Page 1

* 8 1 9 5 1 7 9 *

Operating, Service & Parts Manual

PF50 Series Portable

Filtration Systems

PARTS LIST

INCLUDED

SERIES PF50 & PF50S

Frymaster, a member of the Commercial Food Equipment Service Association, recommends

using CFESA Certified Technicians.

24-Hour Service Hotline 1-800-551-8633

MAY 2010

Page 2

Please read all sections of this manual and retain for future reference.

Installation, maintenance, and repairs should be performed by your Frymaster Dean

Factory Authorized Service Agency.

WARNING

Safe and satisfactory operation of your equipment depends on its proper installation.

Installation MU ST conform to local codes, or in the absence of local codes, with the

latest edition of the National Electric Code, N.F.P.A. 70.

WARNING

ELECTRICAL GROUNDING INSTRUCTIONS

This filter is equipped with a three-prong, grounded plug for your protection against

shock hazard and should be plugged directly into a properly grounded, three-hole

receptacle. Do not cut off, remove or otherwise bypass the grounding prong on this

plug.

If it is necessary to use an extension cord, it MU ST be a three-conductor, grounded

cord of 16 gauge or greater.

DANGER

Do not filter more than one fry tank at a time.

Hot fluid – Do not fill above a point 1-½ inches below the OIL CONTAINER RIM.

WARNING

This filter unit is not suitable for outdoor use. When operating this unit, it MU ST be

placed on a horizontal surface.

WARNING

This filter unit is not suitable for installation in an area where a water jet can be used,

and this appliance MU ST NOT be cleaned with a water jet.

Page 3

NOTICE:

If this filter unit is cleaned with water, disconnect the unit from power source before

cleaning and thoroughly dry the filter unit before reconnecting to electrical power

source.

DANGER

The crumb tray (if equipped) in portable filter systems must be emptied into a fireproof

container at the end of frying operations each day. Some food particles can

spontaneously combust if left soaking in certain shortening material.

NOTICE:

Drawings and photos used in this manual are intended to illustrate operational, cleaning

and technical procedures and may not conform to on-site management operational

procedures.

NOTICE

IF, DURING THE WARRANTY PERIOD, THE CUSTOMER USES A PART FOR THIS

ENODIS EQUIPMENT OTHER THAN AN UNMODIFIED NEW OR RECYCLED PART

PURCHASED DIRECTLY FROM FRYMASTER DEAN, OR ANY OF ITS AUTHORIZED

SERVICE CENTERS, AND/OR THE PART BEING USED IS MODIFIED FROM ITS

ORIGINAL CONFIGURATION, THIS WARRANTY WILL BE VOID. FURTHER,

FRYMASTER DEAN AND ITS AFFILIATES WILL NOT BE LIABLE FOR ANY CLAIMS,

DAMAGES OR EXPENSES INCURRED BY THE CUSTOMER WHICH ARISE DIRECTLY

OR INDIRECTLY, IN WHOLE OR IN PART, DUE TO THE INSTALLATION OF ANY

MODIFIED PART AND/OR PART RECEIVED FROM AN UNAUTHORIZED SERVICE

CENTER.

Page 4

PF50 Series Portable Filtration Systems

Operation, Service & Parts Manual

TABLE OF CONTENTS

Page #

1. INTRODUCTION 1-1

2. IMPORTANT INFORMATION 2-1

3. FILTER PREPARATION 3-1

4. OPERATING/FILTER INSTRUCTIONS 4-1

5. CLEANING AND MAINTENANCE 5-1

6. TROUBLESHOOTING/SERVICE PROCEDURES 6-1

7. PARTS LIST 7-1

Page 5

PF50 SERIES PORTABLE FILTRATION SYSTEMS

CHAPTER 1: INTRODUCTION

1.1 Parts Ordering

Place parts orders directly with your local Frymaster/Dean Factory Authorized Service Center. A

list of FASCs was included with the filter when shipped from the factory. If you do not have access

to this list, please contact the Frymaster/Dean service department at 1-800-551-8633 or 1-318-8651711, or go to Frymaster/Dean’s website at: www.frymaster.com.

To help speed your order, the following information is required:

Model Number Type

Serial Number

Optional Features

Item Part Number Quantity Needed

1.2 Service Information

Call the 1-800-551-8633 or (318) 865-1711 Service Hotline number for the location of your nearest

Factory Authorized Service Center. Always give the model and serial numbers of your filter unit.

Also, identify if your unit is supplied with or without a heater.

To assist you more efficiently, the following information will be needed:

Model Number Type

Serial Number

Optional Features

Nature of Problem:

Additional information (i.e. oil temperature at filter time, time of day and other pertinent

information) may be helpful in solving your service problem.

1-1

Page 6

PF50 SERIES PORTABLE FILTRATION SYSTEMS

CHAPTER 1: INTRODUCTION

1.3 After Purchase

In order to improve service, fill out the following chart with the nearest Frymaster Authorized

Service Technician and FASC in your area.

Authorized Service

Technician/FASC

Address

Telephone/Fax

Filter Model Number

Filter Serial Number

1.4 Safety Information

Before attempting to operate your unit, read the instructions in this manual thoroughly.

Throughout this manual, you will find notations enclosed in double-bordered boxes similar to the

ones below.

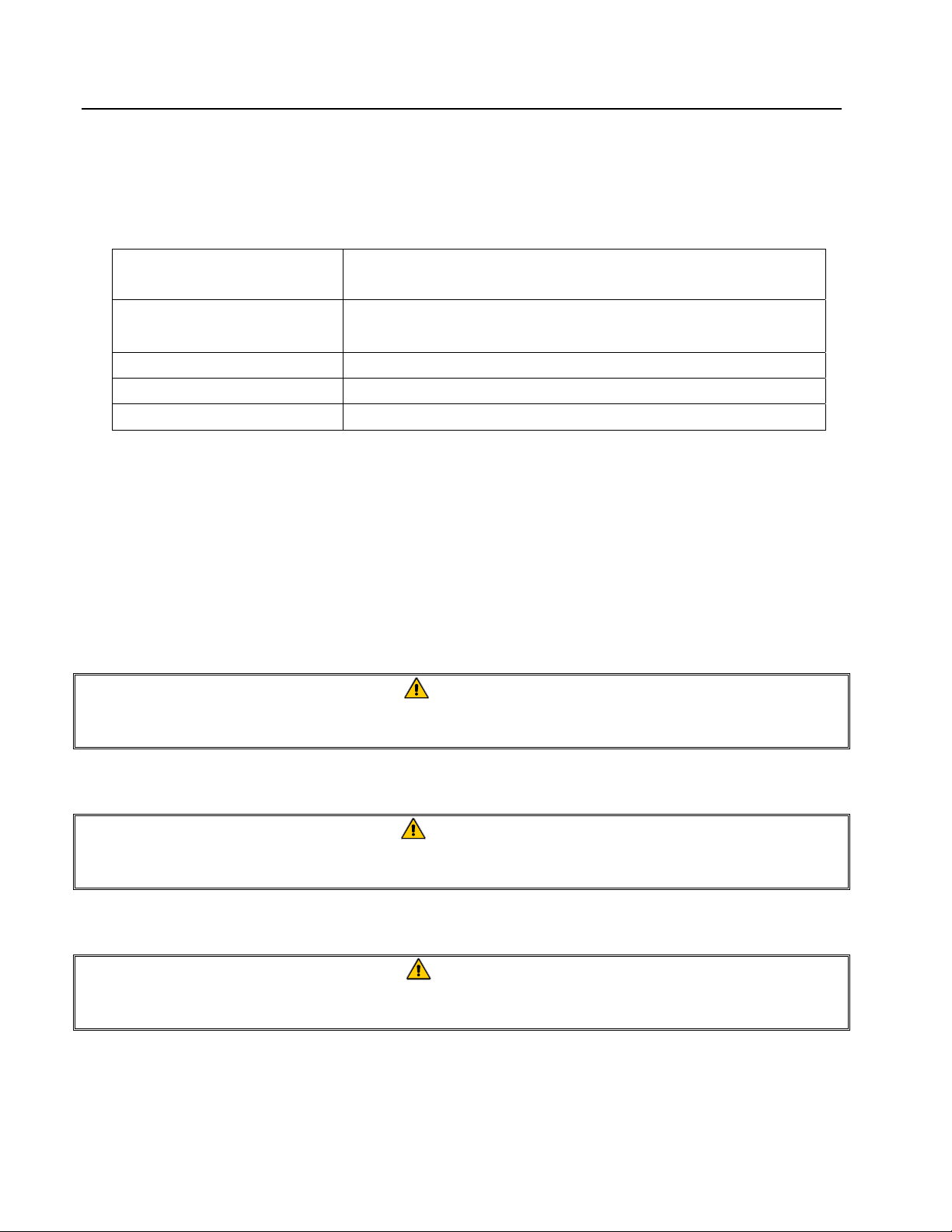

CAUTION

CAUTION boxes contain information about actions or conditions that may cause or result in a

malfunction of your system.

WARNING

WARNING boxes contain information about actions or conditions that may cause or result in

damage to your system, and which may cause your system to malfunction.

DANGER

DANGER boxes contain information about actions or conditions that may cause or result in injury

to personnel, and which may cause damage to your system and/or cause your system to malfunction.

1-2

Page 7

PF50 SERIES PORTABLE FILTRATION SYSTEMS

CHAPTER 1: INTRODUCTION

1.5 Service Personnel

1.5.1 Definitions

A. Qualified and/or Authorized Operating Personnel

1. Qualified/authorized operating personnel are those who have carefully read the information

in this manual and have familiarized themselves with the equipment functions, or have had

previous experience with the operation of equipment covered in this manual.

B. Qualified Installation Personnel

1. Qualified installation personnel are individuals, or firms, corporations, or companies that,

either in person or through a representative, are engaged in and are responsible for the

installation of electrical appliances. Qualified personnel must be experienced in such work,

be familiar with all electrical precautions involved, and have complied with all requirements

of applicable national and local codes.

C. Qualified Service Personnel

1. Qualified service personnel are those who are familiar with Frymaster/Dean equipment and

have been authorized by Frymaster/Dean to perform service on Frymaster/Dean equipment.

All authorized service personnel are required to be equipped with a complete set of service

parts manuals and stock a minimum amount of parts for Frymaster/Dean equipment. A list

of Frymaster/Dean Factory Authorized Service Centers (FASCs) was included with the fryer

when shipped from the factory. Failure to use qualified service personnel will void the

Frymaster/Dean warranty on your equipment.

1-3

Page 8

PF50 SERIES PORTABLE FILTRATION SYSTEMS

CHAPTER 2: IMPORTANT INFORMATION

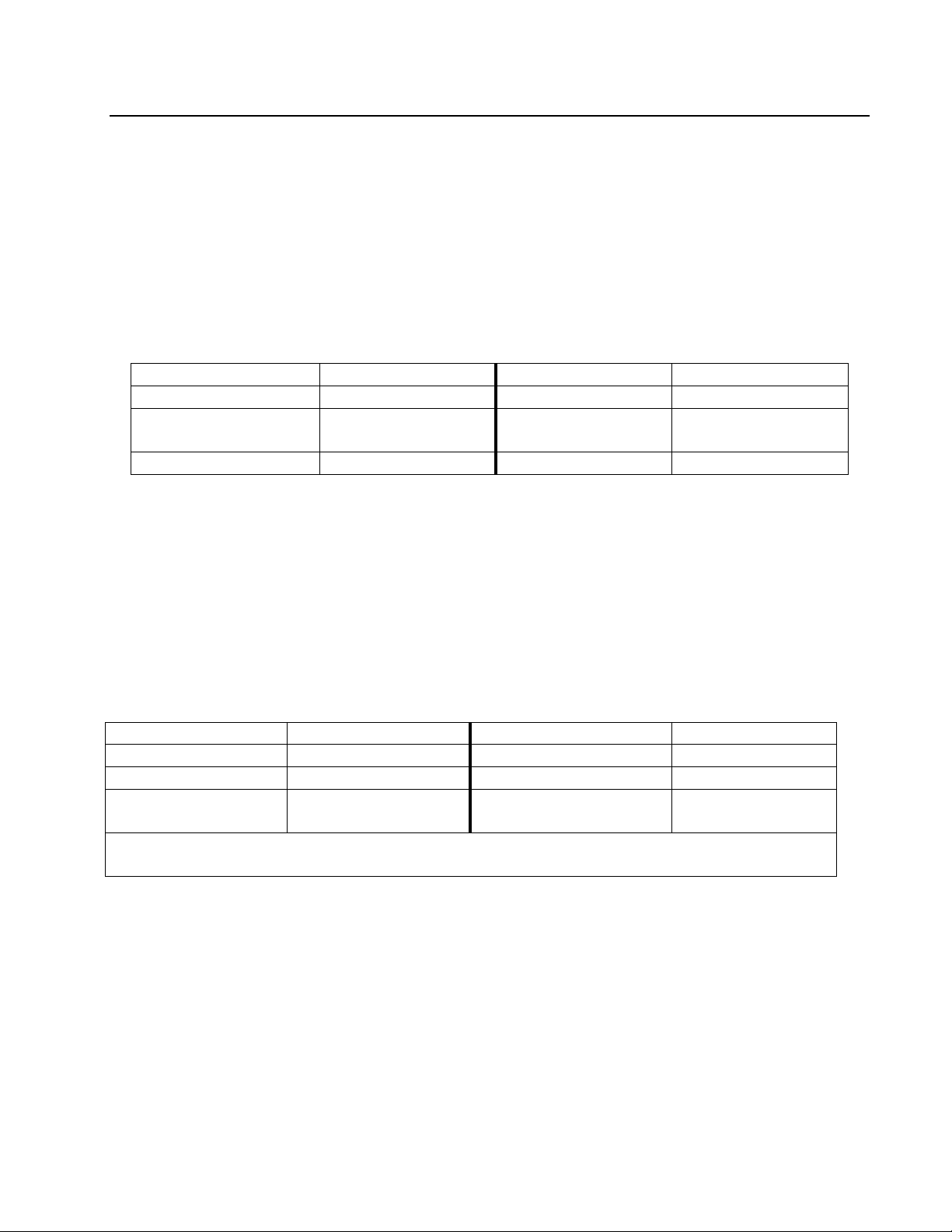

2.1 General

PF50 portable filters can be used with a variety of Frymaster fryers, as well as other manufacturers’

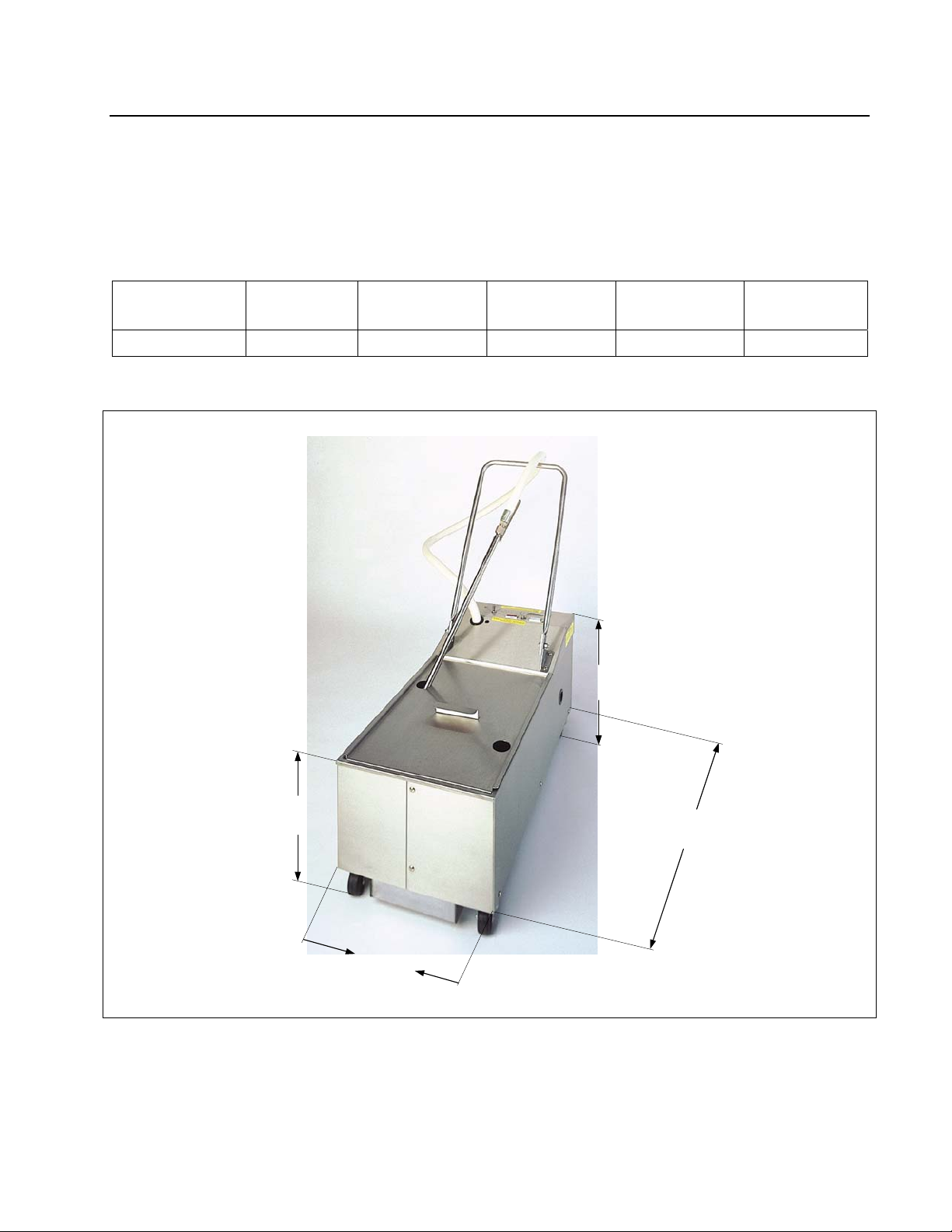

equipment. Oil capacity is approximately 50 pounds. Unit specifications are listed below.

Model Unit Height

(inches)

PF50 13-¼ 13-¼ 30 11-¾ 50

Unit Width

(inches)

Unit Length

(inches)

Tank Height

(inches)

Oil Capacity

(pounds)

Unit

Height

Tank

Height

Unit

Width

PF50 Series portable filter dimensions.

Unit

Length

2-1

Page 9

PF50 SERIES PORTABLE FILTRATION SYSTEMS

CHAPTER 2: IMPORTANT INFORMATION

2.1 General (cont.)

Oil or shortening is gravity-drained from the fryer into the filter ("S" Models), or pumped from the

frypot into the filter pan, and then filtered through filter paper. Filter powder, which enhances the

filtering process, is distributed over the paper prior to filtering.

All units are shipped completely assembled with accessories packed inside the filter pan. All units

are adjusted, tested and inspected at the factory before shipment.

WARNING

The on-site supervisor is responsible for ensuring that operators are made aware of

the inherent dangers of operating a hot oil filter system, particularly the aspects of

oil filtration, and draining/cleaning procedures.

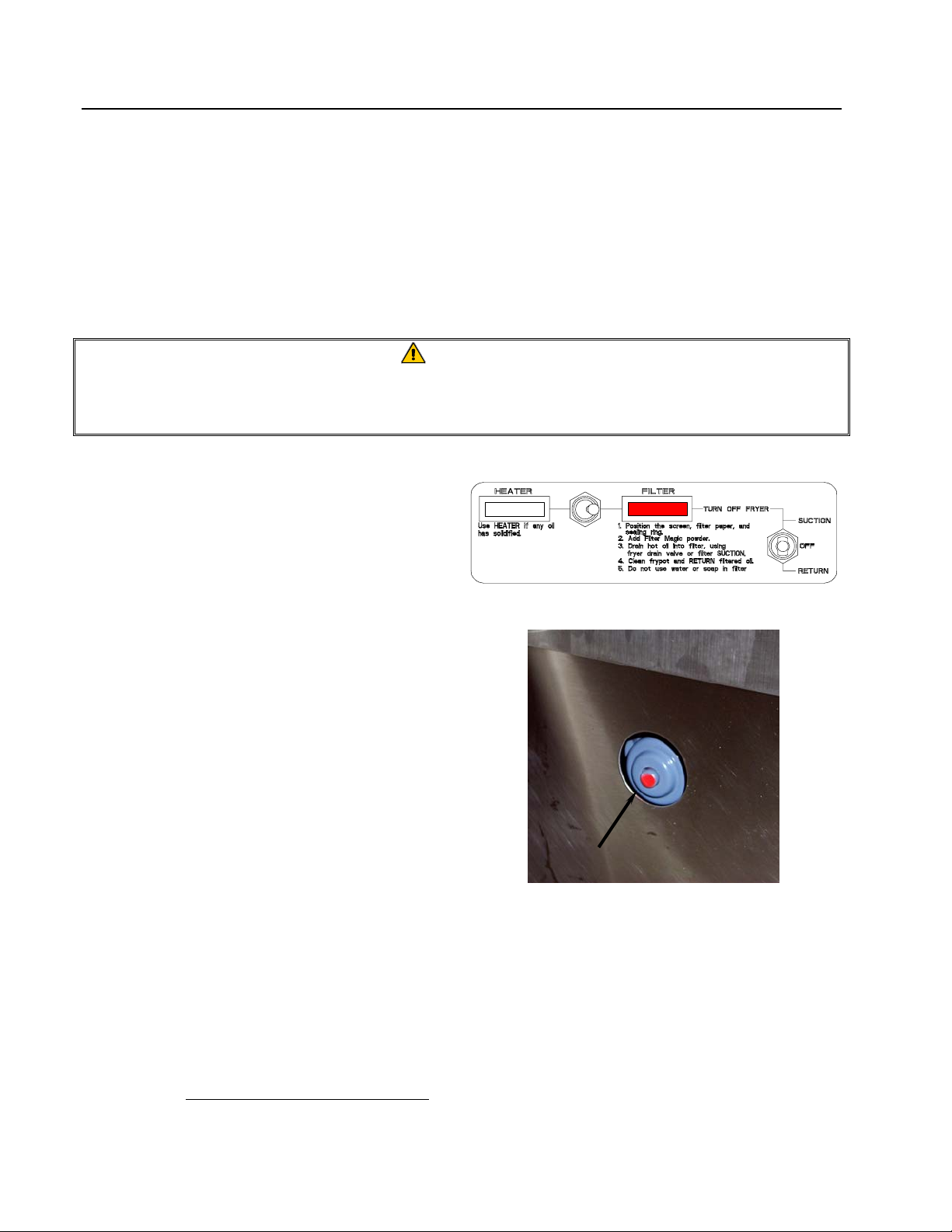

An Off/Return (PF50S) or a Suction/Off/Return

(PF50) switch activates/deactivates the filter

pump. The filter also has a Heater/Filter switch

for use when filtering solid shortening.

A thermal-overload switch on the pump motor

PF50 switch/light panel.

provides protection against overheating.

NOTE: If the thermal overload is triggered,

wait 45 minutes, and then press the

reset button to activate the circuit after

the failure has been detected and

repaired.

The motor thermal overload switch (arrow) is

located on the left side of the filter.

2.2 Rating Plate

Information on the rating plate includes model and serial numbers, as well as electrical requirements.

The rating plate is located on the back housing, near the electrical receptacle. Have the rating plate

information handy when communicating with the factory about a unit or requesting special parts or

information. Without rating plate information

, proper identification of the unit cannot be confirmed.

2-2

Page 10

PF50 SERIES PORTABLE FILTRATION SYSTEMS

CHAPTER 2: IMPORTANT INFORMATION

2.3 Pre-Installation

NOTE: Failure to use qualified service personnel will void the Frymaster warranty.

A. Standards

: Use of this filter unit must be in accordance with all applicable state and local

codes.

DANGER

This portable filter is equipped with a three-prong (grounding) plug for protection

against electrical shock and must be plugged directly into a properly grounded,

three-prong receptacle. DO NOT CUT, REMOVE, OR OTHERWISE BYPASS THE

GROUNDING PRONG ON THIS PLUG!

B. Electrical Connections

: Domestic PF50 filter units require 115V 60 Hz., 15 amp electrical

supply. International/CE units require 230V 50 Hz., 7 amp electrical supply. Units are

equipped with a grounded male receptacle for use with a 16-3 SJT power cord set. If an

extension cord is required, it must be a three-conductor, grounded power cord of at least 16

gauge.

2.4 Unpacking the Filter System

Ensure the container is upright. Unpack the filter carefully and remove all accessories from the

carton. Do not discard or misplace parts and/or accessories; they will be needed for filter setup

and operation. Any accessories or starter kits included with the unit will be packaged inside

the filter tank.

After unpacking, immediately check the equipment for visible signs of shipping damage. If

such damage has occurred, contact the carrier and file the appropriate freight claims. Do not

contact the factory, as the responsibility of shipping damage is between the carrier and dealer

or end-user.

If your equipment arrives damaged:

a. File claim for damages immediately

b. Visible loss or damage

– Be sure this is noted on the freight bill or express receipt and is

signed by the person making the delivery.

c. Concealed loss or damage

– If damage is unnoticed until equipment is unpacked, notify

freight company or carrier immediately, and file a concealed damage claim. This should be

done within 15 days of date of delivery. Retain the shipping container for inspection.

NOTE: Frymaster does not assume responsibility for damage or loss incurred in transit.

– Regardless of extent of damage.

2-3

Page 11

PF50 SERIES PORTABLE FILTRATION SYSTEMS

CHAPTER 3: FILTER PREPARATION

3.1 Assembling The Filter System

On initial installation and before each use, remove all loose parts from the filter, wash all accessories

in hot, soapy water and dry thoroughly. DO NOT WASH INTERIOR OF FILTER PAN WITH

DETERGENT OR WATER! Wipe debris and residue from the filter pan with a damp cloth or

paper towel, then with a dry cloth or paper towel.

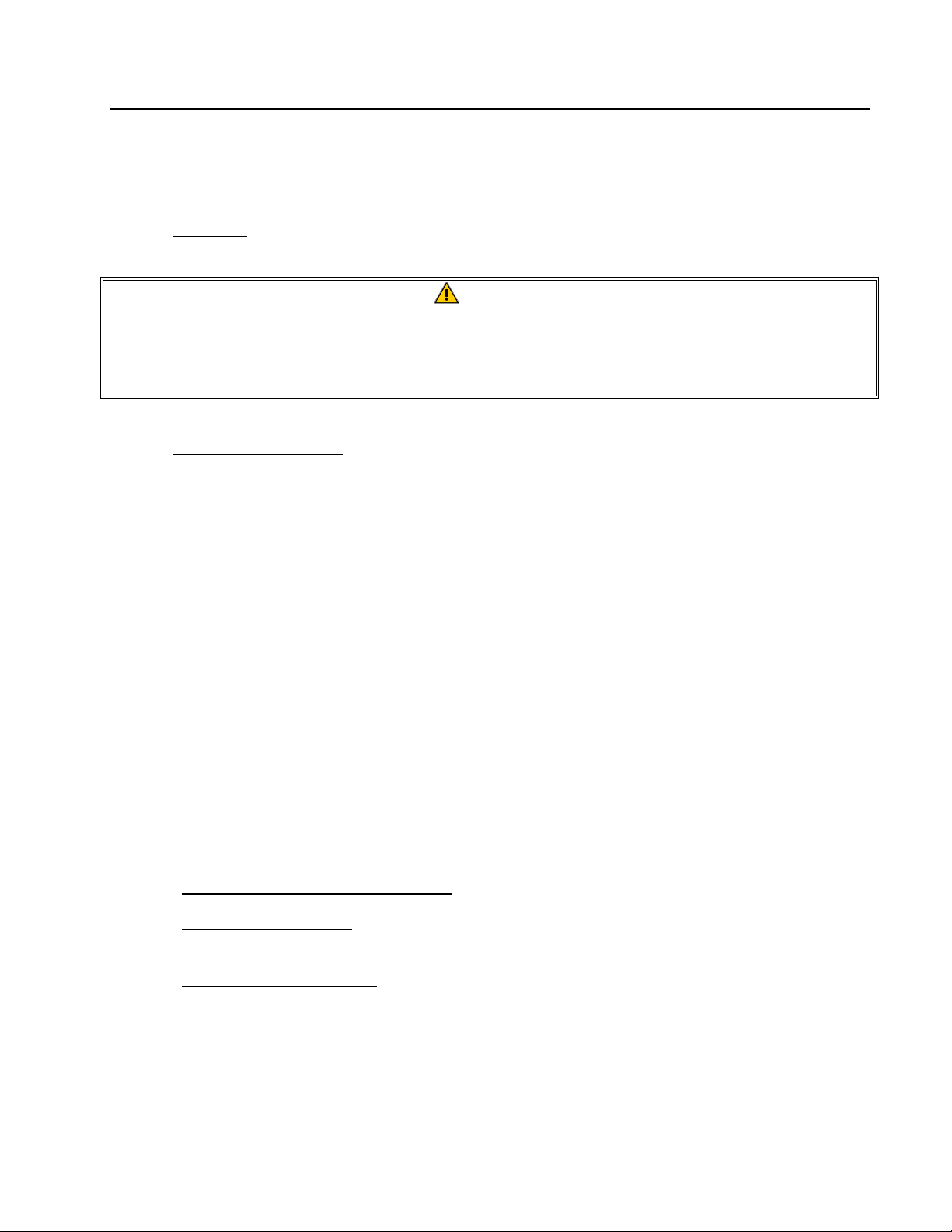

WARNING!

Water, detergent or boil-out solution MU ST N OT be allowed into the filter pan or

filter system. Irreversible pump damage will result if water is allowed into the

system, and the warranty will be voided.

PF50 Series portable filtration systems use a filter support grid, one sheet of filter paper and a holddown ring to secure the filter paper in place.

See illustration for proper assembly.

1. Filter Pan Cover

2. Hold-Down Ring

3. Filter Paper (one sheet)

4. Screen/Support Grid

5. Filter Pan

3

2

5

4

1

3-1

Page 12

PF50 SERIES PORTABLE FILTRATION SYSTEMS

CHAPTER 3: FILTER PREPARATION

3.1 Assembling The Filter System (cont.)

1. Ensure the filter pan is clean and free of all food and breading particles that could prevent the

filter paper from sealing against the bottom of the pan.

2. Place the filter paper support screen between the raised dimples in the bottom of the pan.

3. Place one sheet of filter paper on top of the support screen.

Ensure the paper evenly covers the filter pan bottom.

4. Position the hold-down ring on top of the filter paper and

ensure the filter paper overlaps all sides of the hold-down

ring, forming a tight seal.

5. Place filter pan cover onto the filter pan and assembly is complete.

NOTE:Thefitlerpaperforthisunitis

oversized,whichensuresagoodseal.

Lapexcesspaperupthewallsofthepan.

DoNotfoldthepapertofitthepan.

3-2

Page 13

PF50 SERIES PORTABLE FILTRATION SYSTEMS

CHAPTER 4: OPERATING/FILTERING INSTRUCTIONS

4.1 Filter Operation

WARNING

Use care when draining and filtering oil to avoid the possibility of a serious burn.

1. Sprinkle 8 ounces (1 cup) of filter powder over the filter paper, distributing the powder as evenly

as possible. If filtering a second frypot immediately after the first, add only 4 ounces of filter

powder for the second filtering.

2. Ensure the power cord is securely plugged into the receptacle on the back of the portable filter

(115V Domestic units only). Plug the power cord into a 115V (Domestic) or 230V (Export)

receptacle.

3. If solid shortening is filtered through the portable filter, turn the Heater/Filter switch to HEATER

(see illustration below- PF50 panel shown). The white indicator light will illuminate. Leave the

heater on for 20-30 minutes before operating the filter.

Note: The filter pump cannot be activated while the switch is in the "Heater" position.

4. Ensure the Suction/Off/Return (PF50) or Off/Return (PF50S) switch is OFF. Turn the

Heater/Filter switch to FILTER for filter operation (see illustration below). The red indicator

light will illuminate.

Use the filter heater for 20-30 minutes prior to filtering if solid shortening is filtered.

The Heater/Filter switch must be in the FILTER position before the filter pump can

be operated. The red light will illuminate when the switch is properly positioned.

4-1

Page 14

PF50 SERIES PORTABLE FILTRATION SYSTEMS

CHAPTER 4: OPERATING/FILTERING INSTRUCTIONS

4.1 Filter Operation (cont.)

5. Ensure the oil is at operating temperature [~350° (177°C)]. Turn the fryer off.

WARNING

The filter pan maximum capacity is 50 lbs. DO NOT OVERFILL THE FILTER PAN.

6. PF50 (Return/Suction) Filters Only:

a. Suction Operation: Ensure the filter pan lid is in place to prevent splashing of hot oil. Place

the filter hose nozzle into the frypot. Turn the Suction/Off/Return switch to SUCTION to

start the filter pump (see illustration below). Oil will transfer from the frypot to the filter

pan.

CAUTION

DO NOT insert the tip of the hose nozzle into the sediment area of the frypot (not

applicable to "S" models). Suction of sediment into the hose nozzle will damage the

filter pump. If the pump becomes clogged, stop the pump immediately. Reverse the

pump to discharge particles into the frypot or filter pan.

When the fryer is emptied of oil, place the hose nozzle into the filter pan and turn the

Suction/Off/Return switch to RETURN (see illustration below). Circulate the oil through

the filter for approximately 5 minutes (process known as "polishing"). Polishing the oil

maximizes filtering and extends the life of the oil. After 5 minutes, turn the

Suction/Off/Return switch to OFF.

4-2

Page 15

PF50 SERIES PORTABLE FILTRATION SYSTEMS

CHAPTER 4: OPERATING/FILTERING INSTRUCTIONS

4.1 Filter Operation (cont.)

To flush residual shortening and sediment from the frypot, place a clean metal container

under the frypot drain valve. Open drain valve and place the hose nozzle inside the frypot.

Turn the Suction/Off/Return switch to RETURN. Rinse and flush sediment and debris from

frypot, into the metal container. DO NOT OVERFILL THE CONTAINER. Turn the

Suction/Off/Return switch to OFF after rinsing the frypot.

Wipe any remaining oil or sediment from the frypot with a clean, dry cloth or paper towel.

Close the drain valve. Pour the contents of the metal container into the filter pan, using care

not to splash hot oil. Place the hose nozzle into the frypot and turn the Suction/Off/Return

switch to RETURN. Ensure all oil is returned to the frypot before turning filter off.

Allow the portable filter to cool, then remove and discard the filter paper. Clean the interior

of the filter pan and all components. Do not use detergent or water in the filter pan for

cleaning.

7. PF50S (Return Only) and PF50 (Suction/Return) Filters:

a. Gravity-drain Operation

the filter. Place the filter hose nozzle inside the frypot. Turn the Off/Return (PF50S) or

Suction/Off/Return (PF50) switch to RETURN to start the filter pump (see illustration

below).

: Place filter pan directly under fryer drain valve and drain oil into

Allow the oil to circulate through the frypot and filter for approximately 5 minutes (process

known as "polishing"). Polishing the oil produces maximum filtration and extends the life

of the oil. Rinse any residual oil or sediment from the frypot during the polishing process.

Close the drain valve and return the filtered oil to the frypot. Ensure all oil is returned to the

frypot before turning filter off.

Allow the portable filter to cool, then remove and discard the filter paper. Clean the interior

of the filter pan and all components. Do not use detergent or water in the filter pan for

cleaning.

See Chapter 5 for preventative maintenance/cleaning procedures.

4-3

Page 16

PF50 SERIES PORTABLE FILTRATION SYSTEMS

CHAPTER 5: CLEANING AND MAINTENANCE

5.1 General

Cleaning operations fall into three general categories:

• Wiping unit clean after each filter session;

• Cleaning, changing filter paper and preparing the unit for the next day’s business.

• Weekly cleaning to remove oil deposits and other particles.

WARNING

Do not use water jets to clean this equipment. To do so will damage the unit and

void the warranty.

WARNING

Never operate the filter unit unless cooking oil is at operating temperature.

5.2 Each Filter Use

Each time the PF50 portable filter is used:

• Wash down the insides of the filter pan with hot oil during the filtering process. DO NOT

allow excessive residue buildup to occur inside the filter pan.

• Change filter paper after each filter session or at the end of the day. Scrape excess sediment

from filter paper after each frypot is filtered within a filter session. If oil is not returned to the

frypot within 7 minutes, the filter paper may be clogged. Change filter paper if this occurs.

• Wipe up any oil which may have splashed or spilled.

• Wipe all exterior surfaces of the filter unit.

WARNING

Do not run water or boil-out solution through the portable filter. Doing so will cause

irreparable damage to the pump, and void the warranty.

5-1

Page 17

PF50 SERIES PORTABLE FILTRATION SYSTEMS

CHAPTER 5: CLEANING AND MAINTENANCE

5.3 Daily— Close Of Business

At the close of a working day, filter the oil in all fryers. When the last fryer is filtered, follow these

steps:

1. Ensure the flexible hose and pump lines are clear by running the filter pump for an

additional 15–30 seconds after air bubbles start coming from the oil return line. Drain the

flexible hose as much as possible, especially if solid shortening is used.

2. Remove the filter pan cover and hold-down ring, and then remove the filter paper and filter

paper support screen.

3. Discard filter paper.

4. Wash all filter components with hot soapy water and rinse. DO NOT use soap and/or water

inside the filter pan. Wipe residual oil and sediment from inside the filter pan with a clean

cloth or paper towel.

5. Rinse all parts with clean water (except filter pan interior), and then dry all filter parts

thoroughly

before reassembling.

6. Check the hose fitting on the pump and ensure that it is tight. Check plumbing for leaks.

See Chapter 6 for service procedures. Check plumbing for leaks.

DANGER

The crumb tray (if applicable) in portable filter systems must be emptied into a

fireproof container at the end of frying operations each day. Some food particles

can spontaneously combust if left soaking in certain shortening material.

5.4 Weekly

Follow the same procedure as for "Daily", with these additional steps:

• Clean built-up residue and debris from filter pan by wiping with a clean cloth or paper

towel. DO NOT use soap and/or water inside the filter pan.

properly and function correctly.

• Clean thoroughly under, around, and behind the fryers and filtering area with hot soapy

water and rinse.

• Check the hose connection and tighten if hose becomes loose and starts to leak oil.

Ensure all components fit

5-2

Page 18

PF50 SERIES PORTABLE FILTRATION SYSTEMS

CHAPTER 6: TROUBLESHOOTING/SERVICE PROCEDURES

6.1 Operating Problems

Plugged lines and plugged filter paper account for over 90 percent of filtration system malfunctions.

A general troubleshooting chart, included in this chapter, provides instructions in diagnosing

common malfunctions. Contact a factory-authorized service technician for troubleshooting beyond

the scope of the operator.

A. Plugged Lines

1. To guard against plugged lines when using solid shortening, follow these guidelines:

a. Turn the Heater/Filter switch to HEATER and allow the heater to remain on for 20-30

minutes before attempting a filter cycle.

b. At the end of the filtering cycle, let the filter bubble into the fryer through the flexible

hose for about 15-30 seconds. If it is blowing bubbles, air is moving through the lines

and the filter is less likely to be plugged.

c. When filtering is complete, drain oil or shortening from the hose.

B. Plugged Paper

Improper use of the filter powder will cause a slow oil flow return rate. The first indication of paper

plugging is a surging, jerking movement of the hose. To correct this, review the instructions for the

correct use of filter powder, and change the filter paper more frequently. When filtering several

fryers prior to changing paper, ensure that excess sediment is scraped off the filter paper after

filtering each frypot.

6.2 General Troubleshooting

The following chart contains information to assist in diagnosing the most common malfunctions

with portable filtration systems. Possible solutions and/or corrective actions are given for each

scenario.

If the malfunction cannot be diagnosed using the information in this section, contact your Factory

Authorized Service Agent for repairs.

DANGER

Use extreme care when testing electrical circuits. Live circuits will be exposed.

DANGER

Inspection, testing and repair of gas or electrical equipment should be performed by

qualified personnel.

6-1

Page 19

PF50 SERIES PORTABLE FILTRATION SYSTEMS

CHAPTER 6: TROUBLESHOOTING/SERVICE PROCEDURES

6.2 General Troubleshooting (cont.)

Pump won't

start.

Pump stops

during

filtering

process.

Pump starts

and abruptly

stops.

y Tripped thermal overload switch.

y Incorrect or no line voltage.

y Allow filter unit to cool for at least 45 minutes and

then press (reset) the motor thermal overload

switch.

y Turn filter pump "OFF". Allow oil to cool then empty

pan. Verify filter paper is clean and properly

installed. Refill pan and restart process.

y Reset thermal overload switch.

y Pump is blocked or wiring is loose. Call FASC for

service.

y Motor failed; call FASC for service.

Pumping is

erratic.

Oil not being

returned to

frypot.

y Verify that filter paper is properly installed under

hold-down ring.

y Verify that filter hose connection is tight and secure.

y The filter hose is clogged with debris. Clear hose.

y Clogged filter paper. Scrape off excess sediment or

replace filter paper.

y Filter pan suction tube is blocked. Use a thin,

flexible wire to unclog.

6-2

Page 20

PF50 SERIES PORTABLE FILTRATION SYSTEMS

CHAPTER 6: TROUBLESHOOTING/SERVICE PROCEDURES

6.3 Wiring Diagrams

6.3.1 PF50 115V Wiring

PUMP MOTOR

CONTROL SWITCH

4P

8P

10P

5P

1P

6P

7P

11P

9P

12P

13P

PUMP MOTOR

FILTER

LIGHT

3P

HEATER/FILTER

SWITCH

6.3.2 PF50 230V Wiring

PUMP MOTOR

CONTROL SWITCH

HEATER

LIGHT

HEATER

BLK

2P

14P

10P

5P

4P

8P

1P

6P

7P

11P

15P

WHT

9P

12P

13P

PUMP MOTOR

8051171A

WHITE

BLACK

GREEN

FEMALE

EXT. CORD

FILTER

LIGHT

3P

HEATER/FILTER

SWITCH

2P

HEATER

LIGHT

VIOLET

6-3

14P

HEATER

RED

15P

8051334A

WHITE

BLACK

CORDSET

GREEN

Page 21

PF50 SERIES PORTABLE FILTRATION SYSTEMS

CHAPTER 6: TROUBLESHOOTING/SERVICE PROCEDURES

6.3.3 PF50S 115/230V Wiring

PUMP MOTOR

CONTROL SWITCH

1P

11P

12P

PUMP

MOTOR

FILTER

LIGHT

3P

FILTER

SWITCH

4P

HEATER

LIGHT

HEATER

16P

2P

14P

BLACK

17P

BLACK

6.3.4 PF50/PF50S 115/230V Pump Motor Wiring

15P

WHITE

GREEN

WHITE

GREEN

EXTERNAL

CORD

CORDSET

115V OPTION

230V OPTION

BLK #5

*

L1

3

4

YEL 9P

WHT 11P

BRN 12P

(PF50)

BLK 13P

BRN 12P

RED #8

L2

*

(PF50S)

BLU 10P

* DENOTES BOMBTAIL

115/230V MOTOR WIRING

6-4

Page 22

PF50 SERIES PORTABLE FILTRATION SYSTEMS

CHAPTER 6: TROUBLESHOOTING/SERVICE PROCEDURES

6.4 Service Procedures

6.4.1 Replace Lights/Switches

WARNING

Disconnect power cord from electrical power before servicing.

1. Disconnect power cord from power supply.

2. Remove four screws securing the switch

panel to the control panel.

3. Lift the panel out of the control panel to

access wiring.

4. Mark the wire locations on the defective

switch/light and disconnect the wiring.

5. Install new switch or light, connect the wiring

and install the switch panel. Replace the

screws removed in Step 1.

Remove screws (arrows) securing switch panel

to the control panel.

Mark wiring locations on defective switch/light

before disconnecting wires.

6-5

Page 23

PF50 SERIES PORTABLE FILTRATION SYSTEMS

(

CHAPTER 6: TROUBLESHOOTING/SERVICE PROCEDURES

6.4.2 Replace Heater Strip

1. Disconnect power cord from power supply.

2. Perform Step 2, Section 6.4.3.1, Replace

Motor.

3. Remove screws securing outer panels and

cord-holding bracket. Remove bracket and

the panels.

4. Turn the unit on its side and remove four nuts

securing the filter pan to the base assembly.

Carefully pull the filter pan away from the

base to gain access to heater strip. Use care

not to damage the flexlines connecting the

pan to the pump.

5. Remove foil-insulating tape securing the

heater strip to the pickup tube. Remove the

heater strip from the pickup tube.

6. Remove the remainder of the foil-insulating

tape from the flexline(s) and the pump, and

then remove the heater strip. Note routing of

the heater strip on the pump and flexline(s)

prior to heater strip removal.

Remove screws securing outer panels.

Remove four nuts securing filter pan to base

arrows).

Remove foil-insulating tape to expose heater

strip (arrow).

6-6

Page 24

PF50 SERIES PORTABLE FILTRATION SYSTEMS

CHAPTER 6: TROUBLESHOOTING/SERVICE PROCEDURES

6.4.2 Replace Heater Strip (cont.)

7. 115VAC Filters: Disconnect the black wire

from the heater indicator light on the switch

panel (left, black arrow), and the white wire

from the receptacle (white, white arrow).

230VAC Filters: Disconnect the red wire

connected to the power supply cord (bombtail

connection) and the violet wire connected to

the Heater Indicator light on the switch panel.

8. Starting at the sump on the pan bottom,

install the new heater strip, using foil tape to

secure the heater to the pickup tube (see Step

3, this section).

9. Route the heater strip over the plumbing and

around the pump as previously removed in

Step 4.

10. Complete installation by securing strip with

foil tape. Reconnect the wire connections

disconnected in Step 7, this section.

Reassemble filter by reversing Steps 1-3, this

section.

Heater strip wiring connections at switch panel

and receptacle (115V heater strip shown).

Heater strip routing on flexlines and pump [230V

PF50 (Return/Suction)].

Heater strip installed [115V PF50 (Return/Suction)].

6-7

Page 25

PF50 SERIES PORTABLE FILTRATION SYSTEMS

CHAPTER 6: TROUBLESHOOTING/SERVICE PROCEDURES

6.4.3 Replace Motor/Pump

6.4.3.1 Replace Motor

1. Disconnect power cord from power supply.

2. Perform Step 2, Section 6.4.1. Remove two

screws securing the handle brackets to the

control panel (arrows). Do not remove the

remaining handle-bracket screws. Remove

remaining screws securing control panel to

filter base. Lift the control panel from the

base and work the switch panel through the

control panel opening. Leave the switch

panel wired and set aside, using care not to

stretch and disconnect wiring. Remove

control panel.

3. Remove cord-holder bracket and outer panels

(see Step 3, Section 6.4.2 for reference).

Remove these

screws from handle

brackets to remove

control panel.

Remove screws illustrated to remove control

panel. (Switch panel omitted for clarity.)

Remove cord-holder bracket and outer panels.

6-8

Page 26

PF50 SERIES PORTABLE FILTRATION SYSTEMS

CHAPTER 6: TROUBLESHOOTING/SERVICE PROCEDURES

6.4.3.1 Replace Motor (cont.)

4. Remove four bolts securing the pump to the

motor. Leave the plumbing connected to the

pump. Use care not to damage the flex

supply lines connected to the pump. Remove

the pump gasket for reassembly.

5. Remove six screws securing the motor

bracket from the bottom of the base. Support

the motor with one hand when removing the

screws. Pull the motor/motor-bracket out of

the cabinet and set on floor. Use care not to

damage the motor wiring. Remove four bolts

securing the motor to the motor-bracket.

Place the replacement motor next to the old

motor for ease of rewiring.

6. Remove the cover plate to access the motor

wiring. Splices or bombtails are needed for

two connections. Rewire the replacement

motor using the wiring diagram in Section

6.3.4.

7. Complete installation of replacement motor

by reversing the above steps.

Remove the four bolts securing the pump to the

motor (arrows).

Remove six screws from the base bottom to remove

the motor and motor bracket. Remove four bolts

securing the motor to motor-bracket after removing

the bracket from the base.

.

Two connections require splices or bombtails

(arrows).

6-9

Page 27

PF50 SERIES PORTABLE FILTRATION SYSTEMS

CHAPTER 6: TROUBLESHOOTING/SERVICE PROCEDURES

6.4.3.2 Replace Pump

1. Disconnect power cord from power supply.

2. Perform Steps 2 and 3, Section 6.4.3.1,

Replace Motor.

3. Remove foil insulation tape and heater strip

from pump and flex lines. Remove the heater

strip from the pump and disconnect flexlines

from the check valve connections.

4. Remove pipefittings from pump before

removing pump from motor.

5. Remove four bolts securing the pump to the

motor. Remove the pump and pump gasket.

Fit new pump gasket and install new pump on

motor. Torque pump bolts to 15-foot pounds.

Do not over-tighten the bolts.

6. Reinstall all removed components during

pump removal by reversing the above steps.

Remove foil insulation tape covering the heater

strip and remove heater strip from the pump and

flexlines. Disconnect the flexlines from the

check valve connections.

Remove pipefittings from pump before removing

pump from motor.

Remove four bolts securing the pump to the

motor. Remove pump and gasket from motor.

6-10

Page 28

PF50 SERIES PORTABLE FILTRATION SYSTEMS

CHAPTER 6: TROUBLESHOOTING/SERVICE PROCEDURES

6.4.3.3 Replace Wand Hose

1. Disconnect power cord from power supply.

2. Remove cord-holder bracket and outer panels

(see Step 3, Section 6.4.2 for reference).

3. Unscrew the hose fitting with an open-end

wrench from the elbow on the pump.

4. Install the new hose, using care not to cross-

thread the connections. Use an approved pipe

sealant on the threads to ensure a leak-proof

connection. DO NOT OVER-TIGHTEN

THE CONNECTION.

5. Replace the outer panels and the cord-holder

bracket.

Remove cord-holder bracket and outer panels.

Remove hose fitting (arrow) with an open-end

wrench. Use pipe sealant when installing new

hose.

6-11

Page 29

PF50 SERIES PORTABLE FILTRATION SYSTEMS

7.1 PF50 Parts List

12

CHAPTER 7: PARTS LIST

10

9

11

8

7

21

22

20

1

3

2

4

5

24

13

23

14

15

16

18

19

6

17

29

28

34

35

30

3132

33

25

26

27

36

7-1

Page 30

PF50 SERIES PORTABLE FILTRATION SYSTEMS

CHAPTER 7: PARTS LIST

7.1 PF50 Parts List (cont.)

Item Part # Description

1 823-2813 Pan, Filter (For units with only one pickup tube use P/N 823-2814)

2 806-5223SP Base Assembly (Includes items 3 & 4)

900-9542 Bracket, Motor-Mount – All PF50

900-1748 Brace, End- Filter Base

900-8585 Brace, Rear Cross- Filter Base

3 810-2805 Caster, 2"- Swivel (Without Brake)

4 810-2806 Caster, 2"- Swivel (With Brake)

5 809-0475 Screw- 10-32 x 5/16 Hex

6 900-3751 Bracket, Standoff

7 900-8825 Screen, Filter Paper Support

* 803-0170 Paper, Filter “19.5 x 27.5” 100 sheets

* 803-0002 Powder, Filter - 80 individual packets

8 823-0889 Ring, Hold-down

9 910-3757 Lid, Filter Pan

* 823-5950 Crumb basket

10 826-0993SP Handle, Pan Lid (Includes Screws, Nuts, Washers and Threadlocking Compound)

* 826-1379 Screw, #10 x ½" Phillips (Lid Handle) (Qty. of 10)

* 809-0184 Washer, Lock - #10 (Lid Handle)

* 809-0020 Nut, Cap- 10-24 (Lid Handle)

11 810-1434 Hose Assembly - All PF50 (Can order items 11 & 12 as assembly P/N 806-3825SP)

12 810-1091 Nozzle Assembly - All PF50 (Can order items 11 & 12 as assembly P/N 806-3825SP)

13

826-1712 115V 60HZ 1/3 HP (Includes Motor and Gasket)

826-1270 230V 50/60HZ 1/3 HP (Includes Motor and Gasket)

14 826-1264 Pump, Filter - 4GPM (Includes Pump and Gasket)

15 813-0265 Nipple, ½ x 2-½" NPT BM

16 813-0331 Elbow, With Side Outlet- ½" NPT BM

* 806-3844 Heater Strip, 120V 40W

17 813-0165 Elbow, Street- ½" NPT BM

18 813-0022 Nipple, ½" x Close NPT BM

19 810-0430 Valve, Swing Check - ½"

20 813-0544 Union, ½ NPT x ½" Flexline Hose

21 810-1435 Flexline, ½ x 12" S/S Hose

22 813-0545 Union, ½ x ½" Flexline Hose

* 826-1467

* Not Illustrated

Motor, Filter Pump

Hose Replacement Kit, PF Series Before 07/97

7-2

Page 31

PF50 SERIES PORTABLE FILTRATION SYSTEMS

CHAPTER 7: PARTS LIST

7.1 PF50 Parts List (cont.)

Item Part # Description

23 807-1219 Receptacle, 115V 3-Wire (120V Domestic Units Only)

* 807-1224 Cord, Power - 3-Wire 115V

* 807-0154 Cord, Power - 3-Wire 230V

24 910-8587 Panel, Outer - Left Side- All PF50 Filters

25 910-8586 Panel, Outer - Right Side- PF50 115V Domestic Only

* 210-0795 Panel, Outer - Right Side- PF50 230V Export Only

26 910-3788 Holder, Power Cord - All PF50

27 912-2616 Bracket, Handle- Right – All PF50

28 911-2616 Bracket, Handle- Left – All PF50

* 826-1380 Screw, ¼-20 x ½" Slotted Head (For Handle Bracket) (Qty. of 5)

29 910-9169 Handle, Portable Filter – All PF50

* 826-1389 Bolt, ¼-20 x ¾" Hex Head (Qty. of 10)

* 810-0219 Spacer, Handle Bolt

* 809-0047 Nut, Cap- ¼-20 High Profile S/S

30 824-0403 Panel, Control – All PF50

31 910-0982 Panel, Switch – All PF50

32 802-1302 Label, Switch Panel - PF50 Filters Only

* 802-1438 Label, Switch Panel - PF50S Filters Only

33 807-1040 Switch, Toggle- 3-Way, PF50 Filters Only (PF50S Filters, Use Item #35)

34 807-1060 Light, Indicator- Red Lens (Filter Indicator Light)

35 807-1041 Switch, Toggle- 2-Way SPDT - All PF50

36 807-1061 Light, Indicator- White Lens (Heater Indicator Light)

* Not Illustrated

7-3

Page 32

Shipping Address: 8700 Line Avenue, Shreveport, Louisiana 71106

TEL 1-318-865-1711 FAX (Parts) 1-318-219-7140 FAX (Tech Support) 1-318-219-7135

PRINTED IN THE UNITED STATES

SERVICE HOTLINE

1-800-551-8633

819-5179

MAY 2010

Loading...

Loading...