Page 1

Important Safety Instructions ............................... 3

August 2016

List of materials ................................................... 5

Electrical requirements ......................................... 5

Location requirements .......................................... 6

Product dimensions .............................................. 6

Venting Requirements .......................................... 7

Prepare the location ............................................. 8

Install Range Hood (Ducted version) ..................... 10

Make Electrical Connection .................................... 11

Range Hood Use .................................................. 12

Range Hood Care ................................................. 13

Troubleshooting ................................................... 15

Warranty Information ........................................... 16

USA 1-800-374-4432

www.frigidaire.com

Canada 1-800-265-8352

www.frigidaire.ca

316495194

Page 2

WELCOME & CONGRATULATIONS

EN-2

Congratulations on your purchase of a new range hood! At Electrolux Home Products,

Questions?

1-800-374-4432

(United States)

1-800-265-8352

(Canada)

we are very proud of our product and are completely committed to providing you with the best

service possible. Your satisfaction is our number one priority.

We know you’ll enjoy your new range hood and Thank You for choosing our product. We

hope you consider us for future purchases.

PLEASE CAREFULLY READ AND SAVE THESE INSTRUCTIONS

This Use & Care Manual provides specifi c operating instructions for your model. Use your

range hood only as instructed in this manual. These instructions are not meant to cover

every possible condition and situation that may occur. Common sense and caution must be

practiced when installing, operating and maintaining any appliance.

Please record your model and serial numbers below for future reference.

Please attach sales receipt

here for future reference.

Serial Plate

Location

Model Number:

Serial Number:

Purchase Date:

______________________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

NEED HELP?

Visit the Frigidaire Web Site at: http://www.frigidaire.com

Before you call for service, there are a few things you can do to help us serve you better.

Read this manual.

It contains instructions to help you use and maintain your range hood properly.

If you received a damaged range hood... immediately contact the dealer (or builder)

that sold you the range hood.

Save time and money.

Check the section titled “Troubleshooting”. This section helps you solve common problems

that might occur. If you do need service, you can relax knowing help is only a phone call away.

A list of toll-free customer service numbers is included in the back of this manual. Or call

Frigidaire Customer Services at 1-800-374-4432,

to 8 pm Eastern Standard Time.

Monday through Saturday from 8 am

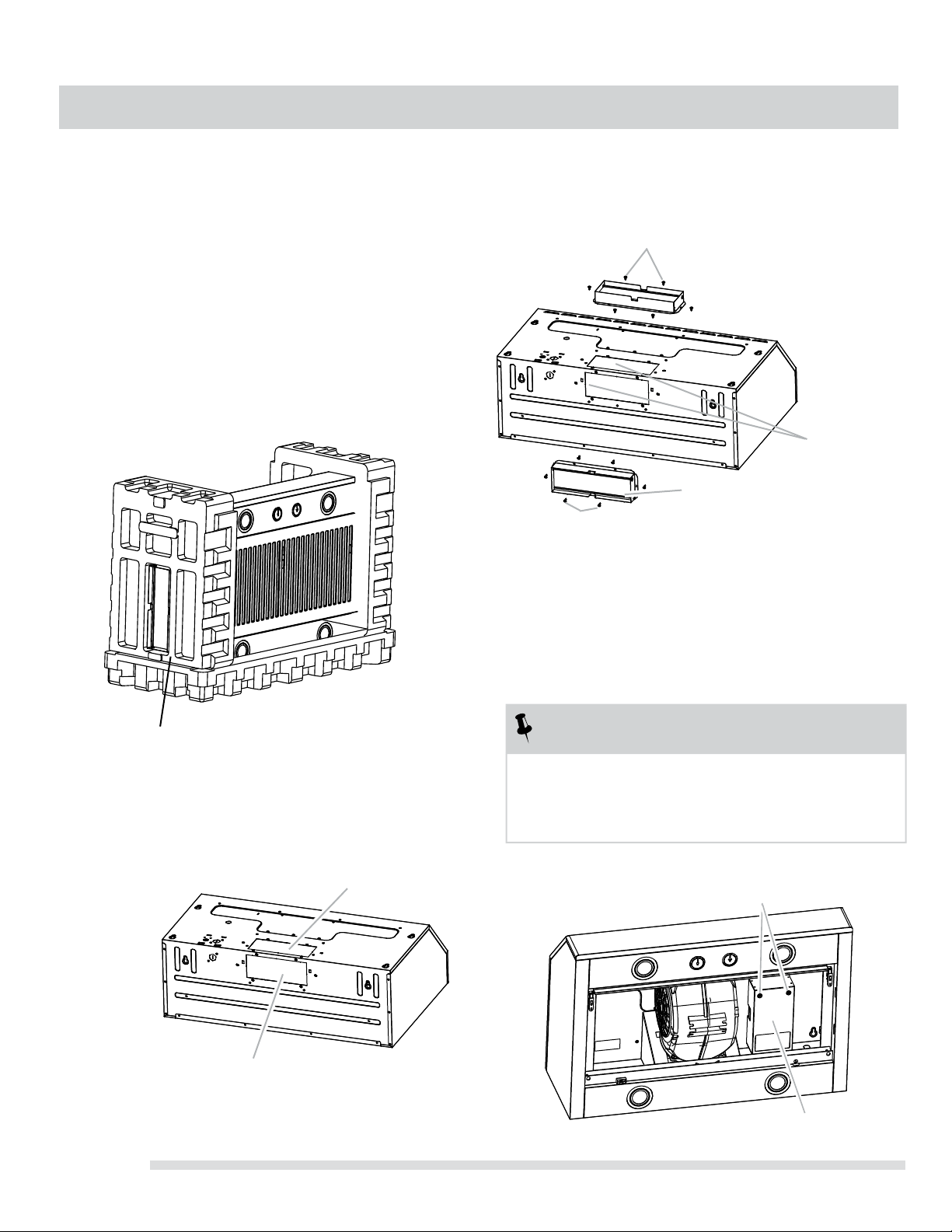

Hinge down the vent grille and remove the grease filters. Refer to page 13 for

additional information

The serial plate is located on the left inside of the range hood

Page 3

Read all instructions before using this appliance.

Save these instructions for future references

Approved for residential appliances

For residential use only

Do not attempt to install or operate your appliance until

you have read the safety precautions in this manual.

Safety items throughout this manual are labeled with a

WARNING or CAUTION based on the risk type.

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety messeges

that follow this symbol to avoid possible injury or deat'h.

WARNING

This symbol alerts you to situations that may

cause serious body harm, death or property

damage.

CAUTION

CAUTION indicates a potentially hazardous

situation which, if not avoided, may result in

minor or moderate injury.

IMPORTANT

IMPORTANT indicates installation, operation,

maintenance or valuable information that is not hazard

related.

IMPORTANT SAFETY INSTRUCTIONS

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK, OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

Use this unit only in the manner intended by the

A.

manufacturer. If you have questions, contact the

manufacturer

Before servicing or cleaning the unit, switch power

B.

off at service panel and lock service panel

disconnecting means to prevent power from

being switched on accidentally. When the service

disconnecting means cannot be locked, securely

fasten a prominent warning device, such as a tag, to

the service panel.

Installation Work and Electrical Wiring Must Be Done

C.

By Qualied Person(s) In Accordance With all

Aplicable Codes & Standards, Including Fire-rated

Construction.

Sufcient air is needed for proper combustion and

D.

exhausting of gases through the ue (Chimney) of fuel

burning equipment to prevent back- drafting. Follow

the heating equipment manufacturers guideline and

safety standards such as those published by the

National Fire Protection Association (NFPA), the

American Society for Heating, Refrigeration and Air

Conditioning Engineers (ASHRAE), and the local code

authorities.

When cutting or drilling into wall or ceiling, do not

E.

damage electrical wiring and other hidden utilities.

Ducted systems must always be vented to the

F.

outdoors.

CAUTION

IMPORTANT SAFETY INSTRUCTIONS

CAUTION

FOR GENERAL VENTILATING USE ONLY. DO NOT

USE TO EXHAUST HAZARDOUS OR EXPLOSIVE

MATERIALS OR VAPORS.

To reduce risk of re and to properly exhaust

air, do not vent ex

walls, ceilings, attics, crawl spaces, or garages.

WARNING

TO REDUCE THE RISK OF FIRE, USE ONLY METAL

DUCT WORK.

Install this hood in accordance with all requirements

specied.

haust air into spaces within

EN-3

Page 4

IMPORTANT SAFETY INSTRUCTIONS

WARNING

To Reduce The Risk Of Fire Or Electric Shock, Do

Not Use This Hood With Any External Solid State

Speed Control Device.

WARNING

TO REDUCE THE RISK OF A RANGE TOP GREASE

FIRE.

Never leave surface units unattended at high

a)

settings. Boilovers cause smoking and greasy

spillovers that may ignite. Heat oils slowly on low or

medium settings.

Always turn hood ON when cooking at high heat or

b)

when ambeing food (l.e. Crepes Suzette, Cherries

Jubilee, Peppercorn Beef Flambe’).

Clean ventilating fans frequently. Grease should not

c)

be allowed to accumulate on fan or lter.

Use proper pan size. Always use cookware

d)

appropriate for the size of the surface element.

WARNING

TO REDUCE THE RISK OF INJURY TO PERSONS,

IN THE EVENT OF A RANGE TOP GREASE FIRE,

OBSERVE THE FOLLOWING:

SMOTHER FLAMES with a close - tting lid, cookie

a)

sheet, or other metal tray, then turn off the gas

burner or the electric element.

PREVENT BURNS. If the ames do not go out

immediately, EVACUATE AND CALL THE

FIRE DEPARTMENT.

NEVER PICK UP A FLAMING PAN - you may be

b)

burned.

DO NOT USE WATER, including wet dishcloths or

c)

towels - a violent steam explosion will result.

Use an extinguisher ONLY if:

d)

You know you have a class ABC extinguisher,

1)

and you already know how to operate it.

The re is small and contained in the area

2)

where it started.

The re department is being called.

3)

You can ght the re with your back to an exit.

4)

OPERATION

Always leave safety grills and lters in place.Without

these components, operating blowers could catch onto

hair, ngers and loose clothing.

The manufacturer declines all responsibility in the

event of failure to observe the instructions given here

for installation,maintenance and suitable use of the

product. The manufacturer further declines all responsibility for injury due to negligence and the warranty of

the unit automatically expires due to improper maintenance.

BE CAREFUL TO

EN-4

Page 5

LIST OF MATERIALS

Wire cutter / stripper

Measuring tape

5/64” drill bit for cabinet pilot holes

EN-5

CAUTION

Remove carton carefully. Wear gloves to protect

against sharp edges.

LIST OF MATERIALS

Parts included in your hood

•

3 1/4" x 10" Rectangular vent damper

•

2 - Grease filters

Use and Care / Installation Manual

•

Mounting screw kit

•

2 - 0.49 * 5.0 cm mounting screws

4 - 0.50 * 1.9 cm mounting screws

6 - 0.40 * 0.8 cm rectangular vent damper screws

2 - plastic wall anchores

Tools/Materials required

•

Wire nuts

•

Metal duct length to suit installation

Vent clamps/duct tape as required

•

UL listed or CSA approved ½” strain relief

•

Remove the protective film covering the product before

•

putting into operation.

•

•

Pencil

•

•

•

Caulking gun and weatherproof caulking compound

•

Flat-blade screwdriver

•

Phillips screwdriver

•

Saber or keyhole saw

••Safety glasses

Gloves

For cabinets with recessed bottoms:

•

Two - 2” (5.1 cm) wide ller strips. Length and

thickness determined by recess dimensions.

•

Four at head wood screws or machine screws

with washers and nuts (to attach ller strips).

NOTE

If configuring for recirculation venting, range hood

model FHWC3050RS

FHWRKT30RS and if using range hood model

FHWC3650RS

would be used.

B

uses recirculation kit

recirculation kit FHWRKT36RS

ELECTRICAL REQUIREMENTS

Observe all governing codes and ordinances.

Ensure that the electrical installation is adequate and in

conformance with National Electrical Code, ANSI/NFPA

70 (latest edition), or CSA Standards C22.1-94, Canadian

Electrical Code, Part 1 and C22.2 No. 0-M91 (latest edition) and all local codes and ordinances.

If codes permit and a separate ground wire is used, it is

recommended that a qualied electrician determine that

the ground path is adequate.

A copy of the above code standards can be obtained

from:

National Fire Protection Association

One Batterymarch Park

Quincy, MA 02269

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131-5575

A 120 volt, 60 Hz., AC only, 15-amp, fused electrical

•

circuit is required.

If the house has aluminum wiring, follow the

•

procedure below:

Connect a section of solid copper wire to the

1.

pigtail leads.

Connect the aluminum wiring to the added

2.

section of copper wire using special conectors

and/or tools designed and UL listed

for joining copper to aluminum.

Follow the electrical connector manufacturer’s recommended procedure. Aluminum/copper connection must

conform with local codes and industry accepted wiring

practices.

Wire sizes and connections must conform with

•

the rating of the appliance as specied on the

model/serial rating plate.

The model/serial plate is located on the left side of

the range hood.

Wire sizes must conform to the requirements of

•

the National Electrical Code, ANSI/NFPA 70 (la

est edition), or CSA Standards C22. 1-94, Canad

Electrical Code, Part 1 and C22.2 No. 0-M91

(latest edition) and all local codes and ordinances.

an

Page 6

LOCATION REQUIREMENTS

C

C. 36” (91.4 cm) base cabinet height

EN-6

IMPORTANT

Observe all governing codes and ordinances.

•

It is the installer’s responsibility to comply with

installation clearances

•

Range hood location should be away from

strong draft areas, such as windows, doors and

strong heating vents.

Cabinet opening dimensions that are shown must

•

be used. Given dimensions provide minimum

clearance.

Grounded electrical outlet is required. See

•

“Electrical Requirements” section.

All openings in ceiling and wall where canopy hood

•

will be installed must be sealed.

For Mobile Home Installations

The installation of this range hood must conform to the

Manufactured Home Construction Safety Standards, Title

24 CFR, Part 328 (formerly the Federal Standard for

Mobile Home Construction and Safety, Title 24, HUD, Part

280) or when such standard is not applicable, the standard for Manufactured Home Installation 1982 (Manufactured Home Sites, Communities and Setups) ANSI

A225.1/NFPA 501A, or latest edition, or with local codes.

'.

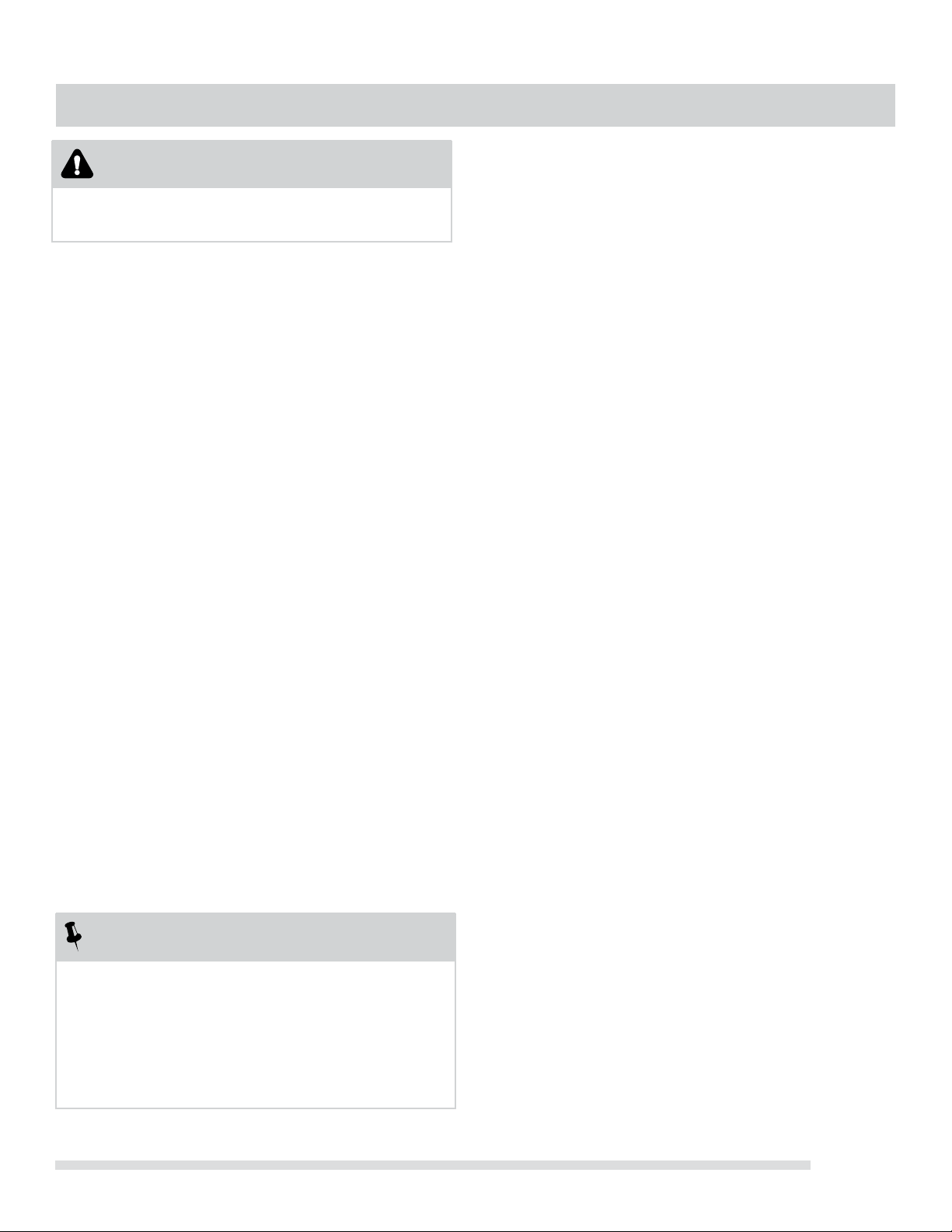

Cabinet Dimensions

B

”

(61.0 cm) min. for electric cooking surfaces

A. 24

27

” (68.6 cm) min. for gas cooking surfaces

30

” (76.2 cm) suggested max.

B. 30” (76.2 cm) min. cabinet opening width for 30” (76.2 cm)

models and 36” (91.4 cm) min. cabinet width for 36” (91.4 cm)

models.

A

PRODUCT DIMENSIONS

hood model Dim A Dim B

FHWC3050RS

30” Hood Model

FHWC3650RS

36” Hood Model

/

29 7 8” (75.8 cm)

B

35 7\/8”

(91.1 cm)

(16.7 cm) (16.7 cm)

9 9/16”

(24.3 cm)

Dim C

3” (7.6cm)6 1/2”

6'(15.2 cm)

Dim D

27 3/4”

(70.5 cm)

33 15/16”

(86.2 cm)

Page 7

•

EN-7

Do not terminate the vent system into an attic or other

enclosed area.

•

Do not use a 4” (10.2 cm) laundry-type wall cap.

•

Use metal vent only.

Rigid metal vent is recommended.

Plastic or metal foil vent is not recommended.

•

The length of vent system and number of elbows

should be kept to a minimum to provide efcient

performance.

For the most efcient and quiet operation:

•

Use no more than three 90° elbows.

•

Make sure there is a minimum of 24” (61 cm) of straight

vent between the elbows if more than 1 elbow is used.

•

Do not install 2 elbows together.

•

Use clamps or duct tape to seal all joints in the

vent system.

•

The vent system at exit must have a cold air damper.

•

Use caulking to seal exterior wall or roof opening

around the cap.

•

Best performances are reached with straight piping,

without elbows and using smooth pipe.

VENTING REQUIREMENTS

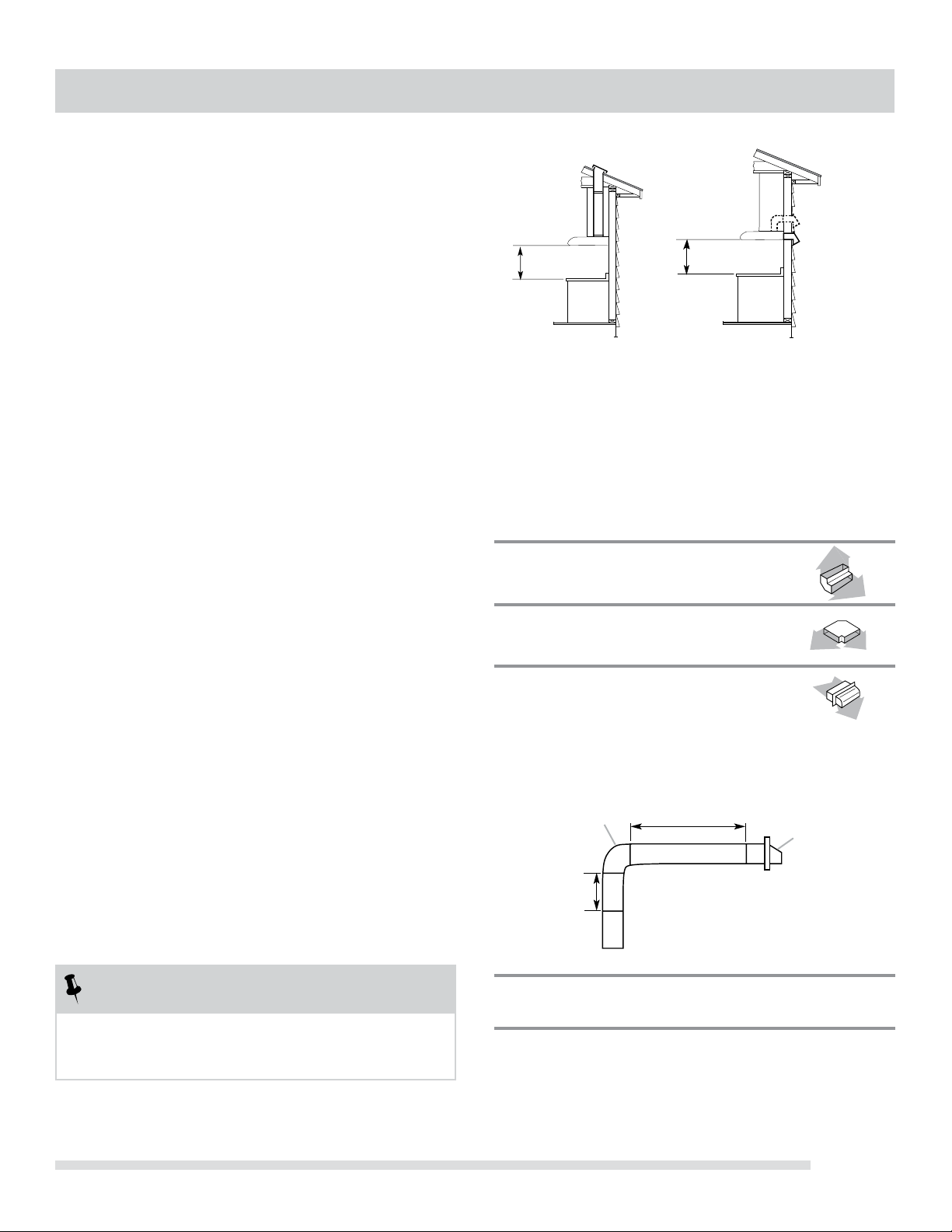

Roof Venting Wall Venting

Calculating Vent System Length

To calculate the length of the system you need, add the

equivalent feet (meters) for each vent piece used in the

system.

These directions are for rectangular vent installation only.

If you choose to use round rigid metal venting the minimum

diameter to use is """"""""''''"'"""" .??????

3¼” x 10” (8.3 cm x 25.4 cm) rectangular Vent System

Vent Piece

8”

Cold Weather Installations

An additional back draft damper should be installed to

minimize backward cold air ow and a thermal break

should be installed to minimize conduction of outside temperatures as part of the vent system. The damper should

be on the cold air side of the thermal break.

The break should be as close as possible to where the

vent system enters the heated portion of the house.

Makeup Air

Local building codes may require the use of makeup air

systems when using ventilation systems greater than

specied CFM of air movement. The specied CFM varies

from locale to locale. Consult your HVAC professional for

specic requirements in your area.

Venting Methods

Vent system can terminate either through the roof or wall.

Use 3¼” x 10” (8.3 x 25.4 cm) rectangular with a maximum

vent length of 35 ft (10.7 m)

NOTE

for vent system.

Flexible vent is not recommended. Flexible vent

creates both back pressure and air turbulence

that greatly reduce performance.

3¼” x 10” (8.3 cm x 25.4 cm) 5.0 ft

90° elbow (1.5 m)

3¼” x 10” (8.3 cm x 25.4 cm) 12.0 ft

flat elbow (3.7 m)

3¼” x 10” (8.3 cm x 25.4 cm) 0.0 ft

wall cap (0.0 m)

Example Vent System

3¼” x 10”

(8.3 x 25.4 cm)

elbow

2 ft

(0.6 m)

Maximum Recommended Length = 35 ft (10.7 m)

1 - 90° elbow = 5.0 ft (1.5 m)

8 ft (2.4 m) straight = 8.0 ft (2.4 m)

1 - wall cap = 0.0 ft (0.0 m)

Length of 3¼” x 10” = 13.0 ft (3.9 m)

(8.3 cm x 25.4 cm) system

6 ft (1.8 m)

Wall Cap

Page 8

VENTING REQUIREMENTS

PREPARE THE LOCATION

NOTE

Before making cutouts, make sure there is

proper clearance within the ceiling, wall or cabinet.

Fitting material is provided to secure

the hood to most types of walls and cabinets.

However, a qualified technician must

verify suitability of the materials in

accordance with the type of wall and cabinet.

1.

Disconnect power.

2.

Select a at surface for assembling the range hood.

Place covering over that surface.

3.

Lift the range hood and set it upside down onto covered

surface.

4.

If cabinet has recessed bottom, add

wide filler strips. Length and

recess dimensions.

machine screws with

strips in locations shown.

3” (7.6 cm)

3” (7.6 cm)

Lift the range hood up under cabinet and determine

5.

Four flat head wood screws or

washers and nuts to attach filler

thickness determined by

Wood filler strips

(recessed cabinet

bottoms only)

Cabinet

bottom

nal location by centering beneath cabinet. Mark on

the underside of cabinet the location of the 4 keyhole

mounting slots on the range hood (See slot dimensions

on page 6).

Set range hood aside on a covered surface.

Mark rear mounting screw hole locations.

"two - 2” (5.1 cm)

Use

6.

5/64” drill bit and drill 4 pilot holes as shown

for top range hood support.

NOTE: Make the drill holes on the thin area of the slot.

Install the 4 - 0.50 cm x 1.9 cm mounting screws in

7.

A. Drill pilot hole

A

pilot holes. Leave about ¼” (6.4 mm) space between

screw heads and cabinet to slide range hood into place.

Install framing for hood rear support

8.

¹⁄4”

(6.4 mm)

If drywall is present, using the rear mounting screw

hole locations marked in the previous step cut away

enough drywall to expose 2 vertical studs at the rear

mounting screw holes locations. Install horizontal

support at least 4” X 2 ” between two wall studs at

the rear mounting screw holes location. The horizontal

support must be flush with the room side of the studs.

Use cleats behind both sides of the support to secure

to wall studs. Reinstall drywall and refinish.

IMPORTANT – Framing must be capable of supporting

100 lbs.

Wall

8-1/2” min. opening for ductwork

View From

Rear

Cleats

2” x4” Min

.

Mounting

Support

EN-8

A

A. Keyhole slot

A

Centerline of

Installation

Space

Page 9

Determine Wiring Hole Location

Determine and clearly mark a vertical centerline on

1.

the wall and cabinet bottom.

A Centerline

A

To wire through top:

Mark a line distance (A) from the right of the

2.

centerline on the underside of the cabinet. Mark the

point on this line that is 1 1/2"(3.8cm) from back wall.

Drill a 1¼” (3.2 cm) diameter hole (B) through the

cabinet at this point.

hood

model

30” & 36”

models

Dim

A

8 5/8”

(21.9 cm)

A

B

1 1/2"(3.8cm)

from wall,

not cabinet frame

Centerline

To wire through wall:

Mark a line distance (A) from the right of the

1.

centerline on the underside of the wall. Mark the point

on this line that is from the underside of

1 1/2"(3.8cm)

the cabinet. Drill a 1¼” (3.2 cm) diameter hole (B)

through the rear wall at this point.

PREPARE THE LOCATION

Roof Venting

To make a 4 ” x 10½” (10.8 cm x 26.7 cm) rectangular

cutout on the underside of cabinet top and bottom:

Mark lines (1.6 cm) and 4 ” (10.8 cm) from the

1.

back wall on the centerline of the underside of cabinet.

Mark lines 5¼” (13.3 cm) to the right and left of the

2.

centerline on the underside of cabinet.

Use saber or keyhole saw to cut a rectangular opening

3.

for vent.

Repeat steps 1-3 for the underside of the top of the

4.

cabinet.

Centerline

Wall Venting

To make a 4 ” x 10½” (10.8 cm x 26.7 cm) rectangle in

the wall:

Make 2 lines by measuring ”

1.

(10.16 cm) down from underside of cabinet and mark on

the centerline on the back wall.

Mark lines 5¼” (13.3 cm) to the right and left of the

2.

centerline on the wall.

Use saber or keyhole saw to cut a rectangular opening

3.

in the wall for the vent.

¼

5

8

Cabinet cutouts

¼

(10.8 cm)

Cabinet

front

¼

5

/8 (1.6 cm)

*

1

"

4 4/

51/4

(13.3 cm)

*From wall, not cabinet frame

(0.63 cm) and

¼”

"

1

5 /

(13.3 cm)

Centerline

"

4

4

B

A

1 1/2"(3.8cm)

hood

model

30” & 36”

models

Dim

A

”

8 5⁄8

(21.9 cm)

”

4

(10.16 cm)

1

⁄ ”

4

(0.63 cm)

51/4”

(13.3 cm)

51/4”

(13.3 cm)

A Centerline

EN-9

Page 10

PREPARE THE LOCATION

EN-10

Install Vent System

Install vent through the vent opening in upper cabinet

1.

or wall. Complete venting system according to the

selected venting method. See “Venting Requirements”

section.

Use caulking to seal exterior wall or roof opening

2.

around the cap.

INSTALL RANGE HOOD

(Ducted version)

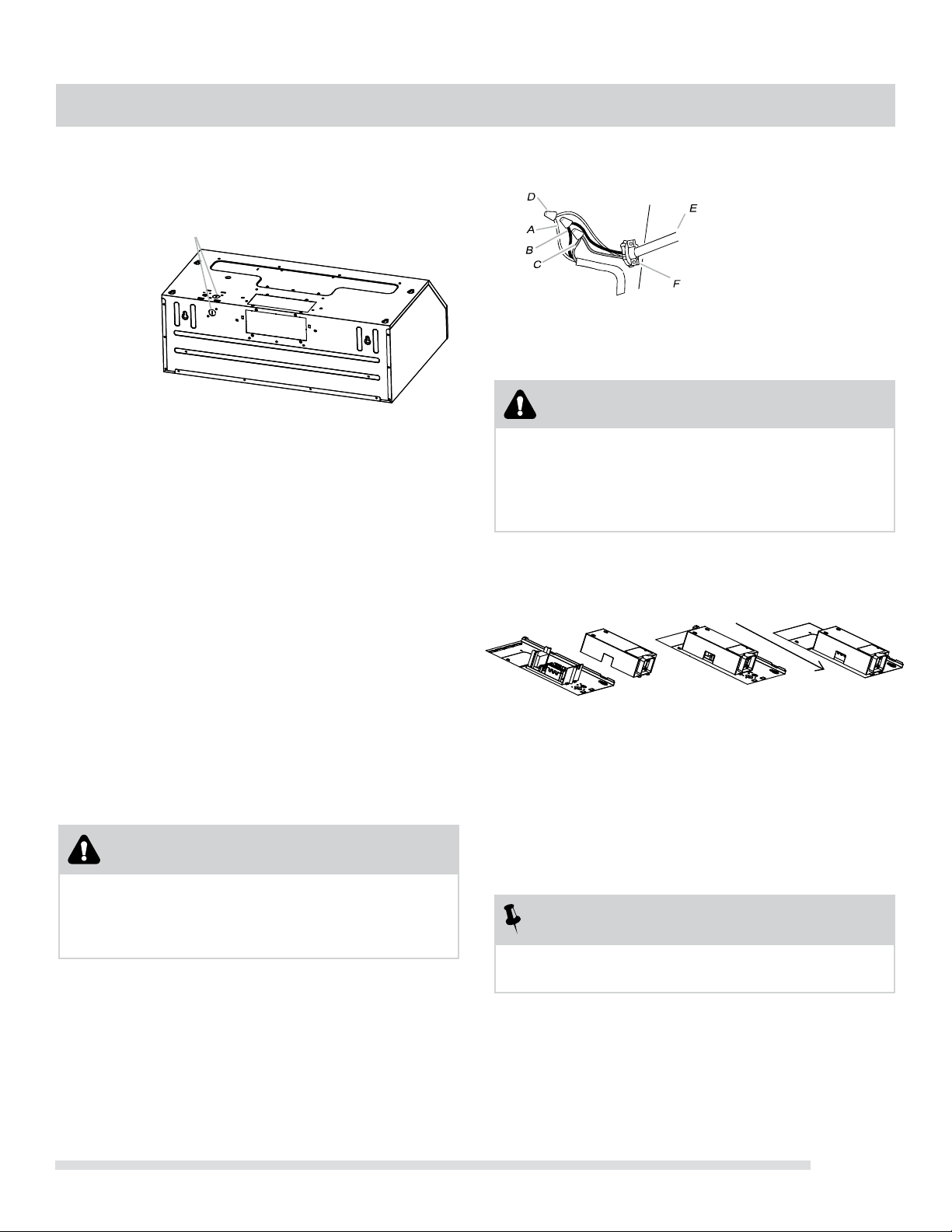

Detach the 3¼” x 10” (8.3 x 25.4 cm) rectangular

1.

damper from the package.

vent

Vent Damper Installation

Install 3¼” x

Attach to range hood using the indicated screws

provided in hardware kit.

If a vent damper is installed with a wall cap with

•

10” (8.3 x 25.4 cm) vent damper.

B

A

B

Install the 3¼” x 10” (8.3 x

25.4 cm) rectangular vent

transition

A. 3¼” x 10” (8.3 x 25.4 cm)

rectangular vent transition

B. 6 - 0.40 x 0.80 cm screws

C. Rectangular vent knockouts

damper, check that they do not interfere with each

other. Remove the vent damper ap if

Power Supply Cable Installation

1.

For direct wire installations, run the home power

supply cable according to the National Electric Code

or CSA standards and local codes and ordinances.

they interfere.

C

A

A. 3¼” x 10” (8.3 x 25.4 cm) rectangular vent damper

For roof installations, remove the top rectangular •

vent knockout A.

rear rectangular vent knockout B.

For wall installations, remove the

A

A. Top rectangular knockout

B. Rear rectangular knockout

B

NOTE

Do not reconnect power until the installation is

complete.

Before starting the installation, remove the

vent grill and grease filters.

Remove the screws from the

2.

Remove terminal box cover

terminal box cover.

and set aside.

B

A. Terminal box cover

B. Screw

A

Page 11

Remove the power supply knockout from the top

Use” section.

1.

2.

6. Reconnect power.

Lift the hood into nal position.

7.

8.

Install

3.

or rear of the vent hood (depending on the incoming

location of your home power supply cable) and

install a UL listed or CSA approved ½” strain relief.

A. Power supply

knockout

4.

Feed enough electrical wire through the ½” UL listed

or CSA approved strain relief to make connections in

the terminal box. Tighten the strain relief screws.

Position the range hood so that the large end of

5.

the keyhole slots are over the mounting screws.

Then push the hood toward the wall so that the screws

are in the neck of the slots. Tighten the mounting screws,

making sure the screws are in the narrow neck of slots.

Add the 2 rear 0.49 * 5.0 cm rear mounting screws

6.

into the narrow neck of the rear keyhole slots.

These should screw into the horizontal support

that was placed between the two wall studs in

section PREPARE THE LOCATION on page 8.

Connect ventwork to hood. Seal joints with vent

clamps or duct tape to make secure and airtight.

Check that back draft dampers work properly.

A

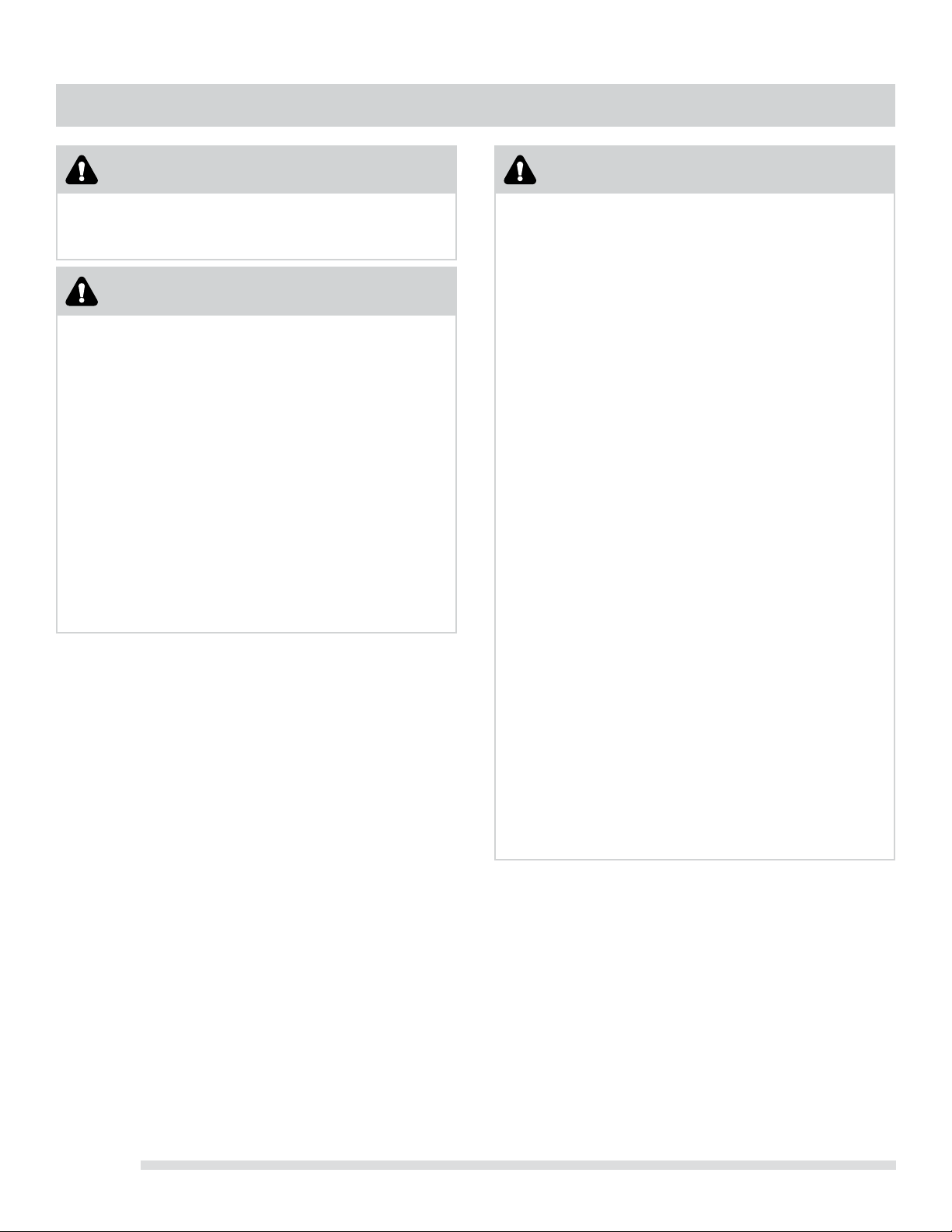

MAKE ELECTRICAL CONNECTION

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

INSTALLING THE HOOD

1. Disconnect power.

A. White wires

B. Black wires

C. Green ground wire

D. UL listed wire connector

E. Home power supply cable

F. UL listed or CSA approved

½” strain relief

2. Use UL listed wire connectors and connect white wires

(A) together.

3. Use UL listed wire connectors and connect black wires

(B) together.

WARNING

Fire Hazard

Electrically ground the blower. Use copper wire.

Connect ground wire to green wire in

terminal box. Failure to do so can result in death,

re, or electrical shock.

4. Connect green (or bare) ground wire from power supply

to green wire in terminal box .

5. Install terminal box cover.

Complete Installation

See “Range Hood Use” section.

If range hood does not operate, check to see whether a

circuit breaker has tripped or a household fuse has blown.

Disconnect power and check wiring connections.

To get the most efcient use from your new

range hood, read the “Range Hood Use” section.

grease lters . See the “Range Hood

Check the operation of the range hood fan and light.

NOTE

EN-1

1

Page 12

Operating the Light

Operating the Fan

RANGE HOOD USE

2

EN-1

RANGE HOOD USE

The range hood is designed to remove smoke and cooking vapors from the cooktop area. For best results, start

the hood before cooking and allow it to operate several

minutes after the cooking is complete to clear all smoke

from the kitchen.

D

A

B

C

A. LED lights

B. Grease filter

C. Vent Grille

D. Control knobs

Range Hood Controls

The hood controls are located at the bottom

front section of the unit.

Light Fan

ON FRONT REAROFF

Knob Graphics Light Icon

Push in on knob to release and then

HI MED LOOFF

Knob Graphics Fan Icon

rotate it counter clockwise for light

On/Front/Rear/Off.

A

Cleaning

WARNING

To Reduce The Risk Of Fire Or Electrical shock

disconnect from power supply before cleaning.

IMPORTANT

Clean the hood and grease lters frequently

according to the following instructions. Replace

grease lter before operating hood.

IMPORTANT

Exterior Surfaces

Do not use soap-lled scouring pads, abrasive cleaners,

Cooktop Polishing Creme, steel wool, gritty washcloths

or paper towels.

To avoid damage to the stainless steel, do not use

cleaners that contain chlorine.

Cleaning Method:

SMUDGE-PROOF™ STAINLESS STEEL

Your range hood has Smudge-Proof

Steel finish.

Clean the stainless with warm soapy

water using a clean sponge or cloth. Rinse with clean

water and dry with a soft clean cloth. DO NOT

cleaners like

Stainless Steel cleaners or any other types

of cleaners containing any abrasive, chlorides, chlorines or

ammonia. It is recommended to use mild dish soap

and water or a 50/50 solution of water and vinegar.

TM

Stainless

USE any

Push in on knob to release and then

rotate it counter clockwise for fan

speeds Hi/Med/Lo/Off.

Page 13

RANGE HOOD CARE

EN-1

To clean or replace grease lter:

Push in at the indicated area to open the

1.

vent grille. The vent grille will hinge down for

access to the grease filters.

PUSH TO OPEN

2.

To remove or install the grease filters push tab

towards the back of the unit.

WARNING

Electrical Shock Haxzard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

Replacing the Front LED lights

1. Remove the vent grille and grease filters.

2. Remove the screws at the front support

and slide the panel back.

To clean grease lter, soak the lters in hot water using

3.

a mild detergent. Rinse well and shake to dry.

NOTE

Do not use ammonia. The aluminum on the

grease filter will corrode and darken.

NOTE

The grease lter is dishwasher safe.

To avoid grease lter damage while cleaning,

place lter into the dishwasher top rack for

cleaning

.

3. Disconnect the front LED lights wiring

Squeeze LED lamp mounting clips and push

4.

down the LED lights as shown below

Squeeze here

Squeeze here

5. Replace with new LED lights

and re-install the front support

P art number 5304503879

3

Page 14

RANGE HOOD CARE

WARNING

Electrical Shock Haxzard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

Replacing the Rear LED lights

1. Remove the vent grille and grease filters.

2. Disconnect the rear LED lamp wiring

3. Squeeze LED lamp mounting clips and push

down the LED lights as shown below.

Squeeze here

Squeeze here

4. Replace with new LED lights.

P art number 5304503879

EN-14

Page 15

Problem Possible Causes Solutions

After installation,

the unit doesn’t

work.

Light works,

but motor is not

turning.

1. The power line and the cable connector

is not connected properly.

2. The wires from the switches are disconnected

or loose.

1. The motor is defective, possible seized. 1. Change the motor.

1. Check the power connections.

2. Make sure the wires on the switches are

connected properly.

2. Make sure the motor wire is plugged into the2. The motor wire is not connected.

terminal box connector.

TROUBLESHOOTING

The unit is

vibrating.

The motor is

working, but the

lights are not.

The hood is

not venting out

properly.

Vent grill or

grease filter

is vibrating.

1. The motor is not secure in place. 1. Tighten the motor in place.

2. Damaged blower wheel. 2. Change the blower.

3. The hood is not secured in place. 3. Check the installation of the hood.

1. Defective lamp. 1. Change the lamp.

2. The lamp is loose.

3. The wires on the light switch are loose. 3. Make sure the wires on light switch are

1. The hood might be hanging to high from the

cook top.

2. The wind from the opened windows or opened

doors in the surrounding area are affecting the

ventilation of the hood.

3. Blockage in the duct opening or duct work. 3. Remove all the blocking from the duct work or

4. The direction of duct opening is against the

wind.

5. Using the wrong size of ducting. 5. Change the ducting to correct size.

1 . Vent grill or grease filter is loose. 1 . Make sure vent grill or grease filter is installed

2 . Make sure the lamp is seated properly.

connected properly.

1 . Check installation instructions.

2. Close all the windows and doors to eliminate

the outside wind ow.

duct opening.

4. Adjust the duct opening direction.

correctly.

EN-1

5

Page 16

Warranty

Your appliance is covered by a one year limited warranty. For one year from your original date of purchase,

Electrolux will pay all costs for repairing or replacing any parts of this appliance that prove to be defective in

materials or workmanship when such appliance is installed, used and maintained in accordance with the provided

instructions.

Exclusions

This warranty does not cover the following:

1. Products with original serial numbers that have been removed, altered or cannot be readily determined.

2. Product that has been transferred from its original owner to another party or removed outside the USA or

Canada.

3. Rust on the interior or exterior of the unit.

4. Products purchased “as-is” are not covered by this warranty.

5. Food loss due to any refrigerator or freezer failures.

6. Products used in a commercial setting.

7. Service calls which do not involve malfunction or defects in materials or workmanship, or for appliances

not in ordinary household use or used other than in accordance with the provided instructions.

8. Service calls to correct the installation of your appliance or to instruct you how to use your appliance.

9. Expenses for making the appliance accessible for servicing, such as removal of trim, cupboards, shelves,

etc., which are not a part of the appliance when it is shipped from the factory.

10. Service calls to repair or replace appliance light bulbs, air lters, water lters, other consumables, or

knobs, handles, or other cosmetic parts.

11. Surcharges including, but not limited to, any after hour, weekend, or holiday service calls, tolls, ferry trip

charges, or mileage expense for service calls to remote areas, including the state of Alaska.

12. Damages to the nish of appliance or home incurred during installation, including but not limited to oors,

cabinets, walls, etc.

13. Damages caused by: services performed by unauthorized service companies; use of parts other than

genuine Electrolux parts or parts obtained from persons other than authorized service companies; or

external causes such as abuse, misuse, inadequate power supply, accidents, res, or acts of God.

DISCLAIMER OF IMPLIED WARRANTIES; LIMITATION OF REMEDIES

CUSTOMER’S SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT REPAIR

OR REPLACEMENT AS PROVIDED HEREIN. CLAIMS BASED ON IMPLIED WARRANTIES, INCLUDING WARRANTIES

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR OR THE

SHORTEST PERIOD ALLOWED BY LAW, BUT NOT LESS THAN ONE YEAR. ELECTROLUX SHALL NOT BE LIABLE

FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES SUCH AS PROPERTY DAMAGE AND INCIDENTAL EXPENSES

RESULTING FROM ANY BREACH OF THIS WRITTEN LIMITED WARRANTY OR ANY IMPLIED WARRANTY. SOME

STATES AND PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL

DAMAGES, OR LIMITATIONS ON THE DURATION OF IMPLIED WARRANTIES, SO THESE LIMITATIONS OR

EXCLUSIONS MAY NOT APPLY TO YOU. THIS WRITTEN WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS. YOU

MAY ALSO HAVE OTHER RIGHTS THAT VARY FROM STATE TO STATE.

If You Need

Service

This warranty only applies in the USA and Canada. In the USA, your appliance is warranted by Electrolux Major Appliances North America, a

division of Electrolux Home Products, Inc. In Canada, your appliance is warranted by Electrolux Canada Corp. Electrolux authorizes no person

to change or add to any obligations under this warranty. Obligations for service and parts under this warranty must be performed by Electrolux

or an authorized service company. Product features or specications as described or illustrated are subject to change without notice.

USA

1.800.944.9044

Electrolux Home Products, Inc.

10200 David Taylor Drive

Charlotte, NC 28262

Keep your receipt, delivery slip, or some other appropriate payment record to establish the warranty period should

service be required. If service is performed, it is in your best interest to obtain and keep all receipts. Service under

this warranty must be obtained by contacting Electrolux at the addresses or phone numbers below.

Canada

1.800.265.8352

Electrolux Canada Corp.

5855 Terry Fox Way

Mississauga, Ontario, Canada

L5V 3E4

Page 17

Tout sur

l'Installation,

l'entretien et l'utilisation

de votre

Importantes consignes de sécurité ....................... 3

Liste des matériels ............................................... 5

Exigences électriques ........................................... 5

Exigences d'emplacement ..................................... 6

Dimensions du produit .......................................... 6

Exigences concernant l'évacuation .............................. 7

Préparer l'emplacement ........................................ 8

Hotte

Installation de la hotte (version à Conduit)

Effectuer un branchement électrique ......................

Utilisation de la hotte .............................................

Entretien de la hotte ..............................................

Dépannage ...........................................................

Informations sur la garantie ...................................

................. 10

11

12

13

15

16

États-Unis 1-800-374-4432

www.frigidaire.com

Canada 1-800-265-8352

www.frigidaire.ca

316495194

Août 2016

Page 18

BIENVENUE ET FÉLICITATIONS

Félicitations pour votre achat d'une nouvelle hotte! À Electrolux Home Products, nous

Avez-vous des

questions?

1-800-374-4432

(États-Unis)

1-800-265-8352

(Canada)

Please attach sales receipt

here for future reference.

sommes très fiers de notre produit et nous nous engageons à vous fournir le meilleur service

possible. Votre satisfaction est notre priorité absolue.

Nous savons que vous apprécierez votre nouvelle hotte et Merci d'avoir choisi notre produit.

Nous espérons que vous nous considérez pour de futurs achats.

VEUILLEZ LIRE ATTENTIVEMENT ET CONSERVER CES INSTRUCTIONS

Ce manuel d'utilisation et d'entretien fournit des instructions de fonctionnement spécifiques

pour votre modèle. Utilisez votre hotte uniquement comme indiqué dans ce manuel. Ces

instructions ne sont pas destinées à couvrir toutes les conditions et situations possibles qui

pourraient survenir. Le bon sens et la prudence doivent être exercés lors de l'installation,

l'exploitation et l'entretien de tout appareil.

Veuillez enregistrer votre modèle et les numéros de série ci-dessous pour de futures

références.

Numéro de modèle: __________________________________________________________

Numéro de série: ____________________________________________________________

Date d'achat:

___________________________________________________________

AVEZ-VOUS BESOIN D'AIDE?

Visiter le site Web de Frigidaire: http://www.frigidaire.com

Avant d'appeler le service, il y a certaines choses que vous pouvez faire pour nous aider à

mieux vous servir.

Lire ce manuel

Il contient des instructions pour vous aider à correctement utiliser et entretenir votre hotte.

Si vous avez reçu une hotte endommagée... contactez immédiatement le revendeur

(ou le constructeur) qui vous a vendu la hotte.

Gagner du temps et de l'argent.

Consulter la section intitulée «Dépannage». Cette section vous aide à résoudre des problèmes

communs qui pourraient survenir. Si vous avez besoin d'un service, détendez-vous, sachant

qu'un coup de téléphone vous garantira de l'aide.

Une liste de numéros de service à la clientèle sans frais est incluse sur le dos de ce manuel. Ou

appeler le Service à la clientèle de Frigidaire au 1-800-374-4432, du lundi au samedi 8

heures-20 heures, heure normale de l'Est.

Emplacement de la plaque de série

FR-2

Pivoter vers le bas la grille du ventilateur et retirer les filtres à graisse. Se reporter à la page 13

pour plus d'informations

La plaque signalétique se trouve sur la gauche à l'intérieur de la hotte

Page 19

IMPORTANTES CONSIGNES DE SÉCURITÉ

Lisez toutes les instructions avant d'utiliser cet appareil.

Conserver ces instructions pour de futures références.

Approuvé pour des appareils résidentiels

Pour uniquement des usages résidentiels

Ne pas tenter d'installer ou d'utiliser votre appareil,

jusqu'à ce que vous ayez lu les consignes de sécurité dans

ce manuel.

Éléments de sécurité présents dans ce guide sont

identifiés par un AVERTISSEMENT ou ATTENTION selon le

type de risque.

Voici le symbole d’alerte à la sécurité. Il est utilisé pour

vous avertir des risques de blessures potentiels. Respecter

tous les messages de sécurité qui suivent ce symbole pour

éviter une blessure ou la mort.

AVERTISSEMENT

Ce symbole vous avertit des situations qui

peuvent causer de sérieux dommages du corps,

la mort ou des dommages matériels.

ATTENTION

ATTENTION signale une situation potentiellement

dangereuse susceptible d'entraîner des blessures

mineures.

IMPORTANT

IMPORTANT indique des informations d'installation,

d'exploitation, d'entretien ou des informations

précieuses qui ne sont pas liées aux dangers.

AVERTISSEMENT

POUR RÉDUIRE LE RISQUE D'INCENDIE, DE

CHOC ÉLECTRIQUE OU DE BLESSURE, SUIVRE

LES INSTRUCTIONS SUIVANTES:

A. Utiliser cet appareil uniquement de la manière prévue

par le fabricant. Si vous avez des questions, contactez

le fabricant.

B. Avant de réparer ou de nettoyer l'appareil, couper le

courant au niveau du panneau de service et verrouiller

le panneau de service, déconnectant des moyens

d'éviter une mise en marche accidentelle. Lorsque le

dispositif de déconnexion ne peut être verrouillé,

apposer un dispositif d'avertissement bien visible,

comme une étiquette, sur le panneau de service.

C. Les travaux d'installation et le câblage électrique

doivent être effectués par une(des) personne(s)

qualifiée(s) en conformité avec tous les codes et

normes applicables, y compris la construction à indice

de résistance au feu.

D. De l'air suffisant est nécessaire pour une bonne

combustion et l'évacuation des gaz par le conduit

(Cheminée) de l'équipement de combustion de

carburant pour empêcher le refoulement de l'air.

Suivre les lignes directrices et les normes de sécurité

des fabricants d'équipement de chauffage, comme

celles publiées par la National Fire Protection

Association (NFPA), l'American Society for Heating,

Refrigeration and Air Conditioning Engineers

(ASHRAE), et les codes des autorités locales.

E. Lorsque vous coupez ou percez un mur ou un plafond,

n'endommagez pas le câblage électrique et les autres

services publics cachés.

F. Les systèmes canalisés doivent toujours évacuer de

l'air vers l'extérieur.

ATTENTION

IMPORTANTES CONSIGNES DE

SÉCURITÉ

ATTENTION

POUR USAGE DE VENTILATION GÉNÉRALE

SEULEMENT. NE PAS UTILISER POUR ÉVACUER

DES MATIÈRES OU DES VAPEURS DANGEREUSES

OU EXPLOSIVES.

Pour éviter tout risque d'incendie et pour assurer

une évacuation d'air appropriée, ne pas évacuer

l'air dans les murs, les plafonds, le grenier, les

faux plafonds ou les garages.

AVERTISSEMENT

POUR RÉDUIRE LE RISQUE D'INCENDIE, UTILISER

UNIQUEMENT DES CONDUITS EN MÉTAL.

Installer cette hotte en conformité avec toutes les

exigences spécifiées.

FR-3

Page 20

IMPORTANTES CONSIGNES DE SÉCURITÉ

AVERTISSEMENT

Pour réduire le risque d'incendie ou d'électrocution,

ne pas utiliser cette hotte avec tout dispositif

externe de contrôle de vitesse semi-conducteur.

AVERTISSEMENT

POUR RÉDUIRE LE RISQUE D'UN INCENDIE DE

GRAISSE.

a) Ne jamais s'éloigner des surfaces d'appareils avec

chaleur élevée. Les débordements causent de la

fumée et les résidus graisseux peuvent s'enflammer.

Chauffer lentement les huiles à feu doux ou moyen.

b) Faire toujours fonctionner la hotte pour une cuisson à

feu vif ou pour faire flamber des repas (c'est-à-dire

crêpes Suzette, cerises Jubilé, steak au poivre).

c) Nettoyer les pales des éventails fréquemment. Éviter

de laisser la graisse s'accumuler sur le ventilateur ou

le filtre.

d) Utiliser la taille de casserole qui convient. Utilisez

toujours l'ustensile de cuisson approprié à la taille de

la surface chauffante de l'élément.

AVERTISSEMENT

POUR RÉDUIRE LE RISQUE DE BLESSURE AUX

PERSONNES EN CAS D'INCENDIE DE GRAISSE,

RESPECTEZ LES POINTS SUIVANTS:

a) ÉTOUFFER LES FLAMMES à l'aide d'un couvercle

hermétique, d’une plaque à biscuits ou d’un autre

plateau de métal et eteindre le brûleur à gaz ou

l'élément électrique. ATTENTION DE NE PAS

VOUS BRÛLER. Si les flammes ne s’éteignent pas

immédiatement, ÉVACUER LES LIEUX ET

APPELER LES POMPIERS.

b) NE JAMAIS PRENDRE UNE CASSEROLE EN

FLAMMES - Vous pouvez vous brûler.

c) NE JAMAIS UTILISER D'EAU, encore moins des

linges ou des serviettes humides, qui risquent de

provoquer une violente explosion de vapeur.

d) Utiliser SEULEMENT un extincteur si:

1. Vous savez que votre extincteur est de catégorie

ABC et que vous savez l’utiliser.

2. L’incendie est mineur et limité à la zone où il a

débuté.

3. Vous avez fait appel aux pompiers.

4. Vous pouvez tenter d’éteindre l’incendie tout en

vous dirigeant vers une sortie proche.

FONCTIONNEMENT

Toujours laisser les grilles de sécurité et les filtres en

place. Sans ces éléments, les ventilateurs en marche

pourraient aspirer les cheveux, les doigts et les

vêtements amples.

Le fabricant décline toute responsabilité en cas de

non-respect des instructions données ici pour

l'installation, l'entretien et l'utilisation appropriée du

produit. En plus, le fabricant décline toute responsabilité

pour les blessures dues à la négligence et la garantie de

l'appareil expire automatiquement à cause d'un mauvais

entretien.

FR-4

Page 21

LISTE DES MATÉRIAUX

ATTENTION

Retirer le carton avec soin. Porter des gants pour se

protéger contre des arêtes vives.

LISTE DES MATÉRIAUX

Pièces incluses dans votre hotte

•

3 1/4 "x 10" Volet motorisé rectangulaire

•

2 - Filtres à graisse

Usage et Soin/Manuel d'installation

•

Kit du vis de fixation

•

2 - 0,49 * 5,0 cm vis de montage

4 - 0,50 * 1,9 cm vis de montage

6 - 0,40 * 0,8 cm Vis du volet motorisé rectangulaire

2 - ancrages muraux en plastique

Outils/Matériaux requis

• Serre-fils

• Longueur du conduit métallique adapté à votre installation

• Collier de serrage d'évacuation /ruban adhésif, si nécessaire

• Décharge de traction de 1/2" homologuée UL ou CSA

• Retirer le film protecteur recouvrant le produit, avant de le

mettre en service.

Mèche de forage de 5/64" pour les trous de guidage de l'armoire

•

• Crayon

• Coupe-fil/Pince à dénuder

• Mètre ruban

• Pistolet à calfeutrer et composé de calfeutrage résistant aux

intempéries

• Tournevis à lame plate

• Tournevis Philips

• Scie sauteuse ou scie à guichet

• Lunettes de sécurité

• Gants

Pour les armoires à fonds creux:

Deux - Larges bandes de remplissage de 2"(5,1 cm).

•

Longueur et épaisseur déterminées par les dimensions

de linteau.

Quatre vis à bois à tête plate ou vis à métaux avec des

•

rondelles et des écrous (pour fixer les bandes de

remplissage).

REMARQUE

Pour installer le recirculation de ventilation, veuillez

utiliser kit de recirculation FHWRKT30RS

modèle FHWC3050RS et utilisee kit de recirculation

FHWRKT36RS

pour modèle

FHWC3650RS

pour

B

EXIGENCES ÉLECTRIQUES

Observer tous les codes et règlements en vigueur.

S'assurer que l'installation électrique est adéquate et en

conformité avec le National Electrical Code, ANSI/NFPA

70 (dernière édition), ou Normes CSA C22.1-94, Code

canadien de l'électricité, Partie 1 et C22.2 N° 0-M91

(dernière édition) et tous les codes et règlements locaux.

Si les codes le permettent et un fil de terre distinct est

utilisé, il est recommandé qu'un électricien qualifié

détermine que le circuit de mise à la terre est adéquat.

Une copie de la norme des codes ci-dessus peut être

obtenue à partir de:

National Fire Protection Association

One Batterymarch Park

Quincy, MA 02269

CSA International

8501 East Pleasant Valley Road

Cleveland, OH 44131-5575

Un circuit électrique à fusibles de 120 volts, 60 Hz.,

•

CA seulement, 15 ampères, est nécessaire.

Si la maison dispose d'un câblage en aluminium, suivre

•

la procédure ci-dessous:

1. Connecter une section de fil de cuivre massif aux

conducteurs pigtail.

2. Connecter le câblage en aluminium à la section

ajoutée de câble en cuivre, en utilisant des

connecteurs et/ou des outils spécialement conçus

et homologués UL pour fixer le cuivre à l'aluminium.

Suivre la procédure recommandée par le fabricant du

connecteur électrique. Connexion de cuivre/d'aluminium

doit être conforme aux codes locaux et aux pratiques de

câblage acceptées par l'industrie.

Les dimensions et les connexions des fils doivent être

•

conformes à la notation de l'appareil, comme indiquée

sur le modèle /la plaque signalétique. Le modèle/la

plaque signalétique se trouve sur la gauche de la

hotte

Les dimensions de fils doivent être conformes aux

•

exigences du National Electrical Code, ANSI/NFPA 70

(dernière édition), ou aux Normes CSA C22. 1-94, le

Canada Electrical Code, Partie 1 et C22.2 N° 0-M91

(dernière édition) et tous les codes et règlements

locaux.

FR-5

Page 22

EXIGENCES D'EMPLACEMENT

IMPORTANT

Observer tous les codes et règlements en vigueur.

Il est de la responsabilité de l'installateur de respecter

•

les distances d'installation.

L'emplacement de la hotte doit être loin des fortes

•

zones d'action, telles que les fenêtres, les portes et les

puissants conduits de chauffage.

Les dimensions d'ouverture de l'armoire qui sont

•

affichées doivent être utilisées. Ces dimensions offrent

un dégagement minimal.

Prise électrique de terre est nécessaire. Voir la section

•

"Exigences électriques".

Toutes les ouvertures, dans le plafond et dans le mur

•

où la hotte d'évacuation sera installée, doivent être

scellées.

Pour les Installation dans une maison mobile

L'installation de cette hotte doit être conforme à la

norme Manufactured Home Construction Safety

Standards, Titre 24 CFR Partie 328 (jadis Federal

Standard for Mobile Home Construction and Safety, Titre

24, HUD, Partie 280) ou lorsque cette norme n'est pas

applicable, la norme de 1982 pour Manufactured Home

Installation (Manufactured Home Sites, Communities and

Setups) ANSI A225.1/NFPA 501A, ou dernière édition, ou

aux codes locaux.

Dimensions de l'armoire

B

A

C

A. 24" (61,0 cm) min. pour les surfaces de cuisson électriques

27" (68,6 cm) min. pour les surfaces de cuisson au gaz

30" (76,2 cm) suggéré au max.

B. Largeur d'ouverture de l'armoire de 30" (76,2 cm) min. pour les modèles de 30"

(76,2 cm) et la largeur d'armoire de 36" (91,4 cm) min. pour les modèles de 36"

(91,4 cm).

C. Hauteur de l'armoire de base de 36" (91,4 cm)

DIMENSIONS DU PRODUIT

FR-6

Modèle de hotte

Modèle de hotte

FHWC3050RS 30"

Modèle de hotte

FHWC3650RS 36"

B

Dim A Dim B

/

29 7 8” (75.8 cm)

7/8” (91.1cm)

35

(16.7 cm) (16.7 cm)

9 9/16”

(24.3 cm)

Dim C

3” (7.6cm)6 1/2”

6'(15.2 cm)

Dim D

27 3/4”

(70.5 cm)

33 15/16”

(86.2 cm)

Page 23

Ne pas évacuer l'air dans le grenier ou tout autre

•

endroit fermé

Ne pas utiliser un capuchon de mur de type

•

blanchisserie de 4" (10,2 cm).

Utiliser uniquement un conduit métallique. Un conduit

•

métallique rigide est recommandé.

Conduit en plastique ou en feuille de métal n'est pas

recommandé.

La longueur du système d'évacuation et le nombre de

•

coudes doivent être réduits au minimum, afin de fournir

des performances efficaces.

Pour le fonctionnement le plus efficace et silencieux:

Ne pas utiliser plus de trois coudes à 90°.

•

S'assurer qu'il ya un minimum de 24" (61 cm) de

•

ventilation droit entre les coudes, si plus de 1 coude

sont utilisés.

Ne pas installer 2 coudes ensembles.

•

Utiliser des pinces ou un ruban adhésif pour sceller

•

tous les joints dans le système d'évacuation.

Le système d'évacuation à la sortie doit avoir un volet

•

de régulation d'air froid.

•

Utiliser du calfeutrage pour sceller l'ouverture du mur

ou du toit extérieur autour du bouchon.

•

Les meilleures performances sont atteintes avec la

tuyauterie droite, sans les coudes et en utilisant un

tuyau lisse.

Installations en temps froids

Un volet anti-refoulement supplémentaire devrait être

installé pour minimiser les reflux d'air froid et une rupture

thermique doit être installée pour minimiser la conduction

des températures extérieures dans le cadre du système

de ventilation. Le volet devrait être sur le côté de l'air

froid de la rupture thermique.

La rupture doit être aussi proche que possible de l'endroit

où le système de ventilation entre dans la partie chauffée

de la maison.

Air de compensation

Les codes locaux de bâtiment peuvent exiger l'utilisation

de systèmes d'air de compensation, lors de l'utilisation

des systèmes de ventilation plus importants que le CFM

spécifié de circulation de l'air. Le CFM spécifié varie d'un

endroit à l'autre. Consultez votre professionnel de CVC

pour des besoins spécifiques dans votre région.

Méthodes d'évacuation

Système d'évacuation peut évacuer de l'air à travers le

toit ou le mur. Utiliser 3¼ "x 10" (8,3 x 25,4 cm)

rectangulaire avec une longueur de conduit maximale de

35 pieds (10,7 m) pour le système d'évacuation.

REMARQUE

Un conduit flexible est déconseillé. Un conduit

flexible crée à la fois une contre-pression et la

turbulence de l'air qui réduisent

considérablement la performance.

EXIGENCES CONCERNANT L'ÉVACUATION

Calcul de la longueur du système d'évacuation

Pour calculer la longueur du système dont vous avez

besoin, ajoutez l'équivalente en pieds (mètres) pour

chaque pièce d'évacuation utilisée dans le système.

Ces directions sont uniquement pour l'installation

d'évacuation rectangulaire.

Si vous choisissez d'utiliser un système d'évacuation rond

et rigide en métal, le diamètre minimum à utiliser est de

8".

Système d'évacuation rectangulaire de ¼” x 10”

(8,3 cm x 25,4 cm)

Pièce d'évacuation

Coude de 90 °

3¼” x 10” (8.3 cm x 25.4 cm)

Coude plat

3¼” x 10” (8.3 cm x 25.4 cm)

Capuchon de mur

3¼” x 10” (8.3 cm x 25.4 cm)

Exemple de système d'évacuation

Longueur maximale recommandée

Coude de 1 - 90 ° = 5.0 pieds (1,5 m)

8 pi (2,4 m) tout droit

1 - capuchon de mur

Longueur de 3 ¼ "x 10"

système (8,3 cm x 25,4 cm)

Évacuation par le toit Évacuation par le mur

5 pieds

3¼” x 10”

(8,3 x 25,4 cm)

Coude

2 pieds

(0,6 m)

72 pieds (1,8 m)

(1,5 m)

12pieds

(3,7 m)

0,0 pieds

(0,00 cm)

= 35 pieds (10,7 m)

= 8.0 pieds (2,4 m)

= 0,0 pieds (0,0 m)

= 156 pulgadas (3,9 m)

Capuchon de mur

FR-7

Page 24

EXIGENCES CONCERNANT L'ÉVACUATION

PRÉPARER L'EMPLACEMENT

REMARQUE

Avant de faire des découpes, s'assurer qu'il y a un

dégagement suffisant dans le plafond, mur ou armoire.

Le matériel de montage est fourni pour fixer la hotte à

la plupart des types de murs et d'armoires. Cependant,

un technicien qualifié doit vérifier la compatibilité des

matériaux en conformité avec le type de mur et

d'armoire.

Débrancher l'alimentation électrique.

1.

Sélectionner une surface plane pour l'assemblage de la hotte.

2.

Placer la couverture sur cette surface.

Soulever la hotte et la mettre à l'envers sur la surface

3.

couverte.

Si l'armoire a un fond creux, ajouter «deux-2" (5,1 cm)

4.

larges bandes de remplissage. Longueur et épaisseur

déterminées par les dimensions de linteau. Quatre vis à bois

à tête plate ou vis à métaux avec des rondelles et des

écrous, pour fixer les bandes de remplissage, dans les

emplacements affichés.

Bandes filtrantes en bois

(fonds d'armoire creux seulement)

3” (7,6 cm)

6.

Utiliser une mèche de forage de 5/64" et percer 4 trous de

guidage comme indiqué pour le support supérieur de la

hotte.

NOTE: Faire des trous de forage sur la zone mince de la fente.

A.Trou de parcelle de forage

A

7.

Installer les vis de montage 4-0,50 cm x 1,9 cm dans les

trous pilotes. Laissez environ }/4“(6,4 mm) d'espace entre les

têtes de vis et l'armoire pour glisser la hotte en place.

¹⁄4”

(6,4 mm)

Installer le cadrage pour le support arrière de la hotte

8.

Si le placoplâtre est présent, en utilisant les emplacements

des trous de vis de montage arrières marqués à l'étape

précédente, couper assez de placoplâtre pour exposer 2

montants verticaux au niveau des emplacements des trous de

vis de montage arrières. Installer le support horizontal au

moins 2"X 4" entre deux poteaux muraux au niveau des

emplacements des trous de vis de montage arrières. Le

support horizontal doit être aligné avec le côté chaud des

poteaux. Utiliser les taquets derrière les deux côtés du

support pour fixer aux poteaux muraux. Réinstaller le

placoplâtre et retoucher.

IMPORTANT - Le cadrage doit être capable de supporter 100

livres.

Fond de l'armoire

3” (7,6 cm)

5.

Soulever la hotte sous l'armoire et déterminer

l'emplacement final en la centrant sous l'armoire. Marquer,

sur la face inférieure de l'armoire, l'emplacement des 4 les

trous de montage des fentes de serrure sur la hotte (Voir

dimensions des fentes à la page 6). Marquer les

emplacements des trous de vis de montage arrière. Placer

la hotte de côté sur une surface couverte.

A

A. Keyhole slot

A

Mur

Ouverture de 8-1/2" min. pour les conduits

Vue de derrière

Taquets

2" X 4" Min. Support

de montage

Ligne médiane de

l'espace d'installation

FR-8

Page 25

PRÉPARER L'EMPLACEMENT

Déterminer l'emplacement du trou de câblage

1.

Déterminer et marquer clairement une ligne médiane

verticale sur le mur et au fond de l'armoire.

Une ligne médiane

A

Pour câbler par le haut:

Marquer une distance en ligne (A) de la droite de la

ligne médiane sur la face inférieure de l'armoire.

Marquer le point sur cette ligne, ce qui est de 1 1/2"

(3,8 cm) du mur arrière. Percer un trou (B) de 1 ¼

"(3,2 cm) de diamètre dans l'armoire au niveau de ce

point.

Modèle de

hotte

Modèle de

30” & 36”

Dim

A

8 5/8

(21.9 cm)

1-1/2" (3,8) du

A

B

mur, pas le cadre

de l'armoire

Ligne médiane

Pour câbler à travers le mur:

Marquer une distance en ligne (A) de la droite de la

1.

ligne médiane sur la face inférieure du mur. Marquer

le point sur cette ligne, ce qui est de 1 1/2" (3,8

cm)de la face inférieure de l'armoire. Percer un trou

(B) de 1 ¼ "(3,2 cm) de diamètre dans le mur arrière

au niveau de ce point.

B

Modèle de

hotte

Modèle de

30” & 36”

A

1 1/2"(3,8cm)

A Ligne médiane

2.

Dim

A

8 5⁄8”

(21.9 cm)

Évacuation par le toit

Pour faire une découpe rectangulaire de 4 ” x 10½”

¼

(10,80 cm x 26,7 cm) sur la face inférieure du haut et du

bas de l'armoire:

Marquer les lignes 5?/8 ” (1,6 cm) et 4 ” (10,80 cm) du

1.

mur arrière sur la ligne médiane de la face inférieure

¼

de l'armoire.

Marquer les lignes 5¼” (13,3 cm) à droite et à

2.

gauche de la ligne médiane sur la face inférieure de

l'armoire.

Utiliser la scie sauteuse ou scie à guichet pour

3.

effectuer une ouverture rectangulaire pour

l'évacuation.

4.

Répéter les étapes 1-3 pour la face inférieure du haut

de l'armoire.

Ligne médiane

Découpes de l'armoire

5

* /

(1,6 cm)

8

1

"

/4

4

(10,8 cm)

5

(13,3 cm)

Depuis le mur, pas le cadre de l'armoire

1

/4

(13,3 cm)

"

5 /

1

"

4

Évacuation par le mur

Pour faire un rectangle de 4 ” x 10½”

¼

(10,8 cm x 26,7 cm) dans le mur:

Faire 2 lignes en mesurant ¼ ” (0,63 cm) and

1.

4”(10,16 cm) vers le bas à partir de la face inférieure

de l'armoire et marquer sur la ligne médiane sur le

mur arrière.

Marquer les lignes 5¼” (13,3 cm) à droite et à

2.

gauche de la ligne médiane sur le mur.

Utiliser la scie sauteuse ou scie à guichet pour

3.

effectuer une ouverture dans le mur pour

l'évacuation.

Armoire avant

Ligne médiane

1

”

4

⁄

(0,63 cm)

”

4

( cm)

10,16

1

5

/4”

(13,3 cm)

51/4”

(13,3 cm)

FR-9

Page 26

PRÉPARER L'EMPLACEMENT

Installer le système d'évacuation

Installer l'évacuation à travers l'ouverture

1.

d'évacuation dans l'armoire supérieure ou le mur.

Système d'évacuation complet selon le procédé

d'évacuation sélectionné. Voir la section «Exigences

concernant l'évacuation».

Utiliser du calfeutrage pour sceller l'ouverture du

2.

mur ou du toit extérieur autour du bouchon.

INSTALLER LA HOTTE

(version à Conduit)

Retirer le volet motorisé rectangulaire de 3¼” x 10”

1.

(8,3 x 25,4 cm) de l'emballage.

Installation du volet motorisé

Installer le volet motorisé de 3¼” x 10” (8,3 x 25,4

cm).

Attacher à la hotte en utilisant les vis indiquées

fournies dans le kit de matériel.

B

Installer la transition d'évacuation

rectangulaire de 3¼"X 10" (8,3 cm x25,4)

A. Transition d'évacuation rectangulaire de

3¼” x 10” (8,3 x 25,4 cm)

B. 6 - vis de 0,40 x 0,80 cm

C. Ouverture rectangulaire d'évacuation

C

A

B

•

Si un volet motorisé est installé avec un capuchon de

mur avec le volet, vérifier qui n'interfèrent pas les uns

avec les autres. Retirer le clapet du volet motorisé s'ils

interfèrent.

Installation du câble d'alimentation électrique

Pour installations directes des fils, faire passer le câble

1.

d'alimentation de la maison selon le National Electric Code

ou normes de la CSA et des codes et règlements locaux.

A

A. Volet motorisé rectangulaire de 3¼"X 10" (8,3 x 25,4 cm)

Pour les installations de toit, enlever l'ouverture

•

d'évacuation rectangulaire supérieure A. Pour les

installations murales, retirer l'ouverture d'évacuation

rectangulaire arrière B.

A

A. Ouverture rectangulaire supérieure

B. Ouverture rectangulaire arrière

B

FR-10

REMARQUE

Ne pas rebrancher l'alimentation jusqu'à ce que

l'installation soit terminée.

Avant de commencer l'installation, retirer la grille

d'évacuation et les filtres à graisse.

Retirer les vis du couvercle de la boîte à bornes.

2.

Retirer le couvercle de la boîte à bornes et mettre de

côté.

B

A. Couvercle de la boîte à bornes

B. Vis

A

Page 27

Retirer l'ouverture d'alimentation par le haut ou

3.

l'arrière de la hotte d'évacuation (en fonction de

l'emplacement entrant du câble d'alimentation

électrique de votre maison) et installer une décharge

de traction de 1/2" homologuée UL ou CSA.

A.Ouverture d'alimentation électrique

Soulever la hotte en position finale.

4.

Faire passe suffisamment de fil électrique à travers la

décharge de traction de 1/2" homologuée UL ou CSA,

pour faire des connexions dans la boîte à bornes.

Serrer les vis de la décharge de traction.

5.

Positionner la hotte de sorte que la grande extrémité

des fentes de serrure sont sur les vis de montage.

Ensuite, pousser la hotte vers le mur, afin que les vis

soient dans le col des fentes. Serrer les vis de

montage, s'assurant que les vis sont dans le col étroit

des fentes.

6.

Ajouter les 2 vis de montage arrières de 0,49*5,0 cm

dans le col étroit des fentes de serrure arrière. Ces

dernières devraient se visser dans le support horizontal

qui a été placé entre les deux poteaux du mur dans la

section PRÉPARER L'EMPLACEMENT à la page 8.

Connecter le système d'évacuation à la hotte. Sceller

7.

les joints avec les colliers de serrage d'évacuation ou le

ruban adhésif pour rendre sûr et étanche à l'air.

Vérifier que les volets anti-refoulement fonctionnent

8.

correctement.

A

EFFECTUER UN BRANCHEMENT

ÉLECTRIQUE

AVERTISSEMENT

Risque d’électrocution

Couper l'alimentation électrique avant l'entretien.

Remplacer toutes les pièces et panneaux avant

de faire fonctionner.

Ne pas le faire peut entraîner la mort ou un choc

électrique.

INSTALLATION DE LA HOTTE

1. Débrancher l'alimentation électrique.

A. Fils blancs

B. Fils noirs

C. Fil de mise à la terre vert

D. Connecteur de fil homologué UL

2. Utiliser les connecteurs de fils homologués UL et

connecter les fils blancs (A) conjointement.

3. Utiliser les connecteurs de fils homologués UL et

connecter les fils noirs (B) ensemble.

AVERTISSEMENT

Risque d'incendie

Mettre à terre le ventilateur. Utiliser du fil de

cuivre.

Brancher le fil de mise à la terre au fil vert dans

boîte à bornes. Ne pas le faire peut entraîner la

mort, un incendie ou un choc électrique.

4. Brancher le fil de mise à la terre vert (ou nu) depuis

l'alimentation au fil vert dans le bornier à bornes.

5. Installer le couvercle de la boîte à bornes.

6. Reconnecter l'alimentation électrique.

Installation complète

1. Installer les filtres à graisse.Voir la section

"Utilisation de la hotte".

2. Vérifier le fonctionnement du ventilateur et de la

lumière de la hotte. Voir la section "Utilisation de la

hotte".

Si la hotte ne fonctionne pas, vérifier si un disjoncteur

a sauté ou un fusible est grillé. Couper l'alimentation et

vérifier les branchements de câblage.

REMARQUE

Pour obtenir l'utilisation la plus efficace de votre

nouvelle hotte, lire la section "Utilisation de la

hotte".

E. Câble d'alimentation de maison

F. Homologué UL ou CSA

décharge de traction de ½"

FR-11

Page 28

UTILISATION DE LA HOTTE

UTILISATION DE LA HOTTE

La hotte est conçue pour éliminer la fumée et les vapeurs

de cuisson de la zone de cuisson. Pour de meilleurs

résultats, allumer la hotte avant la cuisson et lui

permettre de fonctionner pendant plusieurs minutes

après que la cuisson soit éliminée pour enlever toute

fumée de la cuisionnere.

D

A

B

C

A. LED

B. Filtre à graisse

C. Grille d'évacuation

D. Boutons de contrôle

Commandes de la hotte

Les commandes de la hotte sont situées à la partie avant

inférieure de l'appareil.

Lumière

ON FRONT REAROFF

Graphiques du bouton

Icône de lumière

HI MED LOOFF

Graphiques du bouton Icône du

Utilisation de la lumière

Pousser le bouton pour libérer et puis le tourner dans le

sens antihoraire pour allumer/Devant/Arrière/Arrêt.

Fonctionnement du ventilateur

Pousser le bouton pour libérer et puis le tourner dans le

sens horaire pour les vitesses de ventilateur de Hi/Med/Lo/Off.

A

Ventilateur

venlatiteur

Nettoyage

AVERTISSEMENT

Pour réduire le risque d'incendie ou de choc électrique,

débrancher du secteur avant de le nettoyer.

IMPORTANT

Nettoyer fréquemment les filtres de la hotte et de

graisse selon les instructions suivantes. Remplacer le

filtre à graisse avant de faire fonctionner la hotte.

IMPORTANT

Surfaces extérieures

Ne pas utiliser de tampons à récurer savonneux, de

nettoyants abrasifs, crème à polir pour table de cuisson,

de la laine en acier, des débarbouillettes ou des

serviettes en papier granuleuses.

Pour éviter d'endommager l'acier inoxydable, ne pas

utiliser de produits nettoyants qui contiennent du chlore.

Méthode de nettoyage:

RÉSISTANT AUX FROTTEMENTS ACIER INOXYDABLE

Votre hotte a une finition en acier inoxydable et

résistante aux frottements .Nettoyer l'inox avec de l'eau

chaude savonneuse à l'aide d'une éponge ou d'un chiffon

propre. Rincer à l'eau propre et sécher avec un chiffon

doux et propre. NE PAS utiliser de produits de nettoyage

comme les nettoyants en acier inoxydable ou d'autres

types de produits nettoyants contenant des abrasifs, des

chlorures, du chlore ou de l'ammoniaque. Il est

recommandé d'utiliser un savon pour vaisselle doux et de

l'eau ou une solution 50/50 d'eau et de vinaigre.

TM

TM

FR-12

Page 29

ENTRETIENT DE LA HOTTE

Pour nettoyer ou remplacer le filtre à graisse:

1.

Pousser à la zone indiquée pour ouvrir la grille

d'évacuation. La grille d'évacuation pivotera vers le bas

pour l'accès aux filtres à graisse.

POUSSER POUR OUVRIR

2.

Pour retirer ou installer les filtres à graisse, pousser

l'onglet vers l'arrière de l'appareil.

AVERTISSEMENT

Risque d’électrocution

Couper l'alimentation électrique avant l'entretien.

Remplacer toutes les pièces et panneaux avant de

faire fonctionner.

Ne pas le faire peut entraîner la mort ou un choc

électrique.

Remplacement des voyants LED avant

1.Retirer la grille d'évacuation et les filtres à graisse.

2. Retirer les vis sur le support avant et faire glisser

le panneau arrière.

3.

Pour nettoyer le filtre à graisse, faire tremper les filtres

dans l'eau chaude avec un détergent doux. Bien rincer et

secouer pour sécher.

REMARQUE

Ne pas utiliser d'ammoniaque. L'aluminium sur le

filtre à graisse se corrodera et assombrira.

REMARQUE

Le filtre à graisse est lavable au lave-vaisselle.

Pour éviter des dommages du filtre à graisse

pendant le nettoyage, placer le filtre dans le

panier supérieur du lave-vaisselle, pour le

nettoyage.

3. Débrancher le câblage des voyants LED avant

Enclencher les clips de fixation de la lampe LED

4.

et pousser vers le bas les voyants LED comme

indiqué ci-dessous

Enclencher ici

Enclencher ici

5. Remplacer par de nouveaux voyants LED, avec comme

Numéro de pièce 5304503879 et ré-installer le support

avant.

FR-13

Page 30

ENTRETIENT DE LA HOTTE

AVERTISSEMENT

Risque d’électrocution

Couper l'alimentation électrique avant

l'entretien.

Remplacer toutes les pièces et panneaux avant

de faire fonctionner.

Ne pas le faire peut entraîner la mort ou un choc

électrique.

Remplacement des voyants LED arrière

1. Retirer la grille d'évacuation et les filtres à graisse.

2. Débrancher le câblage de la lampe LED arrière.

3. Enclencher les clips de fixation de la lampe LED et

pousser vers le bas les voyants LED comme indiqué

ci-dessous

Enclencher ici

Enclencher ici

4. Enclencher les clips de fixation de la lampe LED et

pousser vers le bas les voyants LED comme indiqué

ci-dessous

FR-14

Page 31

Problème Causes possibles Solutions

Après l'installation,

l'appareil ne

fonctionne pas.

Les voyants

fonctionnent, mais

ce n'est pas le cas

du moteur

L'appareil est

en train de vibrer.

Le moteur

fonctionne, mais

pas les voyants.

La hotte n’évacue

pas correctement

de l'air.

Grille d'évacuation

ou filtre à graisse

est en train de

vibrer.

1. La ligne d'alimentation et le connecteur du

câble ne sont pas correctement connectés.

2. Les fils des interrupteurs sont déconnectés ou

desserrés.

1. Le moteur est défectueux, blocage possible.

2. Le fil du moteur n'est pas connecté.

1. Le moteur n'est pas sécurisé en place.

2. Roue soufflante endommagée.

3. La hotte n'est fixée en place.

1. Lampe défectueuse.

2. La lampe est desserrée.

3. Les fils sur l'interrupteur d'éclairage sont

desserrés.

.

1. La hotte peut être suspendue au-dessus de la

table de cuisson.

2. Le vent provenant d'une fenêtre ou d'une porte

ouverte avoisinante nuit à la ventilation de la

hotte.

3. Blocage dans l'ouverture du conduit ou des

conduits.

4. La direction de l'ouverture du conduit est contre

le vent.

5. Utilisation de la mauvaise taille de canalisation. 5. Modifier la canalisation pour corriger la taille.

1. La grille d'évacuation ou le filtre à graisse sont

desserrés.

a

i

1. Vérifier les connexions électriques.

2. S'assurer que les fils sur les commutateurs sont

correctement connectés.

1. Changer le moteur.

2. S'assurer que le fil du moteur est branché sur le

connecteur de la boîte à bornes.

1. Visser le moteur en place.

2. Modifier le ventilateur.

3. Vérifier l'installation de la hotte.

1. Changer la lampe.