Fuji Electric Micrex-SX Series, NP1AXH8V-MR, NP1AYH8I-MR, NP1AYH8V-MR, NP1AXH8I-MR User Manual

...Page 1

series

USER’S MANUAL

High-speed Multi-range Analog Module

8Ch Voltage Input <Type: NP1AXH8V-MR>

8Ch Current Input <T ype: NP1AXH8I-MR>

8Ch Voltage Output <Type: NP1AYH8V-MR>

8Ch Current Output <Type: NP1AYH8I-MR>

4Ch Voltage Output <Type: NP1AYH4V -MR>

4Ch Current Output <Type: NP1AYH4I-MR>

6Ch Input/Output <Type: NP1A WH6-MR>

FEH206b

Page 2

Preface

This user's manual describes the system configuration, specifications and operating method of the following modules for

MICREX-SX series:

Multi-range analog 8ch voltage input module (type: NP1AXH8V-MR)

Multi-range analog 8ch current input module (type: NP1AXH8I-MR)

Multi-range analog 8ch voltage output module (type: NP1AYH8V-MR)

Multi-range analog 8ch current output module (type: NP1AYH8I-MR)

Multi-range analog 4ch voltage output module (type: NP1AYH4V-MR)

Multi-range analog 4ch current output module (type: NP1AYH4I-MR)

Multi-range analog 6ch input/output module (type: NP1AWH6-MR)

Read this manual carefully to ensure correct operation. When using modules or peripheral devices, be sure to read the

corresponding user's manuals listed below:

<SX-Programmer Expert (D300win)>

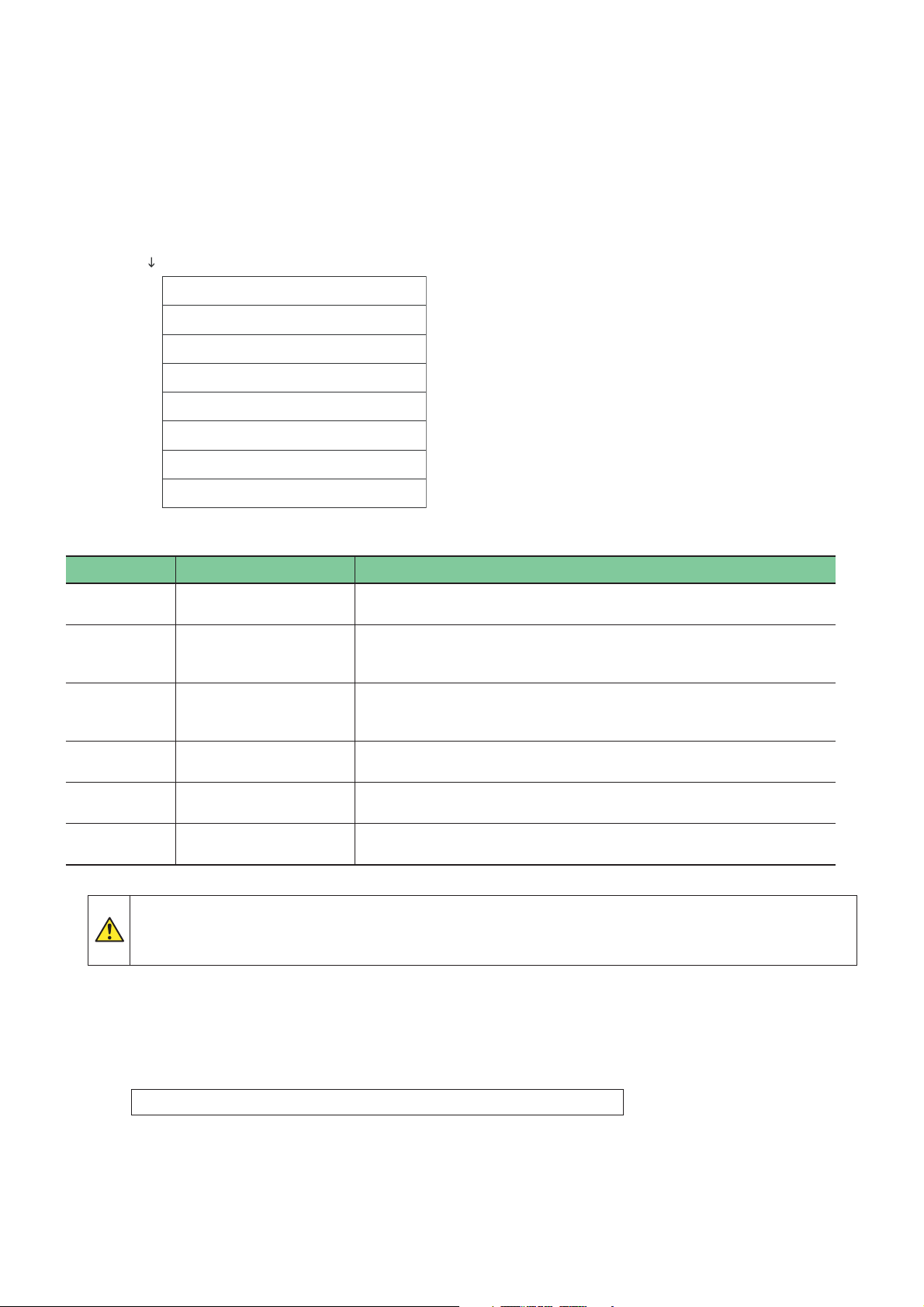

Title Manual No. Contents

User's Manual Instruction,MIC REX-SX series FEH200 Explains the memory, language and system definitions of the

MICREX-SX series.

User's Manual Hardware,

MICREX-SX series SPH

User's Manual D300win <Reference>,

MICREX-SX series

User's Manual D300win <LD/FBD Editor>,

MICREX-SX series

FEH201 Explains the system confi guration, the specifications and

operations of modules in the MICREX-SX series.

FEH257 Explains the methods for installing, the functions and the

operations of D300winV3.

FEH257-1 Explains the operations of LD/FBD added to D300winV3.

<SX-Programmer Standard (Standard loader)>

Title Manual No. Contents

User's Manual Instruction,MIC REX-SX series FEH588 Explains the memory, language and system definitions of the

MICREX-SX series.

User's Manual Hardware,

MICREX-SX series SPH

User's Manual SX-ProgrammerStandard

<Reference>,MICREX-SX series

* This manual is structured such that you can consult it, whether you use SX-Programmer Expert (D300win ) or SX-programmer

standard (Standard loader).

* In addition to the above manuals, the following Fuji Electric FA Components & Systems Co., Ltd. site offers various manuals

and technical documents associated with MICREX-SX.

URL http://www.fujielectric.co.jp/fcs/eng/

FEH201 Explains the system confi guration, the specifications and

operations of modules in the MICREX-SX series.

FEH590 Explains the functions and the operations of SX-Programmer

Standard.

Notes

1. This manual may not be reproduced in whole or part in any form without prior written approval by the manufacturer.

2. The contents of this manual (including specifications) are subject to change without prior notice.

3. If you find any ambiguous or incorrect descriptions in this manual, please write them down (along with the manual No.

shown on the cover) and contact FUJI.

Page 3

Safety Precautions

Be sure to read the "Safety Precautions" thoroughly before using the module.

Here, the safety precautions items are classified into "Warning" and "Caution".

Warning

Caution

Even some items indicated by "Caution" may result in a serious accident.

Both safety instruction categories provide important information. Be sure to strictly observe these instructions.

The items to be cared most are shown below:

: Incorrect handling of the device may result in death or serious injury.

: Incorrect handling of the device may result in minor injury or physical damage.

Warning

Never touch any part of charged circuits as terminals and exposed metal portion while the power is turned ON. It may

result in an electric shock to the operator.

Turn OFF the power before mounting, dismounting, wiring, maintaining or checking, otherwise, electric shock, erratic

operation or troubles might occur.

Place the emergency stop circuit, interlock circuit or the like for safety outside the PLC. A failure of PLC might break or

cause problems to the machine.

Do not connect in reverse polarity, charge (except rechargeable ones), disassemble, heat, deform, throw in a fire or

short-circuit the batteries, otherwise, they might burst or take fire.

If batteries have any deformation, spilled fluids, or other abnormality, do not use them. The use of such batteries might

cause explosion or firing.

Page 4

Safety Precautions

Caution

Do not use one found damaged or deformed when unpacked, otherwise, fire, failure or erratic operation might be caused.

Do not shock the product by dropping or tipping it over, otherwise, it might be damaged or troubled.

Follow the directions of the operating instructions and manual when mounting the product.

If mounting is improper, the product might drop or develop problems or erratic operations.

Use the rated voltage and current mentioned in the operating instructions and manual. Use beyond the rated values

might cause fire, erratic operation or failure.

Operate (keep) in the environment specified in the operating instructions and manual. High temperature, high humidity,

condensation, dust, corrosive gases, oil, organic solvents, excessive vibration or shock might cause electric shock, fire,

erratic operation or failure.

Select a wire size to suit the applied voltage and carrying current. Tighten the wire terminals to the specified torque.

Inappropriate wiring or tightening might cause fire, malfunction or failure, or might cause the product to drop from its

mounting.

Contaminants, wiring chips, iron powder or other foreign matter must not enter the device when installing it, otherwise,

fire, accident, erratic operation or failure might occur.

Remove the dust-cover seals of modules or units after wiring, otherwise, fire, accident, erratic operation or failure might

occur.

Connect the ground terminal to the ground, otherwise, electric shock or erratic operation might occur.

Periodically make sure the terminal screws and mounting screws are securely tightened.

Operation at a loosened status might cause fire or erratic operation.

Put the furnished connector covers on unused connectors, otherwise, erratic operation or failure might occur.

Put the furnished terminal covers on the terminal blocks, otherwise, electric shock or fire might occur.

Sufficiently make sure of safety before program change, forced output, starting, stopping or anything else during a run.

Wrong operation might break or cause problems to the machine

Engage the loader connector in a correct orientation, otherwise, an erratic operation might occur.

Before touching the PLC, discharge any static electricity that may have been collected on your body. To discharge it,

touch a grounded metallic object. Static electricity might cause erratic operation or failure.

Be sure to install the electrical wiring correctly and securely, observing the directions of the operating instructions and

manual. Wrong or loose wiring might cause fire, accident or failure.

When disengaging the plug from the outlet, do not pull the cord, otherwise, break of cable might cause fire or failure.

Do not attempt to change system configurations (such as installing or removing I/O modules) while the power is ON,

otherwise, erratic operation or failure might occur.

Do not attempt to repair the module by yourself, but contact your Fuji Electric agent. When replacing the batteries,

correctly and securely connect the battery connectors, otherwise, fire, accident or failure might occur.

Do not remodel or disassemble the product, otherwise, failure might occur.

Follow the regulations of industrial wastes when the device is to be discarded.

The modules covered in these operating instructions have not been designed or manufactured for use in equipment or

systems which, in the event of failure, can lead to loss of human life.

If you intend to use the modules covered in these operating instructions for special applications, such as for nuclear

energy control, aerospace, medical or transportation, please consult your Fuji Electric agent.

Be sure to provide protective measures when using the module covered in these operating instructions in equipment

which, in the event of failure, can lead to loss of human life or other grade results.

External power supply (such as 24 V DC power supply) which is connected to DC I/O should be strongly isolated from

AC power supply. (Use of EN60950 conforming power supply is recommended.) Otherwise, accident or failure might

be caused.

Page 5

Revision

r.

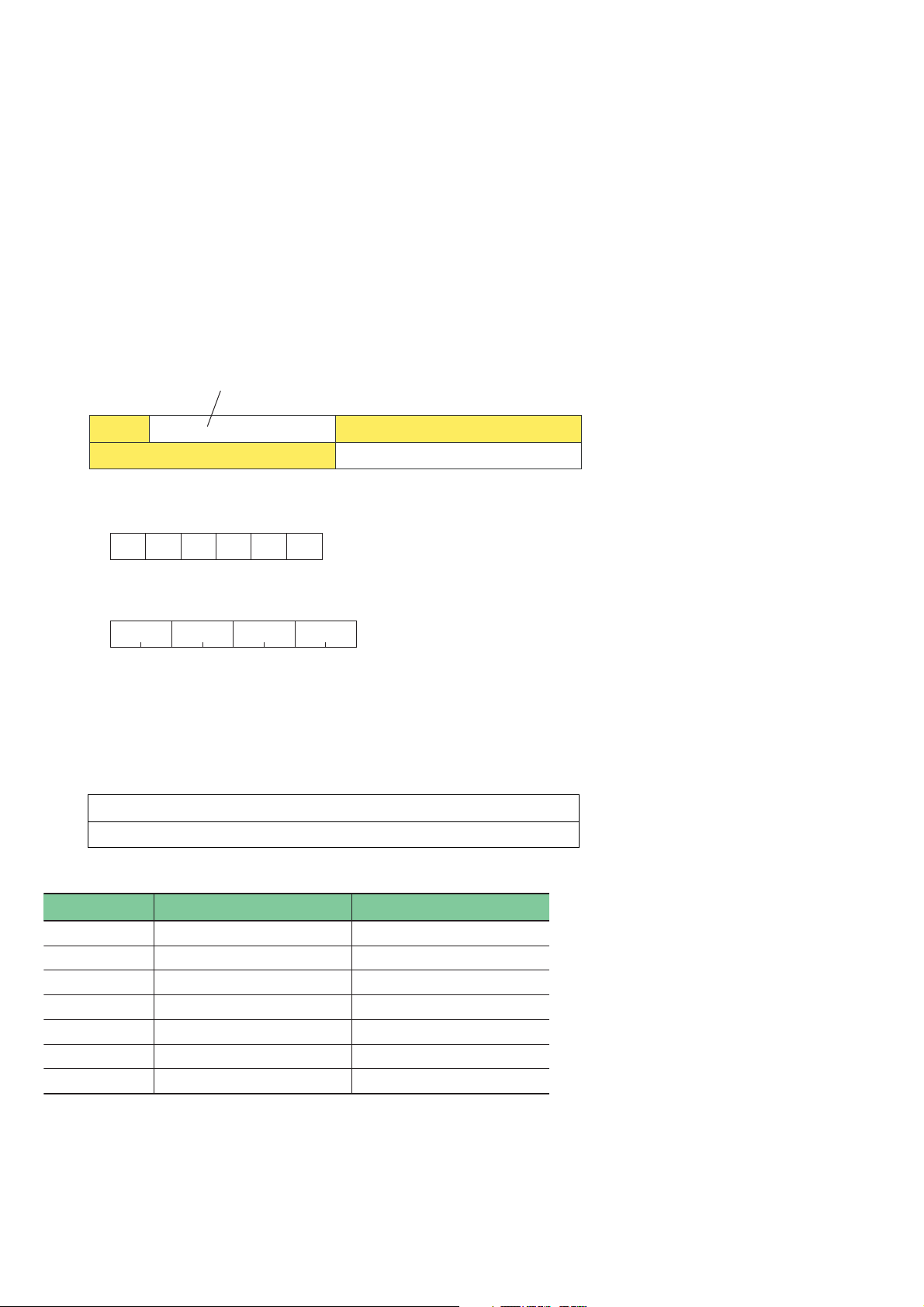

Printed on *Manual No. Revision contents

*Manual No. is shown at lowerrighton the cove

Sep. 2002 FEH206 First edition

Jun. 2004 FEH206a

Apr. 2006 FEH206b

Operati ons when using S X-Programmer Standard were added.

Specifications of Analog Input/Output Module (type: NP1AWH6-MR) were added.

Page 6

Contents

Preface

Safety Precautions

Revisions

Contents

Page

Section 1 General ....................................................................................... 1-1

1- 1 List of Modules ............................................................................................................................... 1-1

1-2 Supported Versions of Program Loader ...................................................................................... 1- 1

Section 2 Specifications ............................................................................ 2-1

2-1 General Specifications .................................................................................................................. 2-1

2-2 Performance Specifications.......................................................................................................... 2-2

2-2-1 8ch voltage input module ................................................................................................................... 2-2

2-2-2 8ch current input module .................................................................................................................... 2-2

2-2-3 8ch voltage output module ................................................................................................................. 2-3

2-2-4 8ch current output module .................................................................................................................. 2-3

2-2-5 4ch voltage output module ................................................................................................................. 2-4

2-2-6 4ch current output module .................................................................................................................. 2-4

2-2-7 6ch input/output module..................................................................................................................... 2-5

2- 3 Conversion Characteristics ........................................................................................................... 2-6

2-3-1 Conversion characteristics of analog voltage input.......................................................................... 2-6

2-3-2 Conversion characteristics of analog current input .......................................................................... 2-8

2-3-3 Conversion characteristics of analog voltage output...................................................................... 2-10

2-3-4 Conversion characteristics of analog current output ...................................................................... 2-12

2-4 Functional Specifications.............................................................................................................2-13

2-4-1 Analog input module functions ........................................................................................................ 2-13

2-4-2 Analog output module functions ...................................................................................................... 2-14

2-4-3 Analog input/output module functions ............................................................................................. 2-15

2- 5 Names and Functions ...................................................................................................................2-16

2-5-1 Analog input module (NP1AXH8V-MR/NP1AXH8I-MR) ................................................................... 2-16

2-5-2 Analog output module (NP1AYH8V-MR, NP1AYH8I-MR, NP1AYH4V-MR, NP1AYH4I-MR) ............. 2-18

2-5-3 Analog input/output module (NP1AWH6-MR) .................................................................................. 2-21

2-6 Dimensions ....................................................................................................................................2-23

Section 3 System Configuration...............................................................3-1

3-1 Mounting on the Base Board ........................................................................................................ 3-1

3-1-1 Mounting position ............................................................................................................................... 3-1

3-1-2 Number of mountable modules......................................................................................................... 3-1

Section 4 Software Interface ..................................................................... 4-1

4-1 Analog Input Module ..................................................................................................................... 4-1

4-1-1 Memory allocation in Switch Batch Setting mode .............................................................................. 4-1

4-1-2 Memory allocation in Software Set Range Operation mode............................................................. 4-2

4-2 Analog Output Module..................................................................................................................4-14

4-2-1 Memory allocation in Switch Batch Setting mode ............................................................................ 4-14

4-2-2 Memory allocation in Software Set Range Operation mode........................................................... 4-16

4-3 Analog Input/Output Module........................................................................................................4-26

4-3-1 Memory allocation in Switch Batch Setting mode ............................................................................ 4-26

4-3-2 Memory allocation in Software Set Range Operation mode........................................................... 4-27

Page 7

Contents

Page

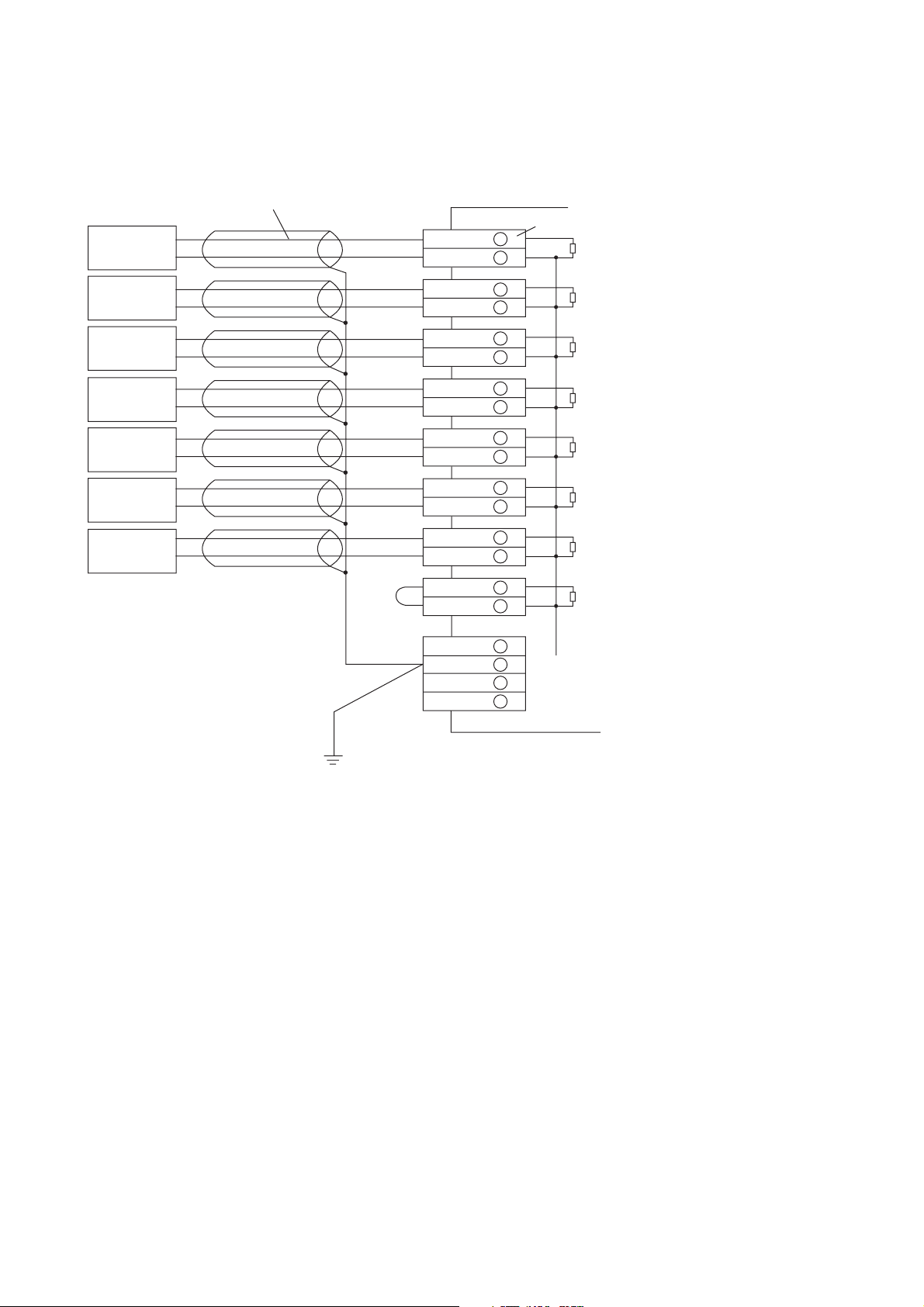

Section 5 Wiring .......................................................................................... 5-1

5-1 Wiring of Analog Input Module .................................................................................................... 5-1

5-1-1 Terminal arrangement........................................................................................................................ 5-1

5-1-2 Wiring example ................................................................................................................................... 5-2

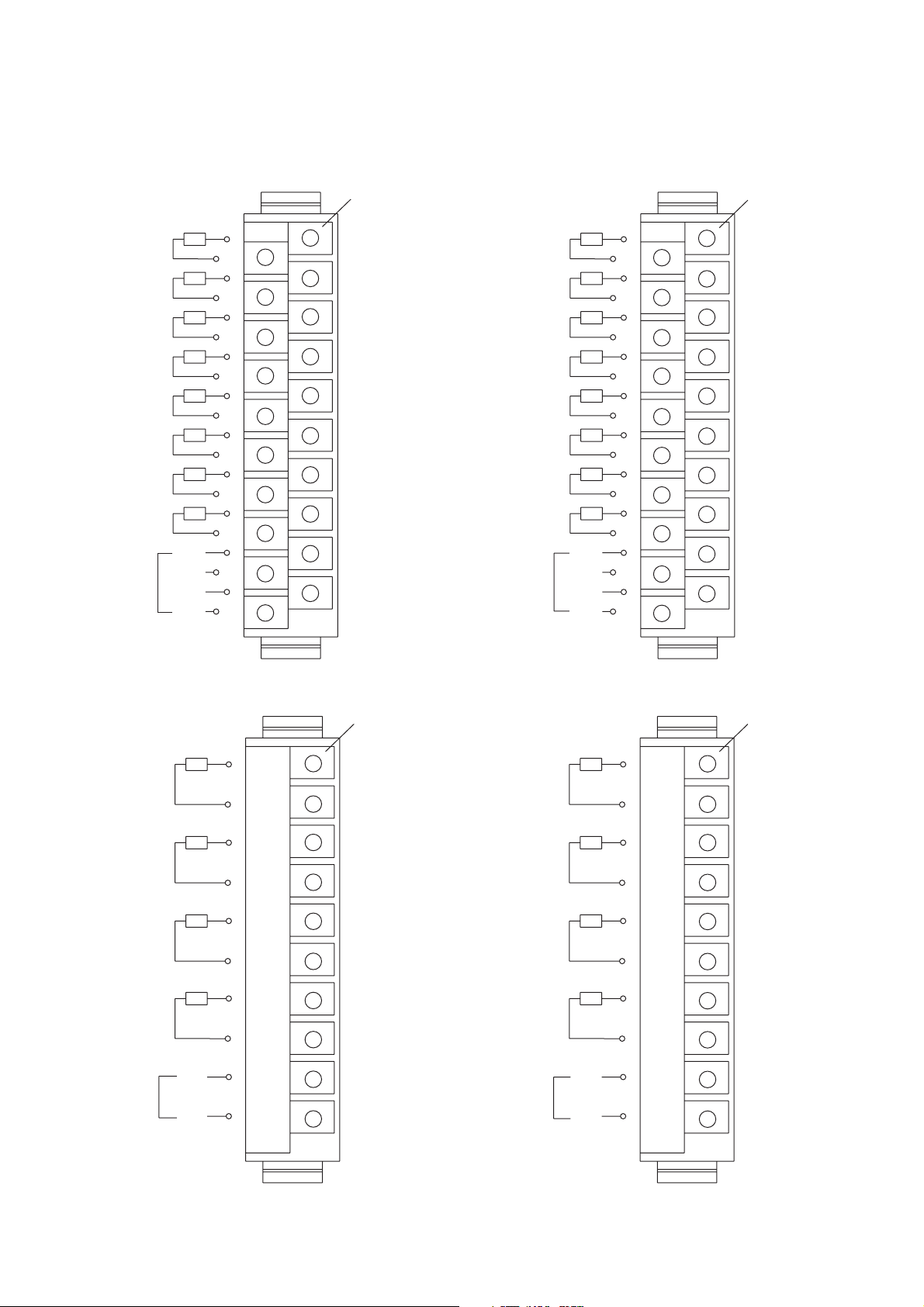

5-2 Wiring of Analog Output Module.................................................................................................. 5-3

5-2-1 Terminal arrangement........................................................................................................................ 5-3

5-2-2 Wiring example ................................................................................................................................... 5-4

5-3 Wiring of Analog Input/Output Module ........................................................................................ 5-5

5-2-1 Terminal arrangement........................................................................................................................ 5-5

5-2-2 Wiring example .................................................................................................................................5-46

Appendix 1 Offset/Gain Adjustment <D300win> .............................. App.1-1

Appendix 1-1 Offset/Gain Adjustment of Analog Input Module ...............................................App.1-1

Appendix 1-2 Offset/Gain Adjustment of Analog Output Module.............................................App.1-6

Appendix 2

Appendix 2-1 Offset/Gain Adjustment of Analog Input Module ...............................................App.2-1

Appendix 2-2 Offset/Gain Adjustment of Analog Output Module.............................................App.2-6

Offset/Gain Adjustment <SX-Programmer Standard>............

App.2-1

Page 8

Section 1 General

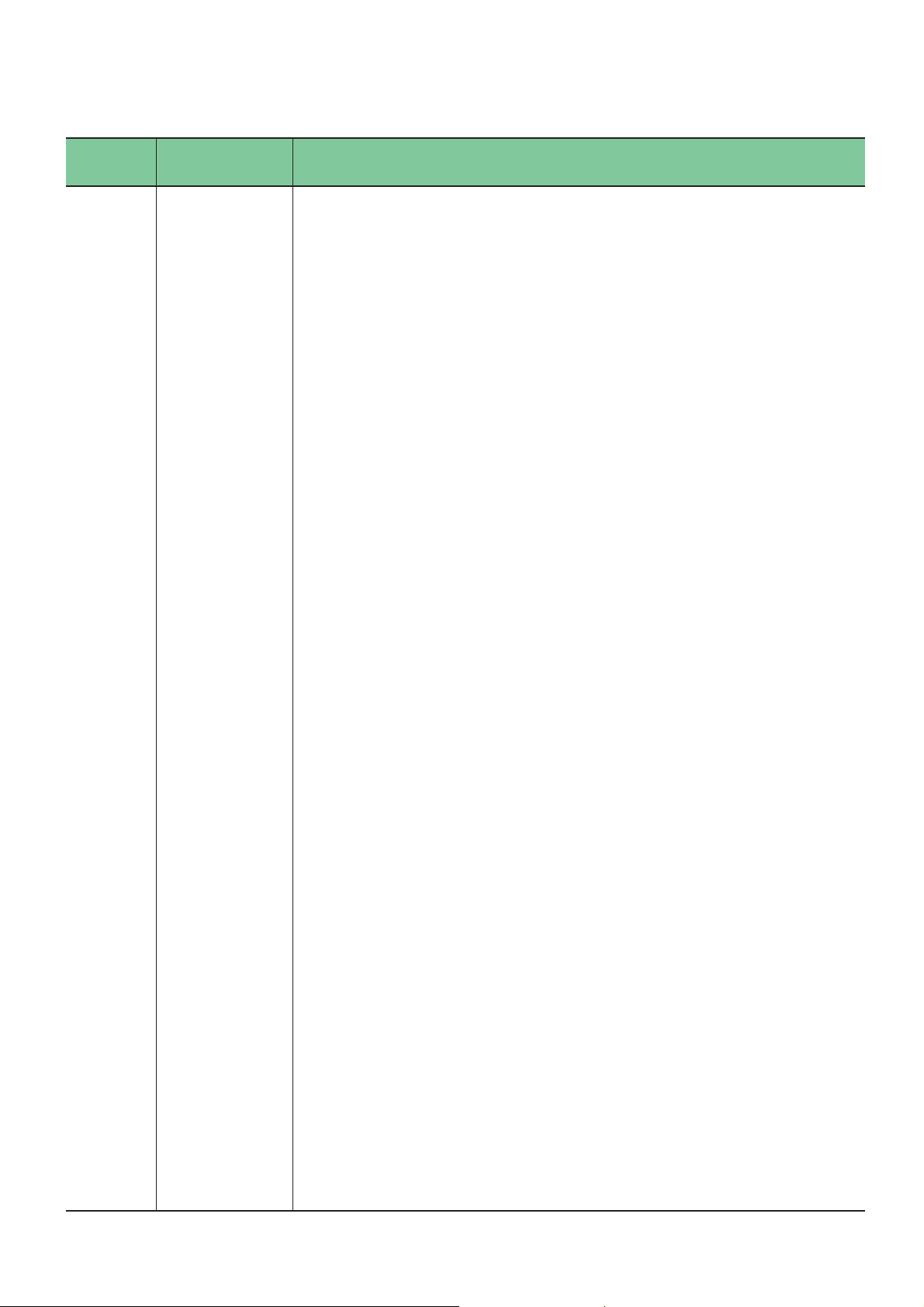

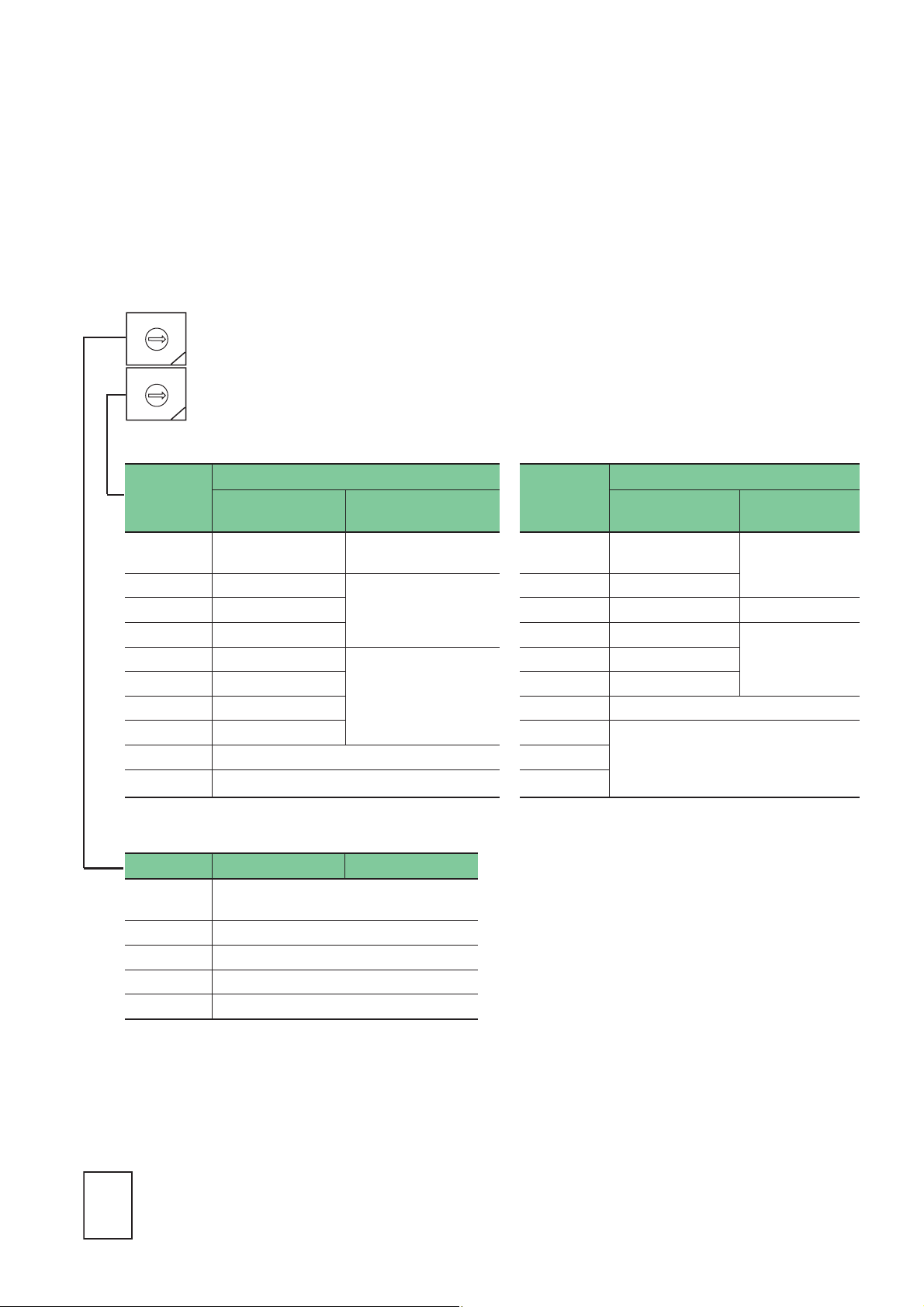

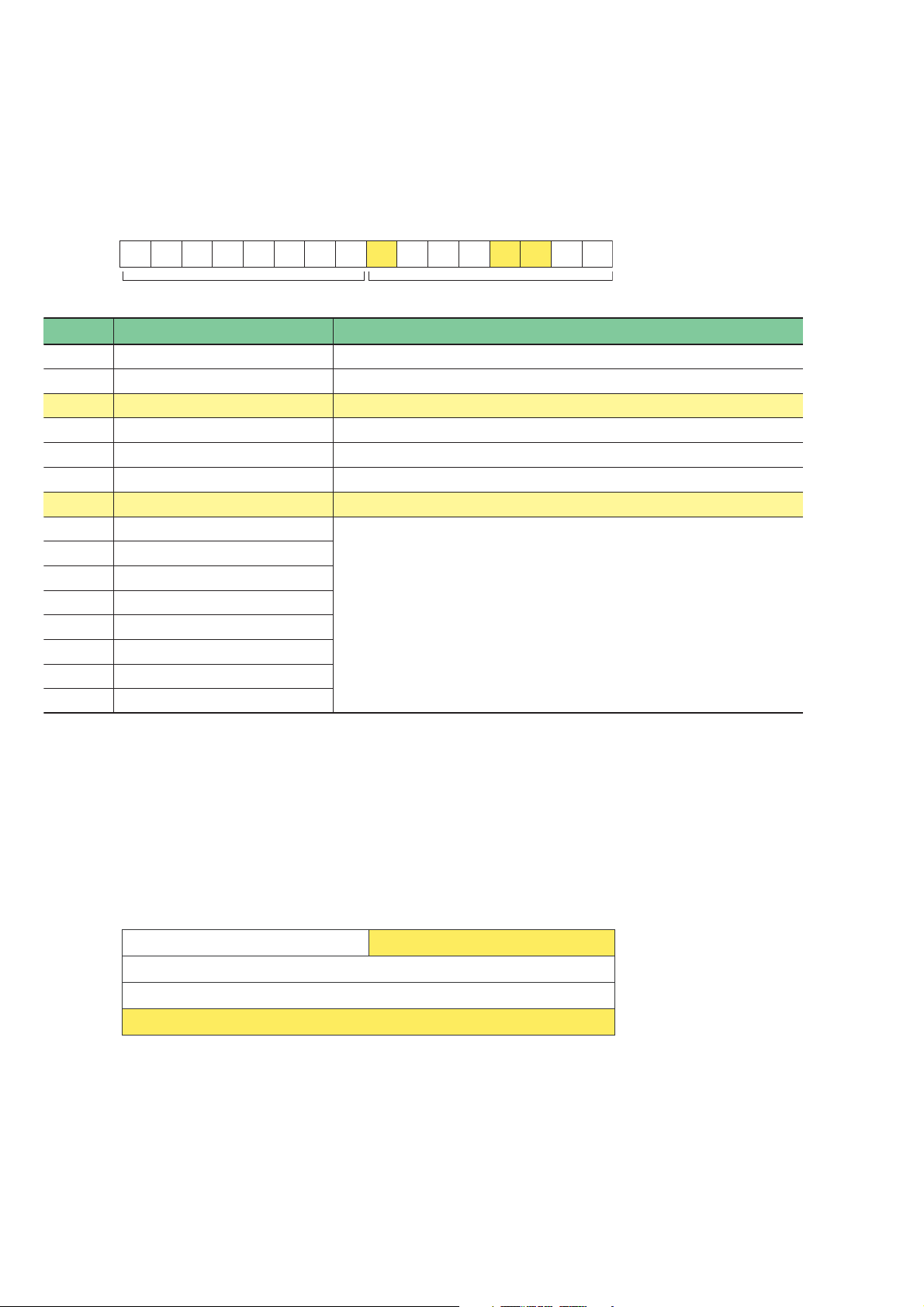

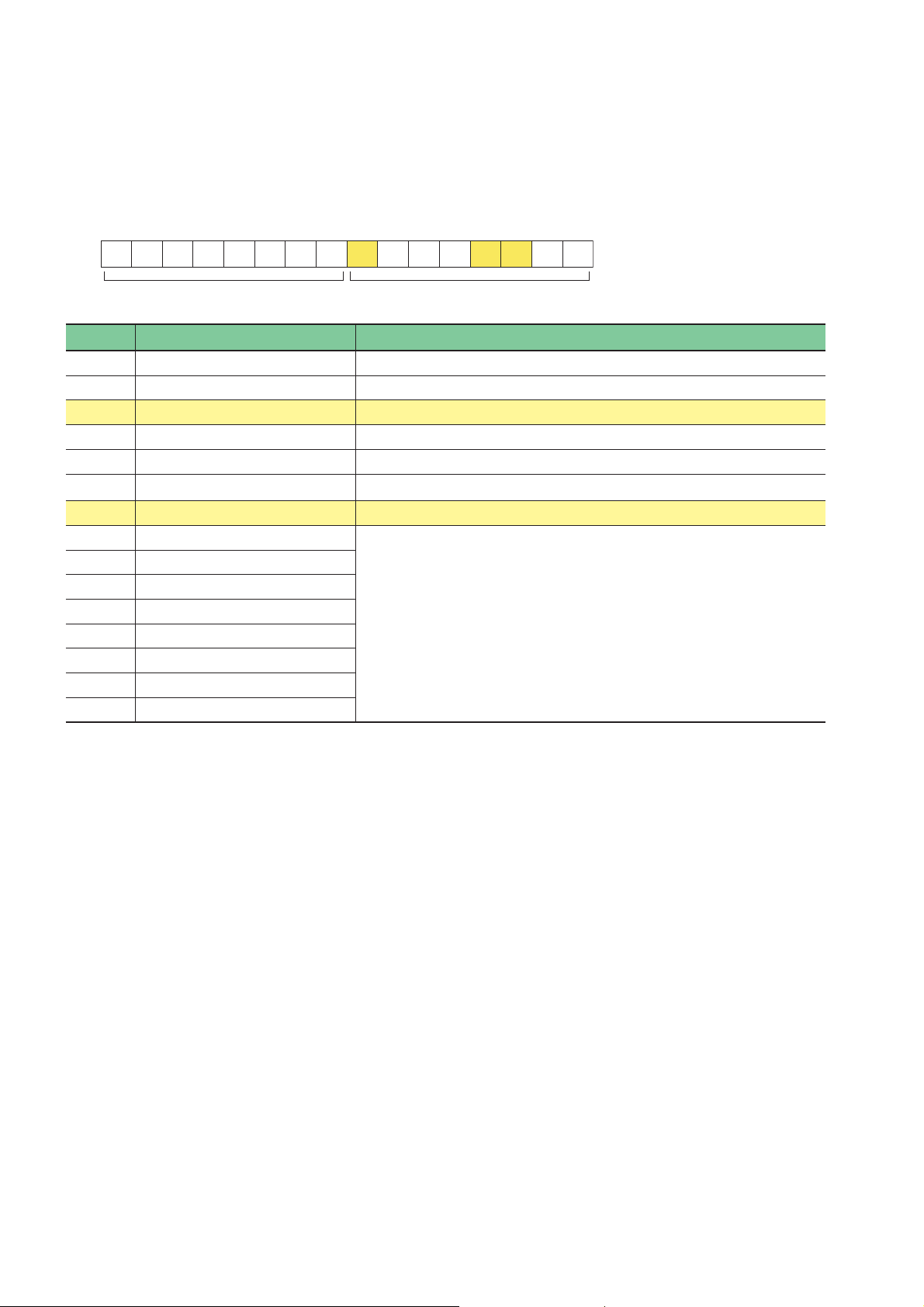

1-1 List of Modules

Analog modules listed below are described in this manual.

Analog voltage input

Type

NP1AXH8V-MR 8 channels - - NP1AXH8I-MR - 8 channels - NP1AYH8VMR - - 8 channels NP1AYH8I-MR - - - 8 channels

NP1AYH4V-MR - - 4 channels NP1AYH4I-MR---4channels

NP1AWH6-MR 4 channels 2 channels

0to5V,1to5V,

0 to 10V, -10 to 10V

Analog currentinput

4 to 20mA, 0 to 20mA,

-20 to 20mA

Analog voltage output

0to5V,1to5V,

0 to 10V, -10 to 10V

Analog currentoutput

0 to 20mA, 4 to 20mA

1-2 Supported Versions of Program Loader

Type

NP1AXH8V-MR

NP1AXH8I-MR

NP1AYH8VMR

NP1AYH8I -MR

NP1AYH4V-MR

NP1AYH4I-MR

NP1AWH6-MR - V3.3.3.0 or later V2.2.3.0 or later

D300winV2

NP4H-SEDBV2

V2.2.0.0 or later V3.0.0.0 or later V2.0.0.0 or later

SX-Programmer Expert

D300winV3

NP4H-SEDBV3

SX-Programmer Standard

NP4H-SWN

1-1

Page 9

Section 2 Specifications

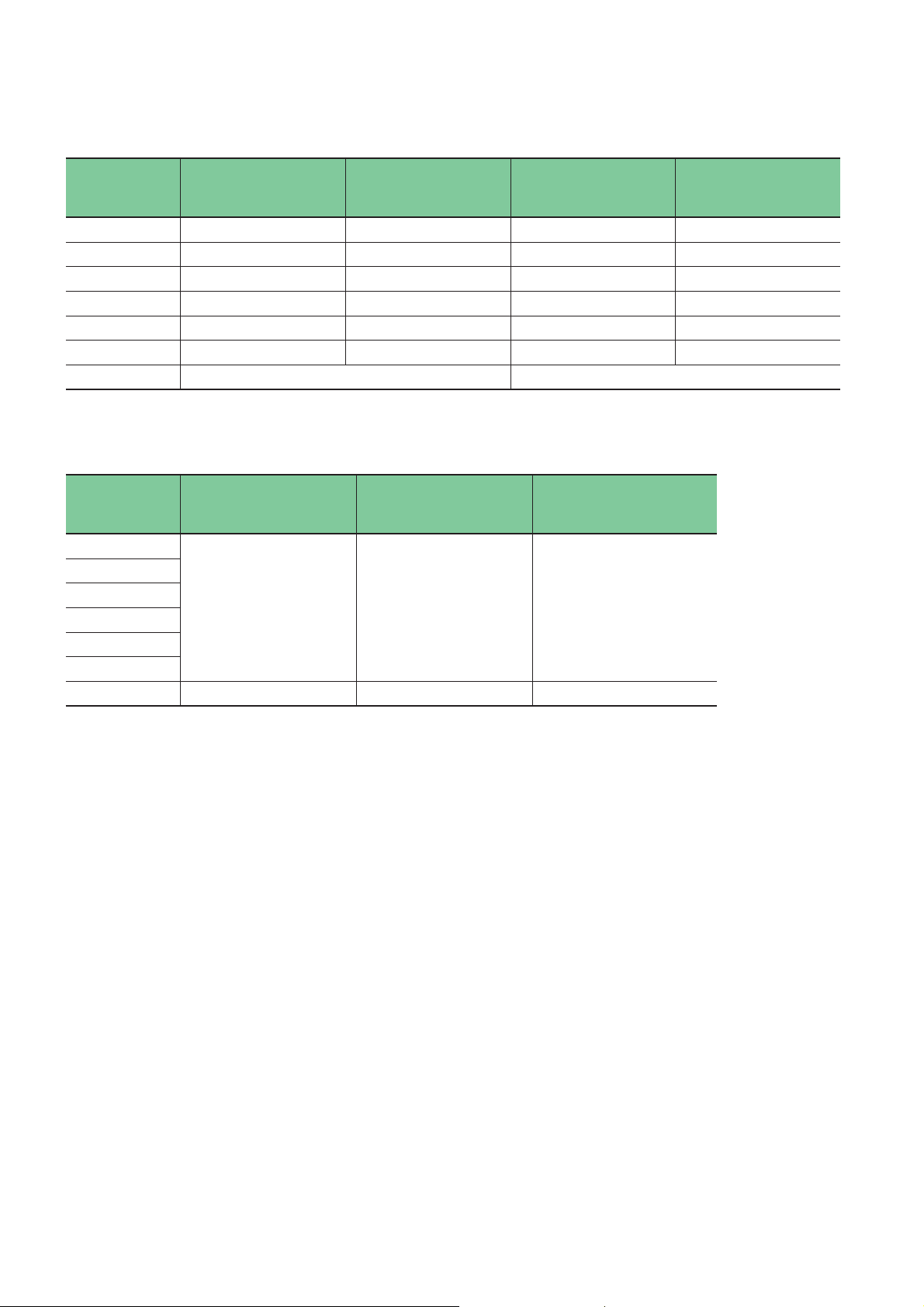

2-1 General Specifications

Item Specification

Physical

environmental

conditions

Mechanical

service

conditions

Electrical

service

conditions

Isolation method Betweenexternal terminal and internal logic circuit:

Dielectric strength 500 V AC , 1 minute (betweenexternal wires connected together and ground)

Insulation resistance 10 MΩ or more with500 V DC megger (betweenexternal wires connected

Internal current

consumption

In stallation

conditions

Mass Analog input NP1AXH8V-RM:approx. 240 g

Outside di mensions W35*H105*D111 mm (protrusion 21 mm)

Operating ambient

temperature

Storage (transportation)

temperature

Relative humidity 20 to 95%RH, no condensation

Pollution degree 2 (no condensation)

Corrosion immunity Free fromcorrosive gases. Not stained with organic solvents

Corrosive gas Free fromcorrosive gases.

Operating altitude 2000 m or less above sea level

Vibration Half amplitude: 0.15 mm, C onstant acceleration: 19.6 m/s

Shock Peak acceleration:147 m/s

Noise immunity Rise time 1 ns, pulse width 1 μs,1.5kV(noisesimulator)

Electrostatic discharge Contact discharge: 6 kV, Aerial di scharge: 8 kV

Radioelectromagnetic field 10 V/m (80 MHz to 1,000 MHz)

Analog input NP1AXH8V-RM:24 V D C, max. 200 mA (supplied from the powermodule)

Analog output NP1AYH8V-RM: 24 V DC, max. 240 mA (supplied from the power module)

Analog input/output NP1AWH6-MR:24V DC, max. 200mA (supplied from the powermodule)

Structure Panelbuilt in type, IP30

Cooling method Natural air cooled

Analog output NP1AYH8V-RM: approx. 240 g

Analog input/output NP1AWH6-MR:approx. 240g

0to+55

-20to70

Transport condition: 70 kPa (equivalentto 3000 m above sea level) or more

2

2 hours in each of X, Yand Z directions, total 6 hours

2

(3 cycles in each di rection)

photocoupler (signal), isolated power supply(DC/DC converter)

Betweenchannels: Notinsulated

together and ground)

NP1AXH8I-RM:24 V D C, max. 200 mA (supplied from the power module)

NP1AYH8I-RM: 24 V DC, max.300 mA (supplied from the powermodule)

NP1AYH4V-RM: 24 V DC, max. 200 mA (supplied from the power module)

NP1AYH4I-RM: 24 V DC, max.200 mA (supplied from the powermodule)

NP1AXH8I-RM:approx. 240 g

NP1AYH8I-RM: approx.240 g

NP1AYH4V-RM: approx. 240 g

NP1AYH4I-RM: approx.240 g

2-1

Page 10

Section 2 Specifications

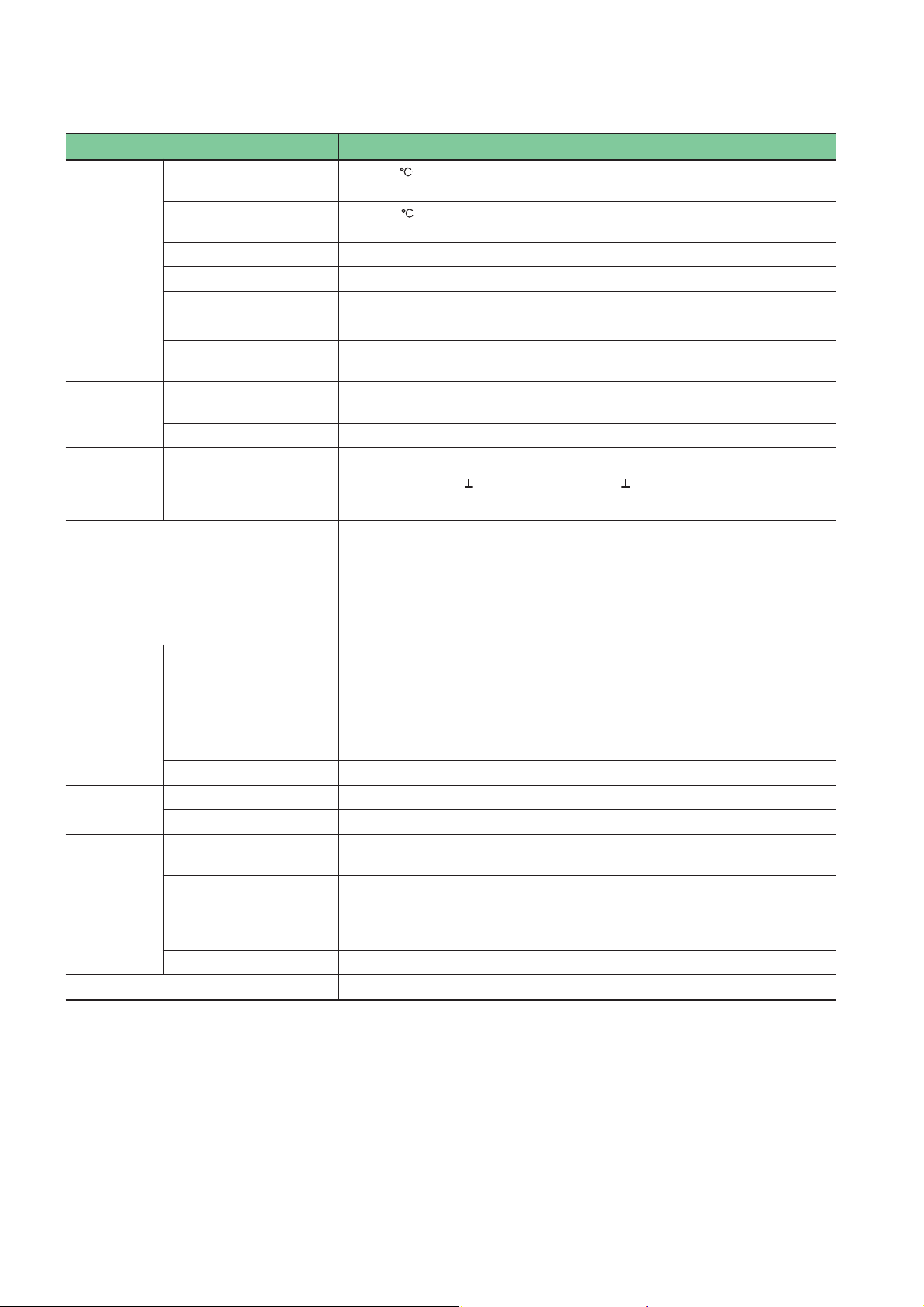

2-2 Performance Specifications

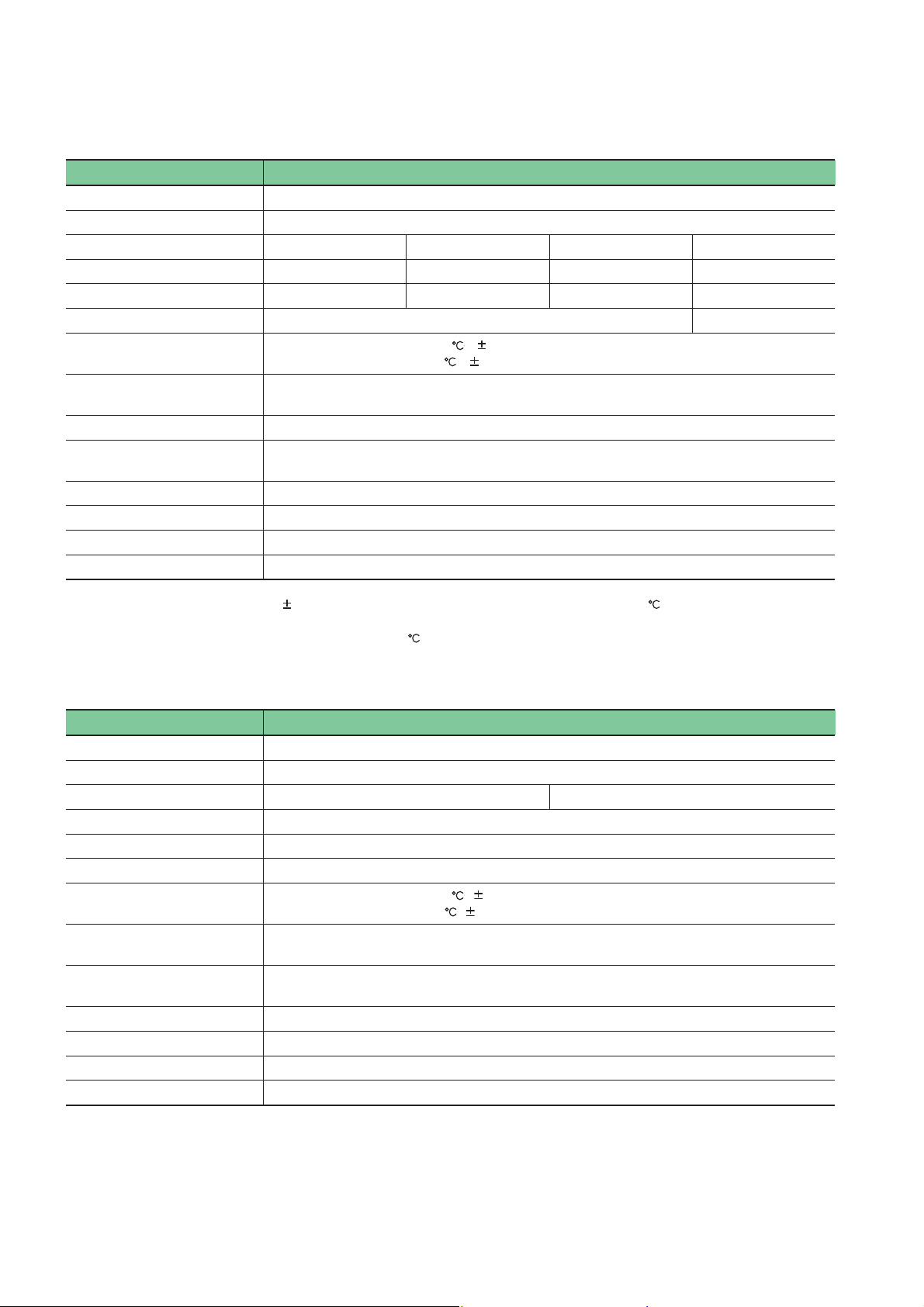

2-2-1 8ch voltage input module

Item Specificatio n

Type NP1AXH8V-MR

No. of input points 8

Analoginputrange 0to5V 1to5V 0to10V -10to10V

Inputimpedance 1 MΩ

Maximum allowable input 15 V

Maximum resolution 1.25 mV 1.25 mV 1.25 mV 1.25 mV

Digital output value (INT type) 0 to 16000 -8000 to 8000

Measurement accuracy A mbient temperature 18 to 28 : 0.1% (of full scale)

Ambienttemperature 0 to 55 : 0.2% (of full scale) (See note 1.)

Sampling time 0.27 ms x (Number of conversion enabled channels + 1)

Inputfiltering time Max. approx. 100 μs(hardfilter)

Inputdelay time Max. 2.5 ms/8 points + takt time (ms)

External connecting method Detachable terminal block: M3 screw, 20 poles

For the signalassignment of terminals, refer to "Section 5 Wiring".

Cable to use Be sure to use shielded twisted pair cable.

Treatment of unused input To basically be short-circuited

No. of occupied slots 1 (one)

No. of occupied words Input: 8 words, output:4 words (fixed)

Note: For the range of 1 to 5 V, 0.3% (of full scale) when ambient temperature is 0 to 55 .

2-2-2 8ch current input module

Item Specificatio n

Type NP1AXH8I-MR

No. of input points 8

Analog input range 4 to 20 mA 0 to 20 mA -20 to 20 mA

Inputimpedance 250 Ω

Maximum allowable input 30 mA

Maximum resolution 2.5 μA

Digital output value (INT type) 0 to 16000

Measurement accuracy A mbient temperature 18 to 28 : 0.1% (of full scale)

Ambienttemperature 0 to 55 : 0.4% (of full scale)

Sampling time 0.27 ms x (Number of conversion enabled channels + 1)

Inputfiltering time Max. approx. 100 μs (hard filter: time constant of primarydelay)

Inputresponse time Max. 2.5 ms/8 points + takt time

External connecting method Detachable terminal block: M3 screw, 20 poles

For the signalassignment of terminals, refer to "Section 5 Wiring".

Cable to use Be sure to use shielded twisted pair cable.

Treatment of unused input To basically be short-circuited

No. of occupied slots 1 (one)

No. of occupied words Input: 8 words, output:4 words (fixed)

2-2

Page 11

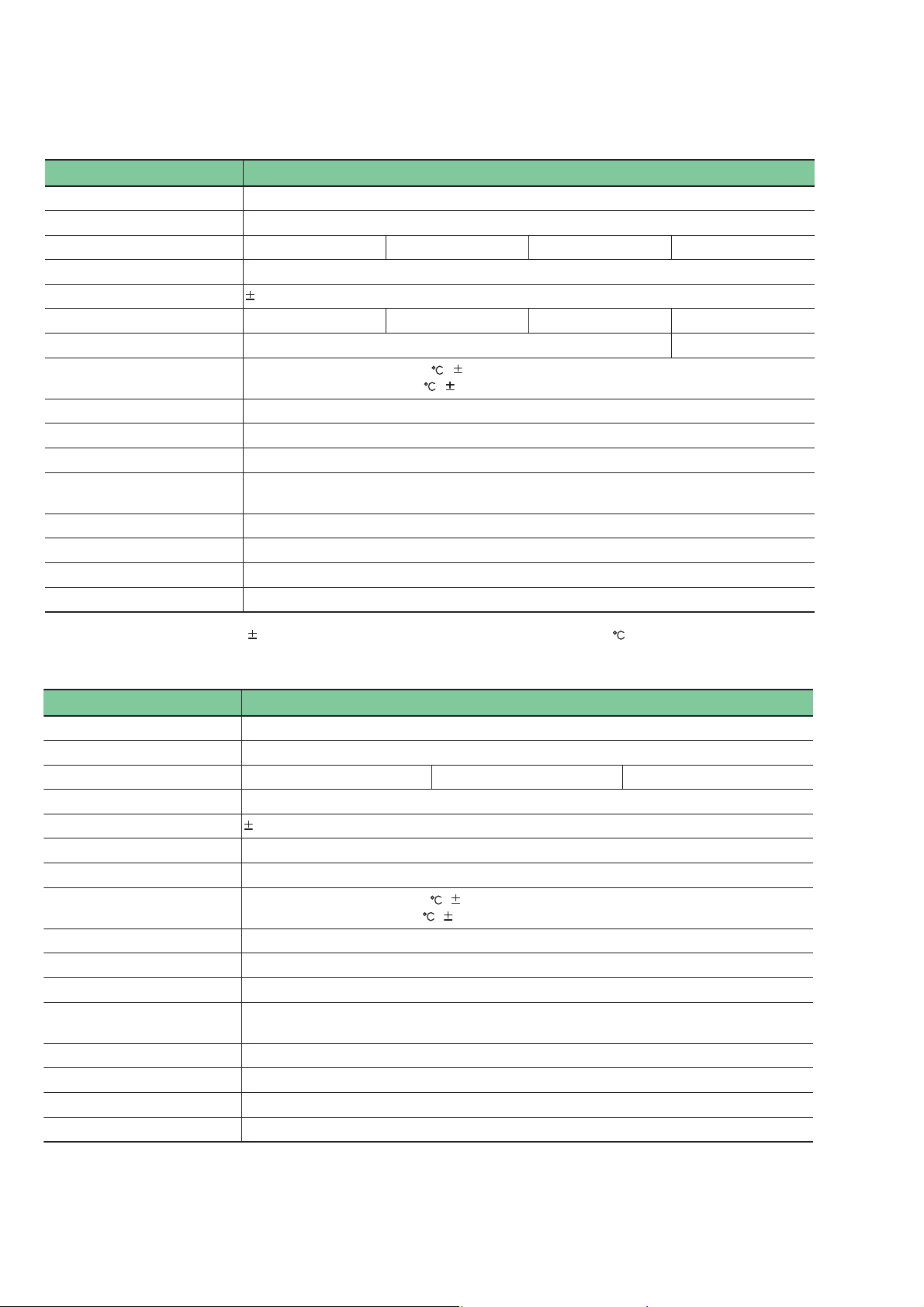

Section 2 Specifications

2-2 Performance Specifications

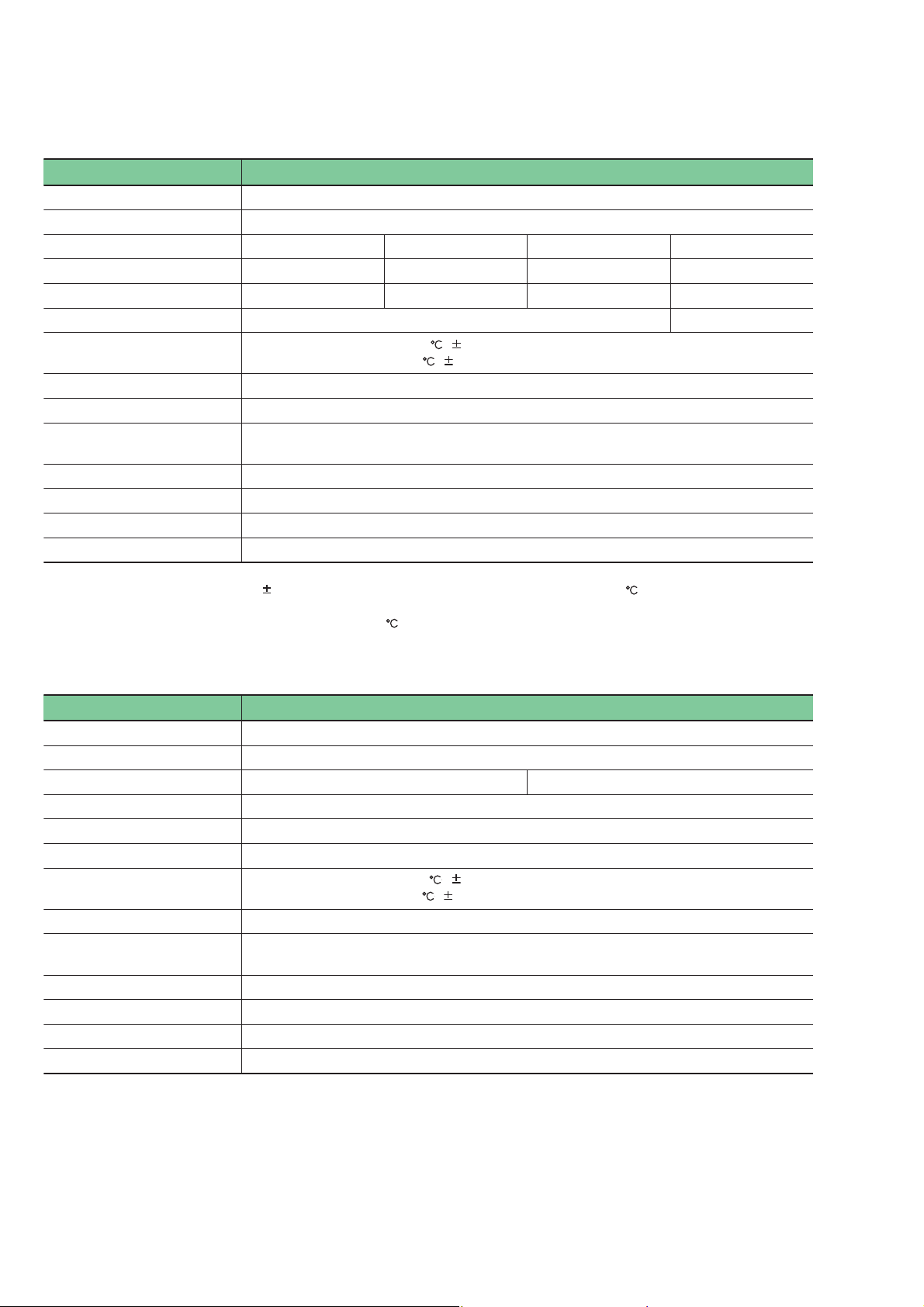

2-2-3 8ch voltage output module

Item Specificatio n

Type NP1AYH8V-MR

No. of output points 8

Analogoutputrange 0to5V 1to5V 0to10V -10to10V

External load resistance Min.500Ω Min. 500Ω Min. 1kΩ Min. 1kΩ

Maximum resolution 1.25 mV 1.25 mV 1.25 mV 1.25 mV

Digital input value (INT type) 0 to 16000 -8000 to 8000

Measurement accuracy A mbient temperature 18 to 28 : 0.1% (of fullscale)

Ambienttemperature 0 to 55 : 0.2% (of full scale) (See note 1.)

Output response time Max. 2.0 ms + takt time (ms)

Max. 1.0 ms + takt time (ms) when output is disabled for channels 5 to 8

Load short-circuit protection Provided. (See note 2.)

External connecting method Detachable terminal block: M3 screw, 20 poles

For the signalassignment of terminals, refer to "Section 5 Wiring".

Cable to use Be sure to use shielded twisted pair cable.

Treatment of unused output T o basically be opened

No. of occupied slots 1 (one)

No. of occupied words Input: 4 words, output:8 words (fixed)

Note 1: For the range of 1 to 5 V, 0.3% (of full scale) when ambient temperature is 0 to 55 .

Note 2: Short-circuit protection for arbitrary one channel. The occurrence of short-circuit on multiple channels in an environment

where ambient temperature is higher than 30 may have a bad influence on internal electronic component of the

module.

2-2-4 8ch current output module

Item Specificatio n

Type NP1AYH8I-MR

No. of output points 8

Analog output range 0 to 20 mA 4 to 20 mA

External load resistance Max. 600Ω

Maximum resolution 2.5 μA

Digital input value (INT type) 0 to 16000

Measurement accuracy A mbient temperature 18 to 28 : 0.1% (of full scale)

Ambienttemperature 0 to 55 : 0.4% (of full scale)

Output response time Max. 2.0 ms + takt time (ms)

Max. 1.0 ms + takt time (ms) when output is disabled for channels 5 to 8

External connecting method Detachable terminal block: M3 screw, 20 poles

For the signalassignment of terminals, refer to "Section 5 Wiring".

Cable to use Be sure to use shielded twisted pair cable.

Treatment of unused output T o basically be short-circuited

No. of occupied slots 1 (one)

No. of occupied words Input: 4 words, output:8 words (fixed)

2-3

Page 12

Section 2 Specifications

2-2 Performance Specifications

2-2-5 4ch voltage output module

Item Specificatio n

Type NP1AYH4V-MR

No. of output points 4

Analogoutputrange 0to5V 1to5V 0to10V -10to10V

External load resistance Min.500Ω Min. 500Ω Min. 1kΩ Min. 1kΩ

Maximum resolution 1.25 mV 1.25 mV 1.25 mV 1.25 mV

Digital input value (INT type) 0 to 16000 -8000 to 8000

Measurement accuracy A mbient temperature 18 to 28 : 0.1% (of full scale)

Ambienttemperature 0 to 55 : 0.2% (of full scale) (See note 1.)

Output response time Max. 1.0 ms + takt time (ms)

Load short-circuit protection Provided. (See note 2.)

External connecting method Detachable terminal block: M3 screw, 10 poles

For the signalassignment of terminals, refer to "Section 5 Wiring".

Cable to use Be sure to use shielded twisted pair cable.

Treatment of unused output T o basically be opened

No. of occupied slots 1 (one)

No. of occupied words Input: 4 words, output:4 words (fixed)

Note 1: For the range of 1 to 5 V, 0.3% (of full scale) when ambient temperature is 0 to 55 .

Note 2: Short-circuit protection for arbitrary one channel. The occurrence of short-circuit on multiple channels in an environment

where ambient temperature is higher than 30 may have a bad influence on internal electronic component of the

module.

2-2-6 4ch current output module

Item Specificatio n

Type NP1AYH4I-MR

No. of output points 4

Analog output range 0 to 20 mA 4 to 20 mA

External load resistance Max. 600Ω

Maximum resolution 2.5 μA

Digital input value (INT type) 0 to 16000

Measurement accuracy A mbient temperature 18 to 28 : 0.1% (of full scale)

Ambienttemperature 0 to 55 : 0.4% (of full scale)

Output response time Max. 1.0 ms + takt time (ms)

External connecting method Detachable terminal block: M3 screw, 10 poles

For the signalassignment of terminals, refer to "Section 5 Wiring".

Cable to use Be sure to use shielded twisted pair cable.

Treatment of unused output T o basically be short-circuited

No. of occupied slots 1 (one)

No. of occupied words Input: 4 words, output:4 words (fixed)

2-4

Page 13

Section 2 Specifications

2-2 Performance Specifications

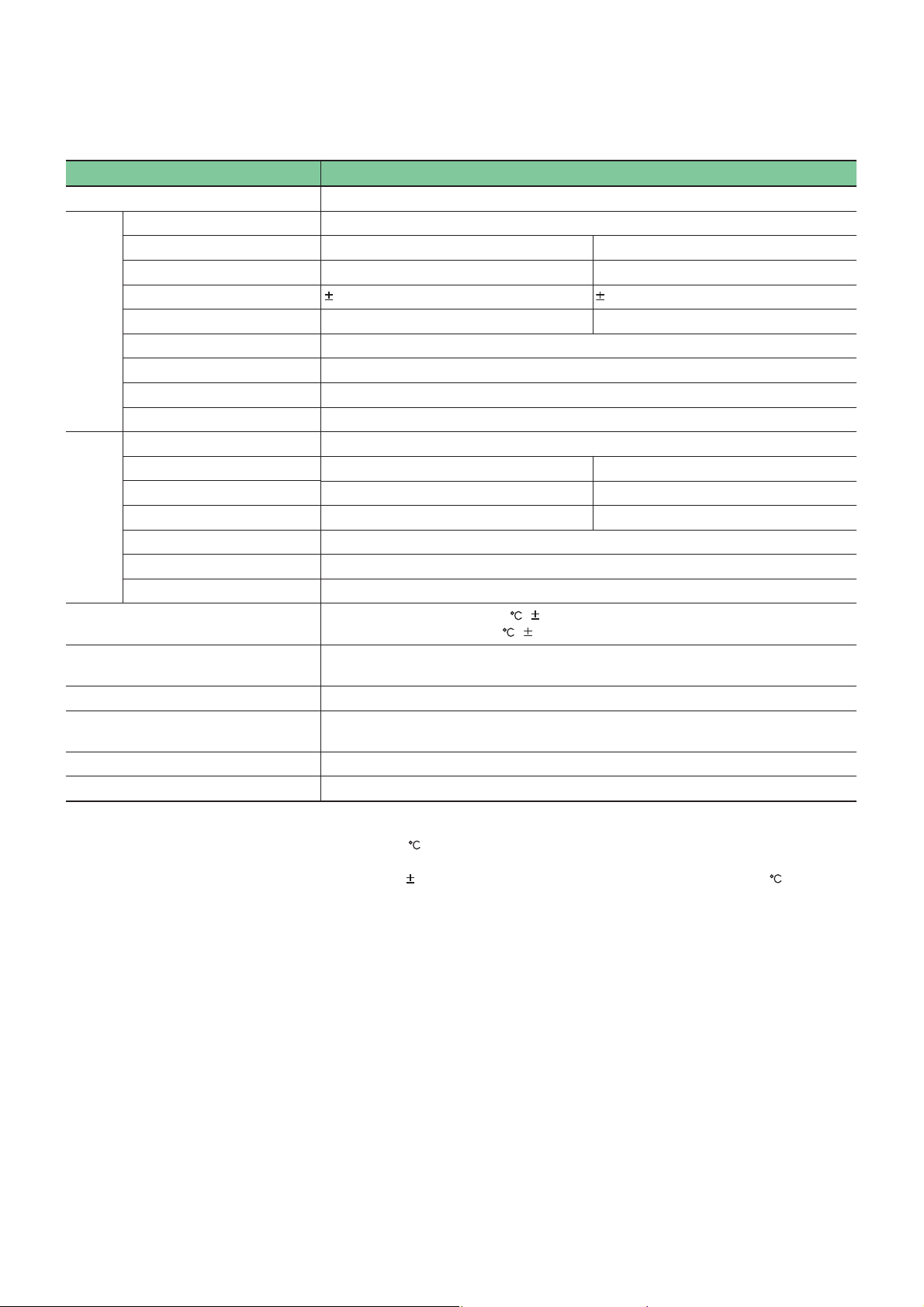

2-2-7 6ch input/output module

Item Specification

Type NP1AWH6-MR

No. of input points 4

Analog input range 0 to 5V, 1 to 5V,0 to 10V, -10 to 10V 0 to 20mA, 4 to 20mA, -20 to 20mA

Inputimpedance 1 MΩ 250 Ω

Maximum allowable input 15 V 30 mA

Analog

input

Analog

output

Measurement accuracy Ambienttemperature 18 to 28 : 0.1% (of full scale)

External connecting method Detachable terminal block: M3 screw, 10 poles

Cable to use Be sure to use shielded twi sted pair cable.

Treatment of unused input I nput: T o basically be short-circuited (between V+ and COM)

No. of occupied slots 1 (one)

No. of occupied words Input: 4 words, Output: 4 words (fixed)

Maximum resolution 0.625 mV 2.5 μA

Digital output value (INT type) 0 to 16000, -8000 to 8000

Sampling time 0.25 ms x (Number of conversion enabled channels + 1)

Inputfiltering time Max. approx. 47 μs (hard filter: time constant of primarydelay)

Inputdelay time Max. 1.0 ms/4 channels + takt time (ms)

No. of output points 2

Analog output range 0 to 5V, 1 to 5V,0 to 10V, -10 to 10V 0 to 20mA, 4 to 20mA

External load resistance Min.2 kΩ Max. 500 Ω

Maximum resolution 0.625 mV 2.5 μA

Digital input value (INT type) 0 to 16000, -8000 to 8000

Output response time Max. 0.5 ms + takt time (ms)

Load short-circuit protection Provided (voltage output) (See note 1.)

Ambienttemperature 0 to 55 : 0.2% (of full scale) (See note 2.)

For the signalassignment of terminals, refer to "Section 5 Wiring".

Output:To basicallybe opened

Note 1: Short-circuit protection for arbitrary one channel. The occurrence of short-circuit on multiple channels in an environment

where ambient temperature is higher than 30 may have a bad influence on internal electronic component of the

module.

Note 2: For the range of 4 to 20 mA and 0 to 20 mA, 0.3% (of full scale) when ambient temperature is 0 to 55 .

2-5

Page 14

Section 2 Specifications

2-3 Conversion Characteristics

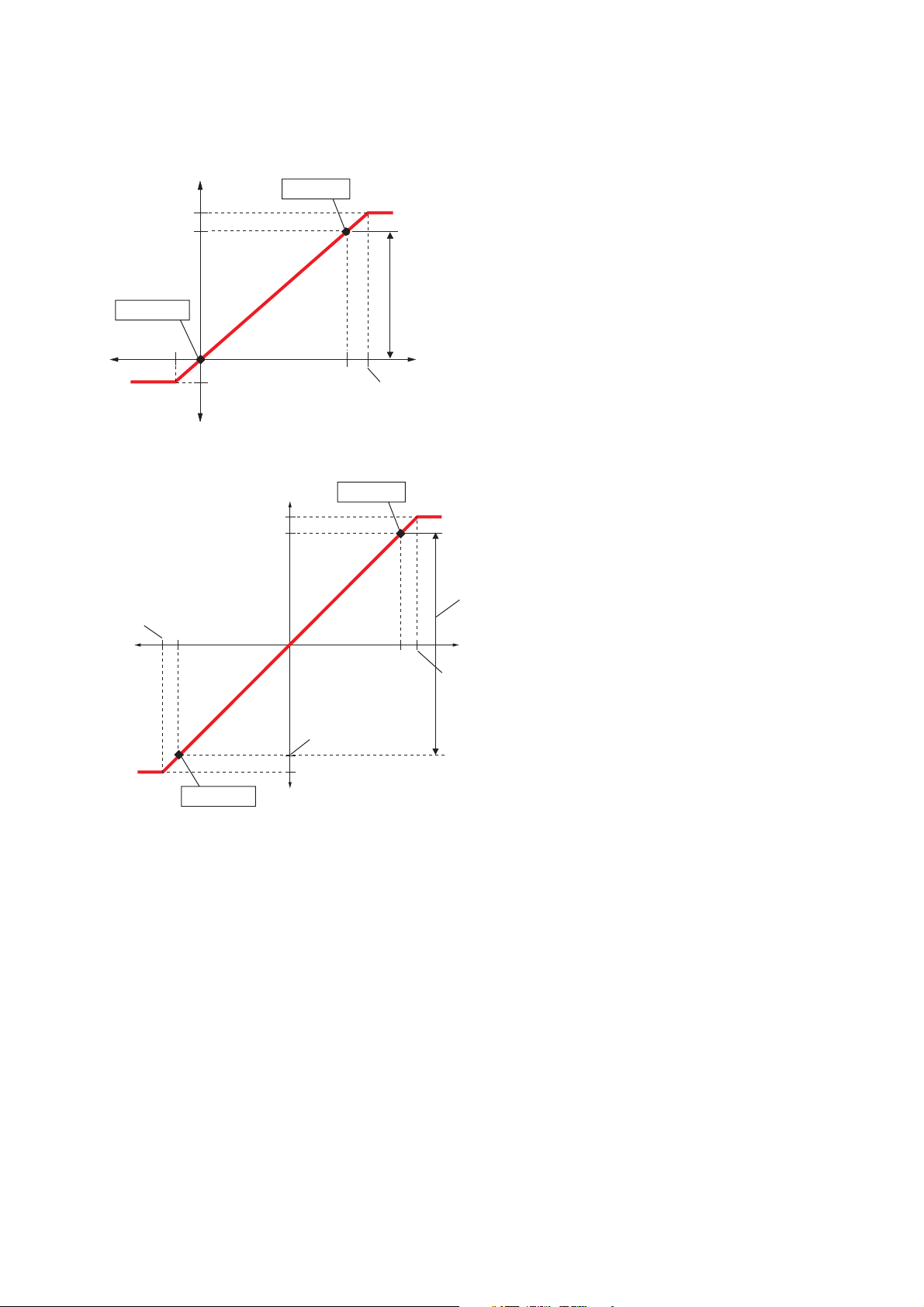

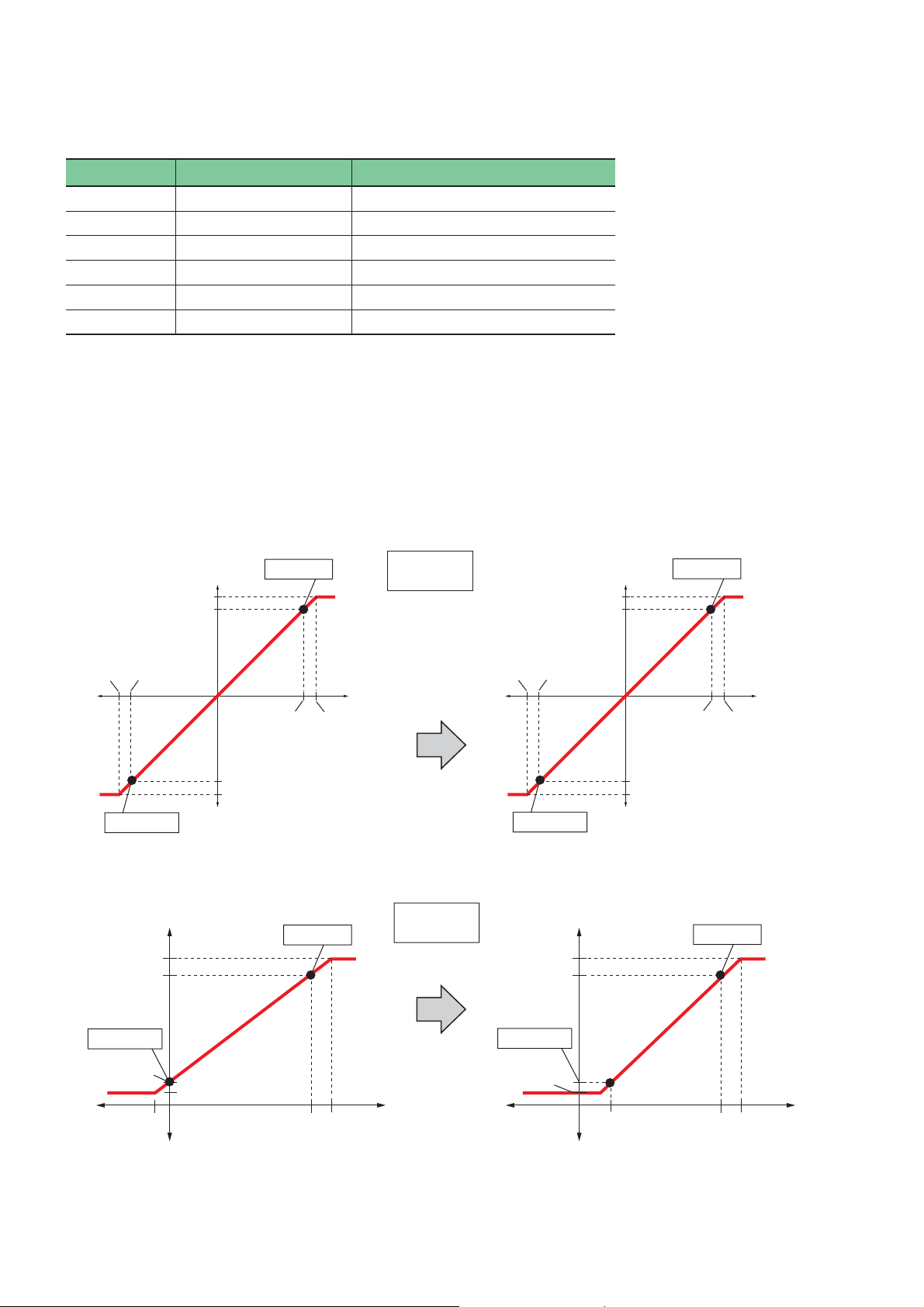

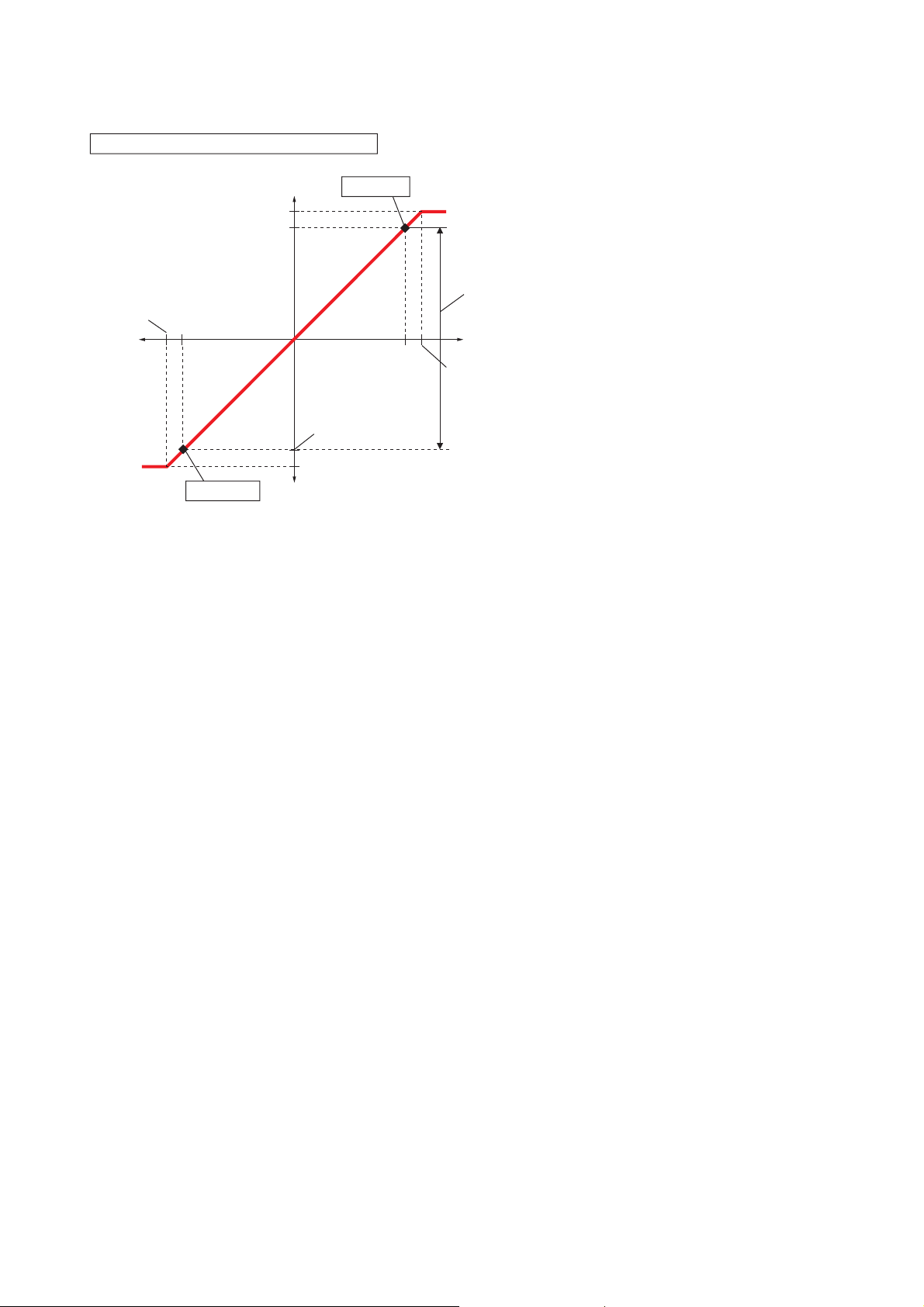

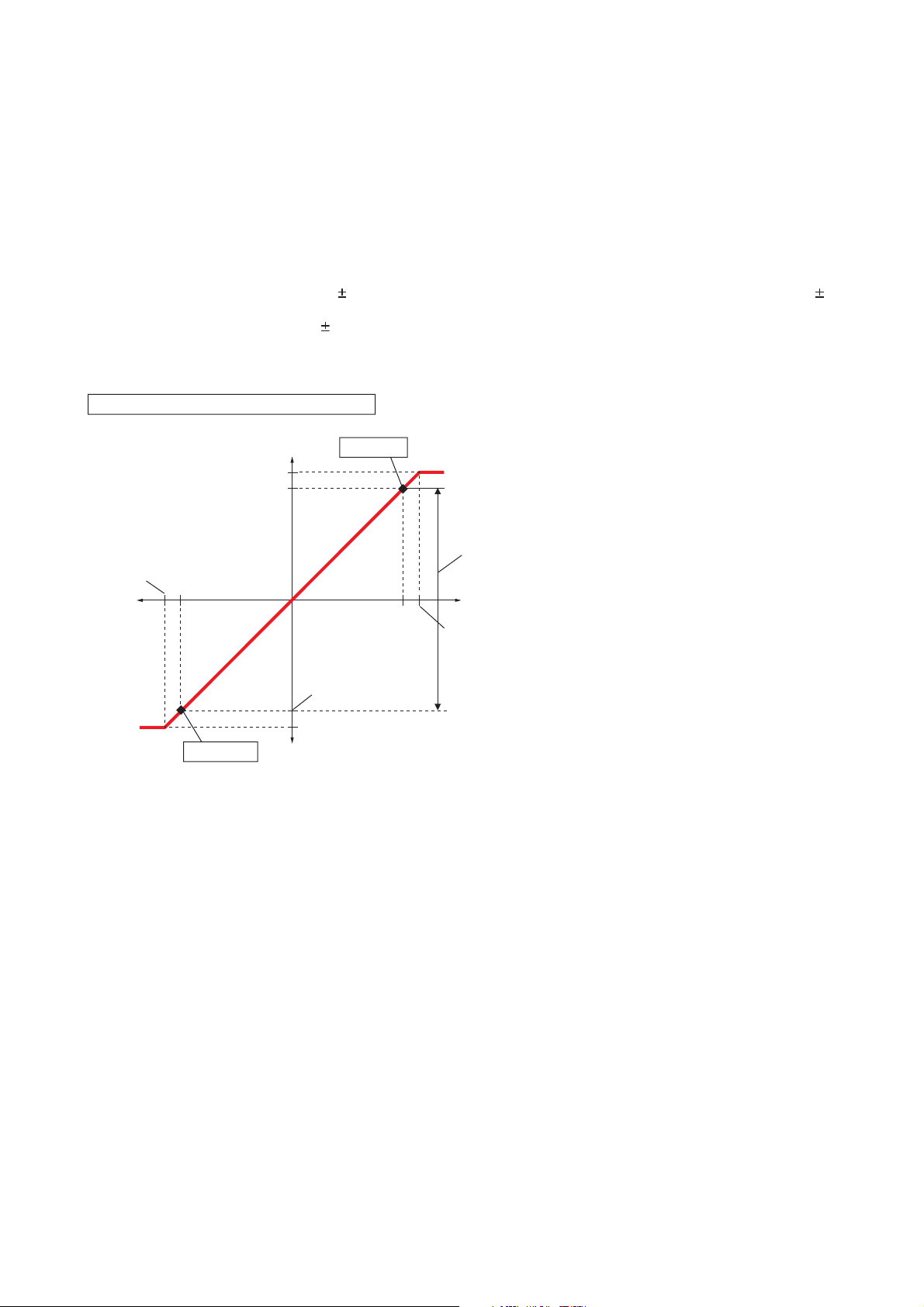

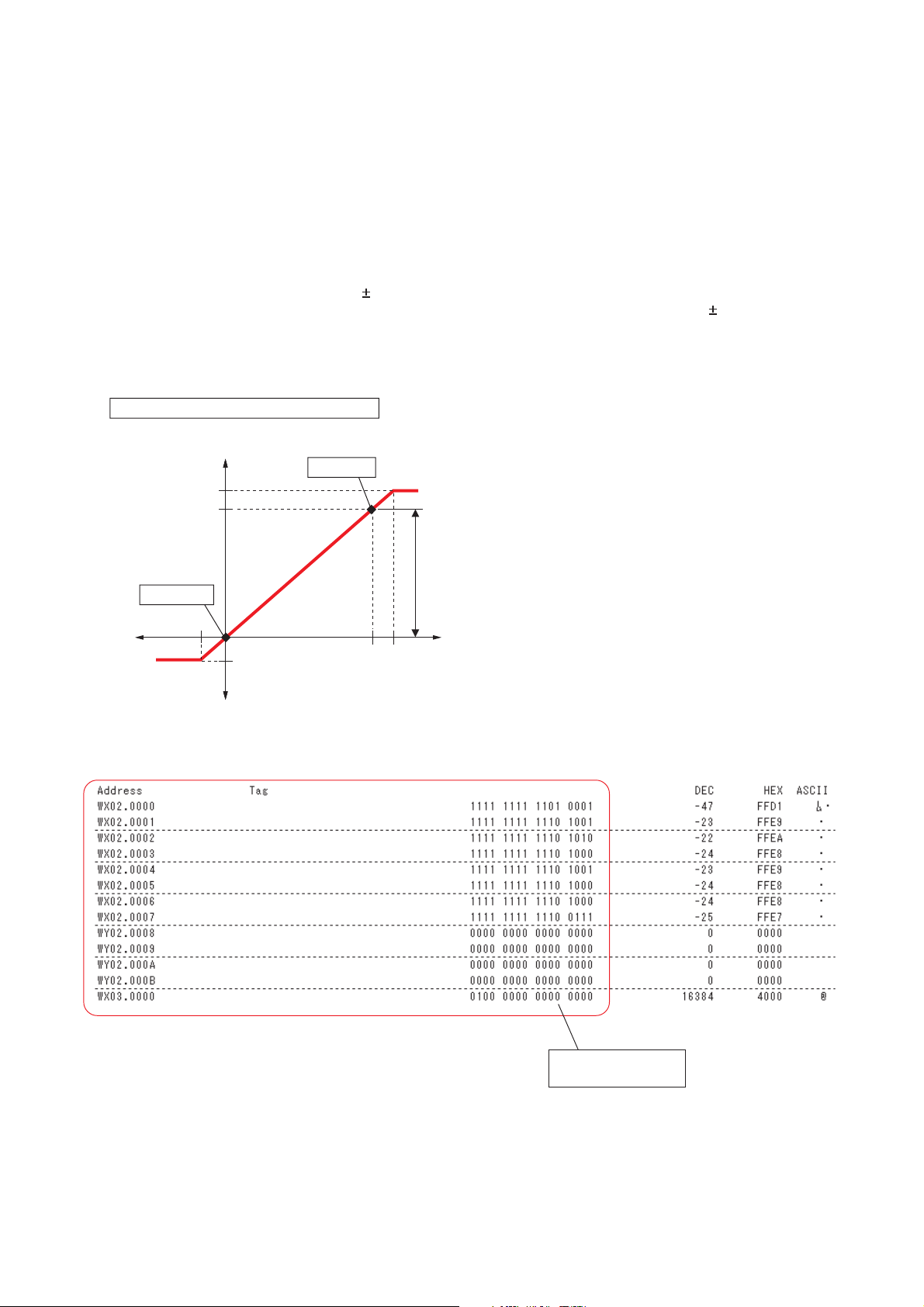

2-3-1 Conversion characteristics of analog voltage input

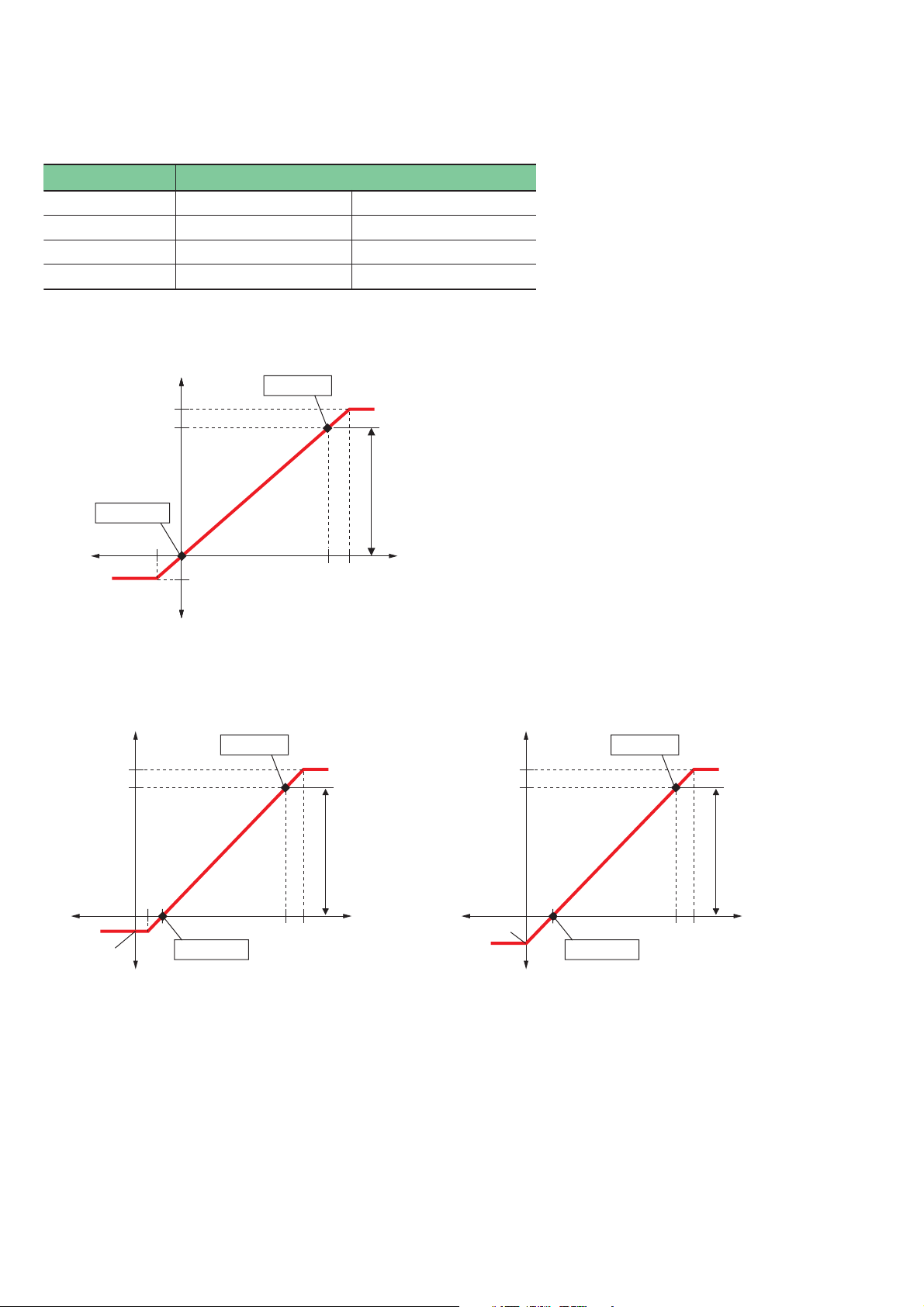

Output range Digital input range

0 to 5 V 0 to 16000 0 to 10000

1 to 5 V 0 to 16000 0 to 10000

0 to 10 V 0 to 16000 0 to 10000

-10 to 10 V -8000 to 8000 0 to 10000

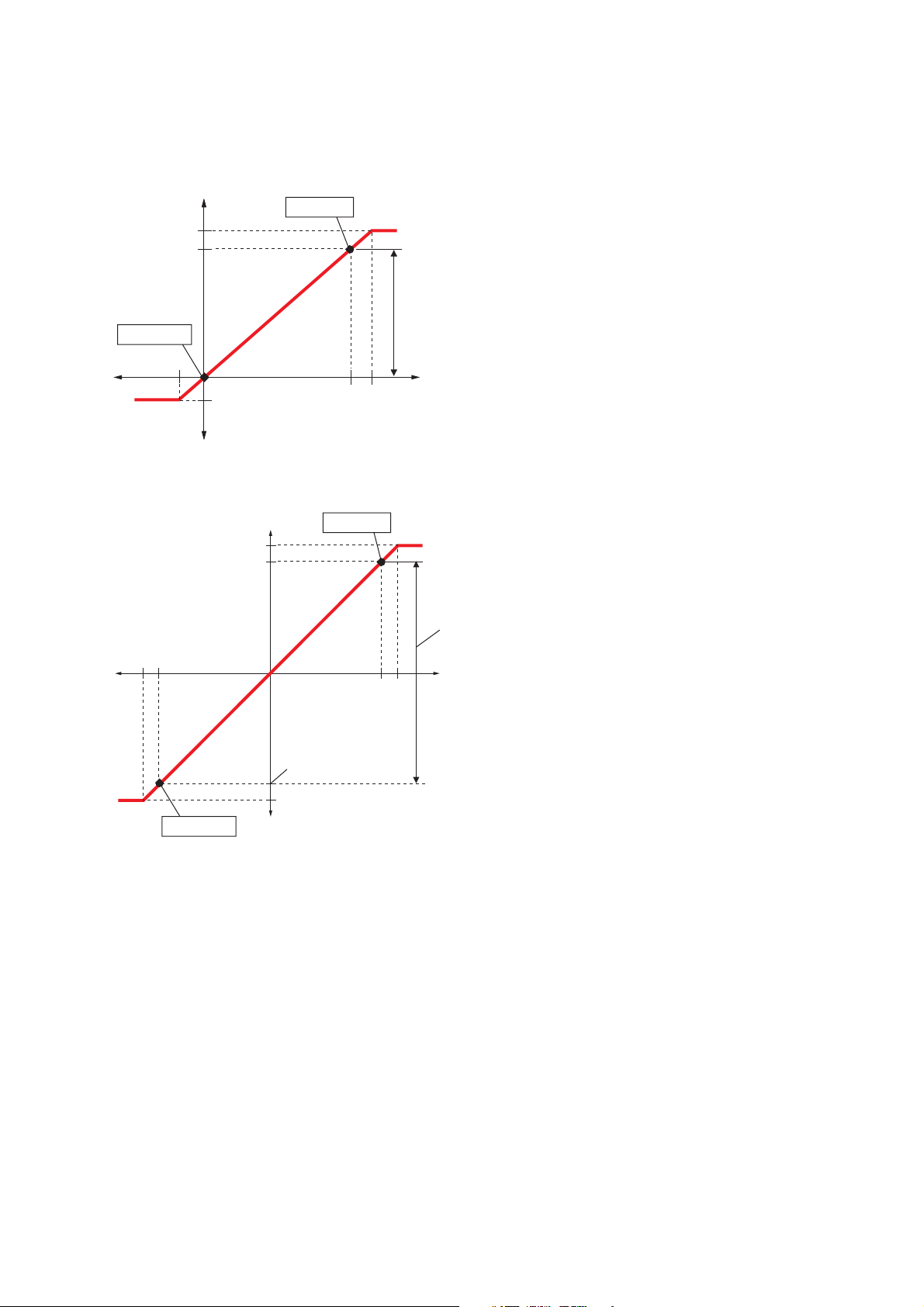

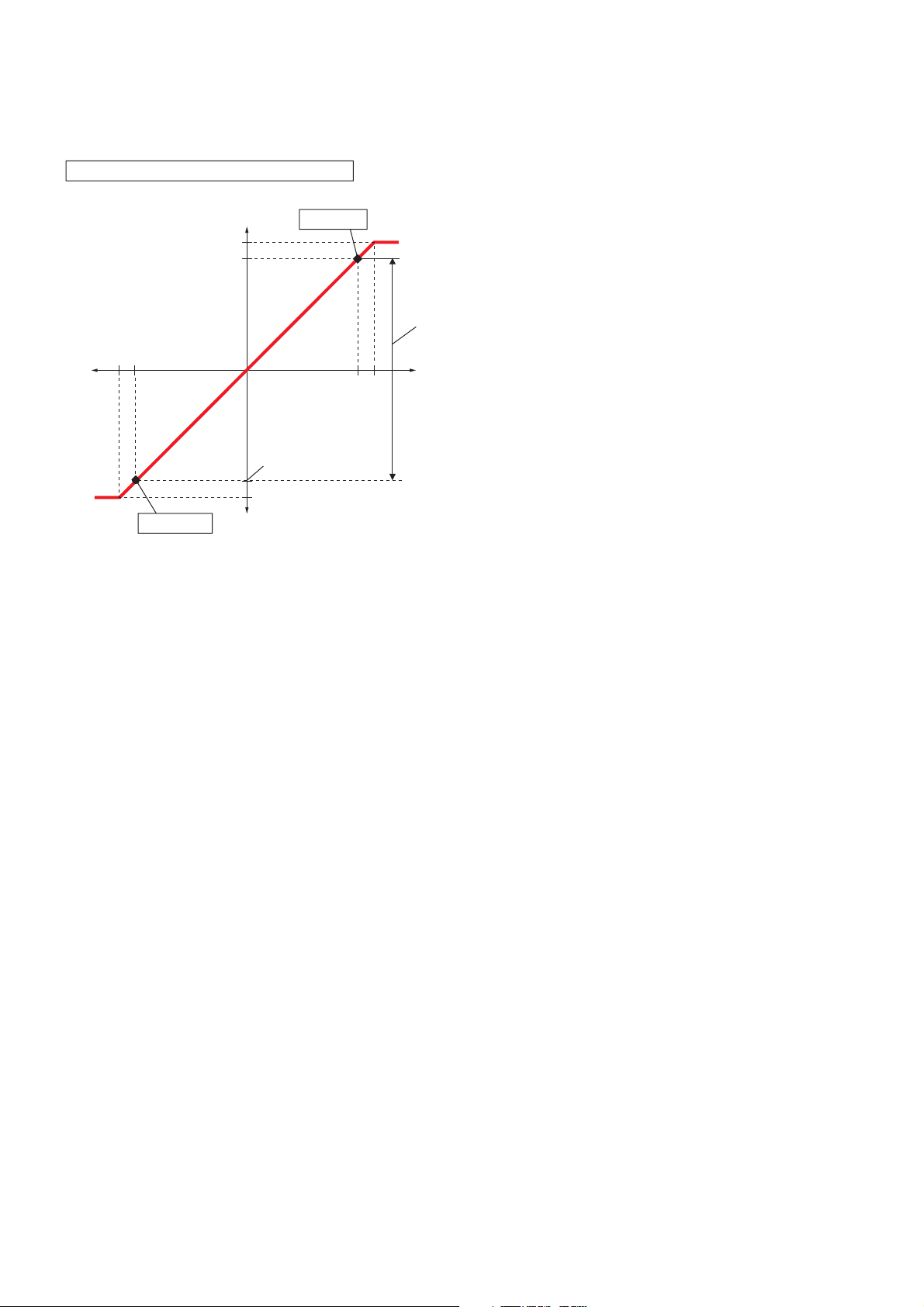

1) Characteristic curve for the input range of 0 to 5 V

Digital output value

(INT type)

Gain value

(10250) 16400

(10000) 16000

(Note)

Practicable digital

output range

Offset value

-0.125

0

-400 (-250)

5 5.125

Analog input voltage (V)

2) Characteristic curve for the input range of 1 to 5 V

Digital output value

(INT type)

Gain value

(10250) 16400

(10000) 16000

(Note)

Practicable digital

output range

(-250) -400

0.9

0

1

Offset value

5 5.1

Analog input

voltage (V)

<NP1AWH6-MR only>

Digital output value

(INT type)

16400

16000

0

-4000

1

Offset value

Gain value

5 5.1

Practicable digital

output range

Analog input

voltage (V)

Note: Parenthesized figures mean the values when the unit of digital output value is % in Fixed Range Operation mode (excl.

NP1AWH6-MR). In software Set Range Operation mode, scaling is necessary to express output values by the %.

2-6

Page 15

Section 2 Specifications

2-3 Conversion Characteristics

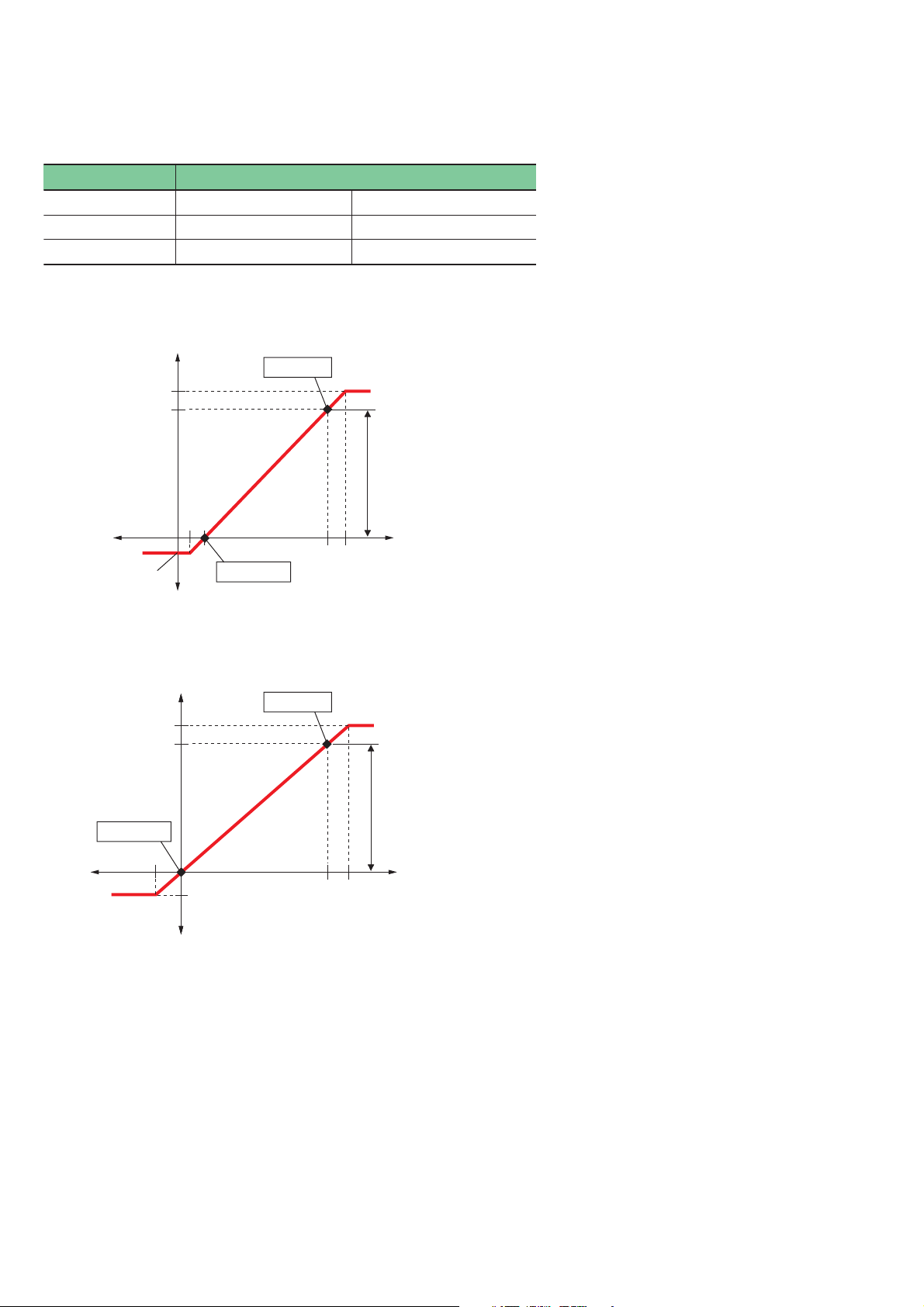

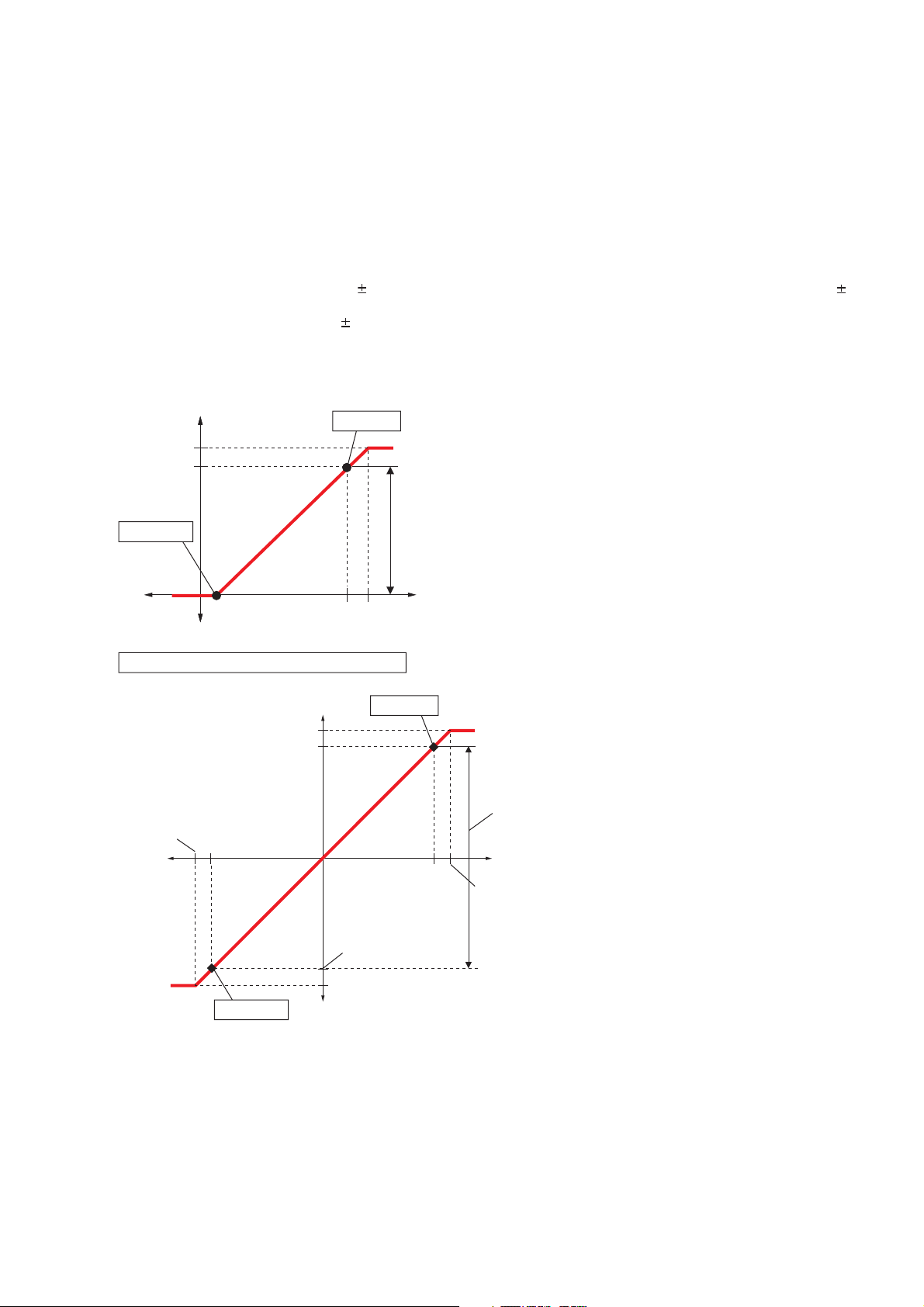

3) Characteristic curve for the input range of 0 to 10 V

Digital output value

(INT type)

Gain value

(10250) 16400

(10000) 16000

(Note)

Practicable digital

output range

Offset value

-0.25

0

-400 (-250)

10 10.25

4) Characteristic curve for the input range of -10 to 10 V

Digital output value

(INT type)

(10125) 8200

(10000) 8000

(Note)

Gain value

Analog input voltage (V)

Practicable digital

output range

-10.25 -10

Offset value

0

-8000 (0)

-8200 (-125)

10 10.25

Analog input voltage (V)

Note: Parenthesized figures mean the values when the unit of digital output value is % in Fixed Range Operation mode (excl.

NP1AWH6-MR). In software Set Range Operation mode, scaling is necessary to express output values by the %.

2-7

Page 16

Section 2 Specifications

2-3 Conversion Characteristics

2-3-2 Conversion characteristics of analog current input

Input range Digitaloutput range

4 to 20 mA 0 to 16000 0 to 10000

0 to 20 mA 0 to 16000 0 to 10000

-20 to 20 mA -8000 to 8000 0 to 10000

1) Characteristic curve for the input range of 4 to 20 mA

Digital output value

(INT type)

Gain value

(10250) 16400

(10000) 16000

(Note)

Practicable digital

output range

3.6

(-250) -400

0

4

Offset value

20 20.4

Analog input current (mA)

2) Characteristic curve for the input range of 0 to 20 mA

Digital output value

(INT type)

Gain value

(10250) 16400

(10000) 16000

(Note)

Practicable digital

output range

Offset value

-0.5

0

-400 (-250)

20 20.5

Note: Parenthesized figures mean the values when the unit of digital output value is % in Fixed Range Operation mode (excl.

NP1AWH6-MR). In software Set Range Operation mode, scaling is necessary to express output values by the %.

Analog input current (mA)

2-8

Page 17

Section 2 Specifications

2-3 Conversion Characteristics

3) Characteristic curve for the input range of -20 to 20 mA

Digital output value

-20.5 -20

(INT type)

(10125) 8200

(10000) 8000

(Note)

0

Offset value

Gain value

Practicable digital

output range

Analog input current (mA)

20 20.5

-8000 (0)

-8200 (-125)

Note: Parenthesized figures mean the values when the unit of digital output value is % in Fixed Range Operation mode (excl.

NP1AWH6-MR). In software Set Range Operation mode, scaling is necessary to express output values by the %.

2-9

Page 18

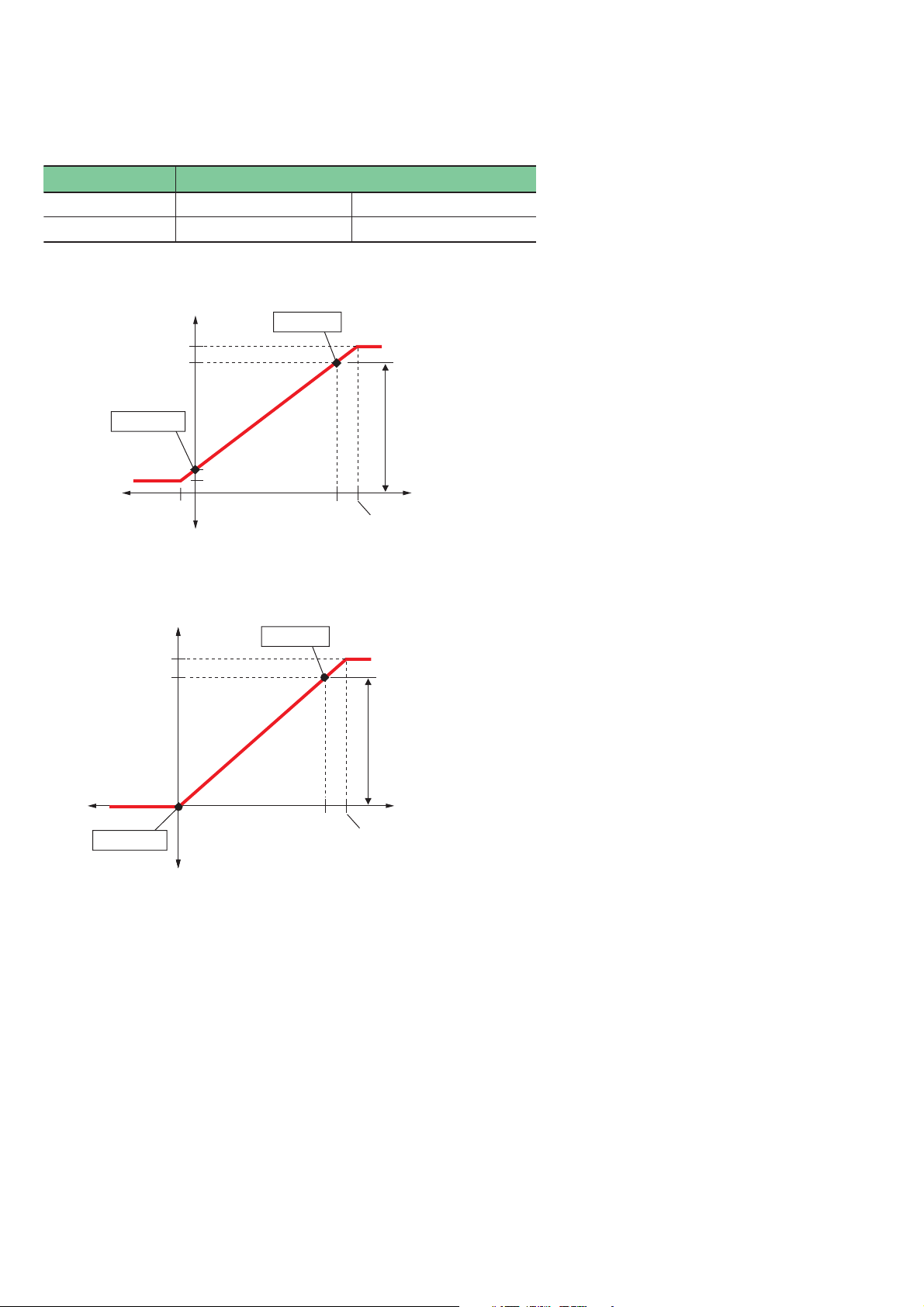

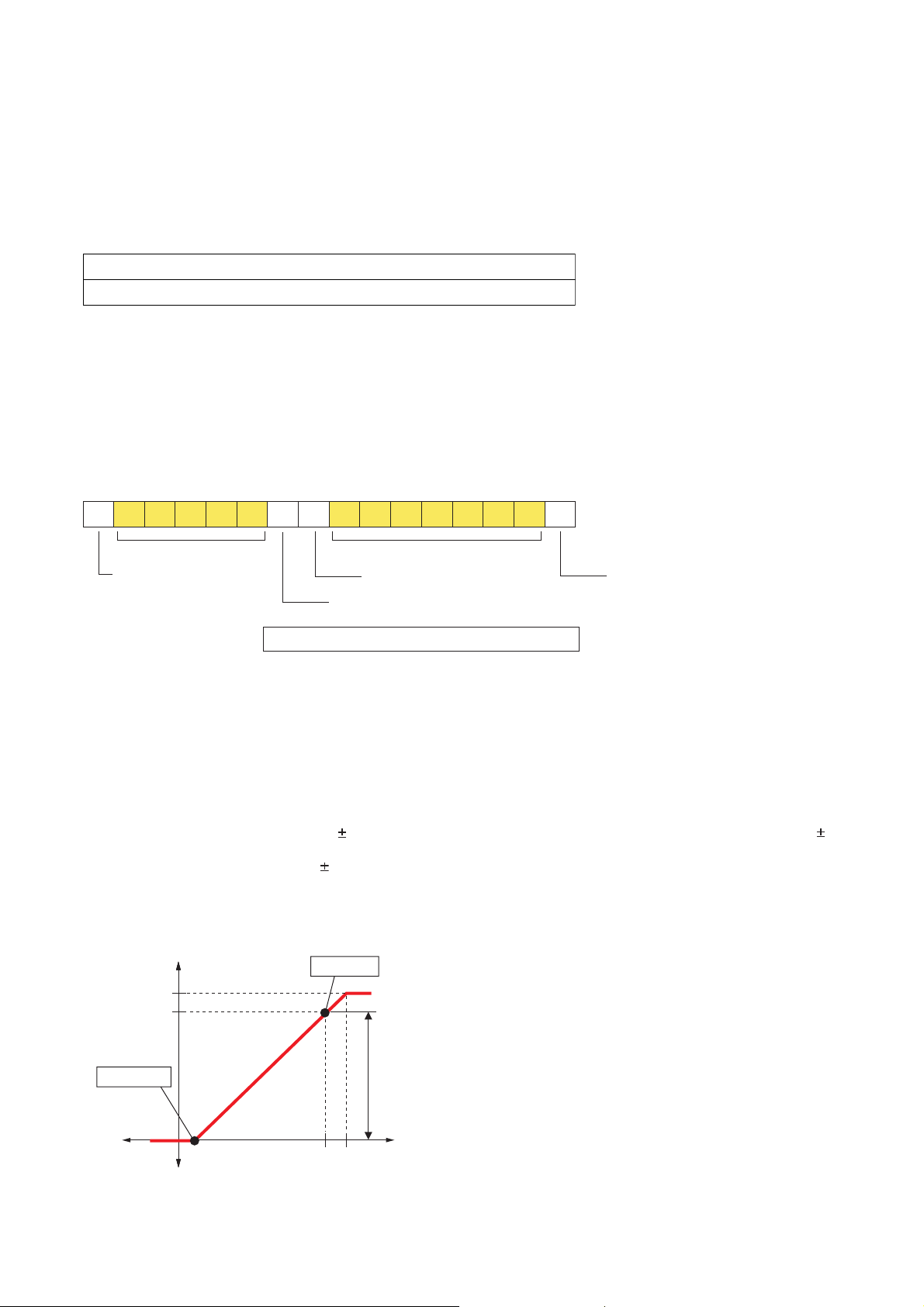

Section 2 Specifications

2-3 Conversion Characteristics

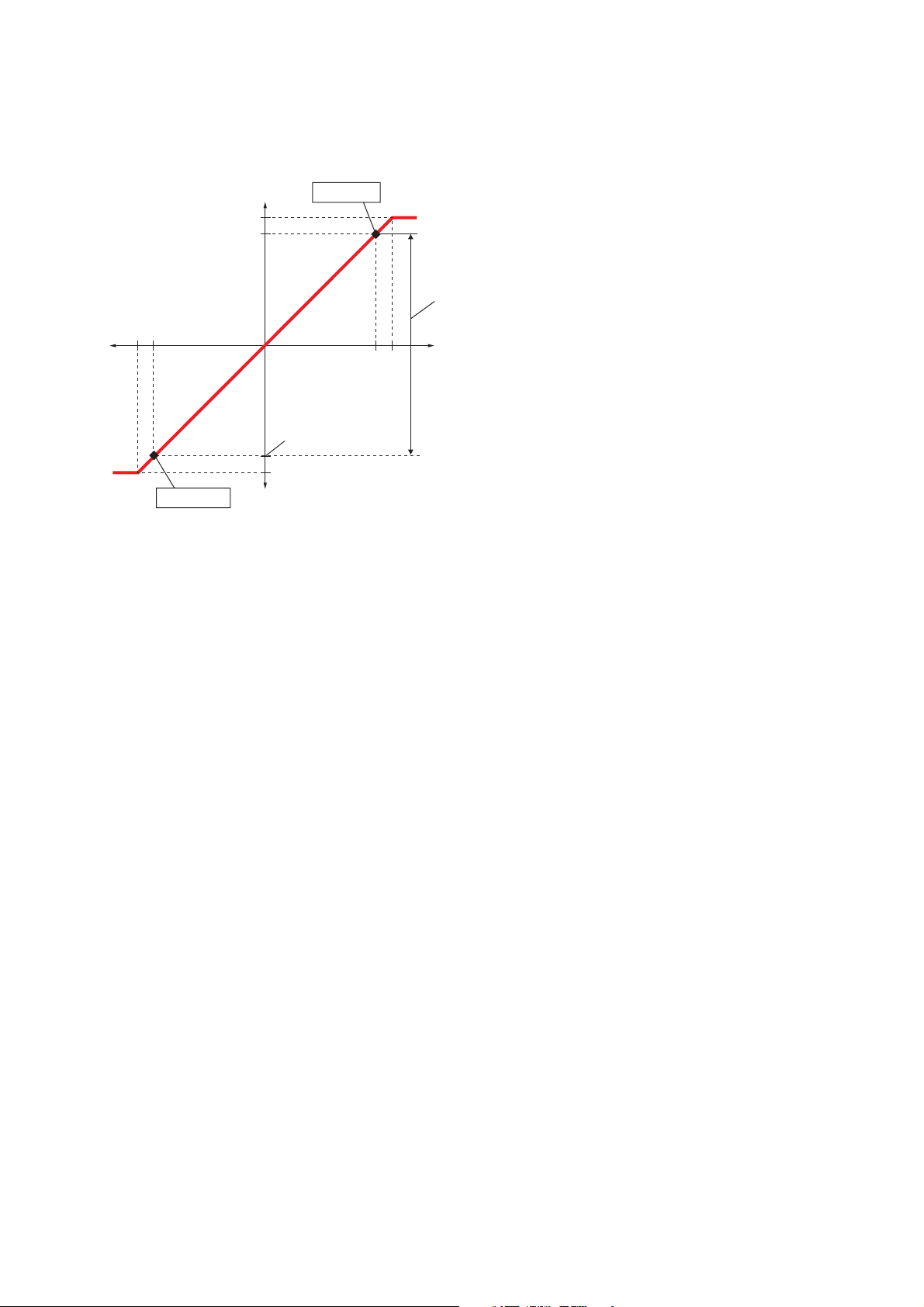

2-3-3 Conversion characteristics of analog voltag output

Output range Digital input range

0 to 5 V 0 to 16000 0 to 10000

1 to 5 V 0 to 16000 0 to 10000

0 to 10 V 0 to 16000 0 to 10000

-10 to 10 V -8000 to 8000 -

1) Characteristic curve for the output range of 0 to 5 V

Analog output voltage (V)

Gain value

5.125

5

(Note)

Offset value

(-250) -400

0

-0.125

16000

(10000)

Practicable analog

output range

Digital input value

(INT type)

16400

(10250)

2) Characteristic curve for the output range of 1 to 5 V

Analog output voltage (V)

Gain value

5.1

5

Offset value

(-250) -400

1

-0.9

0

(Note)

16000

(10000)

Practicable analog

output range

Digital input value

(INT type)

16400

(10250)

Note 1: Parenthesized figures mean the values when the unit of digital input value is % in Fixed Range Operation mode (excl.

NP1AWH6-MR). In Software Set Range Operation mode, scaling is necessary to express input values by the %.

Note 2: If parameter mode is activated in Software Set Range Operation mode, analog output value becomes equal to the

offset value.

2-10

Page 19

Section 2 Specifications

2-3 Conversion Characteristics

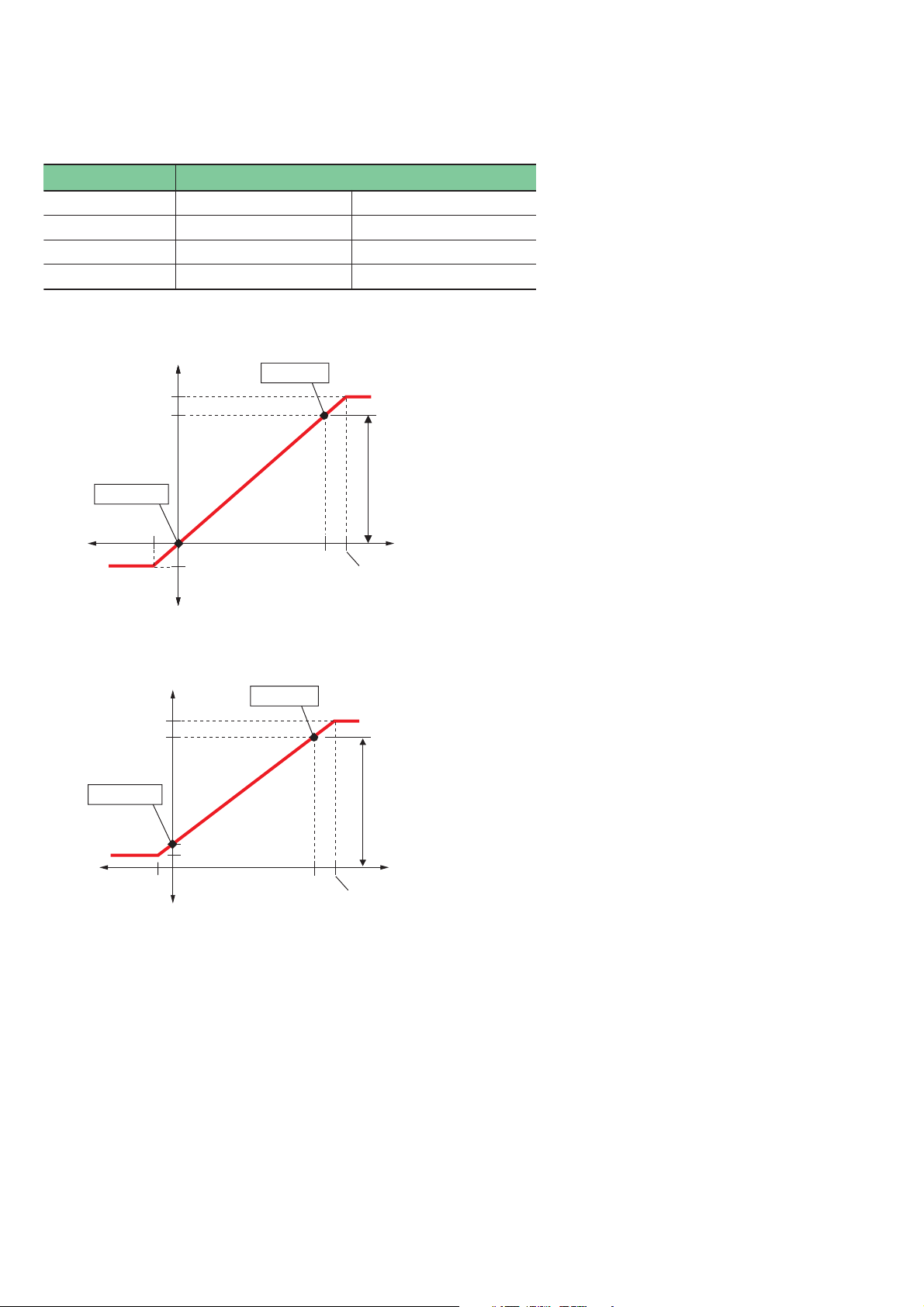

3) Characteristic curve for the output range of 0 to 10 V

Analog output voltage (V)

Gain value

10.25

10

Practicable analog

Offset value

output range

(-250) -400

0

-0.25

(Note)

16000

(10000)

Digital input value

(INT type)

16400

(10250)

4) Characteristic curve for the output range of -10 to 10 V

-8200

(-125)

Analog output voltage (V)

10.25

10

-8000

(Note)

(0)

Offset value

0

-10

-10.25

Gain value

8000

(10000)

Practicable analog

output range

Digital input value

(INT type)

8200

(10125)

Note 1: Parenthesized figures mean the values when the unit of digital input value is % in Fixed Range Operation mode (excl.

NP1AWH6-MR). In Software Set Range Operation mode, scaling is necessary to express input values by the %.

Note 2: For the range of -10 to 10 V, the unit of % cannot be selected by switch setting.

Note 3: If parameter mode is activated in Software Set Range Operation mode, analog output value becomes equal to the

offset value, except that 0 V is output for the range of -10 to 10 V.

2-11

Page 20

Section 2 Specifications

2-3 Conversion Characteristics

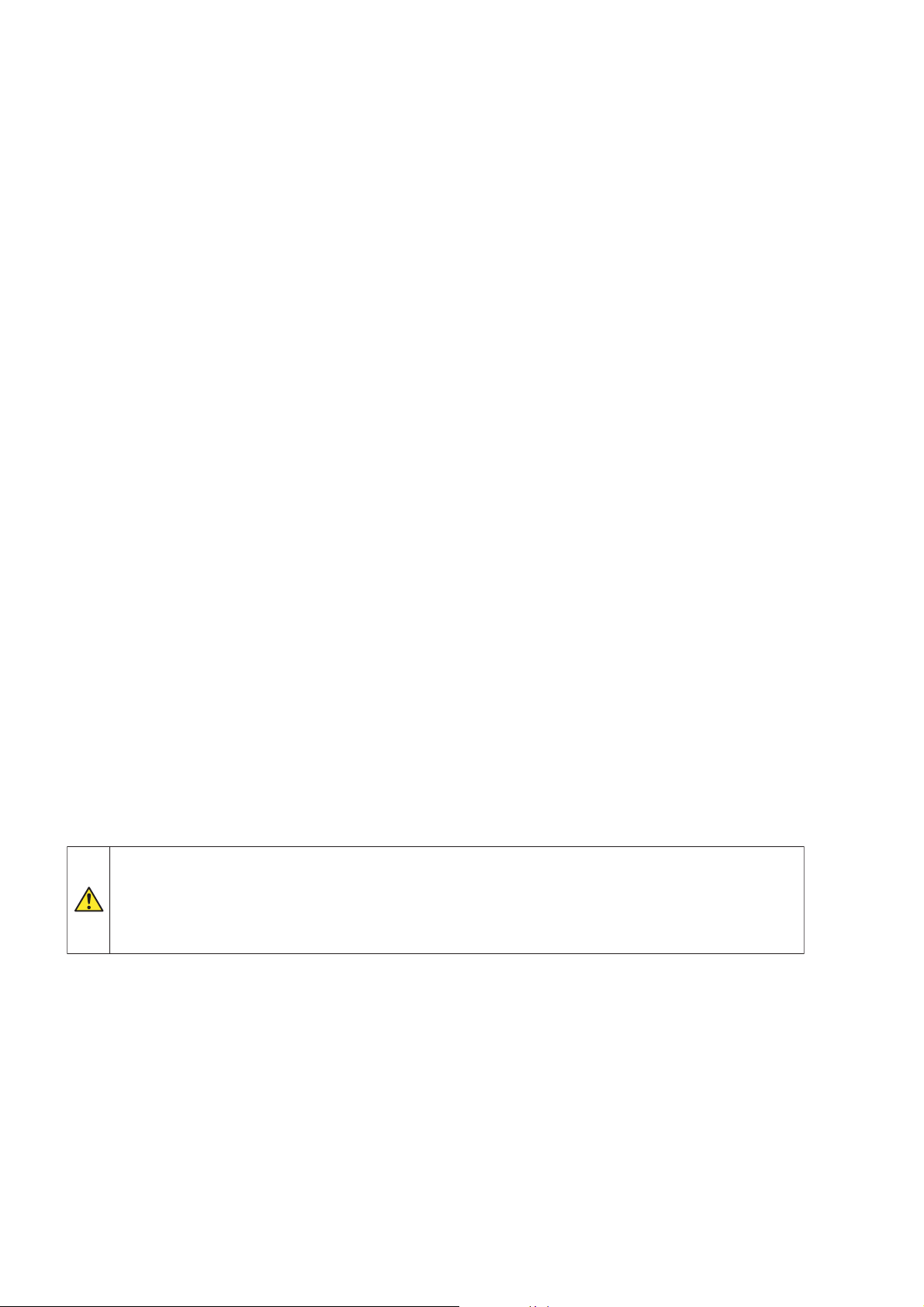

2-3-4 Conversion characteristics of analog current output

Output range Digital input range

4 to 20 mA 0 to 16000 0 to 10000

0 to 20 mA 0 to 16000 0 to 10000

1) Characteristic curve for the output range of 4 to 20 mA

Analog output current (mA)

Gain value

20.4

20

Offset value

(Note)

4

(-250) -400

0

-3.6

(Note)

16000

(10000)

Practicable analog

output range

Digital input value

(INT type)

16400

(10250)

2) Characteristic curve for the output range of 0 to 20 mA

Analog output current (mA)

Gain value

20.5

20

Practicable analog

output range

Offset value

0

16000

(10000)

(Note)

Digital input value

(INT type)

16400

(10250)

Note 1: Parenthesized figures mean the values when the unit of digital input value is % in Fixed Range Operation mode (excl.

NP1AWH6-MR). In Software Set Range Operation mode, scaling is necessary to express input values by the %.

Note 2: If parameter mode is activated in Software Set Range Operation mode, analog output value becomes equal to the

offset value.

2-12

Page 21

Section 2 Specifications

2-4 Functional Specifications

2-4-1 Analog input module functions

(1) Switch batch setting function

With the operation setting switches provided on the module rear panel, it is possible to set the following items for all the

channels in a batch:

Operation range and the unit for digital conversion

Moving average execution times (can be selected from 1, 2, 4 and 8 times).

When the unit of digital output value is set to %, the module operates, regarding

Lower limit value of range as 0.00%,

Upper limit value of range as 100.00%, and

Digital output range as -2.50% to 102.5%.

Note 1: If the Switch Batch Setting function is enabled after scaling values or other parameters have been changed from the

parameter setting window, the changed parameters are not reflected on operation and the parameters return to the

default values.

Note 2: When the switch is set to an invalid value, the status code of “30005” is returned to all the channels.

Note 3: The setting of the switch cannot be checked from application program. Be sure to check the switch setting before the

system is started or before maintenance or replacement is performed.

DD

D For how to set the switch, refer to “2-5 Names and Functions”.

DD

(2) Individual channel operation range setting function

When the operation setting switch on the module rear panel is set to “Software Set Range”, operation range can be set for

individual channel by application program.

(3) Individual channel moving average execution times setting function

When the operation setting switch on the module rear panel is set to “Software Set Range”, moving average execution times

can be set for individual channel by application program. Default is once (sampling operation). Averaging execution times can

be selected from 1, 2, 4 and 8.

Note: The “Average” switch on the module rear panel is disabled.

(4) Individual channel conversion enable/disable setting function

When the operation setting switch on the module rear panel is set to “Software Set Range”, enable/disable of A/D conversion

can be set for individual channel by application program. Default is “enable conversion”.

Sampling time can be reduced by disabling A/D conversion for unused channels. For conversion disabled channels, digital

output value is fixed to 0 (zero).

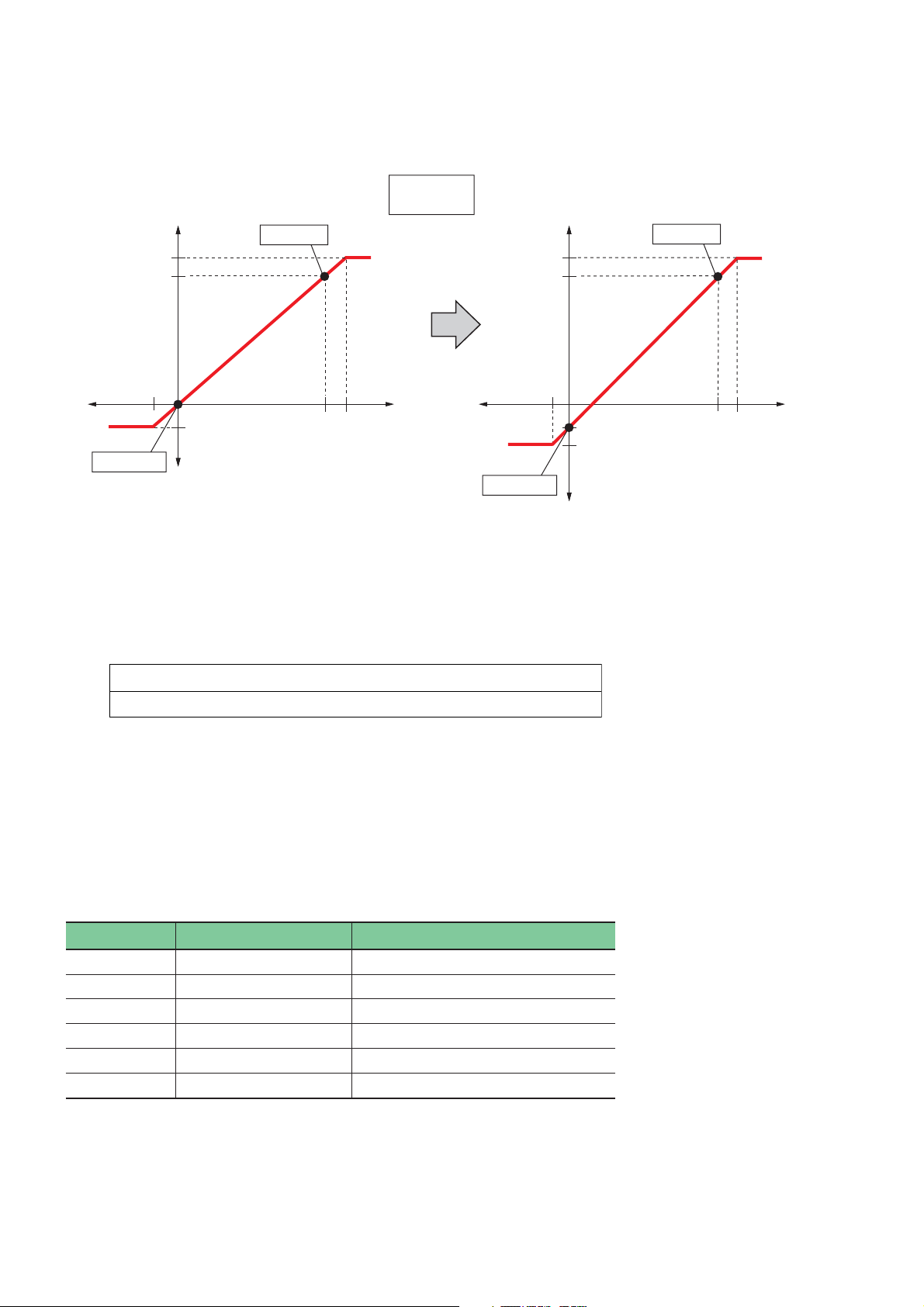

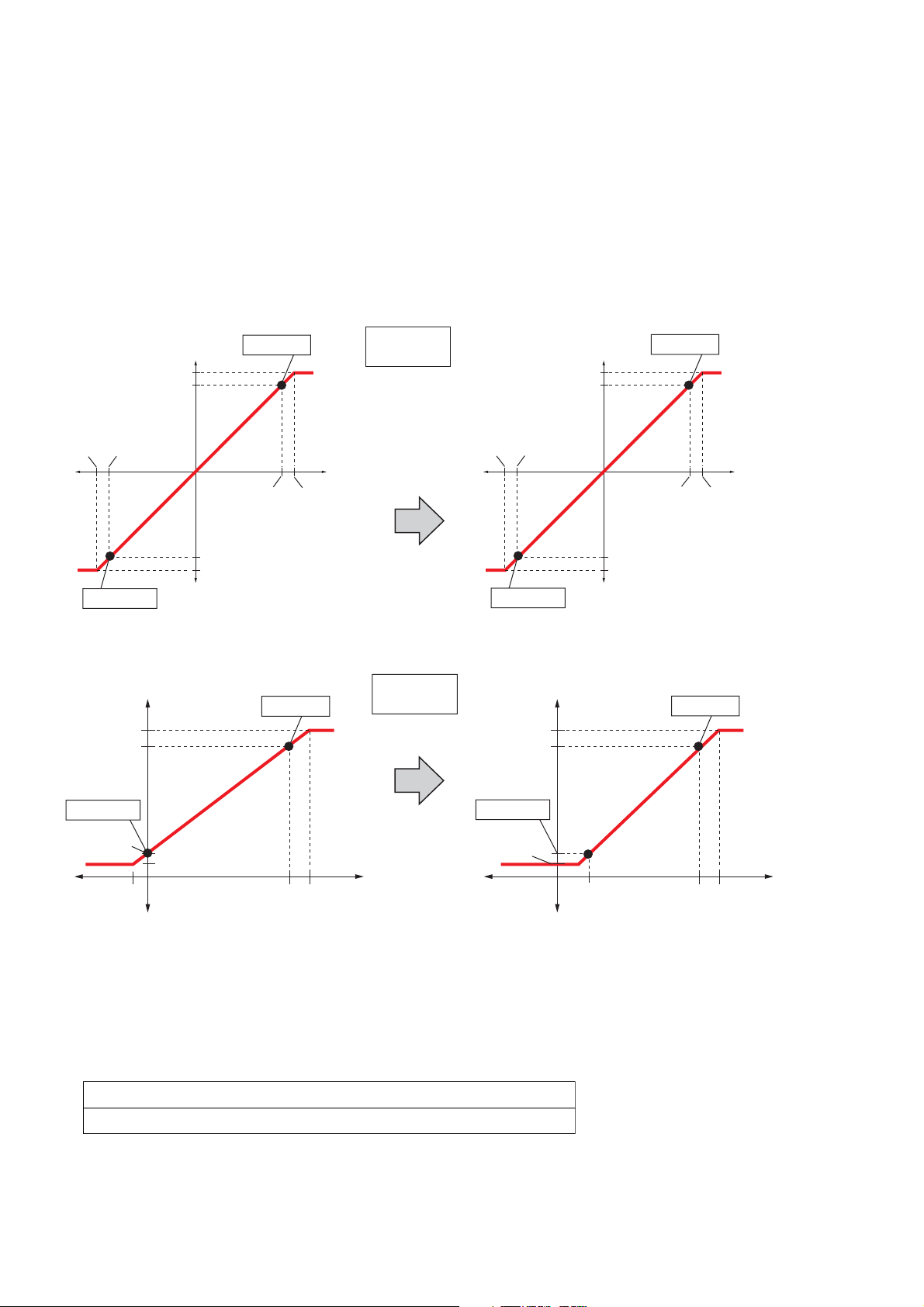

(5) Individual channel gain/offset value fine adjustment function

When the operation setting switch on the module rear panel is set to “Software Set Range”, gain and offset values can finely

be adjusted for individual channel by application program.

* For the detailed specifications and setting, refer to “4-1-2 (6)”.

(6) Scaling function

When the operation setting switch on the module rear panel is set to “Software Set Range”, the scale for A/D conversion can

be set for individual channel by application program.

* For the detailed specifications and setting, refer to “4-1-2 (6)”.

2-13

Page 22

Section 2 Specifications

2-4 Functional Specifications

2-4-2 Analog output module functions

(1) Switch batch setting function

With the operation setting switches provided on the module rear panel, it is possible to set operation range and the unit for

digital input value.

When the unit of digital input value is set to %, the module operates, regarding

Lower limit value of range: 0.00%,

Upper limit value of range: 100.00%

Digital output range: -2.50% to 102.5%.

Note 1: If the Switch Batch Setting function is enabled after scaling values or other parameter have been changed from the

parameter setting window, the changed parameters are not reflected on operation and the parameters return to the

default values.

Note 2: When the switch is set to an invalid value, bit 11 of offset address +0 is set ON.

Note 3: The setting of the switch cannot be checked from application program. Be sure to check the switch setting before the

system is started or before maintenance or replacement is performed.

DD

DFor how to set the switch, refer to “2-5 Names and Functions”.

DD

(2) Individual channel operation range setting function

When the operation setting switch on the module rear panel is set to “Software Set Range”, operation range can be set for

individual channel by application program.

(3) Output enable/disable setting function (analog 8ch output modules only)

When the operation setting switch on the module rear panel is set to “Software Set Range”, “enable output for all channels” or

“enable output for CH1 to CH4, disable output for CH5 to CH8” can be set by application program.

When “enable output for CH1 to CH4, disable output for CH5 to CH8” is set, sampling time is halved, and the output disabled

channels output 0 V or 0 mA.

Note: Because the accuracy of output value is not guaranteed for output disabled channels, these channels may output

slightly offset values.

(4) Individual channel gain/offset value fine adjustment function

When the operation setting switch on the module rear panel is set to “Software Set Range”, gain and offset values can finely

be adjusted for individual channel by application program.

* For the detailed specifications and setting, refer to “4-2-2 (8)”.

(5) Scaling function

When the operation setting switch on the module rear panel is set to “Software Set Range”, the scale for A/D conversion can

be set for individual channel by application program.

* For the detailed specifications and setting, refer to “4-2-2 (8)”.

When the system is started up, the analog value that corresponds to digital value “0” (zero) is output (for

approximately several hundreds milliseconds since the “ONL” LED has lit till the application program starts).

Therefore, for scaling, the value that corresponds to digital value “0” (zero) should be set such that fail safe

operation will be performed. Also when the system is shut down or becomes abnormal, the analog value that

corresponds to digital value "0" (zero) is output (when this module in I/O Reset mode).

2-14

Page 23

Section 2 Specifications

2-4 Functional Specifications

2-4-3 Analog input/output module functions

(1) Switch batch setting function

With the operation setting switches provided on the module rear panel, it is possible to set operation range.

For analog input, it can be set for 4 channels in a batch; for analog output, 2 channels in a batch.

Note 1: If the Switch Batch Setting function is enabled after scaling values or other parameter have been changed from the

parameter setting window, the changed parameters are not reflected on operation and the parameters return to the

default values.

Note 2: When the switch is set to an invalid value, the status code of “30005” is returned to all the channels.

Note 3: The setting of the switch cannot be checked from application program. Be sure to check the switch setting before the

system is started or before maintenance or replacement is performed.

DD

DFor how to set the switch, refer to “2-5 Names and Functions”.

DD

(2) Individual channel operation range setting function

When the operation setting switch on the module rear panel is set to “Software Set Range”, operation range can be set for

individual channel by application program.

(3) Individual channel moving average execution times setting function

When the operation setting switch on the module rear panel is set to “Software Set Range”, moving average execution times

can be set for individual channel by application program. Default is once (sampling operation). Averaging execution times can

be selected from 1, 2, 4 and 8.

(4) Individual channel conversion enable/disable setting function

When the operation setting switch on the module rear panel is set to “Software Set Range”, enable/disable of A/D conversion

can be set for individual channel by application program. Default is “enable conversion”.

Sampling time can be reduced by disabling A/D conversion for unused channels. For conversion disabled channels, digital

output value is fixed to 0 (zero).

(5) Individual channel gain/offset value fine adjustment function

When the operation setting switch on the module rear panel is set to “Software Set Range”, gain and offset values can finely

be adjusted for individual channel by application program.

* For the detailed specifications and setting, refer to “4-3-2 (8)”.

(6) Scaling function

When the operation setting switch on the module rear panel is set to “Software Set Range”, the scale for A/D conversion can

be set for individual channel by application program.

* For the detailed specifications and setting, refer to “4-3-2 (8)”.

2-15

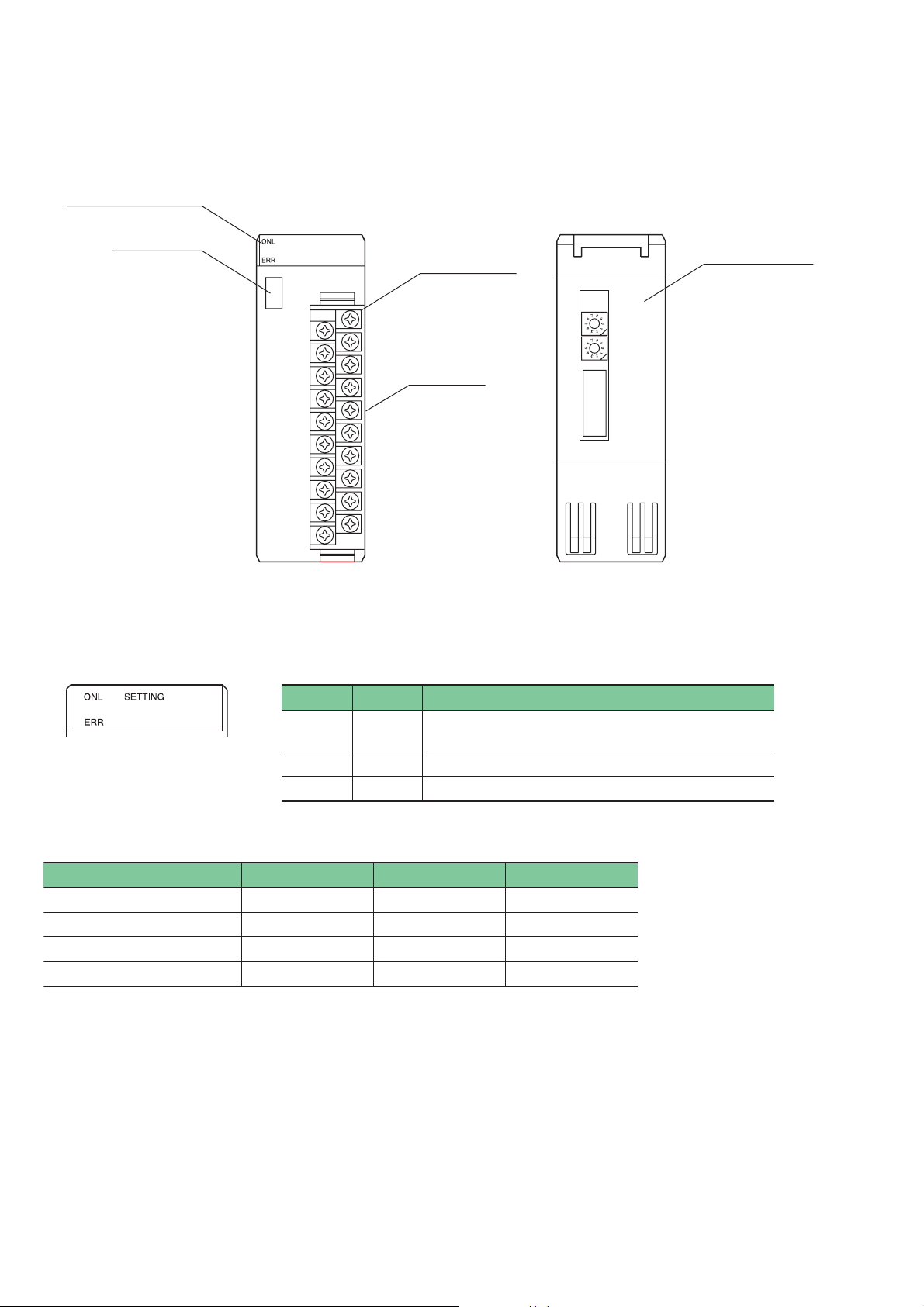

Page 24

Section 2 Specifications

2-5 Names and Functions

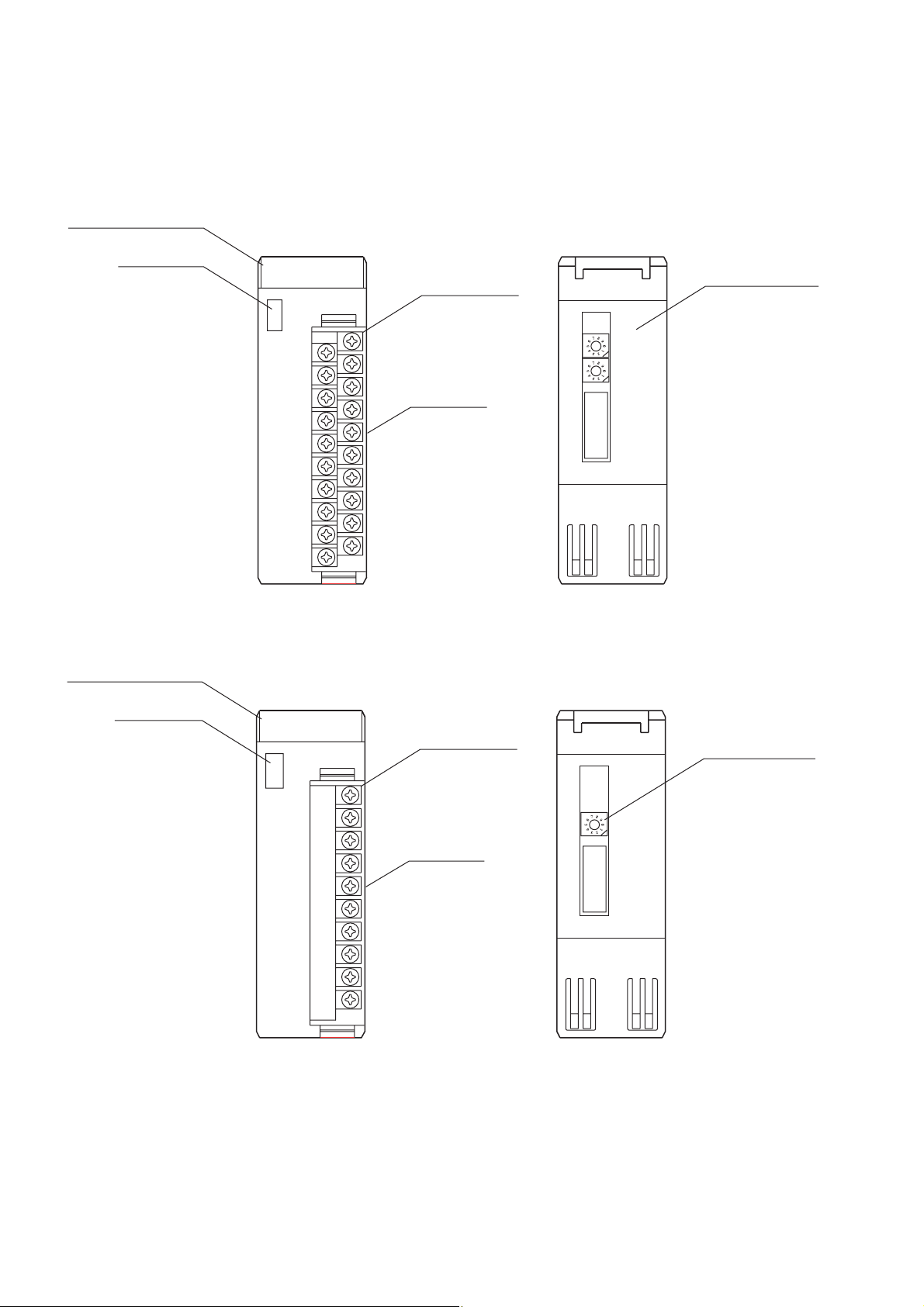

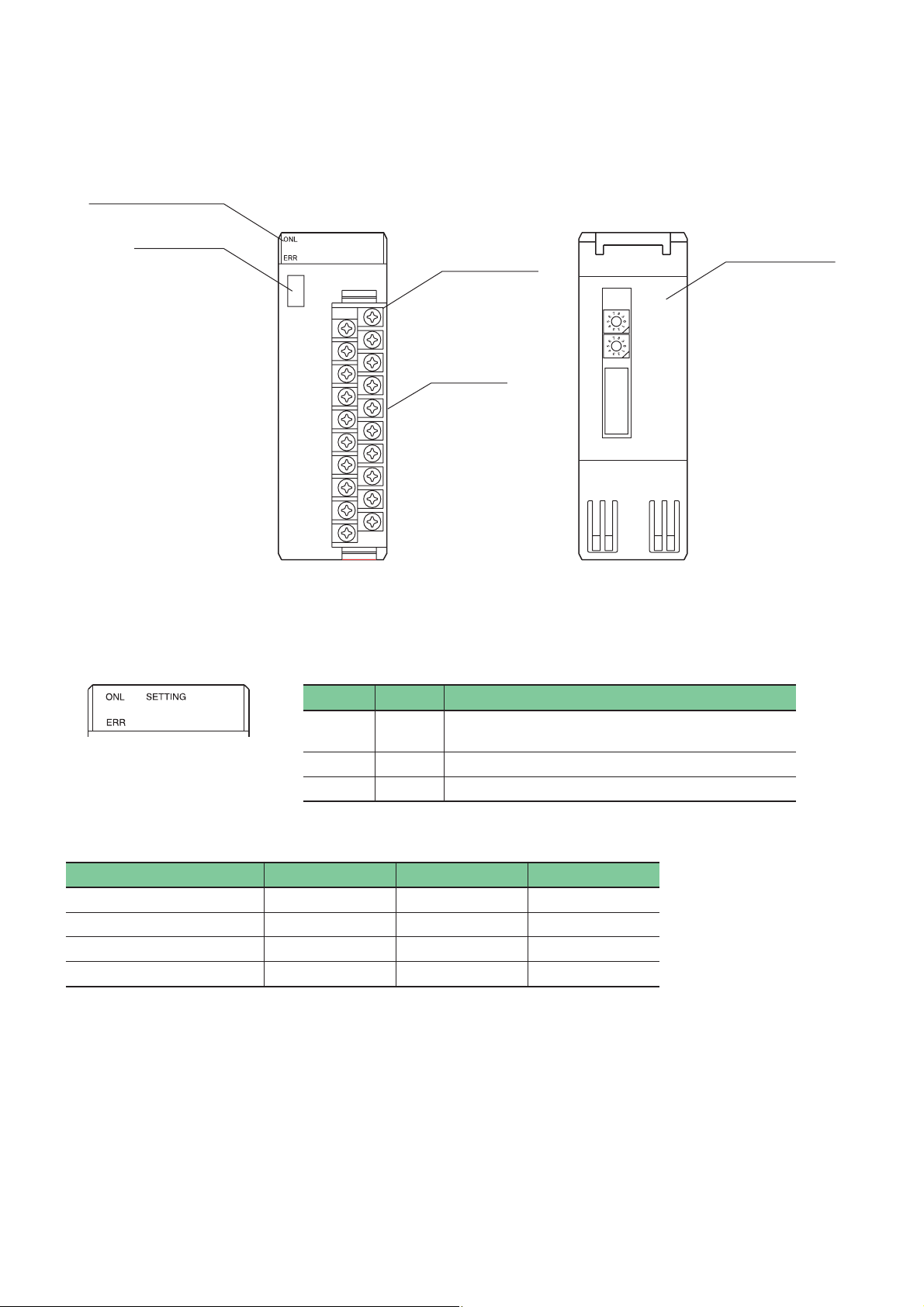

2-5-1 Analog input module (NP1AXH8V-MR/NP1AXH8I-MR)

(1) Names

1) Status indication LED

4) Version seal

Front Rear

(2) Functions

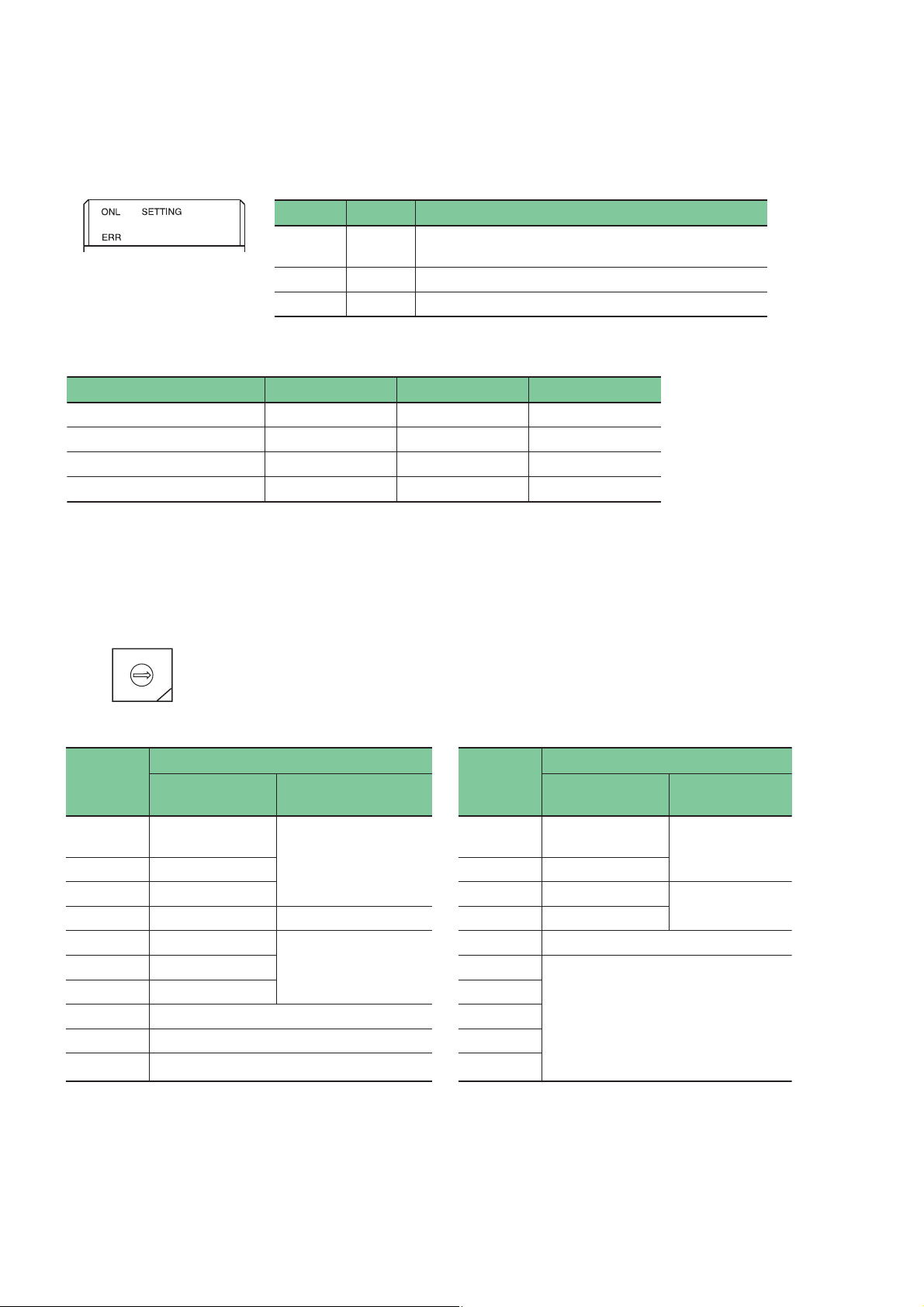

1) Status Indication LED

Indicates the current status of the analog input module.

3) Detachable

terminal block

Specification

name plate

2) Operation setting

switches

Symbol Color Description

ONL Green Lights when the module is operating normally. Blinks

whileconnectingtoSXbus.

ERR Red Lights whenthe module is abnormal.

SETTING Green Blinks while gain or offset value is being adjusted.

<Example of status indication>

O: Li ghting, U: Blinking, -: Unlit

Status ONL (green) ERR (red) SETTING (green)

Initializing

Normally operating O - Adjusting offset/gainvalue O Fatalfault - O -

U

--

U

2-16

Page 25

Section 2 Specifications

2-5 Names and Functions

2) Operation setting switches

These switches are used to set input range and moving average execution times.

“Average” switch: Used to set a same value of moving average execution times for all channels. In Software Set Range

Operation mode, the setting of this switch is ignored, and instead the initial value is used for operation.

For more information, refer to “Section 4 Software Interface”.

“Range” switch: When this switch is set to one of numbers “0” to “7”, same range is set for all channels. It is impossible to

set input range differently for individual channels.

When this switch is set to “8”, Software Set Range Operation mode is activated, and it becomes possible

to set various parameters differently for individual channels. For more information, refer to “Section 4

Software Interface”.

8

7

9

6

0

5

1

4

2

3

I At shipment, both “Average” and “Range” switches are set to “0” (zero).

8

7

9

6

0

5

1

4

2

3

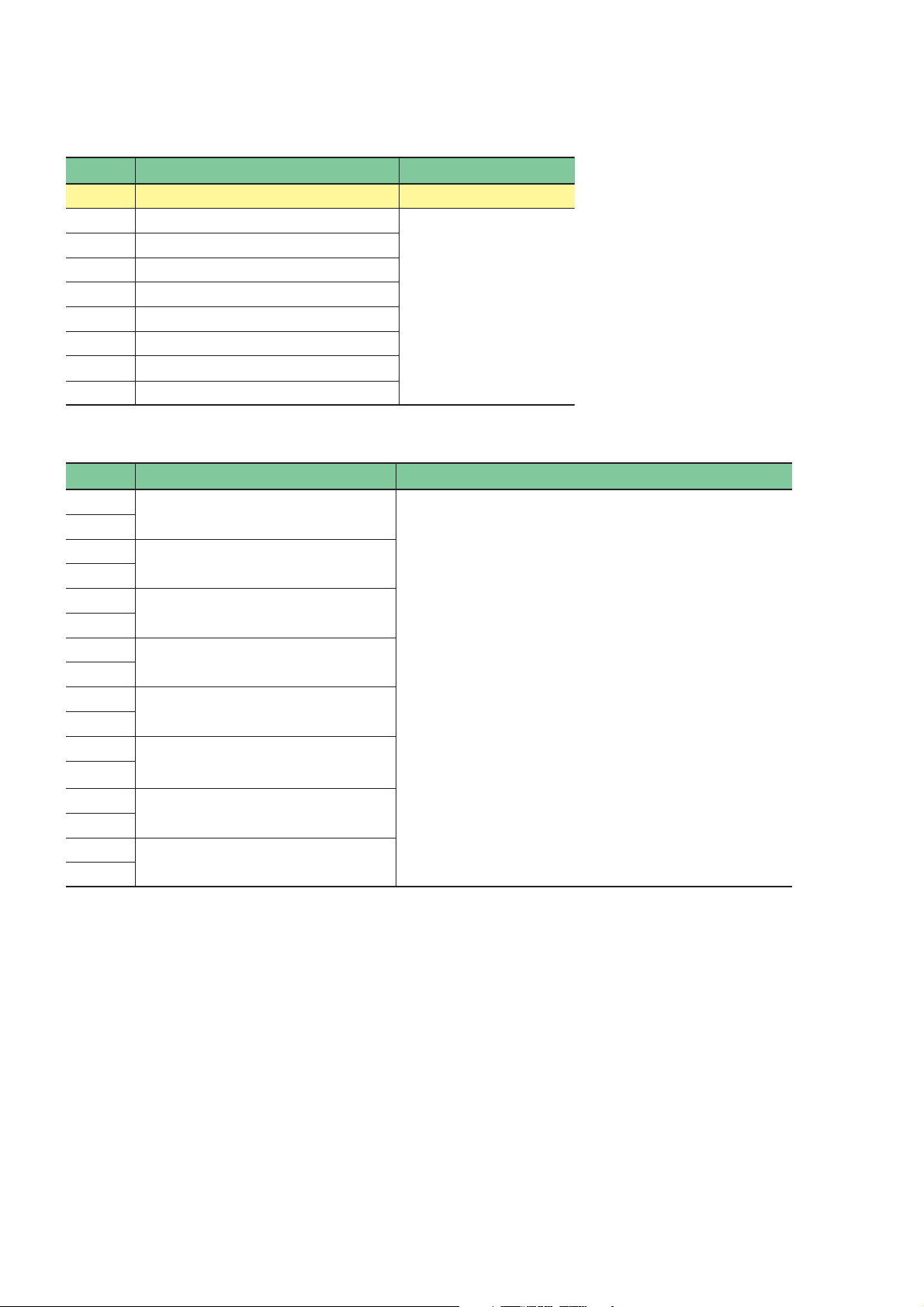

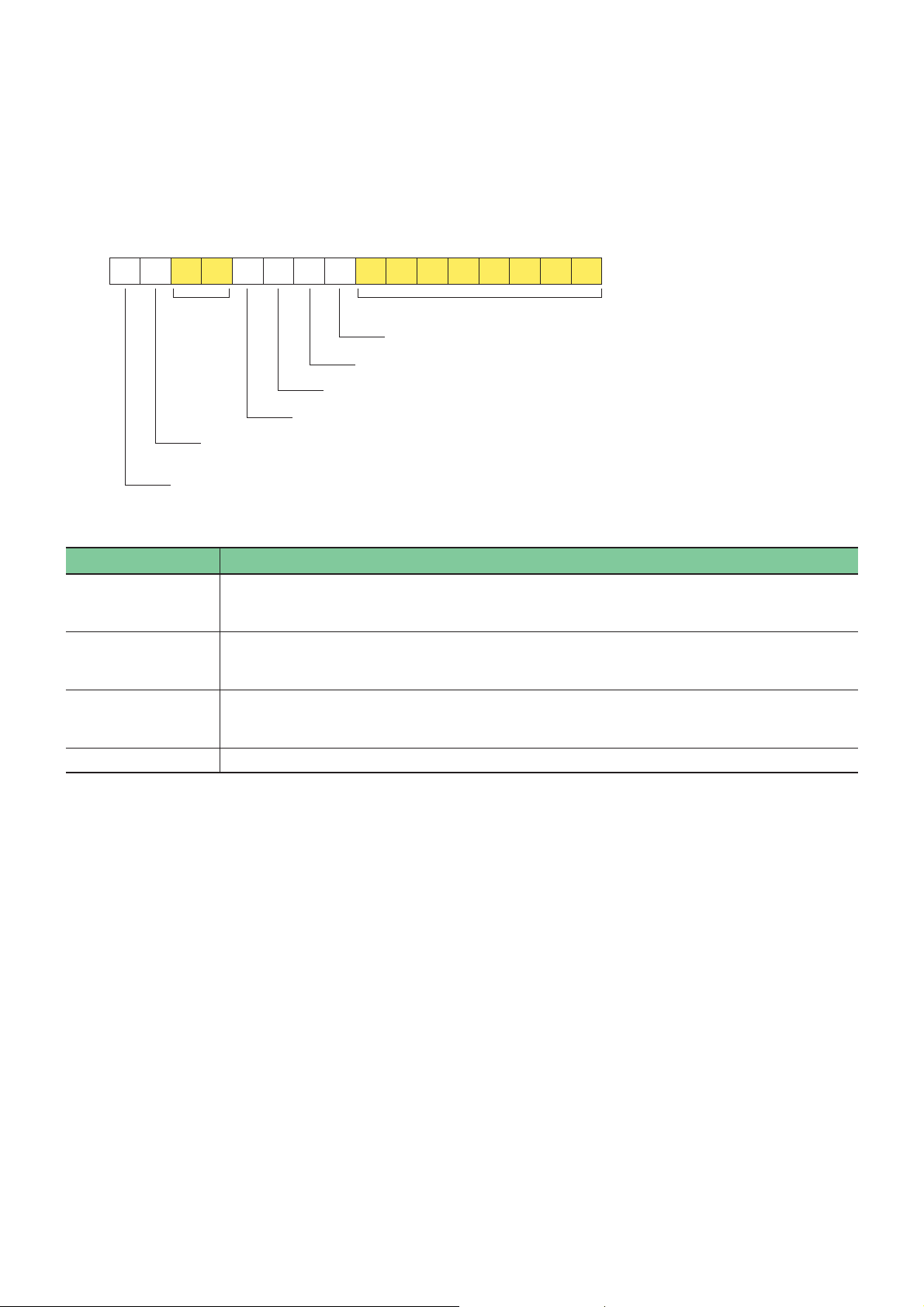

<Range switch setting list>

Switch No.

0

At shipment

NP1AXH8V-MR

Input range

Digital output

range

Switch No.

-10 to 10 V -8000 to 8000 0

At shipment

NP1AXH8I-MR

Input range

4to20mA

Digital output

range

0 to 16000

1 0 to 10 V 0 to 16000 1 0 to 20 mA

2 0 to 5 V 2 -20 to 20 mA -8000 to 8000

3 1to5V 3 4to20mA

0 to 100004 -10 to 10 V 0 to 10000 4 0 to 20 mA

5 0to10V 5 -20to20mA

6 0 to 5 V 6 Software Set Range Operation mode

7 1to5V 7

8 Software Set Range Operation mode (Note1) 8

Unused (Note 2)

9 Unused (Note 2) 9

<Average switch setting list>

Switch No. NP1AXH8V-MR NP1AXH8I-MR

0

Once (no moving average)

At shipment

1Twice

24times

Note 1:

For how to set in Software Set Range Operation mode,

refer to “Section 4 Software Interface”.

Note 2:

If an unused number is set, a “switch setting error” will

occur.

38times

4 to 9 Unused (no moving average)

3) Detachable terminal block

M3 20-pole detachable terminal block. For terminal arrangement, refer to “5-1-1 Terminal arrangement”. For wiring, be sure to

use crimp type terminals and surely tighten them (tightening torque: 0.5 to 0.7 N-m.)

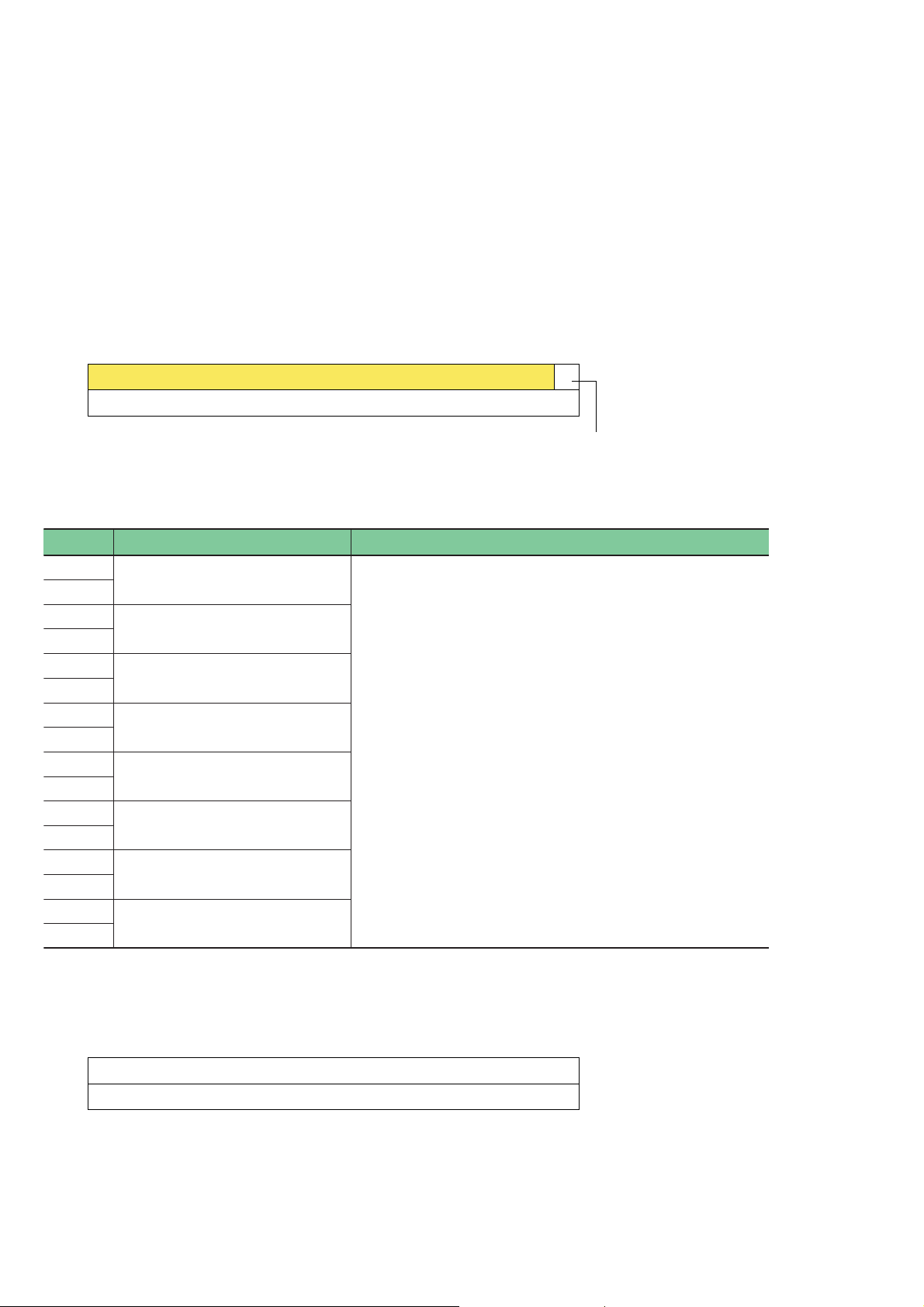

4) Version seal

Versions of the hardware and firmware of the module are indicated on this seal.

2 0

3 0

Hardware version

Firmware version

2-17

Page 26

Section 2 Specifications

2-5 Names and Functions

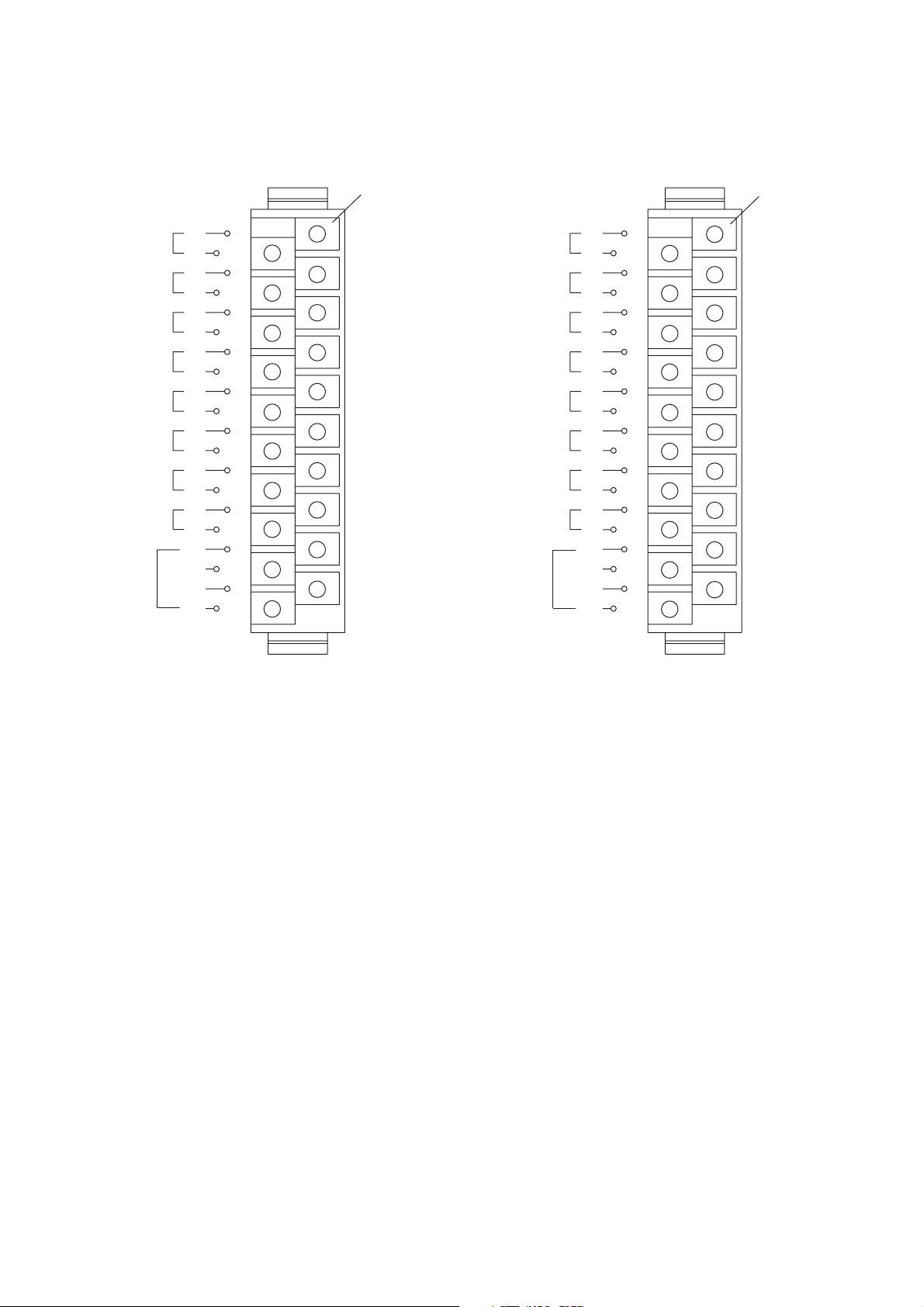

2-5-2 Analog output module (NP1AYH8V-MR, NP1A YH8I-MR, NP1AYH4V-MR, NP1AYH4I-MR)

(1 ) Names

<Analog 8ch output module>

1) Status indication LED

4) Version seal

<Analog 4ch output module>

1) Status indication LED

SETTING

ONL

ERR

Front Rear

3) Detachable

terminal block

Specification

name plate

2) Operation setting

switches

4) Version seal

SETTING

ONL

ERR

Front Rear

3) Detachable

terminal block

Specification

name plate

2) Operation setting

switches

2-18

Page 27

Section 2 Specifications

)

2-5 Names and Functions

(2) Functions

1) Status indication LED

Indicates the current status of the analog output module.

Symbol Color Description

ONL Green Lights when the module is operating normally. Blinks

whileconnectingtoSXbus.

ERR Red Lights whenthe module is abnormal.

SETTING Green Blinks while gain or offset value is being adjusted.

<Example of status indication>

O: Li ghting, U: Blinking, -: Unlit

Status ONL (green) ERR (red) SETTING (green)

Initializing

Normally operating O - Adjusting offset/gainvalue O Fatalfault - O -

U

--

U

2) Operation setting switch

Used to set output range.

“Range” switch: When this switch is set to one of numbers “0” to “7” (“0” to “3” for current output modules), same output

range is set for all channels. It is impossible to set output range differently for individual channel.

When this switch is set to “8” (“4” for current output modules), Software Set Range Operation mode is

activated, and it becomes possible to set various parameters differently for individual channel. For more

information, refer to “Section 4 Software Interface”.

8

7

9

6

0

5

4

3

I At shipment, this switch is set to “0” (zero).

1

2

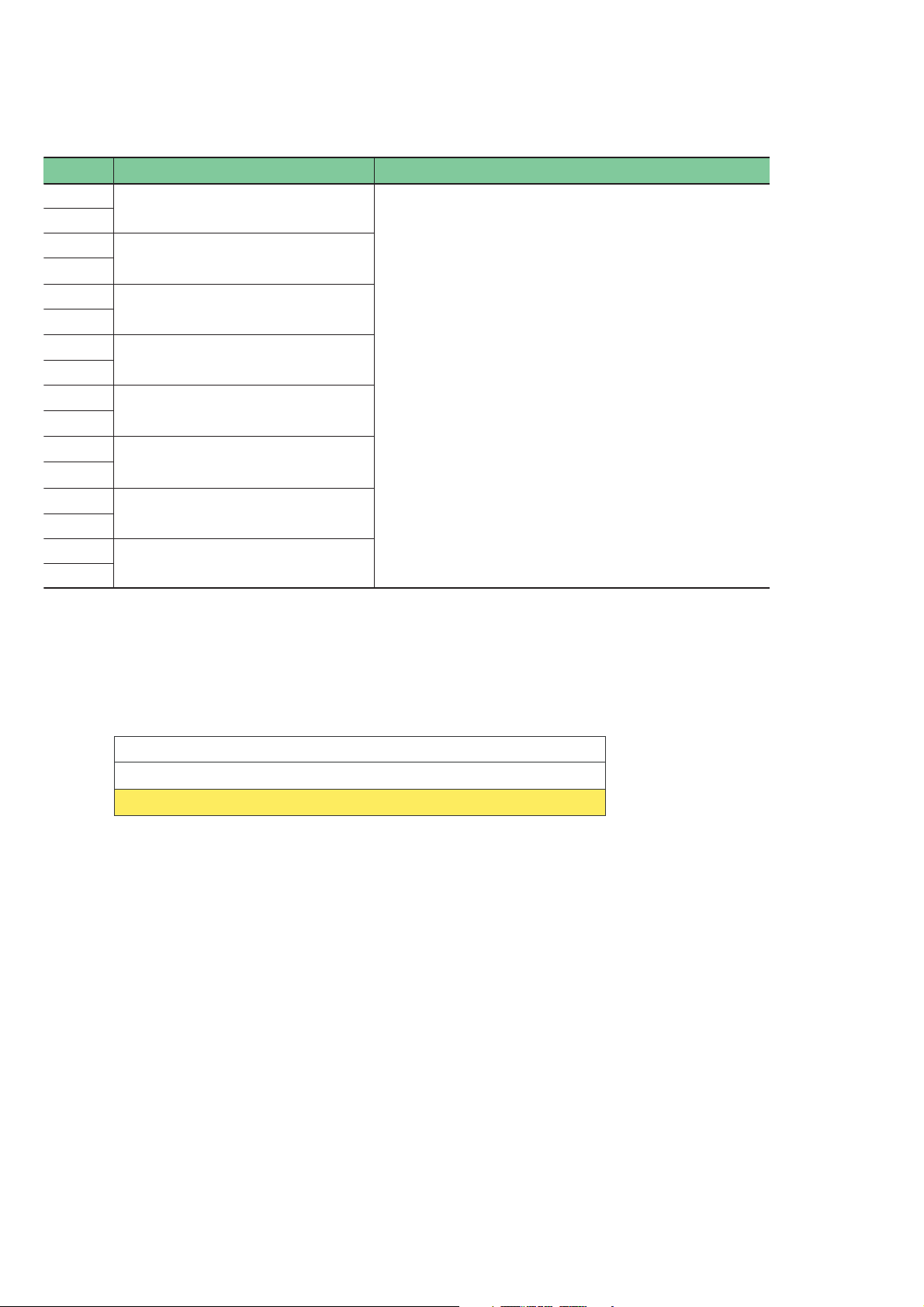

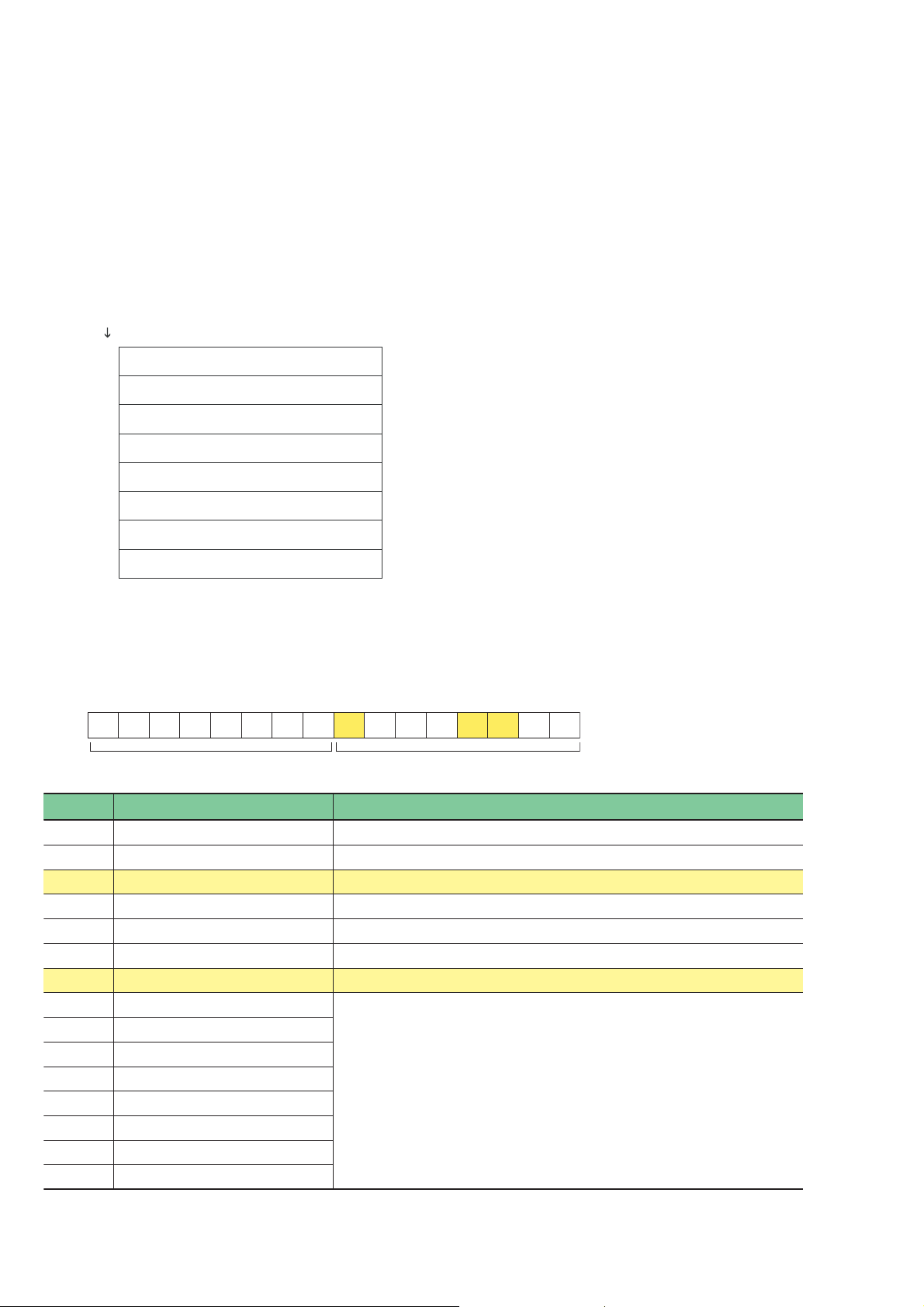

<Range switch setting list>

Switch No.

0

At shipment

NP1AYH8V-MR

Output range

Digital input

range

Switch No.

0 to 10 V 0 to 16000 0

At shipment

NP1AYH8I-MR

Output range

Digital input

range

4 to 20 mA 0 to 16000

1 0to5V 1 0to20mA

2 1 to 5 V 2 4 to 20 mA 0 to 10000

3 -10 to 10 V -8000 to 8000 3 0 to 20 mA

4 0 to 10 V 0 to 10000 4 S oftware Set Range Operation mode

5 0to5V 5

6 1to5V 6

7 Unused (the operationfor switch No. 0) 7

Unused (the operation for switchNo. 0

8 Software Set Range Operation mode (Note) 8

9 Unused (the operationfor switch No. 0) 9

Note: For how to set in Software Set Range Operation mode, refer to "Section 4 Software Interface".

2-19

Page 28

Section 2 Specifications

2-5 Names and Functions

3) Detachable terminal block

M3 20-pole detachable terminal block (M3 10-pole for 4ch output modules). For terminal arrangement, refer to “5-2-1 Terminal

arrangement”. For wiring, be sure to use crimp type terminals and surely tighten them (tightening torque: 0.5 to 0.7 N-m.)

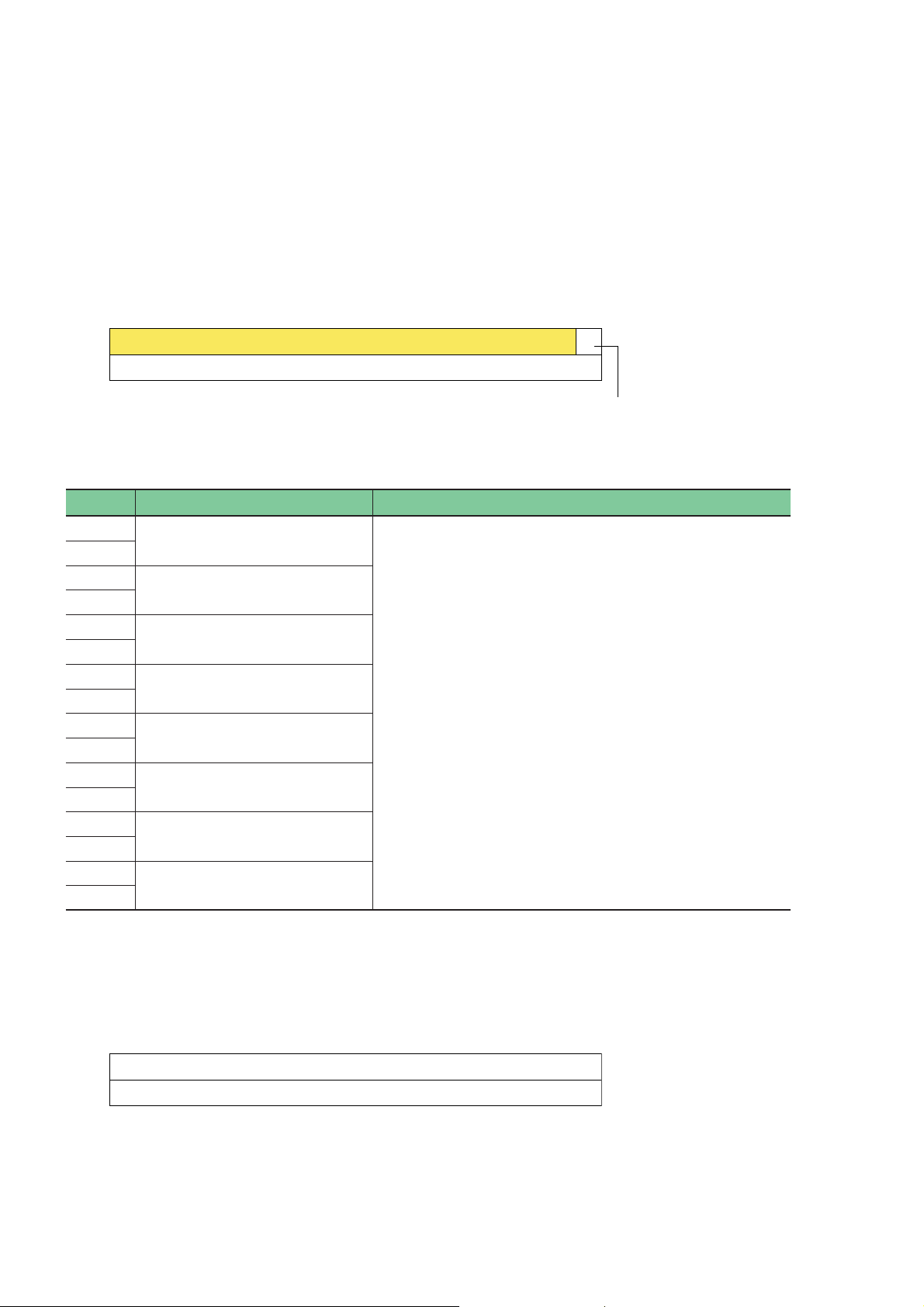

4) Version seal

Versions of the hardware and firmware of the module are indicated on this seal.

2 0

3 0

Hardware version

Firmware version

2-20

Page 29

Section 2 Specifications

2-5 Names and Functions

2-5-3 Analog input/output module (NP1AWH6-MR)

(1 ) Names

1) Status indication LED

4) Version seal

Front Rear

3) Detachable

terminal block

Specification

name plate

(2) Functions

1) Status Indication LED

Indicates the current status of the analog input/output module.

2) Operation setting

switches

Symbol Color Description

ONL Green Lights when the module is operating normally. Blinks

whileconnectingtoSXbus.

ERR Red Lights whenthe module is abnormal.

SETTING Green Blinks while gain or offset value is being adjusted.

<Example of status indication>

O: Li ghting, U: Blinking, -: Unlit

Status ONL (green) ERR (red) SETTING (green)

Initializing

Normally operating O - Adjusting offset/gainvalue O Fatalfault - O -

U

--

U

2-21

Page 30

Section 2 Specifications

2-5 Names and Functions

2) Operation setting switches

These switches are used to set input/output range. When input/output range is set with these switches, the same range is set

for input and output channels. It is impossible to set input range differently for individual channels.

8

7

9

6

0

5

1

4

2

3

8

7

9

6

0

5

1

4

2

3

Switch No. Input range Digital output range Switch No. Output range Digital input range

0

At shipment

1 0to5V 1 0to5V

0to10V

0 to 16000

0

At shipment

0to10V

0 to 16000

2 1to5V 2 1to5V

3 -10 to 10 V -8000 to 8000 3 -10 to 10V -8000 to 8000

40to20mA

5 4 to 20 mA 5 4 to 20 mA

0 to 16000

40to20mA

0 to 16000

6 -20 to 20mA -8000 to 8000 6

7 Software Set Range Operation mode (Note) 7

8 Unused (the operationfor switch No. 0) 8

Unused (the operation for switchNo. 0)

9 Unused (the operationfor switch No. 0) 9

Note: For how to set in Software Set Range Operation mode, refer to "Section 4 Software Interface".

3) Detachable terminal block

M3 20-pole detachable terminal block. For terminal arrangement, refer to “5-3-1 Terminal arrangement”. For wiring, be sure to

use crimp type terminals and surely tighten them (tightening torque: 0.5 to 0.7 N-m.)

4) Version seal

Versions of the hardware and firmware of the module are indicated on this seal.

2 0

Hardware version

3 0

Firmware version

2-22

Page 31

Section 2 Specifications

2-6 Dimensions

(Unit: mm)

35

111

90

105

2-23

Page 32

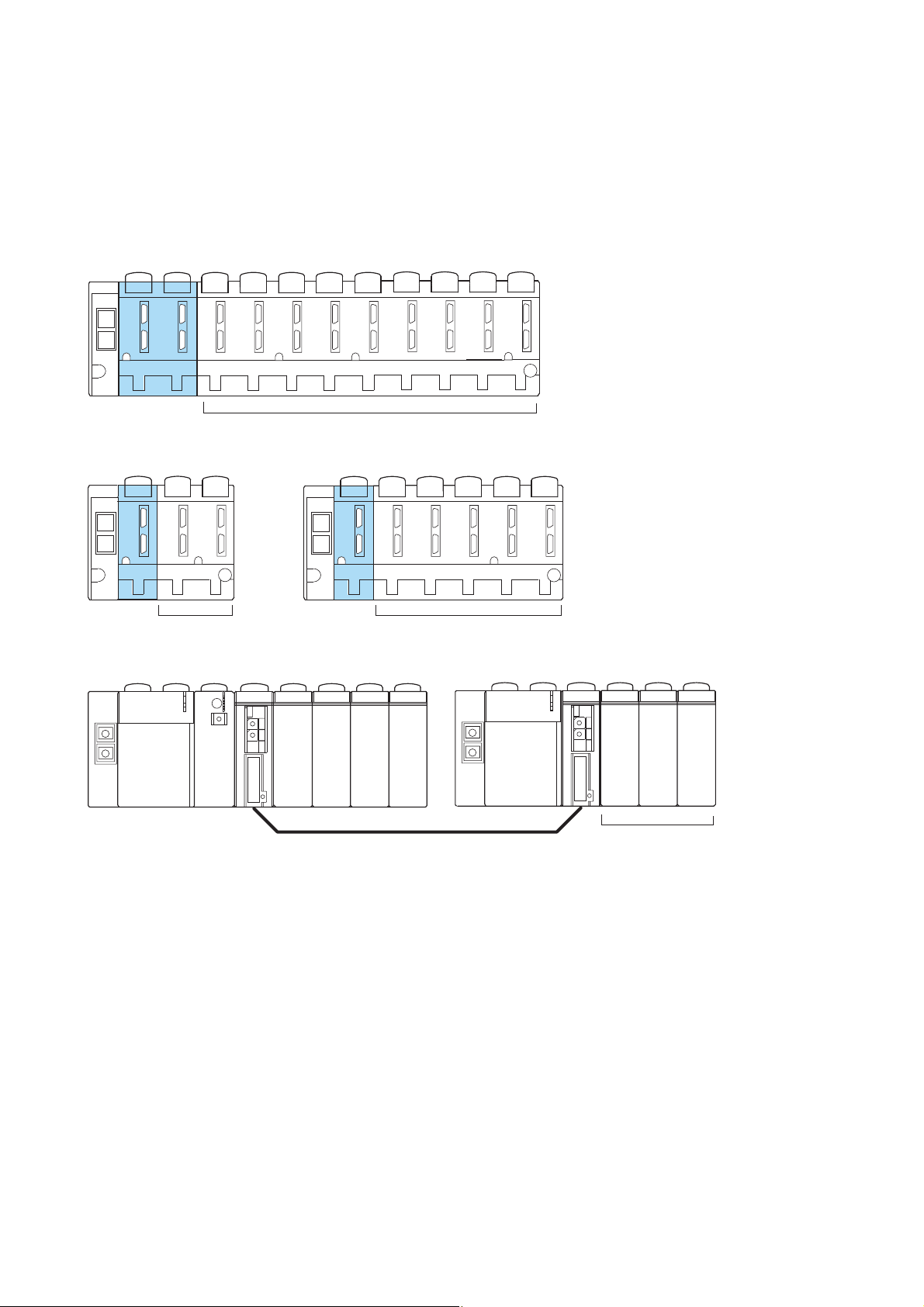

Section 3 System Configuration

3-1 Mounting on the Base Board

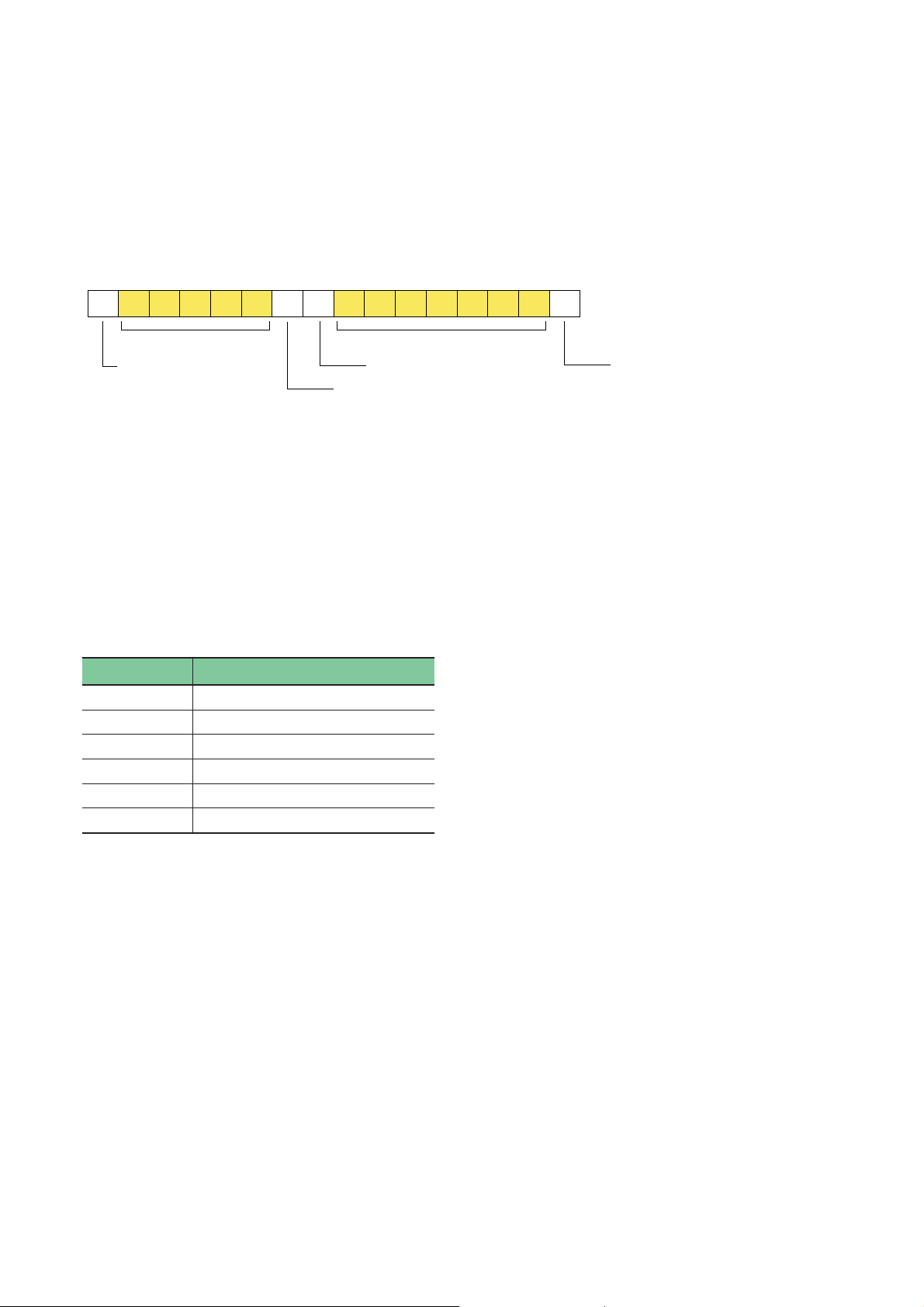

3-1-1 Mounting position

To use these modules, they need to be connected to the SX bus of MICREX-SX series SPH or to the link (remote I/O) of I/O

master module. Their mounting position on the base board is as follows.

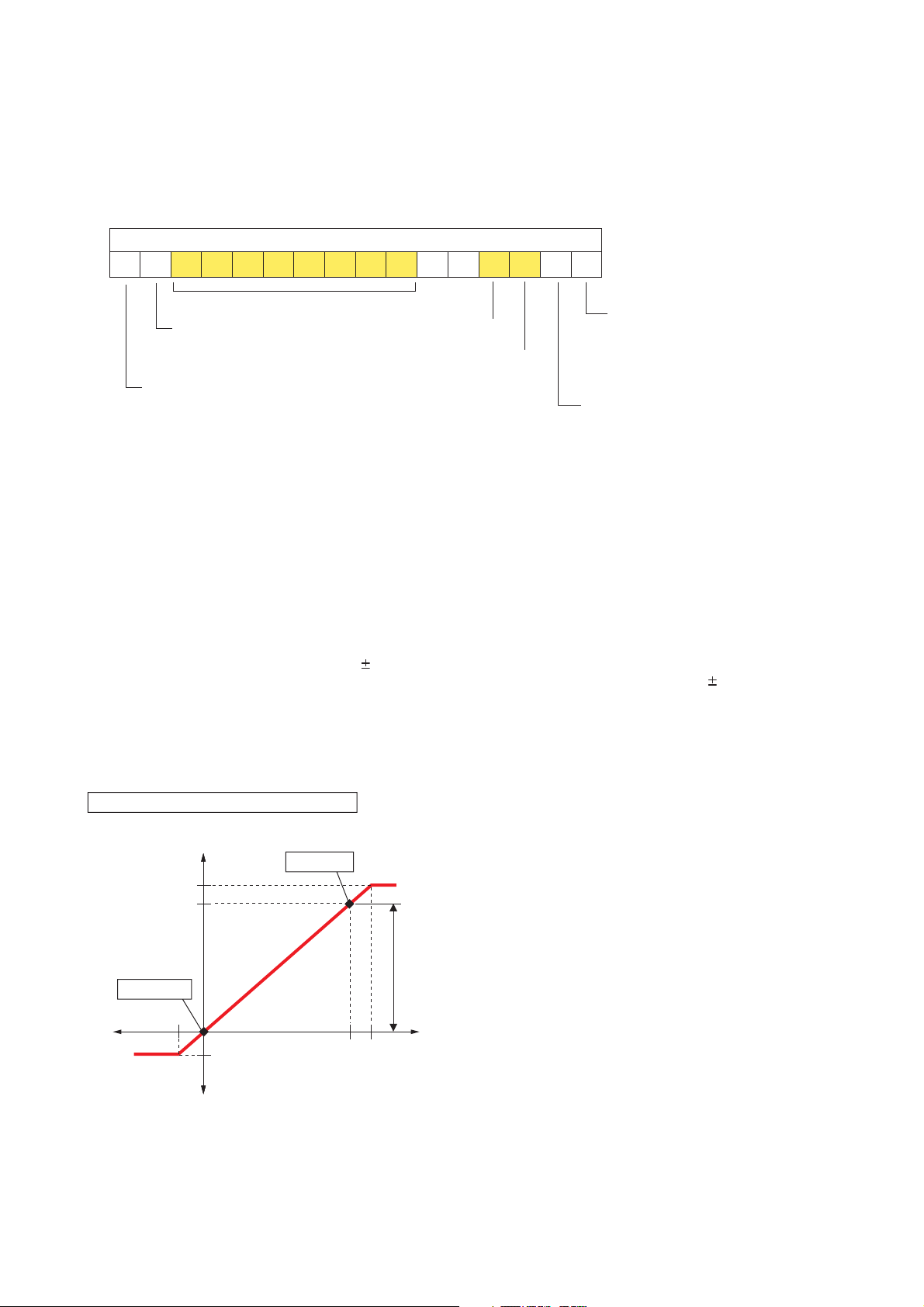

<8/11/13-slot base board>

These modules can be mounted in any slot except those for the power supply module

(the two slots from the left on the base board).

Mountable slots

<3/6-slot base board>

Mountable slots

Note: These modules can be mounted also on the base board of remote I/O such as T-link,OPCN-1 and DeviceNet.

Mountable slots

Mountable slots

3-1-2 Number of mountable modules

It is possible to connect a maximum of 238 modules to the SX bus (a maximum of 254 modules in one configuration including

the link of the I/O master) (due to hardware limitation). It should be noted, however, that the maximum number of analog

voltage/current input modules and analog voltage/current output modules that can actually be connected is limited by the

number of words (512 words) they occupy in the input/output areas (I/Q areas).

Because the number of words occupied by an analog 8ch module is 12 words and that occupied by an analog 4ch output

module and analog input/output module is 8 words, the maximum number of mountable modules becomes as follows:

Analog 8ch modules: 512 words / 12 words = 42 units

Analog 4ch modules / Analog input/output module: 512 words / 8 words = 64 units

Note: Suppose that 42 units of 8ch analog modules are connected in one configuration, then the input/output areas that other

input/output modules can use become 8 words.

3-1

Page 33

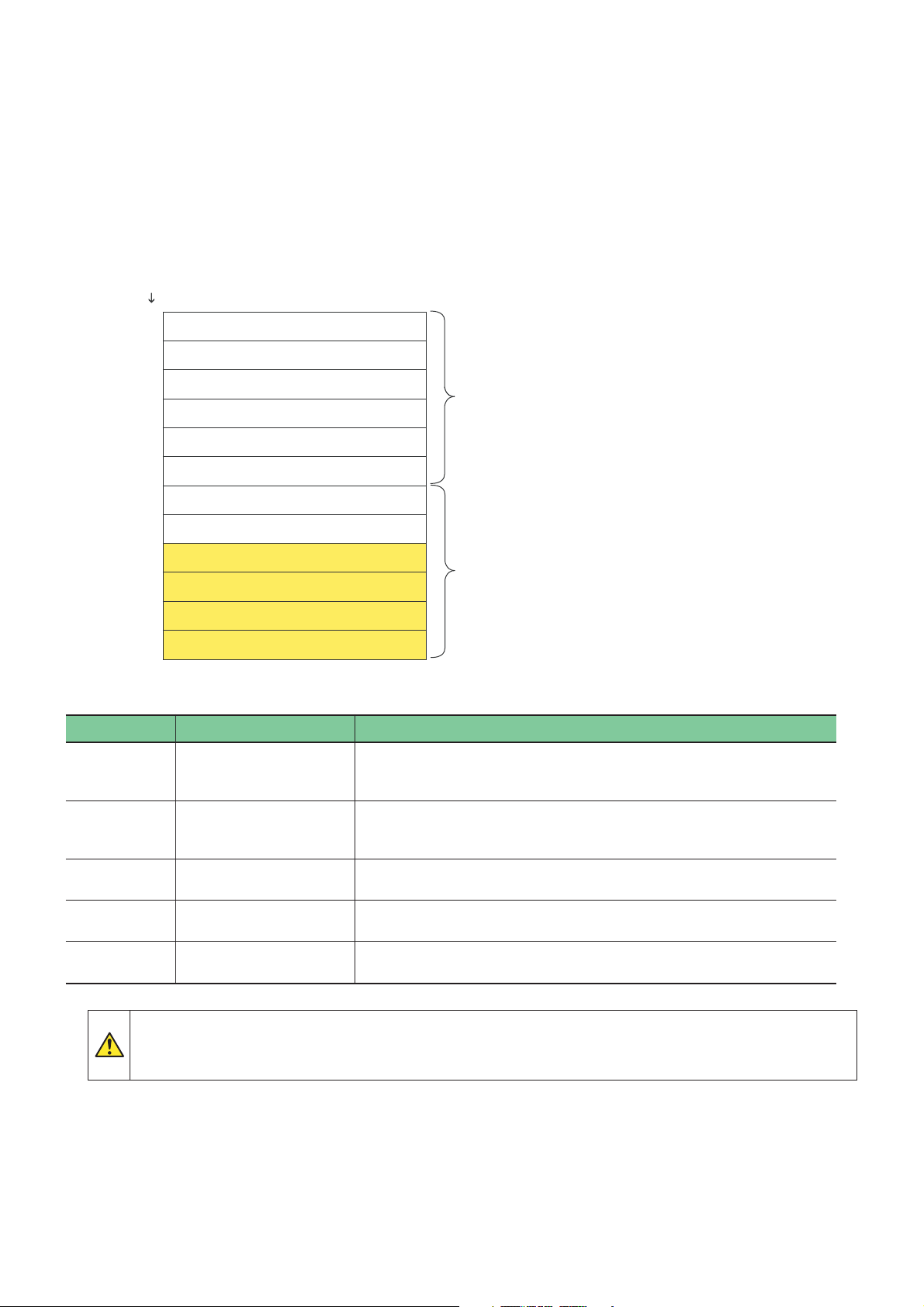

Section 4 Software Interface

4-1 Analog Input Module

NP1AXH8V-MR (voltage input module) and NP1AXH8I-MR (current input module) occupy 12 words of I/O area (input: 8 words,

output: 4 words).

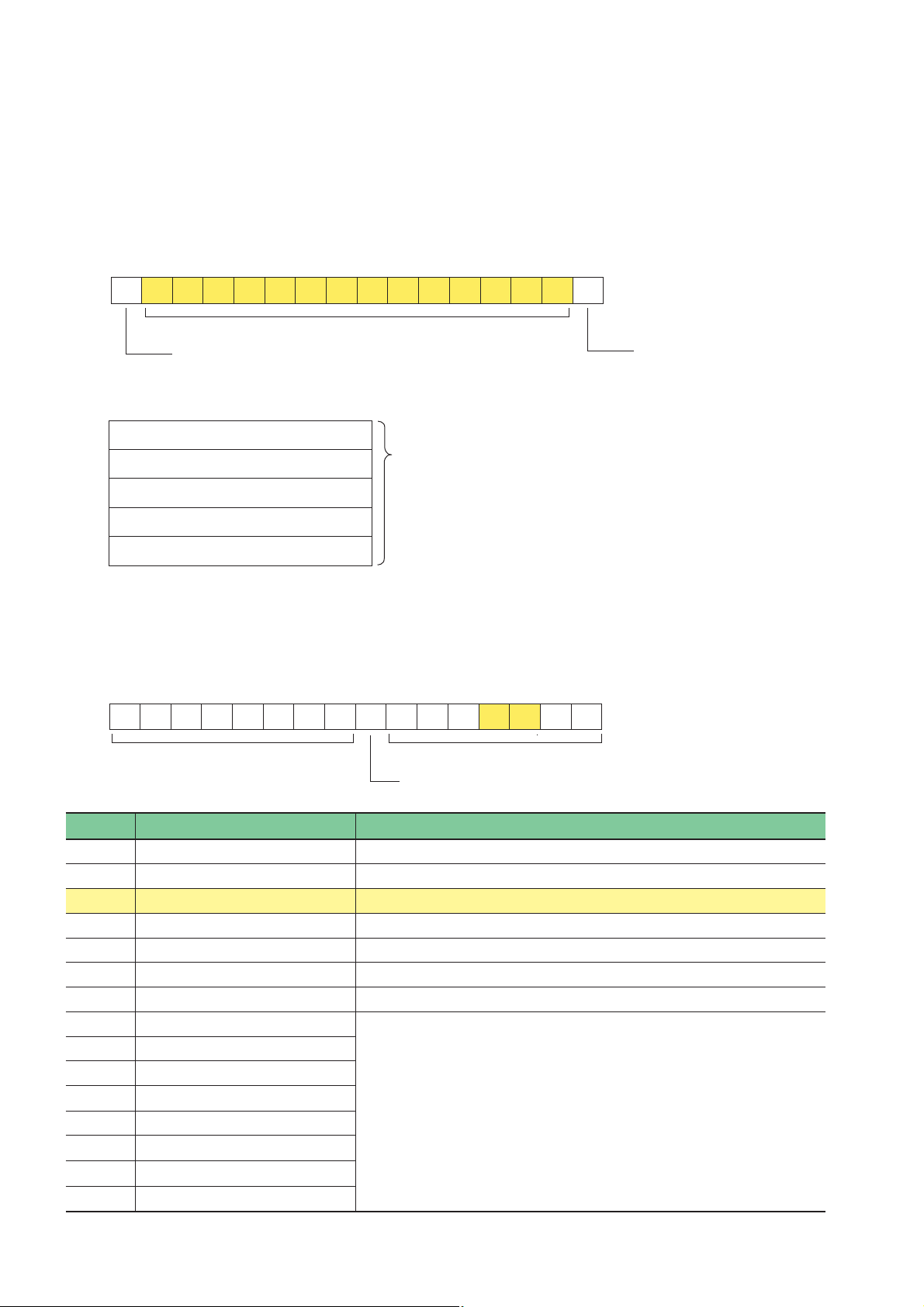

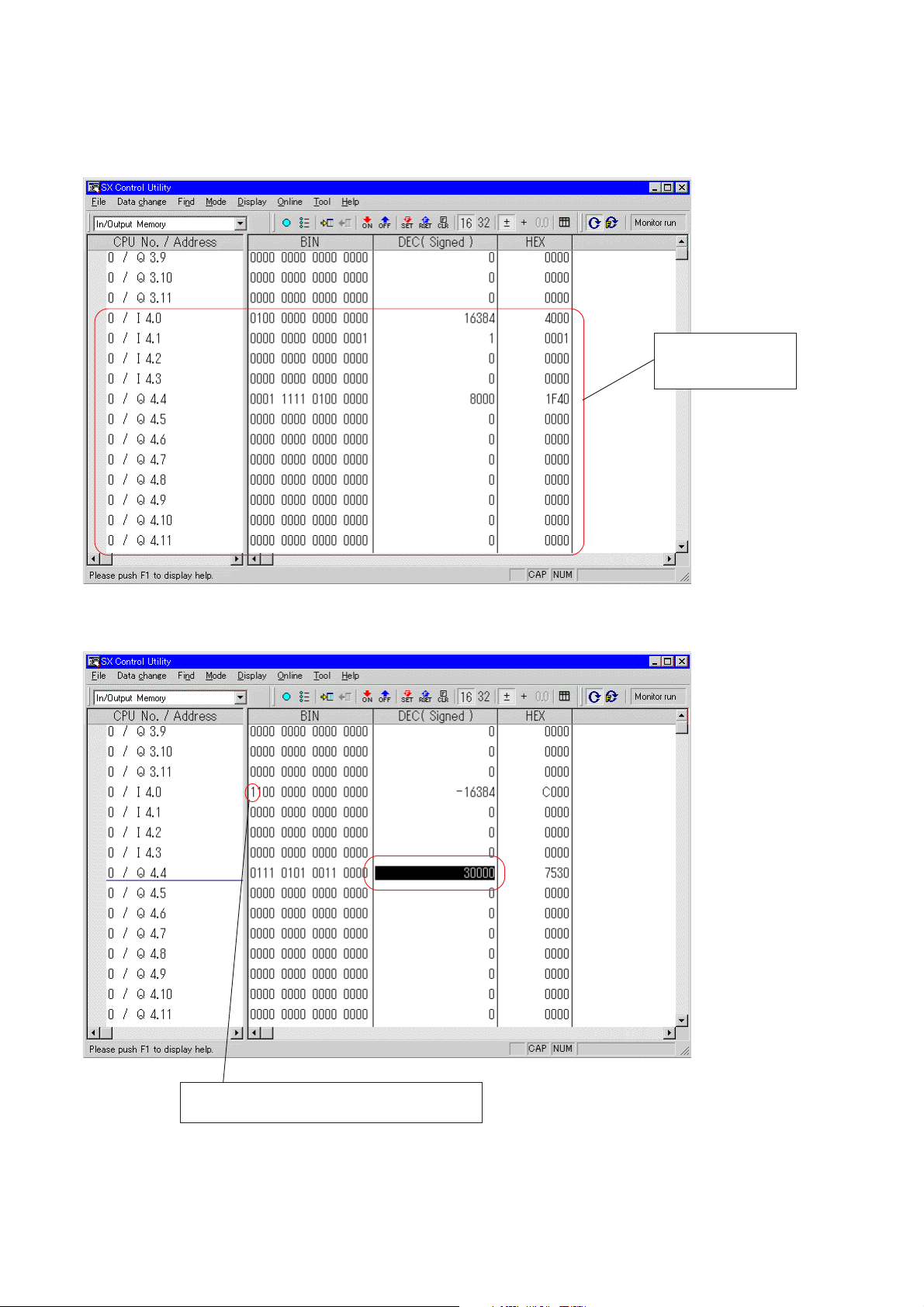

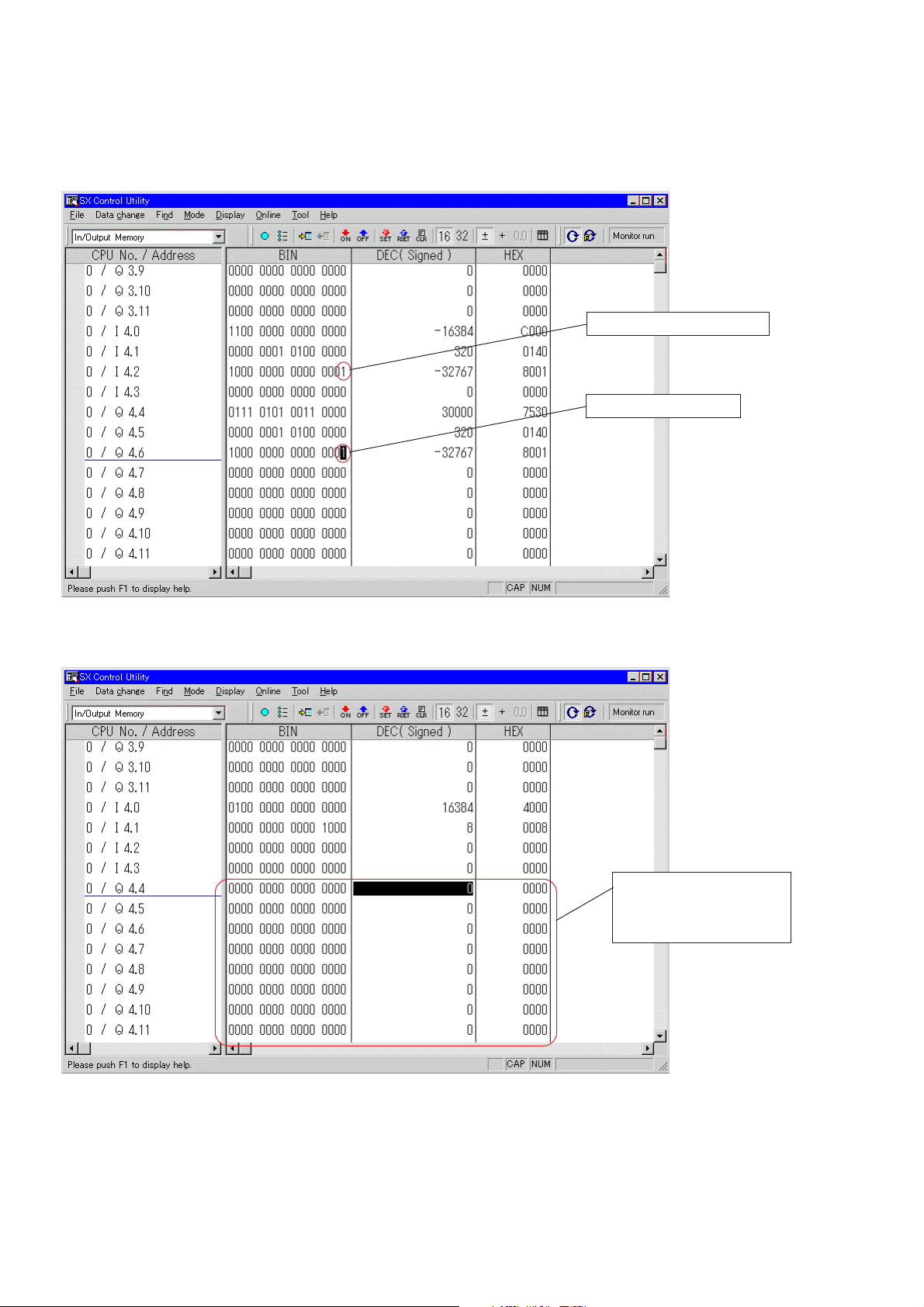

4-1-1 Memory allocation in Switch Batch Setting mode

Moving average execution times for conversion operation is set with the “Average” switch (upper side switch on the module

rear panel), and operation range is set with the “Range” switch (lower side switch on the module rear panel).

Offset

address

15(F)

+0

Channel1 Digitaloutputvalue/Status

+1

Channel 2 Digital output value / Status

+2

Channel 3 Digital output value / Status

+3

Channel4 Digitaloutputvalue/Status

+4

Channel 5 Digital output value / Status

+5

Channel 6 Digital output value / Status

+6

Channel 7 Digital output value / Status

0

This module to CPU module

+7

Channel 8 Digital output value / Status

+8

+9

+10

+11

<Status list>

Status code Error Description

30002

(7532h)

30003

(7533h)

30004

(7534h)

30005

(7535h)

30006

(7536h)

Unused (fixed to 0 (zero))

Unused (fixed to 0 (zero))

Unused (fixed to 0 (zero))

Unused (fixed to 0 (zero))

EEPROM calibrationdata

error (Module fatal fault)

EEPROM user setting data

error

Internal power supplydown

Switch setting error

Conversion error

If the calibration data ofEEPROM is destroyed or if EEPROM cannot be

writtenor read, this erroris notified. Module internalEEPROM is abnormal.

If this error occurred, it is necessary to replace the module.

If the usersetting data of EEPROM is destroyed,this erroris notified.

If this error occurred, allparameters need to be reset. If this error recurs

evenafter parameters are reset, the module seems to have failed.

If the internal power supply of the module becomes down, this error is

notified.

If the operation setti ng switchon the module rear panel is set at invalid

position,this error is notified.

If conversion became abnormalbecause the module failed or was used in an

out-of-spec environment, this erroris notified.

CPU module to this module

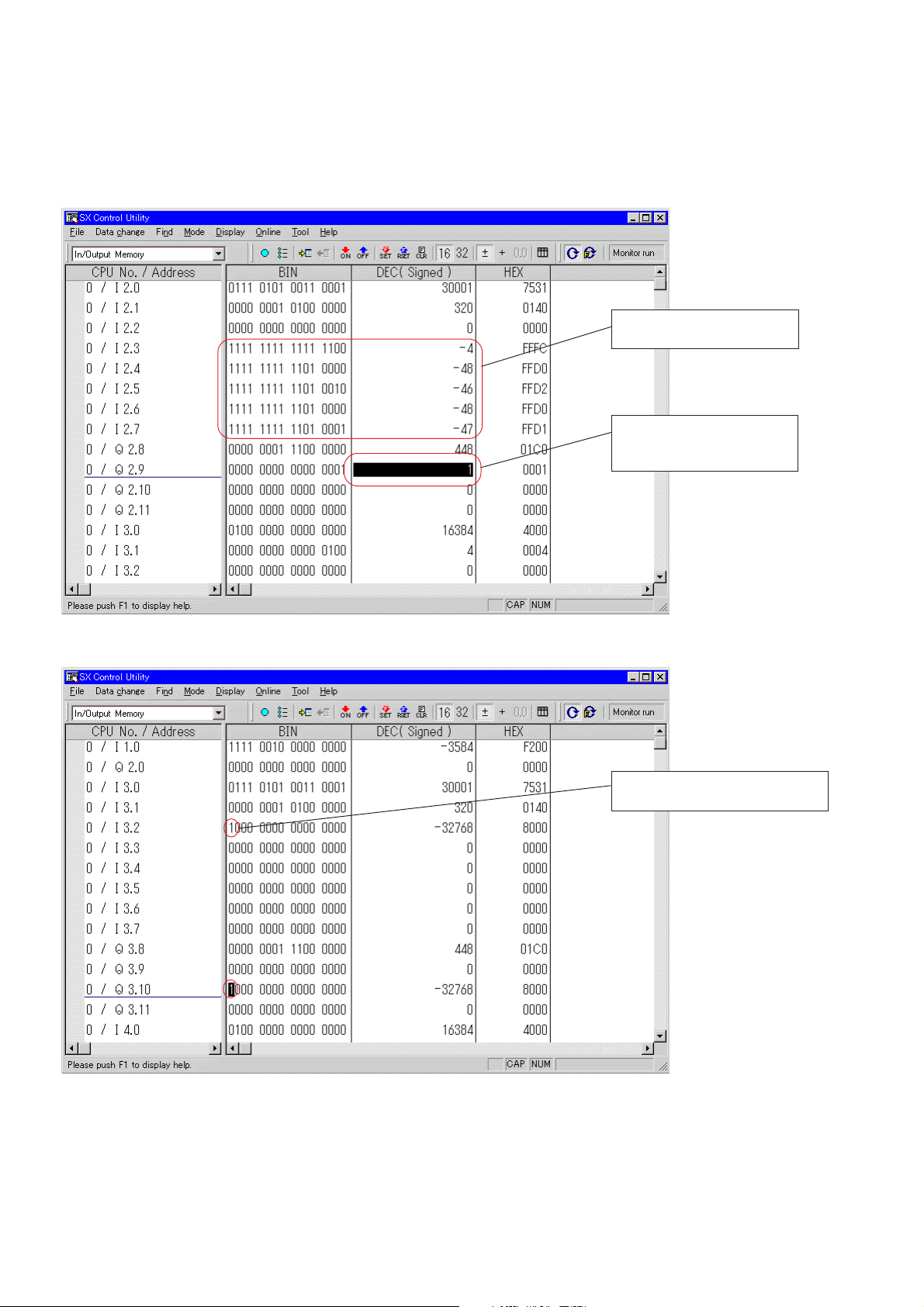

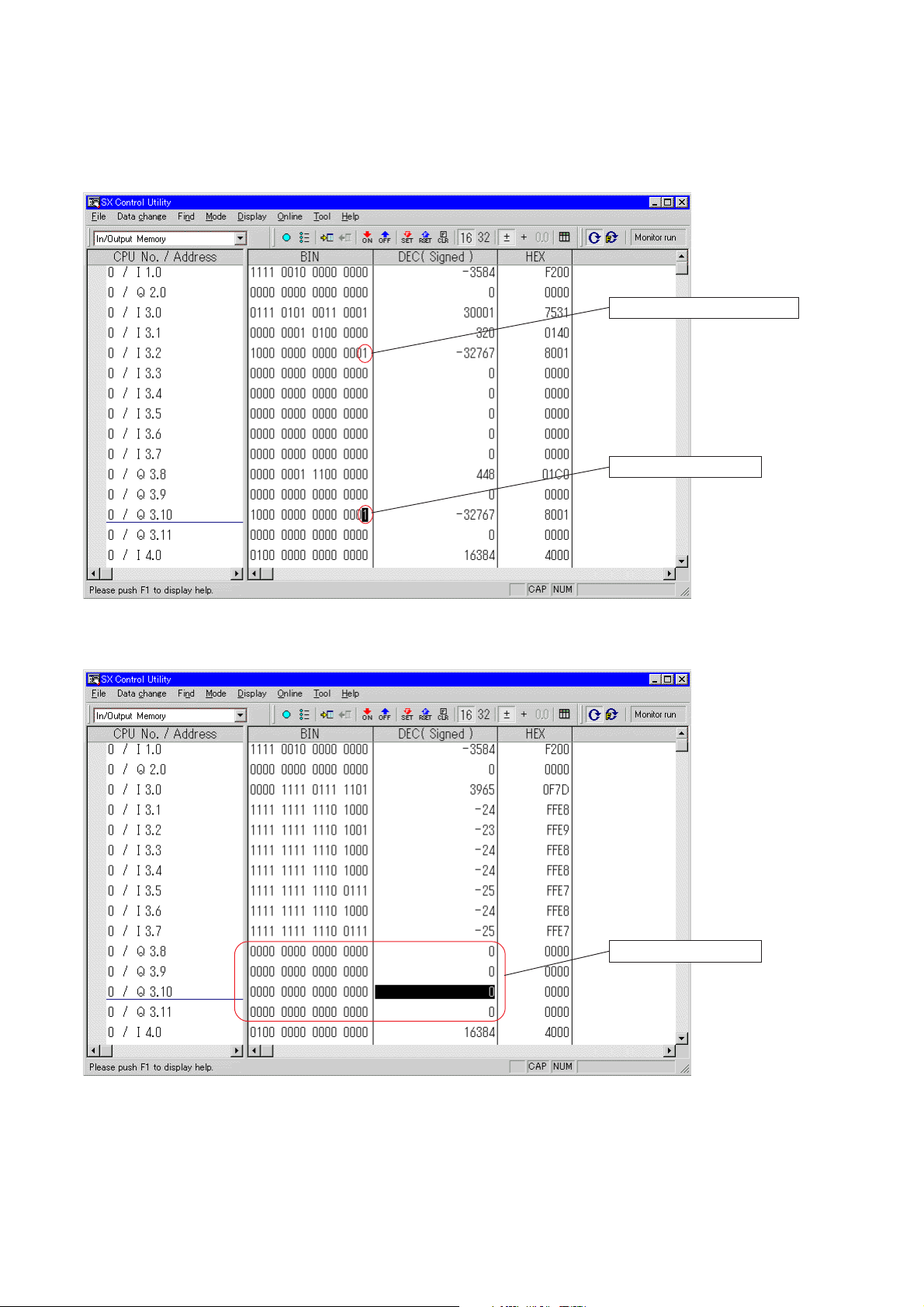

Ordinarily digital output values (INT type) are stored in the registers explained above. If the module becomes

abnormal, the following status code (INT type) is stored in these registers. When making an application program,

be sure to interlock erroneous and normal (A/D conversion) conditions.

4-1

Page 34

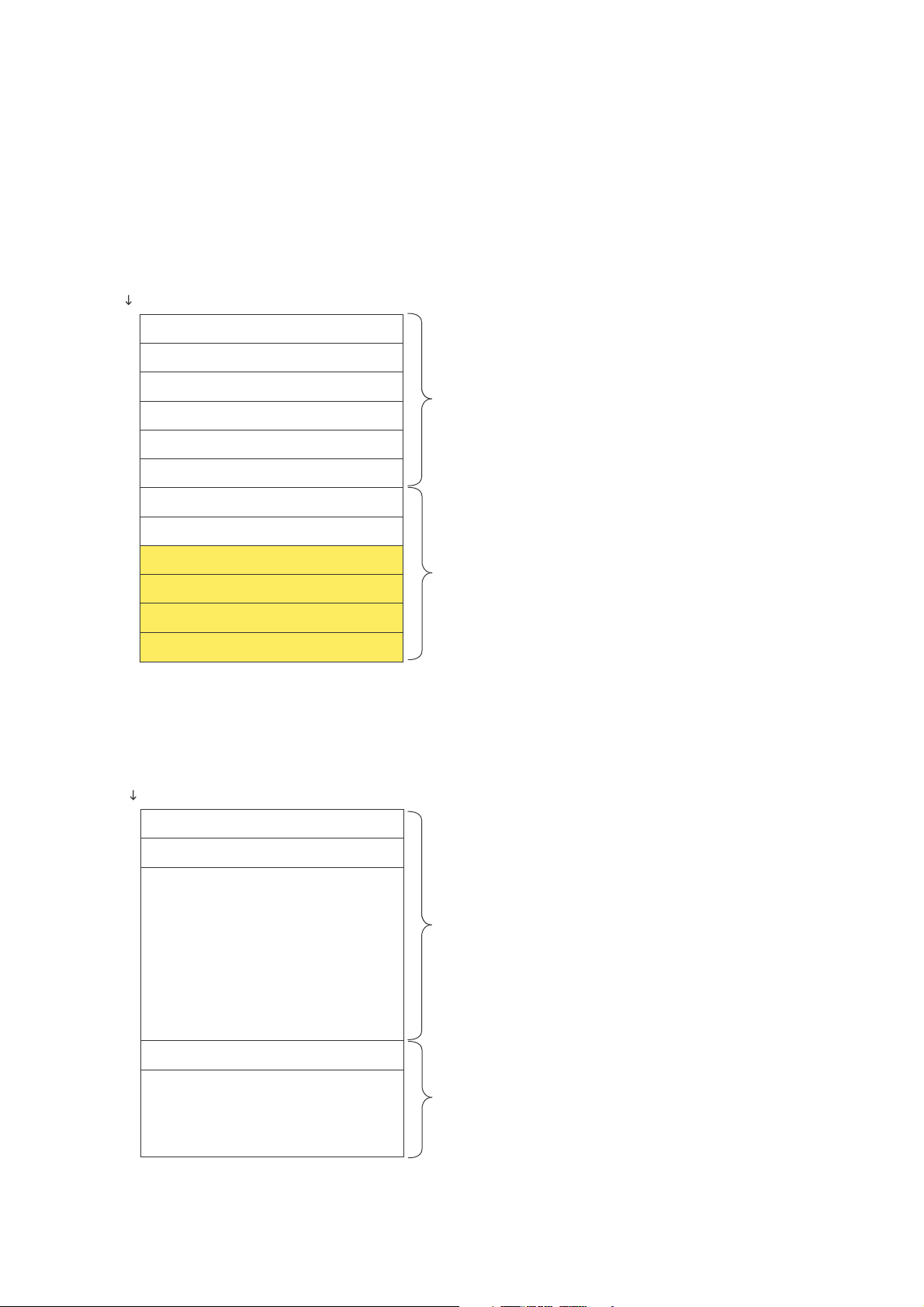

Section 4 Software Interface

4-1 Analog Input Module

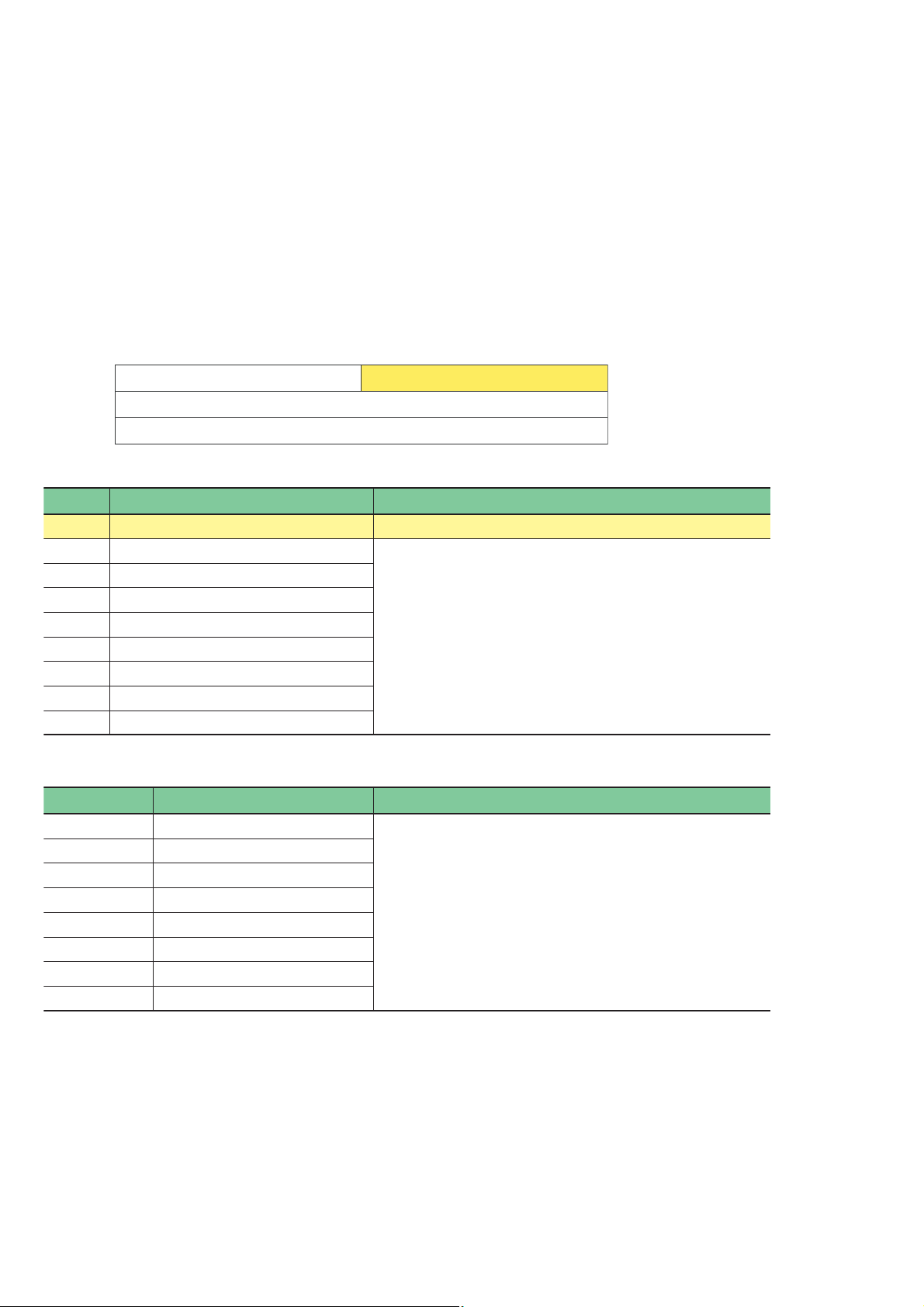

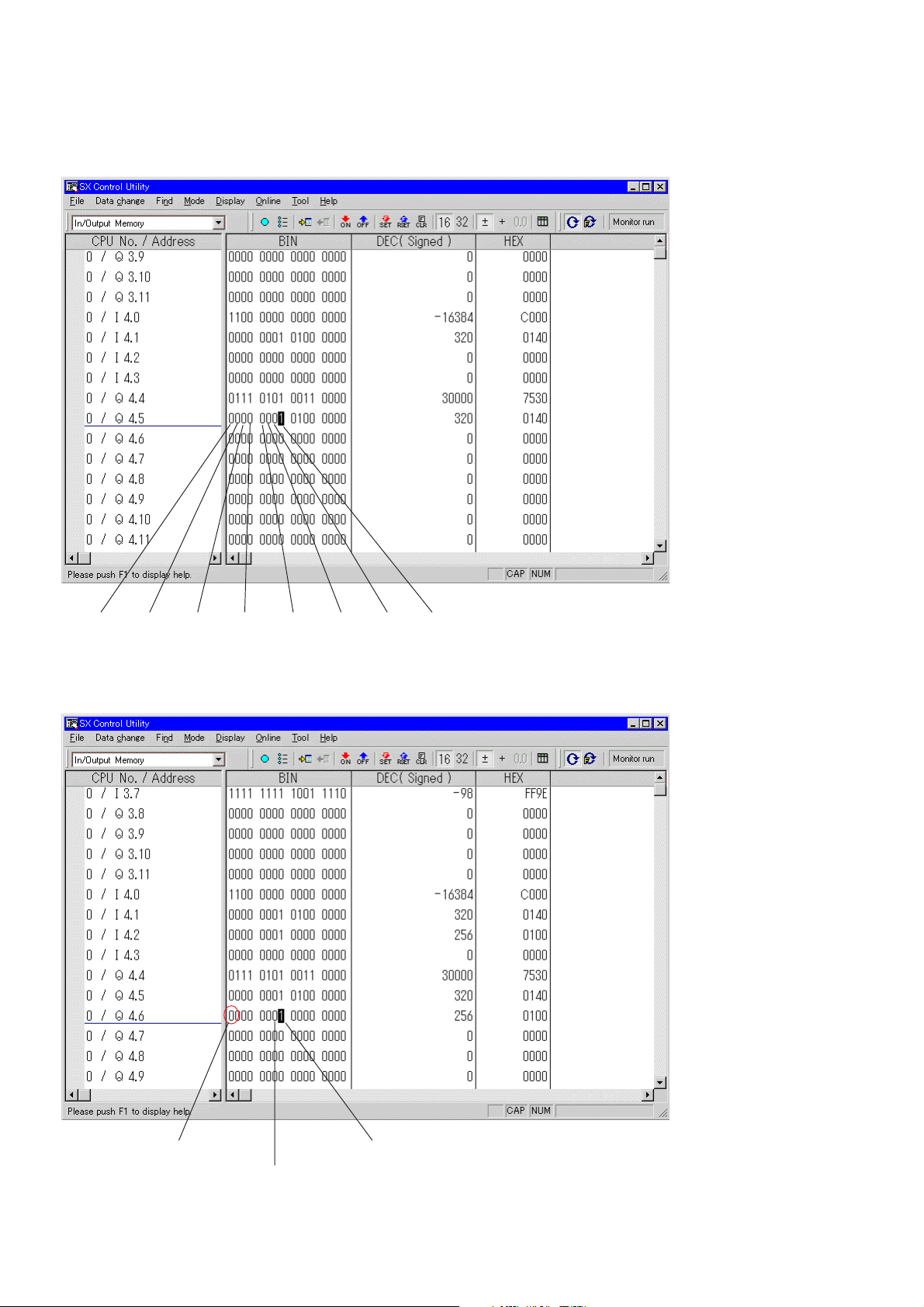

4-1-2 Memory allocation in Software Set Range Operation mode

In Software Set Range Operation mode, memory allocation differs between when operating in A/D conversion mode (during

normal operation) and when operating in parameter mode.

<When operating in A/D conversion mode>

When operating in A/D conversion mode, memory allocation becomes as follows:

Offset

address

15(F)

+0

Channel1 Digitaloutputvalue/Status

+1

Channel 2 Digital output value / Status

+2

Channel 3 Digital output value / Status

+3

Channel4 Digitaloutputvalue/Status

+4

Channel 5 Digital output value / Status

+5

Channel 6 Digital output value / Status

+6

Channel 7 Digital output value / Status

0

This module to CPU module

+7

Channel 8 Digital output value / Status

+8

+9

+10

+11

<When operating in parameter mode>

Parameter mode is activated when bit 7 of the parameter type setting register is set ON. In parameter mode, memory

allocation becomes as follows:

Offset

address

15(F)

+0

+1

+2

+3

+4

+5

Unused (fixed to 0 (zero))

Unused (fixed to 0 (zero))

Unused (fixed to 0 (zero))

Unused (fixed to 0 (zero))

Module status

Parameter typ e setting status

Parameter read data

CPU module to this module

0

This module to CPU module

+6

+7

+8

+9

+10

+11

Parameter type setting

CPU module to this module

Parameter setting data

4-2

Page 35

Section 4 Software Interface

4-1 Analog Input Module

(1 ) Digital output value/status register (offset address: +0 to +7)

When this module is in A/D conversion mode, digital output values and/or statuses are stored in the registers of offset

address +0 to +7.

* When using D300win, assign INT type variables to these registers.

Offset

address

15(F)

+0

Channel1 Digitaloutputvalue/Status

+1

Channel 2 Digital output value / Status

+2

Channel 3 Digital output value / Status

+3

Channel4 Digitaloutputvalue/Status

+4

Channel 5 Digital output value / Status

+5

Channel 6 Digital output value / Status

+6

Channel 7 Digital output value / Status

+7

Channel 8 Digital output value / Status

0

<Status list>

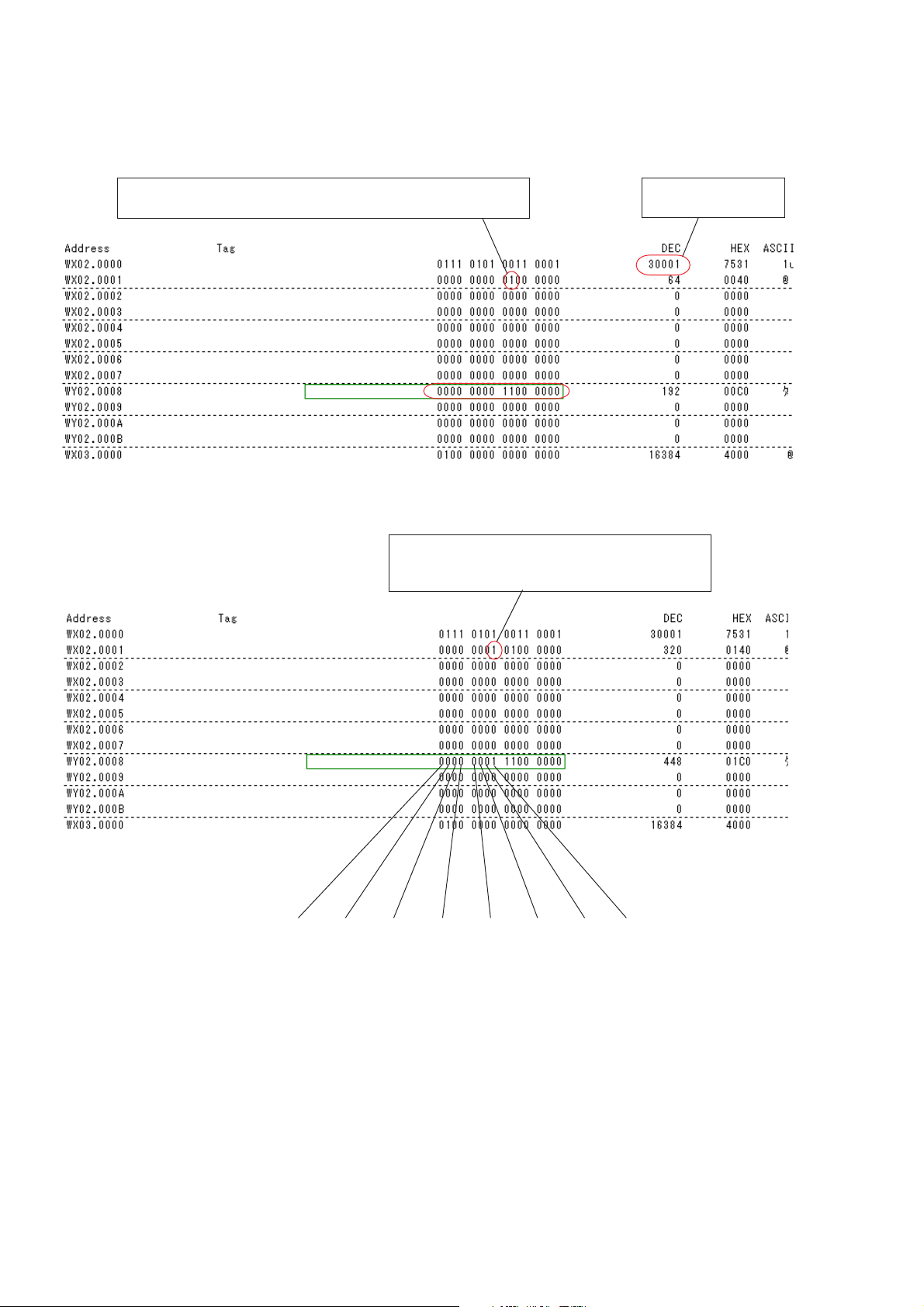

Status code C ondition of modul Descriptio n

30001

(7531h)

30002

(7532h)

30003

(7533h)

30004

(7534h)

30005

(7535h)

30006

(7536h)

Parameter mode Parameters are now being set or read out.

EEPROM calibrationdata

error

(Module fatalfault)

EEPROM user setting data

error

Internal power supplydown

Switch setting error

Conversion error

Ordinarily digital output values (INT type) are stored in the registers explained above. If the module becomes

abnormal, the following status code (INT type) is stored in these registers. When making an application program,

be sure to interlock erroneous and normal (A/D conversion) conditions.

If the calibration data ofEEPROM is destroyed or if EEPROMcannot be

writtenor read, this erroris notified. Module internalEEPROM is abnormal.

If this error occurred, it is necessary to replace the module.

If the usersetting data of EEPROM is destroyed,this erroris notified.

If this error occurred, allparameters need to be reset. If this error recurs

evenafter parameters are reset, the module seems to have failed.

If the internal power supply of the module becomes down, this error is

notified.

If the operation setti ng switchon the module rear panel is set at invalid

position,this error is notified.

If conversion became abnormalbecause the module failed or was used in an

out-of-spec environment, this erroris notified.

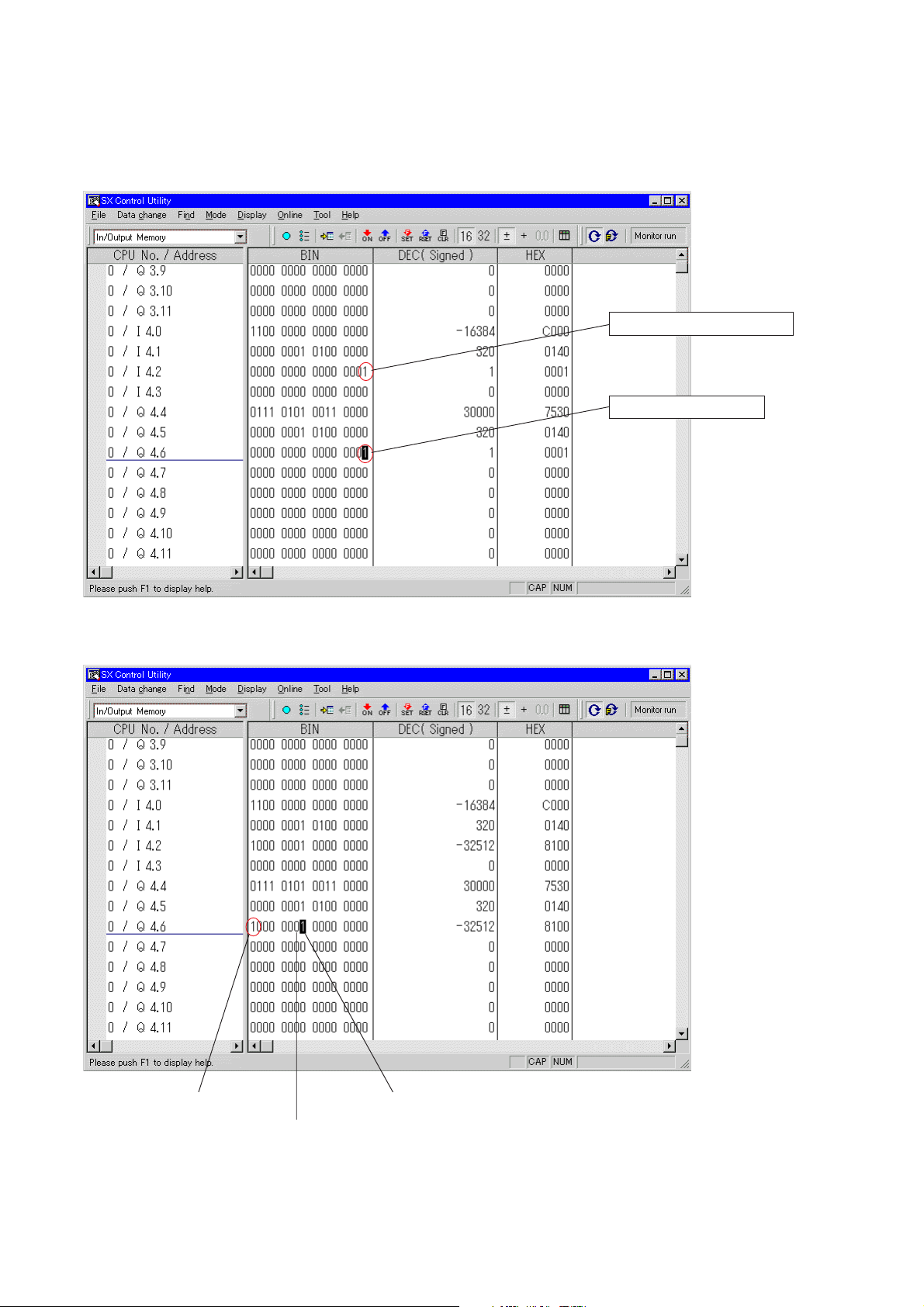

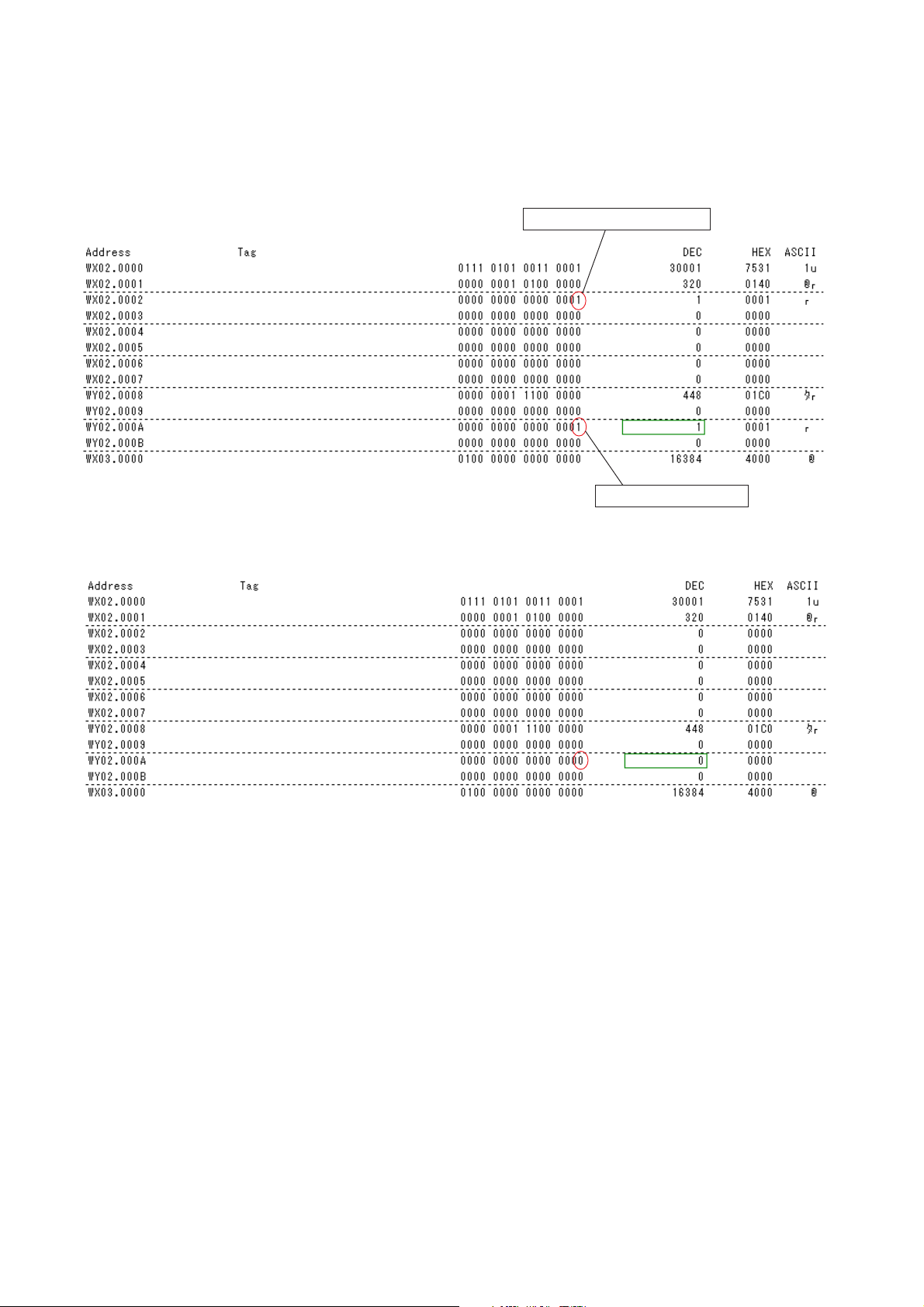

(2 ) Module status register (offset address +0)

When the module is in parameter mode, offset address +0 becomes the “module status register”, in which the code “30001”

(INT type) is stored, indicating that the parameter mode (parameters are now being set or read out) is activated.

* When using D300win, assign an INT type variable to this register.

+0

30001(7531h)

4-3

Page 36

Section 4 Software Interface

4-1 Analog Input Module

(3 ) Parameter type setting status register (offset address +1)

This register stores the information of what parameter is now being written or read by the module.

* When using D300win, assign a WORD type variable to this register. If you access by the bit, assign a BOOL type variable to

each bit.

15(F) 078

+1

Channel No. Parameter type

Bit Flag name Description

0 Operation parameter read mode ON: Operation parameter read mode (allchannels in a batch)

1 Scaling parameterread mode ON: Scaling parameter read mode (individual channel)

2, 3 Unused

4 Operation parameter write mode ON: Operation parameter write mode (all channels in a batch)

5 Scaling parameter write mode ON:Scaling parameter write mode (individual channel)

6 Offset/gain adjustment mode ON: Offset/gainadjustmentmode (indivi dual channel)

7 Unused

8 Channel 1 In "scaling parameter read mode", "scaling parameter write mode" or

9 Channel 2

10(A) Channel 3

11(B) Channel 4

12(C) Channel 5

13(D) Channel 6

14(E) Channel 7

15(F) Channel 8

"offset/gain adjustment mode", one of bits 8 to 15 is set ON to indicate

whi ch channel is nowbeing set or read out.

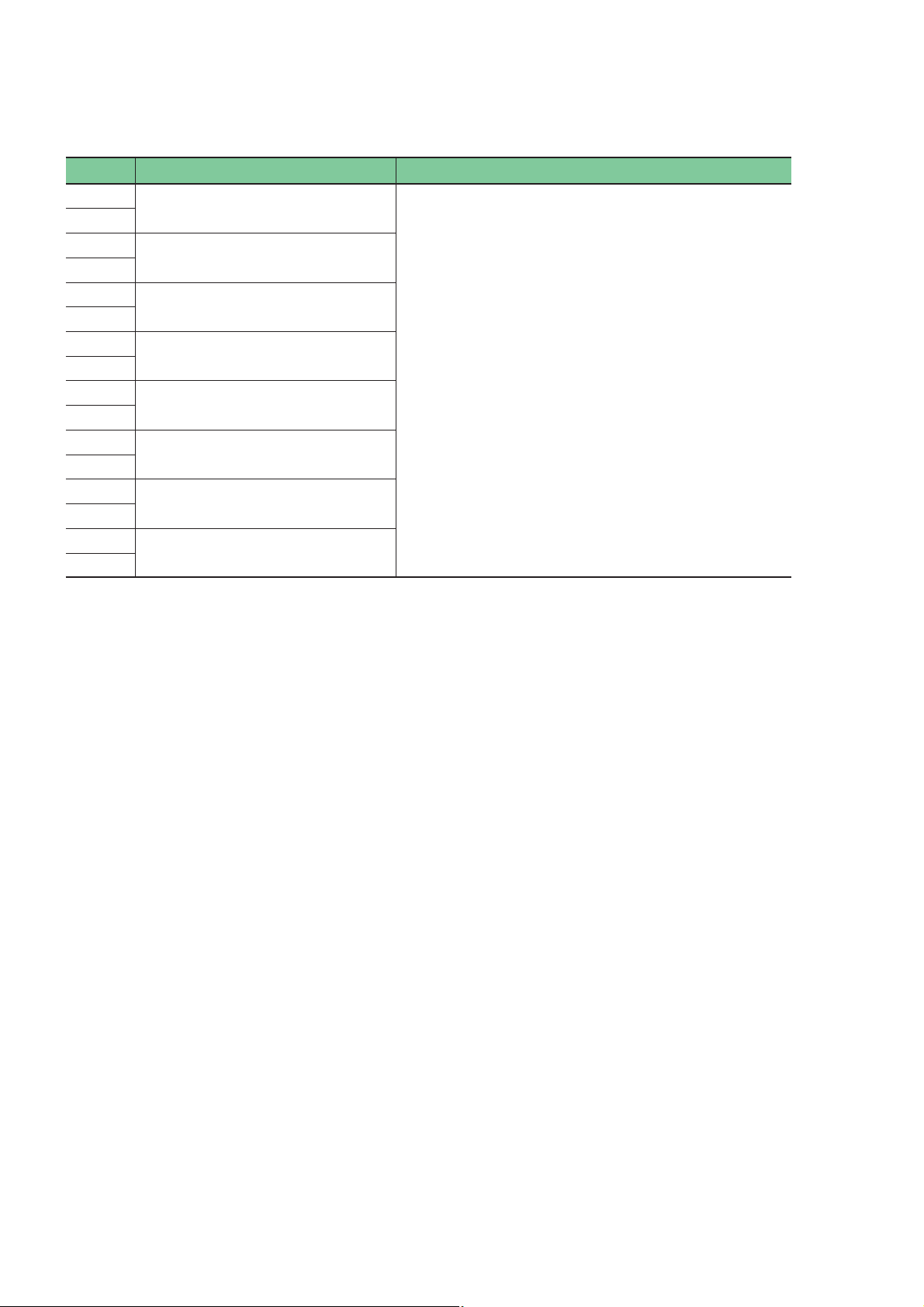

(4) Parameter read data register (offset address +2 to +7)

In “operation parameter read mode”, “scaling parameter read mode” or “offset/gain adjustment mode”, the content of the

setting for the corresponding mode is stored in this register.

1) When operation parameter read mode is activated

When parameter mode (module status register = 30001(7531h)) is activated and bit 0 of the parameter type setting status

register is set ON, the status of the operation parameter is stored.

* When using D300win, assign WORD type variables to these registers.

15(F) 0

+2

+3

+4

+5 to +7

Conversion enable/disable

Input range

Moving average execution times

Unused (fixed to 0 (zero))

Unused (fixed to 0 (zero))

4-4

Page 37

Section 4 Software Interface

f

4-1 Analog Input Module

<Conversion enable/disable, the unit of digital output value> (offset address +2)

Bit Flag name Descriptio n

0to7 Unused

8 Channel 1 Conversion enable/disable OFF: Enable,

9 Channel 2 Conversion enable/disable

10 C hannel 3 C onversion enable/disable

11 Channel 4 Conversion enable/disable

12 C hannel 5 C onversion enable/disable

13 C hannel 6 C onversion enable/disable

14 C hannel 7 C onversion enable/disable

15 C hannel 8 C onversion enable/disable

<Input range setting> (Offset address +3)

ON: Disable

Bit Flag name

0(L)

1(H)

2(L)

3(H)

4(L)

5(H)

6(L)

7(H)

8(L)

9(H)

10 (L)

11 (H)

12 (L)

13 (H)

14 (L)

15 (H)

Channel 1 Input range

Channel 2 Input range

Channel 3 Input range

Channel 4 Input range

Channel 5 Input range

Channel 6 Input range

Channel 7 Input range

Channel 8 Input range

Descriptio n

ThesetrangeisindictedbyacombinationofON/OFFstatuso

two bits.

<NP1AXH8V-MR>

H L

OFF OFF : -10 to 10 V

OFF ON : 0 to 10 V

ON OFF : 0 to 5 V

ON ON : 1 to 5 V

<NP1AXH8I-MR>

H L

OFF OFF : 4 to 20 mA

OFF ON : 0 to 20 mA

ON OFF : -20 to 20 mA

ON ON : 4 to 20 mA

4-5

Page 38

Section 4 Software Interface

4-1 Analog Input Module

<Moving average execution times setting> (offset address +4)

Bit Flag name

0(L)

1(H)

2(L)

3(H)

4(L)

5(H)

6(L)

7(H)

8(L)

9(H)

10 (L)

11 (H)

12 (L)

13 (H)

14 (L)

15 (H)

Channel 1

Moving average execution times

Channel 2

Moving average execution times

Channel 3

Moving average execution times

Channel 4

Moving average execution times

Channel 5

Moving average execution times

Channel 6

Moving average execution times

Channel 7

Moving average execution times

Channel 8

Moving average execution times

Descriptio n

Moving average execution times is indicted by a combination

of ON/OFF status of two bits.

H L

OFF OFF : Once

OFF ON : Twice

ON OFF : 4 times

ON ON : 8 times

2) When scaling parameter read mode is activated

When parameter mode is activated (module status register = 30001) and bit 1 of the parameter type setting status register is

set ON, the scaling parameter setting status of the corresponding channel is stored.

* When using D300win, assign INT type variables to these registers.

15(F) 0

+2

+3

+4 to 7

Offset value

Gain value

Unused (fixed to 0 (zero))

4-6

Page 39

Section 4 Software Interface

4-1 Analog Input Module

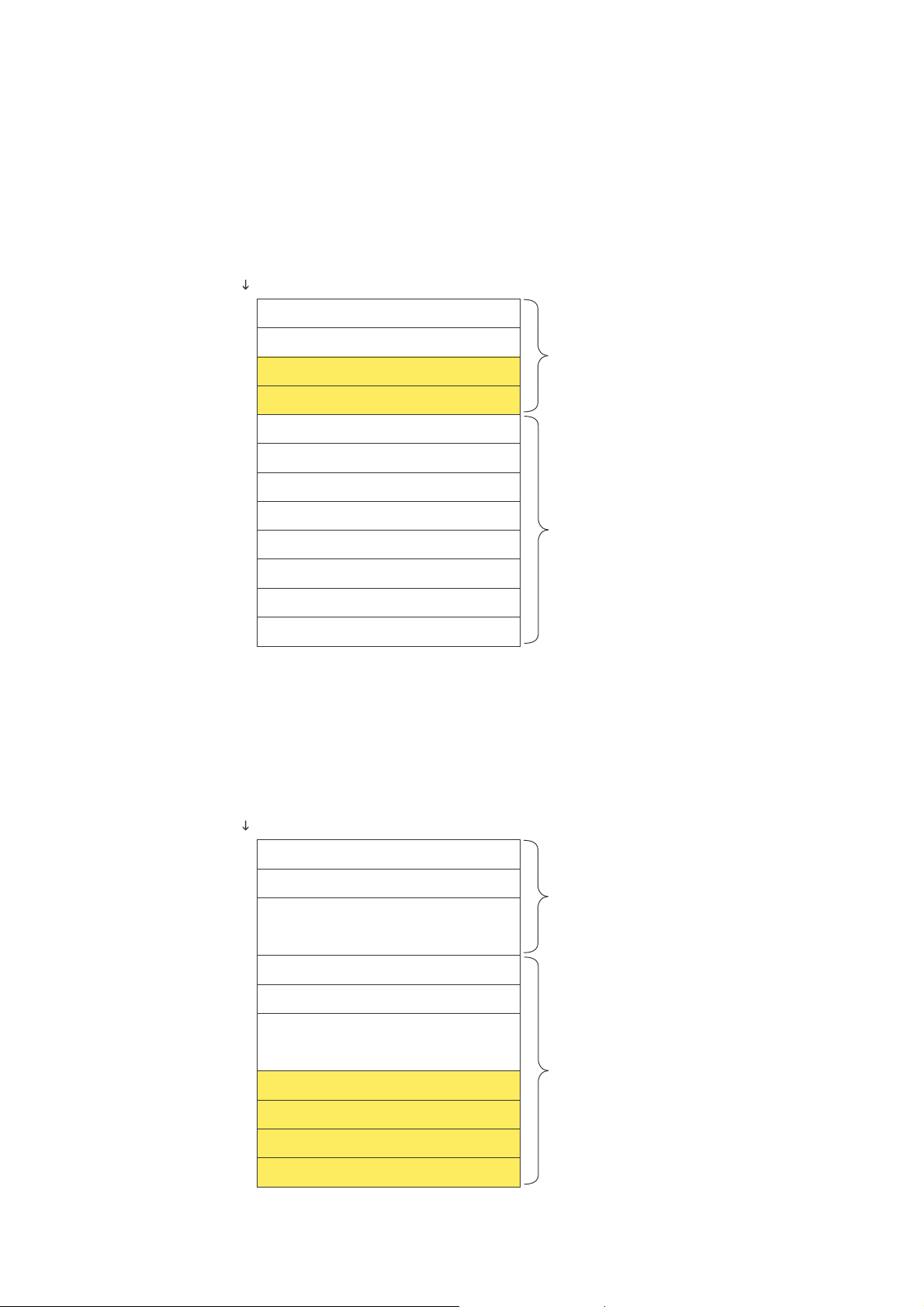

3) When offset/gain adjustment mode is activated

When parameter mode is activated (module status register = 30001(7531h)) and bit 6 of the parameter type setting status

register is set ON, the status of offset/gain adjustment is indicated. For this, the digital output values of the 5 channels starting

with specified channel, EEPROM writing completion flag, and offset/gain value indication flag are displayed.

* When using D300win, assign an WORD type variable to this register (offset address+2). If you access by the bit, assign

a BOOL type variable to each bit.

15(F) 08

+2

Unused (fixed to 0 (zero))

OFF: Offset value is displayed.

ON: Gain value is displayed.

15 0

ON: Module internal EEPROM

writing completed.

+3

+4

+5

+6

+7

Channel n Digital output value

Channel n+1 Digital output value

Channel n+2 Digital output value

Channel n+3 Digital output value

Channel n+4 Digital output value

Parameter setting data (INT type)

(The data for 5 channels starting with the first channel

that is specified by offset address +9 is displayed.)

* When using D300win, assign INT type variables to

these registers.

(5) Parameter type setting register (Offset address +8)

Parameter type and channel number for reading/writing parameters are set in this register.

* When using D300win, assign a WORD type variable to this register. If you access by the bit, assign a BOOL type variable to

each bit.

15(F) 078

+8

Channel No.

Bit Flag name Description

0 Operation parameter read mode ON: Operation parameter read mode (allchannels in a batch)

1 Scaling parameterread mode ON: Scaling parameter read mode (individual channel)

2, 3 Unused

4 Operation parameter write mode ON: Operation parameter write mode (all channels in a batch)

5 Scaling parameter write mode ON:Scaling parameter write mode (individual channel)

6 Offset/gain adjustment mode ON: Offset/gainadjustmentmode (indivi dual channel)

7 Parameter mode ON: Parameter mode, OFF: A/D conversion mode

8 Channel 1 In "scaling parameter read mode", "scaling parameter write mode" or

9 Channel 2

10 Channel 3

11 Channel 4

12 Channel 5

13 Channel 6

14 Channel 7

15 Channel 8

"offset/gain adjustment mode", arbitrarychannel i s specified. In "scaling

parameter read mode", one of bits 8 to 15 is set ON to specify a channel

for whichparameters are to be set. When same data is to be set in

"scaling parameter write mode" or "offset/gain adjustment mode", multiple

arbitrary channels may be specified.

Parameter type

Request to set parameter

4-7

Page 40

Section 4 Software Interface

A

4-1 Analog Input Module

(6) Parameter setting data register (offset address +9 to +1 1)

When bit 7 of the parameter type setting register (offset address +8) is set ON, module status (offset address +0) becomes

“30001” (INT type) and “parameter mode” is activated.

The set values of “operation parameter write” mode, “scaling parameter” mode or “offset/gain adjustment” mode are written in

this register.

1) When operation parameter write mode is activated

In this mode, data is set in the locations as shown below, and “operation parameter write mode flag” (bit 4 of the parameter

type setting register) is set ON.

* When using D300win, assign WORD type variables to these registers. If you access by the bit, assign a BOOL type variable

to each bit.

15(F) 0

+9

+10(A)

+11(B)

<Conversion enable/disable> (offset address +9)

Bit Flag name Descriptio n

0to7 Unused

8 C hannel 1 Conversion enable/disable Conversion is enabled or di sabled whenthe corresponding bit

9 C hannel 2 Conversion enable/disable

10 Channel 3 Conversion enable/disable

11 Channel 4 Conversion enable/disable

12 Channel 5 Conversion enable/disable

13 Channel 6 Conversion enable/disable

14 Channel 7 Conversion enable/disable

15 Channel 8 Conversion enable/disable

<Input range> (offset address +10)

Bit Flag name

0(L),1(H)

2(L),3(H)

4(L),5(H)

6(L),7(H)

8(L),9(H)

10 (L), 11 (H)

12 (L), 13 (H)

14 (L), 15 (H)

Conversion enable/disable

Input range

Moving average execution times

Channel 1 Input range Range is set by a combination of ON/OFF status of two bits.

Channel 2 Input range

Channel 3 Input range

Channel 4 Input range

Channel 5 Input range

Channel 6 Input range

Channel 7 Input range

Channel 8 Input range

Unused (fixed to 0 (zero))

is setto OFF orON.

OFF: E nable,

ON: Disable

Descriptio n

<NP1AXH8V-MR>

H L

OFF OFF : -10 to 10 V

OFF ON : 0 to 10 V

ON OFF : 0 to 5 V

ON ON : 1 to 5 V

<NP1AXH8I-MR>

H L

OFF OFF : 4 to 20 mA

OFF ON : 0 to 20 mA

ON OFF : -20 to 20 m

ON ON : 4 to 20 mA

4-8

Page 41

Section 4 Software Interface

4-1 Analog Input Module

<Moving average execution times> (offset address +11)

Bit Flag name

0(L)

1(H)

2(L)

3(H)

4(L)

5(H)

6(L)

7(H)

8(L)

9(H)

10 (L)

11 (H)

12 (L)

13 (H)

14 (L)

15 (H)

Channel 1

Moving average execution times

Channel 2

Moving average execution times

Channel 3

Moving average execution times

Channel 4

Moving average execution times

Channel 5

Moving average execution times

Channel 6

Moving average execution times

Channel 7

Moving average execution times

Channel 8

Moving average execution times

Descriptio n

Moving average execution times is set by a combination of

ON/OFF status of two bits.

H L

OFF OFF : Once

OFF ON : Twice

ON OFF : 4 times

ON ON : 8 times

4-9

Page 42

Section 4 Software Interface

4-1 Analog Input Module