Page 1

C150-E047-02EN

M3099EX/EH IMAGE SCANNER

OEM MANUAL

Page 2

M3099EX/EH IMAGE SCANNER

OEM MANUAL

Page 3

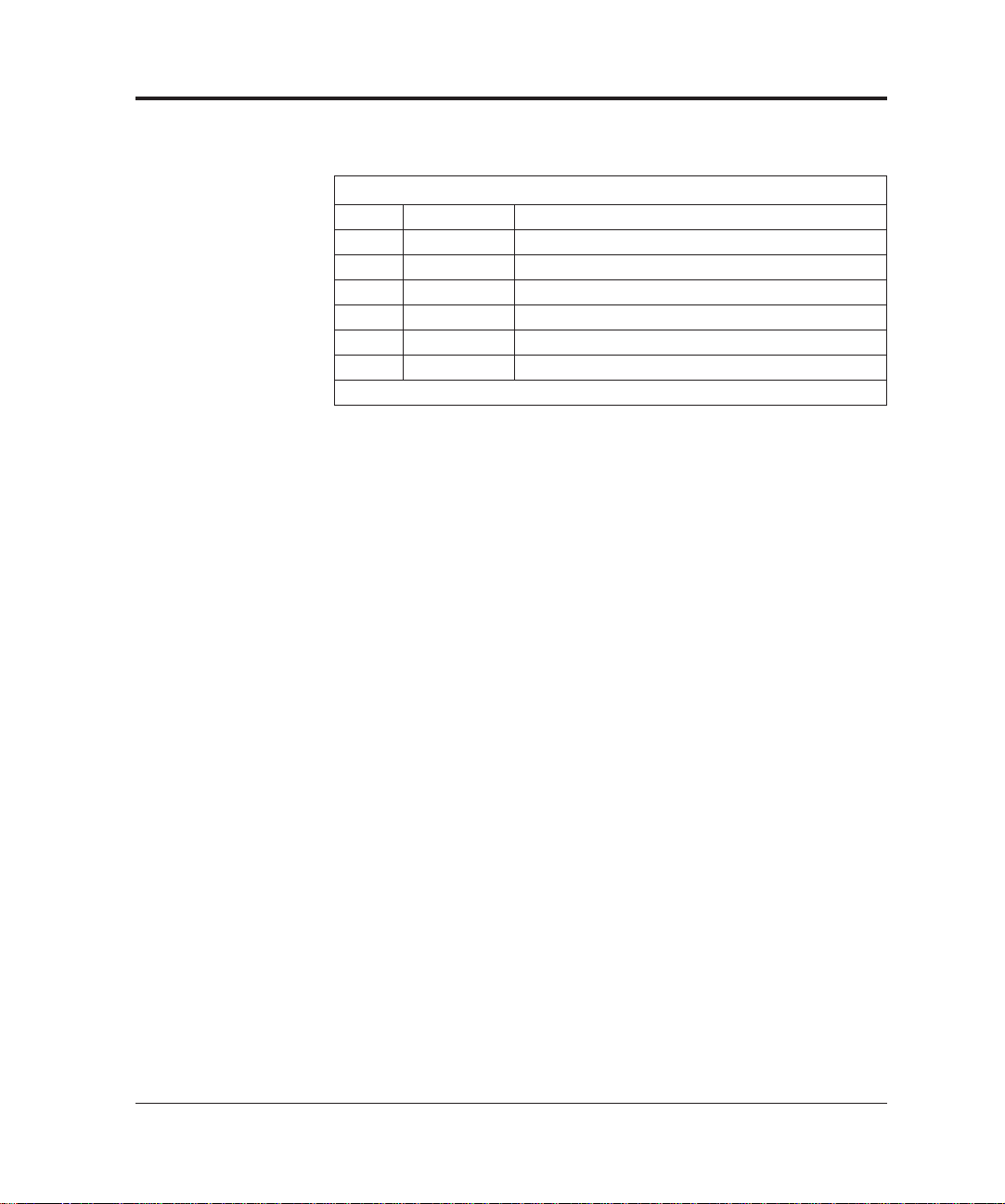

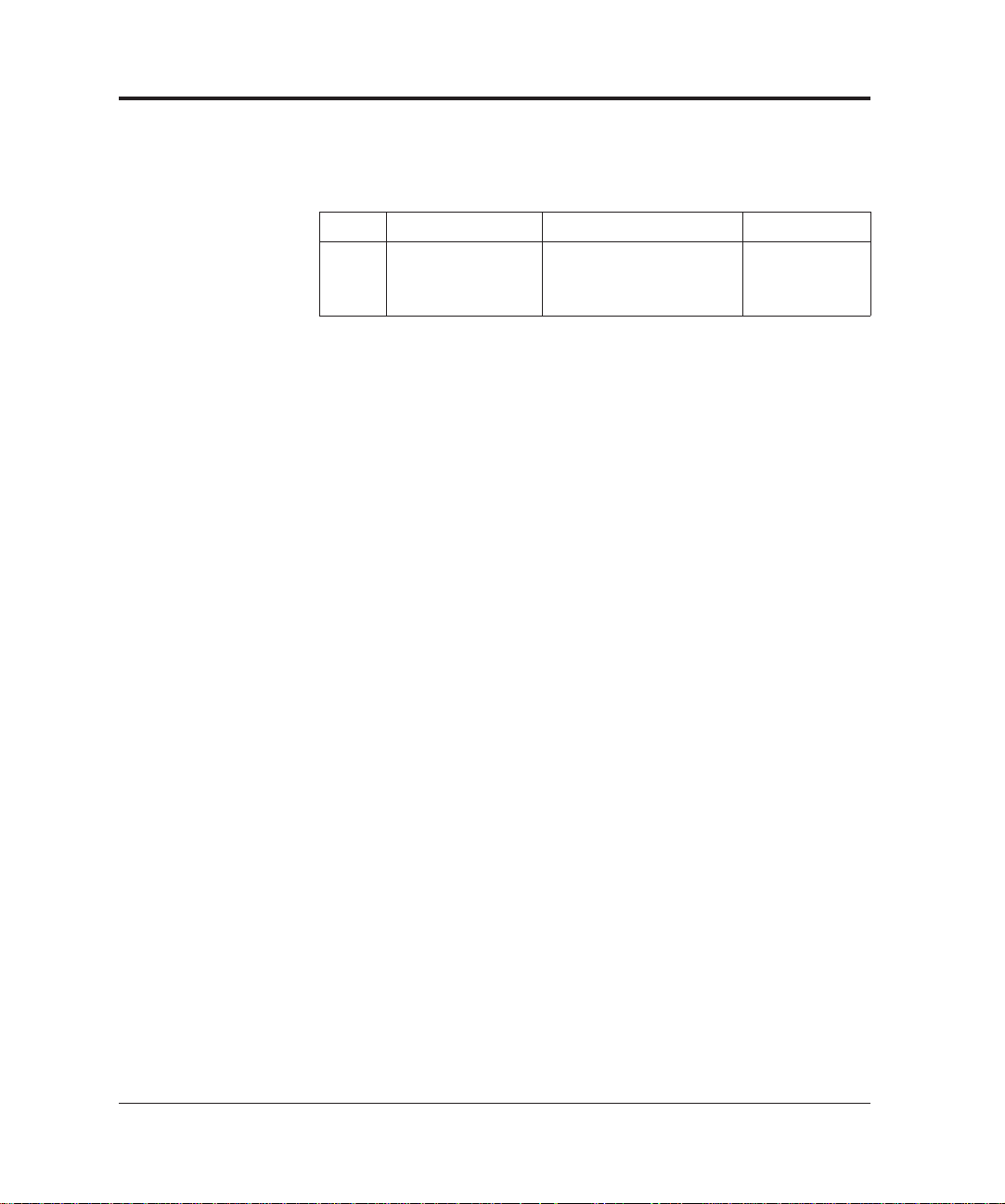

REVISION RECORD

Edition Date published Revised contents

01 January, 1996 First edition

02 April, 1996 Setup mode etc. revised

Specification No. C150-E047-02EN

The contents of this manual may be revised without prior notice.

All Rights Reserved, Copyright © 1996 FUJITSU LIMITED.

Printed in Japan.

No part of this manual may be reproduced in any form without permission.

Address your comments and inquiries on this manual to:

FUJITSU COMPUTER PRODUCTS OF

AMERICA, INC.

2904 Orchard Parkway, San Jose.

California 95134-2022, U.S.A.

TEL: 1-408-432-6333

FAX: 1-408-432-3908

FUJITSU AUSTRALIA LIMITED

475 Victoria Avenue Chatswood.

N.S.W 2067, AUSTRALIA

TEL: 61-2-410-4555

FAX: 61-2-411-8603

FUJITSU CANADA, INC.

2800 Matheson Blvd. East, Mississauga.

Ontario 4X5, CANADA

TEL: 1-905-602-5454

FAX: 1-905-602-5457

FUJITSU DEUTSCHLAND GmbH.

Frankfurter Ring 211,

8000 Munchen 40, F.R, GERMANY

TEL: 49-89-32378-0

FAX: 49-89-32378-100

FUJITSU ESPANA, S.A

Edificio torre Europa

Paseo de la Castellana 95 Madrid 28046, SPAIN

TEL: 34-1-581-8400

FAX: 34-1-581-8125

FUJITSU EUROPE LTD.

2, Longwalk Road, Stockley Park, Uxbridge

Middlesex, UB11 1AB, U.K

TEL: 44-81-573-4444

FAX: 44-81-573-2643

TLX: 263871

FUJITSU FRANCE S.A.

Batiment Aristote, 17 rue Olof palme

94006 Creteil cedex, FRANCE

TEL: 33-14-513-1616

FAX: 33-14-399-0700

FUJITSU HONG KONG Limited

Room 2521, Sum Hung Kai Centre

30 Harbour Road Wanchal, Hong Kong

TEL: 852-827-5780

FAX: 852-827-4724

TLX: 62667

FUJITSU ITALIA S.p.A.

Via Melchiorre Gioia, No. 8-20124 Milano, ITALY

TEL: 39-2-63651

FAX: 39-2-6572257

FUJITSU NORDIC AB

Kung Hans vag, S-191 76 Sollentuna, SWEDEN

TEL: 46-8-626-6000

FAX: 46-8-626-6711

FUJITSU LIMITED

International Operations

Marunouchi 1-6-1, Chiyoda-ku, Tokyo 100, JAPAN

TEL: (81-3) 3216-3211

FAX: (81-3) 3213-7174

TLX: J22833

Cable: “FUJITSU LIMITED TOKYO”

M3099EX/EH OEM Manual

Page 4

Preface

This manual provides technical information required to use the original

equipment manufacturing (OEM) M3099EX/EH image scanner. The

manual is organized as shown below.

Chapter 1 Overview

Chapter 1 provides the scanner features, configuration, and operation.

Chapter 2 Specifications

Chapter 2 provides general, electrical, environmental, physical, and

option specifications.

Chapter 3 Interface Specifications

Chapter 3 provides control interface, and video interface specifications.

Chapter 4 Basic Operation

Chapter 4 provides power switch operation, opening/closing the upper

transport unit, operator panel arrangement and functions, messages,

loading document, and replacement of parts.

Chapter 5 Error Processing and Recovery

Chapter 5 provides how to handles temporary errors and equipment

errors and what the operator should do to recovery.

M3099EX/EH OEM Manual i

Page 5

Chapter 6 Document Specification

Chapter 6 provides document specifications (size, type, limitations,

grounding color area, drop-out color, and job separation sheet) for the

scanner.

Chapter 7 Consumables and Accessories

Chapter 7 provides consumables and accessories.

Chapter 8 Cleaning

Chapter 8 provides cleaning locations and frequencies, cleaning tools,

and procedures.

It is recommended that you thoroughly familiarize yourself with the

contents of this manual before attempting to use the scanner. Operators

in particular must have read Chapter 4, “Basic Operation.”

Conventions

ii M3099EX/EH OEM Manual

Special information, such as warnings, cautions are indicated as follows:

WARNING

A WARNING indicattes that personal injury may result if you do not

follow a procedure correctly.

CAUTION

A CAUTION indicates that damage to the scanner may result if you do

not follow a procedure correctly.

NOTICE

A NOTICE provides “how-to” tips or suggestions to help you perform a

procedure correctly. NOTEs are particularly useful for first-time users.

Page 6

Contents

CHAPTER 1 OVERVIEW ................................................................................... 1-1

Scanner Types .............................................................................. 1-1

Features ........................................................................................ 1-4

Configuration ............................................................................... 1-5

Configuration of the scanner .................................................. 1-5

Arrangement of units ............................................................. 1-6

Operation Overview ..................................................................... 1-7

Operation of the mechanism unit .......................................... 1-7

Operation of the control unit ................................................. 1-8

CHAPTER 2 SPECIFICATIONS ......................................................................... 2-1

General ......................................................................................... 2-1

Electrical Specifications ................................................................ 2-2

Environmental Specifications ....................................................... 2-2

Physical Specifications .................................................................. 2-3

Option Specifications ................................................................... 2-6

CHAPTER 3 INTERFACE SPECIFICATIONS ...................................................... 3-1

Control Interface .......................................................................... 3-1

Connection specifications ...................................................... 3-1

Control interface signals ......................................................... 3-2

Driver/receiver ....................................................................... 3-3

Timing................................................................................... 3-4

Video Interface ............................................................................. 3-5

Video interface signals ............................................................ 3-5

Driver/receiver ....................................................................... 3-6

Data transfer .......................................................................... 3-7

Timing................................................................................. 3-12

Command and Response ............................................................ 3-14

Basic command/response sequence....................................... 3-14

Command............................................................................ 3-17

M3099EX/EH OEM Manual iii

Page 7

Responses............................................................................. 3-61

Command/response correspondence .................................... 3-91

Command/Response Timing Chart ............................................ 3-93

CHAPTER 4 BASIC OPERATION ...................................................................... 4-1

Power Switch Operation............................................................... 4-1

Opening the Upper Transport Unit ............................................. 4-2

Closing the Upper Transport Unit ............................................... 4-2

Operator Panel Arrangement and Functions................................. 4-3

Operator panel arrangement .................................................. 4-3

Operator panel functions ....................................................... 4-3

LCD display .......................................................................... 4-5

Button specification and reading mode setting ....................... 4-8

Operation display................................................................. 4-23

Buzzer Functions ........................................................................ 4-25

Message List ............................................................................... 4-25

Loading Document .................................................................... 4-26

Lamp Replacement ..................................................................... 4-28

Roller ASY Replacement ............................................................. 4-33

Pick Roller Replacement ............................................................. 4-35

Belt Replacement........................................................................ 4-36

Pad Replacement ........................................................................ 4-38

CHAPTER 5 ERROR PROCESSING AND RECOVERY ........................................ 5-1

Device and Operator Actions for Temporary Errors ..................... 5-1

Device and Operator Actions for Equipment Errors ..................... 5-4

CHAPTER 6 DOCUMENT SPECIFICATION ....................................................... 6-1

Document Size ............................................................................. 6-1

Document Quality ....................................................................... 6-2

Document type ...................................................................... 6-2

Ream weight .......................................................................... 6-2

Precautions ............................................................................ 6-2

Document Limitations ................................................................. 6-4

Areas that must not be perforated .......................................... 6-4

Print prohibit areas on the front and back surfaces ................. 6-5

iv M3099EX/EH OEM Manual

Page 8

Grounding Color Area.................................................................. 6-6

Drop-out Color ............................................................................ 6-7

Print density measurement ..................................................... 6-7

Drop-out color standards ....................................................... 6-7

Job Separation Sheet ..................................................................... 6-8

Shape ..................................................................................... 6-8

Document type ...................................................................... 6-8

CHAPTER 7 CONSUMABLES AND ACCESSORIES .......................................... 7-1

Consumables ................................................................................ 7-1

Accessories .................................................................................... 7-2

CHAPTER 8 CLEANING.................................................................................... 8-1

Cleaning Locations and Frequencies ............................................. 8-1

Cleaning Tools ............................................................................. 8-1

Procedure ..................................................................................... 8-2

Cleaning the front-side lamp .................................................. 8-2

Cleaning the rollers ................................................................ 8-5

Cleaning the transport paths .................................................. 8-6

Cleaning the glass surface ....................................................... 8-7

Cleaning the sensors ............................................................... 8-7

APPENDIX A ENDORSER ................................................................................... A-1

A1. Specification .......................................................................... A-1

A2. Panel operation ......................................................................A-2

A2.1 How to set endorser ON (or OFF)...............................A-2

A2.2 How to set the initial number ......................................A-2

A2.3 How to set the print number reset condition ................A-3

A2.4 How to reset print number manually ........................... A-3

A2.5 How to reset print head life counter .............................A-4

A2.6 How to test the printing by the operator panel

operation...................................................................... A-4

A3. Print head handling................................................................A-5

A3.1 Replacing the print head ..............................................A-5

A3.2 Print head position adjustment ....................................A-6

M3099EX/EH OEM Manual v

Page 9

APPENDIX B SETUP MODE ...............................................................................B-1

B1. Activating the setup mode ......................................................B-1

B2. Operational transition in the setup mode ............................... B-1

B3. Contents of the setup mode ................................................... B-2

B3.1 Setting double feed detection ....................................... B-3

B3.2 Setting IPC-2 pre-set mode .......................................... B-4

B3.3 Reset of abrasion counter ............................................. B-6

B3.4 Setting buzzer ............................................................... B-7

B3.5 Setting pre-pick ............................................................B-7

B3.6 Adjusting LCD contrast ............................................... B-8

B3.7 Setting pick speed......................................................... B-8

B3.8 Setting initial value of endorser .................................... B-9

B3.9 Setting reset method of endorser .................................. B-9

B3.10 Reset of endorser .................................................... B-10

B3.11 Reset of ink counter ................................................ B-10

B3.12 Setting RS232C transfer rate .................................. B-10

B3.13 Setting picking start time ........................................ B-10

B3.14 Setting picking time................................................ B-11

B3.15 Setting time-out limit ............................................. B-11

B3.16 Setting hopper time ................................................ B-12

B3.17 Setting heater control ............................................. B-13

APPENDIX C Separation pressure adjustment ................................................ C-1

GLOSSARY OF TERMS .................................................................................................. GL-1

INDEX ...................................................................................................IN-1

vi M3099EX/EH OEM Manual

Page 10

Figures

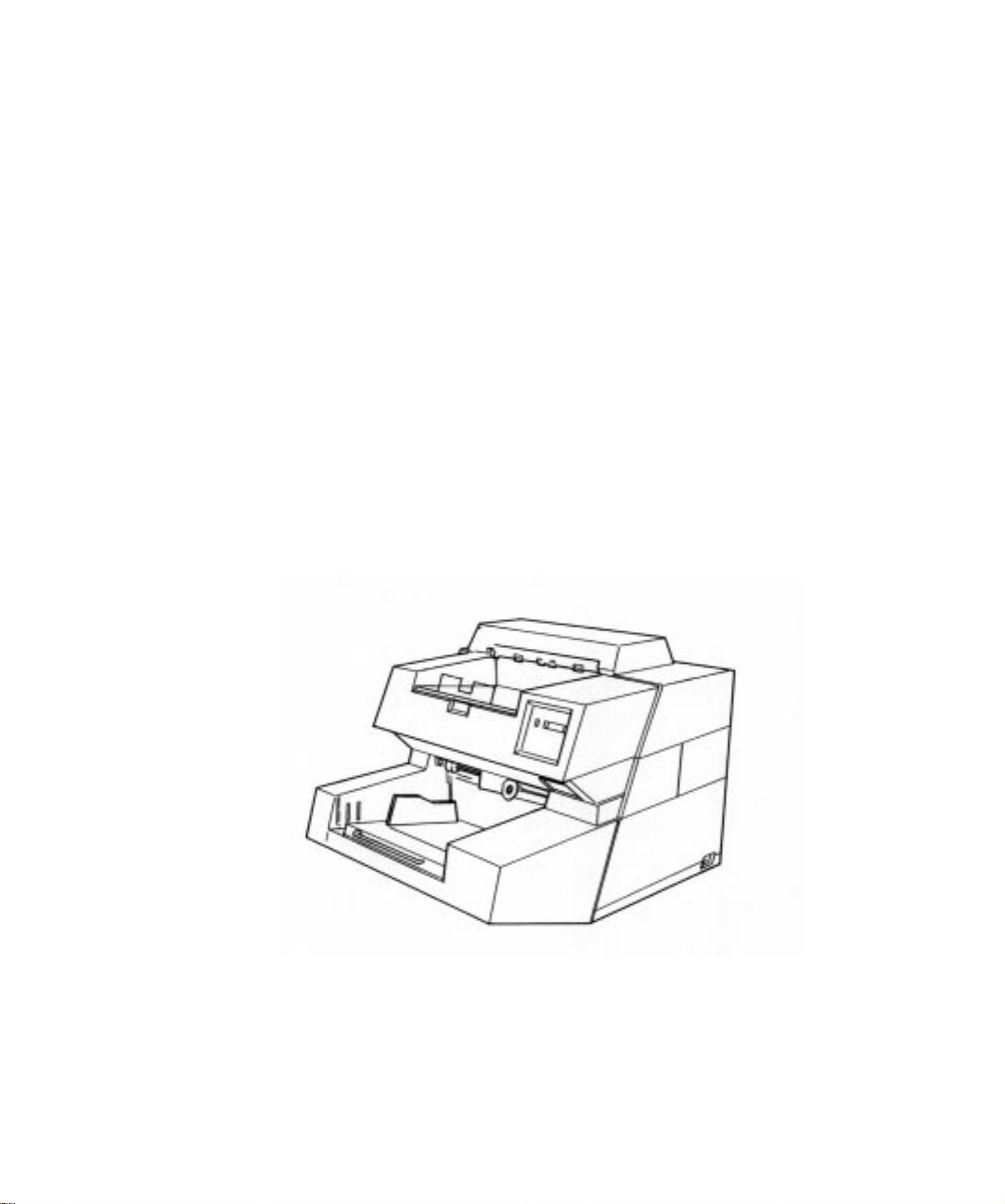

1.1 500 sheets hopper type ......................................................... 1-2

1.2 1000 sheets hopper type ....................................................... 1-3

1.3 Scanner block diagram ......................................................... 1-5

1.4 Arrangement of units ............................................................ 1-6

1.5 Control block diagram ......................................................... 1-8

2.1 Dimensions of 500 sheets hopper type ................................. 2-3

2.2 Dimensions of 1000 sheets hopper type ............................... 2-4

2.3 Service areas ......................................................................... 2-5

3.1 Control interface signal lines ................................................ 3-2

3.2 Video interface signal lines ................................................... 3-5

3.3 Scanning direction................................................................ 3-7

3.4 Scanning data assignment ..................................................... 3-7

3.5 Basic command/response sequence ..................................... 3-14

3.6 Command/response sequence for initialization ................... 3-84

3.7 Command/response sequence for the read operation (1) .... 3-86

3.8 Command/response sequence for the read operation (2) .... 3-88

3.9 Command/response sequence for the read operation (3) .... 3-90

3.10 CLEAR command sequence ............................................... 3-94

3.11 CONTROL command sequence (1/4) to (4/4) .................. 3-95

3.12 START command sequence ............................................... 3-99

3.13 READ command sequence ............................................... 3-100

3.14 SENSE command sequence .............................................. 3-101

3.15 RETURN SENSE command sequence ............................ 3-102

4.1 Power switch location ........................................................... 4-1

4.2 Operator panel arrangement ................................................. 4-3

6.1 Document size...................................................................... 6-1

6.2 Areas that must not be perforated ......................................... 6-4

6.3 Print prohibit areas on the front and back surface................. 6-5

6.4 Grounding color area ........................................................... 6-6

6.5 Spectrum band ..................................................................... 6-7

6.6 Sharp of document ............................................................... 6-8

A.1 Print area.............................................................................. A-1

M3099EX/EH OEM Manual vii

Page 11

Tables

1.1 Types of M3099EH ............................................................. 1-1

1.2 Types of M3099EX .............................................................. 1-2

2.1 General scanner specifications .............................................. 2-1

2.2 Electrical specifications ......................................................... 2-2

2.3 Environmental specifications ................................................ 2-2

2.4 Physical specifications........................................................... 2-5

2.5 Option specifications ............................................................ 2-6

3.1 Transferred data length in main scanning

(portrait mode) ..................................................................... 3-8

3.2 Transferred data length in main scanning

(landscape mode).................................................................. 3-9

3.3 Transferred data length in subscanning (portrait mode) ..... 3-10

3.4 Transferred data length in subscanning (landscape mode) .. 3-11

3.5 Timing specification at binary output................................. 3-13

3.6 Commands......................................................................... 3-17

3.7 Response ............................................................................ 3-61

4.1 Button functions .................................................................. 4-4

4.2 LEDs function...................................................................... 4-5

4.3 Buzzzer functions ............................................................... 4-25

4.4 Messages............................................................................. 4-25

5.1 Device and operator actions for temporary errors ................. 5-1

5.2 Device and operator actions for equipment errors................. 5-4

7.1 Consumables ........................................................................ 7-1

7.2 Accessories............................................................................ 7-2

8.1 Cleaning locations and frequencies ....................................... 8-1

A.1 Endorser specifications ......................................................... A-1

viii M3099EX/EH OEM Manual

Page 12

Chapter 1: Overview

OVERVIEW

Chapter 2: Specifications

6

Chapter 3: Interface Specifications

Chapter 4: Basic Operation

Chapter 5: Error Processing and Recovery

Chapter 6: Document Specification

Chapter 7: Consumables and Accessories

Chapter 8: Cleaning

Appendix A: Endorser

Appendix B: Setup Mode

SPECIFICATIONS

INTERFACE

SPECIFICATIONS

BASIC

OPERATION

ERROR

PROCESSING

AND RECOVERY

DOCUMENT

SPECIFICATION

CONSUMABLES

AND

ACCESSORIES

CLEANING

ENDORSER

SETUP MODE

Appendix C: Separation pressure adjustment

Glossary of Terms

Index

SEPARATION

PRESSURE

ADJUSTMENT

GLOSSARY OF

TERMS

INDEX

Page 13

CHAPTER

OVERVIEW

1

Scanner Types

OVERVIEW

This chapter provides scanner features, configuration, and operation.

The M3099EX/EH is a very fast and highly functional image

scanner developed for volume filing, using charge-coupled device

(CCD) image sensors. This scanner, featuring duplex reading and

high-quality image processing, read documents fed by an automatic

document feeder (ADF).

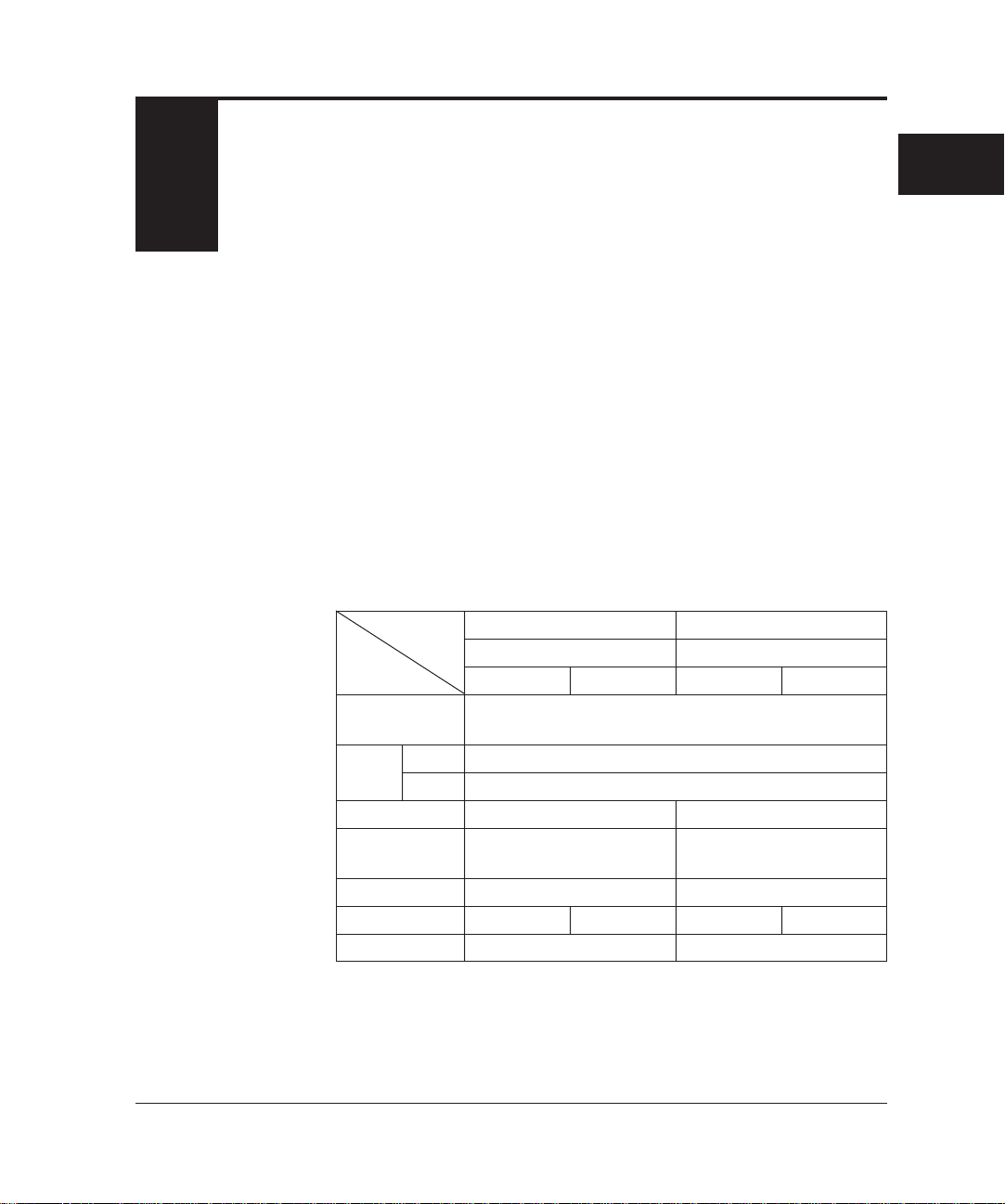

Scanner types of M3099EH and M3099EX are shown in Table 1.1

and 1.2. Those types of the scanner is hereinafter referred to as “this

scanner”.

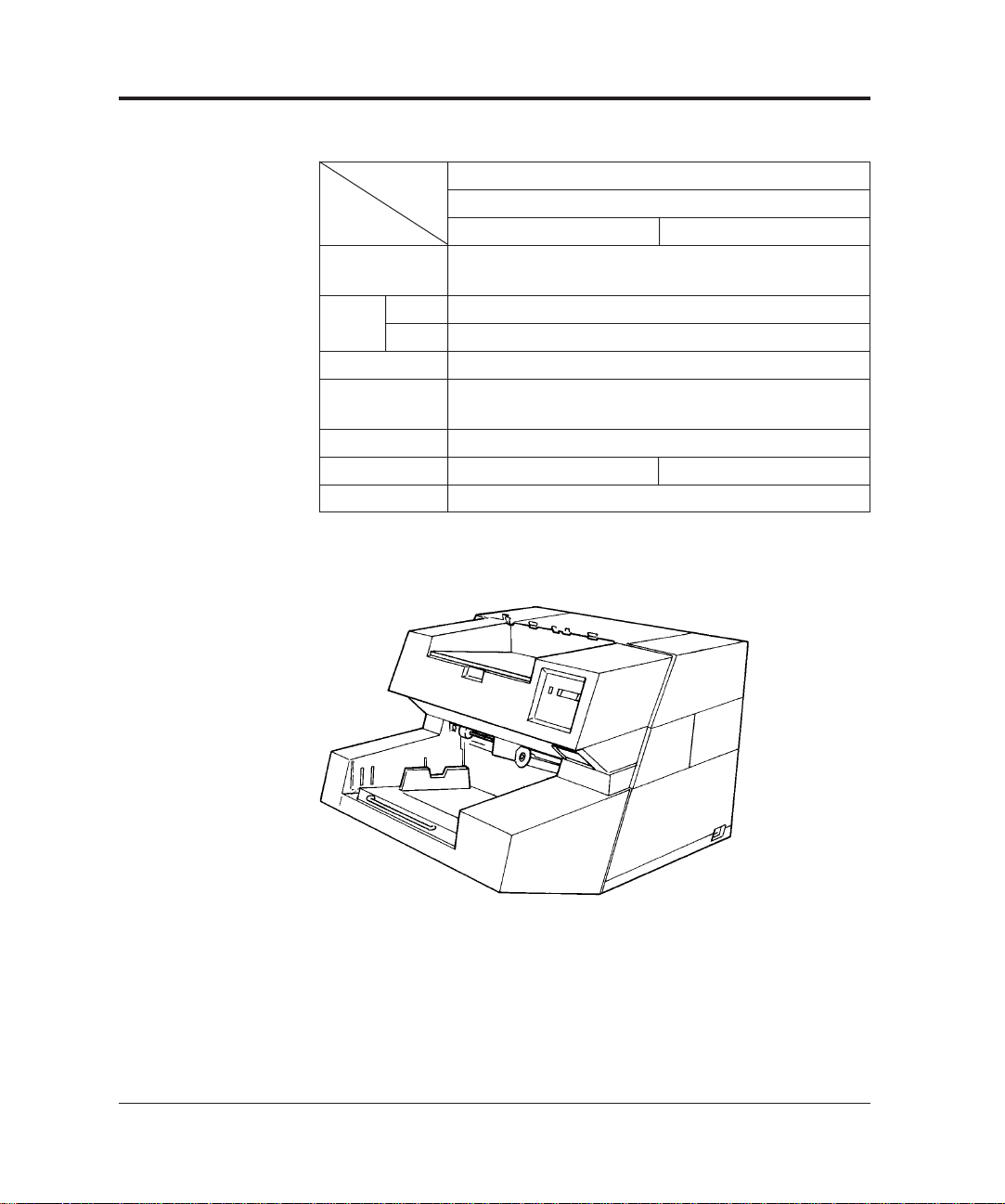

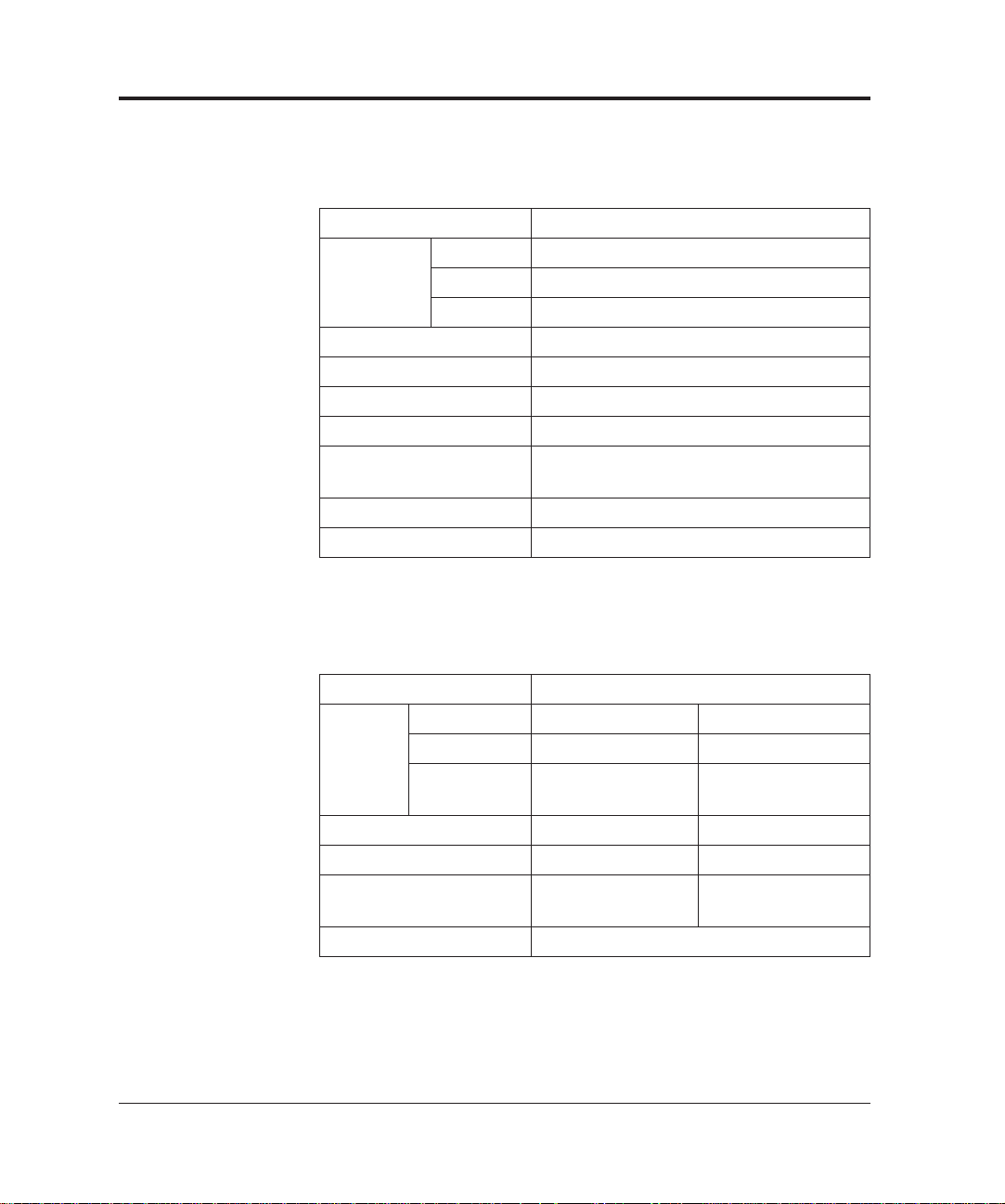

Table 1.1 Types of M3099EH

Type 500 sheets hopper 1000 sheets hopper

with IPC2 with IPC2

Item 100V 200V 100V 200V

Maximum

document size

Scanning Simplex

Duplex

Hopper capacity 500 sheets 1000 sheets

Hight of

the Scanner

IPC2 (option) Installed Installed

Input voltage 100V 200V 100V 200V

Appearance Figure 1.1 Figure 1.2

80 PPM (A4, 200dpi, portrate)

60 PPM (A4, 200dpi, portrate)

470 mm 530 mm

A4/Letter/Legal

M3099EX/EH OEM Manual 1-1

Page 14

Table 1.2 Types of M3099EX

Type 1000 sheets hopper

with IPC2

Item 100V 200V

Maximum

document size

Scanning Simplex

Duplex

Hopper capacity 1000 sheets

Hight of

the Scanner

IPC2 (option) Installed

Input voltage 100V 200V

Appearance Figure 1.2

A3/Double letter

60 PPM (A4, 200dpi, portrate)

50 PPM (A4, 200dpi, portrate)

530 mm

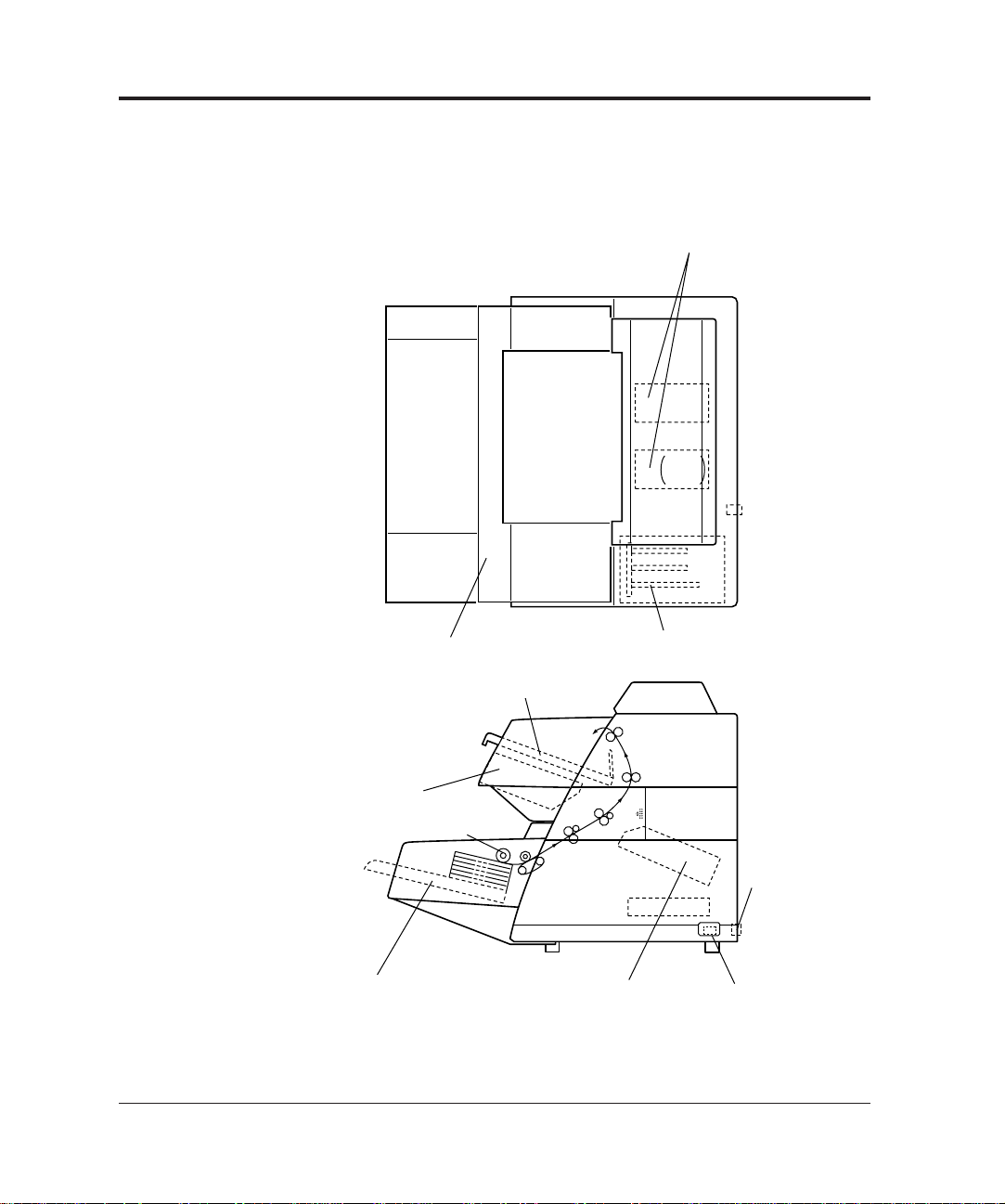

Figure 1.1 500 sheets hopper type

1-2 M3099EX/EH OEM Manual

Page 15

Figure 1.2 1000 sheets hopper type

OVERVIEW

M3099EX/EH OEM Manual 1-3

Page 16

Features

This scanner has the following features:

Duplex reading

Both sides of a document are read at the same time and their data

transferred serially.

Fast reading

This scanner can read documents at high speed: 80 sheets/min (A4,

200dpi) in the simplex reading mode and 60 sheets/min (A4,

200dpi) in the duplex reading mode by M3099EH.

Large-capacity hopper

Up to 1000 sheets (A4, 55 kg) can be loaded on the hopper by the

1000 sheets hopper type.

High-quality image

This scanner uses a compact optical system that provides sharper

focus. Furthermore, the use of new LSI chips produces finer images.

New image processing function

The error diffusion feature is provided as standard. Dithering or

error diffusion can be applied to those areas judged to be

photographs by automatic separation (image processing II option).

1-4 M3099EX/EH OEM Manual

Page 17

Configuration

This section provides configuration and components of the scanner.

Configuration of the scanner

This scanner can be divided into two major sections, mechanism and

control unit.

The mechanism unit consists of a hopper to load documents,

automatic document feeder, upper and lower transport units to

transport documents, a motor drive system, and an optical unit.

The control unit consists of an operator panel, a power supply, a

mechanism driver to drive and control the mechanism unit, an image

processing control, and an interface control.

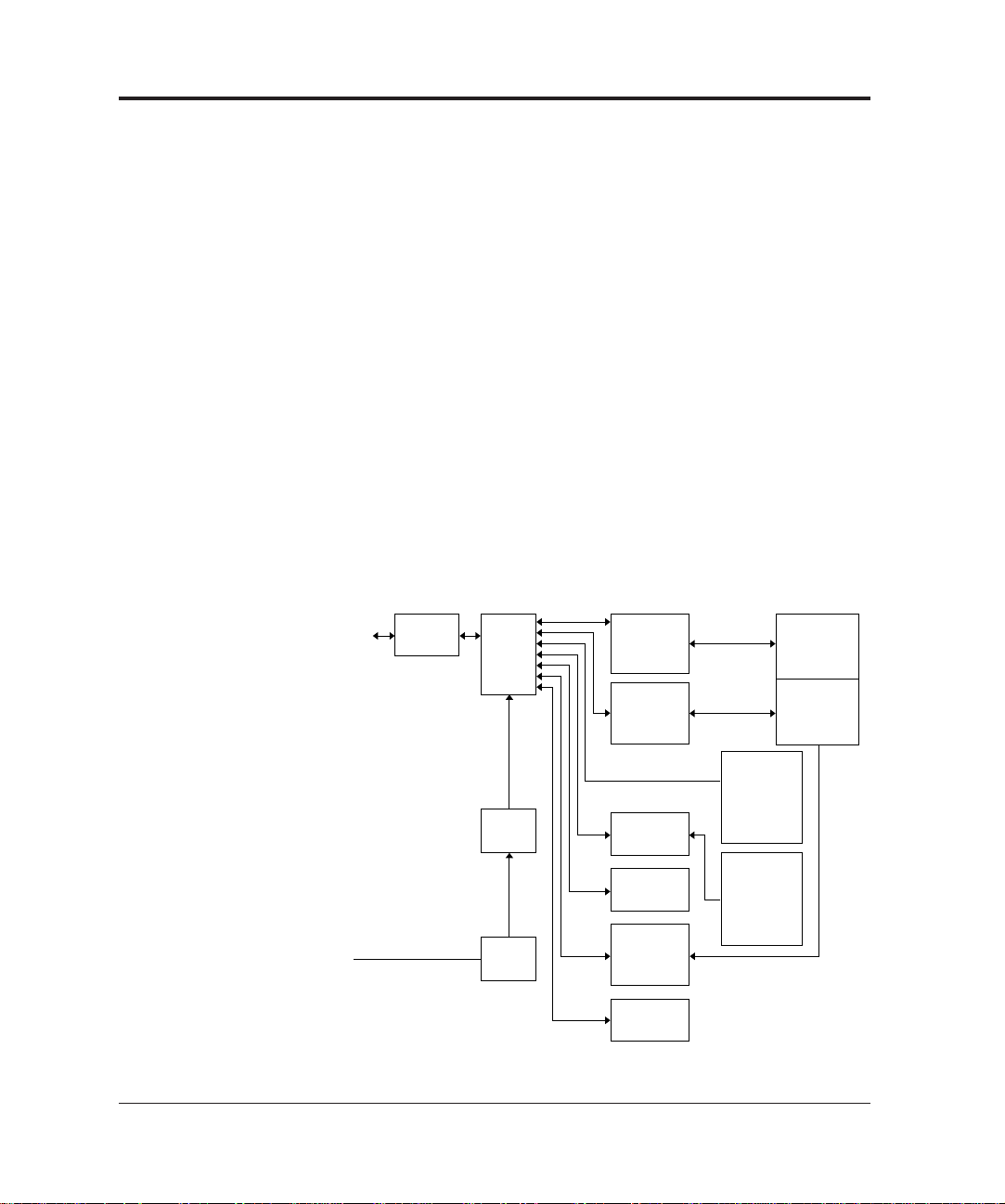

Figure 1.3 shows scanner configuration.

OVERVIEW

Mechanism unit

Transfer

system

Sensor Lamp,

(Front-side) (Back-side) (Back-side)

heater,

inverter

Sensor

board

Lamp,

heater,

inverter

Control unit

Mechanism driver

Fan Operator

panel

: Option

Back-side

reading

board

IPC-2 Extend

(Back-side)

IPC-2 Extend

(Front-side)

Figure 1.3 Scanner block diagram

Printer

Motherboard

memory

board

memory

(Front-side)

Optical

system

Printer

driver

CCD

driver

Video

circuit

Interface

board

RS-232C+VIDEO 100/200VAC

Optical

system

CCD

driver

Video

circuit

Power supply

(5V, 12V)

Power supply

(24V)

M3099EX/EH OEM Manual 1-5

Page 18

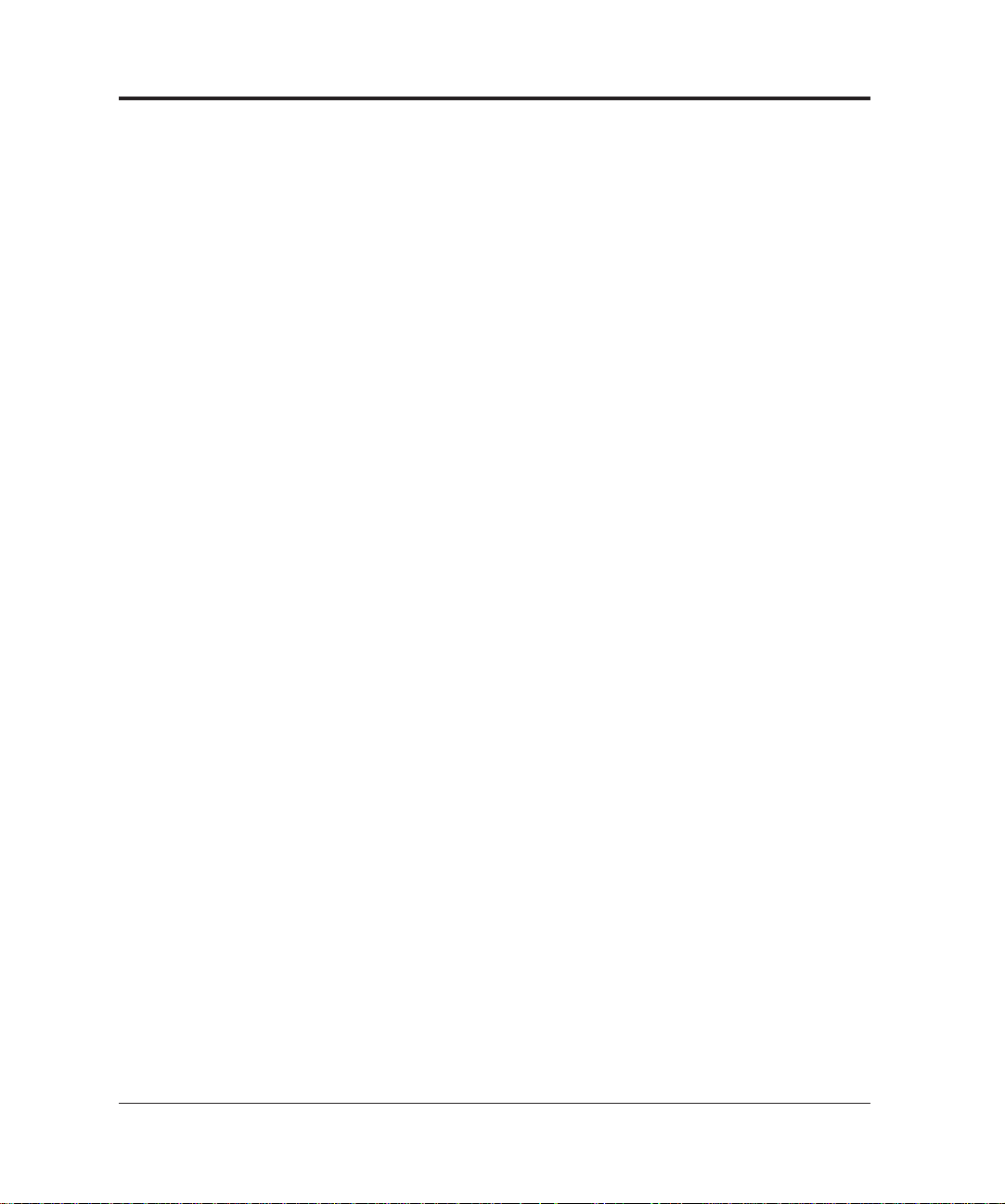

Arrangement of units

Power supply units

(+24V)

+5V

±12V

Control unitOperator panel

Stacker

Optical unit

(front-side)

Automatic document

feeder (ADF)

Hopper

Optical unit

(back-side)

Power switch

Power inlet

Figure 1.4 shows arrangement of these units.

1-6 M3099EX/EH OEM Manual

Figure 1.4 Arrangement of units

Page 19

Operation Overview

This section outlines the operations of the mechanism and control

units of the scanner.

Operation of the mechanism unit

The mechanism unit consists of two optical units (front and back

sides), a hopper and ADF, upper and lower transport units, a motor

drive system, and a stacker. Each optical unit consists of a CCD

image sensor, a lens, and mirrors. The hopper and ADF feeds

stacked documents and the upper and lower transport units transport

the documents. The motor drive system drives these units. The

stacker stores documents.

When the power is turned on, the lamps are lit and the scanner

waits until the light intensities of the lamps become stable. Once the

light intensities have become stable, the scanner is ready for a

command from the host machine.

A document is picked from the hopper and then ADF feeds a

document one by one. The document width is checked and

document top is detected.

The documents are counted, fed, and stacked on the stacker.

OVERVIEW

The lamps illuminate the document, and a lens focuses the images

on CCD for photoelectric conversion processing.

M3099EX/EH OEM Manual 1-7

Page 20

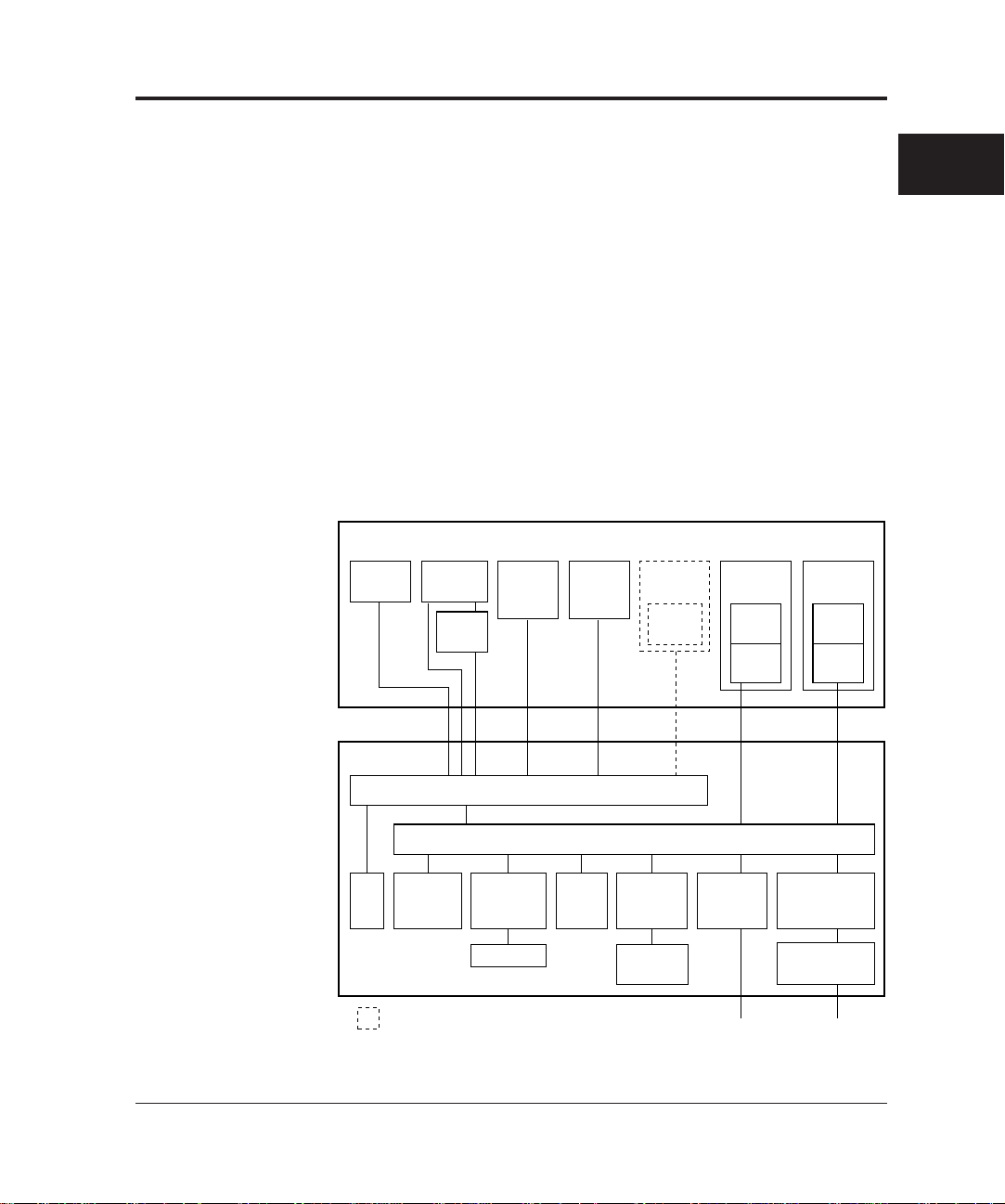

Operation of the control unit

The control unit consists of an operator panel, a power supply unit,

mechanism driver, an image processing control, and an interface

control.

This scanner has the following circuit configuration:

• Operator panel

• Control circuit (MPU)

• Video circuit (front-side/back-side)

• Interface circuit

• Duplex circuit (back-side)

• Motor driver circuit (including a stepper motor, a clutch driver)

• Power supply unit

• Image processing circuit (IPC II option)

• Memory board

Figure 1.5 shows control block diagram.

Host

machine

100 to 120 VAC

220 to 240 VAC

Interface

circuit

Control

circuit

(MPU )

Power

supply

Power

switch

Video

circuit

(front-side)

Video

circuit

(back-side)

Duplex

circuit

Memory

board

Motor

driver

circuit

Operator

panel

Mechanism

unit

ADF

MF

Image

processing

circuit II

(option)

(front-side)

Image

processing

circuit II

(option)

(back-side)

Figure 1.5 Control block diagram

1-8 M3099EX/EH OEM Manual

Page 21

Main control unit

This scanner is controlled by a 80C186 MPU. This scanner consists

of a ROM as a program area, internal registers, an external RAM as a

work area, gate arrays for the MPU peripheral and video circuits,

dither processing and γ conversion RAMs, and error diffusion.

Interface control

RS-232C and video interface

RS-232C interface

The RS-232C interface consists of an ACIA( 8251) and driver-receiver

ICs (145406).

Video interface

This scanner processes a document by the 256-step gray scale. Images

are processed in a way specified by the interface or the operator panel

and transferred serially in eight-bit units. Eight-bit data has V0 at the

left end and V7 at the right end and strobed by VCL.

HGATE ensures the validity of data in the main scanning and

VGATE for the subscanning.

OVERVIEW

The scanner status is basically reported by the RS-232C interface. An

equipment error is reported to the host computer by a FAIL signal in

case that RS-232C communication failed. See Chapter 3 for detailed

specifications of the interfaces.

Resolution

The basic resolution of this scanner is 200dpi. The resolution can be

changed to 240, 300, or 400dpi from the host computer or the

operator panel.

The resolution in the subscanning direction is achieved by changing

the document transport speed.

When the image processing circuit II (IPC II) option is installed, the

linear density is changed by setting the parameter to its internal circuit.

M3099EX/EH OEM Manual 1-9

Page 22

Video amplifier and driver section

This section consists of a CCD drive circuit, a video amplifier

circuit, a white-black level correction circuit, sensors, and also

control circuits for the stepping motor, heater, and lamps.

Image processing section

The IPC II option enables the following image processing functions:

• Automatic separation function (to read documents containing

characters and photographs)

• Inversion function

• Mirror image output function

• Outline extraction function

• Overlay function

• Smoothing, filtering, and noise removing

Power supplies

This scanner has two power supplies. Their output voltages are as

follows:

Power supply 1

• +5V: For logic circuits

• ±12V: For video amplifiers

Power supply 2

• 24V: For lamp, heater, and stepping motor drive

1-10 M3099EX/EH OEM Manual

Page 23

CHAPTER

2

General

SPECIFICATIONS

This chapter provides general, electrical, environmental, physical,

and option specifications.

Table 2.1 list general scanner specifications.

Table 2.1 General scanner specifications

Type

Item

Sensor

Scanning method

Document

size

Light source

Hopper/stacker

capacity

Gray scale (internal)

Output video

Scanning speed (A4,

200dpi, portrait)

Output density

Binarization and

halftone function

Interface

MAX.

MIN.

(64 g/m2)

Simplex

Duplex

500 sheets hopper 1000 sheets hopper

ADF

216 × 356 mm (A4/Letter/Legal) 297 × 432 mm (A3/Double letter)

Standard: 400, 300, 240, 200dpi (Horizontal

scanning and vertical scanning are independent.)

If the image processing II (IPC2) is installed: 50 to

400 dpi (Horizontal scanning and vertical scanning

are independent.)

Standard: Fixed binarization, dither, error diffusion

method. If the image processing II (IPC2) is

installed: Automatic separation, image emphasis,

outline extraction, mirror image, inversion,

simplified DTC. Dynamic threshold, smoothing,

filtering, nois removing.

RS-232C (Control signal) + Local (Video signal)

M3099EH M3099EX

1000 sheets hopper

CCD image sensor

(automatic document feeder)

76 × 63 mm (3" × 2.5")

Green fluorescent lamp

MAX. 500 MAX. 1000 MAX. 1000

sheets sheets sheets

256 steps

Binary/Halftone (64 levels)

80 PPM 60 PPM

60 PPM 50 PPM

& MF

(manual feeder)

SPECIFICATIONS

M3099EX/EH OEM Manual 2-1

Page 24

Electrical Specifications

Table 2.2 lists electrical specifications.

Table 2.2 Electrical specifications

Environmental Specifications

Item

Input power

Power consumption

Rush current

Momentary power failure

Leakage current

Dielectric strength

AC line noise

Heat capacity

Voltage

Phase

Frequency

Specification

100 to 120 VAC/220 to 240 VAC ±10%

Single-phase

50/60 Hz +2%, –4%

0.25 kVA or less

30 A or less

100%, 0.5 Hz

3.5 mA or less

DC 1.8 KV for one minute or more

(between FG and AC lines)

Voltage 1.2 KV pulse duration 5 µs

110 Kcal/H (440 BTU/H)

Table 2.3 lists environmental specifications.

Table 2.3 Environmental specifications

Item

Ambient

conditions

Shock

Stability

Acoustic noise

ESD

Device status

Temperature

Humidity

Specification

Operating

5 to 35°C

20 to 80%

(no condensation)

0.2 G less

5° or less

59 dBA or less

(ISO 7779)

8 KV or more

Not operating

–20 to 60°C

8 to 95%

(no condensation)

0.4 G or less

10° or less

50 dBA or less

(ISO 7779)

2-2 M3099EX/EH OEM Manual

Page 25

Physical Specifications

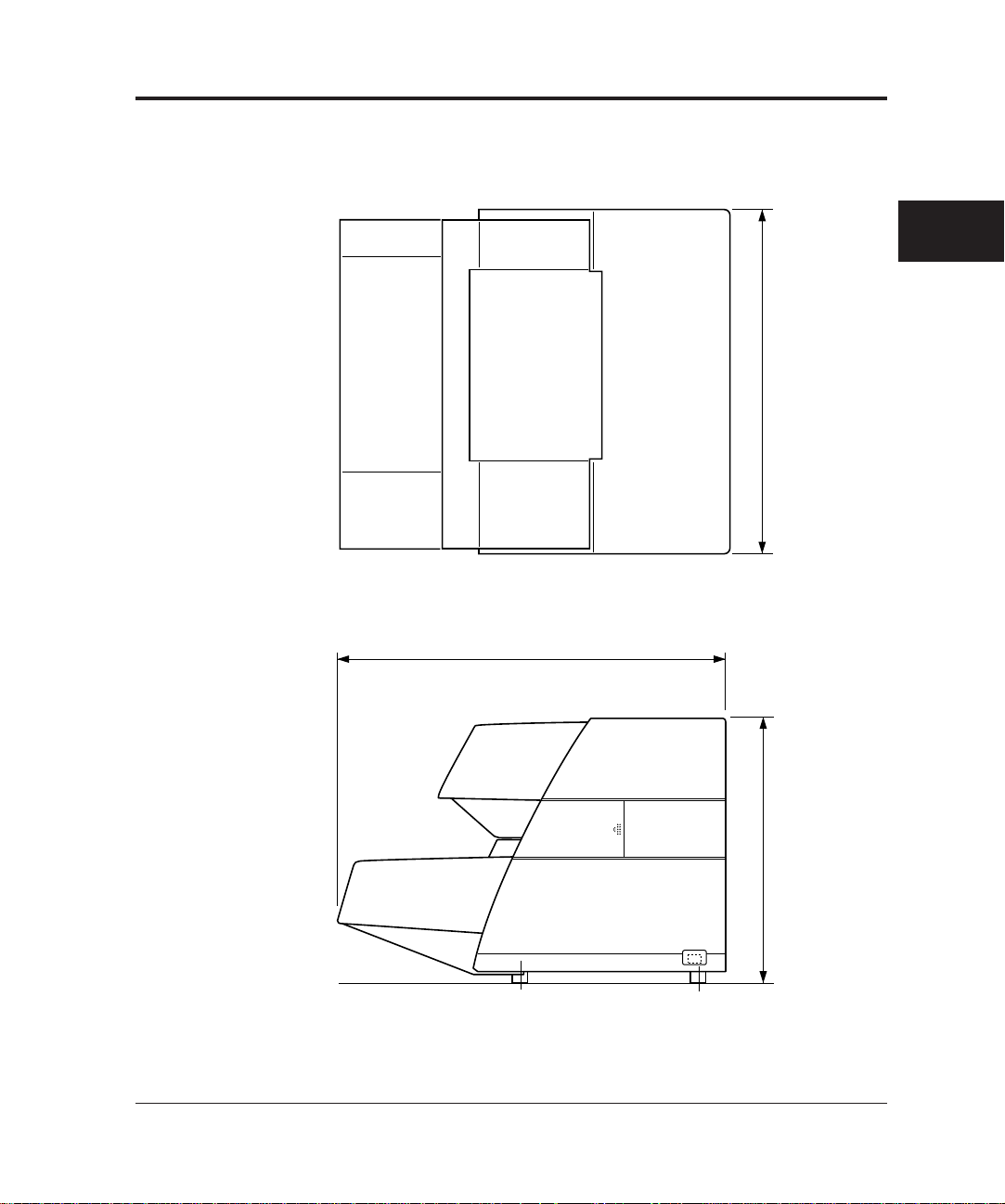

Figure 2.1 to Figure 2.2 show the scanner dimensions, Figure 2.3

shows scanner service areas. Table 2.4 lists physical specifications.

SPECIFICATIONS

610

680

470

(Unit: mm)

Figure 2.1 Dimensions of 500 sheets hopper type

M3099EX/EH OEM Manual 2-3

Page 26

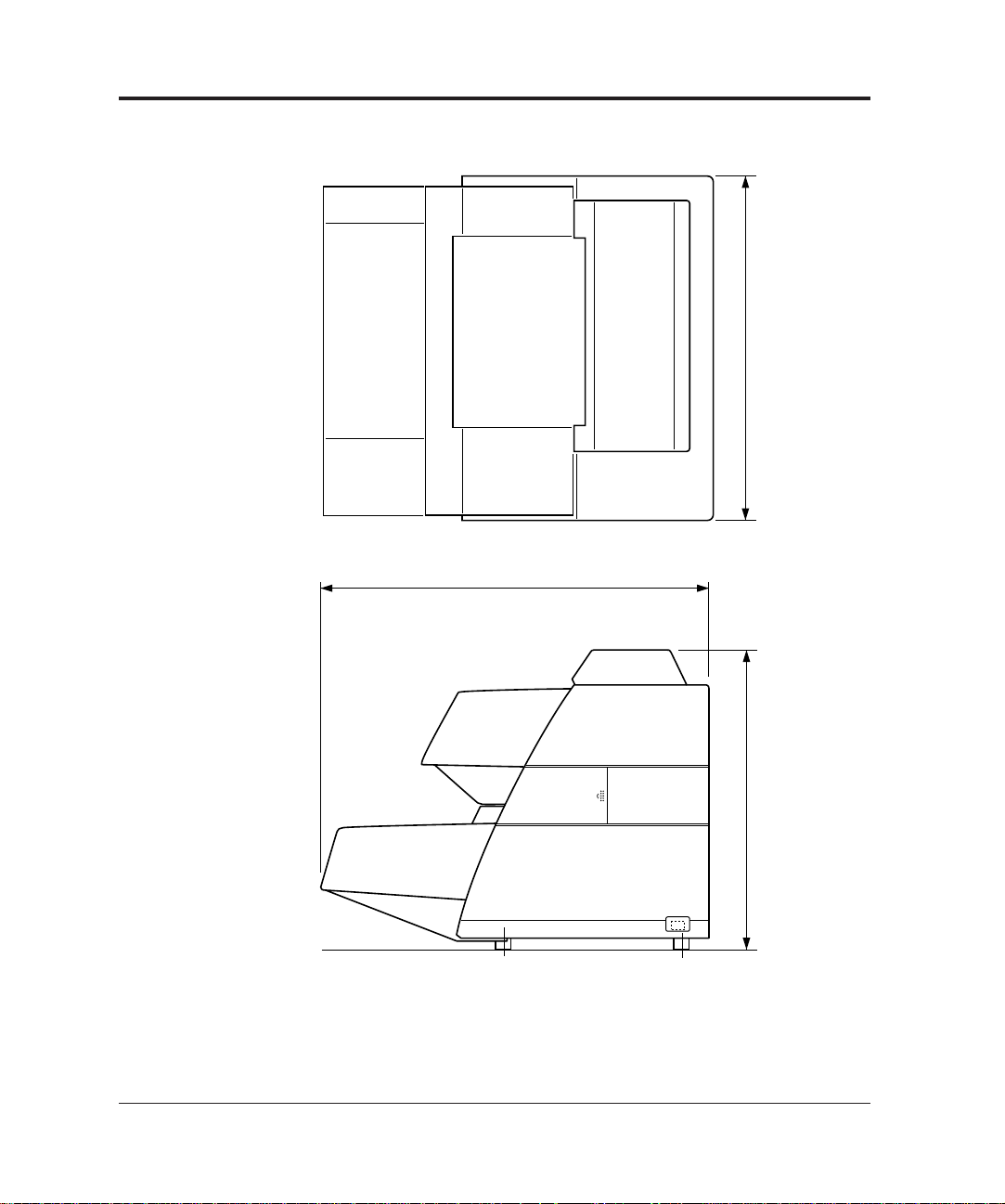

680

610

530

(Unit: mm)

Figure 2.2 Dimensions of 1000 sheets hopper type

2-4 M3099EX/EH OEM Manual

Page 27

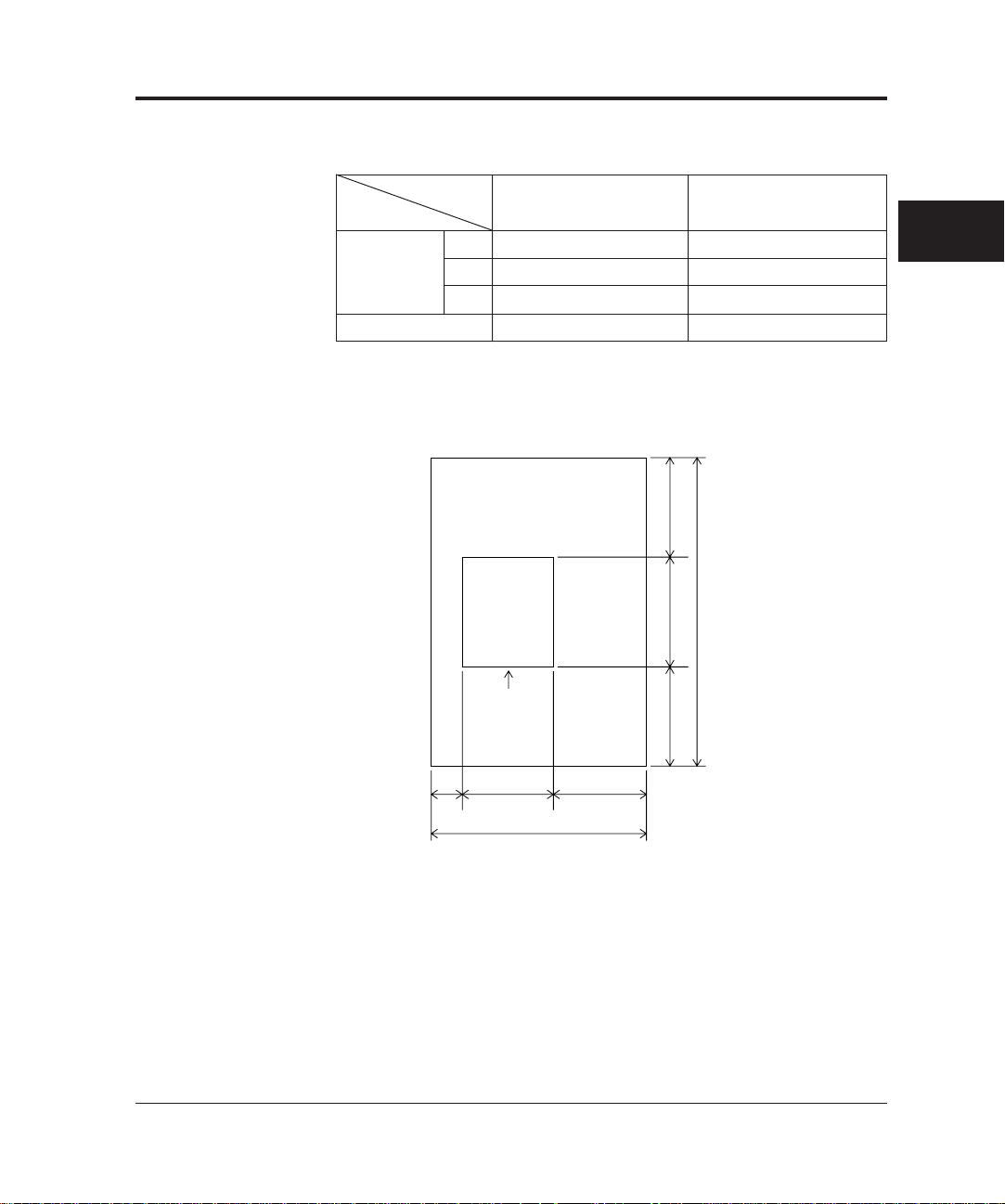

Table 2.4 Physical specifications

Type

Item

Dimensions

Weight

500 sheets hopper type 1000 sheets hopper type

Width

Depth

Height

610 mm 610 mm

680 mm 680 mm

470 mm 530 mm

55kg 65kg

SPECIFICATIONS

600680600

Scanner

F

200 610 600

1,390

1,860

F: Front

(Unit: mm)

Figure 2.3 Service areas

M3099EX/EH OEM Manual 2-5

Page 28

Option Specifications

Table 2.5 lists the scanner option specifications.

Table 2.5 Option specifications

Item

Endorser

Specification

CA01023-D004

Detail

Ink-jet

back-side print

max. 20 characters

Remark

2-6 M3099EX/EH OEM Manual

Page 29

CHAPTER

3

Control Interface

INTERFACE SPECIFICATIONS

This section describes the control interface between the host

computer and the scanner. For details of the interface, refer to the

EIA RS-232C standard.

Connection specifications

Item

Transmission system

Synchronization system

Data length

Stop bit

Data check

Data transfer rate

Maximum connection

Standard

Half-duplex

Start-stop

8 bits

1 bit

Odd parity check

1200, 2400, 4800, 9600 bps

5 m (16 ft.)

EIA RS-232C

0

Start bit

Specification

D1D

D2D3D

Remark

D6D

D

4

5

P

7

Stop

bit

Set by

EEPROM

on Interface

PCA

Default:

4800 bps

INTERFACE

SPECIFICATIONS

M3099EX/EH OEM Manual 3-1

Page 30

Control interface signals

T/D

R/D

RTS

CTS

DTR

DSR

Host computer Scanner

Figure 3.1 Control interface signal lines

Send data (T/D)

This signal is the response and acknowledge for the command sent

on the R/D line.

Received data (R/D)

This line sends the command and acknowledge for a response.

Send request (RTS)

This line sends a request to send a response and acknowledge for the

command.

Transmission enabled (CTS)

This line sends an acceptance of RTS signal.

Terminal ready (DTR)

This signal indicates that the scanner is ready for transmission and

reception.

This signal is set to off when the scanner is turned off, when the

scanner is initially checked after power on.

3-2 M3099EX/EH OEM Manual

Controller ready (DSR)

This signal indicates that the host computer is ready for transmission

and reception.

Page 31

Driver/receiver

• Driver: SN75188 or equivalent

• Receiver: SN75189 or equivalent

To determine the threshold level of the signal at the receiver, the

following circuit must be connected to the response control pins.

–12 V

20 kΩ

To response control pin

100 pF

0V

INTERFACE

SPECIFICATIONS

M3099EX/EH OEM Manual 3-3

Page 32

Timing

RTS

T/D

CTS

a

b

cd

a: +0 ms

b: +0 to 5 ms

c: +0 to 10 ms (more than 1 word length)

d: +0 ms

Scanner → Host computer (At transmission)

3-4 M3099EX/EH OEM Manual

Page 33

Video Interface

This section describes the video interface, which transfers the

scanning data from the scanner to the host computer.

Video interface signals

➤

➤

Host computer Scanner

➤

➤

➤

VCL

HGATE

VGATE

V0 ~ V7 (8 lines)

FAIL

Figure 3.2 Video interface signal lines

(1) VCL

This signal is a sampling clock for the video data V0 to V7.

(2) HGATE

This signal indicates that the main scanning video data is valid.

(3) VGATE

This signal indicates that the subscanning video data is valid.

(4) V0 to V7

INTERFACE

SPECIFICATIONS

These signal lines carry the scanning video data. Logical “0”

indicates a black dot.

(5) FAIL

This signal indicates that a device error (MPU ROM/RAM

error) has occured in the scanner.

M3099EX/EH OEM Manual 3-5

Page 34

Driver/receiver

Driver/receiver for standard connector and µ3096A21 connector.

(1) VCL

Scanner

side

MB463

(2) V0 to V7

MB463, or LS38

Host computer

+5 V

150 Ω

•

330 Ω

0V

1 kΩ

LS240, LS14,

or equivalent

+5 V

•

LS240, LS14,

or equivalent

HGATE, VGATE, FAIL

+5 V

1 kΩ

100 Ω

•

MB463, or LS38

3-6 M3099EX/EH OEM Manual

100 pF

•

LS240, LS14,

or equivalent

0 V

Page 35

Data transfer

Scanning video data is transferred to the host computer trough video

data signal line V0 to V7 in parallel synchronized with VCL.

Transfer sequence

Scanning is performed as sown in Figure 3.3, and the scanning data

is assigned to the video data signal as shown in Figure 3.4. The

scanning data is sent to the host computer in order of scanning.

Main scanning

Subscanning

Figure 3.3 Scanning direction

Main scanning

76543210765 076543210

765432107 012 76543210

INTERFACE

SPECIFICATIONS

Subscanning

7654321 4321076543210

7654321 456 321076543210

Notes:

1. “0” to “7” correspond to the video data signal V0 to V7 respectively.

2. The most significant bit (MSB) of each video data signal is read first.

Figure 3.4 Scanning data assignment

M3099EX/EH OEM Manual 3-7

Page 36

Effect in main scanning

HGATE

∇

VIDEO

X

➤

➤

Y

➤

The values of X, Y, and α are shown in Tables 3.1 and 3.2.

∇ : Reference point of main scanning.

Table 3.1 Transferred data length in main scanning (portrait mode)

Item

Document size

Offset dot

Double-letter* A3 * B4 * A4 B5 A5 LEGAL LETTER

X

12±12

↓↓↓↓

↓

↓↓↓↓

➤

➤

➤

↓↓

↓

↓↓↓↓

α

↓↓↓↓

9±9

8±8

6±6

4864

–

–

–

–

–

3648

–

2920

–

2432

–

Y

Transferred

400 dpi

data

Dummy dots

Offset dot

Transferred

300 dpi

data

Dummy dots

Offset dot

Transferred

240 dpi

data

Dummy dots

Offset dot

Transferred

200 dpi

data

Dummy dots

Note : 1. Data of dummy dots are sent as white.

2. Document size with * mark is available onl for M3099EX.

4400

α

X

Y

3304

α

X

Y

2640

α

X

Y

2200

α

4096

–

↓↓↓

3072

–

2464

–

2048

–

3456

–

2592

–

2080

–

1728

–

3456

–

2592

–

↓↓

2080

–

1728

–

2304

–

↓

1728

–

↓

1384

–

↓

1152

–

3456

3456

–

–

2592

2592

–

–

2080

2080

–

–

1728

1728

–

–

(Unit : lines)

3-8 M3099EX/EH OEM Manual

Page 37

Table 3.2 Transferred data length in main scanning (landscape mode)

Item

400 dpi

Document size

Offset dot

Transferred

data

Dummy dots

Double-letter A3 B4 A4 * B5 * A5 LEGAL LETTER *

X

Y

α

12±12

4680

–

↓↓

4080

–

↓

3312

–

12±12

–

–

–

4400

–

INTERFACE

SPECIFICATIONS

Offset dot

Transferred

300 dpi

data

Dummy dots

Offset dot

Transferred

240 dpi

data

Dummy dots

Offset dot

Transferred

200 dpi

data

Dummy dots

Note : 1. Data of dummy dots are sent as white.

2. Document size with * mark is available onl for M3099EX.

X

Y

α

X

Y

α

X

Y

α

Effect in subscanning

VGATE

∆

9±9

3512

–

8±8

2808

–

6±6

2344

–

3040

–

↓↓

2432

–

2024

–

↓

2480

–

↓

1984

–

↓

1656

–

9±9

–

3304

–

–

–

8±8

–

2640

–

–

–

6±6

–

2200

–

–

–

(Unit : lines)

VIDEO

X

➤

➤

Y

➤

➤

The values of X and Y are shown in Tables 3.3 and 3.4.

∇ : Reference point of subscanning.

M3099EX/EH OEM Manual 3-9

Page 38

Table 3.3 Transferred data length in subscanning (portrait mode)

Item

400 dpi

300 dpi

240 dpi

200 dpi

Document size

Offset dot

Transferred

data

Offset dot

Transferred

data

Offset dot

Transferred

datat

Offset dot

Transferred

data

Double-letter* A3 * B4 * A4 B5 A5 LEGAL LETTER

X

32

Y

6912

X

24

Y

5184

X

20

Y

4160

X

16

Y

3456

↓↓↓↓

6614

4961

3969

3307

↓

5732

↓↓↓

4300

3440

2886

↓↓↓↓

4677

3508

2806

2339

↓↓

4048

3036

↓↓

2429

2024

↓

3307

↓

2480

↓

1984

↓

1654

↓↓↓↓

5600

4200

3360

2800

↓↓↓↓

4400

3300

2640

2200

Note : 1. Document size with * mark is available only for M3099EX.

(Unit : lines)

2. The document size (VGATE) is set to off when the edge of

the document passes the scan position.

3-10 M3099EX/EH OEM Manual

Page 39

Table 3.4 Transferred data length in subscanning (landscape mode)

Item

400 dpi

300 dpi

240 dpi

200 dpi

Document size

Offset dot

Transferred

data

Dummy dots

Offset dot

Transferred

data

Dummy dots

Offset dot

Transferred

data

Dummy dots

Offset dot

Transferred

data

Dummy dots

Double-letter A3 B4 A4 * B5 * A5 LEGAL LETTER *

X

Y

32

3456

↓↓

3456

↓

2304

–

–

α

2592

↓

1728

–

–

X

Y

24

2592

α

X

Y

20

2080

↓↓

2080

1384

–

↓

–

α

1728

↓

1152

–

–

X

Y

16

1728

α

32

3456

INTERFACE

SPECIFICATIONS

24

2592

20

2080

16

1728

Note : 1. Document size with * mark is available only for M3099EX.

(Unit : lines)

2. The document size (VGATE) is set to off when the edge of

the document passes the scan position.

M3099EX/EH OEM Manual 3-11

Page 40

Timing

➤

➤

➤

➤

➤

➤

➤

➤

VCL

t

2

t

1

t

3

t

4

V0 to V7

VCL and V0 to V7

VCL and HGATE

HGATE

VCL

t

5

➤➤➤

Note : VCL is not output when HGATE is off.

~

~

~

~

t

6

➤

HGATE and VGATE

HGATE

VGATE

t

7

➤➤➤

The values of t1 to t8 is shown in Table 3.5.

Note : HGATE is always output.

~

~

~

~

t

8

➤

3-12 M3099EX/EH OEM Manual

Page 41

MIN TYP MAX

t1

t2

t3

t4

t5

t6

t7

t8

700

500

500

100

100

100

100

2000

800

600

600

200

200

200

200

*1

900

700

700

300

300

300

300

[Standard transfer : front-side]

Unit : ns

MIN TYP MAX

t1

t2

t3

t4

t5

t6

t7

t8

300

100

100

100

100

100

100

2000

400

200

200

200

200

200

200

*1

500

300

300

300

300

300

300

[Fast transfer : back-side]

Unit : ns

Table 3.5 Timing specification at binary output

Notes: 1. Timing marked with * varies according to the scanning

area.

INTERFACE

SPECIFICATIONS

M3099EX/EH OEM Manual 3-13

Page 42

Command and Response

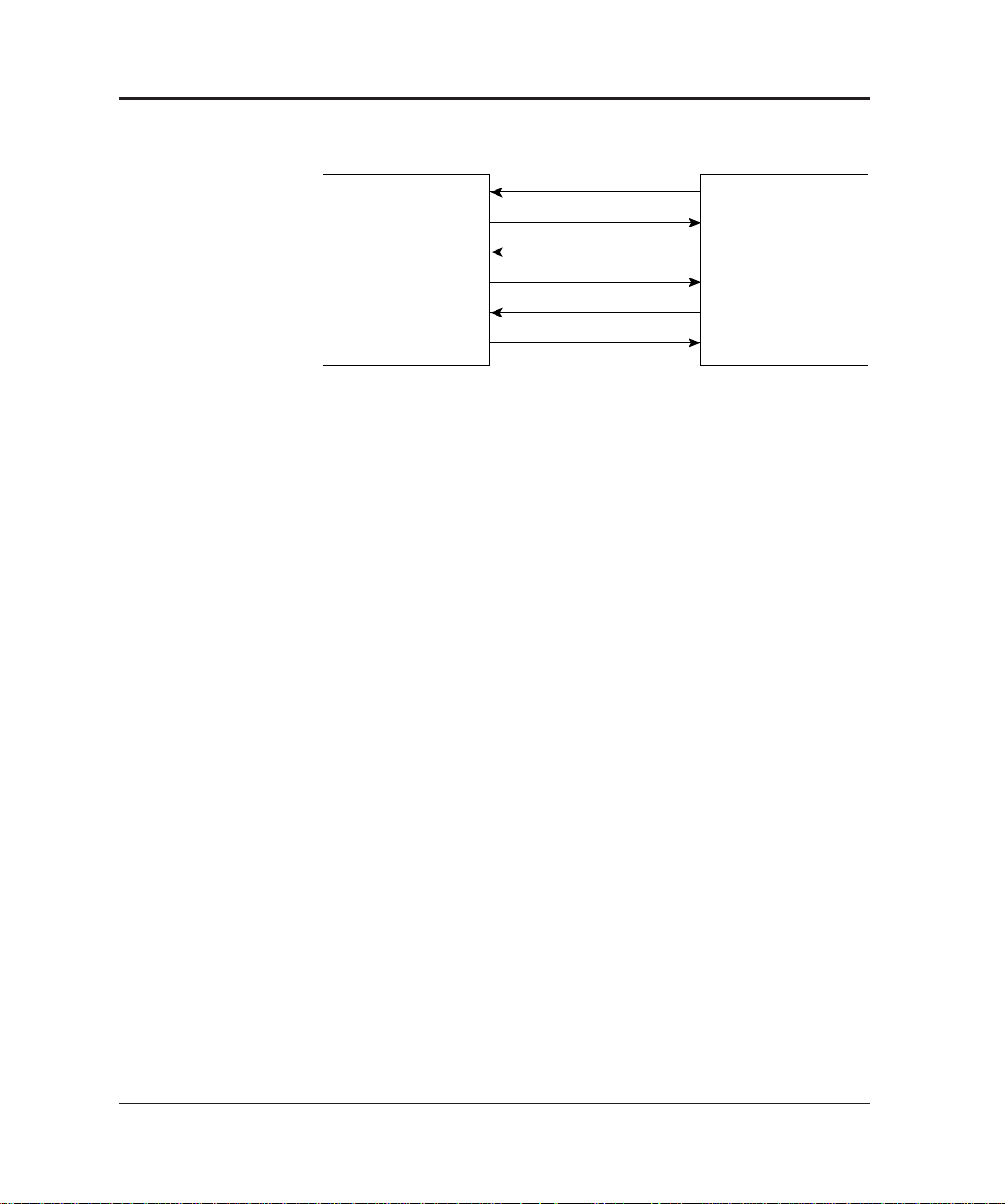

Basic command/response sequence

Data is transmitted between the host computer and the image

scanner in the form of commands and responses. Figure 3.5 shows

the basic command/response sequence.

Host computer

Command

Completion of

command transmission

Command

retransmission

(only twice)

Abnormal

reception

Normal reception

ACK

Reception

error

Scanner

Abnormal

reception

Normal reception

ACK

Reception

error

• Command

processing

• Operation

Response

Response

transmission end

Response

retransmission

(only twice)

Figure 3.5 Basic command/response sequence

3-14 M3099EX/EH OEM Manual

Page 43

Notes:

1. Abnormal reception means that a parity error, framing

error, overrun error, or count error has occurred.

2. Command or response transmission is retried only twice.

3. Upon reception, a command or response is checked for

transmission errors. When the check result has no

problem, ACK is returned immediately to the originating

source. When the check result has problem, data other

than ACK is returned after all data has been received.

Response data

ACK

(Acknowledge)

Parity error

Framing error

Overrun error

Count error

Reception error

4. The originating source of the command/response

monitors the response from the receiving side. ACK

indicates that command/response transmission is

completed.

Details

A command or response has been

received without an error.

A parity error has been detected in

received data.

A framing error or an overrun error has

been detected in received data.

The byte count for the command or

response does not match the number of

bytes transferred.

INTERFACE

SPECIFICATIONS

Code (Hex)

X 'FF'

X'80'

X '81'

X '82'

Reception error causes the command/response to be

transmitted again. The transmission is returned only

twice. After that, the scanner waits for a new command.

5. Response data such as ACK must be retried to the

originating source within 0.5 second.

6. The interval between words in the data stream must be no

more than 10 ms.

M3099EX/EH OEM Manual 3-15

Page 44

Command/response format

The command/response format is as follows.

TEXT Additional fieldCNT CMD/RPS

CNT (count) field

The total number of bytes in the command/response to be

transmitted is represented.

CMD/RPS field

A command or response code is indicated.

TEXT field

Additional information for a command/response, called control or

device information, is indicated.

Additional field

In some commands, additional field exists next to TEXT field.

3-16 M3099EX/EH OEM Manual

Page 45

Command

Commands sent from the host computer to the scanner are as listed

in Table 3.6. The scanner commands are as follows:

Table 3.6 Commands

Command

name

Command

code

Details

INTERFACE

SPECIFICATIONS

CLEAR

CONTROL

IMAGE

CONTROL

PRINT

CONTROL

START

READ

SENSE

RETURN

SENSE

IMAGE

MODE

SENSE

SEND

DITHER 1

SEND

DITHER 2

SEND DATA

INQUIRY

*1: This command can be transmitted only when the image processing

option is connected.

*2: This command can be transmitted only when the endorser option is

connected.

44

58

5A

5E

53

54

41

42

43

46

47

48

40

This command initializes the scanner.

This command can be issued at any time.

This command sets the operation mode of

the scanner and the operation mode in the

main window.

This command sets the image processing

mode of the scanner. (*1)

This command instructs how to print to the

manuscript. (*2)

This command reports the size of a

document to be read.

This command starts reading. The scanner

starts reading according to the operation

mode set previously.

This command requests a status report.

This command requests a status report on

the return of the flatbed read.

This command requests a status report of

the image processing mode of each main

window and the number of pixels (in units

of a byte) per line in the X- direction.

This command transfers the dither and

overlay patterns.

This command transfers the dither, γ curve,

or overlay patterns.

Transfers print pattern and data items. (*2)

This command requests a device

information report.

M3099EX/EH OEM Manual 3-17

Page 46

3

CLEAR command details

Control register start

number.

Image control register start

number.

Print information I

IMAGE MODE SENSE

command details

Dither or overlay pattern

number.

X'00'

Print information III

Command

name

CLEAR

CONTROL

IMAGE

CONTROL

PRINT

CONTROL

START

READ

SENSE

RETURN

SENSE

IMAGE

MODE

SENSE

INQUIRY

SEND

DITHER 1

SEND

DITHER 2

SEND DATA

1

X'03'

X'0X'

X'0X'

X'0B'

X'02'

X'02'

X'02'

X'02'

X'03'

X'02'

X'43'

X'05'

X'XX'

2

X'44'

X'58'

X'5A'

X'5E'

X'53'

X'54'

X'41'

X'42'

X'43'

X'40'

X'46'

X'47'

X'48'

4 or later

Control register

Image control register

Byte 4: Print information II

Byte 5 and 6: Print position X

Byte 7 and 8: Print position Y

Byte 9: Number counter

method

Byte 10 and 11: Number initial

value

Dither or overlay pattern

64 bytes or more

Byte 4 and 5: CNT

Byte 6: Pattern ID

Byte 7 or later: Dither, overlay

or γ curve data

Printing data

3-18 M3099EX/EH OEM Manual

Page 47

CLEAR command

b7 b0

00: POWER ON CLEAR

This command resets the system to the

power-on status.

01: Control register clear

This command intitializes the operation

mode, image processing mode, and

subwindow mode. (*1)

10: Reading stop

This command stops operation during

(VGATE OFF, return) and ejects any

documents remaining in the ADF.

If this command is received after the frontside is reading ends, the scanner is placed

in wait state.

*1: If a CONTROL REGISTER CLEAR command is issued after the

READ command is sent to the scanner but before the Read

Complete

is recieved from the scanner, a command sequence error occur.

Note: "Ready" is the response when this command ends normally.

This command initializes the scanner and can be issued at any time.

b7 b0

b7 b0

CNT

(X‘03’)

CLEAR command details

CMD

(X‘44’)

b7 b0

CLEAR

command

INTERFACE

SPECIFICATIONS

M3099EX/EH OEM Manual 3-19

Page 48

CONTROL command

CNT (X'0X') CMD (X'58')

Control register No.

Control register

b7

b0 b7 b0 b7 b0 b7 b0

Control register No.

#0

#1

#2

#0

#XX

#21

#0

#XX

#21

EXT. control reg.

EXT. control reg.

EXT. control reg.

Control reg. A

Control reg. A

Control reg. B

Control reg. B

10

00

01

11

b7 b6

b7 b6

b7 b6

b7 b6

Selection

of register

Undefined

Front-side

reading

Back-side

reading

REG No.

This command sets the scanner to the operation mode.

Selection of control register

This scanner has an additional function to select control register,

using bits 6 and 7 of byte 3 of the CONTROL command supported

by the existing devices (M3093E, M3096E+, and M3097E).

• Front-side reading or front-side and back-side reading control

register specification

• Back-side reading control register specification

• Extended control register specification

The registers are specified as follows:

3-20 M3099EX/EH OEM Manual

Hereafter, a control register for front-side reading (compatible with

the exiting devices) is called control register A. A control register for

back-side reading is called control register B.

Page 49

Extend control register

Extend control register #0

b7 b0

00#0

Transfer mode (back-side) (*1)

Reading mode specification

0××: Set from the operator panel

100: Front-side reading

11×: Duplex reading

*1: See the 3-23 page.

INTERFACE

SPECIFICATIONS

[00h]

This function specifies how image data in the

back-side memory should be transferred.

000: Transfer mode 0

001: Transfer mode 1

010: Transfer mode 2

011: Transfer mode 3

1××: Reserved

M3099EX/EH OEM Manual 3-21

Page 50

Extend control register #1

This register is not supported.

b7 b0

#1

00

000000

[00h]

X'00' is set when the power is turned on or when a CLEAR

command is issued for initialization.

3-22 M3099EX/EH OEM Manual

Page 51

[Data transfer mode]

Transfer mode Front-side Back-side Ext

Mode 0

Mode 1

Mode 2

C

A

Main

Sub

BD

C

Main

Sub

DB

C

Main

Not supported

DB

C

Not supported

DB

Main

Sub

Sub

A

INTERFACE

SPECIFICATIONS

A

Mirror

A

Mode 3

C

A

Mirror

Not supported

Sub

DB

Main

: Scanning reference position

M3099EX/EH OEM Manual 3-23

Page 52

#2

b7 b0

[00h]

Transfer rate (front-side)

Transfer rate (back-side)

0×××: Depending on devices (800 ns)

1000: Undefined

1001: 800 ns

1010: Undefined

1011: Undefined

1100: Undefined

1101: Undefined

1110: Undefined

1111: Undefined

•This register specifies the front-side and back-side image data

transfer rates.

0×××: Depending on devices

(800 /400ns change by EEPROM)

1000: Undefined

1001: 800 ns

1010: 400 ns

1011: Undefined

1100: Undefined

1101: Undefined

1110: Undefined

1111: Undefined

Extend control register #2

3-24 M3099EX/EH OEM Manual

Page 53

Extend control register #3

#3 00 000000

b7 b0

[00h]

X'00' is set when the power is turned on

or when a CLEAR command is issued

for initialization

This register is not supported.

INTERFACE

SPECIFICATIONS

M3099EX/EH OEM Manual 3-25

Page 54

Control register A#0

X'00' is set when the power is turned on or when a CLEAR

command is issued for initialization.

b7 b0

A#0 0 0 0

Scanning resolution

0×××: Set from the operator panel

1000: 400 dpi

1001: 300 dpi

1010: 240 dpi

1011: 200 dpi

1100:

1101:

Not defined

1110:

1111:

Specified start of reading (*2)

0: Operation panel (*1)

1: Host computer

*1: When the start of reading is specified from the operator panel,

the Ready lamp lights at reception of a START command.

*2 If the manual mode is selected at the operator panel, reading

actually starts when a document is loaded on the scanner.

Control register B#0

b7 b0

B#0

00000000

3-26 M3099EX/EH OEM Manual

Page 55

Control register A#1

Control register B#1

X’00' is set when the power is turned on or when a CLEAR

command is issued for initialization.

b7 b0

A#1

B#1

Density

00×××: Set from the operator panel

01000: Light

01001:

01010: Somewhat light

01011:

01100: Normal

01101:

01110: Somewhat dark

01111: Dark

1××××: Dynamic threshold (*1)

Linedrawing/photograph

0×: Set from the operator panel

10: Linedrawing (*2)

11: Photograph (*2)

*1: This function is valid for image processing circuit (IPC II) option.

When the IPC II option is installed and these bits indicate IXXXX, the

scanner applies the DTC function, and the function of the image control

register are not operated.

INTERFACE

SPECIFICATIONS

Darken more

and more

(*3)

*2 The scanning speed of ADF (sheets/min) in linedrawing mode is different

from that of photograph mode.

*3: When the control resister #19, bit 0 is "0", eight types density are selectable

by control register #1, bit 3 to 0.

And when the control register #19, bit 0 is "1", 256 types density are

sellectable by the control register #20.

M3099EX/EH OEM Manual 3-27

Page 56

b7 b0

*2: Dithered or Error diffusion are selected by control register #19.

000:

001:

010:

011:

100:

101:

110:

111:

Dither pattern No. specification

Built-in/Download

0: Built-in

1: Download

A#2

B#2

00

Specifies halftone

0×: Set from the operator panel

10: Not dithered

11: Dithered or Error diffusion (*2)

• When the built-in pattern is used, the density information shown in the

control register #1 is valid.

• Four patterns (000 to 011) are valid when the built-in pattern is selected.

• When the download pattern is used, the density information shown in

control register #1 is invalid.

• Eight patterns (000 to 111) is valid when the download pattern is

*1:

(*1)

Control register A#2

Control register B#2

X’00' is set when power is turned on or when a CLEAR command

issued for initialization.

3-28 M3099EX/EH OEM Manual

Page 57

Control register A#3

Control register B#3

X’A6' is set when power is turned on or when a CLEAR command is

issued for initialization.

• This register is valid when the IPC II option is installed.

b7 b0

A#3

B#3

DTC

Threshold curve

000: Light

001:

010:

011:

100:

101: Dark

110: Dark

111: Light

γ curve

00: Character recognition 1

01: Character recognition 2

10: Dark image

11: Equalized splitting

For OCR

Daken more

and more

For image scanner

INTERFACE

SPECIFICATIONS

Smoothing mode

00: For OCR

01: For image scanner

10:

Not defined

11:

Filtering

0: Ball-point pen mode

1: Ordinary mode

M3099EX/EH OEM Manual 3-29

Page 58

Control register A#4

Control register B#4

X’20' is set when power is turned on or when a CLEAR command is

issued for initialization.

• This register is valid when the IPC II option is installed.

b7 b0

A#4

B#4

00

(Dynamic threshold mode setting)

Binary data when the threshold equals

video data to be binary-coded. (*1)

0: Output binary data is "1". (Black)

1: Output binary data is "0". (White)

Noise removing of 2 × 2 matrix

0: OFF

1: ON

Noise removing of 3 × 3 matrix

0: OFF

1: ON

Noise removing of 4 × 4 matrix

0: OFF

1: ON

Noise removing of 5 × 5 matrix

0: OFF

1: ON

Enables the noise removing bits

(bits 1-4 when this bit is active).

0: ON

1: OFF

*1: When this bit is "0", the output video data is black if the

gradation of the video data is equal to or larger than threshold.

When this bit is "1", the output video data is white if the

gradation of video data is equal to or larger than threshold.

3-30 M3099EX/EH OEM Manual

Page 59

Control register A#5

X'00' is set when the power is turned on or when a CLEAR

command is issued for initialization. Default document size depends

on the EEPROM setting.

b7 b0

A#5

Standard document size

0000: A0

0001: A1

0010: A2

0011: A3 (Defined only M3099EX)

0100: A4

0101: A5

0110: Double-letter (Defined only M3099EX)

0111: Letter

1000: B0

1001: B1

1010: B2

1011: B3

1100: B4 (Defined only M3099EX)

1101: B5

1110:

1111: Legal

Specifies a vertical or horizontal direction

0: Portrait

1: Landscape

Picking

0: Not specified

1: Specified

Document selection

00: Set from the operator panel

01: Depends on setting from the operator

panel or the size detector of the ADF

10: Depends on the value of the standard

document size setting register.

Not defined

Not defined

Not defined

INTERFACE

SPECIFICATIONS

M3099EX/EH OEM Manual 3-31

Page 60

Control register B#5

B #5

00

b7 b0

Picking

0: Invalid

1: Valid

00 00 0

X’00' is set when the power is turned on or when a CLEAR

command is issued for initialization.

Control register A#6 to #9

Control register B#6 to #9

Not specified for this scanner.

NONSTANDARD DOCUMENT SIZE SETTING REGIS

3-32 M3099EX/EH OEM Manual

Page 61

Control register A#10 to #17

Control register B#10 to #17

Picking area (main window) setting register

#10

b7 b0

#11

b7 b0

LSBMSB MSB LSB MSB LSB MSB LSB

Picking in main scanning

*1

#12

b7 b0

Y1

Y2

#13

b7 b0

b7 b0

Document surface

#14

X2X1

Picking

area

#15

b0

b7

Picking in subscanning

#16

b7

Upper edge

▲

of document

b0

#17

b7

b0

Y2Y1X2X1

INTERFACE

SPECIFICATIONS

▲

Left edge of document

Operation error occurs when the values of X1 + X2 [(#10, #11) +

(#12, #13)] and Y1 + Y2 [(#14, #15) + (#16, #17)] area more than

the values shown below.

Scanner

M3099EX

M3099EH

X1 + X2

4864

3456

M3099EX/EH OEM Manual 3-33

Y1 + Y2

6912

6912

Page 62

• These values must be specified in binary in unit of 1/400-inch.

Reference point

Document

board

Area to be scanned

Front side of scanner

A

B

Note: 1. When the picking is specified, only a specified area of the

document is read. However, when the ADF is used, and

the document length is shorter than the specified area,

read operation is stopped at the edge of document.

2. When the specified area is larger than the double-letter

size, read area specification error occurs.

3. When the jam detection bit (control register #2) is "1", a

setting of Y2 is ignored.

Picking is specified when the scanner is required to read a special area

as shown below.

Picking is applied when bit 5 the control register #5 is "1" and the

address of points A and B is specified in the control registers #10 to

#17.

REG.

CNT CMD

REG.

No.

[Example]

or

CMDCNT

Note: When these registers are specified, four consecutive registers

(#10 to #13 or #14 to #17) must be specified.

3-34 M3099EX/EH OEM Manual

#10 #11 #12 #13

No.

(#14) (#15) (#16) (#17)

#17#16#15#14#13#12#11#10

Page 63

Control register A#18

Control register B#18

X”00" is set when the power is turned on or when a CLEAR

command is issued for initialization.

• This register reserved for future.

b7 b0

INTERFACE

SPECIFICATIONS

A #19

B #19

A #18

B #18

00 00000

0

Control register A#19

Control register B#19

X’00' is set when the power is turned on or when a CLEAR

command is issued for initialization.

b7 b0

00

Read density specification

0: 8 steps (Control register #1 is valid.)

1: 256 steps (Control register #20 is valid.)

Halftone processing method specification

0: Dithering

1: Error diffusion

γ pattern number specification (*1)

0 0 0 : Normal

0 0 1 : Soft

0 1 0 : Sharp

0 1 1

1 0 0 : Three types (0 to 2) if the built-in

1 0 1 patterns are valid.

1 1 0 : Eight types (0 to 7) if the downloading

1 1 1 is enabled.

Download/built-in γ patterns

0: The patterns built into the device are valid.

1: The download patterns are valid.

*1: If the built-in patterns are valid, 0 to 2 ('000' to '010') can be

selected.

M3099EX/EH OEM Manual 3-35

Page 64

Control register A#20

Control register B#20

X’00' is set when the power is turned on or when a CLEAR

command is issued for initialization.

b7 b0

A #20

B #20

Read density

(256-step selection) (*1)

X'00': Default (same as for X'80')

X'01': Light

X'FF': Dark

*1: This register is valid if bit 0 control register #19 is 1.

3-36 M3099EX/EH OEM Manual

Page 65

Control register A#21

Control register B#21

X'00' is set when the power is turned on or when a CLEAR

command is issued for initialization.

A #21

B #21

b7 b0

INTERFACE

SPECIFICATIONS

Contrast specification

X'00': Default (same as for X'80')

X'01': Lowest contrast

X'80': Normal

X'FF': Highest contrast

M3099EX/EH OEM Manual 3-37

Page 66

IMAGE CONTROL command

This command sets the scanner to the operation mode of the image

processing circuit.

Byte 1

CNT

X'0X'

(Byte 3)

Byte 2

CMD

X'5A'

Byte 3

TEXT

Image control

register start number

b7 b0

0

b6

0

Selects image control register A (front-side)

1

Selects image control register B (back-side)

Description

Byte 4

or later

Image control

register

Image control register No.

Front-side/back-side select

Note: If this command is sent to the scanner without image

processing option (IPC II), the scanner sends "Operation

error" as response.

3-38 M3099EX/EH OEM Manual

Page 67

Image control register

When the image processing option (IPC II) is connected, the

following image processing can be excuted. This register sets the

image processing mode.

– Image area automatic separation function (simultaneous reading

or characters and photographs)

– Inversion function (black/white conversion)

– Mirror image output function (right/left conversion)

– Image emphasis, outline extraction function

– Overlay function

– Simplified dynamic threshold.

– Zooming function ranging from 25% to 100% in 1%

increments.

Image control register A#0, B#0

X’00' is set when the power is turned on or when a CLEAR

command is issued for initialization.

b7 b0

#0

00 00000

0

This register must be sent before setting the image control registers

#1 to #8.

INTERFACE

SPECIFICATIONS

M3099EX/EH OEM Manual 3-39

Page 68

Image control register A#1, B#1

X”00" is set when the power is turned on or when a CLEAR

command is issued for initialization.

b7 b0

#1

00 0

Automatic separation specification (*1)

0 x : Set from the operator panel (*2)

1 0 : Automatic separation is not done.

1 1 : Automatic speparation

Conversion mode specification

0 x x : Not operation

1 0 0 : Not provided with white/black conversion.

Not provided with right/left conversion.

1 0 1 : Not provided with white/black conversion.

Provided with right/left conversion.

1 1 0 : Provided with white/black conversion.

Not provided with right/left conversion.

1 1 1 : Provided with white/black conversion.

Provided with right/left conversion.

Note: Image control registers #1 to #3 must be sent in one sequence.

One of automatic separation, image emphasis, outline extract,

overlay can be specified.

*1: Halftone specification (control register #2) is invalid in the

automatic separation mode. However, halftone processing

(dither or error diffusion) for photo area follows control register

#19, and the dither pattern follows control register #2.

*2: When automatic separation specification is based on operator

panel, the bit 7 of image control register #2 and the bit 3 of

image control register #3 must be set to '0'.

3-40 M3099EX/EH OEM Manual

Page 69

b7 b0

Sharpness control (image emphasis)

0 0 0 : Normal

0 0 1 : Emphasis, large Sharp

0 1 0 : Emphasis, middle

0 1 1 : Emphasis, small

1 x x : Smoothing Soft

Outline extraction control

0 0 : Outline extract

0 1 :

1 0 :

1 1 :

Sharpness, outline extraction specification

0 x x : Not operation

1 0 0 : Not operation

1 0 1 : Enables sharpness control.

1 1 0 : Enables outline extraction.

1 1 1 : Not defined

#2

Not defined

Image control register A#2, B#2

X’00' is set when the power is turned on or when a CLEAR

command state is issued for initialization.

INTERFACE

SPECIFICATIONS

M3099EX/EH OEM Manual 3-41

Page 70

b7 b0

Overlay specification (*1)

0 x : Not operation

1 0 : Not overlay

1 1 : Overlay

Overlay mode number specification

0 0 0

0 0 1

0 1 0

0 1 1

1 0 0

1 0 1

1 1 0

1 1 1

Download/built-in overlay pattern

0 : Built-in pattern valid

1 : Download pattern valid

#3

00

(*2)

Image control register A#3, B#3

X’00' is set when the power is turned on or when a CLEAR

command is issued for initialization.

*1: When dither or error diffusion processing is valid by the control

register #2 or operator panel, overlay is not performed even if it

3-42 M3099EX/EH OEM Manual

is valid by this register.

*2: This scanner has six patterns as built-in overlay pattern. ("000"

to "101")

Eight patterns can be registered as download pattern. ("000" to

"111")

The bits 4 to 7 is valid when the overlay specification is valid.

Page 71

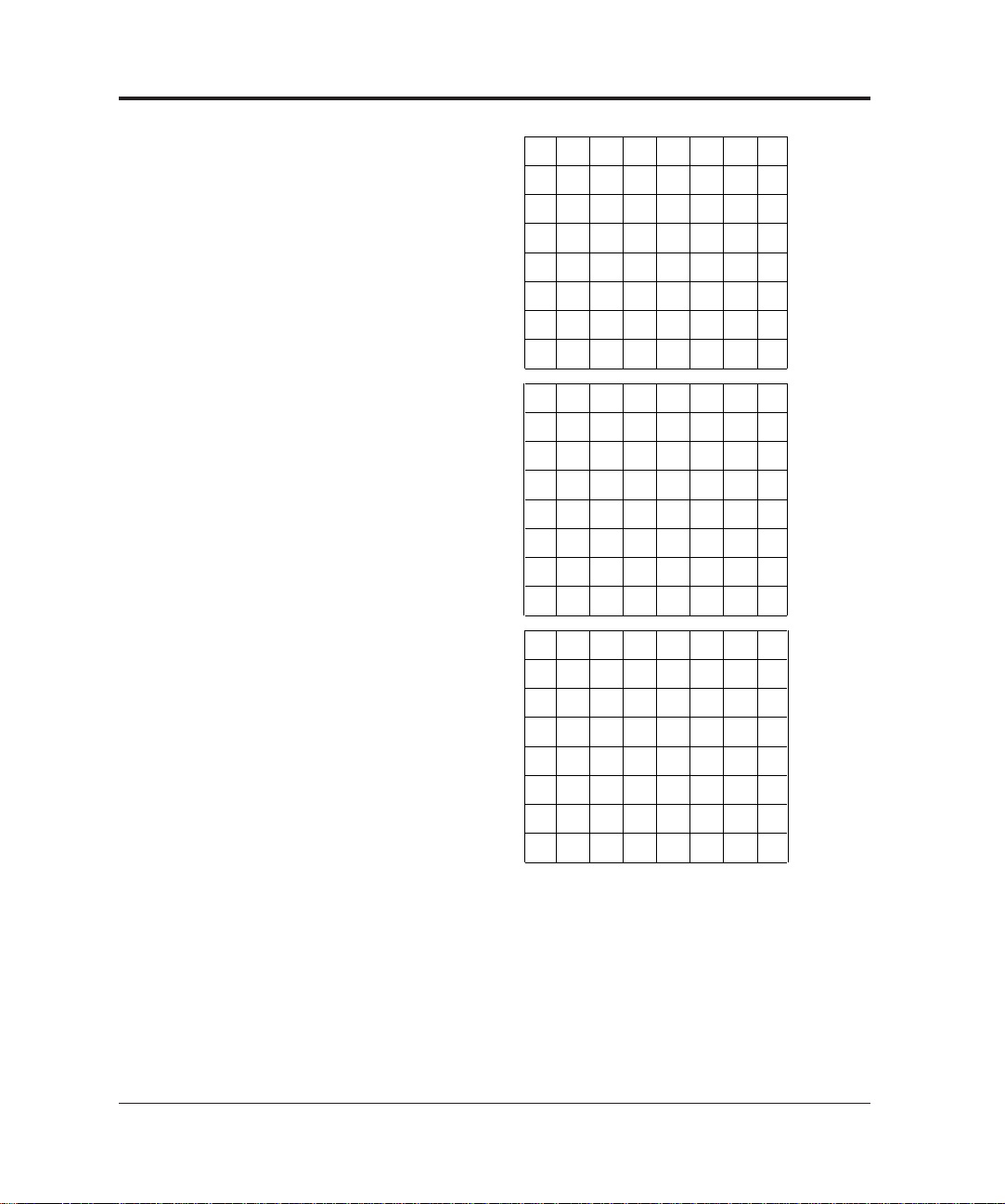

Built-in overlay pattern

00

00

00

00

00

00

00

00

FF

FF

FF

FF

00

00

00

00

FF

FF

FF

FF

No. 0 Horizontal lines 00

00

00

00

00

00

00

00

00

00

00

00

00

FF

FF

FF

FF

FF

FF

FF

FF

FF

FF

FF

FF

FF

FF

FF

FF

00

00

00

FF

FF

FF

FF

00

00

00

00

FF

FF

FF

FF

INTERFACE

SPECIFICATIONS

No. 1 Vertical lines

No. 2 Angled pattern

00

00

00

00

00

00

00

00

FF

FF

00

00

00

00

FF

FF

00

00

00

00

00

00

00

00

FF

FF

FF

00

00

00

00

FF

00

00

00

00

00

00

00

00

FF

FF

FF

FF

00

00

00

00

00

00

00

00

00

00

00

00

00

FF

FF

FF

FF

00

00

00

FF

FF

FF

FF

FF

FF

FF

FF

00

00

FF

FF

FF

FF

00

00

FF

FF

FF

FF

FF

FF

FF

FF

00

00

00

FF

FF

FF

FF

00

FF

FF

FF

FF

FF

FF

FF

FF

00

00

00

00

FF

FF

FF

FF

FF

FF

FF

FF

FF

FF

FF

FF

FF

00

00

00

00

FF