Frigidaire FCS367CHBC, FCS367CHBD, FCS367CHSC, FCS367CHSD, FCS388WHCA Installation Guide

...Page 1

INSTALLATION AND SERVICE MUST BE PERFORMED BY

A QUALIFIED INSTALLER.

IMPORTANT: SAVE FOR LOCAL ELECTRICAL INSPECTOR'S USE.

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE.

If the information in this manual is not followed exactly, a fire or explosion may

result causing property damage, personal injury or death.

FOR YOUR SAFETY:

-- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other

appliance.

m WHATTO DO IFYOU SMELLGAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or the gas supplier.

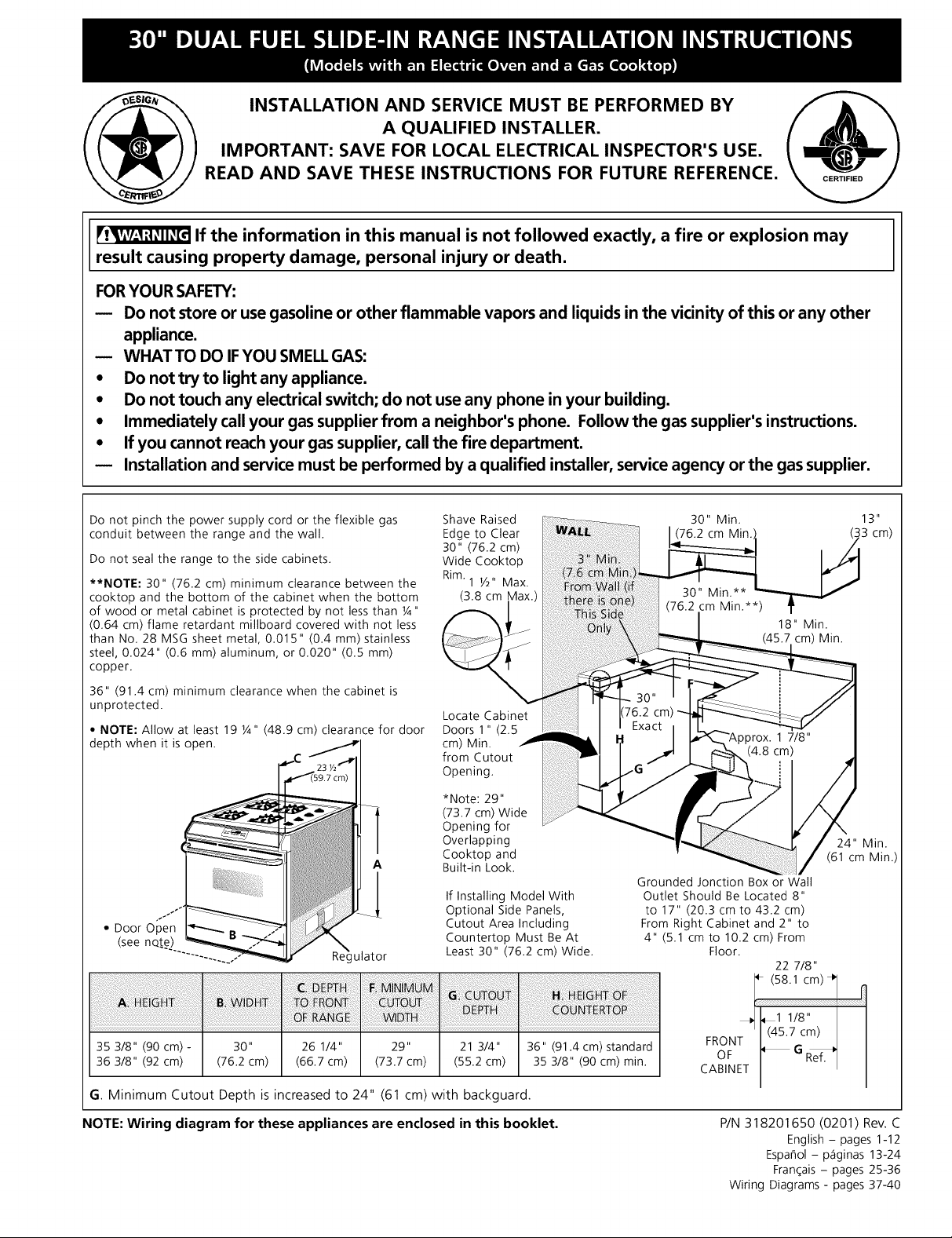

Do not pinch the power supply cord or the flexible gas

conduit between the range and the wall.

Do not seal the range to the side cabinets.

**NOTE: 30" (76.2 cm) minimum clearance between the

cooktop and the bottom of the cabinet when the bottom

of wood or metal cabinet is protected by not less than ¼"

(0.64 cm) flame retardant millboard covered with not less

than No. 28 MSG sheet metal, 0.015" (0.4 mm) stainless

steel, 0.024" (0.6 mm) aluminum, or 0.020" (0.5 mm)

copper.

36" (91.4 cm) minimum clearance when the cabinet is

unprotected.

• NOTE: Allow at least 19 ¼" (48.9 cm) clearance for door

depth when it is open.

• Door Open

(see note)

ulator

Shave Raised

Edge to Clear

30" (76.2 cm)

Wide Cooktop

Rim1 Y2" Max.

(3.8 cm Max.

Locate Cabinet

Doors 1" (2.5

cm) Min.

from Cutout

Opening.

*Note: 29"

(73.7 cm) Wide

Opening for

Overlapping

Cooktop and

Built-in Look.

If Installing Model With

Optional Side Panels,

Cutout Area Including

Countertop Must Be At

Least 30" (76.2 cm) Wide.

30" Min.

(76.2 cm Min.

18" Min.

cm) Min.

Grounded Jonction Box or Wall

Outlet Should Be Located 8"

to 17" (20.3 cm to 43.2 cm)

From Right Cabinet and 2" to

4" (5.1 cm to 10.2 cm) From

Floor.

22 7/8"

13"

3 cm)

24" Min.

(61 cm Min.)

35 3/8" (90 cm) - 30" 26 1/4"

36 3/8" (92 cm) (76.2 cm) (66.7 cm)

29" 21 3/4" 36" (91.4 cm) standard

(73.7 cm) (55.2 cm) 35 3/8" (90 cm) min.

G. Minimum Cutout Depth is increased to 24" (61 cm) with backguard.

NOTE: Wiring diagram for these appliances are enclosed in this booklet.

ol 1/8"

FRONT

OF

CABINET

(45.7 cm)

G R_,.

P/N 318201650 (0201) Rev. C

English - pages 1-12

EspaSol - p_tginas 13-24

Fran_ais - pages 25-36

Wiring Diagrams - pages 37-40

Page 2

Important Notes to the Installer

1. Readall instructions contained in these installation

instructions before installing range.

2. Remove all packing material from the oven

compartments before connecting the gas and electrical

supply to the range.

3. Observe all governing codes and ordinances.

4. Besure to leavethese instructions with the consumer.

Important Note to the Consumer

Keep these instructions with your owner's guide for future

reference.

IMPORTANT SAFETY

INSTRUCTIONS

Installation of this range must conform with local codes

or, in the absence of local codes, with the National Fuel

Gas Code ANSI Z223.1ilatest edition, in United States

or with CAN/CGA-B149.1 and CAN/CGA-B149.2

standards in Canada.

Standard for Mobile Home Construction and Safety,

title 24, Hun (part 280)] or when such standard is not

applicable, the Standard for Manufactured Home

Installation 1982 (Manufactured Home Sites,

Communities and Setups), ANSI Z225.1/NFPA 501A-

latest edition, or with local codes in United States or

with CAN/CSA-Z240 MH, in Canada.

Make sure the wall coverings around the range

can withstand the heat generated by the range.

Before installing the range in an area covered

with linoleum or any other synthetic floor

covering, make sure the floor covering can

withstand heat at least 90°F (32.2°C) above room

temperature without shrinking, warping or

discoloring. Do not install the range over carpeting

unless you place an insulating pad or sheet of ¼" (0.6

cm) thick plywood between the range and carpeting.

Do not obstruct the flow of combustion air at the

oven vent nor around the base or beneath the

lower front panel of the range. Avoid touching the

vent openings or nearby surfaces as they may become

hot while the oven is in operation. This range requires

fresh air for proper burner combustion.

This range has been design certified by the American Gas

Association. As with any appliance using gas and

generating heat, there are certain safety precautions you

should follow. You will find them in the Use and Care

Guide., read it carefully.

• Be sure your range is installed and grounded

properly by a qualified installer or service

technician.

• This range must be electrically grounded in

accordance with local codes or, in their absence,

with the National Electrical Code ANSI/NFPA No.

70--latest edition in United States (see Grounding

Instructions) or with CSA standard C22.1, Canadian

Electrical Code, Part I in Canada.

• The installation of appliances designed for

manufactured (mobile) home installation must conform

with Manufactured Home Construction and Safety

Standard, title 24CFR, part 3280 [Formerly the Federal

TO reduce

@

• All ranges

cantip.

• Injuryto

personscould

result.

• Installanti-tip

device

packed with

range.

the risk of tipping of the

range, the range must be

secured by properly

installed anti-tip bracket

provided with the range.

To check if the bracket is

installed properly, grasp

the top rear edgge of the

range and carefully tilt it

forward to make sure the

range isanchored.

Never leave children alone or

unattended in the area where an appliance is in use.

As children grow, teach them the proper, safe use of all

appliances. Never leave the oven door open when the

range is unattended.

Stepping, leaning or sitting on the

doors or drawers of this range can result in serious

injuries and can also cause damage to the range.

• Do not store items of interest to children in the

cabinets above the range. Children could be

seriously burned climbing on the range to reach items.

• To eliminate the need to reach over the surface

burners, cabinet storage space above the burners

should be avoided.

• Adjust surface burner flame size so it does not

extend beyond the edge of the cooking utensil.

Excessiveflame is hazardous.

• Do not use the oven as a storage space. This

creates a potentially hazardous situation.

• Never use your range for warming or heating the

room. Prolonged use of the range without adequate

ventilation can be dangerous.

• Do not store or use gasoline or other flammable

vapors and liquids near this or any other

appliance. Explosions or fires could result.

• In the event of an electrical power outage, the surface

burners can be lit manually. To light a surface burner,

hold a lit match to the burner head and slowly turn the

Surface Control Knob to LITE. Use caution when

lighting surface burners manually.

• Reset all controls to the "off" position after using

2

a programmable timing operation.

Page 3

CANADA ONLY : This appliance is

equipped with a 4-prong grounding plug for your

protection against shock hazard, and should be

plugged directly into a properly grounded

receptacle. Do not cut or remove the ground prong

from this plug.

FOR MODELS WITH SELF-CLEANFEATURE:

• Remove broiler pan, food and other utensils

before self-cleaning the oven. Wipe up excess

spillage. Follow the precleaning instructions in the Use

and Care Guide.

1. Power Supply Cord Kit (U.S.A.)

The user is responsible for connecting the power supply

cord to the connection block located behind the back

panel access cover.

This appliance may be connected by means of

permanent "hard wiring" (flexible armored or

nonmetallic shielded copper cable), or by means of a

power supply cord kit. Only a power supply cord kit

rated at 125/250 volts minimum, 40 amperes and

marked for use with ranges shall be used. See chart

(below) for cord kit connection opening size rating

information. Cord must have either 3 or 4 conductors.

For mobile homes, new installations, recreational

vehicles, or areas where local codes do not permit

grounding through neutral, a 4 conductor power supply

cord kit rated at 125/250 volts minimum, 40 amperes

and marked for use with ranges should be used (see

Figure 5).

Terminals on end of wires must be either closed loop or

open-end spade lugs with upturned ends. Cord must

have strain-relief clamp.

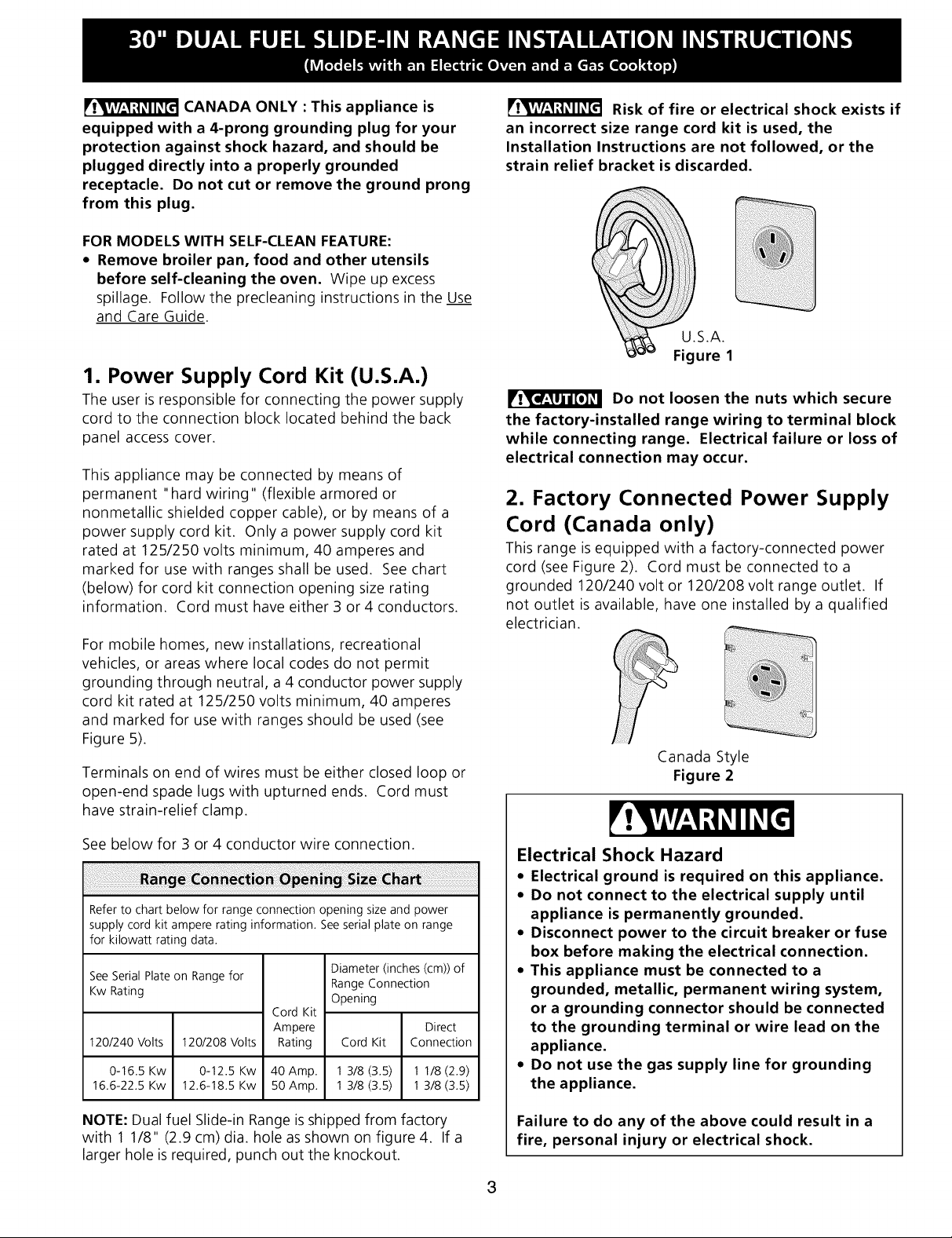

Risk of fire or electrical shock exists if

an incorrect size range cord kit is used, the

Installation Instructions are not followed, or the

strain relief bracket is discarded.

Do not loosen the nuts which secure

the factory-installed range wiring to terminal block

while connecting range. Electrical failure or loss of

electrical connection may occur.

2. Factory Connected Power Supply

Cord (Canada only)

This range isequipped with a factory-connected power

cord (see Figure 2). Cord must be connected to a

grounded 120/240 volt or 120/208 volt range outlet. If

not outlet is available, have one installed by a qualified

electrician.

Canada Style

Figure 2

See below for 3 or 4 conductor wire connection.

Refer to chart below for range connection opening size and power

supply cord kit ampere rating information. See serial plate on range

for kilowatt rating data.

See Serial Plate on Range for

Kw Rating

120/240 Volts

0-16.5 Kw

16.6-22.5 Kw

120/208 Volts Rating

0-12.5 Kw 40 Amp.

12.6-18.5 Kw 50 Amp.

Cord Kit

Ampere

Diameter (inches (cm)) of

Range Connection

Opening

Direct

Cord Kit Connection

1 3/8 (3.5) 1 1/8 (2.9)

1 3/8 (3.5) 1 3/8 (3.5)

NOTE: Dual fuel Slide-in Range isshipped from factory

with 1 1/8" (2.9 cm) dia. hole as shown on figure 4. If a

larger hole isrequired, punch out the knockout.

Electrical Shock Hazard

• Electrical ground is required on this appliance.

• Do not connect to the electrical supply until

appliance is permanently grounded.

• Disconnect power to the circuit breaker or fuse

box before making the electrical connection.

• This appliance must be connected to a

grounded, metallic, permanent wiring system,

or a grounding connector should be connected

to the grounding terminal or wire lead on the

appliance.

• Do not use the gas supply line for grounding

the appliance.

Failure to do any of the above could result in a

fire, personal injury or electrical shock.

3

Page 4

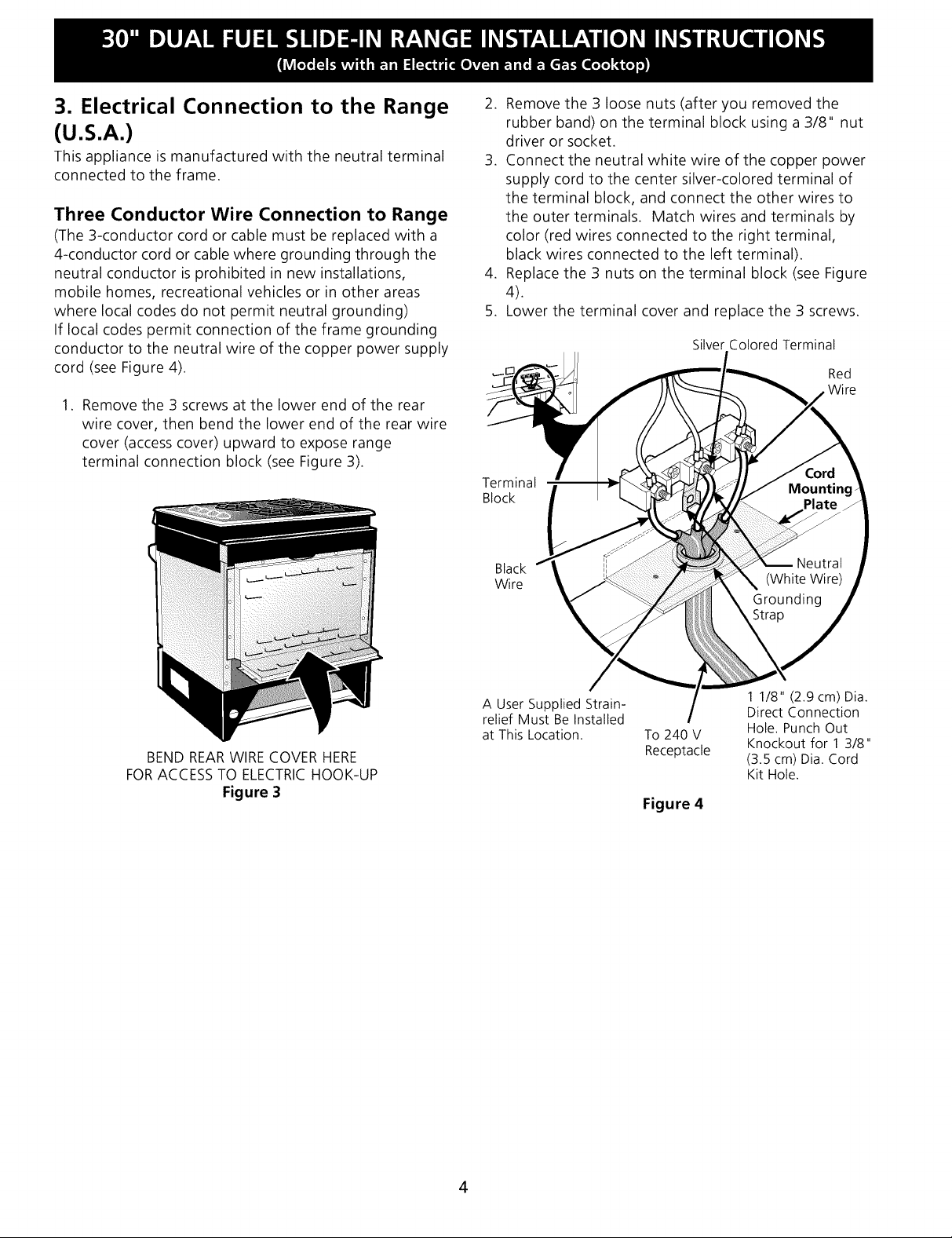

3. Electrical Connection to the Range

(U.S.A.)

This appliance is manufactured with the neutral terminal

connected to the frame.

Three Conductor Wire Connection to Range

(The 3-conductor cord or cable must be replaced with a

4-conductor cord or cable where grounding through the

neutral conductor is prohibited in new installations,

mobile homes, recreational vehicles or in other areas

where local codes do not permit neutral grounding)

If local codes permit connection of the frame grounding

conductor to the neutral wire of the copper power supply

cord (see Figure 4).

1. Remove the 3 screws at the lower end of the rear

wire cover, then bend the lower end of the rear wire

cover (access cover) upward to expose range

terminal connection block (see Figure 3).

2. Remove the 3 loose nuts (after you removed the

rubber band) on the terminal block using a 3/8" nut

driver or socket.

3. Connect the neutral white wire of the copper power

supply cord to the center silver-colored terminal of

the terminal block, and connect the other wires to

the outer terminals. Match wires and terminals by

color (red wires connected to the right terminal,

black wires connected to the left terminal).

4. Replace the 3 nuts on the terminal block (see Figure

4).

5. Lower the terminal cover and replace the 3 screws.

Silver Colored Terminal

Red

Terminal

Block

BEND REAR WIRE COVER HERE

FOR ACCESS TO ELECTRIC HOOK-UP

Figure 3

Black

Wire

A User Supplied Strain-

relief Must Be Installed

at This Location. To 240 V

Receptacle

Figure 4

1 1/8" (2.9 cm) Dia.

Direct Connection

Hole. Punch Out

Knockout for 1 3/8"

(3.5 cm) Dia. Cord

Kit Hole.

4

Page 5

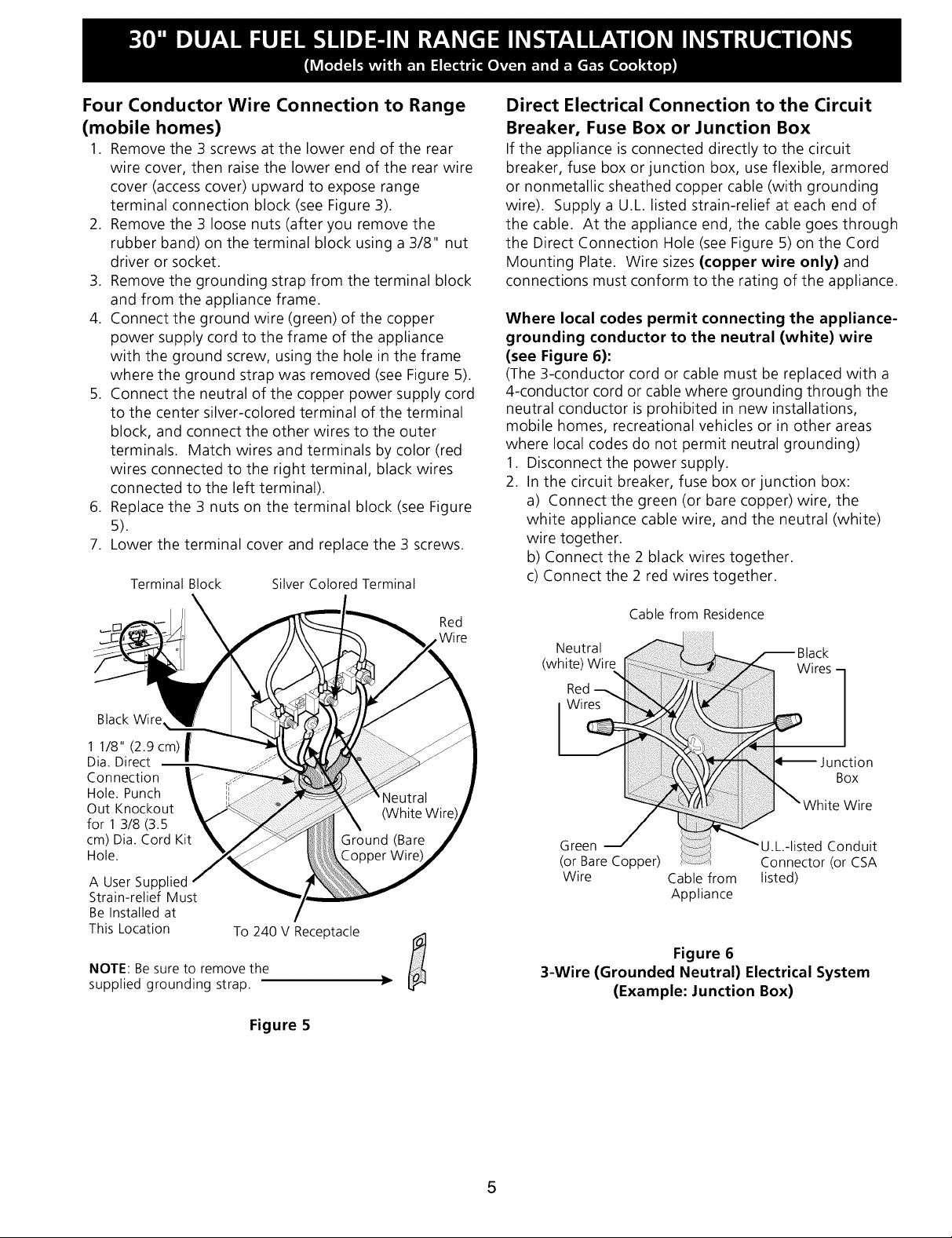

Four Conductor Wire Connection to Range

(mobile homes)

1. Remove the 3 screws at the lower end of the rear

wire cover, then raise the lower end of the rear wire

cover (access cover) upward to expose range

terminal connection block (see Figure 3).

2. Remove the 3 loose nuts (after you remove the

rubber band) on the terminal block using a 3/8" nut

driver or socket.

3. Remove the grounding strap from the terminal block

and from the appliance frame.

4. Connect the ground wire (green) of the copper

power supply cord to the frame of the appliance

with the ground screw, using the hole in the frame

where the ground strap was removed (see Figure 5).

5. Connect the neutral of the copper power supply cord

to the center silver-colored terminal of the terminal

block, and connect the other wires to the outer

terminals. Match wires and terminals by color (red

wires connected to the right terminal, black wires

connected to the left terminal).

6. Replace the 3 nuts on the terminal block (see Figure

5).

7. Lower the terminal cover and replace the 3 screws.

Terminal Block Silver Colored Terminal

Direct Electrical Connection to the Circuit

Breaker, Fuse Box or Junction Box

If the appliance is connected directly to the circuit

breaker, fuse box or junction box, use flexible, armored

or nonmetallic sheathed copper cable (with grounding

wire). Supply a U.L. listed strain-relief at each end of

the cable. At the appliance end, the cable goes through

the Direct Connection Hole (see Figure 5) on the Cord

Mounting Plate. Wire sizes (copper wire only) and

connections must conform to the rating of the appliance.

Where local codes permit connecting the appliance-

grounding conductor to the neutral (white) wire

(see Figure 6):

(The 3-conductor cord or cable must be replaced with a

4-conductor cord or cable where grounding through the

neutral conductor is prohibited in new installations,

mobile homes, recreational vehicles or in other areas

where local codes do not permit neutral grounding)

1. Disconnect the power supply.

2. In the circuit breaker, fuse box or junction box:

a) Connect the green (or bare copper) wire, the

white appliance cable wire, and the neutral (white)

wire together.

b) Connect the 2 black wires together.

c) Connect the 2 red wires together.

Black Wire

1 1/8" (2.9 cm) I

Dia. Direct

Connection

Hole. Punch

Out Knockout

for 1 3/8 (3.5

cm) Dia. Cord Kit

Hole.

A User Supplied

Straimrelief Must

Be Installed at

This Location

NOTE: Be sure to remove the

supplied grounding strap.

n

To 240 V Receptacle

Figure 5

Red

Wi re

Cable from Residence

Neutral Black

(wh ite) Wire Wires -

Red

Box

Wire

Green Conduit

(or Bare Copper) Connector (or CSA

Wire Cable from listed)

Appliance

Figure 6

3-Wire (Grounded Neutral) Electrical System

(Example: Junction Box)

5

Page 6

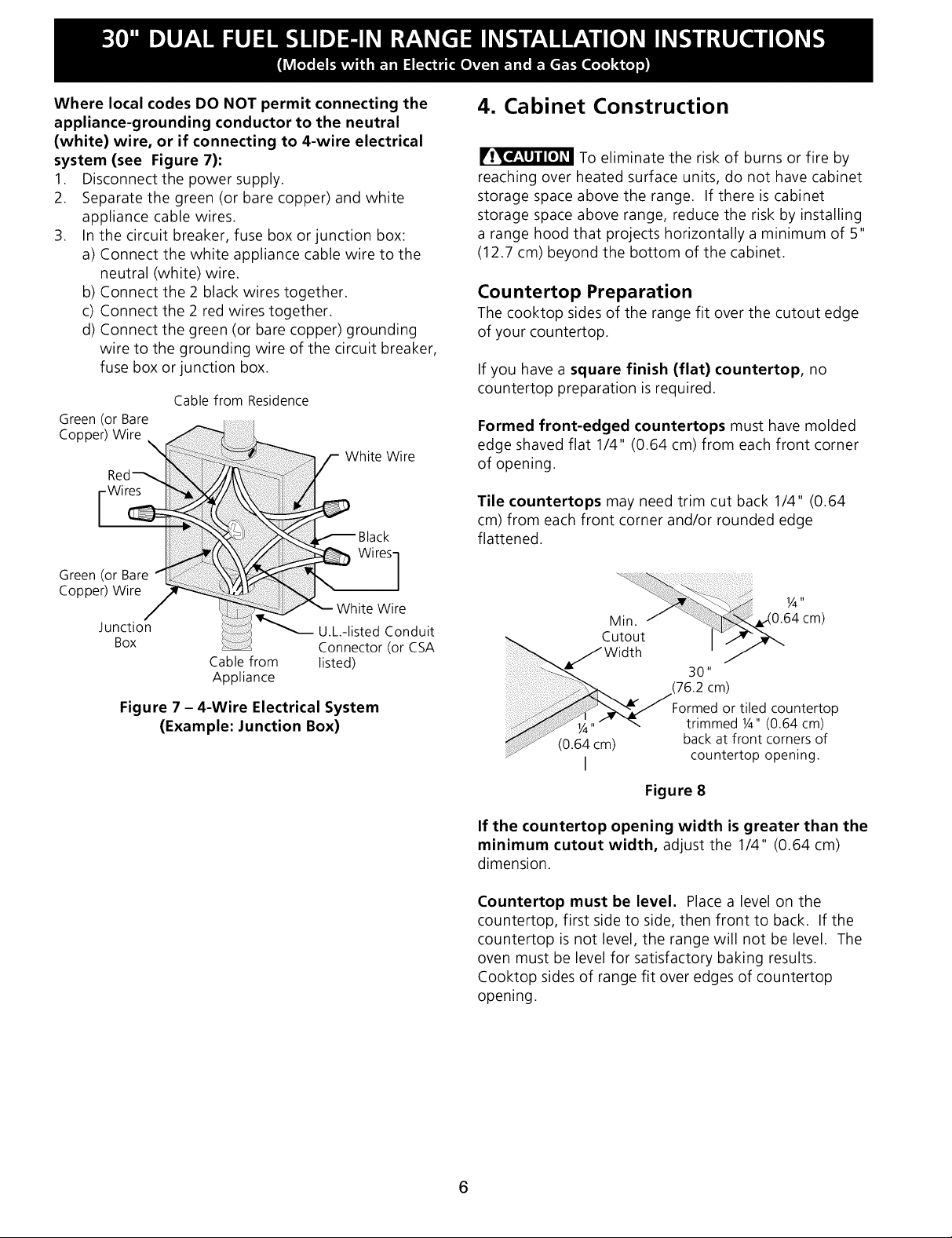

Where local codes DO NOT permit connecting the

appliance-grounding conductor to the neutral

(white) wire, or if connecting to 4-wire electrical

system (see Figure 7):

1. Disconnect the power supply.

2. Separate the green (or bare copper) and white

appliance cable wires.

3. In the circuit breaker, fuse box or junction box:

a) Connect the white appliance cable wire to the

neutral (white) wire.

b) Connect the 2 black wires together.

c) Connect the 2 red wires together.

d) Connect the green (or bare copper) grounding

wire to the grounding wire of the circuit breaker,

fuse box or junction box.

Cable from Residence

Green (or Bare

4. Cabinet Construction

To eliminate the risk of burns or fire by

reaching over heated surface units, do not have cabinet

storage space above the range. If there is cabinet

storage space above range, reduce the risk by installing

a range hood that projects horizontally a minimum of 5"

(12.7 cm) beyond the bottom of the cabinet.

Cou ntertop Prepa ration

The cooktop sides of the range fit over the cutout edge

of your countertop.

If you have a square finish (flat) countertop, no

countertop preparation is required.

Formed front-edged countertops must have molded

edge shaved flat 1/4" (0.64 cm) from each front corner

of opening.

Tile countertops may need trim cut back 1/4" (0.64

cm) from each front corner and/or rounded edge

flattened.

Cable from

Appliance

Connector (or CSA

listed)

Figure 7 - 4-Wire Electrical System

(Example: Junction Box)

countertop opening.

Figure 8

If the countertop opening width is greater than the

minimum cutout width, adjust the 1/4" (0.64 cm)

dimension.

Countertop must be level. Place a level on the

countertop, first side to side, then front to back. If the

countertop is not level, the range will not be level. The

oven must be level for satisfactory baking results.

Cooktop sides of range fit over edges of countertop

opening.

6

Page 7

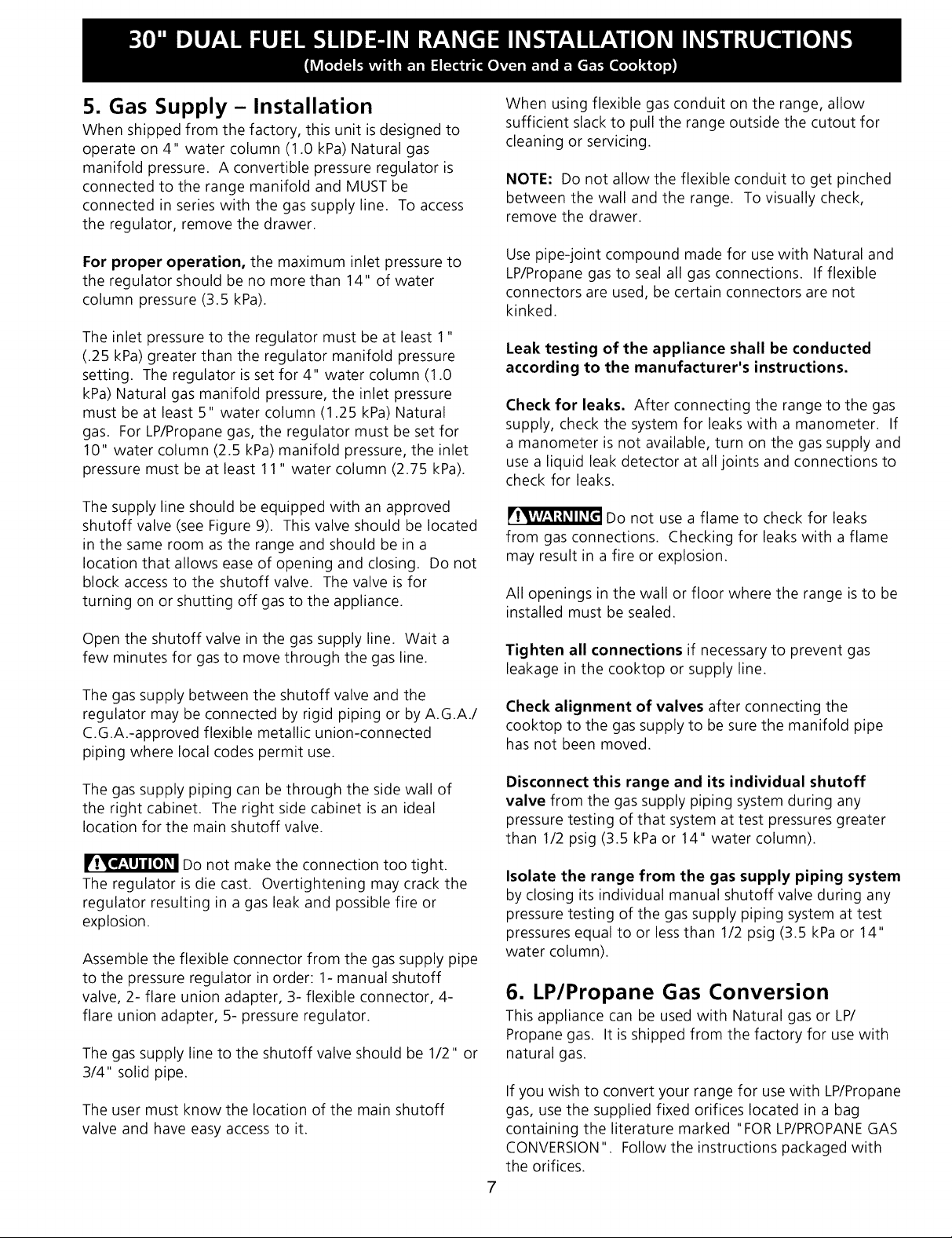

5. Gas Supply- Installation

When shipped from the factory, this unit is designed to

operate on 4" water column (1.0 kPa) Natural gas

manifold pressure. A convertible pressure regulator is

connected to the range manifold and MUST be

connected in series with the gas supply line. To access

the regulator, remove the drawer.

When using flexible gas conduit on the range, allow

sufficient slack to pull the range outside the cutout for

cleaning or servicing.

NOTE: Do not allow the flexible conduit to get pinched

between the wall and the range. To visually check,

remove the drawer.

For proper operation, the maximum inlet pressure to

the regulator should be no more than 14" of water

column pressure (3.5 kPa).

The inlet pressure to the regulator must be at least 1"

(.25 kPa) greater than the regulator manifold pressure

setting. The regulator is set for 4" water column (1.0

kPa) Natural gas manifold pressure, the inlet pressure

must be at least 5" water column (1.25 kPa) Natural

gas. For LP/Propane gas, the regulator must be set for

10" water column (2.5 kPa) manifold pressure, the inlet

pressure must be at least 11 " water column (2.75 kPa).

The supply line should be equipped with an approved

shutoff valve (see Figure 9). This valve should be located

in the same room asthe range and should be in a

location that allows ease of opening and closing. Do not

block access to the shutoff valve. The valve is for

turning on or shutting off gas to the appliance.

Open the shutoff valve in the gas supply line. Wait a

few minutes for gas to move through the gas line.

The gas supply between the shutoff valve and the

regulator may be connected by rigid piping or by A.G.A./

C.G.A.-approved flexible metallic union-connected

piping where local codes permit use.

Use pipe-joint compound made for use with Natural and

LP/Propane gas to seal all gas connections. If flexible

connectors are used, be certain connectors are not

kinked.

Leak testing of the appliance shall be conducted

according to the manufacturer's instructions.

Check for leaks. After connecting the range to the gas

supply, check the system for leaks with a manometer. If

a manometer is not available, turn on the gas supply and

use a liquid leak detector at all joints and connections to

check for leaks.

Do not use a flame to check for leaks

from gas connections. Checking for leaks with a flame

may result in a fire or explosion.

All openings in the wall or floor where the range is to be

installed must be sealed.

Tighten all connections if necessary to prevent gas

leakage in the cooktop or supply line.

Check alignment of valves after connecting the

cooktop to the gas supply to be sure the manifold pipe

has not been moved.

The gas supply piping can be through the side wall of

the right cabinet. The right side cabinet is an ideal

location for the main shutoff valve.

Do not make the connection too tight.

The regulator is die cast. Overtightening may crack the

regulator resulting in a gas leak and possible fire or

explosion.

Assemble the flexible connector from the gas supply pipe

to the pressure regulator in order: 1- manual shutoff

valve, 2- flare union adapter, 3- flexible connector, 4-

flare union adapter, 5- pressure regulator.

The gas supply line to the shutoff valve should be 1/2" or

3/4" solid pipe.

The user must know the location of the main shutoff

valve and have easy access to it.

Disconnect this range and its individual shutoff

valve from the gas supply piping system during any

pressure testing of that system at test pressures greater

than 1/2 psig (3.5 kPaor 14" water column).

Isolate the range from the gas supply piping system

by closing its individual manual shutoff valve during any

pressure testing of the gas supply piping system at test

pressures equal to or lessthan 1/2 psig (3.5 kPa or 14"

water column).

6. LP/Propane Gas Conversion

This appliance can be used with Natural gas or LP/

Propane gas. It is shipped from the factory for use with

natural gas.

If you wish to convert your range for use with LP/Propane

gas, use the supplied fixed orifices located in a bag

containing the literature marked "FOR LP/PROPANEGAS

CONVERSION". Follow the instructions packaged with

the orifices.

7

Page 8

PRESSUREREGULATOR

LOCATION

REAR WIRE

ACCESS

COVER

Flexible Appliance Conduit

Install sufficient length of flexible conduit

to allow the range to be puffed

/_ completely out of the cut-out area for

proper servicing (supplied by user).

RIGHT ....

RANGE

SIDE OF

RANGE 'Y_s_

Flare

Union

Adaptor

Manual

Sutoff Valve

(supplied by

user) Connect

to ½', or 3/4',

solid gas

supply pipe

from the wall

or floor.

GAS

IPPLY

TO

APPLIANCE

Solid Piping Gas Supply

Sutoff

Valve

DRAWER

TO GAS SUPPLY

LINE

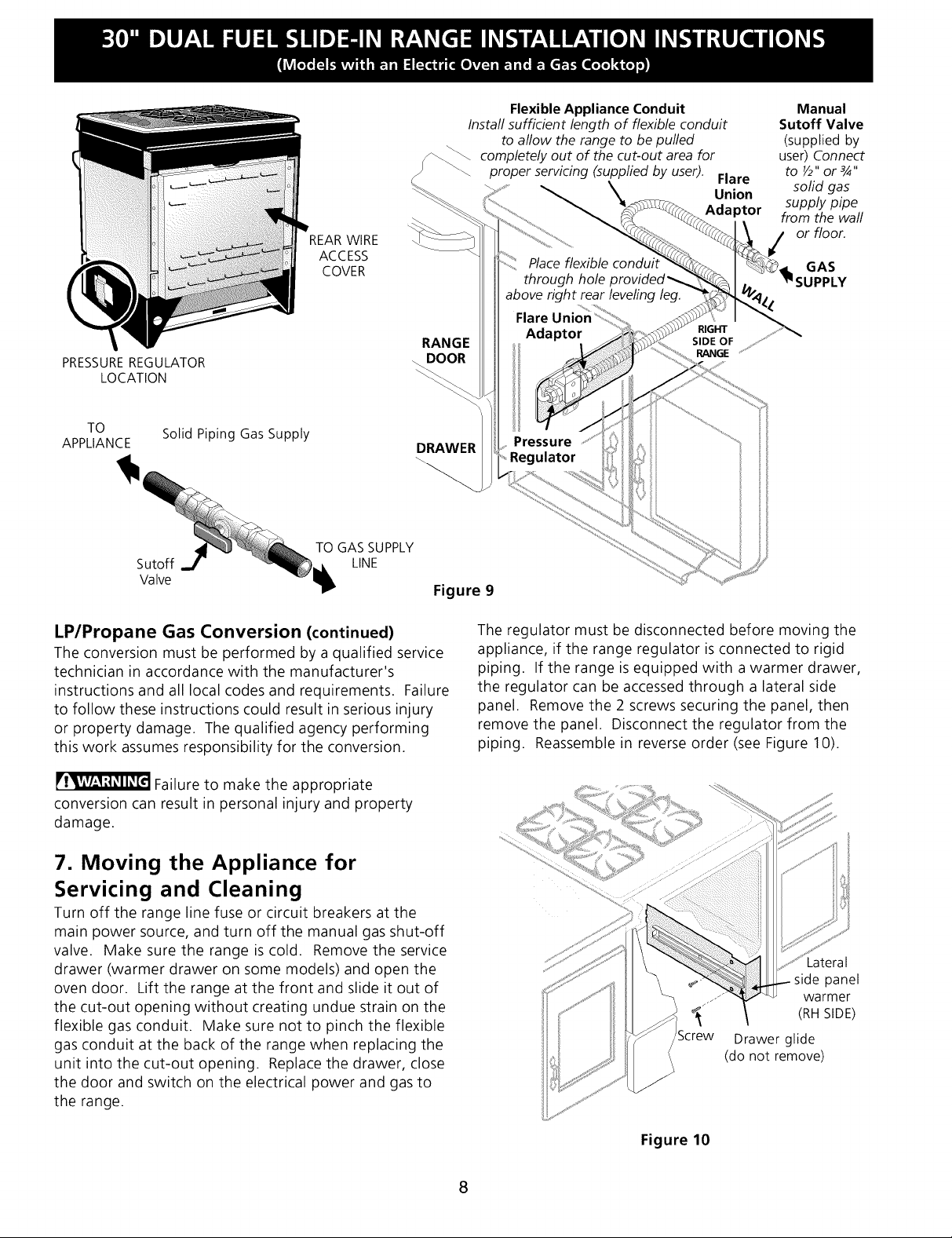

LP/Propane Gas Conversion (continued)

The conversion must be performed by a qualified service

technician in accordance with the manufacturer's

instructions and all local codes and requirements. Failure

to follow these instructions could result in serious injury

or property damage. The qualified agency performing

this work assumes responsibility for the conversion.

Failure to make the appropriate

conversion can result in personal injury and property

damage.

7. Moving the Appliance for

Servicing and Cleaning

Turn off the range line fuse or circuit breakers at the

main power source, and turn off the manual gas shut-off

valve. Make sure the range is cold. Remove the service

drawer (warmer drawer on some models) and open the

oven door. Lift the range at the front and slide it out of

the cut-out opening without creating undue strain on the

flexible gas conduit. Make sure not to pinch the flexible

gas conduit at the back of the range when replacing the

unit into the cut-out opening. Replace the drawer, close

the door and switch on the electrical power and gas to

the range.

Figure 9

The regulator must be disconnected before moving the

appliance, if the range regulator is connected to rigid

piping. If the range isequipped with a warmer drawer,

the regulator can be accessed through a lateral side

panel. Remove the 2 screws securing the panel, then

remove the panel. Disconnect the regulator from the

piping. Reassemble in reverse order (see Figure 10).

panel

.-_ warmer

(RH SIDE)

Screw Drawer glide

(do not remove)

Figure 10

8

Page 9

8. Range Installation

When unpacking the range, do not

discard the 4 shipping bolts. These are to be replaced

on the unit for use as leveling legs and height

adjustments.

,

Installation Without Side Panel(s)

A. The range cooktop overlaps the countertop at

the sides and the range rests on the floor. The

cooktop is 30" (76.2 cm) wide.

B. Install base cabinets 29" (73.7 cm) apart. Make

sure they are plumb and level before attaching

cooktop. Shave raised countertop edge to clear

30" (76.2 cm) wide range top rim.

C. Install cabinet doors 31 " (78.7 cm) min. apart so

as not to interfere with range door opening.

D. Cutout countertop exactly as shown on page 1.

E. A backguard kit can be ordered through your

dealer.

F. Adjust leveling legs so that the underside of the

cooktop is sitting on the countertop.

G. Level the range. The floor where the range

is to be installed must be level (see

Figure 11).

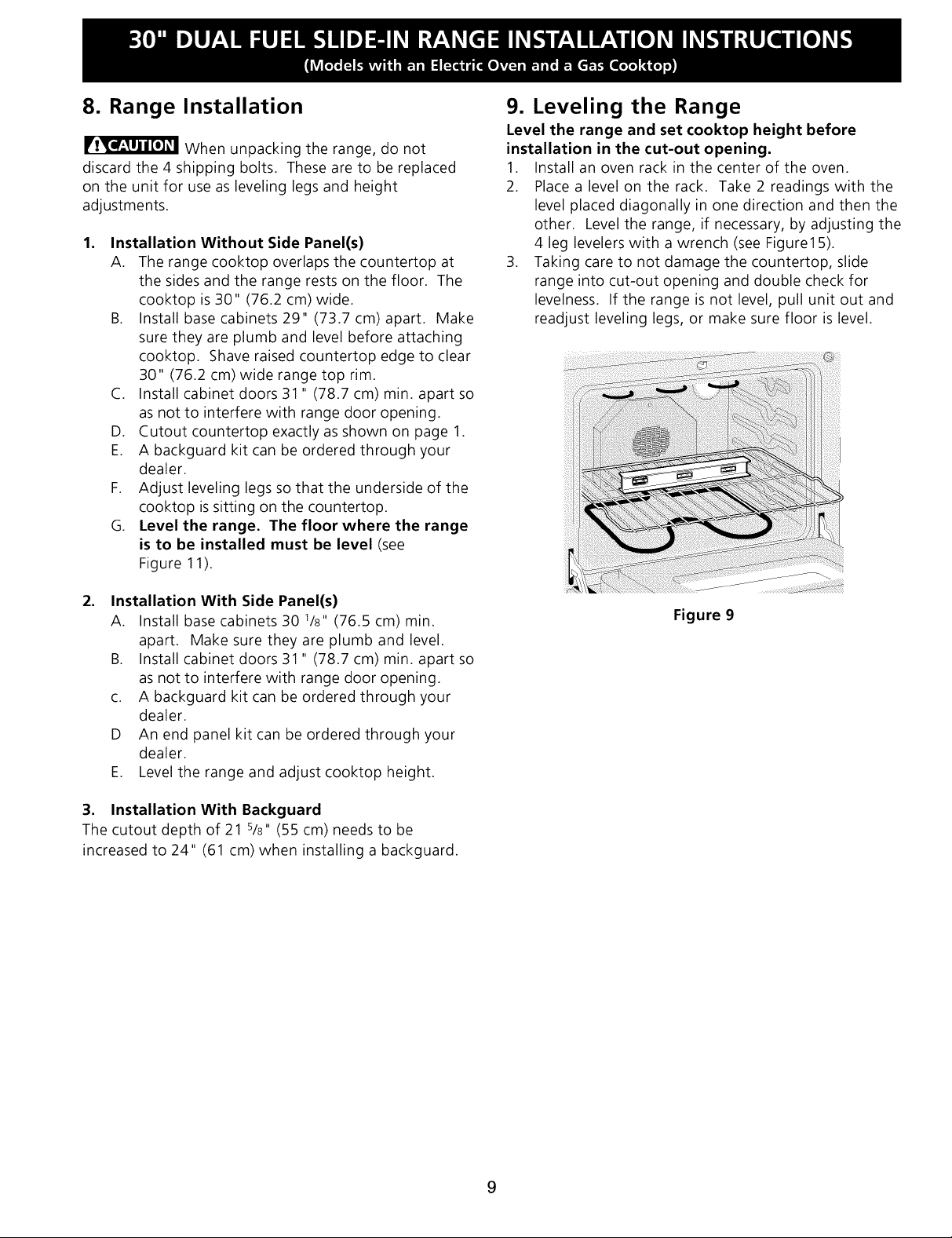

9. Leveling the Range

Level the range and set cooktop height before

installation in the cut-out opening.

1. Install an oven rack in the center of the oven.

2. Place a level on the rack. Take 2 readings with the

level placed diagonally in one direction and then the

other. Level the range, if necessary, by adjusting the

4 leg levelers with a wrench (see Figure1 5).

3. Taking care to not damage the countertop, slide

range into cut-out opening and double check for

levelness. If the range is not level, pull unit out and

readjust leveling legs, or make sure floor is level.

,

Installation With Side Panel(s)

A. Install base cabinets 30 I/8" (76.5 cm) min.

apart. Make sure they are plumb and level.

B. Install cabinet doors 31 " (78.7 cm) min. apart so

as not to interfere with range door opening.

c. A backguard kit can be ordered through your

dealer.

D An end panel kit can be ordered through your

dealer.

E. Level the range and adjust cooktop height.

3. Installation With Backguard

The cutout depth of 21 s/8" (55 cm) needs to be

increased to 24" (61 cm) when installing a backguard.

Figure 9

9

Page 10

10. Check Operation

Refer to the Owner's Guide packaged with the range for

operating instructions and for care and cleaning of your

range.

[Iri_'_!_TP/T_Do not touch the elements or burners.

They may be hot enough to cause burns.

Remove all packaging from the oven before testing.

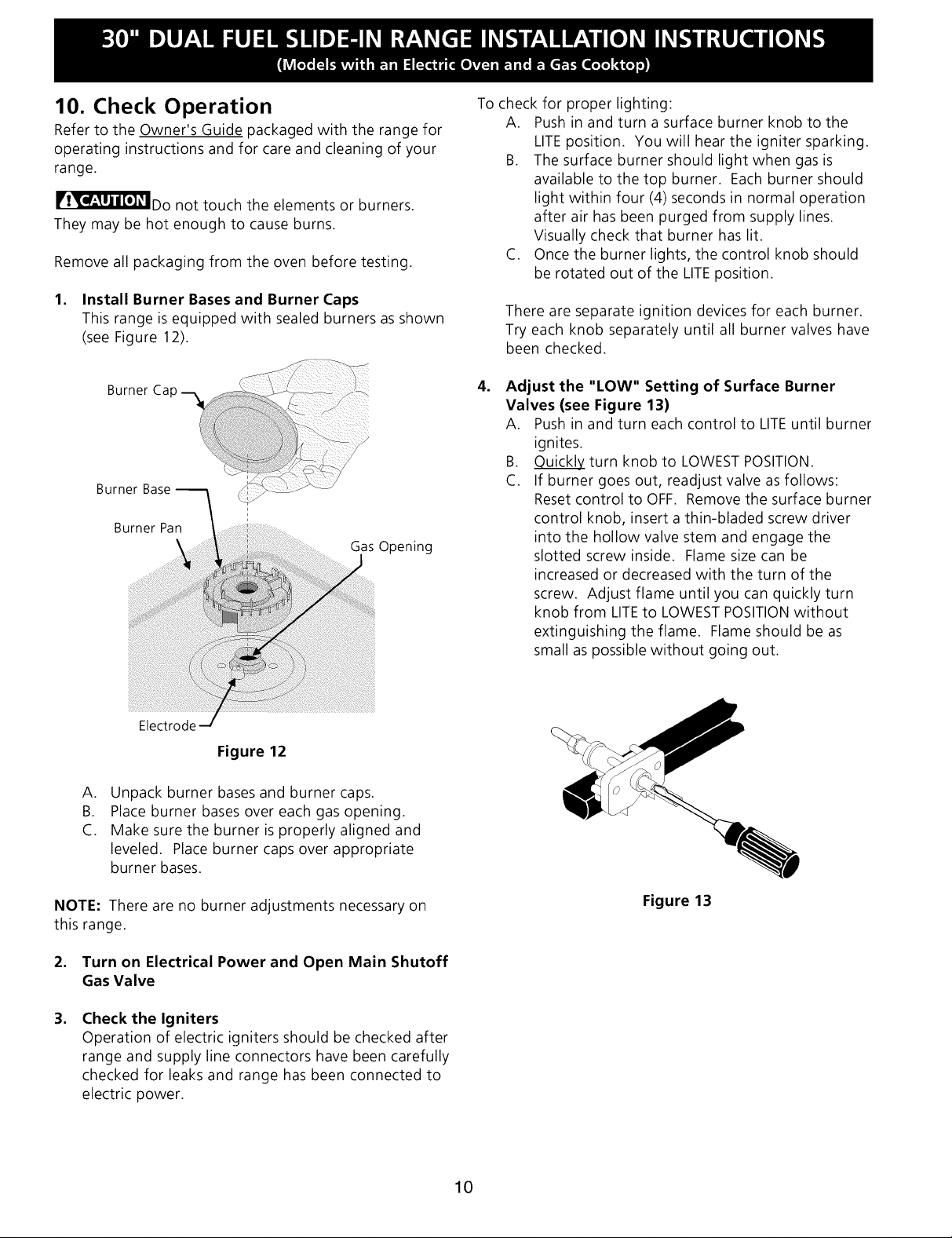

1. Install Burner Bases and Burner Caps

This range isequipped with sealed burners as shown

(see Figure 12).

Burner Cap

Burner Base

Burner Pan

Gas Opening

To check for proper lighting:

A. Push in and turn a surface burner knob to the

LITEposition. You will hear the igniter sparking.

B. The surface burner should light when gas is

available to the top burner. Each burner should

light within four (4) seconds in normal operation

after air has been purged from supply lines.

Visually check that burner has lit.

C. Once the burner lights, the control knob should

be rotated out of the LITEposition.

There are separate ignition devices for each burner.

Try each knob separately until all burner valves have

been checked.

,

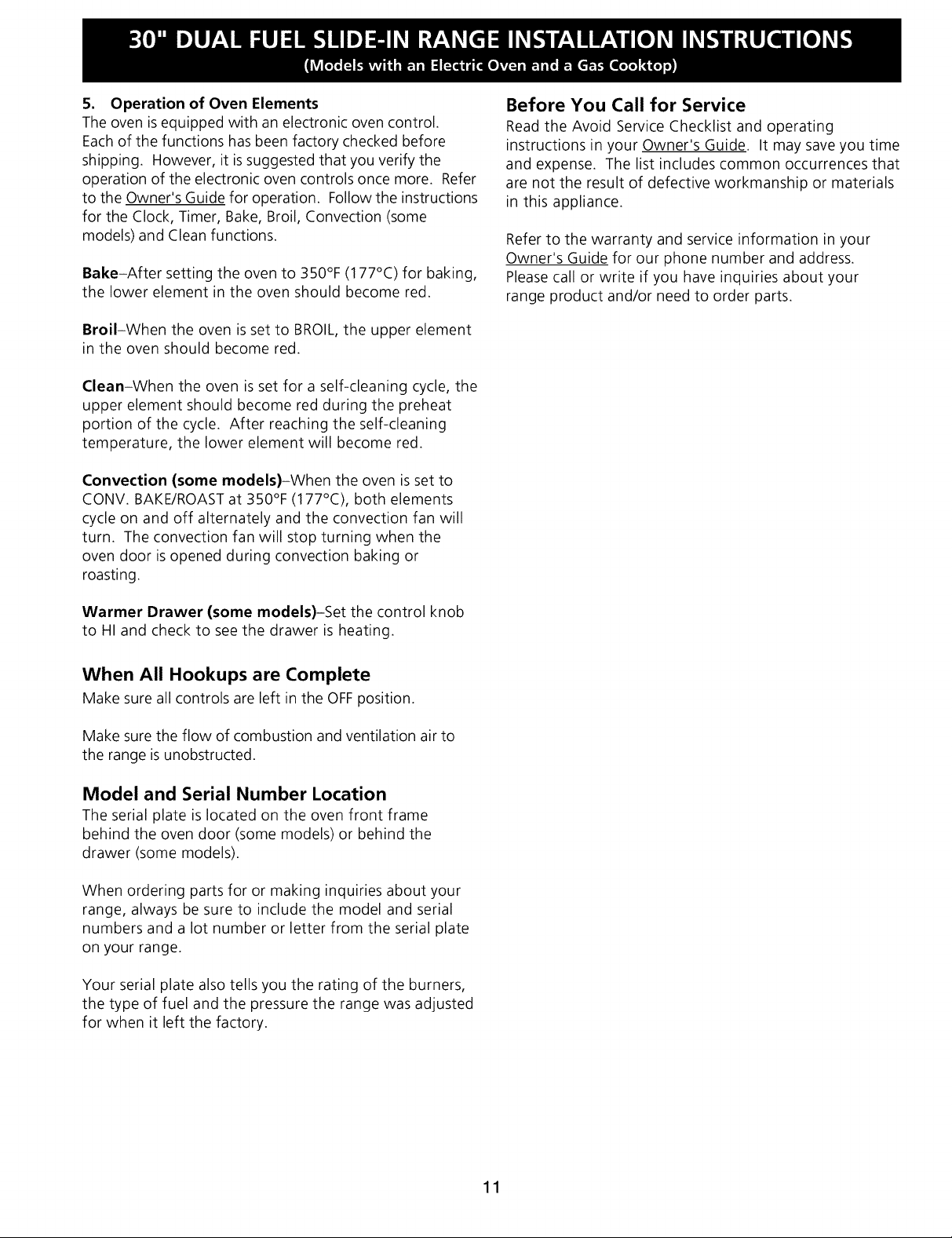

Adjust the "LOW" Setting of Surface Burner

Valves (see Figure 13)

A. Push in and turn each control to LITEuntil burner

ignites.

B. _Q_turn knob to LOWEST POSITION.

C. If burner goes out, readjust valve as follows:

Resetcontrol to OFF. Remove the surface burner

control knob, insert a thin-bladed screw driver

into the hollow valve stem and engage the

slotted screw inside. Flame size can be

increased or decreased with the turn of the

screw. Adjust flame until you can quickly turn

knob from LITEto LOWEST POSITIONwithout

extinguishing the flame. Flame should be as

small as possible without going out.

Electrode

Figure 12

A. Unpack burner bases and burner caps.

B. Place burner bases over each gas opening.

C. Make sure the burner is properly aligned and

leveled. Place burner caps over appropriate

burner bases.

NOTE: There are no burner adjustments necessary on

this range.

2. Turn on Electrical Power and Open Main Shutoff

Gas Valve

,

Check the Igniters

Operation of electric igniters should be checked after

range and supply line connectors have been carefully

checked for leaks and range has been connected to

electric power.

Figure 13

10

Page 11

5. Operation of Oven Elements

The oven isequipped with an electronic oven control.

Eachof the functions has been factory checked before

shipping. However, it issuggested that you verify the

operation of the electronic oven controls once more. Refer

to the Owner's Guide for operation. Follow the instructions

for the Clock, Timer, Bake, Broil, Convection (some

models) and Clean functions.

Bake-After setting the oven to 350°F (177°C) for baking,

the lower element in the oven should become red.

Broil-When the oven is set to BROIL,the upper element

in the oven should become red.

Clean-When the oven is set for a self-cleaning cycle, the

upper element should become red during the preheat

portion of the cycle. After reaching the self-cleaning

temperature, the lower element will become red.

Convection (some models)-When the oven is set to

CONV. BAKE/ROASTat 350°F (177°C), both elements

cycle on and off alternately and the convection fan will

turn. The convection fan will stop turning when the

oven door is opened during convection baking or

roasting.

Before You Call for Service

Read the Avoid Service Checklist and operating

instructions in your Owner's Guide. It may save you time

and expense. The list includes common occurrences that

are not the result of defective workmanship or materials

in this appliance.

Refer to the warranty and service information in your

Owner's Guide for our phone number and address.

Pleasecall or write if you have inquiries about your

range product and/or need to order parts.

Warmer Drawer (some models)-Set the control knob

to HI and check to see the drawer is heating.

When All Hookups are Complete

Make sure all controls are left in the OFFposition.

Make sure the flow of combustion and ventilation air to

the range is unobstructed.

Model and Serial Number Location

The serial plate is located on the oven front frame

behind the oven door (some models) or behind the

drawer (some models).

When ordering parts for or making inquiries about your

range, always be sure to include the model and serial

numbers and a lot number or letter from the serial plate

on your range.

Your serial plate also tells you the rating of the burners,

the type of fuel and the pressure the range was adjusted

for when it left the factory.

11

Page 12

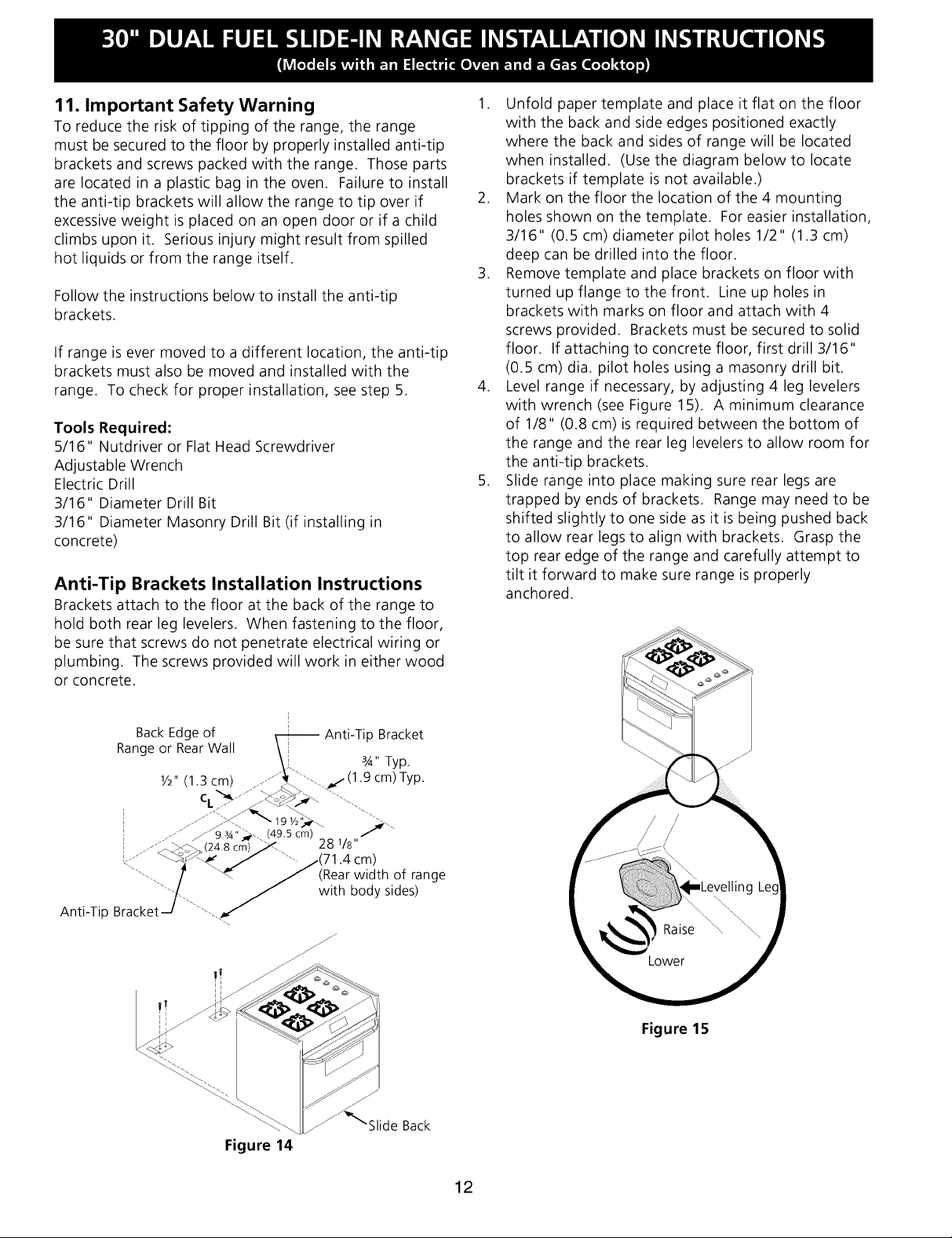

11. Important Safety Warning

To reduce the risk of tipping of the range, the range

must be secured to the floor by properly installed anti-tip

brackets and screws packed with the range. Those parts

are located in a plastic bag in the oven. Failure to install

the anti-tip brackets will allow the range to tip over if

excessive weight is placed on an open door or if a child

climbs upon it. Serious injury might result from spilled

hot liquids or from the range itself.

Follow the instructions below to install the anti-tip

brackets.

If range is ever moved to a different location, the anti-tip

brackets must also be moved and installed with the

range. To check for proper installation, see step 5.

Tools Required:

5/16" Nutdriver or Flat Head Screwdriver

Adjustable Wrench

Electric Drill

3/16" Diameter Drill Bit

3/16" Diameter Masonry Drill Bit (if installing in

concrete)

Anti-Tip Brackets Installation Instructions

Brackets attach to the floor at the back of the range to

hold both rear leg levelers. When fastening to the floor,

be sure that screws do not penetrate electrical wiring or

plumbing. The screws provided will work in either wood

or concrete.

1. Unfold paper template and place it flat on the floor

with the back and side edges positioned exactly

where the back and sides of range will be located

when installed. (Use the diagram below to locate

brackets if template is not available.)

2. Mark on the floor the location of the 4 mounting

holes shown on the template. For easier installation,

3/16" (0.5 cm) diameter pilot holes 1/2" (1.3 cm)

deep can be drilled into the floor.

3. Remove template and place brackets on floor with

turned up flange to the front. Line up holes in

brackets with marks on floor and attach with 4

screws provided. Brackets must be secured to solid

floor. If attaching to concrete floor, first drill 3/16"

(0.5 cm) dia. pilot holes using a masonry drill bit.

4. Level range if necessary, by adjusting 4 leg levelers

with wrench (see Figure 15). A minimum clearance

of 1/8" (0.8 cm) is required between the bottom of

the range and the rear leg levelers to allow room for

the anti-tip brackets.

5. Slide range into place making sure rear legs are

trapped by ends of brackets. Range may need to be

shifted slightly to one side as it is being pushed back

to allow rear legs to align with brackets. Grasp the

top rear edge of the range and carefully attempt to

tilt it forward to make sure range is properly

anchored.

Back Edge of

Range or Rear Wall

Figure 14

Stide

Figure 15

Back

12

Page 13

LA INSTALACION Y EL SERVICIO DEBEN SER EFECTUADOS POR

UN INSTALADOR CALIFICADO.

IMPORTANTE: GUARDE ESTAS INSTRUCCIONES PARA USO DEL

INSPECTOR LOCAL DE ELECTRICIDAD.

LEA Y GUARDE ESTAS INSTRUCCIONES PARA REFERENCIA FUTURA.

_Si la informacion contenida en este manual no es seguida exactamente, puede

ocurrir un incendio o explosion causando dafios materiales, lesion personal o la muerte.

PARASU SEGURIDAD:

-- No almacene ni utilice gasolina u otros vapores y liquidos inflamables en la proximidad de _ste o de

cualquier otto artefacto.

-- QUE DEBE HACER Sl PERCIBEOLOR A GAS:

• No trate de encender ning_n artefacto.

• No toque ning_n interruptor el_ctrico; no use ning_n tel_fono en su edificio.

• Llame a su proveedor de gas desde el tel_fono de un vecino. Siga las instrucciones del proveedor de gas.

• Si no Iogra comunicarse con su proveedor de gas, Ilame al departamento de bomberos.

-- La instalacion y el servicio de mantenimiento deben set efectuados pot un instalador calificado, la agencia

de servicio o el proveedor de gas.

No pellizque el cord6n el6ctrico o el conducto flexible de gas Acepille el borde subido a

entre la estufa y la pared, que deje espacio para un

No selle la estufa a los armarios de lado. anchura de estufa

**NOTA: Un espacio minimo de 30" (76.2 cm) entre la

superficie de la estufa y el fondo del armario cuando el

fondo del armario de madera o metal est,1 protegido por no

menos de 1/4" (0.64 cm) de madera resistente al fuego

cubierta por una lamina met_tlica de MSG, n0mero 28,

0.015" (0.4 mm) de acero inoxidable, 0.024" (0.6 mm) de

aluminio, 6 0.02" (0.5 mm) de cobre.

Un espacio minimo de 36" cuando el armario no est,1

protegido.

• NOTA: Deje por los 19 ¼" (48.9 cm) de espacio libre

para la profundidad de la

puerta cuando

esta abierta.

A

• Puerta abie[ta I

(vea la nota) _

35 3/8" (90 cm) - 30"

36 3/8" (92 cm) (76.2 cm)

26 1/4"

(66.7 cm)

ulador

(73.7 cm) (55.2 cm)

borde 30" (76.2 cm) de

Localise las puertas

del armario 1"

(2.5 cm) min

del hueco de

la abertura.

*Nota: 29" (73.7

cm) Anchura de la

abertura para

plancha

translapadala y

apariencia

encerrada.

Para la instalaci6n de modelos

con paneles laterales opci6nales,

el _trea del hueco incluyendo el

armario debe de estar 30" (76.2

cm) de anchura minimo.

29" 21 3/4"

36" (91.4 cm) standard

35 3/8" (90 cm) min.

30" Min. 13"

76.2 cm Min. cm)

La caja de empalmes o el

enchufe de conexi6n con la

tierra deberia situarse de 8" a

17" (20.3 cm a 43.2 cm) del

armario derecho y de 2" a 4"

(5.1 cm a 10.2 cm) del suelo.

PARTE (45.7 cm)

DELANTERA

DEL

ARMARIO

G. La profundidad mfnima de recortado se aumenta a 24" (61 cm) con el uso de un protector trasero.

18" Min.

(45.7 cm) Min.

24" Min.

(61 cm Min.)

22 7/8"

(58.1 cm) 1 I

_1 1/8"

G R_..

NOTA: Se adjunta el diagrama de cables de esta cocina al final de este libreta. P/N 318201650 (0201) Rev. C

English - pages 1-12

Espa_ol - p_tginas 13-24

Fran_ais - pages 25-36

Diagrama de la instalaci6n al_tmbrica - p_tginas 37-40

Page 14

Notas importantes para el Instalador

1. Lea todas las instrucciones contenidas en este manual

antes de instalar la estufa.

2. Saque todo el material usado en el embalaje del

compartimiento del horno antes de conectar el

suministro el_ctrico o de gas a la estufa.

3. Observe todos los c0digos y reglamentos pertinentes.

4. Deje estas instrucciones con el comprador.

Nota Importante para el Consumidor

Conserve estas instrucciones y el Manual del Usuario para

referencia futura.

IMPORTANTES

INSTRUCCIONES DE

SEGURIDAD

Instalaci6n de esta estufa debe cumplir con todos los

c6digos locales, o en ausencia de c6digos locales con el

C6digo Nacional de Gas Combustible ANSI Z223.1--

01tima edici6nen los Estados Unidos, o el CAN/CGA-

B149.2 en Canada.

El disefio de esta estufa ha sido certificado por la

Asociaci6n de Gas Americana. En _ste como en

cualquier otro artefacto que use gas y genere calor, hay

ciertas precauciones de seguridad que usted debe seguir.

Estas ser_n encontradas en el Manual del Usuario, I_alo

cuidadosamente.

• Asegdrese de que la estufa sea instalada y

conectada a tierra en forma apropiada por un

instalador calificado o por un tdcnico.

• Esta estufa debe ser eldctricamente puesta a tierra

de acuerdo con los cbdigos locales, o en su

ausencia, con el Cbdigo Eldctrico Nacional ANSI/

NFPA No. 70, dltima edicibn en los Estados Unidos

(Yea las instrucciones para la puesta a tierra) o el

c6digo Eldctrico Canadiense CSA Standard C22.1,

Part 1, en Canadd.

T! ,'_I |_vj =1111II=1_ [_ V_'I

• TODASLAS

ESTUFAS

PUEDEN

VOLCARSE.

• ESTOPODRtA

RESULTAREN

LESIONES

PERSONALES.

• INSTALEEL

DISPOSITIVO

ANTIVUELCOS

QUESEHA

EMPACADO

JUNTOCON

ESTAESTUFA.

PARA REDUCIREL RtESGO

DE QUE SEVUELQUE LA

ESTUFA,HAY QUE

ASEGURARLA

ADECUADAMENTE

COLOCANDOLE LOS

SOPORTESANTtVUELCO

QUE SEPROPORCIONAN.

PARACOMPROBAR St

ESTOSESTAN INSTALADOS

Y APRETADOS ENSU

LUGAR COMO SEDEBE,

ASE EL BORDE TRASERO

SUPERIORDE LA ESTUFAY

CUIDADOSAMENTE

INCLiNELA HACIA

ADELANTE PARAASEGURAR

QUE LA ESTUFA SEANCLE.

• La instalaci6n de aparatos disefiados para instalaci6n

en casas prefabricadas (m6viles) debe conformar con el

Manufactured Home Construction and Safety Standard,

t[tulo 24CFR, parte 3280 [Anteriormente el Federal

Standard for Mobil Home Construction and Safety,

t[tulo 24, HUD (parte 280)] o cuando tal est_ndar no se

aplica, el Standard for Manufactured Home Installation

1982 (Manufactured Home sites, Communities and

Setups), ANSI Z225.1/NFPA 501A-edici6n m_s reciente,

o con los c6digos locales en los Estados Unidos o el

CAN/CSA-Z240 MH, en Canada.

• Asegdrese de que el material que recubre las

paredes alrededor de la estufa, pueda resistir el

calor generado por la estufa.

• Antes de instalar la estufa en un _rea cuyo piso

este recubierto con lin61eo u otro tipo de piso

sint_tico, aseg_rese de que _stos puedan resistir

una temperatura de por Io menos 90°F (32.2 °)

sobre la temperatura ambiental sin provocar

encogimiento, deformaci6n o decoloraci6n. No

instale la estufa sobre una alfombra al menos que

coloque una plancha de material aislante de por Io

menos _A" (0.6 cm), entre la estufa y la alfombra.

• No obstruya el flujo del aire de combusti6n en la

ventilaci6n del horno ni tampoco alrededor de la

base o debajo del panel inferior delantero de la

estufa. Evitetocarlasaberturaso_reascercanasde

la ventilaci6n, ya que pueden estar muy calientes

duranteelfuncionamientodel horno. Laestufa

requiere aire fresco para la combusti6n apropiada de

los quemadores.

Nunca deje ni_os solos o

desatendidos en un _rea donde un artefacto est_

siendousado. Amedida que los nifloscrecen,

ens_fieles el uso apropiado y de seguridad para todos los

artefactos. Nunca deje la puerta del horno abierta

cuando la estufa est_ desatendida.

No se pare, apoye o siente en la s

puertas o cajones de esta estufa pues puede resultar

en serias lesiones y puede tambi_n causar da_o a la

estufa.

• No almacene articulos que puedan interesar a los

ni_os en los gabinetes sobre la estufa. Los niEos

pueden quemarse seriamente tratando de trepar a la

estufa para alcanzar estos art[culos.

• Los gabinetes de almacenamiento sobre la estufa

deben ser evitados, para eliminar la necesidad de

tener que pasar sobre los quemadores superiores

de la estufa para Ilegar a ellos.

• Ajuste el tama_o de la llama de los quemadores

superiores de tal manera que _sta no sobrepase el

borde de los utensilios de cocinar. La llama

excesiva es peligrosa.

• No use el horno como espacio de almacenaje. Esto

crear_ una situaci6n potencialmente peligrosa.

14

Page 15

• Nunca use la estufa para calentar el cuarto. El uso

prolongado de la estufa sin la adecuada ventilaci6n

puede resultar peligroso.

• No almacene ni utilice gasolina u otros vapores y

liquidos inflamables en la proximidad de dste o de

cualquier otro artefacto el_ctrico. Puede provocar

incendio o explosi6n.

• En caso de una interrupti6n del servicio el_ctrico, es

pasible de encender los quemadores de superficie a

mano. Para encender un quemadordesuoerficie,

acerque un f6sforo encendido del cabezal del

quemador, y gire delicadamente el bot6n de control de

superficiea LITE(encendido). Tenercuidadoal

encender los quemadores a mano.

• Ajuste todos los controles a la posici6n "OFF"

(apagada) despu_s de haber hecho una operacibn

con tiempo programado.

PARA MODELOS AUTOLIMPIANTES:

• Saque la asadera, alimentos o cualquier otro

utensilio antes de usar el ciclo de autolimpieza del

horno. Limpietodoexcesodederrame dealimentos.

Siga las instrucciones de prelimpiado en el Manual del

Usuario.

CANADA SOLAMENTE: Este aparato esta

equipado con una enchufe de 4 patas puesta a tierra

para su protecci6n contra choque el_ctrico, y debe de

ser conectado directamente en una tomacorriente

correctamente puesta a tierra. No corte ni remueva esta

pata puesta a tierra del enchufe.

1. Juego de Cord6n Eldctrico (Estados

Unidos)

El consumidor tiene la responsabilidad de conectar el

cord6n el_ctrico al bloque de conexi6n ubicado detras de

la cubierta de acceso del panel trasero.

Este el_ctrodom_stico puede ser conectado por medio de

una "conexi6n directa" de cables permanentes (cable

blindado flexible o no metalico recubierto de cobre), o por

medio de un ensamblaje de cord6n de suministro el_ctrico.

Solamente un ensamblaje de cord6n de suministro el_ctrico

con regimen de 125/250 voltios mfnimo, 40 amperios y

marcado para uso con cocinas debe ser utilizado. Vea la

tabla (mas abajo) para informaci6n sobre el tamaflo de

abertura de la conexi6n del ensamblaje de cord6n. El

cord6n debe de tener 3 o 4 conductores.

Para las casas sobre ruedas, las nuevas instalaciones, en los

vehfculos de recreaci6n o en las areas donde los c6digos

locales no permiten la conexi6n del conductor a tierra al

neutro, un ensamblaje de suministro el_ctrico de 4

conductores para estufas, clasificado a 125/250 voltios

mfnimo, 40 amperios mfnimo, debe de ser utilizado (ver la

figura 5).

Los bornes a la extremidad de los alambres deben ser a

curvas cerradas o con extremidades de lenguetas en forma

de U abiertas y curvadas. El cord6n debe de tener una

abrazadera releva de anclaje

Ver la tabla de arriba para conexi6n de alambres de 3 o 4

conductores.

Referirsea la tabla de arribaparael tama_ode aberturade conexiOnde

cocinaadecuada,yla informaci6nsobreel regimende amperiosdel

ensamblaje de cord6n de suministro el_ctrico.

Vea la placa de serie de la

cocina para informaci6n sobre

el regimen de kilovatio.

120/240 Volts 120/208 Volts

0-16.5 Kw 0-12.5 Kw 40 Amp.

16.6-22.5 Kw 12.6-18.5 Kw 50 Amp.

Regimen

de

amperios

de

ensamblaje

del cord6n

Diametro (pulgados

(cm)) de abierta de

conexiOn de cocina.

Ensemblaje ConexiOn

del cord6n directa

1 3/8 (3.5) 1 1/8 (2.9)

1 3/8 (3.5) 1 3/8 (3.5)

Nota: La cocina corrediza fuel dual viene de fabrica con un

agujero d diametro 1 1/8" (2.9 cm) come muestra en la

figura 4. Si un agujero mas largo esta necesario retire la

arandela pre-cortada.

Riesgo de Choque Eldctrico

• Una puesta a tierra estd requerido en este

aparato.

• No Io conecte a la corriente eldctrica hasta que

el aparato haya sido puesto a tierra

permanentemente.

• Desconecte la corriente eldctrica a la caja de

empalmes antes de hacer la conexi6n eldctrica.

• Este aparato debe estar conectado con un

sistema de alambres puesto en tierra, metdlico

y permanente o un conector de puesta a tierra

debe conectarse al terminal de puesta a tierra

o el alambre conductor en el aparato.

• No utilice el suministro de gas para hacer la

puesta a tierra.

La falta de hacer cualquier de las cosas arriba

podria resultar en un incendio, choque eldctrico

o lesiones personales.

Ir_j_l Puede ocurrir riesgo de incendio o

choque el_ctrico si se usa un juego de cord6n de

estufa de tamafio incorrecto, si las instrucciones de

instalaci6n no son seguidas o si no se usa el anclaje

del cable.

15

Page 16

Estilo Estados Unidos

Figura 1

No desate las tuercas que sujetan el

alambraje de cocina que ha sido instalado en la

factoria al bloque terminal, cuando se hace la

conexion de la cocina. Se puede ocurrir el mal

funcionamiento o una interrupcibn del suministro

el_ctrico.

2. Cordbn de fuente de energia conectado

de fabrica (Canad solamente)

Esta estufa viene de fabrica equipada con un cord6n de

fuente deenerg[a (vea a la figura 2). EIcord6n debede

ser conectado a una toma de corriente a tierra de 120/

240 voltios o de 120/208 voltios. Si no hay una toma de

corriente a tierra en la habitaci6n, debe de ser instalada

por un t_cnico calificado.

Estilo Canad_

Figura 2

3. Conexibn Eldctrico de la Estufa

(Estados Unidos)

Este aparato se fabrica con el terminal neutro conectado

al marco.

Nota: Refiere a los diagramas de alambraje al final de

este manual.

LEVANTE LA PARTE MAS BAJA DEL PANEL TRASERO

AQUI PARA TENER ACCESO AL BLOQUE DE

CONEXIONES DE LOS TERMINALES

Figura 3

2. Quite las tres tuercas desatadas (despu_s de remover

la cinta de goma) sobre el bloque terminal usando

un destornillador o una Ilave de casquillo de 3/8".

3. Conecte el cable neutro del cord6n el_ctrico de

cobre al terminal de color de plata en el centro del

bloque, y conecte los otros cabels a los terminales

laterales. Emparejeloscablesylosterminales

segOn el color (cables rojos conectados con el

terminal derecho, cables negros conectados con el

terminal izquierdo.

4. Repone las tres tuercas desatadas sobre el bloque

terminal.

5. Baje la cubierta del terminal y reinstale los tres (3)

tornillos.

Terminal plata

Alambre

'0

Bloque

terminal

Conexibn de tres alambres de conduccibn a

la estufa

(Un cord6n flexible o cable de 3 conductores debe de ser

reemplazado con un cord6n flexible o cable de 4 conducto-

res donde la conexi6n del conductor a tierra al neutro esta

prohibida en las nuevas instalaciones, las casas sobre

ruedas, los vehiculos de recreaci6n o otras _reas donde los

c6digos locales no permiten la conexi6n a tierra al neutro.)

si los c6digos locales permiten la conexi6n del conductor

de tierra del marco con el alambre neutro del cord6n

el_ctrico de cobre (vea Figura 4).

1. Quite los tres tornillos en la parte m_s baja del panel

trasero, luego levante la parte m_s baja del panel

trasero (la cubierta de acceso) exponiendo el bloque

de conexiones de los terminales de la estufa (vea

Figura 3).

Alambre

Negro

Una arazadera de

releva provista debe de

estar instalada a est_

ubicaci6n.

16

Hacia el 240 V

recept_cu Io.

Figura 4

1 1/8" (2.9 cm)

Agujero de la

conexi6n directa.

Retira la arandela

pre-cortada para

1 3/8" (3.5 cm) Dia.

agujero.

Page 17

Conexibn de 4 alambres de conduccibn a la

estufa (casas mbviles)

1. Quite los tres tornillos en la parte m_s baja del panel

trasero, luego levante la parte m_s baja del panel

trasero (la cubierta de acceso) exponiendo el bloque

de conexiones de los terminales de la estufa.

2. Quite las tres tuercas dasatadas (despu_s de remover

la cinta de goma) sobre el bloque termianl usando

un destornillador o una Ilave de casquillo de 3/8".

3. Quite la banda de puesta a tierra del bloque de los

terminalesydel marcodelartefacto. Retenga el

tornillo de puesta a tierra.

4. Conecte el alambre de puesta a tierra (verde) del

cord6n el_ctrico de cobre al marco del artefacto con

el tornillo de puesta a tierra, usando el agujero en el

marco donde se quit6 el tornillo de puesta a tierra

(vea figura 5).

5. Conecte el alambre neutro (blanco) del cord6n

el_ctricodecobrealterminal de color de plata en

el centro del bloque y conecte los otros alambres al

los terminales laterales.

6. Repone las tres tuercas desatadas sobre el bloque

terminal.

7. Baje la cubierta de acceso y vuelva a poner los 3

tornillos.

Bloque terminal Terminal plata

Alambre

rojo

Conexibn el_ctrica directa al cortacircuito, a

la caja de fusibles o la caja de empalmes

Si el aparato est_ conectado directamente al cortacircuito,

a la caja de fusibles o a la caja de empalmes, use un cable

blindado flexible o no metalico recubierto de cobre (con

alambre a tierra). Provee una abrazadera releva de anclaje

homologo UL a cada extremidad del cable. A la

extremidad del el_ctrodom_stico, el cable pase a trav_s del

agujero de la conexi6n directa (ver figura 5) en el cord6n

de la placa de montaje. El tamaflo de los alambres

(alambre de cobre solamente) y las conexiones deben

estar conforme al regimen del el_ctrodom_stico.

Donde los cbdigos locales permitan conectar el

conductor de puesta a tierra del el_ctrodom_stico al

neutral (blanco) (vea figura 6):

(Un cordon flexible o cable de 3 conductores debe de ser

reemplazado con un cordon flexible o cable de 4 conducto-

res donde la conexi0n del conductor a tierra al neutro esta

prohibida en las nuevas instalaciones, las casas sobre

ruedas, los vehfculos de recreaci0n o otras _reas donde los

c0digos locales no permiten la conexi0n a tierra al neutro.)

1. Desconecte el suministro el_ctrico.

2. En el cortacircuito, la caja de fusibles o la caja de

empalmes

a) Conecte el alambre verde (o cobre desnudo), el

alambre blanco del cable del el_ctrodom_stico y el

alambre neutral (blanco)juntos.

b) Conecte los dos alambres negros juntos.

c) Conecte los dos alambres rojos juntos.

Alambre

negro

1 1/8" (2.9 cm) I

Dia. agujero de |

la conexi6n

directa. Retira

arandela pre-

cortada para 1

3/8" (3.5 cm)

dia. agujero.

Una arazadera

releva provista

debe de estar

instalada a est_

ubicaci6n.

NOTA: Asegurese de quitar la

banda de puesta a tierra

prov ista.

Hacia el 240 V receptaculo

Figura 5

Cable de la fuente de

alimentaci6n

Alambre blanco Alambres

(neutro) Negros

Alambres

Rojos

Caja de

empalmes

(neutro)

Alambre

desnudo o verde

Cable de la

estufa

Figura 6

Sistema el_ctrico (ejemplo: caja de empalmes)

de 3 alambres (a tierra neutral)

Conductor de uni6n

listado-UL (listado-CSA)

blanco

17

Page 18

Donde los c6digos locales NO permitan conectar el

conductor de puesta a tierra del el_ctrodom_stico al

neutral (blanco), o si est& conectado con un sistema a

4 alambres (vea figura 7):

1. Desconecte el suministro el_ctrico

2. Separe el alambre verde (o cobre desnudo) y el

alambre blanco del electrodom_stico.

3. En el cortacircuito, la caja de fusibles o la caja de

empalmes.

a. Conecte el alambre blanco del cable del

el_ctrodom_stico al alambre neutral (blanco).

b. Conecte los 2 alambres negros juntos.

c. Conecte los 2 alambres rojos juntos.

d. Conecte el alambre verde (o de cobre desnudo) de

la puesta a tierra del alambre al alambre de

puesta a tierra del cortacircuito, de la caja de

fusibles o de la caja de empalmes.

Cable de fuente de

alimentaci6n

Alambre desnudo

o verde

Rojos

Alambre

blanco

I

Alambres

Alambre

desnudo o

Caja de

empalmes

Conductor de

Cable de la uni6n listado-UL

estufa (o listado-CSA)

negros

Alambre blanco

(neutro)

4. Construccibn de los Armarios

Para eliminar el riesgo de quemaduras

e incendios al tocar superficies sobre calentadas, se

debe evitar colocar espacio para armarios de

almacenamiento sobre las estufas con elementos al

descubierto. Sise instalan armariossobre la estufa, se

pueden reducir tales riesgos instalando una campana

purificadora que se proyecta horizontalemente un

m[nimo de 5" (12.7 cm) m_s afuera de la parte inferior

de los armarios.

Preparacibn del Mostrador

Los lados de la superficie de la estufa se sobreponen a

los bordes recortados del mostrador.

Si el mostrador es cuadrado (piano), no requer[ ninguna

preparaci6n.

Si usted tiene un mostrador de frente formado

(encorvado), hay que resurar cada esquina frontal hasta

que est_ piano hasta 1/4" (0.64 cm) de la abertura.

Los mostradores embaldosados pueden requerer un

recorte de 1/4" (0.64 cm) desde cada esquina delatera

y/o un aplanamiento de los bordes redondeados.

Figura 7 - Sistema el_ctrico de 4 alambres

(ejemplo caja de empalme)

cadaesquina delatera.

Figura 8

Si la anchura de la abertura de superficie del

armario es mayor que la anchura minima del

recortado, ajuste la dimensi6n de 1/4" (0.64 cm).

El mostrador debe estar nivelado. Ponga un nivel

sobre el mostrador, primero de un lado para otro y

despu_sde delante para atr_s. Siel mostrador noest_

nivelado, la estufatampocoloestar_. El hornodebe

estar nivelado para resultados satisfactorios de cocer.

Los lados de la superficie de la estufa se encajan por

encima de los bordes de la abertura del mostrador.

18

Page 19

5. InstalaciOn de la alimentaciOn de

gas

Esta unidad ha sido ajustada para operar con un m01tiple

de admisi0n para gas natural de 4" (1.0 kPa). Un

regulador de presi0n convertible esta conectado a la

wilvula distribuidora y DEBE ser conectado en serie con

la tuberfa de suministro de gas.

Para la operaciOn apropiada, la m_ixima presi0n de

entrada al regulador no debe exceder la presi0n de una

columna de agua de 14 pulgadas (3.5 kPa).

La presi0n de entrada al regulador debe ser por Io

menos 1 pulgada m_is grande que la wilvula distribuidora

(.25 kPa). El regulador ha sidoajustado para gas natural

a 4 pulgadas de presi0n para la wilvula distribuidora (1.0

kPa). La presi0n deentrada debeser porlo menos de 5

pulgadas(1.25 kPa). Para propanolfquidoa 10

pulgadas de presi0n para la wilvula distribuidora (2.5

kPa) la presi0n de entrada debe ser por Io menos de 11

pulgadas (2.75 kPa).

La tuberfa deberfa ser equipada con una wilvula de

cierreaprobada (vea Figura 9). Esta wilvula debe

ubicarse en la misma habitaci0n que la estufa en un

lugar que permita una una facilidad de abrir y cerrar.

No bloqu_e el acceso a la wilvula de cierre. La wilvula

es para abrir o cerrar el suministro de gas al aparato.

Cuando se usa un conducto flexible en la estufa, permita

suficiente flojedad como para sacar la estufa fuera del

recortado para la limpieza y el servicio.

NOTA: No permita queelconductose pellizqueentre la

pared yla estufa. Para verlo, saqueelcaj0n.

Use un compuesto para junturas de tuberfa hecho para

uso con gas natural y de LP/Propano para sellar todas las

conexiones del gas. Si se usan los conectores flexibles

aseg0rese de que no est_n enroscados.

Para verificar si hay fugas en el electrodom_stico

se debe de seguir las instrucciones del fabricante.

Asegl_rese de que no haya escapes de gas. Despu_s

de conectar la estufa al suministro de gas, compruebe el

sistema con un men0metro. Si notiene un man0metro,

abre el gas y use un detector de fugas Ifquido en todas

las junturas y conexiones para averiguar si hay escapes

de gas.

No use llama para controlar que no

hayan p_rdidas de gas. La comprobaci0n de p_rdidas de

gas con una llama puede resultar en un incendio o

explosion.

Se debe sellar todas las aberturas en la pared o el piso

donde la estufa se instala.

Abra la wilvula de cierre en la Ifnea de suministro de

gas. Espere unos minutosa queel gasse mueva porel

tubo.

El suministro de gas entre la wilvula de cierre y el

regulador se puede conectar con tuberfa rfgida o con

tuberfa flexible union met_ilica conectada y aprobada por

la AGA/CGA donde los c0digos locales permiten.

La tuberfa del suministro de gas puede pasar por la

pared lateral delarmarioderecho. Elarmariolateral

derecho es un lugar ideal para la wilvula de cierre

pincipal.

No haga que la conexi0n est_

demadiadoapretada. El reguladorest_i fundidoa

troquel. Apret_indolo demasiado podrfa romper el

regulador resultando en escape de gas y posiblemente

un incendio o explosion.

Monte el conector flexible desde el tubo de suministro

de gas hasta el regulador de presi0n seg0n este orden:

1- wilvula de cierre manual, 2- adaptor de gas, 3-

conector flexible, 4- adaptor de gas, 5- regulador de

presi0n.

Apriete todas las conexiones si hace falta para

prevenir fugas de gas en la superficie de la estufa o en

la linea de suministro.

Aseg_rese del alineamiento de las v_lvulas despu_s

de conectar la superficie de la estufa con el suministro

del gas para cerciorarse de que el tubo de escape no se

haya movido.

Desconecte esta estufa y su v_lvula individual de

cierre del sistema del siministro de gas durante

cualquier prueba de presi0n de ese sistema a presiones

mayores de 1/2 psig (3.5 kPa o 14" columna de agua).

Aisla la estufa del sistema del suministro de gas

cerrando su v_ilvula manual de cierre individual durante

cualquier prueba de presi0n del suministro del gas a

presiones iguales a menos de 1/2 psig (3.5 kPa o 14"

columna de agua).

6. ConversiOn para uso de Propano Liquido

Este aparato puede ser usado con gas natural o propano

Ifquido. Hasidoajustadoen la f_ibrica para operarcon

gas natural solamente.

La tuberfa de suministro de gas debe ser de 1/2" o 3/4"

D.I.

El consumidor debe saber la posici0n de la wilvula

principal de cierre y tener acceso f_icil a ello.

Si desea convertir su estufa para uso con propano

Ifquido, use los orificios provistos ubicados en el bolso

que contiene la literatura titulada "FOR LP/PROPANE

GAS CONVERSION". Siga las instrucciones quevienen

con los orificios.

19

Page 20

UBICACION DEL

REGULADOR DE PRESION

CUBIERTA

DE ACCESO

TRASERA

PUERTA DEL

HORNO

Conector Flexible para Artefactos

(Instale un conducto /o suficientemente

largo para poder sacar /a estufa

tota/mente fuera da /a _rea recortada para

un servicio satisfactorio).

Adaptor

de gas

V&lvula

Manual

Externa de

Cierre

Conecte a un

conducto

s61ido de

suministro de

gas de ½" o

3/_ _'.

IISUMINISTRO

DE GAS

TO

APPLIANCE

Solid Piping Gas Supply

TO GAS SUPPLY

Sutoff LINE

Valve I_

CAJON

Figura 9

Conversibn para uso de Propano Liquido

(continuacibn)

La conversi6n debe ser efectuado por un t_cnico de

servicio capacitado, de acuerdo con las instrucciones del

fabricante y con todos los c6digos y requisitos de las

autoridades correspondentes. El no seguir las

instrucciones podr[a dar como resultado lesiones graves

odahosa la propiedad. EIorganismoautorizado para

Ilevar a cabo este trabajo asume la responsabilidad de la

conversi6n.

La falta de una conversi6n apropiada

puede resultar en lesiones graves y dahos a la

propiedad.

El regulador debe desconectarse antes de mover el

aparato, si el regulador de la estufa se conecta a una

caheria r[gida. Si la estufa seequipa con un caj6n

calentador, el regulador puede accesarse mediante un

panel lateral de lado. Quite los dostornillosque

aseguran el panel, entonces quite el panel. Desconecte

el regulador de la caheria. Reensambleen orden inverso

(consulte Figura 10).

7. La mudanza del aparato para

reparaciones o limpieza

Apague la corriente el_ctrica a la estufa a la fuente de

poder principal, y apague la wilvula de cierre manual de

gas. AsegOrese de que la estufa est6 fresca. Quite el caj6n

de servicio (el caj6n calentador en algunos modelos) y abre

la puerta del horno. Levante la frente de la estufa y

desl[cela fuera de la abertura sin crear tensi6n desmedida

sobre el conducto flexible de gas. AsegOrese de no

pellizque el conducto flexible de gas detr_is de la estufa al

reemplazar la unidad en la abertura. Reemplace el caj6n,

cierre la puerta y enciende el gas y la corriente el_ctrica a

la estufa.

El panel lateral de

lado- calentador

y_ LADO DERECHO)

Tornillo El desliz del

caj6n (nolo quite)

Figura 10

2O

Page 21

8. Instalaci6n de la estufa

Mientras se desembala la estufa, no

deseche los cuatro (4) pernos de embalaje.

Reempl_celos como patas niveladoras y para ajustar la

altura de la unidad.

1. Instalacibn sin los paneles laterales

A. Lasuperficie de la estufa sesobrepone al mostrador

por los lados y la estufa descansa sobre el piso. La

estufa es de 30" (76.2 cm) de anchura.

B. Instale los gabinetes de base con una separaci6n de

29" (73.7 cm). Aseg0rese de que se aplomar y sean

nivelados antes de juntar la estufa. Acepille la parte

levantada del borde del mostrador dejando espacio

para la superficie de la estufa de 30" (76.2 cm).

C. Instale las puertas de los gabinetes con una separaci6n

mfnima de 31" (78.7 cm) para que no obstruyan con

la puerta de la estufa al abrirse.

D. Recorte el mostrador exactamente seg0n el dibujo en

la p_gina 1.

E. Un protector trasero puede pedirse mediante su

negociante.

F. Ajuste alas piernas de nivelaci6n de manera que la

parte de abajo de la plancha de cocinar est_ apoyada

contra el mostrador.

G. Nivele la estufa. El piso donde la estufa se va a

instalar tiene que estar nivelado (Figura 11).

9. Nivelaci6n de la estufa

Nivele la estufa y ajuste la altura de la estufa antes

de instalarla en la abertura.

1. Coloque una parrilla del homo en el centro del horno.

2. Ponga un nivel sobre la parrilla. Tome dos lecturas con

el nivel puesto diagonalmente en una direcci6n y

despu_s en la otra. Nivele la estufa, si es necesario,

ajustando las 4 patas niveladoras con una Ilave de

tuercas (Figura 15).

3. Aseg0rese de no dahar al mostrador, deslice la estufa

dentro de la abertura del hueco y vuelva a verificar a la

nivelaci6n. Si la estufa no est_ nivelada, arranque el

electrodom_stico y vuelva a ajustar a las piernas o

aseg0rese que el suelo est_ nivelado.

2. Instalaci6n con los paneles laterales

A. Instale los gabinetes de base con una separaci6n

mfnima de 30 1/8" (76.5 cm). Aseg0rese de que se

aplomar y sean nivelados.

B. Instale las puertas de los gabinetes con una separaci6n

mfnima de 31" (78.7 cm) para que no obstruyan con

la puerta de la estufa al abrirse.

C. Un protector trasero puede pedirse mediante su

negociante.

D. Un conjunto de paneles laterales puede pedirse

mediante su negociante.

E. Nivele la estufa y ajuste la altura de la estufa.

3. Instalaci6n con un protector trasero

La profundidad del recortado de 21 5/8" (55 cm) necesita

aumentarse a 24"(61 cm) al instalar un protector trasero.

Figura 11

21

Page 22

10. Comprobaci6n del Funcionamiento

Consulte el Manual del Usuario inclu[do con la estufa

para instrucciones de operaci6n y instrucciones para el

cuidado y limpieza de su estufa.

No toque los elementos o quemadores.

Pueden estar bastante calientes para causar

quemaduras.

Quite todo el embalaje de la unidad antes de

comprobarla.

1.

Instale las tapas de los quemadores y de las

tapas de los quemadores.

Esta estufa esta equipada con quemadores sellados

como se muestra m_s abajo (Figura 12).

Tapa del

quemador --_

Base del

quemador

Recogedor Abertu ra

Electrodo

Figura 12

de gas

3.

Comprobaci6n de los Encendedores

El funcionamiento de los encendedores el_ctricos

debe ser comprobado despu_s de que la estufa y los

conectores a la tuber[a de suministro de gas hayan

sido comprobados por escapes y la estufa haya sido

conectada el_ctricamente. Para comprobarqueel

encendido sea correcto:

A. Empuje y gire una perilla del quemador superior

hasta la posici6n LITE (encender). Se podr[a o[r

el encendedor haciendo chispas.

B. El quemador se deber_ encender en cuatro (4)

segundos para un funcionamiento normal, luego

de que el aire haya sido purgado de la tuber[a

de suministro de gas. Controlevisualmente que

el quemador se hay encendido.

C. Luego que el quemador se haya encendido, la

perilla debe ser girada fuera de la posici6n LITE.

Cada quemador tiene su encendedor individual.

Controle las perillas separadamente hasta que todas

las v_lvulas hayan sido controladas.

4.

Ajuste de la Posicibn LOW (BAJA) Para la

V&lvula del Quemador Superior (Figura 13)

A. Gire la perilla a la posici6n LITE (encender) hasta

que el quemador encienda.

B. R_Didamente gire la perilla a la POSICION MAS

BAJA.

C. Si el quemador se apaga, reajuste la v_lvula de

la siguienteforma: Mueva el controla la

posici6n OFF(apagada). Saque la perill ade

control del quemador superior, inserte un

destornillador piano pequefio en el hueco del

v_stago del a v_lvula hsta enganchar el tornillo

interior. EItamaflode la llama puedeser

aumentado o disminuido girando el tornillo.

Ajuste el tamaflo de la llama hasta que pueda

pasar r_pidamente de la posici6n LITE hasta la

posici6n MAS BAJA sin que se apague la llama.

La llama debe ser Io m_s pequefia posible sin

que se apague.

A. Desembale las basas de los quemadores y las

tapas de los quemadores.

B. Coloque una basa de quemador sobre cada

abertura de gas.

C. Asegurese que el quemador est_ correctamente

alineadoy nivelado. Coloquelastapas de los

quemadores sobre las correctas basas de

quemadores.

NOTA: No hacefalta ning0n ajuste dequemadoren

esta estufa.

2. Enciende la corriente el_ctrica y abre la v_lvula

principal de cierre.

Figura 13

22

Page 23

5. Funcionamiento de los Elementos del Horno

El horno estc_ equipado con un control electr6nico. Cada

funci6n ha sido probada en la f_brica antes del transporte.

Sin embargo, sugerimos que Ud. verifique el

funcionamiento de los controles del horno una vez m_s.

V_aseel Manualdel Usuario para laoperaci6n. Siga las

instrucciones par el Reloj Minutero, Cocer, Asar,

Covecci6n (algunos modelos) y las funciones de limpieza.

Cocer/Bake-Despu_s de poner el horno a 350°F (177°C)

para cooer, el element inferior debe ponerse rojo

Asar/BroiI-Cuando estc_ puesto para BROIL, el elemento

superior se debe poner rojo.

Limpieza/Clean-Cuando el horno est_ puesto para un

ciclo de auto-limpieza, el element superior se pondr_

rojo durante el perfodo de precalentamiento del ciclo.

Despu_s de alcanzar la temperatura de auto-limpieza ,

el elemento inferior se pondr_ rojo.

Convecci6nlConvection (algunos modelos)-Cuando

el homo se pone a CONV. BAKE/ROAST a 350°F

(177°C), los dos elementos se enciendan y se apagan

alternando en un ciclo y el ventilador se pone en

marcha. EIventilador deconvecci6n se parar_ cuando

se abre la puerta del homo durante el cocido o el asado

por convecci6n.

Antes de Llamar al Servicio

Lea la secci6n Evite Llamadas de Servicio en su Manual

del Usuario. Estolepodr_ ahorrartiempoygastos. Esta

lista incluye ocurrencias comunes que no son el

resultado de defectos de materiales o fabricaci6n de

este a rtefacto.

Lea la garantfa y la informaci6n sobre el servicio en su

Manual del Usuario para obtener el nOmero de tel_fono

gratuito y la direcci6n del servicio. Por favor Ilame o

escriba si tiene preguntas acerca de su estufa o necesita

repuestos.

Caj6n calentador (algunos modelos)-Ponga la perilla

de control a HI y verifique que se est_ calentando el

caj6n.

Despuds de Terminar la Instalaci6n

Aseg0rese de que todos los controles est_n en la posici6n

OFF (apagada).

AsegOrese de que el fluir del aire de combusti6n y de

ventilaci6n a la estufa no est_ obstruido.

Ubicaci6n del Ndmero de Modelo y de Serie

La placa con el n0mero de serie est_ ubicada en el

marco delantero del homo detr_s de la puerta del homo

(algunos modelos) o detr_s del caj6n (algunos modelos).

Cuando haga pedidos de repuestos o solicite informaci6n

con respecto a su estufa, est_ siempre seguro de incluir

el nOmero de modelo y de serie y el nOmero o letra del

Iote de la placa de serie de su estufa.

La placa con el nOmero de serie tambi_n le da la

potencia nominal de los quemadores, el tipo de

combustible y la presi6n a la cual fu_ ajustada la estufa

en la f_brica.

23

Page 24

11.Importante Advertencia de Seguridad

Para reducir el riesgo de que la estufa se vuelque, es

necesario asegurarla al piso instalando los soportes

antivuelco y los tornillos suministrados con la estufa. Las

piezas se encuentran en un saco de pl_istico en el horno.

Si no se instalan los soportes antivuelco, la estufa se

puede volcar si se coloca exceso de peso en una puerta

abierta osi un niflosesubeaella. Se puedenocasionar

lesiones graves causadas por los I[quidos calientes

derramados o por la estufa misma.

Siga las instrucciones que m_is abajo se indican para

instalar los soportes antivuelco.

Si la estufa es movida a otro lugar, los soportes

antivuelco deben tambi_n ser movidos e instalados en la

estufa. Para controlar la instalaci6n apropiada, vea el

paso n0mero 5.

Herramientas Necesarias:

Llave de tuerca de 5/16" o destornillador para tornillos

de cabeza plana

Llave inglesa

Taladro el_ctrico

Broca de 3/16" de di_imetro

Broca para taladro de mamposter[a de 3/16" de d[a.

(si se est,1 instalando en concreto)

Instrucciones de Instalaci6n del Soporte

Antivuelco

Los soportes se fijan al suelo en la parte trasera de la

estufa para sujetar ambos niveladores de las patas

traseras. Cuando los est_ instalando al piso, aseg0rese

de que los tornillos no penetren el alambrado el_ctrico o

plomer[a. Los tornillos provistos pueden utilizarse en

madera o concreto.

1. Desdoble la plantilla de papel y col6quela plana en

el piso con los bordes laterales y el trasero colocados

exactamente donde la parte trasera y los lados de la

estufa ser_in colocados cuando sea instalada. (Use el