Page 1

Instruction Manual

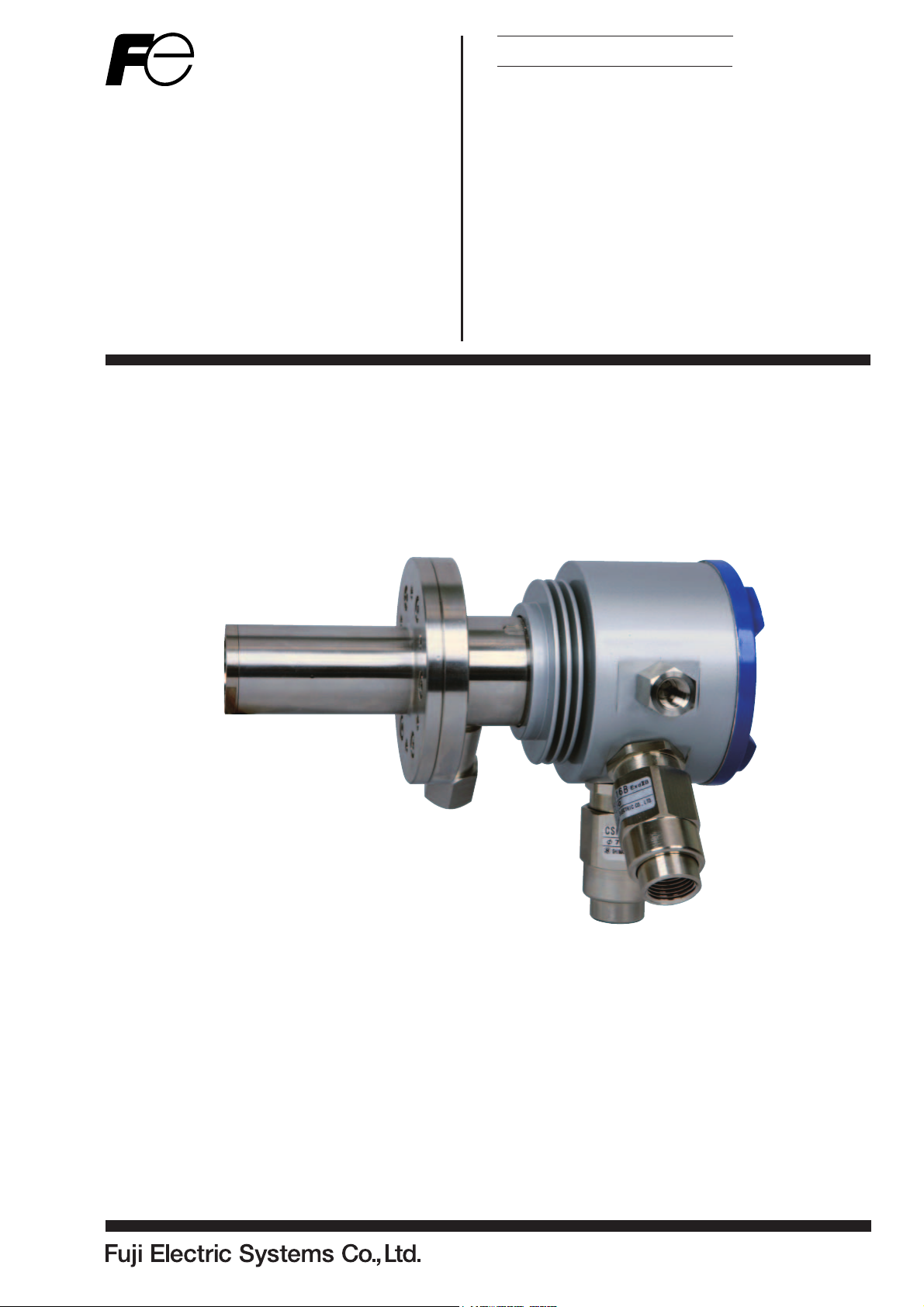

THE DIRECT INSERTION TYPE

ZIRCONIA OXYGEN

ANALYZER DETECTOR

TYPE: ZFKE

INZ-TN5ZFKE-E

Page 2

PREFACE

Thank you very much for your kind purchase of Fuji’s explosion-proof zirconia oxygen analyzer detector (Type

ZFKE).

• Read this instruction manual carefully to get a thorough understanding of how this zirconia oxygen analyzer

works prior to installing, operating and maintaining the zirconia oxygen analyzer.

If abused, unnecessary troubles or failure could occur.

• The specifi cation of this zircoia oxygen analyzer may be subject to change without previous notice for improvements of the product.

• Under no circumstances should this zirconia oxygen analyzer be modifi ed without permission.

If any trouble should occur because of having been modifi ed without permission, we won’t be responsible

for it anyway.

• This instruction manual should be kept in custody by a person who operates the zirconia oxygen analyzer

actually.

• After reading this manual, it should always be kept in a place which allows the person who operates it to

refer to any time as requirfed.

• A due consideration should be given so that this instruction manual is delivered to a fi nal user certainly.

Manufacturer : Fuji Electric Instrumentation Co., Ltd.

Type : Described in the nameplate put on the main body

Date of manufacture : Described in the nameplate put on the main body

Product nationality : Japan

Related instruction manuals

Direct insertion type explosion-proof zirconia oxygen analyzer detector (Type : ZKME) ...... INZ-TN1ZKME-E

Fuji Electric Systems Co., Ltd. 2009

NOTE

• It is prohibited to transfer a part or all of the contents of this manual

without permission.

• The contents of this manual may be subject to change in future without previous notice

©

Issued in May, 2009

i

Page 3

SAFETY PRECAUTIONS

Prior to operating the detector, read this “Safety precautions” carefully for correct use.

• In the precautions shown here, important contents on safety are included. So, be sure to observe them. The safety

precautions have been ranked into “DANGER” and “CAUTION”.

DANGER

CAUTION

: I

If the apparatus is abused, a dangerous condition could arise and it is supposed to

:

PROHIBITION:

DANGER

CAUTION

• When this product is mounted on a furnace which is under operation, take

• In the case of the wiring work, be careful not to drop foreign matters including

• Connect a power source compatible with the specifi ed rating. Connection of

• Before doing the wriring work, be sure to turn off the main power. Otherwise,

• Use proper wiring materials according to the rating of apparatus. If a wiring

:

:

f this apparatus is abused, a dangerous condition could come about and it is

supposed to die or get a serious injury.

get medium injury or a minor injury and a physical damage is supposed to occur.

This indicates a prohibition (act which must not do).

Precautions in installing and wiring

• Although this is explosion-proof type, do not use it in the place where explosive gases always exist (zone 0) to prevent explosion, fi re or otherserious

accidents.

• Install this product in a place compatible with the conditions set forth in

“instruction manual”. The use at a place not conforming to the installation

conditions may result in an electric shock, a fi re and a malfunction.

utmost care with blow-out from the furnace. There is a risk of burn injury.

wire chips into the product. Otherwise, a fi re, failure or malfunction may

result.

power source different from the rating might cause a fi re.

it results in getting an electric shock as the case may be.

material which is not bearable to the rating is employed, it might cause a fi re.

• Never do the work at a place where the product getsw wet with rain directly.

PROHIBITION:

A failure to observe this instruction may result in getting an electric shock or

failure.

ii

Page 4

Precautions in operation, stop, maintenance and check

DANGER:

CAUTION:

• The operating temperature of the detector (tip of ceramic heater) is about 800

Otherwise, there is a fear of getting a burn.

• Before cleaninhg the fl ow guide tube, turn off the main power and cool the

There is a fear of getting a burn.

• Don’t use any other renewal part than those designated by the maker. Other-

• Dispose of the renewal parts such as the maintenance parts as an incombustible

PROHIBITION:

A failure to observe this instruction may result in getting an electric shock or

• In case where combustible gas is contained in the measured gas, check the gas

composition and specifi cations carefully before using. Otherwise, the original

performance is not displayed, and there is a fear of explosion.

• Do the work in a condition where the main power has been turned off. If the

work is done while current is fl owing, there is a fear of getting an electric

shock.

°C and the surface temperature is also very high. So, never touch the detector

by bare hand.

tube down fully.

wise, the original performance is not fully displayed and an accident or failure

may result.

article.

• Never do the work at a place where rain water splases the product directly.

failure.

CAUTION:

Other precaution

• For a failure which cannot be judged even if referring to the instruction manual,

be sure to ask the nearest dealer or Fuji adjustment serviceman for repair. If

dissasembled carelessly, an accident or injury could result.

iii

Page 5

CONTENTS

PREFACE ......................................................................................................................................... i

SAFETY PRECAUTIONS .............................................................................................................. ii

1. Introduction .............................................................................................................................. 1

1.1 General description of zirconia oxygen analyzer ........................................................................1

1.2 Description of fl ameproof ..........................................................................................................1

1.3 Device confi guration of direct insertion type oxygen analyzer ...................................................1

1.4 Description of each component ...................................................................................................2

1.5 Check of type ...............................................................................................................................2

1.6 Check of delivered articles ..........................................................................................................2

2. Mounting .................................................................................................................................. 3

2.1 Mounting location .......................................................................................................................3

2.2 Mounting method ........................................................................................................................3

3. Piping ....................................................................................................................................... 7

3.1 Piping of calibration gas ..............................................................................................................7

3.2 Piping of reference gas inlet ........................................................................................................7

3.3 Piping for blow down air .............................................................................................................7

3.4 Piping drawing ............................................................................................................................8

4. Wiring ..................................................................................................................................... 12

4.1 Before wiring .............................................................................................................................12

4.2 How to open the cover ...............................................................................................................13

4.3 Wiring to each terminal .............................................................................................................13

5. Operation and Stop ................................................................................................................. 15

5.1 Start of operation .......................................................................................................................15

5.2 Stop of operation .......................................................................................................................15

6. Maintenance and Check ......................................................................................................... 16

6.1 Check .........................................................................................................................................16

6.2 Maintenance ..............................................................................................................................17

6.3 Standard output of detector .......................................................................................................19

6.4 Arrangement ..............................................................................................................................20

7. TROUBLESHOOTING ......................................................................................................... 22

8. Appendix ................................................................................................................................ 23

8.1 Specifi cation ..............................................................................................................................23

8.2 Designation of type (code table) ...............................................................................................25

8.3 DEVICE CONFIGURATION .................................................................................................27

8.4 OUTLINE DIAGRAM (Unit:mm) .........................................................................................28

iv

Page 6

1. INTRODUCTION

1.1 General description of zirconia oxygen analyzer

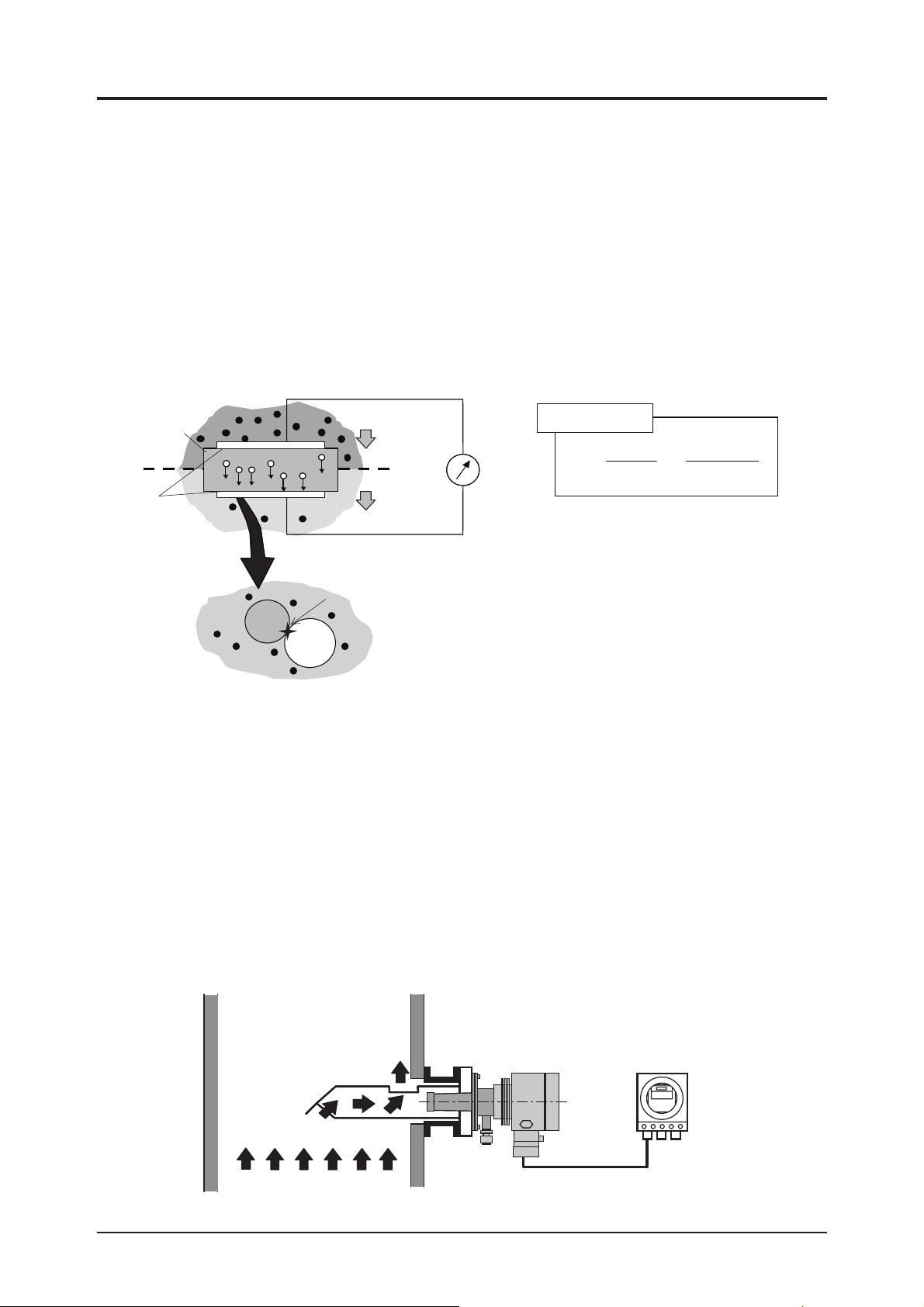

This zirconia oxygen analyzer makes use of the oxygen ion conductivity of solid electrolytes composed

mainly of zirconia (ZrO2) at high temperatures.

If electrodes of platinum or the like are attached to both faces of a solid electrolyte and the faces are on the

conditions of different oxygen partial pressures, an electrochemical reaction causes an electromotive force

between both the electrodes. This phenomenon is called concentration cell action.

Microscopically, it is assumed that electrochemical reactions occur at the interface (three-phase interface)

among a solid electrolyte, electrode and oxygen.

High-oxygen partial pressure side: O2 + 4e– → 2O2– (ionization)

Low-oxygen partial pressure side: 2O2– → O2 + 4e– (molecularization)

An electromotive force (E) generated is expressed as follows with Nernst’s equation:

High-oxygen partial

pressure side P

Solid electrolyte

Electrode

Low-oxygen partial

pressure side P

H

L

Zirconia

Oxygen molecule

2-

2-

O

O

Platinum

O

2

Ionization

Molecularization

O

2

Three-phase interface:

a part where electrochemical

reactions occur.

Electromotive

force

Nernst’s equation

E : Electromotive force

P

reference gas (atmosphere)

PL(O2) : Oxygen partial pressure of a

measured gas

R : Gas constant 8.3144[J・mol-1・K-1]

T : Absolute temperature[K]

F : Faraday constant 9.649×104[c・mol-1]

P

P

H(O2

L(O2

E= 1n

H(O2

RT

4F

) : Oxygen partial pressure of a

)

)

1.2 Description of fl ameproof

Flameproof is the unit that has passed the test conducted by the public institution as an fl ameproof-structured

instrument.

A test certifi cate and a name plate including necessary specifi cations for the purpose of explosion-proof are

attached to such an accepted unit.

Confi rm them and use the unit according to those contents.

On the name plate for instrument of fl ameproof, the 17th digit of type code, either with N for China or T for

Japan, is stated.

The certifi cation mark by public institution is also attached.

1.3 Device confi guration of direct insertion type oxygen analyzer

The direct insertion type zirconia oxygen analyzer consists of the detector with a sensor unit, the fl ow guide

tube that is directly inserted to the stack or the like in order to supply a gas to the detector, and the converter

that performs sensor control, signal processing, output/display, and external transmission. The detector and

converter are connected with a cable.

Stack

Flow guide tube

ConverterDetector

Flow of gas

Cable

(sensor output line, thermocouple output line,

heater power wire)

1

Page 7

1.4 Description of each component

CAUTIONS

• The operating temperature of detector (tip of ceramic heater) is about 800°C and the surface temperature is also very high. So, never touch it by bare hand. Otherwise, there is a fear of getting a burn.

Especially when a fi lter at the end of the detector is replaced, take utmost care.

(1) ZFKE

Furnance environment

(Gas to be measured)

Filter cap

Measured gas

Ceramic heater

Joint for calibration gas

Packing

Heat insulating

material

Thermo sticker

Calibration

gas inlet

Air environment

(Reference gas)

Terminal box

Terminal box lid

Hexagon plug or reference gas inlet

* According to designation of type

Dedicated cable gland

Wiring hole

Caution in handling

• Since the detector is made of porcelain of zirconia, there is a case where it breaks due to drop or

impact. So, be suffi ciently careful.

• The detector is unusable for a plant in which water droplets might run down inside a sampling pipe.

• There is no need to remove M5-hexagon set screw of the terminal box unless otherwise a reference

gas inlet is used. Don’t loosen the screw without thought since a waterproofi ng effect becomes zero.

1.5 Check of type

The name of type has been put in the specifi cation name-plate. Make sure it is as ordered.

Refer to Item 8.2 “Desingation of type”.

1.6 Check of delivered articles

Make sure the following articles have been delivered without lack.

No. Description

Detector 1 unit Confi rmed in Item 1.3

1

Instruction manual (this manual) 1 copy INZ-TN5ZFKE-E

2

3 Packing

Mounting screw, plain & spring washer (M5) Accessories 6 pcs each See Item 2.2.1.

4

Thermo sticker Specifi cation goods 1 sh. See Item 2.2.1.

5

6 Filter cap

7 Spring

8 Hexagonal wrench

Flow guide tube Specifi cation goods As ordered See Item 6.2.2 and 2.2.3.

9

Reference gas inlet Specifi cation goods As ordered See Item 3.2.

10

Classifi cation Q'ty Remark

Accessories 1 sheet See Item 2.2.1.

Specifi cation goods 1 piece See Item 6.2.2

Specifi cation goods 1 piece See Item 6.2.2

Accessories 1 piece See Item 2.2.1

2

Page 8

2. MOUNTING

2.1 Mounting location

DANGER

• Although this is explosion-proof type, do not use it in a place where explosive gases always exist (zone

0) to prevent explosion, fi re or other serious accidents.

CAUTIONS

• Install this product at a place compatible with the following conditions. The use of it at a place not

conforming the installation conditions specifi ed in this manual could cause an electric shock, a fi re

or incorrect operation.

Mount the detector by selecting the places shwon below:

1 Place where there is a space which allows doing daily check and wiring work

2 Place where there is little vibration (acceleration: 2 m/s2, frequency: within 5 to 100 Hz), dust and hu-

midity (equivalent to IP65 or less)

3 Place where peripheral air environment is non-corrosive.

4 Place where there are no electric appliances producing noise trouble (For example : motor, transformer

and appliances bringing about electromagnetic induction trouble and electrostatic induction trouble)

nearby the detector.

5 Place where ambient temperatue and humidity are -10 to +60°C and less than 95% RH .

2.2 Mounting method

CAUTIONS

• When mounting the detector on a furnace which is under operation, take utmost care about the

blowout from the furnace; otherwise, there is a fear of getting a burn.

3

Page 9

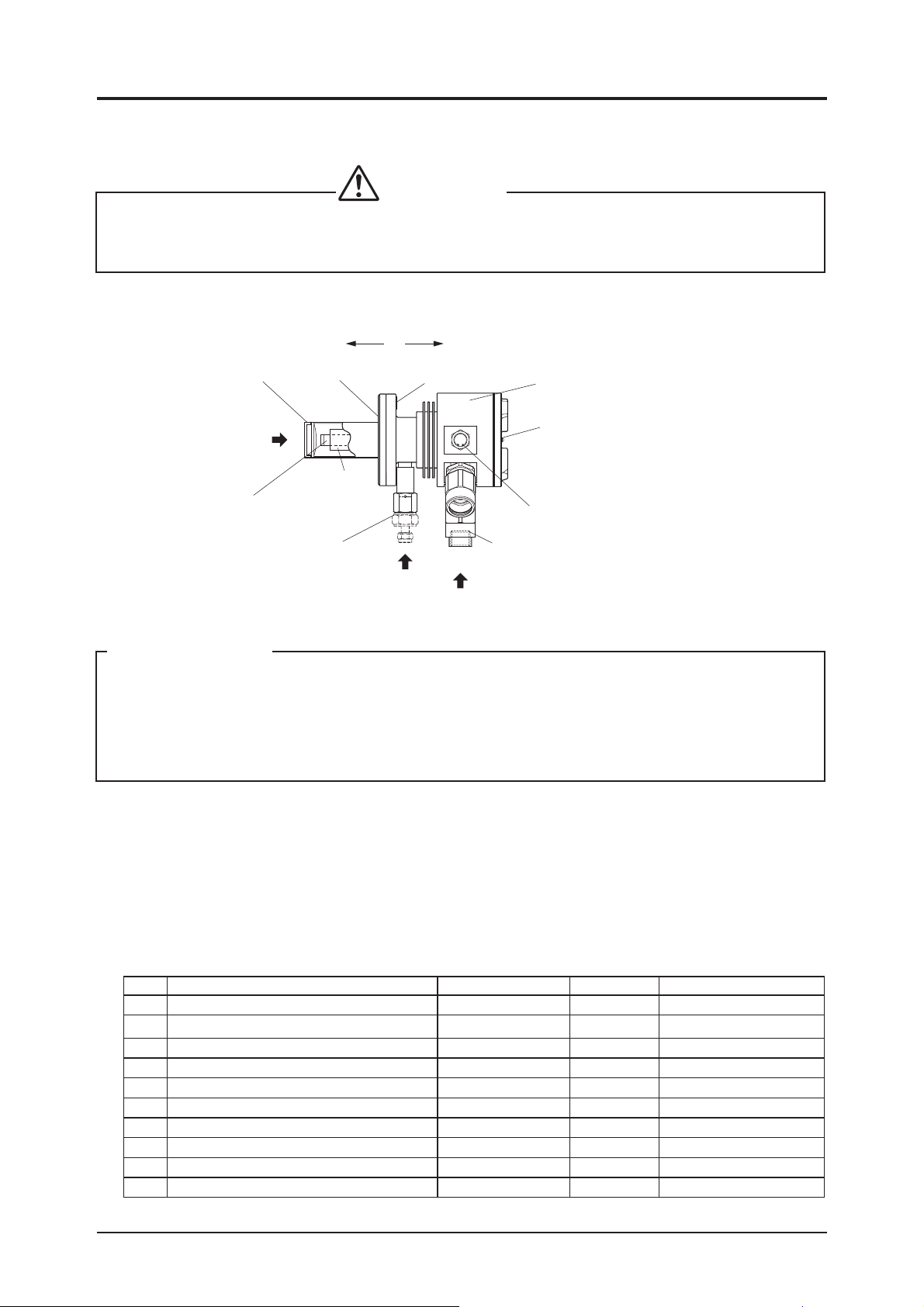

2.2.1 Mounting method of detector

Caution in mounting

Up

Up Up

• Never mount the detector with the tip turned upward or

downward. A failure of the detector may result.

Flow guide tube

Gas flow

Packing

(accessory)

Mounting screw (accessory)

Detector flange

+45°

-45°

Detector

Wiring hole

Down

Thermo sticker

Detector

Down Down

Fixing screw for cover

(use an attached

hexagonal wrench)

1 Attach the packing (accessory, Viton P36) to the detector fl ange. Subsequently, attach the detector to

the fl ange of the fl ow guide tube by fi xing the mounting screws (accessory, M5) and the fl at and spring

washers (accessories) to the three locations (at the opposing corners of six mounting holes) (recommended

tightening torque: 3.5 N · m).

2 Attach the detector so that it is within the range of ±45° to the horizontal plane.

3 Attach the detector so that the wiring hole is located at the bottom.

4 Set the temperature of the detector fl ange to 125°C or less regardless of the measured gas temperature.

<How to check>

• Complete the mounting, piping and wiring work of the detector completed, make sure the color of thermo

sticker 125 put on the detector fl ange is not changing to red in the exhaust gas measuring condition (while

current is fl owing to the detector and the plant is under running). (Usually, the color of thermo sticker is

light pink.)

• If the color has changed to red, it means that the temperature of detector fl ange has been over 125°C. So,

take the following steps:

(a) Change the existing fl ange packing to a thicker one.

(b) Use a longer companion fl ange.

(c) Mount the fl ow guide tube according to Item “2.2.2”.

By taking the above steps, minimize heat transfer from the gas duct wall and lower the temperature.

The thermo sticker does not return to its originatl condition once it discolors. So, after taking the steps, reput a thermo sticker available as an accessory on the detector fl ange and make certain that it does not turn

red. (For the part No. for additional procurement of the thermo sticker, refer to Item “6.4”.

4

Page 10

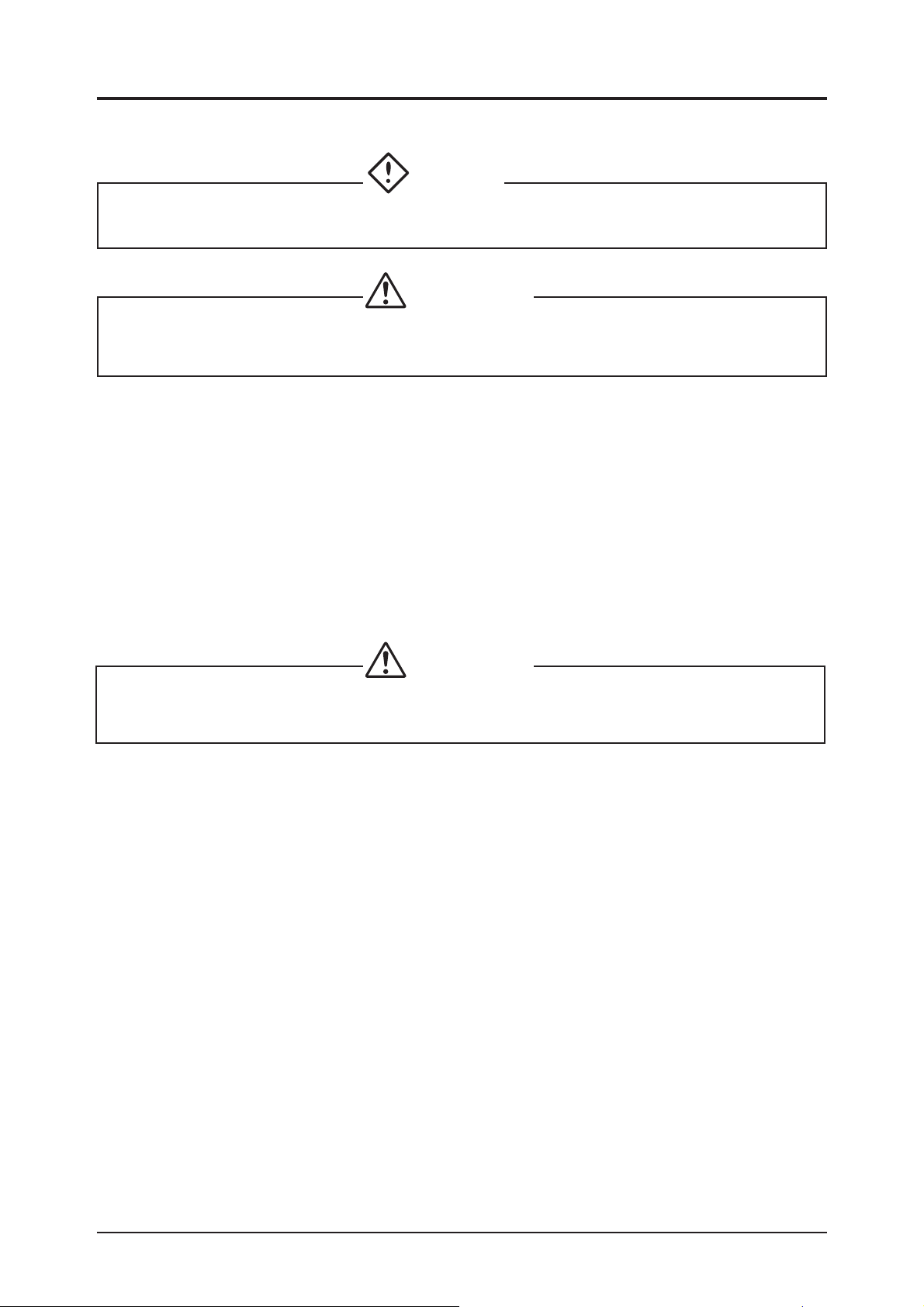

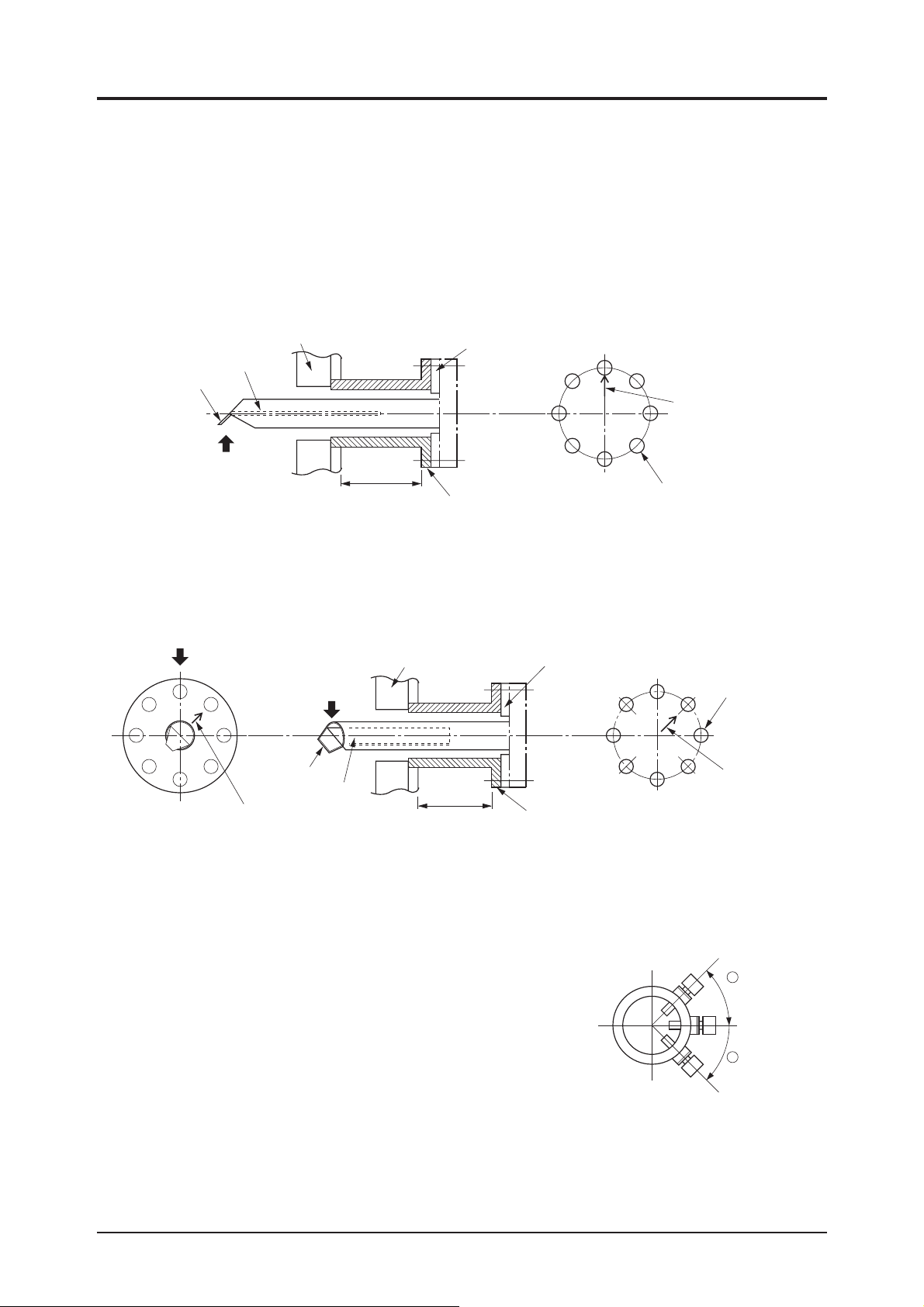

2.2.2 Mounting method of fl ow guide tube

■

■

■

(Designation of type: When 9th to 11th digits are 5A

The fl ange of fl ow tube has mounting holes at 8 locations. These holes are available for regulating an in-

fl ow into the fl ow guide and mounting the tube correctly in the fl owing direction of gas and it is enough if

mounted at 4 locations.

(1) Direction of tongue and Partition plate of fl ow guide tube

1 When exhaust gas temperature is under 200°C and gas fl owing velocity is low

As illustrated below, set the partition plate inside the fl ow guide tube at a right angle to the gas fl ow and

mount the tube so that the tongue turns to an upstream direction relative to the gas fl ow.

■

, 5B

and 5C

■

)

■

Packing (not included

in scope of supply)

Companion flange

(not included in scope of supply)

Arrow mark of

flow guide tube

ø15 (JIS5K-65A)

Partition plate

Tongue

Gas flow

Furnace wall

min.60mm

2 When exhaust gas temperature is 200°C or higher and gas fl owing velocity is fast

As illustrated below, till the partition plate inside the fl ow guide tube 45° to the gas fl ow and mount the

tube so that the tongue turns to a down-steam direction relative to gas fl ow.

Gas flow

Gas flow

Tongue

Partition plate

Arrow mark of flow guide tube

Furnace wall

min.150mm

Packing (not included

in scope of supply)

ø15 (JIS5K-65A)

Arrow mark of

flow guide tube

Companion flange

(not included in scope of supply)

(2) Inserting angle of fl ow guide tube

According to the temperature of exhaust gas and the amount of dust, the inserting angle of the fl ow guide

tube differs. With reference to the following conditions, install a companion fl ange.

1 When exhaust gas temperarture is under 200°C and amount of

dust is under 0.2g/Nm

• Inserting angle: within a range of -45 to +45°

2 When exhaust gas temperature is 200°C or higher and amount of

dust is under 0.2g/Nm

3

3

Up

+

Inserting angle

• Inserting angle: within a range of -20 to +20°

3 When amount of dust is over 0.2g/Nm

• Inserting angle: within a range of 0 to +45°

3

Down

−

Inserting angle

5

Page 11

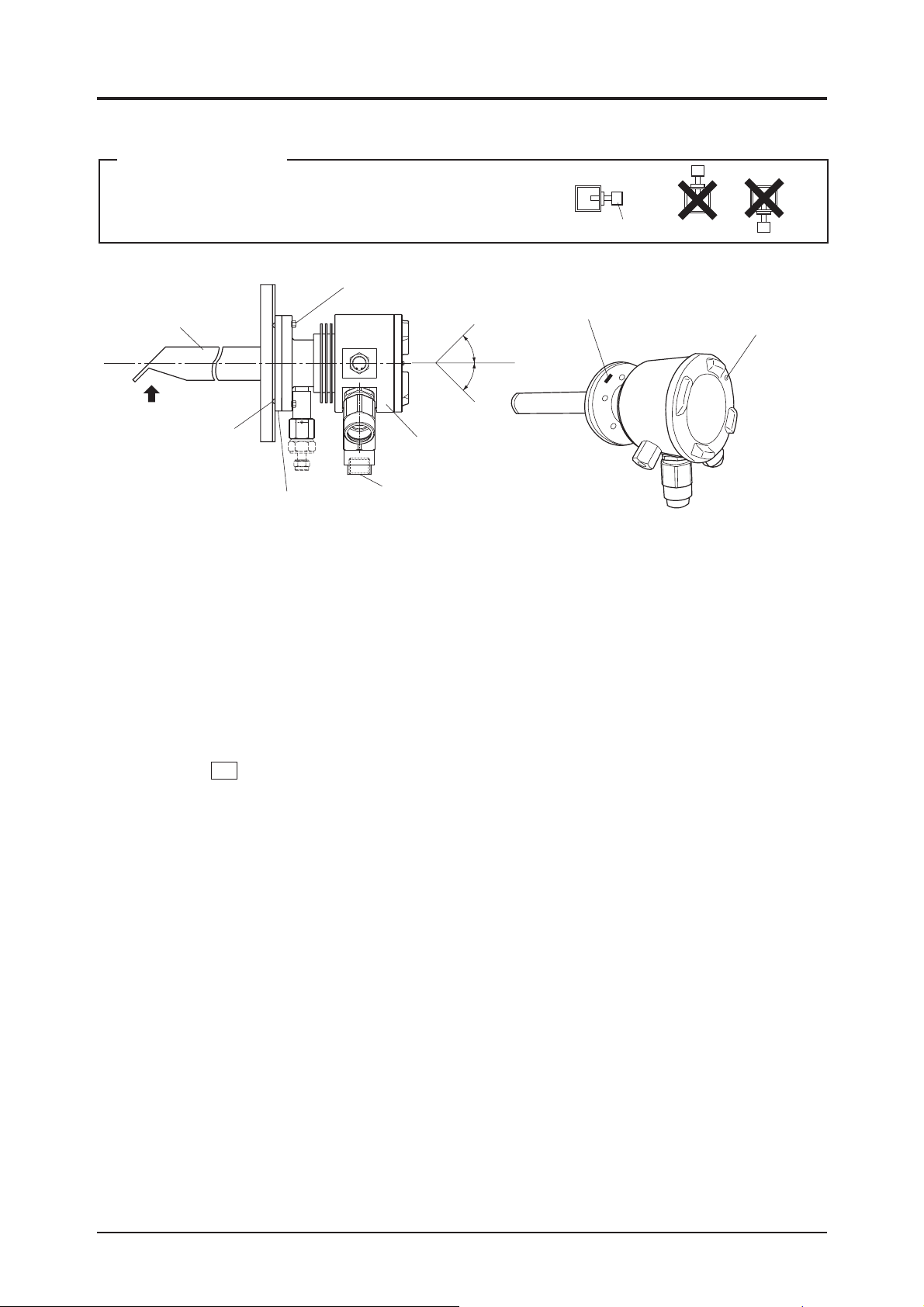

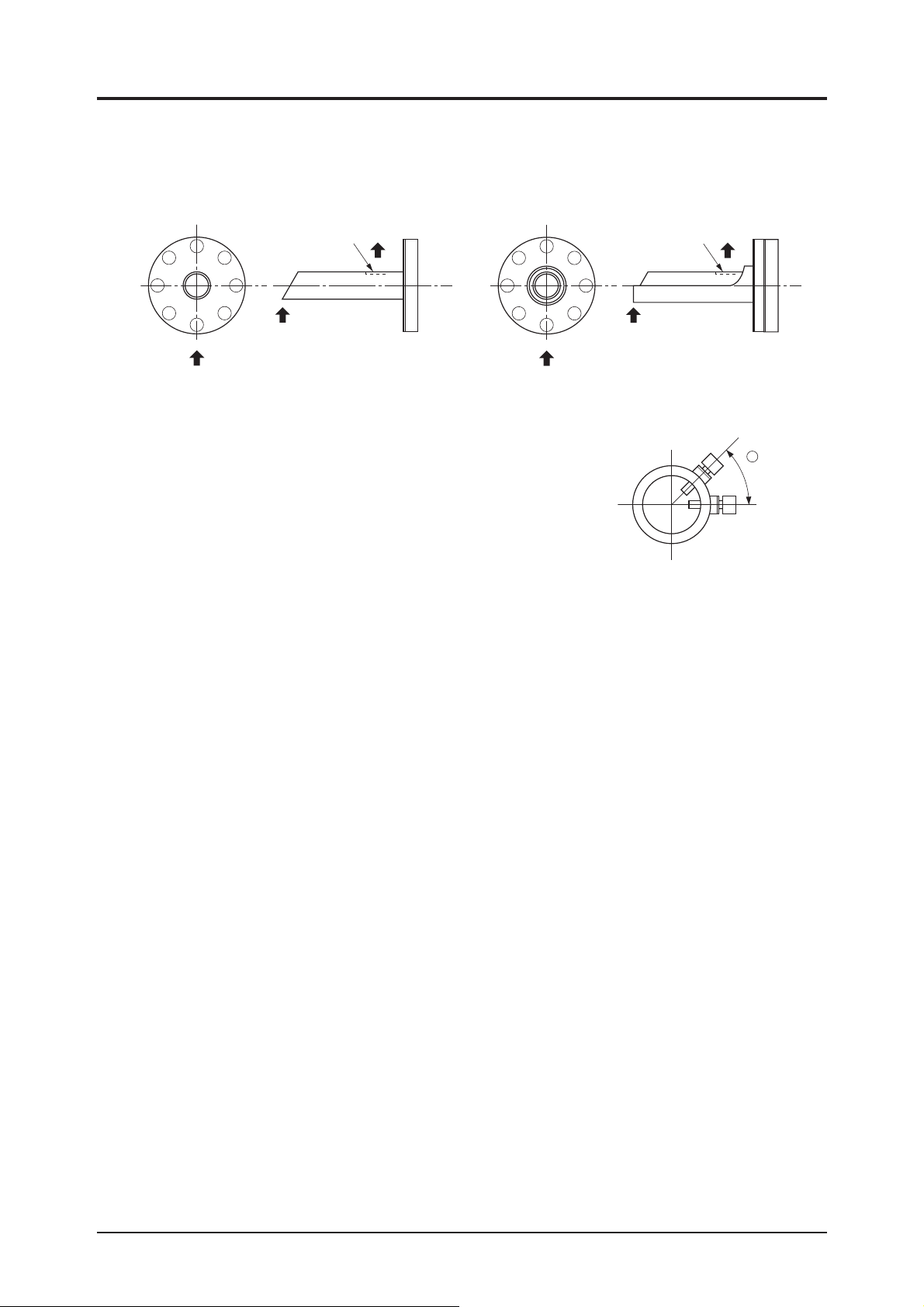

2.2.3 Mounting method of high dust-use fl ow guide tube

(Desingation of type : When 10th digits are D, E, F, G, J, K)

Mount the tube so that the gas outlet turns downward relative to the gas fl ow as shown below.

For high dust

Gas outlet

Gas flow

Gas flow

Fitted with high dust cover

Gas flow

Be careful not to block the gas outlet by the furnace wall or pipe and

keep the periphery of the outlet widely.

Set the inserting angle within a range of 0 to +45°.

Gas outlet

Gas flow

Up

+

Inserting

angle

Down

6

Page 12

3. PIPING

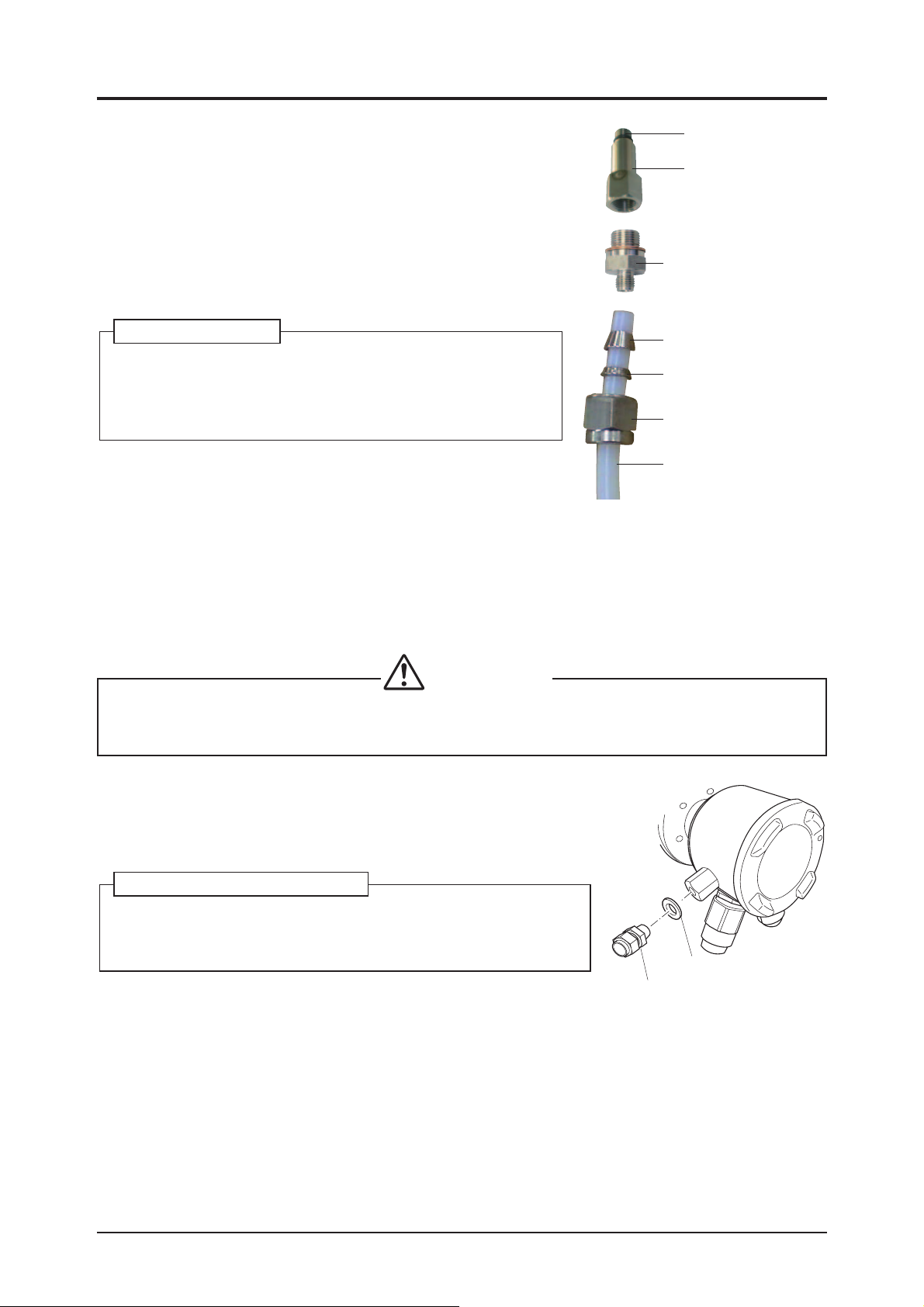

3.1 Piping of calibration gas

As the piping material, use a tefl on-made ø6 mm or ø1/4 inch tube.

• From the coupling attached to the detector, remove 2 nut,

3 front ferrule and 4 back ferrule, put them through the ø6

mm or ø1/4 inch tefl on tube for piping, and then attach it to

coupling.

• For mounting 2 nut, tighten by making about 2 turns with a

spanner after it cannot be turned any more by hand.

Joint for calibration gas:

The joint for calibration gas is a special joint with a built-in

check valve.

If a malfunction occurs, order the joint for calibration gas and

attach it.

3.2 Piping of reference gas inlet

Main body

(calibration gas inlet port)

1 Coupling

5 adapters

3 Frount ferrule

4 Back ferrule

2 Nut

ø6 mm or ø1/4 inch

teflon tube for piping

If the atmosphere around the terminal box is signifi cantly dirty or the humidity of the location is extremely

high, install piping for reference gas.

If the 13th digit of the type is “A” or “B,” the piping for reference gas is delivered together with the detector

body.

CAUTIONS

• When used at an ordinary place (oxygen concentration : 20.6 vol%), the reference gas is unnecessary. So, don’t remove a hexagonal plug of the mounting port of reference gas inlet unnecessarily

since a waterproofness becomes poor.

Refer to the previous section “3.1 Piping to calibration gas” for the

installation method of piping.

Set one of the two reference gas ports as “inlet” and the other as “outlet.”

Install piping so that dust or water does not enter the “outlet.”

Attachment of joints for reference gas:

If you order the joints for reference gas additionally, remove the hexagonal plugs and attach the joints for reference gas (two locations) as shown

in the fi gure on the right.

2 Reference gas inlet

3.3 Piping for blow down air

1 Packing

Connect the blow air inlet (4 locations) of blowdown-fi tted fl ow guide tube by detaching a plug of the upper-

side blow port (1 location) so that drain does not accumulate.

For the blow piping, use a copper tube 15A SGP or larger (tube having larger inside diameter) or ø10/ø8

tefl on tube. And, use L-shape joint or union without bending the pipe wherever possible and keep the piping

length as short as possible.

7

Page 13

3.4 Piping drawing

(1) Flow guide tube system

Rc1/4

(upper side blow port should be selected)

Blow-down, 200 to 300kPa

Flow guide tube

Gas temperature.

600ºC max.

Sample gas outlet

Gas temperature.

600ºC max.

Flow guide tube

for high particulate

Sample gas outlet

Gas temperature.

600ºC max.

Flow guide for high

particulate with cover

RS232C

or

RS485

(option)

Solenoid valve

(not supplied)

15ASGP

tube equivalent

(not supplied)

Detector

(ZFKE)

from (1)

exhaust

AC power

123

6

45

supply

Black

Black

Blue

Yellow

115234567891011121314

+

O2 sensor

input

*4

Red

−

O2

Thermocouple

for combustion

control

+

TC2

White

+

−

TC1

O

2 sensor

thermocouple

input

−

DI1

16

17

AO

+

or

Analog output

4 to 20mA DC

or

0 to 1V DC

Contact input

DI2 DI3

18 19

−

Fault contact

DICOM

20

output

ALARM

Alarm

contact

output

21 22

Blow

contact

output

Maintenance

contact

output

MAINTE

23 24

ZV

ZERO

GAS

Calibrating gas

contact output

Calibrating gas

contact output

COM

25 28

12 3

TM-2

Reduction valve

(unnecessary when supply

air pressure is 200 to 300kPa

15ASGP

tube equivalent

(not supplied)

Converter (ZKME)

TM-1

O2 sensor

heater power input

AC power

SPAN

supply

GAS

AC

L

NSV

26 27

Supply air

*3

PE

φ

6mm or φ1/4 inch tube

for calibration gas

(not supplied)

*2 Ref. gas

Flowmeter

(ZBD4)

(1.5 to 2.0L/min)

Joint

Solenoid valve

(not supplied)

(1) to Detector

φ

6mm or φ1/4 inch tube

for calibration gas

(not supplied)

Note:

*1 Standard gas or instrumentation air can be used in place of span gas.

*2 Instrument quality air or bottled air is available as reference gas instead of ambient air.

*3 Protective earth.

*4 Connect the shield of a exclusive cable with the ground terminal in the converter.

(1.5 to 2.0L/min)

Solenoid valve

(not supplied)

Reduction

valve (ZBD6)

AC power

supply

Standrad gas

for zero point

(ZBM)

Reduction valve

(unnecessary when supply air pressure is 50 to 100kPa)

AC power

supply

*1 Air supply

Reduction vale

(ZBD6)

Span point

*1

Standard gas for

span point (ZBM)

8

Page 14

(2) Flow guide tube system (with valve)

Rc1/4

(upper side blow port should be selected)

Blow-down, 200 to 300kPa

Flow guide tube

Gas temperature.

600ºC max.

Sample gas outlet

Gas temperature.

600ºC max.

Flow guide tube

for high particulate

Sample gas outlet

Gas temperature.

600ºC max.

Flow guide for high

particulate with cover

RS232C

or

RS485

(option)

Solenoid valve

(not supplied)

15ASGP

tube equivalent

(not supplied)

Detector

(ZFKE)

from (1)

exhaust

AC power

123

6

45

supply

Black

Black

Blue

Yellow

115234567891011121314

+

O2 sensor

input

*4

Red

−

O2

Thermocouple

for combustion

control

+

TC2

White

+

−

TC1

O

2 sensor

thermocouple

input

−

DI1

16

17

AO

+

or

Analog output

4 to 20mA DC

or

0 to 1V DC

Contact input

DI2 DI3

18 19

−

Fault contact

DICOM

20

output

ALARM

Alarm

contact

output

21 22

Blow

contact

output

Maintenance

contact

output

MAINTE

23 24

ZV

ZERO

GAS

Calibrating gas

contact output

Calibrating gas

contact output

COM

25 28

12 3

TM-2

Reduction valve

(unnecessary when supply

air pressure is 200 to 300kPa

15ASGP

tube equivalent

(not supplied)

Converter (ZKME)

TM-1

O2 sensor

heater power input

AC power

SPAN

supply

GAS

AC

L

NSV

26 27

Supply air

*3

PE

φ

6mm or φ1/4 inch tube

for calibration gas

(not supplied)

*2 Ref. gas

Flowmeter

(option)

Flowmeter

(ZBD4)

(1.5 to 2.0L/min)

Val ve

(option)

MEASURE

(1) to Detector

φ

6mm or φ1/4 inch tube

for calibration gas

(not supplied)

Note:

*1 Standard gas or instrumentation air can be used in place of span gas.

*2 Instrument quality air or bottled air is available as reference gas instead of ambient air.

*3 Protective earth.

*4 Connect the shield of a exclusive cable with the ground terminal in the converter.

(1.5 to 2.0L/min)

SPAN

ZERO

9

Reduction

valve (ZBD6)

Standrad gas

for zero point

(ZBM)

Reduction vale

(ZBD6)

*1

Standard gas for

span point (ZBM)

Span point

*1 Air supply

AC power

supply

Page 15

(3) Flow guide tube system (with ejector)

Rc1/4

(upper side blow port should be selected)

Blow-down, 200 to 300kPa

Flow guide tube

Gas temperature.

600ºC max.

Calibrating gas

Sample gas outlet

Gas temperature.

600ºC max.

Sample gas outlet

Gas temperature.

600ºC max.

Flow guide for high

particulate with cover

exhaust

Flow guide tube

for high particulate

RS232C

RS485

(option)

or

Solenoid valve

(not supplied)

15ASGP

tube equivalent

(not supplied)

Detector

(ZFKE)

from (1)

exhaust

Flowmeter

(ZBD4)

6

(5 to 10L/min)

123

from (2)

AC power

supply

45

Black

Black

Blue

Yellow

115234567891011121314

+

O2 sensor

*4

Red

−

O2

input

Thermocouple

for combustion

control

+

TC2

White

+

−

TC1

O

2 sensor

thermocouple

input

−

DI1

16

17

AO

+

or

Analog output

4 to 20mA DC

or

0 to 1V DC

Contact input

DI2 DI3

18 19

−

Fault contact

output

ALARM MAINTE

DICOM

20

Alarm

contact

output

21 22

Blow

contact

output

Maintenance

contact

output

23 24

ZV

ZERO

GAS

Calibrating gas

contact output

Calibrating gas

contact output

COM

25 28

12 3

TM-2

Reduction valve

(unnecessary when supply

air pressure is 200 to 300kPa

15ASGP

tube equivalent

(not supplied)

Converter (ZKME)

TM-1

O2 sensor

heater power input

AC power

SPAN

supply

GAS

AC

L

NSV

26 27

Supply air

*3

PE

φ

6mm or φ1/4 inch tube

for calibration gas

(not supplied)

*2 Ref. gas

Flowmeter

(ZBD4)

(1.5 to 2.0L/min)

Joint

(1) to Detector

φ

6mm or φ1/4 inch tube

for calibration gas

(not supplied)

Note:

*1 Standard gas or instrumentation air can be used in place of span gas.

*2 Instrument quality air or bottled air is available as reference gas instead of ambient air.

*3 Protective earth.

*4 Connect the shield of a exclusive cable with the ground terminal in the converter.

(0.2 to 0.5L/min)

Solenoid valve

(not supplied)

Solenoid valve

(not supplied)

(2) to ejector

10

Reduction

valve (ZBD6)

Joint

AC power

supply

Standrad gas

for zero point

(ZBM)

Reduction valve

(unnecessary when supply air pressure is 50 to 100kPa)

AC power

supply

*1 Air supply

Reduction vale

(ZBD6)

Span point

*1

Standard gas for

span point (ZBM)

Page 16

(4) Flow guide tube system (with ejector+valve)

Rc1/4

(upper side blow port should be selected)

Blow-down, 200 to 300kPa

Flow guide tube

Gas temperature.

600ºC max.

Flowmeter

Calibrating gas

Sample gas outlet

Gas temperature.

600ºC max.

Flow guide tube

for high particulate

Sample gas outlet

Gas temperature.

600ºC max.

Flow guide for high

particulate with cover

exhaust

RS232C

(option)

or

RS485

(ZBD4)

(5 to 10L/min)

6

Black

Blue

Yellow

115234567891011121314

+

O2 sensor

input

*4

12 3

TM-2

from (1)

123

Red

−

O2

Thermocouple

for combustion

control

+

TC2

45

Black

White

+

−

TC1

O

2 sensor

thermocouple

input

−

DI1

16

17

from (2)

AO

+

or

Analog output

4 to 20mA DC

or

0 to 1V DC

Contact input

DI2 DI3

18 19

−

Fault contact

output

ALARM MAINTE

DICOM

20

15ASGP

tube equivalent

(not supplied)

Detector

(ZFKE)

exhaust

AC power

supply

Blow

contact

output

Alarm

Maintenance

contact

contact

output

output

21 22

Solenoid valve

(not supplied)

ZV

23 24

ZERO

GAS

Calibrating gas

contact output

Calibrating gas

contact output

O2 sensor

heater power input

SPAN

GAS

COM

26 27

25 28

Reduction valve

(unnecessary when supply

air pressure is 200 to 300kPa

Supply air

15ASGP

tube equivalent

(not supplied)

Converter (ZKME)

TM-1

AC power

supply

AC

NSV

L

*3

PE

Val ve

(option)

MEASURE

φ

6mm or φ1/4 inch tube

for calibration gas

(not supplied)

*2 Ref. gas

Flowmeter

(option)

Flowmeter

(ZBD4)

(1.5 to 2.0L/min)

(1) to Detector

φ

6mm or φ1/4 inch tube

for calibration gas

(not supplied)

Note:

*1 Standard gas or instrumentation air can be used in place of span gas.

*2 Instrument quality air or bottled air is available as reference gas instead of ambient air.

*3 Protective earth.

*4 Connect the shield of a exclusive cable with the ground terminal in the converter.

(0.2 to 0.5L/min)

SPAN

11

ZERO

Reduction

valve (ZBD6)

Standrad gas

for zero point

(ZBM)

Reduction vale

(ZBD6)

*1

Standard gas for

span point (ZBM)

Span point

*1 Air supply

AC power

supply

Page 17

4. WIRING

CAUTIONS

• In the case of the wiring work, be careful not to drop foreign matters including wire chips inside the

product. Otherwise, this might cause a fi re, failure or malfunction.

• Connect a power source compatible with the rating. Connection of a power source not conforming

to the rating may cause a fi re.

• Before proceeding with the wiring work, be sure to turn off the main power supply. Otherwise,

there is a fear of getting an electric shock.

• As the wiring material, use a proper one conforming to the rating of apparatus. The use of a wiring

material which is not bearable to the rating could cause a fi re.

: Make sure to ground (D-class grounding). Take care so that the converter and the detector is the

same electric potential.

PROHIBITION

• Never do the work at a place where the product gets wet with water, such as the rain. Otherwise, an

electric shock or failure may result.

4.1 Before wiring

Put the cables for R thermocouple and element output away from the power cable to take a noise preventive

step.

Use a dedicated cable.

When an exclusive cable is not used, use the following wire rods:

• For heater (2 pcs.) ...............3A or more in rating

• For R thermocouple ............Specifi ed in JIS C1610-1995 (equivalent to RCA-2-G-0.75mm2-S2).

• Recommended wire rod (at 20 ºC)

For wiring of the detector, be sure to use a solderless terminal (for M3).

•

Recommended solderless terminal ............ Solderless terminal prescribed in JIS C 2805 (Nominal designation: R1.25-3)

For heater

Nominal sectional area (mm2) 0.75

Number of composed element wires/

diameter of element wire (mm)

Outside dia. (mm) 1.1 1.14

Thickness of vinyl insulating material (mm) 0.6

Composition

Thickness of vinyl sheath (mm) 1.0 1.5

Max. conductor resistance per unit length (Ω/m) 24.4 —

Test voltage (V) 1000 1500

Insulation resistance per unit length (MΩ•km) 5 40

Rating (A) 7 —

External diameter of sheath (mm)

Element output

compensation conductor

30/0.18

7 to 10

CAUTIONS

•

When you do not use a dedicated cable, make sure to use a cable with the same external diameter as

a sheath which is applicable to a cable gland.

For the reason of protection against injury, install the cable sheathing an appropriate protection equipment,

such as a protection tube of a steel conduit as needed.

In the case of wiring work at the zone 1, take an appropriate prevention countermeasure against gas fl ow to

prevent explosive gas being fl own into the zone 2 or unclassifi ed area through a kind of duct or protection tube.

When connecting 2 cables, and connecting a cable and a cable covered with metal tube for fl ameproof, use a

fl ameproof-structured box.

12

Page 18

4.2 How to open the cover

Loosen the hexagon socket head screw, and open the cover. (use an

attached hexagonal wrench)

4.3 Wiring to each terminal

2 core

wire

Exclusive cable

for converter

4 core

wire

Heater power

100 to 120VAC 50/60Hz

or 200 to 240VAC 50/60Hz

1 Black

2 Black

Thermo couple (R-type)

3 Red

4 White

Sensor output

5 Yellow

6 Blue

Grounding

terminal : M4

5 Yellow

6 Blue

Screw for wiring

connections : M3

Hexagon socket

head screw

1 Black

3 Red

1

2

3

6

4

5

S+

H

T+

6

1

3

S-

H

T-

4 White

2 Black

13

Page 19

Connect the protective grounding to one of the two terminals in the fi gure below. (Class D (Class 3)

grounding, grounding resistance: 100 Ω or less)

Grounding

Grounding

terminal

terminal

5

5

*

*

6

6

• Use the cable more than 0.75mm2 for main ground (earth)

Note

line.

• For solderless terminal, doubly caulk the core and the sheath

5

5

*

*

6

6

Grounding

Grounding

terminal

terminal

separately.

The core should be poked from 0.5 to 1.0 mm.

The core should be so as not to

be seen or not to be come apart.

The crimping (vary by tools)

should clearly be in the

normal place.

No space required between

the insulating material and the wire.

Wiring of grounding terminal

Attach the solderless terminals to

the grounding terminals with them

between the tooth lock washer and

screw with washer.

( recommended tightening torque: 1.8

N·m)

Screw with washer M4

Tooth lock washer

• Use “ ” type of solderless terminal.

Double caulking

14

Page 20

5. OPERATION AND STOP

DANGER

• In case where combustible gas is contained in the measured gas, make sure of the gas composition

and specifi cations carefully before using this product. Otherwise, the original performance is not

displayed and there is a fear of explosion.

• Turn on electricity before closing the cover.

5.1 Start of operation

• When electricity is turned on after completion of wiring and piping work, the detector starts its operation.

• After warm-up at least 10 minutes, start the operation of the furnace.

• After zero calibration and span calibration have fi nished, get to work on the measurement.

• For the method of calibration, refer to each instruction manual of converters (ZKME).

• When the converters (ZKME) are not used, run the zero and span calibration gases and calibrate by converting the output in a stabilized state into oxygen concentration according to the standard output table of

converter in Item. “6.3”.

If using the reference gas, supply it before the calibration. (fl ow rate: 0.2 to 0.5 L/min)

5.2 Stop of operation

If the power is turned on in a state of dew condensation it leads to the failure of detector. Stop the operation

following the procedures described below.

(1) In case of short-term shutdown (about 1 week) of furnace

• Keep the power supply of the detector (converter) turned “ON”. This can prevent the detector from

getting dewed.

Also, note that if “ON-OFF” is repeated in a condition where the detector has dewed (according to the

furnace and ambient conditions), the detector might fail.

• When the ejector is in use, stop the air supply to the ejector.

(2) In case of long-term shutdown of furnace

• Turn off the power of the detector (converter) after the peripheral air of the detector inside the furnace

(especially, temperature and humidity) has become an air environment. Or, turn off the power after

taking the detector out of the furnace and leaving it as it is for 15 minutes or more.

• When the ejector is in use, stop the air supply to the ejector.

15

Page 21

6. MAINTENANCE AND CHECK

CAUTIONS

• Do the work in a condition where the main power supply has been turned off.

If the work is done while current is fl owing, there is a fear of getting an electric shock.

• The operation temperature of the detector (tip of the ceramic heater) is about 800°C and the surface

temperature is also very high. So, never touch it by bare hand. Otherwise, there is a fear of getting a

burn.

• Before proceeding with the cleaning of the fl ow guide tube, turn off the main power and cool the tube

down fully and then, do the work. Otherwise, there is a fear of getting a burn.

• Don’t use other renewal parts than those designated by the maker. Otherwise, the original performance

is not displayed fully and an accident or failure could come about.

• Dispose of the renewal parts including the maintenance parts as an incombustible.

DANGER

• Open the cover 30 minutes after turning the power off. There is a fear of ignition of ambient fl ammable gases by heater's heat.

PROHIBITION

• Never do the work at a place where the product gets wet with water, such as the rain. Otherwise, an

electric shock or failure may result.

6.1 Check

Perform the check periodically for using the product always in good condition. Especially, perform the

checks shown in table below. Moreover, perform the periodic check at a time of checking the furnace or

every 6 months.

Execution of zero & span calibration • When the converters (ZKME) are in use: With reference to the

Check for looseness of cable gland. Retighten the cable gland or if the packing is found deteriorated,

Check of residue in calibration gas cylinder Check it by a primary pressure gauge.

Check of blowdown (when blowdown

nozzle is fi tted)

Check for leak from packing fi tted between

fl ow guide tube and companion fl ange and

O-ring of detector.

Removing detector, check for clogging of

ceramic fi lter of detector.

Check by disconnecting for clogging or

corrosion of fl ow guide tube.

Remove and check if there is not clog in

the lead-in port of the air outlet of ejector.

Periodic check Daily check

Check items Details of checking work

instruction manuals of the converters (ZKME), check once a week

as a rough standard. (calibration gas fl ow rate : 1.5 to 2.0 L/min)

• When the converters (ZKME) are not used: Running the zero and

span calibration gases, make calibration once a week as a rough

standard by converting the output in a stabilized state into oxygen

concentration according to the standard output table of converter in

Item “6.3”.

replace.

Referring to each instruction manual of the converters (ZKME), check

at 200 to 300 kPa.

If either of the packing and O-ring or both of them are found deteriorated, replace with new O-ring (refer to the part No. for procurement

in Item “6.4”) and replace the packing (not included in scope of supply).

When it is necessary to replace the ceramic fi lter, refer to Item “6.2.2”.

Check following the procedure in Item “6.2.3”.

Clean the air outlet and lead-in port.

16

Page 22

6.2 Maintenance

The replacing intervals of sensor unit, ceramic fi lter and packing, and the maintenance periods of fl ow guide

tube and sampling probe differ depending on the working conditions including the components of measured

gas and the amount of dust.

The replacing intervals in a general conditions are shown below. Determine the replacing intervals in the

individual working condition with a period till a fi rst replacement after delivery and operation as a rough

standard.

• Sensor unit ................................................ Yearly

• Filter cap................................................... At 6 month interval

• Flow guide tube ........................................ At 3 to 4 year interval

• Packing ..................................................... Yearly

Please note the followings.

(1) For the fl ameproof type, 3 factors of mechanical strength of detector case, gap, and depth of gap are very

important. Therefore, take care not to scratch on the joint area or screw connection part, or to make an

impact on the case.

(2) If the necessary parts for conservation of fl ameproof (terminal box, screw part of terminal box cover,

joint area, connection between terminal box and fl ange, cable gland, joint for reference gas, etc.)

damaged or corroded, contact us. It is very danger to fi x up them carelessly because change of gap or the

like possibly occurs.

(3) When use them again after repair or mend, check the necessary parts for conservation of fl ameproof

adequately and confi rm that screws have been tighten fi rmly.

Make sure to tighten the cover completely. Do not open the terminal box cover unnecessarily at the site.

Tighten the hexagon socket head screw of the terminal box cover to prevent the cover being opened or

closed unnecessarily at the site. Use the attached hexagonal wrench.

17

Page 23

6.2.1 Replacement of Sensor unit

Caution about the replacement of the sensor unit:

• Check that the sensor unit complies with the specifi cations of the power supply you use.

• Avoid replacing the sensor unit while the current is applied.

• The temperature of the detector becomes high. Replace the sensor unit after the temperature is reduced suffi ciently.

(1) Turn off the power for the detector. (Set the switch of the converter or the main power supply to “OFF”.)

(2) Check that the surface temperature of the detector is reduced suffi ciently.

(3) Remove the hexagon socket head screw for fi xing attached on the terminal box cover (by using the at-

tached wrench).

(4) Remove the six wires connected the terminal block of the sensor unit (M3 screws, six locations).

(5) Remove the ring screws (M3 screws, four locations) fastening the sensor unit .

(6) Remove the sensor unit and o-ring from the detector.

(7) Attach the supplied O-ring of the replacement sensor unit to the groove for the O-ring at the detector.

(8) Attach the replacement sensor unit to the detector.

(Attach the sensor unit so that the rotational direction is as shown in the fi gure below.)

(9) Fasten the sensor unit with the supplied ring pan-head machine screws (M3 screws, four locations).

(recommended tightening torque: 0.7 N·m)

(10) Connect six wires to the terminal block of the sensor unit and attach the terminal block cover.

(11) Attach the terminal box cover.

Groove for the O-ring

O-ring

Detector

2 core

wire

Exclusive cable

for converter

4 core

wire

6.2.2 Replacement of Filter cap

• After turning “OFF” the power of the detector, lower the surface

temperature of the tip (at the Filter cap side) by cooling down fully

with the air.

• After the detector cooled adequately, remove the fi lter cap from the

detector and then remove the spring.

• Attach a fi lter and a new spring to the detector, and then tighten the

cap completely.

Sensor Unit

Pan head screw with

washers (4 pieces)

Heater power

100 to 120V AC 50/60 Hz

or 200 to 240V AC 50/60Hz

1 Black

2 Black

Thermo couple (R-type)

3 Red

4 White

Sensor output

5 Yellow

6 Blue

Grounding

terminal : M4

5 Yellow

6 Blue

Screw for wiring

connections : M3

1 Black

3 Red

1

2

3

6

4

5

S+

H

T+

6

1

3

S-

H

T-

4 White

2 Black

Spring

Filter

6.2.3 Maintenance of fl ow guide tube

18

Page 24

• After removing the fl ow guide tube from the furnace wall and then, from the detector, cool the tube down

fully in the air.

• Remove dust sticking to the outside of the fl ow guide tube by water-washing with the use of a scrubbing

brush.

• Remove dust sticking to the inside of the fl ow guide tube by using a metallic rod or screwdriver.

(Clean so that tube is through at least about 3/4 part of the whole interior.)

• For the fl ow guide tube for high dust, remove together dust sticking around the gas outlet.

6.3 Standard output of detector

For the output voltage of the detector, refer to the standard output table below.

Standard output table (Reference)

Oxygen

concentration

(vol%)

0.01

0.05

0.1

0.5

1.0

1.2

1.4

1.5

1.6

1.8

2.0

2.2

2.4

2.5

2.6

2.8

3.0

3.5

4.0

4.5

5.0

5.5

6.0

6.5

7.0

7.5

Detector output

(mV)

168.15

132.68

117.41

81.94

66.67

62.65

59.25

57.73

56.31

53.71

51.39

49.29

47.37

46.47

45.61

43.98

42.46

39.06

36.12

33.52

31.20

29.10

27.18

25.42

23.79

22.26

Oxygen

concentration

(vol%)

8.0

8.5

9.0

9.5

10.0

11.0

12.0

13.0

14.0

15.0

16.0

17.0

18.0

19.0

20.0

20.6

21.0

22.0

23.0

24.0

25.0

30.0

35.0

40.0

45.0

50.0

Detector output

(mV)

20.84

19.51

18.25

17.06

15.92

13.82

11.91

10.14

8.51

6.99

5.57

4.23

2.97

1.78

0.65

0.00

-0.43

-1.45

-2.43

-3.37

-4.27

-8.29

-11.68

-14.62

-17.22

-19.54

19

Page 25

6.4 Arrangement

No. Description Part No. for procurement

1 Filter cap *ZZPZFKE-TK7N7179C1

2 Spring *ZZPZFKE-TK7N9327P1

3 O-ring for sensor *ZZPZFKE-8552836

4 Joint for calibration gas *ZZPZFKE-TK4J4660C1

*ZZPZFKE-TK7N8173P34

5 Joint for reference gas *ZZPZFKE-TK4J5565C1

6 Adapter for calibration gas joint *ZZPZFKE-TK7N8173P25 For ejector

7 Adapter for calibration gas joint *ZZPZFKE-TK7N8173P1 For ø 6 mm tube

*ZZPZFKE-TK7N8173P3 (Packing)

8 Adapter for calibration gas joint *ZZPZFKE-TK7N8173P2 For ø1/4 inch tube

*ZZPZFKE-TK7N8173P3 (Packing)

9 Adapter *ZZPZFKE-TK7K1652P9 For ø6 mm tube

*ZZPZFKE-TK7J0987P2 (Packing)

10 Adapter *ZZPZFKE-TK7K1652P10 For ø1/4 inch tube

*ZZPZFKE-TK7J0987P2

11 Ejector *ZZPZFKE-TK7P0738C1

12 Cable gland

13 Filter for high particulate

14 Flow guide tube According to the following table “Drawing

13. Filter for high

particulate

*ZZPZFKE-TK7N7181P2

*ZZPZFKE-TK7P0524C1

No. for fl ow guide”

1. Filter cap

(Procured type)

(Packing)

4. Joint for calibration gas

5. Joint for reference gas

Remark

9, 10. Adapter

2. Spring

9, 10. Adapter

11. Ej ect or

3. O-ring for sensor

12. Cable gland

6, 7, 8. Adapter for calibration

gas joint

20

Page 26

Part No. for procurement of fl ow guide

Drawing No. for flow guide

*ZZP-TK7P0526C

Digit of type

Flange size

JIS 5K 65A 01

JIS 5K 80A 02

JIS 5K 100A 03

JIS 10K 65A 04

JIS 10K 80A 05

JIS 10K 100A 06

ANSI 150LB 2B 07

ANSI 150LB 3B 08

ANSI 150LB 4B 09

DIN DN50 PN10 10

DIN DN80 PN10 11

Purpose/Material

For general explosion-proof/SUS316 1

With blowdown nosle/SUS316 2

For high particulate/SUS316 3

With cover for high particulate/SUS316 4

For high particulate/SUS310S 5

With cover for high particulate/SUS310S 6

For high particulate/Titanium 7

With cover for high particulate/Titanium 8

specification

9th digit

7

8

9

A

B

C

D

E

F

G

H

Digit of type

specification

10th digit

F

G

H

J

K

L

M

N

Code for flange

combination

Code for

purpose

combination

300

500

750

1000

Insertion length

Digit of type

specification

11th digit

3

5

7

1

Code for

insertion length

combination

1

2

3

4

21

Page 27

7. TROUBLESHOOTING

CAUTIONS

• If a failure should occur which cannot be judged even if referring to the operation manual, be sure to

ask the nearest dealer or Fuji adjustment serviceman for repair. If disassembled carelessly, there is a

fear of an accident or injury.

Troubles Probable causes Check procedures (normal values) Remedies

• Indication is fi xed.

• Indication response

is slow.

• Temperature alarm

continues coming on

despite 20 minutes

having elapsed after

turning on power.

• Indication is too high

or too low.

• Clogging of ceramic fi lter

of detector and fl ow guide

tube interior

•

Leak from joint and airtightness of mounted part.

• Deterioration of detector • Check by changing zero calibra-

• Decrease of exhaust gas

fl owing velocity

• Disconnection of cable • Check continuity. • Replace cable.

• Error in wiring • Check wiring. • Wire correctly.

• Low supply voltage • Check if supply power is as

• Disconnection of thermocouple

• Blow out of fuse of converters (ZKME)

• Disconnection of detector

heater

• Looseness of fl ange

mounted part or defects

of O-ring or packing (not

included in scope of supply).

• Deterioration of detector • Check airtightness of calibration

• Abnormality of detector

temperature

• Change of ambient air

oxygen concentration of a

terminal box or very high

humidity

• Check visually for fouling of ceramic fi lter of detector and clog-

ging of fl ow guide tube interior

with dust.

• Check for looseness of each joint

and airtightness of mounted part.

tion gas over to span calibration

gas and vice versa if it takes

more than 5 minutes for 90%

response.

• Check exhaust gas responding

time after stop of calibration gas

supply.

specifi ed.

• Check continuity.

• Check if resistance across terminals No. 3 and No. 4 is 2 to 3 Ω.

• Check continuity of fuse. • Exchange fuse(s).

• Check heater resistance as follows (exclusive of wiring resistance):

For 100V : 50 to 55 Ω

For 200V : 240 to 260

• Check airtightness of detection

unit, fl ow guide tube and fl ange

mounted part.

• Check for leak in from periphery. • Shield

gas supply port.

• Check at a time of running zero

and span calibration gases if

detector output (mV) is higher

or lower than others. (Refer to

Table in Item “6.3”).

• Check indicated temperature of

converter.

• Check ambient air oxygen concentration of a terminal box is

20.6 vol%.

Ω

• Clean or exchange ceramic fi lter, if need be.

•

Retighten and replace

joint(s), if need be.

• Replace detector.

• Increase amount of

exhaust gas inside fl ow

guide tube to be taken in.

• Clean fl ow guide tube.

•

Supply correct power.

• Replace detector.

(Refer to each instruction

manual of conver-ters)

(ZKME).

• Replace detector.

• Retighten mounting

screw.

• Exchange O-ring.

• Exchange packing

(not included in scope of

supply

•

Retighten calibration

gas joint.

• Replace detector.

• Use reference gas inlet.

22

Page 28

8. APPENDIX

8.1 Specifi cation

8.1.1 General Specifi cations

• Measuring object: Oxygen in noncombustible gas

• Measuring method: Directly insert type zirconia system

• Measuring range: 0 to 2 ··· 0 to 50 vol% O

2 ranges available in 1 vol% O2 steps

• Repeatability: Within ±0.5 %FS

• Linearity: Within ±2 %FS

• Response time: Within 4 to 7 sec, for 90% (from calibration

gas inlet)

• Warmup time: approx. 10 min

• Analog output: 4 to 20 mA DC (allowable load resistance less

than 500Ω) or 0 to 1 V DC (output resistance

more tha n 100 Ω)

• Power supply: Rated voltage;

100 to 120 V AC (operating voltage 90 to

132 V AC)

200 to 240 V AC (operating voltage 190 to

264V AC)

Rated frequency; 50/60 Hz

• Power consumption: Maximum 240 VA (Detector: approx. 200 VA,

Converter: approx. 40 VA)

Normal 70 VA (Detector: approx. 50 VA,

Converter: approx. 20 VA

8.1.2 Detector Specifi cations (ZFKE)

• Measured gas temperature:

Flow guide tube system; −10 to +600ºC (for

general-use, corrosive gas)

• Measured gas pressure:

−3 to +3 kPa (−306 to +306 mm H

• Flow guide tube: With or without blow-down nozzle

Flange; JIS5K 65A FF

(JIS5K-80AFF for high particulate gas)

Insertion length; 0.3, 0.5, 0.75, 1 m

Other: See. Code Symbols

• Ejector (general-use):

Probe for vacumming up measured gas to

detector (option)

• Operating temperature:

−10 to +60ºC for Primary detecting element

125ºC or less at detector fl ange surface with

power applied

• Storage temperature:

Sensing element: −20 to +70ºC

• Structure: Dust/rain-proof structure (IEC IP66 equivalent)

• Flame proof: See Table 1.

• Filter: SUS316 (fi ltering accuracy 60 μm)

• Main materials of gas-contacting parts:

Detector; Zirconia, SUS316, platinum

Flow guide tube; SUS316

• Calibration gas inlet:

6 mm tube join or ø1/4-inch tube join (as

ø

specifi ed)

• Reference gas inlet (option):

6 mm tube join or ø1/4-inch tube join (as

ø

specifi ed)

• Detector mounting: Horizontal plane ±45º, ambient surrounding

air should be clean.

2

O)

2

• Outer dimensions: (L × max. dia.) 215 mm × 164 mm (detector)

• Mass (approx.) {weight}:

• Finish color: Case: Silver and SUS metallic color

• Ejector air inlet fl ow rate:

• Calibration gas fl ow:

• Blowdown air inlet pressure:

Table 1

TIIS

pending

(

NEPSI EExd IIC T5 Ex II2G

)

Detector; 3.0 kg

Flow guide tube (for corrosive gas, 1 m); 6 kg

Cover: Blue

5 to 10 L/min

1.5 to 2 L/min

200 to 300 kPa {2 to 3 kgf/cm

Detector

Exd IIB T4

2

}

8.1.3 Converter specifi cation (ZKME)

• Concentration value indication:

Digital indication in 4 digits

• Contact output signal:

(1) Contact specifi cation; 6 points, 1a 250 V AC/3A or 30 V DC/3 A

(2) Contact function;

• Under maintenance

• Under blowdown Note3)

• Span calibrating gas

• Zero calibration gas

• Instrument anomalies Note1)

• Alarm Note2)

Note1) The following Instrument errors (1) Thermocouples

break (2) Sensor break (3) Temperature fault

(4) Calibration fault (5) Zero/span adjustment fault

(6) Output error turn the contact-ON

Note2) Alarm selects just one as mentioned below (1) High

(2) Low (3) Upper and Lower (4) High-high

(5) Low-low, it turns ON while operating.

Note3) Under blow down is available in case of option, and it

turns ON while operating.

• Contact input signal:

(1) Contact specifi cation; 3points (the following option)

ON; 0 V (10 mA or less), OFF; 5 V

(2) Contact function;

• External hold

• Calculation reset

• Heater OFF

• Blow down (option)

• Inhibition of calibration

• Calibration start

• Range changee

• Calibration method:

(a) Manual calibration with key operation

(b) Auto. calibration (option)

Calibration cycle; 00 day 00 hour to

99 days 23 hours

(c) All calibration

23

Page 29

•

Calibration gas: • Range settings

Zero gas; 0.010 to 25.00 % O

Span gas: 0.010 to 50.00 % O

• Recommended calibration gas concen-tration

Zero gas; 0.25 to 2.0 % O

Span gas; 20.6 to 21.0 % O

2

2

2

2

(oxygen concentration in the air)

• Blowdown : A function for blowing out with compressed

(option)

air dust that has deposited in the fl ow guide

tube. Blowdown can be performed for a

predetermined time and at predetermined

intervals.

Blowdown cycle; 00 hour 00 minute to

99 hours 59 minutes

Blowdown time; 0 minute 00 second to

0 minutes 999 seconds

• Output signal hold: Output signal is held during calibration,

processing recoverable sensor,processing diagnosis of sensor, warm-up, PID auto tuning,

under set up maintenance mode " available"

and blowdown. The hold function can also be

released.

• Valve and fl ow meter (option):

Selects zero or span gas during manual zero or

span calibration.

• Communication function:

RS232C (MODBUS) standard specifi cation

RS485 (MODBUS) (option)

• Combustion effi ciency display (option):

When you select this display, "rich mode

display" will be an simultaneous display.

This function calculates and displays combustion effi ciency from oxygen concentration and

measured gas temperature.

Thermocouple (R) is required for temperature

measurement.

• Operating temperature:

−20 to +55ºC

• Operating humidity:

95% RH or less, non condensing

• Storage temperature:

−30 to +70ºC

• Storage humidity: 95% RH or less, non condensing

• Construction: Dust-proof, rainproof construction

(corresponding to IP65)

• Explosion proof: See Table 2

• Material: Aluminum case

• Outer dimensions (H x W x D):

470 X 326 X 211 mm (IP65)

• Mass {weight}: IP65: Approx.22 kg (excluding cable and

detector)

• Finish color: Case: Silver

Cover: blue

• Mounting method: Mounted fl ush on panel

Table 2

Converter

TIIS

(pending)

Exd IIB T6

NEPSI EExd IIC T6 Ex II2G

Electrical Safety:

Overvoltage category

; II power supply input

; I relay interfaces

(IEC1010-1)

External overcurrent protective device

; 10A

Equipment interfaces are safety

separated (SELV)

ZFKE, ZKME

24

Page 30

8.2 Designation of type (code table)

8.2.1 Detector

14 151691011121343215678

17

5- -KREFZ

Y

1

2

A

B

1

3

Y

0

Y

0

7

8

9

A

B

C

D

E

F

G

H

F

G

H

J

K

L

M

N

3

5

7

1

1

Cal. gas inlet

Non (G3/8 female screw)

For F6mm tube

For F1/4 inch tube

Ejector for F6mm tube

Ejector for F1/4 inch tube

Power supply

100 to 120VAC 50/60Hz

200 to 240VAC 50/60Hz

Flow guide tube

None

<Flange size>

JIS 5K 65A

JIS 5K 80A

JIS 5K100A

JIS 10K 65A

JIS 10K 80A

JIS 10K 100A

ANSI 150LB 2B

ANSI 150LB 3B

ANSI 150LB 4B

DIN DN50 PN10

DIN DN80 PN10

<Application / meterial>

For corrosive gas / SUS316

With blow-down nozzle / SUS316

For high particular / SUS316

For high particular with cover / SUS316

For high particular / SUS310S

For high particular with cover / SUS310S

For high particular / titanium

For high particular with cover / titanium

<Length>

300mm

500mm

750mm

1000mm

Y

A

B

5

7

C

Reference gas inlet

Non (G1/8 female screw)

for F6mm tube

For F1/4 inch tube

Filter

Standard

For high particular

Instruction manual language

J

Japanese

E

English

Chinese

Specification name plate

1

Standard

Ex. Standard

N

NEPSI

T

TIIS (pending)

Description

8.2.2 Replacement Detector element

Power supply Code symbols

100 to 120V AC ZFK8YY15-0Y0YY-0YY

200 to 240V AC ZFK8YY35-0Y0YY-0YY

25

Page 31

8.2.3 Converter

910111221 345678

E

-11MKZ

1

B

E

1

2

Y

1

2

3

4

5

6

7

13

14

-

Output signal

4 to 20mA DC

0 to 1V DC

Communication function

RS-232C

RS-485

Optional Functions

None

Combustion efficiency display function Note1)

Blowdown

Auto calibration

Combustion efficiency indication

+ Blowdown Note1)

Combustion efficiency indication

+ Auto calibration Note1)

Blowdown + Auto calibration

Combustion efficiency indication + Blowdown

+ Auto calibration Note1)

J

E

C

Y

1

2

1

Note1) When you select this display, rich mode

Instruction manual language

Japanese

English

Chinese

Mounting Option

None (Mounting on panel surface)

With valve

With valve + flowmeter

Specification name plate

Standard

Number of Cable Gland

3

3

4

4

5

5

6

6

7

7

Ex Standard

N

NEPSI

T

TIIS (pending)

will be a simultaneous display.

Description

8.2.4 Exclusive-special cable

921 345678

-1ERZRZ

E

R

YA

YB

YC

YD

YE

YF

YG

YH

YJ

YK

YL

YM

Connectable devices

For Z KME

Types

For R thermocouple

Cable length

6m

10m

15m

20m

30m

40m

50m

60m

70m

80m

90m

100m

Cable end treatment

0

None

1

One side (detector side)

2

Both sides

Description

26

Page 32

8.3 DEVICE CONFIGURATION

The device to be combined differ according to the conditions of the gas to be measured. Select the devices to be

combined with reference to the following table.

Measured gas Device confi guration

Application Temperature Gas Flow DUST Note Detector type Converter type

General-use

(boiler)

For corrosive

gas (refuse

incinerator)

Note (1) Dust volume is approximate value.

(2) Instrument quality air or bottled air is available as reference air by selecting detector with reference air

600ºC or less 5 to 20 m/s Less than 0.2 g/Nm3Fuel; gas, oil ZFKER 5- F Y - ZKME

Less than 10 g/Nm

600ºC or less 5 to 20 m/s Less than 1 g/Nm

Less than 10 g/Nm

Less than 25 g/Nm

Less than 25 g/Nm

3

Fuel: coal

with blow down

3

Included low moisture ZFKER 5- F Y - ZKME

3

Included low moisture

with blow down

3

Included low moisture

with blow down

3

Included high moisture

with blow down

ZFKER 5- G Y - ZKME

ZFKER 5- G Y - ZKME

H

ZFKER 5- K Y -

M

J

ZFKER 5- L Y -

N

ZKME

ZKME

inlet.

27

Page 33

8.4 OUTLINE DIAGRAM (Unit:mm)

(1) Detector (ZFKER: 6th dight code. Y, 1, 2)

Approx. 215

17.5

77

P

View B

Filter

Approx. 126

Approx. 162

32

Approx.

Calibration gas inlet (To order)

SUS316, for φ6mm tube

(the 6th digit is “1”)

Or 1/4 inch tube

(the 6th digit is “2”)

(Not provided if the 6th digit is “Y”)

67

6-

φ

6

φ

Ref. gas inlet (to order)

SUS316, for

(the 13th digit is “A”)

or 1/4 inch tube

(the 13th digit is “B”)

100

φ

φ

6mm tube

Approx.

Exclusive Cable gland

(For power supply)

Exclusive Cable gland

(For signal)

Approx.

(13th digt code A, B)

VIEW A VIEW B

180

Approx. 152

Approx.

140

Approx. 242

(14th digt code 7)

Lock screw M6

External ground

terminal M4

Explotion-proof

name plate

View A

VIEW FROM P

(2) Sensor unit (ZFK8YY)

17.5)

φ

(

(132.7)

(88.4) 3.5

EXTERNAL

CONNECTION DIAGRAM

Heater

Thermocouple

1

2

Black

3

Red White

2-core wire 4-core wire

Exclusive-special cable

20

4-φ3.5(Mount for detector)

φ

35

40

madeinjapan

Element output

45 6

Yellow BlueBlack

T+

S+

H

6

1

3

4

2

5

H

T-

S-

TK4J4664R0

45°

45°

28

Page 34

(3) Detector (ZFKER: 6th dight code. A, B)

P

View B

Filter

Calibration gas inlet

SUS316, for φ6mm tube

(the 6th digit is “A.”)

1/4 inch tube (the 6th digit is “B.”)

Ejector gas outlet

SUS316, for φ6mm tube

(the 6th digit is “A.”)

1/4 inch tube (the 6th digit is “B.”)

Approx. 185

6-

φ

126

Approx.

Approx. 57

6

Ref. gas inlet (to order)

SUS316, for

Or 1/4inch tube (the 13th digit is “B”)

Approx. 215

17.5

77

Calibration

Air out

Approx. 47

Air in

Approx. 37

Approx. 78

φ

6mm tube (the 13th digit is “A”)

Approx. 100

Exclusive Cable gland

(For power supply)

Approx. 21

67

φ

Exclusive Cable gland

Ejector gas inlet

SUS316, for φ6mm tube

(the 6th digit is “A.”)

1/4 inch tube (the 6th digit is “B.”)

(For signal)

Approx.

155

Approx. 140

Approx. 180

(13th digt code A, B)

(14th digt code 7)

VIEW A VIEW B

External ground

terminal M4

Explotion-proof

name plate

Approx. 242

Lock screw M6

View A

VIEW FROM P

EXTERNAL

CONNECTION DIAGRAM

Heater

Thermocouple

1

2-core wire 4-core wire

Exclusive-special cable

2

Black

3

Red White

Element output

45 6

Yellow BlueBlack

29

Page 35

(4) Flow guide tube (for high particulate) (ZFKE: 10th dight code. H, K, M)s)

D

C

67

f

Approx. L

60.5

Gas inlet

t

Approx. 20

6-M5

detector side

Gas outlet

ZFKE MTG. position

Code 11th

L (m)

Mass

Approx.(kg)

3

571

0.5 0.75 1.0

0.3

3.8

3.0

4.8

5.7

L=

(to order)

Z

Blow down

air inlet

Flange size

JIS 5K 65A

JIS 5K 80A

JIS 5K 100A

JIS 10K 65A

JIS 10K 80A

JIS 10K 100A

ANSI 150LB 2B

ANSI 150LB 3B

ANSI 150LB 4B

DIN DN50 PN10

DIN DN80 PN10

N– h

MTG. holes

4-Rc1/4

with plug int.thd.

Code

9th

7

8

9

A

B

C

D

E

F

G

H

DCt f Nh

155

130

180

145

200

165

175

140

185

150

210

175

150

120.7

190

152.4

230

190.5

165

125

200

160

(5) Flow guide tube (for high particulate) (ZFKE: 10th dight code. H, K, M)

4 - Rc 1/4

with plug int thd.

D

C

Blow down air inlet

Select an upper port to

avoid the condensation

in the piping

N - h

MTG. hole

67

38.5

14

14

16

18

18

18

17.5

22.3

22.3

18

20

2

110

2

121

2

141

2

116

2

126

2

151

2

92.1