DIGITAL CAMERA

FinePix S3Pro

CCD Post-shipment Defect

Correction adjustment Manual

US/CA/EU/EG/GE/AS-Model

WARNING

THE COMPONENTS IDENTIFIED WITH THE MARK “ ” ON THE SCHEMATIC

DIAGRAM AND IN THE PARTS LIST ARE CRITICAL FOR SAFETY.

PLEASE REPLACE ONLY WITH THE COMPONENTS SPECIFIED ON THE SCHEMATIC

DIAGRAM AND IN THE PARTS LIST.

IF YOU USE PARTS NOT SPECIFIED, IT MAY RESULT IN A FIRE AND AN

ELECTRICAL SHOCK.

FUJI PHOTO FILM CO., LTD.

Ref.No.:ZM00593-100

Printed in Japan 2005.03

CCD Post-shipment Defect Correction adjustment Manual

SAFETY CHECK-OUT

After correcting the original problem, perform the following

safety check before return the product to the customer.

1. Check the area of your repair for unsoldered or poorly

soldered connections. Check the entire board surface

for solder splasher and bridges.

2. Check the interboard wiring to ensure that no wires are

“pinched” or contact high-wattage resistors.

3. Look for unauthorized replacement parts, particularly

transistors, that were installed during a previous repair.

Point them out to the customer and recommend their

replacement.

4. Look for parts which, though functioning, show obvious

signs of deterioration. Point them out to the customer

and recommend their replacement.

5. Check the B + voltage to see it is at the values

specified.

6. Make leakage - current measurements to determine

that exposed parts are acceptably insulated from the

supply circuit before returning the product to the

customer.

7. CAUTION: FOR CONTINUED

PROTECTION AGAINST FIRE

HAZARD, REPLACE ONLY WITH

SAME TYPE 2.5 AMPERES 125V

FUSE.

2.5A 125V

2.5A 125V

8. WARNING:

RISK OF FIREREPLACE FUSE

AS MARKED

ATTENTION: AFIN D'ASSURER

UNE PROTECTION

PERMANENTE CONTRE LES

RISQUES D'INCENDIE,

REMPLACER UNIQUEMENT

PAR UN FUSIBLE DE MEME,

TYPE 2.5 AMPERES, 125 VOLTS.

TO REDUCE THE ELECTRIC

SHOCK, BE CAREFUL TO

TOUCH THE PARTS.

WARNING!

HIGH VOLTAGE

2

CCD Post-shipment Defect Correction adjustment Manual

CONTENTS

CONTENTS

1. Outline ..................................................................................................................................................4

2. Installing the software on a PC ............................................................................................................. 4

3. Generating CCD post-shipment scratch data (.txt file) .........................................................................5

3-1. Preparations prior to post-shipment scratch data generation ......................................................................................... 5

3-1-1. Camera settings and photography for images used for checking scratches prior to correction ................................5

3-1-2. Checking the locations of pre-correction scratches ................................................................................................... 5

3-1-3. Camera settings and photography for images (RAW images) used for correcting post-shipment scratches ........... 6

3-1-4. Importing the original CCD scratch data ................................................................................................................... 6

3-2. Creating the post-shipment scratch correction data (.txt) ............................................................................................... 7

4. Writing CCD post-shipment scratch data ............................................................................................. 9

4-1. Preparations prior to post-shipment scratch data writing ............................................................................................... 9

4-1-1. Connection method for post-shipment scratch data writing....................................................................................... 9

5. Inspection ........................................................................................................................................... 11

5-1. Shooting images to be used for inspection checking ................................................................................................... 11

5-2. Inspecting post-shipment scratch correction ................................................................................................................ 11

3

CCD Post-shipment Defect Correction adjustment Manual

1. Outline

Use the S3 Pro_Defect detection software to generate the scratch data to be used for correcting CCD scratches (single white

scratches) that occur after shipment from the factory. The generated scratch data is written to the S3 Pro flash ROM using the

S3 Pro_Defect Writing software together with the original scratch data.

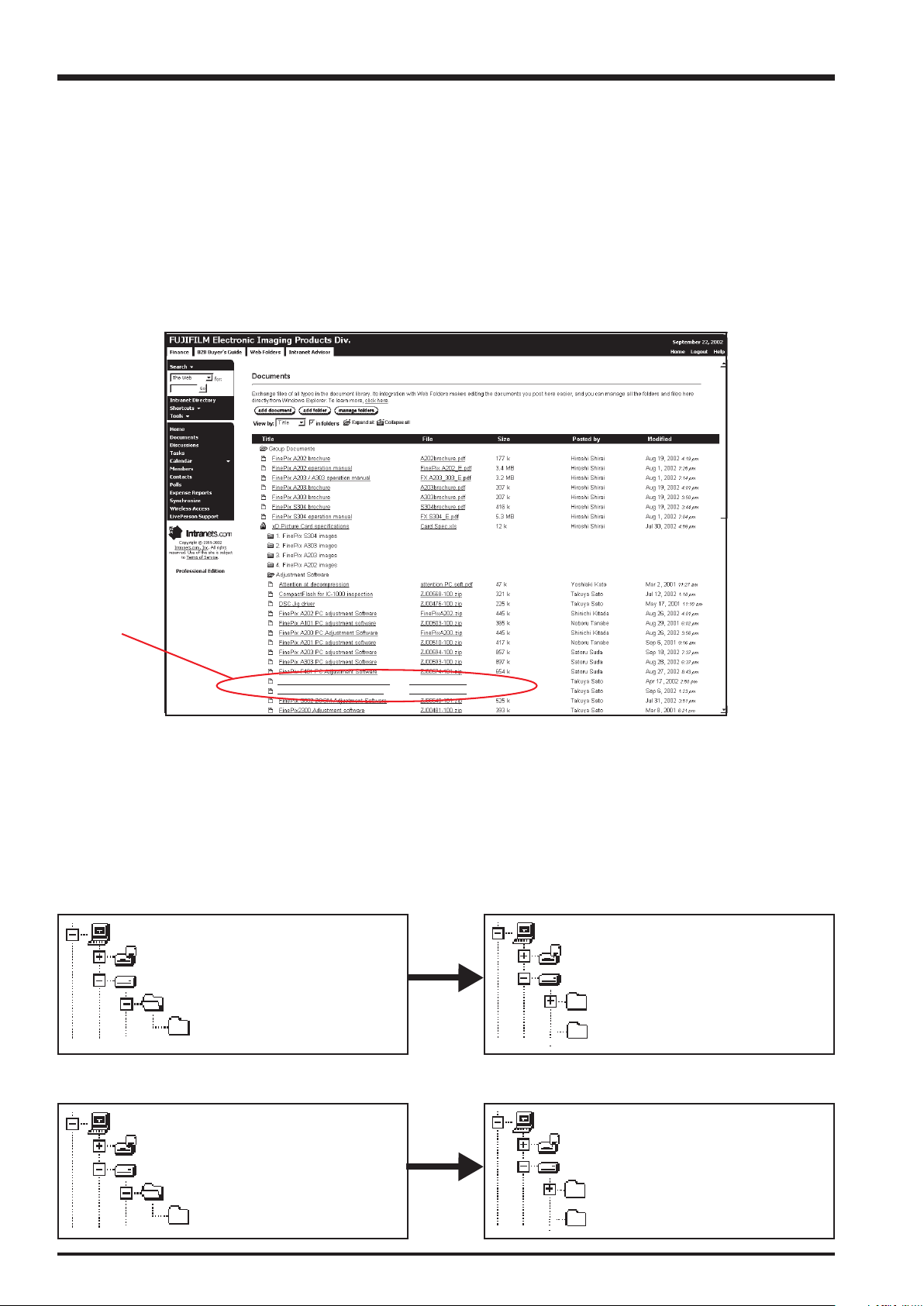

2. Installing the software on a PC

<Step 1>

Download the S3 Pro_Defect detection software (ZJ00900-100) and S3 Pro_Defect Writing software (ZJ00901-100) from the

web server (Fig. 1-(1)).

(1)

S3Pro_Defect detection software ZJ00900-100.zip

S3Pro_Defect Writing software ZJ00901-100.zip

(Fig. 1)

WEB Server: http://fujifilm-di.intranets.com/

<Step 2>

After downloading the software, expand the respective software applications (not shown in the figure).

<Step 3>

(1) Installing the S3 Pro_Defect detection software on a PC

Expanding the software creates the “ZJ00900-100” folder (Fig. 2).

Move (or copy) “S3Pro_DfctDt” to the C: drive (Fig. 3.)

After the file has been moved (or copied), the ZJ00900-100 folder is no longer required and should be deleted from the PC.

My Computer

3.5inch FD(A:)

(Fig. 2)

(C:)

ZJ00900-100

S3Pro_DfctDt

(2) Installing the S3 Pro_Defect Writing software on a PC

Install this software using the procedure described in (1) above.

My Computer

3.5inch FD(A:)

(C:)

ZJ00900-100

S3Pro_DfctDt

(Fig. 3)

My Computer

3.5inch FD(A:)

(C:)

ZJ00901-100

S3Pro_DfctWr

(Fig. 4) (Fig. 5)

My Computer

3.5inch FD(A:)

(C:)

ZJ00901-100

S3Pro_DfctWr

4

Loading...

Loading...