Frymaster VT Service Manual

VT SERIES VERTICAL TOASTER

SERVICE MANUAL

This equipment chapter is to be inserted in

the Equipment Manual

MANUFACTURED

EXCLUSIVELY FOR

McDONALD’S

BY FRYMASTER, L.L.C.

P.O. BOX 51000

SHREVEPORT, LOUISIANA 71135-1000

PHONE 1 (318) 865-1711

1 (800) 24 FRYER

®

TABLE OF CONTENTS

1. WARRANTY STATEMENT ..............................................................................................................................1

1.1 WARRANTY PROVISIONS – VERTICAL TOASTER............................................................................ 1

1.2 PARTS RETURN .................................................................................................................................... 1

1.3 WARRANTY EXCLUSIONS ................................................................................................................... 1

2. PARTS ORDERING AND SERVICE INFORMATION.....................................................................................2

3. VERTICAL TOASTER OPERATIONAL DESCRIPTION ................................................................................3

4. INSTALLATION/SETUP ..................................................................................................................................3

5. OPERATION.....................................................................................................................................................3

6. VIEWING AND ADJUSTING THE SETPOINT ................................................................................................4

7. ADJUSTING BUN COMPRESSION ................................................................................................................4

8. CHANGING BELTS .........................................................................................................................................5

9. OPERATOR TROUBLESHOOTING................................................................................................................6

10. PREVENTIVE MAINTENANCE .......................................................................................................................6

11. SERVICE INFORMATION................................................................................................................................7

11.1 INTRODUCTION .................................................................................................................................... 7

11.2 PARTS LIST ...........................................................................................................................................8

11.3 SERVICE PROCEDURES.................................................................................................................... 17

11.4 TECHNICIAN TROUBLESHOOTING ..................................................................................................22

11.5 PROBE RESISTENCE CHART............................................................................................................ 24

11.6 WIRING DIAGRAMS ............................................................................................................................25

11.7 SCHEMATIC ........................................................................................................................................ 27

Frymaster L.L.C., 8700 Line Avenue 71106, P.O. Box 51000, Shreveport, Louisiana 71135-1000

TEL 318-865-1711 FAX (Parts) 318-219-7140 (Tech Support) 318-219-7135

Printed in the United States Service Hotline 819-5921 June 2003

1-800-24-FRYER

*8195921*

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN

THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

DO NOT OPERATE OR SERVICE THE VERTICAL TOASTER WITHOUT FIRST READING

THIS MANUAL

DO NOT OPERATE THE VERTICAL TOASTER UNLESS IT HAS BEEN PROPERLY

INSTALLED AND CHECKED.

DO NOT OPERATE THE VERTICAL TOASTER UNLESS ALL COVERS AND ACCESS

PANELS ARE IN PLACE AND PROPERLY SECURED.

DO NOT ATTEMPT TO REPAIR OR REPLACE ANY COMPONENT OF THE VERTICAL

TOASTER UNLESS ALL POWER TO THE UNIT HAS BEEN DISCONNECTED.

USE CAUTION WHEN SETTING UP, OPERATING, OR CLEANING THE VERTICAL

TOASTER TO AVOID CONTACT WITH HEATED SURFACES.

HAZARD COMMUNICATION STANDARD (HCS) – THE PROCEDURES IN THIS MANUAL

INCLUDE THE USE OF CHEMICAL PRODUCTS. THESE CHEMICAL PRODUCTS WILL

BE PRINTED IN BOLD FACE, FOLLOWED BY THE ABBREVIATION (HCS) IN THE TEXT

PORTION OF THE PROCEDURE. SEE THE HAZARD COMMUNICATION STANDARD

(HCS) MANUAL FOR THE APPROPRIATE MATERIAL SAFETY DATA SHEET(S) (MSDS).

1. WARRANTY STATEMENT

The Frymaster Corporation makes the following limited warranties to the original purchaser only for this

equipment and replacement parts:

1.1 WARRANTY PROVISIONS – VERTICAL TOASTER

A. The Frymaster Corporation warrants all components against defects in material and workmanship

for a period of 1 year.

B. All parts, with the exception of belts, are warranted for 1 year after installation date of toaster.

(Belts are consumable items.)

C. If any parts become defective during the first year after installation date, Frymaster will also pay

straight-time labor costs to replace the part, plus up to 100 miles/160 km of travel (50 miles/80 km

each way).

1.2 PARTS RETURN

All defective in-warranty parts must be returned to a Frymaster Factory Authorized Service Center

within 60 days for credit. After 60 days, no credit will be allowed.

1.3 WARRANTY EXCLUSIONS

This warranty does not cover equipment that has been damaged due to misuse, abuse, alteration, or

accident such as:

• improper or unauthorized repair;

• failure to follow proper installation instructions and/or scheduled maintenance procedures as

prescribed in your MRC cards;

• improper maintenance;

• damage in shipment;

• abnormal use;

• removal, alteration, or obliteration of the rating plate.

This warranty also does not cover:

• transportation or travel over 100 miles/160 km (50 miles/80 km each way), or travel time over

two (2) hours.

• overtime or holiday charges;

• consequential damages (the cost of repairing or replacing other property which is damaged);

loss of time, profits, use or any other incidental damages of any kind.

There are no implied warranties of merchantability or fitness for any particular use or purpose.

For international warranty, the above procedures apply, except that the customer is responsible for

freight and duty charges.

NOTICE

IF, DURING THE WARRANTY PERIOD, THE CUSTOMER USES A PART FOR THIS ENODIS

EQUIPMENT OTHER THAN AN UNMODIFIED NEW OR RECYCLED PART PURCHASED

DIRECTLY FROM FRYMASTER/DEAN, OR ANY OF ITS AUTHORIZED SERVICE CENTERS,

AND/OR THE PART BEING USED IS MODIFIED FROM ITS ORIGINAL CONFIGURATION, THIS

WARRANTY WILL BE VOID. FURTHER, FRYMASTER/DEAN AND ITS AFFILIATES WILL NOT BE

LIABLE FOR ANY CLAIMS, DAMAGES OR EXPENSES INCURRED BY THE CUSTOMER WHICH

ARISE DIRECTLY OR INDIRECTLY, IN WHOLE OR IN PART, DUE TO THE INSTALLATION OF

ANY MODIFIED PART AND/OR PART RECEIVED FROM AN UNAUTHORIZED SERVICE CENTER.

Service Hotline

1-800-24-FRYER

Page 1

2. PARTS ORDERING AND SERVICE INFORMATION

Parts orders may be placed directly with your local Frymaster Factory Authorized Service Center

(FASC)/Distributor. A list of Frymaster FASCs was included with the unit when shipped from the

factory. If you do not have access to this list, contact the Frymaster Service Department at 1-800-24FRYER or 1-318-865-1711.

To speed up your order, the following information is required:

Model Number

Serial Number

Voltage

Part Number

Quantity Needed

Service may be obtained by contacting your local FASC or Distributor. Service information may be

obtained by calling the Frymaster Service Department. The following information will be needed in

order to assist you quickly and efficiently.

Model Number

Serial Number

Nature of Problem

Also include any other information which may be helpful in solving your service problem.

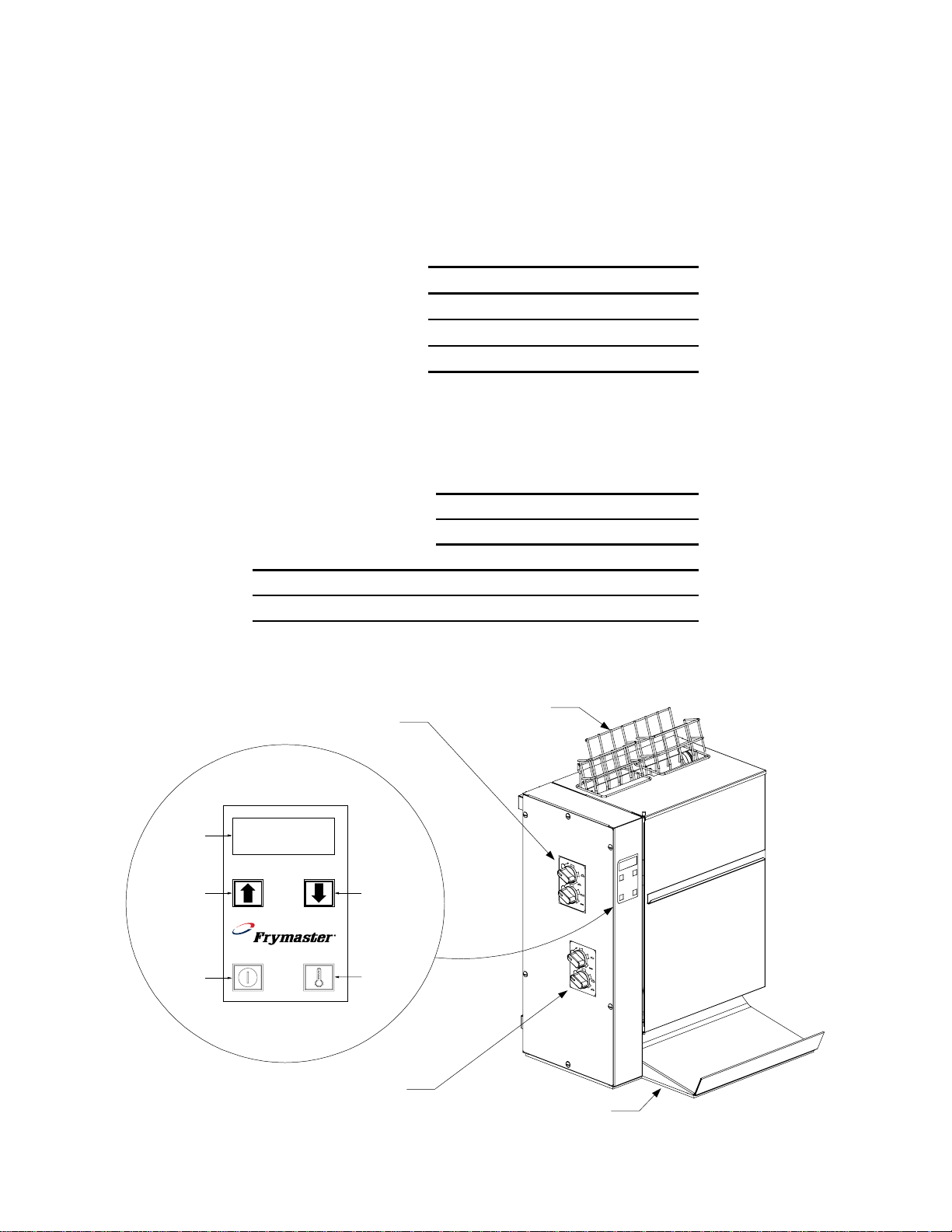

LED

DISPLAY

RAISE

SETPOINT

BUTTON

ON/OFF

BUTTON

REDY

Upper

Compression

Adjustment

Knobs

LOWER

SETPOINT

BUTTON

DISPLAY

TEMPERATURE

BUTTON

Lower

Compression

Adjustment

Knobs

Bun Guide for Heel

and Crown Slots

Heated Holding Tray

Page 2

Service Hotline

1-800-24-FRYER

3. VERTICAL TOASTER OPERATIONAL DESCRIPTION

The Vertical Toaster is designed to produce fresh, uniformly toasted buns on an "as needed” basis.

The countertop-mounted unit consists of a cabinet, a computer, a heating element and a pair of

conveyor assemblies.

When the unit is turned on, an electrical heating element (called a platen) is energized. The platen

heats up to a programmed temperature referred to as the setpoint. At the same time, both conveyor

assemblies are activated. When a bun is placed into one of the slots at the top of the cabinet, the

conveyor belts gently carry it through the unit, with the cut face of the bun passing over the heated

platen. As the bun passes over the platen, it is toasted. At the end of the process, the bun is deposited

onto a heated holding tray that keeps it warm until it is used in a sandwich.

The computer allows the operator to adjust the setpoint to obtain desired toasting characteristics.

Compression adjustment knobs also allow the operator to adjust the compression of heels and crowns

as they pass through the toaster.

4. INSTALLATION/SETUP

Upon arrival, inspect the toaster for concealed damage. Immediately report any damage to the

delivering freight company. Claims must be filed within 15 days after receipt of the unit.

Power Requirements:

ALL ELECTRICALLY OPERATED APPLIANCES MUST BE ELECTRICALLY GROUNDED IN ACCORDANCE WITH LOCAL CODES, OR

PLUGGED INTO A PROPERLY GROUNDED RECEPTACLE. DO NOT CUT OR REMOVE THE GROUNDING PRONG FROM THIS PLUG!

IN THE ABSENCE OF LOCAL CODES, WITH THE NATIONAL ELECTRICAL CODE (ANSI/NFPA NO. 70-1990) OR THE

CORRESPONDING NATIONAL CODE OF THE COUNTRY IN WHICH INSTALLED.

THIS APPLIANCE IS EQUIPPED WITH A GROUNDING PLUG FOR YOUR PROTECTION AGAINST SHOCK HAZARD AND MUST BE

• Voltage: 208VAC or 240VAC depending on model ordered

• Frequency: 60 Hz (non-CE )or 50 Hz (CE and Australian models)

• Phase: Single

• Service: 20 Amp

Setup:

Setup of the toaster consists of unpacking the unit, placing it on a sturdy table or countertop adjacent to

a properly grounded AC outlet of appropriate voltage, removing the cardboard packing inserts, installing

the bun feeder in the slot on top of the cover, and plugging it in. NOTE: The cover must be closed to

install the bun feeder, and the bun feeder must be removed to open the cover.

The unit is shipped with a programmed setpoint of 550°F (288°C), upper crown compression knob set

to 4, lower crown compression knob set to 5, upper heel compression knob set to D, and lower

compression knob set to E. The operator may change these settings to attain desired toasting.

5. OPERATION

1. Press the ON/OFF button. The word LOW will appear in the green LED display window. The

unit will take about 10 minutes to reach operating temperature, at which time the display will change

to REDY, indicating the toaster is ready for use.

Service Hotline

1-800-24-FRYER

Page 3

2. Load buns into the appropriate slots (Heel or Crown) one at a time, with the cut faces toward the

rear of the unit. The unit will toast the buns and transfer them to the heated holding tray.

3. Adjust the setpoint and bun compression as necessary to achieve desired toasting.

6. VIEWING AND ADJUSTING THE SETPOINT

To view the platen temperature, press the button once. The temperature in degrees Fahrenheit will

appear in the green LED display window. To view the current setpoint, press the

setpoint in degrees Fahrenheit will be displayed in the green LED display window. To toggle the

display to Celsius, unplug the unit, then press and hold the

button as the unit is plugged back in.

To change the setpoint:

button twice. The

1. Turn the unit OFF (press the

button). Enter the setpoint programming mode by pressing the ,

, , buttons in that order. The current setpoint will appear in the LED display. To increase

the setpoint, press the

2. When the desired setpoint is displayed, press the

button; to decrease it, press the button.

button once. Press the ON/OFF button. If

the platen is within 20°F (11°C) of the setpoint, the display will show REDY. Otherwise, the display

will show LOW or HIGH until the platen is within 20°F (11°C) of the setpoint, at which time the

display will change to REDY.

7. ADJUSTING BUN COMPRESSION

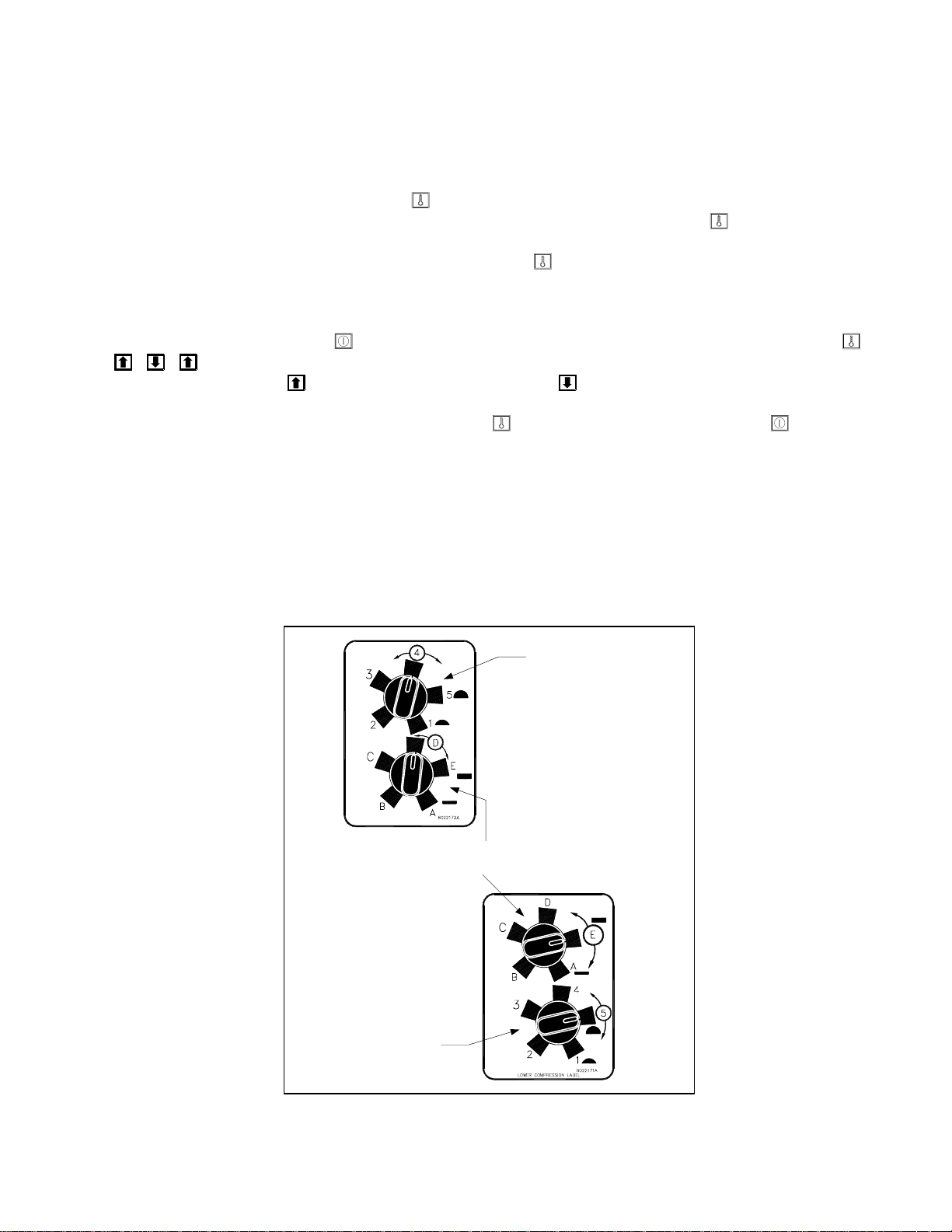

1. There are two pairs of compression adjustment knobs (one pair numbered 1-5, the other lettered AE), as shown in the accompanying illustration. Factory settings are circled.

Crown Compression

Adjustment (1-5)

UPPER COMPRESSION LABEL

Heel Compression

Adjustment (A-E)

Crown Compression

Adjustment (1-5)

2. Settings A and 1 cause the greatest bun compression (that is, the thinnest bun after toasting).

Page 4

Service Hotline

1-800-24-FRYER

8. CHANGING BELTS

1. Turn the unit off (press the ON/OFF button) then unplug it. If the unit has been in operation,

allow it to cool for about 1½ hours. TIP: Change belts in the morning, prior to turning the toaster

on.

2. Remove the bun feeder, and then open the cover.

3. Set the bun compression knobs to positions E and 5.

4. Press down on the top roller and move it to the retracted (down) position. (NOTE: Each side of the

roller must be locked down.)

5. Rotate the tray stabilizer latch upward to unlatch it.

Tray

Stabilizer

Latch

6. Slip the old belt off the rollers and slip the new belt on. When the replacement belt has been

properly positioned between the raised edges of its rollers, rotate the tray stabilizer latch to the

latched position.

7. Press down on the top roller to unlock it and allow it to extend.

8. Close the cover. Return the bun compression knobs to their previous settings.

Service Hotline

1-800-24-FRYER

Page 5

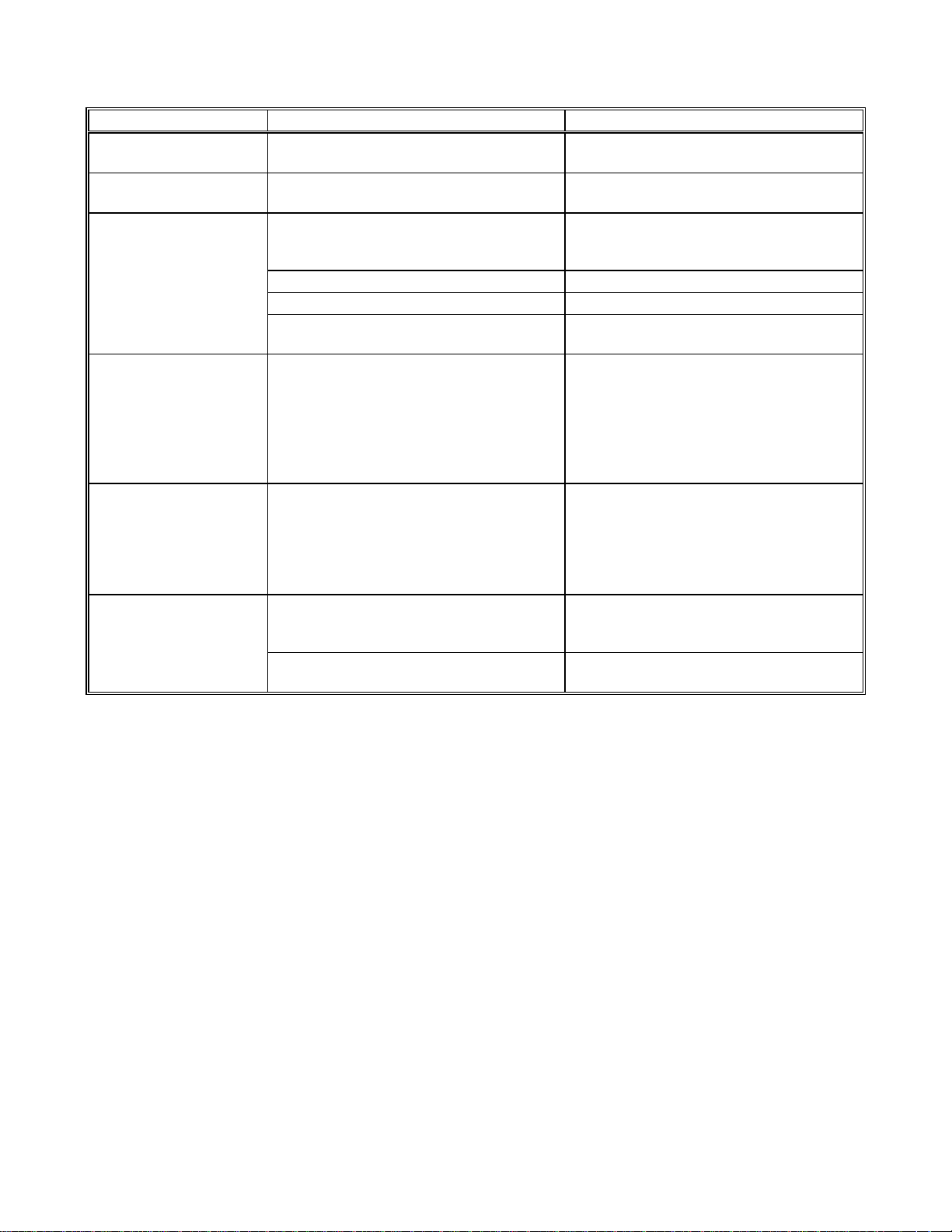

9. OPERATOR TROUBLESHOOTING

PROBLEM PROBABLE CAUSES CORRECTIVE ACTION

PRO1

PRO1 in LED display.

PRO1PRO1

PRO2

PRO2 in LED display.

PRO2PRO2

Bun conveyors do not start

when ON/OFF button is

pressed.

Toasting is consistently too

dark or too light.

Buns are too thick or too

Buns are toasting

inconsistently.

A. Indicates failure of main platen probe or

associated circuitry.

A. Indicates failure of tray heater probe or

associated circuitry.

A. Cover not properly installed.

B. Toaster not plugged in. B. Plug toaster in.

C. Store circuit breaker tripped. C. Reset circuit breaker.

D. Failed cover interlock switch, failed high

limit, failed motor, or failed controller.

A. Improper setpoint programmed and/or

incorrect compression knob setting.

A. Compression knobs on an improper

thin.

setting for desired compression.

A. Belt slippage.

B. Incorrect belt speed, faulty platen heater,

or faulty controller.

A. Call FASC.

A. Call FASC.

A. Make sure cover is correctly positioned so

that the cover interlock switch is

depressed.

D. Call FASC.

A. If toasting is too dark, lower the setpoint

and/or compression setting until desired

toasting is achieved.

If toasting is too light, increase setpoint

and/or compression setting until desired

toasting is achieved.

A. Adjust the compression knobs to achieve

desired compression. Moving them to a

lower setting will increase compression.

Moving them to a higher setting will

decrease compression. Make sure both

pairs of knobs are on the same setting.

A. Shut down and clean unit, paying

particular attention to grooves in rollers

and condition of belts.

B. Call FASC.

10. PREVENTIVE MAINTENANCE

A separate set of Maintenance Requirement Cards (MRCs) is furnished with this manual. In addition to the

checks and services contained in the MRCs, Frymaster recommends that this appliance be inspected by a

Frymaster Factory Authorized Service Technician at least annually as follows:

• Inspect all wiring for signs of chafing, kinking, and/or loose connections.

• Verify that all mechanical and electronic components are securely mounted (i.e., screws and nuts and bolts are

tight.)

• Verify that idler roller springs are in serviceable condition (i.e., rollers are held securely in the top of the

J-slots and belts do not slip).

Page 6

Service Hotline

1-800-24-FRYER

11. SERVICE INFORMATION

11.1 INTRODUCTION

Vertical toasters manufactured for use in the European Union (CE) and those manufactured for use

elsewhere are identical in most respects, but there are some important differences. The paragraphs

that follow summarize the differences and provide a list of the parts that are unique to each model.

The most significant differences are in the electronic components. Units built for the CE and Australian

markets have a 50 Hz motor; all others have a 60 Hz motor. Non-CE and CE/Australian units also use

different transformers, and CE/Australian units have a line filter built into the electrical power supply

system. The line filter and cover are attached to the rear of the cabinet.

Because of the difference in the power cycle frequency (50 Hz vs. 60 Hz), CE and Australian units are

equipped with 10-tooth drive pulleys and a 28-Tooth motor pulley. Standard units have 17-tooth drive

pulleys and an 18-tooth motor pulley. The different pulleys on the CE and Australian units maintain the

correct belt speed even though the RPM of the motor at 50 Hz is slightly slower than that of the motor

at 60 Hz.

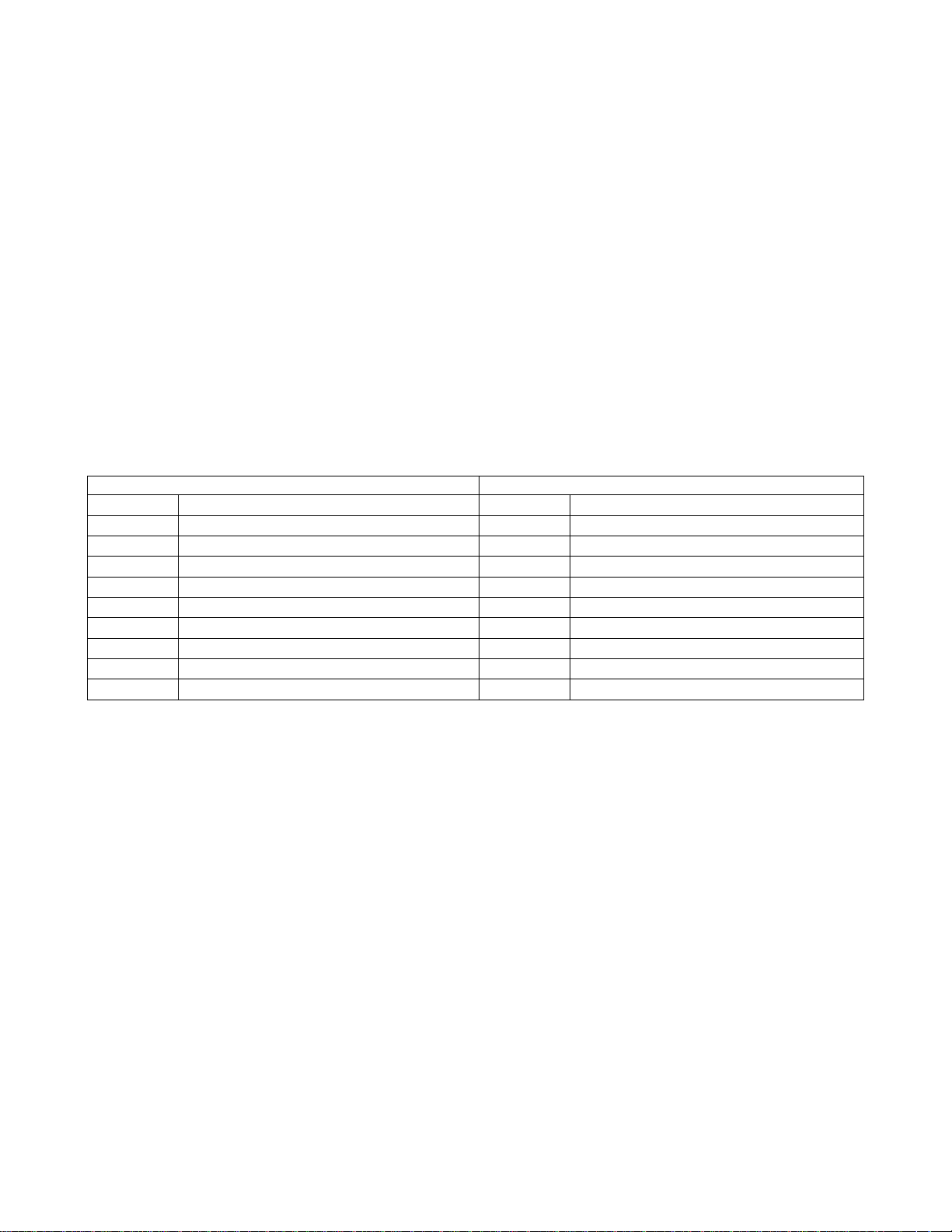

The table below identifies the components that are unique to each configuration.

Components Unique to CE andAustralian Units Components Unique to Non-CE Units

P/N Description P/N Description

807-2191 Transformer (208-240V/12V) 807-0979 Transformer (208-240V/12V)

807-0910 Transformer Fuse, 250V/3A N/A Not used.

106-0781 Transformer and Bracket Assembly N/A Not used.

807-3472 Line Filter N/A Not used.

824-0896 Line Filter Cover N/A Not used.

106-2143 Tensioner Assembly, Drive Belt 106-2723 Tensioner Assembly, Drive Belt

810-2300 28-Tooth Motor Driven Pulley 810-2565 18-Tooth Motor Driven Pulley

810-2301 10-Tooth Dual Belt Drive Pulley 810-2566 17-Tooth Dual Belt Drive Pulley

810-2332 10-Tooth Toasting Belt Drive Pulley 810-2564 17-Tooth Toasting Belt Drive Pulley

The illustrations in the parts list that follows also identify the CE/Australian and Non-CE components.

Service Hotline

1-800-24-FRYER

Page 7

Loading...

Loading...