Page 1

Quick Reference

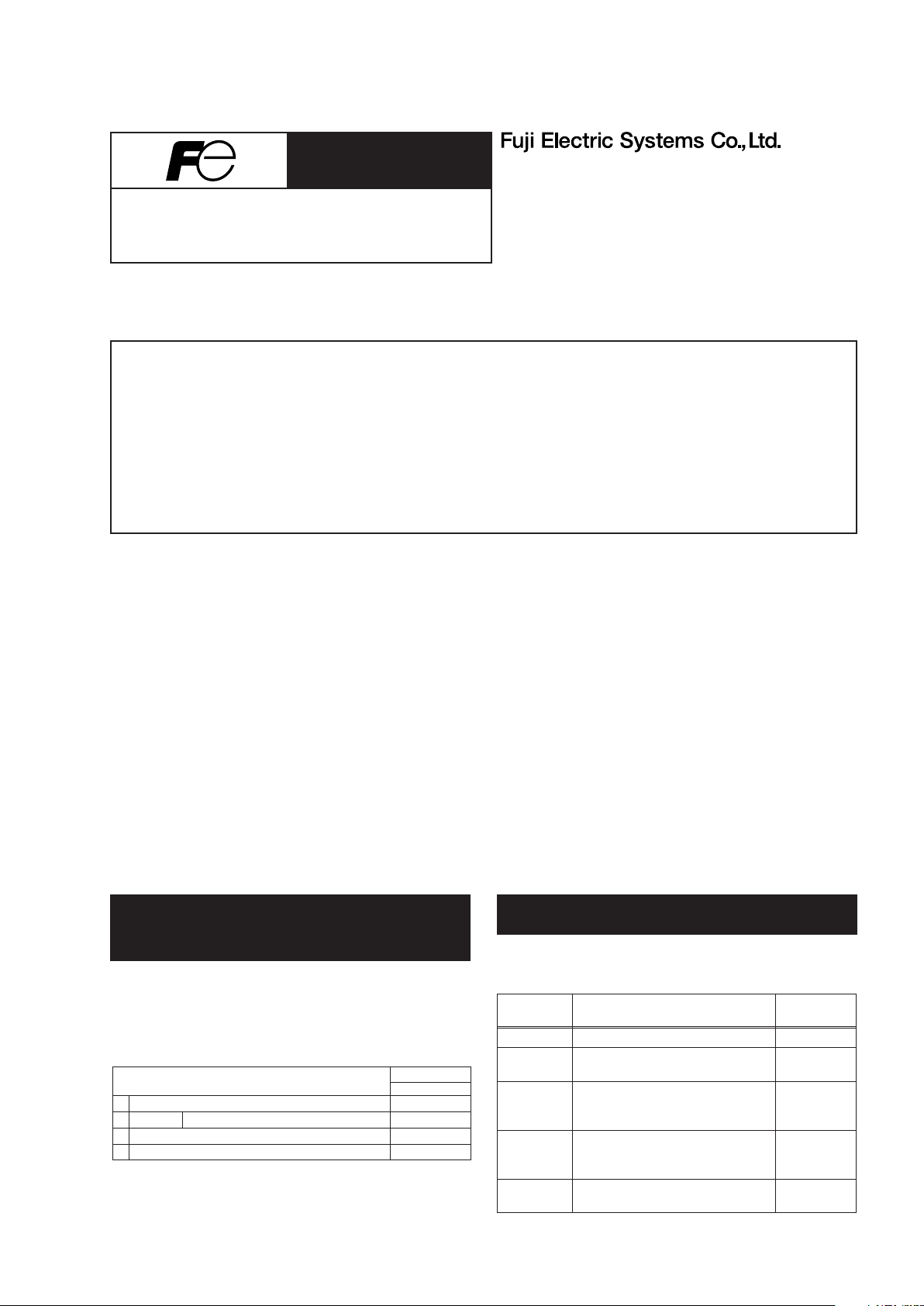

Product name

Panel-mounting bracket

CD-ROM PC support software instruction manual

Quantity

Panel-mounted

2

Power supply noise filter

1

(1)

(3)

Quick reference (this manual)

1

(4)

1

(2)

Content Document

Reference

Number

Specifications

Operation

Method

Communication

Function

Parameter

Loader

(software)

Catalogue

Instruction Manual for

Paperless Recorder (type: PHU)

Communication Functions Instruction

Manual (Ethernet) for

Paperless Recorder

Parameter Loader Instruction Manual for

Paperless Recorder

INP-TN1PHU-E

ECNO: 1016

INP-TN5A0024-E

INP-TN513995-E

Data Viewer

(software)

Data Viewer Instruction Manual for

Paperless Recorder

INP-TN514013-E

PAPERLESS RECORDER

Type : PHU

INP-TN1PHUQR-E

Head office

Gate City Ohsaki, East Tower, 11-2, Osaki 1-chome,

Shinagawa-ku, Tokyo 141-0032, Japan

http://www.fesys.co.jp/eng

Instrumentation Div.

International Sales Dept.

No.1, Fuji-machi, Hino-city, Tokyo 191-8502,

Phone: 81-42-585-6201, 6202 Fax: 81-42-585-6187

http://www.fic-net.jp/eng

Japan

Thank you for your purchasing Fuji Paperless Recorder (Type: PHU).

• Read this instruction manual carefully to ensure correct installation, operation and preparation. Incorrect handling

may lead to accident or injury.

• Specifications of this unit are subject to change without prior notice for improvement.

• Modification of this unit without permission is strictly prohibited.

Fuji will not be bear any responsibility for a trouble caused by such a modification.

• This instruction manual should be kept by the person who is actually using the unit.

• After reading the manual, be sure to keep it at a place easy to access.

• This instruction manual should be delivered to the end user without fail.

Manufacturer : Fuji Electric Instrumentation Co., Ltd.

Type : Shown on nameplate of Recorder

Date of manufacture : Shown on nameplate of Recorder

Product nationality : Japan

CONTENTS

Specifications and Accessories ...................................... 1

Related Information ........................................................ 1

Caution on Safety (Please read first) .............................. 2

For Proper Usage ........................................................... 5

Installation ................................................................ 5

1.

Wiring ....................................................................... 6

2.

Operation Parts and Their Functions ....................... 7

3.

Specifications and

Accessories

Before using the product, confirm that it matches the

type ordered.

(For model code, please refer to page 12.)

Confirm that all of the following accessories are

included.

Note:

Windows is a registered trademark of Microsoft Corporation.

Modbus is a registered trademark of AEG Schneider Auto-

mation International.

Other product names are registered trademarks or trade-

marks of each manufacturer.

Display and Operation Procedure ............................ 8

4.

List of Parameters .................................................... 9

5.

Troubleshooting ....................................................... 11

6.

Specifications ........................................................... 11

7.

Code Symbols ......................................................... 12

8.

Maintenance ............................................................ 12

9.

Related Information

Refer to the following reference materials for details

about the items described in this manual.

– 1 –

Page 2

– 2 –

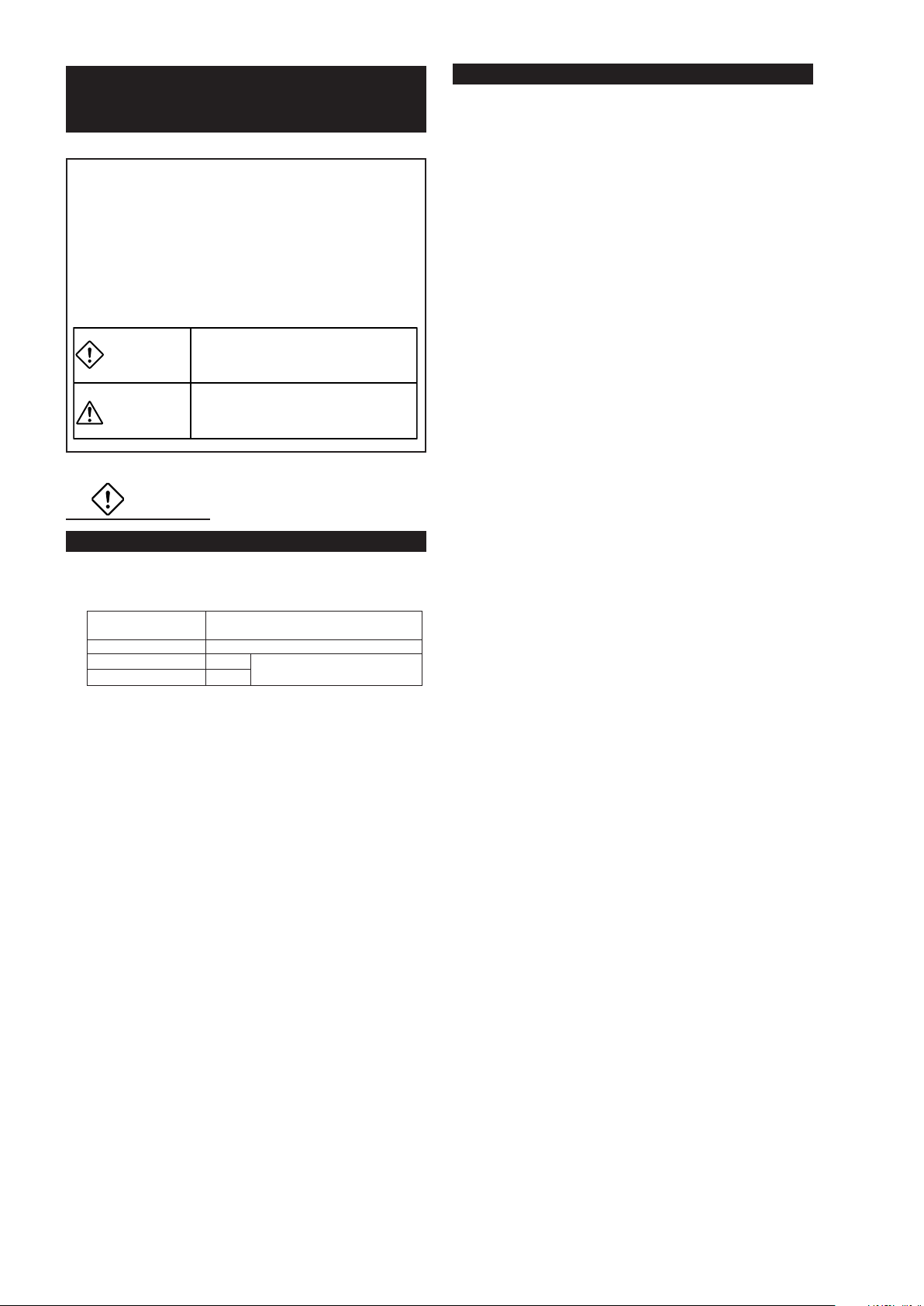

Improper handling may cause

dangerous situations that may

result in death or severe injury.

Improper handling may cause dangerous situations that may result in moderate or light injuries or property damage.

CAUTION

DANGER

Ambient temperature 0 to 50°C (without Ethernet function)

0 to 40°C (with Ethernet function)

Ambient humidity 20 to 80% RH (with no condensation)

Installation category II

Pollution degree 2

by IEC1010-1

Caution on Safety

(Please read first)

Read this “Caution on Safety” carefully before

using the instrument.

• Be sure to observe the instructions shown below,

because they describe important information on

safety. The degree of danger is classified into the

following two levels: “DANGER” and “CAUTION.”

The signs and their meanings are as follows:

1. DANGER

1.2 Maintenance

• Turn off the power before attaching/detaching the

module/unit. Otherwise electric shock, malfunction

or failure may result.

• We recommend you to perform periodic mainte

nance for the safe and continuous use of this instrument, because consumable parts or those which

deteriorate with time are mounted in this instrument.

• Do not block the ventilation holes at the top and the

bottom of this instrument. Otherwise a failure, malfunction, shortened service life, or fire may result.

-

1.1 Installation

• This equipment is intended to be used under the

following conditions.

• IP : 50 (Front) / 20 (Terminal)

• When there is a possibility that the abnormality of

this instrument may cause a major accident or damage to other instruments, externally install an adequate emergency stop circuit or a protection circuit

to prevent accidents.

• This product is provided with a built-in fuse that

cannot be replaced by the customer. Therefore,

we recommend you to separately provide adequate

fuses externally. (Rating: 250V, 2A)

The details of the built-in fuse are as follows.

Type : TR-5 19372, 3.15A (Manufactured by

Wickmann-Werke GmbH)

Rating : 250V, 3.15A, Type: T (Slow-blow type)

• Feed the power-supply voltage to specifications to

prevent damages to and breakdown of the instrument.

• Never turn on the power before all the mounting

and wiring work are finished to prevent electric

shock, malfunction or failure of the instrument.

• Never use this instrument in an environment where

flammable or explosive gases exist, since this is not

of intrinsically safe construction.

• Never disassemble, remodel, modify, or repair this

instrument. Otherwise malfunction, electric shock,

or failure may result.

• Never touch the terminal while the instrument is be

ing energized. Otherwise electric shock or malfunction may result.

-

Page 3

2. Caution

∠α = 60 to 90°

∠α

2.1 Cautions when installing

• Never use the instrument if it is found damaged or

deformed when unpacked. Otherwise a fire, malfunction, or failure may result.

• Check that the instrument is to the proper specifica

tions. Otherwise damage or failure may result.

• Do not give a shock to the instrument by falling or

toppling it. Otherwise damage or failure may result.

• Avoid installing the instrument in the following places.

• A place where the ambient temperature goes

beyond the range from 0 to 50°C (0 to 40°C

when the instrument is mounted with its side face

closely contacted, or provided with Ethernet function)

• A place where the ambient humidity goes beyond

the range from 20 to 80% RH

• A place where condensation occurs

• A place where corrosive gases (sulfuric gases or

ammonia, etc., in particular) or flammable gases

exist

• A place where vibration or impact may be applied

to the instrument (permissible continuous vibration condition: 4.9 m/s2 or lower)

• A place subjected to water, oil, chemicals, vapor,

or steam

• A place subjected to dust and high in salt or iron

content

• A place where inductive interference may have a

great effect, thus causing static electricity, magnetism, or noises

• A place subjected to heat accumulation by radi

ant heat or the like

• A place that is affected by electromagnetic wave

from wireless machine or portable telephones.

• If the instrument is installed near other electronics

instruments, such as TV in particular, noises may

be caused. Take the following measures in these

cases.

• Place the instrument as far from the TV or the ra

dio as possible (1m or more)

• Change the orientation of the antenna of the TV

or the radio.

• Use separate receptacles.

2.2 Cautions when installing to the panel

• When mounting this instrument against the panel,

pay attention not to apply stress to the case. Otherwise the case may be damaged.

• Fix the instrument by fastening the screws at the top

and the bottom of the supplied mounting bracket.

• The panel to be used should be more than 2 mm

thick.

• Excessive torque will cause damage to front panel

frame or result in case deformation.

Tightening torque: 0.2 N·m

• If the panel front is subject to water splashes, use

panel packing between the unit and panel.

• Mount the unit horizontally, with

no tilt to t he left or ri ght (T he

forward tilt should be 0° but the

uni t ma y be incl ined 0 to 30°

rearwards).

2.3 Cautions for wiring connection

-

• Only authorized workers should perform wiring.

Improper wiring may cause fire, failure, or electric

shock.

• Be sure to ground the instrument. Otherwise elec

tric shock or malfunction may result.

• When cables are connected to terminals of the re

corder unit, don’t apply pulling force to them excessively. Excessive force to the terminal may result in

damage to the terminal or cable.

• Use the power cab le that has the performance

equivalent to or higher than 600-V vinyl insulated

power cable (JIS C3307). Install the attached noise

filter within approximately 20cm from the power terminal of this instrument. (Wind the power cable 1 to

2 turns. The internal diameter of the ferrite core is

8mm.) Do not connect two or more instruments in

parallel.

• Up to 2 solderless terminals should be used when

connecting cables to terminals. Be sure to use an

insulation cap.

(Note)

1) At the completion of wiring of the input termi

nals, be sure to close the rear cover to ensure

the compensation of reference contact when

thermocouple input is used.

-

-

In case of thermocouple input, follow the steps

to stabilize temperature at the terminal.

• Be sure to attach input terminal cover.

• Don’t use a thick cable to prevent the effect

of radiation. The cable with a diameter of 0.5

mm or less is recommended.

• Don’t mount other instruments near a fan to

keep temperature stable.

2) For connection of lead wires to terminals, use

of sleeve-insulated clamping terminals (for M3

screw) is recommended.

3) This unit has no power fuse which is remov

able. Mount a power fuse outside the unit as

needed.

Recommended fuse rating: 250V AC, 2A

4) Don’t loosen screws that are secured to the

terminal case and power terminal.

• Input signal cables should be wired separately as

far as possible (30 cm or more) from power lines

and high-voltage lines to minimize the effect of inductive noise. Shielded cables should preferably

be used. In this case, the shield braids should be

earthed at one point.

• If a large noise is generated from the power supply,

provide an isolating transformer and use a noise filter.

• Install the instrument paying attention to prevent

foreign matters such as scraps, electric wire chips,

and iron powder from entering in the instrument.

-

-

-

-

– 3 –

Page 4

– 4 –

• Do not use the wires other than the specified compensation conducting wires for the thermocouple

input connection. Otherwise improper indication or

malfunction may result.

• Use a wiring cable with low resistance and with

small resistance difference among the three wires

for the resistance bulb input connection. Otherwise

improper indication or malfunction may result.

2.4 Cautions in Operation

• Check every six months that the terminal screws

and mounting screws are securely fastened. Loose

screws may cause fire or malfunction.

• When changing the setting during the operation or

forcibly outputting, starting or stopping the instrument, be sure to check that safety is ensured. Improper operation may result in damage or failure of

the instrument.

• Be sure to keep the attached terminal cover mount

ed on the terminal block during the operation. Otherwise electric shock or fire may result.

• Stop using the instrument if it is immersed in water.

Otherwise electric leak, electric shock, or fire may

result.

• Never use organic solvents such as alcohol or ben

zene when cleaning this instrument. Do not directly

water the main unit. Otherwise deterioration, failure, electric leak, electric shock, or fire may result.

When cleaning the main unit, wipe with a dry cloth.

• Dispose the instrument as an industrial waste.

• This product contains a CR Coin Lithium Battery

which contains Perchlorate Material-special handling may apply.

See www.dtsc.ca.gov/hazardouswaste/perchlorate

2) The memory card should be inserted in the prop

er direction and fixed securely to the slot.

3) Don’t turn OFF the power or remove the card

from the slot while data is being written in or read

from the card, or recorded data may be damaged

or lost.

4) We recommend you to back up the data con

tained in the card once a month. If the CF card

is broken, the important log data contained in CF

card will be lost. Be sure to back up the data.

Before using a compact flash card adaptor, check

the capacity of the adaptor. If the capacity of the

memory card to be formatted is larger than that

of the adaptor, do not format the card. If the card

is formatted, a display may appear on Windows

indicating that formatting is completed, but PHU

does not recognize the completion of formatting.

5) Compact flash in the capacity range from 8MB to

512MB can be used.

-

-

6) The data recorded in the compact flash can be

regenerated on the PC by using the data viewer

(contained in the attached CD-ROM).

If the data is recorded in ASCII format, it can be

directly opened in a spreadsheet such as EXCEL.

However, large-amount data cannot be opened

(about 7MB or larger in the case of 6-point input,

and about 4MB or larger in the case of 3-point

input).

In those cases, read in data with the data viewer

(contained in the attached CD-ROM), and perform CSV conversion to divide the file, which allows the data to be read in.

The data recorded in binary format cannot be di

rectly opened in a spreadsheet such as EXCEL.

Be careful not to make the size of a file too large

even if a large-capacity CF card is used. (Keep it

to 10MB or less.)

-

-

-

2.5 Handling memory card (Compact Flash)

• For the memory card, use Sandisk’s compact flash

memory (URL: http://www.sandisk.com). A compact flash manufactured by other companies may

not be used or cause other problems.

1) Be sure to format the memory card with the PC

you use.

Format it as FAT16 or FAT. If it is formatted as

NTFS, for example, it cannot be used because

the PHU does not recognize it.

Page 5

For Proper Usage

<Reference Item>

<Details>

When the display does not make sense.

6

Turn Power On

Wiring

2

Usage (Read before using)

3

Display and Operation Methods

4

List of parameters

5

Operation

Installation

1

Model Designation Confirmation

• Please confirm that the model

delivered matches your order.

• Dimensions

• Panel cutout

• How to install on the panel

• How to handle the memory

card

• How to change the data

display screen

• How to change the parameter

setting screen

• Setting of parameters

Since about 60 minutes is needed until the unit becomes

thermally stable, wait for 60 minutes or more after turning the

power on before making measurements, etc.

• Terminal connection diagram

• Displays during abnormalities.

• Stopping and starting the

recording

AC power source

Protective grounding

Power ON

Double insulation

Power OFF

Electric shock hazard

(unit : mm)

Note1) If other instruments are placed under the recorder unit,

provide a space of 100 mm or more from the instrument or floor.

Dimensions

Panel cutout

PUSH

300

280

220.5

175

26

300

Mounting fixture

281

+2

0

320 MIN

281

+2

0

360 MIN

Panel

t

2 ≤ t ≤ 26

1 Installation

Dimensions/Panel Cutout

Cautions on wiring

• Use crimped terminals matched to the screw size.

Tightening torque should be about 0.2 N·m.

• Do not connect anything to terminals not used.

– 5 –

Page 6

– 6 –

R-MODULER-MODULE

R-MODULE

Rcj

Rcj

R-MODULE

Rcj

Rcj

CH9CH8

+

TC?^V

+

CH6

+

TC?^V

30

CH10

29

TC?^V

+

28

43-44

-

TC?^V

+

‰º’i

LOWER

33

CH16

48

+

CH11

34

TC?^V

CH15

45

-32+

31

TC?^V

46

-

TC?^V

+

47

1716

LOWER

‰º’i

18

CH17

-

38

TC?^V

493950

CH13

35-37

RCJ

36

+

CH12

+

TC?^V

ã’i

42

CH18

54

UPPER

51

+

-

TC?^V

41+40

5352

-

TC?^V

CH14

2724 25-26

CH1

3

TC?^V

1 2

-+

TC?^V

+

4

CH4

12

UPPER

15

ã’i

+

TC?^V

13 14

CH5

CH18

TC?^V TC?^V

+

CH17CH16 RCJ

+

TC?^V

+ +

TC?^V

CH15

TC?^V

CH28

98

-

TC?^V

82

+

TC?^V

97

-83+

LOWER

‰º’i

88

CH29

87

+

102

CH34

+

TC?^V

100

TC?^V

CH33

99

84 85+86

-

-

101

43-44

‰º’i

LOWER

48-4645 47

CH35

CH31

104

93

TC?^V

103

92

-

-

91

CH30

+

89

RCJ

90

-

TC?^V

+

UPPER

CH36

96

108

ã’i

107

TC?^V

+

105

94

+

TC?^V

106

95

-

CH32

49-50 54-535251

TC?^V

CH10

-

2928

TC?^V

+ +

33

CH11

34-3231

TC?^V

30

+ -

38 39

CH13

+-

373635

CH12

TC?^V

ã’i

42

UPPER

-

4140

TC?^V

+

CH14

6

+

CH2

7

TC?^V

5 11-8-109

+

CH3

TC?^V

CH7

21

-

TC?^V

19 20

-

TC?^V

22 23

RCJ

+

DIDI

CH19-CH27

DO32

DO24

CH1-CH9

?iTr?j

DO21-36

DO31

DO22

VPD

VPD DO21

DO29

DO23

DO30

PCD

DO36DO35DO34

DO27 DO28DO26DO25

DO33 PCD

CH28-CH36

DI4

DI12

CH10-CH18

LAN

Communicator

DI11

DI3DI2

DI10

DI1

0V

DI

0V

DI9

0V

DI8

DI16DI14

DI7

DI13

DI6

DI15

DI5

DI1-16

DI

0V

DO15

DO15

DO14DO11 DO12 DO13

?iRY?j

DO11-20

DO1-10

?iRY?j

DO13DO11 DO12 DO14

DO19 DO20DO18DO17DO16

DO20DO18 DO19DO17DO16

DO5

DO5

DO4DO2

DO3

DO1

DO1 DO2 DO4

DO3

DO10

DO9DO8DO7

DO8 DO9DO7DO6

DO6

DO10

N

L

100-240VAC?`

DO1

1

11

DO2

2

12

DO3

3

13

DO4

4

14

DO5

5

15

DO6

6

16

DO7

7

17

DO8

8

18

DO9

9

19

DO10

10

20

DO11

21

31

DO12

22

32

DO13

23

33

DO14

24

34

DO15

25

35

DO16

26

36

DO17

27

37

DO18

28

38

DO19

29

39

DO20

30

40

VPD

41

51

DO21

42

24V DC+

52

DO22

43

53

DO23

44

54

DO24

45

55

DO25

46

56

DO26

47

57

DO27

48

58

DO28

DO29 DO30 DO31 DO32 DO33 DO34 DO35 DO36 0V

49

59

PCD

50

60

Alarm output relay terminal

Input terminal

Note) For current input, connect optional shunt resistors to the voltage input terminals.

(1)

(2)

Alarm output transistor terminal

(4)

DI input terminal

Ethernet terminal

(option)

(6)

(3)

M4 screw

Power supply terminal

100 to 240V AC

50/60Hz

Number of input points = 1 to 9 points

Number of input points = 10 to 18 points

Number of input points = 19 to 27 points

Number of input points = 28 to 36 points

CH6 CH7

RCJ

CH8 CH9

Resistance

bulb

Thermo-

couple

Voltage

++--++--++--++--++-

-

++--++-

-

++--++-

-

CH1 CH2

CH3

CH4 CH5

Resistance

bulb

Thermo-

couple

Voltage

CH15 CH16

RCJ

CH17 CH18

Resistance

bulb

Thermo-

couple

Voltage

++--++--++--++--++-

-

+

+

-

-

+

+

-

-

+

+

-

-

+

+

-

-

CH10 CH11 CH12

CH13

CH14

Resistance

bulb

Thermo-

couple

Voltage

CH24 CH25

RCJ

CH26 CH27

Resistance

bulb

Thermo-

couple

Voltage

+

+

-

-

+

+

-

-

+

+

-

-

+

+

-

-

+

+

-

-

++--++-

-

++--++-

-

CH19 CH20 CH21 CH22 CH23

Resistance

bulb

Thermo-

couple

Voltage

CH33 CH34

RCJ

CH35 CH36

Resistance

bulb

Thermo-

couple

Voltage

++--++--++--++--++-

-

++--++-

-

++--++-

-

CH28 CH29 CH30 CH31 CH32

Resistance

bulb

Thermo-

couple

Voltage

(1) Input terminal: Connect signal cable for each channel.

(2) Alarm output relay terminal: Connect the alarm output relay (DO1 to 20).

(3) Power supply terminal: Connect power cable to L/N terminals. Power source to be connected should be

free from noise.

(4) Alarm output transistor terminal: Connect the alarm output transistor (DO21 to 36).

(5) DI input terminal: Connect the input of DI signal (DI1 to 16).

(6) Ethernet terminal

(5)

DI 0V

61

71

DI1

62

72

DI2

63

73

DI3

64

74

DI4

65

75

DI5

66

76

DI6

67

77

DI7

68

78

DI8

DI9 DI10 DI11 DI12 DI13 DI14 DI15 DI16

69

79

DI 0V

70

80

4328442945304631473248

33 34 35 36493750385139524053415442

97

8298839984

100

85

101

86

102

87 88 89 90

103

91

104

92

105

93

106

94

107

95

108

96

16117

2183194205216 7 8 9221023112412251326142715

7055715672577358745975

60 61 62 63766477657866796780688169

2 Wiring

Page 7

Name Function Name Function

(1) Display unit

(2) Power switch Used to turn the power ON or OFF.

(3) Memory card

slot

(4) Memory card

ejection button

To remove the memory card from the slot,

press this button.

(5) Connector to

parameter

loader

(6)

Allows the Real time trend screen, Bar Graph

Display screen, Analog Meter Display screen,

Digital Display screen, Totalized Value Display

screen, Historical trend screen and other various

Parameter Set screens to be displayed.

When changing parameters by using a loader,

connect the exclusive cable (optional cable: Type;

PHZP1801 or USB cable [USB (A) male – USB

(mini B) male] to the connector.

Memory card

For the memory card, use Sandisk’s compact flash

memory (URL: http://www.sandisk.com). Other

memory cards may case trouble to the recorder.

S1 REC key

S2 DISP key

• Used to start or stop recording.

Pressing once starts recording, and pressing once

again stops recording.

• U

sed to switch displayed contents. Every time it is

pressed, the display is switched in the following

order: (1) (2) (3) (4) (5) (6) (7) and back

to (1).

(1) Real time trend display

(2) Key guidance display

(3) Bar graph/analog meter display

(4) Digital display

(5) Totalizing data display

(6) Event summary display

(7) Ethernet log display

• Used to switch the parameter setting screen to

the data display screen.

S3 SEL key

• Used to switch from the data display screen to the

parameter setting screen.

• Pressing the key on the parameter setting screen

switches to the screen one step up.

Note, however, that pressing the key on the menu

screen does not change screens.

S4 Cursor key

(1) Used for selection on the setting screen or

registration of the set data.

(2) If the key is pressed while the scales are

displayed on the real time trend display screen,

historical trend display screen (*1), or recorded

data display screen, the channels for which

scales are to be displayed can be switched.

(Scale of ch1 scale of ch2 ….. scale

of ch9 scale of ch1 scale of ch2…..)

S5 ENT key

(1) Used to select setting items.

(2) Used to increase or decrease numerical values.

(3) Pressing the key on the real time trend

displays the historical trend screen (*1).

At this time, the window can be scrolled using

the cursor key.

(4) Pressing the or the key on the real time trend

display, bar graph/analog meter display, digital

display, or totalized value display screen

switches group screens as follows.

key: Group 1 2 3 4 5 6 7 8 1 ...

key: Group ... 1 8 7 6 5 4 3 2 1

*1: The screen in the past of the data

currently recorded

*1: The screen in the past of the data

currently recorded

Used for inserting the memory card.

Insert the card straight into the slot as shown in

upper right figure.

Be careful not to forcibly press the card if it is

inserted obliquely. Otherwise the pin on the PHU

may be damaged.

Caution

1. Do not remove the memory card during recording. Refer to the

another Manual in the CD-ROM “Removing memory card

(compact flash)” for the removal of the memory card while

recording is in progress.

2. After inserting the memory card into the slot, don’t remove the

card until the recorder can acknowledge it.

3. Be careful with static electricity when removing the memory card.

Caution

(1)

(2)

(3)

(6) (4) (5)

S5

S4

S3S2S1

3 Operation Parts and Their Functions

– 7 –

Page 8

– 8 –

Data display screens

Parameter setting

(To Real time trend)

Go to Real time trend Go to Parameter setting screen.

(Group8)

(Group7)

(Group6)

(Group5)

(Group8)

(Group7)

(Group6)

(Group5)

(Group4)

(Group8)

(Group7)

(Group6)

(Group5)

(Group8)

(Group7)

(Group6)

(Group5)

(Group3)

(Group2)

Real time

trend

(Group1)

Key

operation

guide

(Group2)

(Group3)

(Group4)

(Group5)

(Group6)

(Group7)

(Group8)

Bar gragh

or

Analog meter

(Group4)

(Group3)

(Group2)

(Group4)

(Group3)

(Group2)

Totalizing

data

Event

summary

Digital

display

Ethernet

log

(Group4)

(Group3)

(Group2)

Historical

trend

Menu screen

Each parameter screen

(Example: channel 1 setting screen)

Input type :

Tag 1 :

Range start :

(1) Enter characters

(2) Select or set the data

Select the item using the keys

or set the numeric character using

the keys. And then press

the key to confirm the data.

If press the , the setting is

canceled.

Select characters using the

keys, and then move

to ENTRY . After that, press the

key to confirm the setting.

If press the , the setting is

canceled.

4 Display and Operation Procedure

Page 9

Parameter name

Basic setting

Setting at delivery (Default value) Setting range Remarks

Channel setting

Display refresh cycle : 1second

Display compression : 1/1

Alarm hysteresis : 0.2%

Alarm latch : OFF

LCD lights out time : 0 *1

DO output at memory : None

File overwrite : OFF

Date format : yyyy/mm/dd

Select language : English

MODBUS station : 1 0 to 255

Input type : K-Type TC

( K thermocouple )

Tag1 : TAG ** (**: channel No.)

Tag2 : Blank

Unit : °C

Decimal point :

*****.*

Input filter : 3seconds

Subtract channel : None

PV shift : 0.0

PV gain : 100.00%

F value calculation function : OFF

Display color : depends on channel No.

Alarm setting

Totalize setting

1 second to 12 hours

1/1, 1/10, 1/30, 1/60

From 0.00 to 100.00%

OFF, ON

*1

LCD keeps

turning on when

set “0”.

0 to 60minutes

None, DO1 to DO36

OFF, ON

yyyy/mm/dd, dd/mm/yyyy, dd-mmm-yy,

mm/dd/yyyy, mmm-dd-yy

English, French

9600, 19200

Skip, K, E, J, T, R, S, B, N, W, L, U,

PN thermocouple, Pt100, JPt100, Ni100, Cu50,

Pt50, 50mV, 500mV, 1-5V and 0-5V range

Up to 8 characters

Up to 8 characters

°C, °F, Engineering unit in case of voiltage input

Input range(range start/end) : 0 to 1200 Engineering value

******,*****.*,****.**,***.***,**.****

0 to 900seconds(In increments of 1 second)

0 to 72 ( No subtraction at 0 )

Engineering value -3276.7 to 3276.7

0.00 to 327.67%

OFF, ON

14 colors

Recording type : MIN/MAX Instantaneous value recording, average value

recording, maximum/minimum value recording

Recording mode : With record With record / Display only

Set point : 0.0°C Engineering value

OFF, H, L

DO relay No. : None

From alarm No.2 to No.4

There are the same items above.

None, DO1 to DO36

Alarm No.1 type : OFF

Totalize calculation : OFF OFF, ON

Totalize type : Periodic Periodic, Daily, Weekly, Monthly, Annual,

Daily(Time set), External

Digital input : DI1 Digital input, Channel alarm

Totalize base time : /h /s, /min, /h, /day

Reset operation : ON OFF, ON

Totalize unit :

-

Can be arbitrarily selected

Totalize cut value : 0.0°C Engineering value

Totalize scaling value : 1 1 to 32767

Up to 8 charactersTotalize tag : STAG**(**: channel No.)

Set the same

input type for

every 2 channels.

MODBUS communication baud rate : 19200

MODBUS parity bit : Odd

Front communicaon : ON

Record data format : ASCII

Time setting :

-

Register data :

DO output at battery : None

File division cycle : No division

None, DO1 to DO36

No division, 1hour, 1day, 1month

None, Odd, Even

OFF, ON

ASCII, Binary

-

-

5 List of Parameters

– 9 –

Page 10

– 10 –

Parameter name

Math chnnel

setting

Setting at delivery (Default value) Setting range Remarks

Math timer setting

Message setting

F value calculation

setting

Display setting

Totalize setting

Formula setting : All formula are blank.

Tag1 : TAG ** (**: channel No.)

Measuring range ( range start/end) :

0.0 to 500.0

Decimal point :

*****.*

H-P, L-P timer cycle : 1min

AVG timer cycle : 1min

SUM timer cycle : 1min

Display configuration : No.1 to 9 = ch1 to 9

Manual reset : OFF

Totalize base time : 00:00

Totalize cycle : 1hour

Weekly base day : Sunday

Monthly base day : 1

Start time,Stop time : 00:00 to 00:00

External input : DI1

Calculation : +, -,*, /

Function : ABS, POW, SQR, LOG, LN, EXP, RH,

MAX, MIN, H-P, L-P, AVG, SUM

Input : Input channel, Totalizer input, Digital input,

Communication input, Constant, Temporary data

Up to 8 characters

Engineering value

******,*****.*,****.**,***.***,**.****

Engineering range ( range start/end) :

0.0 to 500.0

Engineering value

OFF, ON

1 to 32767min

1 to 32767min

1 to 32767min

No.1 to 10, Each provided with ch1 to 72

Decimal point position :

*****.* *****,*****.*,****.**,***.***,**.****

OFF, ON

00:00 to 23:59

10, 20, 30minutes, 1, 2, 3, 4, 6, 12 and 24hours

Sunday to Saturday

1 to 31

00:00 to 23:59

Digital input, Channel alarm

Ethenet setting

IP address : 0.0.0.0

Subnet mask : 0.0.0.0

Default gateway : 0.0.0.0

FTP access control : OFF

Web server function : OFF

0 to 255

0 to 255

0 to 255

FTP server function : OFF

OFF, ON

E-mail setting

SMTP IP address : 0.0.0.0

Sender's mail address : Blank

Sender's mail name : Blank

0 to 255

Up to 64 characters

Up to 32 characters

User account

setting

User name : Blank

Password : Blank

User level : Administrator

Up to 16 characters

Up to 8 characters

Administrator, Engineer, Operator, Guest

Config and record

password

Security mode : Password

Password : 0000

Record Password : 0000

Password, Logon

0000 to 9999

0000 to 9999

Receiver's mail address 1 to 8 : Blank

Up to 64 characters

OFF, ON

OFF, ON

E-mail function : OFF OFF, ON

MODBUS TCP/IP : OFF OFF, ON

Alarm channel : 1

Alarm No. : 1

Text 1, 2 : Blank

PV value affixation :

Channel 1 to 72

1 to 4

Title : Blank

Up to 32 characters

Up to 32 characters

OFF, ON

Receiver's add No. : 1 1 to 8

Mail send test :

Message : Blank Up to 32 characters

Original unit definition

Unit : Blank Up to 7 characters

Constant setting

Constant : 0

-

32767 to 32767

DI setting

DI function : Function invalid Function invalid, Rec start/Rec stop, Fvalue

calc. reset, Totalize start/stop, Totalize reset,

LCD ON

Square rooter : OFF

Input range ( range start/end) : 0 to 1200

Input filter : 3seconds

Subtract channel : None

PV shift : 0.0

PV gain : 100.00%

Tag2 : Blank

Unit : °C

Up to 8 characters

Engineering unit

E-mail

trigger setting

Trigger timing : None None, DI ON, DI OFF, Alarm ON, Alarm OFF,

Warning, Timer cycle

Engineering value

0 to 900seconds (In increments of 1 second)

0 to 72 (No subtraction at 0)

Engineering value -3276.7 to 3276.7

0.00 to 327.67%

Page 11

Display Cause

OVER

Displayed when the measurement signal inputs

exceeding the settable recording range (Table 1).

ERROR

Displayed in the following cases with 50mV, 500mV,

and 5V input.

1) When the measurement signal inputs exceeding

OVER.

2) When the measurement signal inputs lower than

UNDER.

BURNOUT

Displayed in the following cases with TC and PT input.

1) When a break or disconnection of a cable occurs

within the sensor

2) When the measurement signal inputs exceeding

OVER.

3) When the measurement signal inputs lower than

UNDER.

UNDER

Displayed when the measurement signal inputs lower

than the settable recording range.

*1 Usage size of measurement data

Usage size for each sampling is as follows:

ASCII (max.-min. record)

Time : 21 bytes

Measurement data: 16 bytes × number of input points

From the above, if the number of input point is 9ch,

21 + 16 × 9 = 165 bytes

ASCII (instantaneous or average value)

Time : 21 bytes

Measurement data: 8 bytes × number of input points

From the above, if the number of input point is 9ch,

21 + 8 × 9 = 93 bytes

Binary (max.-min. record)

Time : 4 bytes

Measurement data: 4 bytes × number of input points

From the above, if the number of input point is 9ch,

4 + 4 × 9 = 40 bytes

Binary (instantaneous or average value)

Time : 4 bytes

Measurement data: 2 bytes × number of input points

From the above, if the number of input point is 9ch,

4 + 2 × 9 = 22 bytes

Specification

Power voltage :

Power consumption (VA) :

Input measurement

:

range

Record range

:

Input circuit

:

Measurement cycle

:

Record cycle

:

Record type

:

Data storage cycle

:

Record media

:

Data format

:

Alarm type

:

Alarm output (relay)

:

Alarm output

:

(transistor)

Digital input

:

Operating environment :

Operating temperature:

:

Operating humidity :

Storage temperature

:

Storage humidity

:

Installation category

:

Pollution degree

:

Operating altitude

:

Calibration

:

Ethernet :

- protocol :

100 to 240 V AC (10%), 50/60 Hz

80 VA max. (240 V AC)

Range where input reading accuracy is assured.

(See Table 1.)

Settable recording range. (See Table 1.)

Insulated between all channels (functional insulation).

100 msec (Input type : 9 or 18 points)

200 msec (Input type : 27 or 36 points)

1 sec to 12 hours/one time

Select from max.-min. value, instantaneous value, or

average value.

1 min. (when record cycle is less than 1 min.) or

synchronized with record cycle (when record cycle is more

than 2 min.).

Compact Flash (by Sandisk), 512MB max.

Only FAT16 or FAT is supported.

Select from ASCII or binary. Refer to *1 for usage size of

measured data.

Upper limit alarm, lower limit alarm

240V AC/3A, 30V DC/3A

30V DC/0.1A

No-voltage contact input.

Indoor

0 to 50°C (Without Ethernet function)

0 to 40°C (With Ethernet function)

20 to 80% RH (No condensation allowed.)

-

10 to 60°C

5 to 90% RH (No condensation allowed.)

2

2000m max.

Calibrate at least once a year in order to maintain high

measurement accuracy. For calibration, refer to the

instruction manual in the CD-ROM, or contact us.

10 Base-T

Web (server)

FTP (server)

SMTP (client)

MODBUS-TCP (slave)

6 Troubleshooting

Error indications

This recorder is provided with an error display function.

Modify the abnormal conditions as soon as an error

display appears. Make sure to turn off the power before checking the wire connection to modify the abnormal conditions. Otherwise electric shock or a serious

accident may result.

7 Specifications

– 11 –

Page 12

8 Code Symbols

Specifications

4 5 6 7 8

PHU

4

7

8

9

11

12

1

2

3

4

1 1

V

0

0

* *

* *

*

-

E

0

1

2

3

4

5

<Number of input points>

9 points

18 points

27 points

36 points

<DI input>

Without

With (16 points)

<Improvement No.>

<Display language >

English

<Alarm relay output>

Without

Relay 10 points

Relay 20 points

Transistor (open collector)

16 points

Relay 10 points + Transistor

(open collector) 16 points

Relay 20 points + Transistor

(open collector) 16 points

<Ethernet>

Without

With

9 10111213

Digit

0

1

1

Y

E

Type

DC voltage

Thermocouple

B

R

S

K

E

J

T

N

W

L

U

PN

Resistance

bulb

JPt100

Pt100

Ni100

Pt50

Cu50

400 to 1760°C

0 to 1760°C

0 to 1760°C

–200 to 1370°C

–200 to 800°C

–200 to 1100°C

–200 to 400°C

0 to 1300°C

0 to 1760°C

–200 to 900°C

–200 to 400°C

0 to 1300°C

–200 to 600°C

–200 to 600°C

–60 to 180°C

–200 to 600°C

–50 to 200°C

Input range Record range set range

0 to + 50mV

0 to +500mV

+ 1 to + 5V

0 to + 5V

370.0 to 1790.0°C

– 30.0 to 1790.0°C

– 30.0 to 1790.0°C

–230.0 to 1400.0°C

–230.0 to 830.0°C

–230.0 to 1130.0°C

–230.0 to 430.0°C

– 30.0 to 1330.0°C

– 30.0 to 1790.0°C

–230.0 to 930.0°C

–230.0 to 430.0°C

– 30.0 to 1330.0°C

–230.0 to 630.0°C

–230.0 to 630.0°C

–90.0 to 210.0°C

–230.0 to 630.0°C

–80.0 to 230.0°C

– 10.00 to + 55.00mV

– 10.0 to + 550.0mV

+ 0.500 to + 5.500V

– 0.100 to + 5.500V

9 Maintenance

Recommended parts replacement cycle

Front panel : 5 years (degradation of bright

ness of LCD back light.

Pickup repair: including packing

and battery)

Lithium battery : 5 years (pickup repair)

Fuse (external) : 2 years (for preventive mainte

nance)

: rating: 250V AC 2A

Memory card : 6 months

: Back up the data more frequently

than 6 months.

-

-

Table 1 Display Range Set Range

– 12 –

Loading...

Loading...