Page 1

Instruction Manual

DeviceNet Interface Card "OPC-F1-DEV"

Thank you for purchasing our DeviceNet Interface Card OPC-F1-DEV.

• This product is designed to connect the FRENIC-Eco series of inverters to DeviceNet. Read

through this instruction manual and be familiar with the handling procedure for correct use.

• Improper handling blocks correct operation or causes a short life or failure.

• Deliver this manual to the end user of the product. The end user should keep this manual in a

safe place until the DeviceNet Interface Card is discarded.

• For the usage of inverters, refer to the instruction manual prepared for the FRENIC-Eco series

of inverters.

Fuji Electric Systems Co., Ltd. INR-SI47-0904-EU REV 052010

Page 2

Copyright © 2004 Fuji Electric FA Components & Systems Co., Ltd.

All rights reserved.

No part of this publication may be reproduced or copied without prior written permission from Fuji Electric FA Components & Systems Co.,

Ltd.

All products and company names mentioned in this manual are trademarks or registered trademarks of their respective holders.

The information contained herein is subject to change without prior notice for improvement.

Page 3

Preface

Thank you for purchasing our DeviceNet Interface Card OPC-F1-DEV.

Installing this Card on your FRENIC-Eco allows you to connect the FRENIC-Eco to a DeviceNet master unit (e.g., PC and PLC) and control

it as a slave unit using the RUN command, speed reference, and access to function codes.

This product has

Version 18.

DeviceNet is a trademark of Open DeviceNet Vendor Association, Inc. (ODVA).

This manual is designed to serve as a quick guide to the installation and operation of the DeviceNet Interface Card. For a more

complete description, refer to the DeviceNet Interface Card User ’s Manual (MEHT274), which can be downloaded from the following

URL (Fuji Electric FA Components & Systems, Co., Ltd. Technical Information):

http://web1.fujielectric.co.jp/Kiki-Info-EN/User/index.html

been tested by ODVA authorized Independent Test Lab and found to comply with ODVA’s DeviceNet Conformance Test

Certification Logo Mark:

How this manual is organized

This manual is made up of chapters 1 through 11.

Chapter 1 Features

Gives an overview of the main features of the DeviceNet Interface Card.

Chapter 2 Acceptance Inspection

Lists points to be checked upon delivery of the Card and precautions for transportation and storage of the Card. Also presents the

appearance of the Card and provides information on how to obtain an EDS file.

Chapter 3 Installation

Provides instructions and precautions for installing the Card.

Chapter 4 Wiring and Cabling

Provides wiring and cabling instructions around the pluggable connector for the Card. Also gives the specifications for the cables.

Chapter 5 Basic Functions

Provides instructions on how to use the DIP switch to set the data rate (baud rate) and the node address. Also provides the meanings of

the LED indicators.

Chapter 6 Steps to Get Started

Provides the procedures for getting the inverter started using DeviceNet.

Chapter 7 I/O Assembly Instances: Selection and Setup

Provides instructions on how to select the output assembly instances (request to the inverter) and the input assembly instances (response

from the inverter) using the function codes o31 and o32. Also provides information on the factor y default values and presents exampl es of

setting and operation.

Chapter 8 Other Parameters

Provides instructions on how to set DNFaultMode (fault handling), NetCtrl (RUN command), and NetRef (Speed reference).

Chapter 9 List of Function Codes for DeviceNet Option

Lists the inverter's function codes which are specific to DeviceNet.

Chapter 10 Troubleshooting

Provides troubleshooting instructions for certain problems, e.g., when the inverter does not operate as ordered or when an alar m condition

has been recognized.

Chapter 11 Specifications

Lists the general specifications and communications specifications.

1

Page 4

Icons

The following icons are used throughout this manual.

This icon indicates information which, if not heeded, can result in the product not operating to full efficiency, as well as information

concerning incorrect operations and settings which can result in accidents.

This icon indicates information that can prove handy when performing certain settings or operations.

This icon indicates a reference to more detailed information.

Table of Contents

Preface ................................................................................1

How this manual is organized...............................................1

Chapter 1 .........................................................3 Features

Chapter 2 ...................................3 Acceptance Inspection

Chapter 3 ......................................................4 Installation

Chapter 4 .........................................5 Wiring and Cabling

Chapter 5 ..............................................6 Basic Functions

5.1 ..............................................6 SW3 DIP switch

5.2 .....................................7 LED Status Indicators

Chapter 6 .......................................8 Steps to Get Started

Chapter 7

Chapter 8 .........................................16 Other Parameters

Chapter 9

Chapter 10 ...........................................19 Troubleshooting

Chapter 11 Specifications...............................................20

I/O Assembly Instances:

Selection and Setup

7.1

Output Assembly Instance

(request to t

7.2

Input Assembly Instance

he inverter): set by o31

(response from

8.1

DNFaultMode

(Class 0x29, Inst

Attribute 0x10)

8.2

NetCtrl, NetRef

rl: Class 0x29,

(NetCt

.....................................12

.............12

the inverter): set by o32

......13

ance 0x01,

..............................................16

Instance 0x01, Attribute 0x05)

(NetRef: Class 0x2A,

Instance 0x01, Attribute 0x04)

......................17

List of Function Codes for

ption

DeviceNet O

.........................................18

11.1 General Specifications.................................20

11.2 DeviceNet Specifications.............................20

2

Page 5

Chapter 1 Features

y

The Card has the following features:

- Data Rate (baud rate) : 125 kbps, 250 kbps, 500 kbps

- I/O Message : Polling and Change of State supported

- Applicable Profile : AC Drive profile

- Reading and writing all the function codes applicable to the FRENIC-Eco (User Defined Assembly I/O or Explicit Message)

Chapter 2 Acceptance Inspection

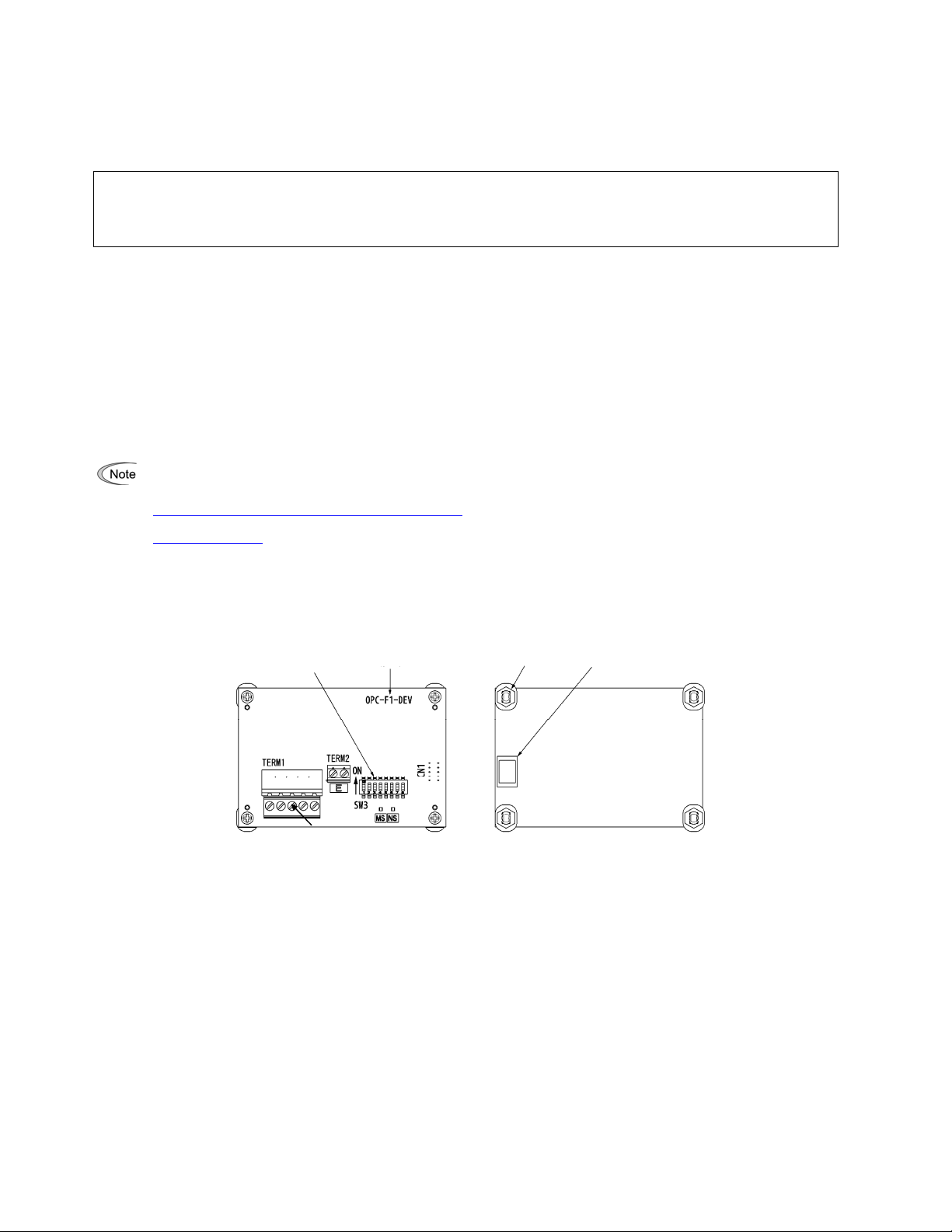

Unpack the package and check that:

(1) A DeviceNet Card is contained in the package.

(2) The DeviceNet Card has not been damaged during transportation--no defective electronic devices, dents, or warp.

(3) The model name "OPC-F1-DEV" is printed on the DeviceNet Card. (See Figure 1.)

If you suspect the product is not working properly or if you have any questions about your product, contact your Fuji Electric representative.

This Card works with any version of the FRENIC-Eco series inverters.

Neither an EDS file nor a terminating resistor comes with this Card.

- An EDS file can be downloaded from any of the following Websites:

http://web1.fujielectric.co.jp/Kiki-Info-EN/User/index.html

(Fuji Electric FA Components & Systems Co., Ltd. Technical Information)

http://www.odva.org

(ODVA Headquarters)

- A terminating resistor of the following specifications must be used: 121 ohm, 1/4 watt, 1% metal-film resistor (that usuall

comes with the master)

SW3: DIP switch

(for setting Baud Rate

and MAC ID)

Model Name

4 Spacers

CN1

LEDs (Status Indicators)

Figure 1 Back of the Card Figure 2 Front of the Card

3

Page 6

Chapter 3 Installation

Turn the power off and wait for at least five minutes for models of 40 HP or below, or ten minutes for models of 50 HP or above, before

starting installation. Further, check that the LED monitor is unlit, and check the DC link circuit voltage between the P (+) and N (-)

terminals to be lower than 25 VDC.

Otherwise, electric shock could occur.

Do not touch any metallic part of the connector for the main unit (CN1) or any electronic component. Otherwise, electronic components

may be damaged by static electricity. Also, the stain or adhesion of sweat or dust may adversely affect the contact reliability of the

connector in the long run.

An accident could occur.

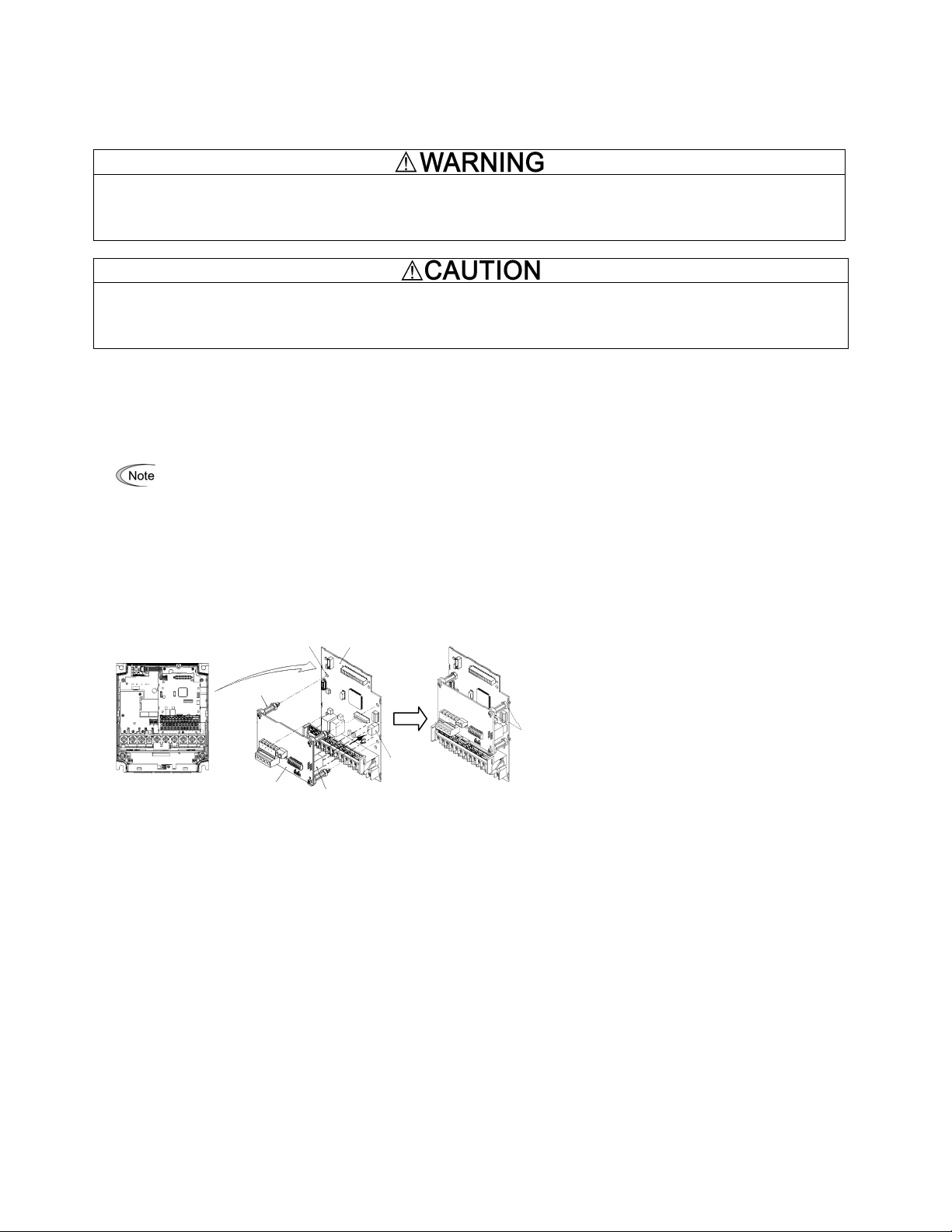

(1) Remove the covers from the inverter to expose the control printed circuit (Figure 3).

For the removal instructions, refer to the FRENIC-Eco Instruction Manual (INR-SI47-1225-E), Cha pter 2, Section 2.3 "Wiring." ( For

ratings of 50 HP or above, also open the keypad enclosure.)

(2) Insert four spacers and connector CN1 on the back of the OPC-F1-DEV (Figure 2) i nto the four spacer holes and Port A (CN4) on the

inverter's control printed circuit board (PCB) (Figure 4), respectively.

Make sure, visually, that the spacers and CN1 are firmly inserted (Figure 5).

(3) Install the wires for the OPC-F1-DEV.

(4) Put the covers back to its original position.

For wiring instructions, see Chapter 4.

For the installation instructions, refer to the FRENIC-Eco Instruction Manual (INR-SI47-1225-E), Chapter 2, Section 2.3 "Wiring."

(For ratings of 40 HP or above, also close the keypad enclosure.)

4 Spacer Holes

Control PCB

4 Spacers

DeviceNet Card

OPC-F1-DEV

Figure 3 FRN010F1S-2U -

FRN020F1S-2U

(example)

Port A

(CN4)

CN1

Figure 4 Mounting the

Card

Make sure that there

is no space between

control PCB and

spacers.

Figure 5 Mounting Completed

4

Page 7

Chapter 4 Wiring and Cabling

(1) To connect the DeviceNet Card, use a special 5-core cable that complies with the DeviceNet specifications. Also observe the wiring

lengths specified in the DeviceNet specifications.

Proper installation of the cable requires specialist knowledge. Be sure to refer to the DeviceNet specifications (published by ODVA)

beforehand.

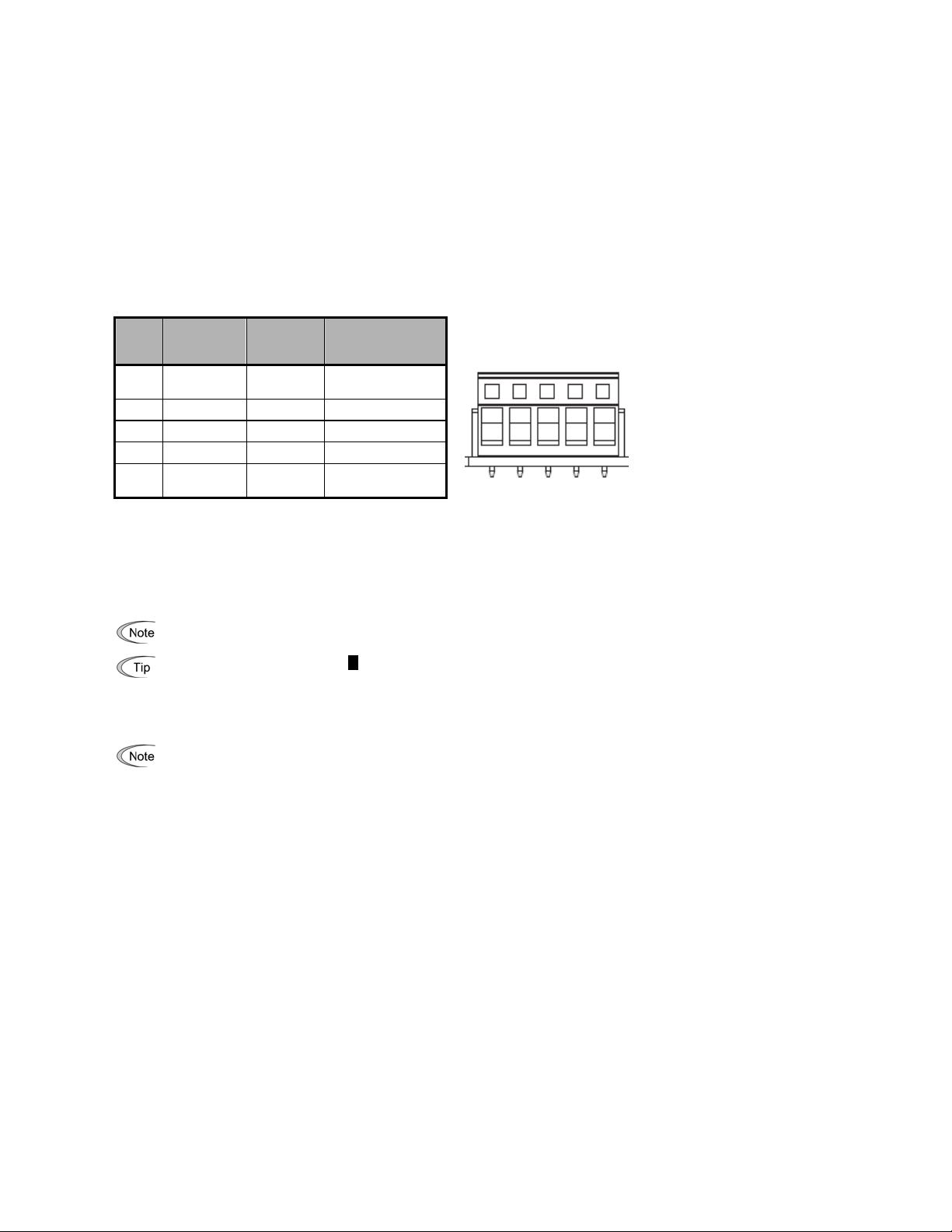

(2) Wiring around the DeviceNet’s pluggable connector (TERM1)

A pluggable 5-pin connector is used (Figure 6).The pluggable connector has five labels corresponding to the five pins. Each label has a

color corresponding to the wire (core) to be connected to its pin. Make sure that the colors of the wires and labels match. Table 1

shows the correspondence between the pin numbers and the colors.

Pin

#

1 Black V- Power supply

2 Blue CAN_L Signal line

3 Metallic SHIELD Cable shield

4 White CAN_H Signal line

5 Red V+ Power supply

Figure 6 Pluggable Connector

A typical pluggable connector meeting the specifications is MSTB 2.5/5-ST-5.08-AU made by Phoenix Contacts.

(3) Wiring around the grounding terminal block (TERM2)

Using a wire, connect one of the two pins to the grounding terminal (zG) on the inverter. Since these two pins are internally

short-circuited, either one will do.

Applicable wire size: AWG20 to 16 (0.5 mm

For protection against external noise and prevention of failures, be sure to connect a grounding wire.

This terminal block is marked with E by its side. "E" signifies the earth (ground).

(4) Terminating resistor

DeviceNet requires that a terminating resistor be installed externally on each end of the trunk line. Check that the trunk line is

terminated on both ends; if not, install (a) terminating resistor(s) on the missing end(s).

The Card does not come with terminating resistors. Use the resistors that come with the master or bu y a pair of resistors

separately.

The specifications are: 121 ohm, 1/4 watt, 1% (metal-film resistor)

Table 1 Layout of Terminal Pins

Color of

Wire

Sheath

Pin

Assignme

nt

Description

(24 VDC, - side)

(24 VDC, + side)

2

to 1.5 mm2)

1 2 3 4 5

5

Page 8

Chapter 5 Basic Functions

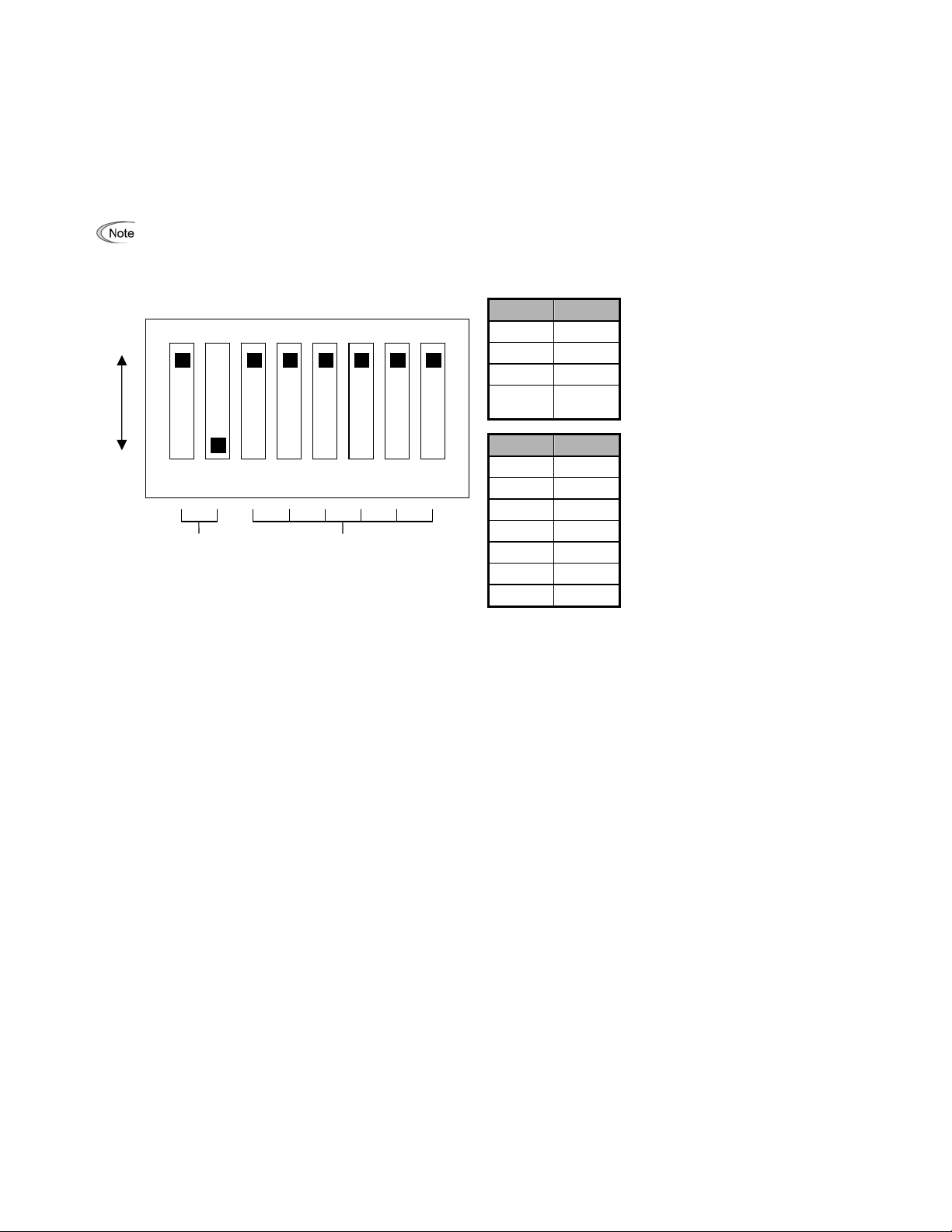

5.1 SW3 DIP switch

The DIP switch specifies the communication data rate (baud rate) and the MAC ID (node address) on DeviceNet. It offers a choice of three

baud rates (125 kbps, 250 kbps, and 500 kbps) and a choice of node address (MAC) ranging from 0 to 63.

Before accessing the DIP switch, make sure that the inverter’s power supply (including the auxiliary power supply) is turned OFF.

If you change the configuration of the DIP switch with the inverter’s power being ON, you need to restart the inverter to validate

the new settings.

The default settings of the DIP switch at factory shipment are: data rate = 500 kbps, node address = 63.

ON

OFF

1 2 3 4 5 6 7 8

Data Rate (DR) Node Address (NA)

Figure 7

DIP Switch Settings (showing an example of Data Rate = 500 kbps and Node Address = 63)

DR (bps) DIP 1-2

125K 00

250K 01

500K 10

Not

allowed

NA DIP 3-8

0 000000

1 000001

2 000010

3 000011

…

62 111110

63 111111

11

…

6

Page 9

5.2 LED Status Indicators 5.2 LED Status Indicators

The two LED status indicators show the status of the Card.

The two LED status indicators show the status of the Card.

The tables below show the states of the LEDs and their meanings. The tables below show the states of the LEDs and their meanings.

*1 Blinks in the pattern specified in the DeviceNet specifications.

*2 er5 cannot be re set until communication is restored. A setting to ignore er5. is available. For details, refer to Chapter 8, Section 8.1

"DNFaultMode."

- MS (Module Status)

Indicates the status of the DeviceNet Card hardware.

- NS (Network Status)

Indicates the status of communication on DeviceNet.

Table 2 MS LED State Table 2 MS LED State

MS LED Meaning Note

Blinks between

green and red

OFF

Lights in green

Lights in red

*1

Running self-diagnostic test upon power-on

Powered OFF

Normal

Hardware error

(Card not properly installed or Card is

This test takes 1

second.

The inverter shows er4.

faulty)

Table 3 NS LED State

NS LED Meaning Note

Blinks between

green and red

OFF

Blinks in green

Lights in green

Blinks in red

Lights in red

*1

Running self-diagnostic test upon power-on

Not on-line

(Checking for the duplicated MAC ID)

On-line and not connected

(Waiting for a request from the master)

On-line and connected

(Communications link is established)

Connection time-out

(The communications link is broken or the

interval of I/O communication is too short.)

Bus-off state or duplicated MAC ID has

been detected.

(E.g., Improper DeviceNet cabling,

mismatch in data (baud) rate, and

duplicated node address)

This test takes 1

second.

The inverter shows er5

*2

The inverter shows

*2

er5

–

–

–

–

–

7

Page 10

Chapter 6 Steps to Get Started

This chapter presents the steps you take from the time the physical connection of DeviceNet is established to the time you start running the

inverter with I/O Message using the DeviceNet master.

I/O Message is a communication process in which cyclic data transmission takes place. Another communication process in

DeviceNet is Explicit Message, in which event-driven data transmission takes place. Explicit Message allows you to directly read

and set/modify function codes and DeviceNet parameters. For details on Explicit Message, refer to the DeviceNet Interface Card

User’s Manual (MEHT274).

(1) Set the DeviceNet master (PLC, PC tool, or Configurator).

- Set the MAC ID (node address) uniquely, so that it does not coincide with any other nodes.

- Set the baud rate. Make sure that all the nodes have the same baud rate.

- Allocate an I/O area corresponding to the I/O assembly instance set for this Card. The I/O area is either 4 bytes or 8 bytes in length.

See (3) on the next page.

- Specify the type of I/O connection (Poll or Change of state).

In the case of the Configurator,

- Install the EDS file.

The Electric Data Sheet (EDS) file defines parameters on the slave. Using it quickly accesses the desired parameters. For this

Card, the file makes it easier to access the inverter's function codes. For how to obtain the EDS file, refer to Chapter 2

"Acceptance Inspection."

The exact settin g procedures depend on the DeviceNet master or the Configurator. For details, refer to the User’s Manual of the

corresponding master.

(2) Configure the DIP switch on this Card.

Before accessing the DIP switch (baud rate and node address), make sure that the power is OFF. For details, see Figure 7 in Chapter

5.

8

Page 11

(3) Set the function codes for the inverter.

r

Power ON the inverter and set the function codes according to the table below.

- o31, o32

Select the I/O assembly instances (I/O formats). o31 is for the output (from master to inverter); o32 is for the input (from inverter to

master). You can specify any combination of input (o31) and output (o32). After modifying the I/O assembly instances, restart the

inverter to validate the new settings on the inverter.

Once you have modified the settings for o31 or o32, be sure to restart the inverter in order to validate the new settings.

Table 4 Setting o31 and o32

o31, o32 Type Instance ID Description

o31=20 20 Basic Speed Control Output 4

o31=21 or 0

(initial value)

Output

(from master

to slave)

21 Extended Speed Control

Output

Length

(bytes)

4

o31=100 100 Fuji Drive Assembly Output 4

o31=102

o32=70 70 Basic Speed Control Input 4

o32=71 or 0

(initial value)

Input

(from slave

to master)

102 User Defined Assembly Output 8

71 Extended Speed Control Input 4

o32=101 101 Fuji Drive Assembly Input 4

o32=103

103 User Defined Assembly Input 8

For the details of instances, refer to Chapter 7.

(4) Set other parameters as necessary.

a) DNFaultMode

This parameter specifies the operation to be performed if a DeviceNet communications error occurs. The factory default is "Trip

immediately with er5 if a DeviceNet communications error occurs."

(Class 0x29; Instance 1; Attribute 16)

For details, refer to Chapter 8.

b) NetCtrl, NetRef

The NetCtrl parameter enables/disables the RUN command sent via DeviceNet; and the NetRef parameter, the Speed reference.

Their factory defaults are "disabled."

(NetCtrl: Class 0x29, Instance 1, Attribute 5)

(NetRef: Class 0x2A, Instance 1, Attribute 4)

For details, refer to Chapter 8.

NetCtrl and NetRef can also be specified from I/O Assembly Instance 21 (see the next page).

(5) Have an I/O connection request issued from the DeviceNet master.

In order for this Card to start DeviceNet communication, the master should send a communication request. For details, refer to the

User’s Manual of the master.

Once I/O connection is established between the master and the slave, the NS LED on this Card changes from blinking green to sol id

green, and communication starts.

Set the I/O scan interval (=EPR) for the Card during I/O connection to at least 10 ms (For example, 10 ms if one maste

controls one slave; 5 ms if one master controls two slaves). It is recommended that you specify at least 20 ms to the I/O scan

interval to minimize the frequency of communications collision and maximize the system’s reliability.

9

Page 12

(6) Examples of I/O communication

F

Presented herein are examples of the format of the I/O Assembly Instance at shipment from the factory.

a) Description of Format

o31 = 21 or 0

Output Assembly Instance ID.21 (output from the master = request to the inverter)

Instance byte bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

21

0 - NetRef NetCtrl - -

Fault

Reset

Run

Reverse

Run Forward

1 (Fixed at 00)

2 Speed Reference (lower byte) (r/min)

3 Speed Reference (upper byte) (r/min)

Run Forward: 1 = Run Forward command

Run Reverse: 1 = Run Reverse command

Fault Reset: 1 = Reset the alarm condition

NetCtrl: 1 = Request for enabling Run command sent from DeviceNet

0 = Request for enabling Run command sent from other than DeviceNet

NetRef: 1 = Request for enabling Speed Reference sent from DeviceNet

0 = Request for enabling Speed Reference sent from other than DeviceNet

Speed Reference: Speed Reference (in r/min)

o32 = 71 or 0

Input Assembly Instance ID.71 (input to the master = response from the inverter)

Instance byte bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

71 0

At

Reference

Ref_

From_Net

Ctrl_

From_Net

Ready

Running

Reverse

Running

Forward

- Faulted

1 Drive State

2 Speed Actual (lower byte) (r/min)

3 Speed Actual (upper byte) (r/min)

Faulted: 1 = The inverter has (and remains) tripped.

Running Forward: 1 = The motor is running forward.

Running Reverse: 1 = The motor is running backward (in the reverse direction).

Ready: 1 = Ready to run

Ctrl_From_Net: 1 = Run command sent from DeviceNet being enabled

0 = Run command sent from other than DeviceNet being enabled

Ref_From_Net: 1 = Speed Reference sent from DeviceNet being enabled

0 = Speed Reference sent from other than DeviceNet being enabled

At Reference: 1 = The motor is running at the reference speed.

Drive State: 3 = Ready, 4 = Enabled, 5 = Stopping, 6 = Fault stop, 7 = Faulted,

1 = Startup, 2 = Not Ready

Speed Actual: Actual rotation speed (in r/min)

b) Actual I/O Data during Running

Presented below are an example of the driving pattern for controlling the inverter and its corresponding I/O data expressed in the

format given above.

orward

Reverse

1800 r/min

300 r/min

Figure

Time (s)

1800 r/min

8 Driving Pattern

10

Page 13

Description of I/O Data (The I/O data are in hexadecimal notation.)

Request: Run command is OFF. Speed Reference = 1800 r/min (= 0708h). Run command and Speed Reference via DeviceNet are

enabled.

60 00 08 07

Response: Stopping. The inverter is ready.

70 03 00 00

Request: Run Forward command. Speed Reference = 1800 r/min (= 0708h). Run command and Speed Reference via DeviceNet are

enabled.

61 00 08 07

Response: The motor is running forward and accelerating. The actual speed is increasing.

74 04 ** **

Request: Run Forward command. Speed Reference = 1800 r/min (= 0708h). Run command and Speed Reference via DeviceNet are

enabled.

61 00 08 07

Response: Running Forward. The actual speed has reached the Reference

F4 04 08 07

Request: Run command is OFF. Speed Reference = 1800 r/min (= 0708h). Run command and Speed Reference via DeviceNet are

enabled.

60 00 08 07

Response: The motor is running forward and decelerating. The actual speed is decreasing.

74 05 ** **

Request: No RUN command. Speed Reference is changed to 300 r/min (= 012Ch). Run command and Speed Reference via

DeviceNet are enabled.

60 00 2C 01

Response: Stopping. The inverter is ready.

70 03 00 00

Request: Reverse command. Speed Reference = 300 r/min (= 012Ch). Run command and Speed Reference via DeviceNet are

enabled.

62 00 2C 01

Response: The motor is running backward (in the reverse direction) and accelerating. The actual speed is increasing.

78 04 ** **

Request: Reverse command. Speed Reference = 300 r/min (= 012Ch). Run command and Speed Reference via DeviceNet are

enabled.

62 00 2C 01

Response: Running in the reverse direction. The actual speed has reached Reference

F8 04 2C 01

Request: Reverse command. Speed Reference is changed to 1800 r/min (= 0708h). Run command and Speed Reference via

DeviceNet are enabled.

62 00 08 07

Response: The motor is running backward (in the reverse direction) and accelerating. The actual speed is increasing.

78 04 ** **

Request: Reverse command. Speed Reference = 1800 r/min (= 0708h). Run command and Speed Reference via DeviceNet are

enabled.

62 00 08 07

Response: Running in the reverse direction. The actual speed has reached Reference

F8 04 08 07

Request: Run command is OFF. Speed Reference = 1800 r/min (= 0708h). Run command and Speed Reference via DeviceNet are

enabled.

62 00 08 07

Response: The motor is running backward (in the reverse direction) and decelerating. The actual speed is decreasing.

78 05 ** **

11

Page 14

Chapter 7 I/O Assembly Instances: Selection and Setup

7.1 Output Assembly Instance (request to the inverter): set by o31

(1) o31 = 20

Output Assembly Instance ID.20 Basic Speed Control Output

Instance byte bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

20

Run Forward: 1 = Run Forward command

Fault Reset: 1 = Reset the alarm condition

Speed Reference: Speed Reference (in r/min)

(2) o31 = 21 or 0 (factory default)

Output Assembly Instance ID.21 Extended Speed Control Output

Instance byte bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

0 - - - - - Fault

1 (Fixed at 00)

2 Speed Reference (lower byte) (r/min)

3 Speed Reference (upper byte) (r/min)

Reset

- Run

Forward

21

0 - NetRef NetCtrl - - Fault

Reset

Run

Reverse

Run

Forward

1 (Fixed at 00)

2 Speed Reference (lower byte) (r/min)

3 Speed Reference (upper byte) (r/min)

Run Forward: 1 = Run Forward command

Run Reverse: 1 = Run Reverse command

Fault Reset: 1 = Reset the alarm condition

NetCtrl: 1 = Request for enabling Run command sent from DeviceNet;

0 = Request for enabling Run command sent from other than DeviceNet

NetRef: 1 = Request for enabling Speed Reference sent from DeviceNet;

0 = Request for enabling Speed Reference sent from other than DeviceNet

Speed Reference: Speed Reference (in r/min)

(3) o31 = 100

Output Assembly Instance ID.100 Fuji Drive Assembly Output

Instance byte bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

100

0 - X5 X4 X3 X2 X1 REV FWD

1 RST XR XF - - - - 2 Frequency command p.u. (lower byte)

3 Frequency command p.u. (upper byte)

Run command

(same as S06)

Frequency

command

(same as S01)

FWD: 1 = Run Forward command

REV: 1 = Run Reverse command

X1 to X5: Communication Terminal Block command

(The exact function to be performed is specified by E01 – E05).

XF, XR: Communication Terminal Block command

(The exact function to be performed is specified by E98 and E99).

RST: 1 = Reset the alarm (fault) condition.

Frequency command p.u.: Specifies the ratio of the frequency to the data of 20000 for the maximum frequency F03. That is, Frequency

command p.u. = Frequency command (Hz)/F03 (Hz) 20000.

12

Page 15

(4) o31 = 102

Output Assembly Instance ID.102 User Defined Assembly Output

User Defined Assembly Output offers a format which allows the user to freely set or modify the function code defined by the user

beforehand. Four function codes are provided for the user to define.

Instance byte bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

102

0 User-defined function code 1 (write) (lower byte) (data of function code specified by o40)

1 User-defined function code 1 (write) (upper byte) (data of function code specified by o40)

2 User-defined function code 2 (write) (lower byte) (data of function code specified by o41)

3 User-defined function code 2 (write) (upper byte) (data of function code specified by o41)

4 User-defined function code 3 (write) (lower byte) (data of function code specified by o42)

5 User-defined function code 3 (write) (upper byte) (data of function code specified by o42)

6 User-defined function code 4 (write) (lower byte) (data of function code specified by o43)

7 User-defined function code 4 (write) (upper byte) (data of function code specified by o43)

User-defined function code 1 (write): write data for the function code specified by o40

User-defined function code 2 (write): write data for the function code specified by o41

User-defined function code 3 (write): write data for the function code specified by o42

User-defined function code 4 (write): write data for the function code specified by o43

Once you have modified the settings for o40 to o43, be sure to restart the inverter in order to validate the new settings.

For details of the write formats for individual function codes, refer to the DeviceNet Interface Card User’s Manual (MEHT274).

If you assign the same function code to more than one "o" code, only the one assigned to the smal lest "o" code number will

become effective, and all the rest will be ignored (treated as "not assigned").

7.2 Input Assembly Instance (response from the inverter): set by o32

(1) o32 = 70

Input Assembly Instance ID.70 Basic Speed Control Input

Instance byte bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

70

0 - - - - - Running

1 (00)

2 Speed Actual (lower byte) (r/min)

3 Speed Actual (upper byte) (r/min)

Faulted: 1 = The inverter has (and remains) tripped

Running Forward: 1 = The motor is running forward.

Speed Actual: Actual rotation speed (in r/min)

Forward

- Faulted

13

Page 16

(2) o32 = 71 or 0 (factory default)

Input Assembly Instance ID.71 Extended Speed Control Input

Instance byte bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

71

0 At

Reference

Ref_

From_Net

Ctrl_

From_Net

Ready Running

Reverse

1 Drive State

2 Speed Actual (lower byte) (r/min)

3 Speed Actual (upper byte) (r/min)

Faulted: 1 = The inverter has (and remains) tripped.

Running Forward: 1 = The motor is running forward.

Running Reverse: 1 = The motor is running backward (in the reverse direction).

Ready: 1 = Ready to run

Ctrl_From_Net: 1 = Run command sent from DeviceNet being enabled

0 = Run command sent from other than DeviceNet being enabled

Ref_From_Net: 1 = Speed Reference sent from DeviceNet being enabled

0 = Speed Reference sent from other than DeviceNet being enabled

At Reference: 1 = The motor is running at the reference speed.

Drive State: 3 = Ready, 4 = Enabled, 5 = Stopping, 6 = Fault stop, 7 = Faulted,

1 = Startup, 2 = Not Ready

Speed Actual: Actual rotation speed (in r/min)

(3) o32 = 101

Input Assembly Instance ID.101 Fuji Drive Assembly Input

Instance byte bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

Running

Forward

- Faulted

101

0 VL TL NUV BRK INT EXT REV FWD

1 BUSY ERR - RL ALM DEC ACC IL

2 Frequency output p.u. (lower byte)

3 Frequency output p.u. (upper byte)

Running status

(same as M14)

Output frequency

(same as M06)

FWD: During forward rotation

REV: During reverse rotation

EXT: During DC braking (or during pre-exciting)

INT: Inverter shut down

BRK: During braking

NUV: DC link circuit voltage established (0 = undervoltage)

TL: During torque limiting

VL: During voltage limiting

IL: During current limiting

ACC: During acceleration

DEC: During deceleration

ALM: Alarm relay (for any fault)

RL: Communications effective

ERR: Function code access error

BUSY: During function code data writing

Frequency output p.u.: Output frequency. Expressed as the ratio of the frequency to the data of 20000 for the maximum

frequency F03. That is, Frequency command p.u. = Frequency command (Hz)/F03 (Hz) 20000.

14

Page 17

(4) o32 = 103

Input Assembly Instance ID.103 User Defined Assembly Input

User Defined Assembly Input offers a format which allows the user to monitor the function codes defined by the user beforehand. Four

function codes are provided for the user to define.

Instance byte bit 7 bit 6 bit 5 bit 4 bit 3 bit 2 bit 1 bit 0

103

0 User-defined function code 1 (read) (lower byte) (data of function code specified by o48)

1 User-defined function code 1 (read) (upper byte) (data of function code specified by o48)

2 User-defined function code 2 (read) (lower byte) (data of function code specified by o49)

3 User-defined function code 2 (read) (upper byte) (data of function code specified by o49)

4 User-defined function code 3 (read) (lower byte) (data of function code specified by o50)

5 User-defined function code 3 (read) (upper byte) (data of function code specified by o50)

6 User-defined function code 4 (read) (lower byte) (data of function code specified by o51)

7 User-defined function code 4 (read) (upper byte) (data of function code specified by o51)

User-defined function code 1 (read): value of the function code specified by o48

User-defined function code 2 (read): value of the function code specified by o49

User-defined function code 3 (read): value of the function code specified by o50

User-defined function code 4 (read): value of the function code specified by o51

Once you have modified the settings for o48 to o51, be sure to restart the inverter in order to validate the new settings.

For details of the formats for individual function codes, refer to the DeviceNet Interface Card User’s Manual (MEHT274).

15

Page 18

Chapter 8 Other Parameters

8.1 DNFaultMode (Class 0x29, Instance 0x01, Attribute 0x10)

This parameter specifies the inverter operation to be performed if a DeviceNet communication error occurs.

Using the function code o27, you can also specify the operation in the event of a communication error in the same way as with

DNFaultMode. The "o27" column in the table below shows the value for o27 corresponding to that of DNFaultMode.

Table 5 Inverter Operations Specified by DNFaultMode

DNFaultMo

Inverter Operation in the Event of an Error Note o27

de

0 Turn OFF Run command immediately.

13

(No error er5 occurs.)

1 Ignore the error. (No error er5 occurs.) 3

2 Ignore the error if the communications link is

restored within the timer value specified by

o28. If the timer value is exceeded, then

decelerate the motor by force and then turn

The forced

deceleration period is

specified by F08.

on er5.

3 Put the motor in forward rotation by force.

(No error er5 occurs.)

4 Put the motor in reverse rotation by force.

(No error er5 occurs.)

100 Put the motor immediately in coast-to-stop

mode and cause an er5 trip.

101 Put the motor in coast-to-stop mode and

cause an er5 stop when the time set by o28

(Timer) has expired.

102 Ignore the alarm condition if the

communications link is restored within the

timer value specified by o28. If the timer

value is exceeded, then put the motor in

coast-to-stop mode by force and then turn on

Forward rotation is

enabled when NetCtrl

= 1.

Reverse rotation is

enabled when NetCtrl

= 1.

0

1

2

er5.

110 Immediately decelerate the motor by force.

When the motor has stopped, turn on er5.

111 When the time set by o28 (Timer) has

expired, put the motor in coast-to-stop mode

and, when the motor has stopped, turn on

er5 .

The forced

deceleration period is

specified by F08.

The forced

deceleration period is

specified by F08.

112 Same as for [DNFaultMode = 2] 12

*1 o27 can have values in the range of 0 to 15. If you specify a value not shown in Table 5 (o27 = 4 to 9), the same operation as for o27 = 0

will be performed.

*1

12

14

15

10

11

16

Page 19

8.2 NetCtrl, NetRef (NetCtrl: Class 0x29, Instance 0x01, Attribute 0x05) (NetRef: Class 0x2A, Instance 0x01, Attribute 0x04)

These parameters specify whether to enable the Run command and Speed Reference coming via DeviceNet.

Table 6 Operations Specified by NetCtrl and NetRef

NetCtrl

Setting

0 (factory

default)

1 Y –

NetRef

0 (factory

default)

1 – Y

Using the function code

y98, you can also specify the operation in the same way as with NetCtrl and NetRef.

Table 7 Operations Specified by y98

y98

0 (factory

default)

1 Y N

2 N Y

3 Y Y

Depending on how the inverter is set (*), the RUN command and Speed Reference coming via DeviceNet may not be enabled,

even if you set NetCtrl and NetRef as shown above.

(*) function code y99, LE (link operation selection), and selection of local/remote.

For details, refer to the FRENIC-Eco User’s Manual (MEH456), Chapter 4 "BLOCK DIAGRAMS FOR CONTROL LOGIC."

RUN

Command

Speed

Reference

N –

– N

Speed

Reference

RUN

Command

N N

Y: Possible via DeviceNet

N: Impossible via DeviceNet

(Possible via keypad, external

terminal block, etc.)

–: Not available

Y: Possible via DeviceNet

N: Impossible via DeviceNet

(Possible via keypad, external

terminal block, etc.)

17

Page 20

Chapter 9 List of Function Codes for DeviceNet Option

Table 8 List of Function Codes for DeviceNet Card

Functio

n Code

Description

o27 Selection of operation in the event of DeviceNet error 0 0 - 15

o28 Timer for start of operation in the event of Error 5.0s 0.0 - 60.0s

o31 *1 Selection of Output Assembly Instance 0 (=21)

o32 *1 Selection of Input Assembly Instance 0 (=71)

o40 *1

o41 *1

o42 *1

o43 *1

Assignment of user-defined function code 1 (write)

Function code data to be assigned to user-defined function

code 1 (write}

Assignment of user-defined function code 2 (write)

Function code data to be assigned to user-defined function

code 2 (write}

Assignment of user-defined function code 3 (write)

Function code data to be assigned to user-defined function

code 3 (write}

Assignment of user-defined function code 4 (write)

Function code data to be assigned to user-defined function

code 4 (write}

o48 *1

Assignment of user-defined function code 1 (read)

Function code data to be assigned to user-defined function

code 1 (read)

o49 *1

o50 *1

o51 *1

Assignment of user-defined function code 2 (read)

Function code data to be assigned to user-defined function

code 2 (read)

Assignment of user-defined function code 3 (read)

Function code data to be assigned to user-defined function

code 3 (read)

Assignment of user-defined function code 4 (read)

Function code data to be assigned to user-defined function

code 4 (read)

*1 To validate these new settings, you need to restart the inverter.

*2 The entry range is from 0 to 255; however, specifying a value other than those given in this table resets the data to the factory default.

*3 The function code data should be specified in a 4-digit hexadecimal format as shown below. To specify the function code data through a

remote keypad or DeviceNet, observe this format. To use a multi-function keypad, you can directly select the function code without

paying attention to that format.

How to set o40 to o51

Using a remote keypad

Specify the function code in a 4-digit hexadecimal notation.

Factory

Default

0000

(no

assignment)

0000

(no

assignment)

0000

(no

assignment)

0000

(no

assignment)

0000

(no

assignment)

0000

(no

assignment)

0000

(no

assignment)

0000

(no

assignment)

Allowable

Range

0, 20, 21,

100, 102

0, 70, 71,

101, 103

any

function

*3

code

any

function

*3

code

any

function

*3

code

any

function

*3

code

any

function

*3

code

any

function

*3

code

any

function

*3

code

any

function

*3

code

*2

*2

Example: For H30: H Type Code 08

30 1E (hexadecimal)

081e

T

able 9 Function Code Type

Type Type Code Function Code Type Type Code Function Code

S 2 0x02

Command/function

data

o 10 0x0A Optional function

M 3 0x03 Monitored data J 14 0x0E Application function

F 4 0x04

Fundamental

function

y 15 0x0F Link function

E 5 0x05 Terminal function W 16 0x10 Monitor 2

C 6 0x06 Control function X 17 0x11 Alarm 1

P 7 0x07 Motor 1 function Z 18 0x12 Alarm 2

H 8 0x08

High performance

function

conve

ntional

0 0x00

Function codes for the

G11’s DeviceNet

Interface Card*

* For details on the G11’s function codes, refer to the User’s Manual of DeviceNet Interface Card (MEHT274).

18

Page 21

Chapter 10 Troubleshooting

If any problem or error occurs during DeviceNet communication, follow the troubleshooting procedures given below.

No Phenomenon/Symptom Probable Causes

1 None of the LEDs on the

Card would light.

2 er4 alarm cannot be reset

(MS LED is lit in red).

3 NS LED is lit in red.

(er5 alarm cannot be

reset.)

4 NS LED is blinking in red.

(er5 alarm has occurred.)

5 NS LED would not light. The master has a problem.

6 NS LED would not light in

green.

7 Even though NS LED

lights in green, the

settings for RUN

command or Speed

Reference cannot be

validated.

8 Although the Speed

Reference has been

validated, the actual

speed is different from it.

The inverter is not powered ON.

The Card is not properly installed.

The Card is faulty.

The Card is not properly installed.

The Card is faulty.

There is a duplicated node address.

There is a mismatch in baud (data) rate.

The network power (24V) is not properly supplied.

Cabling is not properly done.

The inverter has not been restarted after modification of

the DIP switch settings.

The master has a problem.

The cable was broken during communication.

The I/O scan interval is too short.

The cable was broken.

The master has a problem.

The I/O scan interval was set too short at the start of

communication.

The I/O area is invalidly mapped.

There is no I/O connection.

Neither NetCtrl nor NetRef is set to “1.”

On the inverter, the higher-priority RUN command or

Speed Reference is enabled.

There is a mistake in the selection of I/O Assembly

Instances.

The inverter has not been powered OFF and then

powered ON after o31 was modified.

The number of motor poles specified by P01 does not

match the motor.

There is a mistake in the selection of I/O Assembly

Instances.

The inverter has not been restarted after modification of

o31.

The maximum frequency F03 or the frequency upper

limit F15 is set too low.

19

Page 22

Chapter 11 Specifications

11.1 General Specifications

For the items not covered in this section, the specifications of the inverter apply.

Item Specifications

Input power 130 mA at maximum (5 VDC)

Operating ambient temperature

range

Operating ambient humidity range 5 to 95% RH (There shall be no condensation.)

External dimensions 94 x 63 x 23.5 mm(3.7 x 2.48 x 0.93 in)

Applicable inverter FRENIC-Eco

11.2 DeviceNet Specifications

For the items not covered in this section, the DeviceNet Specifications Release 2.0 apply.

Item Specifications

Network input voltage 11 V to 28 V

Network input power 50 mA at maximum (24 VDC)

No. of nodes connected 64 at maximum (including the master)

MAC ID 0 to 63

Insulation 500 VDC (photocoupler insulation)

Transmission rate 500 kbps/250 kbps/125 kbps

Maximum cable length

(Trunk line: thick

cable

Drop line: thin

cable)

Messages supported 1. I/O Message (poll, change of state)

Vendor ID 319 (Fuji Electric Co., Ltd.)

Device type AC drive (code: 2)

Product code 9217

Model name OPC-F1-DEV

Applicable device profile AC Drive

No. of input/output bytes Selectable between 4 and 8 bytes for input and output

Applicable DeviceNet

Specifications

Node type Group 2 only server

-10 to +85C(14 to +185F)

Transmission rate 500 kbps 250 kbps 125 kbps

Trunk line length 100 m

Drop line length 6 m

Total length of drop

lines

2. Explicit Message

(independently)

DeviceNet Specifications Release 2.0 Errata 5

(Certified by ODVA Japan for Conformance Test Version A-18)

(328 ft)

(19.7 ft)

39 m

(128 ft)

250 m

(820 ft)

6 m

(19.7 ft)

78 m

(256 ft)

500 m

(1640 ft)

6 m

(19.7 ft)

156 m

(512 ft)

20

Page 23

DeviceNet Interface Card "OPC-F1-DEV"

Instruction Manual

First Edition, September 2004

Fuji Electric FA Components & Systems Co., Ltd

The purpose of this manual is to provide accurate information in the handling, setting up and operating of DeviceNet Interface Card

"OPC-F1-DEV" for the FRENIC-Eco series of inverters. Please feel free to send your comments regarding any errors or omissions you may

have found, or any suggestions you may have for generally improving the manual.

In no event will Fuji Electric FA Components & Systems Co., Ltd. be liable for any direct or indirect damages resulting from the application of

the information in this manual.

.

Page 24

MEMO

Page 25

Fuji Electric Systems Co., Ltd.

Fuji Electric Corp. of America

47520 Westinghouse Drive Fremont, CA 94539, U.S.A.

Tel.+1-510-440-1060 Fax.+1-510-440-1063

Toll-free support 1-888-900-FUJI(3854)

INR-SI47

-0904-EU Rev 052010 Information subject to change without notice.

http://www.fujielectric.com/fecoa/

Loading...

Loading...