Page 1

Instruction Manual

MICRO CONTROLLER X

COMMUNICATION

FUNCTIONS

(RS-485 MODBUS)

TYPE: PXR

INP-TN512642a-E

Page 2

NOTICE

1. Exemption items from responsibility

The contents of this document may be changed in the future without prior notice.

We paid the utmost care for the accuracy of the contents. However, we are not liable for direct and

indirect damages resulting from incorrect descriptions, omission of information, and use of

information in this document.

Page 3

CONTENTS

1. COMMUNICATION FUNCTIONS

1.1 General

2. SPECIFICATIONS

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

2.1 Communication Specifications

3. CONNECTION

3.1 Terminal Allocation

3.2 Wiring

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

4. SETTING OF COMMUNICATION CONDITION

4.1 Set Items

4.2 Setting Operation Method

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

5. MODBUS COMMUNICATION PROTOCOL

5.1 General

5.2 Composition of Message

5.3 Response of Slave Station

5.4 Function Code

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

5.5 Calculation of Error Check Code (CRC-16)

5.6 Transmission Control Procedure

5.7 FIX Processing (Cautions at write-in of data)

6. DETAILS OF MESSAGE

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

6.1 Read-out of Bit Data [Function code:01

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

]

H

6.2 Read-out of Read-out Only Bit Data [Function code:02

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

6.3 Read-out of Word Data [Function code:03

]

H

6.4 Read-out of Read-out Only Word Data [Function code:04

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

6.5 Write-in of Bit Data (1 bit) [Function code:05

]

H

6.6 Write-in of Word Data (1 word) [Function code:06

6.7 Write-in of Continuous Word Data [Function code:10

7. ADDRESS MAP AND DATA FORMAT

7.1 Data Format

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

7.2 Address Map of Internal Calculation Value Data

7.3 Address Map of Engineering Unit Data

7.4 Additional Explanation of Address Map

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

]

H

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

]

H

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

]

H

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

]

H

1

1

2

2

3

3

4

5

5

6

7

7

8

10

11

12

13

15

16

16

17

19

22

24

25

26

28

28

31

36

41

8. SAMPLE PROGRAM

9. TROUBLESHOOTING

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

-i-

44

49

Page 4

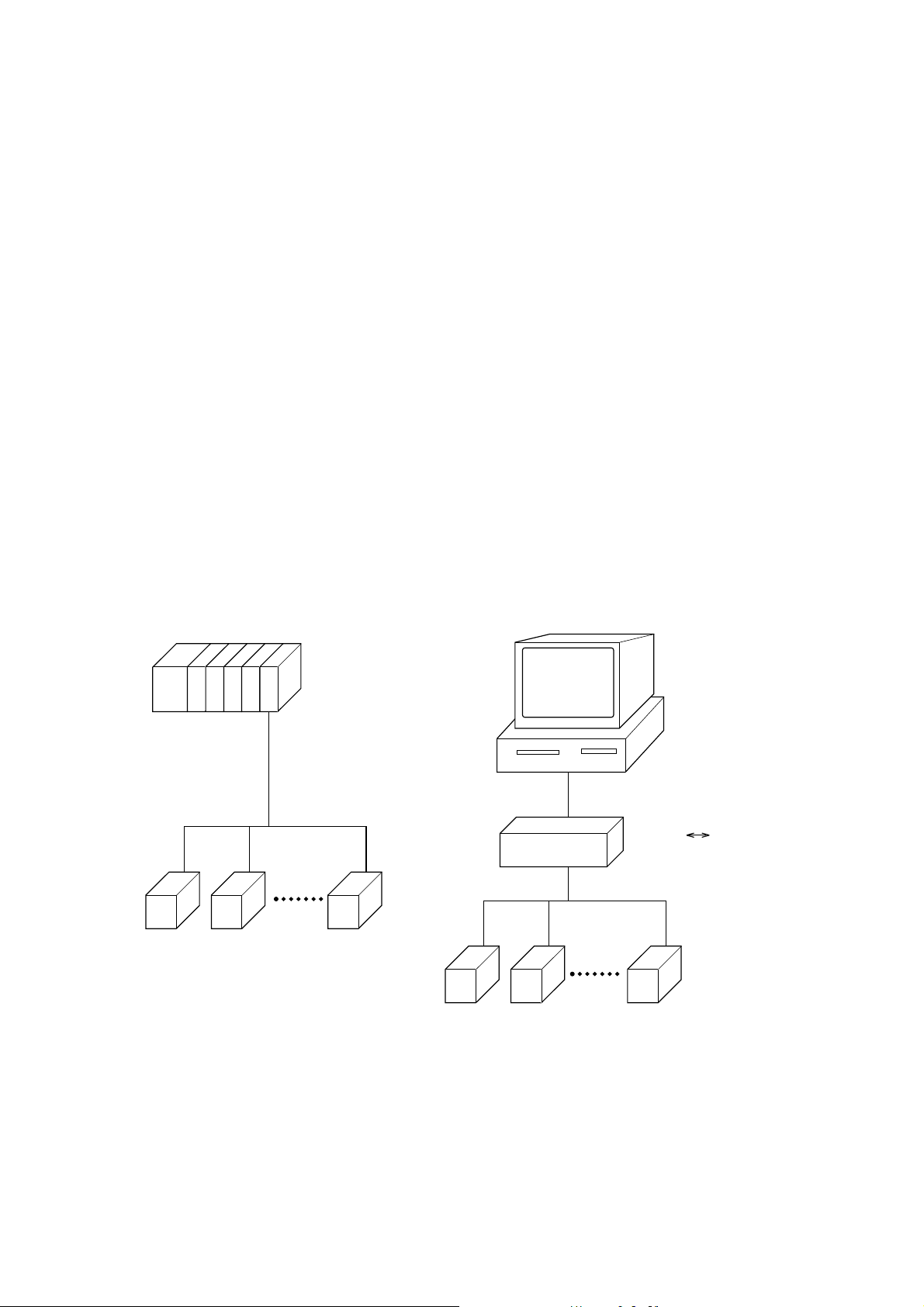

1. COMMUNICATION FUNCTIONS

1.1 General

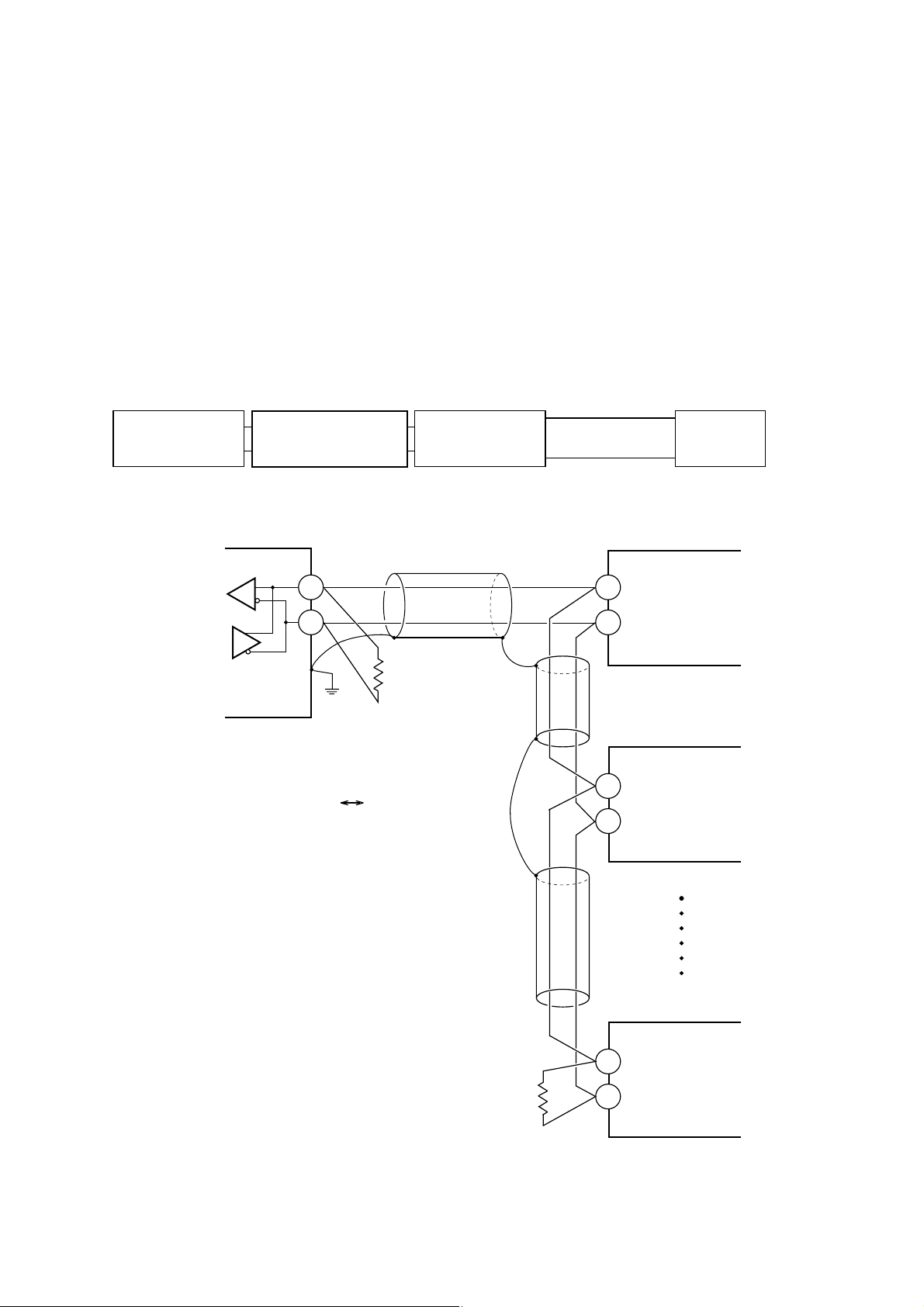

• PXR provides a communication function by RS-485 interface, by which it can transmit and receive data to and

from host computer, programmable controller, graphic display panel, etc.

• The communication system consists of master station and slave stations. Up to 31 slave stations (PXR) can

be connected per master station.

Note that, because the master station can communicate with only one slave station at a time, a party to

communicate with must be specified by the "Station No." set at each slave station.

• In order that the master station and slave station can communicate, the format of the transmit/receive data must

coincide. For the PXR, the format of the communication data is determined by the MODBUS protocol.

• Please use an RS-232C↔RS-485 converter in case of designating a personal computer or other devices which

have an RS-232C interface as a master station.

[RS-232C↔RS-485 converter] (recommended article)

Type: KS-485 (non-isolated type)/SYSTEM SACOM Corp.

Type: SI-30A (isolated type)/SEKISUI ELECTRONICS Co., Ltd.

[Note] MODBUS

Programmable

controller

RS-485

®

is the registered trade mark of Gould Modicon.

Personal

computer

RS-232C

RS-232C RS-485 converter

RS-485

-1-

Page 5

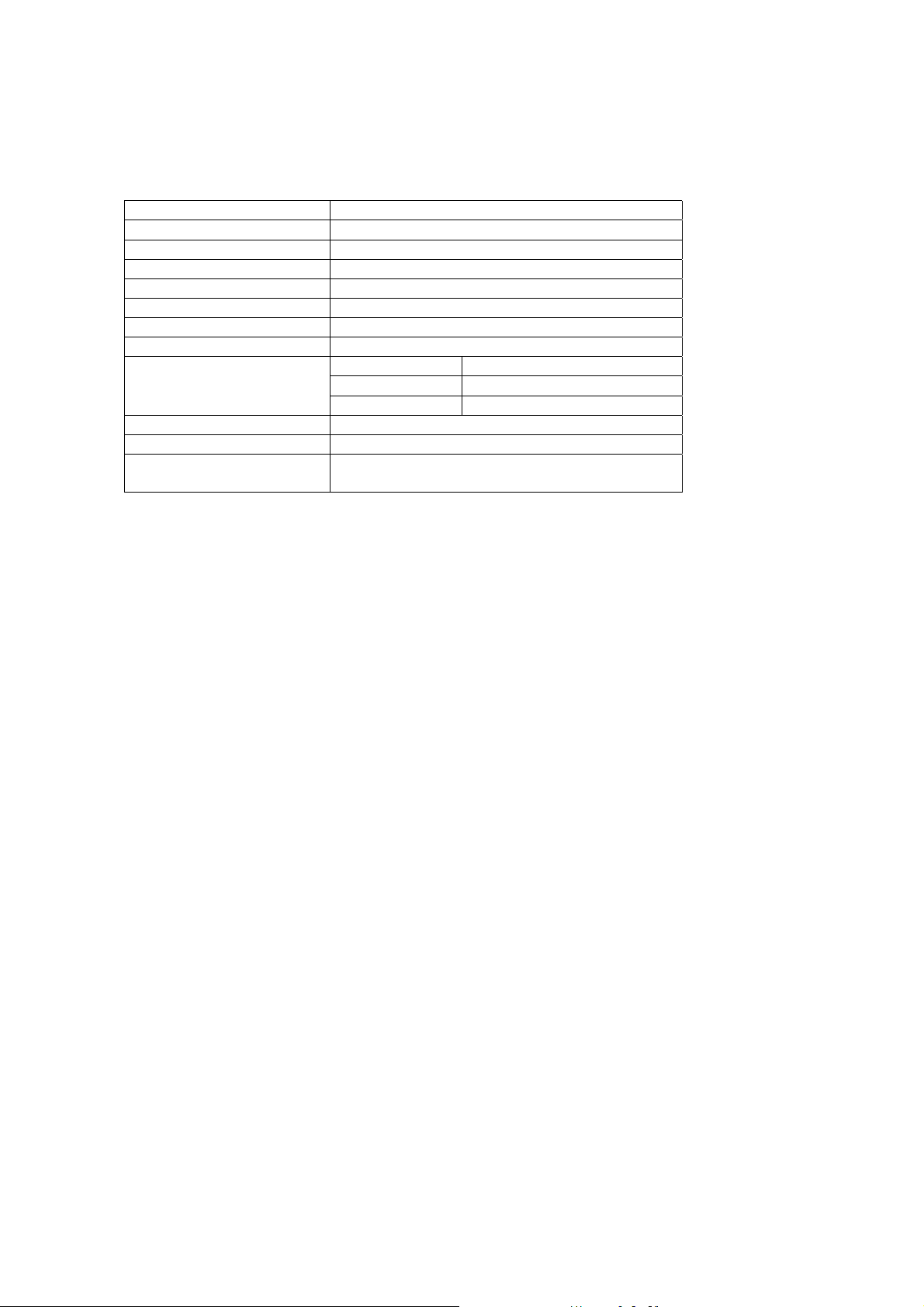

2. SPECIFICATIONS

2.1 Communication Specifications

Item Specification

Electrical specification Based on EIA RS-485

Transmission system 2-wire, semi-duplicate

Synchronizing system Start-stop synchronous system

Connection format 1 : N

Number connectable units Up to 31 units

Transmission distance 500m max. (total extension distance)

Transmission speed 9600bps

Data format

Transmission code HEX value (MODBUS RTU mode)

Error detection CRC-16

Isolation Functional isolation between transmission circuit

Data length 8 bits

Stop bit 1 bit

Parity none, even, odd (selectable)

and others (withstand voltage : 500V AC)

-2-

Page 6

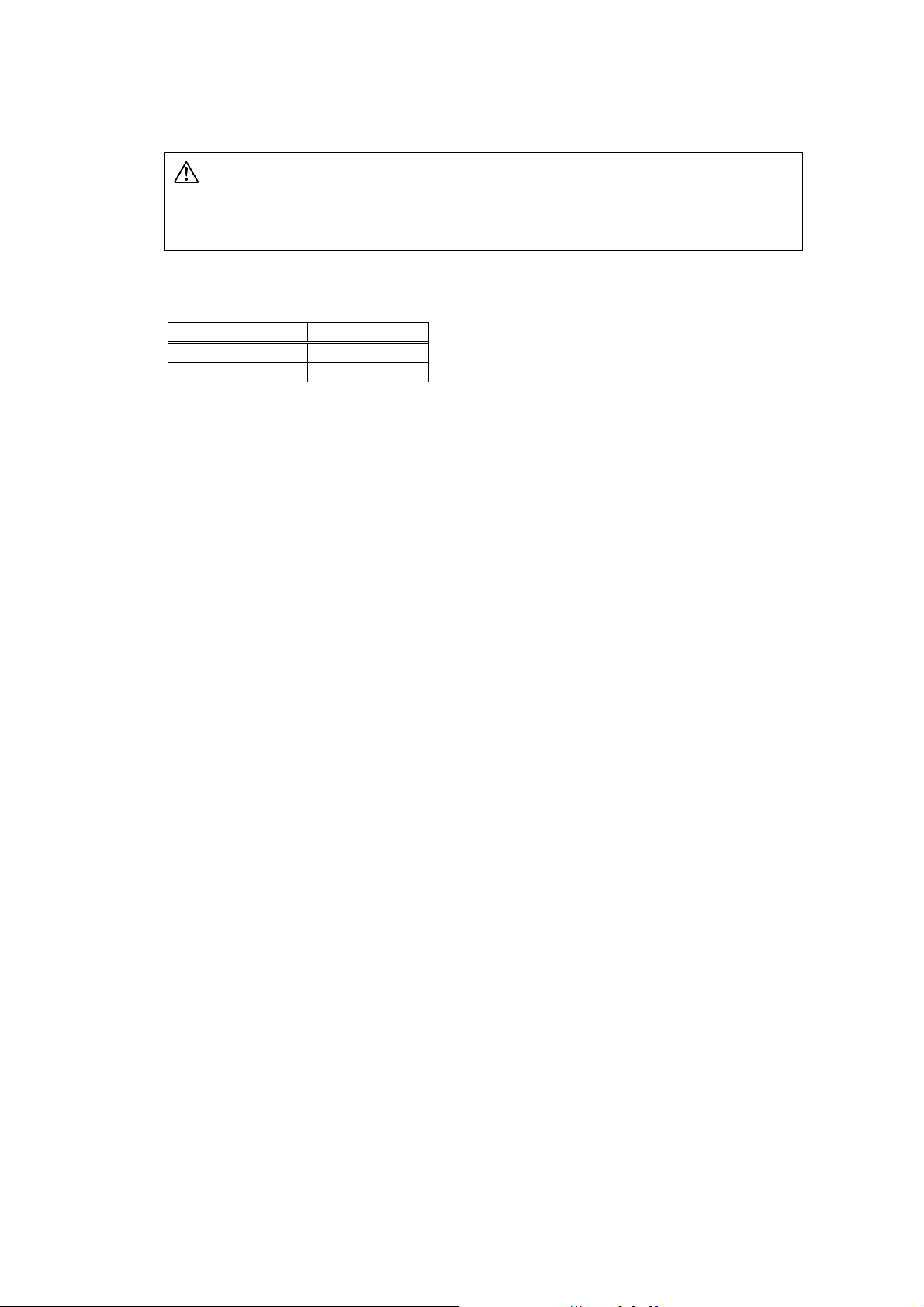

3. CONNECTION

WARNING

For avoiding electric shock and malfunctions, do not turn on the power supply untill all wiring

have been completed.

3.1 Terminal Allocation

Terminal number Signal name

7 +

8 -

-3-

Page 7

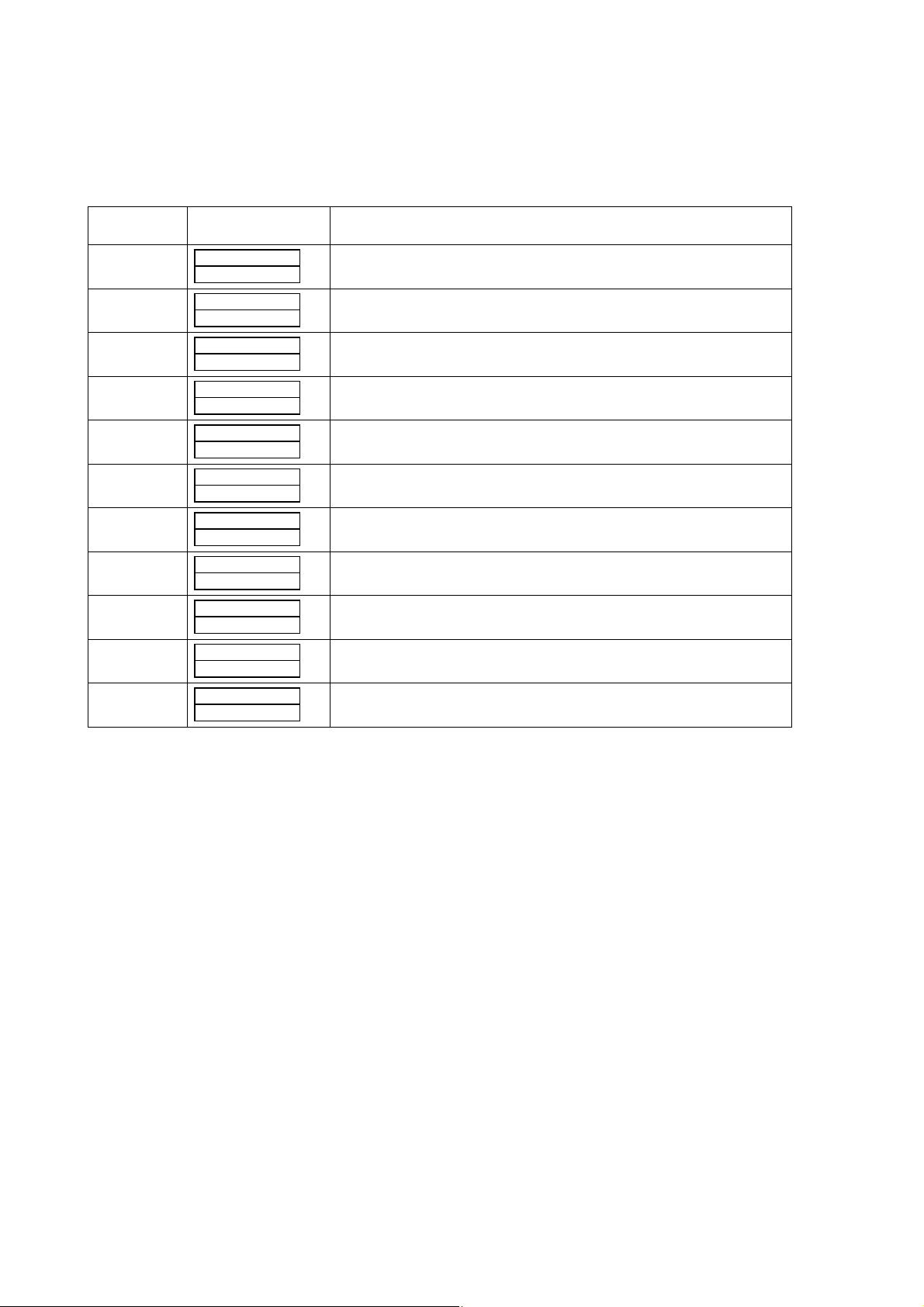

3.2 Wiring

• Use twisted pair cables with shield.

Recommended cable: UL2464, UL2448, etc.

• The total extension length of the cable is up to 500 m. A master station and up to 31 units of the PXR can be

connected per line.

• Both ends of the cable should be terminate with terminating resistors 100Ω1/2W.

• The shield wire of the cable should be grounded at one place on the master station unit side.

• If the PXR is to be installed where the level of noise applied to the PXR may exceed 1000 V, it is

recommended to install a noise filter in the master station side as below.

Recommended noise filter: ZRAC2203-11/TDK

Master station

(

PC, etc.

)

RS-232C⇔RS-485

Master station side

Noise filter PXR

Transmission

cable

Slave station (PXR)

Twisted pair cable with shield

−

FG

Terminating resistor

100Ω(1/2W)

RS-485 interface

or

RS-485 side of the RS-232C RS-485 converter

78+

−

Slave station (PXR)

78+

−

Slave station (PXR)

78+

−

Terminating resistor

100Ω(1/2W)

-4-

Page 8

4.

In order that the master station and instrument (PXR) can correctly communicate, following settings are required.

SETTING OF COMMUNICATION CONDITION

• All communication condition settings of the master station are the same as those of instruments (PXR).

• All instruments (PXR) connected on a line are set to "Station Nos. (STno)" which are different from each other.

(Any "Station No." is not shared by more than one instrument.)

4.1 Set Items

The parameters to be set are shown in the following table. Set them by operating the front panel keys.

Parameter

symbol

―――

―――

―――

CoM Parity setting 0

STno Station No. 1

Transmission speed 9600bps Fixed (can not be changed)

Data length 8 bits Fixed (can not be changed)

Stop bit 1 bit Fixed (can not be changed)

Item

Value at

delivery

Setting range Remarks

0: odd parity

1: even parity

2: none parity

0 to 255

(0:communication function stop)

Set the same

communication

condition to the master

station and all slave

stations.

Set a different value to

each station.

-5-

Page 9

4.2 Setting Operation Method

The following example shows how to set the communication conditions.

Example: Selecting an even parity and “STno=18” on a station.

Key

operation

SEL

(6 seconds)

∨

SEL

∧∨

SEL

∨

SEL

∧∨

SEL

SEL

(3 seconds)

Indication Description

200

200

P-n1

0

STno

0

STno

0

STno

18

STno

18

CoM

0

CoM

0

CoM

1

CoM

1

200

200

Running state (PV/SV indication)

Press the SEL key for approximately 6 seconds. P-n1 appears and

No. 3 block parameter is selected.

Operate the ∨ key repeatedly until STno parameter appears. (If

past over, operate the ∧ key to return.)

Press the SEL key. The numeric value on the lower indicator

blinks and the setting mode is selected.

Operate the ∧ or ∨ key to change the numeric value to 18.

Press the SEL key again. The numeric value stops blinking and

the setting is registered.

Press the ∨ key to display the CoM parameter.

Press the SEL key. The numeric value on the lower indicator

blinks and the setting mode is selected.

Operate the ∧ or ∨ key until the numeric value changes to 1 (even

parity).

Press the SEL key again. The numeric value stops blinking and

the setting is registered.

Press the SEL key for 3 seconds to resume the running indication

(PV/SV indication).

-6-

Page 10

5. MODBUS COMMUNICATION PROTOCOL

5.1 General

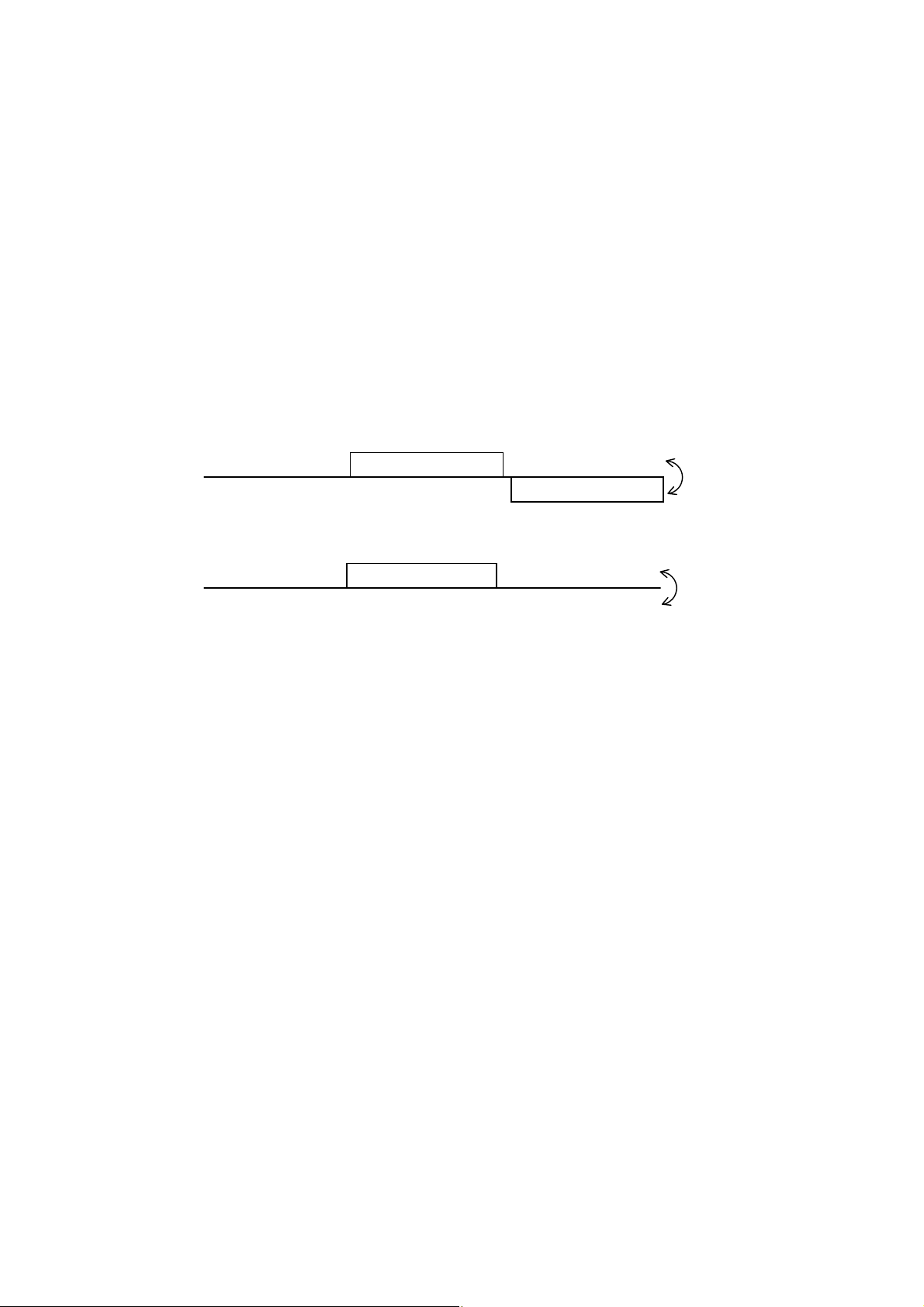

The communication system by the MODBUS protocol is that the communication is always started from the master

station and a slave station responds to the received message.

Transmission procedures is as shown below.

1) The master station sends a command message to a slave station.

2) The slave station checks that the station No. in the received message matches with the own station No. or

not.

3) If matched, the slave station executes the command and sends back the response message.

4) If mismatched, the slave station leaves the command message and wait for the next command message.

a) In case when the station No. in the received command message matches with the own slave station No.

Master to slave

Slave to master

b) In case when the station No. in the received command message mismatches with the own slave station

No.

Master to slave

Slave to master

The master station can individually communicate with any one of slave stations connected on the same line upon

setting the station No. in the command message.

Command message

Command message

Response message

(Not respond)

Data on

the line

Data on

the line

-7-

Page 11

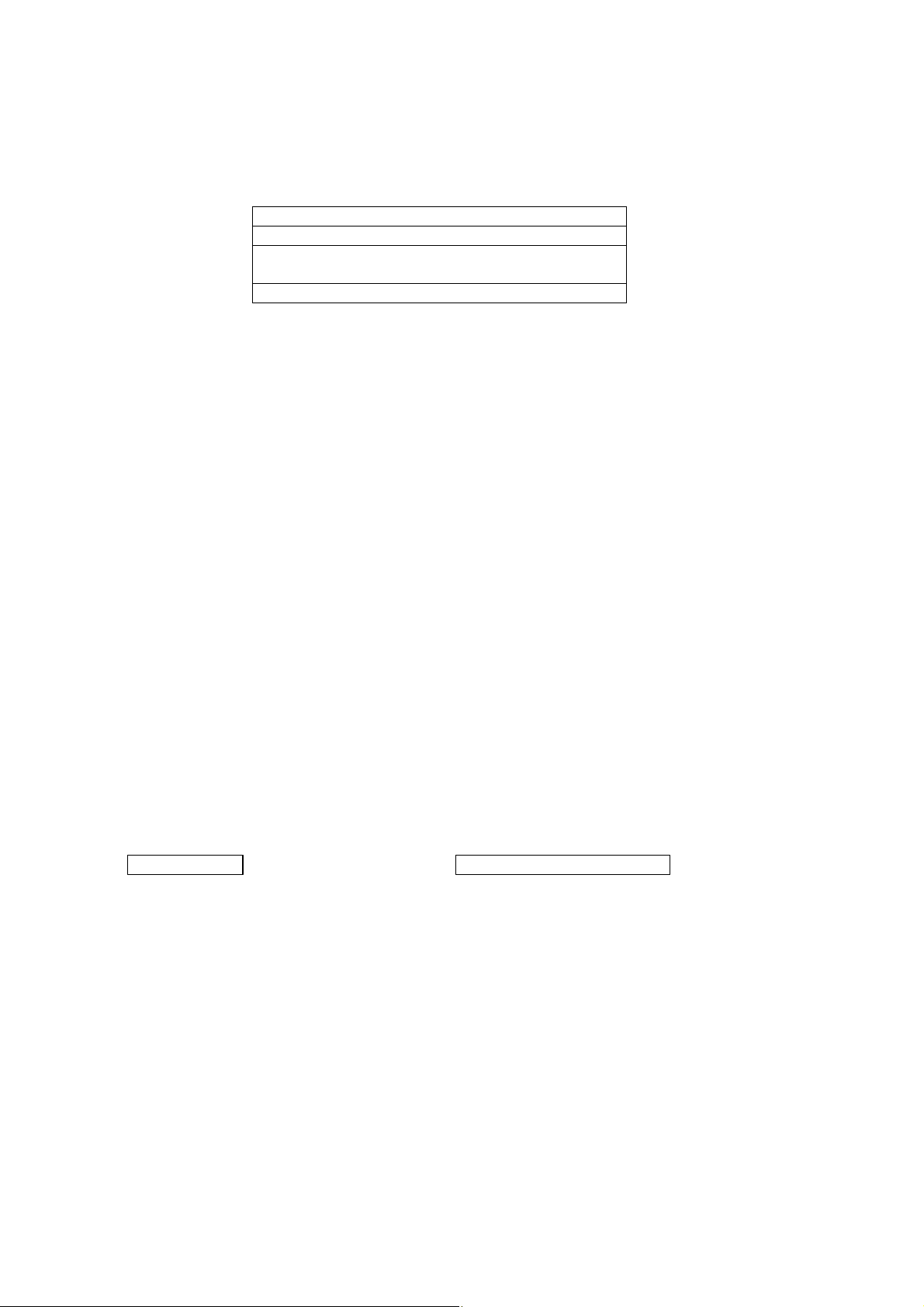

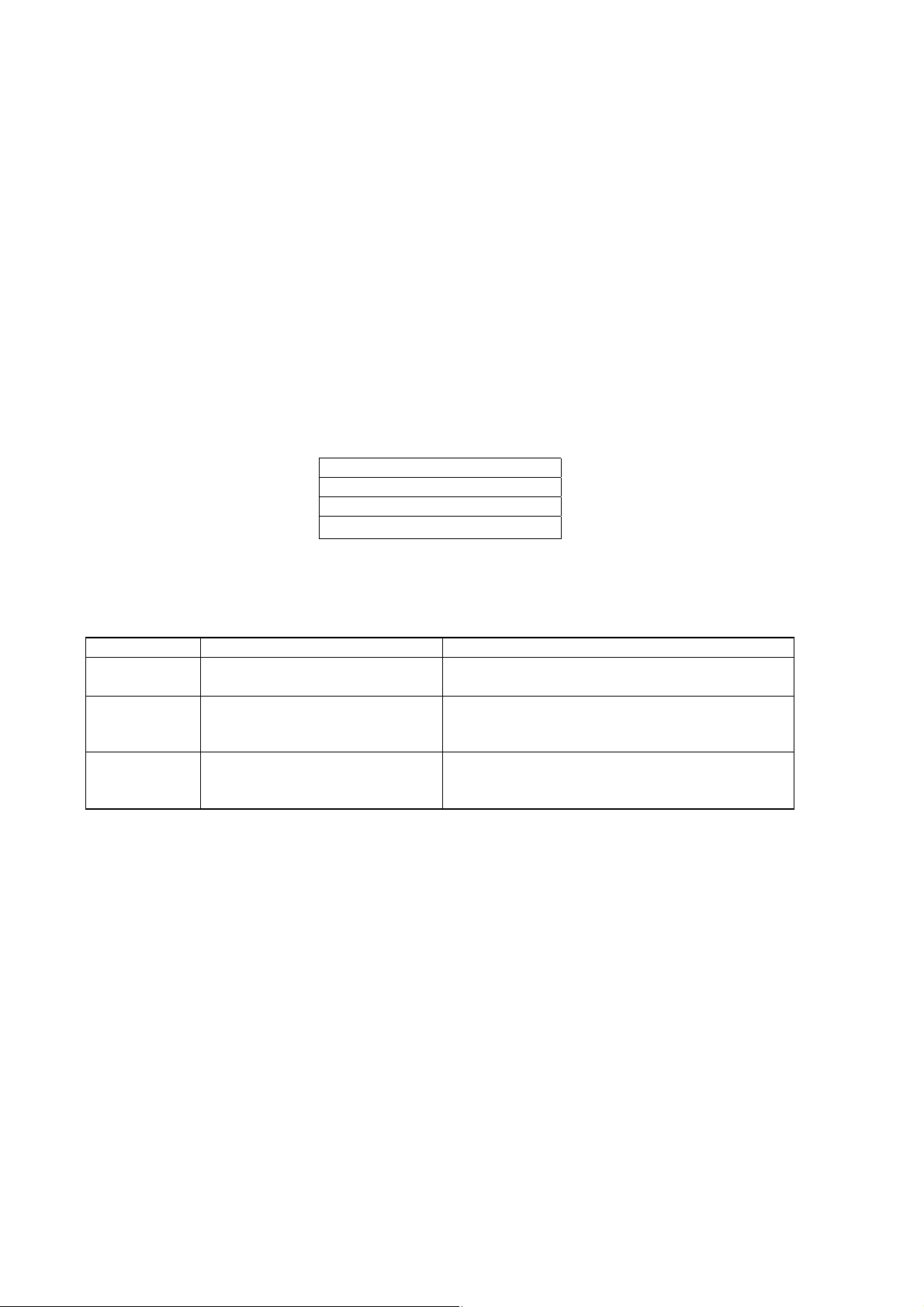

5.2 Composition of Message

Command message and response message consist of 4 fields ; Station No., Function code, Data and Error check

code. And these are send in this order.

Station No. (1 byte)

Function code (1 byte)

Data (2 to 125 bytes)

Error check code (CRC-16) (2 bytes)

Fig. 5-1 Composition of message

In the following, each field is explained.

(1) Station No.

Station No. is the number specifiing a slave station. The command message is received and operated only by

the slave station whose station No. matches with the No. set in the parameter "STno".

For details of setting the parameter "STno", refer to chapter 4.

(2) Function code

This is a code to designate the function executed at a slave station.

For details, refer to section 5.4.

(3) Data

Data are the data required for executing function codes. The composition of data varies with function codes.

For details, refer to chapter 6.

A coil number or a register number is assigned to each data in the temperature controller. For reading/writing

the data by communication, designate the coil number or register number.

Note that the coil number or register number transmitted on message is expressed as its relative address.

The relative address is calculated by the following expression.

The lower 4 digits of the

Relative address

For example, when the resister number designated by a function code is 40003,

Relative address = (lower 4 digits of 40003) – 1

= 0002

is used on the message.

=

Coil number or register number

– 1

-8-

Page 12

(4) Error check code

This is the code to detect message errors (change in bit) in the signal transmission.

On the MODUBUS protocol (RTU mode), CRC-16 (Cycric Redundancy Check) is applied.

For CRC calculation method, refer to section 5.5.

-9-

Page 13

5.3 Response of Slave Station

(1) Response for normal command

To a relevant message, the slave station creates and sends back a response message which corresponds to the

command message. The composition of message in this case is the same as in section 5.2.

Contents of the data field depend on the function code. For details, refer to Chapter 6.

(2) Response for abnormal command

If contents of a command message have an abnormality (for example, non-actual function code is designated)

other than transmission error, the slave station does not execute that command but creates and sends back a

response message at error detection.

The composition of response message at error detection is as shown in Fig. 5-2 The value used for function

code field is function code of command message plus 80

Table 5-1 gives error codes.

Station No.

Function code + 80H

Error code

Error check(CRC-16)

Fig. 5-2 Response message at error detection

.

H

Table 5-1 Error code

Error code Contents Description

01H Illegal function Non-actual function code is designated.

Check for the function code.

02H Illegal data address A relative address of a coil number or resister

number to which the designated function code can

not be used.

03H Illegal data value Because the designation of number is too much,

the area where coil numbers or resister numbers do

not exist is designated.

(3) No response

Under any of the following items, the slave station takes no action of the command message and sends back no

response.

・A station number transmitted in the command message differs from the station number specified to the

slave station.

・ A error check code is not matched, or a transmission error (parity error, etc.) is detected.

・ The time interval between the composition data of the message becomes longer than the time

corresponding to 24 bits. (Refer to section 5.6 Transmission Control Procedure)

・While the data is being written in non-volatile memory after write via communication, the next write is

attempted.

-10-

Page 14

5.4 Function Code

According to MODBUS protocol, coil numbers and register numbers are assigned by function codes.

Each function code acts on specific coil number and register number.

This correspondence is shown in Table 5-2, and the message length by function is shown in Table 5-3.

Table 5-2 Correspondence between function codes and objective address

Function code

No. Function Object

01H Read-out

Coil

0xxxx Read-out/write-in bit data

Coil No. and resister No.

No. Contents

(continuously)

02H Read-out

Input relay

1xxxx Read-out bit data

(continuously)

03H Read-out

Holding register

4xxxx Read-out/write-in word data

(continuously)

04H Read-out

Input register

3xxxx Read-out word data

(continuously)

05H Write-in Coil

06H Write-in Holding register

10H Write-in

Holding register

0xxxx Read-out/write-in bit data

4xxxx Read-out/write-in word data

4xxxx Read-out/write-in word data

(continuously)

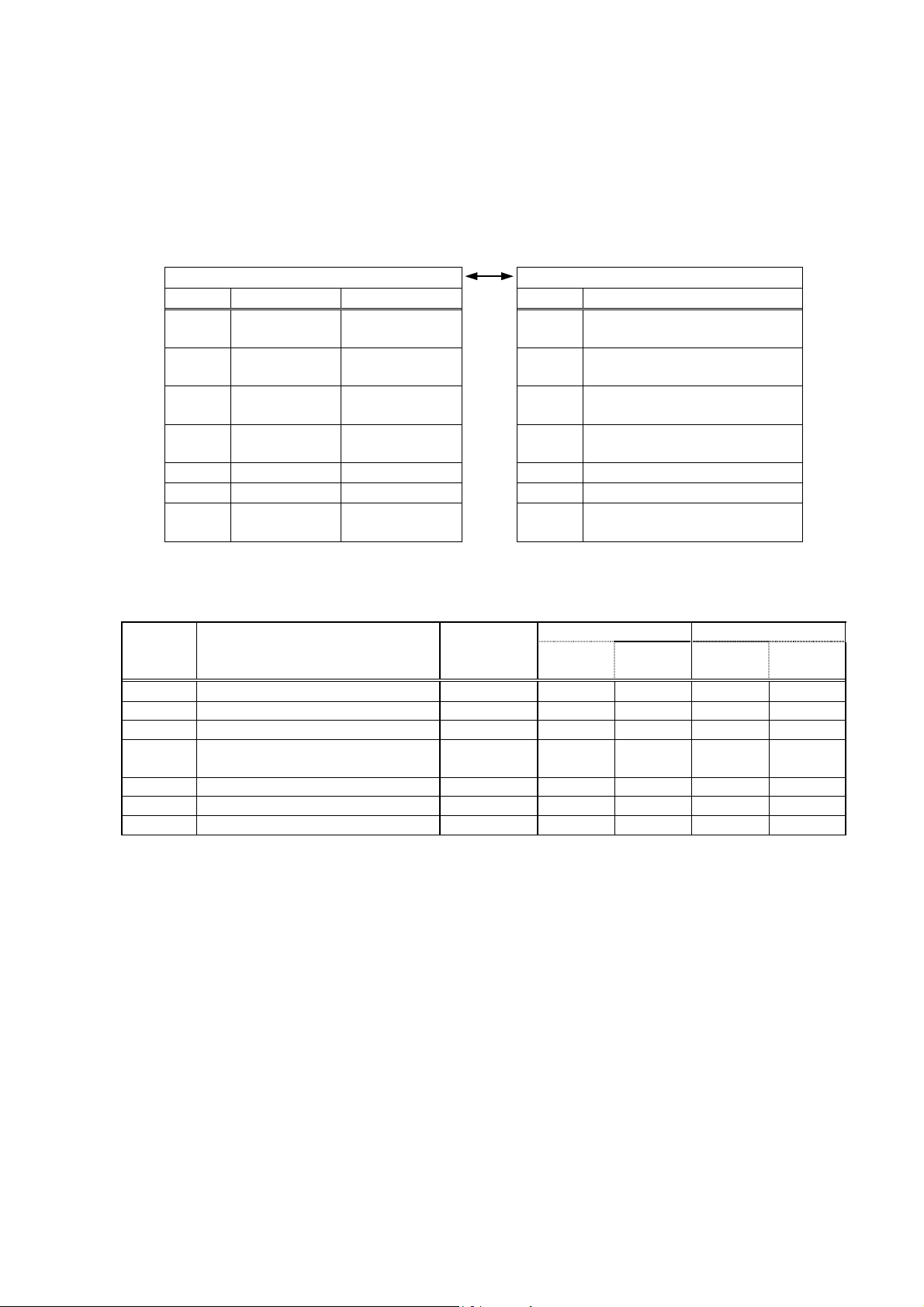

Table 5-3 Function code and message length

[Unit:byte]

Function

code

Contents Number of

designatable

Command message Response message

Minimum Maximum Minimum Maximum

data

01H Read-out of bit data 1bit

02H Read-out of bit data (read-out only) 8 bits

03H Read-out of word data 60 words

04H Read-out of word data

*1

*1

15 words

*1

*1

8 8 6 6

8 8 6 6

8 8 7 125

8 8 7 35

(read-out only)

05H Write-in of bit data 1 bit 8 8 8 8

06H Write-in of word data 1 word 8 8 8 8

10H Write-in of continuous word data 60 words

*1

11 129 8 8

*1) The "Number of designatable data" given above is the limit due to the number of data which the instrument

assigns to coil number and register number (except function codes 05

, 06H).

H

-11-

Page 15

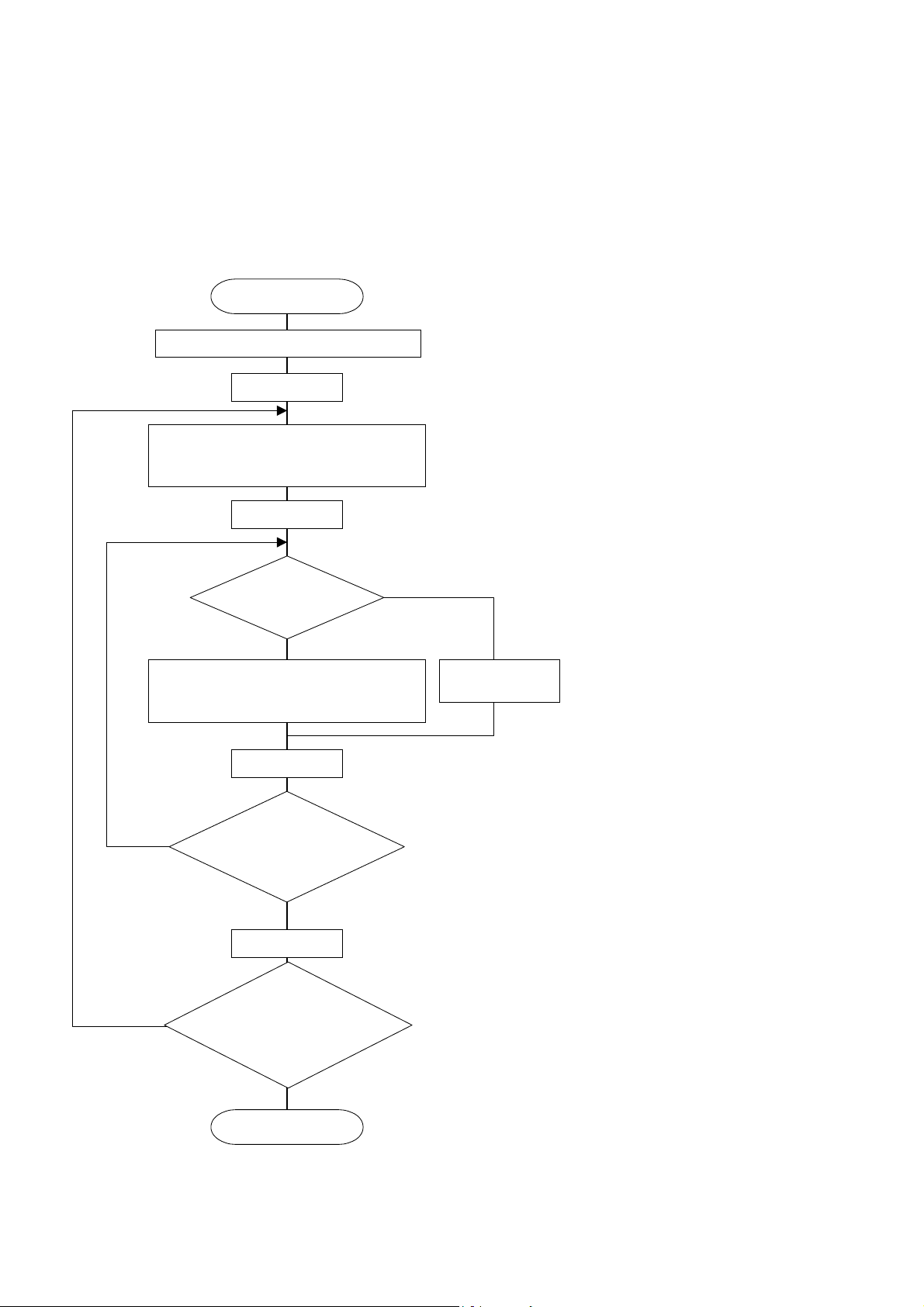

5.5 Calculation of Error Check Code (CRC-16)

t

CRC-16 is the 2-byte (16-bits) error check code. From the top of the message (station No.) to the end of the

data field are calculated.

The slave station calculates the CRC of the received message, and does not respond if the calculated CRC is

different from the contents of the received CRC code.

Fig. 5-3 shows the flow of the CRC-16 calculation system.

Start

Set FFFFH (hexadecimal number) in CR.

Set 1 in J.

Exclusive logical sum (XOR) is executed

with CR and one character (1 byte) of the I

characters, and its results is set in CR.

Set 1 in J.

Bit at right end

of CR is 1?

YES

Shift CR to right by 1 bit, and A001H and

exclusive logical sum (XOR) are executed

and its result is set in CR.

NO

Explanation of variables

CR:CRC error check data (2 bytes)

I:Digits of calculation characters

in command message

J:Check on the number of times

of CR calculation

Shift CR to righ

by 1 bit.

NO

NO

Add 1 to J.

Calculation (8 times) is

finished?

J>8

YES

Add 1 to J.

Calculation of all characters is

completed?

I>All characters

YES

End

Fig. 5-3 Flow of CRC-16 calculation

(Calculation is executed in the order of

command message station No., function

code and data.)

CR calculation result shall be added to

the last command message in the order

of LOW byte and HIGH byte.

-12-

Page 16

5.6 Transmission Control Procedure

(1) Transmission procedure of master station

The master station must proceed to a communication upon conforming to the following items.

(1-1) Before sending a command message, provide 48 bits time or more vacant status.

(1-2) For sending, the interval between bytes of a command message is below 24 bits time.

(1-3) Within 24 bits time after sending a command message, the receiving status is posted.

(1-4) Provide 48 bits time or more vacant status between the end of response message reception and

beginning of next command message sending [same as in (1-1)].

(1-5) For ensuring the safety, make a confirmation of the response message and make an arrangement so

as to provide 3 or more retries in case of no response, error occurrence, etc.

Note) The above definition is for most unfavorable value. For ensuring the safety, it’s recommended the

program of the master to work with safety factors of 2 to 3. Concretely, it is advised to arrange the

program for 9600 bps with 10 ms or more for vacant status (1-1), and within 1 ms for byte interval (1-2)

and changeover from sending to receiving (1-3).

(2) Description

1) Detection of the message frame

Since the communication system uses the 2-wire RS-485 interface, there may be 2 statuses on a line below.

(a) Vacant status (no data on line)

(b) Communication status (data is existing)

Instruments connected on the line are initially at a receiving status and monitoring the line. When 24 bits

time or more vacant status has appeared on the line, the end of preceding frame is assumed and, within

following 24 bits time, a receiving status is posted. When data appears on the line, instruments receive it

while 24 bits time or more vacant status is detected again, and the end of that frame is assumed. I.e., data

which appeared on the line from the first 24 bits time or more vacant status to the next 24 bits time or more

vacant status is fetched as one frame.

Therefore, one frame (command message) must be sent upon confirming the following.

(1-1) 48 bits time or more vacant status precedes the command message sending.

(1-2) Interval between bytes of 1 command message is smaller than 24 bits time.

2) Response of this instrument (PXR)

After a frame detection (24 bits time or more vacant status), this instrument carries out processing with that

frame as a command message. If the command message is destined to the own station, a response

message is returned. Its processing time is 1 to 30 ms (depends on contents of command message).

After sending a command message, therefore, the master station must observe the following.

(1-3) Receiving status is posted within 24 bits time after sending a command message.

-13-

Page 17

Master station → PXR

Master station ← PXR

Data on line

Space time of longer than 5ms is

needed

(longer than 10ms is recommended)

POL1 POL2

1 to 30msec

POL1 response data

POL1 POL2 POL1 response data

-14-

Page 18

5.7 FIX Processing (Cautions at write-in of data)

The instrument is provided inside with a non-volatile memory (EEPROM) for holding the setting parameters.

Data written in the non-volatile memory is not lost even if turning off the power. When setting parameter is

written via communication, the data is stored in the internal memory (RAM) and then written in the non-volatile

memory.

FIX execution writes the parameters stored in the internal memory into the non-volatile memory, but this

function is not required any more because the data is written in non-volatile memory when it is written in the

parameter.

Fig. 5-4 shows the FIX procedure.

Cautions:

・ Write in the non-volatile memory takes approximately 5 seconds at the longest approximately 5 seconds.

・ While writing, do not turn off the power of the PXR. Otherwise, the data in the non-volatile memory will

be destroyed, whereby the PXR could not be used any longer.

・ The non-volatile memory (EEPROM) is a device where the number of write-in times is limited. The

guaranteed number of write-in times of the non-volatile memory used on the instrument is 10,000 minimum.

Therefore, limit the times of change of parameter setting to absolute minimum. Refrain from carrying out

the FIX processing periodically for example or while such is not absolutely required.

Start FIX

Read the FIX bit

with function code : 01

relative address : 0000

No

FIX=0?

Yes

Write ‘1’ into FIX bit

with function code : 05

relative address : 0000

Read the FIX bit

with function code : 01

relative address : 0000

No

FIX=0?

H

H

H

H

H

Yes

End FIX

Fig. 5-4 FIX procedure

-15-

Page 19

6. DETAILS OF MESSAGE

6.1 Read-out of Bit Data [Function code:01

Function code Max. bit number read-out in one message Relative data address Coil number

01H 1 bit 0000H 00001

H

]

(1) Message composition

Command message composition (byte) Response message composition (byte)

Station No. Station No.

Function code Function code

00H Read-out start No.

(relative address)

Read-out bit number

CRC data

* Arrangement of read-out bit data

MSB LSB

0 0 0 0 0 0 0

00H

00H State of the first 8 bits

01

Upper

Lower

H

CRC data

01

H

Upper

Lower

State of read-out bit

(2) Function explanations

The state of the bit of the coil No. 00001 is read-out.

(3) Message transmission (example)

The following shows an example of reading-out the FIX execution request data from No. 1 slave station.

FIX execution request bit Relative address:0000

Command message composition (byte) Response message composition (byte)

Station No.. 01

Function code 01H Function code 01H

Upper 00H Read-out byte number 01H Read-out start No.

(relative address)

bit number

CRC data

* Meaning of read data

MSB LSB

State of FIX execution request 00H= 0 0 0 0 0 0 0 0

No execution of FIX

Lower 00

Upper 00H Upper 51H Read-out

Lower 01

Upper FDH

Lower CA

Station No. 01H

H

State of the first 8 bits 00H

H

H

H

Number of data:01

H

CRC data

H

Lower 88H

↑

-16-

Page 20

6.2 Read-out of Read-out Only Bit Data [Function code:02H]

Function code Max. bit number read-out in one message Relative data address Coil number

02H 8 bits

(1) Message composition

Command message composition (byte) Response message composition (byte)

Station No. Station No.

Function code Function code

Upper Read-out start No.

(relative address)

Read-out bit number

CRC data

Lower

00H State of the read-out bit

Lower 01

Upper

to 08 H Upper

H

CRC data

Lower

* Arrangement of read-out bit data

MSB LSB

(2) Function explanations

01

H

-000F

0000

H

10001-10016

H

Lower

State of the first 1 bit

……

State of the last 1 bit

Bit information data of continuous read-out bit number from the read-out start number.

Read-out bit data are arranged in 8-bit unit and transmitted from the slave station.

When read-out bit data number is not multiple of 8, all the bits (MSB side) not related with the state of the last

8 bits will become "0".

-17-

Page 21

(3) Message transmission (example)

(

The following shows an example of reading-out the state of the alarm 1 and alarm 2 transmitted from No.31

slave station.

Alarm 1 detect data bit Relative address : 000C

Alarm 2 detect data bit Relative address : 000D

Command message composition (byte) Response message composition (byte)

Station No. 1F

H

Function code 02H Function code 02H

Upper 00H Read-out byte number 01H Read-out start No.

(relative address)

Lower 0C

H

Upper 00H Upper 66H Read-out

bit number

CRC data

Lower 02

H

Upper 3AH

Lower 76

H

* Meaning of read-out data

MSB LSB

State of alarm detection of 01

= 0 0 0 0 0 0 0 1

H

alarms 1 and 2

State of the first 2 bits)

Data number : 02H

H

H

Station No. 1FH

State of the first 8 bits 01H

CRC data

Lower 60H

Alarm 2 OFF state

Alarm 1 ON state

-18-

Page 22

6.3 Read-out of Word Data [Function code:03H]

(

Function code Max. word number read-out

in one message

03H 60 words

(1) Message composition

Command message composition (byte) Response message composition (byte)

Station No. Station No.

Function code Function code

Read-out start

No.

relative address)

Read-out word

number

CRC data

Upper

Lower

Upper

Lower

Upper

Lower

* Arrangement of read-out word data

MSB LSB

Upper byte of contents of the first word data

Lower byte of contents of the first word data

Upper byte of contents of the next word data

Lower byte of contents of the next word data

~ ~

Upper byte of contents of the last word data

Lower byte of contents of the last word data

(2) Function explanations

Relative data address Resister No. Kind of data

Internal calculation value

Engineering unit

Read-out word number×2

1 to 60

-0070

0000

03E8

H

-0458

H

40001-40113

H

41001-41113

H

Read-out byte number

Contents of the

first word data

Contents of the

next word data

~ ~

Contents of

Upper

the last word

data

CRC data

Lower

Upper

Lower

Upper

Lower

Upper

Lower

Word data of continuous word numbers from the read-out start No. can be read. Read-out word data are

transmitted from the slave station in the order of upper and lower bytes.

-19-

Page 23

(3) Message transmission

(a) In case of data of internal calculation value

The following shows an example of reading the low and high limits of set value from No. 2 slave station.

Relative address of low limit of set value : 001E

Command message composition (byte) Response message composition (byte)

Station No. 02

Function code 03H Function code 03H

Upper 00H Read-out byte number 04H Read-out start No.

(relative address)

Lower 1EH Upper 00H

Upper 00H

number

CRC data

Lower 02

Upper A4H

Lower 3E

* Meaning of read-out data

Low limit of set value 00 00

(contents of first word data)

High limit of set value 27 10

(contents of next word data)

When input range is 0 to 400℃

Station No. 02H

H

H

Upper D3H

H

Data number : 02H

H

Contents of the

first word data

Contents of the

next word data

CRC data

= 10000(=100.00%FS)

H

= 10000(=100.00%FS)

H

Lower 00H Read-out word

Upper 27H

Lower 10H

Lower 0FH

Low limit of set value =400℃(=100.00%FS)

High limit of set value =400℃(=100.00%FS)

Point

For handling of the internal calculation value, engineering unit and decimal point,

refer to section 7.1.

-20-

Page 24

(b) In case of data of engineering unit

The following shows an example of reading the low and high limits of set value from No. 2 slave station.

Relative address of low limit set value : 0406H Data number : 02H

Command message composition (byte) Response message composition (byte)

Station No. 02

Station No. 02H

H

Function code 03H Function code 03H

Upper 04H Read-out byte number 04H Read-out start No.

(relative address)

Lower 06H Upper 0H

Upper 00H

number

CRC data

Lower 02H

Upper 25H

Lower 09

Upper C8H

H

Contents of the

first word data

Contents of the

next word data

CRC data

Lower 0H Read-out word

Upper 01H

Lower 90H

Lower CFH

* Meaning of read-out data

Low limit of set value 00 00

= 100

H

(contents of first word data)

High limit of set value 01 90

= 400

H

(contents of next word data)

When the position of decimal point is 0 (Parameter P-dP=0),

Low limit of set value =400℃

High limit of set value =400℃

Point

For handling of the internal calculation value, engineering unit and decimal point,

refer to section 7.1.

-21-

Page 25

6.4 Read-out of Read-out Only Word Data [Function code:04H]

Function code Max. word number read-out

in one message

04H 15 words

(1) Message composition

Command message composition (byte) Response message composition (byte)

Station No. Station No.

Function code Function code

Read-out start No.

(relative address)

Upper

Lower Upper

Upper

number

CRC data

Lower

Upper

Lower

* Arrangement of read-out word data

MSB LSB

Upper byte of contents of the first word data

Lower byte of contents of the first word data

Upper byte of contents of the next word data

Lower byte of contents of the next word data

~ ~

Upper byte of contents of the last word data

Lower byte of contents of the last word data

(2) Function explanations

Relative data address Resister No. Kind of data

-000E

0000

H

-03F6

03E8

H

30001-30015

H

31001-31015

H

Read-out byte number

Internal calculation value

Engineering unit

Read-out word number×2

Contents of the

1 to 15

first word data

Contents of the

next word data

~

Lower Read-out word

Upper

Lower

~

Upper Contents of

the last word

data

CRC data

Lower

Upper

Lower

Word data of continuous word numbers from the read-out start No. can be read. Read-out word data are

transmitted from the slave station in the order of upper and lower bytes.

-22-

Page 26

(3) Message transmission

(a) In case of data of internal calculation value

The following shows an example of reading-out the PV from No. 1 slave station.

Relative address of PV:0000

Command message composition (byte) Response message composition (byte)

Station No. 01

Function code 04H Function code 04H

Upper 00H Read-out byte number 02H Read-out start No.

(relative address)

Lower 00

Upper 00H

number

CRC data

Lower 01H

Upper 31H

Lower CA

* Meaning of read-out data

Contents of the first word data 03 46

When input range is 0-400℃,

Data number:01H

H

Station No. 01H

H

Upper 03H

H

H

Contents of the

first word data

CRC data

= 838(=8.38%FS)

H

Lower 46H Read-out word

Upper 38H

Lower 32H

PV=33.5℃(=8.38%FS×400

)

Input range

(b) In case of data of engineering unit

The following shows an example of reading-out the PV value from No. 1 slave station.

Relative address of PV value:03E8

Data number:01H

H

Command message composition (byte) Response message composition (byte)

Station No. 01

Station No. 01H

H

Function code 04H Function code 04H

Upper 03H Read-out byte number 02H Read-out start No.

(relative address)

number

CRC data

Lower E8

Upper 01H

H

Upper 00H

Lower 01H

Upper B1H

Lower BA

H

Contents of the

first word data

CRC data

Lower 4FH Read-out word

Upper 38H

Lower 32H

* Meaning of read-out data

Contents of the first word data 01 4F

= 335

H

When the position of decimal point is 1 (Parameter P-dP=1),

PV=33.5℃(=33.5)

Point

For handling of the internal calculation value, engineering unit and decimal point,

refer to section 7.1.

-23-

Page 27

6.5 Write-in of Bit Data (1 bit) [Function code:05H]

(

(

(

(

Function code Max. bit number written-in one message Relative data address Coil No.

05H 1 bit 0000H 00001

This function has become unnecessary. (The customer can continue using the controller without changing the

program.)

(1) Message composition

Command message composition (byte) Response message composition (byte)

Station No. Station No.

Function code Function code

Write-in designate

00

No.

relative address)

00

Upper Upper State of write-in

designation

CRC data

Lower

Upper Upper

Lower

(2) Function explanations

H

H

0000H=0

FF00

H

=1

Write-in

designate No.

relative address)

State of write-in

designation

CRC data

00

H

00

H

Lower

Lower

0000H=0

FF00

=1

H

Data of "0" or "1" is written in a bit of write-in designation No. bit. When "0" is written-in data of 0000H is

transmitted, and when "1" is written-in, data of FF00H is transmitted.

(3) Message transmission (example:This is the method of FIX execution)

The following shows an example of FIX execution request to No. 1 slave station.

FIX execution request bit Relative address:0000

Command message composition (byte) Response message composition (byte)

Station No. 01

Station No. 01H

H

Function code 05H Function code 05H

Write-in

Upper 00H

designate No.

relative address)

Lower 00

H

Upper FFH Upper FFH State of write-in

designation

CRC data

Lower 00

Upper 8CH Upper 8CH

Lower 3A

H

H

After receiving above command, it takes approximately 100ms to 5s seconds that PXR saves memory data

from RAM to EEPROM.

Caution

If you turn off the PXR during above saving (approximately 100ms to 5s), memory data are broken

and can not be used.

H

Write-in

designate No.

relative address)

State of write-in

designation

CRC data

Upper 00H

Lower 00

H

Lower 00H

Lower 3A

H

Point

For details of FIX processing, refer to section 5.7.

-24-

Page 28

6.6 Write-in of Word Data (1 word) [Function code:06H]

(

(

Function code Max. word number write-in

in one message

06H 1 words

(1) Message composition

Command message composition (byte) Response message composition (byte)

Station No. Station No.

Function code Function code

Write-in

designate No.

relative address)

data

CRC data

Upper

Lower

Upper Upper Write-in word

Lower

Upper Upper

Lower

(2) Function explanation

Designated word data is written in write-in designate No. Write-in data are transmitted from master station in

the order of upper and lower bytes.

(3) Message transmission (example)

Relative data address Resister No. Kind of data

0000

03E8

-0070

H

-0458

H

40001-40113

H

41001-41113

H

Write-in

designate No.

relative address)

Upper

Lower

Internal calculation value

Engineering unit

Write-in word

data

CRC data

Lower

Lower

The following shows an example of setting 100.0 (10000=C3E8H) to the parameter "P" of No.1 slave station.

Parameter "P" Relative address: 0005

(table of internal calculation unit)

H

(or 03ED

(table of engineering value))

H

* Parameter "P" is not in the engineering unit setting, the same value is

written in both tables.

Command message composition (byte) Response message composition (byte)

Station No. 01

Station No. 01H

H

Function code 06H Function code 06H

H

H

In case of

interval

calculation

Write-in

designate No.

(relative address)

State of write-in

designation

CRC data

Lower 05

H

Lower E8H

Lower 75

H

Write-in

designate No.

(relative address)

designation

CRC data

Upper 00H Upper 00H

Lower 05

Upper 03H Upper 03H State of write-in

Lower E8H

Upper 99H Upper 99H

Lower 75

Point

Note!

For handling of internal calculation value, engineering unit and decimal point, refer

to section 7.1.

1)While setting is being locked, response is returned normally, but the command is

not executed.

2)While the data is written in non-volatile memory, response is not returned.

-25-

Page 29

6.7 Write-in of Continuous Word Data [Function code:10H]

Function code Max. word number write-in

in one message

10H 60 words

(1) Message composition

Command message composition (byte) Response message composition (byte)

Station No. Station No.

Function code Function code

Upper Upper Write-in start No.

(relative address)

number

Write-in byte number

Lower

Upper Upper Write-in word

Lower

Upper First write-in

word data

Lower

Upper Next write-in

word data

~ ~

Lower

Upper Last write-in

word data

CRC data

Lower

Upper

Lower

* Arrangement of write-in word data

MSB LSB

Upper byte of contents of the first word data

Lower byte of contents of the first word data

Upper byte of contents of the next word data

Lower byte of contents of the next word data

~ ~

Upper byte of contents of the last word data

Lower byte of contents of the last word data

(2) Function explanation

Relative data address Resister No. Kind of data

0000

03E8

-0070

H

-0458

H

40001-40113

H

41001-41113

H

Internal calculation value

Engineering unit

Write-in start No.

1 to 60

Write-in word number×2

(relative address)

Write-in word

number

CRC data

Lower

Lower

Upper

Lower

Word data of continuous word number is written from write-in start address. Write-in word data are

transmitted from master station in the order of upper and lower bytes.

-26-

Page 30

(3) Message transmission (example)

The following shows an example of writing-in P=100.0, I=10, and D=5.0 to No. 1 slave station.

P=03E8

I=0064

D=0032

Parameter "P" Relative address:0005

(=1000D)

H

(=100D)

H

(=50D)

H

Data number:03

H

H

Command message composition (byte) Response message composition (byte)

Station No. 01

Station No. 01H

H

Function code 10H Function code 10H

Write-in start No.

Upper 00H Upper 00H

Lower 05

H

Upper 00H Upper 00H Write-in word

number

Lower 03H

Write-in byte number 06H Upper 90H

Upper 03H

word data

Lower E8

H

Write-in start No.

Write-in word

number

CRC data

Lower 05H

Lower 03H

Lower 09H First write-in

Upper 00H Next write-in

word data

Lower 64

H

Upper 00H Last write-in

word data

CRC data

Lower 32H

Upper 56H

Lower BE

H

Point

Since the transmission data can not include a decimal point, data of 100.0 is transmitted as

"1000".

For transmission format of each data, refer to the address map (Chapter 7).

-27-

Page 31

7. ADDRESS MAP AND DATA FORMAT

7.1 Data Format

7.1.1 Transmission data format

The MODBUS protocol used in this instrument (PXR) is RTU (Remote Terminal Unit) mode.

Transmitted data is "numeric value" and not "ASCII code".

7.1.2 Internal calculation value and engineering unit

This instrument can handle 2 kinds of set value data or other data which are affected by input range as follows.

1) Internal calculation value : In % with respect to input range (0.00 to 100.00, without decimal point)

2) Engineering unit : Subjected to scaling to actual value according to input range

"Engineering unit" data can be handled with "Internal calculation value" address (register No.) plus 1,000

[Example] The value of "PV = 150" (input range: 0 to 400°C)

Register No. Data (HEX)

Internal

calculation value

Engineering unit 31001 0096H 150

In case of "Internal calculation value" here,

37.50 (%) × 400 (full scale) = 150 (°C) is obtained.

Note that the same data is handled at both addresses if it is not affected by input range.

This handling does not apply to bit data. (Address increased by 1,000 is invalid.)

For data affected by input range, refer to address maps in Sections 7.2 and 7.3.

Note : After changing the input range by communication write-in, pay attention to the decimal point position.

After changing the decimal point position by communication write-in, simultaneously change the lower

limit and upper limit of input range.

Example: Input range 0 to 400 changed into 0.0 to 400.0

a) Face panel operation:

b) Communication write-in:

30001 0EA6H

P-dP=0→1 suffices

P-dP=0→1

P-SL=0→0

P-SU=400→4000

Data (decimal)

3750(37.50%)

must be performed.

-28-

Page 32

7.1.3 Handling of decimal point

Some internally stored data have more digits below decimal point than displayed on the face panel.

No decimal point is added to transmission data.

For data given in the following table, carry out an alignment of decimal point.

(a) Internal calculation value data (address map shown in Section 7.2)

Digits below point Kind Resister No.

Parameter [ P-SL ] 40018 Designate by

parameter [P-dP]

Parameter [ P-SU ] 40019

(0 to 2)

1 digit below point

Parameter [ P ] 40006

Parameter [ i ] 40007

Parameter [ d ] 40008

Parameter [ CooL ] 40010

Parameter [ P-dF ] 40022

Parameter [ HB ] 40039

Parameter [ CT ] 30010

2 digits below point

Data affected by input range See address map (Section 7.2)

Parameter [ dB ] 40011

Parameter [ bAL ] 40013

Parameter [ PLC1 ] 40025

Parameter [ PHC1 ] 40026

Parameter [ PLC2 ] 40027

Parameter [ PHC2 ] 40028

Parameter [ OUT1 ] 30004

Parameter [ OUT2 ] 30005

(b) Engineering unit (address map shown in Section 7.3)

Digits below point Kind Resister No.

Designate by

parameter [P-dP]

(0 to 2)

1 digit below point

Parameter [ P-SL ] 41018

Parameter [ P-SU ] 41019

Data affected by input range See address map (Section 7.3)

Parameter [ P ] 41006

Parameter [ i ] 41007

Parameter [ d ] 41008

Parameter [ CooL ] 41010

Parameter [ P-dF ] 41022

Parameter [ HB ] 41039

Parameter [ CT ] 31010

2 digits below point

Parameter [ dB ] 41011

Parameter [ bAL ] 41013

Parameter [ PLC1 ] 41025

Parameter [ PHC1 ] 41026

Parameter [ PLC2 ] 41027

Parameter [ PHC2 ] 41028

Parameter [ OUT1 ] 31004

Parameter [ OUT2 ] 31005

-29-

Page 33

7.1.4 Data when input is abnormal

When "UUUU" or "LLLL" is displayed on the face panel on account of over-range, under-range or input open-

circuit for example, PV read-out value is 105% or -5% of input range.

Presence of any input abnormality via communication can be detected by:

"Register No. 30008 (or 31008): Input/main unit abnormal status"

-30-

Page 34

7.2 Address Map of Internal Calculation Value Data

Data affected by input range is handled in terms of internal value (0.00 to 100.00% value) before

scaling.

For detailed contents about individual parameter function or setting range, refer to the operation manual

(ECNO: 406).

H

, 05H]

H

0:Not writing-in

1:Writing in memory

]

0:Alarm 1 OFF,1: Alarm 1 ON

0: Alarm 2 OFF,1: Alarm 2 ON

0: Relay output of alarm 1 OFF

1: Relay output of alarm 1 ON

0: Relay output of alarm 2 OFF

1: Relay output of alarm 2 ON

0: HB alarm output OFF

1: HB alarm output ON

0: Alarm 1 OFF,1: Alarm 1 ON

0: Alarm 2 OFF,1: Alarm 2 ON

0:HB alarm output OFF

1:HB alarm output ON

Write-in data

setting range

0:No request

1:Request to write in

Affected by

input range

Affected by

input range

(Same as 10001)

(Same as 10002)

(Same as 10012)

Bit data [read-out/write-in] : Function code [01

Relative

address

0000H 00001 Bit

Coil No. Type Memory contents Read-out data

Write in non-volatile memory

(FIX execution)

Bit data [read-out only] : Function code [02

Relative

address

0000H 10001 Bit Alarm 1 ON/OFF

0001H 10002 (Reserve)

0002H 10003 (Reserve)

0003H 10004 (Reserve)

0004H 10005 Bit Alarm 2 ON/OFF

0005H 10006 (Reserve)

0006H 10007 (Reserve)

0007H 10008 (Reserve)

0008H 10009 Bit

0009H 10010 Bit

000AH 10011 (Reserve)

000BH 10012 Bit HB alarm relay output

000CH 10013 Bit Alarm 1 ON/OFF

000DH 10014 Bit Alarm 2 ON/OFF

000EH 10015 (Reserve)

000FH 10016 Bit HB alarm relay output

Coil No. Type Memory contents Read-out data

Alarm 1 output

(Calculation result of nonexciting alarm)

Alarm 2 output

(Calculation result of nonexciting alarm)

Remarks or

corresponding

parameter

(the same

function as

40001)

Remarks or

corresponding

parameter

-31-

Page 35

Word data [read-out/write-in] : Function code [03

Relative

address

0000H 40001 Word Non-volatile memory write-in

0001H 40002 Word PID/FUZZY/SELF selection

0002H 40003 Word SV value set on face panel

0003H 40004 Word Control RUN/standby

0004H 40005 Word Auto tuning command

0005H 40006 Word P

0006H 40007 Word I

0007H 40008 Word D

0008H 40009 Word

0009H 40010 Word COOL

000AH 40011 Word Dead band

000BH 40012 Word Anti-reset windup

000CH 40013 Word Output convergence value

000DH 40014 Word PV shift

000EH 40015 Word SV offset

000FH 40016 Word Input type code 0 to 16

0010H 40017 Word Temperature unit

0011H 40018 Word Input scale lower limit -1999 to 9999

0012H 40019 Word Input scale upper limit -1999 to 9999

0013H 40020 Word Decimal point place 0 to 2

0014H 40021 (Do not use)

0015H 40022 Word Input filter time constant

0016H 40023 Word RCJ yes/no

0017H 40024 Word MV limit kind 0 to 15

0018H 40025 Word Output 1 lower limit

0019H 40026 Word Output 1 upper limit

001AH 40027 Word Output 2 lower limit

001BH 40028 Word Output 2 upper limit

001CH 40029 (Do not use)

001DH 40030 (Do not use)

001EH 40031 Word Set value (SV) lower limit

001FH 40032 Word Set value (SV) upper limit

0020H 40033 (Do not use)

0021H 40034 (Do not use)

0022H 40035 (Do not use)

0023H 40036 (Do not use)

0024H 40037 (Do not use)

0025H 40038 (Do not use)

0026H 40039 Word Heater burnout alarm set value

0027H 40040 Word Setting lock 0 to 5

Resister

No.

Type Memory contents Read-out data

Hysteresis range at

two-position control

, 06H, 10H]

H

0: Not writing-in

1: Writing in memory

0:PID control

1:FUZZYcontrol

2:SELF tuning control

0 to 10000

(within 0.00 to 100.00% FS within set

value limits)

0: Invalidate standby (RUN)

1:Validate standby

0: Auto tuning

disabled

1: While executing

standard type AT

executed

2: While executing

low PV type AT

executed

0 to 9999(0.0 to 999.9%)

0 to 32000(0 to 3200.0 sec)

0 to 9999(0.0 to 999.9 sec)

0 to 5000(0.00 to 50.00%FS) *

0 to 1000(0.0 to 100.0)

-5000 to 5000(-50.00 to +50.00)

0 to 10000(0.00 to 100.00%) *

-10000 to 10000

(-100.00 to 100.00%)

-1000 to 1000(-10.00 to 10.00%FS) *

-5000 to 5000(-50.00 to 50.00%FS) *

0:℃ 1:°F

0 to 9000(0.0 to 900.0 sec)

0: Disable RCJ compensation

(do not perform reference cold junction

compensation)

1: Enable RCJ compensation (perform

reference cold junction compensation)

-300 to 10300(-3.00 to 103.00%)

-300 to 10300(-3.00 to 103.00%)

-300 to 10300(-3.00 to 103.00%)

-300 to 10300(-3.00 to 103.00%)

0 to 10000(0.00 to 100.00%FS) *

0 to 10000(0.00 to 100.00%FS) *

0 to 500(0.0 to 50.0A)

Write-in data

setting range

0:No request

1:Request to write in

0: Disable auto

tuning

1: Request

execution of

standard type

2: Request

execution of low

PV type AT

Affected by

input range

*

Remarks or

corresponding

parameter

(Same function

as 00001)

CTrL

* Inhibit change

while

controlling

STby

AT

P

i

D

HyS

CooL

db

Ar

bAL

PVOF

SVOF

P-n2

P-F

P-SL

P-SU

P-dP

P-dF

rCJ

PCUT

PLC1

PHC1

PLC2

PHC2

SV-L

SV-H

Hb

LoC

-32-

Page 36

Relative

address

0028H 40041 Word Alarm 1 type 0 to 34

0029H 40042 Word Alarm 2 type 0 to 34

002AH 40043 (Do not use)

002BH 40044 Word

002CH 40045 Word

002DH 40046 (Do not use)

002EH 40047 Word Alarm 1 upper limit set value

002FH 40048 Word Alarm 2 upper limit set value

0030H 40049 (Do not use)

0031H 40050 Word Alarm 1 hysteresis

0032H 40051 Word Alarm 2 hysteresis

0033H 40052 (Do not use)

0034H 40053 Word Alarm 1 ON-delay set value

0035H 40054 Word Alarm 2 ON-delay set value

0036H 40055 (Do not use)

0037H 40056 (Do not use)

0038H 40057 Word Ramp/soak No. 1 target value

0039H 40058 Word Ramp/soak No. 2 target value

003AH 40059 Word Ramp/soak No. 3 target value

003BH 40060 Word Ramp/soak No. 4 target value

003CH 40061 Word Ramp/soak No. 5 target value

003DH 40062 Word Ramp/soak No. 6 target value

003EH 40063 Word Ramp/soak No. 7 target value

003FH 40064 Word Ramp/soak No. 8 target value

0040H 40065 Word Ramp/soak No. 1 ramp time

0041H 40066 Word Ramp/soak No. 1 soak time

0042H 40067 Word Ramp/soak No. 2 ramp time

0043H 40068 Word Ramp/soak No. 2 soak time

0044H 40069 Word Ramp/soak No. 3 ramp time

0045H 40070 Word Ramp/soak No. 3 soak time

0046H 40071 Word Ramp/soak No. 4 ramp time

0047H 40072 Word Ramp/soak No. 4 soak time

0048H 40073 Word Ramp/soak No. 5 ramp time

0049H 40074 Word Ramp/soak No. 5 soak time

004AH 40075 Word Ramp/soak No. 6 ramp time

004BH 40076 Word Ramp/soak No. 6 soak time

004CH 40077 Word Ramp/soak No. 7 ramp time

004DH 40078 Word Ramp/soak No. 7 soak time

004EH 40079 Word Ramp/soak No. 8 ramp time

004FH 40080 Word Ramp/soak No. 8 soak time

0050H 40081 Word Ramp/soak mode 0 to 15

0051H 40082 Word Ramp/soak command

Resister

No.

Type Memory contents Read-out data

Alarm 1 set value or

alarm 1 lower limit set value

Alarm 2 set value or

alarm 2 lower limit set value

For absolute value alarm

For deviation alarm

For absolute value alarm

For deviation alarm

0 to 5000(0.00 to 50.00%FS) *

0 to 5000(0.00 to 50.00%FS) *

0 to 9999(0 to 9999 sec)

0 to 9999(0 to 9999 sec)

0 to 10000

(0.00 to 100.00%FS,

within set value limit)

0 to 5999(0 to 5999 min)

* With main unit parameter,

0: oFF

1: rUn

2: HLd

3: End

Write-in data

setting range

0 to 10000(0.00 to 100.00%FS)

-10000 to 10000

(-100.00 to 100.00%FS)

0 to 10000(0.00 to 100.00%FS)

-10000 to 10000

(-100.00 to 100.00%FS)

Hour Minute

is displayed and set.

Therefore, correspondence occurs as:

3601:Data via communication

∥

6001:Display/setting on main unit

Ramp/soak stopped

Ramp/soak operated

Ramp/soak halted

Ramp/soak ended

0:oFF

Stop ramp/soak

1:rUn

Start ramp/soak

2:HLd

Halt ramp/soak

3: End ランプ

ソーク終了

Affected by

input range

*

*

*

*

*

*

*

*

*

*

*

*

Remarks or

corresponding

parameter

ALM1

ALM2

AL1 or A1-L

AL2 or A2-L

A1-H

A2-H

A1hy

A2hy

dLy1

dLy2

Sv-1

Sv-2

Sv-3

Sv-4

Sv-5

Sv-6

Sv-7

Sv-8

TM1r

TM1S

TM2r

TM2S

TM3r

TM3S

TM4r

TM4S

TM5r

TM5S

TM6r

TM6S

TM7r

TM7S

TM8r

TM8S

MOD

ProG

-33-

Page 37

Remarks or

corresponding

parameter

PTn

SLFb

P-n1

TC

TC2

A1op

A2op

di-1

ONOF

ADJ0

ADJS

dSP1

dSP2

dSP3

dSP4

dSP5

dSP6

dSP7

dSP8

dSP9

dSP10

dSP11

dSP12

dSP13

Note

Relative

address

0052H 40083 Word Ramp/soak pattern selection

0053H 40084 (Do not use)

0054H 40085 Word PV stable range

0055H 40086 (Do not use)

0056H 40087 Word

0057H 40088 Word Control action type code 0 to 19

0058H 40089 Word

0059H 40090 Word

005AH 40091 (Do not use)

005BH 40092 Word Alarm 1 option function

005CH 40093 Word Alarm 2 option function

005DH 40094 (Do not use)

005EH 40095 Word DI1 action setting 0 to 12

005FH 40096 (Do not use)

0060H 40097 Word Hysteresis mode setting

0061H 40098 Word (Do not use)

0062H 40099 Word User zero adjustment

0063H 40100 Word User span adjustment

0064H 40101 Word

0065H 40102 Word

0066H 40103 Word

0067H 40104 Word

0068H 40105 Word

0069H 40106 Word

006AH 40107 Word

006BH 40108 Word

006CH 40109 Word

006DH 40110 Word

006EH 40111 Word

006FH 40112 Word

0070H 40113 Word

Resister

No.

Type Memory contents Read-out data

0: Execute No. 1 to 4 ramp/soak

1: Execute No. 5 to 8 ramp/soak

2: Execute No. 1 to 8 ramp/soak

0 to 10000(0.00 to 100.00%FS) *

Communication DI action

request

Output proportional cycle

(output 1)

Output proportional cycle

(output 2)

DSP1

(parameter mask designation)

DSP2

(parameter mask designation)

DSP3

(parameter mask designation)

DSP4

(parameter mask designation)

DSP5

(parameter mask designation)

DSP6

(parameter mask designation)

DSP7

(parameter mask designation)

DSP8

(parameter mask designation)

DSP9

(parameter mask designation)

DSP10

(parameter mask designation)

DSP11

(parameter mask designation)

DSP12

(parameter mask designation)

DSP13

(parameter mask designation)

*② (refer to section 7.4.)

0: Current output type

1 to 150(1 to 150 sec):

Relay, SSR drive output type

1 to 150(1 to 150 sec)

0 to 7(binary data 000B to 111

0 to 7(binary data 000B to 111

0: off (main unit parameter setting)

1: on (main unit parameter setting)

-5000 to 5000

(-50.00 to 50.00%FS)

-5000 to 5000

(-50.00 to 50.00%FS)

0 to 255

0 to 255

0 to 255

0 to 255

0 to 255

0 to 255

0 to 255

0 to 255

0 to 255

0 to 255

0 to 255

0 to 255

0 to 255

(PTn=1)

(PTn=2)

(PTn=3)

Write-in data

setting range

B

B

Affected by

input range

)

)

*

*

Note) Read-out/write-in data from Resister No. 40083 (ramp/soak pattern selection) correspond to parameter “PTn”

to be displayed as shown below:

Read-out/write-in data Parameter PTn Contents

0 1 1 to 4 ramp/soak executed

1 2 5 to 8 ramp/soak executed

2 3 1 to 8 ramp/soak executed

-34-

Page 38

Word data (read-out only) : Function code [04

Relative

address

0000H 30001 Word Process value (PV)

0001H 30002 Word Currently used set value (SV)

0002H 30003 Word Currently used deviation (DV)

0003H 30004 Word MV (output 1)

0004H 30005 Word MV (output 2)

0005H 30006 Word Station No. 0 to 255

0006H 30007 Word Alarm status

0007H 30008 Word Input/main unit abnormal status

0008H 30009 Word

0009H 30010 Word Heater current

000AH 30011 Word Timer 1 current count

000BH 30012 Word Timer 2 current count

000CH 30013 (Reserve)

000DH 30014 (Reserve)

000EH 30015 Word DI action status

Resister

No.

Type Memory contents

Ramp/soak current running

position

]

H

0 to 10000(0.00 to 100.00%FS) *

0 to 10000(0.00 to 100.00%FS) *

-10000 to 10000

(-100.00 to 100.00%FS)

-300 to 10300(-3.00 to 103.00%)

-300 to 10300(-3.00 to 103.00%)

*③ (refer to Section 7.4.)

*④ (refer to Section 7.4.)

0 to 17

*⑥ (refer to Section 7.4.)

0 to 500(0.0 to 50.0A)

0 to 9999(0 to 9999 sec)

0 to 9999(0 to 9999 sec)

*⑤ (refer to Section 7.4.)

Notes)

• For details of *

to * ⑥ in the table, refer to Section 7.4.

②

• The area marked (Do not use) is a reserve area. Do not write in there.

• Register numbers 30002 (currently used SV) and 40003 (face panel set SV) do not become the same

value while switching-SV is active or ramp/soak is under way. (Example: While SV-1 is selected, the

value of SV-1 is read out of register number 30002.) For reading out SV for monitoring, use SV in

register number 30002.

Read-out data

Affected by

input range

*

Remarks or

corresponding

parameter

(Displayed PV

value)

(Displayed SV

value)

OUT1

OUT2

STno

STAT

CT

TM-1

TM-2

-35-

Page 39

7.3 Address Map of Engineering Unit Data

Data affected by input range is handled in terms of a value (engineering unit) after scaling.

For detailed contents about individual parameter function or setting range, refer to the operation manual

(ECNO: 406).

H

, 05H]

H

0:Not Writing-in

1:Writing in memory

]

0:Alarm 1 OFF,1: Alarm 1 ON

0: Alarm 2 OFF,1: Alarm 2 ON

0: Relay output of alarm 1 OFF

1: Relay output of alarm 1 ON

0: Relay output of alarm 2 OFF

1: Relay output of alarm 2 ON

0: HB alarm output OFF

1: HB alarm output ON

0: Alarm 1 OFF,1: Alarm 1 ON

0: Alarm 2 OFF,1: Alarm 2 ON

0:HB alarm output OFF

1:HB alarm output ON

Write-in data

setting range

0:No request

1:Write-in request

Affected by

input range

(the same

Affected by

input range

(Same as 10001)

(Same as 10002)

(Same as 10012)

function as

40001)

Bit data [read-out/write-in] : Function code [01

Relative

address

0000H 00001 Bit

Coil No. Type Memory contents Read-out data

Write in non-volatile memory

(FIX execution)

Bit data [read-out only] : Function code [02

Relative

address

0000H 10001 Bit Alarm 1 ON/OFF

0001H 10002 (Reserve)

0002H 10003 (Reserve)

0003H 10004 (Reserve)

0004H 10005 Bit Alarm 2 ON/OFF

0005H 10006 (Reserve)

0006H 10007 (Reserve)

0007H 10008 (Reserve)

0008H 10009 Bit

0009H 10010 Bit

000AH 10011 (Reserve)

000BH 10012 Bit HB alarm relay output

000CH 10013 Bit Alarm 1 ON/OFF

000DH 10014 Bit Alarm 2 ON/OFF

000EH 10015 (Reserve)

000FH 10016 Bit HB alarm relay output

Coil No. Type Memory contents Read-out data

Alarm 1 output

(Calculation result of nonexciting alarm)

Alarm 2 output

(Calculation result of nonexciting alarm)

Remarks or

corresponding

parameter

Remarks or

corresponding

parameter

-36-

Page 40

Word data [read-out/write-in]: Function code [03

Relative

address

03E8H 41001 Word

03E9 H 41002 Word PID/FUZZY/SELF selection

03EA H 41003 Word SV value controlled on face panel -1999 to 9999 (within set value limits)

03EB H 41004 Word Control RUN/standby

03EC H 41005 Word Auto tuning command

03ED H 41006 Word P

03EE H 41007 Word I

03EF H 41008 Word D

03F0 H 41009 Word

03F1H 41010 Word COOL

03F2H 41011 Word Dead band

03F3H 41012 Word Anti-reset windup

03F4H 41013 Word Output convergence value

03F5H 41014 Word PV shift

03F6H 41015 Word SV offset

03F7H 41016 Word Input type code 0 to 16

03F8H 41017 Word Temperature unit

03F9H 41018 Word Input scale lower limit -1999 to 9999

03FAH 41019 Word Input scale upper limit -1999 to 9999

03FBH 41020 Word Decimal point place 0 to 2

03FCH 41021 (Do not use)

03FDH 41022 Word Input filter time constant

03FEH 41023 Word RCJ yes/no

03FFH 41024 Word MV limit kind 0 to 15

0400H 41025 Word Output 1 lower limit

0401H 41026 Word Output 1 upper limit

0402H 41027 Word Output 2 lower limit

0403H 41028 Word Output 2 upper limit

0404H 41029 (Do not use)

0405H 41030 (Do not use)

0406H 41031 Word Set value (SV) lower limit

0407H 41032 Word Set value (SV) upper limit

0408H 41033 (Do not use)

0409H 41034 (Do not use)

040AH 41035 (Do not use)

040BH 41036 (Do not use)

040CH 41037 (Do not use)

040DH 41038 (Do not use)

040EH 41039 Word Heater burnout alarm set value

Resister

No.

Type Memory contents Read-out data

Non-volatile memory write-in

(FIX execution)

Hysteresis range at

two-position control

, 06H, 10H]

H

Write-in data

setting range

0: Not writing in

1: Write in memory

0:PID control

1:FUZZYcontrol

2:SELF tuning control

0: Invalidate standby (RUN)

1:Validate standby

0: Auto tuning

disabled

1: While executing

standard type AT

executed

2: While executing

low PV type AT

executed

0 to 9999(0.0 to 999.9%)

0 to 32000(0 to 3200.0 sec)

0 to 9999(0.0 to 999.9 sec)

0 to 9999 (0 to 50% value of input scale) *

0 to 1000(0.0 to 100.0)

-5000 to 5000

(-50.00 to +50.00%)

-1999 to 9999

(0 to 100% value of input scale)

-10000 to 10000

(-100.00 to 100.00%)

-1999 to 9999

(-10 to 10% value of input scale)

-1999 to 9999

(-50 to 50% value of input scale)

0:℃ 1:°F

0 to 9000(0.0 to 900.0 sec)

0: Disable RCJ compensation

(do not perform reference cold junction

compensation)

1: Enable RCJ compensation (perform

reference cold junction compensation)

-300 to 10300(-3.00 to 103.00%)

-300 to 10300(-3.00 to 103.00%)

-300 to 10300(-3.00 to 103.00%)

-300 to 10300(-3.00 to 103.00%)

-1999 to 9999(within input scale) *

-1999 to 9999(within input scale) *

0 to 500(0.0 to 50.0A)

0:No request

1:Request to write in

0: Disable auto

tuning

1: Request

execution of

standard type

2: Request

execution of low

PV type AT

Affected by

input range

*

*

*

*

Remarks or

corresponding

parameter

(Same function

as 00001)

CTrL

* Inhibit change

while

controlling

STby

AT

P

i

D

HyS

CooL

db

Ar

bAL

PVOF

SVOF

P-n2

P-F

P-SL

P-SU

P-dP

P-dF

rCJ

PCUT

PLC1

PHC1

PLC2

PHC2

SV-L

SV-H

Hb

-37-

Page 41

Relative

address

040FH 41040 Word Setting lock 0 to 5

0410H 41041 Word Alarm 1 type 0 to 34

0411H 41042 Word Alarm 2 type 0 to 34

0412H 41043 (Do not use)

0413H 41044 Word

0414H 41045 Word

0415H 41046 (Do not use)

0416H 41047 Word Alarm 1 upper limit set value

0417H 41048 Word Alarm 2 upper limit set value

0418H 41049 (Do not use)

0419H 41050 Word Alarm 1 hysteresis

041AH 41051 Word Alarm 2 hysteresis

041BH 41052 (Do not use)

041CH 41053 Word Alarm 1 ON-delay set value

041DH 41054 Word Alarm 2 ON-delay set value

041EH 41055 (Do not use)

041FH 41056 (Do not use)

0420H 41057 Word Ramp/soak No. 1 target value

0421H 41058 Word Ramp/soak No. 2 target value

0422H 41059 Word Ramp/soak No. 3 target value

0423H 41060 Word Ramp/soak No. 4 target value

0424H 41061 Word Ramp/soak No. 5 target value

0425H 41062 Word Ramp/soak No. 6 target value

0426H 41063 Word Ramp/soak No. 7 target value

0427H 41064 Word Ramp/soak No. 8 target value

0428H 41065 Word Ramp/soak No. 1 ramp time

0429H 41066 Word Ramp/soak No. 1 soak time

042AH 41067 Word Ramp/soak No. 2 ramp time

042BH 41068 Word Ramp/soak No. 2 soak time

042CH 41069 Word Ramp/soak No. 3 ramp time

042DH 41070 Word Ramp/soak No. 3 soak time

042EH 41071 Word Ramp/soak No. 4 ramp time

042FH 41072 Word Ramp/soak No. 4 soak time

0430H 41073 Word Ramp/soak No. 5 ramp time

0431H 41074 Word Ramp/soak No. 5 soak time

0432H 41075 Word Ramp/soak No. 6 ramp time

0433H 41076 Word Ramp/soak No. 6 soak time

0434H 41077 Word Ramp/soak No. 7 ramp time

0435H 41078 Word Ramp/soak No. 7 soak time

0436H 41079 Word Ramp/soak No. 8 ramp time

0437H 41080 Word Ramp/soak No. 8 soak time

0438H 41081 Word Ramp/soak mode 0 to 15

0439H 41082 Word Ramp/soak command

Resister

No.

Type Memory contents Read-out data

Alarm 1 set value or

alarm 1 lower limit set value

Alarm 2 set value or

alarm 2 lower limit set value

-1999 to 9999

For absolute value alarm:

For deviation alarm:

-1999 to 9999

For absolute value alarm:

For deviation alarm:

0 to 9999

(0 to 50% value of input scale)

0 to 9999

(0 to 50% value of input scale)

0 to 9999(0 to 9999 sec)

0 to 9999(0 to 9999 sec)

-1999 to 9999

(within set value limit)

0 to 5999(0 to 5999 min)

* With main unit parameter,

0: oFF

1: rUn

2: HLd

3: End

Write-in data

setting range

0 to 100% value of input scale

–100 to 100% value of input scale

0 to 100% value of input scale

–100 to 100% value of input scale

Hour Minute

is displayed and set.

Therefore, correspondence occurs as:

3601:Data via communication

∥

6001:Display/setting on main unit

Ramp/soak stopped

Ramp/soak operated

Ramp/soak halted

Ramp/soak ended

0:oFF

Stop ramp/soak

1:rUn

Start ramp/soak

2:HLd

Halt ramp/soak

3: End ランプ

ソーク終了

Affected by

input range

*

*

*

*

*

*

*

*

*

*

*

*

*

*

Remarks or

corresponding

parameter

LoC

ALM1

ALM2

AL1 or A1-L

AL2 or A2-L

A1-H

A2-H

A1hy

A2hy

dLy1

dLy2

Sv-1

Sv-2

Sv-3

Sv-4

Sv-5

Sv-6

Sv-7

Sv-8

TM1r

TM1S

TM2r

TM2S

TM3r

TM3S

TM4r

TM4S

TM5r

TM5S

TM6r

TM6S

TM7r

TM7S

TM8r

TM8S

MOD

ProG

-38-

Page 42

Note

Relative

address

043AH 41083 Word Ramp/soak pattern selection

043BH 41084 (Do not use)

043CH 41085 Word PV stable range -1999 to 9999 (Within input scale)

043DH 41086 (Do not use)

043EH 41087 Word

043FH 41088 Word Control action type code 0 to 19

0440H 41089 Word

0441H 41090 Word

0442H 41091 (Do not use)

0443H 41092 Word Alarm 1 option function

0444H 41093 Word Alarm 2 option function

0445H 41094 (Do not use)

0446H 41095 Word DI1 action setting 0 to 12

0447H 41096 (Do not use)

0448H 41097 Word Hysteresis mode setting

0449H 41098 Word (Do not use)

044AH 41099 Word User zero adjustment

044BH 41100 Word User span adjustment

044CH 41101 Word

044DH 41102 Word

044EH 41103 Word

044FH 41104 Word

0450H 41105 Word

0451H 41106 Word

0452H 41107 Word

0453H 41108 Word

0454H 41109 Word

0455H 41110 Word

0456H 41111 Word

0457H 41112 Word

0458H 41113 Word

Resister

No.

Type Memory contents Read-out data

0: Execute No. 1 to 4 ramp/soak

1: Execute No. 5 to 8 ramp/soak

2: Execute No. 1 to 8 ramp/soak

Communication DI action

request

Output proportional cycle

(output 1)

Output proportional cycle

(output 2)

DSP1

(parameter mask designation)

DSP2

(parameter mask designation)

DSP3

(parameter mask designation)

DSP4

(parameter mask designation)

DSP5

(parameter mask designation)

DSP6

(parameter mask designation)

DSP7

(parameter mask designation)

DSP8

(parameter mask designation)

DSP9

(parameter mask designation)

DSP10

(parameter mask designation)

DSP11

(parameter mask designation)

DSP12

(parameter mask designation)

DSP13

(parameter mask designation)

*② (refer to section 7.4.)

0: Current output type

1 to 150(1 to 150 sec):

Relay, SSR drive output type

1 to 150(1 to 150 sec)

0 to 7(binary data 000B to 111

0 to 7(binary data 000B to 111

0: off (main unit parameter setting)

1: on (main unit parameter setting)

-1999 to 9999

(-50 to 50% value of input scale)

-1999 to 9999

(-50 to 50% value of input scale)

0 to 255

0 to 255

0 to 255

0 to 255

0 to 255

0 to 255

0 to 255

0 to 255

0 to 255

0 to 255

0 to 255

0 to 255

0 to 255

Write-in data

setting range

)

B

)

B

Affected by

input range

*

*

*

corresponding

PTn

SLFb

P-n1

TC

TC2

A1op

A2op

di-1

ONOF

ADJ0

ADJS

dSP1

dSP2

dSP3

dSP4

dSP5

dSP6

dSP7

dSP8

dSP9

dSP10

dSP11

dSP12

dSP13

Note) Read-out/write-in data from Resister No. 41083 (ramp/soak pattern selection) correspond to parameter “PTn”

to be displayed as shown below:

Read-out/write-in data Parameter PTn Contents

0 1 1 to 4 ramp/soak executed

1 2 5 to 8 ramp/soak executed

2 3 1 to 8 ramp/soak executed

Remarks or

parameter

-39-

Page 43

Word data (read-out only) : Function code [04

Relative

address

03E8H 31001 Word Process value (PV)

03E9H 31002 Word Currently used set value (SV)

03EAH 31003 Word Currently used deviation (DV)

03EBH 31004 Word MV (output 1)

03ECH 31005 Word MV (output 2)

03EDH 31006 Word Station No. 0 to 255

03EEH 31007 Word Alarm status

03EFH 31008 Word Input/main unit abnormal status