Page 1

Instruction Manual

Profibus DP Interface Option "OPC-E1-PDP"

Thank you for purchasing our PROFIBUS DP Interface Option OPC-E1-PDP.

• This product is designed to connect the FRENIC-Multi series of inverters to PROFIBUS DP

Communications Network. Read through this instruction manual and be familiar with the

handling procedure for correct use.

• Improper handling blocks correct operation or causes a short life or failure.

• Deliver this manual to the end user of the product. The end user should keep this manual in a

safe place until the PROFIBUS DP Interface Option is discarded.

• For the usage of inverters, refer to the instruction manual prepared for the FRENIC-Multi

series of inverters.

Fuji Electric Systems Co., Ltd. INR-SI47-1159-EU REV 052010

Page 2

Copyright © 2007 Fuji Electric FA Components & Systems Co., Ltd.

All rights reserved.

No part of this publication may be reproduced or copied without prior written permission from Fuji Electric FA Components & Systems Co., Ltd.

All products and company names mentioned in this manual are trademarks or registered trademarks of their respective holders.

The information contained herein is subject to change without prior notice for improvement.

Page 3

Preface

Thank you for purchasing our PROFIBUS DP Interface Option OPC-E1-PDP.

This manual has been prepared to help you connect your FRENIC-Multi to a PROFIBUS DP master (Siemens PLC, computer, etc.)

via PROFIBUS DP.

Mounting this option on your FRENIC-Multi allows you to connect th e FRENIC-Multi to a PR OFIBUS DP master node and c ontrol

it as a slave unit using run and frequency com mands, and access to function codes.

This option has the following features:

• PROFIBUS version: DP-V0 compliant

• Transmission speed: 9.6 Kbps to 12 Mbps

• Maximum network cable length per segment: 100 m (12 Mbps) to 1200 m (9.6 Kbps) ( 328 ft (12 Mbps) to 3937 ft (9.6 Kb ps)

• Applicable Profile: PROFIBUS V2 compliant

• Able to read and write all function codes supported in FRENIC-Multi

This instruction manual does not contain inverter handling instructions. Read through this instruction manual in conjunction with the

FRENIC-Multi Instruction Manual (INR-SI47-1204-E) and be f amiliar with proper ha ndling and operation of this product. Im proper

handling might result in incorrect operation, a short life, or eve n a failure of this product.

Keep this manual in a safe place.

Related Publications

Listed below are the other materials related to the use of the PROFIBUS DP Interface Option OPC-E1-PDP. Read them in

conjunction with this manual as necessary.

• RS-485 Communication User's Manual (MEH448)

• FRENIC-Multi Instruction Manual (INR-SI47-1204-E)

The materials are subject to change without notice. Be sure to obtain the latest editions for use.

Safety precautions

Read this manual thoroughly before proceeding with installation, connections ( wiring), operation, o r maintenance and inspecti on .

Ensure you have sound knowledge of the device and familiarize yourself with all safety information and precautions before

proceeding to operate the inverter.

Safety precautions are classified into the following two categories in this manual.

Failure to heed the information indicated by this symbol may lead to dangerous conditions, possibly

resulting in death or serious bodily injuries.

Failure to heed the information indicated by this symbol may lead to dangerous conditions, possibly

resulting in minor or light bodily injuries and/or substantial property damage.

Failure to heed the information contained under the CAUTION title can also result in serious consequences. These safety

precautions are of utmost importance and must be observed at all times.

1

Page 4

Installation and wiring

• Turn the inverter's power OFF and wait at least five minutes. Further, check that the DC link bus voltage between the P (+)

and N (-) terminals is lower than 25 VDC.

• Qualifie d electricians should ca rry out wiring.

Otherwise, electric shock could o ccur.

• Do n ot use the prod ucts that are damaged o r lacking parts.

Doing so could cause a fire, accident, or injur y.

• Prevent lint, paper fibers, sawdust, dust, metallic chips, or other foreign materials from getting into the inverter and the

option.

Otherwise, a fire or an accident might res ult.

• Incor rect handling in installation/removal jobs could cause a failure.

A failure might result.

• Noise may be emitted from the inverter, motor and wires. Implement appropri ate measure to prevent the n earby sensors

and devices from malfunctioning due to such noise.

Otherwise, an accident could occur.

Operation

• Be sure to mount t he inverter's and option's terminal covers before turning the inverter's power ON. Do not remove the

covers while power is applied.

Otherwise electric shock could o ccur.

• Do n ot operate switches with wet hands.

Doing so could cause electric shock.

• If you configure the function codes wrongly or without completely understanding FRENIC-Multi Instruction Manual

(INR-SI47-1204-E) and the FRENIC-Multi User's Manual (M EH457), the motor may rotate with a torque or at a speed not

permitted for the machine. Confirm and adjust the setting of th e function codes befo re running the inverte r.

Otherwise, an accident could occur.

Maintenance and inspection, and parts replacement

• Turn the inverter's power OFF and wait at least five minutes before starting inspection. Further, check that the DC link bus

voltage between the P (+) and N (-) terminals is lower than 25 VDC.

Otherwise, electric shock could o ccur.

• Maintenance, inspection, and parts replacement should be made only b y qualified persons.

• Take off the watch, rings and other metallic objects before starting work.

• Use insulat ed tools.

Otherwise, electric shock or injuries could o ccur.

2

Page 5

Disposal

• Treat the product as an indust rial waste when d isposing of it.

Otherwise injuries could occur.

Others

• Never attempt to modify the product.

Doing so could cause electric shock or injuries.

How this manual is organized

This manual is made up of chapters 1 through 12.

Chapter 1 BEFORE USING THE PR OFIBUS DP INTERFACE OPTION

Lists points to be checked upon delivery of this option and describes the applicable inverters.

Chapter 2 NAMES AND FUNCTIONS

Shows the part names of this option and describes the terminating resistor switch, node address switches, an d status indicator

LEDs.

Chapter 3 MOUNTING THE PROFI BUS DP INTERFACE OPTION

Provides instructions and precautions for mounting this option.

Chapter 4 WIRING AND CABLING

Provides wiring instructions around the terminal blocks on this option and the cable specifications.

Chapter 5 CONFIGURING INVERTER'S FUN CTION CODES FOR PROFIBU S DP COMMUNICATION

Describes the inverter's function codes to be s et for the PROFIBUS DP communications link. Also this chapter lists the related

function codes.

Chapter 6 ESTABLISHING A PROFIBUS COMMUNICATIONS LINK

Guides you to establish a PROFIBUS DP communications link between the PR OFIBUS DP master node and this option (slave

node).

Chapter 7 QUICK SETUP GUIDE FOR RUNNING THE INVERTER

Describes a simple profile (data format) dedicated to i nverter’s run and frequency commands, taking the actual da ta transaction

data as an example.

Chapter 8 DETAILS OF PROFIBUS DP PROFILES

Details PROFIBUS DP profile data formats and parameters supported by this option. Furthermore, this chapter describes how the

master node accesses inverter’s function codes.

Chapter 9 INVERTER REACTION TO PROFIBUS COMMUNIC ATIONS ERRORS

Describes on how the inverter operates if a PROFIBUS communications e rror occurs.

Chapter 10 LIST OF INVERTER ALARM CODES

Lists and explains inverter’s alarm codes.

Chapter 11 TROUBLESHOOTING

Provides troubleshooting instructions for certain problems, e.g., when the inverter does not op erate as orde red or when an alar m

condition has been recognized.

Chapter 12 SPECIFICATIONS

Lists the general specifications and communications specifications.

3

Page 6

Icons

The following icons are used throughout this manual.

This icon indicates information which, if not heeded, can result in the product not operating to full efficiency, as well as

information concerning incorrect operations and settings which can result in accidents.

This icon indicates information that can prove handy when performing certain settings or operations.

This icon indicates a reference to more detailed information.

Table of Contents

Preface ...............................................1 Ch pter 5CONFIGURING INVERTER'S FUNCTI

How this manual is organized......................1

Chapter 1 BEFORE USING THE PROFIBUS Chapter 6 ESTABLISHING A PROFIBUS

DP INTERFACE OPTION...............5 COMMUNICATIONS LINK.............18

1.1 ....................5 Acceptance Inspection Chapter 7 QUICK SETUP GUIDE FOR

Chapter 2 ......6 NAMES AND FUNCTIONS RUNNING THE INVERTER..........19

2.1 ...................................6 Parts Names 7.1 .....Before Proceeding to Data Exchange

2.2 ............6 Terminating Resistor Switch 7.2

2.3 ..................7 Node Address Switches an Inverter..................................19

Setting the Transmission Speed Chapter 8 DETAILS OF PROFIBUS

2.4

(B aud rate) ...................................7 PROFILES.................................... 22

2.5 .....................8 Status Indicator LEDs 8.1 22 Description of PPO Types Supported

2.6 ............................8 RJ-45 Connector 8.2 ............................24 PCD Word Area

Power Supply Terminal Block and 8.3 ............................29 PCV Word Area

2.7

PR OFIBUS DP Terminal Block......8 Chapter 9 INVERTER REACTION TO PROFIBUS

Chapter 3 MOUNTING THE PROFIBUS COMMUNICATIONS ERRORS...... 36

DP INTERFACE OPTION................ 9 Chapter 10 LIST OF INVERTER ALARM

Chapter 4 ........13 WIRING AND CABLING CODES......................................... 37

4.1 ...........13 Basic Connection Diagram Chapter 11 ...........38 TROUBLESHOOTING

4.2 ................................. ..Wiring for Power Supply Terminal Block .................. ..............14 .................39 Chapter 12 SPECIFICATIONS

4.3 ..15 Wiring for PROFIBUS Connector 12.1 ...............39 General Specifications

ON/OFF Timing of the Option and the 12.2 .39 Communications Specifications

4.4

Inverter .....................................16

a ON

CODES FOR PROFIBUS DP

COMMUNICATION........................17

..............................................

Data Transaction Examples in Running

4

Page 7

Chapter 1 BEFORE USING THE PROFIBUS DP INTERFACE OPTION

1.1 Acceptance Inspection

Unpack the package and check the following:

(1) A PROFIBUS DP interface option and the following accessories are contained in the package. (See Figure 1.1.)

- Two option connection cables

(A short one for inverters with a capacity of 5 HP or below and a long one for inverters with a capacity of 7.5 HP or above)

- One ferrite core

- One option fixing screw

- PROFIBUS DP Interface Option Instruction Manual (this manual)

(2) The option and accessories have not been damaged during transportation—there should be no dents or parts missing.

(3) The model name "OPC-E1-PDP" is printed on the nameplate attached to the right side of the option. (See Figure 1.1.)

If you suspect the product is not working properly or if you have any questions about your product, contact your Fuji Electric representative.

Figure 1.1 PROFIBUS DP Interface Option and Accessories

Page 8

Chapter 2 NAMES AND FUNCTIONS

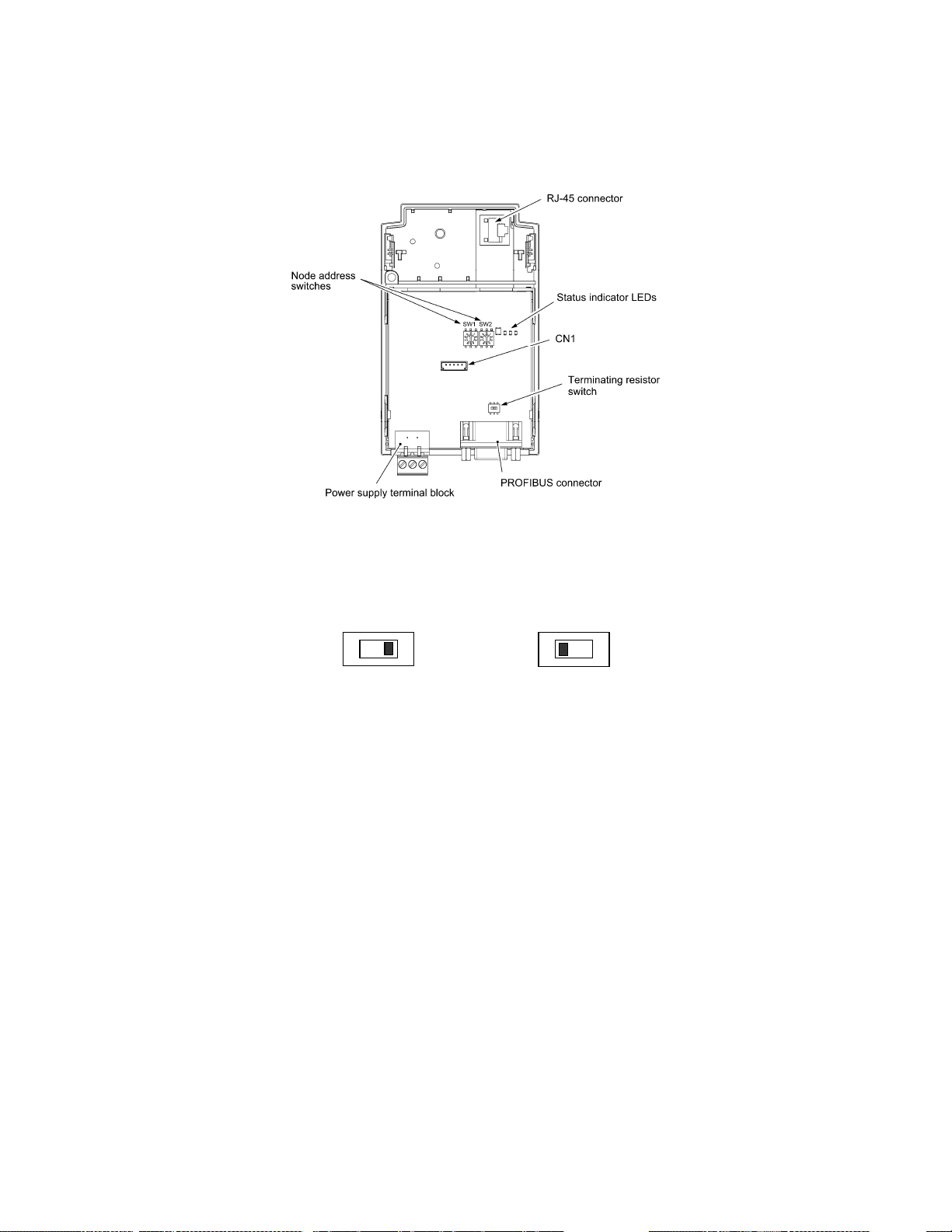

2.1 Parts Names

Figure 2.1 shows the inside view of the PROFIBUS DP interface option with its terminal cover (See Figure 3.3) removed.

Figure 2.1 Parts Names of PROFIBUS DP Interface Option

2.2 Terminating Resistor Switch

The PROFIBUS DP communications network requires insertion of line terminating resistors at its both ends. When this option is mounted on

the inverter at either end of the network, turn this switch ON to insert the terminating resistor.

ON OFF

ON OFF

OFF: No insertion of terminating

resistor

Figure 2.2 Terminating Resistor Switch Settings

ON: Insertion of terminating

resistor

6

Page 9

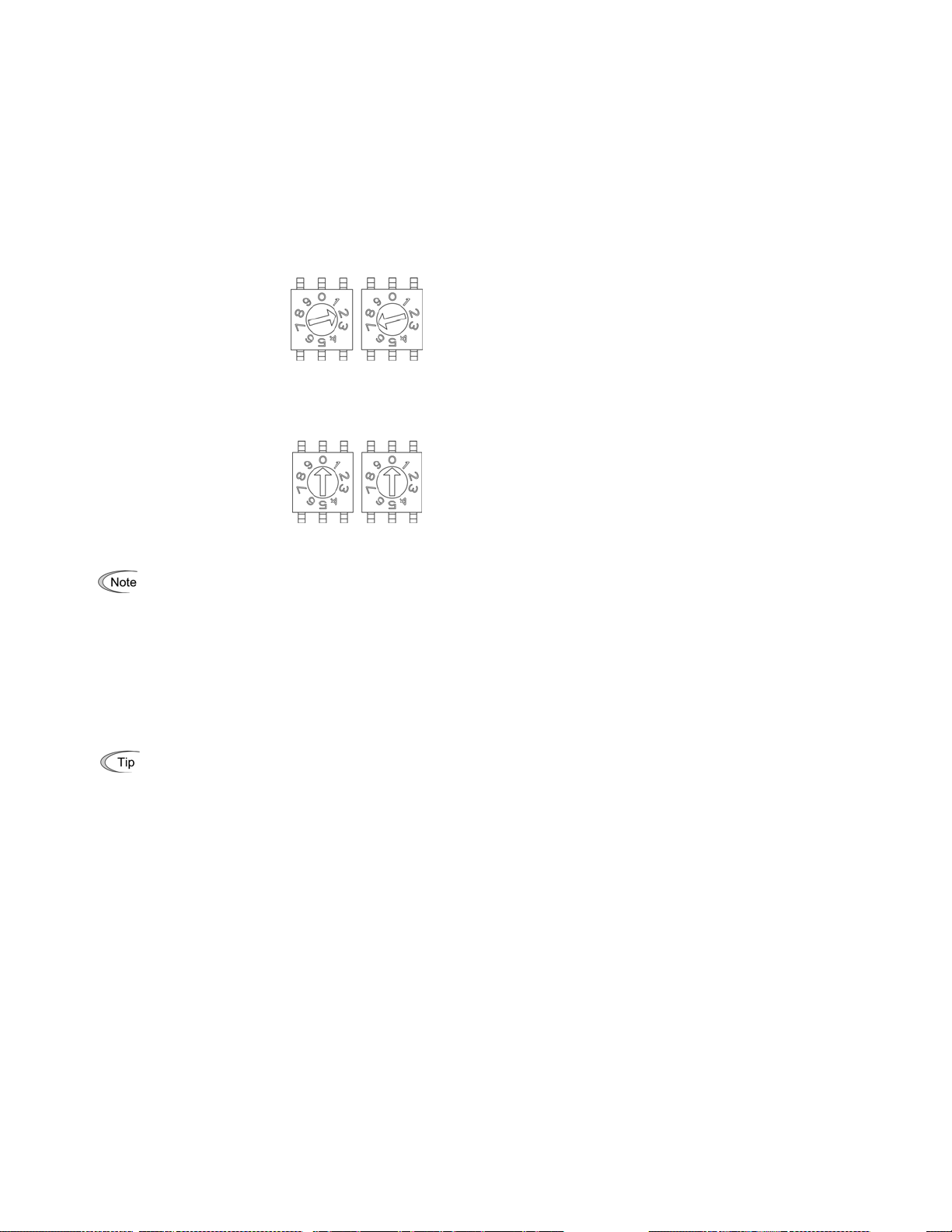

2.3 Node Address Switches

The node address switches (SW1 and SW2) on the interface option are rotary ones that are used to specify the PROFIBUS DP

communications network node address (station address) of the option. The setting range is from 0 to 99 in decimal. The SW1 specifies a 10s

digit of the node address and the SW2, a 1s digit.

The node address can also be specified with the inverter's function code o31. The setting range is from 0 to 125 in decimal. Note that

validating the node address specified with the function code o31 requires setting the node address switches to "00."

Example 1: Setting the node address 27 using the node address switches

SW1 SW2

1. When the inverter and this option are

powered OFF:

Set SW1 to "2."

Set SW2 to "7."

2. Turn the inverter and this option ON.

The setting procedure is completed.

Figure 2.3 Node Address Setting Example 1

Example 2: Setting the node address 125 using the function code o31

SW1 SW2

1. When the inverter and this option are

powered OFF:

Set both the SW1 and SW2 to "0."

2. Turn the inverter and this option ON

and set the function code o31 data to

"125."

Figure 2.4 Node Address Setting Example 2

3. Turn the inverter and this option OFF

and ON.

The setting procedure is completed.

1. The node address switches should be accessed with all the power to the inverter and this option (including the auxiliary power)

being OFF. Setting these switches with the power to the inverter and this option being ON requires turning the power OFF and

ON to validate the new setting.

2. To validate the node address setting using the function code o31, turn the inverter and this option OFF and ON.

3. Setting the function code o31 data to "126" or greater will cause a data setting error. The ERR LED on the option blinks in red

and the inverter issues the alarm code er5.

2.4 Setting the Transmission Speed (Baud rate)

No transmission speed setting is required on the interface option (slave). Setting the transmission speed in the PROFIBUS DP network

master node automatically configures the transmission speed of this option.

This option supports the following transmission speed.

9.6, 19.2, 45.45, 93.75, 187.5, and 500 Kbps

1.5, 3, 6, and 12 Mbps

Page 10

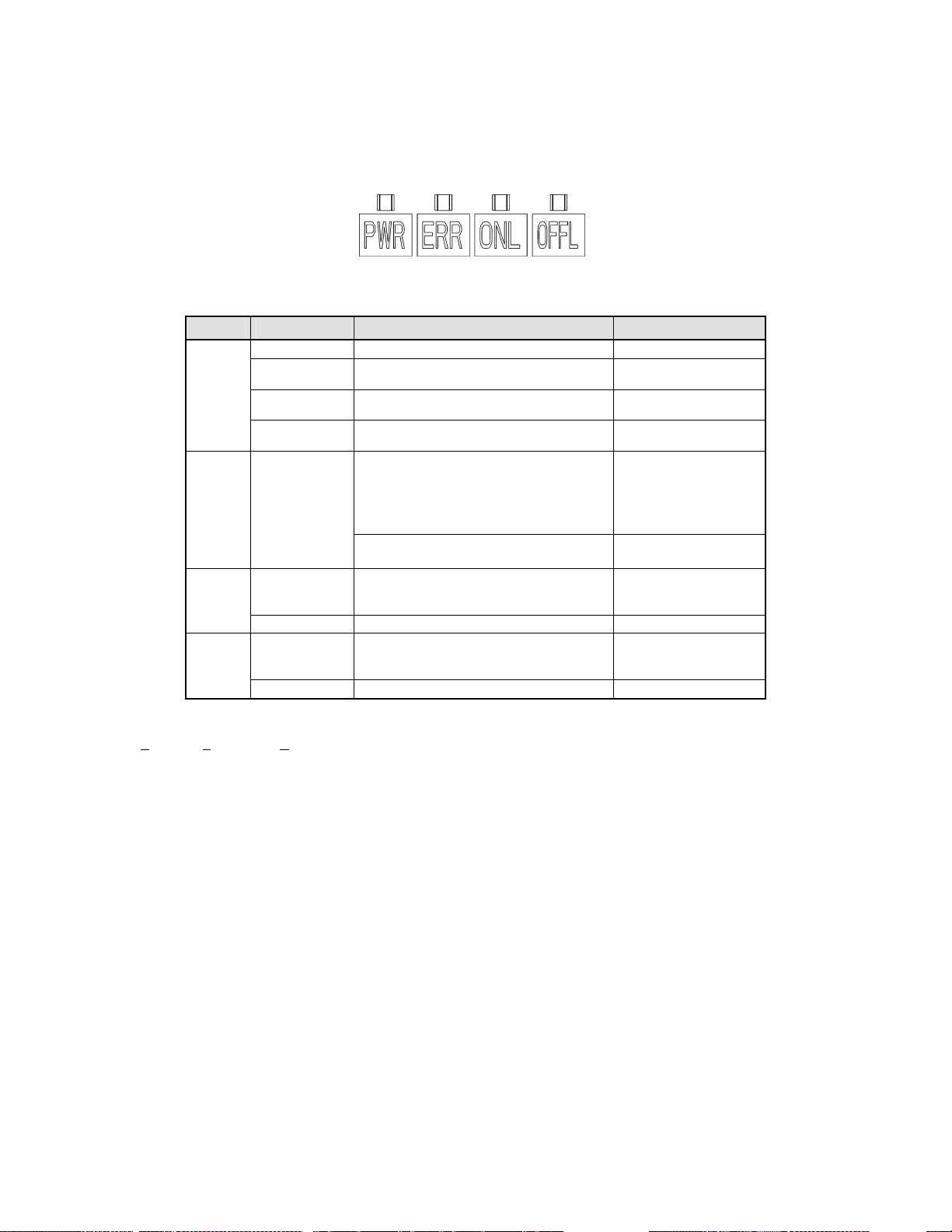

2.5 Status Indicator LEDs

This interface option has four status indicator LEDs shown in Figure 2.5. They indicate the operation status of the option as listed in Table

2.1.

Name Color Meaning Note

Lights in green Normal --Blinks in green

PWR

Blinks in red PROFIBUS communications error

Lights in red

Blinks in red

ERR

Figure 2.5 Status Indicator LEDs

Table 2.1 LED Indications and Operation Status

Self-diagnostic test running or initialization in

progress during powering on sequence

Hardware error

(Option not properly installed or option faulty)

Wrong configuration of PROFIBUS protocol

(Discrepancy between PPO type defined by

the inverter's function code o30 and the one

defined in the PROFIBUS master node)*2

This test takes approx.

0.5 second.

The inverter shows er5.

*1

The inverter shows er4.

---

Wrong configuration of PROFIBUS protocol

(The node address is set to 126 or greater.)

The inverter shows er5.

*1

Online

ONL

Lights in green

(The option communicates normally on the

PROFIBUS network.)

---

OFF Not online ---

Offline

(The option is not connected to PROFIBUS)

---

OFFL

Lights in red

OFF Not offline ---

*1 Configuration for ignoring er5 is possible. For details, refer to Chapter 9, "INVERTER REACTION TO PROFIBUS COMMUNICATIONS

ERRORS."

*2 PPO (P

arameter Process-data Object) type defined in this option should be consistent with that in the PROFIBUS DP master node. To

define the PPO type in this option, use the inverter's function code o30; to define that in the master node, use a configuration tool

designed for the master node.

For defining the PPO type in the master node, refer to the documentation of the master node.

For details about the PPO type, see Chapter 8, "DETAILS OF PROFIBUS DP PROFILES." For details about the function code o30,

see Chapter 5 "CONFIGURING INVERTER'S FUNCTION CODES FOR PROFIBUS DP COMMUNICATION."

2.6 RJ-45 Connector

The RJ-45 connector is used to connect the keypad of the FRENIC-Multi to this option.

The keypad can be detached from the option and mounted on a panel. For details, refer to the FRENIC-Multi Instruction Manual

(INR-SI47-1204-E), Chapter 2, Section 2.4 "Mounting and Connecting a Keypad."

2.7 Power Supply Terminal Block and PROFIBUS DP Terminal Block

The power supply terminal block and PROFIBUS DP terminal block are used to connect the 24V power cable and PROFIBUS DP cable,

respectively, in order to operate this option.

For details, refer to Chapter 4 "WIRING AND CABLING."

8

Page 11

Chapter 3 MOUNTING THE PROFIBUS DP INTERFACE OPTION

Turn the inverter's power OFF and wait at least five minutes. Further, check that the DC link bus voltage between the P (+) and N (-)

terminals is lower than 25 VDC.

Otherwise, electric shock could occur.

• Do not use the products that are damaged or lacking parts.

Doing so could cause a fire, accident, or injury.

• Prevent lint, paper fibers, sawdust, dust, metallic chips, or other foreign materials from getting into the inverter and the option.

Otherwise, a fire or an accident might result.

• Incorrect handling in installation/removal jobs could cause a failure.

• When handling this option, take any antistatic measure or hold the plastic parts taking care not to directly touch the circui t board ;

otherwise, the static electricity charged in your body may damage it.

A failure might result.

Page 12

Before mounting the option, perform the wiring for the main circuit terminals and control circuit terminals.

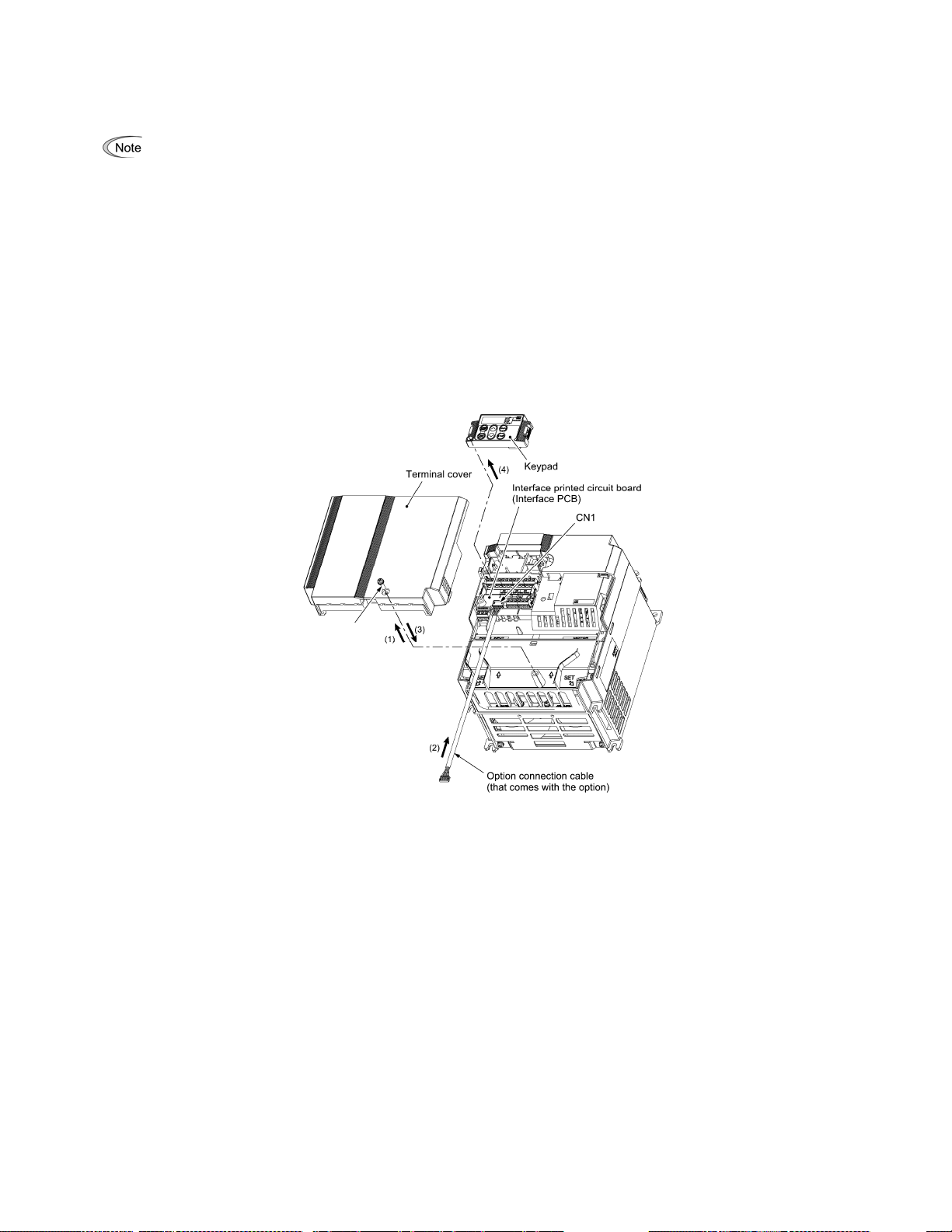

(1) Remove the terminal cover from the inverter.

Note: For inverters with a capacity of 7.5 to 20 HP, you need to remove the terminal cover fixing screw to remove the terminal cover.

For details on how to remove the terminal cover, refer to the FRENIC-Multi Instruction Manual (INR-SI47-1204-E), Chapter 2,

Section 2.3 "Wiring."

(2) Connect the option connection cable to the CN1 connector on the interface printed circuit board (interface PCB) on the inverter.

Use the short cable for inverters with a capacity of 5 HP or below, and the long cable for the ones with a capacity of 7.5 HP or above.

(3) Mount the terminal cover.

For details on how to mount the terminal cover, refer to the FRENIC-Multi Instruction Manual (INR-SI47-1204-E), Chapter 2,

Section 2.3 "Wiring."

(4) Push the hooks provided on both sides of the keypad and pull the keypad up and out of the inverter.

For details on how to remove the keypad, refer to the FRENIC-Multi Instruction Manual (INR-SI47-1204-E), Chapter 2, Section 2.4

"Mounting and Connecting a Keypad."

Terminal cover

fixing screw

(for inverters with a capacity

.5 to 20 HP)

of 7

Figure 3.1

Connecting the Option Connection Cable to the Interface PCB and Removing the Keypad

(For inverters with a capacity of 15 and 20 HP)

10

Page 13

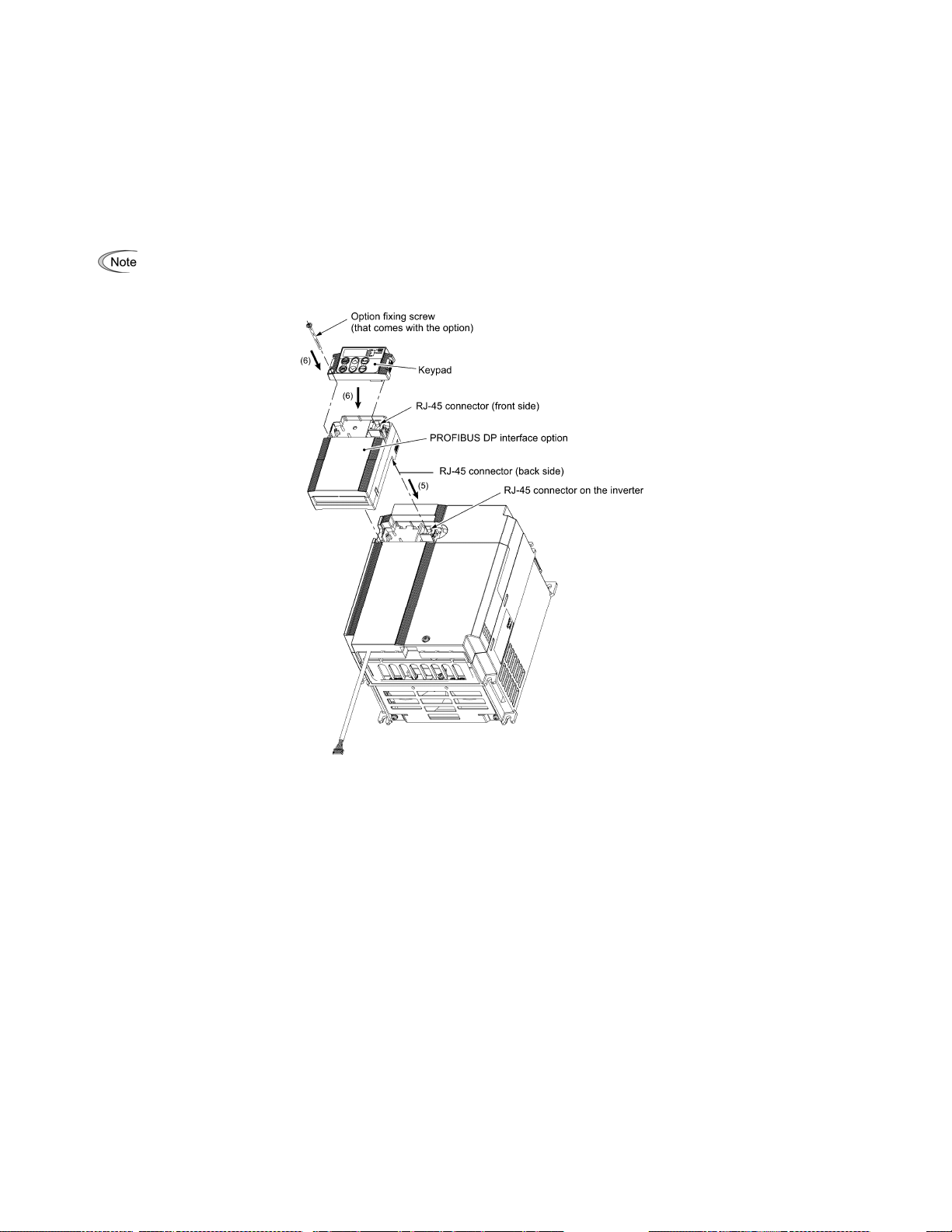

(5) Mount the option on the inverter, making the RJ-45 connector on the back side of the option engage with the RJ-45 connector on the

inverter (to which the keypad had been connected).

(6) Connect the ke ypad to the RJ-45 connector on the front side of the option, then secure the keypad and option to the inverter with the

option fixing screw (that comes with the option).

When using the keypad at a remote site, secure the option without the keypad to the inverter with the screw.

Tightening torque: 0.6 N·m(0.4 lbf·ft)

Take care not to tighten the option fixing screw too much. Doing so could make the screw defective.

Figure 3.2 Mounting the PROFIBUS DP Interface Option and the Keypad

Page 14

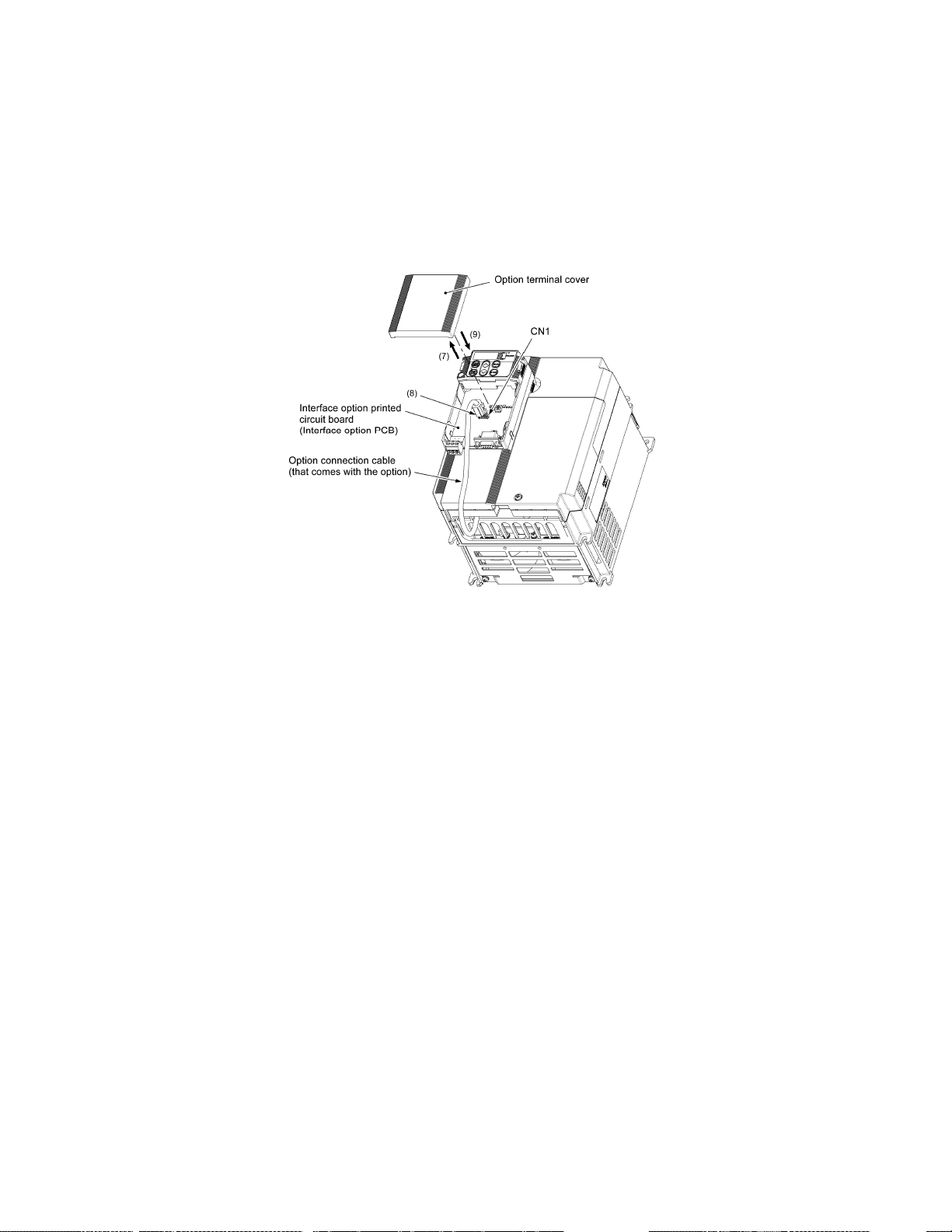

(7) Slightly pull the bottom of the option terminal cover towards you and remove it downward.

(8) Attach the ferrite core to the other end of the option connection cable (whose end has been connected to the interface PCB on the

inverter in step (2) above) and connect the cable to the CN1 connector on the interface option pri nted circuit board (interface option

PCB).

(9) Mount the option terminal cover.

First fit the bosses on the top of the cover into the square holes provided in the option, and then push the bottom of the cover until it

snaps into place.

Figure 3.3 Connecting the Option Connection Cable to the Interface Option PCB

12

Page 15

Chapter 4 WIRING AND CABLING

• Before starting installation, turn the inverter's power OFF and wait at least five minutes. Further, check that the DC link bus voltage

between the P (+) and N (-) terminals is lower than 25 VDC.

• Qualified electricians should carry out wiring.

Otherwise, electric shock could occur.

The inverter, motor, and wiring emit electrical noise. Take appropriate measures to prevent the nearby sensors and devices from

malfunctioning due to such noise.

Otherwise, an accident could occur.

4.1 Basic Connection Diagram

FRENIC-Multi

L1/R U

L2/S

L3/T

V

W

Motor

M

OP C-E 1-PDP

Terminating

resistor switch

PROFIBUS

Power supply

terminal block

24 VDC

power

supply

24V

0V

E

G

Figure 4.1 Basic Connection Diagram

connector

G

PROFIBUS cable

To PROFIBUS

DP

For the 24 VDC power supply to be connected to the power supply terminal block, be sure to use an external 24 V power supply with a

capacity of at least 200 mA. Never use the PLC terminal on the inverter; doing so flows a current exceeding the capacity of the PLC

terminal, resulting in a damaged inverter.

A failure might result.

Page 16

4.2 Wiring for Power Supply Terminal Block

m

This terminal block is used to supply this option with 24 V power to operate it. Perform wiring for the terminal block as described blow.

For the 24 VDC power supply to be connected to the power supply terminal block, be sure to use an external 24 V power supply with a

capacity of at least 200 mA. Never use the PLC terminal on the inverter; doing so flows a cur rent exceeding the capacity of the PLC

terminal, resulting in a damaged inverter.

A failure might result.

(1) Wiring for the power supply terminal block (TERM3)

The terminal block uses a pluggable 3-pin connector as shown in Figure 4.2. Table 4.1 shows the pin assignment.

A typical connector that matches this terminal block is Phoenix Contact MSTB 2.5/3-ST-5.08.

Table 4.1 Pin Assignment on Power Supply Terminal Block

Terminal

Pin #

name

1 24 V Power supply

2 0 V Power supply

Description Remarks

(24 VDC, +

side)

Never use the PLC

terminal on the inverter

for 24 V power.

(24 VDC, side)

3 E Grounding

terminal

Connect the ground

terminal of the inverter

G) to this terminal.

(

For protection against external noise and prevention of failures, be sure to connect a grounding wire.

1 2 3

Figure 4.2 Connectors of the Power Supply

Terminal Block

Table 4.2 lists the recommended wire size, terminal screw size and its tightening torque. Before connecting the cable to the terminal

block, strip the cable wire end. Figure 4.3 shows the recommended wire strip length.

Table 4.2 Recommended Wire Size, Terminal Screw Size, and Its Tightening Torque

for the Power Supply Terminal Block

Wire size Terminal screw

AWG20 to AWG16 (0.5 to 1.5 mm2 ),

wire with rated temperature 105C(221 F) (UL)

recommended

C ble wire a

電線

size

M3

Approx.

6.0 mm(0.24 in)

約6m

Tightening torque

0.5 to 0.6 N·m

(0.37 to 0.44 lbf・ft)

Figure 4.3

Recommended Strip Length of the Cable Wire End for Terminal Connection

14

Page 17

r

(2) Input power requirements

Select the 24 V input power supply that meets the specifications listed in Table 4.3.

Table 4.3 Input Power Requirements

Item Specifications

Input power voltage

21.6 to 27.0 V

range

Current capacity Minimum 200 mA

4.3 Wiring fo r PROFIBUS Connector

(1) To connect this option to PROFIBUS DP network, use a shielded twist pair cable that complies with the PROFIBUS specifications.

The recommended cable is a PROFIBUS FC standard cable 6XV1 830-0EH10 manufactured by Siemens AG.

(2) Wiring for the PROFIBUS connector

The PROFIBUS connector is a 9-pin D-sub female connector shown in Figure 4.4. Table 4.4 shows the pin assignment.

The PROFIBUS cable should have a 9-pin male D-sub connector. The recommended connector is an RS-485 PROFIBUS bus connector

Pin#

Housin

*1

*2 This power suppl y is required whe n an external te rminating resistor (not the on e built in this option) are used (e.g., when using the

For details about wiring for PROFIBUS, refer to the "Installation Guideline for PROFIBUS DP/FMS" and "Handbook PROFIBUS

http://www.profibus.com/pall/meta/downloads/

6GK1 500-0FC00 manufactured by Siemens AG.

Table 4.4 Pin Assignment of the PROFIBUS Connector

Pin

Assignme

nt

g

Shield

Terminal for connecting the cable shield

*1

Description

1 - NC

2 - NC

3 B-Line

4 RTS

5

GND

BUS

Terminal for the positive (+) line of

PROFIBUS cable (red wire)

Data transmission control for the repeater

(direction control)

Ground signal for PROFIBUS cable

6 +5V BUS Power supply for terminating resistors *2

7 - NC

8 A-Line

Terminal for the negative (-) line

(green wire)

9 - NC

Figure 4.4 PROFIBUS Connecto

(Female connector with M2.6 fixing screws)

5 4 3 2 1

9 8

7 6

The Shield terminal on the PROFIBUS connector and Ground terminal (E) on the power supply terminal block (TERM3) are

connected internally.

terminal resistor built in the recommended bus connector described above). Do not use this power supply for any other purposes.

Installation Guideline" published by the PROFIBUS Organization. It can be downloaded for free from the PROFIBUS

Organization's website at:

Page 18

4.4 ON/OFF Timing of the Option and the Inverter

Observe the following instructions about the ON/OFF timing of this option and the inverter.

(1) Power ON

It is recommended that this option be turned ON at the same time as or before the inverter. Turning the inverter ON first may detect no

operation of the option, causing a trip with er4 alarm. The er4 alarm can be reset after this option is turned ON.

(2) Power OFF

It is recommended that this option be turned OFF at the same time as or after the inverter. Turning the option OFF first may cause the

inverter to detect no operation of the option, causing a trip with er4 alarm. Turning the inverter OFF resets the er4 alarm.

The inverter issues an alarm er4 if the option's power stays OFF for approximately 1 second when the inverter power is ON.

16

Page 19

Chapter 5 CONFIGURING INVERTER'S FUNCTION CODES FOR PROFIBUS DP

COMMUNICA TION

To perform data transmission between the inverter equipped with this option and the PROFIBUS DP master node, configure the function

codes listed in Table 5.1.

Table 5.2 lists inverter's function codes related to PROFIBUS DP communication. Configure those function codes if necessary.

For details about function codes, refer to the FRE NIC-Multi Instruction Manual (INR-SI47-1204-E), Chapter 5 "FUNCTION CODES"

and RS-485 Communication User's Manual (MEH448), Chapter 5, Section 5.2 "Data Formats."

Table 5.1 Inverter's Function Code Settings Related to PROFIBUS Communications

Functio

n

codes

o30

1

y98

2

Description

Select PPO type

*

(data format)

Select

*

run/frequency

command source

Factory

default

setting

0 Available data is:

0, 1, 6 to 255: PPO type 1

2 and 5: PPO type 2

3: PPO type 3

4: PPO type 4

0 Available data is:

Frequency

command

0 Inverter Inverter

1 PROFIBUS Inverter

Function code data Remarks

The selected PPO type should be consistent with

that of the master node.

If there is no special problem with your system,

Run

comman

d

setting y98 = 3 is recommended.

2 Inverter PROFIB

3 PROFIBUS PROFIB

*1

After setting up the function code o30, turn the inverter and this option OFF and ON to validate the new setting.

For details about the function code o30, refer to Chapter 8 "DETAILS OF PROFIBUS DP PROFILES."

*2 In addition to y98, the FRENIC-Multi has other function codes related to the run/frequency command source. Setting up those codes

realizes more precise selection of the command sources. For details, refer to the descriptions of H30 and y98 in the FRENIC-Multi

Instruction Manual (INR-SI47-1204-E), Chapter 5 "FUNCTION CODES."

Function

codes

o27 *1

o28 *1

o31 *2

o40 to

o43

o48 to

o51

W90 Show the software version of the

*1 For details about function codes o27 and o28, refer to Chapter 9 "INVERTER REACTION TO PROFIBUS COMMUNICATIONS

ERRORS."

*2 For details about the function code o31, refer to Chapter 2, Section 2.3 "Node Address Switches."

*3 For details about function codes o40 to o43 and o48 to o51, refer to Chapter 8, Section 8.2 (4) "PCD1 to PCD4."

Select the inverter’s operation

mode to apply when a

PROFIBUS communications

error occurs.

Set the operation timer to apply

when a PROFIBUS

communications error occurs.

Set the PROFIBUS network

node address.

Assign the function code writing

data cyclically.

*3

Assign the function code

reading data cyclically.

*3

PROFIBUS interface option on

the LED monitor.

Description

Table 5.2 Other Related Function Codes

Factory

default

setting

0 0 to 15

0.0 s 0.0 s to 60.0 s

0 0 to 255

0

(No

assignmen

t)

0

(No

assignmen

t)

Depends

on the

option

US

US

Function code setting range Remarks

(Setting range: 0 to 125)

0000 to FFFF (hex)

0000 to FFFF (hex)

--(Only for monitoring)

Valid only when both SW1 and SW2 are set to "00."

Setting 126 or greater causes an error, flashing the

ERR LED and issuing an er5.

Valid only when PPO type 2 or 4 is selected.

4-digit decimal

If the version is V.1.23, the LED shows "0123."

Page 20

Chapter 6 ESTABLISHING A PROFIBUS COMMUNI CATIO NS LINK

This chapter guides you to establish a PROFIBUS DP communications link between the PROFIBUS DP master node and this option (slave

node).

Follow the steps below.

Step 1 Configuring the PROFIBUS DP master node equipment

Step 2 Configuring this option and inverter's function codes

Step 3 Powering ON the inverter and this option Initiating the PROFIBUS data transaction

Each of the above steps is detailed below.

Step 1 Configuring the PROFIBUS DP master node equipment

Step 1.1: Specify the master node address (station address) and baud rate.

Step 1.2: Register this option to the master node using the GSD file prepared for the option.

Step 1.3: Choose a PPO type (data format) to be applied to the registered option, from PPO type 1 to PPO type 4.

For details about the configuration of the PROFIBUS DP master node equipment, refer to the user’s manual or documentations of your

master equipment.

For details about PPO types, refer to Chapter 8 "DETAILS OF PROFIBUS DP PROFILES."

IMPORTANT

A GSD file, which is required for registering the PROFIBUS DP interface option to the PROFIBUS master node, does not come with the option.

It is available as a free download from our website at:

http://web1.fujielectric.co.jp/Kiki-Info-EN/User/index.html

(Fuji Electric FA Components & Systems Co., Ltd. Technical Information site)

Before downloading, you are requested to register as a member (free of charge).

Step 2 Configuring this option and inverter’s function codes

Step 2.1: Specify the node address that must be identical with the option address registered to the master node

Step 2.2: Set up the data of inverter function codes o27 and o28, if needed.

Step 2.3: Choose a PPO type from PPO type 1 to PPO type 4, using the inverter’s function code o30.

The PPO type must be identical with the one selected for the mast

For details about function codes o27 and o28, refer to Chapte r 9 "INVERTER REACTION TO PROFIBUS COMMUNICATIONS

.

er node. After changing the data of the function code o30, be

sure to turn the inverter and this option OFF and ON.

ERRORS."

Step 3 Powering ON the inverter and this option Initiating the PROFIBUS data transaction

When the inverter equipped with this option and the PROFIBUS DP master node are correctl y set up, turning the inverter and this option

OFF and ON automatically establishes a PROFIBUS communications link, enabling the data transaction between them. The PWR and ONL

LEDs on the option light in green.

Send run and frequency commands from the master to this option.

For specific data formats and data transaction, refer to Chapter 7 "QUICK SETUP GUIDE FOR RUNNING THE INVERTER" and

Chapter 8 "DETAILS OF PROFIBUS DP PROFILES."

For the wiring, refer to Chapter 4 "WIRING AND CABLING."

18

Page 21

(Byte)

Chapter 7 QUICK SETUP GUIDE FOR RUNNING THE INVERTER

This chapter provides a quick setup guide for running the inverter from a PROFIBUS DP master node according to the simplest data format

(PPO type 3), taking an operation example. PPO type 3 is a simple format dedicated to inverter’s run and frequency commands.

The description of PPO type 3 in this chapter can apply to other PPO types, except the format assignment maps.

To simplify the description, this chapter confines the description to running of an inverter. For more information, refer to Chapter 8

"DETAILS OF PROFIBUS DP PROFILES."

7.1 Before Proceeding to Data Exchange

(1) At the PROFIBUS DP master node, select PPO type 3 for this interface option.

For the setting procedure of PPO types at the PROFIBUS DP master node, refer to the user's manual of your master node

equipment.

(2) Set function codes of your inverter as follows.

F03 = 60 (Maximum frequency in Hz), y98 = 3 (Validate frequency and run commands from PROFIBUS), and o30 = 3 (Select PPO type

3)

Also set the data of function codes o27 and o28, if needed.

After settings are completed, turn the inverter and this option OFF and ON to validate the new settings.

For details about function codes o27 and o28, refer to Chapter 9 "INVERTER REACTION TO PROFIBUS COMMUNICATIONS

7.2 Data Transaction Examples in Running an Inverter

Before providing data transaction examples, this section shows the data frame formats of PPO type 3. The following descriptions are based

on these formats.

Given below is a PROFIBUS DP communication sample in which the master node runs the inverter in the forward direction in 60 Hz.

(1) Turning the inverter and this option ON initiates PROFIBUS DP communication. Immediately after the power is ON, the data in the

ERRORS."

(Byte) 0 1 2 3

Request

(Master Slave)

CTW MRV

CTW: Control word (2 bytes) that sends a run command. The LSB determines ON/OFF of the run command.

MRV: Sends a frequency command that is expressed relative to the maximum frequency (defined by F03 in Hz) being assumed as

4000hex.

(Byte) 0 1 2 3

Response

(Salve Master)

STW MAV

STW: Status word (2 bytes) that sends the running status of the inverter to be monitored at the master node.

MAV: Sends the current output frequency of the inverter to be monitored at the master node, which is expressed relative to the

maximum frequency (defined by F03 in Hz) being assumed as 4000hex.

request/response frames is as follows.

(Byte) 0 1 2 3

Request

(Master Slave)

00 00 00 00

CTW MRV

0 1 2 3

Response

(Salve Master)

02 40 00 00

STW MAV

STW: Dat a 02 indicates that frequency and run commands from PROFIBUS are enabled. Data 40 indicates that the inverter is not

ready to turn a run command ON.

MAV: Data 0000 means that the current output frequency is 0 Hz.

Page 22

(2) In step (1), the inverter is not ready to turn a run command ON as shown in STW.

First, enter the request data "04 7E" to CTW, to make the inverter ready to turn a run command ON. In the example below, the frequency

command 60 Hz (maximum frequency being assumed as 4000hex) is entered to MRV at the same time.

(Byte) 0 1 2 3

Request

(Master Slave)

04 7E 40 00

CTW MRV

CTW: Data 04 enables the contents in this frame. Data 7E requests the inverter to get ready to turn a run command ON.

MRV: The frequency command is 4000hex (= Maximum frequency defined by F03 in Hz).

In response to the above request, this interface option returns the following response to the master node.

(Byte) 0 1 2 3

Response

(Salve Master)

02 31 00 00

STW MAV

STW: Data 02 indicates that frequency and run commands from PROFIBUS are enabled. Data 31 indicates that the inverter is

ready to turn a run command ON.

MAV: The current output frequency is 0 Hz.

(3) Since the inverter has been ready to turn a run command ON, enter run command data "04 7F" to CTW.

(Byte) 0 1 2 3

Request

(Master Slave)

04 7F 40 00

CTW MRV

CTW: Data 04 enables the contents in this frame. Data 7F requests the inverter to turn a run command ON.

MRV: The frequency command is 4000hex (= Maximum frequency defined by F03 in Hz).

In response to the above request, the inverter starts running the motor. The option returns the following response to the master

node.

(Byte) 0 1 2 3

Response

(Salve Master)

02 37 ** **

STW MAV

STW: Data 02 indicates that frequency and run commands from PROFIBUS are enabled. Data 37 indicates that the inverter is

running.

MAV: The output frequency is accelerating.

(4) To stop the inverter, enter data "04 7E" to CTW.

(Byte) 0 1 2 3

Request

(Master Slave)

04 7E 40 00

CTW MRV

CTW: Data 04 enables the contents in this frame. Data 7E requests the inverter to turn the run command OFF.

MRV: The frequency command is 4000hex (= Maximum frequency defined by F03 in Hz).

In response to the above request, the inverter decelerates to a stop. The option returns the following response to the master node.

(Byte) 0 1 2 3

Response

(Salve Master)

02 33/31 ** **

STW MAV

STW: Data 02 indicates that frequency and run commands from PROFIBUS are enabled. Data 33 indicates that the inverter is

decelerating, and data 31 indicates that the inverter is ready to turn a run command ON (when the inverter is stopped).

MAV: The output frequency is decreasing.

20

Page 23

(5) To restart running the inverter, enter data "04 7F" to CTW. To run the inverter in the reverse direction, enter data "0C 7F" instead.

The example below specifies "Run reverse at the frequency of 30 Hz (2000hex)."

(Byte) 0 1 2 3

Request

(Master Slave)

0C 7F 20 00

CTW MRV

CTW: Data 0C enables the contents in this frame and requests the inverter to turn a run reverse command ON. Data 7F requests

the inverter to turn a run command ON.

MRV: The frequency command is 2000hex (Frequency (Hz) = F03 2000hex/4000hex).

In response to the above request, the inverter starts running the motor in the reverse direction. The example below shows a

response indicating that the inverter has reached the commanded frequency level in the reverse direction.

(Byte) 0 1 2 3

Response

(Salve Master)

03 37 E0 00

STW MAV

STW: Data 03 indicates that frequency and run commands from PROFIBUS are enabled and the output frequency arrives the

reference one. Data 37 indicates that the inverter is running.

MAV: The current output frequency is E000hex (2’s complement expression of 2000hex (Frequency = F03 -2000hex/4000hex).

(6) Entering a negative value to MRV also allows the inverter to run in the reverse direction. The example below enters E000hex, 2’s

complement of 2000hex.

(Byte) 0 1 2 3

Request

(Master Slave)

04 7F E0 00

CTW MRV

CTW: Data 04 enables the contents in this frame. Data 7F requests the inverter to turn a run command ON.

MRV: The frequency command is E000hex (-2000hex) (Frequency = F03 -2000hex/4000hex).

In response to the above request, the inverter starts running the motor in the reverse direction. The example below shows a

response indicating that the inverter has reached the commanded frequency level in the reverse direction.

(Byte) 0 1 2 3

Response

(Salve Master)

03 37 E0 00

STW MAV

STW: Data 03 indicates that frequency and run commands from PROFIBUS are enabled and the output frequency arrives the

reference one. Data 37 indicates that the inverter is running.

MAV: The current output frequency is E000hex (Frequency = F03 -2000 hex/400 0hex).

(7) If any trip occurs in the inverter, remove the trip factor and then enter data "04 80" to CTW to cancel the trip. After the trip is cancelled,

enter data "04 00." (Note: The MSB in the 2nd byte (Byte 1) acts as a trip cancellation bit.)

(Byte) 0 1 2 3

Request

(Master Slave)

04 80 10 00

CTW MRV

CTW: Data 04 enables the contents in this frame. Data 80 requests canceling of the trip.

MRV: The frequency command is 1000hex (Frequency = F03 1000hex/4000hex).

Canceling a trip returns the inverter to the state immediately after the power is turned ON. To restart operation using PROFIBUS

network, go back to step (2).

(Byte) 0 1 2 3

Response

(Salve Master)

02 40 00 00

STW MAV

STW: Data 02 indicates that frequency and run commands from PROFIBUS are enabled. Data 37 indicates that the inverter is

running.

MAV: The current output frequency is 0000hex.

Page 24

Chapter 8 DETAILS OF PROFIBUS PROFILES

The interface option supports PROFIdrive V2 of a motor control profile which is instituted by the PROFIBUS Organization. This chapter

describes the PROFIdrive profile.

8.1 Description of PPO Types Supported

The PROFIdrive profile defines several data formats called PPO (Parameter Process-data Object). This interface option supports four PPO

types shown in Figure 8.1. Select a PPO type to apply to the option using the function code o30 (see T able 8.1). Table 8.2 lists the features

of these PPO types. Tables 8.3 and 8.4 list the parts in the PPO.

(Word

/Area)

(Word) 1 2 3 4 5 6 7 8 9 10

PPO

type 2

(Word) 1 2 3 4 5 6

PPO

type 4

PCV PCD

PCA IND PVA

(Word) 1 2 3 4 5 6

PPO

type 1

(Word) 1 2

PPO

type 3

Figure 8.1 Data Formats of PPO Types Supported

CTW

STW

MRV

PCD1 PCD2 PCD3 PCD4

MAV

Table 8.1 Choice of PPO Type Using the Inverter's Function Code o30

Data of o30 PPO Remarks

0, 1, 6 to 255 PPO type 1 Factory default PPO type

2, 5 PPO type 2

3 PPO type 3

Turn the inverter and this option OFF and ON after setting the function code o30 to validate the new setting.

4 PPO type 4

Table 8.2 Featur es of PPO Types

PPO Features

PPO type

1

PPO type

2

PPO type 3 Simplified data format specialized for defining run command/running

PPO type

4

Most typical data format that supports run command/running status

monitor, frequency command/output frequency monitor, and

on-demand accesses to inverter’s function codes.

Fully functional data format that supports run command/running

status monitor, frequency command/output frequency monitor,

on-demand accesses to inverter’s function codes, and cyclic access

to up to four inverter’s function codes previously specified.

status monitor and frequency command/output frequency monitor.

Data format that supports cyclic access to up to four inverter’s

function codes previously specified, in addition to the features of

PPO type 3.

22

Page 25

Table 8.3 Parts in PPO

Parts Description

Parameter area used for cyclic data communication with the PROFIBUS

DP master node. Run command/running status monitor and frequency

PCD

PCV

command/output frequency monitor can be assigned to this area. PPO

type 2 and type 4 additionally can assign arbitrary inverter's function

codes to this area, enabling cyclic data writing and reading, each with up

to four function codes.

Parameter area used for an on-demand access to the parameter

(inverter’s function codes and PROFIdrive specific parameters). PPO type

1 and type 2 support this area.

Table 8.4 Words in PCV and PCD Parts

Parts Words Function Description

CTW/ST

W

Request

Response

CTW: Control word that sends a run command from the

master to the slave.

STW: Status word that returns the inverter’s running status

from the slave to the master as a response.

MRV: Word area that sends a frequency command

expressed relative to the maximum frequency (defined by

F03 in Hz) being assumed as 4000hex, from the master to

the slave.

MAV: Word area that returns the current inverter ’s output

frequency expressed relative to the maximum frequency

(defined by F03 in Hz) being assumed as 4000hex, from the

slave to the master.

Word area that writes data of the inverter's function code

specified by o40.

Word area that cyclically monitors data of the inverter’s

function code specified by o48.

Word area that writes data of the inverter's function code

specified by o41.

Word area that cyclically monitors data of the inverter’s

function code specified by o49.

Word area that writes data of the inverter’s function code

specified by o42.

Word area that cyclically monitors data of the inverter’s

function code specified by o50.

Word area that writes data of the inverter’s function code

specified by o43.

Word area that cyclically monitors data of the inverter’s

function code specified by o51.

PCD

Request

MRV/MA

V

Response

Request

PCD1

Response

Request

PCD2

Response

Request

PCD3

Response

Request

PCD4

Response

Word area that specifies the parameter (for the inverter’s

PCV

PCA

IND

PVA

Request

Response

Request

/Respons

e

Request

/Respons

e

function code and PROFIBUS parameter) and access

method to the parameter such as "write" and "read."

Word area that returns the parameter specified by the

request above and the access result as a response.

Word area that is used to specify indexes of array

parameters and inverter’s function code numbers.

Word area that shows the parameter value written or read.

For details about inverter’s function codes o40 to o43 and o48 to o51, refer to Section 8.2 (4) "PCD1 to PCD4."

The "Request" and "Response" denote data transfer from the PROFIBUS master node to the inverter (slave node) equipped with this

interface option and that from the inverter to the PROFIBUS master node, respectively.

Page 26

8.2 PCD Word Area

The PCD word area controls the cyclic data transfer between the PROFIBUS DP master node and the inverter (slave node) equipped with

this interface option. It consists of CTW (run command), STW (running status monitor), MRV (frequency command), MAV (output frequency

monitor), and PCD1 to PCD4 (cyclic accesses up to four inverter's function codes previously assigned) word areas.

(1) CTW (Control word)

CTW is a word area for controlling the data transfer of run command and its related ones from the PROFIBUS DP master node to the inverter

(salve node) equipped with this interface option.

(bit

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

)

b15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

Table 8.5 Bit Definition in CTW

Command/Sta

Bit

tus

b0 ON/OFF Turn a run command OFF Turn a run command ON

b1 ON2/OFF2 OFF2: Coast to stop

OFF3: Stop command

b2 ON3/OFF3

Enable

b3

b4

b5

b6

operation

Enable ramp

generator

Unfreeze

ramp

generator

Enable

setpoint

Disable inverter operation Enable inverter operation

Fix the inverter output frequency

at 0 Hz

Freeze the RFG with the current

output frequency fixed

Disable Enable ON-bit

b7 ALM RST Do not reset alarm

b8, b9 Not used. --- ---

b10 Enable PCD

Ignore data entered in the PCD

area (CTW+MRV)

b11 Run direction Run in the forward direction Run in the reverse direction

b12 to

Not used. --- ---

b15

For the use under the usual operation conditions, setting b1 through b6 and b10 to "1" could not cause any problem.

The PROFIdrive profile controls an inverter, following the status transition in the interface option. It means that only turning a run

command ON cannot run the inverter. After the inverter undergoes the status transition scheduled by the PROFIdrive profile and

enters the appropriate state, a run command should be turned ON. The status word STW described in the next section informs you

of the current status of the interface option.

For the status transition condition of the PROFIdrive profile, refer to Section (2) "STW (status word)" and Figure 8.2 on the following

pages.

If you do not need any strict control with the status transition, follow the procedure given in Chapter 7 "QUICK SETUP GUIDE

FOR RUNNING THE INVERTER."

False (0) True (1)

ON2: Request the inverter

to be ready for turning a run

command ON (1)

following the deceleration

time specified by the

function code H56

ON3: Request the inverter

to be ready for turning a run

command ON (2)

Enable the ramp frequency

generator (RFG)

Unfreeze RFG command

Reset alarm (Resetting an alarm

makes the option unready to turn

a run command ON.)

Enable data entered in the PCD

area (CTW+MRV)

24

Page 27

(2) STW (Status word)

STW is a word area for monitoring the inverter’s running status.

STW indicates the status transition of the PROFIdrive. The status transition details are shown in Figure 8.2.

(bit

) 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

b15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

Table 8.6 Bit Definition in STW

Bit Status False (0) True (1)

b0

Ready to

switch ON

Not ready to turn a run command

ON

Ready to turn a run command

ON

b1 Ready to run Not ready to run Ready to run

b2 Running state Running disabled Running

b3 ALM No inverter trip present Inverter being tripped

b4 ON2/OFF2 OFF2: b1 in CTW is "0" ON2: b1 in CTW is "1"

b5 ON3/OFF3 OFF3: b2 in CTW is "0" ON3: b2 in CTW is "1"

b6

Run command

ON inhibited

Ready to turn a run command

ON

(logical negation of b0)

Not ready to turn a run command

ON

(logical negation of b0)

b7 Not used. --- ---

b8 FAR

b9 R/L

b10 FDT

b11 to

b15

Not used.

Not reached the reference

frequency

Both frequency and run

commands from PROFIBUS are

invalid

Output frequency has not

reached the level specified by

the function code E31

---

Reached the reference

frequency

Either one of frequency and run

commands from PROFIBUS is

valid

Output frequency has reached or

exceeded the level specified by

the function code E31

---

Page 28

Figure 8.2 illustrates a status transition diagram of the PROFIdrive profile.

Immediately after the inverter and this option are turned ON, the status first moves to S1 "Not ready to turn a run command ON." Bit

manipulation in CTW shifts the status to S2 "Ready to turn a run command ON," S3 "Ready to run" and finally S4 "Running" in sequence. In

S4 state, the inverter enters the running state. Turning a run command OFF in S4 state shifts the status to S5 "Turn a run command OFF."

After the motor stops, the status moves to S2 or S1 state.

In Figure 8.2, to simplify the description, values of Bit 4 to Bit 6 and Bit 10 in CTW are always "1." If any one of these bit values is not

"1," the inverter will not enter the running state even if the status transition properly proceeds.

Inverter power ON

S1: Not ready to

STW: xxxx xxxx x1xx x000

OFF and ON2 and ON3

(CTW: xxxx x1xx x111 x110)

S2: Ready to turn

STW: xxxx xxxx x0xx x001

ON

(CTW: xxxx x1xx x111 x111)

S3: Ready to run

STW: xxxx xxxx x0xx x011

Operation enabled, bit 3 = 1

(CTW: xxxx x1xx x111 1111)

turn a run

command ON

(CTW: bit 2 = 0 or bit 3 = 0)

a run command

ON

(CTW: xxxx x1xx x111 x110)

Operation disabled, bit 3 = 0

(CTW: xxxx x1xx x111 0111)

OFF2 or OFF3

OFF

OFF2 or OFF3

(CTW: bit 2 = 0 or bit 3 = 0)

(CTW: xxxx x1xx x111 1101)

Reset alarm

(CTW: bit 7 = 0 to 1 to 0)

Motor stop detected

Operation disabled, bit 3 = 0

(CTW: xxxx x1xx x111 0110)

OFF2 (Coast to stop)

A trip occurs

in any state

or

OFF2 (Coast to stop)

(CTW: xxxx x1xx x111 1100)

Inverter being

tripped

STW: xxxx xxxx xxxx 1000

Motor stop detected

Operation disabled bit 3 = 0

(CTW: xxxx x1xx x111 001x)

OFF2 (Coast to stop)

(CTW: xxxx x1xx x111 110x)

or

or

STW: xxxx xxxx x0xx x111

OFF

(CTW: xxxx x1xx x111 1110)

(CTW: xxxx x1xx x111 1010)

OFF3

(CTW: xxxx x1xx x111 1011)

S4: Running

ON

(CTW: xxxx x1xx x111 1111)

S5: Turn a run

command OFF

Decelerating to

OFF3

stop

Emergency

decelerating to

stop

STW: xxxx xxxx x0xx x011

Note:

1. Bit states

0: False

1: True

x: Don’t care

2.

The underlined bit in CTW is a

trigger bit for status transition.

Figure 8.2 Status Transition Diagram of PROFIdrive Profile

26

Page 29

(3) MRV (frequency command) and MAV (output frequency)

MRV and MAV are word areas for setting a frequency command and monitoring an output frequency, respectively.

MRV: Frequency command word area that sends a frequenc y command from the PROFIBUS DP master node to an inverter (slave node).

MAV: Output frequency monitoring word area t hat returns the current inverter's output frequenc y to the PROFIBUS DP master node as a

response from the inverter (slave node).

In each word, the frequency is expressed relative to the maximum frequency (defined by F01 in Hz) being assumed as 4000hex. The

conversion expression is shown below.

MAV orMRV

(Hz)Frequency

(Hz)F03 code Function

4000hex

(Hz) F03 code Function(Hz)Frequency or

4000hex

MAV orMRV

A negative value is expressed by 2’ s complement of 4000hex. When the inverter is running in the reverse direction, the value of MAV

(output frequency) is a negative value. Setting a negative value to MRV (frequency command) causes even a run forward command

to run the motor in the reverse direction.

(4) PCD1 to PCD4

PCD1 to PCD4 are word areas exclusively supported by PPO type 2 and type 4. They enable cyclic write request and read (monitor)

response to/from up to four inverter’s function codes previously specified for each of PCD1 to PCD4.

Values written and read to/from the specified function codes are in the same data format as defined in individual inverter's function

codes.

For the formats of inverter's function codes, refer to the RS-485 Communication User's Manual (MEH448), Chapter 5, Section 5.2

"Data Formats."

To assign inverter’s function codes to PCD1 to PCD4 words, use function codes o40 to o43 and o48 to o51 as listed in Table 8.7. Table 8.8

on the next page shows how to use these function codes.

Table 8.7 Function Codes to Assign Inverter’s Function Codes to PCD1 to PCD4 Words

PCD area

PCD1 o40

PCD2 o41

Request

(Write a function code)

PCD3 o42

PCD4 o43

PCD1 o48

Response

(Monitor a function

code)

PCD2 o49

PCD3 o50

PCD4 o51

* PNU915 and PNU916 refer to PROFIdrive specific parameters. For details, refer to Section 8.3 (4) "PROFIdrive specific parameters."

Function

codes

Remarks

Also assignable by PNU915, index 1

*

Also assignable by PNU915, index 2

*

Also assignable by PNU915, index 3

*

Also assignable by PNU915, index 4

*

Also assignable by PNU916, index 1

*

Also assignable by PNU916, index 2

*

Also assignable by PNU916, index 3

*

Also assignable by PNU916, index 4

*

For details of assignment of inverter’s function codes using function codes o40 to o43 and o48 to o51, refer to the descriptions on the

next page.

Page 30

To assign an inverter ’s function code to PCD1 to PCD4 word areas using function codes o40 to o43 and o48 to o51, enter four digit

hexadecimals to specify the function code group and number as listed in Table 8.8.

Function code # in hexadecimal

Function code group (Table 8.8)

• Inverter’s communication-related function codes S01 and S05 act as a reading specific code in this interface option. Therefore,

assigning these codes to a PCD word area as a write request will be ignored.

Bits in the function code S06 are writable except bit 0 and bit 1. Data written in bit 0 and bit 1 will be ignored.

For details about inverter’s communication-related function codes S01, S05 and S06, refer to the RS-485 Communication User's

Manual (MEH448), Chapter 5, Section 5.1 "Communications Dedicated Function Codes."

Table 8.8 Function Code Group Conversion Table

Function

code

group

Group

number

S 2 02hex

M 3 03hex

F 4 04hex

E 5 05hex

C 6 06hex

P 7 07hex

H 8 08hex

Function code name

Command/function

data

Monitor data

Fundamental

functions

Extension terminal

functions

Control functions

Motor parameters 1

High performance

functions

Function

code

group

Group

number

o 10 0Ahex

J 14 0Ehex

y 15 0Fhex

W 16 10hex

X 17 11hex

Z 18 12hex

--- --- ---

Function code name

Option functions

Application functions

Link functions

Monitor data 2

Alarm 1

Alarm 2

---

F Function code group 04hex Example for F26

26 Function code number 1Ahex

"041A"

• After setting up function codes o40 to o43 and o48 to o51, turn the inverter and this option OFF and ON to validate the new setting.

• If a same function code is assigned to the PCD areas using function codes o40 to o43, the function code assigned by the o code

with the youngest number takes effect and other assignments will be ignored.

28

Page 31

8.3 PCV Word Area

The PCV word area controls an on-demand access to parameters (inverter’s function codes and PROFIdrive specific parameters). It is

supported by PPO type 1 and type 2. Its structure is shown below.

(W

ord) 1 2 3

PCV word PCA IND

4

PVA

(H) (L)

Figure 8.3 Structure of PCV Word Area

(1) PCA and IND

These two word areas specify a parameter. Their structures are shown below.

(bit) 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

PC

A

RC SPM PNU

(bit) 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

IND Subindex Not used.

RC: Request code/response code (See Table 8.9.)

SPM: Not used. Fixed at "0."

PNU: Parameter number to be accessed

Subindex: Inverter’s function code number (numeric following a function code group) or an index number of array PROFIdrive specific

parameters.

To specify an inverter ’s function code, use PNU and Subindex areas. Enter "Function code group + 100hex" (see Table 8.8) to the

PNU area, and the function code number to the Subindex area.

For how to specify and read/write an inverter’s function code, refer to Section 8.3 (3) "Access to inverter ’s function codes and

PROFIdrive specific parameters."

Table 8.9 RC Part

RC part Request/response Descriptions

0 No request

1 Read parameter value

Request

(Master Slave)

2 Write parameter value in word

3 to 5 Not used.

6 Read array parameter value

7 Write array parameter in array word

8 Not used.

9 Read element count of array parameter

10 to 15

0 No response

1 Parameter value in word sent normally

Response

(Slave Master)

Not used.

2, 3 Not used.

4 Parameter value in array word sent normally

5 Not used.

6 Normal response to the request of array element count

7 Transmission error (Error code stored in PVA)*

8 to 15

Not used.

* For error codes and information, see Table 8.10.

Page 32

Table 8.10 List of Error Codes for Parameter Access Errors

RC part

Error code

stored in PVA

Error information

word

7 0 Nonexistent parameter specified

1 Parameter value writing inhibited

2 Specified parameter value out of range

3 Invalid Subindex specified

4 Specified parameter not array

11

Parameter write-protect error during inverter running or

digital input terminal (for run command) being ON

17 Read process not executable

101 Link priority error

104 Busy error during parameter writing

(2) PVA word area

PVA is a two-word area that represents write/read parameter values. This interface option uses the lower one word (the fourth word counted

from the PCV word head).

To write a parameter value into an inverter (slave node), enter the value to the master node and se nd the word to the slave. To read a

parameter value, refer to this area of the slave node in response to the previous request. If a parameter access error occurs (Response to

RC part is "7"), the slave node outputs an error code (Table 8.10) to this area and returns the response to the master node.

(bit) 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

PVA

(H)

Not used.

(bit) 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

PVA

(L)

Write/read parameter value or error code (See Table 8.10.)

30

Page 33

(3) Access to inverter’s function codes and PROFIdrive specific parameters

1) Specify the target parameter to be accessed using PNU and Subindex areas (see Figure 8.4).

When specifying an inverter's function code, enter the numeral of "Function code group number + 100hex" (see T able 8.8) to the PNU

area, and "Function code number" to the Subindex area. For example, enter "104 01" for F01.

2) Specify how to access the specified parameter, for example, Write or Read, in the RC area. For details about the RC area, see Table

8.9.

3) To write a parameter value, enter the write data into the PVA lower area and send the word to the salve node. To read a parameter

value from the slave, refer to the PVA lower area in the response from the slave node. If a parameter access error occurs, the RC part

of the response is filled with "7" and the PVA area contains one of the error codes listed in Table 8.10.

Inverter’s communication-related function codes S01 and S05 act as a reading specific code in this interface option. Therefore,

assigning these codes to a PCD word area as a write request will be ignored.

Bits in the function code S06 are writable except bit 0 and bit 1 (FWD and REV commands). Data written in bit 0 and bit 1 will be

ignored.

For details about inverter’s communication-related function codes S01, S05 and S06, refer to the RS-485 Communication User's

Manual (MEH448), Chapter 5, Section 5.1 "Communications Dedicated Function Codes."

Values written and read to/from the specified function codes are in the same data format as defined in individual inverter's function

codes. For the formats of inverter's function codes, refer to the RS-485 Communication User's Manual (MEH448), Chapter 5, Section

5.2 "Data Formats."

(bit) 15 12 10 8 7 0

PCA

RC

(See Table

8.9.)

0 PNU

For an inverter’s function code:

Function code group number + 100hex (See

Table 8.8.)

For PROFIdrive specific parameter:

PNU number (See Table 8.11.)

t) 1

(bi

8 7 0

5

IND Subindex Not used. Fixed at 00hex.

For an inverte

Function code number

For array PROFIdrive specific parameter:

Index number (S ee Table 8.11.)

r’s function code:

(bit) 1

5 87 0

PVA

H) (

Not used. Fixed at 0000hex

(bit) 1

PVA

(L)

The actual parameter access examples are given on the following pages.

87 0

5

Write/read parameter value or error code

(S e Table 8.10.)e

Figure 8.4 How to Access Parameters

Page 34

Example 1: Writing data "15" to the inverter’s function code F26

1) Send the request to write data "15" to the inverter’s function code F26, from the master node to the slave node (inverter)

RC = 2hex Write parameter value (word).

PNU = 104hex, Subindex = 1Ahex Specify F26 (Function code group number 04h + 100hex = 104hex,

Function code number = 1Ahex).

PVA=0000 000F(hex) Enter parameter value 15 (= 000Fhex).

(bit) 1

Request

(Master

Slave)

PVA (H) (Fixed at 0000hex)

PVA (L) 000Fhex

5 87 0

PC

2hex 104hex

A

IND 1Ahex (Fixed at 00hex)

2) Response example sent from the option (normal response from the slave node)

RC = 1hex Requested parameter value is normally returned.

PNU = 104hex, Subindex = 1Ahex Accessed parameter is function code F26.

PVA = 0000 000Fhex Parameter value written is 15.

Response

(Slave

Master)

(bit) 1

5 87 0

PC

1hex 104hex

A

IND 1Ahex (Fixed at 00hex)

PVA

(H)

(Fixed at 0000hex)

PVA (L) 000Fhex

3) Response example for the write data error (Specified parameter value out of range)

RC = 7hex Parameter value transmission error.

PNU = 104hex, Subindex = 1Ahex Accessed parameter is function code F26.

PVA = 0000 0002hex Error code 2 (Specified parameter value out of range)

Response

(Slave

Master)

)

(bit) 1

5

PC

A

121

87 0

1

7hex 104hex

IND 1Ahex (Fixed at 00hex)

PVA

(H)

(Fixed at 0000hex

PVA (L) 0002hex

32

Page 35

Example 2: Reading (monitoring) data from the inverter’s function code y98

1) Send the request to read data from the function code y98, from the master node to the slave node.

RC = 1hex Read parameter value.

PNU = 10Fhex, Subindex = 62hex Specify y98 (Function code group number 0Fhex + 100hex =

10Fhex, Function code number = 62hex)

PVA = 0000 0000hex No entry required for PVA.

(bit) 1

Request

(Master

Slave)

PVA (L) 0000hex

5 87 0

PC

1hex 10Fhex

A

IND 62hex (Fixed at 00hex)

PVA

(H)

(Fixed at 0000hex)

2) Response example sent from the option (normal response from the slave node)

RC = 1hex Requested parameter value is normally returned.

PNU = 10Fhex, Subindex = 62hex Accessed parameter is function code y98.

PVA = 0000 0003hex Parameter value read is 3.

Response

(Slave

Master)

IND

PVA (H)

PVA (L)

PC

A

(bit) 1

87 0

5

1hex 10Fhex

62hex (Fixed at 00hex)

(Fixed at 0000hex)

0003hex

3) Response example for the read data error (Specified function code does not exist)

RC = 7hex Parameter transmission error.

PNU = 10Fhex, Subindex = 64hex Accessed parameter is function code y100.

PVA = 0000 0000hex Error code 0 (Nonexistent parameter specified)

Response

(Slave

Master)

IND

PVA (H)

PVA (L)

(bit) 1

PC

A

87 0

5

7hex 10Fhex

64hex (Fixed at 00hex)

(Fixed at 0000hex)

0000hex

Page 36

Example 3: Reading from an array PROFIdrive specific parameter PNU947 (Alarm history)

1) Send the request to read PNU947 from the master node to the slave node. The example below reads Index 1.

RC = 6hex Read an array parameter.

PNU = 3B3hex, Subindex = 1hex Specify PNU947 (= 3B3hex) and Index 1.

PVA = 0000 0000hex No entry required for PVA.

Request

(Master

Slave)

IND

PVA (H)

PVA (L)

PC

A

(bit) 1

87 0

5

6hex 3B3hex

01hex (Fixed at 00hex)

(Fixed at 0000hex)

0000hex

2) Response example sent from the option (normal response from the slave node)

RC = 4hex Requested array parameter value is normally returned.

PNU = 3B3(hex), Subindex = 01 hex Accessed parameter is PNU947 (=3B3hex), Index 1.

PVA = 0000 7511hex Parameter value read is 7511hex,

PROFIBUS communications error er5

For the values of PNU947, refer to Chapter 10 " LIST OF INVERTER ALARM CODES."

(bit) 1

Response

(Slave

Master)

IND

PVA

PVA (L)

5 87 0

PC

A

4hex 3B3hex

01hex (Fixed at 00hex)

(H)

(Fixed at 0000hex)

7511hex

3) Response example for the read data error (Accessed parameter cannot be read as an array parameter.)

RC = 7hex Parameter transmission error.

PNU = 3B3hex, Subindex = 01hex Accessed parameter is function code y100.

PVA = 0000 0003hex Error code 3 (Invalid Subindex specified)

(bit) 1

Response

(Slave

master)

IND 1Ah x e (Fixed at 0h x) 0 e

PVA

PVA (L) 0003hex

5 87 0

PC

A

(H)

7hex 3B3hex

(Fixed at 0000hex)

34

Page 37

(4) PROFIdrive specific parameters

Table 8.11 lists PROFIdrive specific parameters supported by this option. PNUs with descriptions in the index column are array parameters.

Table 8.11 List of PROFIdrive Specific Parameters

PN

Index Description Range

U

915 1 to 4

Function code assignment to PCD1

to PCD4 (Request)

0000 to

FFFFhex R/W

R/

W

Remarks

Same as o40 to o43.

(Write function code data)

916 1 to 4

Function code assignment to PCD1

to PCD4 (Response)

0000 to

FFFFhex R/W

Same as o48 to o51.

(Read/monitor function code data)

918 None Node (station) address 0 to 125 R

927 None Access permission to PCV area

0: Inhibit to write

1: Permit to write

947 1 Malfunction history (Latest)

9 Malfunction history (Last)

17 Malfunction history (2nd last)

25 Malfunction history (3rd last)

Other

above

than

the

Fixed to 0.

Current baud rate 963 None

0: Not

specified

2: 19.2 Kbps

4: 93.75 Kbps

6: 500 Kbps

8: 3 Mbps

10: 12 Mbps

1: 9.6 Kbps

3: 45.45 Kbps

5: 187.5 Kbps

7: 1.5 Mbps

9: 6 Mbps

0 or 1

Depends

on errors

listed in

Table

10.1.

0 to 10 R

965 None PROFIdrive version Fixed to 2 R

967 None Last CTW sent

968 None Latest STW

970 None

Initialize the inverter

(Changing from "1" to "0" triggers

the initialization.)

0000 to

FFFFhex

0000 to

FFFFhex

0 or 1

R/W Once writing is

inhibited, this PNU

only is writable.

Indicated by

R

PROFIdrive

malfunction codes

whose data formats

differ from the ones

of inverter’s alarm

codes defined by

inverter's function

codes M16 to M19.*

Shows PROFIdrive

V2.

R

R

R/W Functionally

equivalent to H03.

* For the relationship between the malfunction codes and alarm codes, refer to Chapter 10 " LIST OF INVERTER ALARM CODES."

Page 38

Chapter 9 INVERTER REACTION TO PROFIBUS COMMUNICA TIONS ERRORS

The PROFIBUS DP master node can be equipped with a watchdog timer (WDT) that detects communications timeout for monitoring the

communications status. If this option receives no response within the WDT timeout length, it interprets the timeout state as an occurrence of

a communications error.

Inverter's function codes o27 and o28 specify the inverter reaction to be taken after such an error occurrence. (See Table 9.1.)

For the setup of WDT in the PROFIBUS DP master equipment, see the user’s manual of your master equipment.

For the error indication on the option at the time of a communications error, see Chapter 2, Section 2.5 "Status Indicator LEDs."

If a communications error occurs immediately after the inverter and this option are powered on, no er5 trip will be issued. The er5 trip

is issued when a communications error is detected after once the option received data normally.

Table 9.1 Inverter Reaction to PROFIBUS DP Communications Errors Using Function Codes o27 and o28

o27 data o28 data

0,

4 to 9

1 0.0 s to 60.0 s

2 0.0 s to 60.0 s

3,

13 to 15

10 Invalid

11 0.0 s to 60.0 s

12 0.0 s to 60.0 s

Invalid

Invalid

Inverter reaction to PROFIBUS DP

communications errors

Immediately coast to a stop and trip with

er5.

After the time specified by o28, coast to a

stop and trip with er5.

If the inverter receives any data within the

time specified by o28, ignore the

communications error. After the timeout,

coast to a stop and trip with er5.

Keep the current operation, ignoring the

communications error.

(No er5 trip)

Immediately decelerate to a stop. Issue

er5 after stopping.

After the time specified by o28,

decelerate to a stop. Issue er5 after

stopping.

If the inverter receives any data within the

time specified by o28, ignore the

communications error. After the timeout,

decelerate to a stop and trip with er5.

Remarks

During the

communications error

state, the LED

displays the abnormal