Frymaster 18UE Installation Manual

18UE Series Cool Zone Electric Fryers

Installation, Operation & Maintenance Manual

Dean, a member of the Commercial Food Equipment Service Association, recommends using

CFESA Certified Technicians.

24-Hour Service Hotline 1-800-551-8633

Price: $6.00

819-5657

06-00

Please read all sections of this manual and retain for future reference.

Installation, maintenance, and repairs should be performed by your Dean

Factory Authorized Service Center.

CAUTION

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN

THE VICINITY OF THIS OR ANY OTHER COOKING APPLIANCE.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE, OR

MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH. READ THE

INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS THROUGHLY

BEFORE INSTALLING OR SERVICING THIS EQUIPMENT.

WARNING

SAFE AND SATISFACTORY OPERATION OF YOUR EQUIPMENT DEPENDS ON ITS

PROPER INSTALLATION. INSTALLATION MUST CONFORM TO LOCAL CODES, OR IN

THE ABSENCE OF LOCAL CODES, WITH THE LATEST EDITION OF THE NATIONAL

ELECTRIC CODE, N.F.P.A. 70.

i

18UE Series Cool Zone Electric Fryers

TABLE OF CONTENTS

Page #

1. INTRODUCTION 1-1

2. IMPORTANT INFORMATION 2-1

3. INSTALLATION INSTRUCTIONS 3-1

4. FRYER OPERATIONS 4-1

5. COMPUTER/CONTROLLER OPERATION 5-1

6. FILTER OPERATION 6-1

7. PREVENTATIVE MAINTENANCE 7-1

8. TROUBLESHOOTING 8-1

9. PARTS LIST 9-1

ii

DEAN 18UE COOL ZONE SERIES ELECTRIC FRYERS

CHAPTER 1: INTRODUCTION

1.1 Ordering Parts

Customers may order parts directly from their local Authorized Parts Distributor. For this address

and phone number, contact your Maintenance & Repair Center or call the factory. The factory

address and phone numbers are on the cover of this manual.

To speed up your order, the following information is required:

Model Number Type

Serial Number

Optional

Equipment

Item Part Number Quantity Needed

With/Without

Filter

1.2 Service Information

Call the 1-800-551-8633 or (318) 865-1711 Service Hotline number for the location of your nearest

Maintenance & Repair Center. Always give the model and serial numbers of your filter and fryer.

Also, identify which cooking computer or controller is installed on your fryer.

To assist you more efficiently, the following information will be needed:

Model Number Type

Serial Number

With/Without

Filter

Optional

Equipment

Nature of Problem:

Additional information (i.e. cooking environment, time of day, and other pertinent information) may

be helpful in solving your service problem. Communicate with your service technician.

Computer/Controller

1-1

1.3 After Purchase

In order to improve service, have the following chart filled in by the Dean Authorized Service

Technician who installed this equipment.

Authorized Service

Technician/FASC

Address

Telephone/Fax

Model Number

Serial Number

Gas Type

1.4 Safety Information

Before attempting to operate your unit, read the instructions in this manual thoroughly.

Throughout this manual, you will find notations enclosed in double-bordered boxes similar to the

ones below.

CAUTION boxes contain information about actions or conditions that may cause or result in a

malfunction of your system.

CAUTION

Example of a CAUTION box.

WARNING boxes contain information about actions or conditions that may cause or result in

damage to your system, and which may cause your system to malfunction.

WARNING

Example of a WARNING box.

DANGER boxes contain information about actions or conditions that may cause or result in injury

to personnel, and which may cause damage to your system and/or cause your system to malfunction.

DANGER

Hot cooking oil causes severe burns. Never attempt to move a fryer containing hot

cooking oil or to transfer hot cooking oil from one container to another.

1-2

DEAN 18UE COOL ZONE SERIES ELECTRIC FRYERS

CHAPTER 2: IMPORTANT INFORMATION

2.1 General

The Dean 18UE Electric Cool Zone Fryers are energy-efficient, electrically heated units, certified by

Underwriters Laboratory and manufactured to their basic performance and application

specifications. The 18UE is certified by AFNOR for installation and operation in the European

Community (CE).

All units are shipped completely assembled with accessories packed inside the frypots. All units are

adjusted, tested and inspected at the factory before shipment.

CAUTION

The on-site supervisor is responsible for ensuring that operators are made aware of

the inherent dangers of operating a hot oil fryer/filter system, particularly the aspects

of fryer operation, oil filtration, and draining/cleaning procedures.

DANGER

The fryer MUST be connected only to an electricity source that exactly matches

voltage type and phase listed on the attached rating plate.

2.2 Rating Plate

Information on this plate includes the model and serial numbers, as well as electrical requirements.

When communicating with the factory about a unit or requesting special parts or information, this

data is essential for proper identification.

2.3 Pre-Installation

A. GENERAL: All installation and service on this equipment must be performed by qualified,

certified, licensed, and/or authorized installation or service personnel. A list of Dean

Authorized Service Centers is included with the fryer when shipped from the factory.

If you do not have access to this list, please contact the Frymaster/Dean Technical Service

Department using the following phone numbers, 1-800-551-8633 (US/Canada) or 1-318865-1711 (Worldwide).

NOTE: Failure to use qualified service personnel will void the Dean warranty.

2-1

B. STANDARDS: All electrical cooking appliances must be electrically connected and

grounded in accordance with local codes, or in the absence of local codes, with the latest

editions of:

1. United States of America:

National Electric Code Standards ANSI/NFPA # 70.

American National Standards Institute

1430 Broadway

New York, NY 10018

NFPA Standards #96 and #211.

National Fire Protection Association

470 Atlantic Avenue

Boston, MA 02110

2. Canada: Canadian Electrical Code Part 1, CSA-C22.1.

Canadian Standards Association

178 Rexdale Boulevard

Rexdale, ONT

M9W 1R3

3. European Community (CE): All electrical cooking equipment must be electrically

connected and grounded in accordance with local codes, or in the absence of local

codes, with the latest editions of the appropriate national or European Community (CE)

standards.

C. CLEARANCES: The fryer area must be kept free and clear of all combustibles. This unit is

design-certified for the following installations:

1. Other than household use;

2. Non-combustible floor installation equipped with factory-supplied 15 cm (6 inches)

adjustable legs or optional 15 cm (5-inch wheel) rigid rear casters;

3. Combustible construction with a minimum clearance of 15 cm (6 inches) side and 15 cm

(6 inches) rear, and equipped with factory-supplied 15 cm (6-inch) adjustable legs or 15

cm (5-inch wheel) rigid rear casters.

CAUTION

Local building codes usually prohibit a fryer with its open tank of hot oil from being

installed beside an open flame of any type, whether a broiler or the open burner of a

range.

2-2

2.4 Unpacking the Fryer/Component Systems

Ensure the container is upright. Unpack the fryer carefully and remove all accessories from the

carton. Do not discard or misplace these, as they will be needed.

After unpacking, immediately check the equipment for visible signs of shipping damage. If

such damage has occurred, contact the carrier and file the appropriate freight claims. Do not

contact the factory, as the responsibility of shipping damage is between the carrier and the

dealer or end-user.

If your equipment arrives damaged:

a. File claim for damages immediately – Regardless of extent of damage.

b. Visible loss or damage – Be sure this is noted on the freight bill or express receipt and is

signed by the person making the delivery.

c. Concealed loss or damage – If damage is unnoticed until equipment is unpacked, notify

freight company or carrier immediately, and file a concealed damage claim. This should be

done within fifteen (15) days of date of delivery. Retain the shipping container for

inspection.

NOTE: Dean does not assume responsibility for damage or loss incurred in transit.

If your equipment arrives without casters or legs installed, leave the equipment on the pallet

and do not cut the banding straps until ready to install casters or legs.

WARNING

Dean fryers equipped with legs are for permanent installations. Fryers fitted with

legs must be lifted during movement to avoid damage and possible bodily injury. For

a moveable or portable installation, Dean optional equipment casters must be used.

Questions? Call 1-800-551-8633

WARNING

Do not attach accessories to this fryer unless fryer is secured from tipping.

Personal injury may result.

2-3

DEAN 18UE COOL ZONE SERIES ELECTRIC FRYERS

CHAPTER 3: INSTALLATION INSTRUCTIONS

3.1 Installing the Fryer

A. Initial Installation: If installed with legs, do not push against any unit edges to adjust its

position. Use a pallet or lift jack to lift it slightly and place it where it is to be installed.

B. Relocating the Fryer: If relocating a fryer installed with legs, remove all weight from each

leg before moving.

Note: If a leg becomes damaged during movement, contact your service agent for immediate

repair/replacement of the damaged leg.

DANGER

This fryer may tip and cause personal injury if not secured correctly in a stationary

position. Drain all oil/shortening from fryer before moving. Hot oil will splash and

cause severe burns upon contact.

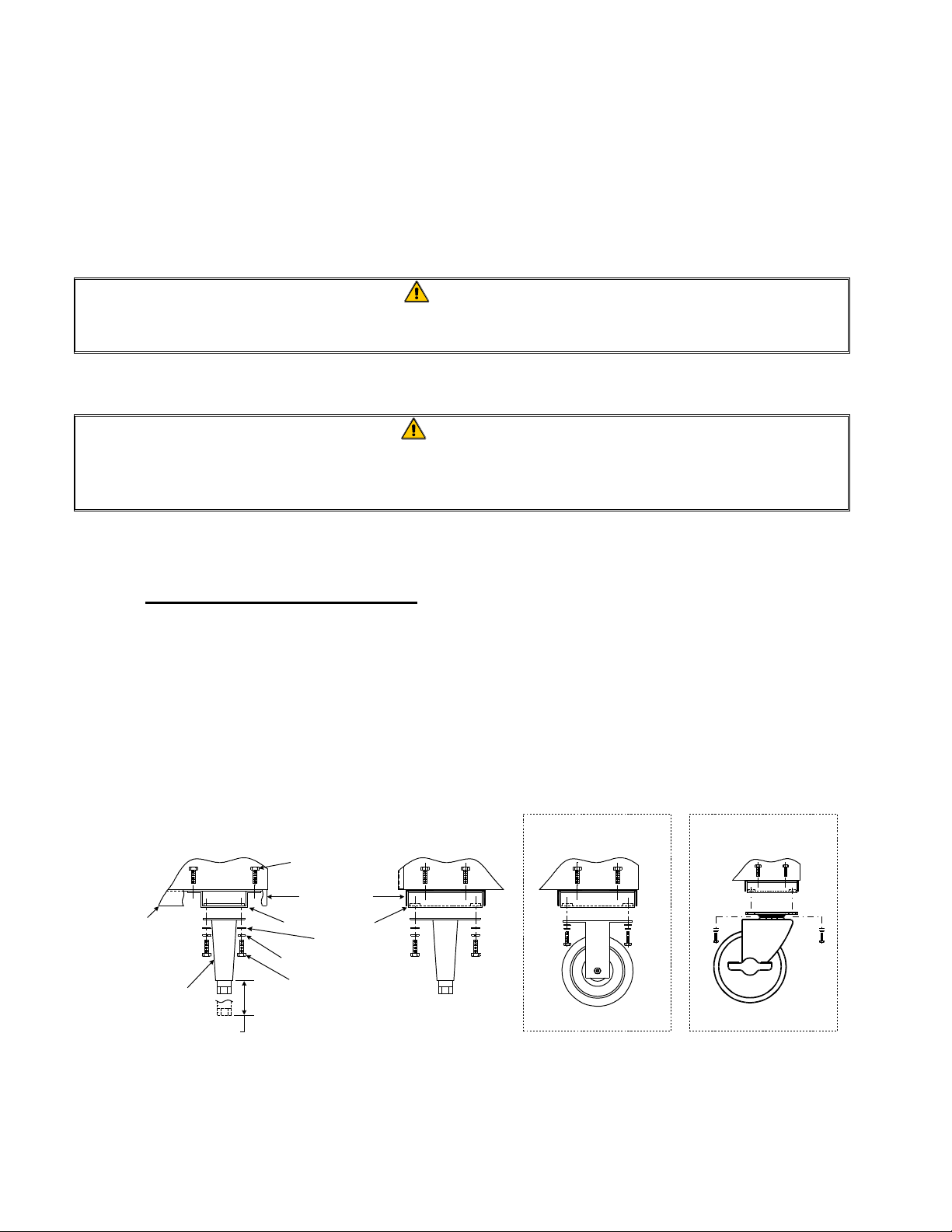

3.2 Leg and Caster Installation

A. General

1. Install legs and rear rigid casters near where the fryer is to be used, as neither are secure

for long transit. Unit cannot be curb mounted and must be equipped with the legs and

rear rigid casters provided.

2. When positioning the fryer, gently lower the fryer into position to prevent undue strain

to the legs and internal mounting hardware. Use a pallet or lift jack to lift and position

the fryer if possible. Tilting the fryer may damage the legs.

3. The rigid casters must be installed on the fryer rear channel assembly only.

4. Proceed to Step 3.3, Leveling, after legs and rear rigid casters are installed to ensure the

fryer is level before using.

B. Leg and Rigid Caster Installation

1. Remove unit from pallet.

2. Carefully raise unit with forklift, pallet jack, or other steady means.

3. Place one lock washer on each hex head screw.

3-1

4. Insert hex head screws with lock washers (1/4-20 threads by 19-mm (¾") long) through

bolt holes of leg mounting plates and mount to the front channel. Mount rigid casters to

the rear channel following the same procedure. A locknut has been attached to the

topside of the base mounting plates at the factory to capture the hex head screw as it is

screwed in.

5. Tighten the bolts to 5.65 joules (50 inch-lbs.) minimum torque.

CAUTION

For caster retrofit, the unit must be at room temperature and drained of shortening

before installing the casters.

WARNING

If optional swivel casters are used, locking casters must be installed on the fryer

front channel. Failure to lock casters prior to operating the fryer will increase the

likelihood of fryer movement, and the potential for injury to the operator.

C. Installing Optional Swivel Casters:

1. Install non-locking casters only at the rear of the unit.

2. Locking casters must be installed at the front of the unit. Locking casters allow the fryer

to be "locked" in position for safe operations.

3. Follow the same instructions for leg installations as given above in steps 3.2, B1-5.

Front View

1/4-20 x 3/4 Hex Bolt

Front Channel or

Front Channel

or Rear Channel

Front or Rear Leg with

Mounting Plate

Adjust as needed

Rear Channel

Leg Support Assembly

Washer

1/4-20 Hex Head Locknut

1/4-20 x 3/4 Hex Bolt

Rear Side View

Optional Caster-

Rear Only

Rear Caster—5" Rigid

Optional Caster-

Front Only

Front Caster—5" Swivel

w/Brake

Leg and Caster (Optional) Mounting Installation

3-2

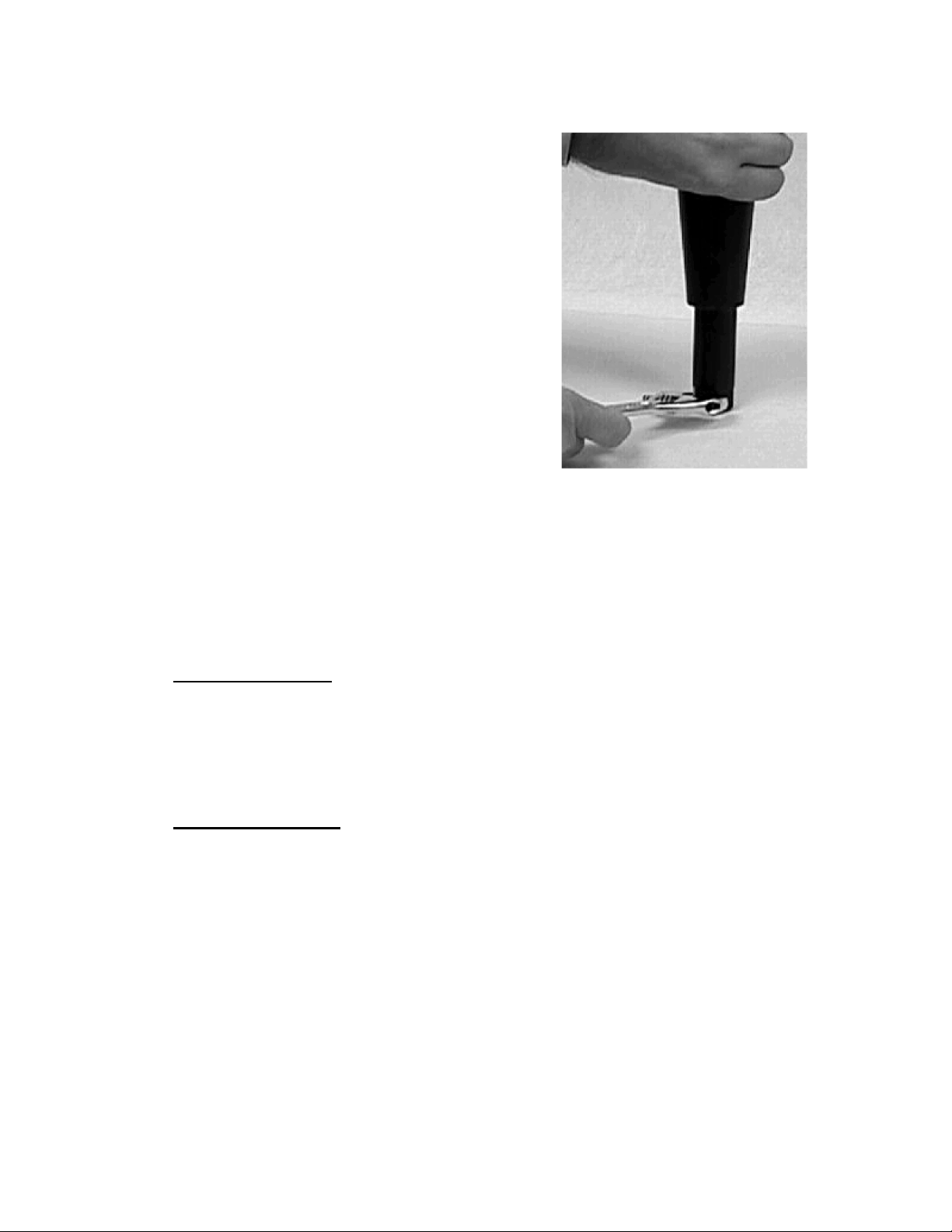

3.3 Leveling the Fryer

A. Place a carpenter’s spirit level across the

top of the fryer and level the unit both

front-to-back and side-to-side. If the

fryer is not level, the unit may not

function efficiently, the oil may not

drain properly for filtering and in a

line-up it may not match adjacent units.

B. Legs (Only)

1. If the floor is smooth and level, level

the unit by using the caster shims.

Adjust to the high corner and measure

with the spirit level.

2. Adjust leg height with an adjustable

wrench, or a 27-mm (1-1/16”) openend wrench by turning the hex bullet

on the bottom of the leg.

Adjusting leg height with an adjustable wrench

3. The hex bullet is for minor leg height adjustment only. Do not adjust more than 22-mm

(1").

C. Rigid Casters (Only):

1. Install the optional rigid casters on the fryer rear channel only. Legs must be installed

on the front channel.

2. There are no thread adjustments for the rigid casters.

D. Swivel Casters (Only):

1. If optional swivel casters are used, the locking swivel casters must be installed on the

fryer front channel. Lock casters prior to operating the fryer.

2. Install non-locking swivel casters on the fryer rear channel only.

3. There are no thread adjustments for the swivel casters.

E. If the floor is uneven or has a decided slope, it is recommended to place the fryer on a

smooth platform. Do not rely on leg threads for adjustments.

F. If the fryer is moved, re-level the fryer following the instructions given in Steps 3.3, A-C.

3-3

G. ANSI Z83.11a-1997 requires a fryer be restrained to prevent tipping when installed in

order to avoid the splashing of hot liquid. The means of restraint may be the manner

of installation, such as connection to battery of appliances or installing the fryer in an

alcove, or by separate means, such as adequate ties. A bracket has been provided on the

fryer back panel for this purpose.

The install must be reviewed at the time of installation to ensure it meets the intent of

these instructions. The on-site supervisor and/or operator(s) should be made aware

that there is a restraint on the appliance and, if disconnection of the restraint is

necessary, to reconnect this restraint after the appliance has been returned to its

originally installed position.

3.4 Electrical Connections

CAUTION

The fryer MUST be connected to the voltage and phase as specified on the rating

and serial number plate located on the back of the fryer door.

A ground wire MUST be connected to the ground terminal provided near the input

power terminal block.

Plan and implement installation in accordance with local codes. Service connections should be

made at the power input terminal block, located through the back lower portion of the fryer and

through the component box, located under the control wireway. It is recommended that this

connection be made by means of an approved, flexible-metallic or rubber-covered electrical cable

and a quick-disconnect plug. This connection should be made by means of a CE, UL, CUL, or CSA

approved quick-disconnect plug. If rigid or flexible-metal conduit connections are required, they

must be made through the rear portion of the fryer cabinet, to the fryer input terminal block.

CAUTION

Connections must be made by qualified service personnel only.

A. Wiring Diagram: It is attached to the inside of the fryer door. Amperage for each unit

depends on the type of installation and accessories supplied with the unit.

B. Emergency Cutoff System: Be sure that each fryer is connected to a dedicated set of contacts

in an emergency cutoff system.

1. Do not attempt to connect the contacts in series.

2. Do not connect more than one fryer to each set of contacts.

3-4

3. The contacts must be normally closed contacts that open during an emergency.

4. Do not apply external voltage to the contacts.

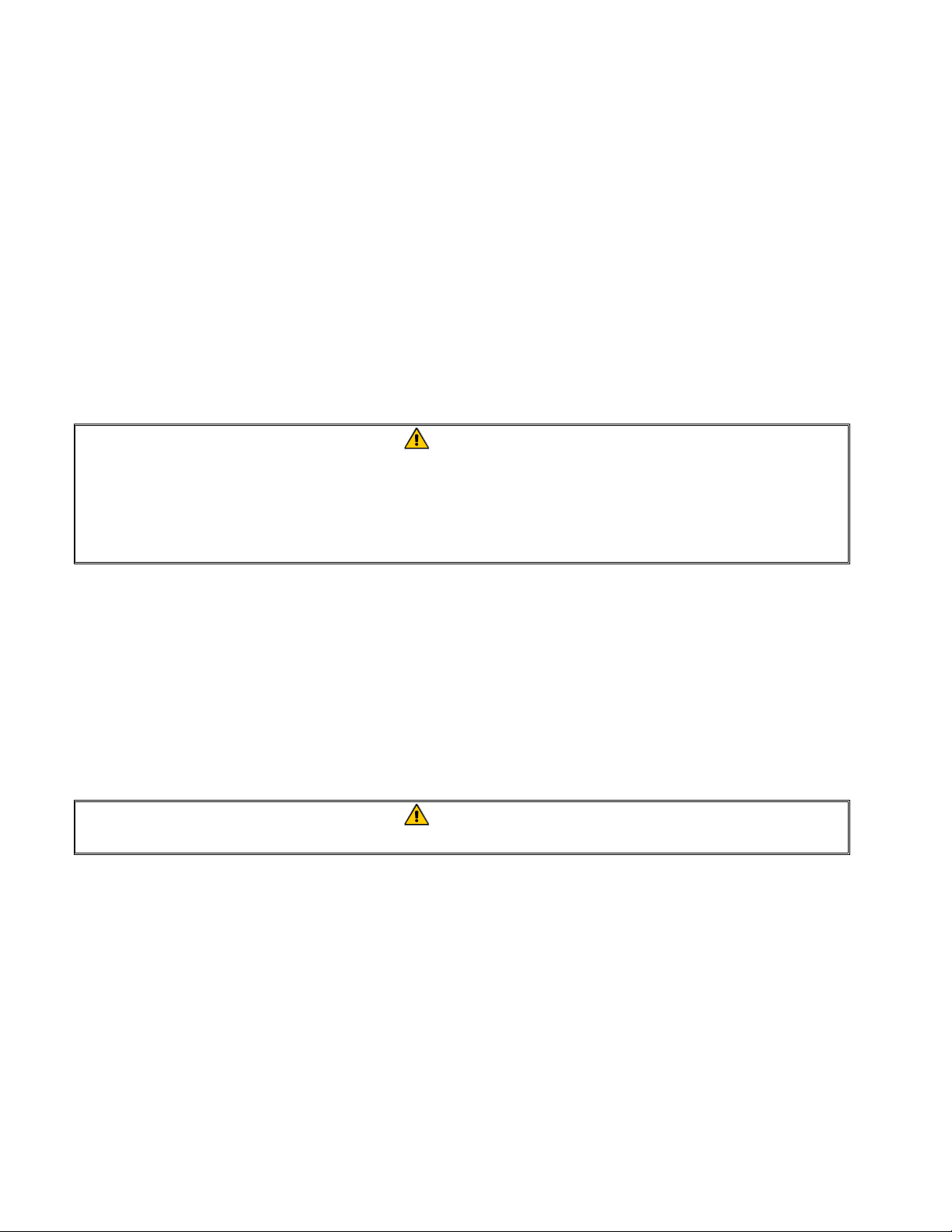

3.5 Operating Switches

A. Fryer/Filter Switches

1. Fryer Power Switch: Located on the right-hand side of the computer. It transfers the

power from the computer to that individual fryer’s heating element circuits.

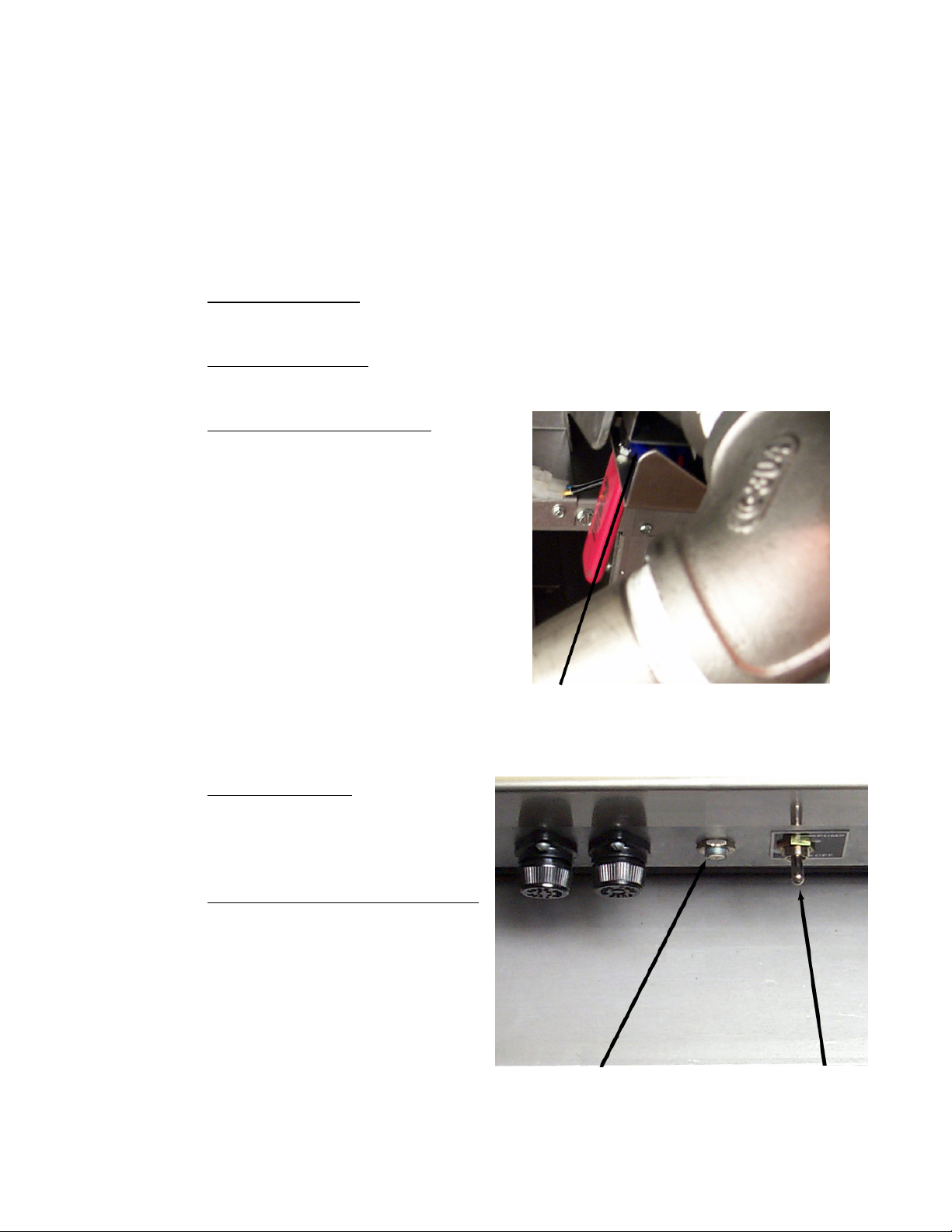

2. Pump Power Switch: Located on the right fryer-cabinet control panel of the fryer

battery. It operates the Super Cascade filter pump motor.

3. Drain Valve Micro-switch: The

computer will display “HELP” when

the drain valve is opened. The

computer will lockout and prevent

any cooking operation until

“EXIT/COOL FILTER” is pressed.

4. Filter Pump Reset: Located in the

right fryer cabinet. This switch

resets the Super Cascade filter pump

motor.

5. Manual Filter Override Switch:

Located in the right fryer control

panel of the fryer battery. This

toggle or rocker switch allows the

operator to manually operate the

Super Cascade Filter if a problem

develops with the auto functions.

Microswitch located on red-handled drain-valve

Filter pump reset switch

Manual filter override switch

3-5

WARNING

If the filter pump safety switch repeatedly trips out, do not continue to reset. A

potential safety hazard exists. Contact an authorized service technician for

troubleshooting.

B. Filter Operation Handles:

1. Red: Drain Valve Handle. Turn to open. This handle (located in the fryer cabinet)

should be in the closed (Down) position except when filtering.

2. Yellow: Oil Return Valve. Turn to open. This handle (located in the fryer cabinet)

should be in the closed (Up) position except when filtering.

C. Fryer Controllers: Your 18UE Fryer System comes equipped with a Compu-Fry

Computer, or a Solid State Analog Controller.

1. Fryer with Compu-Fry Computer

This fryer/filter system is equipped with drain valve safety switches on the two battered

fryers to de-energize the fryer heating elements during the filter process. This is for

additional safety. You should always turn the fryer power switch “OFF” prior to

filtering.

a. Fryer Power Switch: Located on the right-hand side of the computer. It transfers

the power from the computer to that individual fryer’s heating element circuits.

b. Pump Power Switch: Located on the filter cabinet control panel of the fryer battery.

It operates the filter pump motor.

c. Drain Valve Micro-switch: The computer will display “HELP” when the drain

valve is opened. The computer will lockout and prevent any cooking operation

until drain valve is closed.

2. Fryer with Solid State (Analog) Controller

a. Power Switch - controls power to the fryer.

b. Power On Light - indicates when electrical power is on.

c. Temperature Knob - sets desired frying temperature.

d. Heat Mode Light - indicates when elements are on (heating).

3-6

e. Trouble Light - indicates solid state controller system lockout. To reset, turn power

switch OFF for 30 seconds, then ON.

f. Melt Cycle Switch - controls melt cycle operation.

g. Melt Cycle Light - indicates fryer is operating in the melt cycle mode.

Additional information on controller/computer features and functions can be found in Chapter 5.

3-7

DEAN 18UE COOL ZONE SERIES ELECTRIC FRYERS

CHAPTER 4: FRYER OPERATIONS

4.1 Initial Start-Up

A. Cleaning: New units are wiped clean with solvents at the factory to remove any visible signs

of dirt, oil, grease, etc. remaining from the manufacturing process, then coated lightly with

oil. Before any food preparation, wash thoroughly with hot, soapy water to remove any film

residue and dust or debris then rinse out and wipe dry. Also wash any accessories shipped

with the unit. Close the drain-valve completely and remove the crumb screen. Make sure

the screws holding the thermostat and high-limit control sensing bulbs into the vessel are

tight.

4.2 Boil-out Procedure

CAUTION

Do not leave fryer unattended. The boil-out solution may foam and overflow if fryer is

left unattended. Press ON/OFF switch to the OFF position to control this condition.

4.2.1 Fryer with Solid State (Analog) Controller

A. Before switching the fryer ON, close the fry vessel drain valve, fill empty fry vessel with a

mixture of cold water and heavy-duty low-sudsing degreaser compound to the oil level line

scribed in the back of the fry vessel. Follow instructions on bottle when mixing.

B. Press fryer ON/OFF switch to the ON position.

C. Set temperature control knob to 200°F (93°C).

D. Allow the solution to simmer for 45 minutes to one hour. Do not permit the water level to

drop below the oil-level line in fry vessel during boil-out operation.

E. Carefully monitor the fryer during this time to prevent solution from boiling over.

F. Turn the fryer ON/OFF switch to the OFF position.

G. Add sufficient cold water to lower temperature to a safe level. Drain out the solution and

clean the fry vessel thoroughly.

H. Refill the fry vessel with clean water. Rinse the fry vessel twice, drain and dry inside of pot

thoroughly to remove all residual water. Repeat this process for each fry vessel in multibattered fryers.

4-1

Loading...

Loading...