Page 1

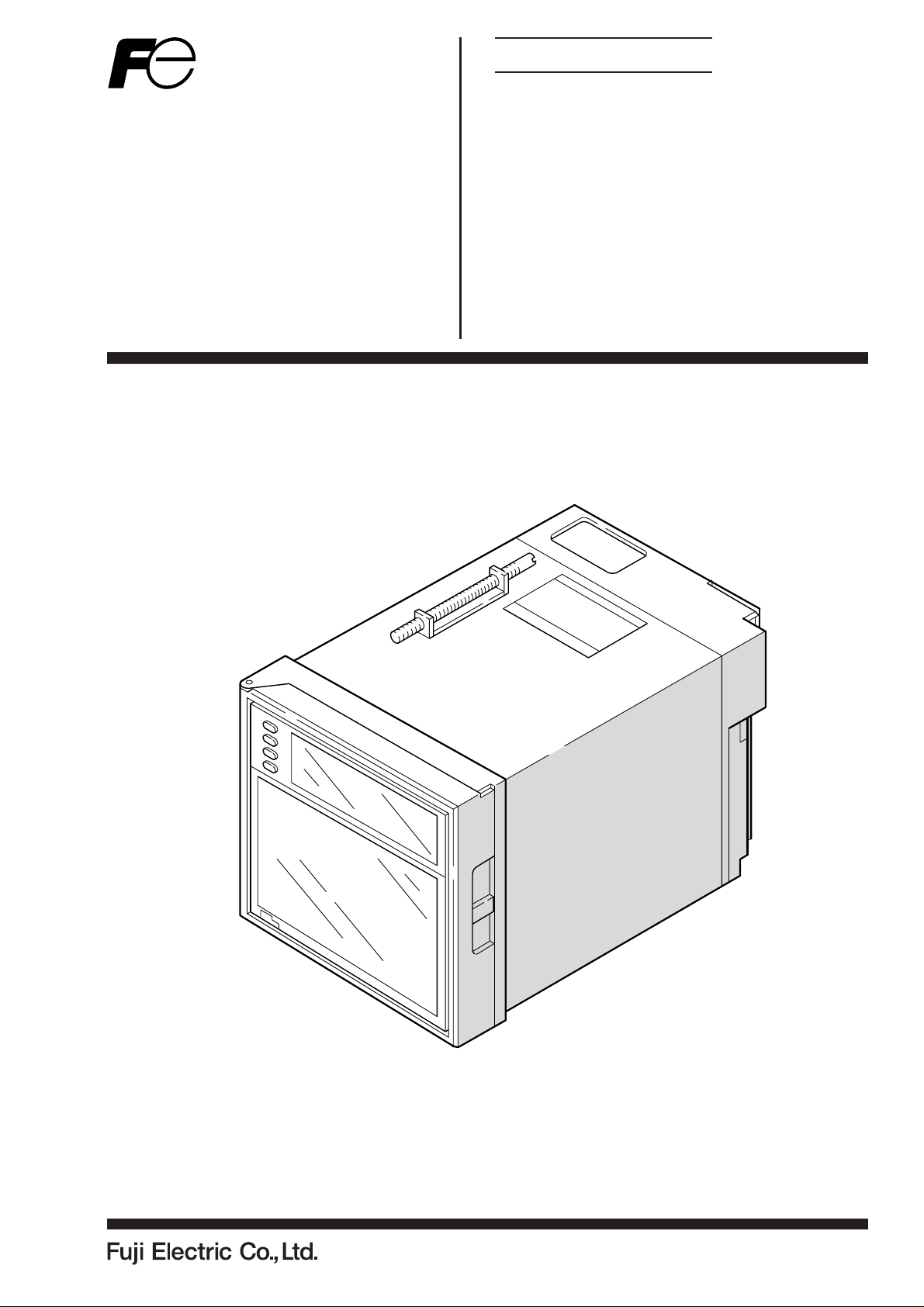

Instruction Manual

MICROJET RECORDER

TYPE: PHC

INP-TN3PHCVi-E

Page 2

PREFACE

Congratulations on your purchase of Fuji Micro-jet Recorder (Type: PHC)

• Read this instruction manual carefully to ensure correct installation, operation and preparation.

Incorrect handling may lead to accident or injury.

• Specifications of this unit is subject to change without prior notice for improvement.

• Modification of this unit without permission is strictly prohibited.

Fuji will not bear any responsibility for a trouble caused by such a modification.

• This instruction manual should be kept by the person who is actually using the unit.

• After reading the manual, be sure to keep it at a place easy to access.

• This instruction manual should be delivered to the end user without fail.

Manufacturer : Fuji Electric Co., Ltd.

Type : Shown on nameplate of Micro-jet recorder

Date of manufacture : Shown on nameplate of Micro-jet recorder

Product nationality : Japan

Request

• It is prohibited to transfer part or all of the manual without

Fuji's permission.

• Description in this manual will be changed without prior

notice.

Fuji Electric Co., Ltd. 1996

Issued in Dec., 1996

Rev. 1st edition July, 1997

Rev. 2nd edition May, 1998

Rev. 3rd edition March, 2000

Rev. 4th edition Nov., 2002

Rev. 5th edition April, 2005

Rev. 6th edition March, 2008

Rev. 7th edition April, 2011

Rev. 8th edition Oct., 2011

Rev. 9th edition March., 2012

- i -INP-TN3PHCV-E

Page 3

CAUTION ON SAFETY

First of all, read this "Caution on safety" before using the unit.

• The cautionary descriptions listed here contain important information about safety, so they should

always be observed. Those safety precautions are ranked to 2 levels, DANGER and CAUTION.

Wrong handling may cause a dangerous situation, in which

DANGER

CAUTION

there is a risk of death or heavy injury.

Wrong handling may invite a dangerous situation, in which

there is a possibility of medium level trouble or slight injury

or only physical damage is predictable.

PROHIBITION

Caution on Installation

DANGER

CAUTION

Items which must not be done are noted.

• This unit is not an explosion-proof type. Do not use it in a place

with explosive gases to prevent explosion, fire or other serious

accident.

• For installation, select a place observing the operating conditions noted in the instruction manual. Installation at an unsuited

place may cause fall, trouble or malfunction.

• The unit must be installed correctly as shown in the instruction

manual. Incorrect installation may cause fall, trouble or malfunction.

• During installation work, keep the inside of the unit free from

entry of cable chips or other foreign objects as it may cause fire,

trouble or malfunction.

• This unit is a component device used for instrumentation. It is

CAUTION

- ii - INP-TN3PHCV-E

mounted on a panel or in a rack in an equipment.

•This unit conforms to IEC61010-1 Safety standards, overvoltage category II and pollution degree 2. Protection class is double

insulation. However the heat sink of power supply on the rear

side is basic insulation.

• Only power supply 24V DC and part of options(with limitations)

are conformed to UL61010-1 standard. Regarding limitations

of power supply, please refer to Item 4.3. Regarding limitations

of option, please refer to Item 1.3 and 12. And if the equipment

is used in a manner not specified by Fuji Electric Co., Ltd., the

protection provided by the equipment may be impaired.

Page 4

CAUTION

Caution of Wiring

DANGER

• EMC conforms to EN61326-1, Class A (used for controlled electromagnetic environment((EMI)) and used for housing

areas((EMS)) Therefore this unit is designed to operate in a controlled electromagnetic environment ,i.e. where radio frequency

transmitters such as mobile phone may not be used in close proximity. In addition emissions which exceed the levels required by

the standard may occur when this unit is connected to other equipment.

• Input signals and communication interface should be of SELV

(safety separated from hazardous voltage).

• Only power supply 24DC V and part of options (with limitations) are conformed to UL61010-1 standard.

Please refer to Item1.3 and 12.

•Wiring work must be performed as specified. If the unit is not

earthed, it would result in electric shocks or malfunction.

• Be sure to connect power source that matches the rating. Connection of incorrect rating of power source may lead to fire.

• Before starting wiring work, be sure to turn OFF the main power

to prevent electric shocks.

• Wiring materials to be used must meet the rating. Use of materials which do not withstand the rating may cause a fire accident.

Caution on Maintenance

DANGER

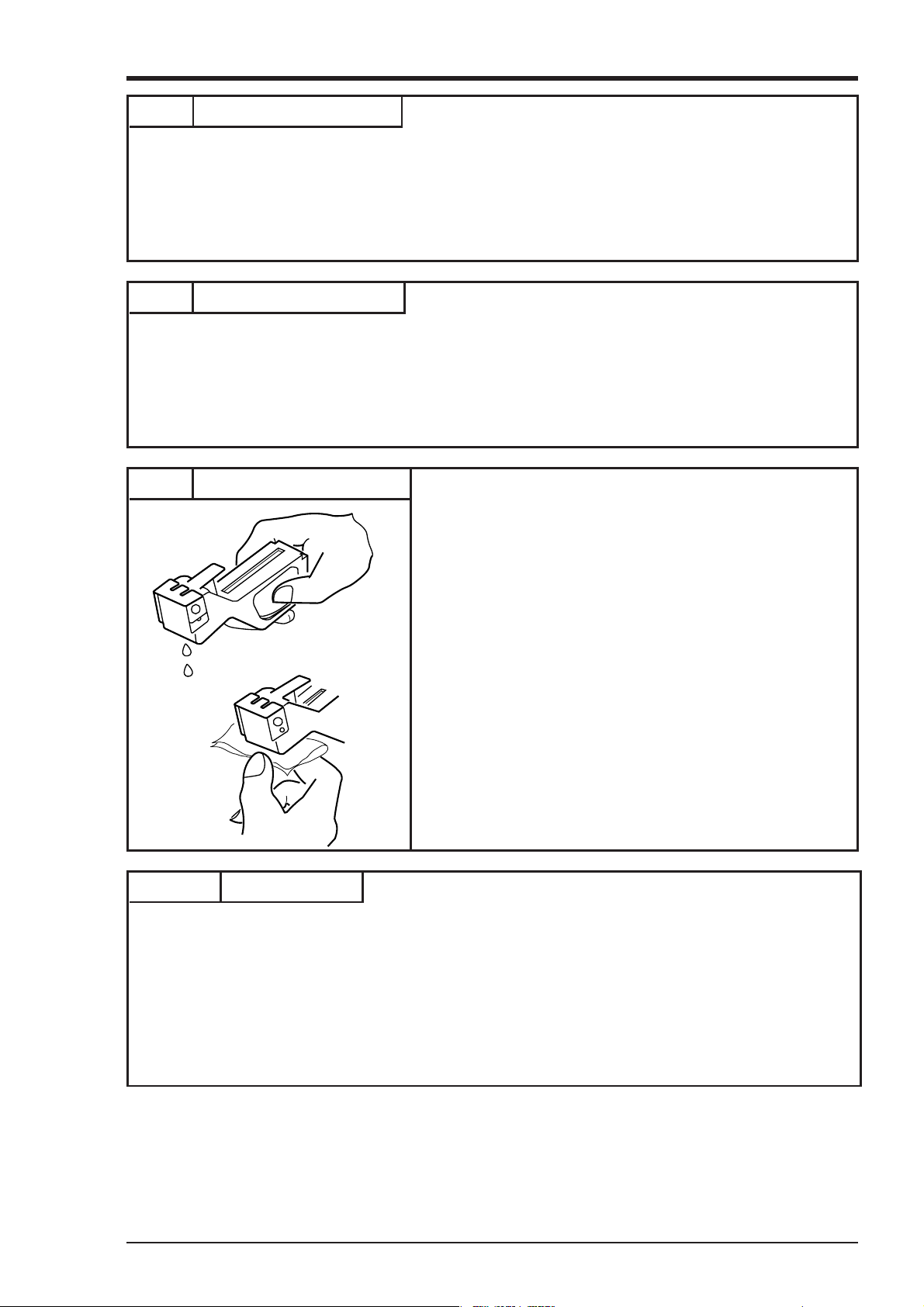

•When disposing of the recording head, put it in a vinyl bag

and seal it to prevent the diffusion of ink. It should be handled

as an imcombustible object when disposing of it.

• Ink is harmful to human body. Observe the following emer-

gency treatments.

.

When ink gets in eyes, wash out for at least 5 minutes

immediately with much clean water, and ask your doctor

for treatment at once.

.

When ink gets on skin, wash out and clean skins with

soap and water.

.

When ink is breathed in, move to a clean place immediately. If necessary, ask your doctor for treatment at once.

• Do not touch the connector at the rear of the carriage mount-

ing the recording head to avoid the risk of electric shocks.

- iii -INP-TN3PHCV-E

Page 5

Caution on Use

r

DANGER

• If the fault or anomaly of the device may cause serious accident or troubles to other devices, externally install appropriate protective circuit to avoid accidents.

•

The instrument has no power fuse. Install it if necessary.

fuse is blown out, check and remove the cause of it, and replace it with new one specified in the instruction manual. Do

not use any other fuse or short it, as it may cause electric

shocks or fire.

• The following safety symbols are used on PHC SERIES.

Caution (To avoid injury, operator must refe

to the explanation in the manual.)

Be careful of electric shock.

Protective ground terminal

Functional ground terminal (do not use this

terminal as a protective ground terminal)

When

Alternating current

Direct current

ON (power)

OFF (power)

- iv - INP-TN3PHCV-E

Page 6

CONTENTS

PREFACE .................................................................................................................................. i

CAUTION ON SAFETY .............................................................................................................ii

1. INTRODUCTION ............................................................................................................. 1-1

1.1 Microjet recorder......................................................................................................................1-1

1.2 Product check ...........................................................................................................................1-1

1.3 Check on type and specification...............................................................................................1-2

2. NAMES AND FUNCTIONS OF PARTS........................................................................... 2-1

3. MOUNTING METHOD..................................................................................................... 3-1

3.1 Mounting location .................................................................................................................... 3-1

3.2 External dimensions and panel cut out dimensions .................................................................3-1

3.3 Method of mounting onto panel ............................................................................................... 3-2

4. WIRING ........................................................................................................................... 4-1

4.1 Before doing the wiring ........................................................................................................... 4-1

4.2 Connection of wires to terminals .............................................................................................4-2

5. SET-UP ............................................................................................................................ 5-1

5.1 Loading chart paper..................................................................................................................5-1

5.2 Recording head installation (replacement)...............................................................................5-5

5.3 Changing the type of input signals......................................................................................... 5-10

6. OPERA TING AND ACTIONS .......................................................................................... 6-1

6.1 Before running the equipment..................................................................................................6-1

6.2 Power switch-on and states ......................................................................................................6-2

6.3 Test pattern print-out ................................................................................................................6-3

6.4 Actions during operation.......................................................................................................... 6-3

6.5 Displays and print-outs on detection (cancellation of alarm) .................................................. 6-5

6.6 Displays and print-outs on occurrence of burn-out.................................................................. 6-5

6.7 Over-range, under-range display and abnormal input display .................................................6-6

6.8 Display and record when chart paper runs out ("Chart End" display) .....................................6-6

6.9 Display and record when the recording head ink is low ("Ink Out" display) ..........................6-6

6.10 Display when data backup batteries need to be replaced ("Battery End" display) .................. 6-7

6.11 Display of fault in recording head carriage ("Carriage Alarm" display).................................. 6-7

6.12 Order of priority of state displays ............................................................................................6-7

7. SETTING AND CHECKING PARAMETERS ................................................................... 7-1

7.1 Setting and checking ................................................................................................................ 7-1

7.2 Outline of procedure for setting parameters............................................................................. 7-4

7.3 Pass code setting....................................................................................................................... 7-6

7.4 Setting the chart speed ............................................................................................................. 7-7

7.5 Setting alarms........................................................................................................................... 7-9

Chapter 3,4 and chapter 8 should be observed for installation and maintenance of the unit. So, it must be performed by qualified engineers.

CAUTION

- v -INP-TN3PHCV-E

Page 7

7.6 Setting the recording mode ....................................................................................................7-10

7.7 Setting record ranges.............................................................................................................. 7-14

7.8 Setting kind of input, skip, unit, filter, scaling and subtraction.............................................. 7-16

7.9 Setting Tag Nos. ..................................................................................................................... 7-22

7.10 Message print specification .................................................................................................... 7-23

7.11 List print-out specification ..................................................................................................... 7-26

7.12 Daily report specification .......................................................................................................7-27

7.13 Specifying totalize function ...................................................................................................7-28

7.14 Transmission specification (option) .......................................................................................7-30

7.15 Setting the time ...................................................................................................................... 7-32

7.16 Method of ink out clear ..........................................................................................................7-33

7.17 Turning the chart illumination lamp on/off (option) .............................................................. 7-34

8. MAINTENANCE-INSPECTION ....................................................................................... 8-1

9. APPLICATION FUNCTIONS ........................................................................................... 9-1

9.1 Adjustment of backlash............................................................................................................ 9-1

9.2 Zero/span adjustment for analog trend recording position.......................................................9-2

9.3 Setting of alarm latch and integrated total value print-out....................................................... 9-3

9.4 Setting of PV shift ....................................................................................................................9-4

9.5 User definable unit ................................................................................................................... 9-5

9.6 Setting of record error external output .....................................................................................9-6

9.7 Calibration of measured value ................................................................................................. 9-6

9.8 Change of record color............................................................................................................. 9-8

9.9 Language selection................................................................................................................... 9-8

10. TROUBLESHOOTING ................................................................................................... 10-1

11. EXAMPLES OF RECORD AND PRINT-OUTS.............................................................. 11-1

11.1 Periodic print-outs, scale print-outs .......................................................................................11-1

11.2 Digital print-out (Instantaneous values) .................................................................................11-2

11.3 Parameter list print-out...........................................................................................................11-2

11.4 Test pattern .............................................................................................................................11-3

11.5 Scale print-outs....................................................................................................................... 11-3

11.6 Daily report print-out .............................................................................................................11-4

11.7 Data sum list print-out............................................................................................................11-5

11.8 Message print (manual print) .................................................................................................11-5

11.9 Logging ..................................................................................................................................11-6

11.10 Alarm print-outs .....................................................................................................................11-6

11.11 Burn-out print-out ..................................................................................................................11-6

11.12 Ink dry-up warning print-out ..................................................................................................11-6

11.13 Record start mark ................................................................................................................... 11-7

11.14 Chart speed change mark .......................................................................................................11-7

11.15 Auto range change mark ........................................................................................................ 11-7

12. SPECIFICATION............................................................................................................ 12-1

- vi - INP-TN3PHCV-E

Page 8

1. INTRODUCTION

1.1 Microjet recorder

① This recorder is a multirange input recorder 100mm wide which can record up to a maximum of 6

points using thermocouple/resistance bulb and DC voltage input signals.

② It effects high-speed recording and gives clear analog trend records and digital print-outs in 6

colors.

③ The analog trend records can be given as continuous record type or as intermittent (dot) records.

(See Section 1.3, Format specification.)

④ As well as providing records of measurement values, the standard unit has a wide range of print-

out functions comprising, e.g., the print-out of dates, chart speed, measurement ranges, Tag Nos.,

daily reports and integrated totals.

⑤ Operation of the equipment is simple thanks to an easy-view display section which permits key-in

of various items of set data.

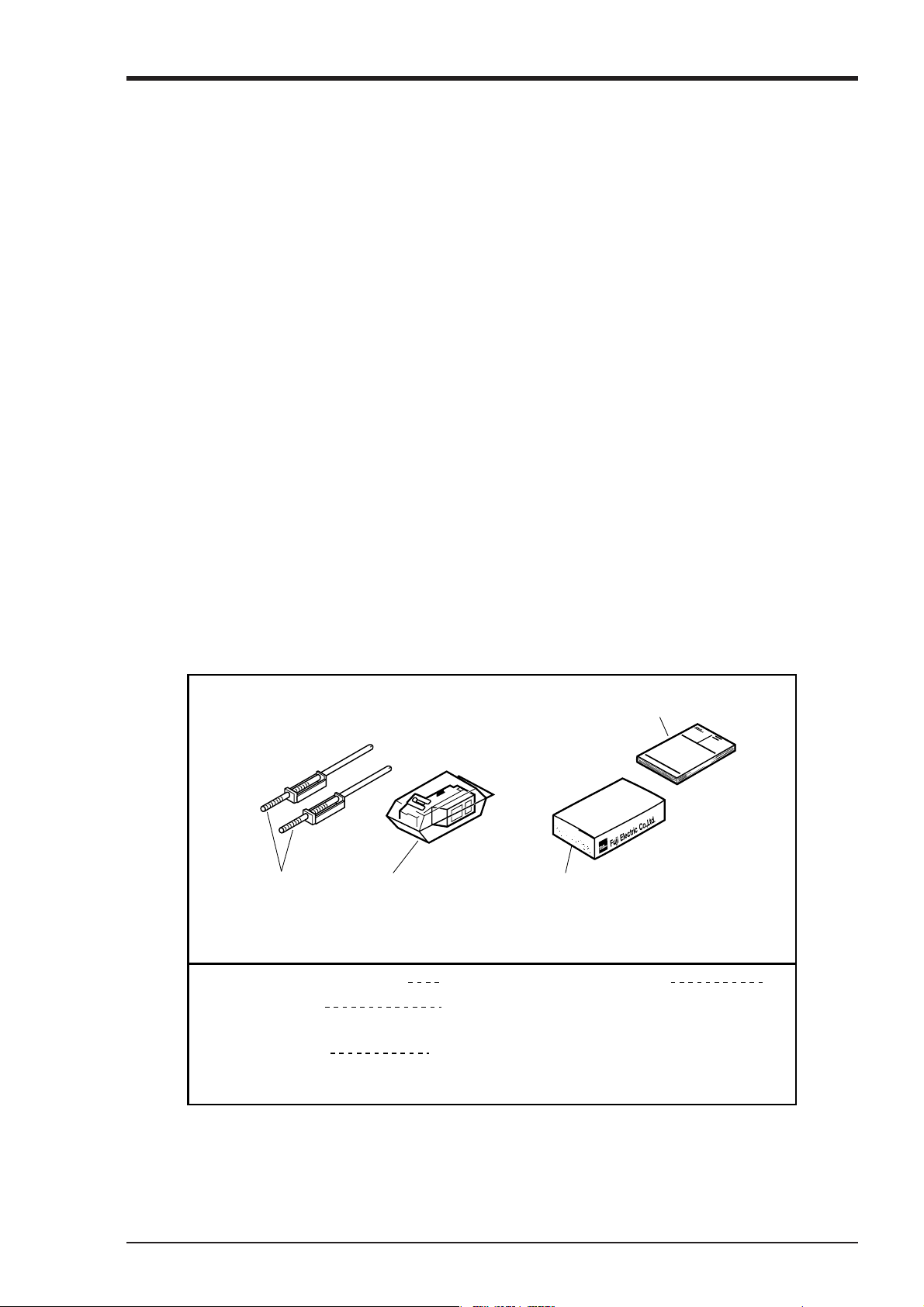

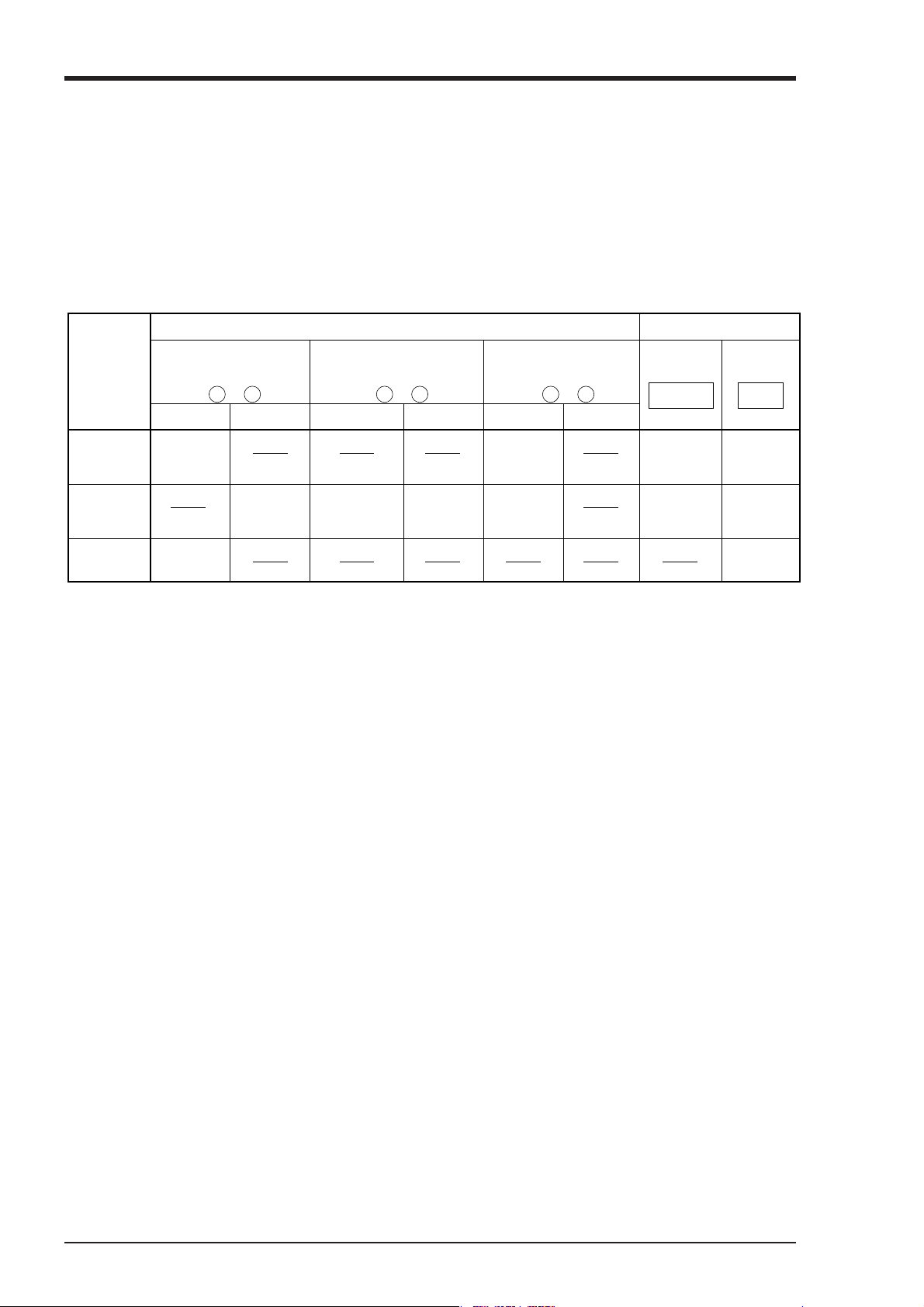

1.2 Product check

Upon receiving the unit, check the appearance and accessories to make sure that they are not damages.

Also, check that the accessories are supplied correctly.

Check on accessories

The unit comes with the accessories shown in Fig. 1-1. Please check that they are all there.

④ Instruction Manual

取

扱

説

明

書

① Panel-mounting

attachments

② Recording head, with

cloth for absorbing ink

(Keep the ink blotting ccloth so as not to be lost.)

① Panel-mounting attachments

② Recording head

with cloth for absorbing ink

③ Recording paper

(The standard recording paper No. is

PEX00DL1-5000B)

2

1

1 pack

富

士

電

機

株

式

会

社

③ Recording paper

④ Instruction Manual 1

Fig. 1-1 Accessories

1 - 1INP-TN3PHCV-E

Page 9

1.3 Check on type and specification

The data plates note the type name, etc. Please check to see that you have got a unit with the specification you ordered. (There are data plates on the top surface of the case and in the main unit.)

12345678 9

PHC 3

1

2

3

6

7

0

1

2

3

4

5

6

0

1

2

3

4

5

6

10 11 12 13 places

V

/

Y

Description

Number of recording points

1 continuous record

2 continuous record

3 continuous record

6 continuous record

6 dot records

Number of input signal points

(thermocouples)

None

1 points

2 points

3 points

4 points

5 points

6 points

Number of input signal points

(resistance bulbs)

None

1 points

2 points

3 points

4 points

5 points

6 points

0

1

2

3

4

5

6

•Value of input signal prior to delivery

Thermocouple : K 0 to 1200°C

D

L

Resistance bulbs : Pt100 0 to 500°C

DC voltage : DC -5 to +5V

•Relations between input signal specifications

and recording channels

Ex.)If 3 thermocouple points, 2 resistance bulb

points and 1 DC voltage points are specified.

channels 1 - 3 are thermocouple

channels 4 - 5 are resistance bulbs and channels 6 is DC voltage.

Note: After purchasing the unit, the type of input sig-

nal can be changed within the number of recording points (see Item 5.3).

Note1) These functions are not conformed to UL61010-1 standard.

Note2) It is conformed to UL61010-1 standard with conditions attached.

Please refer to Item12 "Optional specifications" for details.

• Supplementary supplies

Number of input signal points

(DC voltage)

None

1 points

2 points

3 points

4 points

5 points

6 points

Power Supply

100 to 240V AC 50/60Hz Note 1)

24V DC

A

B

0

1

2

Y

R

Asterisks (*) indicate options

CHART illumination*

Without

With

Alarm output/external control*

None

6-point alarm output (la contact)

/with 3-point external control Note 2)

6-point alarm output (1b contact)

/with 3-point external control Note 1)

Communication*

None

With RS-485 Note 1)

the number of points of the 4th place.

The total number of points should be equal to

Product name Type Specification Sales units

Recording head PHZH1002 1 per unit 1

Recording paper (uniform 50 scale) PEX00DL1-5000B Approximately 15m 6 packs

(6 packs/box)

1 - 2 INP-TN3PHCV-E

Page 10

2. NAMES AND FUNCTIONS OF PARTS

(1) Display section

(6) Keying operation section

(3) Power supply switch

(4) Paper feed

unit drawout

lever

(5) Chart paper holder

Hold the left end of the display unit and

pull it forward as shown above.

(2) Recording head

(1) Display section

For displays such as measurement data and displays of various parameters and comments

Display of units and data for each channel

Display of various parameters, comments

(2) Recording head

This is a recording head which serves for analog trend recording and digital print-outs. As this is

not installed in the main unit at the time of delivery, please install it referring to Section 5.2.

(3) Power supply switch

Used to turn the power on and off.

(4) Paper feed unit drawout lever

When setting (or replacing) chart paper, push down the drawout lever. The paper feed unit will

come out. If it does not come out, pull it forward while holding the lever down.

(5) Chart paper holder

The chart paper holder is used to feed paper smoothly.

2 - 1INP-TN3PHCV-E

Page 11

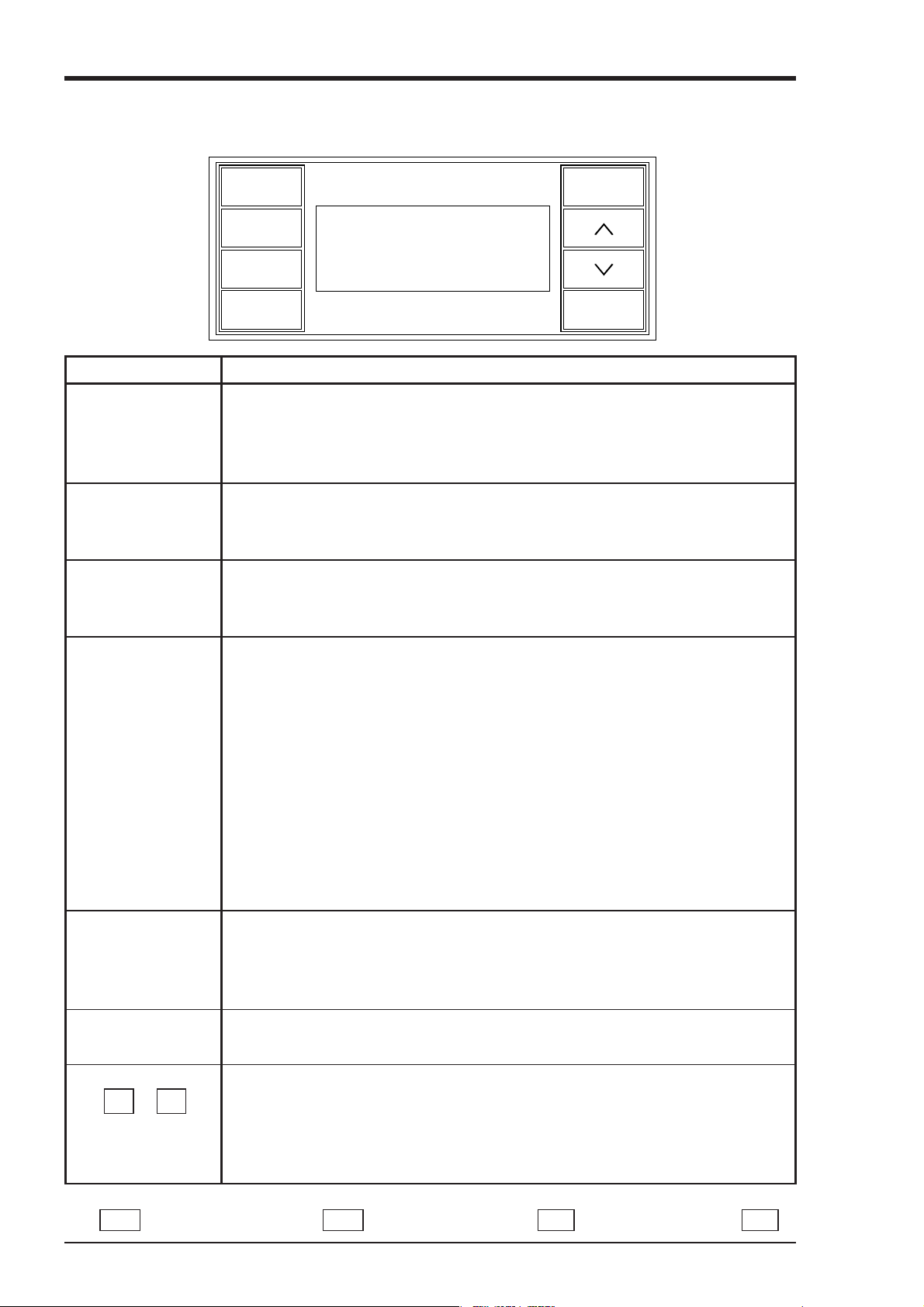

(6) Keying operation section

This is used for setting various parameters, making checks and running the equipment.

Name of key

RECORD

LIST

FEED

RECORD

DISPLAY

LIST

FEED

SELECT

ENTRY

Function

Operation key for starting and stopping recording.

Recording starts when the key is pressed once and stops when the key is pressed

again.

This key is ineffective during print-out of data or lists.

This is used for effecting print-out of data (instantaneous values).

If you wish to stop the print-out partway through, press the key again.

This key is alwys effective.

Chart paper fast-feed key

Feed speed is 3mm/s at the beginning of press, and about 8mm/s after 1 second.

This key is always effective.

DISPLAY

SELECT

ENTRY

∧ ∨

(up) (down)

1. Used for changing the data display. The following 5 items are selected at each

press.

(1) Data of all channels are displayed in order, except for the skip channel.

Data display is updated at intervals of 1 second and channels are selected

every 3 seconds.

(2) Display only of the data of specific channels. The data display is updated

once every second.

(3) No. 1 to 6 channels are displayed simultaneously, and data display is up-

dated at 1 second intervals.

(4) Display of the date and time.

2. This key is used for shifting from a set mode to the data display mode.

This key is ineffective during print-out of data or lists.

1. Used for shifting from the data display mode to a set mode.

2. Is used for effecting sequential read-out of parameters during operation in a

set mode.

This key is ineffective during print-out of data or lists.

Is used to register set data.

This key is effective only during set mode operation.

Used to scroll numerical values up and down.

The values are scrolled up or down 1 count each time the relevant key is pressed.

Holding a key depressed for more than 0.5 seconds results in a fast up/down

scroll at a rate of 5 counts/second and holding it depressed for a further 2 seconds

results in an ultra-fast scroll of 55 counts/second.

Note) In this instruction manual some display of the keys are abbreviated as follows. RECORD key is indicated

REC , DISPLAY key is indicated DISP , SELECT key is indicated SEL , ENTER key is indicated ENT .

2 - 2 INP-TN3PHCV-E

Page 12

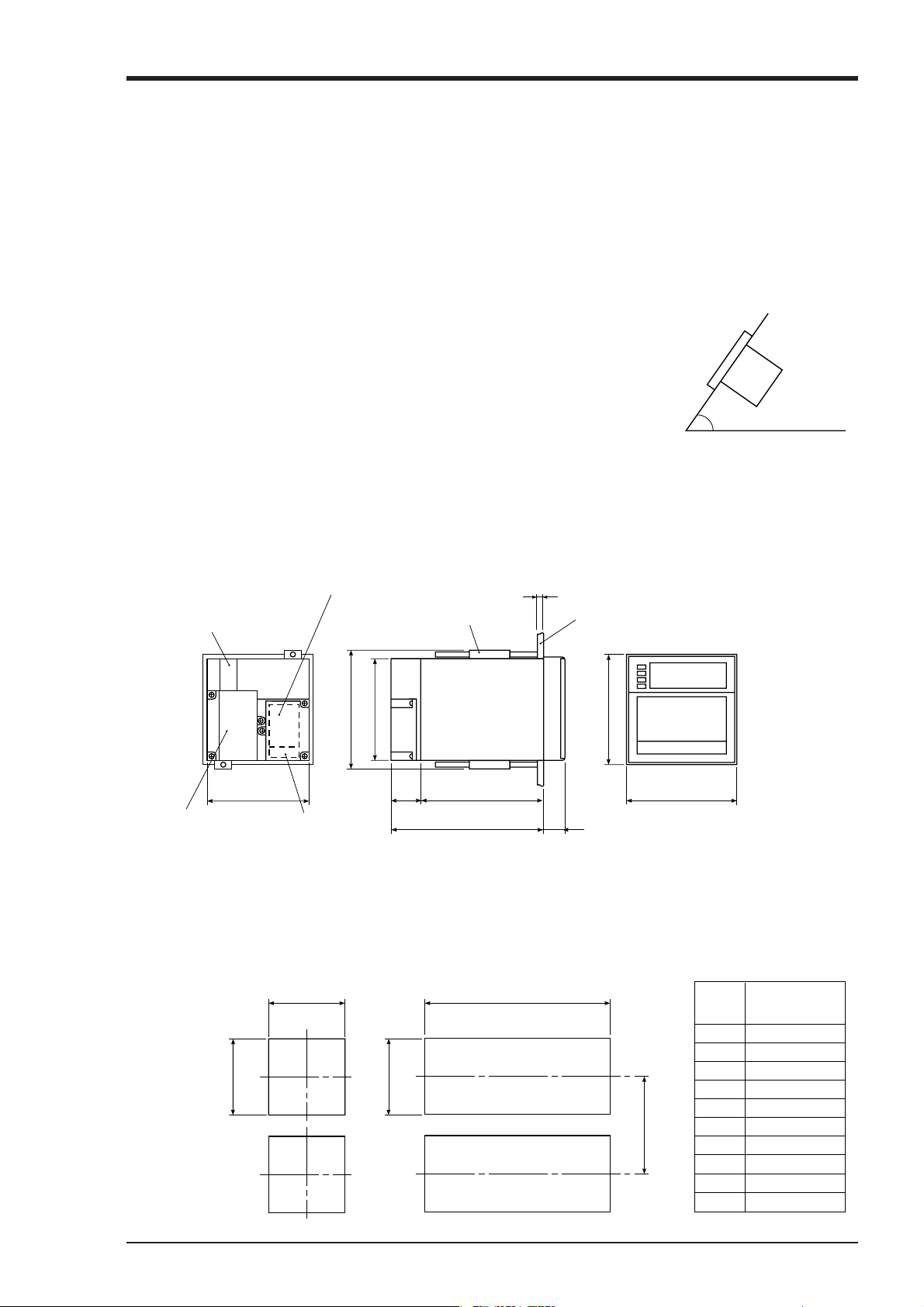

3. MOUNTING METHOD

Power supply terminal

Input terminal

136.4

Alarm external

control unit

(Option)

Transmission

terminal

(Option)

199

41 158

26

136.4

174.4

Mounting attachment

2≦ t ≦30

t

Panel

144

144

PANEL CUTOUT

137

+1.5

0

137

+1.5

0

175

MIN

137

+1.5

0

L

+ 2

0

L

+ 2

0(mm)

For single unit mounting For left/right tight fit mounting

Number

of

units

2

3

4

5

6

7

8

9

10

n

Weight : Approximately 2.1kg (without options)

Approximately 2.2kg (with all options)

Power consumption : Approximately 26VA (100V AC with all options)

Less than 26VA (26.4V DC with all options)

282

426

570

714

858

1002

1146

1290

1434

(144×n)

-

6

This unit is designed to be panel mounted.

3.1 Mounting location

Select the following location for mounting the unit.

(1) A place that is not subject to vibration or impact.

(2) A place where there is no corrosive gas.

(3) A place that is subject to little temperature variation and is close to

normal temperature (23°C)

(4) A place that is not struck directly by strong radiant heat.

(5) As humidity affects the ink and recording paper, select a place that

is in the range 20 to 80% RH.

(6) Mount the unit horizontally, with no tilt to the left or right.

(The forward tilt should be 0° but the unit may be inclined 0 to 30°

rearwards.)

∠ α

α = 60 to 90°

3.2 External dimensions and panel cut out dimensions (unit: mm)

3 - 1INP-TN3PHCV-E

Page 13

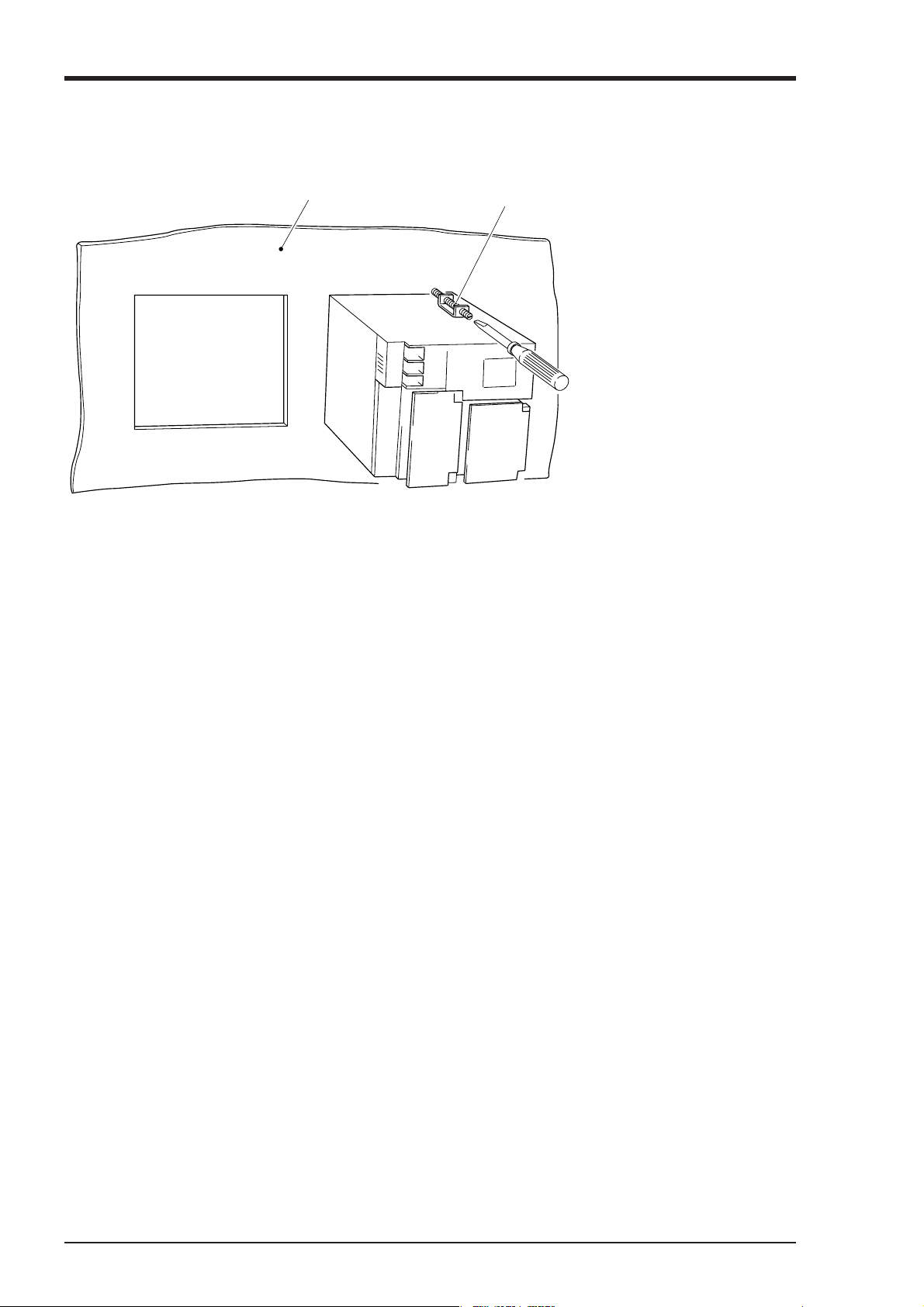

3.3 Method of mounting onto panel

Panel

Screw

• Using the supplied mounting

fixture, tighten the upper and

lower screws until the panel is

fixed.

• The panel to be used should

be more than 2mm thick.

3 - 2 INP-TN3PHCV-E

Page 14

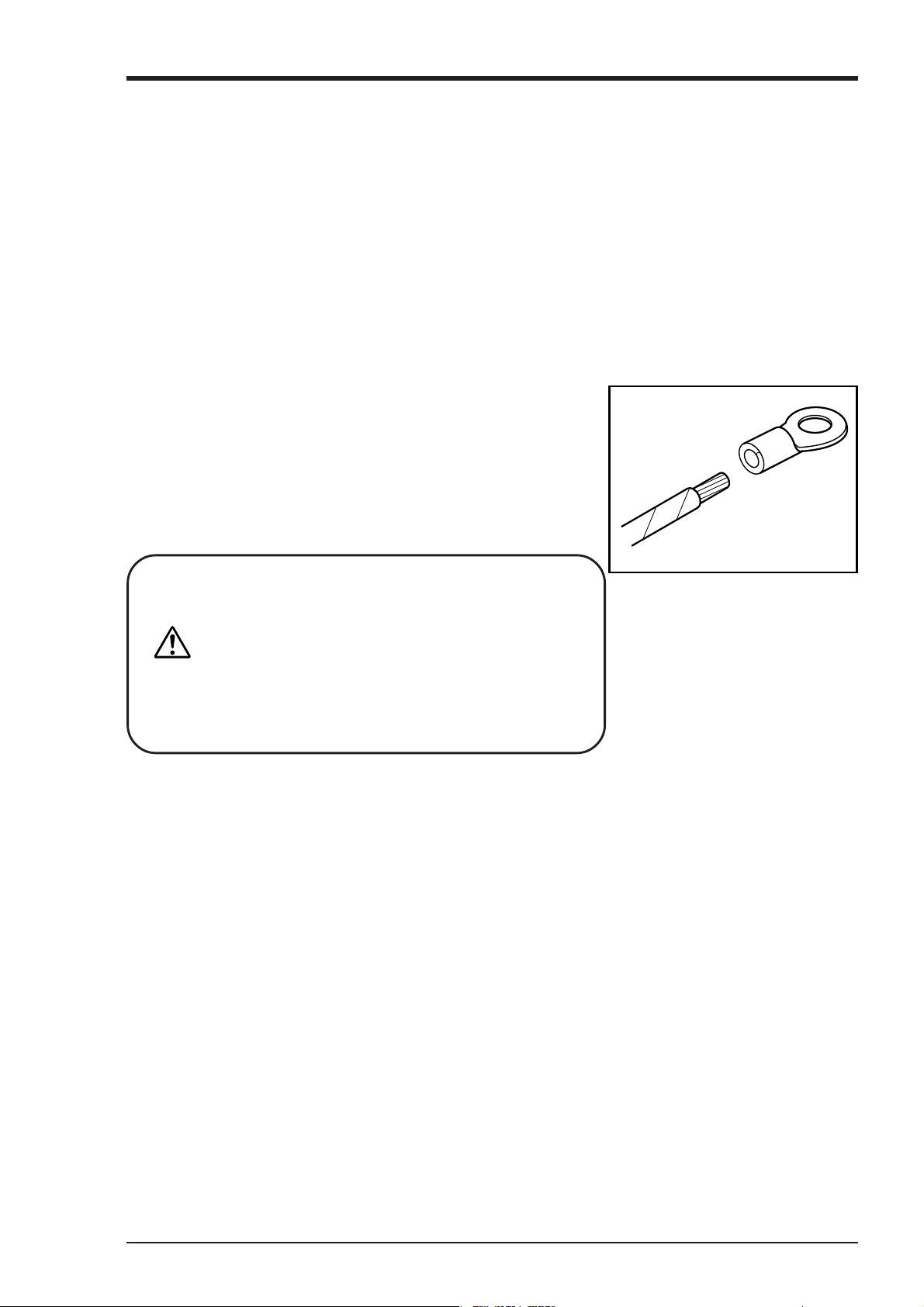

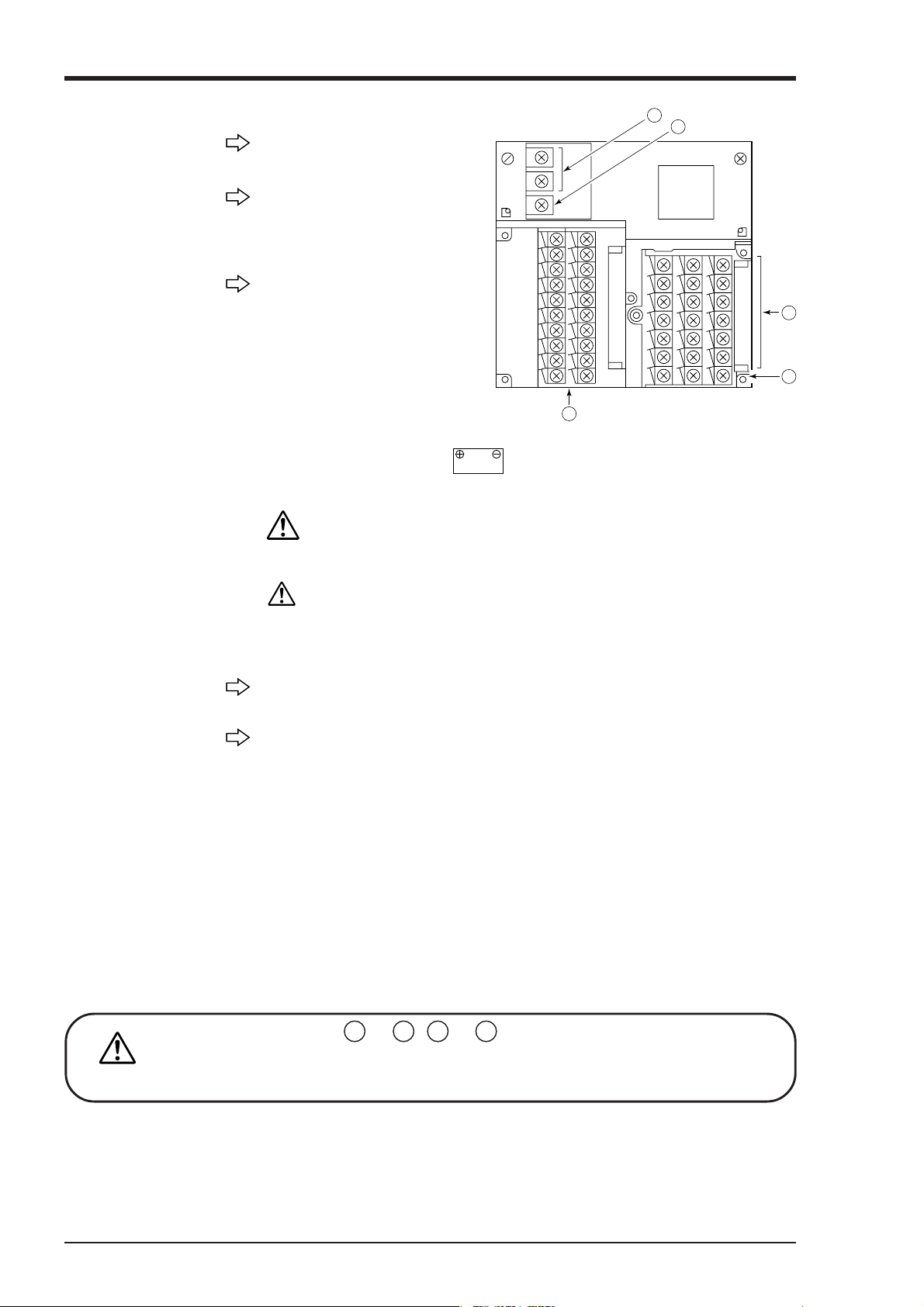

4. WIRING

4.1 Before doing the wiring

To carry out wiring, remove the unit's rear cover (Notes)

① When wiring the power supply unit, use vinyl-insulated 600V cables (JIS C 3307) or equivalent

cables.

② For thermocouple input, be sure to use a compensated lead wire.

③ Input signal cables should be wired separately as far as possible (30cm or more) from power lines

and high-voltage lines to minimize the effect of inductive noise. Shielded cables should preferably

be used. In this case, the shield braids should be earthed at one point.

④ For wiring the terminals, use a maximum of 2 crimp style terminals.

Notes

(1) At the completion of wiring of the input terminals, be sure

to close the rear cover to ensure the compensation of reference contact when thermocouple input is used.

(2) For connection of lead wires to terminals, use of sleeve-

insulated clamping terminals (for M4 screws) is recommended.

CAUTION

The recorder is not provided with a power fuse.

Use an external power fuse.

.

In case the power supply is 100 to 240V AC

Recommended fuse rating : T2A, 250V AC

.

In case the power supply is 24V DC

Recommended fuse rating : Maximum 3A,

minimum 24V DC

4 - 1INP-TN3PHCV-E

Page 15

4.2 Connection of wires to terminals

(1) Input terminals

Connect signal leads for each

channel.

3

4

(2) Alarm,

external

control unit

(option)

(3) Power terminal

Connect the alarm signal outputs

and external control signal inputs

(for alarms 1 to 6, external controls 1 to 3).

1) Connect the power cables to

AC/AC terminals. (Supply

voltage 100 to 240V AC products (9th digit of code symbol: “D”))

This is the power for the

specified type of 100 to 240

V AC (50/60Hz)

2) Connect power cable to

DC24V

ucts (9th digit of code symbol: “L”))

If you apply to exceeding 30V AC (Example: 100V AC and 240V AC)

to 24V DC power materials, the equipment will be broken and never be

fixed.

For UL Certification,this unit is only supplied by 24V DC, comply-

CAUTION

ing with Limited Energy Circuit.

1

5

2

terminals. (Power voltage 24V DC prod-

(4) Ground

terminal

(5) Transmission

terminal

(option)

Alarm output terminals ( 14 to 19 , 24 to 29 ) are of overvoltage category I. Other

terminals (input signals, communication interface) are for SELV signals (safety sepa-

CAUTION

rated from hazardous voltage).

3) Power source to be connected should be free from noise.

D-class grounding with ground resistance of 100Ω or less.

Connect the transmission signals.

4 - 2 INP-TN3PHCV-E

Page 16

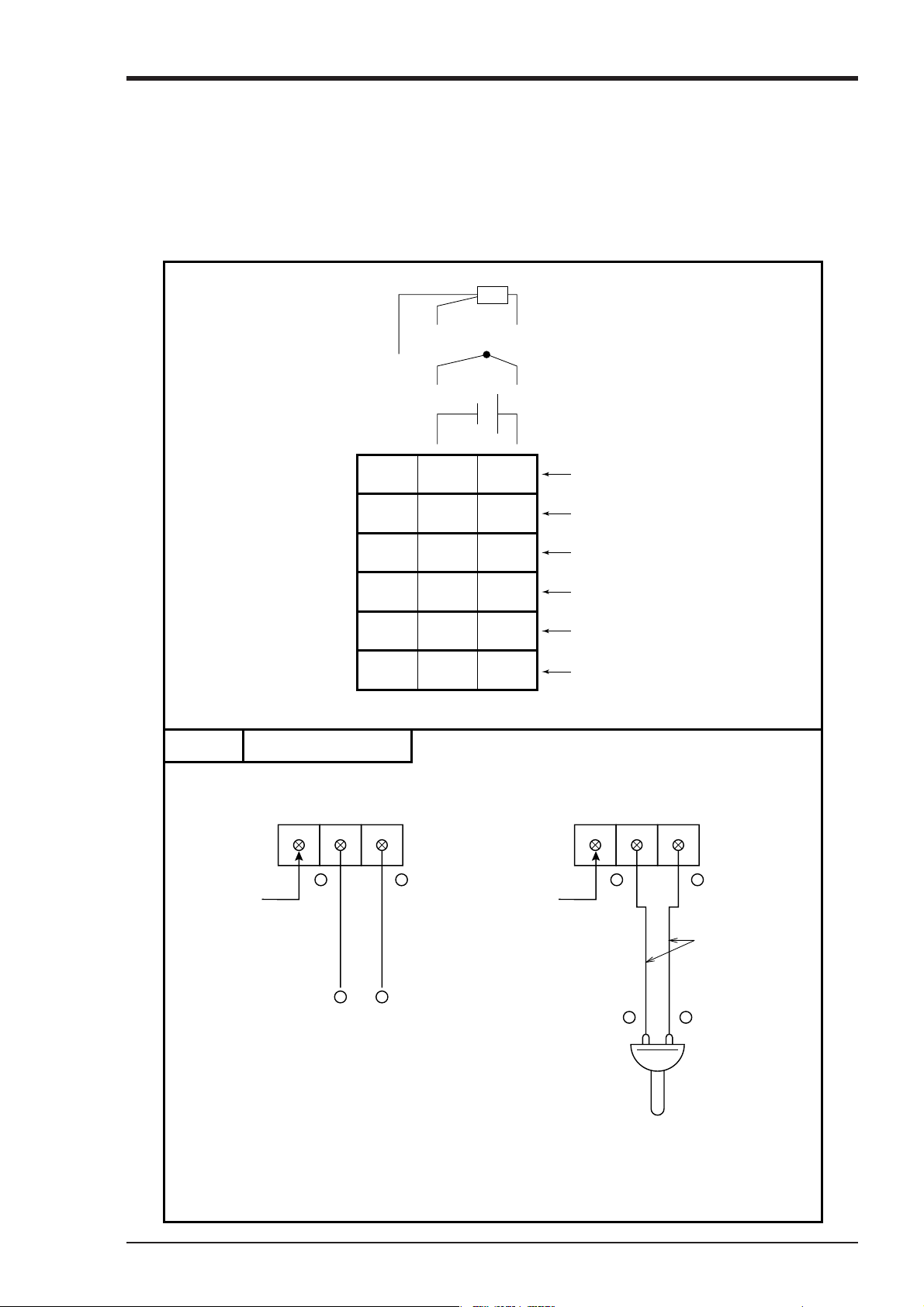

(1) Connection of input terminals

① Each channel has its own input terminal No.

② Connect input terminals confirming the relation between the number of input points shown in the

code symbols and their channels (see Item 1.3).

③ When the kinds of input signals have been changed after purchase of the unit (see Item 5.3), be sure

to connect the terminals of corresponding channels.

Resistance bulb

ABb

Thermocouple

+

DC voltage

Example

Blank

13 12 11

23 22 21

33 32 31

423 42 41

53 52 51

63 62 61

Input terminal wiring

DC voltage input

1213 11 2223 21

–

Input 1

Input 2

Input 3

Input 4

Input 5

Input 6

Thermocouple input

+

–

+

Blank

+

–

DC voltage input

Compensating

leads

–

+

Thermocouple

Note : Avoid using thermocouple input with

wiring parallel to other instruments.

4 - 3INP-TN3PHCV-E

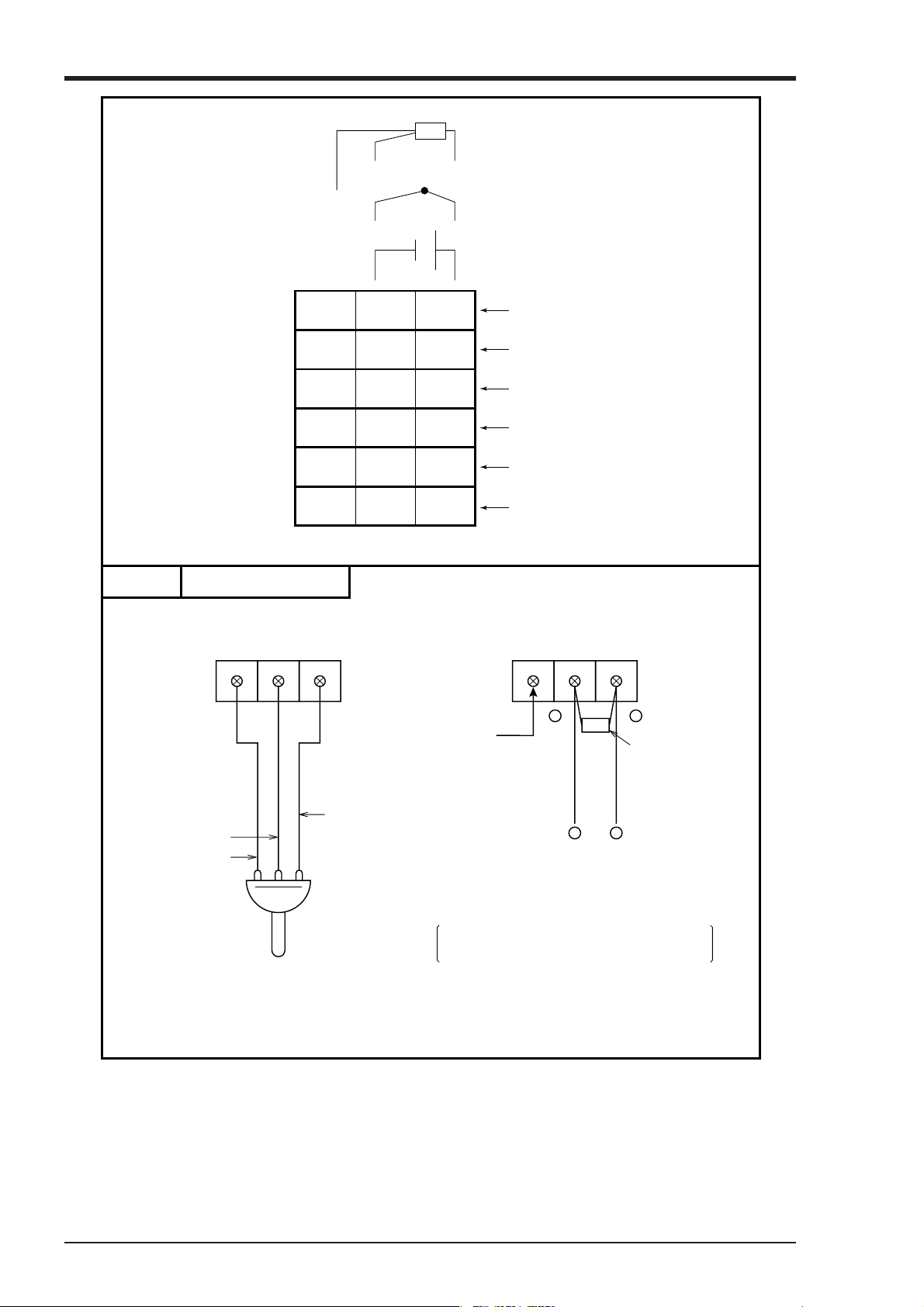

Page 17

Resistance bulb

ABb

Thermocouple

+

DC voltage

Example

13 12 11

23 22 21

33 32 31

423 42 41

53 52 51

63 62 61

Input 1

Input 2

Input 3

Input 4

Input 5

Input 6

Input terminal wiring

Resistance bulb input DC current input

4243 413233 31

bB A

–

Blank

+

Shunt

resistance

A

+

B

b

–

DC current input

Example : 10Ω ±0.1% shunt resistance is used

for 4 to 20mA and 10 to 50mA input.

Resistance

bulb

Note :

In this case, ±500mV input range is

available. See Item 5.3.

DC current is converted into voltage by shunt

resistor (10Ω):

In 4 to 20mA DC : 40 to 200mV DC

In 10 to 50mA DC : 100 to 500mV DC

4 - 4 INP-TN3PHCV-E

Page 18

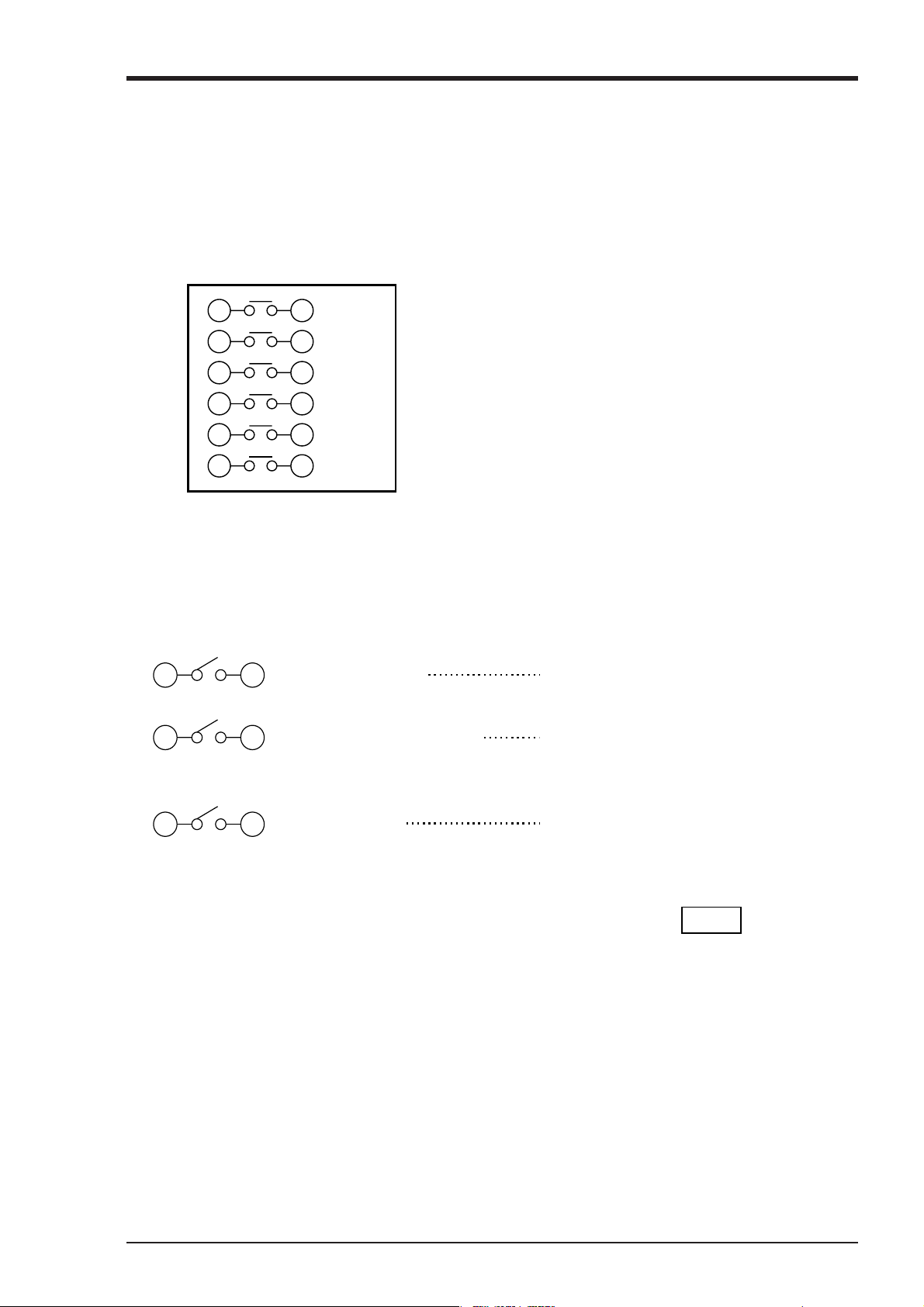

(2) Alarm output/remote control unit (option)

About alarm outputs :

(1) Alarms can be set at 6 points in each channel and alarm outputs are provided as an option for up to

a maximum of 6 points.

(2) When an alarm is detected, the relevant terminals are shorted.

1a contact output : Relay contact capacity 240V AC/3A, 30V DC/3A (resistive load)

1b contact output : Relay contact capacity 125V AC/0.4A, 30V DC/2A (resistive load)

14 24

15 25

16 26

17 27

18 28

19 29

About remote control inputs :

(1) This performs the functions 'Recording operation start/stop', 'Two-stage changeover of recording

paper speed' and 'Data (instantaneous value) print-out' in response to contact signals from outside

the instrument.

(2) There are separate wiring terminals for the different functions.

11 21

Alarm 1

Alarm 2

Alarm 3

Alarm 4

Alarm 5

Alarm 6

(DI1) Record start

Note : If lamps are used on the outside, insert a resistor to pre-

vent surge current.

Also, if relays or solenoids are used, insert elements for

contact protection (diodes, surge killers, etc.).

Recording starts when the contact is closed

and stops wht is open.

12 22

(DI2) Chart speed change

The chart speed is the remote mode speed

when the contact is closed and the normal

operaiton speed when the contact is open.

13 23

(DI3) Data print

Print-out starts when the contact is closed

and goes on right to the end even if the

contact is opened partway throught the printout. If you wish to stop print-out partway

through, press the LIST key on the front

panel.

4 - 5INP-TN3PHCV-E

Page 19

Note 1: As the external control unit is not insulated, use it with interposition of an external relay.

External contact capacity 12V DC/0.05A 1a contact

Note 2: Operation with the external control unit and the front panel switches are shown in the table on

next page.

(The sign "---" in the table does not affect the operation of the unit)

Note 3: When using the message print function or alarm latch function, the meaning of control input is

different. Refer to "7.10 Message print specification" and "9.3 Alarm latch specification".

Remote control

Recording start

(across terminals

11 21

− )

Chart speed change

(across terminals

12 22

− )

Data print-out

(across terminals

− )

ON OFF ON OFF ON OFF

While

recording

is stopped

During

recording

List print

out

Recording

starts

Recording

starts

Recording

stops

Remote

mode chart

speed

Normal

operation

chart speed

List print-

out starts

List print-

out starts

(3) Caution on connection of input signal through barrier

• Thermocouple input and resistance bulb input.

Perform "Calibration of measured value" with the input connected to the barrier recorder because

the barrier internal resistance is added and causes an error in the measured value.

For the calibration method, refer to Item 9.4.

13 23

Front panel swich

RECORD

Recording

starts

Recording

stops

List print-

out starts

List print-

out starts

List print-

out stops

LIST

4 - 6 INP-TN3PHCV-E

Page 20

5. SET-UP

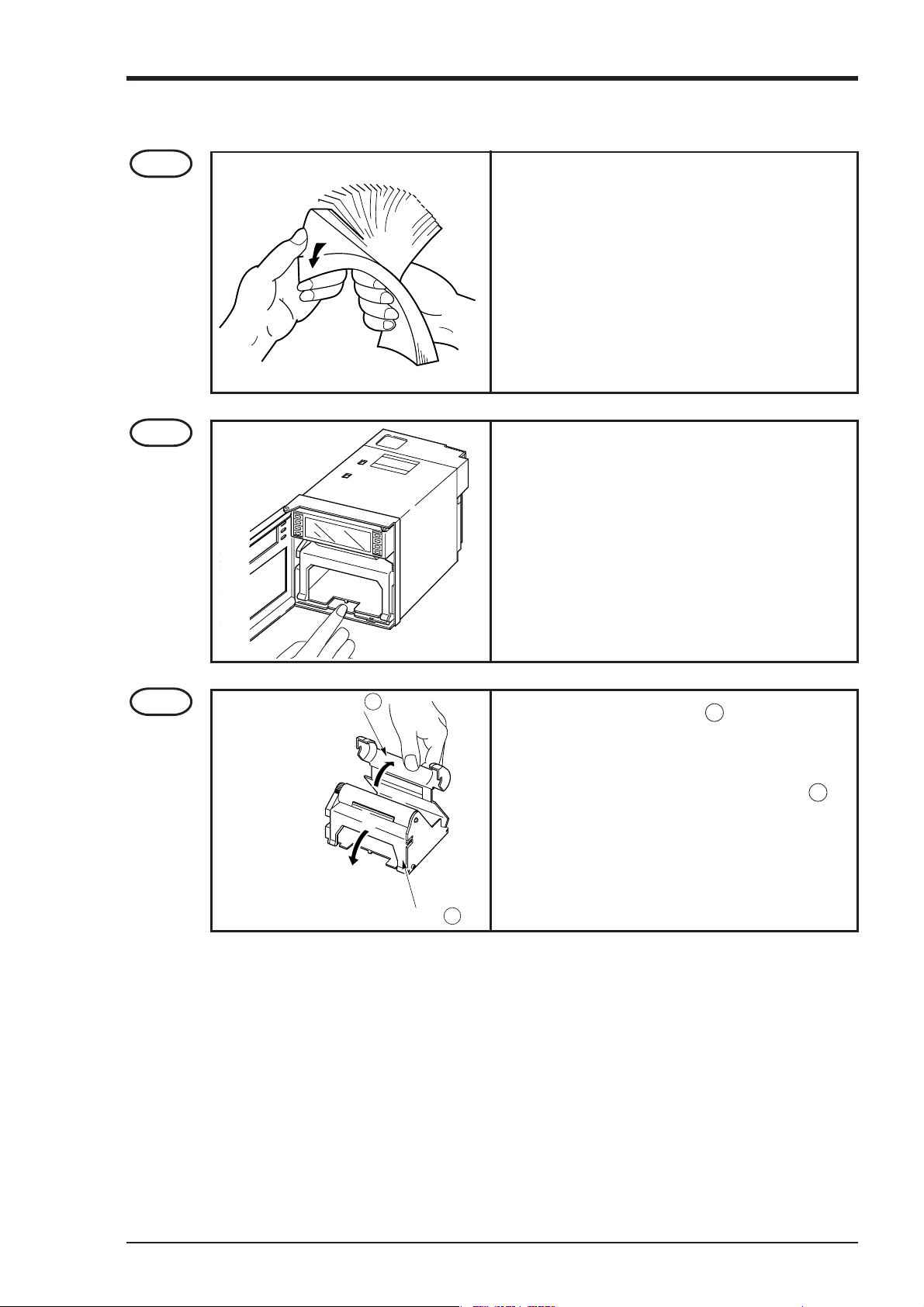

5.1 Loading Chart Paper

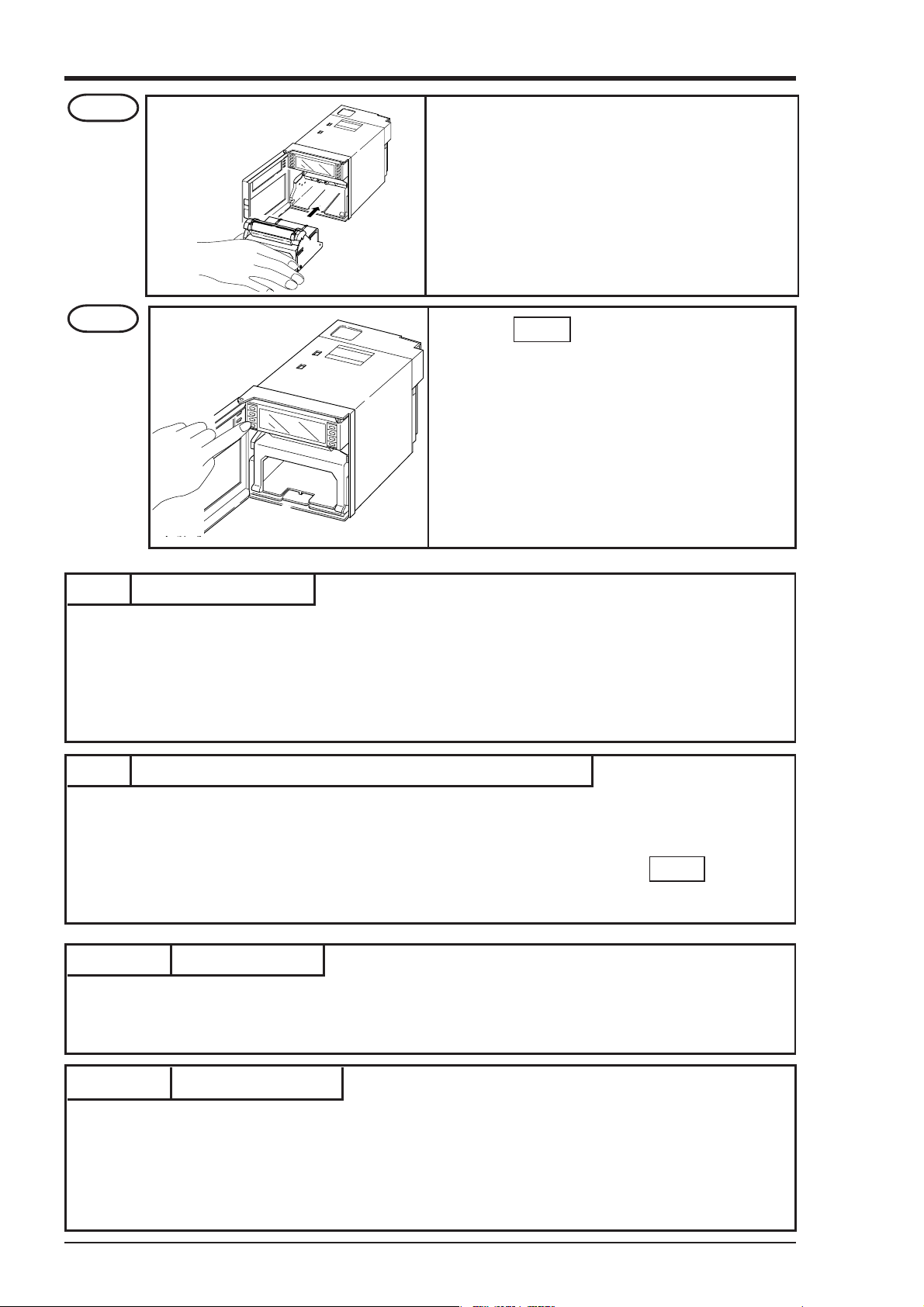

Step 1

Step 2

Prepare chart paper.

Loosen both ends of the chart paper thoroughly to

prevent sheets from being fed together.

Open the front door and press down the paper feed

unit drawout lever.

The paper feed unit will be drawn out.

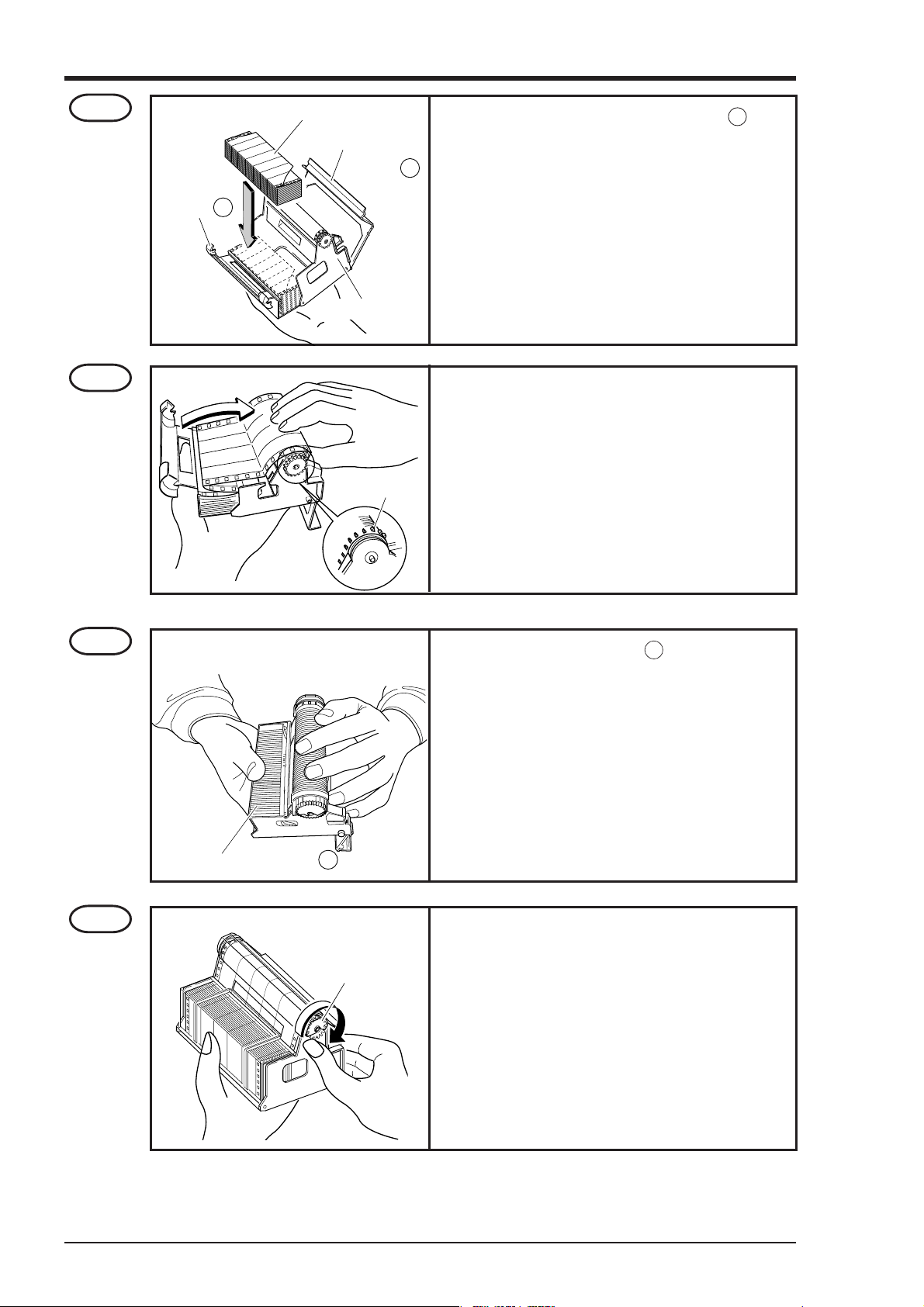

Step 3

Chart paper retainer B

Chart paper retainer A

Hold the chart paper retainer B and open it backward.

Also, hold and open the chart paper retainer A .

5 - 1INP-TN3PHCV-E

Page 21

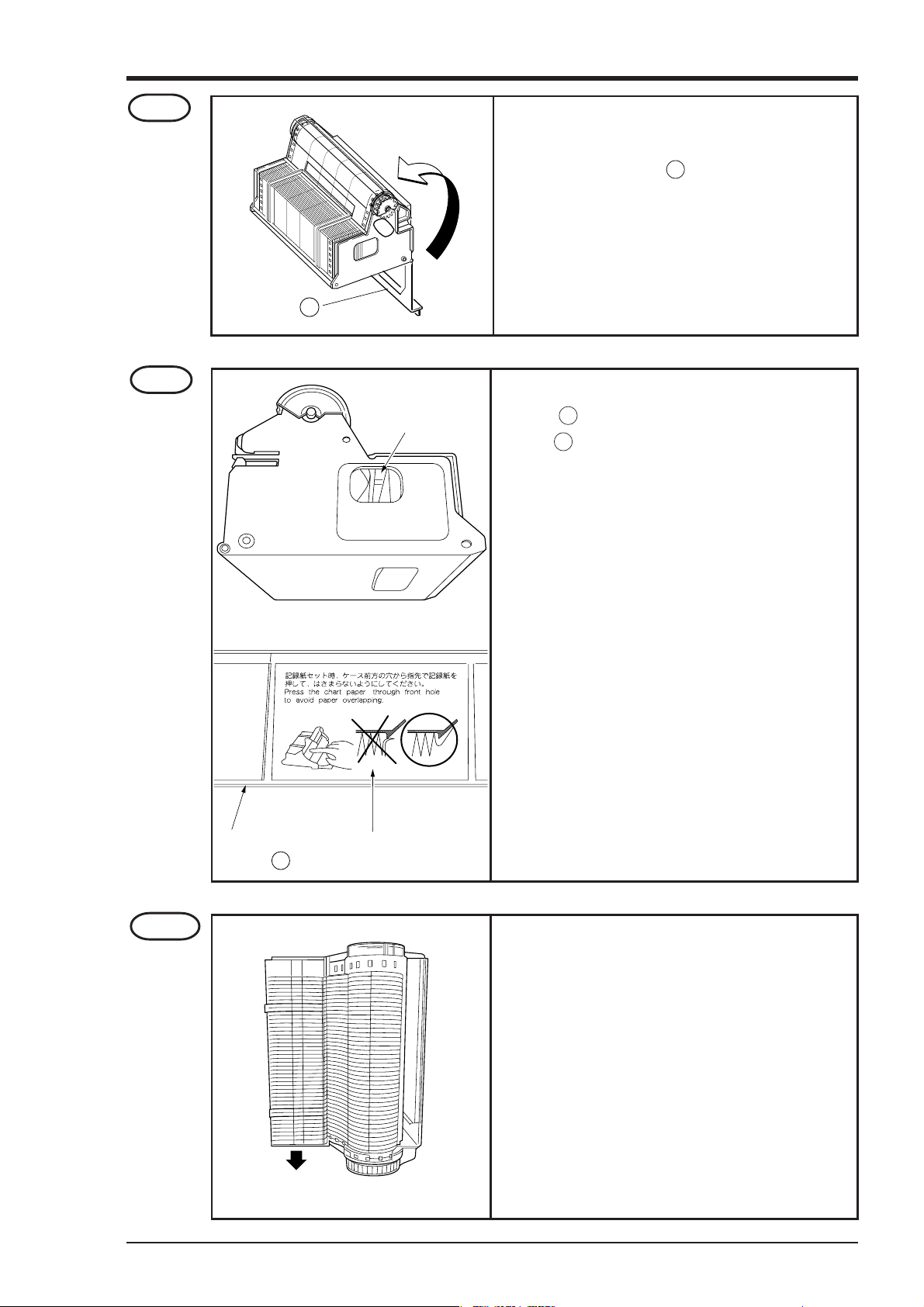

Step 4

Chart paper

retainter B

Chart paper

Paper feed unit

Chart paper

retainter A

Set chart paper in the chart paper retainer B as

illustrated.

Step 5

Step 6

Align the perforations of the chart paper with the

pins.

Pin

Close the chart paper retainer B .

(The chart paper is set vertically).

Chart paper retainter B

Step 7

Turn clockwise the gear of the roller unit with hand

and check that the chart paper shifts forward.

Gear

5 - 2 INP-TN3PHCV-E

Page 22

Step 8

Transfer the chart paper that has been forwarded

into the storage of the paper feed unit. Then close

the chart paper retainer A .

Chart paper

retainter A

Step 9

Check the chart paper

through this hole.

As shown by the caution display on the chart paper

retainer B , if paper is caught in the chart paper

retainer B , paper jam may result.

As shown by the figure at left, check through the

holes on the left and the right side of the paper feed

unit that the chart paper is not caught in the retainer.

Step 10

Chart paper

retainter B

Side provided with long holes

Gather the

chart paper

Caution in setting

a chart paper

The chart paper is provided with long holes and short

holes. Gather the chart paper in the storage to the

side provided with short holes as illustrated on the

left.

Side provided

with short holes

5 - 3INP-TN3PHCV-E

Page 23

Step 11

Mount the paper feed unit in the recorder. At this

time, check that it is properly locked in position.

Step 12

Note 1 Selection of chart paper

The chart paper greatly affects the quality of the printed recording and it is also related to problems such

as paper jamming, etc.

Please be sure to use the pure-quality chart paper specified us.

Chart paper type : PEX00DL1-5000B (50 equal divisions, no time lines)

Press the FEED key and check that the chart

paper is fed out smoothly.

(Feed out about 2 folds of paper.)

<If the paper is not fed out smoothly, go through

the procedure from Step 2 again.>

Note 2 Use of the recorder after it has been left unused for a long time

If the recorder is left unused for a long time with chart paper still in the main unit, the paper 'packs down'

and if the recorder is used straightway there can be problems of paper jamming, etc.

If you use the equipment after it has been left unused for a long time, first press the FEED key to feed

out 2 to 3 folds of the paper.

Reference 1 Chart paper length

The chart paper is approximately 15m long. This permits about 31 days continuous print-out at a paper

feed speed of 20mm/h.

Reference 2 Chart paper end mark

The amount of chart paper remaining is indicated by digits (units : 10cm) on the right-hand side of the

paper. When there is only a small amount left, red letters appear on the right-hand edge.

If the recording paper runs out completely, a recording paper end indicator displays 'Chart end' in the

display section and recording automatically stops.

5 - 4 INP-TN3PHCV-E

Page 24

5.2 Recording head installation (replacement)

The recording head is a combination of a head and ink.

When ink is used out or trouble arises with the head, it can easily be replaced.

Use the recording head carefully observing the “Caution” noted in the later paragraph.

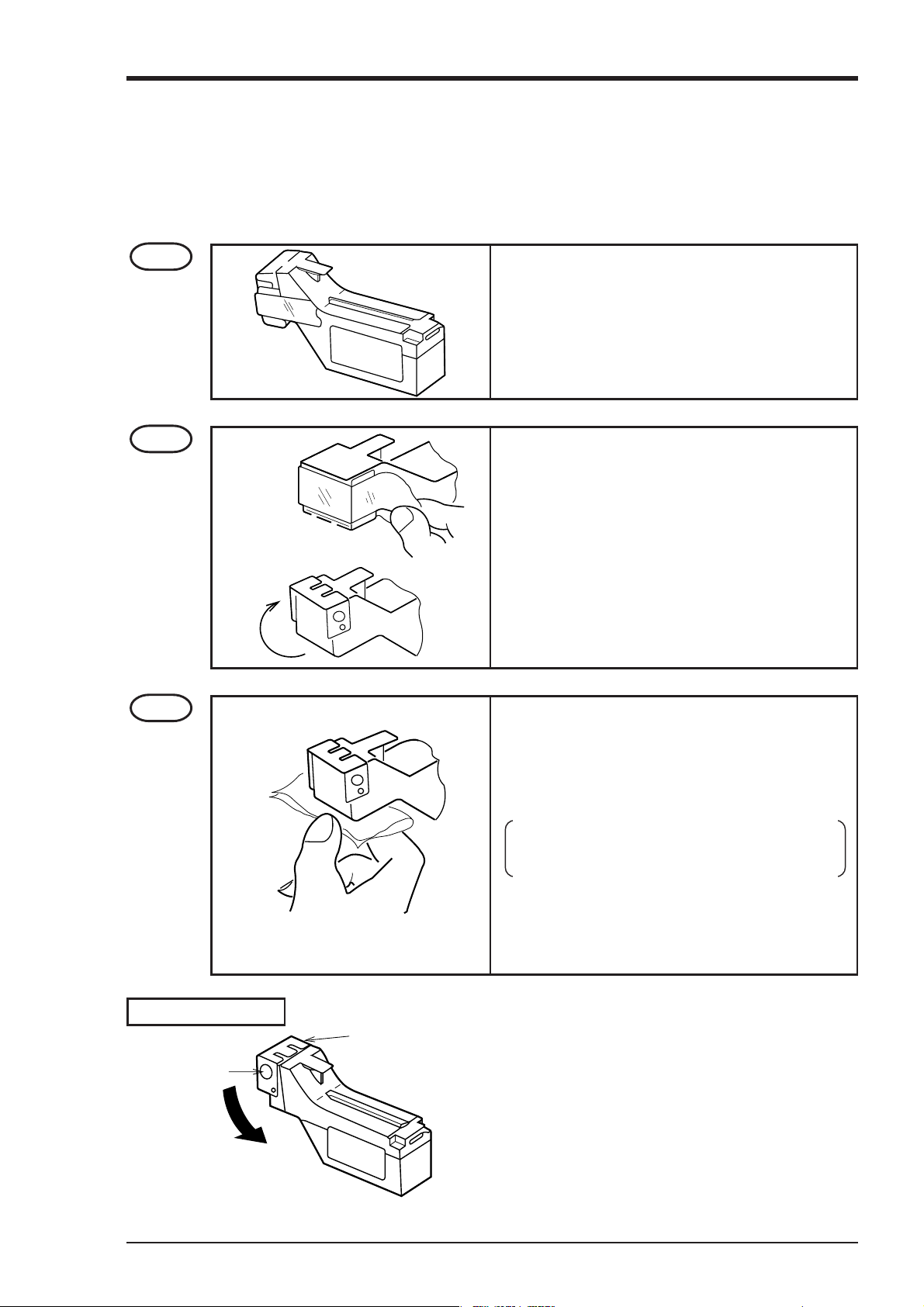

Step 1

Step 2

Get the recording head ready by taking it out of its

aluminium pack.

Tear the tape.

Open the cap by turning it in the direction indicated

by the arrow.

(If the head is not going to be used for a long time,

close the cap back in its original position.)

The cap is integral with the head unit. Turn it about

180° until it stops against the top of the head.

Step 3

How to close the cap

Stopper

• Lightly press the nozzle surface (the surface from

which ink is discharge). Make sure that the cloth

is properly impregnated with the 4 colors blue,

red, yellow and black.

First press the cloth against the surface for 2 to

3 second; if the 4 colors ooze out, it is OK.

Note) Do not use any cloth other than the supplied

one. Also, do not rub the nozzle with the

cloth.

Cap

• Turn the cap in the direction indicated by the arrow and press it firmly until it is retained by the

stopper.

• Ink may leak out if the cap is not properly in place.

5 - 5INP-TN3PHCV-E

Page 25

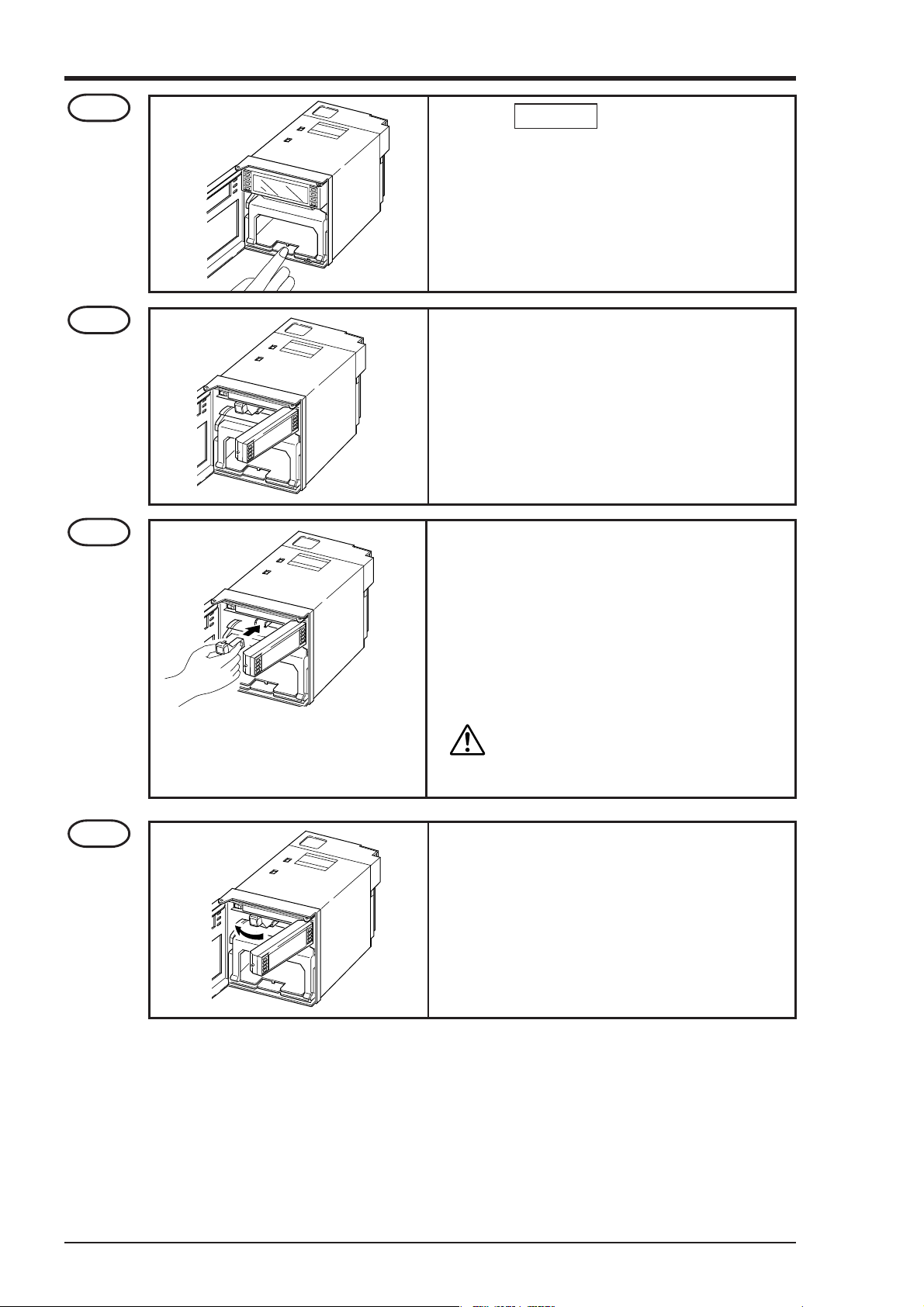

Step 4

• Press the RECORD key. Operate the recorder

after it has been set in recording stop mode.

• Open the front door and press down the paper

feed unit drawout lever.

The paper feed unit will be drawn out.

Step 5

Step 6

Hold the left end of the indicator and pull it forward.

The indicator will turn 90°.

• Hold the recording head horizontal, line it up with

the carriage in the main unit slide it in slowly

and press it firmly until it does not go in any further.

• Take care not to bang the nozzle surface of the

head. Also, avoid touching the nozzle surface with

your hand.

Do not touch the connector at the rear

of the carriage to avoid the risk of mi-

CAUTION

nor electric shocks.

Step 7

Set the indicator in its original position.

5 - 6 INP-TN3PHCV-E

Page 26

Step 8

The above completes installation of the recording head.

The recording head is a consumable part. Replace it with a new one when the ink it contains is

used up.

• Set the paper feed unit in its original position.

Recording head replacement

Draw out the recording head in the manner that is opposite to what is described in Step 6 of the

recording head setting procedure, and replace it with a new recording head.

Always carry out the following procedure after replacing a recording head.

(1) Setting the ink monitor

Perform the following keying actions in order to get correct performance of the ink dry-up warningdetection function.

As in “Clearing the ink monitor” of Section 7.16, press the SELECT key to give an “INK

MONITOR CLEAR” display

INK MONITOR CLEAR

NO

∧

Press the ∧ key to change the flickering “NO” to “YES”.

Next, press ENTRY key.

This completes the setting.

↓

Press the DISPLAY key to return to a data display.

INK MONITOR CLEAR

YES

(2) Test pattern print-out

Print out a test pattern to check that normal recording is possible. See Section 6.3 for the way of

printing out a test pattern.

(3) Adjustment of analog trend recording positions

Referring to Section 9.2, readjust the zero and span on the recording paper.

5 - 7INP-TN3PHCV-E

Page 27

Precautions in handling recording heads

Note 1 If recording is halted and the recorder is not used for a long time

Carry out the following in order to prevent jamming and drying-up of the ink.

Remove the recording head from the main unit, make absolutely sure the cap is closed properly and store the head in a cool, dark place (average temperature 5 to 30°C).

If the head is left installed in the recorder:

Do not switch off the power to the recorder and do not close the cap.

* Periodically, there is an automatic discharge of ink to prevent drying-up.

Leave the recording paper in place in the recorder.

If it is not possible to keep the power switched on, make sure that the cap is closed.

Draw out the paper feed unit using the recording head setting method Step 4 and Step 5 .

Open the indicator and tighten the cap.

Note 2 At the start of use of a recording head

If you are starting to use a new recording head or if the recorder has been left unused for a long time,

always wipe the head's nozzle surface lightly with the accessory cloth and check that the 4 colours

black, blue, red and yellow ooze out properly into the cloth. (See Section 5.2.)

Also, after normal recording is possible. See Section 6.3 for the way of printing out a test pattern.

When the working environment is 15°C or less, perform print-out of "test pattern" after period of several minutes has elapsed since the recording head was mounted. (The recording head has a built-in

heater.)

Note 3 Handling recording heads

•Do not knock or shake recording heads as this can cause faults.

• The inks are not harmful but they are very difficult to remove if they adhere to the skin or to clothes,

so handle heads carefully in order to avoid staining. Also, do not disassemble them.

• If, by accident, it happens that ink gets into your eyes, wash thoroughly with water as an emergency

measure and then immediately consult a specialist doctor.

• When the ink is used out, dispose of its recording head as incombustible object.

• This product is intended to be used where are not dusty.

• Be sure to start to use the product soon after opening package. (Be sure to finish using this within 1

year after opening)

5 - 8 INP-TN3PHCV-E

Page 28

Note 4 Storage of recording heads

• When they are delivered, recording heads are in aluminium packs.

If you are not going to use a head straight-away, leave it sealed and store it in a cool, dark place with

an average temperature of 5 to 30°C.

• Storage period: 1year and half after purchased

Note 5 Shipping of recording head

• Do not ship the unit recording head after the aluminum pack was opened up. If it is necessary to ship

the unit recording head under avoidable circumstances, be sure to close the cap, and ship it as contained in a boxboard in the state where vibration and impack are eased using cushioning materials.

• Always close the cap if you are transporting a head while it is still installed in the recorder main unit.

Note 6 If the ink is not sprayed.

①Hold the recording head with turning the nozzle surface

downward and push the side strong till spilling two drops.

②Absorb the standing ink on the nozzle surface with the cloth

attached.

③Hold the cloth to the nozzle surface again to find all colours

flowed onto cloth.

When ink does not come out, repeat the above operation

( ① through ③ ).

* When working environment is 15°C or less, perform

print-out of "record" or "test pattern" after a period or

several minutes has elapsed since the recording head was

mounted. (The recording head has a built-in heater.)

Reference Ink consumption

When recording at 20mm/h of chart paper feed speed and a given input, the consumption of ink is as

shown below , though it depends on operating conditions.

About 1 year ---------- 1, 2, 3 continuous recording or 6 intermittent recording

About 6 months ------ 6 continuous recording

Alarm of ink consumption is displayed and printed by ink consumption detecting function.

(See Section 11.12 for an example of print-out.)

5 - 9INP-TN3PHCV-E

Page 29

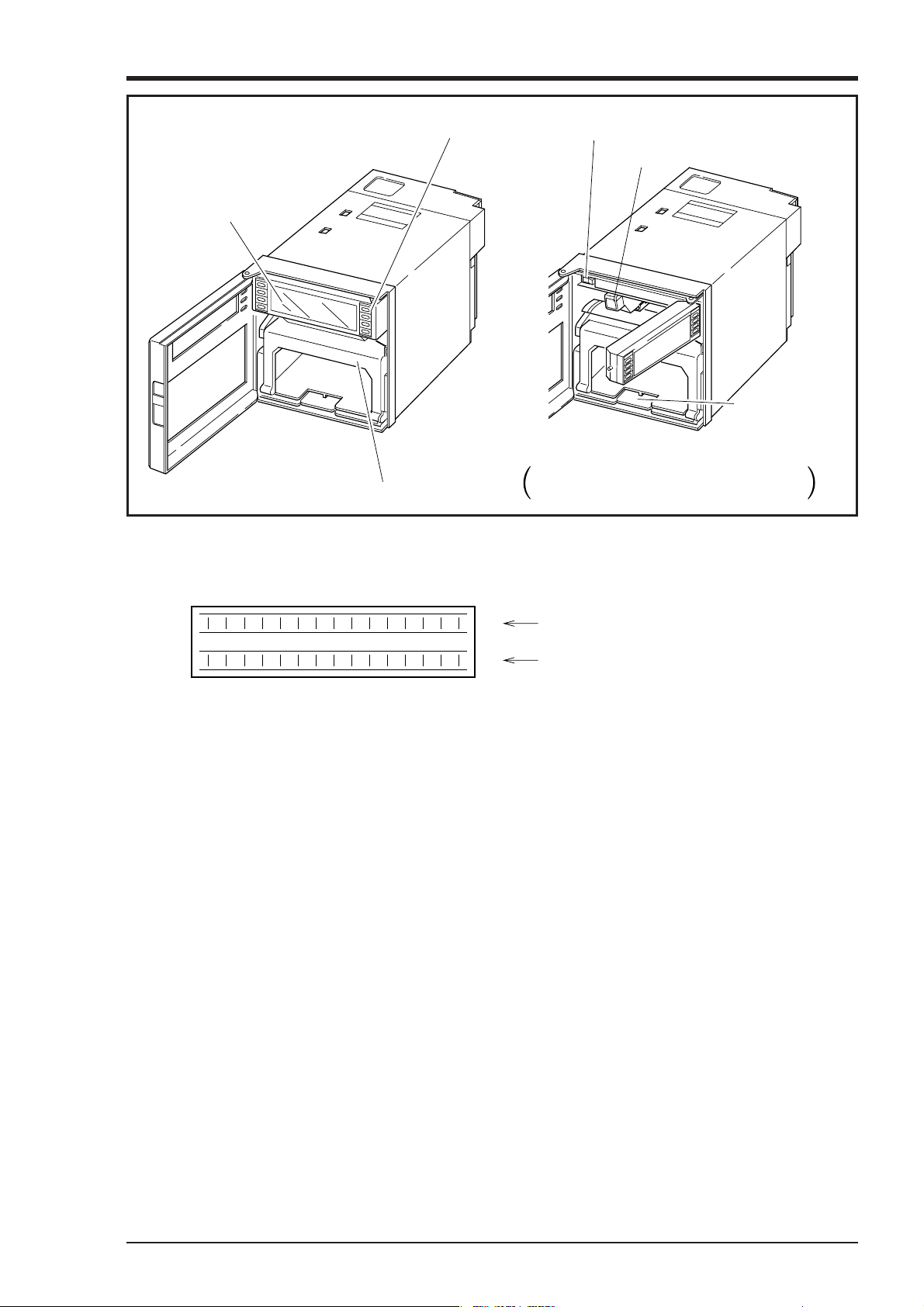

5.3 Changing the type of input signals

This recorder is a multi-input type which permits the input for any channel to be changed to thermocouple, resistance bulb or DC voltage input.

Follow the procedure described below if you with to change the type of input signals subsequent to

purchase.

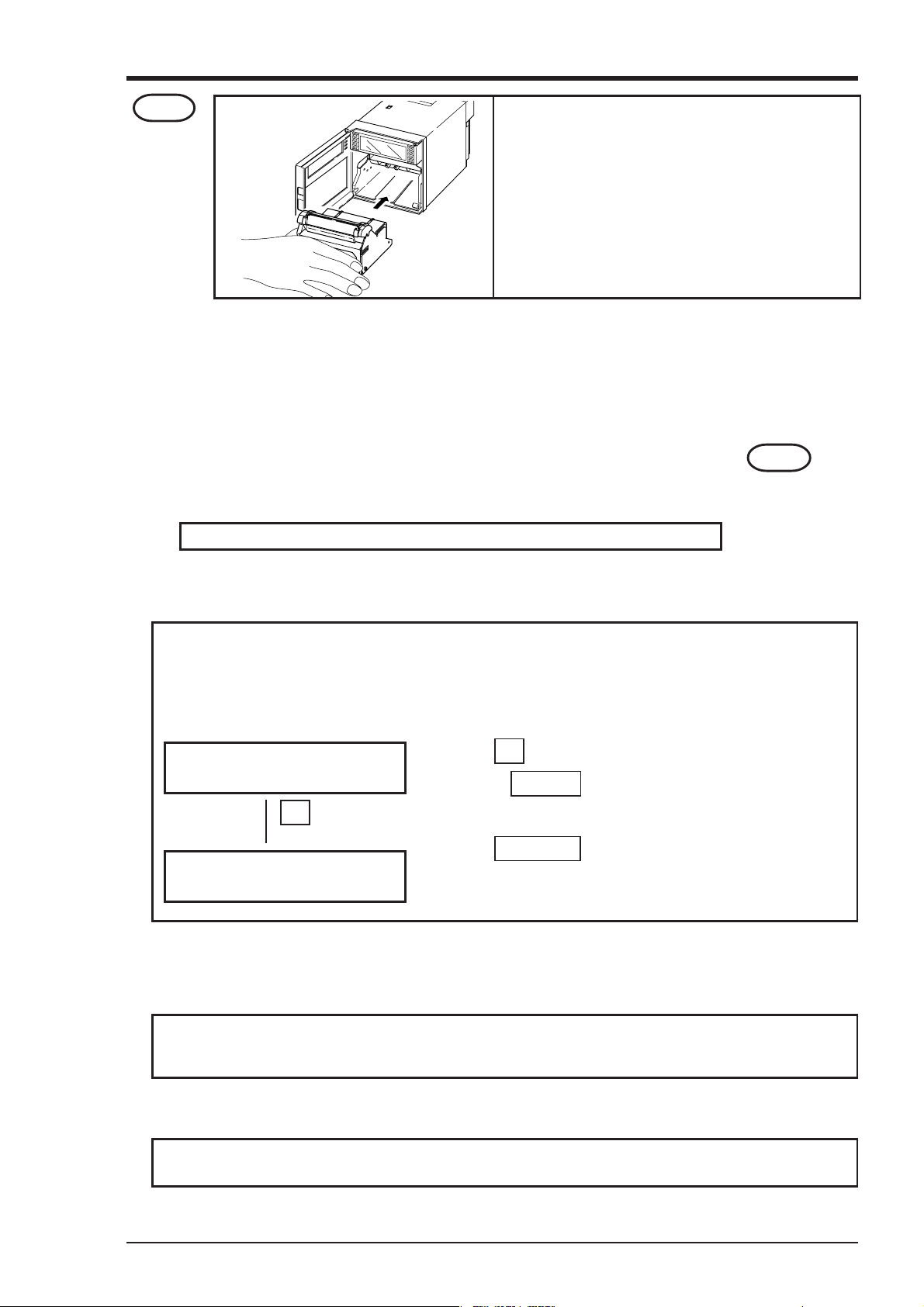

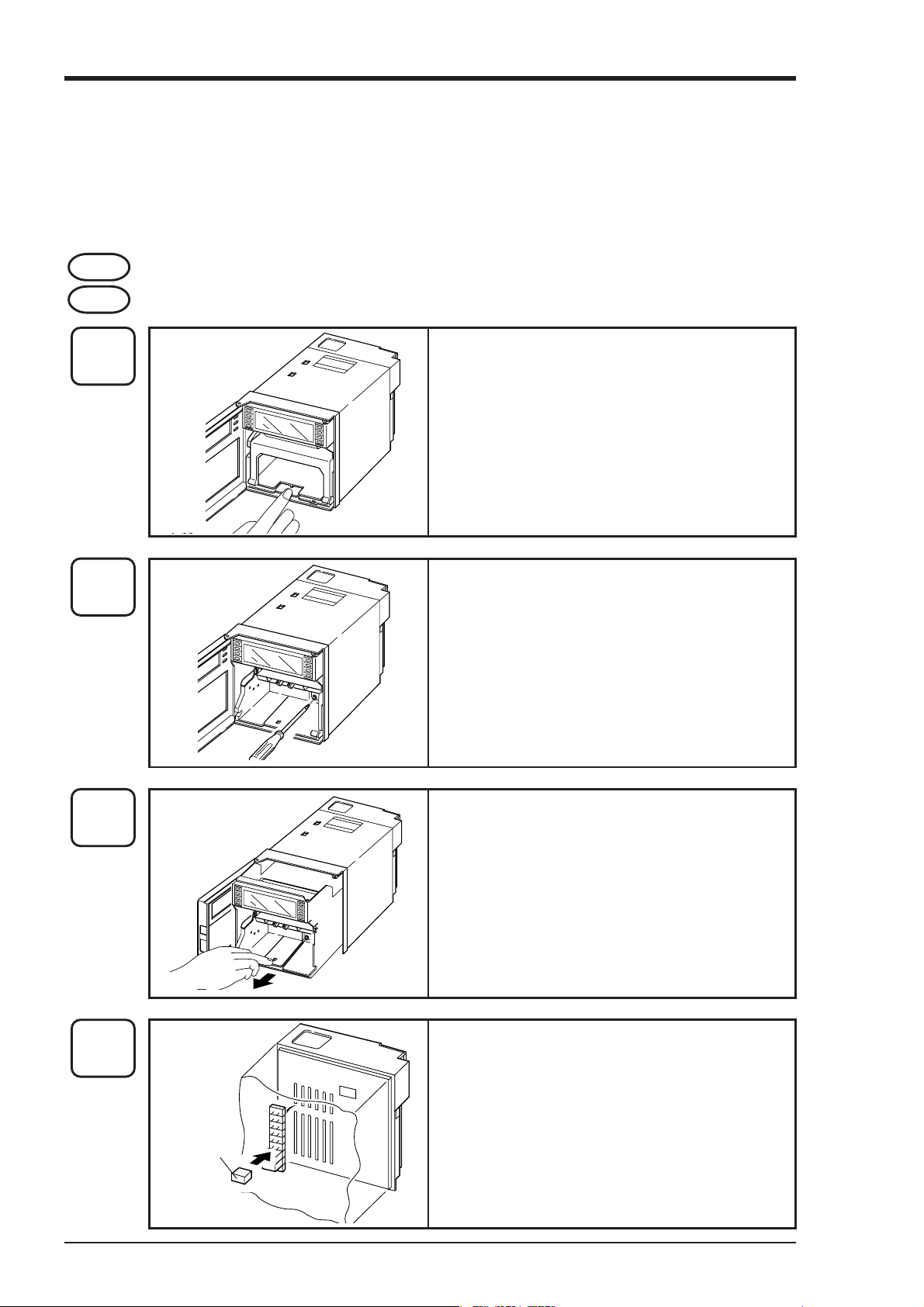

Step 1 Turn off the power.

Step 2 Open the front flap and remove the main unit in the manner shown in the drawings below.

Step

2 - 1

Step

2 - 2

Open the front door and press down the paper feed

unit drawout lever.

The paper feed unit will be drawn out.

Loosen the lock screw (M4) in the unit with a phillips

driver.

Step

2 - 3

Step

2 - 4

Input signal

setting pins

Hold the side or bottom of the frame and pull the

unit forcedly to remove it from the case. It can be

removed easily when the door is opened by about

90°.

Change the setting of each channel pin on the printed

circuit board in the unit.

(See the next page for changing the position of pin.)

* To remove or attach the pins, use pincette or pli-

ers.

5 - 10 INP-TN3PHCV-E

Page 30

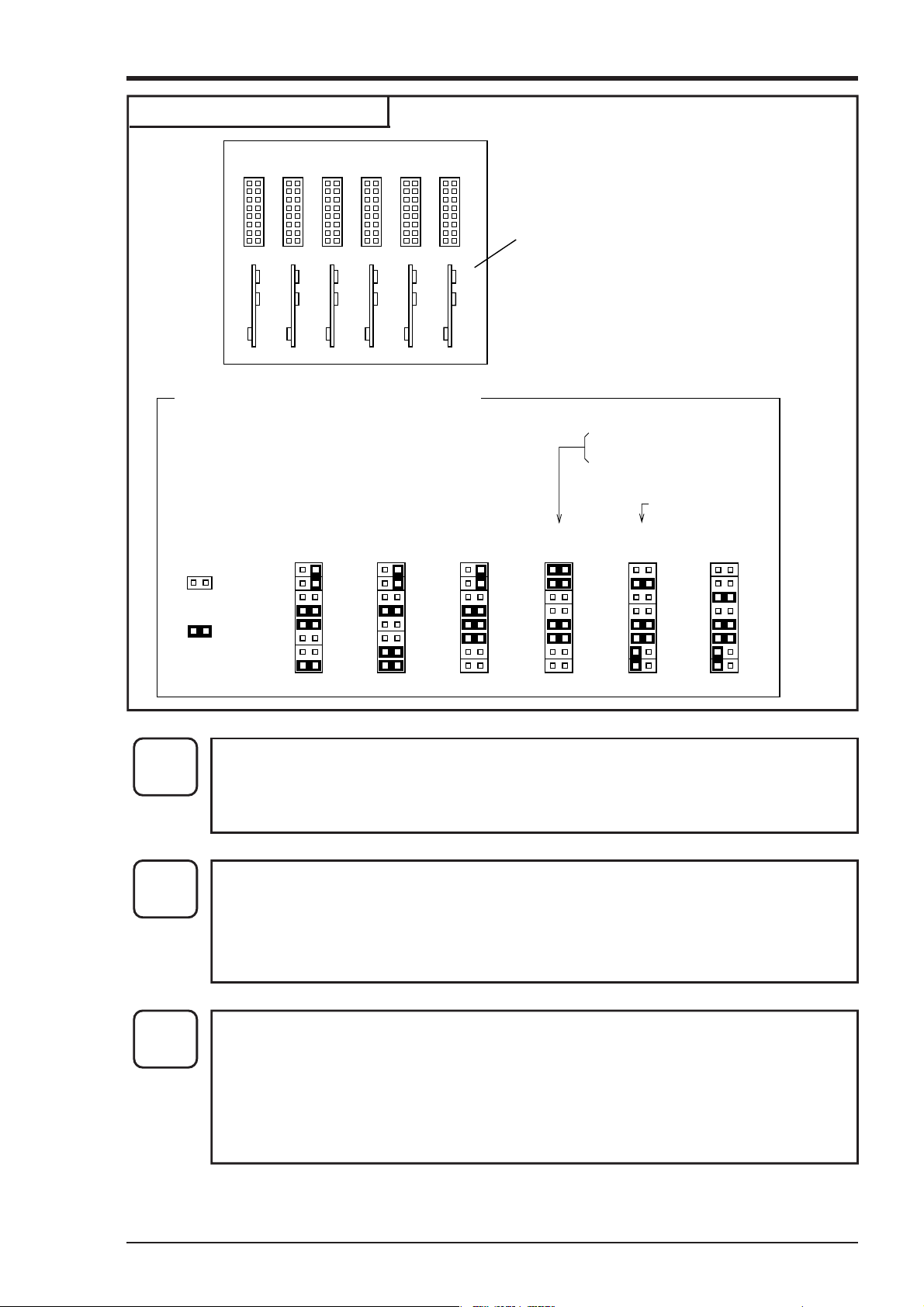

Method of changing pin positions

CH1 CH2 CH3 CH4 CH5 CH6

Pin positions for different types of inputs

Large PC board installed in depth of the case

• Pin setting is required in correspondence with types of

inputs for each channel.

• The set position is as shown below.

MAX.

±50mV

Step

2 - 5

Thermo-

couple

OPEN

SHORT

• After completing the change, push the main unit back into its original place and fix it with

the left and right lock screws.

• Push in the paper feed until it is set as before.

Resistance

bulb

MAX.

±500mV

4 to 20mA DC input

10 to 50mA DC input

1 to 5V DC input

MAX.

±5V

MAX.

±50V

Step

2 - 6

Step

2 - 7

• Change the input terminal wiring to make it correspond to the new input signal type.

• For DC voltage input, provide the input terminals with shunt resistors.

Example: In the case of 4 to 20mA DC input, fit the separately sold shunt resistors (10Ω

and set to ±500mV range input pin positions.

Refer to Section 7.8 and carry out front-panel keyboard operations in order to change setting

in correspondence to changed types of input signals.

[Note] DC current input is converted into voltage by shunt resistor (10Ω):

In 4 to 20mA DC : 40 to 200mV DC range

In 10 to 50mA DC :100 to 500mV DC range

5 - 11INP-TN3PHCV-E

Page 31

6. OPERATION AND ACTIONS

6.1 Before running the equipment:

Check the following points before starting operation.

1

2

3

Setting the chart paper and recording head

① Setting the chart paper ..................................................................................... See Section 5.1

② Setting the recording head ............................................................................... See Section 5.2

Wiring

① Input terminals .................................................................................................

② Alarm terminals (option) ................................................................................. See Section 4.2

③ Power and earth terminals ...............................................................................

}

Conformity of input connection to recording channel

① Code symbols .................................................................................................. See Section 1.3

② Change and settingo type of input signal......................................................... See Section 5.3

6 - 1INP-TN3PHCV-E

Page 32

6.2 Power switch-on and states

(1) Open the front door. Then hold the left end of the indicator and turn it forward.

(2) The power supply switch is at the above left; switch it on.

1) Initial switch-on of power

↓

The recording head moves slowly toward the right end (100%).

↓

After detecting 100%, the recording head moves to the center and stops ant that position.

↓

1 100℃

2) If the power is switched off while recording is stopped and switched on again.

(The state becomes “Recording stopped”)

3) If the power is switched off during recording operation and switched on again.

(The state becomes “Recording in progress”)

The input data and Tag No. are displayed in the display section.

(No recording takes place.)

Recording in progress

↓

Power supply cut off

↓

Display disappears Recording stops

↓

Power turned on again

↓

The recording head moves slowly tooward the right end (100%).

↓

After detecting 100%, the recording head moves to the center and then the right end, and it stops

at that position.

↓

1 100℃

Rec. ON

The input data is displayed in the display section and recording restarts.

6 - 2 INP-TN3PHCV-E

Page 33

6.3 Test pattern print-out

(1) Open the front flap, switch the power supply switch on the press the SELECT key.

(2) Pressing the SELECT key several more times results in the following display.

LIST=1

PARAMETER LIST

(3) Press the ∧ key twice; this gives the following display.

LIST=1

TEST PATTERN

(4) When the ENTRY key is pressed, the following test pattern is printed out.

Yellow Red Orange Blue Green Purple Black

• Check that there is a complete recording in each colour.

If the colours do not come out or are blurred, follow the procedure of Section 5.2 to clean the

recording head nozzle surface.

6.4 Actions during operation

(1) Stopping and starting recording operation ( RECORD key)

•Stopping the recording is possible at anytime during operation.

• Recording is alternately started and stopped each time the RECORD key is pressed.

6 315℃

Rec. ON

During recording operation When recording is stopped

(2) Digital print-out (instantaneous values) ( LIST key)

Example of record

• Measured values can be printed out any time during operation.

• Pressing the LIST key results in a digital print of the time at which the key was pressed and the

measured values and units of all the channels at that time.

• Analog trend recording is stopped during digital printing.

• Completion of digital print-out is followed by a return to analog recording.

• To stop printing during operation, press the LIST key. Analog trend recording is started again.

• Channels which are skipped are printed with the sign “–” (lateral line).

6 315℃

6 - 3INP-TN3PHCV-E

Page 34

(3) Chart paper fast feed ( FEED key)

To effect fast feed regardless of recording, press the FEED key.

•

• The speed is 3mm/s during the first second that the key is held depressed and goes to 8mm/sec

after the elapse of 1 second.

•

When the FEED key is released, there is a return to the set speed.

(4) Changing the display mode ( DISPLAY key)

• Display modes can be selected at any time pressing the DISPLAY key during operation.

There are the following changes in the display mode each time the DISPLAY key is pressed.

•

Measured values

Multipoint

sequential display

DISPLAY

Measured values

One-point

continous display

DISPLAY

Measured values

Multipoint

display

DISPLAY

Time display

1 150℃

Record ON

One-point continous display mark

6* 315℃

Record ON

Ch1 Ch2 Ch3

0.001 25.00 50.00

-3.45 -7.00 -11.00

Ch4 Ch5 Ch6

90 10/30 11:30

Record ON

There is sequential

display starting from

ch1.

Only specified

channel is displayed.

To change channels, get a

channel No. by pressing

the ∨ , ∧ key.

(E.g., channel 6)

Channel 1 to 6 are

display simultaneously.

The current time is

displayed.

DISPLAY

Note) No Record ON is displayed when recording is stopped.

6 - 4 INP-TN3PHCV-E

Page 35

6.5 Displays and print-outs on detection (cancellation) of alarms

(1) If an alarm is detected the display section gives a display as follows.

Example of alarm display

Example: Upper section Ch 2 measured

2 123.5℃

Ch6 ALARM H ALM1

(This display continues until it is cancelled.)

(2) When an alarm detected and cancelled, the relevant details are printed on the right-hand side of the

chart paper.

On detection: The time of detection, channel No., type of alarm, relay No.

...............................................Print-out color: Red

On cancellation: The time of cancellation, channel No., relay No.

............................................Print-out color: Black

Example of alarm print-out

value

Lower section Alarm in Ch 6

H alarm, relay No. 1

2Channel 1 No. 1 H alarm release

Relay No. 1

Release time: 14:58

1Channel 1 No. 1 H alarm generation

Relay No. 1

Generating time: 14:57

(3) If an alarm is detected or a cancellation is made during data print-out or list print-out, the alarm

print-out takes place after completion of the data or list print-out.

(4) Up to a maximum of 30 alarm detection cancellation information can be stored and sequentially

printed out, but if the storage capacity is exceeded because of a large number of detections/cancellations in a short time, information in the overflow portion is discarded and cannot be printed out.

6.6 Displays and print-outs on occurrence of burnt-out

(1) If a thermocouple or resistance bulb wire breaks, the relevant details are indicated in a display

Example of burn-out display

6 BURN - OUT

Rec. ON

0.10.010.001

Burnout

-0.01-0.001

Note: The trend record is switched to the 100% side.

(2) When alarm is generated or released, its data is printed on the right side of chart paper.

(print color: red)

Example: Burn-out in Ch 6

Multipoint display

Example of burn-out print-out

1 BURN - OUT 11:52

Time of occurrence : 11. 52

Channel No. : 1

6 - 5INP-TN3PHCV-E

Page 36

6.7 Over-range, under-range display and abnormal input display

In all cases, for thermocouples, resistance bulbs and DC voltage input, there is a reference range for

input signals. If input is outside preset range an 'Over' or 'Under' display is given.

Example of over/under display

2 OVER ℃

Rec. ON

5 UNDER ℃

Rec. ON

When voltage input is applied and the input signal cable breaks down or an over/under voltage is

inputted, it is displayed as an abnormal input.

Example of abnormal input display

3 ERROR

Rec. ON

0.0 OVER

100.0

(Multipoint display)

0.0 ERROR

100.0

6.8 Display and record when chart paper runs out ("Chart End" display)

When chart paper is used out, the following is displayed and the recording stops automatically.

But display of measured value and alarm monitoring are continued.

6 123.5℃

Chart End

6.9 Display and record when the recording head ink is low ("Ink Out" display)

(1) A display as follows is given on the chart paper when the amount of remaining ink is low.

Ink End' is displayed in the display section.

Example

6 123.5℃

Ink Out

(2) 'Ink Empty' is printed on the right-hand side of the chart paper.

< Print-out color : The color of the ink whose remaining quantity is low >

Note) The sign "Ink End" is displayed when the ink left in the recorder reaches less than 10%, but

recording continues for a while after "Ink End" is displayed. Use a new recording head.

(When ink is used out, recording and printing operation is interrupted immediately)

Under stage: Measured value of Ch 6

Lower stage: Ink end

6 - 6 INP-TN3PHCV-E

Page 37

6.10 Display when data backup batteries need to be replaced ("Battery End" display)

When the voltage of back-up batteries becomes low, a display indicating that they need to be replaced

is given.

'Battery End' is displayed in the display section.

Example

6 123.5℃

Battery End

Replace the batteries promptly when a 'Battery End' display appears page 8-3.

Under stage: Measured value of Ch 6

Lower stage: Battery end

6.11 Display of fault in recording head carriage ("Carriage Alarm" display)

If a fault in the recording head carriage occurs and the recording head can no longer function normally,

a fault display is given and the recording operation stops.

Example

6 123.5℃

Carriage Alarm

When the sign "Carrier Failure" is displayed, turn OFF the power and check the following points.

(1) Is foreign matter adhering to the recording head carrier shaft ?

(2) Is the wire that drives the recording head broken or slack ?

(3) Has the recording paper lifted up and come into contact with the recording head ?

(4) Is the recording head set in place correctly ?

After eliminating the cause of the fault, switch on the power supply of the main unit.

Under stage: Measured value of Ch 6

Lower stage: Carriage failure

6.12 Order of priority of state displays

If the items noted below occur simultaneously, the corresponding displays are given in the indicated

order.

1. Chart end

2. Carriage alarm

3. Ink end

4. Battery end

5. Alarm

Note: When the state displays 1 and 2 above are given, the SELECT key is inoperative.

However, the DISPLAY and FEED keys are operative.

6 - 7INP-TN3PHCV-E

Page 38

7. SETTING AND CHECKING PARAMETERS

7.1 Setting and Checking

① The parameters at the time of shipment are as indicated in the table below. Recorder operations

(displays, analog trend recording) can be effected simply by switching the power on without making any adjustments, but you can set the parameters you require.

② The record ranges are multirange and it is necessary to set the required ranges.

③ Alarms, Tag Nos., Message, scaling, square root extracting and subtract calculation, daily report

and totalize functions are not set. Please set these if they are required. Input filters are set to 3

seconds.

④ After setting up parameter, it is recommended to print out parameter list and retain parameter in

order to find out setting contents later. (refer to the Item 7.11regarding printing out parameter list.)

Note) If you set parameters, always do so after setting chart paper in place.

If chart paper is not installed, the SELECT key is inoperative.

7 - 1INP-TN3PHCV-E

Page 39

(1) Values of parameters at the time of shipment (initial values)

Parameter name

Pass code

Main chart speed

Sub-chart speed

(option)

Alarms

Recording mode

Record range

State at time of shipment

(initial values)

(Cancelled)

20mm/h

20mm/h

No. 1 to 4 : No

Set value : 0

ALM : 0

Trend recording

Periodic print-out : ON

Scale print-out : ON

Recording format :

standard

Thermocouple system:

0 to 1200°C, K

Resistance bulb system:

0 to 500°C, Pt

DC voltage system:

–5 to +5V DC

Remarks

Setting range : 0 to 9999

Setting range : 5 to 1500mm/h

Setting range : 5 to 1500mm/h

Changed by external contact input

4 kinds and 4 points, L, H, RH and RL,

are available for each channel (relay

output: option).

Trend recording/logging recording

selection

Periodic digital print-out on/off selection

Fied interval scale lines, digital, units

printout selection

Standard, auto-range recording, zoom

records, zone recording selection

Specifiation of record range

Method of setting, chekcing

Section 7.3

Section 7.4

Section 7.4

Section 7.5

Section 7.6

Section 7.7

Input selection

TAG No.

Message print

List print-out

Thermocouple:

K thermocouples, °C

Resistance bulb:

Pt100, °C

DC voltage : V

Input filter : 3 seconds

Scaling : OFF

Rooter : OFF

Subtract calculation : OFF

Computation : OFF

Blank

Blank

Print position : 0.0mm

Print timing : Manual

Input type specification,

°C, °F, specification

mV, V specification

Setting range : 0 to 900 seconds

DC voltage input scaling can be set

(working values, units)

DC voltage input rooter (square root

extractor ) can be specified

Recording of differences between

channels can be specified

Up to 8 alphanumeric characters

10-message, alphanumeric :

Within 16 characters

Parameter list print-out, scale print-out,

test pattern print-out, daily report,

totaling list

Skip/copy

setting

Section 7.8

Section 7.9

Section 7.10

Section 7.11

7 - 2 INP-TN3PHCV-E

Page 40

Parameter name

State at time of shipment

(initial values)

Remarks

Method of setting, chekcing

Daily report

Totalize

RS-485

transmission

(option)

Time setting

Ink monitor

clear

Recoding paper

illumination

lamp (option)

Function : OFF

Automatic print-out :

Start time : 00:00

End time : 00:00

Function : OFF

Automatic print-out :

Start time : 00:00

End time : 00:00

Station No. : 1

Baud rate : 19200bps

Stop bit : 1

Parity : odd

Current time setting

NO

ON

Daily report function on/off selection,

start time selection

Daily report list automatic print-out on/

off selection

ON

Daily report operation on/off setting for

each channel

Totalize function on/off selection, start

time selection

Totalize list automatic print-out on/off

ON

selection

Totalize operation on/off setting for

each channel

Specified if there is connection with

parent CPU.

Display in the order –– Year –– Month

–– Day –– Hours –– Minutes

Setting of ink end warning-detection

function. Always set to clear (YES)

after recording head replacement.

Set to "OFF" to turn out the recording

paper illumination lamp.

Section 7.12

Section 7.13

Section 7.14

Section 7.16

Section 7.16

Section 7.17

7 - 3INP-TN3PHCV-E

Page 41

7.2 Outline of Procedure for Setting Parameters

Data display mode key

DISPLAY

SELDISP

Pass code

If pass code specification

is 0, this display is skipped.

SEL

Main chart speed

Section 7.4

SEL

Sub-chart speed <Option>

Section 7.4

SEL

Alarm

Section 7.5

SEL

ENT

Recording mode

SEL

Record range

Logging

Trand

Section 7.6

Section 7.7

ENT

=Description of keys=

●

SEL

: key

●

ENT

: key

●

DISPLAY

●

∧

●

To return to the beginning of parameter settings, press the

key once and then press the key.

Logging interval

Periodic print-out

Scale print-out

SELECT

Whatever the current state, operation moves to the next

mode when this key is pressed.

ENTRY

If this is pressed when data is to be registered following

specification or when registration is not needed, there is a

move to display of the next set item.

:Whatever the current state, there is a return to the data

display mode when this key is pressed.

∨

:These serve for specification and selection of data.

SELECT

ENT

Record format

ENT

Standard

Auto-range

Zone

Zoom

DISPLAY

SEL

Input selection

SEL

TAG No.

SEL

To next page (a)

Section 7.8

Input type unit

Input filter

Section

7.9

ENT

In case of

thermocouples,

resistance bulbs

When OFFDC voltage

Scaling ON/OFF

ENT

Measure range

ENT

Rooter

ENT

Engineering range

ENT

Units

ENT

Subtraction

ENT

7 - 4 INP-TN3PHCV-E

Page 42

(a)(b)

SEL

Message print

SEL

List print-out

SEL

Daily report function

SEL

Totaraize function

SEL

Transmission

SEL

Time setting

Section 7.10

Parameter list

Scale print-out

Test pattern

Daily reort list

Totalize list

Message print

Section

7.12

Section 7.13

<Option>

Section 7.14

Section 7.15

Section 7.11

Section 9 Application

SEL

Ink monitor clear

SEL SEL

Illumination lamp

ON/OFF

SEL

Pass code

specification

SEL

FEED+SEL

Section 7.16

<Option>

Section 7.17

Section 7.3

Back lash calibration

Record zero-span

calibration

SEL

Alarm lach

SEL

PV shift

SEL

Unit preparation

SEL

Record error

external output

DISPLAY

To data displaymode

7 - 5INP-TN3PHCV-E

Page 43

7.3 Pass code setting

Explanation

If the pass code is set to a value other than 0, it is necessary to enter the correct pass code before

changing parameter setting pass code. A numerical value is specified on the screen by means of the

∧ and ∨ keys and is input by the ENT key. If this value is the same as the previously set pass

code, there is a move to a display of the next parameter.

If the pass code is incorrectly specified, the keys are locked as follows.

Preset pass code < 5000

Only the list display is given and it is not possible to change parameter setting.

Preset pass code ≧ 5000

The list display is given, but list print-out is inhibited.

Furthermore, RECORD , LIST , and FEED keys on the front panel are locked.

At the time of shipment, the pass code is set to 0 and the key lock is released.

If the pass code is 0, the pass code display is skipped.

Example Setting of the pass code

Key actuation

SEL

∧ ∨

ENT

DISP

SEL

∧

Explanation

Press the SEL key several times to bring up

the pass code specification display.

Press the ∧ ∨ key to specify the value you

want for the pass code (specification range: 1 to

9999).

Press the ENT key to register the value. When

it has been registered, there is a move to the next

parameter.

Press the DISP key to go to the data display

mode.

Press the SEL key to bring up the pass code

input screen.

Press the ∧ key to give the value of the pass

code that has been specified.

Display

PRESET PASS CODE

□□□□

PRESET PASS CODE

□□□□

MAIN CHART SPEED

□□□□ mm/h

ch1 123.4℃

PASS CODE =?

□ 0

PASS CODE =?

ENT

Press the ENT key to effect registration.

Note: If the value input at this time is differ-

ent from the pass code that has already

been specified, the list screen comes up

(key lock state).

In this case, it is not possible to clear the pass

code, so go through the process again from the

beginning and input the correct value.

If the value input is the same as the pass code

value, there is a move to the next parameter.

LIST=1

PARAMETER LIST

MAIN CHART SPEED

□□□□ mm/h

7 - 6 INP-TN3PHCV-E

Page 44

7.4 Setting the Chart Speed (main chart speed/sub-chart speed)

Explanation

•Main chart speed : This is the procedure fo rsetting the chart speed in normal operation.

The setting range is 5 to 1500mm/h (Can be set in 1mm/h steps.)

• If the case of a continuous recording type, if the chart speed is too fast, the result is dashed line

recording instead of continuous recording. (As a general criterion, 400mm/h or more)

• Please note that the following digital print-outs are not possible if the chart speed is 401mm/h or

more for continous recording or 51mm/h or more for dot recording.

"Periodic print-out", "Message print-out", "Scale print-out", "Alarm printout", "Parameter printout", "Ink Out print-out", "Burn-out".

However, a "Scale print-out", "Message print-out" can be made manually. See Section 7.11.

• On an intermittent recording type, if the chart paper feed speed is fast, it becomes difficult to read

recording due to increase in the space between break points. It is recommended that the recorder be

sued at a speed of 50mm/h or less.

• On a continuous recording type, the recording cycle varies with chart paper feed speed.

400

Sample time (sec.) =

Chart speed (mm/h)

(But not faster than 2 seconds.)

Example)

Chart speed (mm/h) 10 20 25 50 100 200 or more

Sample time (sec.) 40 20 16 8 4 2

• Sample time of intermittent recording type is fixed to 30 seconds.

Example Changing the normal chart speed of 25mm/h to 20mm/h.

Key actuation

SEL

∨

Press the SEL key twice to display the main

chart speed.

Press the ∨ key to set to "20".

Explanation

MAIN CHART SPEED

25 mm/h

MAIN CHART SPEED

20 mm/h

Display

ENT

Press the ENT key to effect registration.

There is a move to display of the next parameter.

SUB CHART SPEED

25 mm/h

7 - 7INP-TN3PHCV-E

Page 45

Explanation

• Sub-chart speed : This is the chart speed when its rate is controlled by an remote control signal.

The setting range is 5 to 1500mm/h. (Can be set in 1mm/h steps.)

The optional external control unit is necessary.

Example Changing the recording paper feed of speed 100mm/h to 150mm/h by an external control

signal (DI)

Key actuation

SEL

∧

ENT

Explanation

Press the SEL key 3 times to display the subchart speed.

Press the ∧ key to set to "150".

Press the ENT key to effect registration.

There is a move to display of the next parameter.

Display

SUB CHART SPEED

100 mm/h

SUB CHART SPEED

150 mm/h

ALARMCh1 HH=OFF

0

7 - 8 INP-TN3PHCV-E

Page 46

7.5 Setting Alarms

Explanation

• Channel : Setting of channel No. for object alarm.

• Alarm No. : Up to 4 points of alarm can be set per channel.

• Kind of alarm : 4 kinds, H, L, RL, RH (setting freely for each channel).

Alarm operation stoops at selection of No. (alarm display, print and alarm output operations are not available).

• Alarm setting value: Setting in industrial values (absolute alarm value)

• ALM : Setting of option alarm unit relay No. (no output at 1 to 6, 0)

Example Chang of alarm No. 1 of channel 1

L → H30°C → 80°C ALM→ 6

Key actuation

Explanation

Display

SEL

ENT

∧

ENT

∧

ENT

∧

ENT

Press the SEL key several times to give the

alarm display. (In cases where pass code = 0)

Select channel to be changed, and press the

∧ key.

Press the ∧ key to change "L" to "H".

Press the ENT key.

Press the ∧ key to change the set value from

"30°C" to "80°C" and press the ENT key.

Press the ∧ key to change the ALM No. from

"1" to "6" and press the ENT key to effect

registration.

When the ENT key is pressed, the

channel No. flashes and the setting is

completed.

Follow the same procedure for setting in

other channels.

ALARM Ch1 NO.1=L

30℃ ALM1

ALARM Ch1 NO.1=L

30℃ ALM1

ALARM Ch1 NO.1=H

30℃ ALM1

ALARM Ch1 NO.1=H

80℃ ALM1

ALARM Ch1 NO.1=H

80℃ ALM1

Note : RH, RL ……High/low limit alarm for variation rate.

Alarm is emmitted when variation rate per input exceeds the set value of each

alarm.

7 - 9INP-TN3PHCV-E

Page 47

7.6 Setting the recording mode

The following recording modes can be set in this section.

① Logging recording (logging)

② Periodic print-out

③ Scale print-out

④ Auto-range recording (auto-range)

⑤ Enlarged/reduced recording (zoom)

⑥ Zone recording (zone)

Setting procedure

RECORD MODE

Logging

∧

∨

RECORD MODE

Trend

ENT

PERIODICPVLIST=ON

SCALEPRINT =ON

ENT

ENT