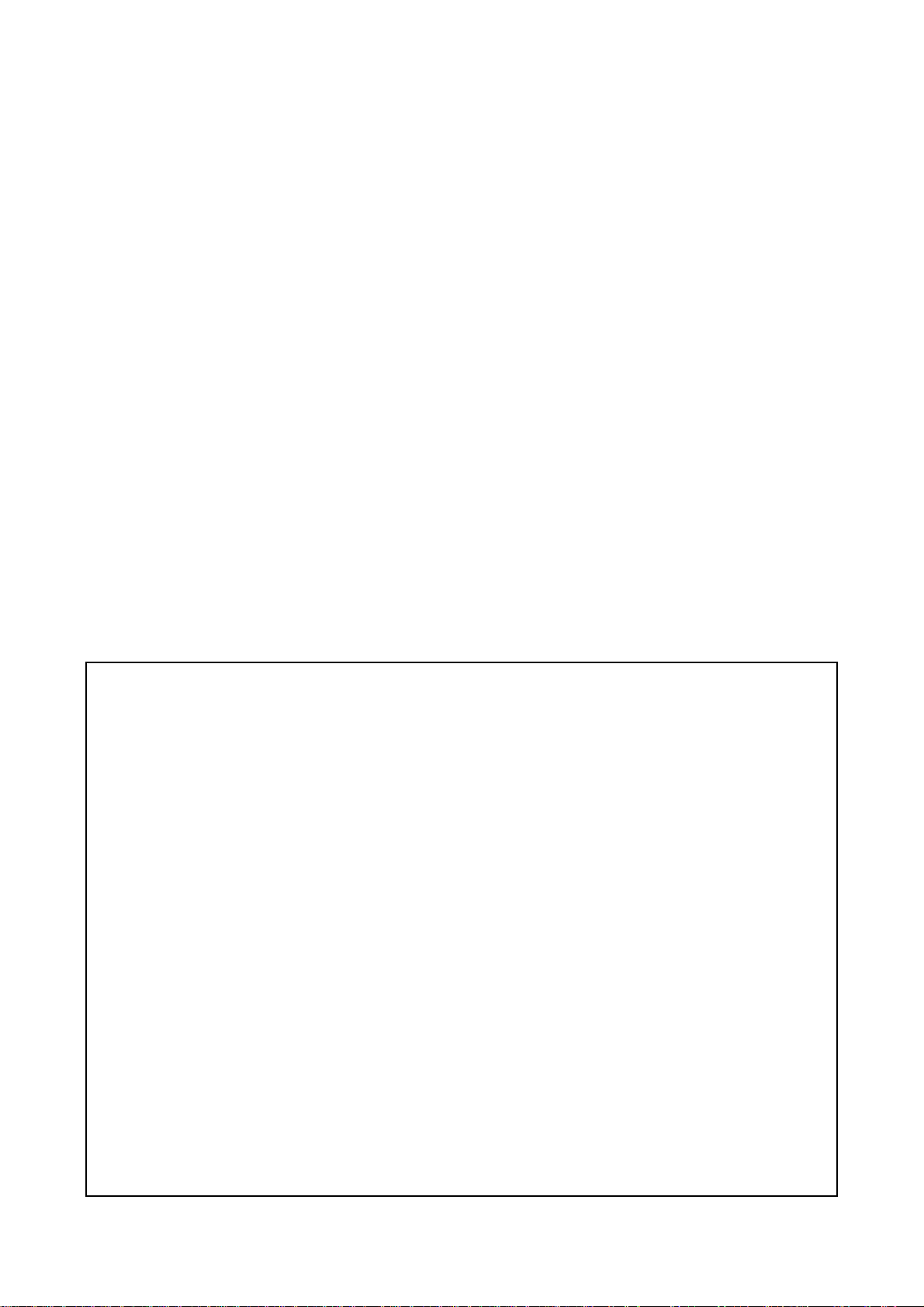

3. Notes on Designing

■ Restrictions of PC board for the user system

Once the header board is connected to the user system, the heights of parts mounted in the space

around the header board are restricted.

The PC board of the user system must be designed with du e consideration given to this rest riction

(Figure 1).

40.0 mm

77.0 mm

50.0 mm

CN1

12

CN2

PROBE CABLE CN B2

99 100

12

CN3

PROBE CABLE CN B1

99 100

80.0 mm

Approximately

30.0 mm *

Approximately

13.0 mm *

* : The height differs slightly de pending on how the YQPA CK and the NQPACK are en-

gaged.

Figure 1 Header board dimensions

2

Page 6

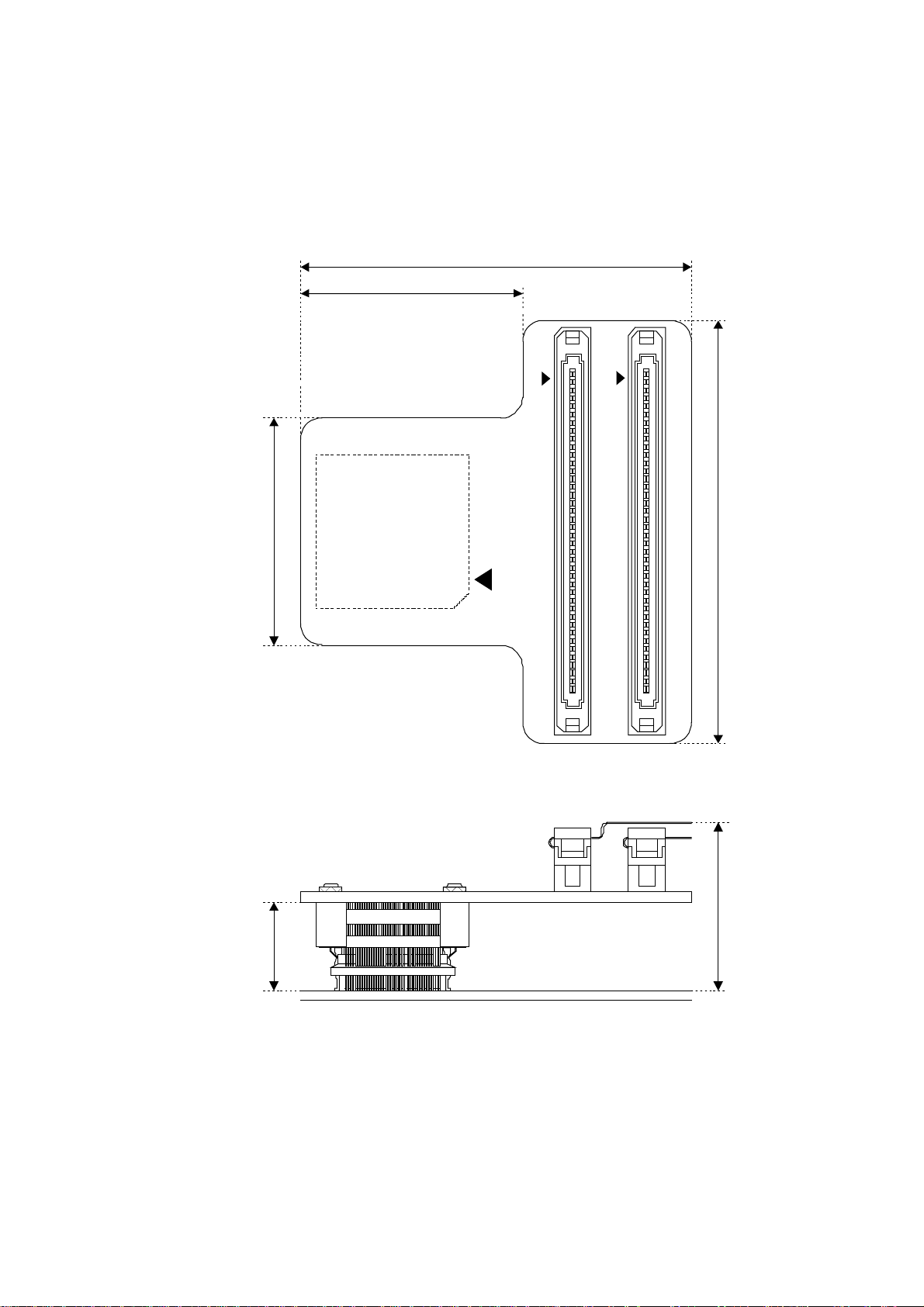

■ MCU footprint design notes

Figure 2 shows the recommended dimensions of the NQPACK footprint mounted on the PC board

of the user system.

The PC board of the user system must be designed with due consideration given to this footprint as

well as to the mass production MCU.

For more information, contact the Tokyo Eletech Corporation.

No.1 Pin

0.65

7.0

0.35

6.0

φ 3.2*

UNIT : mm

19.8

2

3 - φ 1.0*

1

2.4

13.8 2.4

*1 : It is a position of hole (φ1.0) for the guide pin to fit position when NQPACK is mounted.

When the guide pin is not used, it is not necessary to puncture it.

*2 : It is a fixation of screw hole(φ3.2) for IC socket made when NQPACK100RB179-

SL(Tokyo Eletech Corporation, sold separately) is mounted.

When the NQPACK100RB179-SL is not used, it is not necessary.

Figure 2 Recommended dimensions of the footprint for mounting the NQPACK

3

Page 7

4. Procedure for Connecting the User System

Before using the QFP-100P probe header, mount the supplied NQPACK on the user system.

The header board is used combining the adapter board. To connect the header board to the adapter

board, use the flat cable (2 lines) supplied by the emulator sold separately. Refer to the hardware

manuals of the adapter board about the way to connect.

■ Connecting

1. To connect the header board to the user system, match the index mark (▲) on the NQPACKmounted on the user system with the index mark (▲) on the header board and then insert it (See

Figure 3) . The pin of YQPACK is thin and easy to bent. Insert NQPACK after confirm that thep

in of YQPACK is not bent.

2. Insert each screw for securing header board in each of the four drilled holes on the header

board(See Figure 4).

To tighten the screws, use the special screwdriver supplied with the NQPACK to finally tightenthe four screws in sequence. Tightening the screws too tight might result in a defective contact.

Probe cable connector B2

YQPACK

(It arranges at the back)

-

Probe cable connector B1

100RB

TET

NQPACK Index (▲)

User System

Header board Index (▲)

Figure 3 Index Position

4

Page 8

■ Disconnection

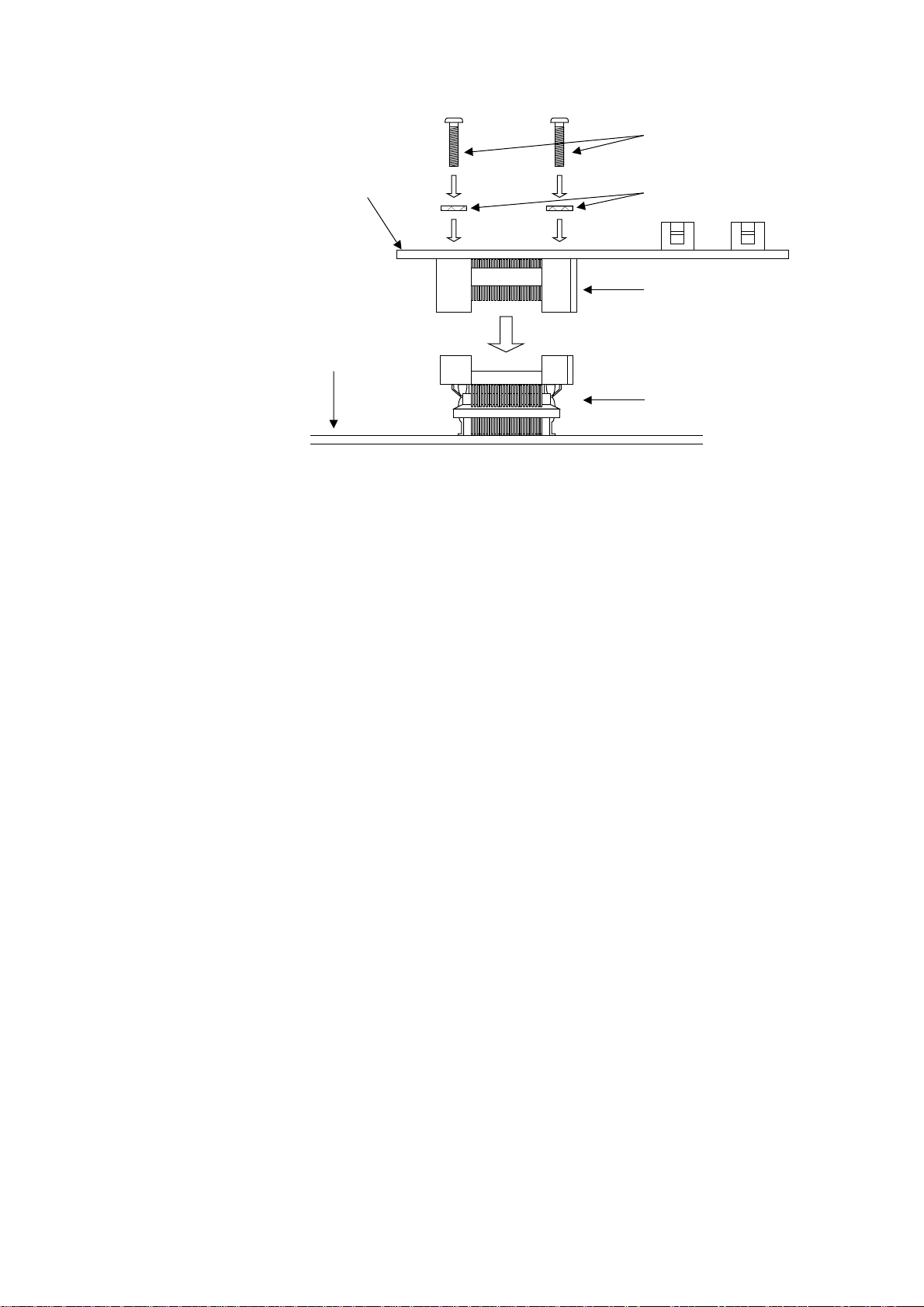

Screws for securing

header board

Header board

Washer

YQPACK

User system

NQPACK

Figure 4 Header board connection

To disconnect the header board from the user syst em, remove all four screws, and then pull the header board straight out of the socket

5

Page 9

5. Mounting Mass Production MCUs

To mount a mass production MCU on the user system, use the supplied HQPACK (See Figure 5).

■ Mounting

1. To mount a mass production MCU on the user system, match the index mark (▲) on the NQPACK mounted on the user system with the index mark (●) on the mass production MCU.

2. Confirm that the mass production MCU is correctly mounted on the NQPACK. Next, insert the

HQPACK into a NQPACK.

The pin of HQPACK is thin and easy to bent. Insert NQPACK after confirm that the pin of HQPACK is not bent.

3. Insert each screw for securing HQPACK in each of the four drilled holes on the HQPACK (See

Figure 5).

To tighten the screws, use the special screwdriver supplied with the NQPACK to finally tighten

the four screws in sequence. Tightening the screws too tight might result in a defective contact.

Screws for securing HQPACK

■ Disconnection

HQPACK

Mass production MCU

User system

NQPACK

Figure 5 Mounting a mass production MCU

To remove the HQPACK, remove all four screws, and pull out the HQPACK vertically.

6

Page 10

6. Connector Pin Assignment

The signal of Evaluation MCU with which it was carried on the adapter board is connected to YQPACK(the same assignments as product ion MCU) via the probe cable connector( B1,B2) on a header

board.

An adapter board and a header board are connected to an emulator main part by the attached flat cable (It is used standard 2 or two long.)connector.

Please check the hardware manual of an emulator or an adap ter board ab out reference of the c onnection method.

■ Pin Assignment

Tables 1 and 2 list the pin assignments among the flat cable connector, the evaluation MCU on the

adapter board, and the production MCU.

For details on the names of signal conductors of the evaluation MCU, refer to the hardware manual

for the adapter board.

Comments in the tables are given below.

*1 : Co nnected to the main power supply of the evaluation MCU.

*2 : Conn ected to the mai n power suppl y (Vcc) of the prod uction MCU. The connection pin num-

bers are 15 and 90.

*3 : Connected to the ground of the evaluation MCU.

*4 : Connected to the ground (Vss) of the production MCU. The connection pin numbers are 16,

44 and 91.

- : Unconnected pin (left open).

7

Page 11

Table 1 Pin assignment of the probe cable connector B1

Probe cable-

Connector

Pin

Numbers

100 *3 *4 99 *3 *4

98 *3 *4 97 80 42

96 208 43 95 148 41

94 259 40 93 *3 *4

92 79 39 91 207 38

90 147 37 89 258 35

88 78 36 87 206 34

86 *3 *4 85 77 32

84 146 33 83 160 49

82 223

80 26

78 94 74 77 269 72

76 219 73 75 95 71

74 *3 *4 73 33 63

72 *1 *2 71 169 62

70 226 58 69 *3 *4

68 275 57 67 34 56

66 105 55 65 167

64 224

62 *3 *4 61 225 60

60 274 64 59 32 61

58 104 59 57 *3 *4

56 170 47 55 106 46

54 227 17 53 163 65

52 *3 *4 51 162 70

50 *3 *4 49 96 68

48 220 69 47 270 67

46 100 66 45 *3 *4

44 97

42 164

40 98

38 *3 *4 37 222 76

36 23

34 165

32 276 45 31 107 24

30 108 23 29 277 21

28 172 22 27 109 20

26 *3 *4 25 173 18

24 229 19 23 228 *2

22 130 12 21 *3 *4

20 292 11 19 193 10

18 131 9 17 194 7

16 247 8 15 132 6

14 *3 *4 13 *3 *4

12 293 5 11 61 4

10 248 3 9 *3 *4

8 133 2 7 195 1

6 62 100 5 63 98

4 134 99 3 294 97

2 *3 *4 1 *3 *4

Evaluation

MCU

Pin Numbers

Production

MCU

Pin Numbers

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

Probe cable-

Connector

Pin

Numbers

81 *3 *4

79 268

63 35 48

43 221

41 273

39 271

35 99 75

33 *3 *4

Evaluation

MCU

Pin Numbers

Production

MCU

Pin Numbers

⎯

⎯

⎯

⎯

⎯

8

Page 12

Table 2 Pin assignment of the probe cable connector B2

Probe cable-

Connector

Pin

Numbers

100 *3 *4 99 *3 *4

98

96 *3 *4 95 217 14

94 267 13 93 *3 *4

92 149 25 91 81 26

90 260 27 89 82 29

88 209 28 87 83

86 *3 *4 85 87

84 218

82 263

80 153

78 8

76 *1 *2 75 84

74 *3 *4 73 272

72 5 31 71 168

70 103

68 166

66 *3 *4 65 210

64 151

62 *3 *4 61 158

60 6

58 92

56 266

54 91

52 215

50 *3 *4 49 88

48 16

46 264

44 213

42 14

40 203

38 *3 *4 37 202

36 299

34 201

32 141

30 110 51 29 230 53

28 278 52 27 262 54

26 *3 *4 25 140 93

24 *3 *4 23 200 92

22 *1 *2 21 *3 *4

20 252 77 19 199 78

18 71 79 17 70 81

16 138 80 15 251 82

14 *3 *4 13 198 84

12 296 83 11 137 85

10 136 86 9 *3 *4

8 197 87 7 295 88

6 250 89 5 64 95

4 135 94 3 196 96

2 *3 *4 1 *3 *4

Evaluation

MCU

Pin Numbers

⎯ ⎯

Production

MCU

Pin Numbers

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

Probe cable-

Connector

Pin

Numbers

97 159 50

83 212

81 *3 *4

79 86

77 150 30

69 *3 *4

67 7

63 261

59 216

57 *3 *4

55 157

53 156

51 155

47 15

45 *3 *4

43 154

41 255

39 143

35 142

33 *3 *4

31 101

Evaluation

MCU

Pin Numbers

Production

MCU

Pin Numbers

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

⎯

9

Page 13

SS01-71045-1E

FUJITSU SEMICONDUCTOR • SUPPORT SYSTEM

2

F

MC-16 Family EMULATOR

QFP-100P PROBE HEADER

MB2147-583

OPERATION MANUAL

May 2005 the first edition

Published FUJITSU LIMITED Electronic Devices

Edited Business Promotion Dept.

Page 14

Loading...

Loading...