Page 1

Instruction Manual

NDIR TYPE

INFRARED GAS

ANALYZER

TYPE: ZKJ-2

INZ-TN2ZKJ-E

Page 2

PREFACE

We are grateful for your purchase of Fuji Electric’s Infrared Gas Analyzer, TYPE:ZKJ.

• First read this instruction manual carefully until an adequate understanding is acquired, and

then proceed to installation, operation and maintenance of the analyzer. Wrong handling

may cause an accident or injury.

• The specifications of this analyzer are subject to change without prior notice for further

product improvement.

• Modification of this analyzer is strictly prohibited unless a written approval is obtained

from the manufacturer. Fuji Electric will not bear any responsibility for a trouble caused

by such a modification.

• This instruction manual shall be stored by the person who actually uses the analyzer.

• After reading the manual, be sure to store it at a place easier to access.

• This instruction manual should be delivered to the end user without fail.

Manufacturer: Fuji Electric Instruments Co., Ltd.

Type: Described in Fuji Electric’s company nameplate on main frame

Date of manufacture: Described in Fuji Electric’s company nameplate on main frame

Product nationality: Japan

Delivered Items

Name Quantity Remarks

Analyzer main frame 1

Input/Output terminal module 1

Connection cable 1

Power cable 1

Fuse 2 250V AC/3A delay type

Cell window mounting tool 1 With mounting block cell

Slide rail 2 Option

Instruction manual 1

Request

• It is prohibited to transfer part or all of this manual without Fuji

Electric’s permission in written format.

• Description in this manual is subject to change without prior

notice for further improvement.

© Fuji Electric Instruments Co., Ltd. 2001

Issued in September, 2001

iINZ-TN2ZKJ-E

Page 3

CAUTION ON SAFETY

First of all, read this “Caution on safety” carefully, and then use the analyzer in the correct way.

• The cautionary descriptions listed here contain important information about safety, so they should

always be observed. Those safety precautions are ranked in 3 levels, “DANGER”, “CAUTION” and

“PROHIBITION”.

DANGER

CAUTION

PROHIBITION

Caution on installation and transport of gas analyzer

DANGER

CAUTION

Wrong handling may cause a dangerous situation, in which

there is a risk of death or heavy injury.

Wrong handling may invite a dangerous situation, in which

there is a possibility of medium-level trouble or slight injury or

only physical damage is predictable.

Items which must not be done are noted.

• This unit is not explosion-proof type. Do not use it in a place

with explosive gases to prevent explosion, fire or other

serious accidents.

• For installation, observe the rule on it given in the instruction

manual and select a place where the weight of gas analyzer

can be endured.

Installation at an unsuited place may cause turnover or fall and

there is a risk of injury.

• For lifting the gas analyzer, be sure to wear protective gloves.

Bare hands may invite an injury.

• Before transport, fix the casing so that it will not open. Otherwise, the casing may be separated and fall to cause an injury.

• The gas analyzer is heavy. It should be transported carefully

by two or more persons if manually required.

Otherwise, body may be damaged or injured.

• During installation work, care should be taken to keep the unit

free from cable chips or other foreign objects. Otherwise, it

may cause fire, trouble or malfunction of the unit.

ii INZ-TN2ZKJ-E

Page 4

DANGER

Caution on piping

In piping, the following precautions should be observed.

Wrong piping may cause gas leakage.

If the leaking gas contains a toxic component, there is a risk

of serious accident being induced.

Also, if combustible gas is contained, there is a danger of

explosion, fire or the like occurring.

• Connect pipes correctly referring to the instruction manual.

• Exhaust should be led outdoors so that it will not remain in

the locker and installation room.

• Exhaust from the analyzer should be relieved in the atmospheric air in order that an unnecessary pressure will not be

applied to the analyzer. Otherwise, any pipe in the analyzer

may be disconnected to cause gas leakage.

• For piping, use a pipe and a pressure reducing valve to which

oil and grease are not adhering. If such a material is adhering,

a fire or the like accident may be caused.

Caution on wiring

CAUTION

DANGER

CAUTION

• Wiring work must be performed with the main power set to

OFF to prevent electric shocks.

• Enforce construction of class-D grounding wire by all means.

If the specified grounding construction is neglected, a shock

hazard or fault may be caused.

• Wires should be the proper one meeting the ratings of this

instrument. If using a wire which cannot endure the ratings, a

fire may occur.

• Be sure to use a power supply of correct rating. Connection of

power supply of incorrect rating may cause fire.

Caution on use

• For correct handling of calibration gas or other reference gases,

carefully read their instruction manuals beforehand.

• Before leaving unused for a long time or restarting after left at

such a status for an extended length of time, follow the directions

of each instruction manual because they are different from

normal starting or shutdown. Otherwise, the performance may

be poor and accidents or injuries may be caused.

• Do not operate the analyzer for a long time with its door left

open. Otherwise, dust, foreign matter, etc. may stick on internal

walls, thereby causing faults.

iiiINZ-TN2ZKJ-E

Page 5

Caution on use

• Do not allow metal, finger or others to touch the input/output

PROHIBITION

Caution on maintenance and check

terminals in the instrument. Otherwise, shock hazard or injury

may occur.

• Do not smoke nor use a flame near the gas analyzer. Otherwise,

a fire may be caused.

• Do not allow water to go into the gas analyzer. Otherwise,

hazard shock or fire in the instrument may be caused.

DANGER

CAUTION

• When doors are open during maintenance or inspection, be sure

to purge sufficiently the inside of the gas analyzer as well as the

measuring gas line with nitrogen or air, in order to prevent

poisoning, fire or explosion due to gas leak.

Be sure to observe the following for safe operation avoiding

the shock hazard and injury.

• Remove the watch and other metallic objects before work.

• Do not touch the instrument wet-handed.

• If the fuse is blown, eliminate the cause, and then replace it

with the one of the same capacity and type as before. Otherwise, shock hazard or fault may be caused.

• Do not use a replacement part other than specified by the

instrument maker. Otherwise, adequate performance will not be

provided. Besides, an accident or fault may be caused.

• Replacement parts such as a maintenance part should be disposed of as incombustibles.

Others

• If the cause of any fault cannot be determined despite reference

CAUTION

iv INZ-TN2ZKJ-E

to the instruction manual, be sure to contact your dealer or Fuji

Electric’s technician in charge of adjustment. If the instrument is

disassembled carelessly, you may have a shock hazard or injury.

Page 6

CONTENTS

PREFACE .....................................................................................................................i

CAUTION ON SAFETY............................................................................................ ii

CONTENTS.................................................................................................................v

1. OVERVIEW..................................................................................................... 1-1

2. NAME AND DESCRIPTION OF EACH UNIT ............................................. 2-1

2.1 Name and description of main unit.....................................................................2-1

2.2 Input/Output terminal module ............................................................................2-2

3. INSTALLATION ............................................................................................. 3-1

3.1 Installation ..........................................................................................................3-2

3.1.1 Installation of analyzer main frame............................................................3-2

3.1.2 Mounting input/output terminal module ....................................................3-3

3.2 Piping..................................................................................................................3-4

3.3 Sampling.............................................................................................................3-7

3.3.1 Conditions of sampling gas ........................................................................3-7

3.3.2 Sampling gas flow ......................................................................................3-7

3.3.3 Preparation of standard gas ........................................................................3-7

3.3.4 Purging of instrument inside ......................................................................3-7

3.3.5 Pressure at sampling gas outlet...................................................................3-8

3.3.6 Example configuration of gas sampling system.........................................3-8

3.4 Wiring.................................................................................................................3-9

3.4.1 Power inlet..................................................................................................3-9

3.4.2 Input/output terminal module.....................................................................3-9

4. OPERATION ...................................................................................................... 4-1

4.1 Preparation for operation ....................................................................................4-1

4.2 Warm-up operation and regular operation..........................................................4-1

5. DESCRIPTION OF DISPLAY AND OPERATION PANELS....................... 5-1

5.1 Name and description of operation panel ...........................................................5-1

5.2 Overview of display and operation panels..........................................................5-2

5.3 Outline of display screen ....................................................................................5-3

5.4 General operation................................................................................................5-6

6. SETTING AND CALIBRATION.................................................................... 6-1

6.1 Changeover of range...........................................................................................6-1

6.2 Calibration Setting..............................................................................................6-2

6.2.1 Setting of calibration concentration............................................................6-2

6.2.2 Setting of manual zero calibration..............................................................6-4

6.2.3 Setting of calibration range ........................................................................6-6

vINZ-TN2ZKJ-E

Page 7

6.2.4 Setting of auto calibration component........................................................6-8

6.3 Alarm setting ....................................................................................................6-10

6.3.1 Setting of alarm values .............................................................................6-10

6.3.2 Hysteresis setting......................................................................................6-12

6.4 Setting of auto calibration.................................................................................6-13

6.4.1 Auto calibration ........................................................................................6-13

6.4.2 Forced stop of auto calibration.................................................................6-15

6.5 Setting of auto zero calibration.........................................................................6-17

6.5.1 Auto zero calibration ................................................................................6-17

6.5.2 Forced stop of auto zero calibration .........................................................6-19

6.6 Peak alarm setting.............................................................................................6-21

6.7 Parameter setting ..............................................................................................6-23

6.8 Maintenance mode............................................................................................6-27

6.9 Calibration ........................................................................................................6-30

6.9.1 Zero calibration ........................................................................................6-30

6.9.2 Span calibration ........................................................................................6-31

7. MAINTENANCE............................................................................................. 7-1

7.1 Daily check .........................................................................................................7-1

7.2 Daily check and maintenance procedures...........................................................7-1

7.3 Maintenance of analyzer unit..............................................................................7-2

7.3.1 Cleaning method for sample cell (pipe cell)...............................................7-2

7.3.2 Cleaning method for sample cell (block cell).............................................7-4

7.3.3 Optical zero adjustment method (optical balance adjustment)...................7-6

7.3.4 Moisture interference compensation adjustment method...........................7-7

7.3.5 Replacement of fuse on analyzer unit ........................................................7-8

8 TROUBLE SHOOTING FOR ANALYZER....................................................... 8-1

8.1 Error message .....................................................................................................8-1

9. SPECIFICATIONS .......................................................................................... 9-1

9.1 General specifications.........................................................................................9-1

9.2 Code symbols......................................................................................................9-4

9.3 Outline diagram ..................................................................................................9-6

vi INZ-TN2ZKJ-E

Page 8

1. OVERVIEW

This infrared gas analyzer (type: ZKJ) measures the concentration of NO, SO2, CO2, CO and CH4 contained in sampling gas on the principle that different atomic molecules have an absorption spectrum in the

wave band of infrared rays, and the intensity of absorption is determined by the Lambert-Beer law.

Since this instrument incorporates a compact paramagnetic O

nents simultaneously by using the built-in O

sensor (up to 4 components if O2 sensor is excluded).

2

Furthermore, use of a microprocessor or large sized liquid crystal display realizes improvement of operability, accuracy and multi-functions.

This instrument is optimum for measuring combustible gas exhausted from boilers or incinerators, and it

is effective for steel gas analysis (blast furnace, steel converter, thermal treatment furnace, sintering

(Pellet equipment), coke furnace), storage and maturity of vegetable and fruit, biochemistry (microbe),

[fermentation], air pollution [incinerator, exhaust gas desulfurization, denitration], automotive emission

(excluding tester), protection against disasters [detection of explosive gas and toxic gas, combustion gas

analysis of new building material], growth of plants, chemical analysis [petroleum refinery plant, petroleum chemistry plant, gas generation plant], environment [landing concentration, tunnel concentration,

parking lot, building management] and various physical and chemical experiments.

sensor, it allows measuring up to 5 compo-

2

1 - 1INZ-TN2ZKJ-E

Page 9

2. NAME AND DESCRIPTION OF EACH UNIT

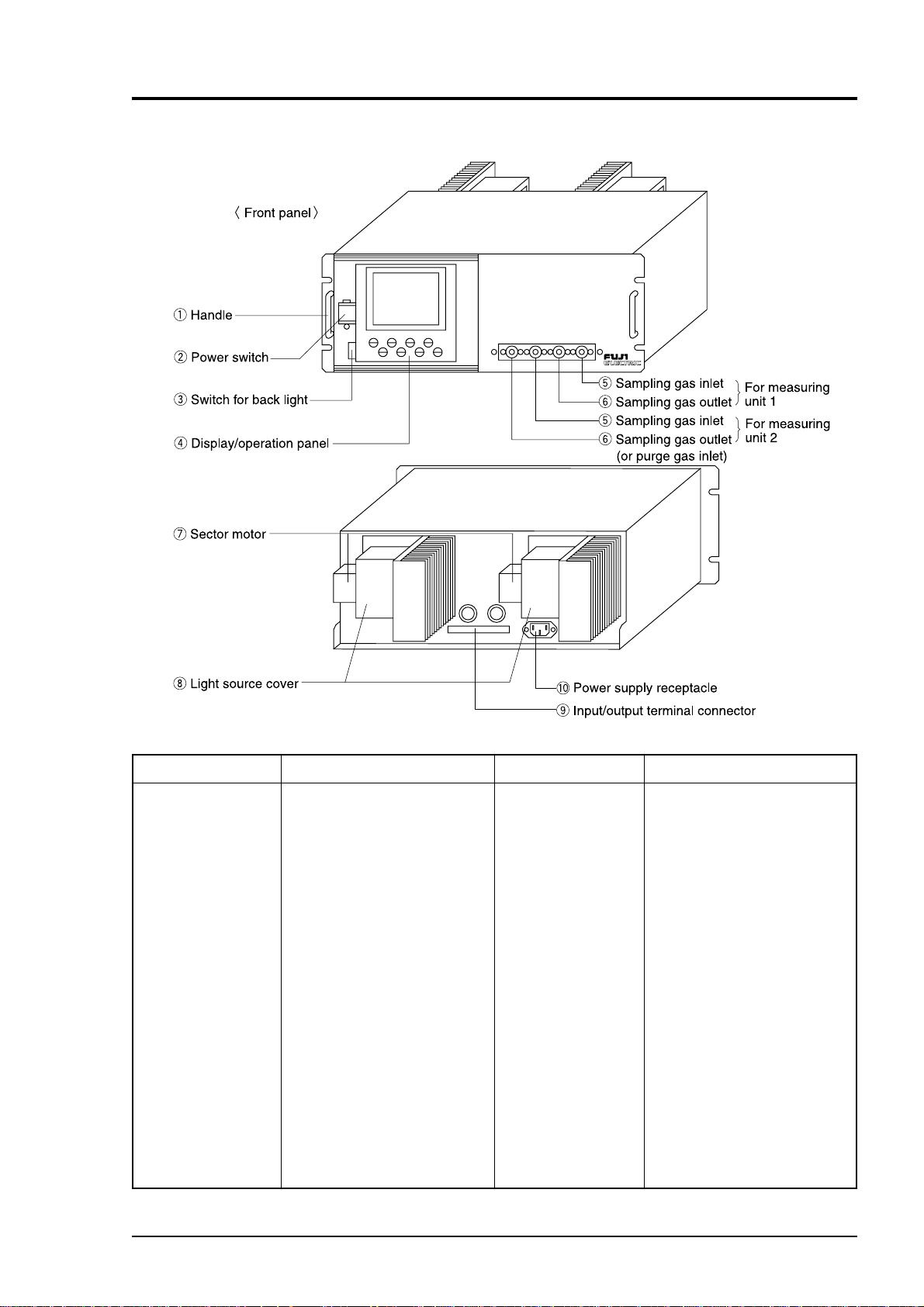

2.1 Name and description of main unit

POWER

DISPLAY

〈Rear panel 〉

Name

q Handle

w Power switch

e Switch for back

light

r Display/operation

panel

t Sampling gas

inlet

y Sampling gas

outlet

Fig. 2-1

Description

Used for withdrawing the main

unit from the panel.

Used for ON/OFF the analyzer.

Used for ON/OFF the back light

of display.

Liquid crysral diaplay and keys

for setting various functions

For connecting to the measuring

gas tube

Connect to the exhaust line. (A

pair of sampling gas inlet/outlet

is provided for each measuring

unit. When ordered with purge,

the piping to measuring unit 2 is

built inside. In this case, the

sample gas outlet for measuring

unit 2 is used for purge gas inlet.)

Name

u Sector motor

i Light source

cover

o Input/output ter-

minal connector

!0 Power inlet

Description

For driving the rotation of sector

Infrared light source is arranged

in the cover.

For connecting to the external

input/output terminal module

For connecting the power cable

2 - 1INZ-TN2ZKJ-E

Page 10

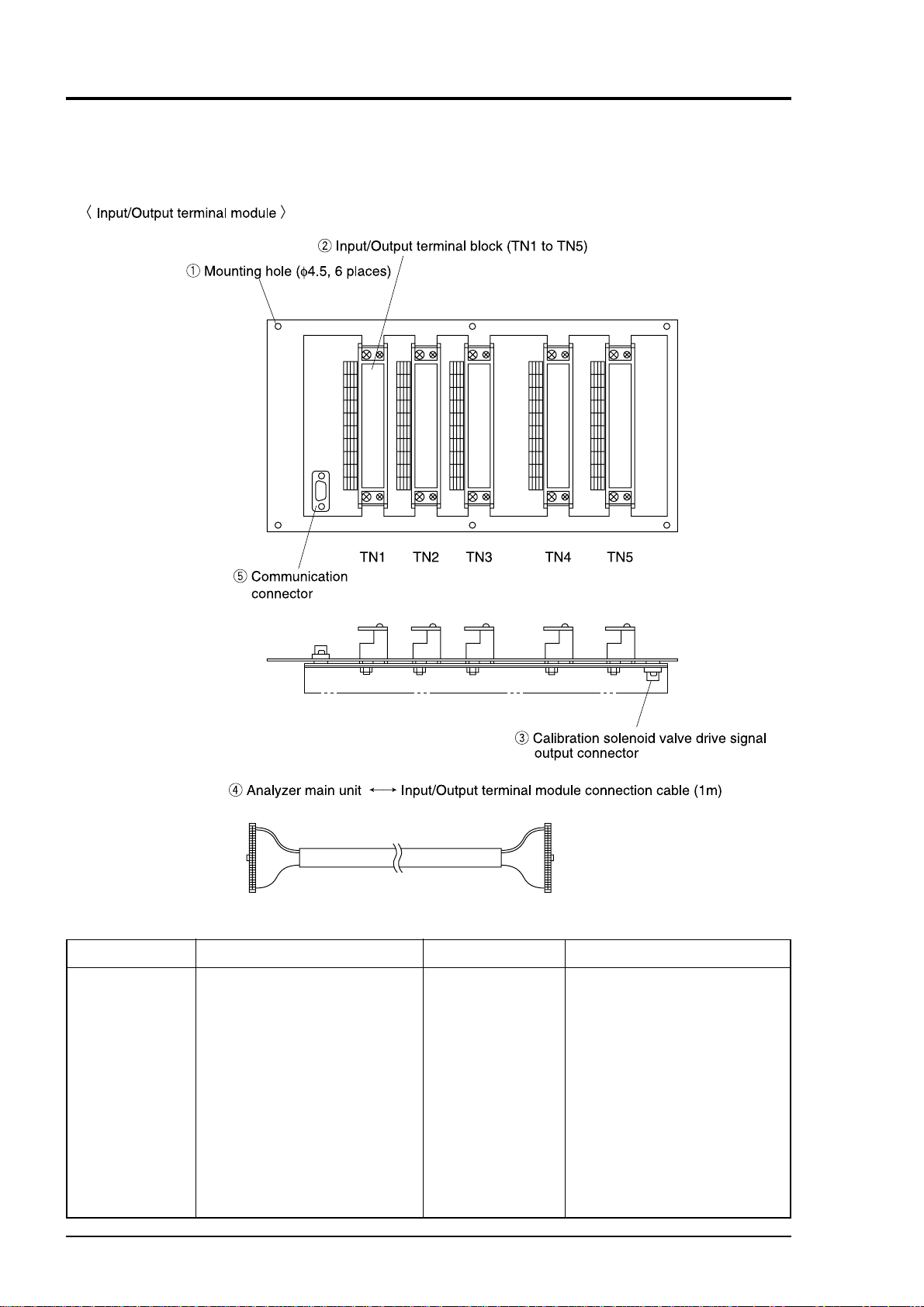

2.2 Input/Output terminal module

This analyzer provides input/output of various signals from the supplied input/outpt terminal

module by connecting the instrument to this module.

Fig. 2-2

Name

q Mounting hole

w Input/output

terminal block

(TN 1 to TN 5)

Description

Used for mounting input/output terminal module.

φ 4.5, 6 places

Input/output terminal for signals

of analog output, range identification contact, alarm contact output,

etc.

Name

e Calibration

solenoid valve

drive signal

output connector

r Input/output

terminal module

connection cable

t Communication

connector

Provides outputs of solenoid valve

drive signal during auto calibration.

Transistor output

(5V, 50mA, 1 contact)

Used for connecting the analyzer

main unit to the input/output

terminal module.

Connect communication cable.

*Please refer to another manual

(INZ-TN513327-E) about

communication function.

Description

2 - 2 INZ-TN2ZKJ-E

Page 11

3. INSTALLATION

DANGER

This unit is not explosion-proof type. Do not use it in a place with explosive gases to prevent

explosion, fire or other serious accidents.

CAUTION

•Entrust the installation, movement or re-installation to a specialist or the supplier. A poor

installation may cause accidental tipover, shock hazard, fire, injury, etc.

•The gas analyzer is heavy. It should be installed with utmost care. Otherwise, it may tip

over or drop, for example, causing accident or injury.

•For lifting the gas analyzer, be sure to wear protective gloves. Bare hands may invite an

injury.

•This unit should be installed in a place which conforms to the conditions noted in the

instruction manual. Otherwise, it may cause electric shocks, fire or malfunction of the unit.

•During installation work, care should be taken to keep the unit free from entry of cable chips

or other foreign objects. Otherwise, it may cause fire, trouble or malfunction of the unit.

3 - 1INZ-TN2ZKJ-E

Page 12

3.1 Installation

3.1.1 Installation of analyzer main frame

Installation methods for the analyzer main unit are divided into 2 types;

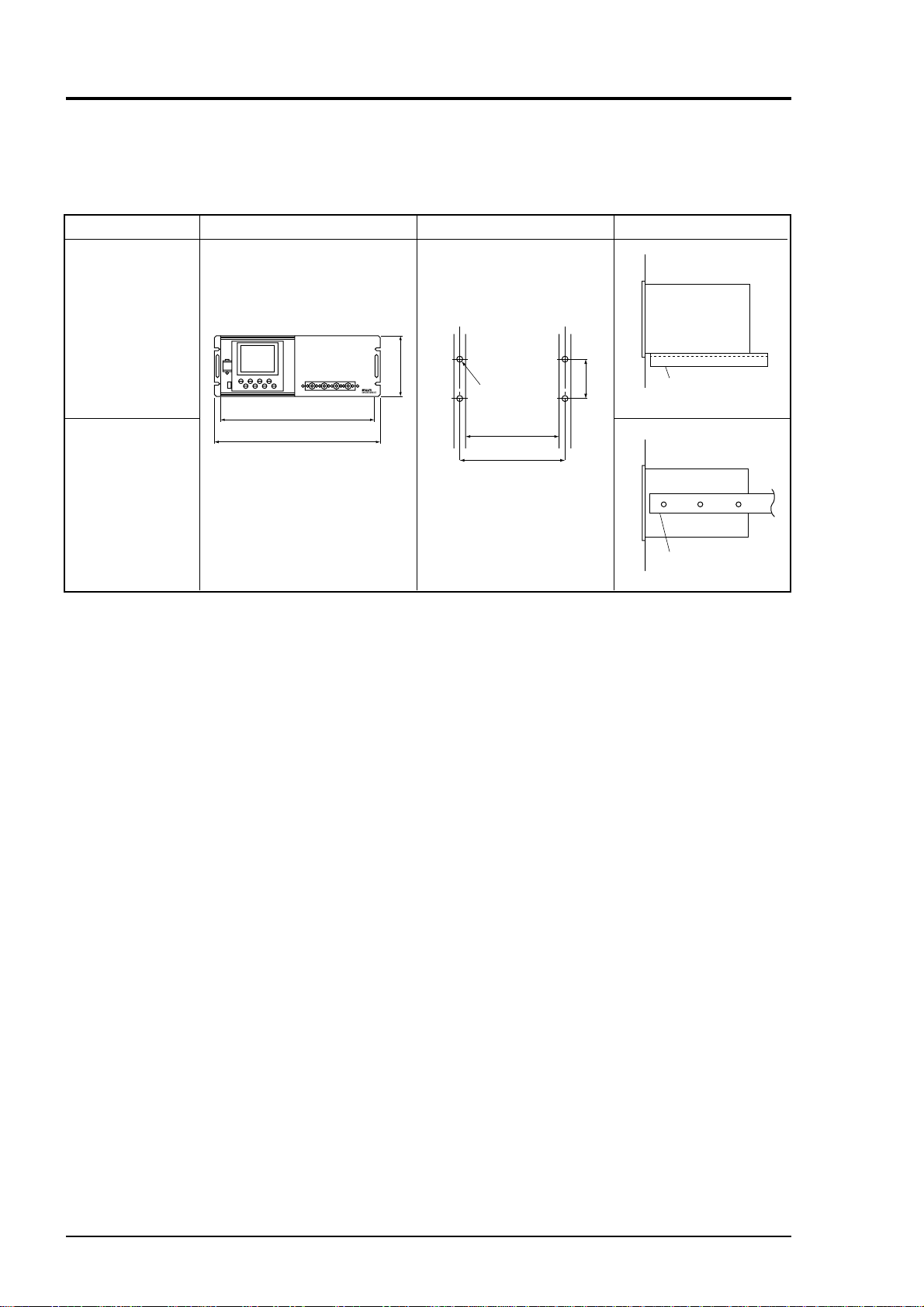

Type External dimensions Mounting dimensions Mounting method

19 inch rack

mounting guide

rail method

19 inch rack

mounting slide

429

483

177

M6

450 or more

465

101.6

Slide rail

(Supports mass)

rail method

Slide rail

(Supports mass)

Note 1 Check and maintenance of the analyzer main unit may be carried out with the top cover detached.

The guide rail method may be used if a space accessible for maintenance is provided at the top of

the main unit. If maintenance space is not provided specially, it is recommended to use the slide

rail method.

Recommended slide rail: Product No.: 305A-24 manufactured by Accuride International Co.

Note 2 For 19 inch rack mounting, the weight of the analyzer is supported with the bottom of the case

(with the side of the case in case of slide rail method). For mounting dimensions of the slide rail,

see “Item 9.3 External diagram”.

Don’t install the analyzer at a place which is exposed to direct sunlight.

The analyzer should be installed at a place where ambient temperature is within 0 to 40°C, and

temperature fluctuation during use is minimum.

3 - 2 INZ-TN2ZKJ-E

Page 13

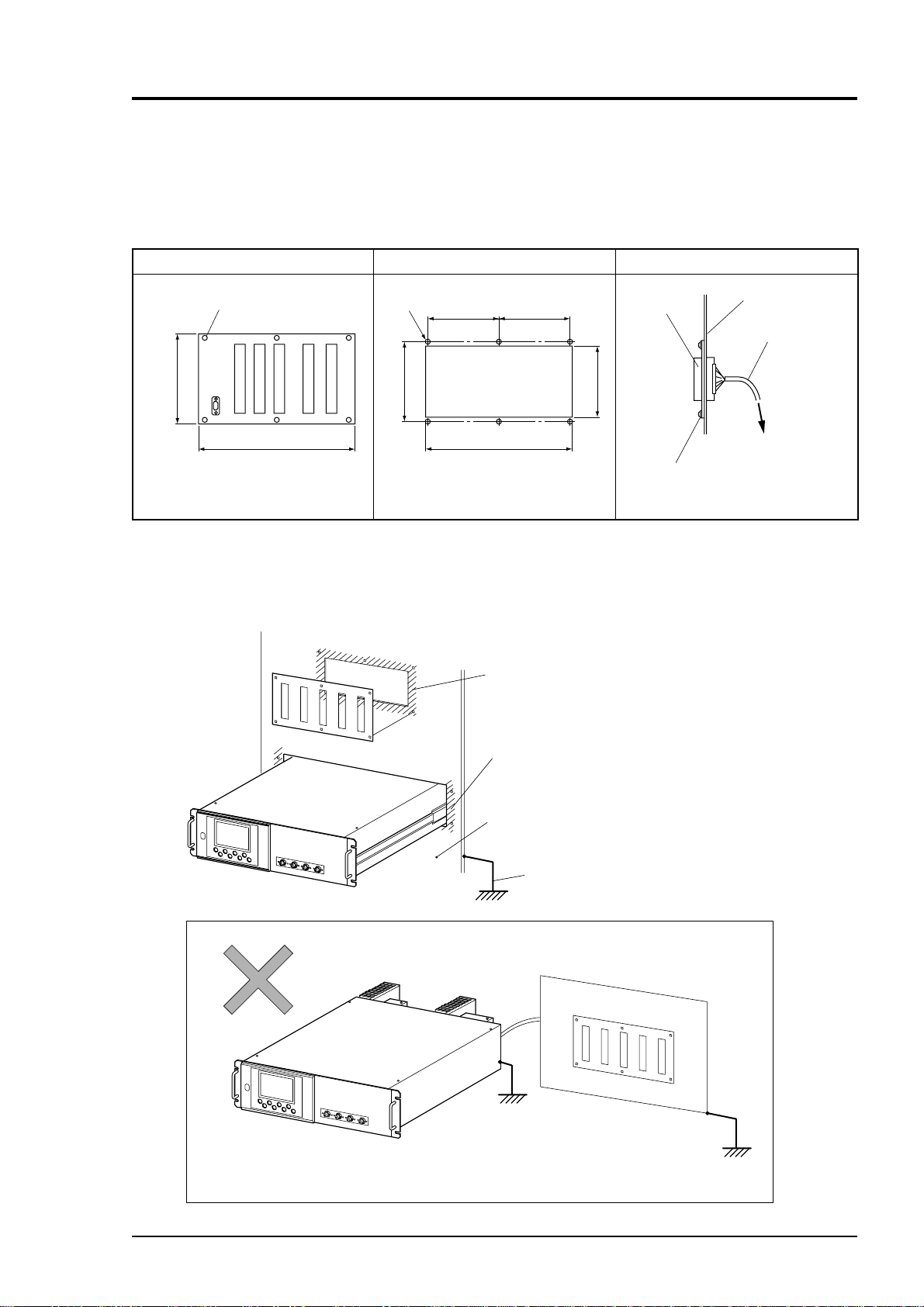

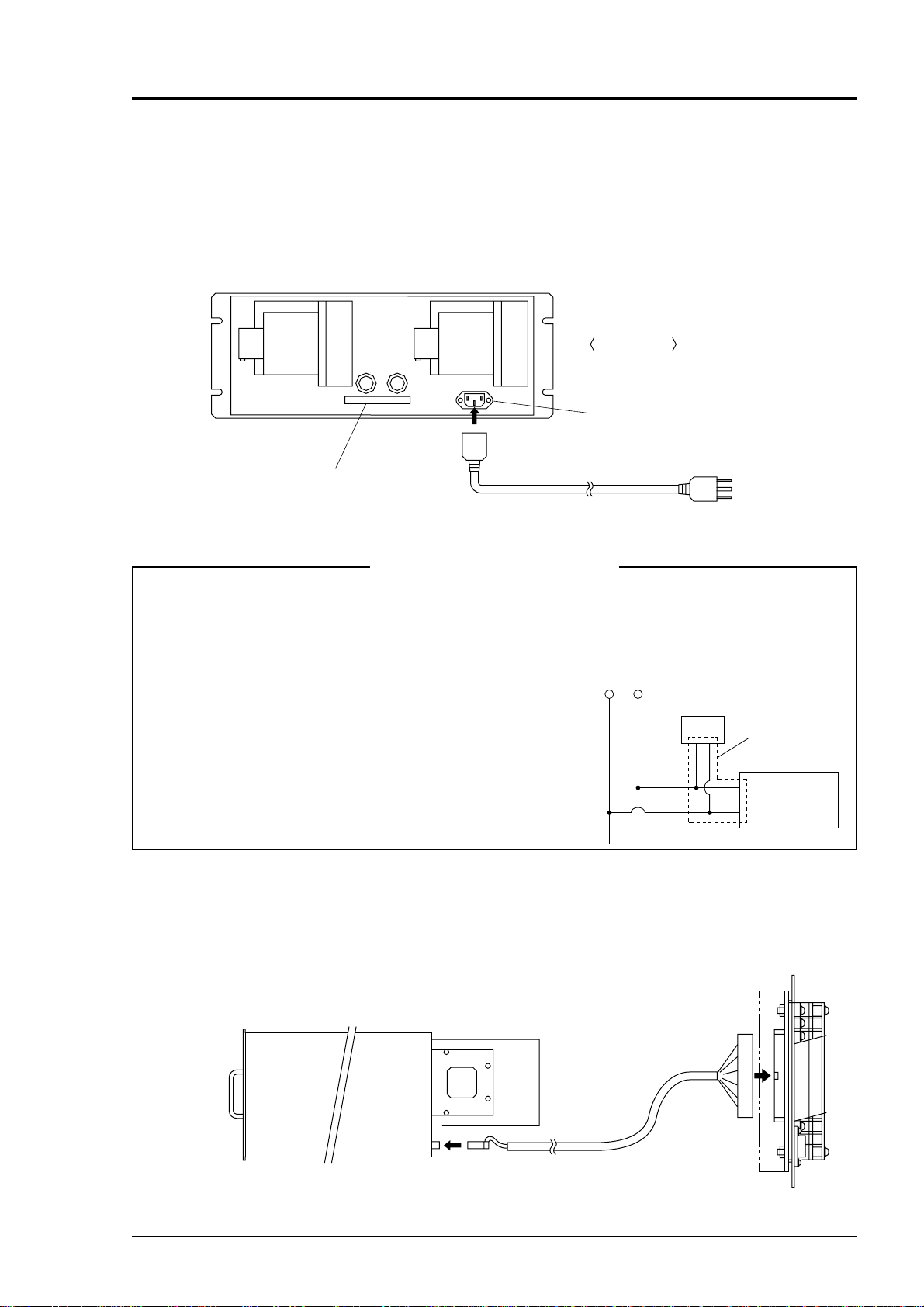

3.1.2 Mounting input/output terminal module

Mount the input/output terminal module on the panel; observing the following method.

(Note) To avoid the effect of noise generated from external units, mount the I/O terminal

module mounting plate on the panel for continuity at the mounting surface and

connect the panel to the same ground as the analyzer main unit.

External dimensions Mounting dimensions Mounting method

4.5 mounting hole (x 6 places)

164

316

M4 screw

154

Cut a hole at 6 places.

Drill a 302 x 142 rectangular hole

in the center.

150 150

302

142142

Note) How to ground analyzer main unit and I/O terminal module

To avoid the effect of noises, etc. from external units, it is

recommended to ground them by the procedure described below.

Bring I/O terminal module sheet metal and

panel into continuity at ///// portion.

Terminal

To analyzer rear panel

Screwed to panel

Panel plate

Connection cable

Bring analyzer main unit and panel into continuity

at ///// portion or rail mounting portion.

(No grounding is required at the power terminal).

Mount the analyzer and I/O terminal module on the

same panel.

Ground the panel casing.

Don’t separate the analyzer and I/O terminal module, and be sure to

*

ground them together.

3 - 3INZ-TN2ZKJ-E

Page 14

3.2 Piping

Piping should be connected to the gas inlets and outlets of the front panel of the analyzer.

• Use a corrosion resistant tube of Teflon, stainless or polyethylene to connect the instrument to

a sampling system. Even if there is a danger of corrosion, refrain from using a tube of rubber

or soft vinyl. The instrument provides inaccurate indication due to gas absorption by piping

materials.

• Pipe connection port is Rc1/4 female thread (or NPT1/4). Piping should be cut as short as

possible for a quick response. About 4 mm inner diameter is recommended.

• Entry of dust into the instrument may result in defective operation. Use a clean piping or

coupling.

Connect the gas tube by the following method.

Sampling gas outlet

For measuring

unit 1

Sampling gas inlet

Sampling gas inlet

Sampling gas outlet

(Purge gas inlet)

For measuring

unit 2

Sampling gas inlet: Attach the gas tube to introduce gas to be measured such as one that has

completed dehumidification process and standard gases for zero and span

calibration to this inlet.

Gas flow to be introduced should be constant within the range of 0.5 L/min

±0.2 L/min.

Sampling gas outlet: Exhaust measured gas through the outlet. Attach the tube to exhaust mea-

sured gas outdoors or to the atmosphere.

Purge gas inlet: It is used for purging the inside of the total gas analyzer . When the ana-

lyzer must be purged, refer to Item 3.3.4 Purging of instrument inside.

Use dry gas N

or instrumentation air for purge gas. (flow rate of 1L/min or

2

more should be used and no dust or mist is contained).

3 - 4 INZ-TN2ZKJ-E

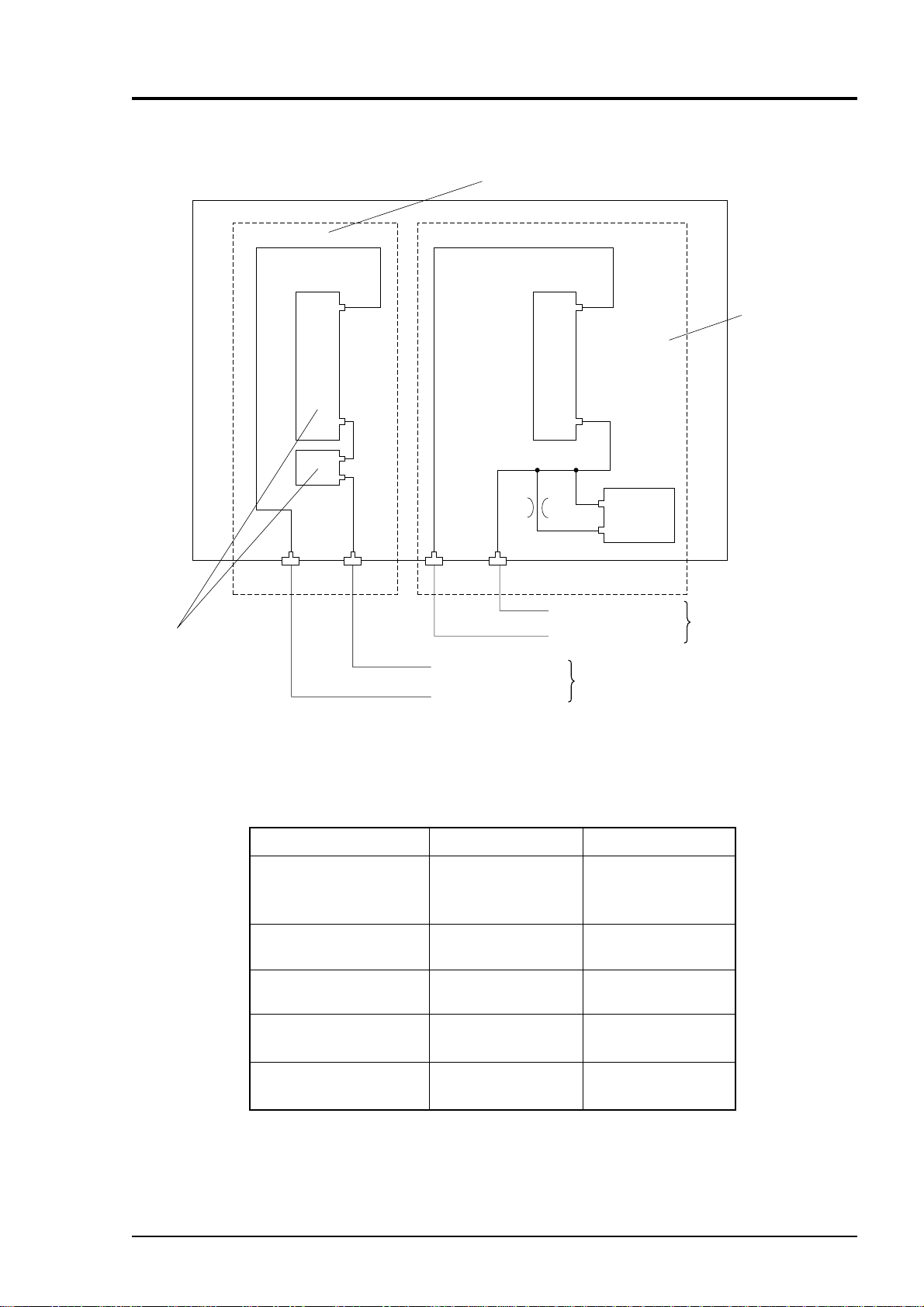

Page 15

Measuring unit 2

Measuring unit 1

Sampling cell

Note)

2 cells may be used

by combination of

range.

OUTLET INLET OUTLET INLET

Sampling gas inlet

Sampling gas outlet

For measuring

unit 1

Sampling gas inlet

Sampling gas outlet

For measuring

unit 2

Built-in

O

2 sensor

Internal piping diagram

Note) When the purge gas inlet is provided, the piping to measuring unit 2 is built inside.

Correspondence of measured components and measuring units

Measuring components

1-component meter for

NO, SO2, CO2, CO and

CH

4

2-component meter for

NO/SO2 and CO2/CO

2-component meter for

NO/CO

3-component meter for

NO/SO2/CO

4-component meter for

NO/SO2/CO2/CO

Measuring unit 1

Each component

NO/SO

2

CO2/CO

NO

NO/SO

2

NO/SO

2

Measuring unit 2

None

None

CO

CO

CO2/CO

Note) When the built-in O2 sensor is provided, it must be con-

nected to the measuring unit 1.

3 - 5INZ-TN2ZKJ-E

Page 16

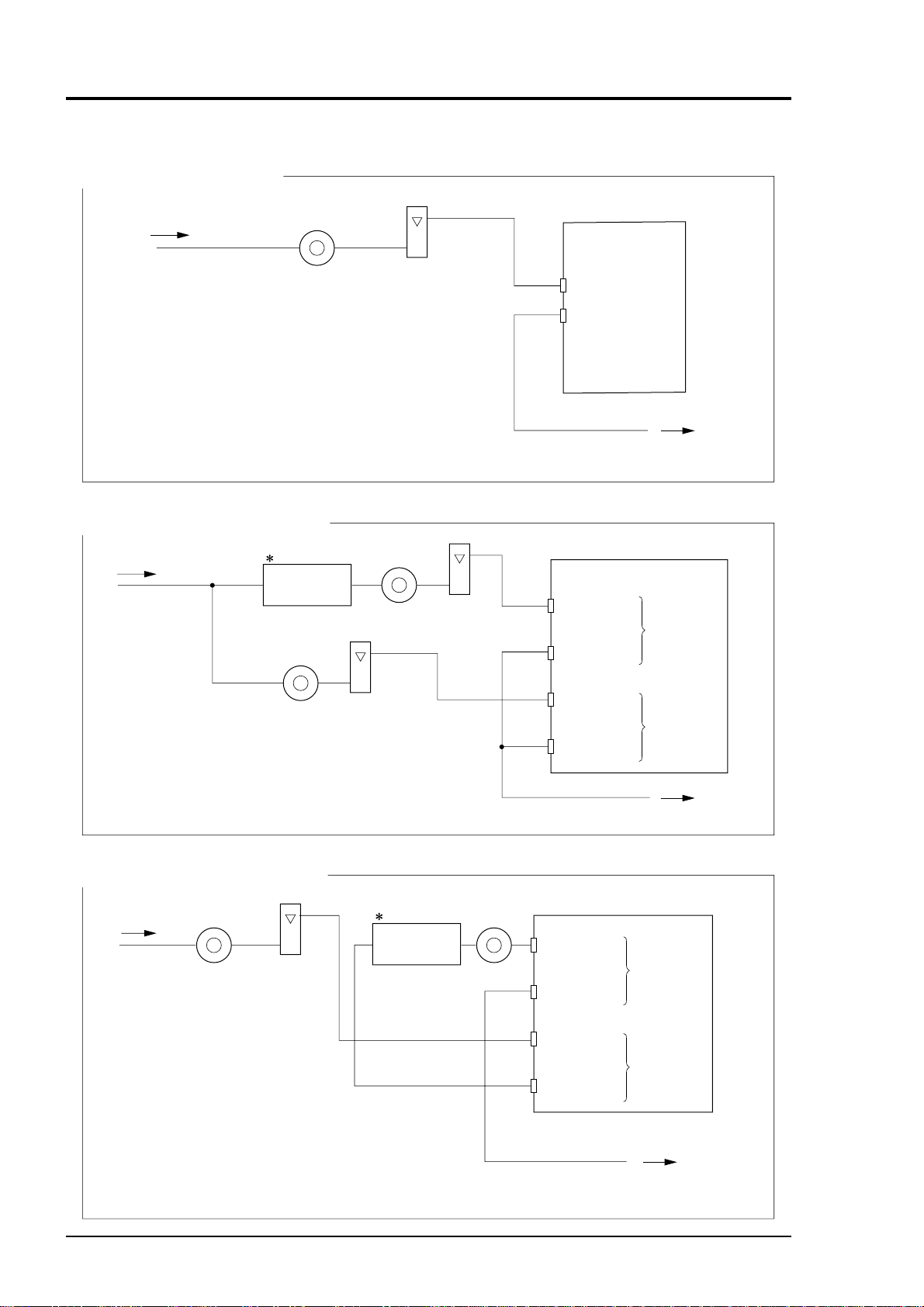

Example of connecting each measuring unit

• One pair of gas inlet/outlet

Sampling gas

• Two pair of gas inlet/outlet - (1)

Sampling gas

NO2/NO

converter

Filter

Flow meter

0.5L/min

Filter

Flow meter

0.5L/min

ZKJ

Sampling gas inlet

Sampling gas outlet

Release to atmosphere.

ZKJ

Sampling gas

inlet

Sampling gas

outlet

Exhaust

For

measuring

unit 1

Filter

Note) The NO

2/NO converter is used when NO measurement is used for NOx measurement.

• Two pair of gas inlet/outlet - (2)

Sampling gas

Filter

Flow meter

0.5L/min

Flow meter

0.5L/min

NO

converter

2/NO

Filter

Sampling gas

inlet

Sampling gas

outlet

Sampling gas

inlet

Sampling gas

outlet

Sampling gas

inlet

Sampling gas

outlet

For

measuring

unit 2

Exhaust

Release to atmosphere.

ZKJ

For

measuring

unit 1

For

measuring

unit 2

Exhaust

Release to atmosphere.

Note) The NO

2/NO converter is used when NO measurement is used for NOx measurement.

3 - 6 INZ-TN2ZKJ-E

Page 17

3.3 Sampling

3.3.1 Conditions of sampling gas

q Dust contained in the sampling gas should be completely removed with a filter. For the final

stage filter, use a filter that allows removing dust particles of 0.3µm.

w Dew point of sampling gas must be lower than the ambient temperature to avoid occurrence

of drain in the gas analyzer. If vapor is contained in the sampling gas, dew point should be

lowered to 0°C by using a dehumidifier.

e If SO

mist is contained in the sampling gas, use a mist filter or cooler to remove SO3 mist.

3

Other mists should be removed by using a mist filter or cooler.

r Corrosive gases such as Cl

2

erable amounts, will shorten the life of instruments.

t Temperature of sampling gas should be within 0 to 50°C. Provide a means that prevents

entry of hot gas directly into the instrument.

3.3.2 Sampling gas flow

Flow of sampling gas should be 0.5L/min ± 0.2L/min.

Avoid flow fluctuation during measurement.

Observe the flow reading by a flowmeter provided as shown in the example of the sampling

system configuration (Item 3.3.6).

3.3.3 Preparation of standard gas

Routine calibration is required by standard gas for keeping this instrument under normal operation

condition (once a week). Prepare a standard gas cylinder for zero calibration and span calibration.

Analyzer without O

measurement

Zero gas

N2 gas

, F2 and HCl, if they are contained in the sampling gas in consid-

Analyzer with built-

2

in O2 sensor

N2 gas

Analyzer with external zirconia O

sensor

Dry air or atmospheric air (Eliminated with CO2 provided)

2

Span gas other

than for O

measurement

Span gas for O

measurement

2

Gas with concentration of 90% or more

of full scale

2

3.3.4 Purging of instrument inside

The inside of instrument need not be purged generally except for the following cases.

q A combustible gas component is contained in sample gas.

w Corrosive gas is contained in the atmospheric air at the installation site.

e The same gas as the sample gas component is contained in the atmospheric air at the installa-

tion site.

In such cases as above, the inside of analyzer should be purged with the air for instrumentation

.

or N

2

Purging flow rate should be about 1L/min.

If dust or mist is contained in purging gas, it should be eliminated completely in advance.

Gas with concentration of 90% or more

of full scale

Gas with concentration of 90% or more

of full scale

Gas with concentration of 90% or

more of full scale

1 to 2% O

2

3 - 7INZ-TN2ZKJ-E

Page 18

3.3.5 Pressure at sampling gas outlet

Pressure at the sampling gas outlet should be adjusted to atmospheric pressure.

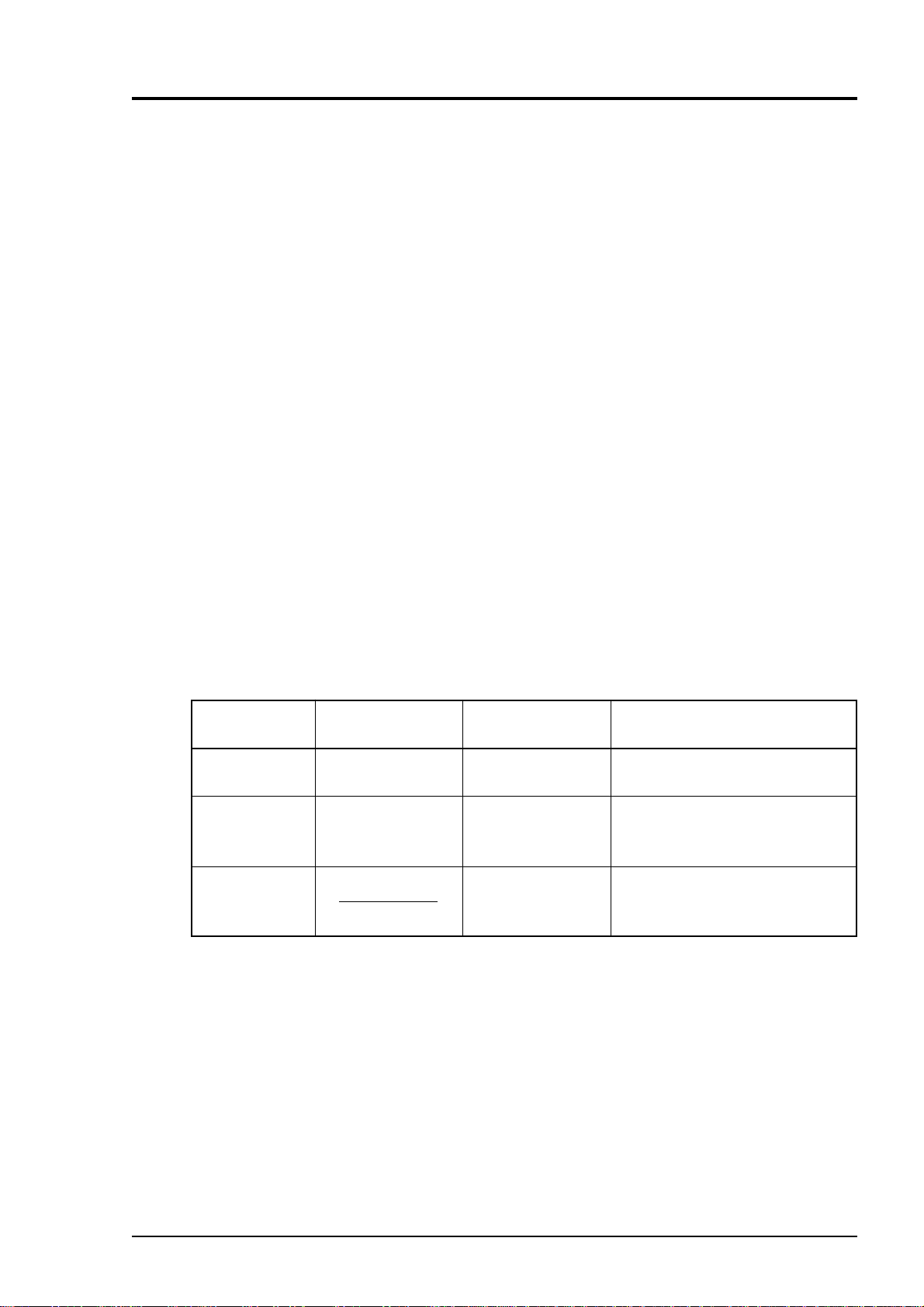

3.3.6 Example configuration of gas sampling system

The following illustrates a typical system configuration for five component gas measurement for

monitoring combustion exhaust gas from boiler, refuse incinerator, etc.

Contact Fuji Electric for system configuration matching the particular use or further information.

Name

q Gas extractor

w

Gas conditioner

e Gas aspirator

r Electronic gas

cooler

t

Solenoid valve

y Membrane filter

Description

Gas extractor with a heating

type stainless steel filter of standard mesh 40µm

For separation of drain, prev ention of drain from being sucked

through secondary filter and

composite operation of constant-pressure bubbler

For aspiration of sample gas

Dries the moisture in sample

gas to a dew point of approx.

2°C.

Used for introducing calibration

gas.

PTFE filter used to eliminate

fine dust particles and permit

monitoring of dust adhering

condition on the front panel of

the gas analyzer.

Name

u Flowmeter

i Standard gas

o Zirconia O2 sensor

!0 NO2/NO converter

Description

Adjusts and monitors the flow

rate of sample gas.

Reference gas used for calibrating zero and span of the analyzer. Total 6 cylinders requir ed

for zero gas air, span gas NO,

SO2, CO, CO2 and O2.

External zirconia oxygen

sensor used for measuring the

oxygen concentration (0 to

25%) in sample gas.

(This is not necessary in case

when O2 sensor is built-in.)

Added to NOx analyzer.

A special catalyst material for

efficient conversion of NO

gas to NO is used.

2

3 - 8 INZ-TN2ZKJ-E

Page 19

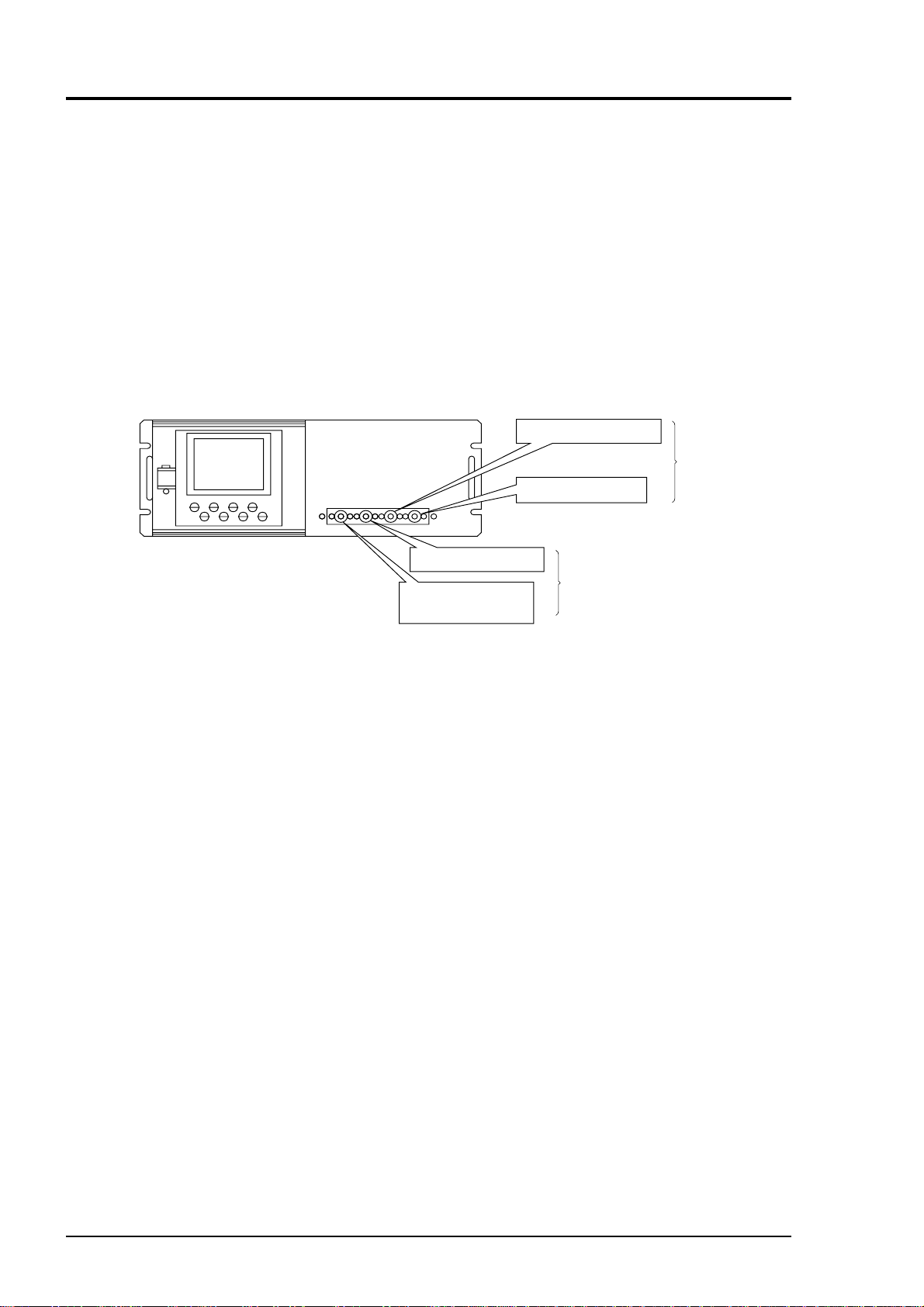

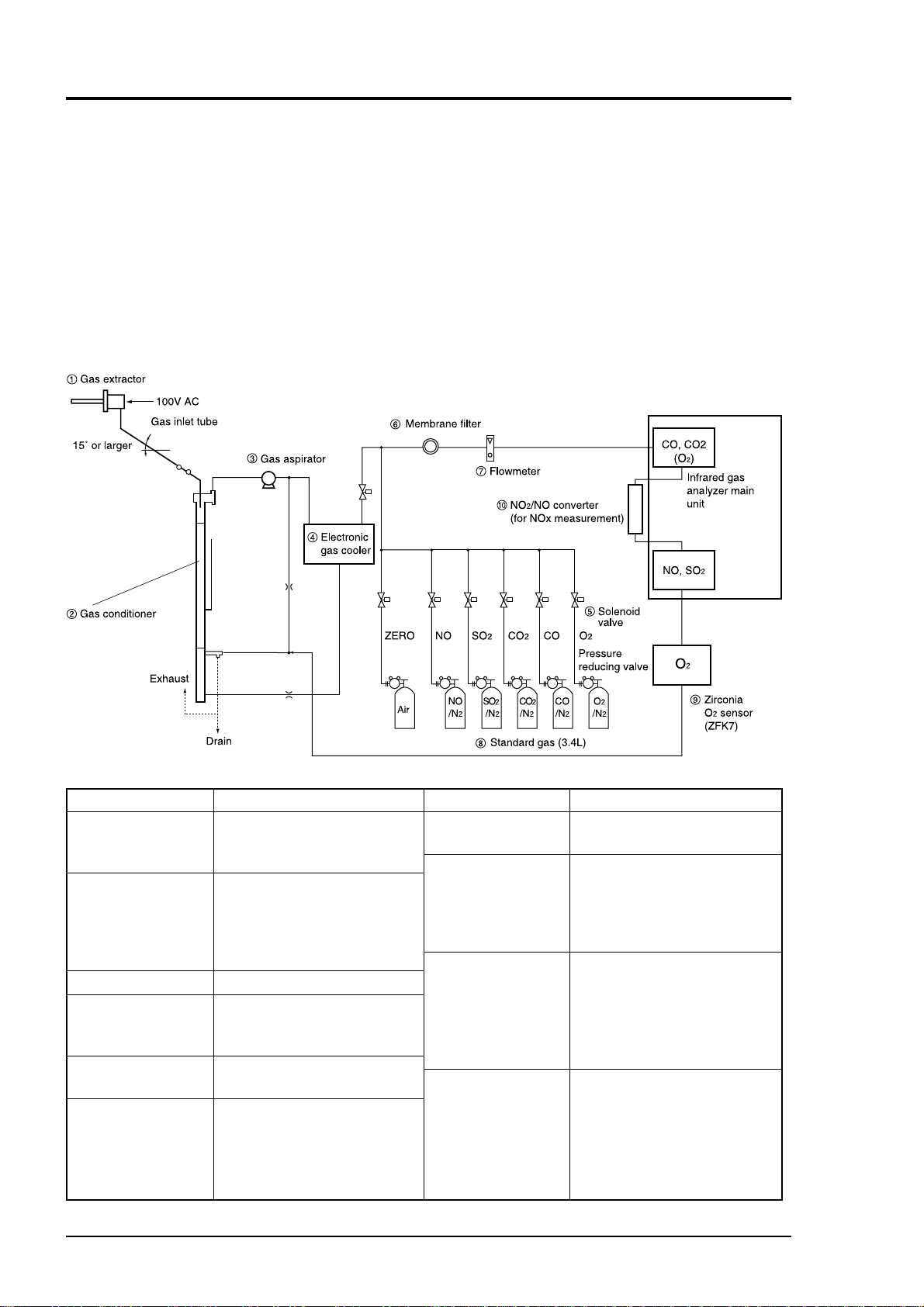

3.4 Wiring

3.4.1 Power inlet

The power inlet is provided at the rear panel.

Connect supplied power cable to this power inlet (Commercial power of 85V AC to 264V AC is

available).

Rear panel

Power inlet

Input/output terminal connector

Grounding 2-pole plug

When noise source is in the vicinity

• Avoid installing this instrument near an electrical unit (high frequency furnace or electric welder)

that generates much electrical noise. If using the instrument near such a noise generating unit is

unavoidable, use a different power line to avoid noise.

Main unit

power supply

• Mount a noise suppressor such as varister (ENA211-2 by

Varistor or

spark killer

Fuji Elctric) or spark killer (S1202 by OKAYA) to the

noise generating unit when noise is generated from relays

or solenoid valves.

Mount the suppressor near the noise generating source,

or it will have no effect.

Install (connect)

near the source.

Noise

generating

source

3.4.2 Input/output terminal module

This analyzer should be connected to the input/output terminal module by supplied exclusive

cable.

Plug this cable connector into the receptacle at the rear panel of the analyzer and the receptacle on

the PC board of the input/output module.

Analyzer

Exclusive cable

(1 meter long)

Input/output

terminal module

3 - 9INZ-TN2ZKJ-E

Page 20

(1) Analog output signal (AO): terminal block 1 q to @0 , terminal block 2 e to y

Output signal: 4 to 20 mADC or 0 to 1 VDC (selected when ordering)

Non-insulated output

Allowable load: 4 to 20 mADC, 550Ω or less

0 to 1 VDC, 100kΩ or less

• Analog output is provided from each terminal corresponding to the channel displayed in the

measurement screen.

All of analog output signals for the instrument are not isolated. It is recommended to isolate

signals individually to prevent interference from unnecessary signals or to prevent external

interference.

(2) O

sensor input: terminal block 2 q – w

2

Input signal:

External zirconia O

External O

analyzer: 0 to 1 VDC (DC input resistor of 1MΩ or more)

2

• It is used when the external zirconia O

• To connect to the output of the external Zirconia analyzer or external O

analyzer: Zirconia O2 sensor signal (Fuji ZFK7 output)

2

analyzer or external O2 analyzer is specified as order.

2

analyzer prepared

2

separately.

• In case of an external O

analyzer, input a signal of 0 to 1 VDC with respect to O2 full scale

2

of the analyzer.

• In case of built-in O

sensor input is not isolated. It is recommended to isolate when an external O2 analyzer is

O

2

analyzer, do not use the terminals.

2

installed apart from this analyzer.

(3) Contact input (DI): terminal block 2 !1 to @0, terminal block 3 t to !0

• It is for a contact input at no voltage. An input is provided when switching to short circuit

(on) or open (off).

• No voltage is applied to the terminals.

(4) Contact output (DO): terminal block 3 !1 to @0, terminal block 4 and terminal block 5

• Contact rating:250VAC/2A, load resistance

• An output is for a relay contact output. An output is provided when switching to conductive

(on) or open (off).

Wiring of analog output signal, O

sensor input and contact input should be fixed separately

2

from the wiring of power supply and contact output.

Note) To avoid the effect of noise generated from external units, be sure to ground the

analyzer main unit. Continue between the I/O module mounting plate and the panel

and connect the panel casing to the same ground as the analyzer.

3 - 10 INZ-TN2ZKJ-E

Page 21

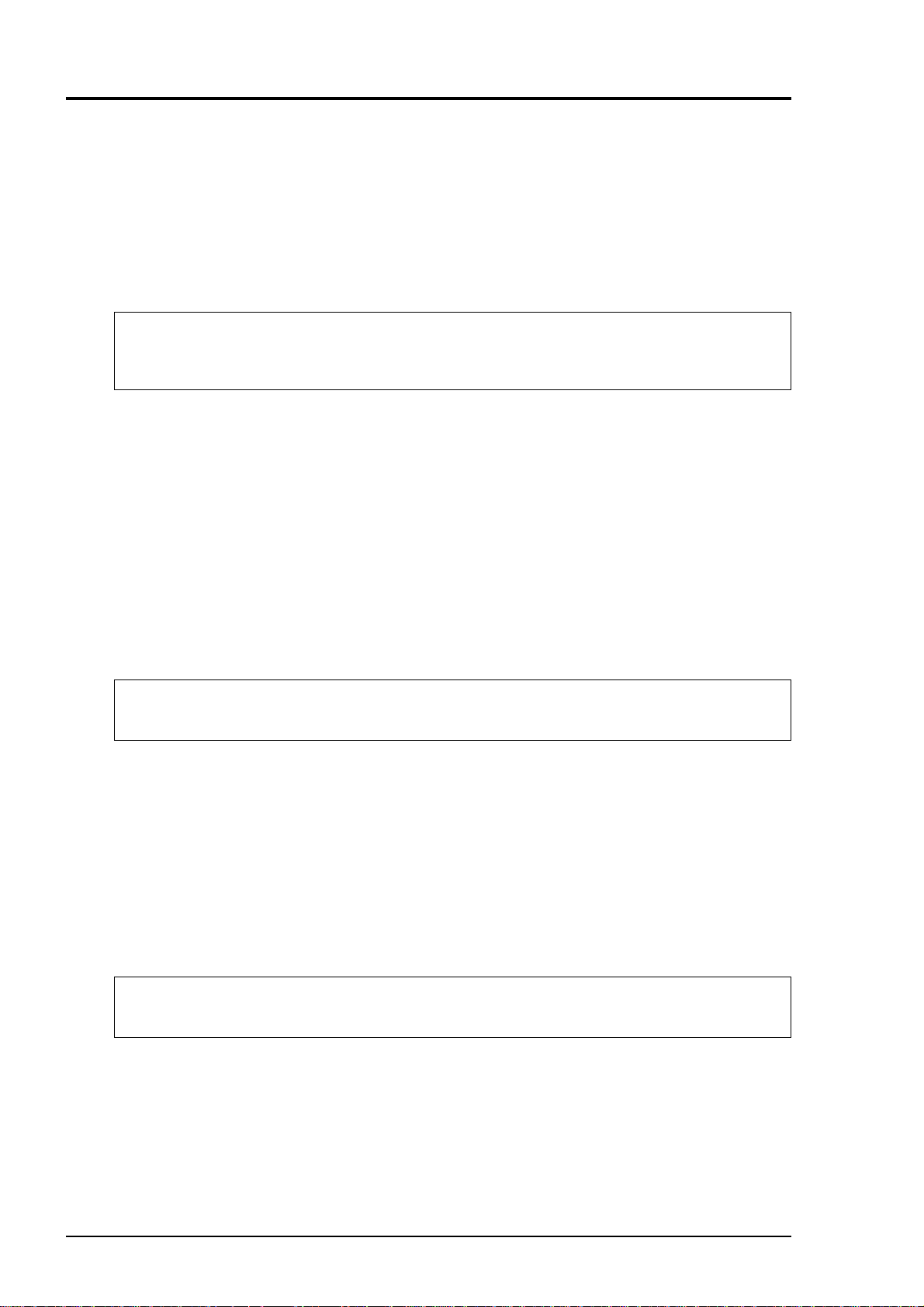

Terminal block 1

<TN1>

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

10

(M3.5 screw)

CH9 output

(CH9_OUT)

CH10 output

(CH10_OUT)

CH8 output

(CH8_OUT)

CH7 output

(CH7_OUT)

CH6 output

(CH6_OUT)

CH1 output

(CH1_OUT)

CH2 output

(CH2_OUT)

CH3 output

(CH3_OUT)

CH4 output

(CH4_OUT)

CH5 output

(CH5_OUT)

+

–

+

–

+

–

+

–

+

–

+

–

+

–

+

–

+

–

+

–

+

–

Terminal block 2

<TN2>

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

10

(M3.5 screw)

CH4 remote range

changeover input

(R_RNG_CH4)

CH5 remote range

changeover input

(R_RNG_CH5)

CH3 remote range

changeover input

(R_RNG_CH3)

CH2 remote range

changeover input

(R_RNG_CH2)

CH1 remote range

changeover input

(R_RNG_CH1)

CH12 output

(CH12_OUT)

CH11 output

(CH11_OUT)

Unassigned

Unassigned

O

2

sensor input

(O

2

_IN)

Note 1

Terminal block 3

<TN3>

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

10

(M3.5 screw)

CH4 range identification

contact output (RNG_IDCH4)

CH5 range identification

contact output (RNG_IDCH5)

CH3 range identification

contact output (RNG_IDCH3)

CH2 range identification

contact output (RNG_IDCH2)

CH1 range identification

contact output (RNG_IDCH1)

Auto calibration

remote start

input (R_CAL)

Average value reset

input (RESET)

Remote hold input

(R_HOLD)

Unassigned

Unassigned

Terminal block 5

<TN5>

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

10

(M3.5 screw)

Unassigned

Power disconnection

alarm output

(POWER_OFF)

CH5 alarm output

(ALM_CH5)

CH4 alarm output

(ALM_CH4)

CH3 alarm output

(ALM_CH3)

CH2 alarm output

(ALM_CH2)

CH1 alarm output

(ALM_CH1)

Unassigned

Terminal block 4

<TN4>

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

10

(M3.5 screw)

Unassigned

Unassigned

Unassigned

Auto calibration status/

maintenance status contact

output (ACAL/MNT)

Calibration error

contact output

(CAL_ALM)

Unassigned

Unassigned

Note 1 : For external O

2

sensor input.

Instrument error

contact output

(FAULT)

Pump ON/OFF

contact output (PUMP)

Peak count alarm

output (PEAK_ALM)

Connector

<CN3>

Solenoid valve drive signal output for calibration

(Transister output)

<D-sub 9P>

Contact output for

zero calibration

Contact output for

sample gas selection

Contact output for CH1

span calibration

Contact output for CH2

span calibration

Contact output for CH3

span calibration

Contact output for CH4

span calibration

Contact output for CH5

span calibration

5V DC relay drive power

1

2

3

4

5

6

7

8

9

(5) List of terminal blocks

3 - 11INZ-TN2ZKJ-E

Page 22

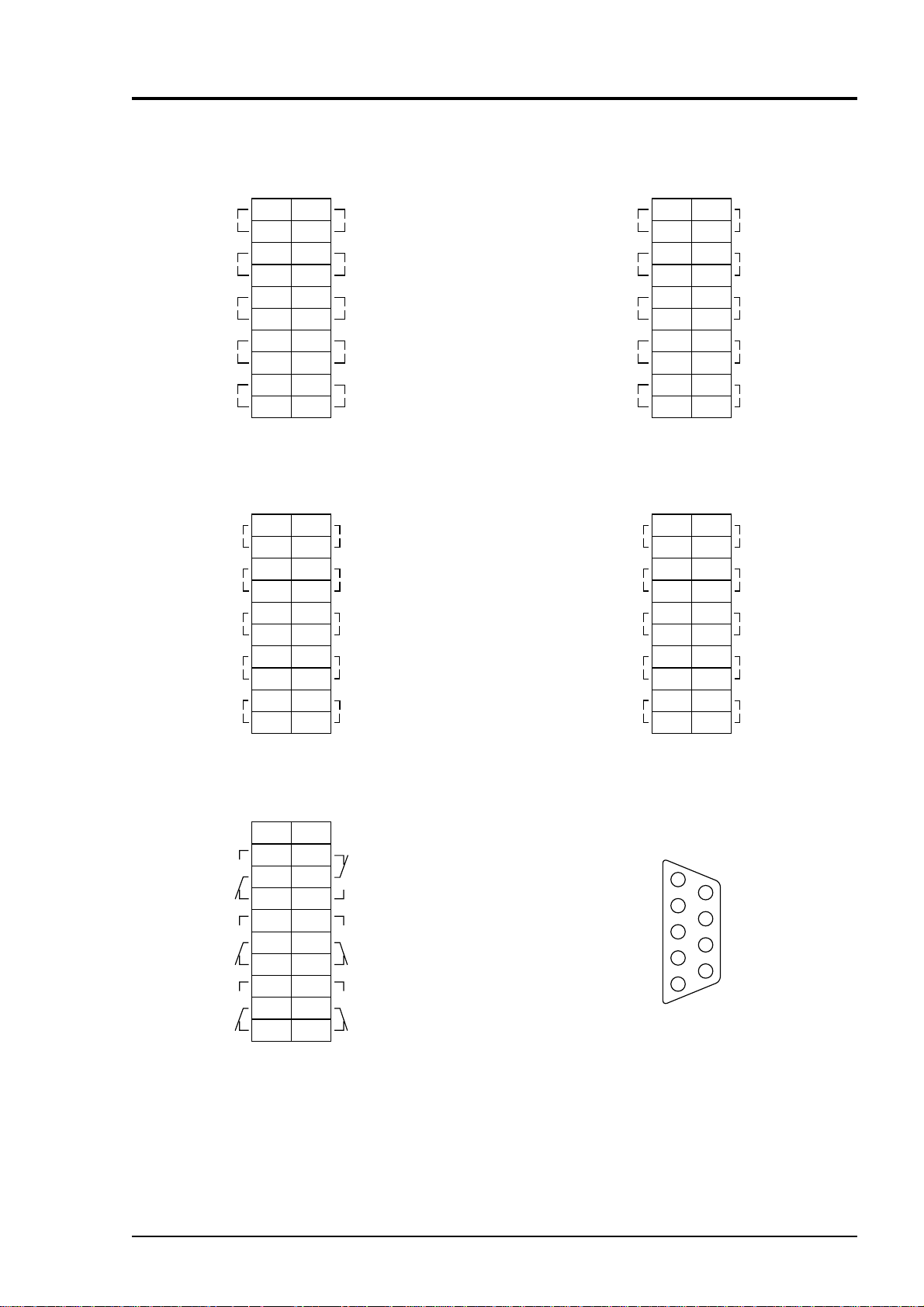

(6) Description on terminal block

Terminal block 1

<TN1>

CH5 output

(CH5_OUT)

CH4 output

(CH4_OUT)

CH3 output

(CH3_OUT)

CH2 output

(CH2_OUT)

CH1 output

(CH1_OUT)

1

–

+

2

3

–

+

4

5

–

+

6

7

–

+

8

9

–

+

10

(M3.5 screw)

12

13

14

15

16

17

18

19

20

CH10 output

–

+

(CH10_OUT)

CH9 output

–

+

(CH9_OUT)

CH8 output

–

+

(CH8_OUT)

CH7 output

–

+

(CH7_OUT)

CH6 output

–

+

(CH6_OUT)

11

Terminal block 2

<TN2>

2 sensor input

O

(O

CH12 output

(CH12_OUT)

CH11 output

(CH11_OUT)

Unassigned

Unassigned

Note 1

2_IN)

1

–

+

2

3

4

5

6

7

8

9

10

(M3.5 screw)

CH5 remote range

11

changeover input

(R_RNG_CH5)

12

CH4 remote range

13

changeover input

14

(R_RNG_CH4)

CH3 remote range

15

changeover input

(R_RNG_CH3)

16

CH2 remote range

17

changeover input

(R_RNG_CH2)

18

CH1 remote range

19

changeover input

(R_RNG_CH1)

20

Note 1: For external O2 sensor input.

Terminal block 2 <TN2>

Terminal block for analog output (non-isolated

output)

Between 1–2: CH5 output

Between 3–4: CH4 output

Between 5–6: CH3output

Between 7–8: CH2 output

Between 9–10: CH1 output

Between 11–12: CH10 output

Between 13–14: CH9 output

Between 15–16: CH8 output

Between 17–18: CH7 output

Between 19–20: CH6 output

Terminal block 2 <TN2>

Between 1–2: O

sensor input

2

(For input of Fuji’s zirconia

oxygen sensor and externally

oxygen sensor. Must not be used

unless external O

sensor is

2

provided.)

Between 3–4: CH12 output

Between 5–6: CH11 output

Between 7–10 For internal connection. Must

not be wired. (Must not be used

as junction terminal).

Between 11–12: CH5 remote range changeover

input

Between 13–14: CH4 remote range changeover

input

Between 15–16: CH3 remote range changeover

input

Between 17–18: CH2 remote range changeover

input

Between 19–20: CH1 remote range changeover

input

Action of remote range changeover

High range is selected when

open. Low range is selected

when short-circuited. For details

of action, see “Item 6.7 Parameter

Setting, Remote Range”.

3 - 12 INZ-TN2ZKJ-E

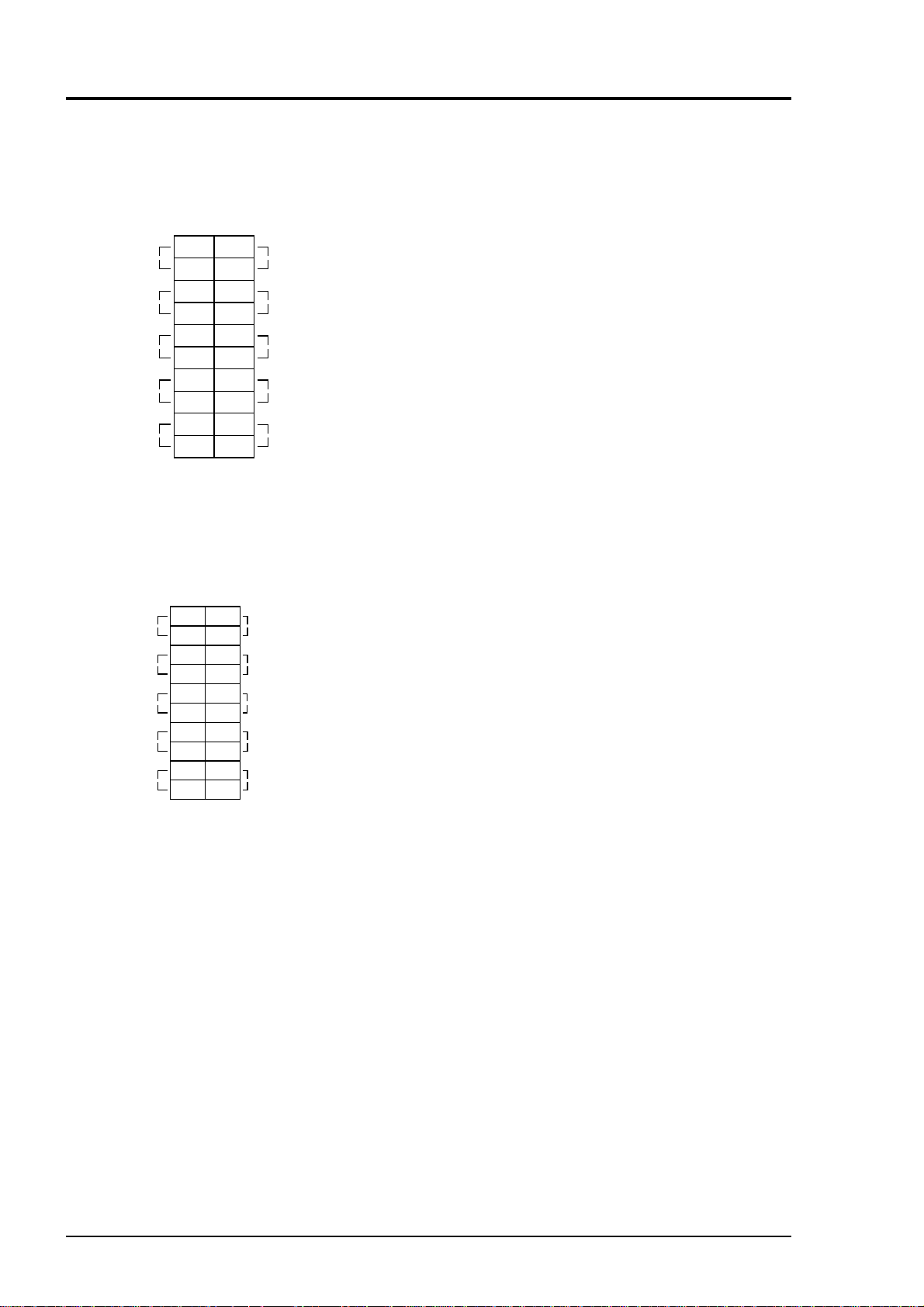

Page 23

Unassigned

Unassigned

Remote hold input

(R_HOLD)

Average value reset

input (RESET)

Auto calibration

remote start

input (R_CAL)

Terminal block 3

<TN3>

11

1

12

2

13

3

14

4

15

5

16

6

17

7

18

8

19

9

20

10

(M3.5 screw)

CH5 range identification

contact output (RNG_IDCH5)

CH4 range identification

contact output (RNG_IDCH4)

CH3 range identification

contact output (RNG_IDCH3)

CH2 range identification

contact output (RNG_IDCH2)

CH1 range identification

contact output (RNG_IDCH1)

Terminal block 3 <TN3>

Between 1–4: For internal connection. Must

not be wired. (Must not be used

as junction terminal.)

Between 5–6: Remote hold input. No hold

when open. Output hold when

short-circuited.

For details, refer to “Item 6.7

Parameter setting, Output Hold”.

Between 7–8: Average value reset input. short-

circuitting the contact input (for

at 1.5 sec min.) resets O

and O

corrected average simulta-

2

average

2

neously. Opening it restarts the

average value.

For details, refer to “Item 6.7

Parameter setting, Average Value

Resetting”

Between 9–10: Automatic calibration remote

start input

After shorting for 1.5 sec. or

more, automatic calibration is

started by the opening input

whether the automatic calibration

setting is ON/OFF.

For details, refer to “Item 6.4

Setting of auto calibration”

Between 11–12: CH5 range identification contact

output

Between 13–14: CH4 range identification contact

output

Between 15–16 CH3 range identification contact

output

Between 17–18: CH2 range identification contact

output

Between 19–20: CH1 range identification contact

output

Action of range identification signal

Range identification contact is

conductive at low range and open

at high range.

3 - 13INZ-TN2ZKJ-E

Page 24

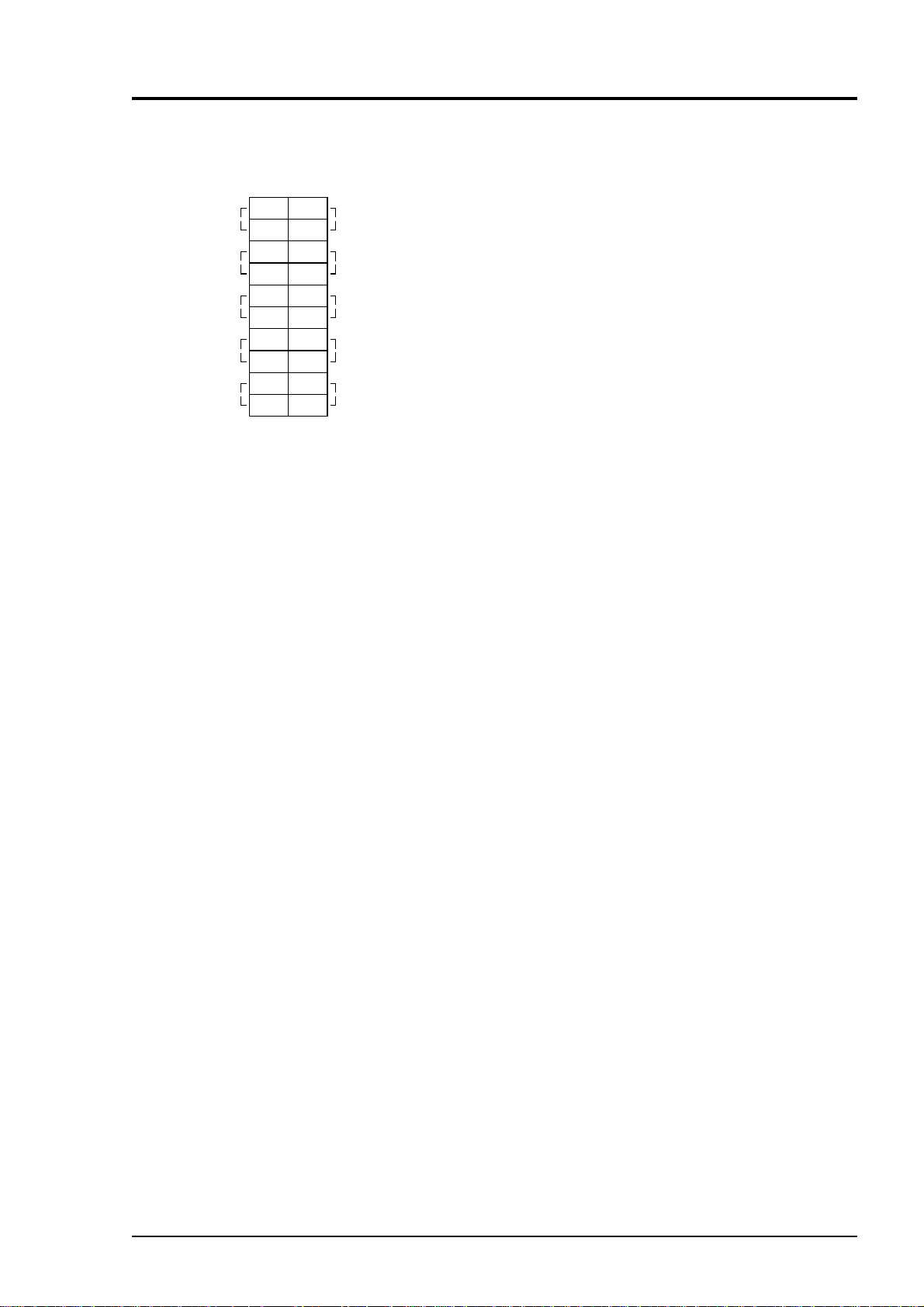

Terminal block 4

Peak count alarm

output (PEAK_ALM)

Auto calibration status/

maintenance status contact

output (ACAL/MNT)

Pump ON/OFF

contact output (PUMP)

Calibration error

contact output

(CAL_ALM)

Instrument error

contact output

(FAULT)

<TN4>

11

1

12

2

13

3

14

4

15

5

16

6

17

7

18

8

19

9

20

10

(M3.5 screw)

Unassigned

Unassigned

Unassigned

Unassigned

Unassigned

Terminal 4 <TN4>

Between 1–2: Peak count alarm contact output

It is conductive when peak count

exceeds the setting time. It

remains open below the setting

time. For setting and operation,

refer to “Item 6.6 Peak alarm

setting”.

Between 3–4: Contact output of auto calibration

status and maintenance contact

When the auto calibration is

carried out and remote hold is

ON, it is conductive. Remains

open otherwise.

Between 5–6: Pump ON/OFF contact output

Used when turning ON/OFF the

pump. It is open during auto and

manual calibration status and

conductive during measurement.

Between 7–8: Calibration error contact output

It is conductive when an error

occurs during zero calibration or

span calibration. It is normally

open.

Between 9–10: It is conductive when an error

occurs to the analyzer unit. It is

normally open.

Between 11–20: For internal connection, wiring is

not allowed. (Do not use it as

junction terminal).

3 - 14 INZ-TN2ZKJ-E

Page 25

Unassigned

CH3 alarm output

(ALM_CH3)

CH2 alarm output

(ALM_CH2)

CH1 alarm output

(ALM_CH1)

Terminal block 5

<TN5>

11

1

12

2

13

3

14

4

15

5

16

6

17

7

18

8

19

9

20

10

(M3.5 screw)

Unassigned

Power disconnection

alarm output

(POWER_OFF)

CH5 alarm output

(ALM_CH5)

CH4 alarm output

(ALM_CH4)

Terminal 5 <TN5>

Between 2, 3 and 4:

CH3 alarm output

When the output exceeds the set value,

it is conductive between 2 and 3, and

open between 3 and 4. Otherwise, it is

open between 2 and 3 and conductive

between 3 and 4.

Between 5, 6 and 7:

CH2 alarm output

When the output exceeds the set value,

it is conductive between 5 and 6, and

open between 6 and 7. Otherwise, it is

open between 5 and 6, and conductive

between 6 and 7.

Between 8, 9 and 10:

CH1 alarm output

When the output exceeds the set value,

it is conductive between 8 and 9, and

open between 9 and 10. Otherwise, it

is open between 8 and 9.

Between 12, 13 and14:

Analyzer unit power OFF output

When the analyzer unit is turned ON,

it is conductive between 12 and 13,

and open between 13 and 14. When

the analyzer unit is turned OFF, it is

open between 12 and 13, and conductive between 13 and 14.

Between 15, 16 and 17:

CH5 alarm output

When the output exceeds the set value,

it is conductive between 15 and 16,

and open between 16 and 17. Otherwise, it is open between 15 and 16,

and conductive between 16 and 17.

Between 18, 19 and 20:

CH4 alarm output

When the output exceeds the set value,

it is conductive between 18 and 19,

and open between 19 and 20. Otherwise, it is open between 18 and 19,

and conductive between 19 and 20.

For detailed action of the alarm

contact, refer to “Item 6.3 Alarm

setting”.

3 - 15INZ-TN2ZKJ-E

Page 26

Connector <CN3>

Solenoid valve drive signal output for calibration

Connector

<CN3>

(Transister output)

Contact output for

sample gas selection

Contact output for

zero calibration

Contact output for CH1

span calibration

Contact output for CH2

span calibration

1

2

3

4

5

<D-sub 9P>

Contact output for CH3

6

span calibration

Contact output for CH4

7

span calibration

Contact output for CH5

8

span calibration

5V DC relay drive power

9

Connector <CN3> provides outputs in combination with calibration action during auto calibration

and manual calibration.

An output is from a transistor (ratings: 5V/50mA).

A transistor is turned ON before starting each calibration.

Sample selection output is ON during measurement and OFF during calibration.

If calibration is not performed, the other transistors are OFF.

In case of auto calibration, sequential output is ON/OFF according to the setting.

Refer to “Item 6.4 Setting of auto calibration”.

Note) No. 9 pin is for solenoid valve ON/OFF relay drive power (5V DC/0.5A, max).

Use No. 9 with reference to the diagram.

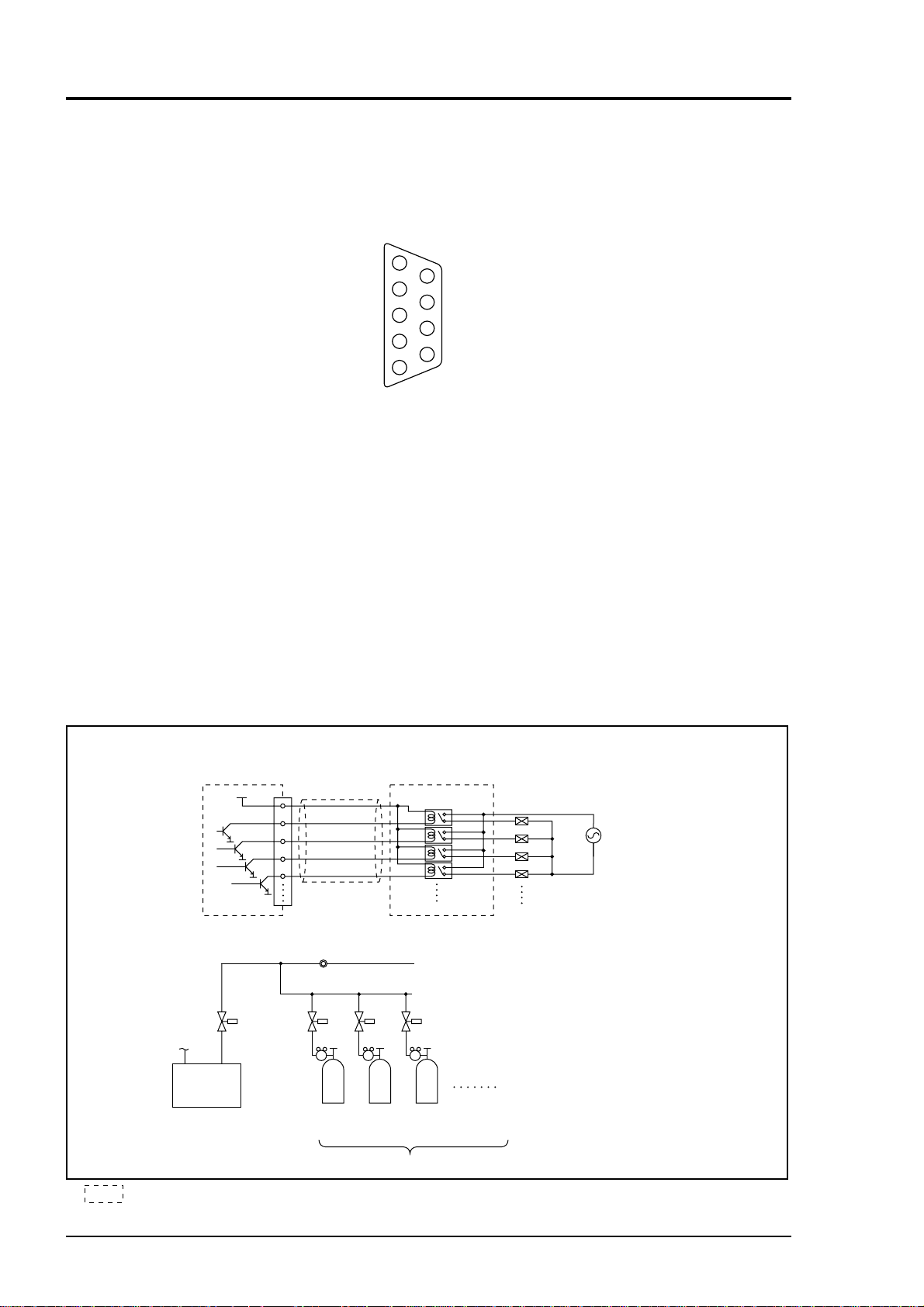

Example of using solenoid valve drive signal output for calibration

<Electrical system>

SV4

CH1

span

Contact relay

Relay board

CH2

span

5V

I/O terminal module

<Gas sampling system>

Electronic

gas cooler

9

1

3

4

5

SV2SV1

Cable

CN3

Membrane filter

SV3

Zero

Standard gas for calibration

SV1

SV2

SV3

SV4

Solenoid valve

drive power

SV1 to SV4: solenoid valves

Refer to “Item 3.3.6 Example configuration

of gas sampling system”.

Relay board (TK7H2949C4) and exclusive cable (D-sub 9p straight cable: 1.5 meters)

are available on request.

3 - 16 INZ-TN2ZKJ-E

Page 27

• Zero calibration

• Span calibration

Zero calibration

output

Zero calibration

output

Pump ON/OFFcontact

Pump ON/OFFcontact

Sample selection

output

CH1 to 5 span

calibration output

CH1 to 5 span

calibration output

Output hold function

Sample selection

output

(with hold ON setting)

ZERO ENT

ENT

Hold extension time.

Calibration gas flow

Calibration gas flow

Output signal hold

Output signal hold

Calibration end

Calibration end

on

off

on

off

on

off

off

Output hold function

(with hold ON setting)

SPAN ENT

ENT

Hold extemsion time.

Note)

When selecting

CH2 using

DOWN and UP

keys.

For CH1 span

calibration

The hold extension time

depends on the gas

flow time of the

automatic calibration

settings.

(7) Timing of solenoid valve drive signal for calibration

qq

q Manual calibration (see “Item 6.9 Calibration”.)

qq

3 - 17INZ-TN2ZKJ-E

Page 28

ww

w In case of automatic calibration (example shown in Item 6.4.1, Automatic calibration settings)

ww

Pump ON/OFF contact

Sample selection output

Zero calibration output

CH1 span calibration output

CH2 span calibration output

CH3 span calibration output

CH4 span calibration output

CH5 span calibration output

Automatic calibration contact

Output hold function

Automatic

calibration

start

Zero calibration

Zero gas

350

CH1 span gas

CH1 span

calibration

350

CH2 span

calibration

CH3 span

calibration

CH4 span

calibration

CH5 span

calibration

Hold

extension time.

3 - 18 INZ-TN2ZKJ-E

Page 29

4. OPERATION

4.1 Preparation for operation

(1) Tube and wiring check

Double-check if tubes of the gas sampling and exhaust ports are correctly connected.

Double-check for proper wiring.

4.2 Warm-up operation and regular operation

(1) Operation procedure

q Turn ON the power switch on the front panel of the analyzer unit.

The measurement screen appears on the front display panel in 1 or 2 seconds.

w Wait for about 4 hours until the instrument is warmed up.

Since about 4 hours are required until the instrument allows accurate measurement, warm

up the instrument with the power ON.

Note) When in warm-up, the concentration reading may be beyond.

upper limit of range or

lower limit of range.

But, it is not an error.

e Setting of various set values

Perform the various settings according to “Chapter 6. Setting and Calibration”.

r Zero calibration and span calibration

Perform zero calibration and span calibration after warm-up operation.

Refer to “Chapter 6.9. Calibration”.

t Introduction and measurement of measuring gas

Introduce the measuring gas into the analyzer unit before starting measurement.

4 - 1INZ-TN2ZKJ-E

Page 30

5.

DESCRIPTION OF DISPLAY AND OPERATION PANELS

This section describes the display unit and operation panel of the analyzer unit. It also explains the name

and description of function on the operation panel.

5.1 Name and description of operation panel

POWER

DISPLAY

MODE

ESC ZERO

ENT SPAN

Fig. 5-1

Name

q MODE key

Used to switch the mode.

Description

Name

t ESC key

Description

Used to return to a previous screen

or cancel the setting midway.

w SIDE key

e UP key

Used to change the selected item

(by moving the cursor) and

numeral digit.

Used to change the selected item

y ENT key

u ZERO key

Used for confirmation of selected

items or values, and for execution

of calibration.

Used for zero calibration.

(by moving the cursor) and to

increase numeral value.

r DOWN key

Used to change the selected item

i SPAN key

Used for span calibration.

(by moving the cursor) and to

decrease numeral value.

Note) The switch for back light is used for turning ON/OFF the back light of display.

The life time of back light is 50000 hours.

Please turn OFF the switch when indication is not necessary, so the life time will be longer.

5 - 1INZ-TN2ZKJ-E

Page 31

5.2 Overview of display and operation panels

• Measurement mode

MODE

• Measurement mode

• Measurement mode

MODE

MODE

• Menu mode

ESC

• Menu mode

1. Changeover of Range

Setting about Calibration

2.

3. Alarm Setting

Setting of Auto Calibration

4.

5.

Setting of Auto Zero calibration

6. Setting of Peak Alarm

7. Parameter Setting

* 2) The peak alarm setting is

added according to the

code symbol when CO

2

and O

components exist.

ESC

ESCMODE

ESC

ESC

ESC

ESC

ESC

ESC

ESC

ESC

* 1

• Changeover of

Range

• Setting about

Calibration

• Alarm Setting

• Setting of Auto

Calibration

• Setting of Auto

Zero calibration

• Setting of

Peak Alarm

• Parameter

Setting

* 1) The panel configuration is changed depending on the

display channel. (The measurement mode screen can

be viewed by scrolling the arrow key up and down).

ZERO

ZERO Calibration

SPAN Calibration

SPAN

• Selection of items

Calibration value

Zero calibration

Calibration range

Auto calibration component

• Selection of items

Start Time

Cycle

Flow Time

Auto calibration ON/OFF

Stop Auto Calibration

• Selection of items

Start Time

Cycle

Flow Time

ON/OFF

Stop Auto zero Calibration

• Selection of items

Peak Alarm ON/OFF

Peak Value

Peak Count

Hysteresis

• Selection of items

Current time : Current time setting

Key lock : Key lock ON/OFF

Remote range : Remote range ON/OFF

Hold : ON/OFF

Response time : Response time (filter)

Average time : Average time setting

Average value reset: Average value resetting

Maintenance mode : Maintenance mode

(entry of password)

Fig. 5-2

5 - 2 INZ-TN2ZKJ-E

Page 32

5.3 Outline of display screen

(1) Measurement mode screen (appears when the power is turned ON)

The measurement screen depends on the number of components. The following screen configuration as shown as an example is for NO, SO

* corrected instantaneous value ..... CV.

** correctted average value .............

, CO2, CO and O2 (output: 12 channel).

2

CV.

AV.

Fig. 5-3 Name and function of measurement mode screen

* For outputs of more than 5 channels, scroll the arrow key

No.

q

Component

display

w

Concentration

display

e

Range display

r

Unit display

Name

Displays component of instantaneous value, corrected instantaneous value, corrected average

value, etc.

Displays measured value of

concentration.

Displays range values.

Displays unit with ppm and

vol%.

Function

No.

t

y

u

i

or to view.

Name

Peak alarm

component

display

Peak alarm

concentration

display

Peak alarm

times

Peak alarm

unit display

Description

Displays peak alarm component.

(Only CO)

Displays peak alarm concentration display.

(Upper limit value)

Displays the alarm times

exceeding the peak value.

Displays units of peak alarm with

times/H.

5 - 3INZ-TN2ZKJ-E

Page 33

• Instantaneous value and concentration value:

The concentration display of CH (component) where sampling components such as “CO2”,

“CO” or “O

are displayed in the component display, indicates current concentration values of

2

the measured components contained in gas that is now under measurement.

correction concentration values:

• O

2

CH components where “cv**” is displayed as “cv CO” in the component display are calculated

from the following equation, by setting sampling components, O

values and O

correction reference value (see item 6.8).

2

instantaneous/concentration

2

Correction output=

21

21

-

On

× Cs

-

Os

K

On: The value of the O

(Value set by application)

Os: Oxygen concentration (%)

correction referance value

2

Cs: Concentration of relevant measured component

K: The value of the fractional part.

where, K is When K

4, K = 4 . When K < 0, K = 4.

When Cs < 0, K = 0.

The converted sampling components are NO

, SO2 and CO only.

X

• O2 correction concentration average value:

In the CH (component) and O

average value where “ **” is displayed as “ CO” in the

2

component display, a value obtained by averaging O

CV

AV

correction concentration value or O

2

CV

AV

correction value in a fixed time is output every 30 seconds.

Averaging time can be changed between 1 minute and 59 minutes or 1 hour and 4 hours accord-

ing to the average time settings (See 6.7, Parameter setting).

(The set time is displayed as “1h” , for instance, in the range display.)

* The measurement ranges of O

correction concentration value and O2 correction concentra-

2

tion average value are the same as that of the measuring components. Also, the measurement range of O

average value is the same as that of O2.

2

2

(2) Setting/selection screen

The setting/selection screen is configured as shown below:

• In the status display area, the current status is displayed.

• In the message display area, messages associated with operation are displayed.

• In the setting item and selection item display area, items or values to be set are displayed,

as required. To work on the area, move the cursor to any item by using UP, DOWN and

SIDE keys.

• LCD screen

Status display area

Cursor

Message display area

Setting item/selection item

display area

Fig. 5-4

5 - 4 INZ-TN2ZKJ-E

Page 34

(3) Contents of measured channel (CH)

The following table gives measurement channels and their contents according to the symbols.

Code symbol

5th digit 6th digit 21th digit

P

A

D

B

E

F

H

G

L

M

N

P

A

B

E

F

H

G

L

M

B

H

G

L

M

B

H

G

L

M

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

A, B, C

A, B, C

A, B, C

A, B, C

A, B, C

A, B, C

A, B, C

A, B, C

A, B, C

A, B, C

A, B, C

A, B, C

A, B, C

A, B, C

A, B, C

A, B, C

A, B, C

A, B, C

A, B, C

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

Y

A

A

A

A

A

A

A

A

A

B

B

B

B

B

C

C

C

C

C

Contents

CH1: NO

CH1: SO

2

CH1: CO

2

CH1: CO

CH1: CH

4

CH1: NO, CH2: SO

2

CH1: NO, CH2: CO

CH1: CO

CH1: NO, CH2: SO

CH1: NO, CH2: SO

CH1: NO, CH2: CH

CH1: NOx, CH2: O

CH1: SO

CH1: CO, CH2: O

CH1: CH

CH1: NOx, CH2: SO

CH6: Corrected NOx average, CH7: Corrected SO

CH1: NOx, CH2: CO, CH3: O

CH6: Corrected NOx average, CH7: Corrected CO average, CH8: O

CH1: CO

CH6: O

CH1: NOx, CH2: SO

CH7: Corrected CO, CH8: Corrected NOx average, CH9: Corrected SO

CH10: Corrected CO average, CH11: O

CH1: NOx, CH2: SO

CH7: Corrected SO

CH10: Corrected SO

CH1: CO, CH2: O

CH1: NO, CH2: CO, CH3: O

CH1: CO2, CH2: CO, CH3: O

CH1: NO, CH2: SO2, CH3: CO, CH4: O

CH1: NO, CH2: SO2, CH3: CO

2

, CH2: CO

2

, CH3: CO

2

, CH3: CO2, CH4: CO

4

, CH3: CO2, CH4: CO

2

, CH3: Corrected NOx, CH4: Corrected NOx average, CH5: O2 average

2

, CH2: O2, CH3: Corrected SO2, CH4: Corrected SO2 average, CH5: O2 average

2

, CH3: Corrected CO, CH4: Corrected CO average, CH5: O2 average

4

, CH2: O2, CH3: O2 average

2

, CH3: O2, CH4: Corrected NOx, CH5: Corrected SO2,

2

, CH4: Corrected NOx, CH5: Corrected CO,

2

, CH2: CO, CH3: O2, CH4: Corrected CO, CH5: Corrected CO average,

2

average

2

, CH3: CO, CH4: O2, CH5: Corrected NOx, CH6: Corrected SO2,

2

average

2

, CH3: CO2, CH4: CO, CH5: O2, CH6: Corrected NOx,

2

, CH8: Corrected CO, CH9: Corrected NOx average,

2

average, CH11: Corrected CO average, CH12 : O

2

, Peak alarm

2

, Peak alarm

2

, Peak alarm

2

2

, CH4: CO, CH5: O2, Peak alarm

2

average, CH8: O2 average

, Peak alarm

2

average

2

average,

2

average

CH1: CO, CH2: O2, CH3: Corrected CO, CH4: Corrected CO average, CH5: O2 average,

Peak alarm

CH1: NOx, CH2: CO, CH3: O

CH6: Corrected NOx average, CH7: Corrected CO

CH1: CO

CH6: O

CH1: NOx, CH2: SO

2

, CH2: CO, CH3: O2, CH4: Corrected CO, CH5: Corrected CO average,

2

average, Peak alarm

2

CH7: Corrected CO, CH8: Corrected NOx average, CH9: Corrected SO

CH10: Corrected CO average, CH11: O

CH1: NOx, CH2: SO

CH7: Corrected SO

CH10: Corrected SO

2

2

, CH8: Corrected CO, CH9: Corrected NOx average,

2

average, CH11: Corrected CO average, CH12 : O

2

, CH4: Corrected NOx, CH5: Corrected CO,

average, CH8: O2 average, Peak alarm

, CH3: CO, CH4: O2, CH5: Corrected NOx, CH6: Corrected SO2,

2

2

average, Peak alarm

average,

, CH3: CO2, CH4: CO, CH5: O2, CH6: Corrected NOx,

2

average, Peak alarm

5 - 5INZ-TN2ZKJ-E

Page 35

5.4 General operation

C H

O

2

0-25

vol%

C H

CO

0-100

ppm

C H

CO

2

0-10

vol%

C H

SO

2

0-100

ppm

C H

NO

X

0-100

ppm

00

.

00

.

000

00

.

000

.

.

C H

O

2

0-25

vol%

C H

CO

0-100

ppm

C H

CO

2

0-10

vol%

C H

SO

2

0-100

ppm

C H

NO

X

0-100

ppm

00

.

00

.

000

00

.

000

.

.

ZERO

SPAN

C H

AV.

O2

PEARK COUNTER

CO 500ppm 0 times/H

0-25

vol%

C H

CO

0-100

ppm

C H

SO2

0-100

ppm

C H

NOX

0-100

ppm

000

.

00

.

00

.

00

.

CV.

AV.

CV.

AV.

CV.

AV.

ESC MODE

ESC MODE

• Measurement mode

The measurement mode can be displayed

up to 5 channels in a single screen. If 5

channels or more are to be displayed in a

single screen, press the

scroll the channel one by one.

or key to

Zero calibration

See 6.9.1.

Span calibration

See 6.9.2.

• Menu mode displays;

Changeover of Range

Setting about Calibration

Alarm Setting

Setting of Auto Calibration

Setting of Auto Zero Calibration

Setting of Peak Alarm

Parameter Setting.

For the setting contents, refer to

“Chapter 6. Setting and calibration”.

Measurement Mode

5 - 6 INZ-TN2ZKJ-E

Page 36

6. SETTING AND CALIBRATION

6.1 Changeover of range

This mode is used to select the ranges of measured components.

MODE

q During measurement, press the

key

to display the User mode.

w Point the cursor to “Changeover of

Range”. Press the

ENT

key.

e The “Channel Selection” screen appears.

Press the

or key until the “ ”

cursor moved selects a desired CH

(component).

ENT

r After selection, press the

key.

MODE

( )

ENT

Note) The range of O

neous values and O

correction instanta-

2

correction

2

average values is automatically

switched by changing the range of

instantaneous value of each CH

(component).

t In the Range Setting screen that appears,

move the cursor by pressing the

or

key to select the range. (The range

with a mark of

y After selection, press the

is currently selected.)

ENT

key.

u Measurement is conducted within the

selected range. The range identification

contact is closed with the low range

(Range 1), and open with the high range

(Range 2).

Note) If the Remote Range is set to ON,

the changeover of range cannot be

performed on the screen.

( )

( )

End of Range Selection

ENT

ENT

To close “Changeover of Range”

To close Changeover of Range, or cancel

the command midway, press the ESC key.

ESC

A previous screen will return.

6 - 1INZ-TN2ZKJ-E

Page 37

6.2 Calibration setting

This mode is used to set calibration concentration and actions. The calibration setting involves

calibration concentration, zero calibration, calibration range and auto calibration component.

6.2.1 Setting of calibration concentration

It allows you to set concentrations of the standard gas (zero and span) of each channel used for

calibration.

MODE

MODE

q During measurement, press the

to display the User mode.

w Point the cursor to “Setting about Cali-

bration” by pressing the

ENT

Press the

key.

or key.

key

e In the “Setting about Calibration” screen

that appears, point the cursor to “Calibration Value” by pressing the

key. Press the

ENT

key.

or

r In the “Calibration Concentration CH

Selection” screen that appears, point the

cursor to CH you want to set by using the

or key. Press the

ENT

key.

ENT

( )

ENT

( )

ENT

6 - 2 INZ-TN2ZKJ-E

Page 38

t In the “Calibration Concentration Selection”

screen that appears, select any concentration

item you want to set by pressing the

,

key.

y In the “Calibration Concentration Value

Setting” screen that appears, enter calibration

gas concentration values (zero and span).

For value entry, press the

or key, and

a 1-digit value increases or decreases. By

pressing the

, the digit moves.

After setting, save the entry by pressing the

ENT

key. The saved value becomes valid

from the next calibration process.

Note) Enter the set values corresponding to

each range. When the O

measurement

2

uses atmospheric for the zero gas, set

the concentration value to 20.60. When

the cylinder air is used, set to the concentration value as indicated on the

cylinder.

To close the setting

To close the calibration concentration value

setting process or cancel this mode midway,

press the ESC key.

ESC

A previous screen will return.

( )

Cursor for setting value

End of Calibration

Concentration Setting

ENT

ENT

Setting range of values

NOx, SO2, CO

measurement and buit-in paramagnetic O

2,

CO, CH4, external O2

2

sensor

External Zirconia O

2

measurement

The setting cannot be performed beyond the range.

Span gas: 1 to 100% of full scale

(Full scale (FS) is the same as each range

value.)

Zero gas: 5 to 25 vol%

Span gas: 0.01 to 5 vol%

6 - 3INZ-TN2ZKJ-E

Page 39

6.2.2 Setting of manual zero calibration

When zero calibration is made manually, set either all measurement components should be

calibrated simultaneously or each component should be calibrated while selecting one by one.

MODE

q During measurement, press the

MODE

key

to display the User mode.

w Point the cursor to “Setting about Cali-

bration” by pressing the

ENT

Press the

key.

or key.

e In the “Setting about Calibration” screen

that appears, point the cursor to “About

ZERO Calibration” by pressing the

key. Press the

ENT

key.

or

( )

ENT

( )

ENT

r In the “Manual Calibration CH Selec-

tion” screen that appears, point the cursor

to CH you want to set by using the

key. Press the

ENT

key.

or

( )

ENT

6 - 4 INZ-TN2ZKJ-E

Page 40

t In the “Manual Calibration Selection”

screen that appears, select “at once” or

“each” by pressing the

or key.

When selecting “at once”, the CH (components) to be set can be zero-calibrated

at the same time. When selecting “each”,

either of the CH (components) to be

selected is zero-calibrated. After setting,

ENT

press the

key.

To close “About ZERO Calibration”

( )

ENT

To close “About ZERO Calibration” setting or to

cancel this mode midway, press the ESC key.

ESC

End of Manual Calibration Setting

A previous screen will return.

Example

Whether “each” or “at once” can be determined for each CH (component).

•Setting “each”

Select the CH (component) on the manual zero calibration screen and then perform

zero calibration.

•Setting “at once”

At a manual zero calibration, zero of CH (components) for which “at once” was selected can

simultaneously be calibrated.

* When the cylinder air or atmospheric air is used for the zero gas, select “At once”.

Manual Calibration screen

• When setting all components to “each”:

A single cursor will appear.

• When setting all components to “at once”:

Cursors will appear at all components

where “at once” is set.

6 - 5INZ-TN2ZKJ-E

Page 41

6.2.3 Setting of calibration range

This mode is used to set if the range of each CH (component) at the calibration (manual calibration

or auto calibration) should be calibrated with a single range or 2 ranges.

MODE

MODE

q During measurement, press the

key

to display the User mode.

w Point the cursor to “Setting about Cali-

bration” by pressing the

ENT

Press the

key.

or key.

e In the “Setting about Calibration” screen

that appears, point the cursor to “About

Calibration Range” by pressing the

key. Press the

ENT

key.

or

r In the “Calibration Range CH Selection”

screen that appears, point the cursor to

the CH you want to set by pressing the

or key. Press the

ENT

key.

( )

( )

ENT

ENT

( )

ENT

6 - 6 INZ-TN2ZKJ-E

Page 42

t In the “Calibration Selection” screen that

appears, select “both” or “current” by

pressing the

or key.

• When selecting “both”, Range 1 and

Range 2 of the set CH are calibrated

together. When selecting “current”, the

range alone displayed at the set CH is

calibrated.

To close “Setting of Calibration Range”

To close “Setting of Calibration Range” or

to cancel this mode midway, press the

ESC key. A previous screen will return.

ESC

End of Manual Calibtation Setting

( )

Example

CH1

NOx

CH2

SO

Range 1: 0 to 100 ppm

Range 2: 0 to 2000 ppm

Range 1: 0 to 100 ppm

Range 2: 0 to 2000 ppm

2

both

current

CH1: Range 1 and Range 2 are calibrated together with zero and span calibration.

CH2: Only currently displayed range is calibrated with zero and span calibration.

Caution

When calibrating the span gas in the interlocked ranges, the same values should

be set in both ranges.

ENT

Manual Calibration screen

When setting NOx and CO to “both”

Two cursors will appear in both ranges (CH1 and CH4).

6 - 7INZ-TN2ZKJ-E

Page 43

6.2.4 Setting of auto calibration component

It sets the CH (component) to be calibrated in the auto calibration.