Page 1

1. Before Using the Product

Thank you for purchasing the FD5000 series. This manual should be passed

on to the person who operates the product. Examine the product for dam-

age caused by transportation or any other defects. If you find any damage or

defects, contact the sales agent from which you purchased the product or

Fuji Electric Instruments Co., Ltd.

1.1 Model Codes

The model lineup of the FD5000 series is shown below. Check that the

model code and specifications of your product match those you specified

when ordering.

Instruction Manual for FD5000 Series 1/12

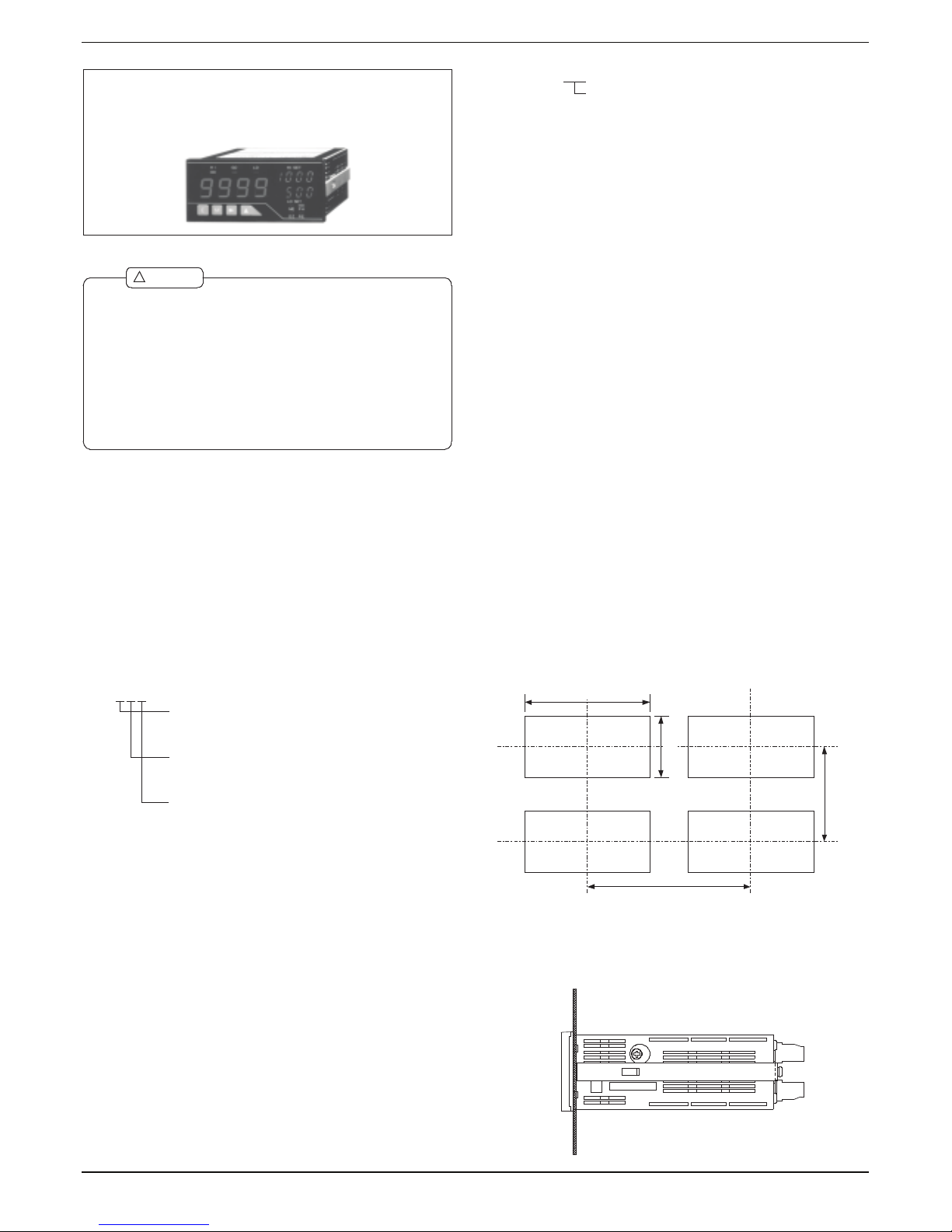

2. Mounting the Product

2.1 Dimensions for Cutting Panel

Cut the panel for mounting according to the following dimensions.

2.2 Mounting the Product to the Panel

To mount the FD5000 to the panel, remove its fittings and insert it through

the hole in the fron t of the panel . From the back of the panel, fix the

product to the panel with the fittings.

92

+0.8

-0

45

+0.6-0

70 mm

min.

120 mm min.

Fuji Electric Instruments Co.,Ltd

0: None

Output unit

1: Comparison

2: Analog

3: RS-232C

4: RS-485

5: Comparison and analog

6: Comparison, analog, and RS-232C

Display unit

1: Single display

2: Multi display

Power unit

1: 100 to 240 V AC ± 10%

7: Comparison, analog, and RS-485

F 5 X X X - X X

2: 9 to 60 V DC

D

01: DC voltage measuring unit (range 11: ± 99.99 mV)

Input unit

5 X X X - X X

D

03: DC current measuring unit

02: DC voltage measuring unit

04: AC voltage measuring unit (average rms)

(range 12: ± 999.9 mV ; range 13: ± 9.999 V)

(range 11: 99.99 mV; range 12: 999.9 mV)

05: AC voltage measuring unit (average rms)

(range 14: 99.99 V; range 15: 600 V)

06: AC voltage measuring unit (true rms)

(range 11: 99.99 mV; range 12: 999.9 mV)

07: AC voltage measuring unit (true rms)

(range 14: 99.99 V; range 15: 600 V)

08: AC current measuring unit (average rms)

(range 23: 9.999 mA; range 24: 99.99 mA)

09: AC current measuring unit (average rms)

(range 23: 9.999 mA; range 24: 99.99 mA)

10: AC current measuring unit (true rms)

(range 26: 5 A)

11: AC current measuring unit (true rms)

12: Resistance measuring unit

13: Temperature measuring unit (TC)

14: Temperature measuring unit (RTD)

15: Frequency measuring unit

(inputs: open collector, logic, and magnet)

16: Frequency measuring unit (input: 50 to 500 Vrms)

17: Strain gauze input unit (load cell)

(range 14: ± 99.99 V ; range 15: ±

600 V)

18: Process signal measuring unit

(range 25: ± 999.9 mA)

(range 13: 9.999 V)

(range 13: 9.999 V)

(range 25: 999.9 mA)

(range 25: 999.9 mA)

(range 26: 5 A)

(

4 to 20 mA or 1 to 5 V

)

(range 23: ± 9.999 mA; range 24: ± 99.99 mA)

MODEL FD5000 SERIES

INSTRUCTION MANUAL

(1) Do not apply a voltage or current exceeding the maximum allowable

value; otherwise, it may damage the equipment.

(2) Use a power voltage within the operation range; otherwise, it may

result in a fire, electrical shock, or malfunction.

(3) The contents of this manual are subject to change without notice.

Although the contents of this manual have been prepared with extra

care, if you have any questions, or find errors or missing

information, contact the sales agent from which you purchased the

product or Fuji Electric Instruments Co.,Ltd.

(4)

After reading this manual thoroughly, keep it in a convenient place

for future reference.

(5)

Caution

!

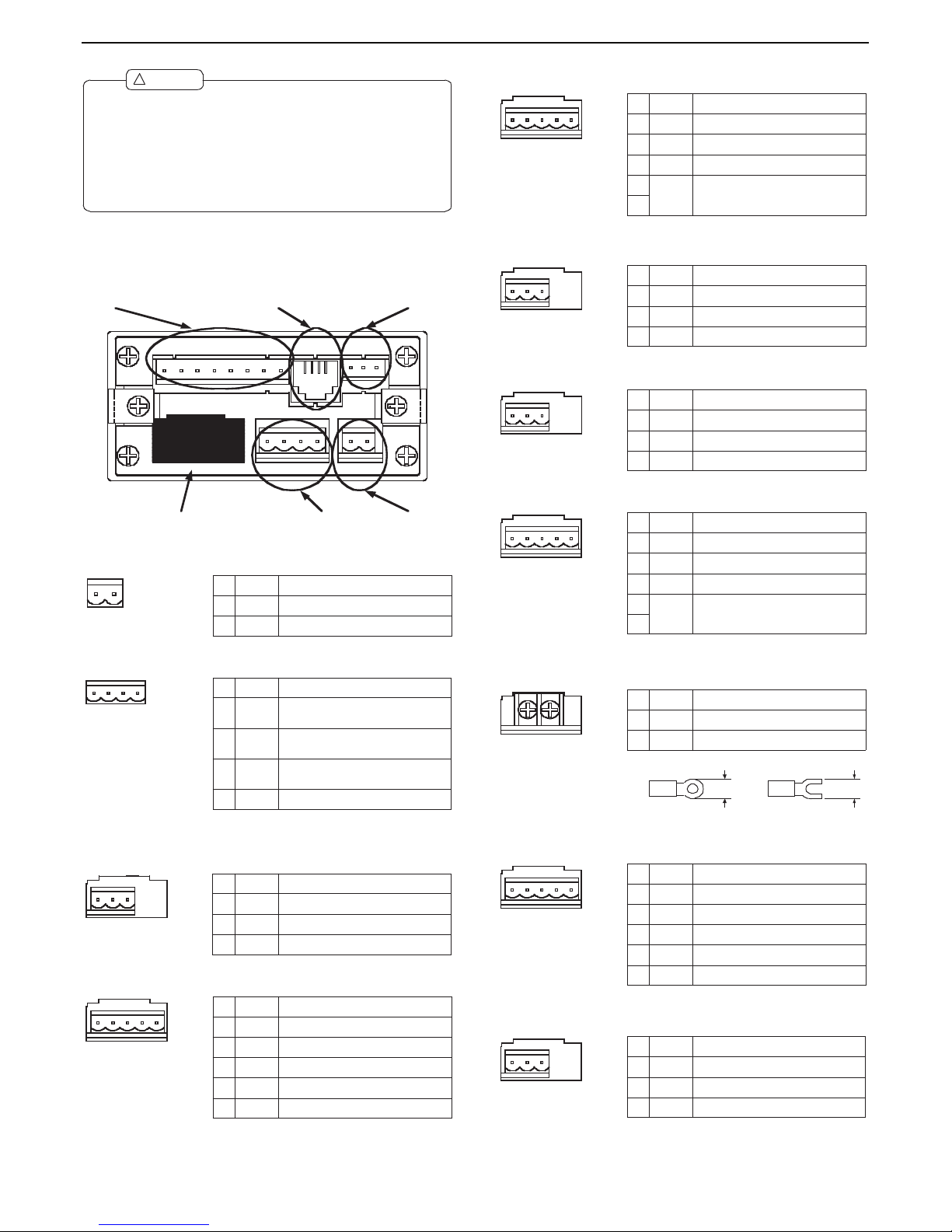

Page 2

External

control

Power

connector

Input (the shape depends on the unit.)

Comparison

output

Serial

communication

Analog output

6 7 8 9 10 11

12 13 14 15 16 17 18 19

202122

23

24 25 26

3. Terminal Arrangement

3.1 Power

3.2 External Controls

3.3 Input Signals

3. 3.1 DC Voltage Meas ur in g Uni t (Range 11 )

3.3 .2 DC Voltage Mea suring Uni t (Range 12)

No.

Name

Description

10

POWER

Power terminal without polarity for both D

C

and AC

11

POWER

Power terminal without polarity for both D

C

and AC

10 11

Name Description

1 12

Positive input terminal for range 12

(± 999.9 mV)

2 13

3 14

No.

1 2 3 4 5

4 15

5 LO Negative input terminal

Positive input terminal for range 13

(± 9.999 V)

Positive input terminal for range 14

(± 99.99 V)

Positive input terminal for range 15

(± 600 V)

3. 3.3 DC Cur re nt Measur in g Unit

3. 3.4 AC Volt ag e Measurin g Unit (Range s 11 to 13)

3. 3.5 AC Volt ag e Mea suring Unit (Rang es 14 and 15)

3. 3.6 AC Current Meas ur in g Uni t (Ranges 23 to 25)

3. 3.7 AC Curr en t Meas ur in g Unit (Ran ge 26)

3. 3.8 Re sis tan ce Me as u ri n g Un it

3. 3.9 Temperature Meas ur in g Uni t (TC)

1 2 3 4 5

Name Description

1 23

Positive input terminal for range 23

(± 9.999 mA)

2 24

3 25

No.

4

LO5Negative input terminal

Positive input terminal for range 24

(± 99.99 mA)

Positive input terminal for range 25

(± 999.9 mA)

1 2 3

Name Description

1 11-12

Positive input terminal for ranges

11 (99.99 mV) and 12(999.9 mV)

2 13

3

No.

LO

Positive input terminal for range

13 (9.999 V)

Common input terminal

1 2 3

Name

Description

1

14

Positive input terminal for range

14 (99.99 V)

2

15

3

No.

LO

Positive input terminal for range

15 (600 V)

Common input terminal

1 2 3 4 5

Name Description

1 23

Positive input terminal for range

23 (9.999 mA )

2 24

3 25

No.

4

LO5Negative input terminal

Positive input terminal for range

24 (99.99 mA)

Positive input terminal for range

25 (999.9 mA)

5.8

mm

min

.

5.8

mm

min

.

Applicable solderless terminals

1 2

Name DescriptionNo.

1 HI

Input terminal

2

LO Input terminal

1 2 3 4 5

Name

Description

1

HI Input terminal for all ranges

2 LO

3 +S

No.

4

LO5

Common terminal (grounding terminal for

input circuit)

Input terminal for all ranges

Constant current for four-wire resistance

measurement (positive)

-S

Constant current for four-wire resistance

measurement (negative)

1 2 3

Name Description

1 +

Positive terminal for thermocouple

2 NC

3

No.

-

Do not connect this terminal.

Negative terminal for thermocouple

Name Description

6 HOLD

Control for hold function. Enabled when

short-circuited or at the same potential as

COM.

7 DZ

Control for digital zero function. Enabled

when short-circuited or at the same

potential as COM.

6 7 8 9

89PH

COM

No.

Control for peak hold function. Enabled

when short-circuited or at the same

potential as COM.

Common for all external control terminals.

(1) Mount the product to a panel that is strong enough to hold the

product. If the panel is not strong enough or the product is not fixed

tightly, it may fall down and cause injury.

(2)

The A5000 does not have a power switch, and will thus be

immediately ready for operation upon connecting it to a power

supply.

(3) If the product is installed inside other equipment, provide sufficient

heat dissipation to ensure that the temperature inside the

equipment does not exceed 50°C .

Caution

!

Output type

0 to 1V

0 to 10V

1 to 5V

4 to 20mA

Note : The ripple ratings for the 4-20 mA output are when the load resistance

of 250 and the output current of 20 mA are applied.

Conversion system : PWM conversion

Resoluton : Equivalent to 13 bits

Scaling : Digital scaling

Response speed : About 0.5 second

Instruction Manual for FD5000 Series 11/12Instruction Manual for FD5000 Series 2/12

1 2 3

Name Description

1

HI Positive input terminal

2 NC

Do not connect this terminal.

3 LO

No.

Negative input terminal

Synchronization system

Character code

Communication control

Signal name used TXD,RXD,SG

Number of connectable

Line length 15m Up to 500 m (total)

Error detection

Communication rate

Data length

lo g Out put

8. 3.3 Co mmu nic ati ng F unc tio n

Page 3

3.3 .1 0 Te mp erature Measu ri ng Unit (RTD)

3.3.11 Frequency Measuring Unit (Open collector, logic, and magnet)

3.3 .1 2 Freque nc y Mea su ring Unit (500 Vrms)

3.3 .13 Strain Gauge Input Unit (Load cell)

3.3.14 Pro ce ss Sig na l Me as ur ing Unit

3.4 Comparison Output

Connection of three-wire sensor

1 2 3

Name

Description

1 A

Resistance sensor wire

2

B

3

No.

C

Elimination of wire resistance

Resistance sensor wire

1 2 3

Name

Description

1

HI

Input terminal

2

NC

3

No.

LO

Do not connect this terminal.

Input terminal

1 2 3 4 5

Name Description

1 +SIG Positive input terminal

2 -SIG

3 +EXC

No.

4

COM5

Common terminal (grounding terminal for

input circuit)

Negative input terminal

Power output for sensor (positive)

-EXC Power output for sensor (negative)

1 2 3

Name

Description

1

V-IN

Positive input terminal for 1 to 5 V range

2

A-IN

3

No.

LO

Positive input terminal for 4 to 20 mA rang

e

Negative input terminal

12 13 14 15 16 17 18 19

Name Description

12 LO-b LO output terminal (b contact)

13 LO-c

14

No.

LO-a

Common terminal for LO output

LO output terminal (a contact)

15 GO-c Common terminal for GO output

16 GO-a

17 HI-b

GO output terminal (a contact)

HI output terminal (b contact)

18 HI-c

19 HI-a

Common terminal for HI output

HI output terminal (a contact)

3.5 Analog Output

3.6 Serial Communication

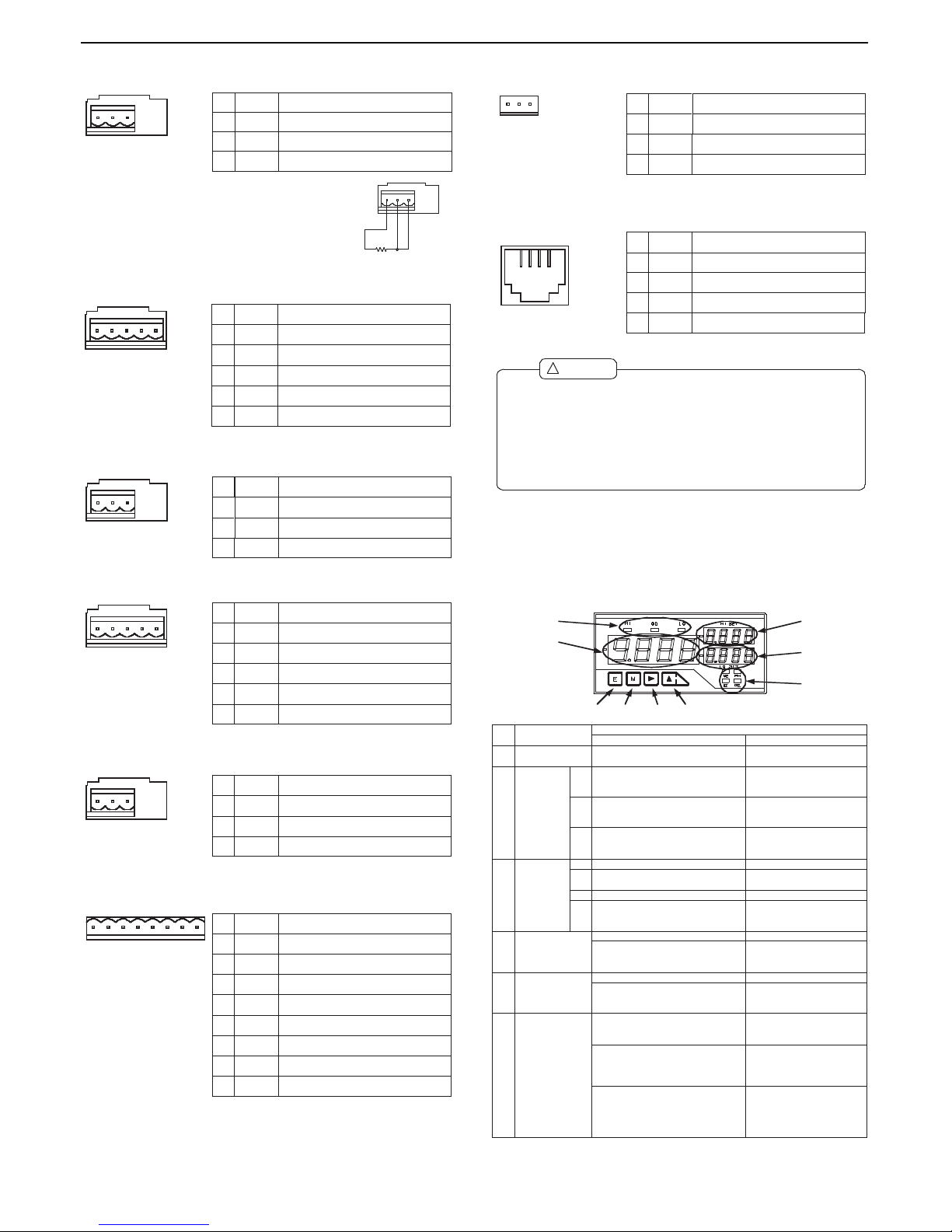

4. Components and their Functions

The front panel design of the FD5000 series of unit meters differs depend-

ing on the display unit selected. The names and functions of each unit are

as shown below.

4.1 Multi-display Unit

24 2526

Name

Description

24

COM

Common terminal for analog output

25

A-OUT

26

No.

V-OUT

Current output terminal (4 to 20 mA)

Voltage output terminal (1 to 5 V, 0 to 1 V,

and 0 to 10 V)

20212223

Name

Description

20

RXD(+)

RS-232C: transmission;

RS-485: Non-reverse output

21

TXD(-)

22

No.

NC

RS-232C: reception;

RS-485: Reverse output

Do not connect this terminal.

23

SG

Common terminal for communications

(1) Use 12 to 28 AWG wire for the power, input (except for range 26),

external control, and comparison output connectors.

(2)

Tighten the screws for the power, input (except for range 26),

external control, and comparison output connectors to a torque of

0.5 to 0.6 Nm.

(3) Use 16 to 28 AWG wire for the analog output connector.

Tighten the screws of analog output connector to a torque of 0.22

to 0.25 Nm.

(4)

Caution

!

Instruction Manual for FD5000 Series 3/12Instruction Manual for FD5000 Series 10/12

1 2 3 4 5

Name Description

1 HI Positive input terminal

2 LO

3 +15V

No.

4

COM5

Common terminal (grounding terminal for

input circuit)

Negative input terminal

Power output for sensor (positive)

0V Power output for sensor (negative)

(1)

(2)

(3)

(4)

(6)

(7) (8) (9)

(5)

No. Name

Main Functions

During measurement During parameter setup

(1) Main display

Indicates the measured value.

IIndicates information on the

parameter to be set.

Judgment

indicators

HI

(2) GO

LO

Indicates the result of judgment and

turns on if the measured value > HI

judgment value.

Indicates the result of judgment and

turns on if LO judgment value

$ the

measured value

$ HI judgment value.

Indicates the result of judgment and

turns on if the measured value < LO

judgment value.

(3)

Function

indicators

ME

Turns on if "digital zero backup" is on.

PH

Turns on if "peak hold/valley hold/peak -

valley hold" is on.

Turns on if "digital zero" is on.

DZ

RE

Turns on if remote control is being

performed through RS-232C or RS-485

interface.

(4) Sub-display 1

Indicates the HI side judgment value.

Indicates the item in the maximum/

minimum/(maximum-minimum)/input

value monitoring mode.

Indicates the LO side judgment value.

Sub-display 2(5)

Indicates information on the item in the

maximum/minimum/(maximumminimum)/input value monitoring mode.

Indicates the item to be set.

(6) Enter key

Pressing the Enter and Mode keys

together changes to the parameter

setting mode.

Pressing the Enter and Increment keys

together changes to the maximum/

minimum/(maximum-minimum)/input

value monitoring mode.

Switches from the maximum/minimum/

(maximum-maximum/minimum/

(maximum-minimum)/input value

monitoring mode to the comparative

judgment reading mode.

Returns to the measurement

mode.

Page 4

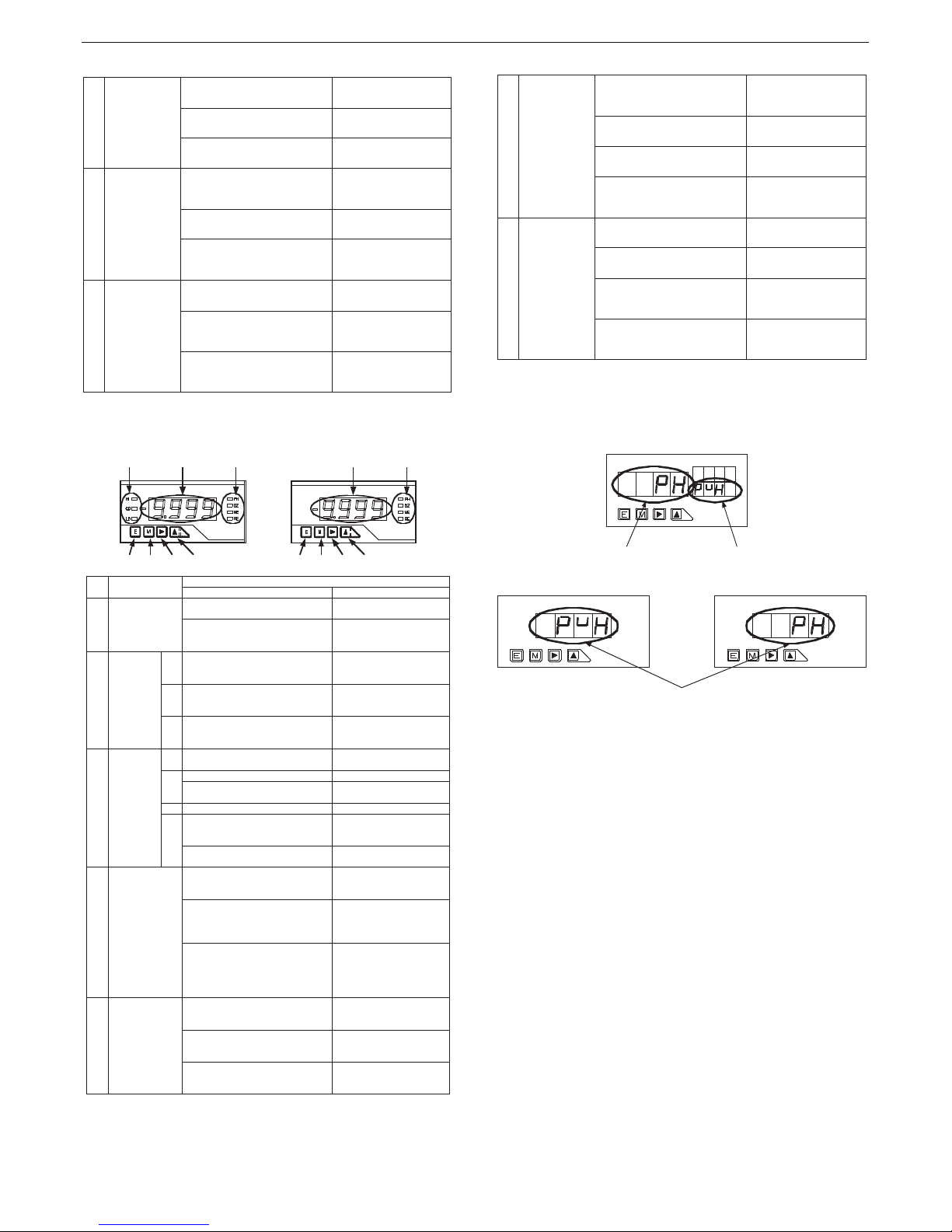

4.2 Single Display Unit

(8) Shift key

Pressing the Shift and Enter keys

together changes to the parameter

checking mode. (Comparator data

can be set.)

Pressing the Shift and Mode keys

together changes to the shift function

setup mode.

Selects from items in the maximum/

minimum/(maximum-minimum)/input

value monitoring mode. (Hold down

the key for about one second.)

Changes the digit to be set.

Holding down the Shift key for about

one second moves to the HI judgment

value indicator.

Increment key(9)

Pressing the Increment and Mode

keys together turns on/off the "Digital

zero" indicator.

Pressing the Increment and Enter

keys changes to the maximum/

minimum/(maximum-minimum)/input

value monitoring mode.

Resets the maximum/minimum/

(maximum-minimum)/input value

monitoring mode. (Hold down the key

for about one second.)

Changes the value or conten

t

of a selected digit.

(Increments the value)

Holding down the Increment key for

about one second moves to the LO

judgment value indicator.

5. Parameter Setup

5.1 Differences between Display Units

5. 1.1 Mu lt i-d is pla y Un it

Note: Pressing the Mode key displays the next parameter.

5. 1.2 Si ngl e Dis pl ay Un it

Note 1: Pressing the mode key with the parameter name shown changes the

display to the parameter information indication. If there is no key

operation for about one second when the parameter name is shown,

the displ ay automati cally chang es to the parame ter informa tion

indication (however, this change does not automatically occur for

parameters PH/S-HI/FSC, etc., right after COND/COM/MET is in-

dicated).

Note 2: Pressing the Mode key when the parameter information indication

is shown results in the next parameter being displayed.

Note 3: If there is no key operation for about 8 seconds with the parameter

information indication shown, the display returns to the parameter

name indication .

Setup contents and parameter name

Setup contents

Parameter name

Range

Measurement

11 99.99mV

Input circuit : Single ended type

12

Operating system : conversion

Maximum sampling rate : 12.5 times per second

Frequency range : 40 Hz to 1 kHz

Response speed : About 1 second

Dead zone : 0 to 99 digits

999.9mV

Range

Measurement

14 99.99V

Input circuit : Single ended type

15

Operating system : conversion

Maximum sampling rate : 12.5 times per second

Frequency range : 40 Hz to 1 kHz

Response speed : About 1 second

Dead zone : 0 to 99 digits

Range

Measurement

11 99.99mV

12

999.9mV

Input circuit : Single ended type

Operating system : conversion

Maximum sampling rate : 12.5 times per second

Frequency range : 40 Hz to 1 kHz

Response speed : About 1 second

Dead zone : 0 to 99 digits

Crest factor : 4:1 at full scale

Range

Measurement

14 99.99V

Input circuit : Single ended type

15

Operating system : conversion

Maximum sampling rate : 12.5 times per second

Frequency range : 40 Hz to 1 kHz

Response speed : About 1 second

Dead zone : 0 to 99 digits

Crest factor : 4:1 at full scale

Range

Measurement

23 9.999mA 1µA

999.9mA 100µA

24

25

Input circuit : Single ended type

Operating system : conversion

Maximum sampling rate : 12.5 times per second

Frequency range : 40 Hz to 1 kHz

Response speed : About 1 second

Dead zone : 0 to 99 digits

Crest factor : 4:1 at full scale

Instruction Manual for FD5000 Series 4/12 Instruction Manual for FD5000 Series 9/12

8. 1.4 AC Volt ag e Measur in g Unit (ave rage value detection : ranges

11 to 13)

8. 1.5 AC Volt ag e Measur in g Unit (ave rage value detection : ranges

14 and 15)

8. 1.6 AC Vo lta ge Measuring Unit (true rms value: rang es 11 to 13)

8. 1.7 AC Voltage Measuring Uni t (tru e rms val ue : rang es 14 and

15 )

8. 1.8 AC Current Measuring Unit (aver age value detec tion: ranges

23 to 25 )

(3)

(1)

(3)

(6) (7) (8) (9)

No.

Name

Main Functions

During measurement

During parameter setup

(1)

Main display

Indicates the measured value.

IIndicates information on the

parameter to be set.

Indicates information on the item in the

maximum/minimum/(maximumminimum)/input value monitoring mode.

Judgment

indicators

HI

(2)

GO

LO

Indicates the result of judgment and

turns on if the measured value > HI

judgment value.

Indicates the result of judgment and

turns on if LO judgment value

$ the

measured value

$ HI judgment value.

Indicates the result of judgment and

turns on if the measured value < LO

judgment value.

(3)

Function

indicators

ME

Turns on if "digital zero backup" is on.

PH

Turns on if "peak hold/valley hold/peak valley hold" is on.

Turns on if "digital zero" is on.

DZ

RE

Turns on if remote control is being

performed through RS-232C or RS-485

interface.

Flashes when linearization data output

values are set.

Flashes when linearization data input

values are set.

(6)

Enter key

Pressing the Mode and Enter keys

together changes to the parameter

setting mode.

Pressing the Enter and Increment keys

together changes to the maximum/

minimum/(maximum-minimum)/input

value monitoring mode.

Switches from the maximum/minimum/

(maximum-maximum/minimum/

(maximum-minimum)/input value

monitoring mode to the comparative

judgment reading mode.

Returns to the measurement

mode.

Mode key

(7)

Pressing the Mode and Enter keys

together changes to the parameter

setting mode.

Selects the item to be set.

Pressing the Mode and Shift keys

together changes to the shift function

setup mode.

Pressing the Mode and Incremental

keys together turns on/off the " Digital

zero" indicator.

(1)(2)

(6) (7) (8) (9)

Mode key(7)

Pressing the Mode and Enter keys

together changes to the parameter

setting mode.

Selects the item to be set.

Pressing the Mode and Shift keys

together changes to the shift function

setup mode.

Pressing the Mode and Incremental

keys together turns on/off the "Digital

zero" indicator.

(8) Shift key

Pressing the Shift and Enter keys

together changes to the parameter

checking mode. (Comparator data

can be set.)

Pressing the Shift and Mode keys

together changes to the shift function

setup mode.

Selects from items in the maximum/

minimum/(maximum-minimum)/input

value monitoring mode. (Hold down

the key for about one second.)

Changes the digit to be set.

Increment key(9)

Pressing the Increment and Mode

keys together turns on/off the "Digital

zero" indicator.

Pressing the Increment and Enter

keys changes to the maximum/

minimum/(maximum-minimum)/input

value monitoring mode.

Resets the maximum/minimum/

(maximum-minimum)/input value

monitoring mode. (Hold down the key

for about one second.)

Changes the value or conten

t

of a selected digit.

(Increments the value)

Page 5

5.2 Moving to the Parameter Setup Mode

5. 3 Data Lists and Default Settings

Instruction Manual for FD5000 Series

5/12

Condition data Comparator data Scaling data Linearization data

Measurement

Pressing the ENTER key saves the data and returns to the measurement mode.

Calibration data

Shift data

(Data are backed up with EEPROM even when the power is turned off.)

Default Equipped

Indication Name value as 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 0 1 2 3 4 5

PVH Peak hold setup PH

¡

RANG Measurement range setup *1 X

¡ ¡ ¡ ¡ ¡ ¡ ¡

X

¡

X

¡ ¡ ¡ ¡ ¡

X

¡

11 15 25 13 15 13 15 25 26 25 26 14 B JPB 14 14 2A

AVG Number of averaging 1

¡ ¡ ¡ ¡ ¡ ¡ ¡ ¡ ¡ ¡ ¡ ¡ ¡ ¡

X X

¡ ¡

MAV Number of moving averaging setup OFF

¡

S.UD Step wide setup 1

¡

BLNK Indication blank setup OFF

¡

UNIT Unit setup C X X X X X X X X X X X X

¡ ¡

X X X X

BAUD Baud rate setup 9600 X X X

¡ ¡

X

DATA Data length setup 7 X X X

¡ ¡

X

P.BIT Parity bit setup E X X X

¡ ¡

X

S.BIT Stop bit setup 2 X X X

¡ ¡

X

T- Delimiter setup CR.LF X X X

¡ ¡

X

ADR Equipment ID setup 00 X X X X¡X

A.OUT Analog output setup OFF X X¡X X

¡

B.UP Digital zero backup setup OFF

¡

LINE Linearization setup CLR

¡

I.SEL Input selection OC X X X X X X X X X X X X X X¡X X X

TR T Tracking zeroing time setup 00

¡

X X

TR V Tracking zeroing width setup *2 01

¡

X X

SNSR Sensor power setup 10 X X X X X X X X X X X X X X X X

¡

X

P

Power-on delay setu

p

OFF

PRO Protect setup OFF

¡

U-NO. Unit number Indication setup ON

¡

S-HI HI side judgment value setup 1000 X¡X X X

¡

S-LO LO side judgment value setup 500 X¡X X X

¡

H-HI HI side hysteresis setup 0 X¡X X X

¡

H-LO LO side hysteresis setup 0 X¡X X X

¡

FSC Full scale Indication value setup *1

¡ ¡ ¡ ¡ ¡ ¡ ¡ ¡ ¡ ¡ ¡ ¡

X X X X X

¡

9999 9999 9999 9999 9999 9999 9999 9999 9999 9999 9999 9999 9999

FIN Full scale input value setup *1

¡ ¡ ¡ ¡ ¡ ¡ ¡ ¡ ¡ ¡ ¡ ¡

X X X X X

¡

9999 9999 9999 9999 9999 9999 9999 9999 5000 9999 5000 9999 *3

OFS Offset indication value setup *1

¡ ¡ ¡ ¡ ¡ ¡ ¡ ¡ ¡ ¡ ¡ ¡

X X X X X

¡

0 0 0 0 0 0 0 0 0 0 0 0 0

OIN Offset input value setup *1

¡ ¡ ¡ ¡ ¡ ¡ ¡ ¡ ¡ ¡ ¡ ¡

X X X X X

¡

0 0 0 0 0 0 0 0 0 0 0 0 *4

PS Pre-scaling value setup 1 X X X X X X X X X X X X X X

¡ ¡

X X

PPR Frequency division setup 1 X X X X X X X X X X X X X X

¡ ¡

X X

DLHI Digital limiter HI value setup 9999

¡

X X X X X X X X

DLLO Digital limiter LO value setup -9999

¡

X X X X X X X X

AOHI Analog output HI indication setup 9999 X X¡X X

¡

AOLO Analog output LO indication setup 0 X X¡X X

¡

DEP Decimal point position setup None

¡

*5

¡

ZERO Zero input value *6 0 X X X X X X X X X X X X X X X X

¡

X

SPIN Span input value *6 2000 X X X X X X X X X X X X X X X X

¡

X

SPAN Span indication 9000 X X X X X X X X X X X X X X X X

¡

X

SHF Shift data setup 0

¡

*1 Each value in the lower part of a cell in the columns on the right is the default value.

*2 Tracking zero width setup parameter is not indicated if the tracking time is set to OFF(0).

*3 5000 for 1 V range and 2000 for 2 A range

*4 1000 for 1 V range and 400 for 2 A range

*5 Linearization data are not set up for the default values.

*6 This value is not indicated if calibration is done using an actual load.

Input unit number

Condition data

Com

p

arator data

Scalin

g

data

Page 6

5. 4 Information on Each Parameter

5.4.1Method of Setting Condition Data

This section shows a typical example of setting the peak hold parameter.

The same method applies to other parameters.

Indication Name Setup options

Default

value

PVH Peak hold setup PH (peak hold)/VH (valley hold)/PVH (peak-valley hold) PH

RANG Measurement range setup *1 *1

AVG

Number of averaging operations

setup

1/2/4/8/10/20/40/80 1

MAV

Number of moving average

operations setup

OFF/2/4/8/16/32 OFF

S.UD Step width setup 1(1digit)/2(2digit)/5(5digit)/0(10digit) 1

BLNK Indication blank setup OFF/B-3/B-2/B-1/ON OFF

UNIT Unit setup C/F C

BAUD Baud rate setup 9600/4800/2400/384(38400)/192(19200) 9600

DATA Data length setup 7(7bit)/8(8bit) 7bit

P.BIT Parity bit setup E (even number), O (odd number), N (none) E

S.BIT Stop bit setup 2(2bit)/1(1bit) 2

T- Delimiter setup CR.LF(CR+LF)/CR CRLF

ADR Equipment ID setup 01 to 99 00

A.OUT Analog output setup OFF/0-1(0 to 1V)/0-10(0 to 10V)/1-5(1 to 5V)/4-20(4 to 20mA) OFF

B.UP Digital zero backup setup OFF/ON OFF

LINE Linearization setup OFF/ON CLR

I.SEL Input selection OC (open collector)/LGC (logic)/MAG (magnet) O.C

TR T Tracking zeroing time setup 00 to 99 00

TR V Tracking zeroing width setup *2 00 to 99 01

SNSR Sensor power setup 10(10V)/05(5V) 10

P

Power on delay time setupOFF/ON OFF

PRO Protect setup OFF/1 to 30 OFF

U-NO. Unit number indication setup OFF/ON ON

S-HI HI side judgment value setup -9999 to 9999 1000

S-LO LO side judgment value setup -9999 to 9999 500

H-HI HI side hysteresis setup -9999 to 9999 0

H-LO LO side hysteresis setup -9999 to 9999 0

FSC Full scale indication value setup -9999 to 9999 *1

FIN Full scale input value setup -9999 to 9999 *1

OFS Offset indication value setup -9999 to 9999 *1

OIN Offset input value setup -9999 to 9999 *1

PS Pre-scaling value setup 0.001 to 5.000 1.000

PPR Frequency division setup 1 to 100 1

DLHI Digital limiter HI value setup -9999 to 9999 9999

DLLO Digital limiter LO value setup -9999 to 9999 -9999

AOHI

Analog output HI indication

setu

p

-9999 to 9999 9999

AOLO

Analog output LO indication

setu

p

-9999 to 9999 0

DEP

Decimal point indication position

setu

p

None/place of 100/place of 101/place of 102/place of 10

3

None

*2 *2

ZERO Zero input value -0.300 to 2.000 0.000

SPIN Span input value 1.000 to 3.000 2.000

SPAN S

p

an indication 0 to 9999 9000

Condition data

Com

p

arator data

Scalin

g

data

Multi-display unit Single display unit

or

(1) Press the Mode and Enter keys together

during measurement.

(2) Press the Mode key to change to the peak

hold setup mode.

(3) For a single display unit, press the Mode key

to change to the parameter information indication.

(The display automatically changes to this

indication in about 1 second, except right after

COND is indicated.)

(4) Press the Increment key a few times to set to

Valley Hold.

(5) Press the Enter key to return to measurement

mode. (Pressing the Mode key changes to the

next parameter).

5.4.2 Method of Sett ing Compara tor Data

This section explains comparator data and shows a typical example of setting

the HI side judgment value. The same method applies to all other parameters.

Note : The setup conditions are HI side judgment value > LO side judgment

value, HI side judgment value % LO side judgment value + LO side

hysteresis, and LO side judgment value $ HI side judgment value-HI

side hysteresis. If these conditions are not satisfied, an error indica-

tion appears and the display returns to the HI side judgment value

setup.

5.4.3 Method of Setti ng Scaling Data

Thi s sectio n explai ns compa rator data and show s a typical example of

setting the full scale indication parameter. The same method applies to all

oth er param eters .

Note : For the Digital limiter, values larger than the DLHI setpoi nt are

not indicated even if signals greater that the value set in the DLHI

parameter are input (for DLLO parameter, values smaller than the

DLLO setpoint are not indicated).

HIGO GO LO GO

HI side hysteresis

range

Indicated value

HI side judgment value

LO side judgment value

LO side hysteresis

range

Judgment

900

500

0

1000

300

150

200

HI side judgment value

: 900

HI side hysteresis value 200:

: 300

150:LO side hysteresis value

LO side judgment value

Multi-display unit Single display unit

or

(1) Press the Mode and Enter keys together

during measurement.

(2) Press the Shift key a few times to display the

comparator data menu.

(6) Press the Enter key to return to the

measurement mode (Pressing the Mode key

changes to the next parameter).

(5) Press the Shift key (change digit) and press

the Increment key (change numeric value) to set

to 10.

&

Note:The decimal point in the selected digit

flashes.

(3) Press the Mode key a few times to display the

parameter to be set.

(4) For a single display unit, press the Mode key

to change to the parameter information indication.

(The display automatically changes to this

indication in about 1 second, except for parameter

S-HI right after COM is indicated.)

Note : For the process signal measuring unit, set the full scale input value

to 5.000 for the 1 V range and to 20.00 for the 2 A range, and set the

offset input value to 1.000 for the 1 V range and to 4.00 for the 2

A range.

The following explains the frequency measuring unit. (The same method

applies to the full scale indication parameter.)

Note : For the frequency measuring unit, set the relationship between the

input and indication using the PS and PPR parameters (parameters

of FSC, FIN, OFS, and OIN are not indicated).

The following explains the scaling of analog output (The same method

applies to the full scale indication parameter.)

Note : For analog output scaling, set the indication value for an output

Indication

Input

5000

10V

Input voltage : 0 to 10V

0 to 5.000:Indication

FSC : 5000

FIN : 9999

OFS : 0

OIN : 0

DLHI : 3000

DLLO : -2000

DEP : The place of 10

3

is lit.

0

DLLO

DLHI3000

-2000

Multi-display unit Single display unit

Indication

Output

AOHI : 5000

AOLO : 0

Instruction Manual for FD5000 Series 6/12 Instruction Manual for FD5000 Series 7/12

Determining the revolution speed (rpm) using the rotary encoder set to 30 pulses per minu

(1)Determine the measurement range by calculating the maximum frequency.

The figure below shows an example where the revolution rises to a maximum speed

about 100 rpm.

(3)The display unit shows 500 if 50 Hz pulse input is measured under range 11 (when

PS=1 and PPR=1 by default). Therefore, the parameters should be set as PS=2 and

PPR=1 so that the decimal point is positioned in the 10

input).

(2)Since the number of pulses determined in (1) is 50 per second (50 Hz), set the range

range 11(for how to set the range, see the section on setting condition data).

Page 7

Note : For the process signal measuring unit, set the full scale input value

to 5.000 for the 1 V range and to 20.00 for the 2 A range, and set the

offset input value to 1.000 for the 1 V range and to 4.00 for the 2

A range.

The following explains the frequency measuring unit. (The same method

applies to the full scale indication parameter.)

Note : For the frequency measuring unit, set the relationship between the

input and indication using the PS and PPR parameters (parameters

of FSC, FIN, OFS, and OIN are not indicated).

The following explains the scaling of analog output (The same method

applies to the full scale indication parameter.)

Note : For analog output scaling, set the indication value for an output

current of 20 mA in the AOHI parameter and set the indication

value for an output current of 4 mA in the AOLO parameter (for 4-

20 mA output).

Multi-display unit Single display unit

or

(1) Press the Mode and Enter keys together

during measurement.

(2) Press the Shift key a few times to change to

the scaling data menu .

(6) Press the Enter key to return to the

measurement mode (Pressing the Mode key

changes to the next parameter).

(5) Press the Shift key (change digit) and press

the Increment key (change numeric value) to set

to 10.

&

Note:The decimal point in the selected digit

flashes.

(3) Press the Mode key a few times to display the

parameter to be set.

(4) For a single display unit, press the Mode key

to change to the parameter information indication.

(The display automatically changes to this

indication in about 1 second, except for parameter

FSC right after MET is indicated.)

Indication

:

4 to 20mA

0.0 to 500.0

:

Output

AOHI : 5000

AOLO : 0

Output

Indication

20mA

5000

4mA

0

5. 4.4 Me th od of Set ti ng Calibration Data

5.4 .4 .1 Ac tual Load Calib ra tion

Actual load calibration means that calibration is carried out by applying actu-

ally measured pressure to a sensor such as a load cell connected to the meter.

5.4 .4 .2 Equivalent Calibra ti on

Equivalent calibration means that calibration is carried out according to the

ratings (specifications) of such a sensor as a load cell. It is not necessary to

connect the sensor or to apply pressure to the sensor.

Multi-display unit Single display unit

or

(1) Press the Shift, Increment, and Enter keys

together during measurement.

(2) Press the Mode key to change to the actual

load calibration mode.

(6) Press the Enter or Mode key to return to the

measurement mode.

(5) Press the Shift key (change digit) and

Increment key (change numeric value) to set

8000.

&

Note:The decimal point in the selected digit

flashes.

(3) Press the Mode key while applying pressure

that will cause the display to show zero.

(4) For a single display unit, press the Mode key

to change to the parameter information indication.

or

(1) Press the Shift, Increment, and Enter key together

during measurement.

(2) Press the Increment key to select the equivalent

calibration mode.

(12) Press the Enter or Mode key to return to the

measurement mode.

(11) Press the Shift key (change digit) and the

Increment key (change numeric value) to set 2000.

&

Note:The decimal point in the selected digit flashes.

(4) Press the Shift key to display the zero-input setup

mode.

(10) For a single display unit, press the Mode key to

display the parameter information indication.

(3) Press the Mode key to move to the equivalent

calibration mode.

&

(5) Press the Shift key (change digit) and the

Increment key (change numeric value) to set 0.004.

Note:The decimal point in the selected digit flashes.

Note:For a single display unit, the unit

automatically returns to ZERO indication if there is

no key operation for about 8 seconds. In such a

case, press the Mode key to return to the numerical

value indication.

(6) Press the Mode key to change to the span input

value setup mode.

&

(7) For a single display unit, press the mode key to

display the parameter information indication.

(8) Press the Shift key (change digit) and the

Increment key (change numeric value) to set 1.002.

(9) Press the Mode key to change to the span

indicating value setup mode.

Multi-display unit Single display unit

Determining the revolution speed (rpm) using the rotary encoder set to 30 pulses per minu

t

(1)Determine the measurement range by calculating the maximum frequency.

The figure below shows an example where the revolution rises to a maximum speed

o

about 100 rpm.

30 × 100

÷

60

Revolution speed per second

Number of pulses per revolution at the

rotary encoder

= 50

Number of pulses per second

(3)The display unit shows 500 if 50 Hz pulse input is measured under range 11 (when

PS=1 and PPR=1 by default). Therefore, the parameters should be set as PS=2 and

PPR=1 so that the decimal point is positioned in the 10

1

digit(100.0 is is indicated 50 Hz

input).

(2)Since the number of pulses determined in (1) is 50 per second (50 Hz), set the range

range 11(for how to set the range, see the section on setting condition data).

Page 8

5.2 Moving to the Parameter Setup Mode

5. 3 Data Lists and Default Settings

5.4 .5 Me thod of Setting Linearizat io n Dat a

The linearization function means a function that changes the slope of straight

lines in the relationship between the input and indication by correcting the relations at arbitrary points.

Linearization data are set using the input value (indicated

value before correction) and the output value (indicated value after correction) at

each arbitrary point.

Note : The setup conditions are N-1 < N-2 … N-15 < N-16.

6. Control Functions

6.1 Hold Function

The Hold function temporarily retains the indication. The hold function is enabled

by shortcircuiting the HOLD and COM terminals or setting both terminals to the same

voltage level. As a result the display unit retains the indication given at that moment.

6.2 Digital Zero Function

The Digital Zero function ze ros the indication given at an arbitrary timing.

Thereafter, the function shows the amount of change from the point of zeroing. However, this function serves as an indication resetting function for a

frequency measuring unit. Thus, the Digital Zero function can be used to reset

the indication when there is no input signal at all.

Note that, the on/off control of the Digital Zero function can be achieved by

means of terminal control or front panel keys. In the case of terminal control,

the Digital Zero function is turned on by shortcircuiting the DZ and COM terminals or setting both terminals to the same voltage level. The indication at that

moment is zeroed. In the case of control with the front panel keys, hold down

the Mode key and press the Increment key for about 1 second to zero the indication at that momen t.

Note : Operation with the control terminals takes priority over operation

with the front panel keys. The Digital Zero function is disabled if

the control term inals are made to go throu gh the off- on-off sequence with the function enabled by means of the front panel keys.

6.3 Peak Hold Function

The Peak Hold function retains one of the maximum (peak hold)/minimum

(valley hold)/maximum - minimum (peak-valley hold) values and provides

output for that value. Selection from these values is made using the condition

data. The peak hold function is enabled by shortcircuiting the PH and COM

terminals or setting both terminals to the same voltage level.

7. Output Function

7.1 Comparison Output Function

The FD5000 series of unit meters is designed so that the two judgment values

HI and LO can be set for the measured (indicated) value to provide the results

of judgment as relay contact output. (This function is effective when the

meter is equipped with a comparison output unit.) For details on the contact

ratings and other specifications, refer to the section “Output Specifications.”

7.2 Analog Output Function

The FD5000 series of unit meters can output an analog signal for an indicated

value (when the meter is equipped with an analog output unit). There are four

output ranges, 0 to 1 V/0 to 10 V/1 to 5 V/4 to 20 mA, from which a selection

can be made using the condition data. In addition, the analog output of the

FD5000 series allows for arbitrary output scaling. This scaling can be achieved

by setting the indication value for an output of the maximum scale value (20

mA for 4–20 mA output range) in the AOHI parameter of the scaling data.

7.3 RS-485 Interface Function

The FD5000 series can be equipped with an RS-485 interface (when the

meter is provided with an RS-485 unit). For details on the RS-485 function,

see the separate manual on communication functions.

7.4 RS-232C Interface Function

The FD5000 series can be equipped with an RS-232C interface (when the

meter is prov ided with an RS-232C unit ). For details on the RS-232C

function, see the separate manual on communication functions.

8. Specifications and External Dimensions

8.1 Input Specifications

8. 1.1DC Vol ta ge Measurin g Unit (range 11)

8. 1.2DC Voltage Mea su ring Unit (rang es 12 to 15)

8. 1.3DC Cur re nt Meas ur in g Unit

Range

Measurement

range

Indication

Highest

resolution

Input

impedance

Maximum

permissible

input

Accuracy

11

± 99.99mV

Offset : ± 9999

Full scale : 0 to ± 9999

10µV

About

100M!

±100V

± (0.1% of FS)

Input circuit : Single ended type

Maximum sampling rate : 12.5 times per second

Noise rejection ratio : NMR (normal mode rejection) 50 dB or more (50 or 60 Hz)

Operating system :

" # conversion

Range

Measurement

range

Indication

Highest

resolution

Input

impedance

Maximum

permissible

input

Accuracy

12 ± 999.9mV

Offset : ± 9999

Full scale : 0 to ± 9999

100µV

About

100M

!

± 100V

± (0.1% of FS)

Input circuit : Single ended type

13 ± 9.999V 1mV

About

1M

!

± 250V

± (0.15% of FS)

± 250V

± 600V

About

10M!

About

10M!

10mV

100mV

14

15

± 99.99V

± 600V

Operating system : " # conversion

Maximum sampling rate : 12.5 times per second

Noise rejection ratio : NMR (normal mode rejection) 50 dB or more (50 or 60 Hz)

Range

Measurement

range

Indication

Highest

resolution

Input

impedance

Maximum

permissible

input

Accuracy

23 ± 9.999mA 1µA

About

10!

± 100mA

Offset : ± 9999

Full scale : 0 to ± 9999

± (0.2% of FS)

± (0.3% of FS)

± 500mA

± 3A

About

1!

About

0.1!

10µA± 99.99mA

± 999.9mA 100µA

24

25

Input circuit : Single ended type

Operating system : " # conversion

Maximum sampling rate : 12.5 times per second

Noise rejection ratio : NMR (normal mode rejection) 50 dB or more (50 or 60 Hz)

Instruction Manual for FD5000 Series

Instruction Manual for FD5000 Series

8/12

Condition data Comparator data Scaling data Linearization data

Measurement

Pressing the ENTER key saves the data and returns to the measurement mode.

(Data are backed up with EEPROM even when the power is turned off.)

(1) Press the Mode key and the Enter key during

measurement.

(2) Press the Shift key a few times to move to the

linearization data menu.

(4) Press the Shift key (change digit) and the

Increment key (change numeric value) and then press

the Mode Key to after the number of data to be

corrected has been set.

&

Note: The decimal point in the selected digit

flashes.

(3) Press the Mode key to move to the setup for the

number of data to be corrected.

&

(10) When all the settings have been made, press the

Enter key to return to the measurement mode.

(8) Press the Mode key to display the setup for output

values of the data to be corrected.

Note: For a single display unit, the unit

automatically returns to N-01 indication if there is

no key operation for about 8 seconds. In this case,

press the Mode key to return to the numeric value

indication.

&

(5) For a single display unit, press the Mode key to

change to the parameter information indication.

(6) Press the Shift key (change digit) and Increment

key (change numeric value) and then press the Mode

key after the N-01 input value has been set.

RE

Note: For a single display unit, RE flashes when

the input value is set and DZ flashes when the

output value is set.

DZ

&

(7) Press the Shift key (change digit) and Increment

key (change numeric value) and then press the Mode

key after the N-01 output value has been set.

RE

Note: For a single display unit, the unit is

automatically returned to N-02 indication if there is

no key operation for about 8 seconds. In this case,

press the Mode key to return to the numeric value

indication.

(9) Press the Shift key (change digit) and Increment

key (change numeric value) and then press the Mode

key after the N-02 input value has been set.

Repeat steps (5) to (9) until all the settings have

been made.

Multi-display unit Single display unit

Indication Name value as 01 02 03 04 05 06 07 08 09 10 11 12 13 14 15 16 17 18 0 1 2 3 4 5

PVH Peak hold setup PH

RANG Measurement range setup *1 X

AVG Number of averaging 1

MAV Number of moving averaging setup OFF

S.UD Step wide setup 1

BLNK Indication blank setup OFF

UNIT Unit setup C X X X X X X X X X X X X

BAUD Baud rate setup 9600 X X X

DATA Data length setup 7 X X X

P.BIT Parity bit setup E X X X

S.BIT Stop bit setup 2 X X X

T- Delimiter setup CR.LF X X X

ADR Equipment ID setup 00 X X X X

A.OUT Analog output setup OFF X X

B.UP Digital zero backup setup OFF

LINE Linearization setup CLR

I.SEL Input selection OC X X X X X X X X X X X X X X

TR T Tracking zeroing time setup 00

TR V Tracking zeroing width setup *2 01

SNSR Sensor power setup 10 X X X X X X X X X X X X X X X X

P

PRO Protect setup OFF

U-NO. Unit number Indication setup ON

S-HI HI side judgment value setup 1000 X

S-LO LO side judgment value setup 500 X

H-HI HI side hysteresis setup 0 X

H-LO LO side hysteresis setup 0 X

FSC Full scale Indication value setup *1

FIN Full scale input value setup *1

OFS Offset indication value setup *1

OIN Offset input value setup *1

PS Pre-scaling value setup 1 X X X X X X X X X X X X X X

PPR Frequency division setup 1 X X X X X X X X X X X X X X

DLHI Digital limiter HI value setup 9999

DLLO Digital limiter LO value setup -9999

AOHI Analog output HI indication setup 9999 X X

AOLO Analog output LO indication setup 0 X X

DEP Decimal point position setup None

ZERO Zero input value *6 0 X X X X X X X X X X X X X X X X

SPIN Span input value *6 2000 X X X X X X X X X X X X X X X X

SPAN Span indication 9000 X X X X X X X X X X X X X X X X

SHF Shift data setup 0

*1 Each value in the lower part of a cell in the columns on the right is the default value.

*2 Tracking zero width setup parameter is not indicated if the tracking time is set to OFF(0).

*3 5000 for 1 V range and 2000 for 2 A range

*4 1000 for 1 V range and 400 for 2 A range

*5 Linearization data are not set up for the default values.

*6 This value is not indicated if calibration is done using an actual load.

Shift data

Condition data

Com

p

arator data

Scalin

g

data

Page 9

Range

Measurement

range

Indication

Highest

resolution

Input

impedance

Maximum

permissible

input

Accuracy

11 99.99mV

Offset : ± 9999

Full scale : 0 to ± 9999

100µV

1M!

or more

± 100V

± (0.2% of FS

+10digit)

Input circuit : Single ended type

12

9.999V 1mV ± 250V13

Operating system : " # conversion

Maximum sampling rate : 12.5 times per second

Frequency range : 40 Hz to 1 kHz

Response speed : About 1 second

Dead zone : 0 to 99 digits

999.9mV

10µV

Range

Measurement

range

Indication

Highest

resolution

Input

impedance

Maximum

permissible

input

Accuracy

14 99.99V

Offset : ± 9999

Full scale : 0 to ± 9999

100mV

1M!

or more

250V

± (0.2% of FS

+10digit)

Input circuit : Single ended type

15

Operating system : " # conversion

Maximum sampling rate : 12.5 times per second

Frequency range : 40 Hz to 1 kHz

Response speed : About 1 second

Dead zone : 0 to 99 digits

600V

10mV

600V

± (0.3% of FS

+10digit)

Range

Measurement

range

Indication

Highest

resolution

Input

impedance

Maximum

permissible

input

Accuracy

11 99.99mV

Offset : ± 9999

Full scale : 0 to ± 9999

100µV

1M!

or more

± 100V

± (0.2% of FS

+20digit)

12

9.999V 1mV ± 250V13

999.9mV

10µV

Input circuit : Single ended type

Operating system : " # conversion

Maximum sampling rate : 12.5 times per second

Frequency range : 40 Hz to 1 kHz

Response speed : About 1 second

Dead zone : 0 to 99 digits

Crest factor : 4:1 at full scale

Range

Measurement

range

Indication

Highest

resolution

Input

impedance

Maximum

permissible

input

Accuracy

14 99.99V

Offset : ± 9999

Full scale : 0 to ± 9999

100mV

1M!

or more

250V

± (0.2% of FS

+20digit)

Input circuit : Single ended type

15

Operating system : " # conversion

Maximum sampling rate : 12.5 times per second

Frequency range : 40 Hz to 1 kHz

Response speed : About 1 second

Dead zone : 0 to 99 digits

600V

10mV

600V

± (0.3% of FS

+20digit)

Crest factor : 4:1 at full scale

Range

Measurement

range

Indication

Highest

resolution

Input

impedance

Maximum

permissible

input

Accuracy

23 9.999mA 1µA

About

10

!

100mA

Offset : ± 9999

Full scale : 0 to ± 9999

± (0.5% of FS

+10digit)

500mA

3A

About

1!

About

0.1!

10µA99.99mA

999.9mA 100µA

24

25

Input circuit : Single ended type

Operating system : " # conversion

Maximum sampling rate : 12.5 times per second

Frequency range : 40 Hz to 1 kHz

Response speed : About 1 second

Dead zone : 0 to 99 digits

Crest factor : 4:1 at full scale

Range

Measurement

range

Indication

Highest

resolution

Input

impedance

Maximum

permissible

input

Accuracy

26 5A 1mA (CT) 8A

Offset : ± 9999

Full scale : 0 to ± 9999

± (0.5% of FS

+10digit)

Input circuit : CT isoration type

Operating system : " # conversion

Maximum sampling rate : 12.5 times per second

Frequency range : 50 Hz or 60Hz

Response speed : About 1 second

Dead zone : 0 to 99 digits

Crest factor : 4:1 at full scale

Range

Measurement

range

Indication

Highest

resolution

Input

impedance

Maximum

permissible

input

Accuracy

23 9.999mA 1µA

About

10!

100mA

Offset : ± 9999

Full scale : 0 to ± 9999

± (0.5% of FS

+20digit)

500mA

3A

About

1

!

About

0.1

!

10µA99.99mA

999.9mA 100µA

24

25

Input circuit : Single ended type

Operating system : " # conversion

Maximum sampling rate : 12.5 times per second

Frequency range : 40 Hz to 1 kHz

Response speed : About 1 second

Dead zone : 0 to 99 digits

Crest factor : 4:1 at full scale

Range

Measurement

range

Indication

Highest

resolution

Input

impedance

Maximum

permissible

input

Accuracy

26 5A 1mA (CT) 8A

Offset : ± 9999

Full scale : 0 to ± 9999

± (0.5% of FS

+20digit)

Input circuit : CT isoration type

Operating system : " # conversion

Maximum sampling rate : 12.5 times per second

Frequency range : 50 Hz or 60Hz

Response speed : About 1 second

Dead zone : 0 to 99 digits

Crest factor : 4:1 at full scale

Range

Measurement

range

Indication

Highest

resolution

Circuit

current

Accuracy

11 99.99!

Offset : ± 9999

Full scale : 0 to ± 9999

10m!

About

5mA

± (0.2% of FS)

Input circuit : Single ended type

12 999.9!

13149.999k!

99.99k!

Operating system : " # conversion

Maximum sampling rate : 12.5 times per second

100m!

1!

10!

About

500µA

About

50µA

About

5µA

Measuring system : Two-wire system or four-wire system

Open-circuit voltage : About 5 V

(internal socket change-over)

Range

Input

sensor

Indication

Highest

resolution

Accuracy

KA

0.1°C

(0.1°F)

± (0.5% of FS)

Input circuit : Single ended type

KB

J

T

Operating system : " # conversion

Maximum sampling rate : 6.25 times per second

S

R

B

K

J

T

S

R

B

K

-50.0 to 199.9°C

(-58.0 to 391.8°F)

-50 to 1200°C

(-58 to 2192°F)

-50 to 1000°C

(-58 to 1832°F)

-50 to 400°C

(-58 to 752°F)

0 to 1700°C

(32 to 3092°F)

-10 to 1700°C

(14 to 3092°F)

100 to 1800°C

(212 to 3272°F)

1°C

(1°F)

± (0.2% of FS)

± (0.6% of FS)

± (0.4% of FS)

Note : The accuracy of range B is applicable

to temperatures of 500°C or more.

± (0.4% of FS)

Cold junction compensation error : ± 2 °C(at 10 through 40°C)

Burnout alarm : It blinks by ---- display.

Internal resistance of sensor : 50! or less

Linearizer : Digital linearizer

8. 1.4 AC Volt ag e Measur in g Unit (ave rage value detection : ranges

11 to 13)

8. 1.5 AC Volt ag e Measur in g Unit (ave rage value detection : ranges

14 and 15)

8. 1.6 AC Vo lta ge Measuring Unit (true rms value: rang es 11 to 13)

8. 1.7 AC Voltage Measuring Uni t (tru e rms val ue : rang es 14 and

15 )

8. 1.8 AC Current Measuring Unit (aver age value detec tion: ranges

23 to 25 )

8. 1. 9 AC C urr en t M eas ur ing Un it (a ver ag e v alu e det ect io n: ra nge

26 )

8.1 .10 AC Current Measur ing U nit ( tr ue rm s val ue : ran ges 2 3 to 25 )

8.1. 11 AC Current Measur in g Unit (tru e rms value: ran ge 26)

8.1. 12 Res ist an ce Mea sur in g Unit

8.1 .1 3 Temperature Mea suring Unit (TC )

Page 10

3.3 .1 0 Te mp erature Measu ri ng Unit (RTD)

3.3.11 Frequency Measuring Unit (Open collector, logic, and magnet)

3.3 .1 2 Freque nc y Mea su ring Unit (500 Vrms)

3.3 .13 Strain Gauge Input Unit (Load cell)

3.3.14 Pro ce ss Sig na l Me as ur ing Unit

3.4 Comparison Output

1 2 3

1 2 3

1 2 3 4 5

1 2 3

12 13 14 15 16 17 18 19

Range

Input

sensor

Indication

Highest

resolution

Accuracy

PA

0.1°C

(0.1°F)

± (0.15% of FS)

Input circuit : Single ended type

JPA

PB

JPB

Operating system : " # conversion

Maximum sampling rate : 12.5 times per second

PT100!

JPt100!

-100.0 to 199.9°C

(-148.0 to 391.8°F)

-100 to 600°C

(-148 to 1112°F)

1°C

(1°F)

± (0.3% of FS)

JPt100!

PT100!

Current through RTD : About 1 mA

External resistance : 10! or less per wire

Linearizer : Digital linearizer

Burnout alarm : It blinks by ---- display.

Range

Indication

Highest

resolution

Accuracy

11

12

13

14

0.1 to 200Hz

1 to 2000Hz

Pre-scale : 0.001 to 5

Frequency division : 1 to 100

0.1Hz

± (0.2% of FS)

0.01 to 20kHz

Measurement

range

0.1 to 200kHz

1Hz

10Hz

100Hz

0 to 10s

1s

100ms

Renewal

time of a

display

Input type Input voltage lebel

Maximum

permissible input

Voltage

500Vrms

Duty ratio : 50%

50 to 500Vrms

Sensor

power

Highest

resolution

Accuracy

5V

10V

-0.3 to +2mV/V

0.5µV/digit

± (0.1% of FS +2digit)

Zero adjusting range

Span adjusting range

1 to 3mV/V

1µV/digit

Input circuit : Single ended type

Operating system : " # conversion

Maximum sampling rate : 12.5 times per second

Noise rejection ratio : NMR (normal mode rejection) 50 dB or more (50 or 60 Hz)

Range

Measurement

range

Indication

Input

impedance

Maximum

permissible

input

Accuracy

1V

1 to 5V

Offset : ± 9999

Full scale : 0 to ± 9999

About

100M

!

± 100V

± (0.2% of FS)

2A 4 to 20mA

About

10

!

± 100mA

Input circuit : Single ended type

Operating system : " # conversion

Maximum sampling rate : 12.5 times per second

Noise rejection ratio : NMR (normal mode rejection) 50 dB or more (50 or 60 Hz)

Instruction Manual for FD5000 Series 3/12Instruction Manual for FD5000 Series 10/12

8.1.14 Temperat ure Measuri ng Unit (RTD)

8.1 .15 Fre quenc y Mea surin g Uni t (op en co llect or, l ogic, and magne t)

8.1 .16 Frequ ency Measu ring Unit (500 Vrms)

8.1.17 Str ain Gage Unit

8.1.18 Process Sig na l Measuring Unit

8.2 Common Specifications

8.3 Output Specifications

8.3 .1 Output for Comparis on

Range

Indication

Highest

resolution

Accuracy

11

12

13

14

0.1 to 200Hz

1 to 2000Hz

Pre-scale : 0.001 to 5

Frequency division : 1 to 100

0.1Hz

±(0.2% of FS)

0.01 to 20kHz

Measurement

range

0.1 to 200kHz

1Hz

10Hz

100Hz

0 to 10s

1s

100ms

Renewal

time of a

display

Input type

Input voltage lebel

Maximum

permissible input

Open collector

Logic

Magnet

LO : 1V or less (5V : 2.2k ! pull up)

LO : 1V or less,HI : 2.5 to 15V

0.3 to 30Vp-p

30V

15V

Duty ratio : 50%

7-segment LED display (character height : 14.2 mm on main

display and 8 mm on sub-display)

Automatically indicated when the calculated result is

negative.

OL or -OL for input signals outside the indication range

-9999 to 9999

Leading zero suppression

HOLD, PH, DZ (reset for frequency measuring unit)

-10 to 70 °C, 60% RH or less

100 to 240 V AC ± 10% for AC power supply unit

9 to 50 V DC for DC power supply unit

Approx. 5 W

96 mm (W) x 48 mm (H) x 146.5 mm (D)

Note : Depth (D) denotes the maximum value.

Weight :

2000 V AC for 1 min. between power terminals and

input terminal, and between power terminals and each

output terminal (AC power supply)

500 V DC for 1 min. between power terminals and input

terminal, and between power terminals and each output

terminal (DC power supply)

100 M! between the above terminals when 500 V DC

is a

pp

lied

500 V DC for 1 min. between input terminal and each

output terminal, and between analog output terminal and

communication terminals

2000 VAC for 1 min between case and each output

terminal (common to both AC and DC supply)

Display :

Polarity indication :

Indication range :

Over-range alarm :

Decimal point :

Can be set at an arbitrary digit.

Zero indication :

External control :

Operating temperature and humidity range :

0 to 50°C, 35 to 83% RH

(non-condensing)

Storage temperature and humidity range :

Power supply :

Power consumption :

External dimensions :

450g

Withstand voltage :

Withstand voltage

:

:

Withstand voltage

Insulation

resistance

:

Conditions for comparison

Indicated value > Upper limit judgment value

Judgment

result

HI

Lower limit judgment value $ Indicated value $ Upper limit judgment value GO

Lower limit judgment value > Indicated value LO

Control system : Micro computer operating system

Judgment value setup range :-9999 to +9999

Hysteresis : Can be set in the range of 1 to 999 digits for each judgment

value

Operating speed : Depends on the sampling rate.

Output method : Relay contact output (Make and break contacts for HI and

LO and make contacts for GO)

Output rating : 240 V AC, 8 A (resistive load) and 30 V DC, 8 A (resistive

load)

1 2 3 4 5

Page 11

Output type

Load resistance

Accuracy

Ripple

0 to 1V

0 to 10V

1 to 5V

4 to 20mA

10k! or more

10k! or more

10k! or more

550! or less

± (0.5% of FS)

± 50mVp-p

± 25mVp-p

Note : The ripple ratings for the 4-20 mA output are when the load resistance

of 250

! and the output current of 20 mA are applied.

Conversion system : PWM conversion

Resoluton : Equivalent to 13 bits

Scaling : Digital scaling

Response speed : About 0.5 second

Instruction Manual for FD5000 Series 11/12Instruction Manual for FD5000 Series 2/12

Synchronization system

BCC (block, check, and character)

check sum

Stop bit

Character code

Communication control

procedure

Signal name used TXD,RXD,SG

Non-inversion (+)

and inversion (-)

Number of connectable

units

1

Line length 15m Up to 500 m (total)

Delimiter CR+LF/CR

7 bits/8 bits

Even parity/odd parity/non-parity

1 bit/2 bits

ASCII code

No procedure

Error detection

RS-232C RS-485

Start and stop synchronization

Full duplexCommunication system

Communication rate

38400bps/19200bps/9600bps/4800bps/2400bps

Start bit 1bit

Data length

Two-wire half duplex

(Polling selecting system)

1 Up to 31 meters

lo g Out put

8. 3.3 Co mmu nic ati ng F unc tio n

8.4 External Dimensions

9. Warranty and After-service

9.1 Warranty

The warranty period shall be one year from the date of delivery. Any failure

that arises during this period and the cause thereof is judged to be obviously

attributable to Fuji Electric Instruments Co., Ltd. shall be remedied at no

cost.

9.2 After-service

This product is manufactured, tested, inspected, and then shipped under

stringent quality control. Should the product fail, however, contact (or

send the product to) your vendor or Fji Electric Instruments directly. (It

is advisable that you send a memo describing the failure in as much detail

as possible along with the product returned.)

Page 12

1. Before Using the Product

Thank you for purchasing the FD5000 series. This manual should be passed

on to the person who operates the product. Examine the product for dam-

age caused by transportation or any other defects. If you find any damage or

defects, contact the sales agent from which you purchased the product or

Fuji Electric Instruments Co., Ltd.

1.1 Model Codes

The model lineup of the FD5000 series is shown below. Check that the

model code and specifications of your product match those you specified

when ordering.

Instruction Manual for FD5000 Series 1/12

(UU- 33 554 )

2002.09

Fuji Electric Instruments Co.,Ltd.

International Sales Dept.

No.1,Fuji-machi,Hino-city,Tokyo,191-8502 Japan

Phone +81-42-585-6201,6202

Fax +81-42-585-6187

Instruction Manual for FD5000 Series UU-33555a 12/12

F 5 X X X - X X

D

(1) Do not apply a voltage or current exceeding the maximum allowable

value; otherwise, it may damage the equipment.

(2) Use a power voltage within the operation range; otherwise, it may

result in a fire, electrical shock, or malfunction.

(3) The contents of this manual are subject to change without notice.

Although the contents of this manual have been prepared with extra

care, if you have any questions, or find errors or missing

information, contact the sales agent from which you purchased the

product or Fuji Electric Instruments Co.,Ltd.

(4)

After reading this manual thoroughly, keep it in a convenient place

for future reference.

(5)

Loading...

Loading...