Frymaster FQE60U FilterQuick easyTouch Installation, Operation And Maintenance Manual

Original Instructions

CAUTION

FOR YOUR SAFETY

Your Growth Is Our Goal

™

FQE60U FilterQuick

easyTouch®

Electric Fryer

Installation, Operation and Maintenance

Manual

This manual is updated as new information and models are released. Visit our website for the latest manual.

Do Not Store or use gasoline

or other flammable vapors

and liquids in the vicinity of

this or any other appliance.

*8197624*

Part Number: FRY_IOM_8197624 01/2019

READ THE INSTRUCTIONS BEFORE USING THE FRYER.

Keep these instructions for future reference.

NOTICE

IF, DURING THE WARRANTY PERIOD, THE CUSTOMER USES A PART FOR THIS FRYMASTER FOOD SERVICE

EQUIPMENT OTHER THAN AN UNMODIFIED NEW OR RECYCLED PART PURCHASED DIRECTLY FROM FRYMASTER

DEAN, OR ANY OF ITS FACTORY AUTHORIZED SERVICERS, AND/OR THE PART BEING USED IS MODIFIED FROM ITS

ORIGINAL CONFIGURATION, THIS WARRANTY WILL BE VOID. FURTHER, FRYMASTER DEAN AND ITS AFFILIATES

WILL NOT BE LIABLE FOR ANY CLAIMS, DAMAGES OR EXPENSES INCURRED BY THE CUSTOMER WHICH ARISE

DIRECTLY OR INDIRECTLY, IN WHOLE OR IN PART, DUE TO THE INSTALLATION OF ANY MODIFIED PART AND/OR

PART RECEIVED FROM AN UNAUTHORIZED SERVICER.

NOTICE

This appliance is intended for professional use only and is to be operated by qualified personnel only. A

Frymaster Authorized Servicer (FAS) or other qualified professional should perform installation, maintenance,

and repairs. Installation, maintenance, or repairs by unqualified personnel may void the manufacturer’s

warranty. See Chapter 1 of this manual for definitions of qualified personnel.

NOTICE

This equipment must be installed in accordance with the appropriate national and local codes of the country

and/or region in which the appliance is installed. See NATIONAL CODE REQUIREMENTS in Chapter 2 of this

manual for specifics.

NOTICE TO U.S. CUSTOMERS

This equipment is to be installed in compliance with the basic plumbing code of the Building Officials and Code

Administrators International, Inc. (BOCA) and the Food Service Sanitation Manual of the U.S. Food and Drug

Administration.

WARNING

Improper installation, adjustment, maintenance or service, and unauthorized alterations or modifications can

cause property damage, injury, or death. Read the installation, operating, and service instructions thoroughly

before installing or servicing this equipment.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable liquids or vapors in the vicinity of this or any other appliance.

NOTICE TO OWNERS OF UNITS EQUIPPED WITH TOUCH SCREEN CONTROLLERS

U.S.

This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions: 1) This

device may not cause harmful interference, and 2) This device must accept any interference received, including

interference that may cause undesired operation. While this device is a verified Class A device, it has been

shown to meet the Class B limits.

CANADA

This digital apparatus does not exceed the Class A or B limits for radio noise emissions as set out by the ICES-003

standard of the Canadian Department of Communications.

Cet appareil numerique n’emet pas de bruits radioelectriques depassany les limites de classe A et B prescrites

dans la norme NMB-003 edictee par le Ministre des Communcations du Canada.

When installed, this appliance must be electrically grounded in accordance with local codes, or in the absence of

local codes, with the National Electrical Code, ANSI/NFPA 70, the Canadian Electrical Code, CSA C22.2, or the

appropriate national code of the country in which installed.

The appliance must be installed and used in such a way that any water cannot contact the fat or oil.

DANGER

WARNING

NOTICE

This appliance is intended to be used for commercial applications, for example in kitchens of restaurants,

canteens, hospitals and in commercial enterprises such as bakeries, butcheries, etc., but not for continuous

mass production of food.

DANGER

The front ledge of this appliance is not a step! Do not stand on the appliance. Serious injury can result from

slips or contact with the hot oil.

NOTICE

Drawings and photos used in this manual are intended to illustrate operational, cleaning and technical

procedures and may not conform to onsite management operational procedures.

DANGER

The crumb tray in fryers equipped with a filter system must be emptied into a fireproof container at the end of

frying operations each day. Some food particles can spontaneously combust if left soaking in certain shortening

material.

WARNING

Do not bang fry baskets or other utensils on the fryer’s joiner strip. The strip is present to seal the joint

between the fry vessels. Banging fry baskets on the strip to dislodge shortening will distort the strip, adversely

affecting its fit. It is designed for a tight fit and should only be removed for cleaning.

DANGER

Adequate means must be provided to limit the movement of this appliance without depending on or

transmitting stress to the electrical conduit. A restraint kit is provided with the fryer. If the restraint kit is

missing contact your local KES.

DANGER

This fryer has a power cord (three-phase) for each frypot. Prior to movement, testing, maintenance and any

repair on your Frymaster fryer; disconnect ALL electrical power cords from the electrical power supply.

DANGER

Keep all items out of drains. Closing actuators may cause damage or injury.

WARNING

This appliance is not intended for use by children under the age of 16 or persons with reduced physical, sensory

or mental capabilities, or lack of experience and knowledge, unless they have been given supervision

concerning use of the appliance by a person responsible for their safety. Do not allow children to play with this

appliance.

DANGER

This appliance must be connected to a power supply having the same voltage and phase as specified on the

rating plate located on the inside of the appliance door.

Use caution and wear appropriate safety equipment to avoid contact with hot oil or surfaces that may cause

severe burns or injury.

WARNING

ii

DANGER

Do not spray aerosols in the vicinity of this appliance while it is in operation.

DANGER

No structural material on the fryer should be altered or removed to accommodate placement of the fryer under

a hood. Questions? Call the Frymaster Dean Service Hotline at 1-800-551-8633.

WARNING

NEVER drain boil out or cleaning solution into a shortening disposal unit (SDU), a built-in filtration unit, a

portable filter unit. These units are not intended for this purpose and will be damaged by the solution and void

the warranty.

DANGER

Prior to movement, testing, maintenance and any repair on your Frymaster fryer; disconnect ALL electrical

power cords from the electrical power supply.

NOTICE

No warranty is provided for any Frymaster fryer used in a mobile or marine installation or concession.

Warranty protection is only offered for fryers installed in accordance with the procedures described in this

manual. Mobile, marine or concession conditions of this fryer should be avoided to ensure optimum

performance.

WARNING

Do not block the area around the base or under the fryers.

WARNING

This equipment is intended for indoor use only. Do not install or operate this equipment in outdoor areas.

WARNING

Do not use water jets to clean this equipment.

If the electrical power supply cord is damaged, it must be replaced by a Frymaster Factory Authorized Servicer

or a similarly qualified person in order to avoid a hazard.

All wiring connections for this appliance must be made in accordance with the wiring diagram(s) furnished with

the appliance. Refer to the wiring diagram(s) supplied with the fryer when installing or servicing this

equipment.

Do not operate this equipment unless all covers and access panels are in place and properly secured.

Building codes prohibit a fryer with its open tank of hot oil being installed beside an open flame of any type,

including those of broilers and ranges.

WARNING

WARNING

WARNING

DANGER

iii

DANGER

Under all circumstances, oil must be removed from the fryer before attempting to move it to avoid spills, falls,

and severe burns. Never attempt to transfer hot oil from one container to another. Fryers may tip and cause

personal injury if not secured in a stationary position.

DANGER

Never operate the appliance with an empty frypot. The frypot must be filled to the fill line with water or

cooking oil before energizing the elements. Failure to do so will result in irreparable damage to the elements

and may cause a fire.

NOTICE

If this equipment is wired directly into the electrical power supply, a means for disconnection from the supply

having a contact separation of at least 3-mm in all poles must be incorporated in the fixed wiring.

NOTICE

This equipment must be positioned so that the plug is accessible unless other means for disconnection from the

power supply (e.g., a circuit breaker) is provided.

NOTICE

If this appliance is permanently connected to fixed wiring, it must be connected by means of copper wires

having a temperature rating of not less than 167°F (75°C).

DANGER

NEVER set a complete block of solid shortening on top of heating elements. To do so will damage the elements

and increase the potential for flash-point shortening temperatures and subsequent fire.

WARNING

Operation, installation, and servicing of this product may expose you to chemicals/products including

[Bisphenol A (BPA), glass wool or ceramic fibers, and crystalline silica], which is [are] known to the State of

California to cause cancer, birth defects or other reproductive harm. For more information go to

www.P65Warnings.ca.gov.

iv

iv

FQE60U FilterQuick™ easyTouch

®

Series Electric Fryers

Installation and Operation Manual

TABLE OF CONTENTS

CHAPTER 1: Introduction

1.1 General................................................................................................................................... 1-1

1.2 Safety Information ............................................................................................................... 1-1

1.3 Controller Information ........................................................................................................ 1-2

1.4 European Community (CE) Specific Information ............................................................. 1-2

1.5 Installation, Operating, and Service Personnel ................................................................ 1-2

1.6 Definitions ............................................................................................................................. 1-3

1.7 Shipping Damage Claim Procedure ................................................................................... 1-3

1.8 Reading Model Numbers .................................................................................................... 1-4

1.9 Service Information .............................................................................................................. 1-4

CHAPTER 2: Installation Instructions

2.1 General Installation Requirements .................................................................................... 2-1

2.1.1 Clearance and Ventilation ...................................................................................... 2-2

2.1.2 Electrical Grounding Requirements ...................................................................... 2-2

2.1.3 Australian Requirements ........................................................................................ 2-2

2.2 Power Requirements ........................................................................................................... 2-3

2.3 Positioning the Fryer ............................................................................................................ 2-4

2.4 Installing the JIB Cradle ........................................................................................................ 2-4

2.5 Installing the Oil Saddle Reservoir ..................................................................................... 2-5

CHAPTER 3: Operating Instructions

3.1 Equipment Setup and Shutdown Procedures .................................................................. 3-2

3.2 Operation .............................................................................................................................. 3-3

3.3 Manual Top-Off, Automatic Topoff and JIB/Oil Saddle Refill.......................................... 3-3

3.3.1 Adding Oil to the Fryer ............................................................................................ 3-4

3.3.1.1 Install the JIB (Jug in Box) Oil Reservoir .................................................... 3-4

3.3.1.2 Adding Oil to the Oil Saddle Reservoir ..................................................... 3-4

3.3.2 Routine Oil Changes ................................................................................................ 3-4

3.3.2.1 Routine Oil Changes JIB (Jug in Box) ......................................................... 3-5

3.3.2.2 Routine Oil Changes (Saddle Oil Reservoir) ............................................ 3-5

CHAPTER 4: Filtration Instructions

4.1 Introduction .......................................................................................................................... 4-1

4.2 Preparing Filtration System for Use with Filter Paper or Filter Pad .............................. 4-1

CHAPTER 5: Preventive Maintenance

5.1 Cleaning the Fryer ................................................................................................................ 5-1

5.2 Daily Checks and Service ..................................................................................................... 5-1

5.2.1 Inspect Fryer and Accessories for Damage ........................................................... 5-1

5.2.2 Clean Inside and Outside Fryer Cabinet ................................................................ 5-1

5.2.3 Clean Built-In Filtration System .............................................................................. 5-1

v

5.2.4 Clean Filter Pan, Detachable Parts and Accessories ............................................ 5-2

5.2.5 Clean Around AIF and ATO Sensors ........................................................................ 5-2

5.2.6 Clean Basket Lift Rods .............................................................................................. 5-2

5.3 Weekly Checks and Service .................................................................................................. 5-2

5.3.1 Clean Behind Fryers .................................................................................................. 5-2

5.4 Monthly Checks and Service ................................................................................................ 5-2

5.4.1 Drain, Clean Frypot and Heating Elements............................................................ 5-2

5.4.2 Deep Cleaning (Boiling Out/Cold Clean) the Frypot ............................................. 5-3

5.4.3 Cleaning the Oil Saddle Reservoir ........................................................................... 5-3

5.4.4 Pre-filter Maintenance .............................................................................................. 5-4

5.4.5 Check FQ4000 Controller Setpoint Accuracy ......................................................... 5-4

5.5 Quarterly Checks and Service ............................................................................................. 5-4

5.5.1 Replace O-rings .......................................................................................................... 5-4

5.6 Annual/Periodic System Inspection .................................................................................... 5-4

5.6.1 Fryer ............................................................................................................................. 5-5

5.6.2 Built-In Filtration System .......................................................................................... 5-5

CHAPTER 6: Operator Troubleshooting

6.1 Introduction ........................................................................................................................... 6-1

6.2 Troubleshooting .................................................................................................................... 6-2

6.2.1 Controller and Heating Problems ........................................................................... 6-2

6.2.2 Error Message and Display Problems .................................................................... 6-3

6.2.3 Filtration Problems .................................................................................................... 6-4

6.2.3.1 Incomplete Filtration .................................................................................. 6-5

6.2.3.2 Clogged Drain Error ................................................................................... 6-6

6.2.3.3 Filter Busy .................................................................................................... 6-6

6.2.4 Basket Lift Problems ................................................................................................. 6-6

6.2.5 Auto Top Off Problems ............................................................................................. 6-7

6.2.6 Bulk Oil System Problems ........................................................................................ 6-7

6.2.7 Error Log Codes ......................................................................................................... 6-8

6.2.8 OQS (Oil Quality Sensor) ........................................................................................ 6-10

APPENDIX A: Bulk Oil Instructions

FQE60U FILTERQUICK™ easyTouch® SERIES ELECTRIC FRYER

CHAPTER 1: INTRODUCTION

NOTE: The Frymaster FQE60U FilterQuick™ easyTouch® fryer requires a start-up,

demonstration and training before normal restaurant operations can begin.

1.1 General

Read the instructions in this manual thoroughly before attempting to operate this equipment. This

manual covers all configurations of FQE60U FilterQuick

model family have most parts in common, and when discussed as a group, will be referred to as FQE60U

FilterQuick

™

easyTouch® electric fryers.

The FQE60U FilterQuick™ easyTouch® electric fryers feature an open frypot with rotating elements,

automatic oil top off and semi-automatic fingertip filtration unit. The Euro-Look design incorporates a

rounded topcap and a large round drain, which ensures that fries and other debris, will be washed into

the filter pan. The FQE60U FilterQuick™ easyTouch® electric fryers are controlled with a FilterQuick™

controller. Fryers in this series come in full arrangements and can be purchased as single units or in

batteries of up to four fryers.

1.2 Safety Information

Before attempting to operate your unit, read the instructions in this manual thoroughly.

Throughout this manual, you will find notations enclosed in double-bordered boxes similar to the one

below.

™

easyTouch® electric models. The fryers in this

DANGER

Hot oil causes severe burns. Never attempt to move a fryer containing hot oil or to transfer hot

oil from one container to another.

CAUTION boxes contain information about actions or conditions that may cause or result in a

malfunction of your system.

WARNING boxes contain information about actions or conditions that may cause or result in

damage to your system, and which may cause your system to malfunction.

DANGER boxes contain information about actions or conditions that may cause or result in injury

to personnel, and which may cause damage to your system and/or cause your system to malfunction.

The FQE60U FilterQuick™ easyTouch® electric fryers incorporate a high-temperature detection feature

which shuts off power to the elements should the temperature controls fail.

1-1

1.3 Controller Information

CE Standard

Example of box used to distinguish CE and

Non-CE specific information.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC rules. While this device is a verified Class A device, it has been shown to

meet the Class B limits. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of the

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at their own expense.

The user is cautioned that any changes or modifications not expressly approved by the party

responsible for compliance could void the user's authority to operate the equipment.

If necessary, the user should consult the dealer or an experienced radio and television technician for

additional suggestions.

The user may find the following booklet prepared by the Federal Communications Commission helpful:

"How to Identify and Resolve Radio-TV Interference Problems". This booklet is available from the U.S.

Government Printing Office, Washington, DC 20402, Stock No. 004-000-00345-4.

1.4 European Community (CE) Specific Information

The European Community (CE) has established certain specific standards regarding equipment of this

type. Whenever a difference exists between CE and non-CE standards, the information or instructions

concerned are identified by means of shadowed boxes similar to the one below.

1.5 Installation, Operating, and Service Personnel

Operating information for Frymaster equipment has been prepared for use by qualified and/or

authorized personnel only, as defined in Section 1.6. All installation and service on Frymaster

equipment must be performed by qualified, certified, licensed, and/or authorized installation or

service personnel, as defined in Section 1.6.

1-2

1.6 Definitions

QUALIFIED AND/OR AUTHORIZED OPERATING PERSONNEL

Qualified/authorized operating personnel are those who have carefully read the information in this

manual and have familiarized themselves with the equipment functions, or who have had previous

experience with the operation of the equipment covered in this manual.

QUALIFIED INSTALLATION PERSONNEL

Qualified installation personnel are individuals, firms, corporations, and/or companies which, either in

person or through a representative, are engaged in and are responsible for the installation of electrical

appliances. Qualified personnel must be experienced in such work, be familiar with all electrical

precautions involved, and have complied with all requirements of applicable national and local codes.

QUALIFIED SERVICE PERSONNEL

Qualified service personnel are those who are familiar with Frymaster equipment and who have been

authorized by Frymaster, L.L.C. to perform service on the equipment. All authorized service personnel

are required to be equipped with a complete set of service and parts manuals, and to stock a minimum

amount of parts for Frymaster equipment. A list of Frymaster Factory Authorized Servicers (FAS’s) is

located on the Frymaster website at www.frymaster.com

. Failure to use qualified service personnel will

void the Frymaster warranty on your equipment

1.7 Shipping Damage Claim Procedure

What to do if your equipment arrives damaged:

Please note that this equipment was carefully inspected and packed by skilled personnel before leaving

the factory. The freight company assumes full responsibility for safe delivery upon acceptance of the

equipment.

1. File Claim for Damages Immediately - regardless of extent of damage.

2. Inspect for and Record All Visible Loss or Damage, and ensure that this information is noted on

the freight bill or express receipt and is signed by the person making the delivery.

3. Concealed Loss or Damage- If damage is unnoticed until equipment is unpacked, notify the freight

company or carrier immediately upon discovery and file a concealed damage claim. This must be

submitted within 15 days of date of delivery. Be sure to retain container for inspection.

Frymaster DOES NOT ASSUME RESPONSIBILITY FOR DAMAGE OR LOSS

INCURRED IN TRANSIT.

1-3

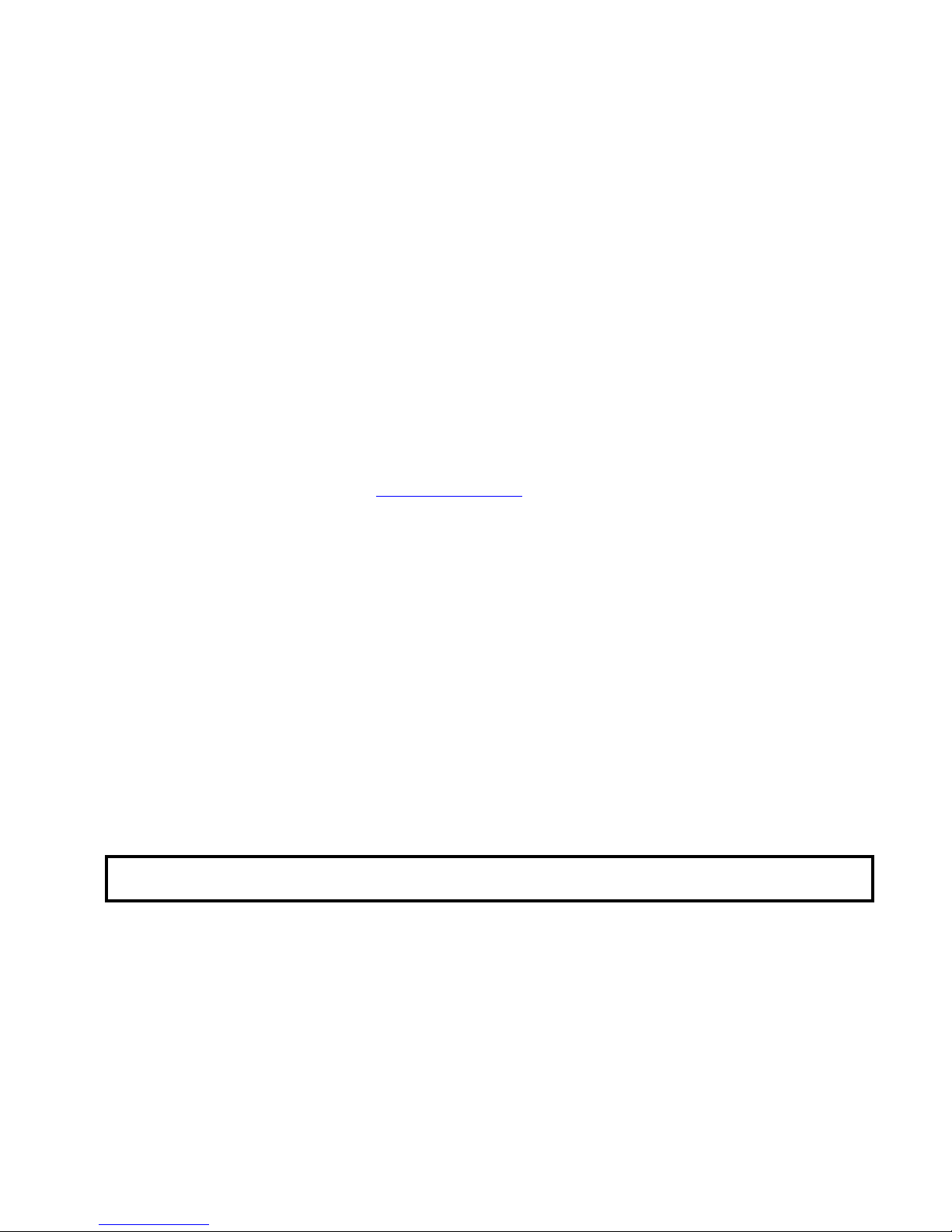

1.8 Reading Model Numbers

1FQE

60U0ZQTZZ17

Number

of vats

Model

Family

Energy

Type

1

Touch

Screen

Controller

Spreader

5

1 = E-Electric, G-Gas

2 = 30, 40, 50, 60lb frypot capacity

3 = U-Open Fryer, T-Tube Fryer

4 = L-Left Side, R-Right Side, M-Middle, X-Mixed Positions, Z-All or

None if # of Split Vats = 0

5 = S-Spreader; Z-none

6 = B-Basket Lift; Z-none

7 = kW 14,17,22 or NG-Natural Gas, PG-Propane Gas, BG-Butane

Gas, LG-LP Mix Gas

Basketlift

6

Quick

Filtration

Fryer

Vat

Capacity

2

Fryer

Type

3

kW or Gas

Type

7

# of

Splits

Position

of

Splits

4

1.9 Service Information

For non-routine maintenance or repairs, or for service information, contact your local Frymaster

Authorized Servicer (FAS). In order to assist you quickly, the Frymaster Authorized Servicer (FAS) or

Service Department representative requires certain information about your equipment. Most of this

information is printed on a data plate affixed to the inside of the fryer door. Part numbers are found in

the Service and Parts Manual. Parts orders may be placed directly with your local FAS or distributor. A

list of Frymaster Factory Authorized Servicers (FAS’s) is located on the Frymaster website at

www.frymaster.com

1-800-551-8633 or 1-318-865-1711 or by email at fryservice@welbilt.com.

The following information will be needed in order to assist you efficiently:

RETAIN AND STORE THIS MANUAL IN A SAFE PLACE FOR FUTURE USE.

. If you do not have access to this list, contact the Frymaster Service Department at

Model Number ________________________________________

Serial Number _________________________________________

Voltage ________________________________________________

Nature of the Problem ________________________________

________________________________________________________

________________________________________________________

1-4

FQE60U FILTERQUICK

™

easyTouch® SERIES ELECTRIC FRYER

CHAPTER 2: INSTALLATION INSTRUCTIONS

2.1 General Installation Requirements

Proper installation is essential for the safe, efficient, trouble-free operation of this appliance.

Qualified, licensed, and/or authorized installation or service personnel, as defined in Section 1.6

of this manual, should perform all installation and service on Frymaster equipment.

Failure to use qualified, licensed, and/or authorized installation or service personnel (as defined

in Section 1.6 of this manual) to install or otherwise service this equipment will void the

Frymaster warranty and may result in damage to the equipment or injury to personnel.

Where conflicts exist between instructions and information in this manual and local or national

codes or regulations, installation and operation shall comply with the codes or regulations in

force in the country in which the equipment is installed.

Service may be obtained by contacting your local Frymaster Authorized Servicer.

NOTICE

All fryers shipped without factory supplied cords and plug assemblies must be hardwired using

flexible conduit to the terminal block located on the rear of the fryer. These fryers should be

wired to NEC specifications. Hardwired units must include installation of restraint devices.

DANGER

Adequate means must be provided to limit the movement of this appliance without depending

on or transmitting stress to the electrical conduit. A restraint kit is provided with the fryer. If

the restraint kit is missing contact your local Frymaster Authorized Servicer (FAS).

NOTICE

If this equipment is wired directly into the electrical power supply, a means for disconnection

from the supply having a contact separation of at least 3-mm in all poles must be incorporated in

the fixed wiring.

NOTICE

This equipment must be positioned so that the plug is accessible unless other means for

disconnection from the power supply (e.g., a circuit breaker) is provided.

NOTICE

If this appliance is permanently connected to fixed wiring, it must be connected by means of

copper wires having a temperature rating of not less than 167°F (75°C).

NOTICE

If the electrical power supply cord is damaged, it must be replaced by a Frymaster Authorized

Servicer or a similarly qualified person in order to avoid a hazard.

2-1

DANGER

This appliance must be connected to a power supply having the same voltage and phase as

specified on the rating plate located on the inside of the appliance door.

DANGER

All wiring connections for this appliance must be made in accordance with the wiring diagram(s)

furnished with the appliance. Refer to the wiring diagram(s) affixed to the inside of the

appliance door when installing or servicing this equipment.

DANGER

Do not attach an apron drainboard to a single fryer. The fryer may become unstable, tip over,

and cause injury. The appliance area must be kept free and clear of combustible material at all

times.

DANGER

Building codes prohibit a fryer with its open tank of hot oil being installed beside an open flame

of any type, including those of broilers and ranges.

In the event of a power failure, the fryer(s) will automatically shut down. If this occurs, turn the power

switch OFF. Do not attempt to start the fryer(s) until power is restored.

2.1.1 Clearance and Ventilation

This appliance must be kept free and clear of combustible material, except that it may be installed on

combustible floors.

A clearance of 6 inches (15cm) must be provided at both sides and back adjacent to combustible

construction. A minimum of 24 inches (61cm) should be provided at the front of the equipment for

servicing and proper operation.

WARNING

Do not block the area around the base or under the fryers.

2.1.2 Electrical Grounding Requirements

All electrically operated appliances must be grounded in accordance with all applicable national and

local codes, and, where applicable, CE codes. All units (cord connected or permanently connected)

should be connected to a grounded power supply system. A wiring diagram is located on the inside of

the fryer door. Refer to the rating plate on the inside of the fryer door for proper voltages.

The equipotential grounding lug allows all the equipment in the same location to be

electrically connected to ensure there is no electrical potential difference between the

units, which could be hazardous.

2.1.3 Australian Requirements

To be installed in accordance with AS 5601 and AS/NZS 3000:2007 local authorities, gas, electricity, and

any other relevant statutory regulations.

If casters are fitted, the installation must comply with AS5601 and AS1869 requirements.

2-2

Loading...

Loading...