Page 1

WallMaster® PTAC

Packaged Terminal Air Conditioners & Heat Pumps

• Standard

• Remote Thermostat

• Seacoast Protected

Installation & Operation Manual

920-087-02 (9-03)

Page 2

920-087-02 (9-03)

3

920-087-02 (9-03)

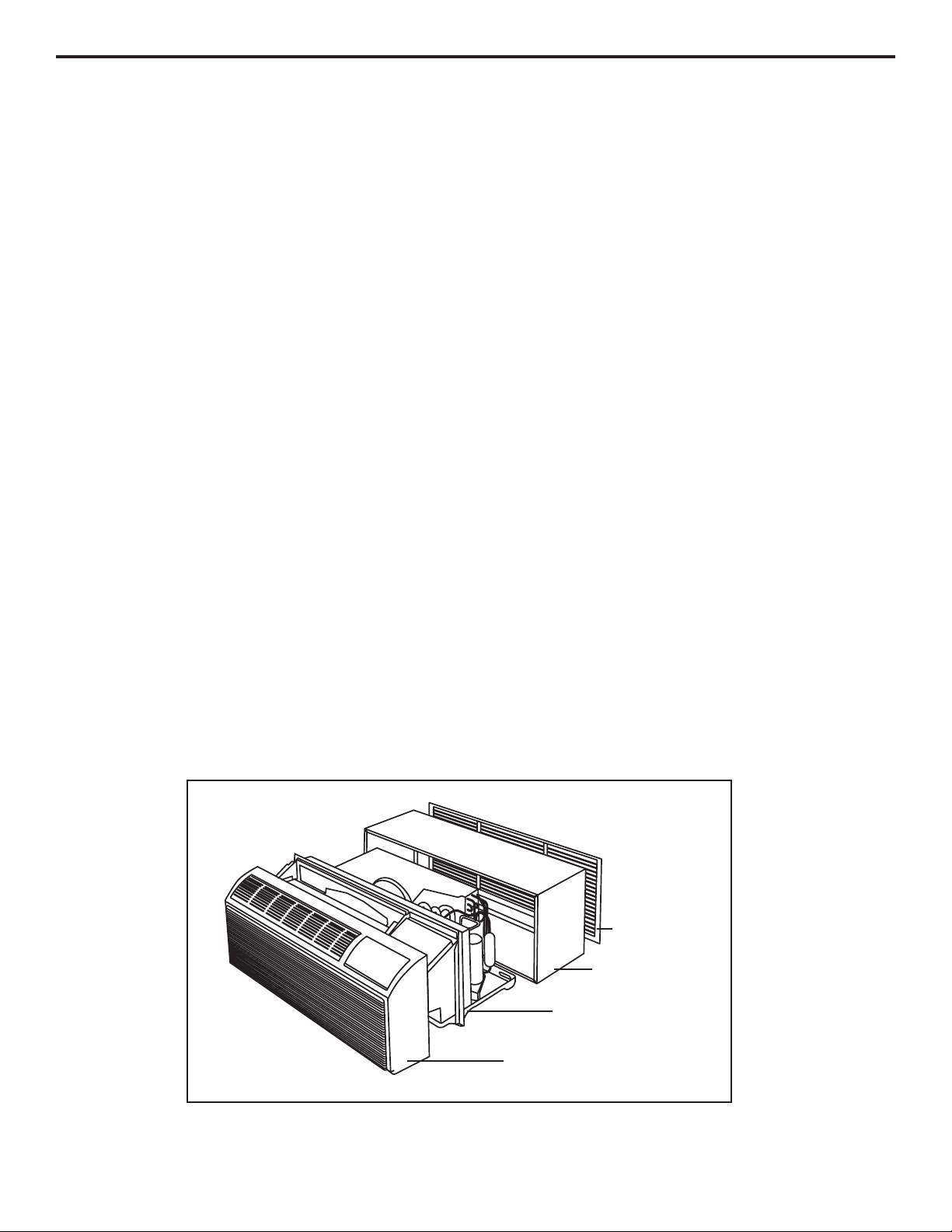

Front cover

Chassis

Wall sleeve

Outdoor grille

Table of Contents

Unit Components.........................................................................................................................................................................................2

P-Series Announcement/Model Number Code............................................................................................................................................3

Installation Recommendations ....................................................................................................................................................................4

Drain Kit Installation................................................................................................................................................................................5-6

Wall Sleeve Installation............................................................................................................................................................................ 7-8

Deep Wall Installation..................................................................................................................................................................................9

Standard Grille Installation........................................................................................................................................................................10

Installation Checklist.................................................................................................................................................................................11

Electrical Rating Tables..............................................................................................................................................................................11

Chassis Installation ............................................................................................................................................................................. 12-13

Standard Unit Operations..........................................................................................................................................................................14

Temperature Limiting Thermostat ..............................................................................................................................................................14

Heating Control (Heat Pumps & Emergency Heat)..................................................................................................................................... 15

Fan Cycle Switch....................................................................................................................................................................................... 15

Fresh Air Vent Control................................................................................................................................................................................ 15

Air Discharge Grille ....................................................................................................................................................................................16

Start-up Checklist......................................................................................................................................................................................16

Appendix A: Remote Thermostat Wiring ...............................................................................................................................................17-18

Appendix B: Electrical Wiring for 265 V Models........................................................................................................................................ 19

Routine Maintenance................................................................................................................................................................................ 20

Basic Troubleshooting Techniques .............................................................................................................................................................21

Accessories .........................................................................................................................................................................................22-23

Warranty ................................................................................................................................................................................................... 24

Typical Unit Components

2

Page 3

920-087-02 (9-03)

Announcing the Friedrich P-Series Packaged Terminal Air Conditioner.

A new approach to reliability and efciency. A totally redesigned Friedrich PTAC.

Thank you for your decision to purchase the newly designed Friedrich Packaged Terminal Air Conditioner

(PTAC). We are condent that you will nd this unit a quiet and efcient example of Friedrich reliability.

This Installation and Operation Manual has been designed to insure maximum satisfaction in the performance

of your unit. For years of trouble-free service, please follow the installation instructions closely. We cannot

overemphasize the importance of proper installation. We have added new information to the basic instructions

to help you achieve success.

Remember, proper installation is not difcult but it is essential.

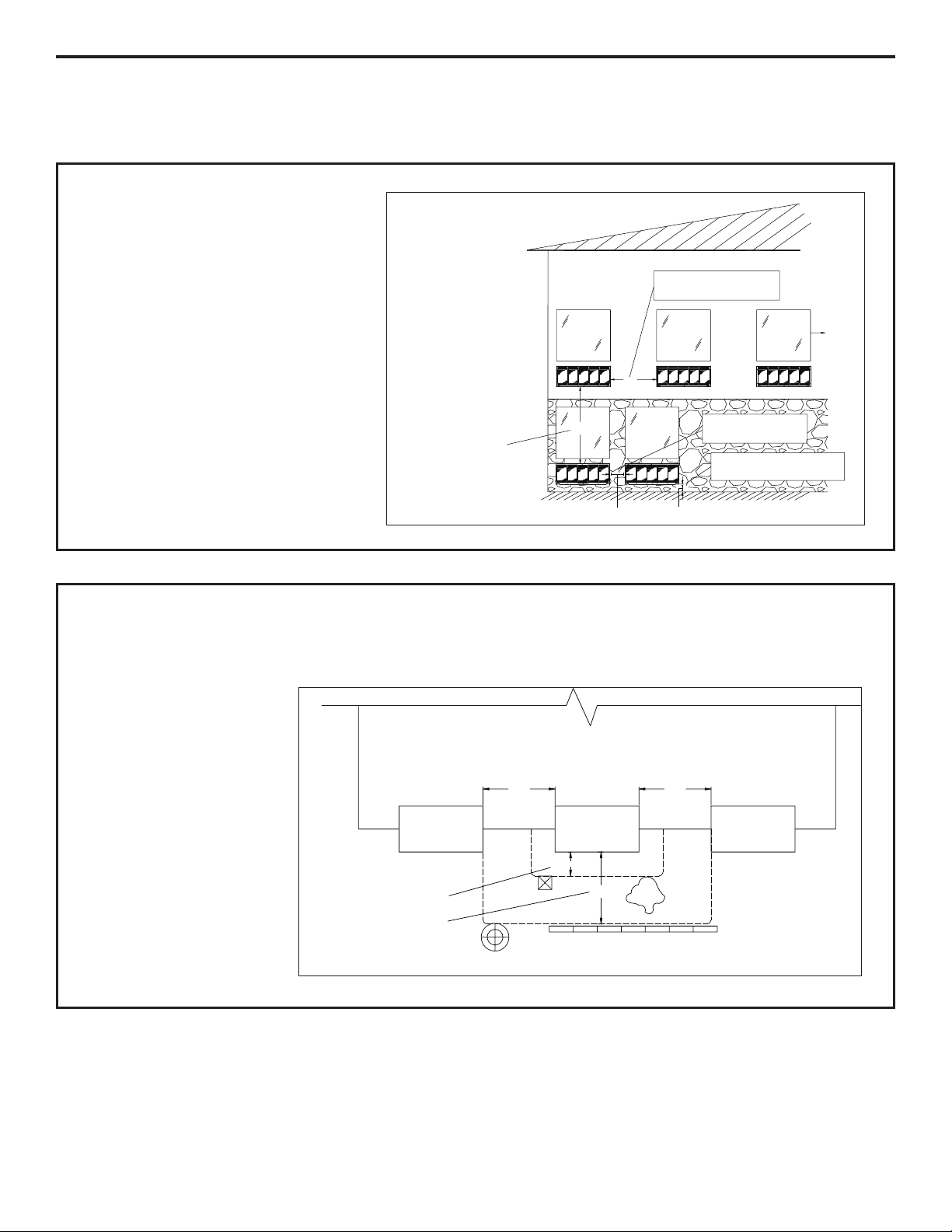

Model Number Code

Series

P = P series

System

X= Accessory

E= Cooling with or

without electric heat

H =Heat Pump with

Auxiliary Heat

Nominal Cooling Capacity

07 = 7,000 Btuh

09 = 9,000 Btuh

12 = 12,000 Btuh

15 = 15,000 Btuh

P H 07 K 3 S A 1

Engineering Digit

Design Series

Options

S = Standard

R = Remote Thermostat

C = Seacoast Protection

X = Remote Thermostat and

Seacoast Protection

Nominal Heater Size

(@ 230V or 265V)

0 = No Heater

2 = 2.5 KW

3 = 3.4 KW

5 = 5.0 KW

Voltage

K = 230/208V - 1 Ph. - 60 Hz.

R = 265V - 1 Ph. - 60 Hz.

Please read this manual thoroughly prior to equipment installation or operation. It is the installer’s responsibility

to properly apply and install the equipment. Installation must be in conformance with the NFPA 70-2002

National Electric Code or current edition and Universal Mechanical Code current edition and applicable local

or national codes.

3

Page 4

920-087-02 (9-03)

5

920-087-02 (9-03)

PTAC

SHRUB

POLE

FENCE OR WALL

PTAC PTAC

TYP. BUILDING ( PLAN VIEW

)

CONDENSING UNIT

12"

36"

36"

36"

36" MIMUMUM, MAJOR

OBSTRUCTIONS

12" MINIMUM, MINOR

OBSTRUCTIONS

BETWEEN PTACs

THREE OR MORE PTACs

BUILDING ELEVATION

ADJACENT 36" MINIMUM

6" MINIMUM FROM GRADE

GROUND FLOOR PTACs

TWO ADJACENT

PTACs 12" MINIMUM

WINDOW

TYP.

VIEW: OUTSIDE

60" VERTICAL MIMUMUM

12"

6"

36"

60"

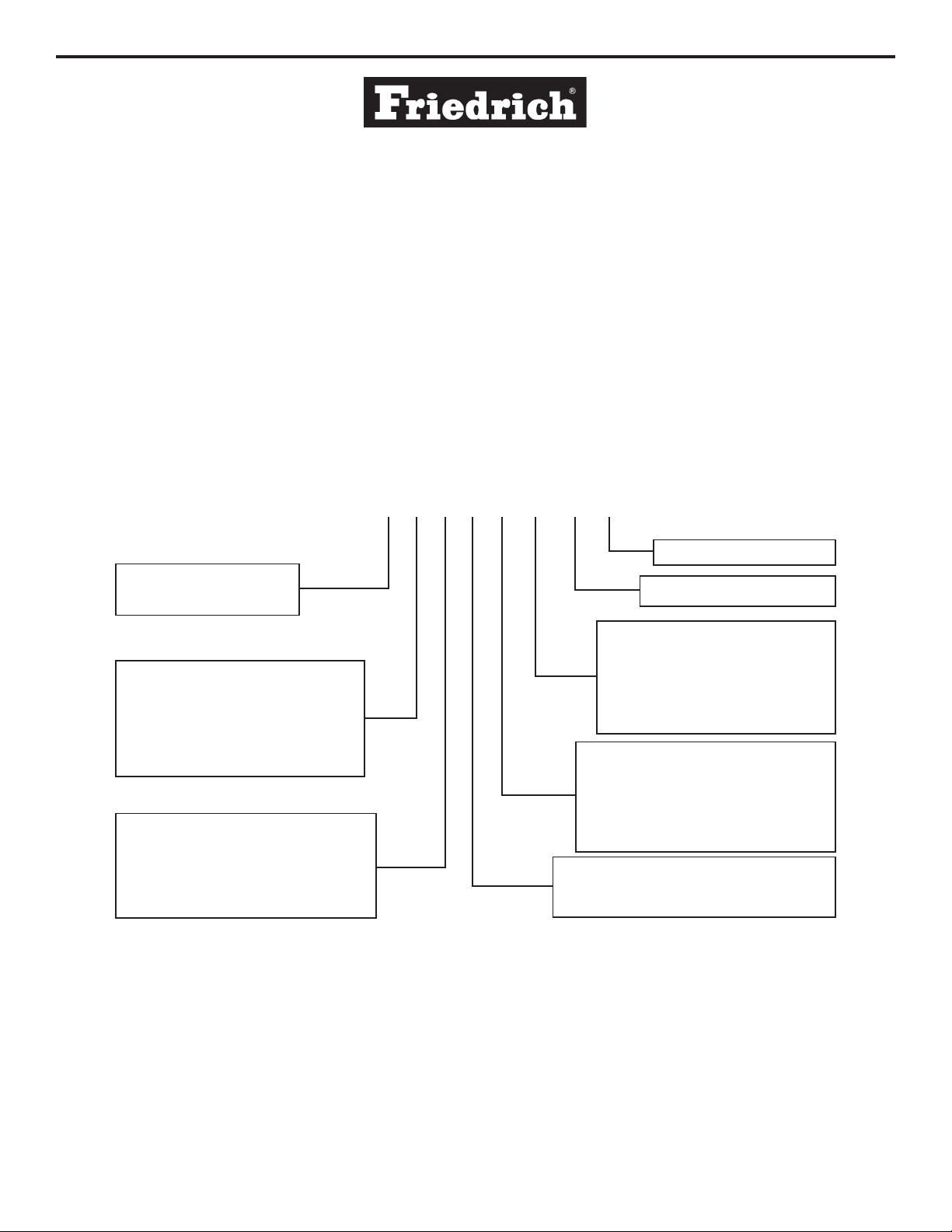

PTAC Installation Recommendations

For proper PTAC unit performance and maximum operating life please refer to the minimum installation clearances below:

Figure 1

PTAC units should be installed

no closer than 12" apart when

two units are side by side. If

three of more PTAC units are to

operate next to one another allow

a minimum of 36" between units.

Also, a vertical clearance of 60"

should be maintained between

units installed.

Figure 2

For PTACs on the ground oor or anytime obstructions are present, use the following guidelines:

• For minor obstructions

such as lamp poles or small

shrubbery a clearance of

12" from the outdoor louver

should be maintained.

• For major obstructions such

as a solid fence, wall or

other heat rejecting device

like a condensing unit, a

minimum distance of 36"

should be kept.

The above suggestions are for reference only and do not represent all possible installations. Please contact the factory

for information regarding affects of other installation arrangements. By following these simple recommendations you

can be condent that your Friedrich PTAC will provide years of worry free operation.

4

Page 5

920-087-02 (9-03)

3"

7.6 cm

Secondary area

Primary area - no foam insulation

If the drain must be located in the

secondary area, the foam insulation

must be cut away and removed to

allow access to the drain.

Screw

Wall sleeve

Gasket

Mounting plate

Nut

Drain tube

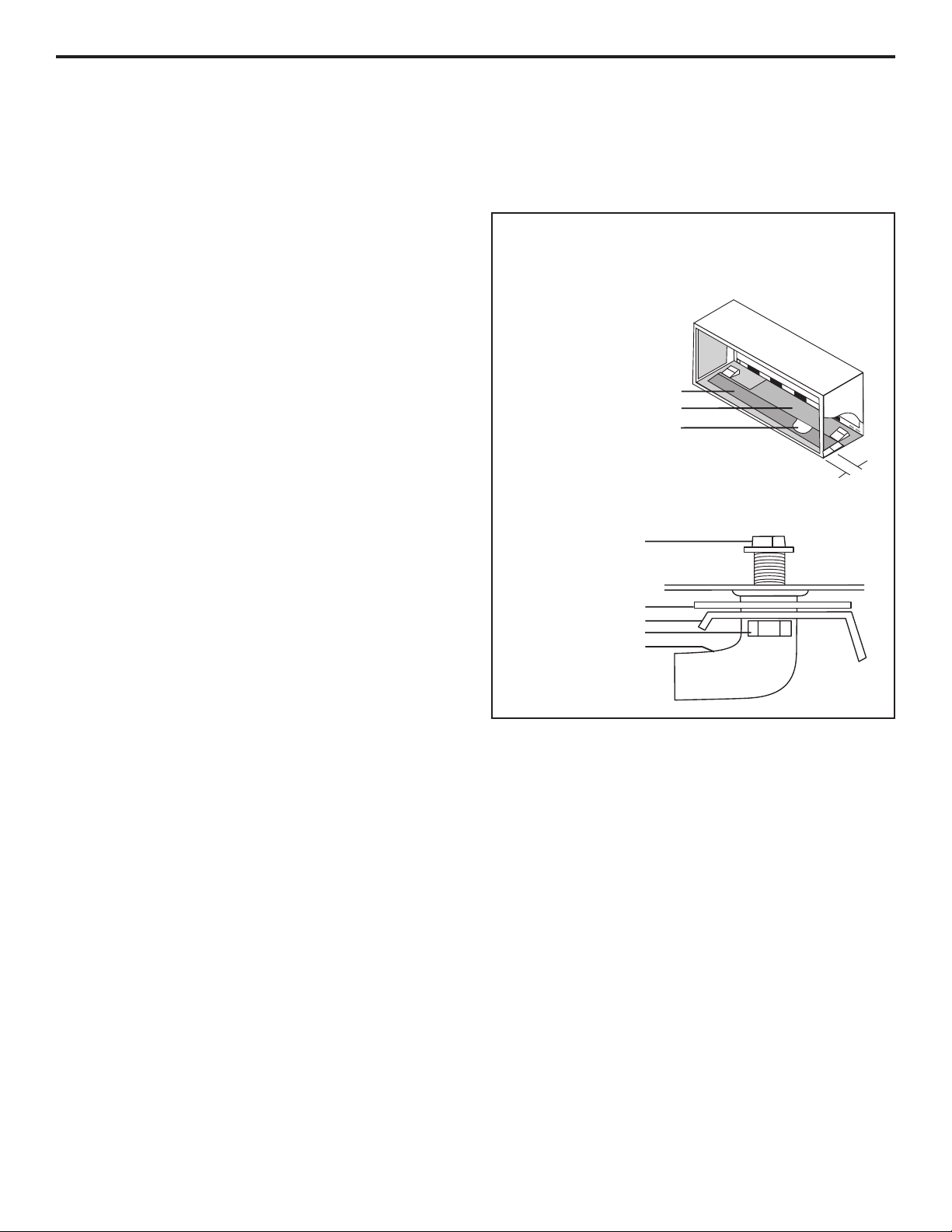

Installation Instructions PXDR10 Drain Kit

NOTE: Determine whether drain will be located within the wall, on the indoor side, or will drain to the exterior of the building. Follow

appropriate instructions below depending on your particular type of installation.

Internal Drain (optional for new construction)

NOTE: If installing an internal drain, you MUST install a drain kit on

the wall sleeve before the wall sleeve is installed.

1. Refer to Figure 3 below and locate the drain within the

"Primary" area for best drainage. Maintain at least a 1/2"

clearance from the embossed area.

2. Using the mounting plate with the 1/2" hole as a template,

mark and drill two, 3/16" mounting holes and a 1/2" drain

hole.

3. Remove the backing from the gasket and mount it on the at

side of the mounting plate. (See Figure 4.) Insert the drain

tube through the hole in the gasket and mounting plate so

the tube ange will be against the wall sleeve.

4. Position the assembly beneath the drilled holes and secure

it with #10-24 x 1/2" machine screws and lock nuts provided.

Seal the tops of the screws with silicone caulking.

Figure 3

Drain Kit Location and Installation

5. Use 1/2" I.D. copper tube, PVC pipe, or vinyl hose (obtained

locally) to connect the internal drain tube to the drain system

in the building.

6. Referring to Detail A on page 6, locate and assemble the

(2) two cover plates and gaskets over the drain holes at the

rear of the wall sleeve. Attach them with the #10 sheet metal

screws provided. Make certain that the four overow slots at

the rear of the wall sleeve are not blocked (See drawing of

the back of the sleeve on page 6).

7. If a deep wall extension (PXWE) is used, after installing the

eld supplied ashing, caulk as required. Be sure to caulk

around the ashing and the wall sleeve where the hole was

drilled for the drain tube.

5

Page 6

920-087-02 (9-03)

7

920-087-02 (9-03)

Foam gasket

Mounting plate

Foam gasket

Mounting plate

1

/2" O.D. tube

#10 sheet metal screws

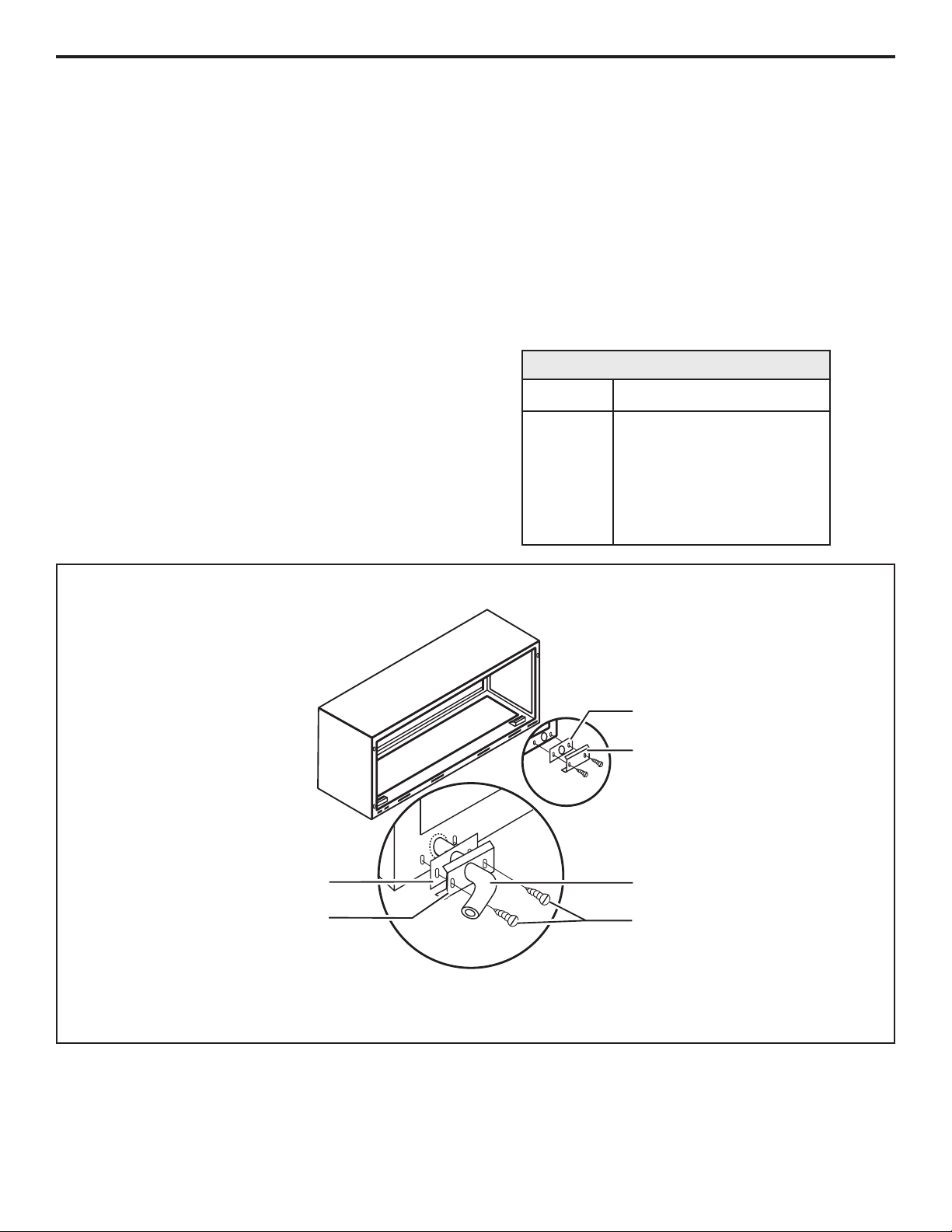

External Drain (for new construction or unit replacement)

When using an external drain system, the condensate is removed through either of two drain holes on the back of the wall sleeve. Select

the drain hole which best meets your drainage situation and install the drain kit. Seal off the other with a cover plate.

Drain Tube Installation

1. Peel the backing tape off the gaskets and apply the sticky

side to one cover plate and one mounting plate as shown

in Details A and B.

2. Place the drain tube through the gasket and the mounting

plate with the ange toward the wall sleeve.

3. Attach the drain tube assembly to one of the two drain

holes at the rear of the wall sleeve. The large ange on

the mounting plate is positioned at the bottom of the sleeve

facing toward the sleeve, Detail B. When the drain tube is

positioned at the desired angle, tighten the screws.

NOTE: If the wall sleeve has not been installed, the drain tube must

be rotated to a horizontal position until after the sleeve

is installed. Tighten the mounting plate screws when the

tube is in the proper position. Make certain that the four

overow slots at the rear of the wall sleeve are not blocked.

(See the drawing below.)

Figure 4

Drain Kit Installation

Cover Plate Installation

4. Mount the foam gasket to the cover plate. Using two #10 x

1/2" sheet metal screws (provided), attach the cover plate

to the remaining drain hole. Make certain the large ange

on the plate is positioned at the bottom of the sleeve.

5. Discard the additional cover plate, gasket, machine screws,

and locknuts.

PXDR1O

QUANTITY

2

1

1

3

4

2

2

COVER PLATES

MOUNTING PLATE

DRAIN TUBE

MOUNTING PLATE GASKETS

#10 X 1/2" MOUNTING SCREWS

10-24 X 1/2" MACH. SCREWS

LOCKNUTS

DESCRIPTION

DETAIL A

DETAIL B

NOTES:

The large ange on the mounting plate is positioned at the bottom of the sleeve facing toward the sleeve. The drain tube must be rotated to a horizontal

position to allow for the wall sleeve to be installed into the wall. Once the wall sleeve is installed, return the drain tube to a downward angle.

6

Page 7

920-087-02 (9-03)

42"

(107.3 cm) min.

50" (127 cm) mi

n.

10"

(25.4 cm)

max.

16 "

(41.3 cm)

13

"

(34.9 cm)

Lintel to support masonry walls

Electrical receptacle

Wall opening

Wall sleeve

Insulation

Smooth side of screw

clip facing into room

Electrical receptacle

Insulation

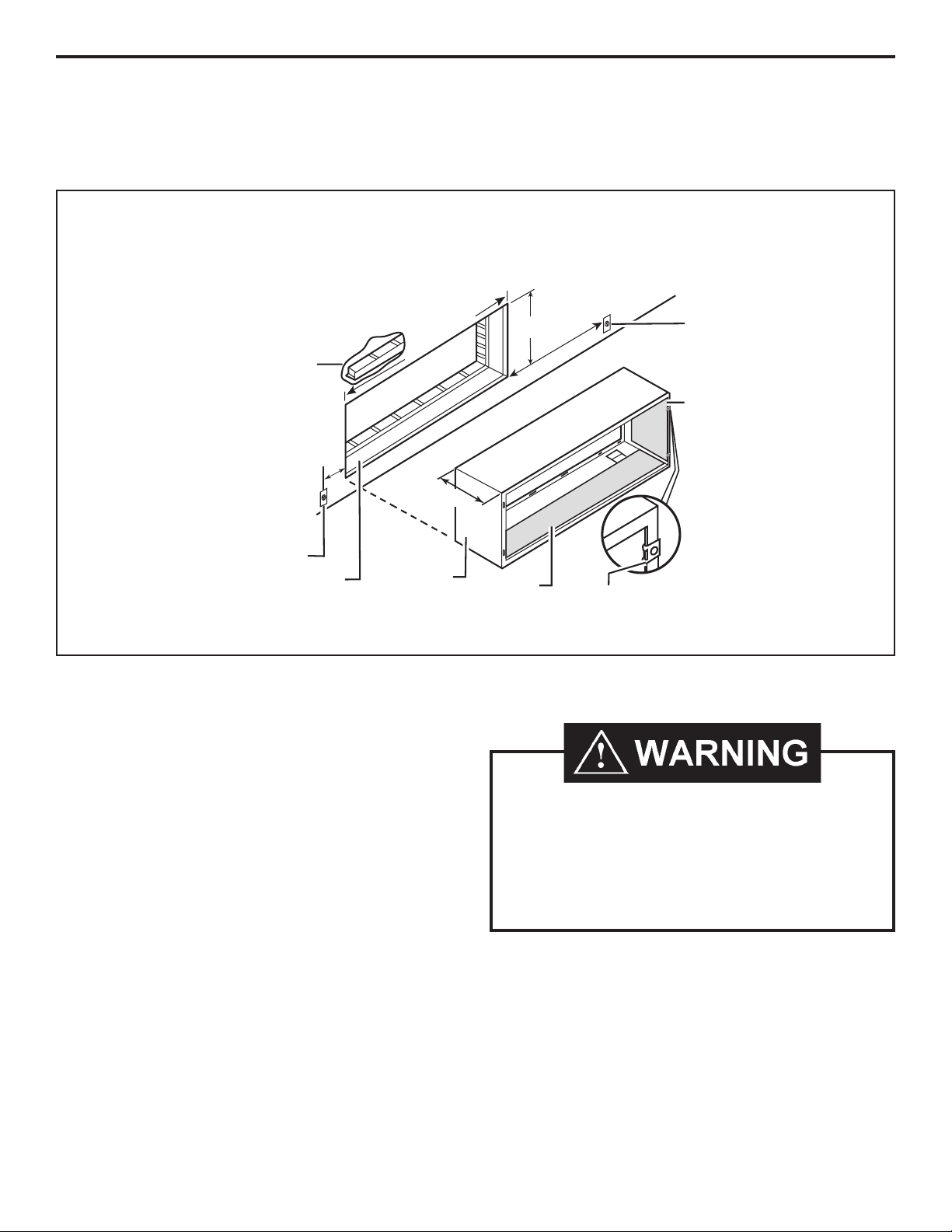

Wall Sleeve Installation Instructions (PXWS)

NOTE: Insure that the unit is only installed in a wall structurally adequate to support the unit including the sleeve, chassis and accessories.

If the sleeve projects more than 8" into the room, a subbase or other means of support MUST be used. Please read these instructions

completely before attempting installation.

Figure 5

Typical Wall Sleeve Installation

For Deep Wall Installation See Section II

The following instructions apply ONLY to walls less than

13 1/4" in depth.

1. From inside the building, position the wall sleeve in the opening

and push it through the wall so it protrudes at least 1/4" on the

outside, note Figure 5.

2. Position the wall sleeve with a slight tilt towards the outside to

facilitate condensate drainage. It should be level side-to-side

and the front should be 1/4 bubble higher than the back. DO

NOT allow any pitch toward the inside.

Turn electric power OFF at the fuse box or service panel

before making any electrical connections and ensure a

proper ground connection is made before connecting line

voltage. Failure to do so can result in property damage,

personal injury and/or death.

Electrical shock hazard.

7

Page 8

9

920-087-02 (9-03)

NOTE: Construct wall opening to comply with all applicable

building codes.

Main studs

Jack studs

Main studs

Jack studs

Lintel

Mounting screw hole

s

No holes in bottom of wall

sleeve unless drain kit is used

13 "

(35 cm)

A

B

"

(6.4 cm)

min.

Wall

Figure 6

Dimensions

920-087-02 (9-03)

Dimension*

No Accessories "

With Subbase 1"

With Lateral Duct "

* If more than one accessory is to be used, use the maximum

dimension. If the wall thickness is more than 13" (35cm) -

(A + " [6.4 mm]), a sleeve extension must be used.

A

Allow

for wall

nishing

(Minimum) Min. Max

(6.4 mm)*"(6.4 mm) ---

(4.5 cm)

(1.9 cm)

Allow for oor nishing

3"

(8.9cm)

"

(6.4 mm) ---

B

5"

(12.7cm)

3. Drill two 3/16" holes through each side of the sleeve

approximately 4" from top and 4" from bottom of sleeve. Screw

four #10 x 1" screws (included) or appropriate fasteners for your

installation, through the holes in the sides of the wall sleeve.

4. Apply sealant around the wall sleeve where it projects through

the inside and outside wall surfaces. Apply the sealant to the

screw heads or the tops of the fasteners used in Step #3.

NOTE: When sealing the sleeve on the outside of the building,

be careful NOT to let the sealant block the two condensate

drain holes or the four overow slots at the bottom ange of

the sleeve.

Figure 7

Lintel Installation

5. If the chassis and exterior grille are to be installed later, leave the

weatherboard and center support in place, otherwise remove

and dispose of them.

6. Provide a support lintel if the wall sleeve is installed in a concrete

or masonry wall. (See Figure 7.)

8

Page 9

920-087-02 (9-03)

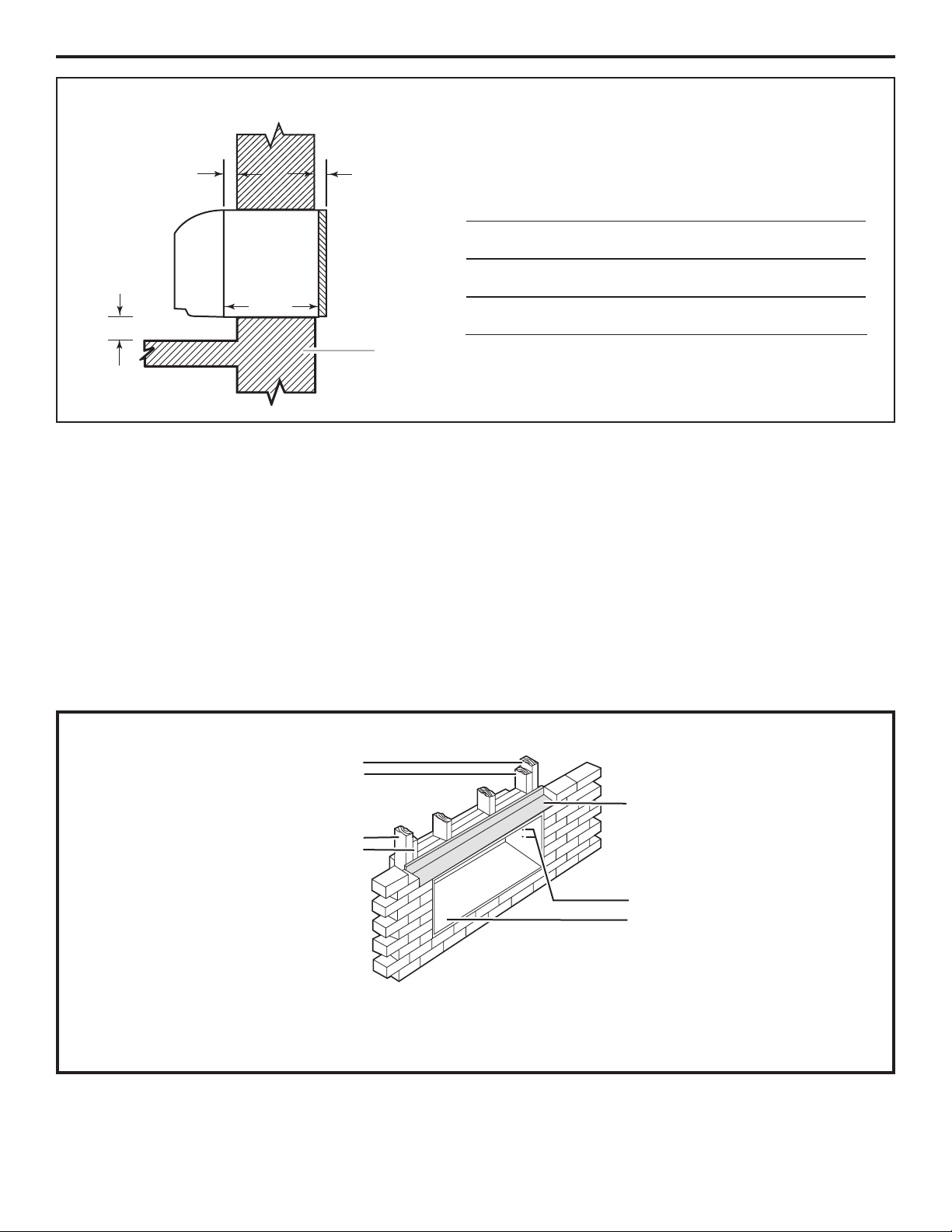

Section II — Deep Wall Installation (PXWE)

If the wall is thicker than allowed in the notes in Figure 6, a sheet

metal wall sleeve extension and ashing MUST be used.

Installation Instructions for the PXWE – 4" Wall Sleeve

Extension

The following points MUST be considered when installing a wall

sleeve extension:

1 Provision must be made to direct excess condensate from

the back of the wall sleeve into the extension then outside

the building or to a drainage system.

2. Air bafes must be mounted to properly direct air ow to and

from the condenser.

3. The wall sleeve extension design must allow for the proper

mounting of the grille.

4. Caulking is required at all sites where condensate or external

water could potentially inltrate into the building.

5. Fabricate and install metal ashing in wall to serve as a drip

panel. Refer to drawing for more information.

6. Condensate notches and overow slots must be kept clear

of sealant and gaskets so condensate can ow freely into the

wall sleeve extension.

NOTE: Improper fabrication or installation of a wall sleeve extension

will impair PTAC performance.

Extension Installation

Secure the wall sleeve extension to the wall sleeve before installing

it in the wall. Refer to Figure 8 for a guide for fabrication of a

condensate drip panel. The panel MUST extend the full depth of

the wall sleeve and the wall sleeve extension.

Pay particular care in sealing and caulking the panel where it makes

contact with the wall sleeve (see Figure 8). After installation in the

wall, secure with fasteners through the sides. Use a good grade

of silicone sealant around the sleeve extension. Seal all exposed

screw heads. When the installation is complete, the outside grille

should be attached to the wall sleeve extension.

Figure 8

Wall Sleeve Extension Sealant Locations

IMPORTANT NOTE: The silicone bead MUST extend 3"

up the side of the two anges to prevent condensate

from leaking.

Wall Sleeve

Outside Edge

Insulation

Air Bafes

Condensate

Drip Panel

Width of Wall

Drip

Edge

(Field

Supplied)

Condensate

Notches (4)

Sealant inside (4) bottom corners

Wall Sleeve Extension, 42" X 16" Frame, 20 gauge minimum, painted or aluminium

PXWE Wall Sleeve

Extension

9

Page 10

920-087-02 (9-03)

11

920-087-02 (9-03)

Plastic handles

Plastic

grommets

Wall sleeve

Weatherboard

Center support

Installation Instructions Model PXGA Standard Grille

1. Remove the center support and weatherboard if still installed

in the sleeve.

2. Insert six plastic grommets into the grille openings from the

outside of the grille as shown in Figure 9.

3. Insert two #8 x 3/8" sheet metal screws (provided) in the top

two outside edge plastic grommets, and tighten them half way

into the grommets.

4. CAUTION: Bodily injury can be caused by grilles falling from

a building during installation. It is recommended that a safety

line be attached to the grille and an anchor point inside the

building during installation.

Figure 9

Figure 9

Standard Grille

5. Grasp the grille by the attached plastic handles. Position it with

the condensate drain knockouts facing down. From inside the

building, maneuver the grille through the wall sleeve and pull

toward you until the screw heads are inserted into the keyhole

slots at the top of the wall sleeve. Tighten the two screws

completely.

6. Insert the remaining screws into the remaining holes and

tighten securely.

PXGA

Quantity

1

6

6

Stamped Aluminum Grille

Plastic Grommets

#8 x 3/8" Sheet Metal Screws

Description

10

Page 11

A. Installation Checklist

920-087-02 (9-03)

Inspect all components and accessories for damage

o

before and after installation.

Remove the cardboard wall sleeve support and grille

o

weatherboard.

Install the recommended Condensate Drain Kits for

o

complete condensate removal.

Ensure that the chassis is installed in a 16" high x 42" wide

o

wall sleeve that is no deeper than

13 3/4". A bafe kit is required if the sleeve exceeds that

Check for proper wall sleeve installation in accordance

o

depth.

with the wall sleeve installation instructions.

Ensure that drapes, bed, bedspread, furniture, etc. DO

o

Check installation of the wall sleeve foam gasket.

o

Check for a subbase kit or other means of structural

o

support which is required for ALL installations projecting

NOT block either return or discharge air grilles.

Inspect the condenser air inlet and outlet for any

o

obstructions (shrubbery, etc.)

more than 8" into room.

B. Electrical Rating Tables

All 230/208 volt units are equipped with power cords. See Appendix B on page 19 for wiring instructions on 265V units.

NOTE: Use Copper Conductors ONLY. Wire sizes are per NEC, check local codes for overseas applications.

Table 1 250 V Receptacles and Fuse Types

Table 2

Recommended branch circuit wire sizes*

AMPS 15 20 * 30

RECEPTACLE

MANUFACTURER PART NUMBERS

Hubbell 5661 5461 9330

P & S 5661 5871 5930

GE GE4069-1 GE4182-1 GE4139-3

Arrow-Hart 5661 5861 5700

TIME-DELAY TYPE FUSE 15 20 30

(or HACR circuit breaker)

HACR – Heating, Air Conditioning, Refrigeration

* May be used for 15 Amp applications if fused for 15 Amp

NOTE: 265 volt units are hard wired.

Wire Size Use ONLY wiring size recommended for single outlet branch circuit.

Fuse/Circuit

Breaker

Grounding

Use ONLY type and size fuse or HACR circuit breaker indicated on unit’s rating plate. Proper current protection to the unit is the responsibility of the

owner. NOTE: A time delay fuse is provided with 265V units.

Unit MUST be grounded from branch circuit through service cord to unit, or through separate ground wire provided on permanently connected units.

Be sure that branch circuit or general purpose outlet is grounded. The eld supplied outlet must match plug on service cord and be within reach of

service cord. Refer to Table 1 for proper receptacle and fuse type. Do NOT alter the service cord or plug. Do NOT use an extension cord.

Nameplate

maximum circuit breaker size

15

20

30

AWG – American Wire Gauge

* Single circuit from main box

** Based on copper wire, single insulated conductor at 60°C

AWG Wire size**

14

12

10

Electric shock hazard.

Turn off electric power before service or installation.

All electrical connections and wiring MUST be installed by a qualied electrician and

conform to the National Electrical Code and all local codes which have jurisdiction.

Failure to do so can result in property damage, personal injury and/or death.

Receptacle

Wire Sizing

The eld supplied outlet must match plug on service cord and be within reach of service cord. Refer to Table 1 for proper receptacle and fuse type.

Do NOT alter the service cord or plug. Do NOT use an extension cord.

Use recommended wire size given in Table 2 and install a single branch circuit. All wiring must comply with local and national codes. NOTE: Use

copper conductors only.

11

Page 12

920-087-02 (9-03)

13

920-087-02 (9-03)

Wall sleeve

Weatherboard

Center support

Compressor

Chassis

shipping bracket

Shipping pallet

Section III – Chassis Installation

* Check to be sure the wall sleeve, extension (if used), grille, and drain kit are installed properly before

chassis installation

1. Remove the weatherboard and center support from

the sleeve (if still in place). Be sure an outdoor grille is

attached.

1

NOTE: To avoid breaking the door or hinge pins, do not apply

excessive force when installing

Pins

2

Control

Door

Front Panel

3. Remove the two chassis shipping brackets from the ends of

the shipping pallet.

IMPORTANT: Use a wall sleeve adapter kit (PXSE) if

installing a P-Series chassis in a T-Series sleeve.

Suffocation hazard

Keep bag away from babies and children.

Do NOT use in cribs, beds or playpens. Destroy

immediately after opening. This bag is NOT a toy.

Failure to do so can result in personal injury and/or death

2. Remove the front cover contained in a protective plastic bag

from chassis. Remove the bag and dispose of it properly.

If the control door is not installed, follow these steps:

• From the front of the cover, slide the right control door pin into

the hole on the right side of the front cover. Slide the left door

pin into the hole on the left side of the front cover opening and

snap it into place.

3

IMPORTANT: When installing a Friedrich P-Series PTAC into an

existing sleeve, it is important to ensure that the unit is installed

completely. Inspection of the air seal between the condenser air

bafes and around the indoor mounting ange is recommended. In

some cases additional gaskets or bafing may be required.

12

Page 13

920-087-02 (9-03)

Wall sleeve

Wall sleeve flange

Chassis flange

and gasket

Chassis

mounting screw

Screw clips

Chassis

flange

4. Center the chassis in the pre-installed sleeve and carefully

push the chassis until the chassis ange and gasket contact

the sleeve ange.

4

Copper refrigerant tubes are NOT handles.

Do NOT use tubing to lift or move chassis.

NOTE: If the unit is mounted ush to the oor, the service cord

MUST be rerouted at the bottom of the front cover on the side closest

to the receptacle. A notch MUST be made in the front cover side

where the cord exits the unit. It is the responsibility of the installer

to create an exit notch. See diagram 8 for suggested opening size

and placement.

at the bottom back corners of the cover. Tighten them into

the quick nuts located on the chassis to secure the cover. If

the unit has been placed such that there is no room to insert

the thumbscrews from the bottom, request a Side Mounting

kit (Part No. PXSM) from Friedrich. Locate the service cord

or conduit in the notch at the bottom right of the front cover.

6

7. If the lters are not already installed in tracks in the plastic

cover, slide them into place.

8. Plug the cord (if applicable) into the appropriate receptacle.

Extra cord may be coiled inside the front cover behind the

return air grille. Restore power to the unit.

7

If a remote thermostat is to be installed, proceed to Appendix A, Step 1. For a 265 V unit, proceed to Appendix B, Step 1.

5

5. Locate the four #10 x 1" chassis mounting screws. Tighten

the screws into the clips - adjacent to the alignment dimples

on the mounting brackets on the wall sleeve ange (two per

side).

6. Install the front cover assembly (including the discharge grille)

by placing the top of the cover onto the 90° angle bracket

along the top of the chassis. Rotate the bottom into place

and insert the included thumb screws into the slots located

To remove the front cover, remove the thumbscrews at

the bottom back corners of the cover (or sides). Pull the

bottom end forward and lift it up to clear the L bracket

across the top of the chassis.

8

Not to scale

13

Page 14

15

920-087-02 (9-03)

C. Standard Unit Operation

Remove

knobs

Control panel

Adjustment

limiting

screws

920-087-02 (9-03)

Rotate the temperature dial in small increments in the

warmer or cooler direction. Moving the dial more than

1/4" at a time may overcompensate and result in an

extreme hot or cold situation.

• If a remote thermostat is installed, see Appendix A,

page 18-20.

Standard Unit Control Panel

Rotary Switch Operation

Control

Temperature

Low and High Cool

Low and High Heat

Fan Only

Operation

The full-range thermostat maintains room

temperature at the desired setting in both

the heating and cooling modes. Turn the dial

counterclockwise for warmer and clockwise

for a cooler temperature.

Operates the unit on cooling. Cooling will not

begin if the room temperature is below 60°F.

Operates the unit on heating. Some models

do not provide this selection.

Circulates air within the room at high fan

speed only. No heating or cooling functions

are active.

COOLING ONLY MODEL HEAT/COOL MODEL

D. Temperature Limiting Thermostat

1. Set the thermostat knob to center of dial.

2. Remove the four screws holding the control panel. Pull up on

the thermostat knob and remove it.

3. Locate the two temperature limiting screws. These screws

are factory installed for a maximum temperature range of 60°90°F. Each hole in the dial plate represents approximately a

4° change from the adjacent hole.

4. To adjust the temperature range, move the temperature

limiting screws to the desired location.

5. Replace the knob when the desired range has been set.

6. Replace the control panel.

EXAMPLE: To set a maximum temperature range of approximately 64° to 86°F, move the screws to the locations shown in the diagram at right.

14

Page 15

920-087-02 (9-03)

E. Heating Control (heat pumps and emergency heat operation)

NOTE: Heat pump models only. Heat pump equipped models use

backup electric resistance heating coils. At extremely low, outdoor

ambient temperatures, the heat pump is automatically disabled and

the unit operates solely on electric resistance heat.

This control is located behind the decorative front cover and is found

on the right side panel of the chassis. Its function is to allow you to

set the temperature range in which the heat pump operates. This

control switches the unit heat operation between heat pump and

electric resistance heat based on the outdoor ambient temperature.

These change-over temperatures are based on the settings of the

control. The factory setting is at the one o'clock position. If you wish

to change the factory set point, insert a at-bladed screwdriver into

the slot and turn counterclockwise to increase the changeover set

point, or clockwise to decrease it.

NOTE: Emergency heat operation only. In the event of a compressor malfunction in the heat pump mode, turn the screw to the extreme

counterclockwise emergency heat position. The heater will then cycle using electric resistance heat only. Note that in the emergency

heat position, the compressor is locked out, disabling both heat pump and cooling operations. CALL A SERVICE PERSON. DO NOT

FORGET TO RETURN THE CONTROL TO ITS ORIGINAL POSITION AFTER REPAIRS ARE MADE OR THE COMPRESSOR WILL

NOT COME ON IN COOLING MODE.

NOTE: The factory set point is recommended for optimum

performance.

F. Fan Cycle Switch

The fan cycle switch is located behind the decorative front cover

below the control panel. It is designed to operate the fan either

continuously or intermittently with the compressor or heating

elements. When the switch is in the CONTINUOUS position, the

fan will run continuously at the selected speed when the unit is

turned on. With the fan cycle switch in the CYCLE position, the fan

will run only when the compressor or heating elements cycle on.

NOTE: It is recommended that this switch be set in the continuous position for maximum comfort and temperature control.

G. Fresh Air Vent Control

The vent control lever is located behind the front cover on the left

side of the unit. The unit is shipped in the closed position with a

locking screw in place. The screw must be removed to operate the

lever. When the lever is back, (OPEN), outside air is mixed with

indoor air. When the lever is forward, (CLOSED), no outside air is

admitted into the room and room air is recycled through the unit.

NOTE: The vent should remain closed for peak operating efciency.

15

Page 16

920-087-02 (9-03)

17

920-087-02 (9-03)

H. Air Discharge Grille

Moving parts hazard.

Turn off electric power before

servicing this component.

Failure to do so can result in property

damage, personal injury and/or death.

The air discharge grille can be redirected to blow air either straight up or at an angle into the room. To change the airow direction, remove

the front cover, locate and remove the six grill retaining screws. Reverse the ends of the grille and refasten the grille to the cover.

I. Start-up Checklist

Inspect all components and accessories for

o

damage before and after installation.

Check installation for compliance with all national

o

and local codes and ordinances.

Read and follow all manufacturer's installation

o

instructions.

Check that circuit breaker(s) and electrical wire

o

sizes are correct. If the unit is supplied with a

power supply cord, insure that it is stored properly.

Check the condensate water drain outlet(s) to

o

make sure they are in compliance with all national

and local codes, that they are adequate for the

removal of condensate water, and that they meet

the approval of the end user.

Strictly follow installation instructions concerning

o

clearances around the unit.

Check the unit air lter, condenser coil and

o

evaporator coil for any obstructions.

Check for proper operation of all components.

o

Instruct the owner or operator of the units operation,

o

and the manufacturer's

recommended routine maintenance schedule.

NOTE: It is highly recommended that a maintenance

schedule log book be prepared for recording

the dates and times of service.

Operate the unit for twenty minutes. Record

o

the unit's indoor/outdoor intake and discharge

temperatures, amperage draw, and power voltage.

Assemble the Warranty Certicate, the Operation

o

and Installation Manual, all accessory installation

instructions and the name, address and telephone

number of the Authorized Friedrich Warranty Service

Company in the area for the owner or operator.

Secure components and accessories, such as the

o

control door and front cover.

NOTE: Units are to be installed, inspected, and checked by qualied service personnel only.

16

Page 17

920-087-02 (9-03)

Typical PTAC/PTHP unit

Used for PTHP only

Wall thermostat

Appendix A: Remote Thermostat Unit Installation

Remote Thermostat Selection & Wiring Guidelines for

Packaged Terminal Air Conditioners

Follow the instructions and recommendations of the thermostat

manufacturer for installation and wiring. Do not use a conventional

heat pump thermostat with emergency electric heat selection for

our heat pump units. Our units make an automatic decision about

turning on electric heat if the heating demand cannot be met by the

heat pump due to low outdoor temperatures.

NOTE: This unit is designed for use with a single stage thermostat only. Improper application of the thermostat may result in property

damage, personal injury or death.

Manual Changeover Thermostat

For Heat Pump equipped units: A single stage, heat/cool

thermostat with a terminal for a reversing valve operation is required.

Terminal "B" should be continuously energized in the heat mode

and terminal "G" should be energized whenever there is a call for

heating or cooling. Typically, a heat/cool thermostat designed for

use with electric heat systems will meet the above requirements.

Honeywell Thermostat Terminal Designation:

TERMINAL LETTER OPERATION CONTACT MADE

Y Cooling During call for cooling.

W Heating During call for heating.

G Fan Continuous if the slider is in the "Fan" position, otherwise, intermittent.

C Common Terminal For thermostats requiring a common terminal

R 24 V to the thermostat Directly from the transformer

B (Heat Pump units Only) Reversing Valve Made continuously during call for heating.

For Non-Heat Pump equipped units: A single stage cooling and heating thermostat is required. Terminal "G" should be

energized whenever a call for heating or cooling is made. Typically a heat/cool thermostat designed for use with electric heat

systems will meet this requirement.

Simplied Wiring Example

Unit Terminal Board

* A-Sufx models do not have a "C" terminal

Thermostat Terminals

NOTE: It is the installer's responsibility to ensure that all control wiring connections are made in accordance with the installation instructions.

Improper connection of the thermostat control wiring and/or tampering with the unit's internal wiring can void the equipment warranty and

may result in property damage, personal injury or death. Other manufacturer's PTACs and even older Friedrich models may have different

control wire connections. Questions concerning proper connections to the unit should be directed to the factory.

17

Page 18

19

920-087-02 (9-03)

Appendix A (continued)

Connection Diagram

208V

60HZ

L2 L1

SMOOTH RIBBED

G

240V

208V

24V

COM

RED

R

Y

BK

SECONDARY

TRANSFORMER

PRIMAR

Y

Remote Contr

ol Unit

Remote Contr

ol Unit

OFF

ON

C W Y R G B

920-087-02 (9-03)

Remote Thermostat 208V Operation

The simplified connection diagram at left shows the factory

congured wiring set for 240V operation. If you are going to use

208V exclusively, switch the two (2) black wires on the 240V post

of the primary side of the transformer to the 208V post. This will

ensure correct secondary (low) voltages for the unit. This is only

required on remote thermostat units.

Auto Changeover Thermostat

A single stage heat/cool thermostat with auto changeover is needed.

The wiring scheme is the same as the manual thermostat.

Remote Thermostat Installation

Follow Steps 1 through 5 (pages 12 and 13), then:

6. Locate the terminal strip on the front of the control box (See

Figure 9). Attach the thermostat subbase wires (eld supplied)

to the appropriately labeled terminals in accordance with the

wiring diagram on the side of the chassis.

7. Carefully route the wires alongside the conduit or service cord.

Attach the other end of the wires to the appropriate terminals

on the thermostat subbase. See the thermostat directions for

proper wiring and mounting of the thermostat.

Figure 10

Terminal Strip Location

If the supply voltage is 208V, the low

voltage transformer MUST be wired for

208V operation. Failure to do so will result

in lower control voltages to the unit and can

damage low voltage components.

CAUTION

Remote Thermostat Unit Operation

These units are controlled by the use of a remote thermostat that will

cycle the unit to maintain desired room temperature. See thermostat

operating instruction sheet for details.

The fan speed switch controls high and low speed fan operation. It is

located on the control panel and is independent of the thermostat.

18

Page 19

920-087-02 (9-03)

Screws

Screws

Fuse holder

Appendix B: Electrical Wiring for 265 Volt Models

NOTE: It is recommended that the PXSB subbase assembly, the PXCJ conduit kit and the PXDS disconnect switch be installed on all

hardwired units. If installing a ush-oor mounted unit, make provisions for all the line voltage power leads and conduit to be removed for

ease of maintenance and service to the chassis.

To install the line voltage power leads and conduit to the chassis, follow the instructions below.

1. Remove the four control box retaining screws (A) and open

the control box.

2. Pull the chassis power lead wires (B) (located on the bottomright side of the control box) through the plastic bushing so

they are located inside the control box.

3. Remove the plastic bushing.

4. Route the line voltage power leads through the hole where

the plastic bushing was located, and secure its conduit (use a

1/2" straight conduit connector, with the locknut on the inside

of the control box.)

Figure 11

Line Voltage Connections

5. Make the appropriate electrical connections within the control

box, then secure the box on the chassis. Detailed instructions

are included with the installation instructions for the conduit

kit (PXCJ).

6. Route the line voltage power conduit from the control

box straight down the right front to the bottom side of the

chassis. This will allow the front cover to be installed without

interference with the electrical conduit.

Inside back of control

panel cover.

19

Page 20

920-087-02 (9-03)

21

920-087-02 (9-03)

J. Routine Maintenance

NOTE: Units are to be inspected and serviced by qualied service personnel only.

1. Clean the unit air intake lter at least every 300 to 350 hours

of operation. Clean the lters with a mild detergent in warm

water and allow to dry thoroughly before reinstalling.

compressed air or vacuum. If using a pressure washer, be

careful not to bend the aluminium n pack. Use a sweeping

up and down motion in the direction of the vertical aluminum

n pack when pressure cleaning coils. Cover all electrical

2. The indoor coil (evaporator coil), the outdoor coil (condenser

coil) and base pan should be inspected periodically (yearly

or bi-yearly) and cleaned of all debris (lint, dirt, leaves, paper,

etc.). Clean the coils and base pan with a soft brush and

components to protect them from water or spray. Allow the unit

to dry thoroughly, inspect all gasket material for deterioration

(replace as necessary), and then reinstall the chassis in the

sleeve.

NOTE: Do not use a caustic coil cleaning agent on coils or base pan. Use a biodegradable cleaning agent and degreaser.

Before reinstalling the chassis in the sleeve, inspect the

indoor blower housing, blower wheel, condenser fan blade,

and condenser shroud periodically (yearly or bi-yearly) and

4. Inspect the surrounding area (inside and outside) to ensure

that the units' clearances have not been compromised or

altered.

clean of all debris (lint, dirt, mold, fungus, etc.) Clean the

blower housing area and blower wheel with an antibacterial /

antifungal cleaner. Use a biodegradable cleaning agent and

degreaser on condenser fan and condenser shroud. Use

warm or cold water when rinsing these items. Allow all items

to dry thoroughly before reinstalling them.

5. Inspect the sleeve and drain system periodically (at least yearly

or bi-yearly) and clean of all obstructions and debris. Clean

both areas with an antibacterial and antifungal cleaner. Rinse

both items thoroughly with water and ensure that the drain

outlets are operating correctly. Check the sealant around the

sleeve and reseal areas as needed.

3. Periodically (at least yearly or bi-yearly): inspect all control

components, both electrical and mechanical, as well as the

power supply. Use proper testing instruments (voltmeter,

ohmmeter, ammeter, wattmeter, etc.) to perform electrical

6. Clean the front cover when needed. Use a mild detergent.

Wash and rinse with warm water. Allow them to dry thoroughly

before reinstalling them in the chassis.

tests. Use an air conditioning or refrigeration thermometer to

check room, outdoor and coil operating temperatures. Use a

sling psychrometer to measure wet bulb temperatures indoors

and outdoors.

20

Filters

Return Air

Grille

Condenser Fan Blade

Discharge Air Grille

Indoor Blower

Indoor Blower

Housing

Front Cover

Condenser Gasket

Condenser Shroud

Evaporator Coil

Gasket

Compressor

Innerwall

Control Panel

Outdoor Grille

Wall Sleeve

Basepan

Page 21

920-087-02 (9-03)

K. Basic Troubleshooting Techniques

Being familiar with the sequence of operation on Standard Controlled Operating Units or the operation of the Remote Thermostat Controlled

Units is important. The following questions and answers may help to identify performance problems.

Environmental Effects - Cooling Mode

Is unit sized to room size area and heat load demand?

Room Width x Length x 3.5 (x-factor) equal a "guesstimate" of the

number of BTU's required for the area. The number of people in the

room, number of electrical devices, solar gains, etc. are all variable

items that can affect proper sizing of the unit. Friedrich recommends

that you consult with an applications engineer for proper sizing.

Is the outdoor temperature 60°F or below?

The unit is designed for outdoor temperatures above 60°F.

Is the indoor temperature 80°F or above?

Ambient indoor temperatures of 80°F or above will take a longer

period of run time to cool down the area. Long run times may

indicate that the unit is undersized.

Is indoor humidity high?

This condition will cause the unit to operate longer to remove

humidity before noticing any cooling effect.

Has the heat load been increased by additional devices such

as computer equipment, or has the room area been increased

where the unit is located?

If conditions have changed, the unit may not be able to cool and

condition as effectively as previously planned.

Environmental Effects - Heating Mode

Is unit properly sized to room area and heat load demand?

Multiplying the Width x Length x 3.5 ("x-factor") provides a

"guesstimate" of the number of BTU's required for the area. The

number of people in the room, number of electrical devices, solar

gains, etc. are all variable items that can affect proper sizing of the

unit. Friedrich recommends that you consult with an applications

engineer for proper sizing.

Is the outdoor temperature 70°F or above? - The unit is designed

for outdoor temperatures below 70°F.

Is the indoor temperature 60°F or below? Ambient indoor

temperatures of 60°F or below will take a longer period of run

time to heat the area. Long run times may indicate that the unit is

undersized.

Has the room area been increased where the unit is located?

If the area where the unit is located has been increased, the unit

may not provide adequate heat.

Insufcient Maintenance and Inspection

Installation errors are the most common cause of poor performance.

Please follow installation instructions carefully. If other problems exist,

see Maintenance and Inspection Troubleshooting Guide below.

Maintenance and Inspection Troubleshooting Guide

CAUSE RESULT

System is not serviced or inspected

regularly (semiannually or annually).

Air lters are not cleaned regularly and

become blocked with particles.

Condenser coil not maintained properly

(blocked with particles).

Evaporator coil not maintained properly

(blocked with particles).

Components that show signs of fatigue

- not replaced.

Condensate drains and drain lines not

maintained.

Can result in premature component failures, poor performance and

increased operating costs.

May result in poor cooling, icing and water problems as well as

component failures and increased operating costs.

May result in poor cooling, component failures and increased costs.

May result in poor cooling, icing and water problems, and increased

operating costs.

May result in multiple service calls, poor performance and increased

operating costs.

May result in water and odor problems.

21

Page 22

920-087-02 (9-03)

23

920-087-02 (9-03)

MODE FAN

Friedrich PTAC Accessories

NEW CONSTRUCTION ACCESSORIES

MODEL NUMBER DESCRIPTION PHOTO

WALL SLEEVE G-90 zinc coated steel is prepared in an elevenstep process, then electrostatically coated with a polyester nish

and cured in an oven for exceptional durability. The wall sleeve

PXWS

is insulated for thermal efciency. 16" High x 42" Wide x 13"

Deep.

PXWS

PXGA

PXAA

PXDB

PXSC

PXDR10

PXWE

PXSB

GRILLE, standard, stamped aluminium, anodized to resist

chalking and oxidation.

ARCHITECTURAL GRILLS that consist of heavy-gauge

6063-T5 aluminium alloy:

Clear, extruded aluminium or dark bronze acrylic enamel

Also available in custom colors.

CONDENSATE DRAIN KIT Attaches to the bottom of the wall

sleeve for internal draining of condensate or to the rear wall sleeve

ange for external draining. Recommended on all units to remove

excess condensate. Packaged in quantities of ten.

DEEP WALL SLEEVE EXTENSION A four inch deep anodized

aluminium extension that attaches to the outside of the wall sleeve

when the wall is greater than eleven inches thick (9" when a

subbase is used, 10 inches when a lateral duct is used).

DECORATIVE SUBBASE Provides unit support for walls less

than six inches thick. Includes leveling legs, side ller panels

and mounting brackets for electrical accessories. Accepts

circuit breaker, power disconnect switch, or conduit kit.

PXDB

PXDR10

PXWE

PXSB

CONDUIT KIT WITH JUNCTION BOX Hard wire conduit kit

with junction box for 208/230V and 256V units (subbase not

required). Kit includes a means of quick disconnect for easy

PXCJ

removal of the chassis. *Required for 265V installations.

PXCJ

DESK CONTROL KIT A eld installed kit which allows the

PXDC

unit to be turned on or off from a remote central station via

a 24V interface.

PXDC

DIGITAL REMOTE THERMOSTAT A Honeywell wall

mounted remote thermostat. Requires proper P-Series

RT2

22

chassis.

RT2

Page 23

920-087-02 (9-03)

Friedrich PTAC Accessories (continued)

ADDITIONAL ACCESSORIES

MODEL NUMBER DESCRIPTION PHOTO

SLEEVE EXTENSION RETROFIT KIT G-90 zinc coated

steel, 2.4" sleeve extension attached to the room side of

PXSE

PXDA

PXDE

the sleeve to allow for the installation of a P-Series Friedrich

PTAC in a T-Series sleeve.

LATERAL DUCT ADAPTER Attaches to the PTAC/PTHP

unit and provides a transition to direct up to 35% of the total

CFM to a secondary room, either left or right of the unit. Kit

includes duct plenum with discharge grille and internal bafe,

adapter and end cap.

LATERAL DUCT EXTENSION A three foot insulated plenum

that attaches to the left or right side of the duct adapter. The

extension can be cut to length by the installer. Maximum

allowable straight extension is fteen feet.

PXSE

PXDA

PXFT

CHASSIS OPTIONS

S

R

C

REPLACEMENT FILTER PACK These are original

equipment return air lters. They are reusable and can be

cleaned by vacuuming, washing, or blowing out, and are sold

in convenient ten packs. (Two lters per chassis)

PXFT

DESCRIPTION DESIGNATOR

STANDARD UNIT Standard PTAC/PTHP chassis. Can be 230/208V or 265V, electric or heat pump.

REMOTE THERMOSTAT Chassis option necessary for wall mounted thermostat control of the unit.

SEACOAST PROTECTION Additional protection for PTAC/PTHP units in a coastal or corrosive environment.

The entire outdoor coil is submerged in a specially formulated enamel coating, then oven-cured for a tough,

corrosion-resistant nish.

23

Page 24

FRIEDRICH WALLMASTER® P-SERIES PACKAGED TERMINAL AIR CONDITIONERS

LIMITED WARRANTY

FRIEDRICH AIR CONDITIONING CO.

Post Ofce Box 1540 · San Antonio, Texas 78295-1540

(210) 357-4400 · FAX (210) 357-4480

SAVE THIS CERTIFICATE. It gives you specic rights, you may also have other rights which may vary from state to state and province to province.

In the event that your unit needs servicing, contact your nearest authorized service center. If you do not know the nearest service center, ask the company that installed

your unit or contact us - see address and telephone number below.

When requesting service: please have the model and serial number from your unit readily available.

Unless specied otherwise herein, the following applies:

PACKAGED TERMINAL AIR CONDITIONERS AND HEAT PUMPS

LIMITED WARRANTY - FIRST YEAR (Eighteen (18) Months from the original date of purchase or twelve (12) months from installation). Any defect in the

unit’s material or workmanship will be repaired or replaced free of charge by our authorized service center during the normal working hours; and

LIMITED WARRANTY - SECOND THROUGH FIFTH YEAR (Sixty-six (66) months from the date of purchase) ON THE SEALED REFRIGERATION SYSTEM.

Any part of the sealed refrigeration system on the P-series that is defective in material or workmanship will be repaired or replaced free of charge (excluding freight

charges) by our authorized service center during normal working hours. The sealed refrigeration system consists of the compressor, metering device, evaporator,

condenser, reversing valve, check valve, and the interconnecting tubing.

These warranties apply only while the unit remains at the original site and only to units installed inside the continental United States, Alaska, Hawaii,

Puerto Rico and Canada. The warranty applies only if the unit is installed and operated in accordance with the printed instructions and in compliance

with applicable local installation and building codes and good trade practices.

For international warranty information, contact the Friedrich Air Conditioning Company - International Division.

Reasonable proof must be presented to establish the original purchase date, otherwise the beginning date of this certicate will be considered to be our shipment date

plus sixty days. Replacement parts can be new or remanufactured. Replacement parts and labor are only warranted for any unused portion of the unit’s warranty.

We will not be responsible for and the user will pay for:

1. Service calls to:

A) Instruct on unit operation. B) Replace house fuses or correct house wiring. C) Clean or replace air lters. D) Remove

the unit from inaccessible locations. E) Correct improper installations.

2. Parts or labor provided by anyone other than an authorized service center.

3. Damage caused by:

A) Accident, abuse, negligence, misuse, riot, re, ood, or acts of God. B) Operating the unit where there is a corrosive atmosphere containing chlorine,

uorine, or any damaging chemicals (other than in a normal residential environment). C) Unauthorized alteration or repair of the unit, which in turn

affects its stability or performance. D) Failing to provide proper maintenance and service. E) Using other than a "Seacoast Protected" unit in a coastal

environment. F) Using an incorrect power source. G) Faulty installation or application of the unit.

We shall not be liable for any incidental, consequential, or special damages or expenses in connection with any use or failure of this unit. We have not

made and do not make any representation or warranty of tness for a particular use or purpose and there is no implied condition of tness for a particular

use or purpose. We make no expressed warranties except as stated in this certicate. No one is authorized to change this certicate or to create for us

any other obligation or liability in connection with this unit. Any implied warranties shall last for one year after the original purchase date. Some states

and provinces do not allow limitations on how long an implied warranty or condition lasts, so the above limitations or exclusions may not apply to you. The provisions

of this warranty are in addition to and not a modication of or subtraction from the statutory warranties and other rights and remedies provided by law.

In case of any questions regarding the provisions of this warranty, the English version will govern.

Revised 8/01

Model No. ____________ Serial No. ______________________

Date Purchased: ______ Installation Location: ____________

Date Installed: ________ Installed by:____________________

Printed in the U.S.A.

920-087-02 (9-03)

Loading...

Loading...