FRIGIDAIRE FPHB2899PF User Manual

PERFORMANCE DATA NO LOAD & NO DOOR OPENINGS AT 37°/0°

CONTROL SETTING

Type A with Run / Start Capacitor |

|

65°F (18°C) Ambient |

90°F (32°C) Ambient |

|||

|

|

|

|

|

|

|

Operating Time |

|

90 to 100% |

100% |

|||

|

|

|

|

|

|

|

Freezer Temperature |

|

-5° to 2°F (-20° to -17°C) |

-1° to 3°F |

(-18° to -16°C) |

||

|

|

|

|

|

|

|

Refrigerator Temperature |

|

34° to 39°F (1° to 4°C) |

34° to 39°F (1° to 4°C) |

|||

|

|

|

|

|

|

|

Low Side Pressure |

|

-2 to 6 psig ( -14 to 41 kPa) |

-2 to 6 psig |

(-14 to 41 kPa) |

||

|

|

|

|

|

|

|

High Side Pressure (last 1/3 cycle) |

|

85 to 105psig (586 to 724kPa) |

120 to 135 psig (827 to 931 kPa) |

|||

|

|

|

|

|

|

|

Wattage (last 1/3 cycle) |

|

30 to 50 |

50 to 70 |

|||

|

|

|

|

|

|

|

Amps (running) |

|

.4 to .8 |

.7 to .9 |

|||

|

|

|

|

|

|

|

Base Voltage |

|

115 vac (127 vac max) |

|

|

|

|

|

|

|

|

|

|

|

|

DEFROST SPECIFICATIONS |

|

|

|

||

|

|

|

|

|

|

|

Cabinet Size |

|

Thermostat |

Heater |

|||

|

|

|

|

|

|

|

|

Cut-in |

Cut-out |

Watts |

|

Ohms |

|

|

|

|

||||

|

|

|

|

|

|

|

26’ & 28’ SD, 23’ CD |

|

25°F (-4°C) |

47°F (8°C) |

500 |

|

26.5 |

|

|

|

|

|

|

|

Electronic Timer - (ADC) Defrost 24 minutes every 6-96 hours of compressor run time.

CONDENSER FAN MOTOR

Watts |

|

RPM |

|

Amps |

|

|

|

|

|

|

|

3.1 |

|

1100 CW Opposite Shaft |

|

0.03 Running |

|

|

|

|

|

|

|

|

FREEZER ICE MAKER SPECIFICATIONS |

|

|

||

|

|

|

|

|

|

Electrical |

|

115 vac (127 vac max) |

|

|

|

|

|

|

|

||

Thermostat |

|

Opens at 48°F ( 9°C), Closes at 15° F ( -9°C) |

|

||

|

|

|

|

|

|

Heater Voltage |

|

115 vac |

|

|

|

|

|

|

|||

FREEZER ICE MAKER CONNECTOR PLUG CONNECTIONS |

|

||||

|

|

|

|

|

|

Wire Number |

|

Wire Color |

|

Connects to: |

|

|

|

|

|

|

|

1 |

|

Green / Yellow |

|

Ground |

|

|

|

|

|

|

|

2 |

|

Yellow |

|

Water Valve |

|

|

|

|

|

|

|

3 |

|

Black |

|

Line |

|

|

|

|

|

|

|

4 |

|

Light Blue |

|

Neutral |

|

|

|

|

|

|

|

FREEZER ICE MAKER INFORMATION

(Where Applicable)

Test Cycling: Remove cover by inserting screwdriver in notch at bottom and prying cover from housing. Use screwdriver to rotate motor gear counterclockwise until holding switch circuit is completed. All components of ice maker should function to complete the cycle.

Water Fill Volume: The water fill adjustment screw will change the fill time. One full turn is equal to 20cc (.68 oz.). The correct fill is 102 to 130cc (3.4 to 4.3 oz.). When a water valve is replaced, the fill volume must be checked.

Water Fill |

|

Adjustment |

|

Motor |

|

Gear |

|

N |

Mounting |

|

Plate |

|

Screws |

Mounting |

|

Plate |

|

Screw |

|

|

Timing |

|

Gear |

CAUTION

CAUTION

All electrical parts and wiring must be shielded from torch flame. DO NOT allow torch to touch insulation; it will char at 200°F and flash ignite (burn) at 500°F. Excessive heat will distort the plastic liner.

|

|

|

|

|

|

|

|

|

SERVICE DATA SHEET |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A00606101 |

|

|

|

|

|

|

|

|

|

ICE & WATER - AUTOMATIC DEFROST |

|||||||

|

|

|

|

|

|

|

|

|

BOTTOM FREEZER - R134a |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

||||||||||||

|

|

|

|

IMPORTANT: PLEASE RETURN THIS SHEET TO ITS ORIGINAL LOCATION. |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Error Codes |

|

|

|

|

|

Special Modes |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Display |

|

|

|

|

|

|

|

Display |

|

|

Activate/Deactivate |

||||

|

|

|

|

|

|

Interpretation |

|

Mode |

|

|

|

|

(press for up to 10 sec. simultaneously) |

|||

|

FZ |

|

FF |

FZ |

|

FF |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-- |

|

|

OP |

|

Open FF Thermistor |

|

Manual Defrost |

|

d |

|

F |

|

+ and - / same to deactivate |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OP |

-- |

|

Open FZ Thermistor |

|

Display / Showroom |

77 |

|

77 |

|

٨ and - / Power-on-Reset (POR) |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-- |

|

|

SH |

|

Shorted FF Thermistor |

|

Sabbath |

|

Sb |

|

Sb |

|

٧ and + / same to deactivate |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

Shorted FZ Thermistor |

|

System Diagnostic |

No FF or FZ display, all |

|

٨ and ٧/ + to deactivate |

|||||

|

SH |

-- |

|

|

|

|

|

|

|

UI LEDs on. |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

UI to Main Control |

|

FFIM Diagnostic |

Numerical display of |

|

٨ and + together to activate / |

|||||

|

SY |

|

CF |

|

Board communication |

|

|

|

|

first test |

|

|

press and hold + to deactivate |

|||

|

|

|

|

|

|

failure; on start up |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

UI Main Control Board |

|

Notes: |

|

|

|

|

|

|

||

|

SY |

|

CE |

|

communication error; after |

• Always check for pin back-outs, pinched or damaged wires before replacing components. |

||||||||||

|

|

|

|

|

|

a period in operation |

|

• Determine whether failure is caused by the component, main control board or wiring. |

||||||||

|

|

|

|

|

|

|

|

|

Contact TID before replacing main control board. |

|||||||

|

SY |

|

EF |

|

Evaporator Fan Failure |

|

||||||||||

|

|

|

|

• Refer to Service Manual for additional information. |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

Fresh Food Ice Maker Diagnostic Mode |

|||||||

|

Activate: |

|

Press freezer + and fresh food + temperature pads for up to 10 sec. simultaneously. |

|||||||||||||

|

|

|

|

|

|

Press + or - to move forward or backward through tests. |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|||||||||

|

Deactivate: |

|

Press fresh food + for up to 10 sec. FFIM Diagnostic Mode will automatically deactivate after 5 min. of inactivity. |

|||||||||||||

|

|

|

|

|

|

NOTE: Silence alarm. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

Test |

|

To activate test |

|

|

|

|

Passing Result |

|||

|

|

|

|

|

|

|

|

|

|

|||||||

|

52C |

|

Ice Maker Thermistor |

|

Activates |

|

FZ display shows temperature sensed by Ice Maker Thermistor. |

|||||||||

|

|

|

|

|

|

|

|

automatically |

|

“OP” if open; “SH” if short |

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|||||||

|

55C |

|

Water Valve |

|

Set |

|

Remove ice tray to collect water into a measuring container to measure water |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

fill. If collecting water into ice tray, first perform test 63C to empty ice tray. |

|||||

|

|

|

|

|

|

|

|

|

|

|||||||

|

57C |

|

Evaporator Fan (FFIM) |

|

Set |

|

“On” on FZ display when fan activated, “OFF” when deactivated. |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

Ice Level Sensor |

|

Activates |

|

Remove ice bucket. |

|

|

|

|||||

|

|

|

|

|

|

|

|

automatically |

Allow bail arm to drop freely. Pass if no alarm when tray returns to “home” position. |

|||||||

|

58C |

|

|

|

|

|

|

|

|

Hold bail arm up. Pass if alarm sounds when tray returns to “home” position. |

||||||

|

|

|

|

|

|

|

|

|

|

|

This test runs continuously until another test is selected. |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

63C |

|

Twist Tray |

|

Set |

|

Remove ice bucket. |

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

FZ display shows “1” and “GOOD”. |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

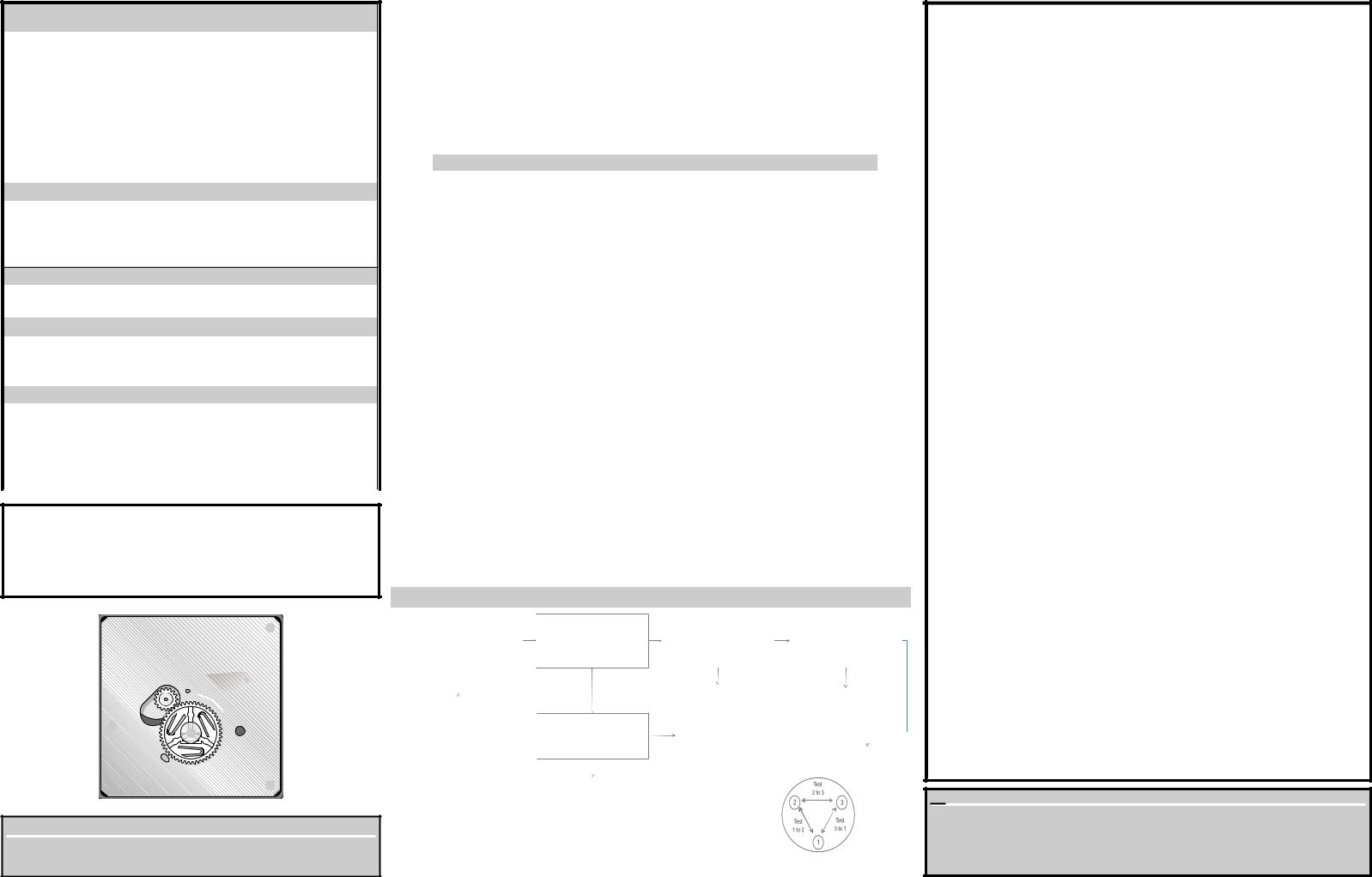

Variable Capacity Compressor (VCC) Diagnostics (select models)

If test 38 fails, diagnose as follows:

→ Check at the connector from the power cord |

|

→ Check at Inverter Board on |

harness into the inverter board, located in |

|

Compressor |

the machine compartment. |

yes |

(BLK and RED wires) |

(PUR and WHT wires) |

|

Is Inverter Board receiving 10-15 |

Is Inverter Board receiving 115 VAC |

|

|

|

VAC and 1-5 VDC from Main |

|

from power supply? |

|

Control Board? |

no |

|

no |

• Check voltage supply. |

|

|

• Check and repair power |

|

|

cord harness wiring and |

|

→ Check at Main Control Board |

connections. |

|

(BLK/WHT and RED/BLK wires) |

|

|

Is Main Control Board sending |

|

|

10-15 VAC and 1-5 VDC to |

|

|

Inverter Board? |

|

|

yes |

|

|

Identify and repair damaged wires or |

|

|

poor connections between Main Control |

|

|

Board and Inverter Board. |

|

→ Remove inverter box from the |

|

→ Check connections from Inverter |

|

|

compressor and check resistance |

|

Board to Compressor |

|

yes |

across compressor winding pairs as |

yes |

Are connections from Inverter |

|

shown. |

||||

|

|

Board to Compressor |

||

|

Is resistance across all winding |

|

||

|

|

|

||

|

pairs equal? |

|

|

|

|

|

|

|

|

|

no |

|

no |

Replace Compressor and |

Identify and repair |

|

Inverter Board. |

||

wires or poor connections |

||

|

||

|

between Inverter Board |

|

|

Compressor. |

no |

|

yes |

|

|

|

|

Replace Main Control Board. |

|

|

VCC Resistance Check |

Replace Inverter Board |

|

|

|

|

Check resistance between terminals 1 and |

|

|

2, 2 and 3, 3 and 1. |

|

|

If all resistances are equal, |

|

|

compressor is operative. |

|

|

|

System Diagnostic Mode |

|

Activate: |

Press freezer + and fresh food + for up to 10 sec. simultaneously. |

|

|

|

|

Deactivate: |

Press fresh food + for up to 10 sec. Diagnostic Mode will automatically deactivate after 5 min. of inactivity. |

|

|

Note: Silence alarm. |

|

|

|

• Tests marked with “*” may not be applicable to this unit and will not be displayed in System Diagnostic Mode.

• Tests displayed in diagnostic mode but not described below are for internal purposes only; advance through.

• View UI display for “on,” “off,” “CL,” “OP,” “SH,” “LO,” “HI” or numerical results of tests.

• Listen for operating sounds; feel for heat or air flow as appropriate to determine results of tests.

|

Test |

To activate test: |

Passing result |

|

|

|

|

-- |

First Screen |

-- |

All LED lights on UI illuminated |

|

|

|

|

-- |

Second Screen |

-- |

All segments on UI temperature displays illuminated |

|

|

|

|

-- |

Third Screen |

-- |

Blank UI display, no lights illuminated, no shadowing; “-” and “+” blinking on |

|

|

|

FF display side to show location. |

|

|

|

|

28 |

Dispenser Paddle |

Press disp. paddle |

“on” on UI when depressed; “off” when released |

|

|

|

|

1* |

Standard |

Press set |

Compressor running when “on”; stopped when “off” |

|

Compressor |

|

|

|

|

|

|

2 |

Defrost Heater |

Press set |

Defrost limit switch must be closed; verify “CL” in test 26. |

|

|

|

Feel for heat from defrost heater when “on”. |

|

|

|

If “OP” in test 26, heater will not activate. |

|

|

|

|

3 |

FF Light |

Press set |

With FF door open, FF lights on when “on”; off when “off” |

|

|

|

|

8 |

Water Valve |

Press set |

Be prepared to collect water at dispenser. |

|

(Dispenser) |

|

Water dispenses when “on”; stops when “off” |

|

|

|

|

9 |

FZ Light |

Press set |

With FZ door open, FZ lights on when “on”, off when “off” |

|

|

|

|

10 |

Auger Motor |

Press set |

FF door must be closed. |

|

|

|

Motor running when “on”; motor stopped when “off” |

|

|

|

|

11 |

Cube/Crush |

Press set |

FF door must be closed. Do not leave solenoid in activated state. |

|

Solenoid |

|

Solenoid activated when “on”; deactivated when “off” |

|

|

|

|

41* |

Perfect Temp Drawer |

Press set |

PTD UI illuminated when “on”, off when “off” |

|

(PTD) |

|

|

|

|

|

|

12* |

VCC Condenser Fan |

Press set |

Fan running when “on”; stopped when “off” |

|

|

|

|

38* |

VCC Compressor |

Press set |

Compressor running when “on”; stopped when “off” |

|

|

|

|

15 |

Evaporator Fan |

Press set |

Fan running for minimum of 10 sec. when “LO” or “HI”; stopped when |

|

|

|

“off”. Feedback failure if fan starts but runs less than 10 sec. Listen for speed |

|

|

|

change from “LO” to “HI”. |

|

|

|

|

36 |

Ice Chute Door |

Depress ice chute door |

“OP” on UI when manually opened; “CL” when closed. Or, using “set,””OP” |

|

|

or press set |

on UI when fully opened or “CL” when fully closed by the motor. |

|

|

|

|

22 |

Damper |

Press set |

With inspection mirror, observe damper open when “OP”; closed when “CL” |

|

|

|

|

23 |

FF Door |

Open/close FF door |

“CL” on UI when door closed; “OP” when open |

|

|

|

|

24 |

FZ Door |

Open/close FZ door |

“CL” on UI when door closed; “OP” when open |

|

|

|

|

26 |

Defrost Limit Switch |

Activates automatically |

“CL” on UI when closed; “OP” when open |

|

|

|

|

29 |

FF Thermistor Mid- |

Activates automatically |

UI shows temperature sensed by FF thermistor; pass if within 10°F of tem- |

|

level |

|

perature measured with gauge at mid-level FF thermistor location. |

|

|

|

“OP-” if open; “SH-” if short |

|

|

|

|

30 |

FZ Thermistor |

Activates automatically |

UI shows temperature sensed by FZ thermistor; pass if within 10°F of temperature |

|

|

|

measured with gage at FZ thermistor location. |

|

|

|

“OP” if open; “SH” if short |

|

|

|

|

33 |

Ambient Thermistor |

Activates automatically |

UI shows temperature sensed at main board; pass if within +20°F/-10°F of |

|

@ Main Board |

|

temperature measured with gauge at main board location. |

|

|

|

“OP” if open; “SH” if short |

|

|

|

|

35* |

FF Thermistor |

Activates automatically |

UI shows temperature sensed by upper level FF thermistor; pass if within 10°F |

|

Upper-Level |

|

of temperature measured with gauge at upper-level FF thermistor location. |

|

|

|

“OP¯” if open; “SH¯” if short |

|

|

|

|

34* |

Ambient Thermistor |

Activates automatically |

UI shows temperature sensed at UI; pass if within +20°F/-10°F of tempera- |

|

@ UI |

|

ture measured with gauge at UI location. “OP” if open; “SH” if short |

|

|

|

|

46 |

Humidity Sensor |

Activates automatically |

“OP” if open, “SH” if short |

|

|

|

AC Heater System: Displays %RH |

|

|

|

DC Heater System: “HI” – heater should be on |

|

|

|

“Lo” – heater should be off |

|

|

|

%RH is displayed when humidity is between “Lo” and “HI” values; heater |

|

|

|

could be on or off. |

|

|

|

|

47* |

Dispenser |

Press set |

AC Heater System: “--” ; test not available |

|

Pocket Heater |

|

DC Heater System: heater on when “on”, off when “off” |

|

|

|

|

0- |

Firmware |

Press set |

Displays digit sequence; record |

|

Parameters |

|

|

|

|

|

|

2- |

Main Board |

Press set |

Displays digit sequence; record |

|

Firmware |

|

|

|

|

|

|

4- |

UI Firmware |

Press set |

Displays digit sequence; record |

|

|

|

|

IMPORTANT SAFETY NOTE

IMPORTANT SAFETY NOTE

The information provided herein is designed to assist qualified repair personnel only. Untrained persons should not attempt to make repairs due to the possibility of electrical shock. Disconnect power cord before servicing this appliance.

IMPORTANT

If any green grounding wires are removed during servicing, they must be returned to their original position and properly secured.

Loading...

Loading...