Page 1

IN-SITU

ZIRCONIA OXYGEN ANALYZER

<HART communication>

DATA SHEET

This oxygen analyzer is used to continuously measure

oxygen concentration in combustion exhaust gas of industrial

boilers or furnaces, and is ideally suited for combustion management and control.

The analyzer system is comprised of the detector and converter coupled together as a complete system. Detector setting configuration includes the detector flow guide tube and

detector sensor. The flow guide tube is inserted directly into

the gas and directs gas to the sensor for measurement. The

converter (ZKM) is comprised of the signal processor, input/

output and communications, display and system controls.

The converter provided with an unconventional sensordiagnostic function ensures long-term stable detecting operation.

FEATURES

1. No need for gas sampling devices

Since the sensor unit is directly inserted into a flue, gas-

sampling devices such as gas aspirator and dehumidifier

are not required, which ensures fast response.

2. Easy maintenance

The sensor in a unit structure mounted to the detector can

be replaced easily. Since the detector and the flow guide

tube are installed separately, you can easily replace the filter at the tip of the detector and can maintain the detector

and the flow guide tube separately according to the degree

of corrosion.

3. High reliability ensured by the sensor diagnostic function

To check the degree of sensor depletion due to gas com-

ponents in the target gas, the converter is equipped with

the sensor diagnostic function, so that you know when to

replace the sensor.

4. Improved safety

The converter cuts off the power supply for the detector

when detecting a burnout of thermocouple for heater

control. The converter also cuts off the power supply at

emergency, in response to an external contact input. These

functions along with the key lock function are equipped as

standard to ensure improved safety.

5. Simple operation

A user can operate the converter or make various settings

on an interactive basis. Display language is available in

English, Japanese, or Chinese.

6. HART communication is available as an option

The HART communication enables remote control.

*HART

®

is a registered trademark of the HART Communi-

cation Foundation.

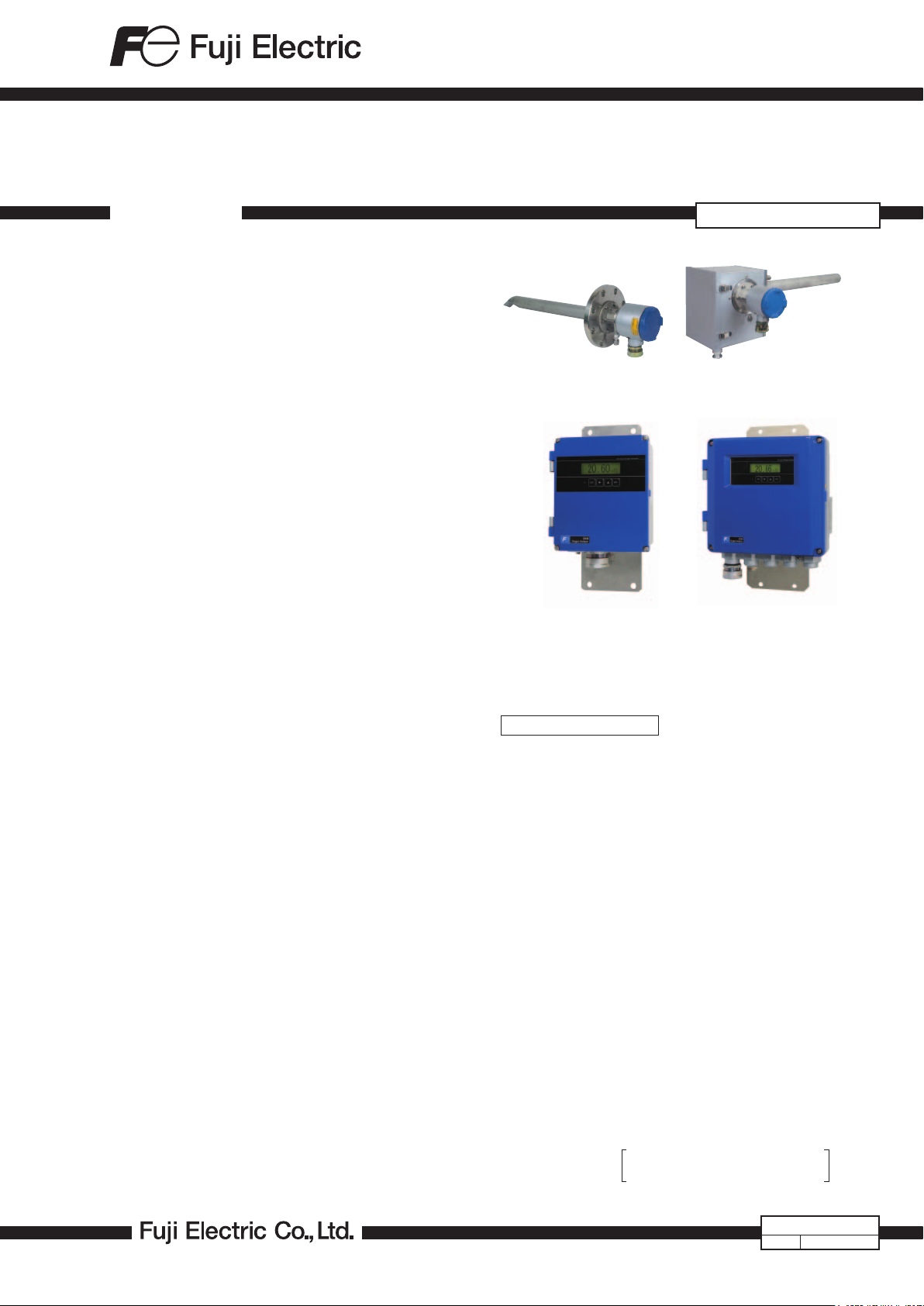

ZFK8, ZKM-2, ZTA

General-use detector

(ZFK8)

<IP66>

Converter (ZKMA)

High-temperature detector

(ZTA)

<IP67>

Converter (ZKMB)

SPECIFICATIONS

General Specifications

Measuring object: Oxygen in noncombustible gas

Measuring method:

Directly insert type zirconia system

Measuring range: 0 to 2 ··· 50 vol% O

(in 1 vol% O2 steps)

Repeatability: Within ±0.5%FS

Linearity: Within ±2%FS

Response time: Within 4 to 7 sec, for 90% (from calibra-

tion gas inlet)

Warmup time: More than 10 min

Analog output: 4 to 20mA DC (allowable load resistance

less than 500W) or 0 to 1V DC (output

resistance more than 100W)

Digital input (option): RS-485 or HART communication

Power supply: Rated voltage;

100 to 120V AC (operating voltage 90

to 132V AC)

200 to 240V AC (operating voltage

190 to 264V AC)

Rated frequency; 50/60Hz

Power consumption:

During warm-up 255VA

During operation 70VA

When the power supply voltage

is 100 or 220 V AC

2

EDSX3-151a

Date

Apr. 25, 2016

Page 2

ZFK8, ZKM-2, ZTA

Detector Specifications (ZFK)

Measured gas temperature:

Flow guide tube system; −10 to +600ºC

(for general-use, corrosive gas)

Ejector system; −10 to +1500ºC (for

high-temperature gas)

−10 to +800ºC (for general-use)

Measured gas pressure:

−3 to +3kPa

Flow guide tube: With or without blow-down nozzle

Flange; JIS5K 65A FF

(JIS5K-80AFF for high particulate gas)

Insertion length; 0.3, 0.5, 0.75, 1m

Ejector (general-use):

Probe for guiding measured gas to

detector

Flange; JIS10K 65A RF

Insertion length; 0.5, 0.75, 1, 1.5m (ac-

cording to customer's specification)

Ejector air inlet flow rate:

5 to 10 L/min

Ejector exhaust gas processing:

Into furnace, returned to flue

Ejector heater temperature drop alarm output:

Alarm output when below 100

ºC Me-

chanical thermostat

N.O. (1a) contact, 200V AC, 2A

Operating temperature:

−10 to +60ºC for Primary detecting ele-

ment

−5 to +100ºC for ejector section

125ºC or less at detector flange surface

with power applied

Storage temperature:

Sensing element: −20 to +70ºC

Ejector: −10 to +100ºC

Structure: Dust/rain-proof structure(IEC IP66

equivalent)

Filter: Alumina(filtering accuracy 50µm) and

quartz paper

Main materials of gas-contacting parts:

Detector; Zirconia, SUS316, platinum

Flow guide tube; SUS304 or SUS316

Ejector (general use); SUS316, SUS304

Ejector; (for high temperature) SiC,

SUS316, SUS304

Calibration gas inlet:

f6mm tube join, f1/4-inch tube join, or

ball valbe (as specified)

Reference air inlet (option):

f6mm tube join or f1/4-inch tube join (as

specified)

Detector mounting:

Horizontal plane ±45º, ambient sur-

rounding air should be clean.

Outer dimensions: (L × max. dia.) 210mm × 100mm (de-

tector)

Mass (approx.) {weight}:

Detector; 1.6kg

Ejector; 15kg (insertion length 1m)

Flow guide tube (general-use, 1m); 5kg

Finish color: Silver and SUS metallic color

Calibration gas flow:

1.5 to 2 L/min

Blowdown air inlet pressure:

2

200 to 300kPa {2 to 3 kgf/cm

}

Converter specification (ZKM)

Concentration value indication:

Digital indication in 4 digits

Contact output signal:

(1) Contact specification; 6 points, 1a 250V AC/3A or 30V DC/3A

(2) Contact function;

• Under maintenance

• Under blowdown

Note3)

• Span calibration gas valve

• Zero calibration gas valve

• Instrument anomalies

• Alarm

• Range identification output

Note2)

Note1)

Note4)

Note1) The following Instrument errors (1) Thermocou-

ples break (2) Sensor break (3) Temperature fault

(4) Calibration fault (5) Zero/span adjustment fault

(6) Output error turn the contact-ON

Note2) Alarm selects just one as mentioned below (1)

High (2) Low (3) Upper and Lower (4) High-high

(5) Low-low, it turns ON while operating.

Note3) Under blow down is available in case of option,

and it turns ON while operating.

Note4) It turns ON during range selection, and turns OFF

when the range 1 is selected.

Contact input signal:

(1) Contact specification; 3points (the following option)

ON; 0V (10mA or less), OFF; 5V

(2) Contact function;

• External hold

• Calculation reset

• Heater OFF

• Blow down (option)

• Inhibition of calibration

• Calibration start

• Range change

Calibration method:

(a) Manual calibration with key operation

(b) Auto. calibration (option)

Calibration cycle; 00 day 00 hour to

99 days 23 hours

(c) All calibration

Calibration gas: • Available range settings

Zero gas; 0.010 to 25.00% O

Span gas: 0.010 to 50.00% O

2

2

• Recommended calibration gas concentration

Zero gas; 0.25 to 2.0% O

Span gas; 20.6 to 21.0% O

2

2

(oxygen concentration in the air)

Blowdown: A function for blowing out with com-

(option)

pressed air dust that has deposited in

the flow guide tube. Blowdown can be

performed for a predetermined time and

at predetermined intervals.

Blowdown cycle; 00 hour 00 minute to

99 hours 59 minutes

Blowdown time; 0 minute 00 second

to 0 minutes 999

seconds

2

Page 3

Output signal hold:

Output signal is held during calibra-

tion, processing diagnosis of sensor,

warm-up, PID auto tuning, under set

up maintenance mode "available" and

blowdown. The hold function can also

be released.

Valve and Flow meter (option):

Selects zero or span gas during manual

zero or span calibration. Mounted on the

side of the converter.

Communication function:

HART communication (option)

RS485 (MODBUS) (option)

Combustion efficiency display (option):

This function calculates and displays

combustion efficiency from oxygen concentration and measured gas temperature.

Thermocouple (R) or thermocouple (K)

is required for temperature measure-

ment.

Range: 0 to 1000°C, Accuracy: ±5°C.

On the version with combustion effi-

ciency display, an alarm function of "rich

mode" indication is also available.

Operating temperature:

−20 to +55ºC

Operating humidity:

95% RH or less, non condensing

Storage temperature:

−30 to +70ºC

Storage humidity: 95% RH or less, non condensing

Enclosure: Dust-proof, rainproof

(corresponding to IP66 or IP67 of IEC)

* when the specified cable gland is at-

tached.

Material: Aluminum case

Outer dimensions (H x W x D):

170 X 159 X 70mm (IP66, Bench type)

220 X 230 X 95mm (IP67)

Mass {weight}: IP66: Approx. 2kg (excluding cable and

detector)

IP67: Approx. 4.5kg (excluding cable and

detector)

Cable:Approx. 4kg/m (with rainproof

flexible conduit)

Finish color: Case: Silver

Cover: Munsell 6PB 3.5/10.5 (blue)

Mounting method: Mounted flush on panel or on pipe

Electrical Safety:

Overvoltage category

; II power supply input

; I relay interfaces

(IEC1010-1)

External overcurrent protective device

; 10A

Equipment interfaces are safety

separated (SELV)

EC Directive Compliance

The product conforms to the requirements of the Low Voltage Directive 2006/95/EC and EMC directive 89/336/EEC

(as amended by Directive 92/31/EEC), both as amended by

Direc-tive 93/68/EEC.

It conforms to following standards for product safety and

electromagnetic compatibility:

EN61010-1 : 2010, EN62311: 2008

Safety requirements for electrical

equipment for measurement, control and

laboratory ese.

“Installation Category II”

“Pollution Degree 2”

“Altitude up to 2187 yard (2,000 m)”

EN61326-1 : 2006, EN61326-2-3: 2006

EN61000-3-2 : 2006, A1: 2009, A2: 2009

EN61000-3-3 : 2008

Electrical equipment for measurment,

control and laboratory use. EMS

requirements.

ZFK, ZKM

3

Page 4

ZFK8, ZKM-2, ZTA

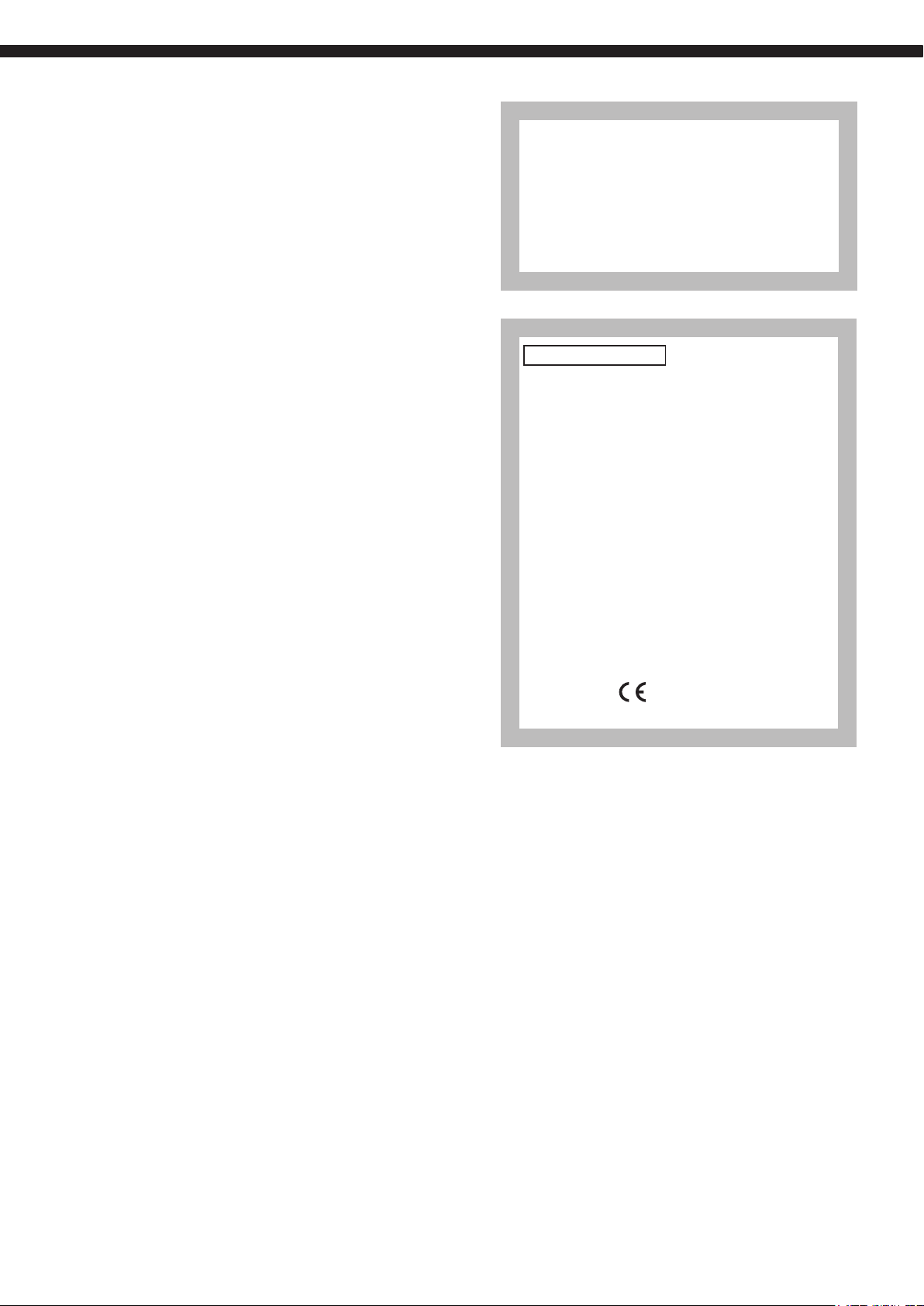

CODE SYMBOLS

(Detector) (Converter)

4 5 6 7 8 9 10 11 12 13 14 15 16

ZFK 8 R 5 - -

Digit Descrip tion Note Code

6 Calibration g as

inlet

7 Power supply 100 to 120 V A C 50/6 0 Hz 1

8 Revision No. 5

9 Flow guide tube

10 fla nge applic ation length

11 no tub e 0Y0

SUS3 04 general use 300 mm 5A3

SUS3 04 general use 500 mm 5A5

SUS3 04 general us e 750 mm 5A7

SUS3 04 general us e 1000 mm 5A1

SUS316 for corros ive gas 300 mm 5B3

SUS316 for corros ive gas 500 mm 5B5

SUS316 for corros ive gas 750 mm 5B7

SUS316 for corros ive gas 1000 mm 5B1

SUS316 with blowd own nozzle 3 00 mm 5C3

SUS317 with blowd own nozzle 5 00 mm 5C5

SUS318 with blowd own nozzle 75 0 mm 5C7

SUS319 with blowd own nozzle 10 00 mm 5C1

SUS316 for high par ticulate 30 0 mm 6D3

SUS317 for high par ticulate 50 0 mm 6D5

SUS318 for high par ticulate 750 mm 6D7

SUS319 for high par ticulate 100 0 mm 6D1

SUS316 for high par ticulate with cover 3 00 mm 6E3

SUS317 for high par ticulate with cover 5 00 mm 6E5

SUS318 for high par ticulate with cover 75 0 mm 6E7

SUS319 for high par ticulate with cover 10 00 mm 6E1

Others ZZZ

12

Heat- retaining

cover

13 Refer ence gas

inlet

14 Filt er spec Standar d 1

15 Inst ruction manual

languag e

16

Specifi cation

namepla te

For ø 6mm tub e (SUS) 1

For ø 1/4 i nch tube (S US) 2

With bal l valve 3

200 to 24 0 V AC 50/6 0 Hz 3

Withou t Y

With A

None Y

For ø 6 mm tube ( SUS) A

For ø 1/4 i nch tube (S US) B

Japanes e J

English E

Chinese C

Standar d (100 to 120 V AC 50 /60 Hz) 1

Standar d (200 to 24 0 V AC 50/6 0 Hz) 2

ZKM 2 - 1 - Y R

Digit Descrip tion Note Code

4 Enclosure IP6 6 A

5 Analog output

signal

6 Communicatio n

functio n

7 Mounting bracket No ne Y

8 Revision No. 2

9 Optional funct ions None Y

10 La nguage Japanes e J

11 Sele ctor valve/

flowmeter

12 — — 1

13 Ca ble gland Withou t Y

14 — — Y

15 — — R

16 Th ermocoupl e

for combus tion

efficie ncy display

*Thermo couple is to be prepare d separately.

Note 2) On the version with combustion efficiency display, an alarm function of "rich mode" indication is

4 5 6 7 8 9 10 11 12 13 14 15 16

IP67 B

4 to 20 mA DC B

0 to 1 V DC E

None Y

RS- 485 2

HART 3

Mounting o n panel surface 1

Pipe moun ting 2

Combus tion efficie ncy display Note 2 1

Blowdown 2

Auto calib ration 3

Combus tion efficie ncy display + Bl owdown Note 2 4

Combus tion efficie ncy display + Au to calibration Note 2 5

Blowdown + A uto calibration 6

Combus tion efficie ncy display + Bl owdown + Auto

calibra tion

English E

Chinese C

None Y

With val ve (For ø6 mm t ube) 1

With val ve + flowmeter ( For ø6 mm tube ) 2

With val ve (For ø1/ 4 inch tube) 3

With val ve + flowmeter ( For ø1/4 inch t ube) 4

With A

None Y

Type R thermo couple R

Type K thermo couple K

also available.

Note 2 7

4 5 6 7 8

ZTA 1 1

Digit Descrip tion Note Code

4 Measured gas

temperatu re

5 — — 1

6 Insertion len gth

[mm]

7 Power supply

voltage

8 Revision No. — 1

(Replacement Detector element)

Power supply Code symbols

100 to 120V AC ZFK8YY15-0Y0YY-0YY

200 to 240V AC ZFK8YY35-0Y0YY-0YY

For high tem perature (+150 0°C max.) 1

General u se (+80 0°C max.) 2

500 B

750 C

1000 D

1500 E

100V/ 115 V AC 50 /60 Hz 1

200V /220 V AC 50 /60Hz 3

230 V AC 5 0/60 Hz 5

(Dedicated cable)(Ejector)

4 5 6 7 8 9

ZRZ K R 1 -

Digit Descrip tion Note Code

Connec table

4

device

5 Type R t hermocoup le R

6 Length

7 N one 6 m YA

8 Revision No. — 1

9 Cable end

treatment

Note 1) F or connection between detector and converter, use a rainproof flexible conduit.

ZKM K

Rainproof fl exible conduit

None 10 m YB

None 15 m YC

None 20 m YD

None 30 m YE

None 40 m YF

None 50 m YG

None 60 m YH

None 70 m YJ

None 80 m YK

None 90 m YL

None 100 m YM

6 m 6 m Note 1 AA

10 m 10 m Note 1 BB

Note 1

15 m 15 m Note 1 CC

20 m 25 m Note 1 DD

None 0

One side ( detector side) 1

Both sides 2

Cable

4

Page 5

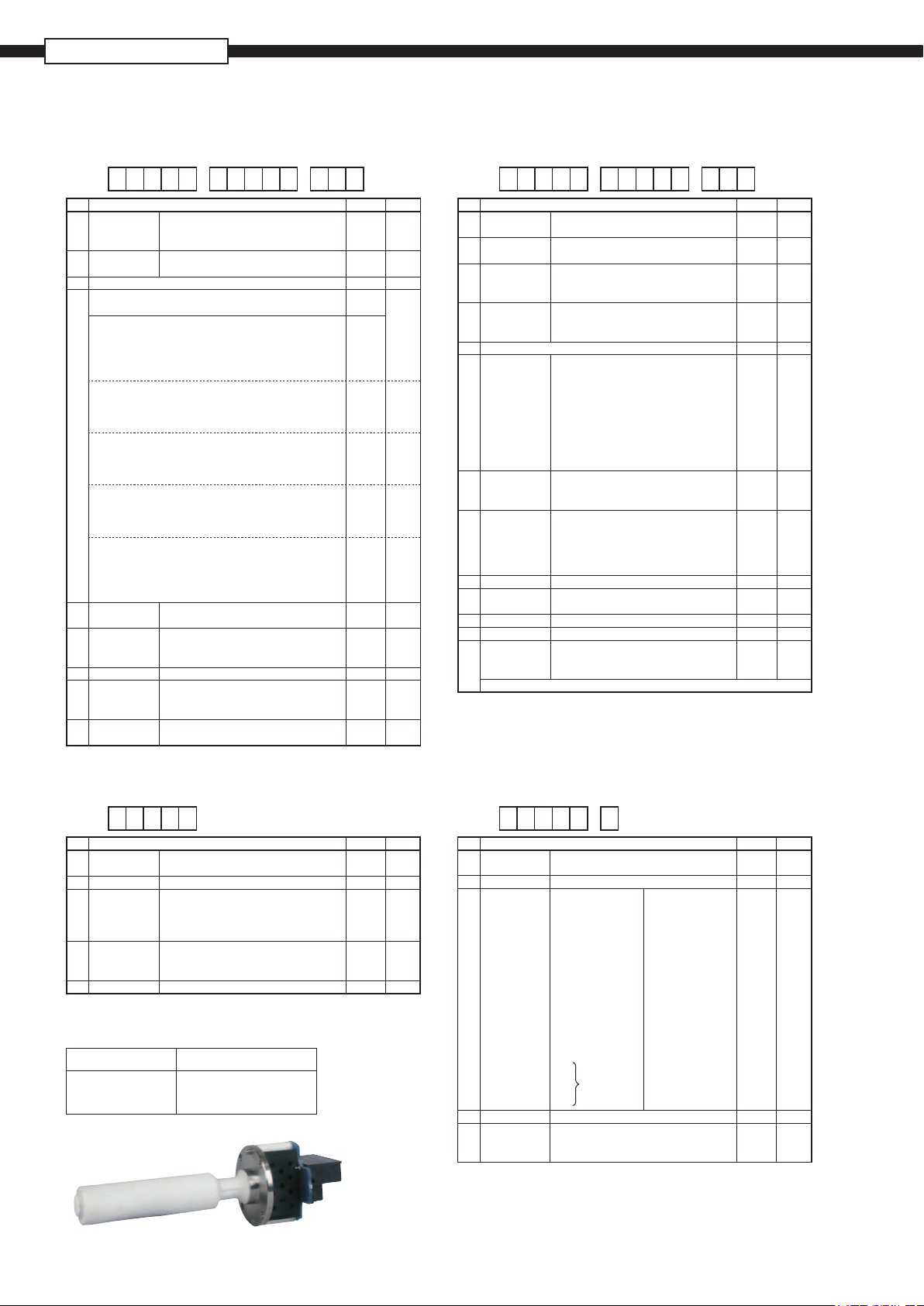

SCOPE OF DELIVERY

Detector ( ZFK) Detector main unit 1

Converter (ZKM ) Converter main unit 1

Ejector ( ZTA) Ejector main unit 1

Dedicated cable

(ZRZ)

Viton O ring 1

Mounting screw (M5 x 16 ) 6

Thermal sticker 1

Ceramic filter 1

Instruction manual 1

Flow guide tube (as specified ) 1

Heat-retaining cover (as specified) 1

Reference gas inlet port ( as specified) 2

Fuse (2.5A) 2

Ferrite core 1

Instruction manual 1

Metal

fittings

Insertion tube 1

Packing 1

M16 nut and washer ( stainless steel) 4

Cable ( of the specified length) 1

Items to be prepared separately:

(1) Standard gas for calibration

Type ZBM

Type ZBM

NSH4-01 (up to 5% O2 range)

NSJ4-01 (over 5% O2 range)

(2) Pressure regulator for standard gas (type ZBD61003)

(3) Flowmeter

Type; ZBD42203, 0.2 to 2L/min (for calibrating gas)

Type; ZBD42403, 1 to 10L/min (for ejector)

Description Q'ty

<For panel mounting >

M8 sems screw (stainless steel) 4

<For pipe mounting >

U bolt (stainless steel) 2

M8 nut and washer (stainless

steel)

Suppor t (stainless steel) 2

CAUTIONS

• If combustible gas (CO, H2 etc.) exists in the measured

gas, error will occur due to burning at the sensor section.

The inclusion of corrosive gas (Si vapor, alkaline metal, P,

Pb etc.) will shorten the life of the sensor.

• When the measured gas temperature is high (+300°C

or higher), the flange should be separated from the

furnace wall in order to bring the detector flange surface

temperature below the specified value +125°C). The flow

guide should be attached in the direction in which the gas

flow to the detector decreases.

• When much dust is included in the gas, the flow guide

tube should be attached at an inclination so that the flow

goes from below to above. And the flow guide tube

should be attached in the direction in which the gas flow

to the detector decreases.

• In the case of a refuse incinerator, automatic blow down

4

of the flow guide should not be performed (to prevent

corrosion of the flow guide tube due to drainage). Blowdown should be performed manually when change in

the indication has become very little with the furnace

stopped.

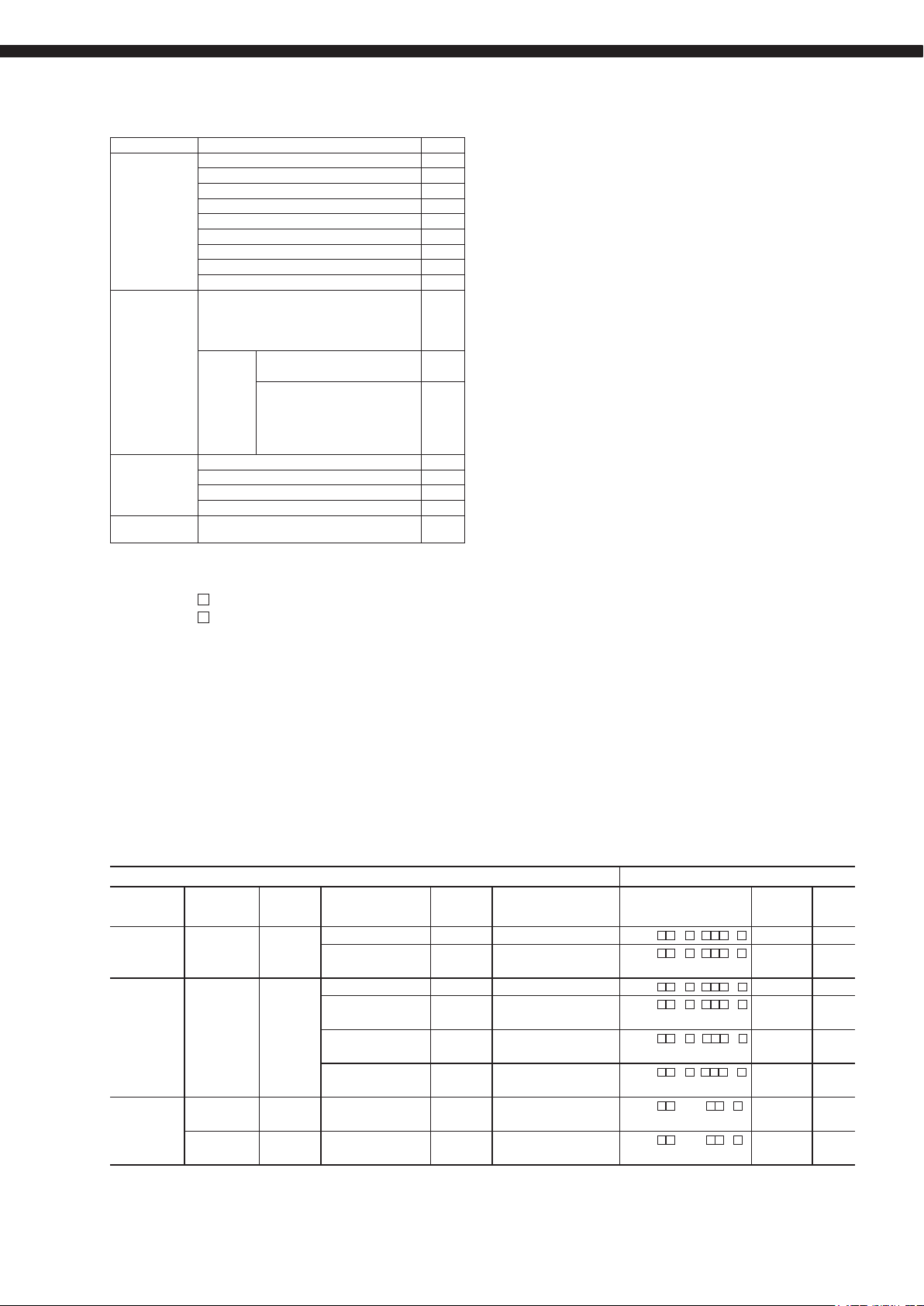

DEVICE CONFIGURATION

The device to be combined differ according to the conditions of the gas to be measured. Select the devices to be combined

with reference to the following table.

Measured gas Device configuration

Application Temperature Gas Flow DUST Heat-

General-use

(boiler)

For corrosive

gas (refuse

incinerator)

General-use

(boiler)

Note (1) Dust volume is approximate value.

(2) Instrument quality air or bottled air is available as reference air by selecting detector with reference air inlet.

600ºC or

less

600ºC or

less

800ºC or

less

1500ºC or

less

5 to 20m/s Less than 0.2g/Nm

Less than 10g/Nm

5 to 20m/s Less than 1g/Nm

Less than 10g/Nm

Less than 25g/Nm

Less than 25g/Nm

Less than

1m/s

Less than

1m/s

Less than 1g/Nm

Less than 1g/Nm

retaining

cover

3

—

3

—

3

—

3

—

3

no

3

yes

3

—

3

— SIC tube

Note Detector type Converter

Fuel; gas, oil

Fuel: coal

with blow down

Included low moisture

Included low moisture

with blow down

Included low moisture

with blow down

Included high moisture

with blow down

SUS316 tube

with blow down

ZFK8R

ZFK8R

ZFK8R

ZFK8R

ZFK8R

ZFK8R

ZFK8R

ZFK8R 5-0Y0 -1

with blow down

5

5- A -1

5

5- C -1

5

5- B -2

5

5- C -2

6

5- D -2

6

5- E -2

5- 0Y0 -1

type

ZKM —

ZKM —

ZKM —

ZKM —

ZKM —

ZKM —

ZKM ZTA2

ZKM ZTA1

Ejector

type

5

Page 6

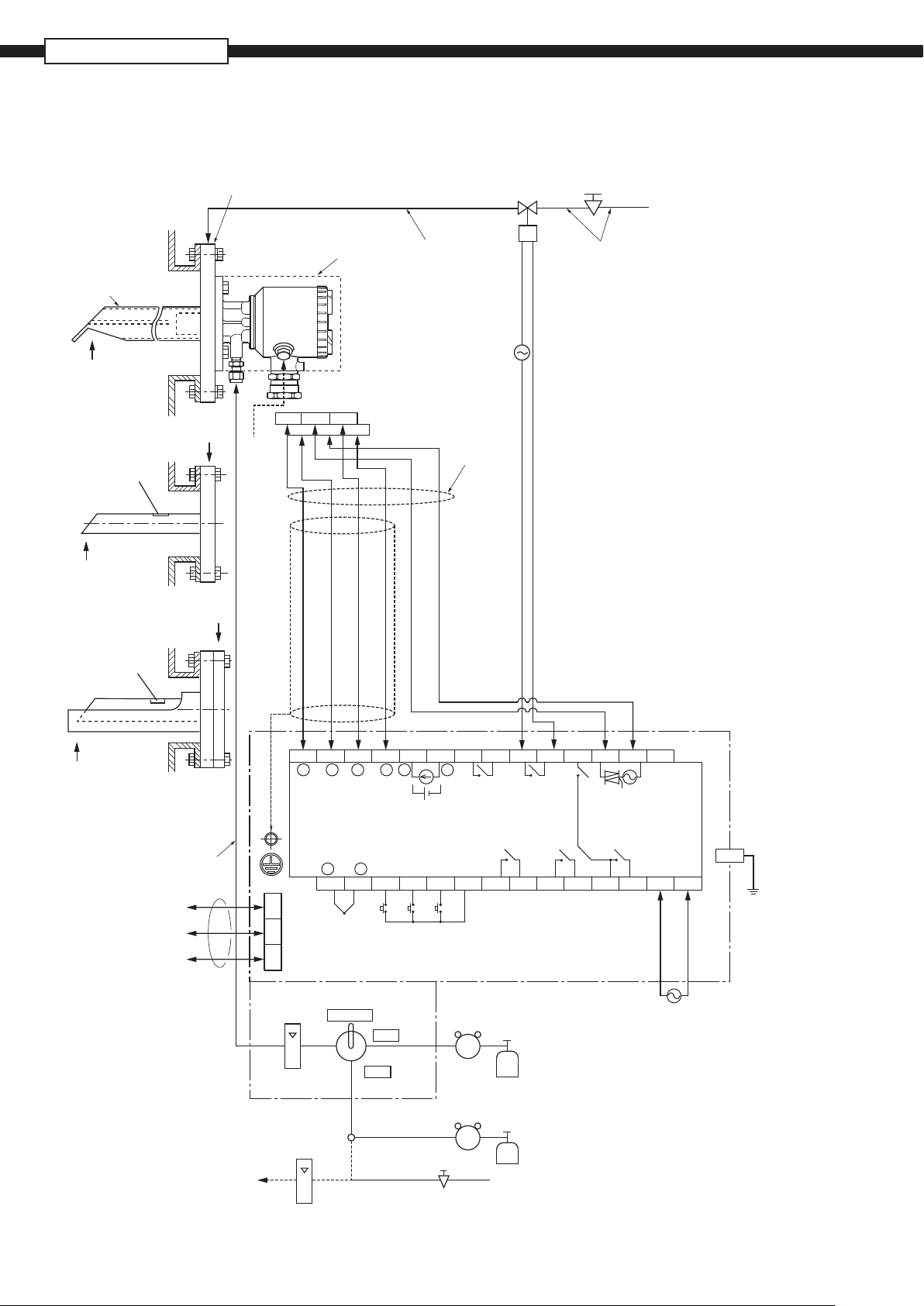

ZFK8, ZKM-2, ZTA

Flow guide tube system (with valve)

CONFIGURATION

Rc1/4

(upper side blow port should be selected)

Blow-down, 200 to 300kPa

Flow guide tube

Gas temperature.

600ºC max.

*2

Ref. air

Sample gas outlet

Gas temperature.

600ºC max.

Flow guide tube

for high particulate

Blue

Heat-retaining cover

123

6

Red

Yellow

Detector

(ZFK8)

45

White

Black

White

15ASGP

tube equivalent

or ø10/ø8 PTFE

pipe or copper pipe

(not supplied)

AC power

supply

Rainproof flexible

conduit.

(Max. 20m)

Solenoid valve

(not supplied)

Pressure regulator

(unnecessary when supply air pressure is

200 to 300kPa)

Supply air

15ASGP

tube equivalent

or ø10/ø8 PTFE

pipe or copper pipe

(not supplied)

Sample gas outlet

Gas temperature.

600ºC max.

Flow guide tube for high

particulate with cover

ø6mm or ø1/4 inch tube

for calibration gas

(not supplied)

RS485

(option)

(Option)

*2 Ref. air

to Detector

1152 3 4 5 6 7 8 9 10 11 1 2 13 14

−

O2

Thermocouple

for combustion

control

+

TC2

+

TC1

Thermocouple

input

−

+

O2 input

*4

16

+

−

Analog output

4 to 20mA DC

or 0 to 1V DC

Contact input

DI1

17

AO

or

DI2 DI3

18 19

−

FAULT BLOW

Fault

contact

output

ALAR M MA INTE

DICO M

20

Alarm

contact

output

21 22

Blow

contact

output

Maintenance

contact

output

23 24

ZV

GAS

Calibrating

gas contact

output

ZERO

1 2 3

TM-2

Flowmeter

Valve

MEASURE

Pressure regulator

(ZBD6)

ZERO

Standard gas

for zero point (ZBM)

*1

Span gas (ZBM)

Flowmeter

SPAN

Pressure regulator

(ZBD6)

*1 Air supply

Pressure regulator

(0.2 to 0.5L/min)

(not supplied)

(unnecessary when

supply air pressure

is 50 to 100kPa)

Converter (ZKM)

TM-1

HEATER

Calibrating gas

contact output

COM

25 28

Note:

AC power

SPAN

supply

GAS

AC

LSV

26 27

*1 Standard gas or instrumentation air

can be used in place of span gas.

*2 Instrument quality air or bottled air is

available as reference air instead of

ambient air.

*3 Protective earth.

*4 Connect the shield of a exclusive cable

with the ground terminal in the converter.

*5 HART communication (option) uses a

4-20mA analog output terminal.

PE

N

*3

6

Page 7

Flow guide tube system

Rc1/4

(upper side blow port should be selected)

Blow-down, 200 to 300kPa

Solenoid valve

(not supplied)

Pressure regulator

(unnecessary when supply air pressure is

200 to 300kPa)

Supply air

Flow guide tube

Gas temperature.

600ºC max.

Sample gas outlet

Gas temperature.

600ºC max.

Flow guide tube

for high particulate

Sample gas outlet

*2

Ref. air

Heat-retaining cover

6

Blue

Yellow

123

Detector

(ZFK8)

45

Red

White

Black

White

15ASGP

tube equivalent

or ø10/ø8 PTFE

pipe or copper pipe

(not supplied)

AC power

supply

Rainproof flexible

conduit.

(Max. 20m)

15ASGP

tube equivalent

or ø10/ø8 PTFE

pipe or copper pipe

(not supplied)

Gas temperature.

600ºC max.

Flow guide tube for high

particulate with cover

+

O2

O2 input

*4

1152 3 4 5 6 7 8 9 10 11 1 2 13 14

ø6mm or ø1/4 inch tube

for calibration gas

(not supplied)

1 2 3

RS485

(option)

TM-2

Flowmeter

(ZBD4)

(1 to 1.5L/min)

*2 Ref. air

to Detector

(0.2 to 0.5L/min)

(not supplied)

*1 Standard gas or instrumentation air can be used in place of span gas.

Note:

*2 Instrument quality air or bottled air is available as reference air instead

of ambient air.

*3 Protective earth.

*4 Connect the shield of a exclusive cable with the ground terminal in

the converter.

*5 HART communication (option) uses a 4-20mA analog output terminal.

+

−

Thermocouple

Thermocouple

for combustion

control

+

−

TC2

16

TC1

input

+

−

4 to 20mA DC

Contact input

DI1

17

Joint

AO

or

Analog output

or 0 to 1V DC

DI2 DI3

18 19

Solenoid valve

(not supplied)

Solenoid valve

(not supplied)

−

FAULT BLOW

Fault

contact

output

ALAR M MAIN TE

DICO M

20

Blow

contact

output

Alarm

Maintenance

contact

contact

output

output

21 22

Pressure regulator

(ZBD6)

23 24

Pressure regulator

(unnecessary when supply air pressure is 50 to 100kPa)

Pressure regulator

(ZBD6)

ZV

ZERO

GAS

Calibrating

gas contact

output

Calibrating gas

contact output

COM

25 28

Standard gas

for zero point (ZBM)

*1

Standard gas for

span point (ZBM)

HEATER

SPAN

GAS

26 27

Span point

Converter (ZKM)

AC power

supply

AC

N

LSV

AC power

supply

*1 Air supply

TM-1

*3

PE

7

Page 8

ZFK8, ZKM-2, ZTA

Ejector system (with valve)

Gas temperature.

1500ºC max.

Bule

Ejector (ZTA)

Detector (ZFK8)

123

6

Black

Yellow

Red

Flowmeter

Ejector (5 to 10L/min)

Power supply

1

2

Heater temperature drop

4

5

Alarm

Copper pipe

ø10/ø8mm

(not supplied)

45

White

White

(ZBD)

Copper pipe ø6/ø4mm

(not supplied)

Solenoid valve

(not supplied)

AC power

supply

Rainproof flexible

conduit.

(Max. 20m)

Pressure regulator

(unnecessary when supply air pressure

is 200 to 300kPa )

Joint

Copper pipe ø10/ø8mm

(not supplied)

Supply air

ø6mm or ø1/4 inch tube

for calibration gas

(not supplied)

RS485

(option)

(Option)

*2 Ref. air

to Detector

1152 3 4 5 6 7 8 9 10 11 1 2 13 14

−

O2

Thermocouple

for combustion

control

+

TC2

+

TC1

Thermocouple

input

−

+

O2 input

*4

16

+

−

Analog output

4 to 20mA DC

or 0 to 1V DC

Contact input

DI1

17

AO

or

DI2 DI3

18 19

−

FAULT BLOW

Fault

contact

output

ALAR M MA INTE

DICO M

20

Alarm

contact

output

21 22

Blow

contact

output

Maintenance

contact

output

23 24

ZV

ZERO

GAS

Calibrating

gas contact

output

Calibrating gas

contact output

COM

1 2 3

TM-2

Flowmeter

Valve

MEASURE

Pressure regulator

(ZBD6)

ZERO

Standard gas

for zero point (ZBM)

*1

Span gas (ZBM)

Flowmeter

SPAN

Pressure regulator

(ZBD6)

*1 Air supply

Pressure regulator

(0.2 to 0.5L/min)

(not supplied)

(unnecessary when

supply air pressure

is 50 to 100kPa)

*1 Standard gas or instrumentation air

Note:

can be used in place of span gas.

*2 Instrument quality air or bottled air is

available as reference air instead of

ambient air.

*3 Protective earth.

*4 Connect the shield of a exclusive cable

with the ground terminal in the converter.

*5 HART communication (option) uses a

4-20mA analog output terminal.

HEATER

Heater

AC power

SPAN

supply

GAS

AC

LSV

26 27

25 28

TM-1

N

AC power

supply

*3

PE

8

Page 9

Ejector system

Gas temperature.

1500ºC max.

Ejector (ZTA)

Detector (ZFK8)

6

Bule

123

Yellow

Black

Red

Flowmeter

Ejector (5 to 10L/min)

Power supply

1

2

Heater temperature drop

4

5

Alarm

Copper pipe

ø10/ø8mm

(not supplied)

45

White

White

(ZBD)

Copper pipe ø6/ø4mm

(not supplied)

Solenoid valve

(not supplied)

AC power

supply

Rainproof flexible

conduit.

(Max. 20m)

Pressure regulator

(unnecessary when supply air pressure

is 200 to 300kPa )

Joint

Copper pipe ø10/ø8mm

(not supplied)

Supply air

1152 3 4 5 6 7 8 9 10 11 1 2 13 14

+

−

O2

O2 input

*4

Thermocouple

for combustion

ø6mm or ø1/4 inch tube

for calibration gas

(not supplied)

control

+

TC2

1 2 3

RS485

(option)

TM-2

(1 to 1.5L/min)

Flowmeter

(ZBD4)

*2 Ref. air

to Detector

(0.2 to 0.5L/min)

(not supplied)

*1 Standard gas or instrumentation air can be used in place of span gas.

Note:

*2 Instrument quality air or bottled air is available as reference air instead

of ambient air.

*3 Protective earth.

*4 Connect the shield of a exclusive cable with the ground terminal in

the converter.

*5 HART communication (option) uses a 4-20mA analog output terminal.

+

−

TC1

Thermocouple

input

−

DI1

16

17

Joint

AO

+

or

Analog output

4 to 20mA DC

or 0 to 1V DC

Contact input

DI2 DI3

18 19

Solenoid valve

(not supplied)

Solenoid valve

(not supplied)

−

FAULT BLOW

Fault

contact

output

ALAR M MA INTE

DICO M

20

Blow

gas contact

contact

output

Alarm

Maintenance

contact

21 22

Pressure regulator

(ZBD6)

contact

output

output

23 24

Pressure regulator (unnecessary when

supply air pressure is 50 to 100kPa)

Pressure regulator

(ZBD6)

ZV

ZERO

GAS

Calibrating

output

Standard gas

for zero point (ZBM)

HEATER

Calibrating gas

contact output

COM

25 28

Span gas

*1 Standard gas for

span point (ZBM)

SPAN

GAS

26 27

*1 Air supply

AC power

supply

AC

LSV

TM-1

N

AC power

supply

*3

PE

9

Page 10

ZFK8, ZKM-2, ZTA

OUTLINE DIAGRAM

ø80

ø67

6-ø6

60°

ø80

ø67

6-ø6

(Unit:mm)

ø26

Ref. Air inlet (to order)

SUS316,for ø6/ø4 tube

or 1/4 inch tube

Approx.62

Filter

Approx.62

Detector (ZFK8)

Heat-retaining cover

5

(To order )

Approx.30

Calibration gas inlet

(To order)

SUS316,for ø6/ø4 tube

or 1/4 inch tube

Heat-retaining cover

5

(to order)

Approx.132

Approx.130

Approx.132

Approx.130

Terminal box

Ground-wire

Screw: M4

Dedicated

Cable gland

Terminal box

EXTERNAL CONNECTION DIAGRAM

ø79

Heater Thermocouple

ø85

125.5

1

Black / White/ red / White/ yellow / blue

2-core wire 4-core wire

3

2

Dedicated cable

Element output

4 5 6

60°

ø26

ZFK8R 3

Ball valve

Ref. air inlet (to order)

SUS316,for ø6/ø4 tube

or 1/4 inch tube

Calibration gas inlet

Rc1/4 INT.THD.

Filter

Approx.100

Valve handle

ø79

125.5

Ground-wire

screw: M4

Dedicated cable gland

ø85

10

Page 11

Sensor unit (ZFK8YY)

(132.7)

(88.4) 3.5

(?17.5)

20

4-φ3.5(Mount for detector)

TK4J4664R0

45°

45°

T+

φ

35

40

S+

6

madeinjapan

5

S-

H

1

3

4

2

H

T-

Flow guide tube

12

Approx. L

Approx. 20

Gas inlet

34

155

130

67

Oxygen detector

Z F K 8 R 5 - 5 A 3

3

2.7

0.3

5 7

0.5

3.3

0.75

4.1

Code 11th

L (m)

MASS

Approx.(kg)

5

7

1

1

1.0

4.8

Z

L=

(to order)

Gas outlet

20

6-M5

detector side

8–15

MTG. holes

Flow guide tube (with blow-down nozzle)

18

Approx. L

Approx. 20

3

60.5

67

Gas inlet

6-M5

detector side

155

130

67

Z F K 8 R 5 - 5 C 3

5

7

1

Oxygen detector

Gas outlet

Blow down air inlet

4-Rc1/4

with plug int.thd.

8–15

MTG. holes

Code 11th

L (m)

Mass

Approx.(kg)

3

0.3

3.0

5 7

0.5 0.75 1.0

3.8

4.8

1

5.7

Z

L=

(to order)

11

Page 12

ZFK8, ZKM-2, ZTA

4 - Rc 1/4

with plug int thd.

6 - M5 Screw

for mounting

to detector

Flange: JIS 5K80A FF

ZFK MTG. position

Packing

Gas flow

Flow guide tube (for high particulate)

180

145

Blow down air inlet

Select an upper port to

avoid the condensation

in the piping

29.5

Gas outlet

Tube (50A SCH40)

800

67

8 - 19

MTG. hole

185

Z F K 8 R 5 - 6 D

50

30

Code 11th

L (m)

Mass

Approx.(kg)

3

0.3

4.5

3

5

7

1

5 7

0.5 0.75 1.0

5.6

8.3

7.0

1

Z

L=

(to order)

4 - Rc 1/4

with plug int thd.

6 - M5 Screw

for mounting

to detector

Flange: JIS 5K80A FF

ZFK MTG. position

Packing

Gas flow

Flow guide tube (for high particulate with cover)

180

145

Blow down air inlet

Select an upper port to

avoid the condensation

in the piping

(175)

50

30

Gas outlet

(790)

67

29.5

800

8 - 19

MTG. holes

Z F K 8 R 5 - 6 E

3

Code 11th

L (m)

Mass

Approx.(kg)

0.3

7.1

5 7

0.5 0.75 1.0

9.0

11.4

3

5

7

1

1

Z

L=

(to order)

13.6

12

Protection tube (65A SCH40)

(38)

Tube (50A SCH40)

Page 13

Flow guide tube (

12

Approx. L

3

Gas inlet

67

60.5

Approx. 40

for corrosive gas)

155

130

67

Oxygen detector

Viewed from P direction

105

140

(JIS 10K65ARF)

8

Gas inlet

25

Ejector air

outlet

(Rc1/4)

Gas outlet

6-M5

detector side

Ejector (ZTA)

42.7

4-M16 bolt

P

L [mm]

500 750 1000 1500

Approx. L

30

EXTERNAL CONNECTION DAIAGRAM

1 2 3 4 5

AC

power supply

AC100/110V

AC200/220V

AC230V

Power consumption: 150 W

Heater temp.drop alarm

Z F K 8 R 5 - 5 B 3

3

Code 11th

L (m)

MASS

Approx.(kg)

8- 15

MTG. holes

190

217

40

35

Blow -down air inlet

(Rc1/4)

Ejector air inlet

(Rc1/4)

40

0.5

0.3

3.3

170

50

45

Cable gland

(A15C)

5 7

4.5

0.75

6.1

5

7

1

1

1.0

7.6

Detector

(ZFK8)

Z

L=

(to order)

13

Page 14

ZFK8, ZKM-2, ZTA

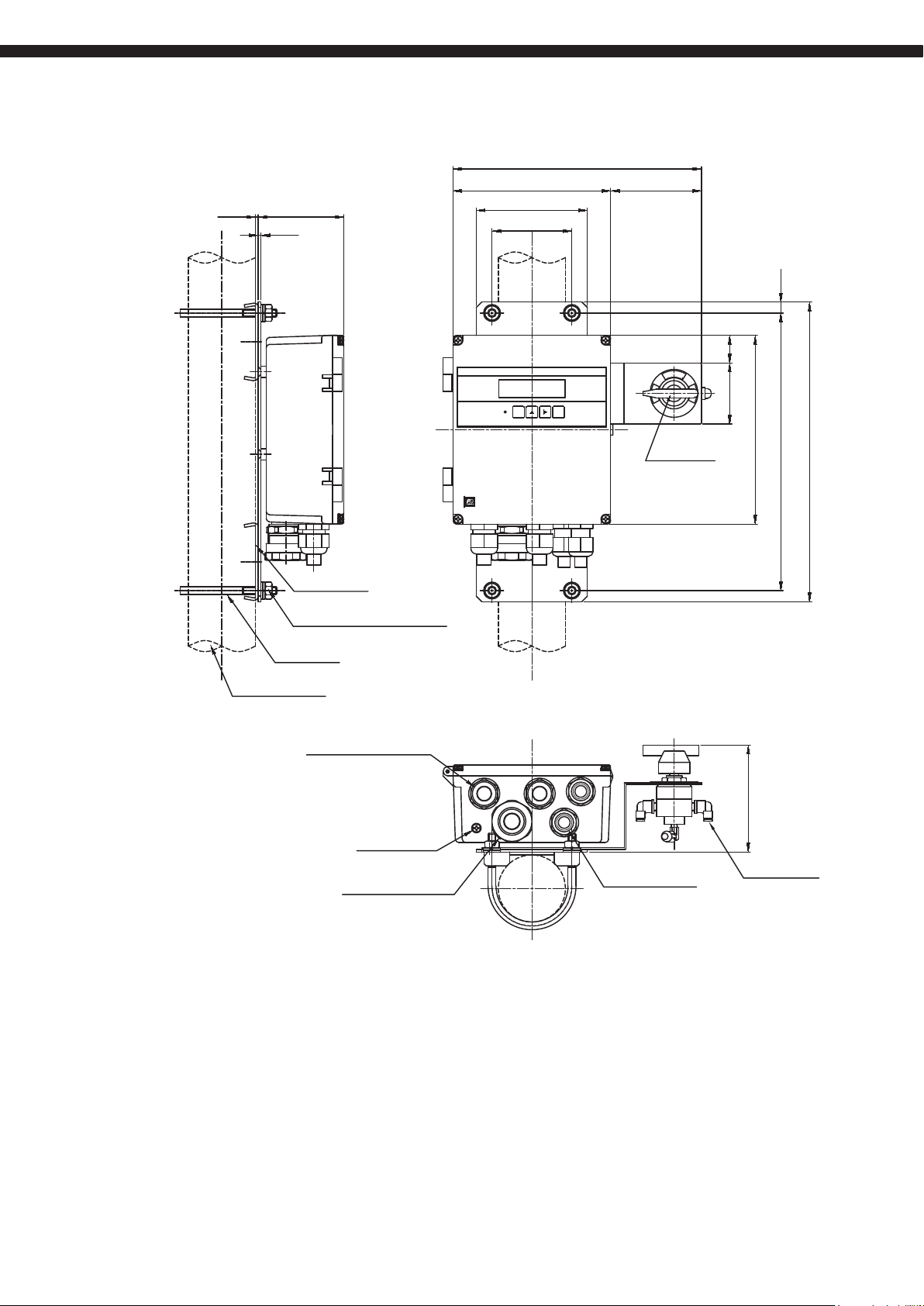

Converter (ZKMA)

<IP66 enclosure>

2.5

77

2-ø21.2, 3-mm depth

For cable gland

Earth terminal (M4)

Waterproof connector for

connection to detector

ZKM

Oxygen Analyzer

142

100

72

Zirconia Oxygen Analyzer

ENTESC

Mounting hole 4-ø9

10

170

250

2-ø17, 3-mm depth

For cable gland

270

*2

Exclusive

cable

Ground

terminal

M4

sensor

O

O2 sensor

input

2

thermocouple

input

1152 3 4 5 6 7 8 9 10 11 12 13 14

−

2

+

TC2

Thermocouple

input type R

(not supplied)

+ +

TC1

DI1

−

16

17

Contact input

Short circuit : on (Current 5mA)

Open : off (Voltage 5V)

+

O

EXTERNAL TERMINAL (TM1) / Terminal M3

Analog

output

4-20mA DC

or 0-1V DC

AO

− −

or

DI2 DI3

18 19

Fault

contact output

250V AC/3A

30V DC/3A

FAULT

ALARM MAINTE

DICOM

21 22

20

Alarm

contact output

250V AC/3A

30V DC/3A

Blow contact

output

250V AC/3A

30V DC/3A

BLOW

ZV

23 24

Maintenance

contact output

250V AC/3A

30V DC/3A

*1

sensor

O

2

heater power

output

ZERO

GAS

HEATER

SPAN

GAS

26 27

25 28

Calibrating gas

contact output

250V AC/3A

30V DC/3A

Note 1) The heater power supply is the same as the converter power supply.

Note 2) Be sure to connect the shield of the cable to the ground in the main body.

Note 3) HART communication (option) uses a 4-20 mA analog output.

AC

N

LSVCOM

AC

Power supply

input

100 to120V AC

200 to 240V AC

RS485 communication

(option) terminal

1

2 3

GND TRX+ TRX-

14

Page 15

Converter (ZKMA)

<IP66 enclosure> with selector valve

77.12.5

2.5

ZKM

Oxygen Analyzer

224

142 82

100

72

Zirconia Oxygen Analyzer

ENTESC

A

E

S

.

M

N

O

Z

S

Valve (option)

10

2555

170

250

270

Support (option)

Spring washer, washer, nut (option)

U bolt (option)

(50A pipe or 2B pipe)

Cable gland (option)

for ø6-ø12 mm tube

Earth terminal (M4)

Waterproof connector for

connection to detector

Cable gland (option)

for ø5-ø10 mm tube

96.5

For ø6 mm tube

or ø1/4 inch tube

15

Page 16

ZFK8, ZKM-2, ZTA

Converter (ZKMA)

<IP66 enclosure> with selector valve and owmeter

77.12.5

2.5

ZKM

Oxygen Analyzer

224

142 82

100

72

Valve

(option)

Zirconia Oxygen Analyzer

ENTESC

A

E

S

.

M

N

O

Z

S

170

250 10

270

Support (option)

Spring washer, washer, nut (option)

U bolt (option)

(50A pipe or 2B pipe)

Cable gland (option)

for ø6-ø12 mm tube

Earth terminal (M4)

Waterproof connector for

connection to detector

Cable gland (option)

for φ5-φ10 mm tube

Flowmeter (option)

116

For ø6 mm tube

or ø1/4 inch tube

16

Page 17

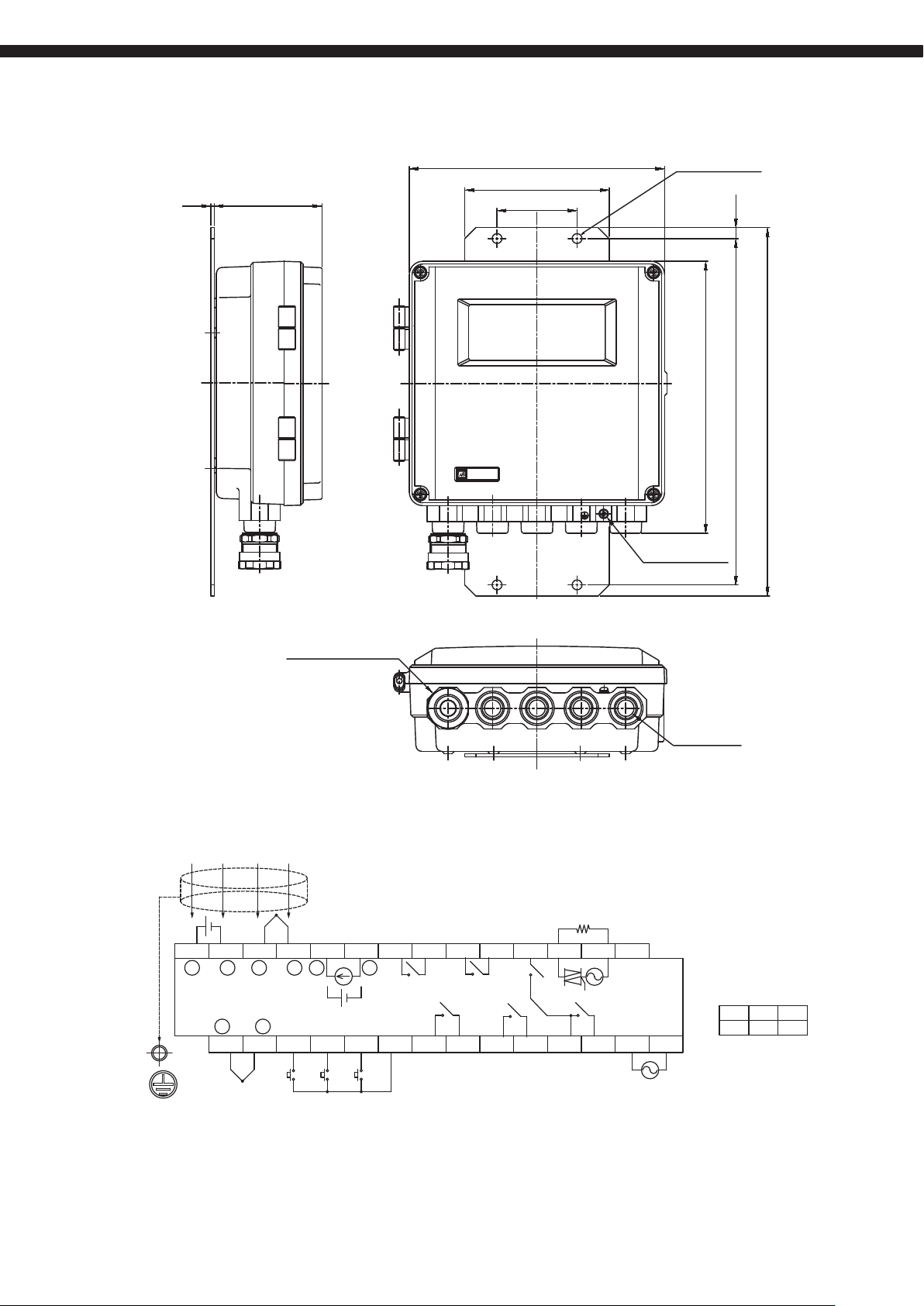

Converter (ZKMB)

<IP67 enclosure>

230

130

973

ZKM

Oxygen Analyzer

72

Mounting hole 4-ø9

245

Earth terminal (M4)

10

312

332

*2

Exclusive

cable

Ground

terminal

M4

Waterproof connector for

connection to detector

sensor

O

O2 sensor

input

2

thermocouple

input

1152 3 4 5 6 7 8 9 10 11 12 13 14

−

2

+

TC2

Thermocouple

input type R

(not supplied)

+ +

TC1

DI1

−

16

17

Contact input

Short circuit : on (Current 5mA)

Open : off (Voltage 5V)

+

O

EXTERNAL TERMINAL (TM1) / Terminal M3

Analog

output

4-20mA DC

or 0-1V DC

AO

− −

or

DI2 DI3

18 19

Fault

contact output

250V AC/3A

30V DC/3A

FAULT

ALARM MAINTE

DICOM

21 22

20

Alarm

contact output

250V AC/3A

30V DC/3A

Blow contact

output

250V AC/3A

30V DC/3A

BLOW

ZV

ZERO

23 24

Maintenance

contact output

250V AC/3A

30V DC/3A

*1

sensor

O

2

heater power

output

GAS

HEATER

SPAN

GAS

26 27

25 28

Calibrating gas

contact output

250V AC/3A

30V DC/3A

100 to120V AC

200 to 240V AC

AC

N

LSVCOM

AC

Power supply

input

4-G1/2

for cable gland

RS485 communication

(option) terminal

1

GND TRX+ TRX-

2 3

Note 1) The heater power supply is the same as the converter power supply.

Note 2) Be sure to connect the shield of the cable to the ground in the main body.

Note 3) HART communication (option) uses a 4-20 mA analog output.

17

Page 18

ZFK8, ZKM-2, ZTA

230 80

Converter (ZKMB)

<IP67 enclosure> with selector valve

973

2.5

130

72

10

A

E

S

.

M

N

O

Z

55 58.5

S

Support (option)

Spring washer, washer, nut (option)

U bolt (option)

(50A pipe or 2B pipe)

Waterproof connector for

connection to detector

ZKM

Oxygen Analyzer

Valve

(option)

Earth terminal (M4)

284

97

312

332

18

For ø6 mm tube

or ø1/4 inch tube

Cable gland (option) × 4

for ø6-ø12 mm tube

Page 19

Converter (ZKMB)

<IP67 enclosure> with selector valve and owmeter

2.5

973

ZKM

Oxygen Analyzer

230 80

130

72

Valve

(option)

10

58.5

A

E

S

.

M

N

O

Z

S

332

312

284

Support (option)

Spring washer, washer, nut (option)

U bolt (option)

(50A pipe or 2B pipe)

Waterproof connector for

connection to detector

Earth terminal (M4)

Cable gland (option) × 4

for ø6-ø12 mm tube

Flowmeter (option)

117

For ø6 mm tube

or ø1/4 inch tube

19

Page 20

Caution on Safety

ZFK8, ZKM-2, ZTA

*Before using this product, be sure to read its instruction manual in advance.

Grobal Sales Section

Instrumentation & Sensors Planning Dept.

1, Fuji-machi, Hino-city, Tokyo 191-8502, Japan

http://www.fujielectric.com

Phone: +81-42-514-8930 Fax: +81-42-583-8275

http://www.fujielectric.com/products/instruments/

Information in this catalog is subject to change without notice.

Print ed in J apan

Loading...

Loading...