Page 1

FRYMASTER BIELA14 SERIES LOV™

This equipment chapter is to be

installed in the Fryer Section of the

Equipment Manual.

MANUFACTURED

8700 Line Ave.

SHREVEPORT, LOUISIANA 71106

PHONE: 1-318-865-1711

TOLL FREE: 1-800-551-8633

1-800-24 FRYER

FAX: 1-318-219-7135

BY

OPERATOR’S MANUAL

ELECTRIC FRYER

FOR YOUR SAFETY

Do Not Store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

TABLE OF CONTENTS

WARRANTY STATEMENT...................................................................................................Page i

INTRODUCTION...................................................................................................................Page 1-1

INSTALLATION INSTRUCTIONS .......................................................................................Page 2-1

OPERATING INSTRUCTIONS.............................................................................................Page 3-1

M2007 COMPUTER INSTRUCTIONS .................................................................................Page 4-1

OPERATING THE BUILT-IN FILTRATION SYSTEM...........................................................Page 5-1

PREVENTIVE MAINTENANCE............................................................................................Page 6-1

OPERATOR TROUBLESHOOTING.....................................................................................Page 7-1

Frymaster L.L.C., 8700 Line Avenue 71106, 5489 Campus Drive 71129

PHONE 318-865-1711 FAX 318-219-7135

PRINTED IN THE UNITED STATES SERVICE HOTLINE 1-800-24-FRYER FEBRUARY 2008

*8196239*

Page 2

NOTICE

IF, DURING THE WARRANTY PERIOD, THE CUSTOMER USES A PART FOR THIS ENODIS

EQUIPMENT OTHER THAN AN UNMODIFIED NEW OR RECYCLED PART PURCHASED

DIRECTLY FROM FRYMASTER DEAN, OR ANY OF ITS FACTORY AUTHORIZED SERVICE

CENTERS, AND/OR THE PART BEING USED IS MODIFIED FROM ITS ORIGINAL

CONFIGURATION, THIS WARRANTY WILL BE VOID. FURTHER, FRYMASTER DEAN AND

ITS AFFILIATES WILL NOT BE LIABLE FOR ANY CLAIMS, DAMAGES OR EXPENSES

INCURRED BY THE CUSTOMER WHICH ARISE DIRECTLY OR INDIRECTLY, IN WHOLE OR

IN PART, DUE TO THE INSTALLATION OF ANY MODIFIED PART AND/OR PART RECEIVED

FROM AN UNAUTHORIZED SERVICE CENTER.

NOTICE

This appliance is intended for professional use only and is to be operated by qualified

personnel only. A Frymaster Dean Factory Authorized Service Center (FASC) or other

qualified professional should perform installation, maintenance, and repairs. Installation,

maintenance, or repairs by unqualified personnel may void the manufacturer’s warranty.

See Chapter 1 of this manual for definitions of qualified personnel.

NOTICE

This equipment must be installed in accordance with the appropriate national and local

codes of the country and/or region in which the appliance is installed. See NATIONAL

CODE REQUIREMENTS in Chapter 2 of this manual for specifics.

NOTICE TO U.S. CUSTOMERS

This equipment is to be installed in compliance with the basic plumbing code of the

Building Officials and Code Administrators International, Inc. (BOCA) and the Food Service

Sanitation Manual of the U.S. Food and Drug Administration.

NOTICE

Drawings and photos used in this manual are intended to illustrate operational, cleaning

and technical procedures and may not conform to onsite management operational

procedures.

NOTICE TO OWNERS OF UNITS EQUIPPED WITH COMPUTERS

U.S.

This device complies with Part 15 of the FCC rules. Operation is subject to the following

two conditions: 1) This device may not cause harmful interference, and 2) This device must

accept any interference received, including interference that may cause undesired

operation. While this device is a verified Class A device, it has been shown to meet the

Class B limits.

CANADA

This digital apparatus does not exceed the Class A or B limits for radio noise emissions as

set out by the ICES-003 standard of the Canadian Department of Communications.

Cet appareil numerique n’emet pas de bruits radioelectriques depassany les limites de

classe A et B prescrites dans la norme NMB-003 edictee par le Ministre des Communcations

du Canada.

Page 3

DANGER

Improper installation, adjustment, maintenance or service, and unauthorized alterations or

modifications can cause property damage, injury, or death. Read the installation, operating,

and service instructions thoroughly before installing or servicing this equipment.

DANGER

The front ledge of this appliance is not a step! Do not stand on the appliance. Serious

injury can result from slips or contact with the hot oil.

DANGER

Do not store or use gasoline or other flammable liquids or vapors in the vicinity of this or

any other appliance.

DANGER

The crumb tray in fryers equipped with a filter system must be emptied into a fireproof

container at the end of frying operations each day. Some food particles can spontaneously

combust if left soaking in certain shortening material.

WARNING

Do not bang fry baskets or other utensils on the fryer’s joiner strip. The strip is present to

seal the joint between the fry vessels. Banging fry baskets on the strip to dislodge

shortening will distort the strip, adversely affecting its fit. It is designed for a tight fit and

should only be removed for cleaning.

DANGER

Adequate means must be provided to limit the movement of this appliance without

depending on or transmitting stress to the electrical conduit. A restraint kit is provided with

the fryer. If the restraint kit is missing contact your local KES.

DANGER

This fryer has a power cord (three-phase) for each frypot and a single five-wire cord for the

entire system. Prior to movement, testing, maintenance and any repair on your Frymaster

fryer; disconnect ALL electrical power cords from the electrical power supply.

DANGER

Keep all items out of drains. Closing actuators may cause damage or injury.

NOTICE

The instructions in this manual for using a bulk oil system for filling and discarding oil are

for an RTI system. These instructions may not be applicable to other bulk oil systems.

Page 4

LOV™ ELECTRIC WARRANTY STATEMENT

Frymaster, L.L.C. makes the following limited warranties to the original purchaser only for this

equipment and replacement parts:

A. WARRANTY PROVISIONS - FRYERS

1. Frymaster L.L.C. warrants all components against defects in material and workmanship for a

period of two years.

2. All parts, with the exception of the frypot, O-rings and fuses, are warranted for two years

after installation date of fryer.

3. If any parts, except fuses and filter O-rings, become defective during the first two years after

installation date, Frymaster will also pay straight-time labor costs up to two hours to replace

the part, plus up to 100 miles/160 km of travel (50 miles/80 km each way).

B. WARRANTY PROVISIONS - FRYPOTS

If a frypot develops a leak within ten years after installation, Frymaster will, at its option, either

replace the entire battery or replace the frypot, allowing up to the maximum time per the

Frymaster time allowance chart hours of straight-time labor. Components attached to the frypot,

such as the high-limit, probe, gaskets, seals, and related fasteners, are also covered by the tenyear warranty if replacement is necessitated by the frypot replacement. Leaks due to abuse or

from threaded fittings such as probes, sensors, high-limits, drain valves or return piping are not

included.

C. PARTS RETURN

All defective in-warranty parts must be returned to a Frymaster Authorized Factory Service

Center within 60 days for credit. After 60 days, no credit will be allowed.

D. WARRANTY EXCLUSIONS

This warranty does not cover equipment that has been damaged due to misuse, abuse, alteration,

or accident such as:

• improper or unauthorized repair (including any frypot which is welded in the field);

• failure to follow proper installation instructions and/or scheduled maintenance procedures as

prescribed in your MRC cards. Proof of scheduled maintenance is required to maintain the

warranty;

• improper maintenance;

• damage in shipment;

• abnormal use;

• removal, alteration, or obliteration of either the rating plate or the date code on the heating

elements;

i

Page 5

• operating the frypot without shortening or other liquid in the frypot;

• no fryer will be warranted under the ten-year program for which a proper start-up form has not

been received.

This warranty also does not cover:

• transportation or travel over 100 miles/160 km (50 miles/80 km each way), or travel over two

hours;

• overtime or holiday charges;

• consequential damages (the cost of repairing or replacing other property which is damaged), loss

of time, profits, use or any other incidental damages of any kind.

There are no implied warranties of merchantability or fitness for any particular use or purpose.

This warranty is applicable at the time of this printing and is subject to change.

ii

Page 6

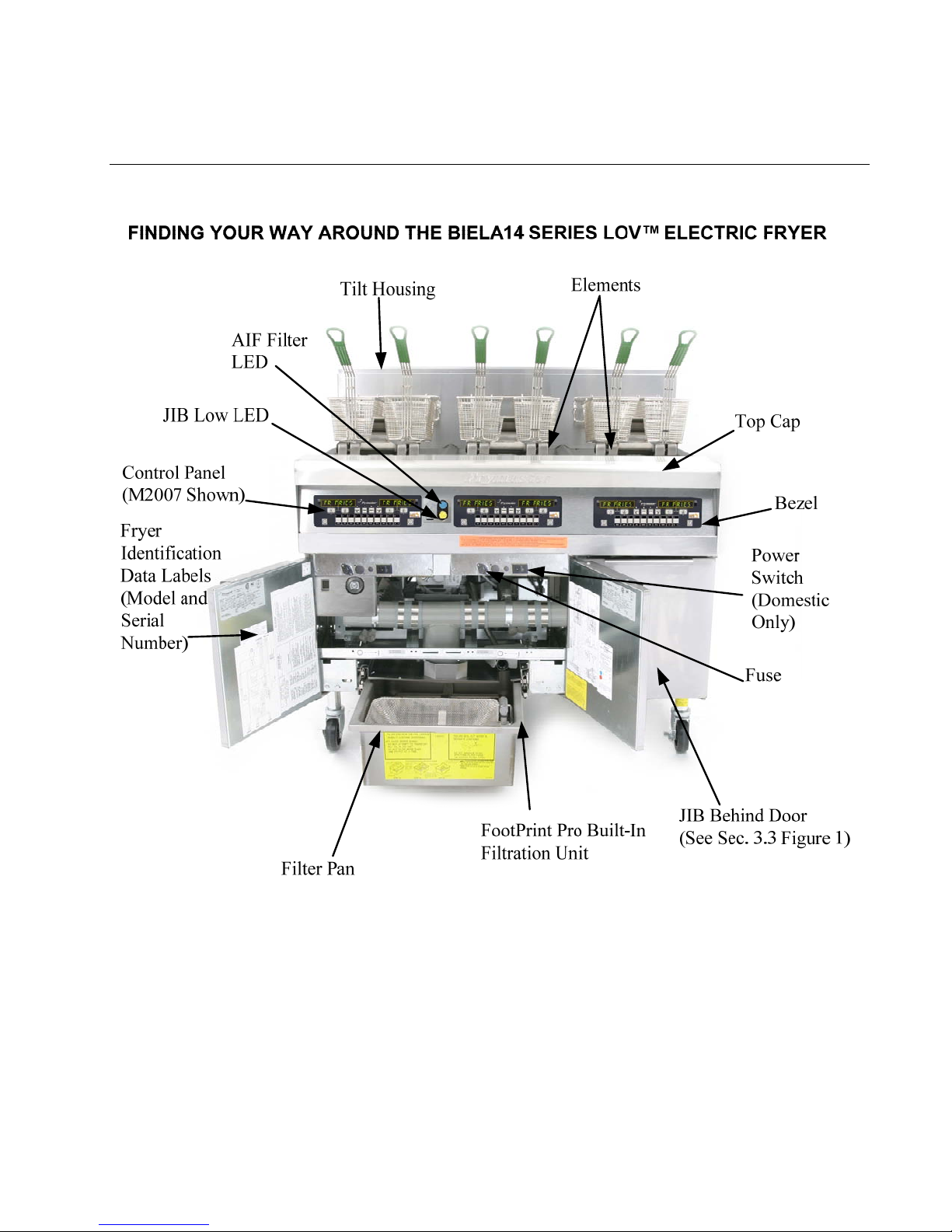

BIELA14 SERIES LOV™ ELECTRIC FRYER

CHAPTER 1: INTRODUCTION

NOTE: The Frymaster BIELA14 fryer requires a start-up, demonstration and training

before normal restaurant operations can begin.

1.1 General

Read the instructions in this manual thoroughly before attempting to operate this equipment. This

manual covers all configurations of McDonald’s BIELA14 LOV™ models. The fryers in this model

family have most parts in common, and when discussed as a group, will be referred to as “LOV™

fryers.

Although similar in appearance to the RE14 McDonald’s electric fryers, the BIELA14 fryers feature

a low oil volume frypot, automatic oil topoff and an automatic intermittent filtration unit. The EuroLook design incorporates a rounded topcap and a large round drain, which ensures that fries and

other debris, will be washed into the filter pan. The BIELA14 LOV™ fryers are controlled with an

M2007 computer. Fryers in this series come in full- or split-vat arrangements, and can be purchased

in batteries of up to five fryers.

1.2 Safety Information

Before attempting to operate your unit, read the instructions in this manual thoroughly.

Throughout this manual, you will find notations enclosed in double-bordered boxes similar to the

one below.

DANGER

Hot oil causes severe burns. Never attempt to move a fryer containing hot oil or to

transfer hot oil from one container to another.

CAUTION boxes contain information about actions or conditions that may cause or result in a

malfunction of your system.

WARNING boxes contain information about actions or conditions that may cause or result in

damage to your system, and which may cause your system to malfunction.

DANGER boxes contain information about actions or conditions that may cause or result in

injury to personnel, and which may cause damage to your system and/or cause your system to

malfunction.

Fryers in this series are equipped with the following automatic safety features:

1. Two high-temperature detection features shut off power to the elements should the temperature

controls fail.

2. A safety circuit on units with filter systems prevents the elements from heating with the drain

valve open.

1-1

Page 7

1.3 Computer Information for the M2007 Computers

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC rules. While this device is a verified Class A device, it has been

shown to meet the Class B limits. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in accordance

with the instruction manual, may cause harmful interference to radio communications. Operation of

the equipment in a residential area is likely to cause harmful interference in which case the user will

be required to correct the interference at their own expense.

The user is cautioned that any changes or modifications not expressly approved by the party

responsible for compliance could void the user's authority to operate the equipment.

If necessary, the user should consult the dealer or an experienced radio and television technician for

additional suggestions.

The user may find the following booklet prepared by the Federal Communications Commission

helpful: "How to Identify and Resolve Radio-TV Interference Problems". This booklet is available

from the U.S. Government Printing Office, Washington, DC 20402, Stock No. 004-000-00345-4.

1.4 European Community (CE) Specific Information

The European Community (CE) has established certain specific standards regarding equipment of

this type. Whenever a difference exists between CE and non-CE standards, the information or

instructions concerned are identified by means of shadowed boxes similar to the one below.

CE Standard

Example of box used to distinguish CE and

Non-CE specific information.

1.5 Installation, Operating, and Service Personnel

Operating information for Frymaster equipment has been prepared for use by qualified and/or

authorized personnel only, as defined in Section 1.6. All installation and service on Frymaster

equipment must be performed by qualified, certified, licensed, and/or authorized installation

or service personnel, as defined in Section 1.6.

1.6 Definitions

QUALIFIED AND/OR AUTHORIZED OPERATING PERSONNEL

Qualified/authorized operating personnel are those who have carefully read the information in this

manual and have familiarized themselves with the equipment functions, or who have had previous

experience with the operation of the equipment covered in this manual.

1-2

Page 8

QUALIFIED INSTALLATION PERSONNEL

Qualified installation personnel are individuals, firms, corporations, and/or companies which, either

in person or through a representative, are engaged in and are responsible for the installation of

electrical appliances. Qualified personnel must be experienced in such work, be familiar with all

electrical precautions involved, and have complied with all requirements of applicable national and

local codes.

QUALIFIED SERVICE PERSONNEL

Qualified service personnel are those who are familiar with Frymaster equipment and who have been

authorized by Frymaster, L.L.C. to perform service on the equipment. All authorized service

personnel are required to be equipped with a complete set of service and parts manuals, and to stock

a minimum amount of parts for Frymaster equipment. A list of Frymaster Dean Factory Authorized

Service Centers (FASC) is included with the fryer when shipped from the factory. Failure to use

qualified service personnel will void the Frymaster warranty on your equipment

1.7 Shipping Damage Claim Procedure

What to do if your equipment arrives damaged:

Please note that this equipment was carefully inspected and packed by skilled personnel before

leaving the factory. The freight company assumes full responsibility for safe delivery upon

acceptance of the equipment.

1. File Claim for Damages Immediately - regardless of extent of damage.

2. Inspect For and Record All Visible Loss or Damage, and ensure that this information is noted

on the freight bill or express receipt and is signed by the person making the delivery.

3. Concealed Loss or Damage- If damage is unnoticed until equipment is unpacked, notify the

freight company or carrier immediately upon discovery and file a concealed damage claim.

This must be submitted within 15 days of date of delivery. Be sure to retain container for

inspection.

Frymaster

DOES NOT ASSUME RESPONSIBILITY FOR DAMAGE OR LOSS

INCURRED IN TRANSIT.

1-3

Page 9

1.8 Service Information

For non-routine maintenance or repairs, or for service information, contact your local Frymaster

Dean Authorized Service Center (FASC). In order to assist you quickly, the Frymaster Dean

Factory Authorized Service Center (FASC) or Service Department representative requires certain

information about your equipment. Most of this information is printed on a data plate affixed to the

inside of the fryer door. Part numbers are found in the Service and Parts Manual. Parts orders may

be placed directly with your local FASC or distributor. Included with fryers when shipped from the

factory is a list of Frymaster Dean FASCs. If you do not have access to this list, contact the

Frymaster Dean Service Department at 1-800-551-8633 or 1-318-865-1711 or by email at

service@frymaster.com.

The following information will be needed in order to assist you efficiently:

Model Number _________________________

Serial Number__________________________

Voltage _______________________________

Nature of the Problem____________________

_____________________________________

_____________________________________

RETAIN AND STORE THIS MANUAL IN A SAFE PLACE FOR FUTURE USE.

1-4

Page 10

BIELA14 SERIES LOV™ ELECTRIC FRYER

CHAPTER 2: INSTALLATION INSTRUCTIONS

2.1 General Installation Requirements

Proper installation is essential for the safe, efficient, trouble-free operation of this appliance.

Qualified, licensed, and/or authorized installation or service personnel, as defined in Section

1.6 of this manual, should perform all installation and service on Frymaster Dean equipment.

Failure to use qualified, licensed, and/or authorized installation or service personnel (as

defined in Section 1.6 of this manual) to install or otherwise service this equipment will void

the Frymaster warranty and may result in damage to the equipment or injury to personnel.

Where conflicts exist between instructions and information in this manual and local or

national codes or regulations, installation and operation shall comply with the codes or

regulations in force in the country in which the equipment is installed.

Service may be obtained by contacting your local Frymaster Dean Factory Authorized Service

Center.

NOTICE

All fryers shipped without factory supplied cords and plug assemblies must be

hardwired using flexible conduit to the terminal block located on the rear of the fryer.

These fryers should be wired to NEC specifications. Hardwired units must include

installation of restraint devices.

DANGER

Adequate means must be provided to limit the movement of this appliance without

depending on or transmitting stress to the electrical conduit. A restraint kit is

provided with the fryer. If the restraint kit is missing contact your local Frymaster

Dean Factory Authorized Service Center (FASC).

NOTICE

If this equipment is wired directly into the electrical power supply, a means for

disconnection from the supply having a contact separation of at least 3-mm in all

poles must be incorporated in the fixed wiring.

NOTICE

This equipment must be positioned so that the plug is accessible unless other

means for disconnection from the power supply (e.g., a circuit breaker) is provided.

NOTICE

If this appliance is permanently connected to fixed wiring, it must be connected by

means of copper wires having a temperature rating of not less than 167°F (75°C).

2-1

Page 11

NOTICE

If the electrical power supply cord is damaged, it must be replaced by a Frymaster

Dean Factory Authorized Service Center technician or a similarly qualified person in

order to avoid a hazard.

DANGER

This appliance must be connected to a power supply having the same voltage and

phase as specified on the rating plate located on the inside of the appliance door.

DANGER

All wiring connections for this appliance must be made in accordance with the

wiring diagram(s) furnished with the appliance. Refer to the wiring diagram(s)

affixed to the inside of the appliance door when installing or servicing this

equipment.

DANGER

Frymaster Dean appliances equipped with legs are for stationary installations.

Appliances fitted with legs must be lifted during movement to avoid damage to the

appliance and bodily injury. For movable installations, optional equipment casters

must be used. Questions? Call 1-800-551-8633.

DANGER

Do not attach an apron drainboard to a single fryer. The fryer may become unstable,

tip over, and cause injury. The appliance area must be kept free and clear of

combustible material at all times.

DANGER

Building codes prohibit a fryer with its open tank of hot oil being installed beside an

open flame of any type, including those of broilers and ranges.

In the event of a power failure, the fryer(s) will automatically shut down. If this occurs, turn the

power switch OFF. Do not attempt to start the fryer(s) until power is restored.

This appliance must be kept free and clear of combustible material, except that it may be installed on

combustible floors.

A clearance of 6 inches (15cm) must be provided at both sides and back adjacent to combustible

construction. A minimum of 24 inches (61cm) should be provided at the front of the equipment for

servicing and proper operation.

WARNING

Do not block the area around the base or under the fryers.

2.1.2 Electrical Grounding Requirements

All electrically operated appliances must be grounded in accordance with all applicable national and

local codes, and, where applicable, CE codes. All units (cord connected or permanently connected)

should be connected to a grounded power supply system. A wiring diagram is located on the inside

of the fryer door. Refer to the rating plate on the inside of the fryer door for proper voltages.

2-2

Page 12

WARNING

To ensure the safe and efficient operation of the fryer and hood, the electrical plug

for the 120-volt line, which powers the hood, must be fully engaged and locked in its

pin and sleeve socket.

2.1.3 Australian Requirements

To be installed in accordance with AS 5601 / AG 601, local authority, gas, electricity, and any other

relevant statutory regulations.

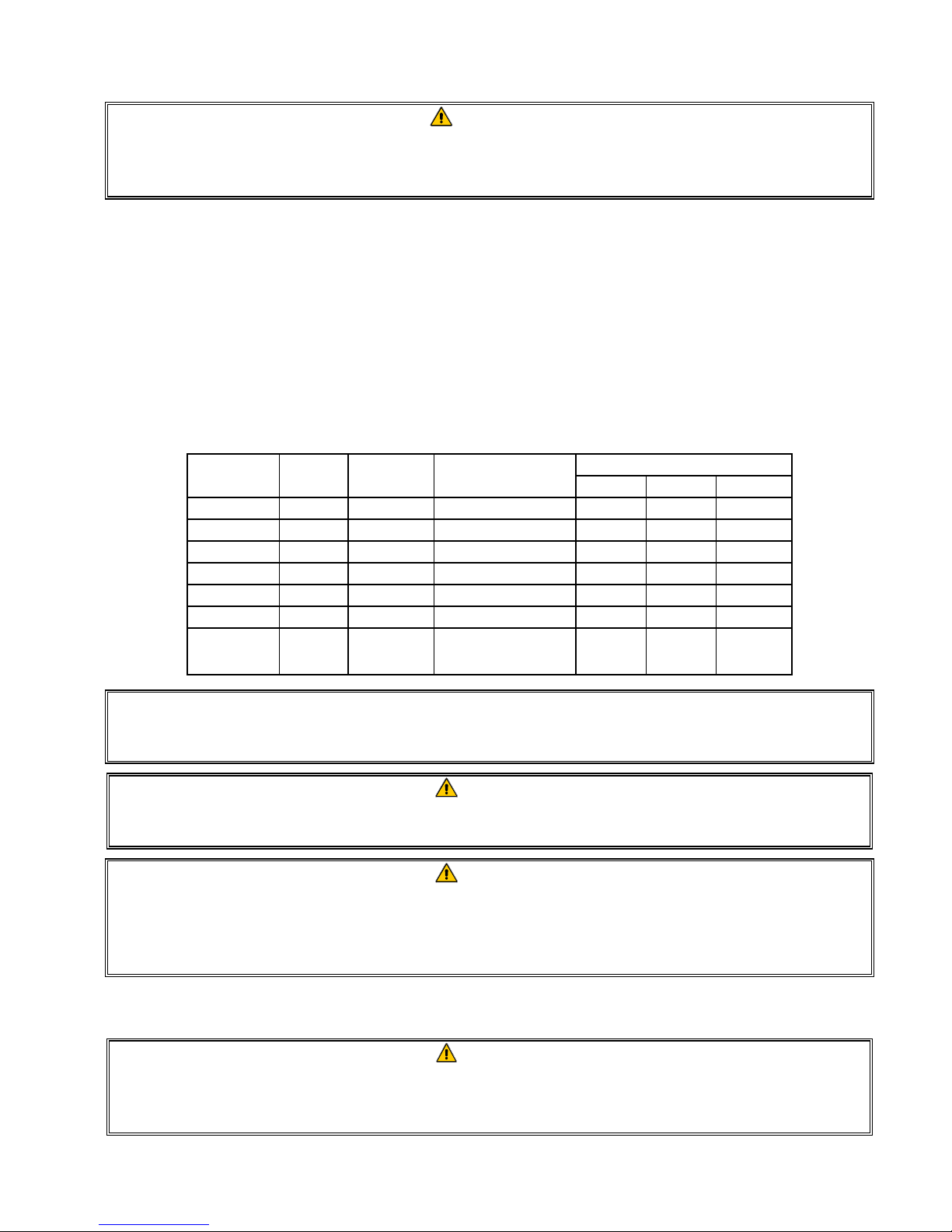

2.2 Power Requirements

The three phase supply plug for the elements is rated at 60 amps, 250 VAC and is NEMA

configuration L15-60P. The control and filter plug is rated at 20 amps, 120/208 VAC and is NEMA

configuration L21-20P. Each fryer should have its cord for the element supply on an individual

circuit as well as the control cord.

WIRE

VOLTAGE PHASE

208 3 3 6 (16) 39 39 39

240 3 3 6 (16) 34 34 34

480 3 3 8 (10) 17 17 17

220/380 3 4 6 (16) 21 21 21

240/415 3 4 6 (16) 20 20 21

230/400 3 4 6 (16) 21 21 21

230/400

France Only

3 4 6 (16) 25 25 25

SERVICE

MIN.

SIZE

AWG

(mm

2

)

AMPS PER LEG

L1 L2 L3

NOTICE

If this appliance is permanently connected to fixed wiring, it must be connected by

means of copper wires having a temperature rating of not less than 167°F (75°C).

DANGER

This appliance must be connected to a power supply having the same voltage and

phase as specified on the rating plate located on the inside of the appliance door.

DANGER

All wiring connections for this appliance must be made in accordance with the

wiring diagram(s) furnished with the appliance. Refer to the wiring diagram(s)

affixed to the inside of the appliance door when installing or servicing this

equipment.

2.3 After Fryers Are Positioned At the Frying Station

DANGER

No structural material on the fryer should be altered or removed to accommodate

placement of the fryer under a hood. Questions? Call the Frymaster Dean Service

Hotline at 1-800-551-8633.

2-3

Page 13

1. Once the fryer has been positioned at the frying station, use a carpenter’s level placed across the

top of the frypot to verify that the unit is level, both side-to-side and front-to-back.

To level fryers, adjust the casters being careful to ensure the fryer(s) are at the proper height in

the frying station.

When the fryer is leveled in its final position, install the restraints provided by the KES to limit

its movement so that it does not depend on or transmit stress to the electrical conduit or

connection. Install the restraints in accordance with the provided instructions. If the restraints are

disconnected for service or other reasons, they must be reconnected before the fryer is used.

DANGER

Adequate means must be provided to limit the movement of this appliance without

depending on or transmitting stress to the electrical conduit. A restraint kit is

provided with the fryer. If the restraint kit is missing contact your local Frymaster

Dean Factory Authorized Service Center (FASC).

DANGER

Hot oil can cause severe burns. Avoid contact. Under all circumstances, oil must be

removed from the fryer before attempting to move it to avoid spills, falls, and severe

burns. Fryers may tip and cause personal injury if not secured in a stationary

position.

2. Close fryer drain-valve(s) and fill frypot with water to the bottom oil level line.

3. Deep Clean (Boil-out) frypot(s) in accordance with the instructions on page 4-27 of this manual.

4. Drain, clean, and fill frypot(s) with cooking oil. (See Equipment Setup and Shutdown

Procedures in Chapter 3.)

2-4

Page 14

BIELA14 SERIES LOV™ ELECTRIC FRYER

CHAPTER 3: OPERATING INSTRUCTIONS

TYPICAL CONFIGURATION (BIELA314 SHOWN)

NOTE: The appearance of your fryer may differ slightly from that

shown depending upon configuration and date of manufacture.

3–1

Page 15

3.1 Equipment Setup and Shutdown Procedures

Setup

DANGER

Never operate the appliance with an empty frypot. The frypot must be filled to the fill line

with water or oil before energizing the elements. Failure to do so will result in irreparable

damage to the elements and may cause a fire.

DANGER

Remove all drops of water from the frypot before filling with oil. Failure to do so will cause

spattering of hot liquid when the oil is heated to cooking temperature.

WARNING

The BIELA14 is not intended to use solid shortening. Use only liquid shortening with this

fryer. The use of solid shortening will clog the oil lines. The oil capacity of the BIELA14

fryer is 31 lbs. (3.7 gallons/14 liters) for a full-vat and 15.5 lbs. (2.5 gallons/7 liters) for a dualvat at 70°F (21°C).

Prior to filling frypots with oil, press the reset button to ensure all drains are closed.

1. Fill the frypot with cooking oil to the bottom OIL LEVEL line located on the rear of the frypot. This will

allow for oil expansion as heat is applied. Do not fill cold oil any higher than the bottom line; overflow

may occur as heat expands the oil.

2. Ensure that the power cord(s) is/are plugged into the appropriate receptacle(s). Verify that the face of the

plug is flush with the outlet plate, with no portion of the prongs visible.

3. Ensure that the power is switched on. Some models are equipped with a master switch located behind the

fryer door cabinet on the front panel of the component box, next to the fuse. This switch MUST

be

switched on prior to switching on the computers.

4. Ensure that the computer is switched ON.

5. Ensure that the oil level is at the top OIL LEVEL line when the oil is at its cooking temperature.

Shutdown

1. Turn the fryer off.

2. Filter the oil and clean the fryers (See Chapters 5 and 6).

3. Place the frypot covers on the frypots.

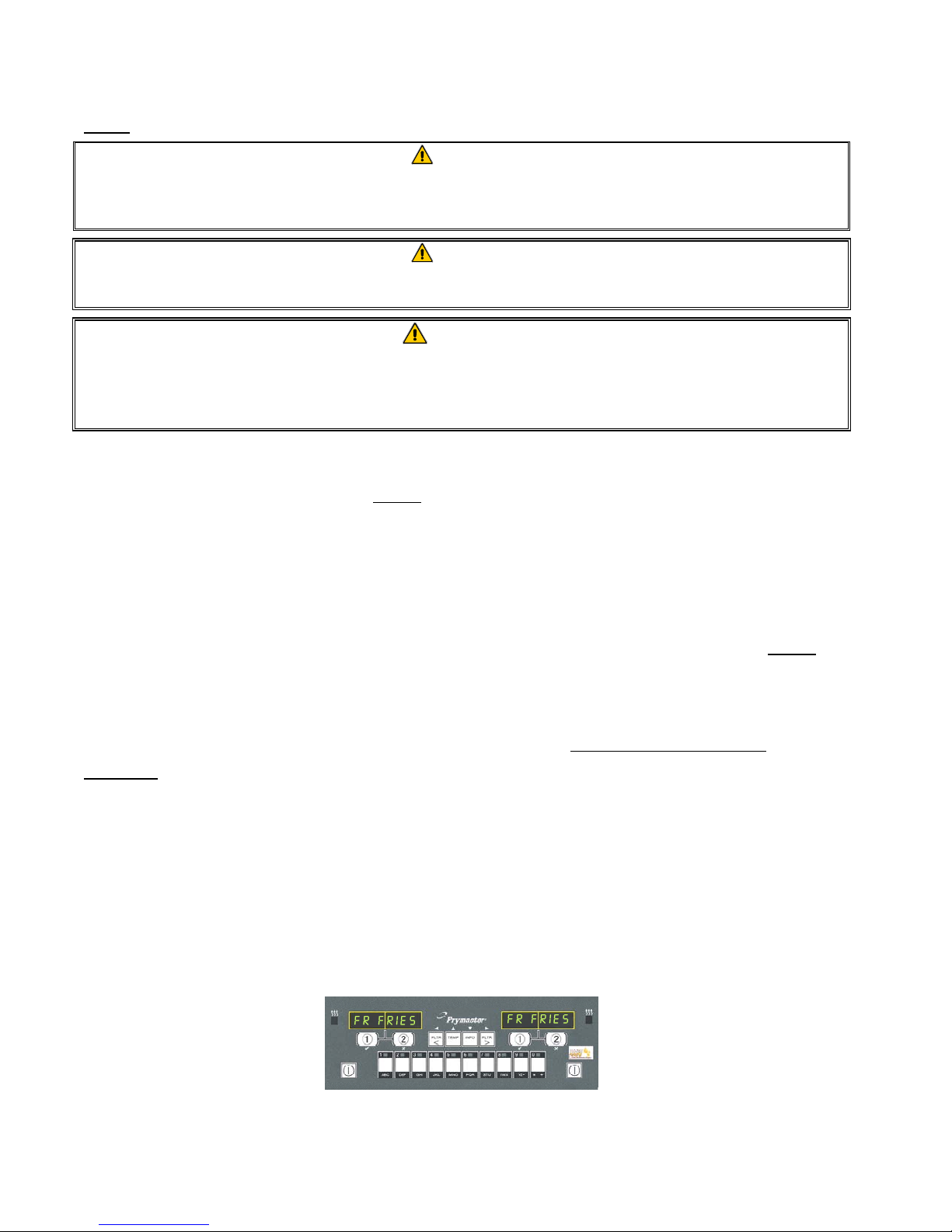

3.2 Operation

If this is the first time the fryer is being used, refer to the frypot deep clean (boil-out) procedure on Page 4-

27.

This fryer is equipped with M2007 computers (illustrated below). Refer to the M2007 Computer Operating

Instructions in Chapter 4 for the computer programming and operating procedures.

Refer to Chapter 5 of this manual for operating instructions for the built-in filtration system.

M2007 COMPUTER

3–2

Page 16

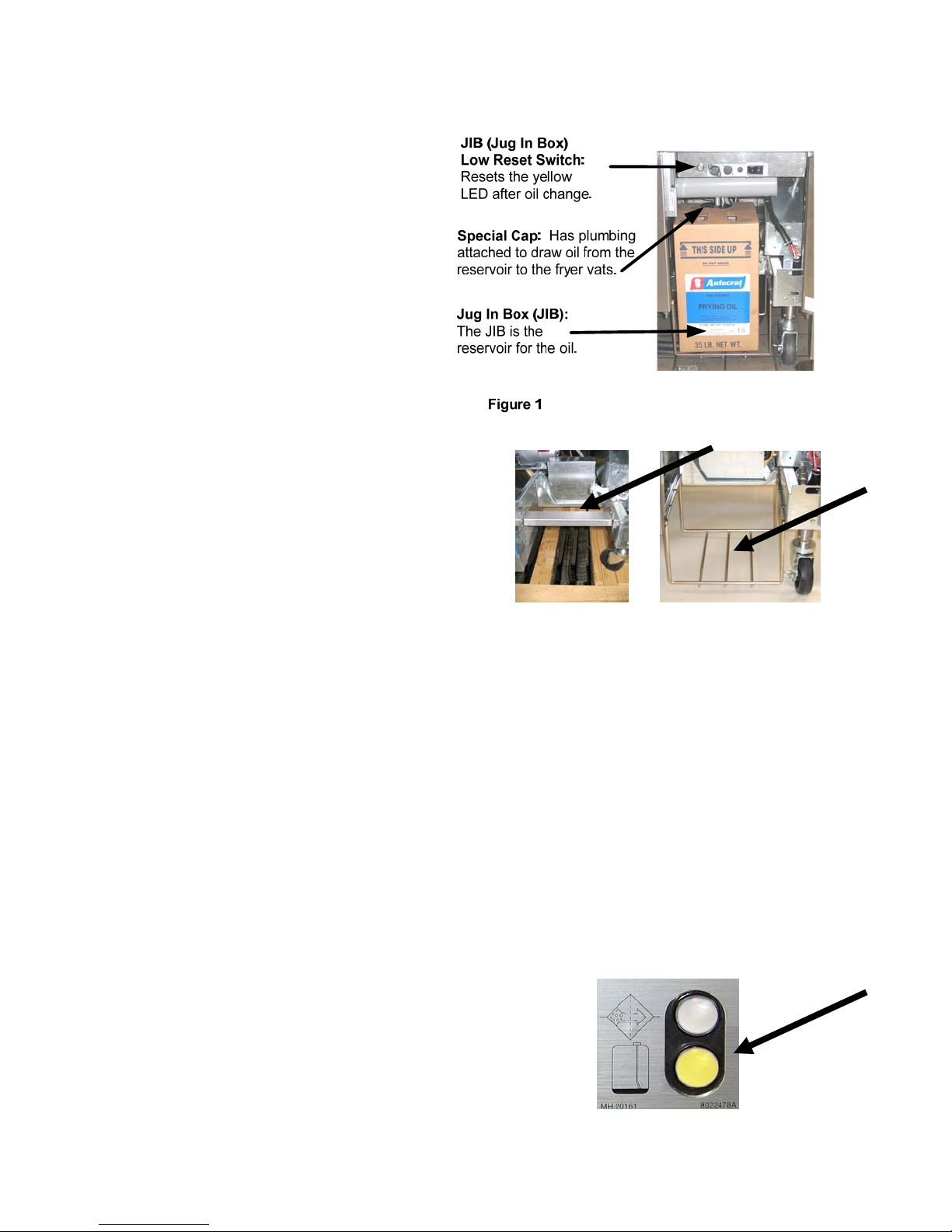

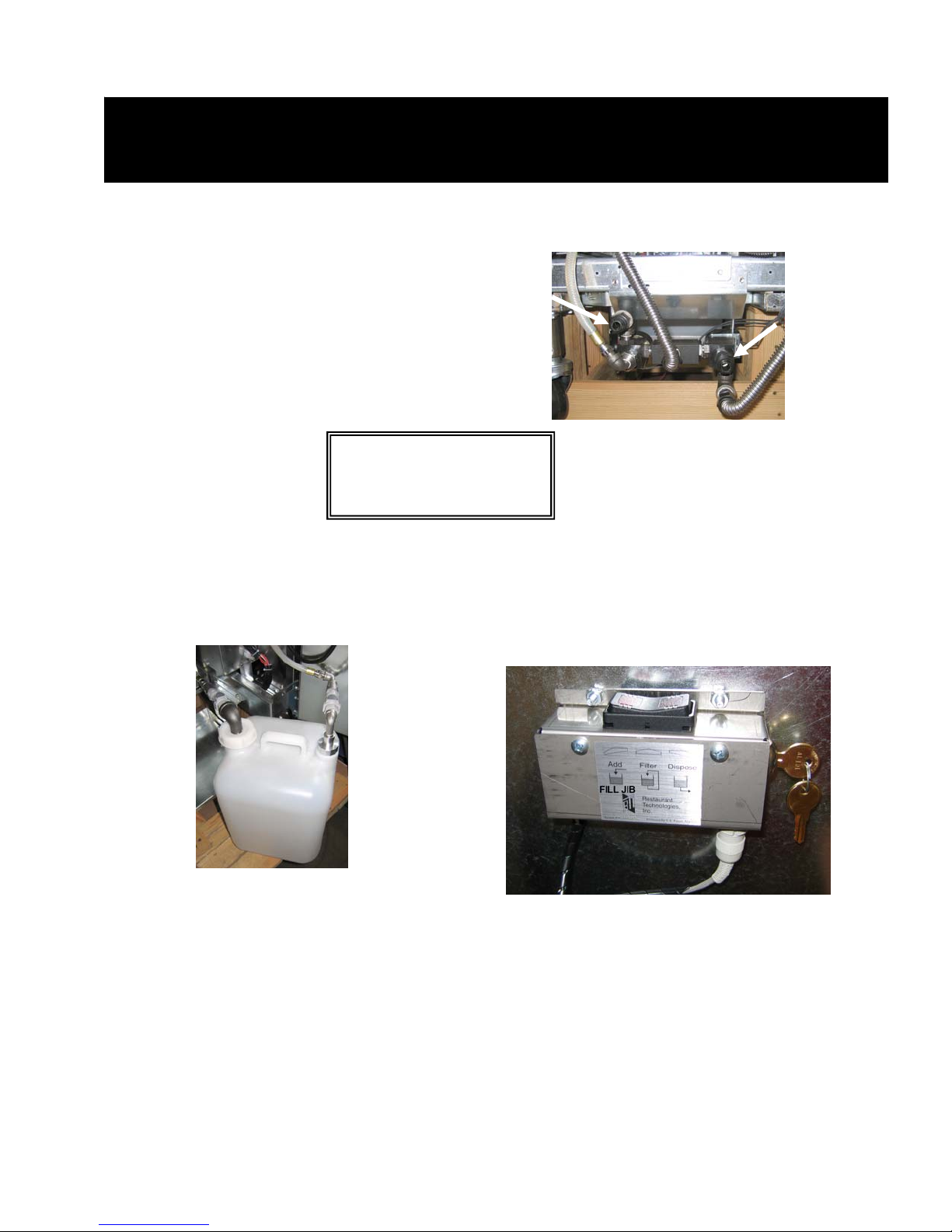

3.3 Low Oil Volume Automatic Refill

When the optional Low Oil Volume

(LOV™) system is in place on the fryer,

oil is continually topped off in the frypots

from a reservoir in the cabinet. The

reservoir holds a 35 pound box of oil. In a

typical operation this will last

approximately two days before changing.

Components of the system are annotated

at the right (see Figure 1).

NOTE: The system is intended to top

off the frypots, not fill them. The frypots

will require manual filling upon startup

and after deep clean (boil-out).

3.3.1 Prepare the System for Use

To prepare the system for its initial

operation, remove cross brace (see Figure

2). Do not replace the screws. Install the

JIB basket shipped in the accessories pack

(see Figure 3). Follow these instructions

to prepare the cabinet for the installation

Figure 2 Figure 3

of the first box of oil and subsequent

boxes of oil.

3.3.2 Install the Oil Reservoir

Remove the original lid from the oil container and foil liner. Replace with the provided cap, which has

connected suction hardware. Ensure the feeder tube from the cap reaches to the bottom of the oil

container.

Place the oil container inside the cabinet and slide it into place (as shown on the following page).

Avoid catching the suction hardware on the cabinet interior as the container is placed in the fryer.

The system is now ready for operation. As the fryer heats to preprogrammed temperatures, the system

will energize and then slowly add oil to the frypot as needed, until the oil reaches an optimal level.

3.3.3 Routine Oil Changes

When the oil reservoir level is low, a

yellow LED is activated (see Figure 4).

Once the reservoir is refilled and/or

replaced, pressing the reset button above

the JIB turns the LED off.

Figure 4

3–3

Page 17

1. Open the cabinet and slide the JIB

from the cabinet (see Figure 5).

2. Remove the cap and pour any remaining oil in the

container into all fry vats equally (see Figure 6).

Figure 5

3. With the jug upright remove the cap

and foil seal (see Figure 7).

Figure 7

WARNING:

Do not add HOT or

USED oil to a JIB.

Figure 6

4. Put the tube in the new full container (see Figure 8).

Figure 8

5. Slide the JIB onto the shelf inside the fryer cabinet (as

seen in Figure 5).

6. Press the JIB reset switch to turn the yellow JIB LED

off (see Figure 9).

Figure 9

3–4

Page 18

NOTE: The instructions in this manual for using a bulk oil system for filling and discarding

oil are for an RTI system. These instructions may not be applicable to other bulk oil

systems.

3.3.4 Bulk Oil Systems

Bulk oil systems have large oil storage

tanks, typically located in the rear of the

restaurant, that are connected to a rear

manifold on the fryer. Waste oil is

Fresh Oil

Connection

Waste Oil

Connection

pumped from the fryer, via the fitting

located on the right, to the disposal tanks

and fresh oil is pumped from the tanks,

thru the fitting located on the left, to the

fryer (see Figure 10).

WARNING:

Do not add HOT or

USED oil to a JIB.

Figure 10

The LOV™ fryers, equipped for use with

bulk oil systems, have an onboard fresh

oil jug with two fittings. The rear one is

for filling the jug and the front for topping

off the frypot from the jug (see Figure 11).

A momentary switch, located inside the door adjacent to

the jug, allows the operator to fill the jug from the bulk oil

storage tank (see Figure 12).

To fill the tank press and hold the ADD button until the

jug is full then release.

Figure 11

Figure 12

3–5

Page 19

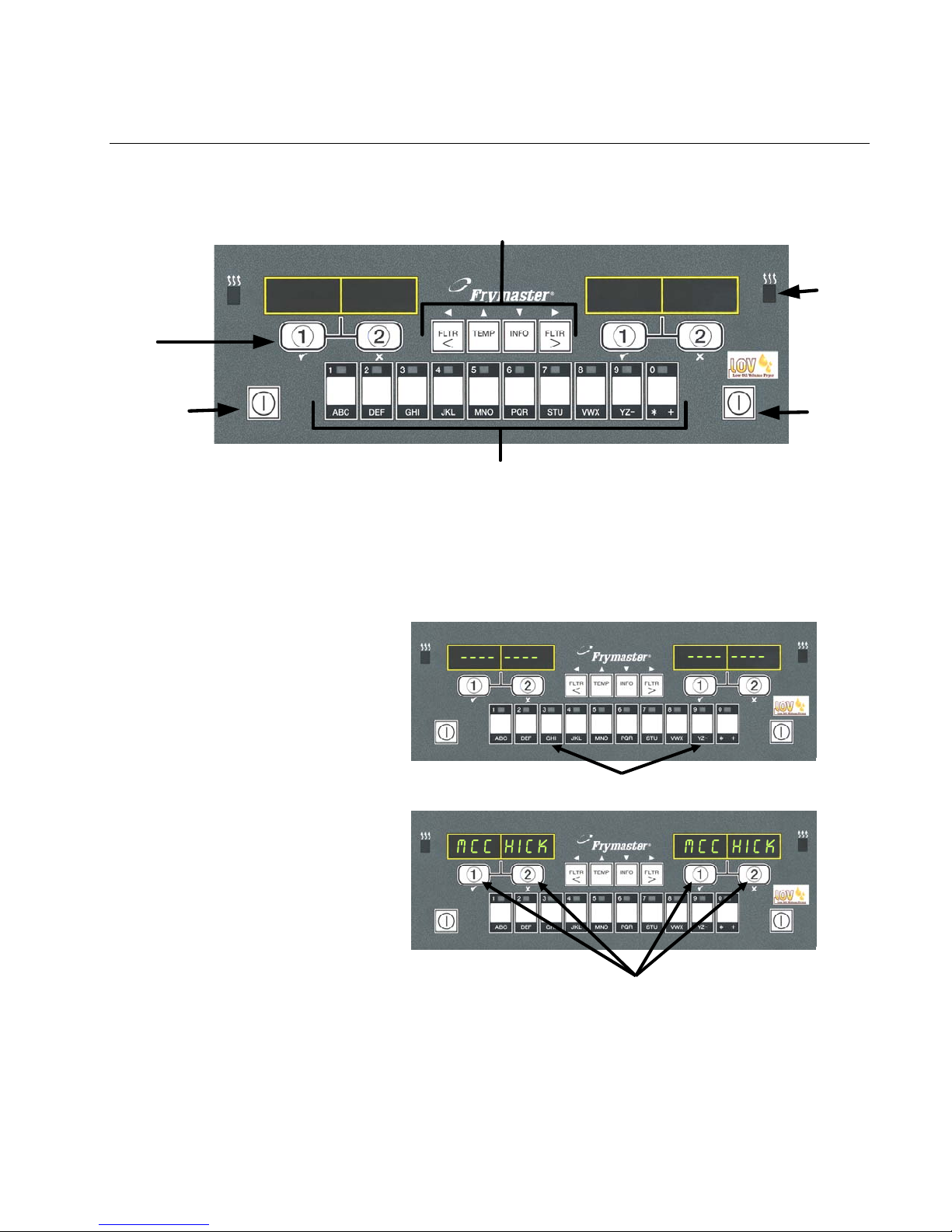

BIELA14 SERIES LOV™ ELECTRIC FRYER

ON/OFF

Cook Cycle

and

Selection

Buttons

ON/OFF

CHAPTER 4: M2007 COMPUTER INSTRUCTIONS

Filter, Temp, Info,

Programming and

Navigation Buttons

FR FRIES

Product Buttons

FR FRIES

4.1 M2007 General Information

Welcome to the M2007, a computer that retains the one-button ease of the M2000 and 100B and the

utility of 40-product menu capability. The computer is easy to use. One button push starts a cook

cycle for an item cooked in a dedicated vat. The same flexible computer on a multi-product vat

requires only two button pushes to

launch a cook cycle. Just choose a

menu item on a product buttons and

press, and then press a cook cycle

button under the display showing

the desired item. The computer can

move seamlessly from McNuggets

to Crispy Chicken to any added

menu item.

Pressing product buttons 3 or 9 displays McChick.

In a typical store setting, the

M2007s on the three-vat fry station

display FR FRIES (shown above)

and will launch a cook cycle with

one push of a cook channel button.

On the chicken/filet station, the

LED display shows dashed lines.

To launch a cook cycle, press a

product button and then press the

cook cycle button that corresponds

Pressing either cook cycle button under the McChick

displays launches a cook cycle.

with the location of the dropped

basket. By pressing the product button for McChicken, McChick will appear in the display. Just

press the cook cycle button corresponding to the location of the appropriate dropped basket.

The M2007 will operate with electric and gas fryers, both full- and split-vat.

Heat

Indicator

Lamp

4-1

Page 20

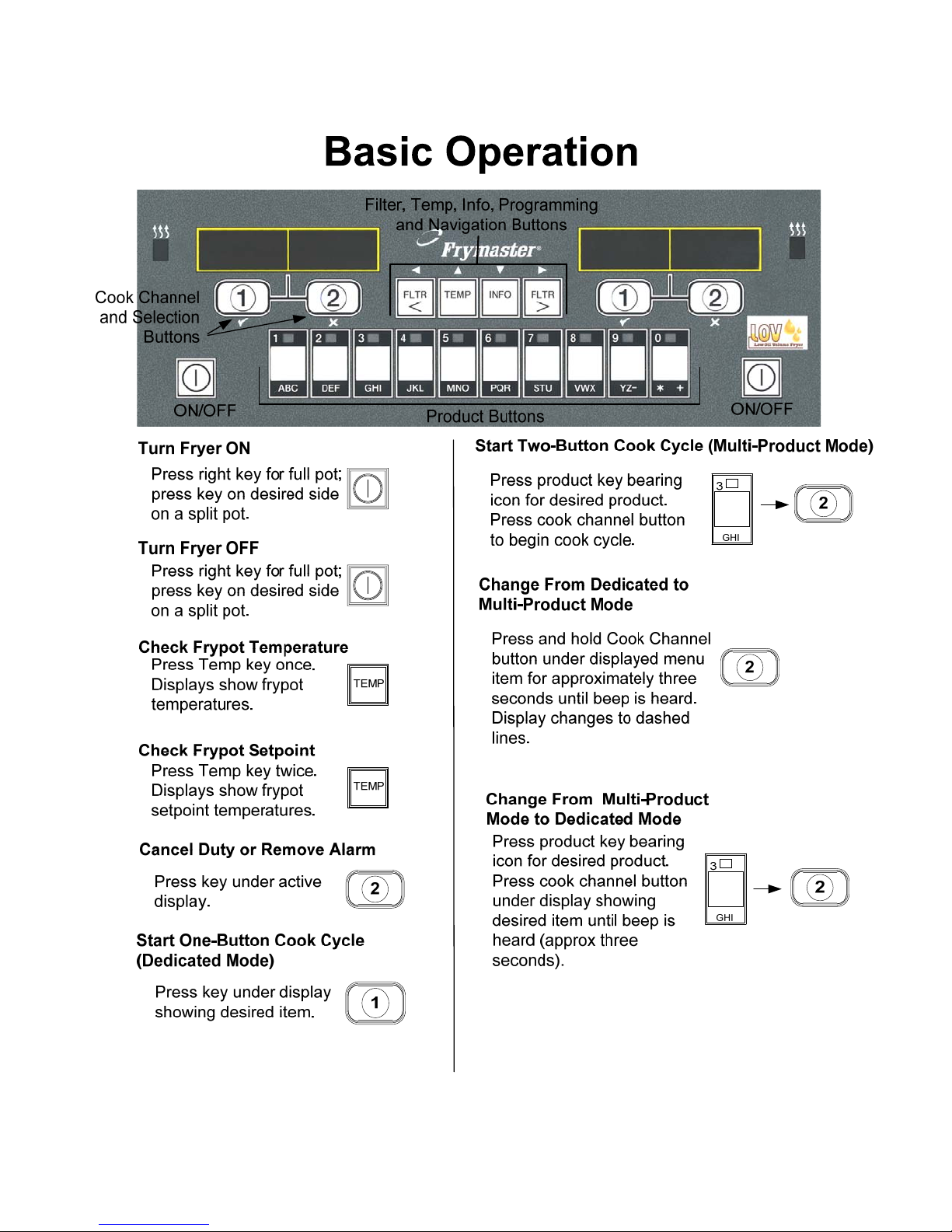

4.2 Basic Operation

4-2

Page 21

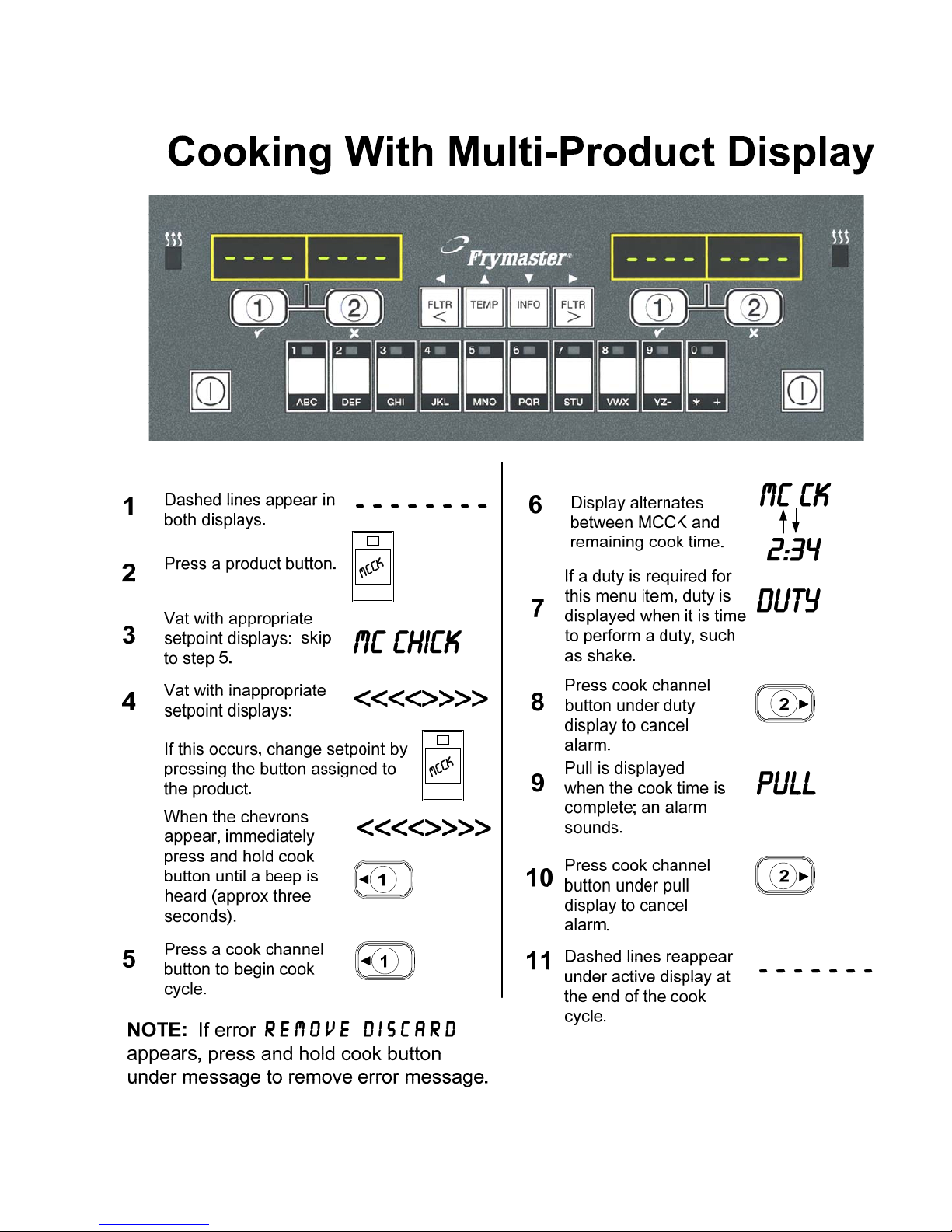

4.3 Cooking with Multi-Product Display

4-3

Page 22

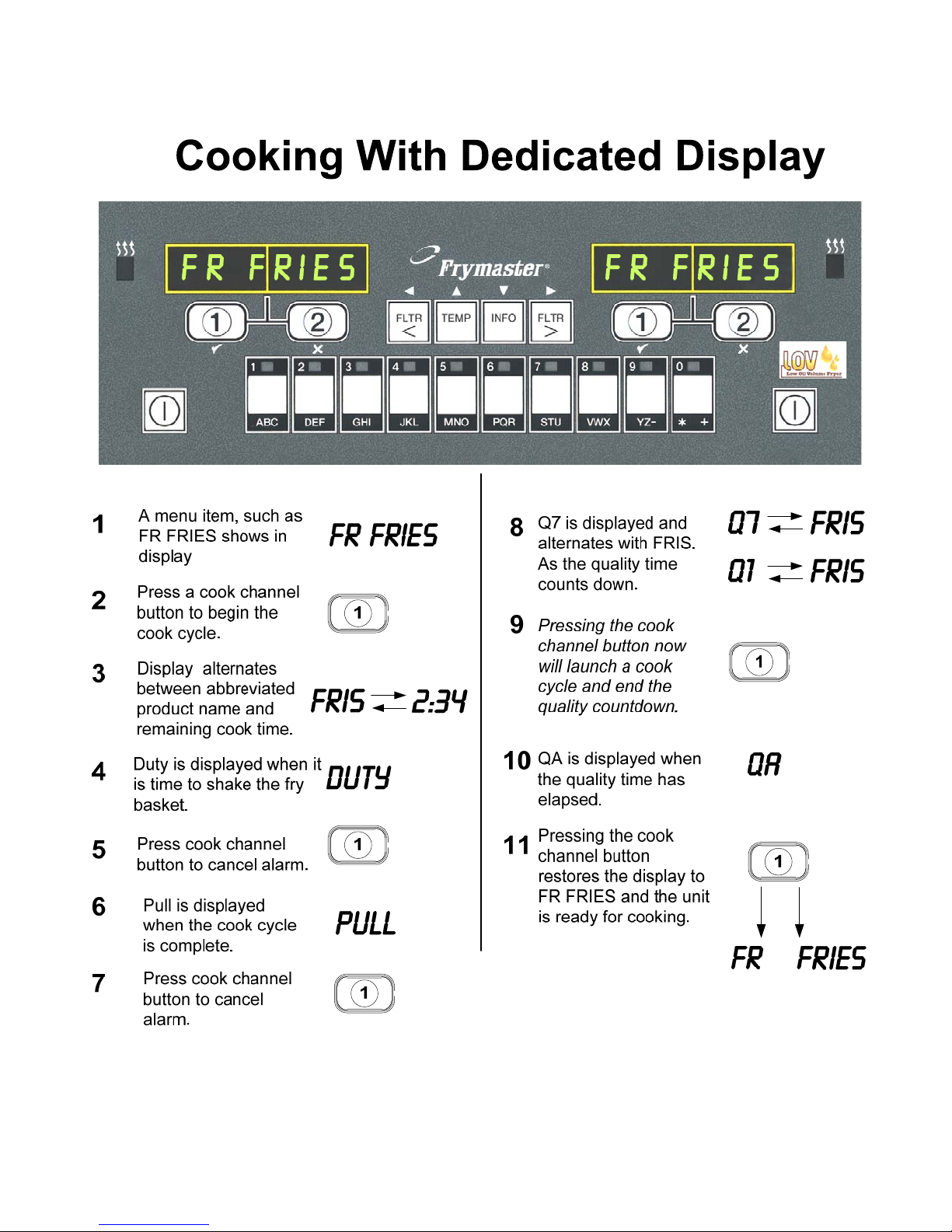

4.4 Cooking with Dedicated Display

4-4

Page 23

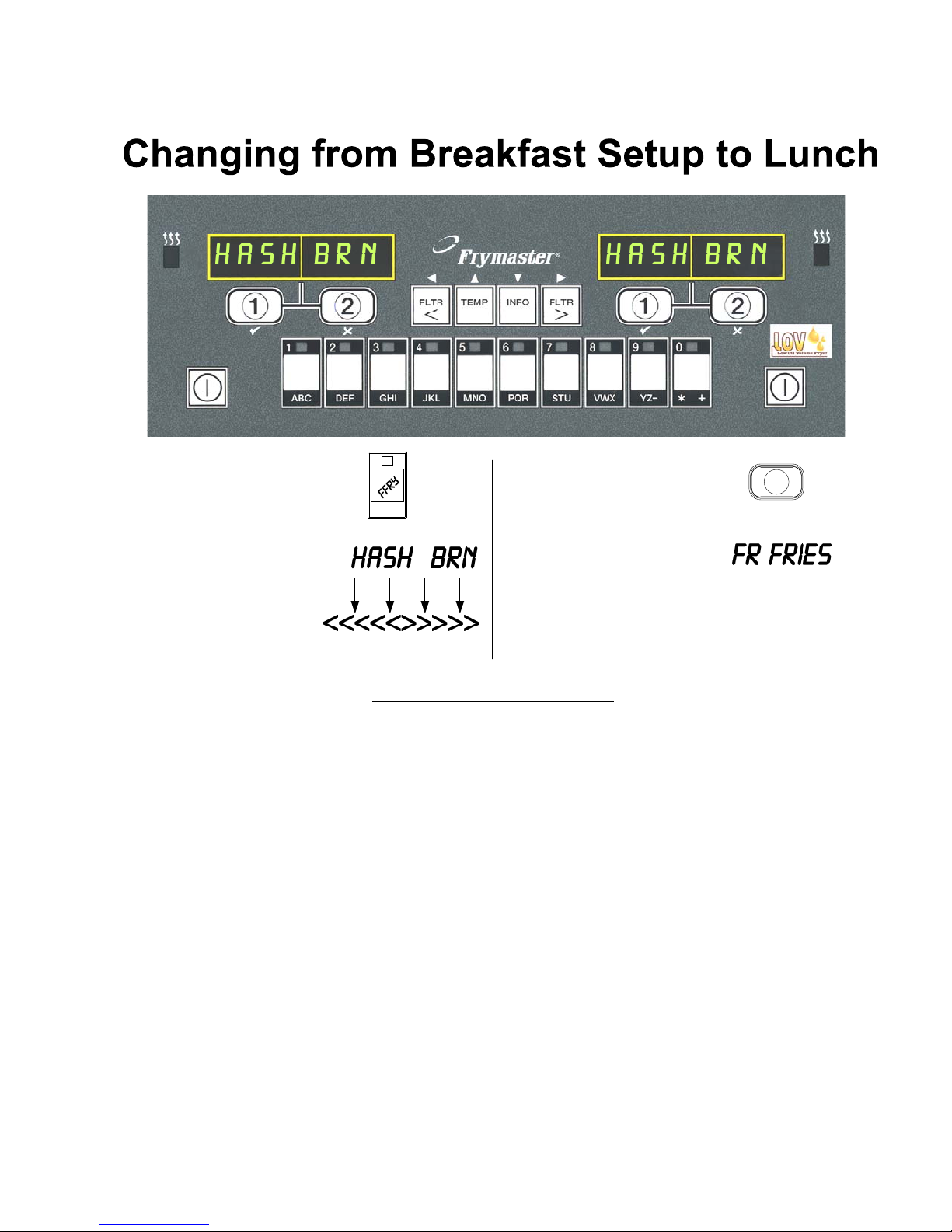

4.5 Changing from Breakfast Setup to Lunch

Press and quickly

1

release product button

for french fries.

Computer will change

from Hash Brn to

2

<<<<<>>>>>; an

alarm will sound.

1

ABC

Change both displays to FR FRIES

Press and hold the cook

3

channel button under the

display until a beep is heard.

Display changes to FR

4

Fries.

1

4-5

Page 24

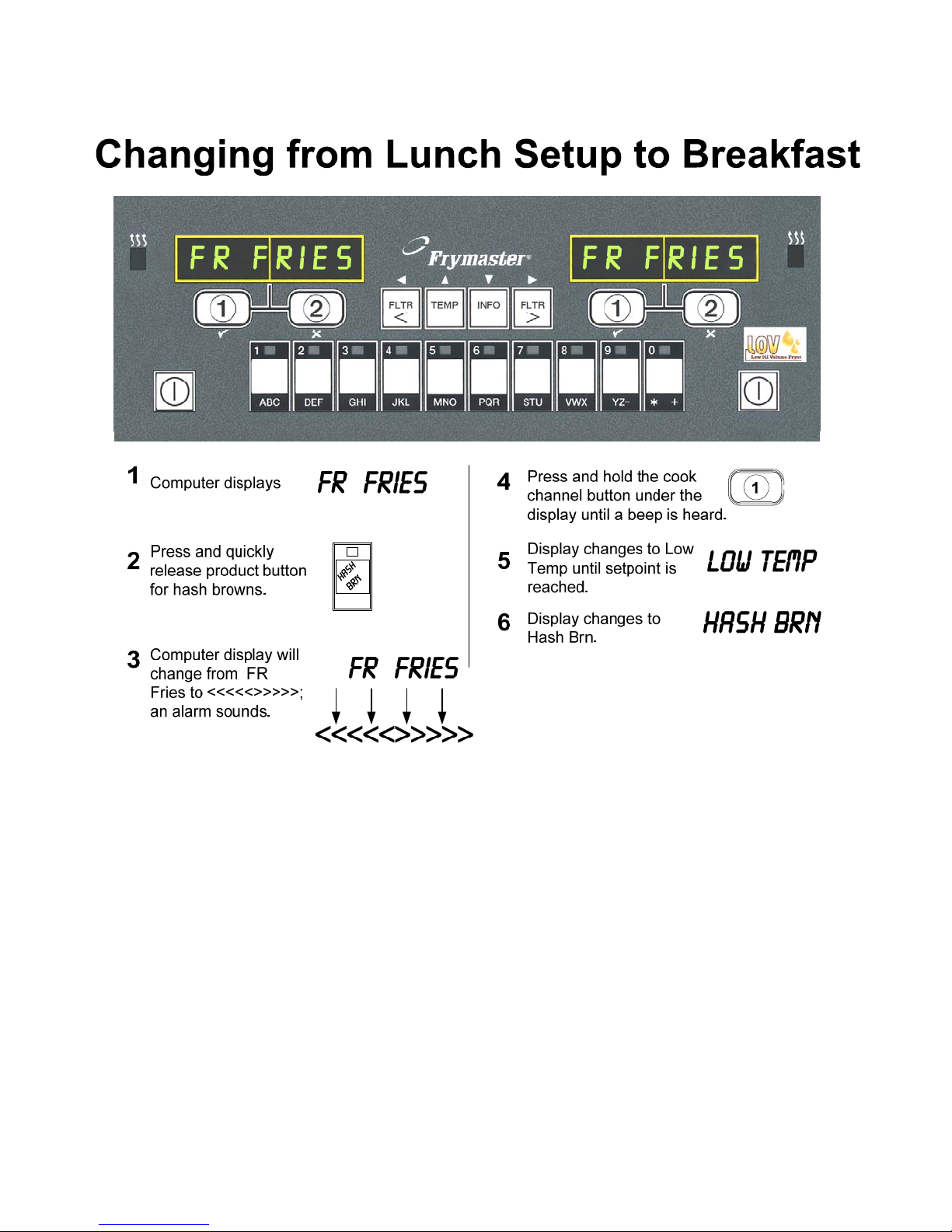

4.6 Changing from Lunch Setup to Breakfast

4-6

Page 25

4.7 M2007 Button Description and Functions

4.7.1 Navigation Buttons

The menu on the M2007 uses 34and tu buttons to

navigate the various menus and submenus (see Figure 1).

Figure 1

When programming, the left screen shows a menu or

submenu item. The right screen is for data entry. Data is

entered with alpha-numeric characters, scrolling through

lists or by toggling between choices (see Figure 2).

Left Display Right Display

Figure 2

During programming if a button is not pushed within one minute, the computer returns to operation

mode.

4.7.2 Filter, Temperature and Info Buttons

The < FLTR and FLTR > buttons (see Figure 1) are used to filter the left and right vats of a split

vat fryer on demand, while the right FLTR > button is used to filter a full vat on demand. The

FLTR buttons, if pressed once will display the amount of cook cycles remaining until a filtration

prompt. When the FLTR button is pressed twice, the date and time of the last filter will be

displayed. The TEMP button, if pressed once while the fryer is on, displays current vat

temperature on both sides. If the TEMP button is pressed twice while the fryer is on, it shows the

setpoint temperatures of the vats. If the fryer is off, the display shows the current versions of

software. The INFO button (see Figure 1), if pressed once when the fryer is on, shows the

recovery time for each vat from the last test. Recovery displays the time required for the fryer to

raise the temperature of the oil 50°F (28°C) between 250°F (121°C) and 300°F (149°C). Maximum

recovery time should not exceed 1:40 for electric or 2:25 for gas. If the INFO button is pressed and

held for three seconds it shows information such as usage, filter statistics and last cook cycles (see

page 4-38 for more details on the INFO button).

4.7.3 Cook Cycle and Selection Buttons

The

buttons are dual-function buttons shared with

the number 1 and 2 buttons. They are located directly

below the LED displays (see Figure 3). Use these buttons

to select or cancel functions. The button is used to back

out of and quit submenus.

Figure 3

4-7

Page 26

4.8 M2007 Menu Summary Tree

Reflected below are the major programming sections in the M2007 and the order in which submenu headings will be

found under the sections in the Installation and Operation Manual.

Adding New Product Menu Items See section 4.10.2

Storing Product Menu Items in Product Buttons See section 4.10.3

Draining, Refilling, and Disposing of Oil See section 4.10.4

Filter Menu

[Press and hold ◄ FLTR or FLTR ►]

Programming

………………………………………………………………………………………………………….. 4.11

Auto Filter

Maint Filter

Dispose

Drain to Pan

Fill Pot from Drain Pan

Fill Pot from Bulk

Level 1 Program

[Press and hold TEMP and INFO buttons, 2 beeps, displays Level 1, enter 1234]

Product Selection

…….……………….....………………………………………………………….. 4.12

..…….....………………………………………………………….. 4.12.1

Name

Cook Time

Temp

Cook ID

Duty Time 1

Duty Time 2

Qual Tmr

AIF Disable

Assign Btn

AIF Clock

..………………………………………………………………………………… 4.12.2

Disabled

Enabled

Deep Clean Mode

High-Limit Test

……..……………………...…………………………………….. 4.12.3

…………….…………………….…………………………………….. 4.12.4

High-Limit Test 1

High-Limit Test 2

Fryer Setup

…………………….……………………………………………………………….. 4.9

Level 2 Program (Manager Level)

[Press and hold TEMP and INFO buttons, 3 beeps, displays Level 2, enter 1234]

Prod Comp

E-Log

Passwords

Alert Tone Volume and Tone

Filter After

Filter Time

Info Mode

………………...………………………...………………………………………..……………………….. 4.14

[Press and hold INFO for 3 seconds, displays Info Mode]

Full/Split Vat Configuration

Filter Stats

Review Usage

Last Load

Sensitivity for product

Log of last 10 error codes

Change passwords

Setup [enter 1234]

Usage [enter 4321]

Level 1 [enter 1234]

Level 2 [enter 1234]

Volume 1-9

Tone 1-3

Sets number of cooks before filter prompt

Sets amount of time between filter cycles

..……………….……………………………………………………………….. 4.14.1

………….……………………………………………………………….. 4.14.2

………………….……………………………………………………………….. 4.14.3

……………………………………………….. 4.13

…………………………………….. 4.13.1

…………………………….. 4.13.2

………………………………………….. 4.13.3

...………………………………………….. 4.13.4

………….. 4.13.5

………….. 4.13.6

4-8

Page 27

4.9 Fryer Setup Mode Programming

The computer, upon initial power up, when changing out a computer or accessed from Level 1,

enters setup mode. These parameters need to be set to allow the auto filtration, logs and other

functions to operate correctly. The setup sets the time, date, date format, language, fryer type, vat

type, oil system type and the temperature scale from F° to C°. These settings should only be changed

by a technician.

On initial power up the computer displays OFF.

1. Press either soft power button or with the computer OFF, enter Level 1 programming mode by

pressing the TEMP and INFO buttons simultaneously until LEVEL 1 is displayed.

2. The computer displays FRYER Setup if initially powering up the computer and/or

ENTER CODE if programming through Level 1.

3. Enter 1234 (see Figure 4).

If initially powering up the computer skip to step 6,

otherwise if programming through Level 1 continue to the

next step.

Figure 4

The computer displays level 1 program for three seconds and sounds an alert.

The computer then displays Product selection.

4. Press the u button to scroll to FRYER SETUP. Press the (1 yes) button (see Figure 7).

Computer displays ENTER CODE.

5. Enter 1234 (see Figure 5).

Figure 5

Computer displays time format.

6. Use the 3and 4 buttons (see Figure 6) to toggle between

24hr and 12hr.

7. With the desired selection displayed, press the (1

Figure 6 Figure 7

yes) button (see Figure 7).

The computer displays ENTER TIME on the left and hh:MM on the right.

Example: 7:30 AM is entered 0730 if using the 12 hour format. 2:30 is entered 1430 if using 24 hour

format.

1

1

2

2

3

4

3

(1234)

4

(1234)

4-9

Page 28

8. Enter time in hours and minutes using the number

buttons 0-9 (see Figure 8).

Figure 8

9. With the desired selection displayed, press the (1

yes) button (see Figure 9).

Figure 9

The computer displays ENTER TIME on the left and AM on the right if 12 hours system is

chosen.

10. Use the 3and 4 buttons (see Figure 10) to toggle

between am and pm if the 12 hour format was

chosen .

11. With the desired selection displayed, press the (1

Figure 10 Figure 11

yes) button (see Figure 11).

The computer displays DATE FORMAT on the left and US on the right.

12. Use the 3and 4 buttons (see Figure 12) to toggle

between US and interntl.

13. With the desired selection displayed, press the (1

Figure 12 Figure 13

yes) button (see Figure 13).

The computer displays enter date on the left and MM-DD-YY or DD-MM-YY on the

right.

Example:

US Format – Mar. 15, 2007 is entered as 031507.

International Format – 15 Mar. 2007 is entered as 150307)

14. Enter the date using the number buttons 0-9 (see

Figure 14).

Figure 14

15. With the desired selection displayed, press the (1

yes) button (see Figure 15).

Figure 15

The computer displays LANGUAGE on the left and ENGLISH on the right.

16. Use the 3and 4buttons to scroll through the

language menu (see Figure 16).

Figure 16

Current languages supported by the M2007 are: English, French, French Canadian, Spanish,

Portuguese, German and Swedish.

4-10

Page 29

17. With the desired selection displayed, press the (1

yes) button (see Figure 17).

Figure 17

The computer displays fryer type on the left and Elec on the right.

18. Use the 3and 4buttons (see Figure 18) to toggle

between elec and gas.

19. With the desired selection displayed, press the (1

Figure 18 Figure 19

yes) button (see Figure 19).

The computer displays VAT type on the left and SPLIT on the right.

20. Use the 3and 4buttons (see Figure 20) to toggle

between split and full.

21. With the desired selection displayed, press the (1

Figure 20 Figure 21

yes) button (see Figure 21).

The computer displays OIl SYSTEM on the left and JIB on the right.

22. Use the 3and 4buttons (see Figure 22) to toggle

between jib and bulk.

Figure 22

NOTE: A JIB system uses a disposable JIB (Jug in a Box). A BULK system has large storage oil

tanks that are connected to the fryer that fills a reservoir.

23. With the desired selection displayed, press the (1

yes) button (see Figure 23).

Figure 23

The computer displays TEMPERATURE on the left and F on the right.

24. Use the 3and 4buttons (see Figure 24) to toggle

between F and C temperature scales.

NOTE: F is used for Fahrenheit, C is used for Celsius.

Figure 24

25. With the desired selection displayed, press the (1

yes) button (see Figure 25).

Figure 25

The computer displays fryer setup changing to off.

4-11

Page 30

4.10 M2007 Common Tasks

Covered in this section are common tasks used in stores:

1. Escaping out of a menu or sub-menu.

2. Adding new product items.

3. Storing menu items in product buttons.

4. Draining, disposing and refilling the vats.

4.10.1 Escape Menu Items

To escape or back out of MENUS and SUB-MENUS, press the (2)

button (Figure 26).

4.10.2 Adding New Product Items to the Menu

This function is used to add additional products to the computer menu.

To add a new product to the menu:

1. With the computer OFF, enter Level 1 programming mode by

pressing the TEMP and INFO buttons simultaneously (see Figure

27) until LEVEL 1 is displayed.

The computer displays ENTER Code and sounds an audible alert.

2. Enter 1234 (see Figure 28).

1

2

Figure 26

Figure 27

3

4

Figure 28

(1234)

The computer displays level 1 program for three seconds.

The computer then displays Product selection.

3. With Product selection displayed, press the (1

yes) button to select a menu item (see Figure 29).

Figure 29

Computer displays PRODUCT Selection for three seconds then displays select

product.

4. With Select Product displayed on the left and Fr Fries

displayed on the right use the

through menu items until the right display reads the menu item to be

modified or a numbered spot is displayed ( ex. PROD 13).

4 button (see Figure 30) to advance

Figure 30

4-12

Page 31

5. Press the (1 yes) button to select the product to modify (see Figure

31).

Figure 31

The computer displays modify alternating with yes no.

6. Press the (1 yes) button to modify selection (see Figure 32) or the

(2 no) button to return to PRODUCT SELECTION.

Figure 32

If yes is chosen, left display shows NAME and the right display shows product name (ex. PROD

13. The right display will show a blinking cursor alternating with a blinking letter under the first

character.

7. Using the number keys, enter the first letter of the new

product (see Figure 33). When entering letters using

the number keys use the following logic (ex. – To enter

B, press the ABC key twice).

Figure 33

The full product name is limited to eight characters including spaces (ex. FR FRIES).

8. Press the 4 button to advance the cursor to the next display space (see

Figure 34). Use the #0 key to insert a space. The 3button can be used

to move the cursor back.

Figure 34

For example, to enter “WINGS”, press the #8 key two times until W appears in the display. Then

use the 4 button to advance the cursor to the next display space. Press the #3 key until I appears.

Continue on until WINGS is spelled out on the display.

9. Once the name appears as it is to be saved, press the ubutton (see

Figure 35) to save the name and scroll to cook time.

Figure 35

10. With cook time displayed on the left and :00

displayed on the right use the number keys (see Figure

36) to enter the product cook time in minutes and

seconds (ex. 3:10 as 310).

Figure 36

11. With the cook time entered, press the u (INFO) button

(see Figure 37) to save the cook time and scroll to

TEMP (cook temperature).

Figure 37

12. With temp displayed on the left and 32F displayed on

the right use the number keys (see Figure 38) to enter the

cook temperature for the product (ex. 335° as 335).

Figure 38

13. With the cook temperature entered, press the u (INFO)

button (see Figure 39) to save the cook temperature value

and scroll to the COOK ID.

Figure 39

4-13

Page 32

14. With cook ID displayed on the left and a blinking P

13 displayed on the right, use the instructions in step eight

to enter a four-letter name for the menu item. This is the

shortened name that alternates with the cook time during a

cook cycle.

15. With the correct cook ID abbreviation entered, press the u

(INFO) button (see Figure 40) to save the cook ID

abbreviation and scroll to the DUTY TIME 1 (Shake

Time), which is used to set the time in the cook cycle the

product should be shaken.

16. With duty time1 displayed on the left and :00

displayed on the right use the number keys to enter the

time in minutes and seconds for the first duty to be

preformed (ex. shake the product after 30 seconds is

entered as 30) (see Figure 41).

17. With duty time 1 (shake time) entered, press the u

(INFO) button (see Figure 42) to save duty time one and

scroll to DUTY TIME 2. If a product called for a

second duty to be preformed after a certain amount of

time, it can be entered here. Use the instructions above

to enter duty time two, otherwise press the u (INFO)

button (see Figure 42) to save the duty time and scroll to

QUAL TMR (Quality Timer) which is used to set the

hold time before the food is to be discarded.

18. With qual tmr displayed on the left and :00

displayed on the right use the number keys to enter the

time in minutes and seconds for the product hold time

(ex. 7:00 minutes as 700) (see Figure 43).

19. With QUAL TMR (hold time) entered, press the u

(INFO) button (see Figure 44) to save the quality time

and scroll to AIF DISABLE

20. With AIF Disable displayed on the left and yes

Figure 40

Figure 41

Figure 42

Figure 43

Figure 44

displayed on the right use the

Figure 45) to toggle between YES and NO. This

feature, if set to yes, disables the AIF (auto intermittent

filtration) for the programmed product. This is used to

prevent co-mingling of product-specific oils.

21. If the AIF DISABLE selection is set to NO press the

u (INFO) button (see Figure 46) to save the AIF disable

selection and scroll to the ASSIGN BTN selection.

3and4 buttons (see

Figure 45

Figure 46

4-14

Page 33

The computer displays ASSIGN BTN on the left and the

chosen product on the right.

To assign the entered product to a button, follow instructions

below.

Figure 47

22. With the chosen product displayed on the right, and ASSIGN BUTTON on the left, press and

hold for three seconds a button between 1-0 to assign the product. The LED in the chosen

product button will illuminate (see Figure 47). To unassign a product from a button, press and

hold the button assigned to that product for three seconds. The LED no longer illuminates.

23. Once the button is assigned, press the u (INFO) button (see Figure 48)

to save the assigned button.

The computer displays name on the left with the product (ex. WINGS)

on the right.

Figure 48

* Note: If additional programming, to add other products, is necessary

necessary press the (2) button (see Figure 50) once and then the

4 button (see Figure 49) and return to step 4.

Figure 49

24. If no further programming is necessary, press the (2) button (see

Figure 50). The computer displays the select product option

with the product (ex. FR FRIEs) on the right screen. Press the (2)

button again (see Figure 50). Computer displays Level 1

Figure 50

program changing to the Product selection prompt.

25. Press the (2) button (see Figure 51) to quit and to return to OFF.

Figure 51

4.10.3 Storing Menu Items in Product Buttons

This function is used to store individual menu items to product buttons for one or two button

cooking.

To store menu items to a specific button:

1. Perform steps 1-6 on pages 4-12 thru 4-13.

2. The computer displays name on the left and the selected product (ex. wings) on the right.

3. Press the t button (see Figure 52) to scroll to the ASSIGN BTN option

used to assign a menu item to a specific product button.

4. The computer displays assign btn on the left and wings on the

right.

Figure 52

4-15

Page 34

5. With assign btn displayed on the left and the

chosen product (ex. wings) displayed on the right,

press and hold for three seconds a button between 1-0 to

assign the product. The LED in the chosen product button

will illuminate (see Figure 53). To unassign a product

Figure 53

from a button, press and hold the button assigned to that

product for three seconds. The LED no longer

illuminates.

6. Once the button is assigned, press the u (INFO) button (see Figure 54) to save

the assigned button.

The computer displays name on the left with the product (ex. WINGS) on the

right.

Figure 54

7. If no further programming is necessary, press the (2) button (see Figure 55)

twice to return to Level 1 program changing to the Product

selection prompt.

8. Press the (2) button again (see Figure 55) to quit and to return to OFF.

Figure 55

4.10.4 Draining and Refilling Vats, and Disposing of Oil

When cooking oil is exhausted, drain the oil into an appropriate container for transport to the

disposal container. Frymaster recommends a McDonald’s Shortening Disposal Unit (MSDU). Do

not drain deep clean (boil-out) solution into an MSDU. NOTE: If using an MSDU built

before January 2004 the filter pan cover must be removed to allow the unit to be positioned beneath

the drain. To remove the cover, lift up on the front edge and pull it straight out of the cabinet. Refer

to the documentation furnished with your disposal unit for specific operating instructions. If a

shortening disposal unit is not available, allow the oil to cool to 100°F (38°C), then drain the oil into

a METAL container with a capacity of FOUR gallons (15 liters) or larger to prevent oil from

spilling.

4.10.4.1 Disposal for Non-Bulk Oil Systems

This option is used to dispose of old oil into either an MSDU or a METAL pot.

1. Remove the filter pan and position the MSDU or METAL container with a capacity of FOUR

gallons (15 liters) or larger under the fryer to drain the oil.

2. With the computer OFF, press and hold the FLTR button (see Figure 56) of

the corresponding vat for three seconds; a chirp sounds

The computer displays filter menu for three seconds, changing to Auto Filter.

Figure 56

4-16

Page 35

3. With Auto Filter displayed, press the u (INFO) button (see

Figure 57) to scroll to dispose.

Figure 57

Computer displays DISPOSE.

4. Press the (1 yes) button to continue (see Figure 58).

The computer display alternates between Dispose and Yes NO.

Figure 58

5. To dispose press the (1 yes) button to continue (see Figure 59).

Figure 59

WARNING

NEVER drain deep clean (boil-out) solution into an MSDU. Deep Clean (boil-out)

solution can cause damage to an MSDU.

DANGER

When draining oil into a disposal unit, do not fill above the maximum fill line located

on the container.

DANGER

Allow oil to cool to 100°F (38°C) before draining into an appropriate METAL container

for disposal.

DANGER

When draining oil into an appropriate METAL container, make sure the container will

hold at least FOUR gallons (15 liters) or more, otherwise hot liquid could overflow

and cause injury.

The computer display alternates between is dispose unit in place and Yes NO. If

NO is selected, the computer displays INSERT DISPOSAL UNIT alternating with IS

DISPOSE UNIT IN PLACE and YES NO.

6. With the MSDU or a METAL container with a capacity of FOUR gallons

(15 liters) or larger is in place, press the (1 yes) button to continue

(see Figure 60).

Figure 60

The heating source is disabled, the drain valve opens and the computer displays disposing for

20 seconds.

The drain valve remains open and the computer displays Vat empty

alternating with yes no.

7. With the vat empty, press the (1 yes) button to continue (see Figure 61).

Figure 61

4-17

Page 36

The computer displays cln vat Complete.

8. Clean the vat with a scrub brush and when complete press the (1 yes)

button to continue (see Figure 62).

Figure 62

The drain valve closes and the vat is ready to be refilled with oil.

4.10.4.2 Refilling JIB Oil Systems

JIB (Jug In Box) oil systems use oil stored in boxed jugs inside the fryer cabinet.

If the oil system was set to JIB during initial setup, the computer displays manual fill pot.

1. Carefully pour oil into the pot until it reaches the low fill line in the fryer.

2. Press the (1 yes) button (see Figure 63) when vat is full.

The computer displays off.

Figure 63

4.10.4.3 Draining and Disposing Oil using Bulk Oil Systems

Bulk oil systems use pumps to move the oil from the fryer to holding tanks for fresh and exhausted

oil. Additional plumbing is used to connect the bulk oil systems to the fryers.

1. With the computer OFF, press and hold the FLTR button of the

corresponding vat for three seconds (see Figure 64).

Computer displays fltr menu for three seconds changing to Auto

Filter.

2. Press the u (INFO) button (see Figure 65) and scroll to dispose .

3. With dispose displayed, press the (1 yes) button to continue (see

Figure 66).

The computer display alternates between Dispose and Yes NO.

If CHK PAN is displayed, remove and replace the filter pan, ensuring that the

pan is seated firmly into the fryer.

4. To dispose press the

(1 yes) button to continue (see Figure 67).

The drain valve remains open and the computer displays Vat empty

alternating with yes no.

5. When the vat is empty, press the (1 yes) button to continue (see Figure

68).

The computer displays cln vat Complete.

Figure 64

Figure 65

Figure 66

Figure 67

Figure 68

4-18

Page 37

6. Clean the vat with a scrub brush and when complete press the 9 (1 yes)

button to continue (see Figure 69) or if waste tank is full, the message clears

and the computer displays OFF.

The computer displays engage dispose switch.

7. Switch the bulk oil system switch to dispose (see Figure 70).

Figure 69

Figure 70

If the bulk oil system waste tank is full, the computer displays RTI TANK FULL. Call the bulk

oil waste provider.

8. Press the 9 (1) button to start disposal (see Figure 71).

Figure 71

The computer displays PAN TO WASTE. The pump transfers the waste oil from the pan to the

bulk oil waste tanks.

The computer displays PAN empty when finished.

9. Press the 8 (2) button (see Figure 72) to run the pump again if the pan has

oil remaining; otherwise continue to the next step.

Figure 72

10. Once the pan is empty, press the 9 (1) button (see Figure 73) to continue to

Section 4.10.4.4.

The vat is ready to be refilled with oil.

Figure 73

The computer displays Disengage dispose switch.

11. Switch off the bulk oil system using the door switch to the center position

(see Figure 74).

Figure 74

12. Press the 9 (1) button to disengage disposal switch (see Figure 75).

Figure 75

4-19

Page 38

4.10.4.4 Refilling the Vat from Bulk Oil Systems after Disposal

The computer displays fill pot from bulk.

The bulk oil refill pump uses a momentary switch. It only pumps when the switch is depressed.

1. Press and hold the 9 (1 yes) button to refill the vat until the oil

reaches the fill line (see Figure 76).

2. With the vat full, release the 9 (1 yes) button.

Figure 76 Figure 77

3. Press the 8 (2) button, when the vat is full, to close the fill valve (see Figure 77).

The computer displays off.

4.11 Filter Menu

The filter menu selections are used for filtering, draining, filling and disposing.

4.11.1 Accessing the Filter Menu

1. Press and hold the filter button for the selected vat for three seconds (see

Figure 78).

Figure 78

Computer displays filter menu for three seconds, changing to Auto Filter.

2. Press the t and u buttons (see Figure 79) to scroll between:

a. auto filter See pg. 5-2

b. maint filter See pg. 5-8

c. dispose See pg. 4-16

d. drain to pan See pg. 4-21

Figure 79

e. fill pot from DRAIN pan See pg. 4-22

f. fill pot from bulk See pg. 4-22

The first two menu items: AUTO FILTER and MANTAINENCE (MANUAL) FILTER are covered

in Chapter 5. The other menu items are covered on the following pages.

The DRAIN TO PAN and FILL POT FROM DRAIN PAN functions are used primarily for

diagnostic purposes. They are used when oil is to be drained to the pan or returned to the frypot.

4-20

Page 39

4.11.2 Drain to Pan

The drain to pan function drains the oil from the frypot to the filter pan.

With the computer OFF

1. Press and hold the filter button for the selected vat to drain for three

seconds (see Figure 80).

Figure 80

Computer displays filter menu for three seconds, changing to Auto Filter.

2. Use the t and ubuttons (see Figure 81) to scroll to drain to

pan.

3. With drain to pan displayed, press the (1) to continue (see

Figure 81

Figure 82).

Figure 82

DANGER

Do not drain more than one frypot at a time into the built-in filtration unit to avoid

overflow and spillage of hot oil that may cause severe burns, slipping and falling.

Computer displays drain to pan alternating with yes no.

4. Press the (1 yes) to continue drain to pan (see Figure 83).

Figure 83

The heating source is disabled and the system checks that the pan is in place. If no pan is detected,

the computer displays chk pan until the pan is detected.

With the pan detected, the drain valve opens. The computer displays draining for 20 seconds.

The drain valve remains open.

The computer displays vat empty, alternating with yes no.

5. Press the (1 yes) button if the vat is empty to continue (see Figure

84).

Figure 84

The drain valve closes and the computer returns to the filter menu prompt for three seconds,

changing to AUTO FILTER.

6. Press the (2) button (see Figure 85) to quit and to return to OFF.

Figure 85

4-21

Page 40

4.11.3 Fill Pot from Drain Pan

Fill pot from drain pan selection is used to refill the frypot from the filter pan.

With the computer OFF.

1. Press and hold the filter button for the vat to be refilled for three seconds

(see Figure 86).

Figure 86

Computer displays filter menu for three seconds, changing to Auto Filter.

2. Use the t and ubuttons to scroll to fill pot from DRAIN pan

(see Figure 87).

Figure 87

3. With fill pot from DRAIN pan displayed, press the (1

yes) to continue (see Figure 88).

Figure 88

Computer displays fill pot from DRAIN pan alternating with yes no.

4. Press the (1 yes) button to continue (see Figure 89).

System checks that the drain valve is closed. The return valve opens and the

Figure 89

filter pump refills the vat.

Computer displays fill vat while refilling.

When the vat is full, the return valve is closed. The pump shuts off. The system checks the oil level,

topping off if necessary.

If the oil temperature is below setpoint the computer displays low temp.

Once fryer reaches setpoint and the computer display changes to the product or dashed lines, the

fryer is ready for use.

4.11.4 Fill Pot from Bulk

Fill pot from bulk selection is used when filling the frypot from a bulk oil system.

Computer displays OFF.

4-22

Page 41

1. Press and hold the filter button for the vat to be refilled for three seconds

(see Figure 90).

Figure 90

Computer displays filter menu for three seconds, changing to Auto Filter.

2. Use the t and ubuttons to scroll to fill pot from bulk (see

Figure 91).

Figure 91

3. With fill pot from bulk displayed, press the (1 yes)

button to continue (see Figure 92).

Figure 92

Computer displays fill pot from bulk, alternating with yes no.

4. Press the (yes) button to continue (see Figure 93).

Figure 93

The system verifies the drain is closed. The bulk oil inlet valve opens and the bulk pump is

energized. The bulk oil refill pump uses a momentary switch. It only pumps as long as the switch is

depressed.

Computer displays fill pot from bulk.

5. Press and hold the (yes) button (see Figure 94). To refill using the

bulk oil refill. When the vat is filled to the lower fill line, release the

(1 yes) button.

Figure 94

6. Press the (2) button to exit (see Figure 95).

Figure 95

The computer displays off.

7. Press the soft power button to begin heating the oil (see Figure 96).

Figure 96

If the oil temperature is below setpoint, the computer displays low temp.

The system then checks the oil level, topping off if necessary.

When the fryer reaches setpoint and the computer display changes to the product or dashed lines, the

fryer is ready for use.

4-23

Page 42

4.12 Programming Level One

Level one programming is used to enter new products, control when AIF (auto intermittent filtration)

is disallowed, and perform deep clean (boil- out) and high-limit tests.

To enter Level 1 programming mode:

1. With the computer OFF, press the TEMP and INFO buttons

simultaneously (see Figure 97) for THREE seconds until LEVEL 1 is

displayed; a chirp sounds.

Figure 97

The computer displays ENTER Code and sounds an alert.

2. Enter 1234 (see Figure 98).

1

2

3

4

Figure 98

(1234)

The computer displays level 1 program for three seconds changing to Product

selection.

3. Press the t and ubuttons (see Figure 99) to scroll between:

a. Product selection See pg. 4-24

b. aif clock See pg. 4-25

Figure 99

c. DEEP CLEAN MODE See pg. 4-27

d. high limit test See pg. 4-30

e. Fryer setup See pg. 4-9

4. With the desired selection displayed, press the (1 yes) button to select

chosen menu item (see Figure 100).

Figure 100

4.12.1 PRODUCT SELECTION

1. To add or edit products in the product selection mode see pg. 4-12 ADDING A NEW

PRODUCT ITEM TO THE MENU Steps 4-30.

The submenus under product selection are:

a. Name – Enter full product name limit eight characters (FR FRIES).

b. cook time – Enter cook time (ex. 3:30 as 0330).

c. temp – Enter cook temperature. (ex. 335° as 335).

d. cook id – Enter four (4) letter product ID (ex. CPSY).

e. qual tmr – Enter quality time for hold time (ex. 7:00).

f. DUTY TIME 1 – Enter the seconds into the cook cycle that the first duty alarm

sounds. (ex. 30 seconds- to shake fries).

g. DUTY TIME 2 – Enter the seconds into the cook cycle that a second duty alarm

sounds.

h. aif disable – Enter YES if AIF is to be disabled for specific products.

i. assign btn – Assigns menu items to a specific button for simplified cooking.

4-24

Page 43

NOTE:

Press the t and u buttons to scroll.

Press the 3and 4buttons to move between positions within the selections.

When entering letters using the number keys use the following logic (ex. – To enter B, press the

ABC key twice).

When entering numbers, press the corresponding button using the 0-9 keys.

Press the t and ubuttons to accept input and move to the next or previous menu item.

2. Press the (2) button once to return to Product selection

prompt (see Figure 101).

Figure 101

3. Press the (2) button (see Figure 102) to quit and to return to OFF .

Figure 102

4.12.2 AIF CLOCK

The AIF Clock mode allows programming of times to lock out the AIF (auto intermittent filtration)

prompt. This is useful for busy times of the day, like the noon rush.

1. Perform steps 1-3 on page 4-24.

2. Use the u (INFO) button to scroll AIF clock (see Figure 103).

Figure 103

3. Press the (1 yes) button to continue (see Figure 104).

Figure 104

The computer displays AIF clock on the left and DISABLED on the right.

4. Use the 3and 4buttons to toggle between: (see Figure 105).

a. disabled

b. enabled

Figure 105

Set this function to enabled if there are times in which the AIF (auto intermittent filtration)

feature is disallowed (ex. noon rush).

5. With enabled displayed, press the (1 yes) button (see Figure 106).

*Skip to step 12 if disabled is chosen.

Figure 106

6. Use the t and u buttons (see Figure 107) to scroll between M-F 1 thru

Sun 4. (ex. On Monday – Friday no filtering is desired during a lunch

rush from 12:00 AM until 1:30 PM. On the computer scroll to M-F 1

12:00 AM.

Figure 107

4-25

Page 44

7. Using the number keys enter the start time when AIF

should be suspended (see Figure 108).

Figure 108

8. Press the 4 button to toggle from AM to PM (see Figure 109).

9. Press the u (INFO) button (see Figure 110). The computer displays 000

DUR. This is the amount of time the AIF is to remain suspended.

10. Use the number keys (see Figure 111) to enter a time

between 0 and 999 minutes (ex. 1½ hours is entered as

90 minutes). Enter 90 for this example. The computer

Figure 111

displays 090 DUR. Four different time periods to

suspend filtration are available M-F 1-4, Sat 1-4 and Sun

1-4.

11. Press the u (INFO) button to accept time and move to the next time period

(see Figure 112).

Figure 109

Figure 110

Figure 112

12. When finished, press the button (see Figure 113) once to exit and return to

PRODUCT selection display. Skip to step 14.

Figure 113

13. If disabled is chosen in step three, the computer displays disabled and sounds an alert

for three seconds.

14. Press the (1 yes) button to accept disabled selection (see Figure

114).

Computer displays Product selection.

Figure 114

15. Press the (2) button (see Figure 115) to quit and to return to OFF.

Figure 115

4-26

Page 45

4.12.3 DEEP CLEAN MODE (BOIL-OUT)

The deep clean mode is used to remove carbonized oil from the frypot.

NOTE: Refer to Kay Chemical “Fryer Deep Clean Procedure” instructions to clean the

LOV™ fryer.

1. Perform steps 1-3 on page 4-24.

The computer displays DEEP CLEAN.

2. Press the (1 yes) button (see Figure 116).

The computer displays DEEP CLEAN, alternating with yes no.

3. Press the (1 yes) button (see Figure 117).

4. Full Vat: Computer displays Oil RMVD, alternating with Yes, No.

Split Vat: Computer displays Deep Clean, alternating with Left,

Rgh. Press the (1) (see Figure 118) or (2) (see Figure 119) button

under the split vat to be cleaned. The computer displays oil rmvd,

Figure 116

Figure 117

Figure 118

alternating with yes no.

Figure 119

5. Empty fry vat: Press the (1 yes) button (see Figure 120). Computer

displays Oil Discarded, changing to Yes No.

Oil-filled Fry Vat: Press the (2 no) button (see Figure 121). Computer

Figure 120

displays Drain Oil.

6. Empty Fry Vat: Press the (1 yes) button (see Figure 120). Skip to 9.

Oil-filled Fry Vat: Press the (1 yes) button.

Figure 121

The computer displays Dispose, alternating with Yes NO.

Bulk Oil System: Ensure a complete and clean filter pan is in place.

JIB Oil System: Ensure an MSDU or suitable metal container is in place under drain.

7. Press the (1 yes) button (see Figure 122).

JIB Oil System: Computer displays is Disposal unit in

place, alternating with yes no. Press the (1 yes) button to

dispose the oil (see Figure 123).

Figure 122

Bulk* Oil System: Computer displays disposing.

*If CHK PAN is displayed, remove and replace the filter pan.

Figure 123

DANGER

When draining oil into a disposal unit, do not fill above the maximum fill line located

on the container.

4-27

Page 46

DANGER

Allow oil to cool to 100°F (38°C) before draining into an appropriate METAL container

for disposal.

DANGER

When draining oil into an appropriate MSDU or METAL container, make sure the

container will hold at least FOUR gallons (15 liters) or more. Otherwise oil could

overflow and can cause injury.

The drain valve opens and the oil is drained into the MSDU for JIB systems or the filter pan for bulk

system. The computer displays disposing.

Bulk or JIB System: The drain valve remains open and the computer displays Vat empty,

alternating with yes no.

8. With the vat empty, press the (1 yes) button (see Figure 124).

Figure 124

The computer displays oil discarded, alternating with yes no.

9. JIB system: Press the (1 yes) button (see Figure 125). Discarded oil is

in MSDU. Skip to step 17.

Figure 125

Bulk system: Press the (2 no) button (see Figure 126). Discarded oil is

in the filter pan.

Referred from Step 6: Press the (1 yes) button. Skip to 17.

Figure 126

Bulk System: The computer displays engage dispose

switch*.

10. Bulk System: Switch the bulk oil system switch to dispose (see

Figure 127).

* If the bulk oil system waste tank is full, the computer displays RTI

TANK FULL. Call the bulk oil waste provider.

Figure 127

11. Bulk System: Press the (1) button (see Figure 128).

Figure 128

The computer displays PAN TO WASTE. The pump transfers the waste oil from the pan to the

bulk oil waste tanks.

The computer displays PAN empty.

12. Bulk System: Pull the filter pan out and ensure the filter pan is empty.

13. Bulk System: Press the (2) button (see Figure 129) to run the pump again

if the pan has oil remaining. The computer will display PAN TO

WASTE.

Figure 129

4-28

Page 47

14. Bulk System: With the pan empty, press the (1) button (see Figure 130).

Figure 130

15. Bulk System: The computer displays Disengage dispose

switch. Place the RTI door switch in the center position (see Figure

131).

Figure 131

16. Bulk System: Press the (1) button to disengage disposal switch (see

Figure 132).

Figure 132

17. Bulk or JIB System: The drain valve closes and the computer displays SOLUTION

added, alternating with Yes NO. Fill frypot to be cleaned with water and cleaning solution

mix. Referring to maintenance requirement card and Kay Chemical provided instructions “Fryer

Deep Clean Procedure” for McDonald’s deep clean (boil-out) procedure.

18. Bulk or JIB System: Press the (1 yes) button (see Figure 133).

Figure 133

19. Bulk or JIB System: The computer displays START CLEAN,

alternating with Yes NO. Press the (1 yes) button (see Figure 134)

to continue and start the cleaning procedure. The vat heats to 195° F (91°

C) for one hour.

Figure 134

The computer displays DEEP CLEAN with a countdown timer on the display.

After one hour the heater shuts off and the computer displays CLEAN DONE with an alarm.

20. Bulk or JIB System: Press the (1 yes) button (see Figure 135) to

silence the alarm.

Figure 135

21. Bulk or JIB System: The computer displays REMOVE SOLUTION

FROM VAT with an alarm. Press the (1 yes) button to silence the

alarm.

Figure 136

DANGER

Allow deep-clean (boil-out) solution to cool to 100°F (38°C) before disposal,