Page 1

Instruction Manual

Remote Keypad "TP-E1"

Thank you for purchasing our Remote Keypad TP-E1.

• This product is designed to remotely control the FRENIC-Mini series of inverters. Read

through this instruction manual and be familiar with the handling procedure for correct use.

• Improper handling blocks correct operation or causes a short life or failure.

• Deliver this manual to the end user of the product. Keep this manual in a safe place until the

Remote Keypad is discarded.

• For the usage of inverters and optional equi pment, refer to the instruction manuals prepared

for the FRENIC-Mini series of inverters and its optional equipment.

Fuji Electric FA Components & Systems Co., Ltd. INR-SI47-0843a-E

Page 2

Copyright © 2003 Fuji Electric FA Components & Systems Co., Ltd.

All rights reserved.

No part of this publication may be reproduced or copied without prior written permissi on from Fuji

Electric FA Components & Systems Co., Ltd.

All products and com pany names mentioned in this manual are trademarks or registered trademarks

of their respective holders.

The information contained herein is subject to change without prior notice for improvement.

Page 3

Preface

Thank you for purchasing our Remote Keypad "TP-E1."

The Remote Keypad allows you to remotely operate FRENIC-Mini series of inverters. Using this

remote keypad, you can perform the operations that are available on the built-in keypad on

FRENIC-Mini inverter, such as running and stopping the motor, monitoring the running status, and

setting the function codes.

In addition, you can perform "data copying": You can read function code data from an inverter, copy

(write) it into another inverter, or verify it.

To use the Remote Keypad, make sure that the FRENIC-Mini inverter is equipped with the RS485

Communications Card (OPC-C1-RS), and connect the two using an optional Remote Operation

Extension Cable (CB-5S, CB-3S, or CB-1S, depending on the distance).

This manual describes how to install the Remote Keypad and the "data copying." For other

operations that are common to the built-in keypad, refer to the FRENIC-Mini Instruction Manual

(INR-SI47-0791-E), Chapter 3.

Before installing and using the Remote Keypad, read through this manual in conjunction with the

FRENIC-Mini User's Manual and make yourself familiar with its proper use. Improper use may

prevent normal operation or cause a failure or reduced life of the inverter.

Related Publications

Listed below are other publications on the FRENIC-Mini to be consulted in conjunction with this

manual as necessary.

• FRENIC-Mini User’s Manual (MEH446)

• RS485 Communications User’s Manual (MEH448)

• Catalog (MEH441/MEH451)

• Application Guide (MEH449)

• FRENIC-Mini Instruction Manual (INR-SI47-0791-E)

• RS485 Communications Card Installation Manual (INR-SI47-0773)

• Rail Mounting Base Installation Manual (INR-SI47-0774)

• Mounting Adapter Installation Manual (INR-SI47-0775)

• Built-in Braking Resistor Installation Manual (INR-SI47-0838)

Note that these publications are subject to change without notice. Make sure that you have the most

up-to-date versions at all times.

Safety precautions

Before proceeding with installation, connecting, cabling, wiring, operation, inspection or

maintenance, read this manual thoroughly. Make sure also that you have sound knowledge of the

product, and familiarize yourself with all safety information and precautions.

Safety precautions are classified into the following two categories in this manual.

Failure to heed the information indicated by this symbol may

lead to dangerous conditions, possibly resulting in death or

serious bodily injuries.

Failure to heed the information indicated by this symbol may

lead to dangerous conditions, possibly resulting in minor or

light bodily injuries and/or substantial property damage.

Failure to heed the information contained under the CAUTION title can also result in serious

consequences. These safety precautions are of utmost importance and must be observed at all

times.

i

Page 4

Operation

• Be sure to install the terminal block cover before turning the power on. Do not remove the

cover during power application.

Otherwise electric shock could occur.

• Do not operate switches with wet hands.

Doing so could cause electric shock.

• If the retry function has been enabled, the inverter may automatically restart after tripping,

depending on its cause, causing the motor driven by it to start rotating. In designing a

system or a facility using the motor driven by the FRENIC-Mini, make sure that such

automatic restart would not cause any personal injury, damage to equipment, or other

unintended incidents.

• If the stall prevention function has been selected, the inverter may operate at an

acceleration/deceleration time or frequenc y different from the set ones. Design the

machine so that safety is ensured even in such cases.

Otherwise an accident could occur.

• The

• If an alarm reset is made with the operation signal turned on, a sudden start will occur.

Otherwise an accident could occur.

• If you have selected "Active" as the mode of Restart after momentary power failure (F14 =

• If you set the function codes wrongly or without completely understanding the instruction

An accident or injuries could occur.

• Do not touch the inverter terminals while the power is applied to the inverter even if the

Doing so could cause electric shock.

key is only effective when function setting (Function code F02) has been

established to enable the

disable the STOP key priority function and enable command (FWD) or (REV), you cannot

stop the inverter output by the

Check that the operation signal is turned off in advance.

4 or 5), the inverter will automatically restart, causing the motor driven by it to start

rotating. In designing a system or a facility using the motor driven by the FRENIC-Mini,

make sure that safety is secured even in such instances.

manuals and the FRENIC-Mini User's Manual, the motor may rotate with a torque or at a

speed not permitted for the machine.

inverter stops.

key. Prepare an emergency stop switch separately. If you

key on the built-in keypad.

ii

Page 5

Installation and cabling/wiring of option cards

• Do not operate the switch SW1 with wet hands.

Doing so could cause electric shock.

• Before starting installing the RS485 Communications Card, first turn off the power, wait

more than 5 minutes, and make sure, using a circuit tester or another appropriate

instrument, that the DC voltage between the P (+) and N (-) terminals of the main circuit is

less than +25 VDC.

Otherwise electric shock could occur.

• A high voltage is present just on the RS485 Communications Card. Do not remove the

cover for the control circuit terminal block (TB) while power is applied.

Doing so could cause electric shock.

• Generally, the sheath of control circuit wires is not reinforced by any insulation. If the

control circuit wires come into direct contact with the live main circuit terminal, therefore,

the sheath may break. Accordingly, there is a possibility that high voltage on the main

circuit may be applied to the control circuit wires. It is DANGEROUS. Be sure to keep the

control wires away from the live main circuit terminals.

An accident or electric shock could occur.

Disposal

• Handle this Remote Keypad or the RS 485 Communications Card as an industrial waste

when disposing of it.

Otherwise injuries could occur.

Others

• Never attempt to modify the inverter.

Doing so could cause electric shock or injuries.

GENERAL PRECAUTIONS

Drawings in this manual may be illustrated without covers or safety shields for explanation of

detail parts. Restore the covers and shields in the original state and observe the description in

the manual before starting operation.

iii

Page 6

How this manual is organized

This manual is made up of chapters 1 through 4.

Chapter 1. BEFORE USING THE REMOTE KEYPAD "TP-E1"

This chapter describes the points to check upon delivery and lists the inverters the Remote Keypad

is designed to interface with.

Chapter 2. INSTALLATION, CABLING, AND WIRING

This chapter describes how to install the Remote Keypad and the RS485 Communications Card and

how to connect them with each other.

Chapter 3. OPERATION USING THE REMOTE KEYPAD "TP-E1"

This chapter describes the functions of the Remote Keypad including data copying, as well as how to

operate the Remote Keypad.

Chapter 4. SPECIFICATIONS

This chapter lists the general specifications such as operating environments, communication

specifications and transmission specifications.

Icons

This manual uses the following icons:

Indicates information that should be observed to make full use of the features and functions

provided by this product and the neglect of which may result in an accident.

Refers you to related or more detailed information.

iv

Page 7

CONTENTS

Preface ................................................................i

Safety precautions..................................................i

How this manual is organized ..................................iv

Chapter 1 BEFORE USING THE

Chapter 2 INSTALLATION, CABLING,

Chapter 3 OPERATION USING THE

Chapter 4 SPECIFICATIONS .............................. 4-1

REMOTE KEYPAD "TP-E1" ............... 1-1

1.1 Check Points.............................................. 1-1

1.2 Inverters with which the Remote

Keypad Interfaces...................................... 1-1

AND WIRING ..................................... 2-1

2.1 Accessories and Parts Required

for Connection............................................ 2-1

2.2 Installing the Remote Keypad .................... 2-2

REMOTE KEYPAD "TP-E1" ............... 3-1

3.1 Familiarizing Yourself with the Remote

Keypad....................................................... 3-1

3.2 Operating the Remote Keypad................... 3-2

3.3 Data Copying ............................................. 3-3

4.1 General Specifications ............................... 4-1

4.2 Communication Specifications................... 4-2

4.3 Transmission Specifications....................... 4-2

v

Page 8

Chapter 1 BEFORE USING THE REMOTE KEYPAD "TP-E1"

1.1 Check Points

Unpack the package and check the following:

(1) The package contains the Remote Keypad and its instruction

manual (this book).

(2) There have been no problems during transportation. In

particular, no parts are damaged or have fallen out of place

nor are there any dents on the body.

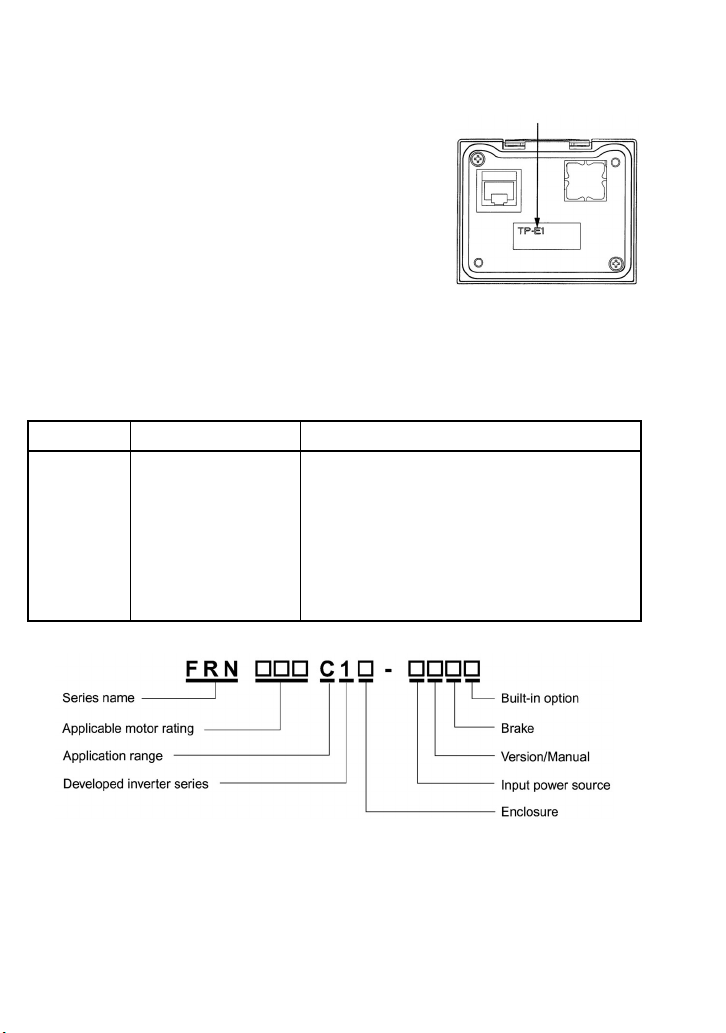

(3) The model name "TP-E1" is inscribed on the back of the

Remote Keypad as shown in Figure 1.1.

If you find any anomalies, contact your dealer or nearest Fuji

Figure 1.1 Back of Remote

Electric sales office.

1.2 Inverters with which the Remote Keypad Interfaces

The Remote Keypad TP-E1 interfaces with the following Fuji inverters:

Series Type of inverter* Remarks

FRENIC-Mini FRN

FRN

(Each

as shown below,

represented by an

alphanumeric character.)

C1S-

C1E-

has its meaning

The Remote Keypad is fully supported by inverters with

a ROM version of C1S10500 or above. (You can check

the inverter’s ROM version by entering

"Maintenance Information" (Menu #5) in Program

Mode.)

There are restrictions on the support for the Remote

Keypad TP-E1 by inverters with a ROM version of

C1S10499 or below. For details, contact your Fuji

Electric sales office.

Model name

Keypad TP-E1

5_14 in

* Type of inverter

For the details of the Inverter type ID, refer to the FRENIC-Mini Instruction Manual

(INR-SI47-0791-E), Chapter 1, Section 1.1 "Acceptance Inspection."

1-1

Page 9

Chapter 2 INSTALLATION, CABLING, AND WIRING

To connect the Remote Keypad to the FRENIC-Mini inverter, first install the RS485 Communications

Card (OPC-C1-RS) on the inverter, and then use an optional Remote Operation Extension Cable

(CB-5S, CB-3S, or CB-1S, depending on the distance) or an off-the-shelf LAN cable to interconnect

them.

2.1 Accessories and Parts Required for Connection

To connect your Remote Keypad TP-E1 to an inverter, you need the following devices and parts:

Accessories/Parts Type or Specifications Remarks

Remote Operation Extension Cable

(Note 1)

RS485 Communications Card OPC-C1-RS Install this into the inverter.

Screws (for mounting the Remote

Keypad)

(Note 2)

Note 1: Alternatively, you can use an off-the-shelf 10BASE-T/100BASE-TX LAN cable (straight type) that meets the

ANSI/TIA/EIA-568A Category 5 standard (maximum length: 20 m).

Recommended LAN Cable (for 1 m):

Manufacturer: Sanwa Supply, Co. Ltd.

Model: KB-10T5-01K

KB-STP-01K (shielded cable, EMC-compliant)

Note 2: Use the screws whose lengths are proper to thickness of the mounting enclosure.

CB-5S, CB-3S, or CB-1S You have a choice of three lengths:

M3 x 12 Get 2 screws beforehand.

5 m, 3 m, and 1 m.

2-1

Page 10

2.2 Installing the Remote Keypad

To mount the Remote Keypad on an enclosure, follow the steps below.

Installation Procedures

Follow the steps below after completing the cabling work for the inverter. First, power off the inverter.

To install the Remote Keypad on an enclosure (see Figure 2.1):

c Cut two square holes on the enclosure as shown in Figure 2.3.

d Mount the Remote Keypad onto the enclosure.

e Install the RS485 Communications Card on the inverter.

f Insert the connector on one end of the Remote Operation Extension Cable or LAN cable into the

RJ-45 modular jack on the Remote Keypad.

g Insert the connector on the other end of the cable into the RJ-45 modular jack on the RS485

Communications Card mounted on the FRENIC-Mini.

To use the Remote Keypad in hand (see Figure 2.2):

Follow steps

e to g above.

Figure 2.1 To Install the Remote Keypad on an

Enclosure

2-2

Figure 2.2 To Use the Remote

Keypad in Hand

Page 11

To install the Remote Keypad on an Enclosure

c Cut a single square hole and two screw holes in the enclosure as shown in Figure 2.3.

Figure 2.3 Dimensions of Square Hole and Screw Holes

d Mount the Remote Keypad TP-E1 onto

the enclosure with 2 screws as shown in

Figures 2.3 and 2.4.

(Recommended tightening torque:

0.7 N•m)

RJ-45 Modular jack

Enclosure

Figure 2.4 Mounting Remote Keypad TP-E1

2-3

M3 x 12

(to be prepared

by customer)

Page 12

e Installing the RS485 Communications Card

• Do not operate the switch SW1 with wet hands.

Doing so could cause electric shock.

• Before starting installing the RS485 Communications Card, first turn off the power, wait

more than 5 minutes, and make sure, using a circuit tester or another appropriate

instrument, that the DC voltage between the P (+) and N (-) terminals of the main circuit is

less than +25 VDC.

Otherwise electric shock could occur.

• A high voltage is present just on the RS485 Communications Card. Do not remove the

cover for the control circuit terminal block (TB) while power is applied.

Doing so could cause electric shock.

• Generally, the sheath of control circuit wires is not reinforced by any insulation. If the

control circuit wires come into direct contact with the live main circuit terminal, therefore,

the sheath may break. Accordingly, there is a possibility that high voltage on the main

circuit may be applied to the control circuit wires. It is DANGEROUS. Be sure to keep the

control wires away from the live main circuit terminals.

An accident or electric shock could occur.

Be sure to turn SW1 (termination resistor on/off

switch) on the RS485 Communications Card to the

OFF position as shown at right. (Upon shipment from

the factory, SW1 is set to OFF.)

Model name

SW1

Install the RS485 Communications

Card following the steps below.

1) If the control circuit terminal

block (TB) cover is in place,

remove it by inserting your

finger in the cutout (near

"PULL") in the bottom of it

and then pulling it towards

you.

Figure 2.5 Setting of SW1 on RS485

Figure 2.6 Removing the Control Circuit Terminal Block Cover

2-4

Communications Card

Page 13

2) Align the RS485 Communications Card with the latch and mount it onto the FRENIC-Mini

so that the connector CN1 on the Card is properly inserted.

Figure 2.7 Installing the RS485 Communications Card

3) Before putting the control circuit TB cover, snip off the barrier of the RS485

Communications Cable outlet with nippers (Figure 2.6).

4) Fit the latches provided on the upper end of the control circuit TB cover into the openings in

the front face of the FRENIC-Mini, and then close the TB cover. Take care not to pinch

control signal wires/cables between the TB cover and the body of the FRENIC-Mini.

f Insert the connector on one end of the Remote Operation Extension Cabl e or LAN cable into the

RJ-45 modular jack on the Remote Keypad TP-E1 (see Figure 2.8).

g Insert the connector on the other end of the cable into the RJ-45 modular jack on the RS485

Communications Card mounted on the FRENIC-Mini.

Figure 2.8 Connecting Remote Keypad to the RS485 Communications Card with Remote Operati on

Extension Cable or LAN Cable

To use the Remote Keypad in hand

Follow steps e to g above.

2-5

Page 14

To comply with EMC Directives

Use an EMC filter built-in inverter.

All the connecting cabl es and wires must be

shielded. As shown in Figure 2.9, remove outer

sheath of the cable to bare the shield layer for

clamping. Ground the shield onto the EMC flange

for EMC compliance using clamps provided.

Length L differs according to the

inverter type. Keep it as short as

possible.

Remove the sheath here.

Figure 2.9 Shielded Wire Connection to Comply

with EMC Directives

Figure 2.10 Grounding Shields to Comply with EMC Directives

For EMC directives, refer to the FRENIC-Mini Instruction Manual (INR-S I47-0791-E),

Chapter 11 "COMPLIANCE WITH STANDARDS."

2-6

Page 15

Chapter 3 OPERATION USING THE REMOTE KEYPAD "TP-E1"

3.1 Familiarizing Yourself with the Remote Keypad

The Remote Keypad is composed of a 4-digit,

7-segment LED monitor, an LED display

section consisting of 5 LEDs, and 6 keys as

shown in Figure 3.1.

7-segment LED monitor

LED display

PROGRAM

/RESET key

FUNCTION

/DATA key

UP key

Figure 3.1 Overview of Remote Keypad

Table 3.1 Names and Functions of Various Parts of Remote Keypad

Group Name Function Remarks

Data display

Keys

LED display

For the operation mode of the FRENIC-Mini and its operating procedures, refer to the

7-segment

LED monitor

key

key

key

key

key Starts the motor.

key Stops the motor.

RUN LED

KEYPAD

CONTROL LED

3 unit LEDs

Displays the running status, data settings,

alarm status, etc., depending on the

operation mode.

Switches the operation mode*.

Depending on the operation mode,

switches the information displayed, fixes

the function code data, or switches the

alarm information displayed.

These keys are used to selects the setting

items displayed on the LED monitor and

change the function code data.

Lights when a Run command is given to

the Inverter.

Lights when the inverter is operating

under the Run command activated by

the

key.

kW, A, Hz, r/min, m/min:

These 3 LEDs together as a group

indicate the unit of the quantity being

monitored.

PRG. MODE:

Two LEDs (right and left) light in

Programming mode.

DOWN key

*Operation mode:

RUN key

STOP key

• Running mode

• Programming

mode

• Alarm mode

See Table 3.2.

FRENIC-Mini Instruction Manual (INR-SI47-0791-E), Chapter 3 "OPERATION USING THE

KEYPAD."

3-1

Page 16

Table 3.2 lists the combinations of the three LEDs on the LED display, which indicate what is

displayed on the 7-segment LED monitor.

Table 3.2 Definition of LEDs on the LED Display

Indication on LED Unit Description

Hz A kW Hz Frequency

Hz A kW A Output current

Hz A kW kW Input power

Hz A kW r/min Load shaft speed

Hz A kW m/min Line speed

Hz A kW - Programming mode :on,: off

When data other than items above is displayed on the 7-segment LED monitor, all of three LEDs on

the LED display are turned off. For details, refer to the FRENIC-Mini Instruction Manual

(INR-SI47-0791-E), Chapter 3, Section 3.3 "Operation in Running Mode," (3) "Monitor the Running

Status."

3.2 Operating the Remote Keypad

The functions and operations of the Remote Keypad are summarized in Table 3.3.

Table 3.3 Functions and Operations of Remote Keypad TP-E1

Function Operation Remarks

Run/Stop

Set up

Monitor the

Running status

Jogging

the motor

Data setting The function code data is set up and confirmed.

Data checking

Drive

monitoring

I/O checking The status of the interface with the outside world is monitored.

Mainte nance

information

Alarm

information

Data copying Function code data is read out, stored, or verified. Refer to Section 3.3.

Pressing the

(forward/reverse); pressing the

decelerate and stop.

Pressing the

PID process command, and also sets the timer.

Items that can be monitored: speed, output current (A), output

voltage (V), timer (s), input power (kW), PID process

command, and PID feedback amount.

♦ In speed monitoring, one of the following can be selected:

• output frequency (before slip compensation) (Hz),

• output frequency (after slip compensation) (Hz),

• set frequency (Hz) • load shaft speed (r/min),

• line speed (m/min) • constant rate of feeding time (min).

When an alarm condition has occurred, the cause of the trip is

displayed as a code.

The FRENIC-Mini is placed in the state that allows jogging

operation using the

Only the function codes that have been changed from the

factory default are displayed or changed further.

Various types of information for confirming the running status

are monitored.

Certain items are checked or monitored during maintenance.

Certain information such as alarm history is monitored and

used in troubleshooting.

key causes the motor to start rotation

key or key sets the set frequency and

key and the

key causes the motor to

key.

For details, refer to

the FRENIC-Mini

Instruction Manual

(INR-SI47-0791-E),

Chapter 3

"OPERATION

USING THE

KEYPAD."

3-2

Page 17

Conflict between the Remote Keypad and the built-in keypad on the FRENIC-Mini

When a Remote Keypad is connected to the FRENIC-Mini, the built-in keypad on the

FRENIC-Mini is automatically disabled to avoid conflicts between them, with the following

exceptions (for safety considerations).

When keypad operation is enabled (F02 = 0, 2, or 3) and the STOP key priority is selected

(H96 = 1 or 3), the

can be stopped by either

key on the FRENIC-Mini is also enabled so that the FRENIC-Mini

key. The key on the FRENIC-Mini is also enabled to

perform an alarm reset.

In any event, the 7-segment LED monitor on the FRENIC-Mini displays the same

information as that on the Remote Keypad.

3.3 Data Copying

Menu #7 of "Data copying" allows you to read function code data out of FRENIC-Mini inverter (for

which function codes have already been set up), to store the function code data block into another

inverter, or to verify function code data. That is, this function compares the function code data saved

in the Remote Keypad with that stored in the inverter.

The following conditions and restrictions apply to data copying:

Some function code data cannot be copied (stored) into another inverter.

For safety considerations, some function code data cannot be copied to another inverter if the

specifications of the destination inverter are different from those of the source inverter. Which

function code data can or cannot be copied is summarized in the FRENIC-Mini Instruction Manual

(INR-SI47-0791-E), Chapter 5, the "Data copy" column of Section 5.1 "Function Code Tables," using

the following designations:

Y : Can be copied unconditionally.

Y

1 : Cannot be copied if the rated capacity differs from the source inverter.

2 : Cannot be copied if the rated input voltage differs from the source inverter.

Y

N : Cannot be copied in any situation. (The function codes marked with N cannot be verified,

either.

Set up manually function code data that cannot be copied individually as necessary, by using Menu

#1 "Data setting" in Programming mode.

If you cannot copy function code data:

Check whether the "

(1) "

E " is blinking ("Write error"): The following cases can be thought of:

E " or "CPE " indicator is blinking.

• The memory of the Remote Keypad contains no data. (You have not read the memory since

delivery or you have aborted a data read operation.)

• The memory of the Remote Keypad contains some invalid or abnormal data.

• The destination inverter type differs from the source inverter type.

• A write operation has been performed while the inverter is running.

• The inverter is in data protection mode.

• The "Enable editing of function code data from keypad" command (WE-KP) is off.

(2) "

CPE " is blinking: The following cases can be thought of:

• The function codes stored in the Remote Keypad are not compatible with those stored in the

inverter. Non-standard function code data may have been stored, or the inverter may have

been upgraded in an incompatible manner. Consult your Fuji Electric sal es office.

3-3

Page 18

Figure 3.2 shows the transition flow between different states of the inverter during data copying

operation, while Table 3.4 shows details of the data copying functions. The memory of the Remote

Keypad can save function code data for one inverter.

Figure 3.2 Status Transition during Data Copying

3-4

Page 19

Basic key operation

If you cannot access all the menus, set function code E52 to "2" ("Full-menu mode").

(1) On the initial menu, select "Data copying" by pressing the key or

7.CPy " is displayed.

"

(2) Press the

key to switch to the List of data copying functions (for example, "

key several times until

EAd "

read operation).

(3) Select the desired function by using the key and

specified function will be carried out (for example, "

(4) W hen the specified function is successfully completed, "

of data copying functions or the initial menu, press the

key and press the

EAd "

will blink).

E d " is displayed. To return to the List

key once or twice, respectively.

Table 3.4 Data Copying Functions

LED

monitor

display

Function Description

EAd Read data Reads function code data from the inverter and saves it into the memory of

the Remote Keypad.

CoPy Copy data

UE Verify data

Pressing the

aborts the read operation, causing "

Note) and the memory of the Remote Keypad to be cleared.

Writes the data stored in the memory of the Remote Keypad into the inverter.

Pressing the

aborts the write (copy) operation, causing "

(see Note) and function code data in the inverter memory to be incompletely

modified. Do not run the inverter in such a state. Retry the write operation or

initialize the inverter data.

If you cannot perform a write (copy) operation, see " If you cannot copy

function code data": on page 3-3.

Compares the function code data stored in the memory of the Remote

Keypad with that stored in the inverter. If any discrepancy is found, the

verification is terminated, and the function code for which the discrepancy is

found starts blinking on the LED monitor. Pressing the

function code; pressing it for the second time resumes the verification from

the next function code.

Pressing the

aborts the verification, causing "

E " is displayed also when there is no function code data in the memory of

"

the Remote Keypad (see Note).

key during the read operation (while "

key during the write operation (while "

E " to blink on the LED monitor (see

E " to blink on the LED monitor

key during the verification (while "

E " to blink on the LED monitor (see Note).

EAd " is blinking)

CoPy " is blinking)

key skips this

UE " is blinking)

(Note) If "E "or "CPE " appears and blinks, press the key to clear it.

for a

key. The

3-5

Page 20

Notes in data copying

• Do not disconnect the Remote Keypad from the inverter during data copying.

If you do so, the following problems will arise with the Remote Keypad and/or inverter depending

upon the actual operation being in progress. Take the necessary action, following the instructions

below.

If a data read operation ( EAd ) was in progress:

The operation in progress is terminated. The read data stored in the memory of the Remote Keypad

becomes invalid (the original data is lost). Data write and verify operations thereafter will result in a

blinking "

E " display. Mount the Remote Keypad again and retry the read operation.

If a write operation ( CoPy ) was in progress:

The operation in progress is terminated. The function code data in the inverter memory i s incompletely

modified. Do not run the inverter in such a state. Mount the Remote Keypad again and retry the write

operation or initialize the inverter data.

If a verify operation ( UE ) was in progress:

The operation in progress is terminated.

If there is no data or abnormal data stored in the memory of the Remote Keypad, the "

monitor.

E " blinks on the

• If an error occurs in communication between the Remote Keypad and inverter during data copying,

the "- - - -" appears on the monitor and the following problems will arise with the Remote Keypad

and/or inverter depending upon the actual operation being in progress. Take the necessary action,

following the instructions below.

If a data read operation ( EAd ) was in progress:

The operation in progress is terminated and "

terminated, the read data stored in the memory of the Remote Keypad becomes invalid (the original data

is lost). Data write and verify operations thereafter will result in a blinking "

When the communications error is removed, the Remote Keypad automatically enters the Running

mode. So, retry the read operation at this point.

If a write operation ( CoPy ) was in progress:

The operation in progress is terminated and "

the inverter memory is modified incompletely. Do not run the inverter in such a state.

When the communications error is removed, the Remote Keypad automatically enters the Running

mode. So, retry the write operation or initialize the inverter data.

If a verify operation ( UE ) was in progress:

The operation in progress is terminated and "

When the communications error is removed, the Remote Keypad automatically enters the Running

mode.

- - - -" appears on the monitor. Once the read operation is

E " display.

- - - -" appears on the monitor. The function code data in

- - - -" appears on the monitor.

3-6

Page 21

Chapter 4 SPECIFICATIONS

4.1 General Specifications

Table 4.1 summarizes the general specifications of the Remote Keypad "TP-E1."

Table 4.1 General Specifications

Item Specifications Remarks

Enclosure Front side: IP40; Rear side: IP20

Environment Indoor only.

Ambient temperature (during operation) -10 to +50°C

Ambient humidity 5 to 95% RH (no condensation)

Atmosphere Shall be free from corrosive gases, flammable

Altitude 1,000 m or below (Note)

Atmospheric pressure 86 to 106 kPa

Vibration 3 mm (max.) : 2 - 9 Hz

Ambient temperature (during storage) -25 to +70°C

Ambient humidity (during storage) 5 to 95% RH (no condensation)

External dimensions See the figure below.

Mass 55 g

gases, dust, and direct sunlight.

9.8 m/s2 : 9 - 20 Hz

2

2 m/s

1 m/s

2

: 20 - 55 Hz

: 55 - 200 Hz

(Note) If the Remote Keypad and the inverter are to be used at an altitude above 1,000 m (but below 3,000

m), the output current of the inverter must be lowered accordingly. For details, refer to the FRENIC-Mini

Instruction Manual (INR-SI47-0791-E), Chapter 2, Section 2.1 "Operating Environment."

External dimensions

4-1

Page 22

4.2 Communication Specifications

Tables 4.2 and 4.3 summarize the communication specifications.

Table 4.2 Hardware Specifications

Item Specifications Remarks

No. of inverters

connected

Connection

cable

Maximum

communication

distance

Connector RJ-45 connector See Table 4.3.

Pin # Signal name Description Remarks

1, 8 Vcc DC power source for Remote Keypad 5 V

2, 7 GND Signal ground GND

3, 6 NC Unassigned (reserved)

4 DX - RS485 communication data ( - )

5 DX + RS485 communication data ( + )

Note) SW1 for the terminating resistor on the RS485 Communications Card must be set to OFF (open).

One inverter for one Remote Keypad

Shall meet the US ANSI/TIA/EIA-568A Category 5

standard (10BASE-T/100BASE-TX, straight).

20 m

Table 4.3 RJ-45 Connector Pin Assignment

Remote Operation

Extension Cables are

available as options

(CB-5S, CB-3S, or

CB-1S, depending on the

distance).

4.3 Transmission Specifications

Table 4.4 summarizes the transmission speci fications.

Table 4.4 Transmission Specifications

Item Specifications Remarks

Area code No need to specify.

Communication protocol Modbus-RTU

Synchronization system Start-stop

Communication system Half-duplex

Communication speed

(Baud rate)

Parity Even parity

Stop bit length 1 bit

Error checking CRC-16

19,200 bps

4-2

There is no need to specify

function codes y01 through y10

for RS485 communication,

which will be ignored anyway.

Page 23

Remote Keypad "TP-E1"

Instruction Manual

First edition, July 2003

Fuji Electric FA Components & Systems Co., Ltd.

The purpose of this manual is to provide accurate information in the handling, setting up and

operating of Remote Keypad "TP-E1" for the FRENIC-Mini series of inverters. Please feel free to

send your comments regarding any errors or omissions you may have found, or any suggestions you

may have for generally improving the manual.

In no event will Fuji Electric FA Components & Systems Co., Ltd. be liable for any direct or indirect

damages resulting from the application of the information in this manual.

Page 24

Fuji Electric FA Components & Systems Co., Ltd.

2003-6 (c03/c03) 1CM

Loading...

Loading...