Page 1

IN-SITU

ZIRCONIA OXYGEN ANALYZER

DATA SHEET

This oxygen analyzer is used to continuously measure

oxygen concentration in combustion exhaust gas of industrial

boilers or furnaces, and is ideally suited for combustion management and control.

The analyzer system is comprised of the detector and converter coupled together as a complete system. Detector setting confi guration includes the detector fl ow guide tube and

detector sensor. The fl ow guide tube is inserted directly into

the gas and directs gas to the sensor for measurement. The

converter (ZKM) is comprised of the signal processor, input/

output and communications, display and system controls.

The converter is equipped with advanced functionality

such as performing the sensor diagnostics and sensor recovery function, so the detector can be used within long term

stability.

FEATURES

1. Gas sampling device is unnecessary

For quick response, insert the detector directly into the

fl ue Gas sampling functions such as a gas aspirator and a

dehumidifi er are not required.

2. Easy maintenance

The sensor equipped with the detector, has unit construc-

tion, it is easy to replace.

By separating the detector and the fl ow guide tube, fi lter

replacement is easy.

3. More reliable than sensor diagnosis, sensor recoverable function

Depending on the concentration of the measurement gas,

the power of the sensor might deteriorate. The equipment

includes sensor recovery function electronically, checking

the deterioration status of the sensor depletion.

Therefore, it has high reliability and long-lasting stability.

4. Safe and secure

System detects thermocouple break for heater control on

the sensor side. Safety functions of isolating power supply

to the detector or isolating power via external contact input

are also.

5. Easy operation

The operation and setting for the converter can be per-

formed interactively, and available as English, Japanese or

Chinese for language display.

ZFK8, ZKM, ZTA

General-use detector

(ZFK8)

<IP66>

Converter (ZKM1)

High-temperature detector

(ZTA)

<IP67>

Converter (ZKM2)

SPECIFICATIONS

General Specifi cations

Measuring object: Oxygen in noncombustible gas

Measuring method:

Directly insert type zirconia system

Measuring range: 0 to 2 ··· setting range at option 2 in 50

vol% O

2

(in 1 vol% O2 steps)

Repeatability: Within ±0.5%FS

Linearity: Within ±2%FS

Response time: Within 4 to 7 sec, for 90% (from calibra-

tion gas inlet)

Warmup time: More than 10 min

Analog output: 4 to 20mA DC (allowable load resistance

less than 500Ω) or 0 to 1V DC (output

resistance more than 100Ω)

Power supply: Rated voltage;

100 to 120V AC (operating voltage 90

to 132V AC)

200 to 240V AC (operating voltage

190 to 264V AC)

Rated frequency; 50/60Hz

Power consumption:

Maximum 240VA (Detector: approx.

200VA, Converter: approx. 40VA)

Normal 70VA (Detector: approx. 50VA,

Converter: approx. 20VA)

EDSX3-137c

Date

May. 20, 2009

Page 2

ZFK8, ZKM, ZTA

Detector Specifi cations (ZFK)

Measured gas temperature:

Flow guide tube system; −20 to +600ºC

(for general-use, corrosive gas)

Ejector system; −20 to +1500ºC (for

high-temperature gas)

−20 to +800ºC (for general-use)

Measured gas pressure:

−3 to +3kPa (−306 to +306mmH

Flow guide tube: With or without blow-down nozzle

Flange; JIS5K 65A FF

(JIS5K-80AFF for high particulate gas)

Insertion length; 0.3, 0.5, 0.75, 1m

Ejector (general-use):

Probe for guiding measured gas to

detector

Flange; JIS10K 65A RF

Insertion length; 0.5, 0.75, 1, 1.5m (ac-

cording to customer's specifi cation)

Operating temperature:

−10 to +60ºC for Primary detecting ele-

ment

−5 to +100ºC for ejector section

125ºC or less at detector fl ange surface

with power applied

Storage temperature:

Sensing element: −20 to +70ºC

Ejector: −10 to +100ºC

Structure: Dust/rain-proof structure(IEC IP66

equivalent)

Filter: Alumina(fi ltering accuracy 50µm) and

quartz paper

Main materials of gas-contacting parts:

Detector; Zirconia, SUS316, platinum

Flow guide tube; SUS304 or SUS316

Ejector (general use); SUS316, SUS304

Ejector; (for high temperature) SiC,

SUS316, SUS304

Calibration gas inlet:

φ6mm tube join, φ1/4-inch tube join, or

ball valbe (as specifi ed)

Reference air inlet (option):

φ6mm tube join or φ1/4-inch tube join (as

specifi ed)

Detector mounting:

Horizontal plane ±45º, ambient sur-

rounding air should be clean.

Outer dimensions: (L × max. dia.) 210mm × 100mm (de-

tector)

Mass (approx.) {weight}:

Detector; 1.6kg

Ejector; 15kg (insertion length 1m)

Flow guide tube (general-use, 1m); 5kg

Finish color: Silver and SUS metallic color

Ejector air inlet fl ow rate:

5 to 10 L/min

Calibration gas fl ow:

1.5 to 2 L/min

Blowdown air inlet pressure:

200 to 300kPa {2 to 3 kgf/cm

2

}

Ejector exhaust gas processing:

Into furnace, returned to fl ue

Heater temperature drop alarm output (ejector):

Alarm output when below 100

ºC Me-

chanical thermostat

2

N.O. (1a) contact, 200V AC, 2A

Converter specifi cation (ZKM)

Concentration value indication:

Digital indication in 4 digits

Contact output signal:

(1) Contact specifi cation; 6 points, 1a 250V AC/3A or 30V DC/3A

(2) Contact function;

• Under maintenance

O)

2

• Under blowdown Note3)

• Span calibration gas valve

• Zero calibration gas valve

• Instrument anomalies Note1)

• Alarm Note2)

Note1) The following Instrument errors (1) Thermocou-

ples break (2) Sensor break (3) Temperature fault

(4) Calibration fault (5) Zero/span adjustment fault

(6) Output error turn the contact-ON

Note2) Alarm selects just one as mentioned below (1)

High (2) Low (3) Upper and Lower (4) High-high

(5) Low-low, it turns ON while operating.

Note3) Under blow down is available in case of option,

and it turns ON while operating.

Contact input signal:

(1) Contact specifi cation; 3points (the following option)

ON; 0V (10mA or less), OFF; 5V

(2) Contact function;

• External hold

• Calculation reset

• Heater OFF

• Blow down (option)

• Inhibition of calibration

• Calibration start

• Range change

Calibration method:

(a) Manual calibration with key operation

(b) Auto. calibration (option)

Calibration cycle; 00 day 00 hour to

99 days 23 hours

(c) All calibration

Calibration gas: • Available range settings

Zero gas; 0.010 to 25.00% O

Span gas: 0.010 to 50.00% O

2

2

• Recommended calibration gas concentration

Zero gas; 0.25 to 2.0% O

Span gas; 20.6 to 21.0% O

2

2

(oxygen concentration in the air)

Blowdown: A function for blowing out with com-

pressed air dust that has deposited in

the fl ow guide tube. Blowdown can be

performed for a predetermined time and

(option)

at predetermined intervals.

Blowdown cycle; 00 hour 00 minute to

99 hours 59 minutes

Blowdown time; 0 minute 00 second

to 0 minutes 999

seconds

Output signal hold:

Output signal is held during calibration,

processing recoverable sensor, processing diagnosis of sensor, warm-up, PID

auto tuning, under set up maintenance

mode "available" and blowdown. The

hold function can also be released.

Page 3

Valve and Flow meter (option):

Selects zero or span gas during manual

zero or span calibration. Mounted on the

side of the converter.

Communication function:

RS232C (MODBUS) standard specifi cation

RS485 (MODBUS) (option)

Combustion effi ciency display (option):

When you select this display, "rich mode

display" will be simultaneously displayed.

This function calculates and displays

combustion effi ciency from oxygen

concentration and measured gas temperature.

Thermocouple (R) is required for tem-

perature measurement.

Operating temperature:

−20 to +55ºC

Operating humidity:

95% RH or less, non condensing

Storage temperature:

−30 to +70ºC

Storage humidity: 95% RH or less, non condensing

Construction: Dust-proof, rainproof construction

(corresponding to IP66 or IP67 of IEC)

Material: Aluminum case

Outer dimensions (H x W x D):

170 X 159 X 70mm (IP66, Bench type)

220 X 230 X 95mm (IP67)

182 X 163.5 X 70.6mm (Bench type)

Mass {weight}: IP66: Approx. 2kg (excluding cable and

detector)

IP67: Approx. 4.5kg (excluding cable and

detector)

Finish color: IP66: Case: Silver

Cover: Pantone Cool Gray 1C-F

IP67: Munsell 6PB 3.5/10.5 (blue)

Cover: Silver (case)

Mounting method: Mounted fl ush on panel or on pipe

Electrical Safety:

Overvoltage category

; II power supply input

; I relay interfaces

(IEC1010-1)

External overcurrent protective device

; 10A

Equipment interfaces are safety

separated (SELV)

The product conforms to the requirements of the

Electromagnetic compatibility Directive 89/336/EEC

as detailed within the technical construction file

number TZ734575. The applicable standards used to

demonstrate compliance are :

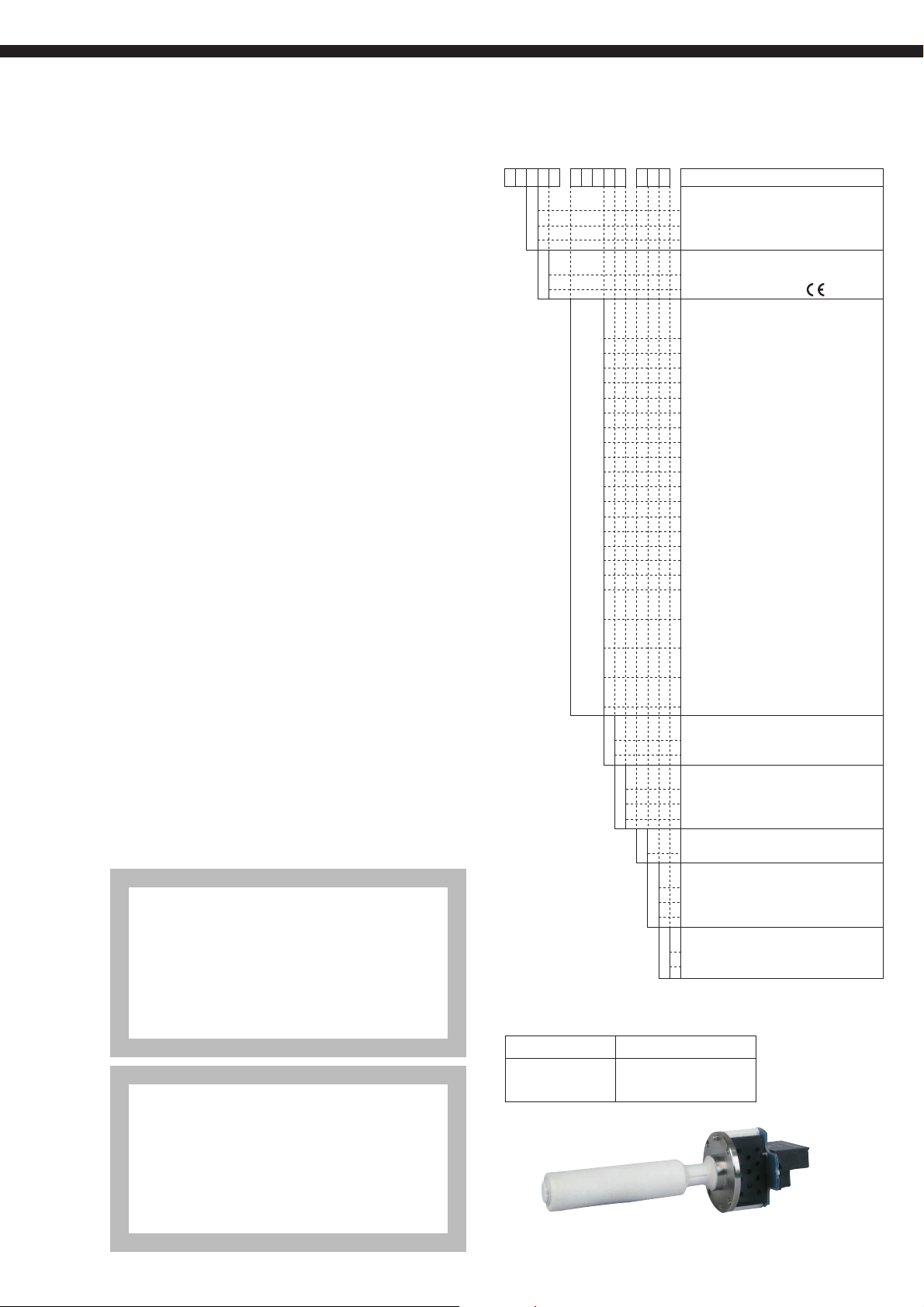

CODE SYMBOLS

(Detector)

14 15 1691011121345678

51R8- -ZFK

1

2

3

1

3

0 Y 0

5 A 3

5 A 5

5 A 7

5 A 1

5 B 3

5 B 5

5 B 7

5 B 1

5 C 3

5 C 5

5 C 7

5 C 1

6 D 3

6 D 5

6 D 7

6 D 1

6 E 3

6 E 5

6 E 7

6 E 1

Z Z Z

Y

A

Y

A

B

(Replacement Detector element)

Power supply Code symbols

100 to 120V AC ZFK8YY15-0Y0YY-0YY

200 to 240V AC ZFK8YY35-0Y0YY-0YY

Cal. gas inlet

For φ6mm tube (SUS)

For φ1/4 inch tube (SUS)

Ball valve

Power supply

100 to 120VAC 50/60Hz

200 to 240VAC 50/60Hz

Flow guide tube

flange application length

None

SUS304 general use 300mm

SUS304 general use 500mm

SUS304 general use 750mm

SUS304 general use 1000mm

SUS316 for corrosive gas 300mm

SUS316 for corrosive gas 500mm

SUS316 for corrosive gas 750mm

SUS316 for corrosive gas 1000mm

SUS316 with blow-down nozzle 300mm

SUS316 with blow-down nozzle 500mm

SUS316 with blow-down nozzle 750mm

SUS316 with blow-down nozzle 1000mm

SUS316 for high particulate 300mm

SUS316 for high particulate 500mm

SUS316 for high particulate 750mm

SUS316 for high particulate 1000mm

SUS316 for high particulate with 300mm

cover

SUS316 for high particulate with 500mm

cover

SUS316 for high particulate with 750mm

cover

SUS316 for high particulate with 1000mm

cover

Others

Protection cover

Without

With

Reference air inlet

Non

For φ6mm tube (SUS)

For φ1/4 inch tube (SUS)

Filter spec.

Standard

1

Instruction manual language

Japanese

J

English

E

Chinese

C

Specification name plate

Standard (100 to 120V AC 50/60Hz)

1

Standard (200 to 240V AC 50/60Hz)

2

Description

EN 55011 : 1992 CLASSA Conducted and Radiated emissions

EN 50082-1 : 1992 Radiated immunity, ESD and FBT

ZFK, ZKM

3

Page 4

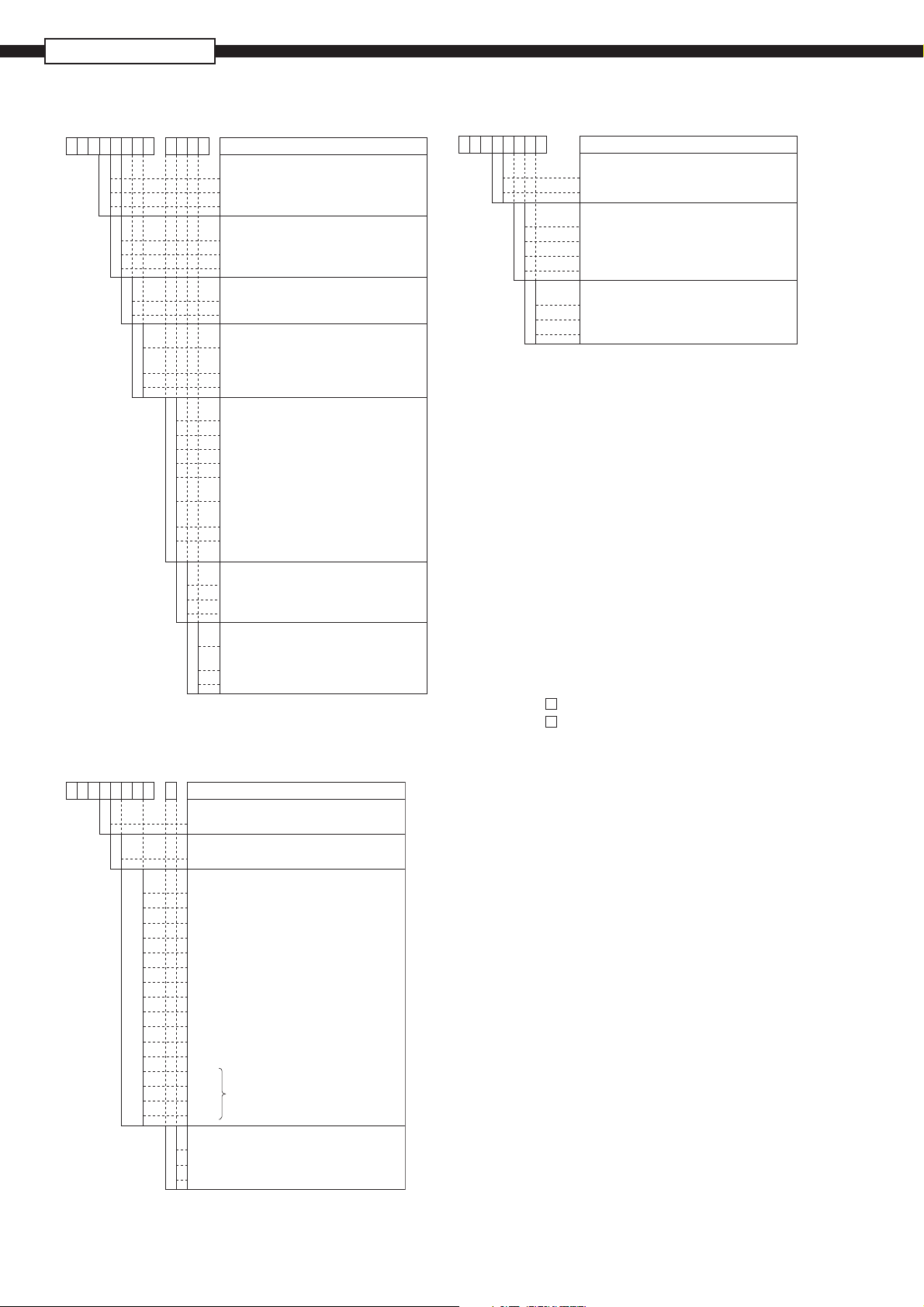

ZFK8, ZKM, ZTA

(Converter)

910111221 345678

-11MKZ

1

2

3

B

E

Z

1

2

Y

1

2

Y

1

2

3

4

5

6

7

J

E

C

Y

1

2

Note4) When you select this display, rich mode

(Exclusive-special cable)

921 345678

-1KRZRZ

K

R

YA

YB

YC

YD

YE

YF

YG

YH

YJ

YK

YL

YM

AA

BB

CC

DD

Connectable devices

For ZKM

Types

For R thermocouple

Conduit length Cable length

None 6m

None 10m

None 15m

None 20m

None 30m

None 40m

None 50m

None 60m

None 70m

None 80m

None 90m

None 100m

6m 6m

10m 10m

15m 15m

20m 20m

Cable end treatment

0

None

1

One side (detector side)

2

Both sides

Note5) For connection between detector and

converter, the conduit to be used should

be rainproof flexible type.

Description

Construction

IP66

IP67

Bench type

Output signal

4 to 20mA DC

0 to 1V DC

Other

Communication function

RS-232C

RS-485

Mounting bracket

None (Specify "None" when the bench

type is selected)

Mounting on panel surface

Pipe mounting

Optional Functions

None

Combustion efficiency display function Note4)

Blowdown

Auto calibration

Combustion efficiency indication

+ Blowdown Note4)

Combustion efficiency indication

+ Auto calibration Note4)

Blowdown + Auto calibration

Combustion efficiency indication + Blowdown

+ Auto calibration Note4)

Display language

Japanese

English

Chinese

Option

None (Specify "None" when the bench

type or the auto calibration is selected)

With valve

With valve + flowmeter

will be a simultaneous display.

Description

Note5

(Ejector)

21345678

11ATZ

1

2

B

C

D

E

1

3

5

Measured gas temperature

For high temperatures (+1500°C max.)

General-use (+800°C max.)

Insertion length [mm]

500

750

1000

150 0

Power supply

100V/115V AC 50/60Hz

200V/220V AC 50/60Hz

230VAC 50/60Hz

Description

SCOPE OF DELIVERY

Detector: Detector main unit × 1, Viton O ring ×

1, mounting screw (M5mm × 16) × 6,

thermal sticker × 1, fl ow guide tube (as

specifi ed) × 1, ceramic fi lter × 1, rain-

proof cover (as specifi ed) × 1, Instruction

manual × 1

Converter: Converter main unit × 1, mounting

bracket set, (as specifi ed) × 1

Accessories (AC250V 500mA T fuse ×

2, AC250V 2.5A T fuse × 2),

Instruction manual × 1

Ejector: Ejector main unit × 1, insertion tube × 1,

M16mm nut, and washer × 4, packing ×

1

Items to be prepared separately:

(1) Standard gas for calibration

Type ZBM

Type ZBM

NSH4-01 (up to 5% O2 range)

NSJ4-01 (over 5% O2 range)

(2) Reduction valve for standard gas (type ZBD61003)

(3) Flowmeter

Type; ZBD42203, 0.2 to 2L/min (for calibrating gas)

Type; ZBD42403, 1 to 10L/min (for ejector)

CAUTIONS

• If combustible gas (CO, H2 etc.) exists in the measured

gas, error will occur due to burning at the sensor section.

The inclusion of corrosive gas (Si vapor, alkaline metal, P,

Pb etc.) will shorten the life of the sensor.

• When the measured gas temperature is high (+300°C

or higher), the flange should be separated from the

furnace wall in order to bring the detector fl ange surface

temperature below the specifi ed value +125°C). The fl ow

guide should be attached in the direction in which the gas

fl ow to the detector decreases.

• When much dust is included in the gas, the fl ow guide

tube should be attached at an inclination so that the fl ow

goes from below to above. And the fl ow guide tube

should be attached in the direction in which the gas fl ow

to the detector decreases.

• In the case of a refuse incinerator, automatic blow down

of the fl ow guide should not be performed (to prevent

corrosion of the fl ow guide tube due to drainage). Blowdown should be performed manually when change in

the indication has become very little with the furnace

stopped.

4

Page 5

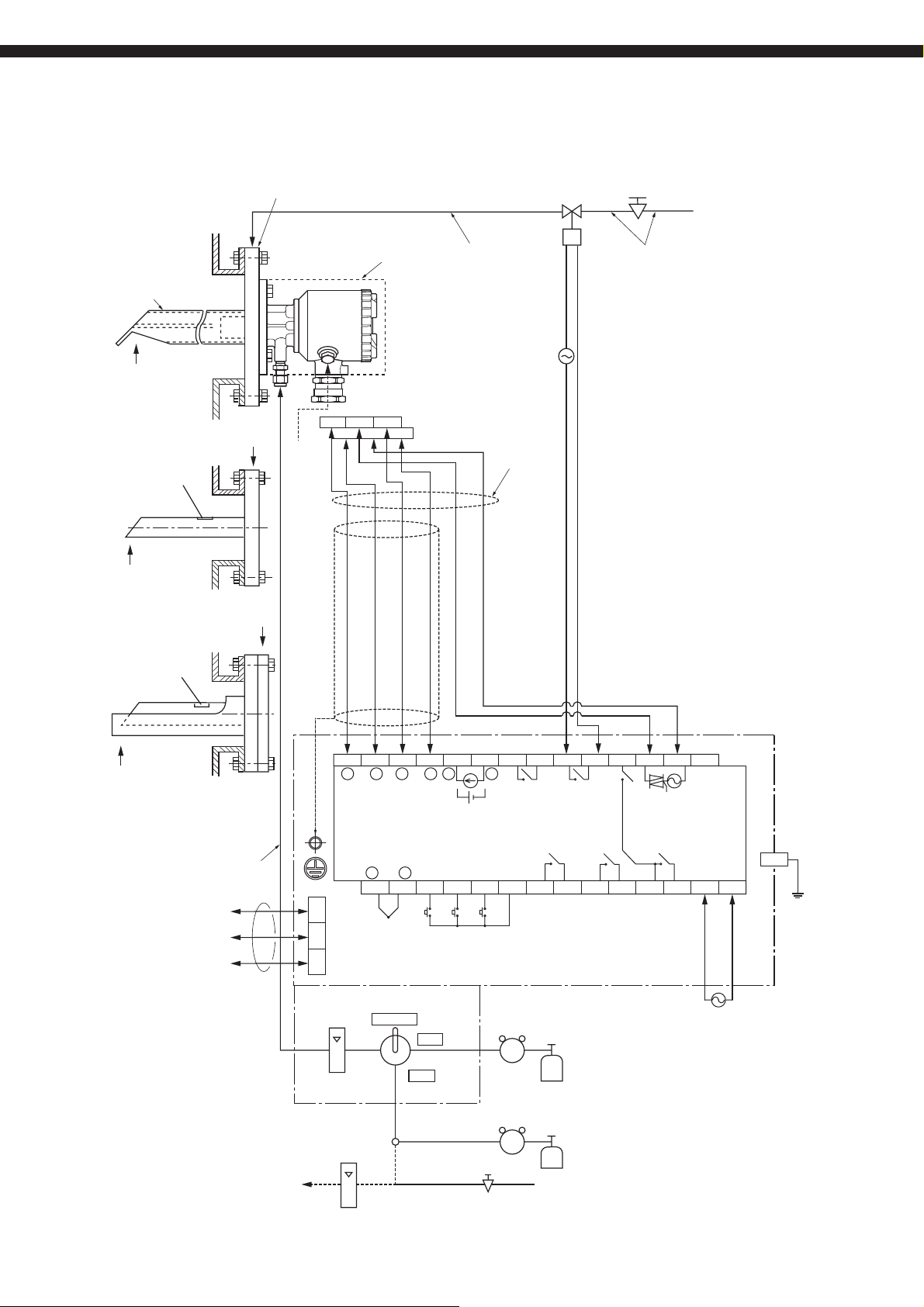

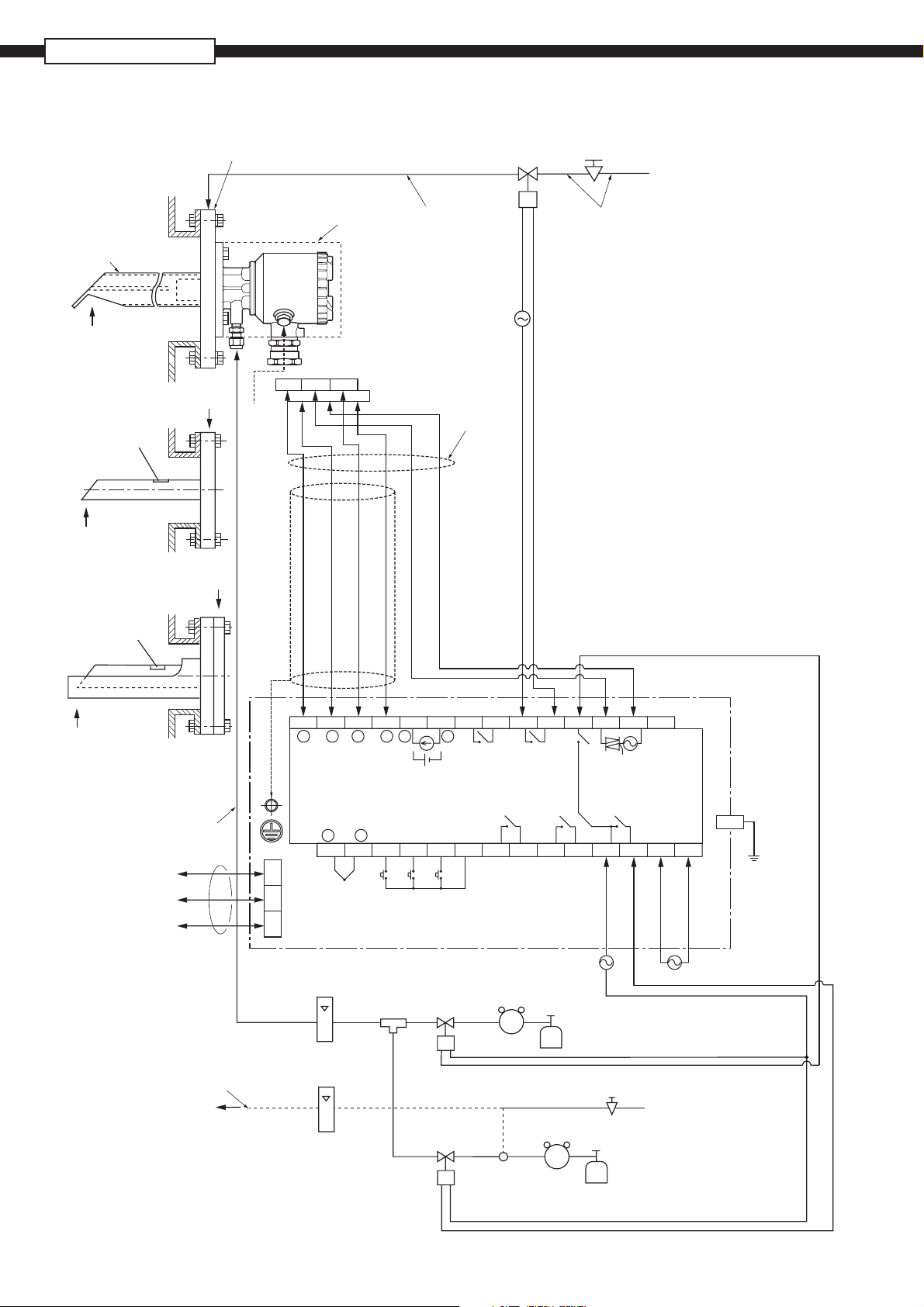

CONFIGURATION

Flow guide tube system (with valve)

Rc1/4

(upper side blow port should be selected)

Blow-down, 200 to 300kPa

Solenoid valve

(not supplied)

Reduction valve

(unnecessary when supply air pressure is

200 to 300kPa)

Supply air

Flow guide tube

Gas temperature.

600ºC max.

Sample gas outlet

Gas temperature.

600ºC max.

Flow guide tube

for high particulate

Sample gas outlet

*2

Ref. air

Blue

6

Ye l l o w

Rainproof cover

Detector

(ZFK8)

123

45

Red

White

Black

White

15ASGP

tube equivalent

or φ10/φ8 PTFE

pipe or copper pipe

(not supplied)

AC power

supply

Rainproof flexible

conduit.

(Max. 20m)

15ASGP

tube equivalent

or φ10/φ8 PTFE

pipe or copper pipe

(not supplied)

Gas temperature.

600ºC max.

Flow guide tube for high

particulate with cover

φ6mm or φ1/4 inch tube

for calibration gas

(not supplied)

RS232C

or

RS485

(option)

(Option)

*2 Ref. air

to Detector

115234567891011121314

+

O2 input

*4

−

O2

Thermocouple

for combustion

control

+

TC2

+

TC1

Thermocouple

input

−

16

+

−

4 to 20mA DC

Contact input

DI1

17

AO

or

Analog output

or 0 to 1V DC

DI2 DI3

18 19

−

FAULT BLOW

Fault

contact

output

ALARM

DICOM

20

Alarm

contact

output

21 22

Blow

contact

output

Maintenance

contact

output

MAINTE

23 24

ZV

GAS

Calibrating

gas contact

output

ZERO

Calibrating gas

contact output

COM

25 28

12 3

TM-2

Flowmeter

Val ve

MEASURE

Reduction valve

(ZBD6)

ZERO

Standard gas

for zero point (ZBM)

*1

Span gas (ZBM)

Note:

Flowmeter

SPAN

Reduction valve

(ZBD6)

*1 Air supply

Reduction valve

(0.2 to 0.5L/min)

(not supplied)

(unnecessary when

supply air pressure

is 50 to 100kPa)

Converter (ZKM)

TM-1

HEATER

AC power

SPAN

supply

GAS

AC

L

NSV

26 27

*1 Standard gas or instrumentation air

can be used in place of span gas.

*2 Instrument quality air or bottled air is

available as reference air instead of

ambient air.

*3 Protective earth.

*4 Connect the shield of a exclusive cable

with the ground terminal in the converter.

*3

PE

5

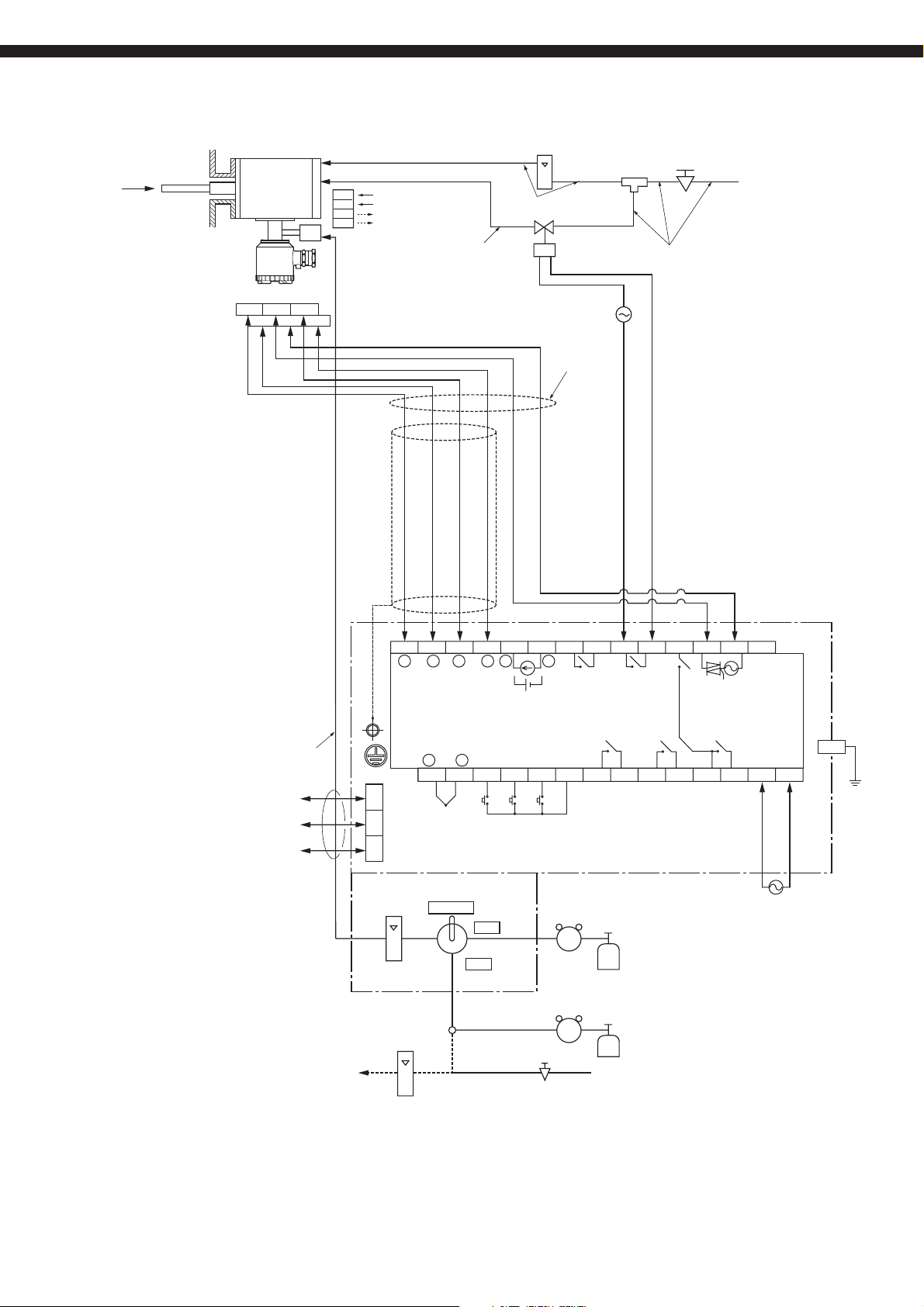

Page 6

ZFK8, ZKM, ZTA

Flow guide tube system

Rc1/4

(upper side blow port should be selected)

Blow-down, 200 to 300kPa

Solenoid valve

(not supplied)

Reduction valve

(unnecessary when supply air pressure is

200 to 300kPa)

Supply air

Flow guide tube

Gas temperature.

600ºC max.

Sample gas outlet

Gas temperature.

600ºC max.

Flow guide tube

for high particulate

Sample gas outlet

*2

Ref. air

Blue

6

Rainproof cover

123

Ye l l o w

Detector

(ZFK8)

45

Red

White

Black

White

15ASGP

tube equivalent

or φ10/φ8 PTFE

pipe or copper pipe

(not supplied)

AC power

supply

Rainproof flexible

conduit.

(Max. 20m)

15ASGP

tube equivalent

or φ10/φ8 PTFE

pipe or copper pipe

(not supplied)

Gas temperature.

600ºC max.

Flow guide tube for high

particulate with cover

+

O2

O2 input

*4

115234567891011121314

φ6mm or φ1/4 inch tube

for calibration gas

(not supplied)

12 3

RS232C

or

RS485

(option)

TM-2

Flowmeter

(ZBD4)

(1 to 1.5L/min)

*2 Ref. air

to Detector

(0.2 to 0.5L/min)

(not supplied)

*1 Standard gas or instrumentation air can be used in place of span gas.

Note:

*2 Instrument quality air or bottled air is available as reference air instead

of ambient air.

*3 Protective earth.

*4 Connect the shield of a exclusive cable with the ground terminal in

the converter.

+

−

Thermocouple

Thermocouple

for combustion

control

+

−

TC2

16

TC1

input

+

−

Analog output

4 to 20mA DC

or 0 to 1V DC

Contact input

DI1

17

Joint

AO

−

or

DI2 DI3

18 19

Solenoid valve

(not supplied)

Solenoid valve

(not supplied)

FAULT BLOW

Fault

contact

output

Alarm

contact

output

ALARM

DICOM

21 22

20

Reduction valve

(ZBD6)

Converter (ZKM)

TM-1

ZV

ZERO

GAS

Calibrating

Blow

gas contact

contact

output

output

Maintenance

contact

output

MAINTE

23 24

Standard gas

for zero point (ZBM)

Reduction valve

(unnecessary when supply air pressure is 50 to 100kPa)

HEATER

Calibrating gas

contact output

COM

25 28

SPAN

GAS

26 27

AC power

supply

NSV

AC

L

AC power

supply

*1 Air supply

Reduction valve

(ZBD6)

Span point

*1

Standard gas for

span point (ZBM)

*3

PE

6

Page 7

Ejector system (with valve)

Ejector (ZTA)

Gas temperature.

1500ºC max.

Detector (ZFK8)

123

6

Black

Ye l l o w

Bule

Red

Flowmeter

Ejector (5 to 10L/min)

Power supply

1

2

Heater temperature drop

4

5

Alarm

Copper pipe

φ10/φ8mm

(not supplied)

45

White

White

(ZBD)

Copper pipe φ6/φ4mm

(not supplied)

Solenoid valve

(not supplied)

AC power

supply

Rainproof flexible

conduit.

(Max. 20m)

Reduction valve

(unnecessary when supply air pressure

is 200 to 300kPa )

Joint

Copper pipe φ10/φ6mm

(not supplied)

Supply air

φ6mm or φ1/4 inch tube

for calibration gas

(not supplied)

RS232C

or

RS485

(option)

(Option)

*2 Ref. air

to Detector

1152 3 4 5 6 7 8 9 10 11 12 13 14

+

O2 input

*4

−

O2

Thermocouple

for combustion

control

+

TC2

+

TC1

Thermocouple

input

−

16

+

−

Analog output

4 to 20mA DC

or 0 to 1V DC

Contact input

DI1

17

AO

or

DI2 DI3

18 19

−

FAULT BLOW

Fault

contact

output

ALARM

DICOM

20

Alarm

contact

output

21 22

Blow

contact

output

Maintenance

contact

output

MAINTE

23 24

ZV

GAS

Calibrating

gas contact

output

ZERO

Calibrating gas

contact output

COM

12 3

TM-2

Flowmeter

Val ve

MEASURE

Reduction valve

(ZBD6)

ZERO

Standard gas

for zero point (ZBM)

*1

Span gas (ZBM)

Flowmeter

SPAN

Reduction valve

(ZBD6)

*1 Air supply

Reduction valve

(0.2 to 0.5L/min)

(not supplied)

(unnecessary when

supply air pressure

is 50 to 100kPa)

TM-1

HEATER

Heater

AC power

SPAN

supply

GAS

AC

NSV

26 27

25 28

*1 Standard gas or instrumentation air

Note:

can be used in place of span gas.

*2 Instrument quality air or bottled air is

available as reference air instead of

ambient air.

*3 Protective earth.

*4 Connect the shield of a exclusive cable

with the ground terminal in the converter.

L

AC power

supply

PE

*3

7

Page 8

ZFK8, ZKM, ZTA

Ejector system

Gas temperature.

1500ºC max.

Detector (ZFK8)

6

Bule

Ejector (ZTA)

123

Black

Ye l l o w

Red

Flowmeter

Ejector (5 to 10L/min)

Power supply

1

2

Heater temperature drop

4

5

Alarm

Copper pipe

φ10/φ8mm

(not supplied)

45

White

White

(ZBD)

Copper pipe φ6/φ4mm

(not supplied)

Solenoid valve

(not supplied)

AC power

supply

Rainproof flexible

conduit.

(Max. 20m)

Reduction valve

(unnecessary when supply air pressure

is 200 to 300kPa )

Joint

Copper pipe φ10/φ6mm

(not supplied)

Supply air

115234567891011121314

+

−

O2

O2 input

*4

Thermocouple

for combustion

φ6mm or φ1/4 inch tube

for calibration gas

(not supplied)

control

+

TC2

12 3

RS232C

or

RS485

(option)

TM-2

(1 to 1.5L/min)

Flowmeter

(ZBD4)

*2 Ref. air

to Detector

(0.2 to 0.5L/min)

(not supplied)

*1 Standard gas or instrumentation air can be used in place of span gas.

Note:

*2 Instrument quality air or bottled air is available as reference air instead

of ambient air.

*3 Protective earth.

*4 Connect the shield of a exclusive cable with the ground terminal in

the converter.

+

−

TC1

Thermocouple

input

−

DI1

16

17

Joint

AO

+

or

Analog output

4 to 20mA DC

or 0 to 1V DC

Contact input

DI2 DI3

18 19

Solenoid valve

(not supplied)

Solenoid valve

(not supplied)

−

FAULT BLOW

Fault

contact

output

ALARM

DICOM

20

Blow

contact

output

Alarm

Maintenance

contact

output

MAINTE

21 22

Reduction

valve (ZBD6)

ZV

ZERO

GAS

Calibrating

gas contact

output

contact

output

23 24

Standard gas

for zero point (ZBM)

Reduction valve (unnecessary when

supply air pressure is 50 to 100kPa)

HEATER

Calibrating gas

contact output

COM

25 28

SPAN

GAS

26 27

AC power

supply

NSV

*1 Air supply

Reduction

valve (ZBD6)

Span gas

*1 Standard gas for

span point (ZBM)

AC

TM-1

L

AC power

supply

*3

PE

8

Page 9

DEVICE CONFIGURATION

The device to be combined differ according to the conditions of the gas to be measured. Select the devices to be combined

with reference to the following table.

Measured gas Device confi guration

Application Temperature Gas Flow DUST Protection

cover

General-use

(boiler)

For corrosive

gas (refuse

600ºC or

less

600ºC or

less

5 to 20m/s Less than 0.2g/Nm

Less than 10g/Nm

5 to 20m/s Less than 1g/Nm

Less than 10g/Nm

incinerator)

Less than 25g/Nm

Less than 25g/Nm

General-use

(boiler)

Note (1) Dust volume is approximate value.

(2) Instrument quality air or bottled air is available as reference air by selecting detector with reference air inlet.

800ºC or

less

1500ºC or

less

Less than

1m/s

Less than

1m/s

Less than 1g/Nm

Less than 1g/Nm

3

—

3

—

3

—

3

—

3

no

3

yes

3

—

3

— SIC tube

Note Detector type Converter

type

Fuel; gas, oil

Fuel: coal

ZFK8R

ZFK8R

5

5- A -1

5

5- C -1

ZKM —

ZKM —

with blow down

Included low moisture

Included low moisture

ZFK8R

ZFK8R

5

5- B -2

5

5- C -2

ZKM —

ZKM —

with blow down

Included low moisture

ZFK8R

6

5- D -2

ZKM —

with blow down

Included high moisture

ZFK8R

6

5- E -2

ZKM —

with blow down

SUS316 tube

ZFK8R

5-0Y0 -1

ZKM ZTA2

with blow down

ZFK8R 5-0Y0 -1

ZKM ZTA1

with blow down

Ejector

type

9

Page 10

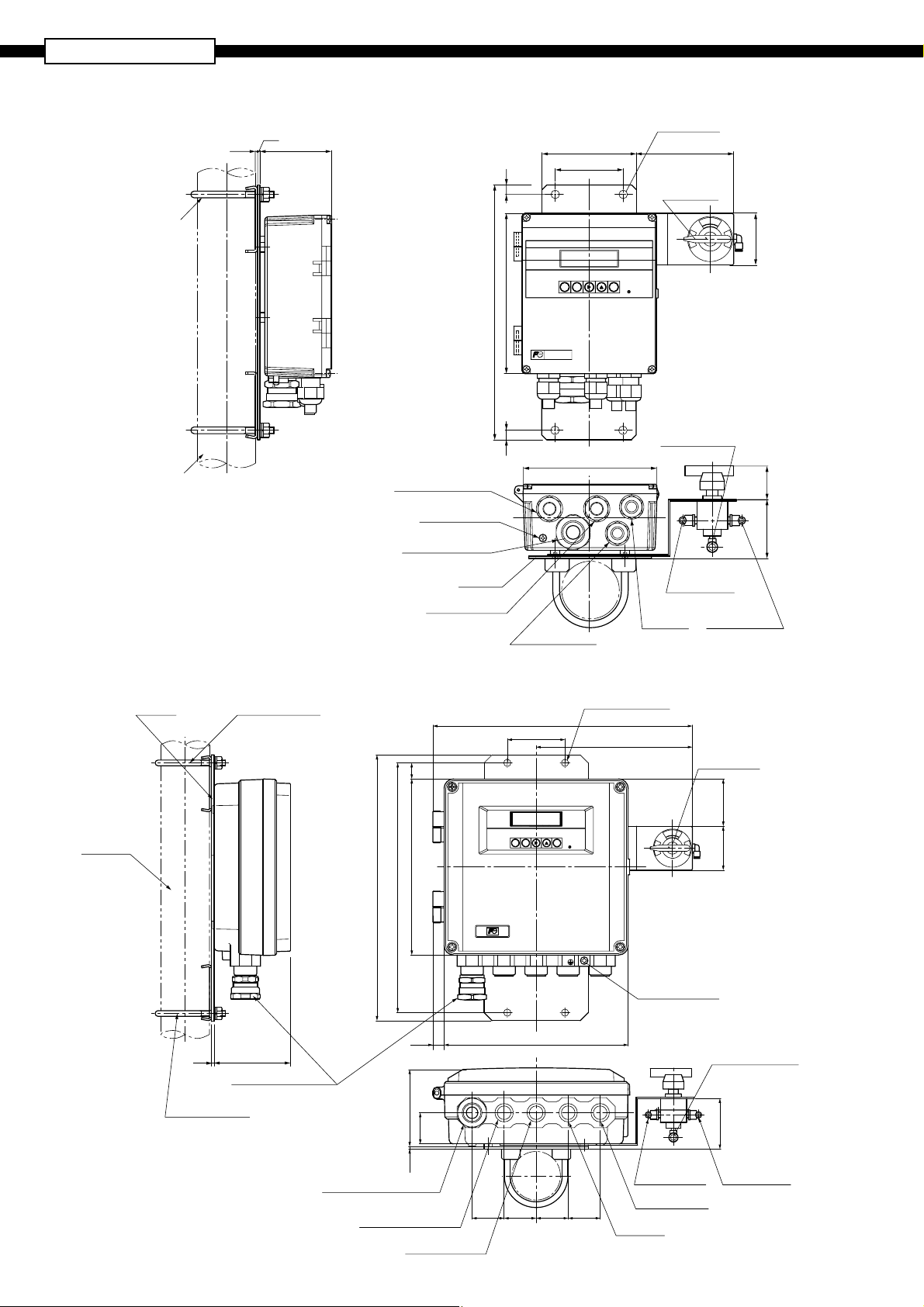

ZFK8, ZKM, ZTA

OUTLINE DIAGRAM

φ

80

φ

67

6-φ6

60°

φ

80

φ

67

6-φ6

(Unit:mm)

26

φ

Ref. Air inlet (to order)

SUS316,for

or 1/4 inch tube

φ6/φ

4 tube

Approx.62

Filter

Approx.62

Detector (ZFK8)

Temp.Proof cover

5

(To order)

Approx.30

Calibration gas inlet

(To order)

SUS316,for

or 1/4 inch tube

φ6/φ

4 tube

5

Temp.proof cover

(to order)

Approx.132

Approx.130

Approx.132

Approx.130

Terminal box

Ground-wire

Screw: M4

Exclusive

Cable gland

Terminal box

EXTERNAL CONNECTION DIAGRAM

79

φ

Heater Thermocouple

85

φ

125.5

1

Black / White/ red / White/ yellow / blue

2-core wire 4-core wire

3

2

Exclusive-special cable

45 6

Element output

60°

26

φ

ZFK8R 3

Ball valve

Ref. air inlet (to order)

SUS316,for

or 1/4 inch tube

φ6/φ

4 tube

Calibration gas inlet

Rc1/4 INT.THD.

Filter

Approx.100

Valve handle

79

φ

125.5

Ground-wire

screw: M4

Exclusive cable gland

85

φ

10

Page 11

Sensor unit (ZFK8YY)

(132.7)

(88.4) 3.5

(?17.5)

20

4-φ3.5(Mount for detector)

TK4J4664R0

45°

45°

T+

φ

35

40

S+

6

madeinjapan

5

S-

H

1

3

4

2

H

T-

Flow guide tube

12

Approx. L

Approx. 20

Gas inlet

34

20

155

130

67

Z F K 8 R 5 - 5 A 3

5

7

1

Oxygen detector

Oxygen detector

Gas outlet

6-M5

detector side

8–15

MTG. holes

Code 11th

L (m)

MASS

Approx.(kg)

3

0.3

2.7

57

0.5

0.75

4.1

3.3

1

1.0

4.8

Z

L=

(to order)

Flow guide tube (with blow-down nozzle)

18

Approx. L

Approx. 20

3

60.5

67

Gas inlet

6-M5

detector side

Gas outlet

Blow down air inlet

155

130

67

4-Rc1/4

with plug int.thd.

8–15

MTG. holes

Z F K 8 R 5 - 5 C 3

3

0.3

3.0

57

0.5 0.75 1.0

3.8

Code 11th

L (m)

Mass

Approx.(kg)

4.8

1

5.7

5

7

1

L=

(to order)

Z

11

Page 12

ZFK8, ZKM, ZTA

Flow guide tube (for high particulate)

4 - Rc 1/4

with plug int thd.

Flange: JIS 5K80A FF

ZFK MTG. position

Packing

Gas flow

180

145

Gas outlet

Tube (50A SCH40)

29.5

800

67

8 - 19

MTG. hole

185

Blow down air inlet

Select an upper port to

avoid the condensation

in the piping

Z F K 8 R 5 - 6 D

50

30

Code 11th

Mass

Approx.(kg)

L (m)

3

0.3

4.5

3

5

7

1

57

0.5 0.75 1.0

5.6

7.0

1

8.3

Z

L=

(to order)

4 - Rc 1/4

with plug int thd.

Flange: JIS 5K80A FF

ZFK MTG. position

Packing

Gas flow

Flow guide tube (for high particulate with cover)

180

145

Blow down air inlet

Select an upper port to

avoid the condensation

in the piping

(175)

50

30

Gas outlet

(790)

67

29.5

800

8 - 19

MTG. holes

Z F K 8 R 5 - 6 E

3

Code 11th

L (m)

Mass

Approx.(kg)

0.3

7.1

57

0.5 0.75 1.0

9.0

11.4

3

5

7

1

1

Z

L=

(to order)

13.6

Protection tube (65A SCH40)

12

(38)

Tube (50A SCH40)

Page 13

Flow guide tube (

12

Approx. L

3

Gas inlet

67

60.5

Approx. 40

for corrosive gas)

155

130

67

Oxygen detector

Viewed from P direction

105

140

(JIS 10K65ARF)

8

Gas inlet

25

Ejector air

outlet

(Rc1/4)

Gas outlet

6-M5

detector side

Ejector (ZTA)

Approx. L

42.7

L [mm]

500 750 1000 1500

30

EXTERNAL CONNECTION DAIAGRAM

1 2 3 4 5

AC

power supply

AC100/110V

AC200/220V

AC230V

Heater temp.drop alarm

4-M16 bolt

P

Z F K 8 R 5 - 5 B 3

3

Code 11th

L (m)

MASS

Approx.(kg)

8- 15

MTG. holes

190

217

40

35

Blow -down air inlet

(Rc1/4)

Ejector air inlet

(Rc1/4)

40

0.5

0.3

3.3

170

50

45

Cable gland

(A15C)

57

4.5

0.75

6.1

5

7

1

1

1.0

7.6

Detector

(ZFK8)

Z

L=

(to order)

13

Page 14

ZFK8, ZKM, ZTA

Converter (ZKM1)

<IP66>

U bolts M8

(option)

Mounting for

2B pipe

2.5

2.5

75

100

Mounting hole

ø9

2-

100

72

1010

Valve (option)

A

E

S

M

N

170

O

OxygenAnalyzer

MODE

ENTER

ESC

POWER

Z

55

S

270

ZKM

OxygenAnalyzer

Calibration gas outlet

(for F6 tube)

153

For contact Input/output

35

Earth terminal (M4)

For sensor (coupling)

F23.5/F15.8 tube

For

Mtg. Plate

For communication

For output

Zero gas inlet

(for F6 tube)

Span gas inlet

(for F6 tube)

62.5

For power supply

Converter (ZKM2)

<IP67>

Bracket

Mounting for

2B pipe

U bolts M8 (option)

5.7

U bolts M8 (option)

95

For sensor (coupling)

For φ23.5/φ15.8 tube

498

312

953.2

20

220

Mounting hole 4-

φ9

324

72

195

Valve (option)

59

A

E

S

.

MODE ESC

ENTER

POWER

M

N

O

Z

55

S

Earth terminal (M4)

14

39

230

Calibration gas outlet

(for φ6 tube)

65

14

For sensor (coupling)

For φ23.5/φ15.8 tube

For contact Input/output

(G1/2)

For communication

(G1/2)

40 40 40 40

Zero gas inlet

(for φ6 tube)

For power supply

(G1/2)

For output

(G1/2)

Span gas inlet

(for φ6 tube)

Page 15

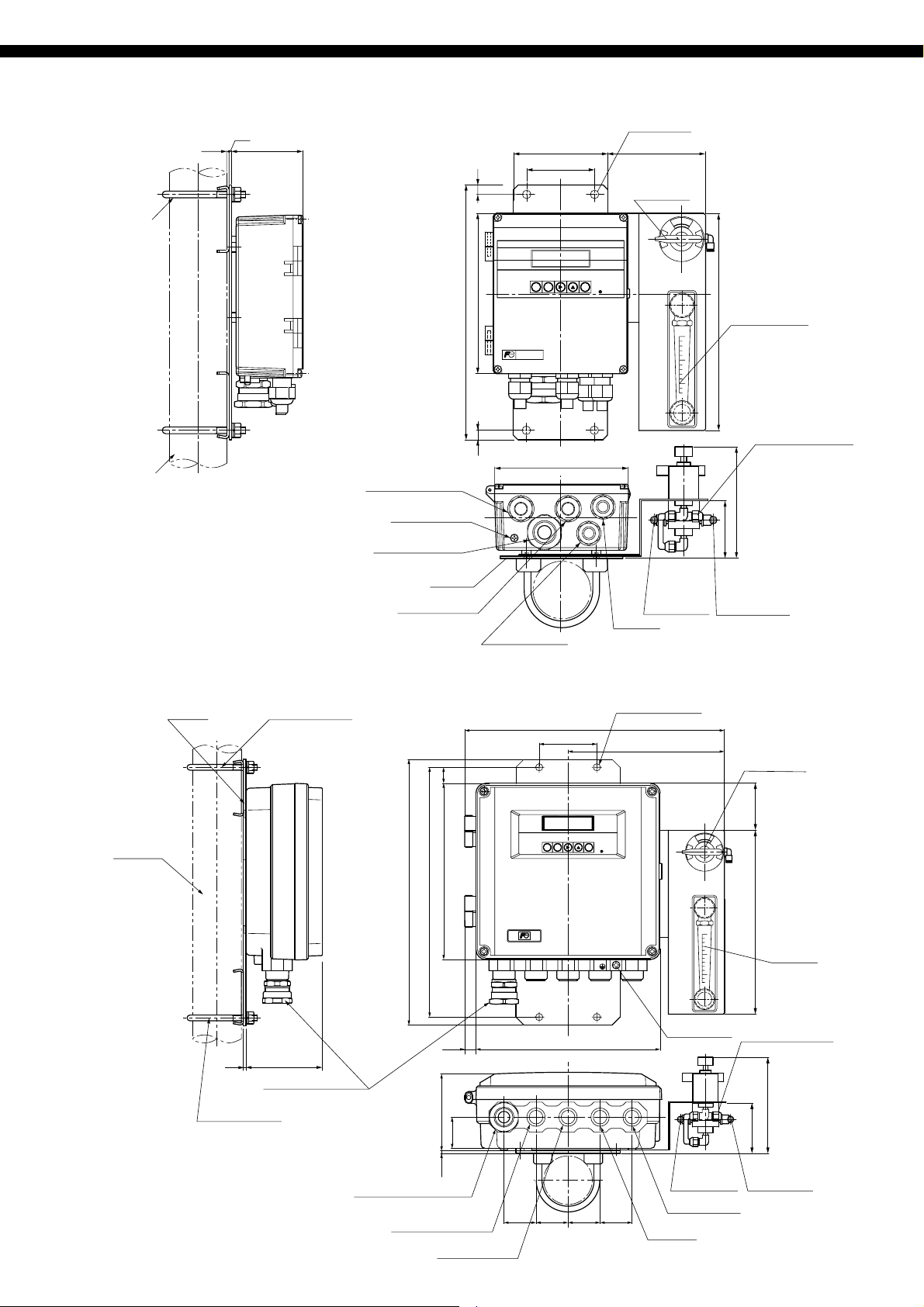

Converter (ZKM1)

<IP66>

2.5

U bolts M8

(option)

2.5

75

100

Mounting hole

ø9

2-

100

72

1010

Valve (option)

A

E

S

M

N

O

OxygenAnalyzer

Z

S

Mounting for

2B pipe

Converter (ZKM2)

<IP67>

Bracket

U bolts M8 (option)

For contact Input/output

Earth terminal (M4)

For sensor (coupling)

F23.5/F15.8 tube

For

Mtg. Plate

For communication

20

170

270

MODE

ESC

ZKM

OxygenAnalyzer

153

For power supply

ENTER

POWER

Flowmeter (option)

230

Calibration gas outlet

(for F6 tube)

(125)

62.5

Zero gas inlet

(for F6 tube)

Span gas inlet

(for F6 tube)

For output

Mounting hole 4-

φ9

324

72

195

Valve (option)

Mounting for

2B pipe

5.7

For sensor (coupling)

For φ23.5/φ15.8 tube

U bolts M8 (option)

59

A

E

S

M

MODE ESC

ENTER

POWER

N

O

Z

S

220

498

312

230

Flowmeter

(option)

Earth terminal

14

230

(M4)

Calibration gas outlet

(for φ6 tube)

95

180

65

Span gas inlet

(for φ6 tube)

For sensor (coupling)

For φ23.5/φ15.8 tube

For contact Input/output

(G1/2)

953.2

39

For communication

40 40 40 40

Zero gas inlet

(for φ6 tube)

For power supply

(G1/2)

For output

(G1/2)

(G1/2)

15

Page 16

ZFK8, ZKM, ZTA

Converter (ZKM3)

<Bench type>

70.6

MadeinJapan

POWERAC

SER.NO.

TYPE

OUTPUTDC

MFD

OXYGENTRANSM

FujiElectricsystemsCo.,Ltd.

50/60Hz60VA

ITTER

10

172

4-F4.5 Mounting hole

163.5

143.5

OxygenAnalyzer

FAULT

ALARM

BLOW

MAIN-

TENANCE

ENTER

POWER

FUSET0.5A

HEATER

FUSET2.5A

POWER

ZV HEATER

COMSV

POWER

MODE ESC

注 意

変換器へ供給する電源電圧は、接続される

検出器の電源電圧に合わせてください。

CAUTION

Powersupplymustbeselected

thesamevoltageofdetector.

TC1+−AO

2

O

+ −

+−

1152 3 4 5 6 7 8 9 10 11 12 13 14

16 17 18 19 20 21 22 23 24 25 2826 27

DI1 DI2 DI3

DICOM

TC2

+−

182

ON

OFF

AC

N

L

*2

Exclusive

cable

Ground

terminal

M4

O

sensor

O2 sensor

input

2

thermocouple

input

1152 3 4 5 6 7 8 9 1011121314

+

O

++

−

TC2

TC1

−

2

+

DI1

16

Thermocouple

input type R

(not supplied)

Contact input

Short circuit : on (Current 5mA)

Open : off (Voltage 5V)

EXTERNAL TERMINAL (TM1) / Terminal M3

Analog

output

4-20mA DC

or 0-1V DC

−−

AO

or

Fault

contact output

250V AC/3A

30V DC/3A

FAULT

ALARM MAINTE

DICOM

20

17

DI2 DI3

18 19

Blow contact

250V AC/3A

30V DC/3A

BLOW

21 22

Alarm

contact output

250V AC/3A

30V DC/3A

output

ZV

23 24

Maintenance

contact output

250V AC/3A

30V DC/3A

*1

O

sensor

2

heater power

output

ZERO

GAS

HEATER

SPAN

GAS

26 27

25 28

Calibrating gas

contact output

250V AC/3A

30V DC/3A

AC

NSVCOM

AC

Power supply

input

100 to120V AC

200 to 240V AC

COMMUNICATION TERMINAL (TM2) /INSERTION TERMINAL

Note 1) The heater power supply is the same

Note 2) Be sure to connect the shield of the

RS232C

RS485

Terminal number

1

2

TXD

RXD

TRX+

TRX–

3

GND

GND

Remarks

Standard

Option

L

as the converter power supply.

cable to the ground in the main body.

Caution on Safety

*Before using this product, be sure to read its instruction manual in advance.

International Sales Div.1

Sales Group

Gate City Ohsaki, East Tower, 11-2, Osaki 1-chome,

Shinagawa-ku, Tokyo 141-0032, Japan

http://www.fesys.co.jp/eng

Phone: 81-3-5435-7280, 7281 Fax: 81-3-5435-7425

http://www.fic-net.jp/eng

Information in this catalog is subject to change without notice.

Printed in Japan

Loading...

Loading...