Page 1

/ Instruction Manual

Digital Input Interface Card

"OPC-G1-DI"

Digital Output Interface Card

"OPC-G1-DO"

Fuji Electric Co., Ltd. INR-SI47-1249c-JE

Page 2

English Version

Page 3

Page 4

Preface

Thank you for purchasing our digital interface card(s).

This instruction manual describes the digital input interface card "OPC-G1-DI" and the digital output interface

card "OPC-G1-DO" designed for the FRENIC-MEGA series of inverters. For descriptions of the former, refer to

Chapter 2 "DIGITAL INPUT INTERFACE CARD"; for the latter, refer to Chapter 3 "DIGITAL OUTPUT

INTERFACE CARD." Chapters 1, 4, and 5 are common to both cards.

Mounting the digital input interface card on your FRENIC-MEGA makes it possible to specify frequency

commands with binary code (8, 12, 15, or 16 bits) or BCD (4-bit Binary Coded Decimal) code.

Mounting the digital output interface card on your FRENIC-MEGA enables monitoring with 8-bit binary code.

Each of the digital input interface card and the digital output interface card can be connected to any one of the

three option connection ports (A-, B-, and C-ports) on the FRENIC-MEGA. Concurrent use of both cards

provides a digital input/output interface.

This instruction manual does not contain inverter handling instructions. Read through this instruction manual in

conjunction with the FRENIC-MEGA Instruction Manual and be familiar with proper handling and operation of

this product. Improper handling might result in incorrect operation, a short life, or even a failure of this product.

Keep this manual in a safe place.

• Read through this instruction manual and be familiar with the digital interface card(s) before

proceeding with installation, connections (wiring), operation, or maintenance and inspection.

• Improper handling might result in incorrect operation, a short life, or even a failure of this product as

well as the motor.

• Deliver this manual to the end user of this product. Keep this manual in a safe place until this product

is discarded.

Safety precautions

Read this manual thoroughly before proceeding with installation, connections (wiring), operation, or

maintenance and inspection. Ensure you have sound knowledge of the device and familiarize yourself with all

safety information and precautions before proceeding to operate the inverter.

Safety precautions are classified into the following two categories in this manual.

Failure to heed the information indicated by this symbol may

lead to dangerous conditions, possibly resulting in death or

serious bodily injuries.

Failure to heed the information indicated by this symbol may

lead to dangerous conditions, possibly resulting in minor or

light bodily injuries and/or substantial property damage.

Failure to heed the information contained under the CAUTION title can also result in serious consequences.

These safety precautions are of utmost importance and must be observed at all times.

Page 5

Installation and wiring

• Before starting installation and wiring, turn OFF the power and wait at least five minutes for inverters

with a capacity of 22 kW or below, or at least ten minutes for inverters with a capacity of 30 kW or

above. Make sure that the LED monitor and charging lamp are turned OFF. Further, make sure,

using a multimeter or a similar instrument, that the DC link bus voltage between the terminals P(+)

and N(-) has dropped to the safe level (+25 VDC or below).

• Qualified electricians should carry out wiring.

Otherwise, an electric shock could occur.

• Do not use the product that is damaged or lacking parts.

Doing so could cause a fire, an accident, or injuries.

• Prevent lint, paper fibers, sawdust, dust, metallic chips, or other foreign materials from getting into

the inverter and the option.

Otherwise, a fire or an accident might result.

• Incorrect handling in installation/removal jobs could cause a failure.

A failure might result.

• Noise may be emitted from the inverter, motor and wires. Implement appropriate measure to prevent

the nearby sensors and devices from malfunctioning due to such noise.

Otherwise, an accident could occur.

Operation

• Be sure to install the front cover before turning the inverter's power ON. Do not remove the cover

when the inverter power is ON.

Otherwise, an electric shock could occur.

• Do not operate switches with wet hands.

Doing so could cause an electric shock.

• If you configure the function codes wrongly or without completely understanding FRENIC-MEGA

Instruction Manual and the FRENIC-MEGA User's Manual, the motor may rotate with a torque or at a

speed not permitted for the machine. Confirm and adjust the setting of the function codes before

running the inverter.

Otherwise, an accident could occur.

Maintenance and inspection, and parts replacement

• Before proceeding to the maintenance/inspection jobs, turn OFF the power and wait at least five

minutes for inverters with a capacity of 22 kW or below, or at least ten minutes for inverters with a

capacity of 30 kW or above. Make sure that the LED monitor and charging lamp are turned OFF.

Further, make sure, using a multimeter or a similar instrument, that the DC link bus voltage between

the terminals P(+) and N(-) has dropped to the safe level (+25 VDC or below).

Otherwise, an electric shock could occur.

• Maintenance, inspection, and parts replacement should be made only by qualified persons.

• Take off the watch, rings and other metallic objects before starting work.

• Use insulated tools.

Otherwise, an electric shock or injuries could occur.

Page 6

Disposal

• Treat the interface card(s) as an industrial waste when disposing of it.

Otherwise injuries could occur.

Others

• Never modify the interface card(s).

Doing so could cause an electric shock or injuries.

Icons

The following icons are used throughout this manual.

This icon indicates information which, if not heeded, can result in the product not operating to full

efficiency, as well as information concerning incorrect operations and settings which can result in

accidents.

This icon indicates information that can prove handy when performing certain settings or operations.

This icon indicates a reference to more detailed information.

Page 7

Table of Contents

Preface ............................................................................... i

Safety precautions ............................................................. i

Chapter 1 BEFORE USING THIS OPTION ..................... 1-1

1.1 Acceptance Inspection ........................................... 1-1

1.2 Applicable Inverters ................................................ 1-2

1.3 Operating Environment .......................................... 1-2

1.4 Installation and Removal of the Interface Card .......1-2

1.4.1 Installing the interface card ............................ 1-3

1.4.2 Removing the interface card .......................... 1-4

1.5 Wiring ..................................................................... 1-5

Chapter 2 DIGITAL INPUT INTERFACE CARD............... 2-1

2.1 Terminal Allocation and Symbol Diagram ................. 2-1

2.2 Connection Diagram ................................................. 2-1

2.3 Terminal Functions ................................................. 2-2

2.4 Electrical Specifications .......................................... 2-2

2.5 Input Interface ........................................................ 2-3

2.5.1 Switching between SINK and SOURCE

for digital input terminals ([I1] to [I16]) ........... 2-3

2.5.2 Connection diagrams for SINK/SOURCE

input modes ................................................... 2-3

2.5.3 Precaution on the use of a contact relay ........ 2-3

2.6 Configuring Inverter's Function Codes ................... 2-4

2.7 Details of Function Codes ...................................... 2-5

Chapter 3 DIGITAL OUTPUT INTERFACE CARD........... 3-1

3.1 Terminal Allocation and Symbol Diagram ............... 3-1

3.2 Connection Diagram ............................................... 3-1

3.3 Terminal Functions ................................................. 3-2

3.4 Electrical Specifications .......................................... 3-2

3.5 Output Interface ......................................................3-2

3.6 Configuring Inverter's Function Code ..................... 3-3

3.7 Details of Function Code ........................................ 3-4

Chapter 4 I/O CHECKING ............................................... 4-1

Chapter 5 PROTECTIVE FUNCTION ............................. 5-1

Page 8

Chapter 1 BEFORE USING THIS OPTION

1.1 Acceptance Inspection

Unpack the package and check the following:

(1) An interface card, two screws (M3 8), and the Digital Input Interface Card/Digital Output Interface Card

Instruction Manual (this manual) are contained in the package.

(2) The interface card is not damaged during transportation--no defective parts, dents or warps.

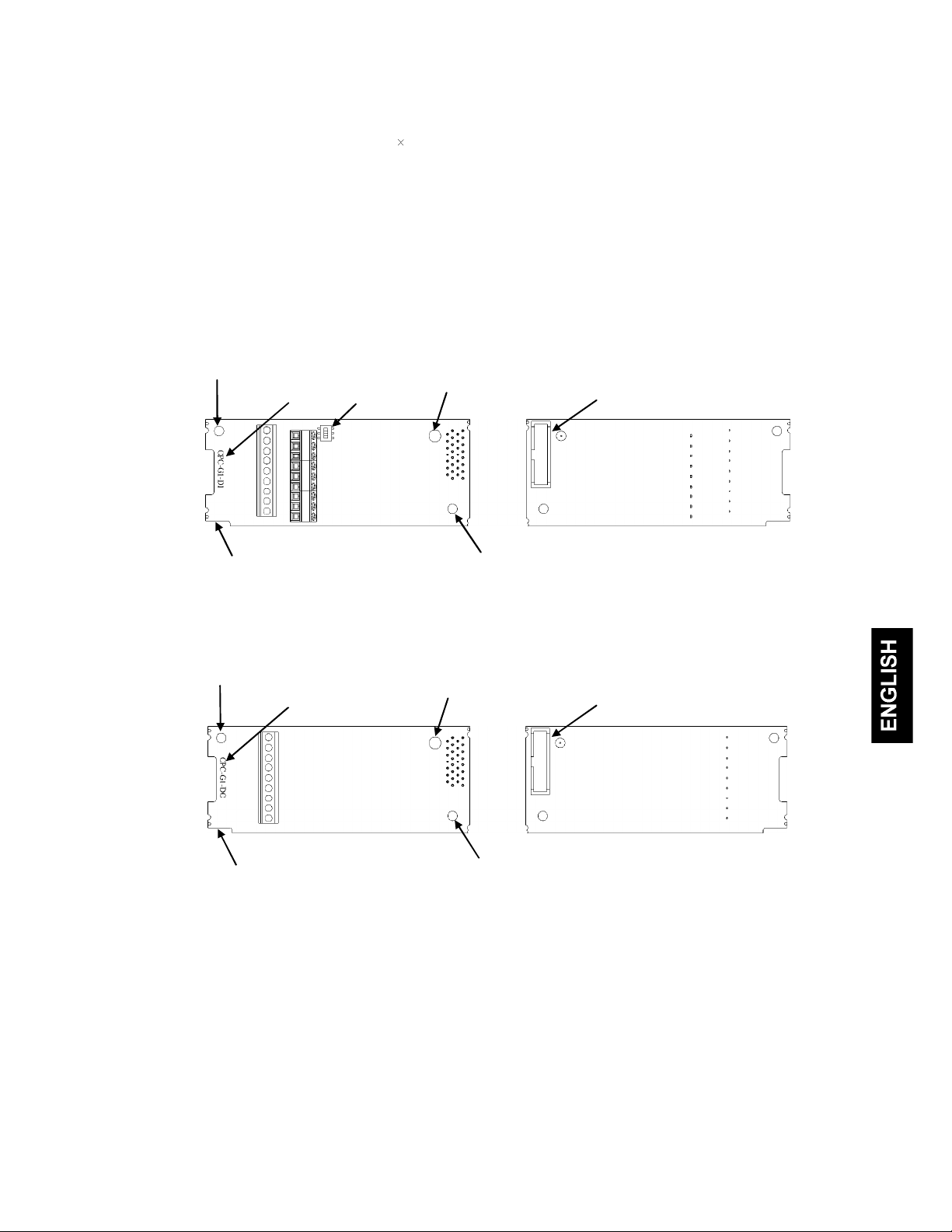

(3) The following model name is printed on the interface card.

• Digital input interface card: "OPC-G1-DI" (See Figure 1.1.)

• Digital output interface card: "OPC-G1-DO" (See Figure 1.2.)

If you suspect the product is not working properly or if you have any questions about your product, contact the

shop where you bought the product or your local Fuji branch office.

Screw hole (left)

Model name

(Front) (Back)

Positioning cutout

Figure 1.1 Name of Parts on Digital Input Interface Card (OPC-G1-DI)

Screw hole (left)

Model name

SW1

Release knob

Release knob

CN1

Screw hole (right)

CN1

(Front) (Back)

Positioning cutout

Figure 1.2 Name of Parts on Digital Output Interface Card (OPC-G1-DO)

Screw hole (right)

1-1

Page 9

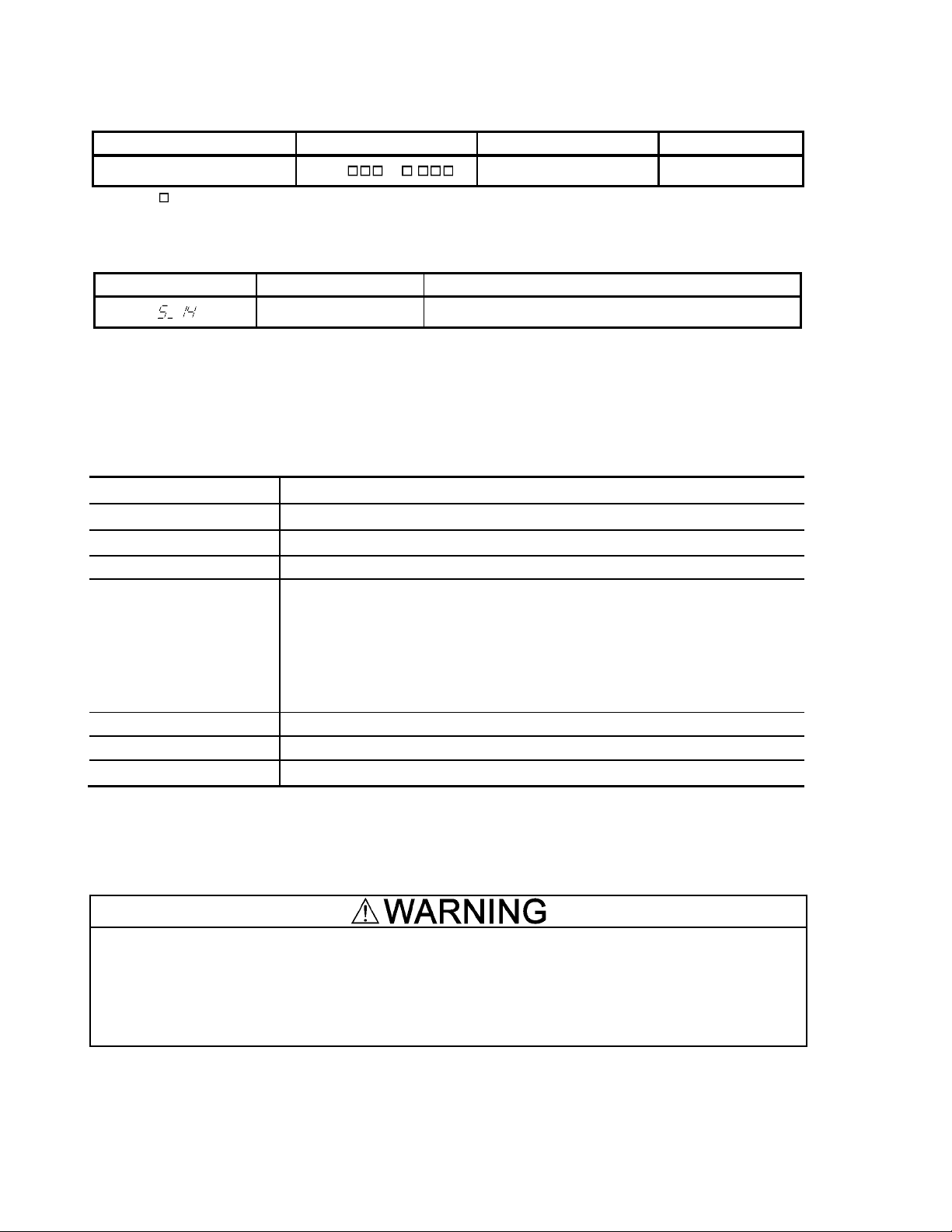

1.2 Applicable Inverters

This interface card is applicable to the following inverters and ROM version.

Table 1.1 Applicable inverter and ROM version

Series Inverter type Applicable motor rating ROM version

FRENIC-MEGA FRN G1 - All capacities 0500 or later

* The boxes replace alphabetic letters depending on the nominal applied motor, enclosure, and power supply voltage.

To check the inverter's ROM version, use Menu #5 "Maintenance Information" on the keypad. (Refer to the

FRENIC-MEGA Instruction Manual, Chapter 3, Section 3.4.6 "Reading maintenance information."

Display on LED Monitor Item Description

Inverter's ROM version Shows the inverter's ROM version as a 4-digit code.

1.3 Operating Environment

Install the inverter equipped with this interface card in an environment that satisfies the requirements listed in

Table 1.2.

Table 1.2 Environmental Requirements

Item Specifications

Site location Indoors

Surrounding temperature

Relative humidity 5 to 95% (No condensation)

Atmosphere

Altitude 1,000 m max.

Atmospheric pressure 86 to 106 kPa

Vibration Refer to the FRENIC-MEGA Instruction Manual, Chapter 2.

(Note) Do not install the inverter in an environment where it may be exposed to lint, cotton waste or moist dust or dirt which will

clog the heat sink of the inverter. If the inverter is to be used in such an environment, install it in a dustproof panel of your

system.

Refer to the FRENIC-MEGA Instruction Manual, Chapter 2.

The inverter must not be exposed to dust, direct sunlight, corrosive gases, flammable

gases, oil mist, vapor or water drops.

Pollution degree 2 (IEC60664-1) (Note)

The atmosphere can contain a small amount of salt.

(0.01 mg/cm2 or less per year)

The inverter must not be subjected to sudden changes in temperature that will

cause condensation to form.

1.4 Installation and Removal of the Interface Card

Before starting installation and wiring, turn OFF the power and wait at least five minutes for inverters with a

capacity of 22 kW or below, or at least ten minutes for inverters with a capacity of 30 kW or above. Make

sure that the LED monitor and charging lamp are turned OFF. Further, make sure, using a multimeter or a

similar instrument, that the DC link bus voltage between the terminals P(+) and N(-) has dropped to the safe

level (+25 VDC or below).

Otherwise, an electric shock could occur.

1-2

Page 10

• Do not use the product that is damaged or lacking parts.

Doing so could cause a fire, an accident, or injuries.

• Prevent lint, paper fibers, sawdust, dust, metallic chips, or other foreign materials from getting into

the inverter and the interface card.

Otherwise, a fire or an accident might result.

• Incorrect handling in installation/removal jobs could cause a failure.

A failure might result.

1.4.1 Installing the interface card

Before mounting the interface card, perform the wiring for the main circuit terminals and control circuit

terminals.

(1) Remove the front cover from the inverter and expose the control printed circuit board (control PCB). As

shown in Figure 1.3, the interface card can be connected to any one of the three option connection ports

(A-, B-, and C-ports) of the inverter.

To remove the front cover, refer to the FRENIC-MEGA Instruction Manual, Section 2.3. For inverters

with a capacity of 30 kW or above, open also the keypad enclosure.

(2) Insert connector CN1 on the back of the interface card (Figure 1.1 or 1.2) into any of the A-port (CN4),

B-port (CN5), and C-port (CN6) on the inverter's control PCB. Then tighten the two screws that come with

the card. (Figure 1.5)

Check that the positioning cutout (shown in Figures 1.1 and 1.2) is fitted on the tab ( in Figure 1.4)

and connector CN1 is fully inserted ( in Figure 1.4). Figure 1.5 shows the interface card correctly

mounted.

(3) Perform wiring on the interface card.

Refer to Section 1.5 "Wiring."

(4) Put the front cover back into place.

To put back the front cover, refer to the FRENIC-MEGA Instruction Manual, Section 2.3. For inverters

with a capacity of 30 kW or above, close also the keypad enclosure.

Figure 1.3 In the case of 0.4 kW

1-3

Page 11

Fit the positioning cutout of the card over the

tab on the inverter to determine the mounting

position.

Insert connector CN1 on the card into any of

the three ports (A-, B- and C-ports) on the

inverter's control PCB.

Note: Be sure to follow the order of and .

Inserting CN1 first may lead to insufficient

insertion, resulting in a contact failure.

Tab

Figure 1.4 Mounting the Interface Card (to B-port)

(Release knob)

Figure 1.5 Mounting Completed (to B-port)

1.4.2 Removing the interface card

Remove the two screws that secure the interface card and pull the release knob (shown above) to take the card

out of the inverter.

1-4

Page 12

1.5 Wiring

• Before starting installation and wiring, turn OFF the power and wait at least five minutes for inverters with

a capacity of 22 kW or below, or at least ten minutes for inverters with a capacity of 30 kW or above.

Make sure that the LED monitor and charging lamp are turned OFF. Further, make sure, using a

multimeter or a similar instrument, that the DC link bus voltage between the terminals P(+) and N(-) has

dropped to the safe level (+25 VDC or below).

• Qualified electricians should carry out wiring.

Otherwise, an electric shock could occur.

• In general, the covers of the control signal wires are not specifically designed to withstand a high voltage

(i.e., reinforced insulation is not applied). Therefore, if a control signal wire comes into direct contact with

a live conductor of the main circuit, the insulation of the cover might break down, which would expose the

signal wire to a high voltage of the main circuit. Make sure that the control signal wires will not come into

contact with live conductors of the main circuit.

Failure to observe this precaution could cause an electric shock or an accident.

Noise may be emitted from the inverter, motor and wires.

Take appropriate measures to prevent the nearby sensors and devices from malfunctioning due to such

noise.

An accident could occur.

Perform wiring for the interface card observing the precautions below. Refer to the connection diagrams shown

in Figure 2.2 (Chapter 2) and Figure 3.2 (Chapter 3), and the wiring examples shown in Figure 1.8.

(1) Turn the inverter's power OFF.

(2) Use shielded wires.

(3) To prevent malfunction due to noise, keep the wiring for the interface card away from the main circuit wiring

and other power lines as far as possible. Never install them in the same wire duct.

(4) Complete wiring before turning the inverter ON.

(5) See Table 1.3 for the specifications of the terminal block on the interface card.

When using stripped wires (without attaching a crimp terminal), strip the wire end by 5 to 7 mm. (Figure 1.6)

When using a crimp terminal, attach a vinyl-insulated ferrule.

Loosen the terminal screw, insert the wire end into above the metal part of the terminal block, and tighten

the screw to fasten it. (Figure 1.7)

Table 1.3 Terminal Specifications

Item Specifications

Wire size

Terminal screw size M2

Tightening torque 0.22 to 0.25 N·m

5 to 7 mm

AWG24 to AWG18 (0.25 to 0.75 mm2 ),

wire with rated temperature 105°C (UL) recommended

Figure 1.6 Wire End Treatment (For Connection to

Terminals on Interface Card)

Figure 1.7 Connecting to a Terminal

on Interface Card

• Route the wiring of the interface circuit terminals as far from the wiring of the main circuit as

possible. Otherwise electric noise may cause malfunctions.

• Fix the interface circuit wires with a cable tie inside the inverter to keep them away from the live

parts of the main circuit (such as the terminal block of the main circuit).

1-5

Page 13

Depending upon the wire type and the number of wires used, the front cover may be lifted by the

wires, which impedes normal keypad operation. If it happens, change the wire type or size.

Route the wires, taking care not to let them go over the control PCB, as shown in Figure 1.8.

Otherwise, malfunctions may occur.

• For inverters with a capacity of 22 kW or below

When grounding the shielded cable, use a

crimp ring terminal with insulation sheath,

R1.25-3 or the like and fasten it together

with the card using this screw.

* Pass the wires from the interface card between the control

circuit terminal block and the front cover.

In the case of 0.4 kW

• For inverters with a capacity of 30 kW or above

In the case of 75 kW

Figure 1.8 Examples of Wiring

1-6

Page 14

Chapter 2 DIGITAL INPUT INTERFACE CARD

2.1 Terminal Allocation and Symbol Diagram

CM I15 I13 I11 I9 I7 I5 I3 I1

2.2 Connection Diagram

I16 I14 I12 I10 I8 I6 I4 I2

Figure 2.1 Terminal Allocation and Symbol Diagram

FRENIC-MEGA

L1/R

L2/S

L3/T

OPC-G1-DI

M1

I16

I15

I14

I13

I12

I11

I10

I9

SW1

I8

I7

I6

I5

I4

I3

I2

I1

(LSB)

CM

U

V

W

SINK

SOURCE

M1

Figure 2.2 Connection Diagram

2-1

Page 15

2.3 Terminal Functions

Table 2.1 lists terminal symbols, names and functions of the terminals on the digital input interface card.

Table 2.1 Terminals and Their Specifications

Terminal

symbol

Name Functions

(1) These digital inputs specify a frequency command

according to the settings made by function codes o19

and o20.

[I1] to [I16] Digital inputs 1 to 16

For details, refer to Section 2.6 "Configuring

Inverter's Function Codes."

(2) SINK/SOURCE is switchable with the slide switch

SW1.

[M1] External power supply input

[CM] Digital common

Power input terminal from the external device for the

interface card (+22 to +27 VDC)

Common terminal for digital input signals

(Equipotent with [CM] terminal of the inverter)

2.4 Electrical Specifications

Table 2.2 lists the electrical specifications for the digital input interface card.

Table 2.2 Electrical Specifications

Terminal

symbol

Item

Min. Max.

Specifications

[I1] to [I16]

Operating voltage

(SINK)

Operating voltage

(SOURCE)

Operating current at ON

(Input voltage is at 0 V)

ON level 0 V 2 V

OFF level 22 V 27 V

ON level 22 V 27 V

OFF level

0 V 2 V

2.5 mA 5 mA

Allowable leakage current at OFF - 0.5 mA

2-2

Page 16

2.5 Input Interface

2.5.1 Switching between SINK and SOURCE for digital input terminals ([I1] to [I16])

The input mode is switchable between SINK and SOURCE for digital input terminals ([I1] to [I16]) by using the

slide switch SW1 on the interface card (Figure 1.1 in Chapter 1). Specify the input mode referring to Table 2.3

below.

Table 2.3 Configuration of Slide Switch SW1

Input mode Slide switch position

SINK (factory default) SINK side

SOURCE SOURCE side

The inverter also has the slide switch SW1 on the control PCB to specify SINK or SOURCE for the

inverter's digital input terminals. Match the setting of SW1 on the interface card with that of the

inverter.

2.5.2 Connection diagrams for SINK/SOURCE input modes

Table 2.4 shows connection diagrams for input interface circuits.

Table 2.4 Connections of Input Interface Circuits

Power

supply

SINK mode SOURCE mode

Connection diagram

SW1

SW1

SINK

SOURCE

SINK

SOURCE

Internal

External

+24 V

I1 to I16

I1 to I16

M1

CM

M1

CM

Inte rfa ce card

+2 4 V

SINK

SOU R C E

CM

Interface card

+2 4 V

SINK

SO U R CE

CM

2.5.3 Precaution on the use of a contact relay

PLC *1

M1

I1 to I16

CM

MEGA

Inte rfa ce card

+24 V

SINK

SOU R C E

CM

*1 The maximum allowable current for terminal

[PLC] on the FRENIC-MEGA is 100 mA.

+24 V

I

M1

1 to I16

CM

Interface c ard

+2 4 V

SINK

SOU R CE

CM

To configure input circuits using contact relays, use highly reliable relays.

2-3

Page 17

2.6 Configuring Inverter's Function Codes

To enable frequency command inputs from this interface card, it is required to set function code data of F01

(Frequency Command 1) or C30 (Frequency Command 2) to "11" (Digital input interface card). Also specify the

polarity and input mode of the frequency command using function codes o19 (DI polarity) and o20 (DI mode)

provided for options, respectively.

Table 2.5 lists function codes and their parameters. The function codes o19 and o20 become available when the

digital input interface card is connected to the inverter.

Table 2.5 Function Codes and Parameters

Drive control *4

Function

code

F01

C30

o19

o20

*1 "Without polarity" when o20 = 4 or 5 (BCD).

*2 Y: Possible, N: Impossible

*3 Y: Possible, N: Impossible

*4 Y: Applicable, N: Not applicable

Frequency Command 1

Frequency Command 2

DI option

Name Data setting range

0: / keys on keypad

1: Voltage input to terminal [12]

2: Current input to terminal [C1]

3: Sum of voltage and current inputs

5: Voltage input to terminal [V2]

7: Terminal command UP/DOWN

8: / keys on keypad

11: Digital input interface card

12: Pulse train input

0: Without polarity

(DI polarity)

(DI mode) 0: 8-bit binary frequency command

1: With polarity *

1: 12-bit binary frequency command

2: 15-bit binary frequency command

3: 16-bit binary frequency command

4: 4-digit BCD frequency command

5: 4-digit BCD frequency command

to terminals [12] and [C1]

control

(balanceless-bumpless switching

available)

(option)

1

(0 to 99.99 Hz)

(0 to 500.0 Hz)

w/o

PG

w/

PG

V/f

N Y 0 Y Y Y

N Y 0 Y Y Y

N Y 0 Y Y Y

BCD: Binary Coded Decimal

For details, refer to the FRENIC-MEGA Instruction Manual.

2-4

Page 18

M

2.7 Details of Function Codes

Table 2.6 shows the configuration of function codes o19 and o20 and the details of the terminal functions.

Turning the terminal input OFF or ON sets each bit data to "0" or "1," respectively.

Table 2.6 Details of Function Codes

No. o19 o20 Input signal name Terminal function and configuration details

0 0

0 1

0 2

8-bit binary

frequency command

12-bit binary

frequency command

15-bit binary

frequency command

I16 I15 I14 I13 I12 I11 I10 I9 I8 I7 I6 I5 I4 I3 I2 I1

Invalid

Frequency command

Hold signal

When I16 is OFF (0), the interface circuit updates the frequency

command according to the input data.

When I16 is ON (1), the interface circuit discards the input data and

holds the current frequency command.

Setting resolution = Maximum frequency (1/255)

I16I15I14I13I12I11I10I9I8I7I6I5I4I3I2I

Invalid

Frequency com mand

Hold signal

When I16 is OFF (0), the interface circuit updates the frequency

com mand according to the input data.

When I16 is ON (1), the interface circuit discards the input data and

holds the current frequency com mand.

Setting resolution = Maximum frequency (1/4095)

MSB

I16I15I14I13I12I11I10I9I8I7I6I5I4I3I2I

Frequency command

Hold signal

When I16 is O FF (0), the interface circuit updates the frequency

com mand according to the input data.

When I16 is ON (1), the interface circuit discards the input data and

holds the current frequency com mand.

Setting resolution = Maximum frequency (1/32767)

LSBMSB

LS B MSB

1

LS B

1

0 3

0, 1 4

0, 1 5

16-bit binary

frequency command

4-digit BCD

frequency command

(0 to 99.99 Hz)

4-digit BCD

frequency command

(0 to 500.0 Hz)

SB

I16 I15 I14 I13 I12 I11 I10 I9 I8 I7 I6 I5 I4 I3 I2 I1

Frequency com mand

LS B

Setting resolution = Maximum frequency (1/65535)

I16I15I14I13I12I11I10I9I8I7I6I5I4I3I2I

Tens place

of Hz

Units place

of Hz

Tenth place

of Hz

Hundredth place

LS B MSB

1

of Hz

Frequency can be specified within the range of 0 to 99.99 Hz (Setting

resolution = 0.01 Hz).

If a frequency command exceeding the maximum frequency is input,

the maximum frequency applies.

I16 I15 I14 I13 I12 I11 I10 I9 I8 I7 I6 I5 I4 I3 I2 I1

Hundreds place

of Hz

Tens place

of Hz

Units place

of Hz

Tenth place

Hold signal

When I16 is OFF (0), the interface circuit updates the frequency

com mand according to the input data.

When I16 is ON (1), the interface circuit discards the input data and

holds the current frequency comm and.

LS B MSB

of Hz

Frequency can be specified within the range of 0 to 500.0 Hz. (Setting

resolution = 0.1 Hz).

If a frequency command exceeding the maximum frequency is input,

the maximum frequency applies.

2-5

Page 19

No. o19 o20 Input signal name Terminal function and configuration details

1 0

1 1

1 2

8-bit binary

frequency command

12-bit binary

frequency command

15-bit binary

frequency command

I16 I15 I14 I13 I12 I11 I10 I9 I8 I7 I6 I5 I4 I3 I2 I1

Invalid

Frequency com mand

Hold signal

When I16 is OFF (0), the interface circuit updates the frequency

com mand according to the input data.

When I16 is ON (1), the interface circuit discards the input data and

holds the current frequency com mand.

Frequency setting range:

-(Maximum frequency) to +(Maximum frequency)

= -128 to +127

Setting resolution = Maximum frequency x (1/127)

I16I15I14I13I12I11I10I9I8I7I6I5I4I3I2I

Invalid

Frequency com mand

Hold signal

When I16 is OFF (0), the interface circuit updates the frequency

com mand according to the input data.

When I16 is ON (1), the interface circuit discards the input data and

holds the current frequency com mand.

Frequency setting range:

-(Maximum frequency) to +(Maximum frequency)

= -2048 to +2047

Setting resolution = Maximum frequency (1/2047)

I16I15I14I13I12I11I10I9I8I7I6I5I4I3I2I

Frequency com mand

Hold signal

When I16 is OFF (0), the interface circuit updates the frequency

com mand according to the input data.

When I16 is ON (1), the interface circuit discards the input data and

holds the current frequency com mand.

Frequency setting range:

-(Maximum frequency) to +(Maximum frequency)

= -16384 to +16383

Setting resolution = Maximum frequency (1/16383)

LS B MSB

LS B MSB

1

LS B MSB

1

1 3

16-bit binary

frequency command

MSB

I16I15I14I13I12I11I10I9I8I7I6I5I4I3I2I

Frequency com mand

Frequency setting range:

-(Maximum frequency) to +(Maximum frequency)

= -32768 to +32767

Setting resolution = Maximum frequency (1/32767)

2-6

LS B

1

Page 20

Chapter 3 DIGITAL OUTPUT INTERFACE CARD

3.1 Terminal Allocation and Symbol Diagram

O8 O7 O6 O5 O4 O3 O2 O1 M2

Figure 3.1 Terminal Allocation and Symbol Diagram

3.2 Connection Diagram

FRENIC-MEGA

L1/R

L2/S

L3/T

U

V

W

OPC-G1-DO

(MSB)

O8

O7

O6

O5

O4

O3

O2

(LSB)

O1

CM

Figure 3.2 Connection Diagram

Ry

Ry

Ry

Ry

Ry

Ry

Ry

Ry

24 VDC

3-1

Page 21

3.3 Terminal Functions

Table 3.1 lists terminal symbols, names and functions of the terminals on the digital output interface card.

Table 3.1 Terminals and Their Specifications

Terminal

symbol

[O1] to [O8] Transistor outputs 1 to 8

[M2]

Transistor output common

Name Functions

These digital terminals output various status (e.g., output

frequency, output current) specified by function code o21 as

an 8-bit parallel signal.

Common terminal for transistor output signals.

This terminal is electrically isolated from terminals [CM],

[11]s, and [CMY].

3.4 Electrical Specifications

Table 3.2 lists the electrical specifications for the digital output interface card.

Table 3.2 Electrical Specifications

Terminal

symbol

[O1] to [O8]

Operating voltage

Source current at ON 50 mA

Leakage current at OFF 0.1 mA

Item

ON level 2 V

OFF level 27 V

Specifications

Max.

3.5 Output Interface

Table 3.3 shows connection diagrams for output interface circuits.

Table 3.3 Connections of Output Interface Circuits

Connection diagram

SINK

mode

SOURCE

mode

Interface card

M2

O1 to O8

24 V

Interface card

M2

O1 to O8

24 V

3-2

Page 22

3.6 Configuring Inverter's Function Code

Function code o21 (DO mode selection) provided for options specifies the item to be monitored by digital signals

of this digital output interface card.

Table 3.4 lists the function code and its parameters. The function code o21 becomes available when the digital

output interface card is connected to the inverter.

Table 3.4 Function Code and Parameters

Drive control *3

Function

code

o21 DO option

(DO mode selection)

Name Data setting range

0: Output frequency

(before slip compensation)

1: Output frequency

(after slip compensation)

2: Output current

3: Output voltage

4: Output torque

5: Load factor

6: Input power

7: PID feedback amount

8: PG feedback value

9: DC link bus voltage

13: Motor output

15: PID command (SV)

16: PID output (MV)

w/o

PG

w/

PG

V/f

Y Y 0 Y Y Y

*1 Y: Possible, N: Impossible

*2 Y: Possible, N: Impossible

*3 Y: Applicable, N: Not applicable

For details, refer to the FRENIC-MEGA Instruction Manual.

3-3

Page 23

3.7 Details of Function Code

Table 3.5 shows the configuration of function code o21 and the details of the terminal functions.

Turning the terminal output OFF or ON sets each bit data to "0" or "1," respectively.

Table 3.5 Details of Function Code

Function

code

o21

Data

0

1

2 Output current

3 Output voltage

Output signal

name

Output frequency

(before slip

compensation)

Output frequency

(after slip

compensation)

Terminal function and configuration details

Terminal output = (Output frequency/Maximum frequency) 255

Terminal output = (Output frequency/Maximum frequency) 255

Terminal output

= (Output current/(Inverter rated output current x 2)) 255

Terminal output =(Output voltage/250 V) 255, for 200 V class series

= (Output voltage/500 V) 255, for 400 V class series

4 Output torque

Terminal output = (Output torque/(Motor rated torque x 2)) 255

5 Load factor

Terminal output = (Load factor/(Motor rated load x 2)) 255

6 Input power

Terminal output = (Input power/ (Inverter rated output x 2)) 255

PID feedback

7

amount

Terminal output

= (PID feedback amount/100% of feedback amount) 255

3-4

Page 24

Function

code

o21

Data

8

9

Output signal

name

PG feedback

value

DC link bus

voltage

13 Motor output

15

PID command

(SV)

Terminal function and configuration details

Terminal output

= (PG feedback value/100% of synchronous speed at maximum frequency) 255

Terminal output

= (DC link bus voltage/500 V) 255, for 200 V class series

= (DC link bus voltage/1000 V) 255, for 400 V class series

Terminal output = (Motor output/(Motor rated output 2)) 255

Terminal output = (PID command/100% of feedback value) 255

16

PID output

(MV)

Terminal output = (PID output/Maximum frequency) 255

3-5

Page 25

Chapter 4 I/O CHECKING

Using Menu #4 "I/O Checking" in FRENIC-MEGA program mode displays the I/O status of external signals on

the LED monitor of the keypad.

Figure 4.1 Menu Transition in Menu #4 "I/O Checking"

Basic key operation

To check the status of the I/O signals, set function code E52 to "2" (Full-menu mode) beforehand.

(1) Turn the inverter ON. It automatically enters Running mode. In that mode, press the key to switch to

Programming mode. The function selection menu appears.

(2) Use the and keys to display "I/O Checking" ( ).

(3) Press the key to proceed to a list of I/O check items (e.g. ).

(4) Use the and keys to display "Option control circuit terminal (I/O)" ( ), then press the key.

The corresponding I/O check data appears. Using the and keys switches the display method

between the segment display and hexadecimal display.

(5) Press the key to return to the list of I/O check items. Press the key again to return to the menu.

For details of Menu #4 "I/O Checking," refer to the FRENIC-MEGA Instruction Manual, Chapter 3, Section

3.4 "Programming Mode."

4-1

Page 26

The I/O status of the digital interface card(s) can be displayed with ON/OFF of the LED segment or in

hexadecimal.

Signals are assigned to the LED segments as shown below.

Table 4.1 Display with ON/OFF of LED Segments

Segment LED4 LED3 LED2 LED1

a O1 I9 I1

b O2 I10 I2

c O3 I11 I3

d O4 I12 I4

e O5 I13 I5

f O6 I14 I6

g O7 I15 I7

dp O8 I16 I8

Table 4.2 Segment Display for I/O Signal Status in Hexadecimal

LED number LED4 LED3 LED2 LED1

Bit 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Input terminal I16 I15 I14 I13 I12 I11 I10 I9 I8 I7 I6 I5 I4 I3 I2 I1

Output terminal - - - - - - - - O8 O7 O6 O5 O4 O3 O2 O1

Binary 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 1

Hexadecimal

on

the LED

monitor

4-2

Page 27

Chapter 5 PROTECTIVE FUNCTION

Option communications error ( )

Problem A communications error occurred between the digital interface card(s) and the inverter.

Possible Causes What to Check and Suggested Measures

(1) There is a problem with the

connection between the

interface card and the

inverter.

(2) Strong electrical noise.

(3) Two or more interface cards of

the same type are mounted.

When no o code is displayed even if a digital interface card is mounted, check whether the

connector on the interface card is firmly engaged with that of the inverter. In this case, does not

appear.

Check whether the connector on the interface card is firmly engaged with that of

the inverter.

Reload the interface card into the inverter.

Check whether appropriate noise control measures have been implemented (e.g.

correct grounding and routing of signal wires, communications cables, and main

circuit wires).

Implement noise control measures.

Check whether two or more interface cards of the same type are mounted.

Limit the number of interface cards of the same type on an inverter to only

one.

5-1

Page 28

Digital Input Interface Card

"OPC-G1-DI"

Digital Output Interface Card

"OPC-G1-DO"

Instruction Manual

First Edition, November 2007

Fourth Edition, April 2011

Fuji Electric Co., Ltd.

The purpose of this manual is to provide accurate information in the handling, setting up and operating of

the digital input interface card and digital output interface card for the FRENIC-MEGA series of inverters.

Please feel free to send your comments regarding any errors or omissions you may have found, or any

suggestions you may have for generally improving the manual.

In no event will Fuji Electric Co., Ltd. be liable for any direct or indirect damages resulting from the

application of the information in this manual.

Page 29

URL http://www.fujielectric.co.jp/

Fuji Electric Co., Ltd.

Gate City Ohsaki, East Tower, 11-2, Osaki 1-chome,

Shinagawa-ku, Tokyo, 141-0032, Japan

Phone: +81 3 5435 7283 Fax: +81 3 5435 7425

URL http://www.fujielectric.com/

2011-04 (D11c/L08) 1CM

Loading...

Loading...