Frymaster SR42 Series, SR62 Series, SR52 Series Installation, Operation And Maintenance Manual

Original Instructions

CAUTION

FOR YOUR SAFETY

Your Growth Is Our Goal

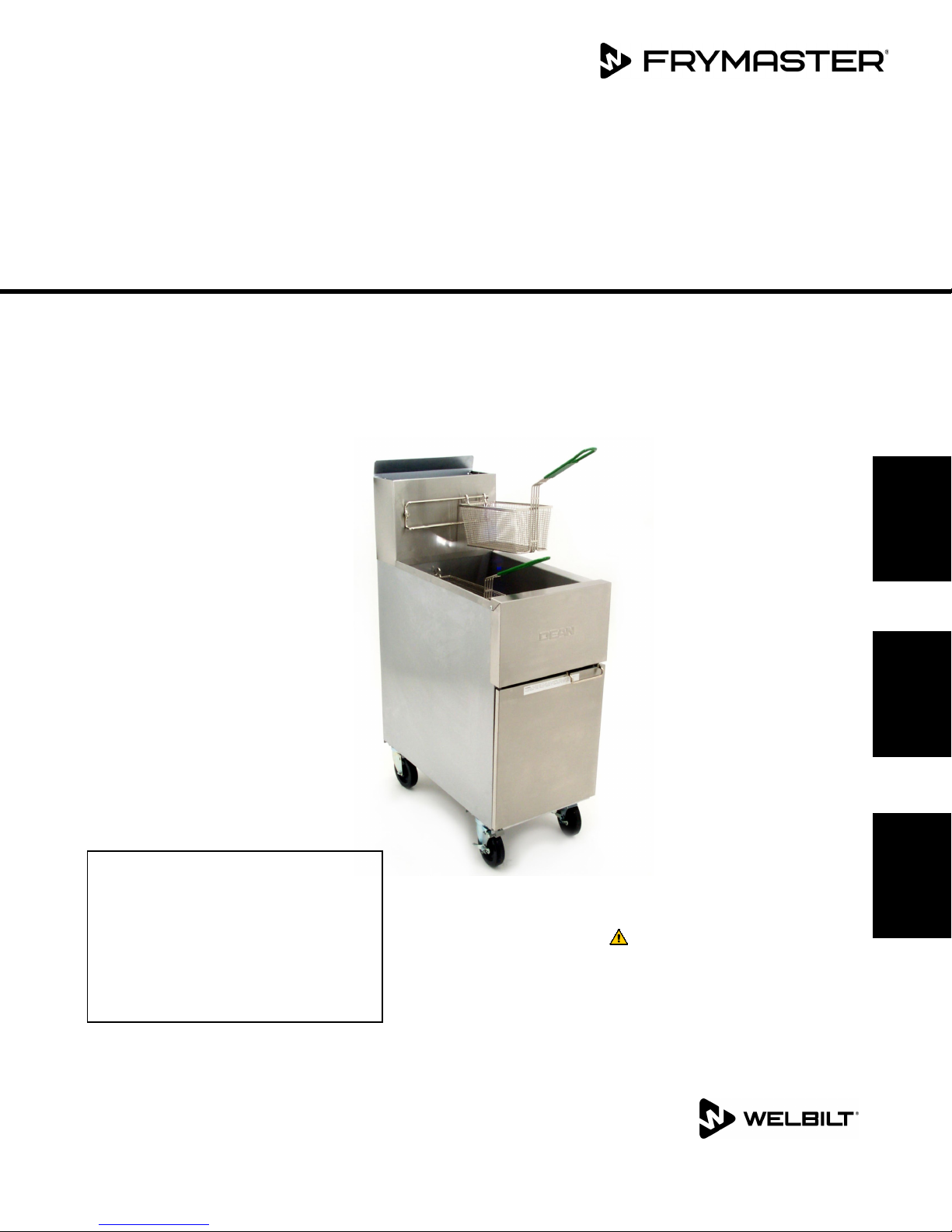

Dean Super Runner Series SR42,

SR52, SR62

Gas Fryers

Installation, Operation and Maintenance

Manual

This manual is updated as new information and models are released. Visit our website for the latest manual.

ENGLISH

Do Not Store or use gasoline

or other flammable vapors

and liquids in the vicinity of

this or any other appliance.

*8197501*

Part Number: FRY_IOM_8197501 02/2019

ESPAÑOL

FRANÇAIS

READ THE INSTRUCTIONS BEFORE USING THE FRYER.

Keep these instructions for future reference.

NOTICE

This appliance is intended for professional use only and is to be operated by qualified personnel only. A

Frymaster/DEAN Factory Authorized Servicer (FAS) or other qualified professional should perform

installation, maintenance, and repairs. Installation, maintenance, or repairs by unqualified personnel may

void the manufacturer’s warranty.

NOTICE

This equipment must be installed in accordance with the appropriate national and local codes of the

country and/or region in which the appliance is installed.

NOTICE TO U.S. CUSTOMERS

This equipment is to be installed in compliance with the basic plumbing code of the Building Officials and

Code Administrators International, Inc. (BOCA) and the Food Service Sanitation Manual of the U.S. Food

and Drug Administration.

DANGER

Improper installation, adjustment, maintenance or service, and unauthorized alterations or modifications

can cause property damage, injury, or death. Read the installation, operating, and service instructions

thoroughly before installing or servicing this equipment. Only qualified service personnel may convert

this appliance to use a gas other than that for which it was originally configured.

DANGER

Adequate means must be provided to limit the movement of this appliance without depending upon the

gas line connection. Single fryers equipped with legs must be stabilized by installing anchor straps. If a

flexible gas line is used, an additional restraining cable must be connected at all times when the fryer is

in use.

DANGER

The front ledge of the fryer is not a step! Do not stand on the fryer. Serious injury can result from slips

or contact with the hot oil.

DANGER

Do not store or use gasoline or other flammable liquids or vapors in the vicinity of this or any other

appliance.

DANGER

Instructions to be followed in the event the operator smells gas or otherwise detects a gas leak must be

posted in a prominent location. This information can be obtained from the local gas company or gas

supplier.

NOTICE

IF, DURING THE WARRANTY PERIOD, THE CUSTOMER USES A PART FOR THIS FRYMASTER DEAN

FOOD SERVICE EQUIPMENT OTHER THAN AN UNMODIFIED NEW OR RECYCLED PART PURCHASED

DIRECTLY FROM FRYMASTER/DEAN, OR ANY OF ITS AUTHORIZED SERVICERS, AND/OR THE PART

BEING USED IS MODIFIED FROM ITS ORIGINAL CONFIGURATION, THIS WARRANTY WILL BE VOID.

FURTHER, FRYMASTER/DEAN AND ITS AFFILIATES WILL NOT BE LIABLE FOR ANY CLAIMS, DAMAGES

OR EXPENSES INCURRED BY THE CUSTOMER WHICH ARISE DIRECTLY OR INDIRECTLY, IN WHOLE OR

IN PART, DUE TO THE INSTALLATION OF ANY MODIFIED PART AND/OR PART RECEIVED FROM AN

UNAUTHORIZED SERVICER.

WARNING

This appliance is not intended for use by children under the age of 16 or persons with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been given

supervision concerning use of the appliance by a person responsible for their safety. Do not allow children

to play with this appliance.

NOTICE

The Commonwealth of Massachusetts requires any and all gas products to be installed by a licensed

plumber or pipe fitter.

Register Your Warranty Online at

http://fm-hal.frymaster.com/qsys.lib/cgi.lib/swr290.pgm

ENGLISH

SUPER RUNNER SERIES GAS FRYERS

CHAPTER 1: INSTALLATION INSTRUCTIONS

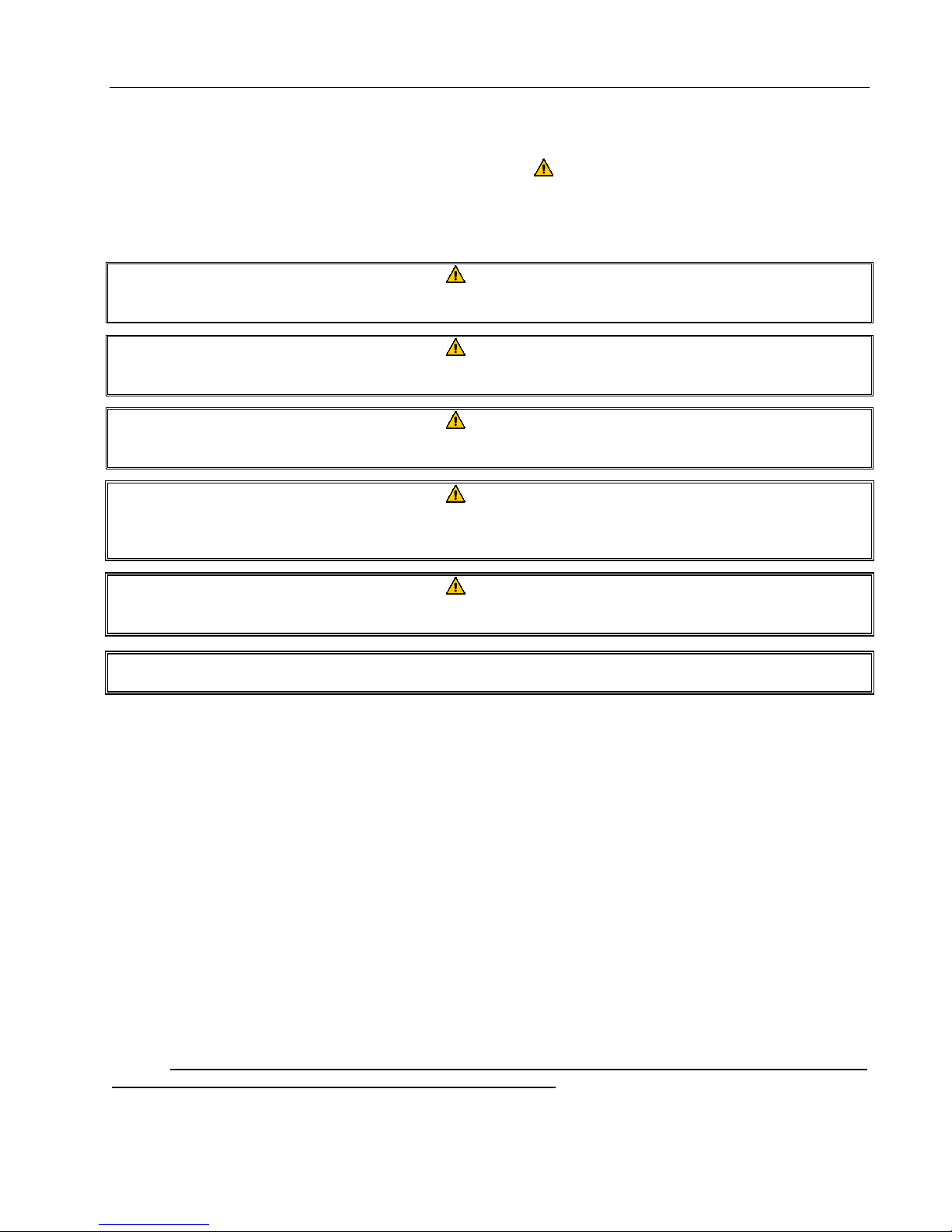

1.1 Safety Information

Before attempting to operate your unit, read the instructions in this manual thoroughly. Throughout this manual you will

find notations enclosed in double-bordered boxes with the symbol

actions or conditions that may cause or result in injury to personnel or damage to your system, and/or cause your system

to malfunction.

1.2 General Installation Instructions

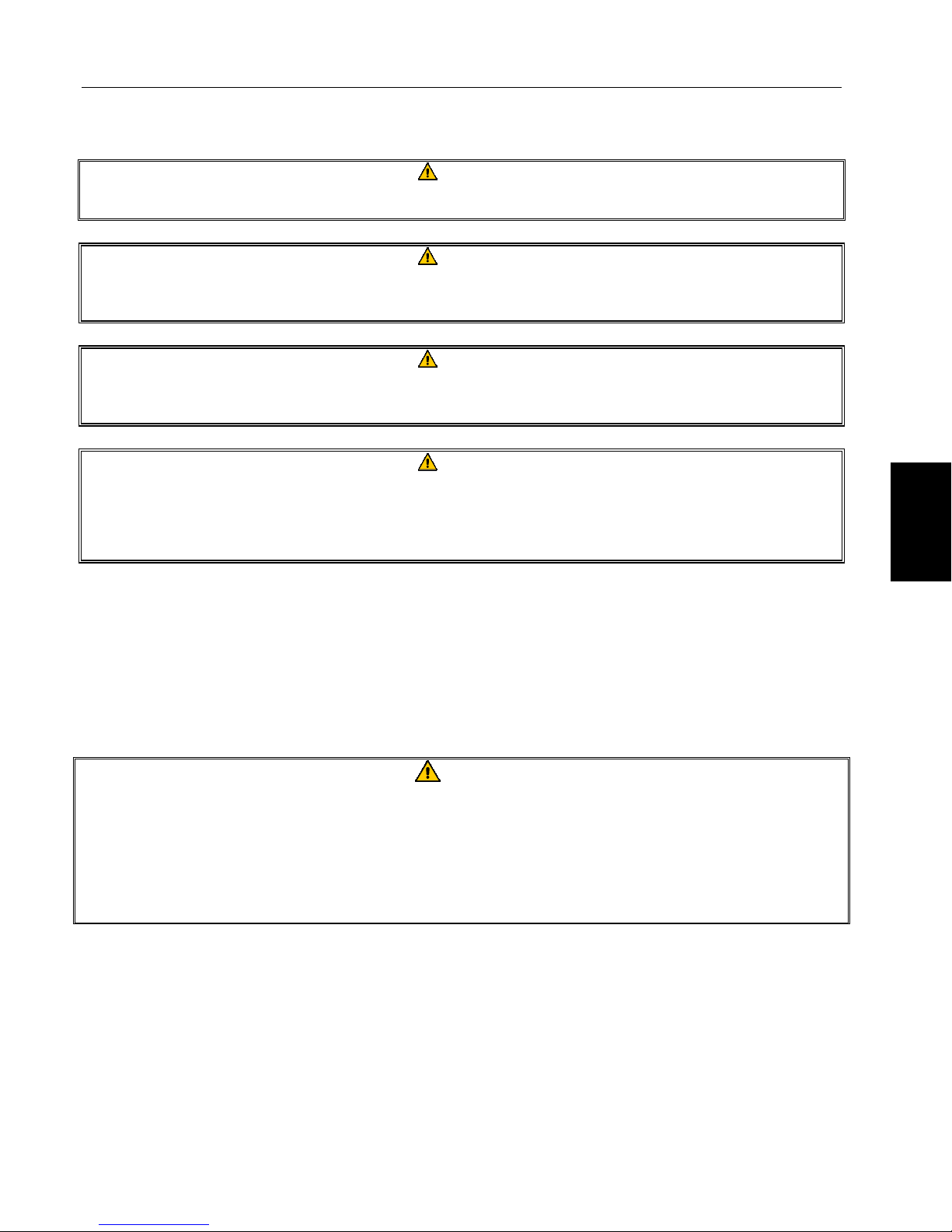

DANGER

Building codes prohibit a fryer with its open frypot of hot oil being installed beside an open flame of any

type, including those of broilers and ranges.

DANGER

This appliance must be installed with sufficient ventilation to prevent the occurrence of unacceptable

concentrations of substances harmful to the health of personnel in the room where it is installed.

DANGER

No structural material on the fryer should be altered or removed to accommodate placement of the fryer

under a hood.

DANGER

Single fryers must be restrained to prevent tipping when installed in order to avoid the splashing of hot

liquid. The means of restraint may be the manner of installation, such as connection to battery of

appliances or installing the fryer in an alcove, or by separate means, such as straps or chains.

DANGER

Do not attach an apron drainboard to a single unit. The appliance may become unstable, tip over, and

cause injury. The appliance area must be free and clear of combustible material at all times.

NOTICE

This appliance is only for professional use and shall be used by qualified personnel only.

CLEARANCE AND VENTILATION

This fryer must be installed with a 6-inch (150-mm) clearance at both sides and back when installed adjacent to

combustible construction. No clearance is required when installed adjacent to

minimum of 24-inches (600-mm) clearance should be provided at the front of the fryer.

The fryer flue opening must not be placed close to the intake of an exhaust fan, and the fryer must never have its flue

extended in a "chimney" fashion. An extended flue will change the combustion characteristics of the fryer. To provide

the airflow necessary for good combustion and burner operation, the areas surrounding the fryer front, sides, and rear

must be kept clear and unobstructed.

The fryer must be installed in an area with an adequate air supply and adequate ventilation. Adequate distances must be

maintained from the flue outlet of the fryer to the lower edge of the ventilation filter bank. Filters should be installed at

an angle of 45°. Place a drip tray beneath the lowest edge of the filter. For U.S. installation, NFPA standard No. 96

states, "A minimum distance of 18-inches (450-mm) should be maintained between the flue outlet and the lower edge of

the grease filter". Frymaster recommends that the minimum distance be 24-inches (600-mm) from the flue outlet to the

bottom edge of the filter.

INSTALLATION

NOTE: Unless special ordered, this fryer is designed for operation at altitudes of 2000 feet (610 meters) and below.

The unit must be modified for operation above 2000 feet (610 meters).

. The information contained in the box concerns

non-combustible construction. A

1-1

SUPER RUNNER SERIES GAS FRYERS

G20

20/25

G31

37

G20

20

I2E

G31

50

I3P

DK

Denmark

G20

20

I2H

G20

20

G31

37 and 50

G20/G25

20/25

G31

37 and 50

G20

20

G31

37

G20

20

G31

37 and 50

G20

20

G31

37

IT

Italy

G20

20

I2H

G20/G25

20/25

G31

50

G25

25

G31

50

G20

20

G31

37

CHAPTER 1: INSTALLATION INSTRUCTIONS

For units equipped with legs: Lift the unit and move it into its final position. Do not drag or push the fryer into position.

Doing so may damage the legs. Level the unit front to back and side to side. If the fryer is not level, the unit will not

function efficiently. Super Runner Series gas fryers cannot be curb mounted and must be equipped with either legs or

casters provided.

A. Adjust leg height with an adjustable or 1-1/16-inch (27-mm) open-end wrench by turning the hexagon-shaped foot

on the bottom of the leg. NOTE: The foot is for minor leg height adjustment only. Do not adjust outward more

than ¾-inch (19-mm).

B. When leveling the unit, the leg body should be held firmly to keep the leg from bending or rotating while turning the

foot to the required height.

For units equipped with casters: Roll the unit into its final position and lock the front casters.

1.3 Pre-Connection Preparation

WARNING

If the incoming gas pressure is in excess of ½" PSI (3.45 kPa/35 mbar), a step-down regulator will be

required.

CE UNITS ONLY:

Dean Super Runner gas fryers have obtained CE markings for countries and gas categories shown below:

Countries Supply Pressures and Gas (mbar) Appliance Categories

ENGLISH

BE Belgium

DE Germany

IIE(R)B3P

ES Spain

FR France

GB Great Britain

GR Greece

IR Ireland

LU Luxembourg

NL The Netherlands

PT Portugal

II2H3P

II2ESI3P

II2H3P

II2H3P

II2H3P

II2E3P

II2L3P

II2H3P

NON-CE UNITS ONLY:

NATIONAL CODE REQUIREMENTS:

This equipment is to be installed in compliance with the Basic Plumbing Code of the Building Officials and Code

Administrators International, Inc. (BOCA) and the Food Service Sanitation Manual of the U.S. Food and Drug

Administration.

equipment stamped "NAT" only to natural gas and that stamped "PRO" only to LP (Propane) gas.

This equipment is manufactured to use the type of gas specified on the rating plate attached to the door. Connect

1-2

SUPER RUNNER SERIES GAS FRYERS

Model

Gas Type

Orifice Size

Manifold Pressure KPa

Manifold Pressure Inches WC

SR62GN

Nat

2.53 mm

0.9 KPa

3.6”

SR62GP

Prop

1.6 mm

2.4 KPa

9.6”

SR42GN

Nat

2.8 mm

0.87 KPa

3.5”

SR42GP

Prop

1.65 mm

2.5 KPa

10”

NOMINAL

(kW)

G20

G31

2.40

1.51

12,0

22,0

4,8

8,8

5/BLUE

5/RED

Blue

Red

26N

16LP

G20

G31

2.40

1.51

12,0

22,0

4,8

8,8

4/BLUE

4/RED

Blue

Red

26N

16LP

G20

G31

2.40

1.51

12,0

22,0

4,8

8,8

3/BLUE

3/RED

Blue

Red

26N

16LP

*SR prefix- Super Runner Series

*GM suffix- gas millivolt system with no electrical supply connections required

NOMINAL

(BTU)

NAT

LP

2.53(#39)

1.51(#53) 4 11 5 5

26N

16LP

NAT

LP

2.53(#39)

1.51(#53) 4 11 4 4

26N

16LP

NAT

LP

2.80(#35)

1.70(#51)

3.5

10 3 3

26N

16LP

*SR prefix- Super Runner Series

*GM suffix- gas millivolt system with no electrical supply connections required

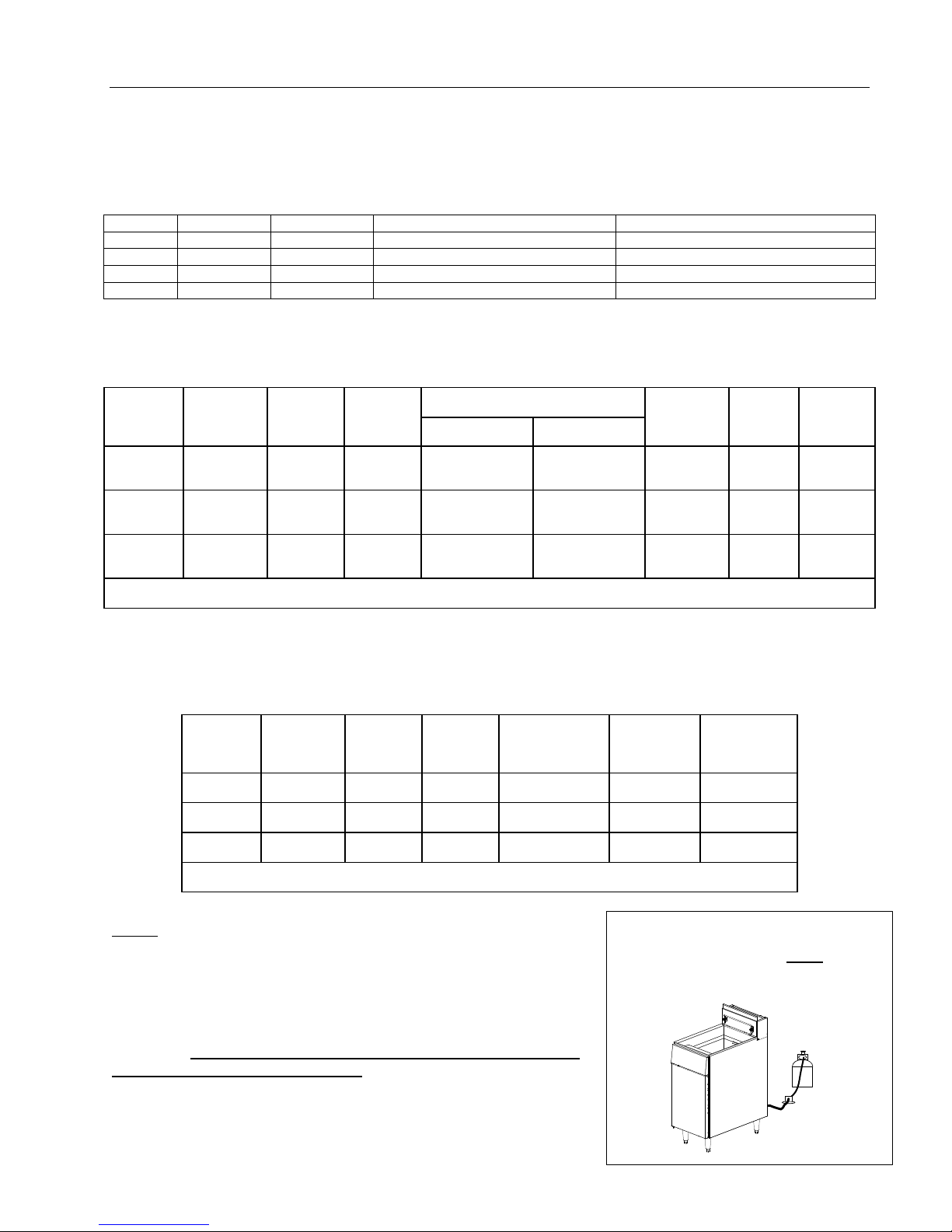

Propane Applications:

Proper Regulator Must Be Installed

Regulator

Propane Applications:

CHAPTER 1: INSTALLATION INSTRUCTIONS

AUSTRALIAN REQUIREMENTS:

To be installed on a firm, level surface in accordance with AS 5601 / AG 601, local authority, gas, electricity, and any

other relevant statutory regulations. The Australian orifice size and manifold pressures are listed below for the SR42 and

SR62 fryers.

CE UNITS ONLY:

Nominal Heat Inputs (Qn), Gas Type, Orifice Size, Pressures and Adjustments, Orifice Quantity/Color, Burner Markings

and Pilot Markings are listed in the table below:

MODEL*

HEAT INPUT-

Qn

GAS TYPE

ORIFICE

SIZE (MM)

MANIFOLD GAS PRESSURE

MBAR INCH W.C.

ORIFICE

QTY/ COLOR

BURNER

MARKING

PILOT

MARKING

SR62 GM 37.5

SR52 GM 30

SR42 GM 26

G25

G25

G25

2.40

2.40

2.40

17,5

17,5

17,5

7,0

7,0

7,0

5/BLUE

4/BLUE

3/BLUE

Blue

Blue

Blue

26N

26N

26N

NON-CE UNITS ONLY:

Nominal Heat Inputs (Qn), Gas Type, Orifice Size, Pressures and Adjustments, Orifice Quantity, and Pilot Markings are

listed in the table below:

MODEL*

SR62 GM 150

SR52 GM 120

SR42 GM 105

HEAT INPUT-

Qn

GAS TYPE

ORIFICE

SIZE (MM)

MANIFOLD GAS

PRESSURE

(INCH W.C.)

ORIFICE

QUANTITY

PILOT

MARKING

NOTE: Outlet gas pressure must be adjusted strictly within the above

requirements 5 to 10 minutes after the appliance is operating.

1.4 Connection to the Gas Supply Line

NOTE: The gas supply (service) line must be the same size or greater

than the fryer inlet line. This appliance is equipped with a ½-inch (15mm) inlet. The gas supply line must be sized to accommodate all gasfired equipment connected to the line. Consult the local gas company

or supplier, or your local contractor for minimum supply line

requirements.

1-3

Proper Regulator Must Be

Installed

SUPER RUNNER SERIES GAS FRYERS

CHAPTER 1: INSTALLATION INSTRUCTIONS

NOTE: If quick-disconnect supply lines or flex lines are used, increase supply line size to ¾-inch (22-mm) or

larger.

DANGER

A manual shut-off valve must be installed in the gas supply (service) line upstream of this appliance and in

a position where it can be reached quickly in the event of an emergency.

DANGER

The fryer must be connected to the gas supply specified on the rating and serial number plate located on

the inside of the appliance door. DO NOT ATTACH THIS APPLIANCE TO A GAS SUPPLY FOR WHICH IT IS

NOT CONFIGURED!

DANGER

Before connecting new pipe to this appliance, the pipe must be blown out thoroughly to remove all foreign

material. Foreign material in the burner and gas valve will cause improper and potentially dangerous

operation.

DANGER

All connections must be sealed with a joint compound suitable for the gas being used and all connections

must be tested for leaks using a solution of soapy water before lighting any pilots. Never use matches,

candles, or any other ignition source to check for leaks. If gas odors are detected, shut off the gas supply

to the appliance at the main shut-off valve and immediately contact the local gas company or an authorized

service agency for service.

Adequate means must be provided to limit the movement of fryers without depending upon the gas line connections. If a

flexible gas hose is used, a restraining cable must be connected at all times when the fryer is in use. NOTE: The

installation must be inspected after it is complete to ensure it meets the intent of these instructions. The on-site

supervisor and/or operator(s) should be informed that the appliance is installed with restraints. If restraints are

removed to move fryer (cleaning beneath and behind, relocation, etc.), ensure that they are re-installed when

fryer is returned to its permanently installed position.

1.5 Gas Conversion Procedures

ENGLISH

This appliance was configured at the factory for a specific type of gas. Converting from one gas type to

another requires the installation of specific gas-conversion components.

Switching to a different type of gas without installing the proper conversion components may result in fire

or explosion. NEVER ATTACH THIS APPLIANCE TO A GAS SUPPLY FOR WHICH IT IS NOT CONFIGURED!

Conversion of this appliance from one type of gas to another should only be performed by qualified,

licensed, and authorized installation or service personnel, as defined in Section 1.5 of this manual.

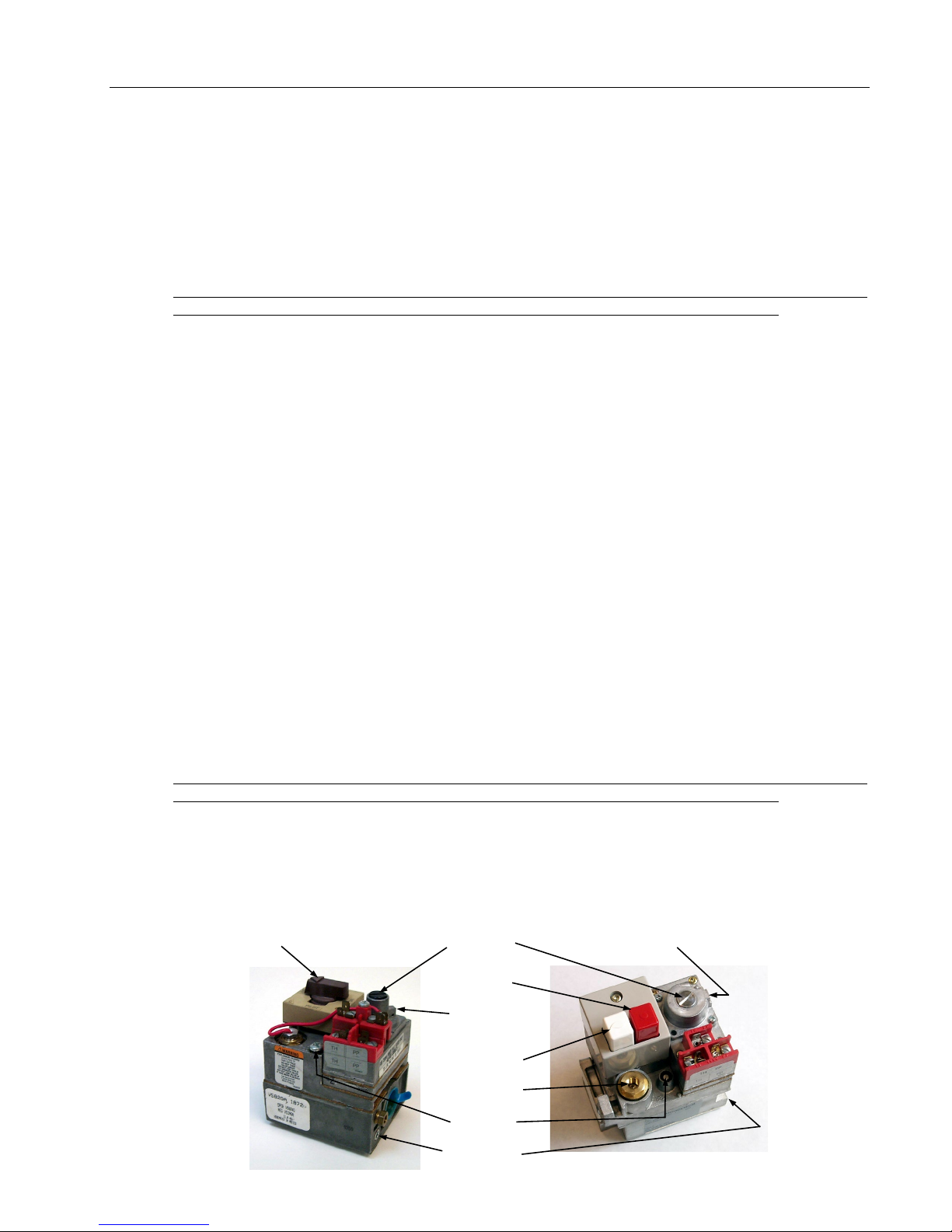

CE UNITS ONLY:

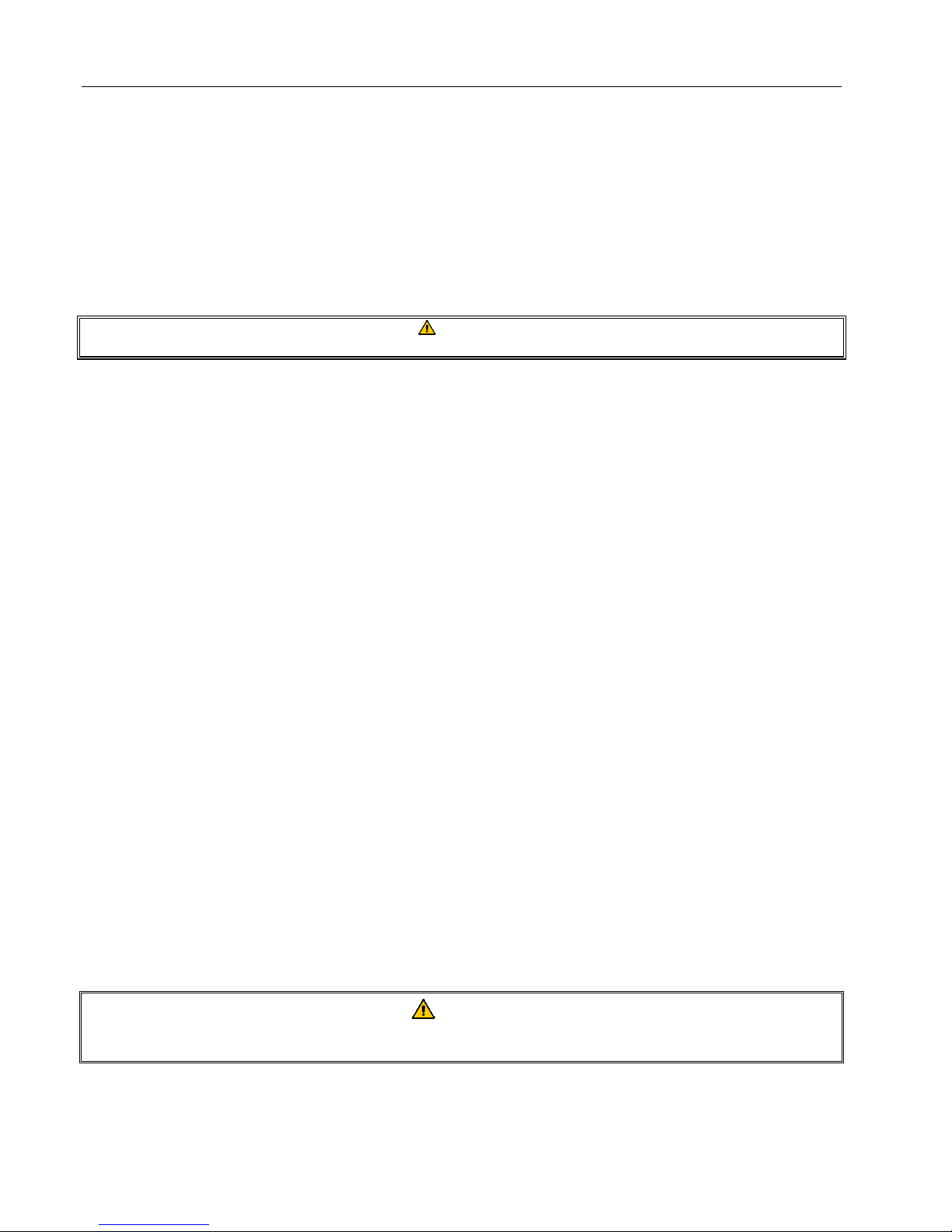

See gas valve illustration and gas valve, burner and orifice location when performing the following conversions.

When converting from G20 to G25 gas, the following procedures apply:

♦ Equipment replacement is not required.

♦ Adjust orifice gas pressure to the appropriate value listed in the table on page 1-3 by turning the gas valve

"adjustment screw".

DANGER

1-4

SUPER RUNNER SERIES GAS FRYERS

Typical Non-CE Gas Valve

ON Button

(pilot gas flow)

OFF Button

Pressure Flow

Adjustment

Thermocouple

Connection

Pilot Flow

Adjustment

Vent tube

connection

ON/PILOT/OFF

Knob

Vent Tube

Connection

Pressure Tap

Typical CE Gas Valve

CHAPTER 1: INSTALLATION INSTRUCTIONS

♦ After adjustment, replace the adjustment-screw cover.

When converting from G20 (or G25) gas to G31 propane (or vice-versa), the following procedures apply:

♦ Burner orifices and pilot orifice MUST be replaced.

♦ Adjust orifice gas pressure to the appropriate value listed in the table on page 1-3 by turning the gas-valve

adjustment screw.

♦ After adjustment, replace the adjustment-screw cover.

♦ Affix the new label included with the conversion kit next the existing rating plate stating that the gas type has

been converted. Remove any references to the previously used gas from the existing rating plate.

When converting from G20 (20 mbar) to G25 (25 mbar), or vice-versa, or G31 (37 mbar) to G31 (50 mbar), the

following procedures apply:

♦ Check pilot-adjustment and adjust as necessary.

♦ Other adjustments are not necessary.

Conversion from one gas family to another (i.e. changing from natural gas to propane) requires special components.

Obtain the necessary components using the cross-reference in Section 1.6, Gas Conversion Components.

Conversions can only be executed by qualified, factory-authorized personnel.

NON-CE UNITS ONLY:

See gas valve illustration below and gas valve, burner and orifice location on page 1-6 when performing the following

conversions.

When converting from natural gas to propane (or vice-versa), the following procedures apply:

♦ Burner orifices and pilot orifice MUST be replaced (see page 1-6 for required component part numbers).

♦ Adjust orifice gas pressure by turning the gas-valve adjustment screw (see page 1-3 for gas types and

pressures).

♦ After adjustment, replace the adjustment-screw cover.

♦ Affix the new label included with the conversion kit next the existing rating plate stating that the gas type has

been converted. Remove any references to the previously used gas from the existing rating plate.

Conversion from one gas family to another (i.e. changing from natural gas to propane) requires special components.

Obtain the necessary components using the table on page 1-6.

Conversions can only be executed by qualified, factory-authorized personnel.

1-5

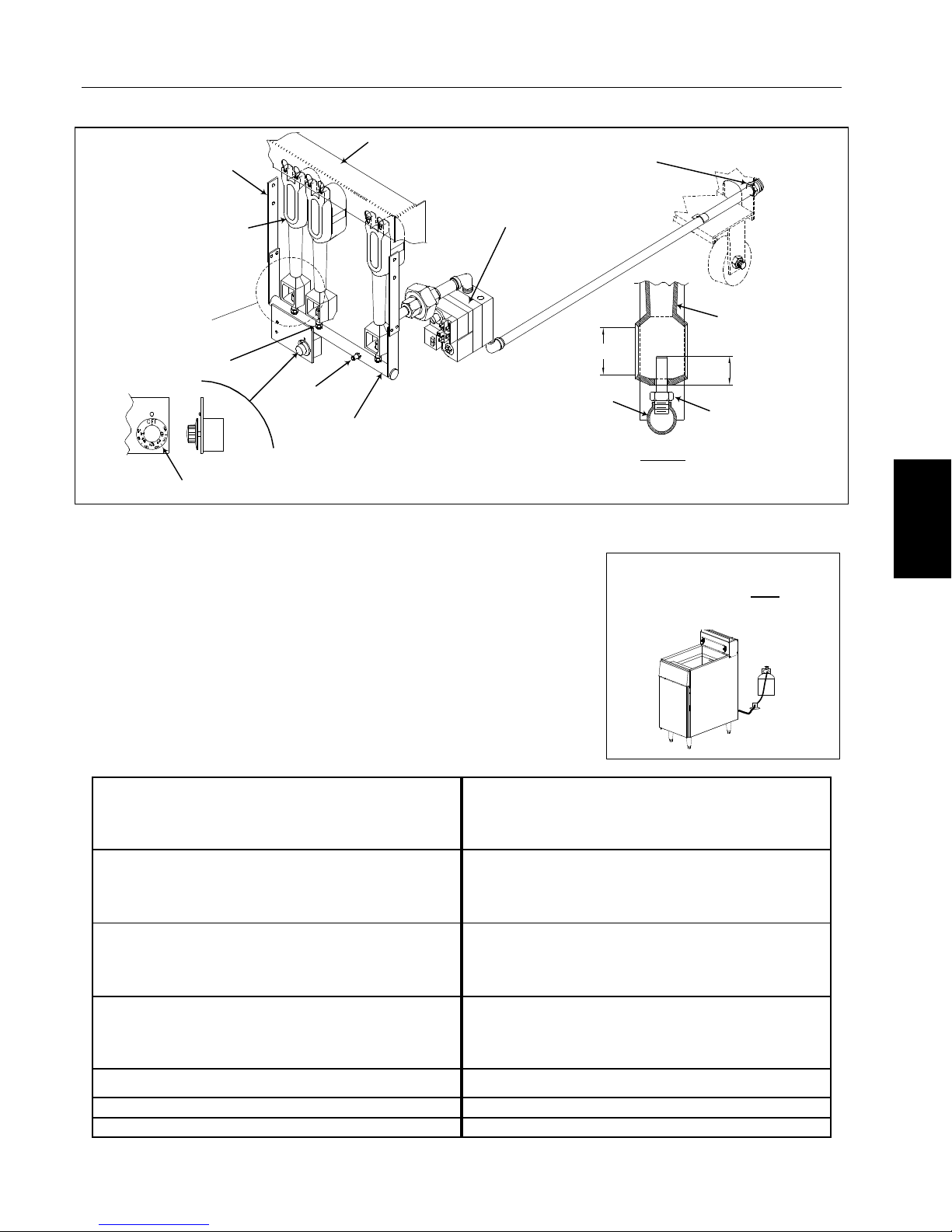

SUPER RUNNER SERIES GAS FRYERS

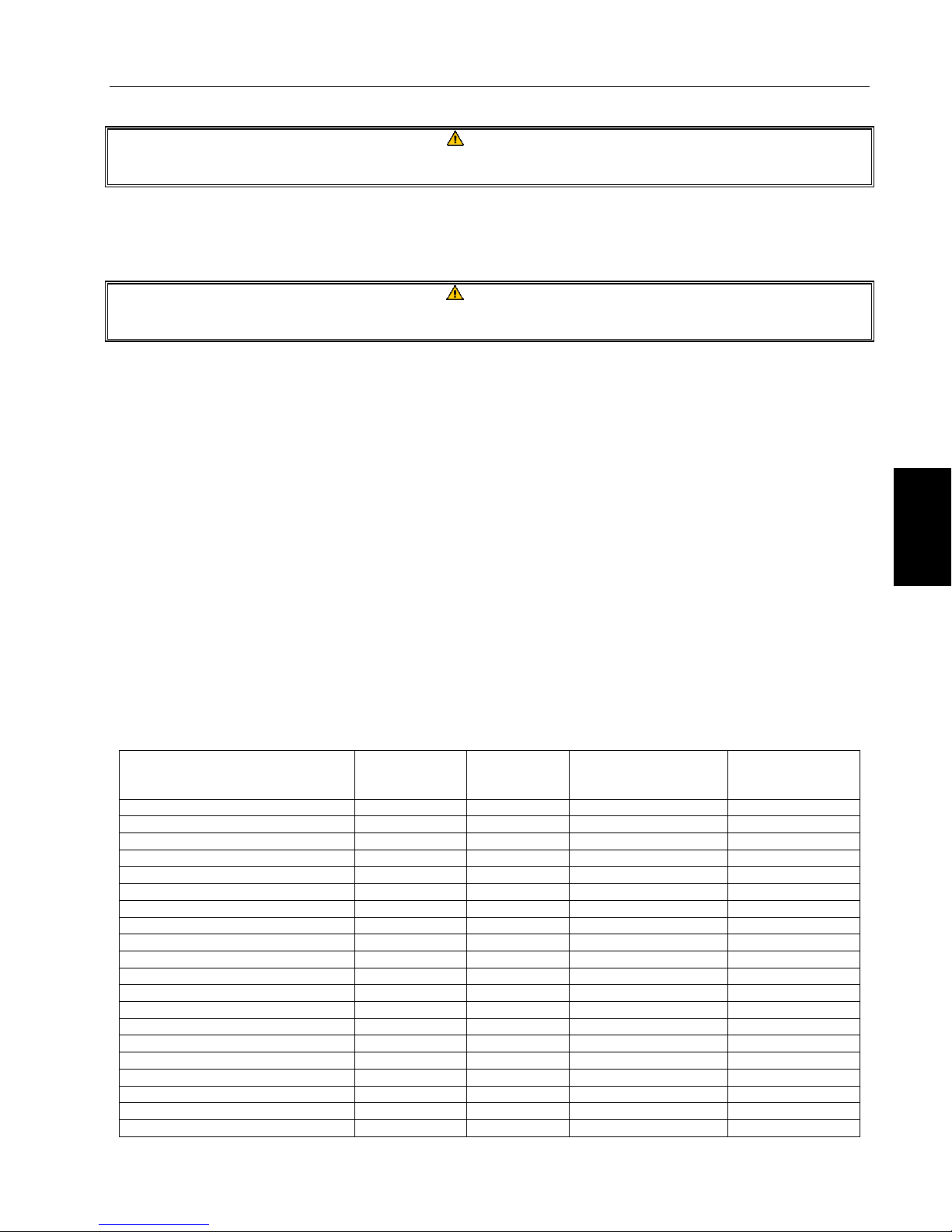

Frypot Assembly

Gas Valve

Manifold Support Bracket

Gas Burner

See Detail A

Pressure

Test

Spigot

Orifice

Temperature

Control

Gas

Manifold

Assembly

1/2—3/4 Reducer

Bushing

Burner

Gas Manifold

Burner/Orifice Location

Detail A

Orifice

1.30-inch [33-mm ]

1.63-inch [41-mm ]

Non-CE Natural Gas to Propane Kits

SR62 - 8262020

Non-CE Propane To Natural Gas Kits

SR62 - 8262021

SR42 CE Natural Gas to Propane Conv. Parts

1-8022530 – Label, Conversion Date

SR42 CE Propane To Natural Gas Conv. Parts

1-8022530 – Label, Conversion Date

SR52 CE Natural Gas to Propane Conv. Parts

1-8022530 – Label, Conversion Date

SR52 CE Propane To Natural Gas Conv. Parts

1-8022530 – Label, Conversion Date

SR62 CE Natural Gas to Propane Conv. Parts

1-8022530 – Label, Conversion Date

SR62 CE Propane To Natural Gas Conv. Parts

1-8022530 – Label, Conversion Date

Bushing, NPT Flush, SR 42 series only

Bushing, NPT Flush, SR 42 series only

Pilot Orifice (16LP) CE & Non-CE

Pilot Orifice (26N) CE & Non-CE

Burner Orifice, 1.51mm- CE ONLY: All Super Runner

Burner Orifice, 2.40mm (#42)- CE ONLY: All Super

Typical gas valve, burner and orifice locations (SR42 shown above).

Propane Applications

:

Proper Regulator

Must

Be Installed

Regulator

Propane Applications:

CHAPTER 1: INSTALLATION INSTRUCTIONS

ENGLISH

1.6 Gas Conversion Components

Use the following components to convert from natural gas to propane and viceversa. See Section 1.5 for orifice quantities required for conversion.

SR42 - 8261817

SR52 - 8262018

1-8102400 - Pilot Orifice (16LP)

3-8103465 - Burner Orifice, 1/8” 1.51mm (#53)

Proper Regulator Must Be

Installed

SR42 - 8262017

SR52 - 8262019

1-8100811 - Pilot Orifice (26N)

3-8103464 - Burner Orifice, 2.40mm (#42)

1-8102400 - Pilot Orifice (16LP)

3-8102059 - Burner Orifice, 1.51mm (.250-18)

2-8102400 - Pilot Orifice (16LP)

3-8102059 - Burner Orifice, 1.51mm (.250-18)

1-8100811 - Pilot Orifice (26N)

3-8102060 - Burner Orifice, 2.40mm (.250-18)

2-8100811 - Pilot Orifice (26N)

3-8102060 - Burner Orifice, 2.40mm (.250-18)

1-6

SUPER RUNNER SERIES GAS FRYERS

Series

Runner Series

Burner Orifice, 1.51mm (#53)- NON-CE ONLY: SR52

& SR62 Series Only

Burner Orifice, 2.53mm (#39)- NON-CE ONLY: SR52

& SR62 Series Only

Burner Orifice, 1.70mm (#51)- NON-CE ONLY: SR42

Series Only

Burner Orifice, 2.80mm (#35)- NON-CE ONLY: S42

Series Only

CHAPTER 1: INSTALLATION INSTRUCTIONS

* Burner orifices listed above are for fryers operating at altitudes of 2000 feet (610 meters) or less. For altitudes

greater than 2000 feet (610 meters), contact the factory for the correct orifice size.

1-7

SUPER RUNNER SERIES GAS FRYERS

OFF

ON

PILOT

OFF

ON

PILOT

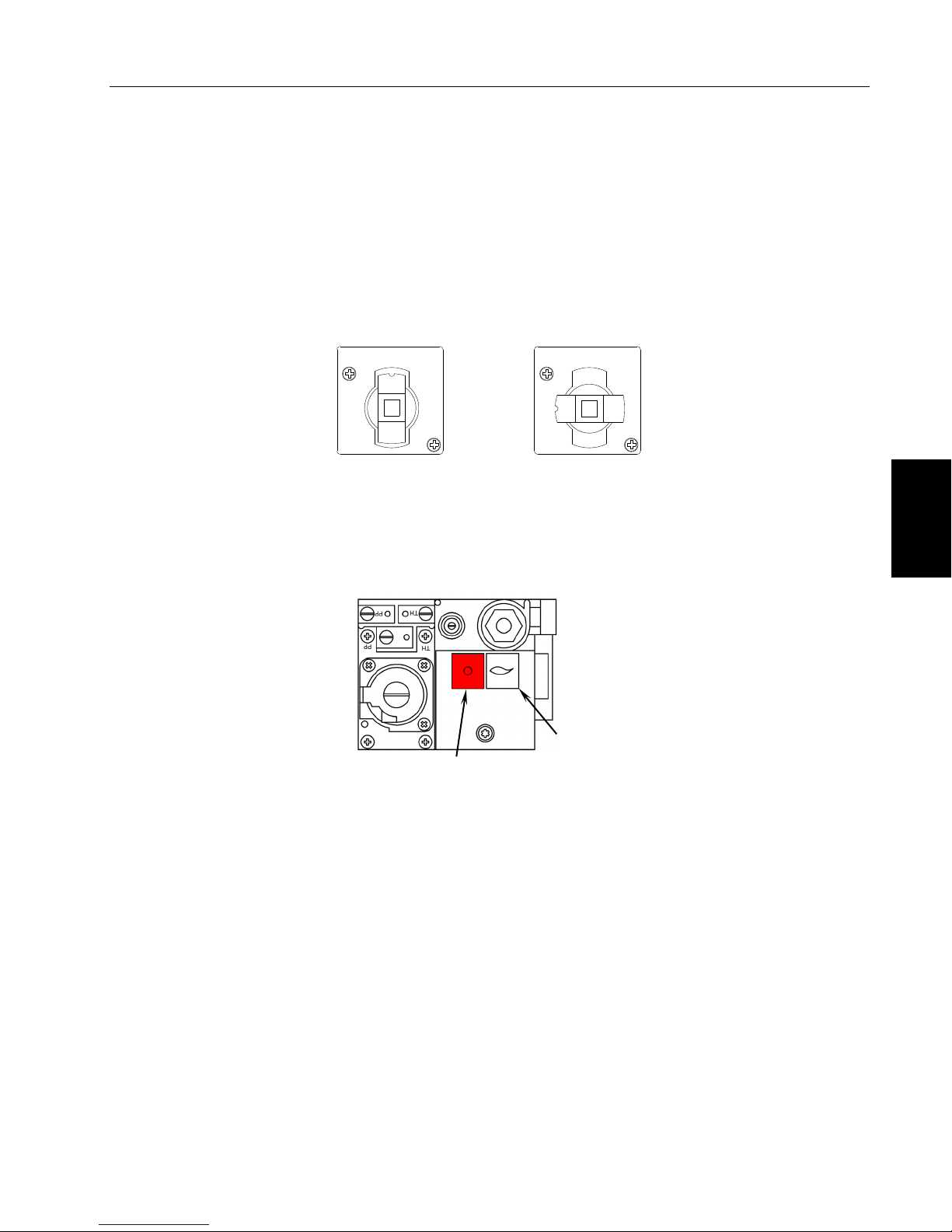

PILOT Position ON Position

Pilot/On Button

Off Button

CHAPTER 2: OPERATION

2.1 Initial Startup

Wash the unit and accessories thoroughly with hot, soapy water to remove any film residue, dust or debris. Rinse and

wipe dry. Close the drain valve completely. Ensure the operating thermostat and high-limit thermostat sensing bulbs

inside the frypot are securely seated in the holding clamp.

2.1.1 Operating the Gas Valve

NON-CE UNITS ONLY:

Rotate the knob counter-clockwise to the ON or PILOT positions. Depress and rotate the knob clockwise to turn the

valve OFF.

ENGLISH

CE UNITS ONLY:

Depress white button to light pilot and turn gas valve on. Depress red button to turn the valve off.

2.1.2 Pilot Lighting Procedures

NOTE: This fryer was tested, adjusted and calibrated to sea level conditions before leaving the factory. Adjustments

may be necessary to meet local conditions, and are to be performed only by qualified service personnel. Adjustments are

the responsibilities of the customer or dealer and are not covered by Dean warranty.

The pilot is located high in the cabinet center, at the base of the frypot. Use a long match or taper to light the pilot.

Perform the following steps in sequence before lighting the pilot:

NON-CE UNITS ONLY:

1. Turn off the manual shut-off valve on the incoming gas supply line.

2. Turn the operating thermostat to the OFF position.

3. Depress and turn the gas valve knob to the OFF position.

4. Wait at least 5 minutes for any accumulated gas to disperse.

2-1

SUPER RUNNER SERIES GAS FRYERS

CHAPTER 2: OPERATION

5. Fill the frypot with oil, shortening or water to the bottom OIL LEVEL line scribed on the frypot back. Ensure

heating tubes are covered in liquid prior to engaging burners.

NOTE: If solid shortening is used, pack the shortening into the frypot, ensuring the shortening is packed beneath,

between and above the tubes prior to operating fryer.

6. Open the manual shut-off valve on the incoming gas supply line and rotate the gas valve knob to the PILOT

position.

7. Push and hold the knob in and apply a lighted match or taper to the pilot burner head. Continue to hold the knob in

for about 60 seconds after the flame appears on the pilot. Release the knob. The pilot should remain lit.

DANGER

If the pilot fails to remain lit, turn the gas valve "OFF" and wait 5 minutes before attempting to re-light.

CE UNITS ONLY:

1. Ensure that the following steps are done in sequence before lighting or re-lighting the pilot:

2. Turn off the manual shut-off valve on the incoming service line.

3. Turn the operating thermostat "OFF".

4. Depress the red button on the safety control valve to turn "OFF".

5. Wait at least 5 minutes for any accumulated gas to disperse.

6. Fill the frypot with oil, shortening or water to the bottom OIL LEVEL line scribed on the frypot back. Ensure

heating tubes are covered in liquid prior to engaging burners.

NOTE: If solid shortening is used, pack the shortening into the frypot, ensuring the shortening is packed beneath,

between and above the tubes prior to operating fryer.

7. Open the manual shut-off valve on the incoming service line.

8. Apply a lighted match or taper to the pilot burner head. (If fryer is equipped with a piezo ignitor, go to Step 9).

9. Press the white button on the gas valve and hold approximately 45 seconds to 1 minute, until the pilot stays lit. (If

fryer is equipped with a piezo ignitor, press and hold the white button, then repeatedly press the piezo ignitor button

until the pilot lights. Release the white button after approximately 45 seconds to 1 minute.)

10. If the pilot does not stay lit, depress the white button and re-light the pilot, holding the button in longer before

releasing. Trapped air may necessitate re-lighting the pilot several times until a constant gas flow is attained.

11. When the pilot stays lit, release the white button.

2.1.3 Lighting the Burners

NEVER set a complete block of solid shortening on top of the heating tubes. To do so will damage the

heating tubes and frypot, and void the warranty.

1. Ensure the frypot is filled with oil or shortening to the lower of the two oil level lines embossed on the back wall of

the frypot. NOTE: If solid shortening is used, pack the shortening into the frypot, ensuring the shortening is packed

beneath, between and above the tubes prior to operating fryer.

WARNING

2-2

SUPER RUNNER SERIES GAS FRYERS

PART #

CE

PART #

PART #

PART #

Operating Thermostat

807-3515

807-1692

807-3515

807-1692

High-Limit Thermostat

807-3516

807-3560

807-3680

807-3560

Thermopile

810-2033

807-3565

810-2033

807-3565

Thermocouple

N/A

812-1284

N/A

812-1284

Pilot Burner, Natural Gas

810-2032

810-2032

810-2032

810-2032

Pilot Burner, Propane Gas

810-2155

810-2155

810-2155

810-2155

Pilot Bracket, AGA

N/A

200-6564

N/A

200-6564

Pilot Thermopile Bracket

N/A

810-2401

N/A

810-2401

Piezo Ignitor Trigger

N/A

810-1001

N/A

810-1001

Piezo Ignitor Bracket

N/A

200-1868

N/A

200-1868

Piezo Ignitor Electrode

N/A

807-3540

N/A

807-3540

Orifice, Natural

810-2040

810-2060

810-2048

810-2060

Orifice, Natural, units built after 4/07

810-3097

810-3101

N/A

N/A

Orifice, Propane

810-2064

810-2059

810-2059

810-2059

Orifice, Propane, units built after 4/07

810-3099

810-3102

N/A

N/A

Gas Valve, Natural

807-1603

807-2122

807-1603

807-2122

Gas Valve, Propane

807-1604

807-2121

807-1604

807-2121

Leg

810-2053

810-2053

810-2053

810-2053

Caster, 5-inch w/o Brake

810-0356

810-0356

810-0356

810-0356

Caster, 5-inch w/Brake

810-0357

810-0357

810-0357

810-0357

CHAPTER 2: OPERATION

DANGER

"Dry-firing" the fryer will cause damage to the frypot and can cause a fire. Always ensure that shortening,

cooking oil or water covers the burner tubes before lighting the burners.

2. With the pilot lit, push down and slowly turn the gas valve knob to the ON position.

3. Rotate the operating thermostat knob to the desired frying temperature. The burner should light and burn with a

strong blue flame.

DANGER

If the pilot and burners go out, the fryer must be completely shut down at least five minutes before re-

lighting.

2.2 Shutting the Fryer Down

For temporary shutdown, turn the operating thermostat to the OFF position and cover the frypot.

For complete shutdown, turn the operating thermostat to the OFF position, turn the gas valve knob to the OFF position

(Non-CE) or press the red button (CE) and cover the frypot.

2.3 Daily Operation

1. Do not allow grease to accumulate or harden on the frame, body, or flue of the fryer. Clean the fryer inside and out

with a solution of detergent and hot water daily.

2. Filter the cooking oil by draining the frypot through a filter cone at least daily. After the oil has been drained from

the frypot, remove any residue from the pot, using a scraper if necessary.

3. Clean the frypot at least once each week by filling it to just below the upper oil level mark with water. Add one cup

of detergent and bring the solution to a boil. Allow the solution to simmer for 10-15 minutes, then drain and rinse

the frypot with clean water twice. Add ¼ cup of white vinegar to the last rinse to neutralize any alkalinity remaining

from the detergent. Wipe the frypot surfaces with a dry towel before refilling with cooking oil. If the fryer is not to

be used immediately after cleaning, it is suggested that the inside of the frypot be wiped down with a light coat of

cooking oil to prevent rust.

2.4 Recommended Spare Parts

ENGLISH

DESCRIPTION

SR42- NON-

SR42- CE

2-3

SR52/SR62- NON-CE

SR52/SR62- CE

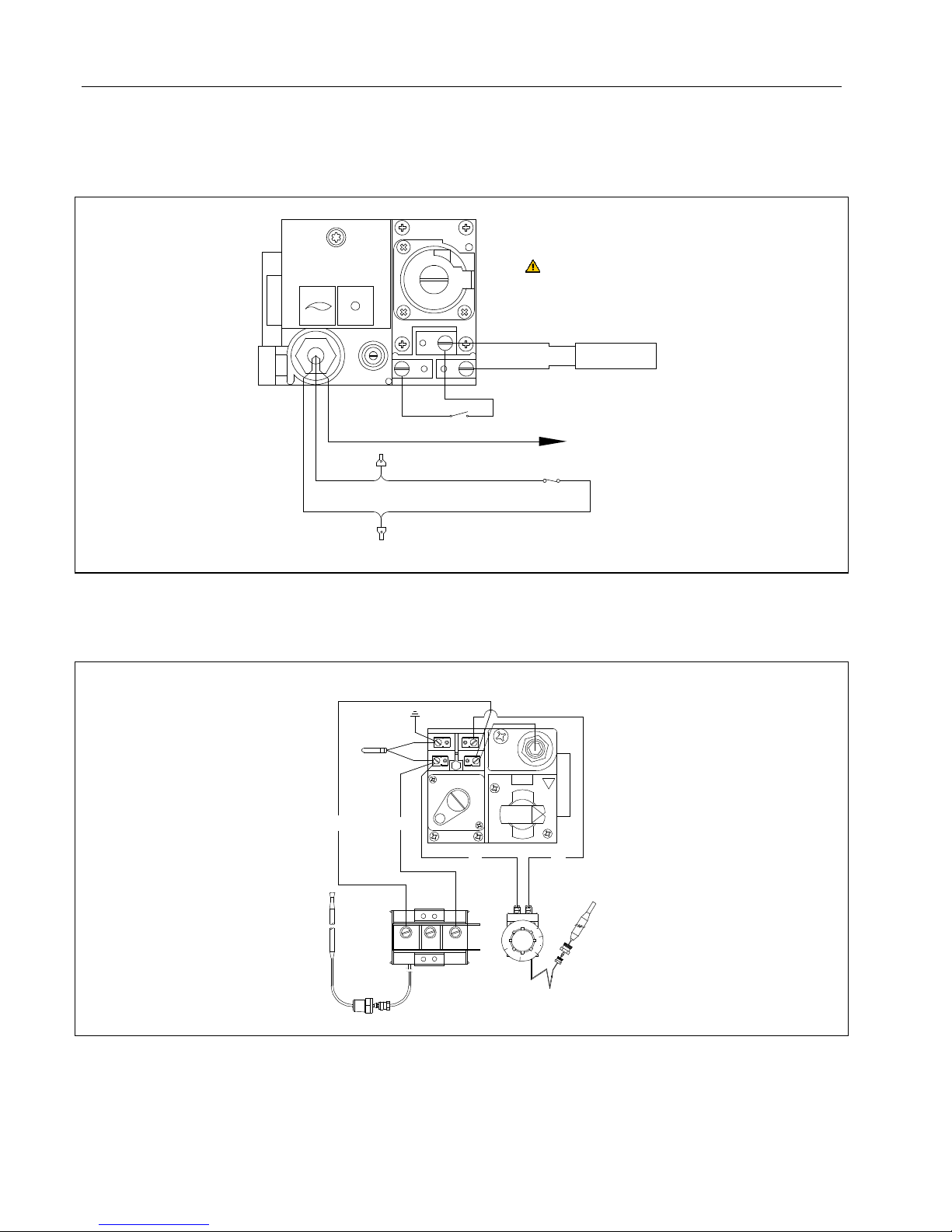

WARNING

DO NOT CONNECT ANY EXTERNAL

ELECTRICAL POWER TO THIS UNIT

THERMOPILE

HONEYWE LL 807-3565

COAXIAL LEAD TO

THERMOCOU PLE 812-1284

HIGH-LIMIT

OPERATING

THERMOSTAT

HONEYWELL CE

PP

TH

PP

TH

300

N/O

COM N/C

200

250

OFF

1C

4C

3C

HONEYWELL

1/2 P.S.I.

ON

HONEYWELL

PILOT

1/2 P.S.I.

PILOT

ADJ.

350

400

2C

C

HONEYWELL 1/2 P. S.I.

HIGH-LIMIT

OPERATING

THERMOST AT

PILOT

GENERATOR

CONTROL CIRCUIT

2.5 Wiring Diagram

CE UNITS ONLY:

SUPER RUNNER SERIES GAS FRYERS

CHAPTER 2: OPERATION

NON-CE UNITS ONLY:

2-4

Loading...

Loading...