Page 1

FUJITSU SEMICONDUCTOR

SUPPORT SYSTEM

SS702-00001-2v0-E

New 8FX Family

8-bit MICROCONTROLLER

BGM ADAPTOR

MB2146-07-E

OPERATION MANUAL

Page 2

PREFACE

Thank you for purchasing the New 8FX Family All Series BGM adapter (model number: MB214607-E).

The product is a development support tool for dev eloping and e valuating applied products which use

Fujitsu Semiconductor microcontrollers (hereafter MCU) that have a BDSU module. This manual

describes how to handle the New 8FX F amily All Series BGM adapter . Be sure to read it before using

the product.

For information on the MCU supported by this product, contact the sales or support representative.

Note: This product does not correspond to the MB95200H/210H/220H series of the New 8FX fam-

ily.

Please use MB2146-08-E for the MB95200H/210H/220H series.

■ Using the product safely

This manual contains important information required for using the product safely. Be sure to read

through the manual before using the product and follow the instructions contained therein to use it

correctly.

In particular, carefully read “■ Caution of the products described in this manual” at the beginning of

this manual to understand the requirements for safe use of the product before using it.

After reading the manual, keep it handy for future reference.

■ TRADEMARK

2

• F

MC is the abbreviation of FUJITSU Flexible Microcontroller.

• REALOS, S

OFTUNE are trademarks of Fujitsu Semiconductor Limited, Japan.

■ Related manuals

You should refer to the following manuals as well:

• “HARDWARE MANUAL” for each type of MCU

• “DATA SHEET” for each type of MCU

• “S

OFTUNE Workbench OPERATION MANUAL”

• “S

OFTUNE Workbench USER’S MANUAL”

• “S

OFTUNE Workbench COMMAND REFERENCE MANUAL”

■ European RoHS compliance

Products with an -E suffix on the part number are European RoHS compliant products.

■ Notice on this document

All information included in this document is current as of the date it is issued. Such information is

subject to change without any prior notice.

Please confirm the latest relevant information with the sales representatives.

i

Page 3

■ Caution of the products described in this document

The following precautions apply to the product described in this manual.

WARNING

Electric shock,

Damage

Electric shock,

Damage

CAUTION

Cuts, Damage

Damage

Damage

Damage

Damage

Damage

Damage

Damage

Indicates a potentially hazardous situation which could result in death or serious

injury and/or a fault in the user’s system if the product is not used correctly.

Before performing any operation described in this manual, turn off all the power

supplies to the system.

Performing such an operation with the power on may cause an electric shock or

device fault.

Once the product has been turned on, do not touch any metal part of it.

Doing so may cause an electric shock or device fault.

Indicates the presence of a hazard that may cause a minor or moderate injury, damages to this product or devices connected to it, or may cause to loose software resources and other properties such as data, if the device is not used appropriately.

Before moving the product, be sure to turn off all the power supplies and unplug the

cables. Watch your step when carrying the product. Do not use the product in an

unstable location such as a place exposed to strong vibration or a sloping surface.

Doing so may cause the product to fall, resulting in an injury or fault.

Do not place anything on the product or expose the product to physical shocks. Do

not carry the product after the power has been turned on.

Doing so may cause a malfunction due to overloading or shock.

Since the product contains many electronic components, keep it away from direct

sunlight, high temperature, and high humidity to prevent condensation. Do not use

or store the product where it is exposed to much dust or a strong magnetic or electric field for an extended period of time.

Inappropriate operating or storage environments may cause a fault.

Use the product within the ranges given in the specifications.

Operation over the specified ranges may cause a fault.

To prevent electrostatic breakdown, do not let your finger or other object come into

contact with the metal parts of any of the connectors. Before handling the product,

touch a metal object (such as a door knob) to discharge any static electricity from

your body.

Before turning the power on, in particular, be sure to finish making all the required

connections. Furthermore, be sure to configure and use the product by following the

instructions given in this document.

Using the product incorrectly or inappropriately may cause a fault.

Always turn the power off before connecting or disconnecting any cables from the

product. When unplugging a cable, unplug the cable by holding the connector part

without pulling on the cable itself. Pulling the cable itself or bending it may expose

or disconnect the cable core, resulting in a fault.

It is recommended that it be stored in the original packaging. Transporting the product may cause a damage or fault. Therefore, keep the packaging materials and use

them when re-shipping the product.

ii

Page 4

Copyright ©2011-2013 FUJITSU SEMICONDUCTOR LIMITED All rights reserved

• FUJITSU SEMICONDUCTOR LIMITED, its subsidiaries and affiliates (collectively, "FUJITSU

SEMICONDUCTOR") reserves the right to make changes to the information contained in this document without notice. Please contact your FUJITSU SEMICONDUCTOR sales representatives before order of FUJITSU

SEMICONDUCTOR device.

• Information contained in this document, such as descriptions of function and application circuit examples is presented

solely for reference to examples of operations and uses of FUJITSU SEMICONDUCTOR device. FUJITSU

SEMICONDUCTOR disclaims any and all warranties of any kind, whether express or implied, related to such information, including, without limitation, quality, accuracy, performance, proper operation of the device or non-infringement. If you develop equipment or product incorporating the FUJITSU SEMICONDUCTOR device based on such

information, you must assume any responsibility or liability arising out of or in connection with such information or

any use thereof. FUJITSU SEMICONDUCTOR assumes no responsibility or liability for any damages whatsoever

arising out of or in connection with such information or any use thereof.

• Nothing contained in this document shall be construed as granting or conferring any right under any patents, copyrights, or any other intellectual property rights of FUJITSU SEMICONDUCTOR or any third party by license or otherwise, express or implied. FUJITSU SEMICONDUCTOR assumes no responsibility or liability for any infringement

of any intellectual property rights or other rights of third parties resulting from or in connection with the information

contained herein or use thereof.

• The products described in this document are designed, developed and manufactured as contemplated for general use

including without limitation, ordinary industrial use, general office use, personal use, and household use, but are not

designed, developed and manufactured as contemplated (1) for use accompanying fatal risks or dangers that, unless

extremely high levels of safety is secured, could lead directly to death, personal injury, severe physical damage or other

loss (including, without limitation, use in nuclear facility , aircraft flight control system, air traf fic control system, mass

transport control system, medical life support system and military application), or (2) for use requiring extremely high

level of reliability (including, without limitation, submersible repeater and artificial satellite). FUJITSU

SEMICONDUCTOR shall not be liable for you and/or any third party for any claims or damages arising out of or in

connection with above-mentioned uses of the products.

• Any semiconductor devices fail or malfunction with some probability. You are responsible for providing adequate designs and safeguards against injury, damage or loss from such failures or malfunctions, by incorporating safety design

measures into your facility , equipments and products such as redundancy , f ire protection, and prev ention of overcurrent

levels and other abnormal operating conditions.

• The products and technical information described in this document are subject to the Foreign Exchange and Foreign

Trade Control Law of Japan, and may be subject to e xport or import laws or re gulations in U.S. or other countries. You

are responsible for ensuring compliance with such laws and regulations relating to export or re-export of the products

and technical information described herein.

• All company names, brand names and trademarks herein are property of their respective owners.

iii

Page 5

1. Checking the Delivered Product

Before using the product, make sure that the package contains the following items:

• BGM adaptor * : 1

• USB cable (1.0m) : 1

• Interface cable : 1

• Hardcopy (China RoHS report) : 1

* : Referred to as the adaptor.

1

Page 6

2. Introduction

MB2146-07-E is a tool used for Fujitsu Semiconductor New 8FX MCU. It is updated from MB214608-E and silimar to MB2146-08-E in appearance. MB2146-07-E has inherited all functions of

MB2146-08-E. It is updated to obtain a better performance and new functions.

This operation manual is applicable to all series of FUJITSU SEMICONDUCTOR 8-bit microcontroller except MB95200H/210H/220H.

Notes : • The New 8FX series BGM adaptor (MB2146-07-E) has no compatibility with F

B95100 series BGM adaptor (MB2146-09, MB2146-09A-E) and New 8FX family MB95200H/210H/

220H types and its option parts.

If different MCUs and the BGM adaptor or the option parts are connected, there is the possibility that

they will not operate correctly or damage devices.

Avoid using the combination of different types of BGM adaptors and devices.

• This product does not correspond to the MB95200H/210H/220H series in the New 8FX family. Use

MB2146-08-E for the MB95200H series.

A variety of optional parts are av ailable for this adaptor that may be purchased separately as needed.

Consult a sales or support representative for details.

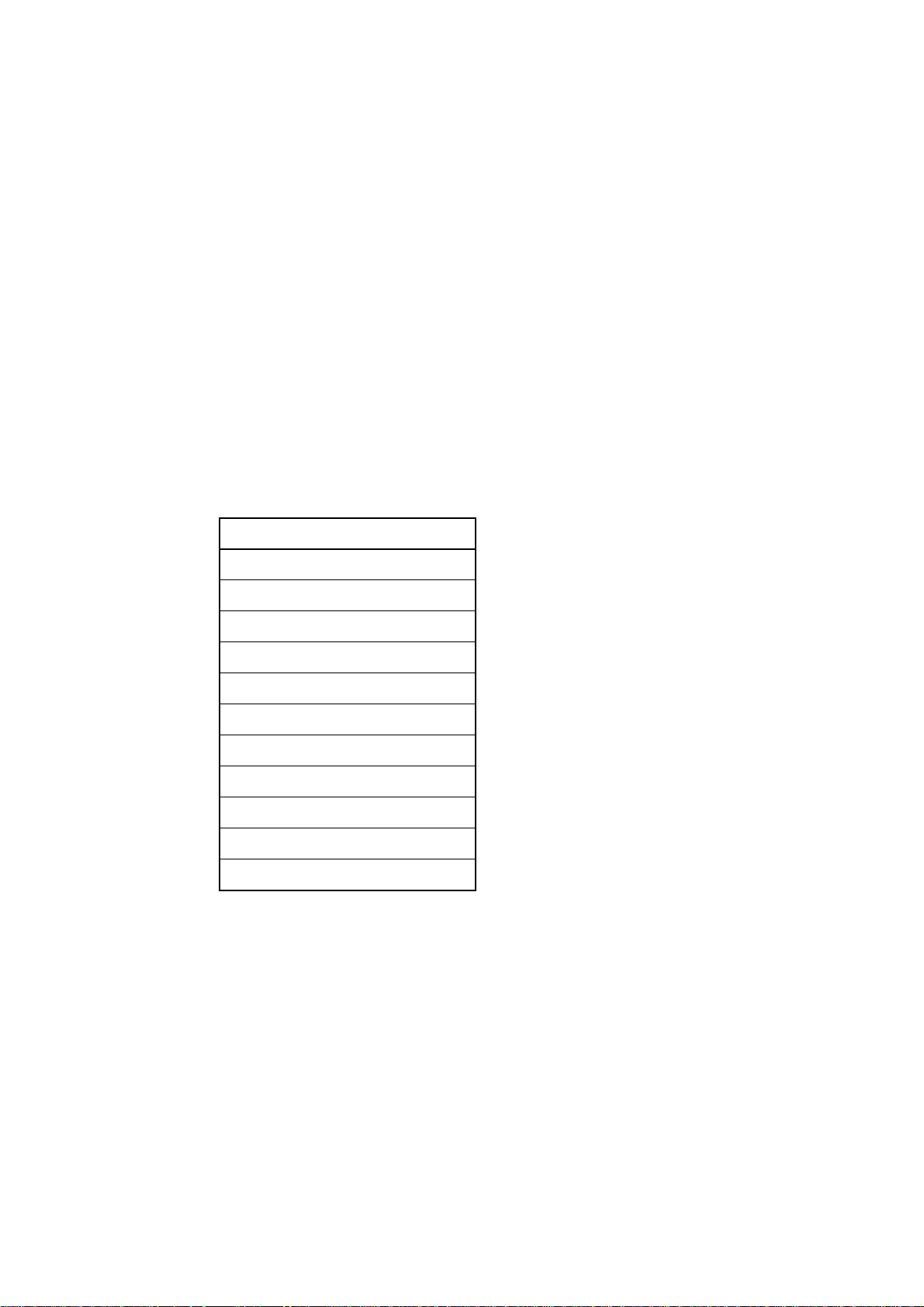

Following table describes the sort of New 8FX MCU.

MCU Type

MB95260 series

MB95310 series

MB95330 series

MB95370 series

MB95350 series

2

MC-8FX family

MB95390 series

MB95410 series

MB95430 series

MB95560 series

MB95630 series

Following develop product

2

Page 7

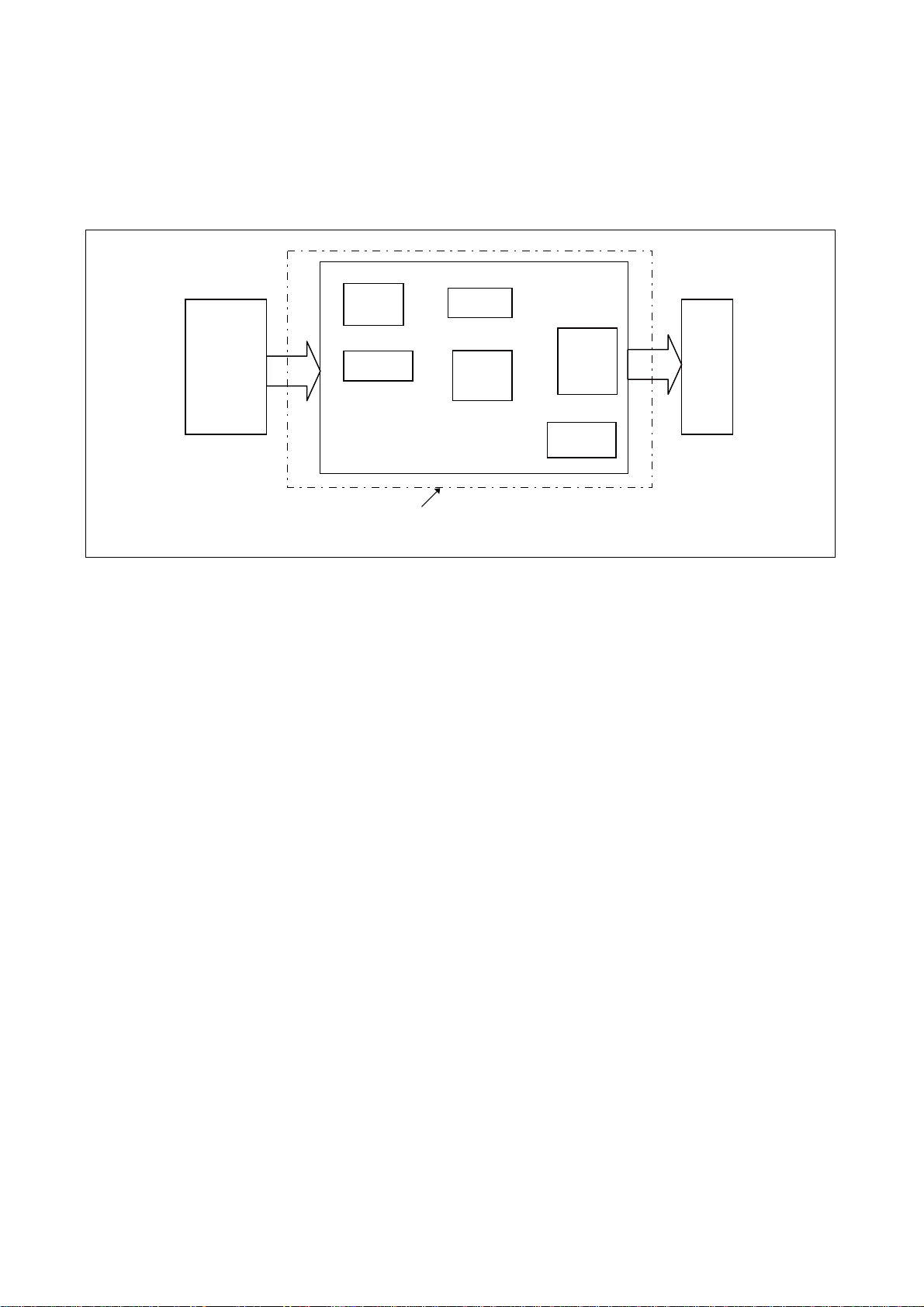

3. System Configuration

■ Use as Emulator System

The adaptor is connected to the host computer and the user system, and it can be used as the emulator

by control via the host computer. See "SOFTUNE Workbench OPERATION MANU AL" for the details on the emulation debugger software operation in the host computer.

Figure1 shows the system construction when used as the emulator system.

PC USB

interface

Gates

circuit

USB socket

MB2146-07-E

LED

MCU

Figure 1 System Configuration

Debug

interface

Key

Target

MCU

3

Page 8

4. Interface Overview

Status LED

Mode key

Interface cable

Power supply

LED

Power supply

key

USB connector

User interface connector

This chapter describes the BGMA interface.

4.1 MB2146-07-E Appearance

Figure 2 shows the BGMA appearance

Figure 2 BGMA Appearance

4

Page 9

4.2 BGMA UART Interface

The UART interface is mainly used between BGMA and MCU board. BGMA sends command to

MCU by UART, and receives the MCU feedback by UART too.

The speed of UAR T communication is related to U AR T baud rate. Follo wing table lists the baud rate.

MCU Type Baud Rate Remark

MB95260 series

MB95310 series

MB95330 series

Table 1 Baud Rate List

MB95370 series

MB95350 series

MB95390 series

MB95410 series

MB95430 series

MB95560 series 62500

MB95630 series

and following develop MCU

When the adaptor interface connector is mounted on the user system, connect the MCU to the adaptor interface connector according to the following specifications.

Table 2 Pin Interface

Evaluation

Connector

pin number

Input / output

MCU

connection

pin name

1

BGMA*

1

← MCU*

2

UVCC

2-GND

62500

While synchronization and start debug,

125kbps

While synchronization and start debug,

500kbps

500K While synchronization and start debug, 1Mbps

Function Remarks

User power supply input Connected to the MCU Vcc pin.

Vss pin Connected to the MCU Vss pin.

3

4

BGMA ← MCU

5-RSV

6

BGMA → MCU

7-RSV

8

BGMA ← MCU,

BGMA → MCU

9-RSV

10 - RSV

-RSV - RSTOUT

User System reset input Connected to user system reset circuit

--

VCC

BGMA power output BGMA supplies power to MCU Vcc

--

DBG

Communication line 1 line UART

--

--

*1 : BGMA means the BGM adaptor.

*2 : MCU means the evaluation MCU.

Note : The MB2146-07-E pin assignment has no compatibility with the MB2146-09 and MB2146-09A-E pin

assignments. It is impossible to use these two BGM adaptors for different MCUs. If used by mistake,

there is a possibility that the debug system will not operate correctly or could be damaged.

Also, some functions are added and deleted as the MB2146-08-E upper compatibility product. See the

MCU hardware manual in use for the details about the connection of the user system and adaptors.

5

Page 10

5. Feature list

■ Function Description of BGMA

The MB2146-07-E BGMA is updated from MB2146-08-E. The updated features are described below.

• BGMA power supply is DC 5V (Power supply from the USB pin)

• UART Baud rate Max speed improved:

Data in MB95260H, MB95310L, MB95370L, MB95330H, MB95390H, MB95350L,

MB95410H and MB95470H series are updated at 125kbps, data in MB95560H series is updated at 500kbps and data in MB95630H and later series are updated at 1Mbps.

• Baud rate selection between 500kbps and 1Mbps (in MB95630H series and following dev elop

MCU)

• Clock up enable function

• RAM Monitoring Function

• 16 bytes data continuous read

• 8 bytes data continuous write

• Supply power to target board seletable

• Power supply key to control BGMA power

• LED to show BGMA operation result

• Update BGMA by connection to PCs

• Flexible operation voltage range to target MCU power supply : 1.8V*

*1 : for 3.3V power supply MCU, the voltage range is 1.8V to 3.6V

*2 : for 5V power supply MCU, the voltage range is 2.4V to 5.5V

1

to 5.5V*2

The following shows the power supply state indicated by the BGMA LED.

Table3 Power supply indication of BGMA

LED Status Information

Green & Red OFF Both BGMA and target board power supply off

Green ON BGMA Power supply on only

Red ON Target board power supply on only

Orange ON Both BGMA and target board power supply on

The following shows the status indicated by the BGMA LED.

Table4 Status indication of BGMA

LED Status Information

Green & Red OFF Idle mode

Green

Red

ON Standalone mode

Blinking Standalone programming, target CR trimming

ON

Twinkling Reserved

Program (standalone, USB programmer, Trimming) error,

logging data write error

ON Logging will full soon

Orange

6

Twinkling Logging data record time is over 255 × (8kbyte-9)

Page 11

6. Performance Description

■ Operating Description of BGMA

This chapter describes the BGMA operation.

6.1 Debug Function

Open the project file in SOFTUNE Workbench which supports New 8FX and execute the setup related

to the debug. The following shows the supplemental description about the special settings.

6.1.1 ICE Type

Select, the ICE type MB2146-07.

6.1.2 Monitor Program Auto-load

If a user wants to update the internal program code for the BGMA when starting debugging, check

Setup Wizard Dialog Box in Monitor Program Auto-load, as shown in Figure 3.

6.1.3 Device Type

Select the device name to USB in Type Field, as shown in Figure 4 below.

Figure 3 Monitor Program Auto-load

Figure 4 Device Type

7

Page 12

6.1.4 Settings of Oscillation and Communication Speed

In this dialig box, a user can select MCU external clock value in Frequency (main) Field, and enable

or disable clock up in Response Speed Optimization Field.

Figure 5 Clock Setting

6.1.5 Power Supply To Target

This item enables BGMA to supply power to the target MCU board.

Figure 6 Power Supply

Note : If the user current is greater than the max current (200mA), the system will show the power error and

stop the power supply.

8

Page 13

6.1.6 Flash Memory Synchronization

This dialog box is used to select the Flash memory synchronous function when starting debug. If the

dialog box is selected, the S

OFTUNE will read all MCU flash data to SOFTUNE.

Figure 7 Flash Synchronization

9

Page 14

6.2 RAM Monitoring Function

When debugging, a user can open RAM Monitoring Window to watch the MCU RAM status.

User can watch 32 bytes RAMs on the RAM Monitoring at the same time.

6.2.1 Enable RAM Monitoring Function

Right-click the blank area in the RAM Monitoring Windo w and select monitoring from the shortcut

menu to enable the RAM Monitoring function, as shown in Figure 9.

Figure 8 RAM Monitoring Window

Figure 9 RAM Monitoring Function

10

Page 15

6.2.2 Set Register

Select Setup from the shortcut menu in Figrue 9, and RAM Monitoring Setup window pops up, as

shown in Figure 10.

Set the RAM to be watched in Address field, and select Word from the Size Drop-down List Box.

When the address and size are selected, a user can click “Append” to confirm this operation and can

select another RAM address. When all RAMs are selected, a user can click “OK” key to ensure those

settings and close the window.

After that, a user can monitor all selected RAMs in RAM Monitoring window , as shown in Figure 11.

Figure 10 RAM Monitoring Setup

Figure 11 RAM Monitoring Status

11

Page 16

7. How to Upgrade BGMA FW (firmware)

This chapter describes how to update the BGMA FW.

The BGMA FW can be updated by PC. The tool “PC Helper.e xe” can be used to update the FW. The

following section describes the upgrading of BGMA FW in detail.

7.1 Use SOFTUNE Upgrade FW

When using SOFTUNE, a user can upgrade the BGMA FW.

The following is the method:

(1) Copy EmlCmnB_896.mhx file in the directry of "..\Softune\896" where Softune is installed.

Figure 12 The examle of adding HEX file

(2) Connect BGMA to PC.

(3) Turn on the BGMA power.

Figure 13 Power-on BGMA

12

Page 17

(4) Enable S

OFTUNE Upgrade function.

Select “Monitor program auto-loading” in S

Figure 14 Enable Softune Upgrade function

(5) Right-click S

OFTUNE “Debug” and select “start debug”.

OFTUNE. For the detailed operation, see sector 6.1.2.

Figure 15 Start Debug Icon

13

Page 18

(6) When the following window pops up, turn off the power supply of target board.

Figure 16 Power-off

(7) Press the “OK” button, the following sub-window will pop up.

Figure 17 S

OFTUNE Upgrade

(8) If a user wants to stop the upgrading, press the “Abort” button.

(9) If the “Abort” button is not pressed, the Softune continues upgrading.

(10) When 100% upgrade is finished, the BGMA FW upgrading is completed.

When the version of the monitor program is the same, updating is not done.

14

Page 19

7.2 FW Upgrade Using PC Helper Programmer

Figure 18 Tool Interface

Step:

(1) Connect BGMA to PC.

(2) Open PC Helper programmer.

(3) Open “FW Upgrade”, like the following picture.

Figure 19 FW Upgrade Interface

(4) If the BGMA item shows “Connected” and the color is green like the picture above, the

BGMA and PC connect normally.

(5) Press “Open” item to choose the BGMA HEX file, the following picture is a sample.

Figure 20 Hex File Sample

15

Page 20

(6) When the HEX file is choosen, press “Upgrade” item to upgrate BGMA FW.

(7) When the sub-window pops up, select recommend item and “OK”.

(8) When downloading is successfully completed, "Download Successful" is shown as follows.

Figure 21 Successful Sample

16

Page 21

SS702-00001-2v0-E

FUJITSU SEMICONDUCTOR • SUPPORT SYSYEM

New 8FX Family

8-bit MICROCONTROLLER

BGM ADAPTOR MB2146-07-E

OPERATION MANUAL

May 2013 the second edition

Published FUJITSU SEMICONDUCTOR LIMITED

Edited Sales Promotion Department

Page 22

Loading...

Loading...