Page 1

Instruction Manual

Synchronous Operation Card

"OPC-E1-SY"

Thank you for purchasing our synchronous operation card.

• Read through this instruction manual and be familiar with the synchronous operation card

before proceeding with installation, connections (wiring), operation, or maintenance and

inspection.

• Deliver this manual to the end user of this product. Keep this manual in a safe place until

this product is discarded.

• Specifications of this card are subject to change without prior notice for improvement.

Fuji Electric FA Components & Systems Co., Ltd. INR-SI47-1218-E

Page 2

Copyright © 2007 Fuji Electric FA Components & Systems Co., Ltd.

All rights reserved.

No part of this publication may be reproduced or copied without prior written permission from Fuji

Electric FA Components & Systems Co., Ltd.

All products and company names mentioned in this manual are trademarks or registered

trademarks of their respective holders.

The information contained herein is subject to change without prior notice for improvement.

Page 3

Preface

Thank you for purchasing our synchronous operation card "OPC-E1-SY."

Mounting this card into your FRENIC-Multi inverter enables the inverter to drive two motors

equipped with pulse generators in three synchronous operation modes--speed synchronous

operation, standby synchronous operation and simultaneous start synchronous operation modes.

Read through this instruction manual in conjunction with the FRENIC-Multi Instruction Manual

(INR-SI47-1094-E) and be familiar with proper handling and operation of this product. Improper

handling might result in incorrect operation, a short life, or even a failure of this product.

This instruction manual does not contain inverter handling instructions. Refer to the FRENIC-Multi

Instruction Manual (INR-SI47-1094-E), and keep this manual in a safe place.

Safety precautions

Read this manual thoroughly before proceeding with installation, connections (wiring), operation, or

maintenance and inspection. Ensure you have sound knowledge of the device and familiarize

yourself with all safety information and precautions before proceeding to operate the inverter.

Safety precautions are classified into the following two categories in this manual.

Failure to heed the information indicated by this symbol may

lead to dangerous conditions, possibly resulting in death or

serious bodily injuries.

Failure to heed the information indicated by this symbol may

lead to dangerous conditions, possibly resulting in minor or

light bodily injuries and/or substantial property damage.

Failure to heed the information contained under the CAUTION title can also result in serious

consequences. These safety precautions are of utmost importance and must be observed at all

times.

i

Page 4

Installation and wiring

• Turn the inverter's power OFF and wait for at least five minutes before starting

installation and wiring.

• Qualified electricians should carry out wiring.

Otherwise, electric shock could occur.

• Do not use the products that are damaged or lacking parts.

Doing so could cause failure or injuries.

• Prevent lint, paper fibers, sawdust, dust, metallic chips, or other foreign materials from

getting into the inverter.

Otherwise, a fire or an accident might result.

• Incorrect handling in installation/removal jobs could cause a failure.

A failure might result.

• Noise may be emitted from the inverter, motor and wires. Implement appropriate

measure to prevent the nearby sensors and devices from malfunctioning due to such

noise.

Otherwise, an accident could occur.

Operation

• Be sure to mount the terminal cover before turning the power ON.

Do not remove the cover while the power is on.

Doing so could cause electric shock.

• Confirm and adjust the setting of the function codes before running the inverter.

Otherwise, an accident could occur.

Maintenance and inspection, and parts replacement

• Turn the inverter's power OFF and wait for at least five minutes before starting

inspection or parts replacement.

Otherwise, electric shock could occur

• Maintenance, inspection, and parts replacement should be made only by qualified

persons.

• Take off the watch, rings and other metallic objects before starting work.

• Use insulated tools.

Otherwise, electric shock or injuries could occur.

ii

Page 5

Disposal

• Treat the product as an industrial waste when disposing of it.

Otherwise injuries could occur.

Others

• Never attempt to modify the product.

Doing so could cause electric shock or injuries.

Icons

The following icons are used throughout this manual.

This icon indicates information which, if not heeded, can result in the inverter not

operating to full efficiency, as well as information concerning incorrect operations and

settings which can result in accidents.

This icon indicates information that can prove handy when performing certain settings

or operations.

This icon indicates a reference to more detailed information.

iii

Page 6

Table of Content

Preface ..............................................................................................................................i

Safety precautions .........................................................................................................i

Chapter 1 BEFORE USING THE INVERTER............................................................ 1-1

1.1 Acceptance Inspection ..................................................................................... 1-1

1.2 Mounting the Synchronous Operation Card..................................................... 1-2

1.3 Pulse Generator (PG) Specifications and PG1-Mounting Instructions............. 1-3

1.3.1 PG specifications ....................................................................................... 1-3

1.3.2 Connection between the synchronous operation card and PGs

on reference and slave motors .................................................................. 1-4

1.3.3 Wiring procedure for the PGs and the synchronous operation card ......... 1-5

1.3.4 Setting up the power supply for PGs......................................................... 1-6

1.3.5 Option terminals on the synchronous operation card................................ 1-6

1.3.6 Arrangement of option terminals on the synchronous operation card....... 1-6

Chapter 2 CONNECTION DIAGRAMS...................................................................... 2-1

Chapter 3 PREPARATION FOR OPERATING........................................................... 3-1

Chapter 4 SYNCHRONOUS OPERATION CONTROL ............................................. 4-1

4.1 Specifications of Synchronous Operation ........................................................ 4-1

4.2 Overview of Synchronous Operation ............................................................... 4-2

4.2.1 Standby synchronous operation ................................................................ 4-2

4.2.2 Simultaneous start synchronous operation................................................ 4-3

4.3 Block Diagrams ................................................................................................ 4-4

4.4 List of Function Codes ..................................................................................... 4-6

4.5 Unavailable Function Codes ............................................................................ 4-8

4.6 Configuring Function Codes............................................................................. 4-8

4.6.1 Motor constant data ................................................................................... 4-8

4.6.2 Data setting for synchronous operation ..................................................... 4-8

Chapter 5 CONFIGURATION EXAMPLES AND ADJUSTMENT GUIDE .................. 5-1

5.1 Typical Configuration and Pulse Setting .......................................................... 5-1

5.1.1 Speed reduction ratio setting ..................................................................... 5-1

5.1.2 Wiring of PGs............................................................................................. 5-3

5.2 Key Points on Function Code Configuration and Adjustment Guide................ 5-4

5.3 Function Code Configuration Examples........................................................... 5-6

5.3.1 For position synchronous operation (o60 = 1 or 2), #1.............................. 5-6

5.3.2 For position synchronous operation (o60 = 1 or 2), #2.............................. 5-7

5.3.3 For speed synchronous operation (o60 = 0).............................................. 5-8

5.4 Checking PG Pulse Rate ................................................................................. 5-9

Chapter 6 PROTECTIVE FUNCTIONS ..................................................................... 6-1

6.1 Overspeed Alarm (OS) .................................................................................... 6-1

6.2 Excessive Speed Deviation Alarm (ErE) ......................................................... 6-2

6.2.1 Function codes .......................................................................................... 6-2

6.2.2 Excessive speed deviation detection......................................................... 6-2

6.3 Excessive Deviation Alarm (Ero)..................................................................... 6-3

6.3.1 Function codes .......................................................................................... 6-3

iv

Page 7

Chapter 1 BEFORE USING THE INVERTER

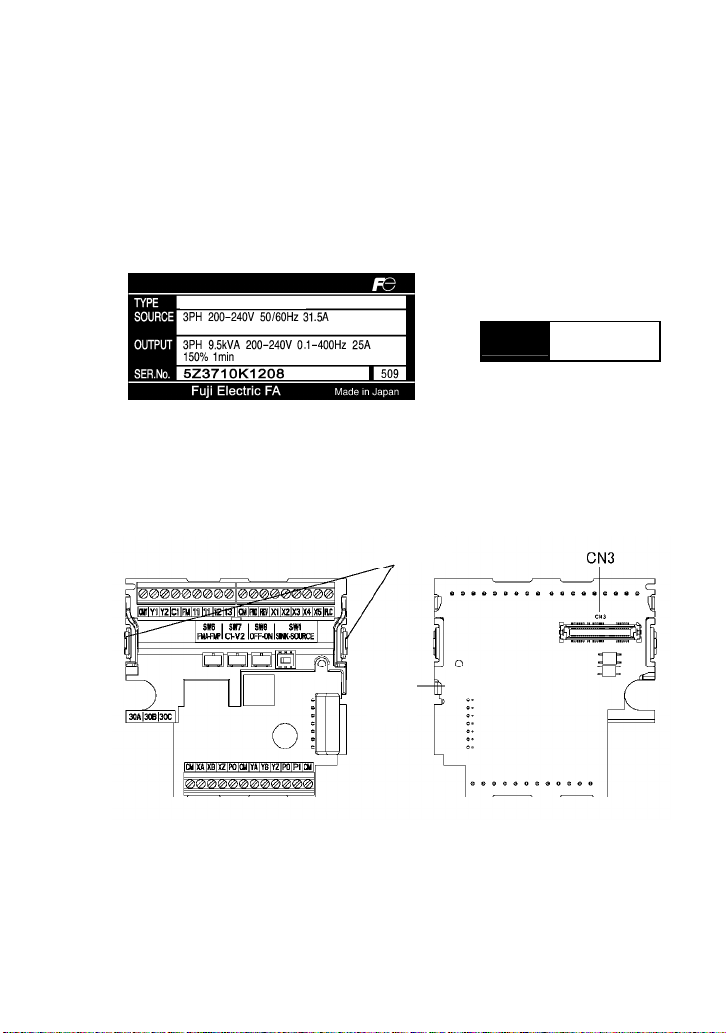

1.1 Acceptance Inspection

Unpack the package and check the following:

(1) The synchronous operation card is the model you ordered.

(2) The card is not damaged during transportation--no defective parts or lacking parts.

(3) The model name "OPC-E1-SY" is printed on the card. (See Figure 1.3.)

(4) The card is applicable to your inverter.

Applicable inverters have "-2SYZ," "-4SYZ," or "-7SYZ" at the end of the inverter type printed

in the TYPE column on the main and sub nameplates labeled on inverters.

FRN5.5E1S-2SYZ

TYPE

SER.No.

FRN5.5E1S-2SYZ

5Z3710K1208

Hooks

Model

name

OPC-E1-SY

(a) Main nameplate (b) Sub nameplate

Figure 1.1 Nameplates

If you suspect the product is not working properly or if you have any questions about your product,

contact your Fuji Electric representative.

Figure 1.2 Figure 1.3

1-1

Page 8

1.2 Mounting the Synchronous Operation Card

• Turn the power OFF and wait for at least five minutes before starting installation.

Otherwise, electric shock could occur.

• Do not use the product that is damaged or lacking parts.

Doing so could cause a failure and injuries.

• Prevent lint, paper fibers, sawdust, dust, metallic chips, or other foreign materials from

getting into the inverter.

Otherwise, a fire or an accident might result.

• Incorrect handling when mounting or removing the product could cause a failure.

A failure might result.

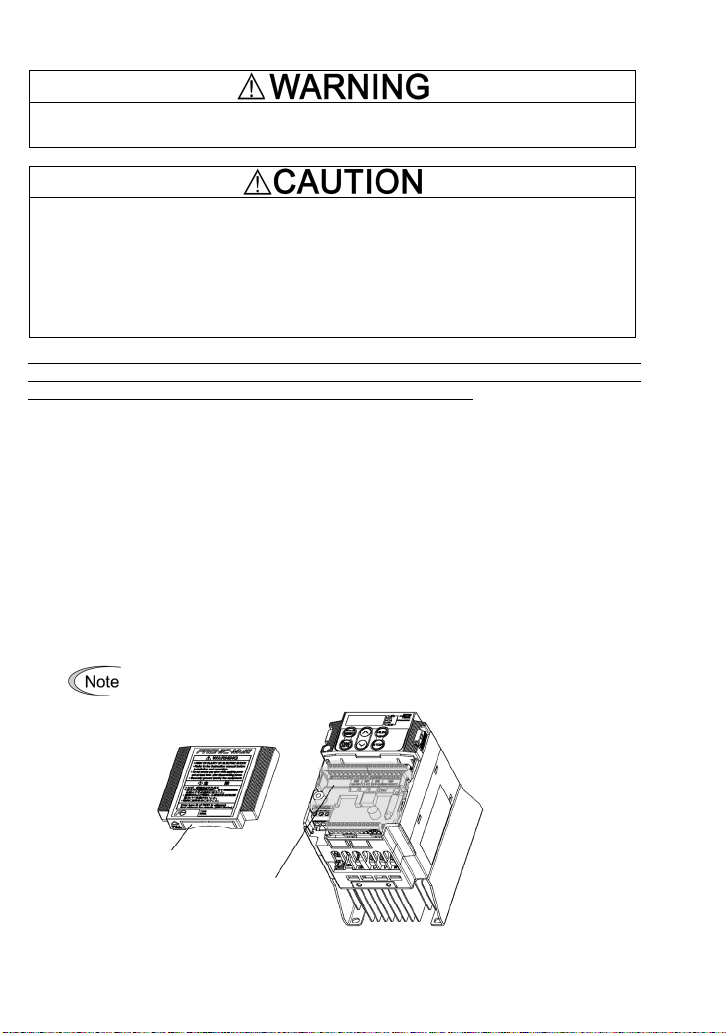

When handling the synchronous operation card and interface printed circuit board (interface PCB),

take any antistatic measure or hold their hooks taking care not to directly touch their circuit boards;

otherwise, the static electricity charged in your body may damage them.

(1) Remove the terminal cover.

For details on how to remove the terminal cover, refer to the FRENIC-Multi Instruction

Manual (INR-SI47-1094-E), Chapter 2, Section 2.3 "Wiring."

(2) If the interface PCB is mounted on the inverter, push the hooks provided on both ends of the

interface PCB and pull it up and out of the inverter with both hands. (Store the removed

interface PCB for future use.)

(3) Connect the CN3 connector (shown in Figure 1.3) on the synchronous operation card to the

connector on the inverter until it clicks into place.

(4) For inverters of 0.75 kW or below: Before reinstalling the terminal cover, cut off the barrier (see

Figure 1.4) of the terminal cover using nippers or the like.

(5) Reinstall the terminal cover, taking care not to pinch control signal lines.

When reinstalling the terminal cover, refer to the FRENIC-Multi Instruction Manual

(INR-SI47-1094-E), Chapter 2, Section 2.3 "Wiring."

For inverters of 3.7 kW or below: When performing the wiring for the main

circuit terminals, you need to remove the synchronous operation card

beforehand.

Barrier of the cable outlet

Synchronous operation card

Figure 1.4

1-2

Page 9

1.3 Pulse Generator (PG) Specifications and PG Mounting Instructions

• Using the pulse generator (PG) whose specifications are not satisfied may cause the

inverter and equipment to malfunction.

Doing so could cause failure or injuries.

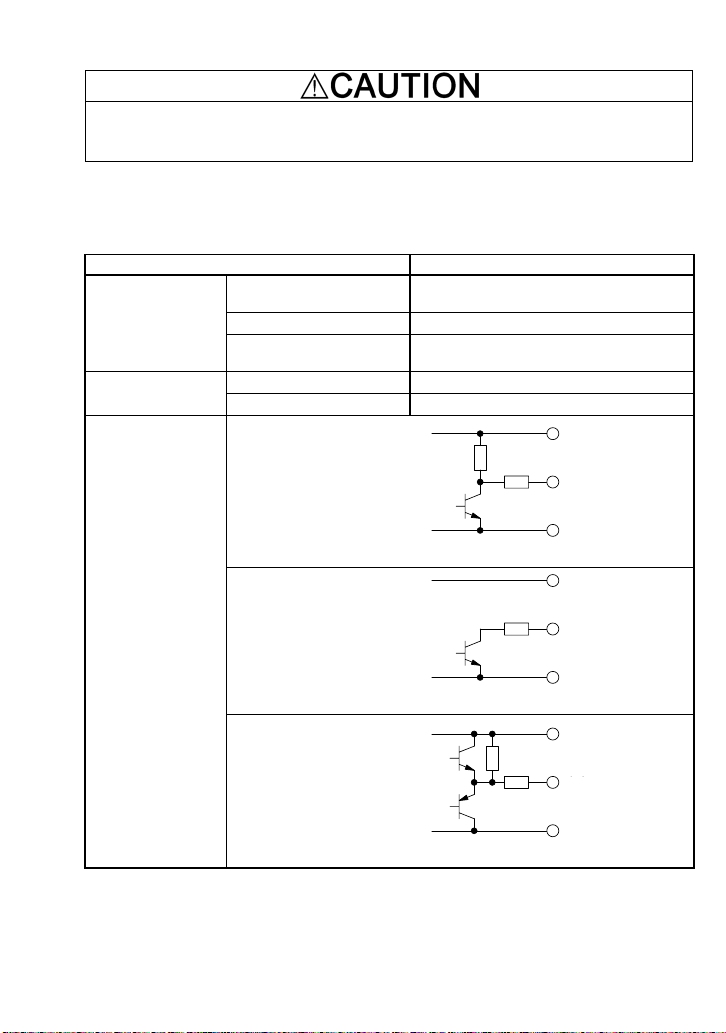

1.3.1 PG specifications

Table 1.1 lists the specifications of PGs applicable to the synchronous operation card.

Table 1.1 Specifications of Applicable PG and Synchronous Operation Card

Item Specifications

A and B phases (Incremental system),

Z phase

20 to 3000 P/R

5 VDC ±10% / 100 mA

(200 mA, when a single PG is mounted.)

+5 VDC ±10% / 200 mA

+5 VDC ±10%, 200 mA or more

Vcc

Applicable PG

PG power supply

Encoder system

Pulse resolution

Input power requirements

Internal power supply

External power supply

Voltage output

Circuit configured with the

grounded-emitter

Output

出力

transistor whose collector

outputs voltage

Open collector

0V

Vcc

(pull-up resistor: 620Ω)

Output signal type

Voltage output circuit

出力

Output

configured without resistor

between the output

terminal and the collector

Complementary

0V

Vcc

(totem-pole push-pull)

Constant voltage output

出力

Output

circuit configured with an

emitter follower

0V

Note 1: The wiring length between the PG and inverter should not exceed 20 m.

Note 2: When the PG power is 200 mA or more, use an external power supply.

Note 3: The external power supply should satisfy the voltage specifications of the PG.

Note 4: The reference and slave motors should use pulse generators with the same pulse

resolution.

1-3

Page 10

Select PGs that match the DC characteristics of the synchronous operation card listed in the table

below.

Table 1.2 DC Characteristics of the Synchronous Operation Card

Terminals XA, XB, XZ, YA, YB, YZ Min. Max.

High level input voltage VIH 3.8 V --

Low level input voltage VIL

(Input current 9 mA or less)

Low level input current IIL

(when an internal power supply is used, VIL=0V)

-- 1.2 V

-- 9 mA

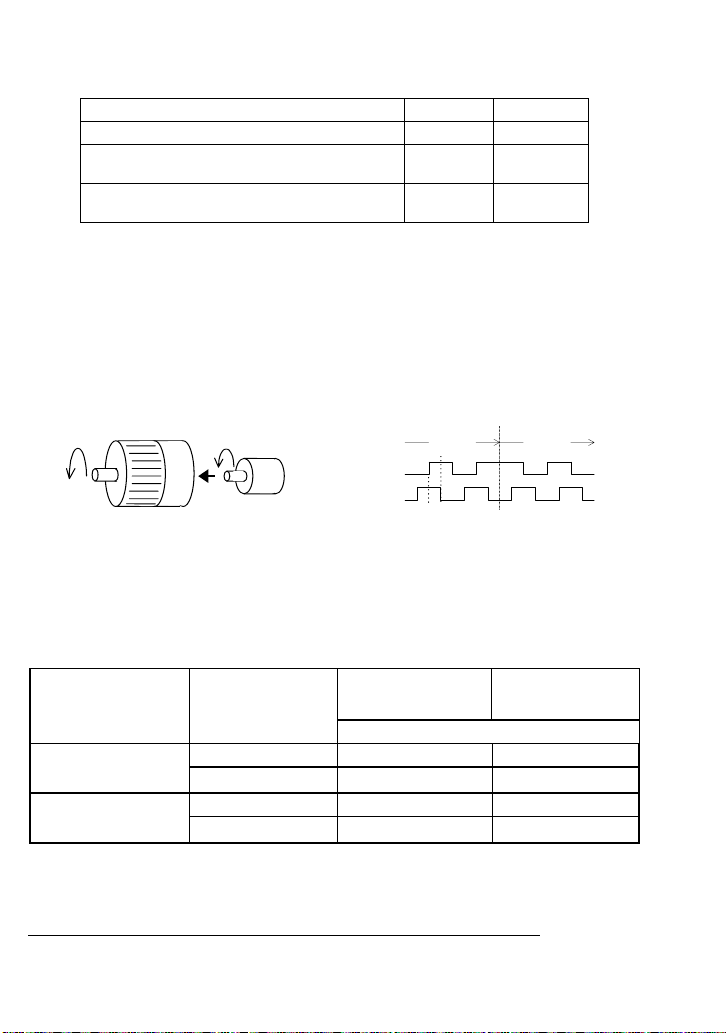

1.3.2 Connection between the synchronous operation card and PGs on reference and slave motors

Connect the PG output signal wires for the reference motor to terminals XA, XB, and XZ on the

synchronous operation card and those for the slave motor, to terminals YA, YB, and YZ.

The counterclockwise rotation when viewed from the motor output shaft is regarded as "forward

rotation" (see Figure 1.5). The PG output signal wires should be connected so that the PG output

pulse during rotation in the forward direction forms the forward signal as shown in Figure 1.6 (B

phase advances 90 degrees from A phase).

Forward direction

A phase input

B phase input

Motor

Figure 1.5 Forward Direction of Motor and PG Figure 1.6 Rotational Direction and Output Signal

Table 1.3 lists the relationship between the connection of reference PG output signals, the

rotational direction of the reference PG, and the rotational direction of the slave motor that receives

PG

of PG

90°

Forward

signal

Reverse

signal

a run command (FWD or REV).

Table 1.3 Connection of the Reference PG Output Signals and Rotational Direction of the Slave Motor

A and B phase output

signals issued from the

reference PG

If connected to

terminals XA and XB

normally

If connected to

terminals XA and XB

reversely

* If the reference inverter rotates the motor in such a direction that the slave inverter stops, the

pulse count continues so as to cause an Ero excessive deviation alarm. After that, if the

reference inverter rotates the motor in the same direction as the slave inverter, the synchronous

operation restarts from the position where the deviation becomes zero.

When the rotational

direction of the

reference PG is:

Forward Forward Stop *

Reverse Stop * Reverse

Forward Stop * Reverse

Reverse Forward Stop *

If the slave motor

receives a run forward

command (FWD):

It rotates in the following direction.

Note: Synchronous operation in the direction opposite to the reference PG rotation

If the slave motor

receives a run reverse

command (REV):

To drive the slave PG in the direction opposite to the reference PG rotation in synchronous

operation, connect the B and A phase output signals issued from the reference PG to terminals XA

and XB, respectively. (See Table 1.3.)

1-4

Page 11

1.3.3 Wiring procedure for the PGs and the synchronous operation card

• Turn the inverter's power OFF and wait for at least five minutes before starting

connection.

• Qualified electricians should carry out wiring.

Otherwise, electric shock could occur.

• Noise may be emitted from the inverter, motor and wires. Implement appropriate

measure to prevent the nearby sensors and devices from malfunctioning due to such

noise.

Otherwise, an accident could occur.

Wire each PG to the synchronous operation card, observing the following precautions and referring

to the connection diagrams given in Figures 2.1 and 2.2.

(1) Turn the inverter's power OFF.

(2) Use a shielded wire for wiring between the PG and the synchronous operation card.

(3) To prevent malfunction due to noise, keep the wiring away from the main circuit wiring of the

inverter and the power wiring of other devices as far as possible (at least 10 cm). Do not route

them in the same duct.

(4) Complete the wiring for the PG before turning the inverter's power ON.

(5) The wire size applicable to the option connection terminal on the inverter is AWG 18-24.

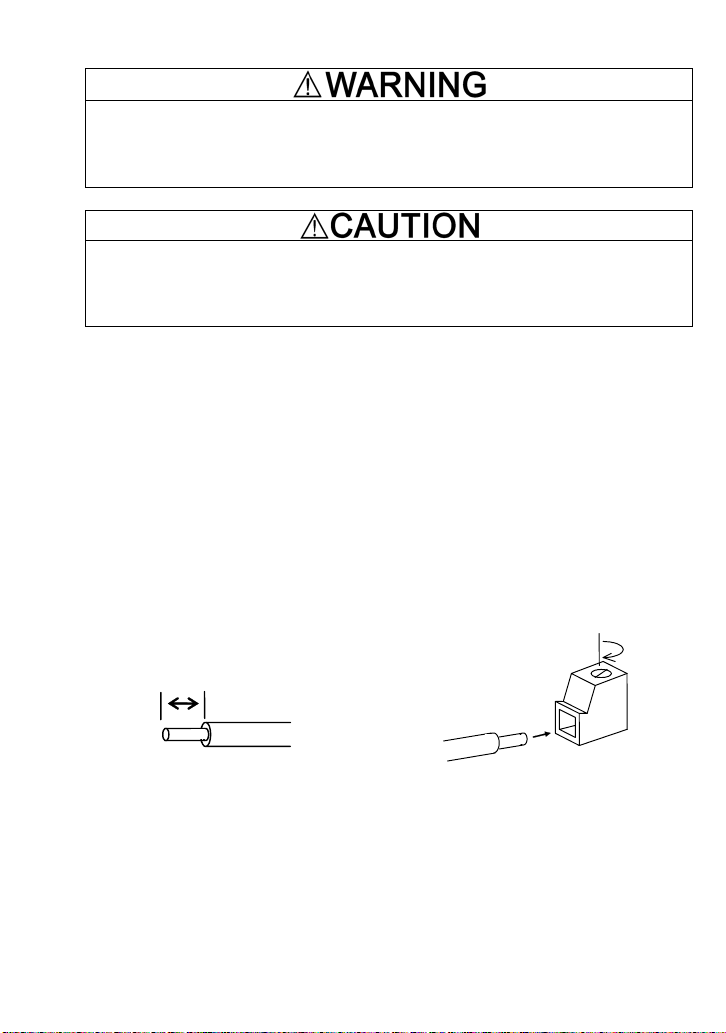

When using a wire with its end being stripped, strip its end by 5 to 7 mm. When using a ferrule,

use a vinyl-insulated ferrule.

Loosen the fixing screw, insert the wire end into the opening of the terminal block, and tighten

the screw.

5 to 7 (mm)

Figure 1.7 Stripping the Wire End Before Connection to Terminal Block

Recommended wire: AWG 18-24 for rated temperature 105°C (UL)

1-5

Page 12

1.3.4 Setting up the power supply for PGs

When using an internal power supply

Connect the power supply wire to terminal [PO] on the synchronous operation card.

When using an external power supply

Connect the power supply wire to terminal [PI] on the synchronous operation card.

1.3.5 Option terminals on the synchronous operation card

Table 1.4 lists terminal symbols, names and functions of the option terminals on the synchronous

operation card.

Table 1.4 Option Terminals and Their Specifications

Classification

Note: Incorrect wiring of A/B phase could fail to run the motor normally or cause an inverter trip.

Terminal

symbol

External power supply

PI

input

PO Power supply for PG

CM PG common

XA A phase pulse input X

XB B phase pulse input X

PG/ Pulse input

XZ Z phase pulse input X

YA A phase pulse input Y

YB B phase pulse input Y

YZ Z phase pulse input Y

Name Functions

Power input terminal from the external device

External power supply capacity:

5 VDC ±10%, 200 mA or more

Power output terminal

5 VDC ±10%, Maximum output 200 mA

Common terminal for power supply and PG input

Input terminal for A phase signal issued from

reference PG

Input terminal for B phase signal issued from

reference PG

Input terminal for Z phase signal issued from

reference PG

Input terminal for A phase signal issued from

slave PG

Input terminal for B phase signal issued from

slave PG

Input terminal for Z phase signal issued from

slave PG

Input signal status (pulse rate) on terminals [XA], [XB], [XZ], [YA], [YB], and [YZ] can be

checked by using Menu #4 "I/O Checking" (4_15, 4_16, 4_17 and 4_18) on the

inverter's keypad. For the operating procedure, refer to the FRENIC-Multi Instruction

Manual (INR-SI47-1094-E). (Function code E52 = 2)

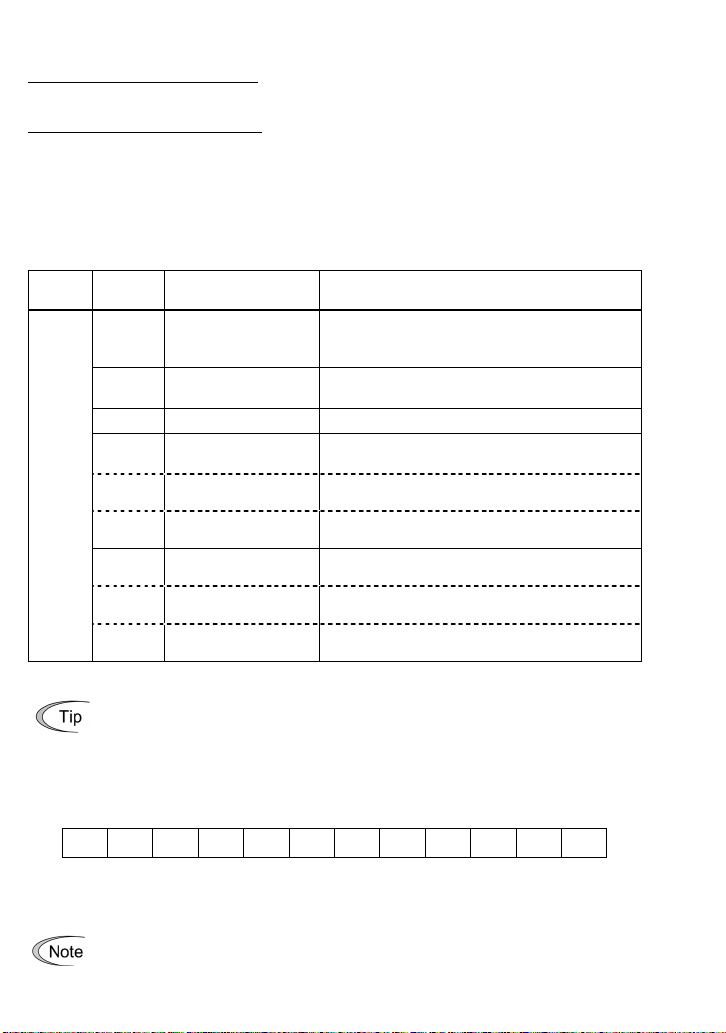

1.3.6 Arrangement of option terminals on the synchronous operation card

CM XA XB XZ PO CM YA YB YZ PO PI CM

Screw size: M2

Tightening torque: 0.22 to 0.25 N·m

Terminal [PLC] on the synchronous operation card cannot supply power to external

equipment. Use the terminal only for receiving power from external equipment.

Figure 1.8 Option Terminals

1-6

Page 13

Chapter 2 CONNECTION DIAGRAMS

Figure 2.1 shows connection diagram examples for synchronous operation.

Ⅰ.インバータ内部電源使用時

1. When using inverter internal power supply

Reference

FRN-E1S-SYZ

L1/R

L2/S

L3/T

G

OPC-E1-SY

U

V

W

PI

PO

YA

YB

YZ

CM

PO

XA

XB

XZ

CM

Slave

motor

追従側

M M

PG

motor

基準側

PG

Ⅱ.外部電源使用時

2. When using external power supply

FRN-E1S-SYZ

G

OPC-E1-SY

U

V

W

PI

PO

YA

YB

YZ

CM

PO

XA

XB

XZ

CM

5Vdc ±10%

L1/R

L2/S

L3/T

Slave

追従側

motor

M M

PG

Reference

基準側

motor

PG

Figure 2.1 Connection Diagrams for Synchronous Operation

In order to conform the inverter to the requirements of EMC Directive, ground the shields of the

PG cables to the inverter as shown below.

1. When using inverter internal power supply

Ⅰ.インバータ内部電源使用時

Reference

FRN-E1S-SYZ

L1/R

L2/S

L3/T

G

OPC-E1-SY

U

V

W

PI

PO

YA

YB

YZ

CM

PO

XA

XB

XZ

CM

Slave

motor

追従側

motor

M M

PG

基準側

PG

2. When using external power supply

Ⅱ.外部電源使用時

FRN-E1S-SYZ

L1/R

L2/S

L3/T

G

OPC-E1-SY

U

V

W

PI

PO

YA

YB

YZ

CM

PO

XA

XB

XZ

CM

Slave

motor

追従側

M M

PG

Reference

motor

基準側

PG

5Vdc ±10%

Figure 2.2 Connection Diagrams for Compliance with EMC Directive

Note: For details about applicable PGs, see Table 1.1 in Chapter 1, Section 1.3.1 "PG specifications."

2-1

Page 14

Chapter 3 PREPARATION FOR OPERATING

After completion of mounting and wiring but before turning the inverter's power ON, check the

followings.

(1) The wiring is correct.

(2) There is no cable waste or screws left.

(3) The screws and terminals are firmly tightened.

(4) The straggling wires at ferrules are not short-circuited to other terminals.

Furthermore, after powering the inverter ON but before starting inverter operation, check the

followings.

• Check the wiring surely before running the inverter. Incorrect wiring causes the inverter

or other devices to malfunction.

Failure to do so could cause failure or injuries.

• Be sure to mount the terminal cover before turning the power ON.

Do not remove any cover while the power is ON.

Doing so could cause electric shock.

• Confirm and adjust the configuration of the function codes before running the inverter.

Otherwise, an accident could occur.

3-1

Page 15

Chapter 4 SYNCHRONOUS OPERATION CONTROL

The synchronous operation control enables the slave inverter to detect the reference motor rotation

with PG signals and synchronize the slave motor with the reference motor in rotation speed and

position.

The synchronous operation is available in three modes--Speed synchronous (o60 = 0), standby

synchronous (o60 = 1), and simultaneous start synchronous (o60 = 2) operation.

Reference motor's PG signals should be input to terminals XA, XB, and XZ, and slave motor's ones,

to terminals YA, YB, and YZ.

4.1 Specifications of Synchronous Operation

Table 4.1 lists the specifications of the synchronous operation.

Table 4.1 Specifications of Synchronous Operation

Item Specifications Remarks

Control

Electrical

requirements

Speed control range 180 to 3600 r/min

Position control accuracy

Input pulse rate 75 p/s to 30 kp/s

For the procedure on how to calculate the PG input pulse rate based on the inverter

output frequency, refer to Section 5.4 "Checking PG Pulse Rate."

±5°

4-pole motors and PGs with 1000 P/R

Speed reduction ratio = 1:1

During running at constant speed

Maximum wiring length: 20 m

A/B phase encoders

4-1

Page 16

4.2 Overview of Synchronous Operation

4.2.1 Standby synchronous operation

In standby synchronous operation (o60 = 1), the inverter controls the slave motor to synchronize its

Z phase with the reference motor's Z phase, based on the first detected Z phases (positions) of those

two motors after the start of synchronous operation. The slave motor could cause a single cycle

delay at a maximum (on standby) at the start of operation.

Once the slave motor starts running after standby, it will never go standby unless the synchronous

operation is cancelled (see Note 1 below).

The Z phase synchronization angles of the reference and slave motors can be adjusted with the

function code o66.

The inverter integrates the position pulses for each of the reference and slave motors and controls

the slave motor's rotation speed and position to keep the difference between those two motors

(hereafter called deviation) at zero.

If any incorrect count due to electrical noise or other factors is found in the integrated count of A/B

phases, the inverter corrects the error based on the Z phase difference.

If the deviation between those two motors falls below the synchronization completion detection angle

(specified by o67), the SY synchronization completion signal will be issued. If synchronization is lost

so that the deviation exceeds 100 times the excessive deviation setting (specified by o68), the

inverter shuts down its output with the Ero alarm.

Reference PG

rotation speed

Run command

for slave motor

t

t

Slave PG

rotation speed

Reference PG

phase angle

Slave PG

phase angle

SY

Note 1: Synchronous operation cancellation conditions

The synchronous operation is canceled when:

- The run command for the slave motor is turned OFF,

- The protective function is activated, or

- The inverter switches to a single motor drive. (Assign terminal command Hz2/Hz1 and switch the

output

360°

0°

360°

0°

OFF ON

Synchronization completedStart of standby

Figure 4.1 Standby Synchronous Operation

frequency command source with F01/C30.)

4-2

t

t

t

t

Page 17

4.2.2 Simultaneous start synchronous operation

In simultaneous start synchronous operation (o60 = 2), the inverter controls the rotation speed and

position of the slave motor to maintain the phase difference between the reference and slave motors

at the time when the single motor drive operation is switched to the synchronous operation. That is,

it keeps the deviation between the integrated position pulses of the reference and slave motors at

zero.

If the deviation falls below the synchronization completion detection angle (specified by o67), the SY

synchronization completion signal will be issued. If synchronization is lost so that the deviation

exceeds 100 times the excessive deviation setting (specified by o68), the inverter shuts down its

output with the Ero alarm.

If any incorrect count due to electrical noise or other factors is found in the integrated count of A/B

phases, the inverter corrects the error based on the Z phase difference.

If the run command for the slave motor is turned OFF, the inverter continues to monitor the motor

positions as long as the synchronous operation is not switched to the single motor drive operation.

When the run command is turned ON again, the inverter restarts to control the slave motor to

maintain the Z phase difference between the reference and slave motors.

Reference PG

rotation speed

Run command

for slave motor

Slave PG

rotation speed

Reference motor

integrated pulses

Slave motor

integrated pulses

0

0°

0

0°

Excessive deviation detected

t

t

t

Deviation of

position

SY

output

Reference PG

phase angle

Slave PG

phase angle

OFF

360゜

0゜

360゜

0゜

ON

Correct the integrated values so that the Z phase

difference becomes the same as the first applied one.

Slave PG

Z phase

Reference

PG Z phase

Figure 4.2 Simultaneous Start Synchronous Operation

4-3

t

t

t

t

Page 18

4.3 Block Diagrams

Output

frequency

[F42]

/[A14]

Frequency command

+

+

+

+

[o13]

Slip

frequency

calculation

V/f control without PG (F42/A14=0)

processor

decelerator

Accelerator/

(*2)

[F15]

[F07][F08]

[F16]

V/f control without PG (F42/A14=1, 2)

[E10][E11]

(*3)

Slip

frequency

calculation

[o02] [o03]

-

+

[o04]

ErE

speed

Excessive

V/f speed control with PG (F42/A14=3, 4)

output

The frequency limiter (Low) limits the referenc e frequency.

The frequency limiter (High) limits th e reference frequency.

input terminals switches between frequency command 1 (F01) and

frequency command 2 (C30). It can be used for switching between

synchronous operation and single motor drive operation .

Using the terminal command Hz2/Hz1 assigned to one of the digital

[o18]

(*1)

(*2)

deviation

detection

[o17]

(*3)

(*1)

Hz2/Hz1

Terminal command

[o06][o05]

[o08]

by F01 or C30

Speed

[P01]/[A15]

converter

[o07]

[P01]/[A15]

[o10]

[o012]

Speed

[o011]

converter

[o09]

input

Hardware Software

Reference

PG A/B

input

Reference

phase input

PG Z phase

Slave PG

A/B phase

input

Z phase

Slave PG

Figure 4.3 Block Diagram for Speed Synchronous Operation (o60 = 0)

4-4

Page 19

Output

frequency

[F42]

/[A14]

+

+

+

+

[o13]

Slip

frequency

calculation

V/f control without PG (F42/A14=0)

processor

decelerator

Accelerator/

(*2)

[F15]

(*3)

[F16]

Main speed

by F01 or C30

Frequency command

(*2)

[F15]

+

+

[o63],[o64]

Limiter

regulator

[o61]=1.0

+

APR

[o06]

Speed

converter

[o07]

+

Position

deviation

[o05] [o08]

[P01]/[A15]

+

-

[F07][F08]

[E10][E11]

[o62]

[o12]

[o11]

V/f control without PG (F42/A14=1,2)

Hz2/Hz1 (*1)

Terminal command

SY signal

completion

Synchronization

Slip

frequency

calculation

[o02] [o03]

-

+

[o04]

output

Ero output

[o68]

deviation

detection

[o67]

Excessive

detection

[P01]/[A15]

Speed

+

angle

+

Offset

converter

[o66]

ErE

output

[o18]

speed

V/f speed control with PG (F42/A14=3,4)

deviation

detection

Excessive

[o10][o09]

[o12]

[o11]

[o17]

Using the terminal command Hz2/Hz1 assigned to

one of the digital input terminals switches between

frequency command 1 (F01) and frequency command

2 (C30). It can be used for switching between

synchronous operation and single motor drive

operation.

The frequency limiter (Low) limits the reference frequency.

The frequency limiter (High) limits the r eference frequency.

(*1)

(*3)

(*2)

[o65]

[o12]

[o11]

according to Z phase

Frequency compensator

(encoder position deviation)

[o09]

Accumulator

input

phase

Hardware Software

PG A/B

Reference

Reference

PG Z phase

input

Accumulator

input

Slave PG

A/B phase

input

Z phase

Slave PG

Figure 4.4 Block diagram for Position Synchronous Operation (o60 = 1, 2)

4-5

Page 20

4.4 List of Function Codes

Table 4.2 lists function codes related to synchronous operation control.

Table 4.2 Function Codes

Change

Code Name Data setting range Unit

F01

Frequency Command 1

(C30)

(Frequency Command 1)

F42

Control Mode

(A14)

Selection

E01

E02

Terminal [X1], [X2], [X3],

E03

[X4], [X5] function

E04

E05

Terminal [FWD], [REV]

E98

function

E99

E20,

Terminal [Y1],

E21,

[Y2], [30A/B/C]

E27

Reference/

o01

Slave PG Input

o02 Speed Control (P Gain) 0.01 to 200.00 -- 10.00 Y

o03 (Integral time) 0.000 to 5.000 s 0.100 Y

o04 (Filter time constant) 0.000 to 5.000 s 0.020 Y

Reference PG

o05

Pulse

o06 (Filter time constant) 0.000 to 5.000 s 0.005 Y

o07

o08

Slave PG

o09

Pulse

o10 (Filter time constant) 0.000 to 5.000 s 0.005 Y

o11 (Pulse count factor 1) 1 to 9999 -- 1 N

o12 (Pulse count factor 2) 1 to 9999 -- 1 N

o13 Speed Control (Output limiter) 0.00 to 100.00 % 100.00 Y

Speed

o17

Deviation

o18 (Excessive deviation timer) 0.0 to 10.0 s 1.5 Y

*1 For position synchronization (o60 = 1 or 2), use pulse generators with the same pulse resolution at both

the reference and slave motors.

(Encoder pulse resolution)*10: Same as o09

(Encoder pulse resolution)

(Excessive deviation level)

(Function)

(Function)

(Input mode) 2: A/B phase pulse -- 2 N

(Pulse count factor 1)

(Pulse count factor 2)

0 to 3, 5, 7, 11, 12

(Set F01 or C30 to

12.)

0 to 4

(Set F42 or A14 to

3 or 4 for selecting

speed control

with optional PG

interface.)

11 (1011): Hz2/Hz1

Select frequency

command 2/1

(Only the related

items indicated)

29 (1029): SY

Synchronization

completed

(Only the related

items indicated)

20 to 3600

0: Same as o11

1 to 9999

0: Same as o12

1 to 9999

20 to 3600 P/R 1024 N

*1

0 to 50 % 20 Y

Default

setting

--

--

-- -- N

-- -- N

P/R 0 N

-- 0 N

-- 0 N

(2)

(0)

when

running

0

0

N

N

4-6

Page 21

Code Name Data setting range Unit

PG Error

Processing

ErE

o19

Synchronous

Operation

o60

(Main speed

o61

o62 (APR P gain) 0.00 to 200.00 -- 15.00 Y

(APR positive output

o63

(APR negative output

o64

(Z phase alignment

o65

(Synchronous offset

o66

(Synchronization

o67

(Excessive deviation

o68

For function codes not listed above, see the FRENIC-Multi Instruction Manual (INR-SI47-1094-E),

Chapter 5, "Function Codes." For codes that are listed above and also in the FRENIC-Multi

Instruction Manual, descriptions in this manual precede.

Table 4.2 Function Codes (Continued)

0: Continue to run

(Detection cancel)

1: Stop running

(Alarm mode 1)

2: Stop running

(Alarm mode 2)

0: Speed synchronous

operation

(Mode selection)

regulator gain)

completion detection

detection range)

1: Position synchronous

operation (Standby)

2: Position synchronous

operation

(Simultaneous start)

Fixed to 1.0 -- 1.0 Y

20 to 200,

limiter)

999: Without limiter

20 to 200,

limiter)

999: Without limiter

0.0 to 10.0 -- 1.0 Y

gain)

0 to 359 deg 0 Y

angle)

0 to 100 deg 15 Y

angle)

0.0 to 6553.5 -- 6553.5 Y

Change

Default

setting

-- 2 N

-- 0 N

% 999 Y

% 999 Y

when

running

4-7

Page 22

4.5 Unavailable Function Codes

The following function codes are not available.

H70 Overload Prevention Control

J01 PID Control (Mode selection)

J65 Overload Stop (Mode selection)

J73 to J88 Position Control

4.6 Configuring Function Codes

To enable synchronous operation, be sure to select the speed control with optional PG interface

(F42/A14 = 3, 4). Other function codes should be configured as described below.

When configuring the function codes, refer to Chapter 5 "FUNCTION CODE CONFIGURATION

EXAMPLES AND ADJUSTMENT GUIDE."

4.6.1 Motor constant data

Configure function codes F03 to F05, P01 to P03, P06 to P12 and P99, referring to the FRENIC-Multi

Instruction Manual (INR-SI47-1094-E), Chapter 5 "Function Codes."

When using motor 2, configure A01 to A03, A15 to A17, A20 to A26, and A39.

4.6.2 Data setting for synchronous operation

F01 Frequency Command 1

C30 Frequency Command 2

Select the pulse train input (F01/C30 = 12) as a reference command source.

Switching between synchronous operation and single motor operation is possible using the

Hz2/Hz1 terminal command (see Figure 4.4). The switching example is given below.

(Example) Turning terminal [X1] ON for single motor operation during which a digital

frequency command drives the inverter

Set F01 and C30 data to "12" and "0," respectively. And set E01 data to "11" to assign the

Hz2/Hz1 command to terminal [X1].

It is recommended to perform switching between synchronous operation and single motor

operation when the inverter is stopped. Switching when the inverter is running may activate

the protective function. To avoid it, decrease the difference between the output frequency and

the reference frequency after switching.

4-8

Page 23

F07 Acceleration Time 1

F08 Deceleration Time 1

E10 Acceleration Time 2

E11 Deceleration Time 2

Also in synchronous operation, the inverter controls the output frequency according to the

acceleration/deceleration time as usual. Specify the acceleration/deceleration time as short

as possible. Be careful that, if the acceleration/deceleration time longer than that of the

reference inverter is specified, the following capability of the slave motor will be lost.

F42 Control Mode Selection 1

A14 Control Mode Selection 2

For synchronous operation, set the F42 (A14) data to "3" or "4" to select the V/f control with

optional PG interface or dynamic torque vector control with optional PG interface,

respectively.

o01 Reference/Slave PG Input (Input mode)

For synchronous operation, the o01 data is fixed to "2: A/B phase pulse."

o02 Speed Control (P Gain)

o03 Speed Control (Integral time)

These function codes specify the PI constants of the slave motor's speed controller. The

expression below shows the transfer function of the regulator.

(1kf

PS

Kp : P gain (o02)

: Integral time (o03)

T

I

* : Slip frequency

f

S

ε : Speed deviation

s : Laplace operator

Suppose that the P gain is 1.0 when the speed deviation ε = 100% (Maximum Frequency F03

(A01)) and f

is 1% of the maximum frequency.

S

Suppose that the I integral time = 1.000 seconds when the o03 data is 1.000.

Setting an excessive P gain may cause system hunting. A roughly recommended P gain

should not exceed 35.00 in the ordinary system.

Modifying F03 (A01) data requires readjustment of o02 and o03 data.

1

ε)

×+=*

sT

I

4-9

Page 24

o04 Speed Control (Filter time constant)

This function code specifies a time constant determining a linear delay of the low pass filter for

the speed command given by pulse train. Use this function code to suppress an overshoot

that occurs, for example, when the speed command varies.

o05 Reference PG Pulse (Encoder pulse resolution)

o09 Slave PG Pulse (Encoder pulse resolution)

Set the encoder pulse resolution of the reference motor to o05, and that of the slave motor

(driven by the inverter) to o09. For position synchronization (o60 = 1 or 2), be sure to use PGs

with the same encoder pulse resolution for both the reference and slave motors. When o05 =

0, the inverter recognizes that o05 = o09 and operates accordingly.

o06 Reference PG Pulse (Filter time constant)

o10 Slave PG Pulse (Filter time constant)

o06 and o10 specify time constants determining a linear delay of the low pass filter for the

speed feedbacks given by reference and slave PGs, respectively. Use these function codes,

for example, when the large ripple components superpose the feedback pulse train.

o07 Reference PG Pulse (Pulse count factor 1)

o08 Reference PG Pulse (Pulse count factor 2)

o11

o12

Slave PG Pulse (Pulse count factor 1)

Slave PG Pulse (Pulse count factor 2)

If the slave motor has reduction gears etc., specify the slave PG pulse count factors 1 and 2.

Pulley

(Transmission ratio c /d )

Radius: d

YA,YB,YZ

Power

supply

L1/R,L2/S,L3/T

Conveyer

PG

Radius: c

Inverte r

FRN-E1S-SYZ

(Transmission ratio

No. of

teeth: b

Motor

No. of

teeth: a

Gear train

a/b)

No. of

teeth: a

U,V,W

Figure 4.5 Speed Control Model Using a PG

Slave motor shaft speed =

Pulse count factor 2 (o12)

Pulse count factor 1 (o11)

Pulse count factor 2 (o12) b d

Pulse count factor 1 (o11)

× Encoder shaft speed

=

a

×

c

For synchronous operation, it is recommended that the reduction ratios (pulse count factors)

of the reference and slave sides be identical. To make them identical, set both o07 and o08

data to "0," applying the pulse count of the slave PG to that of the reference PG. If the

reduction ratios are different between the two, refer to Section 5.1 "Typical Configuration and

Pulse Setting."

4-10

Page 25

o13 Speed Control (Output limiter)

This function code specifies the output limit percentage for the speed controller (PI controller).

Specification of 100.00% is equivalent to the maximum speed (maximum frequency).

To suppress the frequency control amount (PI controller output) to the extent of the motor's

slip frequency in the speed control mode, use this function.

o60 Synchronous Operation (Mode selection)

This function code specifies the synchronous operation mode.

Table 4.3 Data for Function Code o60

Data for o60 Synchronous Operation Mode Synchronization system Z phase signal

0 Speed synchronous operation Speed synchronization Not required.

1 Standby synchronous operation

2

Simultaneous start synchronous

operation

Position synchronization Required.

o61 Synchronous Operation (Main speed controller gain)

This function code is fixed at 1.0 and cannot be changed.

o62 Synchronous Operation (APR P gain)

This function code determines the response of the automatic position regulator (APR). (See

Figure 4.4.)

If the APR output reaches the maximum frequency when the phase angle deviation (position

deviation) between the reference and slave PGs becomes equal to the pulse rate at the

maximum frequency, that gain is assumed to be 1.0.

Setting a too large value to the gain data easily causes hunting, and setting a too small value

results in a large steady-state deviation.

o63 Synchronous Operation (APR positive output limiter)

o64 Synchronous Operation (APR negative output limiter)

These function codes specify the limits of APR output relative to the reference motor speed.

(See Figures 4.4 and 4.6.)

Specification of "999" disables the limiter.

Reference

motor speed

Position

deviation

o61

o63

APR

o62

+

+

ASR

o64

Figure 4.6 Operation of APR Output Limiter

4-11

Page 26

S

o65 Synchronous Operation (Z phase alignment gain)

Specify a large value to this function code data when the steady-state deviation is large.

If the APR output reaches the maximum frequency when the phase angle deviation between

the reference and slave PGs (position deviation) becomes 10% of the pulse rate at the

maximum frequency, that gain is assumed to be 1.0.

o66 Synchronous Operation (Synchronous offset angle)

In standby synchronous operation, the slave inverter delays starting to synchronize the Z

phase of the slave motor with that of the reference motor by the offset angle specified by this

function code.

o67 Synchronous Operation (Synchronization completion detection angle)

This function code specifies the synchronization completion detection angle.

If the absolute value of the phase angle deviation (position deviation) between the reference

and slave PGs becomes equal to or below the synchronization completion detection angle

specified by o67, the inverter issues a synchronization completion signal SY, provided that

the E20, E21, or E27 data (Terminal function) is set to "29" (Synchronization completed).

Once turned ON, the synchronization completion signal SY is kept ON for 100 ms.

Synchronization

completion

detection signal

ON

OFF

Y

-o67 o67

0°

Position deviation

Figure 4.7 Synchronization Completion Detection Signal SY

o68 Synchronous Operation (Excessive deviation detection range)

This function code specifies the detection range for excessive deviation alarm (Ero). If the

absolute value of the phase angle deviation (position deviation) between the reference and

slave PGs exceeds 100 times the o68 setting, the inverter issues an alarm Ero and shuts

down its output.

Excessive

deviation alarm

Ero

-o68×100 o68×100

ON

OFF

0°

Position deviation

Figure 4.8 Excessive Deviation Alarm Ero

4-12

Page 27

Chapter 5 CONFIGURATION EXAMPLES AND ADJUSTMENT GUIDE

5.1 Typical Configuration and Pulse Setting

5.1.1 Speed reduction ratio setting

Figure 5.1 shows the system configuration applicable to the synchronous operation, taking a

conveyer system as an example.

Table 5.1 lists the availability of position synchronous operation and the setting values for pulse

count factors 1/2 depending on the speed reduction ratio of each reduction gear when the position

synchronous operation is enabled (o60 = 1, 2). Table 5.2 shows the settings for the speed

synchronous operation (o60 = 0).

Reference conveyer Slave conveyer

Speed reduction ratio Sm

Slave

motor

Speed reduction

Cm

ratio

Power

supply

R, S, T

Reference

motor

FRN-E1S

U, V, W

Speed reduction

ratio Cp

Reference

PG

YA, YB, YZXA, XB, XZ

Figure 5.1 Configuration Example of Conveyer Synchronization System

Table 5.1 Availability of Position Synchronous Operation (o60 = 1 or 2) and Settings

Speed reduction ratio

conditions

Motor

reduction

gear

PG

reduction

gear

Cm = Sm Cp = Sp

Cm ≠ Sm Cp = Sp

Cm = Sm Cp ≠ Sp

Cm x Cp = Sm x Sp

Cm ≠ Sm Cp ≠ Sp

Speed/position synchronization

of conveyer belts

Available Available

Available Available

Not available

speed conveyer Reference

- In position synchronous operation, be sure to use pulse generators with the same pulse resolution at

both the reference and slave sides. The pulse resolution should be set to o09. Set the o05 data to "0."

The equations in the above table are for cases where the reference and slave motors have the same

number of poles.

- For configuration examples, refer to Sections 5.3.1 and 5.3.2.

speed conveyer Slave

Speed reduction ratio Sp

Slave PG

Sp

=

Cp

FRN-E1S-SYZ

+

OPC-E1-SY

Speed/position

synchronization

of

PG shafts

Available

Available

Available

Pulse count

factor

0o07

=

0o08

=

o12

=

o11

U, V, W

1

SpSm

×

5-1

Page 28

Table 5.2 Settings for Speed Synchronous Operation (o60=0)

Settings at

reference side

For reference PG o05

For slave PG o09

- Speed synchronous operation is possible even if the number of poles of the reference motor is different

from that of the slave motor.

Set the number of poles of the slave motor to P01/A15.

- For the configuration example, refer to Section 5.3.3.

PG pulse

resolution

Pulse count factor

1

o08

=

o07

o12

o11

CpSm

×

1

=

SpSm

×

Remarks

When the pulse resolution of the reference

PG is identical with that of the slave PG

(specified by o09), set the o05 data to "0" so

that the inverter recognizes that o05 = o09

and operates accordingly.

If the pulse count factors of the reference PG

are identical with those of the slave PG, set

both o07 and o08 data to "0" so that the

inverter recognizes that o07 = o11 and o08 =

o12 and operates accordingly.

--

5-2

Page 29

5.1.2 Wiring of PGs

Table 5.3 shows three wiring patterns of reference and slave PGs according to the rotational

directions of those PGs in relation to that of the slave motor.

Table 5.3 System Configuration and Wiring of PGs

System configuration examples Wiring of PGs

Reference conveyer Slave conveyer

Reference

Slave PG

Power

supply

XA, XB, XZ

R, S, T

PG

YA,YB,YZ

FRN-E1S-SYZ

+

OPC-E1-SY

Slave motor

ForwardForwardForward

U, V, W

Reference PG

Î Normal connection to

terminals XA and XB

Slave PG

Î Normal connection to

terminals YA and YB

Reference conveyer Slave conveyer

Reverse

Reference PG

Power

XA, XB, XZ

supply

R, S, T

Reference conveyer Slave conveyer

Forward

Power

supply

Reference

R, S, T

YA,YB,YZ

PG

Slave PG

Slave PG

YA,YB,YZXA, XB, XZ

Forward

Reverse

FRN-E1S-SYZ

+

OPC-E1-SY

FRN-E1S-SYZ

+

OPC-E1-SY

5-3

Forward

Forward

Slave motor

U, V, W

Slave motor

U, V, W

Reference PG

Î Reverse connection

to terminals XA and

XB

Slave PG

Î Normal connection to

terminals YA and YB

Reference PG

Î Normal connection to

terminals XA and XB

Slave PG

Î Reverse connection

to terminals YA and

YB

Page 30

5.2 Key Points on Function Code Configuration and Adjustment Guide

In a trial run of your system, check the following function codes and use their settings as an

adjustment guide.

o05

Reference pulse (Encoder pulse resolution)

o07 (Pulse count factor 1)

o08 (Pulse count factor 2)

o09 Slave pulse (Encoder pulse resolution)

o11 (Pulse count factor 1)

o12 (Pulse count factor 2)

P01/A15 Motor (No. of poles)

In synchronous operation, it is necessary to set up the PGs and speed reduction ratio properly

depending on the system configuration. Refer to Section 5.1.1.

- It is recommended that the speed reduction ratio be at 1/1 to 1/30.

- The PG pulse rate for the reference and slave PGs should be set within the range from 75 p/s and

30 kp/s.

Table 5.4 Reduction Ratio Settings

Setting value o60 = 0 o60 = 1 or 2

Synchronization mode Speed synchronous operation Position synchronous operation

Z phase signal Connection not required Connection required

Reference

pulse

Slave

pulse

No. of

motor

poles

o05

(Encoder

pulse

resolution)

o07, o08

(Pulse count

factor)

o09

(Encoder

pulse

resolution)

o11, o12

(Pulse count

factor)

P01

(A15)

If the pulse resolution of the slave

PG is identical with that of the

reference PG (o05):

o05 = 0

If it is not identical:

o05 = Pulse resolution of slave PG

See Table 5.2. See Table 5.1.

Set the pulse resolution of the

slave PG.

See Table 5.2. See Table 5.1.

Set the number of poles of the

slave motor.

Always o05 = 0

Position synchronous operation is

not possible when the pulse

resolutions of the reference and

slave PGs are different.

It is recommended that the speed

reduction ratio (pulse count factor)

be identical for both the reference

and slave PGs.

Set the pulse resolution of the

slave PG, which is equal to that of

the reference PG.

It is recommended that the speed

reduction ratio (pulse count factor)

be identical for both the reference

and slave PGs.

Use the motors with the same

number of poles at both the

reference and slave sides.

5-4

Page 31

F42/A14 Control Mode Selection

P02/A16 Motor (Rated capacity) P03/A17 Motor (Rated current)

P06/A20 (No-load current) P07/A21 (%R1)

P08/A22 (%X) P12/A26 (Rated slip frequency)

If motor constants to be set to P06 (A20), P07 (A21), P08 (A22), and P12 (A26) are unknown,

select "3: V/f control with optional PG interface" with F42 (A14). Even in that case, set the

motor constants to P02 (A16) and P03 (A17).

If all of the motor constants to be set to P02 (A16), P03 (A17), P06 (A20), P07 (A21), P08

(A22), and P12 (A26) are known, select "4: Dynamic torque vector control with optional PG

interface" with F42 (A14).

o02 Speed Control (P Gain) o04

Speed Control

(Filter time constant)

o03 (Integral time)

There is no need to change these function codes data related to automatic speed regulator

(ASR) from the factory defaults.

o06 Reference Pulse (Filter time constant)

Usually, there is no need to change this function code data from the factory default. If there is

a large backlash due to the mounting condition of the reference PG, set two times the factory

default "0.005 s."

Slave Pulse (Filter time constant)

o10

o62 Synchronous Operation (APR P Gain)

It is necessary to adjust these function codes data depending on the speed reduction ratio

and running frequency range and starting mode of the slave motor. The adjustment guide is

shown below.

Table 5.5 Adjustment Guide for Function Codes o10 and o62

Speed reduction ratio

Slave pulse (filter time constant)

Synchronous operation (APR P gain)

o65

Synchronous operation (Z phase alignment gain)

o11

o12

o10

o62

1

1

0.005s

(factory default)

Large

15.00

(factory

default)

1

15

1

30

Large

Small

Usually, there is no need to change this function code data from the factory default. If both

the speed reduction ratio and the encoder pulse resolution are small, it may be necessary to

reduce this alignment gain from the factory default "1.0."

5-5

Page 32

5.3 Function Code Configuration Examples

5.3.1 For position synchronous operation (o60 = 1 or 2), #1

Reference conveyer Slave conveyer

U, V, W

=

Slave

motor

1

5

Reduction ratio Cm

FRN-E1S

Power

supply

R,S,T

1

=

5

No. of poles = 4

Reference

motor

U, V, W

Reduction

ratio Cp

=

XA, XB, XZ

1

Reference PG Slave PG

3

YA, YB,

YZ

Reduction ratio

1000 P/R1000 P/R

1

=

Sp

3

FRN-E1S-SYZ

OPC-E1-SY

Reduction ratio Sm

No. of poles = 4

+

Figure 5.2 Configuration Example of Position Synchronization System (Gear-driven)

Table 5.6 Wiring of PG (See Table 5.3.)

Reference side Slave side

PG

OPC-E1-SY

A

B

Z

XA

XB

XZ

PG

A

B

Z

OPC-E1-SY

YA

YB

YZ

Table 5.7 For Position Synchronous Operation (o60 = 1 or 2) (See Table 5.1.)

P01 Motor (No. of poles) 4

o05

o07 (Pulse count factor 1) 0

o08 (Pulse count factor 2) 0

o09

o11 (Pulse count factor 1) 1

o12 (Pulse count factor 2) 15

Function Code Setting Remarks

Set the number of poles of the slave motor.

Reference Pulse

(Encoder pulse resolution)

Always set "0."

0

The o05 data is interpreted as the same as o09 data.

The o07 data is interpreted as the same as o11 data.

The o08 data is interpreted as the same as o12 data.

Slave Pulse

(Encoder pulse resolution)

In position synchronous operation, be sure to set the

1000

same value for both the reference and slave PGs.

1

o12

=

×

o11

SpSm

15

1

=

=

1

1

×

315

Table 5.8 Rotational Direction

Rotational direction of: Run command at slave inverter

Reference motor Reference PG Slave PG

Run forward

FWD

Run reverse

REV

Forward (FWD) Forward Forward Forward Stop *

Reverse (REV) Reverse Reverse Stop * Reverse

* If the reference inverter rotates the motor in such a direction that the slave inverter stops, the

pulse count continues so as to cause an

inverter rotates the motor in the same direction as the slave inverter, the synchronous operation

ero

excessive deviation alarm. After that, if the reference

restarts from the position where the deviation becomes zero.

5-6

Page 33

5.3.2 For position synchronous operation (o60 = 1 or 2), #2

Radius

r

Radius

r

Cpa

Cpb

=80

=40

Reference

PG

2000 P/R

Radius

r

Spa

YA, YB, YZXA, XB, XZ

=80

Slave PG

Radius

r

=40

Spb

2000 P/R

Radius

r

Sma

FRN-E1S-SYZ

+

OPC-E1-SY

=150

Radius

r

Smb

=30

No. of poles

= 6

r

FRN-E1S

Power

supply

Reference conveyer Slave conveyer

Radius

=150

Cma

R, S, T

Radius

r

Cmb

Reference

=30

No. of poles

= 6

motor

U, V, W

Figure 5.3 Configuration Example of Position Synchronous Operation System (Pulley-driven)

Table 5.9 Setting for Position Synchronous Operation (o60=1 or 2) (Refer to Table 5.1)

Function code Setting Remarks

P01 Motor (No. of poles) 6 Set the number of poles of the slave motor.

Reference Pulse

o05

(Encoder pulse resolution)

o07 (Pulse count factor 1) 0

o08 (Pulse count factor 2) 0

Slave Pulse

o09

(Encoder pulse resolution)

o11 (Pulse count factor 1) 1

o12 (Pulse count factor 2) 10

Always set "0."

0

The o05 data is interpreted as the same as o09

data.

The o07 data is interpreted as the same as o11

data.

The o08 data is interpreted as the same as o12

data.

In position synchronous operation, be sure to set

2000

the same value for both the reference and slave

PGs.

Each speed reduction ratio is calculated

according to the pulley's radius as shown below.

The reduction ratio of the slave motor is:

r

Smb

Sm

r

Sma

The reduction ratio of the slave PG is:

r

Spb

Sp

r

Spa

150

40

1

30

===

5

===

2180

Therefore, o11 and o12 data is as follows.

10

1

1

o12

o11

=

SpSm

×

=

=

1

1

×

215

U, V, W

Slave

motor

5-7

Page 34

5.3.3 For speed synchronous operation (o60 = 0)

Reference conveyer Slave conveyer

Reduction ratio

Sp

A

B

Z

1

=

CpSm

×

1

=

SpSm

×

Run forward

1

=

3

FRN-E1S-SYZ

+

OPC-E1-SY

OPC-E1-SY

YA

YB

YZ

1

=

1

×

215

1

=

1

×

315

FWD

10

1

15

1

No. of poles

Run reverse

PG

YA, YB,

YZ

Reduction ratio

Slave PG

1000 P/R2000 P/R

Reduction ratio

FRN-E1S

Power

supply

R, S, T

Cm

1

=

4

Reference

motor

No. of poles

= 6

U, V, W

Reduction

ratio Cp

1

=

2

XA, XB, XZ

Reference

Figure 5.4 Configuration Example of Speed Synchronous Operation System (Gear)

Table 5.10 Wiring of PG (See Table 5.3.)

Reference side Slave side

OPC-E1-SY

PG

A

B

Z

XA

XB

PG

XZ

* In speed synchronous operation, Z phase is not required.

Table 5.11 For Speed Synchronous Operation (o60 = 0) (See Table 5.2.)

P01

o05

o07 (Pulse count factor 1) 1

o08 (Pulse count factor 2) 10

o09

o11 (Pulse count factor 1) 1

o12 (Pulse count factor 2) 15

Function code Setting Remarks

Motor (No. of poles)

Reference Pulse

(Encoder pulse resolution)

Slave Pulse

(Encoder pulse resolution)

4 Set the number of poles of the slave motor.

In speed synchronous operation, the pulse

resolution of the reference PG needs not

2000

necessarily be the same as that of the slave PG.

o08

=

o07

In speed synchronous operation, the pulse

1000

resolution of the slave PG needs not necessarily

be the same as that of the reference PG.

o12

=

o11

Table 5.12 Rotational Direction

Rotational direction of: Run command at slave inverter

Reference motor Reference PG Slave PG

Forward (FWD) Reverse Forward Forward Forward

Reverse (REV) Forward Reverse Reverse Reverse

= 4

U, V, W

REV

1

=

Sm

5

Slave

motor

5-8

Page 35

5.4 Checking PG Pulse Rate

Before starting synchronous operation, run the motors separately and check that the data settings

for number of motor poles (P01), encoder pulse resolution (o09), and pulse count factor 1/2

(o11/o12) conform to the actual system configuration.

The PG pulse rate can be checked with the keypad by using Menu #4 "I/O Checking, item 4_15: PG

pulse rate 1 (reference side)" and "item 4_17: PG pulse rate 2 (slave side)." For details, refer to the

FRENIC-Multi Instruction Manual (INR-SI47-1094-E), Section 3.4.5 "Checking I/O signal status."

Given below is an example of checking PG pulse rate.

(Example)

No. of motor poles = 4P (P01 = 4)

Encoder pulse resolution = 1000 P/R (o09 = 1000)

Pulse count factor 1/2 = 1/30 (o11 = 1, o12 = 30)

Under these above conditions, run the motor at 20 Hz. Then the motor speed and the pulse rate

can be calculated as follows.

Motor speed (r/min) = 120 x Frequency/No. of poles = 120 x 20/4 = 600 (r/min) = 10 (r/s)

Pulse rate (p/s) = Motor speed (r/s) x Encoder pulse resolution (P/R) x Pulse count factor 1/2

= 10 x 1000 x 1/30 = 333.3333 ≈ 333 (p/s)

Use Menu #4 "I/O Checking, item 4_17" and check that "0.333" is displayed on the keypad. Note

that, on the keypad, displayed value = pulse rate (p/s)/1000.

Note: The maximum input pulse rate that the synchronous operation card (OPC-E1-SY) supports

is 30 kp/s. If the pulse rate from the PGs exceeds the maximum limit, synchronous operation is not

available.

5-9

Page 36

Chapter 6 PROTECTIVE FUNCTIONS

If any inverter protective function is activated to issue an alarm, the inverter displays the

corresponding alarm code on the LED monitor of the keypad and shuts down its output. Accordingly,

the motor coasts to a stop.

Table 6.1 lists alarm codes related to the synchronous operation card. For other alarm codes, refer to

the FRENIC-Multi Instruction Manual (INR-SI47-1094-E), Chapter 6 "TROUBLESHOOTING."

Table 6.1 Related Alarm Codes

Alarm

code

Overspeed alarm Y

OS

Excessive speed deviation alarm C

ErE

Excessive deviation alarm NA

Ero

Y: Always active. The protective function for the alarm is always active when the control is enabled.

C: Conditionally active. The protective function for the alarm is active when the control is enabled and

the protective function is enabled with the function code. The factory default is "enabled."

NA: Not available when the control is enabled.

Alarm name

Speed

control

Alarm for:

Synchronous

operation control

Refer to

Section:

NA 6.1

Y 6.2

Y 6.3

If any of the protective functions has been activated, first remove the cause. Then, after checking

that the all run commands are set to off, reset the alarm. Note that if the alarm is reset when any

run command is set to on, the inverter may supply the power to the motor, which may cause the

motor to rotate.

Injury may occur.

6.1 Overspeed Alarm (OS)

Table 6.2 Overspeed Alarm Specifications

Alarm code Descriptions

• The inverter issues this alarm when the detected speed exceeds the 1.2 times

the minimum value of either (1) or (2) below.

(1) For the selected motor,

OS

Maximum frequency (F03 or A01) + Torque limiter (Frequency increment

limit for braking, H76)

(2) Frequency limiter, High (F15)

• This protective function works when the inverter is outputting with the speed

control with PG being enabled (F42 or A14 = 3 or 4 and PG/Hz is ON).

6-1

Page 37

6.2 Excessive Speed Deviation Alarm (ErE)

Table 6.3 Excessive Speed Deviation Alarm Specifications

Alarm code

ErE

• This protective function recognizes a PG error by software based on the

relationship between the speed command and the detected speed.

• When the speed deviation between the speed command and the detected

speed has exceeded the excessive speed deviation level specified by o17

during the period longer than the timer setting specified by o18, the protective

function issues this alarm.

• This protective function provides two choices--"Stop running" (o19 = 1 or 2)

and "Continue to run" (o19 = 0) when it is activated. When the latter is

selected, the inverter continues to run with output to terminal [Y] without

issuing an alarm.

• This protective function works when the inverter is outputting with the speed

control with PG being enabled (F42 or A14 = 3 or 4 and PG/Hz is ON). It does

not, however, during DC braking or idling due to overload.

• This alarm occurs when no Z phase is detected although the slave PG has

rotated two cycles or more in synchronous operation.

This alarm is contained in alarm category "Y" in Table 6.1, so it cannot be

disabled by any function code.

Descriptions

6.2.1 Function codes

Table 6.4 lists function codes related to excessive speed deviation alarms.

Table 6.4 Related Function Codes

Change

Code Name Data setting range Unit

o17

Excessive Speed Deviation Level

o18

Excessive Speed Deviation Timer

o19

PG Error Processing

E20 Terminal Y1 Function 0

Terminal Y2 Function

E21

Terminal 30A/B/C Function

E27

0 to 50

0.0 to 10.0

0: Continue to run

1: Stop running (Alarm mode 1)

2: Stop running (Alarm mode 2)

76(1076):

PG error signal PG-ERR

Default

% 20

s 1.5

-- 2

--

6.2.2 Excessive speed deviation detection

Table 6.5 and Figure 6.1 show the relationship between PG error detection conditions and error

processing (o19.)

Table 6.5 o19 Data and Error Detection

Data for o19 Conditions determining the excessive speed deviation Alarm

0: Continue to run

1: Stop running

(Alarm mode 1)

2: Stop running

(Alarm mode 2)

Any status of

the timer setting specified by o18.

Any status of

the timer setting specified by o18.

to in Figure 6.1 is kept exceeding

to in Figure 6.1 is kept exceeding

None Active

ErE Inactive

setting

7

99

when

running

Y

Y

N

N

PG-ERR

output

6-2

Page 38

, :

A/B phases of the PG reversely wired

, :

Excessive speed deviation

|Detected speed| > |Speed command|

, :

PG wire broken or the load locked

, :

Excessive speed deviation

|Detected speed| < |Speed command|

⑥

Detected speed

Hysteresis width

= o17 |× Base spe ed|

①

Base speed

⑧

-0.1Hz to +0.1Hz

④

③

Hysteresis width

= o17 |× Speed command|

⑦

Base speed

②

⑤

Speed

command

Figure 6.1 Excessive Speed Deviation Detection and Speed Command

When an

the keypad by using Menu #6 "Alarm Information, Item 6_21 Error sub code." The

relationship between the error code and error factors in Figure 6.1 are: 1 for

for

manual. (Refer to the description of function code E52.)

Ero alarm occurs, the current error factor (any of

or , 5 for or , and 7 for or . For details, refer to the inverter’s instruction

to ) can be displayed on

6.3 Excessive Deviation Alarm (Ero)

Table 6.6 Excessive Deviation Alarm Specifications

Alarm code Descriptions

This alarm occurs when the position deviation (absolute value) between the

Ero

6.3.1 Function codes

Table 6.7 lists function codes related to an excessive deviation alarm.

Code Name Data setting range

Excessive deviation

o68

reference and slave PGs exceeds 100 times the o68 setting during synchronous

operation. This alarm is contained in alarm category "Y" in Table 6.1, so it cannot

be disabled by any function code.

Table 6.7 Related Function Codes

Unit

(Hysteresis width)

0.0 to 6553.5 -- 6553.5 Y

6-3

Default

setting

or , 3

Change

when

running

Page 39

Synchronous Operation Card "OPC-E1-SY"

Instruction Manual

First Edition, May 2007

Fuji Electric FA Components & Systems Co., Ltd.

The purpose of this instruction manual is to provide accurate information in handling, setting up

and operating of the synchronous operation card. Please feel free to send your comments

regarding any errors or omissions you may have found, or any suggestions you may have for

generally improving the manual.

In no event will Fuji Electric FA Components & Systems Co., Ltd. be liable for any direct or indirect

damages resulting from the application of the information in this manual.

Page 40

Fuji Electric FA Components & Systems Co., Ltd.

Mitsui Sumitomo Bank Ningyo-cho Bldg., 5-7, Nihonbashi, Odemma-cho, Chuo-ku, Tokyo,

103-0011, Japan

Phone: +81 3 5847 8011 Fax: +81 3 5847 8172

URL http://www.fujielectric.co.jp/fcs/

2006-12 (L12/L12) XXCM

Loading...

Loading...