Page 1

Instruction Manual

ZIRCONIA OXYGEN

ANALYZER CONVERTER

Type: ZKMA, ZKMB

INZ-TN2ZKMA-E

Page 2

PREFACE

We are grateful for your purchase of Fuji Direct Insertion Type Zirconia Oxygen Analyzer Converter (ZKM).

First read this instruction manual carefully until an adequate understanding is acquired, and

then proceed to installation, operation and maintenance of the converter. Improper handling

may result in accidents or injury.

The specifications of this converter will be changed without prior notice for further product

improvement.

Modification of this converter is strictly prohibited unless a written approval is obtained

from the manufacturer. Fuji will not bear any responsibility for a trouble caused by such a

modification.

This instruction manual shall be stored by the person who actually uses the converter.

After reading through the manual, be sure to keep it near at hand for future reference.

This product falls within category 9 (Monitoring and control instruments including indus-

trial monitoring and control instruments) of Annex 1 of EU RoHS directive (2011/65/EU).

Please do not use it for consumer use.

This instruction manual should be delivered to the end user without fail.

Manufacturer: Fuji Electric Co., Ltd.

Type: Described in the nameplate put on the main body

Date of manufacture: Described in the nameplate put on the main body

Product nationality: Japan

Related instruction manual

Direct insertion type zirconia oxygen analyzer detector (Type: ZFK8) ·········· INZ-TN5ZFK8-E

Issued in October 2015

It is prohibited to transfer part or all of this manual without Fuji

Notice

Electric’s permission in written format.

Description in this manual is subject to change without prior no-

tice.

Fuji Electric Co., Ltd. 2015

INZ-TN2ZKMA-E

- i -

Page 3

SAFETY PRECAUTIONS

First of all, read this “SAFETY PRECAUTIONS” carefully, and then use in the correct way.

Installation, transportation, wiring, use, maintenance of this product shall be carried out by suitably trained

personnel.

First-time users should operate the instrument under the supervision of a fully competent person in the

operation.

Be sure to observe the instructions shown below, because they describe important information on safety.

Those safety precautions are ranked in 3 levels, “DANGER”, “CAUTION” and “PROHIBITION”.

If operation is incorrect, a dangerous situation may occur, resulting in

DANGER

CAUTION

PROHIBITION

death or serious injuries.

If handled wrongly, a dangerous situation may occur, and medium trouble or slight injury may be caused and only property damage may be

caused.

Items which must not be done are noted.

The items noted under “

All the items are important and must be fully observed.

DANGER

CAUTION

CAUTION

Caution on installation and transportation

” may also result in serious trouble depending on circumstances.

This unit is not explosion-proof type. Do not use it in an atmosphere

of explosive gases. Otherwise serious accidents such as explosion or

fire may result.

This unit should be installed in a place which conforms to the condi-

tions noted in the instruction manual. Otherwise, it may cause electric

shocks, fire, failure or malfunction of the unit.

During installation work, care should be taken to keep the unit free

from entry of cable chips or other foreign objects. Otherwise, it may

cause fire, failure or malfunction of the unit.

For installation, observe the rule on it given in the instruction manual

and select a place where the weight of converter can be endured. Installation at an unsuited place may cause turnover or fall and there is a

risk of injury.

Be sure to wear gloves when handling the unit.

Bare hands may invite an injury.

Before transport, fix the door so that it will not open. Otherwise, the

door may be separated and fall to cause an injury.

- ii -

INZ-TN2ZKMA-E

Page 4

Cautions on wiring

Be sure to turn off all the power before performing wiring. Otherwise

CAUTION

DANGER

CAUTION

electric shock may result.

Be sure to perform class D grounding work.

Otherwise, electric shock or failure may result.

Select a proper wiring material that satisfies the ratings of the instru-

ment. Otherwise, electric shock or fire may result.

Connect power source of correct rating. Connection of a power source

of incorrect rating may lead to a risk of fire.

Cautions on use

If unusual smell or sound has been produced, immediately stop the

instrument. Any discharge produced may cause a fire.

Leaving the converter unused for a long time or restarting it after dis-

use requires procedures different from normal operation or suspension

procedures. Be sure to follow the instructions in each instruction manual. Otherwise, intended performance may not be achieved, or accidents or injury may result.

Do not operate the converter for a long time with its door left open.

Otherwise, dust, foreign matter, etc. may stick on internal walls, thereby causing failure.

PROHIBITION

CAUTION

CAUTION

wise, failure, electric shock or injury may result.

Caution on maintenance and inspection

Before maintenance and check, be sure to turn off the main power

supply and wait until the detector is cooled adequately. Otherwise,

you may suffer a burn.

Before removing the detector from the flue for maintenance and

check, make sure the furnace is stopped. Otherwise, you may suffer a

burn.

Before working, take off a wrist watch, finger ring or the like metallic

accessories. And never touch the instrument with a wet hand. Otherwise, you will have electric shocks.

If the fuse is blown, eliminate the cause, and then replace it with the

one of the same capacity and type as before. Otherwise, it may cause

electric shocks or failure.

Others

If the cause of a failure cannot be identified by referring to the instruc-

tion manual, be sure to contact your dealer or Fuji’s technician in

charge of adjustment. Disassembling the instrument carelessly may

result in electric shock or injury.

Do not use a replacement part other than specified by the instrument

maker. Otherwise, adequate performance will not be provided. Besides, an accident or failure may be caused.

Replacement parts such as a maintenance part should be disposed of

as incombustibles.

Do not touch the input/output terminals with metal or finger. Other-

INZ-TN2ZKMA-E

- iii -

Page 5

WARRANTY AND MAINTENANCE

1. Scope of application

To use this equipment, the following conditions must be met:

the use of the equipment incurs no risk of a serious accident even if a failure or malfunction occurs on the

equipment, and

in case of product failure or malfunction, safety measures such as redundant design, prevention of mal-

function, fail safe system, foolproof mechanism are provided outside of the equipment.

Be sure to use this instrument under the conditions or environment mentioned in this instruction manual.

Please consult us for specifications for the following applications:

Radiation-related facilities, systems related to charging or settlement, or other usages which

may have large impact on lives, bodies, property, or other rights or interests.

2. Operating conditions and environment

Refer to “Caution on Safety”.

3. Precautions and prohibitions

Refer to “Caution on Safety”.

4. Warranty

4-1. Period of warranty

1) Warranty period for this product including accessories is one year after delivery.

2) Warranty period for the parts repaired by our service providers is six months after the completion of repair.

4-2. Scope of warranty

1) If any failure or malfunction attributable to Fuji Electric occurs in the period of warranty, we shall pro-

vide the product after repairing or replacing the faulty part for free of charge at the place of purchase or

delivery.

The warranty does not apply to failure or malfunctions resulting from:

a) inappropriate conditions, environment, handling or usage that is not instructed in a catalog, instruction

book or user's manual, or overuse of the product

b) other devices not manufactured by Fuji Electric

c) improper use, or an alteration or repair that is not performed by Fuji Electric

d) inappropriate maintenance or replacement of expendable parts listed in the instruction book or the

catalog

e) damages incurred during transportation or fall after purchase

f) any reason that Fuji Electric is not responsible for, including a disaster or natural disaster such as

earthquake, thunder, storm and flood damage, or inevitable accident such as abnormal voltage.

- iv -

INZ-TN2ZKMA-E

Page 6

2) Regardless of the time period of the occurrence, Fuji Electric is not liable for the damage caused by the

factors Fuji Electric is not responsible for, opportunity loss of the purchaser caused by malfunction of Fu-

ji Electric product, passive damages, damage caused due to special situations regardless of whether it was

foreseeable or not, and secondary damage, accident compensation, damage to products that were not

manufactured by Fuji Electric, and compensation towards other operations.

5. Failure diagnosis

Regardless of the time period of the occurrence, if any failure occurs, the purchaser shall perform a primary

failure diagnosis. However, at the purchaser's request, Fuji Electric shall provide the diagnosis service for a

fee. In such a case, the purchaser shall be charged for the service.

6. Service life

This product, excluding limited-life parts and consumable parts, is designed for a service life of 10 years un-

der a general condition (average ambient temperature of 30°C).

The service life may be shortened depending on operating conditions and environment. To ensure the service

life, it is important to perform planned maintenance of the product including limited-life parts and consuma-

ble parts.

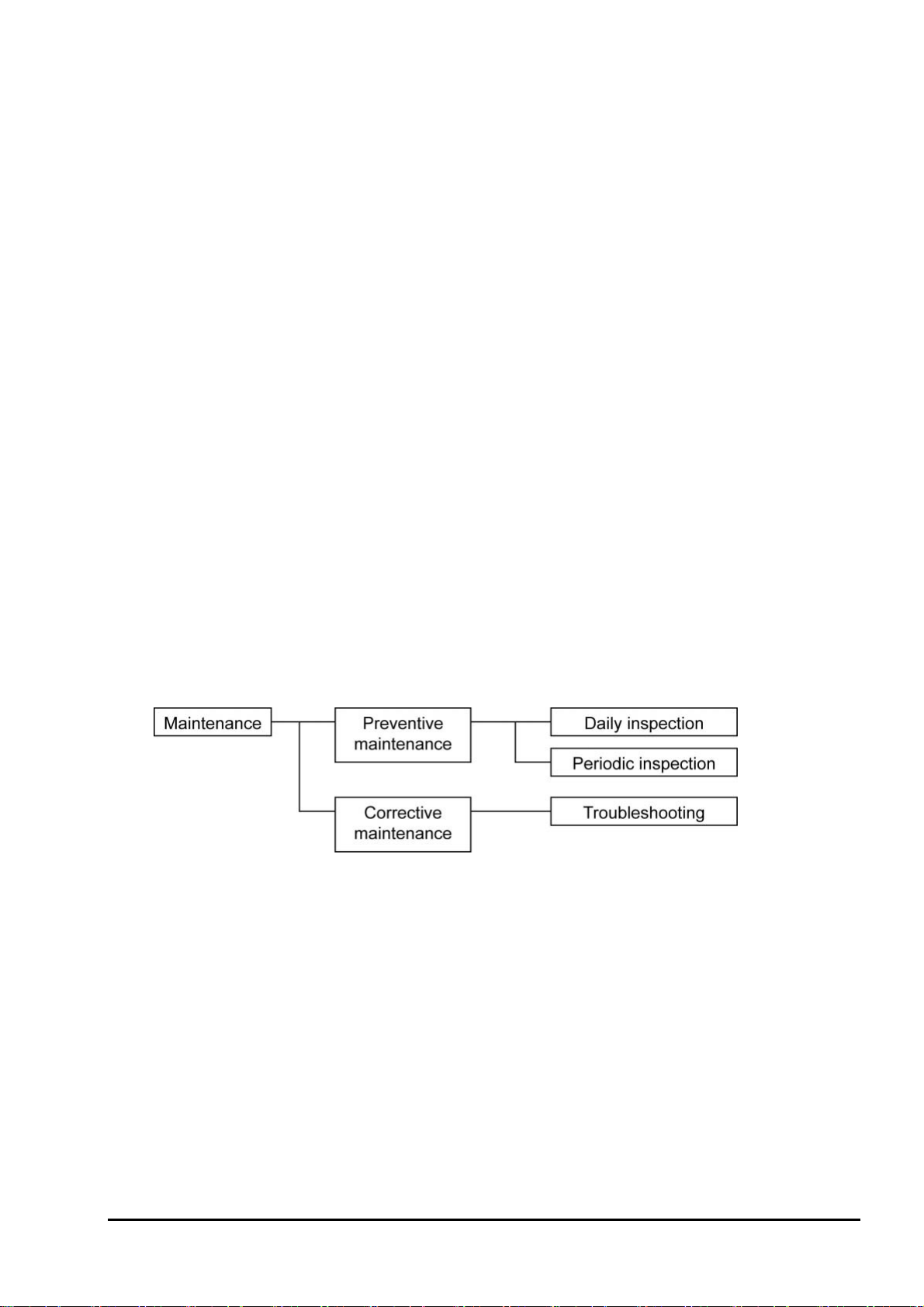

7. Maintenance plan

Maintenance can be divided into “preventive maintenance” and “corrective maintenance”. Preventive

maintenance can further classified into “daily inspection” and “periodic inspection”. Preventive maintenance

is achieved through systematic implementation of "daily inspection" and "periodic inspection".

(1) Daily inspection

Be sure to perform daily inspection prior to operation to check for any problem in daily operation. For the

specific items of daily inspection, refer to Chapter 9, “MAINTENANCE AND CHECK”.

(2) Periodic inspection

Periodic inspection is to replace limited-life parts before their service lives are over, thus preventing failure.

Inspection interval: 6 months to 12 months. If you are using the instrument under harsh environment, we

recommend you to shorten the inspection interval. For the specific items of periodic inspection, refer to

Chapter 9, “MAINTENANCE AND CHECK”.

(3) Corrective maintenance

Corrective maintenance is a measure to be taken after a trouble has occurred. Refer to 9.5 “Troubleshooting”.

If the measures mentioned in this instruction manual do not solve the problem, please contact our sales office

or service office.

INZ-TN2ZKMA-E

- v -

Page 7

8. Limited-life parts and consumable parts

This product contains the following limited-life parts and consumable parts which may affect the service life

of the product itself.

(1) LCD

Design life: approx. five years for continuous use

Symptoms of LCD screen's end-of-life: deterioration of display, backlight failure, etc.

Factors which affect LCD's life: temperature. The life is shortened by half when the temperature rises

by 10°C. (Arrhenius' law)

Replacement: Estimate the lifetime of LCD according to your operating environment, and have the

LCD replaced at appropriate time.

(2) Aluminum electrolytic capacitors

Design life: 5 years under general working conditions (annual average of ambient temperature: 30°C)

Symptoms when a capacitor loses its capacity: deterioration of power quality, malfunction

Factors which affect capacitor life: temperature. The life is shortened by half when the temperature

rises by 10°C. (Arrhenius' law)

Replacement: Estimate the lifetime of capacitor according to your operating environment, and have

the capacitor replaced or overhauled at appropriate time, at least once in 10 years.

Do not use capacitors beyond its lifetime. Otherwise, electrolyte leakage or depletion may cause odor, smoke,

or fire. Please contact Fuji Electric or its service providers when an overhaul is required.

9. Spare parts and accessories

Refer to “Checking of contents of the package” or Chapter 9, “MAINTENANCE AND CHECK” for details.

10. Period for repair and provision of spare parts after product discontinuation (maintenance period)

The discontinued models (products) can be repaired for five years from the date of discontinuation. Also,

most spare parts used for repair are provided for five years from the date of discontinuation. However, some

electric parts may not be obtained due to their short life cycle. In this case, repair or provision of spare parts

may be difficult even in the above period.

Please contact Fuji Electric or its service providers for further information.

- vi -

INZ-TN2ZKMA-E

Page 8

Contents

PREFACE ..........................................................................................................................................................i

SAFETY PRECAUTIONS ............................................................................................................................. ii

WARRANTY AND MAINTENANCE ...........................................................................................................iv

CHECKING OF CONTENTS OF THE PACKAGE .................................................................................... x

STORAGE CONDITIONS .............................................................................................................................. x

1. GENERAL .................................................................................................................................................... 1

1.1 Direct insertion type zirconia oxygen analyzer ........................................................................................ 1

2. OPERATING PARTS AND THEIR FUNCTIONS ................................................................................... 2

2.1 Outline Drawing ....................................................................................................................................... 2

2.2 Terminal block .......................................................................................................................................... 3

2.3 Didplay and operation panel ..................................................................................................................... 3

2.4 Internal constitution .................................................................................................................................. 4

3. INSTALLATION .......................................................................................................................................... 5

3.1 Installation site .......................................................................................................................................... 5

3.2 How to install the converter ...................................................................................................................... 6

3.2.1 Mounting on panel (ZKMA) ............................................................................................................. 6

3.2.2 Pipe mounting (ZKMA) ..................................................................................................................... 6

3.2.3 Mounting on panel (ZKMB) ............................................................................................................. 7

3.2.4 Pipe mounting (ZKMB) .................................................................................................................... 7

4. WIRING AND PIPING ................................................................................................................................ 8

4.1 Before wiring ............................................................................................................................................ 8

4.2 Wiring to terminals ................................................................................................................................... 9

4.2.1 Wiring to power supply and detector ................................................................................................. 9

4.2.2 Cable gland and input and output lines ............................................................................................ 10

4.2.3 Allocation of the terminal block ....................................................................................................... 11

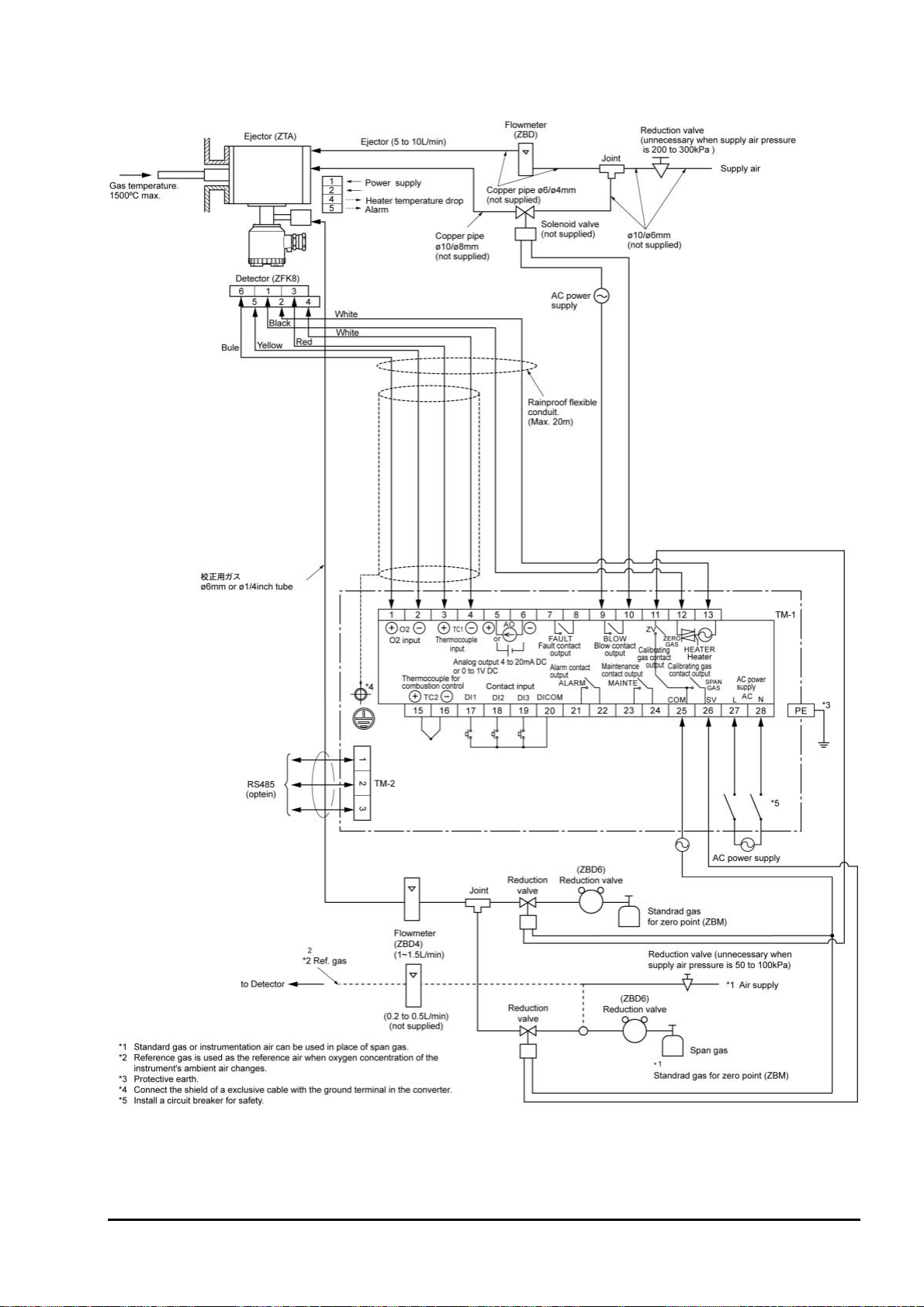

4.3 Wiring and piping diagram ..................................................................................................................... 12

4.4 Handling of standard gas (An article on separate order) ........................................................................ 16

5. OPERATION .............................................................................................................................................. 17

5.1 Preparation for operation ........................................................................................................................ 17

5.2 Key operation flow diagram (outline) .................................................................................................... 19

5.3 Initial parameter value table ................................................................................................................... 23

5.3.1 Parameters related to measurement .................................................................................................. 23

5.3.2 Parameters related to calibration ...................................................................................................... 23

5.3.3 Parameters related to blowdown (displayed if the option is provided) ............................................ 24

5.3.4 Parameters related to maintenance ................................................................................................... 24

5.3.5 Other parameters .............................................................................................................................. 25

6. OPERATION START AND STOP .......................................................................................................... 27

6.1 Operation start ........................................................................................................................................ 27

6.2 Operation stop ......................................................................................................................................... 27

6.3 Actions during operation ......................................................................................................................... 28

6.4 Check the contents of display ................................................................................................................. 29

6.4.1 Check of state information ............................................................................................................... 29

6.4.2 Checking the error information ........................................................................................................ 30

6.4.3 Checking the alarm information ....................................................................................................... 30

6.5 Oxygen detector standard output voltage ............................................................................................... 31

INZ-TN2ZKMA-E

- vii -

Page 9

7. CALIBRATION ......................................................................................................................................... 32

7.1 Preparation ............................................................................................................................................. 32

7.2 Manual calibration ................................................................................................................................. 33

7.3 Auto calibration (option) ........................................................................................................................ 35

7.4 Remote calibration ................................................................................................................................. 37

7.5 All calibration (option) ........................................................................................................................... 39

8. BLOWDOWN (OPTION)......................................................................................................................... 40

8.1 Preparation for blowdown ...................................................................................................................... 40

8.2 Manual blowdown.................................................................................................................................. 40

8.3 Automatic blowdown ............................................................................................................................. 41

8.4 Remote blowdown ................................................................................................................................. 43

9. MAINTENANCE AND CHECK .............................................................................................................. 45

9.1 Checking ................................................................................................................................................ 45

9.2 Spare parts .............................................................................................................................................. 45

9.3 Replacement of fuse ............................................................................................................................... 46

9.4 Adjustment of monitor contrast .............................................................................................................. 47

9.5 Troubleshooting ..................................................................................................................................... 48

10. SETTING AND OPERATING OF PARAMETER ............................................................................... 50

10.1 Measured menu .................................................................................................................................... 50

10.1.1 Display range setting screen .......................................................................................................... 50

10.1.2 Decimal point position setting screen ............................................................................................ 51

10.1.3 Full scale setting screen ................................................................................................................. 52

10.1.4 Setting screen for calculation time of maximum and minimum values appears ........................... 53

10.2 Calibration menu .................................................................................................................................. 54

10.2.1 Automatic calibration setting (option) ........................................................................................... 54

10.2.2 Date and time for starting automatic calibration (option) ............................................................. 55

10.2.3 Cycle time setting of automatic calibration (option) ..................................................................... 56

10.2.4 Performing all calibration (option) ................................................................................................ 57

10.2.5 Performing a manual span calibration ........................................................................................... 58

10.2.6 Performing a manual zero calibration ........................................................................................... 59

10.2.7 Calibration gas setting ................................................................................................................... 60

10.2.8 Calibration waiting setting (option) ............................................................................................... 61

10.2.9 Calibration error clear ................................................................................................................... 62

10.2.10 Operation setting screen of calibration range .............................................................................. 63

10.3 Blowdown menu (option) .................................................................................................................... 64

10.3.1 Automatic blowdown setting ......................................................................................................... 64

10.3.2 Date and time setting of automatic blowdown .............................................................................. 65

10.3.3 Automatic blowdown cycle setting ............................................................................................... 66

10.3.4 Procedure for setting blowdown time ............................................................................................ 67

10.3.5 Perfoming manual blowdown ........................................................................................................ 68

10.4 Maintenance menu ............................................................................................................................... 69

10.4.1 Error log display ............................................................................................................................ 69

10.4.2 Clearing error logs ......................................................................................................................... 71

10.4.3 Alarm log display .......................................................................................................................... 72

10.4.4 Clearing alarm logs ....................................................................................................................... 73

10.4.5 Performing a manual sensor check ................................................................................................ 74

10.4.6 Maintenance mode setting ............................................................................................................ 75

10.4.7 Password setting ............................................................................................................................ 76

10.4.8 PID auto tuning ............................................................................................................................. 77

10.5 Parameter menu ................................................................................................................................... 78

10.5.1 Current date and time setting ......................................................................................................... 78

10.5.2 Contact input setting ...................................................................................................................... 79

10.5.3 Selection of alarm contact output .................................................................................................. 80

10.5.4 High limit setting of oxygen concentration ................................................................................... 81

- viii -

INZ-TN2ZKMA-E

Page 10

10.5.5 Lower limit setting of oxygen concentration ................................................................................. 82

10.5.6 HH limit setting of oxygen concentration ...................................................................................... 83

10.5.7 LL limit setting of oxygen concentration ....................................................................................... 84

10.5.8 Hysteresis Setting ........................................................................................................................... 85

10.5.9 Hold treatment setting (maintenance hold) ................................................................................... 87

10.5.10 Hold value setting (maintenance hold) ........................................................................................ 88

10.5.11 Setting of hold setting value (maintenance hold) ........................................................................ 89

10.5.12 Setting of measurement recovery time (maintenance hold) ........................................................ 90

10.5.13 Hold treatment setting (error hold).............................................................................................. 91

10.5.14 Hold value setting (error hold) ..................................................................................................... 92

10.5.15 Setting of hold setting value (error hold) .................................................................................... 93

10.5.16 Setting of key lock ....................................................................................................................... 94

10.5.17 Setting of automatic OFF time ..................................................................................................... 95

10.5.18 Station number setting .................................................................................................................. 96

10.5.19 Adjustment screen for analog output 0% ..................................................................................... 97

10.5.20 Adjustment screen for analog output 100% ................................................................................. 98

10.5.21 Fuel coefficient setting (option) ................................................................................................... 99

10.6 Factory menu ...................................................................................................................................... 100

10.6.1 Password setting screen ................................................................................................................ 100

11. SPECIFICATIONS ................................................................................................................................ 101

11.1 Specifications ...................................................................................................................................... 101

11.2 Code symbols ...................................................................................................................................... 104

INZ-TN2ZKMA-E

- ix -

Page 11

CHECKING OF CONTENTS OF THE PACKAGE

Check that all of the following are contained in the delivered package.

(1) Zirconia Oxygen Analyzer Converter main unit 1 unit

(2) Accessories 1 set (Refer to the table below.)

Table 1 Standard accessories

No. Item Q'ty Remarks

1 Fuse 2 250 V T 2.5 A

2 Ferrite core 1 For power cable

3 Instruction manual 1

Instruction manual (RS485

4

communication or HART

communication)

5 Mounting bracket 1 set

Japanse, English, or Chinese (depends on the specification)

When you specified RS485 communication or HART

1

communication.

Language: Japanse, English, or Chinese (as specified)

For panel mount version: M8 sems screw (stainless

steel), 4 pcs

For pipe mount version: U bolt (stainless steel ), 2 pcs

: M8 nut, washer (stainless steel) 4 pcs

: support 2 pcs

STORAGE CONDITIONS

Store the unit in a location that meets the following conditions:

(1) Vibration, dust, dirt, and humidity are minimal.

(2) A place not subjected to radiated heat from a heating furnace, etc.

(3) The atmosphere is non-corrosive.

(4) The ambient temperature is within the range from -30°C through 70°C (no condenstaion) and the

ambient humidity is 95%RH or lower.

- x -

INZ-TN2ZKMA-E

Page 12

1. GENERAL

This manual describes the installation, operation, and the maintenance of the zirconia oxygen analyzer converter. Read it carefully before using the converter. For the detector, flow guide tube and ejector used with

the converter, refer to relevant instruction manuals.

1.1 Direct insertion type zirconia oxygen analyzer

The direct insertion type zirconia oxygen analyzer consists of a direct insertion type zirconia detector (type

ZFK) and converter (type ZKM).

The analyzer intended for the measurement of oxygen concentration in exhaust gas is used for combustion

control.

Caution

Power voltage for the converter must conform to that for the detector to be connected. Don’t use any

power voltage different from the power specifications of the detector. Otherwise it may result in damage

to the detector.

100/120V AC50/60Hz for ZFK8R1

200/240V AC50/60Hz for ZFK8R3

Operating environment

1) Operating temperature: -20 to 55°C

2) Operating humidity: 95%RH or less, non condensing

3) Power voltage: 100 to 120V AC 50/60Hz or 200 to 240V AC 50/60Hz

4) Pollution degree: 2

5) Installation category: II

6) Altitude: up to 2000m

INZ-TN2ZKMA-E

- 1 -

Page 13

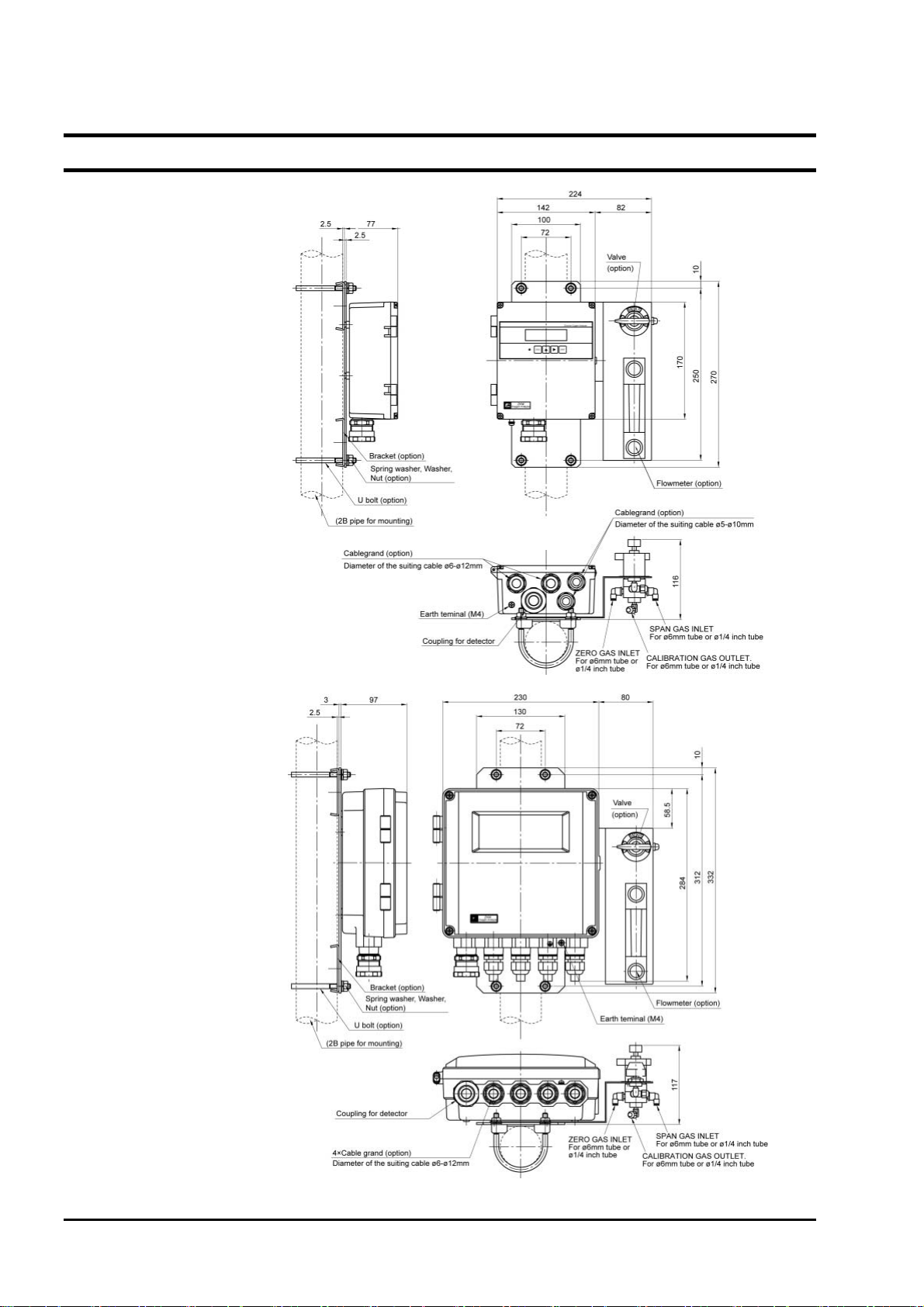

2. OPERATING PARTS AND THEIR FUNCTIONS

2.1 Outline Drawing

(1) ZKMA

(2) ZKMB

- 2 -

INZ-TN2ZKMA-E

Page 14

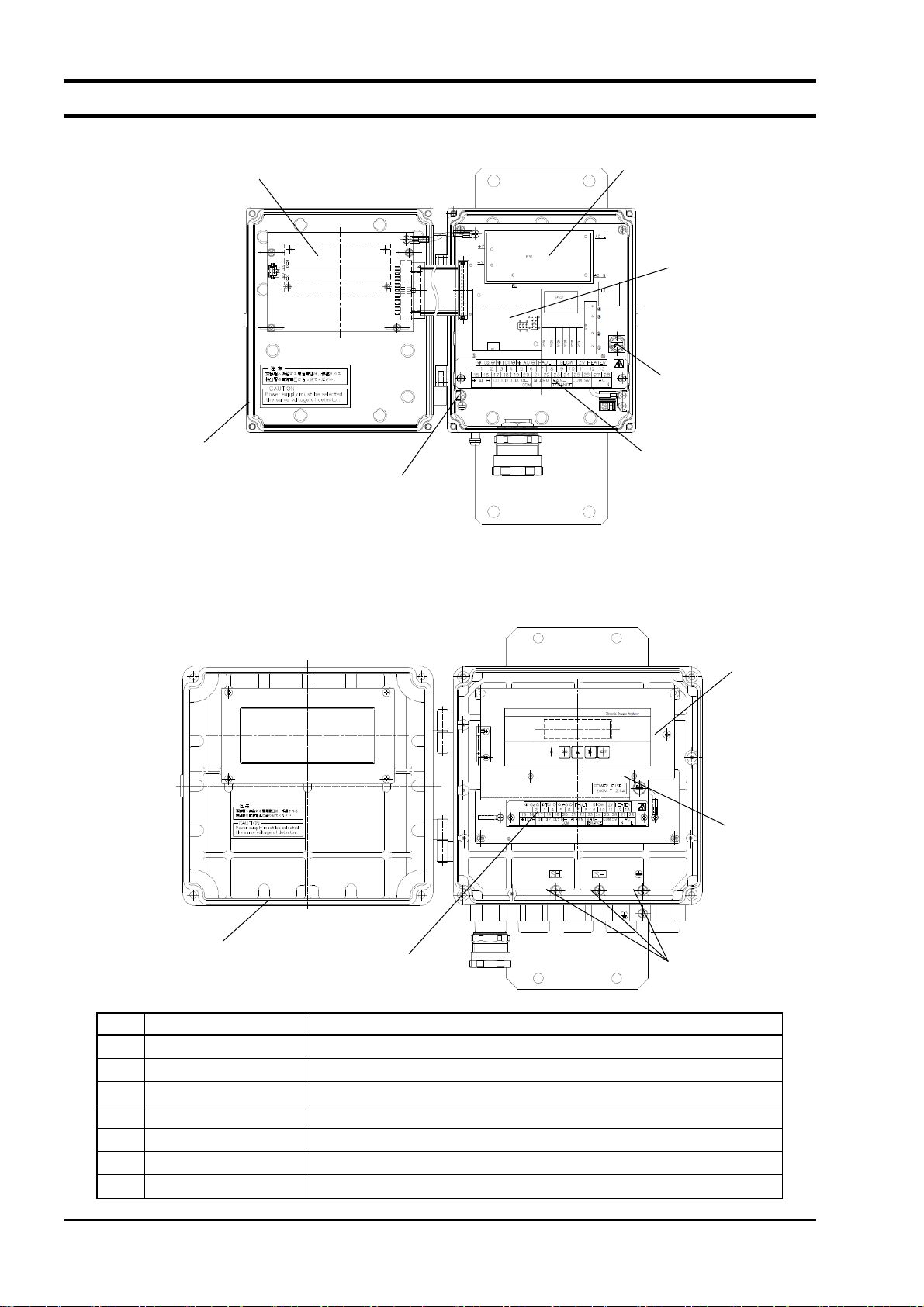

2.2 Terminal block

2.3 Didplay and operation panel

LED

①

ESC key

⑥

⑤

Digit key

No. Name Description

Display unit

①

LED Lights during power supply.

②

ESC key Used to return to the previous screen or exit the setting.

③

Digit key

④

Up key

⑤

ENT key Used to determine the setting values or to start calibration or

⑥

Displays the concentration value and setting values.

Used to change the setting values.

other operations.

④

Display

①

Up key

ENT key

③

INZ-TN2ZKMA-E

- 3 -

Page 15

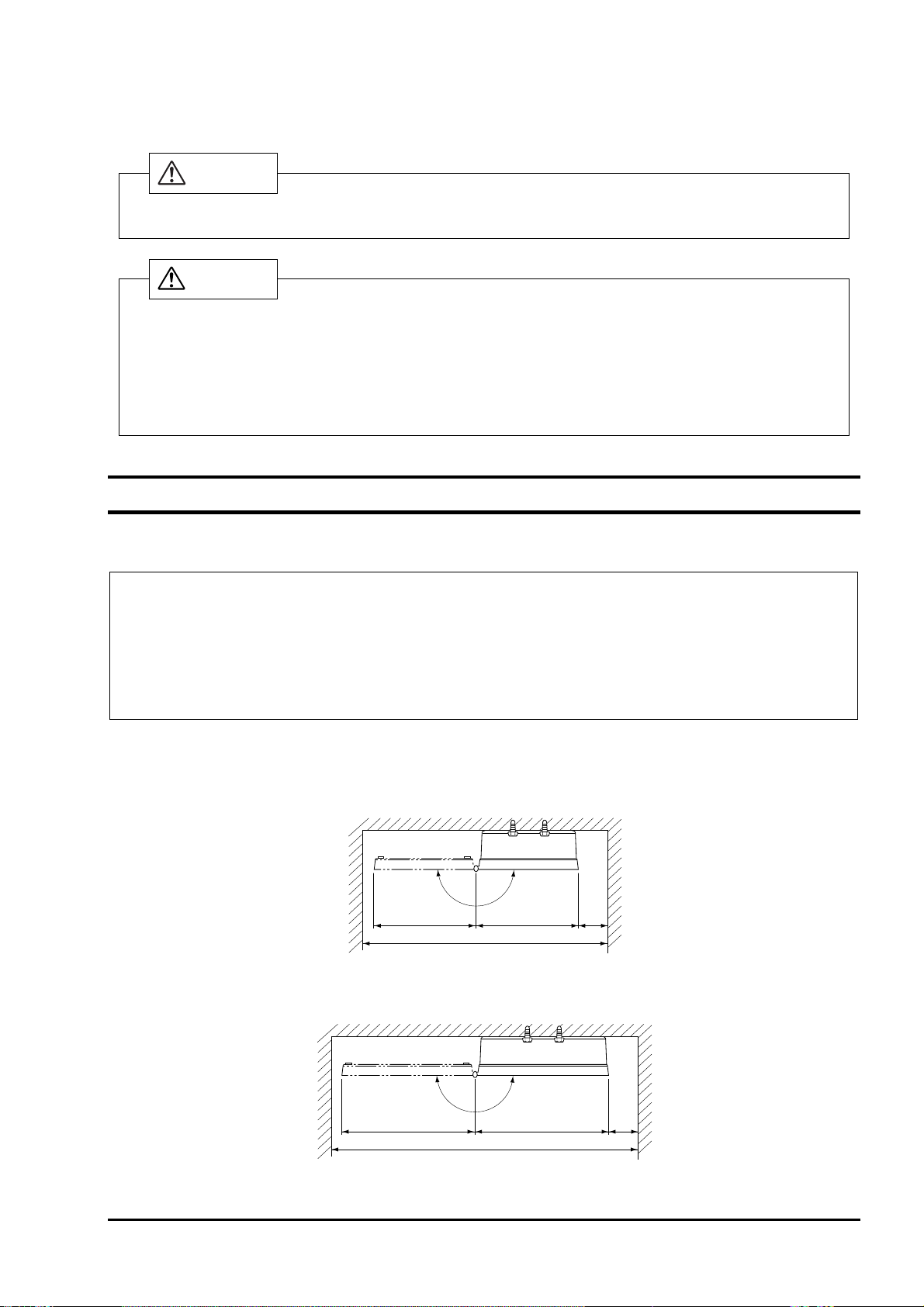

2.4 Internal constitution

(1) ZKMA

I/O board

CPU board

②

①

Communication

③

board (optional)

Fuse

⑦

Packing

④

Earth terminal

⑥

⑤

Terminal block

(2) ZKMB

You can see the CPU board, the I/O board, and the communication board (optional) if you remove the M3

screw and open the inner cover.

Packing

⑦

No. Name Description

CPU board The liquid crystal display and the memory circuit are installed.

①

I/O board The input/output circuit and the power circuit are installed.

②

Communication board RS485 communication board or HART communication board is installed.

③

Fuse Protects the CPU board and the I/O board from over-current.

④

Terminal block

⑤

Earth terminal Used as frame gland (FG).

⑥

Case packing Protects electrical components from water and dust.

⑦

Terminal block

⑤

Terminals for power cable, detector cable, and input/output cables.

Earth terminal

⑥

M3 screw

Fuse

④

- 4 -

INZ-TN2ZKMA-E

Page 16

3. INSTALLATION

DANGER

This unit is not explosion-proof type. Do not use it in an atmosphere of explosive gases. Otherwise

serious accidents such as explosion or fire may result.

For installation, observe the rule on it given in the instruction manual and select a place where the

weight of converter can be endured. Installation at an unsuited place may cause turnover or fall and

there is a risk of injury.

Before transport, fix the door so that it will not open. Otherwise, the casing may be separated and fall

to cause an injury.

During installation work, care should be taken to keep the unit free from entry of cable chips or other

foreign objects. Otherwise, it may cause fire, failure or malfunction.

CAUTION

3.1 Installation site

Install the converter in a place that satisfies the following conditions.

(1) Space for periodic inspection and wiring work is available.

(2) Vibration, dust, dirt, and humidity are minimal.

(3) A place not subjected to radiated heat from a heating furnace, etc.

(4) The atmosphere is non-corrosive.

(5) Away from electrical devices that may cause noise trouble (such as motor and transformer), and

equipment that may cause electromagnetic or electrostatic induction trouble.

(6) A place where ambient temperature and humidity are -20 to +55°C and 95%RH or less.

Secure at least 100 mm of space between the converter and nearby wall. Also secure a space of opening the

front cover for maintenance.

Secure a cable wiring space under the case.

E

P

O

400 or more

N

147147

100

or

more

Unit: mm

Top view of mounting (ZKMA)

INZ-TN2ZKMA-E

N

E

P

O

240

580 or more

240

Top view of mounting (ZKMB)

- 5 -

100

or

more

Unit: mm

Page 17

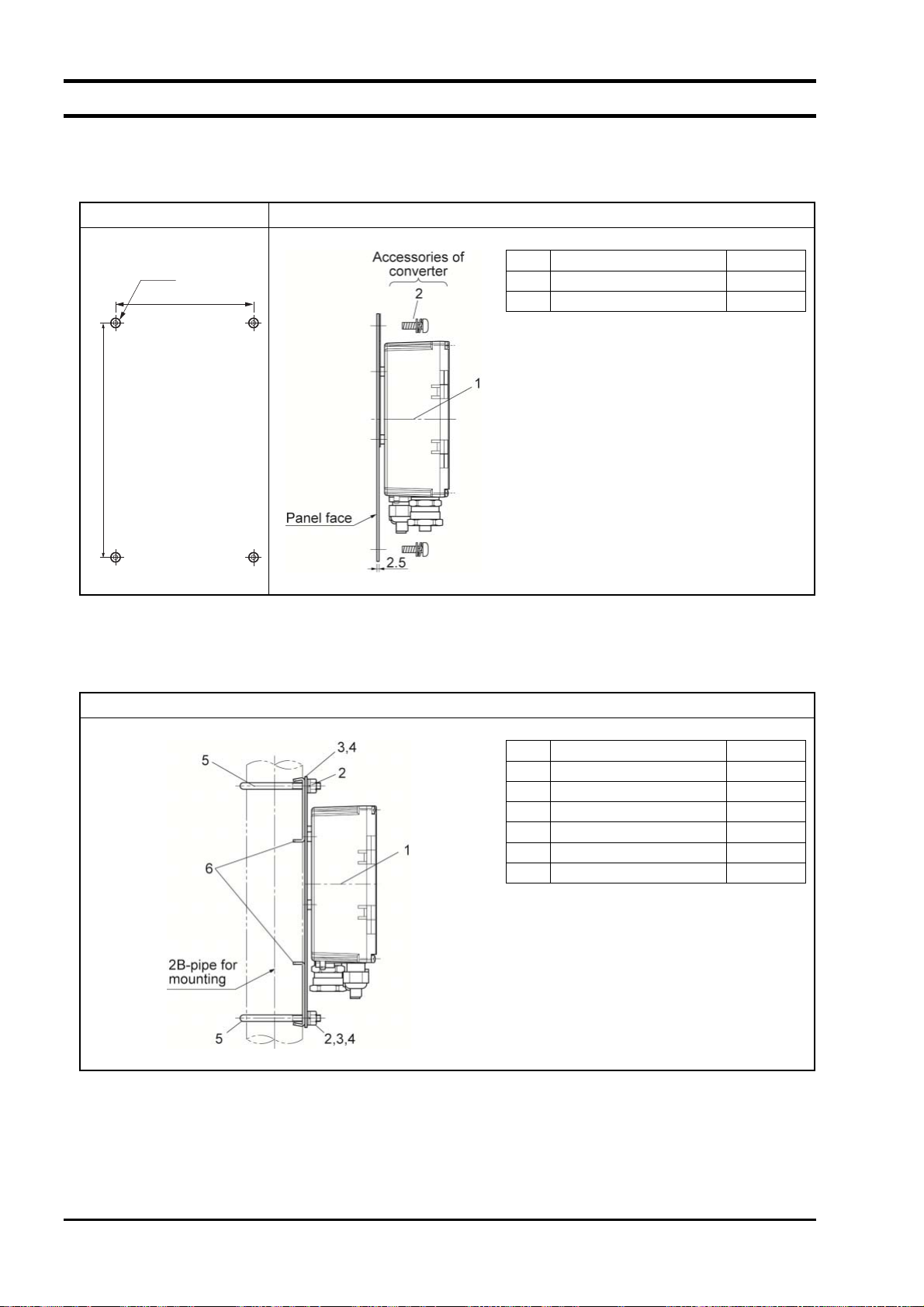

3.2 How to install the converter

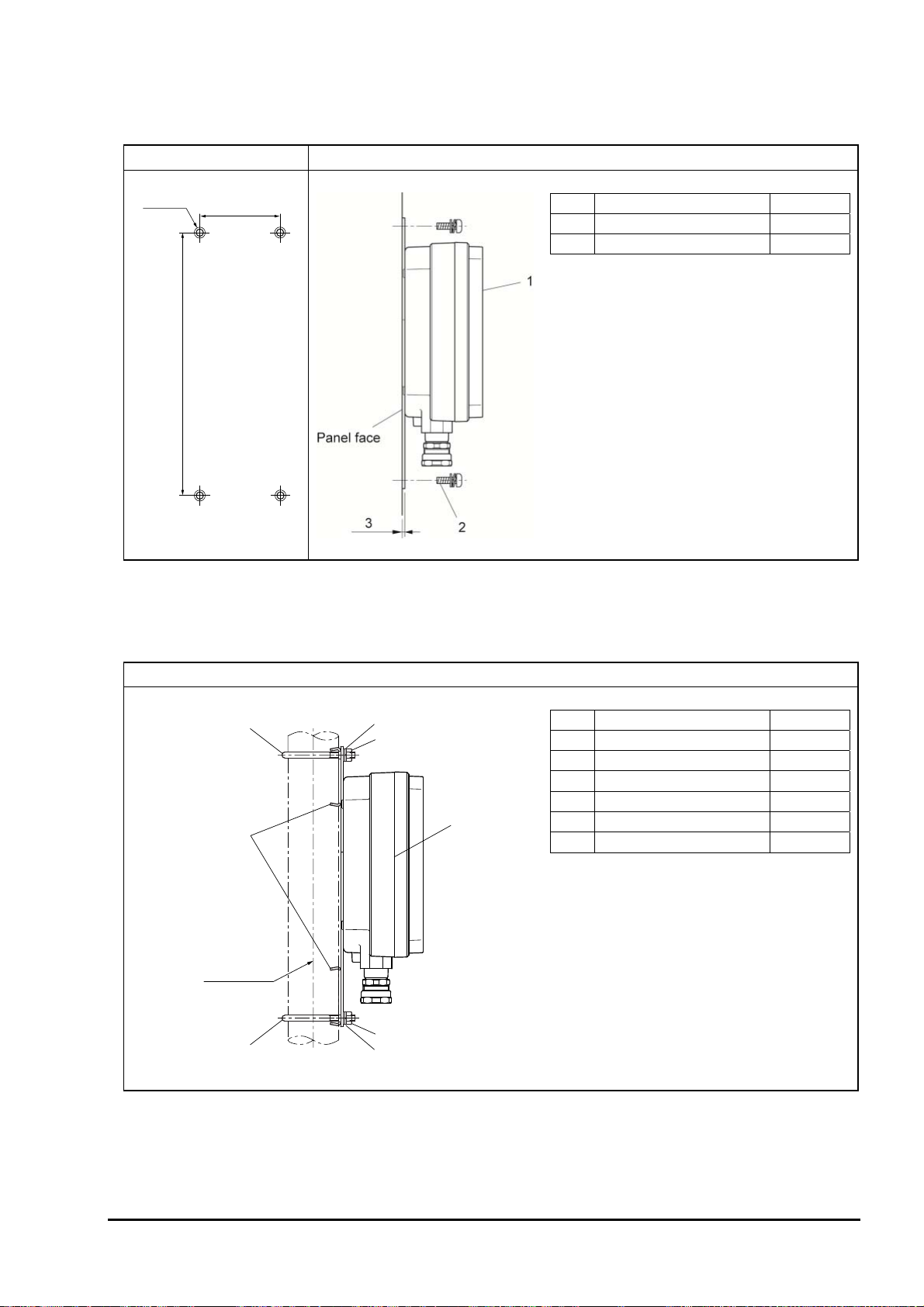

3.2.1 Mounting on panel (ZKMA)

Mounting dimensions Installation

4-M8

72

250

No. Name Quantity

Code Standard tightening torque

Unit: mm

1 Converter 1

2 Sems screw (M8×12) 4

M8

12.5 [N・m]

3.2.2 Pipe mounting (ZKMA)

Installation

No. Name Quantity

1 Converter 1

2 Hexagon nut (M8) 4

3 Spring washer (M8) 4

4 Plain washer (M8) 4

5 U bolt (M8) 2

6 Support panel 2

Code Standard tightening torque

M8

12.5 [N・m]

- 6 -

INZ-TN2ZKMA-E

Page 18

3.2.3 Mounting on panel (ZKMB)

Mounting dimensions Installation

No. Name Quantity

4-M8

72

Code Standard tightening torque

312

Unit: mm

1 Converter 1

2 Sems screw (M8×12) 4

M8

12.5 [N・m]

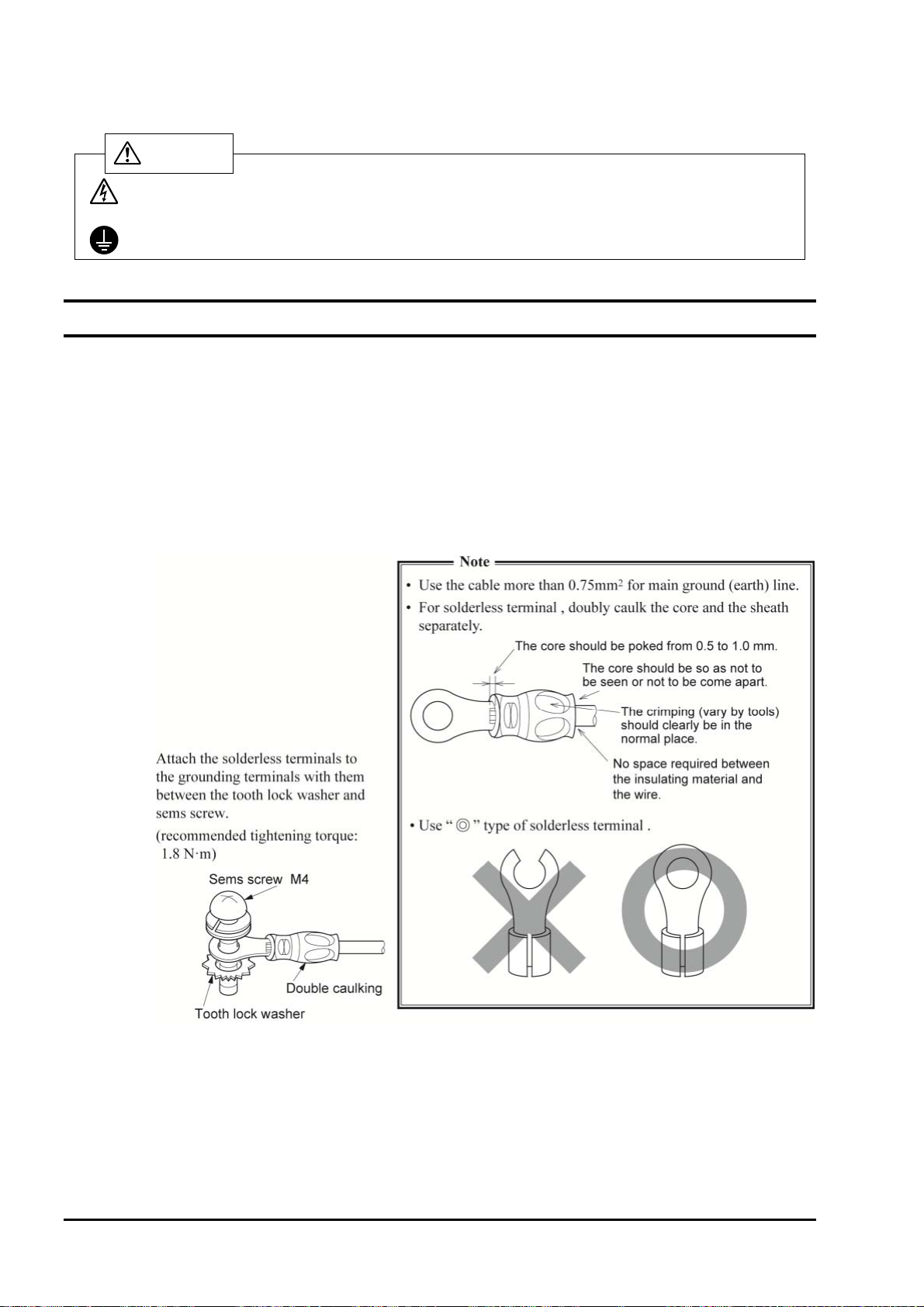

3.2.4 Pipe mounting (ZKMB)

5

6

Pipe for

mounting

5

3,4

2

2

3,4

Installation

1

No. Name Quantity

1 Converter 1

2 Hexagon nut (M8) 4

3 Spring washer (M8) 4

4 Plain washer (M8) 4

5 U bolt (M8) 2

6 Support panel 2

Code Standard tightening torque

M8

12.5 [N・m]

INZ-TN2ZKMA-E

- 7 -

Page 19

4. WIRING AND PIPING

: Wiring work must be carried out with all power supplies turned off. Otherwise electric

CAUTION

shock may result.

: Be sure to ground the Converter. (Class D grounding)

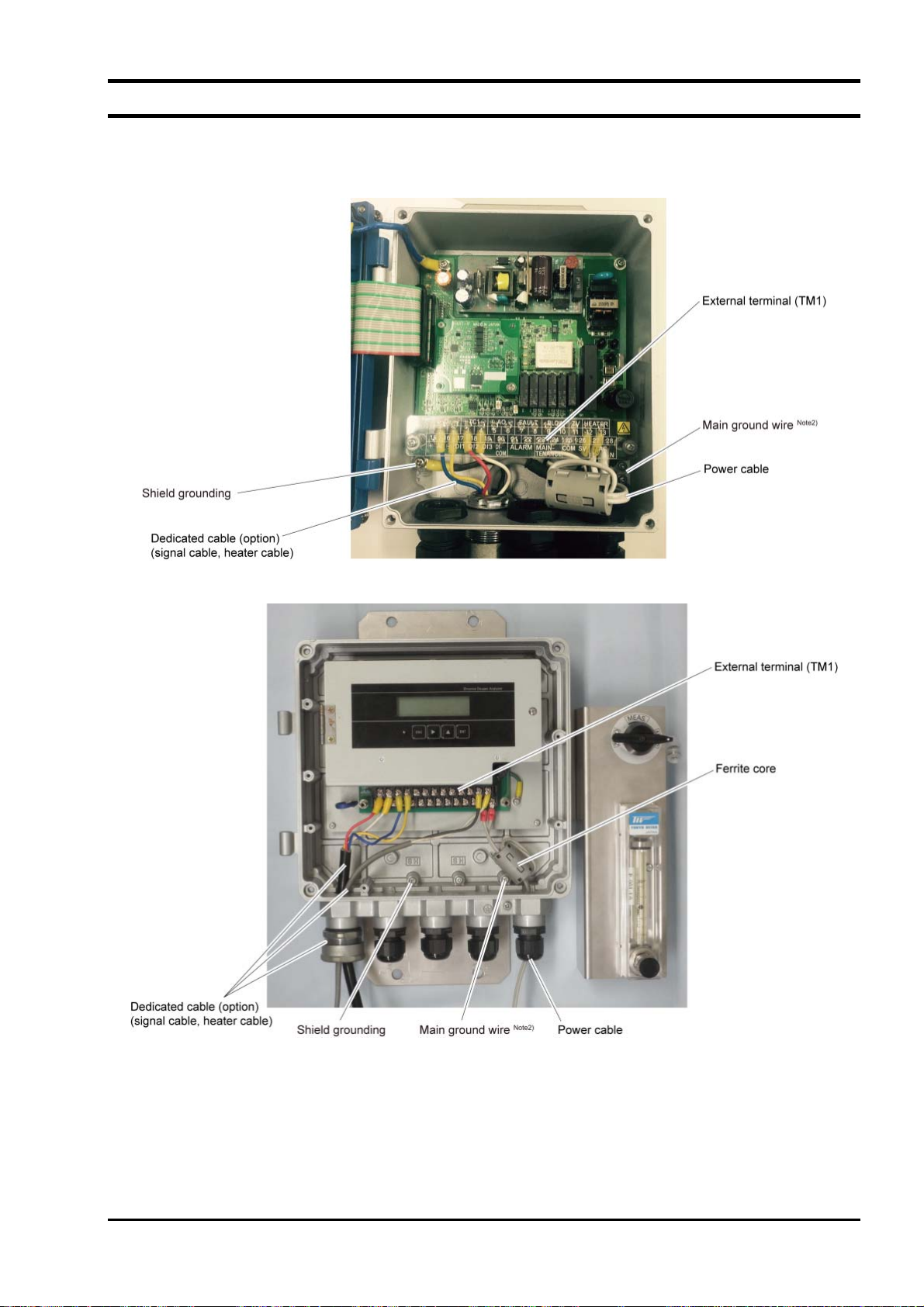

4.1 Before wiring

(1) Power voltage for the converter must conform to that for the detector to be connected.

(2) Power supply wiring

Use 1.25sq 600V vinyl insulated cable (JISC3307) or equivalent as power supply cable.

Use the main ground wire longer than the L1 and L2 lines.

Fix the part of the AC cable sheath that is more inner than the cord bushing by 3 mm or more.

Use a solderless terminal for the end of the AC cable. For the main ground wire, use the solderless

terminal whose core wire and sheath are caulked separately (double caulking).

Connect the ground wire to the following:

M4 screw / round terminal of the main ground wire / tooth lock washer / casing

(3) Provide adequate protection of the exclusive cable (6 cores in total), which connects the detector to

converter, using wire protection tube, etc. Separate these cables from the power cable (noise prevention).

(4) Keep the wire for output signals as far as possible (more than 30cm) from the power line and heavy

current lines to prevent induced noise. Also, wherever possible use a shielded cable and earth one

point of the shield.

Note) For connection of the lines to the external terminals, use of ring crimp solderless terminal

with insulation sleeve is recommended.

- 8 -

INZ-TN2ZKMA-E

Page 20

4.2 Wiring to terminals

4.2.1 Wiring to power supply and detector

(1) <ZKMA>

(2) <ZKMB>

Note 1: Fix the exclusive cable (O

that its sheath is 10 mm or less.

When attaching the nut, turn it by hand until it does not move and then tighten it with a spanner

by about 1/4 turn.

Note 2: Wire a protective earth to earth terminal of above figure. (Class D, grounding resistance: 100Ω

or less)

Note 3: Wind the power cable around the ferrite core twice.

INZ-TN2ZKMA-E

sensor input / O2 sensor thermocouple input) with the cable gland so

2

- 9 -

Page 21

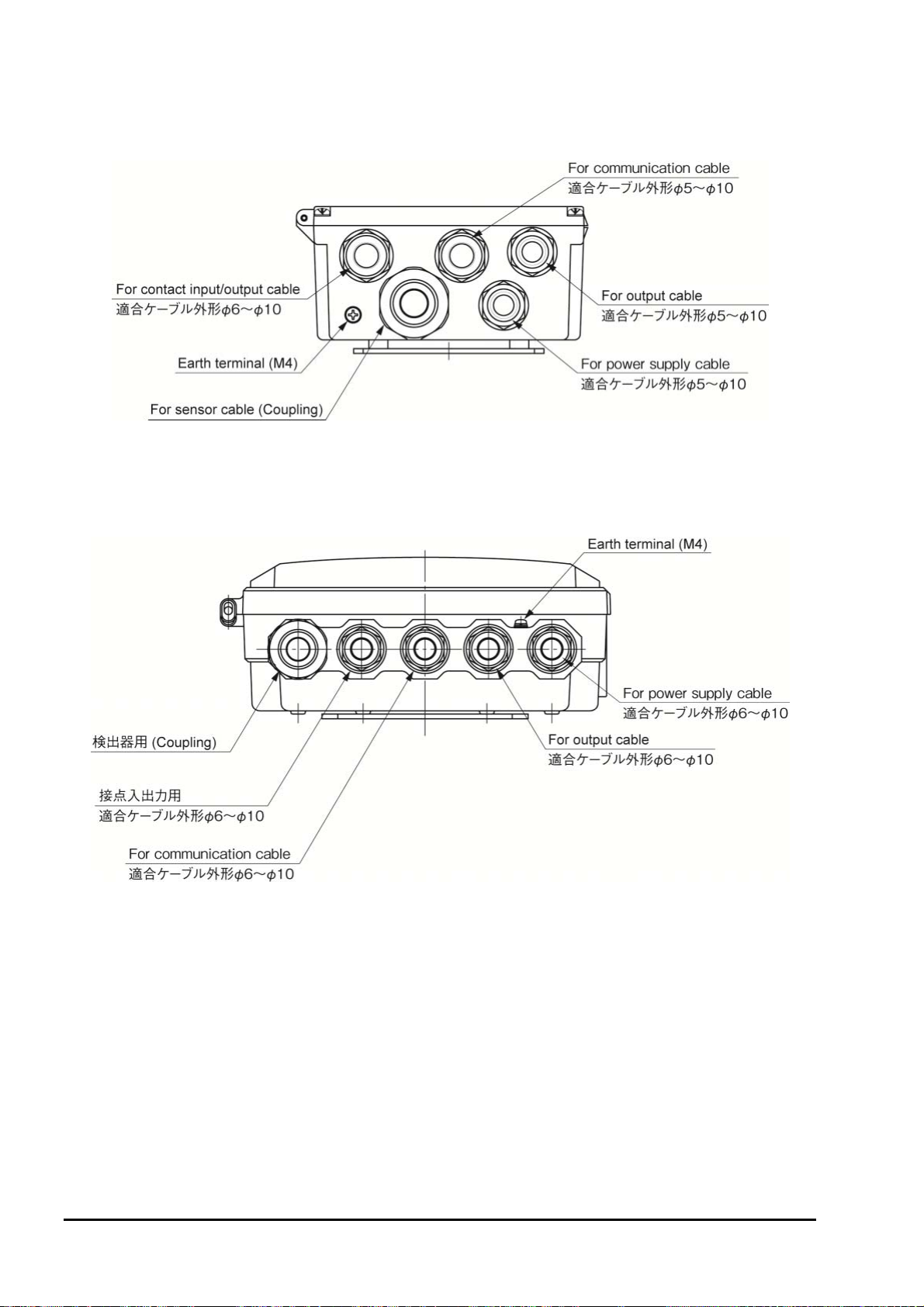

4.2.2 Cable gland and input and output lines

(1) <ZKMA>

(2) <ZKMB>

- 10 -

INZ-TN2ZKMA-E

Page 22

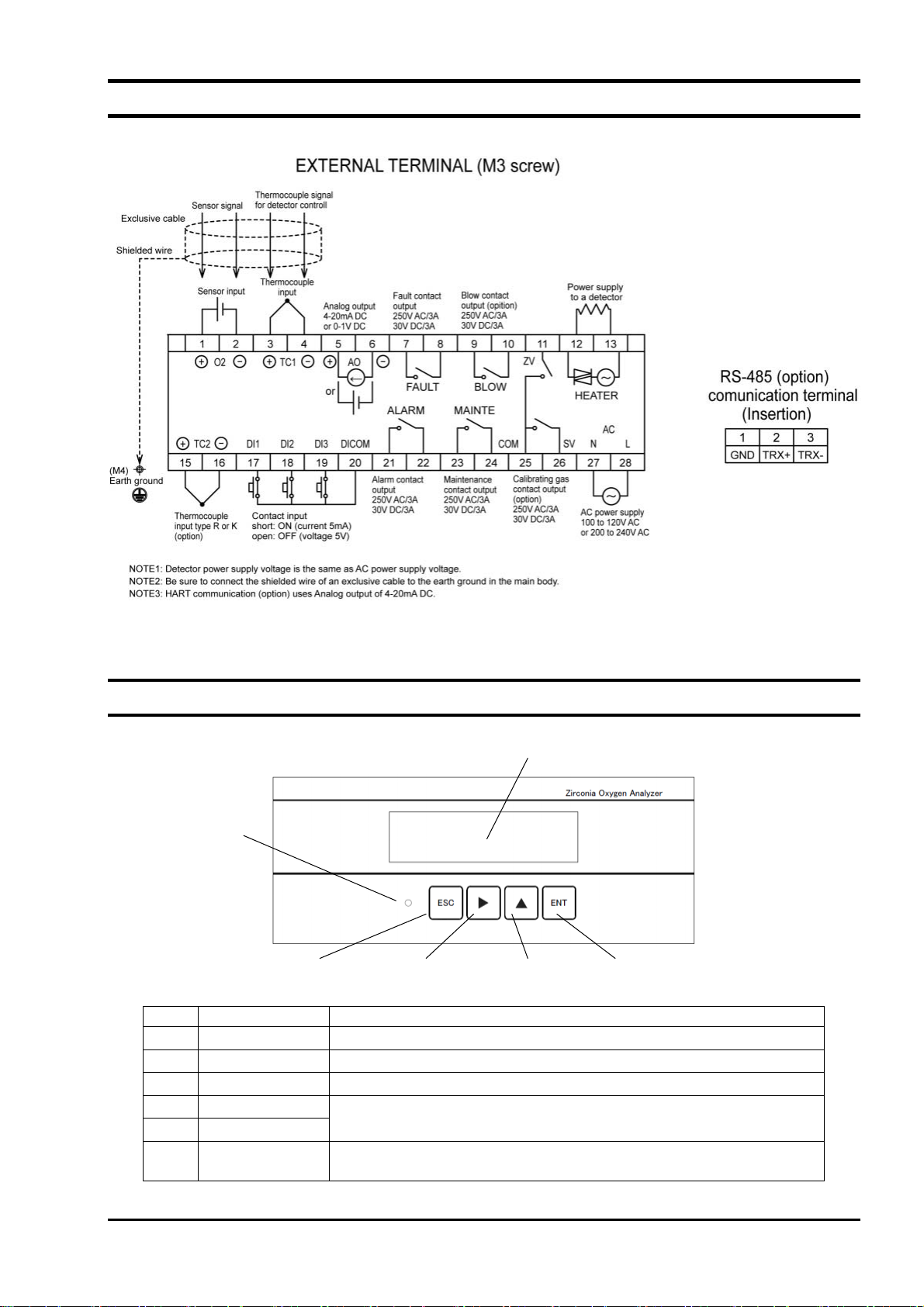

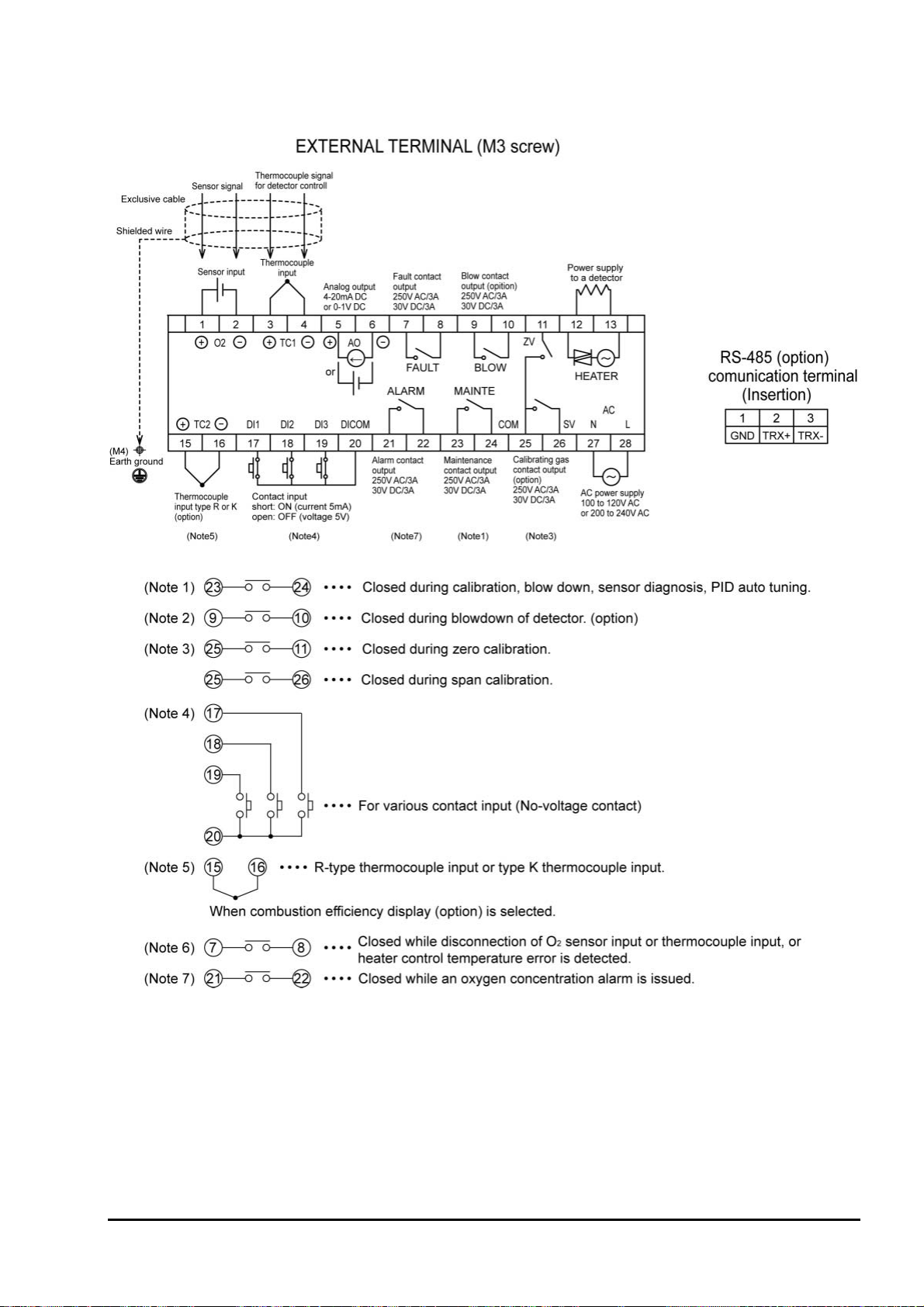

4.2.3 Allocation of the terminal block

INZ-TN2ZKMA-E

- 11 -

Page 23

4.3 Wiring and piping diagram

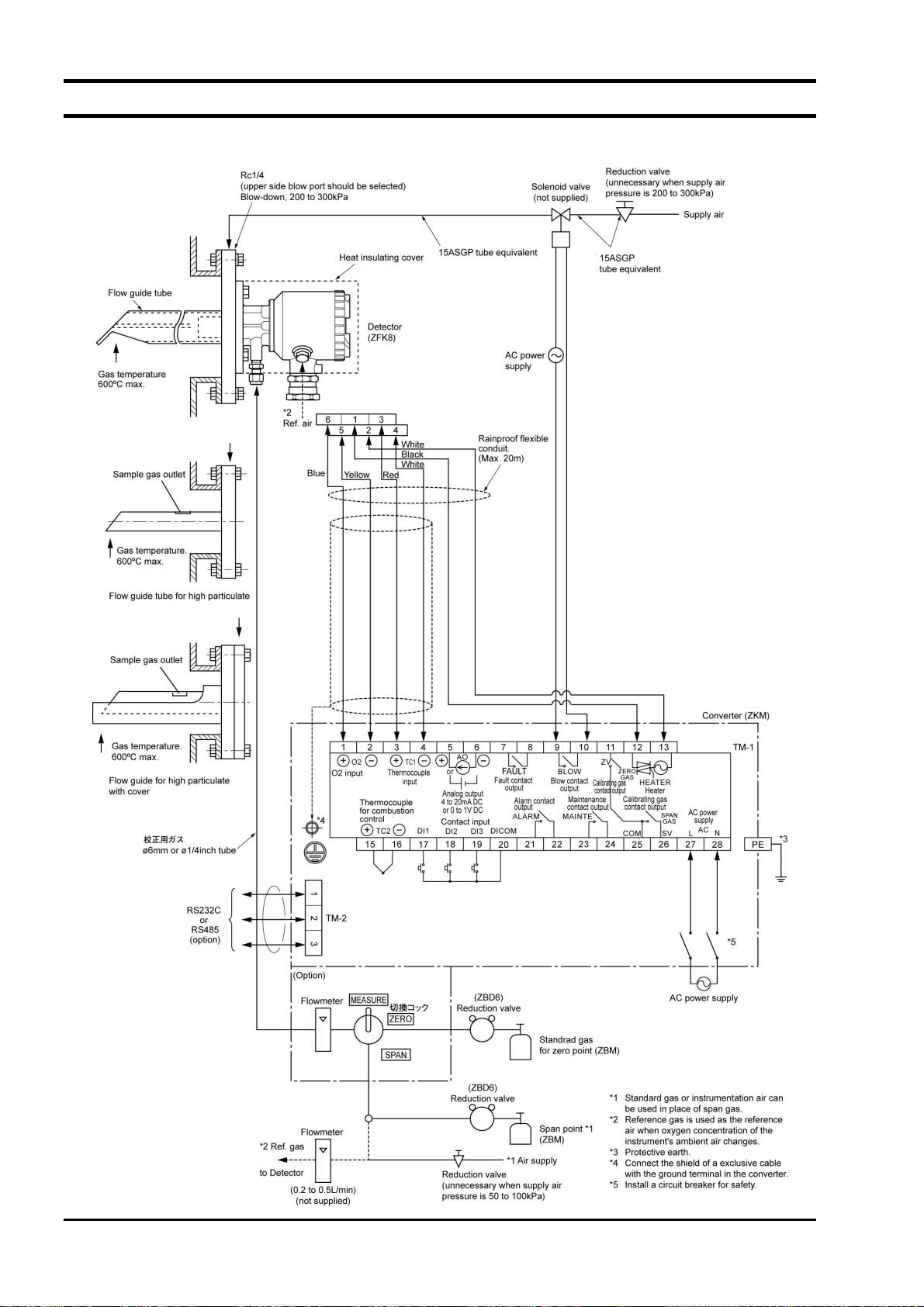

4.3.1.1 Flow guide tube system

- 12 -

INZ-TN2ZKMA-E

Page 24

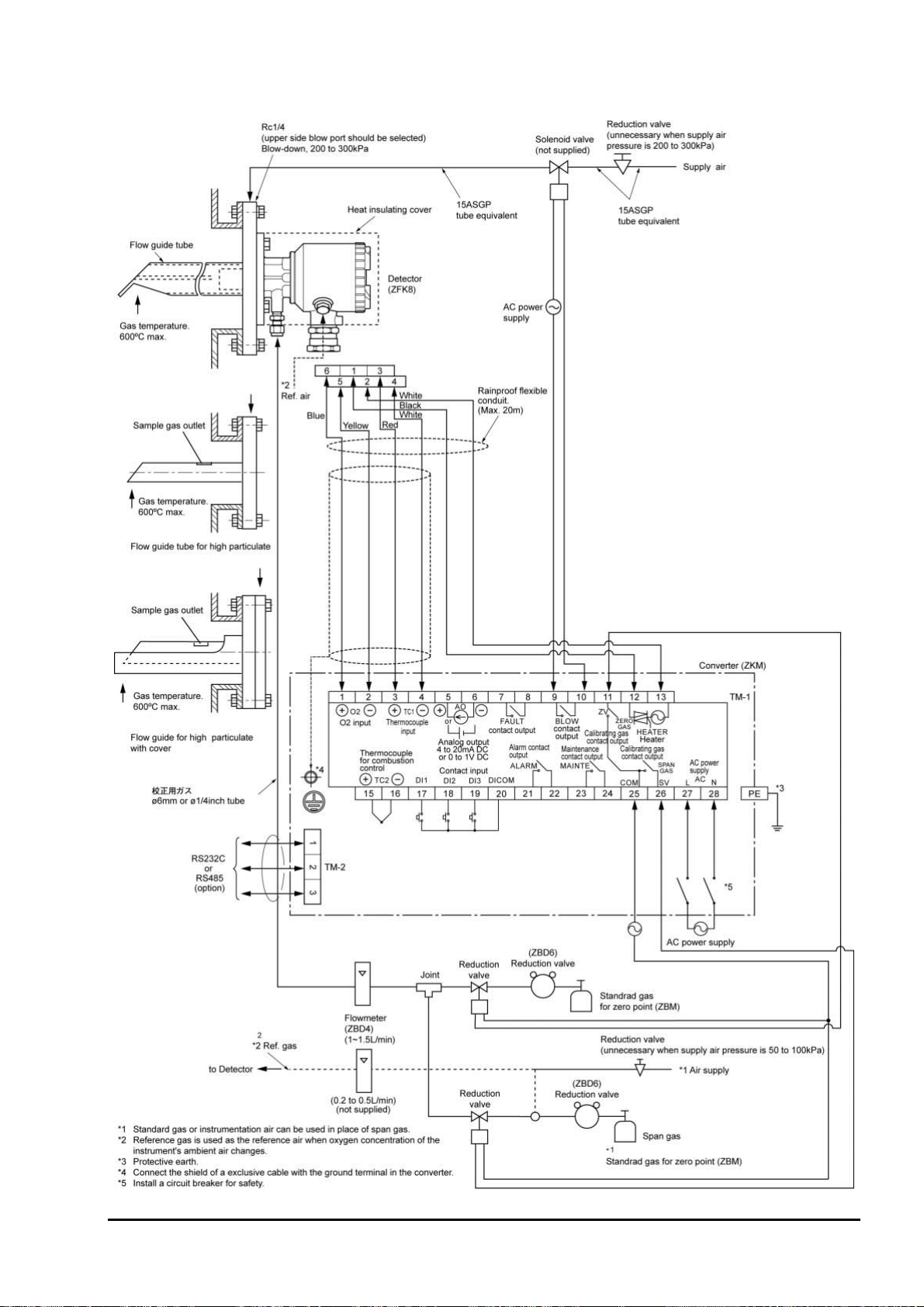

4.3.1.2 Flow guide tube system (with valve)

INZ-TN2ZKMA-E

- 13 -

Page 25

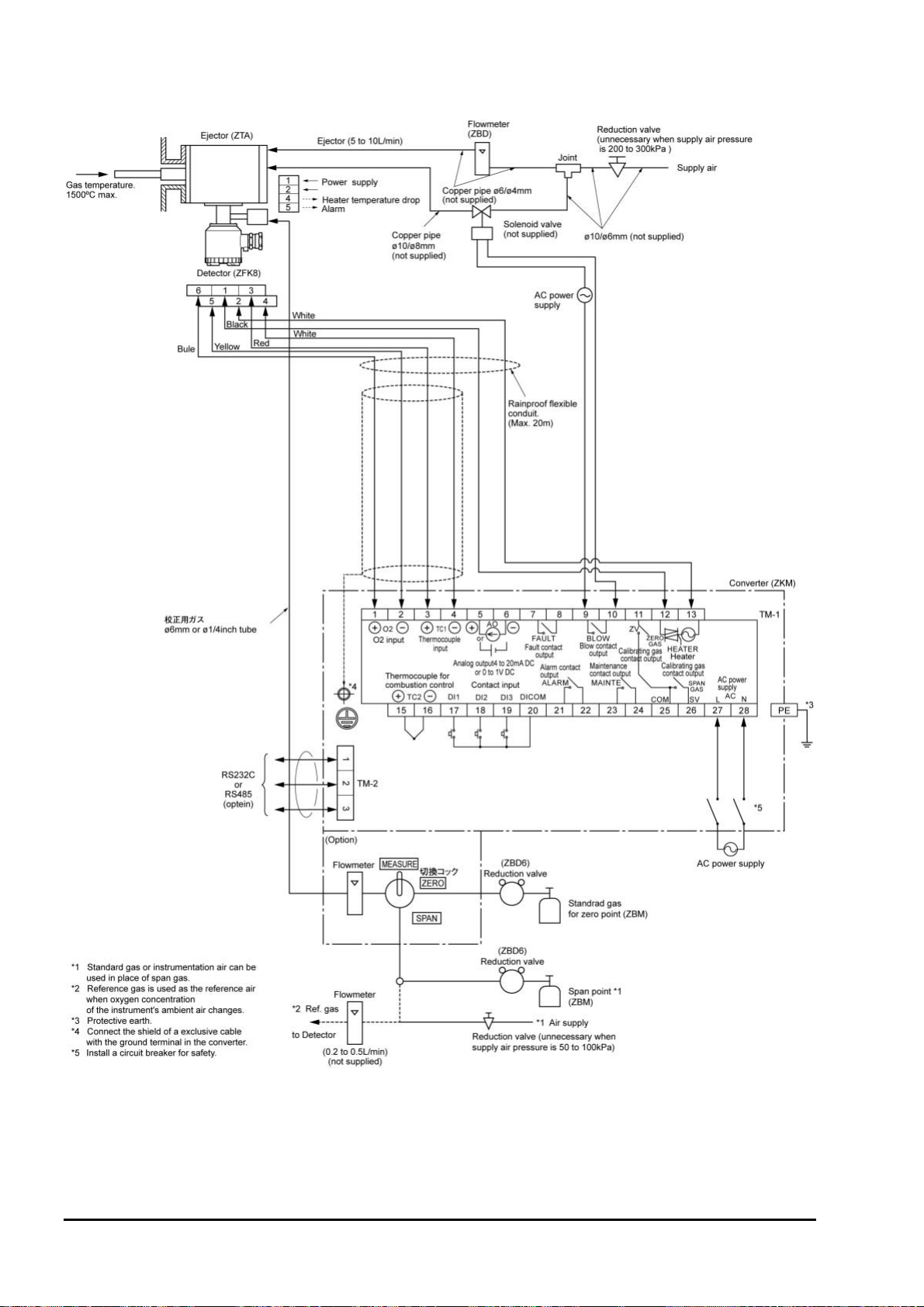

4.3.1.3 Ejector system

- 14 -

INZ-TN2ZKMA-E

Page 26

4.3.1.4 Ejector system (with valve)

INZ-TN2ZKMA-E

- 15 -

Page 27

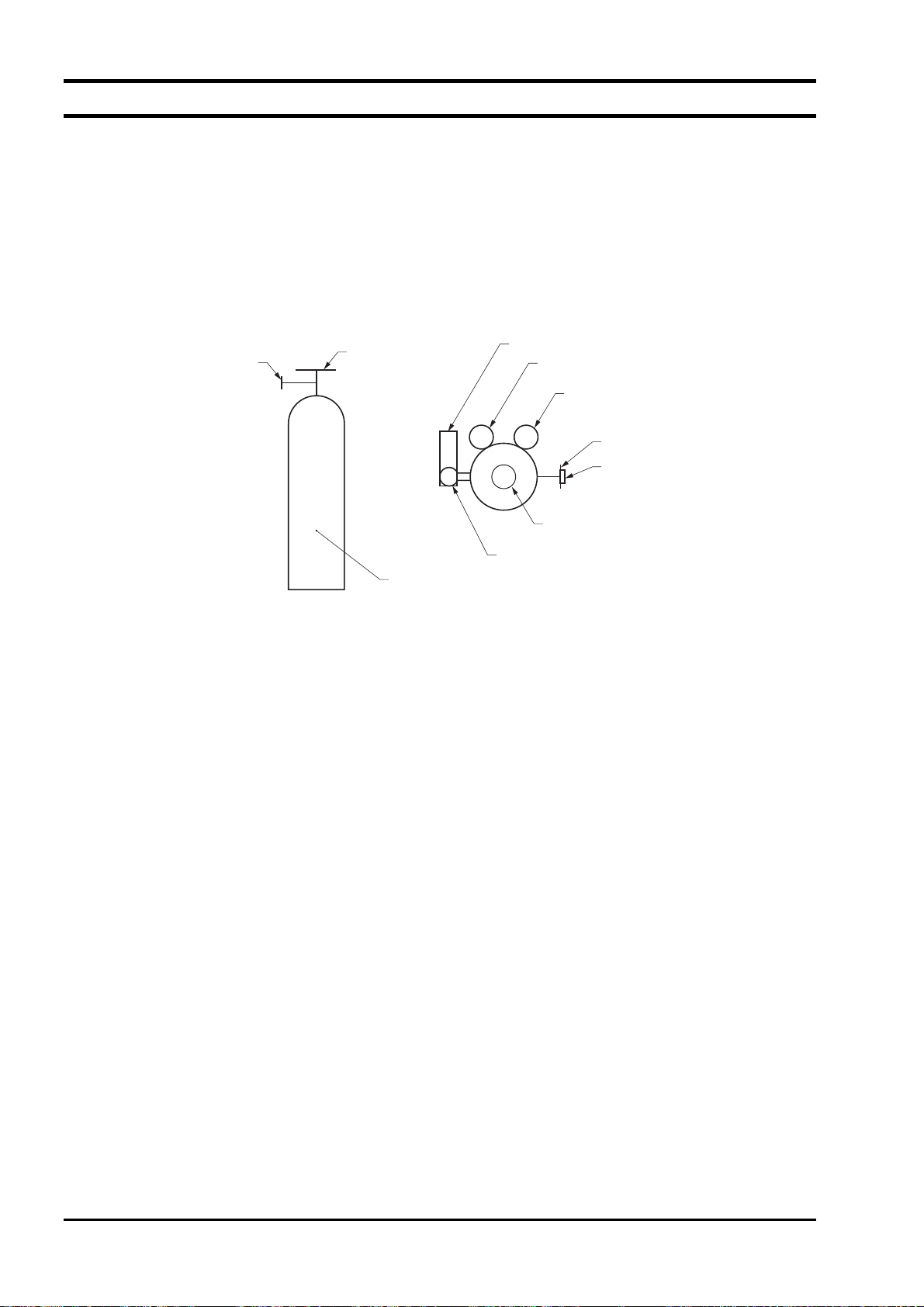

4.4 Handling of standard gas (An article on separate order)

4.4.1.1 Operation

(1) Make sure the handle is closed on the high pressure gas container, then detach the cap nut.

(2) Attach the high pressure gas container using the cap nut with packing of the pressure reduction valve.

(3) Make sure the secondary pressure adjusting valve is turned fully counterclockwise (pressure not ap-

plied) and the outlet needle is turned fully clockwise (closed), then open the handle.

(4) Turn the secondary pressure adjusting valve clockwise and set to the normal value of 20 to 30 kPa,

then open the outlet needle slowly to allow the gas to flow.

Pressure reduction valve

(WR11FS)

Fow rater

Secondary

pressure meter

Primary pressure

meter

Cap nut

Handle

Cap nut

Packing

Secondary pressure

adjusting valve

Outlet needle

High pressure

gas container

4.4.1.2 Piping

(1) The gas outlet of the pressure reduction valve is of Rc 1/4 (internal thread).

Prepare the joint and tube (such as 6/ 4 teflon tube).

4.4.1.3 Caution

(1) Fasten securely, so there is no gas leakage from the pressure reduction valve connection or from

threaded part of the joint.

(2) Store high pressure gas containers in a place protected from direct sunlight and rain.

(3) After use, be sure to close the handle.

- 16 -

INZ-TN2ZKMA-E

Page 28

5. OPERATION

5.1 Preparation for operation

Preparation can be performed after installation or on the bench.

(1) Wiring check (Refer to “4.2”, “4.3”)

(2) Confirmation of the power supply specifications (Please check the main power supply and the

power supply voltage specification of the detector.)

(3) Power ON.

The analyzer turns on when the power is supplied. (Refer to “2.4”)

OXYGEN ANALYZER

VER . YY/MM

WARM-UP

HEATER 234 °C

The message shown left appears on the LCD screen.

After about 6 seconds, the display is automatically switched to the

warming-up screen.

(4) Warm-up

Warm-up takes 10 minutes or less. Then the analyzer starts temperature control for the detector

ZFK.

Note 1: If the temperature control completes within 10 minutes, the analyzer stops warm-up to

start operation. When you first use the analyzer, proceed to the step 5 “PID auto tuning”.

Note 2: Even if the temperature control does not complete within 10 minutes, the analyzer stops

warm-up to start operation, however, for 7 minutes after the warm-up stoped, the analyzer

cannot detect the error of the heater temperature nor display it. (Carry out the step 5 “PID

auto tuning” during this period.)

(5) PID auto tuning

When you first use the analyzer, perform the PID auto tuning within 7 minutes after the stop of

warm-up, in the state that the the detector ZFK is connected. Refer to Chapter 10 for the

procedures of the PID auto tuning. When the PID auto tuning is finished, the analyzer perform

warm-up again to check if tempertature control is possible, and then starts operation.

(6) Parameter setting

Move to each Menu with reference to the paragraph “5.2 Key operation flow diagram (outline)”,

and set a necessary parameter. Refer to the paragraph “5.3 Initial parameter value table”.

If you need to change a parameter, refer to the “Chapter 10”.

(7) Calibration

At the first operation, perform manual calibration after warm-up using a calibration gas.

Refer to “chapter 7” for calibration procedures.

INZ-TN2ZKMA-E

- 17 -

Page 29

(8) Auto calibration (option)

Automatic calibration may be performed at specified time intervals.

Refer to “7.3” for automatic calibration settings.

(9) Blowdown (option)

A flow guide tube blowdown feature prevents the flow guide tube from clogging due to dust in

the gas stream.

Refer to “chapter 8” for operation procedures.

Operation

- 18 -

INZ-TN2ZKMA-E

Page 30

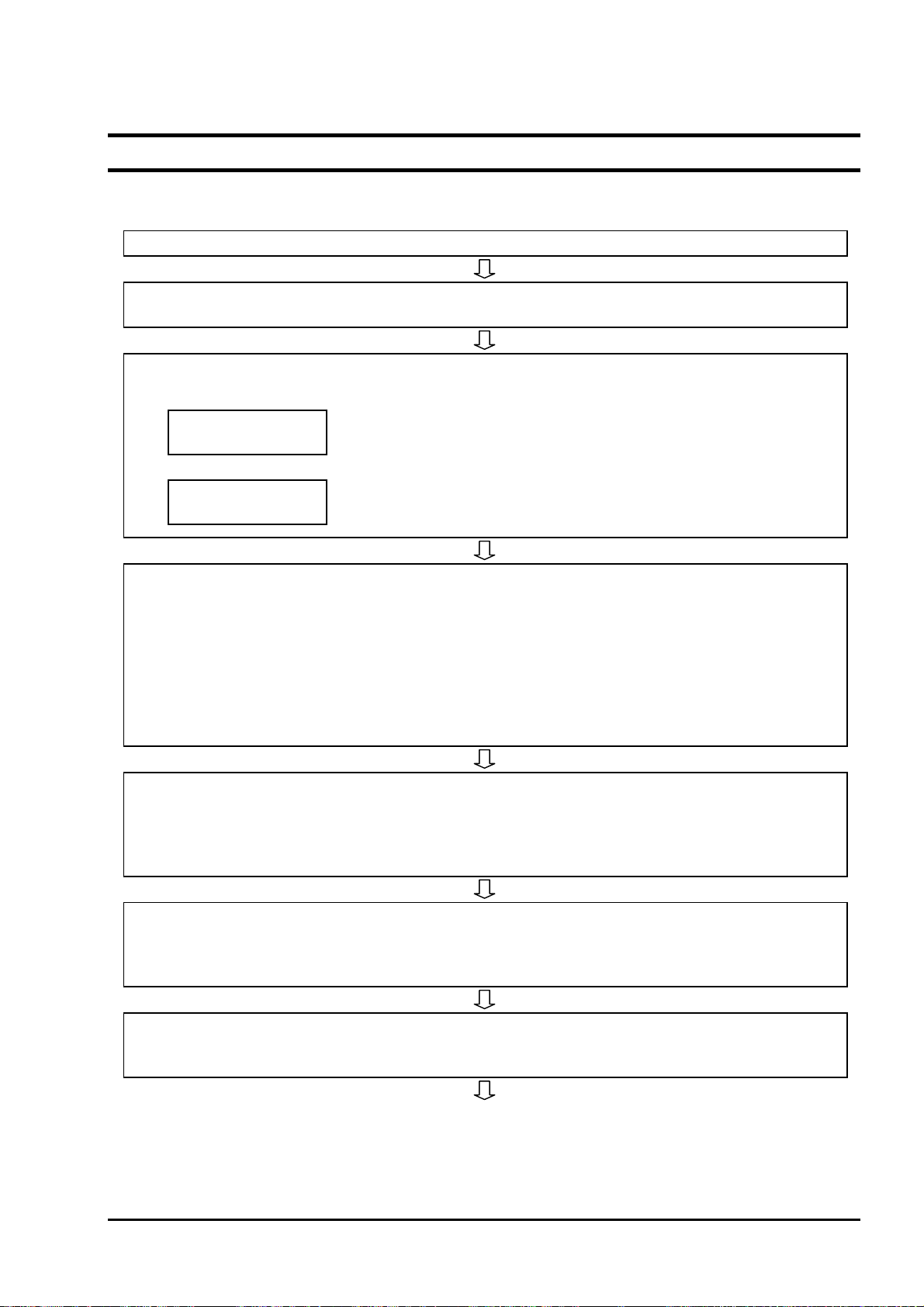

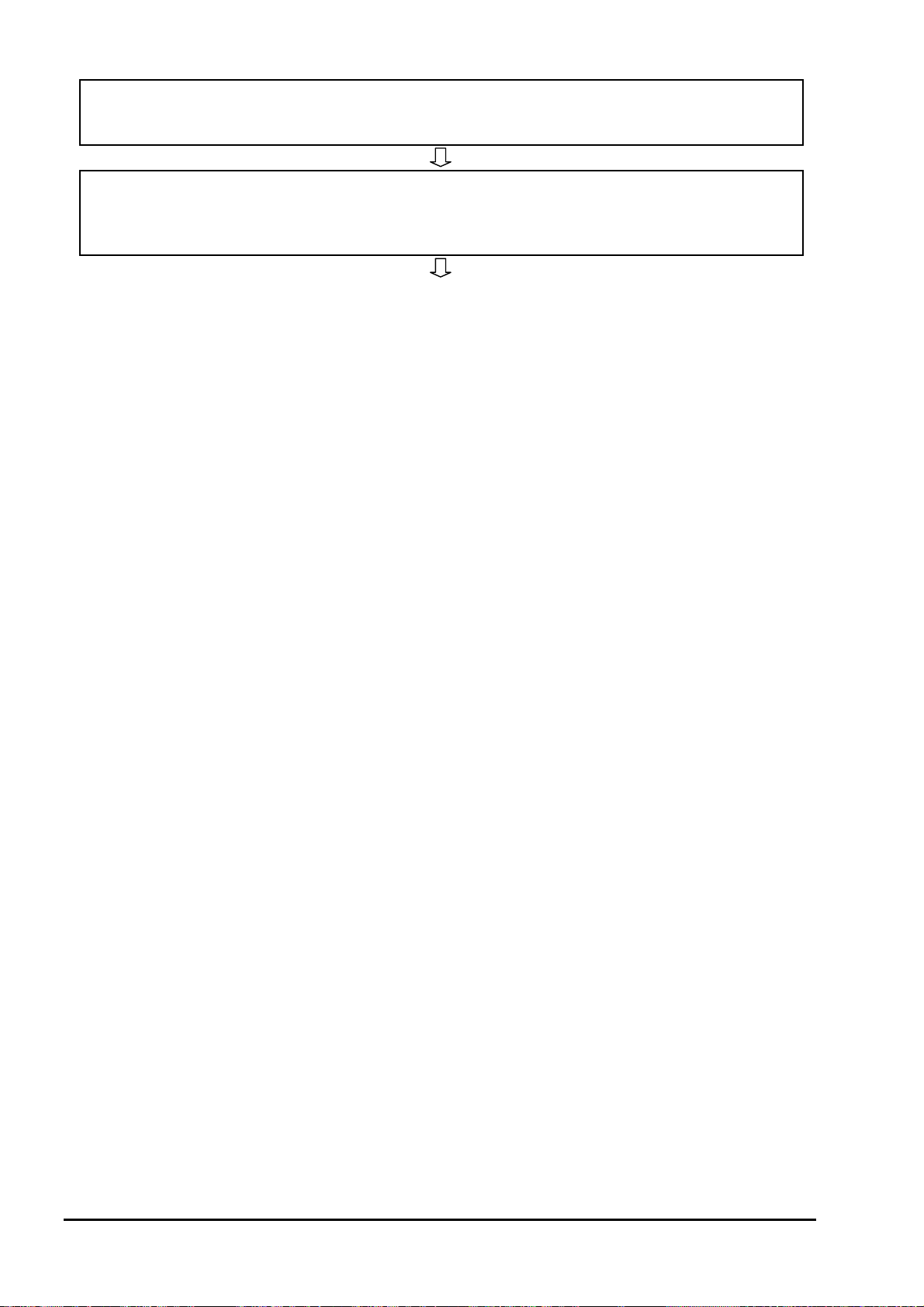

5.2 Key operation flow diagram (outline)

INZ-TN2ZKMA-E

- 19 -

Page 31

- 20 -

INZ-TN2ZKMA-E

Page 32

INZ-TN2ZKMA-E

- 21 -

Page 33

- 22 -

INZ-TN2ZKMA-E

Page 34

5.3 Initial parameter value table

5.3.1 Parameters related to measurement

Parameter setting Displayed message Range Initial value

Display range

DISPLAY RANGE

RANGE1 RANGE2

Range1 or Range2 Range-1 10.1.1

Reference

paragraph

Decimal point position

Range1

Range2

Full scale

Range1

Range2

Calculation time of maximum and minimum values

DECIMAL POINT

00.00

FULL SCALE

25.00

CALCULATE TIME

024 h

[00.00]

[0.000]

2 to 50 in 1 vol% steps 25.00 vol% 10.1.3

0 to 240 hour in 1-hour

steps

[00.00] 10.1.2

24 hour 10.1.4

5.3.2 Parameters related to calibration

Parameter setting Displayed message Range Initial value

Auto calibration function

(Displayed if the option is

provided.)

Date and time for starting

automatic calibration

(Displayed if the option is

provided.)

Automatic calibration

cycle time

(Displayed if the option is

provided.)

Calibration gas concentration-1

calibration gas concentration-2

Calibration wait time

AUTO CALIBRATION

YES NO

START DATE

99/01/01 00:00

AUTO CAL. CYCLE

07d 00h

SPAN ZERO

20.600% 01.000%

CAL. WAIT TIME

020 s

YES or NO

Date and time in the future in the calendar

00d 00h to 99d23h

(h: 00 to 23)

Span:

00.010 to 50.000 vol%

Zero:

00.010 to 25.000 vol%

in 0.001 vol% steps

10 to 999 sec.

in 1 sec. steps

Invalid

(Auto calibration

function: Invalid)

99/01/01 00:00 10.2.2

07d 00h 10.2.3

Span:

20.600 vol%

Zero:

01.000 vol%

300 sec. 10.2.8

Reference

paragraph

10.2.1

10.2.7

Calibration range setting

INZ-TN2ZKMA-E

ABBOUT CAL. RANGE

BOTH CURRENT

Set calibration range

Current or both range

- 23 -

BOTH 10.2.10

Page 35

5.3.3 Parameters related to blowdown (displayed if the option is provided)

Parameter setting Displayed message Range Initial value

Automatic blowdown

function

BLOW DOWN

YES NO

YES or NO

NO

(The automatic

blowdown function is invalid.)

Date and time for starting

automatic blowdown

START DATE

99/01/01 00:00

Date and time in the future in the calendar

99/01/01 00:00 10.3.2

Automatic blowdown

cycle time

AUTO BLOW CYCLE

24h 00m

00h 00m to 99h 59m

(m: 00 to 59)

24h 00m 10.3.3

Blowdown time

BLOW DOWN TIME

030 s

0 to 999 sec. in 1 sec.

steps

30 sec. 10.3.4

Reference

paragraph

10.3.1

5.3.4 Parameters related to maintenance

Parameter setting Displayed message Range Initial value

Maintenance mode

Password

MAINTENANCE MODE

YES NO

NEW PASSWORD

0123

YES or NO NO 10.4.6

0000 to 9999 0000 10.4.7

Reference

paragraph

- 24 -

INZ-TN2ZKMA-E

Page 36

5.3.5 Other parameters

Parameter setting Displayed message Range Initial value

Current date and time

Contact inputs 1 to 3

Alarm contact output

Upper limit of oxygen

concentration

Range-1

Range-2

Lower limit of oxygen

concentration

Range-1

Range-2

Upper 2 limit of oxygen

concentration

Range-1

Range-2

Lower 2 limit of oxygen

concentration

Range-1

Range-2

Hysteresis

(Oxygen concentration

alarm)

Range-1

Range-2

Analog output hold function

Maintenance hold

Output value of analog

output hold

Maintenance hold

Setting the value of analog output hold

Maintenance hold

Error hold

Error hold

Error hold

DATE SET

00/00/01 00:00

DI 1

NONE

DO ALARM SET

ALARM NONE

HIGH ALARM

50.000 vol%

LOW ALARM

00.020 vol%

H-HIGH ALARM

55.000 vol%

L-LOW ALARM

00.010 vol%

HYSTERESIS

10 %

OUTPUT HOLD

YES NO

OUTPUT SELECT

0%

HOLD VALUE

000 %

Date and time in the calendar

DI1 to DI3

[NONE]

[BLOW DOWN ON]

[HEATER OFF]

[PROHIBIT CAL.]

[REMOTE CAL.]

[REMOTE HOLD]

[CALCULATE REST]

[OUTPUT RANGE]

[ALARM NONE]

[HIGH ALARM]

[LOW ALARM]

[H-HIGH ALARM]

[L-LOW ALARM]

[H/L ALARM]

[HH/LL ALARM]

0.001 to 55.000 vol% in

0.001 vol% steps

0.001 to 55.000 vol% in

0.001 vol% steps

0.001 to 55.000 vol% in

0.001 vol% steps

0.001 to 55.000 vol% in

0.001 vol% steps

0 to 20 % in 1 % steps 10 % 10.5.8

YES or NO

[0 %] (4 mA/0V)

[100 %] (20 mA/1V)

[Last output value]

[Setting value]

0 to 100 % in 1 % steps 0 %

(14/01/01/ 00:00) 10.5.1

DI1

[NONE]

DI2

[NONE]

DI3

[NONE]

[ALARM NONE] 10.5.3

50.000 vol% 10.5.4

00.020 vol% 10.5.5

55.000 vol% 10.5.6

00.010 vol% 10.5.7

NO

(Analog output

hold function is

invalid.)

[0 %](4 mA/0V)

Reference

paragraph

10.5.2

10.5.9

10.5.13

10.5.10

10.5.14

10.5.11

10.5.15

INZ-TN2ZKMA-E

- 25 -

Page 37

Parameter setting Displayed message Range Initial value

Measurement recovery

time

Key lock function

MEAS. WAIT TIME

010 s

KEY LOCK

YES NO

0 to 300 sec. in 1 sec.

steps

YES or NO

10 sec. 10.5.12

No

(Key lock function is invalid.)

Automatic OFF time

BACKLIGHT TIME

10 m

0 to 99

in 1-minute steps

10 minutes 10.5.17

Station No.

STATION NO

01

0 to 99 01 10.5.18

FUEL COEFFICIENT

FUEL COEFF.

0.70

0.00 to 1.99 0.70 10.5.21

Reference

paragraph

10.5.16

- 26 -

INZ-TN2ZKMA-E

Page 38

6. OPERATION START AND STOP

6.1 Operation start

After correct wiring and piping has been completed, turn on the converter to start measurement.

Note: 10 min. of warm-up time is necessary after power ON.

Caution of before starting operation

(1) Furnace operation should be started after an elapsed time of 10 minutes from the point of turn-

ing ”ON” the power supply of this unit

(2) When a detector is to be installed in a furnace already in operation, take care to blow out harmful

gas from the furnace and then install the fully warmed up detector quickly.

(3) Control of detector temperature may get unstable depending on the ambient temperature, power

supply voltage, and other conditions. In such a case (especially when you first use the analyzer),

perform PID auto-tuning after the stop of warm-up (Refer to 10.4.8 PID auto tuning).

6.2 Operation stop

6.2.1.1 When a process (furnace etc.) is to be shutdown for a short time i.e. a week

or so

It is strongly recommended to keep the detector in operation to avoid possible deterioration of platinum electrodes in the detector and detector break-down due to repetition of power ON-OFF in a moisture absorption

state.

In case of the detector with an ejector (option), shutdown the air source.

6.2.1.2 When a process (furnace etc.) is to be shutdown for a long time

Turn OFF the power switch of the instrument after gas in the furnace has been replaced completely by ambient air.

INZ-TN2ZKMA-E

- 27 -

Page 39

6.3 Actions during operation

While the instrument is operating, the following displays can be changed.

- 28 -

INZ-TN2ZKMA-E

Page 40

6.4 Check the contents of display

The condition of the unit is displayed on the left of the LCD with three letters. The maximum of three items

are displayed on one display. If there are four or more items, “▼” is displayed at the bottom of the screen.

Scroll the screen with the

The unit displays the following three pieces of information:

(1) Condition information (“6.4.1”), (2) Error information (“6.4.2”), (3) Alarm information (“6.4.3”)

key to display the fourth and subsequent items.

6.4.1 Check of state information

Display

message

WUP Warm-up Appears during warm-up

CAL Auto calibration Appears during auto calibration

S Span calibration

Z Zero calibration

SCK Sensor check Displayed during sensor check.

SRC Sensor recovery Displayed during sensor recovery.

BLW Automatic blowdown Displayed during automatic blowdown.

RIC Rich mode

KYL Key Lock Displayed during key lock

RHO Remote heater is off. Displayed while remote heater is off.

RCP Remote calibration is prohibited. Displayed while remote calibration is prohibited.

RAH Remote analog output hold Displayed during remote analog output hold.

RCL Remote calibration Displayed during remote calibration.

RBL Remote blowdown Displayed during remote blowdown.

OVR Over range Displayed when an input is out of the range.

State Remarks

Displayed together with “CAL” or “RIC” during span

calibration.

Displayed together with “CAL” or “RIC” during zero

calibration.

Combustion efficiency option

Displayed when electromotive force is 200mV but no

more than 260mV

INZ-TN2ZKMA-E

- 29 -

Page 41

6.4.2 Checking the error information

Display

message

Er1 Fault of heater temperature

Er2 Disconnection detection

Er3 Sensor error Appears when the A/D value is saturated.

Er4 Span calibration error

Er5 Zero calibration error

State Remarks

Appears when control temperature of the heater exceeds

the set range.

The heater control is stopped.

Appears when disconnection is detected at the sensor, or

thermocouples for temperature control.

The heater control is stopped.

Appears when the span calibration is abnormal.

(The calibration gas is unstable. / The calibration factor

setting is inappropriate.)

Appears when the zero calibration is abnormal.

(The calibration gas is unstable. / The calibration factor

setting is inappropriate.)

6.4.3 Checking the alarm information

Display

message

ALM Oxygen concentration error

H High limit error Appears together with ALM.

L Lower limit error Appears together with ALM.

HH HH limit error Appears together with ALM.

LL LL limit error Appears together with ALM.

You can select one of the following seven alarms to output to the alarm contact (Contact No. 21 and 22 of the

external terminal blocks) when an oxygen concentration error occurs.

(1) [Not used] : No alarm is output to the contact output.

(2) [High limit alarm] : Alarm contact is output when an high limit alarm occurs.

(3) [Lower limit alarm] : Alarm contact is output when a lower limit alarm occurs.

(4) [HH limit alarm] : Alarm contact is output when an HH limit alarm occurs.

(5) [LL limit alarm] : Alarm contact is output when a LL limit alarm occurs.

(6) [High/lower limit alarm] : Alarm contact is output when an high or lower limit alarm occurs.

(7) [HH / LL limit alarm] : Alarm contact is output when an HH or LL limit alarm occurs.

State Remarks

Appears when the oxygen concentration exceeds any of

specified HH / High / Lower / LL limit values.

(Refer to “10.5.4” to “10.5.8”)

- 30 -

INZ-TN2ZKMA-E

Page 42

6.5 Oxygen detector standard output voltage

O2 concentration

(%)

0.01 176.38 5.0 32.73 25.0 -4.475

0.1 123.15 10.0 16.71 30.0 -8.689

0.5 85.95 15.0 7.333 40.0 -15.34

1.0 69.93 20.0 0.683 50.0 -20.50

1.5 60.56 20.6 0 – –

2.0 53.91 21.0 -0.445 – –

Output value

(mV)

O2 concentration

(%)

Output value

(mV)

O2 concentration

(%)

Output value

(mV)

INZ-TN2ZKMA-E

- 31 -

Page 43

7. CALIBRATION

In order to maintain good accuracy, proper calibration using standard gas is necessary. The following 4

methods of calibration are provided.

(1) Manual calibration (“7.2”), (2) Auto calibration (option) (“7.3”),

(3) Remote calibration (“7.4”), (4) All calibration (option) (“7.5”)

7.1 Preparation

Check of piping and wiring

Perform wiring and piping correctly referring to Item “4.3”. At this time, the main valve of standard

gas should be left open. Since high pressure is present at piping connections, use cap nut joints and take

special care with regard to air-tightness. Calibration gas flow should be 1.5 ± 0.5 L/min.

Setting of calibration gas concentration

Referring to “10.2.7 Calibration gas setting” set the oxygen concentration in standard gas cylinder to

be used.

Setting of calibration range

Set the range for calibration according to “10.2.10 Operation setting screen of calibration range.”

- 32 -

INZ-TN2ZKMA-E

Page 44

7.2 Manual calibration

Description

Span/zero is calibrated once by key operation.

Calibration must be made in the order of span and zero.

Perform calibration after a calibration gas is supplied to the detector and the output signal of the de-

tector becomes stable.

If the unit does not have an auto calibration function, the operator shall perform open and close opera-

tions, or adjust the flow rate of calibration gas.

During calibration, if the analog output hold function (maintenance hold) is enabled, the analog output

signal is held at the set value. Even after the calibration, the hold is maintained during the set time as a

measurement recovery time.

Procedure

Operation

(example)

Executes span calibration and zero calibration.

Key operation Description

(1)

(2)

(3) Oxygen concentration value and cell electromotive force are

(4)

(5) After the calibration is completed, the display returns to the

Press the key to perform manual span calibration.

Press the key to determine the span calibration factor.

Display the screen on the right in accordance with the key operation summary and press the key, the manual span

calibration screen appears.

If supplying calibration gas manually (without the autocalibration function)

The operator shall open the span gas valve manually and adjust

the flow rate to 1.5 ± 0.5 L/min.

In the case of unit with the auto calibration function, an external solenoid valve can be driven by using the contact output

signal from the terminal block.

displayed.

Wait until the oxygen concentration is stabilized.

During the process, the oxygen concentration value and cell

electromotive force are highlighted.

screen on the right.

Displayed message

(LCD)

CALIBRATION MENU

MANUAL SPAN CAL.

MANUAL SPAN CAL.

START

MANUAL SPAN CAL.

20.61 % 000.1 mV

MANUAL SPAN CAL.

20.61 % 000.1 mV

CALIBRATION MENU

MANUAL SPAN CAL.

(6) If the operator opened the span gas valve manually, close the

valve.

(7)

Display the screen on the right in accordance with the key operation summary and press the

calibration screen appears.

key, the manual zero

INZ-TN2ZKMA-E

- 33 -

CALIBRATION MENU

MANUAL ZERO CAL.

Page 45

(8)

(9) Oxygen concentration value and cell electromotive force are

(10)

(11) After the calibration is completed, the display returns to the

(12) If the operator open the zero gas valve manually, close the

Press the key to perform manual zero calibration.

If supplying calibration gas manually (without the autocalibration function)

The operator shall open the span gas valve manually and adjust

the flow rate to 1.5 ± 0.5 L/min.

In the case of unit with the auto calibration function, an external solenoid valve can be driven by using the contact output

signal from the terminal block.

displayed.

Wait until the oxygen concentration is stabilized.

Press the key to determine the zero calibration factor.

During the process, the oxygen concentration value and cell

electromotive force are highlighted.

screen on the right.

valve.

How to cancel

MANUAL ZERO CAL.

START

MANUAL ZERO CAL.

2.01 % 053.9 mV

MANUAL ZERO CAL.

2.01 % 053.9 mV

CALIBRATION MENU

MANUAL ZERO CAL.

Press the

After the cancellation, be sure to close the valves of span gas and zero gas.

key to cancel the operation.

- 34 -

INZ-TN2ZKMA-E

Page 46

7.3 Auto calibration (option)

Description

Calibration is performed at time intervals set in advance.

The solenoid valve is driven by contact signal to feed the standard gas for automatic calibration with

span gas and zero gas.

“CAL” is displayed on the left of the measurement screen during automatic calibration.

If the output signal hold is set, the output signal is held to the set value during calibration.

After the calibration, the hold is maintained until the time set in the measurement recovery time elapses.

For automatic calibration, it is necessary to set “10.2.2 Date and time for starting automatic calibra-

tion (option)”, “10.2.3 Cycle time setting of automatic calibration (option)”, “10.2.7 Calibration

gas setting”, “10.2.8 Calibration waiting setting (option)”, and “10.5.12 Setting of measurement recovery time (maintenance hold)”.

Refer to Sections “4.2” and “4.3” for the wiring of solenoid valves.

Procedure

Operation

(example)

Key operation Description

(1)

(2)

(3)

(4)

INZ-TN2ZKMA-E

Setting the automatic calibration so that it is performed every four days from 13:00,

2015/02/25

Display the screen on the right in accordance with the key op-

Press the key.

Press the key to set the value.

eration summary and press the key.

The auto calibration valid/invalid setting screen appears.

Use the

Press the

key to select the auto calibration valid (YES).

key to set the value.

- 35 -

Displayed message

(LCD)

CALIBRATION MENU

SET AUTO CAL

SET AUTO CAL

AUTO CALIBRATION

AUTO CALIBRATION

YES NO

AUTO CALIBRATION

YES

Page 47

(5) The screen on the right appears.

(6)

(7)

(8)

(9) The screen on the right appears.

(10)

Press the key.

Press the

the

The date and time for starting automatic calibration screen ap-

pears.

Use the

date and time.

(Set the date and time of the future.)

Press the

Press the

the

The cycle time setting of automatic calibration screen appears.

key.

and key to set the auto calibration starting

key.

key to display the screen on the right and press

key to set the value.

key to display the screen on the right and press

SET AUTO CAL

AUTO CALIBRATION

SET AUTO CAL

START DATE

START DATE

15/02/25 13:00

START DATE

15/02/25 13:00

SET AUTO CAL

START DATE

SET AUTO CAL

AUTO CAL. CYCLE

(11)

(12)

(13) The display returns to the screen on the right.

Press the key.

Use the

time.

Press the

and key to set the auto calibration cycle

key to set the value.

How to cancel

Press the

key to cancel the operation.

Note

Automatic calibration is not performed under the following conditions.

Warm-up is being performed.

Contact of “Prohibition of calibration” is being input.

Contact of “Heater off” is being input.

AUTO CAL. CYCLE

04d 00h

AUTO CAL. CYCLE

04d 00h

SET AUTO CAL

AUTO CAL. CYCLE

- 36 -

INZ-TN2ZKMA-E

Page 48

7.4 Remote calibration

This function is available only for the version with auto-calibration.

You can perform all calibration by the contact input of the external terminal block.

To perform remote calibration, install piping and wiring for the standard gas cylinder and the solenoid valve

according to Section 4.

(1) Set one of the contact inputs DI 1 to 3 to “Remote calibration” in accordance with the following op-

eration procedure.

(2) Close the contact set to the “Remote contact” for one second or more (depending on the settings of

(17) to (19) and (20) of the terminal block).

(3) Remote calibration is started. “RCL” is displayed on the left of the display panel, which disappears

when the calibration is completed.

DI1 DI3DI2 DI COM

17 18 19 20

You can arbitrarily set the contact input functions.

You can arbitrarily set the contact inputs (17), (18), (19) and (20) of the external terminal block (see “10.5.2

Contact input setting”).

Piping and wiring for the standard gas cylinder and the solenoid valve shall be installed.

Description

You can perform all calibration by the contact input using this function.

The solenoid valve is driven by contact signal from the terminal block to feed the standard gas for

automatic calibration with span gas and zero gas.

Refer to Sections “4.2” and “4.3” for the wiring of solenoid valves.

Procedure

Operation

(example)

Key operation Description

(1)

(2)

Executes remote calibration.

Display the screen on the right in accordance with the key operation summary and press the key.

The contact input setting screen appears.

Press the

Press the

key several times and select one of DI 1 to DI 3.

key.

Displayed message

(LCD)

PARAMETER MENU

DIGITAL INPUT

DIGITAL INPUT

DI

(3)

(4)

INZ-TN2ZKMA-E

Press the key.

Contact is set.

Press the

Press the

key several times and select “REMOTE CAL.”.

key to set the value.

DI 1

NONE

DI 1

REMOTE CAL.

- 37 -

Page 49

(5)

Press the key.

DI 1

REMOTE CAL.

(6)

(7) Close the contact set to the “REMOTE CAL.”

The screen on the right appears.

Press the key several times and return to the measurement screen.

Remote calibration is performed.

How to cancel

Press the

key to cancel the operation.

Note

Automatic calibration is not performed under the following conditions.

Warm-up is being performed.

Contact of “Remote blow” is being input.

Contact of “Prohibition of calibration” is being input.

Contact of “Heater off” is being input.

DIGITAL INPUT

DI 1

12.34

Vol%

- 38 -

INZ-TN2ZKMA-E

Page 50

7.5 All calibration (option)

Description

Perform sensor maintenance [sensor check (setting), sensor recovery (setting)], span and zero calibra-

tion once for each sequentially by key operation.

Actuate the solenoid valve attached to the exterior by the contact signal from the terminal block and

supply standard gases sequentially. Span and zero gas calibration are automatically performed.

If the output signal hold is set, the output signal is held to the set value during calibration. After the

calibration, the hold is maintained until the time set in the measurement waiting time elapses.

To perform sensor maintenance (sensor check, sensor recovery) during calibration, “10.4.5 Perform-

ing a manual sensor check” are required.

Note that the sensor recovery is performed if it is determined to be required by the sensor check.

Refer to Sections “4.2” and “4.3” for the wiring of solenoid valves.

Procedure

Operation

(example)

Executes all calibration.

Key operation Description

(1)

(2)

(3) The value of the concentration of oxygen and the cell electro-

(4) After the all calibration is completed, the display returns to the

Press the key to perform all calibration.

Display the screen on the right in accordance with the key operation summary and press the key, the all calibration

performing screen appears.

motive force are displayed while executing the all calibration.

screen on the right.

How to cancle

Press the

key to cancel the operation.

Displayed message

(LCD)

CALIBRATION MENU

ALL CALIBRATION

ALL CALIBRATION

START

ALL CALIBRATION

20.61 % 000.1 mV

CALIBRATION MENU

ALL CALIBRATION

INZ-TN2ZKMA-E

- 39 -

Page 51

N

N

N

N

8. BLOWDOWN (OPTION)

In order to prevent the flow guide tube from clogging with dust contained in gas being measured, dust deposits in the flow guide tube is removed by blowing compressed air such as instrumentation air, etc. Use the

blowdown function by one of the following three methods.

(1) Manual blowdown (“8.2”), (2) Automatic blowdown (“8.3”),

(3) Remote blowdown (“8.4”)

8.1 Preparation for blowdown

Wiring/piping check

Perform wiring and piping correctly referring to Item. “4.3”. Since high pressure is applied to the piping,

be sure to use blind-nut type joints at connections. Special care should be taken with regard to airtightness.

Setting of blowdown time

Referring to “10.3.4 Procedure for setting blowdown time”, set blowdown time.

8.2 Manual blowdown

Description

You can perform blowdown operation once by key operation using this function.

Procedure

Operation

(example)

Key operation Description

(1)

(2)

(3) While executing, the screen on the right appears.

(4) After the calibration is completed, the display returns to the

Press the key to perform manual blowdown.

Performing manual blowdown

Display the screen on the right in accordance with the key operation summary and press the key, the manual blowdown

performing screen enters.

screen on the right.

Displayed message

(LCD)

BLOW DOWN MENU

MANUAL BLOW DOW

MANUAL BLOW DOW

ENTRY

MANUAL BLOW DOW

11.11 vol%

BLOW DOWN MENU

MANUAL BLOW DOW

How to cancel

Press the

key to cancel the operation.

- 40 -

INZ-TN2ZKMA-E

Page 52

A

8.3 Automatic blowdown

Description

Blowdown operation is performed at time intervals set in advance.

Using contact signal from the terminal block, drive the solenoid valve and remove dust by blowing

instrumentation air, etc. into the flow guide tube with blowdown nozzle.

“BLW” is displayed on the left of the measurement screen during automatic blowdown.

If the output signal hold is set, the output signal is held to the set value before start of blowdown dur-

ing blowdown. After the calibration, the hold is maintained until the time set in the measurement waiting time elapses.

To perform automatic blowdown, “10.3.2 Date and time setting of automatic blowdown” and

“10.3.3 Automatic blowdown cycle setting” and “10.3.4 Procedure for setting blowdown time” are

required.

Automatic blowdown

Blowdown contact

nalog output signal

Contact output for maintenance

starting date

Closed Closed

Hold Hold

Automatic blowdown

interval

Hold

prolong

Procedure

Operation

(example)

Key operation Description

(1)

(2)

(3)

(4)

(5) The screen on the right appears.

Press the key.

Press the key.

Setting the blowdown so that it is performed for 30 seconds every 24 hours from 13:00,

08/02/25

Display the screen on the right in accordance with the key operation summary and press the key.

The auto blowdown valid/invalid setting screen appears.

Use the

Press the

key to select the auto blowdown valid (YES).

key to set the value.

Displayed message

(LCD)

BLOW DOWN MENU

SET AUTO BLOW

SET AUTO BLOW

AUTO BLOW

BLOW DOWN

YES NO

BLOW DOWN

YES

SET AUTO BLOW

AUTO BLOW

(6)

Press the

the

The date and time setting of automatic blowdown screen ap-

pears.

key to display the screen on the right and press

key.

SET AUTO BLOW

START DATE

INZ-TN2ZKMA-E

- 41 -

Page 53

(7)

(8)

Press the key.

Use the

and key to set the auto blowdown starting

date and time.

(Set the date and time of the future.)

Press the

key to set the value.

(9) The screen on the right appears.

(10)

Press the

the

key to display the screen on the right and press

key.

The auto setting blowdown interval screen appears.

(11)

(12)

Use the

Press the

and key to set the auto blowdown interval.

key to set the value.

Press the key.

START DATE

15/02/25 13:00

START DATE

15/02/25 13:00

SET AUTO BLOW

START DATE

SET AUTO BLOW

AUTO BLOW CYCLE

AUTO BLOW CYCLE

24h 00m

AUTO BLOW CYCLE

24h 00m

(13) The screen on the right appears.

(14)

Press the

the

key to display the screen on the right and press

key.

The setting blowdown time screen appears.

(15)

(16)

Press the key.

Use the

and key to set the blowdown time.

(Common with the manual blowdown.)

Press the

key to set the value.

(17) The display returns to the screen on the right.

How to cancel

Press the

key to cancel the operation.

SET AUTO BLOW

AUTO BLOW CYCLE

SET AUTO BLOW

BLOW DOWN TIME

BLOW DOWN TIME

030 S

BLOW DOWN TIME

030 S

SET AUTO BLOW

BLOW DOWN TIME

- 42 -

INZ-TN2ZKMA-E

Page 54

8.4 Remote blowdown

You can perform blowdown by the contact input of the external terminal block.