Frigidaire FFEW2415QB Wiring Diagram

SERVICE DATA SHEET

Resistance Temperature Detector

Wall Ovens with ES 100/105 Electronic Oven Control

NOTICE - This service data sheet is intended for use by

persons having electrical and mechanical training and a level of

knowledge of these subjects generally considered acceptable

in the appliance repair trade. The manufacturer cannot be

responsible, nor assume any liability for injury or damage of any

kind arising from the use of this data sheet.

SAFE SERVICING PRACTICES

To avoid the possibility of personal injury and/or property

damage, it is important that safe servicing practices be

observed. The following are examples, but without limitation, of

such practices.

1. Before servicing or moving an appliance remove power

cord from electrical outlet, trip circuit breaker to OFF, or

remove fuse.

2. Never interfere with the proper installation of any safety

device.

3. GROUNDING: The standard color coding for safety ground

wires is GREEN or GREEN WITH YELLOW STRIPES.

Ground leads are not to be used as current carrying conductors. It is extremely important that the service technician

reestablish all safety grounds prior to completion of service.

Failure to do so will create a potential safety hazard.

4. Prior to returning the product to service, ensure that:

• All electric connections are correct and secure.

• All electrical leads are properly dressed and secured

away from sharp edges, high-temperature components,

and moving parts.

• All uninsulated electrical terminals, connectors, heaters,

etc. are adequately spaced away from all metal parts and

panels.

• All safety grounds (both internal and external) are correct-

ly and securely reassembled.

Oven Calibration

Set the electronic oven control for normal baking at 350°F.

Obtain an average oven temperature after a minimum of 5

cycles. Press CANCEL or CLEAR OFF to end bake mode.

Oven Temperature Adjustment (some models)

1. Press & hold the BAKE key pad and release after the

display shows the factory temperature setting of 00. If the

oven temperature has been previously adjusted from the

factory setting, the latest adjusted value will appear in the

display instead.

2. You may increase the oven temperature in 5°F increments

with each press of the UP ARROW key pad. You may also

adjust the oven temperature downward in 5°F increments

with each press of the DOWN ARROW keypad (total adjustment range is +35°F to -35° F).

3. To accept the change, wait until the oven control provides

the acceptance beep (See important notes).

4. The oven temperature adjustment has been made by the

oven control and the display will return to the time of day.

Important notes:

• The oven temperature adjustment may be made if your

oven control has been set for °C (Celsius) temperature

display mode. In this case each press of the UP ARROW

or DOWN ARROW key pad will adjust in 1°C increments

upward (maximum +18°C) or downward (maximum -18°C),

depending on which arrow keypad is pressed.

• If at any time during the process of adjusting the oven

temperature feature you decide not to make the change,

press the CANCEL or CLEAR OFF key pad once before the

acceptance beep.

• The oven temperature adjustment feature can not be modi-

ed if BAKE or BROIL is active.

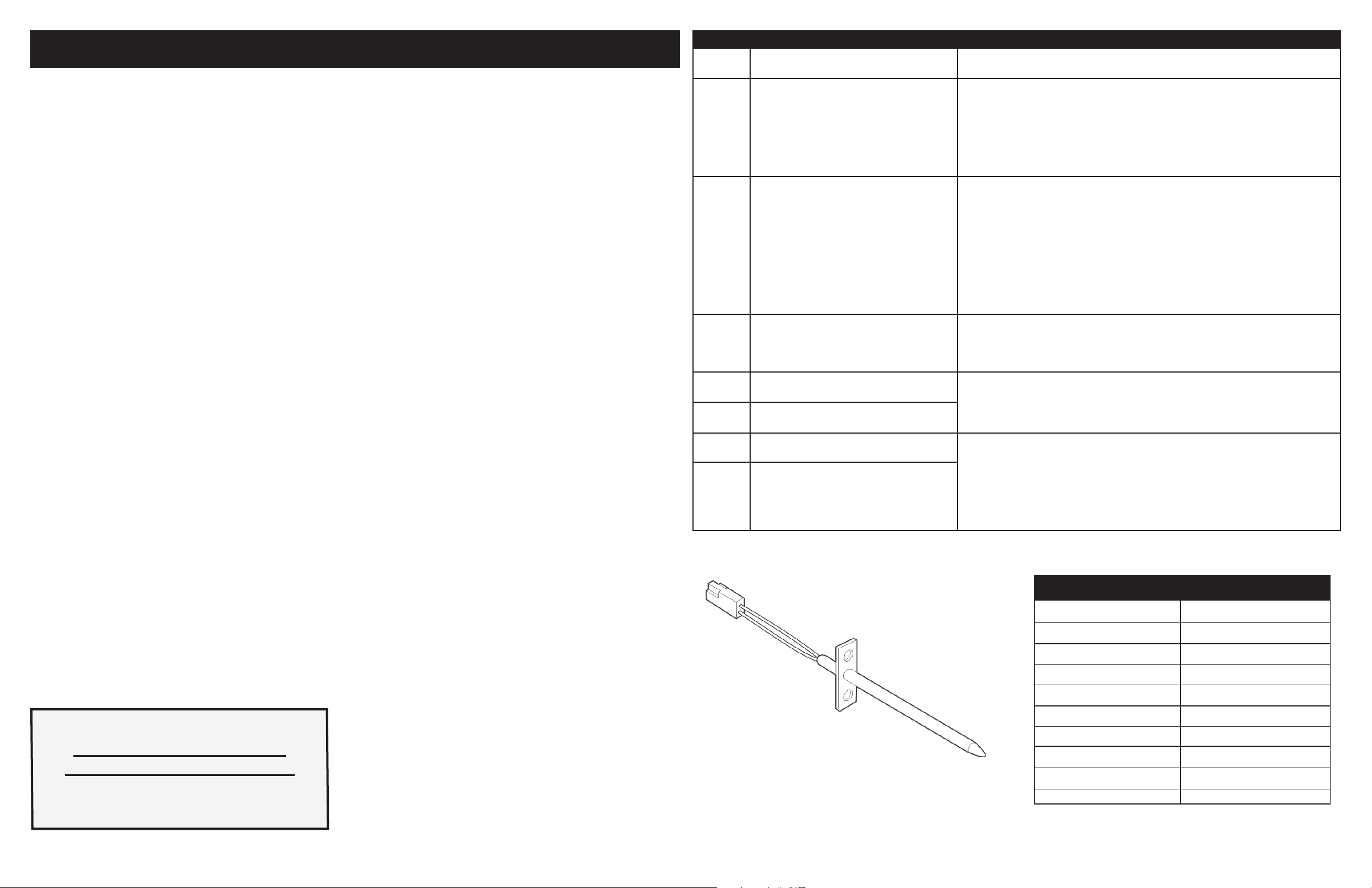

Electronic Oven Control (E.O.C.) Fault Code Descriptions

Fault

Code

F1 • Shorted keypad.

F3 • Open RTD sensor probe.

F10 Runaway temperature. Check RTD Sensor Probe & replace if necessary. If oven is overheating,

F11 Shorted keypad.

F13 Bad EEPROM identication/checksum

F30 Open probe connection. 1. Check resistance at room temperature & compare to RTD Sensor

F31 Shorted probe connection.

Likely Failure Condition/Cause Suggested Corrective Action

1. Disconnect power, wait 30 seconds and reapply power. If fault returns

• Control’s internal checksum may

have become corrupted.

• Control has sensed a potential runaway oven condition. Control may

have shorted relay, RTD sensor

probe may have gone bad.

Note: The EOC will initially display

an F1 for this condition. The EOC

thinks a runaway oven condition

exists.

• Shorted RTD sensor probe.

Note: The F3 for shorted probe

should only occur when the oven is

active or when an attempt is made

to enter a mode.

Bad micro identication.

error.

upon power-up, replace EOC.

2. Check RTD sensor probe and replace if necessary. If oven is overheating, disconnect power. If oven continues to overheat when the

power is reapplied, replace EOC. Severe overheating may require the

entire oven to be replaced, should damage be extensive.

3. Replace EOC.

1. Check resistance at room temperature and compare to RTD sensor

resistance chart. If resistance does not match the chart, replace RTD

sensor probe.

2. Check resistance at room temperature, if less than 500 ohms, replace

RTD sensor probe.

disconnect power. If oven continues to overheat when the power is reapplied,

replace EOC. Severe overheating may require the entire oven to be replaced

should damage be extensive

1. Disconnect power, wait 30 seconds and reapply power.

2. If fault returns upon power-up, replace EOC.

resistance chart. If resistance does not match the RTD chart replace RTD

Sensor Probe. Check Sensor wiring harness between EOC & Sensor

Probe connector.

2. Check resistance at room temperature, if less than 500 ohms, replace

RTD Sensor Probe. Check for shorted Sensor Probe harness between

EOC & Probe connector.

IMPORTANT

DO NOT REMOVE THIS BAG

OR DESTROY THE CONTENTS

WIRING DIAGRAMS AND SERVICE

INFORMATION ENCLOSED

REPLACE CONTENTS IN BAG

A04967802 EN REV A (1509)

RTD SCALE

Temperature °F (°C)

32 ± 1.9 (0 ± 1.0)

75 ± 2.5 (24 ± 1.3)

250 ± 4.4 (121 ± 2.4)

350 ± 5.4 (177 ± 3.0)

450 ± 6.9 (232 ± 3.8)

550 ± 8.2 (288 ± 4.5)

650 ± 9.6 (343 ± 5.3)

900 ± 13.6 (482 ±7.5)

Probe circuit to case ground

Resistance (ohms)

1000 ± 4.0

1091 ± 5.3

1453 ± 8.9

1654 ± 10.8

1852 ± 13.5

2047 ± 15.8

2237 ± 18.5

2697 ± 24.4

Open circuit/infinite resistance

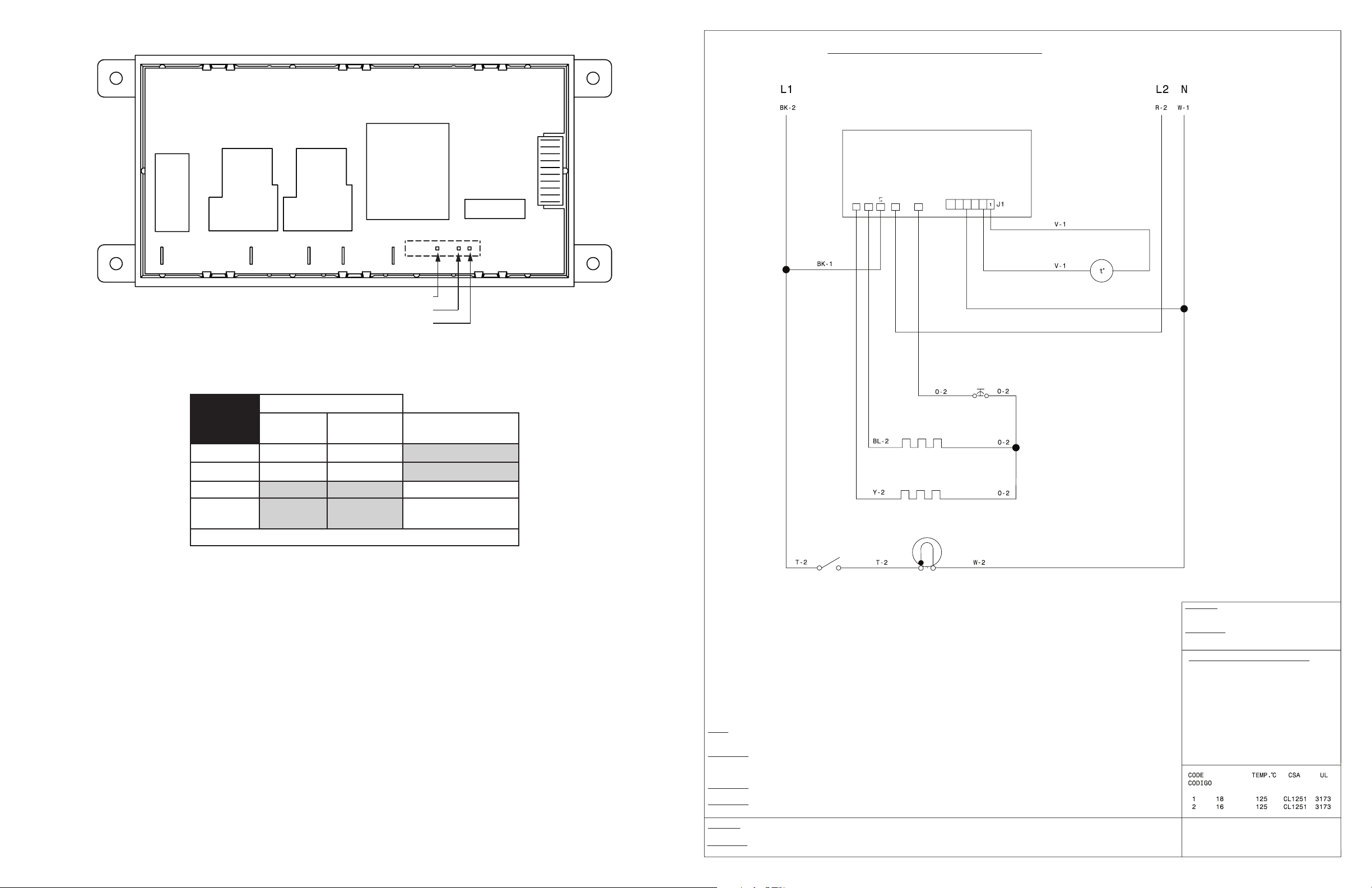

BAKE

TEMPERATURE PROBE

BAKE

BROIL

BROIL

ELECTRIC

DLB

RELAY

L1

TEMPERATURE PROBE

L2 IN

NEUTRAL

L2 OUT

J1

OVEN CIRCUIT // CIRCUIT DU FOUR

TIMER ES 105

MINITERIE ES 105

DLB ENTREÉ

CUISSON

BAKE

GRIL

BROIL

DLB IN

DLB SORTIE

DLB OUT

TEMPERATURE PROBE

SONDE À TEMPÉRATURE

CIRCUIT

ANALYSIS

MATRIX

EOC Relays

L1 to Bake L1 to Broil Door Switch

COM-NC

Bake X X*

Broil X

Door Open X

Door

Closed

Note: X= Check listed circuits *= Alternates with Bake element

THERMAL CIRCUIT BREAKER

DISJONCTEUR THERMIQUE

BROIL ELEMENT

ÉLÉMENT DE GRILLAGE

BAKE ELEMENT

ÉLÉMENT DE CUISSON

OVEN LAMP

LAMPE DU FOUR

OVEN LAMP SWITCH

INTERRUPTEUR DE LAMPE DU FOUR

NOTE:

OVEN CONDITION:

ALL CONTROLS SET TO “OFF” AND OVEN DOOR CLOSED.

REMARQUES:

ÉTAT FOUR:

TOUTES LES COMMANDES SONT DÉSACTIVÉES ET LA PORTE DU FOUR EST FERMÉE.

IMPORTANT:

COPPER WIRE MUST BE USED FOR CONNECTIONS TO CONDUIT WIRE.

IMPORTANT:

FIL DE CUIVRE DOIT ÊTRE UTILISÉ POUR LES CONNEXIONS À FIL CONDUIT.

CAUTION:

DISCONNECT POWER BEFORE SERVICING UNIT.

ATTENTION:

DÉBRANCHEZ L'APPAREIL AVANT DE PROCÉDER À LA RÉPARATION.

CAUTION:

DISCONNECT POWER BEFORE SERVICING

UNIT.

ATTENTION:

DÉBRANCHEZ L'APPAREIL AVANT DE

PROCÉDER À LA RÉPARATION.

COLOR CODE // CODE DE COULEURS

GY=GREY/GRIS

G =GREEN/VERT

W =WHITE/BLANC

R =RED/ROUGE

O =ORANGE

Y =YELLOW/JAUNE

BR=BROWN/BRUN

BL=BLUE/BLEU

BK=BLACK/NOIR

V = VIOLET

T =TAN/OCRE

GAUGE

CALIBRE

Loading...

Loading...