Page 1

*8196115*

Flatbottom Series Electric Fryers

(Models 1824E, 2424E and Combinations)

Service & Parts Manual

Frymaster, a member of the Commercial Food Equipment Service Association, recommends

using CFESA Certified Technicians.

24-Hour Service Hotline 1-800-551-

8633

SEPTEMBER 2011

Page 2

NOTICE

IF, DURING THE WARRANTY PERIOD, THE CUSTOMER USES A PART FOR THIS MANITOWOC

FOOD SERVICE EQUIPMENT OTHER THAN AN UNMODIFIED NEW OR RECYCLED PART

PURCHASED DIRECTLY FROM FRYMASTER DEAN, OR ANY OF ITS AUTHORIZED SERVICE

CENTERS, AND/OR THE PART BEING USED IS MODIFIED FROM ITS ORIGINAL

CONFIGURATION, THIS WARRANTY WILL BE VOID. FURTHER, FRYMASTER DEAN AND ITS

AFFILIATES WILL NOT BE LIABLE FOR ANY CLAIMS, DAMAGES OR EXP ENSES INCUR RED B Y

THE CUSTOMER WHICH ARISE DIRECTLY OR INDIRECTLY, IN WHOLE OR IN PART, DUE TO

THE INSTALLATION OF ANY MODIFIED PART AND/OR PART RECEIVED FROM AN

UNAUTHORIZED SERVICER.

DANGER

Copper wire suitable for at least 167°F (75°C) must be used for power connections.

DANGER

The electrical power supply for this appliance must be the same as indicated on the

rating and serial number plate located on the inside of the fryer door.

DANGER

This appliance must be connected to the voltage and phase as specified on the rating

and serial number plate located on the inside of the fryer door.

DANGER

All wiring connections for this appliance must be made in accordance with the wiring

diagrams furnished with the equipment. Wiring diagrams are located on the inside of

the fryer door.

DANGER

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this

or any other appliance.

WARNING

Do not attach accessories to this fryer unless fryer is secured from tipping. Personal

injury may result.

WARNING

Frymaster fryers equipped with legs are for permanent installations. Fryers fitted with

legs must be lifted during movement to avoid damage and possible bodily injury. For a

moveable or portable installation, Frymaster optional equipment casters must be used.

Questions? Call 1-800-551-8633

WARNING

Do not use water jets to clean this equipment.

DANGER

All wiring connections for this appliance must be made in accordance with the wiring

diagrams furnished with the equipment. Wiring diagrams are located on the inside of

the fryer door.

WARNING

This equipment is intended for indoor use only. Do not install or operate this

equipment in outdoor areas.

ii

Page 3

Flatbottom Series Electric Fryers

TABLE OF CONTENTS

Page

CHAPTER 1 – SERVICE PROCEDURES 1-1

1.1 General 1-1

1.2 Calibrating the Thermatron Controller

1.3 Accessing the Control Box Electronics

1.4 Replacing an Thermatron Temperature Control Board 1-3

1.5 Replacing a Transformer 1-3

1.6 Replacing a Contactor 1-4

1.7 Replacing a Safety Drain Relay 1-4

1.8 Replacing a Breaker 1-4

1.9 Replacing a Thermatron Potentiometer 1-4

1.10 Replacing a Temperature Sensor and High-Limit Thermostat 1-5

1.11 Replacing Heating Elements inside Frypot 1-6

1.12 Replacing Heating Element under the Frypot 1-7

1.13 Replacing a Frypot 1-7

1.14 Cleaning a Seized Pump 1-7

1.15 Probe Resistance Chart 1-9

1.16 Element Wattage/Amperage Calculation Charts 1-9

1.17 Troubleshooting Guides 1-10

1.18 Wiring Diagrams 1-13

CHAPTER 2 – PARTS LIST 2-1

2.1 Accessories 2-1

2.2 Cabinetry

2.3 Control Panels, Wireways and Related Components 2-8

2.4 Electronics Components 2-10

2.5 Filter Components

2.6 Elements and Related Components 2-16

2.7 Harnesses 2-17

2.8 Oil Discharge Assembly

2.9 Oil Return Assembly 2-20

2.10 Drain Valves and Associated Parts

2.11 Drain and Oil Return Components 2-22

2.12 Wiring Connectors, Pin Terminals and Power Cords

1-1

1-3

2-2

2-12

2-19

2-21

2-25

iii

Page 4

FLATBOTTOM SERIES ELECTRIC FRYERS

CHAPTER 1: SERVICE PROCEDURES

1.1 General

Before performing any maintenance on your Frymaster Dean Flatbottom Electric fryer, you must

disconnect the electrical power supply.

When electrical wires are disconnected, it is recommended that they be marked to facilitate

reassembly.

DANGER

Hot cooking oil will cause severe burns. Never attempt to move this appliance when filled

with hot cooking oil, or to transfer hot cooking oil from one container to another.

DANGER

This equipment should be unplugged when servicing, except when electrical circuit tests are

required. Use extreme care when performing such tests.

This appliance may have more than one electrical power supply connection point.

Disconnect all power cords before servicing.

Inspection, testing and repair of electrical components should be performed by an

authorized service agent only.

A Thermatron system incorporates a temperature-control circuit board, a potentiometer, and a

temperature probe.

1. Thermatron with Melt Cycle Option Enabled: Set Thermatron to the working temperature. The

elements will cycle on approximately 5 seconds, and off for approximately 15 seconds until the

temperature reaches 66°C (150°F). The Thermatron will then switch to normal operation.

1.2 Thermatron Calibration

If the Thermatron controller requires adjustment, do the following:

1. Set Thermatron controller dial to the desired shortening temperature and wait for the shortening

temperature to stabilize.

2. When shortening temperature reaches setpoint (elements will cycle on and off, indicating

setpoint temperature has been reached), check the temperature with a high-quality immersion

thermometer.

3. Loosen the knob setscrew and rotate the knob to the correct temperature setting on the

Thermatron faceplate.

4. Check the temperature again with a high-quality immersion thermometer to confirm that the

setting is correct.

5. Re-tighten the knob setscrew at the calibrated position.

1-1

Page 5

Rocker

Switch

Panel

Control Box

Access

Drain Nipple

Extension

Bracket

IDENTIFYING PARTS

Drain

Breakers

Thermatron

Controller

Contactor

Safety Drain

Relay

Transformer

Control Box

Breaker

Terminal Block

Thermatron Board

1-2

Page 6

1.3 Accessing the Control Box Electronics

(Interface Board, Transformer, Contactor, Breakers, Transformer and Relay)

1. Unplug all power cords.

2. Open front door of cabinet and remove the two bolts holding down the drain nipple extension

bracket.

3. Remove the three screws from bottom of control box access panel.

4. Remove the four screws in the corner of rocker switch access panel. Twist the rocker panel and

push through the access panel opening.

5. Unplug the Thermatron connector and remove access panel and set aside.

1.4 Replace Thermatron Board

1. Unplug all power cords. Perform Procedure 1.3, Steps 1-5, Accessing Control Box Electronics.

2. Remove all wiring from the terminals of the Thermatron board, ensuring that each wire is

marked for reattachment.

3. Remove the nuts from each corner of the Thermatron temperature control board and slide the

board from the studs. Ensure that standoffs remain in place on studs, prior to installing new

board. Install the new board by reversing the previous procedures. Ensure that wiring and wire

harnesses are connected to the proper terminals.

1.5 Replace Transformer

1. Unplug all power cords. Perform Procedure 1.3, Steps 1-5, Accessing Control Box Electronics.

2. Remove all wiring from the terminals of the transformer to be replaced.

3. Remove the screws that secure the transformer to the component box.

4. Install the new transformer by reversing the preceding procedures. Make sure you reconnect the

wiring to the proper terminals and the harnesses to the correct connectors.

1-3

Page 7

1.6 Replace Contactor

1 Unplug all power cords. Perform Procedure 1.3, Steps 1-5, Accessing Control Box Electronics.

2. Identify faulty contactor. Remove all wiring connected to the contactor terminals inside the

component box. Tape wire-pairs together and mark each wire-set or wire for reassembly.

3. Remove contactor-mounting screws and remove the contactor.

4. Install the new contactor and connect the wiring removed in Step 2.

5. Reassemble in reverse order.

1.7 Replace Safety Drain Relay

1. Unplug all power cords. Perform Procedure 1.3, Steps 1-5, Accessing Control Box Electronics.

2. The safety drain relay is located in the top left corner of the access cabinet.

3. Carefully remove the relay hold down spring.

4. Pull relay to the left and out of the socket.

5. Install the new relay by reversing the preceding procedures.

1.8 Replace Breakers

1. Unplug all power cords. Perform Procedure 1.3, Steps 1-5, Accessing Control Box Electronics.

2. Identify faulty breaker. Remove all wiring connected to the breaker terminals inside the

component box. Tape wire-pairs together and mark each wire-set or wire for reassembly.

3. Remove breaker-mounting screws and remove the breaker.

4. Install the new breaker by reversing the preceding procedures.

1.9 Replace Thermatron Potentiometer

1. Unplug all power cords.

2. Open front door of cabinet and remove the four screws in corners of potentiometer panel.

3. Unplug connector.

4. Install the new potentiometer by reversing the preceding procedures.

1-4

Page 8

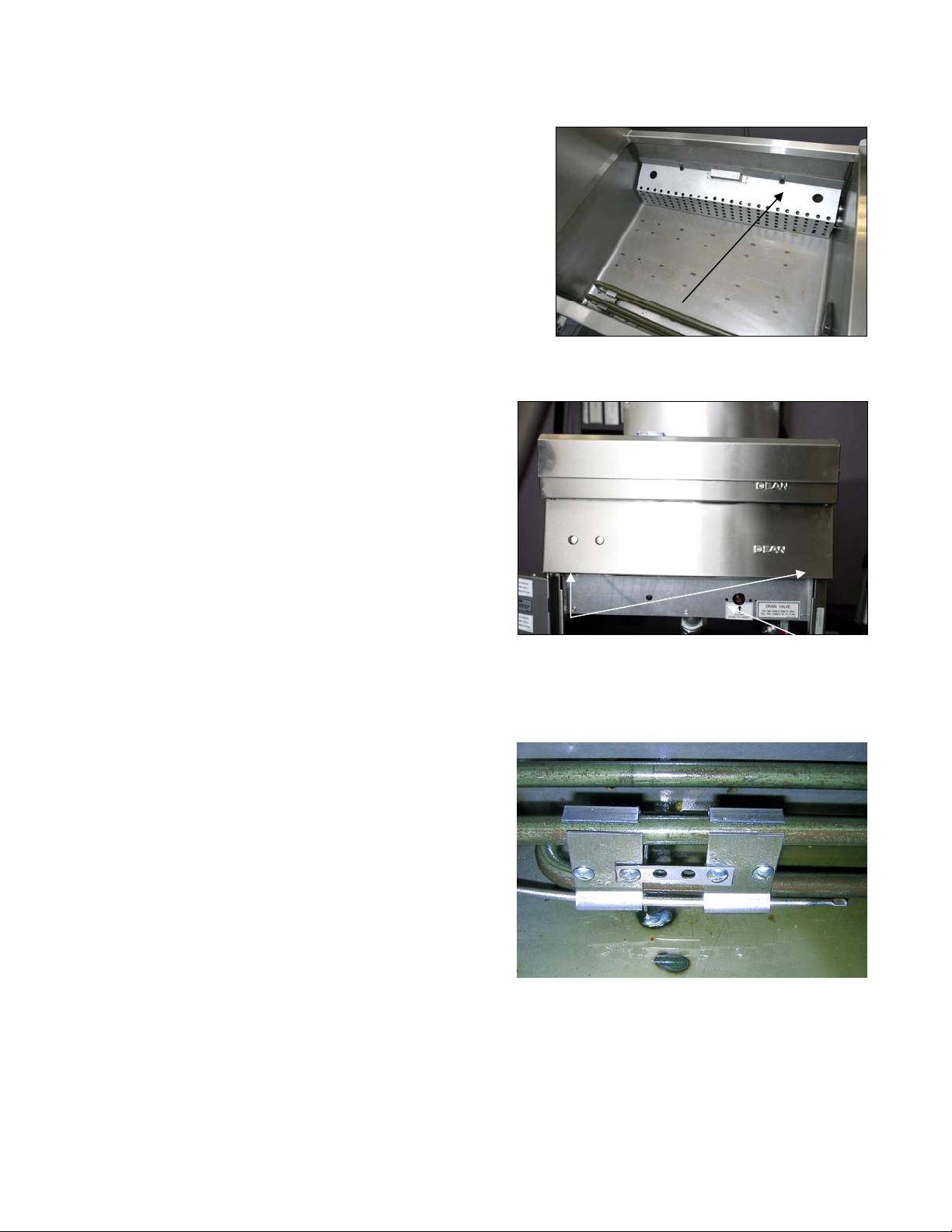

1.10 Replace Temperature Sensor and High-Limit Thermostat Probes

1. Unplug all power cords.

2. Drain the cooking oil from the frypot and

leave the drain open.

3. Lift up and remove the element

guardplate.

4. Remove the two screws from the bottom

of the faceplate cover.

5. After removing screws, gently tilt up and

lower faceplate. Note that when lowering

Element Guardplate

the faceplate, the door will lower and

swing out to be set aside as well.

6. Remove the six screws from the top access

cover.

7. After removing screws, remove panel by

lowering down the front of the frame and

pushing in on the high-limit reset switch

so that it will slide down. To make

reassembly easier, push out the black

grommet and snap back in when

completely reassembled.

8. Remove the screws securing the probe

bracket to the elements and remove the

Underside of

faceplate has

two screws.

Top access cover

has six screws.

probe bracket.

9. Remove the metal clamps securing the

probe to the elements.

10. Disconnect the wire plug containing the

probe wiring.

11. Using an open end wrench, loosen the

temperature probe. Thread the probe wire

through the hole and remove the probe.

Remove the screws from probe brackets.

1-5

Page 9

12. Thread the new probe wire through the

hole in front of the fryer. The probe

assembly should be oriented in the same

manner as the probe being replaced. Place

the new probe assembly onto the element,

and ensure that the probe extends 1”

beyond the front of the bracket before

securing the bracket. Also ensure that the

springs are on each probe under each

bracket.

13. Apply Loctite PST567 sealant to

replacement threads.

14. Screw the replacement probe into the

frypot and tighten 170-180 inch-pounds

torque. DO NOT OVERTIGHTEN.

15. Reattach the connector and reassemble in

High-Limit Thermostat Temperature

Sensor

reverse order.

1.11 Replace Heating Elements inside Frypot

1. Perform Procedure 1.10, Replace

Temperature Probe, Steps 1-9.

2. Remove the four screws from the two

brackets in the rear of the frypot that

secure the element to the frypot.

3. Remove wires from the elements by

loosening and removing the nuts.

4. Remove element using an open-end

wrench or other suitable tool to loosen the

compression fitting.

Remove screws here.

5. Gently remove the element by sliding out into the frypot and lifting up as you remove it.

6. Insert new element and reassemble in reverse order.

1-6

Page 10

1.12 Replace Heating Element under the Frypot

1. Perform Procedure 1.10, Replace Temperature Probe, Steps 1-9.

2. Remove the wires from the element by removing the nuts on each end of the element.

3. Remove the screws attaching the element bracket to the cabinet.

4. Gently slide the element out by pulling towards the front of the fryer.

5. Insert new element and reassemble in reverse order.

1.13 Replace Frypot

1. Perform Procedure 1.10, Replace Temperature Probe, Steps 1-9.

2. Perform Procedure 1.3, Accessing the Control Box Electronics, Steps 1-5.

3. Perform Procedure 1.8, Replace High-Limit, Steps 1-4.

4. Disconnect the element wires.

5. Remove the screws holding the back panels to the frame.

6. Remove the screws securing the frypot to the front frame of the fryer.

7. Carefully lift the frypot from the cabinet.

8. Remove the drain valve from the old frypot and install on the new frypot.

9. Apply Loctite Sealant PST 567 to the high-limit threads. Install high-limit into the new frypot.

10. Follow the preceding steps in reverse to install the new frypot into the fryer.

11. NOTE: Apply Loctite Sealant PST 567 to all pipefittings prior to installation.

1.14 Cleaning a Seized Pump

If the pump motor overloads, a circuit breaker will trip and the motor will not start until the breaker

is reset. If the pump motor does not start, press the white reset button located under the component

box, inside the cabinet.

If the pump starts after resetting the breaker, then something is causing the motor to overload. A

major cause of overload is filtering several frypots sequentially, creating thermal overload on the

1-7

Page 11

motor. Allow the pump motor to cool at least 30 minutes before resuming operation, and allow time

for the motor to cool between frypots.

Motor overload can be caused by:

• Solidified shortening in the pan or filter lines,

or

• Attempting to filter unheated oil.

Cold oil is more viscous, causing the pump motor to trip a breaker. Always filter with the oil at

operating temperature [~350°F (177°C)].

If the motor runs but the pump does not, there is a blockage in the pump or lines. Incorrectly sized

or installed paper/pads will allow food particles and sediment to pass through the filter pan and into

the pump. When sediment enters the pump, the gears bind, causing the motor to overload, again

tripping the breaker. Shortening that has solidified in the pump will produce the same result.

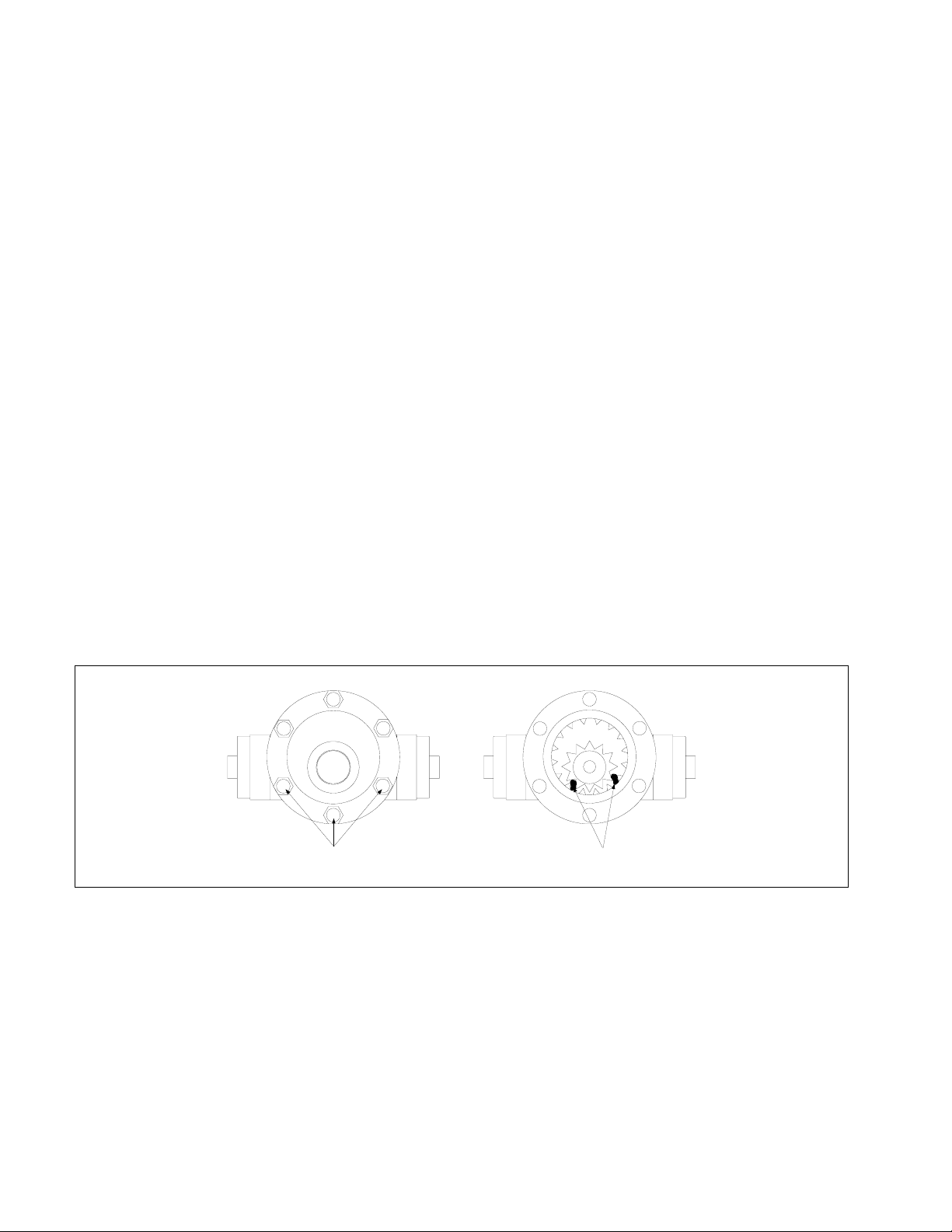

A pump seized by debris or hard shortening must be disassembled, cleaned, and reassembled. Use

the following procedure:

1. Disconnect power to the filter system.

2. Remove the front cover of the pump to access the gears inside (see illustration below- 8-GPM

pump shown), if the pump is accessible inside the cabinet.

Remove bolts to remove

pump cover.

Remove debris or hardened

shortening to free gears.

3. If the front cover is not accessible, the pump must be removed from the pump motor (remove

input/output plumbing from the pump prior to removing pump). Remove three setscrews from

the pump-shaft housing to disengage the pump from the motor. Remove the gears and

thoroughly clean all internal components. Ensure the inside of the pump housing is free of any

debris or hardened shortening before reassembling. Failure to completely clean the inside

housing and ring gear will cause gear binding after reassembly.

Filter paper/pads that are the wrong size or installed incorrectly will also allow food particles and

sediment to pass through and clog the suction tube in the bottom of the filter pan. Particles large

enough to block the suction tube may indicate that the crumb tray is not being used.

1-8

Page 12

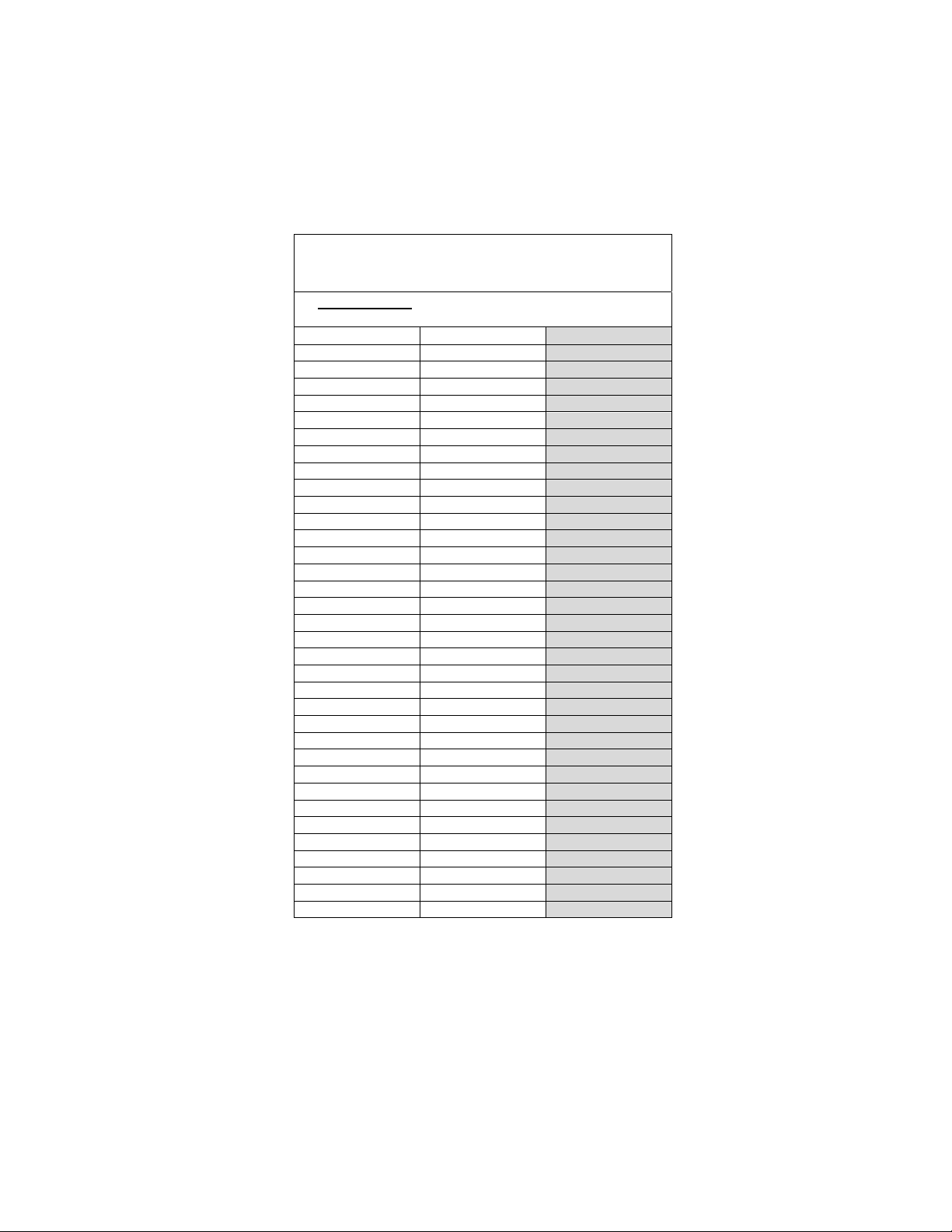

1.15 Probe Resistance Chart

Use the chart below when testing temperature probes and probe circuits for proper operation.

Probe Resistance Chart

Current-Style Thermatron Systems (Probe wire

color: Two Black Wires or Two Brown Wires)

° Celsius ° Fahrenheit Ohms (± 3%)

21 70 108130

27 80 84606

32 90 66721

38 100 53020

43 110 42452

49 120 34206

54 130 27735

60 140 22641

66 150 18588

71 160 15349

77 170 12741

82 180 10635

88 190 8925

93 200 7527

99 210 6391

104 220 5470

110 230 4705

116 240 4030

121 250 3441

127 260 2967

132 270 2583

138 280 2255

143 290 1977

149 300 1729

154 310 1496

160 320 1320

166 330 1170

171 340 1051

177 350 942

182 360 840

188 370 750

193 380 676

199 390 605

204 400 541

1-9

Page 13

b

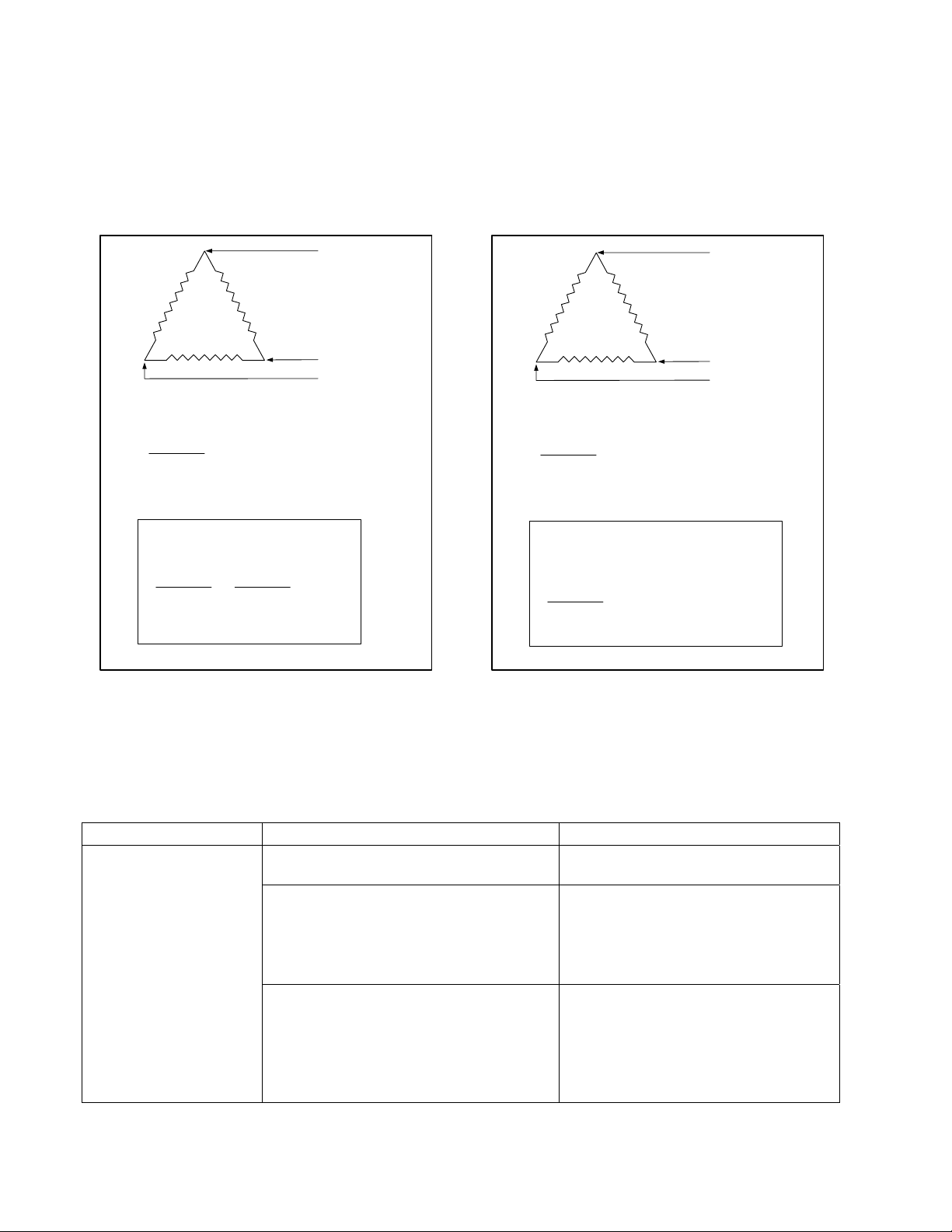

1.16 Element Wattage/Amperage Calculation Charts

Use the charts below when changing voltages or determining amperage for a given element

configuration.

L1

L1

Three Phase

Amperage

L2

L3

To determine Three Phase Amperage, solve for

Single Phase first:

Wattage

Voltage

Then divide the Single Phase Amperage by 1.73 to

determine Three Phase Amperage.

Example:

17,000W

= 40.944 Amps per Phase

= Single Phase Amps

70.833 Amps

240V

=

1.73

To compute the New Wattage Rating of an element if a

different voltage is applied, use the following formula:

New Voltage

[]

Old Voltage

= New Wattage Rating

Example:

If 208V supply is applied to a 17 kW element

rated for 240V, the calculation is as follows:

208V

[]

240V

= 12.77 kW

Three Phase

Wattage

L2

L3

2

kW Listed

X

2

X

17,000 Watts

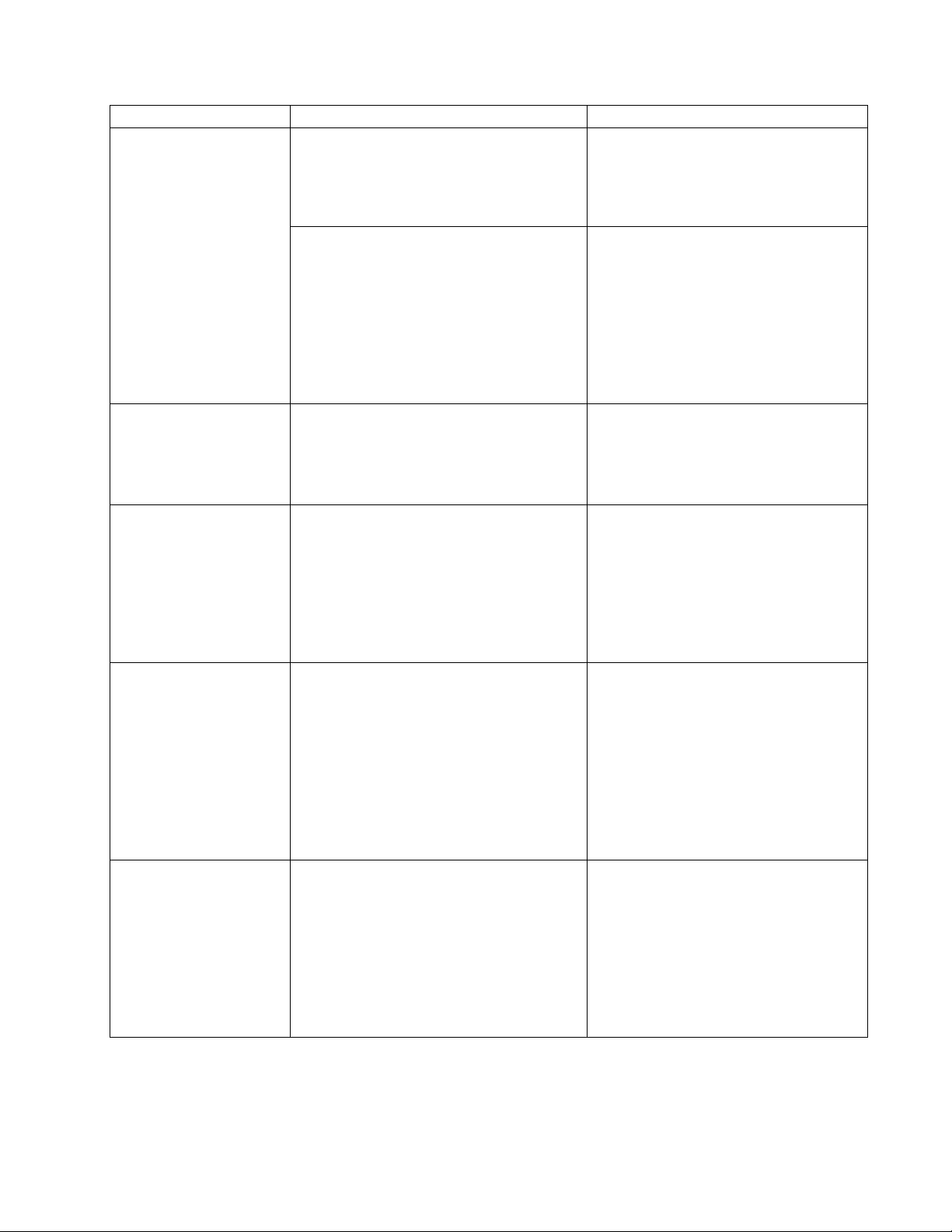

1.17 Troubleshooting

1.17.1 Control and Heating Problems

Problem Probable Causes Corrective Action

A. Power cord is not plugged in or circuit

breaker is tripped.

B. Controller has failed.

Controller won't

activate.

C. Power supply component or

temperature control board has failed.

A. Plug power cord in and verify that

circuit breaker is not tripped.

B. If available, substitute a controller

known to be working for the

suspect controller. If the substitute

controller functions correctly, order

a new controller.

C. If any of the components in the

power supply system (including the

transformer and temperature control

oard) fail, power will not be

supplied to the controller and it will

not function.

1-10

Page 14

Problem Probable Causes Corrective Action

Fryer does not heat.

Fryer repeatedly

cycles on and off when

first started.

Fryer heats until high-

limit trips with heat

indicator ON.

Fryer heats until high-

limit trips without

heat indicator ON.

Fryer stops heating

with heat indicator

ON.

A. Controller has failed.

B. One or more other components have

failed.

Fryer is in melt-cycle mode.

Temperature probe or controller has

failed.

Contactor, element or controller has

failed.

The high-limit thermostat or contactor

has failed.

A. If available, substitute a controller

known to be working for the

suspect controller. If the substitute

controller functions correctly, order

a new controller.

B. If the circuitry in the fryer control

system cannot determine the frypot

temperature, the system will not

allow the element to be energized

or will de-energize the element if it

is already energized. If the

contactor, element, or associated

wiring fails, the element will not

energize.

In fryers equipped with Thermatron

controllers, burners cycle on

approximately 5 seconds and off for

15 seconds until the temperature

reaches 66°C (150°F).

If available, substitute a controller

known to be working for the suspect

controller. If the substitute controller

functions correctly, order a new

controller. If the substitution of the

controller does not resolve the

problem, the most likely cause is a

failed temperature probe.

If available, substitute a controller

known to be working for the suspect

controller. If the substitute controller

functions correctly, order a new

controller from FAS. If the

substitution of the controller does not

resolve the problem, the most likely

cause is a contactor that has failed in

the closed position or an element that

has failed.

The fact that the heat indicator is ON

indicates that the controller is

functioning properly and is calling for

heat. The high-limit thermostat

functions as a normally closed switch.

If the thermostat fails, the "switch"

opens and power to the elements is

shut off. If the contactor fails to close,

no power is supplied to the elements.

1-11

Page 15

1.17.2 Filtration Problems

b

Problem Probable Causes Corrective Action

A. Verify that the power cord is fully

plugged in. If so, verify that circuit

breaker is not tripped.

B. Pump blockages are usually caused

by sediment

due to improperly sized or installed

filter paper and failure to use the

crumb screen.

uildup in the pump

Filter pump won't

start.

A. Power cord is not plugged in or circuit

breaker is tripped.

B. Blockage in filter pump.

Test: Close the drain valve and pull

the filter pan out from the fryer.

Activate the pump. If the pump motor

hums for a short time then stops, the

probable cause is blockage of the

pump itself.

1-12

Page 16

1.18 Wiring Diagram

1.18.1 240V prior to June 2008

8051434C

1-13

Page 17

1.18.2 24V after June 2008

1-14

Page 18

FLATBOTTOM SERIES ELECTRIC FRYERS

2.1 Accessories

CHAPTER 2: PARTS LIST

1

3

2

4

Item

1 210-3703 Hanger, Basket 2424E

2 106-2840SP Cover Assembly, Frypot 1824

106-2839SP Cover Assembly, Frypot 2424

3

4 823-4127 Crumb Tray

5 823-3934 Vessel Divider

6 803-0209 Brush, Frypot Cleaning

* 823-3660 Crumb Scoop

* Not Illustrated

Part Number Description

803-0197 Fryer Friend 27” (Cleanout Rod)

5

6

2-1

Page 19

2.2 Cabinetry

2.2.1 Backs, Bases, Casters, Sides, Etc. (11824E, 12424E Non-Filter)

7

6

3

8

45

1

9

10

2

11

2-2

Page 20

Item

1

2

3

4

5

6

7

8

9

*

*

10

*

*

11

*

*

*

* Not Illustrated

Part Number Description

106-2176 Cabinet Assembly, 11824E Non-Filter

106-2175 Cabinet Assembly, 12424E Non-Filter

200-2903 Channel, Base 1824

200-2971 Channel, Base 2424

210-3341 Door, Duct Access

823-3725 Side, 18 S/S LH Cabinet

823-4276 Side, 24 S/S LH Cabinet

823-4266 Side, 24 ALZ LH Cabinet

823-3727 Side, 18 S/S RH Cabinet

823-4277 Side, 24 S/S RH Cabinet

823-4267 Side, 24 ALZ RH Cabinet

823-4063 Support, Caster

200-2005 Back, Structural

200-1500 Back, Structural

210-9276 Upper Cap 1824E

210-9277 Upper Cap 2424E

200-4511 Hinge, Door

826-1117 Caster Assembly, 5” Wheel w/o Brake

810-0356 5” Wheel w/o Brake

826-1389 Screw, ¼-20x ¾ Hex Head ZP (Pkg. of 10)

809-0191 Washer, Lock ¼ Spring ZP

826-1118 Caster Assembly, 5” Wheel w/ Brake

810-0357 5" Wheel w/ Brake

826-1389 Screw, ¼-20x ¾ Hex Head ZP (Pkg. of 10)

809-0191 Washer, Lock ¼ Spring ZP

810-2053 Leg, Black Adjustable w/Mount Plate

826-1362 Nut, ¼-20 Hex ZP (Pkg. of 10)

826-1389 Screw, ¼-20x ¾ Hex Head ZP (Pkg. of 10)

809-0191 Washer, Lock ¼ Spring ZP

2-3

Page 21

2.2.2 Backs, Bases, Casters, Sides, Etc. (SCF 22424E and 32424E)

4

22

24

12

23

1516

17

1 9

19 18

13

11

7

10

2 5

8

3

20

14

6

21

2-4

Page 22

Item

106-2206 Cabinet Assembly, U224E

106-2204 Cabinet Assembly, SCF32424E

106-3136 Cabinet Assembly, 2424E SS

1 200-2624 Upright, Rear

2 200-2632 Support, Inner Panel

3 200-2643 Base Frame Lower Plate

4 200-2717 Support, Pump Motor D180

5 200-2935 Post, 2424 Door

6 200-2971 Channel, Base 32424

200-4696 Channel, Base 2424

7 200-3356 Cover, Lower Base Frame

8 200-4696 Channel, Base 2424

9 200-5209 Brace, 2424 Rear Cross Aluminized

10 200-5210 Bridge, Base 2424

11 210-3341 Door, Duct Access

12 823-3725 Side W/A, 1824E S/S LH Cabinet

823-4276 Side W/A, 2424E S/S LH Cabinet

13 823-3727 Side W/A, 1824E S/S RH Cabinet

823-4277 Side W/A, 2424E S/S RH Cabinet

14 823-3728 Side W/A, 1824E LH Cabinet Aluminized

15 823-3729 Side W/A, 1824E RH Cabinet Aluminized

16 823-3730 Panel W/A, U224E Cabinet LH Inside

823-4271 Panel, W/A, 2424E Cabinet LH Inside

17 823-3731 Panel W/A, U224E Cabinet RH Inside

823-4272 Panel, W/A, 2424E Cabinet RH Inside

18 823-4063 Caster Support

19 823-4064 Caster Channel Support

20

*

*

21

*

*

22

23

24

* Not Illustrated

Part Number Description

826-1117 Caster Assembly, 5” Wheel w/o Brake

810-0356 5” Wheel w/o Brake

826-1389 Screw, ¼-20x ¾ Hex Head ZP (Pkg. of 10)

809-0191 Washer, Lock ¼ Spring ZP

826-1118 Caster Assembly, 5” Wheel w/ Brake

810-0357 5” Wheel w/ Brake

826-1389 Screw, ¼-20x ¾ Hex Head ZP (Pkg. of 10)

809-0191 Washer, Lock ¼ Spring ZP

200-4150 Back, Upper Cabinet 2424

200-4152 Back, Lower Cabinet 2424

200-4154 Back, Lower L/R Cabinet 2424

2-5

Page 23

2.2.3 Door Assembly and Component Parts

1

8

2

4

3

5

6

9

10

11

7

Item

1

Part Number Description

106-2788 Door Assembly 1824

106-2784

106-4067SP

Door Assembly 2424

Pin Assembly, Door

806-4487SP Pin, Hinge Cover & Door

810-0658 Retaining Ring (Unplated)

2 200-4588 Liner, Inner Door 1824

200-4577 Liner, Inner Door 2424

3 809-0191 Washer, ¼” Lock Spring ZP

4 809-0266 Screw, #10-½” Phil TR Head ZP

5 809-0918 Screw, #10-24 X ½”

6 810-0179 Button Plug ½”

7 810-0180 Handle, Door

8 826-1343 Spring, Door Hinge Lock

9 810-1105 Magnet, (Offset) Door

10 816-0529 Bumper, Rubber Self Adhesive

11 824-1150 Panel, W/A Outer Door 1824

824-1149 Panel, W/A Outer Door 2424

2-6

Page 24

2.2.4 Flue Caps, Top Caps, and Related Components

1

2

5

8

11

3

14

6

4

9

12

15

7

10

13

Item

Part Number Description

1 823-4100 Deflector, 2424 Oil

2 210-4317 End Strip, 24L 18R Oil

3 210-4313 Joiner Strip (Joins frypots within a system)

4 210-4598 Joiner Strip, 18/2424 (Joins one fryer system to another)

5 823-4684 Fluecap, 2-2424

6 823-3474 Deflector, 2424 Short Oil

7 823-4101 Deflector, 24L 18R Oil

8 210-4802 Fluecap, 1-2424

9 823-3699 Top Assembly, One-Piece Standard Flue 1824 (use 823-3264 for 2424)

10 823-3622 Top Assembly, One-Piece Short Flue 1824 (use 823-3473 for 2424)

11 823-4916 Marine Edge 1824 (use 823-4917 for 2424)

12 210-9276 Upper Cap 1824E (use 210-9277 for 2424)

13 106-3253SP Frame Assembly, Single Crumb Dump

14 106-1638SP Frame Assembly, Double Crumb Dump

15 823-4125 Insert, Crumb Dump

2-7

Page 25

2.3 Control Panels, Wireways, and Related Components

17

24

18

4

11

20 21

23

16

22

5

8

7

6

19

14

2

12

3

1

10

13

15

9

2-8

Page 26

Item

Part Number Description

1 106-2046 Plate Assembly, SCF2 Thermatron PCB Component

826-2031 Thermatron Kit, 115/220V includes 106-0165

2 106-0165 PCB, SCF2 Thermatron Board 115/230

106-3729 PCB, Thermatron Extended Melt Cycle 24V

106-2108 Breaker Assembly, 3-Pole 240VAC Circuit

3 807-3748 Breaker, 3-Pole 240VAC Circuit

4 810-2342 Plate, Circuit Breaker Mounting

5 106-2119 Relay/Transformer Bracket Assembly, 208/240VAC (Non-CE Units)

6 807-3611 Relay, 24 VAC Coil

7 807-3613 Spring, Relay Hold Down

8 807-3682 Transformer, 230V

807-2180 Transformer, 208-240V/24V 50VA

9 106-2120SP Fuse Assembly, 5 Amp w/Leads

10 807-3750 Fuse, 300V 5 Amp

826-1988 Fuse Holder, with Fuse 300V 5 Amp

11 200-1921 Support, Circuit Breaker

12 200-3237 Plate, Control Box Mounting

13 807-0070 Terminal, Ground Lug

14 807-0074 Contactor, 3 Pole 600 V 40 Amp

15 807-3610 Block, Dean Terminal 1501-AL-9CU

16 807-3622 Connector, 1” X 45 Degree

17 807-3625 Conduit, 1” Liquid-Tite Flex

18 807-3744 Connector, 1” X 90 Degree

19 826-1371 Screw, Drill #8 x ½ Hex HD ZP (package of 25)

20 809-0428 Bolt, ¼-20 x ½ Hex HD ZP GR5

21 809-0825 Nut, KEPS, ¼ -20, Hex HD SS

22 823-3694 Control Box, 2424E

23 823-3717 Control Box, SCF224E RH

24 823-3691 Control Box, SCF224E LH

* 823-3719 Control Box, 1824E

* 816-0574 Bushing, Heyco 1.375 - 16

* Not Illustrated

2-9

Page 27

2.4 Electronic Components

1

5

6

2

3

4

7

8

10

11

12

13

9

2-10

Page 28

3

Item Part Number Description

1 106-2135SP Panel Assembly, Power/Reset/Boil-Out

807-3574 Switch, Power

807-3576 Switch, Reset

807-3579 Switch, Boil-Out

2 807-3611 Relay, 24VAC Coil (Optional Safety Drain Relay)

3 826-2031 PCB Board, 115/230V (Thermatron Board Kit)

4 106-3777 Faceplate Assembly, Thermatron

106-1955 Harness Assembly, SCF32424 Potentiometer

807-3536 Pot, Dean Temp Control 1k Ohm

802-2052 Label, Thermatron Face Plate

* 106-3309 Faceplate Assembly, TMT 1824E/2424E

802-2052 Label, TMT Dial

816-0534 Knob / Go Control (PS-125-PL-2)

* 106-0850 Faceplate Assembly, Thermatron /14G

802-2134 Label, Thermatron "Go" Face

210-3377 Face Plate, Thermatron Retro

5 807-3610 Block, Dean Terminal 1501-AL-9CU

6 807-3748 Breaker, 3-Pole 240VAC Circuit

7 807-0074 Contactor, 40 amp 208/240VAC coil 50/60Hz

807-2284 Contactor 50 amp 24VAC coil 50/60Hz

810-1202 Contactor 40 amp 3 pole

8 807-3682 Transformer, 230VAC

810-2180 Transformer, 208-240V/24V 50VA

9 807-2103 Microswitch, CE Straight Lever

10 106-2148 Probe Assembly, 1824E/2424E Temperature

11 807-3759 Thermostat, High-Limit w/Manual Reset

12

106-2607SP Go Sensor Assembly (90° Bend)

807-3567 Sensor Probe (Go)

813-0617 Fitting

/16 " CCX ¼ " NPT

13 807-3905 Light, Green Indicator 250V

807-3906 Light, Red Indicator 250V

* Not Illustrated

2-11

Page 29

2.5 Filter Components

r

,

2.5.1 Filter Pan Assembly

7

7

8

9

10

11

12

Filter Paper Configuration

2

5

4

3

Magnasol Leaf Configuration

8

1

6

Refer to Section 2.5.2 for parts

breakdown of this caddy assembly.

Item Part Number Description

1 106-3675SP Filter Screen Assembly, 2424

810-2237 Magnasol Leaf w/ 11x19 Retrofit includes hose

2 810-2700 Nipple, Quick Disconnect Snaptite

3 810-2759 Filter, Screen 2424

4 810-2760 Compression Cap

5 813-0867 Nipple, ⅜ X 6 ½ SS

6 823-3480SP Pan W/A, BI-18 Portable/Stationary

7 823-3492 Lid W/A, SCF2424 LJS

823-4885 Lid W/A, Flatbottom 3” Drain

8 823-3509 Crumb Basket W/A, LJS-UFF

* 810-2100 Motor, Pump 120/230 V 1/3 HP

* 810-2098 Pump, 8 GPM Filte

9 823-4280 Ring W/A, Hold Down SCF22424E

10 823-4274 Pan W/A, Filter 2424E

11 810-2172 Disconnect, Male Quick Release

12 813-0851 Nipple ⅜ X 5” BM

13 813-0006 Bushing, Hex ½ to ⅜ NPT BM

14 813-0460 Nipple, ½ x 3” NPT BM Pipe

15 813-0165

16 813-0062

* Not Illustrated

Elbow St ½ x ½ NPT 90° BM

Elbow

½ BM 90°

13

15

16

14

2-12

Page 30

2.5.2 Filter Pan Caddy Assembly

6

7

8

5

2

1

4

Item Part Number Description

106-1693SP Filter Pan Caddy Assembly SCF2424

1 200-2627 Brace, Cross

2 200-2641 Filter Frame Side, 2424SCF

3 200-2642 Filter Frame Front & Rear

4 809-0054 Nut, Elastic Stop, 10-32 Zn Pl

5 809-0767 Screw, 10-32 X ½ Phil Tr Hd SS

6 809-0823 Nut, Nylock, ¼-20

7 810-2805 Caster, 2” Filter Pan

8 826-1389 Screw, ¼-20x ¾ Hex Head ZP (package of 10)

* Not Illustrated

3

2-13

Page 31

2.5.3 Under Fryer Filter (UFF) Components

26

16

26

29

29

26

30

10

10

25

10

27

28

Right-Flush configuration

10

23

22

2

21

20

19

34

19

13

19

18

24

illustrated.

4

3

17

16

11

15

13

10

33

32

14

9

12

31

1

5

8

6

7

2-14

Page 32

Item Part # Component

1 810-2100 Motor, 120-230VAC ⅓-HP Filter Pump

2 810-2098 Pump, 8 GPM Filter

3 810-2245 Hose, 16¾-inch Filter Pan to Pump

4 810-2173 Disconnect- Female, ½-inch

5 813-0735 Reducer, ½-inch to ⅜-inch NPT Bell

6 813-0869 Elbow, ⅜-inch NPT Street

7 810-2762 Disconnect, ⅜-inch Female with Radial Collar

8 813-0625 Nipple, Black ⅜-inch NPT

9 813-0251 Nipple, ½ -inch X 4.5-inch NPT

10 813-0614 Fitting, ½-inch X ⅜-inch 37° Flare

11 106-3659SP Flush Valve Assembly, Complete

810-2125 Valve, ⅜-inch Flush

200-6089 Actuator Handle, Flush Valve (Left-Oriented Flush Valves Only)†

200-6202 Actuator Handle, Flush Valve (Right-Oriented Flush Valves Only)†

106-3604SP Bracket Assembly, Microswitch

807-2103 Microswitch, Straight Lever

816-0220 Insulation, Microswitch

901-2348 Cover, Microswitch (Left-Oriented Flush Valves Only)†

902-2348 Cover, Microswitch (Right-Oriented Flush Valves Only)†

12 810-2170 Disconnect, ½-inch Male

13 813-0022 Nipple, ½-inch X Close NPT

14 813-0165 Elbow, ½-inch X 90° NPT Street

15 813-0062 Elbow, ½-inch X 90° NPT

16 813-0625 Nipple, ⅜-inch X Close NPT

17 813-0006 Bushing, ½-inch to ⅜-inch NPT Hex

18 813-0613 Plug, ½-inch NPT Hex

19 813-0003 Tee, ½-inch NPT

20 813-0093 Nipple, ½-inch X 4-inch NPT

21 813-0173 Union, ½-inch NPT

22 813-0673 Nipple, ½-inch X 8.5-inch NPT

23 813-0087 Nipple, ½-inch X 1.5-inch NPT

24 813-0833 Nipple, ½-inch X 15.5-inch NPT

* 813-0368 Nipple, ½-inch X 16-inch NPT

25 810-2270 Tubing, Filter Pump to Rear Oil Return

26 813-0730 Tee, ⅜-inch NPT

27 813-0644 Nipple, ⅜-inch X 1.5-inch NPT

28 813-0631 Elbow, ⅜-inch X 90° NPT

29 810-2262 Tubing, Rear Oil Return

30 813-0452 Plug, ⅜-inch NPT Pipe

31 810-2757 Handle, Drain Flush

32 816-0549 Sleeve, Blue Vinyl (Drain Flush Handle Cover)

33 200-6135 Bracket, Flush Handle (Mounts to Inner Panel)

34 813-0463 Plug, Pipe ½ NPT BM

* Not Illustrated

†

Valve stem pointing to left- left-oriented; Valve stem pointing to right- right oriented.

2-15

Page 33

2.6 Elements and Related Components

1

4

8

5

3

2

6

9

7

Item

Part Number Description

1 826-1831 Element, 240V/6.3kw Heating (includes mounting hardware)

826-1805 Element, 208V/6.3kw Heating (includes mounting hardware)

2 823-3760 Heater W/A, 208V/6.3kw Element

823-3836 Heater W/A, 240V/6.3kw Element

3 200-1376 Bracket, Restraining

4 823-4573 Plate, Element Retaining

5 210-3320 Heating Element Spacer

6 210-3322 Heater Support Plate

7 210-3321 High Limit Clamp

210-4265 Thermostat Clamp

8 810-2164 Spacer Spring 3/16”

9 823-3885 Plate W/A, Element Guard

* 809-0840 Screw, 10-32 x ½ Rd SL HD ZP

* KIT7594 Flatbottom Electric Element Bracket Modification Kit

* Not Illustrated

2-16

Page 34

2.7 Harnesses

1 2 3

5

6 7 8

4

9 10 11 12

13 161514

2-17

Page 35

Item

Part Number Description

1 106-1262 Harness Assembly, Boil Out Board

2 106-1652 Harness, Drain Valve MSW-WW

3 106-1955 Harness Assembly, FB Thermostat

4 106-1978 Harness Assembly, 2424 Heat Light

5 106-2122 Harness Assembly, 208VAC Go Board

6 106-2132 Harness Assembly, Boil Out

106-2139 Wire Assembly, Power Switch

7 106-2134 Harness Assembly, Drain Valve

8 106-2138 Wire Assembly, Power

9 106-2141 Harness Assembly, Element

10 106-2145 Harness Assembly, 208VAC Ext

11 106-2146 Harness Assembly, Potentiometer

12 106-2159 Harness Assembly, Oil Return MSW-CBX/Add On

13 106-2191 Harness Assembly, SCF24E Heater Strip

14 106-2331 Harness Assembly, Oil Return MSW-CBX/Add On

15 106-2332 Wire Assembly, 48.7 Ohms Complete

16 106-2825 Harness Assembly, Pump Motor

* 108-2095 Assembly, Wire Flat bottom Electric Relay

* 108-2096 Assembly, Wire Flat bottom

* Not illustrated

2-18

Page 36

2.8 Oil Discharge Assembly

12

5

10

9

1

11

3

6

4

8

2

7

Item Part Number Description

106-2184

Oil Discharge Assembly, SCF 2424E includes 106-2194 and

106-2192

106-2194 Oil Discharge Assembly, 2424E Component

1 810-2357 Tubing, 24E Flush Line

2 813-0003 Tee, ½ NPT BM

3 813-0022 Nipple, ½ x Close NPT BM

4 813-0087 Nipple, ½ NPT X 1 ½ BM

5 813-0156 Plug, ½ NPT Hex Head BM Pipe

6 813-0173 Union, ½ NPT BM

7 813-0368 Nipple, ½ NPT X 16.00 BM

8 813-0613 Flare Fitting ½ -37 Degree X ½

9 813-0614 Flare Fitting, ½ -37 Degree X ⅜

10 813-0625 Nipple, Black, ⅜ X Close NPT BM

11 813-0632 Elbow, Street, ⅜ -90 Deg

12 813-0730 Tee, ⅜ NPT Black

* 816-0548 Cap, Vinyl Yellow

* Not Illustrated

2-19

Page 37

2.9 Oil Return Assembly

3

1

2

6

10

7

5

8

Oil Return Assembly 24E (P/N 106-2192) Illustrated

Item Part Number Description

106-2188 Oil Return Assembly 1824E LH

106-2183 Oil Return Assembly 1824E RH

106-2192 Oil Return Assembly 24E LH

106-2189 Oil Return Assembly 24E RH

106-3130 Oil Return Assembly 2424E LH

106-3131 Oil Return Assembly 2424E RH

1 200-1143 Retainer, Oil Return Valve Nut

2 810-2125 Ball Drain Valve ⅜”

3 810-2363 Tubing, Rear Vessel Flush Line 24E

810-2671 Tubing, Rear Vessel Flush Line 2424E

810-2362 Tubing, Rear Vessel Flush Line 1824E

810-2316 Tubing, Flare 14.73” 3” Drains

4 813-0452 Plug, Pipe ⅜ NPT BM

5 813-0614 Flare Fitting, ½-37degree X ⅜

813-0613 Flare Fitting ½-37 Deg x ½ 3” drains

6 813-0625 Nipple, Black, Close ⅜ NPT BM

7 813-0631 Elbow ⅜ X 90 Degree

8 813-0632 Elbow, Street, ⅜-90 Degree

9 813-0730 Tee, ⅜ NPT Black

10 823-3713 Lever W/A, Oil Return FB Electric

823-4270 Lever, W/A, Oil Return 2424E

* 810-2262 Tubing, Oil Drain Valve UFF 50

* 810-2673 Tubing, Flush Line Pot-To-Pot 2424E

* Not Illustrated

4

9

2-20

Page 38

2.10 Drain Valve and Associated Parts

1

2

5

6

7

8

9

10

Plastic Washer

(furnished with Item 11)

11

Nut

(furnished with Item 11)

4

3

Item Part Number Description

1 816-0211 Sleeve, Red Drain Valve Handle

2 210-8558 Handle, 2424 Drain Valve

3 809-0564 Stud, ¼ - 20 x 1 ½

4 200-1257 Retainer, Drain Valve Nut

5 826-1366 Nut, 4-40 KEPS HX (Pkg. of 25)

6 901-2348 Cover, Safety Switch LH

902-2348 Cover, Safety Switch RH

7 807-2103 Switch, CE Micro Straight Lever

8 816-0220 Insulation, RF Switch

9 809-0988 Washer, Nylon

10 106-3604 Bracket Assembly, Switch

11 810-2052 Valve, Drain 1¼” w/ Nut

* 823-3463 Valve w/ Microswitch Holder, 1¼” Drain (Older Units)

* 814-0047 Sleeve, Red Handle Drain Valve (Older Units)

* 807-2104 Microswitch, Drain Valve Roller Lever (Older Units)

* Not Illustrated

2-21

Page 39

2.11 Drain and Oil Return Components

2.11.1 Standard 1 ½” Drains

)

h

.

t

t

s

h

e

u

g

l

i

n

f

4

2

8

1

/

4

2

4

2

-

2

2

3

i

R

b

h

t

a

i

n

c

o

w

t

4

h

g

2

g

n

i

i

8

r

b

m

u

2

r

a

f

l

n

P

o

(

1

h

t

i

w

0

1

3

4

8

h

t

)

.

s

h

t

u

g

e

l

i

f

4

2

8

1

/

4

2

4

2

3

n

i

R

h

b

t

i

n

a

o

c

w

t

4

f

g

2

e

n

l

i

8

b

r

1

a

m

f

h

t

u

i

l

n

o

P

w

(

5

1

7

0

2

9

1

8

1

n

o

t

f

h

)

.

s

e

4

2

8

6

1

2

8

1

5

1

3

1

1

/

4

2

4

2

3

6

1

4

1

t

u

L

e

l

f

n

n

i

h

o

b

t

i

a

4

c

w

2

t

f

8

g

e

1

n

l

i

b

r

h

t

i

a

m

f

w

u

l

P

(

7

1

1

0

1

1

2-22

9

2

1

8

Page 40

2.11.1 Standard 1 ½” Drain and Oil Return Components Parts List

ITEM PART # COMPONENT

826-1824 Frypot Kit, 2424E (No Front Return)

1 823-3732SP Frypot Assembly, 1824ECF Electric

823-3721SP Frypot Assembly, 2424ECF Electric

2 813-0768 Tee, 1824 Right Drain Flush

3 810-2276 Nipple, UFF Drain Line

4 809-0884 Nut, Slip-Joint

5 816-0544 O-Ring

6 200-1845 Tube, 1⅝-inch X 24½-inch Drain Manifold

7 810-2556 Tube, Front Oil Return

8 813-0868 Plug, 1½-inch NPT Pipe

9 813-0732 Nipple, 1½-inch X 2-inch NPT Toe

10 813-0765 Tee, 1½-inch X 1¼-inch X 1½-inch

11 813-0391 Nipple, 1¼-inch X Close NPT

12 810-2052 Valve, Drain 1¼-inch

13 813-0659 Cap, 1½-inch NPT Pipe

14 813-0143 Nipple, 1¼-inch X 2½-inch NPT Toe

15 813-0760 Tee, 1½-inch X 1¼-inch X 1½-inch NPT Drain

16 813-0686 Cap, Drain Flush End (1824G Left)

17 813-0165 Elbow, ½-inch X 90° NPT Street

18 200-1838 Tube, 1⅝-inch X 17½-inch Drain Manifold

19 813-0632 Elbow, ⅜-inch X 90° NPT Street

20 810-2125 Valve, ⅜-inch Oil Return Ball

* 823-3465 Handle, UFF Oil Return

* 816-0548 Cap, Yellow Vinyl Oil Return Handle

21 813-0614 Fitting, ½-inch X ⅜-inch 37° Flare

22 823-3174 Plug, Frypot Drain

* Not illustrated.

2-23

Page 41

2.11.2 Euro-Look 3” Round Drains and Components

1

2

6

4

8

3

5

7

Item Part Number Description

1 823-4853 Tube W/A, 3” Flatbottom Left Drain w/ Drain Flush

2 823-4876 Tube W/A, 3” Flatbottom Down Spout

3 823-4854 Tube W/A, 3” Flatbottom Middle Drain

4 816-0625 Sleeve 3”

5 809-0969 Clamp 3”

6 200-8131 Tube, 2424 3” Middle Down Spout Connector 9.21”

200-8135 Tube, 1824 3” Middle Connector 10.38”

200-8129 Tube, 2424 3” Middle Down Spout Connector 8.71”

7 823-4850 Tube W/A, 3” Flatbottom Right Drain w/ Drain Flush

8 200-8128 Tube, 2424 3” Drain Connector 16½ ”

200-8130 Tube, 24 3” Right Drain Connector 16”

200-8132 Tube, 18 3” Right End Connector 9.88”

* 823-4883 Handle W/A, Drain Flatbottom 3” Drains

* 816-0630 Cap, Vinyl Black

* Not Illustrated

2-24

Page 42

2.12 Wiring Connectors, Pin Terminals and Power Cords

1

2

8

3 4 65

9

10

11

Item Part Number Description

1 807-3530 Terminal, Push-On Insulated

2 807-3537 Terminal, Push-On Fully Insulated

3 807-0155 9-Pin Male

4 807-0156 9-Pin Female

5 807-0157 6-Pin Male

6 807-0158 6-Pin Female Panel Mount

7 807-1062 3-Pin Male

8 807-1068 2-Pin Cap 94V-2 White M&L

9 807-2135 6-Pin Hi-Amp Male

10 807-2136 6-Pin Hi-Amp Female

11 807-2360 3-Pin Female

12 807-3232 4-Pin M&L Female Cap

13 807-3557 6-Pin Housing Cap

* 807-3618 9-Pin Male

* 807-3619 4-Pin Female

* 106-3636 Power Cord Assembly

* Not Illustrated

12

7

13

2-25

Page 43

THIS PAGE INTENTIONALLY LEFT BLANK

Page 44

Dean, 8700 Line Avenue, Shreveport, Louisiana 71106

TEL 1-318-865-1711 FAX (Parts) 1-318-219-7140 FAX (Tech Support) 1-318-219-7135

PRINTED IN THE UNITED STATES

SERVICE HOTLINE

1-800-551-8633

819-6115

SEPTEMBER 2011

Loading...

Loading...