Page 1

PRIMERGY BX630 S2

Scalable Server Blade

Operating Manual

Edition October 2008

Page 2

Comments… Suggestions… Corrections…

The User Documentation Department would like to

know your opinion of this manual. Your feedback helps

us optimize our documentation to suit your individual

needs.

Feel free to send us your comments by e-mail to

manuals@ts.fujitsu.com.

Certified documentation

according to DIN EN ISO 9001:2000

To ensure a consistently high quality standard and

user-friendliness, this documentation was created to

meet the regulations of a quality management system

which complies with the requirements of the standard

DIN EN ISO 9001:2000.

cognitas. Gesellschaft für Technik-Dokumentation mbH

www.cognitas.de

Copyright and Trademarks

Copyright © 2009 Fujitsu Technology Solutions GmbH.

© cognitas. Gesellschft für Technik-Dokumentation mbH 2009 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2533-002.fm

All rights reserved.

Delivery subject to availability; right of technical modifications reserved.

All hardware and software names used are trademarks of their respective manufacturers.

Page 3

Contents

1 Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Concept and target group of this manual . . . . . . . . . . . . 6

1.2 Documentation overview . . . . . . . . . . . . . . . . . . . . 7

1.3 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4 Notational conventions . . . . . . . . . . . . . . . . . . . . 12

1.5 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . 13

2 Overview: Installation Procedure . . . . . . . . . . . . . . . 15

3 Important notes . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1 Notes on safety . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2 CE conformity . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.3 Environmental protection . . . . . . . . . . . . . . . . . . . 20

4 Installing the Hardware . . . . . . . . . . . . . . . . . . . . 23

4.1 Installation Steps . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2 Unpacking the Server Blade . . . . . . . . . . . . . . . . . . 23

4.3 Installing the Server Blade in the Basic Unit . . . . . . . . . 24

4.4 Connecting Devices . . . . . . . . . . . . . . . . . . . . . . 28

5 Installation and Operation . . . . . . . . . . . . . . . . . . . 31

5.1 Control and Connection Panel . . . . . . . . . . . . . . . . 32

5.2 Switching the Server Blade On/Off . . . . . . . . . . . . . . 35

5.3 Configuring the Server Blade . . . . . . . . . . . . . . . . . 35

5.4 Updating the Firmware (BIOS and BMC) . . . . . . . . . . . 38

BX630 S2 Operating Manual

Page 4

Contents

6 BIOS Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.1 Entering the BIOS Setup . . . . . . . . . . . . . . . . . . . . 43

6.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.3 Main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.4 Advanced menu . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.4.1 Peripheral Configuration . . . . . . . . . . . . . . . . . . . . . 50

6.4.2 Advanced System Configuration . . . . . . . . . . . . . . . . . 53

6.4.3 Power On/Off menu . . . . . . . . . . . . . . . . . . . . . . . . 54

6.4.4 IPMI menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.4.4.1 IPMI LAN parameters . . . . . . . . . . . . . . . . . . . . . 59

6.5 Security menu . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6.6 Server menu . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

6.6.1 CPU Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.6.2 Memory Status . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.6.3 Console Redirection . . . . . . . . . . . . . . . . . . . . . . . 69

6.7 Boot menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.8 Exit menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2537-002.fm

7 Troubleshooting and Tips . . . . . . . . . . . . . . . . . . . . 73

8 Hot-plug components . . . . . . . . . . . . . . . . . . . . . . 75

8.1 Hot-plug disk drives . . . . . . . . . . . . . . . . . . . . . . . 75

8.2 Handling hard disk drives and HDD modules . . . . . . . . . 77

8.3 Installing/removing the dummy module . . . . . . . . . . . . 78

8.4 Installing/removing a hard disk module . . . . . . . . . . . . 79

Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Operating Manual BX630 S2

Page 5

1 Preface

The PRIMERGY BX630 S2 server blade is a scalable AMD-based dual-socket

server blade. It offers several new forward-looking technologies such as quadcore processors, 2.5-inch SAS or SATA-II hard disk drives, four 1-Gbit/s

onboard Ethernet LAN channels and an optional dual-channel 4-Gbit/s Fibre

Channel (FC) connection. Two BX630 S2 dual-socket server blades can be

connected to form a quad-socket server blade with 16 processor cores.

Dual-socket server blade Quad-socket server blade

Figure 1: PRIMERGY BX630 S2 configurations

The PRIMERGY BX630 S2 scalable server blade is designed for the BX600 S3

basic unit, but it can also be installed in slots 1-3 and 5-9 of the BX600 S2 basic

unit.

I In the latter case, however, only 2 of the 4 onboard Ethernet channels of

the BX630 S2 server blade can be used.

Security functions in the BIOS Setup protect the data on the server blade from

unauthorized manipulation.

BX630 S2 Operating Manual 5

Page 6

Concept and target group of this manual Preface

Depending on the configuration, the PRIMERGY BX630 S2 scalable server

blade occupies one or two slots in the PRIMERGY BX600 S2 or the BX600 S3

basic unit.

1.1 Concept and target group of this manual

This operating manual is intended for those responsible for installing the

hardware and ensuring that the system runs smoothly. It contains all the information you need to put your PRIMERGY BX630 S2 server blade into operation.

The information in this manual refers to the BX630 S2 dual-socket server blade.

How to connect two BX630 S2 dual-socket server blades to form a quad-socket

server blade is described in the Options Guide.

For a brief overview of the installation steps see chapter 2 on page 15ff.

To understand the various expansion options, you will need to be familiar with

the fields of hardware and data transmission and you will require a basic

knowledge of the underlying operating system.

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2504-002.fm

6 Operating Manual BX630 S2

Page 7

Preface Documentation overview

1.2 Documentation overview

Information on your PRIMERGY BX630 S2 is provided in the following

documents:

– Flyer "Quick Start Software - Quick Installation Guide" (only provided as

hard copy)

– Manual "Safety Notes and other Important Information"

– Manual "Guarantee"

– Manual "Ergonomics"

– Manual "Returning used devices"

– Flyer "Helpdesk"

– Operating Manual for PRIMERGY BX630 S2 Scalable Server Blade

– Options Guide for PRIMERGY BX630 S2 Scalable Server Blade

I PRIMERGY manuals are available in PDF format on the ServerBooks

DVD. The ServerBooks DVD is part of the ServerView Installation

Manager Suite supplied with every server.

The PDF files of the manuals can also be downloaded free of charge

from the Internet. The overview page showing the online documentation

available on the Internet can be found using the URL:

http://manuals.ts.fujitsu.com. The PRIMERGY server documentation can

be accessed using the Industry standard servers navigation option.

If you need a replacement copy of the ServerBooks DVD, send the

details of your server to the following e-mail address: rlc@ts.fujitsu.com.

Further sources of information:

– Manual for the monitor

– Documentation for boards and drives

– Documentation for your operating system

– Information files on your operating system

I For information on installing and operating PRIMERGY BX6xx server

blades that applies to all server blade models, see the operating manual

for your PRIMERGY BX600 S2 or BX600 S3 basic unit.

BX630 S2 Operating Manual 7

Page 8

Features Preface

1.3 Features

Processors

In the BX630 S2 dual-socket server blade, one (basic configuration) or two

AMD Opteron quad-core processors of the 23xx DP and 83xx MP series ensure

extremely high data throughput and system performance.

All processors have a 2-MB second-level cache (SLC).

I It is not possible to use CPUs with different clock rates or cache capacity

in a server blade.

In the BX630 S2 quad-socket server blade, only processors of the

Opteron 83xx MP series are allowed.

For upgrading processors see the Options Guide; for exchanging processors

see the Service Supplement.

Memory

The BX630 S2 dual-socket server blade has eight memory slots. Each

processor is assigned four memory slots. Two memory slots make up one

memory bank. The memory slots must be fitted by bank, i.e. with pairs of

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2504-002.fm

memory modules. The server blade supports memory modules of the type

DDR2 667 with 512 MB, 1 GB, 2 GB or 4 GB capacity, so the maximum configuration is 32 GB (64 GB in a quad-socket server blade). ECC with memory

scrubbing and ChipKill™ are supported. Only memory modules of the same

capacity can be installed in the same memory bank.

How to install memory modules is described in the Options Guide.

LAN availability

The BX630 S2 dual-socket server blade has two onboard Ethernet LAN

controllers with two 1-Gbit/s Ethernet channels each. The Ethernet LAN

connection can be implemented via switch blades or via pass-thru blades on the

back of the basic unit. For more information see the operating manual for the

basic unit.

I You can only use the two 1-Gbit/s Ethernet channels of the second

onboard LAN controller in connection with the BX600 S3 basic unit and

the Gbit Ethernet LAN switch blade (SB9f) 12 x 1 Gbit.

8 Operating Manual BX630 S2

Page 9

Preface Features

Graphics controller

The PRIMERGY BX630 S2 scalable server blade has an onboard graphics

controller (Matrox MGA-200) which is integrated in the iRMC controller. You can

connect a monitor via the VGA interface (via breakout cable) on the front of the

server blade or via the KVM blade on the back of the basic unit.

Optional Fibre Channel or Ethernet I/O module (daughter card)

You can fit the BX630 S2 dual-socket server blade with an I/O daughter card to

connect to a SAN or for additional Ethernet connections. The BX630 S2 quadsocket server blade allows two I/O daughter cards to be installed.

To be able to use the additional I/O functionality, at least one FC pass-thru blade

or switch blade, or Ethernet pass-thru blade or switch blade must be installed in

slot NET3 of the basic unit.

The following I/O daughter cards are available:

– 4-Gbit/s Fibre Channel I/O module (PCIe), allows transfer rates of 1, 2 or 4

Gbit/s and supports multiple Fibre Channel storage subsystems with the

corresponding versions.

I You can operate the 4-Gbit/s Fibre Channel I/O module only with a

BX600 S3 basic unit and only in combination with a Brocade SW4016 D4 Fibre Channel switch blade or with a 4 Gbit FC pass-thru

blade. For more information see the operating manual for the

BX600 S3 basic unit.

– Gigabit Ethernet I/O module (PCIe), also supports TOE (TCP/IP offload

engine) and iSCSI

– 10-Gbit Ethernet I/O module (PCIe)

I The 10-Gbit Ethernet I/O module (PCIe) can only be used in combi-

nation with a 10-Gbit switch blade 10/2. For more information see the

operating manual for the basic unit.

I You must not install server blades with different I/O modules in the same

BX600 S2 or BX600 S3 basic unit.

How to install I/O modules later is described in the Options Guide.

BX630 S2 Operating Manual 9

Page 10

Features Preface

High availability and reliability

When memory data is accessed, 1-bit errors in the main memory are recognized and automatically corrected with the ECC (Error Correcting Code)

method.

ASR&R (Automatic Server Reconfiguration and Restart) restarts the system in

the event of an error and automatically "hides" the defective system components.

The PDA (Prefailure Detection and Analyzing) technology from Fujitsu

Technology Solutions analyzes and monitors all components that are important

for system reliability.

The onboard SAS RAID controller supports RAID levels 0 and 1 by default, thus

increasing the system's availability. If you are using SATA-II hard disk drives, you

can implement RAID levels 0 and 1 using Promise 20319 to increase the

system's availability.

Server management

Server management is implemented using the supplied ServerView software and

PDA technology. PDA reports the threat of a system error or overloading to the

system administrator in good time, so that preventive measures can be taken.

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2504-002.fm

ServerView allows the management of all PRIMERGY servers in the network via

a central console. ServerView supports the following functions:

● Monitoring of the ambient and CPU temperatures

● Watchdog timer for Automatic Server Reconfiguration and Restart (ASR&R)

if memory modules or processors fail

● Power monitoring

● End-of-life monitoring of the fans with prefailure notification

● Watchdog timer for monitoring the operating system and applications with

ASR&R

The supplied deployment software simplifies and speeds up the installation of

multiple servers. For further information see the relevant documentation.

For further information on the ServerView server management software see the

relevant documentation.

10 Operating Manual BX630 S2

Page 11

Preface Features

ServerView Installation Manager

The enclosed ServerView Installation Manager software allows you to configure

your server system quickly according to your requirements. User-friendly

menus guide you through the installation of the server operating systems.

Service and support

PRIMERGY servers have a service-friendly, modular architecture, thus

enabling quick and simple maintenance. The flash-EPROM program supplied

with the utilities from Fujitsu Technology Solutions allows fast BIOS updating via

the USB interface.

The two redundant hot-pluggable management blades of the PRIMERGY

BX600 S2 and BX600 S3 basic unit with independent LAN and COM ports for

administration allow complete remote administration of the server blade.

Together they allow remote diagnosis for system analysis, remote configuration

and a remote restart even in the event of an operating system failure or

hardware errors.

BX630 S2 Operating Manual 11

Page 12

Notational conventions Preface

1.4 Notational conventions

The following notational conventions are used in this manual:

Text in italics indicates commands or menu items.

“Quotation marks” indicate names of chapters and terms that are being

emphasized.

Ê describes activities that must be performed in the order

shown.

V CAUTION! pay particular attention to texts marked with this symbol.

Failure to observe this warning may endanger your life,

destroy the system or lead to the loss of data.

I indicates additional information, notes and tips.

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2504-002.fm

12 Operating Manual BX630 S2

Page 13

Preface Technical data

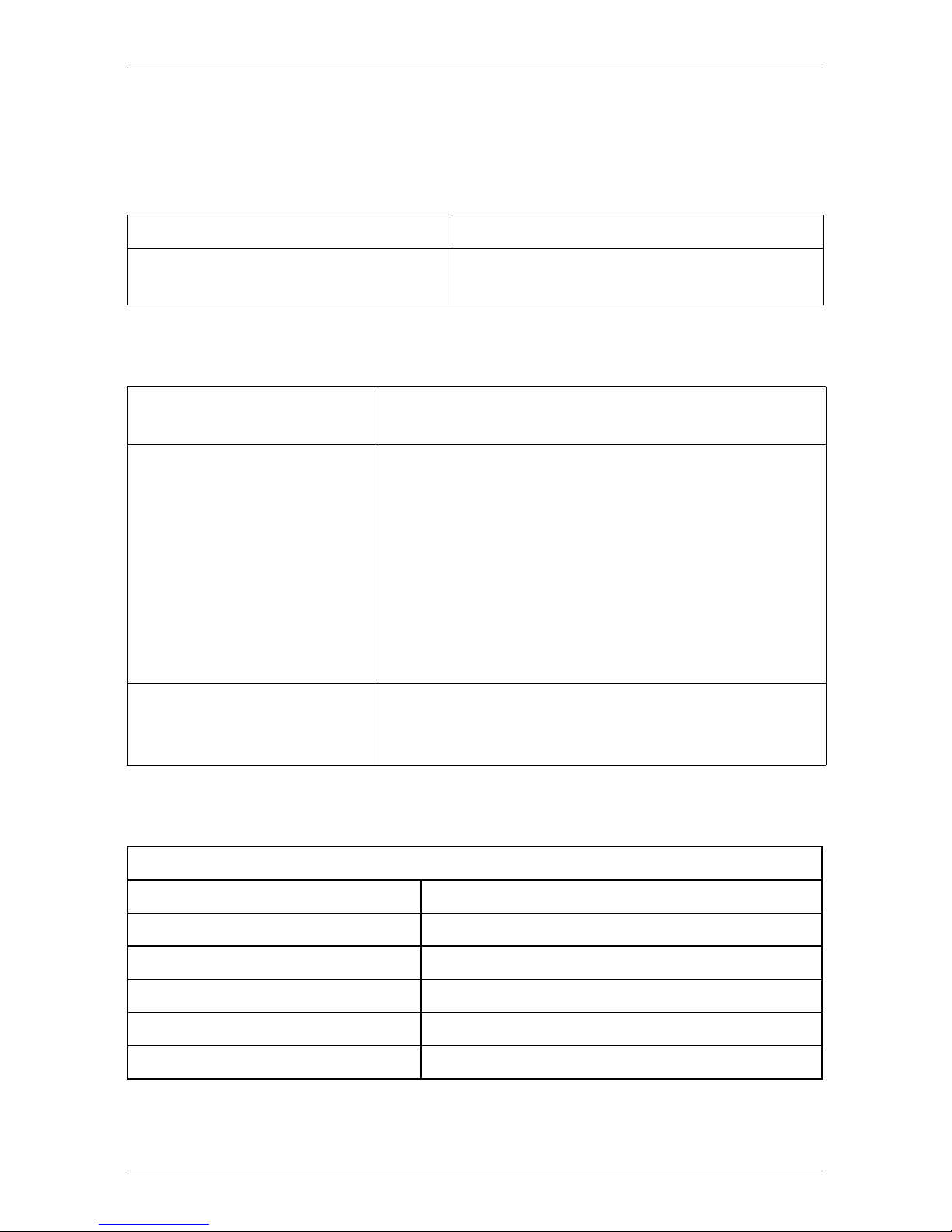

1.5 Technical data

Electrical specifications

Power consumption ~ 380 W (full configuration)

Thermal dissipation min. ~ 750 kJ/h,

max. ~ 1000 kJ/h

Compliance with regulations and standards

Product safety and

ergonomics

Electromagnetic

compatibility

IEC 60950-1 / EN 60950-1, UL/CSA 60950-1,

CNS 14336 / GB 4943 / EN 50371

FCC class A

CNS 13438 class A; VCCI class A

AS/NZS CISPR 22 class A / GB 9254 class A

GB 17625

Interference emissions EN 55022 class A

Harmonic current EN 61000-3-2

Flicker EN 61000-3-3

Interference immunity EN 55024, EN 300386

CE marking

to EU directives

Low Voltage Directive 2006/95/EC

(Product Safety)

Electromagnetic Compatibility 2004/108/EC

Certification

Product safety

Global CB

Europe ENEC

Germany GS, CE

USA/Canada CSA

Japan VCCI

China/Taiwan BSMI

BX630 S2 Operating Manual 13

/ CSA

US

C

Page 14

Technical data Preface

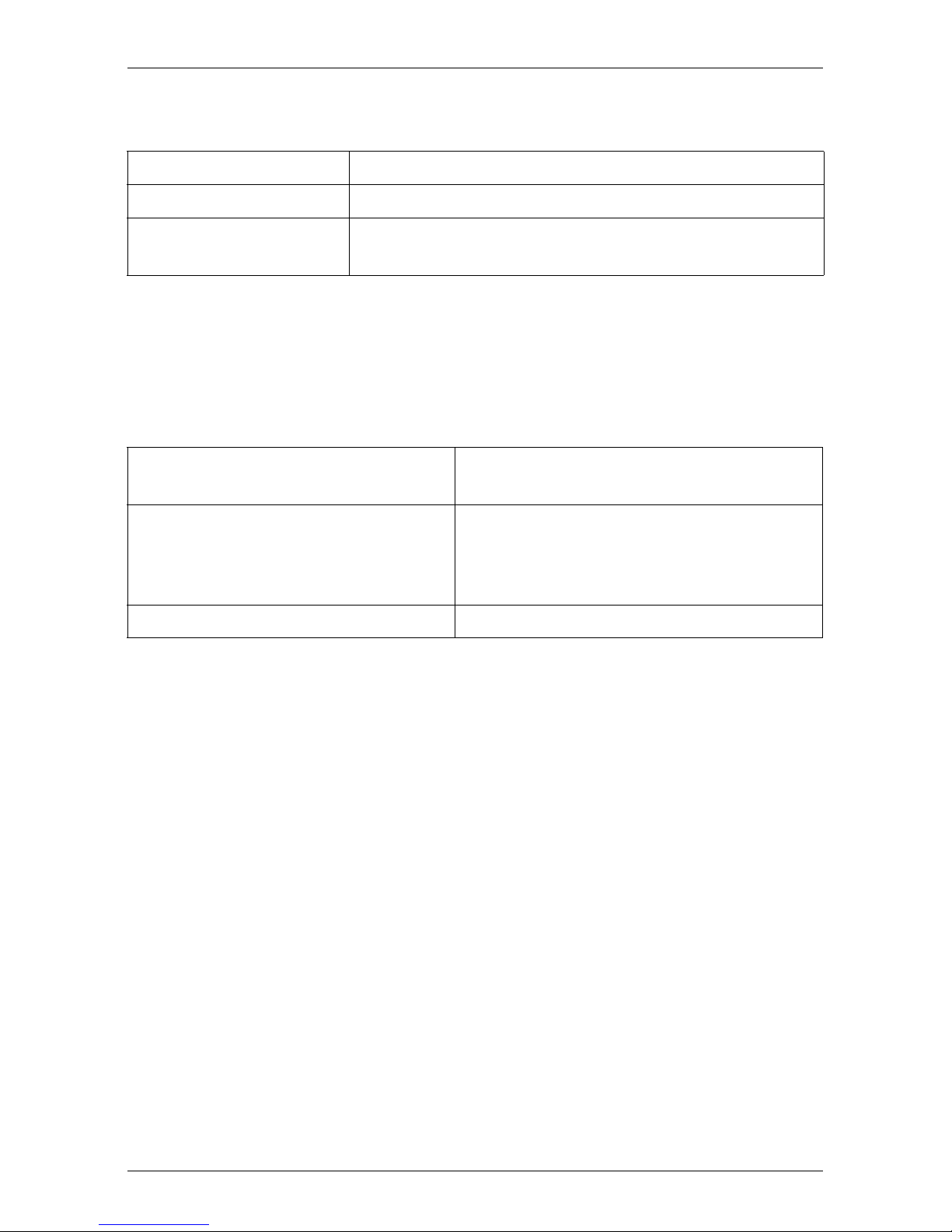

Mechanical specifications

Width 286 mm

Depth 470 mm (520 mm incl. handles and plugs)

Height 43 mm (quad-socket server blade: 86 mm;

1 or 2 slots in the basic unit)

Weight

Max. 6 kg (quad-socket server blade: 12 kg).

Ambient conditions

Environment class 3K2

Environment class 2K2

EN 60721 / IEC 721 Part 3-3

EN 60721 / IEC 721 Part 3-2

Temperature:

Operation (3K2) 5 °C .... 35 °C

Transport (2K2) -20 °C .... 60 °C

Humidity 10%...85%

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2504-002.fm

Condensation during operation must be avoided!

14 Operating Manual BX630 S2

Page 15

2 Overview: Installation Procedure

This chapter provides an overview of the steps you must perform to install your

PRIMERGY BX630 S2 scalable server blade in your basic unit. The links take

you to the sections with more detailed descriptions of the individual steps.

Ê First read the chapter “Important notes” starting on page 17, in particular the

section “Notes on safety”.

Ê Unpack the server blade, check the delivery for damage sustained during

transport and that the delivery corresponds to the specifications in the

delivery note (see section 4.2 on page 23).

Ê Mount the server blade into your BX600 S2 or BX600 S3 basic unit (see

section 4.3 on page 24).

Ê Familiarize yourself with the control and display elements on the front of the

server blade (see chapter “Installation and Operation” on page 31).

Ê Install the operating system and the applications on the server blade.

To do this, you have the following options:

– Cloning the server blade from a remote image server using RemoteDeploy.

This is recommended if the following are available:

– the RemoteDeploy software

– a suitable clone image

– a deployment server and a LAN connection

– Remote installation with ServerView Installation Manager

This installation method is recommended if a LAN connection and a

DHCP server (deployment server) are available but the requirements for

cloning are not met.

BX630 S2 Operating Manual 15

Page 16

Overview: Installation Procedure

– Local installation with or without ServerView Installation Manager

The local installation is the least convenient method. It is only recommended if the requirements for a remote installation or cloning are not

met.

If you want to use an operating system that is not supported by

ServerView Installation Manager, you can of course install it directly without

ServerView Installation Manager.

I For more information on the remote or local installation of server

blades see the ServerView Installation Manager manual, which contains

a Quick Step Guide and a detailed description of the individual installation options and wizards. A PDF version of the ServerView

Installation Manager manual is available on the PRIMERGY

ServerBooks DVD.

For how to clone server blades see the RemoteDeploy manual (a

PDF file is available on the PRIMERGY ServerBooks DVD).

For information on installing and operating the PRIMERGY BX600 S2 or

BX600 S3 basic unit, see the operating manual of your basic unit.

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2505-002.fm

16 Operating Manual BX630 S2

Page 17

3 Important notes

This chapter provides safety instructions which you must observe when

handling your server blade.

3.1 Notes on safety

I The following safety instructions are also provided in the manual “Safety

notes and other important information”.

This device complies with the relevant safety regulations for IT equipment,

including electronic office machines for use in an office environment.

If you have any questions, please contact your sales outlet or the Fujitsu

Technology Solutions customer service center.

V CAUTION!

The activities described in this manual should only be performed by

engineers, service personnel or technical specialists. Equipment repairs

should only be performed by qualified staff! Any failure to observe the

guidelines in this manual could endanger the user (through electric

shock, fire hazards) or damage the equipment. Please note that any

unauthorized opening of the device will result in the invalidation of the

warranty and exclusion from all liability.

Before setting up

V CAUTION!

● During installation and before operating the device, please read the

instructions on environmental conditions for your device (see section

“Technical data” on page 13).

● If the device is brought in from a cold environment, condensation may

form both inside and on the outside of the machine.

Before operating the device, wait until it is absolutely dry and has

reached approximately the same temperature as the installation site.

Failure to observe these guidelines can lead to material damage of

the device.

BX630 S2 Operating Manual 17

Page 18

Notes on safety Important notes

V CAUTION!

● Transport the device only in its original packaging or in packaging

which protects it from knocks and jolts.

Installation and operation

V CAUTION!

● Read the notes on installation and operation in the operating manual

for your BX600 S2 or BX600 S3 basic unit.

Batteries

V CAUTION!

● Incorrect replacement of batteries can lead to risk of explosion. The

batteries may only be replaced with identical batteries or with a type

recommended by the manufacturer (see Options Guide).

● Do not throw batteries into the trash can. They must be disposed of

in accordance with local regulations on special waste.

● The German battery act obligates consumers in Germany to return

waste batteries to the distributor or to the return points established by

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2506-002.fm

Please note the following:

● If you pass the system on to someone else, you should also give them the

corresponding documentation.

the public waste management authorities.

● Replace the lithium battery on the system board only as described in

the Options Guide.

● All batteries containing pollutants are marked with a crossed-out

garbage can accompanied by the chemical symbol of the heavy

metal that classifies the battery as a pollutant:

Cd Cadmium

Hg Mercury

Pb Lead

18 Operating Manual BX630 S2

Page 19

Important notes Notes on safety

Modules with Electrostatic-Sensitive Devices

Modules with electrostatic-sensitive devices are identified by the following

sticker:

Figure 2: ESD label

When you handle components fitted with ESDs, you must always observe the

following points:

● Switch off the system and remove the power plugs from the power outlets

before installing or removing components with ESDs.

● You must always discharge static build-up (e.g. by touching a grounded

object) before working with such components.

● Any devices or tools that are used must be free of electrostatic charge.

● Wear a suitable grounding cable that connects you to the external chassis of

the system unit.

● Always hold components with ESDs at the edges or at the points marked

green (touch points).

● Do not touch any connectors or conduction paths on an ESD.

● Place all the components on a pad which is free of electrostatic charge.

I For a detailed description of how to handle ESD components, see the

relevant European or international standards (EN 61340-5-1,

ANSI/ESD S20.20).

BX630 S2 Operating Manual 19

Page 20

CE conformity Important notes

3.2 CE conformity

The system complies with the requirements of the EC directives

2004/108/EC regarding “Electromagnetic Compatibility” and

2006/95/EC “Low Voltage Directive”. This is indicated by the CE

marking (CE = Communauté Européenne).

3.3 Environmental protection

Environmentally-friendly product design and development

This product has been designed in accordance with the Fujitsu Technology

Solutions standard for “environmentally friendly product design and development”. This means that key factors such as durability, selection and labeling

of materials, emissions, packaging, ease of dismantling and recycling have

been taken into account.

This saves resources and thus reduces the harm done to the environment.

Energy-saving information

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2506-002.fm

Devices that do not need to be constantly switched on should be switched off

until they are needed as well as during long breaks and after completion of work.

Packaging information

Do not throw away the packaging. You may need it later for transporting the

system. If possible, the equipment should only be transported in its original

packaging.

Information on handling consumables

Please dispose of printer consumables and batteries in accordance with the

applicable national regulations.

In accordance with EU directives, batteries must not be disposed of with

unsorted domestic waste. They can be returned free of charge to the manufacturer, dealer or an authorized agent for recycling or disposal.

All batteries containing pollutants are marked with a symbol (a crossed-out

garbage can). They are also marked with the chemical symbol for the heavy

metal that causes them to be categorized as containing pollutants:

20 Operating Manual BX630 S2

Page 21

Important notes Environmental protection

Cd Cadmium

Hg Mercury

Pb Lead

Labels on plastic casing parts

Please avoid sticking your own labels on plastic parts wherever possible, since

this makes it difficult to recycle them.

Returns, recycling and disposal

The device must not be disposed of with domestic waste. This

device is labeled in compliance with European directive

2002/96/EC on waste electrical and electronic equipment (WEEE).

This directive sets the framework for returning and recycling used

equipment and is valid across the EU. When returning your used

device, please use the return and collection systems available to

you. Further information can be found at

www.ts.fujitsu.com/recycling

..

Details regarding the return and recycling of devices and consumables within

Europe can also be found in the “Returning used devices” manual, via your local

Fujitsu Technology Solutions branch or from our recycling center in Paderborn:

Fujitsu Technology Solutions

Recycling Center

D-33106 Paderborn

Tel. +49 5251 8 18010

Fax +49 5251 8 18015

BX630 S2 Operating Manual 21

Page 22

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2506-002.fm

Page 23

4 Installing the Hardware

V CAUTION!

Make sure you observe the safety notes in the chapter Important notes.

The server blade must not be exposed to extreme environmental conditions (see “Ambient conditions” on page 14). It must be protected from

dust, humidity and heat.

4.1 Installation Steps

The installation steps are described in detail in the following sections of this

chapter:

● Unpacking the system ( see 4.2 on page 23).

● Installing the server blade in the basic unit (see 4.3 on page 24).

● Connecting the server blade (see 4.4 on page 28).

4.2 Unpacking the Server Blade

V CAUTION!

Make sure you observe the safety notes in the chapter “Important notes”

on page 17 starting on page 17.

Unpack the server blade only at the place where you want to set it up.

Keep the original packaging of the server blade. You may need it for future

transport.

Ê Unpack all the individual parts.

Ê Check the delivery for damage sustained during transport.

Ê Check that the delivery corresponds to the specifications in the delivery

note.

The type label is located at the front right on the underside of the server blade.

If the delivery is damaged or does not match the delivery note, contact your

supplier immediately!

BX630 S2 Operating Manual 23

Page 24

Installing the Server Blade in the Basic Unit Installing the Hardware

Notify your supplier immediately if you discover any transport damage or if the

packaging content does not match the delivery note.

4.3 Installing the Server Blade in the Basic Unit

Depending on the configuration, the PRIMERGY BX630 S2 Scalable Server

Blade occupies one or two of the ten slots in the PRIMERGY BX600 S2 or

BX600 S3 basic unit. This section describes how to install the BX630 S2 dualsocket server blade in the basic unit.The BX630 S2 quad-socket server blade is

installed in the same way.

V CAUTION!

● Make sure you observe the safety notes and the information on

handling electrostatic-sensitive devices in the section “Notes on

safety” on page 17.

● Server blade boots automatically after installation in a switched-

on BX600 S3 basic unit with management blade S3.

If you insert a BX630 S2 server blade into a switched-on BX600 S3

basic unit with management blade S3, the server blade will automatically perform a POST (Power-On Self-Test) and then switch itself off.

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2507-002.fm

You may not switch off the server blade during the automatic boot

process!

If the BX600 S3 basic unit is switched off when the server blade is

installed, the POST will be performed automatically after the basic

unit is switched on.

● PRIMERGY BX630 S2 server blades are not for use in slots 4 an 10

of the PRIMERGY BX600 S2 basic unit.

Removing the Dummy Module

Any unused slots in the BX600 S2 or BX600 S3 basic unit are fitted with appropriate dummy modules to comply with the electromagnetic compatibility (EMC)

regulations and ensure sufficient cooling of the system components.

To add a server blade, you must first remove the dummy module from the corresponding slot.

24 Operating Manual BX630 S2

Page 25

Installing the Hardware Installing the Server Blade in the Basic Unit

!

Figure 3: Removing the dummy module for a server blade

Ê Undo the locking mechanism of the handles by pressing the green inside

touch points of the two handles (1). This undoes the locking handles of the

dummy module.

Ê Swivel the top handle upward and the bottom handle downward (2) simulta-

neously until the locking mechanism of the dummy module disengages and

releases the module.

Ê Pull the dummy module completely out of the slot (3).

V CAUTION!

Keep the dummy module for future use. If a server blade is removed

again and not replaced with a new one, the dummy module must be

reinstalled because of cooling, fire protection and EMC regulations.

Install the dummy module in the same way as the server blade as described in

the section below.

BX630 S2 Operating Manual 25

Page 26

Installing the Server Blade in the Basic Unit Installing the Hardware

Installing the Server Blade

V CAUTION!

Make sure you observe the safety notes and the information on handling

electrostatic-sensitive devices in the section “Modules with Electrostatic-

Sensitive Devices” on page 19.

I Make sure you install the server

A

2

Ê Undo the locking mechanism of the

1

blade in the correct direction.

The control panel (A) must be at

the top.

handles of the server blade by first

pressing the green inside touch

points of the two handles (1) at the

same time.

Ê Then turn the locking handles

outward (2) into the unlocked

position.

Ê Hold the locking handles in the

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2507-002.fm

1

2

Figure 4: Inserting the server blade

unlocked position and push the

server blade as far as possible into

the slot.

26 Operating Manual BX630 S2

Page 27

Installing the Hardware Installing the Server Blade in the Basic Unit

Ê Press the locking handles inward

until the locking mechanism

engages fully.

Figure 5: Final engaging of the locking mechanism

Removing the server blade

Remove the server blade in the same way as the dummy module (see

“Removing the Dummy Module” on page 24).

V CAUTION!

If a server blade has been removed and no new blade is installed in its

place, you must install a dummy module in the empty slot.

BX630 S2 Operating Manual 27

Page 28

Connecting Devices Installing the Hardware

4.4 Connecting Devices

All the connections required for operating the BX630 S2 Scalable Server Blade

are made via the midplane of the PRIMERGY BX600 S2 or BX600 S3 basic

unit. When you install the server blade, connections to the infrastructure

modules on the back of the basic unit are made automatically by means of plug

connectors:

– Power supply units

– Management blade(s) for server administration

– KVM blade for connecting a monitor, keyboard and mouse

– Ethernet switch blade(s) and/or pass-thru blades for connecting to the LAN

– Fibre channel switch blades or pass-thru blades for connection to a SAN

(optional, requires installation of an FC daughter card in the server blade,

see Options Guide)

For information on connecting external devices via the infrastructure modules of

the BX600 S2 or BX600 S3 basic unit, see the basic unit operating manual.

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2507-002.fm

28 Operating Manual BX630 S2

Page 29

Installing the Hardware Connecting Devices

USB/VGA connection

1

2

A

Figure 6: USB/VGA connectionon on the BX630 S2 server blade and breakout cable

The PRIMERGY BX630 S2 Scalable Server Blade has a USB/VGA connector

on the front (A).. Connecting an external device via the USB/VGA connector

requires a special cable with two USB plugs (2) and a VGA plug (3)..

I The USB/VGA breakout cable is supplied with the basic unit.

For information on connecting external devices via the infrastructure

module of the basic unit, see the operating manual for your basic unit .

BX630 S2 Operating Manual 29

Page 30

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2507-002.fm

Page 31

5 Installation and Operation

V CAUTION!

Make sure you observe the safety notes in the chapter “Important notes”

on page 17.

This chapter explains how to set up and operate the BX630 S2 scalable server

blade once you have installed it in the PRIMERGY BX600 S2 or BX600 S3 basic

unit.

– The position and function of the elements on the control and connection

panel of the server blade are described in section 5.1 on page 32.

– The different possible ways of switching the server blade on and off are

described in section 5.2 on page 35.

– Section 5.3 on page 35 explains how to configure the server blade with

ServerView Installation Manager.

– Section 5.4 on page 38 explains how to update the server blade firmware.

BX630 S2 Operating Manual 31

Page 32

Control and Connection Panel Installation and Operation

5.1 Control and Connection Panel

9

8

1

2

3

4

5

6

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2508-002.fm

7

Figure 7: Control panel

32 Operating Manual BX630 S2

Page 33

Installation and Operation Control and Connection Panel

1 Voltage/Selection indicator (two-color LED)

Dark: The BX600 S2 or BX600 S3 basic unit is off, 5 V standby voltage

is not present, or the server blade is not installed properly.

Glows green: Server blade is running.

Glows orange: Server blade is off but basic unit is running (5 V standby voltage is

present).

Flashes green: Server blade is switched on and selected for identification, or this

server blade is in a critical state.

Flashes

orange:

Flashes green-

orange

Flashes green-

dark-orange

Server blade is switched off and selected for identification, or this

server blade is in a critical state.

Server blade is in standby mode (ACPI function) or in a critical

state.

Server blade is in standby mode (ACPI function) and selected for

identification, or this server blade is in a critical state.

2 On/Off button fully compatible with the Advanced Configuration Power Interface

(ACPI)

If you press the On/Off button when the BX600 S2 or BX600 S3 basic unit is on (5 V

standby voltage is present) and the server blade is switched off, the power_up

command is sent to the management blade and the server blade is switched on.

If you press the On/Off button for less than 4 seconds when the server blade is

running, the power_off command is sent to the management blade and the server

blade is switched off by the management blade (graceful shutdown).

If you press the On/Off button for more than 4 seconds when the server blade is

running, the server blade is switched off immediately.

3 KVM/MP error indicator (two-color LED)

Dark: KVM has not been activated for this server blade.

Glows green: KVM has been activated for this server blade.

Flashes

orange:

Flashes green-

orange:

4 KVM button (keyboard/video/mouse)

Pressing this button switches the keyboard, monitor and mouse to this server blade.

5 I/O status of the optional I/O module (green LED)

I/O Dark: System is off or signal synchronization has failed.

Green: System is switched on and online.

BX630 S2 Operating Manual 33

KVM has not been activated for this server blade, and this blade

has been deactivated to save energy.

KVM has been activated for this server blade, and this blade has

been deactivated to save energy.

Page 34

Control and Connection Panel Installation and Operation

6 NIC indicator (green LED)

Dark: System or server blade is off and LAN interface is not active.

Glows green: Existing LAN connection.

Flashes green: Active LAN.

7 USB/VGA connector

Connector for adapter cable with two USB ports for external devices (e.g. floppy disk

drive, CD/DVD drive or hard disk drive, mouse or keyboard) and a VGA port.

I A special cable is required! (See figure 6 on page 29)

8 Hard disk access (green LED)

Dark: Hard disk drive not active.

Glows green: Hard disk drive active.

9 Hard disk drive indicator (orange LED)

Dark: No error

Glows orange: Server blade is on and hard disk drive has an error.

Flashes slowly

(1Hz)

Flashes quickly

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2508-002.fm

(3Hz)

Reconstruction (RAID message)

Identification of hard disk localization (RAID message)

34 Operating Manual BX630 S2

Page 35

Installation and Operation Switching the Server Blade On/Off

5.2 Switching the Server Blade On/Off

V CAUTION!

If you switch the server blade on and the connected monitor only displays

flickering stripes, switch it off again immediately (see chapter “Trouble-

shooting and Tips” on page 73).

Switching the Server Blade On/Off via the Control Panel

The basic unit must be switched on.

You can switch the server blade on or off using one of the following methods:

– To switch the server blade on, press the On/Off button of the server blade

(position 2 in figure 7 on page 32).

To switch the server blade off, press the On/Off button of the server blade

(position 2 in figure 7 on page 32) for 4 seconds.

– Defined switch-on/switch-off time

The server blade is switched on or off at the time defined in ServerView.

– After power failure

A server blade that was already on when the power failed, automatically

switches on again when power resumes (depending on the BIOS setting,

see section “Power On/Off menu” on page 54??? in chapter “BIOS Setup”

on page 39).

I With the basic unit, you can also switch the installed server blades on an

off via the control panel of the overall system as well as via the Web

interface of the management blade. For detailed information see the

operating manual for your basic unit.

5.3 Configuring the Server Blade

PRIMERGY BX6xx server blades can be set up using one of the following

methods:

– Local installation with or without ServerView Installation Manager

– Remote installation, see the section ServerView Installation Manager Remote

Installation in the ServerView Installation Manager manual on the ServerBooks

DVD.

BX630 S2 Operating Manual 35

Page 36

Configuring the Server Blade Installation and Operation

– Copying the clone images from a remote image repository to the relevant

server blades (for further information see the RemoteDeploy manual on the

ServerBooks DVD (version 5.210 or later)).

I The optional RemoteDeploy software package can be obtained from

the Fujitsu Technology Solutions customer service center

(order number U15000-C286).

Reference Installation

A reference installation of a server blade performed using ServerView Installation

Manager is used as the basis for a clone image. The image is created and then

used by RemoteDeploy for fast installation and configuration of other server

blades.

I For details on using ServerView Installation Manager, see the operating

manual for ServerView Installation Manager on the PRIMERGY

ServerBooks DVD, which is part of the PRIMERGY ServerView Suite

provided with each server system.

Preparing the Hardware

To implement initial installation of the server blade or perform subsequent

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2508-002.fm

modifications, you must meet the the following conditions.

– The relevant server blade must be connected to a CD-ROM drive and a

diskette drive via the USB/VGA interface.

– A monitor, a keyboard and a mouse must be connected to KVM blade on the

rear of the BX600 basic unit.

– the relevant server blade must be switched to by pressing the KVM button.

Perform the following steps to prepare the installation of a server blade:

Ê Connect the breakout cable to the USB/VGA port on the front of the relevant

server blade (figure 6 on page 29).

Ê Connect the data cable of the CD-ROM drive and, if required, also the floppy

disk drive to the USB ports of the breakout cable (see figure 6 on page 29).

Ê Make sure that the basic unit is switched on.

Ê To switch the server blade on, press the On/Off button on the control panel

(position 2 in figure 7 on page 32).

Ê If the CD-ROM drive and the floppy disk drive are not supplied with power

via the USB ports of the breakout cable, connect them directly to the mains.

36 Operating Manual BX630 S2

Page 37

Installation and Operation Configuring the Server Blade

Ê Connect the monitor, keyboard and mouse to the KVM blade on the rear of

the basic unit. For information see the BX600 S2 or BX600 S3 basic unit

operating manual.

Ê Press the KVM button (position 4 in figure 7 on page 32) on the control panel

of the server blade to switch the keyboard, mouse and the monitor of the

KVM blade to the server blade.

Preparing the Software

Booting from the CD-ROM drive

Boot the relevant server blade from the ServerView Installation Manager CD to

install the operating system. In some cases this may require that you change a

few settings:

Ê Insert the ServerView Installation Manager CD in the CD-ROM drive and press

the On/Off button (position 2 in figure 7 on page 32) on the control panel of

the server blade.

Ê Press the KVM button (position 4 in figure 7 on page 32) on the control panel

of the server blade to switch the keyboard, mouse and the monitor of the

KVM blade to the server blade. Wait a few seconds for the monitor to be

activated.

Ê When prompted, press [F2] to call up the BIOS setup of the server blade.

Ê In the BIOS setup menu select the Boot submenu and enable Boot from CD-

ROM Drive.

Ê Press [ESC] twice and select Exit Saving Changes from the Exit menu.

Once the server blade has booted from the ServerView Installation Manager CD,

the startup screen is displayed.

BX630 S2 Operating Manual 37

Page 38

Updating the Firmware (BIOS and BMC) Installation and Operation

5.4 Updating the Firmware (BIOS and BMC)

All the files required for updating the server blade components are available

from http://download.ts.fujitsu.com.

You can update both the firmware of the server blade BIOS and the firmware of

the server blade BMC.

I BMC stands for Baseboard Management Controller. The BMC on the

server blade collects management information and sends it to the

management blade.

There are three possible ways of updating the firmware of the server blade

BIOS and the server blade BMC:

– Updating the firmware of the server blade with TFTP.

For detailed information see the operating manual for your basic unit.

– Updating the firmware of the server blade with GlobalFlash.

For detailed information see the GlobalFlash manual.

– Updating the firmware of the server blade from a USB stick.

To update the firmware of the BX630 S2 Server Blade from a USB stick,

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2508-002.fm

proceed as follows:

Ê Create a bootable USB stick using the selfextracting USB stick image you

downloaded from http://download.ts.fujitsu.com.

Ê Connect the breakout cable to the relevant server blade. Connect the USB

stick to the other end of the breakout cable.

Ê Switch on the server blade or restart it. The firmware update is performed

automatically.

I You may have to change the order of the boot devices in the BIOS to

enable booting from the USB stick. For further information see the

section “Boot menu” on page 71 chapter BIOS Setup and the

operating manual for ServerView Installation Manager .

38 Operating Manual BX630 S2

Page 39

6 BIOS Setup

In the BIOS Setup you can set the system functions and the hardware configuration of a server blade.

I The scope of the displayed BIOS parameters may differ depending on

the configuration.

The server blade comes with default settings in effect. You can change these

settings in the BIOS Setup menus. Your changes will take effect as soon as you

save the settings and quit the BIOS Setup.

The following lists illustrate the structure of the BIOS Setup menus. The

numbers in brackets refer to the pages on which the individual functions are

described.

Main – Basic system configuration

System Time [46]

System Date [46]

Sync RTC with Mgmt. Blade [46]

POST Errors [46]

SM Error Halt [47]

Boot Diagnostic Screen [47]

Numlock [47]

Boot Menu [47]

Base Memory / Extended Memory [47]

Advanced – Advanced system configuration

Peripheral Configuration [50]

Serial # [50]

Serial Multiplexer [51]

Onboard USB Controller [51]

USB BIOS Legacy Support [51]

Master HD Controller [51]

Slave HD Controller [51]

SAS Option ROM Scan [52]

Master LAN # [52]

Slave LAN # [52]

BX630 S2 Operating Manual 39

Page 40

Master Daughtercard [52]

Slave Daughtercard [52]

Remote Boot [52]

Management LAN [52]

Advanced System Configuration [53]

High Precision Event Timer [53]

Power On/Off [54]

Power off Source [54]

Software [54]

Power Button [54]

Power Failure Recovery [54]

IPMI [56]

SEL Load [56]

BIOS Setup

Clear System Event Log [56]

Event Log Full Mode [56]

System Event Log [57]

Entry Number [57]

Sensor Type[57]

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2509-002.fm

Sensor [57]

Event Type [57]

Sensor Event [57]

Event Data [57]

Timestamp [57]

SDRR Browser [57]

SDR Record ID [57]

Entity ID [57]

Entity Inst [57]

SDR ID [58]

Sensor No.[58]

Sensor Type [Units] [58]

Sensor Value[58]

Sensor Value (max)[58]

Sensor Value (min) [58]

Entity ID [58

40 Operating Manual BX630 S2

]

Page 41

BIOS Setup

LAN Settings [58]

DHCP [59]

Local IP Address [59]

Subnet Mask [59]

Gateway Address [59]

Reset Configuration Data [48]

Multiprocessor Specification [49]

Security – Security functions

Supervisor Password [60]

User Password [60]

Set Setup Password [60]

Setup Password Lock [61]

Set System Password [61]

System Password Mode [61]

Setup Prompt [61]

Flash Write [62]

Server – Server management

O/S Boot Timeout [63]

Action [63]

ASR&R Boot Delay (min) [63]

Boot Retry Counter [64]

Temperature Monitoring [64]

CPU Status [65]

Node # (1-4) CPU Status [65]

Re-enable Failed CPUs [66]

Memory Status [67]

Memory Scrubbing [67]

SW Mem Hole Remap [68]

DRAM Bank Interleave [68]

Node Interleave [68]

Memory on Master Board [68]

CPUn (1-4) - DIMMm (1-7) + DIMMm+1 (2-8) [68]

BX630 S2 Operating Manual 41

Page 42

Memory on Slave Board [68]

Re-enable Failed DIMMs [69]

Console Redirection [69]

Port [69]

Baud Rate [69]

Protocol [70]

Flow Control [70]

Console Connection [70]

Mode [70]

# of video pages to support [70]

Boot – System start

Boot priority order [71]

BIOS Setup

CPUn (1-4) - DIMMm (1-7) + DIMMm+1 (2-8) [68]

Excluded from Boot order [72]

Exit – Save settings and terminate BIOS Setup

Save Changes & Exit [72]

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2509-002.fm

Discard Changes & Exit [72]

Get Default Values [72]

Load Previous Values [72]

The following sections describe how to call up and use the BIOS Setup as well

as the individual menus and possible settings.

42 Operating Manual BX630 S2

Page 43

BIOS Setup Entering the BIOS Setup

6.1 Entering the BIOS Setup

Ê Start the server blade (cold or warm start).

The subsequent procedure depends on the current setting of the Boot Menu

parameter in the Boot menu (see also section “Boot menu” on page 71):

Boot Menu = Disabled

With this parameter setting, you can open the Main menu.

Boot Menu = Enabled

With this parameter setting, you can open the Main menu or a pop-up

boot menu.

Opening the Main menu

Ê Press the [F2] function key.

Ê Enter the Setup password (if defined) and confirm your entry by pressing

Enter.

Opening the pop-up boot menu

Use this function if you do not want to start your system from the drive that is set

as the first option in the Boot Sequence parameter in the Boot menu.

Ê Press [ESC].

A pop-up boot menu is displayed.

Ê Use the Ê or Ë cursor keys to select the drive from which you want to start

the operating system, and confirm your selection by pressing Enter. The

selection options are the same as the possible settings of the Boot priority

order parameter in the Boot menu.

If a drive is marked with an exclamation mark (!), you cannot select it for

booting.

I The option you select only applies to the current system start. The

next time you start the system, the settings of the Boot Sequence

parameter in the Boot menu will apply again.

Ê To start the BIOS Setup, select the Setup parameter and confirm your

selection with Enter. The Main menu opens and, if applicable, you must

enter and confirm the Setup password.

BX630 S2 Operating Manual 43

Page 44

Operation BIOS Setup

6.2 Operation

1

2

4

3

Figure 8: BIOS Setup screen structure

The BIOS Setup screen is structured as follows:

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2509-002.fm

Menu bar (1)

Use the À and  cursor keys to select a menu.

Workspace (2)

The workspace contains the information for the selected menu and the

settings you can make. Use the Ê and Ë cursor keys to select the

parameter whose setting you want to change.

A [Ê] in the left margin indicates that a parameter contains submenus.

To display a submenu, select the relevant parameter and press Enter.

Pressing [ESC] returns you from the submenu to the superordinate

menu.

An asterisk (*) indicates configuration conflicts that must be resolved.

Square brackets ([ ]) enclosing a parameter value indicate that this value

can be changed with the [+] and [-] keys.

Control bar (3)

The control bar shows all the keys you can use to navigate and change

settings in the BIOS Setup.

[F1] Function key for displaying additional information

44 Operating Manual BX630 S2

Page 45

BIOS Setup Operation

[Esc] Function key for quitting a submenu

ÊË Cursor keys for selecting a parameter

ÀÂ Cursor keys for selecting a menu

[+][-] Keys for changing parameter values

Press Enter

Press Enter to perform a menu-dependent action

[F9] Load the default values for all menus

I Pressing the [F7] function key discards all the changes you

have made in this BIOS session and resets the values that

were in effect when you opened the BIOS Setup.

[F10] Save the changed values and quit the BIOS Setup.

Information area (4)

The information area displays brief information on the selected

parameter.

BX630 S2 Operating Manual 45

Page 46

Main menu BIOS Setup

6.3 Main menu

Figure 9: Main menu

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2509-002.fm

System Time / System Date

Sets the system time and date.

The system time has the format HH:MM:SS, and the system date has the

format MM/DD/YYYY. Use the tab keys to position the cursor within the

individual input fields.

I If the system time and date are incorrect after you switch the

system off and back on again, the lithium battery is empty and

needs to be replaced.

Sync RTC with Mgmt. Blade

Switches synchronization of the real-time clock with the time of the

management blade on (Enabled) or off (Disabled).

POST Errors

Defines whether the system start is aborted and the system is stopped if

an error is detected.

Halt On All Errors or Enabled

If the self-test detects an error, the system start is aborted and the

system is stopped after the self-test.

46 Operating Manual BX630 S2

Page 47

BIOS Setup Main menu

No Halt On Any Errors or Disabled

The system start is not aborted. If possible, the error is ignored.

SM Error Halt – error handling for system monitoring

Configures the system behavior during the self-test in the event of a

system monitoring error reported by the iRMC (e.g. fan monitoring,

temperature monitoring).

This setting only takes effect if the setting Halt On All Errors is selected

for POST Errors in the Boot Options menu.

Enabled

If the iRMC reports an error to the BIOS, the system start is

aborted and the system is stopped after the self-test.

Disabled

The system start is not aborted if the iRMC reports an error to the

BIOS. The error is only displayed.

Boot Diagnostic Screen

Defines whether the screen displays a logo instead of the start information.

Enabled

The logo is displayed. If an error occurs or if you press the [F3] or

{Esc} key, the display switches to the start information.

Disabled

The start information is displayed on the screen.

Numlock

Defines the setting of the NumLock key after system start.

Auto The state of the NumLock key is not changed.

On The NumLock key is switched on.

Off The NumLock key is switched off.

Boot menu

Defines whether the pop-up Boot menu can be called with the [F12]

function key when the BIOS Setup is called during the POST (Enabled)

or not (Disabled).

Base Memory / Extended Memory

Indicates the size of the available main memory.

BX630 S2 Operating Manual 47

Page 48

Advanced menu BIOS Setup

6.4 Advanced menu

Figure 10: Advanced menu

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2509-002.fm

Peripheral Configuration

Calls a submenu for setting up the interfaces and controllers (see section

“Peripheral Configuration” on page 50).

Advanced System Configuration

Calls a submenu for setting the High Precision Event Timer (see section

“Advanced System Configuration” on page 53).

Power On/Off

Calls a submenu for setting the power-on and power-off options of the

server blade (see section “Power On/Off menu” on page 54).

IPMI Calls a submenu with the settings of the Intelligent Platform Management

Interface (see section “IPMI menu” on page 56).

Reset Configuration Data

Defines whether the configuration data is reinitialized when the server

blade is started.

48 Operating Manual BX630 S2

Page 49

BIOS Setup Advanced menu

Yes After the server blade is started, the plug&play functionality

identifies the new configuration data to initialize the installed

boards and drives and resets this field to No. You must enter the

configuration data of non-plug&play components manually.

No After the server blade is started, the plug&play functionality

initializes the installed boards and drives with the configuration

data that is currently in effect. The configuration data of non-

plug&play components is not changed.

Multiprocessor Specification

Sets the version of the multiprocessor table used.

I For compatibility reasons, some operating systems require

version 1.1.

BX630 S2 Operating Manual 49

Page 50

Advanced menu BIOS Setup

6.4.1 Peripheral Configuration

Figure 11: Peripheral Configuration

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2509-002.fm

Serial #

Defines how the address and the interrupt of the corresponding serial

interface are configured.

Auto Automatic configuration with an available combination of address

and interrupt.

Disabled

The interface is disabled.

Enabled

User-configured. This setting requires the manual configuration of

the base I/O address and the IRQ in an extra line.

OS Controlled

Operating system configuration.

50 Operating Manual BX630 S2

Page 51

BIOS Setup Advanced menu

Serial Multiplexer

Defines whether the serial interface can be used by the system or by the

iRMC.

System

The serial interface can be used by the system or by the operating

system.

iRMC

The serial interface can be used by the iRMC. The operating

system cannot use the serial interface.

Onboard USB Controller

Defines whether the USB (Universal Serial Bus) controller of the system

board is Enabled or Disabled.

USB BIOS Legacy Support

Defines whether the USB keyboard and mouse emulation is Enabled or

Disabled.

This emulation is also required if you want to start the operating system

from a USB device.

If emulation is enabled, the USB keyboard or the USB mouse can also

be used with operating systems that do not support USB. The operating

system can be started from a USB device if this is also supported by the

operating system.

With emulation disabled, the USB keyboard or mouse can only be used

if supported by the operating system. The operating system cannot be

started from a USB device.

Master HD Controller

Slave HD Controller

Enables or disables the SAS controller on the system board of the master

module or of the slave module of a quad-socket server blade.

Enabled

The SAS controller is enabled.

Disabled

The SAS controller is disabled.

I In a dual-socket server blade, this parameter is not interpreted.

BX630 S2 Operating Manual 51

Page 52

Advanced menu BIOS Setup

SAS Option ROM Scan

Defines whether the SAS BIOS is started by the system BIOS when the

onboard SAS controller is initialized (Enabled) or not (Disabled).

I To be able to start an operating system from an SAS controller,

this controller must be controlled by a BIOS.

Master LAN #

Slave LAN #

Defines whether the onboard LAN controller 1 and/or 2 of the master

module or the slave module of a quad-socket server blade is enabled.

Channel 1 & 2

Channels 1 and 2 of the relevant onboard LAN controller are

enabled.

Channel #

Channel 1 or 2 of the relevant onboard LAN controller is enabled.

Disabled

The relevant onboard LAN controller is disabled.

I For a dual-socket server blade, the parameters Slave LAN 1 and

Slave LAN 2 are not interpreted.

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2509-002.fm

Master Daughtercard

Slave Daughtercard

Defines whether the optional I/O daughter card of the master module or

of the slave module of a quad-socket server blade is enabled (Enabled)

or not (Disabled).

I In a dual-socket server blade, the Slave Daughtercard parameter is

not interpreted.

Remote Boot

Defines whether the operating system can be booted via the relevant I/O

daughter card (Enabled) or not (Disabled).

Management LAN

Defines whether the LAN port of the iRMC for remote control of the

system is Enabled or Disabled.

52 Operating Manual BX630 S2

Page 53

BIOS Setup Advanced menu

6.4.2 Advanced System Configuration

Figure 12: Advanced System Configuration

High Precision Event Timer

This option allows you to make the system's high-precision event timer

available to the operating system. This timer is also known as the “multimedia timer“.

Enabled

The operating system can use the timer.

Disabled

The timer is not visible to the operating system.

BX630 S2 Operating Manual 53

Page 54

Advanced menu BIOS Setup

6.4.3 Power On/Off menu

Figure 13: Power On/Off menu

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2509-002.fm

Power off Source

Defines how the system can be switched off if the ACPI function is not

enabled.

Software

Defines whether the system can be switched off by a software

program (Enabled) or not (Disabled).

Power Button

Defines whether the system can be switched off via the on/off

button on the front of the system (Enabled) or not (Disabled).

Power Failure Recovery

Defines the system state after the system is restarted due to a power

failure.

Always Off

The system switches on, checks its current state (i.e. initializes

itself) and switches off again.

54 Operating Manual BX630 S2

Page 55

BIOS Setup Advanced menu

I During the brief initialization, all WakeUp sources are recon-

figured, so that the system can be woken via the LAN etc. If this

option is Disabled, the system can only be switched on using the

on/off button.

Always On

The system switches on.

Previous State

The system switches on, checks its current state and returns to

the state it was in before the power failure (ON or OFF).

Disabled

The system does not switch on.

BX630 S2 Operating Manual 55

Page 56

Advanced menu BIOS Setup

6.4.4 IPMI menu

Figure 14: IPMI menu

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2509-002.fm

SEL Load

Indicates in percent how full the system event log is.

Clear System Event Log

Defines whether the system event log file is to be cleared the next time

the system is started. All system events and errors are written to this file.

Disabled

The system event log is not deleted.

Enabled

The system event log is deleted the next time the system is

started.

Event Log Full Mode

Defines whether the system event log can be overwritten or not.

Overwrite

If the system event log is full, the oldest entries in each case are

overwritten by new entries.

56 Operating Manual BX630 S2

Page 57

BIOS Setup Advanced menu

Maintain

If the system event log is full, no more entries are written to it. The

system event log must be deleted so that the system can create a

new system event log.

System Event Log

Opens the submenu of the system event log viewer. The system event

log file stores all the events and errors that occur in the system.

Entry Number

Shows the number of the current system event log entry.

You can go to the previous/next entry with the - or + key on the

numeric keypad.

Sensor Type

Shows the sensor type that has triggered the current event.

Sensor

Indicates the sensor that triggered the current event.

Event Type

Indicates the type of the current event.

Sensor Event

Shows the current event in plain text. The data from Event Data are

evaluated for this purpose.

Event Data

Shows the data of the current event as a number code.

Timestamp

Shows the data and time at which the current event occurred.

SDRR Browser

Displays the values of the individual sensor data records. Use the [+] and

[-] keys on the numeric keypad to navigate between the individual

records.

SDR Record ID

Identifier of the sensor data record

Entity ID

Module to which the sensor belongs

Entity Inst

Number of the sensor within the module

BX630 S2 Operating Manual 57

Page 58

Advanced menu BIOS Setup

SDR ID

Sensor type

Sensor No.

Serial number of the sensor

Sensor Type [Units]

Type and unit of the sensor

Sensor Value

Measured value of the sensor

Sensor Value (max)

Maximum permissible sensor value

Sensor Value (min)

Minimum permissible sensor value

LAN Settings

Opens the submenu for the iRMC LAN settings (see section “IPMI LAN

parameters” on page 59).

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2509-002.fm

58 Operating Manual BX630 S2

Page 59

BIOS Setup Advanced menu

6.4.4.1 IPMI LAN parameters

Figure 15: IPMI LAN Settings menu

DHCP

Defines whether DHCP support for the iRMC is Enabled or Disabled.

Using the DHCP (Dynamic Host Configuration Protocol) network

protocol, the iRMC can have an IP address assigned to it automatically

by a DHCP server in the network. In this case, you do not have to enter

an IP address manually under Local IP Address.

Local IP Address

Ê Enter the IP address of the system's LAN board, using numeric

characters only.

Subnet Mask

Ê Enter the subnet mask of your LAN segment, using numeric

characters only.

Gateway Address

Ê Enter the gateway address of the system's LAN board, using numeric

characters only.

BX630 S2 Operating Manual 59

Page 60

Security menu BIOS Setup

6.5 Security menu

Figure 16: Security menu

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2509-002.fm

Supervisor Password / User Password

Indicates whether a supervisor or user password has been defined

(Installed) or not (Not installed).

Set Supervisor Password

When you press the Enter key, a window is opened in which you can

define the supervisor password. The supervisor password prevents

unauthorized BIOS Setup calls.

To delete an existing supervisor password without defining a new one,

open the password definition window, enter the current password and

press Enter three times.

I Deleting the supervisor password also deletes the user password.

60 Operating Manual BX630 S2

Page 61

BIOS Setup Security menu

Setup Password Lock

Defines the effect of the supervisor password.

I Requirement: A supervisor password must have been defined.

Standard

The supervisor password prevents unauthorized BIOS Setup

calls.

Extended

The supervisor password prevents unauthorized Setup calls and

locks the keyboard during device initialization. This prevents

unauthorized access to settings of installed modules with their

own BIOS.

The BIOS of a module can only be accessed if the supervisor

password is entered during initialization. The user is not prompted

to enter a password.

Set User Password

When you press the Enter key, a window is opened in which you can

define the user password. The user password prevents unauthorized

access to the system.

I Requirement: A supervisor password must have been defined.

System Password Mode

Defines the effect of the user password.

I Requirement: A supervisor password and a user password must

have been defined.

System

After the device is started, the operating system is started. Select

this option if you are using a USB keyboard.

Keyboard

After the device is started, the operating system is started with the

keyboard and mouse locked. This lock is released by entering the

user password. A prompt to enter a password is not displayed.

Setup Prompt

Defines whether the Setup prompt is displayed during system start

(Enabled) or not (Disabled).

BX630 S2 Operating Manual 61

Page 62

Security menu BIOS Setup

Flash Write

Defines whether the system BIOS is write-protected.

Enabled

The system BIOS can be written to or deleted.

Disabled

The system BIOS cannot be written to or deleted.

© cognitas. Gesellschft für Technik-Dokumentation mbH 2008 Pfad: H:\April\PRIMERGY_Rebranding\von Walte r\bx630_s2_ba\Archiv\bx630s2-ba-en \OBJ_DOKU-2509-002.fm

62 Operating Manual BX630 S2

Page 63

BIOS Setup Server menu

6.6 Server menu

Figure 17: Server menu

O/S Boot Timeout

Defines whether the system is restarted (Enabled) or not (Disabled) if the

operating system cannot establish a connection to a server management

process within a defined period of time. In this case, the server

management firmware assumes a system startup error.

I If the operating system has no server management process, you

must set this parameter to Disabled to prevent the server

management firmware from initiating a restart by mistake. The

watchdog timer and the server management process (agent) are

installed with ServerView.

Action

Defines the behavior following an OS Boot Timeout (Continue - No

Action; Reset; Power cycle).

ASR&R Boot Delay (min)

Defines the delay of the system restart after a shutdown due to an error

(1 - 30 minutes). The restart occurs after the set waiting time has

elapsed.

BX630 S2 Operating Manual 63

Page 64

Server menu BIOS Setup

Boot Retry Counter

Defines the maximum number of attempts (0-7) to start the operating

system. This parameter depends on the setting of the O/S Boot Timeout

parameter on the one hand. On the other hand, other critical system

errors can lead to a restart of the system and thus to a decrease in the

counter value. After the last attempt, the system is finally shut down, or,

if configured, the diagnostic system is started.

Temperature Monitoring

Defines whether the system is shut down (Enabled) or not (Disabled) if the

ambient temperature or a processor's temperature rises above a critical

point.

If the operating system has an active server management process, this

monitors the temperatures and shuts down the system if critical temperature values occur.

After a shutdown, the system restarts after the period of time defined for