Page 1

Instruction Manual

Digital Interface Option "OPC-E1-DIO"

Thank you for purchasing our digital interface option.

• Read through this instruction manual and be familiar with the digital interface option before

proceeding with installation, connections (wiring), operation, or maintenance and inspection.

• Improper handling might result in incorrect operation, a short life, or even a failure of this

product as well as the motor.

• Deliver this manual to the end user of this product. Keep this manual in a safe place until this

product is discarded.

Fuji Electric Systems Co., Ltd. INR-SI47-1285-EU REV 052010

Page 2

Copyright © 2008 Fuji Electric FA Components & Systems Co., Ltd.

All rights reserved.

No part of this publication may be reproduced or copied without prior written permission from Fuji Electric FA Components & Systems Co.,

Ltd.

All products and company names mentioned in this manual are trademarks or registered trademarks of their respective holders.

The information contained herein is subject to change without prior notice for improvement.

Page 3

Preface

Thank you for purchasing our digital interface option.

Mounting the digital interface option on your FRENIC-Multi makes it possible to specify frequency commands with binary code ( 8 or 12

bits) or BCD (4-bit Binary Coded Decimal) code. It also enables monitoring with 8-bit binary code.

This instruction manual does not contain inverter handling instructions. Read through this instruction manual in conjunction with the

FRENIC-Multi Instruction Manual and be familiar with proper handling and operation of this product. Improper handling might result in

incorrect operation, a short life, or even a failure of this product.

Keep this manual in a safe place.

Safety precautions

Read this manual thoroughly before proceeding with installation, connections (wiring), operation, or maintenance and inspection. Ensure

you have sound knowledge of the device and familiarize yourself with all safety information and precautions before proceeding to operate

the inverter.

Safety precautions are classified into the following two categories in this manual.

Failure to heed the information indicated by this symbol may lead to dangerous conditions, possibly

resulting in death or serious bodily injuries.

Failure to heed the information indicated by this symbol may lead to dangerous conditions, possibly

resulting in minor or light bodily injuries and/or substantial property damage.

Failure to heed the information contained under the CAUTION title can also result in serious consequences. These safety precautions are

of utmost importance and must be observed at all times.

i

Page 4

Installation and wiring

• Before starting installation and wiring, turn the inverter's power OFF and wait at least five minutes. Further, check with a

multimeter or the similar instrument that the DC link bus voltage between the P (+) and N (-) terminals is lower than 25 VDC.

• Qualified electricians should carry out wiring.

Otherwise, an electric shock could occur.

• Do not use the product that is damaged or lacking parts.

Doing so could cause a fire, an accident, or injuries.

• Prevent lint, paper fibers, sawdust, dust, metallic chips, or other foreign materials from getting into the inverter and the option.

Otherwise, a fire or an accident might result.

• Incorrect handling in installation/removal jobs could cause a failure.

A failure might result.

• Noise may be emitted from the inverter, motor and wires. Implement appropriate measure to prevent the nearby sensors and

devices from malfunctioning due to such noise.

Otherwise, an accident could occur.

Operation

• Be sure to install the terminal cover and option terminal cover before turning the inverter's power ON. Do not remove the cover

when the inverter power is ON.

Otherwise, an electric shock could occur.

• Do not operate switches with wet hands.

Doing so could cause an electric shock.

• If you set the function codes wrongly or without completely understanding the FRENIC-Multi Instruction Manual and the

FRENIC-Multi User's Manual, the motor may rotate with a torque or at a speed not permitted for the machine. C onfirm and

adjust the setting of the function codes before running the inverter.

Otherwise, an accident could occur.

ii

Page 5

Maintenance and inspection, and parts replacement

• Before proceeding to the maintenance/inspec tion jobs, turn the inverter's power OFF and wait at least five minutes. Further,

check with a multimeter or the similar instrument that the DC link bus voltage between the P (+) and N (-) terminals is lower than

25 VDC.

Otherwise, an electric shock could occur.

• Maintenance, inspection, and parts replacement should be made only by qualified persons.

• Take off the watch, rings and other metallic objects before starting work.

• Use insulated tools.

Otherwise, an electric shock or injuries could occur.

Disposal

• Treat the interface card(s) as an industrial waste when disposing of it.

Otherwise injuries could occur.

Others

• Never modify the interface option(s).

Doing so could cause an electric shock or injuries.

iii

Page 6

Icons

The following icons are used throughout this manual.

This icon indicates information which, if not heeded, can result in the product not operating to full efficiency, as well as information

concerning incorrect operations and settings which can result in accidents.

This icon indicates information that can prove handy when performing certain settings or operations.

This icon indicates a reference to more detailed information.

Table of Contents

Preface .............................................i

Safety precautions.................................. i

Chapter 1 BEFORE USING THE

INVERTER........................................1-1

1.1 Acceptance Inspection............. 1-1

1.2 Applicable Inverters ................. 1-1

1.3 Installation of the Interface Option1-2

1.4 Wiring for the Interface Option.1-6

1.5 Terminal Allocation of Interface Option

PCB..........................................1-7

Chapter 2 WIRING............................2-1

2.1 Connection Diagram ................ 2-1

2.2 Terminal Functions................... 2-2

2.3 Electrical Specifications ........... 2-2

2.4 Input Interface .......................... 2-3

2.4.1 Switching between SINK and

SOURCE for digital input terminals

([I1] to [I12] and [SEL]).......2-3

2.4.2 Connection diagrams for

SINK/SOURCE input

modes..........................................2-3

2.4.3 Precaution on the use of a contact

relay....................................2-4

2.5 Output Interface ....................... 2-4

Chapter 3 CONFIGURING INVERTER'S

FUNCTION CODE...........3-1

Chapter 4 DETAILS OF FUNCTION

CODES .......................................4-1

Chapter 5 I/O CHECKING ................5-1

Chapter 6 PROTECTIVE FUNCTION6-1

iv

Page 7

Chapter 1 BEFORE USING THE INVERTER

1.1 Acceptance Inspection

Unpack the package and check the following:

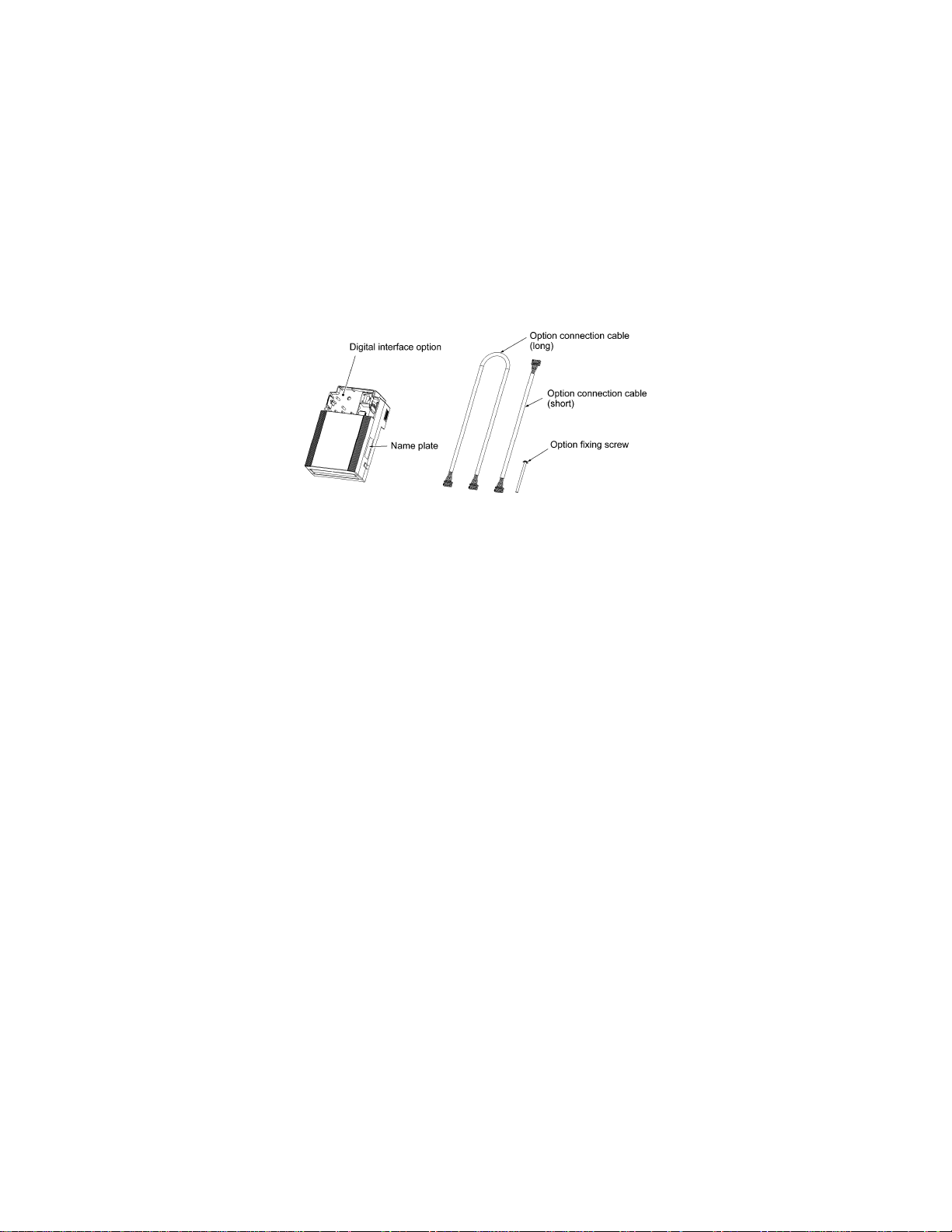

(1) A digital interface option and the following accessories are contained in the package. (See Figure 1.1.)

- Two option connection cables

(A short one for inverters with a capacity of 5 HP or below and a long one for inverters with a capacity of 7.5 HP or above)

- One option fixing screw

- Digital Interface Option Instruction Manual (this manual)

(2) The interface option and accessories have not been damaged during transportation—there should be no dents or parts missing.

(3) The model name "OPC-E1-DIO" is printed on the nameplate attached to the right side of the interface option. (See Figure 1.1.)

If you suspect the product is not working properly or if you have any questions about your product, contact your Fuji Electric representative.

Figure 1.1 Digital Interface Option and Accessories

1-1

Page 8

1.2 Installation of the Interface Option

Turn the inverter's power OFF and wait for at least five minutes. Further, check that the DC link bus voltage between

the P (+) and N (-) terminals is lower than 25 VDC.

Otherwise, electric shock could occur.

• Do not use the product that is damaged or lacking parts.

Doing so could cause a fire, accident, or injury.

• Prevent lint, paper fibers, sawdust, dust, metallic chips, or other foreign materials from getting into the inverter

and the interface option.

Otherwise, a fire or an accident might result.

• Incorrect handling in installation/removal jobs could cause a failure.

A failure might result.

When handling the interface option, take any antistatic measure or hold the plastic parts taking care not to directly touch the circuit board;

otherwise, the static electricity charged in your body may damage it.

1-2

Page 9

Before mounting the interface option, perform the wiring for the main circuit terminals and control circuit terminals on the inverter.

(1) Remove the terminal cover from the inverter.

Note: For inverters with a capacity of 7.5 to 20 HP, you need to remove the terminal cover fixing screw to remove the terminal cover.

For details on how to remove the terminal cover, refer to the FRENIC-Multi Instruction Manual (INR-SI47-1204-E), Chapter 2,

Section 2.3 "Wiring."

(2) Connect the option connection cable to the CN1 connector on the interface printed circuit board (interface PCB) on the inverter.

Use the short cable for inverters with a capacity of 5 HP or below, and the long cable for the ones with a capacity of 7.5 HP or above.

(3) Mount the terminal cover.

For details on how to mount the terminal cover, refer to the FRENIC-Multi Instruction Manual, Chapter 2, Section 2.3 "Wiring."

(4) Push the hooks provided on both sides of the keypad and pull the keypad up and out of the inverter.

For details on how to remove the keypad, refer to the FRENIC-Multi Instruction Manual, Chapter 2, Section 2.4 "Mounting and

Connecting a Keypad."

Terminal cover

fixing screw

(for inverters with a

acity of 7.5 to 20 HP)

cap

Figure 1.2 Connecting the Option Connection Cable to the Interface PCB and

Removing the Keypad (For inverters with a capacity of 15 and 20 HP)

1-3

Page 10

(5) Mount the interface option on the inverter, making the RJ-45 connector on the back side of the option engage with the RJ-45 connector on

the inverter (to which the keypad had been connected).

(6) Connect the keypad to the RJ-45 connector on the front side of the interface option, then secure the ke ypad and interface option to the

inverter with the option fixing screw (that comes with the interface option).

When using the keypad at a remote site, secure the interface option without the keypad to the inverter with the screw.

Tightening torque: 0.6 N·m(0.4 lbf·ft)

Take care not to tighten the option fixing screw too much. Doing so could make the screw defective.

Figure 1.3 Mounting the Digital Interface Option and the Keypad

1-4

Page 11

(7) Slightly pull the bottom of the option terminal cover towards you and remove it downward.

(8) Connect the other end of the option connection ca ble (whose end has been connected to the interface PCB on t he inverter in step (2 )

above) to the CN1 connector on the interface option printed circuit board (interface option PCB).

(9) Mount the option terminal cover.

First fit the bosses on the top of the cover into the square holes provided in the interface option, and then push the bo ttom of the cover

until it snaps into place.

Figure 1.4 Connecting the Option Connection Cable to the Interface Option PCB

1-5

Page 12

1.3 Wiring for the Interface Option

• Before starting installation, turn off the power to the inverter and wait for at least five minutes. Further, check the DC link circuit

voltage between the P (+) and N (-) terminals to be lower than 25 VDC.

• Qualified electricians should carry out wiring.

Otherwise, electric shock could occur.

The inverter, motor, and wiring emit electrical noise. Take appropriate measures to prevent the nearby sensors and devices from

malfunctioning due to such noise.

Otherwise, an accident could occur.

Perform wiring for the interface card observing the precautions below. Refer to the connection diagrams shown in Figure 2.1 in Chapter 2.

(1) Turn the inverter's power OFF.

(2) Use shielded wires.

(3) To prevent malfunction due to noise, keep the wiring for the interface option PCB away from the main circuit wiring and other power lines

as far as possible (at least 10 cm). Never install them in the same wire duct.

(4) Complete wiring before turning the inverter ON.

(5) The wire size applicable to the terminals on the interface option is AWG24 to AWG18(0.20 mm

When using stripped w ires (without att a ching a crimp terminal), strip the wire end by 5 to 7 mm(0.2 to 0.28 in) (Figure 1.5) When using a

crimp terminal, attach a vinyl-insulated ferrule.

Loosen the terminal screw, insert the wire end into above the metal part of the terminal block, and tighten the screw to fasten it. (Figure

1.6)

Approx.

6.0 mm(0.24 in)

Figure 1.5 Wire End Treatment

(For Connection to Terminals

on Interface Option)

Figure 1.6 Connecting to a Terminal

on Interface Option

Recommended wire: AWG24 to AWG18(0.20 mm2 to 0.82 mm2 ), with rated temperature 105C(221 F) (UL)

2

to 0.82 mm2 )

1-6

Page 13

1.4 Terminal Allocation on the Interface Option PCB

M1 SEL I11 I9 I7 I5 I3 I1 O8 O6 O4 O2

CM I12 I10 I8 I6 I4 I2 CM M2 O7 O5 O3 O1

* Screw size: M2

* Tightening torque: 0.22 to 0.25 N・m(0.16 to 0.18 lbf・ft)

Figure 1.7 Terminal Allocation on the Interface Option PCB

1-7

Page 14

Chapter 2 WIRING

2.1 Connection Diagram

PLC

CM

M1

CM

24 VDC

Figure 2.1 Connection Diagram

2-1

Page 15

2.2 Terminal Functions

Table 2.1 lists terminal symbols, names and functions of the terminals on the digital interface option.

Table 2.1 Terminals and Their Specifications

Terminal

symbol

Name Functions

[I1] to [I12] Input terminals For entry of frequency commands

[SEL] Input terminal For entry of Hold signal

[M1]

[CM]

External power supply for

input terminal

Common terminal for

input

For external power supply for frequency

command input

Common terminal for frequency

command input

[O1] to [O8] Output terminals For monitoring

[M2]

Common terminal for

output

For monitoring

2.3 Electrical Specifications

Table 2.2 lists the electrical specifications for the digital interface option.

Table 2.2 Electrical Specifications

Termin

al

symbo

l

[I1]

to

[I12],

SEL

[O1]

to

[O8]

Item

Symb

ol

Conditions

Input voltage at ON VIL Vcc = 22 V 0 V - 2 V

Vcc = 24 V VIL = 0

Output current at

ON

V

IIL

Vcc = 27 V VIL = 0

V

Output voltage at

SINK mode

OFF

Leakage current at

OFF

VIH 22 V 24 V 27 V

IIH - - 0.5 mA

Input voltage at ON VIL 22 V 24 V 27 V

Input voltage at OFF VIH 0 V 1 V 5 V

Vcc = 24 V VIL = 0

Input current at ON IIL

SOURCE mode

V

Vcc = 27 V VIL = 0

V

SINK current at ON IOL Vo = 27 V - - 50 mA

Output voltage at

ON

Output voltage at

OFF

SINK mode

Leakage current at

OFF

SOURCE current at

ON

Output voltage at

ON

Output voltage at

OFF

SOURCE mode

Leakage current at

OFF

VOL IOL = 50 mA - 2 V 3 V

VOH -

IOH Vo = 24 V - - 0.5 mA

IOL Vo = 27 V - -

VOL IOL = -50 mA - 2 V 3 V

VOH -

IOH Vo = 24 V - -

Specifications

Min. Typical Max.

- 3.2 mA -

- - 4.5 mA

- 3.2 mA -

- - 4.5 mA

24

VDC

24

VDC

27

VDC

-50

mA

27

VDC

-0.5

mA

2-2

Page 16

Input Interface

2.3.1 Switching between SINK and SOURCE for digital input terminals ([I1] to [I12] and [SEL])

The input mode is switchable between SINK and SOURCE for digital input terminals ([I1] to [I12] and [SEL]) by using the slide switch SW11

on the interface option PCB (Figure 1.7 in Chapter 1). Specify the input mode referring to Table 2.3 below.

Table 2.3 Configuration of Slide Switch SW11

Input mode Slide switch position

SINK (factory

default)

SOURCE

SINK side

SOURCE

side

SINK SOURCE

SINK SOURCE

2.3.2 Connection diagrams for SINK/SOURCE input modes

Table 2.4 shows connection diagrams for input interface circuits.

supply

Power

Table 2.4 Connections of Input Interface Circuits

Connection diagram

SINK mode SOURCE mode

Internal

External

24 V

[PLC ]

[M1]

[I1] to [I 12],

[SEL]

[CM ]

[CM]

[CM]

[I1 ] to [I 12],

[SEL]

[CM]

FR ENIC -M ulti

24 to 27 VDC

Common

[M1]

SINK

SOURCE

SINK

SOURCE

Digi ta l in te rface

option

CM

Digital interface

option

CM

24 V

[M1]

[I1] to

[I12],

[SEL]

[CM]

[CM]

[M1]

[I1] to

[I12],

[SEL]

[CM]

24 to 27 VDC

SINK

SOURCE

Common

Digital interface

option

CM

SINK

SOURCE

Digital interface

option

CM

FRENIC- Multi

[PLC]

2-3

Page 17

2.3.3 Precaution on the use of a contact relay

To configure input circuits using contact relays, use highly reliable relays.

2.4 Output Interface

Table 2.5 shows connection diagrams for output interface circuits.

Connection diagram

SINK mode

SOURCE mode

Table 2.5 Connections of Output Interface Circuits

24 V

24 V

[M2]

[O1] to

[O8]

[O1] to

[O8]

[M2]

Digital interface

option

Digital interface

option

The output interface circuit should be configured with an external power supply. In the SINK mode, the positive (+) side of the external power

supply should be connected to terminal [M2] on the interface option, and in the SOURCE mode, the negative (-) side.

2-4

Page 18

Chapter 3 CONFIGURING INVERTER'S FUNCTION CODE

Tables 3.1 and 3.2 list the function code and its parameters.

Table 3.1 Definition of Frequency Command Sources (Input)

Function

code

F01

(C30)

o20 Select input

Note: Terminal [SEL] comes to be exclusive to Hold signals. When SEL = 0, the interface option receives input data (I1 to I12).

Function

code

o21

(Note 1) Output frequency monitor = (Output frequency / Maximum frequency) 255

(Note 2) Output current monitor = (Output current / (Inverter's rated output current 2)) 255

(Note 3) Output voltage monitor = (Output voltage / 250 V) 255: For 200 V class series

= (Output voltage / 500 V) 255: For 400 V class series

(Note 4) Output torque monitor = (Output torque / (Motor rated torque 2) 255

(Note 5) Load factor monitor = (Load factor / (Motor rated load 2)) 255

(Note 6) Input power monitor = (Input power / (Inverter's rated output 2)) 255

(Note 7) PID feedback amount monitor = (PID feedback amount / Feedback amount 100%) 255

(Note 8) DC link bus voltage monitor = (DC link bus voltage / 500 V) 255: For 200 V class series

= (DC link bus voltage / 1000 V) 255: For 400 V class series

(Note 9) Motor output monitor = (Motor output / (Motor rated output 2)) 255

(Note 10)PID command (SV) monitor = (PID command / Feedback amount 100%) 255

(Note 11)PID output (MV) monitor = (PID output / Maximum frequency) 255

(Note 12)Terminal output signals RUN, FDT, FAR, LU, OL, IPF (assigned to the general-purpose programmable output terminals) are issued

If the monitored value exceeds 100%, "11111111 (255)" is output.

individually as bit information. For details of bit information (output bit position), refer to Table 4.2 in Chapter 4 "DETAILS OF

FUNCTION CODES."

Name Data Description Remarks

Frequency

Command 1

(Frequency

Command 2)

mode

Name Data Monitoring item Remarks

Select

output

mode

Other

than 11

Table 3.2 Monitor Items Selectable (Output)

Frequency command sourced from the digital

11

interface option

Frequency command specified by function codes

0 8-bit, binary frequency command

1 12-bit, binary frequency command

4 3-digit, BCD frequency command (0 to 99.9 Hz)

5 3-digit, BCD frequency command (0 to 999 Hz)

BCD: Binary Coded Decimal

Output frequency (before slip

0

compensation)

Output frequency (after slip

1

compensation)

Output current

2

Output voltage

3

Output torque

4

Load factor

5

Input power

6

PID feedback amount

7

DC link bus voltage

9

Motor output

13

PID command (SV)

15

PID output (MV)

16

Individual signal output (Note 12)

99

100%/8-bit (Note

1)

100%/8-bit (Note

1)

200%/8-bit (Note

2)

100%/8-bit (Note

3)

200%/8-bit (Note

4)

200%/8-bit (Note

5)

200%/8-bit (Note

6)

100%/8-bit (Note

7)

100%/8-bit (Note

8)

200%/8-bit (Note

9)

100%/8-bit (Note

10)

100%/8-bit (Note

11)

(Note)

3-1

Page 19

Chapter 4 DETAILS OF FUNCTION CODES

Tables 4.1 and 4.2 show the configuration of function codes o19 and o20 and the details of the terminal functions.

Table 4.1 Definition of Frequency Command Sources (Input)

Functi

on

code

o20

Input signal

Data

name

0 8-bit binary

frequency

command

1 12-bit

binary

frequency

command

4 3-digit BCD

frequency

command

(0 to 99.9

Hz)

5 3-digit BCD

frequency

command

(0 to 999

Hz)

Terminal function and configuration details

MSB

SEL

I12 I11 I10 I9 I8 I7 I6 I5 I4 I3 I2 I1

Invalid

Hold signal

When SEL = 0, data update is available.

When SEL = 1, data update is not available.

Frequency command

LSB

(1) Setting resolution = Specified maximum frequency (1/255)

(2) Upper/lower limiters are given priority..

MSB

I12 I11 I10 I9 I 8 I7 I6 I5 I4 I3 I2 I1

SEL

Frequency command

Hold signal

When SEL = 0, data update is available.

When SEL = 1, data update is not available.

LSB

(1) Setting resolution = Specified maximum frequency (1/4095)

(2) Upper/lower limiters are given priority..

Tenth place

of Hz

LSB

MSB

I12 I11 I10 I9 I8 I7 I6 I5 I4 I3 I2 I1

SEL

Tens place

of Hz

Hold signal

When SEL = 0, data update is available.

When SEL = 1, data update is not available.

Units place

of Hz

(1) Frequency can be specified within the range of 0 to 99.9 Hz (Setting

resolution = 0.1 Hz).

(2) Upper/lower limiters are given priority..

(3) If a frequency command exceeding the maximum f requency is input,

the maximum frequency is output.

MSB

I12 I11 I10 I9 I8 I7 I6 I5 I4 I3 I2 I1

SEL

Hundreds place

of Hz

Hold signal

When SEL = 0, data update is available.

When SEL = 1, data update is not available.

Tens place

of Hz

Units place

of Hz

LSB

(1) Frequency can be specified within the range of 0 to 999 Hz (Setting

resolution = 1 Hz).

(2) Upper/lower limiters are given priority..

(3) If a frequency command exceeding the maximum f requency is input,

the maximum frequency is output.

4-1

Page 20

Table 4.2 Monitor Items Selectable (Output)

Functi

on

Data

code

o21 0 Output

Output signal

name

frequency

(before slip

compensatio

n)

1 Output

frequency

(after slip

compensatio

n)

2 Output

current

Terminal function and configuration details

LSBMSB

O1O2O3O4O5O6O7O8

100% of maximum frequency /8 bits

LSBMSB

O1O2O3O4O5O6O7O8

100% of maximum frequency /8 bits

LSBMSB

O1O2O3O4O5O6O7O8

200% of inverter's rated output current / 8 bits

3 Output

voltage

LSBMSB

O1O2O3O4O5O6O7O8

100% of 250 V / 8 bits: 200 V class series

100% of 500 V / 8 bits: 400 V class series

4 Output torque

LSBMSB

O1O2O3O4O5O6O7O8

200% of motor rated torque / 8 bits

5 Load factor

LSBMSB

O1O2O3O4O5O6O7O8

200% of motor rated load / 8 bits

6 Input power

LSBMSB

O1O2O3O4O5O6O7O8

200% of inverter's rated output / 8 bits

7 PID feedback

amount

LSBMSB

O1O2O3O4O5O6O7O8

100% of feedback amount / 8 bits

4-2

Page 21

Table 4.2 Monitor Items Selectable (Output) (Continued)

Functio

n code

Data

o21 9 DC link bus

Output signal

name

voltage

Terminal function and configuration details

LSBMSB

O1O2O3O4O5O6O7O8

100% of 500 V / 8 bits: 200 V class series

100% of 1000 V / 8 bits: 400 V class series

13 Motor output

LSBMSB

O1O2O3O4O5O6O7O8

200% of motor rated output / 8 bits

15 PID

command

(SV)

LSBMSB

O1O2O3O4O5O6O7O8

100% of feedback amount / 8 bits

16 PID output

(MV)

LSBMSB

O1O2O3O4O5O6O7O8

100% of maximum frequency / 8 bits

99 Individual

signal output

Fixed

at "0"

LSBMSB

O1O2O3O4O5O8 O7 O6

:

RUN

Inverter running

:

FDT

Frequency detected

:

FAR

Frequency arrival signal

:

LU

Undervoltage detected

(Inverter stopped)

:

Inverter output limiting

IOL

:

Auto-restarting after

IPF

momentary power failure

Individual output signals are functionally equivalent to the

general-purpose output terminals on the inverter.

4-3

Page 22

Chapter 5 I/O CHECKING

Using Menu #4 "I/O Checking" in Program mode of the FRENIC-Multi displays the I/O status of external signals on the LED monitor of the

keypad.

For details of Menu #4 "I/O Checking," refer to the FRENIC-Multi Instruction Manual (INR-SI47-1204-E), Chapter 3, Section 3.4

"Programming Mode."

The I/O status of the digital interface option can be displayed with ON/OFF of the LED segment or in hexadecimal.

Signals are assigned to the LED segments as shown below.

Table 5.1 Display with ON/OFF of LED Segments

Segment LED4 LED3 LED2 LED1

a — O1 I9 I1

b — O2 I10 I2

c — O3 I11 I3

d — O4 I12 I4

e — O5 SEL I5

f — O6 — I6

g — O7 — I7

dp — O8 — I8

Table 4.2 Segment Display for I/O Signal Status in Hexadecimal

LED number LED4 LED3 LED2 LED1

Bit 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Input terminal - - - SEL I12 I11 I10 I9 I8 I7 I6 I5 I4 I3 I2 I1

Output terminal - - - - - - - - O8 O7 O6 O5 O4 O3 O2 O1

5-1

Page 23

Chapter 6 PROTECTIVE FUNCTION

Option communications error (er4 )

Problem A communications error has occurred between the digital interface option and the inverter.

Possible Causes

(1) There is a problem with the

connection between the interface

option and the inverter.

(2) Strong electrical noise.

Check whether the connector on the interface option is firmly engaged with

that of the inverter.

Reload the option card into the inverter.

Check whether appropriate noise control measures have been implemented

(e.g. correct grounding and routing of signal wires, communications cables,

and main circuit wires).

Implement noise control measures.

When no o code is displayed even if a digital interface option is mounted, check whether the connector on the interface option

is firmly engaged with that of the inverter. In this case, er4 does not appear.

What to Check and Suggested Measures

6-1

Page 24

Digital Interface Option "OPC-E1-DIO"

Instruction manual

Fuji Electric FA Components & Systems Co., Ltd.

First Edition, February 2008

The purpose of this instruction manual is to provide accurate information in handling, setting up and operating of the digital interface option. Please feel free

to send your comments regarding any errors or omissions you may have found, or any suggestions you may have for generally improving the manual.

In no event will Fuji Electric FA Components & Systems Co., Ltd. be liable for any direct or indirect damages resulting from the application of the information

in this manual.

Page 25

MEMO

Page 26

Fuji Electric Systems Co., Ltd.

Fuji Electric Corp. of America

47520 Westinghouse Drive Fremont, CA 94539, U.S.A.

Tel.+1-510-440-1060 Fax.+1-510-440-1063

Toll-free support 1-888-900-FUJI(3854)

INR-SI47

-1285-EU Rev 052010 Information subject to change without notice.

http://www.fujielectric.com/fecoa/

Loading...

Loading...