使用说明书

氧化锆氧变换器

通信功能(MODBUS)

型号:ZKM

INZ-TN5A0506-C

- 目录 -

1. 关于通信功能 ·········································································································································· 1

1.1 概述 ··················································································································································· 1

2. 规格 ························································································································································ 2

2.1 通信规格 ············································································································································ 2

3. 连接 ························································································································································ 3

3.1 跨接器的设定····································································································································· 3

3.2 端子配置(TM2)······························································································································ 3

3.3 连接 ··················································································································································· 4

4. 通信条件设定 ·········································································································································· 6

4.1 设定项目 ············································································································································ 6

4.2 设定操作 ············································································································································ 6

5. MODBUS通信协议 ·································································································································· 7

5.1 概述 ··················································································································································· 7

5.2 信息的结构········································································································································· 8

5.3 从机的应答········································································································································· 9

5.4 功能代码 ·········································································································································· 10

5.5 错误校验代码(CRC-16)的计算 ·····································································································11

5.6 传送控制步骤··································································································································· 13

6. 信息的详细内容····································································································································· 15

6.1 读取字数据[功能代码:03H] ········································································································ 15

6.2 读取只读字数据[功能代码:04H]································································································· 16

6.3 写入字(1 个字)数据[功能代码:06H]······················································································· 17

6.4 写入连续字数据[功能代码:10H]································································································· 18

7. 地址映射表和数据格式·························································································································· 19

7.1 数据格式 ·········································································································································· 19

7.1.1 传输数据格式····························································································································· 19

7.1.2 小数点位置及测量单位的设定方法····························································································· 19

7.1.3 测量数据超过范围时的操作········································································································ 19

7.2 地址映射表······································································································································· 20

-i-

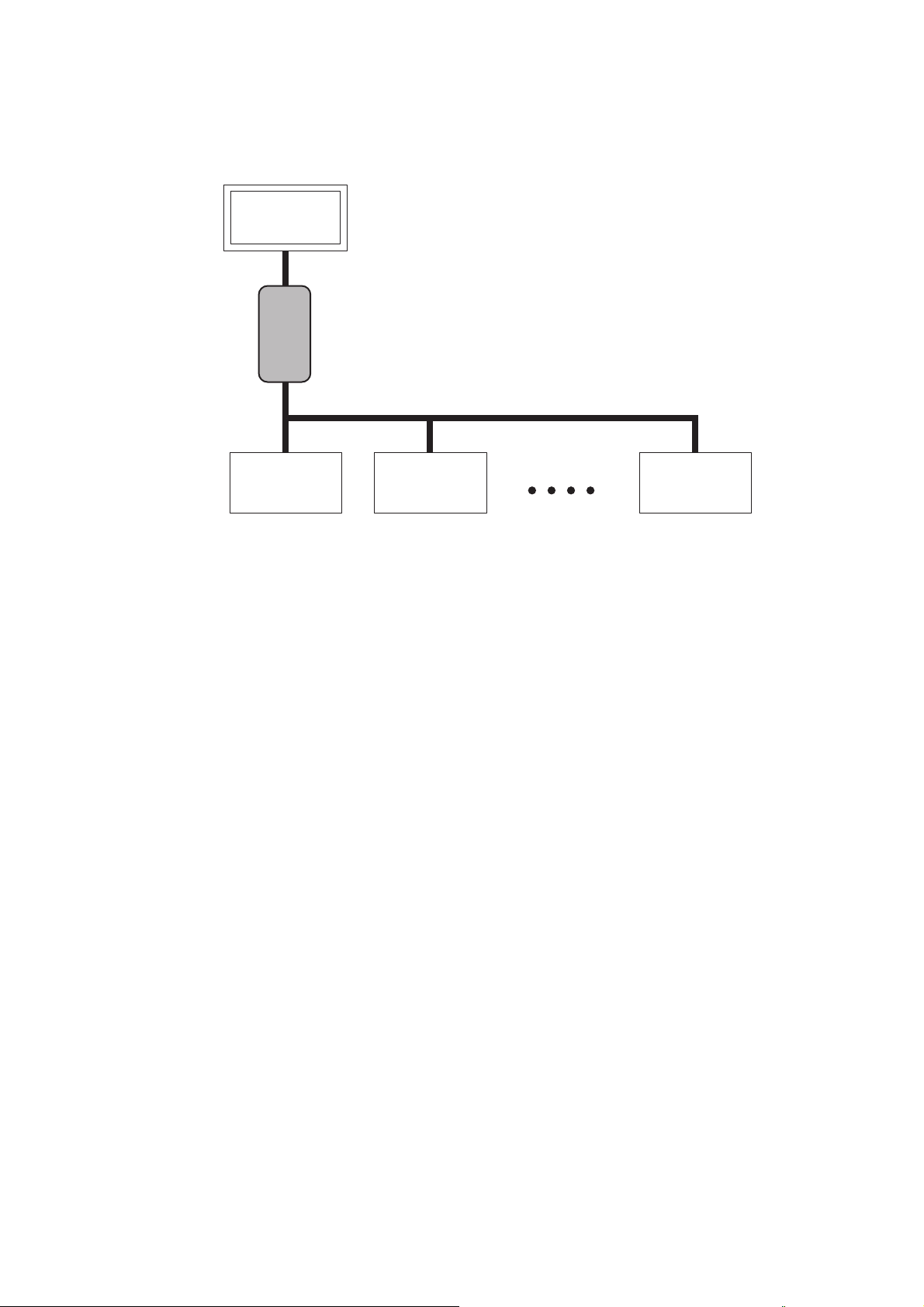

1.1 概述

• 本装置具有通过 RS-232C 及 RS-485 接口进行通信的功能,能够与上位计算机等进行双向数据传

输。

• 通信系统由主机和从机构成。

使用 RS-485 接口时,1 台主机(上位计算机、可编程控制器、图示面板等)最多可以连接 31 台

从机(本装置)。

使用 RS-232C 接口时,1 台主机只可以连接 1 台从机(本装置)。

• 由于每次可以通信的从机仅限 1 台,所以主机要通过设定至各从机的“站号”确定通信对象。

• 为了主机和从机之间进行通信,接收、发送数据的格式必须相同。本装置根据 MODBUS 通信协

议确定了通信数据的格式。

1. 关于通信功能

-1-

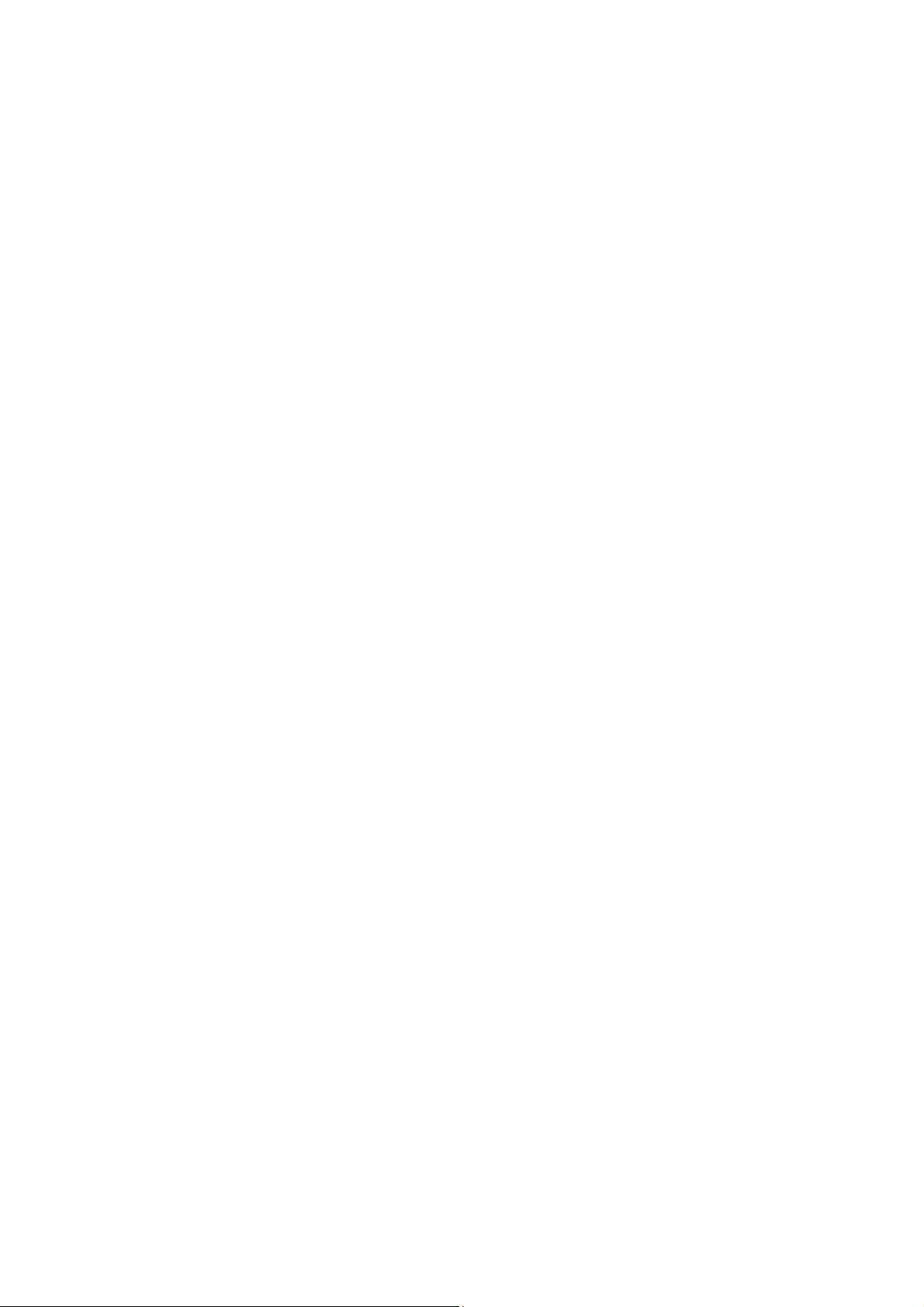

2.1 通信规格

① RS-232C 接口

项目 规格

电气规格 符合 EIA RS-232C 标准

通信方式 2线式 半双工

同步方式 起止式同步

连接状态 1:1

最多连接装置数 1台

传输速率

数据格式

传输代码 HEX 值(MODBUS RTU 模式)

错误校验

隔离 通信部位与其它部位为非隔离

② RS-485 接口

2. 规格

38400 bps

数据长度 8位

停止位 1位

奇偶校验 无

X 流程控制 无

CRC-16

项目 规格

电气规格 符合 EIA RS-485 标准

通信方式 2线式 半双工

同步方式 起止式同步

连接状态 1:N

最多连接装置数 31 台

通信距离 最长 500m(最长)

通信速率

数据格式

传输代码 HEX 值(MODBUS RTU 模式)

错误校验

隔离 与内部回路为隔离

38400 bps

数据长度 8位

停止位 1位

奇偶校验 无

X 流程控制 无

CRC-16

信号线与接地之间为功能隔离

-2-

ࡻ

为了防止触电及故障,在所有配线连接完成之前,请勿通电。

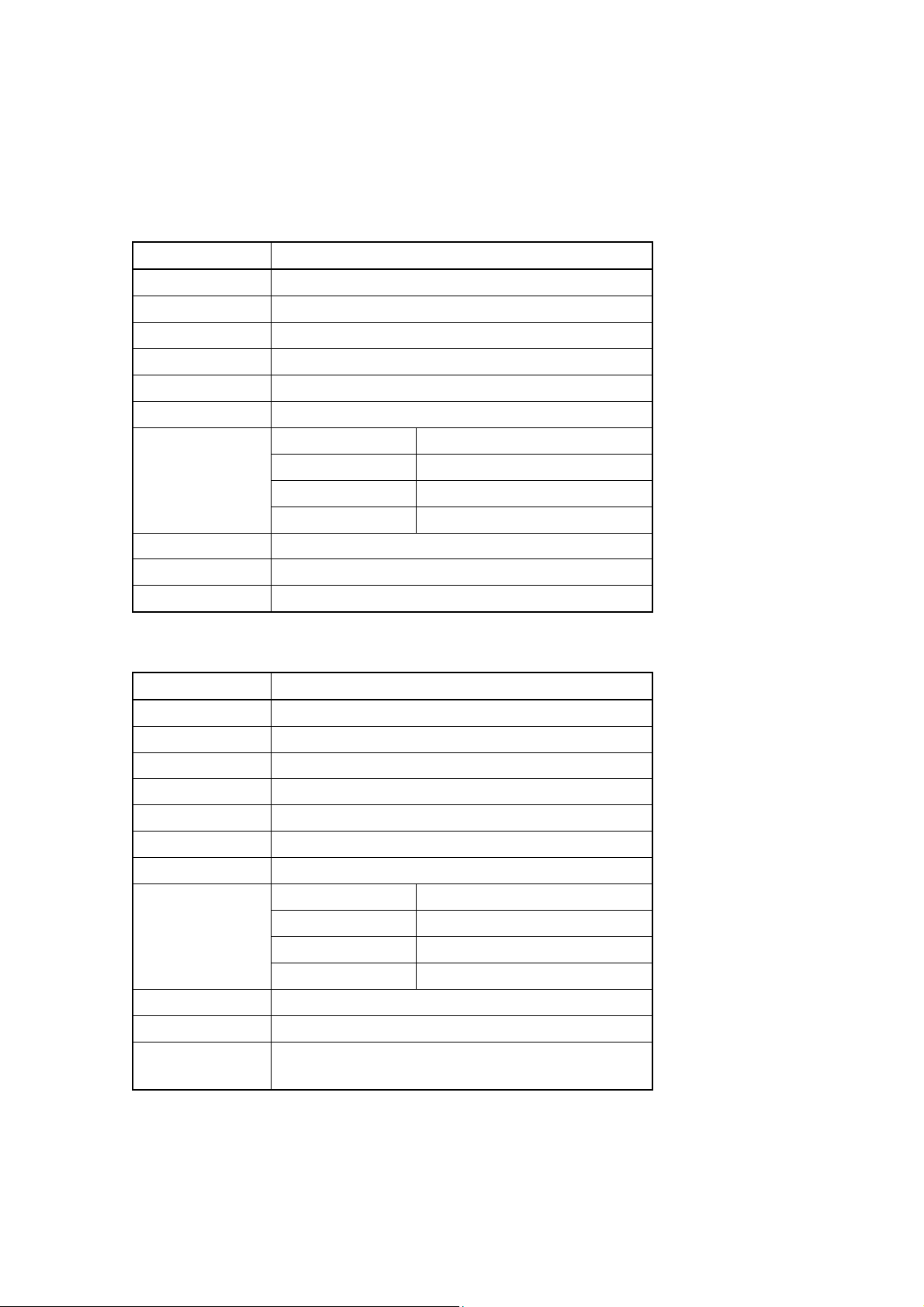

3.1 跨接器的设定

按照通信类型,请切换跨接器。

3. 连接

通信类型

RS232C

RS485

JP1 JP2 JP5

3-5

4-6

1-3

2-4

3-5

4-6

1-3

2-4

3.2 端子配置(TM2)

① RS-232C 接口

端子号 信号名称 引脚连接图

1

2

3

② RS-485 接口

端子号 信号名称 引脚连接图

1 RTxD+

2 RTxD–

3

Transmit Data (TXD)

Recive Data (RXD)

信号接地

信号接地

2-3

1-2

123

123

-3-

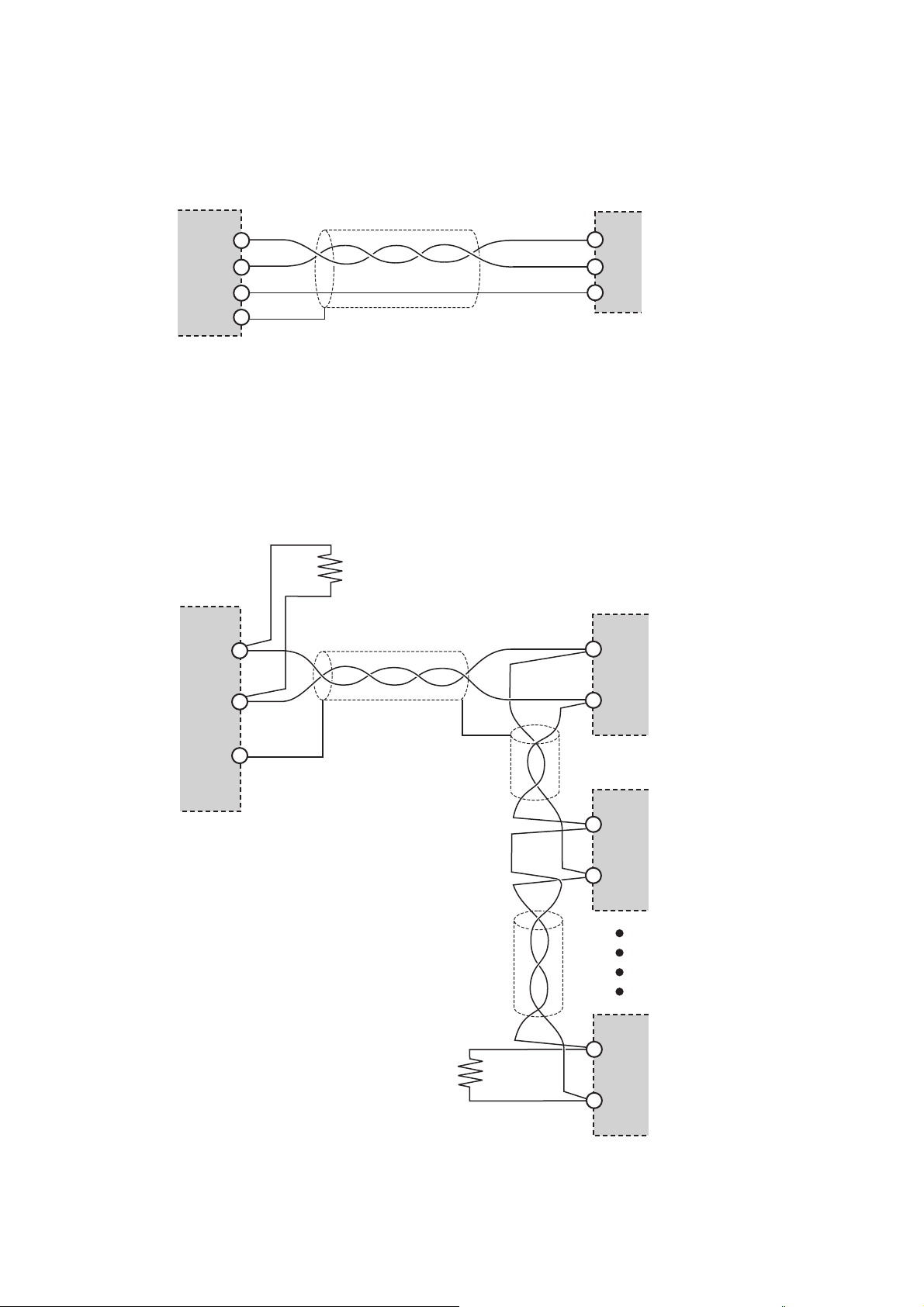

3.3 连接

① RS-232C 接口

᎐

ൺב༺ღ

۰˄ZKM˅

RXD

TXD

TXD

RXD

SG SG

FG

② RS-485 接口

• 请使用屏蔽双绞线连接。

(我们推荐的电线为:KPEV-SB(古河电工制造))

• 电缆最大长度为 500m。在 1 线路上可以连接 1 台主机和最多 31 台从机(本装置)。

• 请将终端电阻 100Ω(1/2W 以上)接在线路两端。

• 请将屏蔽线在靠主机的一点接地。

፮ޤݢᏟ

᎐

+

100Ω˄1/2W˅

ൺב༺ღ

۰˄ZKM˅

RTxD+

-

RTxD

-

SG

+

-

+

፮ޤݢᏟ

100Ω˄1/2W˅

-

• 并不一定要连接 SG,但是连接 SG 可以减少因噪声引起的通信错误。

-4-

• 在对本装置施加的噪声等级超过 500V 的环境下使用本装置时,我们建议您在靠主机的线路上

使用噪声过滤器(如下图)。

[噪声过滤器](推荐产品):ZRAC2203-11(TDK 制造)

᎐

ወ໌ࣰఌධ

RS-485

ׁᎧ

• 通信期间如果 EMC 发生问题,请在通信电缆上装上铁氧体芯,用来降噪。

铁氧体芯(推荐产品): ZCAT 系列(TDK 制造)

MSFC 系列(森宫电机制造)

-5-

4. 通信条件设定

为了主机与本装置之间能够正常通信,需要进行下列设定:

• 主机与本装置的所有通信条件应设定为同一条件。

• 连接在同一线路上的所有本装置需设定各不相同的“站号”。(请确保没有相同站号的装置)

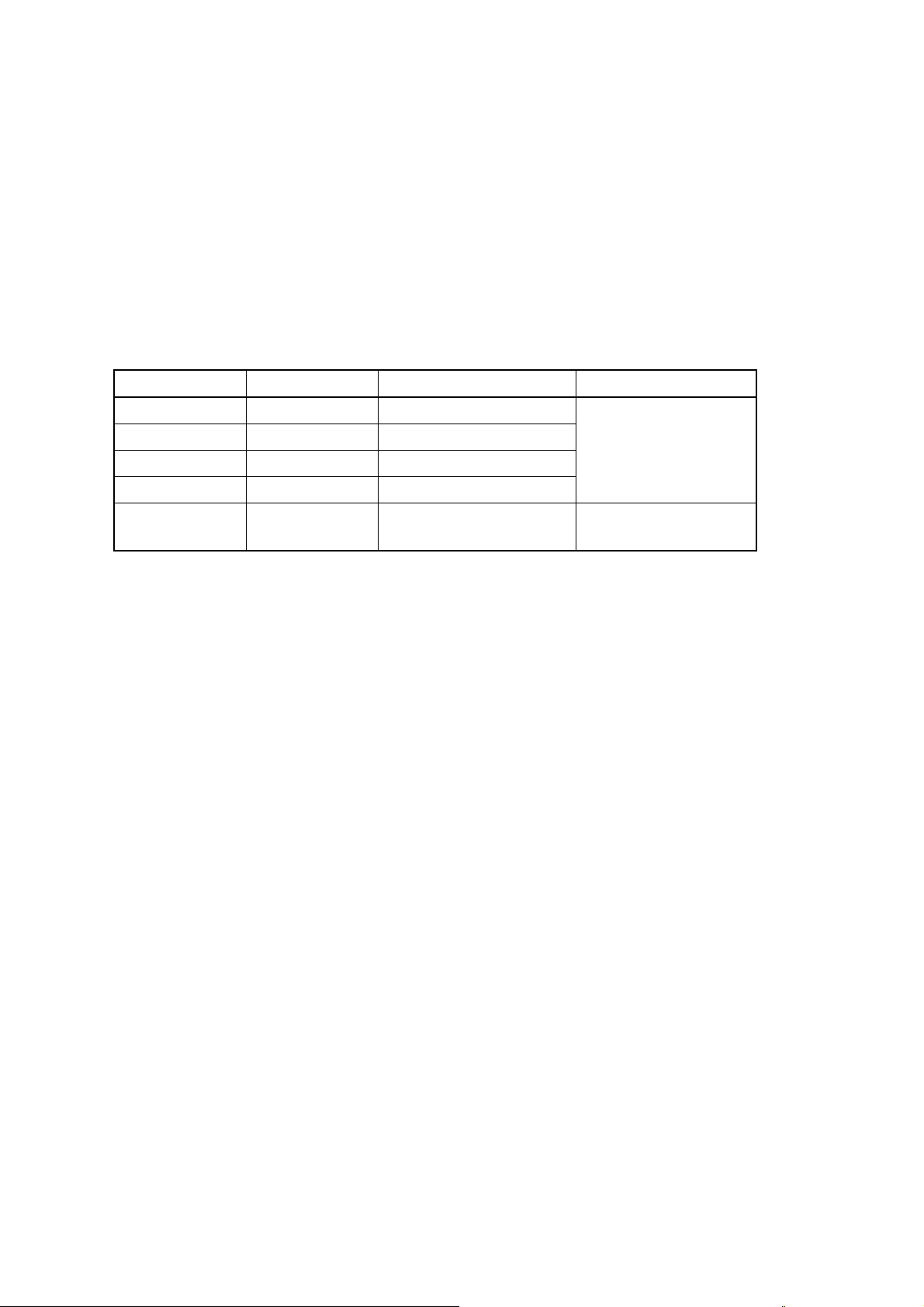

4.1 设定项目

下表为设定项目。请通过正面的操作键进行设定。

项目 出厂值 设定范围 备注

通信速度

数据长度 8位 固定(不能变更)

停止位 1位 固定(不能变更)

奇偶校验设定 无 固定(不能变更)

站号

4.2 设定操作

请在参数设定画面上进行站号设定。(参见使用说明书)

38400bps

1

固定(不能变更)

0~31

(0:停止通信功能)

请将主机及所有站号的

从机设定为同一条件。

请对各从机设定各不相

同的站号。

-6-

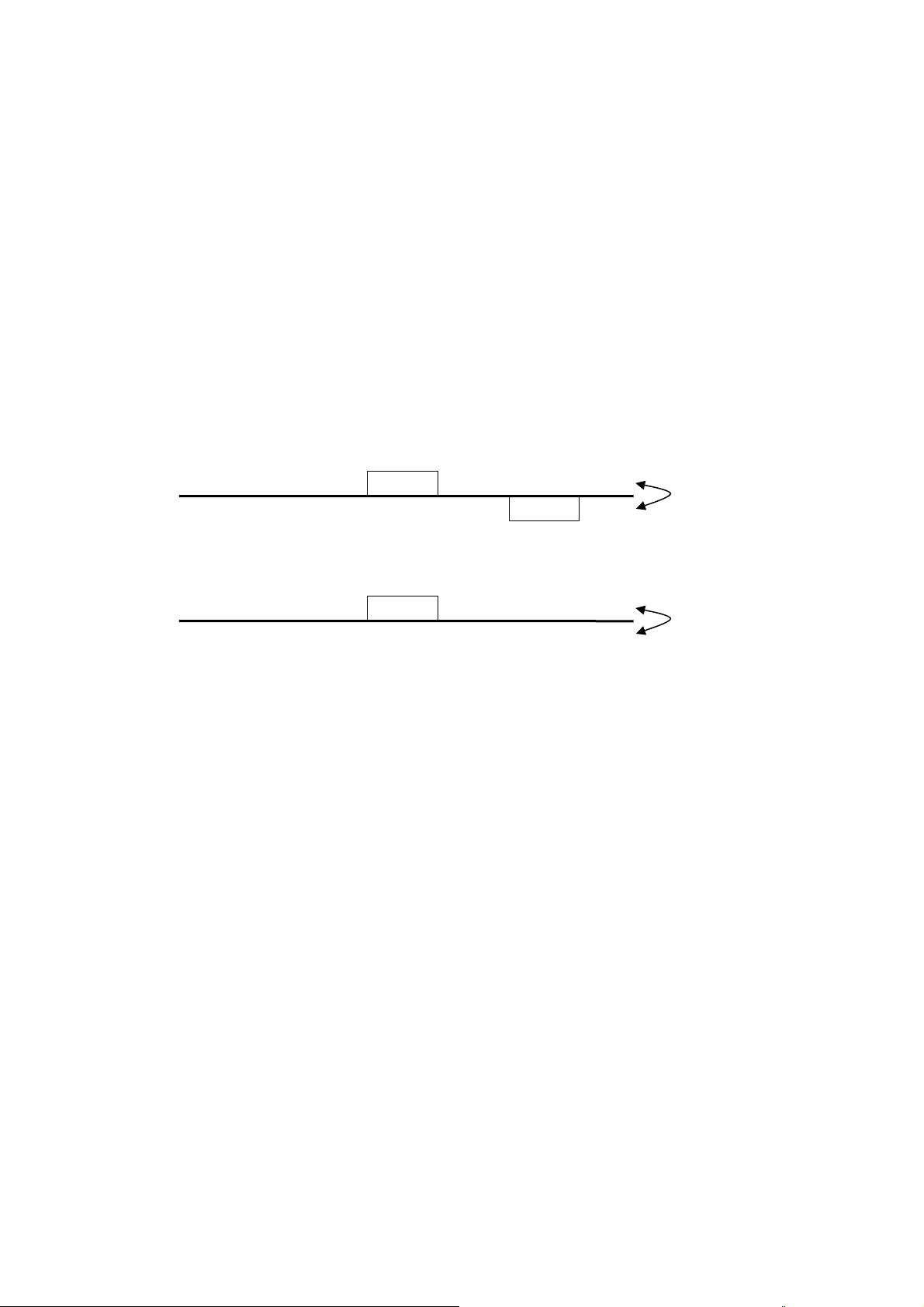

5.1 概述

基于 MODBUS 通信协议的通信系统,通常采用“从主机开始通信,从机分别应答”的形式。

传输的顺序如下:

1)主机向从机发送指令信息。

2)子机确认接收的信息中的站号是否与本站的站号相同。

3)如果一致,则执行指令,并返回应答信息。

4)如果不一致,则丢弃接收的指令信息,等待下一个指令信息。

(a) 指令信息中的的站号与本站的站号相同时,

主机 → 从机

主机 ← 从机

(b) 指令信息中的站号与本站的站号不同时,

主机 → 从机

主机 ← 从机

主机通过在指令信息中指定从机的某一个站号,可以与连接在同一线路上的多台从机分别进行通

5. MODBUS 通信协议

指令信息

应答信息

指令信息

(无应答)

通信线上的数据

通信线上的数据

信。

-7-

5.2 信息的结构

指令信息及应答信息由站号、功能代码、数据区以及错误校验代码 4 个部分构成,并按此顺序发

送。

下面就是各部分的介绍:

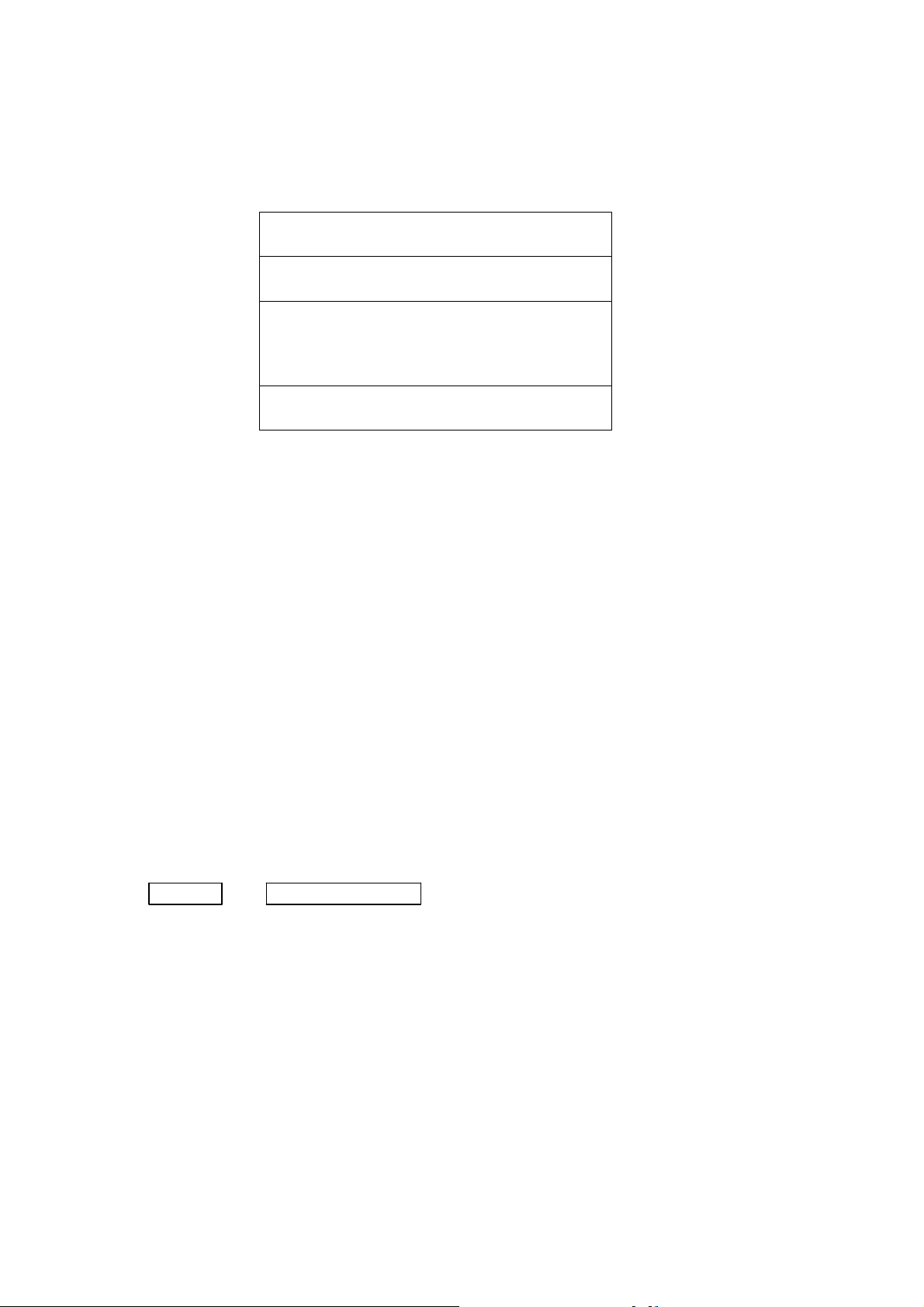

(1) 站号

站号(1 字节)

功能代码(1 字节)

数据区(2~133 字节)

错误校验代码(CRC-16)(2 字节)

图 5-1 信息的结构

这是从机的指定编号。仅可由在分析仪参数设定画面上设定为相同“站号”的从机来执行指令。

(2) 功能代码

这是让从机执行的功能的代码。

详细内容请参见

(3) 数据区

这是执行功能代码所需的数据。数据的结构根据功能代码而不同。详细内容请参见第 6 章。

线圈号和寄存器号配置到本装置内部的各个数据。请指定线圈号和寄存器号来执行该数据的通

信。

相对地址 =

例如,由某功能代码指定的寄存器号为 40003 时,

相对地址 = (40003 的低 4 位)- 1

在信息上使用此地址。

(4) 错误校验代码

5.4 节。

⎛

⎜

⎝

= 0002

线圈号 或 寄存器号

的低4位

⎞

-1

⎟

⎠

这是检测信号传输过程中出现的信息错误(位的变化)所需的代码。

MODBUS 通信协议(RTU 模式)使用 CRC-16(Cycric Redundancy Cheek:循环冗余校验)。

CRC计算方法请参见

5.5 节。

-8-

5.3 从机的应答

(1) 正常时的应答

从机生成与各信息对应的应答信息,并回复。此时的信息结构与 5.2 节所解释的相同。

数据区的内容根据功能代码而不同。详细内容请参见第 6 章。

(2) 异常时的应答

指令信息的内容中出现传输错误之外的差错(指定了不存在的功能代码等)时,从机不执行此指

令,并生成错误应答信息。

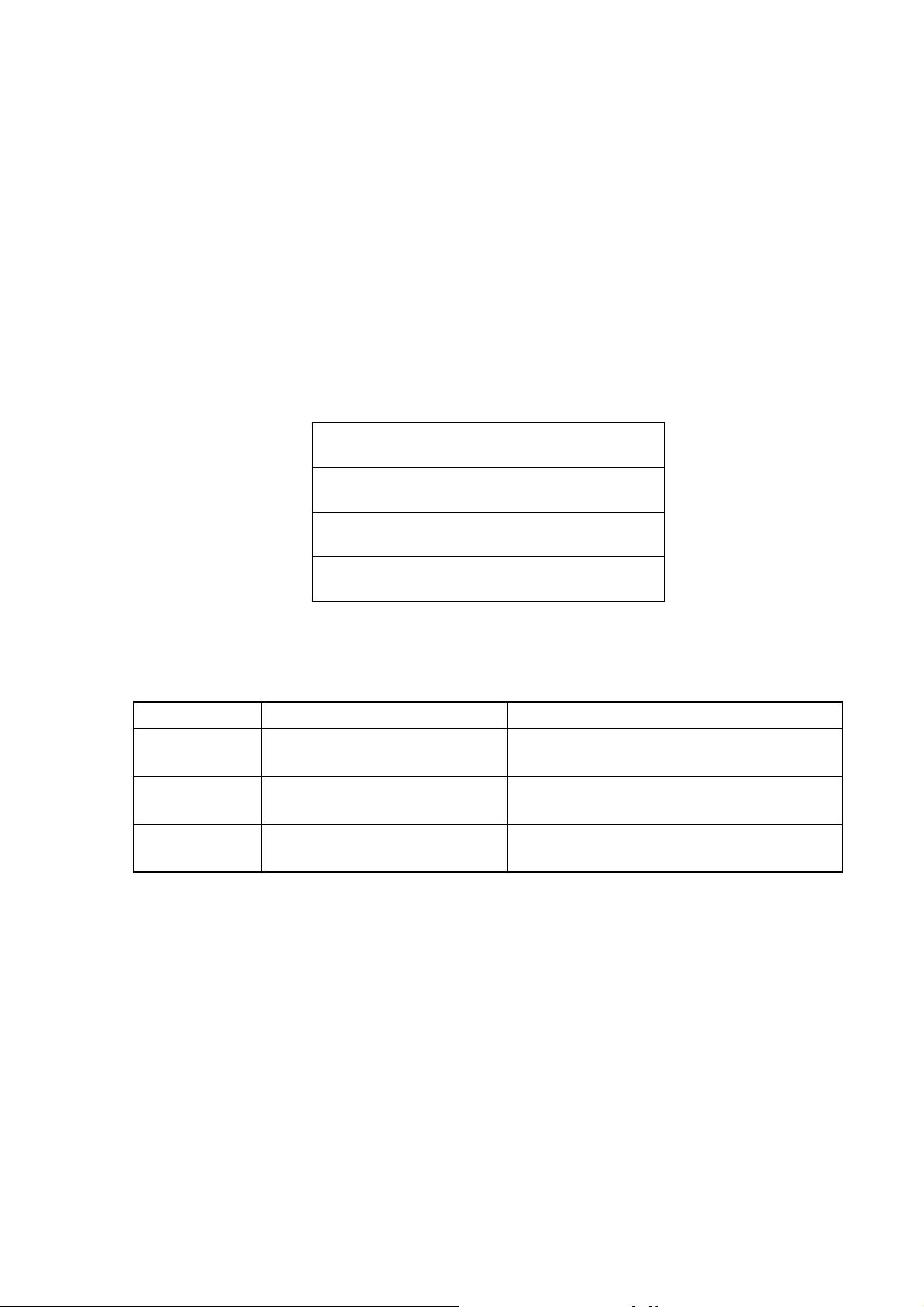

错误代码 内容 说明

01H

02H

03H

(3) 无应答

错误应答信息的结构如

错误代码如

表 5-1 所示。

功能代码出错

线圈、寄存器的地址出错

线圈、寄存器的个数错误

图 5-2 所示,功能代码为指令信息的功能代码加上 80H的数值。

站号(1 字节)

功能代码 + 80H(1 字节)

错误代码(1 字节)

错误校验代码(CRC-16)(2 字节)

图 5-2 错误应答信息

表 5-1 错误代码

指定了不存在的功能代码。

请确认功能代码。

指定了该功能代码无法使用的线圈号、寄存

器的相对地址。

由于指定的个数过多,指定了不存在的线圈

号、寄存器号。

从机在下列情况下,从机不执行指令信息,也不做应答。

• 指令信息中指定的站号与给从机设定的站号不一致时

• 错误校验代码不一致时,或检测出传输错误(奇偶校验错误等)时。

• 结构信息的数据间隔(空白状态)超过 24 位时间时。(请参见

-9-

5.6 传送控制步骤)

Loading...

Loading...