Page 1

Service & P arts Manual

WallMaster® Thru-the-Wall

M

P

r

e

w

o

P

72

Cool

n

®

a

F

Money Saver

e

d

o

M

d

e

e

p

S

ly

n

O

n

a

F

Clock

t

e

S

Start Time

r

e

im

T

r

u

o

H

Off

/

n

O

r

u

o

H

/

p

m

Stop Time

e

T

WM-Svc-Prts-07 (3-07)

WS08B10A-C

WS10B10A-C

WS14B10A-C

WS10B30A-C

WS13B30B-C

WS16B30A-C

WE10B33A-B

WE13B33B-B

WE16B33A-B

WY10B33A-B

WY13B33A-B

Page 2

TABLE OF CONTENTS

Warranty .....................................................................................................................................................3

Routine Maintenance ................................................................................................................................4

Unit Identifi cation ......................................................................................................................................5

Performance Data .....................................................................................................................................6

Electrical Data ...........................................................................................................................................7

Functional Component Defi nitions .........................................................................................................8

Electronic Controls ...................................................................................................................................9

Rotary Controls .......................................................................................................................................10

Refrigeration Sequence of Operation ...................................................................................................11

Sealed Refrigeration Repairs ........................................................................................................... 12-13

Refrigerant Charging ..............................................................................................................................13

General Troubleshooting .................................................................................................................. 14-20

Wiring Diagrams ................................................................................................................................ 21-25

Parts Diagram ..........................................................................................................................................26

Parts Lists .......................................................................................................................................... 27-29

2

Page 3

Friedrich Air Conditioning Company

£

P.O. Box 1540

San Antonio, TX 78295

210.357.4400

www.friedrich.com

WALLMASTER

THRU-THE-WALL AIR CONDITIONERS

LIMITED WARRANTY

FIRST YEAR

ANY PART: If any part supplied by FRIEDRICH fails because of a defect in workmanship or material within twelve months from

date of original purchase, FRIEDRICH will repair the product at no charge, provided room air conditioner is reasonably accessible

for service. Any additional labor cost for removing inaccessible units and/or charges for mileage related to travel by a Service

Agency that exceeds 25 miles one way will be the responsibility of the owner. This remedy is expressly agreed to be the exclusive

remedy within twelve months from the date of the original purchase.

SECOND THROUGH FIFTH YEAR

SEALED REFRIGERANT SYSTEM: If the Sealed Refrigeration System (defined for this purpose as the compressor, condenser

coil, evaporator coil, reversing valve, check valve, capillary, filter drier, and all interconnecting tubing) supplied by FRIEDRICH in

your Room Air Conditioner fails because of a defect in workmanship or material within sixty months from date of purchase,

FRIEDRICH will pay a labor allowance and parts necessary to repair the Sealed Refrigeration System; PROVIDED FRIEDRICH will

not pay the cost of diagnosis of the problem, removal, freight charges, and transportation of the air conditioner to and from the

Service Agency, and the reinstallation charges associated with repair of the Sealed Refrigeration System. All such cost will be the

sole responsibility of the owner. This remedy is expressly agreed to be the exclusive remedy within sixty months from the date of the

original purchase.

APPLICABILITY AND LIMITATIONS: This warranty is applicable only to units retained within the Fifty States of the U.S.A., District

of Columbia, and Canada. This warranty is not applicable to:

1. Air filters or fuses.

2. Products on which the model and serial numbers have been removed.

3. Products which have defects or damage which results from improper installation, wiring, electrical current

OBTAINING WARRANTY PERFORMANCE: Service will be provided by the FRIEDRICH Authorized Dealer or Service

Organization in your area. They are listed in the Yellow Pages. If assistance is required in obtaining warranty performance, write

to: Room Air Conditioner Service Manager, Friedrich Air Conditioning Co., P.O. Box 1540, San Antonio, TX 78295-1540.

LIMITATIONS: THIS WARRANTY IS GIVEN IN LIEU OF ALL OTHER WARRANTIES. Anything in the warranty

notwithstanding, ANY IMPLIED WARRANTIES OF FITNESS FOR PARTICULAR PURPOSE AND/OR MERCHANTABILITY

SHALL BE LIMITED TO THE DURATION OF THIS EXPRESS WARRANTY. MANUFACTURER EXPRESSLY DISCLAIMS AND

EXCLUDES ANY LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGE FOR BREACH OF ANY EXPRESSED OR

IMPLIED WARRANTY.

NOTE: Some states do not allow limitations on how long an implied warranty lasts, or do not allow the limitation or exclusion of

consequential or incidental damages, so the foregoing exclusions and limitations may not apply to you.

OTHER: This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

PROOF OF PURCHASE: Owner must provide proof of purchase in order to receive any warranty related services.

All service calls for explaining the operation of this product will be the sole responsibility of the consumer.

All warranty service must be provided by an Authorized FRIEDRICH Service Agency, unless authorized by FRIEDRICH prior to

repairs being made.

characteristics, or maintenance; or caused by accident, misuse or abuse, fire, flood, alterations and/or misapplication

of the product and/or units installed in a corrosive atmosphere, default or delay in performance caused by war,

government restrictions or restraints, strikes, material shortages beyond the control of FRIEDRICH, or acts of God.

(10-04)

3

Page 4

ROUTINE MAINTENANCE

NOTE: Un its are to be inspected and serviced by qualifi ed service personnel only.

Routine maintenance is required annually or semi-annually, depending upon annual usage.

1. Clean the unit air intake fi lter at least every 250 to 300 fan hours of operation or when the unit’s indicator light is on if

so equipped. Clean the fi lters with a mild detergent in warm water and allow to dry thoroughly before reinstalling.

2. The indoor coil ( evaporator coil), the outdoor coil (condenser coil) and base pan should be inspected periodically (yearly

or bi-yearly) and cleaned of all debris (lint, dirt, leaves, paper, etc. ). Clean the coils and base pan with a soft brush and

compressed air or vacuum. If using a pressure washer, be careful not to bend the aluminium fi n pack. Use a sweeping

up and down motion in the direction of the vertical aluminum fi n pack when pressure cleaning coils. Cover all electrical

components to protect them from water or spray. Allow the unit to dry thoroughly before reinstalling it in the sleeve.

NOTE: Do not use a caustic coil cleaning agent on coils or base pan. Use a biodegradable cleaning agent and degreaser.

Inspect the indoor blower housing, evaporator blade, condenser fan blade, and condenser shroud periodically (yearly or

bi-yearly) and clean of all debris (lint, dirt, mold, fungus, etc.) Clean the blower housing area and blower wheel with an

antibacterial / antifungal cleaner. Use a biodegradable cleaning agent and degreaser on condenser fan and condenser

shroud. Use warm or cold water when rinsing these items. Allow all items to dry thoroughly before reinstalling them.

3. Periodically (at least yearly or bi-yearly): inspect all control components, both electrical and mechanical, as well as the

power supply. Use proper testing instruments (voltmeter, ohmmeter, ammeter, wattmeter, etc.) to perform electr ical

tests. Use an air conditioning or refrigeration ther mometer to chec k room, outdoo r and coil operating temperatures.

Use a sling psychrometer to measure wet bulb temperatures indoors and outdoors.

4. Inspect the surrounding area (inside and outside) to ensure that the units’ clearances have not been compromised or

altered.

5. Inspect the sleeve and drain system periodically (at least yearly or bi-yearly) and clean of all obstructions and debris.

Clean both areas with an antibacterial and antifungal cleaner . Rinse both items thoroughly with water and ensure that

the drain outlets are operating correctly. Check the sealant around the sleeve and reseal areas as needed.

6. Clean the front cover when needed. Use a mild detergent. Wash and rinse with warm water. Allow it to dry thoroughly

before reinstalling it in the chassis.

4

Page 5

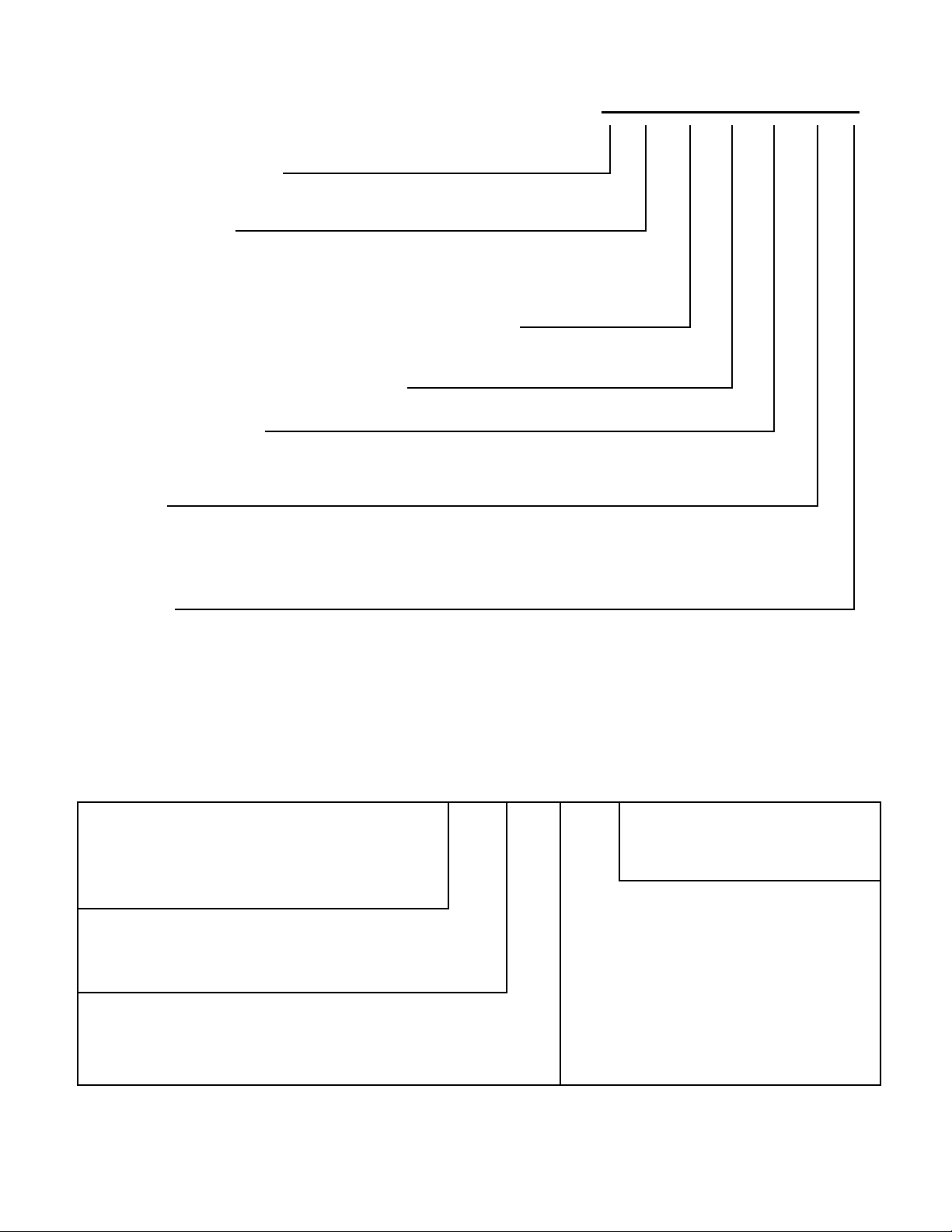

FRIEDRICH ROOM MODEL NUMBER CODE

W S 08 B 1 0 B

1st DIGIT - FUNCTION

W = Thru-The-Wall, WallMaster Series

2nd DIGIT - TYPE

S = Straight Cool

E = Electric Heat

Y = Heat Pump

3rd & 4th DIGITS - APPROXIMATE BTU/HR (Cooling)

Heating BTU/HR capacity listed in Specifi cations/Performance Data Section

5th DIGIT - ALPHABETICAL MODIFIER

6th DIGIT - VOLTAGE

1 = 115 Volts

3 = 230-208 Volts

7th DIGIT

0 = Straight Cool & Heat Pump Models

ELECTRIC HEAT MODELS

3 = 3 KW Heat Strip, Nominal

8th DIGIT

Major Change

RAC SERIAL NUMBER IDENTIFICATION GUIDE

Serial Number

Decade Manufactured

L=0 C=3 F=6 J=9

A=1 D=4 G=7

B=2 E=5 H=8

Year Manufactured

A=1 D=4 G=7 K=0

B=2 E=5 H=8

C=3 F=6 J=9

Month Manufactured

A=Jan D=Apr G=Jul K=Oct

B=Feb E=May H=Aug L=Nov

C=Mar F=Jun J=Sept M=Dec

L C G R 00001

Production Run Number

Product Line

R = RAC

P = PTAC

E = EAC

V = VPAK

H = Split

5

Page 6

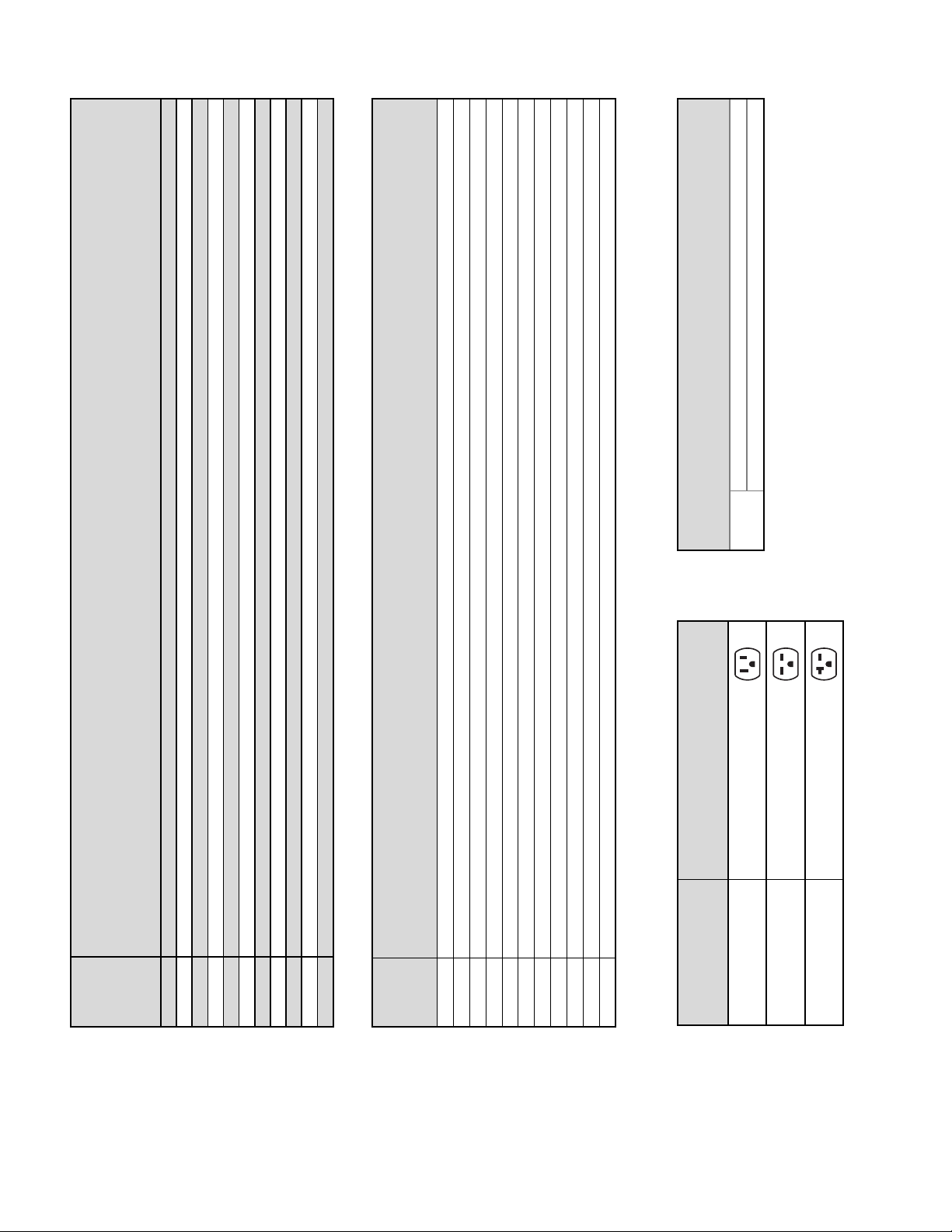

PERFORMANCE DATA

FUSE

BREAKER

OPERATING

PRESSURES ELECTRICAL RATINGS R-22 REF.

Amps

60 Hertz

RPM

Motor

CFM

Evap

OZ.

Charge in

Locked

Rotor Amps

Heat

Amps

Cool

Amps

Sub-

Cooling

Heat

Super

Lbs.

Net Weight

Room

Side Air

Circulation

Removal

Moisture

Pints/Hr.

EER

Ratio

Energy

Efficiency

Watts

Heating

Amps

Heating

Finished Hole

Thru-the-wall

Height Width

Outside

Minimum

Extension

Minimum

Extension

Into Room

with

Front

Depth

16 3/4" 27" 16 3/4" 23" 7 1/2" 9/16" 17 1/4" 27 1/4"

Model Height Width Depth

Sleeve Dimensions

WSC Sleeve

15 3/4" 26 1/2" 21" – – – – –

Chassis

Temp

Liquid

Temp

Suction

Temp

Discharge

TEMP.

DEG. F

CONDENSER

TEMP. DEG. F

EVAPORATOR

Temp .

Drop F. E(in) E (out) Suction Discharge

TEMP. DEG. F

EVAPORATOR AIR

* Rating Conditions: 80 degrees F, room air temp. & 50% relative humidity, with 95 degree F, outside air temp & 40% relative humidity

Calculate the heat loss of the space to be heated. As long as the heat loss does not exceed the resistance heating capacity rating of the unit, the heating performance will be satisfactory. Change-over

from heat pump operation to resistance operation on models indicated is automatic at a preset outside ambient temperature of approximately 35°F. If condensate disposal is desired, an optional drain

kit is available. DEFROST CONTROL: Initiated at 20°F (outdoor coil temperature) and terminated at 43°F (outdoor coil temperature). During defrost, the compressor stops and the electric heat starts,

then operates with the fan to maintain indoor comfort. Below 43°F, the unit remains in electric heat mode. During electric heat mode, the unit will achieve the following ratings: 11000/9100 BTU/h,

16.0/14.7 amps, and 3550/2950 watts. DEFROST DRAIN: Drain automatically opens at approximately 50°F in outdoor base pan for defrost condensate disposal.

Air

Discharge

WS08B10A 55 25 55 55 127 165 61 102 18 25 87 281 7.1 36.2 20.5 257 1100 15

WS10B10A 52 28 53 51 128 176 68 105 16 24 79 293 9.0 45.0 22.0 248 1100 15

WS14B10A 52 28 52 52 128 179 63 99 14 28 82 297 12.4 58.0 44.9 293 1300 15

WS10B30A 55 25 53 57 131 179 68 106 16 23 77 289 4.6 26.0 22.5 235 1100 15

WS13B30B 51 29 52 50 128 174 57 100 13 30 78 295 6.5 27.4 35.2 281 1300 15

WS16B30A 52 28 51 53 121 154 54 99 18 32 74 315 7.7 35.0 47.6 292 1421 15

WE10B33A 53 27 54 52 126 180 82 99 16 31 82 289 4.6 15.2 45.0 38.0 225 1074 20

WE13B33B 52 29 52 51 127 180 64 103 13 29 80 295 6.5 15.7 27.4 35.0 274 1318 20

WE16B33A 52 28 51 5 3 121 174 57 10 0 18 30 74 315 6.5 16.1 35.0 3 5.2 281 1305 20

WY10B33A 53 27 54 52 126 180 66 99 16 31 82 225 4.6 4 / 15.2 26.0 38.0 225 1074 20

WY13B33A 52 29 52 51 127 180 64 103 16 29 80 300 6.5 5.6 / 15.7 27.4 35.0 260 1200 20

Watts

Cooling

Wall

Outlet

Circuit Rating

Plug Face

Breaker

Appearance

(NEMA#)

125V - 15A 5 - 15P

250V - 15A 6 - 15P

or T-D Fuse

Model Numbers

WS08B10A, WS10B10A,

WS14B10A

250V - 20A 6 - 20P

WS10B30A, WS13B30A,

WS16B30A

WE10, WE13, WE16

WY10, WY13

Amps

Cooling

BTU/h Volts Rated

Heating

Capacity

BTU/h

Cooling

Capacity

Model #

WS08B10A 8000 — 115 6.8 762 — — 10.5 1.3 245 93

WS10B10A 10000 — 115 8.7 954 — — 10.5 2.4 245 103

WS14B10A 13500 — 115 12.0 1415 — — 9.5 3.3 295 112

WS10B30A 10000/10000 — 230/208 4.6/5.0 1005/996 — — 10.0/10.0 2.1 260 101

WS13B30B 12500/12000 — 230/208 6.3/6.7 1404/1379 — — 8.9/8.7 3.3 280 109

WS16B30A 15800/15000 — 230/208 7.8/8.5 1756/1705 — — 9.0/8.8 4.2 290 119

WE10B33A 10000/10000 11000/9100 230/208 4.6/5.0 1005/996 16.0/14.7 3550/2950 10.0/10.0 2.1 260 103

WE13B33B 12500/12000 11000/9100 230/208 6.3/6.7 1404/1379 16.0/14.7 3550/2950 8.9/8.7 3.3 280 111

WE16B33A 15800/15000 11000/9100 230/208 7.8/8.5 1756/1705 16.0/14.7 3550/2950 9.0/8.8 4.2 290 121

WY10B33A 10100/9800 8100/7800 230/208 4.6/4.8 1013/976 3.9/4.0 857/821 10.0/10.0 2.5 230 107

WY13B33A 12500/12100 10400/10000 230/208 6.4/6.8 1389/1352 5.4/5.7 1182/1136 9.0/9.0 3.2 280 116

Installation Information

6

Page 7

ELECTRICAL DATA

Wire Size Use ONLY wiring size recommended for

single outlet branch circuit.

Fuse/Circuit Use ONLY type and size fuse or HACR

Breaker circuit breaker indicated on unit’s rating

plate. Proper current protection to the unit

is the responsibility of the owner.

Grounding Unit MUST be grounded from branch

circuit through service cord to unit, or

through separate ground wire provided on

permanently connected units. Be sure that

branch circuit or general purpose outlet is

grounded.

Receptacle The fi eld supplied outlet must match plug on

service cord and be within reach of service

cord. Do NOT alter the service cord or plug.

Do NOT use an extension cord. Refer to

the table above for proper receptacle and

fuse type.

ELECTRIC SHOCK HAZARD.

T urn off electric power before service or installation.

All electrical connections and wiring MUST be

installed by a qualifi ed electrician and conform to the

National Electrical Co de and all local codes which

have jurisdiction.

Failure to do so can result in property damage,

personal injury and/or death.

The consumer - through the AHAM Room Air Conditioner Certifi cation Program - can be certain

that the AHAM Certifi cation Seal accurately states the unit’s cooling and heating capacity rating,

the amperes and the energy effi ciency ratio.

7

Page 8

FUNCTIONAL COMPONENTS

A. Me c h anica l c o m p onents

Bellows condensate valve

T emperature-sensitive valve that opens up to drain off condensate water when the outside temperature falls below 40°F

and closes when the outside temperature reaches 58°F.

Plenum assembly

Diffuser with directional louvers used to direct the conditioned airfl ow.

Blower wheel

Attaches to the indoor side of the fan motor shaft and is used for distributing unconditioned, room side air though the heat

exchanger and delivering conditioned air into the room.

Slinger fan blade

Attaches to the outdoor side of the fan motor shaft and is used to move outside air through the condenser coil, while

slinging condensate water out of the base pan and onto the condenser coil, thus lowering the temperature and pressures

within the coil.

B. Electrical components

Thermostat

Used to maintain the specifi ed room side comfort level

System switch

Used to regulate the operation of the fan motor, the compressor or to turn the unit off. For troubleshooting, refer to the

wiring diagrams and schematics in the back of this service manual.

Capacitor

Reduces line current and steadies the voltage supply, while greatly improving the torque characteristics of the fan motor

and compressor motor.

MoneySaver® switch

When engaged, it sends the power supply to the fan motor through the thermostat, which allows for a cycle-fan operation.

Fan Motor

Dual-shafted fan motor operates the indoor blower wheel and the condenser fan blade simultaneously.

Solenoid

Used to energize the reversing valve on all heat pump units.

Heating elem en t

Electric resistance heater, available in 3.3, 4.0 or 5.2 kW on select T winT emp® models.

Heat anticip at or

Used to provide better thermostat and room air temperature control.

C. Hermetic components

Compressor

Motorized device used to compress refrigerant through the sealed system.

Reversing valve

A four-way switching device used on all heat pump models to change the fl ow of refrigerant to permit heating or cooling.

Check valve

A pressure-operated device used to direct the fl ow of refrigerant to the proper capillary tube, during either the heating or

cooli ng c ycle.

Capillary tube

A cylindrical meter device used to evenly distribute the fl ow of refrigerant to the heat exchangers (coils.)

8

Page 9

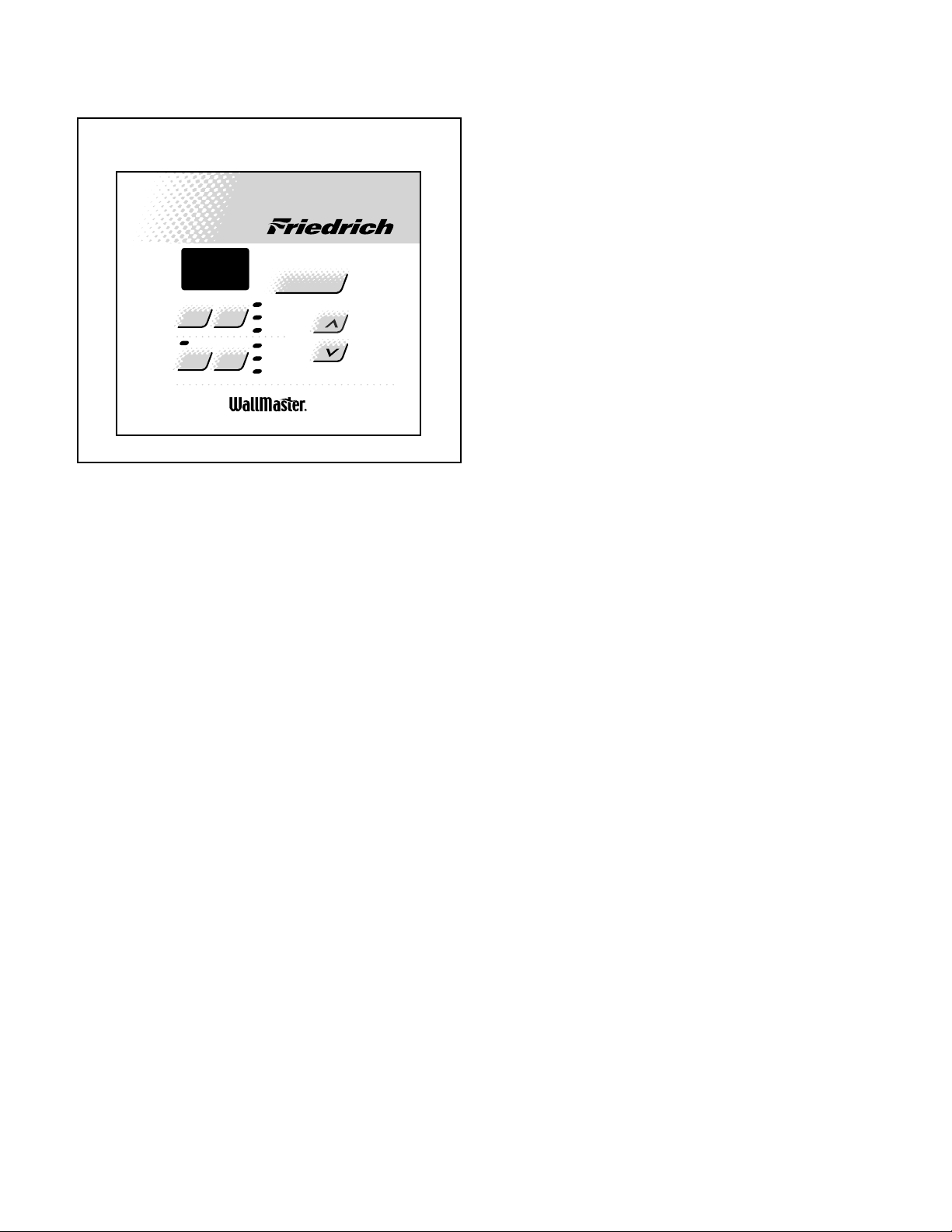

SYSTEM CONTROL PANEL

(“WS” Models)

Figure 6: System Control Panel

PM

Speed

Timer

On/Off

72

Fan

Mode

Hour

Set

Cool

MoneySaver

Fan Only

Clock

Start Time

Stop Time

Power

®

Tem p/H our

TESTING THE ELECTRONIC CONTROL

CHECKING ROOM TEMPERATURE

1. Check the room temperature at the electronic control

pad by pressing at the same time the “FAN SPEED”

button and the temperature “UP” button on XQ & WS

models.

2. The indoor temperature will display for 10 seconds.

Indoor temperature can be viewed in all modes,

including the TEST mode. The display can be changed

back to SET temperature by pressing any key, except

the ON/OFF button, or after 10seconds has elapsed.

ACTIVATING TEST MODE

Activate test mode by pressing at the same time the “MODE ”

button and the temperature “DOWN” button on XQ & WS

models. LEDs for Hour , Start, and Stop will blink 1bps while

Test Mode is active.

Test Mode has duration of 90 minutes. Test Mode

can be activated under any conditions, including O ff.

Test Mode is cancelled by pressing the On/Off button,

unplugging the unit, or when the 90 minutes is timed

out. All settings revert to the factory default settings of

Cool, 75 degrees F, Timer and Set Hour features are

nonfunctional.

Activating Err or C ode Mode ( Submode of Test Mode)

Unit must be in T est Mode to enter Error Code Mode

1. Activate Error Code Mode by pressing the “TIMER

ON/OFF” button on XQ & WS model s. LED for the

“TIMER ON/OFF” will fl ash 1bps while Error Code

Mode is active. Pressing the “TEMP/HR + ” button will

display 00. Consecutive presses will scroll through all

error codes logged. Press the “TEMP/HR - ” button

to see the reverse order of all error codes logged.

When the end of logged error codes is reached the

temperature set point will appear .

IMPORTANT

Error Codes are cleared from the lo g by exiting from Error

Code Mode. To exit on X Q & WS models, press Timer On/

Off but ton. Or unplug unit to exit Error Code Mo de. Plug

unit in after 5 seconds to resume normal operation of unit.

ERROR CODE LISTINGS

E1 SHORT CYCLE SITUATION: Defi ned as

compressor powered on before the three minute

time delay ten times in one hour. In vestigate and

correct short cycling problem.

E2 KEYBOARD STUCK ERROR: If key button(s)

are pressed continuously for twent y seconds or

more. If MODE key is stuck, unit will default to

cool. Exit Error Code M ode to see if error “ E2 ”

is no longer displayed and unit is functioning.

Replace board if “E2 ” still displays after exiting

Error Code Mode.

E3 FROST PROBE OPEN: Normal operation is

allowed. Ohm frost probe. Replace probe if ohm

value not read. If ohm value present replace

board.

E4 FROST PROBE SHORT: Normal operation

allowed. Replace probe.

E5 INDOOR PROBE OPEN: Control assumes

indoor ambient temperature is 90 degree F and

unit will operate. Ohm indoor probe. Replace

probe if ohm value not read.

E6 INDOOR PROBE SHORT: Control assumes

ambient temperature is 90 degree F and unit will

operate. Replace probe.

T est Mode overrides the three-minute lockout, all delays

for compressor and fan motor start / speed change, and

no delay when switching modes.

Te st Mode default settings are ON, Money Saver, 60

degrees F, and High fan speed.

NOTE: All Error Code displays for Frost & Indoor Probe

will allow unit to operate. Unit may or will ice up if faulty

components not replaced.

9

Page 10

Frost Probe Sensor: Disables compressor at 35 degrees

MAX

MAX

F +/- 3 degrees F

Indoor Probe Sensor: Control range is 60 degrees F to 90

degrees F +/- 2 degrees F

SYSTEM CONTROL SWITCH - TEST

Disconnect leads from control switch. Turn control to position being tested (see Figure 8). There must be continuity

as follows:

Indoor temperature will be displayed by pressing:

(XQ / WS Units) The Fa n Sp eed button and the Temp U p

button.

The indoor temperature will be displayed for 10 seconds.

The display will change back to the Set Point temperature by

pressing any key button except for the On/Off button. The

indoor temperature can be viewed in all mo des, including

test mode.

Keep Alive: The electronic control has a memory to retain

all functions and status as set up by the user in the event

of a power failure. Once power is restored to the unit

there is a two second delay before the fan comes on and

approximately three minutes delay before the compressor

is activated, providing that the mode was set for cooling and

the set point temperature has not been met in the room.

SYSTEM CONTROL SWITCH

(“WE” & “WY” Models)

An eight position switch is used to regulate the operation

of the fan motor, compressor and electric heater.

The unit can be operated in cooling or heating mode with

the compressor or electric heater on and the fan motor

operating on low, medium or high speed.

1. “Off” Position-no continuity between terminals.

2. “Lo Cool” Position-between terminals “C” and “3”,

“C2” and “2”, “LO” and “M/S”, “AR” and “5”.

3. “Med Cool” Position-between terminals “C” and “3”,

“C2” and “2”, “M” and “M/S”, “AR” and “5”.

4. “Hi Cool” Position-between terminals “C” and “3”,

“C2” and “2”, “H” and “M/S”, “AR” and “5”.

5. “Hi Heat” Position-between terminals “C” and “1”,

“C2” and “4”, “H” and “M/S”, “AR” and “5”.

6. “Med Heat” Position-between terminals “C” and “1”,

“C2” and “4”, “M” and “M/S”, “AR” and “5”.

7. “Lo Cool” Position-between terminals “C” and “1”,

“C2” and “4”, “LO” and “M/S”, “AR” and “5”.

8. “Fan Only” Position-between terminals “L1”, “M”

and “2”.

Figure 8: System Control Switch

(Heat Pump & Electric Heat Models)

The fan motor can also be operated independently on

medium speed. See switch section as indicated on

decorative control panel, in Figure 7.

Figure 7: System Control Panel

Fan

Off

Only

High

Cool

Low

Cool

Med

Cool

HEAT

COOL

Low

Heat

Med

Heat

High

Heat

Allow 3 min. between restarts

!

NOTE:

Units will operate in constant fan in the cooling mode and

auto fan in the heating mode.

10

Page 11

REFRIGERATION SYSTEM SEQUENCE OF OPERATION

A good understanding of the basic operation of the refrigeration system is essential for the service technician. Without

this understanding, accurate troubleshooting of refrigeration

system problems will be more diffi cult and time consu ming,

if not (in some cases) entirely impossible. The refrigeration

system uses four basic principles (laws) in its operation they

are as follows:

1. “ Heat always flows from a warmer body to a cooler

body . ”

2. “Heat must be added to or removed from a substance

before a change in state can occur”

3. “Flow is always from a higher pressure area to a lower

pressure area.”

4. “The temperature at which a liquid or gas changes state

is dependent upon the pressure.”

The refrigeration cycle begins at the compressor. Starting

the compressor creates a low pres sure in the suction line

which draws refrigerant gas (vapor) into the compressor.

The compressor then “compresses” this refrigerant, raising

its pressure and its (heat intensity) T emperature .

The refrigerant leaves the compressor through the discharge

line as a hot high pressure gas (vapor). The refrigerant enters

the condenser coil where it gives up some of its heat. The

condenser fan moving air across the coil’s fi nned surface

facilitates the transfer of heat from the refr igerant to the

relatively cooler outdoor air.

the evaporator coil. As it enters the evaporator coil, the

larger area and lower pressure allows the refrigerant to

expand and lower its temperature (heat intensity). This

expansion is often referred to as “boiling”. Since the unit’s

blower is moving Indoor air across the fi nned surface of

the evaporator coil, the expanding refrigerant absorbs

some of that heat. This results in a lowering of the indoor

air temperature, hence the “cooling” effect.

The expansion and absorbing of heat cause the liquid

refrigerant to evaporate (i.e. change to a gas). Once the

refrigerant has been evaporated (changed to a gas), it is

heated even further by the air that continues to fl ow across

the evaporator coil .

The particular system design determines at exactly what

point (in the evaporator) the change of state (i.e. liquid to a

gas) takes place. In all cases, howev er, the refrigerant must

be totally evaporated (changed) to a gas before leav ing

the evaporator coil .

The low pressure (suction) created by the compressor

causes the refrigerant to leave the evaporator through the

suction line as a cool low pressure vapor. The refrigerant

then returns to the compressor, where the cycle is

repeated.

Refrigerant System Components

When a suffi cient quantity of heat has been removed from

the refrigerant gas (vapor), the refrigerant will “condense”

(i.e. change to a liquid). Once the refrigerant has been

condensed (changed) to a liquid it is cooled even further by

the air that continues to fl ow across the condenser coil.

The RAC design determines at exactly w hat point (in the

condenser) the change of state (i.e. gas to a liquid) takes

place. In all cases, however, the refrigerant must be totally

condensed (changed) to a liquid before leaving the condenser

coil.

The refrigerant leaves the condenser coil through the

liquid line as a warm high pressure liquid. It next will pass

through the refrigerant drier (if so equipped). It is the

function of the drier to trap any moisture present in the

system, contaminants, and large particulate matter.

The liquid refrigerant next enters the metering device. The

metering device is a capillary tube. The pur pose of the

metering device is to “meter” (i.e. control or measure ) the

quantity of refrigerant entering the evaporator coil.

In the case of the capillary tube this is accomplished

(by design) through size (and length) of device, and the

pressure difference present across the device.

Suction

Line

Evaporator

Coil

Metering

Device

Refrigerant Drier

Discharge

Line

Condenser

Coil

Compressor

Liquid

Line

SEALED REFRIGERATION SYSTEM REP AIRS

IMPORTANT

ANY SEALED SYSTEM REPAIRS TO COOL -ONLY

MODELS REQUIRE THE INSTALLATION OF A

LIQUID LINE DRIER. ALSO, ANY SEALED SYSTEM

REPAIRS TO HEAT PUMP MODELS REQUIRE THE

INSTALLA TION OF A SUCTION LINE DRIER.

Since the evaporator coil is under a lower pressure (due to

the suction created by the compressor) than the liquid line,

the liquid refrigerant leaves the metering device entering

11

Page 12

SEALED REFRIGERATION SYSTEM

REPAIRS

EQUIPMENT REQUIRED:

1. Voltmeter

2. Ammeter

3. Ohmmeter

4. Vacuum Pump (capable of 200 microns or less

vacuum.)

5. Acetylene Welder

6. Electronic Halogen Leak Detector (G.E. T ype H-6 or

equivalent.)

7. Accurate refrigerant charge measuring device such

as:

a. Balance Scales - 1/2 oz. accuracy

b. Charging Board - 1/2 oz. accuracy

8. High Pressure Gauge - (0 - 400 lbs.)

9. Low Pressure Gauge - (30 - 150 lbs.)

10. Vacuum Gauge - (0 - 1000 microns)

EQUIPMENT MUST BE CAPABLE OF:

HERMETIC COMPONENT REPLACEMENT

The following procedure applies when replacing components in the sealed refrigeration circuit or repairing

refrigerant leaks. (Compressor, condenser, evaporator,

capillary tube, refrigerant leaks, etc.)

1. Recover the refrigerant from the system at the process tube located on the high side of the system by

installing a line tap on the process tube. Apply gauge

from process tube to EPA approved gauges from

process tube to EPA approved recovery system.

Recover CFCs in system to at least 5%.

2. Cut the process tube below pinch off on the suction

side of the compressor.

3. Connect the line from the nitrogen tank to the suction

process tube.

4. Drift dry nitrogen through the system and unsolder

the more distant connection fi rst. (Filter drier, high

side process tube, etc.)

5. Replace inoperative component, and always install a

new fi lter drier. Drift dry nitrogen through the system

when making these connections.

6. Pressurize system to 30 PSIG with proper refrigerant

and boost refrigerant pressure to 150 PSIG with dry

nitrogen.

1. Evacuation from both the high side and low side of

the system simultaneously.

2. Introducing refrigerant charge into high side of the

system.

3. Accurately weighing the refrigerant charge actually

introduced into the system.

4. Facilities for fl owing nitrogen through refrigeration

tubing during all brazing processes.

7. Leak test complete system with electric halogen leak

detector, correcting any leaks found.

8. Reduce the system to zero gauge pressure.

9. Connect vacuum pump to high side and low side of

system with deep vacuum hoses, or copper tubing.

(Do not use regular hoses.)

12

Page 13

10. Evacuate system to maximum absolute holding pressure of 200 microns or less. NOTE: This process can

be speeded up by use of heat lamps, or by breaking

the vacuum with refrigerant or dry nitrogen at 5,000

microns. Pressure system to 5 PSIG and leave in

system a minimum of 10 minutes. Release refrigerant, and proceed with evacuation of a pressure of

200 microns or less.

1 1. Break vacuum by charging system from the high side

with the correct amount of refrigerant specifi ed. This

will prevent boiling the oil out of the crankcase.

NOTE: If the entire charge will not enter the high

side, allow the remainder to enter the low side in

small increments while operating the unit.

12. Restart unit several times after allowing pressures

to stabilize. Pinch off process tubes, cut and solder

the ends. Remove pinch off tool, and leak check the

process tube ends.

SPECIAL PROCEDURE IN THE CASE OF MOTOR

COMPRESSOR BURNOUT

1. Recover all refrigerant and oil from the system.

2. Remove compressor, capillary tube and fi lter drier

from the system.

3. Flush evaporator condenser and all connecting

tubing with dry nitrogen or equivalent, to remove

all contamination from system. Inspect suction and

discharge line for carbon deposits. Remove and

clean if necessary.

ROTARY COMPRESSOR SPECIAL

TROUBLESHOOTING AND SERVICE

Basically, troubleshooting and servicing rotary compressors is the same as on the reciprocating compressor with

only a few exceptions.

1. Because of the spinning motion of the rotary, the

mounts are critical. If vibration is present, check the

mounts carefully.

2. The electrical terminals on the rotary are in a different order than the reciprocating compressors. The

terminal markings are on the cover gasket. Use your

wiring diagram to insure correct connections.

REFRIGERANT CHARGE

1. The refrigerant charge is extremely critical. Measure charge carefully - as exact as possible to the

nameplate charge.

2. The correct method for charging the rotary is to

introduce liquid refrigerant into the high side of the

system with the unit off. Then start compressor and

enter the balance of the charge, gas only, into the

low side.

The introduction of liquid into the low side, without

the use of a capillary tube, will cause damage to

the discharge valve of the rotary compressor.

NOTE: All inoperative compressors returned to

Friedrich must have all lines properly plugged with

the plugs from the replacement compressor.

4. Reassemble the system, including new drier strainer

and capillary tube.

5. Proceed with processing as outlined under hermetic

component replacement.

13

Page 14

TROUBLESHOOTING TOUCH TEST CHART: TO SERVICE REVERSING VALVES

NORMAL FUNCTION OF VALVE

VALVE

OPERATING

CONDITION

Normal Cooling

Normal Heating

Valve will not

shift from cool

to heat.

Valve will not

shift from cool

to heat.

Starts to shift

but does not

complete

reversal.

Apparent

leap in heating.

Will not shift

from heat to

cool.

NOTES :

COIL

Compressor

from Compressor

DISCHARGE TUBE

Tube to INSIDE

SUCTION TUBE to

COIL

LEFT Pilot

RIGHT Pilot

Capillary Tube

Tube to OUTSIDE

Capillary Tube

* TEMPERATURE OF VALVE BODY

** WARMER THAN VALVE BOD Y

1 2 3 4 5 6 POSSIBLE C A US ES CORRECTIONS

Hot Cool

Hot Cool

Check Electrical circuit and coil

Check refrigeration charge

Hot Cool Cool,

Hot Cool

Hot Cool

Warm Cool

Hot Warm Warm Hot *TVB Hot

Hot Warm Warm Hot Hot Hot Both ports of pilot open.

Hot Hot Hot Hot *TVB Hot Body damag e. Replace v al ve

Hot Hot Hot Hot Hot Hot Both ports of pilot open.

Hot Cool

Hot Cool

Hot Cool

Hot Cool

Hot Cool

Hot Cool

Warm Cool

Cool

as (2)

Hot

as (1)

as (2)

Cool,

as (2)

Cool,

as (2)

Cool,

as (2)

Hot,

as (1)

Hot,

as (1)

Hot,

as (1)

Hot,

as (1)

Hot,

as (1)

Hot,

as (1)

Warm,

as (1)

Hot

*TVB TVB

as (1)

Cool

*TVB TVB

as (2)

MALFUNCTION OF VALVE

No voltage to coil. Repair electrical circuit.

Defective coil. Replace co i l .

Low charge. Repair leak, recharge system.

Pressure differential too high. Recheck system.

Hot,

*TVB Hot

as (1)

Hot,

*TVB *TVB Clogged pi l o t t u b e s .

as (1)

Hot,

as (1)

as (1)

Cool,

as (2)

Cool,

as (2)

Cool,

as (2)

Cool,

as (2)

Cool,

as (2)

Cool,

as (2)

Cool,

as (2)

Hot Hot

Hot,

*TVB Warm Defective Compressor. Replace compressor

*TVB *TVB Piston needle on end of slide leaking.

** WVB ** WVB Pilot needle and piston needle leaking.

*TVB *TVB Pressur e d i ffe r e n ti a l t o o h i g h .

Hot *TVB Dirt in bleeder hole.

Hot *TVB Piston cup leak.

Hot Hot Defective pilot. Repla ce v alv e .

Warm *TVB Defective compressor . Replace co m pr es so r

Pilot valve okay. Dirt in one bleeder hole.

Piston cup leak

Both ports of pilot open. (Back seat port

did not cl ose).

Not enough pressure differential at start

of stroke or not enough fl ow to maintain

pressure differential.

Body damage. Replace valve

Valve hung up at mid-stroke. Pumping

volume of compressor not suffi cient to

maintain reversal.

Clogged pilot tube.

Deenergize solenoid, raise head pressure,

reenergize solenoid to break dirt loose.

If unsuccessful, remove valve, wash

out. Check on air before installing. If no

movement, replace valve, add strainer to

discharge tube, mount valve horizontally.

Stop unit. After pressures equalize, restart

with solenoid energized. If valve shifts,

reattempt with compressor running. If still

no shift, replace valve.

Raise head pressure, operate solenoid to

free. If still no shift, replace valve.

Raise head pressure, operate solenoid to free

partially clogged port. If still no shift, replace

valve.

Check unit for correct operating pressures

and charge. Raise head pressure. If no

shift, use valve with smaller port.

Raise head pressure, operate solenoid. If

no shift, use valve with smaller ports.

Raise head pressure, operate solenoid. If

no shift, use valve with smaller ports.

Raise head pressure, operate solenoid. If no

shift, replace valve.

Operate valve several times, then recheck.

If excessive leak, replace valve.

Operate valve several times, then recheck.

If excessive leak, replace valve.

Stop unit. Will reverse during equalization

period. Recheck system

Raise head pressure, operate solenoid to

free dirt. If still no shift, replace valve.

Raise head pressure, operate solenoid.

Remove valve and wash out. Check on air

before reinstalling, if no movement, replace

valve. Add strainer to discharge tube.

Mount valve horizontally.

Stop unit. After pressures equalize, restart

with solenoid deenergized. If valve shifts,

reattempt with compressor running. If it

still will not reverse while running, replace

the valve.

14

Page 15

COOLING ONLY ROOM AIR CONDITIONERS: TROUBLESHOOTING TIPS

Problem Possible Cause Action

Low voltage

T-stat not set cold enough or

inoperative

Compressor hums but cuts off on

Compressor

does not run

Problem Possible Cause Action

Fan motor

does not run

B10 overload

Open or shorted compressor

windings

Open overload Test overload protector & replace if inoperative

Open capacitor Test capacitor & replace if inoperative

Inoperative system switch

Broken, loose or incorrect wiring

Inoperative system switch Test switch & replace if inoperative

Broken, loose or incorrect wiring Refer to applicable wiring diagram

Open capacitor Test capacitor & replace if inoperative

Fan speed switch open Test switch & replace if inoperative

Inoperative fan motor

Check voltage at compressor. 115V & 230V

units will operate at 10% voltage variance

Set t-stat to coldest position. Test t-stat & replace if inoperative

Hard start compressor. Direct test compressor.

If compressor starts, add starting components

Check for continuity & resistance

Test for continuity in all positions. Replace if

inoperative

Refer to appropriate wiring diagrams to check

wiring

Test fan motor & replace if inoperative (be sure

internal overload has had time to reset)

Problem Possible Cause Action

Undersized unit Refer to industry standard sizing chart

Set to coldest position. Test t-stat & replace if

necessary

Use pressure wash or biodegradable cleaning

agent to clean

Close doors. Instruct customer on use of this

feature

Check amperage draw against nameplate. If

not conclusive, make pressure test

Does not cool or

only cools slightly

T-stat open or inoperative

Dirty fi lter Clean as recommended in Owner's Manual

Dirty or restricted condenser or

evaporator coil

Poor air circulation Adjust discharge louvers. Use high fan speed

Fresh air or exhaust air door open

on applicable models

Low capacity - undercharge Check for leak & make repair

Compressor not pumping properly

15

Page 16

Problem Possible Cause Action

Replace fuse, reset breaker. If repeats, check

Fuse blown or circuit tripped

fuse or breaker size. Check for shorts in unit

wiring & components

Power cord not plugged in Plug it in

Unit does not run

System switch in "OFF" position Set switch correctly

Inoperative system switch Test for continuity in each switch position

Loose or disconnected wiring at

switch or other components

Check wiring & connections. Reconnect per

wiring diagram

Problem Possible Cause Action

Dirty fi lter Clean as recommended in Owner's Manual

Check for dirty or obstructed coil. Use

Restricted airfl ow

pressure wash or biodegradable cleaning

agent to clean

Evaporator coil

freezes up

Inoperative t-stat Test for shorted t-stat or stuck contacts

Short of refrigerant De-ice coil & check for leak

Inoperative fan motor Test fan motor & replace if inoperative

De-ice coil. Check temp. differential (delta T)

Partially restricted capillary tube

across coil. Touch test coil return bends for

same temp. Test for low running current

Problem Possible Cause Action

Unit undersized. Test cooling performance &

replace with larger unit if needed

Check for partially iced coil & check

temperature split across coil

Check for oil at silver soldered connections.

Check for partially iced coil. Check split across

coil. Check for low running amperage

Check operation of t-stat. Replace if contacts

remain closed.

Compressor runs

continually & does

not cycle off

Excessive heat load

Restriction in line

Refrigerant leak

T-stat contacts stuck

T-stat incorrectly wired Refer to appropriate wiring diagram

Problem Possible Cause Action

Disconnect power to unit. Remove cover

T-stat contacts stuck

of t-stat & check if contacts are stuck. If so,

replace t-stat

T-stat does not turn

unit off

T-stat set at coldest point

Turn to higher temp. setting to see if unit

cycles off

Incorrect wiring Refer to appropriate wiring diagrams

Unit undersized for area to be

cooled

Refer to industry standard sizing chart

16

Page 17

Problem Possible Cause Action

Overload inoperative. Opens too

soon

Compressor restarted before

system pressures equalized

Check operation of unit. Replace overload if

system operation is satisfactory

Allow a minimum of 2 minutes to allow

pressures to equalize before attempting to

restart. Instruct customer of waiting period

Check voltage with unit operating. Check for

Compressor runs

for short periods

only. Cycles on

overload

Low or fl uctuating voltage

Incorrect wiring Refer to appropriate wiring diagram

Shorted or incorrect capacitor

Restricted or low air fl ow through

condenser coil

Compressor running abnormally

hot

other appliances on circuit. Air conditioner

should be in separate circuit for proper voltage

& fused separately

Check by substituting a known good capacitor

of correct rating

Check for proper fan speed or blocked

condenser

Check for kinked discharge line or restricted

condenser. Check amperage

Problem Possible Cause Action

Place jumper across t-stat terminals to check if

unit operates. If unit operates, replace t-stat.

T-stat does not

turn unit on

Loss of charge in t-stat bulb

Loose or broken parts in t-stat Check as above

Incorrect wiring Refer to appropriate wiring diagram

Problem Possible Cause Action

Poorly installed

Refer to Installation Manual for proper

installation

Fan blade striking chassis Reposition - adjust motor mount

Noisy operation

Compressor vibrating

Check that compressor grommets have not

deteriorated. Check that compressor mounting

parts are not missing

Improperly mounted or loose

cabinet parts

Check assembly & parts for looseness,

rubbing & rattling

Problem Possible Cause Action

Evaporator drain pan overfl owing Clean obstructed drain trough

Evaporator drain pan broken or cracked.

Reseal or replace

Check installation instructions. Reseal as

required

Clean the dirty evaporator coil. Use pressure

wash or biodegradable cleaning agent to clean

Water leaks into

the room

Condensation forming on base pan

Poor installation resulting in rain

entering the room

Condensation on discharge grille

louvers

Chassis gasket not installed Install gasket, per Installation manual

Downward slope of unit is too

steep

Refer to installation manual for proper

installation

17

Page 18

Problem Possible Cause Action

Water "spitting"

into room

Sublimation:

When unconditioned saturated,

outside air mixes with conditioned

air, condensation forms on the

cooler surfaces

Downward pitch of installation is

too steep

Restricted coil or dirty fi lter

Ensure that foam gaskets are installed in

between window panes & in between the

unit & the sleeve. Also, ensure that fresh

air/exhaust vents (on applicable models) are in

the closed position & are in tact

Follow installation instructions to ensure that

downward pitch of installed unit is no less than

1/4" & no more than 3/8"

Clean & advise customer of periodic cleaning

& maintenance needs of entire unit

Problem Possible Cause Action

Excessive moisture

Insuffi cient air circulation thru area

to be air conditioned

Oversized unit Operate in "MoneySaver" position

Adjust louvers for best possible air circulation

Inadequate vapor barrier in

building structure, particularly

Advise customer

fl oors

Problem Possible Cause Action

T-stat differential too narrow Replace t-stat

T-stat short cycles

Plenum gasket not sealing,

allowing discharge air to short

cycle t-stat

Restricted coil or dirty fi lter

Check gasket. Reposition or replace as

needed

Clean & advise customer of periodic cleaning

& maintenance needs of entire unit

Problem Possible Cause Action

Anticipator (resistor) wire

disconnected at t-stat or system

Refer to appropriate wiring diagram

switch

Prolonged off

cycles (automatic

operation)

Anticipator (resistor) shorted or

open

Disconnect plus from outlet. Remove resistor

from bracket. Insert plug & depress "COOL"

& "FAN AUTOMATIC" buttons. Place t-stat to

warmest setting. Feel resistor for temperature.

If no heat, replace resistor

Partial loss of charge in t-stat bulb

causing a wide differential

Replace t-stat

Problem Possible Cause Action

Outside water

leaks

Evaporator drain pan cracked or

obstructed

Water in compressor area

Obstructed condenser coil

Fan blade/slinger ring improperly

positioned

Repair, clean or replace as required

Detach shroud from pan & coil. Clean &

remove old sealer. Reseal, reinstall & check

Use pressure wash or biodegradable cleaning

agent to clean

Adjust fan blade to 1/2" of condenser coil

18

Page 19

HEAT / COOL ROOM AIR CONDITIONERS: TROUBLESHOOTING TIPS

Problem Possible Cause Action

Disconnect power to unit. Remove resistor

Heat anticipator (resistor) shorted

(on applicable models)

Room temperature

uneven

(Heating cycle)

Problem Possible Cause Action

Unit will not defrost

Wide differential - partial loss of

t-stat bulb charge

Incorrect wiring

Incorrect wiring Refer to appropriate wiring diagram

Defrost control timer motor not

advancing (applicable models)

Defrost control out of calibration

(applicable models)

Defrost control contacts stuck

Defrost control bulb removed from

or not making good coil contact

from t-stat bulb block. Plus in unit & allow to

operate. Feel resistor for heat. If not heat,

replace resistor

Replace t-stat & check

Refer to appropriate wiring diagram. Resistor

is energized during "ON" cycle of compressor

or fan.

Check for voltage at "TM" & "TM1" on timer. If

no voltage, replace control

If outside coil temperature is 25°F or below,

& preselected time limit has elapsed, replace

defrost control

If contacts remain closed between terminals

"2" & "3" of the defrost control after

preselected time interval has passed, replace

control

Reinstall & be assured that good bulb to coil

contact is made

Problem Possible Cause Action

Check if operating properly. Instruct customer

on proper use of control

Check heat rise across coil. If unit operates

effi ciently, check if insulation can be added

to attic or walls. If insulation is adequate,

recommend additional unit or larger one

T-stat should close at 38°F. Check continuity

of control. If temperature is below 38F, replace

control

Check for adequate fan air across heater.

Check control for open at 160°F & close at

150°F

Does not heat

adequately

Exhaust or fresh air door open

Dirty fi lter Clean as recommended in Owner's Manual

Unit undersized

Outdoor t-stat open (applicable

models)

Heater hi-limit control cycling on &

off

Shorted supplementary heater Ohmmeter check, approx. 32-35 ohms

Incorrect wiring Check applicable wiring diagram

19

Page 20

Problem Possible Cause Action

Incorrect wiring Refer to applicable wiring diagram

Defective solenoid coil Check for continuity of coil

Unit cools when

heat is called for

Reversing valve fails to shift

Block condenser coil & switch unit to cooling.

Allow pressure to build up in system, then

switch to heating. If valve fails to shift, replace

valve.

Inoperative system switch Check for continuity of system switch

Problem Possible Cause Action

Heating capillary tube partially

restricted

Check for partially starved outer coil. Replace

heating capillary tube

Switch unit several times from heating to

Cooling adequate,

but heating

insuffi cient

Check valve leaking internally

Reversing valve failing to shift

completely; bypassing hot gas

cooling. Check temperature rise across

coil. Refer to specifi cation sheet for correct

temperature rise

Deenergize solenoid coil, raise head pressure,

energize solenoid to break loose. If valve fails

to make complete shift, replace valve.

20

Page 21

WIRING DIAGRAM: MODELS WS08B10A-C, WS10B10A-C,

WS14B10A-C, WS10B30A-C, WS13B30C

21

Page 22

WIRING DIAGRAM: MODELS WS16B30A-C

22

Page 23

WIRING DIAGRAM: MODELS WE10B33A-B, WE13B33B-B

23

Page 24

WIRING DIAGRAM: MODELS WE16B33A-B

24

Page 25

WIRING DIAGRAM: MODELS WY10B33A-B, WY13B33A-B

25

Page 26

WS, WE & WY SERIES CHASSIS PARTS

14

17

16

7

30

32

31

12

20

19

27

25

26

Electronic

Control Box

and Controls

43

1

39

Electro

Mechanical

Control Box

44

41

and Controls

1

43

18

5

13

45

8

Models Only

For Heat & Cool

46

2

41

47

39

6

48

26

46A

Page 27

WALLMASTER PARTS 2007

REF DESCRIPTION PART NO. 115V 230V CODE

ELECTRICAL PARTS

WS08B10A-C

WS10B10A-C

WS14B10A-C

WS10B30A-C

WS13B30B-C

WS16B30A-C

WE10B33A-B

WE13B33B-B

WE16B33A-B

WY10B33A-B

WY13B33A-B

1 ELECTRONIC BOARD 61921198 1 1 1 331

1 ELECTRONIC BOARD 61921199 1 1 1 331

* REMOTE CONTROL 61826606 1 1 1 1 1 1 350

1 THERMOSTAT 25043302 1 1 1 1 1 120

2 THERMOSTAT, DEF. 61350314 1 1 122

3 OVERLOAD 61764507 1 190

3 OVERLOAD 61764519 1 190

3 OVERLOAD 61764528 1 190

3 OVERLOAD 61764554 1 1 1 190

3 OVERLOAD 61764555 1 1 190

3 OVERLOAD 61764556 1 1 190

4 CAPACITOR 61080533 1 150

4 CAPACITOR 61080569 1 150

4 CAPACITOR 61080535 1 150

4 CAPACITOR 61080540 1 1 1 150

4 CAPACITOR 61080526 1 1 150

4 CAPACITOR 61080537 1 1 1 150

5 SUPPLY CORD 60500327 1 1 1 220

5 SUPPLY CORD 60500326 1 1 1 1 1 220

5 SUPPLY CORD 60500325 1 1 1 220

6 SWITCH SYS. 8 POS. 60607204 1 1 1 1 1 130

7 FAN MOTOR 61871470 1 110

7 FAN MOTOR 61871471 1 1 1 110

7 FAN MOTOR 61871472 1 1 110

7 FAN MOTOR 61871473 1 1 1 110

7 FAN MOTOR 61871474 1 1 110

8 HEATER 62101210 1 1 1 1 1 210

9 SOLENOID and REVERSING VALVE 25022032 1 1 240

REFRIGERATION SYSTEM PARTS

WS08B10A-C

WS10B10A-C

WS14B10A-C

WS10B30A-C

WS13B30B-C

WS16B30A-C

WE10B33A-B

WE13B33B-B

WE16B33A-B

WY10B33A-B

WY13B33A-B

10 REVERSING VALVE and SOLENOID 25022032 1 1 500

11 CHECK VALVE 61824400 1 1 510

* FILTER DRIER 60308101 1 1 1 1 1 1 1 1 1 480

* SUCTION DRIER 61828200 1 1 480

12 COMPRESSOR 61562832 1 600

12 COMPRESSOR 62199700 1 600

12 COMPRESSOR 62199701 1 600

12 COMPRESSOR 62199702 1 1 1 600

12 COMPRESSOR 62199703 1 1 1 600

12 COMPRESSOR 62199704 1 1 600

13 EVAPORATOR COIL 62102300 1 1 1 1 400

13 EVAPORATOR COIL 62103300 1 1 400

13 EVAPORATOR COIL 62103303 1 1 1 400

13 EVAPORATOR COIL 62103305 1 1 400

14 CONDENSER COIL 62103400 1 1 1 410

14 CONDENSER COIL 62103401 1 1 410

14 CONDENSER COIL 62103402 1 1 410

14 CONDENSER COIL 62103500 1 1 1 410

14 CONDENSER COIL 62103501 1 410

* CAPILLARY TUBE 03760513 1 1 471

* CAPILLARY TUBE 03760547 1 1 1 471

* CAPILLARY TUBE 01390000 1 1 471

* CAPILLARY TUBE 03760550 1 471

* CAPILLARY TUBE 03760511 1 471

* CAPILLARY TUBE 03760548 1 1 471

* Part Not Shown

27

Page 28

WALLMASTER PARTS 2007

REF DESCRIPTION PART NO. 115V 230V CODE

CHASSIS PARTS

WS08B10A-C

WS10B10A-C

WS14B10A-C

WS10B30A-C

WS13B30B-C

WS16B30A-C

WE10B33A-B

WE13B33B-B

WE16B33A-B

WY10B33A-B

WY13B33A-B

16 SHROUD, CONDENSER 62102000 1 1 1 1 1 1 1 1 1 1 1 720

17 FAN BLADE, COND. 62101500 1 1 1 1 1 1 1 1 1 1 1 710

18 BLOWER WHEEL, EVAP. 60610604 1 1 1 1 1 1 1 1 1 1 1 700

19 BLOWER FRONT 62100600 1 742

19 BLOWER FRONT 62100601 1 1 1 1 1 1 1 1 1 1 742

20 SCROLL 62102100 1 1 1 1 1 1 1 1 1 1 1 777

25 BASE PAN 62100914 1 730

25 BASE PAN 62100915 1 1 1 1 1 730

25 BASE PAN ASLY. 61606219 1 1 1 1 1 730

26 BELLOWS,DRAIN VALVE 60179903 1 1 1 1 1 801

27 DRAIN PAN, ASSY. 62101901 1 1 1 1 1 1 1 1 1 1 1 840

* GROMMET, comp. 61028900 3 3 3 3 3 3 3 3 3 3 3 790

* BOLT, comp. 91400400 3 3 3 3 3 3 3 3 3 3 3 791

* COUNTER WEIGHT 61715800 2 2 2 2 2 2 2 2 2 2 2 999

30 RETAINER CUP,FAN MTR 60640600 3 3 3 3 3 3 3 3 3 3 3 999

31 GROMMET,FAN MTR 60640500 3 3 3 3 3 3 3 3 3 3 3 999

32 NUT,FAN MTR 91003000 3 3 3 3 3 3 3 3 3 3 3 999

39 PANEL, CTRL. MOUNT 62100002 1 1 1 1 1 1 1 1 1 1 1 999

41 BRACKET CONRTOL 62100802 1 1 1 1 1 1 1 1 1 1 1 999

43 ESCUTCHEON, HTG/COOL 62101107 1 1 1 1 1 760

44 KNOBS, CRTL. 61911605 2 2 2 2 2 761

* HOLDER, AIR FILTER 60865900 2 2 2 2 2 2 2 2 2 2 2 756

* HOLDER, THERMOSTAT 61900500 1 1 1 1 1 999

* HOLDER, THERMISTER 61925001 1 1 1 1 1 1 999

45 FILTER, AIR 60865811 1 1 1 1 1 1 1 1 1 1 1 754

* FRONT COMPLETE 61607005 1 1 1 1 1 1 1 1 1 1 1 750

46 FRAME HOOD 62103205 1 1 1 1 1 1 1 1 1 1 1 750

47 GRILLE, INTAKE 61612705 1 1 1 1 1 1 1 1 1 1 1 772

48 GRILLE, EXHAUST 61612805 1 1 1 1 1 1 1 1 1 1 1 773

53 END CAP, GRILLE 61613205 1 1 1 1 1 1 1 1 1 1 1 999

* WEATHER SEAL GASKET 61578101 1 1 1 1 1 1 1 1 1 1 1 999

* HARDWARE, SCREWS 60846020 1 1 1 1 1 1 1 1 1 1 1 999

* GASKET, CHASSIS 61717301 1 1 1 1 1 1 1 1 1 1 1 780

* CARTON 61841919 1 1 1 1 1 1 1 1 1 1 1 999

OPTIONAL ACCESSORIES

* START KIT 61008903 1 1 1 1 1 1 1 1 1 1 1 160

55 SLEEVE (ONLY) 61603611 1 1 1 1 1 1 1 1 1 1 1 770

57 GRILLE, STAMPED 61603011 1 1 1 1 1 1 1 1 1 1 1 771

* Part Not Shown

28

Page 29

WS - WE - WY SERIES SLEEVE PARTS

REF DESCRIPTION PART NO.

1 SLEEVE ASSEMBLY 61603611 1 1 111111111

2 PANEL, WEATHER INNER 61603201 1 1 111111111

3 GRILLE, LOUVERED 61603011 1 1 111111111

4 PANEL, WEATHER OUTER 61603303 1 1 111111111

WS, WE & WY SERIES SLEEVE PARTS

4

2

1

3

29

Page 30

Friedrich Air Conditioning Co.

Post Office Box 1540 • San Antonio, Texas 78295-1540

4200 N. Pan Am Expressway • San Antonio, Texas 78218-5212

(210) 357-4400 • FAX (210) 357-4480

www.friedrich.com

Printed in the U.S.A.

WM-Svc-Prts-07 (3-07)

Loading...

Loading...