Page 1

Instruction Manual

Program Controller X

Type : PVX

INP–TN1PVXa-E

Page 2

PREFACE

This User’s Manual is intended for providing the reader with essential information on Program

Controller X, type PVX, hoping that the unit can be properly operated to the benefit of the user.

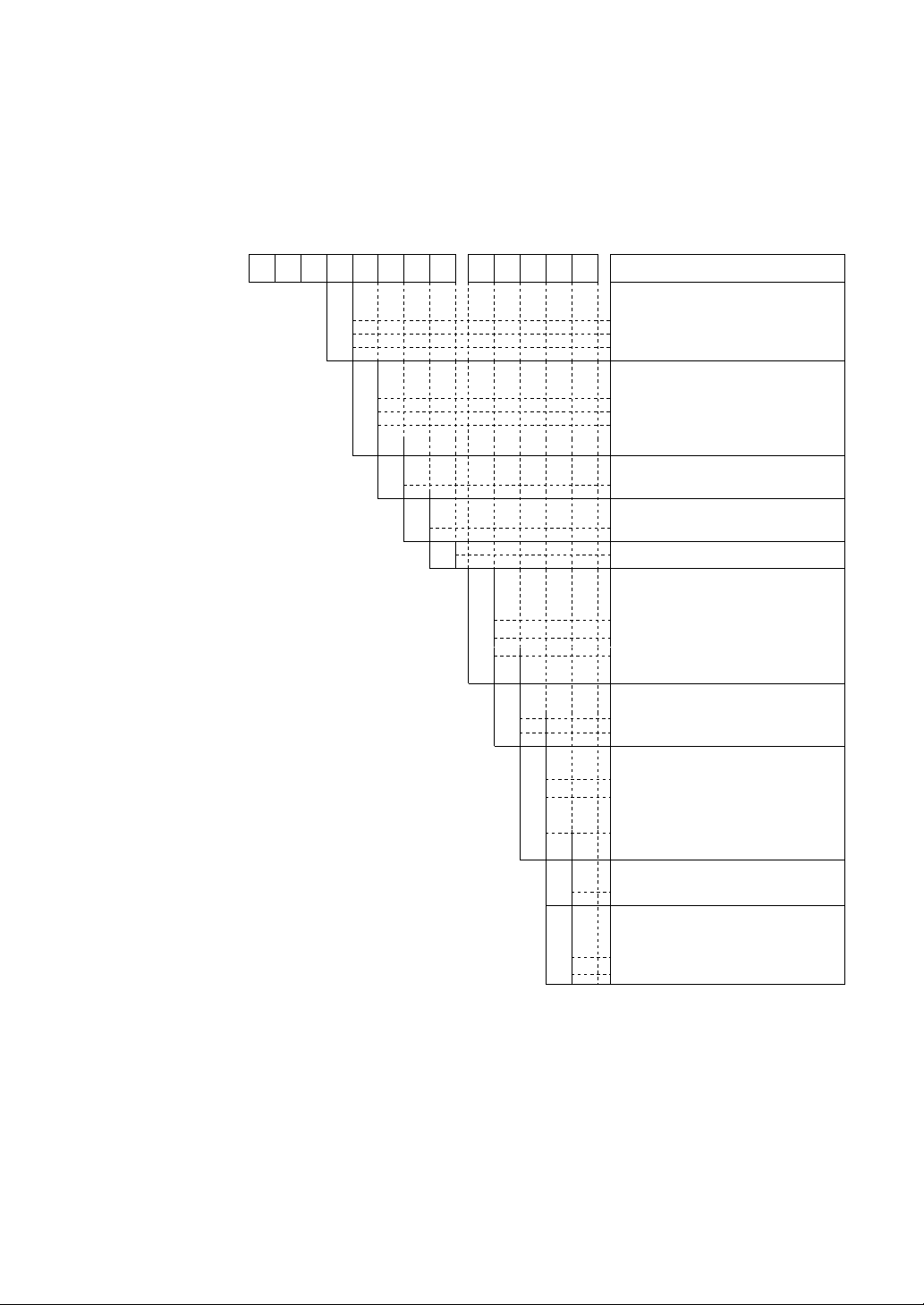

■ Code Symbols

12345678 910111213

PVX 1

1

2

3

C

P

D

T

S

1

Control output

Relay contact output

SSR/SSC drive output

DC4 to 20mA output

Digital input

External command input (4 points)

Pattern select input (4 points)

External command input + Pattern

select input

Time signal output 1 to 4

Provided

Status output (Operating profile output)

Provided

Modification No.

Extended digital output (Open

collector output: 2 points)

Y

T

A

Not provided

To be used as time signal (TS5, 6)

To be used as alarm (ALM3, 4)

Contents

Y

R

0

1

2

• Scope of supply

Program controller, panel fixtures, and

user’s manual

Y

E

J

■ List of Abbreviations frequently used in this Manual:

CLR: Clear

DSP: Display

PTN: Pattern

SEL: Select

ENT: Enter

HLD: Hold

SFT: Shift

REST: Reset

ALM: Alarm

MAN: Manual

PTN: Pattern

PV: Processing Variable

Loader interface

Not provided

Provided

Auxiliary signal output

Not provided

Voltage output:

1 point

Voltage output:

2 points

Communication facility

Not provided

User’s manual, instructions and

setting

English version

Japanese version

Note)

1 to 5 VDC at

the shipment

from factory

DV: Deviation

SV: Set Value

TM: Time

MV: Manipulating Value

A/M: Auto/Manual

– i –

Page 3

CONTENTS

PREFACE ................................................................................................................ i

Code Symbols ......................................................................................................................... i

List of Abbreviations frequently used in this Manual:............................................................ i

Overview ................................................................................................................................. iv

Explanation of Front Panel......................................................................................................v

Explanation of Keys and How to Use Them ........................................................................... v

SECTION 1 BEFORE STARTING OPERATION .................................................... 1-1

1. Changing Displays on Operating Screen ......................................................................... 1-1

2. Operation.......................................................................................................................... 1-1

3. Parameter Setting Overview ............................................................................................ 1-3

SECTION 2 PROGRAMMING.................................................................................. 2-1

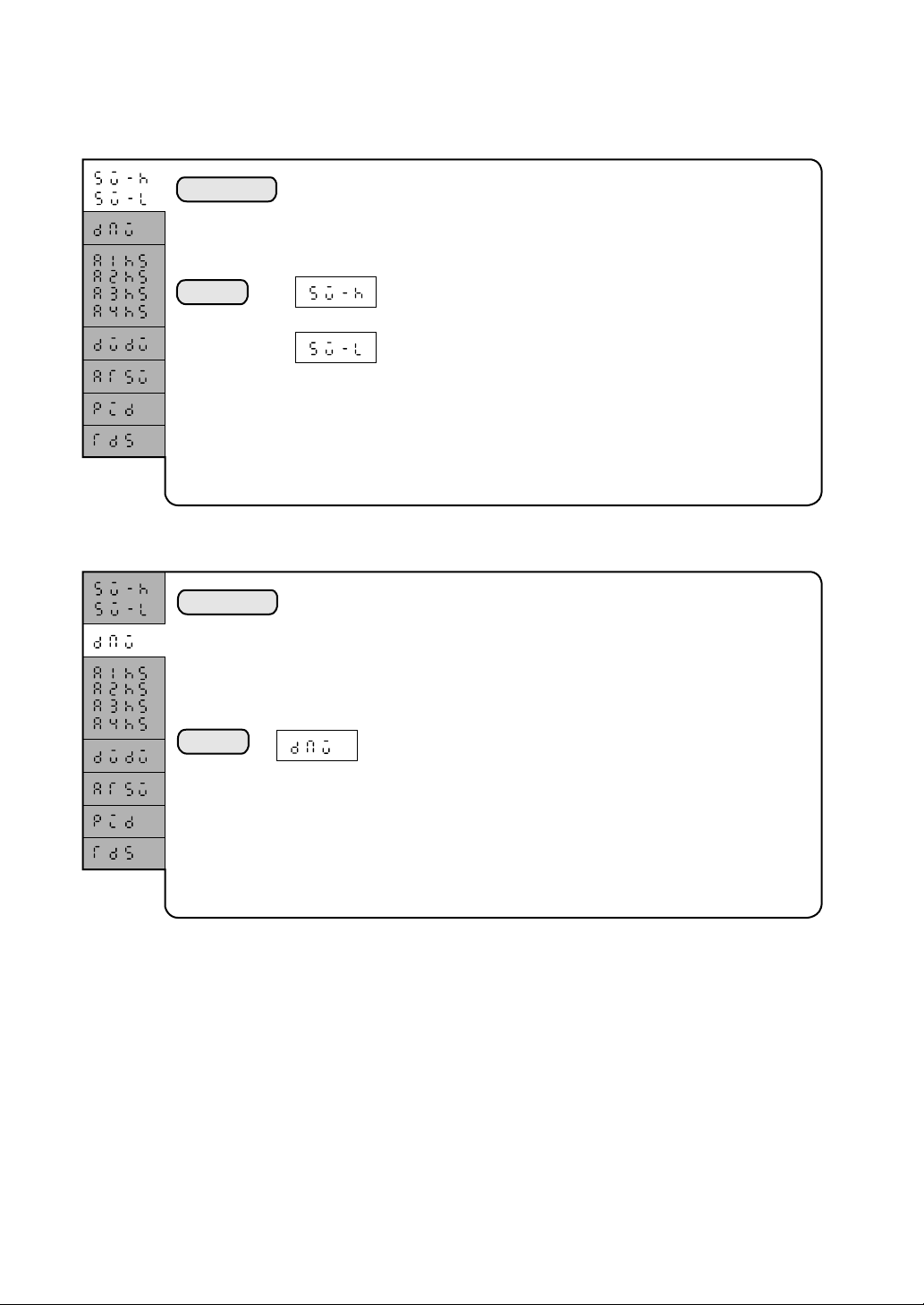

1. Parameter Structure and Parameter Calling Method........................................................ 2-1

2. Program Pattern Setting (Program Pattern Setting Channel) ........................................... 2-2

2.1 Program pattern structure .......................................................................................................................... 2-2

2.2 Pattern Setting [Setting of a set value (SV) and time] .............................................................................. 2-4

2.3 Setting of supplementary functions ........................................................................................................... 2-6

2.3.1 Setting of PID group......................................................................................................................... 2-6

2.3.2 Setting of alarm values 1 to 4........................................................................................................... 2-7

2.3.3 Setting of time signal........................................................................................................................ 2-8

2.3.4 Guarantee soak (Waiting for PV to follow) ..................................................................................... 2-9

2.3.5 PV Start (Allowing the program to start from the current PV)........................................................ 2-10

2.3.6 Cyclic Operation (Repetitious execution of a pattern)..................................................................... 2-11

2.3.7 Pattern-Link Operation (Successive pattern execution)................................................................... 2-12

2.4 Editing Program Pattern ............................................................................................................................ 2-13

2.4.1 Segment insertion (a new segment is created between segments) ................................................... 2-13

2.4.2 Segment erasure (a segment in a pattern is erased).......................................................................... 2-13

2.4.3 Copying a pattern ............................................................................................................................. 2-14

2.4.4 Pattern erasure .................................................................................................................................. 2-15

2.4.5 Erasure of all patterns....................................................................................................................... 2-15

2.4.6 Change of running program ............................................................................................................. 2-16

3. Setting of PID Group (PID Setting Channel)................................................................... 2-17

3.1 Structure of PID Setting Channel.............................................................................................................. 2-17

3.2 Setting of each parameter .......................................................................................................................... 2-18

3.2.1 Setting of proportional zone (P), integration time (I), and differentiation time (D) ........................ 2-20

3.2.2 Setting of blind zone......................................................................................................................... 2-20

3.2.3 Manipulating value (MV) upper and lower limits............................................................................ 2-21

3.2.4 Reversing specification .................................................................................................................... 2-21

3.2.5 Non-linear gain................................................................................................................................. 2-22

3.2.6 Integration break point ..................................................................................................................... 2-22

3.2.7 Manual reset ..................................................................................................................................... 2-23

SECTION 3 SETTING UP .. Start-up and specification changes .............................. 3-1

1. Structure of System Setup Channel ................................................................................. 3-1

2. Setting of Each Parameter ................................................................................................ 3-3

2.1 Setting of PV input type and input range .................................................................................................. 3-3

2.2 Setting of PV display unit (°C or°F) and 0.1°C (°F) notation

(for thermocouple or resistance bulb) ....................................................................................................... 3-4

2.3 Setting of full scale and base scale in the engineering unit notation

(for DC voltage and current input) ............................................................................................................ 3-5

2.4 PV filter (reducing the wander of PV arising from noise) ........................................................................ 3-6

2.5 PV shift (shifting zero point of PV) .......................................................................................................... 3-6

2.6 Start mode (defining a startup mode at resumption of power supply) ...................................................... 3-7

– ii –

Page 4

2.7 MV proportional period (for relay-drive or SSR/SSC-drive output) ........................................................ 3-7

2.8 Setting of preset MV (defining MV in the reset state) .............................................................................. 3-8

2.9 Burnout MV setting (defining MV at the burnout) ................................................................................... 3-8

2.10 Setting of alarm type ................................................................................................................................. 3-9

2.11 AO output type (sending PV, SV, and MV to auxiliary analog output) ................................................... 3-10

2.12 AO range and scale (scaling auxiliary analog output) .............................................................................. 3-11

2.13 Time unit (switching from hr:min to min:sec or vice versa) ..................................................................... 3-11

2.14 Setting of time display type (switching from remaining time to lapsed time or vice versa) ..................... 3-12

2.15 END signal output time ............................................................................................................................. 3-12

2.16 Guarantee soak waiting allowance and setting of max. wait time ............................................................ 3-13

2.17 Setting of T-link station number ............................................................................................................... 3-13

3. Various Operating Methods ............................................................................................. 3-14

3.1 In this unit the operation mode (operating profile) can be changed over as illustrated below.................. 3-14

3.2 Auto tuning................................................................................................................................................ 3-15

3.3 Fixed value operation ................................................................................................................................ 3-16

3.4 Manual operation....................................................................................................................................... 3-17

3.5 Remote operation (Option)

(for the entry of external commands and selected pattern and the output of status) ................................. 3-17

SECTION 4 ADVANCED USAGE ........................................................................... 4-1

1. Structure of expert parameter channel ............................................................................. 4-1

2. Setting of each parameter................................................................................................. 4-2

2.1 Set value (SV) upper and lower limits ...................................................................................................... 4-2

2.2 Manipulating value (MV) variation limit.................................................................................................. 4-2

2.3 Setting of alarm 1 to 4 hysteresis allowances............................................................................................ 4-3

2.4 DV differentiate specification D operation of PID is differentiated for DV............................................. 4-3

2.5 AT SV mode

Auto tuning in the low PV type ................................................................................................................. 4-4

2.6 AT PID mode

Obtaining PI control parameter ................................................................................................................. 4-4

2.7 Transmission write protect

The SV change via transmission is inhibited. ........................................................................................... 4-5

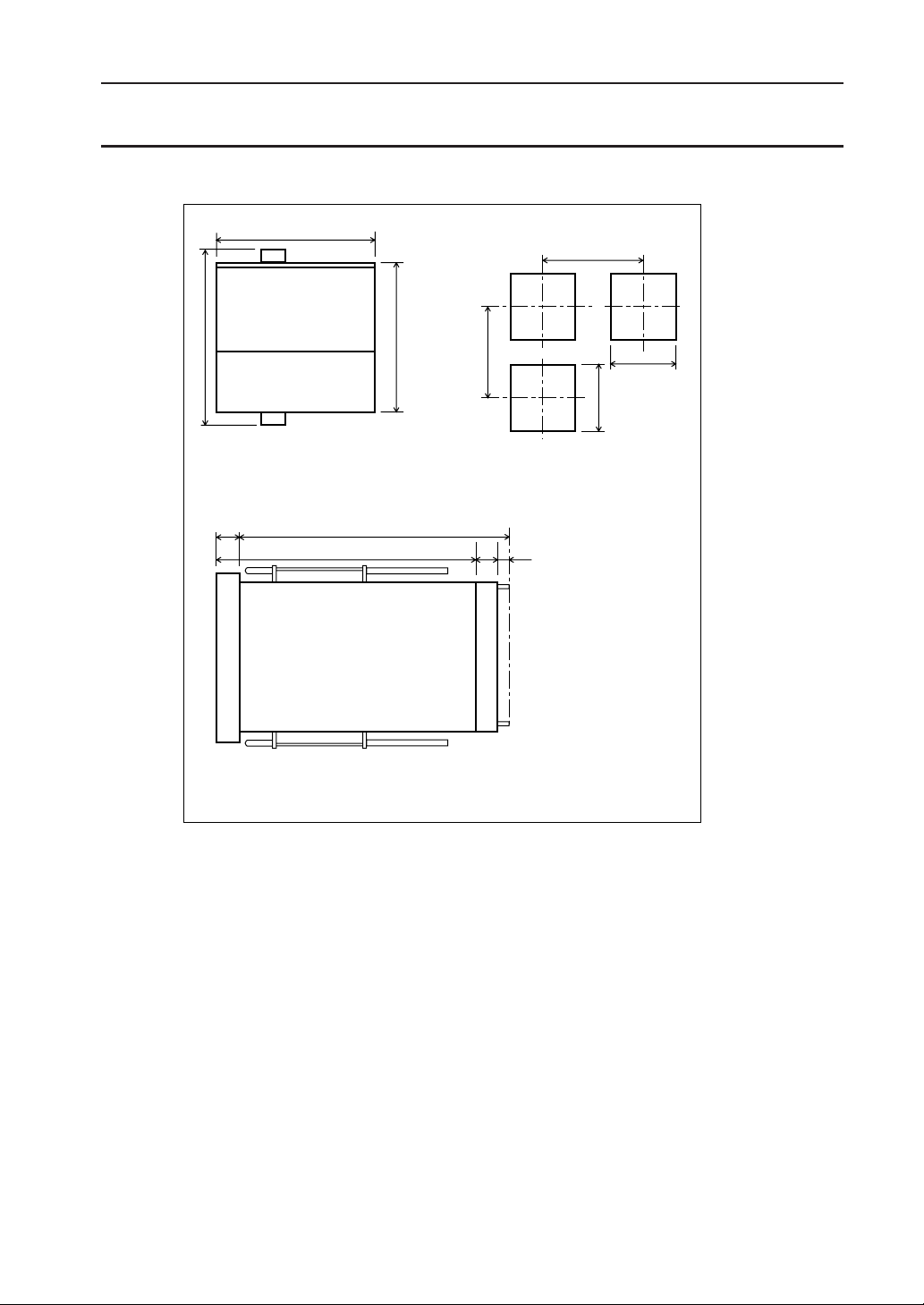

SECTION 5 INSTALLATION AND WIRING ......................................................... 5-1

1. Outline Diagrams ............................................................................................................. 5-1

2. Installation........................................................................................................................ 5-1

2.1 Appropriate locations for installation........................................................................................................ 5-1

2.2 How to install the unit ............................................................................................................................... 5-2

3. Wiring .............................................................................................................................. 5-2

3.1 Cautions for wiring.................................................................................................................................... 5-2

3.2 Noise control measures ............................................................................................................................. 5-2

3.3 For connection of load circuit ................................................................................................................... 5-3

3.4 Wiring for the input 1 to 5 VDC ............................................................................................................... 5-3

3.5 External wiring diagram............................................................................................................................ 5-3

SECTION 6 APPENDIX ............................................................................................ 6-1

1. Specifications ................................................................................................................... 6-1

2. [Program Pattern Preparation Form] ................................................................................ 6-3

3. Parameter List .................................................................................................................. 6-4

– iii –

Page 5

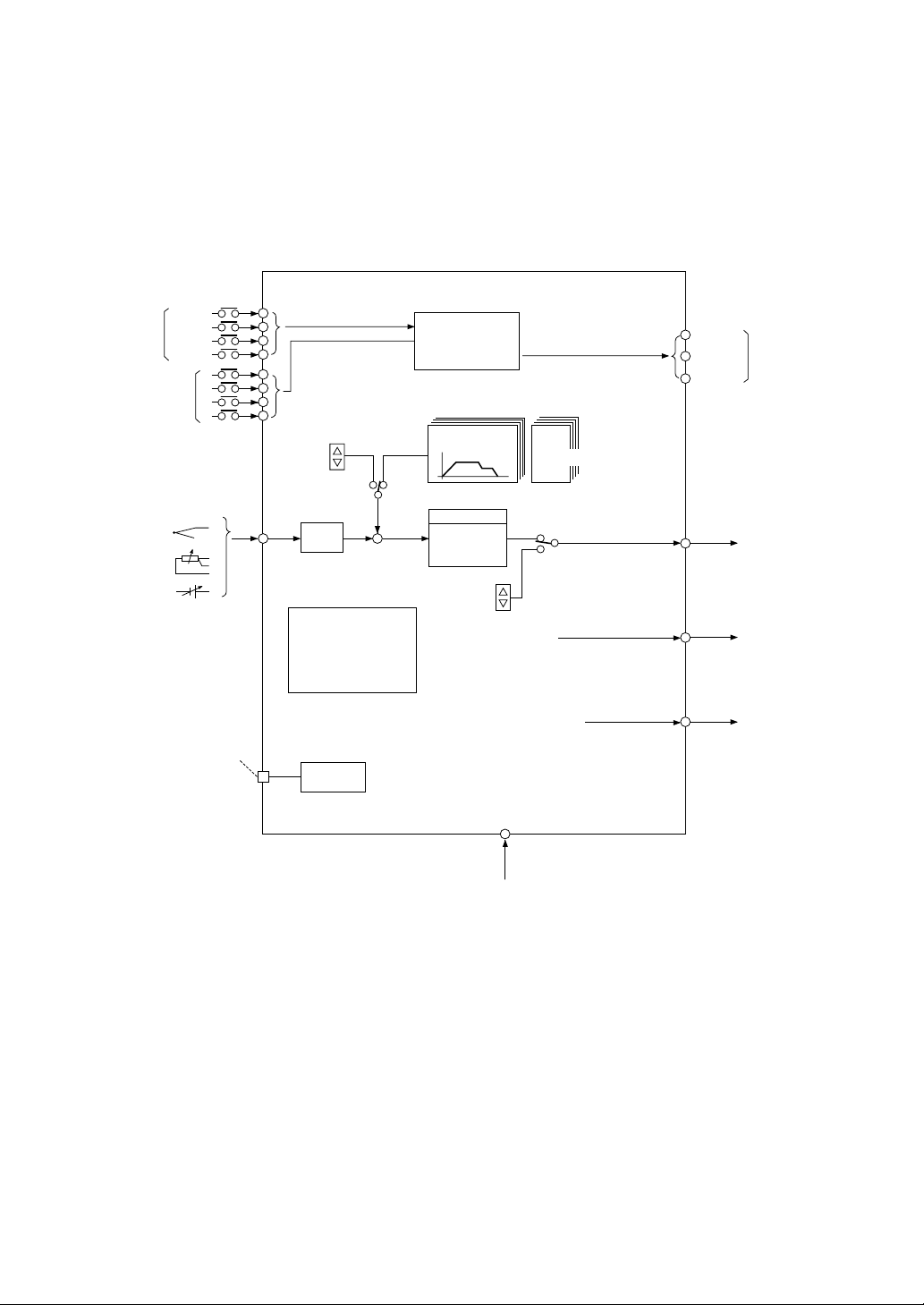

■ Overview

This Program Controller, 96 mm × 96 mm in the front-view size, incorporates a microprocessor to

perform the programmed control for Processing variables, such as temperature, humidity, pressure,

flow rate, rotating speed.

Reset

External

command

Pattern select input

Run

Hold

input

Advance

Sensor input

Full multi-input

Loader interface

Conforming to (RS-232C)

(Option)

DI

•External command

input

•Pattern select input

Program

SV

•Status output

9 patterns 9 sets

Program setting

20 segment

PID with autotuning

•Auxiliary analog

output

1/2 points

(PV/SV/MV)

•Time signal output

4 points (+2 points) See Note.

•Alarm output

2 points (+2 points) See Note.

3

2

2

2

1

2

0

2

AI

Fixed SV

Fixed

(FIX)

PV

Filter

•Guarantee soak function

•PV start function

•Pattern concatenate

function

•Pattern repeat function

(99 times max.)

Communication facility

Reset

Run/Hold

End

Control

parameter

Such as PID

Auto

Man

Manual operation

3 points

MV

Reset

Run/Hold

End

Control output

AO

(Option)

DO

Status

output

– iv –

Power supply

100 to 240 VAC

Note: (+2 points) denotes that either time

signal or alarm output may be

supplemented as an option.

Page 6

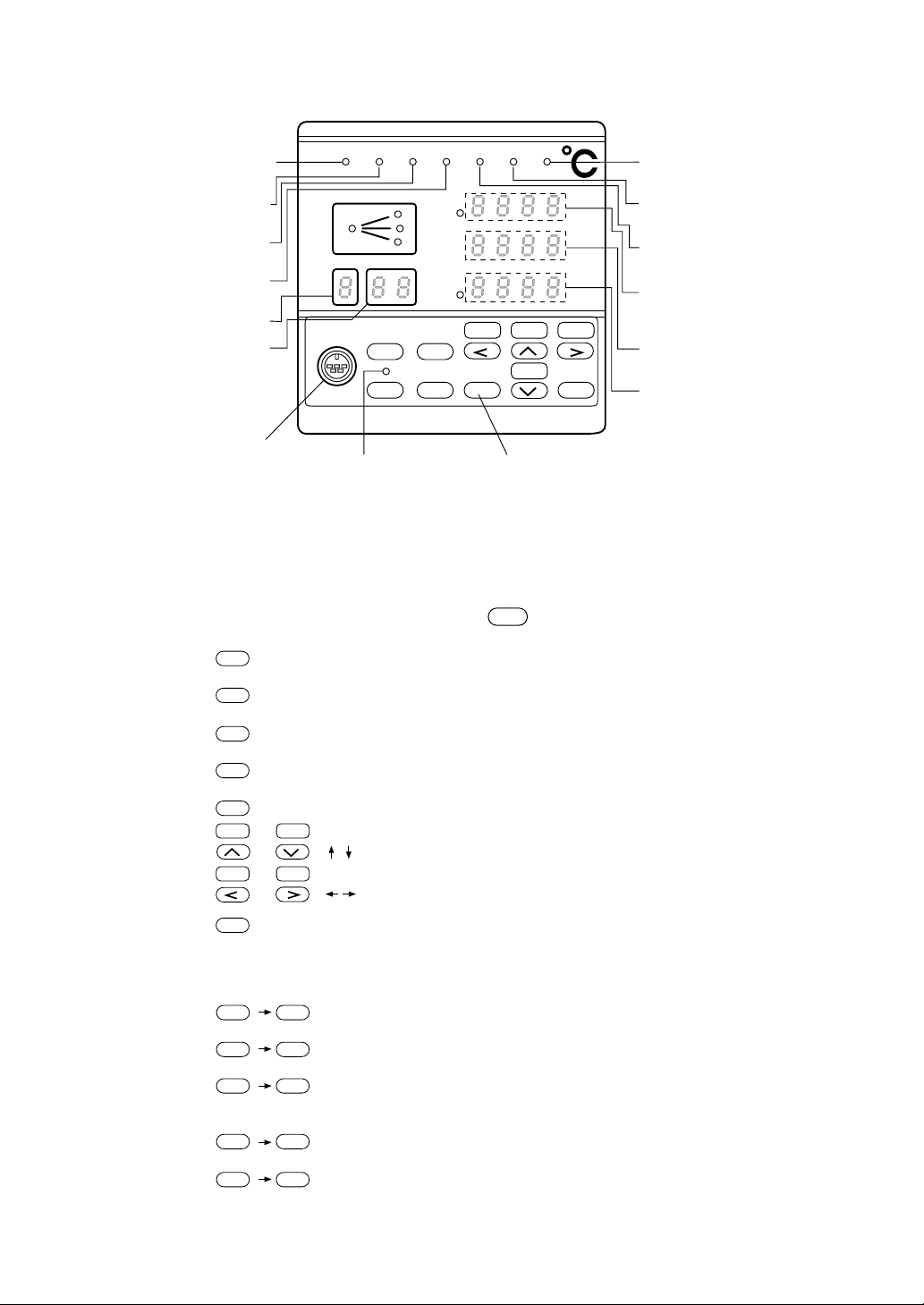

■ Explanation of Front Panel

is selected

(See the description below)

SFT

Lights while the program

operation is running

Lights while the program

operation is being held

Lights when the program

operation is ended

Lights when manual

control mode is applied

Program number display

Segment number display

Program loader connector

■ Explanation of Keys and How to Use Them

Keys are provided in two lines: the upper line and lower line.

To use a function in the lower line, depress an appropriate key as it is.

To use a function in the upper line, depress

CLR

DSP

FIX

PTN

A/M

SEL

AT

INS

END

ENT

RUN HLD

REST

SFT

SFT DSP

SFT PTN

SFT SEL

SFT

SFT

RUN HLD END MAN ALM TS C

Lights while the control

output is ON

PROFILE

PTN SEG

LOADER CLR FIX

DSP

PTN

SFT

SEL INS ENT

DV

TM

MV

PV

SV

REST

ATA/M

HLD

ADVRUN

COPY

Lights when an event occurs

due to time signal

Lights when an alarm is

generated

Process variable display

(Deviation display while

LED indicator is lighted)

Set value display or

parameter name display

Time display. Manipulating

value display or parameter set

value display when LED

indicator is lighted.

Lights when upper key

Program set key

key once and a key to be used.

: To be used for changing the display.

: To be used for selecting a program pattern.

: To be used for selecting a parameter.

: To be used for inserting a program pattern.

: To be used for data setting and entry.

: Cursor keys to be used for selecting a parameter and for changing a data value.

ADV

: Cursor keys to be used for selecting a parameter and for selecting a column.

: To be depressed when a key function in the upper line is used. When this key is depressed, the

LED embedded in this key will light by toggle action, thus indicating that a key in the upper line

has been selected.

By depressing the key once again, the LED will go off, indicating that a key function in the

lower line has been selected.

CLR

: To be used for erasing a program pattern.

FIX

: To be used when entering the fixed-value operating mode.

A/M

: To be used when switching from AUTO to MANUAL, or vice versa. The AUTO

mode and the MANUAL mode are alternately changed over by depressing the key

with a toggle mechanism.

AT

INS

: To be used when starting the auto tuning.

COPY

: To be used when copying a program pattern.

ENT

– v –

Page 7

SECTION 1 BEFORE STARTING OPERATION

Devia-

Operation starts from segment 1.

Set value

Set value

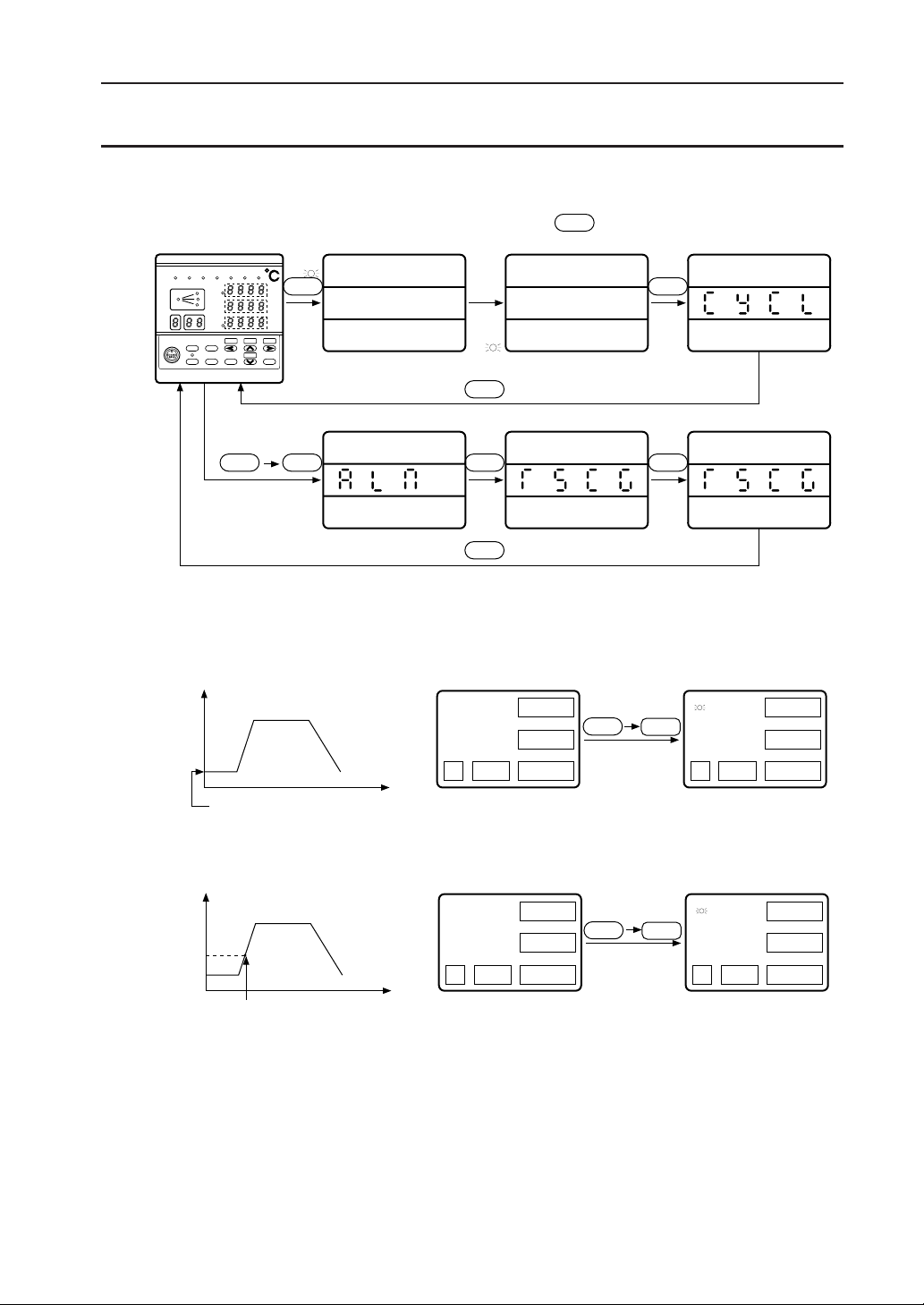

1. Changing Displays on Operating Screen

Various operation displays can be changed by depressing

RUN ADV

HLD

tion

DSP

COPYA/M

ENT

PV

SV

TM

Manipulating

value

DSP

DSP

RUN ENDHLD MAN CALM TS

PV

DV

SV

TM

MV

LOADER

CLR FIX

DSP PTN

SFT SEL INS

REST

Alarm 1 to 2 status Time signal status Time signal status

DSP

2. Operation

(1) Starting the operation

DSP

PV

SV

MV

SFT

key.

DSP

DSPDSPSFT

RUN

PV

No. of cycles

RUN

(2) Starting the operation at the current temperature (PV start function)

Present value

Operation starts at the present

temperature.

This operation is performed only when YES has been assigned to PV Start (PVST) in the program

pattern mode.

If NO is assigned in the setting, the normal operation (1) is performed.

Time

Time

(Reset state) (Running state)

RUN

SFT

RUN

(Reset state) (Running state)

1-1

Page 8

(3) Suspending the operation

Present position

This is an instance when the program

RUN

SFT

HLD

running operation is temporarily held

while operating the unit.

(Running state) (Holding state)

To resume the program running operation, follow the step for (1) Starting the operation.

HLD

(4) Ending the operation

Resetting is performed in the running

state or in the holding state.

(5) Advancing a segment while in the

running operation

A next segment is forcedly advanced while in the running operation.

One segment is advanced

Set value

for operation.

Time

RUN

SFT

Rest

(Running or Holding state) (Reset state)

RUN

SFT

(Running state)

RUN

Adv

(Running state)

1-2

Page 9

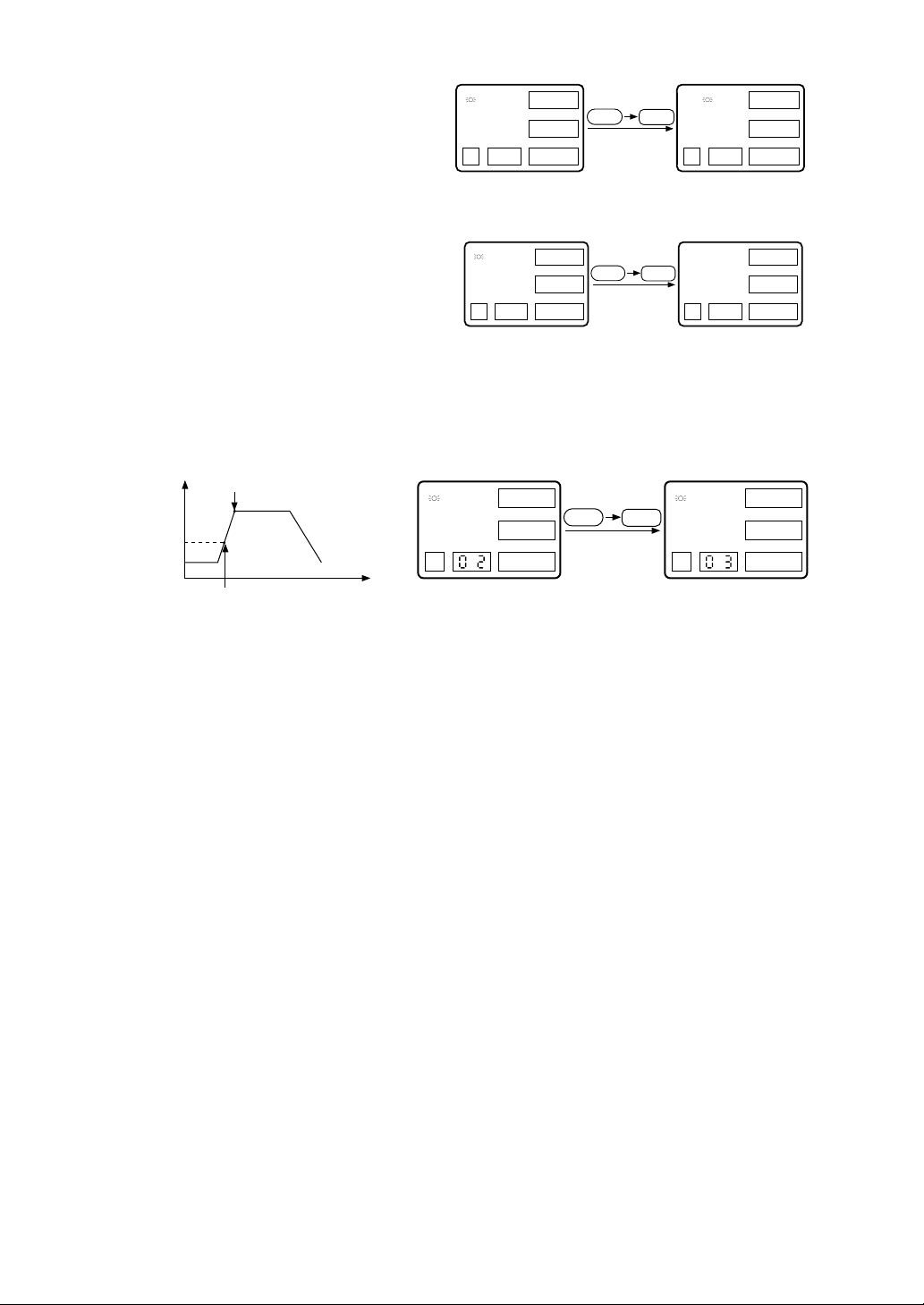

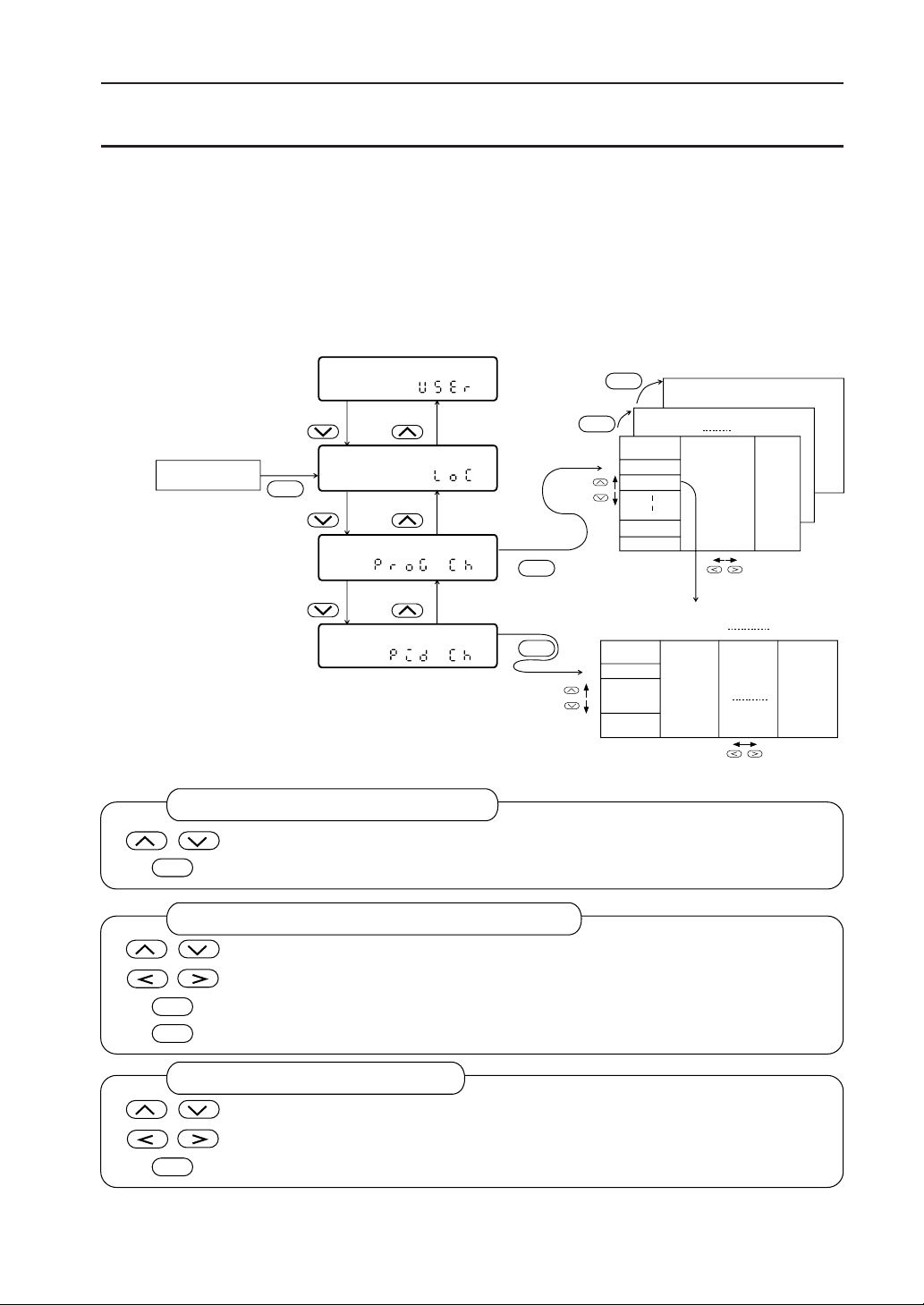

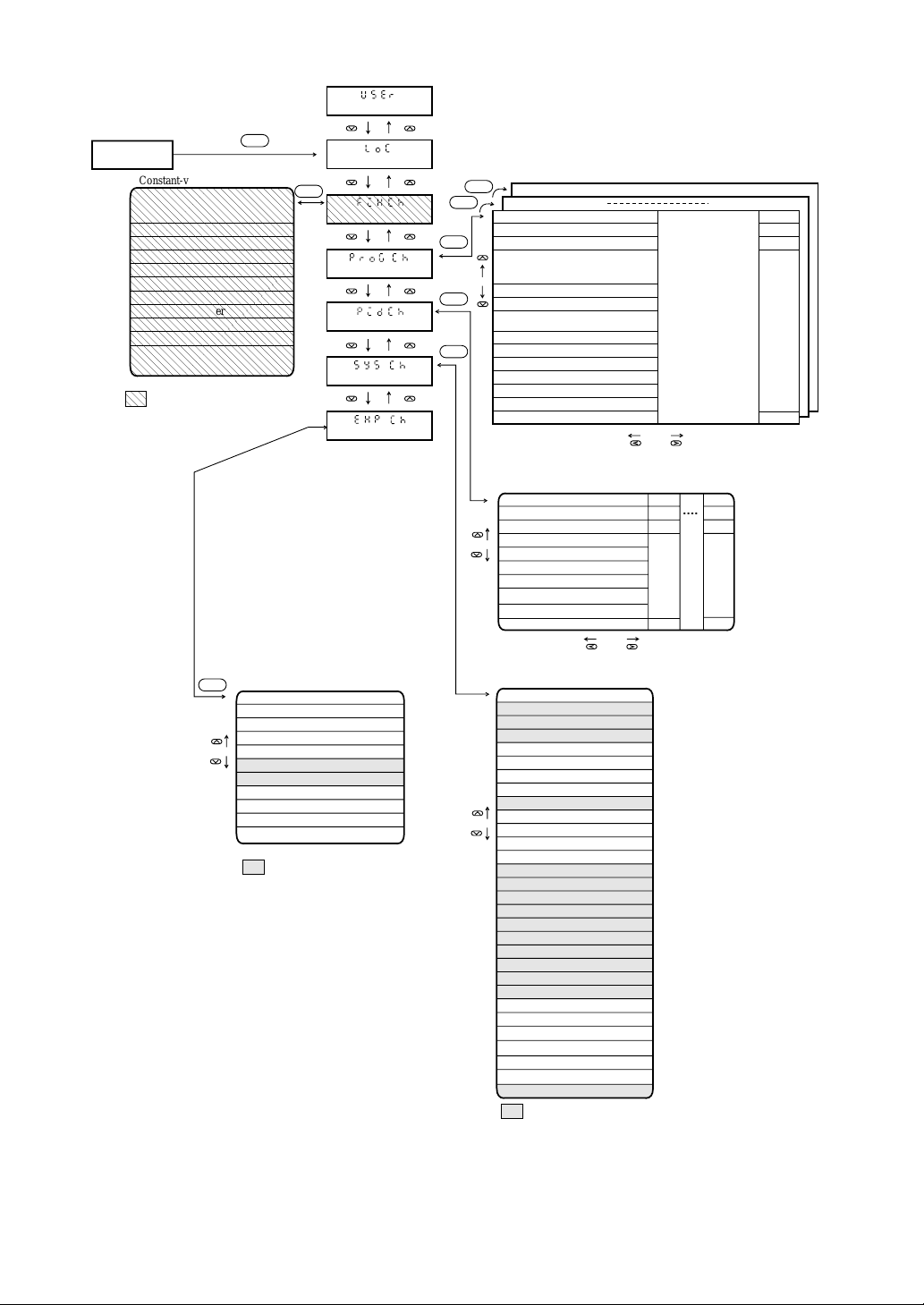

3. Parameter Setting Overview

The unit parameter structure and parameter calling methods are shown below.

User level

Keep on pressing for 3 seconds.

Operating status

display

SEL

Setting lock

Program pattern set

channel

Parameter for setting

a program pattern

(see section 2)

SEL

End user

0

Set

maker

1

Expert

2

PID channel

System setup channel

Expert channel

Parameter for setting

a PID group

(see section 2)

SEL

Parameter to be

set for operation

SEL

SEL

(see section 3)

Parameter to be set

for more advanced use

(see section 4)

For details of paramters in each channel, see the Parameter List at the end of this Manual.

User level

Parameter display range may be changed by setting the user level.

0: End user

Displays parameters in the unshadowed area . The displayed

parameters are needed for program pattern setting.

1: Set maker

Displays parameters in the unshadowed area plus darkshadowed area . The displayed parameters are needed for

setting up the unit.

2: Expert

Displays parameters in the light-shadowed area in addition

to the unshadowed and dark-shadowed areas . The

displayed parameters are needed for more advanced use of this

unit.

1-3

Page 10

Setting lock

This is a setting lock parameter for prevention of an erroneous setting.

0: Total release

1: Operation release

Enables the setting of all parameters, with no setting locked.

With the setting locked, no change can be made for parameter

values. Permits only the running operation and reset operation.

2: Total lock

All the setting operations are locked. Inhibits a change in

parameter value and the running operation. (However, parameter

call and display are allowed)

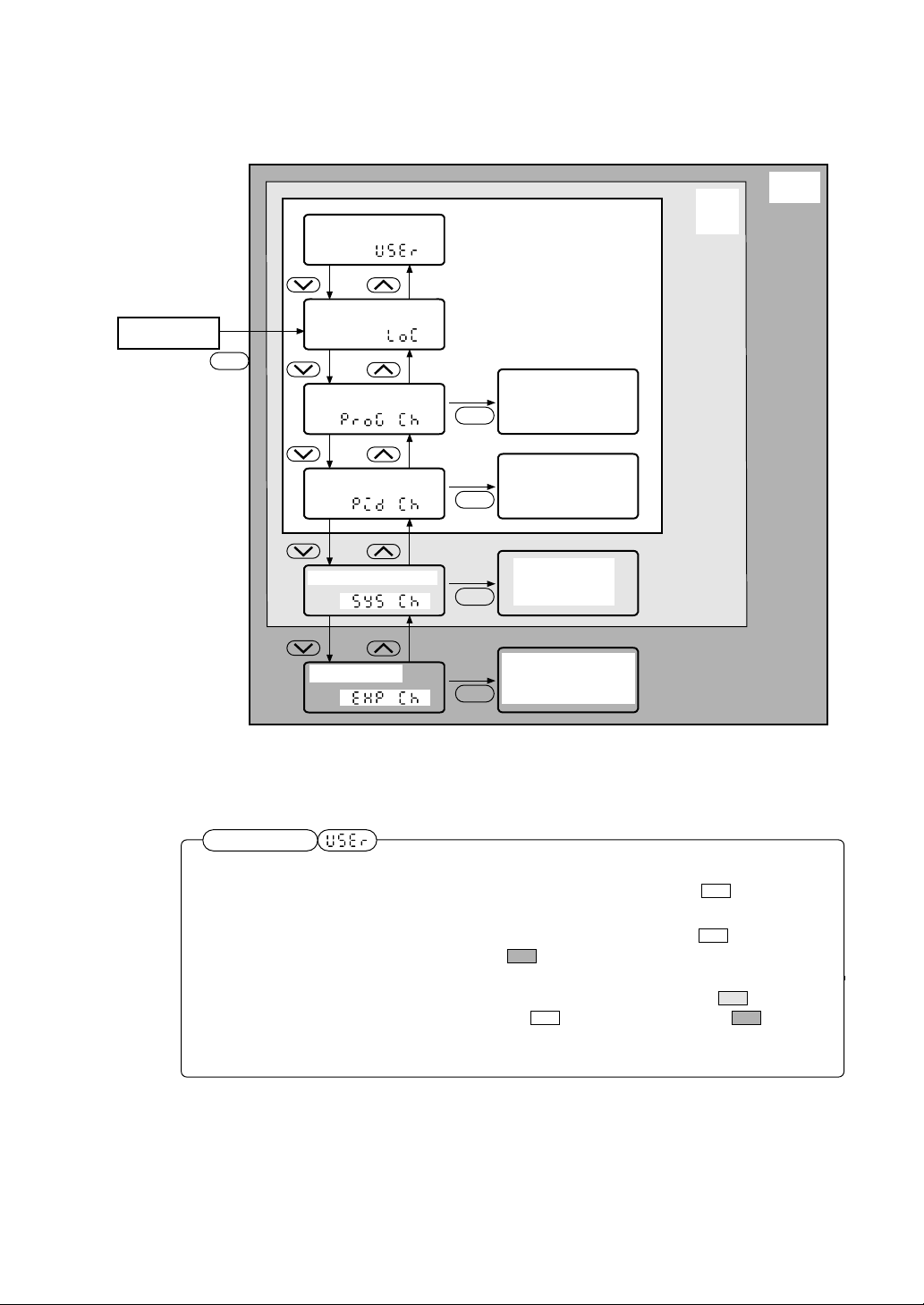

Data change and registration procedures

Call a parameter

Enter data setting mode

Change data

Entry

Depress key.

Depress key.

ENT

,

: for scrolling data up and down

,

: for for changing a column

ENT

Blinks

1-4

Page 11

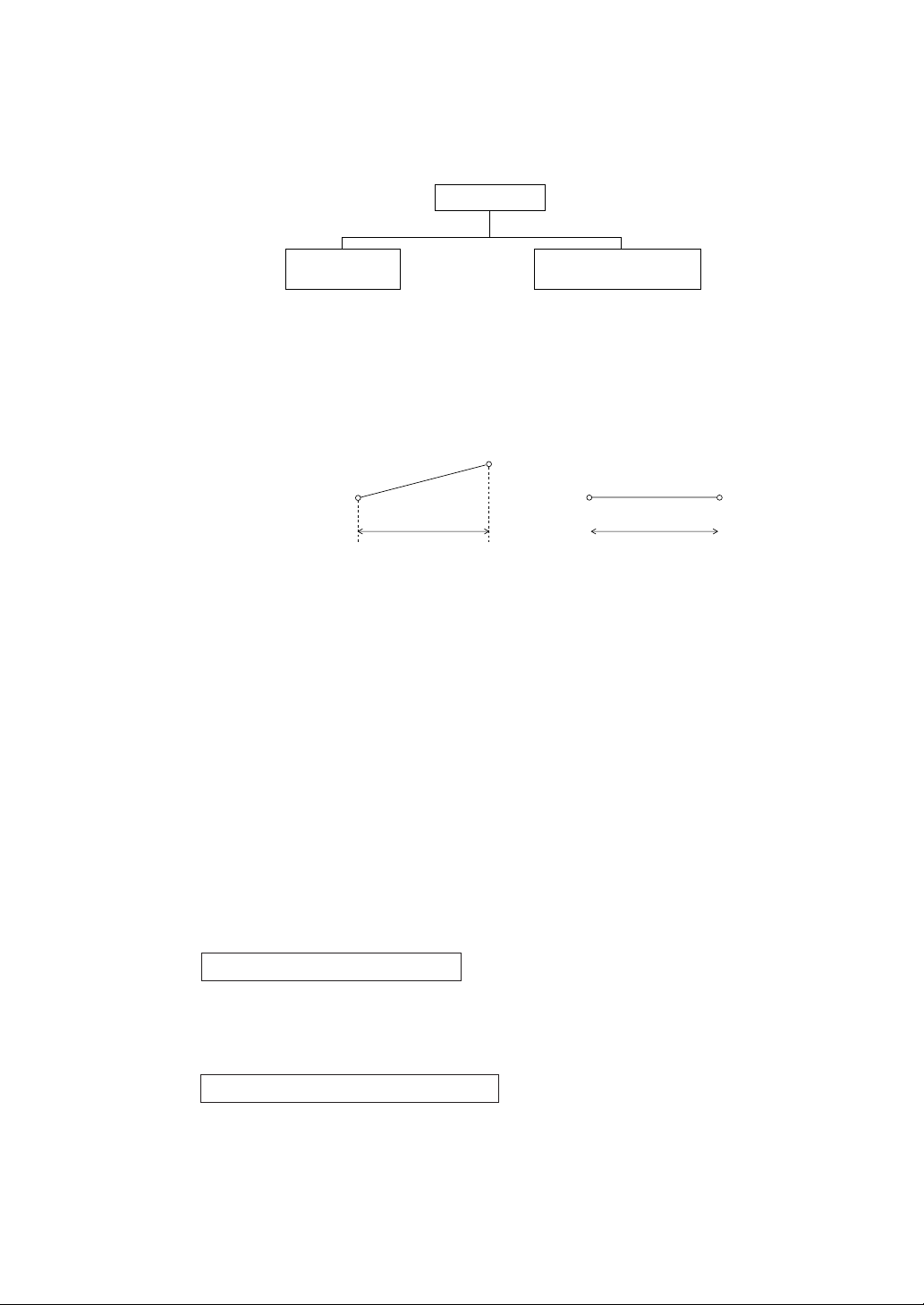

SECTION 2 PROGRAMMING

Channel menu screen

Programmers are requested to read this section carefully.

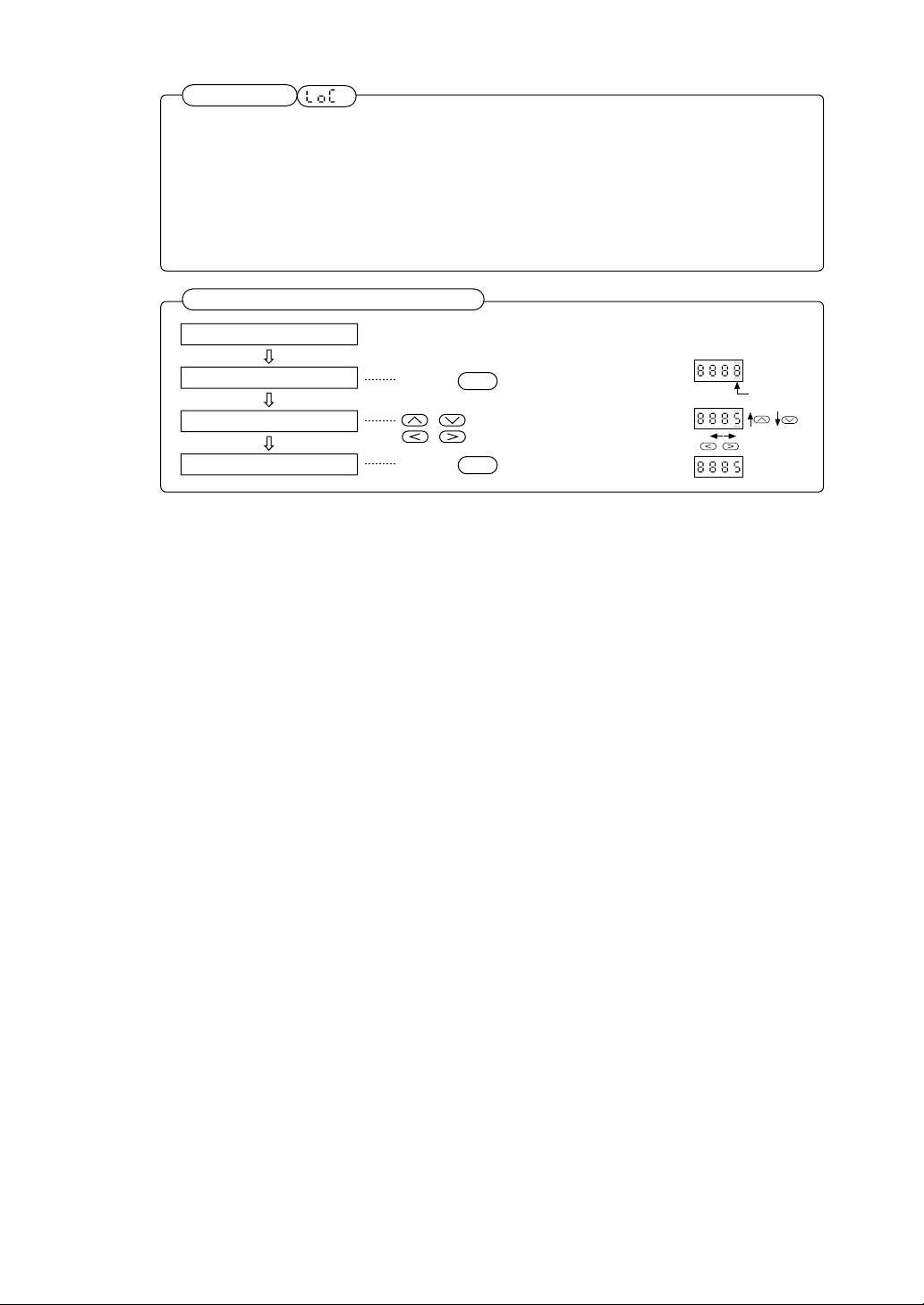

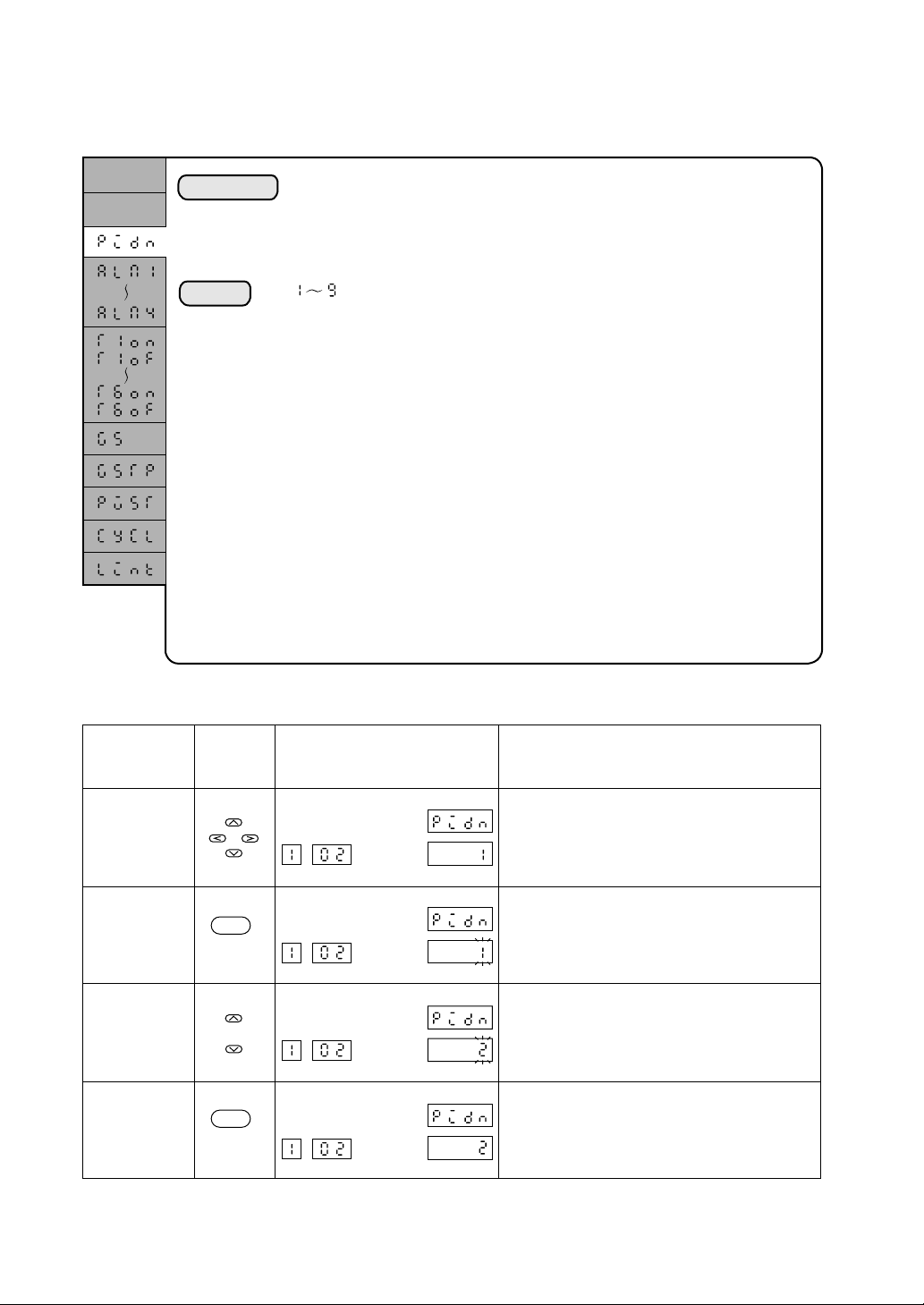

1. Parameter Structure and Parameter Calling Method

With this unit, nine 20-segment program patterns can be registered. Control parameters, such as PID

to be used in each segment, can be specified out of nine PID groups as illustrated below.

A program pattern is set with the program pattern setting channel, while a PID group is set with the

PID setting channel.

Operation profile

User level

Setting lock

DSP

Program pattern

PID set channel

()

()

Setting channel

()

()

Key operation on the channel menu screen

: Moves up and down in the channel menu.

SEL

: Selects a channel on display.

User

level

SEL

SEL

PTN

PTN

Segment 1 Segment 20

SV

TM

PID No.

No. 1 No. 2 No. 9

P

I

D

MAN

Pattern 9

Pattern 2

Pattern 1

Key operation on the program pattern setting channel

: Various parameters are moved up and down within one segment.

: A segment is moved up and down within one pattern.

PTN

SEL

: Patterns (1 to 9) are moved.

: Returns to the channel menu.

Key operation on PID setting channel

: Various parameters are moved up and down within one PID group.

: PID groups (1 to 9) are moved right and left.

SEL

: Returns to the channel menu.

2-1

Page 12

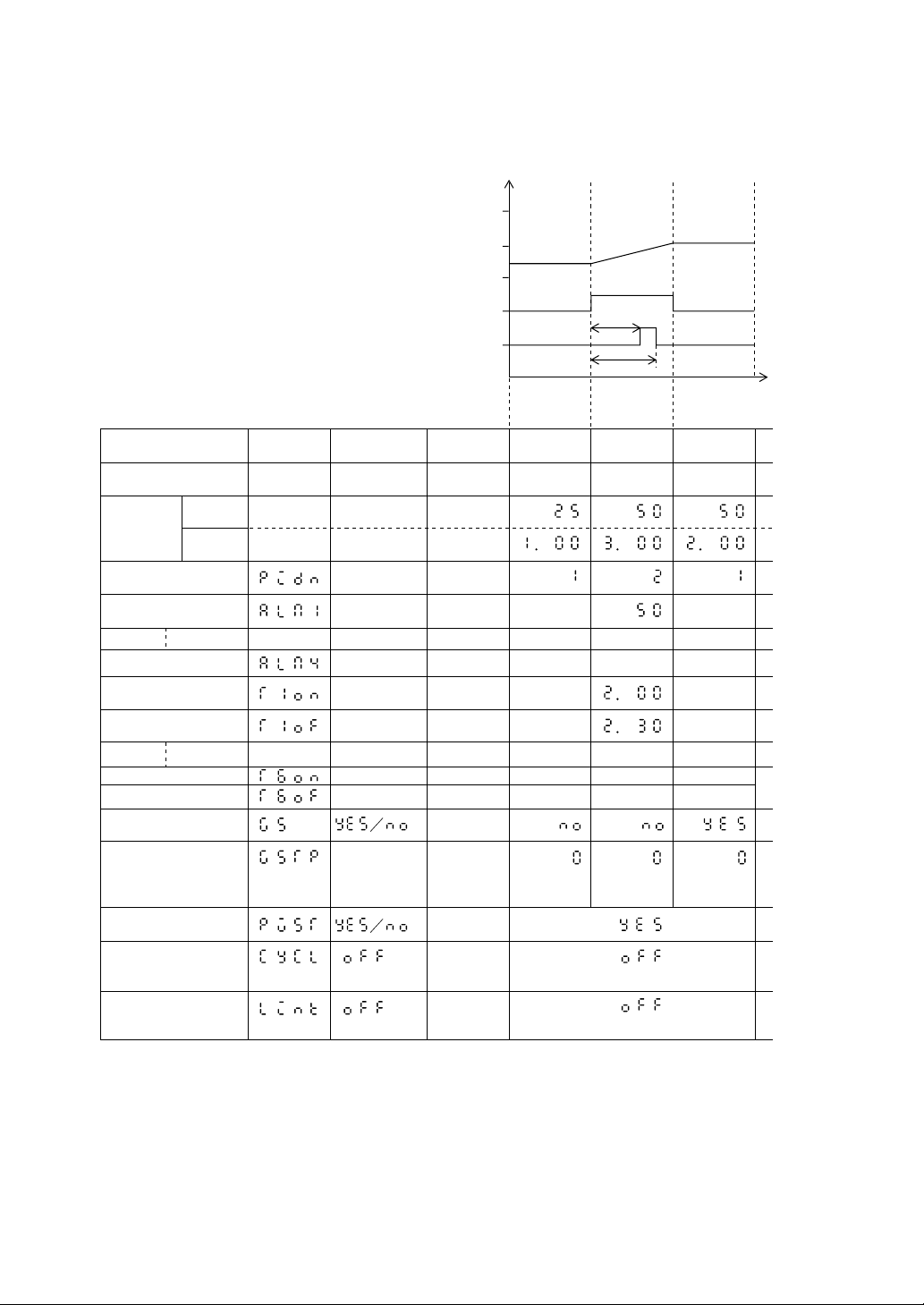

2. Program Pattern Setting (Program Pattern Setting Channel)

2.1 Program pattern structure

SV °C

100

50

0

[Programming map]

Segment

Pattern

PID No.

Alarm 1 set value

Alarm 4 set value

Time signal 1 ON time

Time signal 1 OFF time

Time signal 6 ON time

Time signal 6 OFF time

Guarantee soak Yes/No

Set value

Time

Display Setting range

Set value

Time

0 to 10000

0:00 to 99:59

1 to 9

0 to 10000

0:00 to 99:59

0:00 to 99:59

ALM1

T10N

T10F

Notation

Engineering

unit

hr:min or

min:sec

Number

Alarm

display

hr:min or

min:sec

hr:min or

min:sec

YES/NO

ON time

OFF time

12 3

Time

(hr:min)

Guarantee soak type

PV start

Number of cyclic

operations

Link pattern No.

0:Up and down

1:Down

2:Up

0 to 99

1 to 9

YES/NO

OFF or

1 to 99

OFF or

1 to 9

2-2

Page 13

The programming for this unit can be accomplished by setting parameters necessary for each of

In the case of ramp segment

In the case of soak segment

Segment n

Time setting for segment n Time setting for segment n

Set value for

segment n

Set value for

segment n

Set value for

segment n–1

Set value for

segment n–1

segments.

For each segment setting, the pattern setting (Setting of set value and time) and other supplementary

functional setting (such as PID number, alarms, and time signal) are required.

Program setting

Pattern setting

(Set value and time

setting)

Supplementary function setting

(PID No., alarm, time signal, and

so on)

1) Pattern setting

• The pattern setting includes the setting of a set value and time for each segment.

• Segment “n” would be a segment to which the process will flow from the set value for

segment “n-1” to the set value for segment “n” at the time set for segment “n.”

Example 1) In the event of segment 2 (n=2) on the programming map (Pages 2 to 3):

A pattern in which the process will flow from 25°C (set value for segment 1) to

50°C (set value for segment 2) in 3:00 hours(time setting for segment 2). This is

called “ramp segment.”

Example 2) In the event of segment 3 (n=3) on the programming map (Pages 2 to 3):

A pattern in which the process will flow from 50 °C (set value for segment 2) to 50

°C (set value for segment 3) in 2:00 hours(time setting for segment 3).This is

called “soak segment.”

• The first segment will always be a soak segment, because of no set value for segment “n-1.”

Example 3) For segment 1 on the programming map (pages 2 to 3), the process will be soaked

for 1:00 hour (time setting for segment 1) at a temperature of 25 °C (set value for

segment 1).

2) Setting for other supplementary functions

The setting of some supplementary functions is made for each segment, while the setting of others

is made only for one in a pattern.

Parameters to be set for each segment

• Setting of PID group number

• Setting of alarms 1 to 2 (or 1 to 4)

• Setting of time signals 1 to 4 (or 1 to 6)

• Setting of guarantee soak

Parameter to be set only for one in a pattern

• PV start specification

• Cycle setting

• Setting of pattern link

For particulars of each setting, see an appropriate section for each parameter.

2-3

Page 14

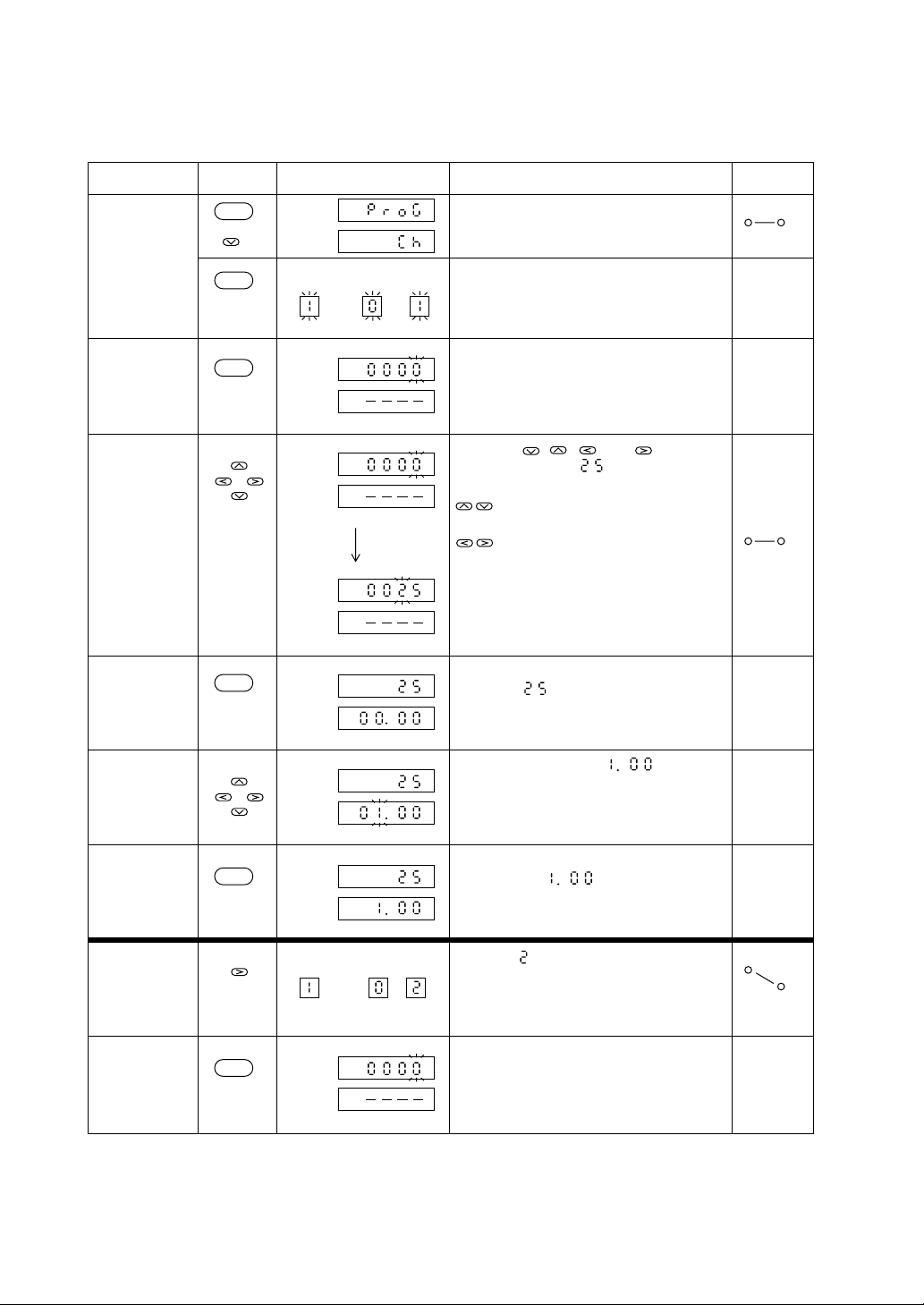

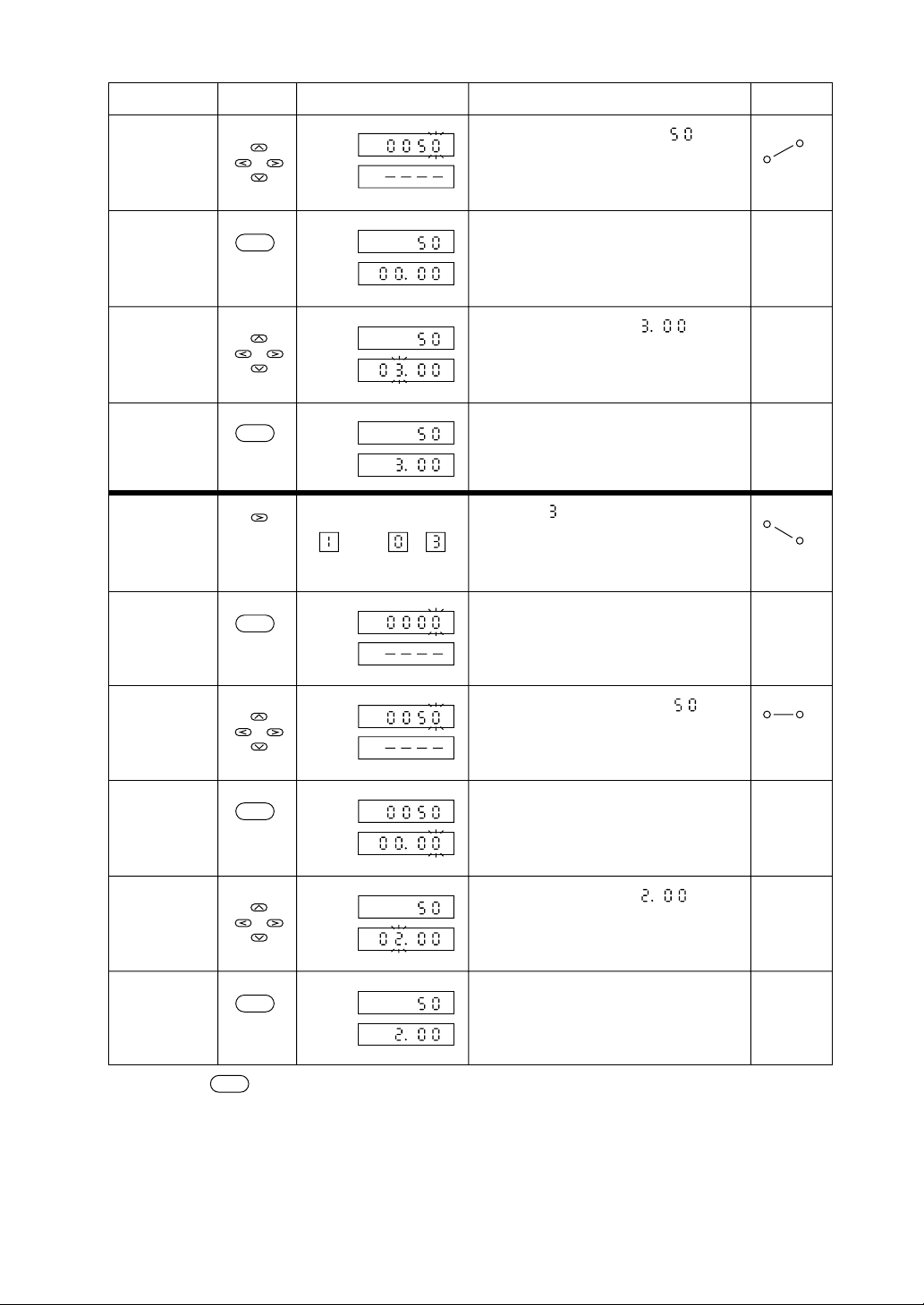

2.2 Pattern Setting...........[Setting of a set value (SV) and time]

Applicable

Operation

Segments 1 through 3 are registered according to the examples of program patterns.

Step Display Explanation

Invoking a

parameter

key(s)

SEL

Program setting channel menu is invoked.

See “1. Parameter structure and Parameter

calling method.”

Enters the program setting channel.

Pattern and segment displays will blink.

Enters the set value mode and the set value

will blink.

By using , , , and keys, the

data is changed to .

: For decrement and increment of

Entering the

setting mode

(set value)

Changing data

(set value)

SEL

ENT

Pattern

Set

value

Time

Set

value

Time

Segment

data

: For selecting columns

Set

value

Time

Entering the

data entry set

mode (time)

ENT

Set

value

Time

The set value blinking will terminate and

the data “ ” is entered.

Concurrently, the time setting will blink,

entering into the time setting mode.

profile

Changing data

(time)

Entering data

(time)

Invoking

parameter

(segment

change)

Entering the

set value mode

ENT

ENT

Set

value

Time

Set

value

Time

Pattern Segment

Set

value

Time

The data is changed to .

The time setting blinking will terminate

and the data “ ” is entered.

Segment is invoked.

2-4

Page 15

Step Display Explanation

Changing data

Applicable

key(s)

Set

The set value is changed to “ ”

value

Time

Operation

profile

Entering the

data entry

time setting

mode

Changing data

(time)

Entering data

(time)

Invoking

Parameter

Entering the

set value

mode

Changing data

ENT

ENT

ENT

Set

value

Time

Set

value

Time

Set

value

Time

Pattern Segment

Set

value

Time

Set

value

Time

The time is changed to “ .”

Segment is invoked.

The set value is changed to “ ”

Entering the

data entry

time setting

mode

Changing data

ENT

Set

value

Time

Set

The time is changed to “ .”

value

Time

Entering data

ENT

Set

value

Time

Note: Depress key for returning to the operating screen.

DSP

2-5

Page 16

2.3 Setting of supplementary functions

2.3.1 Setting of PID group

Set value

Time

Explanation

Setting

The PID group number (l to 9) is set for the use in that segment. In this

manual, the grouping of P, I, and D parameters and output limiters to be used

for the control operation is called “PID group.” The setting of PID group

contents is made through the PID setting channel.

: The PID group number is set.

A PID group number 2 is assigned to segment 2.

Step Display Explanation

Invoking

parameter

Applicable

key(s)

Pattern Segment

Set

value

PIDN in segment 2 is invoked.

Time

Entering the

setting mode

ENT

Pattern Segment

Set

value

The data will blink.

Time

Changing data

Pattern Segment

Set

value

The set value is changed to “2.”

Time

Entry

ENT

Pattern Segment

Set

value

The data blinking will terminate and the

data is entered.

Time

2-6

Page 17

2.3.2 Setting of alarm values 1 to 4

Set value

Time

Explanation

A set value is established for the alarm to be generated in that segment. The

alarms are provided at two points (ALMl and ALM2) as a standard and,

optionally, it may be expanded to a total of four points (with additional points

ALM3 and ALM4).

For setting, engineering units are used. The setting range is 0 to 100% of the

input range.

Setting

0 to 100% (To be displayed in engineering units.)

Example) Where the input range of an instrument is 0 to 400°C, a value

Associated parameters

*: A change of the setting is not required for the ordinary use.

is used for the setting, if the alrm is to be generated at 300°C.

~

: Alarm type

(See System Setup Parameters)

*

~

: Alarm hysteresis

(Expert parameter)

2-7

Page 18

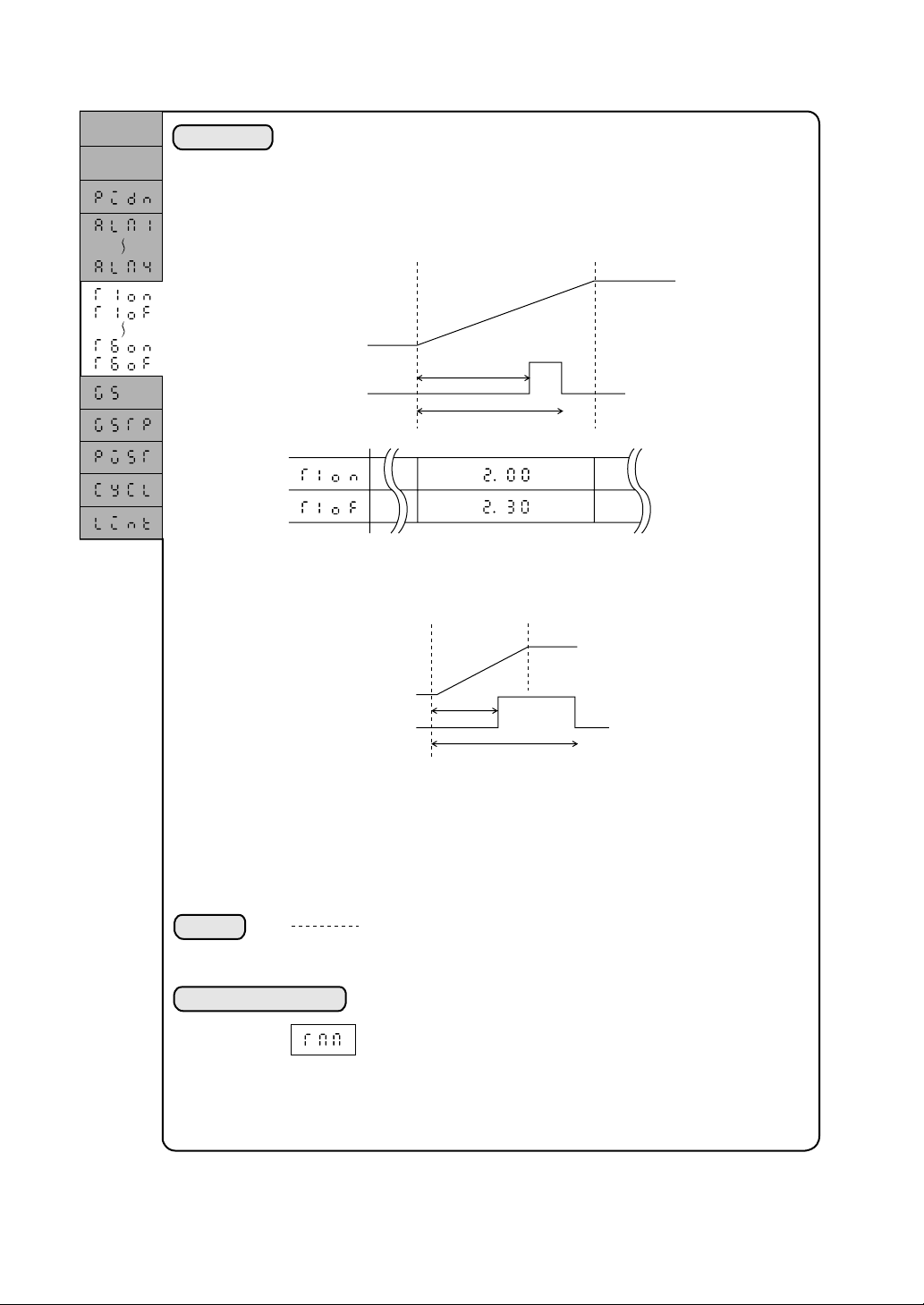

2.3.3 Setting of time signal

Set value

Time

Explanation

A time setting is made for the time signal.

The time signal will function to turn on/off the digital output (open collector)

according to the program running. For this unit, 4-point or 6-point time signal

may be provided.

The time signal setting can be established by setting an ON time and OFF time

starting from the beginning of a segment to be set.

ON time

Time signal 1

OFF time

• The time may be set even beyond the segment. Where, however, a time is set

again in the later segment, the preceding time setting will be nullified and the

present time setting will be validated because one timer is provided for each

time signal.

• In one segment only one ON and one OFF setting are allowed for each time

signal.

• In the reset state the time signal outputs will be all OFF.

• The time signal timer will be stopped in the holding state.

• The time signal output immediately before the end of operation will be

retained when the unit operation is ended.

Setting

0.00 to 99.59

Associated parameters

ON time

OFF time

: No setting

: 0 hr:0 min to 99 hr:59 min (or 0 min:0 sec to 99 min:59 sec)

: Time unit setting (switching between hr:min and min:sec)

(System setup parameter)

2-8

Page 19

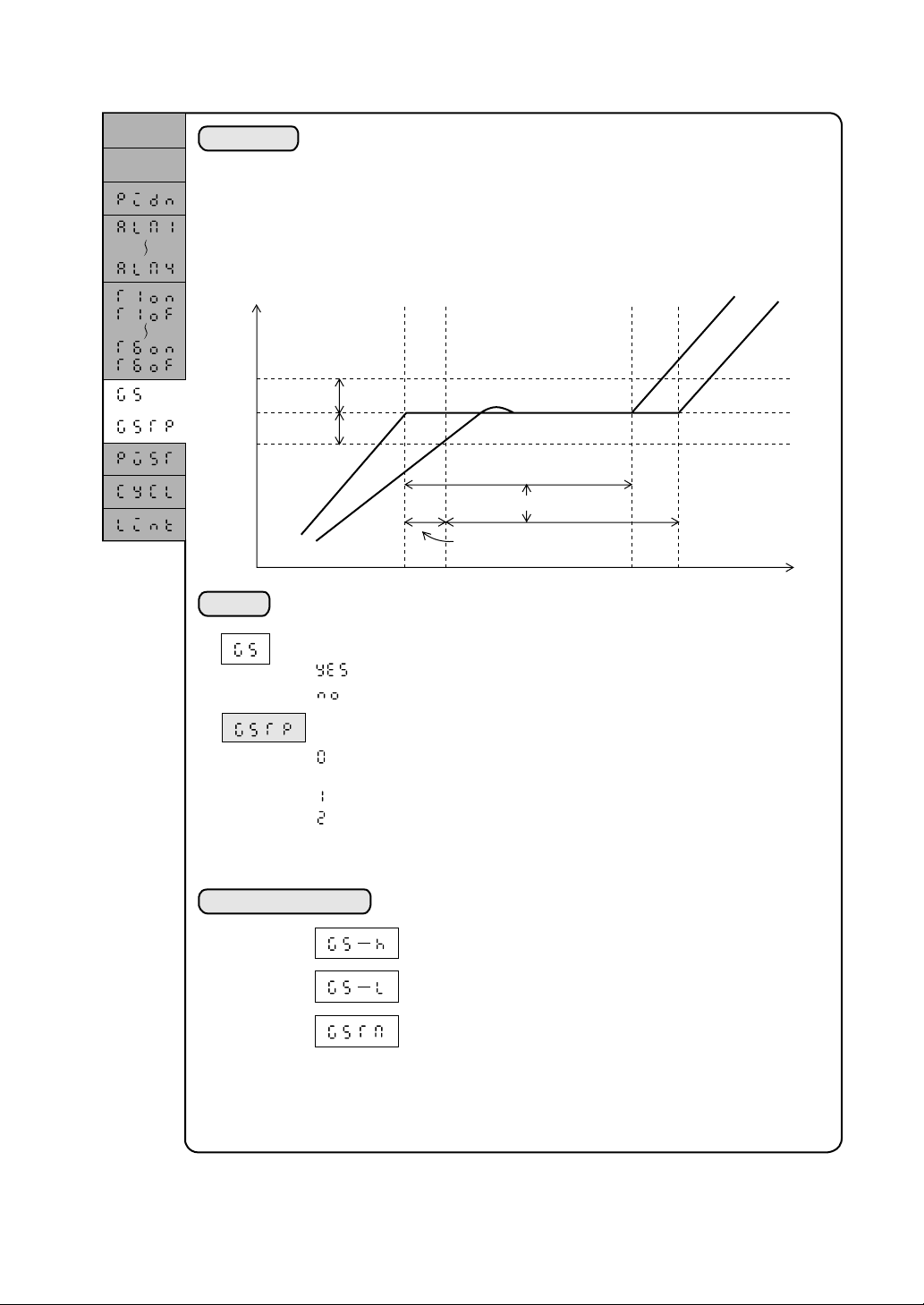

2.3.4 Guarantee soak............... (Waiting for PV to follow)

Set value

Time

Explanation

PV

Guarantee

soak

Guarantee

soak

Setting

• This is a function to suspend the timer operation at the beginning of a

segment for waiting, where the Process variable fails to follow the

running program in the program control.

When the Process variable enters a specified zone, the timer operation

will start again.

• The waiting is performed only once at the beginning of the segment.

Therefore, the timer operation will not be suspended again after the

Process variable once enters the guarantee soak zone and leaves out of

the zone after starting the progress of time.

Upper limit

setting

Lower limit

setting

Pattern that was set

Pattern actually executed

SV

PV

Set time for the segment

Timer operation will

suspend during this period.

Guarantee soak provided or not provided

* Guarantee soak type (Expert parameter)

* Note that this is an expert parameter and is displayed only

when Expert (2) is selected in the user level setting (USER).

Associated parameters

: Guarantee soak provided

: Guarantee soak not provided

: Wait until the PV enters the upper and lower zones.

(Standard)

: Wait until the measured value enters the lower zone.

: Wait until the measured value enters the upper zone.

: Guarantee soak upper limit setting (system setup parameter)

: Guarantee soak lower limit setting (system setup parameter)

: Guarantee soak max. wait time (system setup parameter)

2-9

Page 20

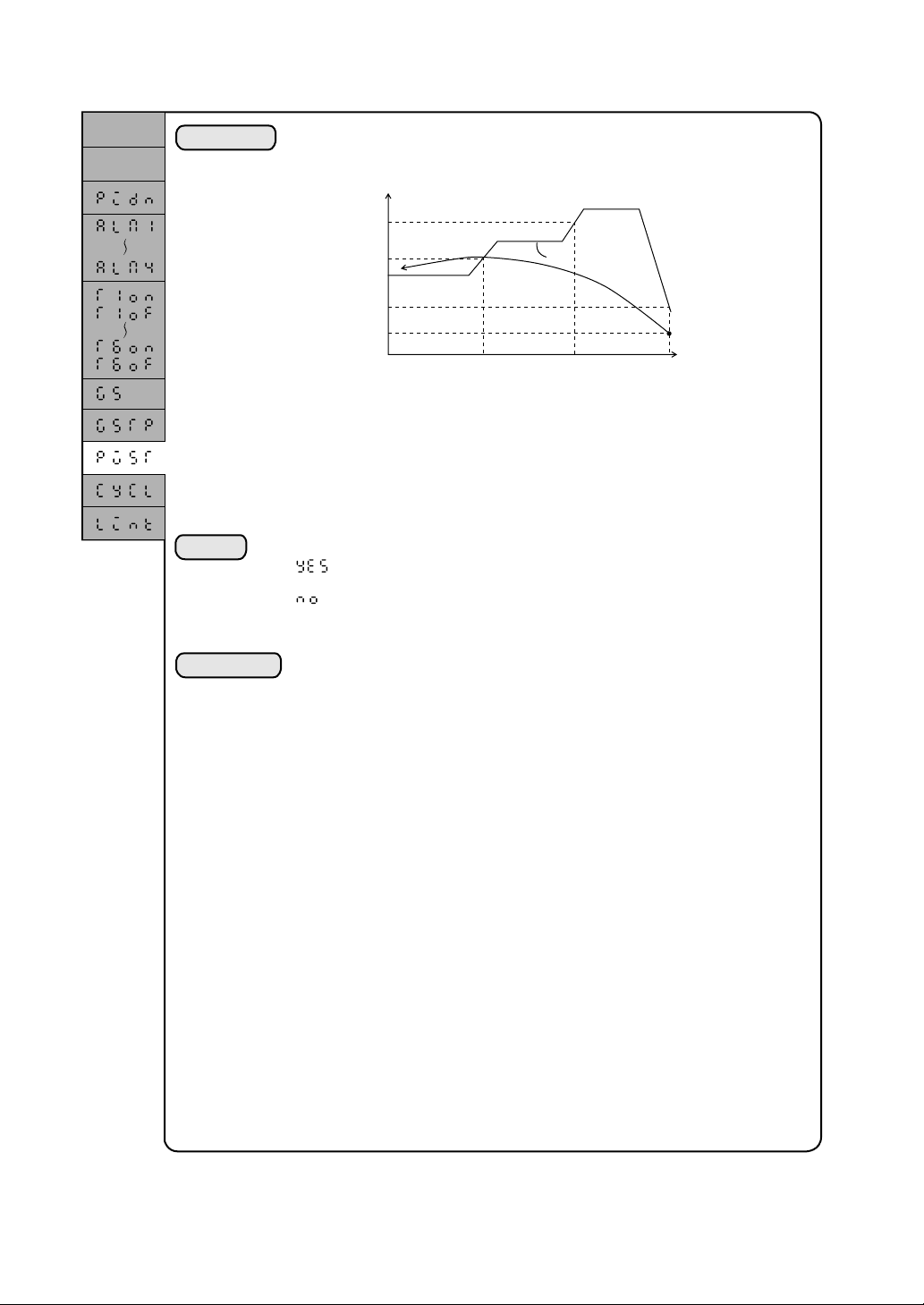

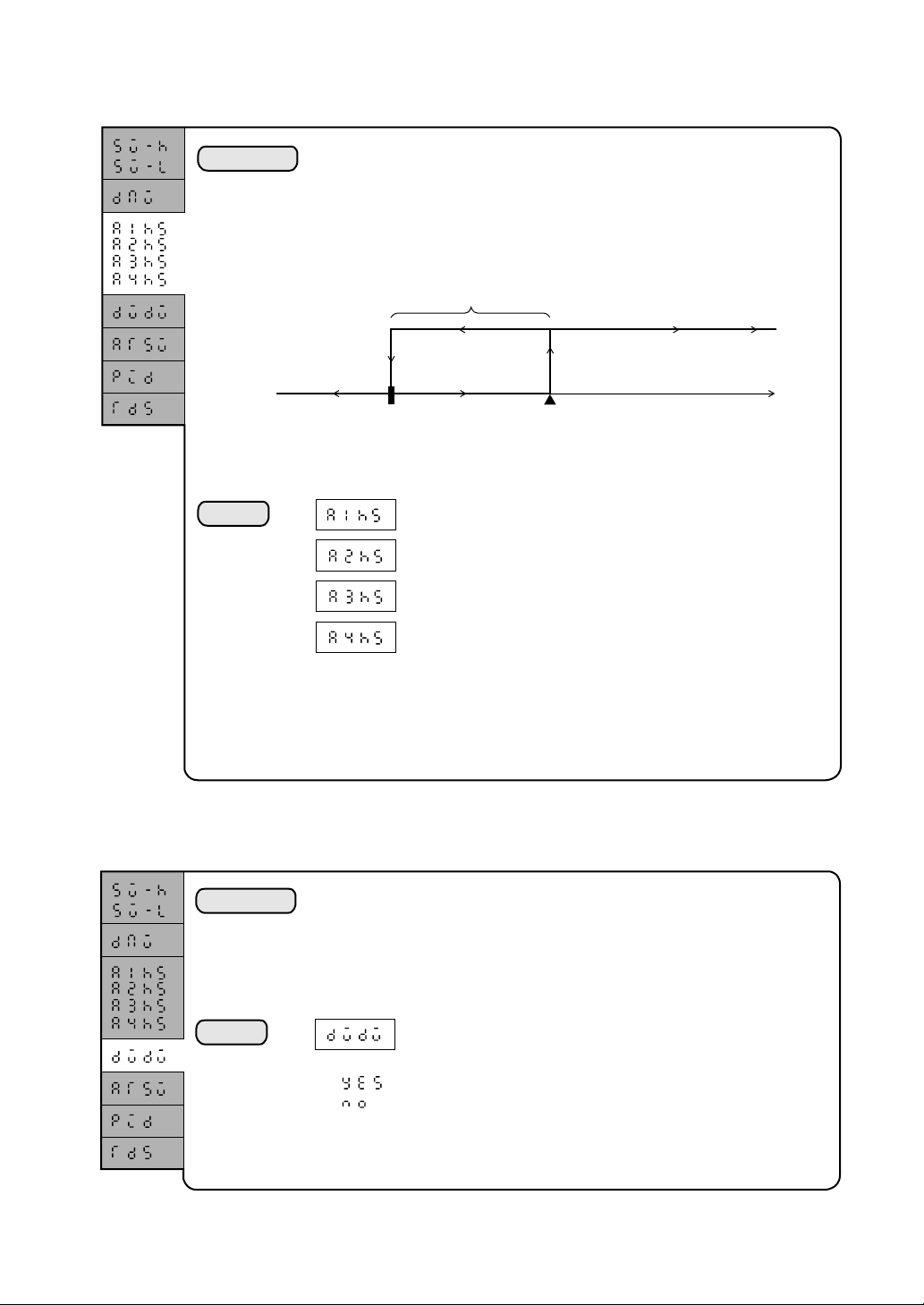

2.3.5 PV Start........... (Allowing the program to start from the current PV)

Set value

Time

Explanation

Setting

This function includes the seeking of a first point at which the PV

matches the program pattern after the start of a program and the starting

of the unit operation from that point.

Set value

①

②

Start

③

④

Start of ④

Note: Where there is no match point as in case ④, the operation will start

from the first segment.

• There is no difference between the PV start and the ordinary start in

the time-dependent relation between the program pattern and other

supplementary functions, such as time signal.

: PV start available

: PV start unavailable

Start of ② Start of ① Start of ③

SV

Time

Supplement

Only one parameter assignment is allowed for a single pattern. (The

setting is possible for any segment)

2-10

Page 21

2.3.6 Cyclic Operation........... (Repetitious execution of a pattern)

Set value

Time

Explanation

Setting

This is a function for the repetitious execution of the same program pattern.

Where the number of cyclic operations is assigned, the re-start will begin

with the first segment after the completion of the final segment.

• For the number of cyclic operations, the number of times of repetititious

operations is assigned for the setting. Therefore, the number of times of the

actual execution would be the number of cyclic operations plus one.

Number of times of execution = Set value for cyclic operation + 1[time]

Example) Where a program pattern is executed three times:

“2” is assigned to “ ”

Set value

One time Two times Three times

Time

: Cyclic operation is not performed.

: The number of times of repetition (Cyclic operations are

performed)

(The program pattern will be executed “set value + l” times)

Supplement

Only one parameter assignment is allowed for a single pattern.

(The setting is possible for any segment.)

2-11

Page 22

2.3.7 Pattern-Link Operation..........(Successive pattern execution)

Set value

Time

Explanation

Setting

This is a function for the consecutive execution of one pattern after the other

pattern is completed. For a program pattern with a link pattern number

assigned, the first segment with the assigned pattern number will be executed

after the final segment is completed.

Example) Where pattern 3 is executed consecutively after pattern 1:

“ ” is assigned to “ ” in pattern 1.

Set value

Pattern 1 Pattern 3

Time

: Pattern link operation is not performed.

: After one pattern is completed, a pattern with assigned number

is executed consecutively.

Relationship between link pattern and cyclic operation

The cyclic operation and the pattern link operation can be assigned in combination. In this case, the

cyclic operation is preferentially executed; after completion of the cyclic operation, the link pattern

will be executed.

Pattern 2 Pattern 5

Cycle 3

Link 5

4 times 3 times

Cycle 2

2-12

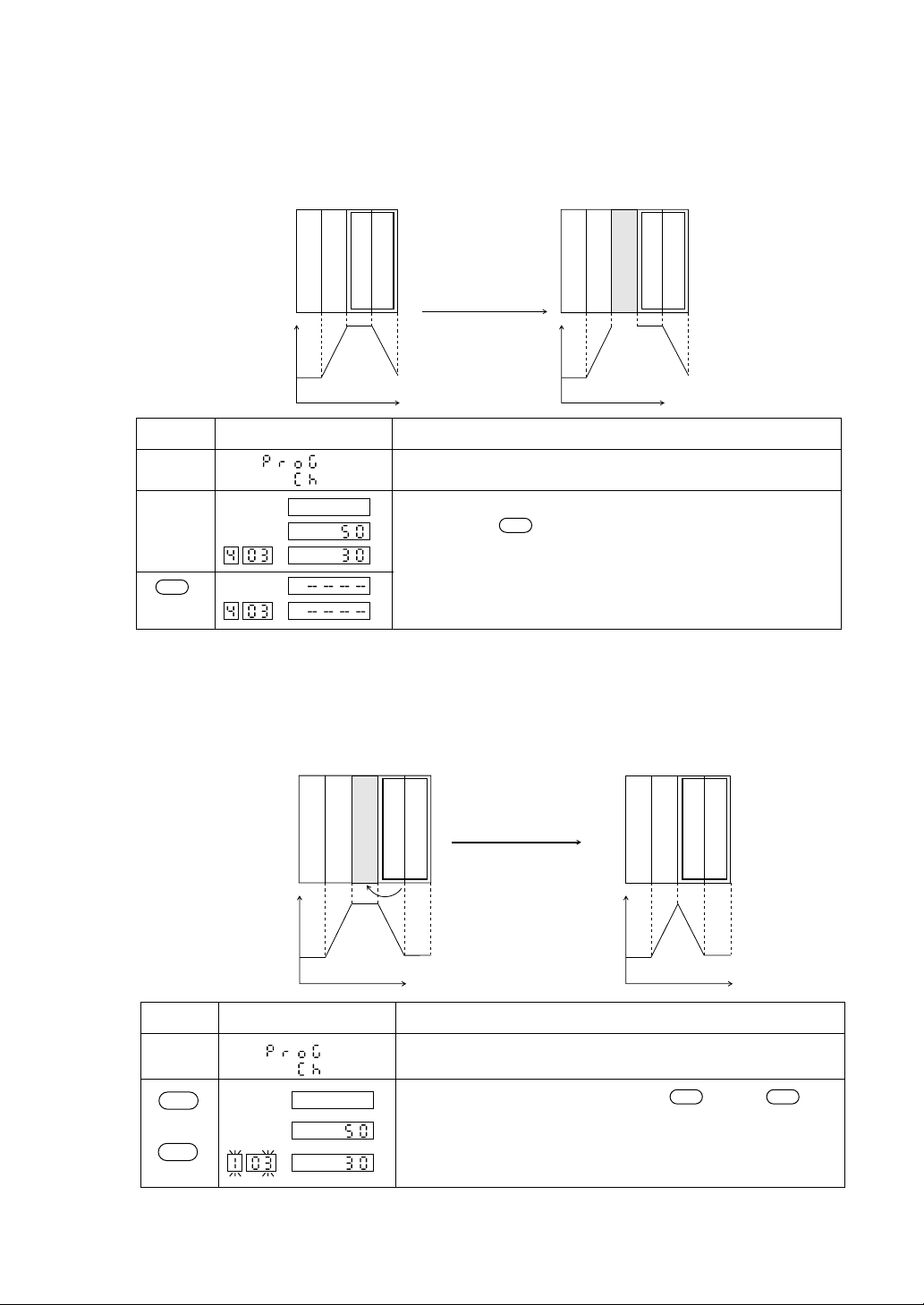

Page 23

2.4 Editing Program Pattern

Key

1234 12345

Time

Time

Key

1234 12345

TimeTime

2.4.1 Segment insertion (a new segment is created between segments)

A new segment is inserted between segments.

To be inserted between

segment 2 and segment 3

Set valueSet value

operation

Display Explanation

This display is generated by referring to section 1.3

Parameter Setting Overview.

A pattern and a segment are selected.

By depressing key, the segment is inserted.

INS

As a result, the previous segment is shifted backward by one

segment.

INS

2.4.2 Segment erasure (a segment in a pattern is erased)

A segment is erased from a program pattern.

Segment 3 is erased

Set valueSet value

operation

SFT

CLR

DSP

Display Explanation

This display is generated by referring to Section 1.3 Parameter

Setting Overview.

A segment to be erased is selected. The key and key

SFT DSP

are depressed. The segment is erased and the succeeding

segment is shifted forward for the setting.

2-13

Page 24

2.4.3 Copying a pattern

A created program pattern is copied to another pattern.

Example) Pattern 1 is copied to Pattern 4.

Pattern 9

Pattern 1

Display ExplanationKey operation

COPY

SFT

ENT

Copy

Pattern 4

This display is generated by referring to Section 1.3

Parameter Setting Overview.

The program pattern sender assignment status is established

by depressing key and key.

SFT

ENT

A sender is assigned by using and keys.

ENT

By depressing key, receiver assignment status is

established.

ENT

A receiver is assigned by using and keys.

ENT

Copying operation will start by depressing key.

After completing the copying operation, a display “Copy

ENT

done” will be generated for a second.

Cautions in the copying operation

• Prior to the generation of the sender pattern, the program must be registered for entry.

The selection of an unassigned pattern at the sender will result in a sender error.

(Sender error)

• The receiver pattern must be erased. The selection of an assigned pattern at the sender will result in a

receiver error.

(Receiver error)

2-14

Page 25

2.4.4 Pattern erasure

Part of a program pattern is erased.

Key operation

COPY

SFT

ENT

ENT

ENT

Display Explanation

2.4.5 Erasure of all patterns

All the program patterns are erased.

Key operation

COPY

SFT ENT

Display Explanation

This display is generated by referring to Section 1.3

Parameter Setting Overview.

By depressing key and key, the program

SFT

ENT

pattern sender assignment status is generated.

A display “CLR” is generated by depressing key.

The destination assignment status is generated by

depressing key. Using key and key, a

ENT

program pattern to be erased is specified.

The erasing operation is performed by depressing key.

ENT

After completing the erasing, a display “Copy done” will

appear for a second.

This display is generated by referring to section 1.3

Parameter Setting Overview.

By depressing key and key, the program

SFT

ENT

pattern sender assignment status is generated.

A display “CLR” is generated by depressing key.

ENT

ENT

The destination assignment status is generated by

depressing key. A display “ALL” is generated by

ENT

depressing key.

All patterns are erased by depressing key.

ENT

After erasing, a display “Copy done” will appear for a

second.

2-15

Page 26

2.4.6 Change of running program

The set value is suddenly changed at this point.

The set value is changed

This unit operates only when a set pattern has been copied to a running pattern (Pattern 0) in

the pattern start timing. That is, the operation is always performed in pattern 0. For this

reason, any change in patterns 1 through 9 during the operation will have no impact on the

running operation. Change pattern 0, if any change is required for running program. (In this

case, the operation will have no impact by the change of a segment already executed)

Pattern 9

Pattern 1

Copying after

start of

operation

Pattern 0

Operating pattern

Caution: A set value will be suddenly changed according to a new setting when a set value

and time are changed in the segment under the execution. (In the case of the ramp

segment)

The change of a set value or time for the segment under execution should be

avoided, if an abrupt change in the set value is undesirable.

at this point.

Old pattern

New pattern

2-16

Page 27

3. Setting of PID Group (PID Setting Channel)

Group number1Group number2Group number

3.1 Structure of PID Setting Channel

A group of control parameters such as P,I, and D is assigned.

For this unit, a lump sum of control paramters such as P, I, and D manipulating value limits

(MV limits) is called “PID group.” Nine types of PID groups are available for setting.

When running a program, select and use one out of the nine types of control parameters for

each segment. (See PID number parameters)

Processing

status

SEL

Key lock

DSP

Program pattern channel

(

PID channel

)

(

)

(

)

SEL

Proportional

zone

Integral time

Differential time

Blind zone

MV upper limit

MV lower limit

Reverse

specification

Non-linear gain

Integral break

point

Manual reset

9

Code Name Setting range Remarks

P

I

d

GAP

MV-H

MV-L

Proportional zone

Integral time

Differential time

Dead zone

Manipulating

value (MV)

Upper limit

Manipulating

value (MV)

0.0 to 999.9

0 to 3200

0.0 to 900.0

0 to 50% of input

range

–5.0 to 105.0

–5.0 to 105.0

Notation

%

Second

Second

Engineering

unit

%

%

Lower limit

REV

KnL

Ar

MAN

Reverse operation

assignment

Non-linear gain

Integral break point

Manual reset

: Reverse operation

: Normal operation

–327.7 to 327.7%

0 to 100% of input

range

–5.0 to 105.0

YES/NO

%

Engineering

unit

%

Expert parameter

2-17

Page 28

3.2 Setting of each parameter

For PID group number 1, the following setting is made:

P=10.0%, I=50 seconds, and D=30.0 seconds.

Step

Invoking

parameter (P)

Entering data

setting mode

Changing data

Entry

Applicable

key

SEL

ENT

ENT

Display Explanation

Pattern Segment

PID ch is invoked by referring to “1. Parameter

Structure and Calling Method.”

By depressing key, the proportional zone

SEL

display will appear and concurrently the segment

display will blink. A number in the segment

represents a pertinent PID group number.

Use and keys to assign the PID group

number. In this case, the PID group number "1" is

assigned and no operation is required.

Depress key. The time display will start

ENT

blinking.

Use , , and keys to change the

numerical value for the proportional zone. In this

case, 10% is used.

Depress key. The PID group number will

ENT

blink again.

Invoking

parameter (I)

Entering data

setting mode

( )

ENT

By depressing key, the integral time (I) display

will appear.

(Use and keys to change any other group

number.)

Depress key to bring a state in which the

ENT

integral time can be input. Then the time display

will start blinking.

2-18

Page 29

Step

Changing data

Applicable

key

Display Explanation

Use , , , and keys to change the

numerical value for the integral time.In this case,

50(seconds) is set.

Entry

Invoking

data (I)

Entering data

setting mode

Changing data

Entry

ENT

( )

ENT

ENT

Depress key. The PID group number will

ENT

blink again.

By depressing key, the differential time (D)

display will appear.

(Use and keys to change any other group

number.)

Depress key to bring a state in which the

ENT

differential time can be input. The time display

will then blink.

Use , , , and keys to change the

numerical value for the differential time. A value

of 30.0(seconds) is used in this case.

Depress key, so that the segment display will

ENT

blink.

2-19

Page 30

3.2.1 Setting of proportional zone (P), integration time (I), and differentiation time (D)

Explanation

The proportional zone (P), Integral time (I), and differential time (D) are

assigned for the PID control.

Setting

1) Proportional zone (P)

0.0% : Two position control is performed.

0.1 to 999.9% : PID control is performed.

2) Integral time (I)

0 [sec] : The integral operation is eliminated.

1 to 3200[sec] : An integral time is assigned.

3) Differential time (D)

0.0[sec] : The differential time is eliminated.

0.1 to 900.0[sec] : A differential time is assigned.

Associated parameters

The blind zone setting is required when the two position operation is

performed with P=0.

3.2.2 Setting of blind zone

Explanation

The blind-zone functional operation will vary with the value of P.

1) P = 0 ········ In the two position operation

This function is to improve the control stability through the prevention of

the output fluctuation in the neighborhood by shifting the operating point

at the time when the Process variable rises and falls.

GAP GAP

Output ON

Setting

Output OFF

SV

PV

2) P ≠ 0 In the PID control

This function is to reduce wasteful manipulation to a minimum by

suspending the control, with the deviation (DV) set to "0" in the

neighborhood of the set value.

This function is used, where the PV may be in the neighborhood of the

set value (a reasonable amount of offset is allowed), as in the liquid level

control in a tank.

Deviation after the blind zone

(GAP) calculation

GAP GAP

Deviation

SV

No control is exercised during this period,

with no manipulating value (MV) changed.

0 to 100% of input range :

Display in engineering unit

2-20

Page 31

3.2.3 Manipulating value (MV) upper and lower limits

Explanation

Setting

Caution

The upper limit and the lower limit of manipulating value (MV) are

determined by set values, where the limitation of manipulating value (in

upward or downward movement) is required for processing reason or for the

convenience of an operating terminal.

When manipulating value (MV) is limited, the I operation in the direction that

the MV is leaving from the limit value will be cut, therefore, preventing an

over-integration by the limitation.

Limited MV

MV-H

MV-L

0% 100%

MV-L MV-H

Prior to MV

limitation

Upper limit of manipulating value (MV)

–5.0 to 105.0%

Lower limit of manipulating value (MV)

–5.0 to 105.0%

Set the MV-H and MV-L so that the MV-H is greater than MV-L.

3.2.4 Reversing specification

Explanation

Setting

This parameter is to change over the control; from the normal operation to the

reverse operation, or vice versa.

Normal operation : to be used for a process in which the PV falls with an

Reverse operation: to be used for a process in which the PV rises with an

:For reverse operation

:For normal operation

increment of the MV.

increment of the MV.

2-21

Page 32

3.2.5 Non-linear gain

Expert parameter

Explanation

DV

GAP

GAP

Setting

–327.6 to 327.6%

Associated parameters

Blind zone

3.2.6 Integration break point

Explanation

DV

100%

This function performs the setting of blind zone

(GAP) and the control of a non-inear gain.

50%

By using this function, the non-linear gain can be

0%

controlled by making the gain larger or smaller in

the neighborhood of the set value (SV).

Expert parameter

PV

SV

Setting

If the integral operation is involved in the control

operation, an overshoot will occur due to an

overintegration at the initial stage.

The overshoot is therefore prevented by limiting the

range of the integral operation. This setting is made

for an upper and lower limits with respect to the SV.

AR

AR

The integration

is eliminated

The integration

is eliminated

0 to 100% (Engineering unit) of the input range

2-22

Page 33

3.2.7 Manual reset

Expert parameter

Explanation

Setting

The setting is made to assign "0" to the offset (steady-state deviation) when

using the unit only with P operation.

This set value is added to the MV for the output.

SV

PID operation

PV

MV

+

+

Manual reset

Manipulating value (MV)

–25.0 to 125.0%

2-23

Page 34

SECTION 3 SETTING UP...Start-up and specifica-

tion changes

Read this section carefully when incorporating this unit into a system and starting up the system.

It is assumed that the reader of this section is already familiar with the basic operating method of this

unit. If not, the reader should read SECTION 1 BEFORE STARTING OPERATION before proceeding to this section.

1. Structure of System Setup Channel

What is System Setup Channel?

The system setup channel is a channel through which basic parameters, such as the input specifications

of PV and type of alarm, are set for the use of this unit to be incorporated into the system.

The setting and confirmation of parameters for this channel are required at the time of the system startup or when the specifications are changed.

Operation

profile display

User level

()

Setting lock

SEL

()

Program pattern

setting channel

()

PID channel

()

System setup channel

()

The system setup channel display

will appear only when the user level

is set to ‘1’ (Set maker).

SEL

PV input type

PV unit

PV full scale

PV base scale

Position of decimal point

Time constant of filter

PV shift

Start mode

MV proportional period

Preset MV value

MV at burnout

Alarm 1 type

Alarm 2 types

Alarm 3 types

Alarm 4 types

AO 1 output type

AO 1 output range type

AO 1 full scale

AO 1 base scale

AO 2 output type

AO 2 output range type

AO 2 full scale

AO 2 base scale

Time unit

Time display type

END signal output time

Guarantee soak - Upper limit

Guarantee soak - Lower limit

Guarantee soak - Max. wait time

Station number

3-1

Page 35

Code Name Setting range Notation Remarks

PVT

PVU

PVF

PVB

PVD

TF

SFT

STM

C1

PSET

BURN

AL1T

AL2T

AL3T

AL4T

PV input type

PV unit

PV full scale

PV base scale

Position of

decimal point

Time constant of filter

PV shift

Start mode

MV proportional

period

Preset MV value

MV set value at burnout

Alarm 1 type

Alarm 2 type

Alarm 3 type

Alarm 4 type

See Input code table

0: °C

1: °F

0 to 1000

0 to 1000

0: No decimal position

1: the first decimal position

2: the second decimal position

3: the third decimal position

0.0 to 900.0

–50.0 to 50.0% of the

input range

0: Continuous start

1: Reset start

1 to 120

–5 to 105.0

–5 to 105.0

See Alarm Type Table.

See Alarm Type Table.

See Alarm Type Table.

See Alarm Type Table.

–

–

–

–

–

Second

Engineering

unit

–

Second

%

%

–

–

–

–

Either one is

displayed depending on

the PV input type.

To be displayed if relay

or SSR drive output.

To be displayed if expanded

alarms (3&4) are installed.

0: PV

AO1T

AO1R

AO1F

AO1B

AO 1 output type

AO 1 output range type

AO 1 full scale

AO 1 base scale

1: SV

2: MV

0: 1–5V

1: 0–5V

2: 0–10V

0 to 100.0% of

the input range

0 to 100.0% of

the input range

–

–

Engineering

unit

Engineering

unit

To be displayed if auxiliary

analog signal output is

provided.

0: PV

AO2T

AO2R

AO2F

AO2B

TMU

TMDT

ENDT

GS-H

GS-L

GSTM

AO 2 output type

AO 2 output range type

AO 2 full scale

AO 2 base scale

Time unit

Time display type

END signal output time

Guarantee soak:

upper limit

Guarantee soak:

lower limit

Guarantee soak:

max. wait time

1: SV

2: MV

0: 1 to 5V

1: 0 to 5V

2: 0 to 10V

0 to 100.0% of

the input range

0 to 100.0% of

the input range

0: hr:min

1: min:sec

0: remaining time

1: lapsed time

0 to 99.59

0 to 50.0

0 to 50.0

00 to 99.59

–

–

Engineering

unit

Engineering

unit

Remaining

time

Lapsed time

Engineering

unit

Engineering

unit

Hr:Min

(Min:Sec)

To be displayed if 2-point

auxiliary analog signal

output is provided.

Hr:min or min:sec

display depending on the setting

of time unit.

Hr:min or min:sec

display depending on the setting

of time unit.

To be displayed only when

STN

Station number

00 to 99

T-link transmission is

provided.

3-2

Page 36

2. Setting of Each Parameter

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

●

2.1 Setting of PV input type and input range

Explanation

The PV input type and the input range are selected from the table

below so that the setting can be made in codes.

Table 1. Input signal and manipulation range

Input signal Input type

Resistance

bulb,

JIS(IEC)

Resistance

bulb

(Former

JIS)

Thermocouple

DC

voltage

Direct

Pt100

Pt100

Pt100

Pt100

Pt100

Pt100

Pt100

Pt100

JPt100

JPt100

JPt100

JPt100

JPt100

JPt100

JPt100

J

J

K

K

K

R

B

T

T

E

E

S

N

U

WRe5-26

PL-II

DC1 to 5V

DC0 to 5V

DC0 to 10V

DC0 to 1V

DC0 to 100mV

DC0 to 10mV

DC4 to 20mV

00

01

02

03

04

05

06

07

10

11

12

13

14

15

16

20

21

22

23

24

25

26

27

28

29

2A

2B

2C

2D

2E

2F

40

41

42

43

44

45

40*

current

Notes:

• The 0.1°C/°F notation is not provided for a temperature span greater than

Manipulation

range Code (°C)

0 to 150°C

0 to 300°C

0 to 500°C

0 to 600°C

–50 to 100°C

–100 to 200°C

–199.9 to 600°C

–199.9 to 850°C

0 to 150°C

0 to 300°C

0 to 500°C

0 to 600°C

–50 to 100°C

–100 to 200°C

–199.9 to 600°C

0 to 400°C

0 to 800°C

0 to 400°C

0 to 800°C

0 to 1200°C

0 to 1600°C

0 to 1800°C

–199.9 to 200°C

–150 to 400°C

0 to 800°C

–199.9 to 800°C

0 to 1600°C

0 to 1300°C

–199.9 to 400°C

0 to 2300°C

0 to 1300°C

From –999 to 9999

(Scaling range)

* The current must be input on

1 to 5 volts, with a 250-ohm

resistor (optional) connected

to terminal numbers 38 and

39.

Manipulation

range Code (°F)

32 to 302°F

32 to 527°F

32 to 932°F

32 to 1112°F

–58 to 212°F

–148 to 392°F

–328 to 1112°F

–328 to 1562°F

–148 to 392°F

–328 to 1112°F

–328 to 1472°F

32 to 302°F

32 to 527°F

32 to 932°F

32 to 1112°F

–58 to 212°F

32 to 752°F

32 to 1472°F

32 to 752°F

32 to 1472°F

32 to 2192°F

32 to 2912°F

32 to 3727°F

–328 to 392°F

–238 to 752°F

32 to 1472°F

32 to 2912°F

32 to 2372°F

–328 to 752°F

32 to 4172°F

32 to 3272°F

1000°C/°F.

• No guaranty is provided for the accuracy at a temperature below 200 .

• The LLLL display will not appear even with an input of zero ohm within a

range from -199.9 to 850 for the resistance bulb input.

• For the resistance bulb input , the LLLL or UUUU display will appear when

B-wire is broken.

0.1 °C

notation

×

×

×

×

×

×

×

0.1 °F

notation

×

×

×

×

×

×

×

×

×

×

×

×

×

×

×

×

3-3

Page 37

2.2 Setting of PV display unit (°C or°F) and 0.1°C (°F) notation

(for thermocouple or resistance bulb)

Explanation

Setting

Example of setting

The setting is made for temperature display; whether the PV is

expressed in the unit of 1°C (°F) or 0.1°C (0.1°F).

The changeover between and °F is accomplished by the PV

unit , while the changeover between 1°C and 0.1°C is

done by the decimal point position parameter.

PV unit

Position of decimal point 0: 1°C notation

Note: If the input span exceeds 1000°C /°F, the display in the

unit of 0.1°C /°F is not available.

1) The display in the unit of 0.1 is executed with an input

temperature, –150 to 100 to the resistance bulb (JIS).

PVT=4 (Pt100 in the range from –150 to 100 )

PVU=0 (°C notation)

PVd=1 (0.1°C notation)

2) The display in the unit of °F is executed with an input

temperature of 0 to 400°C to K thermocouple.

PVT=22 (K in the range from 0 to 400°C)

PVU=1 (°F notation)

PVd=0 (1°F notation)

0: °C notation

1: °F notation

1: 0.1°C notation

3-4

Page 38

2.3 Setting of full scale and base scale in the engineering unit notation (for DC voltage and current input)

Explanation

Pressure gauge

0 to 10kgf/cm

DC4 to 20mA 0 to 100% 0.0 to 10.0%

Setting

The DC voltage and the current are input within the range from 0

to 100% of the input range. The units of these values are converted

(scaling) into units being used for actual processing (engineering

units). Such units are called “engineering units.”

This unit permits the display of scaling an input measured value

between 0 and 100% within the range from –999 to 9999.

Example) A display of 0.0 to 10.0 is obtained from the input value

measured with a 0-10kgf/cm

receiving the value at 4 to 20 mA DC.

This unit

2

Scaling

PV full scale setting (–999 to 9999)

The setting is made for a desired value to be

displayed at 100% input.

PV base scale setting (–999 to 9999)

The setting is made for a desired value to be

displayed at 0% input.

Position of decimal point

The setting is made for a decimal place.

2

pressure gauge by

Display

4.3

Example of setting

0: No decimal point

1: the first decimal position

2: the second decimal position

3: the third decimal position

Note) The setting must be made so that the full scale setting is

greater than the base scale setting.

Good example)

Bad example)

With an input of 4 to 20 mA DC a display of 0.0 to 10.0 will

appear.

PVT = 40 ············· 4 to 20 mA DC input range code

PVF = 100 ··········· A display of 100 by 100%(20 mA) input.

PVF = 0 ··············· A display of 0 by 0% (4 mA) input.

PVd = 1 ··············· The first decimal position

PVF=500

PVb=–250

PVF=–250

PVb=500

3-5

Page 39

2.4 PV filter ....... (reducing the wander of PV arising from noise)

Explanation

Setting

The measurement fluctuation due to the input noise is reduced to a

minimum. Where the value of P (proportional zone) is small, a

small variation of PV will produce a large MV, thus bringing

about an effect of stabilizing the control with a filter. For this unit,

a first-order-lag filter is used and the setting is made with a firstorder-lag time constant.

without filter

PV

63.2%

time

time constant

The time constant is defined as a time required for the input

value to attain 63.2% of the original input value.

Large

↑

Time constant

↓

Small

0.0 : PV filter is not used.

0.1 to 900.0 sec.: PV filter is applied according to the assigned

·············

·············

·············

Setting of PV filter time constant

Slow

↑

Response

↓

Fast

time constant (second).

2.5 PV shift (shifting zero point of PV)

Explanation

Setting

This is a function to shift a PV by a set value.

PV

–50% to 50% of the input range (Notation in engineering units)

+

PV shift set value

PV shift setting

3-6

+

Display

SV

PID operation

Page 40

2.6 Start mode... (defining a startup mode at resumption of power supply)

Explanation

Setting

The start mode is defined when the power supply is resumed.

Two types of the start mode is available: continuous and reset.

Continuous: the operation at the time of power failure is resumed.

Reset : the reset state is established.

Start mode

0: continuous

1: reset

2.7 MV proportional period .... (for relay-drive or SSR/SSC-drive output)

Explanation

This is the setting for the MV proportional period in the relay

output or in the SSR/SSC-driven output.

In the relay output or the SSR/SSC-driven MV, the value of MV,

0 to 100%, is output by means of pulse width modulation

(PWM). The setting is made for this period. Although the

shorter period brings about better response, thus improving the

controllability, the frequency of ON/OFF operation will increase.

The setting, therefore, should be made in consideration of the

service life of the operating terminal.

(Since the SSR/SSC-driven output involves no problem of the

service life, the setting of 1 second is recommended.)

Output ON

Output OFF

Setting

Example) The operation in the case of MV=60%

60%

40%

Output proportional

period

Output proportional period

1 to 120 sec.

3-7

12 sec. 0.6 sec.

8 sec. 0.4 sec.

in the case of 20 sec. in the case of 1 sec.

Page 41

2.8 Setting of preset MV .... (defining MV in the reset state)

Explanation

Setting

The value of MV is defined in the reset mode.

In the reset mode a value assigned to this parameter is an output

as the MV.

Preset MV setting

–5.0 to 105.0%

2.9 Burnout MV setting ..... (defining MV at the burnout)

Explanation

The setting is made for an output value of MV at the time of the

input burnout or at a fault state such as the trouble with the unit.

Because this being an uncontrollable state, the value should be

set so that the processing may be developed into the safe side.

Setting

MV setting at the burnout

–5.0 to 105.0%

3-8

Page 42

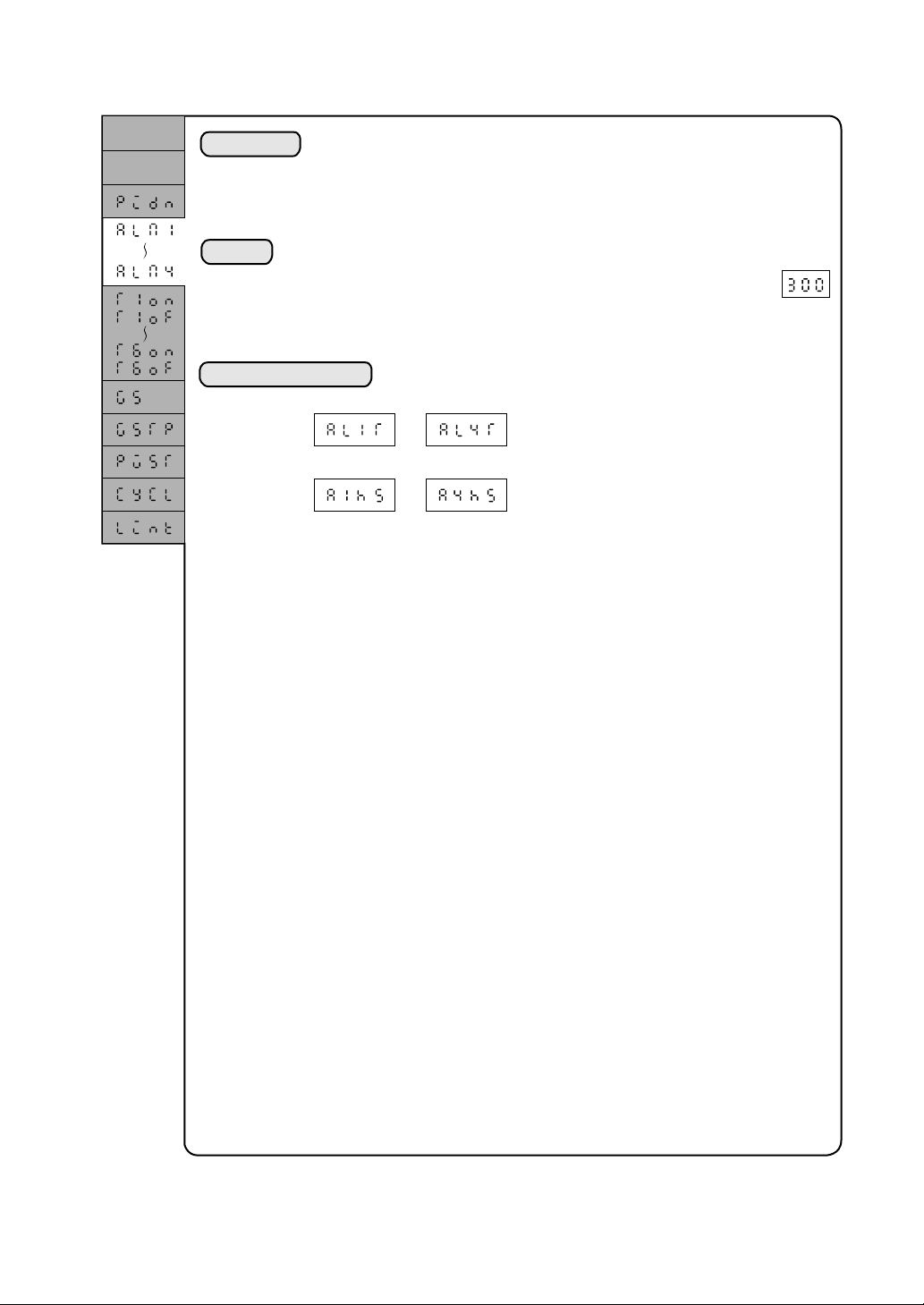

2.10 Setting of alarm type

Explanation

Setting

The type of alarms, 1 to 4, (3 and 4 are optional) is assigned.

Setting of alarm types 1 to 4

Code Type

0

1

2

3

4

5

6

7

8

9

10

11 to 18

No alarm

Upper

threshold

Lower

threshold

Upper

deviation

Lower

deviation

Upper

deviation

(Turn-over)

Lower

deviation

Upper and

lower deviation

(Turn-over)

Upper and

lower deviation

(Turn-over)

Guarantee

soak timeout alarm

fault

with HOLD for 1 - 8 above

No alarm is used.

Alarm set value

Alarm set value

Alarm set value

SV

Alarm set value

SV

Alarm set value

Where the PV fails to enter the specified range before

the maximum wait time is lapsed

Where the unit becomes faulty, such as the input

burnout

SV

SV

Alarm set value

SV

SV

PV

PV

PV

PV

Alarm set value

PV

PV

PV

Alarm set value

PV

What is an alarm with "HOLD"?

The alarm with "HOLD" is a type of

alarm to be generated, where the PV

enters an alarming range without

causing the alarm ON, letting the PV

to leave the alarming range, but again

enters the alarming range.

This is an effective function for using

a deviation alarm in step-type

programming.

The alarm standby (supervision for alarm OFF and deviation from the range) is performed in the

following cases:

• when the alarm set value is changed

• when the alarm type is changed

• when the set value (SV) is changed (however, no standby is performed when the SV is changed in

the ramp segment.)

Upper & lower

PV

limit deviation

alarm

Pattern

Time

Upper & lower

limit deviation

alarm

Upper & lower

limit deviation

alarm with HOLD

3-9

Page 43

2.11 AO output type ..... (sending PV, SV, and MV to auxiliary analog

output)

Explanation

Setting

Caution

The setting is made for the type of a signal to be sent to auxiliary

analog signal outputs 1 and 2.

AO1T and AO2T AO output type

0: PV

1: SV

2: MV

If PV is selected in the AO output type, about 10.5 V is output in

the input burnout.

3-10

Page 44

2.12 AO range and scale ......(scaling auxiliary analog output)

Explanation

Setting

Caution

The outgoing analog signal for this unit, with 0 to 10 VDC output

capability, permits a change in the range and the scaling for the

connection with other receiving instruments.

AO output range

0: 1 to 5V

1: 0 to 5V

2: 0 to 10V

AO output full-scale

A desired output value, 100% of the AO output range, is assigned

in engineering units.

• When the output type is PV or SV:

0 to 100% of the input range (in the industrial value notation)

• When the output type is MV:

0 to 100% (in the percentage notation)

AO output base scale

A desired value for 0% output of the AO output range is assigned

in the engineering unit notation.

• When the output type is PV or SV:

0 to 100% of the input range (in engineering units)

• When the output type is MV:

0 to 100% (in percentages)

If the input range is 0 to 400 , a set value (SV) of 50 to 350 is

output to AO1 on 0 to 5 VDC.

AO1T=1 ·············· SV is output.

AO1r=1 ··············· An output range of 0 to 5 VDC

AO1F=350 ·········· 100% output at 350°C

AO1b=50 ············· 0% output at 50°C

2.13 Time unit ..........(switching from hr:min to min:sec or vice versa)

Explanation

Setting

A time unit is set for the time display or for time setting.

TMU time unit

0: hr:min

1: min:sec

3-11

Page 45

2.14 Setting of time display type ...... (switching from remaining time to

lapsed time or vice versa)

Explanation

Setting

Either "Remaining time indication" or "Lapsed time indication"

is set for the time display in the operating screen.

0: Remaining time indication

1: Lapsed time indication

2.15 END signal output time

Explanation

The setting is made for the time of turning on the END signal

(optional) in the profile output of this unit at the end of a program.

TMdT Type of time display

Setting

ENDT END signal output time

0.0 to 99.59 hr:min

(min:sec)

3-12

Page 46

2.16 Guarantee soak waiting allowance and setting of max. wait time

Explanation

• Garantee soak wait time allowance

This is the time setting for the resumption of time counting in

the guarantee soak.

Upper set value for guarantee soak

Lower set value for guarantee soak

Pattern

• Max. wait time in the guarantee soak

A function to resume the time counting automatically at the

lapse of a predetermined time even if the measured value has

not entered the guarantee soak wait time while waiting in the

guarantee soak.

Setting

0 to 50% of the input range (in engineering unit)

0.0 to 99.59 hr:min (min:sec)

Supplement

This unit is capable of generating an alarm when the time

counting is resumed automatically at the lapse of the max. wait

time while waiting in the guarantee soak. (See section 3.2 (10)

Alarm Type Setting)

The time countting is suspended for this period.

Guarantee soak upper & lower

threshold values

G5TM Max. wait time in guarantee soak

2.17 Setting of T-link station number

Explanation

Setting

T-link station number is assigned.

STN T-link station number

0 to 99

3-13

Page 47

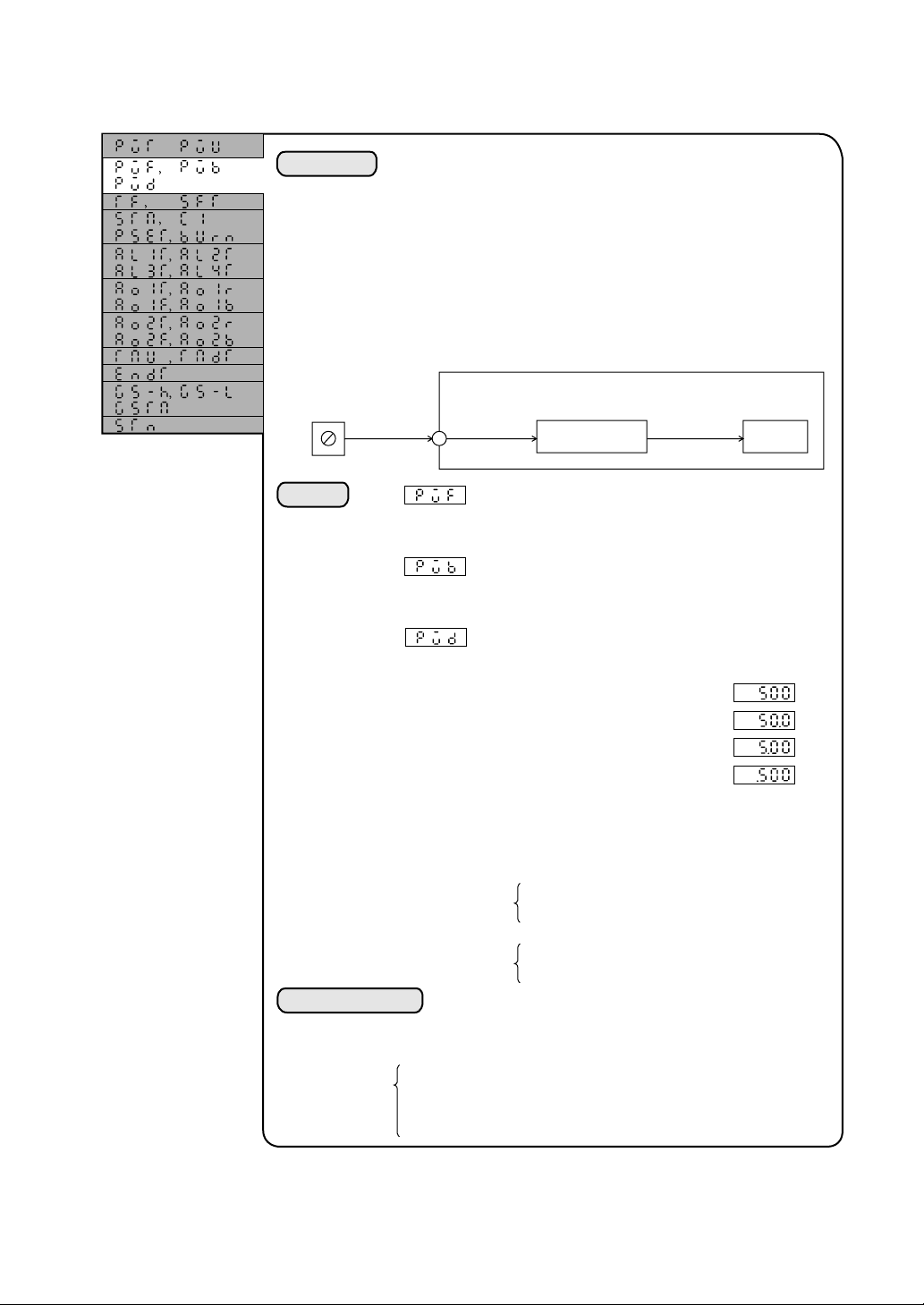

3. Various Operating Methods

3.1 In this unit the operation mode (operating profile) can be changed over as illustrated below.

Not required for the ordinary use.

A/M FIX A/M

SFT SFL SFT SFL

SFT

PTN

Fixed-value

manual operation

Behaviors of SV and MV in various modes

• Program reset mode ········ Stand-by mode in the running of a program

SV ········· SV value in the 1st segment of the current pattern selected

MV ········ Preset MV

• Program (Run, hold, and end) ········ Program running mode

SV ········· According to the program pattern

MV ········ Automatic (calculated value by PID)

Fixed-value

automatic operation

Program (reset)

Holding Running

End

Manual program

operation

RUN

SFT

HLD

SFT

RST

SFT

• The changeover to the fixed-value automatic mode can be made only from the program reset mode.

• Manual program operation ··········· The mode switched from the program mode to the manual

operation. In this case, the program will run in its own course.

However, the program will keep on running by switching to the

manual operation while the program is running.