Page 1

PORTABLE TYPE

ULTRASONIC FLOWMETER

Easy Measurement Anytime Anywhere

Compact and Lightweight—Only 1 kg

Easy-to-Install Detector

Consumed Energy Calculation

21A1-E-0009d

Page 2

Clamp-on Detector & Portable Transmitter

You can start measurement anytime you wish without interrupting the plant operation

15

16

17

18

1

2

4

3

7

6

5

8

27

10

9

11

28

12

13

29

14

20

30

24

25

26

19

22

Display Operation keys Side

1

Date & time

2

SD memory card

3

Measurement

mode

4

AI/AO status

5

Ultrasonic signal

level indicator

6

Battery indicator

7

Site name

2

8

Quick logger start/

stop button

9

Kind of data

10

Switch to graph

view

11

Unit

12

Totalizer reset

13

Totalizer ON/OFF

14

Measurement

status

21

23

15

Power ON/OFF

16

Backlight ON/OFF

17

Print out or data-saving

on SD card

18

Charging status

19

Power supply

20

Up key

21

Down key

22

Left key

23

Right key

ESC

24

Escape key

ENT

25

Enter key

MENU

26

Menu key

Flow transmitter (FSC)

27

Downstream

sensor

28

Upstream

sensor

29

AI/AO

30

12 V DC power

Page 3

Select the best confi guration for your application

Sensor 1 Sensor 2

Flow

Sensor 1

Sensor 2

Flow

Sensor 1 Sensor 2

Flow

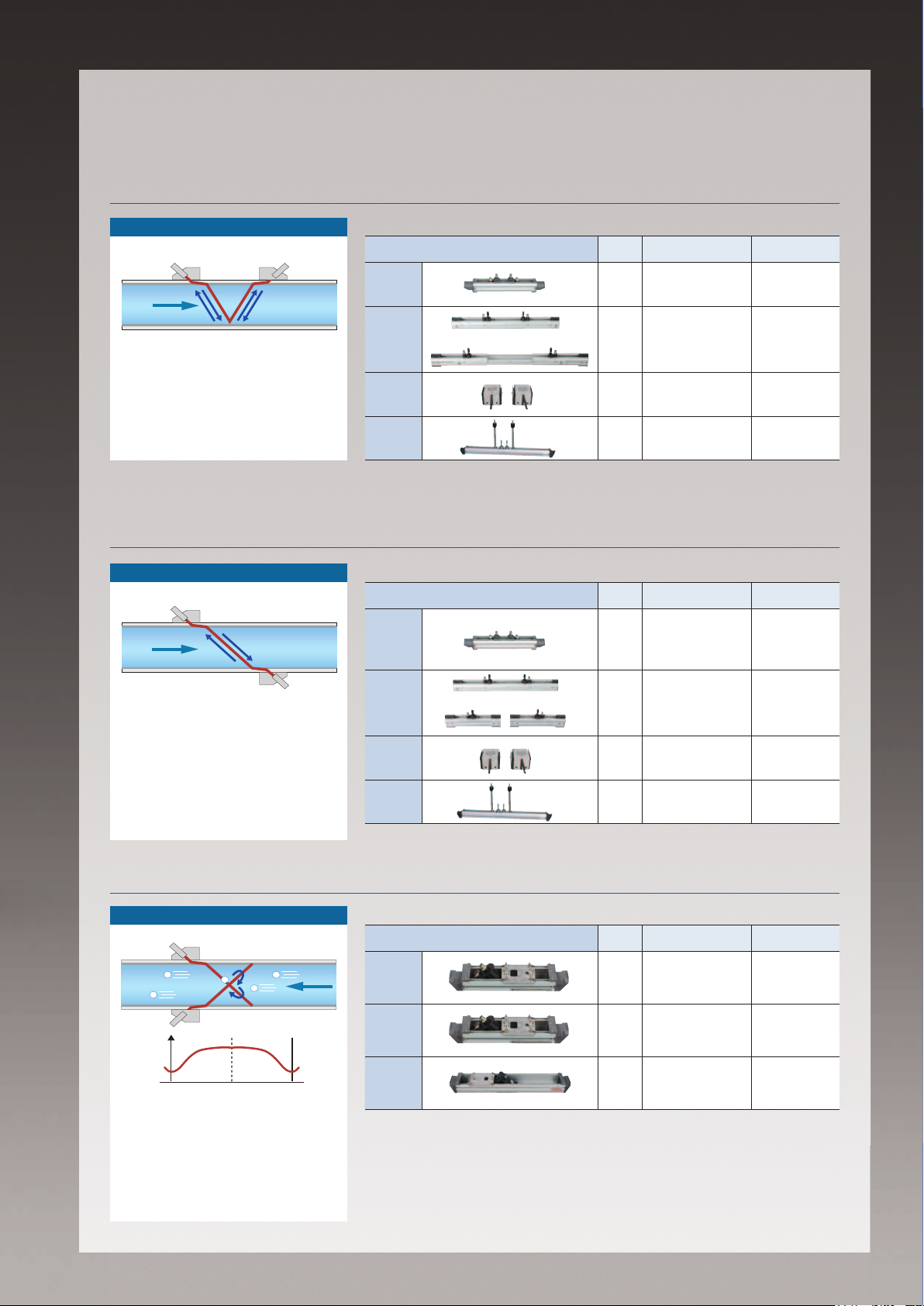

Transit time difference: V method

Principle

Sensor 1 Sensor 2

Flow

A pair of sensors aligned on the outside

wall of a pipe. The sensors emit ultrasonic pulse in turn, and detect the transit time difference of the pulse, by which

the fl ow rate is calculated.

Detectors

For small

diameter

pipes

Extendable rail

type

For large

pipes

For high

tempera-

ture

Transit time difference: Z method

Principle

Sensor 1

Flow

Detectors

For small

diameter

pipes

Appearance Model Pipe diameter (mm)

FSSD 13 to100 -40 to +100

Extended

↓

FSSC 50 to 600 -40 to +120

FSSE 200 to 3000 -40 to +80

FSSH 50 to 250 -40 to +200

Appearance Model Pipe diameter (mm)

FSSD 150 to 300 -40 to +100

Fluid tempera-

ture (ºC)

Fluid tempera-

ture (ºC)

A pair of sensors installed on the outside wall of a pipe, facing each other

slantingly. The sensors emit ultrasonic

pulse in turn, and detect the transit time

difference of the pulse. This method is

used mainly when the V method is not

available due to the space limitation, or

when the fl uid has high turbidity.

Pulse doppler method: for real-time fl ow pro le analysis

Sensor 1

Air bubbles

Sensor 2

velocity

The frequency of ultrasonic pulses refl ected by air bubbles or solid particles

changes according to the fl ow velocity.

The pulse doppler flowmeter uses this

frequency shift to determine the flow

velocity pro le.

Principle

Reflection

Sensor 2

Sensor 1Sensor 2Flow

CenterPipe wall Pipe wall

Flow

Extendable rail

type

For large

pipes

For high

tempera-

ture

Detectors

Small

Middle

Large

Separated

↓

FSSC 200 to 1200 -40 to +120

FSSE 200 to 6000 -40 to +80

FSSH 150 to 400 -40 to +200

Appearance Model Pipe diameter (mm)

FSDP2 40 to 200 -40 to +100

FSDP1 100 to 400 -40 to +80

FSDP0 200 to 1000 -40 to +80

Fluid tempera-

ture (ºC)

3

Page 4

Designed for Ease-of-Use

Easy Measurement Anytime Anywhere

Handy and battery-powered design allows you to take

measurement when and where needed.

Real-Time Monitoring of Flow Pro le

Using the ow transmitter FSC in combination with the

optional pulse doppler detector (FSD) enables realtime monitoring of ow pro le

(option).

Consumed Energy Calculation

A function to obtain thermal energies exchanged via

uid used in air-conditioning systems. The transmitter

calculates the consumed thermal energy based on the

forward ow temperature, the return ow temperature,

and the ow rate.

4–20 mA DC output (1 point)

Flow

Temperature sensor

T1: Forward flow temperature

Heat

source

Temperature sensor

Data Management on PC

transmitter

transmitter

Flow

Detector (FSS)

Q: flow rateT2: Return flow temperature

Data in SD card can be transmitted to your PC through

a USB cable.

Consumed thermal energy

q = K‧ Q‧(T1 -T2)

K: heat coefficient

(K for heating = 4.123)

Load

Flow pro le indication

Carrying Case

The dedicated case accommodates all the necessary

equipment including:

●

Flow transmitter

●

Detector (FSSC or FSSD)

●

Acoustic coupler (silicone grease)

●

Signal cable

●

Analog I/O cable

●

Strap parameter loader software)

●

AC power adapter

●

Power cable

●

Mounting belt

●

USB cable

●

CD-ROM (instruction manual,

Loader software provided

Parameter setting screen

Flow trend screen

Flow pro le screen

Carrying case

4

Page 5

Data Storage on SD Card

Easy-to-Mount Detector

The transmitter automatically saves the measured data

on SD memory card at user-specifi ed cycle. You can

also send the data through USB port to your PC.

For example, a 512 MB memory card can store the data of two

years' worth (at a data save cycles of 30 s, 14 kinds of data).

SD card up to 8 GB can be used.

Cover

USB port

SD memory card slot

Multilingual Display

Mounting detector requires no tools. You can start

measurement anytime.

On-Site Printing (option)

You can print out the measured data or screenshot by

the dedicated printer.

English

Chinese

Easy-to-See LCD

Received waveform

Logger data

12 Hours of Continuous Operation

with Built-in Battery

FSC can serve long hours of outdoor measurement.

Accessories for Comfortable Operation

(option)

· Hand strap

Helps you hold the transmitter

· Stand

Holds the transmitter at an easy-to-see angle

* The hand strap and the stand cannot be used simultaneously.

5

Page 6

Visualization of water use

Amount of water used

Applications

Reduction of Water Used in Plant Utilities

Visual depiction of a facility’s water use results in more effective

management of water consumption.

Measurement

in the right place

at the right time

Building C

Building B

Main pipe

1 2 3 4 5 6 7 8 9 10

Building A Building B Building C

(Day)

Spool piece

ultrasonic owmeter

Energy Consumption in Air-Conditioning Systems

Calculates the thermal energy received and sent with liquid in

air-conditioning system.

Flow transmitter

Temperature

sensor

TS: Forward flow temperature

Heat source Load

Temperature

sensor

Detector (FSS)

Q: flow rateTR: Return flow temperature

Building A

4–20 mA DC Analog Output (1 point)

Flow rate or

Consumed thermal energy

Serial Communication (USB port)

Cooling mode, heating mode, or heating/

cooling auto switching mode

Corrosive Fluid

Ultrasonic owmeters can take measurement on glass,

metallic, and plastic pipes.

Strong alkali

6

Strong acid

Wash Water in Food Manufacturing

Plants

Easier installation and lower maintenance compared to

mechanical owmeters or Coriolis owmeters

Food

processing

equipment

Wash water

Page 7

Ordering Code Select a code for each digit to congure the model for your application.

5 6 7 8 9 10 11

F S C S 3 - 0

Flow transmitter

Digit

Specications Code

Transmitter unit

5

Standard unit 1

Standard unit + printer 2

Flow velocity prole

6

None 0

With (A detector for ow velocity prole measurement is required)

AC power adapter + cable

125 V AC (Japan, North America) A

7

250 V AC (EU, Korea) B

250 V AC (China) C

Revision code 3

8

SD memory card

9

None 0

With (512 MB) 1

Instruction manual / default language setting

None / English Y

With / Japanese J

11

With / English E

With / Chinese C

Scope of Delivery

1. Transmitter unit

2. AC power adapter with AC/DC conversion cable

3. Power cable

4. Analog I/O cable (1.5 m)

5. USB cable (1 m)

6. Carrying case

Flow transmitter (FSC)

Transmit time

method ow

detector (FSS)

Pulse doppler

ow detector

(FSDP)

* Parameter loader software is available from our website at:

http://www.fujielectric.com/products/instruments/

7. Strap

8. Signal cable (5 m × 2)

9. CD-ROM (instruction manual, parameter loader

software)

Option (as specied by order)

1. SD memory card (512 MB)

2. Printer (with 1 roll of paper)

3. Instruction manual

1. Detector unit

2. Signal cable conversion cable (provided when the

detector is FSSE)

3. Mounting belt or wire (as specied by order)

4. Silicone grease or silicone-free grease (as speci-

ed by order)

1. Detector unit

2. Mounting belt or wire

3. Silicone grease (100 g)

4 5 6 7 8 9 10

F S S 1 -

Detector (transit time difference method)

Digit

Type

Extendable rail type

For small diameter pipes

4

For large pipes

For high temperature

1

Guide rail

5

Standard 1

Long (Selectable when the 4th code is D)

Mounting belt

None Y

Stainless belt (for pipe diameters ≤ 300 mm) A

Plastic cloth belt (for pipe diameters ≤ 300 mm) B

6

SS belt with screws (for pipe diameters ≤ 600 mm) C

Wire (for pipe diameters ≤ 1500 mm) D

Wire (for pipe diameters ≤ 6000 mm) E

Acoustic coupler

None Y

Silicone-free grease B

7

Silicone grease

Grease for high temperature (Selectable when the 4th code is H)

Revision code 1

8

Waterproof treatment

9

None Y

3

With*

(Selectable when the 4th code is C or E) B

Tag plate

10

None Y

Stainless steel tag plate (The tag number need to be specied.)

*1: Select an appropriate mounting belt in 6th code in reference to the following table.

Mounting method

V method A, B, or C C D

Z method C D D

Possible combination of 4th code and 6th code

Y

A

B

C

6th code

D

E

*2: Normally, select the silicone grease as an acoustic coupler. A silicone grease comes

in a 100 gram tube.

*3: Two 10-meter signal cables are included. Waterproof treatment makes the detector

submersible for ve days.

Detector

(pulse doppler method, for ow velocity prole measurement)

Model Specications

FSDP20Y1 Small (40 mm to 200 mm)

FSDP10Y1 Middle (100 mm to 400 mm)

FSDP00Y1 Large (200 mm to 1000 mm)

Specications Code

∅

50–1200 mm C

∅

13–100 mm D

∅

200–6000 mm E

∅

50–400 mm H

*1

*2

≤ 300 mm ≤ 600 mm ≤ 1200 mm

4th code

C D E H

✔ ✔ ✔ ✔

✔ ✔ ✔

✔ ✔

✔ ✔ ✔

✔ ✔

✔

3

C

D

A

7

Page 8

Specications

Fluid

Pipe inner

diameter

Fluid temperature

Velocity

Accuracy

Output cycle

Path

Display

Analog output

Analog input

Power supply

voltage

Transmitter

enclosure

Transmitter

dimensions

Transmitter

weight

SD card

Uniform liquid through which ultrasonic wave can

propagate (water, distilled water, alcohol, etc.)

13 mm to 6000 mm (depending on detector)

-40°C to +200°C (depending on detector)

0 to ±32 m/s (minimum ±0.3 m/s)

±1.0% of rate (depending on ow velocity)

1 s

1 path, transit time method

Color LCD with back light

4–20 mA DC (1 point)

4–20 mA DC / 1–5 V DC (2 points)

Built-in battery (12 hours of continuous operation)

IP64 (no printer version)

210 × 120 × 65 mm (no printer version)

Approx. 1 kg

512 MB (stores 2 years’ worth data)

Dimensions

Serial

communication

Functions

Options

Transmission data:

Data stored in SD card (instantaneous value, total

value, etc.)

Through USB port

Cable length: up to 3 m

Damping time constant (0 to 100 s)

Instantaneous value (10-digit) *The ow rate unit is

selectable

Total value (10-digit) *The ow rate unit is selectable

Consumed energy calculation

Self-diagnosis (battery power, received wave)

Flash memory (measurement parameters for pipe,

uid, sensor, etc)

Number of registration sites: 32

Zero point adjustment (by setting zero or clearing

zero)

Graph view, waveform view

Language (Japanese, English, Germain, French,

Spanish, Chinese)

Bidirectional ow measurement

Low ow cut-off (0–5 m/s)

Printer: screen hard copy, periodic printing and

logged data printing

Detector for ow velocity prole measurement:

displays ow velocity prole of instantaneous value

and average value

210±2.5

SD memory card slot

Flow transmitter (FSCS1) Flow transmitter with printer (FSCS2)

65±1.8

DOWNSTREAM

UPSTREAM

AI/AO

DC12V

SENSOR

120±1.8 65±1.8

DOWNSTREAM

UPSTREAM

AI/AO

DC12V

Power switch

USB port

USB

2-M4, Depth5 (both sides)

Sensor (downstream)

SENSOR

Sensor (upstream)

Analog input/output

DC power input

Approx. 320±4.5

SD memory card slot

120±1.8

Power switch

USB port

USB

Printer

2-M4, Depth5 (both sides)

Sensor (downstream)

Sensor (upstream)

Analog input/output

DC power input

Information in this catalog is subject to change without notice.

Read the instruction manuals thoroughly before using the products.

Instrumentation & Sensors Planning Dept.

1, Fuji-machi, Hino-city, Tokyo 191-8502, Japan

http://www.fujielectric.com

Phone: +81-42-514-8930 Fax: +81-42-583-8275

http://www.fujielectric.com/products/instruments/

Printed in Japan 2018-1/5 FOLS

Loading...

Loading...