Page 1

M3097DG

Image Scanner

OEM Manual

C150-E103-01EN

Page 2

Page 3

REVISION RECORD

Edition Date published Revised contents

01 Dec. 1997 First Edition

Specification No.: C150-E103-01EN

The contents of this manual is subject to change

without prior notice.

All Rights Reserved,

Copyright 1997 FUJITSU LIMITED

Page 4

This page is intentionally left blank.

Page 5

CONTENTS

Chapter 1 General.......................................................................................................... 1-1

1.1 General description..................................................................................................................... 1-1

1.2 Appearance and parts name......................................................................................................... 1-2

Chapter 2 Specifications ................................................................................................. 2-1

2.1 Basic specifications..................................................................................................................... 2-1

2.2 Option specifications ................................................................................................................... 2-2

2.3 Reading limitation depending on the memory installed................................................................. 2-3

2.4 Physical specifications................................................................................................................. 2-4

2.5 Regulation conformity................................................................................................................. 2-4

2.6 Document specifications.............................................................................................................. 2-5

2.6.1 Paper size ............................................................................................................................ 2-5

2.6.2 Paper conditions................................................................................................................... 2-6

2.6.3 ADF capacity....................................................................................................................... 2-8

2.6.4 Areas that must not be perforated (for ADF reading only)...................................................... 2-9

2.6.5 Grounding color area...........................................................................................................2-10

2.6.6 Job separation sheet.............................................................................................................2-11

Chapter 3 Image Functions............................................................................................ 3-1

3.1 Overview of the image functions.................................................................................................. 3-1

3.2 Basic image functions.................................................................................................................. 3-3

3.2.1 Output resolution ................................................................................................................. 3-3

3.2.2 Main Window Clipping........................................................................................................ 3-3

3.2.3 Binary reading ..................................................................................................................... 3-9

3.2.4 Halftone reading .................................................................................................................3-10

3.2.5 Grayscale reading................................................................................................................3-12

3.2.6 Compression.......................................................................................................................3-12

3.3 Optional image function.............................................................................................................3-13

3.3.1 DTC mode function (Auto I mode) ....................................................................................... 3-13

3.3.2 IPC mode (Auto II mode).....................................................................................................3-20

3.3.3 Sub-Window ....................................................................................................................... 3-27

3.3.4 Zooming.............................................................................................................................3-28

3.3.5 Dither download..................................................................................................................3-28

3.3.6 Gamma download................................................................................................................3-28

Chapter 4 Storage and Installation ................................................................................ 4-1

i

Page 6

4.1 Packaging box and storage condition ............................................................................................ 4-1

4.2 Components in the packaging box................................................................................................4-2

4.3 Installation procedure..................................................................................................................4-2

4.3.1 Removing the carrier fixing bracket ...................................................................................... 4-2

4.3.2 Connections .........................................................................................................................4-4

4.3.3 Mounting the stacker............................................................................................................ 4-4

4.3.4 SCSI-ID setting...................................................................................................................4-5

Chapter 5 Operation and Maintenance..........................................................................5-1

5.1 Operator panel operation ............................................................................................................. 5-1

5.1.1 Operator panel function........................................................................................................ 5-1

5.1.2 Manual Feed mode ............................................................................................................... 5-2

5.1.3 Setup mode .......................................................................................................................... 5-3

5.1.4 Function of CE mode............................................................................................................5-6

5.2 Document setting ........................................................................................................................ 5-7

5.2.1 Document setting on ADF paper chute .................................................................................. 5-7

5.2.2 Document setting on flatbed................................................................................................ 5-10

5.3 Cleaning................................................................................................................................... 5-11

5.4 Consumable .............................................................................................................................. 5-12

Chapter 6 Error display and Recovery........................................................................... 6-1

6.1 Error display............................................................................................................................... 6-1

6.1.1 Temporary error................................................................................................................... 6-1

6.1.2 Alarm .................................................................................................................................. 6-1

6.2 Jam clearance.............................................................................................................................. 6-2

Appendix A Scanner Interface....................................................................... Appendix A-1

A.1 Physical Specifications ................................................................................................Appendix A-2

A.2 SCSI Bus ....................................................................................................................Appendix A-5

A.2.1 System configuration............................................................................................Appendix A-5

A.2.2 Bus signals...........................................................................................................Appendix A-6

A.2.3 Bus signal drive conditions...................................................................................Appendix A-7

A.3 Bus Phases..................................................................................................................Appendix A-8

A.3.1 BUS FREE phase................................................................................................ Appendix A-11

A.3.2 ARBITRATION phase........................................................................................Appendix A-11

A.3.3 SELECTION phase.............................................................................................Appendix A-13

A.3.4 RESELECTION phase........................................................................................Appendix A-14

A.3.5 INFORMATION TRANSFER phases ..................................................................Appendix A-15

ii

Page 7

A.4 Commands................................................................................................................ Appendix A-20

A.4.1 RESERVE UNIT command ................................................................................ Appendix A-22

A.4.2 RELEASE UNIT command................................................................................. Appendix A-24

A.4.3 INQUIRY command........................................................................................... Appendix A-25

A.4.4 REQUEST SENSE command .............................................................................. Appendix A-41

A.4.5 SEND DIAGNOSTIC command.......................................................................... Appendix A-46

A.4.6 TEST UNIT READY command .......................................................................... Appendix A-48

A.4.7 SET WINDOW command ................................................................................... Appendix A-49

A.4.8 SET SUBWINDOW command............................................................................ Appendix A-69

A.4.9 OBJECT POSITION command ........................................................................... Appendix A-77

A.4.10 SEND command................................................................................................. Appendix A-81

A.4.11 READ command ................................................................................................ Appendix A-87

A.4.12 MODE SELECT (6) ........................................................................................... Appendix A-94

A.4.13 MODE SENSE (6) ............................................................................................Appendix A-100

A.4.14 SCAN...............................................................................................................Appendix A-104

A.5 Status: STATUS phase (target → initiator).............................................................Appendix A-106

A.6 Messages .................................................................................................................Appendix A-107

A.6.1 ATN detection...................................................................................................Appendix A-107

A.6.2 Message types ...................................................................................................Appendix A-107

A.7 Command Sequence .................................................................................................Appendix A-115

A.7.1 Initial sequence.................................................................................................Appendix A-115

A.7.2 Command sequence to read................................................................................Appendix A-116

A.7.3 READ command sequence.................................................................................Appendix A-119

A.8 Status Transition of Logical Unit..............................................................................Appendix A-124

A.9 Error Table..............................................................................................................Appendix A-125

Appendix B Interface deference between M3097DG and M3093DG ............ Appendix B-1

B.1 Product identification.................................................................................................. Appendix B-1

B.2 Window width and length............................................................................................ Appendix B-1

B.3 Buffering capability..................................................................................................... Appendix B-2

B.4 Window data limitation............................................................................................... Appendix B-2

B.5 Paper size specification ............................................................................................... Appendix B-3

B.6 Paper width X limitation of nonstandard size document ................................................ Appendix B-3

B.7 The limitation of grayscale output ................................................................................ Appendix B-4

B.8 Paper size at DATA IN phase after Read command....................................................... Appendix B-4

B.9 General Remarks......................................................................................................... Appendix B-5

B.9.1 Command sequence .............................................................................................. Appendix B-5

B.9.2 Additional sense code/ Additional sense code qualifier........................................... Appendix B-5

iii

Page 8

Appendix C Throughput................................................................................Appendix C-1

C.1 Offline test..................................................................................................................Appendix C-1

C.2 Online test .................................................................................................................. Appendix C-1

iv

Page 9

Chapter 1 General

1.1 General description

M3097DG image scanner is an ideal input device for Electric filling systems, Facsimiles, optical

character readers (OCR), computer aided design (CAD) systems, and automatic publishing systems.

M3097DG is basically the scanner which have the duplex scanning feature with the basis of M3097G+

and with the interface compatibility to M3097G+ and M3093DG. The features of the scanner are focused

on as follows.

(1) Duplex reading

This scanner can read duplex document with one scanning to reduce the scanning workload.

(2) Excellent paper-handling

This scanner can scan various kind of the document such as the size from A3 to A6.

(3) Fast reading

This scanner scans with the following scanning speed.

Simplex, A4, 200 dpi: 36 PPM (A4,200 dpi)

Duplex, A4, 200 dpi: 60 IPM (A4,200 dpi)

(4) High quality image

This scanner reads the documents with 400 dpi basic resolution.

(5) Image processing

This scanner basically supports dither and error diffusion. Various image processing is available

when supported IPC option.

(6) New functions

Following functions are available for instance.

• Double feed detection

• Easy setting for some documents (IPC pre-setting function)

• Manual feed mode

1-1

Page 10

General

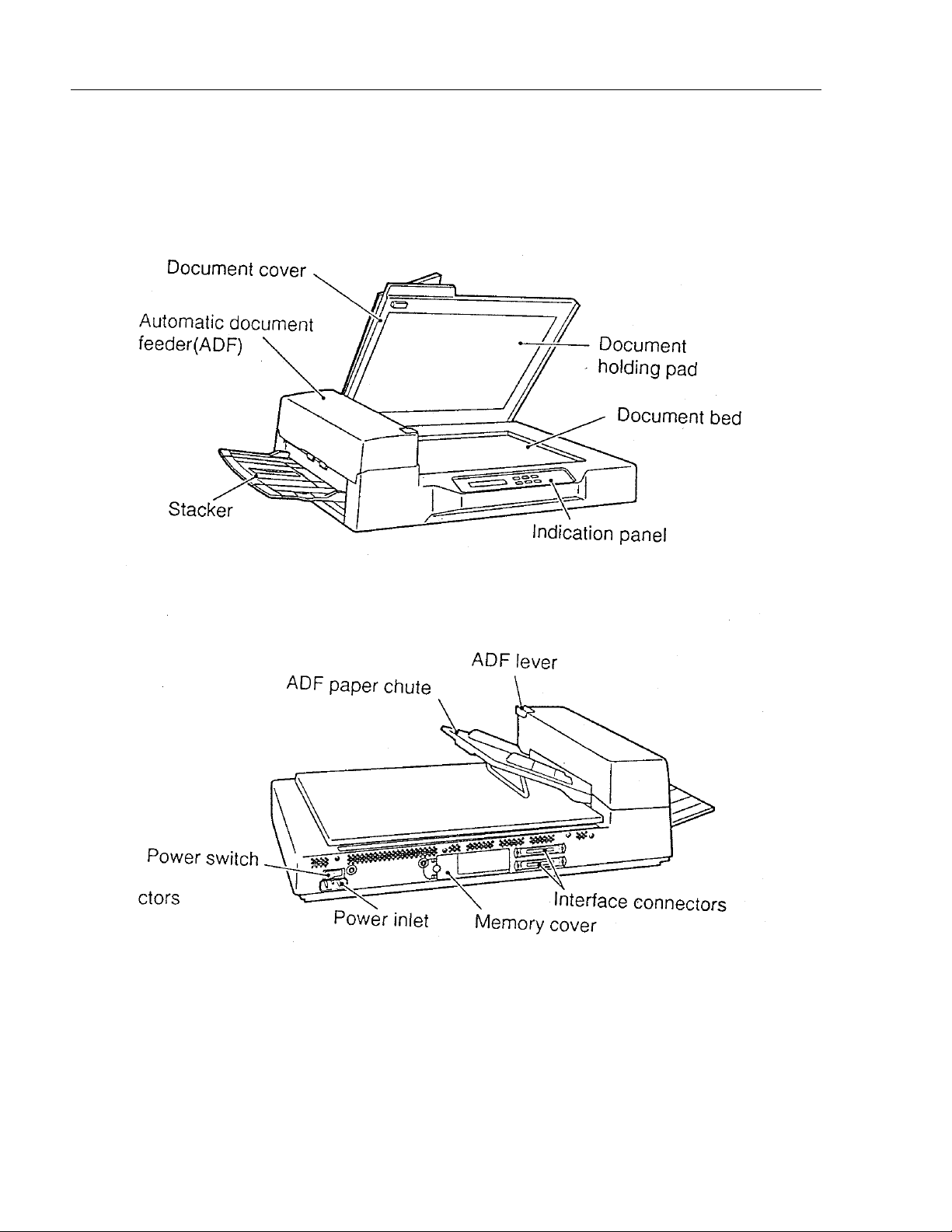

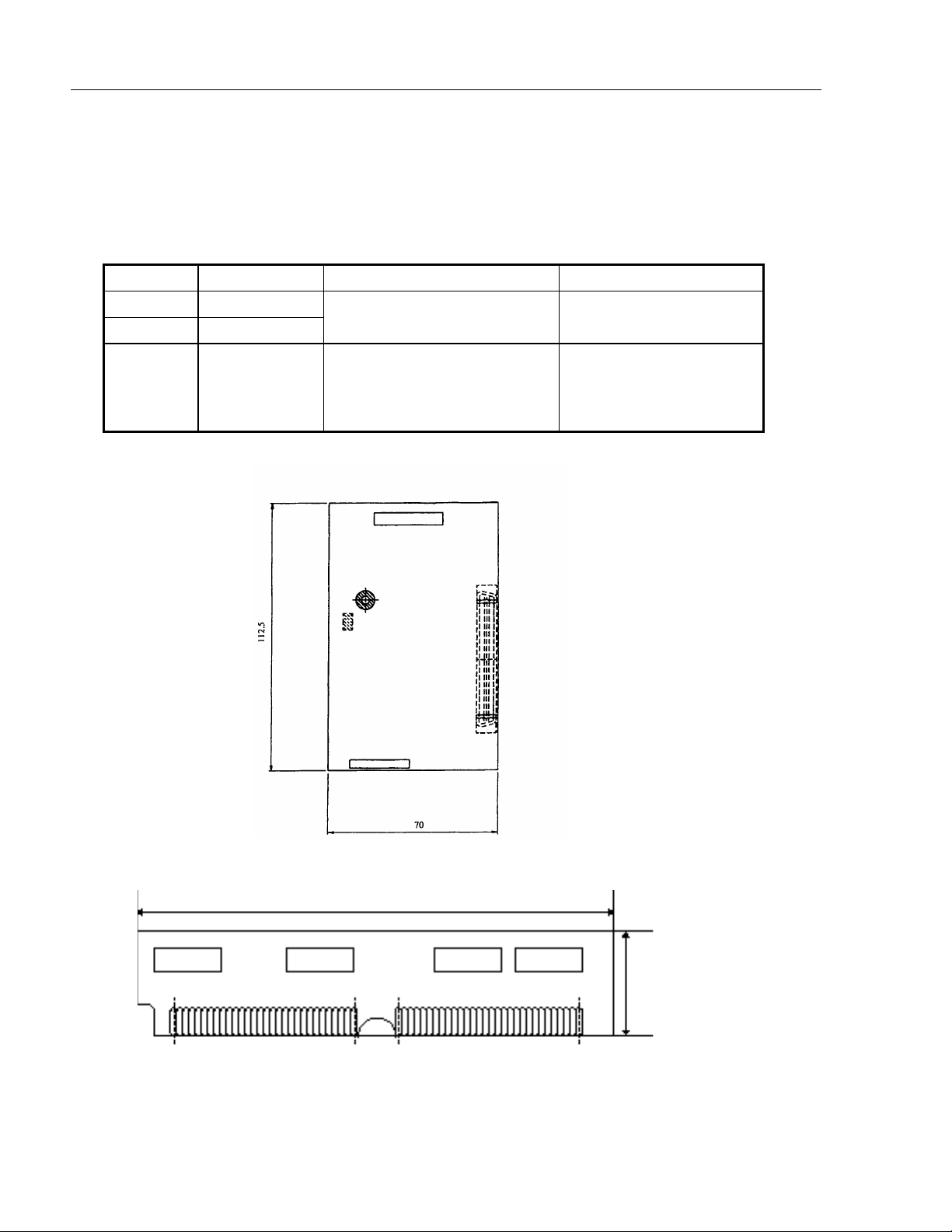

1.2 Appearance and parts name

Appearance and parts name is shown in Fig. 1.1.

1-2

Figure 1.1 Part name of M3097DG

Page 11

Chapter 2 Specifications

2.1 Basic specifications

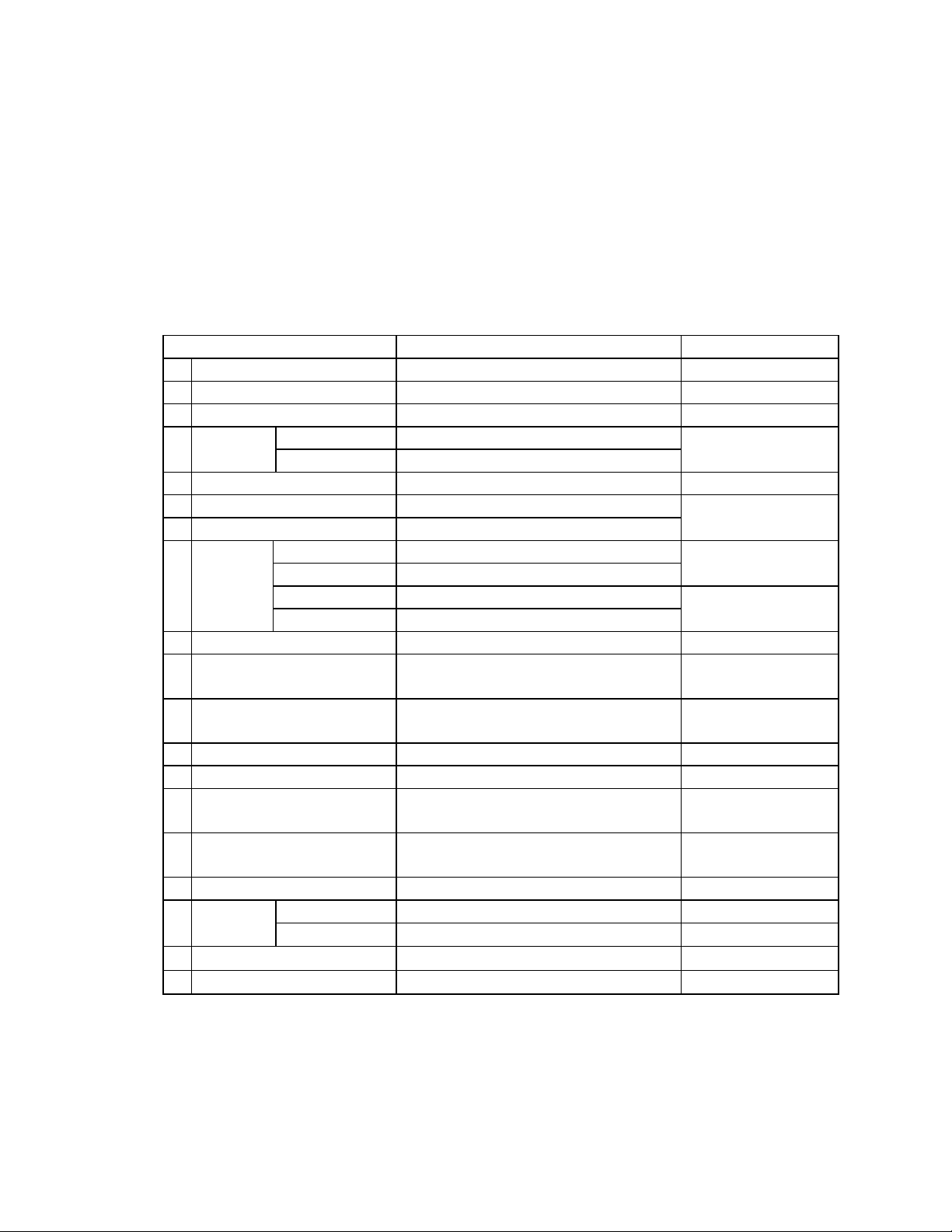

Basic specifications of M3097DG are shown in Table 2.1.

Table 2.1 Basic Specifications of M3097DG

Item M3097DG Remarks

1 Operating method Flatbed and ADF

2 Image sensor CCD

3 Light source Xe Discharge tube (green)

Minimum A6 4 Document

size

5 Basic resolution 400 dpi

6 Output resolution 100/150/200/240/300/400/600 dpi

7 Zooming of IPC option 50 to 800dpi

8 Scanning

speed

9 Halftone patterns Dither/Error diffusion

10 Compression

(MH, MR, MMR)

11 Capacity of ADF 100 sheets A4, 64g/m

12 Interface SCSI-2

13 Video output Binary / Halftone / Grayscale

14 Power requirements 100 to 120VAC, 50/60 Hz

15 Operating environment Temperature : 5°C to 35°C

16 Basic memory 16 MB

18

Scanner size 234H x 696W x 497D (mm)

19

Scanner weight

Maximum A3 or DL

FB, A4,400 dpi 2.4 sec.

FB, A4,200 dpi 1.2 sec.

ADF, Simplex 36 PPM

ADF, Duplex 60 IPM

No option required

200 to 240VAC, 50/60 Hz

Relative humidity : 20 to 80%

IPC IPC-2D or IPC-3D17 Option

Memory 16 MB See section 2.3

20 kg

See section 2.3

A4, 200 dpi

2

See section 2.6.3

2-1

Page 12

Specifications

2.2 Option specifications

Following options are available for this scanner.

Table 2.2 Option of the scanner

Name Parts Number When the option required? Remarks

IPC-2D CA01952-0192

IPC-3D CA02919-0511

Memory TBD - When reading 601 dpi or more

- When the image processing of

Section 3.3 required.

(See section 2.3)

Either IPC-2D or IPC-3D

can be installed at a time.

One memory option can be

installed per scanner.

16 Mbyte, 72 pin, EDO

SIMM 60 ns, non-parity

2-2

Figure 2.1 IPC-2D/3D option

108

23.5

Figure 2.2 Extended memory option

Page 13

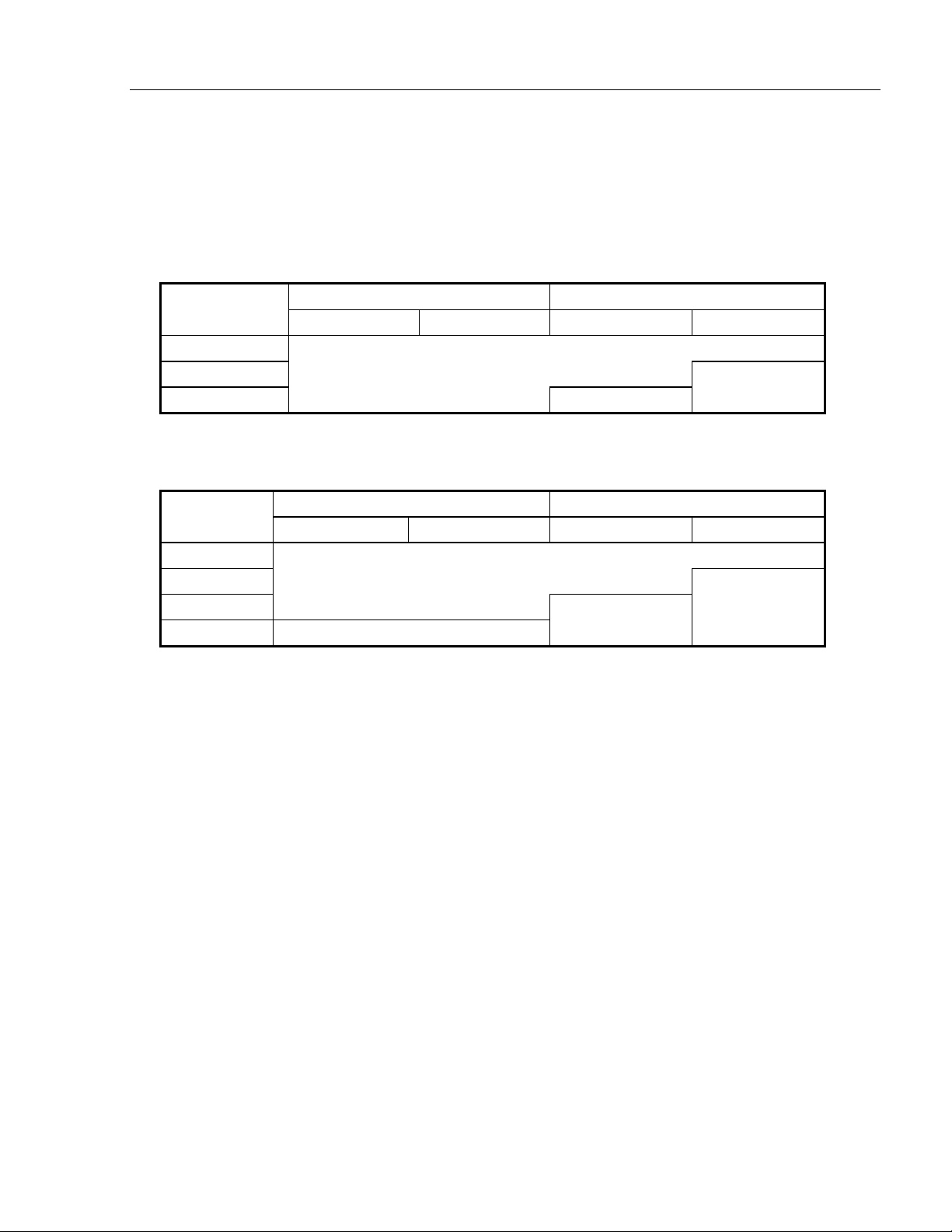

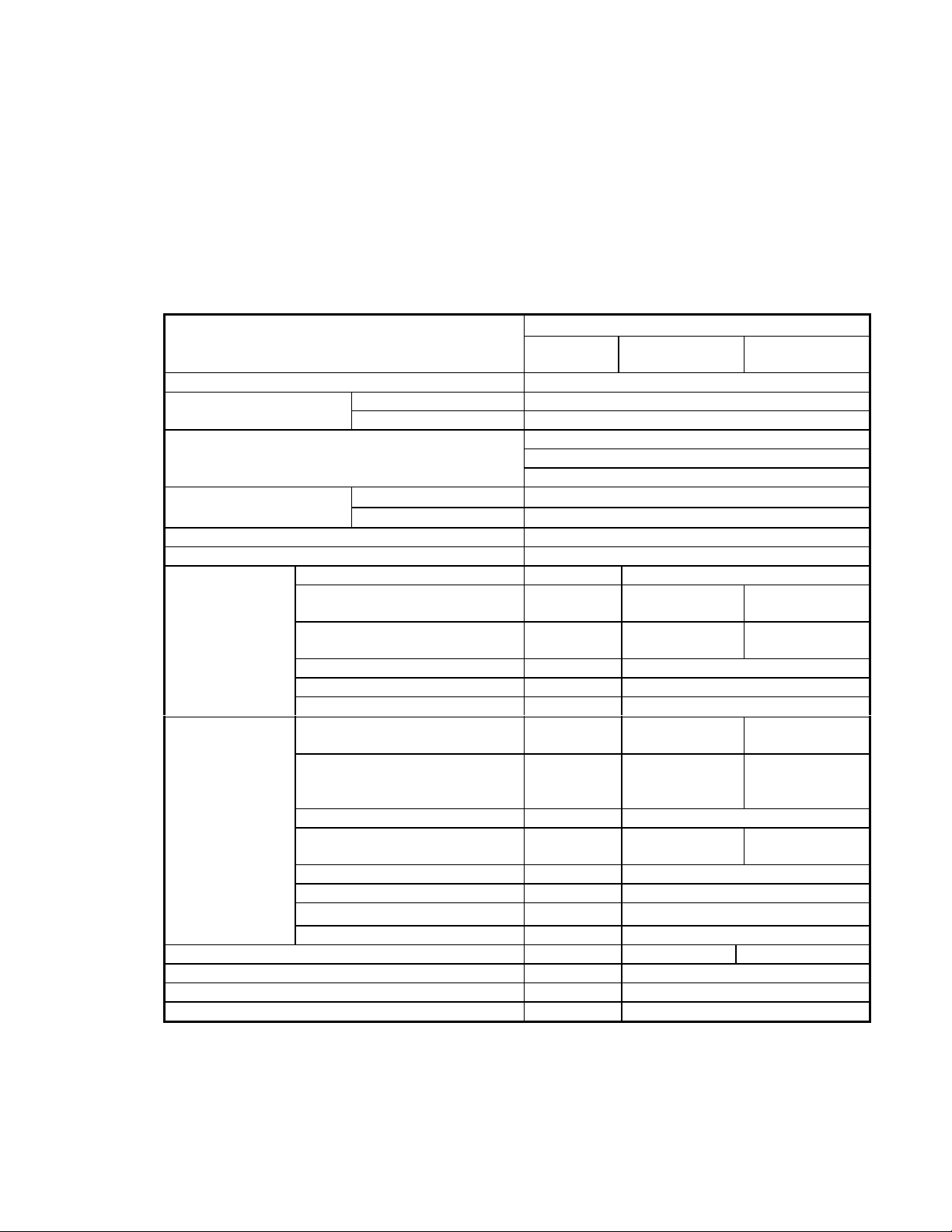

2.3 Reading limitation depending on the memory installed

2.3 Reading limitation depending on the memory installed

M3097DG have the limitation of reading depending on the memory installed as shown in Table 2.3 and

2.4.

Table 2.3 The reading limitation of M3097DG without option

Binary GrayscaleOutput

resolution

100/150/200 dpi

300/400 dpi

600 dpi Not supported *2

*2 Setting itself may be rejected.

Table 2.4 The reading limitation of M3097DG at zooming of IPC-2D or IPC3D option

50 to 200 dpi

201 to 400 dpi

401 to 600 dpi

601 to 800 dpi Supported *1

Simplex Duplex Simplex Duplex

Supported (No additional memory)

Not supported *2

Binary GrayscaleZooming

Simplex Duplex Simplex Duplex

Supported (No additional memory)

Not supported *2

Not supported *2

*1 Memory option required, otherwise the possibility of Image transfer error exists.

*2 Setting itself may be rejected.

2-3

Page 14

Specifications

2.4 Physical specifications

Table 2.5 Physical specifications

No. Item M3097DE/DG

1 Dimensions

(mm)

2 Weight (Kg) 20 ( 44.2 lb)

3 Power

requirements

4 Power consumption (VA) 120

5 Heat capacity 78 kcal ( 312 BTU/H)

6 Surge current (A) 30

7 Momentary power failure 100 % 0.5 Hz

8 Leakage current (mA) 0.75 or less

9 Dielectric strength AC 1.5 KV or more for one minute or

10 AC line noise

Temperature (°C)

(%)

(degree)

15 ESD (KV) 8 or more

(dBA)

Height 234 ( 9.2 in.)

Width 696 (27.4 in.)

Depth 497 (19.6 in.)

Voltage (VAC)

Phase Single

Frequency 50/60 Hz +2% -4%

Operating +5 to +3511

Non operating -20 to +60

Operating 20 to 80 (No condensation)12 Relative humidity

Non operating 8 to 95 (No condensation)

Operating 0.213 Vibration (G)

Non operating 0.4

Operating 514 Indication

Non operating 10

Operating 53 or less (ISO DIS 9296)16 Acoustic noise

Non operating 40 or less (ISO DIS 9296)

100 to 120, 200 to 240 VAC ±10%

more (between FG and AC lines)

Voltage 1.2 KV pulse duration 5 µs

2.5 Regulation conformity

Item Conformed regulation Regulation mark on the

UL 1950

CSA 22.2 950

EN60950 1992/A1:1993/A2:1993 Yes, GS mark by TUV

EMI

etc.

2-4

FCC Part15 Class A Yes

EN55022 1994 Class B EMI

EN50082-1 1992 Immunity

EN61000-3-2 1995 Harmonic emission

EN61000-3-3 1995

Table 2.6 Regulation conformity

Remarks

scanner

Yes, CSA NRTL-C markSafety

Yes, CE mark

Voltage variation

Page 15

2.6 Document specifications

2.6 Document specifications

When using the flatbed, any condition of the paper can be read except paper size and ground color

specification.

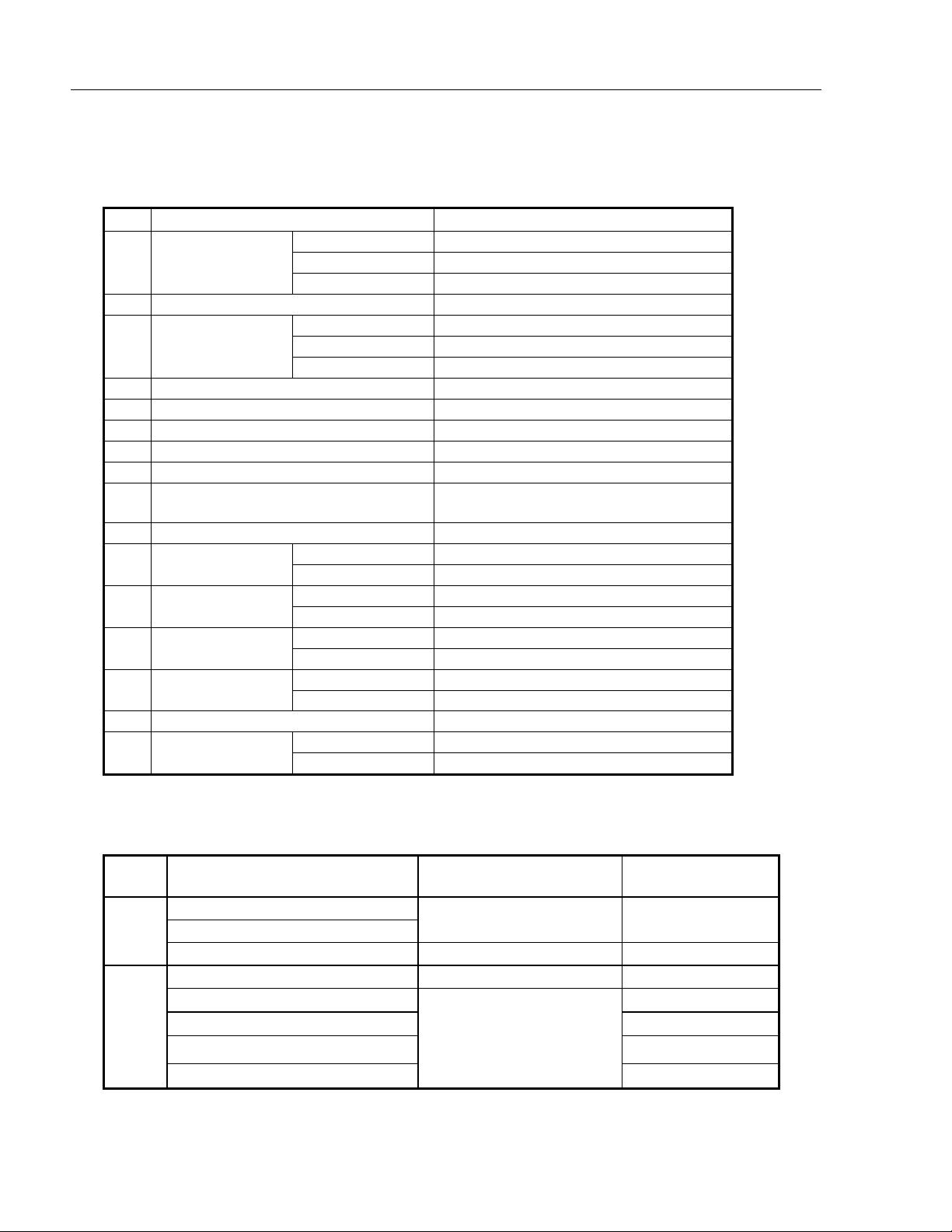

2.6.1 Paper size

A

B

↑

Feeding direction

Maximum Minimum

A B A B

148 105297 432

105 148

Figure 2.3 Paper size

Paper size conversion table

Category Dimensions Category Dimensions

Letter 8.5 x 11 in (216 x 279 mm) A3 11.7 x 16.54 in (297 x 420 mm)

Legal 8.5 x 14 in (216 x 356 mm) A4 8.3 x 11.7 in (210 x 297 mm)

Ledger 11 x 17 in (279 x 432 mm) A5 5.83 x 11.7 in (148 x 210 mm)

Executive 7.25 x 10.5 in (184 x 267 mm) B4 10.1 x 14.3 in (257 x 364 mm)

B5 7.2 x 10.1 in (183 x 257 mm)

(Unit : mm)

2-5

Page 16

Specifications

2.6.2 Paper conditions

1) Paper type

• Woodfree paper

• PPC paper, Specified by XEROX Corporation

When using another paper, check that it is successfully fed by ADF before performing a scanning

operation.

2) Paper weight

13.9 lbs (52g/m2 ) to 27.8 lbs (104g/m2 )

3) Items to avoid

• The following documents may be hard to read by ADF.

Before you start the large quantity reading, check that the document is read appropriately. If the

ADF reading is not appropriate, read them by flatbed.

- Paper with a clip or staple

- Paper that has ink which is not dry.

- Paper thickness is not constant, such as an envelope.

- Paper that has large rumples or curl. (See Note 3)

- Paper that has folds or tears.

- Tracing paper

- Coating paper

- Carbon paper.

- Paper size that is out of standard.

- Items other than paper, such as clothes, metal sheet, or OHP film.

- Photographic paper

- Paper that has notches on its side.

- Paper that has a shape other than square.

- Paper that is very thin.

2-6

Note 1:

The important document which shall not be torn must be read by flatbed.

Note 2:

Carbon-less papers have the chemical composition which damages the pad pick roller. Therefore,

note the following remarks

Cleaning: If the miss pick occurs frequently, clean the pad and pick roller in

accordance with the Operator’s guide.

Page 17

2.6 Document specifications

Replacement of parts: The life of the pad and the pick roller may be shorter than the case that PPC

document is fed.

Replacement cycle of the pad and the pick roller may be around 100,000

sheets depending on the paper quality and cleaning cycle.

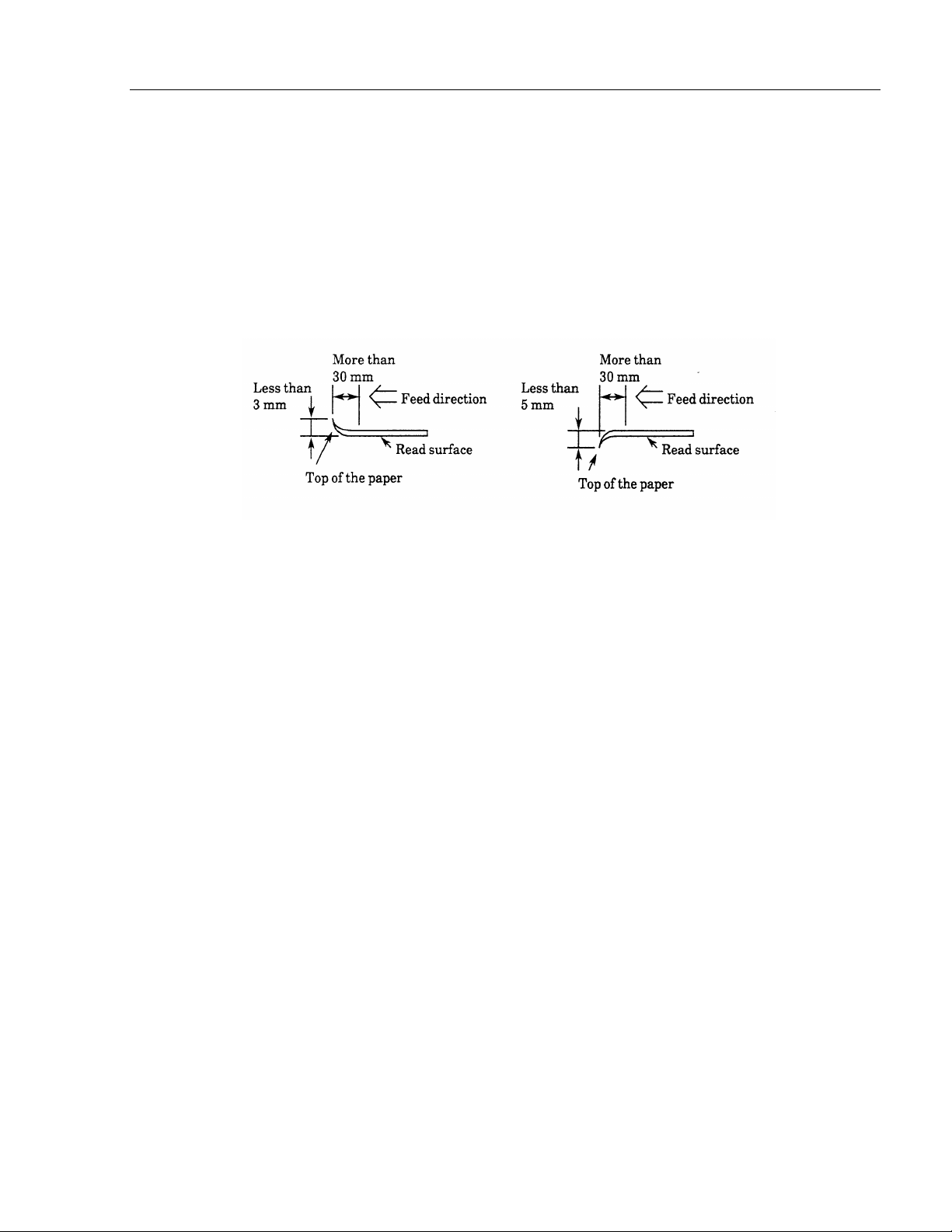

Note 3:

Paper should be straightened to fit the condition below.

2-7

Page 18

Specifications

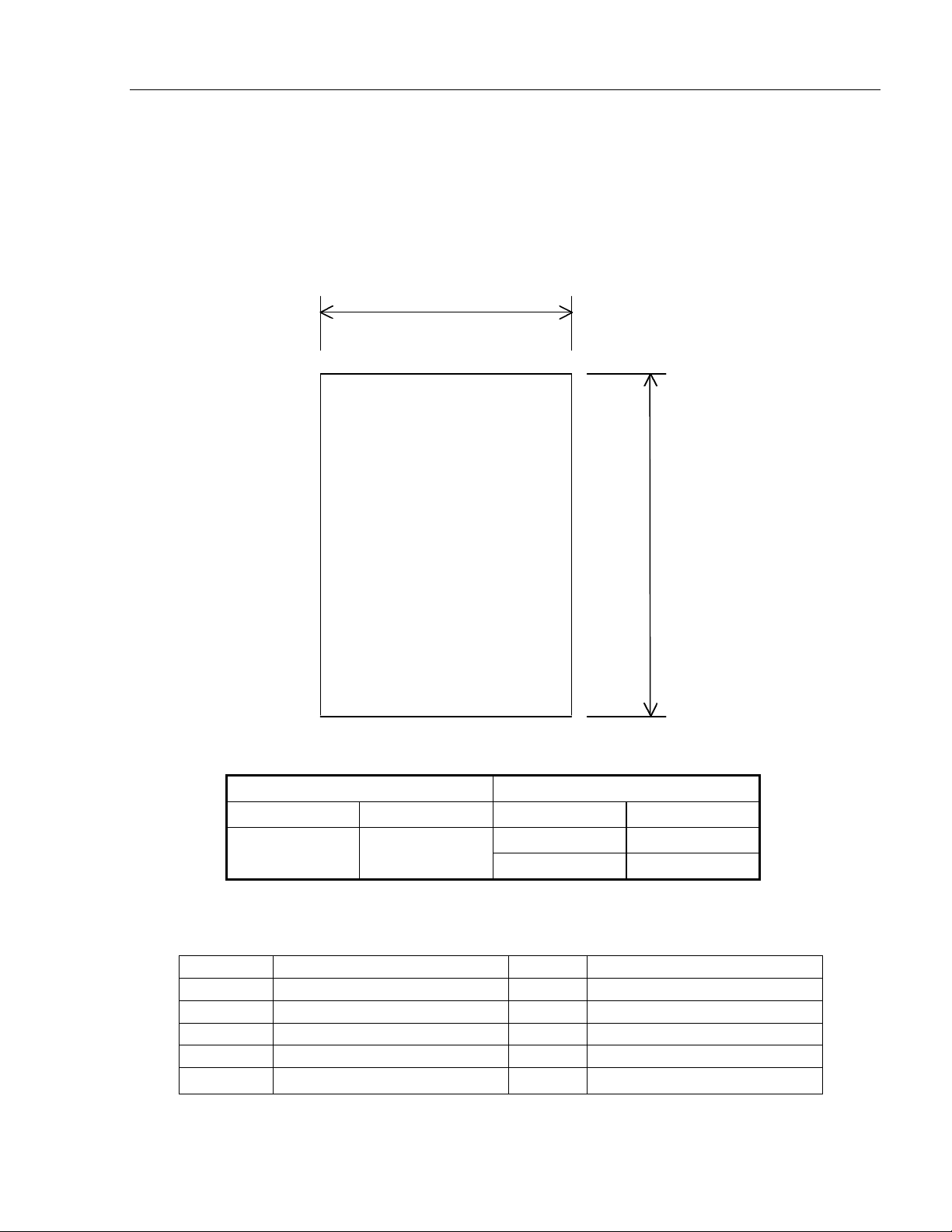

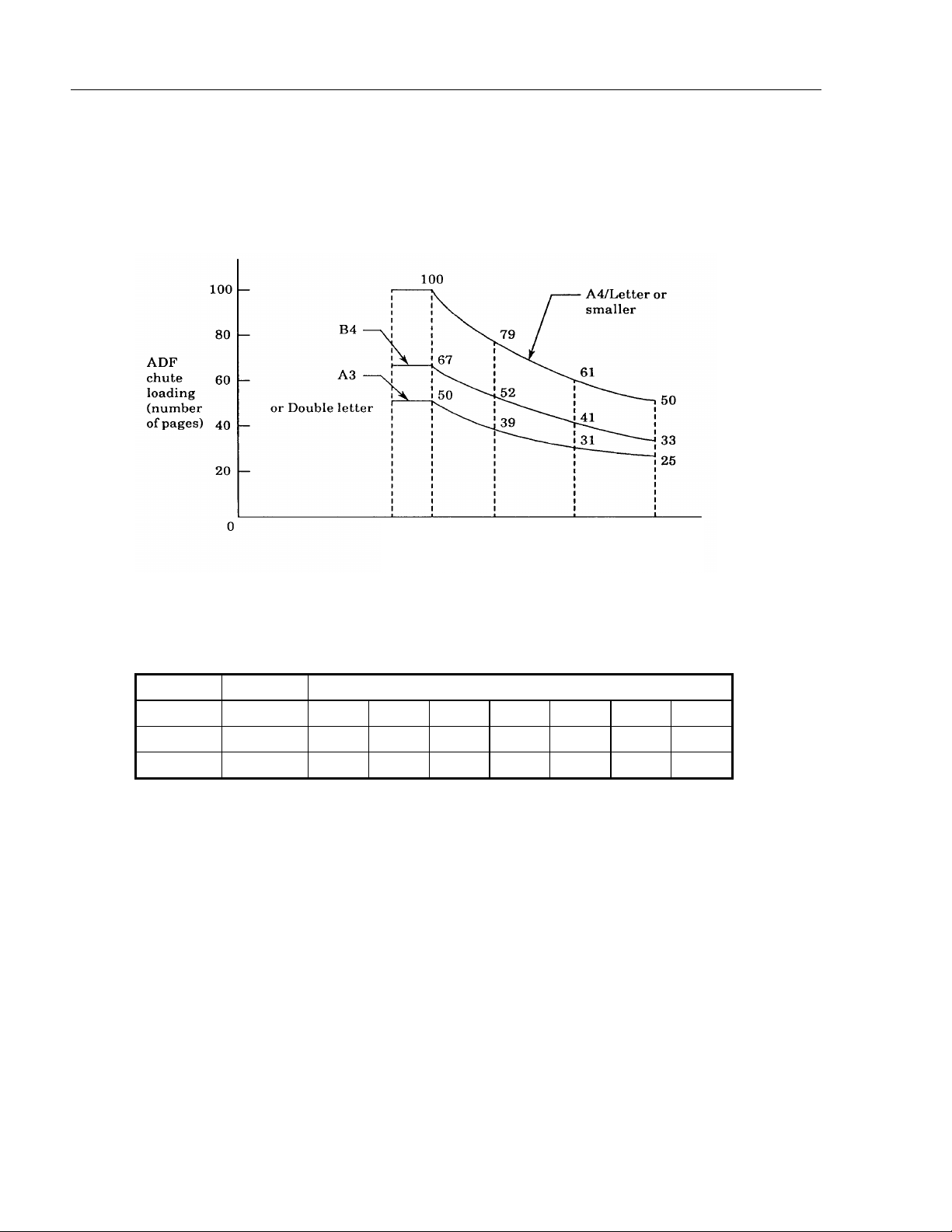

2.6.3 ADF capacity

The number of pages that can be loaded into ADF chute depends on the paper size and ream

weight. This information is shown in the following Figure:

52 64 81 104 127

g/m

2

Figure 2.4 ADF capacity

Paper weight conversion table

Country Unit Conversion

Japan Kg/ream 45 55 64.6 77.5 90 109.8 135

USA lb 13.9 17 20 24 27.9 34 41.8

Europe g/m

2

52 64 75 90 104 127 157

2-8

Page 19

2.6 Document specifications

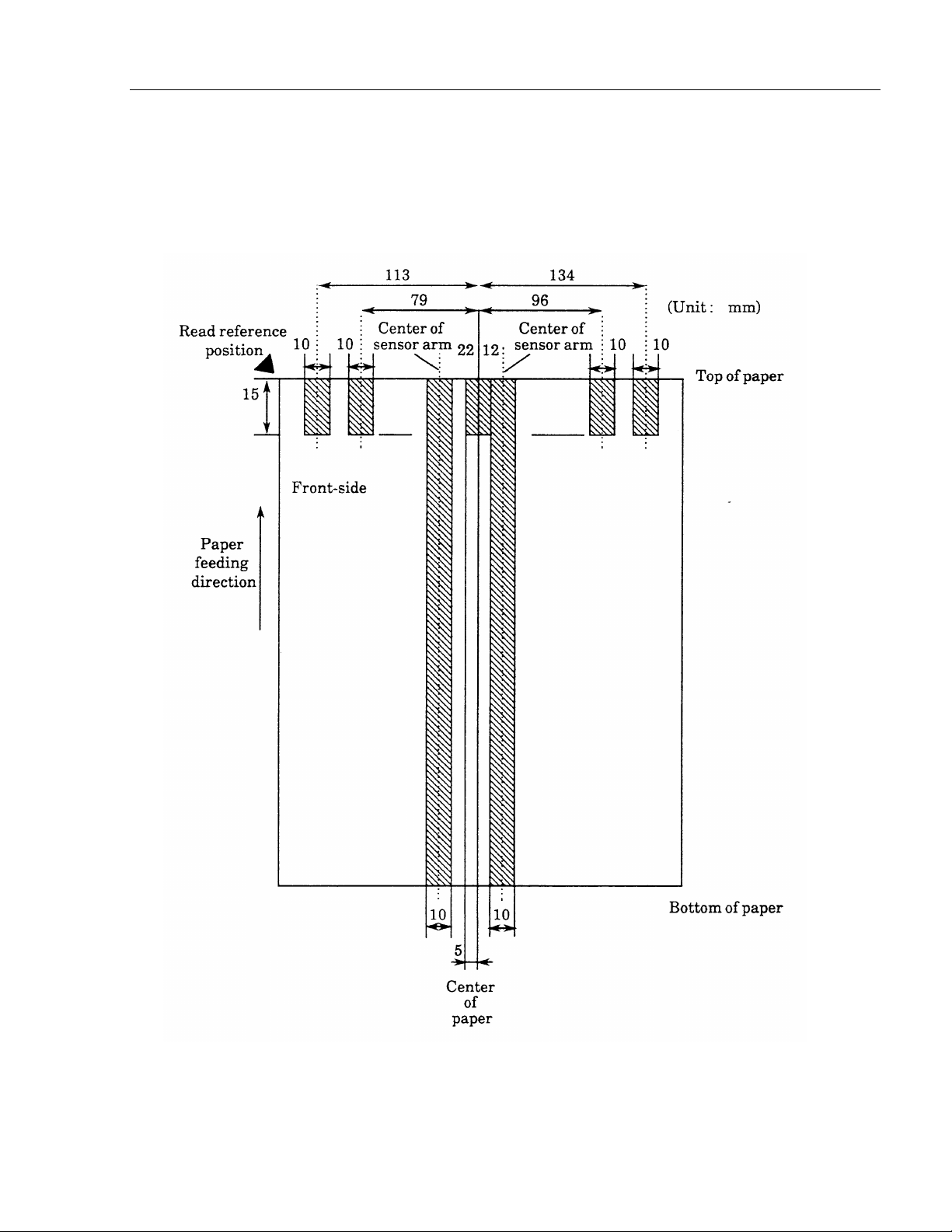

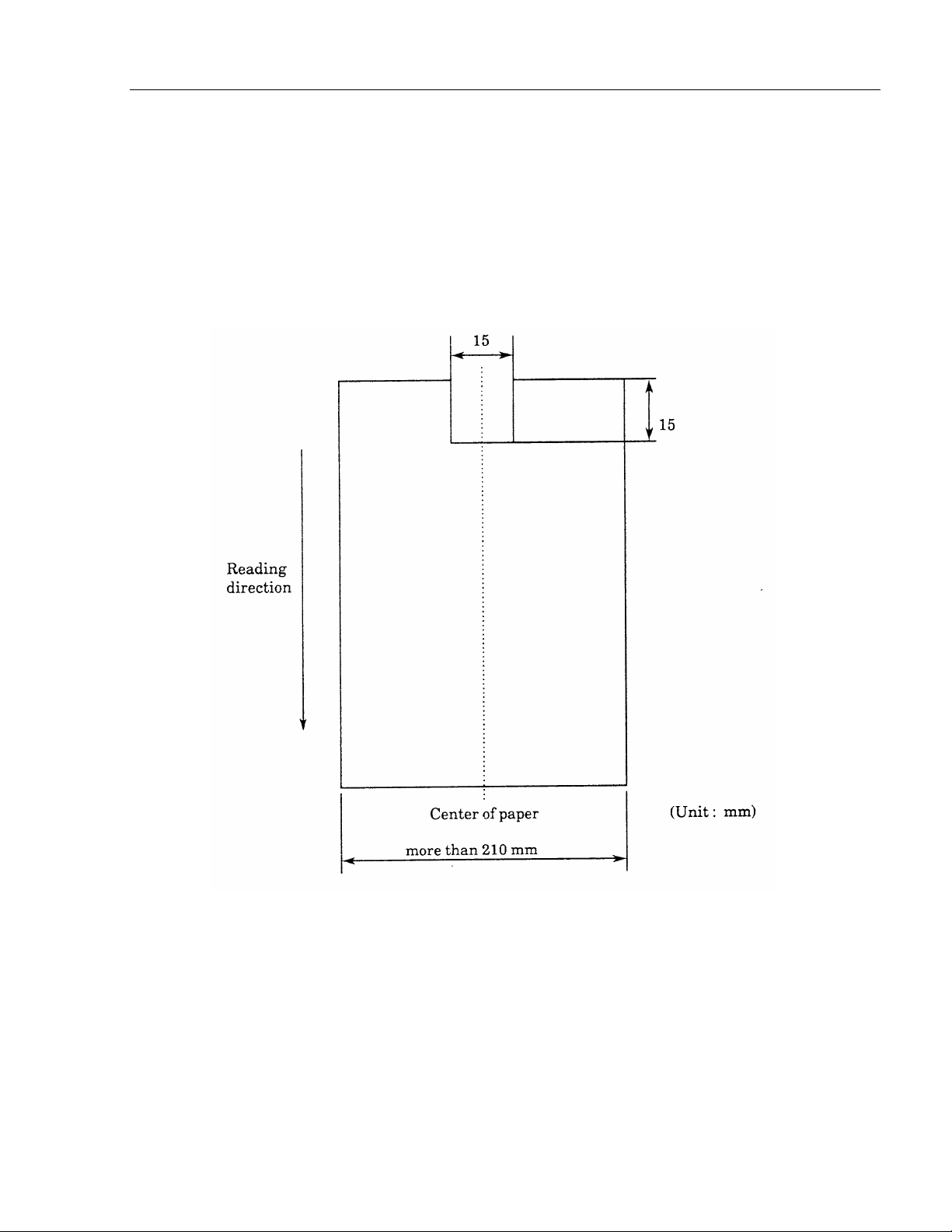

2.6.4 Areas that must not be perforated (for ADF reading only)

Perforations in the shaded areas may cause Jam error. If you must read data from such paper, use

the flatbed

Figure 2.5 Areas that must not be perforated

2-9

Page 20

Specifications

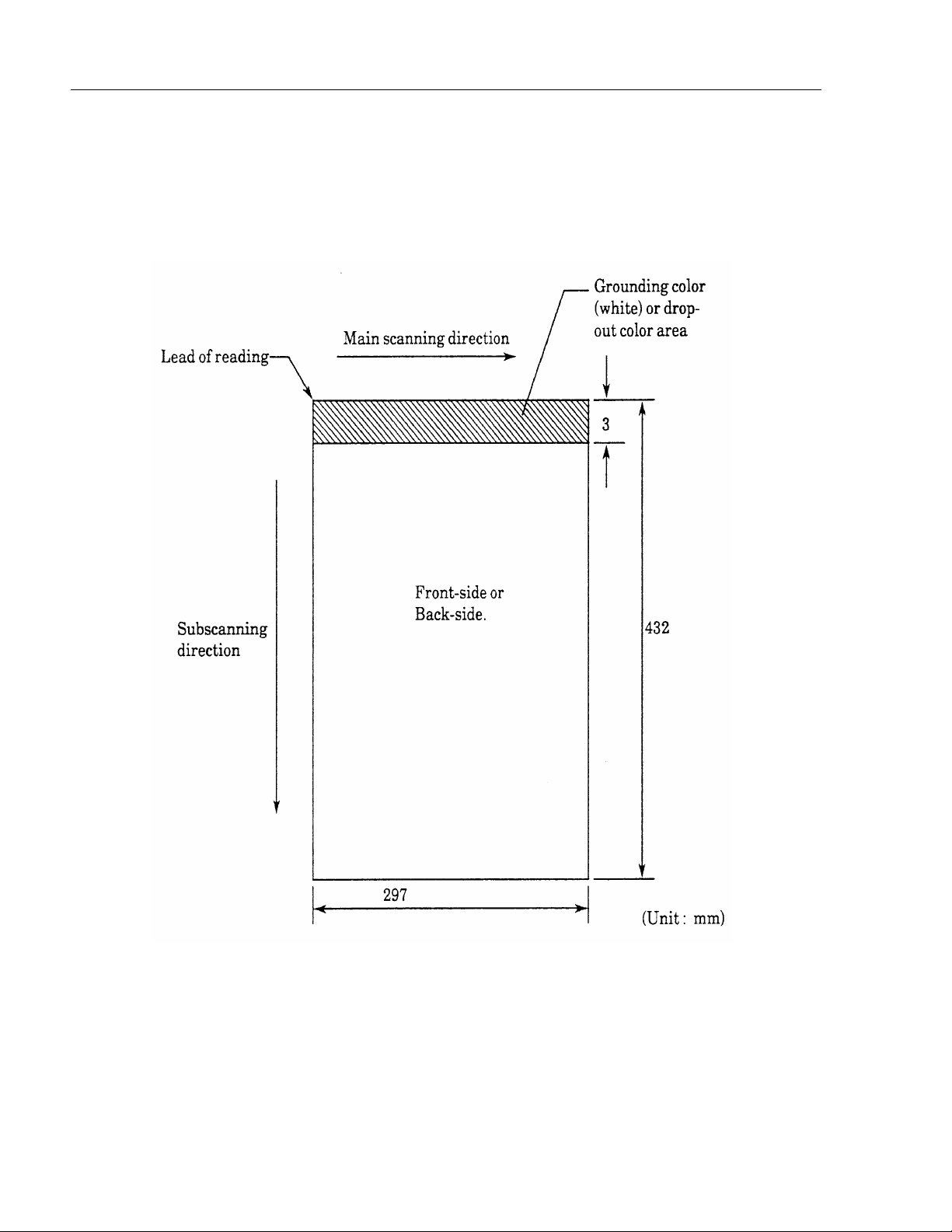

2.6.5 Grounding color area

The color of the shaded area shown in Figure 2.6 should be paper grounding color (white) or dropout color. If not, set White level following OFF (Photograph) before reading.

2-10

Figure 2.6 Grounding color area

Page 21

2.6.6 Job separation sheet

The following figure shows the basic shape of the Job separation sheet. When Job separation sheet

is scanned, the scanner can detect and inform it to the Host computer (See section A.4.11 READ

command/Detected paper information).

Paper condition is such that described in section 2.6.1 or 2.6.2. And the paper size must be A4 or

larger (210 mm or wider)

2.6 Document specifications

Figure 2.7 Job separation sheet

2-11

Page 22

Chapter 3 Image Functions

3.1 Overview of the image functions

The image functions of this scanner are summarized in Table 3.1 and Table 3.2.

Table 3.1 Image functions

Selectable parameters

Section No. and Image function

3.2.1 Output resolution 100/150/200/240/300/400/600 dpi

(1) Offset and size See section 3.3.2 (1)3.2.2 Main Window

clipping

3.2.4 Halftone reading

3.2.5 Grayscale reading Contrast

3.2.6 Compression MH/MR/MMR

(1) Pre-filter N/A Ordinary/Ball-point Pen

(2) Gradation N/A High Contrast

3.3.1 DTC

mode

*1 *2

3.3.2 IPC mode

*1

3.3.3 Sub window N/A Max. 4 Ignored *8

3.3.4 Zooming N/A See Table 2.4

3.3.5 Dither downloading N/A Max. 8 patterns

3.3.6 Gamma downloading N/A Max. 5 patterns

*1 DTC and IPC mode functions are exclusive.

*2 In IPC-3D, DTC and IPC mode Simplified DTC use the same algorithm.

*3 In IPC-3D, The Gradation parameter is ignored.

(3) Dynamic threshold curve N/A 8 types

(4) Equal to white N/A ON/OFF

(5) Noise Removal N/A OFF / 2x2 / 3x3 / 4x4 / 5x5

(6) Smoothing N/A Image/OCR

Simplified Dynamic Threshold

*2 *5

IPC-2 like Simplified Dynamic

Threshold *5

(1) Image Emphasis N/A High/Mid/Low

Image Emphasis (smooth) N/A Smooth Background

(2) Outline Extraction N/A ON/OFF

(3) Automatic Separation N/A ON/OFF *6

(4) Mirror image N/A ON/OFF

(5) Black and White reverse N/A ON/OFF

(2) Page end detection ON/OFF

(1) Dither Four built-in patterns

(2) Error diffusion ON/OFF

No IPC

option

Density

Contrast3.2.3 Binary reading

White level following ON/OFF

N/A 7 steps

N/A N/A 7 steps

with IPC-2D

option

/Ordinary

(Darkness)

(variance rate)

With IPC-3D

option

Ignored *3

8 steps

(Sensitivity) *2

7 steps

(Sensitivity) *4

(Sensitivity)

High/Mid/Low

Removal *7

3-1

Page 23

Image Functions

*4 In IPC-3D, a seven step parameter is used like as with the Simplified Dynamic Threshold but the

algorithm is different.

*5 In IPC-3D, if both Simplified DTC and Image Emphasis are specified, the Simplified DTC algorithm is

activated. At that time, both the Simplified Dynamic Threshold and Image Emphasis High/Mid/Low

parameters are in affect.

*6 In IPC-3D, if Automatic Separation is specified, then Simplified Dynamic Threshold and Image

Emphasis/Smoothing are ignored.

*7 In IPC-3D, if Smoothing is specified, then Background Removal is applied. Rhis effect is similar to

IPC-2D Smoothing.

*8 In IPC-3D, Sub-windows are not available and are ignored if specified.

Table 3.2 Functions which are available for main window and sub-window

Image

composition

Item

X, Y resolution o x o x o x o

Upper left X, Y o o o o o o o

Width, length o o o o o o o

Threshold o o

Brightness

Contrast o o o o o o o

Bit per pixel 01 01 01 01 01 01 08

Halftone pattern

Compression o x o x o (*5) x x

Subwindow list o x o x o x x

Paper

specification

D

T

DTC (*1) o x o (*2) x o (*2) x

C

Outline

emphasis

Outline

extraction

I

Automatic

P

separation

C

Simplified DTC o (*4) o (*4)

RIF (reverse

image format)

Mirror image o x o x o x

Binary black and

white

Main

window

▲ ▲

▲ ▲

o x o x o x o

o o o o o o

o (*3) o (*3)

o (*4) o (*4) o (*4) o (*4) o (*4) o (*4)

o o o o o o o (*6)

Sub-

window

Dithering Error diffusion

Main

window

▲ ▲ ▲ ▲

o o o o

o o o o

Sub-

window

0100

Main

window

Sub-

window

02

Gray

scale

Main

window

3-2

Page 24

3.2 Basic image functions

o: Can be specified.

x: Cannot be specified.

▲: Enabled if automatic separation is specified, otherwise ignored.

: Can be specified but not enabled.

*1 If DTC is specified, IPC can be specified but not enabled.

*2 The image is not guaranteed.

*3 Can be specified but not enabled if Image Emphasis is also specified.

*4 Can be specified but not enabled if Outline Extraction is also specified.

*5 Not recommended because the compression is inefficient.

3.2 Basic image functions

The command and data name in [ ] beneath the section title shows the location for the reference in

Appendix A.

3.2.1 Output resolution

[A.4.7 SET WINDOW command/X,Y resolution]

Selectable output resolution is shown in Table 2.3. The default is 400 dpi.

The output resolutions of 100/150/200/240/300/600 dpi are converted from 400 dpi by an electrical

method. The X direction resolution (XR) and Y direction resolution (YR) can be specified

independently. If IPC option is installed, Zooming function is available (see section 3.3.4). The

output resolution with IPC option is shown in Table 2.4.

3.2.2 Main Window Clipping

(1) Offset and Size

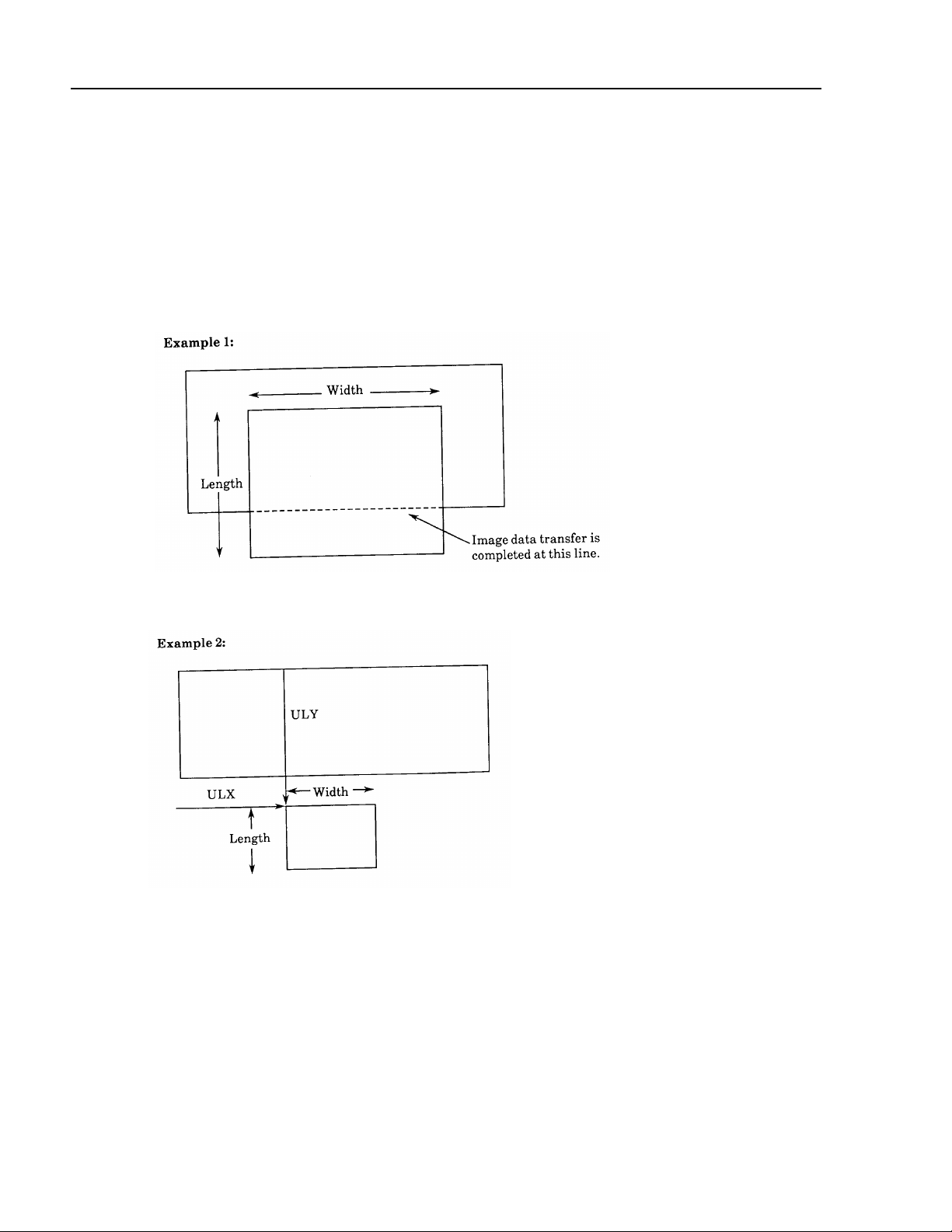

[A.4.7 SET WINDOW command / Upper left, Width, Length]

Offset is the length of ULX and ULY in Figure 3.1 and 3.2 with 1/1200 in unit.

It is important that the Origin point of the offset is deferent between Flatbed (FB) and ADF. When

reading with ADF, user must specify the size of the document. Then the scanner set the origin point

of that document size (X1) according to the size specified. (see Figure 3.2) If user specifies wrong

document size, unintentional offset may be given.

When specifying the offset, you must count in the mechanical offset error of the scanner as shown in

Table 3.3. You can adjust the offset with Setup mode of operator panel, scanner by scanner.

3-3

Page 25

Image Functions

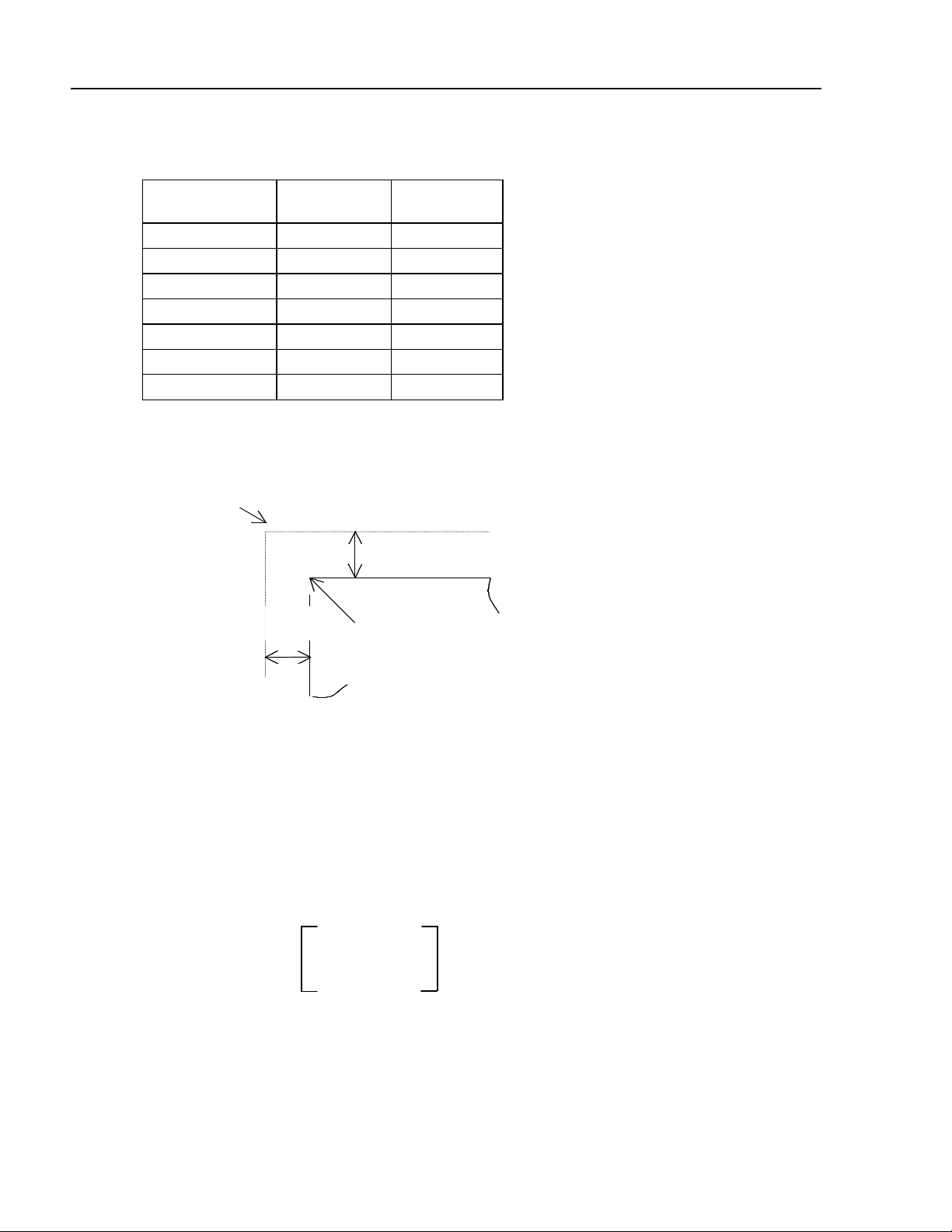

Table 3.3 Mechanical offset error of the scanner

Output

resolution

600 dpi 18 ± 18 24 ± 24

400 dpi 12 ± 12 16 ± 16

300 dpi 9 ± 9 12 ± 12

240 dpi 8 ± 8 10 ± 10

200 dpi 6 ± 6 8 ± 8

150 dpi 5 ± 5 6 ± 6

100 dpi 3 ± 3 4 ± 4

*1 When the document skewed, X0 and Y0 represents the minimum length of the offset along with the

edge.

Origin point of ULX, ULY

X0 (dots) *1 Y0 (dots) *1

Y0

X0

Actual origin point of the sheet

Size is the length of W and L in Figure 3.1 and 3.2 with 1/1200 in unit. The scanner rounds up the

value to byte. The output pixels in main scanning direction and output lines in sub-scanning direction

are obtained as follows.

a) Output pixels in main scanning direction

Scanning width : W (1/1200 in) = 10200

Output resolution: XR (dpi) = 400

[XR x W/1200]

Output pixel = --------------------- = 425 (byte) *

8

* Values under 0 in [ ] are omitted

3-4

Page 26

3.2 Basic image functions

ULX

Y

W

b) Output lines in sub-scanning direction

Scanning length L (1/1200 in) = 13200

Output resolution YR (dpi) = 400

Output line = [YR x L/1200 ] = [400 x 13200/1200 ] = 4400 (line) *

* Values under 0 in [ ] are omitted

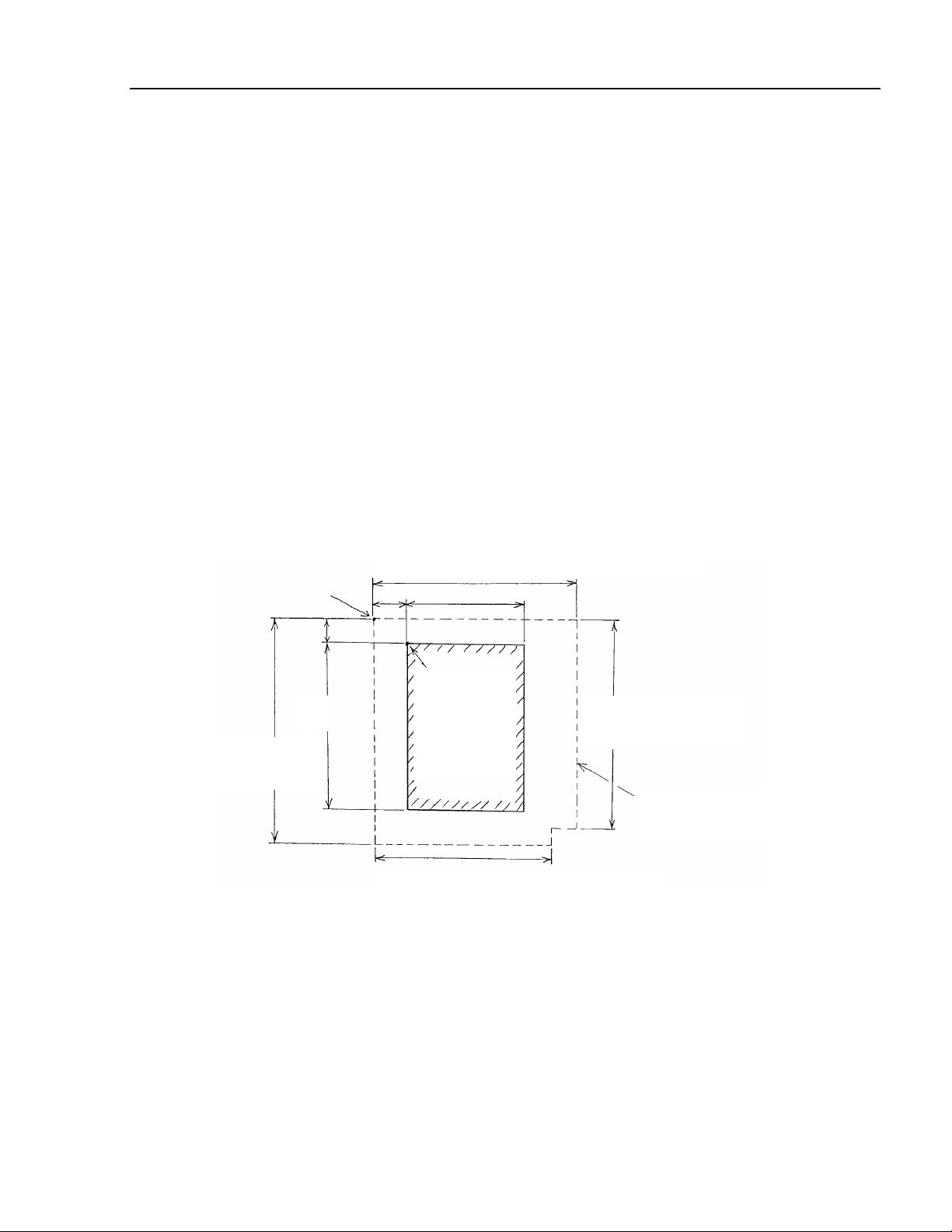

The physical limitations of the Main Window Clipping at Flatbed (FB) and ADF reading are

illustrated in Figure 3.1 and 3.2 respectively.

NOTICE: This is not the guaranteed specification but the scanner may read the long document

which fits the following condition.

i) 0 < ULY + L ≤ 33072 (@1/1200 in.)

ii) L ÷ 1200 × YR ≤ 16383 line

iii)The memory installed is enough for reading.

Origin point P

UL

20736 (@ 1/1200 in.)

= 17.28 in. (438.9 mm)

14592 (@ 1/1200 in.) = 12.16 in. (308.8 mm)

Origin point

L

of the clipped

area

13200 (@ 1/1200 in.) = 11 in. (279.4 mm)

19842 (@ 1/1200 in.)

= 16.54 in (412.0 mm)

Maximum size which

can be clipped

Figure 3.1 The window position and limitation of FB reading

3-5

Page 27

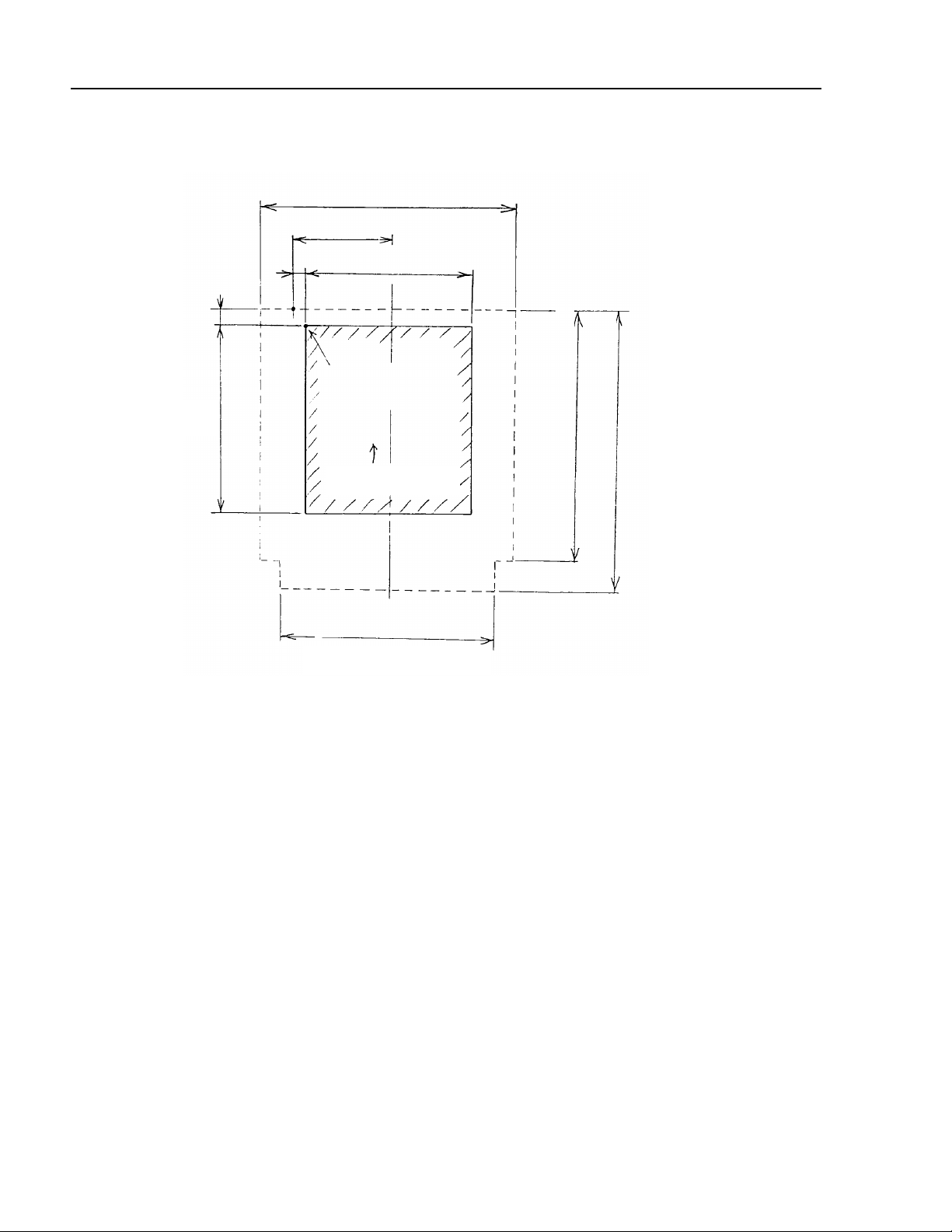

Image Functions

19842 (@ 1/1200 in.) = 16.54 in. (412.0 mm)

20736 (@ 1/1200 in.) = 1728 in. (438.9 mm)

1

W

ULY

13200 (@ 1/1200 in.)

14592 (@ 1/1200 in.) = 12.16 in. (308.8 mm)

X

ULX

Origin point of

the clipped area

L

Feed direction

= 11 in. (279.4 mm)

Figure 3.2 The window position and limitation of ADF reading

The Matrix size of the clipped Main Window is limited as shown in Figure 3.3. The unit of the

number in Figure 3.3 is 1/1200 in.

3-6

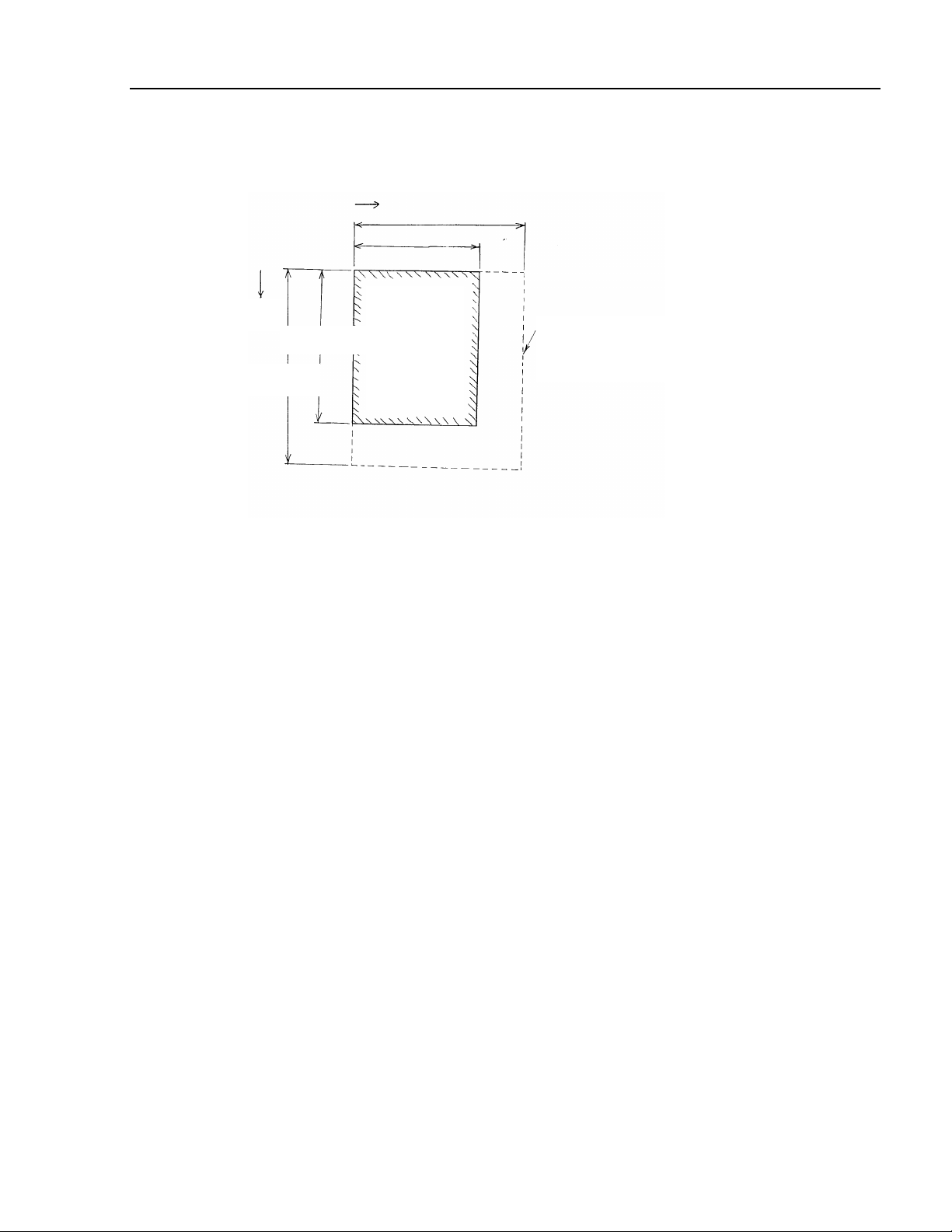

Page 28

W

9278 dots

7296 dots

3.2 Basic image functions

L

10368 line

13824 line

Note: W must be greater than 9, and L must be

greater than 1.

Maximum

output size

without

Extended

Memory

option

Figure 3.3 Matrix size limitation of the Window

Maximum output size with

Extended Memory option

3-7

Page 29

Image Functions

(2) Page End Detection

[A.4.11 READ command / Detected paper length]

This function cuts the reading operation when page end is detected, even if all of the window length

L (sub-scanning length) is not read yet. This function is useful to reduce the image data and increase

the throughput. When Page End Detection is set ON, the image data which is out of the page end is

deleted. (Example 2)

3-8

Page 30

3.2.3 Binary reading

[A.4.7 SET WINDOW command / Image Composition = X’00’]

Following three parameters are available when binarizing the image. The 256 levels of the density at

each pixel is processed by Contrast and binarized by Threshold. When the White level following is se

ON, the white level of the CCD output follows the background of the document. So this is useful for

line art drawing but not for photograph.

Parameter value Effect of parameter Default

Threshold

*1

Contrast X’01’

Gamma

pattern

White level

following

Table 3.4 Parameter of Binarization

X’01’

to

X’10’

to

X’FF’

to

X’10’

to

X’FF’

X’01’

X’02’

X’03’

X’80’

to

X’84’

ON The threshold follows the background of

OFF The threshold do not follow the

Brightest

Normal

Darkest

Mostly soft contrast

Normal

Mostly sharp contrast

Normal

Soft

Sharp

Use download pattern

the document. (*2)

background of the document.

3.2 Basic image functions

X’80’

(*1)

X’80’

X’01’

ON

*1 When the IPC-2D or IPC-3D is installed, the Threshold varies along with the control of DTC mode or

IPC mode.

*2 3 mm from top of the document must be white or drop-out color (See section 2.6.5)

3-9

Page 31

Image Functions

3.2.4 Halftone reading

[A.4.7 SET WINDOW command/Image Composition = X’01’]

This scanner supports two types of halftone image, that is Dither and Error Diffusion.

(1) Dither

[A.4.7 SET WINDOW command / Halftone type = X’01’]

This is a way of producing halftone images with white and black pixels. The scanned image is

processed by the unit of group of pixels.

At first a reference table called “dither matrix” is specified. Each element in the matrix (8x8) has a

threshold value of 256 levels. Allocation of threshold values in the dither matrix is called “dither

pattern”. Group of the scanned images are compared with the dither pattern, and each element is

decided whether it is black or white. Number of black pixels corresponds to a level of scale,

producing pseudo grayscale images.

Four built-in dither patterns are available.

(2) Error diffusion

[A.4.7 SET WINDOW command / Halftone type = X’02’]

This is a way of producing halftone (Pseudo grayscale) images with white and black pixels. Optical

density of pixels and its adjacent pixels are totaled and black pixels are repositioned in the order of

density in accordance with relations between adjacent pixels.

This scheme aims to minimize errors between scanned density and printed density on the average.

Density data of adjacent pixels are modified by diffusing errors on the objective pixel into several

pixels to be binarized. This scheme is aimed to keep high levels of grayscale and high resolution,

producing high quality halftone. Especially when dotted halftone images like photos on the

newspaper are scanned, this scheme suppresses moire patterns.

Following parameters are available for this function

3-10

The parameters which affects the Halftone image are shown in Table 3.5.

Page 32

3.2 Basic image functions

Table 3.5 Parameters of Halftone

Parameter value Effect of parameter Default

Brightness X’01’

to

X’80’

to

X’FF’

Contrast X’01’

to

X’80’

to

X’FF’

Gamma pattern

Halftone

scheme

Dither

pattern

X’01’

X’02’

X’03’

X’80’

to

X’84’

X’80’ to X’87’ downloaded pattern *1

Error Diffusion

X’00’ For dark photo

X’01’ For dark text and photo mix

X’02’ For light photo

X’03’ For light text and photo mix

Brightest

Normal

Darkest

Mostly soft contrast

Normal

Mostly sharp contrast

Normal

Soft

Sharp

Use download pattern

X’80’

X’80’

X’01’

Dither

*1 IPC-2D or OPC-3D required. (See section 3.3.5)

NOTICE: The density of the halftone can not be adjusted by the Threshold in Table 3.4 but be adjusted

by the Brightness in Table 3.5.

3-11

Page 33

Image Functions

3.2.5 Grayscale reading

[A.4.7 SET WINDOW command / Image Composition = X’02’]

Eight bit Grayscale reading is available. Following image processing functions can be specified for

grayscale reading. (See Table 3.2)

• X,Y resolution (XR,YR)

• Main window offset (ULX, ULY)

• Main window size (W, L)

• Contrast

• Black and White reverse

NOTICE: The throughput of the grayscale reading may 1/2 slower than binary reading.

NOTICE: The output resolution is limited as shown in Table 2.3 and 2.4.

3.2.6 Compression

[A.4.7 SET WINDOW command/Compression type, argument]

Following parameters are selectable for Compression. When a compression is selected, memory

option required.

Table 3.6 Parameter of Compression

Parameter Value Effect of parameter Argument Remarks

No X’00’ No compression

MH X’01’ MH compression

MR X’02’ MR compression K parameter

MMR X’03’ MMR compression

3-12

Page 34

3.3 Optional image function

Image functions in this section are available when IPC-2D or IPC3D option is installed.

The name of command and data in [ ] beneath the section title show the location for the reference in

Appendix A.

3.3.1 DTC mode function (Auto I mode)

[A.4.7 SET WINDOW command / DTC selection = X’40’]

This mode is designed to scan for better image quality to provide OCR (Optical Character Reader).

Threshold algorithm was developed to capture important text features for recognition purpose. The

image processing is deferent between IPC-2D and IPC-3D as follows.

IPC-2D : Note that the DTC image processing is composed by the following sub-functions.

3.3 Optional image function

IPC-3D: Dynamic Threshold is identical to the Simplified Dynamic Threshold in IPC mode. (See

section 3.3.2)

NOTICE 1: Threshold, Brightness, and Contrast settings are ignored in DTC mode.

NOTICE 2: Gamma correction is also ignored in DTC mode.

3-13

Page 35

Image Functions

(1) Pre-filter

[A.4.7 SET WINDOW command / DTC mode]

The pre-filter performs filtering before processing the Dynamic Threshold. Ordinary and Ballpoint Pen are selectable in Pre-filter.

Name of

parameter

Ordinary X’00’ Linear gamma curve

High Contrast X’10’ Makes low contrast

Use Ordinary basically. For the texts written by ball-point pens, use of Ball-point Pen may better

for OCR. This is because, the texts written by ball-point pens actually have two thin lines per

stroke. To human eye, this is not big problem, but OCR may not recognize the text. The Ballpoint Pen filter detects lighter areas compared to the surroundings and increases the density of

the lighter area. puts these two lines into one solid line. This can prevents cuts, void or too thin

lines.

Table 3.7 Parameter of Pre-filter

value Effect with IPC-2D Effect with IPC-3D Default

Linear gamma curve

X’00’

Image clear (for dark

background document)

3-14

Page 36

3.3 Optional image function

(2) Gradation

[A.4.7 SET WINDOW command / DTC mode]

Gradation specifies the gamma curve correction before processing Dynamic Threshold. When

scanning news papers or old documents which background is dark, it is desirable that the gamma

curve has coarse steps in the lighter side and fine steps in the darker side. This is called High

Contrast gamma curve.

γ curve

As the Dynamic Threshold with IPC-3D includes an automatic contrast adjustment, High Contrast

setting is not required.

Table 3.8 Parameter of Gradation

Parameter Value Effect with IPC-2D Effect with IPC-3D Default

Ordinary X’xxx00xxx’ Normal gamma curve

(for general document)

High Contrast X’xxx10xxx’ Makes low contrast Image

clear

* for dark background document such as newspaper or old document

Normal gamma

curve

No effect

X’00’

3-15

Page 37

Image Functions

(3) Dynamic Threshold Curve

[A.4.7 SET WINDOW command/DTC mode]

For the Dynamic Threshold function, the threshold is changed with the average optical density of

a small area (e.g. 5 x 5 pixel area).

Relation between the threshold and maximum density is formed as a curve when the threshold is

expressed in the Y-axis and the maximum density in the X-axis. This curve is called “threshold

curve”.

This function allows a customer to select a threshold curve. Several different curves are prepared, one

is the OCR type and other is the image type. The characteristic of the curve is deferent between IPC2D and IPC-3D.

IPC-2D: The image type curve has steeper inclination in the middle of the curve. For OCR type

curve, the customer can select type (inclination) and density level.

PC-3D: 8 curves are available which adjusts the sensitivity of the image

The parameter of Dynamic Threshold are as follows.

Table 3.9 The deference of Dynamic Threshold Curve parameter

Option Parameter Value Selectable parameter Default

IPC-2D

IPC-3D 0

0 for OCR

to

5 for OCR

6 for

Image

7 for

Image

to

4

to

7

B’xxxxx000’

to

B’xxxxx101’

B’xxxxx110’

B’xxxxx111’

B’xxxxx000’

to

B’xxxxx100’

to

B’xxxxx111’

Brightest

Darkest

makes bright image to dark

makes dark image to bright

Decrease the noise

Normal

makes image sharp but increases

noise

6 for

image

4

3-16

Page 38

3.3 Optional image function

(4) Equal to White

Equal to White ON

Equal to White

OFF

[A.4.7 SET WINDOW command/DTC mode]

Equal to White specifies the result of binaizing when the value of a pixel equals the threshold.

The default is Equal to White OFF.

The effect of this parameter is slight but, if the scanned image text is bold, set to Equal to White.

If the scanned Image text is too narrow or lost, set to Equal to Black (Equal to White OFF).

Table 3.10 Parameter of Noise Removal

Parameter Value Effect Default

B’xxxxxxx1’

B’xxxxxxx0’

Equal to White

Equal to Black

Equal to White ON

3-17

Page 39

Image Functions

(5) Noise Removal

[A.4.7 SET WINDOW command / DTC mode]

Noise Removal reduces the isolated spot noise after Dynamic Threshold. If the image is noisy.

Turn on the Noise Removal and set the granularity to the size of noise to be removed. The

parameter of Noise Removal is as follows.

Table 3.11 Parameter of Noise Removal

Parameter Value Effect Default

OFF

2x2

3x3

4x4

5x5

NOTICE: In IPC-3D, Noise Removal is ignored when the OCR smoothing is ON.

B’001xxxxx’

B’0000001x’

B’0000010x’

B’0000100x’

B’0001000x’

Noise Removal is not done

2x2 or smaller dot is removed

3x3 or smaller dot is removed

4x4 or smaller dot is removed

5x5 or smaller dot is removed

OFF

3-18

Page 40

3.3 Optional image function

(6) Smoothing

[A.4.7 SET WINDOW command / DTC mode]

Smoothing in DTC mode is done after binarizing. This function smooths a slant line or curve by

eliminating jagged edges on the line. An irregularly protruding portions are removed and an

Irregularly cut portions are filled In. The parameters of smoothing are as follows. The Image

Smoothing do no smoothing. If an image scanned in low resolution and the outline is jagged,

specify the OCR smoothing. When OCR smoothing is specified with IPC-3D, Noise removal is

not done.

Table 3.12 Parameter of Smoothing

Parameter Value Effect with IPC-2D Effect with IPC-3D Default

Image Smoothing X’x00xxxxx’ No smoothing No smoothing

OCR Smoothing X’x01xxxxx’ Smooth is done Smooth is done *1

*1 Noise removal is ignored.

X’00’

NOTICE: In IPC-3D, Noise removal is ignored, when OCR smoothing is specified.

3-19

Page 41

Image Functions

3.3.2 IPC mode (Auto II mode)

[A.4.7 SET WINDOW command/DTC SELECTION = X’00’ or X’80’]

In this mode, the algorithm of dynamic threshold is deferent between IPC-2D and IPC-3D.

This mode is recommended for general electric filing purpose.

Option Algorithm of the Dynamic Threshold Condition

IPC-2D: Simplified Dynamic Threshold Anytime

IPC-3D:

a) Simplified Dynamic Threshold

The Simplified Dynamic Threshold is effective to obtain sharp images or capture texts having colored

backgrounds. This effect is similar to Image Emphasis. The difference is that the Simplified Dynamic

Threshold does not emphasis the background. This is useful for forms, checks and most real world

document.

In IPC mode, Simplified Dynamic Threshold was a simplified implementation of the Dynamic

threshold. In IPC-2D, Simplified Dynamic Threshold is no simpler, but sometimes more effective

than Dynamic Threshold for background texts. In IPC-3D, both Dynamic Threshold are the same and

sophisticated.

Simplified Dynamic Threshold When Image Emphasis is not

IPC-2 like Simplified Dynamic

Threshold

specified

When Image Emphasis is

specified

3-20

Page 42

3.3 Optional image function

b) IPC2 like Simplified Dynamic Threshold

IPC-3D supports IPC-2 like Simplified Dynamic Threshold for compatibility purpose. When both

Image Emphasis and Simplified Dynamic Threshold are set, it is regarded as IPD-2 like Simplified

Dynamic Threshold. In this case, IPC-3D Sensitivity parameters in Simplified Dynamic Threshold

are used as the Variance Rate, and Image Emphasis parameters are used for emphasis. The IPC-2 like

Simplified Dynamic Threshold increases resolution.

The conceptual image processing flow in the IPC mode is shown below.

3-21

Page 43

Image Functions

(1) Image Emphasis

[A.4.7 SET WINDOW command / Image Emphasis]

Image Emphasis performs filtering to emphasize image edges or to smooth (IPC-2D) or remove

background noise (IPC-3D). If text edges are not clear or faint, turn on the Image Emphasis.

Three levels of Image Emphasis, High/Mid/Low, are available. As a side effect, Image Emphasis

also emphasizes the noise. It is better to set Image Emphasis higher to obtain good image, until

the noise is not perceptible.

In IPC-2D, Smooth is also available which works as negative emphasis so image edges becomes

faint even if original is ordinary sharp.

In IPC-3D, Background Removal is available instead of Smooth. Background Removal is

effective to remove background tones. For the case of the texts surrounded by halftone pattern

such as dither, background should be removed to emphasize the text. Background is useful for

such cases.

The algorithm of Smooth and Background Removal is deferent but the outputs are similar.

Option Parameter Value Effect Default

IPC-2D

IPC-3D

Table 3.13 Parameter of Image Emphasis

OFF X’00’ No emphasis and smoothing

High

Mid

Low

Smooth X’80’ to X’FF’ Negative effect of emphasis

OFF X’00’

High

Mid

Low

Background

removal

X’01’ to X’2F’

X’30’ to X’4F’

X’50’ to X’7F’

X’01’ to X’2F’

X’30’ to X’4F’

X’50’ to X’7F’

X’80’ to X’FF’ Removes noisy background

High emphasis

Medium emphasis

Low emphasis

No emphasis and background

removal

High emphasis

Medium emphasis

Low emphasis

OFF

Off

3-22

Page 44

3.3 Optional image function

3-23

Page 45

Image Functions

(2) Outline Extraction

[A.4.7 SET WINDOW command / Outline extraction]

The Outline function extracts the edges from images. This function is rarely used. It may be used

in DTP for image effects or image sensing.

Parameter Value Effect Default

OFF X’00’ Outline Extraction is disabled.

ON X’80’ Outline Extraction is enabled.

Table 3.14 parameter of Outline Extraction

OFF

3-24

Page 46

3.3 Optional image function

(3) Automatic Separation

[A.4.7 SET WINDOW command / Automatic Separation]

With this feature, the scanner automatically recognize the text areas and photo areas on the

document. For the areas that are recognized as text areas, scanned data are processed as pure

binary with no halftone algorithm (fixed threshold or automatic binarization). For areas that are

recognized as photo areas, scanned data are processed with a halftone algorithm (Dither or Error

Diffusion).

Table 3.15 Parameter of Automatic Separation

Parameter Value Effect Default

OFF X’00’ Automatic Separation OFF

OFF

ON X’80’ Automatic Separation ON *1 *2

*1 Simplified DTC and Image Emphasis are available for binary regions.

*2 In IPC-2D, other image processing as Simplified Dynamic Threshold and Image Emphasis are ignored.

3-25

Page 47

Image Functions

(4) Mirror image

[A.4.7 SET WINDOW command / Mirror image]

A scanned image is turned over symmetrically in the main scan direction, generating a mirrored

reflection of an image.

Parameter Value Effect Default

OFF X’00’ Mirror Image OFF

ON X’80’ Mirror Image ON

Table 3.16 Parameter of Mirror Image

OFF

3-26

Page 48

(5) Black and White reverse

[A.4.7 SET WINDOW command/RIF (reverse image format)]

Black and White Reverse turns the black part of the image white and white part of the image

black. This effect is similar to the negative/positive image from camera.

Table 3.17 Parameter of Black and White Reverse

Parameter Value Effect Default

OFF X’00’ Black and White Reverse OFF

ON X’80’ Black and White Reverse ON

3.3.3 Sub-Window

[A.4.8 SET SUBWINDOW command]

In the Main Window specified in section 3.2.1, muximum four small portions on each front and back

side of the document can be clipped as Sub-Window. In each Sub Window, the deferent scanning

methods which is shown in Fig 3.2 can be specified.

NOTICE 1: IF the area specified for any sub window does not fit in the area of the main window,

3.3 Optional image function

OFF

the portion of the area outside the main window area is ignored. Only the portion where

the main and sub window overlap (shown hatched) is processed.

NOTICE 2: If sub-windows in a main window overlap with each other as a result of the values

ULX, ULY, W and L , the scanner returns the error.

3-27

Page 49

Image Functions

3.3.4 Zooming

[A.4.7 SET WINDOW command/X,Y resolution]

Zooming is the function to enlarge or reduce the image from 400 dpi. X and Y independent variable

resolutions are supported. This zooming is processed in grayscale, so smooth and non-distorted

images can be obtained even when halftone is applied.

NOTICE: Resolution is converted by an electrical method. Therefore , no matter how high

NOTICE: Zooming rate of back side reading must be same as front side.

resolution is specified, small texts or narrow lines will not be resolved more clearly than

400 dpi image does.

3.3.5 Dither download

[A.4.10 SEND command/SEND data]

User’s own dither pattern is downloaded with this function. Four built-in dither patterns are available

basically and 8 more dither patterns can be downloaded.

3.3.6 Gamma download

[A.4.10 SEND command/SEND data]

Gamma downloading is supported to scan with user’s own gamma correction pattern. Two built-in

gamma patterns, Ordinary and High contrast, are basically available. And five more gamma patterns

can be downloaded.

NOTICE: When the downloaded gamma pattern is specified for grayscale reading, the last two bit

of the pixel output data is always B’00’.

Zooming (800 dpi at 200%)

3-28

Page 50

Storage and Installation

Chapter 4 Storage and Installation

4.1 Packaging box and storage condition

Physical specification of the packaging box are listed in Table 4.1

Table 4.1 Physical specifications of the packaging box

Item Specification Remarks

Size of the

box

Weight of the box 29 kg

Doggy door

Label for scanner

identification

Conditi

on of

storage

Width 670 mm

Depth 915 mm

Height 375 mm

Yes (size : 285 × 50 mm)

Attached on the side of the packaging

box.

Label contents;

• Scanner type

• Scanner Parts number

• Serial number

Temperature -20°C to 60°C less than 15°C /hr

Humidity 8 to 95% with no

Stacking less than 8 stories

See Figure 4.1

condensation

4-1

Doggy door

915

375

670

Label

Figure 4.1 Packaging box

Page 51

Storage and Installation

4.2 Components in the packaging box

Following components are included in the packaging box. Note that the power cable is deferent

between the scanner for USA/North America and the scanner for Europe.

Table 4.2 The components in the box

Quantity per boxName of the component

USA, North

America version

Scanner 1 1

Inspection report 1 1

Operator’s Guide 1 1 Manual

Cleaning and maintenance 1 1 Manual

Pad ASY 1 1 See Section 5.4

Power

cable

Stacker 1 1

Terminator 1 1

for 100V 1 for 200V - 1

Europe version

Description

4.3 Installation procedure

4.3.1 Removing the carrier fixing bracket

1) Set the scanner on the edge of the desk so that the ADF extends from the

4-2

Page 52

4.3 Installation procedure

2) Look at the bottom of the scanner to find the carrier fixing bracket.

3) Remove the screw, and remove the carrier fixing bracket from position A . Then install the

carrier fixing bracket at position B .

4-3

Page 53

Storage and Installation

Back of the image

to the

4.3.2 Connections

Connect the cables as follows;

(1) Set the power switch OFF. (see Figure 1.1)

(2) Connect the power cable.

Connect the power cable to the power inlet (see Figure 1.1) on the back of the image

scanner.

Connect the other end of the power cable to a power outlet.

(3) Connect the interface cables

Connect the interface cables to the interface connectors (see Figure 1.1) and fasten the

cables with catches or screws. Connect the other end of each Interface cable to the host

computer.

4.3.3 Mounting the stacker

Hook the pins on the stacker to the claws on the image scanner.

Interf

Terminator

If the image

scanner is at

the terminal

side, connect

the terminator

4-4

Page 54

4.3.4 SCSI-ID setting

The default of SCSI-ID is 5. SCSI-ID is set by Setup mode of operator panel. The procedure to

set SCSI ID is;

(1) Turn the power ON by pressing “I” side of the power switch (see Figure 1.1). The scanner

displays “Scanner Ready” on the lower line of LCD.

Scanner Ready >

(2) Then press “Next” button. The scanner displays “Mode select 1”.

(3) Then press “Next” button. The scanner displays “Mode select 2” meaning that setup mode is

ready. Then press “enter” button.

Mode select 2

Setup mode Change?

(4) Then press “enter” button. The scanner displays as follows.

4.3 Installation procedure

Mode select 1

Manual mode

change?

*01 Double Feed Check

= No/Yes --> 10/15/20mm

(5) Press “Previous” once, then the scanner displays “SCSI ID” on the upper line of the LCD.

*10 SCSI ID

= 0/1/2/3/4/5/6/7

(6) Select SCSI ID by pressing “ è “ or “ ç “ button, and press “Enter”. (SCSI ID is set.)

(7) Press “Exit” to return to “Scanner Ready” screen.

4-5

Page 55

Chapter 5 Operation and Maintenance

5.1 Operator panel operation

5.1.1 Operator panel function

Operator pane has one LCD, six buttons and three LEDs as follows. The functions of each button

and LED are shown in Table 5.1.

Paper counter

50

Scanner Ready 100000

Abrasion counter

Table 5.1 Functions of buttons and LEDs

Name of the button

and LED

(↑) (↓) (STOP)

Previous Next Exit 0 Power

0 READ

ç è

Function

(START)

Enter 0 Check

Button

LED

Next LCD displays the next screen on the screen flow chart of Figure

5.1 or 5.2. The settings you have made is effective.

Previous LCD displays the backward screen of the screen flow chart of

Figure 5.1 or 5.2. The settings you have made is effective.

ç

è

Exit When “Check” LED lights, pressing this button releases error

ENTER Registers the parameter selected by cursor.

Power Indicates that the scanner is ON.

READ Indicates that the scanner is reading documents.

Check

Moves the cursor (the blinking part) to the left

Moves the cursor (the blinking part) to the right

status (turn off “Check” and returns to “Scanner Ready” screen).

When you are setting on the operator, pressing this button returns

to “Scanner Ready” screen immediately. Note that the setting you

have select is effective after pressing this button.

If it blinks at one second cycle, it means that some temporary

error occurs. (See section 6.1)

If it blinks at four seconds cycle, ADF cleaning is necessary.

If it lights, it means that some alarm occurred. (See section 6.1)

Table 5.2 Functions of the counter

Counter Function

Paper counter Paper counter counts the scanned sheet from the start of reading to

Hopper empty or an error detection.

Abrasion counter Abrasion counter counts the accumulated number of the scanned

sheet. This counter increments at every 10 sheets. Use this counter

to check the cleaning cycle or parts replacement cycle.

5-1

Page 56

Operation and Maintenance

M1

To Manual Feed mode

M3

To Setup mode

M4

5.1.2 Manual Feed mode

In this mode, the scanner waits for some predetermined time without issuing “Hopper empty” after

all documents are read. This predetermined time (time-out limit) is specified by Setup mode.

Therefore you can set next documents on ADF chute without interrupting reading operation. The

procedures for setting manual feed mode are as follows.

(1) Turn the power ON by pressing “I” side of the power switch (see Figure 1.1). The scanner displays

“Scanner Ready”.

Scanner Ready

(2) Press “Next” button. Then the scanner displays “Mode select 1”

Mode select 1

M Manual mode change?

(3) Then press “Enter” button. Then the scanner displays following screen.

M01 Manual feed

= No/Yes

(4) Select “Yes” by pressing “è” button, and press “Enter”. Now the Manual Feed mode is set.

(5) Press “Exit” to return to “Scanner Ready “ screen.

Note that “Manual Feed” is shown on the upper left of the LCD. This means that the scanner is in

Manual Feed mode.

Manual Feed

Scanner Ready

M1 At Manual Feed mode

xxx

Scanner Ready xxxx

Next

Mode select 1

M Manual mode Change?

Previous

Exit

Enter

Previous

Enter

Mode select 2

! Setup mode Change?

Next

Figure 5.1 Mode change

Manual Feed xxx

Scanner Ready xxxx

5-2

Page 57

5.1.3 Setup mode

Operator can set following items by Setup mode.

Table 5.3 Functions of Setup mode

No Item Description Selectable

5.1 Operator panel operation

Default

parameters

1

2 IPC pre-setting Scanner automatically sets the

3 Reset of

4 Pick start time

4

5

Double feed

check

Abrasion counter

setting

Time-out limit

setting *

ADF front offset

setting *

Double feed is detected by checking

the document length one by one.

recommended reading parameters.

Five sets of recommended

parameters are available.

Abrasion counter can be reset. - -

The time from the document

insertion to the start of picking is

specified. User can select most

comfortable Pick start time for the

job.

The time that the scanner waits for

next document insertion after last

document scanned can be specified.

Horizontal and vertical offset of the

front side image by ADF is

specified.

Tolerance:

No/10/15/20

mm

Document:

No/1/2/3/4/5

Time:

0.2 to 9.8 sec 1.0 sec

Time:

27 values from

1 to 1999 sec

Offset:

H: -2 to +3mm

V: -2 to +3mm

No

No

30 sec

Offset:

H: 0 mm

V: 0 mm

6

7 FB offset

8 IPC/Memory

9 SCSI ID setting SCSI ID is selectable SCSI ID:

* This offset means the deference from the value adjusted by automatic offset adjustment.

ADF back offset

setting *

setting*

status display

Horizontal and vertical offset of the

back side image by ADF is

specified.

Horizontal and vertical offset of the

FB image is specified.

The type of IPC option (IPC-2D or

IPC-3D) and total memory installed

are displayed.

Offset:

H: -2 to +3mm

V: -2 to +3mm

Offset:

H: -2 to +3mm

V: -2 to +3mm

1/2/3/4/5/6/7 5

Offset:

H: 0 mm

V: 0 mm

Offset:

H: 0 mm

V: 0 mm

5-3

Page 58

Operation and Maintenance

The procedures for setting Setup mode are as follows.

(1) Turn the power ON by pressing “I” side of the power switch (see Figure 1.1). Then the

scanner displays “Scanner Ready”

Scanner Ready >

(2) Press “Next” button. Then the scanner displays “Mode select 1”,

Mode select 1

M Manual mode change?

(3) Press “Next” button again. Then the scanner displays “Mode select 2”

Mode select 2

! Setup mode Change?

(4) Press “Enter” button. Now the scanner is in Setup mode.

(5) At first the screen is S41 in the screen flow chart next page. Select items by pressing “Next”

or “Previous” buttons, and select parameters by pressing “ç” or “è” buttons, and press

“Enter” button to set the parameter. Finally close the Setup mode by pressing “Exit” button.

The flow chart of the Setup mode is in Figure 5.2

5-4

Page 59

5.1 Operator panel operation

Previous

Previous

Previous

M4

M3

Next

Next,Enter,Exit

Enter

Enter

No/Yes

Next

Next,Enter

Next,Enter

Next,Enter

Next,

Enter

Mode select 1

M Manual feed Change?

Mode select 2

! Setup mode Change?

To M1

(Figure 5.1)

Previous

Previous

Exit

Enter

Enter

S42

Next, NO Enter

S43

Next, NO Enter

S44

S45

S46

S47

S48

S49

S4A

S4B

S31

M01 Manual feed

=No/Yes

from S4B

S41

!01 Double Feed Check

=No/Yes → 10/15/20 mm

!02 IPC Pre-set

=No/Yes → 1/2/3/4/5

!03 Abrasion counter

=xxxxxx Reset No/Yes

!04 Pick start time

= 0.2 Sec

!05 Time-out limit

= 30 Sec

!06 ADF Front Offset

Change? No/Yes

No

!07 ADF Back Offset

Change? No/Yes

Next, No Enter

!08 FB Offset

Change? No/Yes

Next, No Enter

!09 IPC/Memory Status

IPC-2D / 32MB(TOTAL)

Next,Enter

!10 SCSI ID

= 0 / 1 / 2 / 3 / 4 / 5 / 6 / 7

Next,Enter

Previous

Previous

Previous

Previous

Previous

Previous

Previous

to M1

Enter at Yes

!02-1 IPC Host Setting

Ignore Yes/No

Enter at Yes

!03-1 Are you sure?

No/Yes

Enter at yes

!06-1 Return to default?

No/Yes

!06-2 Front Offset H

H= +0.0 mm (+:Left)

!06-3 Front Offset V

V= +0.0 mm (+:Up)

Enter at Yes

!07-1 Return to default?

No/Yes

!07-2 Back Offset H

H= +0.0 mm (+:Left)

Enter

!07-3 Back Offset V

V= +0.0 mm (+:Up)

Enter at Yes

!08-1 Return to default?

!08-2 FB Offset H

H= +0.0 mm (+:Left)

Enter

Enter

Enter

Enter

Enter

Enter

Enter

Figure 5.2 Flow chart of the Setup mode

Enter

!08-3 FB Offset V

V= +0.0 mm (+:Up)

5-5

Page 60

Operation and Maintenance

5.1.4 Function of CE mode

CE mode is available only for maintenance person, so the details of the CE mode are shown in the

maintenance manual of this scanner. In this section only the items of the CE mode is shown in

table 5.4 as a reference.

Items Features

T01 Single Test feed Scanner tests the FB or ADF single sheet reading.

T02 Multi Test feed Scanner continuously tests the feeding and AGC control

T03 Offset Adjsutment Scanner automatically adjusts the offset of FB image,

T04 EEPROM Setting This function supports the inquiry and over-writing of the

Table 5.4 Function of CE mode

Scanner tests not only the feeding but also AGC control of

carrier unit and Optical unit.

unit “Exit” is pressed.

ADF front image and ADF back image.

EEPROM data.

T05 OP Panel Test

T06 ADF Sensor Test

T07 PROM Version Scanner displays the firmware version in PROM.

T08 Life Counter

T09 Baud Rate

T10 Product ID

T11 Memory Test Scanner tests the image memory.

Scanner tests the function of the LCD, LEDs and switches

on the operator panel.

Scanner tests the switches on ADF indicating the ON/OFF

real time status on LCD.

Scanner displays the accumulated sheet number wich ADF

has fed.

This function supports the baud rate setting of RS232C.

Baud rate is selectable from 9600/4800/2400/1200 bps.

This function supports the setting of Product ID of SCSI

interface.

Product ID is selectable from

M3099G/M3097DG/M3097G/M3093DG/M3093GX/M30

96G/M3096GX.

5-6

Page 61

5.2 Document setting

5.2.1 Document setting on ADF paper chute

The procedures for setting the document on ADF are as follows.

NOTICE: Note that the documents follows section 2.6 “Document Specifications”.

(1) Pull up the ADF paper chute as follows:

Hold the document feeder with one hand and pull up the ADF paper chute with the other

hand to set the shaft in position B.

ADF paper chute

5.2 Document setting

Rotation direction

Bar

Operating position

(2) Fan the document

Fan the document to loose static electricity and prevent double feed or jam.

5-7

Page 62

Operation and Maintenance

(3) Angle the document edges as follows to avoid double feed.

a) Lift the documents holding the both ends with both hands.

b) Hold the documents tightly with your left hand, and bend the documents as shown in

B.

c) Grip tightly with your right hand, loosen the grip of your left hand, and straighten the

documents as shown in C.

(4) Place the documents on ADF paper chute as follows

a) Open the right and left guides of the ADF paper chute about 5 mm wider than the

document width

b) Place the documents with front side down onto ADF paper chute with the top edges

facing the ADF.

c) Adjusts the right and left guides to the document sides. Skewing may occur if there is

a gap between the guides and documents.

d) Slides the documents down until they touch the pick roller in the ADF. If the

documents hit the pick roller in ADF hard, two or more sheets may be fed at once.

Make sure that the upper end of documents are not turned.

5-8

Page 63

5.2 Document setting

NOTICE: The number of the documents to be placed on ADF paper chute is limited as

described in section 2.6.3.

(6) Start read operation. After reading, remove the documents from the stacker.

NOTICE: If a wrong document size or mode is selected, the document may not be read

correctly. For example;

- Portrait and landscape setting

- If 3mm of the leading edge of the document is not white or drop-out color,

set

White level following OFF.

5-9

Page 64

Operation and Maintenance

5.2.2 Document setting on flatbed

The procedures for setting the document on ADF are as follows.

(1) Open the document cover.

(2) Place the document with face down on the document bed. Correct any curled or folded parts

of the document.

(3) Position the long side (in landscape mode) or the short side (in portrait mode) of the

document to the left side of the document bed.

(4) Position the left top corner of the document to the reference mark. If the document is not

placed correctly, scanned image position may be incorrect.

(5) Close the document cover slowly.

(6) Start the read operation. After reading, open the document cover and remove the document.

5-10

Page 65

5.3 Cleaning

Cleaning is important to keep stable scanning. Cleaning section, tool and cycle are explained in Table 5.5.

Table 5.5 Cleaning of the scanner

No Cleaning section Tool Cleaning cycle

1 Pad

ADF

2 Rubber rollers

(Pick roller, Feed

roller, Ejection rollers)

3 Plastic rollers*2

(Coupled feed roller)

4 White part of the guide

5 Glass

Dry cloth and

Isopropyle

alcohol *1

or

Cleaning paper *1

5,000 sheets

5.3 Cleaning

6

7 Document holding pad

FB

8

*1 Fujitsu recommends to use following cleaning tools, ask your dealer or Fujitsu sales representative

if it is available.

Tool name Part number Description

Cleaner F1 CA91001-2316 Isopropyl alcohol 100ml

Cleaning paper CA91001-2314 10 absorbent sheets

*2 Fujitsu recommends to use following cleaning tool when the plastic roller is heavily soiled.

Tool name Part number Description

Cleaner F2 CA91001-2317 Organic solvent 70ml

*3 Do not use organic solvents such as a thinner.

*4 Make sure no liquid enters the scanner from the edges of the document bed glass.

Sheet guide or other

area

Document bed (glass)

Dry cloth and

neutral cleanser

*3 *4

5-11

Page 66

Operation and Maintenance

5.4 Consumable

Operator needs to replace following parts. It is recommended to use abrasion counter on the operator

panel and schedule the replacement of parts. Parts to be replacement cycle are as follows.

The parts replacement procedures are described in the Operator’s Guide.

Table 5.6 Parts replacement

No Part name Part number Replacement cycle Remarks

1 Pad ASY PA03951-0021 Every 100,000 sheets or

annually *1

2 Pick roller PA03951-0025 Every 200,000 sheets or

annually *1

One per scanner

One set per scanner

(two rollers are in one

set)

*1 These replacement cycle may be shortened depending on the paper scanned and bad scanner

cleaning. When carbon-less paper is used, the replacement cycle becomes short so these parts must

be prepared earlier than above.

5-12

Figure 5.3 Pad ASY

Page 67

5.4 Consumable

(Two rollers are included)

Figure 5.4 Pick roller

5-13

Page 68

Chapter 6 Error display and Recovery

6.1 Error display

6.1.1 Temporary error

(1) Hopper empty

Paper Empty

(2) Jam

Paper Jam

(3) ADF cover open

ADF-Cover Open

(4) Double feed error

Double Feed Error

This message is displayed if there is no more paper on

the ADF paper chute during a read operation in ADF

mode. Fill the ADF paper chute with paper. To enable

the read operation, press the stop button

This message is displayed if a document is jammed in

the ADF. See section 6.2 for removing jammed

documents.

This message is displayed if the ADF is not closed

completely. Close the ADF completely, and enable

the read operation.

This message is displayed when the ADF detects the

Double feed error. Check the document and re-scan

the document.

NOTICE: The scanner stores the length of the first sheet. And scanner compares the length of

NOTICE: The scanner can not detect the Double feed error when the documents completely

6.1.2 Alarm

One of the following message is displayed if an error occurs in the scanner. If one of the following

error message is displayed, turn the power off and then on again. If the same message is displayed,

contact your service representative.

(1) Optical alarm front

Optical Alarm(F)

(2) Optical alarm back

Optical Alarm(B)

scanned document with first sheet. Double feed is detected when the scanned