Page 1

FilterQuick™ FQE30

Electric Fryer

Service Manual

This manual is updated as new information and models are released. Visit our website for the latest manual.

FOR YOUR SAFETY

Do Not Store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

*8197110*

Part Number: FRY_SM_8197110 06/2015

Original Instructions

Page 2

NOTICE

IF, DURING THE WARRANTY PERIOD, THE CUSTOMER USES A PART FOR THIS MANITOWOC FOOD

SERVICE EQUIPMENT OTHER THAN AN UNMODIFIED NEW OR RECYCLED PART PURCHASED

DIRECTLY FROM FRYMASTER, OR ANY OF ITS FACTORY AUTHORIZED SERVICERS, AND/OR THE

PART BEING USED IS MODIFIED FROM ITS ORIGINAL CONFIGURATION, THIS WARRANTY WILL BE

VOID. FURTHER, FRYMASTER DEAN AND ITS AFFILIATES WILL NOT BE LIABLE FOR ANY CLAIMS,

DAMAGES OR EXPENSES INCURRED BY THE CUSTOMER WHICH ARISE DIRECTLY OR INDIRECTLY,

IN WHOLE OR IN PART, DUE TO THE INSTALLATION OF ANY MODIFIED PART AND/OR PART

RECEIVED FROM AN UNAUTHORIZED SERVICER.

NOTICE

This appliance is intended for professional use only and is to be operated by qualified personnel

only. A Frymaster Authorized Servicer (FAS) or other qualified professional should perform

installation, maintenance, and repairs. Installation, maintenance, or repairs by unqualified

personnel may void the manufacturer’s warranty.

NOTICE

This equipment must be installed in accordance with the appropriate national and local codes

of the country and/or region in which the appliance is installed.

DANGER

All wiring connections for this appliance must be made in accordance with the wiring diagrams

furnished with the equipment. Wiring diagrams are located on the inside of the fryer door.

DANGER

Copper wire suitable for at least 167°F (75°C) must be used for power connections.

DANGER

The electrical power supply for this appliance must be the same as indicated on the rating and

serial number plate located on the inside of the fryer door.

DANGER

This appliance must be connected to the voltage and phase as specified on the rating and serial

number plate located on the inside of the fryer door.

NOTICE TO U.S. CUSTOMERS

This equipment is to be installed in compliance with the basic plumbing code of the Building

Officials and Code Administrators International, Inc. (BOCA) and the Food Service Sanitation

Manual of the U.S. Food and Drug Administration.

DANGER

Improper installation, adjustment, maintenance or service, and unauthorized alterations or

modifications can cause property damage, injury, or death. Read the installation, operating, and

service instructions thoroughly before installing or servicing this equipment.

DANGER

The front ledge of this appliance is not a step! Do not stand on the appliance. Serious injury can

result from slips or contact with the hot oil.

ii

Page 3

NOTICE TO OWNERS OF UNITS EQUIPPED WITH CONTROLLERS

U.S.

This device complies with Part 15 of the FCC rules. Operation is subject to the following two

conditions: 1) This device may not cause harmful interference, and 2) This device must accept

any interference received, including interference that may cause undesired operation. While

this device is a verified Class A device, it has been shown to meet the Class B limits.

CANADA

This digital apparatus does not exceed the Class A or B limits for radio noise emissions as set

out by the ICES-003 standard of the Canadian Department of Communications.

Cet appareil numerique n’emet pas de bruits radioelectriques depassany les limites de classe A

et B prescrites dans la norme NMB-003 edictee par le Ministre des Communcations du Canada.

DANGER

Do not store or use gasoline or other flammable liquids or vapors in the vicinity of this or any

other appliance.

DANGER

The crumb tray in fryers equipped with a filter system must be emptied into a fireproof container

at the end of frying operations each day. Some food particles can spontaneously combust if left

soaking in certain shortening material.

WARNING

Do not bang fry baskets or other utensils on the fryer’s joiner strip. The strip is present to seal

the joint between the fry vessels. Banging fry baskets on the strip to dislodge shortening will

distort the strip, adversely affecting its fit. It is designed for a tight fit and should only be

removed for cleaning.

WARNING

Do not attach accessories to this fryer unless fryer is secured from tipping. Personal injury may

result.

WARNING

This equipment is intended for indoor use only. Do not install or operate this equipment in

outdoor areas.

DANGER

Adequate means must be provided to limit the movement of this appliance without depending

on or transmitting stress to the electrical conduit. A restraint kit is provided with the fryer. If the

restraint kit is missing contact your local KES.

DANGER

Prior to movement, testing, maintenance and any repair on your Frymaster fryer, disconnect all

electrical power from the fryer.

iii

Page 4

Table of Contents

Section 1: Service Procedures

CAUTIONARY STATEMENTS .................................................................................................................................................................. i

ELECTRICAL POWER SPECIFICATIONS ............................................................................................................................................. v

1.1 General ................................................................................................................................................................................ 1-1

1.1.1 Reading Model Numbers ................................................................................................................................ 1-1

1.2 Replacing a Controller or Controller Wiring Harnesses ....................................................................................... 1-1

1.3 Replacing Component Box Components ................................................................................................................ 1-2

1.4 Replacing a High-Limit Thermostat ........................................................................................................................... 1-3

1.5 Replacing a Temperature Probe ................................................................................................................................. 1-4

1.6 Replacing a Heating Element ....................................................................................................................................... 1-5

1.7 Replacing Contactor Box Components .................................................................................................................... 1-7

1.8 Replacing a Frypot ........................................................................................................................................................... 1-9

1.9 Built-In Filtration System Service Procedures ....................................................................................................... 1-10

1.9.1 Filtration System Problem Resolution ............................................................................................... 1-10

1.9.2 Replacing the Filter Motor, Filter Pump and Related Components ........................................ 1-11

1.9.3 Replacing the Filter Transformer or Filter Relay ............................................................................. 1-12

1.10 Basket Lift Service Procedures ................................................................................................................................... 1-14

1.11 ATO (Automatic Top-Off) Service Procedures ...................................................................................................... 1-14

1.11.1 ATO (Automatic Top-Off) Troubleshooting) ........................................................................................ 1-15

1.11.2 ATO (Automatic Top-Off) Board Pin Positions and Harnesses ....................................................... 1-17

1.11.3 Replacing the ATO board, ATO Pump Relay or Transformer .......................................................... 1-18

1.11.4 Replacing the ATO Pump or Solenoid .................................................................................................... 1-18

1.12 MIB (Manual Interface Board) Service Procedures .............................................................................................. 1-18

1.12.1 Manually Draining, Refilling or Filtering using the MIB board ....................................................... 1-19

1.12.2 MIB (Manual Interface Board) Troubleshooting .................................................................................. 1-20

1.12.3 MIB (Manual Interface Board) Pin Positions and Harnesses ............................................................ 1-22

1.12.4 MIB (Manual Interface Board) Display Characters .............................................................................. 1-23

1.12.5 Replacing the MIB Board ............................................................................................................................ 1-23

1.12.6 Control Power Reset Switch ...................................................................................................................... 1-23

1.13 Bulk Service Issues ......................................................................................................................................................... 1-24

1.13.1 Bulk MIB Tests ................................................................................................................................................. 1-24

1.13.2 Bulk Wiring ...................................................................................................................................................... 1-25

1.13.3 Bulk Oil System Plumbing Schematic .................................................................................................... 1-26

1.13.4 Bulk Oil Test Quick Reference ................................................................................................................... 1-26

1.14 AIF (Automatic Intermittent Filtration) Service Procedures ............................................................................ 1-28

1.14.1 AIF (Automatic Intermittent Filtration) Troubleshooting................................................................ 1-29

1.14.2 AIF (Automatic Intermittent Filtration) Actuator Board Pin Positions ........................................ 1-30

1.14.3 Replacing an AIF (Automatic Intermittent Filtration) Board .......................................................... 1-31

1.14.4 Replacing a Rotary Actuator ...................................................................................................................... 1-31

1.15 FilterQuick

1.15.1 FilterQuick

1.15.2 FilterQuick

1.15.3 Service Required Errors ............................................................................................................................... 1-35

1.15.4 Error Log Codes.............................................................................................................................................. 1-36

1.15.5 FilterQuick

1.15.6 FilterQuick

1.15.7 FilterQuick

1.16 Loading and Updating Software .............................................................................................................................. 1-40

1.17 FilterQuick

1.18 Interface Board Diagnostic Chart ............................................................................................................................. 1-42

1.19 Probe Resistance Chart ................................................................................................................................................ 1-43

Wiring Diagrams

See 8197225 FilterQuick Elec Wiring Diagrams Manual

Part Number: Part Number: FRY_SM_8197110 iv

™

Controller Service Procedures ........................................................................................................... 1-32

™

Data Network Flowchart ...................................................................................................................... 1-41

™

Controller Troubleshooting ............................................................................................... 1-32

™

Controller Useful Codes ...................................................................................................... 1-34

™

Filter Error Flowchart ............................................................................................................ 1-37

™

Controller Menu Summary Tree ....................................................................................... 1-38

™

Controller Pin Positions and Harnesses ......................................................................... 1-39

Page 5

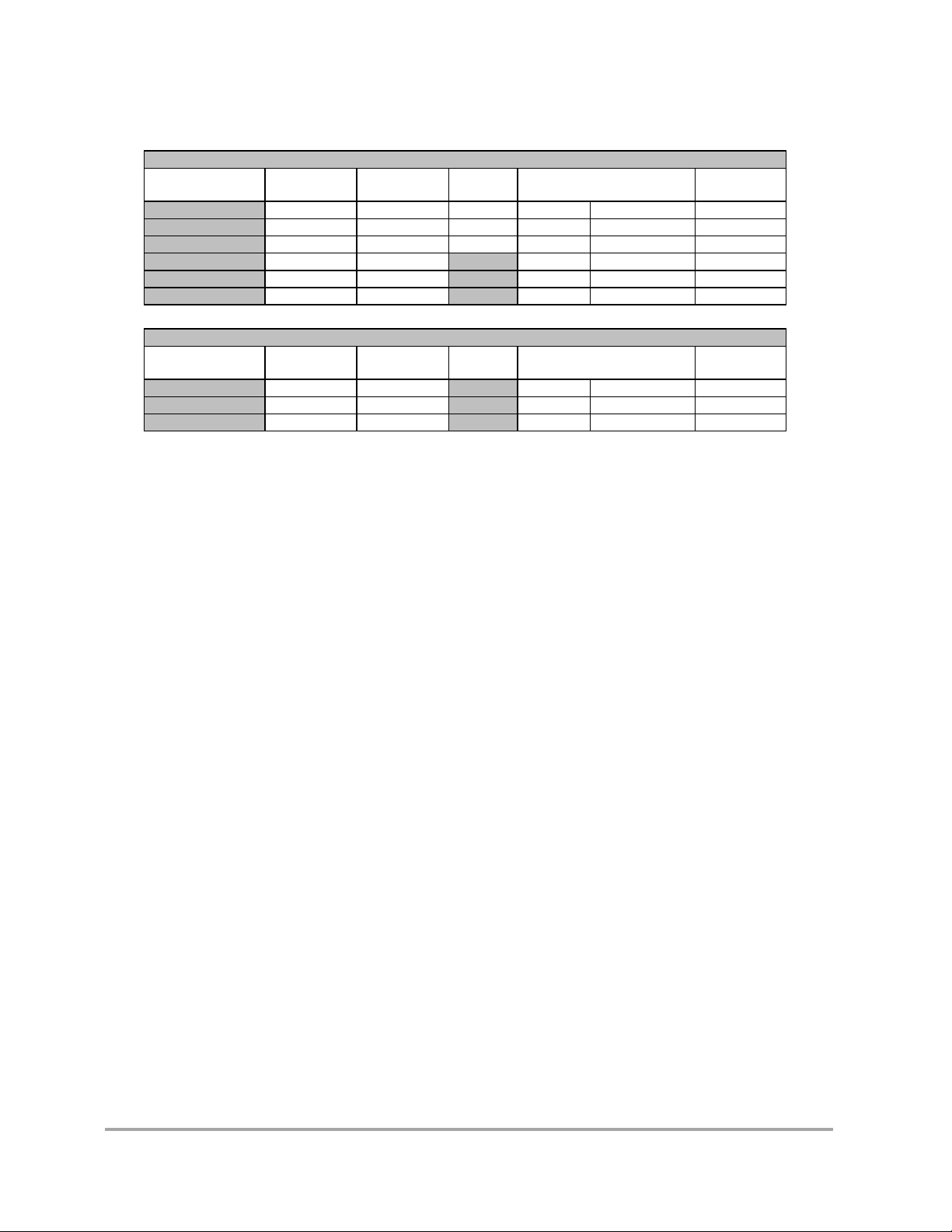

ELECTRICAL POWER SPECIFICATIONS

Three (3) Phase Requirements

MODEL kW VOLTAGE

FQEL14 14 208 3 6 (4.11) 39

FQEL14 14 240 3 6 (4.11) 34

FQEL14 14 480 3 8 (2.59) 17

FQEL14 14 220/380 4 6 (4.11) 22

FQEL14 14 230/400 4 6 (4.11) 21

FQEL14 14 240/415 4 6 (4.11) 20

Single (1) Phase Requirements

MODEL kW VOLTAGE

FQEL14 14 208 2 3 (5.83) 67

FQEL14 14 220 2 3 (5.83) 63

FQEL14 14 240 2 4 (5.19) 58

WIRE

SERVICE

WIRE

SERVICE

Part Number: Part Number: FRY_SM_8197110 v

MINIMUM WIRE SIZE

AWG (mm)

MINIMUM WIRE SIZE

AWG (mm)

AMPS

(per leg)

AMPS

(per leg)

Page 6

FILTERQUICK™ FQE30 SERIES ELECTRIC FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.1 General

Before performing any maintenance on your Frymaster fryer, disconnect the fryer from the electrical

power supply.

WARNING

To ensure the safe and efficient operation of the fryer, the electrical plug(s) must be

fully engaged and locked in their pin and sleeve socket.

When electrical wires are disconnected, it is recommended that they be marked in such a way as to

facilitate re-assembly.

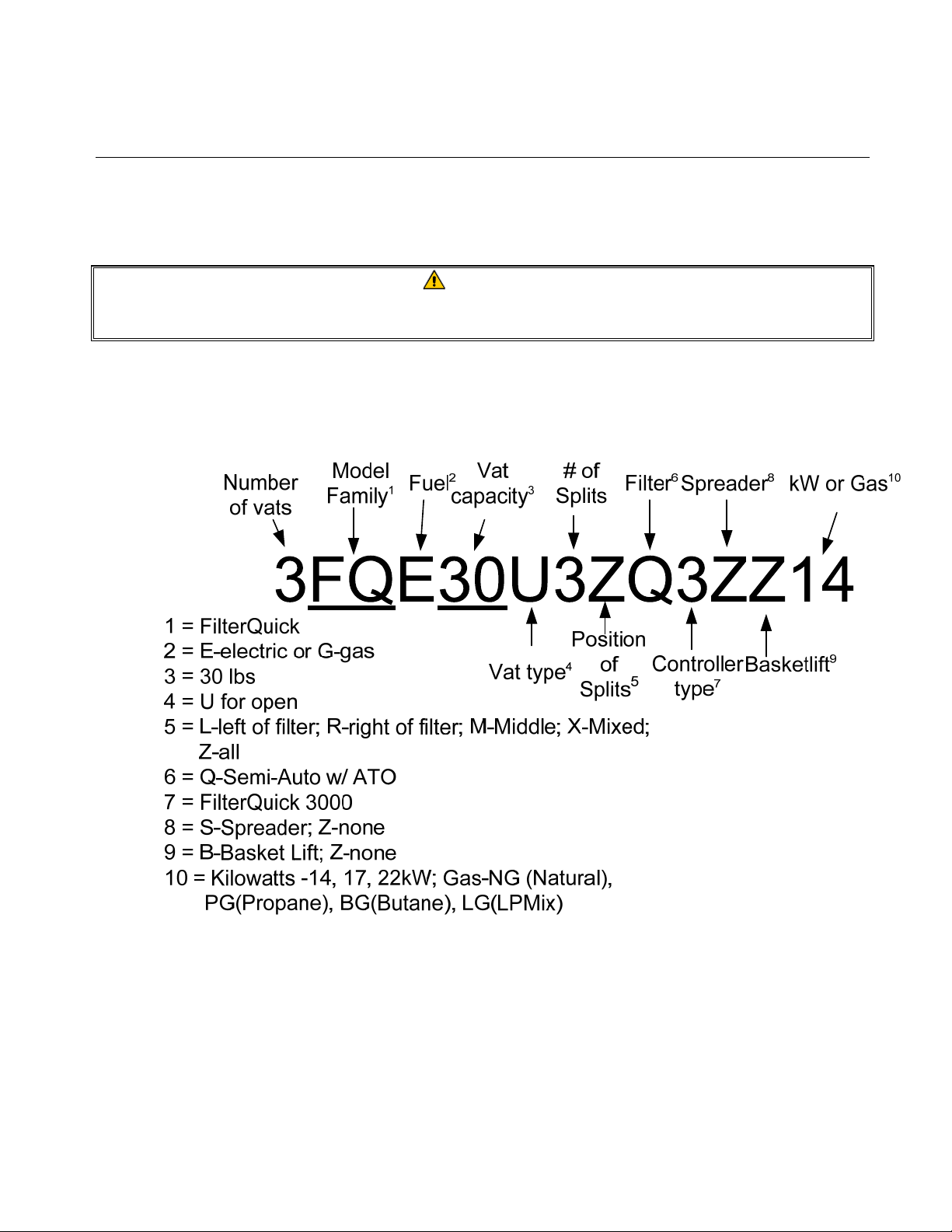

1.1.1 Reading Model Numbers

1.2 Replacing the Controller or the Controller Wiring Harnesses

1. Disconnect the fryer from the electrical power supply.

2. Unscrew the filter push pull handle knobs.

3. Open the control panel by removing the screws on the bottom of the bezel. Carefully lower the

bezel.

4. Remove the two screws from the upper corners of the controller. The controller is hinged at the

bottom and will swing open from the top.

1-1

Page 7

5. Unplug the wiring harnesses from the connectors on the back of the controller marking their

r

position for reassembly and disconnect the grounding wires from the terminals. Remove the

controller by lifting it from the hinged slots in the control panel frame.

Ground Wire Terminal

Communication Wires

Drain Switch

and LED

Ground Wire Terminal

20-Pin Connecto

Locator Wire

5. Install the replacement controller. Reinstall the control panel assembly by reversing steps 1 thru 5.

6. Setup the controller following the instructions on page 1-3 in the FilterQuick

™

Controller

Operation manual. Setup MUST be performed prior to readdress.

7. Once setup is complete on all replaced controllers, CYCLE POWER TO ENTIRE FRYER

SYSTEM. See section 1.12.6 to reset control power.

8. Check software version and if necessary update the software. If a software update was necessary,

follow the instructions to update the software in section 1.16.

1.3 Replacing Component Box Components

1. Disconnect the fryer from the electrical supply.

2. Drain cooking oil below the level of the probe or thermostat.

3. Unscrew the filter push pull handle knobs.

4. Open the control panel by removing the screws on the bottom of the bezel. Carefully lower the

bezel.

5. Remove the top two screws in the upper corners of the controller.

6. Swing the controller out from the top and allow it to rest on its hinge tabs.

7. Disconnect the controller wiring harness and ground wire from the back of the controller and

remove the controller by lifting it from the hinge slots in the control panel frame.

8. Disconnect the wiring from the component to be replaced, being sure to make a note of where each

wire was connected.

9. Dismount the component to be replaced and install the new component, ensuring that any required

spacers, insulation, washers, etc. are in place.

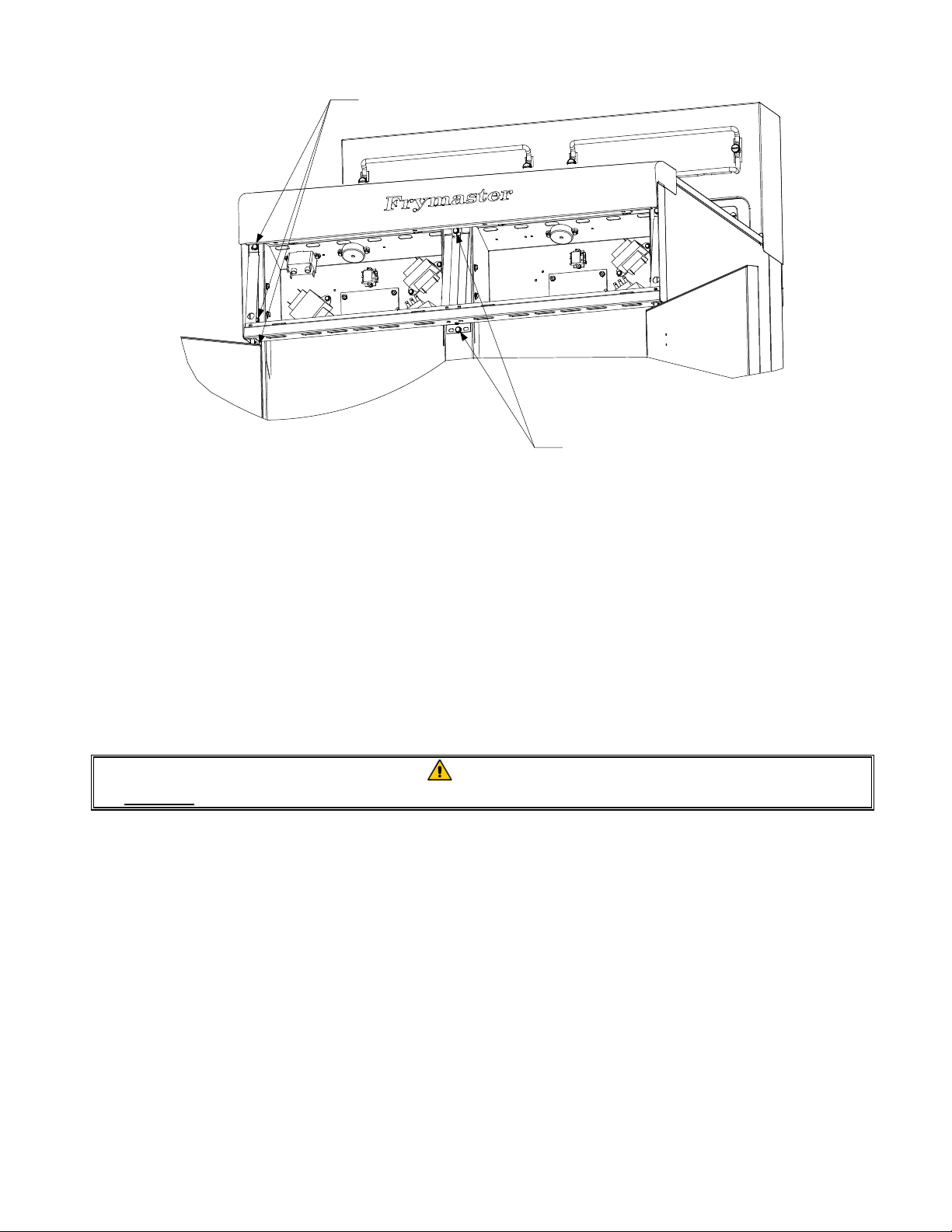

NOTE: If more room to work is required, the control panel frame assembly may be removed by

removing the hex-head screws which secure it to the fryer cabinet (see illustration below). If this

option is chosen, all controller assemblies must be removed per steps 1 thru 7 above. The cover

plate, on the lower front of the component box, may also be removed to allow additional access if

desired.

1-2

Page 8

Remove these three

screws at each end.

Remove these two screws

from the center supports.

Removing the Control Panel Frame and Top Cap Assembly

10. Reconnect the wiring disconnected in step 7, referring to your notes and the wiring diagrams on

the fryer door to ensure that the connections are properly made. Also, verify that no other wiring

was disconnected accidentally during the replacement process.

11. Reverse steps 1 through 8 to complete the replacement and return the fryer to service.

1.4 Replacing a High-Limit Thermostat

1. Remove the filter pan and lid from the unit. Drain the frypots into a Shortening Disposal Unit

(SDU) or other appropriate METAL container using the controller “drain to pan option” or using

the MIB board in manual mode.

DANGER

DO NOT drain more than one full frypot or two split frypots into the SDU at one time.

2. Disconnect the fryer from the electrical power supply and reposition it to gain access to the rear of

the fryer.

3. Remove the four screws from both the left and right sides of the lower back panel.

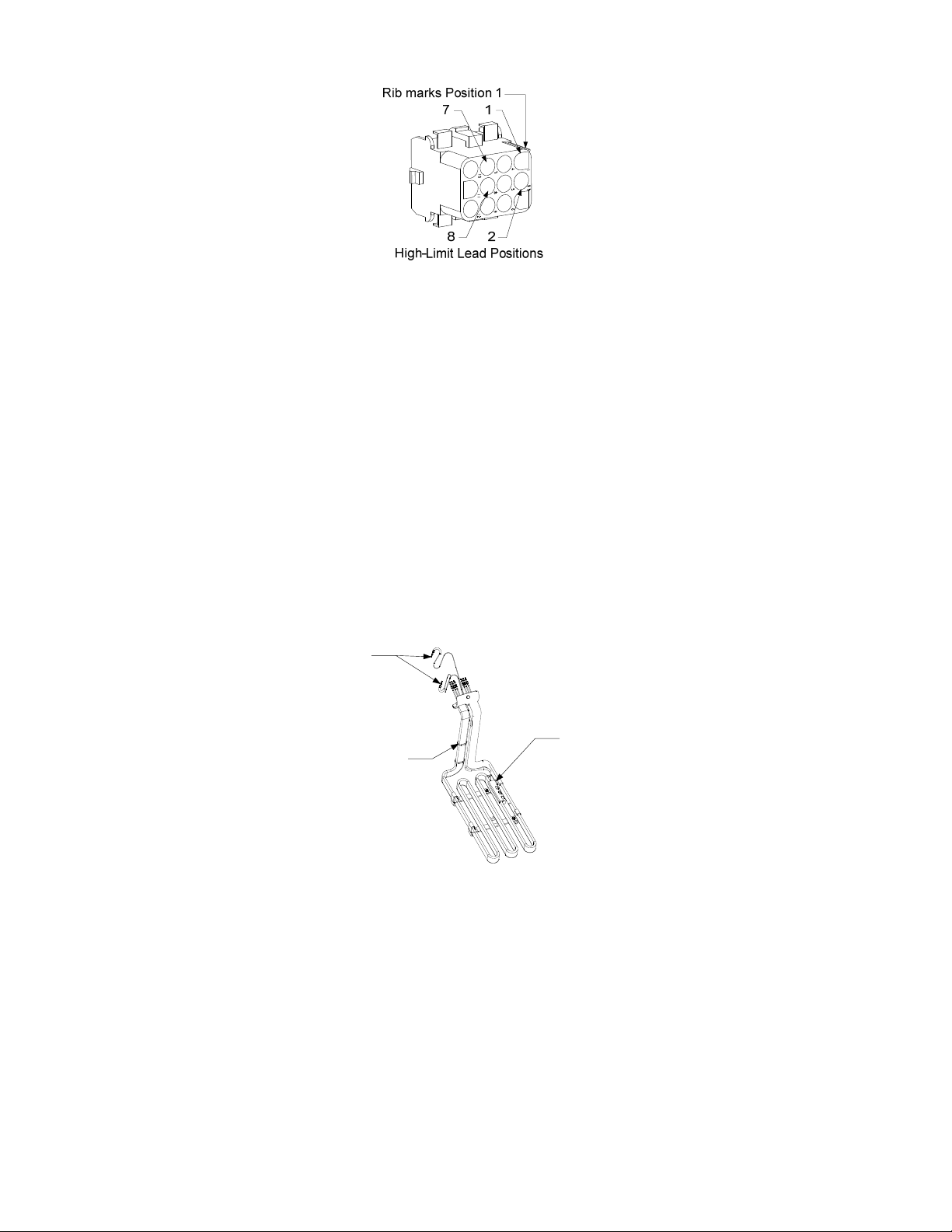

4. Locate the high-limit that is being replaced and follow the two-black wires to the 12-pin connector

C-6. Note where the leads are connected prior to removing them from the connector. Unplug the

12-pin connector C-6 and using a pin-pusher push the pins of the high-limit out of the connector.

5. Carefully unscrew the high-limit thermostat to be replaced.

6. Apply Loctite™ PST 567 or equivalent sealant to the threads of the replacement and screw it

securely into the frypot.

7. Insert the leads into the 12-pin connector C-6 (see illustration below). For full-vat units or the left

half of a dual-vat unit (as viewed from the rear of the fryer) the leads go into positions 1 and 2 of

the connector. For the right half of a dual-vat unit (as viewed from the rear of the fryer), the leads

go into positions 7 and 8. In either case, polarity does not matter.

1-3

Page 9

8. Reconnect the 12-pin connecting plug C-6. Use wire ties to secure any loose wires.

9. Reinstall the back panels, contactor plug guards, reposition the fryer under the exhaust hood, and

reconnect it to the electrical power supply to return the fryer to service.

1.5 Replacing a Temperature Probe

1. Lift the element out of the oil.

2. Disconnect the fryer from the electrical power supply and reposition it to gain access to the rear of

the fryer.

3. Remove the four screws from both sides of the lower back panel. Then remove the two screws on

both the left and right sides of the back of the tilt housing. Lift the tilt housing straight up to

remove from the fryer.

4. Locate the red (or yellow) and white wires of the temperature probe to be replaced. Note where

the leads are connected prior to removing them from the connector. Unplug the 12-pin connector

C-6 and using a pin-pusher push the pins of the temperature probe out of the connector.

5. Remove the securing probe bracket and metal tie wraps that secure the probe to the element (see

illustration below). Remove the ground clip on the probe shield.

Probe

Leads

Probe

Metal Wire Tie

Bracket

6. Gently pull on the temperature probe and grommet, pulling the wires up the rear of the fryer and

through the element tube assembly.

7. Insert the replacement temperature probe (wires first) into the tube assembly ensuring that the

grommet is in place. Secure the probe to the elements using the bracket which was removed in

Step 5 and the metal tie wraps which were included in the replacement kit.

8. Route the probe wires out of the tube assembly following the element wires down the back of the

fryer through the Heyco bushings to the 12-pin connector C-6. Secure the wires to the sheathing

with wire ties. Attach the ground clip.

9. Insert the temperature probe leads into the 12-pin connector C-6 (see illustration below). For full-

vat units or the right half of a dual-vat unit (as viewed from the rear of the fryer) the red (or

yellow) lead goes into position 3 and the white lead into position 4 of the connector. For the left

half of a dual-vat unit (as viewed from the rear of the fryer), the red (or yellow) lead goes into

1-4

Page 10

position 9 and the white lead into position 10. NOTE: Right and left refer to the fryer as viewed

from the rear.

10. Secure any loose wires with wire ties, making sure there is no interference with the movement of

the springs. Rotate the elements up and down, making sure that movement is not restricted and

that the wires are not pinched.

11. Reinstall the tilt housing, back panels and contactor plug guards. Reposition the fryer under the

exhaust hood and reconnect it to the electrical power supply to return the fryer to service.

1.6 Replacing a Heating Element

1. Perform steps 1-5 of section 1.5, Replacing a Temperature Probe.

2. Disconnect the wire harness containing the probe wiring, where the temperature probe is attached

to the element being replaced. Using a pin pusher, disconnect the probe wires from the 12-pin

connector.

3. In the rear of the fryer disconnect the 6-pin connector for the left element (as viewed from the front

of the fryer) or the 9-pin connector for the right element from the contactor box. Press in on the

tabs on each side of the connector while pulling outward on the free end to extend the connector

and release the element leads (see photo below). Pull the leads out of the connector and out of the

wire sleeving.

4. Raise the element to the full up position and support the elements.

5. Remove the hex head screws and nuts that secure the element to the tube assembly and pull the

element out of the frypot. NOTE: The nuts inside the tube can be held and removed using the RE

element tube nut spanner, PN# 2304028. Full-vat elements consist of two dual-vat elements

clamped together. For full-vat units, remove the element clamps before removing the nuts and

screws that secure the element to the tube assembly.

6. If applicable, recover the probe bracket and probe from the element being replaced and install

them on the replacement element. Install the replacement element in the frypot, securing it with the

1-5

Page 11

nuts and screws removed in Step 5 to the tube assembly. Ensure the gasket is between the tube and

element assembly.

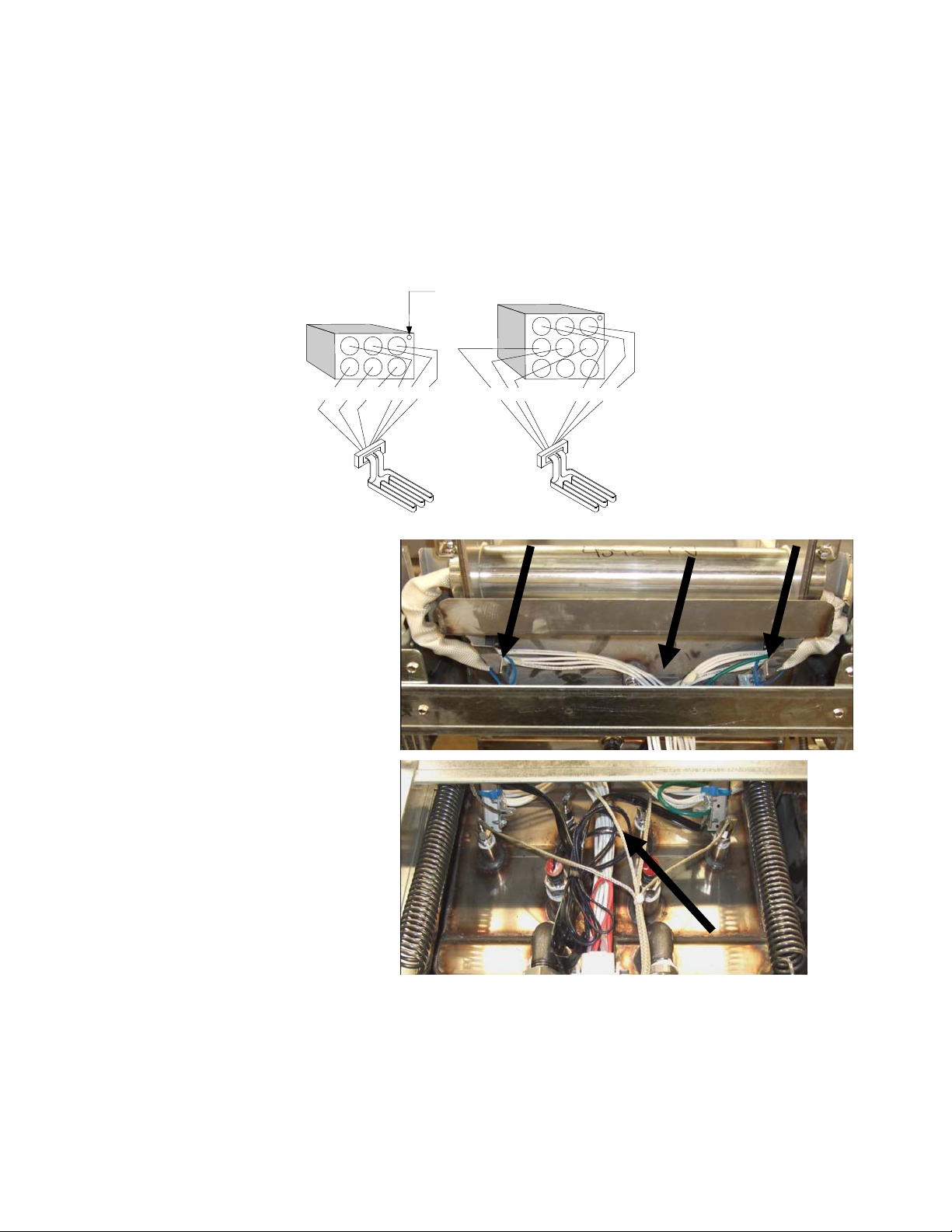

7. Route the element leads through the element tube assembly and into the wire sleeving to prevent

chafing. Ensure that the wire sleeving is routed back through the Heyco bushing, keeping it clear

from the lift springs (see phots below and on the next page). Also ensure that the wire sleeving

extends into the tube assembly to protect the edge of the tube assembly from chafing the wires.

Press the pins into the connector in accordance with the diagram below, and then close the

connector to lock the leads in place. NOTE: It is critical that the wires be routed through the

sleeving to prevent chafing.

Index Marker marks

Position 1

14253

6

5L 4L6L 1L2L3L

14253

6

R

6

789

5

4R

R

2

1R

3R

R

Full vat element wire routing

Pull the element wires through the

bushings on either side of the frypot

and down the back. Element wires

should be routed to the right of the

ATO temperature probe on the back

wall of the frypot.

Dual vat element wire routing

Pull the element wires through the

bushings on either side of the frypot

and down the back. Element wires

should be routed to the center of the

frypot between the ATO temperature

probes.

1-6

Page 12

Element grounding and wire

routing

To ground the element wires, use the

hole in the frypot frame located under

the bushing that the element wires pass

through. Using a screw through the

ground wires ring terminal, connect it

to the frypot using the probe ground

clip. Use a tie wrap to tie up half of the

element wires after the wires are pulled

through the bushing. Do not pull tie

wrap tight, leave it slack at about one

inch

8. Reconnect the element connector ensuring that the latches lock.

9. Insert the temperature probe leads into the 12-pin wiring harness connector (see illustration

below). For full-vat units or the right half of a dual-vat unit, the red lead goes into position 3 and

the white into position 4. For the left half of a dual-vat unit, the red lead goes into position 9 and

the white into position 10. NOTE: Right and left refer to the fryer as viewed from the rear.

10. Reconnect the 12-pin connector of the wiring harness disconnected in Step 2.

11. Lower the element to the full down position.

12. Reinstall the tilt housing, back panels and contactor plug guard. Reposition the fryer under the

exhaust hood, and reconnect it to the electrical power supply.

1.7 Replacing Contactor Box Components

1. If replacing a contactor box component in boxes above the filter pan, first remove the filter pan

and lid from the unit. If replacing components in fryers that have ATO boxes, the ATO box may

require removal.

2. Disconnect the fryer from the electrical power supply.

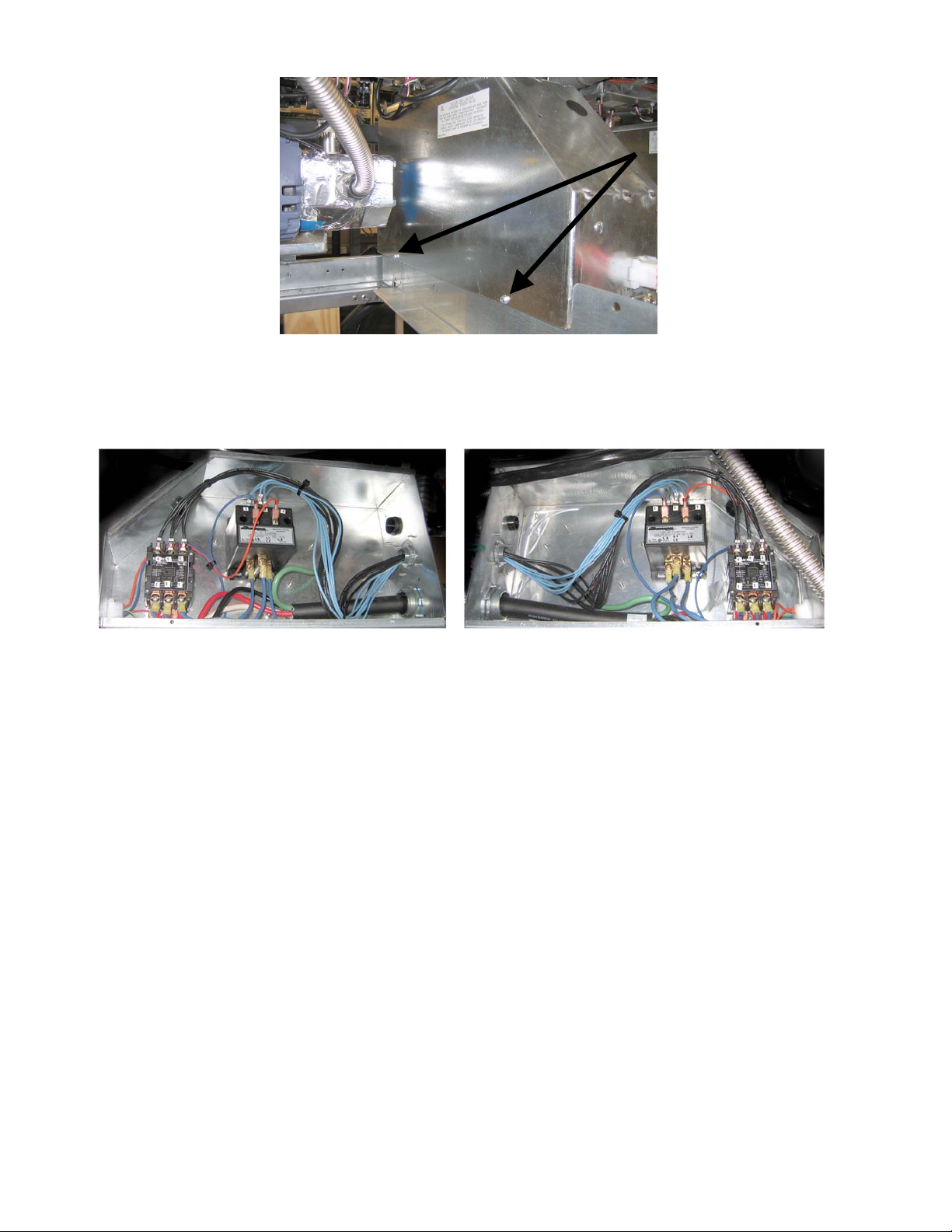

3. Remove the two screws securing the cover of the contactor box. The contactor boxes above the

filter pan are accessed by sliding under the fryer. They are located to the left and right above the

guide rails (see photo below). The contactor boxes for frypots not over the filter pan are accessed

by opening the fryer door directly under the affected frypot.

1-7

Page 13

Remove two screws to

access contactor box

components above the

filter pan

.

4. The contactors and relays are held on by threaded pin studs so that only removal of the nut is

required to replace the component.

5. After performing necessary service, reverse steps 1-4 to return the fryer to operation.

Left and right views of mechanical contactor box components.

Sometimes it is necessary to remove the entire contactor box to repair. Below are the instructions for

removing the far left contactor box.

1. Remove fryers from hood and remove all power to fryers.

2. Remove lower back panel.

3. Remove filter pan, lid and downspout splash shield.

4. Remove clevis clip from dispose handle at rear of fryer and let handle drop out of waste valve

bracket.

5. Remove two screws holding waste valve handle at front of fryer and remove bracket and handle

from fryer.

6. Remove AIF board and tuck wires out of the way of the contactor box for box removal.

7. Remove shipping brace that supports filter pump shelf brace to top of contactor box.

8. Remove contactor box cover.

9. Unplug all wiring from front and rear of contactor box.

10. Remove two screws that hold element wire shield to rear of contactor box and remove wire shield.

11. Remove two screws that support contactor box at rear of box.

12. Remove two screws that support contactor box at front of box.

13. Lift contactor box up to clear left frame rail and slide to the right far enough that the left rear

corner of the pump and motor shelf protrude inside of the contactor box slightly.

14. Tip front of contactor box down and to the right slightly and then pull out from opening where

filter pan lid would rest.

15. Reverse above steps for reinstallation.

1-8

Page 14

1.8 Replacing a Frypot

1. Drain the frypot into the filter pan or, if replacing a frypot over the filter system, into a Shortening

Disposal Unit (SDU) or other appropriate METAL container. If replacing a frypot over the filter

system, remove the filter pan and lid from the unit.

DANGER

DO NOT drain more than one full frypot or two split frypots into the SDU at one time.

2. Disconnect the fryer from the electrical power supply and reposition it to gain access to both the

front and rear.

3. Disconnect the fryer from the electrical supply.

4. Drain cooking oil below the level of the probe or thermostat.

5. Unscrew the filter push pull handle knobs.

6. Open the control panel by removing the screws on the bottom of the bezel. Carefully lower the

bezel.

7. Remove the top two screws in the upper corners of the controller.

8. Swing the controller out from the top and allow it to rest on its hinge tabs.

9. Disconnect the controller wiring harness and ground wire from the back of the controller and

remove the controller by lifting it from the hinge slots in the control panel frame (see illustration

and photo on page 1-1).

10. Remove the controllers by lifting them from the hinge slots in the control panel frame.

11. Remove the tilt housing and back panels from the fryer. The tilt housing must be removed first in

order to remove the upper back panel.

12. To remove the tilt housing, remove the hex-head screws from the rear edge of the housing. The

housing can be lifted straight up and off the fryer.

13. Remove the control panel by removing the screw in the center and the nuts on both sides.

14. Loosen the component boxes by removing the screws, which secure them in the cabinet.

15. Dismount the top cap by removing the nuts at each end that secure it to the cabinetry.

16. Remove the hex head screw that secures the front of the frypot to the cabinet cross brace.

17. Remove the top-connecting strip that covers the joint with the adjacent frypot.

18. Unscrew the nut located on the front of each section of drain tube, and remove the tube assembly

from the fryer.

19. Remove the actuators from the drain and return valves and disconnect the wiring.

20. Disconnect any auto filtration probes and auto top off sensors and wiring.

21. At the rear of the fryer, unplug the 12-pin connector C-6 and, using a pin pusher, disconnect the

high-limit thermostat leads. Disconnect any other probe wiring.

22. Disconnect the oil return flexline(s).

23. Raise the elements to the “up” position and disconnect the element springs.

24. Remove the machine screws and nuts that secure the element tube assembly to the frypot.

Carefully lift the element assembly from the frypot and secure it to the cross brace on the rear of

the fryer with wire ties or tape.

25. Carefully lift the frypot from the fryer and place it upside down on a stable work surface.

26. Recover the drain valve(s), oil return flexline connection fitting(s), actuators, AIF boards and high-

™

limit thermostat(s) from the frypot. Clean the threads and apply Loctite

PST 567 or equivalent

sealant to the threads of the recovered parts and install them in the replacement frypot.

27. Carefully lower the replacement frypot into the fryer. Reinstall the hex head screw removed in

step 11 to attach the frypot to the fryer.

1-9

Page 15

28. Position the element tube assembly in the frypot and reinstall the machine screws and nuts

removed in step 24.

29. Reconnect the oil return flexlines to the frypot, and replace aluminum tape, if necessary, to secure

heater strips to the flexlines.

30. Insert the high-limit thermostat leads disconnected in step 21 (see illustration on page 1-3 for pin

positions).

31. Reconnect the actuators, ensuring the correct position of the drain and return valves.

32. Reconnect the auto filtration and auto top off probes.

33. Reinstall the drain tube assembly.

34. Reinstall the top connecting strips, top cap, tilt housing and back panels.

35. Reinstall controllers in the control panel frame and reconnect the wiring harnesses and ground

wires.

36. Reposition the fryer under the exhaust hood and reconnect it to the electrical power supply.

1.9 Built-in Filtration System Service Procedures

1.9.1 Filtration System Problem Resolution

One of the most common causes of filtration problems is placing the filter pad/paper on the bottom of

the filter pan rather than over the filter screen.

CAUTION

Ensure that filter screen is in place prior to filter pad/paper placement and filter pump

operation. Improper screen placement is the primary cause of filtration system

malfunction.

Whenever the complaint is “the pump is running, but no oil is being filtered,” check the installation of

the filter pad/paper, and ensure that the correct size is being used. While you are checking the filter

pad/paper, verify that the O-rings on the pick-up tube

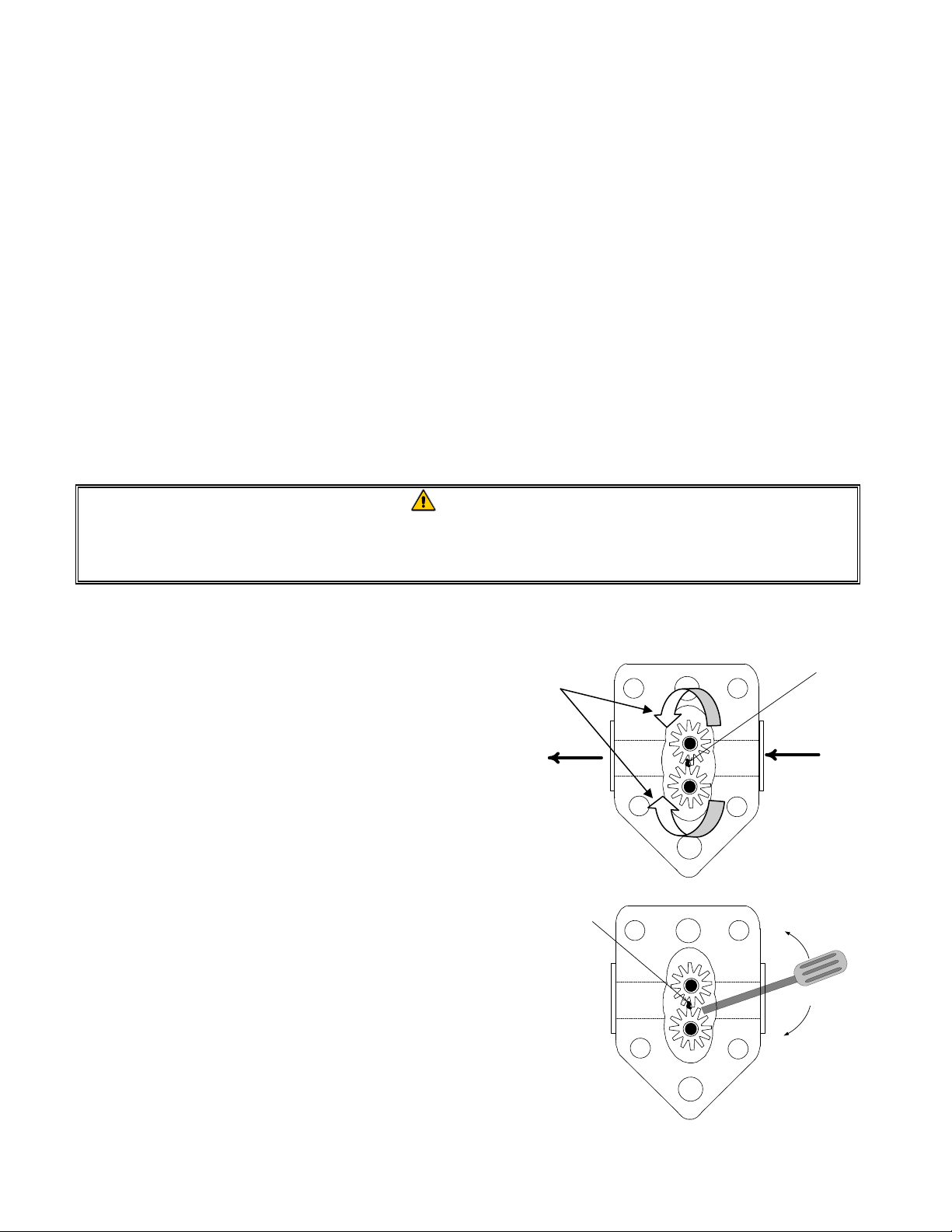

of the filter pan are in good condition. A missing or

Gear Rotation

Sediment Particle

worn O-ring allows the pump to take in air and

decrease its efficiency.

If the pump motor overheats, the thermal overload

Oil Flow

will trip and the motor will not start until it is reset. If

the pump motor does not start, press the red reset

switch (button) located on the rear of the motor.

If the pump starts after resetting the thermal overload

switch, then something is causing the motor to

overheat. A major cause of overheating is when

several frypots are filtered sequentially, overheating

Sediment Particle

Up for reverse

the pump and motor. Allow the pump motor to cool

at least 30 minutes before resuming operation. Pump

overheating can be caused by:

Solidified shortening in the pan or filter lines,

Down for forward

or

Attempting to filter unheated oil or shortening

(cold oil is more viscous, overloading the

pump motor and causing it to overheat).

1-10

Page 16

If the motor runs but the pump does not return oil, there is a blockage in the pump. Incorrectly sized

or installed paper/pads will allow food particles and sediment to pass through the filter pan and into

the pump. When sediment enters the pump, the gears bind, causing the motor to overload, again

tripping the thermal overload. Shortening that has solidified in the pump will also cause it to seize,

with the same result.

A pump seized by debris or hard shortening can usually be freed by manually moving the gears with a

screwdriver or other instrument.

Disconnect power to the filter system, remove the input plumbing from the pump, and use a

screwdriver to manually turn the gears.

● Turning the pump gears in reverse will release a hard particle.

● Turning the pump gears forward will push softer objects and solid shortening through the pump

and allow free movement of the gears.

Incorrectly sized or installed paper/pads will also allow food particles and sediment to pass through

and clog the suction tube on the bottom of the filter pan. Particles large enough to block the suction

tube may indicate that the crumb tray is not being used. Pan blockage can also occur if shortening is

left in the pan and allowed to solidify. Blockage removal can be accomplished by forcing the item out

with an auger or drain snake. Compressed air or other pressurized gases should NEVER be used to

force out the blockage.

1.9.2 Replacing the Filter Motor, Filter Pump, and Related Components

1. Remove the filter pan and lid from the unit. Drain the frypots into a Shortening Disposal Unit

(SDU) or other appropriate metal container.

DANGER

DO NOT drain more than one full frypot or two split frypots into the SDU at one time.

2. Disconnect the fryer from the electrical power supply and reposition it to gain access to both the

front and rear.

3. Disconnect the flexline running to the oil-return manifold at

the rear of the fryer as well as the pump suction flexline at

the end of the filter pan connection (see photo to the right).

4. Loosen the nut and bolt which secure the bridge to the oil-

return manifold.

5. Remove the cover plate from the front of the motor and

disconnect the motor wires.

6. Remove the two nuts and bolts which secure the front of the

bridge to the cross brace and carefully slide the bridge

rearward off the cross brace until its front end can be

lowered to the floor. Undo the single nut holding it in place

in back. Be careful not to let the rear of the bridge slip off

the manifold at this point.

7. Get a good grip on the bridge, carefully pull it forward off

Disconnect flexlines indicated by

the arrows.

the oil-return manifold, and lower the entire assembly to the

floor. Once on the floor, pull the assembly out the front of the fryer.

1-11

Page 17

8. When required service has been completed, reverse steps 4-7 to reinstall the bridge.

9. Reconnect the unit to the electrical power supply, and verify that the pump is functioning correctly

using the MIB board in manual mode (i.e., using the fill function when engaged, the motor should

start and there should be strong suction at the intake fitting and outflow at the rear flush port.)

10. When proper operation has been verified, reinstall the back panels and the filter pan and lid.

11. Reconnect it to the electrical power supply and reposition the fryer under the exhaust hood to

return the fryer to service.

1.9.3 Replacing the Transformer or Filter Relay

Disconnect the fryer from the electrical power supply. Remove the left controller from the fryer to

expose the interior of the left component box. The transformer and relay on the left are located as

shown in the illustration below. NOTE: The right component box is identical to the left except that

the transformer and relay on the left side are not present. Once replaced, reconnect the power.

When replacing a filter relay in the left component box, ensure the 24VDC relay (8074482) is used.

Similar Frymaster fryers use a 24VAC relay, which can lead to confusion. The 24VDC is used in the

FilterQuick™ fryer.

1.10 Basket Lift Service Procedures

FQE30™ Series electric fryers may be equipped with automatic basket lifts. Basket lifts always come

in pairs, although each operates independently.

A modular basket lift (illustrated on the following page) is a self-contained sub-assembly consisting

of a pair of toothed rods, which support removable basket lift arms, a pair of reversible-drive gear

motors, and four microswitches. The gear motors engage the teeth of the rods, moving them up or

down depending upon the motors’ direction of rotation. The microswitches at the upper and lower

limits of movement stop the motors when the basket is in the full up or full down position.

Timing circuitry in the controller initiates and stops basket lift operation depending upon the variables

programmed by the operator. When the product button is pressed, the timing circuitry activates a coil

in the basket lift relay to supply power to the lower microswitch. The microswitches stop the motor at

the lift’s upper and lower travel limits and reverse the direction of current flow thus reversing the

motor direction.

When the product button is pushed on the controller, current flows through a coil in the basket lift

relay, causing the lower circuit to be activated. The basket lift lowers, closing the normally open

upper-micro-switch. When the downward-moving rod opens the lower normally closed microswitch,

the power to the motor ceases to flow. When the controller times out, the current to the relay coil is

cut, allowing the upper circuit to be activated. The basket lift rises and re-closes the lower

1-12

Page 18

microswitch. When the basket lift rod clears the upper microswitch, the microswitch reopens, power

to the circuit is cut, and the motor stops. Pushing the product button restarts the cycle.

Problems with the basket lift can be grouped into three categories:

● Binding/jamming problems

● Motor and gear problems

● Electronic problems

100-120V Configuration

208-250V Configuration

Binding and Jamming Issues

Noisy, jerky or erratic movement of the lifts is usually due to lack of lubrication of the rods and their

bushings. Apply a light coat of Lubriplate® or similar lightweight white grease to the rod and

bushings to correct the problem.

With the modular basket lift, another possible cause of binding is improper positioning of the motor,

which prevents the gear from correctly engaging the teeth in the rod. To correct the problem, loosen

the screws that hold the motor in place and move it forward or backward until the rod has just enough

slack to be rotated slightly.

Motor and Gear Issues

With the modular basket lift, the most likely problem to be encountered in this category is erratic

motion of the lift due to a worn drive gear. Failure to keep the lift rod and bushings properly

lubricated will cause unnecessary wear of the gear. The problem is corrected by replacing the worn

gear.

If the lift cycles correctly but fails to remain in the up position (i.e., goes up, but then slowly settles

back down into the frypot), the problem is a failed motor brake. A failed motor brake cannot be

repaired and requires replacement of the motor itself.

If power is reaching the motor but the motor fails to run, the motor is burned out and must be replaced.

1-13

Page 19

Electronic Issues

Within this category are problems associated with the relays, microswitches, capacitors, resistors,

interface board, wiring, and controls. The most common problem in this category is a lift that

continuously travels up and down. This is usually caused by a microswitch that is out of adjustment.

Troubleshooting the electronics of a modular basket lift is simply a process of verifying current flow

through the individual components up to and including the motor. Using a multimeter set to the 250

VAC range, check the connections on both sides of the component for the presence of the applied line

voltage. The schematic below and the wiring diagram on page 2-8 and 2-9 can identify the

components and wiring connection points.

1.11 ATO (Automatic Top-off) Service Procedures

The automatic top-off system is activated when the oil level falls below a sensor in the rear of the

frypot. The signal is sent to the ATO board to engage the return actuator to the frypot and turn on the

ATO pump. The pump draws oil from the JIB (Jug In Box) through the rear return manifold into the

rear of the frypot. Once the oil level has satisfied the sensor, the pump turns off and the actuator

closes.

The ATO board is located inside the box, behind the JIB (see Figure 1).

The power for the ATO board is supplied from the right hand

component box. The power passes through the transformer inside the

ATO box to the board.

Figure 1

1-14

Page 20

1.11.1 ATO (Automatic Top-off) Troubleshooting

Problem Probable Causes Corrective Action

Frypot tops off cold.

Incorrect setpoint

A. J5 connection unplugged

No power to ATO board

B. Fuse blown

C. Transformer malfunction

One vat tops off but

other vats fail to top off.

Incorrect vat tops off.

A. Loose wire connection.

B. Actuator issue

A. Wired incorrectly.

B. Flexlines connected to wrong vat.

A. Filter error ex ists.

One vat doesn’t top off.

B. Actuator, pump, loose connection, RTD

or ATO issue.

A. Empty JIB.

B. Crumb build up around sensor.

C. Probe temperature lower than setpoint.

D. Oil is too cold.

E. Bad Connection

Frypots won’t top off.

F. ATO board power loss

G. Failed transformer/harness

H. ATO pump failed

I. Failed ATO board.

J. ATO lines/pump plugged

Ensure setpoint is correct.

A. Check to ensure J5 on front of ATO board

is fully locked into connector.

B. Ensure fuse below right control box is not

blown and fuse on the right side of ATO

box is not blown.

C. Check that proper voltage is present at

transformer. See table in section 1.11.2.

A. Ensure all wiring harnesses are securely

connected to ATO board and solenoids.

B. Check return actuator to ensure actuator is

functional.

A. Check wiring.

B. Switch flexlines to correct vat.

A. Clear filter error properly. When

CHANGE FILTER PAPER YES/NO is

displayed, do NOT press any button until

the pan has been removed for at least

thirty seconds. After thirty seconds the

controller returns to OFF or last display.

B. Check actuator, ATO pump, ATO board,

wire connections and RTD.

A. Ensure JIB has oil.

B. Clean crumbs from opening surrounding

sensor.

C. Check to see that fryer is heating. Fryer

temperature must be at setpoint. Check

probe resistance. If probe is bad, replace

the probe.

D. Ensure that the oil in the JIB is above

70°F (21°C).

E. With the controller OFF, press the

temperature button and ensure the ATO

software version appears. If not, the

connection between the AIF and the ATO

board may be bad. Ensure the 6-pin CAN

connectors are tight between AIF (J4 and

J5) and ATO (J10) boards.

F. Power to the ATO board has been cut off.

Restore power to the board and clear any

service required errors.

G. Ensure transformer in ATO box is

functioning properly. Check power fro m

transformer to ATO board. Ensure all

harnesses are plugged securely into place.

H. Ensure pump is operational. Check

voltage to pump. Replace the pump if

defective.

I. Check for proper voltages using the pin

position chart found on page 1-17. If

ATO found defective, replace ATO board

and clear any errors.

J. Clear the lines/pump.

1-15

Page 21

Problem Probable Causes Corrective Action

A. Ensure fuse on right side of ATO box is

secure and good. If the controller above

the ATO box is missing power check the

fuse below the component box.

B. With the controller OFF, press the

Controller displays

SERVICE

REQUIRED – ATO

BOARD

A. Loose or bad fuse

B. Bad Connection

C. ATO Board power loss

temperature button and ensure the ATO

software version appears. If not, the

connection between the AIF and the ATO

board may be bad. Ensure the 6-pin CAN

connectors are tight between AIF (J4 and

J5) and ATO (J9 or J10) boards.

C. Power to the ATO board has been cut off.

Ensure there is correct voltage to the

ATO transformer. Restore power to the

board and clear any service required

errors.

1-16

Page 22

1.11.2 ATO (Automatic Top-Off) Board Pin Positions and Harnesses

Pin

Connector From/To Harness #

RTI Add Solenoid

ATO Pump Relay

J8

J4 (Rear) /

J5 (Front)

J1 - Vat #1

J2 - Vat #2

J3 - Vat #3

J6

J10

J9 AIF J5 8074547

JIB Reset Switch

Bulk Fresh Oil Solenoid

ATO Pump Relay

JIB Reset Switch

Transformer 8074553

ATO 4 & 5 Battery

Jumper

ATO RTD

Network Resistor

(pins 2 & 3)

or to next ATO Board (4

& 5 vat units)

8074671

8074657

8262569- Probe

Kit,

8074845 – 28”

Ext., 8074655 –

20” Ext.,

8074552

(Network

resistor),

8074546 to next

ATO board

# Function Voltage

1 24VAC Ret

2

3

4 24VAC Ret

5

6

7

8 JIB Low Reset

9 24VAC

10

11

12 24VAC

13

14

15

16 Ground

1 24VAC Ret

2 24VAC Blue

3

4

5 12VAC Ret

6 12VAC Brown

7 Jumper

8 Jumper Black

1 DV - Probe Ground

2 DV - Probe Red

3 FV - Probe Ground White

4 FV - Probe Red

1

2

1 Ground Black

2 CAN Lo Red

3 CAN Hi White

4 5VDC+ 5VDC Black

5 24VDC 24VDC Red

6 Ground White

1 Ground Black

2 CAN Lo Red

3 CAN Hi White

4 5VDC+ 5VDC Black

5 24VDC 24VDC Red

6 Ground White

Wire

Color

24VAC Black

24VAC Black

16VDC

24VAC Red

24VAC Red

16VDC

24VAC

12VAC

Ohm

Ohm

Black

Red

Orange

Red

Black

White

1-17

Page 23

1.11.3 Replacing the ATO board, ATO pump relay or Transformers

Disconnect the fryer from the electrical power

supply. Locate the ATO box (see Figure 1 on page

12), behind the JIB (Jug In Box). Remove the cover

to expose the transformers and relay (see Figure 2).

Mark and unplug any wires or harnesses. Replace

the defective component and reattach all wires or

harnesses. Replace the cover. Once replaced,

CYCLE POWER TO ENTIRE FRYER

SYSTEM. See section 1.12.6 on page 1-23 to reset

control power. Check software version and if

necessary update the software. If a software update

Figure 2

was necessary, follow the instructions to update the

software in section 1.16.

Press the temperature button on one of the FilterQuick™ controllers, with the controller in the OFF position, to

verify software version of the ATO. If the version is not visible, the ATO may not be connected properly.

1.11.4 Replacing the ATO Pump or Solenoid

Disconnect the fryer from the electrical power

supply. Locate the ATO pump (see Figure 4), behind

the ATO box. Mark and unplug any wires or

harnesses. Press up from the bottom on the quick

disconnects to release the plumbing (see Figure 5).

The plumbing can be pulled from the pump. Loosen

the four nuts attaching the pump to the pump tray.

Replace the defective component and reverse above

steps. Once replaced, reconnect the power

.

Figure 4 Figure 5

1.12 MIB (Manual Interface Board) Service Procedures

The MIB (Manual Interface Board) oversees and controls filtration. It receives and sends data over the CAN

(Controller Area Network) to and from various sensors and controllers. It activates the filtration cycle,

controlling when actuators should open and close.

The MIB controller is located inside the left cabinet (see Figure 6). In normal operation a cover hides the MIB

controls and only the LED display is visible. The cover is held in place with three torx screws. In normal

operation, an “A” is displayed for automatic mode. The MIB control board is useful for diagnostic purposes. It

allows manual operation of both the actuators and filter pump without using the controller.

Mode Display

Vat Selector

Switch

Manual /Auto

Figure 6: MIB controller cover.

Switch

Figure 7

Reset Switch

Drain Switch

Return Switch

1-18

Page 24

Buttons and LED’s

Manual – This button is used to toggle between auto and manual filtration mode. A corresponding

LED is lit when in Manual mode. When pressed, a message will be sent to all vats, indicating the

mode has changed.

The following buttons are inoperable in auto mode:

Select - This button is used to scroll through available vats, choosing one to be manually filtered.

Drain – This button is used to open and close the drain on the vat indicated on the display. It’s

embedded LED indicates the following activity:

Blink: Actuator is moving or awaiting a response from the AIF board.

Constant Illumination: Drain open.

No Illumination: Drain closed.

Return – This button is used to open and close the return valve on the vat indicated on the display.

When pressed and held, it also turns on and off the pump. It’s embedded LED indicates the following

activity:

Blink: Actuator is moving or awaiting a response from the AIF board.

Constant Illumination: Return valve open.

No Illumination: Return valve closed.

1.12.1 Manually Draining, Refilling or Filtering using the MIB board

Press the manual/auto switch to set to manual.

The LED on the manual key will illuminate and

a vat number is displayed (see Figure 8).

Press the vat selector switch to change vats (see

Figure 9).

Pressing the drain or the return switch

illuminates and activates the drain or return valve

for the vat indicated. Pressing and holding the

return switch while the return is open activates

the filter motor and pump (see Figure 10).

Pressing the manual/auto switch will return to

automatic mode.

1-19

Figure 8

Figure 9

Figure 10

Page 25

1.12.2 MIB (Manual Interface Board) Troubleshooting

Problem Probable Causes Corrective Action

A. Ensure filter pan is fully inserted into fryer.

If the MIB board displays a “P” the pan is

not fully engaged into the pan switch.

B. Ensure the oil level is above the top oil

level sensor.

C. Ensure MIB board is in “A” automatic

mode.

D. Remove and replace cover and see if

filtration will start.

E. Replace filter relay with part number

8074482 24VDC relay.

Auto filtration won’t

start.

A. Filter pan out of position.

B. Oil level too low.

C. Ensure MIB board is not in

manual mode.

D. Ensure MIB cover is not

damaged and pressing against

buttons.

E. Filter relay has failed.

F. Filter motor thermal switch is

tripped.

F. Press filter motor thermal switch.

MIB display shows

something other than

an “A” or vat number.

No power present at

the MIB board

MIB will not clear

error.

An error has occurred and

displayed character indicates

error.

Transformer has failed in left

component box.

Error remains in non-volatile

memory.

See MIB display diagnostics on page 1-23 for

explanation.

Check output on the left transformer in left

component box; should read 24VAC. If not

replace transformer.

Press and hold reset button in top right corner

of MIB board for five seconds. The drain,

return and manual/auto LEDS will illuminate

and the MIB will reset and clear any remaining

errors from memory. Allow 60 seconds to reset.

If an error still exists, then another issue exists.

A. Ensure the CAN bus system is terminated at

BOTH ENDS (on the controller connector

J6 and on the ATO board connector J9) with

a resistor equipped 6-pin connector.

B. Unplug and reseat all wiring harnesses in

CAN system. Resistance between pins 2

and 3 on the CAN network connectors

MIB indicates

incorrect number of

vats.

A. Network is not terminated

correctly.

B. Wiring harnesses are loose or

damaged.

C. An AIF board issue.

D. Locator pin issue.

should be 120 ohms.

C. With the controller OFF, press the

temperature button and check software

version numbers on all FilterQuick™

controllers and ensure all display an AIF

version. If an AIF version is missing, the

AIF board may be missing power or bad.

Check pins 5 and on J4 and J5 of the

affected AIF board for proper voltage.

D. The locator pin in J2 of the AIF board is

either loose or in the incorrect position. See

the charts on page 2-6 of this manual for

proper pin position.

1-20

Page 26

Problem Probable Causes Corrective Action

MIB board alternating

“E” and “vat number

and side”.

Network error on the CAN bus

communication.

A. Ensure the CAN bus system is terminated at

BOTH ENDS (on the FilterQuick™

controller connector J6 and on the ATO

board connector J10) with a resistor

equipped 6-pin connector.

B. With the controller OFF, press the

temperature button and ensure the AIF

version appears. If not, the 24V to the AIF

boards may be missing. Ensure all 6-pin

CAN connectors are tight between the

FilterQuick™ controller (J6 and J7), MIB

(J1 and J2), AIF (J4 and J5) and ATO (J10)

boards.

C. With the controller OFF, press the

temperature button and ensure the ATO

version appears. If not, check the CAN wire

harness between the AIF board J4 or J5 and

the ATO board J9 or J10. The ATO fuse on

the right side of the ATO box may be loose

or blown; the 110V to the ATO transformer

may be missing or the transformer bad. The

J4/J5 connector may be loose. Is the right

controller functioning? If not the fuse below

the contactor box may be loose or blown.

D. Check to see if MIB has 24V on pins 5 and

6 of J2. Check to see if 24V is present on

pins 5 and 6 of wire harness plugging into J4

or J5 of the first AIF board. If 24V missing,

check the pins. Replace the harness if

necessary.

E. Check continuity between each color wire

on the CAN connectors into J7 on the far

right controller and J10 on back of the ATO

board (black to black, white to white, and

red to red), and ensure there is no continuity

between different color wires (black to red,

red to white, and white to black).

F. Ensure black controller locator wires are

connected from ground to correct pin

position (see drawing 8051979 page 2-6).

G. Ensure all boards have the corner ground

wire attached and tightened.

H. The locator pin in J2 of the AIF board is

either loose or in the incorrect position. See

the charts on page 2-6 of this manual for

proper pin position.

I. Bad MIB and/or AIF board.

J. Broken resistor lead. Unwrap the resistor

leads and check ends.

1-21

Page 27

1.12.3 MIB (Manual Interface Board) Pin Positions and Harnesses

Connector From/To Harness # Pin # Function Voltage Wire Color

1 Ground Black

2 CAN Lo Red

J1 Controller J7 8074546

3 CAN Hi White

4

5

6

1 Ground Black

2 CAN Lo Red

J2 AIF J5 8074850

3 CAN Hi White

4 5VDC+ 5VDC Black

5 24VDC 24VDC Red

6 Ground White

J5

Transformer

Filter Relay

Bulk Open Switch

Bulk Closed Switch

Pan Switch

Bulk Open Switch

Bulk Closed Switch

8075800

Bulk

8075780

Non-Bulk

1 24VAC

2 24VAC Ret White

3 Pump Motor

4 Pump Motor Green

5

6

7 Open Switch +

8 Closed Switch +

24VAC

24VDC

9

10

11 Pan Sw +

12 Pan Sw - Red

24VDC

13

14

15 Ground - White

16 Ground - Green

Black

Red

Black

Red

Black

1 From bulk oil transformer 24VAC Black

2 Common Return White

To bulk oil fresh oil pump

3

relay 24VAC Green

4

J6

To Bulk connection in

rear of fryer

8075789

5

6

7

From bulk oil "Waste Tank

Full Sensor" Test Pins 2 to

8

8

24VAC –

Full

0VAC –

Not Full

Red

1-22

Page 28

1.12.4 MIB (Manual Interface Board) Display Characters

A – Auto Mode – Auto Filtration enabled.

E – Drain or return valve is not in desired state. The display will alternate between E and the corresponding vat

number. Ensure the actuator is plugged in and an error does not exist.

– Three horizontal lines indicate the AIF temperature sensor did not detect that the vat was full during

auto filtration.

n – Network Error - An “n” displays for 10 seconds if no communication is received from the cooking

controller within ten seconds after a power on or MIB reset.

P – Pan Switch – Filter pan is improperly seated. Filtration is suspended.

r – Reset Switch - Reset the vat closes all of the valves on the vat. If displayed for some time, there is probably

a problem with the board.

1 – 5 – Numbers which correspond to the vats with either an “L” indicating the left side of a split vat or “r”

indicating the right side of a split vat or a full vat. These numbers are displayed in manual mode.

1.12.5 Replacing the MIB Board

Disconnect the fryer from the electrical power supply. Remove the torx screws from the MIB cover, exposing

the MIB board (see Figure 11). Removing the screw at top center lets the MIB board hinge down. Carefully

remove the plugs on the rear of the board (see Figure 12). Replace with a new MIB board and reverse steps to

reassemble. Once replaced, CYCLE POWER TO ENTIRE FRYER SYSTEM. See next section to reset

control power. Check software version # and if necessary update the software. If a software update was

necessary, follow the instructions to update the software on in section 1.16 ensuring the MIB reset button is

pressed and held for five seconds at the end of the update to update the MIB.

Figure 11

1.12.6 Control Power Reset Switch

The control power reset switch is a momentary

rocker switch located behind the control box

(see Figures 13 and 14) above the JIB that

resets all power to all the controllers and

boards in the fryer. It is necessary to reset all

power after replacing any controller or board.

Press and hold the switch for at least ten

seconds when resetting the control power to

ensure power has sufficiently drained from

boards.

Figure 12

Figure 13 Figure 14 (Rear view of Control Box)

1-23

Page 29

1.13 Bulk Service Issues

1.13.1 Bulk MIB Tests

The FilterQuick™™ fryer will ONLY operate with bulk systems that have the three-pole

float switch. If the float switch is the older two-pole switch, call the bulk oil provider.

These float switches are polarity specific which may short to ground and damage an

MIB board.

Normal measurements (MIB J6 8-pin connector with everything connected)

AC voltage measurements:

Pin 1 to Pin 2 - 24 VAC.

Pin 2 to Pin 8 - 24 VAC when waste tank is full, 0 VAC when it is not full.

Pin 2 to Pin 3 - 24 VAC when RTI fill pump is on, 0 VAC when it is off.

Using the bulk test box, PN# 108-0716 allows a quick and easy way to check the 24VAC, the waste

full switch and when the bulk fresh oil pump is operating.

Troubleshooting

All return and drain valves should be closed and pump should be off while the MIB is resetting. If any

of the valves or the pump is on during reset, the MIB board is bad or wires are shorted.

Bulk fresh oil pump is not operating or JIB is not filling:

See page 1-25 to ensure that no other function is taking priority over adding oil to jug.

1. Reset the power; wait 60 seconds and see if the valve opens.

With the JIB button pressed:

2. Voltage at MIB board from Pin 1 to Pin 2 should be 24 VAC; if not, check connections from bulk

fresh oil pump 24VAC transformer and check transformer.

3. Voltage at MIB board from Pin 1 to Pin 3 should be 24 VAC when filling JIB or vat; if not, the MIB

board is bad or wires to pump relay are shorted or both.

4. Voltage at Add pump relay should be 24 VAC; if not, check wiring from MIB board. The relay is

located at the fresh oil tank pump system.

5. Check voltage at ATO board on J8. Pin 9 to Pin 1 should be 24 VAC with the orange button

pressed.

Waste full signal:

Pin 2 to Pin 8 should be 24 VAC when full, 0 VAC when not full; if no voltage level change, the

connection from bulk oil waste switch or MIB board is bad.

1-24

Page 30

1.13.2 Bulk Wiring

1-25

Page 31

1.13.3 Frymaster FilterQuick™ Fryer and Bulk Oil System Plumbing Schematic

New Oil

Waste Oil

Tank

Tank

Bulk Oil Company

Components

New Oil Pump

Fryer Components

Check

Valve

Bulk Oil

Manifold

Solenoid

Valve

Top-0ff

Jug

Manual

Dispose

Valve

Return

Valves

Check

Top-0ff

Pump

Valve

Bypass

Check

Valve

Filter Pump

Check Valve

Frypots

Drain

Ball

Valves

Built-in Filter Pan

Fryer

Filter

Pump

1.13.4 Bulk Oil Test Quick Reference

DISPOSE TO WASTE, REFILL VAT FROM BULK:

1. Hold down “Filter” button until controller beeps twice.

2. Scroll to “Dispose” using “Right Arrow" button then press “” button.

3. “Dispose? Yes/No” is displayed.*

4. Press “Yes” to dispose of oil in pot.

5. “Start Dispose” is displayed with blinking LED.

6. Pull the drain handle

7. “Draining” followed by “Flushing” is displayed.

8. “Vat Empty? Confirm” is displayed.

9. Press “Confirm”.

10. “Close Drain” is displayed with blinking LED.

11. Push the drain handle in towards the fryer.

12. “Open Dispose Valve” is displayed.

13. Open dispose valve by pulling completely forward to start disposal.

14. “Disposing” is displayed for four minutes.

15. “Remove Filter Pan” is displayed.

16. Slide the filter pan slightly out of the fryer.

17. “Is Pan Empty? Yes No” is displayed.

18. Press “Yes” if filter pan is empty. Select “No” if pan still has oil in it.

1-26

Page 32

19. “Insert Filter Pan” is displayed.

20. Insert the filter pan.

21. “Close Dispose Valve” is displayed.

22. Close dispose valve ensuring the handle is pushed completely towards the fryer.

23. “Fill Vat From Bulk? Yes/No” is displayed.

24. Press “Yes”.

25. “Press and Hold Yes Arrow to Fill” alternating with “Yes” is displayed.

26. Hold down “Yes” to fill pot to desired level.

27. “Filling” is displayed while button is depressed.

28. “Continue Filling Yes/No” is displayed

29. Press “Yes” to continue filling or “No” to Exit program.

*NOTE: If the waste tank is full, the controller displays “Waste Tank Full.” Call bulk oil

provider.

DISPOSE TO WASTE:

1. Hold down “Filter” button until controller beeps twice.

2. Scroll to “Dispose” using “Right Arrow" button then press “” button.

3. “Dispose? Yes/No” is displayed.*

4. Press “Yes” to dispose of oil in pot.

5. “Start Dispose” is displayed with blinking LED.

6. Pull the drain handle

7. “Draining” followed by “Flushing” is displayed.

8. “Vat Empty? Confirm” is displayed.

9. Press “Confirm”.

10. “Close Drain” is displayed with blinking LED.

11. Push the drain handle in towards the fryer.

12. “Open Dispose Valve” is displayed.

13. Open dispose valve by pulling completely forward to start disposal.

14. “Disposing” is displayed for four minutes.

15. “Remove Filter Pan” is displayed.

16. Slide the filter pan slightly out of the fryer.

17. “Is Pan Empty? Yes No” is displayed.

18. Press “Yes” if filter pan is empty. Select “No” if pan still has oil in it.

19. “Insert Filter Pan” is displayed.

20. Insert the filter pan.

21. “Close Dispose Valve” is displayed.

22. Close dispose valve ensuring the handle is pushed completely towards the fryer.

23. “Fill Vat From Bulk? Yes/No” is displayed.

24. Press “No” if you wish to leave pot empty and exit.

*NOTE: If the waste tank is full, the controller displays “Waste Tank Full.” Call bulk oil

provider.

FILL VAT FROM BULK:

1. Hold down “Filter” button until controller beeps twice.

2. Scroll down to “Fill Vat from Bulk” using “Right Arrow" button then press “” button.

3. “Fill Vat from Bulk? Yes/No” is displayed.

4. Press “Yes”.

5. “Press and Hold Yes to Fill / Yes” is displayed.

6. Press and hold down “YES” to fill pot to desired level.

7. “Filling” is displayed during fill.

1-27

Page 33

8. Release button to stop filling.

9. “Continue Filling? Yes/No” is displayed.

10. Press “NO” to exit.

FILL JUG FROM BULK:*

1. When “Top Off Oil Empty” is displayed, the top-off jug is empty.

2. To refill jug press and hold the orange reset button above the jug until the jug is full.

3. Release the button to stop filling.

*NOTE: The jug may not fill if any of the following are in progress:

If FILTER NOW? YES/NO, CONFIRM YES/NO, or SKIM VAT is displayed, the fill jug button is

disabled until either a filter is complete or until no is chosen.

The system also checks these conditions. The following must be met before jug fill is allowed.

Solenoid closed

Orange fill button pressed longer than 3 sec.

Waste valve closed

Filter Now? Yes/No, Confirm Yes/No, or Skim Vat cannot be displayed

System power cycle (all boards – controllers, MIB, AIF and ATO) after changing setup from

JIB to Bulk (use momentary reset). Ensure reset is pressed and held for at least ten seconds.

No filtration or other filter menu selection can be in process.

Other factors that may not allow fill jug from bulk –

Defective solenoid

Defective switch

Bulk fresh oil pump issue

Bulk fresh oil relay issue

If using multiple fryer systems that are both attached to the bulk fresh oil system, they may not be

able to fill both units at the same time if they have a bulk fresh oil unit with a single head. Some

bulk fresh oil units have dual heads which can fill more than one fryer simultaneously.

1.14 AIF (Automatic Intermittent) Filtration Service Procedures

The AIF (Automatic Intermittent Filtration) board controls the

actuators that open and close the drain and return valve. The

AIF boards are located inside a protective housing under each

frypot (see Figure 13).

Figure 13

1-28

Page 34

1.14.1 AIF Troubleshooting

Problem Probable Causes Corrective Action

A. Check pins 5 and 6 of J2 at the MIB

board. Should read 24VDC. Check

voltage on pins 5 and 6 at the other

end of harness and ensure 24VDC is

present. Continue to check pins 5 and

6 for 24VDC on plugs J4 and J5 on the

AIF boards.

B. Ensure the actuator is plugged into the

proper connection (J1 for FV return, J3

for DV return and J6 for FV drain and

J7 for DV drain).

C. Check power on the connector of the

problem actuator while trying to

manually open or close an actuator.

Pins 1 (Black) and 4 (White) should

read +24VDC when the actuator is

opening. Pins 2 (Red) and 4 (White)

should measure -24VDC when the

actuator is closing). If either voltage is

missing, the AIF board is likely bad.

Test the actuator by plugging into

another connector. If the actuator

operates, replace the board.

D. Check resistance of the potentiometer

between pin 3 (blue wire) and pin 4

(gray/white wire). Closed should read

0-560Ω. Open should read 3.8K Ω –

6.6K Ω.

E. If proper voltages are present at the

connector and actuator doesn’t operate,

reset power to the fryer. If it still

doesn’t operate replace the actuator.

A. Ensure the actuator is plugged into

correct connection (J1 for FV return,

J3 for DV return and J6 for FV drain

and J7 for DV drain).

B. Ensure the locator pin is in proper

position in plug J2. See table B on

page 2-6.

Actuator doesn’t

function.

Actuator functions on

wrong vat.

A. No power to the AIF board.

B. Actuator is unplugged.

C. AIF board failure.

D. Actuator readings are out of tolerance.

E. Actuator is bad

A. Actuator plugged into wrong connector.

B. Locator pin is in wrong position.

1-29

Page 35

1.14.2 AIF (Auto Intermittent Filtration) Actuator Board Pin Positions and Harnesses

Connector From/To Harness PN

J1

J2

J3

J4

J5

J6

J7

FV Return

Actuator

FV AIF RTD

DV AIF RTD

Locator Pin

Locator

DV Return

Actuator

MIB J2 or

AIF J5

AIF J4 or

ATO J10

FV Drain

Actuator

DV Drain

Actuator

N/A

N/A

8074547

AIF Board

Communication

and Power

8074547

AIF Board

Communication

and Power

N/A

N/A

Pin

# Function Voltage

1 Ret + (Open) 24VDC Black

2 Ret – (Closed) 24VDC Red

3 Ret Position Blue

4 Ground White

1 Ground White

2 FV - Temp Red

3 Ground White

4 DV - Temp Red

5

6

7

8

9

10

11 Locator Vat #5

12 Locator Vat #4

13 Locator Vat #3

14 Locator Vat #2

15 Locator Vat #1

16 Locator Signal Black

1 Ret + (Open) 24VDC Black

2 Ret – (Closed) 24VDC Red

3 Ret Position Blue

4 Ground White

1 Ground Black

2 CAN Lo Red

3 CAN Hi White

4 5VDC+ 5VDC Black

5 24VDC 24VDC Red

6 Ground White

1 Ground Black

2 CAN Lo Red

3 CAN Hi White

4 5VDC+ 5VDC Black

5 24VDC 24VDC Red

6 Ground White

1 Drain + (Open) 24VDC Black

2 Drain – (Closed) 24VDC Red

3 Drain Position Blue

4 Ground White

1 Drain + (Open) 24VDC Black

2 Drain – (Closed) 24VDC Red

3 Drain Position Blue

4 Ground White

Wire

Color

Black

1-30

Page 36

1.14.3 Replacing an AIF (Automatic Intermittent Filtration) board

Disconnect the fryer from the electrical power supply. Locate the AIF board to be replaced under a frypot.

Mark and unplug the harnesses. The AIF board assembly is held in place with one screw in the front of the

assembly (see Figure 14). Remove the screw and the front of the assembly drops down (see Figure 15) and

the back tab slides out of the bracket attached to the frypot (see Figure 16). Reverse steps to reassemble,

ensuring that the new AIF assembly slides into the slot in the rear of the bracket. Once complete, CYCLE

POWER TO ENTIRE FRYER SYSTEM. See section 1.12.6 on page 1-23 to reset control power. Check

software version # and if necessary update the software. If a software update was necessary, follow the

instructions to update the software in section 1.16.

Figure 14 Figure 15 Figure 16

1.14.4 Replacing a Rotary Actuator

Disconnect the fryer from the electrical power supply. Locate the actuator to be replaced and mark and

unplug the actuator. The actuators are held in place by two hex key screws. Loosen the 3/32” hex key

screws. It may be necessary to remove a gas line to the burner when removing a drain actuator. Remove

the actuator from the valve stem. Align the actuator with the valve stem and attach the new actuator.

Tighten the two hex key screws. Reconnect power and test the actuator.

NOTE: Rotary actuators have two different part numbers, which are mirror images of each other that

correspond to their mounting position.

1-31

Page 37

1.15 FilterQuick™ Controller Service Procedures

1.15.1 FilterQuick™ Controller Troubleshooting

Problem Probable Causes Corrective Action

A. Press the ON/OFF switch to turn the