Page 1

Super Runner 38 Series Gas Fryers (CE)

CE ONLY

Installation & Operation Manual

Dean, a member of the Commercial Food Equipment Service Association, recommends using

CFESA Certified Technicians.

24-Hour Service Hotline 1-800-551-8633

Price: $6.00

819-5707

04-99

Page 2

danger

.

AUSTRALIA ONLY:

OIL TEMPERATURE

Keep the oil temperature in the fryer to a maximum of 190°C. Higher

temperatures will cause rapid breakdown of the oil and give you no faster

cooking.

At 205°C to 210°C the life of the oil is only one third of its life at 190°C. In

addition, increased decomposition causes the oil o smoke badly even if the

temperature is lowered to 190°C again.

High temperatures give you no advantage, cost you money and increase the fire

TEMPERATURA DELL?OLÍO

Page 3

THIS PRODUCT HAS BEEN CERTIFIED AS COMMERCIAL COOKING EQUIPMENT

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE, OR

AND MUST BE INSTALLED BY PROFESSIONAL PERSONNEL AS SPECIFIED.

WE SUGGEST INSTALLATION, MAINTENANCE AND REPAIRS

SHOULD BE PERFORMED BY YOUR DEAN FACTORY

AUTHORIZED SERVICE AGENCY.

FOR YOUR SAFETY,

INSTRUCTIONS TO BE FOLLOWED IN CASE THE USER SMELLS GAS ARE TO

BE POSTED IN A PROMINENT LOCATION. THIS INFORMATION SHALL BE

OBTAINED BY CONTACTING THE LOCAL GAS COMPANY OR GAS SUPPLIER.

FOR YOUR SAFETY,

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE

VAPORS OR LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER

GAS APPLIANCE.

IMPORTANT

SAFE AND SATISFACTORY OPERATION OF YOUR EQUIPMENT DEPENDS ON

ITS PROPER INSTALLATION. INSTALLATION MUST CONFORM WITH LOCAL

CODES, OR IN ABSENCE OF LOCAL CODES, WITH THE NATIONAL FUEL GAS

CODE, ANSI Z223.1; THE NATURAL GAS INSTALLATION CODE, CAN/CGAB149.1; OR THE PROPANE INSTALLATION CODE, CAN/CGA-B149.2.

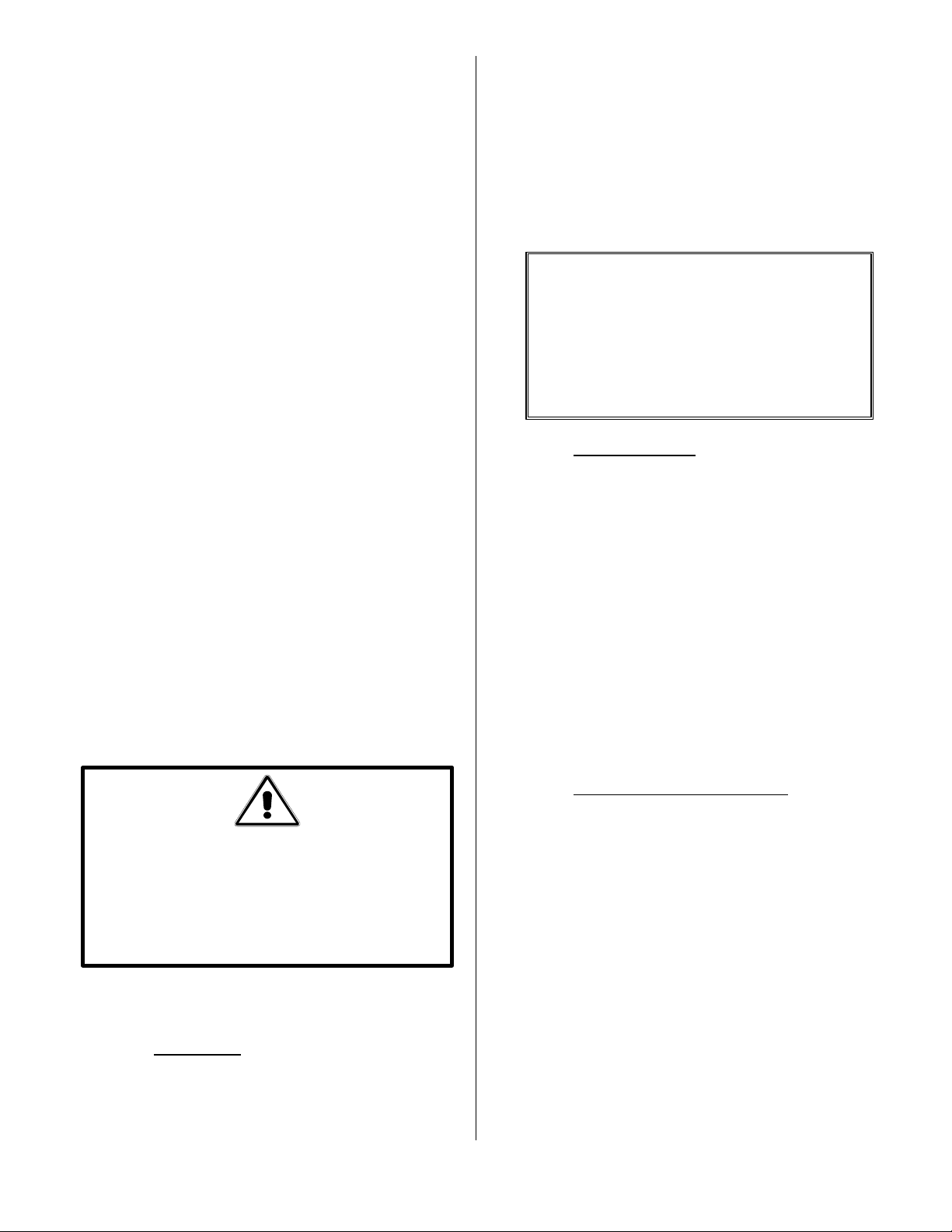

WARNING!

MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH.

READ THE INSTALLATION, OPERATING AND MAINTENACE

INSTRUCTIONS THROUGHLY BEFORE INSTALLING OR SERVICING THIS

EQUIPMENT.

Page 4

SUPER RUNNER 38 SERIES

GAS FRYER

INSTALLATION, OPERATION, & PARTS MANUAL

TABLE OF CONTENTS

PAGE

1. FACTORY PARTS ORDERING AND SERVICE 2

2. IMPORTANT INFORMATION 3

3. INSTALLATION 6

4. FRYER OPERATIONS 13

5. CLEANING AND MAINTENANCE 18

6. TROUBLESHOOTING 19

7.

1. FACTORY PARTS ORDERING & SERVICE

COMPONENT LISTING AND INSTALLATION STANDARDS

24

1.1 ORDERING PARTS:

Customers may order parts directly from their

local Authorized Parts Distributor. For this

address and phone number, contact your

Maintenance & Repair Center or call the

factory. The Dean Industries Service Hotline

phone number is 1-800-551-8633 (US/Canada)

or 1-318-865-1711 (Worldwide).

To speed up your order, the following

information is required:

Model Number

Type

Serial Number

Type of Gas

Item Part Number

Quantity Needed

1.2 SERVICE INFORMATION:

Call the service hotline number on the cover of

this manual for the location of your nearest

Maintenance & Repair Center or contact the

factory direct. Always give the model and

serial numbers of your filter and fryer.

To assist you more efficiently, the following

information will be needed:

Model Number

Type

Serial Number

Type of Gas

Nature of Problem

Any other information which may be helpful in

solving your service problem.

1.3 AFTER SALES:

In order to improve service, have the following

chart filled in by the Dean Authorized Servicer

who installed this equipment.

Authorized Servicer

Address

Telephone/Fax

Model #

Serial #

Type:

Fryer Equipped For:

2

Page 5

2. IMPORTANT INFORMATION

being installed beside an open flame of

2.1 DESCRIPTION:

The Dean Super Runner gas fryers are

energy-efficient, gas-fired units, designcertified by the International Approval

Services (AGA/CGA), NSF International,

Australian Gas Agency, Gaz de France

and manufactured to their basic

performance and application

specifications.

All units are shipped completely

assembled with accessories packed inside

the fryer vessel. All units are adjusted,

tested and inspected at the factory before

shipment. Sizes, weights and input rates

of all models are listed in this manual.

NOTE: The on-site supervisor is responsible

for ensuring that operators are made

aware of inherent dangers of operating

a deep fat fryer, particularly aspects of

oil filtration, draining, and cleaning of

the fryer.

2.2 RATING PLATE:

This is attached to the inside front door

panel. Information provided includes the

kW/hr (BTU/hr) input of the burners, outlet

gas pressure in millibars (inches WC) and

whether the unit has natural or propane gas

orifices.

1. A manual gas shut-off valve must

be installed in the gas supply line

ahead of the fryer(s) for safety and

ease of future service.

2. The Dean CE Super Runner 38 gas

fryers are millivolt systems and do

not require an electric power

supply for the fryers.

CAUTION

Local building codes usually prohibit a

fryer with its open tank of hot oil from

any type, whether a broiler or the open

burner of a range.

b. CLEARANCES: The fryer area must

be kept free and clear of all

combustibles. This unit is designcertified for the following installations:

1. Other than household use;

2. Non-combustible floor installation

equipped with factory-supplied

6"/15 cm adjustable legs;

3. Combustible construction with a

minimum clearance of 6"/15 cm

side and 6"/15 cm rear, and

equipped with factory-supplied

6"/15 cm adjustable legs.

DANGER!

THE FRYER MUST BE CONNECTED

ONLY TO THE TYPE OF GAS

IDENTIFIED ON THE ATTACHED

RATING PLATE.

2.3 PRE-INSTALLATION:

a. GENERAL: Only a licensed plumber

should install any gas-fired equipment.

c. U.S. installations must meet:

American National Standard Institute

ANSI Z83.11

American Gas Association

8501 E. Pleasant Valley Road

Cleveland, OH 44131

National Electrical Code

ANSI/NFPA #70

American National Standard Institute

1430 Broadway

New York, NY 10018

NFPA Standards #96 and #211

National Fire Protection Association

470 Atlantic Avenue

Boston, MA 02110

3

Page 6

d. Canadian installations must meet:

Canadian Electric Code c22.1, part 1

Canadian Standards Association

178 Rexdale Blvd.

Rexdale, ONT, M9W 1R3

CAN 1-B149 Installation Codes

Canadian Gas Association

55 Scarsdale Road

Don Mills, ONT, M3B 2R3

e. CE/EXPORT STANDARDS: Fryer

installation must conform with local

codes, or in the absence of local codes,

with the appropriate national or

European Community (CE) standards.

f. COMPONENT LISTING AND

INSTALLATION STANDARDS: See

Chapter 7 for a listing of various noncooking components often supplied as a

part of food service equipment and the

applicable standards.

2.4 ALTITUDE:

a. Do not connect this fryer to an exhaust

duct.

b. Correct installation and adjustment

will ensure adequate air flow to the

fryer system. Proper input is 2m3 per

hour per KW for gas supplied.

c. A commercial, heavy-duty fryer must

vent its combustion wastes to the

outside of the building. It is essential

that a deep fat fryer be set under a

powered exhaust hood or that an

exhaust fan be provided in the wall

above the unit, as exhaust gas

temperatures are approximately 8001000°F (427-538°C). Check air

movement during installation. Strong

exhaust fans in the exhaust hood or in

the overall air conditioning system can

produce slight air drafts in the room.

d. Do not place the fryer’s flue outlet

directly into the plenum of the hood, as

it will affect the gas combustion of the

fryer.

a. GENERAL: The correct orifices are

installed at the factory if operating

altitude is known at time of the

customer’s order.

b. US (ONLY): The fryer input rating

(BTU/hr) is for elevations up to 2000

feet. For elevations above 2,000 feet,

the rating should be reduced four

percent (4%) for each additional 1000

feet above sea level.

c. CE/EXPORT: The fryer input rating

(in m3/hr) is for elevations up to 610

m. For elevations above 610m, the

rating should be reduced four percent

(4%) for each additional 305 m above

sea level.

2.5 AIR SUPPLY & VENTILATION:

Keep the area around the fryer clear to

prevent obstruction of combustion and

ventilation air flow as well as for service and

maintenance.

e. Never use the interior of the fryer

cabinet for storage or store items on

shelving over or behind the fryer.

Exhaust temperatures can exceed

800°F (427ºC) and may damage or

melt items stored in or near the fryer.

f. Adequate distance must be maintained

from the flue outlet of the fryer(s) to

the lower edge of the filter bank. A

minimum of 18"/45 cm should be

maintained between the flue(s) and the

lower edge of the exhaust hood filter.

g. Filters and drip troughs should be part

of any industrial hood, but consult

local codes before constructing and

installing any hood. The duct system,

the exhaust hood and the filter bank

must be cleaned on a regular basis and

kept free of grease.

4

Page 7

2.6 RECEIVING AND UNPACKING:

Temperature:

Check that the container is upright.

Unpack the fryer carefully and remove all

accessories from the carton. Do not

discard or misplace these, as they will be

needed.

After unpacking, immediately check the

equipment for visible signs of shipping

damage. If such damage has occurred,

contact the carrier and file the appropriate

freight claims. Do not contact the factory,

as the responsibility of shipping damage is

between the carrier and the dealer or enduser.

If your equipment arrives damaged:

a. File claim for damages immediately,

regardless of extent of damage.

b. Visible loss or damage: Be sure this is

noted on the freight bill or express

receipt and is signed by the person

making the delivery.

0º Celsius = 32º Fahrenheit

Temp. in degrees Celsius = (Temperature in

degrees Fahrenheit (F) – 32) X 0.555

100° Celsius = (212º Fahrenheit –32) X 0.555

c. Concealed loss or damage: If damage

is unnoticed until equipment is

unpacked, notify freight company or

carrier immediately, and file a

concealed damage claim. This should

be done within fifteen (15) days of

date of delivery. Be sure to retain

container for inspection.

NOTE: Dean Does Not Assume Responsibility

For Damage Or Loss Incurred In

Transit.

2.7 CONVERSION OF UNITS:

Pressure:

1 mbar = 10.2 mm water column (mm WC)

= 0.4 inch WC

20 mbar = 204 mm WC = 8 inch WC

1 Inch W.C = 25.4 mm WC = 2.5 mbar

Heat Input:

1 kW = 3410 BTU/hr

100 BTU/hr = 0.293 KW

5

Page 8

3. INSTALLATION

room temperature and drained of

3.1 POSITIONING:

a. Initial Installation: If the fryer is

installed with legs, do not push the

fryer to adjust its position. Use a pallet

or lift jack to lift the fryer slightly and

place the fryer where it is to be

installed.

b. Relocating The Fryer: Before

relocating a fryer installed with legs,

remove all weight from each leg before

moving.

If a leg becomes damaged during

movement, contact your service agent

for immediate repair/replacement of

that leg.

CAUTION

This fryer may tip and cause personal

injury if not secured in a stationary

position. Remove all shortening before

moving the fryer as it may cause severe

burns upon contact.

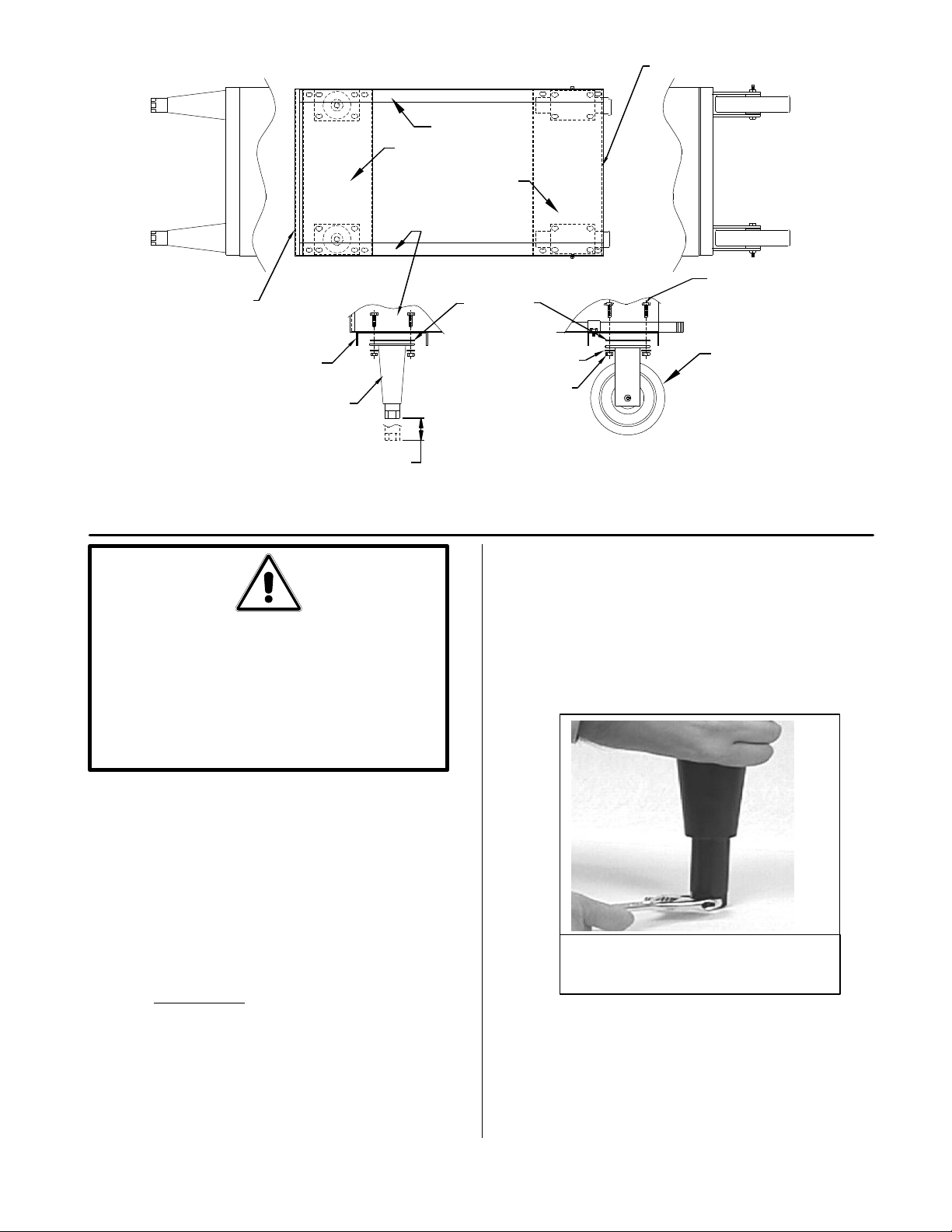

3.2 LEG AND CASTER INSTALLATION:

a. General:

1. Install legs and casters (optional)

near where the fryer is to be used, as

neither are secure for long transit.

Unit cannot be curb mounted and

must be equipped with the legs (or

legs and optional rigid casters)

provided.

4. Proceed to Step 3.3, Leveling, after

legs and/or optional rear rigid casters

are installed to ensure the fryer is

level before using.

b. Leg Installation:

1. Remove unit from pallet.

2. Carefully raise unit with forklift,

pallet jack, or other steady means.

3. Insert hex head bolts (1/4-20 threads

by 19mm (¾") long) from top of side

panels and channels through bolt

holes of leg mounting plates as

shown in the Figure 3-1 on the next

page.

4. Mount washer and lock nuts (1/4-20

threads Stover lock nut) from bottom

of the leg mounting plates. The lock

nut has a portion of threads

deflected. Make sure the nut starts

freely on the bolt like a common nut

until the deflected thread portion is

reached.

5. On the front door hinge corner, the

bolts will be inserted first through

the holes of the hinge plate, then

followed with side panel, channel,

and leg mounting plate.

6. Tighten the bolts and nuts with each

bolt to 5.65 joules (50 inch-lbs.)

minimum torque.

CAUTION

For caster retrofit, the unit must be at

2. When positioning the fryer, gently

lower the fryer into position to

prevent undue strain to the legs and

internal mounting hardware. Use a

pallet or lift jack to lift and position

the fryer if possible. Tilting the fryer

may damage the legs.

3. If the optional rigid casters are to be

installed on the fryer, the casters

must be installed on the fryer rear

channel assembly only.

shortening before installing the casters.

b. Installing Optional Rear Rigid Casters:

1. Install casters only at the rear of the

unit as shown in the Figure 3-1.

2. Follow the same instructions for leg

installations as given above in steps

3.2.b.1-6.

6

Page 9

NOT LEVEL, THE FRYER MAY TIP

Side Panel

Front Channel

Rear Channel

Side Panel

Structural Back

Front Door

Front Channel

1/4-20 HX HD Lock Nut

Front Leg w/Mounting Plate

P/N 2698

Adjust as needed.

Leg and Rigid Caster Installations

WARNING!

A FRYER MUST BE LEVEL BEFORE

FILLING WITH OIL. IF THE FRYER IS

Caster Shims

(P/N 900-2949)

if required.

Washer P/N 1008

(P/N 2701)

Figure 3-1

19mm (1/4 - 20 x 3/4 in)

HX Bolt (P/N 1007)

Rear Rigid Caster

15.2 cm/6 in

(P/N 2701)

2. Adjust leg height with an adjustable

or 1-1/16” open end wrench by

turning the hex bullet on the bottom

of the leg.

3. The hex bullet is for minor leg

height adjustment only. Do not

adjust more than 22mm (1").

OVER AND MAY CAUSE INJURY TO

THE OPERATOR.

3.3 LEVELING:

a. Place a carpenter’s spirit level across

the top of the fryer and level the unit

both front-to-back and side-to-side. If

it is not level, the unit may not function

efficiently, the oil may not drain

properly for filtering and in a line-up it

may not match adjacent units.

b. Legs (Only):

1. If the floor is smooth and level,

level the unit by using the caster

shims. Adjust to the high corner

and measure with the spirit level.

ADJUST LEG HEIGHT WITH

AN ADJUSTABLE WRENCH

4. When leveling the unit, the leg body

should be held firmly to keep the leg

from rotating while turning the hex

bullet foot to the required height.

7

Page 10

c. Rigid Casters (Only):

USING MORE THAN TWO SHIMS PER

1. Install the optional rigid casters on

the fryer rear channel only.

necessary, to reconnect this restraint

after the appliance has been returned

to its originally installed position.

2. Do not use more than two metal

shims per caster.

3. There are no thread adjustments for

the rigid casters.

WARNING!

DO NOT USE MORE THAN TWO

METAL SHIMS PER LEG/CASTER.

LEG/CASTER MAY CAUSE THE

FRYER TO BECOME UNSTABLE, TIP

OVER, AND MAY CAUSE INJURY TO

THE OPERATOR.

d. If the floor is uneven or has a decided

slope, it is recommended to place the

fryer on a smooth platform. Do not

rely on leg thread or caster shims for

adjustments.

e. If the fryer is moved, re-level the fryer

following the instructions given in

Steps 3.3.a-c.

f. This fryer must be restrained to prevent

tipping when installed in order to avoid

the splashing of hot liquid. The means

of restraint may depend on the type of

application, such as connecting to a

battery of appliances or installing the

fryer in an alcove, or by separate

means, such as restraining devices. A

bracket has been provided on the fryer

back panel for this purpose.

The install must be reviewed at the

time of installation to ensure it meets

the intent of these instructions. The

on-site supervisor and/or operator(s)

should be made aware there is a

restraint on the appliance and, if

disconnection of the restraint is

NOTICE

If the fryer cannot be adjusted to perform

correctly, or you have any questions about

this install, contact your local authorized

service agency.

3.4 GAS CATEGORIES:

The Dean Super Runner 38 Series Gas

Fryers have obtained CE markings for

countries and gas categories shown below:

Countries Supply Pressures

and Gas (mbar)

BE Belgium

DE Germany

DK Denmark G20 20 I2H

ES Spain

FR France

GB Great Britain

GR Greece

IR Ireland

IT Italy G20 20 I2H

LU Luxembourg

The

NL

Netherlands

PT Portugal

G20 20/25 I2E (R) B

G31 37 I3P

G20 20 I2E

G31 50 I3P

G20 20

G31 37 and 50

G20/G25 20/25

G31 37 and 50

G20 20

G31 37

G20 20

G31 37 and 50

G20 20

G31 37

G20/G25 20/25

G31 50

G25 25

G31 50

G20 20

G31 37

Appliance

Categories

II2H3P

II2ESI3P

II2H3P

II2H3P

II2H3P

II2E3P

II2L3P

II2H3P

3.5 GAS CONNECTIONS: The gas

supply (service) line must be the same size

or greater than the fryer inlet line. This

fryer is equipped with a 19 mm (3/4”)

male ISO 7.1 inlet; however, the gas

supply lines must be sized to

8

Page 11

accommodate all the gas-fired equipment

joint compound suitable for LP gas, and

pressures in excess of 3.45

KPa (½ PSIG).

that may be connected to that gas supply.

Consult your contractor, gas company,

supplier, or other knowledgeable

authorities.

installed at the factory. While the

valve can be adjusted in the field,

only qualified service personnel

should make any adjustments with

the proper test equipment.

a. Manual shut-off valve: This gas

service supplier-installed valve must

be installed in the gas service line

ahead of the fryer in the gas stream

and in a position where it can be

reached quickly in the event of an

emergency. This shut-off valve must

be installed only by an authorized

person to the requirements of the local

gas authorities.

CAUTION

The fryer must be isolated from the gas

supply piping system by closing its

individual, manual shut-off valve

during any pressure testing of the gas

supply piping system at pressures equal

to or less than 3.45 KPa (½ PSIG).

b. Pressure regulating:

1. External gas regulators are not

normally required on this fryer, as

that function is performed by a

safety control valve.

2. Australia: The following color

codes are used to indicate the type

of gas for which the fryer and

components are to be used:

Gas Type Color Code

Natural Black

Propane Orange

d. Rigid Connections: The fryer can be

connected singularly or as part of a

cooking line. Check any installersupplied intake pipe(s) visually and

clean threading chips, or any other

foreign matter before installing into a

service line. If the intake pipes are not

clear of all foreign matter, the orifices

will clog when gas pressure is applied

CAUTION

All connections must be sealed with a

all connections must be tested with a

soapy solution before lighting any pilots.

2. If the incoming pressure is in

excess of 3.45 KPa (½” PSIG), a

step-down regulator will be

required. Your local servicer

should check the manifold

pressure with a manometer.

CAUTION

The fryer and its individual shut-off valve

must be disconnected from the gas supply

piping system during any pressure testing

of the gas supply piping system at test

c. Orifices:

1. The fryer can be ordered to operate

on any available gas. The correct

safety control valve, appropriate

gas orifices, and pilot burner are

e. Flexible Couplings & Connectors:

1. General: A restraining bracket is

provided on the structural back of

the fryer to prevent the unit from

moving from its installed position.

The fryer must be restrained by

means independent of the flexible

coupling or connector in order to

limit the movement of the fryer.

2. US/Canada Standards: If the unit is

to be installed with flexible

couplings and/or quick disconnect

fittings, the installer must use a

heavy-duty, AGA design-certified

commercial flexible connector of at

least 3/4" (19mm) NPT (with

suitable strain reliefs) in compliance

9

Page 12

with the Standards for Connectors

NEW CONNECTION IS NOT ONLY

for Movable Gas Appliances, ANSI

Z21.69. Quick disconnect devices

must comply with the Standard for

Quick-Disconnect Devices for Use

with Gas Fuel, ANSI Z21.41.

Domestic connectors are not

suitable!

If the unit is to be installed with

casters, flexible connectors must be

used and the same ANSI standards

mentioned on the previous page

apply. Locking front casters are

provided to limit the movement of

the appliance without depending on

the connectors or associated piping.

CAUTION

Any modification, adaptation, or gas

conversion must be performed by qualified

personnel only. Failure to use qualified

personnel will void the Dean warranty.

3.7 ADJUSTMENTS / ADAPTATION TO

DIFFERENT GASES:

a. Proper operation of appliances

requires operator to scrupulously

respect the following adjustments in

terms of:

1. gas inputs and pressures, air

adjustment;

3. CE Standards: If the unit is to be

installed with flexible coupling, use

a commercial flexible coupling

certified as NF D 36123 (or other

national standard) or a quick

disconnect device certified NF D

36124 (or other national standard).

f. Piping Sizes: According to the number

of fryers to be connected, the gas supply

line must be sized as indicated in the

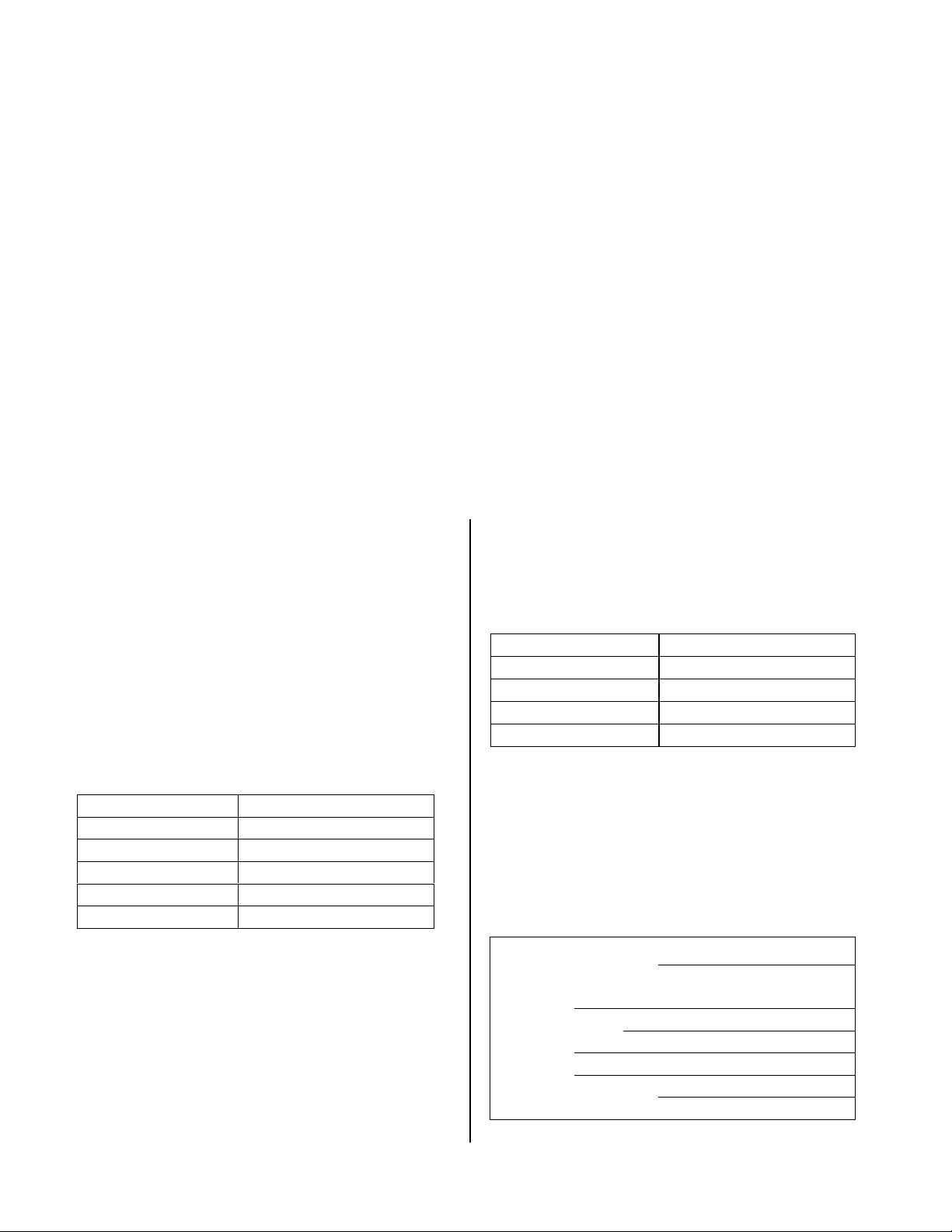

chart below:

Number

of Fryers

Natural Gas

Propane Gas

(*) When exceeding 6 meters for a

configuration of more than 4 fryers, it is

necessary to provide a 33mm (1 ¼”) rigid

gas connection.

1 2 to 3

19mm

(3/4”)

13mm

(1/2”)

25mm

(1”)

19mm

(3/4”)

4 and

more (*)

33mm (1

¼”)

25mm

(1”)

2. voltage and polarities of electrical

power supply.

b. Dean gas fryers are manufactured to

use the type of gas and pressure

specified on the rating plate. When

changing gas, adaptation must be

performed by qualified personnel.

Failure to use qualified personnel will

void the Dean warranty.

NOTICE

The installer is required to test the complete

fryer operation prior to leaving the

installation site.

3.8 GAS INPUTS:

a. Nominal Qn Heat Input is:

SR38G: 15 kW.

b. Inputs for different gases are as

follows:

WARNING

PUTTING AN OPEN FLAME BESIDE A

DANGEROUS, BUT WILL OFTEN

MISS SMALL LEAKS THAT A SOAPY

SOLUTION WILL FIND.

10

G20

G25

G31 Propane

Natural Gas

(Type H)

Natural Gas

(Type L)

20 mbar : 1,58 M3/H

25 mbar: 1,84 M3/H

37 mbar: 1,16 KG/H

Page 13

3.9 CHART: ADJUSTMENT TO DIFFERENT GASES

GASES AND

PRESSURES SUPPLY

G20

18 mbar

G25

25 mbar

G31

31 mbar

(1)

Diameter and markings of

injectors

Burner

Pilot TJ024 TJ024 TJ013 "red"

(2) Gas pressure at the

regulator (mbar/inches WC)

Burner air adjustment No Air Adjustment No Air Adjustment No Air Adjustment

1.90 mm 1.90 mm 1.28 mm

"blue" marking "blue" marking "red" marking

12.0 mbar/5.00 in WC 17.5 mbar/7.03 in WC 22.0 mbar/8.83 in WC

NOTE: Outlet gas pressure must be controlled with precision 5 to 10 minutes after appliance is

operating.

(1) – (2): For controls and adjustments, please refer to "gas valve" illustration.

(Pilot : adjustment of flame’s volume may be achieved by turning the screw that is mounted on the gas

valve).

♦ Adjust gas pressure to orifices by turning

the gas valve adjustment screw.

♦ After adjustment, seal the screw.

WARNING!

CONVERTING A FRYER FROM ONE

GAS TYPE TO ANOTHER SHOULD BE

PERFORMED BY AUTHORIZED

SERVICE PERSONNEL ONLY.

♦ See Gas Valve diagrams on page 11.

♦ Change label "fryer equipped for" and

affix it to the rating plate. Erase gas that is

not used.

c. Important : for the same gas:

3.10 STEPS TO FOLLOW DURING

GAS CONVERSION (CE Only):

a. From G20 to G25:

♦ No replacement of equipment.

♦ Adjust gas pressure to orifices by

turning the gas valve "adjustment

screw".

♦ After adjustment, seal the screw.

♦ See Gas Valve diagrams on page 11.

b. From G20 (or G25) to G31 propane (or

vice versa).

♦ Replacement of burners orifices and

pilot.

♦ G25 / 25 mbar or 20 mbar

♦ G31 / 37 mbar

♦ no change is to be executed on the

appliance.

d. When changing gas family – i.e changing

from natural gas to propane, please order

the necessary kit as indicated hereafter.

Specific gas conversion kit part numbers

can be found at the bottom of the parts list

found in Chapter 6.

This change can only be executed by a

qualified and factory authorized personnel.

1. The complete kits for gas conversion include

the following parts:

11

Page 14

SR38G Natural Gas to Propane Kit

1/8"

/ 3 mm

QTY REF DESCRIPTION

1 TJ013 Pilot injector

3 14-0067-59

1 Label

Appareil réglé pour : G31 / 37

Burner injector

(diam. 1.28 mm)

Fryer equipped for : G31/37

SR38G Propane to Natural Gas Kit

QTY REF DESCRIPTION

1 TJ024 Pilot injector

3 14-0067-49

1 Label

Fryer equipped for : G25 / 25 *

Burner injector

(diam. 1.90 mm)

Appareil réglé pour : G20 / 20

3.11 ELECTRICAL CONNECTIONS:

The wiring diagram is attached to the

inside of the fryer door. The diagram can

also be found on page 16, Chapter 6,

Troubleshooting. The fryer is equipped

with a millivolt control system which

does not need an outside power source.

Super Runner Gas

Valve, Burner, and

Orifice Locations

Super Runner Gas Valve

Adjustment

Figure 3-3

Inlet Pressure Tap

Figure 3-2

Outlet Pressure

Tap

1/8 " / 3 mm

12

Page 15

4. FRYER OPERATIONS

CHECKING FOR BURNER

4.1 INITIAL START-UP:

a. CLEANING: New units are wiped

clean with solvents at the factory to

remove any visible signs of dirt, oil,

grease, etc. remaining from the

manufacturing process, then coated

lightly with oil. Wash thoroughly with

hot, soapy water to remove any film

residue and dust or debris before food

preparation, then rinse out and wipe

dry. Wash also any accessories

shipped with the unit. Close the drainvalve completely and remove the

crumb screen. Make sure the screws

holding the thermostat and limit

control sensing bulbs into the vessel

are tight.

may be necessary on installation to

meet local conditions, low gas

pressure, differences in altitude,

variations in gas characteristics, to

correct possible problems caused by

rough handling or vibration during

shipment, and are to be performed only

by qualified service personnel. These

are the responsibilities of the customer

and/or dealer and are not covered by

Dean Industries’ warranty.

1. The inlet pipe at the lower rear of

the fryer brings incoming gas to

the pilot safety control valve,

then to the pilot and/or main

burners. The pilot is located high

in the cabinet center, at the base

of the fryer vessel. It will require

a long match or taper to light.

Drain Shut-Off Valve

WARNINGS!

DO NOT USE AN OPEN FLAME TO

CHECK FOR THE PRESENCE OF GAS

INSIDE THE FRYER CABINET.

IF PILOT FAILS TO LIGHT, WAIT 5

MINUTES BEFORE RELIGHTING TO

ALLOW ANY ACCUMULATED GAS TO

DISSIPATE.

b. INITIAL PILOT LIGHT: All Dean

Industries’ fryers are tested, adjusted

and calibrated to sea level conditions

before leaving the factory.

Adjustments to assure proper operation

Pilot

WARNING!

WHEN LIGHTING PILOTS AND

PERFORMANCE, DO NOT STAND

WITH YOUR FACE CLOSE TO THE

BURNERS…THEY MAY LIGHT

WITH A “POP” AND COULD CAUSE

FLASH BACK AND FACIAL BURNS.

2. Ensure that the following steps are

done in sequence before lighting or

re-lighting the pilot:

13

Page 16

a) Turn off the manual shut-off

valve on the incoming service

line.

b) Turn the operating thermostat

“OFF”.

c) Depress the pilot gas cock dial

on the safety control valve and

turn “OFF”.

Pilot Gas Cock Dial

air and a constant gas flow is

attained.

6. When the pilot stays lit, turn the

gas cock dial to “ON”.

7. Turn the thermostat to any “ON”

setting and watch to make sure the

main burner ignites from the pilot.

Operating Thermostat

d) Wait at least 5 minutes for any

accumulated gas to disperse.

1. Fill fryer tank with liquid oil (or

water during testing) to the “oil

level” line scribed into the rear

wall of the tank.

2. Open the manual shut-off valve on

the incoming service line.

3. Apply a lighted match or taper to

the pilot burner head.

4. Turn the safety valve gas cock to

“Pilot”, depress and hold the dial

until the pilot stays lit when the

dial is released. This may take a

minute or longer.

5. If the pilot does not stay lit,

depress the dial and re-light it,

holding the dial in longer before

releasing. It may be necessary to

re-light the pilot several times until

the lines are purged of any trapped

WARNING

IF GAS ODORS ARE DETECTED THE

GAS SUPPLY MUST BE SHUT OFF AT

THE MAIN SHUT-OFF VALVE AND

THE LOCAL GAS COMPANY OR

AUTHORIZED SERVICE AGENCY

CONTACTED FOR SERVICE.

4.2 HEATING THE VESSEL: This

step will check main burner operation,

initial thermostat calibration, and clean the

vessel for initial food production.

a. Fill the fryer vessel with hot or cold

water to the oil level line scribed in the

back of the tank.

b. Set the operating thermostat/

temperature controller dial to 104°C

(220°F), just above that of boiling

water.

c. The main burner will ignite.

14

Page 17

d. Reset the temperature controller to

DANGEROUS.

93°C (200°F).

e. The burners should shut-off just as the

water starts to boil.

f. When satisfied that the burners and

thermostat are operating properly,

drain the vessel of water and dry

thoroughly. Refill it with shortening

as directed below.

4.3 FINAL PREPARATION:

a. When using a liquid shortening

(cooking oil), fill the fryer to the “oil

level” line scribed into the back of the

fryer vessel.

b. When using a solid shortening, either

melt it first with another appliance, or

cut into small pieces and tightly pack

it below the heat tubes, between the

heat tubes, and on top of the heat

tubes, leaving no air spaces and being

careful not to disturb the sensing

bulbs. Make sure the crumb screen is

removed before placing solid

shortening in the fryer. Melt this

shortening by turning the burners

“ON” for about five or ten seconds,

“OFF” for a minute, etc. until the

shortening is melted. If you see any

smoke coming from the oil while

melting this way, shorten the “ON”

cycle and lengthen the “OFF” cycle.

Smoke shows that you are scorching

the shortening and reducing its useful

life.

c. When the fryer vessel is filled and the

shortening melted, place the crumb

screen over the heat tubes.

DANGER!

NEVER MELT A SOLID BLOCK

OF SHORTENING BY SETTING

IT WHOLE ON TOP OF THE

HEATING TUBES. THIS IS

UNSAFE, INEFFICIENT AND

4.4 GENERAL USE OF THE FRYER:

a. For consistent quality product,

convenience and long-term savings, use

a high-quality liquid frying compound.

b. If using solid shortening, never melt a

block of shortening by setting it on top

of the heating tubes. This is dangerous

and can easily cause the vessel heat tube

to burn through, warp, or overstress the

welded seams.

c. Although 177°C (350°F) is the

recommended temperature for most

cooking operations, set the fryer at the

lowest possible temperature which

produces a high quality end product

while ensuring maximum life of frying

compound.

When the fryer is not in use, the

thermostat should be set lower than that

used during cooking. Light loads, too,

may be cooked at lower temperatures.

A good operator will experiment to

determine the optimum temperature and

load conditions for the various food

items to be cooked.

d. Before starting operation, turn the

operating thermostat to the probable

working temperature; wait for the

temperature to stabilize then check

with a high-quality immersion

thermometer.

4.5 OPENING: At opening time, always

visually check the fryer for:

a. The combination or main gas valve is

“OFF”.

b. Fry vessel is filled with liquid oil to

the oil level line scribed into the rear

wall of the fry vessel tank.

15

Page 18

c. To light the fryer:

Operating Thermostat

1. Open the manual shut-off valve on

the incoming service line.

2. Apply a lighted match or taper to

the pilot burner head.

3. Turn the safety valve gas cock to

“Pilot”, depress and hold the dial

until the pilot stays lit when the

dial is released. This may take a

minute or longer.

Pilot Gas Cock Dial

4. If the pilot does not stay lit,

depress the dial and re-light it,

holding the dial in longer before

releasing. It may be necessary to

hold the depress the pilot cock for

several minutes or re-light the pilot

several times until the lines are

purged of any trapped air and a

constant gas flow is attained.

5. When the pilot stays lit, turn the

gas cock dial to “ON”.

6. Turn the thermostat to the desired

cooking temperature and allow the

fry vessel to heat for

approximately 30 minutes before

cooking. This will allow the fryer

to stabilize the oil temperature at

the desired setpoint which ensures

quality cooking.

4.6 TURN ON PROCEDURES:

a. If fryer is empty, pour enough frying

compound into the vessel to fill the

vessel to the “oil level” line scribed on

the rear wall.

b. When using a solid shortening, either

melt it first, or cut into small pieces and

tightly pack it below the heat tubes,

around the heat tubes, and on top of the

heat tubes, leaving no air spaces around

the heat tubes and being careful not to

disturb the sensing bulbs. Melt this

shortening by turning the burners “ON”

for about five or ten seconds, “OFF”

for a minute, etc. until the shortening is

melted. If you see any smoke coming

from the oil while melting this way,

shorten the “ON” cycle and lengthen

the “OFF” cycle. Smoke shows that

you are scorching the shortening and

reducing its useful life.

c. Turn the temperature controller to

177°C (350°F). In less than 30

minutes, the frying compound

temperature will stabilize and be ready

for production.

CAUTION

When filtering, never leave the filter

unattended. The action of the oil moving

through the lines could knock a flexible

return hose out of the fryer, spraying hot oil

and causing severe burns.

16

Page 19

4.7 CHIP PRODUCTION RATE

(Australia):

Based on a recommended thermostat

temperature setpoint of 177°C (350°F) and

a cook time of 2.7 minutes, the production

of 6 mm (1/4") cut frozen chips should be

from 26.3 to 27.22 KG/hr (58 to 60 lbs/hr).

Production rate will be influenced both by

the moisture content of the chip, and the

age/quality of the shortening used.

4.10 SHUT-DOWN:

When closing down for periods longer than

overnight:

a. Drain the frying compound and clean

the vessel thoroughly.

b. Either discard the frying compound or

return it filtered to the vessel and then

cover it.

4.8 FILTERING:

Detailed operating and troubleshooting

information about Dean filtration systems

can be found in the operating manual

provided with your filter unit.

a. The frying compound should be

filtered at least daily or even more

frequently if cooking is heavy. This

ensures the longest life possible for the

frying compound, gives better taste to

the food being prepared and minimizes

flavors being transferred from batch to

batch.

b. When completing a filter cycle, always

close the return valve(s) at the fryer(s)

to avoid siphoning oil out of the fryer

into the filter and open the valve at the

filter to promote draining of the return

lines into the filter pan.

c. Non-stainless Fry Vessels Only: If

frying compound is discarded, lightly

coat the inside of the non-stainless

vessels with fresh frying compound to

prevent rusting of the bare mild steel

frying vessels.

d. Turn the control knob on the

combination gas valve “OFF”.

e. Turn the manual valve on the incoming

gas service line to “OFF”.

f. Disconnect the power cord for the

portable filter unit from the wall socket.

c. If using solid shortening, always make

sure the return lines are clear before

turning off the filter motor and hang

any flexible lines up to drain. Solid

shortening will solidify as it cools,

eventually clogging the lines.

4.9 CLOSING:

a. When closing at night, filter the oil in

all fryers and drain the filter lines.

b. Cover the open tanks of oil.

c. Turn the control knob on the

combination gas valve “OFF”.

d. Turn filter power switch “OFF”.

WARNINGS

DO NOT GO NEAR THE AREA

DIRECTLY OVER THE FLUE OUTLET

WHILE THE FRYER IS OPERATING.

ALWAYS WEAR OIL-PROOF,

INSULATED GLOVES WHEN

WORKING WITH THE FRYER FILLED

WITH HOT OIL.

ALWAYS DRAIN HOT OIL INTO A

METAL CONTAINER. HOT OIL CAN

MELT PLASTIC BUCKETS AND

CRACK GLASS CONTAINERS.

17

Page 20

5. CLEANING & MAINTENANCE

DO NOT LET WATER SPLASH INTO THE

TANK OF HOT OIL. IT WILL SPLATTER

ALTERATIONS, SERVICE OR

DO NOT DRAIN WATER INTO

FILTER. WATER WILL DAMAGE

THE FILTER PUMP.

WARNING!

IF THE FRYER IS NOT COMPLETELY

EMPTY OF OIL, ADJUSTMENTS,

MAINTENANCE CAN CAUSE

PROPERTY DAMAGE AND PERSONAL

INJURY.

5.1 GENERAL: Any piece of equipment

works better and lasts longer when

maintained properly and kept clean. Keep the

fryer must be kept clean during the working

day. Clean the fryer at the end of each day.

5.2 DAILY: Wash all removable parts. Clean

all exterior surfaces of the body. Do not use

cleansers, steel wool, or any other abrasive

material on stainless steel. Filter the cooking

oil and replace if necessary. The oil should

be filtered more often than daily under heavy

use conditions.

f. Refill with clear water, set operating

thermostat to 220°F (104°C), and boil

again. Once boiling is completed, turn

operating thermostat “OFF”, drain, rinse,

and dry thoroughly.

CAUTION

Do not let water boil down to the point that

tubes are exposed as this will damage them.

g. Immediately refill with cooking oil or

frying compound as directed in Section

4.3.

WARNING!

AND CAN CAUSE SEVERE BURNS.

5.3 WEEKLY:

a. Completely drain the oil from the fry

vessel into either the filter or a steel

container. Do not use a plastic bucket or

glass container.

b. Clean the vessel with a good grade of

cleaner or hot water and a strong

detergent.

c. Close the drain valve and refill with

either the cleaning solution or water and

detergent.

d. Set operating thermostat to 220°F

(104°C). Bring to a rolling boil, then

turn the heat down and let the mixture

stand until deposits and/or carbon spots

can be removed with the Teflon brush.

e. Scrub tank walls, bottom and heating

tubes. Then drain vessel and rinse in

clear water.

5.4 PERIODIC: The fryer should be checked

and adjusted periodically by qualified service

personnel as part of a regular kitchen

maintenance program.

5.5 STAINLESS STEEL: All stainless steel

fryer body parts should be wiped regularly

with hot, soapy water during the day and with

a liquid cleaner designed for this material at

the end of each day.

a. Do not use steel wool, abrasive cloths,

cleansers or powders!

b. Do not use a metal knife, spatula or any

other metal tool to scrape stainless steel!

Scratches are almost impossible to

remove.

c. If it is necessary to scrape the stainless

steel to remove any encrusted materials,

soak the area first to loosen the material,

then use a wood or nylon scraper only.

18

Page 21

6. TROUBLESHOOTING

6.1 PROCEDURES: The problems and possible solutions given in this section cover those most

commonly encountered. To troubleshoot, perform the test set-up at the beginning of each

condition. Follow each step in sequence as shown in the troubleshooting flowcharts.

6.2 SET-UP: Follow start-up procedures found in Section 3.7, Initial Start-Up, on page 8 of this

manual. Attempt to light the pilot and then follow the flowchart below.

6.3 PILOT FAILS TO LIGHT:

1. Check to see that gas lines are

connected.

2. Re-light pilot. When attempting to re-

Pilot fails to light.

light the pilot, ensure combination gas

valve manual knob is depressed for at

least one minute. If pilot doesn’t light,

go to step 3.

3. Call for service.

6.4 FRYER FAILS TO HEAT:

1. Check to ensure gas valve is set to the

“ON” position.

2. Set operating thermostat to 350°F

Fryer fails to heat fry vessel.

FOR DETAILED TROUBLESHOOTING AND SERVICE-RELATED INFORMATION, CALL

THE DEAN SERVICE HOTLINE AT 1-800-551-8633 (US/Canada) or 1-318-865-1711

(Worldwide).

(177°C) and observe fryer. Do the

main burners come on and heat the fry

vessel? If no, go to step 3.

3. Call for service.

19

Page 22

6.5 MILLIVOLT WIRING DIAGRAMS:

6.5.1 US/Canada/CE:

White

Combination Gas

Valve

Red

Thermopile

Red

Red

Hi-Limit

6.5.2 Australia (Only):

Operating

Thermostat

Black

Black

20

Page 23

6.6 EXPLODED PARTS DIAGRAM:

12

9

8

26

6

5

1

7

15

2

11

24

10

16

14-0684-2

14-0684-3

14-0684-3

14

18

20

3

17

19

37

4

30

36

13

28

35

21

33

25

31

22

21

23

29

A

29

B

TO ITEM 19

TO ITEM 19

27

Page 24

6.7 SUPER RUNNER 38 GAS PARTS LIST:

Item No. Description Dean P/N

1 Flue Assembly 12203

2

3

4 Front and Rear Channel 12-0373

5

6 Probe Retainer Top 18-0091

7 Grid Assembly 12081

8 Basket Hanger Alum Steel 12-0310-1

Structural Back Upper

Structural Back Lower

Side Panel Painted

Side Panel Stainless Steel

Japan/Australia 12202-1

Vessel Assembly

Mild Steel (M/S) US/CE/Export (March 1998

Vessel Assembly

Stainless Steel

(S/S)

US (before March 1998) 12082NV

and later) (except Japan &

Australia)

Japan/Australia 12202-2

US (before March 1998) Not Used

US/CE/Export (March 1998

and later) (except Japan &

Australia)

12-0401

12-0402

12-0380

12-0381

12188-1

12188-2

9 Frying Basket 2607

10 Clean-out Rod 14-0193

11 Drain Valve 2066-1

12

13 Drain Extension Nipple 44-1363

14

15 Burner Heat Shield 12-0349

16

17 Gas Manifold 36-0027

18

19

Vessel Back Panel Assembly Alum Steel

Vessel Back Panel Assembly S/S

Orifice, Natural Gas-USA,AUST(BLK)

Orifice, Natural CE-G20(BLU),G25(BLU)

Orifice, Propane Gas-USA,AUST(ORG)

Orifice, Propane CE-G31(RED)

Burner, L/H

Burner, Center

Burner, R/H

Pilot Burner, Natural Gas

Pilot Burner, Propane Gas

Thermopile, for MV System-USA,Aust

Thermocouple, Aust MV

12204-1

12204-2

14-0067-38(2.58MM)

14-0067-49(1.90MM)

14-0067-52(1.61MM)

14-0067-59(1.28MM)

14-0912-1

14-0912-2

14-0912-3

2146

2147

2513

1149

22

Page 25

Item No. Description Dean P/N

20

21

21

22

23

24 Diffuser 36006

25 Front Panel Stainless 12-0309-2

26 Vessel Vat Cover 12-0355

27

28 Leg w/mounting plate, 4 hole 2698

Operating Thermostat

Operating T-Stat, Knob Only

Hi-Limit Switch - USA, Aust 435oF set point

Hi-Limit Switch – CE 410oF set point

Comb Gas Valve, Honeywell, Natural-USA

Comb Gas Valve, Robertshaw, Natural-USA

Comb Gas Valve, Robertshaw, Nat-Aust

Comb Gas Valve, HW CE Nat – G20, G25

Comb Gas Valve, Robertshaw, Propane-USA

Comb Gas Valve, Robertshaw, Prop-Aust

Comb Gas Valve, HW CE Prop – G31

Adapter Robertshaw (ECO), Aust, (FOR 2719 & 2720)

Connector (ECO), CE (FOR 8072122 & 8072121)

2557

1205

2507

2687

2587

1896

2719

8072122

2589

2720

8072121

2722

8121256SP

29A

29B

30 Rigid Caster 2700

31 Handle 1039

32 Door Handle 1039-2

33 Cabinet Door 12183-2

34 Frame Assembly SR38FRCOMP

35 Lower Hinge Bracket 12-0379

36 Shim Leg and Caster 4 hole 9002949

Igniter,Piezo (Australia)

Electrode (Australia)

8101001

2560

ITEMS NOT SHOWN ON PARTS DRAWINGS:

Pilot Assembly, Comp, HW, Nat Gas USA 14200-1; Propane Gas 14200-2

Pilot Bracket, Aust/CE, Electrode/Thermopile Adapting, 12-0400

Conversion Kit, Honeywell, Nat to Prop, USA, 12192; Prop to Nat, 12191

Conversion Kit, Robertshaw, Nat to Prop, USA, 12109-2

Conversion Kit, Robertshaw, Nat to Prop, Australia, 12217 (Instructions 12218)

Conversion Kit, Robertshaw, Prop to Nat, Australia, 12221

23

Page 26

7. COMPONENT LISTING AND INSTALLATION STANDARDS

(U.S.A. AND CANADA ONLY)

The following is a selection of listing and installation standards applicable to non-cooking

components often supplied as part of food service equipment. The selection is not intended to

be complete and other nationally recognized standards may be appropriate. This listing was

current as of the revision date shown on the cover of this manual.

LISTING

INSTALLATION

COMPONENT

STANDARD

Grease Extractor ANSI/UL 710-1990 ANSI/NFPA 96-1991

Power Ventilators ANSI/UL 705-1984 ANSI/NFPA 96-1987

Filter Unit

Fire Ext. (CO2)

Fire Ext. (Dry Chemical)

Fire Ext. (Water)

Fire Ext. (Foam) ANSI/NFPA 11-1988

Automatic Sprinklers ANSI/UL 199-1990 ANSI/MFPA 13-1989

ANSI/UL 900-1987

ANSI/UL 586-1990

ANSI/UL 154-1990

CAN/ULC-S503-M90

ANSI/UL 299-1990

CAN/ULC-S504-M89

ANSI/US 626-1990

CAN4-S507-M83

STANDARD

ANSI/NFPA 96-1987

ANSI/NFPA 96-1987

ANSI/NFPA 12-1989

ANSI/NFPA 17-1990

ANSI/MFPA 13-1989

Smoke Detectors

Heat Detectors for Fire

Protective Signaling Devices

ANSI/UL 521-1988

CAN/ULC-S530-1978

ANSI/UL 521-1988

ULC-S530-1978

24

ANSI/NFPA 72B-1986

ANSI/NFPA 72B-1986

Page 27

Dean, 8700 Line Avenue, Shreveport, Louisiana 71135

TEL 1-318-865-1711 FAX (Parts) 1-318-219-7140 (Tech Support) 1-318-219-7135

PRINTED IN THE UNITED STATES

SERVICE HOTLINE

1-800-551-8633

Price: $6.00

819-5707 04-99

Loading...

Loading...