Page 1

Page 2

Page 3

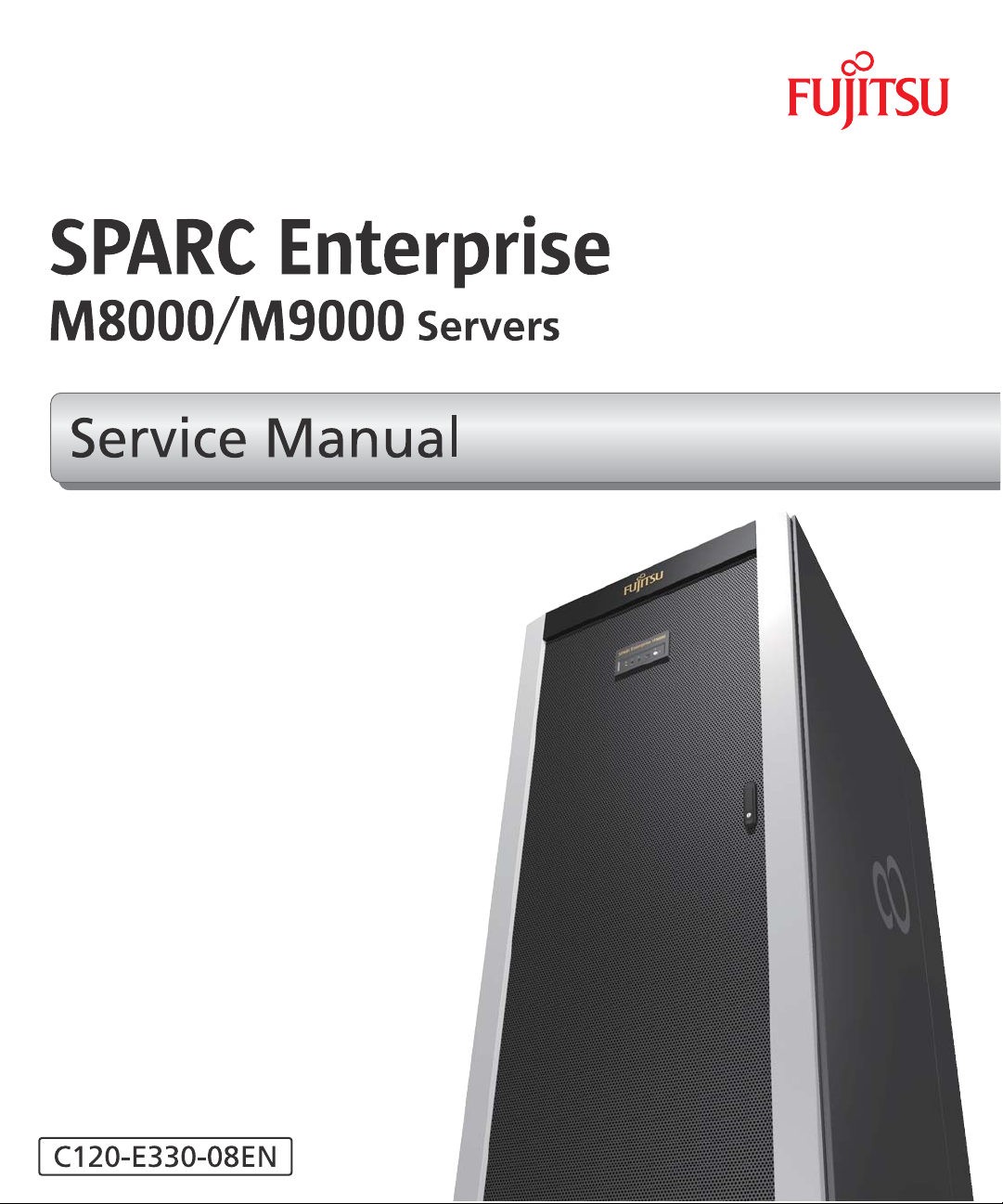

SPARC Enterprise

™

M8000/M9000 Servers

Service Manual

Manual Code C120-E330-08EN

Part No. 819-7877-15

August 2009, Revision A

Page 4

Copyright 2007-2009 FUJITSU LIMITED, 1-1, Kamikodanaka 4-chome, Nakahara-ku, Kawasaki-shi, Kanagawa-ken 211-8588, Japan. All rights

reserved.

Sun Microsystems, Inc. provided technical input and review on portions of this material.

Sun Microsystems,Inc. andFujitsu Limited eachown orcontrol intellectualproperty rights relating to products andtechnology described in

this document,and such products, technology andthis documentare protectedby copyright laws, patents andother intellectual property laws

and internationaltreaties. Theintellectual propertyrights of SunMicrosystems, Inc.and Fujitsu Limited in suchproducts, technologyand this

document include,without limitation, one or moreof theUnited States patentslisted athttp://www.sun.com/patentsand one or more

additional patentsor patent applications in theUnited States or other countries.

This documentand the product and technologyto whichit pertains are distributedunder licenses restricting theiruse, copying, distribution,

and decompilation.No part of such productor technology,or of thisdocument, maybe reproducedin any form by anymeans without prior

written authorizationof Fujitsu Limited and SunMicrosystems, Inc.,and their applicablelicensors, ifany.The furnishingof this documentto

you doesnot give you any rightsor licenses, express or implied,with respectto theproduct or technology to whichit pertains,and this

document doesnot contain or representany commitment ofany kindon the partof FujitsuLimited or SunMicrosystems, Inc.,or anyaffiliate of

either ofthem.

This documentand the product and technologydescribed inthis document mayincorporate third-partyintellectual propertycopyrighted by

and/or licensedfrom suppliersto Fujitsu Limitedand/or SunMicrosystems, Inc.,including software and font technology.

Per theterms of the GPL orLGPL, a copy of thesource codegoverned by the GPL orLGPL, as applicable, is availableupon requestby the End

User.Please contactFujitsu Limited orSun Microsystems,Inc

This distribution may include materials developed by third parties.

Parts of the product may be derived from Berkeley BSD systems, licensed from the University of California. UNIX is a registered trademark

in the U.S. and in other countries, exclusively licensed through X/Open Company, Ltd.

Sun, Sun Microsystems, the Sun logo, Java, Netra, Solaris, Sun Ray, Answerbook2, docs.sun.com, OpenBoot, and Sun Fire are trademarks or

registered trademarks of Sun Microsystems, Inc., or its subsidiaries, in the U.S. and other countries.

Fujitsu and the Fujitsu logo are registered trademarks of Fujitsu Limited.

All SPARC trademarks are used under license and are registered trademarks of SPARC International, Inc. in the U.S. and other countries.

Products bearing SPARC trademarks are based upon architecture developed by Sun Microsystems, Inc.

SPARC64 is a trademark of SPARC International, Inc., used under license by Fujitsu Microelectronics, Inc. and Fujitsu Limited.

The OPEN LOOK and Sun™ Graphical User Interfacewas developed by Sun Microsystems, Inc. for itsusers and licensees. Sun acknowledges

the pioneering efforts of Xerox in researching and developing theconcept of visual or graphical user interfaces forthe computer industry. Sun

holds anon-exclusive license from Xeroxto the Xerox Graphical User Interface, whichlicense alsocovers Sun’s licenseeswho implementOPEN

LOOK GUIs and otherwise comply with Sun’s written license agreements.

United StatesGovernment Rights - Commercial use.U.S. Governmentusers aresubject to thestandard governmentuser license agreements of

Sun Microsystems,Inc. andFujitsu Limited andthe applicableprovisions ofthe FARand itssupplements.

Disclaimer: The only warranties granted by Fujitsu Limited, Sun Microsystems, Inc. or any affiliate of either of them in connection with this

document or any product or technology described herein are those expressly set forth in the license agreement pursuant to which the product

or technology is provided. EXCEPT AS EXPRESSLY SET FORTH IN SUCH AGREEMENT, FUJITSU LIMITED, SUN MICROSYSTEMS, INC.

AND THEIRAFFILIATES MAKENO REPRESENTATIONSOR WARRANTIES OF ANY KIND (EXPRESS OR IMPLIED) REGARDINGSUCH

PRODUCT OR TECHNOLOGY OR THIS DOCUMENT, WHICH ARE ALL PROVIDED AS IS, AND ALL EXPRESS OR IMPLIED

CONDITIONS, REPRESENTATIONS AND WARRANTIES, INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTY OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT, ARE DISCLAIMED, EXCEPT TO THE

EXTENT THAT SUCH DISCLAIMERS ARE HELDTO BE LEGALLY INVALID. Unless otherwiseexpressly set forth in such agreement, to the

extent allowed by applicable law, in no event shall Fujitsu Limited, Sun Microsystems, Inc. or any of their affiliates have any liability to any

third party under any legal theory for any loss of revenues or profits, loss of use or data, or business interruptions, or for any indirect, special,

incidental or consequential damages, even if advised of the possibility of such damages.

DOCUMENTATION IS PROVIDED “AS IS” AND ALL EXPRESS OR IMPLIED CONDITIONS, REPRESENTATIONS AND WARRANTIES,

INCLUDING ANYIMPLIED WARRANTY OF MERCHANTABILITY, FITNESSFOR A PARTICULARPURPOSE OR NON-INFRINGEMENT,

ARE DISCLAIMED, EXCEPT TO THE EXTENT THAT SUCH DISCLAIMERS ARE HELD TO BE LEGALLY INVALID.

Please

Recycle

Page 5

Copyright 2007-2009 FUJITSU LIMITED, 1-1, Kamikodanaka 4-chome, Nakahara-ku, Kawasaki-shi, Kanagawa-ken 211-8588, Japon. Tous

droits réservés.

Entrée et revue tecnical fournies par Sun Microsystems, Incl sur des parties de ce matériel.

Sun Microsystems, Inc. et Fujitsu Limited détiennent et contrôlent toutes deux des droits de propriété intellectuelle relatifs aux produits et

technologies décrits dans ce document. De même, ces produits, technologies et ce document sont protégés par des lois sur le copyright, des

brevets, d’autreslois sur la propriétéintellectuelle et des traités internationaux. Les droits de propriété intellectuelle de SunMicrosystems, Inc.

et Fujitsu Limited concernant ces produits, ces technologies et ce document comprennent, sans que cette liste soit exhaustive, un ou plusieurs

des brevets déposésaux États-Unis et indiqués à l’adresse http://www.sun.com/patents de même qu’unou plusieurs brevets ouapplications

brevetées supplémentaires aux États-Unis et dans d’autres pays.

Ce document, le produit et les technologies afférents sont exclusivement distribués avec des licences qui en restreignent l’utilisation, la copie,

la distribution et la décompilation. Aucune partie de ce produit, de ces technologies ou de ce document ne peut être reproduite sous quelque

forme quece soit, parquelque moyen quece soit, sans l’autorisation écrite préalablede Fujitsu Limitedet de Sun Microsystems, Inc., etde leurs

éventuels bailleurs de licence. Ce document, bien qu’il vous ait été fourni, ne vous confère aucun droit et aucune licence, expresses ou tacites,

concernant le produitou la technologie auxquelsil se rapporte. Par ailleurs, il ne contient nine représente aucun engagement,de quelque type

que ce soit, de la part de Fujitsu Limited ou de Sun Microsystems, Inc., ou des sociétés affiliées.

Ce document, et le produit et les technologies qu’il décrit, peuvent inclure des droits de propriété intellectuelle de parties tierces protégés par

copyright et/ou cédés sous licence par des fournisseurs à Fujitsu Limited et/ou Sun Microsystems, Inc., y compris des logiciels et des

technologies relatives aux polices de caractères.

Par limites du GPL ou du LGPL, une copie du code source régi par le GPL ou LGPL, comme applicable, est sur demande vers la fin utilsateur

disponible; veuillez contacter Fujitsu Limted ou Sun Microsystems, Inc.

Cette distribution peut comprendre des composants développés par des tierces parties.

Des parties de ce produit pourront être dérivées des systèmes Berkeley BSD licenciés par l’Université de Californie. UNIX est une marque

déposée aux Etats-Unis et dans d’autres pays et licenciée exclusivement par X/Open Company, Ltd.

Sun, Sun Microsystems, le logo Sun, Java, Netra, Solaris, Sun Ray, Answerbook2, docs.sun.com, OpenBoot, et Sun Fire sont des marques de

fabrique ou des marques déposées de Sun Microsystems, Inc., ou ses filiales, aux Etats-Unis et dans d’autres pays.

Fujitsu et le logo Fujitsu sont des marques déposées de Fujitsu Limited.

Toutes les marques SPARC sont utilisées sous licence et sont des marques de fabrique ou des marques déposées de SPARC International, Inc.

aux Etats-Unis et dans d’autres pays. Les produits portant les marques SPARC sont basés sur une architecture développée par Sun

Microsystems, Inc.

SPARC64 est une marques déposée de SPARC International, Inc., utilisée sous le permis par Fujitsu Microelectronics, Inc. et Fujitsu Limited.

L’interface d’utilisation graphique OPEN LOOK et Sun™ a été développée par Sun Microsystems, Inc. pour ses utilisateurs et licenciés. Sun

reconnaît les effortsde pionniers de Xerox pour la recherche et le développementdu concept des interfaces d’utilisation visuelle ou graphique

pour l’industrie de l’informatique. Sun détient une license non exclusive de Xerox sur l’interface d’utilisation graphique Xerox, cette licence

couvrant également les licenciés de Sun qui mettent en place l’interface d’utilisation graphique OPEN LOOK et qui, en outre, se conforment

aux licences écrites de Sun.

Droits du gouvernement américain - logiciel commercial. Les utilisateurs du gouvernement américain sont soumis aux contrats de licence

standard de Sun Microsystems, Inc. et de Fujitsu Limited ainsi qu’aux clauses applicables stipulées dans le FAR et ses suppléments.

Avis de non-responsabilité: les seules garanties octroyéespar Fujitsu Limited,Sun Microsystems,Inc. ou toutesociété affiliée del’une ou l’autre

entité enrapport avec cedocument ou toutproduit ou toutetechnologie décrit(e) dansles présentes correspondent aux garanties expressément

stipulées dans le contrat de licence régissant le produit ou la technologie fourni(e). SAUF MENTION CONTRAIRE EXPRESSÉMENT

STIPULÉE DANS CE CONTRAT, FUJITSU LIMITED, SUN MICROSYSTEMS, INC. ET LES SOCIÉTÉS AFFILIÉES REJETTENT TOUTE

REPRÉSENTATION OU TOUTE GARANTIE, QUELLE QU’EN SOIT LA NATURE (EXPRESSE OU IMPLICITE) CONCERNANT CE

PRODUIT,CETTE TECHNOLOGIE OUCE DOCUMENT, LESQUELS SONT FOURNIS ENL’ÉTAT. ENOUTRE, TOUTES LESCONDITIONS,

REPRÉSENTATIONS ETGARANTIES EXPRESSES OU TACITES, Y COMPRIS NOTAMMENTTOUTE GARANTIE IMPLICITE RELATIVE À

LA QUALITÉ MARCHANDE, À L’APTITUDE À UNE UTILISATION PARTICULIÈRE OU À L’ABSENCE DE CONTREFAÇON, SONT

EXCLUES, DANS LA MESURE AUTORISÉE PAR LA LOI APPLICABLE. Sauf mention contraire expressément stipulée dans ce contrat, dans

la mesure autoriséepar la loi applicable, en aucun cas Fujitsu Limited,Sun Microsystems, Inc. ou l’une de leurs filiales nesauraient être tenues

responsables envers une quelconque partie tierce, sous quelque théorie juridique que ce soit, de tout manque à gagner ou de perte de profit,

de problèmes d’utilisation ou de perte de données, ou d’interruptions d’activités, ou de tout dommage indirect, spécial, secondaire ou

consécutif, même si ces entités ont été préalablement informées d’une telle éventualité.

LA DOCUMENTATION EST FOURNIE “EN L’ETAT” ET TOUTES AUTRES CONDITIONS, DECLARATIONS ET GARANTIES EXPRESSES

OU TACITES SONTFORMELLEMENT EXCLUES,DANS LA MESURE AUTORISEE PARLA LOI APPLICABLE, Y COMPRISNOTAMMENT

TOUTE GARANTIE IMPLICITE RELATIVE A LA QUALITE MARCHANDE, A L’APTITUDE A UNE UTILISATION PARTICULIERE OU A

L’ABSENCE DE CONTREFACON.

Page 6

Page 7

Contents

Preface xvii

1. Safety and Tools 1–1

1.1 Symbols 1–1

1.1.1 Text Conventions 1–1

1.1.2 Prompt Notations 1–2

1.1.2.1 Command syntax 1–2

1.1.3 Environmental Requirements for Using This Product 1–3

1.1.4 Conventions for Alert Messages 1–3

1.1.4.1 Alert Messages in the Text 1–3

1.2 Precautions 1–4

1.2.1 Operating Environment of the Product 1–4

1.2.2 Maintenance 1–4

1.2.3 Conversion and Reuse of This Product 1–5

1.3 Tools Required for Maintenance 1–5

2. Product Overview and Troubleshooting 2–1

2.1 System Views 2–1

2.1.1 SPARC Enterprise M8000 Server 2–3

2.1.2 SPARC Enterprise M9000 Server (Base Cabinet) 2–6

v

Page 8

2.1.3 SPARC Enterprise M9000 Server (Expansion Cabinet) 2–9

2.2 Labels 2–11

2.2.1 System Name Plate Label, Rating Label, ID Label (Japan) or EZ

Label (besides Japan), and Standard Label 2–11

2.2.2 Labels About Handling 2–15

2.3 Operator Panel 2–16

2.3.1 Operator Panel Location 2–16

2.3.2 Appearance and Operations 2–17

2.3.3 LED 2–18

2.3.4 Switch 2–20

2.4 Determining Which Diagnostics Methods To Use 2–21

2.5 Checking the Server and System Configuration 2–23

2.5.1 Checking the Hardware Configuration and FRU Status 2–23

2.5.1.1 Checking the Hardware Configuration 2–24

2.5.2 Checking the Software and XSCF Firmware Configurations 2–24

2.5.2.1 Checking the Software Configuration 2–25

2.5.2.2 Checking the Firmware Configuration 2–26

2.5.3 Downloading the Error Log Information 2–26

2.6 Error Conditions and Action To Be Taken 2–26

2.6.1 Predictive Self-Healing Tools 2–27

2.6.2 Monitoring Output 2–28

2.6.3 Messaging Output 2–29

2.7 LED Error Display 2–30

2.7.1 When target FRU is indicated by LEDs 2–31

2.7.2 When target FRU is not indicated by LEDs 2–31

2.8 Using the Troubleshooting Commands 2–34

2.8.1 Using the showlogs Command 2–34

2.8.2 Using the fmdump Command 2–35

2.8.3 Using the fmadm Command 2–35

vi SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

Page 9

2.8.3.1 fmadm config Command 2–35

2.8.3.2 fmadm faulty Command 2–36

2.8.3.3 fmadm repair Command 2–36

2.8.4 Using the fmstat Command 2–37

2.9 Traditional Solaris Troubleshooting Commands 2–37

2.9.1 iostat Command 2–38

2.9.1.1 Options 2–38

2.9.2 prtdiag Command 2–39

2.9.2.1 Options 2–39

2.9.3 prtconf Command 2–44

2.9.3.1 Options 2–45

2.9.4 netstat Command 2–46

2.9.4.1 Options 2–46

2.9.5 ping Command 2–47

2.9.5.1 Options 2–48

2.9.6 ps Command 2–49

2.9.6.1 Options 2–49

2.9.7 prstat Command 2–50

2.9.7.1 Options 2–50

3. Periodic Maintenance 3–1

3.1 Cleaning a Tape Drive Unit 3–1

3.2 Cleaning an Air Filter (Server) 3–2

3.3 Cleaning an Air Filter (I/O Unit) 3–5

4. FRU Removal Preparation 4–1

4.1 Types of Replacement Procedures 4–2

4.1.1 FRU Replacement 4–2

4.2 Active Replacement 4–3

Contents vii

Page 10

4.2.1 Disconnecting a FRU from a Domain 4–3

4.2.1.1 Disconnecting a CMU/IOU 4–3

4.2.1.2 Disconnecting a PCI card 4–4

4.2.2 Disconnecting and Replacing a FRU 4–5

4.2.3 Configuring a FRU into a Domain 4–6

4.2.3.1 Configuring CMU/IOU 4–6

4.2.3.2 Configuring a PCI card 4–7

4.2.4 Confirming the Hardware 4–7

4.3 Hot Replacement 4–12

4.3.1 Disconnecting and Replacing a FRU 4–12

4.3.2 Confirming the Hardware 4–15

4.4 Cold Replacement 4–18

4.4.1 Powering the Server Off 4–18

4.4.2 Powering the Server On 4–19

4.4.2.1 From the Operator Panel 4–19

4.4.2.2 From the Maintenance Terminal 4–20

4.4.3 Confirming the Hardware 4–20

4.5 Power-On/Off of Main Line Switch 4–24

4.5.1 Types of Power Supply 4–24

4.5.1.1 AC Input Power 4–25

4.5.1.2 Power System 4–27

4.5.2 Power-On/Off Procedures of Main Line Switch 4–27

4.5.2.1 Power-On 4–28

4.5.2.2 Power-Off 4–28

4.5.3 Main Line Switch Locations 4–28

4.5.3.1 SPARC Enterprise M8000 Server Single-Phase Power

Feed 4–29

4.5.3.2 SPARC Enterprise M8000 Server Single-Phase and Dual

Power Feed 4–30

viii SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

Page 11

4.5.3.3 SPARC Enterprise M8000 Server Three-Phase Power

Feed 4–31

4.5.3.4 SPARC Enterprise M9000 Server Single-Phase Power

Feed 4–32

4.5.3.5 SPARC Enterprise M9000 Server Single-Phase and Dual

Power Feed 4–33

4.5.3.6 SPARC Enterprise M9000 Server Three-Phase Power

Feed 4–34

4.6 Emergency Switch-Off 4–35

4.7 Cable Routing of the SPARC Enterprise M8000 Server 4–35

4.7.1 Cable Routing When the External I/O Expansion Unit Mounted

4–35

4.7.1.1 Precautions For Cable Routing 4–36

4.7.1.2 When Three External I/O Expansion Units Mounted

4–38

4.7.1.3 For Server Using Three-phase Power Feed 4–42

4.7.1.4 When One External I/O Expansion Unit Mounted 4–

46

5. Internal Components Access 5–1

5.1 How to Open and Close Doors 5–1

5.2 Corresponding Components and Doors That Can Be Accessed 5–2

5.3 How to Remove a Door 5–3

5.4 How to Remove a Side Panel 5–4

6. Replacement of CPU/Memory Board Unit (CMU), CPU, and DIMM 6–1

6.1 Overview of the CMU 6–1

6.2 CPU Upgrade 6–5

6.2.1 SPARC64 VII CPU Modules Added to a New Domain 6–5

6.2.2 SPARC64 VII Processors Added to an Existing Domain 6–8

6.2.2.1 Preparing to Add SPARC64 VII Processors to anExisting

Domain 6–8

Contents ix

Page 12

6.2.2.2 Adding a SPARC64 VII CPU Module to a Domain

Configured With SPARC64 VI 6–10

6.2.2.3 Upgrading a SPARC64 VI CPU Module to SPARC64 VII

on an Existing Domain 6–11

6.3 Active Replacement and Hot Replacement 6–12

6.4 Cold Replacement 6–21

6.5 CPU and DIMM Replacement 6–25

6.5.1 Replacing a CPU Module 6–27

6.5.2 Memory Module Mounting Conditions 6–37

6.5.2.1 Confirmation of DIMM Information 6–38

6.5.2.2 DIMM Mounting Conditions 6–39

6.5.3 DIMM Replacement 6–41

7. I/O Unit (IOU) Replacement 7–1

7.1 Overview of the IOU 7–2

7.2 Active Replacement and Hot Replacement 7–8

7.3 Cold Replacement 7–16

8. FAN Unit Replacement 8–1

8.1 Overview of the FAN Unit 8–2

8.2 Active Replacement and Hot Replacement 8–8

8.3 Cold Replacement 8–13

9. Power Supply Unit (PSU) Replacement 9–1

9.1 Overview of the PSU 9–1

9.2 Active Replacement and Hot Replacement 9–8

9.3 Cold Replacement 9–11

10. Operator Panel Replacement 10–1

10.1 Overview of the Operator Panel 10–1

10.2 Cold Replacement 10–4

x SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

Page 13

11. XSCF Unit Replacement 11–1

11.1 Overview of the XSCFU 11–1

11.2 Active Replacement and Hot Replacement 11–5

11.3 Cold Replacement 11–11

12. Hard Disk Drive (HDD) Replacement 12–1

12.1 Overview of the HDD 12–1

12.2 Active Replacement 12–2

12.3 Cold Replacement 12–5

13. PCI Slot Device Replacement 13–1

13.1 Overview of PCI Slot Devices 13–1

13.2 Active Replacement 13–3

13.3 Hot Replacement 13–16

13.4 Cold Replacement 13–19

14. CD-RW/DVD-RW Drive Unit Replacement 14–1

14.1 Overview of a CD-RW/DVD-RW Drive Unit 14–1

14.2 Active Replacement 14–4

14.3 Hot Replacement 14–9

14.4 Cold Replacement 14–11

15. Tape Drive Unit Replacement 15–1

15.1 Overview of the Tape Drive Unit 15–1

15.2 Active Replacement 15–5

15.3 Hot Replacement 15–9

15.4 Cold Replacement 15–10

16. Clock Control Unit Replacement 16–1

16.1 Overview of the CLKU 16–1

16.2 Cold Replacement 16–3

Contents xi

Page 14

17. Crossbar Unit Replacement 17–1

17.1 Overview of XBUs 17–1

17.2 Cold Replacement 17–3

18. AC Section Replacement 18–1

18.1 Overview of ACSs 18–1

18.2 Cold Replacement 18–5

19. DDC Replacement 19–1

19.1 Overview of the DDC 19–1

19.2 Active Replacement and Hot Replacement 19–3

19.3 Cold Replacement 19–6

20. Backplane Replacement 20–1

20.1 Overview of the BP 20–1

20.2 Cold Replacement 20–1

20.2.1 M8000/M9000 BPs 20–2

20.2.2 PSU BP 20–14

20.2.3 FAN BP 20–21

21. Sensor Unit Replacement 21–1

21.1 Overview of the SNSU 21–1

21.2 Cold Replacement 21–4

22. Media Backplane Replacement 22–1

22.1 Overview of the MEDBP 22–1

22.2 Cold Replacement 22–5

23. Switch Backplane Replacement 23–1

23.1 Overview of SWBPs 23–1

23.2 Cold Replacement 23–5

xii SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

Page 15

24. Addition and Deletion of a RDPF Option, Power Cabinet, and M9000

Expansion Cabinet 24–1

24.1 Addition and Deletion of Rack-mountable Dual Power Feed 24–2

24.1.1 Overview of RDPF 24–2

24.1.2 Addition and Deletion 24–3

24.1.2.1 Addition 24–3

24.1.2.2 Deletion 24–12

24.2 Addition and Deletion of Power Cabinet 24–12

24.3 Addition and Deletion of M9000 Expansion Cabinet 24–15

25. Addition and Deletion of CMU, DIMM, IOU, HDD, PCI Cards and TAPEU

25–1

25.1 Addition 25–2

25.1.1 Active Addition 25–2

25.1.2 Cold Addition 25–3

25.2 Deletion 25–4

25.2.1 Active Deletion 25–5

25.2.2 Cold Deletion 25–5

A. System Configuration A–1

A.1 Installation Conditions A–1

A.2 System Configuration A–2

A.2.1 SPARC Enterprise M8000 Server A–2

A.2.2 SPARC Enterprise M9000 Server (Base Cabinet) A–4

A.2.3 SPARC Enterprise M9000 Server (Base Cabinet + Expansion

Cabinet) A–6

B. Components B–1

B.1 CPU Memory Board Unit B–4

B.2 CPU Module B–5

B.3 Memory B–7

Contents xiii

Page 16

B.4 I/O Unit B–8

B.5 Hard Disk Drive B–10

B.6 PCI Cassette B–10

B.7 IOU Onboard Device Card B–12

B.8 Link Card (External I/O Expansion Unit Connection Card) B–13

B.9 Crossbar Unit B–14

B.10 Clock Control Unit B–16

B.11 XSCF Unit B–17

B.12 CD-RW/DVD-RW Drive Unit B–19

B.13 Tape Drive Unit B–20

B.14 Operator Panel B–21

B.15 Sensor Unit B–23

B.16 Power Supply Unit B–24

B.17 AC Section B–25

B.18 FAN Unit B–30

B.19 Power Cabinet B–32

B.20 Rack-mountable Dual Power Feed B–34

B.21 Backplane B–35

B.22 DDC B–37

B.23 PSU Backplane B–38

B.24 FAN Backplane B–39

B.25 Media Backplane B–42

B.26 Switch Backplane B–43

C. External Interface Specifications C–1

C.1 Serial Port C–1

C.2 UPC Port C–2

C.3 USB Port C–2

C.4 Connection Diagram for Serial Cable C–3

xiv SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

Page 17

D. UPS Controller D–1

D.1 Overview D–1

D.2 Signal Cable D–1

D.3 Configuration of Signal Lines D–2

D.4 Power Supply Conditions D–4

D.4.1 Input Circuit D–4

D.4.2 Output Circuit D–4

D.5 UPS Cable D–5

D.6 Connections D–6

D.7 UPC port D–7

E. XSCF Unit Replacement When XCP 1040 or 1041 Is in the Server E–1

Abbreviations Abbreviations–1

Index Index–1

Contents xv

Page 18

xvi SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

Page 19

Preface

This manual a maintenance manual for the SPARC Enterprise™ M8000/M9000

servers. The manual explains basic operations and detailed replacement procedures

for field-replaceable units (FRUs), which are components that can be replaced at the

customer's site.

As a rule, Fujitsu certified service engineers on the SPARC Enterprise M8000/M9000

servers. However, another person such as the system administrator may perform

some of the simple work, under the direction of one of the service engineers. This

manual is intended for the service engineers and other persons described above.

Notes precede the chapters, sections, and paragraphs that cover the work that only

Fujitsu-certified service engineers are allowed to perform. Follow instructions for all

work.

This section explains:

■ “Glossary” on page xvii

■ “Structure and Contents of This Manual” on page xviii

■ “SPARC Enterprise M8000/M9000 Servers Documentation” on page xxi

■ “Product Handling” on page xxiv

■ “Limitations and Cautions” on page xxvi

■ “Fujitsu Welcomes Your Comments” on page xxvii

Glossary

For the terms used in the “SPARC Enterprise M8000/M9000 Servers

Documentation” on page xxi, refer to the SPARC Enterprise

M3000/M4000/M5000/M8000/M9000 Servers Glossary.

xvii

Page 20

Structure and Contents of This Manual

This manual is organized as described below:

■ PART I Basic Information for Maintenance and Troubleshooting

Provides notes on handling the SPARC Enterprise servers and rules about

operation and descriptions, and it also describes the required tools for

maintenance.

■ Chapter 1 Safety and Tools:

Provides notes on handling the SPARC Enterprise servers and rules about

operation and descriptions, and it describes the required tools for maintenance.

■ Chapter 2 Product Overview and Troubleshooting:

Provides information that is required in troubleshooting.

■ Chapter 3 Periodic Maintenance:

Explains the maintenance work that must be performed regularly regardless of

whether a problem has occurred. The actual work is limited to preventing dust

in the environment from creating pollution.

■ Chapter 4 FRU Removal Preparation:

Explains the required basic operations for replacing components.

■ PART II Maintenance

Explains how to remove and replace FRUs.

■ Chapter 5 Internal Components Access:

Explains how to access each part of the system.

■ Chapter 6 Replacement of CPU/Memory Board Unit (CMU), CPU, and DIMM:

Explains how to replace each storage device.

■ Chapter 7 I/O Unit (IOU) Replacement:

Explains the replacement procedures for an I/O unit (IOU).

■ Chapter 8 FAN Unit Replacement:

Explains the replacement procedures for a fan unit.

xviii SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

Page 21

■ Chapter 9 Power Supply Unit (PSU) Replacement:

Explains the replacement procedures for a power supply unit (PSU).

■ Chapter 10 Operator Panel Replacement:

Explains the replacement procedures for the operator panel.

■ Chapter 11 XSCF Unit Replacement:

Explains the replacement procedures for an XSCF unit.

■ Chapter 12 Hard Disk Drive (HDD) Replacement:

Explains the replacement procedures for a hard disk drive (HDD).

■ Chapter 13 PCI Slot Device Replacement:

Explains the replacement procedures for a device mounted in a PCI slot of an

IOU.

■ Chapter 14 CD-RW/DVD-RW Drive Unit Replacement:

Explains the replacement procedures for the CD-RW/DVD-RW drive unit.

■ Chapter 15 Tape Drive Unit Replacement:

Explains the replacement procedures for the tape drive unit.

■ Chapter 16 Clock Control Unit Replacement:

Explains the replacement procedure for the clock control unit.

■ Chapter 17 Crossbar Unit Replacement:

Explains the replacement procedure for a crossbar unit.

■ Chapter 18 AC Section Replacement:

Explains the replacement procedures for a fan unit.

■ Chapter 19 DDC Replacement:

Explains the replacement procedure for the DDC.

■ Chapter 20 Backplane Replacement:

Explains the replacement procedure for a backplane.

■ Chapter 21 Sensor Unit Replacement:

Explains the replacement procedure for the sensor unit.

■ Chapter 22 Media Backplane Replacement:

Explains the replacement procedure for the media backplane.

■ Chapter 23 Switch Backplane Replacement:

Explains the replacement procedure for the switch backplane.

Preface xix

Page 22

■ Chapter 24 Addition and Deletion of a Rack-mountable Dual Power Feed Option,

Power Cabinet, and M9000 Expansion Cabinet:

Explains the replacement procedures for rack-mountable dual power

feed(RDPF).

■ Chapter 25 Addition and Deletion of CMU, DIMM, IOU, HDD, PCI Cards and

TAPEU:

Explains the procedures for adding a unit to the SPARC Enterprise

M8000/M9000 servers and deleting a unit from the SPARC Enterprise

M8000/M9000 servers.

■ Appendix A System Configuration:

Describes the installation conditions and configuration of the SPARC

Enterprise server.

■ Appendix B Components:

Provides figures showing the components that compose the SPARC Enterprise

servers.

■ Appendix C External Interface Specifications:

Describes the specifications of the connectors provided on the SPARC

Enterprise server unit.

■ Appendix D UPS Controller:

Describes the connection of UPC interface, which controls UPS

(Uninterruptible Power Supply).

■ Appendix E XSCF Unit Replacement When XCP 1040 or 1041 Is in the Server:

Provides a replacement procedure to use when the server uses an older version

of XCP firmware than is present in the replacement XSCFU.

■ Abbreviations

Provides the full spellings of abbreviations used in this manual.

■ Index

Provides keywords and corresponding reference page numbers so that the

reader can easily search for items in this manual as necessary.

xx SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

Page 23

SPARC Enterprise M8000/M9000

Servers Documentation

The manuals listed below are provided for reference.

Book Titles Manual Codes

SPARC Enterprise M8000/M9000 Servers Site Planning Guide C120-H014

SPARC Enterprise Equipment Rack Mounting Guide C120-H016

SPARC Enterprise M8000/M9000 Servers Getting Started Guide C120-E323

SPARC Enterprise M8000/M9000 Servers Overview Guide C120-E324

Important Safety Information for Hardware Systems C120-E391

SPARC Enterprise M8000/M9000 Servers Safety and Compliance Guide C120-E326

External I/O Expansion Unit Safety and Compliance Guide C120-E457

SPARC Enterprise M8000/M9000 Servers Unpacking Guide C120-E327

SPARC Enterprise M8000/M9000 Servers Installation Guide C120-E328

SPARC Enterprise M8000/M9000 Servers Service Manual C120-E330

External I/O Expansion Unit Installation and Service Manual C120-E329

SPARC Enterprise M3000/M4000/M5000/M8000/M9000 Servers RCI

Build Procedure

SPARC Enterprise M3000/M4000/M5000/M8000/M9000 Servers

Administration Guide

SPARC Enterprise M3000/M4000/M5000/M8000/M9000 Servers XSCF

User’s Guide

SPARC Enterprise M3000/M4000/M5000/M8000/M9000 Servers XSCF

Reference Manual

SPARC Enterprise M4000/M5000/M8000/M9000 Servers Dynamic

Reconfiguration (DR) User’s Guide

SPARC Enterprise M4000/M5000/M8000/M9000 Servers Capacity on

Demand (COD) User’s Guide

SPARC Enterprise M3000/M4000/M5000/M8000/M9000 Servers RCI

User’s Guide

SPARC Enterprise M8000/M9000 Servers Product Notes Go to the Web

C120-E361

C120-E331

C120-E332

Go to the Web

C120-E335

C120-E336

C120-E360

Preface xxi

Page 24

Book Titles Manual Codes

External I/O Expansion Unit Product Notes C120-E456

SPARC Enterprise M3000/M4000/M5000/M8000/M9000 Servers

C120-E514

Glossary

SPARC Enterprise /PRIMEQUEST Common Installation Planning

C120-H007

Manual

xxii SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

Page 25

1. Manuals on the Web

The latest versions of all the SPARC Enterprise Series manuals are available at the

following websites.

Global Site

http://www.fujitsu.com/sparcenterprise/manual/

Japanese Site

http://primeserver.fujitsu.com/sparcenterprise/manual/

Note – Product Notes are available on the website only. Please check for the most

recent update on your product.

2. Documentation CD

For the Documentation CD, please contact your local sales representative.

■ SPARC Enterprise M8000/M9000 Servers Documentation CD (C120-E364)

3. Manual on the Enhanced Support Facility x.x CD-ROM disk

■ Remote maintenance service

Book Title Manual Code

Enhanced Support Facility User's Guide for REMCS C112-B067

4. Manual (man page) provided in the system

XSCF man page

Note – The man page can be referenced on the XSCF Shell, and it provides the same

content as the SPARC Enterprise M3000/M4000/M5000/M8000/M9000 Servers XSCF

Reference Manual.

5. Sun Microsystems Software (for Solaris OS, etc.) Related Manuals

http://docs.sun.com

6. Information on Using the RCI function

This manual does not contain an explanation of the RCI build procedure. For

information on using the RCI function, refer to the RCI Build Procedure and RCI

User’s Guide provided on the website.

Preface xxiii

Page 26

Product Handling

Maintenance

Caution – Certain tasks in this manual should only be performed by a certified

service engineer. User must not perform these tasks. Incorrect operation of these

tasks may cause electric shock, injury, or fire.

■ Installation and reinstallation of all components, and initial settings

■ Removal of front, rear, or side covers

■ Mounting/de-mounting of optional internal devices

■ Plugging or unplugging of external interface cards

■ Maintenance and inspections (repairing, and regular diagnosis and maintenance)

Caution – The following tasks regarding this product and the optional products

provided from Fujitsu should only be performed by a certified service engineer.

Users must not perform these tasks. Incorrect operation of these tasks may cause

malfunction.

■ Unpacking optional adapters and such packages delivered to the users

■ Plugging or unplugging of external interface cards

Remodeling/Rebuilding

Caution – Any modification and/or recycling of this product and its components

may be carried out only by a certified service engineer and must not be done by the

customer under any circumstances. Otherwise, electric shock, injury or fire may

result.

xxiv SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

Page 27

Emission of Laser Beam (Invisible)

Caution – The main unit and high-speed optical interconnect cabinet contain

modules that generate invisible laser radiation. Laser beams are generated while the

equipment is operating, even if an optical cable is disconnected or a cover is

removed. Do not look at any light-emitting part directly or through an optical

apparatus (e.g., magnifying glass, microscope).

Preface xxv

Page 28

Limitations and Cautions

Power Control and Operator Panel Mode Switch

When you use the remote power control utilizing the RCI function or the automatic

power control system (referred to below as APCS), you can disable this remote

power control or the APCS by switching to Service mode on the operator panel.

Disabling these features ensures that you do not unintentionally switch the system

power on or off during maintenance. Note system power off with the APCS cannot

be disabled with the mode switch. Therefore, be sure to turn off automatic power

control via APCS before starting maintenance.

If you switch the mode while using the RCI or the automatic power control, the

system power is controlled as follows.

Function Mode switch

Locked Service

RCI Remote power-on/power-off

operations are enabled.

Automatic

power control

To use the RCI function, see the SPARC Enterprise

M3000/M4000/M5000/M8000/M9000 Servers RCI Build Procedure and the SPARC

Enterprise M3000/M4000/M5000/M8000/M9000 Servers RCI User’s Guide which are

available on the website of manuals.

To use the APCS, see the Enhanced Support Facility User's Guide for Machine

Administration Automatic Power Control Function (Supplement Edition) .

xxvi SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

Automatic power-on/poweroff operations are enabled.

Remote power-on/power-off

operations are disabled.

Automatic power-on is

disabled, but power-off

remains enabled.

Page 29

Fujitsu Welcomes Your Comments

If you have any comments or requests regarding this document, or if you find any

unclear statements in the document, please state your points specifically on the form

at the following URL.

For Users in U.S.A., Canada, and Mexico:

http://www.computers.us.fujitsu.com/www/support_servers.shtml?support

/servers

For Users in Other Countries:

SPARC Enterprise contact

http://www.fujitsu.com/global/contact/computing/sparce_index.html

Preface xxvii

Page 30

xxviii SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

Page 31

PA R T

I Basic Information for Maintenance and

Troubleshooting

Part I provides maintenance information, explains methods of problem analysis,

troubleshooting, and basic operations for replacing FRUs.

Page 32

Page 33

CHAPTER

1

Safety and Tools

This chapter provides notes on handling the high-end server descriptions and rules

about operation, and it lists the tools required for maintenance.

This information is explained in the following sections:

■ Section 1.1, “Symbols” on page 1-1

■ Section 1.2, “Precautions” on page 1-4

■ Section 1.3, “Tools Required for Maintenance” on page 1-5

1.1 Symbols

1.1.1 Text Conventions

This manual uses the following fonts and symbols to express specific types of

information.

Fonts/symbols Meaning Example

AaBbCc123 What you type, when

contrasted with on-screen

computer output.

This font represents the

example of command input in

the frame.

XSCF> adduser jsmith

1-1

Page 34

Fonts/symbols Meaning Example

AaBbCc123 The names of commands, files,

and directories; on-screen

computer output.

This font represents the

example of command input in

the frame.

Italic Indicates the name of a

reference manual.

" " Indicates names of chapters,

sections, items, buttons, or

menus.

1.1.2 Prompt Notations

The following prompt notations are used in this manual.

Shell Prompt Notations

XSCF XSCF>

C shell machine-name%

C shell super user machine-name#

Bourne shell and Korn shell $

Bourne shell and Korn shell super user #

OpenBoot™ PROM ok

XSCF> showuser -P

User Name: jsmith

Privileges: useradm

auditadm

See the SPARC Enterprise

M3000/M4000/M5000/M8000/M

9000 Servers XSCF User’s Guide .

See Chapter 2, "Product

Overview and

Troubleshooting."

1.1.2.1 Command syntax

The command syntax is as follows:

■ A variable that requires input of a value is enclosed in <>.

■ An optional element is enclosed in [ ].

■ A group of options for an optional keyword is enclosed in [ ] and delimited by |.

■ A group of options for a mandatory keyword is enclosed in {} and delimited by |.

■ The command syntax is shown in a box.

Example:

XSCF> showuser -a

1-2 SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

Page 35

1.1.3 Environmental Requirements for Using This Product

This product is a computer that is intended to be used in a computer room. For

details on the operational environment, see the SPARC Enterprise M8000/M9000

Servers Site Planning Guide.

1.1.4 Conventions for Alert Messages

This manual uses the following conventions to show alert messages, which are

intended to prevent injury to the user or bystanders as well as property damage, and

important messages that are useful to the user.

This indicates a hazardous situation that could result in death or serious

personal injury (potential hazard) if the user does not perform the

procedure correctly.

This indicates a hazardous situation that could result in minor or moderate

personal injury if the user does not perform the procedure correctly. This

signal also indicates that damage to the product or other property may

occur if the user does not perform the procedure correctly.

This indicates information that could help the user to use the product more

effectively.

1.1.4.1 Alert Messages in the Text

An alert message in the text consists of a signal indicating an alert level followed by

an alert statement. Alert messages are indented to distinguish them from regular text

as shown in the following example. Also, a space of one line precedes and follows an

alert statement.

The tasks listed below for this product and optional product provided by Fujitsu

should be performed only by authorized service personnel.

The user must not perform these tasks. Incorrect operation of these tasks may cause

electric shock, injury, or fire.

■ Installation and reinstallation of all components

■ Removal of front, rear, or side covers

■ Mounting/unmounting of optional internal devices

■ Connecting/disconnecting of external interface cables

■ Maintenance (repair and regular diagnosis and maintenance)

Chapter 1 Safety and Tools 1-3

Page 36

1.2 Precautions

The following notes must be observed in maintenance work:

1.2.1 Operating Environment of the Product

Use the SPARC Enterprise in the correct operating environment. The SPARC

Enterprise are assumed to be used in a computer room. For details of the operating

environment, see the SPARC Enterprise M8000/M9000 Servers Site Planning Guide.

1.2.2 Maintenance

The work listed below is to be performed by authorized service engineers. Persons

who are not authorized service engineers must not perform the work. Otherwise,

electric shock, injury, or fire may result.

■ Installation, transport, and initial setup of each device

■ Removal of the front, rear, or a side cover.

■ Mounting or removing internal optional components

■ Connecting or disconnecting an external interface cable

■ Maintenance (repair, regular diagnosis, and maintenance)

The work listed below is to be performed by authorized service engineers. Persons

who are not authorized service engineers must not perform the work. Otherwise, an

equipment failure may result.

■ Unpacking or installing products, such as an optional adapter, that are delivered

to the customer

■ Connecting or disconnecting an external interface cable

1-4 SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

Page 37

1.2.3 Conversion and Reuse of This Product

If this product is converted or a used article of this product is overhauled for the

purpose of reuse, unexpected injury on users and bystanders or damage to their

property may result.

1.3 Tools Required for Maintenance

The maintenance work described in Chapter 6 to Chapter 24 requires maintenance

software to confirm that the SPARC Enterprise and other components are operating

correctly and to collect status information and log data about the server and

components. The work for mounting, removing, or replacing a specific component

requires screwdrivers, and special tools such as an antistatic wrist strap. These items

are listed in

TABLE 1-1 Maintenance Tools

No. Name Use

1 Torque wrench

[8.24 N*m (84 kgf*cm)]

2 Sockets for 10 mm (M6) torque

wrench

3 Sockets for 13 mm (M8) torque

wrench

4 Torque wrench extension

5 Torque screwdriver

[0.2 N*m (2.0 kgf*cm)]

6 Slotted bit Used to secure the clock cables between the cabinets if the

7 Wrist strap For antistatic purposes

8 Conductive mat For antistatic purposes

9 CPU module replacement tool For mounting and removing CPU Modules (accessory)

10 SunVTS Test program

TABLE 1-1.

Used to fix the bus bars of the power cabinet.

Used to replace the BP_A in the SPARC Enterprise M8000

server.

Used to fix the bus bars of the power cabinet.

Used to secure the clock cables between the cabinets if the

expansion cabinet of the SPARC Enterprise M9000 server is

mounted.

expansion cabinet of the SPARC Enterprise M9000 server is

mounted.

Chapter 1 Safety and Tools 1-5

Page 38

Caution – Be sure to wear an antistatic wrist strap when handling components.

Place removed components on an antistatic conductive mat. Failure to do so may

result in serious damage or injury.

1-6 SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

Page 39

CHAPTER

2

Product Overview and Troubleshooting

This chapter provides information that is required in troubleshooting.

This information is explained in the following sections:

■ Section 2.1, “System Views” on page 2-1

■ Section 2.2, “Labels” on page 2-11

■ Section 2.3, “Operator Panel” on page 2-16

■ Section 2.4, “Determining Which Diagnostics Methods To Use” on page 2-21

■ Section 2.5, “Checking the Server and System Configuration” on page 2-23

■ Section 2.6, “Error Conditions and Action To Be Taken” on page 2-26

■ Section 2.7, “LED Error Display” on page 2-30

■ Section 2.8, “Using the Troubleshooting Commands” on page 2-34

■ Section 2.9, “Traditional Solaris Troubleshooting Commands” on page 2-37

2.1 System Views

This section provides views of the high-end server. The figures can be used to locate

the component in the server to be subjected to maintenance.

In terms of its structure, the high-end server consists of a cabinet that includes

various mounted components and a front door, rear door, and side covers that

protect the mounted components. The side covers are removed when cabinets are

connected to each other or when the dual power feed option is connected to the

cabinet. The operator panel, which is mounted on the front door, is always

accessible. Each door can be locked with a key so that only the administrator can

open it.

2-1

Page 40

The front and rear views of FIGURE 2-1, FIGURE 2-2, FIGURE 2-4, FIGURE 2-5, FIGURE 2-7,

and

FIGURE 2-8 include names and abbreviations for field-replaceable units (FRUs).

Components that are mounted inside the system are shown

and

FIGURE 2-9. The abbreviations are used in messages and the like. If multiple

FIGURE 2-3, FIGURE 2-6,

FRUs of the same type are mounted, the number sign # and a sequential number is

added to their names to distinguish them from one another. Owing to the reduced

scale, certain components (FRUs) are difficult to show in the figures. Accordingly,

the layout of these components as viewed from one side is indicated in the table

connected by a lead line to the component location.

2-2 SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

Page 41

2.1.1 SPARC Enterprise M8000 Server

FIGURE 2-1 Front View - M8000

PSU

DDC

XSCFU

TAPEU

DVDU

SNSU

FAN_B

CMU

FAN_A

Air Filter

Chapter 2 Product Overview and Troubleshooting 2-3

Page 42

FIGURE 2-2 Rear View - M8000

ACS

FAN_B

IOU

Air Filter

2-4 SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

Page 43

PSUBP_B

PSUBP_A

FIGURE 2-3 Internal View - M8000

FANBP_C

MEDBP

FANBP_C

BP_A

SWBP

Chapter 2 Product Overview and Troubleshooting 2-5

Page 44

2.1.2 SPARC Enterprise M9000 Server (Base Cabinet)

FIGURE 2-4 Front View - M9000 (Base Cabinet)

PSU

TAPEU

DVDU

SNSU

FAN_A

ACS

XBU

CLKU

XSCFU

IOU

Air Filter

2-6 SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

Page 45

FIGURE 2-5 Rear View - M9000 (Base Cabinet)

FAN_A

CMU

IOU

Air Filter

Chapter 2 Product Overview and Troubleshooting 2-7

Page 46

FIGURE 2-6 Internal View - M9000 (Base Cabinet)

PSUBP_A

BP_B

MEDBP

SWBP

FANBP_B

FANBP_A

2-8 SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

Page 47

2.1.3 SPARC Enterprise M9000 Server (Expansion Cabinet)

FIGURE 2-7 Front View - M9000 (with the Expansion Cabinet)

PSU

cable support bracket

TAPEU

DVDU

SNSU

FAN_A

ACS

XBU

CLKU

XSCFU

IOU

Air Filter

Chapter 2 Product Overview and Troubleshooting 2-9

Page 48

FIGURE 2-8 Rear View - M9000 (with the Expansion Cabinet)

FAN_A

CMU

IOU

Air Filter

2-10 SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

Page 49

FIGURE 2-9 Internal View - M9000 (with the Expansion Cabinet)

PSUBP_A

BP_B

MEDBP

SWBP

2.2 Labels

FANBP_B

FANBP_A

2.2.1 System Name Plate Label, Rating Label, ID Label (Japan) or EZ Label (besides Japan), and Standard Label

The important labels affixed on this server are shown in FIGURE 2-10 and FIGURE 2-11.

The actual description on the labels may differ from

■ The system name plate label includes the model number, serial number, and

hardware version, all of which are required for maintenance and management.

■ The rating label, which is affixed near the AC power supply, includes the power

input rating for the AC power supply.

Chapter 2 Product Overview and Troubleshooting 2-11

FIGURE 2-10 and FIGURE 2-11.

Page 50

■ The ID label or EZ label is affixed on the front door of the server, and it includes

the model name and serial number, both of which are written on the system name

plate label.

ID label (Japan)

■ The standard label is affixed near the system name plate label, and it includes the

EZ label (besides Japan)

certification standards that apply:

Safety: NRTL/C

Electrical interference: VCCI-A, FCC-A, DOC-A, and MIC

Safety and electrical interference: CE

2-12 SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

Page 51

FIGURE 2-10 M8000 Label Location

System Name Plate Label

Front Rear

Standard label

Chapter 2 Product Overview and Troubleshooting 2-13

Page 52

FIGURE 2-11 M9000 Label Location

System Name Plate Label

Front

Rear

Standard label

2-14 SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

Page 53

2.2.2 Labels About Handling

The labels shown below, which are affixed on the high-end server, provide field

engineers with important information on component removal and mounting.

Caution – Never peel off the labels.

■ Removing and installing a CPU/memory board unit (CMU)

■ Removing a crossbar unit (XBU)

Chapter 2 Product Overview and Troubleshooting 2-15

Page 54

■ Removing an I/O unit (IOU)

2.3 Operator Panel

The operator panel controls the high-end server power. The operator panel is usually

locked with a key to prevent the server from being mistakenly powered off through

an operator error during system operation.

Before starting maintenance work, ask the system administrator to unlock the

operation panel.

2.3.1 Operator Panel Location

FIGURE 2-12 indicates the location of the operator panel (OPNL) of the high-end

servers. The expansion cabinet is not equipped with the operator panel.

2-16 SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

Page 55

OPNL

FIGURE 2-12 Operator Panel Location (at the Front of M8000)

2.3.2 Appearance and Operations

The operator panel can be used while the front door of the server is closed. Field

engineers, and the system administrator use the operation panel to check the

operating state of the server and to perform system power operations. To check the

operating state of the server, look at the LEDs. The operating state of the server is

checked by observing the LEDs, and the power supply is operated with the POWER

switch.

FIGURE 2-13 shows the appearance of the operator panel.

Chapter 2 Product Overview and Troubleshooting 2-17

Page 56

FIGURE 2-13 Operator Panel

2.3.3 LED

TABLE 2-1 lists the states of the server that are displayed with the LEDs on the

operator panel.

The blinking period is one second (frequency of 1 Hz).

Besides the states listed in

of the server using combinations of the three LEDs.

TABLE 2-1, the operator panel also displays various states

TABLE 2-2 indicates the states that

are usually displayed in the course of operation from the power-on to power-off of

the high-end server.

TABLE 2-1 State Display by the LEDs (Operator Panel)

LED Name Light color Description of function and state

POWER Green Indicates whether power to the SPARC Enterprise server is on.

Off Indicates the power-off state.

Lit Indicates the power-on state.

Blinking The power-off sequence is in progress.

STANDBY Green Indicates whether the XSCF can be powered on.

XSCF Off Indicates that the system cannot be powered on.

Blinking Indicates that initialization processing of the SPARC

Enterprise server is in progress after main line

switches were switched on.

Lit Indicates that the system can be powered on.

2-18 SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

Page 57

TABLE 2-1 State Display by the LEDs (Operator Panel) (Continued)

LED Name Light color Description of function and state

CHECK Amber Indicates the operating status of the SPARC Enterprise server.

Off Normal state. Otherwise, this indicates that the main

line switches were switched off or a power failure

occurred.

Blinking

(*1)

Indicates that the operator panel is the maintenance

target device.

Lit Indicates that the server cannot be started.

Note – *1)If the maintenance target component is indicted by a blinking CHECK

LED, the LED may be called a locater.

TABLE 2-2 State Display by LED Combination (Operator Panel)

LED

POWER XSCF

STANDBY

CHECK

Description of the state

Off Off Off The main line switch is switched off.

Off Off On The main line switch is switched on.

Off Blinking Off The XSCF is being initialized.

Off Blinking On An error occurred in the XSCF.

Off On Off • The XSCF is on standby.

• The system is waiting for power-on of the air conditioning

system.

On On Off • Warm-up standby processing is in progress (power-on is

delayed).

• The power-on sequence is in progress.

• The system is in operation.

Blinking On Off • The power-off sequence is in progress.

• Fan termination is being delayed.

Chapter 2 Product Overview and Troubleshooting 2-19

Page 58

2.3.4 Switch

The operator panel has the mode switch, which sets the operation mode, and the

POWER switch, which is used to power on and off the system.

TABLE 2-3 Switches (Operator Panel)

Switch Name Description of function

Mode This key switch is used to set an operation mode for the server.

Insert the special key that is under the customer’s control, to

switch between modes.

Locked Normal operation mode

• The system can be powered on with the POWER switch, but

it cannot be powered off with the POWER switch.

• The key can be pulled out at this key position.

Service Mode for maintenance

• The system can be powered on and off with the POWER

switch.

• The key cannot be pulled out at this key position.

• Maintenance is performed in Service mode while the server

is stopped.

POWER This switch is used to control the server power.

Power-on and power-off are controlled by pressing this switch

in different patterns, as described below.

Holding down for a

short time

(less than 4 seconds)

Holding down for a

long time in Service

mode

(4 seconds or

longer)

Regardless of the mode switch state, the server (all domains) is

powered on.

At this time, processing for waiting for facility (air

conditioners) power-on and warm-up completion is

skipped.(*1)

• If power to the server is on (at least one domain is

operating), shutdown processing is executed for all domains

before power-off processing.

• If the system is being powered on, the power-on processing

is cancelled, and the system is powered off.

• If the system is being powered off, the operation of the

POWER switch is ignored, and the power-off processing is

continued.

Note – *1)In normal operation, the server is powered on only when the computer

room environmental conditions satisfy the specified values. Then, the server

remains in the reset state until the operating system is booted.

2-20 SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

Page 59

TABLE 2-4 Meanings of the Mode Switch

Function Mode Switch

Locked Locked

Inhibition of Break Signal Reception Enabled. Reception of the break signal

can be enabled or disabled for each

domain using setdomainmode.

Power On/Off by power switch Only power on is enabled Enabled

Disabled

2.4 Determining Which Diagnostics Methods To Use

When an error occurs, a message is often displayed on the monitor. Use the

flowcharts in

FIGURE 2-14 to find the correct methods for diagnosing problems.

Chapter 2 Product Overview and Troubleshooting 2-21

Page 60

FIGURE 2-14 Diagnostic Method Flow Chart

OS panic occurred or there’s an

error on performance

Start

Check OS console and XSCF

console for error information displayed

Check /var/adm/messages

on Solaris OS

FMA message?

YES

Execute

information

fmadm to display fault

Message ID

available?

e-mail sent or not by

XSCF mail function?

NO

Is there error message

on XSCF console?

NO

NO

YES

YESNO

Execute showlogs or fmadm

on XSCF to display the fault

information

YES

Write down the displayed fault

information

Use fmadm ?

NO

YES

Enter Message ID in

http://sun.com/msg/ to

refer to fault information

Trouble

resolved?

YES

2-22 SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

NO

Collect information about your

server

Contact service engineer

End

Page 61

2.5 Checking the Server and System Configuration

Before and after maintenance work, the state and configuration of the server and

components should be checked and the information saved. For recovery from a

problem, conditions related to the problem and the repair status must be checked.

The operating conditions must remain the same before and after maintenance.

A functioning server without any problems should not display any error conditions.

For example:

■ The syslog file should not display error messages.

■ * mark is not displayed in SCF shell command showhandconf

■ The administrative console should not display error messages.

■ The server processor logs should not display any error messages.

■ The Solaris™ Operating System (Solaris OS) message files should not indicate any

additional errors.

2.5.1 Checking the Hardware Configuration and FRU Status

To replace a faulty component and perform the maintenance on the server it is

important to check and understand the hardware configuration of the server and the

state of each hardware component.

The hardware configuration refers to information that indicates to what layer a

component belongs in the hardware configuration.

The status of each hardware component refers to information on the condition of the

standard or optional component in the server: temperature, power supply voltage,

CPU operating conditions, and other times.

The hardware configuration and the status of each hardware component can be

checked from the maintenance terminal using XSCF Shell commands.

TABLE 2-5 lists commands for checking the hardware configuration and status. For

details, see the SPARC Enterprise M3000/M4000/M5000/M8000/M9000 Servers XSCF

Reference Manual.

Chapter 2 Product Overview and Troubleshooting 2-23

Page 62

TABLE 2-5 Commands for Checking Hardware Configuration and Status

Command Description

showhardconf Displays the system layer that includes a faulty component.

showstatus Displays the status of a component. This command is used to check only a faulty

component.

showboards Displays the use status of individual devices and resources.

showdcl Displays domain configuration information (hardware resource information).

showfru Displays device setting information.

ioxadm Displays the FRU status of external I/O expansion unit as normal or abnormal.

Also some conditions can be checked based on the lit and/ or blinking state of the

component LEDs (

TABLE 2-11 and TABLE 2-12).

2.5.1.1 Checking the Hardware Configuration

Login authority is required to check the hardware configuration. The following

procedure for these checks can be made from the maintenance terminal. Ask the

system administrator for necessary information, such as a password. For the detailed

procedure, see the SPARC Enterprise M3000/M4000/M5000/M8000/M9000 Servers

XSCF User’s Guide.

1. Log in to the XSCF.

2. Execute the showhardconf command.

XSCF> showhardconf

The showhardconf command will print the hardware configuration information

to the screen. See the SPARC Enterprise M3000/M4000/M5000/M8000/M9000 Servers

XSCF User’s Guide for more detailed information.

2.5.2 Checking the Software and XSCF Firmware Configurations

The software and firmware configurations and versions affect the operation of the

server. To change the configuration or investigate a problem, check the latest

information and check for any problems in the software.

Software and firmware varies according to users.

2-24 SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

Page 63

■ The software configuration and version can be checked in the Solaris Operating

System. Refer to the Solaris OS documentation for more information.

■ The firmware configuration and versions can be checked from the maintenance

terminal using XSCF Shell commands. Refer to the SPARC Enterprise

M3000/M4000/M5000/M8000/M9000 Servers XSCF User’s Guide for more detailed

information.

Check the software and firmware configuration information with assistance from the

system administrator. However, if you have received login authority from the

system administrator, the following commands can be used from the maintenance

terminal for these checks:

TABLE 2-6 Commands for Checking the Software Configuration

Command Description

showrev(1M) Displays information on patches applied to the system.

uname(1) Outputs current information regarding the system to the standard output.

TABLE 2-7 Commands for Checking the XSCF Firmware Configuration

Command Description

version(8) XSCF Shell command that outputs the current firmware version information.

showhardconf(8) XSCF Shell command that displays what layer of the system includes a faulty

component.

showstatus(8) XSCF Shell command that displays the status of a component. This command is used

when only a faulty component is to be checked.

showdcl(8) XSCF Shell command that displays the configuration information of a domain

(hardware resource information).

showfru(8) XSCF Shell command that displays the setting information of a device.

2.5.2.1 Checking the Software Configuration

The following procedure for these checks can be made from any terminal window

terminal.

1. Execute the showrev command.

# showrev

The showrev command will print the system configuration information to the

screen.

Chapter 2 Product Overview and Troubleshooting 2-25

Page 64

2.5.2.2 Checking the Firmware Configuration

Login authority is required to check the firmware configuration. The following

procedure for these checks can be made from the maintenance terminal:.

1. Log in to the XSCF.

2. Execute the version command.

XSCF> version

The version command will print the firmware version information to the screen.

See the SPARC Enterprise M3000/M4000/M5000/M8000/M9000 Servers XSCF User’s

Guide for more detailed information.

2.5.3 Downloading the Error Log Information

If you want to download the error log information, use the XSCF log fetch function.

The XSCF Unit has an interface with external units so that a service engineer can

easily obtain useful maintenance information such as error logs

Connect the maintenance terminal, and use the CLI or BUI to issue a download

instruction to the maintenance terminal to download Error Log information over the

XSCF-LAN.

Note – When the XSCF unit has a redundant configuration, log in also to the

standby XSCF and obtain the log file in the same manner.

2.6 Error Conditions and Action To Be Taken

This section describes error conditions and relevant corrective actions.

This work is explained in the following sections:

■ Section 2.6.1, “Predictive Self-Healing Tools” on page 2-27

■ Section 2.6.2, “Monitoring Output” on page 2-28

■ Section 2.6.3, “Messaging Output” on page 2-29

Details of the fault information, see the SPARC Enterprise

M3000/M4000/M5000/M8000/M9000 Servers XSCF User’s Guide.

2-26 SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

Page 65

You can find more detailed descriptions of Solaris OS Predictive Self-Healing at the

website below:

http://www.sun.com/bigadmin/features/articles/selfheal.html

Predictive self-healing is an architecture and methodology for automatically

diagnosing, reporting, and handling software and hardware fault conditions. This

new technology lessens the time required to debug a hardware or software problem

and provides the administrator and technical support with detailed data about each

fault.

2.6.1 Predictive Self-Healing Tools

In Solaris OS, the fault manager runs in the background. If a failure occurs, the

system software recognizes the error and attempts to determine what hardware is

faulty. The software also takes steps to prevent that component from being used

until it has been replaced. Some of the specific activities the software takes include:

■ Receives telemetry information about problems detected by the system software

■ Diagnoses the problems

■ Initiates pro-active self-healing activities. For example, the fault manager can

disable faulty components.

The state of a FRU, group of FRUs, or part of a FRU, that has been isolated

because a fault was detected. The isolation is usually done to prevent possibly

faulty components from affecting other system components. The part that is

isolated is not always the faulty part alone; a normal part may be degraded to

isolate the faulty part. If a function required for the operation of the system is

degraded, a system failure may result.

■ When possible, causes the faulty FRU to provide an LED indication of a fault in

addition to populating the system console messages with more details

TABLE 2-8 shows a typical message generated when a fault occurs. The message

appears on your console and is recorded in the /var/adm/messages file.

Note – The message in TABLE 2-8 indicates that the fault has already been diagnosed.

Any corrective action that the system can perform has already taken place. If your

server is still running, it continues to run.

Chapter 2 Product Overview and Troubleshooting 2-27

Page 66

TABLE 2-8 Predictive Self Healing Message

Output displayed Description

Nov 1 16:30:20 dt88-292 EVENT-TIME: Tue Nov 1 16:30:20 PST 2005 EVENT-TIME: the time stamp of

the diagnosis.

Nov 1 16:30:20 dt88-292 PLATFORM: SUNW,A70, CSN: -, HOSTNAME:

dt88-292

Nov 1 16:30:20 dt88-292 SOURCE: eft, REV: 1.13 SOURCE: Information on the

Nov 1 16:30:20 dt88-292 EVENT-ID:

afc7e660-d609-4b2f-86b8-ae7c6b8d50c4

Nov 1 16:30:20 dt88-292 DESC:

Nov 1 16:30:20 dt88-292 A problem was detected in the PCI-Express

subsystem

Nov 1 16:30:20 dt88-292 Refer to http://sun.com/msg/SUN4-8000-0Y for

more information.

Nov 1 16:30:20 dt88-292 AUTO-RESPONSE: One or more device instances

may be disabled

Nov 1 16:30:20 dt88-292 IMPACT: Loss of services provided by the device

instances associated with this fault

Nov 1 16:30:20 dt88-292 REC-ACTION: Schedule a repair procedure to

replace the affected device. Use Nov 1 16:30:20 dt88-292 fmdump -v -u

EVENT_ID to identify the device or contact Sun for support.

PLATFORM: A description of the

server encountering the problem.

Diagnosis Engine used to

determine the fault.

EVENT-ID: The Universally

Unique event ID for this fault.

DESC: A basic description of the

failure.

WEBSITE: Where to find specific

information and actions for this

fault.

AUTO-RESPONSE: What, if

anything, the system did to

alleviate any follow-on issues

IMPACT: A description of what

that response might have done.

REC-ACTION: A short description

of what the system administrator

should do.

2.6.2 Monitoring Output

To understand error conditions, collect monitoring output information, by using the

commands shown below.

TABLE 2-9 lists the commands for checking the monitoring output.

2-28 SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

Page 67

TABLE 2-9 Commands for Checking the Monitoring Output

Command Operand Description

showlogs(8) console XSCF firmware collects console logs of console messages that were output

through the XSCF. This command collects all the console messages displayed to

users.

monitor Logs the messages displayed in the message window of the BUI/CLI.

panic Saves as panic logs the console logs that are logged when a reset is received after

a panic notification.

ipl Collects the console data generated during a period from power-on of a domain

to completion of operating system startup (system running).

2.6.3 Messaging Output

To understand error conditions, collect messaging output information, by using the

commands shown below.

TABLE 2-10 lists the commands for checking the messaging output.

Chapter 2 Product Overview and Troubleshooting 2-29

Page 68

TABLE 2-10 Commands for Checking the Messaging Output

Command Operand Description

showlogs env Collects the temperature history log. The SPARC Enterprise server environmental

temperature data and power status are collected at a 10-minute interval. The data

is stored for a maximum of six months.

power Collects the log of power events and reset events. The target range covers the

SPARC Enterprise server, External I/O Expansion units, and UPSs.

event Collects the message which accompanies the command or the progress of

operation such as Dynamic Reconfiguration (DR), the status of operation on the

operator panel, the event such as the shut down request to OS due to power

failure or abnormal temperature, as event log. This information is used to analyze

faults and investigate the use status of individual devices at a customer's site, and

it is kept as a maintenance work history.

error Information on the SPARC Enterprise server hardware faults detected by the SCF,

POST/OpenBoot PROM, or ESF machine management and software monitoring

error information are logged as SCF error logs. The showlogs error command

can display with hexadecimal codes the error information stored in the SCF error

log and information on faulty components.

fmdump(1M)

fmdump(8)

Hardware and software are automatically diagnosed according to the fault

management architecture (FMA), and the diagnosis results and errors are

automatically recorded. The fmdump command can display the recorded

information. It is provided as a Solaris OS command and XSCF Shell command.

The information can be checked at the site at the specified URL by using a

displayed message ID.

Each error message logged by the predictive self-healing architecture has a code

associated with it as well as a web address that can be followed to get the most

up-to-date course of action for dealing with that error.

Refer to the Solaris OS documentation for more information on predictive

self-healing.

2.7 LED Error Display

This section explains the LEDs of each FRU that are to be checked when the relevant

FRU is replaced. Each LED can be checked after the door of a cabinet is opened.

Whether the state of the entire system is normal can be learned by checking the

operator panel (outside). When an error occurs in an individual hardware

component in the system, the LEDs of the FRU containing the hardware component

2-30 SPARC Enterprise M8000/M9000 Servers Service Manual • August 2009

Page 69

that has caused the error indicate that an error has occurred. The LEDs on the

operator panel (back) indicate the status of the operator as a single unit. However,

some FRUs like DIMMs do not have LEDs.

Whether a FRU without LEDs is in the normal state can be checked by executing the

XSCF Shell commands showhardconf and ioxadm from a maintenance terminal.

For details of the commands, see the SPARC Enterprise

M3000/M4000/M5000/M8000/M9000 Servers XSCF Reference Manual.

2.7.1 When target FRU is indicated by LEDs

When an error message is displayed at the system console and the cause of the error

is in hardware, a faulty FRU must be removed and replaced. Each FRU is equipped

with an LED to indicate whether an error has occurred in the FRU and an LED to

indicate whether the FRU can be removed. Most FRUs are named READY LED and

CHECK LED. In some cases, names are not indicated but the icons are always

printed or icon labels are always affixed. Such FRUs include the back of the operator

panel, XSCFUs, CMUs, XBUs, CLKUs, FANs, and HDDs.

2.7.2 When target FRU is not indicated by LEDs

For some FRUs, the READY LED and CHECK LED are not used as the names of the

LEDs that are checked at replacement. Even in such a case, the same icons as those

for the READY LED and CHECK LED are used so that the meaning of LEDs can be

understood. Even if the names of LEDs are not indicated, the icons are always

printed or icon labels are always affixed.

TABLE 2-11 LED Display That Should Be Checked When a FRU Is Replaced (Common)

LED Display and meaning

READY

(green)

Indicates whether the unit is operating (whether it is configured into the system).

Lit Indicates that the FRU is operating. The FRU cannot be disconnected and

removed from the system. Therefore, the FRU cannot be replaced.

Blinking Indicates that the FRU is being configured into the system (or, for an XSCFU,

being initialized) or being disconnected from the system. However, for a PSU, it

indicates that the main line switch has been switched on.

Off Indicates that the FRU is stopped and disconnected from the system. Therefore,

the FRU can be replaced.

Chapter 2 Product Overview and Troubleshooting 2-31

Page 70

TABLE 2-11 LED Display That Should Be Checked When a FRU Is Replaced (Common) (Continued)

LED Display and meaning

CHECK

(amber)

Indicates either that the unit contains an error or that the unit is a target device for replacement.

Lit Indicates that an error has been detected in the hardware of the FRU. (For an

HDD, the LED is lit according to the instruction from the software or

middleware.)

Blinking (*1) Indicates that the FRU is to be replaced.

Off Indicates that the state of the FRU is normal.