Page 1

SPARC Enterprise M4000/M5000 Servers

Service Manual

Part No.: 819-2210-14,

Manual Code: C120-E352-07EN

December 2010, Revision A

Page 2

Copyright ©2007, 2010,Oracle and/orits affiliates.All rightsreserved.

FUJITSU LIMITEDprovided technicalinput andreview on portions of this material.

Oracle and/orits affiliatesand FujitsuLimited eachown orcontrol intellectual propertyrights relatingto productsand technologydescribed inthis

document, andsuch products,technology andthis documentare protected bycopyright laws,patents, andother intellectualproperty lawsand

international treaties.

This documentand theproduct andtechnology towhich itpertains are distributed underlicenses restrictingtheir use, copying, distribution,and

decompilation. Nopart ofsuch productor technology,or ofthis document,may bereproduced inany formby anymeans withoutprior written

authorization ofOracle and/orits affiliatesand FujitsuLimited, andtheir applicablelicensors, ifany. Thefurnishings ofthis documentto youdoes not

give youany rightsor licenses,express orimplied, withrespect to the product ortechnology towhich itpertains, andthis documentdoes notcontain or

represent any commitment of any kind on the part of Oracle or Fujitsu Limited, or any affiliateof eitherof them.

This documentand theproduct andtechnology describedin thisdocument mayincorporate third-party intellectual propertycopyrighted by and/or

licensed fromthe suppliersto Oracleand/or itsaffiliates and Fujitsu Limited, including software andfont technology.

Per theterms ofthe GPLor LGPL,a copyof thesource codegoverned bythe GPLor LGPL,as applicable,is availableupon request by theEnd User. Please

contact Oracleand/or itsaffiliates orFujitsu Limited.

This distributionmay includematerials developedby thirdparties.

Parts ofthe productmay be derivedfrom BerkeleyBSD systems,licensed from the Universityof California. UNIXis aregistered trademarkin the U.S.and

in othercountries, exclusivelylicensed throughX/Open Company,Ltd.

Oracle andJava areregisteredtrademarks ofOracle and/orits affiliates.Fujitsu andthe Fujitsulogo areregisteredtrademarks ofFujitsu Limited.

All SPARC trademarksareused underlicense andare registered trademarksof SPARC International,Inc. inthe U.S.and othercountries. Products bearing

SPARCtrademarks are based uponarchitecturesdeveloped byOracle and/orits affiliates.SPARC64 is atrademark ofSPARC International, Inc.,used

under licenseby FujitsuMicroelectronics, Inc. and Fujitsu Limited. Other names may be trademarks of their respectiveowners.

United StatesGovernment Rights- Commercialuse. U.S. Governmentusers are subject tothe standard government userlicense agreementsof Oracle

and/or itsaffiliates andFujitsu Limitedand theapplicable provisions of theFARand itssupplements.

Disclaimer: Theonly warrantiesgranted byOracle andFujitsu Limited,and/or anyaffiliate ofeither ofthem inconnection withthis documentor any

product ortechnology describedherein are thoseexpressly setforth inthe licenseagreement pursuantto whichthe product or technologyis provided.

EXCEPT ASEXPRESSLYSET FORTH INSUCH AGREEMENT, ORACLE ORFUJITSU LIMITED,AND/OR THEIRAFFILIATES MAKE NO

REPRESENTATIONS ORWARRANTIESOF ANYKIND (EXPRESSOR IMPLIED)REGARDING SUCHPRODUCT ORTECHNOLOGY ORTHIS

DOCUMENT,WHICH AREALL PROVIDEDAS IS,AND ALLEXPRESS ORIMPLIED CONDITIONS,REPRESENTATIONS ANDWARRANTIES,

INCLUDING WITHOUTLIMITATION ANYIMPLIED WARRANTY OFMERCHANTABILITY, FITNESS FORA PARTICULAR PURPOSEOR NONINFRINGEMENT,ARE DISCLAIMED,EXCEPT TOTHE EXTENTTHAT SUCH DISCLAIMERSARE HELDTO BE LEGALLY INVALID. Unless

otherwise expresslyset forthin suchagreement, to the extent allowed by applicable law,in noevent shallOracle orFujitsu Limited,and/or anyof their

affiliates haveany liabilityto anythird party under any legal theory for any loss of revenuesor profits,loss ofuse ordata, orbusiness interruptions,or for

any indirect,special, incidentalor consequentialdamages, evenif advisedof thepossibility ofsuch damages.

DOCUMENTATION ISPROVIDED “ASIS” ANDALL EXPRESSOR IMPLIEDCONDITIONS, REPRESENTATIONSAND WARRANTIES,

INCLUDING ANYIMPLIED WARRANTY OFMERCHANTABILITY,FITNESS FORA PARTICULAR PURPOSEOR NON-INFRINGEMENT, ARE

DISCLAIMED, EXCEPTTO THEEXTENT THAT SUCHDISCLAIMERS AREHELD TOBE LEGALLY INVALID.

Please

Recycle

Page 3

Copyright ©2007, 2010,Oracle et/ouses sociétésaffiliées. Tous droits réservés.

FUJITSU LIMITEDa fourniet vérifiédes donnéestechniques decertaines partiesde cecomposant.

Oracle et/ouses sociétésaffiliées etFujitsu Limiteddétiennent etcontrôlent chacunedes droits de propriétéintellectuelle relatifs auxproduitset

technologies décritsdans cedocument. Demême, cesproduits, technologieset cedocument sontprotégés par des lois sur le copyright, des brevets,

d’autres loissur lapropriété intellectuelle et des traités internationaux.

Ce document,le produitet lestechnologies afférents sont exclusivementdistribués avecdes licencesqui en restreignentl’utilisation, lacopie, la

distribution etla décompilation.Aucune partiede ceproduit, deces technologiesou dece documentne peutêtre reproduite sousquelque formeque ce

soit, parquelque moyenque cesoit, sansl’autorisation écritepréalable d’Oracleet/ou sessociétés affiliéeset deFujitsu Limited,et deleurs éventuels

bailleurs delicence. Cedocument, bienqu’il vousait étéfourni, nevous confèreaucun droit et aucunelicence, expressesou tacites, concernant leproduit

ou latechnologie auxquelsil serapporte. Parailleurs, ilne contientni nereprésente aucunengagement, dequelque typeque cesoit, dela partd’Oracle ou

de FujitsuLimited, oudes sociétésaffiliées del’une oul’autre entité.

Ce document,ainsi queles produitset technologiesqu’il décrit,peuvent inclure des droitsde propriété intellectuellede partiestierces protégéspar

copyright et/oucédés souslicence pardes fournisseursà Oracleet/ou sessociétés affiliéeset FujitsuLimited, ycompris deslogiciels etdes technologies

relatives auxpolices decaractères.

Conformément auxconditions dela licenceGPL ouLGPL, unecopie ducode sourcerégi parla licenceGPL ouLGPL, selonle cas,est disponiblesur

demande parl’Utilisateur final.Veuillez contacter Oracleet/ou sessociétés affiliées ou FujitsuLimited.

Cette distributionpeut comprendre des composantsdéveloppés pardes partiestierces.

Des partiesde ceproduit peuventêtre dérivées des systèmes Berkeley BSD, distribués sous licence par l’Université de Californie. UNIX est une marque

déposée auxÉtats-Unis etdans d’autrespays, distribuéeexclusivement souslicence parX/Open Company,Ltd.

Oracle etJava sontdes marquesdéposées d’OracleCorporation et/oude sessociétés affiliées. Fujitsu etle logoFujitsu sontdes marquesdéposées de

Fujitsu Limited.

Toutesles marques SPARC sontutilisées souslicence etsont desmarques déposéesde SPARC International,Inc., auxÉtats-Unis et dans d’autres pays.Les

produits portantla marque SPARC reposent sur des architectures développéespar Oracleet/ou sessociétés affiliées.SPARC64 est unemarque de SPARC

International, Inc.,utilisée souslicence parFujitsu Microelectronics, Inc. etFujitsu Limited.Tout autre nom mentionné peut correspondreà desmarques

appartenant àd’autres propriétaires.

United StatesGovernment Rights- Commercialuse. U.S. Governmentusers are subject tothe standard government userlicense agreementsof Oracle

and/or itsaffiliates andFujitsu Limitedand theapplicable provisions of theFARand itssupplements.

Avisde non-responsabilité : les seulesgaranties octroyées par Oracleet FujitsuLimited et/outoute sociétéaffiliée de l’une ou l’autreentité enrapport

avec cedocument outout produitou toutetechnologie décritsdans lesprésentes correspondent aux garantiesexpressément stipuléesdans le contrat de

licence régissantle produitou latechnologie fournis.SAUF MENTIONCONTRAIRE EXPRESSÉMENTSTIPULÉE DANSCE CONTRAT,ORACLE OU

FUJITSU LIMITEDET LESSOCIÉTÉS AFFILIÉESÀ L’UNE OUL’AUTREENTITÉ REJETTENTTOUTE REPRÉSENTATIONOU TOUTE GARANTIE,

QUELLE QU’ENSOIT LANATURE(EXPRESSE OUIMPLICITE) CONCERNANTCE PRODUIT, CETTETECHNOLOGIE OUCE DOCUMENT,

LESQUELS SONTFOURNIS ENL’ÉTAT. ENOUTRE, TOUTESLES CONDITIONS,REPRÉSENTATIONS ETGARANTIES EXPRESSESOU TACITES, Y

COMPRIS NOTAMMENT TOUTEGARANTIE IMPLICITERELATIVEÀ LAQUALITÉ MARCHANDE,À L’APTITUDE ÀUNE UTILISATION

PARTICULIÈRE OUÀ L’ABSENCE DE CONTREFAÇON, SONTEXCLUES, DANSLA MESUREAUTORISÉE PARLA LOIAPPLICABLE. Saufmention

contraire expressément stipulée dansce contrat,dans lamesure autoriséepar laloi applicable,en aucuncas Oracle ou FujitsuLimited et/ou l’une ou

l’autre deleurs sociétésaffiliées ne sauraient être tenuesresponsables enversune quelconquepartie tierce,sous quelquethéorie juridiqueque cesoit, de

tout manqueà gagnerou deperte deprofit, deproblèmes d’utilisation ou de perte de données, ou d’interruptionsd’activités, oude toutdommage

indirect, spécial,secondaire ou consécutif, même si ces entités ont été préalablement informées d’une telle éventualité.

LA DOCUMENTATIONEST FOURNIE« EN L’ÉTAT » ETTOUTE AUTRECONDITION, DÉCLARATIONET GARANTIE,EXPRESSE OUTACITE,EST

FORMELLEMENT EXCLUE,DANS LAMESURE AUTORISÉEPAR LA LOIEN VIGUEUR,Y COMPRISNOTAMMENT TOUTE GARANTIE

IMPLICITE RELATIVE ÀLA QUALITÉMARCHANDE, ÀL’APTITUDEÀ UNEUTILISATIONPARTICULIÈRE OUÀ L’ABSENCE DE

CONTREFAÇON.

Page 4

Page 5

Contents

Preface xvii

1. Safety and Tools 1–1

1.1 Safety Precautions 1–1

1.2 System Precautions 1–2

1.2.1 Electrical Safety Precautions 1–2

1.2.2 Equipment Rack Safety Precautions 1–2

1.2.3 Filler Boards and Filler Panels 1–3

1.2.4 Handling Components 1–3

2. Fault Isolation 2–1

2.1 Determining Which Diagnostics Tools to Use 2–1

2.2 Checking the Server and System Configuration 2–4

2.2.1 Checking the Hardware Configuration and FRU Status 2–4

2.2.1.1 Checking the Hardware Configuration 2–5

2.2.2 Checking the Software and Firmware Configuration 2–6

2.2.2.1 Checking the Software Configuration 2–7

2.2.2.2 Checking the Firmware Configuration 2–7

2.2.3 Downloading the Error Log Information 2–8

2.3 Operator Panel 2–8

v

Page 6

2.4 Error Conditions 2–14

2.4.1 Predictive Self-Healing Tools 2–14

2.4.2 Monitoring Output 2–17

2.4.3 Messaging Output 2–17

2.5 LED Functions 2–18

2.6 Using the Diagnostic Commands 2–21

2.6.1 Using the showlogs Command 2–21

2.6.2 Using the fmdump Command 2–22

2.6.2.1 fmdump -V Command 2–22

2.6.2.2 fmdump -e Command 2–23

2.6.3 Using the fmadm faulty Command 2–23

2.6.3.1 fmadm repair Command 2–23

2.6.3.2 fmadm config Command 2–24

2.6.4 Using the fmstat Command 2–24

2.7 Traditional Oracle Solaris Diagnostic Commands 2–25

2.7.1 Using the iostat Command 2–26

2.7.1.1 Options 2–26

2.7.2 Using the prtdiag Command 2–27

2.7.2.1 Options 2–27

2.7.3 Using the prtconf Command 2–30

2.7.3.1 Options 2–30

2.7.4 Using the netstat Command 2–32

2.7.4.1 Options 2–33

2.7.5 Using the ping Command 2–34

2.7.5.1 Options 2–34

2.7.6 Using the ps Command 2–35

2.7.6.1 Options 2–35

2.7.7 Using the prstat Command 2–36

vi SPARC Enterprise M4000/M5000 Servers Service Manual • December 2010

Page 7

2.7.7.1 Options 2–36

2.8 Other Issues 2–37

2.8.1 Can’t Locate Boot Device 2–37

3. Periodic Maintenance 3–1

3.1 Tape Drive Unit 3–1

3.1.1 Cleaning the Tape Drive Unit 3–1

4. FRU Replacement Preparation 4–1

4.1 FRU Replacement Method 4–1

4.2 Active Replacement 4–4

4.2.1 Removing a FRU From a Domain 4–4

4.2.2 Removing and Replacing a FRU 4–5

4.2.3 Adding a FRU Into a Domain 4–5

4.2.4 Verifying Hardware Operation 4–6

4.3 Hot Replacement 4–6

4.3.1 Removing and Replacing a FRU 4–7

4.3.2 Verifying Hardware Operation 4–9

4.4 Cold Replacement (Powering the Server Off and On) 4–12

4.4.1 Powering the Server Off Using Software 4–12

4.4.2 Powering the Server On Using Software 4–13

4.4.3 Powering the Server Off Manually 4–14

4.4.4 Powering the Server On Manually 4–14

4.4.5 Verifying Hardware Operation 4–15

5. Internal Components Access 5–1

5.1 Sliding the Server In and Out to the Fan Stop 5–1

5.1.1 Sliding the Server Out of the Equipment Rack 5–2

5.1.2 Sliding the Server Into the Equipment Rack 5–4

5.2 Top Cover Remove and Replace 5–5

Contents vii

Page 8

5.2.1 Removing the Top Cover 5–5

5.2.2 Replacing the Top Cover 5–8

5.3 Fan Cover Remove and Replace 5–8

5.3.1 Removing the Fan Cover 5–8

5.3.2 Replacing the Fan Cover 5–10

6. Storage Devices Replacement 6–1

6.1 Hard Disk Drive Replacement 6–1

6.1.1 Accessing the Hard Disk Drive 6–4

6.1.2 Removing the Hard Disk Drive 6–4

6.1.3 Installing the Hard Disk Drive 6–5

6.1.4 Securing the Server 6–5

6.1.5 Accessing the Hard Disk Drive Backplane of the M4000 Server 6–6

6.1.6 Removing the Hard Disk Drive Backplane of the M4000 Server 6–6

6.1.7 Installing the Hard Disk Drive Backplane of the M4000 Server 6–7

6.1.8 Securing the Server 6–8

6.1.9 Accessing the Hard Disk Drive Backplane of the M5000 Server 6–9

6.1.10 Removing the Hard Disk Drive Backplane of the M5000 Server 6–

10

6.1.11 Installing the Hard Disk Drive Backplane of the M5000 Server 6–

10

6.1.12 Securing the Server 6–11

6.2 CD-RW/DVD-RW Drive Unit (DVDU) Replacement 6–12

6.2.1 Identifying the Type of CD-RW/DVD-RW Drive Unit 6–15

6.2.2 Accessing the CD-RW/DVD-RW Drive Unit 6–16

6.2.3 Removing the CD-RW/DVD-RW Drive Unit 6–16

6.2.4 Installing the CD-RW/DVD-RW Drive Unit 6–17

6.2.5 Securing the Server 6–17

6.2.6 Accessing the CD-RW/DVD-RW Drive Backplane of the M4000

Server 6–18

viii SPARC Enterprise M4000/M5000 Servers Service Manual • December 2010

Page 9

6.2.7 Removing the CD-RW/DVD-RW Drive Backplane of the M4000

Server 6–18

6.2.8 Installing the CD-RW/DVD-RW Drive Backplane of the M4000

Server 6–19

6.2.9 Securing the Server 6–19

6.2.10 Accessing the CD-RW/DVD-RW Drive Backplane of the M5000

Server 6–20

6.2.11 Removing the CD-RW/DVD-RW Drive Backplane of the M5000

Server 6–21

6.2.12 Installing the CD-RW/DVD-RW Drive Backplane of the M5000

Server 6–21

6.2.13 Securing the Server 6–22

6.3 Tape Drive Unit Replacement 6–23

6.3.1 Accessing the Tape Drive Unit 6–26

6.3.2 Removing the Tape Drive Unit 6–26

6.3.3 Installing the Tape Drive Unit 6–27

6.3.4 Securing the Server 6–27

6.3.5 Accessing the Tape Drive Backplane of the M4000 Server 6–28

6.3.6 Removing the Tape Drive Backplane of the M4000 Server 6–29

6.3.7 Installing the Tape Drive Backplane of the M4000 Server 6–29

6.3.8 Securing the Server 6–30

6.3.9 Accessing the Tape Drive Backplane of the M5000 Server 6–31

6.3.10 Removing the Tape Drive Backplane of the M5000 Server 6–32

6.3.11 Installing the Tape Drive Backplane of the M5000 Server 6–32

6.3.12 Securing the Server 6–33

7. Power Systems Replacement 7–1

7.1 Power Supply Unit Replacement 7–1

7.1.1 Accessing the Power Supply Unit 7–4

7.1.2 Removing the Power Supply Unit 7–4

7.1.3 Installing the Power Supply Unit 7–5

Contents ix

Page 10

7.1.4 Securing the Server 7–5

8. I/O Unit Replacement 8–1

8.1 PCI Cassette Replacement 8–4

8.1.1 Accessing the PCI Cassette 8–5

8.1.2 Removing the PCI Cassette 8–5

8.1.3 Installing the PCI Cassette 8–6

8.1.4 Securing the Server 8–7

8.2 PCI Card Replacement 8–7

8.2.1 Removing the PCI Card 8–7

8.2.2 Installing the PCI Card 8–8

8.3 I/O Unit Replacement 8–10

8.3.1 Accessing the I/O Unit 8–10

8.3.2 Removing the I/O Unit 8–10

8.3.3 Installing the I/O Unit 8–11

8.3.4 Securing the Server 8–12

8.4 I/O Unit DC-DC Converter Replacement 8–12

8.4.1 Accessing the I/O Unit DC-DC Converter (DDC_A#0 or

DDC_B#0) 8–14

8.4.2 Removing the I/O Unit DC-DC Converter (DDC_A #0 or DDC_B

#0) 8–14

8.4.3 Installing the I/O Unit DC-DC Converter (DDC_A #0 or DDC_B

#0) 8–17

8.4.4 Securing the Server 8–21

8.4.5 Accessing the I/O Unit DC-DC Converter Riser 8–21

8.4.6 Removing the I/O Unit DC-DC Converter Riser 8–22

8.4.7 Replacing the I/O Unit DC-DC Converter Riser 8–24

8.4.8 Securing the Server 8–24

9. XSCF Unit Replacement 9–1

x SPARC Enterprise M4000/M5000 Servers Service Manual • December 2010

Page 11

9.1 XSCF Unit Replacement 9–1

9.1.1 Accessing the XSCF Unit 9–3

9.1.2 Removing the XSCF Unit 9–4

9.1.3 Installing the XSCF Unit 9–5

9.1.4 Securing the Server 9–5

10. Fan Modules Replacement 10–1

10.1 Fan Module Replacement 10–1

10.1.1 Accessing the 60-mm Fan Module 10–4

10.1.2 Removing the 60-mm Fan Module 10–5

10.1.3 Installing the 60-mm Fan Module 10–6

10.1.4 Securing the Server 10–6

10.1.5 Accessing the 172-mm Fan Module 10–7

10.1.6 Removing the 172-mm Fan Module 10–8

10.1.7 Installing the 172-mm Fan Module 10–9

10.1.8 Securing the Server 10–9

10.1.9 Accessing the 60-mm Fan Backplane 10–10

10.1.10 Removing the 60-mm Fan Backplane 10–11

10.1.11 Installing the 60-mm Fan Backplane 10–12

10.1.12 Securing the Server 10–12

10.1.13 Accessing the SPARC Enterprise M4000 172-mm Fan Backplane

10–13

10.1.14 Removing the SPARC Enterprise M4000 172-mm Fan Backplane

10–13

10.1.15 Installing the M4000 Server 172-mm Fan Backplane 10–16

10.1.16 Securing the Server 10–16

10.1.17 Accessing the M5000 Server 172-mm Fan Backplane 10–17

10.1.18 Removing the M5000 Server 172-mm Fan Backplane 10–17

10.1.19 Installing the M5000 Server 172-mm Fan Backplane 10–20

10.1.20 Securing the Server 10–20

Contents xi

Page 12

11. Memory Board Replacement 11–1

11.1 Memory Board Replacement 11–1

11.1.1 Accessing the Memory Board 11–4

11.1.2 Removing the Memory Board 11–5

11.1.3 Installing the Memory Board 11–6

11.1.4 Securing the Server 11–6

11.2 DIMM Replacement 11–7

11.2.1 Confirmation of DIMM Information 11–8

11.2.2 Memory Installation Configuration Rules 11–9

11.2.3 Installing Memory: 11–10

11.2.4 Accessing the DIMMs 11–10

11.2.5 Removing the DIMMs 11–11

11.2.6 Installing the DIMMs 11–12

11.2.7 Securing the Server 11–12

12. CPU Module Replacement 12–1

12.1 CPU Module Replacement 12–1

12.1.1 Accessing the CPU Module 12–4

12.1.2 Removing the CPU Module 12–5

12.1.3 Installing the CPU Module 12–6

12.1.4 Securing the Server 12–6

12.2 CPU Upgrade 12–7

12.2.1 SPARC64 VII/SPARC64 VII+ CPU Modules Added to a New

Domain 12–8

▼ Adding a SPARC64 VII/SPARC64 VII+ CPU Module to a New

Domain 128

12.2.2 SPARC64 VII/SPARC64 VII+ Processors Added to an Existing

Domain 12–11

▼ Preparing to Add SPARC64VII/SPARC64 VII+ Processors to an

Existing Domain 1211

xii SPARC Enterprise M4000/M5000 Servers Service Manual • December 2010

Page 13

▼ Adding a SPARC64 VII/SPARC64 VII+ CPU Module to a Domain

Configured With

SPARC64 VI 12-13

12.2.3 Upgrading a SPARC64 VI CPU Module to SPARC64 VII/SPARC64

VII+ on an Existing Domain 12–15

13. Motherboard Unit Replacement 13–1

13.1 Motherboard Unit Replacement 13–1

13.1.1 Accessing the M4000 Server Motherboard Unit 13–4

13.1.2 Removing the M4000 Server Motherboard Unit 13–5

13.1.3 Installing the M4000 Server Motherboard Unit 13–6

13.1.4 Securing the Server 13–6

13.1.5 Accessing the M5000 Server Motherboard Unit 13–7

13.1.6 Removing the M5000 Server Motherboard Unit 13–8

13.1.7 Installing the M5000 Server Motherboard Unit 13–10

13.1.8 Securing the Server 13–11

13.2 DC-DC Converter Replacement 13–12

13.2.1 Accessing the M4000 Server DC-DC Converter 13–14

13.2.2 Removing the M4000 Server DC-DC Converter 13–15

13.2.3 Installing the M4000 Server DC-DC Converter 13–16

13.2.4 Securing the Server 13–16

13.2.5 Accessing the M5000 Server DC-DC Converter 13–17

13.2.6 Removing the M5000 Server DC-DC Converter 13–18

13.2.7 Installing the M5000 Server DC-DC Converter 13–18

13.2.8 Securing the Server 13–18

13.3 Motherboard Unit Upgrade 13–19

13.3.1 Notes on Upgrading 13–19

13.3.2 Replacing a Motherboard Unit as an Upgrade in an Existing

Domain 13–20

14. Backplane Unit Replacement 14–1

Contents xiii

Page 14

14.1 Backplane Unit Replacement 14–1

14.1.1 Accessing the M4000 Server Backplane Unit 14–3

14.1.2 Removing the M4000 Server Backplane Unit 14–5

14.1.3 Installing the M4000 Server Backplane Unit 14–7

14.1.4 Securing the Server 14–8

14.1.5 Accessing the M5000 Server Backplane Unit 14–9

14.1.6 Removing the M5000 Server Backplane Unit 14–10

14.1.7 Installing the M5000 Server Backplane Unit 14–12

14.1.8 Securing the Server 14–12

15. Operator Panel Replacement 15–1

15.1 Operator Panel Replacement 15–1

15.2 Accessing the Operator Panel 15–4

15.2.1 Removing the Operator Panel 15–4

15.2.2 Installing the Operator Panel 15–7

15.2.3 Securing the Server 15–7

A. Components List A–1

B. Rules for System Configuration B–1

B.1 Server Configuration B–1

C. FRU List C–1

C.1 Server Overview C–1

C.2 System Boards C–3

C.2.1 Motherboard Unit C–3

C.2.2 CPU Module C–4

C.2.3 Memory Board C–5

C.3 Backplane Unit C–6

C.4 I/O Unit C–6

xiv SPARC Enterprise M4000/M5000 Servers Service Manual • December 2010

Page 15

C.5 Power C–7

C.6 FAN Module C–8

C.7 eXtended System Control Facility Unit C–9

C.8 Drives C–10

C.8.1 Hard Disk Drive C–10

C.8.2 CD-RW/DVD-RW Drive Unit (DVDU) C–11

C.8.3 Tape Drive Unit (TAPEU) C–11

D. External Interface Specifications D–1

D.1 Serial Port D–2

D.2 UPC (UPS Control) Port D–3

D.3 USB Port D–3

D.4 Connection Diagram for Serial Cable D–4

E. UPS Controller E–1

E.1 Overview E–1

E.2 Signal Cables E–1

E.3 Signal Line Configuration E–2

E.4 Power Supply Conditions E–3

E.4.1 Input circuit E–3

E.4.2 Output circuit E–4

E.5 UPS Cable E–4

E.6 UPC Connector E–5

F. Air Filters F–1

F.1 M4000 and M5000 Servers Air Filter F–2

F.1.1 Command Operations Procedures F–2

F.2 Air Filter Installation for the M4000 Server F–3

F.2.1 Removing the Air Filter From the M4000 Server F–8

F.3 Air Filter Installation for the M5000 Server F–9

Contents xv

Page 16

F.3.1 Removing the Air Filter from the M5000 Server F–13

F.3.2 Servicing the Air Filter F–14

G. Abbreviations G–1

Index Index–1

xvi SPARC Enterprise M4000/M5000 Servers Service Manual • December 2010

Page 17

Preface

This service manual describes how to service the SPARC Enterprise M4000/M5000

servers from Oracle and Fujitsu. This document is intended for authorized service

providers. References herein to the M4000 server or M5000 server are references to

the SPARC Enterprise M4000 or SPARC Enterprise M5000 server.

This document is written for maintenance providers who have received formal

service training. A single engineer service model is used for servicing SPARC

Enterprise M4000/M5000 midrange servers with one exception: When the

motherboard of a SPARC Enterprise M5000 server must be removed and that server

is mounted above waist high in the rack, then two engineers or a platform must be

used for safety.

This section explains:

■ “SPARC Enterprise M4000/M5000 Servers Documentation” on page xviii

■ “Text Conventions” on page xix

■ “Notes on Safety” on page xx

■ “Documentation Feedback” on page xx

xvii

Page 18

SPARC Enterprise M4000/M5000

Servers Documentation

For the web location of all SPARC Enterprise M4000/M5000 servers documents, refer

to the SPARC Enterprise M4000/M5000 Servers Getting Started Guide packaged with

your server.

Product notes are available on the website only. Please check for the most recent

update for your product.

Note – For Sun Oracle software-related manuals (Oracle Solaris OS, and so on), go

to: http://docs.sun.com

Book Titles Sun/Oracle Fujitsu

SPARC Enterprise M4000/M5000 Servers Site Planning Guide 819-2205 C120-H015

SPARC Enterprise Equipment Rack Mounting Guide 819-5367 C120-H016

SPARC Enterprise M4000/M5000 Servers Getting Started Guide

SPARC Enterprise M4000/M5000 Servers Overview Guide 819-2204 C120-E346

SPARC Enterprise M3000/M4000/M5000/M8000/M9000 Servers Important

Legal and Safety Information

SPARC Enterprise M4000/M5000 Servers Safety and Compliance Manual 819-2203 C120-E348

External I/O Expansion Unit Safety and Compliance Guide 819-1143 C120-E457

SPARC Enterprise M4000 Server Unpacking Guide 821-3043 C120-E349

SPARC Enterprise M5000 Server Unpacking Guide 821-3044 C120-E350

SPARC Enterprise M4000/M5000 Servers Installation Guide 819-2211 C120-E351

SPARC Enterprise M4000/M5000 Servers Service Manual 819-2210 C120-E352

External I/O Expansion Unit Installation and Service Manual 819-1141 C120-E329

SPARC Enterprise M/3000/4000/M5000/M8000/M9000 Servers

Administration Guide

*

821-3045 C120-E345

821-2098 C120-E633

821-2794 C120-E331

SPARC Enterprise M/3000/4000/M5000/M8000/M9000 Servers XSCF User’s

Guide

SPARC Enterprise M3000/4000/M5000/M8000/M9000 Servers XSCF

Reference Manual

xviii SPARC Enterprise M4000/M5000 Servers Service Manual • December 2010

821-2797 C120-E332

Varies per release Varies per release

Page 19

Book Titles Sun/Oracle Fujitsu

SPARC Enterprise M4000/M5000/M8000/M9000 Servers Dynamic

Reconfiguration (DR) User ’s Guide

SPARC Enterprise M4000/M5000/M8000/M9000 Servers Capacity on

Demand (COD) User’s Guide

SPARC Enterprise M3000/M4000/M5000/M8000/M9000 Servers Product

†

Notes

SPARC Enterprise M4000/M5000 Servers Product Notes Varies per release Varies per release

External I/O Expansion Unit Product Notes 819-5324 C120-E456

SPARC Enterprise M3000/M4000/M5000/M8000/M9000 Servers Glossary 821-2800 C120-E514

* All getting started guides are printed documents.

† For XCP version 1100 or later

821-2796 C120-E335

821-2795 C120-E336

Varies per release Varies per release

Text Conventions

This manual uses the following fonts and symbols to express specific types of

information.

Fonts/symbols Meaning Example

AaBbCc123 What you type, when contrasted

with on-screen computer output.

This font represents the example of

command input in the frame.

AaBbCc123 The names of commands, files, and

directories; on-screen computer

output.

This font represents the example of

command input in the frame.

Italic Indicates the name of a reference

manual

" " Indicates names of chapters,

sections, items, buttons, or menus

XSCF> adduser jsmith

XSCF> showuser -P

User Name: jsmith

Privileges: useradm

auditadm

See the SPARC Enterprise

M/3000/4000/M5000/M8000/M900

0 Servers XSCF User’s Guide.

See Chapter 2, "System Features."

Preface xix

Page 20

Notes on Safety

Read the following documents thoroughly before using or handling any SPARC

Enterprise M4000/M5000 server.

■ SPARC Enterprise M3000/M4000/M5000/M8000/M9000 Servers Important Legal and

Safety Information

■ SPARC Enterprise M4000/M5000 Servers Safety and Compliance Guide

Documentation Feedback

If you have any comments or requests regarding this document, go to the following

web sites.

■ For Oracle users:

http://docs.sun.com

■ For Fujitsu users in U.S.A., Canada, and Mexico:

http://www.computers.us.fujitsu.com/www/support_servers.shtml?s

upport/servers

■ For Fujitsu users in other countries, refer to this SPARC Enterprise contact:

http://www.fujitsu.com/global/contact/computing/sparce_index.html

xx SPARC Enterprise M4000/M5000 Servers Service Manual • December 2010

Page 21

CHAPTER

1

Safety and Tools

This chapter describes safety and tools information. The information is organized

into the following topics:

■ Section 1.1, “Safety Precautions” on page 1-1

■ Section 1.2, “System Precautions” on page 1-2

1.1 Safety Precautions

To protect both yourself and the equipment, observe the following safety

precautions.

TABLE 1-1 ESD Precautions

Item Problem Precaution

ESD

jack/wrist or

foot strap

ESD mat ESD An approved ESD mat provides protection from static damage when used

ESD

packaging

box

Electrostatic

Discharge (ESD)

ESD Place the board or component in the ESD safe packaging box after you

Connect the ESD connector to your server and wear the wrist strap or foot

strap when handling printed circuit boards. There are two antistatic strap

attachment points on the chassis:

1. Right side towards the front

2. Left side towards the rear

with a wrist strap or foot strap. The mat also cushions and protects small

parts that are attached to printed circuit boards.

remove it.

1-1

Page 22

Caution – Attach the cord of the antistatic wrist strap directly to the server. Do not

attach the antistatic wrist strap to the ESD mat connection.

The antistatic wrist strap and any components you remove must be at the same

potential.

1.2 System Precautions

For your protection, observe the following safety precautions when servicing your

equipment:

■ Follow all cautions, warnings, and instructions marked on the equipment.

■ Never push objects of any kind through openings in the equipment, as they might

touch dangerous voltage points or short out components that could result in fire

or electric shock.

■ Refer servicing of equipment to qualified personnel.

1.2.1 Electrical Safety Precautions

Ensure that the voltage and frequency of the power outlet to be used match the

electrical rating labels on the equipment.

Wear antistatic wrist straps when handling any magnetic storage devices,

system boards, or other printed circuit boards.

Use only properly grounded power outlets as described in the SPARC Enterprise

M4000/M5000 Servers Installation Guide.

Caution – Do not make mechanical or electrical modifications. The manufacturer is

not responsible for regulatory compliance of modified servers.

1.2.2 Equipment Rack Safety Precautions

All equipment racks should be anchored to the floor, ceiling, or to adjacent frames,

using the manufacturer’s instructions.

1-2 SPARC Enterprise M4000/M5000 Servers Service Manual • December 2010

Page 23

Free-standing equipment racks should be supplied with a stabilizer feature, which

must be sufficient to support the weight of the server when extended on its slides.

This prevents instability during installation or service actions.

Where a stabilizer feature is not supplied and the equipment rack is not bolted to the

floor, a safety evaluation must be conducted by the installation or service engineer.

The safety evaluation determines stability when the server is extended on its slides,

prior to any installation or service activity.

Prior to installing the equipment rack on a raised floor, a safety evaluation must be

conducted by the installation or service engineer. The safety evaluation ensures that

the raised floor has sufficient strength to withstand the forces upon it when the

server is extended on its slides. The normal procedure in this case would be to fix the

rack through the raised floor to the concrete floor below, using a proprietary

mounting kit for the purpose.

Caution – If more than one server is installed in an equipment rack, service only one

server at a time.

1.2.3 Filler Boards and Filler Panels

Filler boards and panels, which are physically inserted into the server when a board

or module has been removed are used for EMI protection and for air flow.

1.2.4 Handling Components

Caution – There is a separate ground located on the rear of the server. It is

important to ensure that the server is properly grounded.

Caution – The server is sensitive to static electricity. To prevent damage to the

board, connect an antistatic wrist strap between you and the server.

Caution – The boards have surface-mount components that can be broken by flexing

the boards.

To minimize the amount of board flexing, observe the following precautions:

Chapter 1 Safety and Tools 1-3

Page 24

■ Hold the board by the handle and finger hold panels, where the board stiffener is

located. Do not hold the board at the ends.

■ When removing the board from the packaging, keep the board vertical until you

lay it on the cushioned ESD mat.

■ Do not place the board on a hard surface. Use a cushioned antistatic mat. The

board connectors and components have very thin pins that bend easily.

■ Be careful of small component parts located on both sides of the board.

■ Do not use an oscilloscope probe on the components. The soldered pins are easily

damaged or shorted by the probe point.

■ Transport the board in its packaging box.

Caution – The heat sinks can be damaged by incorrect handling. Do not touch the

heat sinks while replacing or removing boards. If a heat sink is loose or broken,

obtain a replacement board. When storing or shipping a board, ensure that the heat

sinks have sufficient protection.

Caution – On the PCI cassette, when removing cables such as LAN cable, if your

finger can’t reach the latch lock of the connector, press the latch with a flathead

screwdriver to remove the cable. Forcing your finger into the clearance can cause

damage to the PCI card.

1-4 SPARC Enterprise M4000/M5000 Servers Service Manual • December 2010

Page 25

CHAPTER

2

Fault Isolation

This chapter describes overview and fault diagnosis information. The information is

organized into the following topics:

■ Section 2.1, “Determining Which Diagnostics Tools to Use” on page 2-1

■ Section 2.2, “Checking the Server and System Configuration” on page 2-4

■ Section 2.3, “Operator Panel” on page 2-8

■ Section 2.4, “Error Conditions” on page 2-14

■ Section 2.5, “LED Functions” on page 2-18

■ Section 2.6, “Using the Diagnostic Commands” on page 2-21

■ Section 2.7, “Traditional Oracle Solaris Diagnostic Commands” on page 2-25

■ Section 2.8, “Other Issues” on page 2-37

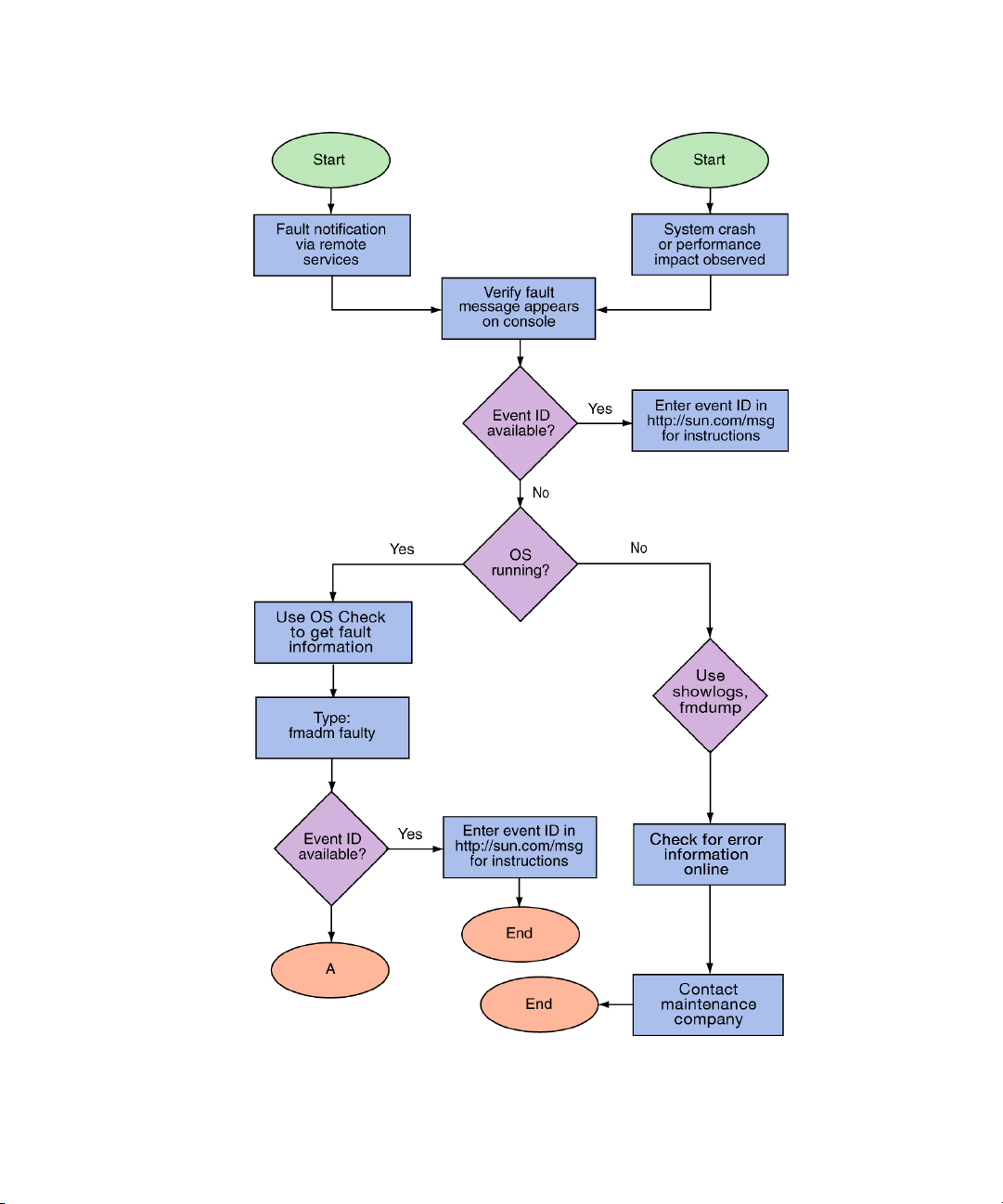

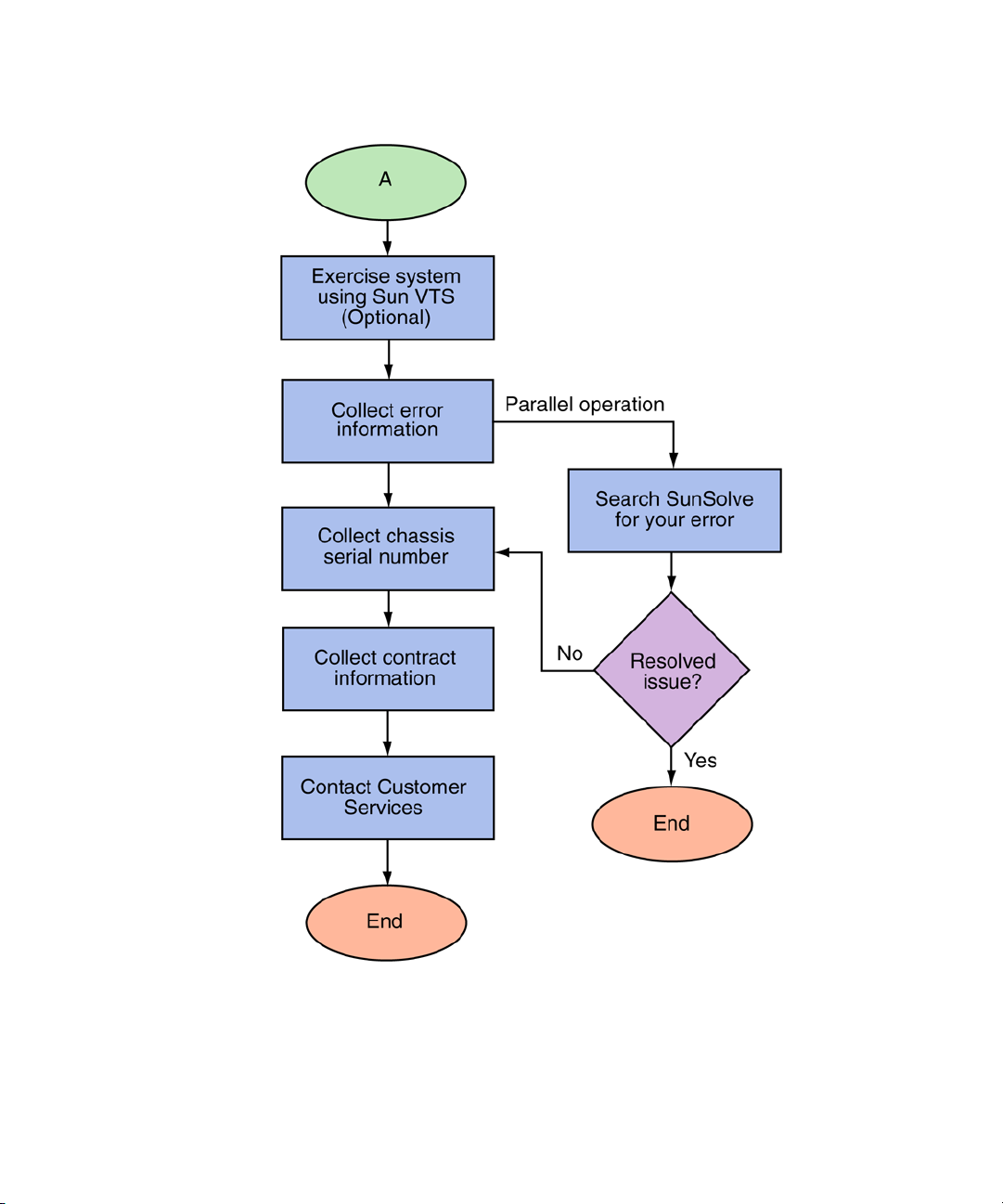

2.1 Determining Which Diagnostics Tools to Use

When a failure occurs, a message is often displayed on the monitor. Use the

flowcharts in

problems.

FIGURE 2-1 and FIGURE 2-2 to find the correct methods for diagnosing

2-1

Page 26

FIGURE 2-1 Diagnostic Method Flow Chart

No

2-2 SPARC Enterprise M4000/M5000 Servers Service Manual • December 2010

Page 27

FIGURE 2-2 Diagnostic Method Flow Chart—Traditional Data Collection

Chapter 2 Fault Isolation 2-3

Page 28

2.2 Checking the Server and System Configuration

Before and after maintenance work, the state and configuration of the server and

components should be checked and the information saved. For recovery from a

problem, conditions related to the problem and the repair status must be checked.

The operating conditions must remain the same before and after maintenance.

A functioning

For example:

■ The syslog file should not display error messages.

■ The XSCF Shell command showhardconf does not display the * mark.

■ The administrative console should not display error messages.

■ The server processor logs should not display any error messages.

■ The Oracle Solaris Operating System message files should not indicate any

additional errors.

server without any problems should not display any error conditions.

2.2.1 Checking the Hardware Configuration and FRU Status

To replace a faulty component and perform the maintenance on the server it is

important to check and understand the hardware configuration of the server and the

state of each hardware component.

The hardware configuration refers to information that indicates to which layer a

component belongs in the hardware configuration.

The status of each hardware component refers to information on the condition of the

standard or optional component in the server: temperature, power supply voltage,

CPU operating conditions, and other times.

2-4 SPARC Enterprise M4000/M5000 Servers Service Manual • December 2010

Page 29

The hardware configuration and the status of each hardware component can be

checked from the maintenance terminal using eXtended System Control Facility

(XSCF) Shell commands, as shown in the following table.

TABLE 2-1 Commands for Checking Hardware Configuration

Command Description

showhardconf Displays hardware configuration.

showstatus Displays the status of a component. This command is used when

only a faulty component is checked.

showboards Displays the status of devices and resources.

showdcl Displays the hardware resource configuration information of a

domain.

showfru Displays the setting information of a device.

Also some conditions can be checked based on the On or blinking state of the

component LEDs (see

TABLE 2-3).

2.2.1.1 Checking the Hardware Configuration

Login authority is required to check the hardware configuration. The following

procedure for these checks can be made from the maintenance terminal:

1. Log in with the account of the XSCF hardware maintenance engineer.

2. Type showhardconf.

XSCF> showhardconf

The showhardconf command prints the hardware configuration information to

the screen. See the SPARC Enterprise M3000/M4000/M5000/M8000/M9000 Servers

XSCF User ’s Guide for more detailed information.

Chapter 2 Fault Isolation 2-5

Page 30

2.2.2 Checking the Software and Firmware Configuration

The software and firmware configurations and versions affect the operation of the

server. To change the configuration or investigate a problem, check the latest

information and check for any problems in the software.

Software and firmware varies according to users:

■ The software configuration and version can be checked in the Oracle Solaris OS.

Refer to the Solaris 10 documentation for more information.

■ The firmware configuration and versions can be checked from the maintenance

terminal using XSCF Shell commands. Refer to the SPARC Enterprise

M3000/M4000/M5000/M8000/M9000 Servers XSCF User’s Guide for more detailed

information.

Check the software and firmware configuration information with assistance from the

system administrator. However, if you have received login authority from the system

administrator, the commands shown in the table can be used from the maintenance

terminal for these checks.

TABLE 2-2 Commands for Checking Software and Firmware Configuration

Command Description

showrev(1M) System administration command that displays information system

patches.

uname(1) System administration command that outputs the current system

information.

version(8) XSCF Shell command that outputs the current firmware version

information.

showhardconf(8) XSCF Shell command that indicates information on components

mounted on the server.

showstatus(8) XSCF Shell command that displays the status of a component. This

command is used when only a faulty component is to be checked.

2-6 SPARC Enterprise M4000/M5000 Servers Service Manual • December 2010

Page 31

TABLE 2-2 Commands for Checking Software and Firmware Configuration (Continued)

Command Description

showboards(8) XSCF Shell command that indicates information on eXtended system

board (XSB). It can indicate information on XSB that belongs to the

specified domain and information on all XSBs mounted. The

eXtended System Board (XSB) combines the hardware resources of a

physical system board. The SPARC Enterprise servers can generate

one (Uni-XSB) or four (Quad-XSB) XSB(s) from one physical system

board.

showdcl(8) XSCF Shell command that displays the configuration information of a

domain (hardware resource information).

showfru(8) XSCF Shell command that displays the setting information of a

device.

2.2.2.1 Checking the Software Configuration

The following procedure for these checks can be made from the domain console:

1. Type showrev.

# showrev

The showrev command prints the system configuration information to the

screen.

2.2.2.2 Checking the Firmware Configuration

Login authority is required to check the firmware configuration. The following

procedure for these checks can be made from the maintenance terminal:

1. Log in with the account of the XSCF hardware maintenance engineer.

2. Type version(8).

XSCF> version(8)

The version(8) command prints the firmware version information to the

screen. See the SPARC Enterprise M3000/M4000/M5000/M8000/M9000 Servers XSCF

User’s Guide for more detailed information.

Chapter 2 Fault Isolation 2-7

Page 32

2.2.3 Downloading the Error Log Information

If you want to download the error log information, use the XSCF log fetch function.

The eXtended System Control facility unit (XSCFU) has an interface with external

units so that a maintenance engineer can easily obtain useful maintenance

information such as error logs

Connect the maintenance terminal, and use the command-line interface (CLI) or

browser user interface (BUI) to issue a download instruction to the maintenance

terminal to download Error Log information over the XSCF-LAN.

2.3 Operator Panel

When no network connection is available the operator panel is used to start or stop

the server. The operator panel displays three LED status indicators, a Power switch,

and a security keyswitch. The panel is located on the front of the server, in the upper

right.

When the server is running, the Power and XSCF STANDBY LEDs (green) should be

lit and the CHECK LED (amber) should not be lit. If the CHECK LED is lit, search

the system logs to determine what is wrong.

The three LED status indicators on the operator panel provide the following:

■ General system status

■ System problem alerts

■ Location of the system fault

FIGURE 2-3 and FIGURE 2-4 show the operator panel.

2-8 SPARC Enterprise M4000/M5000 Servers Service Manual • December 2010

Page 33

FIGURE 2-3 M4000 Server Operator Panel

Location Number Component

1 POWER LED

2 XSCF STANDBY LED

3 CHECK LED

4 Power switch

5 Mode switch (keyswitch)

6 Antistatic ground socket

1

2

3

4

5

6

l

Chapter 2 Fault Isolation 2-9

Page 34

FIGURE 2-4 M5000 Server Operator Panel

Location Number Component

1 POWER LED

2 XSCF STANDBY LED

3 CHECK LED

4 Power switch

5 Mode switch (keyswitch)

6 Antistatic ground socket

1

2

3

4

5

6

Additional LEDs are located in various locations in the server. For more information

about LED indicator locations, see Section 2.5, “LED Functions” on page 2-18.

2-10 SPARC Enterprise M4000/M5000 Servers Service Manual • December 2010

Page 35

The Operator panel LEDs operate as described in TABLE 2-3.

TABLE 2-3 Operator Panel LEDs and Switches

Icon Name Color Description

POWER LED Green Indicates the server power status.

• On: Server has power.

• Off: Server is without power.

• Blinking: The power-off sequence is in progress.

XSCF

STANDBY

LED

Green Indicates the readiness of the XSCF.

• On: XSCF unit is functioning normally.

• Off: XSCF unit is stopped.

• Blinking: Under system initialization after server

power-on, or under system power-on process.

Indicates that server detected a fault.

CHECK LED Amber

• On: Error detected that disables the startup.

• Off: Normal, or server power-off (power failure).

• Blinking: Indicates the position of fault.

Power switch Switch to direct server power on/power off.

The Locked setting:

• Normal key position. Power on is available with the

Mode switch

(keyswitch)

Power switch, but power off is not.

• Disables the Power switch to prevent unauthorized

users from powering the server on or off.

• The Locked position is the recommended setting for

normal day-to-day operations.

The Service setting:

• Service should be provided at this position.

• Power on and off is available with Power switch.

• The key cannot be pulled out at this position.

Chapter 2 Fault Isolation 2-11

Page 36

The state displayed by LED combination is described in TABLE 2-4.

TABLE 2-4 State Display by LED Combination (Operator Panel)

LED

XSCF

STANDBY CHECK

Off Off Off The circuit breaker is switched off.

Off Off On The circuit breaker is switched on.

Off Blinking Off The XSCF is being initialized.

Off Blinking On An error occurred in the XSCF.

Off On Off The XSCF is on standby.

On On Off Warm-up standby processing is in progress

Blinking On Off The power-off sequence is in progress.

Description of the statePOWER

The system is waiting for power-on of the air

conditioning system.

(power-on is delayed).

The power-on sequence is in progress.

The system is in operation.

Fan termination is being delayed.

2-12 SPARC Enterprise M4000/M5000 Servers Service Manual • December 2010

Page 37

The operator panel mode switch is used to set the operation mode. The operator panel

power switch is used to power on and off the server.

TABLE 2-6 lists the settings and

corresponding functions of the mode switch on the operator panel.

TABLE 2-5 Switches (Operator Panel)

Name Description of Function

Mode switch Used to set an operation mode for the server. Insert the special key that is under the

customer’s control, to switch between modes.

Locked Normal operation mode.

The system can be powered on with the power switch, but it

cannot be powered off with the power switch.

The key can be pulled out at this key position.

Service Mode for maintenance.

The system can only be powered on and off with the power

switch.

The key cannot be pulled out at this key position.

Maintenance is performed in Service mode while the server

is stopped.

Because remote power control and automatic power control

of the server are disabled in Service mode, unintentional

power on can be prevented.

Power switch Used to control the server power. Power on and power off are controlled by pressing this

switch in different patterns, as described below.

Holding down for a short time

(less than 4 seconds)

Regardless of the mode switch state, the server (all domains)

is powered on.

At this time, processing for waiting for facility (air

conditioners) power on and warm-up completion is skipped.

Holding down for a long time

in Service mode

(4 seconds or longer)

If power to the server is on (at least one domain is

operating), shutdown processing is executed for all domains

before the system is powered off.

If the system is being powered on, the power-on processing

is cancelled, and the system is powered off.

If the system is being powered off, the operation of the

Power switch is ignored, and the power-off processing is

continued.

Chapter 2 Fault Isolation 2-13

Page 38

TABLE 2-6 Meanings of the Mode Switch

Function Mode Switch

State Definition Locked Service

Inhibition of Break Signal Reception Enabled. Reception of the

break signal can be enabled or

disabled for each domain

using setdomainmode.

Power On/Off by power switch Only power on is enabled Enabled

Disabled

2.4 Error Conditions

Always access the following web site first to interpret faults and obtain information

on FMA messages.

http://www.sun.com/msg

This web site can be used in the event of an Oracle Solaris or domain failure or to

look up specific FMA error messages it will not provide details on XSCF errors.

The web site directs you to provide the message ID that your software displayed. The

web site then provides knowledge articles about the fault and corrective action to

resolve the fault. The fault information and documentation at this web site is

updated regularly.

Predictive self-healing is an architecture and methodology for automatically

diagnosing, reporting, and handling software and hardware fault conditions. This

new technology lessens the time required to debug a hardware or software problem

and provides the administrator and technical support with detailed data about each

fault.

2.4.1 Predictive Self-Healing Tools

In the Solaris 10 software, the fault manager runs in the background. If a failure

occurs, the system software recognizes the error and attempts to determine what

hardware is faulty. The software also takes steps to prevent that component from

being used until it has been replaced. Some of the specific actions the software takes

include:

■ Receives telemetry information about problems detected by the system software.

2-14 SPARC Enterprise M4000/M5000 Servers Service Manual • December 2010

Page 39

■ Diagnoses the problems.

■ Initiates pro-active self-healing activities. For example, the fault manager can

disable faulty components.

■ When possible, causes the faulty FRU to provide an LED indication of a fault in

addition to populating the system console messages with more details.

TABLE 2-7 shows a typical message generated when a fault occurs. The message

appears on your console and is recorded in the /var/adm/messages file.

Note – The message in TABLE 2-7 indicates that the fault has already been diagnosed.

Any corrective action that the system can perform has already taken place. If your

server is still running, it continues to run.

Chapter 2 Fault Isolation 2-15

Page 40

TABLE 2-7 Predictive Self-Healing Message

Output Displayed Description

Nov 1 16:30:20 dt88-292 EVENT-TIME: Tue Nov 1 16:30:20

PST 2005

Nov 1 16:30:20 dt88-292 PLATFORM: SUNW,A70, CSN: -,

HOSTNAME: dt88-292

EVENT-TIME: the time stamp of

the diagnosis.

PLATFORM: A description of the

server encountering the problem.

Nov 1 16:30:20 dt88-292 SOURCE: eft, REV: 1.13 SOURCE: Information on the

Diagnosis Engine used to

determine the fault.

Nov 1 16:30:20 dt88-292 EVENT-ID:

afc7e660-d609-4b2f-86b8-ae7c6b8d50c4

Nov 1 16:30:20 dt88-292 DESC:

Nov 1 16:30:20 dt88-292 A problem was detected in the

EVENT-ID: The Universally

Unique event ID for this fault.

DESC: A basic description of the

failure.

PCI-Express subsystem

Nov 1 16:30:20 dt88-292 Refer to

http://sun.com/msg/SUN4-8000-0Y for more information.

WEB SITE: Where to find specific

information and actions for this

fault.

Nov 1 16:30:20 dt88-292 AUTO-RESPONSE: One or more

device instances may be disabled.

AUTO-RESPONSE: What, if

anything, the system did to

alleviate any follow-on issues.

Nov 1 16:30:20 dt88-292 IMPACT: Loss of services

provided by the device instances associated with this

IMPACT: A description of what

that response might have done.

fault.

Nov 1 16:30:20 dt88-292 REC-ACTION: Schedule a repair

procedure to replace the affected device. Use Nov 1

16:30:20 dt88-292 fmdump -v -u EVENT_ID to identify the

REC-ACTION: A short description

of what the system administrator

should do.

device or contact Sun for support.

2-16 SPARC Enterprise M4000/M5000 Servers Service Manual • December 2010

Page 41

2.4.2 Monitoring Output

To understand error conditions, collect the monitoring output information. For the

collection of the information, use the commands shown in

TABLE 2-8 Commands for Checking the Monitoring Output

Command Operand Description

showlogs(8) console Displays console of Domain.

monitor Logs messages that are displayed in the message window.

panic Logs output to the console during a panic.

ipl Collects console data generated during the period of the

power on of a domain to the completion of the operating

system start.

2.4.3 Messaging Output

To understand error conditions, collect messaging output information, use the

commands shown in

TABLE 2-9 Commands for Checking the Messaging Output

TABLE 2-9.

TABLE 2-8.

Command Operand Description

showlogs env Displays the temperature history log. The environmental

temperature data and power status are indicated in 10-minute

intervals. the data is stored for a maximum of six months.

power Displays the power and reset information.

event Displays information reported to the operating system and

stored as event logs.

error Displays error logs.

fmdump(1M)

fmdump(8)

Displays fault management architecture diagnostic results and

errors. It is provided as an Oracle Solaris command and XSCF

Shell command.

Each error message logged by the predictive self-healing architecture has a code

associated with it as well as a web address that can be followed to get the most

up-to-date course of action for dealing with that error.

Refer to the Oracle Solaris 10 documentation for more information on predictive

self-healing.

Chapter 2 Fault Isolation 2-17

Page 42

2.5 LED Functions

LED lights help the user find the component and provide information on the state of

the component.

This section explains the LEDs of each component that are to be checked when a

component is replaced. Most components are equipped with LEDs that help indicate

which component has the error and an LED to indicate whether the component can

be removed.

Some components, such as DIMMs, do not have LEDs. The state of a component

without LEDs can be checked using the showhardconf and ioxadm XSCF Shell

commands from the maintenance terminal. See the SPARC Enterprise

M3000/M4000/M5000/M8000/M9000 Servers XSCF User’s Guide for more detailed

information.

TABLE 2-10 describes the LEDs and their functions.

TABLE 2-10 Component LEDs

LED Name Display and Meaning

READY (green) Indicates whether the component is operating.

On Indicates that the component is operating. The component

cannot be disconnected and removed from the server while

the READY LED is On.

Blinking Indicates that the component is being configured (or

disconnected).

For an XSCF unit it indicates that it is being initialized.

Off Indicates that the component is stopped. The component can

be disconnected and replaced.

CHECK

(amber)

Indicates that the component contains an error or that the component is a

target for replacement.

On Indicates that an error has been detected.

Blinking Indicates that the component is ready to be replaced. The

blinking LED acts as a locator.

Off Indicates no known error exists.

2-18 SPARC Enterprise M4000/M5000 Servers Service Manual • December 2010

Page 43

TABLE 2-11 describes the components and their LEDs.

TABLE 2-11 Component LED Descriptions

Component LED Type LED Display Meaning

XSCF unit ACTIVE On (green) Indicates that the XSCF unit is active.

Off Indicates that the XSCF unit is on standby.

XSCF unit and IO

(display part for

LAN)

ACTIVE On (green) Indicates that the communication is being

performed through the LAN port.

Off Indicates that no communication is being

performed through the LAN port.

LINK SPEED On (amber) Indicates that the communication speed for the

LAN port is 1G bps.

On (green) Indicates that the communication speed for the

LAN port is 100M bps.

Off Indicates that the communication speed for the

LAN port is 10M bps.

PCI slot POWER On (green) Indicates that the power to the PCI slot is turned

on. The PCI card cannot be removed.

Off Indicates that the power to the PCI slot is turned

off. The PCI card can be removed.

ATTENTION On (amber) Indicates that an error occurred in the PCI slot.

Blinking (amber) Indicates that the card in this PCI slot is a target

device for replacement.

Off Indicates the normal state of the PCI slot.

Chapter 2 Fault Isolation 2-19

Page 44

TABLE 2-11 Component LED Descriptions (Continued)

Component LED Type LED Display Meaning

Power supply unit

(PSU)

READY On (green) Indicates that the power is turned on and being

supplied.

Blinking (green) Indicates that the power is being supplied to the

power supply unit, but the power supply unit is

not turned on.

Off Indicates that power is not being supplied to the

power supply unit.

CHECK On (amber) Indicates that an error occurred in the power

supply unit.

Off Indicates the normal state of the power supply

unit.

LED_AC On (green) Power supply unit has AC applied and is

supplying 12V.

Off Indicates that AC is out of the specified

operating range and 12V is not being supplied

from the power supply unit.

LED_DC On (green) Power supply unit has AC applied and is

supplying 48V. Standby pinhole provides a

manual backup to turn off 48V power.

Off Indicates that 48V is not being supplied from

the power supply unit.

Fan ATTENTION On (amber) Indicates that an error occurred.

Blinking (amber) Indicates that the fan is a target device for

replacement.

2-20 SPARC Enterprise M4000/M5000 Servers Service Manual • December 2010

Page 45

2.6 Using the Diagnostic Commands

After the message in TABLE 2-7 is displayed, you might desire more information about

the fault. For complete information about troubleshooting commands, refer to the

Oracle Solaris 10 man pages or the XSCF Shell man pages. This section describes

some details of the following commands:

■ showlogs

■ fmdump

■ fmadm

■ fmstat

2.6.1 Using the showlogs Command

The showlogs command displays the contents of a specified log in order of time

stamp starting with the oldest date. The showlogs command displays the following

logs:

■ error log

■ power log

■ event log

■ temperature and humidity record

■ monitoring message log

■ console message log

■ panic message log

■ IPL message log

An example of the showlogs output.

XSCF> showlogs error

Date: Oct 03 17:23:11 UTC 2006 Code: 80002000-ccff0000-0104340100000000

Status: Alarm Occurred: Oct 03 17:23:10.868 UTC 2006

FRU: /FAN_A#0

Msg: Abnormal FAN rotation speed. Insufficient rotation

XSCF>

Chapter 2 Fault Isolation 2-21

Page 46

2.6.2 Using the fmdump Command

The fmdump command can be used to display the contents of any log files associated

with the Oracle Solaris fault manager.

The fmdump command produces output similar to

EXAMPLE 2-1. This example

assumes there is only one fault.

EXAMPLE 2-1 fmdump Output

# fmdump

TIME UUID SUNW-MSG-ID

Nov 02 10:04:15.4911 0ee65618-2218-4997-c0dc-b5c410ed8ec2 SUN4-8000-0Y

2.6.2.1 fmdump -V Command

You can obtain more detail by using the -V option.

# fmdump -V -u 0ee65618-2218-4997-c0dc-b5c410ed8ec2

TIME UUID SUNW-MSG-ID

Nov 02 10:04:15.4911 0ee65618-2218-4997-c0dc-b5c410ed8ec2 SUN4-8000-0Y

100% fault.io.fire.asic

FRU: hc://product-id=SUNW,A70/motherboard=0

rsrc: hc:///motherboard=0/hostbridge=0/pciexrc=0

At least three lines of new output are delivered to the user with the -V option.

■ The first line is a summary of information you have seen before in the console

message but includes the time stamp, the UUID and the Message-ID.

■ The second line is a declaration of the certainty of the diagnosis. In this case we

are 100 percent sure the failure is in the ASIC described. If the diagnosis might

involve multiple components you might see two lines here with 50% in each (for

example)

■ The FRU line declares the part that needs to be replaced to return the server to a

fully operational state.

■ The rsrc line describes which component was taken out of service as a result of

this fault.

2-22 SPARC Enterprise M4000/M5000 Servers Service Manual • December 2010

Page 47

2.6.2.2 fmdump -e Command

To get information of the errors that caused this failure you can use the -e option, as

shown in the following example.

XSCF> fmdump -e

TIME CLASS

Oct 03 13:52:48.9532 ereport.fm.fmd.module

Oct 03 13:52:48.9610 ereport.fm.fmd.module

Oct 03 13:52:48.9674 ereport.fm.fmd.module

Oct 03 13:52:48.9738 ereport.fm.fmd.module

2.6.3 Using the fmadm faulty Command

The fmadm faulty command can be used by administrators and service personnel

to view and modify system configuration parameters that are maintained by the

Oracle Solaris fault manager. The command is primarily used to determine the status

of a component involved in a fault, as shown in the following example.

# fmadm faulty

STATERESOURCE / UUID

-------- -------------------------------------------------------degraded dev:////pci@1e,600000

0ee65618-2218-4997-c0dc-b5c410ed8ec2

# fmadm repair

0ee65618-2218-4997-c0dc-b5c410ed8ec2

The PCI device is degraded and is associated with the same UUID as seen above. You

might also see “faulted” states.

2.6.3.1 fmadm repair Command

If fmadm faulty occurs, the faulty FRU (CPU, memory, or I/O unit) is replaced,

and then the fmadm repair command needs to be executed to clear FRU

information on the domain. If the fmadam repair command is not executed, error

messages continue to be output.

Chapter 2 Fault Isolation 2-23

Page 48

If fmadm faulty occurs, the FMA resource cache on the OS side can be cleared

without problems; the data in it need not match the hardware failure information

retained on the XSCF side.

# fmadm repair

STATERESOURCE / UUID

-------- -------------------------------------------------------degraded dev:////pci@1e,600000

0ee65618-2218-4997-c0dc-b5c410ed8ec2

2.6.3.2 fmadm config Command

The fmadm config command output shows you the version numbers of the

diagnosis engines in use by your server, as well as their current state. You can check

these versions against information on the My Oracle Support web site to determine if

you are running the latest diagnostic engines, as shown in the following example.

XSCF> fmadm config

MODULE VERSION STATUS DESCRIPTION

eft 1.16 active eft diagnosis engine

event-transport 2.0 active Event Transport Module

faultevent-post 1.0 active Gate Reaction Agent for errhandd

fmd-self-diagnosis 1.0 active Fault Manager Self-Diagnosis

iox_agent 1.0 active IO Box Recovery Agent

reagent 1.1 active Reissue Agent

sysevent-transport 1.0 active SysEvent Transport Agent

syslog-msgs 1.0 active Syslog Messaging Agent

XSCF>

2.6.4 Using the fmstat Command

The fmstat command can report statistics associated with the Oracle Solaris fault

manager. The fmstat command shows information about DE performance. In the

example below, the fmd-self-diagnosis DE (also seen in the console output) has

received an event which it accepted. A case is “opened” for that event and a

diagnosis is performed to “solve” the cause for the failure. See the following

example.

2-24 SPARC Enterprise M4000/M5000 Servers Service Manual • December 2010

Page 49

XSCF> fmstat

module ev_recv ev_acpt wait svc_t %w %b open solve memsz bufsz

eft 0 0 0.0 0.0 0 0 0 0 3.3M 0

event-transport 0 0 0.0 0.0 0 0 0 0 6.4K 0

faultevent-post 2 0 0.0 8.9 0 0 0 0 0 0

fmd-self-diagnosis 24 24 0.0 352.1 0 0 1 0 24b 0

iox_agent 0 0 0.0 0.0 0 0 0 0 0 0

reagent 0 0 0.0 0.0 0 0 0 0 0 0

sysevent-transport 0 0 0.0 8700.4 0 0 0 0 0 0

syslog-msgs 0 0 0.0 0.0 0 0 0 0 97b 0

XSCF>

2.7 Traditional Oracle Solaris Diagnostic Commands

These superuser commands can help you determine if you have issues in your

workstation, in the network, or within another server that you are networking with.

The following commands are described in this section:

■ “Using the iostat Command” on page 2-26

■ “Using the prtdiag Command” on page 2-27

■ “Using the prtconf Command” on page 2-30

■ “Using the netstat Command” on page 2-32

■ “Using the ping Command” on page 2-34

■ “Using the ps Command” on page 2-35

■ “Using the prstat Command” on page 2-36

Most of these commands are located in the /usr/bin or /usr/sbin directories.

Note – For additional details, options, examples, and the most up to date

information for each command refer to that command’s man page.

Chapter 2 Fault Isolation 2-25

Page 50

2.7.1 Using the iostat Command

The iostat command iteratively reports terminal, drive, and tape I/O activity, as

well as CPU utilization.

2.7.1.1 Options

TABLE 2-12 describes options for the iostat command and how those options can

help troubleshoot the server.

TABLE 2-12 Options for iostat

Option Description How It Can Help

No option Reports status of local I/O devices. A quick three-line output of device status.

-c Reports the percentage of time the

system has spent in user mode, in system

mode, waiting for I/O, and idling.

-e Displays device error summary statistics.

The total errors, hard errors, soft errors,

and transport errors are displayed.

-E Displays all device error statistics. Provides information about devices: manufacturer,

-n Displays names in descriptive format. Descriptive format helps identify devices.

-x For each drive, reports extended drive

statistics. The output is in tabular form.

Quick report of CPU status.

Provides a short table with accumulated errors.

Identifies suspect I/O devices.

model number, serial number, size, and errors.

Similar to the

information. This helps identify poor performance of

internal devices and other I/O devices across the

network.

-e option, but provides rate

The following example shows output for one iostat command.

# iostat -En

c0t0d0 Soft Errors: 0 Hard Errors: 0 Transport Errors: 0

Vendor: SEAGATE Product: ST973401LSUN72G Revision: 0556 Serial No: 0521104T9D

Size: 73.40GB <73400057856 bytes>

Media Error: 0 Device Not Ready: 0 No Device: 0 Recoverable: 0

Illegal Request: 0 Predictive Failure Analysis: 0

c0t1d0 Soft Errors: 0 Hard Errors: 0 Transport Errors: 0

Vendor: SEAGATE Product: ST973401LSUN72G Revision: 0556 Serial No: 0521104V3V

Size: 73.40GB <73400057856 bytes>

Media Error: 0 Device Not Ready: 0 No Device: 0 Recoverable: 0

Illegal Request: 0 Predictive Failure Analysis: 0

#

2-26 SPARC Enterprise M4000/M5000 Servers Service Manual • December 2010

Page 51

2.7.2 Using the prtdiag Command

The prtdiag command displays configuration and diagnostic information. The

diagnostic information identifies any failed component.

The prtdiag command is located in the /usr/platform/platform-name/sbin/

directory.

Note – The prtdiag command might indicate a slot number different than that

identified elsewhere in this document. This is normal.

2.7.2.1 Options

TABLE 2-13 describes options for the prtdiag command and how those options can

help troubleshooting.

TABLE 2-13 Options for prtdiag

Option Description How It Can Help

No option Lists components. Identifies CPU timing and PCI cards installed.

-v Verbose mode. Displays the

time of the most recent AC

power failure and the most

recent hardware fatal error

information.

Provides the same information as no option. Additionally

lists fan status, temperatures, ASIC, and PROM revisions.

Chapter 2 Fault Isolation 2-27

Page 52

The following example shows output for the prtdiag command in verbose mode.

# prtdiag -v

System Configuration: xxxx Server

System clock frequency: 1012 MHz

Memory size: 262144 Megabytes

==================================== CPUs ====================================

CPU CPU Run L2$ CPU CPU

LSB Chip ID MHz MB Impl. Mask

--- ---- ---------------------------------------- ---- --- ----- --- 00 0 0, 1, 2, 3, 4, 5, 6, 7 2660 11.0 7 192

00 1 8, 9, 10, 11, 12, 13, 14, 15 2660 11.0 7 192

00 2 16, 17, 18, 19, 20, 21, 22, 23 2660 11.0 7 192

00 3 24, 25, 26, 27, 28, 29, 30, 31 2660 11.0 7 192

01 0 32, 33, 34, 35, 36, 37, 38, 39 2660 11.0 7 192

01 1 40, 41, 42, 43, 44, 45, 46, 47 2660 11.0 7 192

01 2 48, 49, 50, 51, 52, 53, 54, 55 2660 11.0 7 192

01 3 56, 57, 58, 59, 60, 61, 62, 63 2660 11.0 7 192

============================ Memory Configuration ============================

Memory Available Memory DIMM # of Mirror Interleave

LSB Group Size Status Size DIMMs Mode Factor

--- ------ ------------------ ------- ------ ----- ------- --------- 00 A 65536MB okay 4096MB 16 no 8-way

00 B 65536MB okay 4096MB 16 no 8-way

01 A 65536MB okay 4096MB 16 no 8-way

01 B 65536MB okay 4096MB 16 no 8-way

========================= IO Devices =========================

IO Lane/Frq

LSB Type LPID RvID,DvID,VnID BDF State Act, Max Name

Model Logical Path

-----------00 PCIe 0 bc, 8532, 10b5 2, 0, 0 okay 8, 8 pci-pciex10b5,8532

NA /pci@0,600000/pci@0

00 PCIe 0 bc, 8532, 10b5 3, 8, 0 okay 8, 8 pci-pciex10b5,8532

NA /pci@0,600000/pci@0/pci@8

00 PCIe 0 bc, 8532, 10b5 3, 9, 0 okay 1, 8 pci-pciex10b5,8532

NA /pci@0,600000/pci@0/pci@9

00 PCIx 0 8, 125, 1033 4, 0, 0 okay 100, 133 pci-pciexclass,060400

NA /pci@0,600000/pci@0/pci@8/pci@0

00 PCIx 0 8, 125, 1033 4, 0, 1 okay --, 133 pci-pciexclass,060400

NA /pci@0,600000/pci@0/pci@8/pci@0,1

2-28 SPARC Enterprise M4000/M5000 Servers Service Manual • December 2010

Page 53

The prtdiag -v output continued.

IO Lane/Frq

LSB Type LPID RvID,DvID,VnID BDF State Act, Max Name

Model Logical Path

-----------00 PCIx 0 2, 50, 1000 5, 1, 0 okay --, 133 scsi-pci1000,50

LSI,1064 /pci@0,600000/pci@0/pci@8/pci@0/scsi@1

00 PCIx 0 10, 1648, 14e4 5, 2, 0 okay --, 133 network-pci14e4,1648

NA /pci@0,600000/pci@0/pci@8/pci@0/network@2

00 PCIx 0 10, 1648, 14e4 5, 2, 1 okay --, 133 network-pci14e4,1648

NA /pci@0,600000/pci@0/pci@8/pci@0/network@2,1

01 PCIe 16 bc, 8532, 10b5 2, 0, 0 okay 8, 8 pci-pciex10b5,8532

NA /pci@10,600000/pci@0

01 PCIe 16 bc, 8532, 10b5 3, 8, 0 okay 8, 8 pci-pciex10b5,8532

NA /pci@10,600000/pci@0/pci@8

01 PCIe 16 bc, 8532, 10b5 3, 9, 0 okay 1, 8 pci-pciex10b5,8532

NA /pci@10,600000/pci@0/pci@9

01 PCIx 16 8, 125, 1033 4, 0, 0 okay 100, 133 pci-pciexclass,060400

NA /pci@10,600000/pci@0/pci@8/pci@0

01 PCIx 16 8, 125, 1033 4, 0, 1 okay --, 133 pci-pciexclass,060400

NA /pci@10,600000/pci@0/pci@8/pci@0,1

01 PCIx 16 2, 50, 1000 5, 1, 0 okay --, 133 scsi-pci1000,50

LSI,1064 /pci@10,600000/pci@0/pci@8/pci@0/scsi@1

01 PCIx 16 10, 1648, 14e4 5, 2, 0 okay --, 133 network-pci14e4,1648

NA /pci@10,600000/pci@0/pci@8/pci@0/network@2

01 PCIx 16 10, 1648, 14e4 5, 2, 1 okay --, 133 network-pci14e4,1648

NA /pci@10,600000/pci@0/pci@8/pci@0/network@2,1

==================== Hardware Revisions ====================

System PROM revisions:

---------------------OBP 4.24.13 2010/02/08 13:17

=================== Environmental Status ===================

Mode switch is in LOCK mode

=================== System Processor Mode ===================

SPARC64-VII mode

Chapter 2 Fault Isolation 2-29

Page 54

2.7.3 Using the prtconf Command

Similar to the show-devs command run at the ok prompt, the prtconf command

displays the devices that are configured.

The prtconf command identifies hardware that is recognized by the Oracle Solaris

OS. If hardware is not suspected of being bad yet software applications are having

trouble with the hardware, the prtconf command can indicate if the Oracle Solaris

software recognizes the hardware, and if a driver for the hardware is loaded.

2.7.3.1 Options

TABLE 2-14 describes options for the prtconf command and how those options can

help troubleshooting.

TABLE 2-14 Options for prtconf

Option Description How It Can Help

No option Displays the device tree of

devices recognized by the OS.

-D Similar to the output of no

option, however the device

driver is listed.

-p Similar to the output of no

option, yet is abbreviated.

-V Displays the version and date of

the OpenBoot PROM firmware.

If a hardware device is recognized, then it is probably

functioning properly. If the message “

attached)

sub-device, then the driver for the device is corrupt or

missing.

Lists the driver needed or used by the OS to enable the

device.

Reports a brief list of the devices.

Provides a quick check of firmware version.

” is displayed for the device or for a

(driver not

The following example shows output for the prtconf command.

# prtconf

System Configuration: Sun Microsystems sun4u

Memory size: 8064 Megabytes

System Peripherals (Software Nodes):

SUNW,SPARC-Enterprise

scsi_vhci, instance #0

packages (driver not attached)

SUNW,builtin-drivers (driver not attached)

deblocker (driver not attached)

2-30 SPARC Enterprise M4000/M5000 Servers Service Manual • December 2010

Page 55

The prtconf output continued.

disk-label (driver not attached)

terminal-emulator (driver not attached)

obp-tftp (driver not attached)

ufs-file-system (driver not attached)

chosen (driver not attached)

openprom (driver not attached)

client-services (driver not attached)

options, instance #0

aliases (driver not attached)

memory (driver not attached)

virtual-memory (driver not attached)

pseudo-console, instance #0

nvram (driver not attached)

pseudo-mc, instance #0

cmp (driver not attached)

core (driver not attached)

cpu (driver not attached)

cpu (driver not attached)

core (driver not attached)

cpu (driver not attached)

cpu (driver not attached)

cmp (driver not attached)

core (driver not attached)

cpu (driver not attached)

cpu (driver not attached)

core (driver not attached)

cpu (driver not attached)

cpu (driver not attached)

pci, instance #0

ebus, instance #0

flashprom (driver not attached)

serial, instance #0

scfc, instance #0

panel, instance #0

pci, instance #0

pci, instance #0

pci, instance #1

pci, instance #3

scsi, instance #0

tape (driver not attached)

disk (driver not attached)

sd, instance #0 (driver not attached)

sd, instance #2

sd, instance #4

network, instance #0

network, instance #1 (driver not attached)

pci, instance #4

Chapter 2 Fault Isolation 2-31

Page 56

network, instance #0 (driver not attached)

pci, instance #2

SUNW,qlc, instance #0