Fuji Electric ZKG Service Manual

Instruction Manual

PARAMAGNETIC OXYGEN

ANALYZER

TYPE: ZKG

OXYGEN ANALYZER

INZ-TN2ZKG-E

PREFACE

We are grateful for your purchase of Fuji Electric’s paramagnetic oxygen analyzer (ZKG).

• First read this instruction manual carefully until an adequate understanding is acquired, and then proceed

to installation, operation and maintenance of the gas analyzer. Wrong handling may cause an accident or

injury.

• The specifications of this analyzer will be changed without prior notice for further product improvement.

•Modification of this gas analyzer is strictly prohibited unless a written approval is obtained from the

manufacturer. Fuji Electric will not bear any responsibility for a trouble caused by such a modification.

• This instruction manual shall be stored by the person who actually uses the gas analyzer.

• After reading the manual, be sure to store it at a place easier to access.

• This instruction manual should be delivered to the end user without fail.

Delivered items

Name Q’ty Remarks

Analyzer main frame 1 —

Panel mounting bracket 2

Fuse 2 250V AC 0.5A delay type

Instruction manual 1 —

Manufacturer: Fuji Electric Instrumentation Co., Ltd.

Type: Described in nameplate on main frame

Date of manufacture: Described in nameplate on main frame

Product nationality: Japan

© Fuji Electric Systems Co., Ltd. 2003

Request

• It is prohibited to transfer part or all of this manual without Fuji

Electric’s permission in written format.

• Description in this manual will be changed without prior notice for

further improvement.

INZ-TN2ZKG-E i

Issued in March, 2003

CONTENTS

PREFACE .........................................................................................................................i

Caution on safety .................................................................................................................. iii

1. GENERAL AND PRINCIPLE OF OPERATION.................................................... 1

1.1 General......................................................................................................................... 1

1.2 Principle of measurement ............................................................................................ 1

2. NAME AND EXPLANATION OF EACH PART ................................................... 3

2.1 Name and explanation of each part ............................................................................. 3

3. INSTALLATION ...................................................................................................... 4

3.1 Mounting...................................................................................................................... 4

3.1.1 Outline diagram...................................................................................................................4

3.1.2 Cautions on installation.......................................................................................................5

3.2 Piping........................................................................................................................... 5

(1) Piping method ...................................................................................................................5

(2) Piping diagram ..................................................................................................................6

(3) Conditions of sample gas ..................................................................................................7

(4) Flow rate of sample gas ....................................................................................................7

(5) Preparation of standard gases ...........................................................................................7

(6) Purging inside the instrument ...........................................................................................7

3.3 Wiring .......................................................................................................................... 8

(1) Wiring method ..................................................................................................................8

(2) Power terminal ..................................................................................................................8

4. OPERATION ............................................................................................................ 9

4.1 Operating procedure .................................................................................................... 9

4.2 Preparations for operation............................................................................................ 9

(1) Installation ........................................................................................................... 9

(2) Purging inside the instrument............................................................................ 10

(3) Turning on the power ........................................................................................ 10

(4) Warm-up............................................................................................................ 10

(5) Zero calibration ................................................................................................. 10

(6) Span calibration ................................................................................................. 10

4.3 Start of measurement ................................................................................................. 10

4.4 Stop ............................................................................................................................ 10

5. CALIBRATION ...................................................................................................... 11

5.1 Zero calibration and span calibration ........................................................................ 11

(1) Zero calibration ................................................................................................. 11

(2) Span calibration ................................................................................................. 11

ii INZ-TN2ZKG-E

6. CHECK AND MAINTENANCE ............................................................................. 12

6.1 Check ......................................................................................................................... 12

6.1.1 Check of sample gas flow rate ..........................................................................................12

6.2 Maintenance............................................................................................................... 12

6.2.1 Spare parts.........................................................................................................................12

6.2.2 Replacement of fuse..........................................................................................................13

6.2.3 Replacement of filter.........................................................................................................13

6.2.4 Coarse zero/span adjustment.............................................................................................14

(1) Coarse zero adjustment ............................................................................................14

(2) Coarse span adjustment............................................................................................14

7. TROUBLESHOOTING............................................................................................ 15

8. SPECIFICATIONS ................................................................................................... 17

INZ-TN2ZKG-E iii

CAUTION ON SAFETY

First of all, read this “Caution on safety” carefully, and then use the analyzer in the correct way.

• The cautionary descriptions listed here contain important information about safety, so they should always be observed.

Those safety precautions are ranked in 2 levels; DANGER and CAUTION.

Wrong handling may cause a dangerous situation, in which there is a risk of

DANGER

CAUTION

Caution on installation and transport of gas analyzer

death or heavy injury.

Wrong handling may invite a dangerous situation, in which there is a possibility of medium-level trouble or slight injury or only physical damage is

predictable.

DANGER

• This unit is not explosion-proof type. Do not use it in a place with explosive gases to prevent explosion, fire or

other serious accidents.

CAUTION

• This unit should be installed in a place which conforms to the conditions noted in the instruction manual. Otherwise, it may cause electric shocks, fire or malfunction of the unit.

• During installation work, care should be taken to keep the unit free from entry of cable chips or other foreign

objects. Otherwise, it may cause fire, trouble or malfunction of the unit.

• For lifting the gas analyzer, be sure to wear protective gloves. Bare hands may invite an injury.

• Before transport, fix the casing so that it will not open. Otherwise, the casing may be separated and fall to cause

an injury.

iv INZ-TN2ZKG-E

Caution on piping

DANGER

• In piping, the following precautions should be observed. Wrong piping may cause gas leakage.

If the leaking gas contains a toxic component, there is a risk of serious accident being induced.

Also, if combustible gas is contained, there is a danger of explosion, fire or the like occurring.

• Connect pipes correctly referring to the instruction manual.

• Exhaust should be led outdoors so that it will not remain in the locker and installation room.

• Exhaust from the analyzer should be relieved in the atmospheric air in order that an unnecessary pressure will not

be applied to the analyzer. Otherwise, any pipe in the analyzer may be disconnected to cause gas leakage.

• For piping, use a pipe and a pressure reducing valve to which oil and grease are not adhering. If such a material

is adhering, a fire or the like accident may be caused.

Caution on wiring

CAUTION

• The unit must be earthed as specified. Otherwise, it may cause electric shocks, malfunction, etc.

•Be sure to use a power supply of correct rating. Connection of power supply of incorrect rating may cause fire.

• Wiring work must be performed with the main power set to OFF to prevent electric shocks.

•Wires should be the proper one meeting the ratings of this instrument. If using a wire which cannot endure the

ratings, a fire may occur.

Caution on use

DANGER

• When handling the standard gas such as calibration gas, read the instruction manual of the standard gas carefully

and use the gas correctly.

CAUTION

• Do not operate the instrument continuously with the door kept open. Otherwise injury may result..

•During operation, avoid opening the casing and touching the internal parts. Otherwise, you may suffer a burn or

shock hazard.

INZ-TN2ZKG-E v

Caution on maintenance and check

DANGER

• Before working with the casing open, be sure to turn off power supply, and perform air and N2 gas purging of not

only the analyzer inside, but also the sample gas line and reference gas line. In addition, carefully prevent oil and

grease from adhering to the restrictor, filter, packing, etc. Otherwise, poisoning, fire or explosion may be caused

due to gas leakage, etc.

CAUTION

• Before working, take off a wrist watch, finger ring or the like metallic accessories. And never touch the instrument with a wet hand. Otherwise, you will have a shock hazard.

• If the fuse is blown, eliminate the cause, and then replace it with the one of the same capacity and type as before.

Otherwise, shock hazard or fault may be caused.

Others

CAUTION

• If the cause of any fault cannot be determined despite reference to the instruction manual, be sure to contact your

dealer or Fuji Electric’s technician in charge of adjustment. If the instrument is disassembled carelessly, you may

have a shock hazard or injury.

• Do not use a replacement part other than specified by the instrument maker. Otherwise, adequate performance

will not be provided. Besides, an accident or fault may be caused.

•Replacement parts such as a maintenance part should be disposed of as incombustibles, or in accordance with the

local waste-disposal requirements.

vi INZ-TN2ZKG-E

1. GENERAL AND PRINCIPLE OF OPERATION

1.1 General

The magnetic force type (dumbbell type) oxygen analyzer is an instrument utilizing the magnetic property of

oxygen. By detecting the deviation of the dumbbell generated by the difference of magnetization of oxygen in

the dumbbell and the sample gas, oxygen can be measured quantitatively with linear output. Since the magnetic

susceptibility of oxygen is larger than that of other gases, almost no gases interfere with oxygen. As distinct from

pressure detection type analyzers, no standard gas is required.

1.2 Principle of measurement

All gases have positive or negative magnetic susceptibilities as shown in Table 1-1.

Among these gases, O2, NO and NO2 have high positive magnetic susceptibilities and are attracted strongly by

magnetic field, whereas the others are diamagnetic substances. NO and NO2 may be contained in combustion gas

at negligibly low concentrations.

It is therefore possible to measure O2 contents in various types of gases by utilizing its magnetic susceptibility.

Fig. 1-1 illustrates the principle to detect O2 contained in a gas.

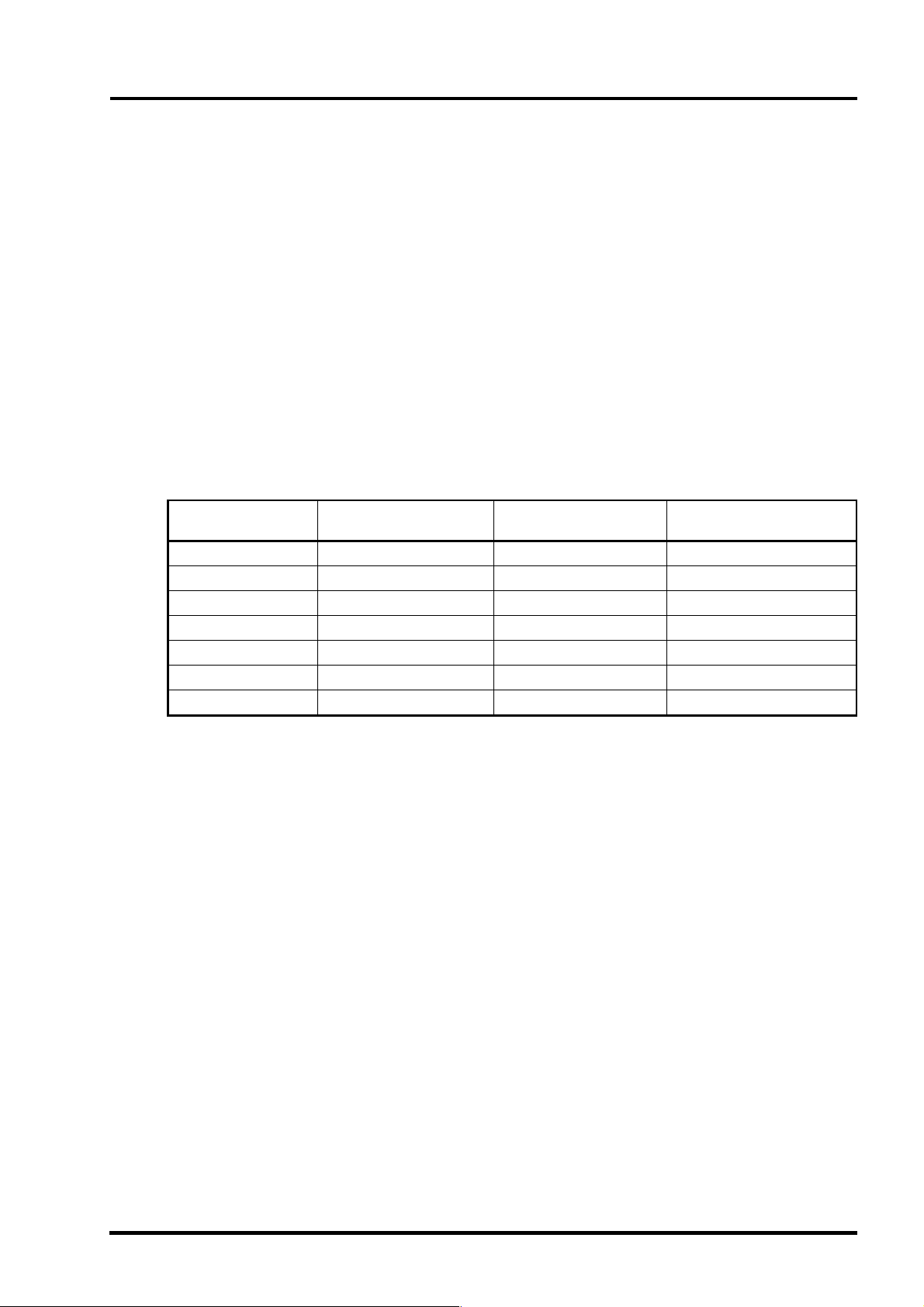

Table 1-1 Relative magnetic susceptibilities of various gases

Kind of gas

Oxygen +100 Nitrogen

Air +21 (dry air) Chlorine

Carbon dioxide

Argon

Ammonia

Ethane

Methane

Relative magnetic

susceptibility

-

0.61 Hydrogen

-

0.58 Acetylene

-

0.58 Nitrous oxide -0.58

-

0.83 Nitrogen monoxide +43.8

-

0.37 Nitrogen dioxide +28.0

Kind of gas

Relative magnetic

susceptibility

-

-

-

-

0.42

0.13

0.12

0.38

INZ-TN2ZKG-E 1

Loading...

Loading...