Page 1

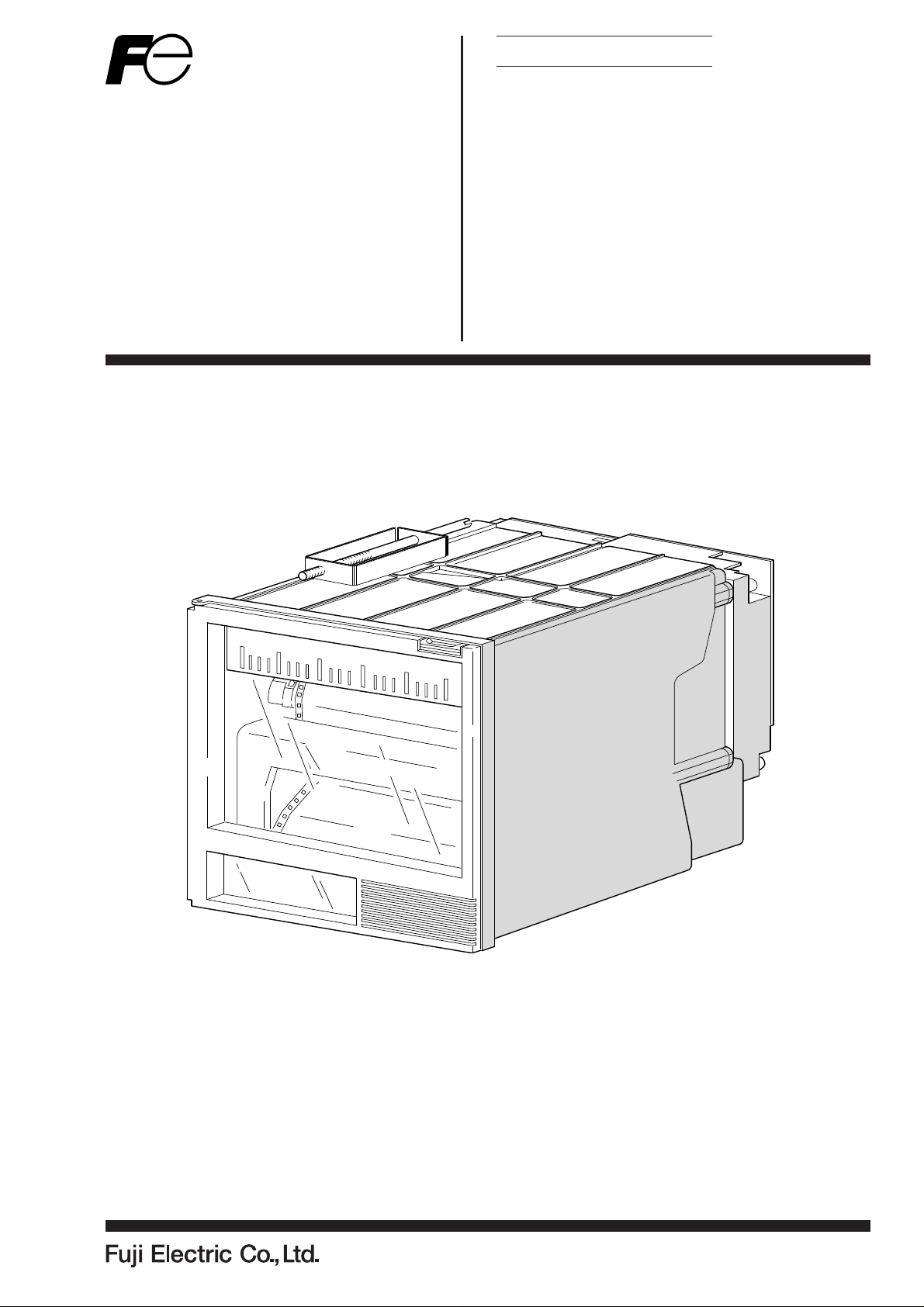

Instruction Manual

MICROJET RECORDER E

TYPE: PHE–2

INP-TN2PHEVd-E

Page 2

PREFACE

Congratulations on your purchase of Fuji Microjet Recorder (Type: PHE)

• Read this instruction manual carefully to ensure correct installation, operation and preparation.

Incorrect handling may lead to accidnt or injury.

• Failure to comply with the instructions contained in this manual may reduce the safety of the instrument.

• Specifications of this unit is subject to change without prior notice for improvement.

• Modification of this unit without permission is strictly prohibited.

Fuji will not bear any responsibility for a trouble caused by such a modification.

• This instruction manual should be kept by the person who is actually using the unit.

• After reading the manual, be sure to keep it at a place easy to access.

• This instruction manual should be delivered to the end user without fail.

Manufacturer : Fuji Electric Co., Ltd.

Type : Shown on nameplate of Microjet recorder

Date of manufacture : Shown on nameplate of Microjet recorder

Product nationality : Japan

Request

• It is prohibited to transfer part or all of the manual without Fuji's

permission.

• Description in this manual will be changed without prior notice.

© Fuji Electric Co., Ltd. 1999

Issued in November, 1999

Rev. 1st edition April, 2000

Rev. 2nd edition April, 2005

Rev. 3rd edition April, 2011

Rev. 4th edition May, 2014

- i -INP-TN2PHEV-E

Page 3

CAUTION ON SAFETY

First of all, read this “Caution on safety” before using the unit.

• The cautionary descriptions listed here contain important information about safety, so they should

always be observed. Those safety precautions are ranked 2 levels, DANGER and CAUTION.

Wrong handling may cause a dangerous situation, in which

DANGER

there is a risk of death or heavy injury.

Wrong handling may invite a dangerous situation, in which

there is a possibility of medium level trouble or slight injury

CAUTION

or only physical damage is predictable.

PROHIBITION

Caution on Installation

DANGER

CAUTION

Items which must not be done are noted.

• This unit is not an explosion-proof type. Do not use it in a place

with explosive gases to prevent explosion, fire or other serious

accident.

• For installation, select a place observing the operating conditions noted in the instruction manual. Installation at an unsuited

place may cause fall, trouble or malfunction.

• The unit must be installed correctly as shown in the instruction

manual. Incorrect installation may cause fall, trouble or malfunction.

• During installation work, keep the inside of the unit free from

entry of cable chips or other foreign objects as it may cause fire,

trouble or malfunction.

This unit is a component device used for instrumentation. It is

CAUTION

- ii - INP-TN2PHEV-E

mounted on a panel or in a rack.

• The unit conforms to EN61010-1 Safety Standards, and is designed for protection class I, overvoltage Category II and pollution degree 2, except the alarm output terminal (overvoltage category I).

• EMC conforms to EN50081-1 (1992) and EN50082-1 (1992),

(both used for housing areas), except that the noise level of the

power terminal is rated for Class A (used for commercial and

industrial areas).

• Input signals and communication interface should be of SELV

(safety separated from hazardous voltage).

Page 4

Caution of Wiring

DANGER

Caution on Maintenance

DANGER

• Wiring work must be performed as specified. If the unit is not

earthed, it would result in electric shocks or malfunction.

• Be sure to connect power source that matches the rating. Connection of incorrect rating of power source may lead to fire.

• Before starting wiring work, be sure to turn OFF the main power

to prevent electric shocks.

• Wiring materials to be used must meet the rating. Use of materials which do not withstand the rating may cause a fire accident.

• When disposing of the recording head, put it in a vinyl bag

and seal it to prevent the diffusion of ink. It should be handled

as an imcombustible object when disposing of it.

• Ink is harmful to human body. Observe the following emer-

gency treatments.

.

When ink gets in eyes, wash out for at least 5 minutes

immediately with much clean water, and ask your doctor

for treatment at once.

.

When ink gets on skin, wash out and clean skins with

soap and water.

.

When ink is breathed in, move to a clean place immediately. If necessary, ask your doctor for treatment at once.

• Do not touch the connector at the rear of the carriage mount-

ing the recording head to avoid the risk of electric shocks.

Caution on Use

DANGER

• If the fault or anomaly of the device may cause serious accident or troubles to other devices, externally install appropriate protective circuit to avoid accidents.

• This device does not have a power switch. The device has a

fuse, but you cannot replace it. Mount a fuse if necessary.

• When fuse is blown out, check and remove the cause of it,

and replace it with new one specified in the instruction manual.

Do not use any other fuse or short it, as it may cause electric

shocks or fire.

- iii -INP-TN2PHEV-E

Page 5

Caution on Use

r

DANGER

• The following safety symbols are used on PHE SERIES.

Caution (To avoid injury, operator must refe

to the explanation in the manual.)

Be careful of electric shock.

Protective ground terminal

Functional ground terminal (do not use this

terminal as a protective ground terminal)

Alternating current

Direct current

ON (power)

OFF (power)

- iv - INP-TN2PHEV-E

Page 6

CONTENTS

PREFACE .................................................................................................................................. i

CAUTION ON SAFETY..............................................................................................................ii

1. INTRODUCTION ............................................................................................................. 1-1

1.1 Microjet recorder......................................................................................................................1-1

1.2 Product check ...........................................................................................................................1-1

1.3 Check on type and specification............................................................................................... 1-2

2. NAMES AND FUNCTIONS OF PARTS........................................................................... 2-1

3. MOUNTING METHOD..................................................................................................... 3-1

3.1 Mounting location .................................................................................................................... 3-1

3.2 External dimensions and panel cut out dimensions .................................................................3-1

3.3 Method of mounting onto panel ...............................................................................................3-2

4. WIRING ........................................................................................................................... 4-1

4.1 Before wiring............................................................................................................................4-1

4.2 Caution on power source wiring .............................................................................................. 4-1

4.3 Connection to terminals ...........................................................................................................4-2

5. SET-UP ............................................................................................................................ 5-1

5.1 Loading chart paper..................................................................................................................5-1

5.2 Recording head installation (replacement)...............................................................................5-5

6. OPERATION AND ACTIONS .......................................................................................... 6-1

6.1 Before running the equipment:.................................................................................................6-1

6.2 Turning on power and status ....................................................................................................6-2

6.3 Printing the test pattern ............................................................................................................6-2

6.4 Operation in normal mode........................................................................................................6-3

6.5 Displays and print-outs on detection (cancellation) of alarms................................................. 6-4

6.6 Displays and print-outs on occurrent of burnt-out ................................................................... 6-4

6.7 Indication of over-range, under-range display and abnormal input display.............................6-5

6.8 Display of fault in recording head carriage.............................................................................. 6-5

6.9 Display of skipped parameter...................................................................................................6-5

Chapter 3,4 and chapter 8 should be observed for installation and mainte-

CAUTION

nance of the unit. So, it must be performed by qualified engineers.

- v -INP-TN2PHEV-E

Page 7

7. SETTING AND CHECKING PARAMETERS ................................................................... 7-1

7.1 Setting and Checking ............................................................................................................... 7-1

7.2 Outline of procedure for setting parameters............................................................................. 7-2

7.3 Key lock setting/release ............................................................................................................ 7-3

7.4 Setting the Chart Speed (main chart speed) ............................................................................. 7-4

7.5 How to list ................................................................................................................................ 7-5

7.6 How to print the scale (manually) ............................................................................................ 7-6

7.7 How to set ON/OFF of periodic print-out ................................................................................ 7-7

7.8 How to set ON/OFF of scale print-out ..................................................................................... 7-8

7.9 How to set the input filter ....................................................................................................... 7-10

7.10 How to set the alarm ............................................................................................................... 7-11

7.11 Selecting whether to start recording when turning on........................................................... 7-13

7.12 Setting of date and time.......................................................................................................... 7-14

8. MAINTENANCE - INSPECTION ..................................................................................... 8-1

8.1 Maintenance/inspection items .................................................................................................. 8-1

8.2 Battery replacement procedure................................................................................................. 8-2

9. ADJUSTMENT MODE ..................................................................................................... 9-1

9.1 How to adjust the printing and recording (adjust the backlash) ............................................... 9-1

9.2 How to position the analog trend recording (position the head zero/span) .............................. 9-2

9.3 How to set the PV shift ............................................................................................................. 9-3

9.4 How to set the sub chart speed ................................................................................................. 9-5

9.5 How to set the skip ................................................................................................................... 9-6

9.6 Head selection .......................................................................................................................... 9-7

9.7 How to calibrate measured value (ADJUST) ........................................................................... 9-8

10. TROUBLESHOOTING ................................................................................................. 10-1

11. EXAMPLES OF RECORDING AND PRINTING .......................................................... 11-1

11.1 Periodic print-out and scale print-out ..................................................................................... 11-1

11.2 Digital print-out (Instantaneous values) ................................................................................. 11-2

11.3 Parameter listing..................................................................................................................... 11-2

11.4 Test pattern ............................................................................................................................. 11-3

11.5 Scale print-outs (manual print-outs)....................................................................................... 11-3

11.6 Alarm print-outs ..................................................................................................................... 11-4

11.7 Burn-out print-out .................................................................................................................. 11-4

11.8 Record start mark ................................................................................................................... 11-4

11.9 Chart speed change mark ....................................................................................................... 11-4

12. SPECIFICATION .......................................................................................................... 12-1

APPENDIX 1. MOUNTING OF PHE OPTIONAL UNITS ...................................................... A-1

APPENDIX 2. SYSTEM PARAMETER SETTING ................................................................. B-1

- vi - INP-TN2PHEV-E

Page 8

1. INTRODUCTION

We thank you for purchasing Microjet Recorder PHE.

The instruction manual describes installation, operation, maintenance, etc. of Microjet Recorder. Read

it carefully before use.

1.1 Microjet recorder

① This recorder (100mm wide) is used to record up to 6 points of input signals from a thermocouple,

resistance bulb and DC voltage.

② Analog trend data and digital print data are color recorded clearly and quickly.

③ Analog trend data can be recorded continuously or intermittently (see Item 1.3 “Check on type and

specification”).

④ Besides recording measured values, chart paper feed speed, measurement range, etc. can be printed

as standard functions.

1.2 Product check

Upon receiving the unit, check the appearance and accessories to make sure that they are not damages.

Also, check that the accessories are supplied correctly.

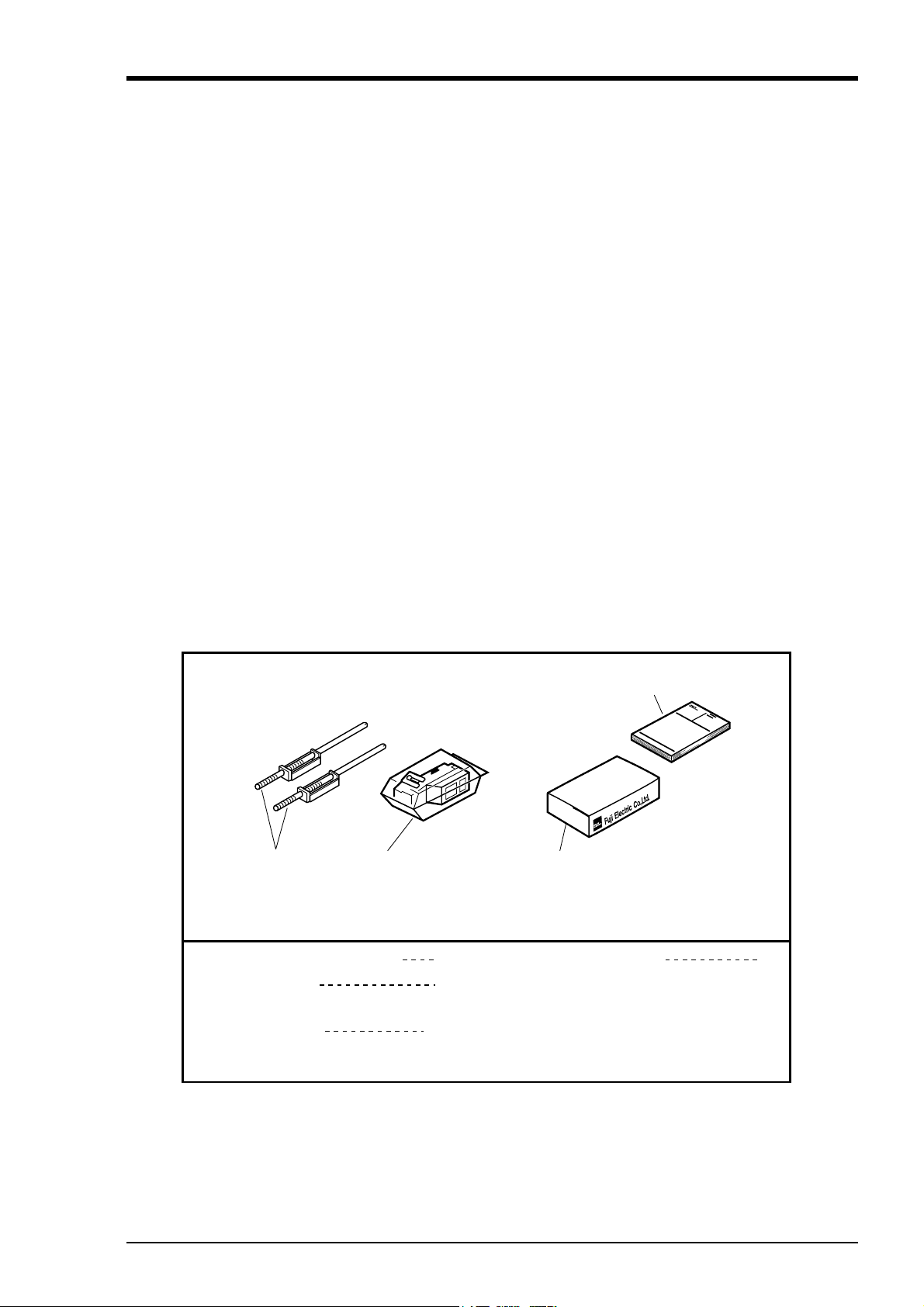

Check on accessories

The unit comes with the accessories shown in Fig. 1-1. Please check that they are all there.

④ Instruction Manual

取

扱

説

明

書

① Panel-mounting

attachments

② Recording head, with

cloth for absorbing ink

(Keep the ink blotting cloth so as not to be lost.)

① Panel-mounting attachments

② Recording head

with cloth for absorbing ink

③ Recording paper

(The standard recording paper No. is

PEX00DL1-5000B)

2

1

1 pack

富

士

電

機

株

式

会

社

③ Recording paper

④ Instruction Manual 1

Fig. 1-1 Accessories

1 - 1INP-TN2PHEV-E

Page 9

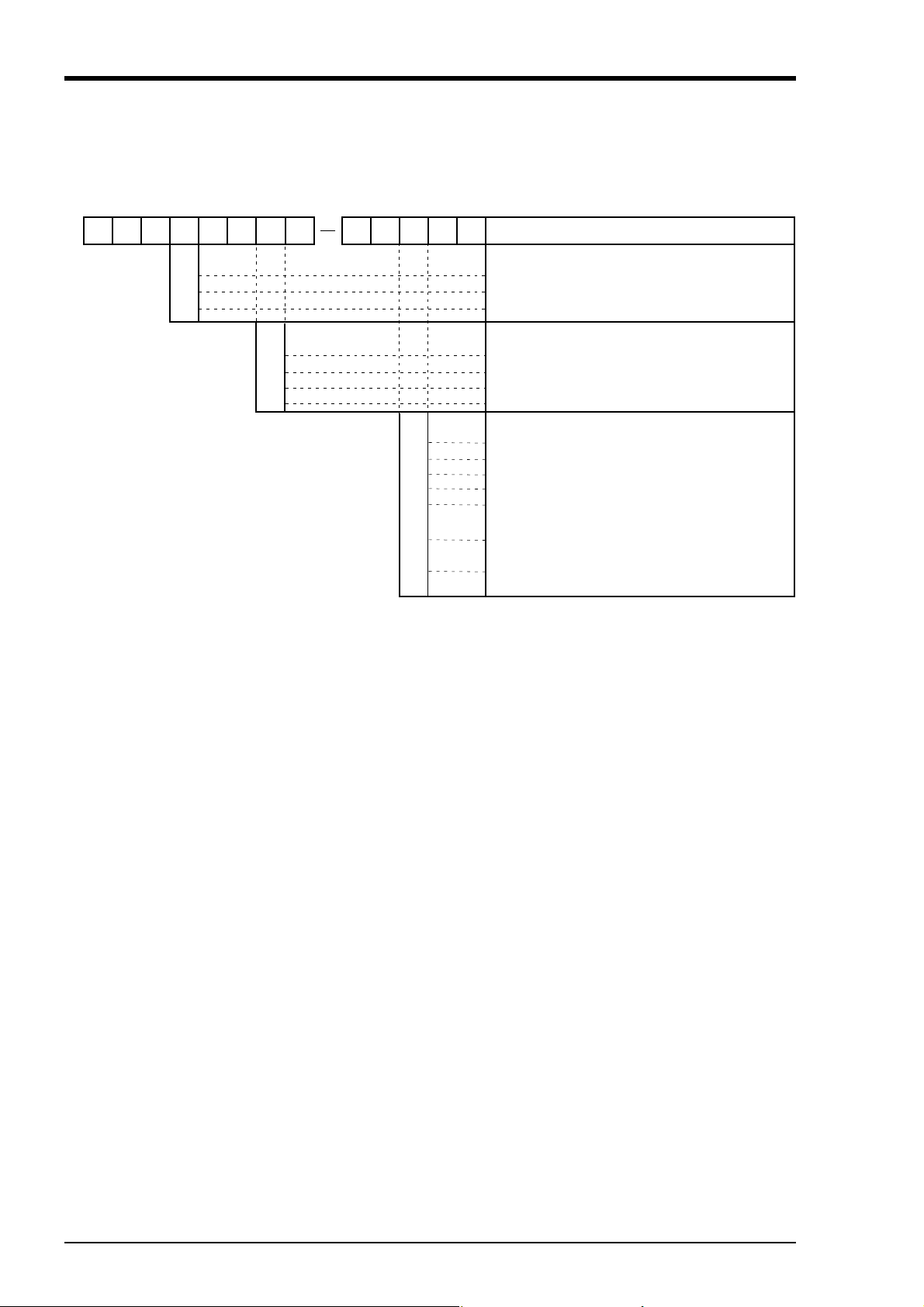

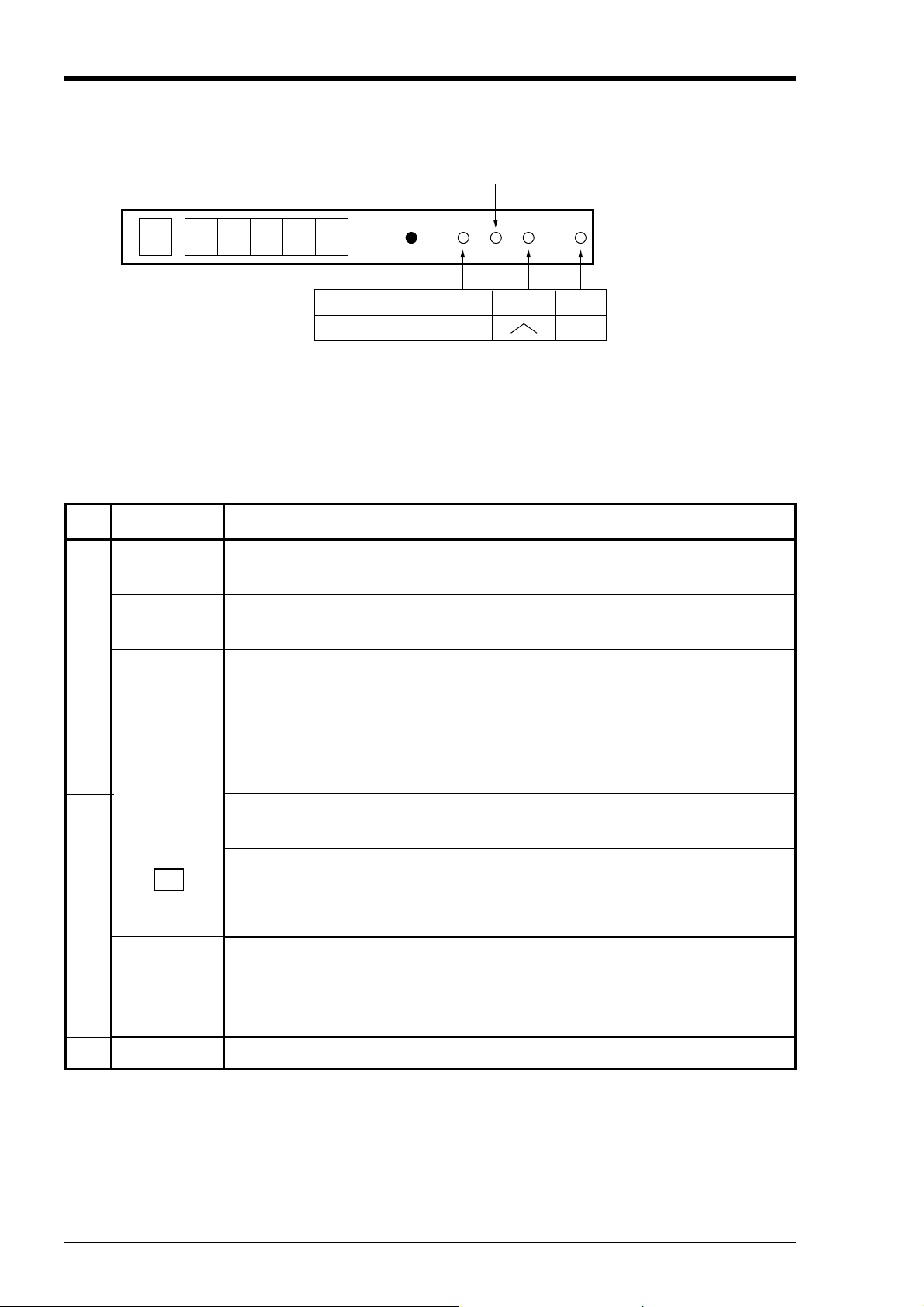

1.3 Check on type and specification

12345678 9

PHE 00 2

1

2

9

1

2

3

4

Input : Universal (Programmable)

Range : Field settable (Programmable)

10 11 12 13

VVV E

0

1

2

3

A

B

C

Recording points

1 continuous recording

2 continuous recording

6 intermittent recording

Power supply · Temperature Unit

100 to 120VAC 50/60Hz °C

200 to 240VAC 50/60Hz °C

100 to 120VAC 50/60Hz °F

200 to 240VAC 50/60Hz °F

Alarm output/external control input (1 point)

Without

2 points alarm output (1 continuous only)

4 points alarm output (2 continuous only)

6 points alarm output (6-intermittent only)

2 points alarm output/External control

4 points alarm output/External control

6 points alarm output/External control

Description

(1 continuous only)

(2 continuous only)

(6-intermittent only)

Note) 1. Initial set before delivery is ;

• Thermocouple K type 0 to 1200°C

2. Shunt resistor (10Ω±0.1%) should be ordered separately

for current input.

Shunt Resistor : Ordering code PHZT1101

Note) Items to specify when ordering except model : PHE □00

1. Code symbols (according to above table)

2. Recording range (scale) and unit in case of DC voltage

and DC current input.

For 2 continuous type, recording range and unit should

be specified for each channel 1 and channel 2.

3. Recording range should be specified with 3 or more

effective figures.

exp. 0 to 100, 0.0 to 10.0, 0.00 to 1.00

Note) Change of kinds of input signal

When changing the kinds of input signal, some adjustments

may become necessary. For adjustments, refer to Appendix, page B-6.

1 - 2 INP-TN2PHEV-E

Page 10

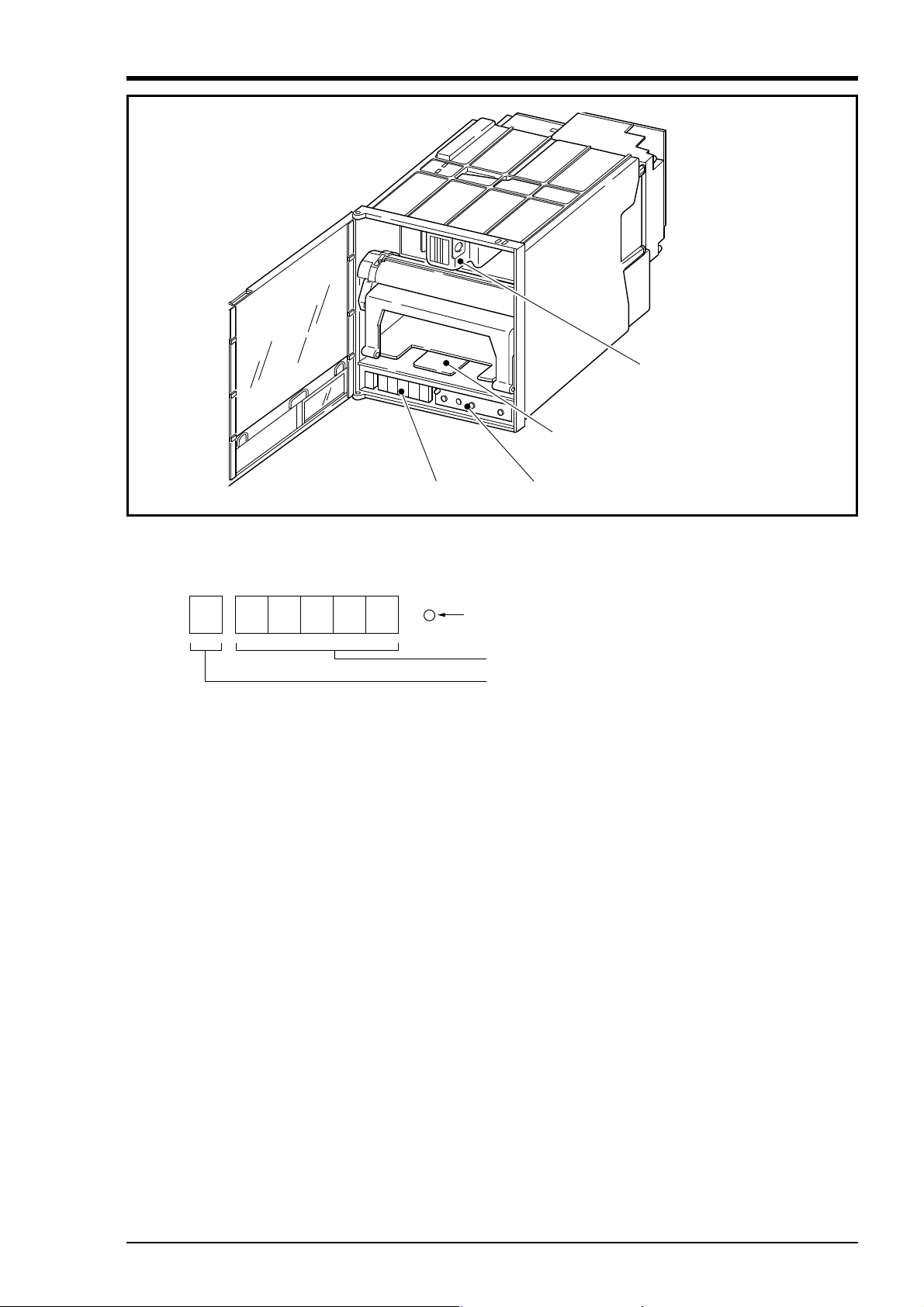

2. NAMES AND FUNCTIONS OF PARTS

Display unit

er

d.

③Paper feed unit drawout lev

②Recording head

①

(1) Display unit

Time, measurement data, set values and comments are displayed.

④Function key board

Under recording Lamp (LED) ON

Measured value and set value are displaye

Channel is displayed.

(2) Recording head

Used for analog trend recording and digital printing. (Recording head is not mounted in the

recorder prior delivery. It should be mounted referring to Item 5.2)

(3) Paper feed unit drawout lever

When setting (replacing) chart papaer, press down the drawout lever and the paper feed unit will be

drawn out. If it is not drawn out automatically, pull out the paper feed unit by hand while pressing

down the lever.

2 - 1INP-TN2PHEV-E

Page 11

(4) Function key board

Used for setting or confirming parameters and for operating the recorder.

Reset switch

DSPNormal mode

Setting mode

・Normal mode : Measured value or the states of alarm of each channel is displayed. This

mode is started at power ON.

・Setting mode : This mode is used for setting chart speed or alarm.

Name of key

REC

(record)

FEED

(feed)

DSP

(display)

Normal mode

Recording start/stop function key. Recording is started at the first press of the key

and stops at the second press.

Chart paper fast feed key

Feed speed becomes fast by pressing the key for more than 3 seconds.

1. Used for changing display data . The following 2 functions are selected at

each press of the key.

(1) Data of all channels are displayed in order, except for the skip channel.

(2) Display only of the data of specific channels.

SEL ENT

FEED REC

Function

ENT

(entry)

∧

(up)

Setting mode

SEL

(select)

Reset switch

2. Used when shifting from normal mode to setting mode (press the key for more

than 3 seconds)

Used to register set data and to start or stop list printing.

Used to change set data. Chart paper fast feed is effected during list printing.

1. Used to read parameters in order in setting mode. This key can not be used

during list printing.

2. Used when shifting from setting mode to normal mode (press the key for more

than 3 seconds)

Used to reset the recorder (The operation is the same as that at power ON/OFF.)

2 - 2 INP-TN2PHEV-E

Page 12

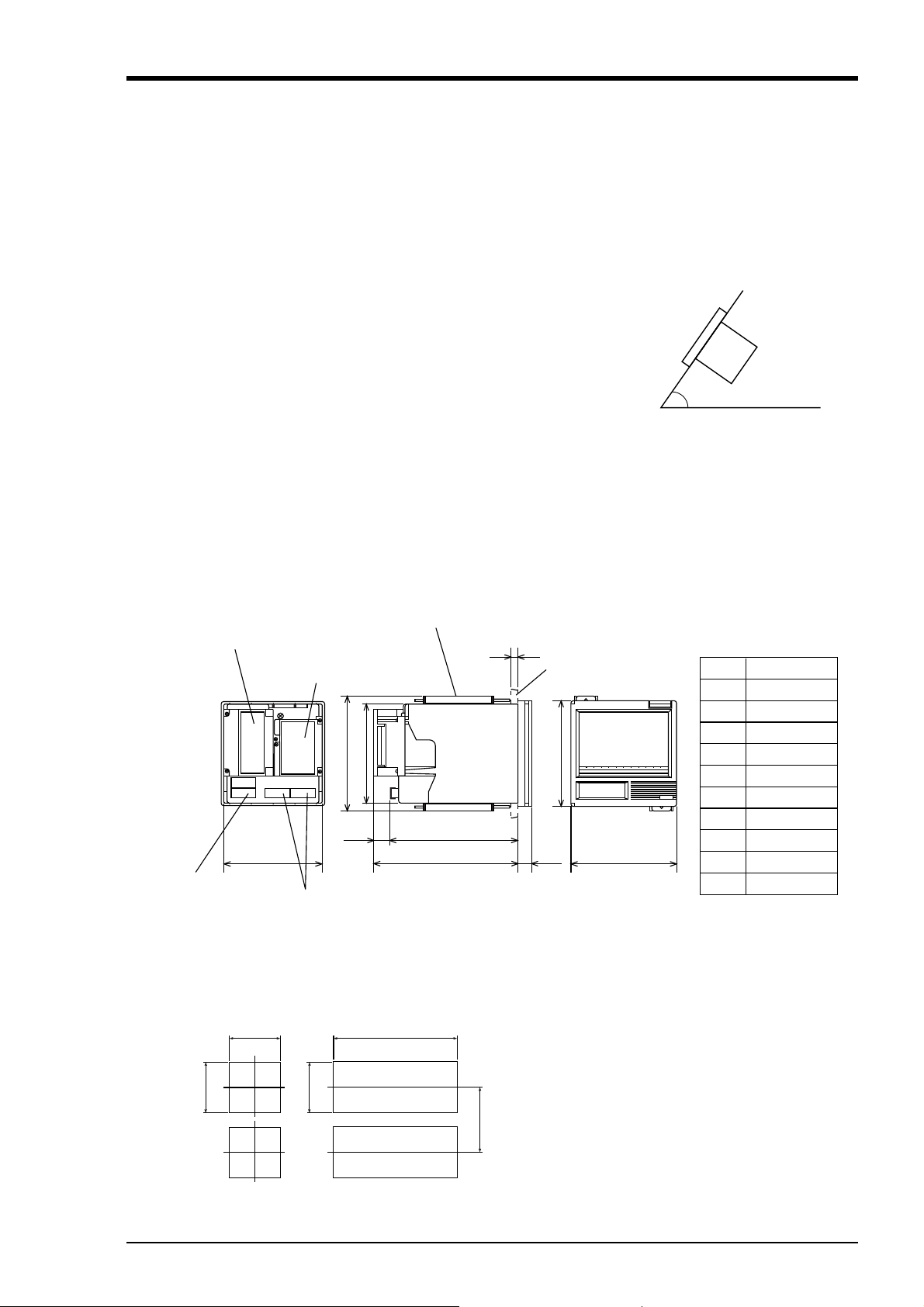

3. MOUNTING METHOD

P

F

g

P

This unit is designed to be panel mounted.

3.1 Mounting location

Select the following location for mounting the unit.

(1) A place that is not subject to vibration or shock.

(2) A place where there is no corrosive gas.

(3) A place that is subject to little temperature variation and is close to

normal temperature (23°C)

(4) A place that is not struck directly by strong radiant heat.

(5) As humidity affects the ink and recording paper, select a place that

is in the range 45 to 80% RH.

(6) Mount the unit horizontally, with no tilt to the left or right.

(The forward tilt should be 0° but the unit may be inclined 0 to 30°

rearwards.)

(7) A place where you can operate the power switch (or the circuit

breaker) of the device without difficulty.

∠α

α=60to90°

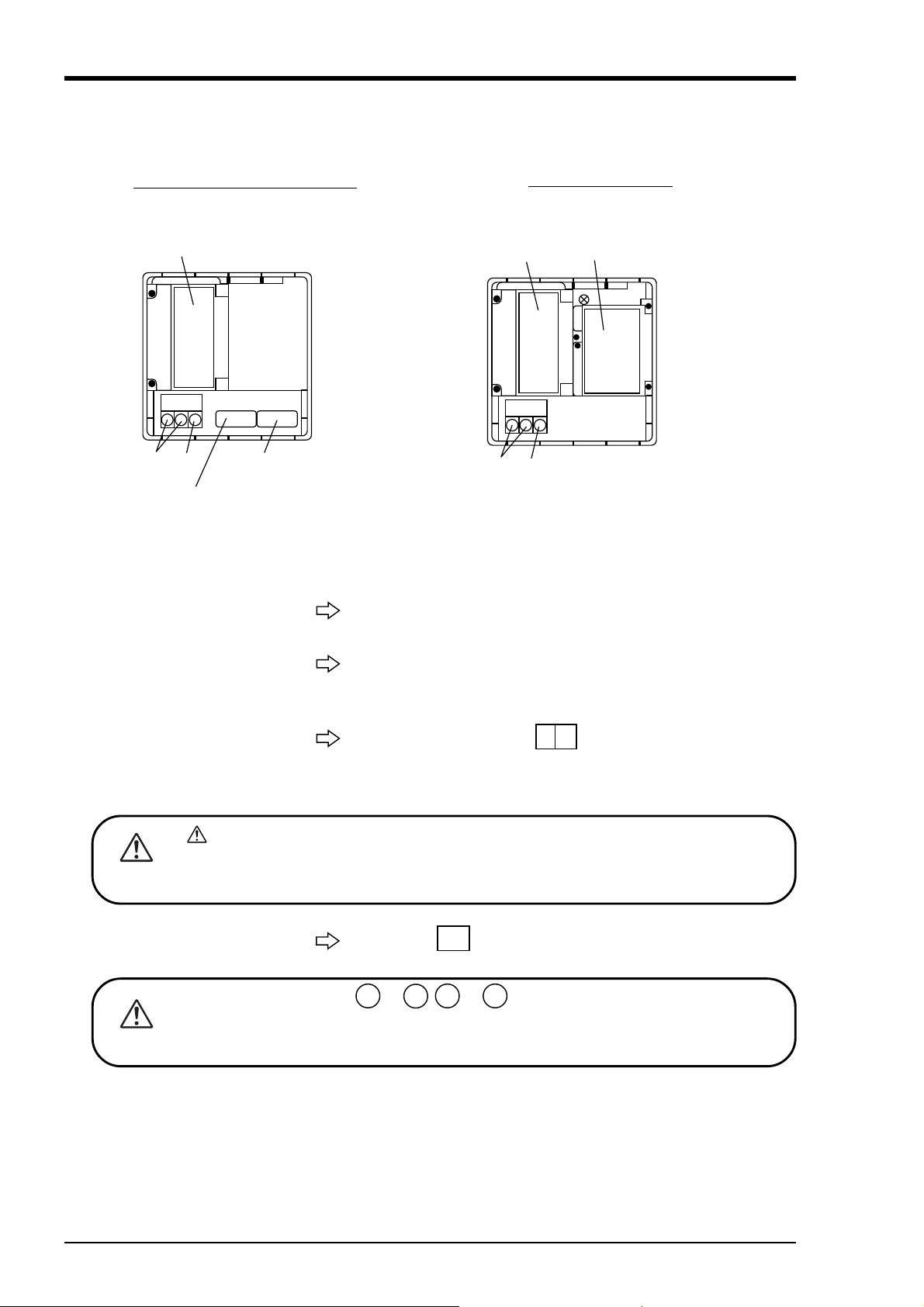

3.2 External dimensions and panel cut out dimensions (unit: mm)

Mounting attachment

Alarm external control terminal (option)

Input terminal (for 6 dot)

161

136.5

22 175

136.4 144

ower supply terminal

Input terminal (for 1, 2 continuous)

197

ANEL CUTOUT

or single unit mounting For left/right tight fit mountin

+1.5

137

0

+1.5

0

137

+1.5

0

137

+1.5

L

0

2≦t≦30

t

Panel

144

19

Number of

units

Mass : Continuous type Approx. 1.3kg

(without alarm terminal)

Approx. 1.5kg

(with alarm terminal)

Intermittent type Approx. 1.5kg

(without alarm terminal)

Approx. 1.7kg

(with alarm terminal)

175Min

Power consumption :

Approx. 13VA (100V AC, without option)

Approx. 15VA (100V AC, with all options)

2

3

4

5

6

7

8

9

10

n

+ 1.5

L

0 (mm)

282

426

570

714

858

1002

1146

1290

1434

(144×n)−6

3 - 1INP-TN2PHEV-E

Page 13

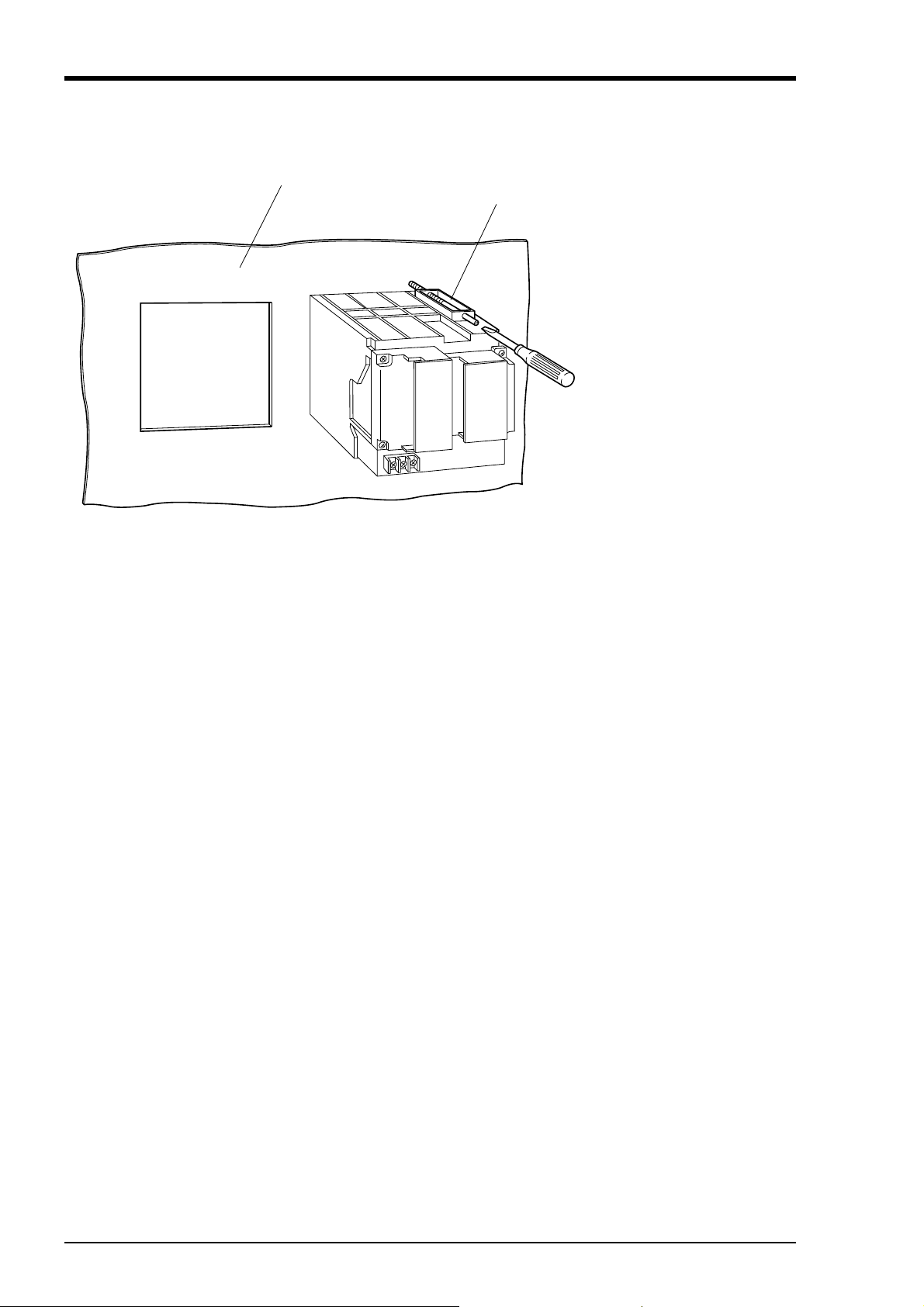

3.3 Method of mounting onto panel

Panel

Screw

• Using the supplied mounting

fixture, tighten the upper and

lower screws until the panel is

fixed.

• The panel to be used should

be more than 2mm thick.

3 - 2 INP-TN2PHEV-E

Page 14

4. WIRING

D

R

C

N

4.1 Before wiring

① For thermocouple input, be sure to use a compensated lead wire.

② Input signal cables should be wired separately as far as possible (30cm or more) from power lines

and high-voltage lines to minimize the effect of inductive noise. Shielded cables should preferably

be used. In this case, the shield braids should be earthed at one point.

Notes

(1) At the completion of wiring of the input terminals, be sure

to close the rear cover to ensure the compensation of reference contact when thermocouple input is used.

(2) For connection of lead wires to terminals, use of sleeve-

insulated clamping terminals (for M4 screws) is recommended.

4.2 Caution on power source wiring

This device has a power fuse, but it cannot be replaced. Mount an external fuse if

necessary.

AUTIO

① When connecting power cable and earth cable to terminals, be sure to use crimp style terminals

with insulated sleeves (M4 screw).

② For power cable connection, be sure to use 600V vinyl insulated cable or equivalent.

③ A switch (or a circuit-breaker) must be included in the installation.

④ A switch (or a circuit-breaker) must be suitably located and easily reached.

⑤ A switch (or a circuit-breaker) must be marked as the disconnecting device for this equipment.

⑥ Supply wiring shall be prepared by installers in accordance with national regulations.

ANGE

Recommended fuse rating: 250 V AC, T1A or equivalent

・ Before making a wiring work, be sure to turn OFF the main power to prevent

the risk of electric shocks. After wiring, be sure to close the cover.

・ Wiring materials to be used must meet the rating. Use of materials which do

not withstand the rating may cause a fire accident.

・ Wring work must be performed as specified. If the unit is not earthed, it

would result in electric shocks or malfunction.

4 - 1INP-TN2PHEV-E

Page 15

4.3 Connection to terminals

1)

For 2 continuous (channel 2)

②

For 6 dot (channel 1 to 6)

C

N

C

N

1, 2 continuous recording

④③

①

① Input terminal

①For 1, 2 continuous (channel

Connect signal cable for each channel.

6 dot recording_

①

②

④③

② Alarm/external control unit

(option)

③ Power terminal

mark on the power terminal indicates caution for electric shock. The voltage

AUTIO

applied on power terminal after wiring is 100 to 120 V AC or 200 to 240 V. Be sure

to put the cover on the power terminal after wiring to avoid electric shock.

④ Earth terminal

Alarm output terminals ( 11 to 16 , 21 to 26 ) are of overvoltage category I. Other

terminals (input signals, communication interface) are for SELV signals (safety sepa-

AUTIO

rated from hazardous voltage).

Connect the alarm signal output and external control signal input (for alarms 1 to 6, external control).

Connect power cable to L N terminal. Power source to be

connected should be free from noise .

(Code symbol : 100 to 120V AC or 200 to 240 V AC, 50/60 Hz)

Connect to PE terminal (Class-3, less than 10 Ω).

4 - 2 INP-TN2PHEV-E

Page 16

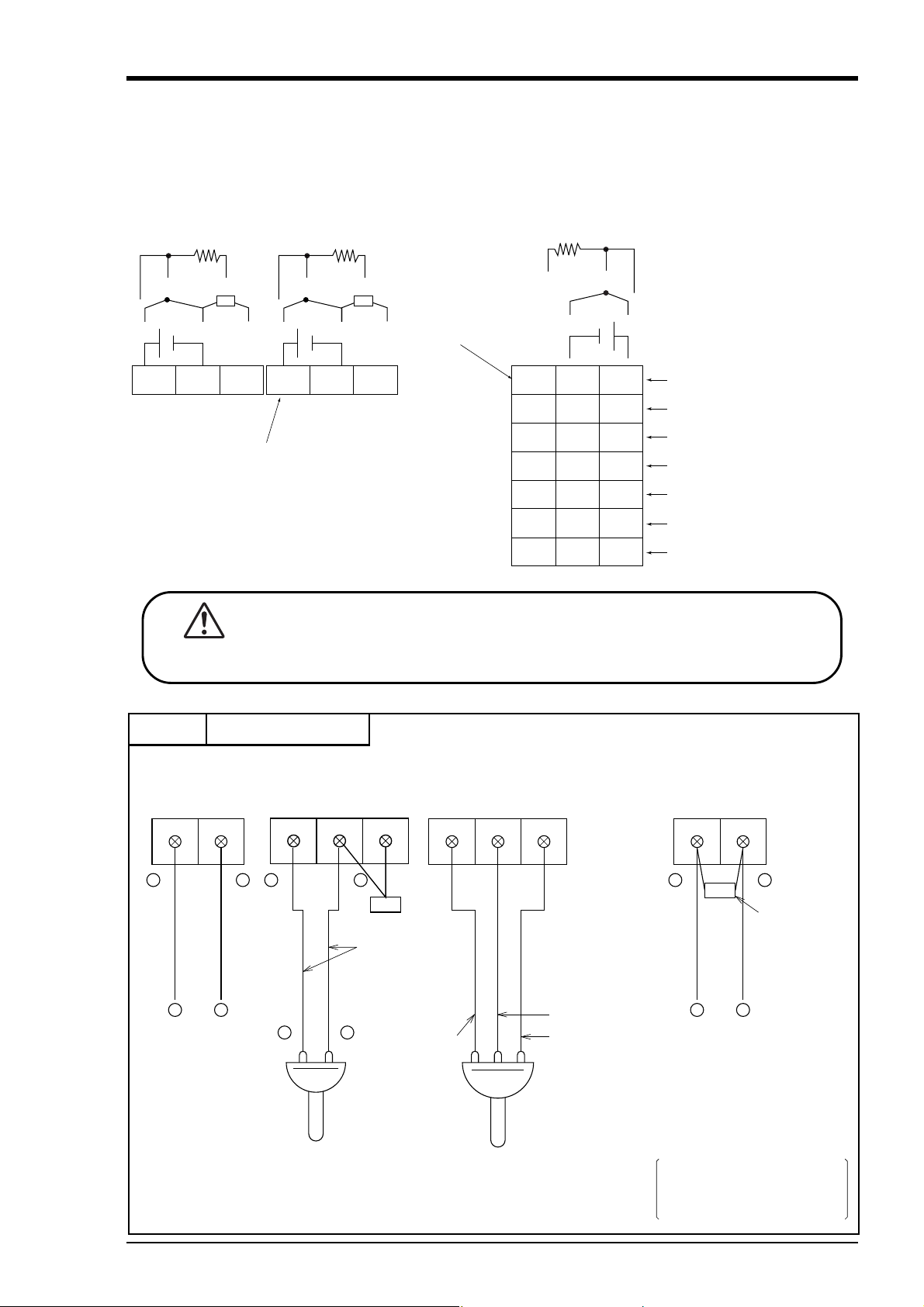

(1) Connection of input terminals

)

+

D

R

① Input terminal No. is determined for each channel.

② Connect input terminals according to the relation between the number of points of input signal and

channel shown in Code Symbols (see Item 1.3).

[For 1, 2 continuous] [For 6 dot]

Bb

RCJ module RCJ module

21 22 23

2 continuous

ANGE

ABbA

− −+

Terminal No.

11 12 13 Input 1

1 continuous

Terminal No.

ABb

131211

232221

333231

434241

535251

636261

737271

Resistance bulb (RTD

+−

Thermocouple (Tc)

DC voltage (V)

Input 2

Input 3

Input 4

Input 5

Input 6

NC

・ Before starting wiring work, be sure to turn OFF the main power to prevent

the risk of electric shocks.

Example

Input terminal wiring

DC voltage input Thermocouple input

11

12

+

11 11

12−13 12 13 11

+

−

RCJ module

Compensating

leads

+

−

DC votlage input

+

−

Thermocouple

Note : Avoid using thermocouple

input with wiring parallel

to other instruments.

<1, 2 continuous>

Resistance bulb input DC current input

bB A

Black (b)

White (B)

Red (A)

+

+

DC current input

Example : 10Ω ±0.1% shunt

Resistance bulb

In this case, ±500mV

input range is available.

12

−

Shunt

resistance

−

resistance is used for

4 to 20mA and 10 to

50mA input.

4 - 3INP-TN2PHEV-E

Page 17

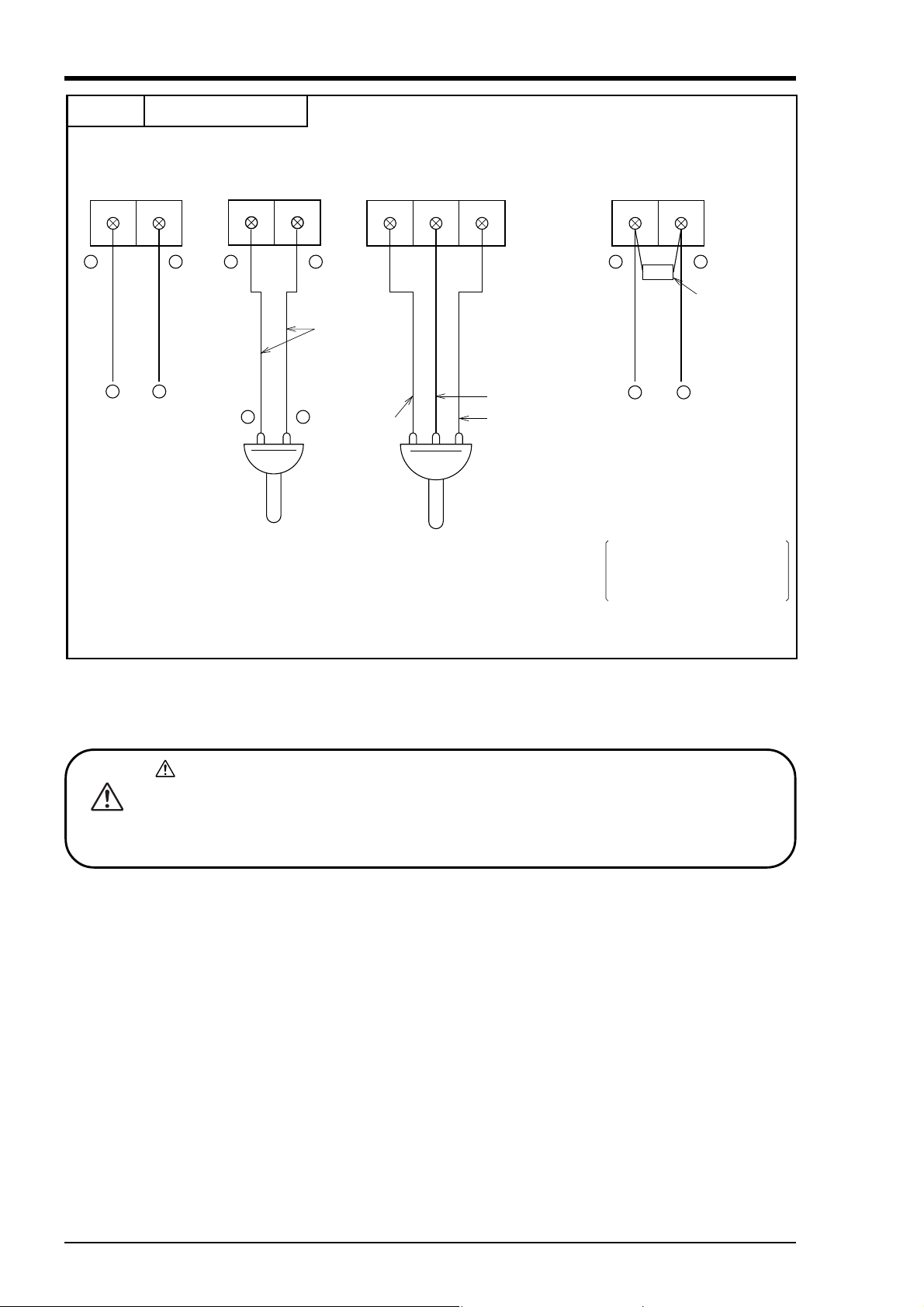

Example

C

N

Input terminal wiring

<6 dot>

DC voltage input Thermocouple input

12+11

−

12 1311 12 11 12 11

−

+

Compensating

leads

+

−

DC votlage input

−

+

Thermocouple

Note : Avoid using thermocouple

input with wiring parallel

to other instruments.

Resistance bulb input DC current input

AB b

Red (A)

White (B)

Black (b)

−

−

DC current input

Example : 10Ω ±0.1% shunt

resistance is used for

Resistance bulb

4 to 20mA and 10 to

50mA input.

Note : The line between channels

is not insulated only at

In this case, ±500mV

input range is available.

input from resistance bulb.

Be sure to use an insulated

type resistance bulb input unit.

+

Shunt

resistance

+

AUTIO

mark on the input terminal indicates caution for electric shock. Put a terminal cover on

after wiring to avoid electric shock. Use the sensor or equipment with basic insulation or

supplementary insulation to connect to the input terminal.

DC voltage/current input signal should be separated from hazardous voltage.

4 - 4 INP-TN2PHEV-E

Page 18

(2) Alarm output/remote control unit (option)

n

D

R

C

N

About alarm outputs :

① Alarm setting (2 points) is provided for each input channel. Alarm output is option and selected

from among 2 points, 4 points and 6 points.

② When an alarm is generated, the relevant terminals are shorted.

1a contact output : Relay contact capacity 240V AC/3A, 30V DC/3A (resistive load)

③ Alarm 1 to 6 corresponds to DO output No. 1 to 6 on the alarm setting panel. For details, refer to

the alarm setting method under Item 7.10.

11 21

Alarm 1

Note : If lamps are used on the outside, insert a resistor to pre-

12 22

13 23

14 24

15 25

16 26

Alarm 2

Alarm 3

Alarm 4

Alarm 5

Alarm 6

vent surge current.

Also, if relays or solenoids are used, insert elements for

contact protection (diodes, surge killers, etc.).

External control unit

① This unit has a function “Chart speed selection” using contact signals from the outside of the

recorder.

② Wiring

17 27 (DI) Chart speed selection Sub-chart speed at short,

and main chart speed at ope

Note 1) The external control unit is not insulated and should be used with a relay connected to the

outside.

External contact capacity : 12V DC/0.05A, 1a contact

Note 2) Recording start/stop operation is selected by setting sub-chart speed to 0 mm/h.

For details, refer to the sub-chart speed under Item 9.4.

mark on the terminal of alarm output/external control unit indicates caution for

electric shock. Be sure to put the terminal cover on after wiring to avoid electric

AUTIO

shock. Use the equipment with basic insulation or supplementary insulation to connect to the terminal of alarm output/external control unit.

・ Before starting wiring work, be sure to turn OFF the main power to prevent

the risk of electric shocks.

ANGE

4 - 5INP-TN2PHEV-E

Page 19

(3) Caution on connection of input signal through barrier

A) Thermocouple input and resistance bulb input.

Perform "Calibration of measured value" with the input connected to the barrier recorder because

the barrier internal resistance is added and causes an error in the measured value.

For the calibration method, refer to Item 9.7.

B) When using Fuji Zener Barrier (PWZ), a power source 100V AC line (100 to 120V AC) should

be used to ensure safe operation of the unit.

4 - 6 INP-TN2PHEV-E

Page 20

5. SET-UP

C

A

5.1 Loading chart paper

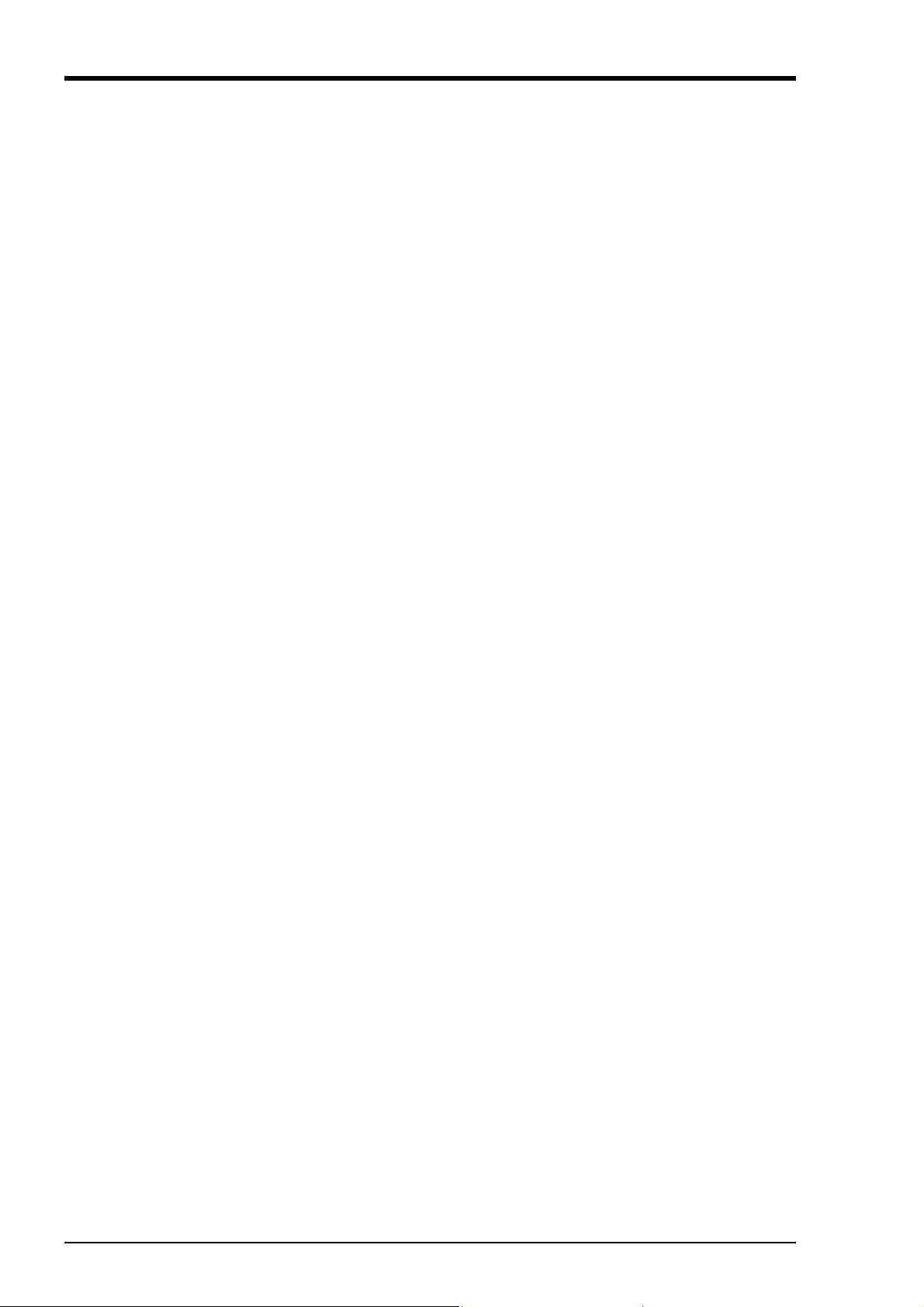

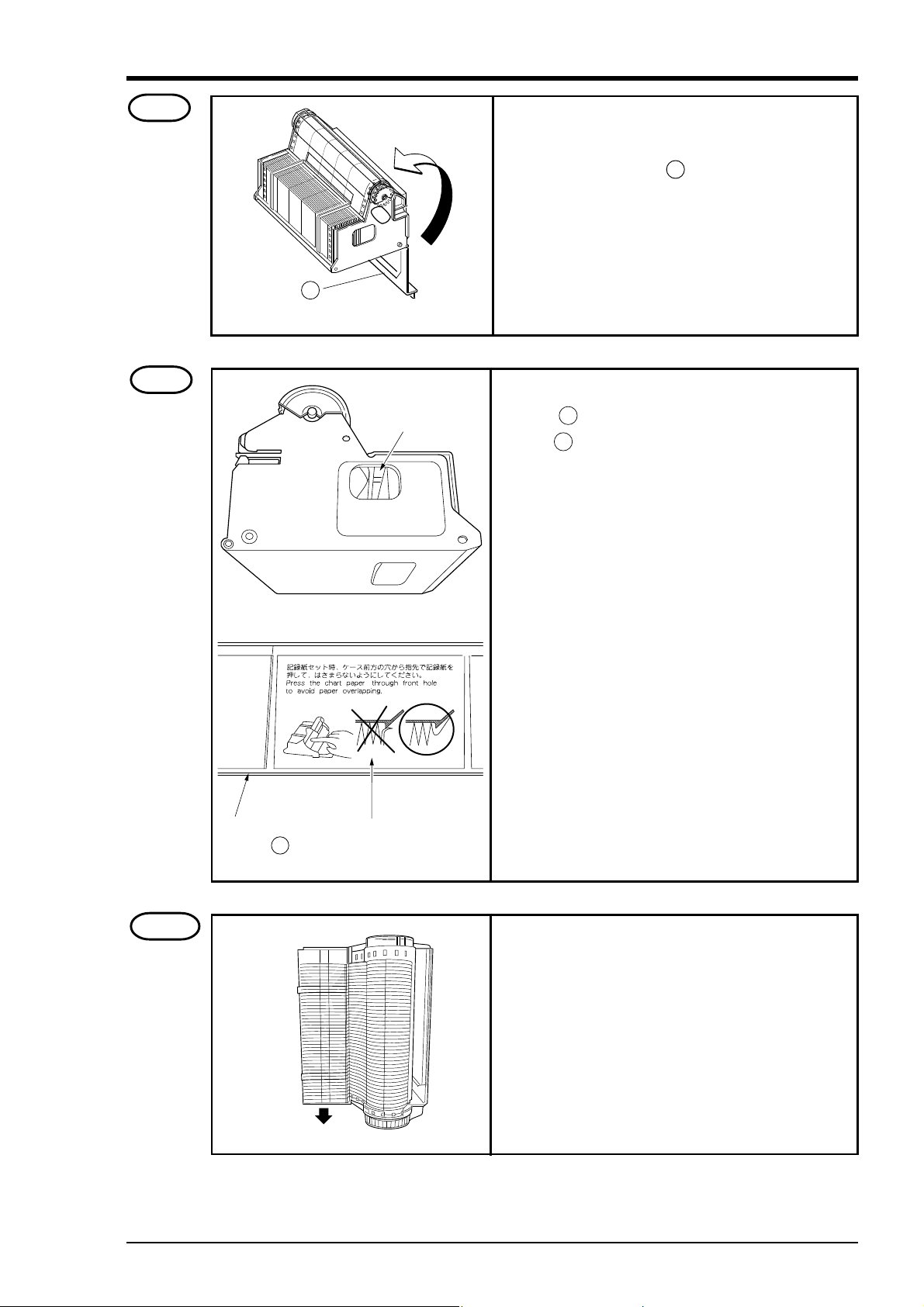

Step 1

Step 2

Prepare chart paper.

Loosen both ends of the chart paper thoroughly to

prevent sheets from being fed together.

Open the front door and press down the paper feed

unit drawout lever.

The paper feed unit will be drawn out.

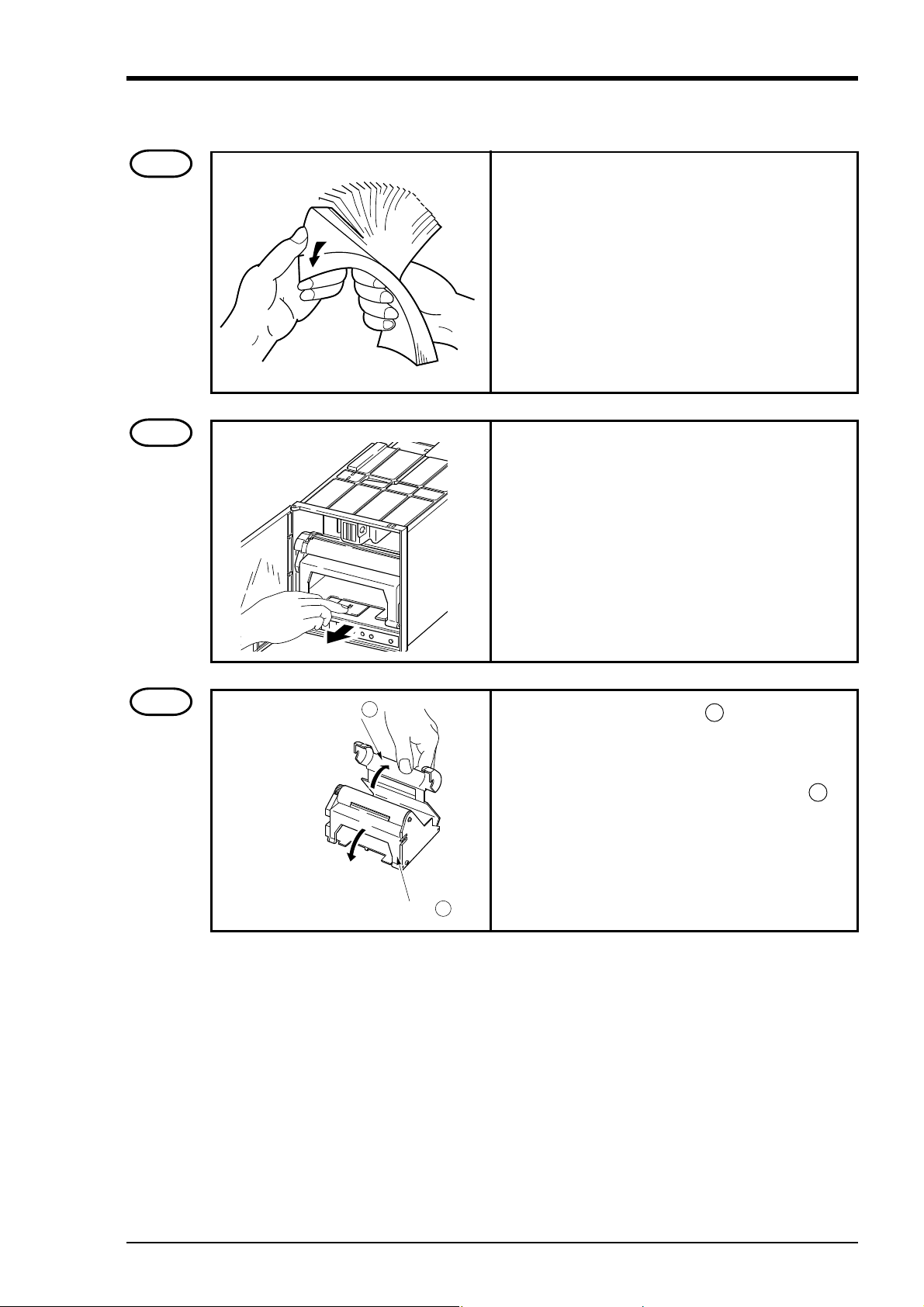

Step 3

hart paper retainer B

Hold the chart paper retainer B and open it backward.

Also, hold and open the chart paper retainer A .

Chart paper retainer

5 - 1INP-TN2PHEV-E

Page 21

C

r

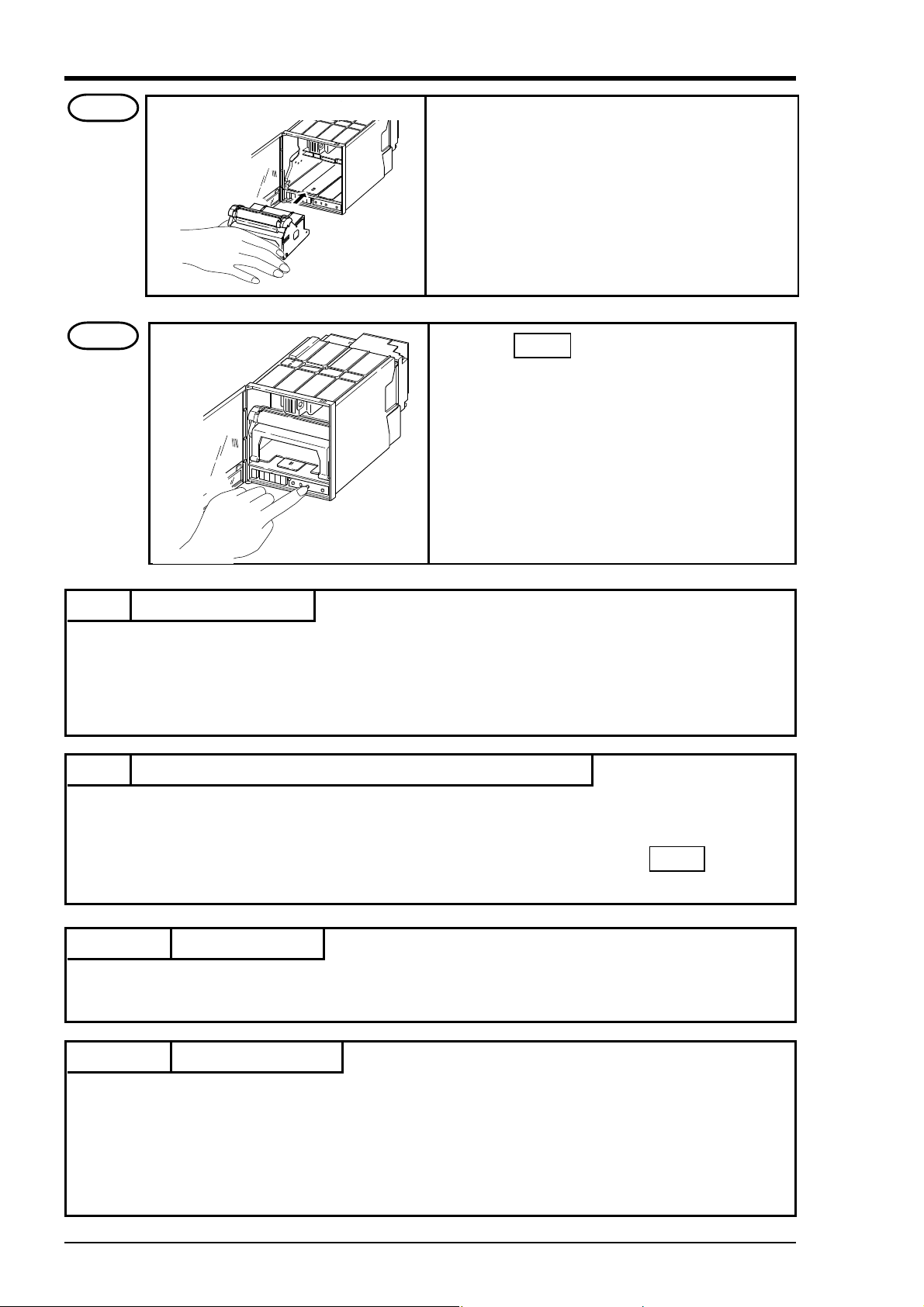

Step 4

hart paper

etainter B

Chart paper

Paper feed unit

Chart paper

retainter A

Set chart paper in the chart paper retainer B as

illustrated.

Step 5

Step 6

Align the perforations of the chart paper with the

pins.

Pin

Close the chart paper retainer B . (The chart paper

is set vertically).

Chart paper retainter B

Step 7

Turn clockwise the gear of the roller unit with hand

and check that the chart paper shifts forward.

Gear

5 - 2 INP-TN2PHEV-E

Page 22

C

r

r

es

Step 8

Transfer the chart paper that has been forwarded

into the storage of the paper feed unit. Then close

the chart paper retainer A .

hart paper

etainter A

Step 9

Chart paper

retainter B

Check the chart pape

through this hole.

Caution in setting

a chart paper

As shown by the caution display on the chart paper

retainer B , if paper is caught in the chart paper

retainer B , paper jam may result.

As shown by the figure at left, check through the

holes on the left and the right side of the paper feed

unit that the chart paper is not caught in the retainer.

Step 10

Side provided with long hol

The chart paper is provided with long holes and short

holes. Gather the chart paper in the storage to the

side provided with short holes as illustrated on the

left.

Gather the

chart paper

Side provided

with short holes

5 - 3INP-TN2PHEV-E

Page 23

Step 11

Mount the paper feed unit in the recorder. At this

time, check that it is properly locked in position.

Step 12

Press the FEED key and check that the chart

paper is fed out smoothly.

(Feed out about 2 folds of paper.)

<If the paper is not fed out smoothly, go through

the procedure from Step 2 again.>

Note 1 Selection of chart paper

The chart paper greatly affects the quality of the printed recording and it is also related to problems such

as paper jamming, etc.

Please be sure to use the pure-quality chart paper specified us.

Chart paper type: PEX00DL1-5000B (50 equal divisions, no time lines).

Note 2 Use of the recorder after it has been left unused for a long time

If the recorder is left unused for a long time with chart paper still in the main unit, the paper 'packs down'

and if the recorder is used straightway there can be problems of paper jamming, etc.

If you use the equipment after it has been left unused for a long time, first press the FEED key to feed

out 2 to 3 folds of the paper.

Reference 1 Chart paper length

The chart paper is approximately 15m long. This permits about 31 days continuous print-out at a chart

speed of 20mm/h.

Reference 2 Chart paper end mark

The remainder of chart paper is indicated by numerals on the right of paper (unit : 10cm). When it

becomes small, a red band will appear on the right to indicate that the chart paper needs to be replaced

with new one.

(Note) The recorder is not provided with a chart paper end sensor. When chart paper is used out, stop

recording or replace the chart paper with new one.

5 - 4 INP-TN2PHEV-E

Page 24

5.2 Recording head installation (replacement)

S

The recording head is a combination of a head and ink.

When ink is used out or trouble arises with the head, it can easily be replaced.

Use the recording head carefully observing the “Caution” noted in the later paragraph.

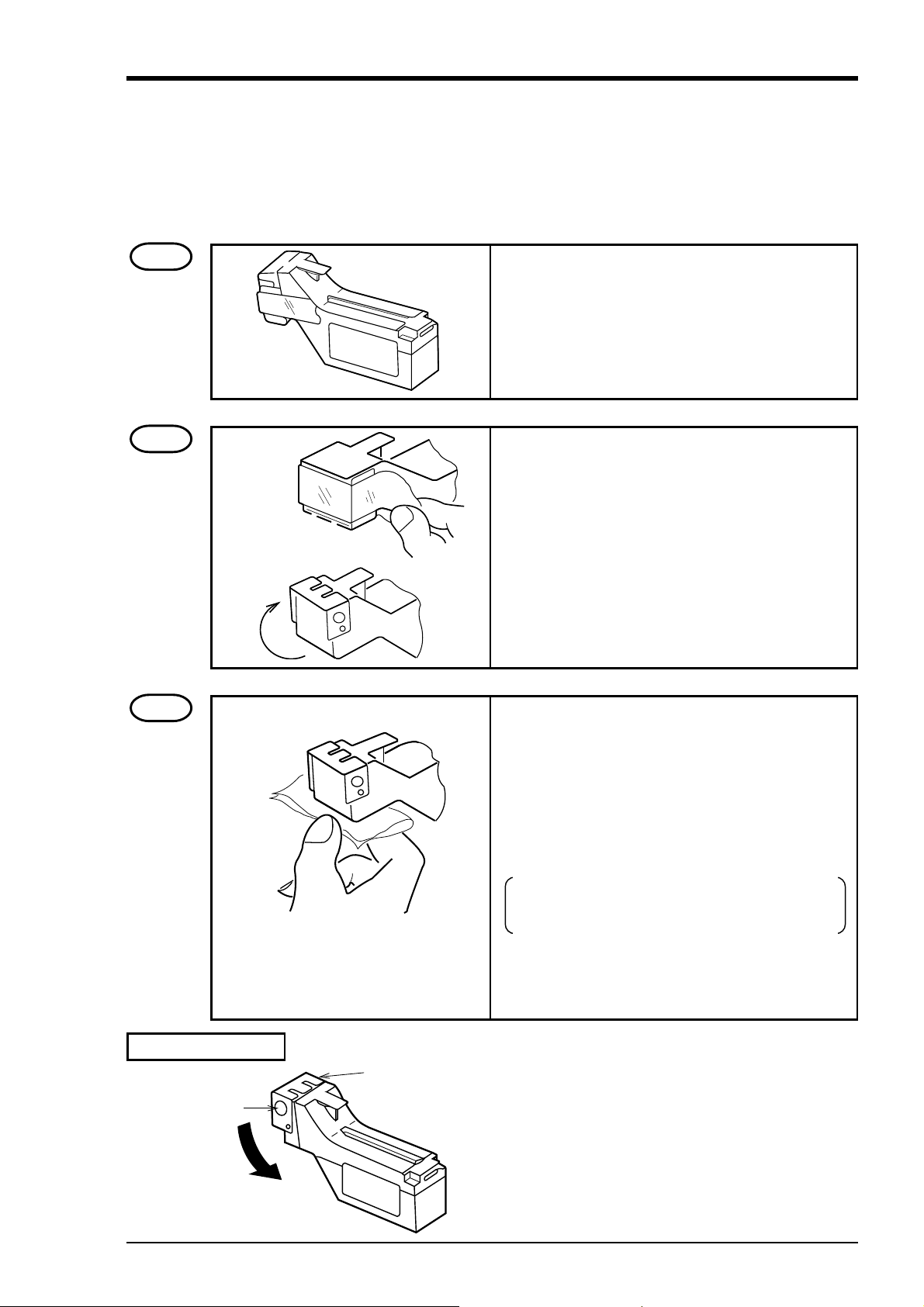

Step 1

Step 2

Get the recording head ready by taking it out of its

aluminium pack.

Tear the tape.

Open the cap by turning it in the direction indicated

by the arrow.

(If the head is not going to be used for a long time,

close the cap back in its original position.)

The cap is integral with the head unit. Turn it about

180° until it stops against the top of the head.

Step 3

How to close the cap

Cap

topper

• Lightly attach the supplied cloth to the nozzle

(ink ejecting side) to such up the ink. For the

standard head, check to make sure that 4-color

ink, blue, red, yellow and black, are soaked into

the cloth (for the 2-color head, 2 colors of ink are

soaked).

First press the cloth against the surface for 2 to

3 second; if the 4 colors ooze out, it is OK.

Note) Do not use any cloth other than the supplied

one. Also, do not rub the nozzle with the

cloth.

• Turn the cap in the direction indicated by the arrow and press it firmly until it is retained by the

stopper.

• Ink may leak out if the cap is not properly in place.

5 - 5INP-TN2PHEV-E

Page 25

Step 4

R

C

N

• Press the REC key. Operate the recorder after it

has been set in recording stop mode.

• Open the front door and press down the paper

feed unit drawout lever.

The paper feed unit will be drawn out.

Step 5

Step 6

ecording head

Nozzle cariage

• Hold the recording head horizontally, line it up

with the carriage in the main unit, slide it in

slowly and press it firmly until it does not go in

any further.

• Take care not to bang the nozzle surface of the

head. Also, avoid touching the nozzle surface with

your hand.

Do not touch the connector at the rear

AUTIO

of the carriage to avoid the risk of minor electric shocks.

・Set the paper feed unit in its original position.

The above completes installation of the recording head.

The recording head is a consumable part. When the built-in ink is used out, replace the head with

new one.

It comes in 2 types, one is for the 1, 2 continuous recording (PHZH2002) and another for the 6 dot

recording (PHZH1002). Choose the type of the head according to the recording mode of the recorder.

5 - 6 INP-TN2PHEV-E

Page 26

Recording head replacement

Draw out the recording head in the manner that is opposite to what is described in Step 5 of the

recording head setting procedure, and replace it with a new recording head.

Always carry out the following procedure after replacing a recording head.

(1) Test pattern print-out

Print out a test pattern to check that normal recording is possible. See Section 6.3 for the way of

printing out a test pattern.

(2) Adjustment of analog trend recording positions

Referring to Section 9.2, readjust the zero and span on the recording paper.

5 - 7INP-TN2PHEV-E

Page 27

Precautions in handling recording heads

D

Handling recording heads

• Do not knock or shake recording heads as this can cause faults.

• The inks are not harmful but they are v ery dif ficult to remove if they adhere to the skin or

ANGER

to clothes, so handle heads carefully in order to avoid staining. Also, do not disassemble

them.

• If, by accident, it happens that ink gets into your eyes, wash thoroughly with water as an

emergency measure and then immediately consult a specialist doctor.

• When the recording head is empty of ink, it should be disposed of as a incombustible

object or returned to our office for reuse (recycling).

Note 1 If recording is halted and the recorder is not used for a long time

Carry out the following in order to prevent jamming and drying-up of the ink.

Remove the recording head from the main unit, make absolutely sure the cap is closed properly and store the head in a cool, dark place (average temperature 5 to 30°C).

If the head is left installed in the recorder:

Do not switch off the power to the recorder and do not close the cap.

* Periodically, there is an automatic discharge of ink to prevent drying-up.

Leave the recording paper in place in the recorder.

If it is not possible to keep the power switched on, make sure that the cap is closed.

Draw out the paper feed unit using the recording head setting method Step 4 .

Open the indicator and tighten the cap.

Note 2 At the start of use of a recording head

If you are starting to use a new recording head or if the recorder has been left unused for a long time,

always wipe the head's nozzle surface lightly with the accessory cloth and check that the ink oozes out

properly into the cloth. (See Step 3.)

Also, after normal recording is possible. See Section 6.3 for the way of printing out a test pattern.

When the working environment is 15°C or less, perform print-out of "test pattern" after period of several minutes has elapsed since the recording head was mounted. (The recording head has a built-in

heater.)

Note 3 Storage of recording heads

When they are delivered, recording heads are in aluminium packs.

If you are not going to use a head straight-away, leave it sealed and store it in a cool, dark place with an

average temperature of 5 to 30°C.

5 - 8 INP-TN2PHEV-E

Page 28

Note 4 Shipping of recording head

• Do not ship the unit recording head after the aluminum pack was opened up. If it is necessary to ship

the unit recording head under avoidable circumstances, be sure to close the cap, and ship it as con-

tained in a boxboard in the state where vibration and impack are eased using cushioning materials.

• Always close the cap if you are transporting a head while it is still installed in the recorder main

unit.

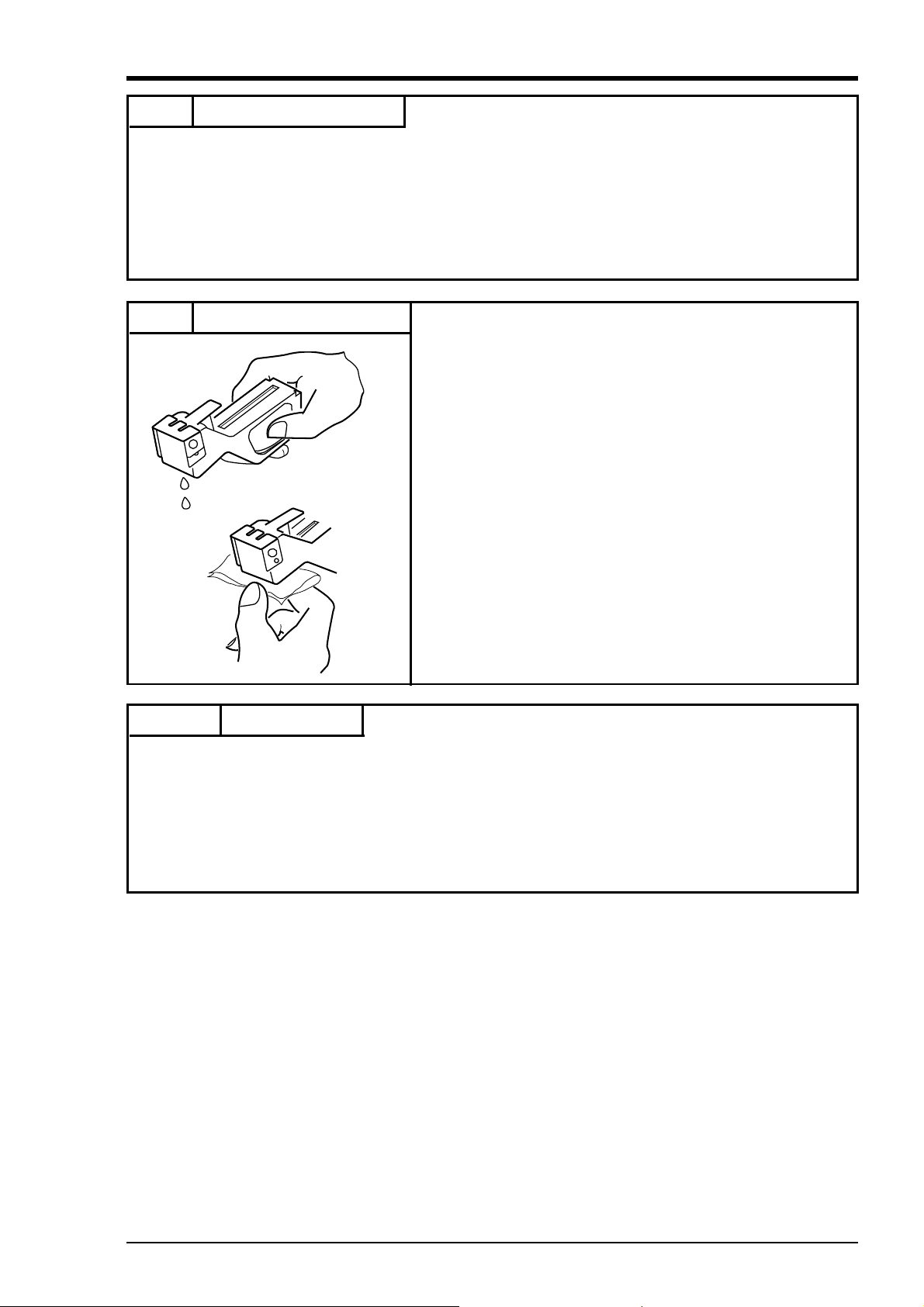

Note 5 If the ink is not sprayed.

①Hold the recording head with turning the nozzle surface

downward and push the side strong till spilling two drops.

②Absorb the standing ink on the nozzle surf ace with the cloth

attached.

③Hold the cloth to the nozzle surface again to find the ink

flowed onto cloth.

When ink does not come out, repeat the above operation

( ① through ③).

* When working environment is 15°C or less, perform

print-out of "record" or "test pattern" after a period or

several minutes has elapsed since the recording head was

mounted. (The recording head has a built-in heater.)

Reference Ink consumption

When recording at 20mm/h of chart speed and a given input, the consumption of ink is as sho wn belo w,

though it depends on operating conditions.

1 continuous recording --------- about 20 months

2 continuous recording --------- about 12 months

6 dot recording ------------------ about 8 months

5 - 9INP-TN2PHEV-E

Page 29

6. OPERATION AND ACTIONS

6.1 Before running the equipment:

Check the following points before starting operation.

1

2

3

Setting the chart paper and recording head

① Setting the chart paper ..................................................................................... See Section 5.1

② Setting the recording head ............................................................................... See Section 5.2

Wiring

① Input terminals .................................................................................................

② Alarm terminals (option) ................................................................................. See Section 4.3

③ Power and earth terminals ...............................................................................

}

Conformity of input connection to recording channel

① Code symbols .................................................................................................. See Section 1.3

6 - 1INP-TN2PHEV-E

Page 30

6.2 Turning on power and status

C

N

The instrument has no power switch. Engaging the power cord with power source turns it on.

1) Turning on power for the first time

↓

The recording head slowly moves toward the left end (0% side).

↓

After detecting the 0% position, the recording head moves to the approximate central position.

↓

The current time appears on the display section, approximately 30 seconds later in case of 6 dot type.

2) Whether to start recording when turning on is as in “7.11 /Selecting whether to start

recording when turning on”.

・ Prior to delivery of the unit, the recording condition at power ON is set in

“Record Stop” mode. When starting the recording operation at the time of

AUTIO

recovery of power failure during operation, turn ON the power and set the

unit in “Record Start” mode referring to Item 7-11.

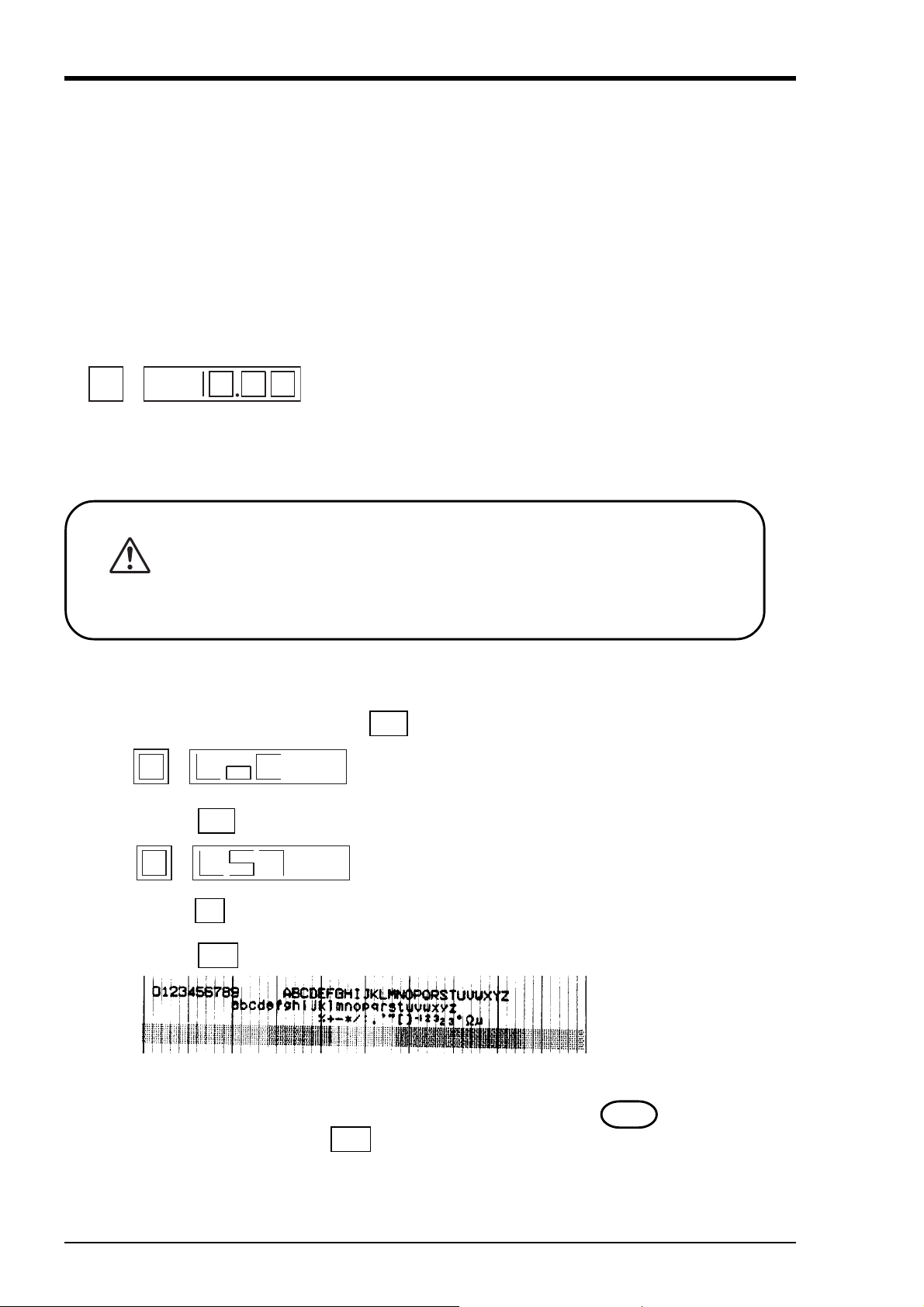

6.3 Printing the test pattern

① Open the front door and press the DSP key for 3 seconds to display the following.

②

Press the SEL key two times to display the following.

Press the ∧ key until “0” turns “2”.

③

④

Press the ENT key to print the test pattern below.

Note 1) Make sure all colours are recorded. If any colour is not developed or is unclear, apply the

furnished cloth carefully on the nozzle end to wipe it. (See 5.2, Step 3 ..)

Note 2) To quit print-out, press the ENT key again.

6 - 2 INP-TN2PHEV-E

Page 31

6.4 Operation in normal mode

ed

1

2

(1) Stopping and starting the recording operation ( REC key)

• Only in the normal mode, recording can be started or stopped.

Each press of REC key alternately selects recording operation or recording stop.

•

LED lit

Recording in progress

(2)

Quick feed of recording chart ( FEED key)

Not recording

LED extinguish

• Hold down the FEED key to quickly feed the recording chart, overriding the normal chart speed.

(3) Changing the display mode ( DSP key)

Pressing the DSP key changes the display mode.

•

•

Each press of DSP key selects the next display mode.

(The number of screens depends on 1 continuous, 2 continuous or 6 dot recording.)

Time display

1 continuous

Measured value・

sequential display

Sequentially displays ch 1 and

subsequent every 3 seconds.

DSP

CH1 Measured value・

fixed display

continuous

CH2 Measured value・

fixed display

continuous

CH3 Measured value・

fixed display

CH4 Measured value・

fixed display

CH5 Measured value・

fixed display

DSP

DSP

DSP

DSP

Display ch 1 only.

Display ch 2 only.

Display ch 3 only.

Display ch 4 only.

Display ch 5 only.

DSP

CH6 Measured value・

fixed display

Display ch 6 only.

6 dot

6 - 3INP-TN2PHEV-E

Page 32

6.5 Displays and print-outs on detection (cancellation) of alarms

① When an alarm has occurred, its contents appear on the display section. They appear for 1 second

every 3 seconds while displaying a measured value.

Note)In case of fixed display of measured value, the alarm status for the fixed channel only appears.

Example of alarm display

Example: Alarm No.1 and No.2 of ch 1

has occurred.

② When an alarm detected and cancelled, the relevant details are printed on the right-hand side of the

chart paper.

On detection: The time of detection, channel No., type of alarm,

----Print-out color: Red (6 dot), Red (1,2-continuous)

On cancellation: The time of cancellation, channel No., type of alarm

----Print-out color: Black (6 dot), Blue (1,2-continuous)

Channel 1 No. 1 H alarm

←

release

←

Release time: 17 : 40

Channel 1 No. 1 H alarm

generation

Generating time: 17 : 37

③ If an alarm is detected or a cancellation is made during data print-out or list print-out, the alarm

print-out takes place after completion of the data or list print-out.

④ Up to a maximum of 30 alarm detection cancellation information can be stored and sequentially

printed out, but if the storage capacity is exceeded because of a large number of detections/cancellations in a short time, information in the overflow portion is discarded and cannot be printed out.

6.6 Displays and print-outs on occurrent of burnt-out

① If a thermocouple or resistance bulb has burnt our, its contents appear.

Example of alarm display

Example: Ch 1 burnt out.

Note: Trend recording overswings toward the maximum side of the recording range.

② If a burn-out occurs, its contents are printed on the right of recording chart (in red).

Example of burn-out print-out

1 BUNOUT 11 : 52

Occurrence time : 11 : 52

Channel No. : 1

6 - 4 INP-TN2PHEV-E

Page 33

6.7 Indication of over-range, under-range display and abnormal input display

For any of thermocouple, resistance bulb and voltage inputs, the measurable input signal range is fixed.

If the input is beyond the specified range, “over” or “under” appears.

Example of over/under display

An input error indication appears if the voltage input signal line has been open-circuited or if the voltage input signal is further beyond over/under.

Example of abnormal input display

6.8 Display of fault in recording head carriage

If the recording head does not operate properly any more because the recording head running section is

erroneous, an error appears and the recording operation stops.

Example

If "C. ALM " has appeared, turn OFF power and check the following points.

(1) Check whether the recording head running shaft is clogged with foreign matters? (If contaminated,

wipe off by dry rag.)

(2) Check whether the recording head drive belt is cut or loose?

(3) Check whether the recording chart floats, thereby touching the recording head?

(4) Check whether the recording head is correctly installed?

After eliminating the cause of error, turn on the instrument again.

6.9 Display of skipped parameter

The channel for which the parameter setting is skipped appears as “ ” on the display section. In

the case, recording alarm and operations are not carried out at all.

Example

6 - 5INP-TN2PHEV-E

Page 34

7. SETTING AND CHECKING PARAMETERS

7.1 Setting and Checking

① Parameters are factory set as given in the table below. Turning on power as they are initiates

operation (indication, analog trend recording). As required, change the parameter setting.

② Alarm and PV shift are not set. Set them as necessary. Note that the input filter is set at 3 seconds.

Note) Before setting any parameter, install the recording chart.

(1) Parameters as set by factory (initial values)

Prameter name

Key lock

Main chart speed

Periodic print-out

Scale print-out

Input filter

Alarm

Whether to start

recording when

turning on

Factory setting

(initial values)

OFF (0)

20mm/h

ON (1)

ON (1)

3 seconds

Alarm type : N

DO output

at

H, L

Recording stop

No.: 0

Alarm set

value : 0

(0)

Remarks

Set to "1" for key lock

Settable range : 10,20,24,30,50,120,200

300,400,1000,1200,1500

Set to "1" for periodic print-out

Set to "1" for scale print-out

Settable range:0 to 255 for each channel

Alarm No.1 and 2

No alarm : N

H alarm : H

L alarm : L

Settable range 0 to 6

0 : No DO output

To alarm setting range of each kind of

input.

Set to "1" for getting ready to record

when turning on .

Set to "0" for record stop when turning

on .

How to check

setting

Item 7.3

Item 7.4

Item 7.7

Item 7.8

Item 7.9

Item 7.10

Item

7.11

7 - 1INP-TN2PHEV-E

Page 35

7.2 Outline of procedure for setting parameters

〈Normal mode〉

Time & measured

Note 1)

data display screen

SEL

(Press 3 sec)

(Setting mode)

Key lock

Main chart

speed

Listing

Scale print-out

Periodic print-out

ON/OFF setting

Scale print-out

ON/OFF setting

Input filter

Alarm setting

Whether turning

on power gets

ready to record

Time setting

DSP

Item

7.3

SEL

Item

7.4

SEL

Item

7.5

SEL

Item

7.6

SEL

Item

7.7

SEL

Item

7.8

SEL

Item

7.9

SEL

Item

7.10

SEL

Item

7.11

SEL

Item

7.12

SEL

(Press 3 sec)

Key lock time

When set at "1"

〈 Setting mode〉

Key lock

〈Adjusting mode〉

Backlash

adjustment

Head zero/

span adjustment

PV shift setting

Sub chart speed

Skip setting

Head selection

〈Adjusting mode〉

Backlash

adjustment

Head zero/span

adjustment

PV shift setting

〈Calibration mode〉

Measured value

calibration

SEL

For maker

︿

Item

9.1

SEL

Item

9.2

SEL

Item

9.3

SEL

Item

9.4

SEL

Item

9.5

SEL

Item

9.6

SEL

SEL

SEL

︿

Item

9.7

SEL

(Press 3 sec)

SEL

+

︿

First, press the key and hold

it down, then press the key.

SEL

(Press 3 sec)

(3 sec)

SEL

+

SEL

Do not use

Note 1) By pressing the "SEL" key for 3 seconds on any mode (setting mode, adjustment mode and

calibration mode), the screen returns to the normal mode.

7 - 2 INP-TN2PHEV-E

Page 36

7.3 Key lock setting/release

Explanation

When parameters need not be changed after setting, you are advised to lock the key to prevent them

from being changed accidentally. When the key is locked, the SEL key is used only for display of list

printing and scale printing.

Key lock ON 1

Key lock OFF 0

Operation

contents

Keying

DSP

∧

ENT

SEL

Operation

contents

Keying

Lock the key.

(ex.)

Explanation

Press the DSP key for 3 seconds to select the

setting mode. (key lock display appears.)

Press the ∧ key until "1" is selected.

Press the ENT key to register and transfer to

display of the next parameter.

Press the SEL key for 3 seconds to select the

normal mode.

Unlock the keys.

(ex.)

Explanation

Display

Display

DSP

∧

ENT

SEL

Press the DSP key for 3 seconds to select the

setting mode. (key lock display appears.)

Press the ∧ key until "0" is selected.

Press the ENT key to register and transfer to

the next parameter display.

Press the SEL key for 3 seconds for setting in

normal mode.

7 - 3INP-TN2PHEV-E

Page 37

7.4 Setting the Chart Speed (main chart speed)

Explanation

• Main chart speed : Set the recording chart speed in normal operation to one of 10, 20, 24, 30, 50,

120, 200, 300, 400, 1000, 1200 and 1500.

• If the case of a continuous recording type, if the chart speed is too fast, the result is dashed line

recording instead of continuous recording. (As a general criterion, 1000mm/h or more)

• On a dot recording type, if the chart speed is fast, it becomes difficult to read recording due to

increase in the space between break points. It is recommended that the recorder be sued at a speed

of 50mm/h or less.

• On a continuous recording type, the recording cycle varies with chart speed.

Recording cycle(sec.) =

Chart speed (mm/h)

(But not faster than 2 seconds.)

Example)

Chart speed (mm/h) 10 20 30 50 120 200

Recording cycle (sec.) 40 20 13 or 14 8 3 or 4 2

• The recording cycle for dot recording type is 30 seconds fixed.

Operation

contents

Keying

DSP

SEL

Changing the normal recording chart speed from 20 to 30mm/h.

(ex.)

Explanation

Press the DSP key for 3 seconds to display

the setting mode. (key lock display appears.)

Press the SEL key to display the main chart

speed.

400

Display

∧

ENT

SEL

Press the ∧ key for selecting "30".

Press the ENT key to register and transfer

display of next parameter.

Press the SEL key for 3 seconds for setting in

normal mode.

7 - 4 INP-TN2PHEV-E

Page 38

7.5 How to list

Explanation

• Use for arbitrarily printing the prameter list, instantaneous value list, test pattern or scale.

Listing Print-out contents

Instantaneous value Each channel measured value (instantaneous value)

listing and engineering unit, time, channel number

Parameter listing Input signal, input range, recording range, unit,

alarm, input filter, chart speed, etc.

Test pattern print-out Colour patterns and test characters

Scale print-out Scale of desired channel (Refer to 7.6)

• Analog trend recording is stopped by listing but is automatically resumed after end of listing.

Operation

contents

Keying

DSP

Print a test pattern.

(ex.)

Explanation

Press the DSP key for 3 seconds to display

the setting mode. (key lock display appears.)

Display

Set value

0

1

2

Next screen

SEL

∧

ENT

Press the SEL key twice for displaying the

listing.

Press the ∧ key for selecting "2" Test pattern.

Press the ENT key to start printing.

To stop printing, press the ENT key again.

Pressing the ∧ key while listing rapidly

[

[

feeds the chart paper.

SEL

•Instantaneous value list ----------- For print-out example, refer to 11.2.

•Parameter list ----------------------- For print-out example, refer to 11.3.

•Test pattern ------------------------- For print-out example, refer to 11.4.

After completion of printing, press the SEL key

for 3 seconds for setting in normal mode.

Blink

Note 1) When resuming the analog trend recording after the end of listing in case of continuous

recording type, the input values preceding and following the listing are recorded as continuous line.

7 - 5INP-TN2PHEV-E

Page 39

7.6 How to print the scale (manually)

Explanation

• Use for arbitrary scale print-out.

Number of recording point Settable range

1 continuous 1

2 continuous 1 to 2

6 dot 1 to 6

• Scale can be printed even while recording.

• Analog trend recording is stopped by scale print-out but is automatically resumed after the

end of listing.

Operation

contents

Keying

(ex.)

DSP

SEL

∧

ENT

Print 2 continuous type 2 ch scale.

Explanation

Press the DSP key for 3 seconds to display

the setting mode. (key lock display appears.)

Press the SEL key three times for displaying

the scale print-out.

Press the ∧ key for selecting "2" (2 ch).

Press the ENT key to start printing.

To stop printing, press the ENT key again.

Pressing the ∧ key while listing rapidly

[

feeds the chart paper.

[

Display

Blink

SEL

✻Scale print-out--------------------- For print-out example, refer to 11.5.

7 - 6 INP-TN2PHEV-E

After completion of printing, press the SEL key

for 3 seconds for setting in normal mode.

Page 40

7.7 How to set ON/OFF of periodic print-out

Explanation

• Selects whether or not to print the instantaneous values at fixed intervals while recording.

• Prints the following items at fixed intervals according to the chart speed.

[Printing start line, channel No., measured value, unit, chart speed, current time]

• Alternately selects periodic print-out and scale print-out.

Periodic print-out ON 1

Periodic print-out OFF 0

• For details, refer to "Relation between chart speed and printing" in Item 7.8.

Operation

contents

Keying

(ex.)

DSP

SEL

∧

ENT

SEL

Periodic print-out (ON).

Explanation

Press the DSP key for 3 seconds to display

the setting mode. (key lock display appears.)

Press the SEL key four times for displaying

ON/OFF of periodic print-out.

Press the ∧ key for selecting "1".

Press the ENT key to register and transfer to

the next parameter display.

Press the SEL key for 3 seconds for setting in

normal mode.

Display

7 - 7INP-TN2PHEV-E

Page 41

7.8 How to set ON/OFF of scale print-out

Explanation

• Selects whether or not to print the scale while recording.

• The scale print-out for each channel sequentially is effected alternately with periodic print-out.

• The printing interval is automatically determined by chart feed speed.

Scale print-out ON 1

Scale print-out OFF 0

• For details, refer to "Relation between chart speed and printing" on Page 7-9.

Operation

contents

Keying

(ex.)

DSP

SEL

∧

ENT

SEL

Scale print-out (ON).

Explanation

Press the DSP key for 3 seconds to display

the setting mode. (key lock display appears.)

Press the SEL key five times for displaying

the scale print-out.

Press the ∧ key for selecting "1".

Press the ENT key to register and transfer to

the next parameter display.

Press the SEL key for 3 seconds for setting in

normal mode.

Display

7 - 8 INP-TN2PHEV-E

Page 42

Relationship between chart speed and printing

• The following items depend on the recording chart speed.

① Printing action : Provided that the printing is available, periodic print-out, scale, alarm, burn-

out or channel No. digital print-out is available while recording.

② Periodic print-out, scale print-out cycle : Print-out interval is determined by the chart speed.

Periodic print-outs and scale print-out are effected

alternately.

③ Recording cycle : 1 continuous or 2 continuous recording cycles are determined by the chart

speed. 6 dot recording cycle is 30 seconds fixed regardless of the chart

speed.

Chart speed

10mm/h

20mm/h

24mm/h

30mm/h

50mm/h

120mm/h

200mm/h

300mm/h

400mm/h

1000mm/h

1200mm/h

1500mm/h

① Printing

Printable

Unprintable

1, 2 continuous recording 6 dot recording

②

action

Periodic print-

out cycle

8 h

4 h

4 h

4 h

2 h

1 h

30 min

20 min

20 min

6 min

6 min

4 min

③

Recording

cycle

40 sec.

20 sec.

16 or 17 sec.

13 or 14 sec.

8 sec.

3 or 4 sec.

2 sec.

2 or 3 sec.

2 sec.

2 sec.

2 sec.

2 or 3 sec.

① Printing

action

Printable

Unprintable

②

Periodic print-

out cycle

30 min

20 min

20 min

6 min

6 min

4 min

8 h

4 h

4 h

4 h

2 h

1 h

③

Recording

cycle

30 sec.

fixed

Note 1) Digital print-out is not made if 1, 2 continuous version has 1000 mm/h or higher chart speed.

Only printing start line is recorded.

Note 2) Digital print-out is not made if 6 dot version has 120 mm/h or higher chart speed. Only

printing start line is recorded.

Note 3) Periodic print-out or scale print-out is not executed even if their time has come if listing is

being executed then. Similarly, the periodic print-out or scale print-out being executed is

stopped if listing is activated then, and the print-out is not recovered even after the end of

listing.

7 - 9INP-TN2PHEV-E

Page 43

7.9 How to set the input filter

Explanation

• Sets the input filter (time constant) for each channel.

• Settable in 1 second steps within the range of 0 to 255 seconds.

Operation

contents

(ex.)

Keying

DSP

SEL

∧

ENT

∧

Change the time constant of channel 2 from 3 to 2.

Explanation

Press the DSP key for 3 seconds to display

the setting mode. (key lock display appears.)

Press the SEL key six times for displaying

the input filter setting.

Press the ∧ key to change the channel 1 to

channel 2.

Press the ENT key 3 times to blink 1-place.

Press the ∧ key several times for changing

3 to 2.

Display

Blink

ENT

SEL

Press the ENT key to register.

Press the SEL key for 3 seconds for setting in

normal mode.

7 - 10 INP-TN2PHEV-E

Page 44

7.10 How to set the alarm

Explanation

• Channel : Setting of channel No. for object alarm.

• Alarm No. : Up to 2 alarms can be set per channel.

• Kind of alarm : 2 kinds, H and L (settable freely for each alarm).

N selected delivers no alarm (gives no alarm display nor alarm output).

• Alarm set value : Setting in engineering values (see Table 1 Alarm settable range).

• DO output No. : Setting of option alarm unit relay No. (0 to 6, no output at 0).

DO output can also be used for common setting (OR output).

DO output No.

Alarm kind

Alarm No.

Channel No.

Note 1) Set the sign concurrently with digit 5. (Refer to the next page)

Note 2) Blank for plus or " − " for minus.

Operation

contents

Keying

DSP

SEL

( ∧ )

ENT

Change the alarm No. 1 for channel 1.

(ex.) N →H 0.0℃→80.0℃DO0→ 2

Explanation

Press the DSP key for 3 seconds to display

the setting mode. (key lock display appears.)

Press the SEL key seven times for displaying

the alarm setting.

Press the ∧ key until a channel to change is

selected and press the ENT key.

Alarm set value

Alarm set value sign

Display

( ∧ )

ENT

( ∧ )

ENT

Press the ∧ key until an alarm No. to change

is selected and press the ENT key.

Press the ∧ key until "N" turns "H" and

press the ENT key.

7 - 11INP-TN2PHEV-E

Page 45

Keying

Explanation

Display

∧

ENT

ENT

∧

ENT

SEL

Table 1 : Alarm settable range

Press the ∧ key until "0" turns "2".

Press the ENT key to display the alarm set

value.

Press the ENT key twice for blinking the 10places.

Press the ∧ key for turning "0" to "8".

Press the ENT key three times for displaying

the alarm setting. The set value is registered.

Press the SEL key for 3 seconds for setting in

normal mode.

Blinking

・Change of symbol digit

and 5th digit

Kind Alarm settable range

Thermocouple

Resistance JPt100 -230.0 to630.0℃ -382.0 to 1166.0°F

bulb Pt100 -230.0 to630.0℃ -382.0 to 1166.0°F

DC voltage -55.00 to 55.00mV

scalling OFF -550.0 to 550.0mV

B 370.0 to 1790.0℃ 698.0 to 3254.0°F

R - 30.0 to 1790.0℃ - 22.0 to 3254.0°F

S - 30.0 to 1790.0℃ - 22.0 to 3254.0°F

K -230.0 to 1400.0℃ -382.0 to 2552.0°F

E -230.0 to 830.0℃ -382.0 to 1526.0°F

J -230.0 to 1130.0℃ -382.0 to 2066.0°F

T -230.0 to 430.0℃ -382.0 to 806.0°F

N - 30.0 to 1330.0℃ - 22.0 to 2426.0°F

W - 30.0 to 1790.0℃ - 22.0 to 3254.0°F

L -230.0 to 930.0℃ -382.0 to 1706.0°F

U -230.0 to 430.0℃ -382.0 to 806.0°F

P N - 30.0 to 1330.0℃ - 22.0 to 2426.0°F

-5.500 to 5.500V

-55.00 to 55.00V

︿

︿

︿

︿

︿

︿

key

DC voltage -32767 to 32767

scalling ON

[decimal point anywhere]

︿

︿

7 - 12 INP-TN2PHEV-E

Page 46

7.11 Selecting whether to start recording when turning on

Explanation

• Selects whether turning on power gets ready to record or not.

Not ready to record 0

Ready to record 1

Operation

contents

Keying

(ex.)

DSP

SEL

∧

ENT

SEL

Turning on power does not get ready to print (OFF).

Explanation

Press the DSP key for 3 seconds to display

the setting mode. (key lock display appears.)

Press the SEL key eight times for displaying

whether turning on power gets ready to record

or not.

Press the ∧ key for turning "1" to "0".

Press the ENT key to register and transfer to

the next parameter display.

Press the SEL key for 3 seconds for setting in

normal mode.

Display

7 - 13INP-TN2PHEV-E

Page 47

7.12 Setting of date and time

Explanation

• Built-in clock is properly set before product shipment. However, if the clock does not

keep good time or when the battery is replaced, reset the time.

Operation

contents

DSP

SEL

∧

ENT

(ex.)

Explanation

Press the DSP key for 3 seconds to display

the setting mode (key-lock display).

Press the SEL key 9 times to display the

"Time Setting" screen.

When nothing is displayed in the left-most

digit and T is displayed in the 2nd digit from

left, the "Time Setting" screen is displayed.

Press the ∧ key to change the digit of

10'clock. Note) For setting, use a 24H system.

Press the ENT key to register and shift to the

digit of 1 o'clock.

Display

∧

ENT

∧

ENT

∧

Similarly, set date and year.

Press the ∧ key to change the digit of 1

o'clock.

Press the ENT key to register and shift to the

digit of 10 min.

Press the ∧ key to change the digit of 10

min.

Press the ENT key to register and shift to the

digit of 1 min.

Press the ∧ key to change the digit of 1

min.

Date Setting screen

Year Setting screen

7 - 14 INP-TN2PHEV-E

Page 48

8. MAINTENANCE - INSPECTION

8.1 Maintenance/inspection items

Carry out periodic maintenance and inspection to keep the equipment in good condition.

Pay particular attention to the items noted below and make replacement with spares when necessary.

Inspection,

Maintenance Items

Recording head

replacement:

Inspection of the

recording head

Procedure

The recording head is a consumable part.

If there is no more ink, replace the head with a new one.

Ink consumption varies depending on the contents of records, but writing for

about one year is possible at a chart speed of 20mm/h.

To get spares, quote the following type.

Recording head type: PHZH2002/1, 2 continuous recording type

PHZH1002/6 dot recording type

In normal conditions, there is no need for preventive maintenance of the recording head.

However, in a high-temperature or very dusty environment, periodically wiping

the nozzle surface prevents accumulation of dust and ink and so prevents nozzle

blockage that is liable to be caused by such accumulation.

To absorb ink, use the supplied "Ink blotting cloth"

If the recording head is left unused for a long time without using the cap,

ink may not be absorbed when the blotting cloth is attached to the nozzle of

the recording head. In such a case, wet the blotting cloth with water end

attach it to the nozzle for several 10 seconds until the ink is absorbed sufficiently.

Recording paper

replacement

Battery replacement

Cleaning of

traveling shaft

In continuous operation at a chart speed of 20mm/h, the recording paper lasts

about 31 days.

When there is only a small amount of recording paper left, a red band is printed

on the right-hand edge of the paper. When this happens, refer to section 5.1 and

replace the recording paper.

To get supplementary paper, quote the following type.

Recording paper type: PEX00DL1-5000B

Replace the battery every 5 years. Type of battery unit: TK7J1145C2

Wipe off dust, if found, on the shaft for traveling the record head horizontally

with clean cloth. Otherwise accurate recording may not be made.

Do not lubricate the traveling shaft. Lubricating can cause inaccurate recording.

8 - 1INP-TN2PHEV-E

Page 49

Inspection,

Maintenance Items

Transfer of

record head

Cleaning

Procedure

• Do not transfer the record head taken out of the aluminum bag alone. If the

transfer is unavoidable, make sure to tighten the cap and place the record

head in a cardboard box with sufficient cushioning materials to reduce vibration and impact.

• Make sure to tighten the cap when transferring the record head in a state

installed in a recorder main unit.

Do not use organic solvents such as alcohol or benzine for cleaning the device.

Do not let the device get wet. Otherwise, deterioration, failure, electric leakage,

or fire may occur. Use a dry cloth to clean the device.

8 - 2 INP-TN2PHEV-E

Page 50

8.2 Battery replacement procedure

1

2

3

S

se

D

R

* The battery should be replaced every 5 years. If the battery power is lost, time and date cannot be

registered when the AC power is not supplied.

* Battery replacement should be done only by the personnel with electrical knowledge after reading

the following instructions.

* Open the front door and replace the battery, using the following procedure.

Turnoffthemainpowerandtherecordertoavoidelectricshock.

ANGE

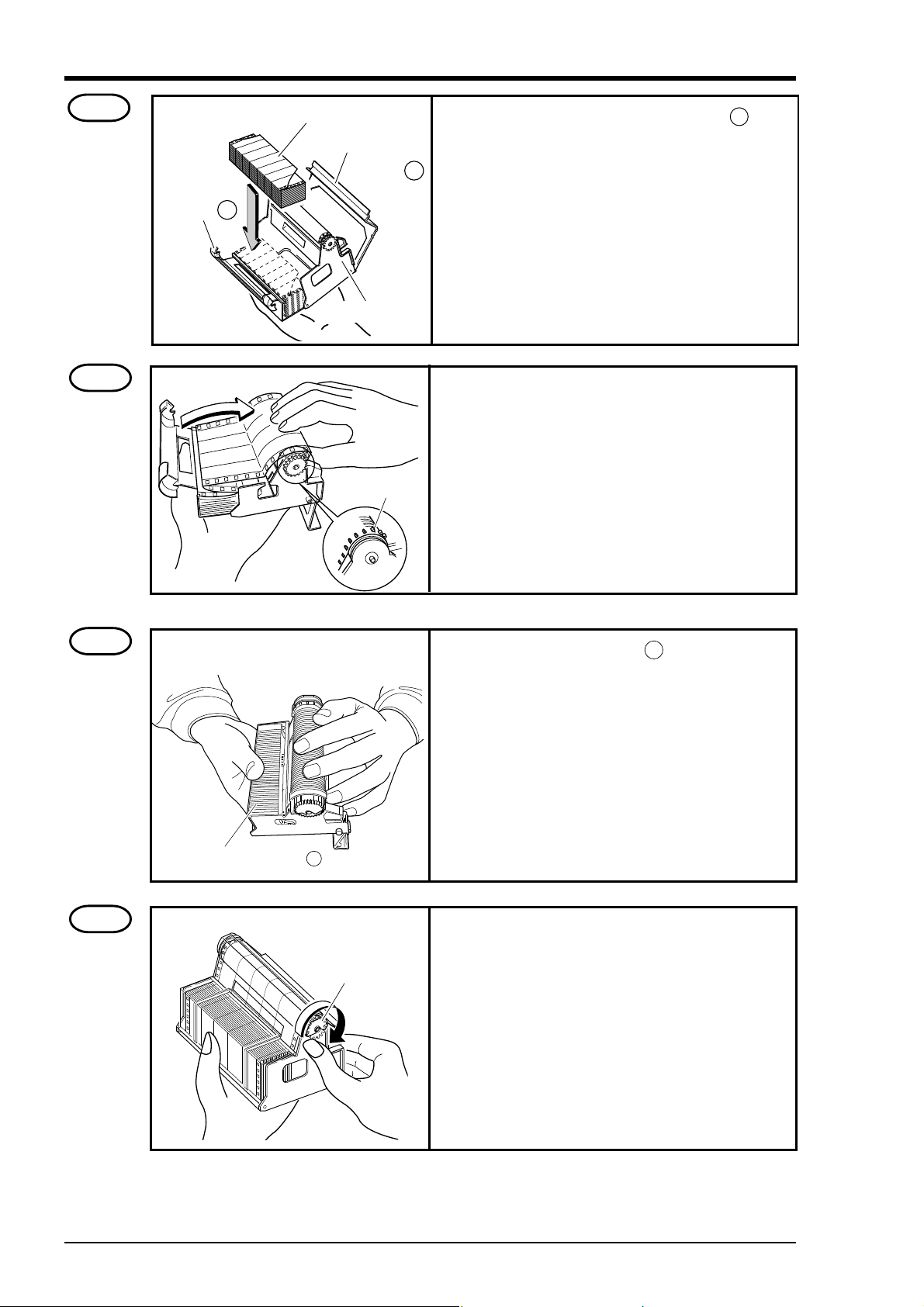

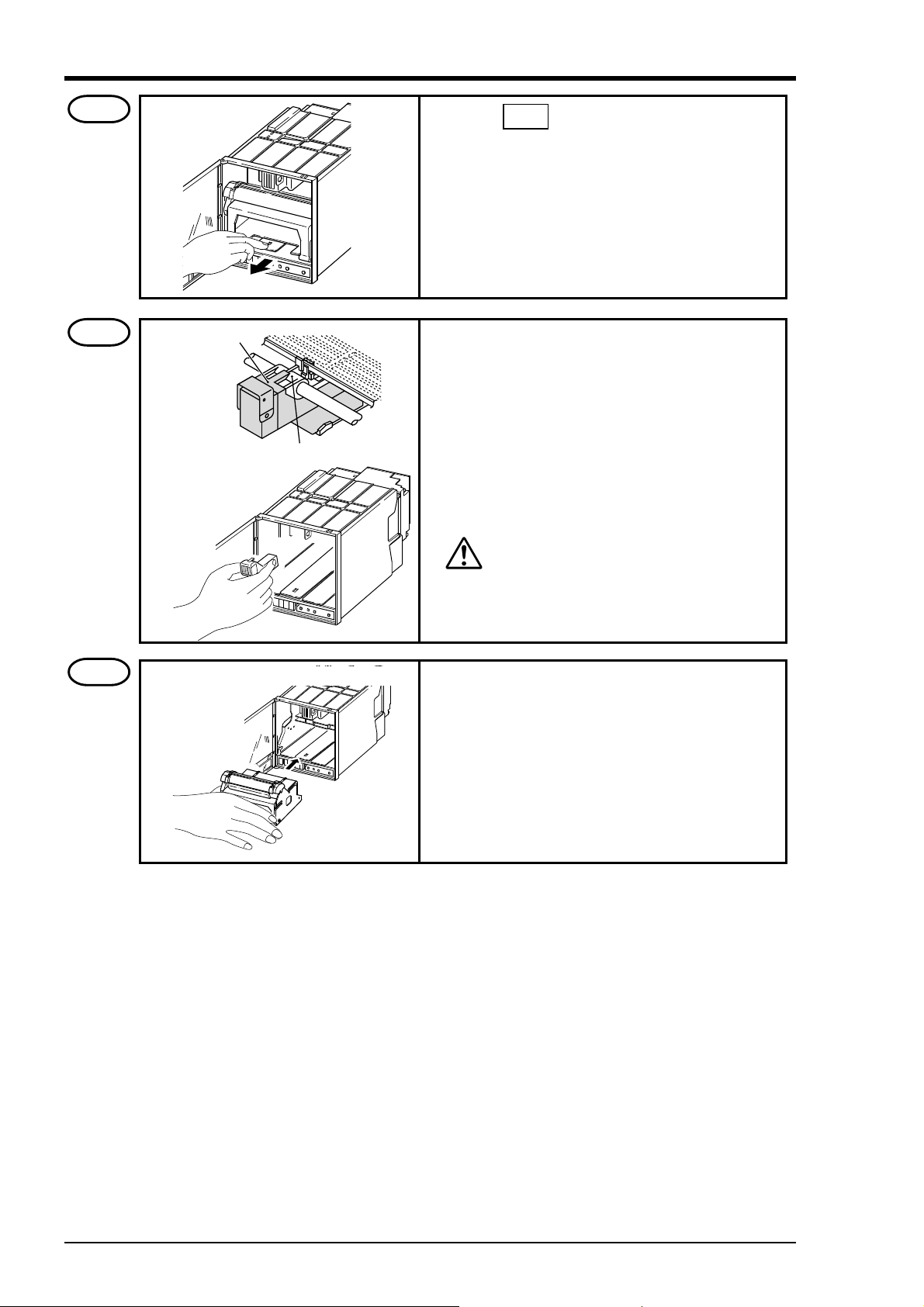

Step 1

Step 2

Lock screw

RTD

TC

V

INPUT1

INPUT1

INPUT1

INPUT1

RCJ module

−

+

11 21 31 4

12 22 32 4

13 23 33 4

When an RCJ module is attached, it should

be removed.

Loosen the lock screw (M4) of the main unit,

using a screwdriver + .

Step 3

ide panel

Bottom panel

Hold the slide panel or the bottom panel with

your fingers, and pull it with force toward you.

The main unit will be removed from the case.

Ca

Main unit

8 - 3INP-TN2PHEV-E

Page 51

Step 4

A

B

C

D

E

F

S

se

el

Interface board

Alarm external control terminal

Step 5

ide panel

Inputterminal

RTD

TC

V

INPUT1

INPUT1

INPUT1

INPUT1

INPUT1

INPUT1

−

12 22 32 42 52 62 72

13 23 33 43 53 63 73

When an alarm is provided, remove the

screws, A, B and C (M2.5), then remove the

alarm external control terminal. In the case

+

11 21 31 41 51 61 71

of 6 dot points, remove the screws, D, E and

F (M2.5), and then remove the input terminal.

Pull out and remove the main unit from the

case.

Pull out and remove the display cover from

the main unit.

Display cover

Main unit

Step 6 Removal of interface board

①

③

②

Ca

Full the interface board toward you while

pressing the side panel outward. The interface board will be removed.

Side pan

8 - 4 INP-TN2PHEV-E

Page 52

Step 7 Removal of main board

M

w

ain board

Step 8 Removal of battery

Pawl

Put the main unit upside down and lift up the

main board while pressing the side panel outward, and the main board will be removed.

Remove the battery fixing screw (M3), and

the battery will be removed.

Battery

Battery fixing scre

8 - 5INP-TN2PHEV-E

Page 53

Step 9 Removal of CN6

CN6

Remove the tip (CN6) of the battery from the

main board.

Step 10