Page 1

M3096EX AND M3096GX

IMAGE SCANNER

OPERATOR’S GUIDE

C150-E009-07EN

Page 2

REVISION RECORD

Edition

01

02

03

04

05

06

07

Date published

June, 1994

August, 1994

Janualy, 1995

April, 1995

September, 1995

January, 1996

August, 1996

Revised contents

First edition

Contents revised

Contents revised

Pick Roller replacement procedure added

Pad replacement procedure added

Appendix C, Declaration of Conformity added

Declaration of Conformity revised

Specification No.: C150-E009-07EN

This digital apparatus does not exceed the Class A limit for radio noise emissions from digital apparatus set out in the Radio

interference Regulations of the Canadian Department of Communications.

Le présent appareil numérique n’ément pas de bruits radioélectriques dépassant les limites applicables aux appareils

numériques de la classe A prescridtes dans le Réglesment sur le brouillage radioélectrique édicté par le ministere des

Communications du Canada.

Maschinenlärmlnformationsverordnung 3. GSGV, 18.01.1991:Der arbeisplatzbezogene Schalldruckpegel beträgt 70

dB(A)oder weniger gemäß ISO 7779.

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

The contents of this manual is subject to change

without prior notice.

All Rights Reserved,

Copyright 1994, 1995, 1996 FUJITSU LIMITED

i

Page 3

Conventions Special information, such as warnings, cautions are indicated as

follows:

WARNING

A WARNING indicates that personal injury may result if you do not

follow a procedure correctly.

CAUTION

A CAUTION indicates that damage to the scanner may result if you

do not follow a procedure correctly.

NOTICE

A NOTICE provides “how-to” tips or suggestions to help you perform

a procedure correctly. NOTEs are particularly useful for first-time

users.

ii

Page 4

CONTENTS

page

CHAPTER 1 PREFACE .....................................................................................................1-1

CHAPTER 2 COMPONENTS ............................................................................................2-1

2.1 Checking the Components ..........................................................................................2-1

2.2 Part Names and Functions............................................................................................2-2

2.2.1 Exterior view of image scanner ...........................................................................2-2

2.2.2 Functions of each part ..........................................................................................2-3

2.3 Indication Panel Functions (standard model)...............................................................2-4

2.3.1 Indicators .............................................................................................................2-4

2.4 Operator Panel Functions (LCD model) ......................................................................2-4

2.4.1 Indicators .............................................................................................................2-5

2.4.2 Buttons and liquid crystal display screen ............................................................2-5

2.4.3 Liquid crystal display screen ...............................................................................2-6

2.4.4 Messages ............................................................................................................2-11

CHAPTER 3 INSTALLATION AND CONNECTIONS .................................................3-1

3.1 Precautions ...................................................................................................................3-1

3.2 Removing the Carrier Fixing Bracket ..........................................................................3-2

3.3 Connections..................................................................................................................3-3

3.4 Mounting the Stacker ...................................................................................................3-5

3.5 SCSI -ID Setting ..........................................................................................................3-6

CHAPTER 4 OPERATIONS ..............................................................................................4-1

4.1 Turning on the Power...................................................................................................4-1

4.2 Reading a Document in Flatbed Mode ........................................................................4-2

4.2.1 Reading a standard-size document ......................................................................4-2

4.2.2 Reading a page from a thick book .......................................................................4-3

4.2.3 Reading a document larger than the document board..........................................4-4

4.3 Reading Documents in ADF Mode..............................................................................4-5

iii

Page 5

CHAPTER 5 MAINTENANCE ..........................................................................................5-1

5.1 Removing Jammed Documents ...................................................................................5-1

5.2 Notes on Daily Use ......................................................................................................5-2

5.3 Cleaning .......................................................................................................................5-2

5.3.1 Cleaning the document cover, document holding pad, and document bed .........5-2

5.3.2 Cleaning the ADF ................................................................................................5-3

5.4 Consumables/Periodical replacement parts .................................................................5-4

5.4.1 Parts number and replacement cycle ...................................................................5-4

5.4.2 Replacing pad ASY .............................................................................................5-4

5.4.3 Replacing pick roller............................................................................................5-5

CHAPTER 6 TROUBLESHOOTING ...............................................................................6-1

APPENDIX A ..........................................................................................................................A-1

A.1 Installation Specifications ...........................................................................................A-1

A.2 External Dimensions ...................................................................................................A-2

APPENDIX B ..........................................................................................................................B-1

B.1 Test mode for maintenance .........................................................................................B-1

APPENDIX C ..........................................................................................................................C-1

C.1 Option ..........................................................................................................................C-1

C.2 IPC-2/CMP-2 option board installation ......................................................................C-1

iv

Page 6

FIGURES

page

2.1 Received components ..................................................................................................2-1

2.2 M3096EX/GX parts names ..........................................................................................2-2

2.3 M3096EX/GX Indication panel ...................................................................................2-4

2.4 M3096EX (LCD model) operator panel ......................................................................2-4

3.1 SCSI-ID setting ............................................................................................................3-6

4.1 Flatbed reading.............................................................................................................4-3

4.2 Removing the document cover.....................................................................................4-4

4.3 ADF paper chute setting ..............................................................................................4-7

4.4 Loading the document..................................................................................................4-9

5.1 Removing jammed documents.....................................................................................5-1

5.2 Cleaning the document cover, document holding pad, and document bed..................5-2

5.3 Cleaning the ADF ........................................................................................................5-3

5.4 Pick Roller replacement ...............................................................................................5-5

5.5 Move the Retaining spring ...........................................................................................5-6

5.6 Slide the Pick Roller ....................................................................................................5-6

5.7 Remove the Pick Roller ...............................................................................................5-6

A.1 External dimensions ....................................................................................................A-2

v

Page 7

TABLES

page

1.1 The differences between the M3096EX and the M3096GX........................................1-1

3.1 SCSI-ID setting ............................................................................................................3-6

6.1 Check items..................................................................................................................6-1

A.1 Installation specifications............................................................................................A-1

B.1 LED at an error ............................................................................................................B-2

vi

Page 8

CHAPTER 1 PREFACE

This manual describes how to operate the M3096EX and M3096GX image scanners. An image

scanner optically reads image information from a document and outputs the information to the

host system. The differences between the M3096EX and the M3096GX image scanners are

listed in table 1.1.

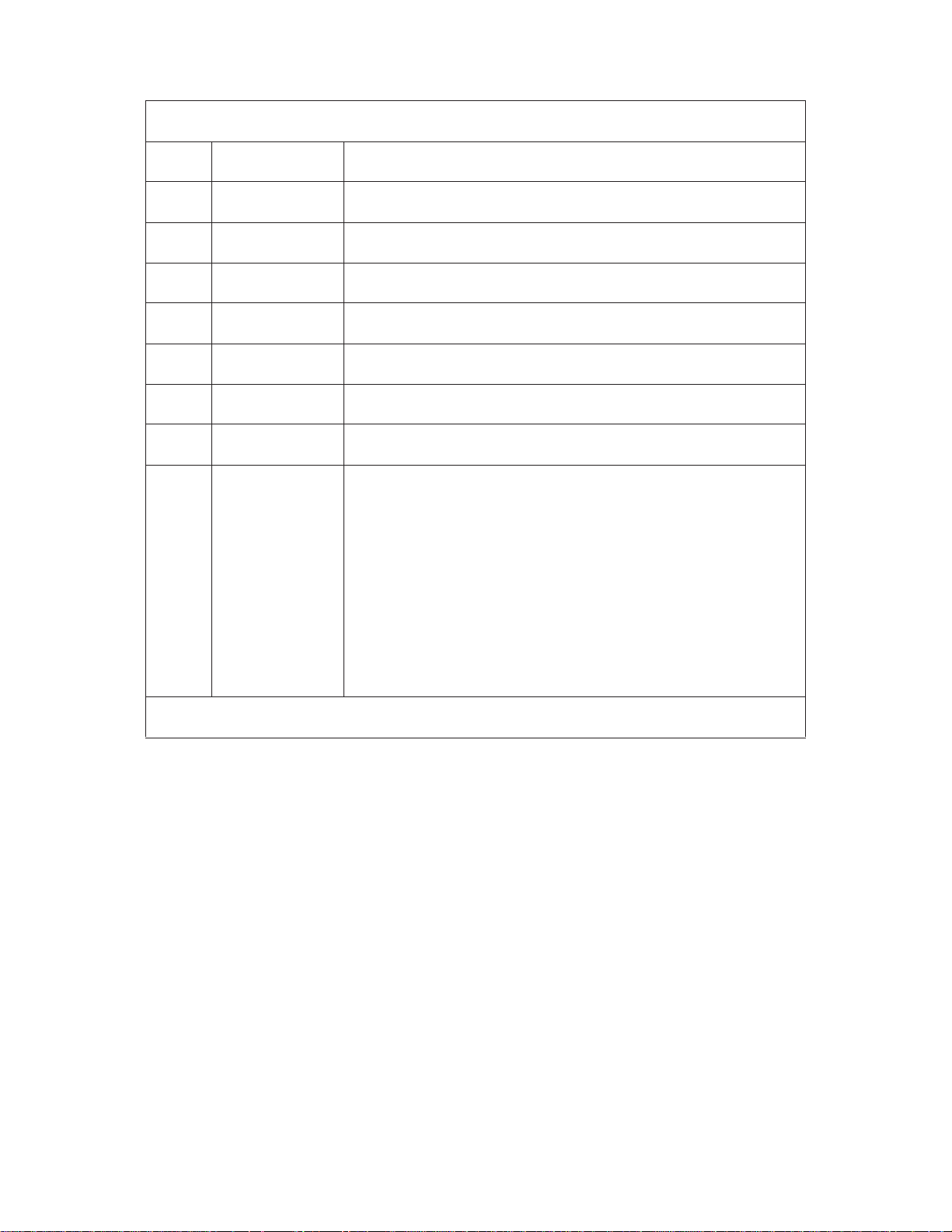

Table 1.1 The differences between the M3096EX and the M3096GX

Model number

M3096EX

LCD model

Standerd model

M3096GX

(Standerd

*Standerd model is the model which does not have LCD on operator panel.

This manual should be read before operating the image scanner to ensure correct operation.

Note on Copyright Act

This document cannot be reproduced or copied for any use other than private without the

author’s permission.

*

model)

Interface

RS232C

+

VIDEO

SCSI2

Shipping

models

North America

Europe

North America

Europe

Image size

A3 size or

double-letter

size

Automatic

document feeder

Yes

Max. 50 pages

(A4)

1 – 1

Page 9

This page is intentionally left blank.

1 – 2

Page 10

CHAPTER 2 COMPONENTS

2.1 Checking the Components

2.2 Part Names and Functions

2.3 Indication Panel Functions

2.4 Operator Panel Functions

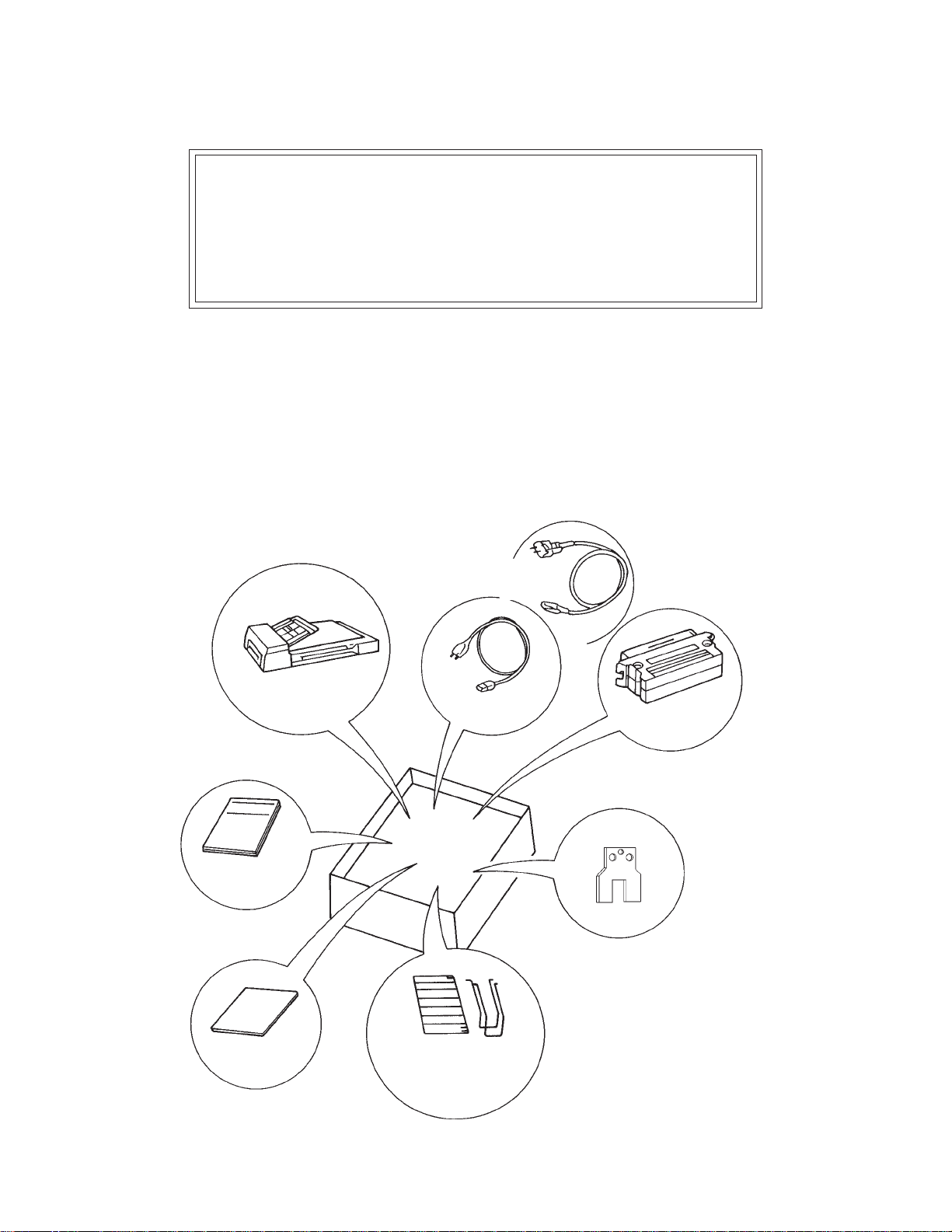

After unpacking image scanner, confirm that all the components have been received. This

section describes the components of the image scanner and their functions.

2.1 Checking the Components

These high precision components must be handled with care. Confirm

that all the components shown in figure 2.1 have been received. If

any component is missing, please contact your local Fujitsu sales

person.

Image scanner

Operator’s Guide

(this manual)

Power cable

for Europe

Power cable for

North America

Terminator

(for M3096GX)

Pads

Inspection

report

One stacker and

two extensions

Figure 2.1 Received components

2 – 1

Page 11

2.2 Part Names and Functions

This section shows the exterior view of image scanner. This section

also provides names of each part and describes their functions.

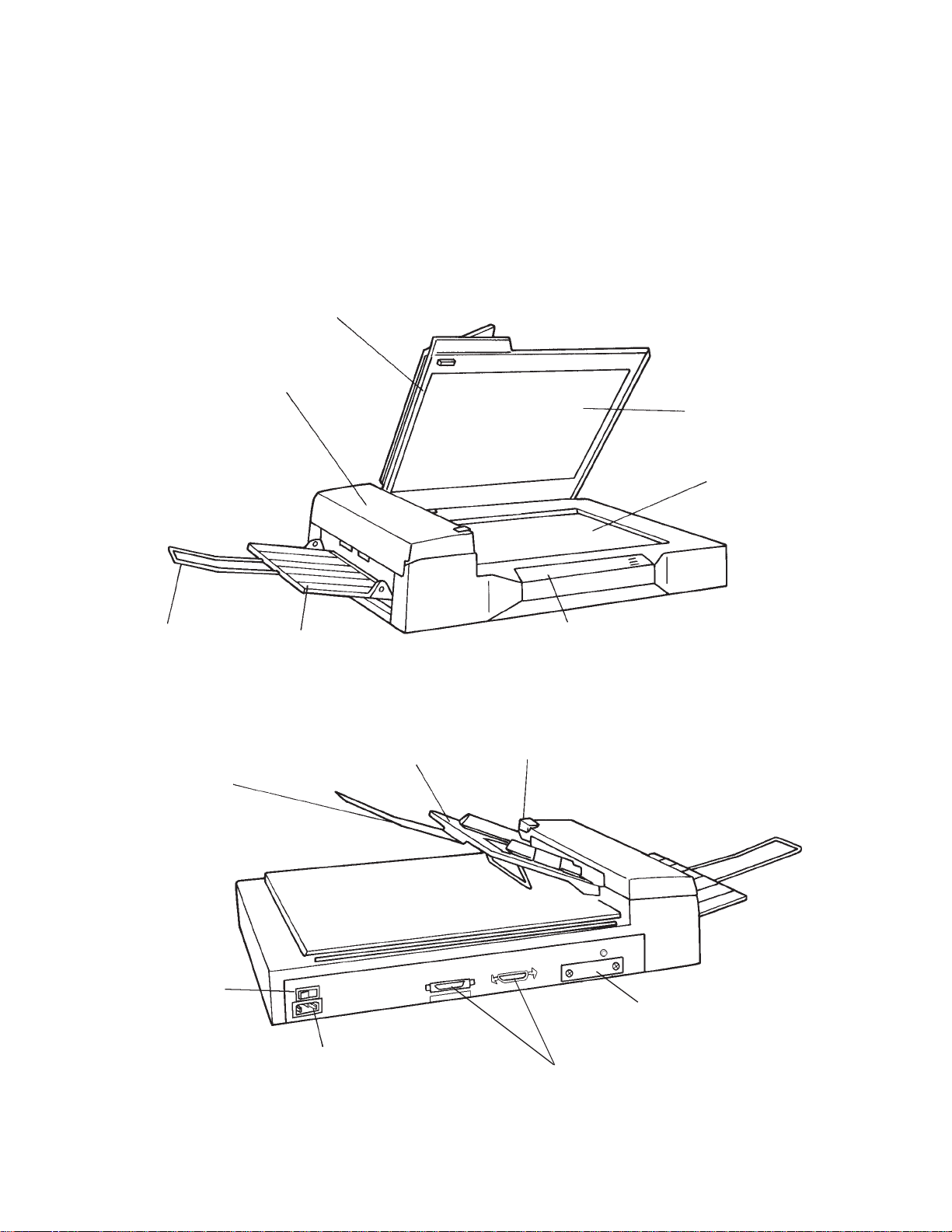

2.2.1 Exterior view of image scanner

The image scanner can read a document of A3 or double-letter size at

maximum.

Document cover

Automatic document

feeder (ADF)

Document

holding pad

Document

bed

Extension

Extension

Power switch

Stacker

Power inlet

ADF paper chute

Indication panel (Standerd model)

Operator panel (LCD model)

ADF lever

Third party slot opening

(M3096EX)

Interface connectors

2 – 2

Figure 2.2 M3096EX/GX parts names

Page 12

2.2.2 Functions of each part

Document cover: Closed over and holds a document to be

Document bed: A document to be read is placed on the

Document holding pad: Presses a document to the document bed.

Automatic document feeder (ADF):

Stacker: Stacks the read documents.

Extension: Keeps the stacked documents from

Power switch: Turns the power on or off.

Indication panel: The indication panel indicates the status

ADF paper chute: Holds the documents to be fed by the

read.

bed also called Flatbed (FB).

Automatically feeds documents to the

reading position.

overhanging.

of the scanner.

automatic document feeder.

ADF lever: Opens or closes the automatic document

feeder to remove documents jammed in

the feeder.

Power inlet: To be connected to an AC power outlet

with the power cable.

Interface connectors: To be connected to the host system with

interface cables.

Third party slot opening: Reserved. (M3096EX)

2 – 3

Page 13

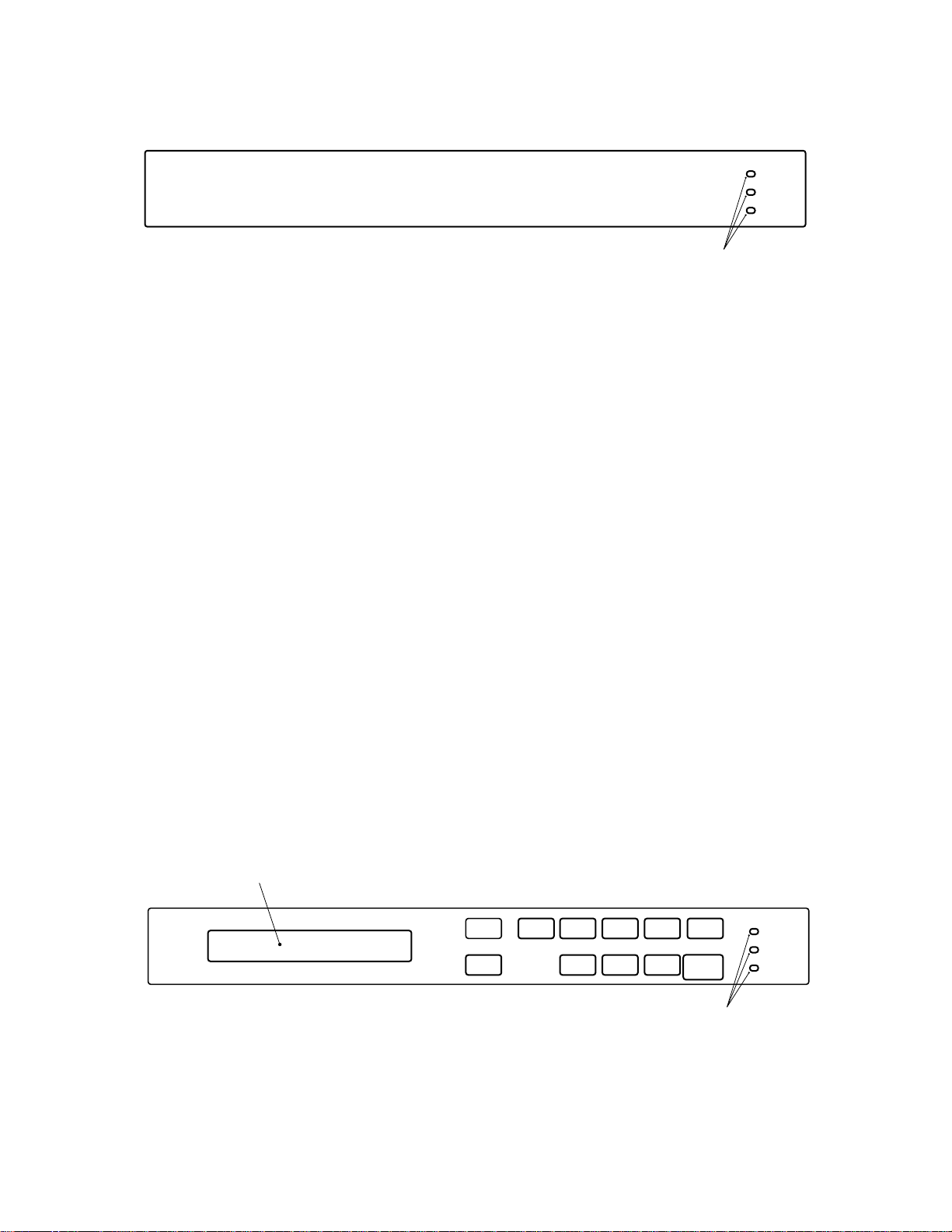

2.3 Indication Panel Functions (standard model)

Figure 2.3 M3096EX/GX Indication panel

2.3.1 Indicators

The meaning of each indicator is as follows:

Power indicator (Green):

Lights to indicate the power is on.

Read (reading in progress) indicator (Green) :

Lights to indicate reading is in progress.

Power

Read

Check

Indicators

Check (device check) indicator (Yellow):

Lights if a device error occurs which may result in a service

call. This indicator blinks if a document is jammed in the

automatic document feeder. This indicator turns off when the

jammed documents are re-moved from the feeder and the

feeder is closed.

This indicator blinks in four seconds period if the ADF cleaning is necessary. (See 5.3.2)

2.4 Operator Panel Functions (LCD model)

The operator panel has indicators and a liquid crystal display screen

for displaying image scanner status. The operator panel also has

operation buttons.

Liquid crystal display screen

Mode 1

Mode 2

ADF

Buttons

Size

Landscape

Density

Halftone

Resolution

Document

Stop

Start

Power

Ready

Check

Indicators

2 – 4

Figure 2.4 M3096EX (LCD model) operator panel

Page 14

2.4.1 Indicators

The meaning of each indicator is as follows:

Power indicator (Green):

Lights to indicate the power is on.

Read indicator (Green) :

In manual mode, when this lamp is lit, it indicates that the start

switch is enabled.

Check (device check) indicator (Yellow):

Lights if a device error occurs which may result in a service

call. This indicator blinks if a document is jammed in the

automatic document feeder. This indicator turns off when the

jammed documents are removed from the feeder and the feeder

is closed.

2.4.2 Buttons and liquid crystal display screen

The function of each button is as follows:

Start button:

Read operation can be started in either manual or automatic

mode. To start reading in manual mode, press this button while

the ready indicator is lit.

• Manual mode: Reading is started by the start button.

• Automatic mode: Reading is started by a command from

the host system.

Stop button:

This button is effective regardless of whether the scanner is in

manual or automatic mode. Press this button to stop the read

operation. When this button is pressed, the image scanner

operates as follows:

• Reading in flatbed mode: Reading is immediately stopped.

• Reading in ADF mode: Reading is immediately stopped

and documents being fed are ejected to the stacker.

After cleaning a jam, press the stop button to clear the

“Paper Jam” message displayed on the screen. The

ready screen will then be displayed to indicate that the

scanner is ready to read.

2 – 5

Page 15

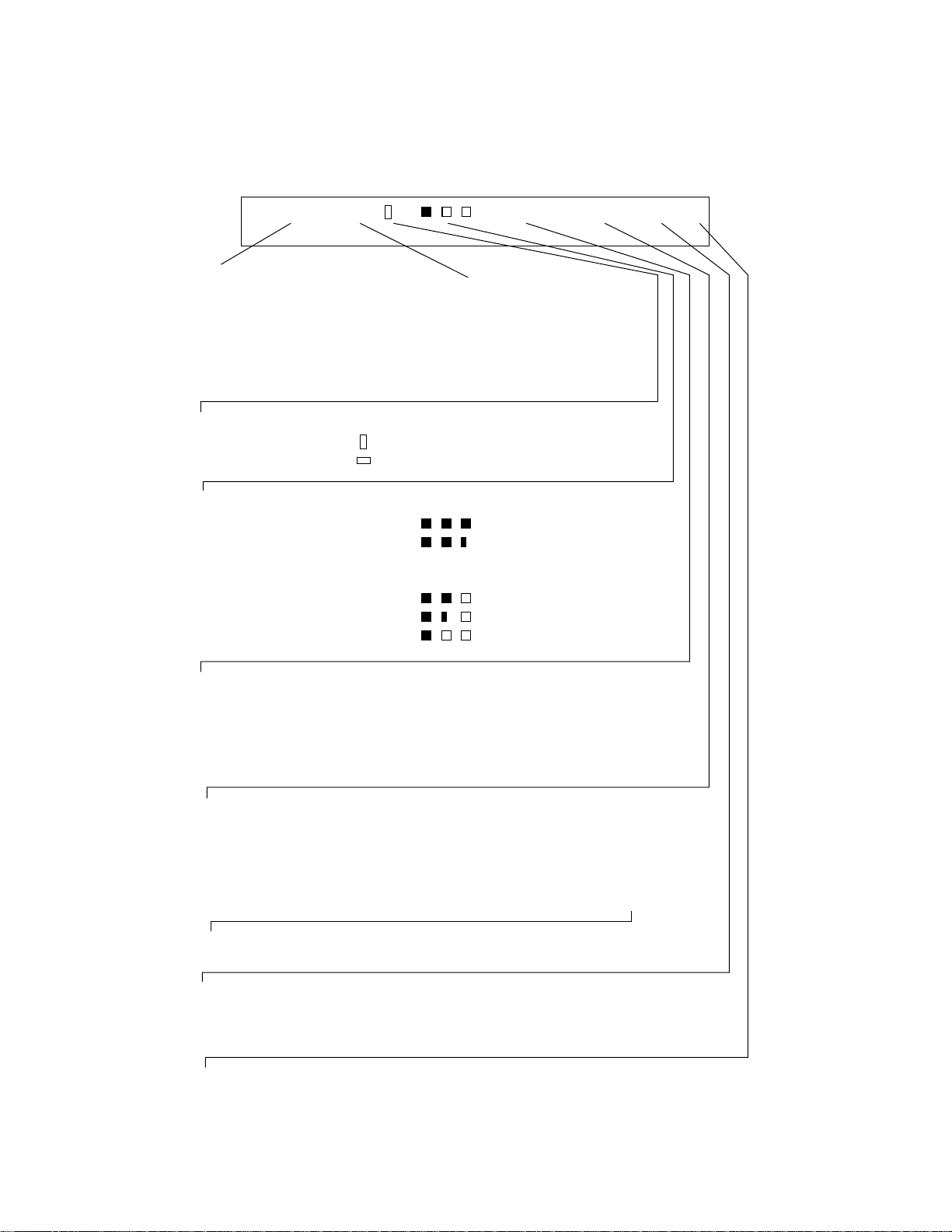

2.4.3 Liquid crystal display screen

The screen has two message lines. The current read mode status is

displayed in the upper line, and messages and the modes set by the

buttons are displayed in the lower line.

Upper line

Lower line

AFDA004>.L4

Reading mode Display

Flatbed

Automatic document feeder

: FB

: ADF

Doument orientation Display

Portrait:

Landscape:

:

:

Density

Very dark

Dark

Dynamic threshold

Simplified dynamic threshold

Normal

Light

Very light

Display

:

:

:

AT

:

AT2

:

:

:

Size

Double-letter size

Letter size

Legal size

A3 size

A4 size

If the optional PC board

1

}

is installed

Display

: DL

: LT

: LG

: A3

: A4

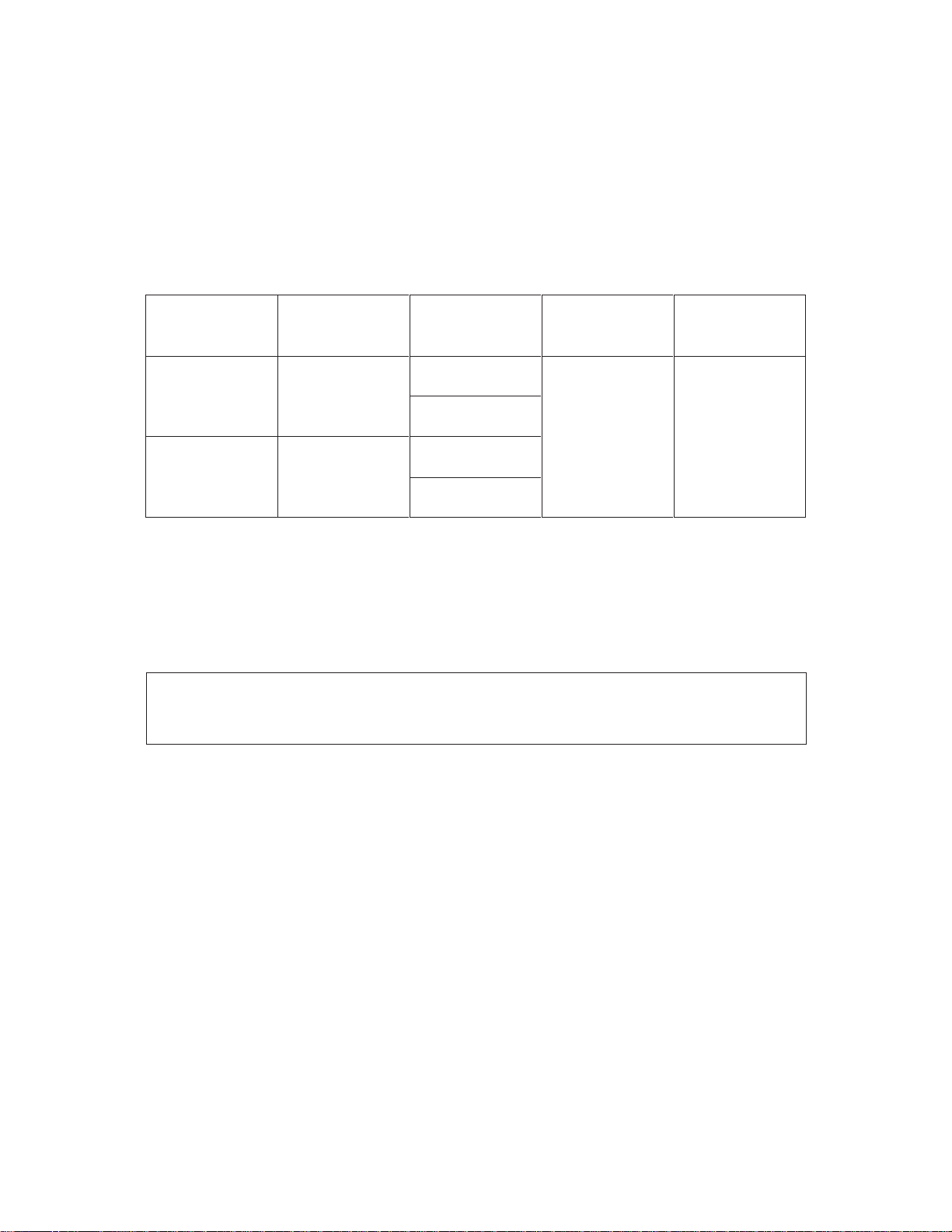

Resolution

400 dpi

300 dpi

240 dpi

200 dpi

Halftone processing

No halftone processing

Dither processing

Error diffusion processing

Automatic separation (by dither processing)

Automatic separation (by error diffusion processing)

Display

: 400

: 300

: 240

: 200

Display

:

: HT1

: HT2

: LP1

: LP2

If the optional PC

board is installed

If the optional PC board is not installed, automatic separation cannot be done.

Line or photo selection Display

To read a photo document

To read a line document

: P.

: L.

Image processing board (optional) installed

No

Yes

:

: >

2 – 6

Page 16

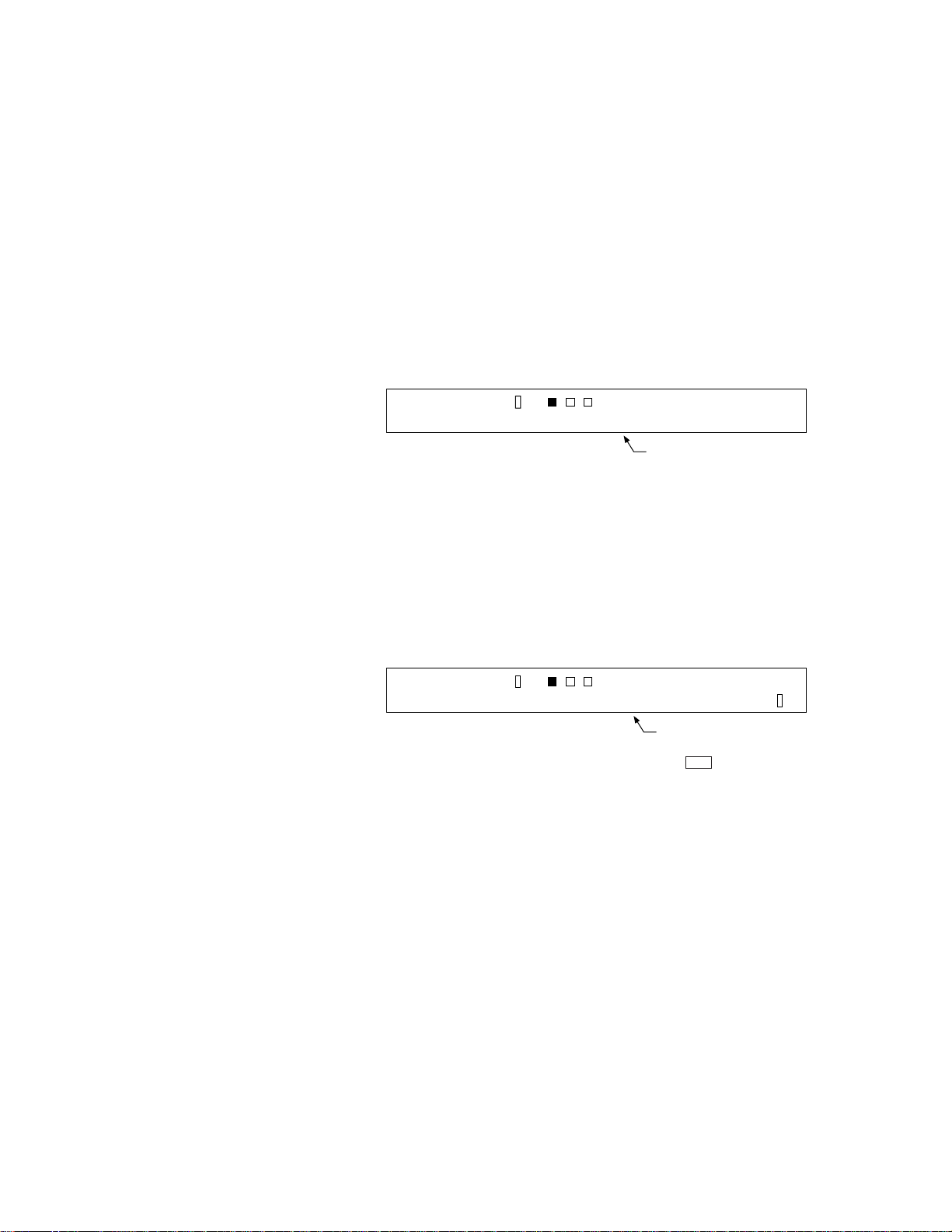

The ADF, size, density, resolution, landscape, half-tone, document,

and mode 1 and 2 buttons described below are effective unless otherwise specified by the host system.

Automatic document feeder (ADF) button:

Selects whether to feed documents automatically by ADF or

manually on the flatbed. When this button is pressed, the lower

line is displayed as shown in Screen 1. Each time this button is

pressed, “FB” or “ADF” starts blinking in turn, and the read

operation status displayed in the upper line changes accordingly.

Screen 1 — The upper line shows a typical example.

Upper line

Lower line

AFDA

eRBF:da

004

FDA

Blinking

Size button:

Selects a document size. When this button is pressed, the lower

line is displayed as shown in Screen 2. Each time this button is

pressed, “DLT”, “LT”, “LG”, “A3”, or “A4” starts blinking in

turn, and the size displayed on the upper line changes accordingly.

Screen 2 — The upper line shows a typical example.

Upper line

Lower line

LFDA

:eziSLLG

TD

TL 4A3A

004

Blinking

If the direction indicated on the upper line is “ ”, only “LT”

or “A4” can be selected.

>.L4

>.LG

2 – 7

Page 17

Density button:

Selects a density for the read operation. When this button is

pressed, the lower line is displayed as shown in Screen 3. Each

time this switch is pressed, the blinking part in the lower line

changes, and the density indicated on the upper line changes

according to the blinking part.

Screen 3 — The upper line shows a typical example.

Upper line

Lower line

LFDA

neD: A

. Tu

Blinking

004

The lower line is displayed as shown below. (See the beginning

of this section for the upper line.)

Display (lower line) Explanation

Very dark

Blinking

order

If the

optional

PC board

is installed:

AT ( Au o21

{

AT (Au o

t)

t)

Dark

Dynamic threshold

Simplified dynamic threshold

Normal

Light

Very light

Resolution button:

Selects a resolution for the read operation. When this button is

pressed, the lower line is displayed as shown in Screen 4. Each

time this button is pressed, “400”, “300”, “240”, or “200” starts

blinking in turn, and the resolution indicated on the upper line

changes accordingly.

otA(

>.PG

)1

Screen 4 — The upper line shows a typical example.

Upper line

Lower line

LFDA

seR004:.

G

0032042

Blinking

004

>.P

00

2 – 8

Page 18

Landscape button:

Specifies whether reading is done in landscape or portrait mode.

When this button is pressed, the lower line is displayed as

shown in Screen 5. Each time this button is pressed, the blinking part changes in turn, and the mode indicated on the upper

line changes accordingly.

Screen 5 — The upper line shows a typical example.

Upper line

Lower line

LFDA

:eziSLTLD

004

GLT4A3A

Explanation:

Display

: Landscape mode. This mode can be selected only if

the document size displayed on the upper line is LT or

A4.

: Portrait mode.

Halftone button:

Specifies whether to perform halftone processing (dither or

error diffusion). When this button is pressed, the lower line is

displayed as shown in Screen 6. Each time this button is

pressed, the blinking part changes in turn, and the halftone

indication on the upper line changes accordingly.

Screen 6 — The upper line shows a typical example.

Upper line

Lower line

LFDA

tflaHO:eno

Blinking

004

THFF

1

Not displayed unless the

optional PC board is installed.

Blinking

1TH

>.PT

>.LG

Blinking

order

Explanation:

Display (lower line)

“OFF” blinking

“HT1” blinking

“HT2” blinking

(changed from HT1)

“LP1” blinking

(changed from HT2)

“LP2” blinking

(changed from LP1)

Explanation

: Line Art (Halftone

Processing off)

: Halftone processing

(dither)

: Halftone processing

(error diffusion)

: Automatic separation

(dither)

: Automatic separation

(error diffusion)

Select one of these settings to

read data such as photographs,

illustrations, or colored maps.

If photographs and characters

are mixed in a document, the

characters are read clearly and

the photographs are read in

halftone. This setting is only

available if the optional PC

board is installed.

2 – 9

Page 19

Document button:

Selects the type of document. When this button is pressed, the

lower line is displayed as shown in Screen 7. Each time this

button is pressed, “LINE” or “PHOTO” starts blinking in turn,

and the document selection indication displayed on the upper

line changes accordingly.

Screen 7 — The upper line shows a typical example.

Upper line

Lower line

COD.L:.

LFDA

enL(

i .(Photo)

003

P)

Blinking

Explanation:

Display (lower line) Explanation

P.(Photo) : For light adjustment or when there is a

dark background color on the document,

select P. (Photo).

L.(Line) : Select this setting to read line drawings.

NOTICE :When L. (Line) is selected, the top 3-mm part of the

read area should be left blank (grounding color) by

specifying a drop-out color.

Mode 1 and 2 button:

These buttons are used for maintenance.

1TH

>.PG

2 – 10

Page 20

2.4.4 Messages

Error messages (temporary errors)

If a temporary error occurs in the scanner, one of the following messages is displayed.

epaPpmEryt

This message is displayed if there is no more paper on the

ADF paper chute during a read operation in ADF mode.

Fill the ADF paper chute with paper. To enable the read

operation, press the stop button.

paPaJrem

This message is displayed if a document is jammed in the

ADF. See section 5.1 for removing jammed documents.

AoC–FDOrevnep

This message is displayed if the ADF is not closed

completely. Close the ADF completely, and enable the

read operation.

2 – 11

Page 21

Error messages (device errors)

One of the following messages is displayed if an error occurs in the

scanner. If one of the following error messages is displayed, turn the

power off and then on again. If the same message is displayed,

contact your service representative.

citplAlamraO

eMinahcAlacmral

uFes

mlAraLpma

–

FtoMBromlArauFes–

Operation status messages

Operation status is displayed as shown by the following messages:

aWgnimrNpu–!!wo

The power is on.

The power is on.

RwoNniaegd!

Reading is in progress.

Reading is in progress.

LFDA

e

da

004

2TH>.LG

yR

2 – 12

The scanner is ready for operation in the manual mode.

The scanner is ready for operation in the manual mode.

Press the start button to start the read operation.

Press the start button to start the read operation.

Please clean Pick–roller

Page 22

CHAPTER 3 INSTALLA TION AND CONNECTIONS

3.1 Precautions

3.2 Removing the Carrier Fixing Bracket

3.3 Connections

3.4 Mounting the Stacker

3.5 SCSI-ID Setting

This chapter explains how to install and connect the image scanner.

3.1 Precautions

Do not install the image scanner in the following places and environments. See the appendix A.1 “Installation Specifications” for the

information such as size of installation space.

Place the scanner away from electrical noise

sources and strong magnetic fields. If the

image scanner is used near an air conditioner,

copying machine, or TV set, the scanner may

operate incorrectly.

Keep the scanner out of the sun and away

from heaters. These environments may

shorten scanner life or cause hardware

failures.

Do not install the scanner in a place where

vibrations may occur. This environment may

cause hardware failures or may cause the

scanner to operate incorrectly.

CAUTION

Place the image scanner on a level surface.

Place the image scanner so that the rubber

pads are secured on a flat and solid desktop.

Do not install the scanner in a humid, dusty,

or damp places. These enviroments may

shorten scaner life or cause hardware failures. Do not place the image scanner where

liquid spills may occur. Place it on a flat and

even surface.

Be aware of static electricity. If static

electricity is generated, the scanner may

operate incorrectly. Be sure that the flooring

and the desk are made of materials that do

not generate static electricity.

3 – 1

Page 23

3.2 Removing the Carrier Fixing Bracket

To keep the scanner from being damaged during shipping, the carrier

unit is fixed with a bracket. After placing the carrier unit at the

installation place, remove this bracket as explained below.

① Place the image scanner on the edge of the desk top so that the left side (where ADF

is placed) of the scanner extends from the desk top. Do not set the image scanner

upside down or on its side.

×

×

② Remove the carrier fixing bracket from position A. Then install the carrier fixing

bracket at position B.

Front side

Enlarged

Bottom view

Carier bracket (Position for

storage, position for shipment)

Enlarged section A enlarged

3 – 2

Carier bracket

(Position for operation)

B

ADF side

A

Carier bracket

(Position for shipment)

Page 24

3.3 Connections

Connect the image scanner using the following procedure.

① Set the power switch to off.

② Connect the power cable.

Connect the power cable to the power inlet on the back of the image scanner.

Connect the other end of the power cable to a power outlet.

Power switch

Power inlet

Power cable

③ Connect the interface cables (for M3096EX).

Connect the interface cables to the interface connectors and fasten the cables

with catches and screws as shown below.

Connect the other end of each interface cable to the host computer.

Back of the image scanner

Interface cable for RS232C

Power outlet

for North America

for Europe

Catches

Interface cable for video

To the host systemScrews

3 – 3

Page 25

(M3096GX)

Connect the interface cables to the interface connectors and fasten the cables

with the catches. Connect the other ends of the cables to the host system. If the

image scanner is at the terminal side, connect the terminator.

Back of the image scanner

Catches

Catches

Interface cables

To the

host

system

Terminator

If the image scanner is at

the terminal side, connect

the terminator to the

connector to which an

interface cable is not

connected.

3 – 4

Page 26

3.4 Mounting the Stacker

Mount the stacker and extensions using the following procedure.

① Mount the stacker.

Hook the pins on the stacker to the claws on the image scanner.

Stacker

Pin

Claw

② Mount the extensions.

Mount extensions to the stacker and to the ADF paper chute.

Extension

Extension

ADF paper chute

Stacker

3 – 5

Page 27

3.5 SCSI-ID Setting

Use the address switches to set the device address. After the setting

turn the scanner on.

Address switch

Figure 3.1 SCSI-ID setting

Table 3.1 SCSI-ID setting

ID

0 to 7

8, 9

* When the scanner is terminated device, the termination connector

must be connected on one side of the connectors.

Contents

Available

No Operation

3 – 6

Page 28

CHAPTER 4 OPERATIONS

4.1 Turning on the Power

4.2 Reading a Document in Flatbed Mode

4.3 Reading Documents in ADF Mode

Documents can be read in the flatbed mode or automatic document feeder (ADF) mode. In the

flat-bed mode, each document is placed on the document bed and is read one by one. In ADF

mode, documents are fed and read automatically.

This section explains how to turn on the power and how to read documents.

4.1 Turning on the Power

This section explains how to turn on the power.

Press "I" on the power switch. When the power is turned on, the

power indicator is lit.

Power indicator

Press "0" on the power switch to turn off the power.

Power switch

Power ONPower OFF

4 – 1

Page 29

4.2 Reading a Document in Flatbed Mode

This section explains how to read a document placed on the document

bed.

4.2.1 Reading a standard-size document

If the size of the document is smaller than the document bed, read the

document using the following procedure:

① Open the document cover.

② Place the document face down on the document board. Correct

any curled or folded parts of the document.

③ Position the long side (in landscape mode) or the short side (in

portrait mode) of the document to the left side of the document

bed.

④ Position the left top of the document to the reference mark. If the

document is not placed correctly, reading cannot be done correctly.

⑤ Close the document cover slowly. If the document cover is

closed too quickly, the document may move.

⑥ Start the read operation. Do not press on or open the document

cover during the read operation.

⑦ After reading, open the document cover to remove the document.

4 – 2

Page 30

Reference mark

Document

Document cover

Indication panel

Document bed

Figure 4.1 Flatbed reading

Landscape mode

Long side

4.2.2 Reading a page from a thick book

3

To read a page from a thick book, remember the following points:

① Do not close the document cover forcibly. Keep the cover open

for reading.

Portrait mode

Document bed

3

Short side

Document

② Any document parts that are not in contact with the glass will not

be read correctly.

③ Do not move the document during the read operation.

4 – 3

Page 31

4.2.3 Reading a document larger than the document board

If the size of the document is larger than the document board, read the

document using the following procedure:

① Open the document cover at an angle of about 80°, then slide the

cover to the direction of the arrow to remove it.

② Place the document face down on the document bed.

③ Place the document cover over the document.

④ Read the document.

⑤ After the read operation, remove the document, replace the

document cover. Mount the document cover to the original

position, and close the document cover.

Document cover

80°

Document bed

Figure 4.2 Removing the document cover

NOTICE: Do not remove the document cover for any other purpose.

4 – 4

Page 32

4.3 Reading Documents in ADF Mode

This section explains how to read documents using the automatic

document feeder. If the following steps are not closely followed, a

feed error may occur.

① Check the documents as follows:

(a) Paper quality

• Wood-free paper.

• PPC paper; Specified by XEROX Corporation.

(b) Paper weight

• 13.91bs to 27.81bs

(c) Paper size

• Letter, Double Letter, Legal, A3, A4, A5, B4, B5

(d) Items to avoid

• The following documents may be hard to read by ADF. Before

you start the large quantity reading, check that the document is

read appropriately. If the reading is not appropriate, read them

by flatbet.

– Paper with a clip or staple.

– Paper that has ink which is not dry.

– Paper thickness is not constant, such as an envelope.

– Paper that has large rumples or curl. (See NOTICE)

– Paper that has folds or tears.

– Tracing paper.

– Coating paper.

– Carbon paper.

– Paper that is smaller than A5 size or larger than A3 width.

– Items other than paper, such as clothes, metal sheet, or OHP

film.

– Photographic paper.

– Paper that has perforations on its side.

– Paper that has a shape other than square.

– Paper that is very thin.

NOTICE : The important document which shall not be torn must be

read by flatbet.

NOTICE : Carbonless papers have the chemical composition which

damages the pad and pickroller. Therefore, note the following remarks.

Cleaning : If the miss pick occurs frequently, clean the pad

Replacement of parts : The life of the pad and the pickroller

and pickroller in accordance with the section

5.3.2.

may be shorter than the case that PPC document

is fed. Replacement cycle of the pad and the

pickroller may be 100,000 sheets or more if the

paper quality is good and cleaning is done well.

Before you start the large quantity reading,

check the replacement cycle of them and prepare

pads and pickrollers.

4 – 5

Page 33

NOTICE: Paper should be straightened to fit the condition below.

More than

30 mm

Top of the paper

Less than

3 mm

More than

30 mm

Top of the paper

Feed direction

Read surface

Less than

5 mm

② Switch the paper select lever.

Switch the lever in the following procedures:

• Open the automatic document feeder (ADF) while lifting up the

ADF lever.

• Set the paper select lever.

Plain paper: “NORMAL”

Heavy paper: “THICK”

• Reset the ADF. (Check that the ADF lever is set at the “NORMAL” position.)

NOTICE: Always reset the paper select lever to “NORMAL” posi-

tion, unless you feed the thick paper.

Feed direction

Read surface

ADF lever

Automatic document

feeder (ADF)

(THICK mode) (NORMAL mode)

Paper select lever

ADF frame

4 – 6

Section A enlargerd

Page 34

③ Pull up the ADF paper chute as follows:

• Hold the document cover with one hand and pull up the ADF

paper chute with the other hand to set the shaft in position B.

ADF paper chute

Document cover

ADF paper chute

Rotation direction

Shaft

Position for storage

position A

Position for operation

position B

Figure 4.3 ADF paper chute setting

④ Fan the documents as follows:

• Take a 15 to 20 mm thickness of documents. Lightly hold both

ends with both hands. Bend the documents into an arch as

shown below.

• Then hold the documents tightly with both hands, and

straighten the documents. The center of documents swell and

air is introduced between the documents.

• Repeat this operation two or three times.

• Turn the documents 90°, and repeat the operation again.

15 to 20 mm

4 – 7

Page 35

⑤ Take documents to be placed in the ADF paper chute. The

thickness of the documents to be placed in the ADF paper chute is

limited depending on the size of the documents as follows:

A4 or letter size or smaller: 4 mm or less

Size larger than A4: 2 mm or less

⑥ Angling the documents

Angle the document edges as follows:

• Place the documents face down with the top to the left as shown

in A. The long side is the top for landscape mode and the short

side is the top for portrait mode.

• Lift the documents holding the both ends with both hands.

• Hold the documents tightly with your left hand and bend the

documents as shown in B.

• Grip tightly with your right hand, loosen the grip of your left

hand, and straighten the documents as shown in C.

• Repeat these operations until the top is angled 20° or less as

shown in D.

Top

A

B

C

(For portrait mode)

D

20° or less

4 – 8

Page 36

⑦ Open the right and left guides of the ADF paper chute about 5

mm wider than the document width.

⑧ Place the documents face down onto the ADF paper chute with

the top edges facing the automatic feeder hole.

⑨ Adjust the guides to the document sides. Skewing may occur if

there is a gap between the guides and documents.

⑩ Slide the documents down until they touch the far end of the

automatic feeder opening. If the documents hit the far end hard,

two or more pages may be fed at once. Make sure that the upper

end of documents are not turned.

Start the read operation. If a wrong document size or mode

11

(portrait or landscape) is selected, the document may not be read

entirely.

NOTICE:

Unless 3 mm of the leading edge of forms are not white or dropout color, set the document type to “Photo.”

After reading, remove the documents from the stacker.

12

Automatic document feeder

Guide

Figure 4.4 Loading the document

Portrait Landscape

Guide

Documents

ADF paper chute

Guide lever

Automatic document feeder

ADF paper chute

Short side

Long side

Documents

4 – 9

Page 37

This page is intentionally left blank.

4 – 10

Page 38

CHAPTER 5 MAINTENANCE

5.1 Removing Jammed Documents

5.2 Notes on Daily Use

5.3 Cleaning

5.4 Consumables/Periodical replacement parts

This section explains how to remove jammed documents, and provides notes on daily use and

cleaning.

5.1 Removing Jammed Documents

If documents jam while being fed by the ADF, remove the jammed

documents as follows:

① Remove the documents from the ADF paper chute.

② Pulling up the ADF lever, open the automatic document feeder.

③ Remove the jammed documents.

④ Close the ADF until the ADF lever locks.

Automatic document feeder (ADF)

Figure 5.1 Removing jammed documents

ADF lever

5 – 1

Page 39

5.2 Notes on Daily Use

Note the following points on daily use:

NOTICE

• Do not look directly at the light source during the read operation.

Keep the document cover in place.

NOTICE

• See Section 5.3 “Cleaning”, to clean the document cover, document

holding pad, document bed, and the automatic document feeder.

Especially, clean the automatic document feeder (ADF) periodically.

For the cleaning cycle, see Section 5.3.2, “Cleaning the ADF.”

5.3 Cleaning

This section explains how to clean the image scanner.

5.3.1 Cleaning the document cover, document holding pad, and document bed

• Use a dry cloth or a cloth with a neutral cleanser to remove dirt from

the document cover, document holding pad, and document bed. Do

not use organic solvents such as a thinner.

• Make sure that no liquid enters the scanner from the edges of the

document bed glass.

Document cover

Document holding pad

Document bed

Cloth

Neutral cleanser

Thinner

Figure 5.2 Cleaning the document cover, document holding pad, and document bed

5 – 2

Page 40

5.3.2 Cleaning the ADF

Clean the automatic document feeder (ADF) once every 5,000 pages.

The cycle depends on the types of documents used (paper quality, a

level of toner fusing on paper).

① Pull the ADF lever up to open the ADF.

② Use the dry cloth or a cloth with ethyl alcohol to softly remove

dirt and dust as follows.

Pad: Wipe the pad in a downward direction (indi-

cated by the arrow). Be careful not to hook

the pick spring when wiping.

Glass: Wipe the glass lightly.

Pick roller : Wipe the roller softly. Be careful not to

damage the surface of the roller.

Feed roller and coupled feed roller:

Wipe the rollers softly. Be careful not to

damage the surface of the rollers.

ADF lever

Pad

Ejection roller and coupled ejection roller:

Wipe the rollers softly. Be careful not to

damage the surface of the rollers.

Sheet guide (white part):

Wipe the sheet guide softly.

③ Close the ADF to lock the ADF lever.

Pick spring

Feed roller

Ejection roller (Clean the roller

on the opposite side also.)

Pick rollers

Automatic document feeder

Sheet guide (white part)

Glass

Coupled feed roller

Figure 5.3 Cleaning the ADF

5 – 3

Page 41

5.4 Consumables/Periodical replacement parts

5.4.1 Parts number and replacement cycle

Customer is responsible to change these items periodically.

No.

1

2

*1: These replacement cycle may vary by the paper quality and cleaning result. When PPC

paper is used, replacement cycle may be 300,000 sheets or more by good cleaning. Before

you start the large quantity reading, evaluate the replacement cycle and prepare pads and

pickrollers.

*2: This part may not be provided in some countries due to the conformability of safety regula-

tion. Before the order of the pick roller, contact your sales agent or Fujitsu service representative.

5.4.2 Replacing pad ASY

Part name

Pad ASY

Pick roller

Part number

PA02201-0020

PA02201-0025 (*2)

Replacement cycle

Every 100,000 pages or annually (*1)

Every 200,000 pages or annually (*1)

① Lift up the ADF lever and open the ADF.

② Insert a coin in the slot or hold the both sides of the pad ASY,

then slide it to the direction of the arrow to remove the pad.

Pad ASY

ADF lever

Slot

5 – 4

Page 42

③ Insert the pad assembly into the ADF frame hole (the bigger one),

slide the assembly to the direction of the arrow until it clicks.

ADF frame

Pad assy

NOTICE : Set the paper select lever to "N", before removing pad ASY

(See Section 4.3).

NOTICE : Pad can be replaced by aligning the holes of the pad with

the pins of the pad holder.

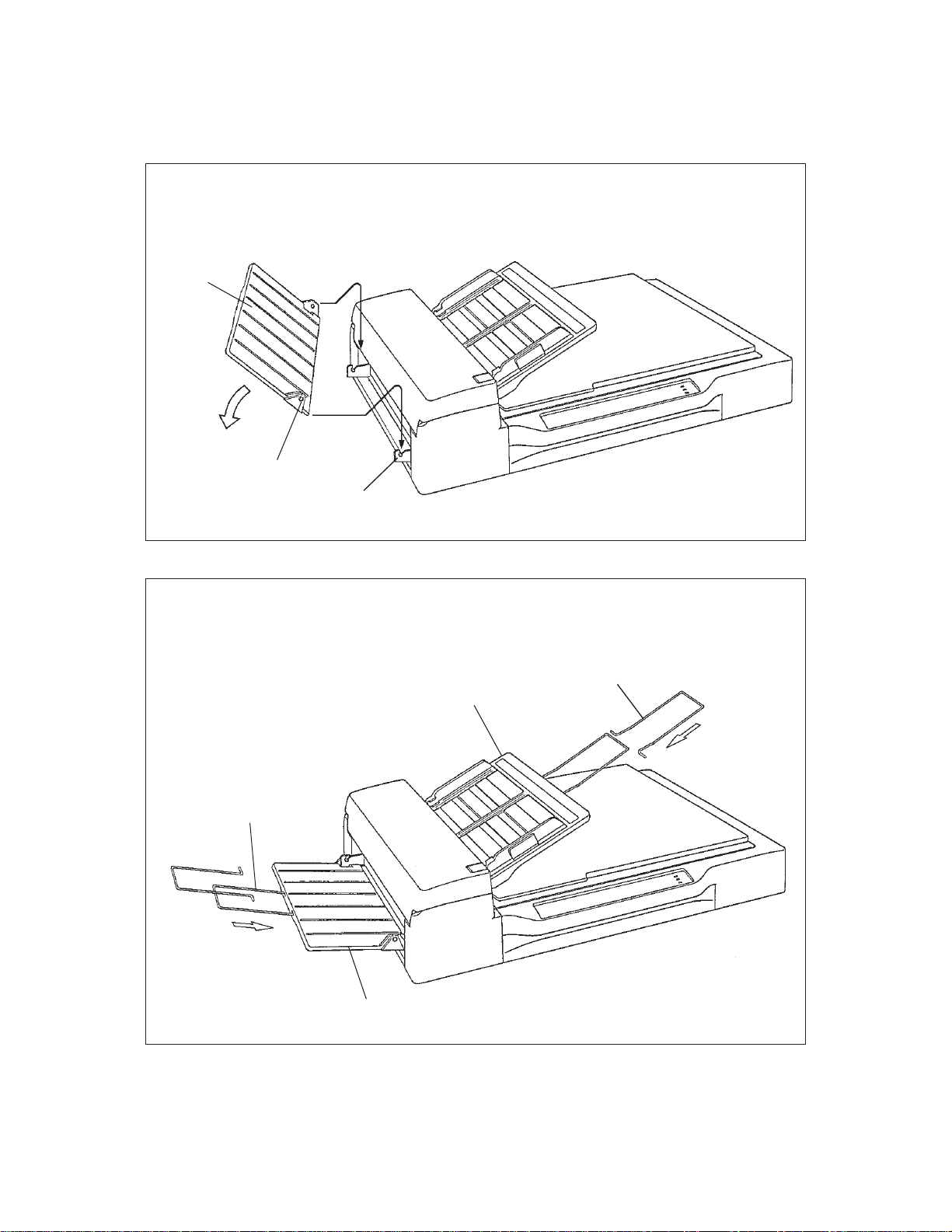

5.4.3 Replacing pick roller

Replace the pickroller as follows.

(a) Pull the cap up to open the ADF

unit.

(b) Remove two thumb screws shown

in Figure 5.4. And remove the

Guide A.

Pad holder

Pad

Pick spring

Thumb Screw

Cap

Guide A

Thumb Screw

Figure 5.4 Pick Roller replacement

5 – 5

Page 43

(c) Pinch the retaining spring and slide

it toward the roller. Free bearing A

from the bracket by sliding it

toward the roller.

(d) Slide the pick roller shaft in the

direction of arrow B and remove

the shaft from bearing B. The

roller shaft can then be lifted and

removed as shown in Figure 5.7.

Bearing A

Retaining spring

Figure 5.5 Move the Retaining spring

A

B

Bearing A

Figure 5.6 Slide the Pick Roller

(e) Remove the bearing B.

(f) Mount the new pick roller in reverse

order of removal.

Bearing B

Figure 5.7 Remove the Pick Roller

NOTICE: When mounting the Guide A, note that the hooks of the retaining spring are

not pressed by the Guide A. (See figure bellow)

Guide A

5 – 6

Retaining spring

Page 44

CHAPTER 6 TROUBLESHOOTING

If a problem occurs, use Table 6.1 to resolve the problem.

Table 6.1 Check items

Problem

No power

Read operation

does not start.

Possible cause

The power switch was not

turned on.

The power cable was not

connected correctly.

——————————

The documents were not

placed on the ADF correctly.

The ADF was not closed

completely.

The interface cables were not

connected correctly.

Terminator was not connected. (M3096GX)

Response

Press the power switch.

Connect the power cable correctly.

Turn off the power once and make an

attempt to turn on the power again. If the

power is not turned on, contact your

Fujitsu service representative.*

Insert the first a few pages into the slot.

Make sure that the ADF is closed completely.

Connect the interface cables correctly.

Connect the terminator.

Pictures and

photographs are

not read correctly.

Characters and

lines are not

read correctly.

Image is distorted or unclear.

Halftone processing was not

selected.

The document bed, document holding pad, or inside

ADF is dirty.

Simple binarization was not

done.

The document bed, document holding pad, or the

inside of the ADF is dirty.

The document was moved

during the read operation.

The document was not in

contact with the glass.

Select a halftone mode from the host

system.

Clean the dirty parts as explained in

Section 5.3, “Cleaning.”

Select a binarization mode from the host

computer.

Clean the dirty parts as explained in

Section 5.3, “Cleaning.”

Keep the document cover closed during

reading so that the document will not be

moved.

Adjust the document so that it is in

contact with the glass.

6 – 1

Page 45

Table 6.1 Check items (continued)

Problem

The check

indicator is on.

“Please clean

Pick-roller” is

displayed on the

operator panel

during the read

operation in the

ADF.

Or check

indicator blinks

at four seconds

period.

Possible cause

The carrier fixing bracket

was not removed.

——————————

The pick roller is dirty.

The unallowable document

was read in the automatic

document feeder.

(See Section 4.3.)

Response

Remove the carrier fixing bracket as

explained in Section 3.2, “Removing the

Carrier Fixing Bracket.”

Turn the power off then on again. If the

check indicator turns on again, contact the

sales person in charge or a Fujitsu service

representative.*

When the power is turned off, the message is cleared.

Even if the message is displayed, the read

operation can be continued. Clean the

pick roller after the read operation.

(See Section 5.3.2.)

If a document not meeting the scanner

specifications is read in the automatic

document feeder, the document is not fed

smoothly and an error message may be

displayed.

Read the document in the flat bed station.

Paper double feed

Miss pick

Paper jam

* Please chack the test mode in appendix B, if possible, before calling the service representa-

tive and inform status of the indicators.

Pad is dirty.

Pad is worn out.

Pick roller is dirty.

Pick roller is worn out.

Some foreign particles are in

ADF.

Clean the Pad. (See Section 5.3.2)

Replace the pad. (See Section 5.4.2)

Clean the Pick roller. (See Section 5.3.2.)

Replace the Pick roller.

(See Section 5.4.3)

Clean the ADF (See Section 5.3.2) or

remove any foreign particles.

6 – 2

Page 46

APPENDIX A

A.1 Installation Specifications

Table A.1 Installation specifications

SpecificationItem

External dimensions (mm)

Weight (kg)

Input power

Power

Temperature and

humidity allowed

ranges

Voltage

Number of phases

Frequency

Temperature

Humidity

Width

696

17.5

100 to 120 VAC, 200 to 240 VAC

Single-phase

50/60 Hz

100 VA

Operation

5 to 35°C

20 to 80%

Depth

497

Idle

–20 to 60°C

8 to 95%

Height

173

A – 1

Page 47

A.2 External Dimensions

497

173

696

(Unit: mm)

Figure A.1 External dimensions

A – 2

Page 48

APPENDIX B

B.1 Test mode for maintenance

CAUTION: Please follow the procedure here or the offset data may be changed incor-

rectly. If the scanner does not react as the procedure below, turn off the

scanner and start from the beginning.

(1) Activating a test mode

Open the ADF cover and set the sensors to the following state before turning on the

image scanner. The image scanner can be placed in the maintenance mode by pulling out

the empty sensor lever and setting the A4 size sensor lever to down position (do not

change the setting of other paper size sensors) with the ADF cover fully opened (see

Figure below). If the image scanner is placed in the maintenance mode, the POWER lamp

blinks. If the POWER lamp does not blink, turn off the power and try again. Then close

the ADF.

(Setting of the ADF sensors for maintenance mode)

- A4 size sensor: DOWN

- Empty sensor: UP

Empty sensor

A4 size sensor

Open the ADF cover.

UP

DOWN

OMR sensor

B – 1

Page 49

(2) Activating the continuous operation test

Open the ADF and close it again. If no document is loaded on the ADF within five

seconds after closing the ADF cover, the image scanner runs in flatbed mode. If documents are loaded on the ADF within five seconds after closing the ADF cover, the image

scanner continuously feeds the document from ADF. Once the image scanner start

reading documents in the flatbed mode, it does not feed documents from ADF even if

documents are loaded on the ADF.

(3) Ending the test in flatbed mode

To stop the carrier movement in flatbed mode, open the ADF cover. If the ADF cover is

opened, the POWER lamp starts blinking immediately after the carrier returns to the

home position.

(4) Ending the test in ADF mode

If the ADF document hopper is empty, feeding documents from the ADF ends. To restart

feeding, open the ADF cover and close it again. Then load documents on the ADF document hopper within five seconds after closing the ADF cover.

(5) LED status on error

If an error occurs during the test, the LED indicates as shown in table B.1.

If paper is jammed in the ADF, remove the jam and close the ADF. The CHECK lamp

stops blinking about three seconds after closing the ADF cover. To feed the document

from ADF, open and close the ADF.

Table B.1 LED at an error

Errors/Alarm

Paper jam

Carrier drive alarm

Optical system alarm

Motor fuse failure

Lamp fuse failure

POWER lamp

On

Blink

Blink

Blink

Blink

READ lamp

Off

Off

Off

On

On

CHECK lamp

Blink

On

Blink

On

Blink

B – 2

Page 50

APPENDIX C

C.1 Option

Name Specfication Scanner feature

IPC-2 CA01952-0191 M3096EX Image processing

M3096GX • Automatic separation

• Image emphasis

• Outline extraction

• Mirror image

• Dynamic threshold

• Noise removing

• Smoothing

CMP-2 CA01952-0196 M3096GX • 4Mbyte memory

• MH/MR/MMR compression

Contact your Fujitsu sales agent for more information

C.2 IPC-2/CMP-2 option board installation

WARING: Follow the outlined procedure to avoid danger from electrical components.

(1) Verify that the scanner power is turned off.

(2) Remove the AC cable from the year of the scanner.

(3) Remove the two screws securing the power supply and the interface PCA assembly. Pul

out the assembly slighly using the tab in the direction shown by the arrow.

CAUTION: Do not pull on the flat cable too strongly or it may be damaged.

Tab

screws

flat cable

(inside)

C – 1

Page 51

(4) Remove the flat cable connector and detach the power supply and PCA assembly.

Flat cable

Flat cable connector

(5) Connect the IPC-2 option board connector and tighten the screw.

(6) Where a CMP-2 is installed, remove the screw from the memory board and detach the

memory board. Connect the CMP-2 option board connector and tighten the screw.

Screw for IPC-2

CMP-2 option board or memory PCA (M3096GX)

Screw for memory or CMP-2 (M3096GX)

IPC-2 option board

(not shown)

(7) Attach the power supply and PCA assembly in the reverse order of removal.

C – 2

Page 52

Comments concerning this manual can be directed to one of the following addresses:

FUJITSU LIMITED

International Operations

Marunouchi 1-6-1, Chiyoda-ku, Tokyo 100,

JAPAN

TEL: (81-3) 3216-3211

FAX: (81-3) 3213-7174

TLX: J22833

Cable: “FUJITSU LIMITED TOKYO”

FUJITSU COMPUTER PRODUCTS OF

AMERICA, INC.

2904 Orchard Parkway, San Jose.

California 95134-2022, U.S.A.

TEL: 1-408-432-6333

FAX: 1-408-432-3908

FUJITSU CANADA, INC.

2800 Matheson Blvd. East, Mississauga.

Ontario 4X5, CANADA

TEL: 1-905-602-5454

FAX: 1-905-602-5457

FUJITSU DEUTSCHLAND GmbH.

Frankfurter Ring 211,

8000 Munchen 40, F.R, GERMANY

TEL: 49-89-32378-0

FAX: 49-89-32378-100

FUJITSU EUROPE LTD.

2, Longwalk Road, Stockley Park, Uxbridge

Middlesex, UB11 1AB, U.K

TEL: 44-81-573-4444

FAX: 44-81-573-2643

TLX: 263871

FUJITSU NORDIC AB

Kung Hans vag, S-191 76 Sollentuna, SWEDEN

TEL: 46-8-626-6000

FAX: 46-8-626-6711

FUJITSU ITALIA S.p.A.

Via Melchiorre Gioia, No. 8-20124 Milano,

ITALY

TEL: 39-2-63651

FAX: 39-2-6572257

FUJITSU FRANCE S.A.

Batiment Aristote, 17 rue Olof palme

94006 Creteil cedex, FRANCE

TEL: 33-14-513-1616

FAX: 33-14-399-0700

FUJITSU AUSTRALIA LIMITED

475 Victoria Avenue Chatswood.

N.S.W 2067, AUSTRALIA

TEL: 61-2-410-4555

FAX: 61-2-411-8603

FUJITSU HONG KONG Limited

Room 2521, Sum Hung Kai Centre

30 Harbour Road Wanchal, Hong Kong

TEL: 852-827-5780

FAX: 852-827-4724

TLX: 62667

FUJITSU ESPANA, S.A

Edificio torre Europa

Paseo de la Castellana 95 Madrid 28046, SPAIN

TEL: 34-1-581-8400

FAX: 34-1-581-8125

Page 53

Reader Comment Form

We would appreciate your comments and suggestions for improving this publication.

Publication No. Rev. Letter Title Current Date

How did you use this publication? Is the material presented effectively?

Learning Installing Sales Fully Well Well

Reference Maintaining Operating Covered illustrated Organized

Clean

What is your overall rating of this publication?

Very Good Fair Very Poor

Good Poor

Your other comments may be entered here. Please be specific and

give page, paragraph and line number references where applicable.

What is your occupation?

Your Name & Return Address

Loading...

Loading...