Page 1

Instruction Manual

PAPERLESS RECORDER

COMMUNICATION

FUNCTION

(RS-485 MODBUS/Ethernet)

TYPE: PHL

INP-TN513979c-E

Page 2

Note: MODBUS® is the registered trade mark of AEG Schneider Automaion International.

Note: GW-BASIC, Windows 98 and MS-DOS are registered trademarks of Microsoft Corporation.

NOTICE

1. Exemption items from responsibility

The contents of this document may be changed in the future without prior notice.

We paid the utmost care for the accuracy of the contents. However, we are not liable for direct and

indirect damages resulting from incorrect descriptions, omission of information, and use of

information in this document.

Page 3

CONTENTS

1. COMMUNICATION FUNCTIONS .....................................................................................................1

1.1 General ...............................................................................................................................................1

1.2 Overview of MODBUS slave communication function (RS-485 interface)......................................1

1.3 Overview of Ethernet communication functions................................................................................2

2. SPECIFICATIONS ...............................................................................................................................3

2.1 Communication Specifications...........................................................................................................3

3. CONNECTION.....................................................................................................................................4

3.1 Communication Terminal Allocation.................................................................................................4

3.2 Wiring.................................................................................................................................................5

SETTING OF COMMUNICATION CONDITION

4.

4.1 Set Items.............................................................................................................................................6

4.2 Setting Operation Method ..................................................................................................................7

5. MODBUS COMMUNICATION PROTOCOL ....................................................................................8

5.1 General ...............................................................................................................................................8

5.2 Composition of Message ....................................................................................................................9

5.3 Response of Slave Station ................................................................................................................11

5.4 Function Code ..................................................................................................................................12

5.5 Calculation of Error Check Code (CRC-16) ....................................................................................13

5.6 Transmission Control Procedure ......................................................................................................14

5.7 FIX Processing (Cautions in data write)...........................................................................................16

6. DETAILS OF MESSAGE...................................................................................................................17

6.1 Read-out of Word Data [Function code: 03

Read-out of Read-out Only Word Data [Function code: 04H]

6.2

6.3 Write-in of Continuous Word Data [Function code: 10

7. ADDRESS MAP AND DATA FORMAT ...........................................................................................23

7.1 Data Format......................................................................................................................................23

7.2 Address Map.....................................................................................................................................25

7.3 Additional Explanation of Address Map..........................................................................................39

.....................................................................................6

] ..................................................................................17

H

.............................................................19

]................................................................21

H

8. SAMPLE PROGRAM ........................................................................................................................48

9. ETHERNET COMMUNICATION FUNCTIONS..............................................................................53

9.1 LAN port specification.....................................................................................................................53

9.2 Connection to the terminal ...............................................................................................................53

9.3 Connection........................................................................................................................................53

9.4 Setting Ethernet communicating conditions.....................................................................................54

9.5 Ethernet communicating conditions setting operation .....................................................................54

10. FTP SERVER FUNCTION.................................................................................................................55

10.1 Description of FTP server function ..................................................................................................55

10.2 Setting FTP server function..............................................................................................................57

10.3 FTP server function setting operation ..............................................................................................57

10.4 FTP server operation ........................................................................................................................58

11. WEB SERVER FUNCTION...............................................................................................................59

11.1 Description of web server function ..................................................................................................59

11.2 Setting web server function..............................................................................................................59

- i -

Page 4

11.3 Web server function setting operation..............................................................................................59

11.4 Web server operation .......................................................................................................................60

11.5 Web monitor screen .........................................................................................................................60

12. E-MAIL SEND FUNCTION..............................................................................................................63

12.1 Description of E-mail send function ................................................................................................63

12.2 Setting E-mail function ....................................................................................................................63

12.3 E-mail function setting operation.....................................................................................................64

12.4 E-mail send test operation................................................................................................................67

12.5 E-mail send contents ........................................................................................................................67

13. MODBUS TCP/IP FUNCTION .........................................................................................................68

13.1 Description of MODBUS TCP/IP function......................................................................................68

13.2 Setting MODBUS TCP/IP function ................................................................................................. 68

13.3 MODBUS TCP/IP function setting operation..................................................................................68

13.4 MODBUS TCP/IP communication protocol....................................................................................69

14. TROUBLESHOOTING......................................................................................................................71

- ii -

Page 5

1. COMMUNICATION FUNCTIONS

1.1 General

• This equipment provides a communication function (optional) using an RS-485 interface and also a

communication function (optional) using an Ethernet interface.

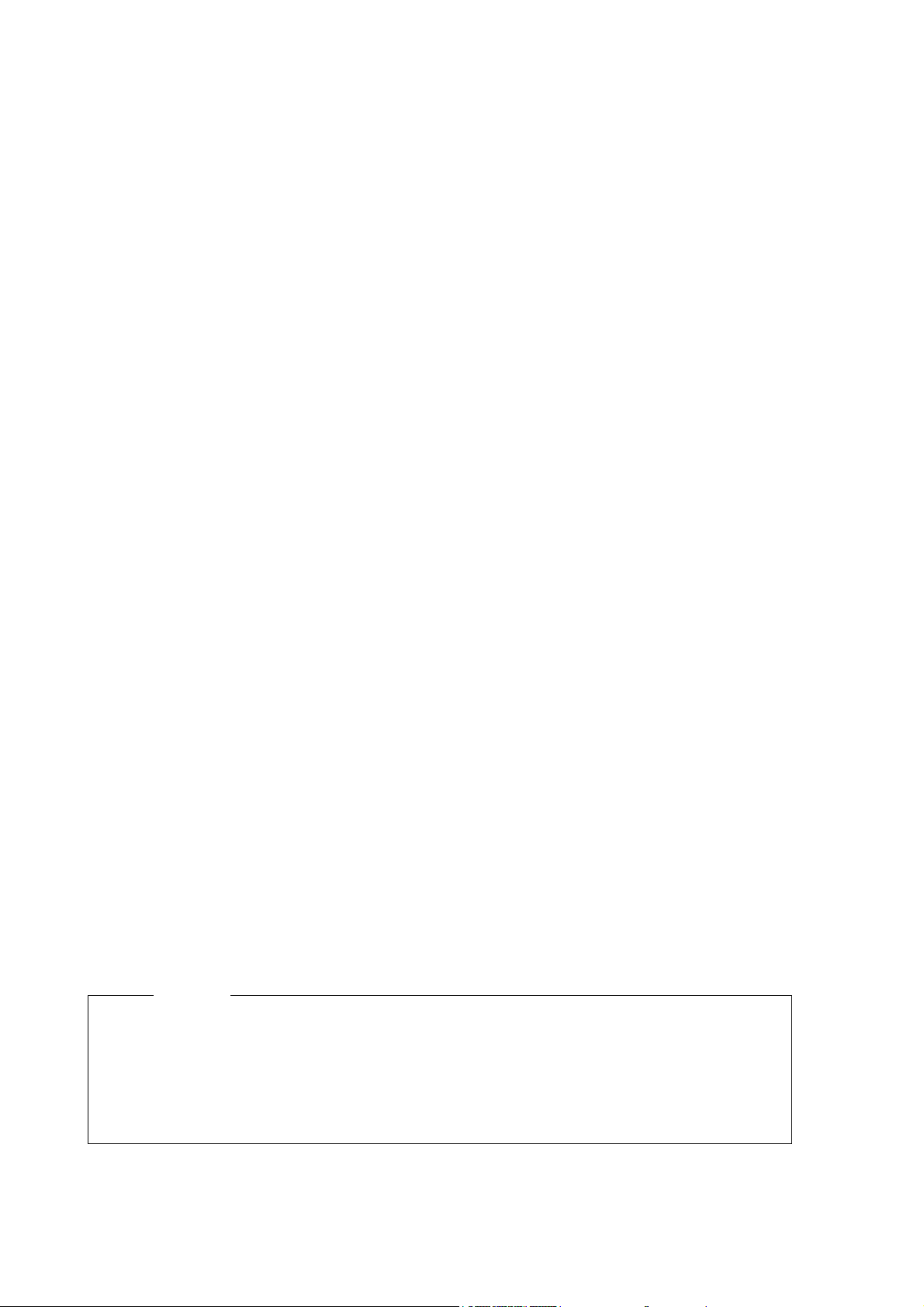

1.2 Overview of MODBUS slave communication function

(RS-485 interface)

See Chapter 2 through Chapter 8 for the method for use of MODBUS slave communication function in detail.

• The MODBUS slave communication function permits exchange of data with host computer, programmable

controller, graphic display panel, etc.

• The communication system consists of master station and slave stations. Up to 31 slave stations (PHL) can

be connected per master station.

Note that, because the master station can communicate with only one slave station at a time, a party to

communicate with must be specified by the “MODBUS Station No.” set at each slave station.

• In order that the master station and slave station can communicate, the format of the transmit/receive data must

coincide. For the PHL, the format of the communication data is determined by the MODBUS protocol.

• Please use an RS-232C ⇔ RS-485 converter in case of designating a personal computer or other devices which

have an RS-232C interface as a master station.

[RS-232C ⇔ RS-485 converter] (recommended article)

Type: K3SC-10 (isolated type)/ OMRON Corporation.

Programmable

controller

RS-485

RS-232C

RS-485

Caution:

When using the RS-232C ⇔ RS-485 converter, pay attention to cable connection between the converter and

master station. If the cable is not connected correctly, the master station and slave station cannot communicate.

In addition, be careful about communication settings such as baud rate and parity set for the converter.

Personal

computer

RS-232C RS-485 converter

- 1 -

Page 6

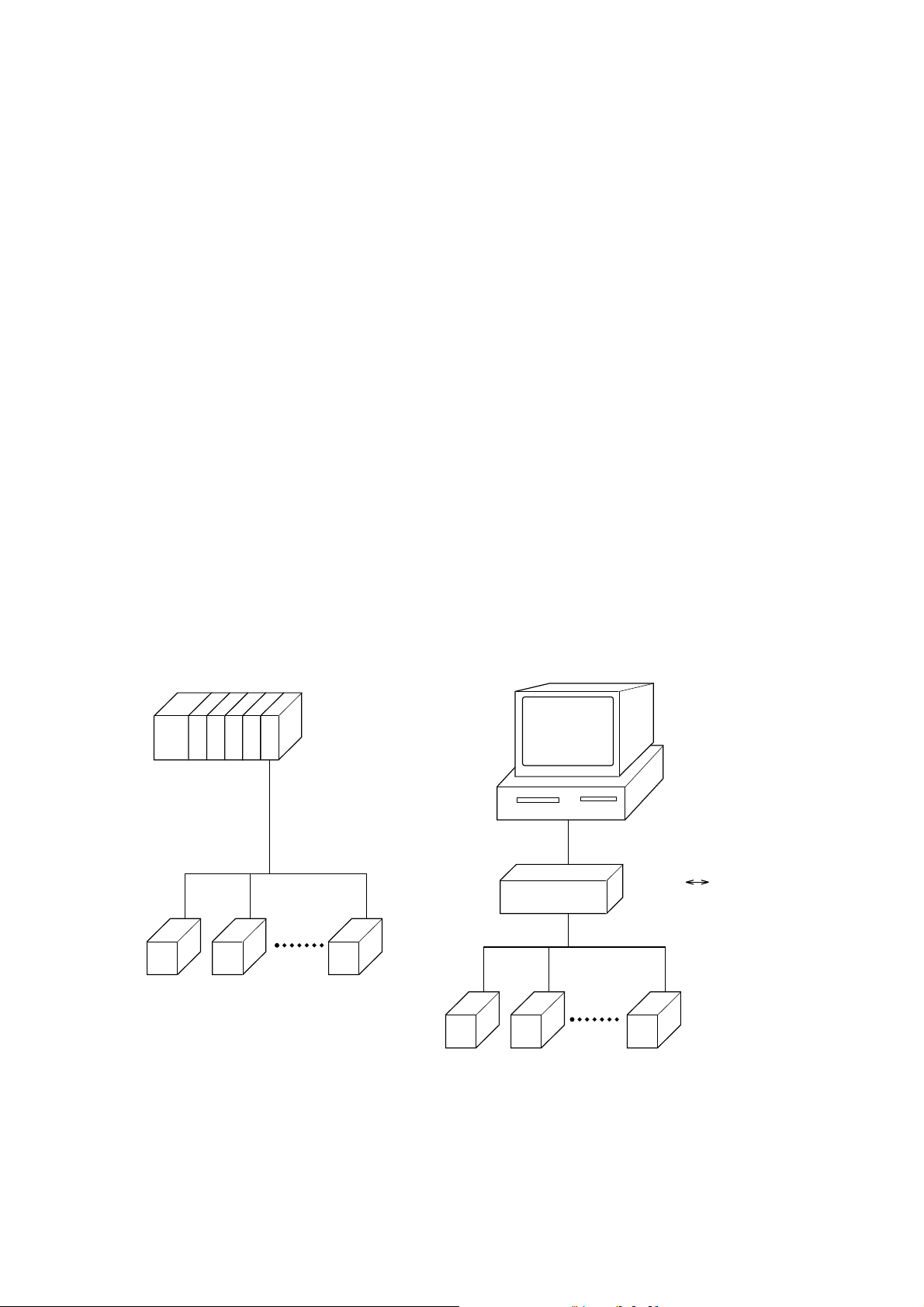

1.3 Overview of Ethernet communication functions

See Chapter 10 and Chapter 11 for the method for use of Ethernet communication functions in detail.

• The following functions are available as Ethernet communication functions.

(1) FTP server function

Permits take-out of files from the compact flash of the paperless recorder, using personal computer's

browser (Internet Explorer) or DOS prompt.

(2) Web server function

Permits check of measured values and event information recorded in the paperless recorder, using personal

computer's browser (Internet Explorer).

(3) E-mail send function

Permits E-mail transmission in a fixed period and also on occurrence of an alarm.

(4) MODBUS TCP/IP function

Permits exchange of data with host computer, programmable controller, graphic display panel, etc. by

MODBUS TCP/IP communication.

- 2 -

Page 7

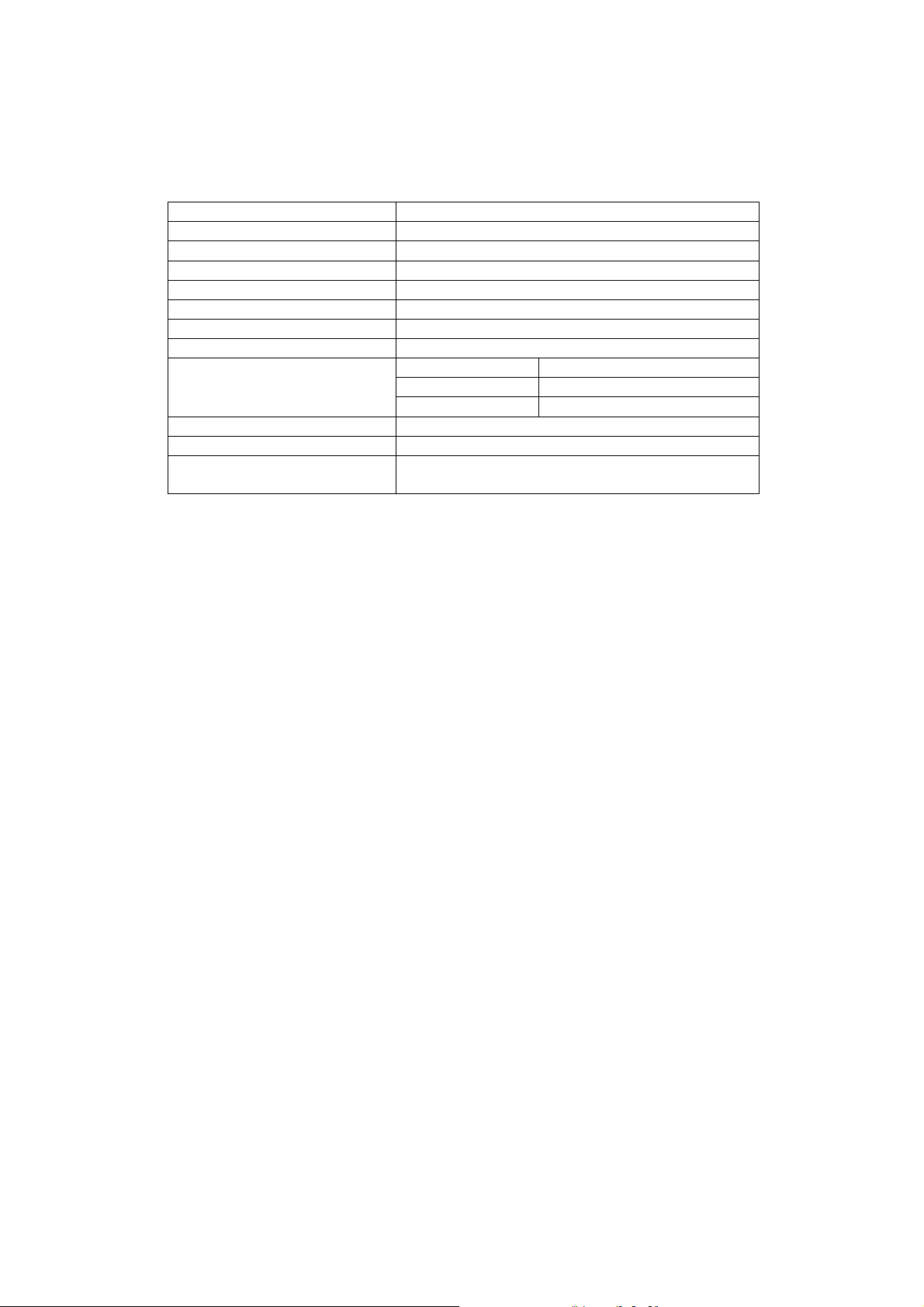

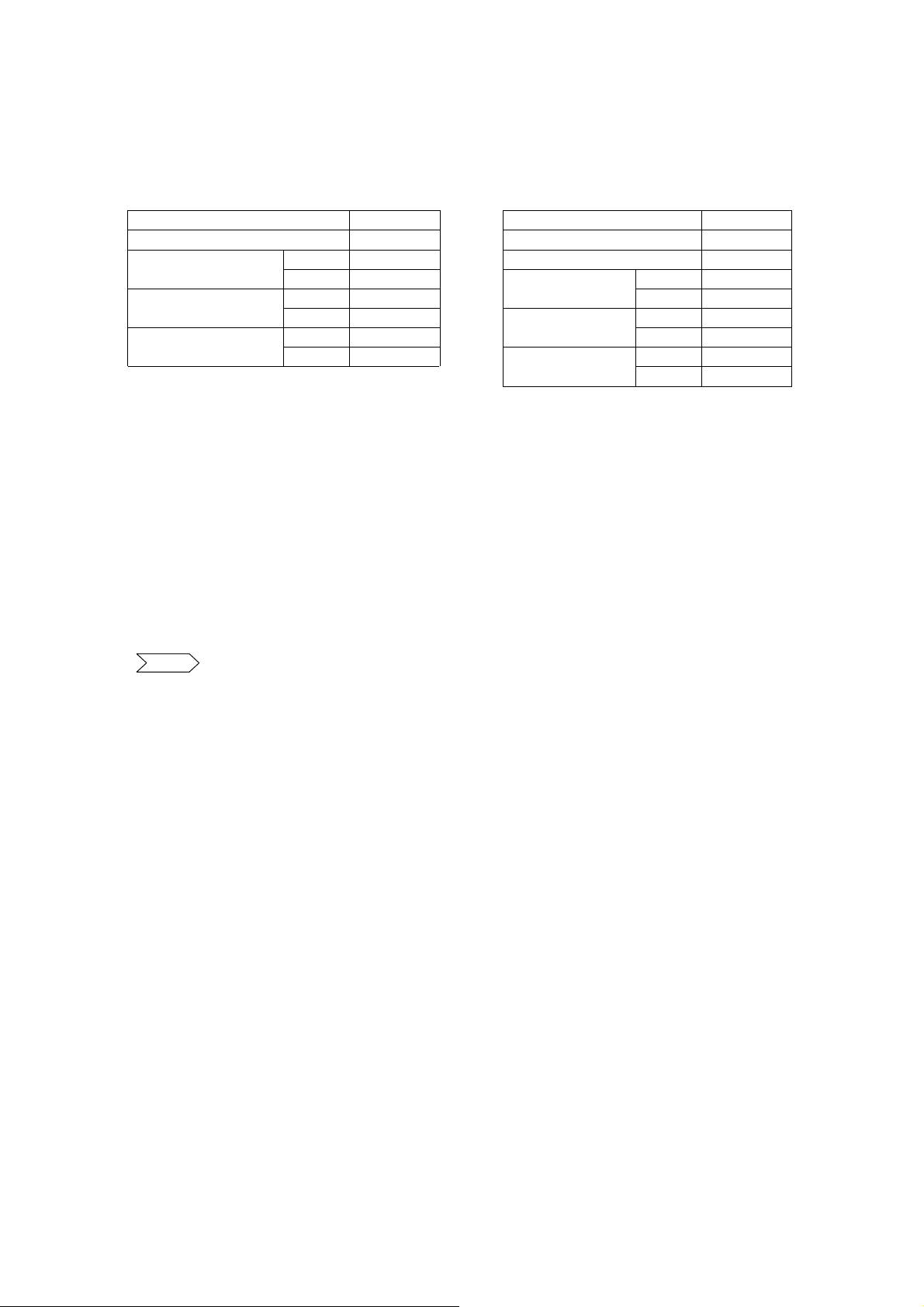

2. SPECIFICATIONS

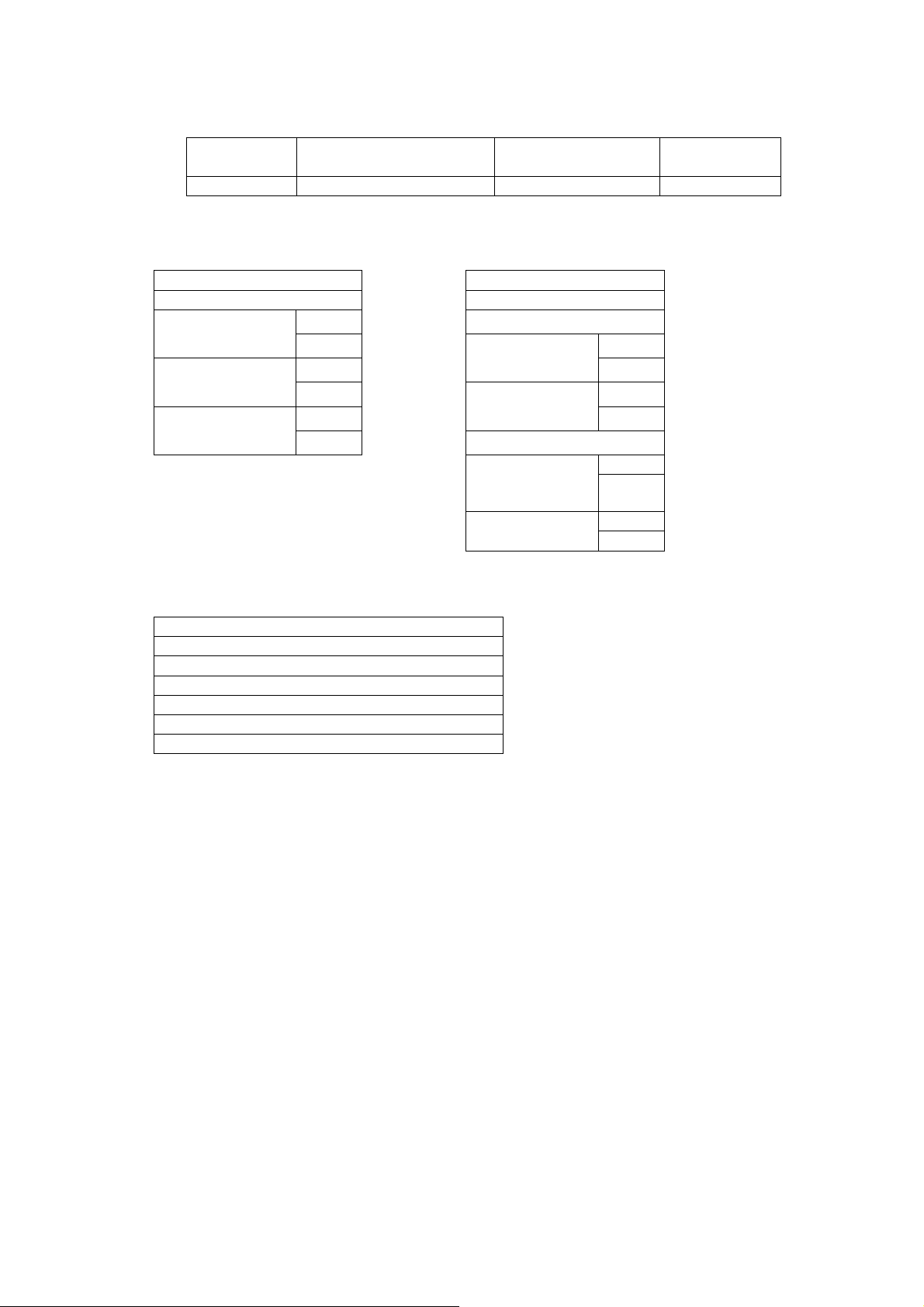

2.1 Communication Specifications

Item Specification

Electrical specification Based on EIA RS-485

Transmission system 2-wire, semi-duplicate

Synchronizing system Start-stop synchronous system

Connection format 1: N

Number connectable units Up to 31 units

Transmission distance 500 m max. (total extension distance)

Transmission speed 9600, 19200 bps

Data format Data length 8 bits

Stop bit 1 bit

Parity none, even, odd (selectable)

Transmission code HEX value (MODBUS RTU mode)

Error detection CRC-16

Isolation

Functional isolation between transmission circuit

and ground (withstand voltage: 500V AC)

- 3 -

Page 8

3. CONNECTION

WARNING

For avoiding electric shock and malfunctions, do not turn on the power supply untill all wiring

have been completed.

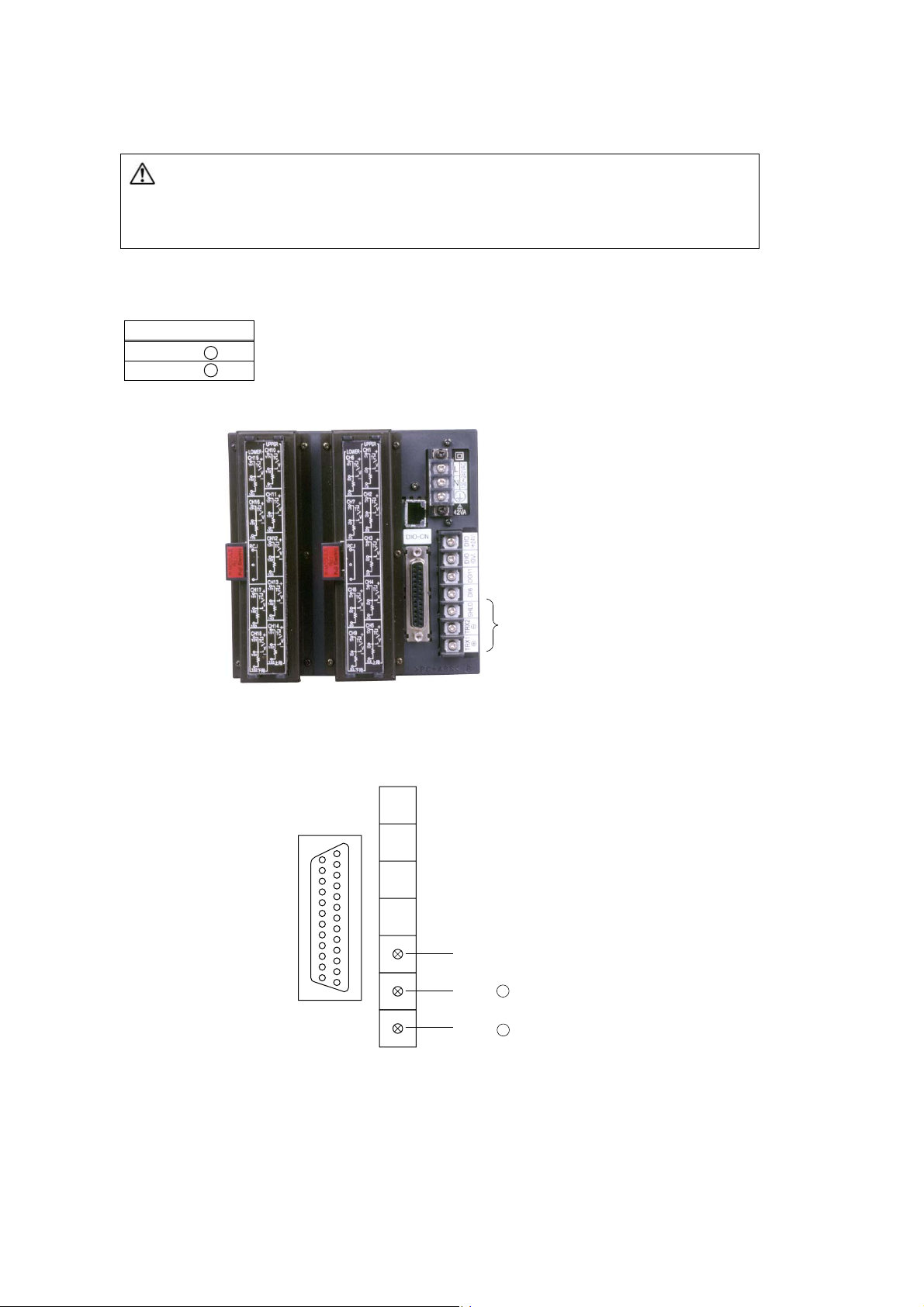

3.1 Communication Terminal Allocation

Signal name

TRX2 –

TRX1 +

Communication

Terminal

Communication Terminal

Shield

-

TRX2

TRX1 +

- 4 -

Page 9

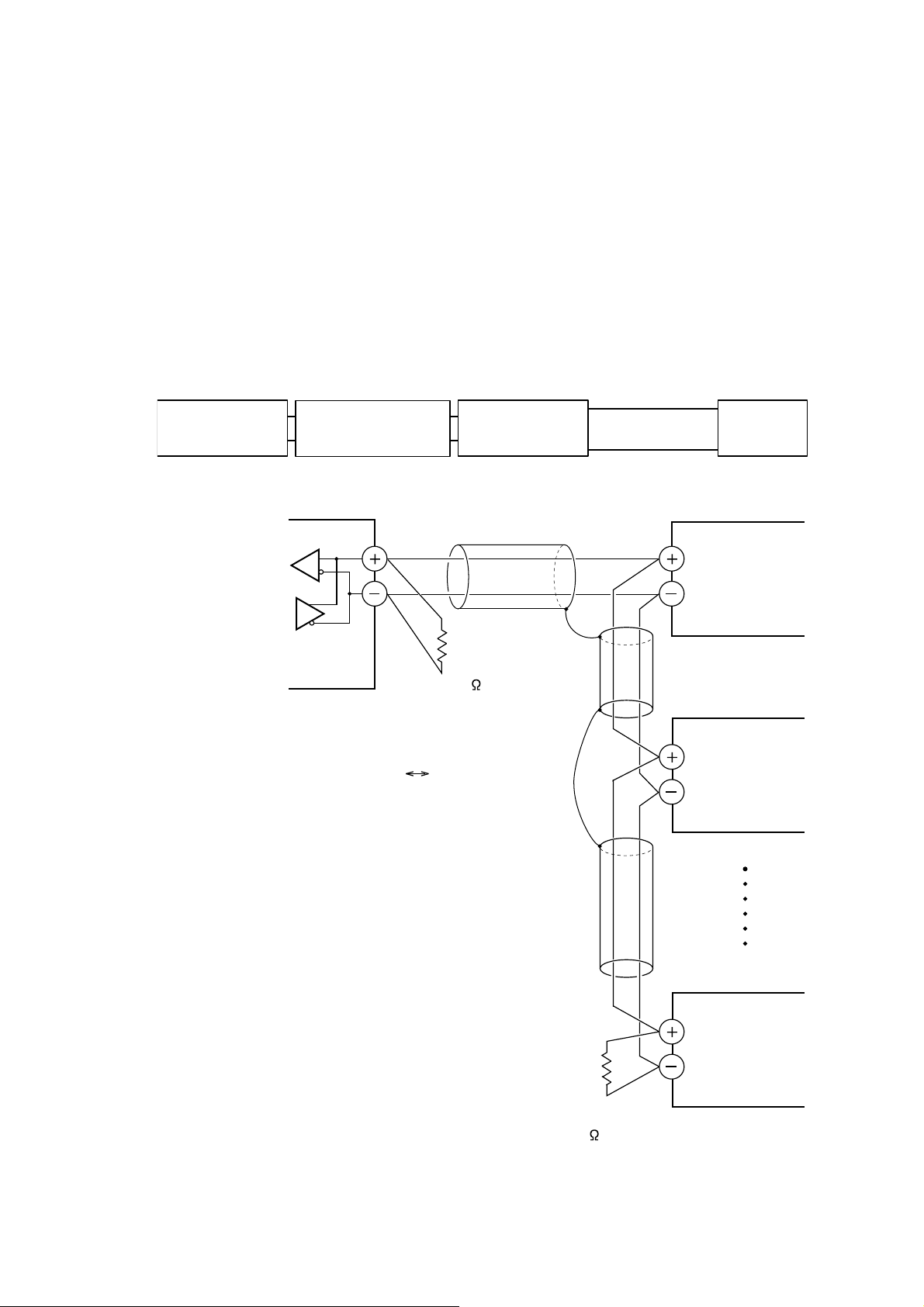

3.2 Wiring

Use twisted pair cables with shield.

Recommended eable: UL2464, UL2448, etc.

• The total extension length of the cable is up to 500 m. A master station and up to 31 units of the PHL can be

connected per line.

• Both ends of the cable should be terminate with terminating resistors 100Ω (1/2W).

• The shield wire of the cable should be grounded at one place on the master station unit side.

• If the PHL is to be installed where the level of noise applied to the PHL may exceed 1000 V, it is recommended

to install a noise filter in the master station side as below.

Recommended noise filter: ZRAC2203-11/TDK

Master station

(PC, etc.)

RS-232C⇔RS-485

Master station side

Noise filter PHL

Transmission

cable

Slave station (PHL)

FG

RS-485 interface

or

RS-485 side of the RS-232C

(Recomended converter:

K3SC-10/OMRON Corporation)

Twisted pair cable with shield

Terminating resistor

100

(1/2W)

RS-485 converter

TRX1

TRX2

Slave station (PHL)

TRX1

TRX2

Slave station (PHL)

TRX1

TRX2

Terminating resistor

100 (1/2W)

- 5 -

Page 10

4.

In order that the master station and instrument (PHL) can correctly communicate, following settings are required.

• All communication condition settings of the master station are the same as those of instruments (PHL).

• All instruments (PHL) connected on a line are set to “ MODBUS Station No.” which are different from each

SETTING OF COMMUNICATION CONDITION

other. (Any “ MODBUS Station No.” is not shared by more than one instrument.)

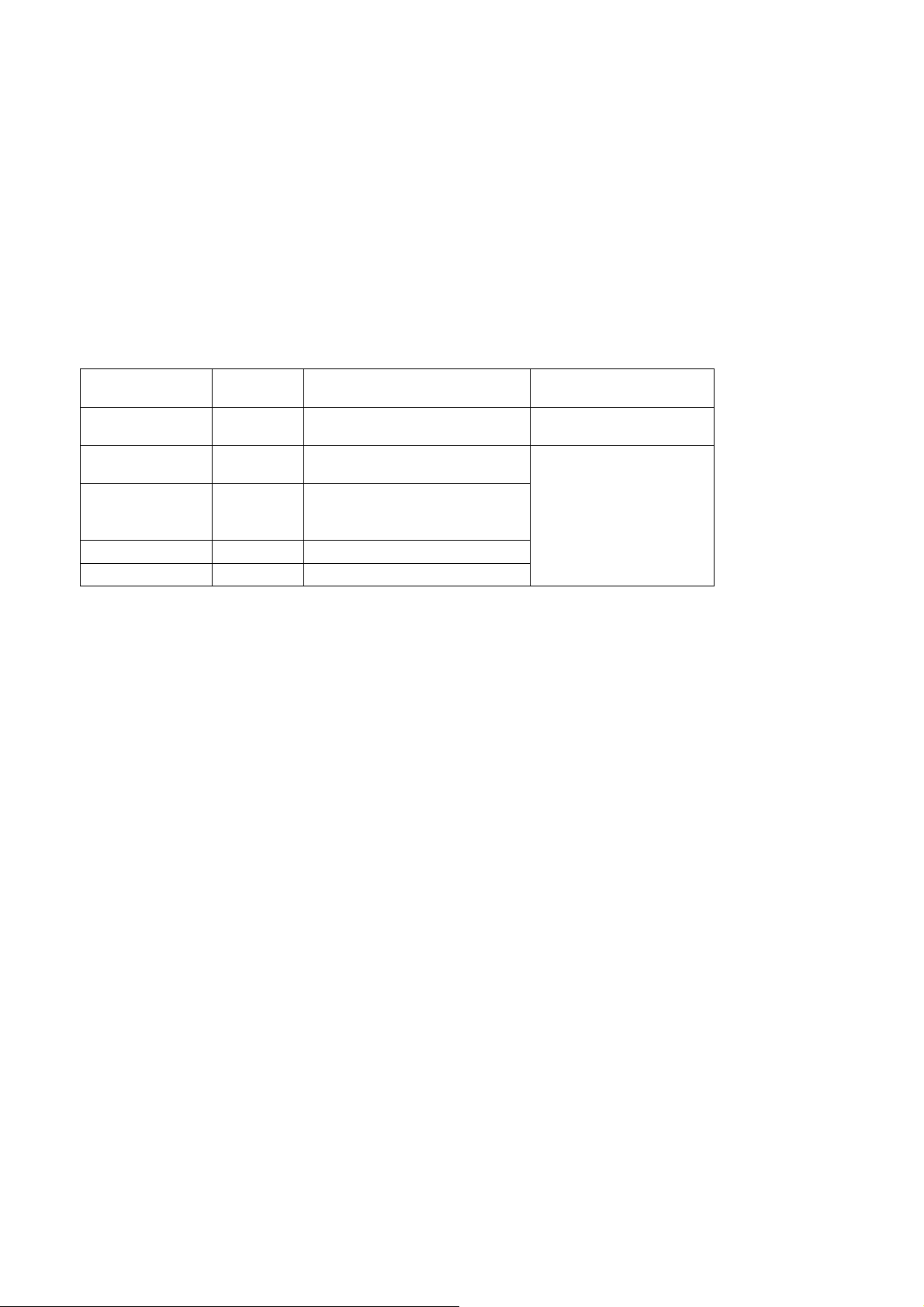

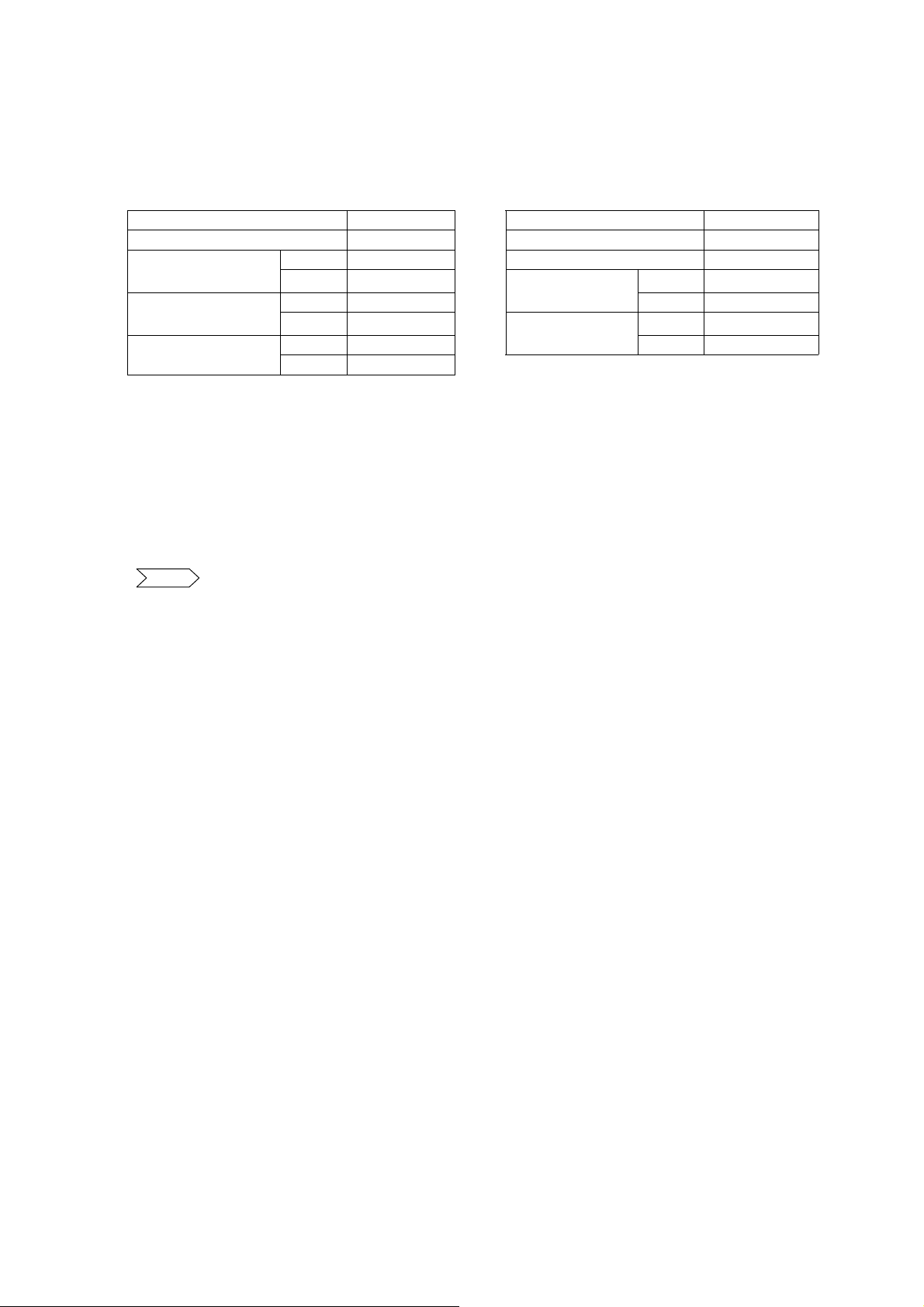

4.1 Set Items

The parameters to be set are shown in the following table. Set them by operating the front panel keys.

Item

Station No. 1

Transmission

speed

Parity setting Odd

Data length

Stop bit

Value at

delivery

0 to 255

(0: communication function stop)

19200 bps 9600bps, 19200bps

None: None parity

Odd: Odd parity

Even: Even parity

8 bit

1 bit

Fixed (can not be changed)

Fixed (can not be changed)

Setting range Remarks

Set a different value to

each station.

Set the same communication condition to the

master station and all

stave stations.

- 6 -

Page 11

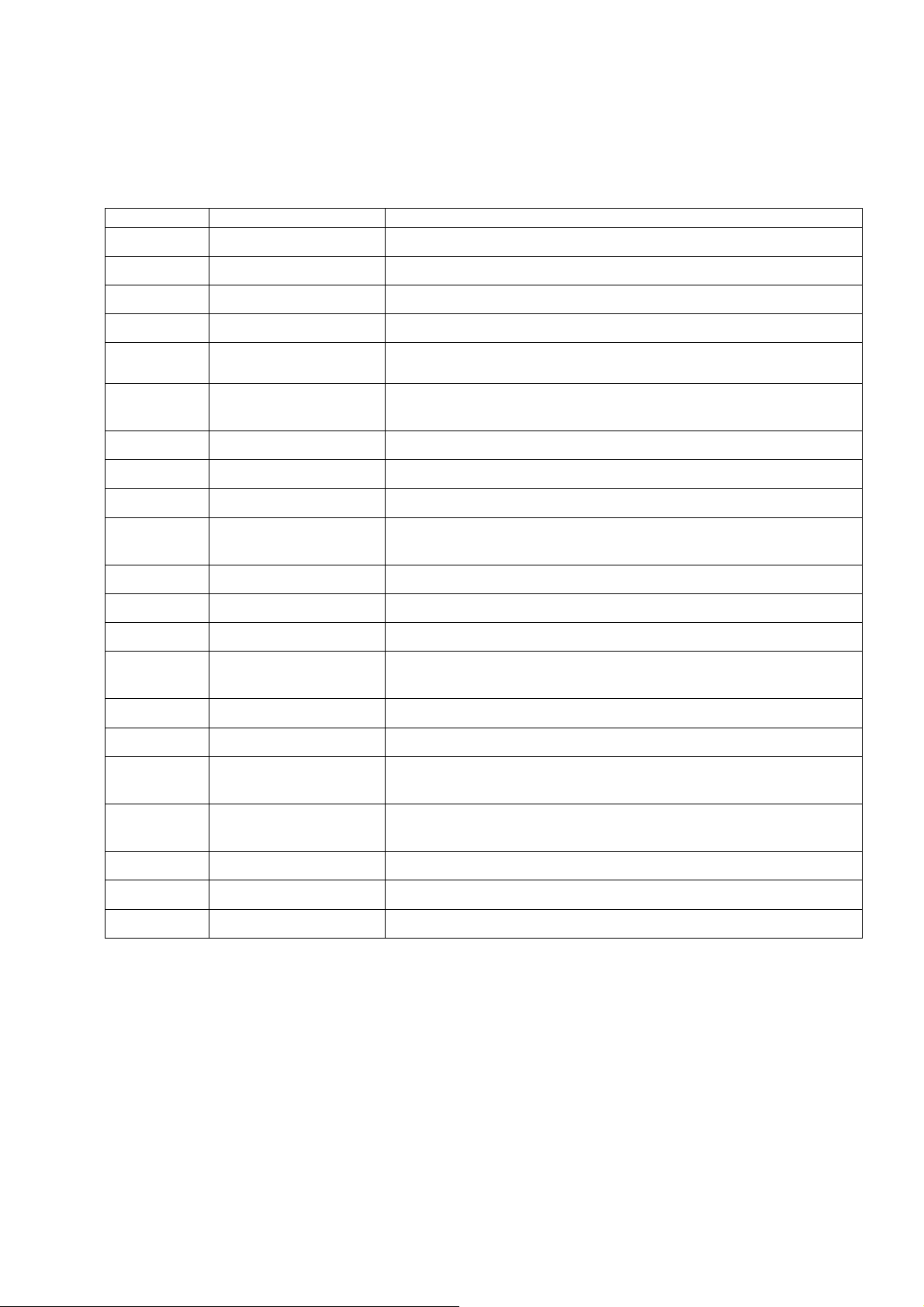

4.2 Setting Operation Method

The following example shows how to set the communication conditions.

Example: Selecting an even parity and “STno=10 and 9600bps” on a station.

Keys used Display Meanings

Trend display Operation state (Trend display)

SEL Menu

Press the [SEL] key to display the Menu screen.

ENT Parameter setting Press the [ENT] key to the Parameter setting screen.

ENT Basic setting

∨

ENT

∨

MODBUS Station NO

Numeric value entering

screen

<010>

ENT MODBUS Station NO

∨

ENT

∧

MODBUS baud rate

Baud rate selection

screen

9600

ENT MODBUS baud rate

∨

ENT

∨

MODBUS parity

Parity bit selection

screen

Even

Press the [ENT] key to the Basic setting screen.

Press the [

key pressed more than six times, use the [

Press the [ENT] key to display the Numeric value entering screen.

Use [<], [>] ,[∧], or [∨] key to change the numeric value to 10.

Press the [ENT] key to confirm the MODBUS Station NO.

Press the [∨] key to select the MODBUS baud rate.

∨] key six times to select MODBUS Station NO. (When the

∧] key to back)

Press the [ENT] key to display the Baud rate selection screen.

Press the [

Press the [ENT] key to confirm the baud rate.

Press the [∨] key to select the MODBUS parity.

Press the [ENT] key to display the Parity bit selection screen.

Press the [∨] key to select “Even”.

∧] key to select “9600”.

ENT MODBUS parity

DISP

ENT

Selection screen for

saving the settings

Confirmation screen for

saving the settings

ENT Trend display

Power OFF -

Power ON Trend display

Press [ENT] key to confirm the parity bit.

Press the [DISP] key to display a screen asking you want to save the

setting.

Press the [ENT] key to save the setting. (The confirmation screen

appears.)

The Trend screen appears.

Turn off the power.

Turn on the power once again to complete the setting.

- 7 -

Page 12

5. MODBUS COMMUNICATION PROTOCOL

5.1 General

The communication system by the MODBUS protocol is that the communication is always started from the master

station and a slave station responds to the received message.

Transmission procedures is as shown below.

1) The master station sends a command message to a slave station.

2) The slave station checks that the station No. in the received message matches with the own station No. or

not.

3) If matched, the slave station executes the command and sends back the response message.

4) If mismatched, the slave station leaves the command message and wait for the next command message.

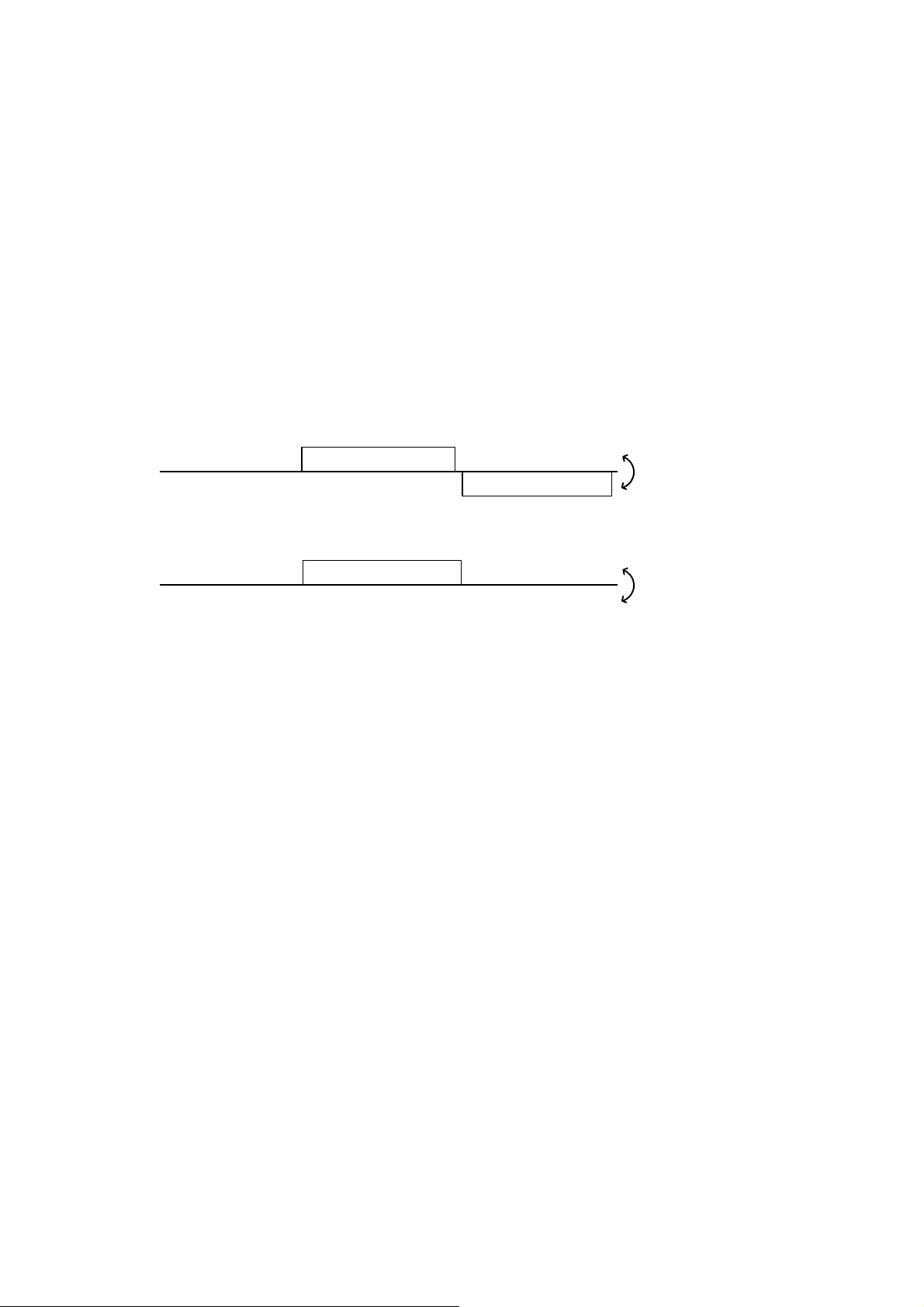

a) In case when the station No. in the received command message matches with the own slave station No.

Master to slave

Slave to master

b) In case when the station No. in the received command message mismatches with the own slave station

No.

Master to slave

Slave to master

5) To assure safety, provide a structure where the response message is checked and retry is made three (3)

times or more if no response is made or an error occurs.

The master station can individually communicate with any one of slave stations connected on the same line upon

setting the station No. in the command message.

Command message

Command message

Response message

(Not respond)

Data on

the line

Data on

the line

- 8 -

Page 13

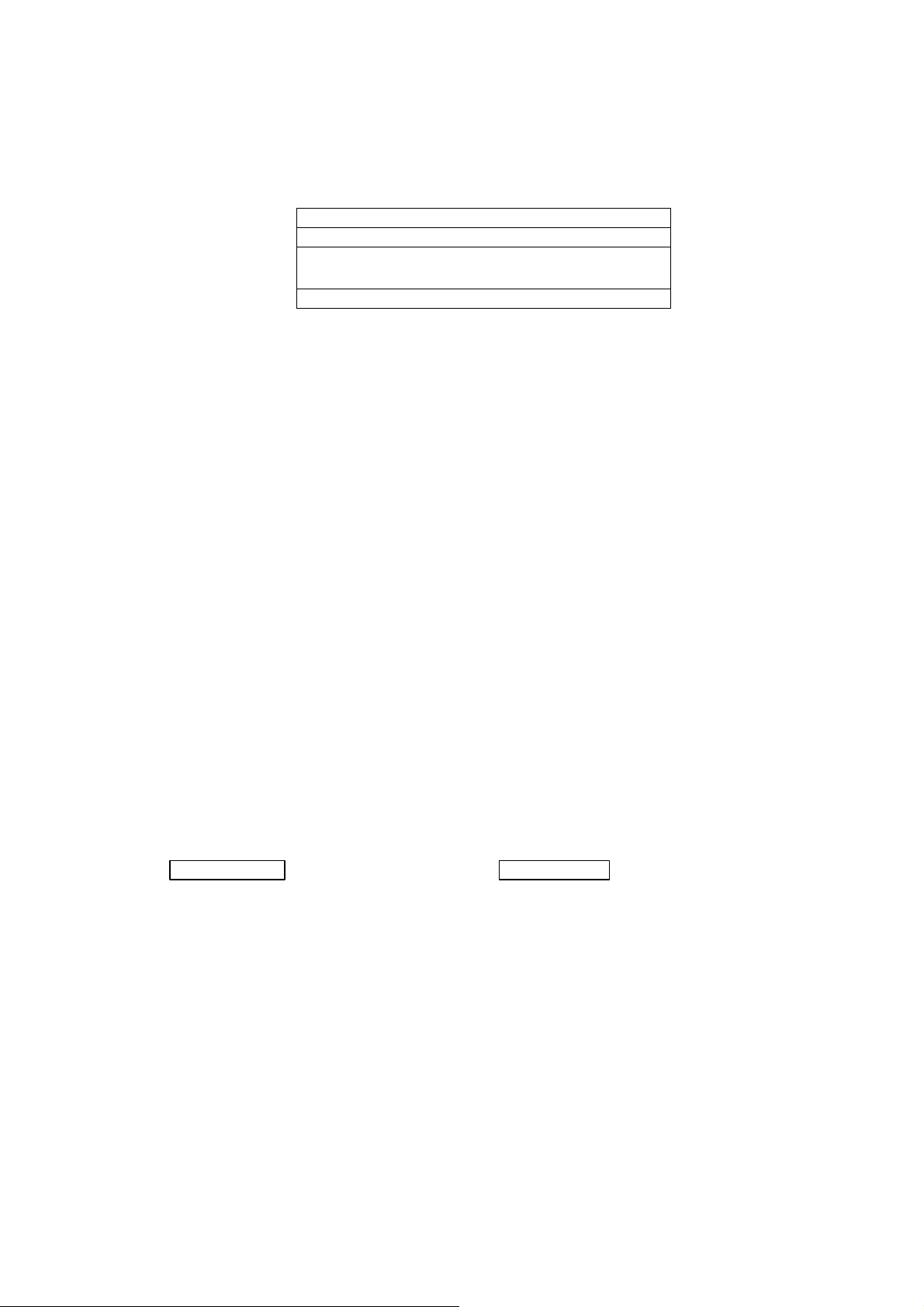

5.2 Composition of Message

Command message and response message consist of 4 fields ; Station No., Function code, Data and Error check

code. And these are send in this order.

Station No. (1 byte)

Function code (1 byte)

Data (2 to 133 bytes)

Error check code (CRC-16) (2 bytes)

Fig. 5-1 Composition of message

In the following, each field is explained.

(1) Station No

Station No. is the number specifiing a slave station. The command message is received and operated only by

the slave station whose station No. matches with the No. set in the parameter “ MODBUS Station No.”

For details of setting the parameter “ MODBUS Station No.”, refer to chapter 4.

(2) Function code

This is a code to designate the function executed at a slave station.

For details, refer to section 5.4.

(3) Data

Data are the data required for executing function codes. The composition of data varies with function codes.

For details, refer to chapter 6.

A register number is assigned to each data in the recorder. For reading/writing

the data by communication, designate the register number.

Note that the register number transmitted on message is expressed as its relative address.

The relative address is calculated by the following expression.

The lower 4 digits of the

Relative address

For example, when the resister number designated by a function code is 40003,

Relative address = (lower 4 digits of 40003)

= 0002

is used on the message.

=

register number

-

1

- 1

- 9 -

Page 14

(1) Error check code

This is the code to detect message errors (change in bit) in the signal transmission.

On the MODUBUS protocol (RTU mode), CRC-16 (Cycric Redundancy Check) is applied.

For CRC calculation method, refer to section 5.5.

- 10 -

Page 15

5.3 Response of Slave Station

(1) Response for normal command

To a relevant message, the slave station creates and sends back a response message which corresponds to the

command message. The composition of message in this case is the same as in section 5.2.

Contents of the data field depend on the function code. For details, refer to Chapter 6.

(2) Response for abnormal command

If contents of a command message have an abnormality (for example, non-actual function code is designated)

other than transmission error, the slave station does not execute that command but creates and sends back a

response message at error detection.

The composition of response message at error detection is as shown in Fig. 5-2 The value used for function

code field is function code of command message plus 80

Table 5-1 gives error codes.

Station No.

Function code + 80H

Error code

Error check (CRC-16)

.

H

Error code Contents Description

01H Illegal function code Non-actual function code is designated.

02H Illegal data address A relative address of a resister number to which the

03H Illegal data number Because the designation of number is too much,

(3) No response

Under any of the following items, the slave station takes no action of the command message and sends back no

response.

• A station number transmitted in the command message differs from the station number specified to the

slave station.

• A error check code is not matched, or a transmission error (parity error, etc.) is detected.

• The time interval between the composition data of the message becomes longer than the time

corresponding to 24 bits. (Refer to section 5.6 Transmission Control Procedure)

• Station No. of a slave station is set to 0.

Fig. 5-2 Response message at error detection

Table 5-1 Error Code

Check for the function code.

designated function code can not be used.

the area where resister numbers do not exist is

designated.

- 11 -

Page 16

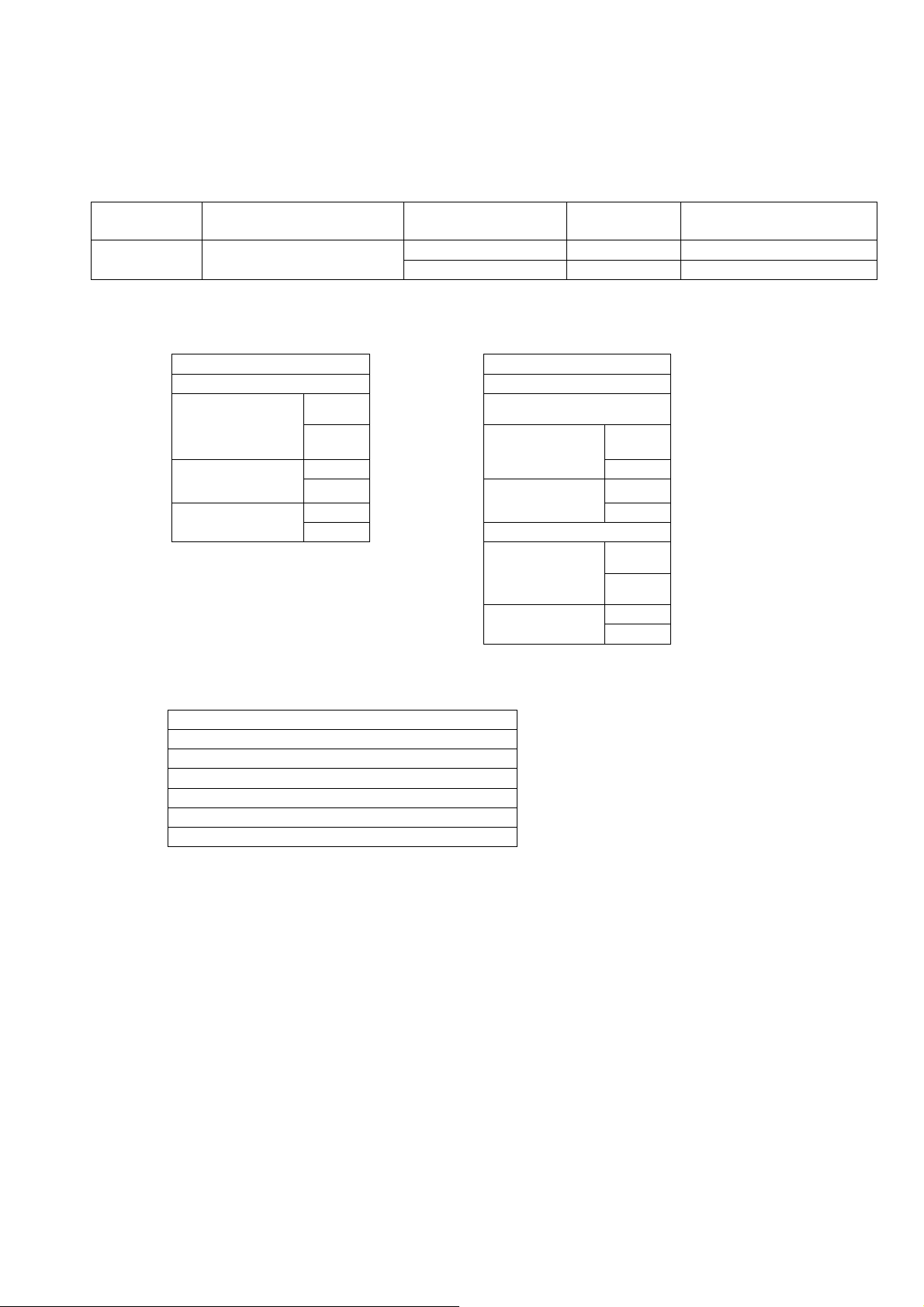

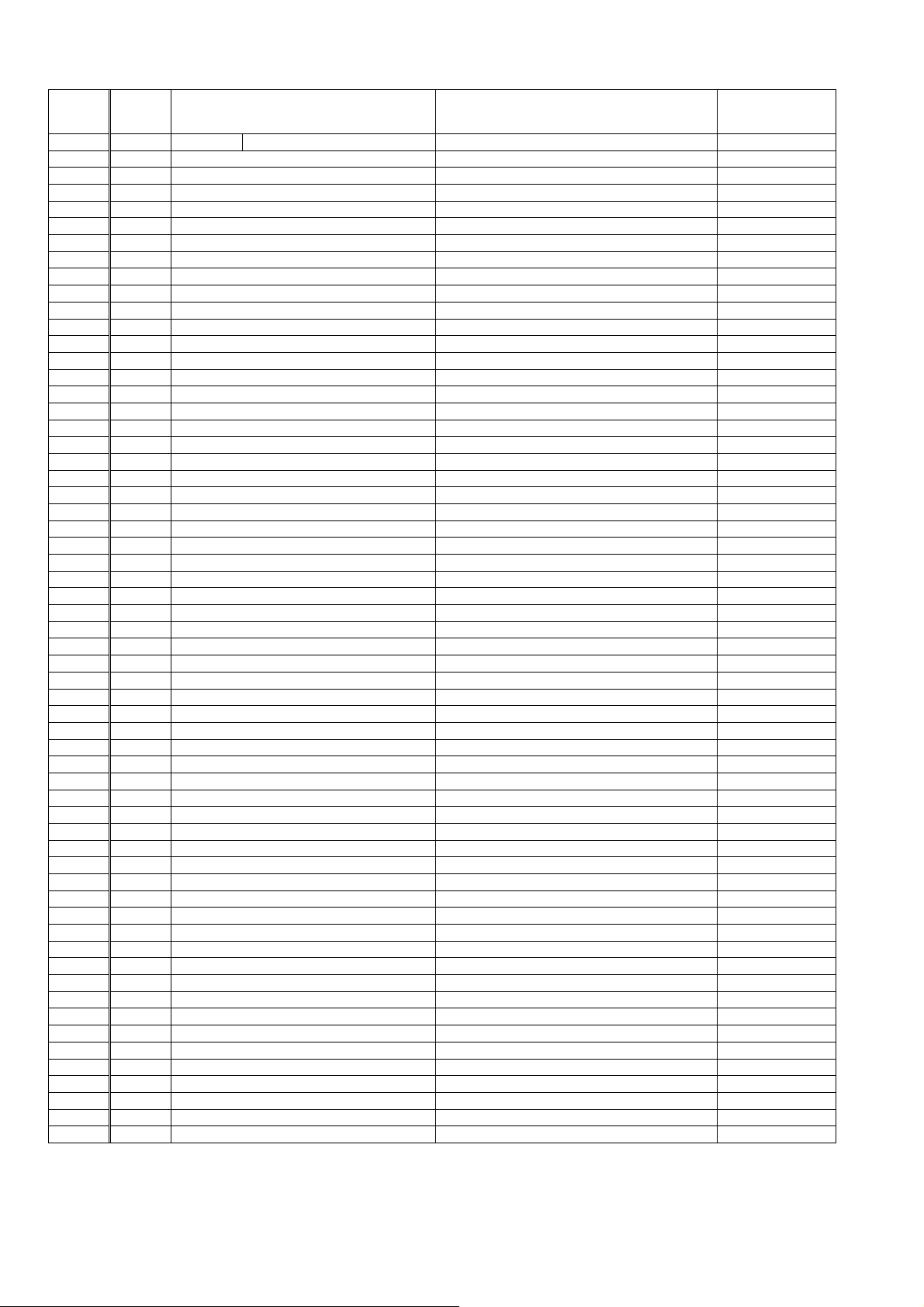

5.4 Function Code

According to MODBUS protocol, register numbers are assigned by function codes.

Each function code acts on specific register number.

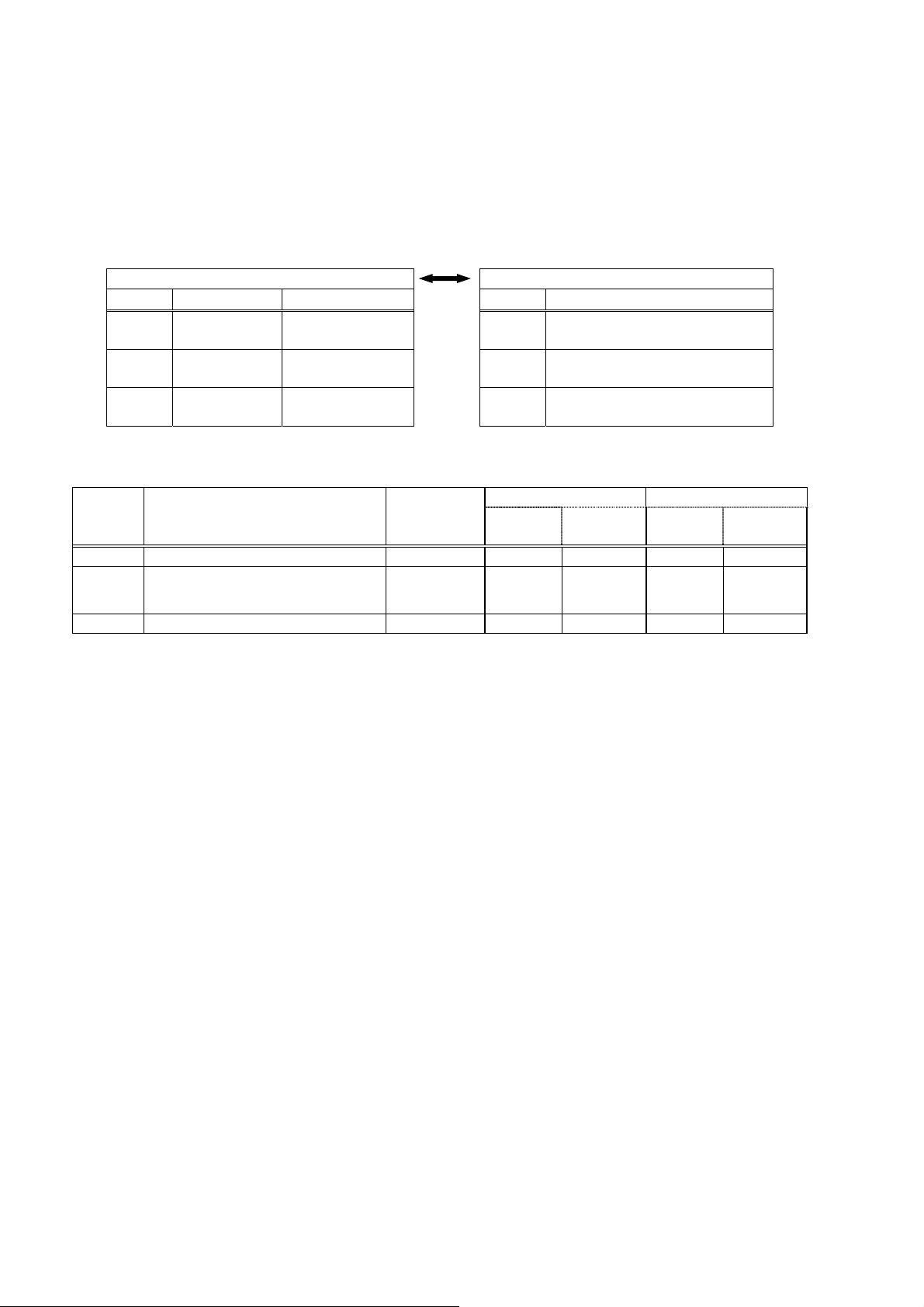

This correspondence is shown in Table5-2, and the message length by function is shown in Table5-3.

Table5-2 Correspondence between function codes and objective address

Function code

No. Function Object

03H

04H

10H

Function

code

03H Read-out of word data 64 words 8 8 7 133

04H

10H Write-in of continuous word data 64 words 11 137 8 8

Read-out

(continuously)

Read-out

(continuously)

Write-in

(continuously)

Contents

Read-out of word data

(read-out only)

Holding register

Input register

Holding register

Table5-3 Function code and message length

Number of

designatable

data

64 words 8 8 7 133

No. Contents

4xxxx Read-out/write-in word data

3xxxx Read-out word data

4xxxx Read-out/write-in word data

Command message Response message

Minimum Maximum Minimum Maximum

Resister No.

[Unit: byte]

- 12 -

Page 17

r

e

5.5 Calculation of Error Check Code (CRC-16)

CRC-16 is the 2-byte (16-bits) error check code. From the top of the message (station No.) to the end of the data

field are calculated.

The slave station calculates the CRC of the received message, and does not respond if the calculated CRC is

different from the contents of the received CRC code.

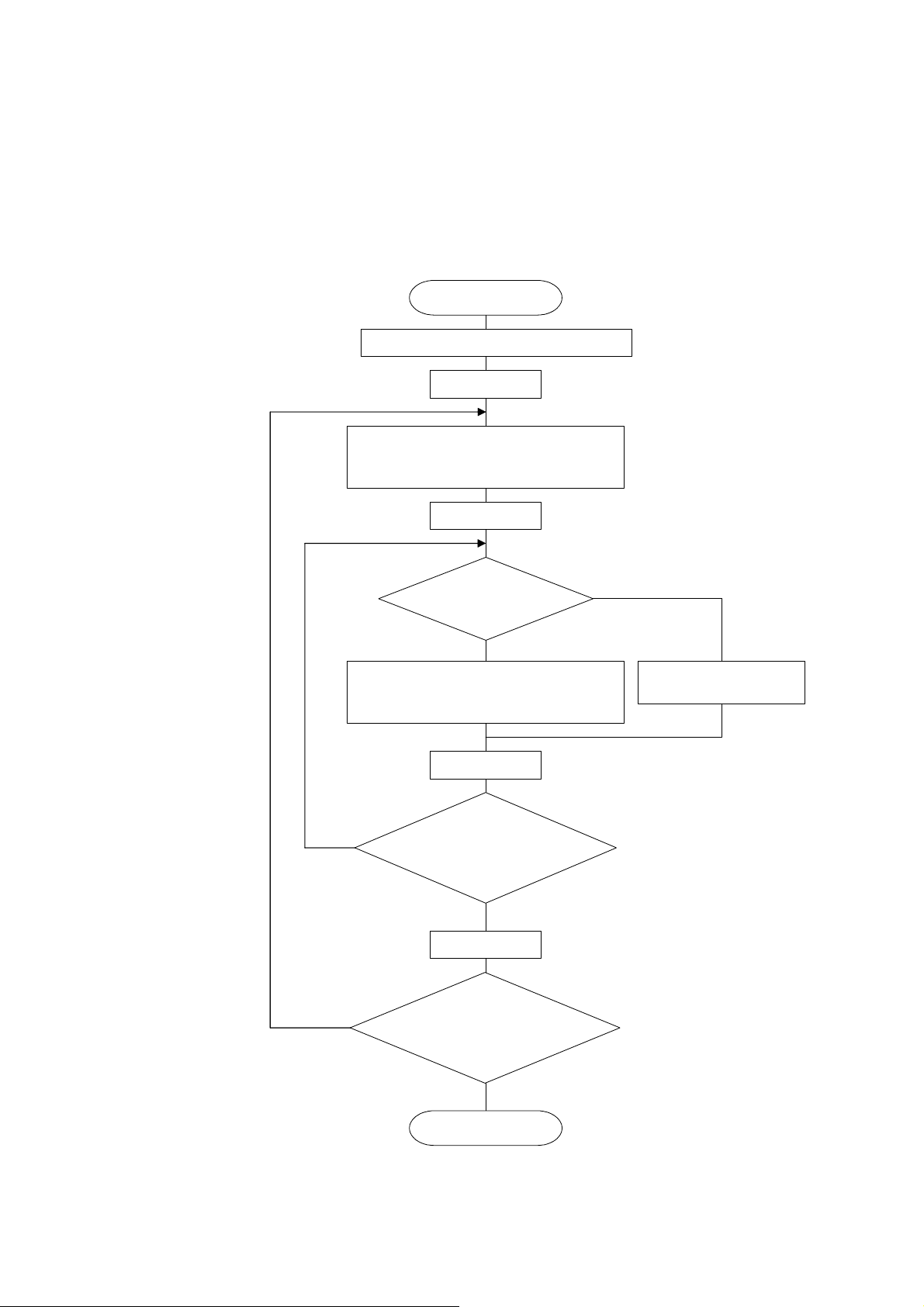

Fig. 5-3 shows the flow of the CRC-16 calculation system.

Set FFFFH (hexadecimal number) in CR.

Exclusive logical sum (XOR) is executed

with CR and one character (1 byte) of the I

characters, and its results is set in CR.

Start

Set 1 in I.

Set 1 in J.

Explanation of variables

CR : CRC error check data (2 bytes)

I : Digits of calculation characters

in command message

J : Check on the number of times

of CR calculation

Bit at right end

of CR is 1?

YES

Shift CR to right by 1 bit, and A001H and

exclusive logical sum (XOR) are executed

and its result is set in CR.

Add 1 to J.

NO

NO

Calculation (8 times)

is finished?

J>8

YES

Add 1 to I.

Calculation of all characters is

completed?

I>All characters

YES

End

NO

Shift CR to right by 1 bit.

(Calculation is executed in the orde

of command message station No.,

function code and data.)

CR calculation result shall be added

to the last command message in th

order of LOW byte and HIGH byte.

Fig. 5-3 Flow of CRC-16 calculation

- 13 -

Page 18

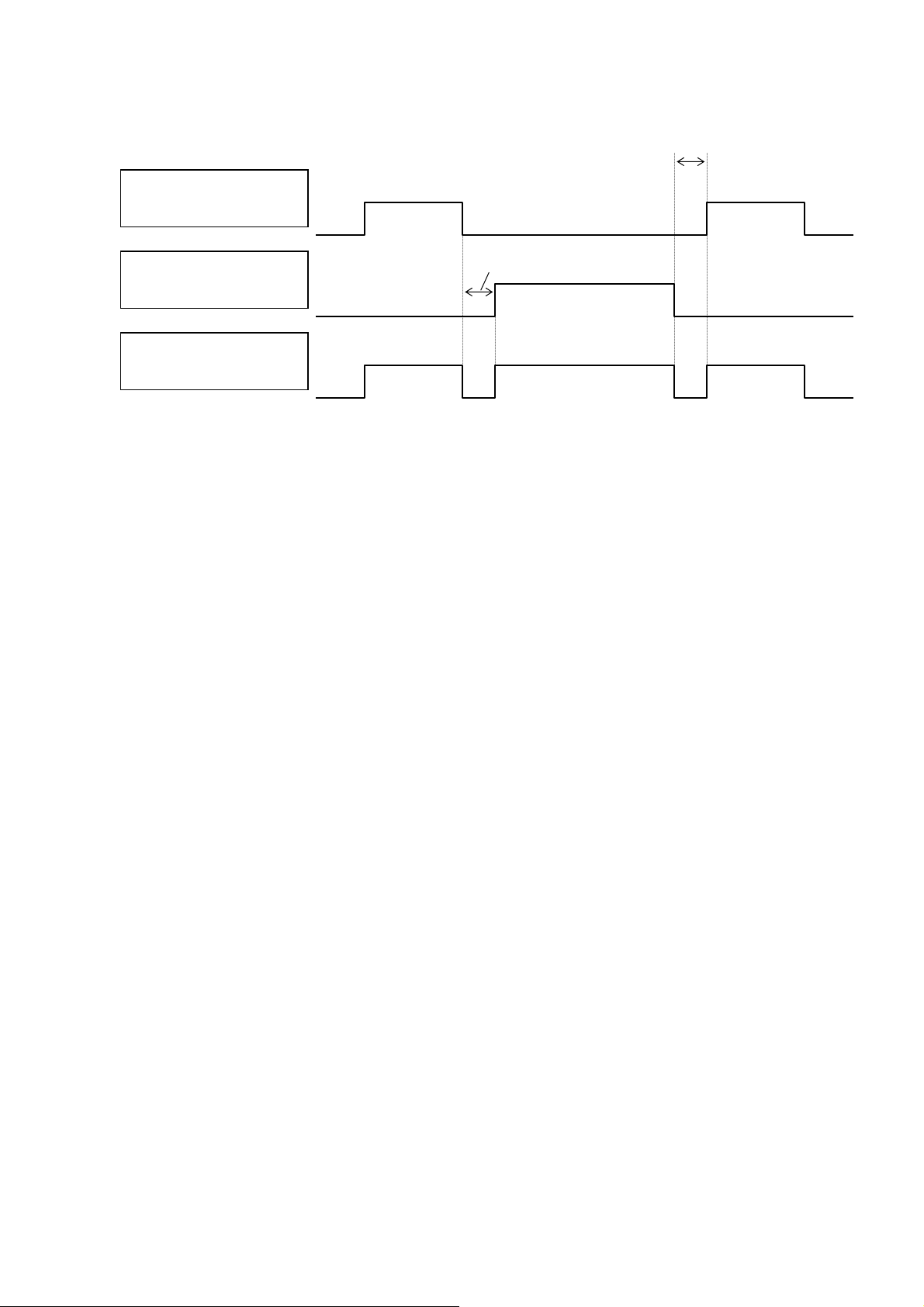

5.6 Transmission Control Procedure

(1) Transmission procedure of master station

The master station must proceed to a communication upon conforming to the following items.

(1-1) Before sending a command message, provide 48 bits time or more vacant status.

(1-2) For sending, the interval between bytes of a command message is below 24 bits time.

(1-3) Within 24 bits time after sending a command message, the receiving status is posted.

(1-4) Provide 48 bits time or more vacant status between the end of response message reception and

beginning of next command message sending [same as in (1-1)].

(1-5) For ensuring the safety, make a confirmation of the response message and make an arrangement so

as to provide 3 or more retries in case of no response, error occurrence, etc.

Note) The above definition is for most unfavorable value. For ensuring the safety, it’s recommended the

program of the master to work with safety factors of 2 to 3. Concretely, it is advised to arrange the

program for 9600 bps with 10 ms or more for vacant status (1-1), and within 1 ms for byte interval

(1-2) and changeover from sending to receiving (1-3).

(2) Description

1) Detection of the message frame

Since the communication system uses the 2-wire RS-485 interface, there may be 2 statuses on a line below.

(a) Vacant status (no data on line)

(b) Communication status (data is existing)

Instruments connected on the line are initially at a receiving status and monitoring the line. When 24 bits

time or more vacant status has appeared on the line, the end of preceding frame is assumed and, within

following 24 bits time, a receiving status is posted. When data appears on the line, instruments receive it

while 24 bits time or more vacant status is detected again, and the end of that frame is assumed. I.e., data

which appeared on the line from the first 24 bits time or more vacant status to the next 24 bits time or more

vacant status is fetched as one frame.

Therefore, one frame (command message) must be sent upon confirming the following.

(1-1) 48 bits time or more vacant status precedes the command message sending.

(1-2) Interval between bytes of 1 command message is smaller than 24 bits time.

2) Response of this instrument (PHL)

After a frame detection (24 bits time or more vacant status), this instrument carries out processing with that

frame as a command message. If the command message is destined to the own station, a response

message is returned. Its processing time is 300 to 500 ms (depends on contents of command message).

After sending a command message, therefore, the master station must observe the following

(1-3) Receiving status is posted within 24 bits time after sending a command message.

- 14 -

Page 19

Space time of longer than 5 ms is

needed.

(longer than 10 ms is recommended.)

Master

station

Master

station

→

← PHL

Data on line

PHL

POL1

500 ms max

POL1 response data

POL1 POL2 POL1 response data

POL2

- 15 -

Page 20

5.7 FIX Processing (Cautions in data write)

The instrument is provided inside with a non-volatile memory (F-ROM) for holding the setting parameters.

Data written in the non-volatile memory is not lost even if turning off the power.

To hold parameters that were written in the internal memory via communication after turning off the power, the FIX

process is effective. It allows parameters to be written in nonvolatile memory.

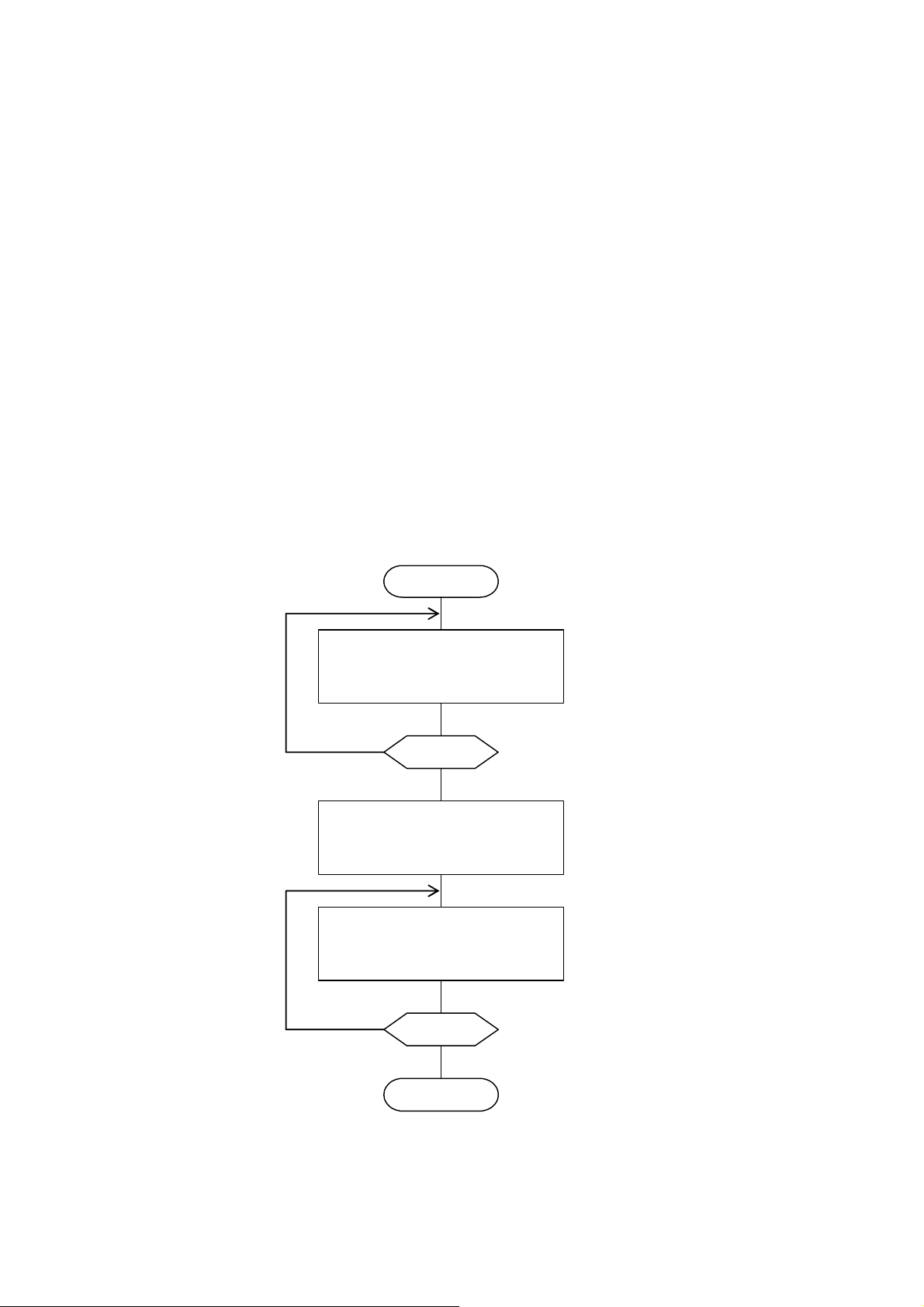

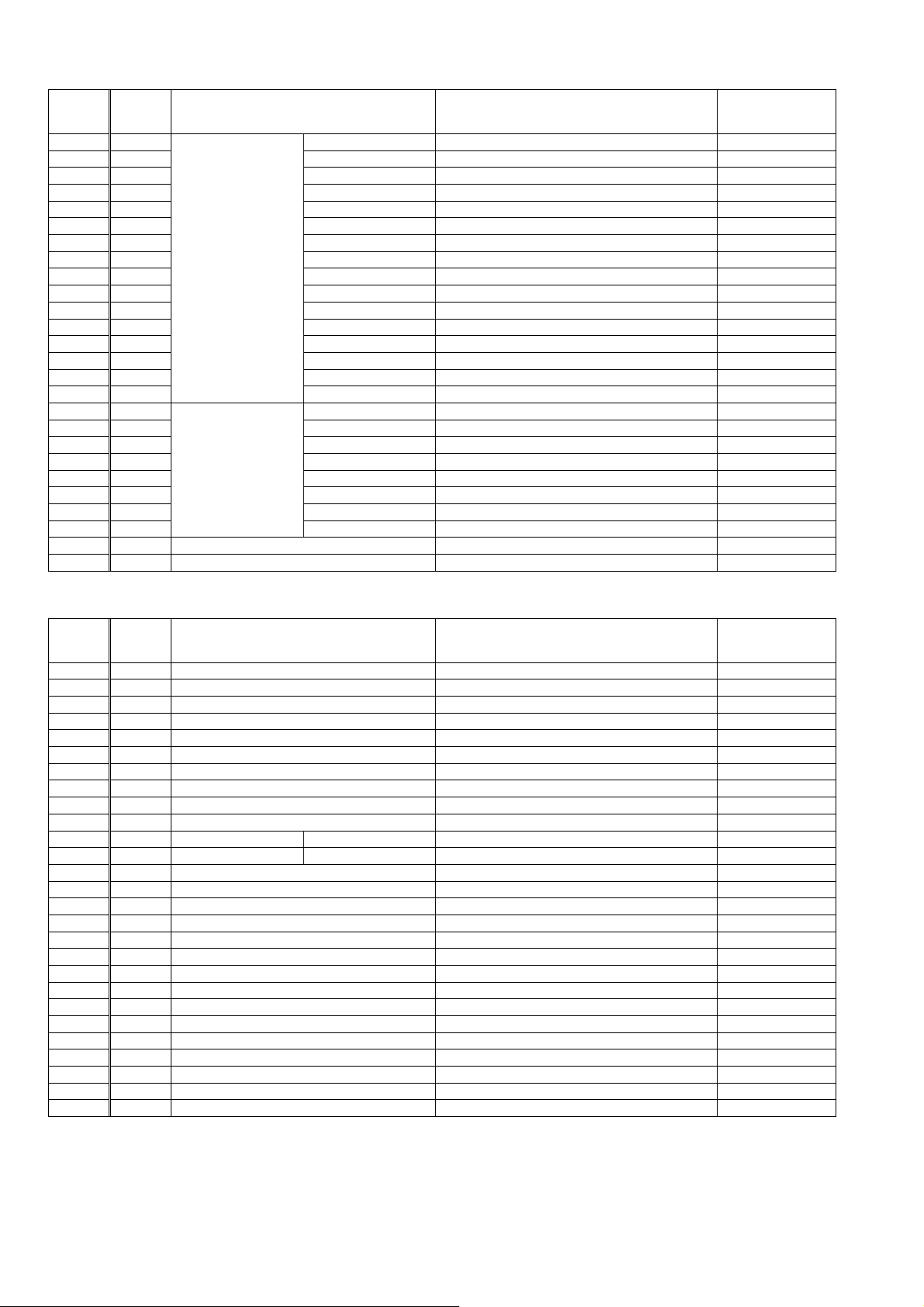

Fig.5-4 shows the FIX procedure.

Cautions:

•

Write in the non-volatile memory takes approximately 2 seconds.

• While writing, do not turn off the power of the PHL. Otherwise, the data in the non-volatile memory will be

destroyed, whereby the PHL could not be used any longer.

• Don’t change parameters on the front panel when performing the FIX procedure, or memory error may result.

• The non-volatile memory (F-ROM) is a device where the number of write-in times is limited. The

guaranteed number of write-in times of the non-volatile memory used on the instrument is 100,000 minimum.

Therefore, limit the times of change of parameter setting to absolute minimum. Refrain from carrying out

the FIX processing periodically for example or while such is not absolutely required.

Start FIX

Read the FIX data

with function code : 03

H

relative address : 1387

No

FIX=0?

Yes

Write ‘1’ into FIX data

with function code : 10

H

relative address : 1387

Read the FIX data

with function code : 03

H

relative address : 1387

No

FIX=0?

Yes

H

H

H

End FIX

Fig.5-4 FIX procedure

- 16 -

Page 21

6. DETAILS OF MESSAGE

6.1 Read-out of Word Data [Function code: 03H]

Function code

03H 64 words

Max. word number read-out

in one message

(1) Message composition

Command message composition (byte) Response message composition (byte)

Station No. Station No.

Function code Function code

Read-out start

No.

(relative address)

number

CRC data

* Arrangement of read-out word data

MSB LSB

Upper byte of contents of the first word data

Lower byte of contents of the first word data

Upper byte of contents of the next word data

Lower byte of contents of the next word data

~

Upper byte of contents of the last word data

Lower byte of contents of the last word data

Upper Read-out byte number Read-out word number×2

Lower Upper

Upper

Lower

Lower

Upper

(2) Function explanations

Relative data address Register No. Kind of data

0000H to 1386H 40001 to 44999 Storage enable data

to 176FH 45000 to 46000 Storage disable data

1387

H

Contents of the

1 to 64

first word data

Contents of the

next word data

~~

Contents of

the last word

data

CRC data

~

Lower Read-out word

Upper

Lower

Upper

Lower

Lower

Upper

Word data of continuous word numbers from the read-out start No. can be read. Read-out word data are

transmitted from the slave station in the order of upper and lower bytes.

- 17 -

Page 22

(3) Message transmission (example)

Reading range start and range end in Channel 1 from No. 2 station is shown below.

Relative address of range start in Channel 1: 001B

Command message composition (byte) Response message composition (byte)

Station No. 02

Function code 03H Function code 03H

Upper 00H Read-out byte number 04H Read-out start No.

(relative address)

number

CRC data

* Meaning of data to be read

Channel 1 Range start 00 00

(contents of the first word data)

Channel 1 Range end 0F A0

(contents of the next word data)

Where the unit is

°C with decimal point position set at 1,

Channel 1 Range start = 0.0

Channel 1 Range end = 400.0

Point

For “Point” decimal point, refer to Section 7.1

Lower 1B

Upper 00H

Lower 02

Lower B4H

Upper 3F

°C

°C

(Register No.40028), Data number: 02H

H

Station No. 02H

H

Upper 00H

H

H

Lower CCH

H

= 0

H

= 4000

H

Contents of the

first word data

Contents of the

next word data

CRC data

Lower 00H Read-out word

Upper 0FH

Lower A0H

Upper BBH

- 18 -

Page 23

6.2

Read-out of Read-out Only Word Data [Function code: 04H]

Function code

04H 64 words 0000H to 07CFH 30001 to 32000

(1) Message composition

Command message composition (byte) Response message composition (byte)

Station No. Station No.

Function code Function code

Read-out start No.

(relative address)

Read-out word

number

CRC data

* Arrangement of read-out word data

MSB LSB

Upper byte of contents of the first word data

Lower byte of contents of the first word data

Upper byte of contents of the next word data

Lower byte of contents of the next word data

~

Upper byte of contents of the last word data

Lower byte of contents of the last word data

(2) Function explanations

Max. word number read-out

in one message

Upper

Lower

Upper

Lower

Lower

Upper

Read-out byte number Read-out word number×2

Upper

1 to 64

Contents of the

first word data

Contents of the

next word data

~~

the last word

data

CRC data

Relative data address Register No.

Lower

Upper

Lower

Upper Contents of

Lower

Lower

Upper

~

Word data of continuous word numbers from the read-out start No. can be read. Read-out word data are

transmitted from the slave station in the order of upper and lower bytes.

- 19 -

Page 24

(3) Message transmission (example)

Reading measured values in Channel 2 from No. 1 station is shown below.

Relative address of measured value in Channel 2: 0065

Command message composition (byte) Response message composition (byte)

Station No. 01

Function code 04H Function code 04H

Upper 00H Read-out byte number 02H Read-out start No.

(relative address)

number

CRC data

* Meaning of data to be read

Channel 2 Measured value 01 4F

(contents of the first word data)

Where the unit is °C with decimal point position set at 1

Channel 2 Measured value = 33.5

Point

For “Point” decimal point, refer to Section 7.1.

Lower 65

Upper 00H

Lower 01

Lower 21H

Upper D5

°C

(Register No.30102), Data number: 01H

H

Station No. 01H

H

Upper 01H

H

H

H

= 335

H

Contents of the

first word data Lower 4FH Read-out word

CRC data

Lower F9H

Upper 54H

- 20 -

Page 25

6.3 Write-in of Continuous Word Data [Function code: 10H]

Function code

Max. word number write-in

in one message

10H 64 words

(1) Message composition

Command message composition (byte) Response message composition (byte)

Station No. Station No.

Function code Function code

Upper Upper Write-in start No.

(relative address)

number

Write-in byte number

Lower

Upper Upper Write-in word

Lower

Upper First write-in

word data

Lower

Upper Next write-in

word data

~ ~

Lower

Upper Last write-in

word data

CRC data

Lower

Lower

Upper

* Arrangement of write-in word data

MSB LSB

Upper byte of contents of the first word data

Lower byte of contents of the first word data

Upper byte of contents of the next word data

Lower byte of contents of the next word data

Upper byte of contents of the last word data

Lower byte of contents of the last word data

(2) Function explanation

Relative data address Register No. Kind of data

0000H to 1386H 40001 to 44999 Storage enable data

to 176FH 45000 to 46000 Storage disable data

1387

H

Write-in start No.

(relative address)

Lower

Write-in word

1 to 64

Write-in word number×2

number

CRC data

Lower

Lower

Upper

~~

Word data of continuous word number is written from write-in start address. Write-in word data are

transmitted from master station in the order of upper and lower bytes.

- 21 -

Page 26

(3) Message transmission (example)

Writing Subtract channel = channel 2, PV shift = 20.0°C, and PV gain = 110.0% in

Channel 1 of No. 1 station is shown below.

Subtract channel = 0002H (= 2D : channel 2)

PV shift = 00C8H (= 200D)

Input filter = 044CH (= 1100D)

Relative address of Subtract channel in Channel 1: 0014

Command message composition (byte) Response message composition (byte)

Station No. 01

Function code 10H Function code 10H

Upper 00H Upper 00H Write-in start No.

(relative address)

number

Write-in byte number 06H Lower 41H

word data

word data

word data

CRC data

Point

Caution

Since the transmission data can not include a decimal point, data of 110.0 is

transmitted as “1100”.

For transmission format of each data, refer to the address map (Chapter7)

If the write-in command message is sent to any slave station during the

FIX process, response is not returned from it.

Lower 14

Upper 00H Upper 00H Write-in word

Lower 03

Upper 00H

Lower 02

Upper 00H Next write-in

Lower C8

Upper 04H Last write-in

Lower 4C

Lower 5DH

Upper CB

(Register No.40021), Data number: 03H

H

Station No. 01H

H

Write-in start No.

H

H

H

H

H

H

(relative address)

Write-in word

number

CRC data

Lower 14H

Lower 03H

Upper CDH First write-in

- 22 -

Page 27

7. ADDRESS MAP AND DATA FORMAT

7.1 Data Format

7.1.1 Transmission data format

The MODBUS protocol used in this instrument (PHL) is RTU (Remote Terminal Unit) mode.

Transmitted data is “numeric value” and not “ASCII code”.

- 23 -

Page 28

7.1.2 Control of decimal point

A decimal point is not included on the transmission data.

Align decimal point for data that have decimal point (decimal point is eliminated in transmission, and added in

receiving).

7.1.3 Data with input error

When input error (Over, Under, Burnout or Error) occurs in display data, read data from measured values are as

follows.

Display data Read data

Over 32767

Under

Bunout

Error

Detection of input error during communication can be performed at address 30131 = Channel status.

-

32767

-

32768

-

32768

7.1.4 Range of write-in data

When data is written in each parameter, the write-in data should be kept within the setting range. PHL accepts the

write-in data beyond the range. However, be careful since the PHL performance will not be guaranteed.

- 24 -

Page 29

7.2 Address Map

For detailed contents about individual parameter function or setting range, refer to the operation manual.

Data type Long: long data The data of this address is manipulated in unit of word. 1 data/2 address

Word: word data The data of this address is manipulated in unit of word. 1 data/1 address

Byte: byte data The data of this address is manipulated in unit of byte. A maximum of 2 data/1 address

Bit: Bit data The data of this address is manipulated in unit of bit. A maximum of 16 data/1 address

7.2.1 Word data [read-out / write-in] : Function code [03H, 10H]

Register

No.

4XXXX

Data

type

40001 Byte 1st, 2nd characters Set Tag 1 (8 characters) by the ASCII code.

40002 Byte 3rd, 4th characters

40003 Byte 5th, 6th characters

40004 Byte

40005 Byte 1st, 2nd characters Set Tag 2 (8 characters) by the ASCII code.

40006 Byte 3rd, 4th characters

40007 Byte 5th, 6th characters

40008 Byte

40009 Word Color 1 to 14 (Please refer to Table 1.)

40010 Word Input type 0 to 33 (Please refer to Table 2.)

40011 Word Input filter 0 to 900 (0 to 900 sec)

40012 Word Unit 0 to 167 (Please refer to Table 3.)

40013 Word Scaling 0: OFF, 1: ON

40014 Word Masuring start

40015 Word Masuring end

40016 Word Engineering start

40017 Word Engineering end

40018 Word Decimal point 0 to 4 (Please refer to Table 5.)

40019 Word Square rooter 0: OFF, 1: ON

40020 Word Logarithmic display 0: OFF, 1: ON

40021 Word Subtract channel

40022 Word PV shift

40023 Word PV gain 0 to 32767 (0.00 to 327.67%)

40024 Word Reserve

40025 Word Reserve

40026 Word Recording mode 0: With record, 1: Display only

40027 Word Recording type 0: Min-Max rec., 1: Point record, 2: Average rec.

40028 Word Range start

40029 Word Range end

40030 Word Reserve

40031 Word Reserve

40032 Word Reserve

40033 Word Reserve

40034 Word Reserve

40035 Word Reserve

40036 Word Fvalue caluculation 0: OFF, 1: ON

40037 Word Totalize caluculation 0: OFF, 1: Totalizer, 2: Counter, 3: Timer

40038 Byte 1st, 2nd characters Set Totalize Tag (8 characters) by the ASCII code.

40039 Byte 3rd, 4th characters

40040 Byte 5th, 6th characters

40041 Byte

40042 Word Totalize unit 0 to 167 (Please refer to Table 3.)

40043 Word Totalize cut value

40044 Word Totalize scale value 1 to 32767

40045 Word Totalize type 0 to 6 (Please refer to Table 7.)

40046 Word External input 0 to 129 (Please refer to Table 8.)

40047 Word Totalize base time 0: /s, 1: /min, 2: /h, 3: /day

40048 Word Reset operation 0: OFF, 1: ON

40049 Word

Memory contents Read-out data / Write-in data setting range Remarks

Tag 1

7th, 8th characters

Tag 2

7th, 8th characters

-

1000 to 5500 (Please refer to Table 4.)

-

1000 to 5500 (Please refer to Table 4.)

-

32767 to 32767

-

32767 to 32767

Channel 1

setting

(64

words)

0 to 30 (0: Subtract OFF, 1 to 30: channel 1 to

30)

-

32767 to 32767

-

32767 to 32767 (Please refer to Table 6.)

-

32767 to 32767 (Please refer to Table 6.)

Totalize

tag

7th, 8th characters

-

32767 to 32767 (Please refer to Table 6.)

Totalize reset input 0 to 130 (Please refer to Table 9.)

- 25 -

Page 30

Register

No.

Data

type

40050 Word Reserve

to Reserve

40065 Word Channel 2 setting Same allocation as in Channel 1

to

40129 Word Channel 3 setting Same allocation as in Channel 1

to

40193 Word Channel 4 setting Same allocation as in Channel 1

to

40257 Word Channel 5 setting Same allocation as in Channel 1

to

40321 Word Channel 6 setting Same allocation as in Channel 1

to

40385 Word Channel 7 setting Same allocation as in Channel 1

to

40449 Word Channel 8 setting Same allocation as in Channel 1

to

40513 Word Channel 9 setting Same allocation as in Channel 1

to

40577 Word Channel 10 setting Same allocation as in Channel 1

to

40641 Word Channel 11 setting Same allocation as in Channel 1

to

40705 Word Channel 12 setting Same allocation as in Channel 1

to

40769 Word Channel 13 setting Same allocation as in Channel 1

to

40833 Word Channel 14 setting Same allocation as in Channel 1

to

40897 Word Channel 15 setting Same allocation as in Channel 1

to

40961 Word Channel 16 setting Same allocation as in Channel 1

to

41025 Word Channel 17 setting Same allocation as in Channel 1

to

41089 Word Channel 18 setting Same allocation as in Channel 1

to

41153 Word Channel 19 setting Same allocation as in Channel 1

to

41217 Word Channel 20 setting Same allocation as in Channel 1

to

41281 Word Channel 21 setting Same allocation as in Channel 1

to

41345 Word Channel 22 setting Same allocation as in Channel 1

to

41409 Word Channel 23 setting Same allocation as in Channel 1

to

41473 Word Channel 24 setting Same allocation as in Channel 1

to

41537 Word Channel 25 setting Same allocation as in Channel 1

to

41601 Word Channel 26 setting Same allocation as in Channel 1

to

41665 Word Channel 27 setting Same allocation as in Channel 1

to

41729 Word Channel 28 setting Same allocation as in Channel 1

to

41793 Word Channel 29 setting Same allocation as in Channel 1

to

41857 Word Channel 30 setting Same allocation as in Channel 1

to

Memory contents Read-out data / Write-in data setting range Remarks

- 26 -

Page 31

Register

No.

Data

type

41921 Word Alarm type 0: OFF, 1: H alarm, 2: L alarm

41922 Word Set point

41923 Word

41924 Word

41925 Word Alarm type 0: OFF, 1: H alarm, 2: L alarm

41926 Word Set point

41927 Word

41928 Word

41929 Word Alarm type 0: OFF, 1: H alarm, 2: L alarm

41930 Word Set point

41931 Word

41932 Word

41933 Word Alarm type 0: OFF, 1: H alarm, 2: L alarm

41934 Word Set point

41935 Word

41936 Word

41937 Word Channel 2 alarm setting Same allocation as in Channel 1

to

41953 Word Channel 3 alarm setting Same allocation as in Channel 1

to

41969 Word Channel 4 alarm setting Same allocation as in Channel 1

to

41985 Word Channel 5 alarm setting Same allocation as in Channel 1

to

42001 Word Channel 6 alarm setting Same allocation as in Channel 1

to

42017 Word Channel 7 alarm setting Same allocation as in Channel 1

to

42033 Word Channel 8 alarm setting Same allocation as in Channel 1

to

42049 Word Channel 9 alarm setting Same allocation as in Channel 1

to

42049 Word Channel 9 alarm setting Same allocation as in Channel 1

to

42065 Word Channel 10 alarm setting Same allocation as in Channel 1

to

42081 Word Channel 11 alarm setting Same allocation as in Channel 1

to

42097 Word Channel 12 alarm setting Same allocation as in Channel 1

to

42113 Word Channel 13 alarm setting Same allocation as in Channel 1

to

42129 Word Channel 14 alarm setting Same allocation as in Channel 1

to

42145 Word Channel 15 alarm setting Same allocation as in Channel 1

to

42161 Word Channel 16 alarm setting Same allocation as in Channel 1

to

42177 Word Channel 17 alarm setting Same allocation as in Channel 1

to

42193 Word Channel 18 alarm setting Same allocation as in Channel 1

to

42209 Word Channel 19 alarm setting Same allocation as in Channel 1

to

42225 Word Channel 20 alarm setting Same allocation as in Channel 1

to

42241 Word Channel 21 alarm setting Same allocation as in Channel 1

to

42257 Word Channel 22 alarm setting Same allocation as in Channel 1

to

42273 Word Channel 23 alarm setting Same allocation as in Channel 1

to

Memory contents Read-out data / Write-in data setting range Remarks

-

32767 to 32767 (Please refer to Table 6.)

-

32767 to 32767 (Please refer to Table 6.)

-

32767 to 32767 (Please refer to Table 6.)

-

32767 to 32767 (Please refer to Table 6.)

Channel 1

alarm

setting

(16

words)

Alarm

No.1

DO relay No. 0 to 28 (0: None, 1 to 28: DO1 to 28)

Alarm

No.2

DO relay No. 0 to 28 (0: None, 1 to 28: DO1 to 28)

Alarm

No.3

DO relay No. 0 to 28 (0: None, 1 to 28: DO1 to 28)

Alarm

No.4

DO relay No. 0 to 28 (0: None, 1 to 28: DO1 to 28)

Reserve

Reserve

Reserve

Reserve

- 27 -

Page 32

Register

No.

Data

type

42289 Word Channel 24 alarm setting Same allocation as in Channel 1

to

42305 Word Channel 25 alarm setting Same allocation as in Channel 1

to

42321 Word Channel 26 alarm setting Same allocation as in Channel 1

to

42337 Word Channel 27 alarm setting Same allocation as in Channel 1

to

42353 Word Channel 28 alarm setting Same allocation as in Channel 1

to

42369 Word Channel 29 alarm setting Same allocation as in Channel 1

to

42385 Word Channel 30 alarm setting Same allocation as in Channel 1

to

42401 Word Reserve

to Reserve

42425 Byte 1st, 2nd characters Set Display name (16 characters) by the ASCII code.

42426 Byte 3rd, 4th characters

42427 Byte 5th, 6th characters

42428 Byte 7th, 8th characters

42429 Byte 9th, 10th characters

42430 Byte 11th, 12th characters

42431 Byte 13th, 14th characters

42432 Byte

42433 Word Display No.1 0: None, 1 to 30: ch1 to 30

42434 Word Display No.2 0: None, 1 to 30: ch1 to 30

42435 Word Display No.3 0: None, 1 to 30: ch1 to 30

42436 Word Display No.4 0: None, 1 to 30: ch1 to 30

42437 Word Display No.5 0: None, 1 to 30: ch1 to 30

42438 Word Display No.6 0: None, 1 to 30: ch1 to 30

42439 Word Display No.7 0: None, 1 to 30: ch1 to 30

42440 Word Display No.8 0: None, 1 to 30: ch1 to 30

42441 Word Display No.9 0: None, 1 to 30: ch1 to 30

42442 Word

42443 Word Display group 2 setting Same allocation as Display group 1

to

42461 Word Display group 3 setting Same allocation as Display group 1

to

42479 Word Display group 4 setting Same allocation as Display group 1

to

42497 Word Reserve

42498 Word Trend direction 0: Vertical, 1: Horizontal

42499 Word Channel index 0: CH No.disp., 1: Tag No.disp., 2: Unit Disp.

42500 Word Scale display 0: OFF, 1: ON

42501 Word Reserve

42502 Word

42503 Word Display group 2 setting2 Same allocation as Display group 1

to

42508 Word Display group 3 setting2 Same allocation as Display group 1

to

42513 Word Display group 4 setting2 Same allocation as Display group 1

to

42518 Word Reserve

42519 Word Reserve

42520 Word Reserve

42521 Word

42522 Word Display group 2 setting2 Same allocation as Display group 1

to

42526 Word Display group 3 setting2 Same allocation as Display group 1

to

42530 Word Display group 4 setting2 Same allocation as Display group 1

to

42534 Word Reserve

to Reserve

Memory contents Read-out data / Write-in data setting range Remarks

Display

name

Display

group 1

setting

(18

words)

Display

group 1

setting2

(5 words)

Display

group 1

setting3

(4 words)

Display No.10 0: None, 1 to 30: ch1 to 30

Display divided 1 to 20

Analog meter 0: Bar graph, 1: Analog meter

15th, 16th characters

- 28 -

Page 33

Register

No.

Data

type

42541 Word Totalize base time 0 to 1439 (0 to 1439min = 00:00 to 23:59)

42542 Word Totalize cycle 0 to 9 (Please refer to Table 10.)

42543 Word Weekly base day 0 to 6 (Please refer to Table 11.)

42544 Word Monthly base day 1 to 31 (1 to 31day)

42545 Word Dayly (time) start time 0 to 1439 (0 to 1439min = 00:00 to 23:59)

42546 Word Dayly (time) stop time 0 to 1439 (0 to 1439min = 00:00 to 23:59)

42547 Word External input 0 to 129 (Please refer to Table 8.)

42548 Word H-P, L-P timer cycle 1 to 32767 (1 to 32767min)

42549 Word AVG timer cycle 1 to 32767 (1 to 32767min)

42550 Word SUM timer cycle 1 to 32767 (1 to 32767min)

42551 Word Formula1 1st calculation (Please refer to Table 12.)

42552 Word argument1

42553 Word argument2

42554 Word Formula1 2nd calculation

42555 Word argument1

42556 Word argument2

42557 Word Formula1 3rd calculation

42558 Word argument1

42559 Word argument2

42560 Word Formula2 1st calculation

42561 Word argument1

42562 Word argument2

to

42584 Word Formula4 3rd calculation

42585 Word argument1

42586 Word

42587 Word Math channel 20 setting Same allocation as Channel 19

to

42623 Word Math channel 21 setting Same allocation as Channel 19

to

42659 Word Math channel 22 setting Same allocation as Channel 19

to

42695 Word Math channel 23 setting Same allocation as Channel 19

to

42731 Word Math channel 24 setting Same allocation as Channel 19

to

42767 Word Math channel 25 setting Same allocation as Channel 19

to

42803 Word Math channel 26 setting Same allocation as Channel 19

to

42839 Word Math channel 27 setting Same allocation as Channel 19

to

42875 Word Math channel 28 setting Same allocation as Channel 19

to

42911 Word Math channel 29 setting Same allocation as Channel 19

to

42947 Word Math channel 30 setting Same allocation as Channel 19

to

42983 Word Constant1 Value

42984 Word Dicimal point 0 to 4

to

43021 Word Constant20 Value

43022 Word Dicimal point 0 to 4

43023 Word Reserve

to Reserve

43032 Word Time setting Time set request 1: Time set request.(Automatically clear)

43033 Word Time setting Year 1 to 99 (2001 to 2099year)

43034 Word Month 1 to 12 (1 to 12month)

43035 Word Day 1 to 31 (1 to 31day)

43036 Word Hour 0 to 23 (0 to 23hour)

43037 Word Minute 0 to 59 (0 to 59minute)

43038 Word Reserve

43039 Word Reserve

43040 Word Refreshment cycle 0 to 19 (Please refer to Table 14.)

Memory contents Read-out data / Write-in data setting range Remarks

Math

CH 19

setting

(36

words)

argument2

-

32767 to 32767 (Please refer to Table 13.)

-

32767 to 32767 (Please refer to Table 13.)

Attention:

Don’t change the

time absolutely

during recording

and totalizing.

- 29 -

Page 34

Register

No.

Data

type

43041 Word Reserve

43042 Word LCD lights-out time 0 to 60 (0: ON all the time, 1 to 60: 1 to 60min)

43043 Word File division cycle 0 to 4 (Please refer to Table 15.)

43044 Word Memory full alarm 0 to 28 (0: None, 1 to 28: DO1 to 28)

43045 Word Record data format 0: Ascii, 1: Binary

43046 Word Target temperture

43047 Word Z value

43048 Word Decimal point 0 to 4 (Please refer to Table 16.)

43049 Word Reserve

43050 Word

43051 Word Battery alarm 0 to 28 (0: None, 1 to 28: DO1 to 28)

43052 Word Data format 0 to 4 (Please refer to Table 17.)

43053 Word File overwrite 0: OFF, 1: ON

43054 Word Display compression 0: 1/1, 1: 1/10, 2: 1/30, 3: 1/60

43055 Word Select language 0: English, 1: French

43056 Word Alarm hysteresis 0 to 10000 (0.00 to 100.00%)

43057 Word Alarm latch 0: OFF, 1: ON

43058 Word MODBUS Station No. 0 to 255 (0: Communication OFF)

43059 Word MODBUS baud rate 0: 9600bps, 1: 19200bps

43060 Word MODBUS parity 0: None, 1: Odd, 2: Even

43061 Word Configuration password 0 to 9999

43062 Word CF manager password 0 to 9999

43063 Word Record password 0 to 9999

43064 Word Security mode 0: Password, 1: Logon

43065 Word Reserve

43066 Word Reserve

43067 Word Trend back color 0: White, 1: Black

43068 Word Historical back color 0: White, 1: Black

to Reserve

43081 Byte Messege 1st, 2nd characters Set Message (32 characters) by the ASCII code.

43082 Byte 3rd, 4th characters

43083 Byte 5th, 6th characters

43084 Byte 7th, 8th characters

43085 Byte 9th, 10th characters

43086 Byte 11th, 12th characters

43087 Byte 13th, 14th characters

43088 Byte 15th, 16th characters

43089 Byte 17th, 18th characters

43090 Byte 19th, 20th characters

43091 Byte 21th, 22th characters

43092 Byte 23th, 24th characters

43093 Byte 25th, 26th characters

43094 Byte 27th, 28th characters

43095 Byte 29th, 30th characters

43096 Byte 31th, 32th characters

43097 Word Reserve

43098 Word Reserve

43099 Word Messege timing 0 to 2 (Please refer to Table 18.)

43100 Word Messege timing argument 1

43101 Word Messege timing argument 2

43102 Word

43103 Word Messege No.2 setting Same allocation as Message No. 1

to

43125 Word Messege No.3 setting Same allocation as Message No. 1

to

43147 Word Messege No.4 setting Same allocation as Message No. 1

to

43169 Word Messege No.5 setting Same allocation as Message No. 1

to

43191 Word Messege No.6 setting Same allocation as Message No. 1

to

43213 Word Messege No.7 setting Same allocation as Message No. 1

to

Memory contents Read-out data / Write-in data setting range Remarks

FValue calculation

Message

No.1

setting

(22

Word s)

Reserve

Reset temperature

-

32767 to 32767 (-3276.7 to 3276.7°C)

-

32767 to 32767 (-3276.7 to 3276.7°C)

-

32767 to 32767 (-3276.7 to 3276.7°C)

- 30 -

Page 35

Register

No.

Data

type

43235 Word Messege No.8 setting Same allocation as Message No. 1

to

43257 Word Messege No.9 setting Same allocation as Message No. 1

to

43279 Word Messege No.10 setting Same allocation as Message No. 1

to

43301 Byte 1st, 2nd characters Set original unit (7 characters) by the ASCII code.

43302 Byte 3rd, 4th characters

43303 Byte 5th, 6th characters

43304 Byte 7th, characters

43305 Byte Reserve

43306 Byte Reserve

43307 Byte

43308 Byte Original unit 2 setting Same allocation as Original unit 1

to

43315 Byte Original unit 3 setting Same allocation as Original unit 1

to

43322 Byte Original unit 4 setting Same allocation as Original unit 1

to

43329 Byte Original unit 5 setting Same allocation as Original unit 1

to

43336 Byte Original unit 6 setting Same allocation as Original unit 1

to

43343 Byte Original unit 7 setting Same allocation as Original unit 1

to

43350 Byte Original unit 8 setting Same allocation as Original unit 1

to

43357 Byte Original unit 9 setting Same allocation as Original unit 1

to

43364 Byte Original unit 10 setting Same allocation as Original unit 1

to

43371 Byte Original unit 11 setting Same allocation as Original unit 1

to

43378 Byte Original unit 12 setting Same allocation as Original unit 1

to

43385 Word

to

43496 Word DI 1 function 0 to 5 (Please refer to Table 19.)

43497 Word DI 2 function 0 to 5

43498 Word DI 3 function 0 to 5

43499 Word DI 4 function 0 to 5

43500 Word DI 5 function 0 to 5

43501 Word DI 6 function 0 to 5

43502 Word DI 7 function 0 to 5

43503 Word DI 8 function 0 to 5

43504 Word DI 9 function 0 to 5

43505 Word DI 10 function 0 to 5

43506 Word RCJ ON/OFF 0: OFF, 1: ON

43507 Word Reserve

43508 Word Reserve

43509 Word Reserve

43510 Word Front communication 0: OFF, 1: ON

43511 Word Rec.start adjust OFF 0: OFF, 1: ON

43512 Word Do not write

to Do not write

Memory contents Read-out data / Write-in data setting range Remarks

Original unit 1 setting

Reserve

Reserve

Reserve

- 31 -

Page 36

Register

No.

Data

type

44001 Byte 1st, 2nd characters Do not write

44002 Byte 3rd, 4th characters Do not write

44003 Byte 5th, 6th characters Do not write

44004 Byte 7th, 8th characters Do not write

44005 Byte 9th, 10th characters Do not write

44006 Byte 11th, 12th characters Do not write

44007 Byte 13th, 14th characters Do not write

44008 Byte 15th, 16th characters Do not write

44009 Byte 17th, 18th characters Do not write

44010 Byte 19th, 20th characters Do not write

44011 Byte 21th, 22th characters Do not write

44012 Byte 23th, 24th characters Do not write

44013 Byte 25th, 26th characters Do not write

44014 Byte 27th, 28th characters Do not write

44015 Byte 29th, 30th characters Do not write

44016 Byte

44017 Byte 1st, 2nd characters Do not write

44018 Byte 3rd, 4th characters Do not write

44019 Byte 5th, 6th characters Do not write

44020 Byte 7th, 8th characters Do not write

44021 Byte 9th, 10th characters Do not write

44022 Byte 11th, 12th characters Do not write

44023 Byte 13th, 14th characters Do not write

44024 Byte

44025 Word Do not write

to Do not write

Memory contents Read-out data / Write-in data setting range Remarks

PILC data

31th, 32th characters Do not write

Serial number

15th, 16th characters Do not write

Following register No. 45000 to 45500 will not be recorded in the main unit.

Register

No.

Data

type

45000 Word Register data request 1: Register data (Automatically clear)

45001 Word Reserve

45002 Word Fvalue calculation reset request 1: Fvalue reset (Automatically clear)

45003 Word Prohibiting the writing to the memory card 0: Writing permission, 1: Writing prohibition

45004 Bit Recorder control (Please refer to Table 20.)

45005 Bit Message request (Please refer to Table 21.)

45006 Word Totalize reset request 1: Totalize reset (Automatically clear)

45007 Word Alarm latch clear request 1: Alarm latch clear (Automatically clear)

45008 Word Do not write

to Do not write

45051 Bit Totalize reset request Channel 1 to 16 (Please refer to Table 22.)

45052 Bit of each channel Channel 17 to 30

45053 Word

to Word

45061 Word Communication input 1 : M01

45062 Word Communication input 2 : M02

45063 Word Communication input 3 : M03

45064 Word Communication input 4 : M04

45065 Word Communication input 5 : M05

45066 Word Communication input 6 : M06

45067 Word Communication input 7 : M07

45068 Word Communication input 8 : M08

45069 Word Communication input 9 : M09

45070 Word Communication input10 : M10

45071 Word Communication input11 : M11

45072 Word Communication input12 : M12

to Do not write

Memory contents Read-out data / Write-in data setting range Remarks

-

32767 to 32767

-

32767 to 32767

-

32767 to 32767

-

32767 to 32767

-

32767 to 32767

-

32767 to 32767

-

32767 to 32767

-

32767 to 32767

-

32767 to 32767

-

32767 to 32767

-

32767 to 32767

-

32767 to 32767

Reserve

Reserve

- 32 -

Page 37

The following addresses are recorded in the main unit.

Register

No.

Data

type

45501 Word Reserve

45502 Word E-mail function 0: OFF, 1. ON

45503 Word FTP server function 0: OFF, 1: ON

45504 Word FTP access control 0: OFF, 1: ON

45505 Word Web server function 0: OFF, 1: ON

45506 Word Reserve

45507 Word Reserve

45508 Word MODBUS TCP/IP function 0: OFF, 1. ON

45509 Word IP address 1st number 0 to 255

45510 Word 2nd number 0 to 255

45511 Word 3rd number 0 to 255

45512 Word 4th number 0 to 255

45513 Word Subnet mask 1st number 0 to 255

45514 Word 2nd number 0 to 255

45515 Word 3rd number 0 to 255

45516 Word 4th number 0 to 255

45517 Word Default gateway 1st number 0 to 255

45518 Word 2nd number 0 to 255

45519 Word 3rd number 0 to 255

45520 Word 4th number 0 to 255

45521 Word SMTP IP address 1st number 0 to 255

45522 Word 2nd number 0 to 255

45523 Word 3rd number 0 to 255

45524 Word 4th number 0 to 255

45525 Byte Sender’s mall address 1st, 2nd characters Set address (64 characters) by the ASCII code.

45526 Byte 3rd, 4th characters

45527 Byte 5th, 6th characters

45528 Byte 7th, 8th characters

45529 Byte 9th, 10th characters

45530 Byte 11th, 12th characters

45531 Byte 13th, 14th characters

45532 Byte 15th, 16th characters

45533 Byte 17th, 18th characters

45534 Byte 19th, 20th characters

45535 Byte 21th, 22th characters

45536 Byte 23th, 24th characters

45537 Byte 25th, 26th characters

45538 Byte 27th, 28th characters

45539 Byte 29th, 30th characters

45540 Byte 31th, 32th characters

45541 Byte 33th, 34th characters

45542 Byte 35th, 36th characters

45543 Byte 37th, 38th characters

45544 Byte 39th, 40th characters

45545 Byte 41th, 42th characters

45546 Byte 43th, 44th characters

45547 Byte 45th, 46th characters

45548 Byte 47th, 48th characters

45549 Byte 49th, 50th characters

45550 Byte 51th, 52th characters

45551 Byte 53th, 54th characters

45552 Byte 55th, 56th characters

45553 Byte 57th, 58th characters

45554 Byte 59th, 60th characters

45555 Byte 61th, 62th characters

45556 Byte 63th, 64th characters

45557 Byte Sender’s mail name 1st, 2nd characters Set name (32 characters) by the ASCII code.

45558 Byte 3rd, 4th characters

45559 Byte 5th, 6th characters

Memory contents Read-out data / Write-in data setting range Remarks

- 33 -

Page 38

Register

No.

Data

type

45560 Byte 7th, 8th characters

45561 Byte 9th, 10th characters

45562 Byte 11th, 12th characters

45563 Byte 13th, 14th characters

45564 Byte 15th, 16th characters

45565 Byte 17th, 18th characters

45566 Byte 19th, 20th characters

45567 Byte 21th, 22th characters

45568 Byte 23th, 24th characters

45569 Byte 25th, 26th characters

45570 Byte 27th, 28th characters

45571 Byte 29th, 30th characters

45572 Byte 31th, 32th characters

45573 Byte Receiver’s mail 1st, 2nd characters Set address (64 characters) by the ASCII code.

45574 Byte address 1 3rd, 4th characters

45575 Byte 5th, 6th characters

45576 Byte 7th, 8th characters

45577 Byte 9th, 10th characters

45578 Byte 11th, 12th characters

45579 Byte 13th, 14th characters

45580 Byte 15th, 16th characters

45581 Byte 17th, 18th characters

45582 Byte 19th, 20th characters

45583 Byte 21th, 22th characters

45584 Byte 23th, 24th characters

45585 Byte 25th, 26th characters

45586 Byte 27th, 28th characters

45587 Byte 29th, 30th characters

45588 Byte 31th, 32th characters

45589 Byte 33th, 34th characters

45590 Byte 35th, 36th characters

45591 Byte 37th, 38th characters

45592 Byte 39th, 40th characters

45593 Byte 41th, 42th characters

45594 Byte 43th, 44th characters

45595 Byte 45th, 46th characters

45596 Byte 47th, 48th characters

45597 Byte 49th, 50th characters

45598 Byte 51th, 52th characters

45599 Byte 53th, 54th characters

45600 Byte 55th, 56th characters

45601 Byte 57th, 58th characters

45602 Byte 59th, 60th characters

45603 Byte 61th, 62th characters

45604 Byte 63th, 64th characters

45605 Byte Receiver's mail address 2 Same allocation as Receiver's mail address 1

to

45637 Byte Receiver's mail address 3 Same allocation as Receiver's mail address 1

to

45669 Byte Receiver's mail address 4 Same allocation as Receiver's mail address 1

to

45701 Byte Receiver's mail address 5 Same allocation as Receiver's mail address 1

to

45733 Byte Receiver's mail address 6 Same allocation as Receiver's mail address 1

to

45765 Byte Receiver's mail address 7 Same allocation as Receiver's mail address 1

to

45797 Byte Receiver's mail address 8 Same allocation as Receiver's mail address 1

to

45829 Word Reserve

to Reserve

45901 Byte User1 User name 1st, 2nd characters Set name (16 characters) by the ASCII code.

45902 Byte setting 3rd, 4th characters

45903 Byte 5th, 6th characters

Memory contents Read-out data / Write-in data setting range Remarks

- 34 -

Page 39

Register

No.

Data

type

45904 Byte 7th, 8th characters

45905 Byte 9th, 10th characters

45906 Byte 11th, 12th characters

45907 Byte 13th, 14th characters

45908 Byte 15th, 16th characters

45909 Byte Password 1st, 2nd characters Set name (8 characters) by the ASCII code.

45910 Byte 3rd, 4th characters

45911 Byte 5th, 6th characters

45912 Byte 7th, 8th characters

45913 Word User level

45914 Word Reserve

45915 Byte User 2 setting Same allocation as User 1

to

45929 Byte User 3 setting Same allocation as User 1

to

45943 Byte User 4 setting Same allocation as User 1

to

45957 Byte User 5 setting Same allocation as User 1

to

45971 Byte User 6 setting Same allocation as User 1

to

45985 Byte User 7 setting Same allocation as User 1

to

45999 Byte User 8 setting Same allocation as User 1

to

46013 Word Reserve

to Reserve

46101 Byte E-mail Title 1st, 2nd characters Set title (32 characters) by the ASCII code.

46102 Byte trigger 1 3rd, 4th characters

46103 Byte setting 5th, 6th characters

46104 Byte 7th, 8th characters

46105 Byte 9th, 10th characters

46106 Byte 11th, 12th characters

46107 Byte 13th, 14th characters

46108 Byte 15th, 16th characters

46109 Byte 17th, 18th characters

46110 Byte 19th, 20th characters

46111 Byte 21th, 22th characters

46112 Byte 23th, 24th characters

46113 Byte 25th, 26th characters

46114 Byte 27th, 28th characters

46115 Byte 29th, 30th characters

46116 Byte 31th, 32th characters

46117 Byte Text 1 1st, 2nd characters Set text 1 (32 characters) by the ASCII code.

46118 Byte 3rd, 4th characters

46119 Byte 5th, 6th characters

46120 Byte 7th, 8th characters

46121 Byte 9th, 10th characters

46122 Byte 11th, 12th characters

46123 Byte 13th, 14th characters

46124 Byte 15th, 16th characters

46125 Byte 17th, 18th characters

46126 Byte 19th, 20th characters

46127 Byte 21th, 22th characters

46128 Byte 23th, 24th characters

46129 Byte 25th, 26th characters

46130 Byte 27th, 28th characters

46131 Byte 29th, 30th characters

46132 Byte 31th, 32th characters

46133 Byte Text 2 1st, 2nd characters Set text 2 (32 characters) by the ASCII code.

46134 Byte 3rd, 4th characters

46135 Byte 5th, 6th characters

46136 Byte 7th, 8th characters

46137 Byte 9th, 10th characters

Memory contents Read-out data / Write-in data setting range Remarks

0: Administrator, 1: Engineer, 2: Operator,

3: Guest

- 35 -

Page 40

Register

No.

Data

type

46138 Byte 11th, 12th characters

46139 Byte 13th, 14th characters

46140 Byte 15th, 16th characters

46141 Byte 17th, 18th characters

46142 Byte 19th, 20th characters

46143 Byte 21th, 22th characters

46144 Byte 23th, 24th characters

46145 Byte 25th, 26th characters

46146 Byte 27th, 28th characters

46147 Byte 29th, 30th characters

46148 Byte 31th, 32th characters

46149 Word Trigger timing (Please refer to Table 23.)

46150 Word Trigger timing argument 1

46151 Word Trigger timing argument 2

46152 Word PV value affixation 0: OFF, 1: ON

46153 Word Receiver's mail address No. (Please refer to Table 24.)

46154 Word Reserve

46155 Byte E-mail trigger 2 setting Same allocation as E-mail trigger 1

to

46209 Byte E-mail trigger 3 setting Same allocation as E-mail trigger 1

to

46263 Byte E-mail trigger 4 setting Same allocation as E-mail trigger 1

to

46317 Byte E-mail trigger 5 setting Same allocation as E-mail trigger 1

to

46371 Byte E-mail trigger 6 setting Same allocation as E-mail trigger 1

to

46425 Byte E-mail trigger 7 setting Same allocation as E-mail trigger 1

to

46479 Byte E-mail trigger 8 setting Same allocation as E-mail trigger 1

to

46533 Byte E-mail trigger 9 setting Same allocation as E-mail trigger 1

to

46587 Byte E-mail trigger 10 setting Same allocation as E-mail trigger 1

to

46641 Word Reserve

to Reserve

47000 Word Final address Reserve

Memory contents Read-out data / Write-in data setting range Remarks

- 36 -

Page 41

7.2.2 Word data [read-out only] : Function code [04H]

Register

No.

3xxxx

Data

type

30001 Bit System information (Please refer to Table 25.)

30002 Bit Reserve

30003 Bit DO information DO 1 to 16 (Please refer to Table 26.)

30004 Bit DO 17 to 28

30005 Bit Reserve

30006 Bit DI information (Please refer to Table 27.)

to Reserve

30086 Word Memory cord utilization 0 to 1000 (0.00 to 100.0%, 100.0% = Memory Full)

to Reserve

30093 Bit Channel 1 to 4 (Please refer to Table 28.)

30094 Bit Channel 5 to 8

30095 Bit Channel 9 to 12

30096 Bit Channel 13 to 16

30097 Bit Channel 17 to 20

30098 Bit Channel 21 to 24

30099 Bit Channel 25 to 28

30100 Bit

30101 Word Channel 1

30102 Word Channel 2

30103 Word Channel 3

to

30129 Word Channel 29

30130 Word

30131 Word Channel 1 0: Normal, 1: Burnout, 2: Over, 3: Under, 4: Error

30132 Word Channel 2 0: Normal, 1: Burnout, 2: Over, 3: Under, 4: Error

30133 Word Channel 3 0: Normal, 1: Burnout, 2: Over, 3: Under, 4: Error

to

30160 Word

30161 Long Totalizing value Channel 1

30162 Long Channel 1

30163 Long Channel 2

30164 Long Channel 2

to

30219 Long Channel 30

30220 Long Channel 30

30221 Long Totalizing start time Channel 1 Greenwich Time

30222 Long Channel 1

30223 Long Channel 2 Greenwich Time

30224 Long Channel 2

to

30279 Long Channel 30 Greenwich Time

30280 Long Channel 30

30281 Long Totalizing end time Channel 1 Greenwich Time

30282 Long Channel 1

30283 Long Channel 2 Greenwich Time

30284 Long Channel 2

to

30339 Long Channel 30 Greenwich Time

30340 Long Channel 30

30341 Long Previous totalized Channel 1

30342 Long value Channel 1

30343 Long Channel 2

30344 Long Channel 2

to

30399 Long Channel 30

30400 Long Channel 30

30401 Long Previous totalized Channel 1 Greenwich Time

30402 Long start time Channel 1

30403 Long Channel 2 Greenwich Time

30404 Long Channel 2

to

Memory contents Read-out data Remarks

Channel Alarm

information

Channel 29 to 30

-

32767 to 32767 (No decimal point)

-

32767 to 32767 (No decimal point)

-

Measured value

Channel 30

Channel status

Channel 30 0: Normal, 1: Burnout, 2: Over, 3: Under, 4: Error

32767 to 32767 (No decimal point)

-

32767 to 32767 (No decimal point)

-

32767 to 32767 (No decimal point)

-

999999999 to 999999999 (No decimal point)

-

999999999 to 999999999 (No decimal point)

-

999999999 to 999999999 (No decimal point)

-

999999999 to 999999999 (No decimal point)

-