Page 1

series

USER'S MANUAL

PULSE TRAIN OUTPUT POSITIONING

CONTROL MODULE

FEH215

Page 2

Preface

This User’s Manual explains the pulse train output

positioning control module.

Read this manual carefully to ensure correct operation.

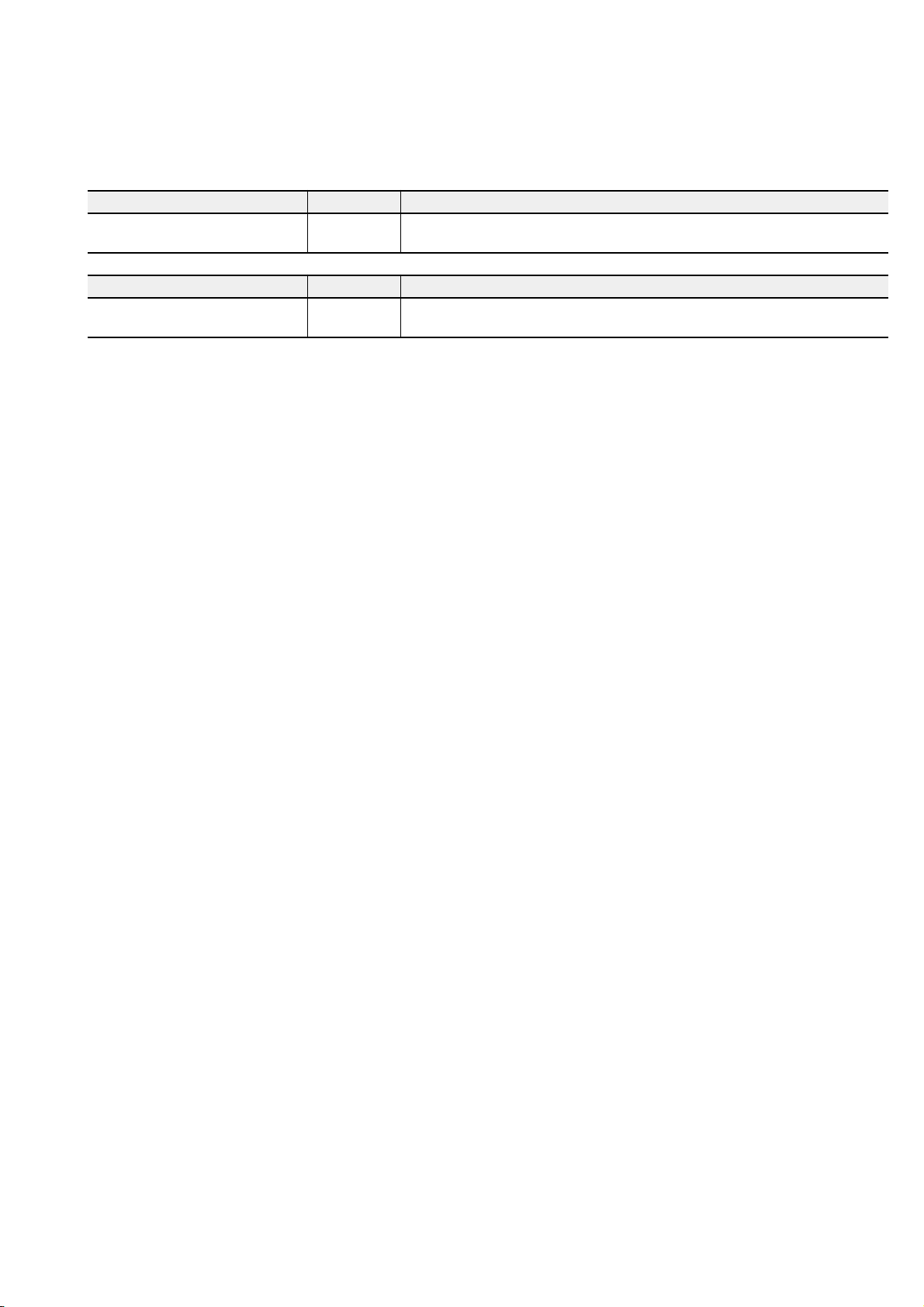

eltiT .oNlaunaM stnetnoC

XS-XERCIM,noitcurtsnIlaunaMs'resU

HPSseires

s'resUXS-XERCIM,erawdraHlaunaM

HPSseires

,>noitcudortnI<niw003DlaunaMs'resU

seiresXS-XERCIM

,>ecnerefeR<niw003DlaunaMs'resU

seiresXS-XERCIM

dnammocgolanAlaunaMs'resU

,eludomdenibmoclortnocgninoitisop

HPSseiresXS-XERCIM

gninoitisopniartesluPlaunaMs'resU

XS-XERCIM,eludomdenibmoclortnoc

HPSseires

002HEF ehtfosnoitinifedmetsysdnaegaugnal,yromemehtsnialpxE

102HEFdnasnoitacificepseht,noitarugifnocmetsysehtsnialpxE

052HEF dnagnimmargorpeht,niw003DfosnoitarepocisabehtsnialpxE

152HEF snoitarepoehtfolladnaniw003DfonocidnaunemehtsnialpxE

312EHF lortnocgninoitisopdnammocgolanaehtfosnoitarepoehtsnialpxE

412HEF lortnocgninoitisopniarteslupehtfosnoitarepoehtsnialpxE

When using modules or peripheral devices, be sure to read

the corresponding user’s manuals listed below.

.seiresXS-XERCIM

.seiresXS-XERCIMehtniseludomfosnoitarepo

.seiresXS-XERCIMrofgnirotinom

.niw003Dfo

.eludomdenibmoc

.eludomdenibmoc

Notes

1. This manual may not be reproduced in whole or part in any form without prior written approval by the manufacturer.

2. The contents of this manual (including specifications) are subject to change without prior notice.

3. If you find any ambiguous or incorrect descriptions in this manual, please write them down (along with the manual No.

shown on the cover) and contact FUJI.

Page 3

Safety Precautions

Be sure to read the “Safety Precautions” thoroughly before

using the module.

Warning

Caution

Even some items indicated by “Caution” may also result in a

serious accident.

: Incorrect handling of the device may result in death or serious injury.

: Incorrect handling of the device may result in minor injury or physical damage.

Here, the safety precaution items are classified into

“Warning” and “Caution.”

Both safety instruction categories provide important

information. Be sure to strictly observe these instructions.

Warning

◊ Never touch any part of charged circuits as terminals and exposed metal portion while the power is turned ON. It may result

in an electric shock to theoperator.

◊ Turn OFF the power before mounting, dismounting, wiring, maintaining or checking, otherwise, electric shock, erratic

operation or troubles might occur.

◊ Place the emergency stop circuit, interlock circuit or the like for safety outside the PC. A failure of PC might break or cause

problems to the machine.

◊ Do not connect in reverse polarity, charge (except rechargeable ones), disassemble, heat, throw in fire or short-circuit the

batteries, otherwise, they might burst or take fire.

◊ If batteries have any deformation, spilled fluids, or other abnormality, do not use them. The use of such batteries might cause

explosion or firing.

◊ Do not open the FG terminal with the LG-FG short circuited. (It must be grounded, otherwise it might cause electric shock.)

Page 4

Safety Precautions

Caution

◊ Do not use one found damaged or deformed when unpacked, otherwise, failure or erratic operation might be caused.

◊ Do not shock the product by dropping or tipping it over, otherwise, it might be damaged or troubled.

◊ Follow the directions of the operating instructions when mounting the product. If mounting is improper, the product might

drop or develop problems or erratic operations.

◊ Use the rated voltage and current mentioned in the operating instructions and manual. Use beyond the rated values might

cause fire, erratic operation or failure.

◊ Operate (keep) in the environment specified in the operating instructions and manual. High temperature, high humidity,

condensation, dust, corrosive gases, oil, organic solvents, excessive vibration or shock might cause electric shock, fire,

erratic operation or failure.

◊ Select a wire size to suit the applied voltage and carrying current. Tighten the wire terminals to the specified torque.

Inappropriate wiring or tightening might cause fire, malfunction, failure, or might cause the product to drop from its

mounting.

◊ Contaminants, wiring chips, iron powder or other foreign matter must not enter the device when installing it, otherwise,

erratic operation or failure might occur.

◊ Remove the dust-cover seals of modules after wiring, otherwise, fire, accidents, failure or fault might occur.

◊ Connect the ground terminal to the ground, otherwise, an erratic operation might occur.

◊ Periodically make sure the terminal screws and mounting screws are securely tightened.

Operation at a loosened status might cause fire or erratic operation.

◊ Put the furnished connector covers on unused connectors, otherwise, failure or erratic operation might occur.

◊ Install the furnished terminal cover on the terminal block, otherwise, electric shock or fire might occur.

◊ Sufficiently make sure of safety before program change, forced output, starting, stopping or anything else during a run.

The wrong operation might break or cause machine problems.

◊ Engage the loader connector in a correct orientation, otherwise, an erratic operation might occur.

◊ Before touching the PC, discharge any static electricity that may have been collected on your body. To discharge it, touch

a grounded metallic object. Static electricity might cause erratic operation or failure of the module.

◊ Be sure to install the electrical wiring correctly and securely, observing the operating instructions and manual. Wrong or

loose wiring might cause fire, accidents, or failure.

◊ When disengaging the plug from the outlet, do not pull the cord, otherwiase, break of cable might cause fire or failure.

◊ Do not attempt to change system configurations (such as installing or removing I/O modules) while the power is ON,

otherwise, failure or erratic operation might occur.

◊ Do not attemp to repair the module by yourself -- contact your Fuji Electric agent. When replacing the batteries, correctly

and securely connect the battery connectors, otherwise, fire, accidents or failure might occure.

◊ To clean the module, turn power off and wipe the module with a cloth moistened with warm water. Do not use thinner or

other organic solvents, as the module surface might become deformed or discolored.

◊ Do not remodel or disassemble the product, otherwise, a failure might occur.

◊ Follow the regulations of industrial wastes when the device is to be discarded.

◊ The modules covered in these operating instructions have not been designed or manufactured for use in equipment or

systems which, in the event of failure, can lead to loss of human life.

◊ If you intend to use the modules covered in these operating instructions for special applications, such as for nuclear

energy control, aerospace, medical, or transportation, please consult your Fuji Electric agent.

◊ Be sure to provide protective measures when using the module covered in these operating instructions in equipment

which, in the event of failure, may lead to loss of human life or other grave results.

Page 5

nodetnirP .oNlaunaM* stnetnocnoisiveR

9991yaM512HEFnoitidetsriF

Revision

.revocehtnonwohssi.oNlaunaM*

Page 6

Contents

Preface

Safety Precautions

Revision

Contents

Page

Section 1 General ...............................................................................................1-1

1-1 Precautions.............................................................................................................................................1-1

1-2 Functional Overview ..............................................................................................................................1-2

1-2-1 Overview of NP1F-HP2 functions ................................................................................................................. 1-2

1-2-2 Overview of NP2F-LEV functions ................................................................................................................. 1-3

Section 2 System Configuration .......................................................................2-1

2-1 Configuration of Peripheral Equipment...............................................................................................2-1

2-2 Applied System ......................................................................................................................................2-2

2-2-1 Applicable CPU ............................................................................................................................................. 2-2

2-2-2 Applied system configuration ........................................................................................................................ 2-2

2-3 Loader and Software Modules to be used...........................................................................................2-3

Section 3 Specifications

3-1 General Specifications (NP1F-HP2) .....................................................................................................3-1

3-1-1 General specifications (NP2F-LEV) .............................................................................................................. 3-2

3-2 Specifications (NP1F-HP2) .....................................................................................................................3-3

3-2-1 Specifications (NP2F-LEV) ........................................................................................................................... 3-3

3-3 Names......................................................................................................................................................3-4

3-3-1 NP1F-HP2 (for 2 axes).................................................................................................................................. 3-4

3-3-2 NP2F-LEV (Signal converter) ....................................................................................................................... 3-6

3-4 Dimensions .............................................................................................................................................3-8

3-4-1 NP1F-HP2 (for 2 axes).................................................................................................................................. 3-8

3-4-2 NP2F-LEV (Signal converter) ....................................................................................................................... 3-8

Section 4 Wiring..................................................................................................4-1

4-1 Mounting Precautions............................................................................................................................4-1

4-1-1 Number of mountable modules (NP1F-HP2)................................................................................................ 4-1

4-1-2 Wiring precautions......................................................................................................................................... 4-2

4-1-3 Wiring example of the external wiring connector.......................................................................................... 4-2

4-2 Connector Pin Layout for the External Connection (NP1F-HP2) ......................................................4-3

4-2-1 External I/O signal specifications (NP1F-HP2)............................................................................................. 4-4

4-3 Connector Pin Layout for the External Connection (NP2F-LEV) ....................................................4-11

4-3-1 External I/O signal specifications (NP2F-LEV) ........................................................................................... 4-12

4-3-2 External I/O signal interface (NP2F-LEV) ................................................................................................... 4-13

4-4 Connecting............................................................................................................................................4-15

4-4-1 Connecting sample of a servo motor .......................................................................................................... 4-15

4-5 I/O Wiring...............................................................................................................................................4-18

Section 5 Memory Map ......................................................................................5-1

5-1 NP1F-HP2 Memory Map (Internal Memory List) ..................................................................................5-1

5-2 I/O Area of NP1F-HP2.............................................................................................................................5-2

5-2-1 NP1F-HP2 (read area: address No. 0 to No. 7) ........................................................................................... 5-3

Page 7

Contents

5-2-2 NP1F-HP2 (Write area, address Nos. 8 to 15) ........................................................................................... 5-14

5-3 Setting Method and Effective Bits ......................................................................................................5-32

Section 6 Parameter s (Registers) .....................................................................6-1

6-1 Parameters (Registers) ..........................................................................................................................6-1

6-2 Relationship between Parameters (Registers)....................................................................................6-2

6-3 Detailed Description of Parameters (Registers) .................................................................................6-4

Section 7 Positioning Function.........................................................................7-1

7-1 Positioning Function of the Pulse Train Output Positioning Control Module (NP1F-HP2).............7-1

7-2 Functions of Pulse Train Output Positioning Control Module (NP1F-HP2)......................................7-2

7-2-1 Command pulse count control ...................................................................................................................... 7-3

7-2-2 Command pulse frequency control ............................................................................................................... 7-4

7-2-3 Trapezoidal acceleration/deceler ation .......................................................................................................... 7-5

7-2-4 Automatic deceleration point calculation ...................................................................................................... 7-7

7-2-5 Deceleration point setting.............................................................................................................................. 7-8

7-2-6 Continuous frequency rewriting .................................................................................................................... 7-9

7-2-7 Setti n g d a t a t o a r e g i s t e r ............................................................................................................................... 7-9

7-2-8 Data reading from register .......................................................................................................................... 7-10

7-2-9 Current value data reading.......................................................................................................................... 7-11

7-2-10 Manual operation....................................................................................................................................... 7-12

7-2-11 Original point return motion ....................................................................................................................... 7-12

7-2-12 Positioning operation................................................................................................................................. 7-14

7-2-13 Interrupt point positioning motion.............................................................................................................. 7-15

7-2-14 Deceleration-and-stop/quick stop motion ................................................................................................. 7-16

7-2-15 Operation when an emergency stop error has been detected .................................................................7-17

7-2-16 Operation when an ± OT error has been detected ................................................................................... 7-18

7-2-17 Command pulse counting ......................................................................................................................... 7-20

7-2-18 Operation when a transmission error has been detected ........................................................................ 7-21

Section 8 Troubleshooting.................................................................................8-1

8-1 LED Indication ........................................................................................................................................8-1

8-2 Error Indication.......................................................................................................................................8-2

Appendix........................................................................................................App.-1

Appendix-1 Parameters..........................................................................................................................App.-1

Appendix-2 Memory map.......................................................................................................................App.-2

Appendix-3 Terminology ........................................................................................................................App.-3

Appendix-4 Current Consumption and Mass of Modules in MICREX-SX Series.............................App.-5

Page 8

Section 1 General

Page

1-1 Precautions .............................................................................................................. 1-1

(1) Handling precautions as precision device .......................................................................................... 1-1

(2) Precautions concerning operating conditions and environment ......................................................... 1-1

1-2 Functional Overview................................................................................................ 1-2

1-2-1 Overview of NP1F-HP2 functions ......................................................................................1-2

1-2-2 Overview of NP2F-LEV functions ...................................................................................... 1-3

Page 9

Section 1 General

1-1 Precautions

The NP1F-HP2 is a pulse train output positioning control

module which is connected to a high-performance CPU

module and a standard CPU module of a MICREX-SX

Precautions for using the NP1F-HP2 are as follows:

(1) Handling precautions as precision device

1) Do not drop the device.

2) Avoid installing the device in places subject to

strong vibrations.

3) Avoid installing the device in places where

harmful gas (corrosive gas) exists.

4) Avoid installing the device within the same panel

as high-tension (3000 V or 6000 V

or more) devices.

5) Avoid sharing the same power supply with

equipment which produces high noise

(e.g. inverter).

6) Avoid using the device in places where the

temperature is too high or low, or the

humidity is too high.

Operating ambient temperature: 0 to 55°C

Operating ambient humidity: 20 to 95% RH

7) In places with extremely low humidity, excessive

static electricity tends to build up.

When you touch the NP1F-HP2 in such an

environment, be sure to touch a metal

ground in advance in order to discharge the static

electricity which is charged on your body.

series via an SX bus. It is used in combination with a pulse

train input command-type servo amplifier + motor or with a

stepping motor driver to perform high-accuracy positioning.

(2) Precautions concerning operating conditions and

environment

When the NP1F-HP2 is used in the following conditions or

environment, secure enough margin for the rated

specifications and functions (performance), take sufficient

fail-safe measures, and be sure to consult with personnel at

your Fuji Electric sales office.

1) Storage or use in conditions or an environment

which is not described in the operating

instructions or user’s manual.

2) Applications in nuclear power generation control,

railways, aircraft, railcars, incinerator equipment,

medical facilities,amusement machines, safety

devices, etc.

3) Applications where a great effect on human life or

property may be anticipated and a high degree

safety is required.

1-1

Page 10

1-2 Functional Overview

1-2-1 Overview of NP1F-HP2 functions

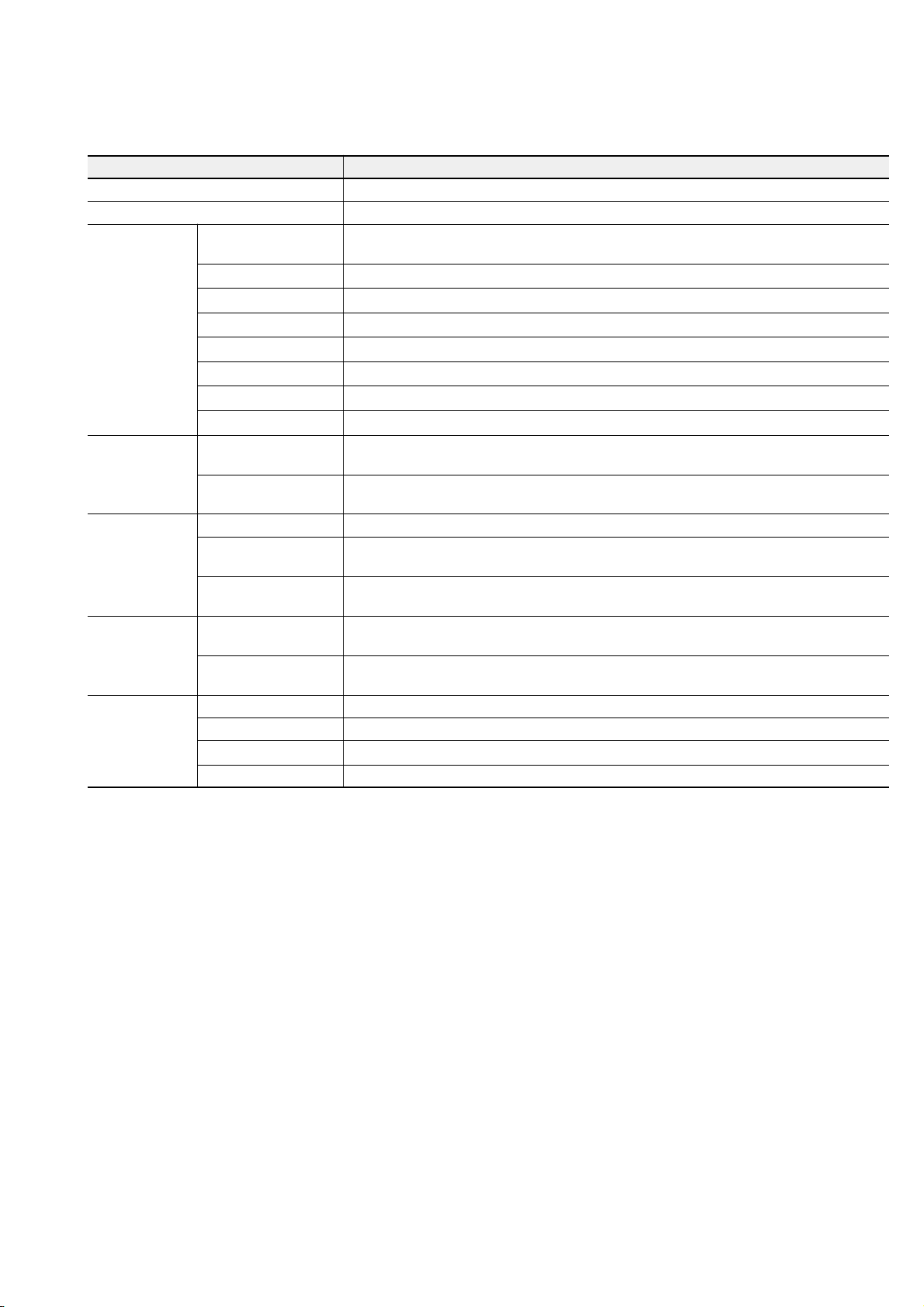

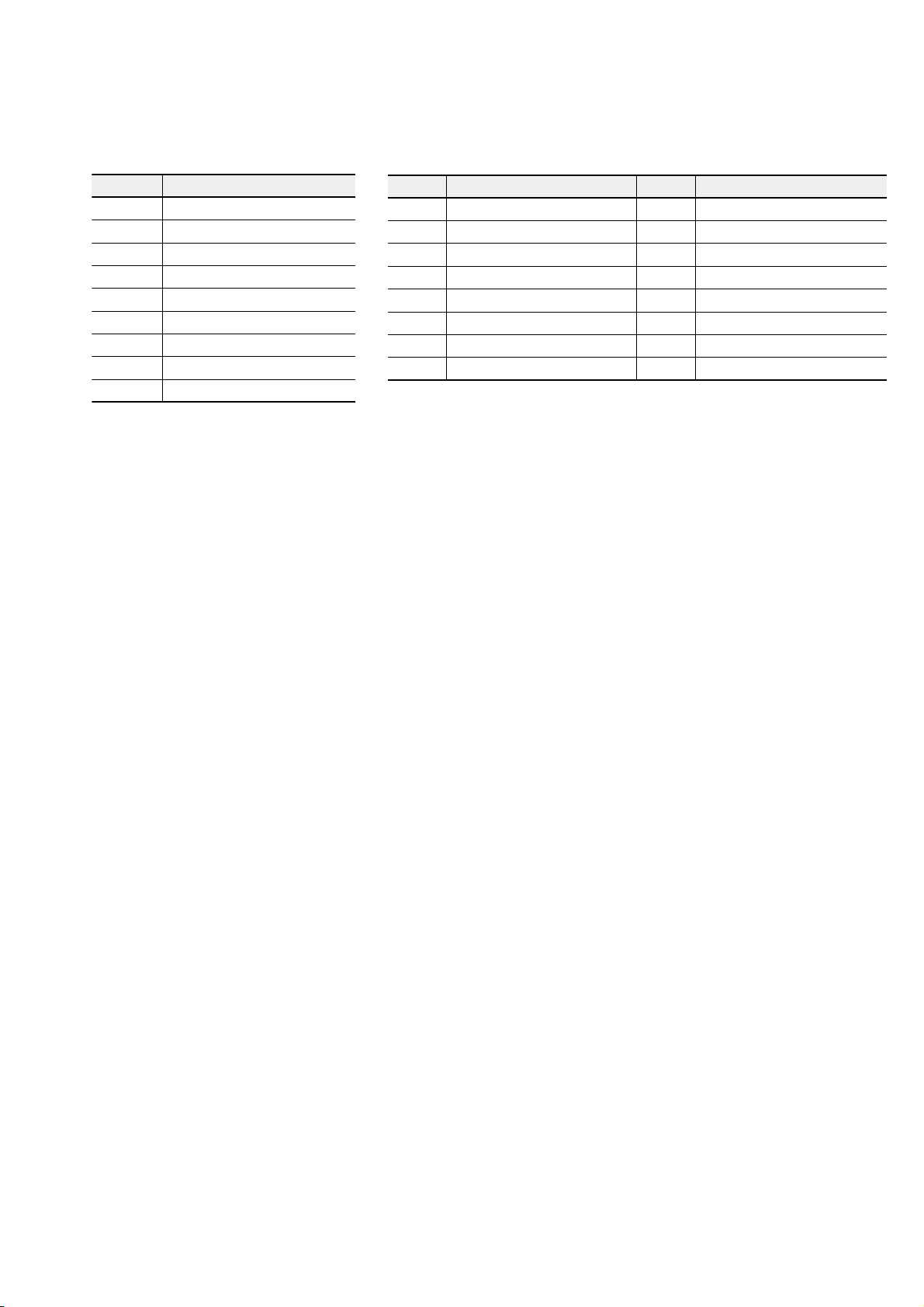

metI noitpircseD

sexalortnocforebmuN

epyttuptuO

ycneuqerfdnammoc.xaM

citsiretcarahcnoitareleced/noitareleccA

tniopnoitarelecedfonoitaluclaC

)F/Ilaires(F/IedisUPC )sdrow61:latot,sdrow8:tuptuo,sdrow8:tupni(2PH-F1PN

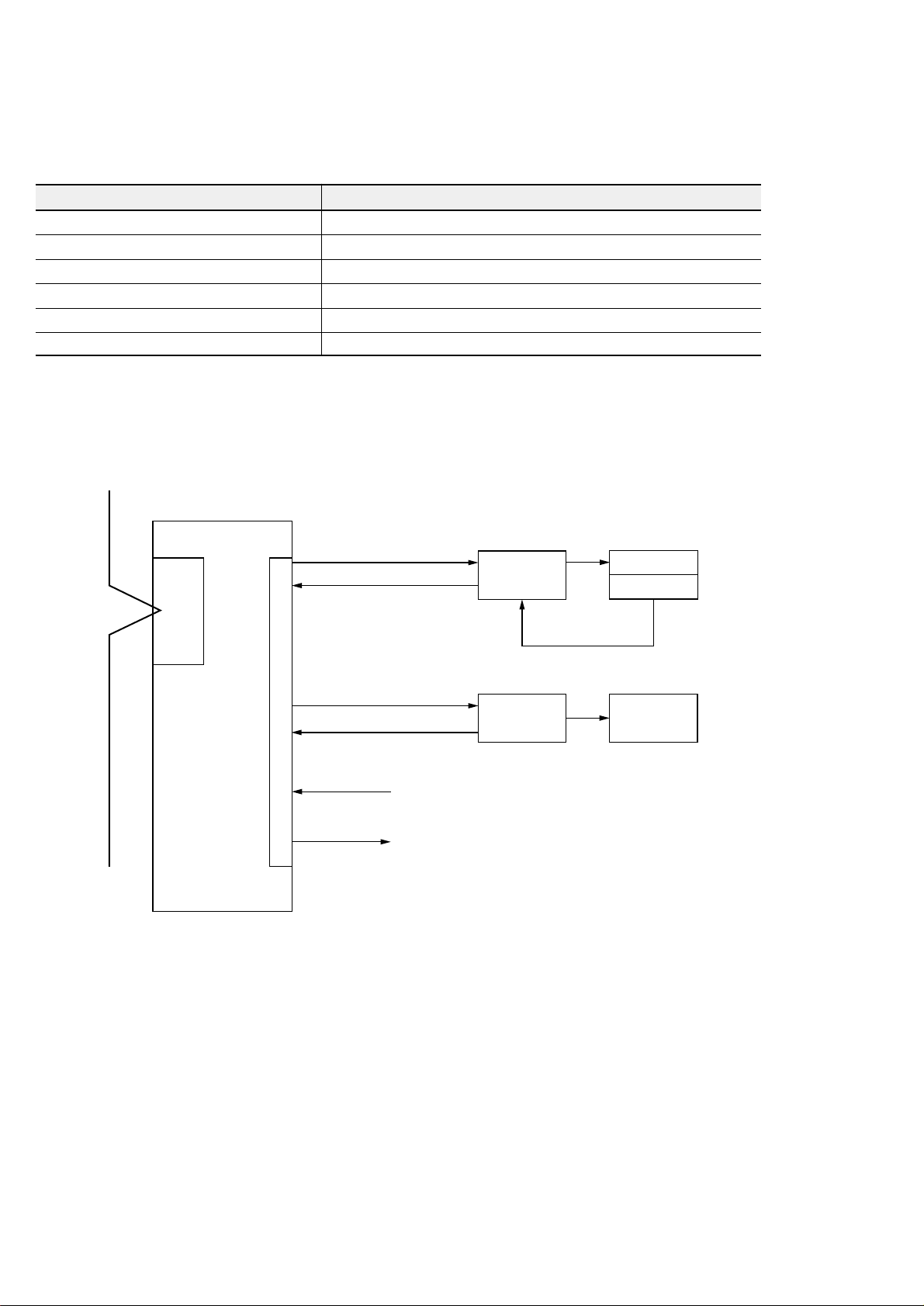

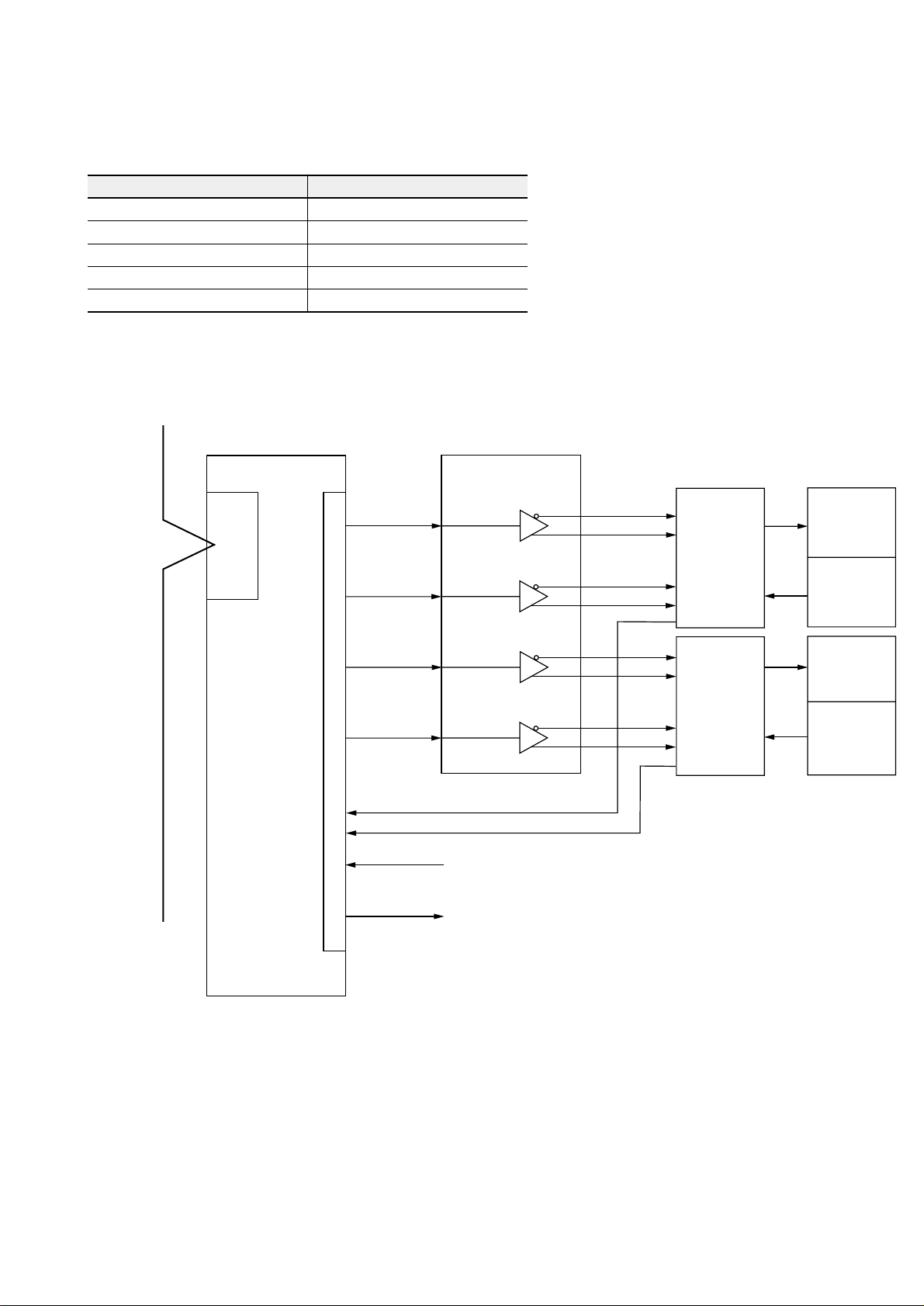

A sample connection configuration of the NP1F-HP2 is shown

below:

Sample connection configuration of the NP1F-HP2

2

zHk052

)eslupesrever+eslupdrawrof(tuptuoniartesluprotcellocnepO

noitareleced/noitareleccaladiozeparT

noitaluclaccitamotuA

SX bus

NP1F-HP2

Serial I/F

X-axis forward/reverse pulse

Feedback pulse phase-Z

External I/Fs

Y-axis forward/reverse pulse

Timing output (TIM)

Servo

amplifier

Stepping

driver

DI : X axis (EMG, ±OT, origin LS, interrupt (5 points))

DO: Command output from CPU module (2 points)

Motor

Encoder

Motor

1-2

Page 11

1-2-2 Overview of NP2F-LEV functions

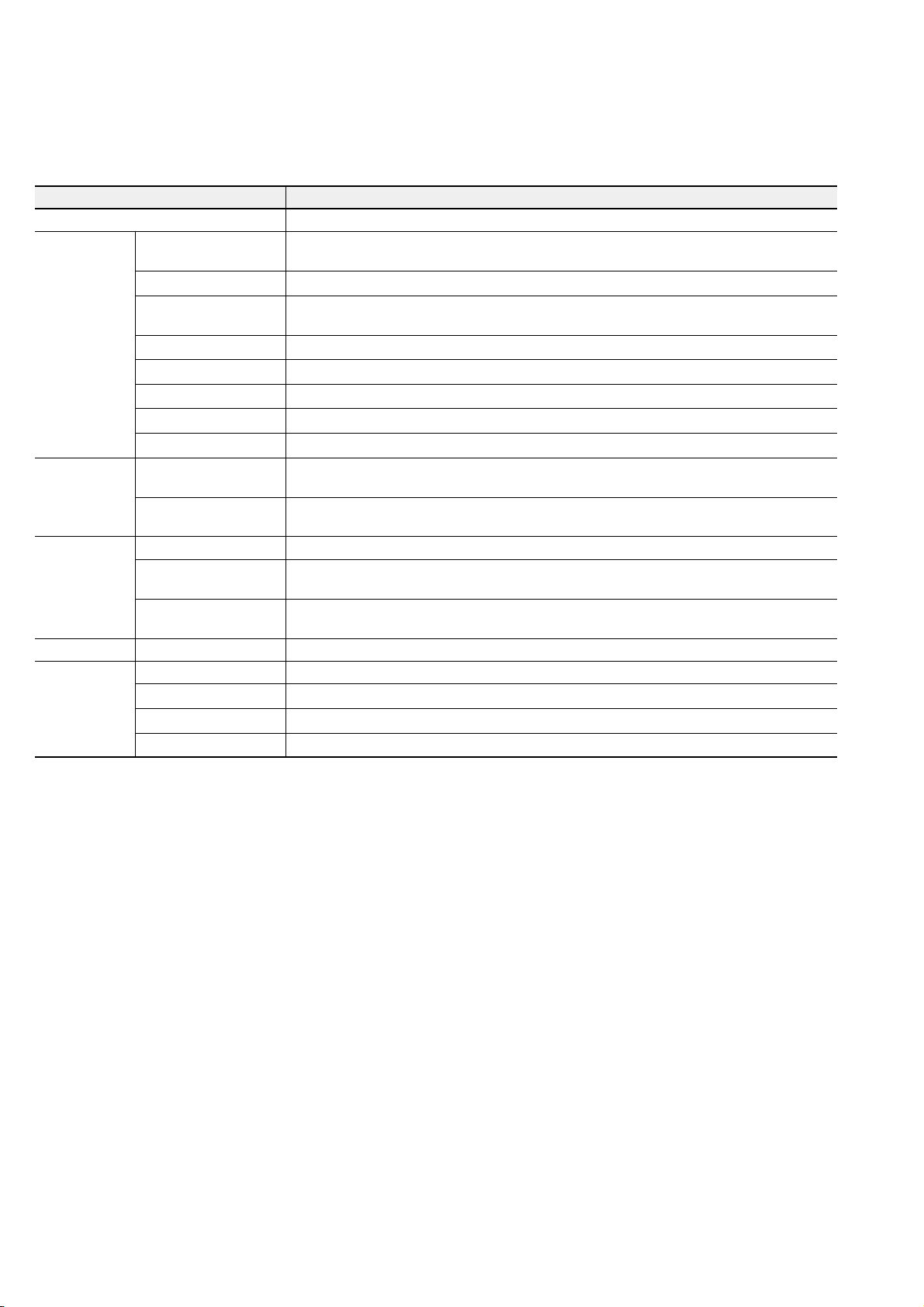

metI noitpircseD

slennahcnoisrevnocforebmuN)sexa4rof(4

epyttupnItupnirotcellocnepO

ycneuqerftupnIzHM1

epyttuptuO)revirdenil(langislaitnereffiD

ycneuqerftuptuOzHM1

A sample connection configuration of NP2F-LEV and NP1F-HP2

is shown below:

Sample connection configuration of the NP2F-LEV

1-2 Functional Overview

SX bus

NP1F-HP2

Serial I/F

X-axis

forward pulse

X-axis

External I/Fs

reverse pulse

Y-axis

forward pulse

Y-axis

reverse pulse

CH1 phase-Z

CH2 phase-Z

NP2F-LEV

Servo

amplifier

X-axis

differential

input

Servo

amplifier

Y-axis

differential

input

DI: X-/Y-axis (5 points/axis, EMG, ±OT, origin LS, interrupt)

DO: Command output from CPU module (2 points/axis)

Motor

Encoder

Motor

Encoder

1-3

Page 12

Section 2 System Configuration

Page

2-1 Configuration of Peripheral Equipment................................................................. 2-1

2-2 Applied System ........................................................................................................ 2-2

2-2-1 Applicable CPU .................................................................................................................. 2-2

2-2-2 Applied system configuration .............................................................................................2-2

(1) For a 2-axis system ............................................................................................................................ 2-2

(2) Sample extensions (for 8-axis system) ............................................................................................... 2-2

2-3 Loader and Software Modules to be used............................................................. 2-3

Page 13

Section 2 System Configuration

2-1 Configuration of Peripheral Equipment

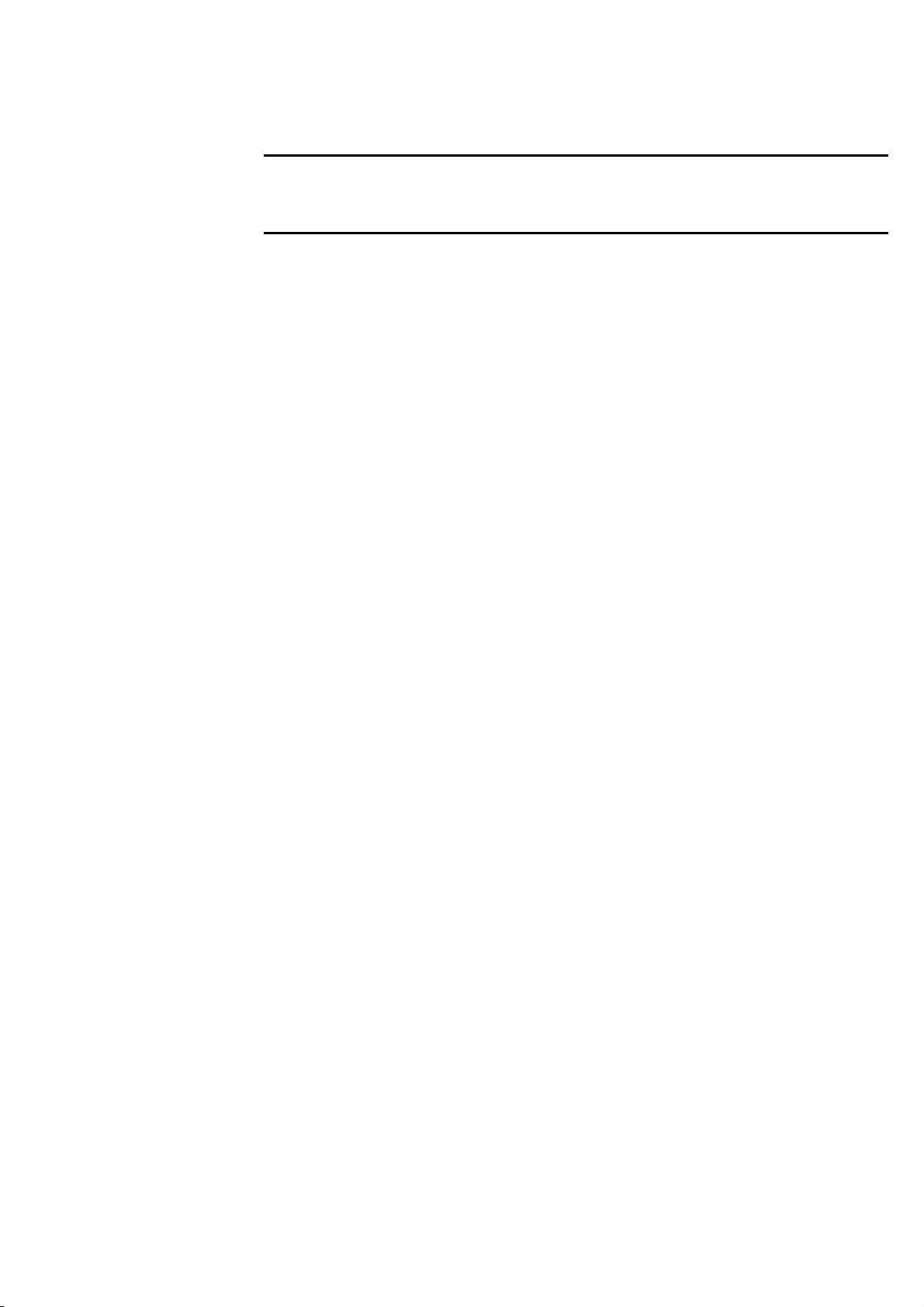

The overall configuration of the NP1F-HP2 including a

MICREX-SX series CPU and peripheral equipment is shown

below:

Overall configuration

MICREX-SX CPU

module

NP1PSNP1PH-

Various-type

FBs for

positioning

D300win

positioning

loader software

SX bus

Positioning

control module

NP1F-HP2

Timing

output

*1

Signal converter

NP2F-LEV

Phase-Z

Stepping motor

driver

Servo

amplifier

Stepping motor

: Area covered by this manual

Motor

Encoder

Precaution:

This module only contains the basic functions for positioning processing. Motion-related functions (manual motion, original

point return motion, etc.) are processed by the expansion FB (function block) which is integrated into the MICREX-SX series

CPU module.

*1 When this module is combined with a differential signal input-type servo amplifier or a stepping motor driver, a signal

converter is needed.

2-1

Page 14

2-2 Applied System

2-2-1 Applicable CPU

The NP1F-HP2 can be used with a MICREX-SX series CPU.

1) High-performance CPU module ..... NP1PS-

2) Standard CPU module ................... NP1PH-

3)

4)

5)

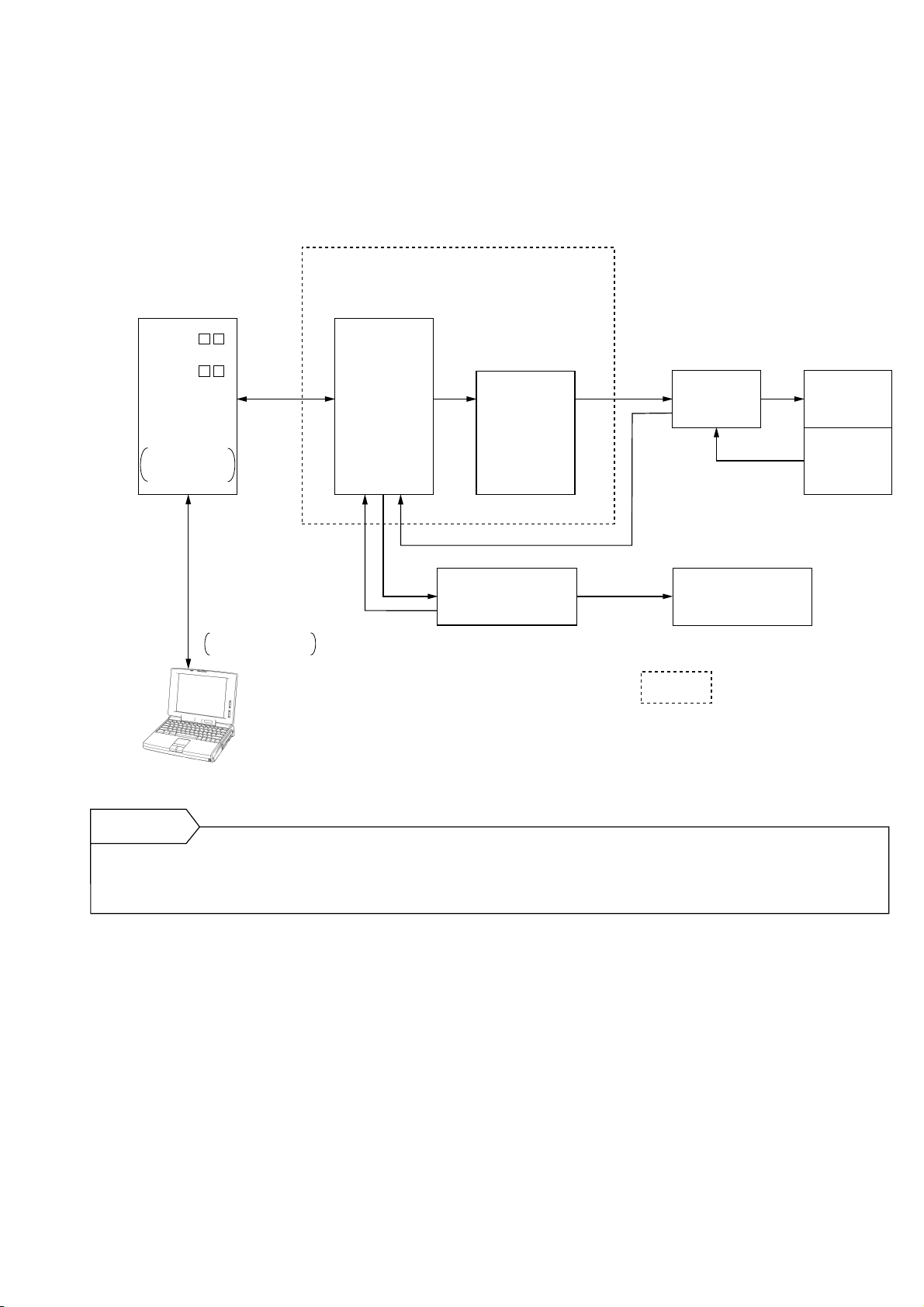

2-2-2 Applied system configuration

The NP1F-HP2 is connected to the CPU module via an SX bus.

Sample connections are shown below:

(1) For a 2-axis system

Power supply module : NP1S-22

CPU module : NP1PSBase board : NP1BS-06

Positioning control module : NP1F-HP2

Power supply

module

Positioning

CPU module

control module

Input

module

Output

Input module : NP1X1606-W

module

Output module : NP1Y16R-08

(2) Sample extensions (for 8-axis system)

Positioning

module

control module

Output

module

Power supply

module

Power supply

module

: SX bus terminating plug

(NP8B-BP)

CPU module

Input

For how to mount the modules, refer to Section 4.

Input

Positioning

control module

Positioning

Positioning

control module

Power supply module : NP1S-22

CPU module : NP1PSBase board : NP1BS-06

Positioning control module : NP1F-HP2

Extension cable : NP1C-P3

module

Input module : NP1X1606-W

Output module : NP1Y16R-08

control module

2-2

Page 15

2-3 Loader and Software Modules to be used

The following loader and software modules are necessary to

operate the NP1F-HP2.

erawtfosredaoL epyT noitacilppA

gnimmargorpdetpadaniw003D

loottroppus

erawtfoS epyT noitacilppA

)BF(kcolbnoitcnufnoisnapxE

lortnocgninoitisoprofegakcap

DES-H4PN .UPCehtrofsmargorpnoitacilpparotinom/etirw/daer/retsigeR

FPTP-N4PN detalopretni-isauq,noitareposixatnednepednirofsmargorpnoitacilppA

.detcelesebnacnrutertnioplanigirodnanoitarepolaunam,noitom

2-3

Page 16

Section 3 Specifications

Page

3-1 General Specifications (NP1F-HP2) ....................................................................... 3-1

3-1-1 General specifications (NP2F-LEV) ................................................................................... 3-2

3-2 Specifications (NP1F-HP2)....................................................................................... 3-3

3-2-1 Specifications (NP2F-LEV) ................................................................................................3-3

3-3 Names .......................................................................................................................3-4

3-3-1 NP1F-HP2 (for 2 axes) ......................................................................................................3-4

3-3-2 NP2F-LEV (Signal converter) ............................................................................................ 3-6

3-4 Dimensions...............................................................................................................3-8

3-4-1 NP1F-HP2 (for 2 axes) ......................................................................................................3-8

3-4-2 NP2F-LEV (Signal converter) ............................................................................................ 3-8

Page 17

metI noitacificepS

htgnertscirtceleiD )dnuorgemarfdnasniprotcennocO/Ineewteb(etunim1CAV0051

ecnatsisernoitalusnIm01 Ω )dnuorgemarfdnasniprotcennocO/Ineewteb(reggemCDV005htiweromro

tneibmagnitarepO

erutarepmet

erutarepmetegarotS07+ot02- ° C

lacisyhP

latnemnorivne

snoitidnoc

lacinahceM

ecivres

snoitidnoc

lacirtcelE

ecivres

snoitidnoc

ylppusrewoP

noitallatsnI

snoitidnoc

tsuD

noitarbiV s/m6.91:noitareleccatnatsnoC,mm51.0:edutilpmaflaH

kcohSs/m741:kaepnoitareleccA

egrahcsid

dleif

ylppus

gnilooCgniloocriA

ssaM

ytidimuhevitaleR )noitasnednoconHR%59ot5:noitidnoctropsnarT(noitasnednoconHR%59ot02

eergednoitulloP2

ytinumminoisorroC .retawroliognittuc,stnevloscinagrohtiwdeniatstoN.sesagevisorrocmorfeerF

edutitlagnitarepOlevelaesevobasselrom0002

erusserpcirehpsomtA

ytinummiesioN1htdiweslup,sn1emitesir,Vk1 µ )rotalumisesion(s

citatsortcelE

citengamortceleoidaR

rewoPlanretxE

tnerruclanretnI

noitpmusnoc

noitcurtsnoC )epytdetnuomlenaP(epytkcolbgnidliuB:2PH-F1PN

snoisnemiD)mm(09Dx501Hx53W:2PH-F1PN

Section 3 Specifications

3-1 General Specifications (NP1F-HP2)

55+ot0 ° C

tsudevitcudnocmorfeerF

)edutitlam0003ottnelaviuqe(eromroaPk07

2

,

2

.sexaralucidneprepyllautumeerhtfohcaerofsemiteerhT

:egrahcsidtcatnoC ± Vk6

:egrahcsidlaireA ± Vk8

)zHM0001otzHM08(m/V01

Am53,CDV42:O/IroF

sselroAm59:2PH-F1PN

:2PH-F1PNg081.xorppA

.sruohxislatot,sexaralucidneprepyllautumeerhtfohcaerofsruohowT

3-1

Page 18

3-1 General Specifications (NP1F-HP2)

3-1-1 General specifications (NP2F-LEV)

metI noitacificepS

dohtemnoitalosI detalosisiylppusrewoplanretxE,)langistuptuodnalangistupnineewteb(detalositoN

lacisyhP

latnemnorivne

snoitidnoc

lacinahceM

ecivres

snoitidnoc

lacirtcelE

ecivres

snoitidnoc

ylppusrewoPylppusrewoplanretxEAm04,CDV42:O/IroF

noitallatsnI

snoitidnoc

tsuD

noitarbiV

kcohS

dleif

gnilooC

ssaM

tneibmagnitarepO

erutarepmet

erutarepmetegarotS

ytidimuhevitaleR

eergednoitulloP

ytinumminoisorroC

edutitlagnitarepO

erusserpcirehpsomtA

ytinummiesioN1htdiweslup,sn1emitesir,Vk5.1 µ )rotalumisesion(s

egrahcsidcitatsortcelE

citengamortceleoidaR

noitcurtsnoC )epytdetnuomlenaP(epytkcolbgnidliuB:VEL-F2PN

snoisnemiD

55ot0 ° C

07+ot52- ° C

noitasnednoconHR%59ot02

tsudevitcudnocmorfeerF

2

2

s/m741:kaepnoitareleccA

:egrahcsidtcatnoC ± Vk6

:egrahcsidlaireA ± Vk8

)zHM0001otzHM08(m/V01

gniloocriA

g031.xorppA:VEL-F2PN

)noitasnednoconHR%59ot5:noitidnoctropsnarT(

.retawroliognittuc,,stnevloscinagrohtiwdeniatstoN.sesagevisorrocmorfeerF

levelaesevobasselrom0002

)edutitlam0003ottnelaviuqe(eromroaPk07

2

s/m6.91:noitareleccatnatsnoC,mm51.0:edutilpmaflaH

,

.sruohxislatot,sexaralucidneprepyllautumeerhtfohcaerofsruohowT

.sexaralucidneprepyllautumeerhtfohcaerofsemiteerhT

)mm(59Dx59Hx8.93W:VEL-F2PN

3-2

Page 19

metI noitacificepS

noitcurtsnoC)deipuccotols1(epyteludoM

sdrowdeipuccO )sdrow8:tuptuO,sdrow8:tupnI(2PH-F1PN

sexalortnocfo.oNsexa2

lortnocgninoitisoPpoolnepO

noitareleced/noitareleccA

scitsiretcarahc

atadnoitisoP2.xaM

dnammoC

deeps

noitcnuflortnoC )kcolBnoitcnuF(BFnoisnapxeehtybdellortnoC

epyttuptuOtuptuorotcellocnepO

rotautcanoitanibmoC noitcnuftupniniarteslupderaperpmetsysovreS

ycneuqerfdnammoCzHk052

3-2-1 Specifications (NP2F-LEV)

metI noitacificepS

noitcurtsnoC)deipuccotols1(epyteludoM

sexalortnocfo.oN)slennahc4rof(sexa4

langistupnI

langistuptuO

ycneuqerftupnIzHM1.xaM

epyttupnIrotcellocnepO

ycneuqerftuptuOzHM1.xaM

epyttuptuOlangislaitnereffiD

3-2 Specifications (NP1F-HP2)

)edomnoitarenegeslupni(noitareleced/noitareleccaladiozeparT

23

dnammoc/eslup1-

3-3

Page 20

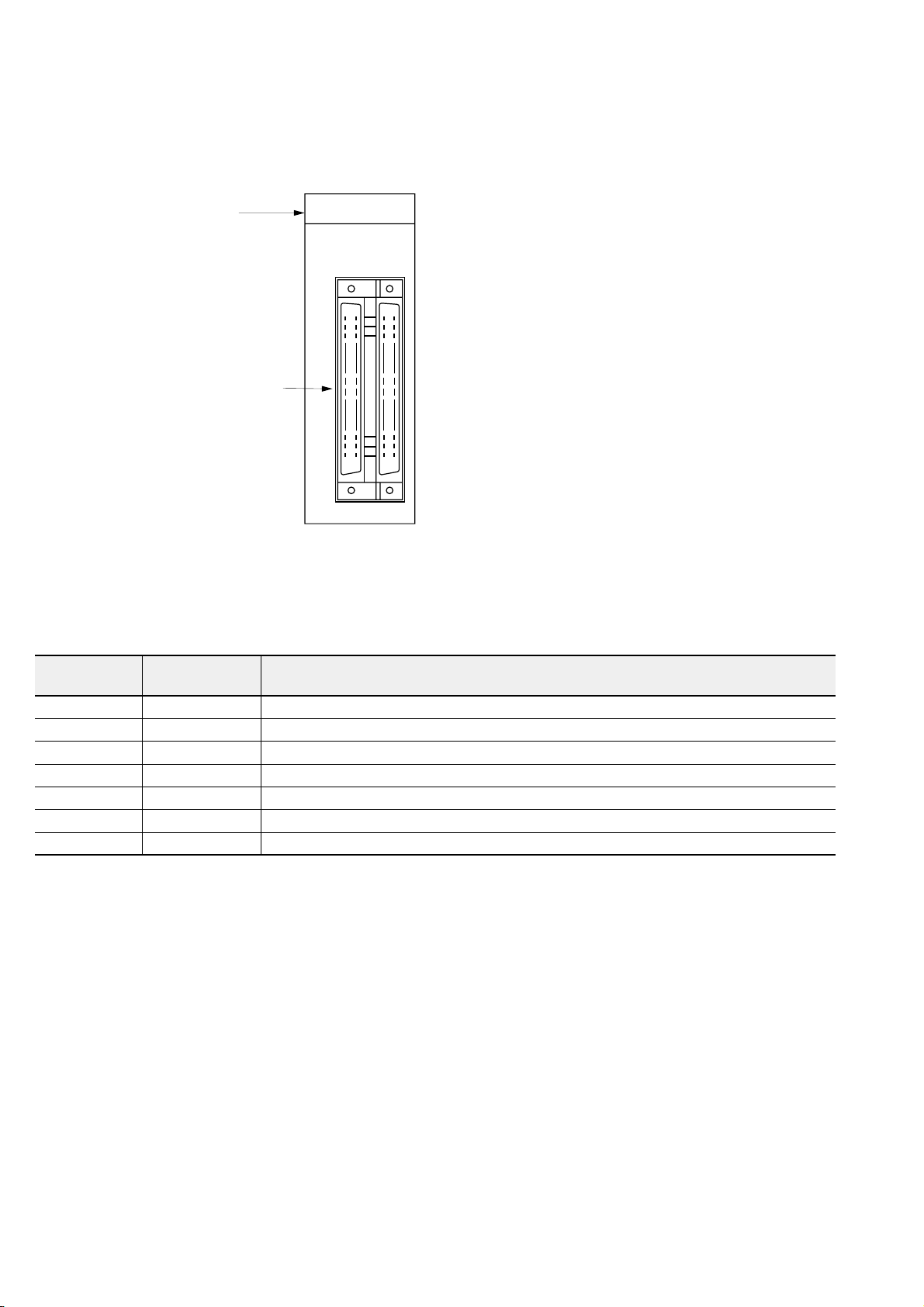

3-3 Names

3-3-1 NP1F-HP2 (for 2 axes)

1) Status indication LED

ONL RDY

ERR ALM

CH1

EMG+OT-OT

CH2

2) External I/O signal connector

CH1 CH2

1) Status indication LED

This LED indicates the operation status and the error status

of NP1F-HP2. LED color means as shown below.

• Green: This is used to confirm the operation, not emergency.

• Red : Any fault status is detected, a state of emergency.

DELnoitacidnI

)2HC/1HC(

emaN

noitpircseD

)2HC/1HC(

)neerG(LNOlamronsubXS.lamronsisubXSnehwnosnruT

)deR(RRElamronbasubXS )revonoitaivedasaemaS(.subXSnisruccororrenanehwnosnruT

)neerG(YDRydaeR.lamronsieludomehtnehwnosnruT

)deR(MLArorrE .erawdrahehtniromargorpnoitacilppaehtnisruccororrenanehwnosnruT

)deR(GMEpotsycnegremE )etoN()tcatnocCN:langisO/IlanretxE(.NOsitupnipotsycnegremeehtnehwnosnruT

)deR(TO+levartrevO )etoN()tcatnocCN:langisO/IlanretxE(.NOsitupninoitceridsulpehtnehwnosnruT

)deR(TO-levartrevO )etoN()tcatnocCN:langisO/IlanretxE(.NOsitupninoitceridsunimehtnehwnosnruT

Note: Indication LEDs (EMG/±OT) operate with the external input signal. Only the status of input signals are indicated.

3-4

Page 21

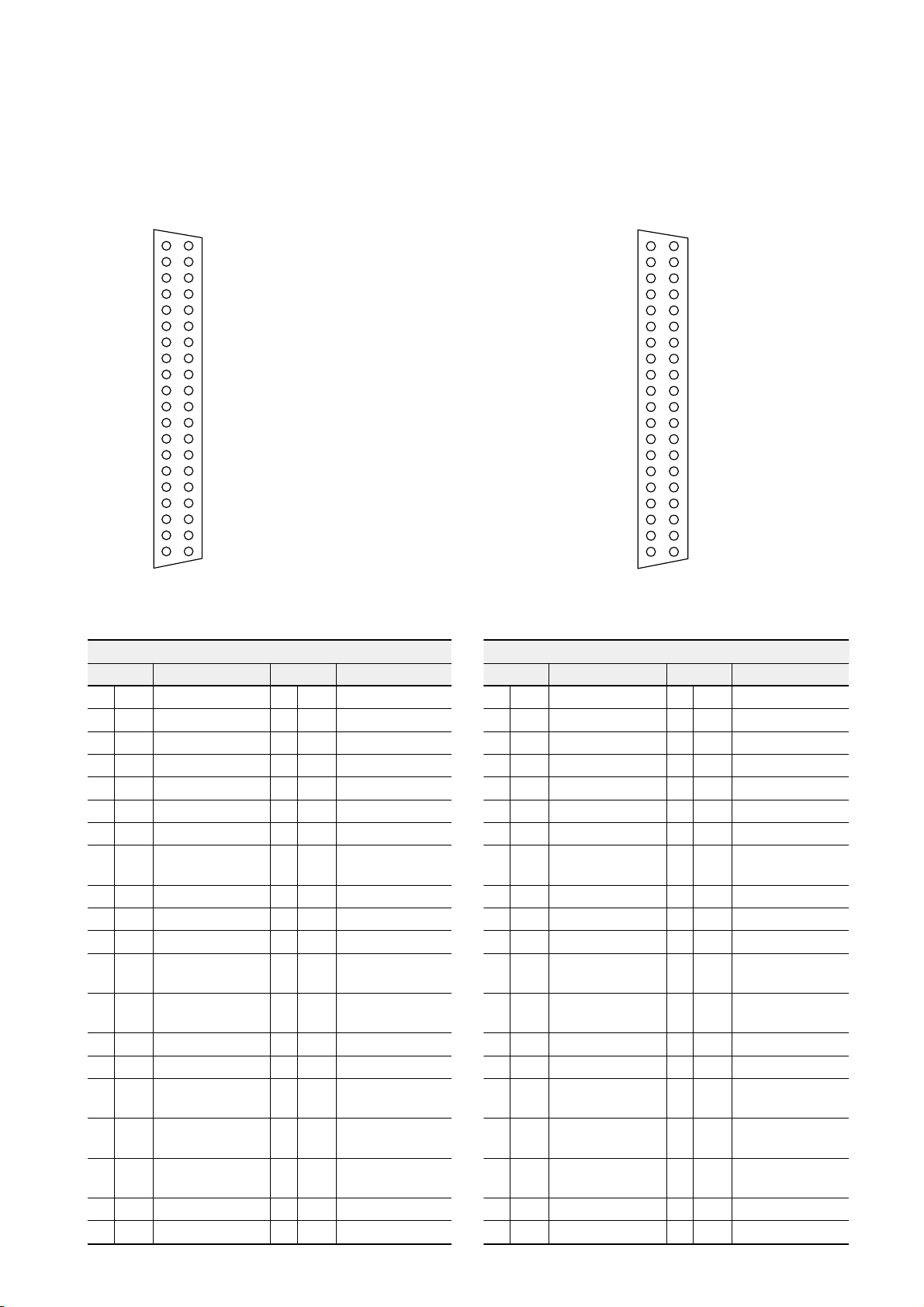

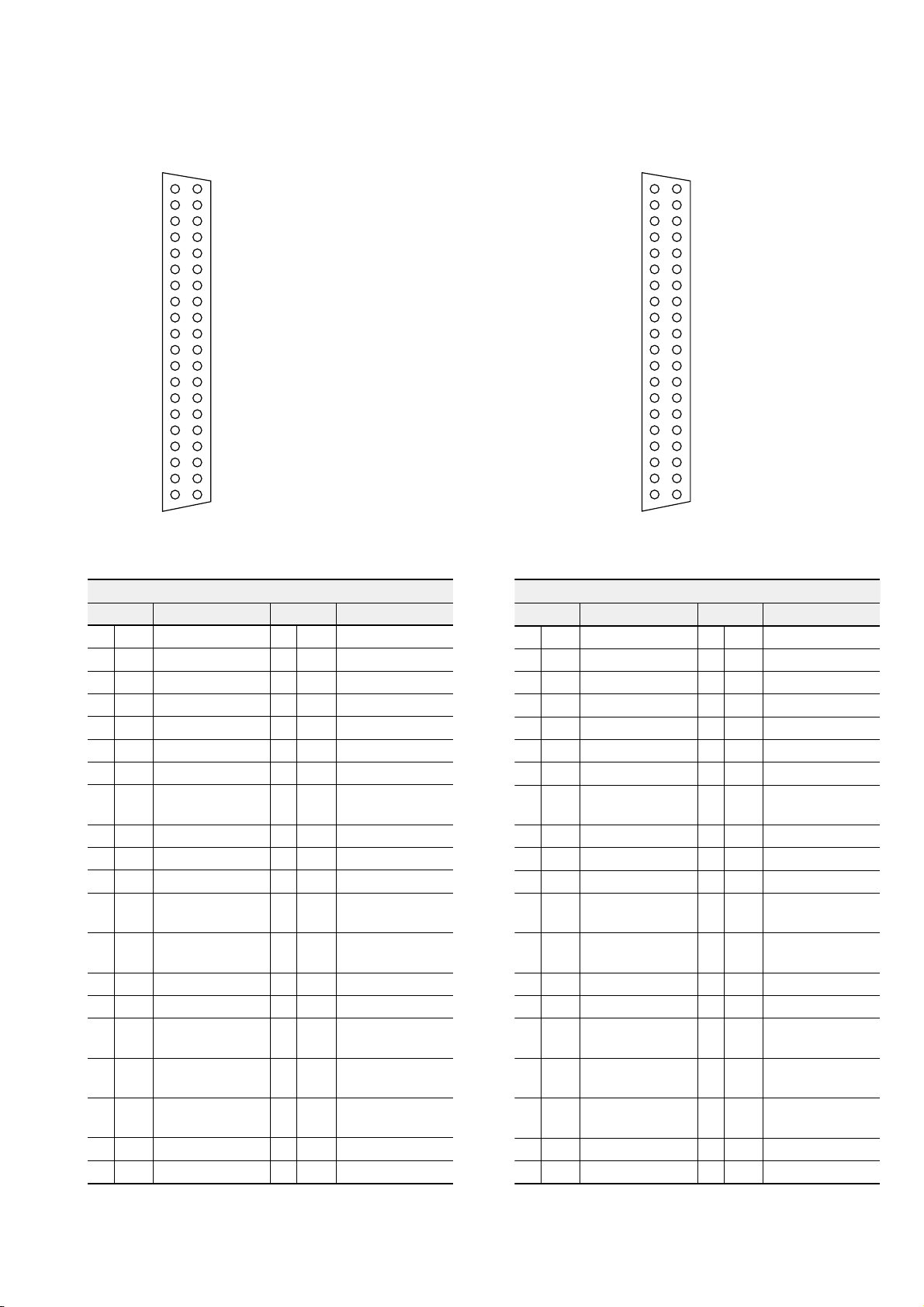

2) Connector pin layout for the external I/O signal

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Connector pin layout (40-pin)

B/A

CH2

A front view A front view

B/A

CH1

3-3 Names

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Connector pin layout (40-pin)

Signal name Signal name

1HC

.oNniP emanlangiS .oNniP emanlangiS

0202BCDV420202ACDV42

9191BCDV09191ACDV0

8181BMOC8181AMOC

7171BtupniTO-7171AtupniGME

6161BtupniTO+6161AtupniSLnigirO

5151B1MOCtupnI5151AtupnitpurretnI

4141B1MOCtupnI4141A1MOCtupnI

3131B

2121B2oD2121A1oD

1111BMOCtuptuO1111AMOCtuptuO

0101BMOC0101AMOC

99B

88B

77BC.N77AC.N

66BC.N66AC.N

55B

44B

33B

22BC.N22AC.N

11BC.N11AC.N

20

19

18

Usable connector

17

• NP1F-HP2 side

16

Connector···FCN-365P040-AU (Fujitsu)

15

Connector···N630-3651-T927 (Fujitsu)

14

13

For details of the connector, refer to “4-5 I/O Wiring.”

12

11

10

9

8

7

6

5

4

3

2

1

V42:tuptuoroF

CD

tuptuo

tuptuoesluP

MOC

DNG

MOC

MOC

3131A

eslupesreveR

99A

88A

eslupkcabdeeF

55A

44A

33A

CD

tuptuo

MOC

DNG

V42:tuptuoroF

eslupdrawroF

tuptuoesluP

eslupkcabdeeF

eslupkcabdeeF

Z-esahp

eslupkcabdeeF

Z-esahp*

2HC

.oNniP emanlangiS .oNniP emanlangiS

0202BCDV420202ACDV42

9191BCDV09191ACDV0

8181BMOC8181AMOC

7171BtupniTO-7171AtupniGME

6161BtupniTO+6161AtupniSLnigirO

5151B2MOCtupnI5151AtupnitpurretnI

4141B2MOCtupnI4141A2MOCtupnI

3131B

2121B2oD2121A1oD

1111BMOCtuptuO1111AMOCtuptuO

0101BMOC0101AMOC

99B

88B

77BC.N77AC.N

66BC.N66AC.N

55B

44B

33B

22BC.N22AC.N

11BC.N11AC.N

CD

tuptuo

MOC

DNG

MOC

MOC

V42:tuptuoroF

3131A

eslupesreveR

99A

tuptuoesluP

88A

eslupkcabdeeF

55A

44A

33A

V42:tuptuoroF

CD

eslupdrawroF

tuptuo

tuptuoesluP

MOC

eslupkcabdeeF

DNG

eslupkcabdeeF

Z-esahp

eslupkcabdeeF

Z-esahp*

3-5

Page 22

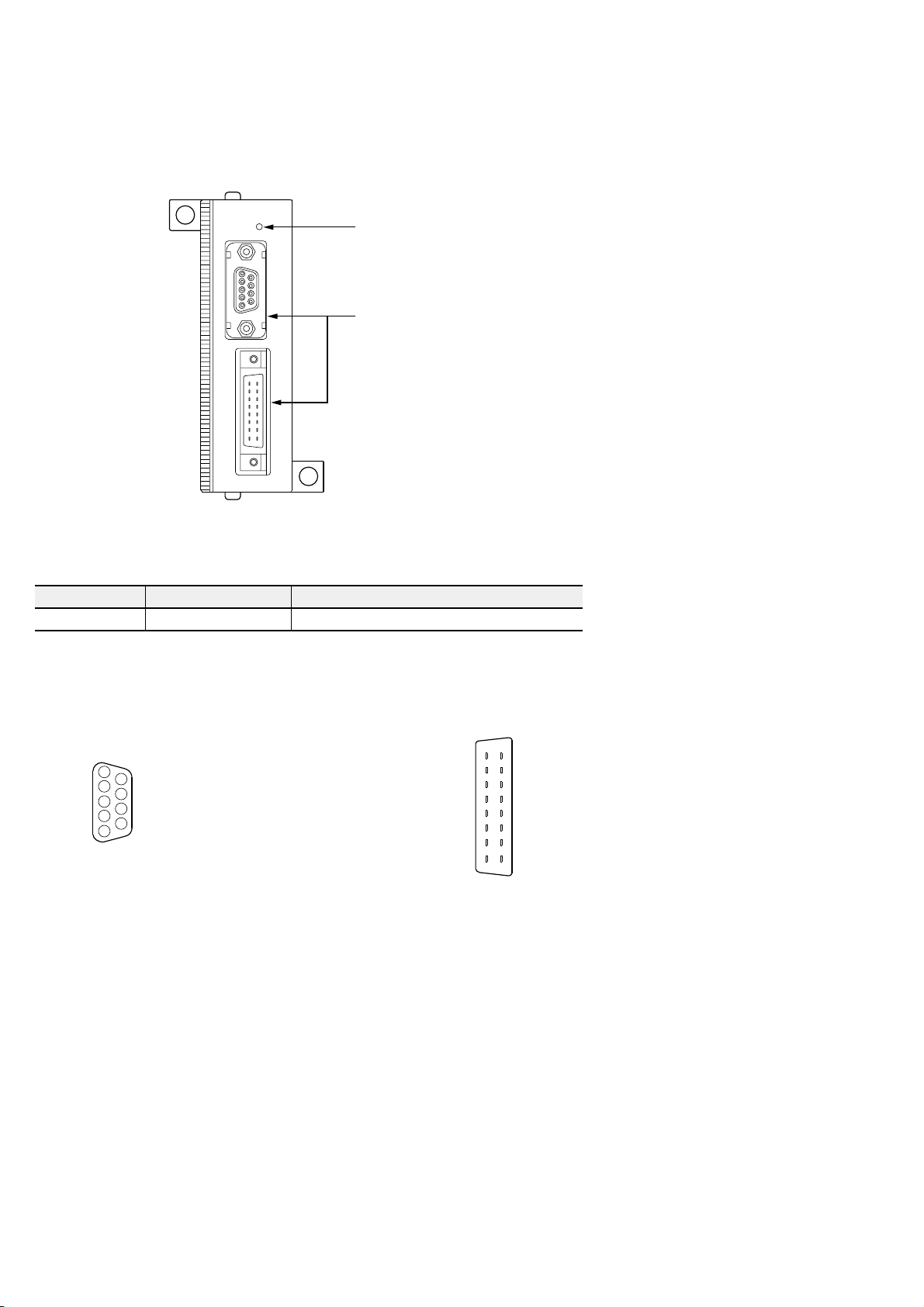

3-3 Names

3-3-2 NP2F-LEV (Signal converter)

PWR

1) Status indication LED

2) External I/O signal connector

LEV

1) Status indication LED

Status indication LED of NP2F-LEV

DELnoitacidnI emaN noitpircseD

)neerG(RWPylppusrewoplamroN.lamronsirewopCDV42nehwnosnruT

2) Connector pin layout for the external I/O signal

A front view (the upper side) A front view (the lower side)

Connector pin layout (9-pin) Connector pin layout (16-pin)

1

1

2

3

4

5

9

8

7

6

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Usable connector Usable connector

• NP2F-LEV side • NP2F-LEV side

Connector···DELC-J9SAF-10L6 (JAE made) Connector···FCN-365P016-AU (Fujitsu)

Use the following connector cover Use the following connector cover

Connector···DEM-9P (JAE made) Connector···FCN-361J016-AU (Fujitsu)

Cover··········DE-C1-J6 (JAE made) Cover··········FCN-360C016-E (Fujitsu)

3-6

Page 23

Signal name (the upper side) Signal name (the lower side)

.oNniP emanlangiS

1V0

2V0

3V0

4V0

5V0

6)1ON(tupnirotcellocnepO

7)2ON(tupnirotcellocnepO

8)3ON(tupnirotcellocnepO

9)4ON(tupnirotcellocnepO

.oNniP emanlangiS .oNniP emanlangiS

1A)P1ON(tuptuolaitnereffidV51B)N1ON(tuptuolaitnereffidV5

2A)P2ON(tuptuolaitnereffidV52B)N2ON(tuptuolaitnereffidV5

3A)P3ON(tuptuolaitnereffidV53B)N3ON(tuptuolaitnereffidV5

4A)P4ON(tuptuolaitnereffidV54B)N4ON(tuptuolaitnereffidV5

5AV5_DNG5BV5_DNG

6ACN6BCN

7A)V42_DNG(CDV07B)V42_DNG(CDV0

8ACDV428BCDV42

3-3 Names

3-7

Page 24

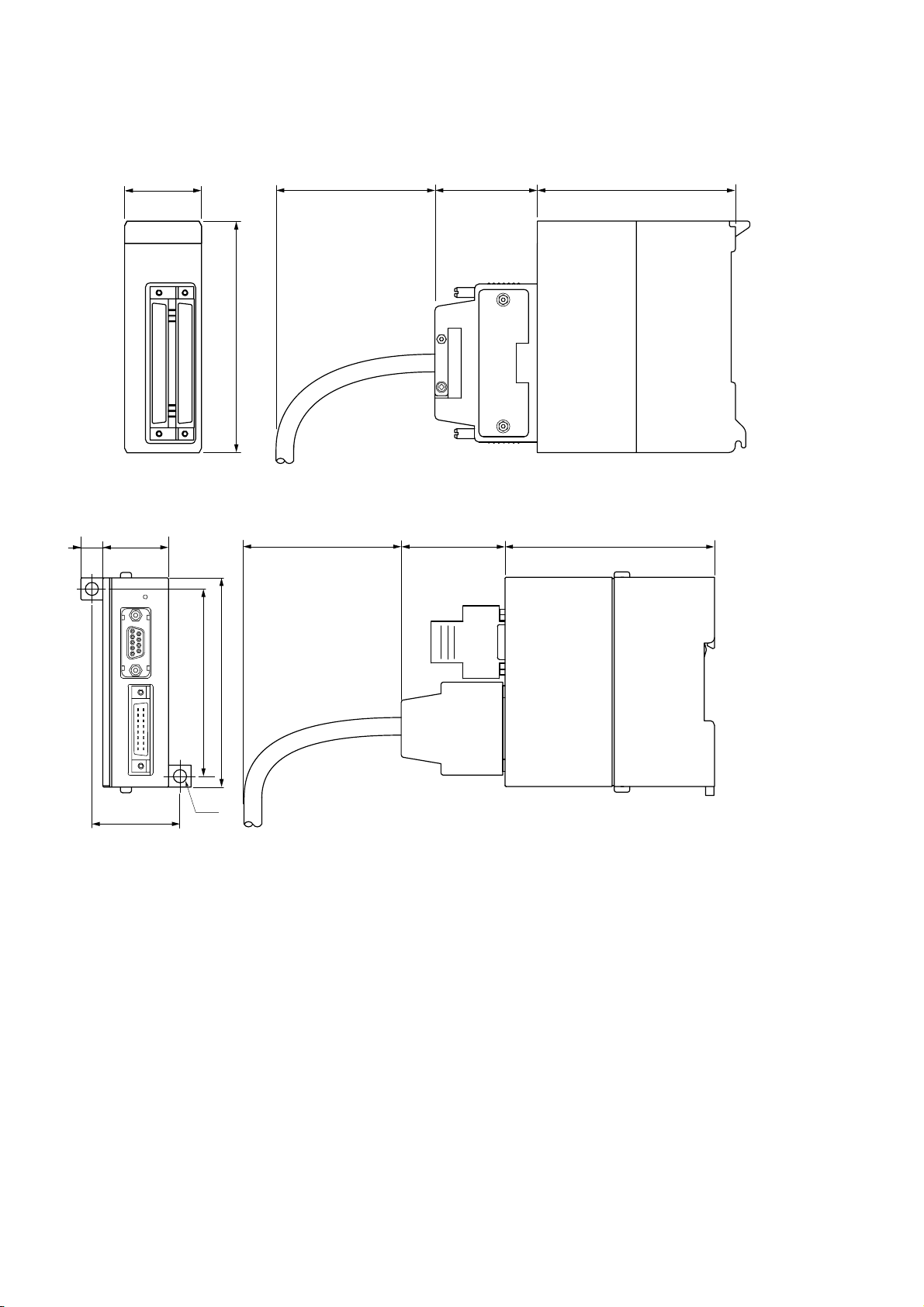

3-4 Dimensions

3-4-1 NP1F-HP2 (for 2 axes)

35

105

3-4-2 NP2F-LEV (Signal converter)

(75)

(46.5)

90

29.8

10

85

95

40

ø6

(75)

95(47.2)

3-8

Page 25

Section 4 Wiring

Page

4-1 Mounting Precautions .............................................................................................4-1

4-1-1 Number of mountable modules (NP1F-HP2) ..................................................................... 4-1

4-1-2 Wiring precautions .............................................................................................................4-2

4-1-3 Wiring example of the external wiring connector ...............................................................4-2

(1) Connector type ................................................................................................................................... 4-2

(2) Connector cover type......................................................................................................................... 4-2

4-2 Connector Pin Layout for the External Connection (NP1F-HP2).........................4-3

4-2-1 External I/O signal specifications (NP1F-HP2) ..................................................................4-4

4-3 Connector Pin Layout for the External Connection (NP2F-LEV).......................4-11

4-3-1 External I/O signal specifications (NP2F-LEV) ................................................................ 4-12

4-3-2 External I/O signal interface (NP2F-LEV) ........................................................................ 4-13

4-4 Connecting .............................................................................................................4-15

4-4-1 Connecting sample of a servo motor ...............................................................................4-15

(1) When the NP1F-HP2 generates the forward pulse or the reverse pulse.......................................... 4-15

(2) Forward pulse command, reverse pulse command .......................................................................... 4-15

(3) Connecting sample of FALDIC-II and NP1F-HP2 ............................................................................. 4-16

(4) Connecting sample of a stepping motor and NP1F-HP2 .................................................................. 4-17

4-5 I/O Wiring ................................................................................................................4-18

(1) Wiring of a connector type module

Page 26

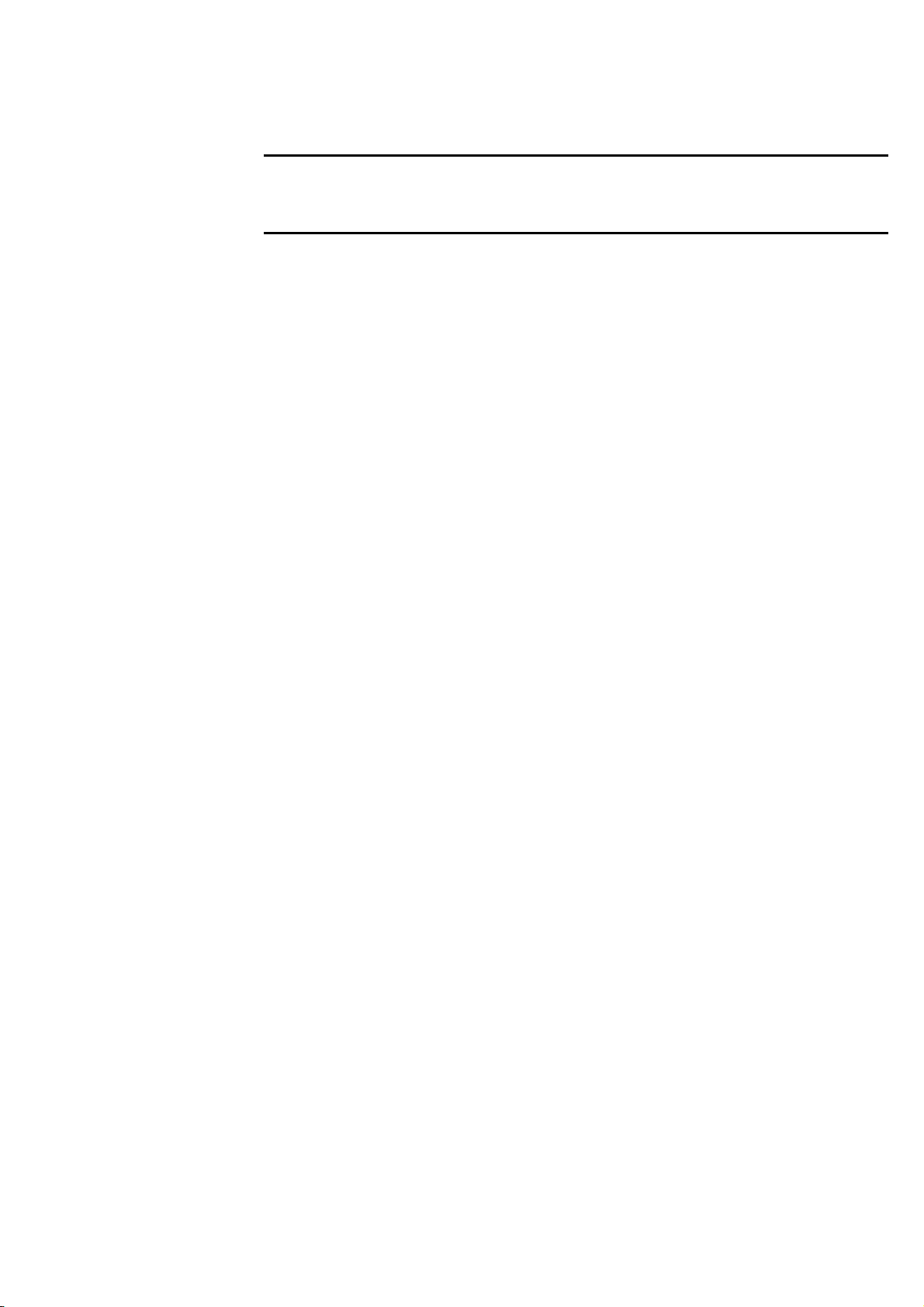

4-1-1 Number of mountable modules (NP1F-HP2)

1) To mount the NP1F-HP2 to the base board where

the CPU module and the power supply module

are mounted on, take the following precautions.

1) Supplied power (Power supply module)

epyT )CDV42(tnerructuptuO

22-S1PNA64.1

)gnipoleveD(24-S1PNA64.1

2) Current consumption

Section 4 Wiring

4-1 Mounting Precautions

The number of mountable modules to the base

board in MICREX-SX is shown below.

)epyT(eludoM tnerruC

UPCecnamrofrep-hgiHA2.0

)2PM-F1PN(lortnocgninoitisopsexa2A590.0

)2AM-F1PN(lortnocgninoitisopsexa2A51.0

)2PH-F1PN(lortnocgninoitisopsexa2A590.0

)2CH-F1PN(retnuocdeeps-hgiHA580.0

)1SR-L1PN(noitacinummocesopruplareneGA11.0

)2CP-F1PN(dracCPA21.0

)1SA-L1PN(i-SAA1.0

)1PJ-L1PN(1-NCPJA31.0

)1LP-L1PN(knil-PA61.0

)1LT-L1PN(retsamknil-TA41.0

skrameR

noitpmusnoc

3) Current consumption of the positioning control

module

NP1F-HP2: 0.095A/ module

For the current consumption of I/O module, refer to

“Appendix-4 Current consumption and Mass of

Calculation method for the number of mountable modules

T-link master

CPU

1.46A - (0.2A + 0.14A + 0.07A)

0.095A (NP1F-HP2)

2) Installation conditions of the positioning control

module base on that conditions of MICREX-SX

Base board

= 11.05 = 11 module

MICREX-SX series.”

series. User’s Manual Hardware, MICREX-SX

series······FEH201

4-1

Page 27

4-1 Mounting Precautions

4-1-2 Wiring precautions

Precautions of wiring the positioning control module and the

external device are shown below.

1) The cable length between the positioning control

module and the driver varies with the driver type.

Confirm the specifications of the driver.

2) I/O wiring

· Do not bundle up or close the I/O cables to the

power cables or the main circuit cables.

· If these cables are closed near, separate the

ducts or wire them separately.

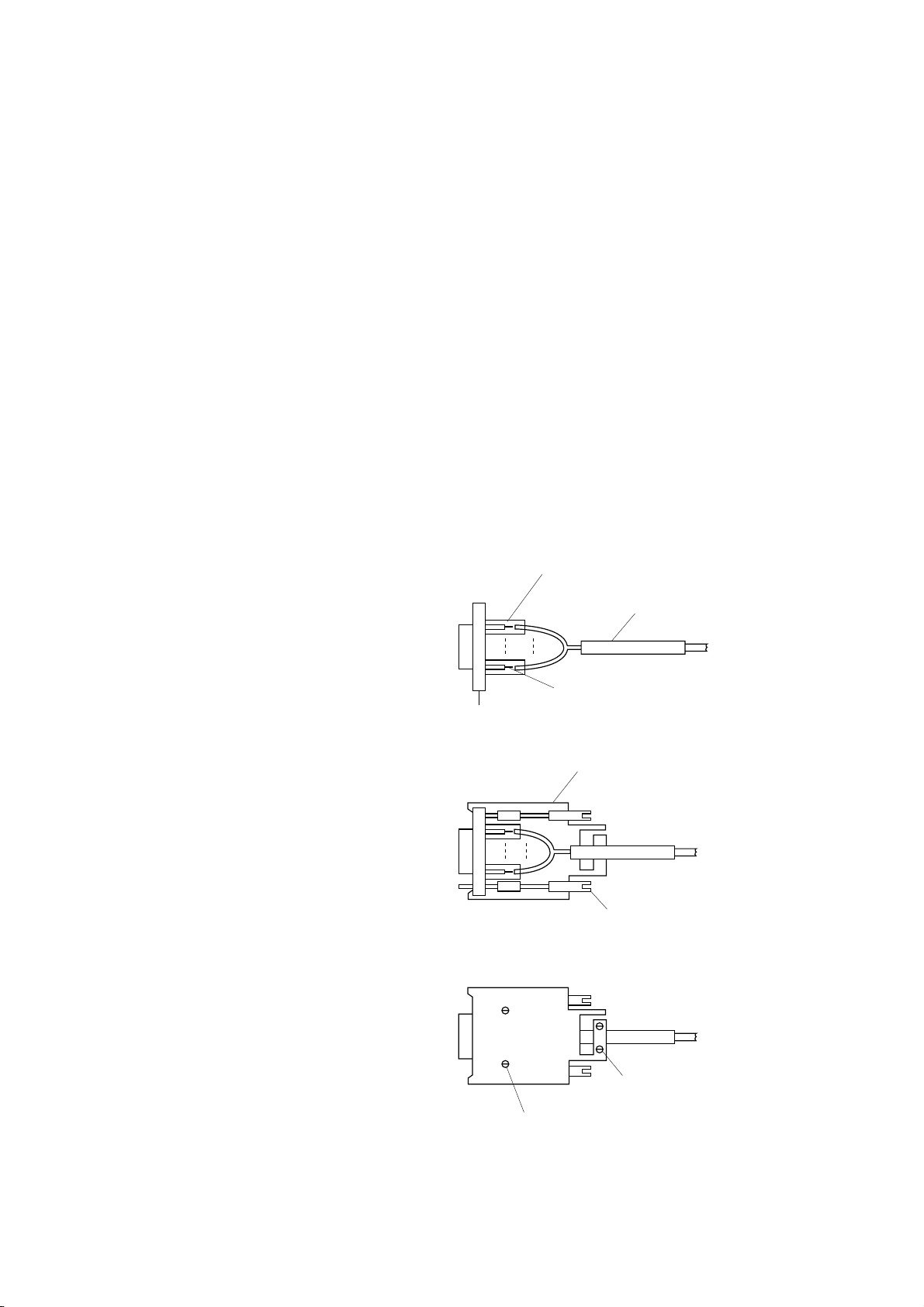

4-1-3 Wiring example of the external wiring

connector

(1) Connector type (2) Connector cover type

FCN-360C040-B (Fujitsu) FCN-361J040-AU (Fujitsu)

· If I/O wiring cannot be separated from the power

cables or the main circuit cables, bound shield

cables must be used and both ends of the shield

must be connected to SG (0V).

· To wire the pulse output, shielded cables must

be used.

· If the ducts are used for wiring, the ducts must

be grounded.

· To wire the open collector, the length of shielded

cable should be 3m or less.

1) Let the wires through the heat-shrinkable

tube. Let each wire through the insulation

tube, and solder them. The heatshrinkable tube is shrunk by a drier.

2)Mount the connector on the case (the

lower), and set the screw.

* Twist the wire in the connector case.

3) Put the case (the upper), and turn screws.

Insulation tube

Heat-shrinkable tube

Soldering

Connector

Case (the lower)

Screw

* For details of usable connector, refer to “4-5 I/O Wiring.”

4-2

Nut, screw and washer

Screw and nut

Page 28

2HC

.oNniP emanlangiS .oNniP emanlangiS

0202BCDV420202ACDV42

9191BCDV09191ACDV0

8181BMOC8181AMOC

7171BtupniTO-7171AtupniGME

6161BtupniTO+6161AtupniSLnigirO

5151B2MOCtupnI5151AtupnitpurretnI

4141B2MOCtupnI4141A2MOCtupnI

3131B

V42:tuptuoroF

CD

3131A

V42:tuptuoroF

CD

2121B2oD2121A1oD

1111BMOCtuptuO1111AMOCtuptuO

0101BMOC0101AMOC

99B

eslupesreveR

tuptuo

99A

eslupesreveR

tuptuo

88B

tuptuoesluP

MOC

88A

tuptuoesluP

MOC

77BC.N77AC.N

66BC.N66AC.N

55B

eslupkcabdeeF

DNG

55A

eslupkcabdeeF

DNG

44B

MOC

44A

eslupkcabdeeF

Z-esahp

33B

MOC

33A

eslupkcabdeeF

Z-esahp*

22BC.N22AC.N

11BC.N11AC.N

4-2 Connector Pin Layout for the

External Connection (NP1F-HP2)

CH1

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

B/A

Signal name Signal name

1HC

.oNniP emanlangiS .oNniP emanlangiS

0202BCDV420202ACDV42

9191BCDV09191ACDV0

8181BMOC8181AMOC

7171BtupniTO-7171AtupniGME

6161BtupniTO+6161AtupniSLnigirO

5151B1MOCtupnI5151AtupnitpurretnI

4141B1MOCtupnI4141A1MOCtupnI

3131B

2121B2oD2121A1oD

1111BMOCtuptuO1111AMOCtuptuO

0101BMOC0101AMOC

99B

88B

77BC.N77AC.N

66BC.N66AC.N

55B

44B

33B

22BC.N22AC.N

11BC.N11AC.N

*1 Do not use NC terminals as repeating terminals.

*2 Feedback pulse GND (A5, B5) are connected internal.

*3 Output COM (A11, B11) are connected internal.

CD

MOC

DNG

MOC

MOC

tuptuo

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

V42:tuptuoroF

eslupesreveR

tuptuoesluP

eslupkcabdeeF

Connector pin layout (40-pin)

· Usable connector

· NP1F-HP2 side

Connector···FCN-365P040-AU (Fujitsu)

Connector···N630-3651-T927 (Fujitsu)

For details of the connector, refer to “4-5 I/O Wiring.”

V42:tuptuoroF

eslupdrawroF

tuptuoesluP

eslupkcabdeeF

eslupkcabdeeF

Z-esahp

eslupkcabdeeF

Z-esahp*

3131A

99A

88A

55A

44A

33A

CD

tuptuo

MOC

DNG

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

CH2

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

B/A

4-3

Page 29

4-2 Connector Pin Lay out for the

External Connection (NP1F-HP2)

*4 For output: 24V DC (A13, B13) are connected internal.

*5 0V DC (A19, B19) are connected internal.

*6 24V DC (A20, B20) are connected internal.

*7 Input COM1 (A14, B14, B15) are connected internal. (Input COM1 is not connected to Input COM2.)

*8 Input COM2 (A14, B14, B15) are connected internal. (Input COM1 is not connected to Input COM2.)

*9 B3, B4, B5, A5, A10, B10, B11, A11, B18, A18, A19 and B19 are connected internal.

*10 For detail specifications of the above signals, refer to 4-2-1.

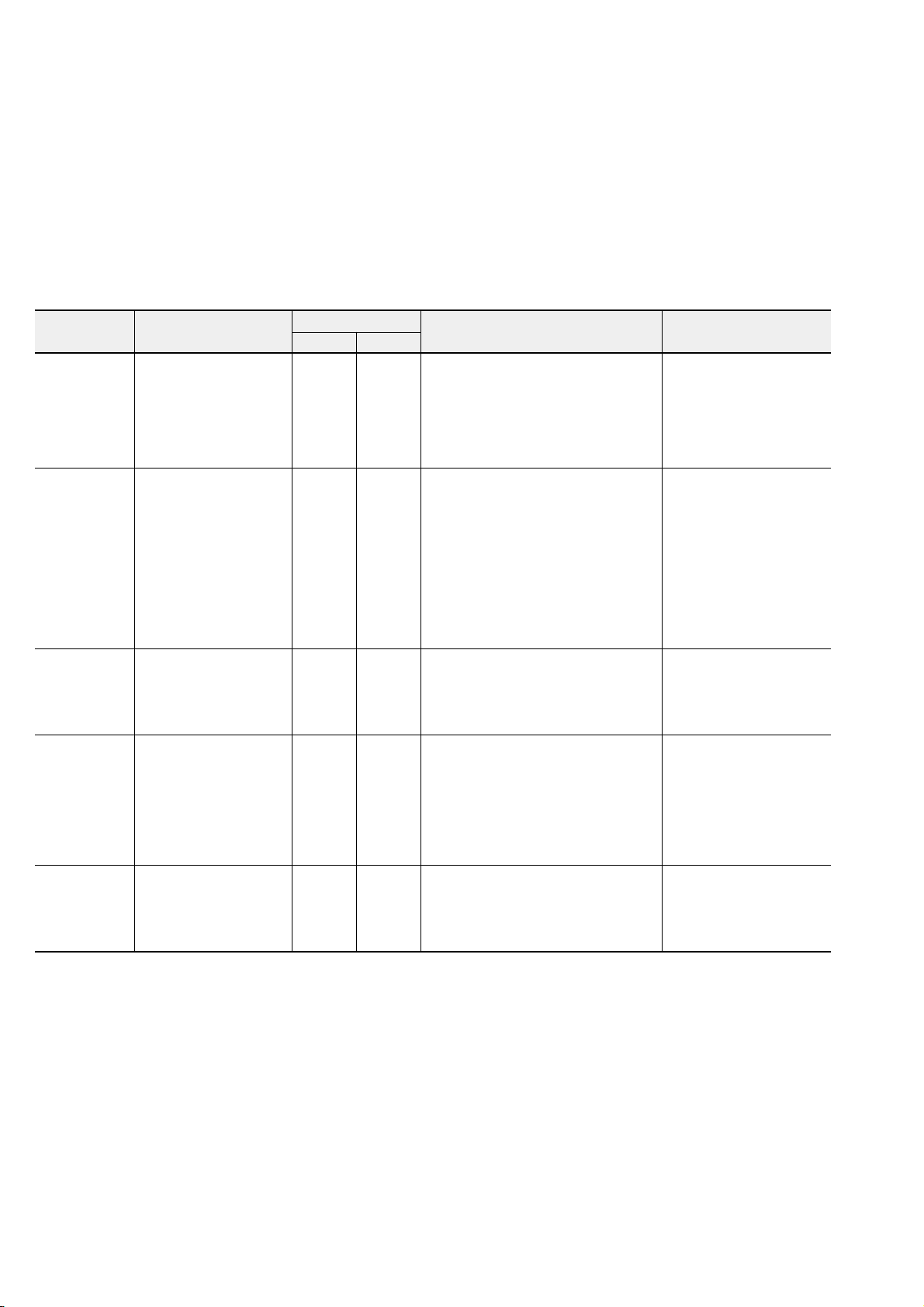

4-2-1 External I/O signal specifications (NP1F-HP2)

emanlangiS lobmyslanimreT .oNniprotcennoC noitcnuF noitacificepS

edis1HC edis2HC

Z-esahp*eslupkcabdeeF3A-1HC3A-2HClangisZ-esahpeslupkcabdeeffotupnICDV5egatlovtupnidetaR

eslupkcabdeeF

)tupnI(langis

tupnitpurretnI51A-1HC51A-2HCreggirtgninoitisoptpurretnifotupnICDV42egatlovtupnidetaR

tupniSLnigirO61A-1HC61A-2HCSLnigirofotupnI

tupniGME71A-1HC71A-2HC)tcatnocCN(potsycnegremefotupnI

langislanretxE

)tupnI(

tuptuoesluP

)tuptuO(langis

tuptuolanretxE

)tuptuO(langis

ylppusrewoP

)tupnI(

tupniTO+61B-1HC61B-2HC)tcatnocCN(noitceridsulpfotupnI

tupniTO-71B-1HC71B-2HC)tcatnocCN(noitceridsunimfotupnI

2,1MOCtupnI41A-1HC41A-2HClangistupnilanretxerofrewopnommoC

2,1MOCtupnI41B-1HC41B-2HClangistupnilanretxerofrewopnommoC

2,1MOCtupnI51B-1HC51B-2HClangistupnilanretxerofrewopnommoC

1OD21A-1HC21A-2HClangistuptuolanretxeroFtniop/A1.0.xaM

2OD21B-1HC21B-2HClangistuptuolanretxeroF

MOCtuptuO11A-1HC11A-2HCylppusrewoplanretxefonommoC

MOCtuptuO11B-1HC11B-2HCylppusrewoplanretxefonommoC

CDV42+02A-1HC02A-2HCylppusrewopV42+CDV42 ± %01

CDV42+02B-1HC02B-2HCylppusrewopV42+

CDV091A-1HC91A-2HCnommocylppusrewoP

CDV091B-1HC91B-2HCnommocylppusrewoP

Z-esahpeslupkcabdeeF4A-1HC4A-2HClangisZ-esahpeslupkcabdeeffotupnI

DNGeslupkcabdeeF5A-1HC5A-2HClangisV0eslupkcabdeeffotupnI

DNGeslupkcabdeeF5B-1HC5B-2HClangisV0eslupkcabdeeffotupnI

MOCtuptuoesluP8A-1HC8A-2HCMOCesluPtniop/Am05.xaM

tuptuoeslupdrawroF9A-1HC9A-2HCeslupnoitceridsulP

MOCtuptuoesluP8B-1HC8B-2HCMOCesluP

tuptuoeslupesreveR9B-1HC9B-2HCeslupnoitceridsuniM

CDV42:tuptuoroF31A-1HC31A-2HC)TUPNI(ylppusrewoplanretxE

CDV42:tuptuoroF31B-1HC31B-2HC)TUPNI(ylppusrewoplanretxE

tnerructupnidetaR

tniop/Am04

021ecnadepmitupnI Ω ro

ssel

ycneuqerfesluptupnI

sppk005.xaM

tnerructupnidetaR

tniop/Am06

k6.3ecnadepmitupnI Ω ro

ssel

ycneuqerfesluptuptuO

sppk052.xaM

A3.0tnerrucegruS

htgnertstnerrucegruS

sm01

4-4

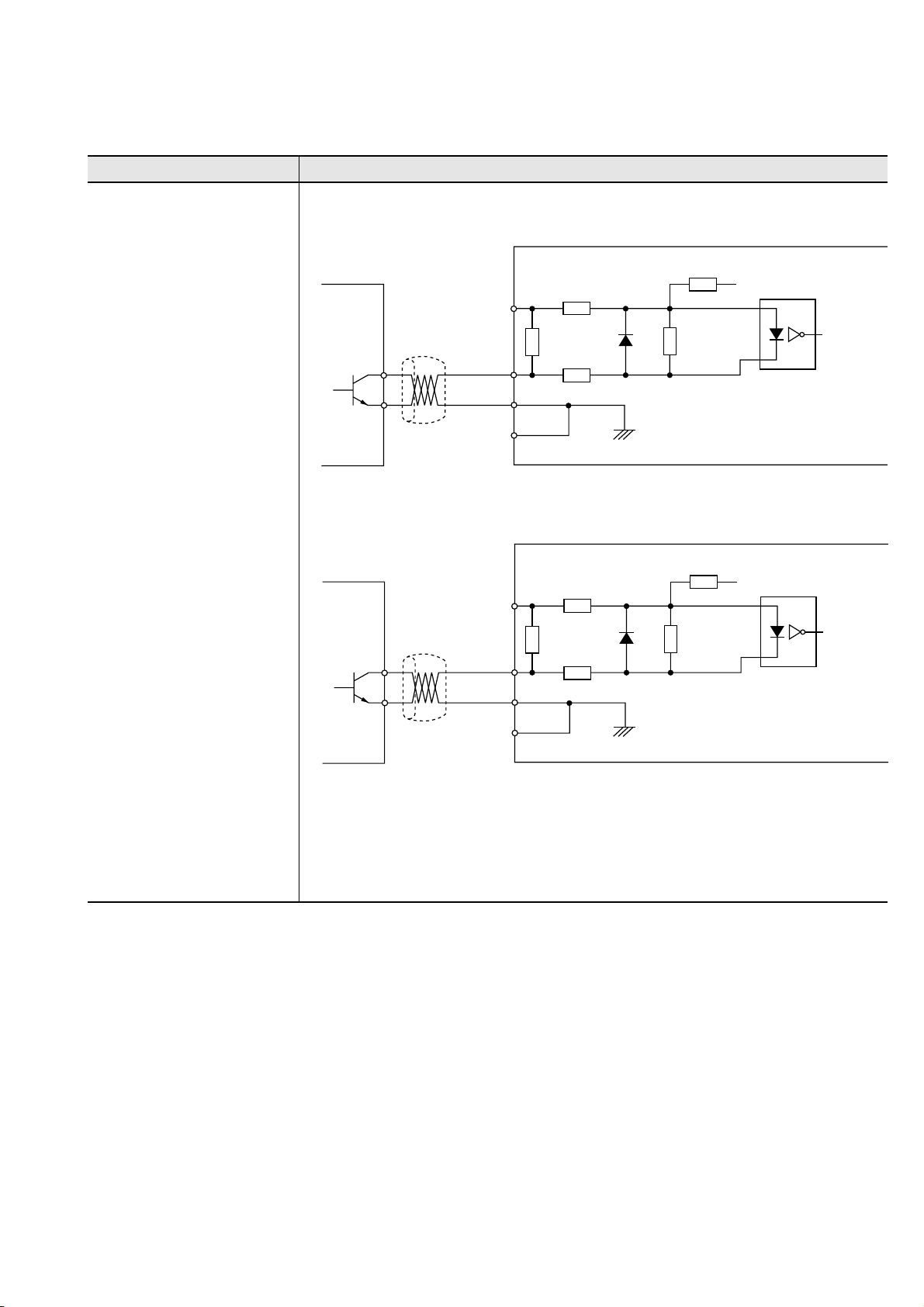

Page 30

Signal name Circuit

Feedback pulse signal

(input)

4-2 Connector Pin Layout for the

External Connection (NP1F-HP2)

Servo side

Phase-Z

Servo side

Phase-Z

CH1-A4

CH1-A3

CH1-A5

CH1-B5

CH2-A4

CH2-A3

CH2-A5

220Ω

220Ω

120Ω

120Ω

120Ω

120Ω

120Ω

510Ω

120Ω

510Ω

+5V

Phase-Z

CH1 side

+5V

Phase-Z

CH2-B5

When the feedback pulse signal is driven by a open collector.

CH2 side

4-5

Page 31

4-2 Connector Pin Lay out for the

External Connection (NP1F-HP2)

Signal name Circuit

Feedback pulse signal

(input)

Servo side

Phase-Z

Servo side

Phase-Z

CH1-A4

CH1-A3

CH1-A5

CH1-B5

CH2-A4

CH2-A3

CH2-A5

120Ω

220Ω

120Ω

220Ω

120Ω

120Ω

120Ω

510Ω

120Ω

510Ω

+5V

Phase-Z

CH1 side

+5V

Phase-Z

CH2-B5

When the feedback pulse signal is driven by a line driver.

CH2 side

4-6

Page 32

Signal name Circuit

4-2 Connector Pin Layout for the

External Connection (NP1F-HP2)

External input signal

(input)

-OT

+OT

Emergency

stop

Origin LS

Interrupt

+24V

CH1-A14

CH1-B17

CH1-B16

CH1-A17

CH1-A16

CH1-A15

1.8kΩ

1.8kΩ

1.8kΩ

1.8kΩ

1.8kΩ

1.8kΩ

1.8kΩ

1.8kΩ

1.8kΩ

1.8kΩ

820Ω

820Ω

820Ω

820Ω

820Ω

-OT

+OT

Emergency

stop

Origin LS

+24V

CH2-A14

CH2-B17

CH2-B16

CH2-A17

CH2-A16

1.8kΩ

1.8kΩ

1.8kΩ

1.8kΩ

1.8kΩ

1.8kΩ

1.8kΩ

1.8kΩ

CH1 side

820Ω

820Ω

820Ω

820Ω

Interrupt

CH2-A15

1.8kΩ

1.8kΩ

820Ω

CH2 side

4-7

Page 33

4-2 Connector Pin Lay out for the

External Connection (NP1F-HP2)

Signal name Circuit

Pulse output signal

(output)

1kΩ

1kΩ

CH1 side

1kΩ

1kΩ

CH1-A9

CH1-A8

CH1-B9

CH1-B8

CH2-A9

CA

*CA

CB

*CB

CM

Servo side

CA

1kΩ

CH2-A8

1kΩ

CH2-B9

1kΩ

CH2-B8

1kΩ

CH2 side

*CA

CB

*CB

CM

Servo side

When the servo device has a interface which inputs the output of a open collector externally

4-8

Page 34

Signal name Circuit

External output

signal

3.9kΩ

4-2 Connector Pin Layout for the

External Connection (NP1F-HP2)

+24V

CH1-A13

CH1 side

3.9kΩ

CH1-A12

CH1-A11

CH1-B12

CH1-B11

Ry

Ry

+24V

3.9kΩ

3.9kΩ

CH2-A13

CH2-A12

CH2-A11

CH2-B12

CH2-B11

Ry

Ry

CH2 side

4-9

Page 35

4-2 Connector Pin Lay out for the

External Connection (NP1F-HP2)

Signal name Circuit

Power supply

0V

+24V

Power supply

0V

+24V

CH1-A19

CH1-A20

CH1-B19

CH1-B20

CH1 side

CH2-A19

CH2-A20

Power supply

CH2-B19

CH2-B20

CH2 side

4-10

Page 36

4-3 Connector Pin Lay out for the External

A front view (the upper side) Signal name

Connector pin layout (9-pin)

1

2

3

4

5

Usable connector

• NP2F-LEV1 side

Connector ··· DELC-J9SAF-13L6 (JAE made)

Use the following connector cover.

Connector ··· DE-9P-N (JAE made)

Cover ·········· DE-C1-J6 (JAE made)

6

7

8

9

.oNniP emanlangiS

1V0

2V0

3V0

4V0

5V0

6)1ON(tupnirotcellocnepO

7)2ON(tupnirotcellocnepO

8)3ON(tupnirotcellocnepO

9)4ON(tupnirotcellocnepO

Connection (NP2F-LEV)

A front view (the lower side) Signal name

Connector pin layout (16-pin)

A

1

2

3

4

5

6

7

8

Usable connector

• NP2F-LEV side

Connector ··· FCN-365P016AU (Fujitsu)

Use the following connector cover.

Connector ··· FCN-361J016-AU (Fujitsu)

Cover ·········· FCN-360C016-B (Fujitsu)

B

1

2

3

4

5

6

7

8

.oNniP emanlangiS .oNniP emanlangiS

1A)P1ON(tuptuolaitnereffidV51B)N1ON(tuptuolaitnereffidV5

2A)P2ON(tuptuolaitnereffidV52B)N2ON(tuptuolaitnereffidV5

3A)P3ON(tuptuolaitnereffidV53B)N3ON(tuptuolaitnereffidV5

4A)P4ON(tuptuolaitnereffidV54B)N4ON(tuptuolaitnereffidV5

5AV5_DNG5BV5_DNG

6ACN6BCN

7A)V42_DNG(CDV07B)V42_DNG(CDV0

8ACDV428BCDV42

4-11

Page 37

4-3 Connector Pin Lay out for the External

Connection (NP2F-LEV)

4-3-1 External I/O signal specifications (NP2F-LEV)

emanlangiS lobmyslanimreT .oNniprotcennoC noitcnuF noitacificepS

nommoctupnI5,4,3,2,1langistupnirofnommoCtupnidetaR

rotcennocedistupnI

)nip-9(

rotcennocedistuptuO

)nip-61(

langistupniroF6 )1NI(langistupniroF

langistupniroF7 )2NI(langistupniroF

langistupniroF8 )3NI(langistupniroF

langistupniroF9 )4NI(langistupniroF

nommoctuptuO1B)1TUO(langistuptuorofnommoCAm03.xaM

2B)2TUO(langistuptuorofnommoC

3B)3TUO(langistuptuorofnommoC

4B)4TUO(langistuptuorofnommoC

langistuptuoroF1A)1TUO(langistuptuoroF

2A)2TUO(langistuptuoroF

3A)3TUO(langistuptuoroF

4A)4TUO(langistuptuoroF

ylppusrewoprofnommoC5B,5AnommocedisV5

7B,7AnommocedisV42

ylppusrewoproftupnI8B,8AedisV42+

Am02tnerruc

esluptupnI

ycneuqerf

zHM1.xaM

esluptuptuO

ycneuqerf

zHM1.xaM

CDV42 ± %01

4-12

Page 38

4-3 Connector Pin Lay out for the External

4-3-2 External I/O signal interface (NP2F-LEV)

Signal name Circuit

Input side connector

(9-pin)

Connection (NP2F-LEV)

CH1 side

(Pulse output)

A9

A8

B9

B8

220Ω

6

220Ω

7

220Ω

8

220Ω

9

1

2

3

390Ω

390Ω

390Ω

390Ω

+5V

+5V

+5V

+5V

10kΩ

10kΩ

10kΩ

10kΩ

4

5

Converter side

4-13

Page 39

4-3 Connector Pin Lay out for the External

Connection (NP2F-LEV)

Signal name Circuit

Output side connector

(16-pin)

A1

B1

A2

B2

A3

B3

A4

B4

A8

A7

B8

B7

A5

0V

Servo side

+24V

4-14

B5

Connector side

Page 40

4-4 Connecting

4-4-1 Connecting sample of a servo motor

· The relationship between the pulse generated by the

NP1F-HP2 and the rotation of a servo motor is as shown

below.

Note: Forward rotation and reverse rotation of the Fuji’s ser vo motor are reserved for other manufactures.

The direction indication of the motor rotation is

the shaft view from the motor mounted side.

CCW

(Counterclockwise) Forward rotation

(1) When the NP1F-HP2 generates the forward pulse or

the reverse pulse

Forward pulse····CCW

Reverse pulse····CW

(at 2-phase pulse input)

Forward pulse

Reverse pulse

(2) Forward pulse command, reverse pulse command

Forward pulse

Reverse pulse

H

L

H

L

CCW

“H”

(Clockwise) Reverse rotation

CW

Plus direction pulse

CW

“H”

“H”“H”

Command pulse is output as 50% duty rate.

Minus direction pulse

4-15

Page 41

4-4 Connecting

(3) Connecting sample of FALDIC-II and NP1F-HP2

Pulse train positioning

control combined module

NP1F-HP2

Servo amplifier

RYG***HA-VV

Servo motor

GRH***BG-**

Forward pulse output

Pulse output COM

Reverse pulse output

E5V

Pulse output COM

Feedback pulse

Feedback pulse

Feedback pulse

Feedback pulse

phase-Z

*phase-Z

GND

GND

A9

A8

B9

B8

A4

A3

A5

B5

9

CA

34

*CA

10

CB

35

*CB

33

M5

36

FA

38

FB

40

FZ

39

M5

41

M5

3

P10

5

VIN1

4

M5

28 N10

7

VIN2

6

M5

30

VIN3

29

M5

32

VIN4

31

M5

CN1

M5

P5

P5

M5

M5

*A

*B

*Z

*1

*2

*3

U

V

W

E

1

CN2

2

13

14

9

A

20

8

B

19

Z

Dedicated cable

RYWE810

7

18

6

1

17

5

2

16

4

3

U

V

W

E

14

8

1

2

3

4

5

6

7

8

9

10

11

12

15

+5V

OV

A

*A

B

*B

Z

*Z

1

*1

2

*2

3

*3

Shield

Motor

Encoder

15

Output COM

Output COM

For output: 24V DC

For output: 24V DC

Input COM1

Input COM1

0V DC

0V DC

24V DC

24V DC

Do1

Output COM

Do2

Interrupt input

Input COM

Origin LS

EMG

+OT input

-OT input

(ch1 side)

A11

B11

A13

B13

A14

B14

A19

B19

A20

B20

A12

B12

A15

A16

A17

B16

B17

P24

N24

External I/O

N24

+24V

DC

Power

supply

0V

P24

N24

PC

PC

25

P24

24

P24

18

M24

17

M24

50 CONT1

(RUN)

49 CONT2

(FWD)

48 CONT3

(REV)

47 CONT4

(RST)

46 CONT5

(X1)

23 CONT6

(X2)

CONT7

22

(Pulse train magnification)

21 CONT8

(P function)

30B

TB

30C

CN1

(

Zero deviation

M24

M5

(RDY)

P24

12

45OUT1

44OUT2

43OUT3

42OUT4

20OUT5

19OUT6

26M5

27M5

P24

PC

)

2MON1

1MON2

R

S

T

Note: When the emergency stop is

input to the servo amplifier,

assign it to the CONT signal.

Power

supply

3ø

200V

4-16

Page 42

(4) Connecting sample of a stepping motor and NP1F-HP2

Pulse train positioning

control combined module

NP1F-HP2

Stepping motor

driver

4-4 Connecting

Forward pulse

Pulse output

Reverse pulse

Pulse output

E5V

Feedback pulse

Feedback pulse

Feedback pulse

Feedback pulse

Output COM

For output: 24V DC

Input COM1

Input COM

24V DC

Interrupt input

Origin LS input

EMG input

+OT input

-OT input

output

COM

output

COM

phase-Z

phase-Z

GND

GND

0V DC

A9

A8

B9

B8

A4

A3

A5

B5

A11

A13

A14

A19

A20

A15

A16

A17

B16

B17

+24V

+5V

+CW

-CW

+CCW

-CCW

TIM

COM

Stepping motor

BLACK

RED

GREEN

BLUE

AC100V

AC100V

4-17

Page 43

4-5 I/O Wiring

·I/O wiring depends on the module type, connected external

devices, electrical specifications and the environment.

(1) Wiring of a connector type module

Usable connector and applicable cable size are shown below.

noitacifissalC )ustijuF(epyT eziselbaC

epytderedloS

)etoN(

:tekcoS

UA-040J163-NCF

Soldered type

Crimp type

:revocrotcennoC

B-040C063-NCF

sselro32GWA

2

mm62.0(

)sselro

Note: For the soldered type connector, NP8V-CN1 (Fuji) is supplied.

4-18

Page 44

Section 5 Memory Map

Page

5-1 NP1F-HP2 Memory Map (Internal Memory List) .................................................... 5-1

5-2 I/O Area of NP1F-HP2 .............................................................................................. 5-2

5-2-1 NP1F-HP2 (read area: address No. 0 to No. 7)................................................................. 5-3

(1) Bit data signal (status signal, lower word, ch1: address No. 0, ch2: address No.4) ........................... 5-3

(2) Bit data signal (status signal, upper word, ch1: address No. 1, ch2: address No. 5) ....................... 5-10

(3) Current value area (ch1: address No. 2: lower word; address No. 3: upper word,

ch2: address No. 6: lower word; address No. 7: upper word) .......................................................... 5-13

5-2-2 NP1F-HP2 (Write area, address Nos. 8 to 15) ................................................................ 5-14

(1) Bit command signal (write signal, lower word ch1: address No. 8, ch2: address No. 12) ................ 5-14

(2) Bit command signal (write signal, ch1: address No. 9, ch2: address No. 13, upper word)............... 5-26

(3) Set value area (write signal, ch1: address Nos. 10 and 11, ch2: address Nos. 14 and 15).............. 5-31

5-3 Setting Method and Effective Bits........................................................................ 5-32

Page 45

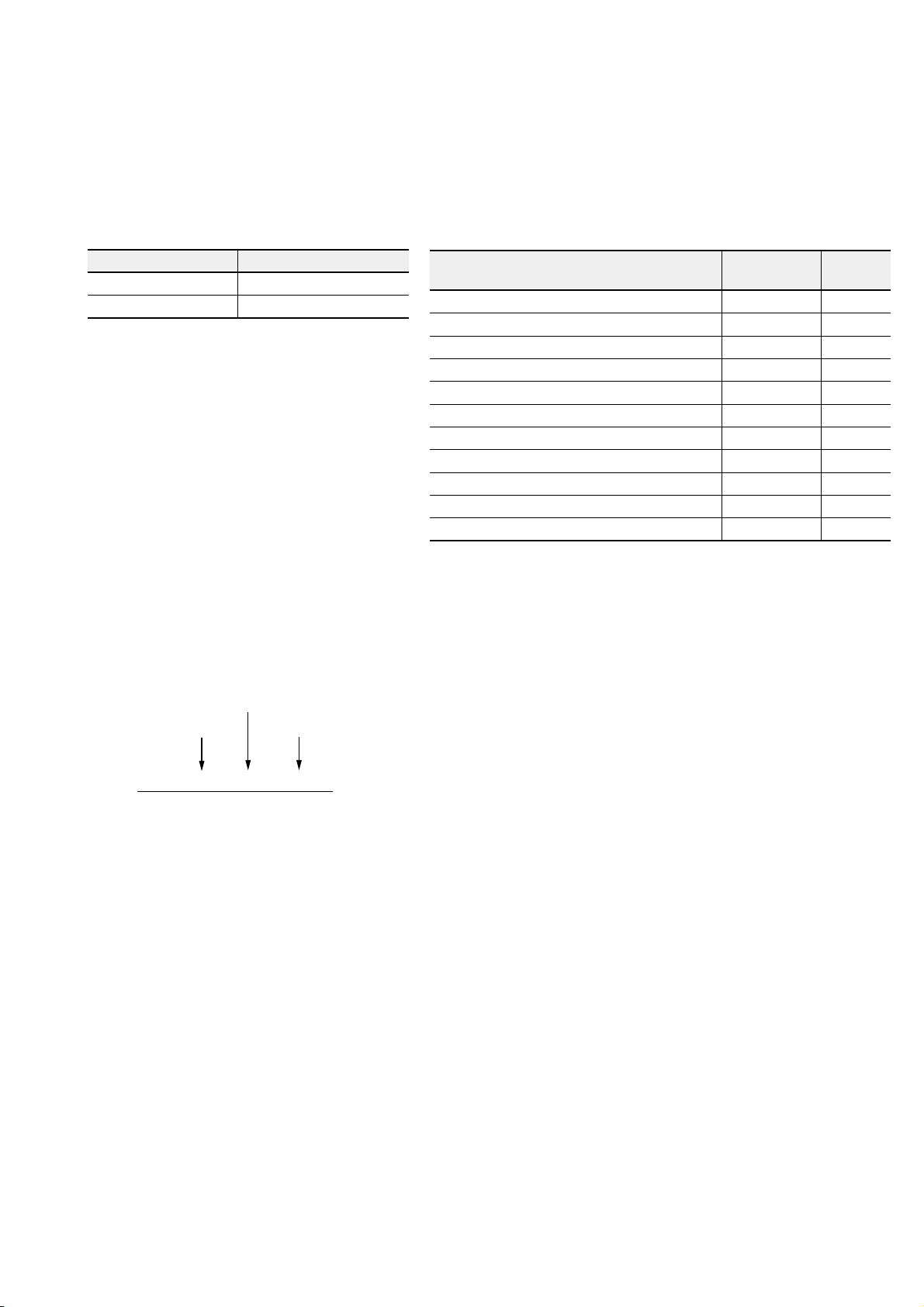

5-1 NP1F-HP2 Memory Map (Internal Memory List)

· The memory map for THE NP1F-HP2 is shown below.

Data is passed from the CPU via an SX bus and I/O area

(I/Q area).

CPU program

I/O area (occupies 16 words)

0retsigerycneuqerftegraT

1retsigerycneuqerfesaB

Write

Read

2retsigerycneuqerftnerruC

3retsigereslupdnammoC

4retsigertniopnoitareleceD

51retsigernoitareleced/noitareleccA

62retsigernoitareleced/noitareleccA

7retsigernoitacilpitlumdeepS

8retnuoceslupdnammoC

:

:

:

13devreseR

Section 5 Memory Map

)yromemlanretnI(pamyromem2PH-F1PN

.oNsserddA emaN

:

:

:

5-1

Page 46

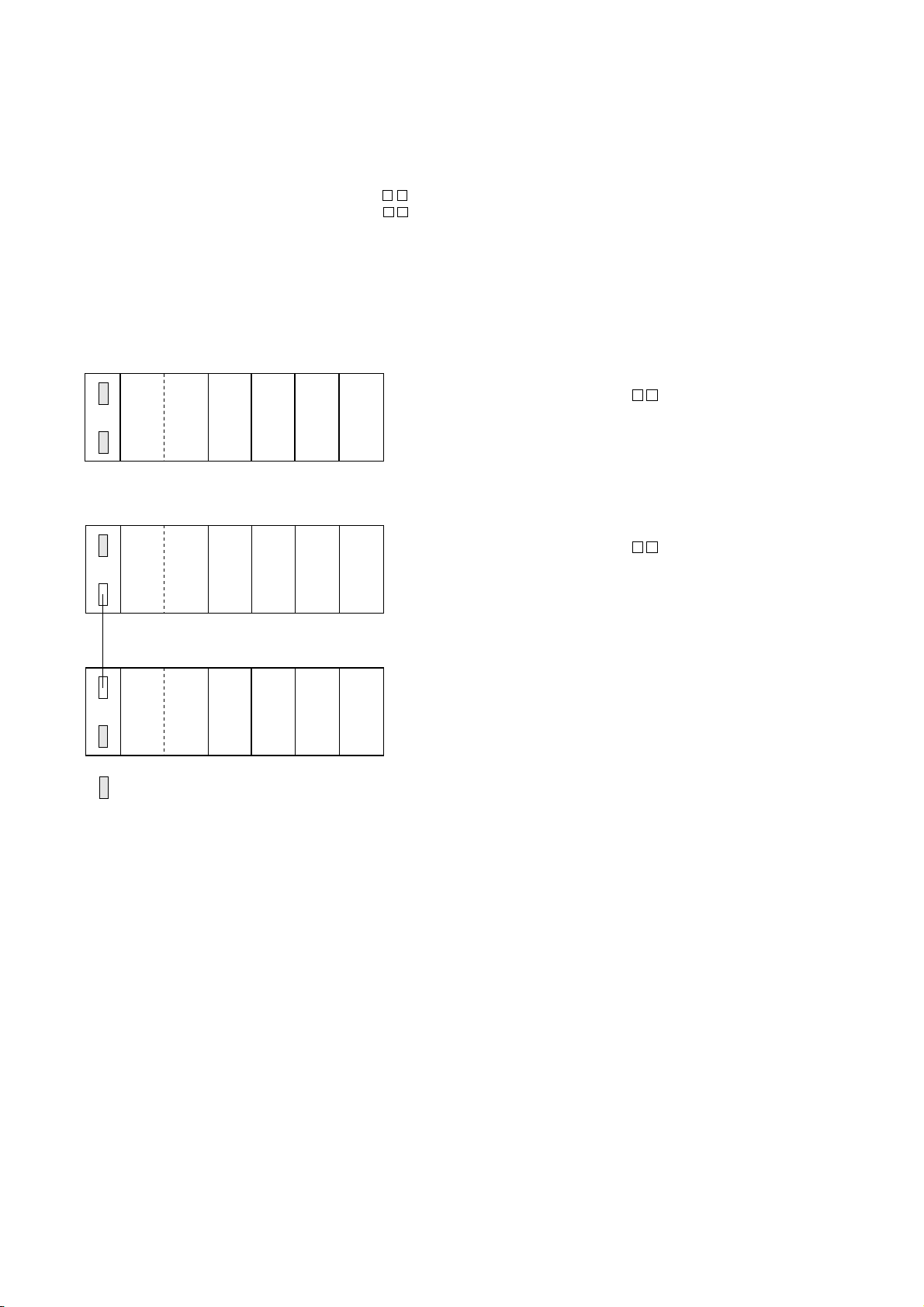

5-2 I/O Area of NP1F-HP2

The I/O area (I/Q area) of the NP1F-HP2 is shown below:

10 9 8 7 6 5 4 3 2 1 0

Address No.

0 Ch1 Bit data signal : Read area

1 Ch1 Bit data signal : Read area

2 Ch1 Current value data : Read area

3

4 Ch2 Bit data signal : Read area

5

14

15

Ch1 Current value data : Read area

Ch2 Bit data signal : Read area

13

12

11

lower word

HP2 to PC

upper word

HP2 to PC

lower word

HP2 to PC

upper word

HP2 to PC

lower word

HP2 to PC

upper word

HP2 to PC

lower word

HP2 to PC

upper word

HP2 to PC

lower word

PC to HP2

upper word

PC to HP2

lower word

PC to HP2

upper word

PC to HP2

6 Ch2 Current value data : Read area

7 Ch2 Current value data : Read area

8

9 Ch1 Bit command signal : Write area

10

11

12

13

14

15

Ch1 Bit command signal : Write area

Ch1 Set value : Write area

Ch1 Set value : Write area

Ch2 Bit command signal : Write area

Ch2 Bit command signal : Write area

Ch2 Set value : Write area

Ch2 Set value : Write area

lower word

PC to HP2

upper word

PC to HP2

lower word

PC to HP2

upper word

PC to HP2

The I/O area of NP1F-HP2 occupies 16 words.

5-2

Page 47

5-2 I/O Area of NP1F-HP2

5-2-1 NP1F-HP2 (read area: address No. 0 to No. 7)

(1) Bit data signal (status signal, lower word, ch1: address No. 0, ch2: address No.4)

.oNtiB emanlangiS noitpircseD

0desutoN"0"syawlA

1orezeslupdnammoC ".0"siretsigereslupdnammocehtfoeulavehtelihw"1"

2dnegninoitisoP .deppotssahgnittuptuoeslupehtnehw"1"

3noitceridnoitatortnerruC

4teserretnuoceulavtnerrucotesnopseR dnammocteserretnuoceulavtnerrucotlangisesnopseR

5gnignahcdeepS

6tcetedlangisZ-esahP .detcetedsiZ-esahpnehw"1",delbanesinoitcetedlangisZ-esahpelihW

7tcetednoitisoptpurretnI

8desutoN"0"syawlA

9gnitareleced/gnitareleccA noitareleced/noitareleccagnirud"1"

01rorrepotsycnegremE detcetedsirorrepotsycnegremenehw"1"

11rorreTO+detcetedsirorreTO+nehw"1"

21rorreTO-detcetedsirorreTO-nehw"1"

31desutoN"0"syawlA

41desutoN"0"syawlA

51rorrenoissimsnarT

tuptuo

.detucexe

.detceted

gniebsieslupesrevernehw"1";tuptuogniebsieslupdrawrofnehw"0"

si)retsigerycneuqerftegrat(ataddeepsfognitirwsuounitnoc,"1"elihW

silangistpurretniehtnehw"1",delbanesinoitcetedlangistpurretnielihW

)1etoN(detcetedsirorrenoissimsnartnehw"1"

A detailed explanation of individual signal names is given on

the following pages.

Precautions:

· The transmission error detect signal is output to channel 1. (NP1F-HP2 only)

· When the Pulse Train Positioning Control Combined Module (NP1F-MP2) or the Analog Command Positioning Control

Combined Module (NP1F-MA2) is used, a transmission error detection signal is output to the Ch1 area or the Ch2 area.

5-3

Page 48

5-2 I/O Area of NP1F-HP2

1) Description of signal names

)desutoN(:emanlangiS(0tiB

<Description>

)oreZesluPdnammoC:emanlangiS(1tiB

<Description>

· This signal becomes “1” while the command pulse register

is “0”. The command pulse register becomes “1” when

pulse output is completed, when the command pulse

register reset command is issued.

Register select

(PC to HP2)

Set value data

(PC to HP2)

Write command

(PC to HP2)

Response to write command

(HP2 to PC)

Start command

(PC to HP2)

Positioning end

(HP2 to PC)

Command pulse zero

(HP2 to PC)

“1”

(0010)

(10,000)

“1”

“1”

“1”

“1”

“1”

Pulse outputting

“1”

5-4

Page 49

)dnEgninoitisoP:emanlangiS(2tiB

(

)

<Description>

· This signal becomes “1” while the command pulse output

is stopped. This signal also becomes “1” while the start

5-2 I/O Area of NP1F-HP2

command is “1,” even when the command pulse output

is stopped.

Start command

(PC to HP2)

Positioning end

(HP2 to PC)

Precautions:

·

If there are not many pulse counts, the command pulse outputting ends in a short time.

<Description>

· Indicates which direction to output the command pulse in.

“0”: forward; “1”: reverse

“1”“1”“1”

“1”

Pulse outputting

Pulse outputting

)noitceridnoitatortnerruC:emanlangiS(3tiB

·The bit data for the direction of rotation is changed over

when pulse output is started by the start command.

“1”

Rotating direction select

(PC to HP2)

Start command

(PC to HP2)

Positioning end

(HP2 to PC)

Rotating direction

HP2 to PC

“1”“0”

“1”“1”

“1”“1”

Outputting reverse pulseOutputting forward pulse

“1”“0”

5-5

Page 50

5-2 I/O Area of NP1F-HP2

<Description>

· This is a response signal to the current value counter

reset command or command pulse register reset

commands.

)teseRretnuoCeulaVtnerruCotesnopseR:emanlangiS(4tiB

This signal becomes “1” while the current value counter

reset command or command pulse register reset

command is “1.”

Current value counter reset command

(PC to HP2)

Command pulse register reset command

(PC to HP2)

Response to current counter reset

(HP2 to PC)

Current value counter is reset. Command pulse register is reset.

gnignahCdeepS:emanlangiS(5tiB

<Description>

· This is a response signal to the speed change command.

While this signal is “1,” the values stored in the set value

data area are continuously written in the “target

“1”

“1”

“1”“1”

frequency register.” Frequency (speed) data can be

changed from the CPU module. (For details, refer to the

paragraph for speed change command.)

)tceteDlangiSZ-esahP:emanlangiS(6tiB

<Description>

· This signal becomes “1” when an effective phase-Z

signal is detected after the phase-Z signal detect

command has become “1.”

· While this signal is “1,” the lower word of the current

value counter when phase-Z was detected is output in

current value data area.

· When the phase-Z signal detect command has become

“0,” this signal becomes “0,” and current value data area

(upper word) returns to the current value counter upper

word output mode.

(For details, refer to the paragraph for phase-Z signal

detect command.)

5-6

Page 51

)tceteDnoitisoPtpurretnI:emanlangiS(7tiB

<Description>

· This signal becomes “1” when the interrupt signal is

detected after the interrupt position detect command has

become “1.”

· While this signal is “1,” the lower word of the current

value counter when the interrupt signal was detected is

output in current value data area.

)desutoN:emanlangiS(8tiB

5-2 I/O Area of NP1F-HP25-2 I/O Area of NP1F-HP2

· When interrupt position detect command becomes “0,”

this signal becomes “0,” and current value data area

returns to the current value counter upper word output

mode.

(For details, refer to the paragraph for interrupt position

detect command.)

<Description>

)gnitareleceD/gnitareleccA:emanlangiS(9tiB

<Description>

· This signal becomes “1” while the accelerating/

decelerating operation is being executed by this module

Frequency

Start command

(PC to HP2)

“1”

(while the frequency of the command pulse is changing).

Time

Positioning end

(HP2 to PC)

Accelerating/decelerating

(HP2 to PC)

“1”

“1”

“1”

5-7

Page 52

5-2 I/O Area of NP1F-HP2

)rorrEpotSycnegremE:emanlangiS(01tiB

<Description>

· This signal becomes “1” when it is detected that the

emergency stop input signal has become “OFF” (NC

contact signal). After the emergency stop input signal has

been returned to the normal state, when the rising edge

at which alarm reset signal changes from “0” to “1” are

detected, this signal becomes “0.”

· While this signal is “1,” the start command is not

accepted.

(For details, refer to the paragraph for emergency stop

motion.)

Emergency stop signal input

(external input)

Emergency stop error

(HP2 to PC)

Alarm reset

(PC to HP2)

Error signal cannot be reset because the emergency stop signal input is OFF.

)rorrETO+:emanlangiS(11tiB

<Description>

· When the +OT signal is enabled, this signal becomes “1”

the moment the +OT input signal becomes “OFF” (NC

contact signal) and an +OT error is detected.

· After the +OT input signal has been returned to the

normal state, when the rising edge at which alarm reset

signal changes from “0” to “1” are detected, this signal

ON OFF

“1”

“1”

returns to “0.”

· When an +OT error is detected, no command in the

forward direction will be accepted.

· Enabling/disabling of +OT signal detection is selected by

the control register.

(For details, refer to the paragraph for ±OT error motion.)

“1”

5-8

+OT input

(external input)

+OT error

(HP2 to PC)

Alarm reset

(PC to HP2)

ON OFF

“1”

“1”“1”

Error signal cannot be reset because +OT input is OFF.

Page 53

)rorrETO-:emanlangiS(21tiB

<Description>

· When the -OT signal is enabled, this signal becomes “1”

when the -OT input signal becomes “OFF” (NC contact

signal) and an -OT error is detected.

· After the -OT input signal has been returned to the

normal state, when the rising edge at which alarm reset

signal changes from “0” to “1” are detected, this signal

5-2 I/O Area of NP1F-HP2

returns to “0.”

· When an -OT error is detected, no command in the

reverse direction will be accepted.

· Enabling/disabling of -OT signal detection is selected by

the control register.

(For details, refer to the paragraph for ±OT error motion.)

(external input)

(HP2 to PC)

Alarm reset

(PC to HP2)

<Description>

-OT input

-OT error

ON OFF

“1”

“1”“1”

Error signal cannot be reset because -OT input is OFF.

))desutoN(:emanlangiS(31tiB

<Description>

))desutoN(:emanlangiS(41tiB

5-9

Page 54

5-2 I/O Area of NP1F-HP2

)rorrEnoissimsnarT:emanlangiS(51tiB

<Description>

· When the error monitoring signal does not change for a

given period of time (which is set in the error monitoring

timer register), this signal becomes “1.” When the rising