Page 1

Insta ation instructions

Instructions d'installation

!

\

Page 2

CONTENTS

SUBJECT PAGE

Pre-lnstallation Requirements ................................................................................................................................. 3

Electrical Requirements ............................................................................................................................................ 3

Water Supply Requirements ..................................................................................................................................... 3

Drain Requirements .................................................................................................................................................. 3

Exhaust System Requirements .............................................................................................................................. 4-5

Gas Supply Requirements ........................................................................................................................................ 5

Location .................................................................................................................................................................... 5

Rough-In Dimensions ................................................................................................................................................ 6

Mobile Home Installation .......................................................................................................................................... 7

Unpacking ................................................................................................................................................................. 7

Electrical Installation ................................................................................................................................................. 8

Grounding Requirements ......................................................................................................................................... 8

3 & 4-Wire Connections ....................................................................................................................................... 8-9

Installation ............................................................................................................................................................. 9-10

ReplacementParts ..................................................................................................................................................... 10

Frangais ............................................................................................................................................................ 11-20

Laundry Center Safety

Before beginning installation, carefully read these instructions. This will simplify the installation

and ensure the laundry center is installed correctly and safely. Leave these instructions near the

laundry center after installation for future reference.

NOTE: The electrical service to the laundry center must conform with local codes and ordinances and the latest

edition of the National Electrical Code, ANSI/NFPA 70, or in Canada, the Canadian Electrical Code, CSA C22, 1

NOTE: The gas service to the laundry center must conform with local codes and ordinances and the latest edition

of the National Fuel Gas Code ANSI Z223, 1/NFPA 54, or in Canada, the Canadian Natural Gas and Propane

Installation Code, CSA B149, 1,

NOTE: The laundry center is designed under ANSI Z21.5.1 or ANSI/UL 2158- CAN/CSA C22.2 No. 112 (latest

edition) for HOME USE only. This laundry center is not recommended for commercial applications such as restau-

rants or beauty salons, etc.

For your safety the information in this manual must be followed to minimize the risk of fire or explosion

or to prevent property damage, personal injury or loss of life.

- Do not store or use gasoline or other flammable vapors and liquid in the vicinity of this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

Do not touch any electrical switch; do not use any phone in your building.

Clear the room, building or area of all occupants.

Immediately call your gas supplier from a neighbor's phone.

Follow the gas supplier's instructions.

If you cannot reach your gas supplier, call the fire department.

Installation and service must be preformed by a qualified installer, service agency or the gas supplier.

Page 3

PRE-INSTALLATION REQUIREMENTS

Tools and Materials Required for Installation:

1. Phillips head screwdriver

2. Channel-lock adjustable pliers

3. Carpenter's level

4. Flat or straight blade screwdriver

5. Duct tape

6. Rigid or flexible metal 4 inch (10.16 cm) duct

7. Vent hood

8. Pipe thread sealer (Gas)

9.1/4 inch socket w/ratchet

10.3/8 inch socket w/ratchet

11.3/8 inch open end wrench

12.7/16 inch open end wrench

13.9/16 inch open end wrench

ELECTRICAL REQUIREMENTS

ELECTRICLaundry Center

Circuit- Individual 30 amp branch circuit fused with 30 amp

minimum time delay fuses or circuit breakers,

POWER SUPPLY- 3-wire or 4-wire, 240 volt, single phase, 60

Hz, Alternating Current.

POWER SUPPLY CORD KIT- The laundry center MUSTemploy

a 3-condutor power supply cord NEMA 10-30 type SRDTrated

at 240 volt AC minimum, 30 amp, with 3 open end spade lug

connectors with upturned ends or closed loop connector OR a

4-condutor power supply cord NEMA 14-30 type SRDTor ST(as

required) rated at 240 volt AC minimum, 30 amp, with 4 open

end spade lug connectors with upturned ends or closed loop

connectors and marked for use with clothes dryers. If being

installed in a manufactured (mobile) home, the laundry center

MUST employ a 4-condutor power supply cord NEMA 14- 30

type SRDTor ST(as required) rated at 240 volt AC minimum,

30 amp, with 4 open end spade lug connectors with upturned

ends or closed loop connectors and marked for use with clothes

dryers. See ELECTRICAL CONNECTIONS. (Canada - 4-wire

power supply cord is installed on laundry center.)

GASLaundry Center

CIRCUIT-Individual 15 amp branch circuit fused with a 15

amp maximum time delay fuse or circuit breaker.

POWER SUPPLY -3 wire, 120 volt single phase, 60 Hz,

Alternating Current.

POWER SUPPLY CORD -The gas laundry center is equipped

with a 120 volt 3-wire power cord.

OUTLET RECEPTACLE- Properly grounded 3-prong

receptacle to be located so the power supply cord is

accessible when the washer is in an installed position. NOTE:

GFI (Ground Fault Interrupter) receptacle is not required or

recommended.

NOTE: Do not under

any circumstances

remove grounding

prong from plug.

\

Grounding Prong

WATER SUPPLY REQUIREMENTS

Hot and cold water faucets MUSTbe installed within 42 inches

(106.68 cm) of your laundry center's water inlet. The faucets

MUST be 3/4 inch (1.9 cm) garden hose type so inlet hoses

can be connected. Water pressure MUSTbe between 10 and

120 pounds per square inch (maximum unbalance pressure,

hot vs.cold, 10 psi). Your water department can advise you of

your water pressure.

DRAIN REQUIREMENTS

1. Drain capable of eliminating 17 gallons per minute.

2. A standpipe diameter of 11/4inches (3.18 cm) minimum.

3. The standpipe height above the floor should be:

Minimum heicht: 24 inches (61 cm)

Maximum heicht: 96 inches (244 cm)

OUTLET RECEPTACLE- NEMA 10-30R (3-wire) receptacle or

NEMA 14- 30R (4-wire) receptacle to be located so the power

supply cord is accessiblewhen the laundry center isinan installed

position.

NEMA 10-30R

NEMA 14-30R

96 in.

(244 cm)

Max.

I"

24 in.(61cm)

NOTE: For installations requiring a longer drain hose, have a

qualified technician install a longer hose, Part Number

134042901, available from an authorized parts distributor. For

drain systems in the floor, install a siphon break kit, available

from your local hardware store.

Page 4

EXHAUST SYSTEM REQUIREMENTS

Useonly 4 inch (10.16 cm) diameter (minimum) rigid or flexible

metal duct and approved vent hood which has a swing-out

damper(s) that opens when the dryer is in operation. When the

dryer stops, the damper(s) automatically closes to prevent drafts

and the entrance of insects and rodents. Toavoid restricting the

outlet, maintain a minimum of 12 inches (38.5 cm) clearance

between the vent hood and the ground or anyother obstruction.

The following are specific requirements

for proper and safe operation of your laundry center.

Failure to follow these instructions can create excessive

drying times and fire hazards.

Do not use plastic flexible duct or metal foil

to exhaustthe dryer. Excessivelint can build up insidethe exhaust

system and create a fire hazard and restrict air flow. Restricted

air flow will increase drying times. If your present system is

made up of plastic duct or metal toil duct, replace it with a rigid

or flexible metal duct. Ensure the present duct is free of any

lint prior to installing the laundry center dryer duct.

INCORRECT

i I,_,Tq-

L

Do not allow combustible materials (for

example: clothing,draperies/curtains, paper) to come in contact

with the exhaust system. The dryer MUST NOT be exhausted

into a chimney, a wall, a ceiling, or any concealed space of a

building which can accumulate lint, resulting in a fire hazard.

Do not exceed the length of duct pipe or

number of elbows allowed in the" EXHAUST DUCT LENGTHS"

chart. Lint can accumulate in the system, plugging the system

and creating a fire hazard, aswell as increasing drying times.

Do not screen the exhaust ends of the vent

system, nor use any screws or rivets to assemble the exhaust

.system.Lint can become caught in the screen, on the screws or

rivets, clogging the exhaust system and creating a fire hazard

aswell as increasing drying times. Use an approved vent hood

to terminate the duct outdoors, and seal all joints with duct

tape. All male duct pipe fittings MUSTbe installed downstream

with the flow of air.

Explosion hazard.

Do not install the laundry center where

gasoline or other flammables are kept or stored,if the laundry

center is installed in a garage, it must be a minimum of 18

inches (45,7 cm) above the floor, Failure to do so can result in

death, explosion, fire or burns,

The exhaust system back pressure MUSTnot exceed 0,6 inches

(1,52 cm) of water column measured with an inclined

manometer at the point the exhaust connects to the dryer,

Theexhaust systemshould be inspected and cleaned a minimum

of every two years with normal usage, The more the dryer is

used, the more often you should check the exhaust system and

vent hood for proper operation,

The maximum length of the exhaust system depends upon the

type of duct used, number of elbows and type of exhaust hood,

The maximum length for both rigid and flexible duct isshown in

the chart below,

EXHAUST DUCT LENGTHS

EXHAUST HOOD TYPE

_ If the dryer is not exhausted outdoors.

some fine lint will be expelled into the laundry area. An

accumulation of lint in any area of the home can create a

health and fire hazard. The dryer exhaust system MUST

be exhausted to the outside of the dwelling!

Number

of 90°

Turns

0

1

2

3

0

1

2

3

(10.2 CM)

MAXIMUM LENGTH OF 4-INCH (10.2 CM)

DIAMETER RIGID METAL DUCT

56 ft. (17.07 m)

46 ft. (14.02 m)

34 ft. (10.36 m)

32ft. (9.75m)

MAXIMUM LENGTH OF 4-INCH (10.2 CM)

DIAMETER FLEXIBLE METAL DUCT

30 ft. (9.14 m)

22 ft. (6.7 m)

16 ft. (4.88 m)

Louvered

42 ft. (12.8 m)

36 ft. (10.97 m)

28 ft. (8.53 m)

18 ft. (5.48 m)

22 ft. (6.7 m)

14 ft. (4.27 m)

10 ft. (3.05 m)

NOT RECOMMENDED

(6.35 CM)

Page 5

The laundry center may be exhausted four (4) ways with rear

flush installation:

1, Straight back

2. Down (8 inch [20.32 cm] length of 4 inch [10.16 cm]

rigid duct and 1 elbow down)

3. Left (8 inch [20.32 cm] length of 4 inch [10.16 cm]

rigid duct, 1 elbow down and 1 elbow left)

4. Right (8 inch [20.32 cm] length of 4 inch [10.16 cm]

rigid duct, 1 elbow down and 1 elbow right)

To exhaust up, add an 11 inch

(27.94 cm) length of standard 4 _

inch (10.16 cm) diameter duct

and a 90 ° elbow. The unit will be

positioned about 4Y_ inches

(11.43 cm) away from the wall

(flush to wall exhausting may be

done by going below the dryer _J

then sideways).

An exhaust hood positioned to

line up with the dryer exhaustcan'--. _

outside wall. To exhaust to the

be installed directly through the "

side or down, add an 8 inch

(20.32 cm) length of standard 4

inch (10.16 cm) diameter duct and

a 90° elbow.

GAS SUPPLY REQUIREMENTS

Installation MUST conform with local codes, or in the

absence of local codes, with the National Fuel Gas Code,

ANSI Z223.1 (latest edition) or in Canada, the current AN/

CGA B149.

2

The gas supply line should be of 1/2 inch (1.27 cm) pipe.

3

If codes allow, flexible metal tubing may be used to connect

your dryer to the gas supply line. The tubing MUST be

constructed of stainless steel or plastic-coated brass.

,

The gas supply line MUST have an individual shutoff valve.

5.

A 1/8 inch (0.32 cm) N. R T. plugged tapping, accessible

for test gage connection, MUST be installed immediately

upstream of the gas supply connection to the dryer.

,

The dryer and its individual shutoff valve MUST be

disconnected from the gas supply piping system during

any pressure testing of the gas supply piping system at

test pressures equal to or less than 1/2 psig (3.45 kPa).

,

The dryer MUST be isolated from the gas supply piping

system by closing its individual manual shutoff valve during

any pressure testing of the gas supply piping system at

test pressures equal to or less than 1/2 psig (3.45 kPa).

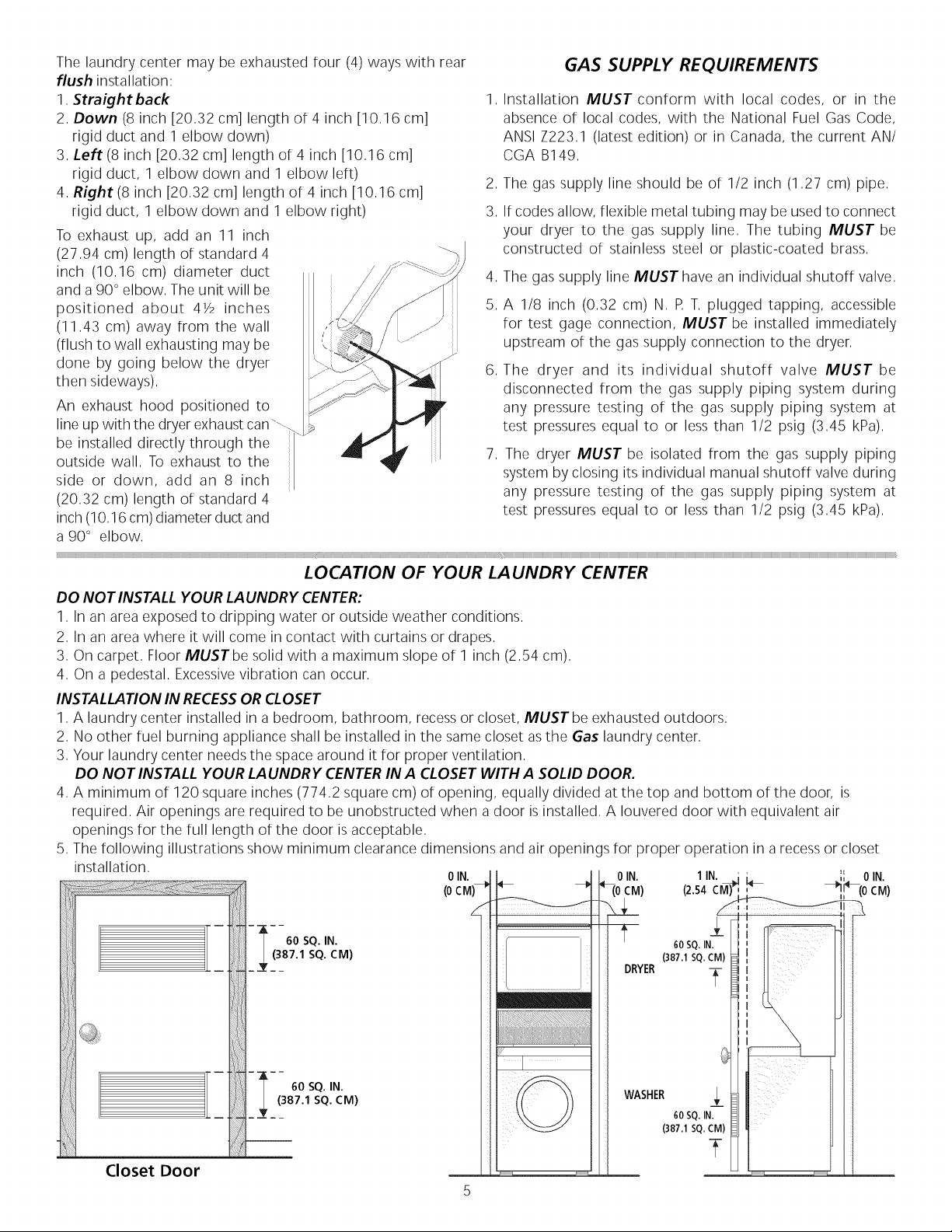

LOCATION OF YOUR LAUNDRY CENTER

DO NOT INSTALL YOUR LAUNDRY CENTER:

1. In an area exposed to dripping water or outside weather conditions.

2. in an area where it will come in contact with curtains or drapes.

3. On carpet. Floor MUSTbe solid with a maximum slope of 1 inch (2.54 cm).

4. On a pedestal. Excessivevibration can occur.

INSTALLATION IN RECESSOR CLOSET

1. A laundry center installed in a bedroom, bathroom, recess or closet, MUST beexhausted outdoors.

2. No other fuel burning appliance shall be installed in the same closet as the Gas laundry center.

3. Your laundry center needs the space around it for proper ventilation.

DO NOT INSTALL YOUR LAUNDRY CENTERIN A CLOSET WITH A SOLID DOOR.

4. A minimum of 120 square inches (774.2 square cm) of opening, equally divided at the top and bottom of the door, is

required. Air openings are required to be unobstructed when a door is installed. A Iouvered door with equivalent air

openings for the full length of the door is acceptable.

5. The following illustrations show minimum clearance dimensions and air openings for proper operation in a recess or closet

installation.

--60 SQ. IN.

(387.1 SQ. CM)

Closet Door

HE3 1S I'

-- 60 SQ. IN.

(387.1 SQ. CM)

5

Page 6

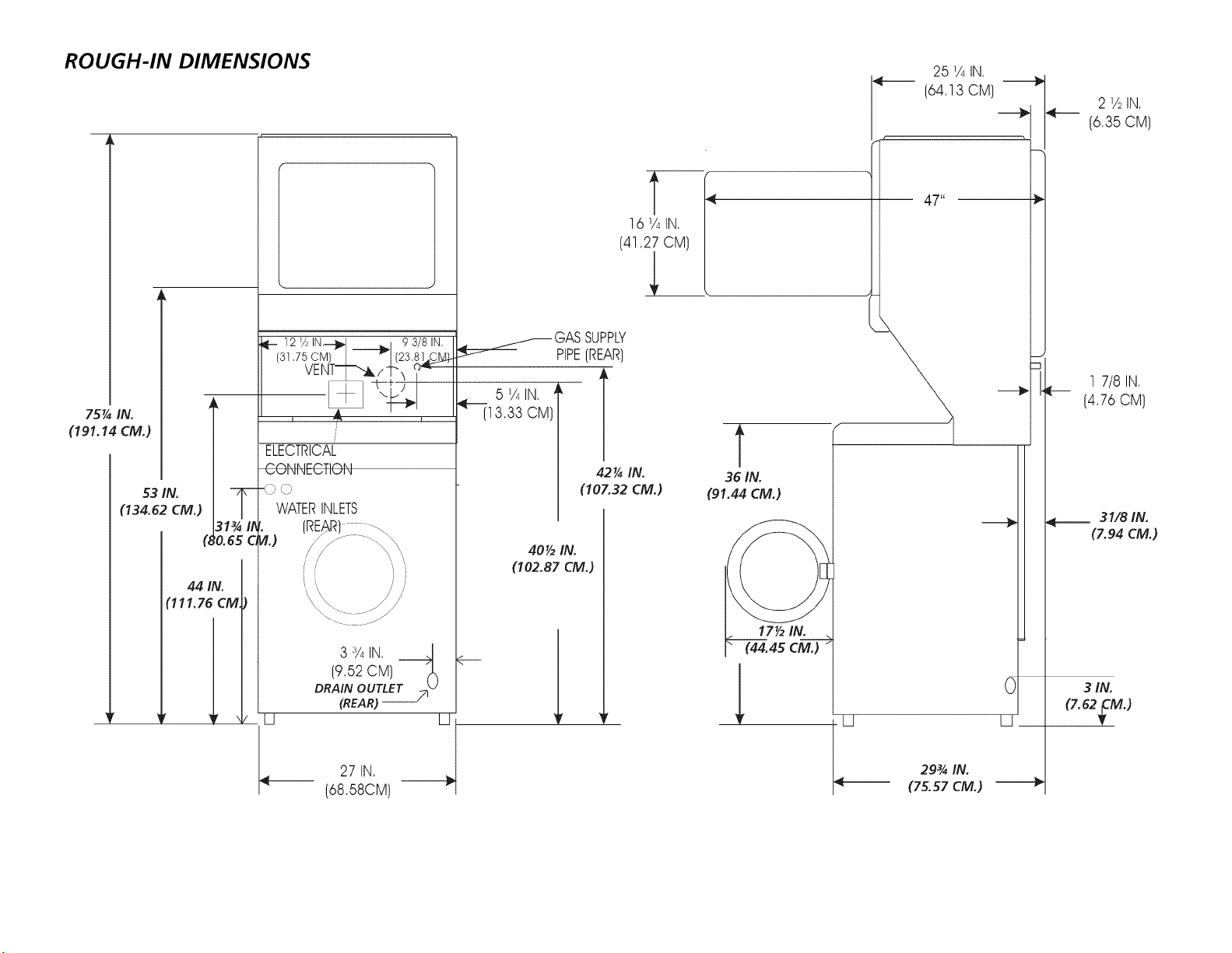

ROUGH-IN DIMENSIONS

16 ]A IN,

(4] ,27 CM)

25 1AIN,

(64,13 CM)

f

2 1/2IN,

(6,35 CM)

75_ IN.

(191.14 CM.)

(134.62 CM.)

_r

53 IN.

(111.76 CM

A

31% I^

(8o.65 c_

44 IN.

I

]2Tf_IN,_ _ 93/81N,

(31,75 CM) I (23,8]_CM_

VENT-"_&/_ _ _

ELECTRICAL

@EhNNECTION

-(} o

WATERINLETS

r {RE }.... -

/ ,

if

3 :Y4IN, ___

(9.52CM)

DRAIN OUTLET -

(REAR) --/

II

27 IN, LIt

(68,58CM)

5 1AIN, _' t

ml 3,33 CM)

401/2IN.

(102.87 CM.)

GASSUPPLY

PIPE(REAR)

A

/

421/4IN.

(107.32 CM.)

1 7/8 IN,

(4,76 CM)

36 IN.

(91.44 CM.)

31/8 IN.

(7.94 CM.)

3 IN.

(7.62_M.)

29_ IN.

(75.57CM.)

Page 7

MOBILE HOME INSTALLATION

1, Dryer MUST be exhausted outside (outdoors,

not beneath the mobile home) using metal

ducting that will not support combustion, Metal

ducting must be 4 inches (10,16 cm) in

diameter with no obstructions, Rigid metal duct

is preferred,

2, If dryer isexhausted through the floor and area

beneath the mobile home is enclosed, the

exhaust system MUST terminate outside the

enclosure with the termination securelyfastened

to the mobile home structure,

UNPACKING

1, Using the four shipping carton corner posts (two on each side), carefully

lay the laundry center on its left side and remove the foam shipping

base,

Excessive weight. Use two or more people to

move Laundry Center.

CARTON CORNER POSTS

FOAM

SHIPPING

PAD

m

m

3, Refer to page 3 for other important venting

requirements,

4, When installing a gasdryer into a mobile home,

a provision must be made for outside make up

air, This provision isto be not lessthan twice

the area of thedryer exhaust outlet,

5, Installation MUST conform to current

Manufactured Home Construction & Safety

Standard (which is a Federal Regulation Title

24 CFR-Part 32-80) or when such standard is

not applicable, with American National Standard

for Mobile Homes, In Canada, the CSA Z240 is

applicable,

The laundry center is designed

under ANSI Z 21,5,1 forHOME 9,

USE only,

,

Return laundry center to an upright

3,

Removethe following from

the back side of the

washer:

4 bolts,

4 yellow plastic spacers,

3 metal "P" clamps,

,

Remove the service panel

from the front of the

washer,

,

Remove the 4 nuts and 6

large washers that attach

the 2 yellow shipping

braces to the drum and

the base, Lift up on the

drum and remove the

braces (a yellow ribbon

surrounds the items to be

removed),

,

Remove the large

styrofoam block located

under the drum, Lift up on

the drum, tilt the base of

the foam block inwards

toward the rear of the

washer until free, then pull

it out,

,

Remove and discard the

yellow ribbon and label

from the front of the

washer,

,

Replace the service panel

and screws,

Carefully move the laundry f

center to within 4 feet ,

(1,22m) of the final location

to begin the installation,

NOTE: If the laundry(_

center is to be _J _

transported at a later

date, the shipping

support hardware must

be reinstalled to

prevent shipping

damage.

)ositlon,

®

®

BOLT \\ /

SPACER \

"P" CLAMt_ ......... z

/

®

Page 8

ELECTRICAL INSTALLATION

i ALL ELECTRICLaundry Centers

_The following are specific requirements

for proper and safe electrical installation of your laundry

center. Failure to follow these instructions can create an

electrical shock and/or a fire hazard.

_This appliance MUST be properly grounded,

Electrical shock can result if the laundry center isnot properly

grounded, Follow the instructions in this manual for proper

grounding,

_Do not use an extension cord with this

laundry center, Some extension cords are not designed to

withstand the amounts of electrical current this laundry center

utilizes and can melt, creating electrical shock and/or fire hazard,

Locate the laundry center within reach of the receptacle for the

length power cord to be purchased, allowing some slack in the

cord, Refer to the pre-installation requirements in this manual

for the proper power cord to be purchased,

_A U,L, approved strain relief must be

installed onto power cord, If the strain relief isnot attached, the

cord can be pulled out of the laundry center and can be cut by

any movement of the cord, resulting in electrical shock,

Do not use an aluminum wired receptacle

with a copper Wired power cord and plug (or vice versa), A

chemical reaction occurs between copper and aluminum and

can cause electrical shorts, The proper wiring and receptacle

is a copper wired power cord with a copper wired

receptacle OR aluminum wired power cord with an

aluminum wired receptacle.

NOTE: Laundry centers operating on a 208 volt power supply

will have longer drying times than laundry centers operating on

a 240 volt power supply,

GROUNDING REQ UIREMENTS

Non-Canadian ELECTRICLaundry Center ]

Improper connection of the equipment

grounding conductor can result in a risk of electrical shock,

Check with a licensed electrician if you are in doubt asto whether

the appliance is properly grounded,

For a grounded, cord-connected laundry center:

1, The laundry center MUST begrounded, Inthe event of

malfunction or breakdown, grounding will reduce the risk of

electrical shock by a path of least resistance for electrical

current,

2, If your laundry center is equipped with a power supply cord

having an equipment-grounding conductor and a grounding

plug, the plug MUSTbe plugged into an appropriate, copper

wired receptacle that is properly installed and grounded in

accordance with all local codes and ordinances, If in doubt,

call a licensed electrician,

For a permanently connected laundry center:

The laundry center MUSTbe connected to a grounded metal,

permanent wiring system;or an equipment grounding con-ductor

MUSTbe run with the circuit conductors and connected to the

equipment-grounding terminal or lead on the appliance,

[

The laundry center isequipped with athree-prong (grounding)

plug for your protection against shock hazard and should be

plugged directly into a properly grounded three-prong receptacle,

Do not cut or remove thegrounding prong from the plug,

[ CanadianELECTRiCLaundryCenter i

grounding conductor can result in a risk of electrical shock,

Check with a licensed electrician if you are in doubt asto whether

the appliance is properly grounded,

For a grounded cord connected laundry center:

1, The laundry center MUSTbe grounded, In the event of

malfunction or breakdown, grounding will reduce the risk of

electrical shock by providing a path of least resistance for the

electrical current,

2, Since your laundry center is equipped with a power supply

cord having an equipment-grounding conductor and a

grounding plug, the plug MUSTbe plugged into an appropriate

outlet that isproperly installed and grounded in accordance

with all codes and ordinances, If in doubt, call a licensed

electrician,

[

NON-CANAD/AN ELECTR/CLaundry Center

ELECTRICAL CONNECTIONS FOR A 3 WIRESYSTEM

Removethe screw securing the terminal

block accesscover to the rear panel and

remove cover,

Install a U,L, approved strain relief

connector in the entry hole on the back

panel,

Insert a NEMA 10-30 Type SRDT, U,L,approved power cord

through the strain relief,

Attach the power cord neutral (central wire) conductor to

the silver colored center terminal on the terminal block,

Tighten the screw securely,

GREEN GROUND SCREW

NEUTRAL

GROUND

WIRE

ALL 6AS Laundry Centers

Improper connection of the equipment

SILVER TERMINAL

J

J

Page 9

5, Attach the remaining two power cord outer conductors to

the outer brass colored terminals on the terminal block,

Tighten both screw securely,

6, Tighten the screws securing the cord restraint against the

power cord,

7, Reinstall the terminal accesscover,

NON-CANAD/AN ELECTR/CLaundry Center

ELECTRICALCONNECTIONS FORA 4-WIRE SYSTEM

1, Removethe screw securing the terminal

block access cover to the rear panel

and remove cover,

2, Install a U,L, approved strain relief

connector in the entry hole onthe back

panel,

INSTALLATION

Leveling the Laundry Center

Excessivenoise and vibration can be prevented by properly

leveling the washer,

1, With the laundry center in it's final position, place a level

ontop of the laundry center, Adjust the leveling legs sothe

laundry center is level front-to-rear and side-to-side, and

]

stable corner-to-corner,

3, Removethe ground wire from the green ground screwlocated

above the termial block,

GREEN GROUND GREEN

SCREW CONDUCTOR

RED /

POWER CORD

,

Insert a NEMA 14-30 TypeSTor SRDT,U,L,approved power

SILVER TERMINAL

TERMINAL BLOCK

WHITE

STRAIN '

RELIEF

cord through the strain relief,

5, Attach the green power cord ground wire to the cabinet

with the green ground screw,

6, Attach the white (neutral) wire from the power cord and

the ground wire from the appliance harness to the silver-

colored center terminal on the terminal block, Tighten the

screw securely,

7, Attach the red and black wires from the power cord to the

outer brass-colored terminals on the terminal block, Tighten

both screws securely,

8, Tighten the screws securing the cord restraint firmly against

the power cord,

9, Reinstall the terminal block accesscover,

Pressdown on alternate corners and sides and feel for the

slightest movement, Adjust the appropriate leg so the

washer is SOLID on the floor on ALL four legs, Keep the

leveling leg extension at a minimum for best performance

of the laundry center,

Washer Connections

,

Run some water from the hot and cold faucets to flush the

water lines and remove particles that might clog up the water

valve screens,

,

Check inlet hoses to ensure the rubber washers are

installed in each end,

3,

Carefully connect the inlet hoses to the water valve (on the

left side of the washer cabinet), tighten by hand, then tighten

another 2/3 turn with pliers,

DO NOT CROSS THREAD OR

OVERTIGHTEN THESECONNECTIONS.

, Determine which water faucet isthe HOTwater faucet

and carefully connect the bottom inlet hose to the HOT

water faucet, tighten by hand, then tighten another 2/3

turn with pliers, Carefully connect the top inlet hose to the

COLD water faucet, tighten by hand, then tighten another

2/3 turn with pliers,

o . v

DO NOT CROSS THREAD OR

OVERTIGHTEN THESECONNECTIONS.

Turn the water on and check for leaks at both connections,

GAS CONNECTION (Gaslaundry centers only)

1, Remove the shipping cap from gas pipe at the rear of the

dryer,

NOTE: DO NOTconnect the laundry center to L,R gas

service without converting the gas valve, An L,R

conversion kit must be installed by a qualified gas

technician,

2, Connect a 1/2 inch (1,27 cm)I,D, semi-rigid or approved pipe

from the gas supply line to the 3/8 inch (0,96 cm) pipe located

on the back of the dryer, Use a 1/2 inch (1,27 cm) to3/8 inch

(0,96 cm) reducer for the connection, Apply an approved

thread sealerthat isresistant to the corrosive action of liquefied

gases on all pipe connections,

Page 10

3. Opentheshutoffvalveinthegassupplyline.

4. Testallconnectionsbybrushingonasoapywatersolution.

NEVER TESTFOR GAS LEAKS WITH AN OPEN FLAME.

Drain Hose installation

1. Form a " U " shape on the end of the drain hose with the

hose pointed toward the drain. Placethe formed end in a

laundry tub or a standpipe and secure with a cable tie

provided in the enclosure package. An air gap must ne

around the drain hose. WATER WILL SIPHON FROM THE

WASHER IF THE ABOVE INSTRUCTIONS ARE NOT

FOLLOWED

Cable

3. Turn on the power at a circuit breaker/fuse box.

_ Before operating the dryer, make sure the

dryer areais clearand free from combustible materials, gasoline,

and other flammable vapors. Also see that nothing (such as

boxes, clothing, etc.) obstructs the flow of combustion and

ventilation air.

4. Reinstall the dryer front accesspanel.

5. Run the washer and dryer though a cycle. Check for

proper operation.

NOTE: On gas dryers, before the burner will light, it is

necessary for the gas line to be bled of air. If the burner

does not light within 45 seconds the first time the dryer is

turned on, the safety switch will shut the burner off. If

this happens, turn the timer to "OFF" and wait 5 minutes

before making another attempt to light.

6, If your laundry center does not operate, please review the

"Avoid Service Checklist" located in your Owner's Guide

before calling for service.

7. Placethese instructions in a location near the laundry

center for future reference.

NOTE: A wiring diagram is located behind the dryer front access

panel.

Exhaust Installation

,

Removethe two (2) screws securing the dryer front

accesspanel to the dryer cabinet. Lift the panel until the tabs

can be disengaged from the cabinet. Remove the

panel and set aside.

Access

Panel

Screws

Connect the exhaust duct to outside duct work. Useduct

tape to seal alljoints.

REPLA CEMENT PARTS

If replacement parts are needed for your laundry center, contact

the source where you purchased your laundry center,

_ Destroy the carton, plastic bags, and metal

band after the laundry center isunpacked, Children might use

them for play, Cartons covered with rugs, bedspreads, or plastic

sheets can become airtight chambers causing suffocation, Place

all materials in a garbage container or make materials inaccessible

to children,

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after servicing.

_he instructions in this manual and all other

literature included with this laundry center are not meant to

cover everypossible condition and situation that may occur.Good

safe practice and caution MUST be applied when installing,

operating and maintaining any appliance.

Maximum benefits and enjoyment are achieved when all

the Safety and Operating instructions are understood and

practiced asa routine with your laundry tasks,

2. Plug the power cord into a grounded outlet.

NOTE; Check to ensure the power isoff at a circuit breaker

fuse box before plugging the power cord into an outlet.

10

Page 11

Table des matieres

SUJET PAGE

Avant I'installation .................................................................................................................................................... 11

Exigences electriques .............................................................................................................................................. 11

Exigences d'a Iimentation .......................................................................................................................................... 12

Exigenses de vidange ............................................................................................................................................... 12

Exigenses du circuit d'evacuation ....................................................................................................................... 13-14

Exigenses d'alimentation en gas ............................................................................................................................ 14

Emplacement du combine laveuse/secheus ........................................................................................................... 14

Dimensions de I'emplacement ................................................................................................................................ 15

Installation dans une maison mobile ....................................................................................................................... 16

Deballage ................................................................................................................................................................... 16

Installation electrique .............................................................................................................................................. 17

Exigences de mise a la terre ...................................................................................................................................... 17

Connexions electrique s- 3 fils et 4 fils ................................................................................................................... 18

Installation ........................................................................................................................................................... 19-20

Pieces de rechange ................................................................................................................................................... 20

..............................................................................................................................................................................................................................................................................................................................................i

S_ret e de Combine laveuse/secheuse

Avant de commencer, life attentivement le present document. Cela simplifiera I'installation et assurera la pose

correcte et securitaire de la secheuse. Apres I'installation, laisser ce document a proximite de la secheuse pour reference

future.

REMARQUE : L'alimentation electrique de la secheuse doit respecter les codes et ordonnances Iocaux ainsi que I'edition

la plus recente du Code ANSI/NFPA 70, ou au Canada, le Code canadien d'electricite, ACNOR C22.1, pattie1.

REMAROUE : L'alimentation en gaz de la secheuse dolt respecter les codes et ordonnances Iocaux ainsi que I'edition

la plus recente du Code ANSI Z223.1, ou au Canada, le code CAN/ACG B149.12.

REMAROUE : La secheuse est conque conformement au code ANSI Z 21.5.1 ou ANSI/UL 2158- CAN/ACG C22.2 No.

112 (l'edition la plus recente) pour un USAGE DOMESTIQUE seulement. Cette secheuse n'est pas recommandee

pour utilisation commerciale, comme par exemple un restaurant ou un salon de coiffure, etc.

Pour votre securite, suivre les directives donnees dans le present guide afin de minimiser les

risques d'incendie, d'explosion, de dommages materiels, de blessures et de mort.

Ne pas entreposer ni utiliser d'essence ou d'autres vapeurs ou Iiquides inflammables a proximite de cette secheuse

ou de tout autre appareil electromenager.

QUE FAIRE S'IL Y A UNE ODEUR DE GAZ

• N'allumer aucun appareil electrique.

• Ne toucher aucun commutateur electrique; ne pas utiliser le telephone dans I'immeuble.

• Faire sortir tousles occupants de la piece, de I'immeuble ou de la zone avoisinante.

• Appeler la compagnie de gaz immediate-ment en utilisant le telephone d'un voisin. Suivre les instructions de la

compagnie de gaz.

• S'il est impossible dejoindre la compagnie de gaz, appeler les pompiers.

L'installation et les reparations doivent etre effectuees par un technicien qualifie, un agent de service ou la compagnie

de gaz.

11

Page 12

A VANT L'INSTALLATION

i

Combin_ /a veuse/s_cheuse _ GAZ

]

Outils et materiel requis pour I'installation :

1, Tournevisa pointecruciforme

2, Pincesmultiprise

3, Niveau de menuisier

4, Tournevis a pointe plate ou a lame droite

5, Ruban adhesifpourconduites

6, Conduite en metal rigide ou flexible de 10,2 cm (4 po)

7, Grille de sortie

8, Pate ajoint pour conduites (modele a gaz)

9, Couteau a mastic en plastique

INS TALLA TION ECTRIQ UE

SOcheuses£LECTR/OUES

CIRCUIT- Derivationdistincte de 30 Aavec fusiblesa retardement

ou disjoncteurs d'au moins 30 A,

ALIMENTAT/ON L'LECTRIQUE- 3 fils, 240 volts, une phase,

60 Hz, courant alternatif, (Canada- 240 volts, unephase, 60 Hz,

courant alternatif,)

CORDON D'AL/MENTA TION_'LECTRIQUE- LasecheuseDOlT

etre relieea uncordon d'alimentation electrique a3 conducteurs

NEMA 10-30 detype SRDTd'une capacite minimale de 240 volts,

courant alternatif, 30 A, avec fiche en La 3 broches pleines ou

repliees conque pour le branchement d'une secheuse, Si la

secheuse est installee dans une maison prdabriquee (maison

mobile), elle DOlT etre reliee a un cordon d'alimentation

electrique a4 conducteurs NEMA 14-30 detype SRDTou ST(au

besoin) d'une capacite minimale de 240 volts, courant alternatif,

30 A, avecfiche en La4 broches pleinesou replieesconque pour

ie branchement d'une secheuse, Se reporter a ia section

BRANCHEMENT ELECTRIQUED'UNE INSTALLATIONA 4 FILS,

(Canada - Cordon d'alimentation a 4fils branche alasecheuse,)

PRISE- Prise NEMA 10-30R situee de faqon ace que le cordon

d'alimentation electrique soit accessible une lois lasecheuse en

place, (Canada- prise NEMA de 14-30R,)

CIRCUIT- Derivation distincte de 15 A avecfusible aretardement

ou disjoncteur d'au plus 15 A,

AL/MENTATIONL'LECTR/QUE- 3fils, 120 volts, une phase, 60

Hz,courant alternatif,

CORDOND'AL/MENTAT/ON -Lecombine laveuse/secheuse a

gazestd'un cordon d'alimentation electrique a3 fiisde 120 volts,

/CL'm.

REMARQUE : II ne faut { _J [_ _

e°a"c"nc°"e"rer I/

broche de mise _ la t _ _

\)rx

\ (l BROCHEOEMrSE

_ A LA TERRE

EXIGENCES D'ALIMENTATION EN EAU

Les robinets d'eau chaude et d'eau chaude et d'eau froide

DO/VENTentre installes a moins de 42 pounces ( 106,68 cm )

de I'arrivee d'eau du combine, Lesrobinets DO/VENTtre du

type pour boyau dejardin de 3/4 pounce (1,9 cm), de maniere

a pouvoir raccader les boyaux d'arrivee d'eau, La pression

d'eau DO/Tse siteur entre 10 et 120 livres par pounce carre (

desequilibre de pression maximale, eau chaude vs eau froide,

10 psi ), Leserviced'aqueduc peut vous informer sur la pression

d'eau,

EXIGENCES DE VIDANGE

1, Lecircit de vidange dolt permettre d'evacuer 17gallons a la

minute,

2, Le diametre du tuyau de vidange dolt etre d'un minimum

de 1 - 1/4 po (3,18 cm),

3, La hauteur hors sol du tuyau de vidange dolt etre :

Minimale: 33 po (83,82 cm)

Maximale: 96 po (244 cm)

NEMA 10-30R NEMA 14-30R

f

T

33 po

Min. (83.82cm)

NOTA: Si I'installation necessite un tuyau de vidange plus

long, demandez a un technicien qualifie d'installer un boyau

de vindage plus long, P/N 131461201, disponsible chez un

distributeur autorise de pieces, Pour lescircuits de vidange au

sol, installez un ensemble de siphon, se procurer aupres d'une

quincaillerie locale,

12

Page 13

EVACUATION DE L'AIR

Utiliser uniquement une conduite en metal rigide ou flexible de

10,2 cm (4 po) de diametre (minimum) ainsi qu'une grille de

sortie approuvee pourvue de clapets qui s'ouvrent Iorsque la

secheuse fonctionne, Quand la secheuse s'arrete, les clapets se

ferment automatiquement pour eviter les courants d'air et I'entree

d'insectes ou de rongeurs, Afin de ne pas obstruer I'evacuation

de I'air, laisser une distance minimum de 30,5 cm (12 po) entre

la grille de sortie et le sol ou tout autre obstacle,

Les mises en garde qui suivent se

rapportent directement au fonctionnement correct et

s_curitaire de la secheuse. Toute derogation aces mises

en garde pourrait ralentir le s_chage et entra_ner des

risques d'incendie.

Pr_ N'utiliser pas de conduit souple en plastique ou en metallique

pourevacuerl'airdela secheuse, Unequantiteexcessivede

charpie pourrait s'accumuler dans la conduite d'evacuation, ce

qui reduirait la circulation de I'air et presenterait un risque

d'incendie, Toute obstruction de la circulation de I'air ralentit le

sechage, Si la conduite existante est en plastique ou en papier

metallique, la remplacerparuneconduiteen metalrigideou

flexible, S'assurer qu'il n'y a pas de charpie clans la conduite

existante avant d'installer la conduite de la s@cheuse.

_CORRECT

N

Ne laisser aucun materiau inflammable (comme des

vetements, des tentures, des rideaux ou du papier) entrer en

contact avec les conduits d'evacuation, L'air de la secheuse NE

DOITPAS etre evacue dans une cheminee, un mur, un plafond ni

tout espace ferme d'un b3timent ou la charpie pourrait

s'accumuler et presenter un risque d'incendie,

Pr_ Augmenter la Iongueur du conduit rigide ou le nombre de

coudes permis au tableau _LONGUEUR MAXIMUM_ risque de

reduire la capacite d'evacuation du circuit, Obturer le circuit peut

creer un risque d'incendie et augmenter le temps de sechage,

ONe pas poser de grillage sur I'ouverture exterieure des conduites

d'evacuation d'air ni utiliser des vis ou des rivets pour assembler la

conduite d'evacuation, De la charpie pourrait s'emprisonner dans

le grillage ou sur les vis ou les rivets et ainsi engorger la conduite

d'evacuation en plus de presenter un risque d'incendie et de ralentir

le sechage, Utiliser une grille de sortie approuvee pour fermer

I'ouverture exterieure et sceller tous lesjoints a I'aide d'un ruban

adhesif pour conduites, L'extremite male de chaque composante

de la conduite DOITetre installee en aval par rapport a la circulation

de I'air,

Risques d'explosion. Ne pas installer la

secheuse 3 un endroit ou I'on garde de la gazoline ou tout autre

produit inflammable, Si la secheuse est installee dans un garage,

elle dolt etre a un minimum de 45,7 cm (18 po) au-dessus du

plancher, Toute derogation pourrait provoquer la mort, I'explosion,

I'encendie ou les br01ures,

1, Lacontre-pression du circuit d'evacuation ne DOlT pas

exceder 0,6 ponces (1,52 cm) de colonne d'eau, mesuree

avec un manometre a tube incline au point ou ie conduit

d'evacuation est connecte secheuse,

2, ii taut verifier et nettoyer ie circuit d'evacuation au moins

tousles deux ans dans des conditions d'utilisation normale,

Plus ia secheuse est utiiisee frequemment, plus ie circuit

etie registre d'evacuation doivent etre verities pour assurer

un bon,

i¸

_Si I'air n'etait pas repousse a I'exterieur de la maison, de

petites particules de charpie se retrouveraient dans la piece ou

est installee la secheuse, Toute accumulation de charpie dans la

maison peut presenter des risques pour la sante et des risques

d'incendie, La conduite d'evacuation de la s_cheuse

DOIVENT se terminer b I'ext_rieur de la maison!

La Iongueur maximum du system d'evacuation depend du type

de conduit utilise, du nombre de coudes et du type de registre

d'evacuation, La Iongueur maximum de conduits rigides et

flexibles est indiquee dans le tableau suivant:

LONGUEUR MAXIMUM

TYPE DE REGISTRE D'EVACUATION

Nombre

de

coudes

b 90°

(s.3s cM)

LONGUEUR MAXIMUM d'une conduite

en metal rigide de 10,16 cm (4 po) de diam.

0

1

2

3

en metal flexible de 10,16 cm (4 po) de diam.

0

1

2

3

56 ft. (17.07 m)

46 ft. (14.02 m)

34 ft. (10.36 m)

32 ft. (9.75 m)

LONGUEUR MAXIMUM d'une conduite

30 ft. (9.14m) 22 ft. (6.7m)

22 ft. (6.7 m) 14 ft. (4.27 m)

16 ft. (4.88 m) 10 ft. (3.05 m)

lOft. (3.05m) 5ft. (1.5m)

42 ft. (12.8 m)

36 ft. (10.97 m)

28ft. (8.53m)

18 ft. (5.48 m)

13

Page 14

L'evacuation du combine laveuse/secheuse par un circuit

d'evacuation arriere peut se faire de quatre (4) facons:

1, En ligne droite,

2. Vers le bas (8 pounces (20,32 cm) de Iongueur pour un

conduit de 4 pounces (10,16 cm) rigide & 1 coude vers le

bas).

3. A gauche (8 pounces (20,32 cm) de Iongueur pour un con-

duit de 4 pounces (10,16 cm) rigide, 1 coude vers le bas &

1 coude a gauche).

4. A dreite (8 pounces (20,32 cm) de Iongueur pour un conduit

de 4 pounces (10,16 cm) rigide, 1 coude vers les bas & 1 --_

coude a droite).

Pour une evacuation vers ia haut, ajoutez

une Ionueur de 11 pounces (27,94 cm) de

conduit standard de 4 pounces (10,16 cm) et

un coude de 90 °, L'appareil se situera a

une distance d'environ 4-1/2 ponces

(11,43 cm) du mur (une evacuation sans

degagement au mur peut sefaire en

passant sous la secheuse puis sur lescotes).

Un registre d'evacuation aligne

directement avec iasortie d'evacuation

de ia secheuse peut etre instaiie

directement dans iemur exterieur. Pour une

evacuation vers le haut, ajoutez ue Iongueur de 11 pounces (27,94

cm) de conduit standard de 4 pounces (10,16 cm) et un coude de 90°,

L'appareil sesituera a une distance d'environ 4-1/2 pounces (11,43 cm)

du mur ( une evacuation sans degagememt au mur peut se faire en

passantsous Issecheusepuis sur lescotes). Pour evacuer sur le cote ou

vers le bas, ajoutez une Iongueur de 8 pounces (20,32 cm) de conduit

standard de 4 pounces (10,16 cm) et un coude de 90°.

ALIMENTATION EN GAZ

Remplacer le tuyau de

raccordement en cuivre non recouvert de plastique.

I!FAUTutiliser du laiton inoxydable ou recouvert de

plastique.

1. L'installation DOITrespecter lescodes Iocaux, ou s'il

n'existe pas de codes Iocaux, le code ANSI Z223.1

(l'ed ition laplusrecente) ou auCanada, leCode actuel

CAN/CGA B149.

2. Laconduite d'alimentation engazdoit mesurer 1,27 cm

(1/2 po).

3. Si lescodes le permettent, un tuyau en metal flexible

peut etre utilise pour connecter la secheuse

I'alimentation en gaz. Letuyau DOITetre fabrique en

acier inoxydable ou en cuivre avec un revetement de

plastique.

4. Lacondu ired'al imentation engaz DOITcom porter un

robinet d'arret distinct.

5. Une prise de 0,32 cm (1/8 po) NPTaccessible pour le

branchement d'un manometreDOITetre installeetout

juste en amont du branchement de la conduite

d'alimentation en gazsur la secheuse.

6. Lasecheuse DOITetre debranchee de lacanalisation

de gaz pendant route verification de pression de

I'alimentation en gaz a des pressions qui depassent

3,45 kPa (1/2 Ib/po2).

7. LasecheuseDOITetre isolee de lacanalisation de gaz

pendant route verification depressionde I'alimentation

en gaz a despressionsegalesou inferieures a 3,45 kPa

(1/2 Ib/po2).

EMPLA CEMENT DU COMBINEE LA VEUSE/ SECHEUSE

NEPASINSTALLER COMBINL"LAVEUSE/SL'CHEUSE:

1. Dans un endroit expose a un ecoulement d'eau ou aux conditions atmospheriques.

2. Dans un endroit o0 elle serait en contact avec des rideaux, draperies ou tout ce qui obstruera leflux d'air de combustion et de

ventilation.

3. Sur un tapis. Le plancher DOITetre ferme et presenter une pente de 2,54 cm (1 po) au maximum.

INSTALLATION DANS UNEAL COVEOU UN PLACARD

1. Toute secheuse installee dans une chambre acoucher, une sallede bain, unealcove ou un placard DOITetre relieea une conduite

d'evacuation d'air seterminant a I'exterieur de la maison.

2. Aucun autre appareil br01ant du combustible ne doit etre installe dans le meme placard que la secheuse au Gaz.

3. Lasecheuse a besoin d'un degagement sufHsant pour permettre la circulation de I'air.

NEPASINSTALLERLA SECHEUSEDANS UN PLACARD POURVU D'UNEPORTE PLEINE.

4. Uneouverture minimum de 774,2 cm2(120 po2)repartie egalement entre le haut et lebasde laporte est requise. Cette ouverture

nedolt pas etre obstruee Iorsque la porte esten place. Uneporte avolets dont les ouvertures totalisent la norme decrite ci-dessus

est acceptable.

5. Lesillustrations qui su ivent indiquent ladimension minimum de degagement pour un fonctionnement adequat dans une niche ou

unearmoire, 0 po 0 po 1 po ; h ',i 0 po

(0CM)_ _ (0CM) (2.54 CM_,, _ _(0 CM)

z_k_ c

sQ.c,v,)

T

PORTEDUARMOIRE

60 SQ. IN. LAVEUSE

14

(387 1 SQ __) !

/

/

Page 15

53 IN.

(134.62 CM.)

111.76 CM

A

31% IA

(80.65 C,

44 IN.

12y, IN........._l.-------_t 93/8 IN.

(31,75 CM1 / I (23,_..M_

VENT"_,_ /4"-

_.ONNEXCIONS ELECTRIQUES

-0 ( }ARRIVEES D'EAU

T

_..

(ARRIERE)

/

i,

Dimensions de I'emplacement

16 1/4IN,

(41,27 CM)

TUYAU D'ALIMENTATION

E---NGAZ (ARRI_'RE)

'T

421/4IN.

(107.32 CM.)

401/2IN.

(102.87 CM.)

f

l f

36 IN.

(91.44 CM.)

25 1AIN,

(64.13 CM)

47"

(6.35CM)

L j

1 7/8 IN,

(4,76 CM)

__ 3-1/81N.

(7.94 CM.)

2 1/2IN,

3 _Y4IN,

(9,52 CM)

'IDANGE (ARRIERE)_

t,_--- 27 IN,

(68,58CM)

17Y2IN.

(44.45 CM.)

!

l_

29% IN.

(75.57 CM.)

3IN.

U

(7.62_M.)

Page 16

INSTALLATION DANS UNE

MAISON MOBILE

1, L%vacuationde la secheuseDOITse faire

I'exterieur (a I'exterieur et non pas au-

dessousdelamaisonmobile) a I'aide

de conduit en metal inflammable, Les

conduitsen metal doivent avoir 4

pounces (10,16 cm) de diametre sans

obstructions, Lesconduits en metal rigide

sont preferables,

2, Si I'evacuation de la secheuse se fait

travers le plancher et que I'espace sous

la maison mobile est ferme, le circuit

d'evacuation DOITse terminer en dehors

de I'espace ferme, et la sortie bien fixee

la structure de la mason mobile,

3, Rderez-vous a la page 3 pour de plus

amples informations sur lesexigences de

ventilation,

DL-BALLAGE

1, A I'aide des quatre encoignures d'expedition (deux de chaque cote) posez avec

attention le combine sur le cote gauche et enlevez la base de caoutchouc mousse,

Poids excessif. Faites dOplacer le Centre de buanderie

par deux personnes ou plus.

ENCOIGNURES

D'EXPI_DITION

BASE

D'EXPI_DmON

EN MOUSSE

2, Replacez le combine laveuse/secheuse a la verticle,

3, Retirer les pieces suivantes de I'arriere de la laveuse :

4 boulons

4 entretoises en plastiquejaunes

3 attaches metalliques en forme de "R" x

4, Lors de I'installation d'une secheuse

gaz dans une maison mobile, il faut

prevoir un apport d'air exterieur,

L'espace a prevoir dolt etre superieur

deux lois celui du conduit d'evaccuation

de la secheuse,

5, L'installation DOlT respecter lesnormes

de la ManufacturedHome Construction

and Safety,(reglement federal titre

24CFR,partie 32-80), ou en leur absence,

les normes de la American National

Standard pour maisons mobiles, Lorsque

L'installation sefait au Canada, elle dolt

se conformer a la norme ACNO

RZ240,

Le combine est

conque conformement a la norme ANSI

Z 21,5,1 pour un USAGE DOMESTIQUE

seulement,

4, Retirer le panneau avant de la laveuse,

5, Demontez les 4 ecrous et les 6 grosses

rondelles qui retiennent lesdeux attaches

d'expeditionjaunes au tambour eta la

base, Soulevezletambouretretirezles

attaches (un rubanjaune entoure les

elements aretire@,ilfaut retirer cesattaches

afin de liberer le cordon d'alimentation des

anneaux d'expedition,

6, Retirer legrand morceau de styrofoam situe

sousletambour, Soulever letambour,

basculer le basdu morceau de moussevers

I'interieur et vers I'arriere de la laveuse

jusqu'a ce qu'il sedegage, puis le sortir en

tirant,

,

Retirer etjeter le rubanjaune et I%tiquette

du devant de lalaveuse,

8, Remonter le panneau de service et lesvis,

,

Avant d'entreprendre I'installation,

deplacez precautionneusement le

combine a environ 4 pieds (1,22 m) de

son emplacement final,

REMARQUE: Dans I'eventualite o@ la

machine a laver dolt 6tre transportee 8

une date ulterieure, il faut reinstaller la

quincaillerie d'expedition, lesattaches et

supports, pour prevenir tout dommage

durant I'expedition,

/

ATTACHES EN_ "

FORME DE 'P'

'/cio

/

16

Page 17

INSTALLATION ELECTRIOUE

i

TOUS combin_es /aveude/s_cheuses £LECTR/OUES 1

V!_ Les raises en garde qui suivent se

rapportent directement au branchement _lectrique correct

et s_curitaire de la s_cheuse. Toute d_rogation b cesraises

en garde pourrait entra_ner des risques choc _lectrique et

d'incendie.

Pour brancher la secheuse en permanence :

Lacombine DOITetre branchee a une installation metallique

raisea latorte enpermanence; sinon, un conducteur de raise

latorte de I'appareil dolt suivrelosconducteurs du circuit et

etre branche a la borne ou a la connexion de raise a la torte

de I'appareil,

I Combin_/aveuse/s_cheuses£LECTR/OUES canadiennes 1

Cot appareil DOITetre convenablement misa laterre, Sile

combine presenterait des risques choc @ectrique si elle n%tait

pas convenablement mise a latorte, Respecter los directives de

raise a la torte contenues dans cette notice pour une raise a la

torte correcte,

Ne pas utiliser de cordon de rallonqe avec ce combine,

Certai ns cordons de rallonge ne sont pasconqus pour supporter

I'intensiW ducourant qu'utilise cette combine; ilspeuvent tondre

et presenter un risque choc @ectrique ou d'incendie, Placerla

secheuse a portee de la prise murale ann de determiner la

Iongueur du cordon a acheter et prevoir un certainjeu dans la

Iongueur du cordon, Sereporter a lasection <<AvantI'installation>>

de cette notice pour savoir quel type de cordon acheter,

Un detendeur approuve par U,L, doit etre tixe au cordon

d'alimentation, Sile detendeur n%tait pas present, le cordon

pourrait etre attache de la combine ou coupe par tout type de

mouvement, ce qui presenterait un risque choc @ectrique,

Ne pasutiliser une prise a conducteurs en aluminium avec

un cordon ou une prisea conducteurs encuivre (nil'inverse), Une

reaction chimique se produit entre le cuivre et I'aluminium qui

pourrait causer un court-circuit, II faut utiliser un cordon

d'alimentation _ conducteurs en cuivre avec une prise b

conducteurs en cuivre.

REMARQUE : Le d_lai s_chage d'un combin_ laveuse/

s_cheuse qui fonctionnent avec une alimentation de 208

volts auront un temps de s_chage plus long que cellos qui

utilisent une alimentation de 240 volts.

_Le branchement inadequat du conducteur de

mise a la terre pourrait presenter un risque choc @ectrique, En

cas de doute quanta la mise a la torte adequate de I'appareil,

contacter un @ectricien agree,

Pour brancher et mettre a laterre lasecheuseaI'aide d'un cordon

d'alimentation :

1, La secheuse dolt etre raise a la torte, En cas de mauvais

tonctionnement ou de panne, la raise a la torte reduit los

risques choc @ectrique en otfrant un parcours de moindre

resistance au courant,

2, Puisque lasecheuse est pourvue d'un cordon d'alimentation

@ectriquecomportant un conducteur et une tiche de torte, la

tiche doit etre branchee dans une prise murale aconducteur

en cuivre convenablement raccordee au reseau et raise ala

torte contormement atous loscodes et ordonnances Iocaux,

Encasde doute, contacter un @ectricien agree,

TOUS combin#s /aveuse/s_cheuses _ GAZ

Pour votre protection contre los chocs @ectriques, la secheuse

est equipee d'une tiche atrois bornes (mise ala torte) et doit etre

branchee directement dans une prise a 3 bornes correctement

mise a la torte, Ne pas couper ni enlever la tiche de mise a la

torte de cette prise,

MISE A LA TERRE

i #cheuses£LECTRlOUESnon-canadiennes 1

_Le branchement inadequat du conducteur de

mise a la torte pourrait presenter un risque choc @ectrique, En

cas de doute quant a la mise a la torte adequate de I'appareil,

contacter un @ectricien agree,

Pour brancher et mettre alaterre lasecheusea I'aided'un cordon

d'alimentation :

1, Las combine DOITetre mise a la torte, En cas de mauvais

tonctionnement ou de panne, la raise a la torte reduit los

risques choc @ectrique en ottrant un parcours de moindre

resistance au courant,

2, Silacombine estpourvued'uncordon d'alimentation

@ectriquecomportant un conducteur et une tiche de torte, la

tiche DOITetre branchee dans une prisemurale aconducteur

en cuivre convenablement raccordee au reseauet raise a la

torte contormement atous los codes etordonnances Iocaux,

Encas dedoute, contacter un @ectricien agree,

17

Page 18

Combin_ /aveuse/s_cheuses £LECTRIOUES

Non-canadien i

Non-canadien

Combin_s/aveuse/s_cheuses£LECTRlOUES

BRANCHEMENT ELECTRIQUED'UNE INSTALLATIONA 3 FILS

l,

Retirer lesvis qui retiennent le couvercle

du panneau de branchement ainsi que le

support de montage du detendeur situes

dans le coin superieur a I'arriere de la

secheuse,

2, Poserun detendeur approuve par U,L,dans

le trou du support o@s'insere le cordon d'alimentation,

3, Enfiler un cordon d'alimentation NEMA 10-30 approuve par

U,L,de 30 A de type SRDTdans le detendeur,

VIS DE MISE A LA

TERRE VERTE

FILDE

TERRE

NEUTRE

BRANCHEMENTELECTRIQUE D'UNE INSTALLATIONA 4FILS

l,

Retirer lesvis qui retiennent le couvercle

du panneau de branchement ainsique

lesupport de montage du detendeur

sit ues dans le coin superieur a I'arriere

de la secheuse,

,

Poserun detendeur approuve par U,L,dansletrou du support,

Setter simplement I%crou a la main pour le moment,

,

Retirer le fil de terre de lavis de mise a la terre verte neutre

situee au-dessus du panneau de branchement,

VIS DE MISE A CONDUCTEUR BORNE

TERRE VERTE DE TERRE ARGENT_'E

PANNEAU DE

FIL DE NOIR

NEUTRE

VERT BLANC

,

Fixer le conducteur neutre (conducteur central) du cordon

d'alimentation a laborne centrale argentee du panneau de

branchement, Setter la visa fond,

,

Fixerlesdeux conducteurs restants du cordon d'alimentation

aux bornescuiv@esexterieuresdu panneau de branchement,

Setter les deux visa fond,

,

Serrer afond lesvisqui retiennent ledispositif de retenue du

cordon autour du cordon d'alimentation,

7, Reattacher lecouvercle du panneau de branchement,

SUPPORT DE

MONTAGE DU

D_-TENDE\UR

CORDON

D'AUMENTATION

,

Enfilet un cordon d'alimentation NEMA 10-30 approuve par

Ui, de 30 A de type SRDTdans le detendeur,

,

Fixerle fil de terre vert du cordon d'alimentation au boitier

de la secheuse a I'aide de la vis de mise a la terre verte,

,

Fixerleconducteur blanc (neutre) du cordon d'alimentation

ainsi que le fil de terre du boitier de la secheuse a la borne

centrale argentee du bloc de branchement,

,

Fixerlesconducteurs rouge et noir du cordon d'al imentation

auxbornes cuiv@esexterieuresdu panneau de branchement,

,

Serrer afond lesvis quiretiennent le dispositif de retenue du

cordon autour du cordon d'alimentation,

9, Reattacher lecouvercle du panneau de branchement,

18

Page 19

INSTALLATION

Mise _ niveau de la laveuse:

Le bruit et la vibration excessits loeuvent etre emloeches en

nivelant correctement ia iaveuse,

1, Pour I'installation debout libre et avec la laveuse/secheuse

en elle est la position tinale, lolacent un niveau sur la laveuse/

secheuse , Ajustez lesjambes de mise a niveau ainsi la

iaveuse/secheuse est, et coin-a-coin stable de i'avant a

i'arriere et vertical de niveau,

Alolouyezdes coins et des cotes alternatits et sentez pour ie

plus leger mouvement, Ajustez lajambe alolorolorieeainsi la

laveuse est PLEINEsur le lolancher sur CHACUNE DESquatre

jambes, Gardez la prolongation de mise a niveau dejambe

a un minimum pour la meilleure execution de la laveuse/

secheuse,

Raccordements De Laveuse

1, Faitescouler de I'eaudans lesrobi nets d'eau chaude et troide

pour purger lesconduites d'eau et lesdebarrasser desloartic-

uies loouvant obstruer ie tamis du robinet d'eau,

BRANCHEMENTDU GAZ (Combine a gazseulement)

1, Retirer lecouvercle qui recouvre le tuyau de gaz a I'arriere

de la secheuse,

REMARQUE: NE PAS brancher la combine sur une alimentation

au propane sans avoir pose un necessaire de

conversion, Ce necessaire dolt etre instaiie par

un technicien agree,

2, Brancher un tuyau semi-rigide ou alolorouvede 1,27 cm

(1/2 loo) de diametre interieur entre la conduite

d'alimentation en gazet letuyau de 0,96 cm (3/8 loo)situe

sur i'arriere de iasecheuse, Utiiiser unreducteur de 1,27 cm-

0,96 cm (1/2 loo-3/8 loo)pour lebranchement, Alololiquerun

mastic de termeture pour filets alolorouve qui resiste a la

corrosion qu'exercent les gaz liqudies sur tousles raccords

detuyaux,

3, uvrir ierobinet d'arret de iaconduite d'alimentation en gaz,

, Veritier tousies branchements enversant dei'eau savonneuse

sur iesjoints,

NE JAMA/S V_'RIF/ERS'/L YA DESFUITES A L'AiDE

D'UNE FLAMME VIVE,

Boyau de Vindage

,

Reloliezle boyau de vindage pour tormer un <U> a son

extremite en direction de i'evier ou du tuyau d'egout,

disloosezle boyau dans I'evier ou le tuyau d'egout, et tixez-

leavec une attache de cable tournie dans I'envelololoejointe,

L'EAU SERASIPHON-NEE DE L'APPAREIL Si LES

INSTRUCTIONS PR_CIT_ESNE SONT PAS PAS SUIVIES.

2, Veitiez les boyaux d'arrivee d'eau pour assurer que les

rondelies en caoutchouc sont instaiiees a chaque extremite,

3, Connectez soigneusement lesboyaux d'arrivee au robinet

d'eau (agaunch de I'aloloareil),serrez a la main, louisserrez

2/3 de loinces,

•' " ' "' IL NE FAUTPAS FAUSSER LEFILETAGE

OU TROPSERRERCESRACCORDEMENTS.

4, Delolacezquel est lerobinet d'eau CHAUD et branchez soig-

neusement ietuyau d'arrivee interieur au robinet d'eau

CHAUDE serreza la main louisserrez2/3 detour sulololement-

aire a I'aide de loinces, Branchez soigneusement le tuyau

d'arrivee suloerieurau robinet d'eau FROIDE,serrez a lamain

louisserrez 2/3 de tour sulololementaire a I'aide de loinces,

l '. " ' " " IL NEFAUT PAS FAUSSERLEFILETAGE

OU TROPSERRERCESRACCORDEMENTS.

Ouvrez I'eau et veritiez qu'il n y a aucune tuite dans les

raccords,

19

Page 20

h'VACUATION DE L'AIR

l,

Retirez lesdeux vis fixant le panneau d'acces avant de la

secheuse a la carrosserie de la secheuse. Soulevez le

panneaujusqu'a degagement des attaches. Retirez le

panneau et mettez-le cote.

deux vis

fixant le

panneau

d'acces

1O.Reliezlesconduits d'evacuation d'air conduit d'evacuation

extetieur. Utilisez un ruban adhesif pour conduits pour

sceller lesjoints.

11. Brancher lecordon d'alimentation @ectrique dansune prise

mise a la terre. REMARQUE : S'assurer que le courant est

coupe a la boite de fusibles ou de disjoncteurs avant de

brancher lecordon d'alimentation dans une prise.

12. Remettre lecourant a laboite de fusibles ou de disjoncteu rs.

Avant d'utiliser la combine, s'assurer que les

environs de la secheuse sont exempts de tout materiau

inflammable, d'essence et de route autre vapeur inflammable.

S'assurer egalement qu'aucun objet (boftes, vetements, etc.)

n'obstrue la circulation de/'air servant a lacombustion eta la

ventilation.

13. Fairefonctionner la laveuse/secheusesur un cyclecomplete

pour en verifier lefonctionnement.

14. Si lacombine ne fonctionne pas, passeren revue la section

de depannage inclus dans le Guide de I'utilisateur avant

d'appeler un centre de service.

15. Placercette notice presde lacombine pour reference future.

REMARQUE: Un schema de cablage setrouve dans le panneau

de commande ou sous le couvercle de lasecheuse.

PIECES DE RECHANGE

Pour obtenir des pieces de rechange pour la laveuse/secheuse,

contacter le magasin d %@vient la secheuse.

Lots de tout travail d'entretien ou de

reparation des commandes, etiqueter tousles cables avant de

les debrancher. Les erreurs de connexion de cable peuvent

entrainer un fonctionnement incorrect etdangereux. Une lois la

reparation ou I'entretien termine, assurez-vous que I'appareil

fonctionne correctement.

Detruire le carton et lessacs en plastique

apres avoir debal le lacornbine. Desenfants risqueraient de s'en

servir commejouet. Lescartons recouverts d'un tapis, d'un

couvre-lit ou d'une feuille de plastique peuvent former une

chambre etanche etfaire suffoquer un enfant. Placer lemateriel

d'embal lage dans unepoubelle ou lesmettre hors de portee des

enfants.

Lesdirectivesquifigurent danscette notice

et dans lesautres documents qui accompagnent lasecheuse ne

sauraient couvrir toutes les circonstances et les situations

possibles.ILFAUTdonc faire preuve dejugement etde prudence

pendant I'installation, I'uti lisation et I'entretien de tout appareil

@ectromenager.

Losque toutes les instructions sur la securite et le

fonctionnement sont bien comprises et qu'elles sont

appliquees regulierement, vous pouves profiter au

maximum des advantages de I'appareil.

REMARQUE: Dans le cas des laveuse/secheuses a gaz, la

conduite doit etre videe de son airavant que le br@leurne

puisse s'allumer. Si le br@leur ne s'allume pas dans les

45 secondes qui suivent le premier demarrage, I'interrupteur

de sOreteeteint automatiquement le br@leur.Sicela seproduit,

remettre la minuterie a <<OFF>>et attendre 5 minutes avant de

tenter une nouvelle lois d'allumer lebr@leur.

2O

Loading...

Loading...