Page 1

CC-M MULTI-LOOP CONTROLLER

FOUR COMPLEX PROCESSES. ONE SIMPLE SOLUTION.

Fuji Electric brings its extensive knowledge and experience in process control instrumentation into the new, state-of-the-art multi-

loop process controller, the CC-M. Intelligent integration of control and communications is the hallmark of this unique controller.

It is one of the most compact in the industry for a controller with this much sophistication and flexibility. Get up to four control

loops with a variety of control methods, advanced network features, extensive I/O expansion, data-logging with robust storage,

and user-friendly 16-color LCD display — all for a price that is unbeatable. CC-M is used in water treatment, combustion furnace,

multi-point gas analysis, chemical injection and incineration systems, to name a few.

• Multiple Loops

Up to 4 control loops, with 4 control outputs and 8 PID blocks.

• Choice of Several Control Methods

Single loop, multi-loop, cascade, ratio, PLC.

• Program Loader

Program via PC using exclusive loader software

• Advanced Network Interface

Connect multiple units with PC, PLC or to several I/O modules

• Data-Logging

Sample and store up to 1.35 million data points

• Colorful Graphical Display

16-color back-lit LCD; view trends, bar graphs, parameter menu, process status, etc.

• Back-Up Operation

Back-up unit takes over control if main unit fails

Information subject to change without notice. Prices in USD.

Page 2

CC-M, CONTINUED

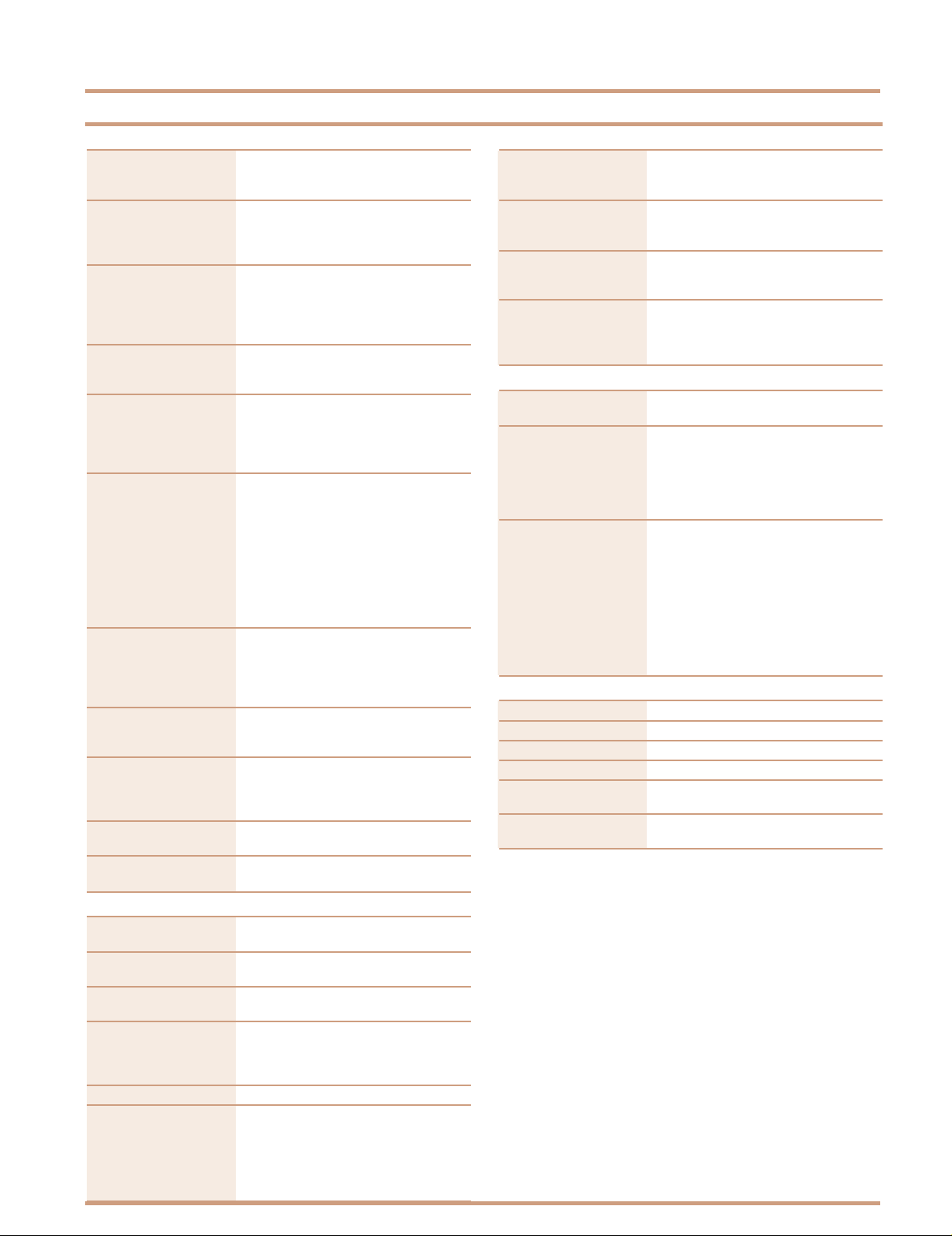

CC-M SPECIFICATIONS

GENERAL

NUMBER OF LOOPS & PID 1 Loop: 1 control output/2 PID

(Selectable from the 2 Loops: 2 control outputs/4 PID

following) 4 Loops: 4 control outputs/8 PID

PROGRAMMING METHOD Control and computation functions are

implemented by combining function software

modules called Wafers. Configuration could be

performed from the keypad or from a PC.

PROGRAM CAPACITY 48 Wafers x 4 loops (max. 192 wafers); 2ksteps

of ladder. Wafer types include Primary PID,

Secondary PID, Arithmetic and Logic operators,

Square-root extraction, Ramp function, Averaging,

Sample & hold, Pulse width modulation, etc.

PROGRAMMING LOADER Wafer connections and operating parameters

SOFTWARE can be entered, edited, uploaded or downloaded

from a PC

SOFT PLC Using a PC-based configuration software such as

ISaGRAF®, PLC control can be implemented.

CC-M supports three IEC61131-3-based formats–

Ladder, Sequential Function and Function Block,

Structured Text, and Instruction List

DISPLAY 16-color graphic LCD with CFL back-light and

contrast adjustment. CC-M has three kinds of

menu screens for set-up and monitoring.

Menu 1: Select from Loop Panel screen, Bar graph

display, trend screen, Alarm status display, Analog

and digital input/output indication screen.

Menu 2: 8 different parameter setting screens

Menu 3: 5 different screens for wafer connection,

system definition, function definition and

communication setting.

BACK-UP OPERATION An optional back-up unit can be installed. In case

of a fault condition in the main unit, a balanceless

and bumpless transfer of control from the main

unit to the back-up unit can be achieved for

manual control of the process outputs.

DATA STORAGE Data from 32 different trends can be sampled

simultaneously and stored on compact flash

memory cards.

MEMORY CARD INTERFACE Capacity: 4, 20, 30 MB (30MB holds 1.35 million

data points)

Sampling Frequency: 1 second to 2 hrs.

Storage Format: ASCII

POWER SUPPLY VOLTAGE 85 to 26VAC, 47 to 63 Hz. 20 to 30 VDC (option)

RANGE

POWER CONSUMPTION 60 VA or less( 85 to 264 VAC). 30Ωor less

(20 to 30 VDC)

INPUT

NUMBER OF INPUTS 8 process inputs, or 6 process inputs and 2

temperature inputs, 10 digital inputs

PROCESS INPUTS 0 to 5 VDC, 1 to 5 VDC (default) and 0 to 10VDC.

For mA input, a 250Ω shunt resistor is required

TEMPERATURE INPUTS Thermocouple: J, K, R, B, T, E, S, N, U, WRe5-26,

PL II. RTD: Pt100

INPUT ACCURACY Process Inputs: ±0.1% of full span (FS) ±1 digit

Thermocouple: ±0.2% FS ±1 digit; B type – ±5%

for 0-400°C, S; R type – ±1% for 0-500°C

RTD: ±0.2% FS ±1 digit

INPUT SAMPLING TIME 100 ms

DIGITAL INPUTS 10 digital inputs available. No-voltage contact or

transistor input

Contact Rating: 30 VDC, 10mA

No-Voltage Contact Resistance: 200Ωor less

at ON. 100kΩ or more at OFF

Transistor Contact: 0V at ON, 24V at OFF, 8mA

Information subject to change without notice. Prices in USD.

OUTPUT

NUMBER OF OUTPUTS Up to 4 analog control outputs available,

one for each loop. 4 auxiliary analog outputs,

10 digital outputs

CONTROL OUTPUTS 4 to 20mA DC

Accuracy: ±0.2% FS

Load Resistance: 600Ω or less

AUXILIARY ANALOG 0 to 5V, 1to 5V, or 0 to 10 VDC

OUTPUTS Accuracy: ±0.1% FS

Load Resistance: 15kΩ or more

DIGITAL OUTPUTS Transistor open collector

1 V max. at ON, 10 mA max at. OFF

Output Rating: 30 VDC, 100mA max.

(resistive load)

COMMUNICATIONS

SIMULTANEOUS NETWORK CC-M can have two kinds of network interfaces

INTERFACE simultaneously — High-level and Low-level

HIGH-LEVEL NETWORK Allows CC-M to communicate with PC, PLC or

INTERFACE other controllers

Communication Protocol: Modbus®

Mode: EIARS-485, multi-drop, half-duplex,

bit-serial, 19.2kbps.

Number of Connectable Units: Max. 31 units

LOW-LEVEL NETWORK Allows CC-M to expand the number of

INTERFACE inputs/outputs

Communication Protocol: OPTO22® MISTIC

Mode: EIARS-485, half-duplex, bit-serial,

57.6kbps.

I/O Expansion: Max. 4 analog I/O;

Max. 32 digital I/O

I/O Modules: OPTO22 SNAP I/O® series.

Total number of connectable units depend on

the number of I/O points.

STRUCTURE

DIMENSIONS 72 x 144 x 280 mm (panel cutout: 68 x 138 mm)

WEIGHT 1.9 kg

PROTECTION IP54 (front face)

FLAME RESISTANCE UL94V-0

GENERAL SAFETY Conforms to IEC1010-1 (1990),

EN 61010-1 (1993)

EMC Emission EN 50081-2 (1994),

Immunity EN 50082-2 (1995)

Page 3

CC-M, CONTINUED

CC-M ORDERING INFORMATION

P D 3A A 2 B 1 C C D E E F 0

To create a part number fill in the boxes above with the appropriate number and/or letter from the corresponding box below.

Box A: Number of Control Loops

1 = 1 Loop $ 1,450

2 = 2 Loops 1,950

4 = 4 Loops 2,700

Number of control loops is the number of 4-20mA ‘control’ outputs.

Box B: Input Signal

A = DC 1–5V/4–20mA DC* N/C

C = Thermocouple** 180

D = RTD/Pt100** 180

* For current input, a precision 250Ωshunt resistor is used,

one per loop is included. Additional resistors are available.

** Thermocouple or RTD inputs are optional. If more are desired,

external transducers should be used.

Box C: Power Supply Voltage

A = 100–240 VAC N/C

B = 24 VDC N/C

Box D: Hard Manual Back-Up Unit

Y = None N/C

A = 1 Loop 180

B = 2 Loops 295

C = 4 Loops 355

Box E: Communications/Memory Card

Interface

Code = MODBUS RS-485 / OPTO22 / Memory Card Interface

Y = Without / Without / Without N/C

M = Without / Without / With $ 85

C = RS485 / Without / Without 74

U = RS485 / Without / With 158

D = RS485 / RS485 / Without 279

R = RS485 / RS485 / With 355

• Communication cable and impedance terminators are optional items.

• RS-485 communications uses Modbus protocol. OPTO 22 option

does not include modules. These are sold separately. To use OPTO 22

equipment, a brain module, module rack, and at least one module

must be purchased.

• Memory Card option only records trend data using standard

compact-flash type memory cards. Cards up to 32MB can be used

and are available as COMPACT FLASH_MB.

Box F: Programming Method

1 = Wafer N/C

2 = Soft PLC Function (ISaGRAF)* 60

* ISaGraf conforms to IEC1131. ISaGRAF programming tool is

optional item. Soft PLC and Wafer programming cannot function

simultaneously. To change programming method between ‘Wafer’

and ‘Soft PLC’, hardware modification is required.

CC-M ACCESSORIES

COMPACT FLASH CARD 16MB $ 85

COMPACT FLASH CARD 32MB 160

COMPACT FLASH CARD READER: PARALLEL PORT 90

CC-M LOADER SOFTWARE* N/C

CC-M LOADER CABLE (SERIAL PORT CONNECTION)* 35

SNAP-B3000-ENET OPTO 22 BRAIN** 695

SNAP-B8M OPTO 22 8-Module Rack 94

SNAP-B16M OPTO 22 16-Module Rack 161

SNAP-AOA-3 OPTO 22 Single-Channel 4–20mA AO 150

SNAP-AIV OPTO 22 2-Channel -10 to +10 VDC AI 182

SNAP-ODC5SRC OPTO 22 4-Channel DC Out. 5–60 VDC, 5 VDC logic source 42

SNAP-ODC5SNK OPTO 22 4-Channel DC Out. 5–60 VDC, 5 VDC logic source 42

SNAP-IDC5 OPTO 22 4-Channel Input. 10–32 VDC, 5 VDC logic 42

* CC-M Loader Cable to be used with software for uploading and downloading programs from the PC to the CC-M.

** To use the OPTO 22 functions, customers must purchase at the minimum, a brain, a rack, and an input or output module.

Information subject to change without notice. Prices in USD.

Loading...

Loading...